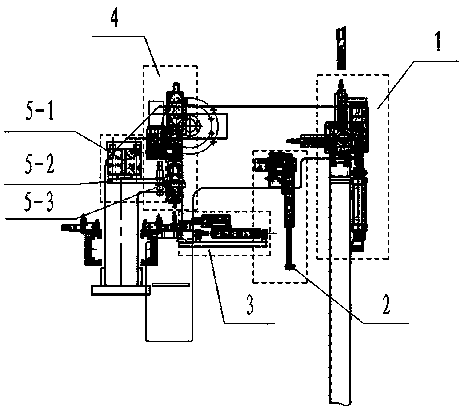

Prelubricated rotary plug-feeding mechanism

A pre-lubrication and plug feeding technology, which is applied in the direction of closing plug, plug feeding, plug pretreatment, etc., can solve the problems of hose scratches, hose crushing, and low success rate of plugging, so as to improve work efficiency and reduce Small scratches, the effect of reducing the risk of plastic debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

[0034] Meanwhile, since what is described below are only some embodiments, the embodiments in the present application and the features in the embodiments can be combined with each other under the condition of no conflict.

[0035] Such as Figures 4 to 6 As shown, the initial position of the plug feeding and turning assembly 1 is set at the plug receiving station, the plug receiving seat 1-14 is connected to the sealing plug 7, and the plug clamping air claw 1-12 drives the clamping hand 1-13 to clamp the sealing plug 7, Then the lifting cylinder 1-9 falls (retracts), and the turning cylinder 1-7 drives the plug feeding turning shaft 1-1, which drives the sealing plug 7 to rotate 90° to the plug feeding station. After the lifting cylinder 1-9 is in place, the sealing plug 7 is transported in place, the sealing plug 7 is taken away by the subsequent pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com