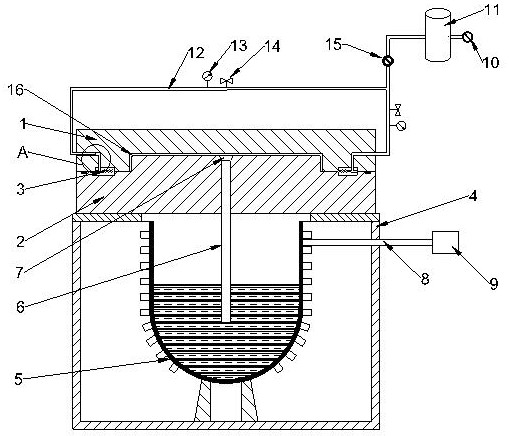

Vacuum low-pressure casting device and method for large aluminum and magnesium alloy castings

A vacuum low-pressure, magnesium alloy technology, applied in the field of low-pressure casting, can solve the problems of complex equipment, low cost, uncontrollable casting cost, etc., and achieve the effect of high product quality, high production efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

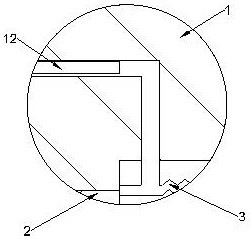

[0047] Vacuum low-pressure casting of a large A356 aluminum alloy casting product. There are 2 exhaust blocks and 2 vacuum channels respectively.

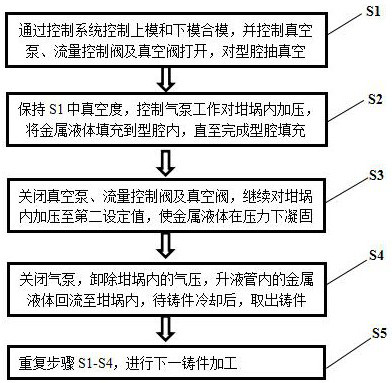

[0048] Specific steps are as follows:

[0049] S1. Control the clamping of the upper mold and the lower mold through the control system, and control the opening of the vacuum pump, flow control valve and vacuum valve to vacuumize the cavity so that the vacuum degree in the cavity is 0.02MPa. (The degree of vacuum in this example is expressed in absolute pressure, the same below.)

[0050] S2. Maintain the vacuum degree in S1, and control the operation of the air pump to pressurize the inside of the crucible so that the air pressure in the crucible reaches 0.06 MPa. The mold is preheated to 170-180°C, and the metal liquid melted to 680°C is filled into the cavity until the cavity is filled;

[0051] S3. After filling the cavity, close the vacuum pump, flow control valve and vacuum valve through the control system, continue to con...

Embodiment 2

[0058] Vacuum low-pressure casting of a large A356 aluminum alloy casting product, with 4 exhaust blocks and 4 vacuum channels respectively.

[0059] Specific steps are as follows:

[0060] S1. Control the clamping of the upper mold and the lower mold through the control system, and control the opening of the vacuum pump, flow control valve and vacuum valve to vacuumize the cavity so that the vacuum degree in the cavity is 0.02MPa;

[0061] S2. Maintain the vacuum degree in S1, and control the operation of the air pump to pressurize the inside of the crucible so that the air pressure in the crucible reaches 0.06 MPa. The mold is preheated to 170-180°C, and the metal liquid melted to 680°C is filled into the cavity until the cavity is filled;

[0062] S3. After filling the cavity, close the vacuum pump, flow control valve and vacuum valve through the control system, continue to control the air pump to pressurize the crucible, increase the air pressure in the crucible to 0.12MP...

Embodiment 3

[0066] Vacuum low-pressure casting of a large A356 aluminum alloy casting product, with 2 exhaust channels.

[0067] Specific steps are as follows:

[0068] S1. Control the clamping of the upper mold and the lower mold through the control system, and control the opening of the vacuum pump, flow control valve and vacuum valve to vacuumize the cavity so that the vacuum degree in the cavity is 0.01MPa;

[0069] S2. Maintain the vacuum degree in S1, and control the operation of the air pump to pressurize the inside of the crucible so that the air pressure in the crucible reaches 0.06 MPa. The mold is preheated to 170-180°C, and the metal liquid melted to 680°C is filled into the cavity until the cavity is filled;

[0070] S3. After filling the cavity, close the vacuum pump, flow control valve and vacuum valve through the control system, continue to control the air pump to pressurize the crucible, increase the air pressure in the crucible to 0.12MPa, and maintain this pressure for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com