Device and method for synthesizing ethylene bis-fatty acid amide by continuous flow

A technology of fatty acid amide and ethylene bis, applied in the field of ethylene bis fatty acid amide synthesis, can solve the difficulty in forming large-scale and intelligent industrialization technology, influence product market development and high value-added, ammonium salt intermediate product color. To solve problems such as depth and depth, to achieve the effect of shortening material residence and reaction time, good product quality consistency and stability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

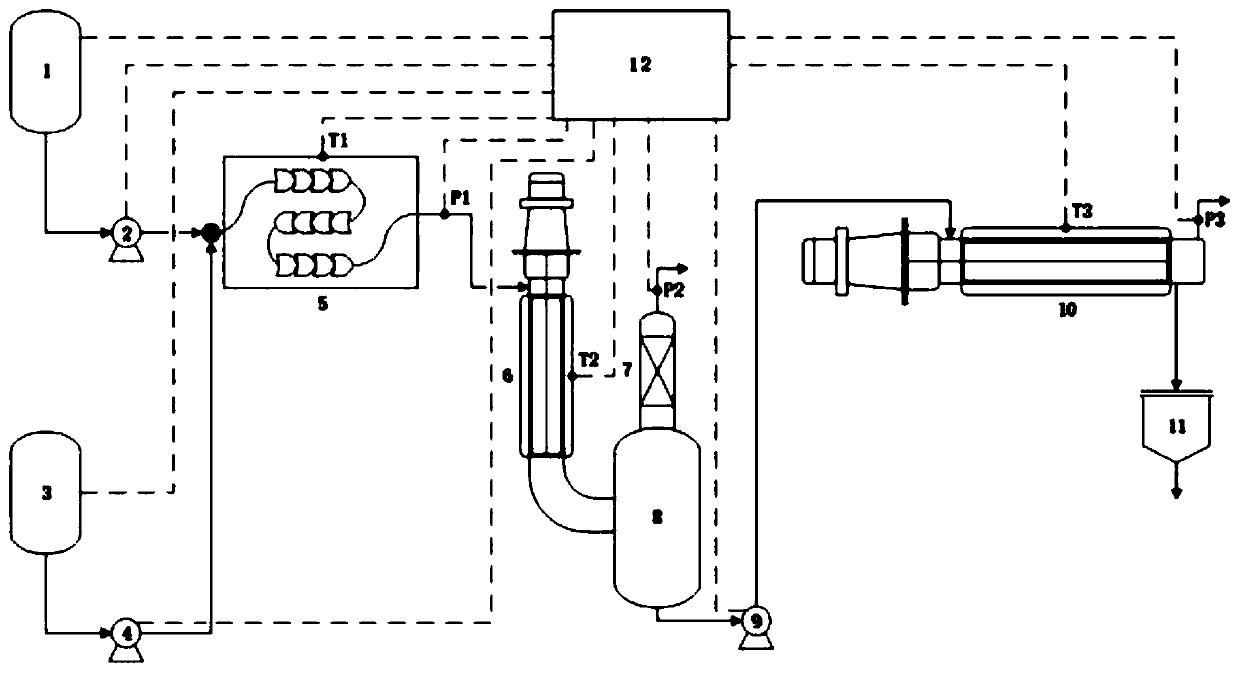

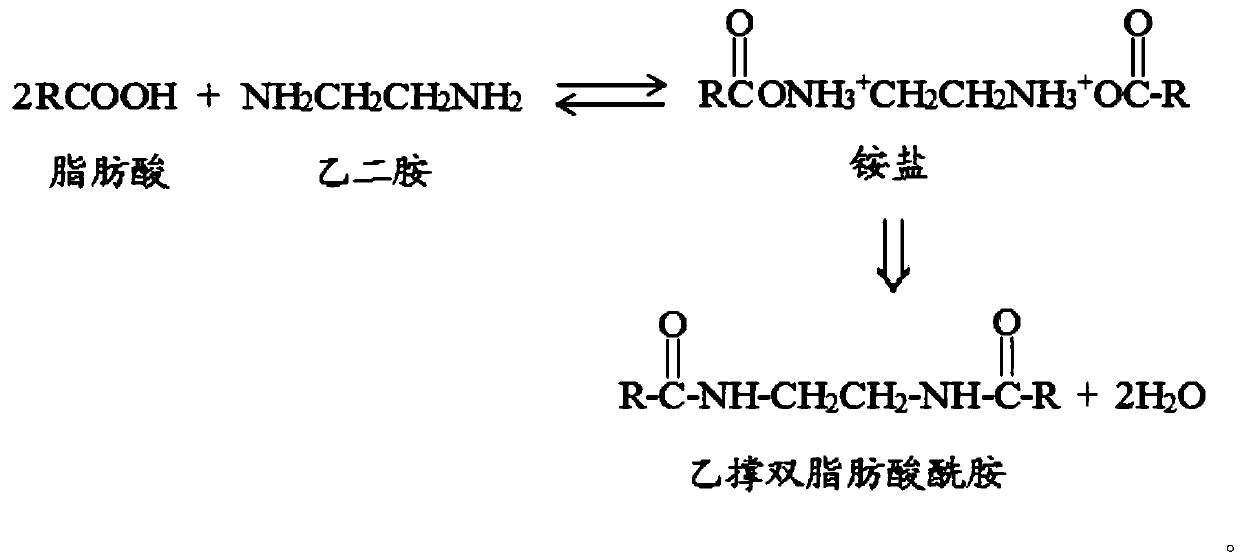

[0060] The fatty acid is specifically selected from stearic acid, and stearic acid and ethylenediamine are used as raw materials. figure 1 Shown device carries out the method for continuous flow synthetic ethylene bis stearic acid amide (EBS), comprises the following steps:

[0061] Stearic acid is stored in the fatty acid storage tank 1, the temperature of the fatty acid storage tank 1 is controlled to be 110±2°C, and it is continuously pumped into the microchannel mixing reactor 5 by the fatty acid metering pump 2, and the flow rate of the stearic acid is 300kg / h ; Ethylenediamine is stored in the ethylenediamine storage tank 3, and the temperature of the ethylenediamine storage tank 3 is controlled to be 75 ± 2°C, and is continuously pumped into the microchannel mixing reactor 5 by the ethylenediamine metering pump 4, and the ethylenediamine The flow rate of amine is 33.2kg / h;

[0062] Control the temperature (T1) in the microchannel mixing reactor 5 to be 140±2°C, the pre...

Embodiment 2

[0068] The fatty acid is specifically selected from oleic acid, and oleic acid and ethylenediamine are used as raw materials. figure 1 Shown device carries out the method for continuous flow synthetic ethylene bisoleic acid amide (EBO), comprises the following steps:

[0069]Store oleic acid in fatty acid storage tank 1, control the temperature of fatty acid storage tank 1 to be 80±2°C, and continuously pump it into microchannel mixing reactor 5 by fatty acid metering pump 2, and the flow rate of oleic acid is 200kg / h; Ethylenediamine is stored in the ethylenediamine storage tank 3, and the temperature of the ethylenediamine storage tank 3 is controlled to be 70±2°C, and is continuously pumped into the microchannel mixing reactor 5 by the ethylenediamine metering pump 4. The flow rate is 21.2kg / h;

[0070] Control the temperature (T1) in the microchannel mixing reactor 5 to be 95±2°C, the pressure (P1) at the discharge port to be 0.20-0.40MPa, and control the flow of oleic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com