Production technology and equipment of car dimmer switch

A dimmer switch, production process technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor quality consistency, high production costs, and high management costs, and achieve good product quality consistency and equipment occupancy. The effect of small area and low staff turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

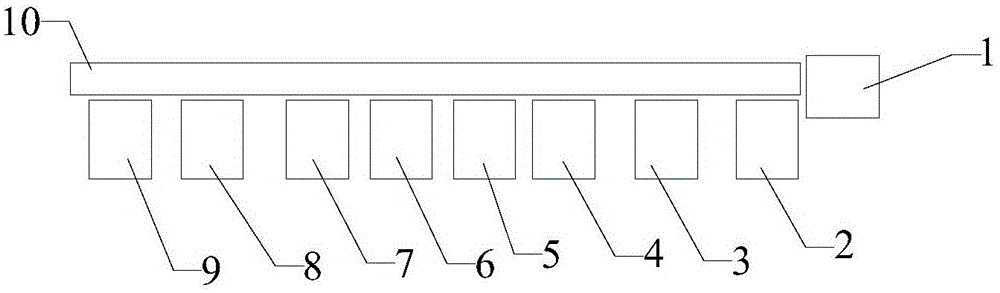

[0061] Please refer to Figure 1 to Figure 8 As shown, the first embodiment of the present invention is:

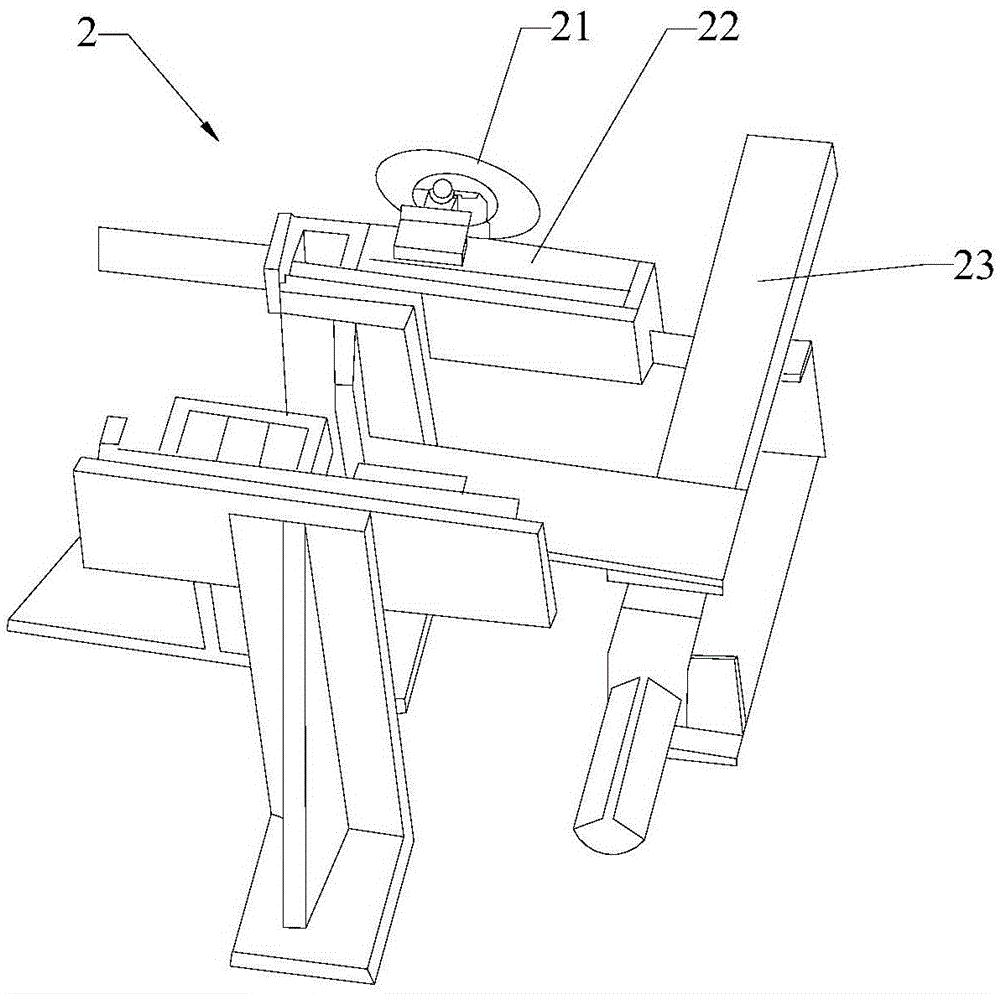

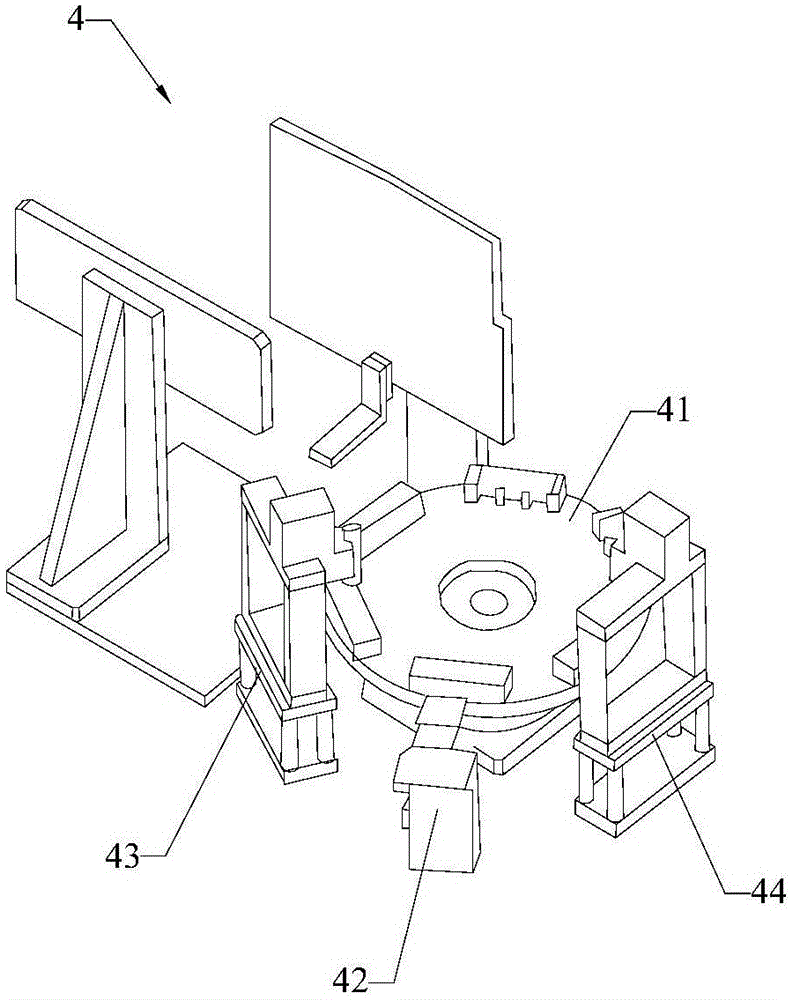

[0062] An automobile dimmer switch production equipment, comprising a conveyor belt module 10 and a PCBA loading machine 1, a PCBA sub-board module 2, a terminal inserting module 3, a terminal welding module 4, and oiling, which are sequentially arranged along the conveyor belt module 10. Module 5, runner and reed feeding module 6, spring loading module 7, steel ball loading and turntable module, clamping jaw module 8 and assembly module 9; the PCBA sub-board module 2 includes a circular knife 21 , a flat knife, a sliding rail 22 and a PCBA carrier 23, the sliding rail 22 is arranged perpendicular to the PCBA carrier 23, the circular knife 21 is slidably arranged on the sliding rail 22; the plug-in terminal module 3 includes a first manipulator The terminal welding module 4 includes a turntable 41, a PCBA turning module 42, a first welding device 43 and a second welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com