Injector filling machine

A technology for a syringe and a filling machine, applied in the field of pharmaceutical equipment, can solve the problems of long filling cycle, complex structure and low production capacity of the syringe, and achieve the effects of reducing the filling cycle, simple structure and layout, and simple filling and plugging process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in more detail below in conjunction with the accompanying drawings. It should be noted that the following description of the present invention with reference to the accompanying drawings is only illustrative rather than limiting. Different embodiments can be combined with each other to form other embodiments not shown in the following description.

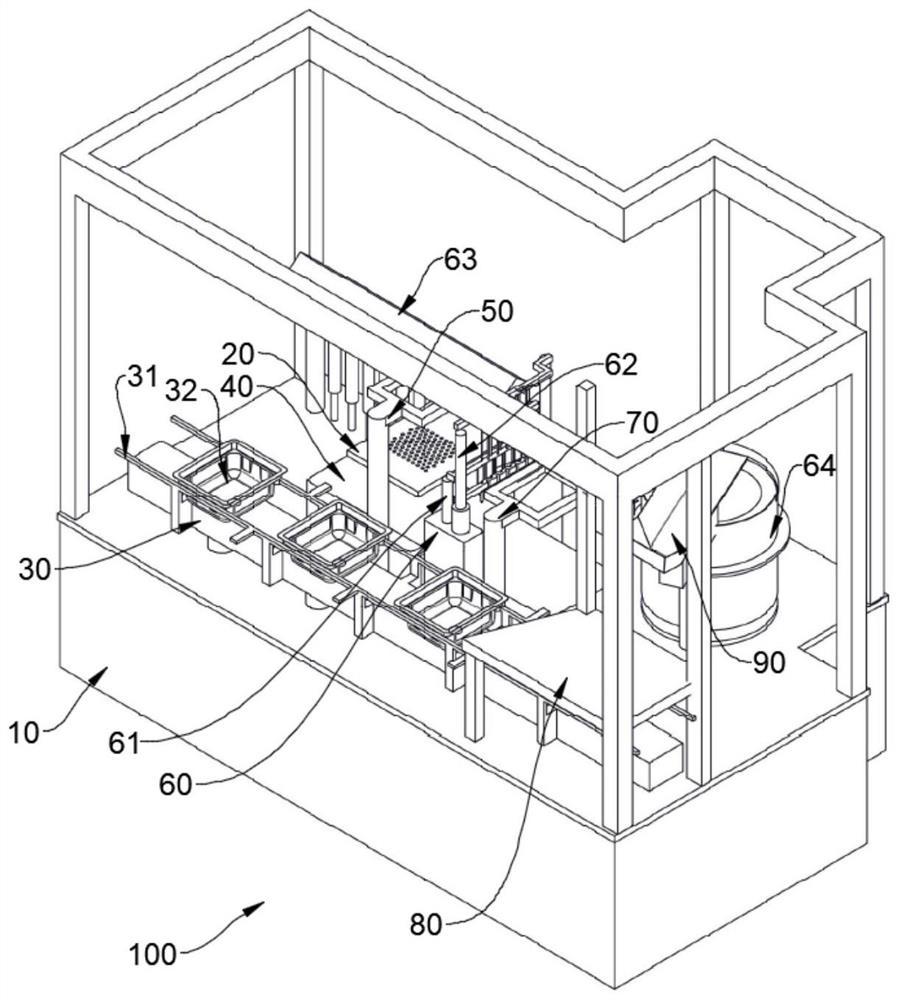

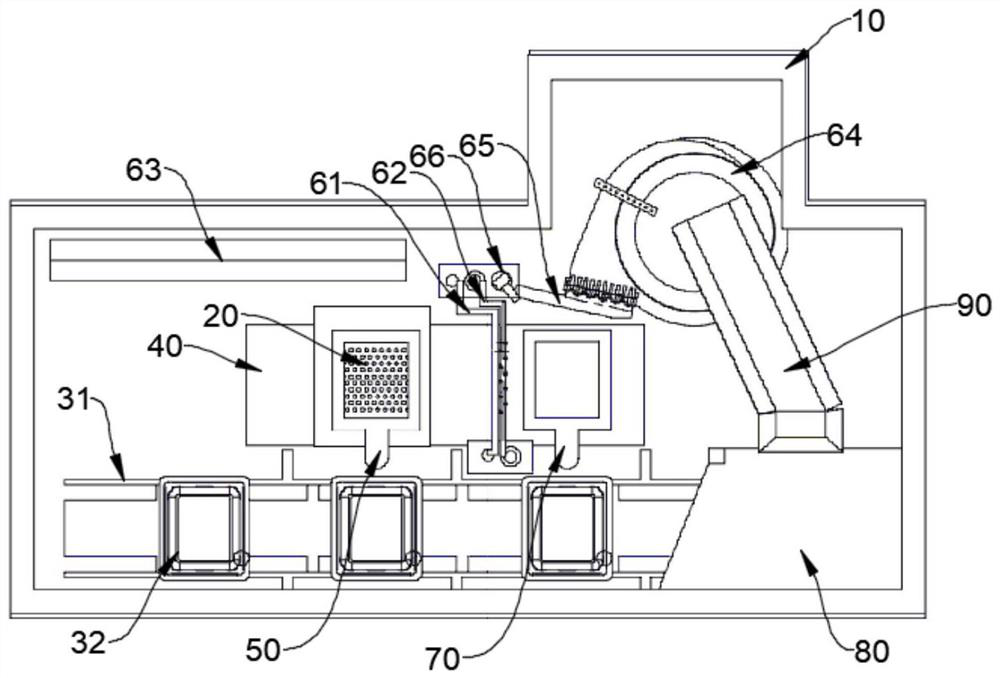

[0030] see figure 1 and figure 2 , In one embodiment of the present invention, a novel syringe filling machine 100 is provided. The syringe filling machine 100 has a simple structure, takes up less space, takes less time in the filling process, and has better applicability.

[0031] The syringe filling machine 100 includes: a hollow body 10, and the inner space of the body 10 is equipped with: a nest plate 20 for placing syringes, a conveying mechanism 30, a mobile platform 40, a feeding mechanism 50, and a filling and stoppering mechanism 60 and blanking mechanism 70. Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com