Electric tool used for pipefitting chamfering

A chamfering, electric technology used in electric tooling. It can solve the problems of low production efficiency and poor product quality, and achieve the effect of high production efficiency, convenient operation and good product quality consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

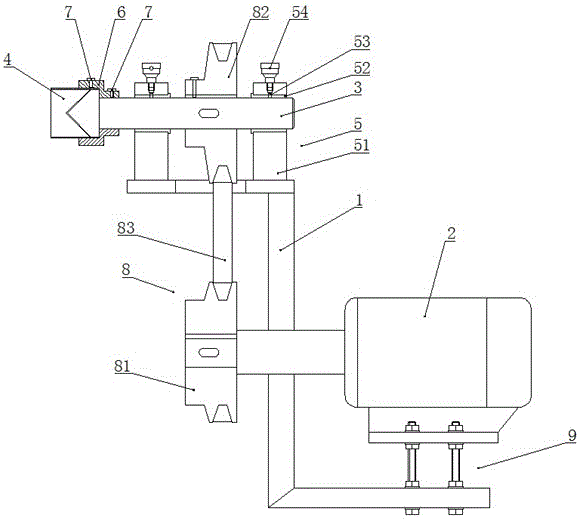

[0025] like figure 1 As shown, an electric tool for pipe chamfering includes a frame 1 , a driving motor 2 , a rotating shaft 3 and a cutter head 4 .

[0026] exist figure 1 Among them, the rotating shaft 3 is rotatably supported on the top of the frame 1 via a support member 5 . The support member 5 includes a bearing seat 51 and a bearing 52 , wherein the bearing seat 51 is fixed on the top of the frame 1 , and the bearing 52 is supported between the rotating shaft 3 and the bearing seat 51 .

[0027] like figure 1 As shown, in order to strengthen the lubrication of the bearing 52, an oil injection hole 53 is opened on the bearing seat 51. The inner end of the oil injection hole 53 communicates with the bearing 52, and an oil cap 54 is threaded on the outer end of the oil injection hole 53. The oil cap 54 blocks the oil injection hole 53 .

[0028] like figure 1 As shown, the cutter head 4 is non-rotatably connected to the end of the rotating shaft 3 through the cutter ...

Embodiment 2

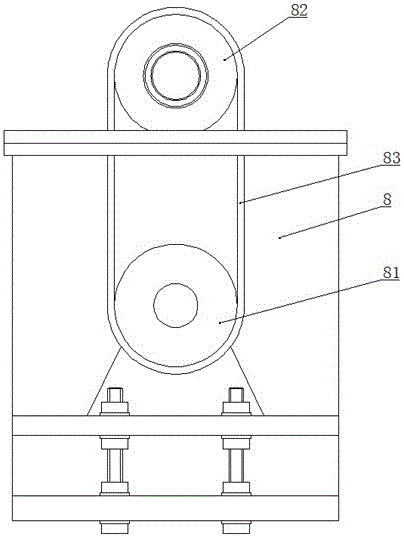

[0036] exist Figure 5 , Image 6 Among them, an electric tooling for pipe chamfering is the same as that of Embodiment 1 in that it includes a frame 1 and a driving motor 2 , and the driving motor 2 is fixed on the bottom of the frame 1 .

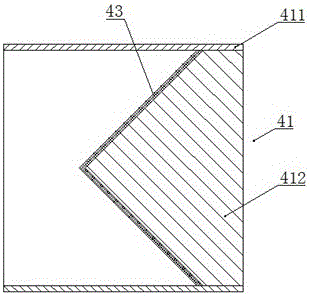

[0037] like Figure 5 , Image 6 As shown, it is different from Embodiment 1 in that: there are two rotating shafts 3, which are arranged in parallel, and the two ends of each rotating shaft 3 are respectively supported on the top of the frame 1 through support members 5; The end of 3 is non-rotatably provided with cutter head seat 6 through lock piece 7, and inner chamfering rotary cutter head 41, outer chamfering rotary cutter head 42 are respectively provided with on two cutter head seats 6.

[0038] exist Figure 5 , Image 6 Among them, the transmission part 8 includes a driving pulley 81, two driven pulleys 82 and a transmission belt 83, the driving pulley 81 is non-rotatably assembled on the output shaft of the driving motor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com