Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Silk obtaining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon

InactiveCN104195649APerformance is not affectedIncrease productivityDe-gumming silkSilk obtainingPolymer scienceOrganic chemistry

The invention discloses a method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon. The method and device for processing the silk floss winter clothes raw materials by the silkworm light defective cocoon are achieved through the following steps of alkali soaking, cocoon stripping, cleaning and dewatering, degumming agent dipping, cleaning and dewatering, softening agent dipping, cleaning and dewatering, and drying. According to the method and device, the silkworm light defective cocoon is processed to be the silk floss winter clothes raw materials, light defective cocoon and basin residues are completely utilized, processed silk floss is soft and clean, the processing method and device are simple, the production efficiency is high, and the production cost is low.

Owner:YIZHOU ZHUANGGE SILK

Method for separating and refining silk reeling leftovers

InactiveCN102206875AAvoid it happening againReduce processing timeAnimal materialSilk obtainingEnvironmental hygieneDecomposition

The invention discloses a method for separating and refining silk reeling leftovers, which is characterized by comprising the following steps: (a) artificially sorting and removing impurities; (b) separating pupae and cotton; (c) preimpregnating at low temperature; (d) dehydrating; (e) refining and blanching; (f) taking out the material, and flushing; (g) dehydrating; (h) softening; (i) dehydrating; and (j) baking. Since the pupae / cotton separation is firstly adopted and the decomposition step in the original technique is removed, the invention avoids massive wastewater and peculiar smell generated in the pupae decomposition process, and pupa powder which can be used as precious animal albumen is obtained. The experiment indicates that one ton of waste leftovers can be used for obtaining 650 kilograms of pupa powder and about 300 kilograms of silk cotton by using the method disclosed by the invention. The processing time is shortened from eight days to one day. Thus, the invention completely achieves the goals of short processing cycle, less wastewater, no influence on air and environmental hygiene and low processing cost.

Owner:NANCHONG YINHAI SILK

Method for utilizing damaged cocoons to product high-elasticity silk quilt

InactiveCN103876540AHigh elastic recovery rateElasticSilk obtainingBed-coversEngineeringFar infrared

The invention relates to the technical field of mulberry silk, in particular to a method for utilizing damaged cocoons to product a high-elasticity silk quilt. The method includes taking a certain amount of the damaged cocoons and weighing the same; performing vacuum infiltration on the weighed damaged cocoons; puffing to enable texture of the damaged cocoons to be loose; cooling prior to reeling silk from the cocoons; adopting chitosan, anion far infrared material and microcapsule technology to perform multifunctional finishing on silk floss to enable the silk floss to have functions of being antibacterial, highly heat-insulating and lasting in fragrance; drying the silk floss through drying equipment; processing the silk floss into a finished product before vacuum packaging. By the method, the problem that a silk-padded quilt produced by conventional processes is low in elastic recovery rate and prone to knotting after being used for a period of time is solved, added value of products is increased, production efficiency of enterprises is improved, competitiveness of the enterprises is enhanced, improving of agricultural efficiency and increasing of farmer income can be promoted.

Owner:XINYUAN COCOON SILK GROUP

Silk reeling technology for hollow cocoon, dry solid cocoon and live pupa cocoon

InactiveCN1721589APlay the role of turning waste into treasureSave energySilk obtainingRoom temperatureThermal water

This invention relates to hollow pulp cocoon, dried cocoon and live cocoon filature process, which vacuums the waste hollow pulp cocoon or dried cocoon discarded in traditional process and dips the cocoon under room temperature after being boiled and goes through dispel liquid composed of sodium silicate, sodium carbonate, red oil, borax, hydrogen dioxide solution, surface activity agent and water and finally through filature and shading and processing into silk.

Owner:郑丽玮

Preparation method of goose down and silk quilt

The invention relates to a preparation method of a goose down and silk quilt. The method comprises the following processing steps: (1) putting matured silkworms on a silking web; (2) stripping the silk to obtain floss pieces; (3) soaking the obtained floss pieces in warm water with a detergent, and then fishing out; (4) carrying out refined cooking on the floss pieces in boiling water for degumming; (5) cleaning and dewatering; (6) removing impurities, reshaping and drying; (7) weighing the dried floss pieces, and pulling for bulking; (8) cutting the floss pieces; (9) pulling the floss pieces open piece by piece, laying the floss pieces in a criss-cross way, flatly placing a goose down patting on the silk floss when half of the floss pieces are left, and continuously laying the floss pieces; checking and finishing a floss patting; (10) respectively adding two layers of silk leaking prevention gauze onto the upside and the underside of the floss patting; (11) covering with a patting cover; (12) quilting the patting cover and a silk floss patting, and then shaping. The goose down and silk quilt provided by the invention not only maintains the characteristics of being soft, close fitted, skin-friendly and comfortable of a silk quilt, but also has the excellent thermal insulation property of a down quilt.

Owner:GUANGXI GUIHUA SILK CO LTD

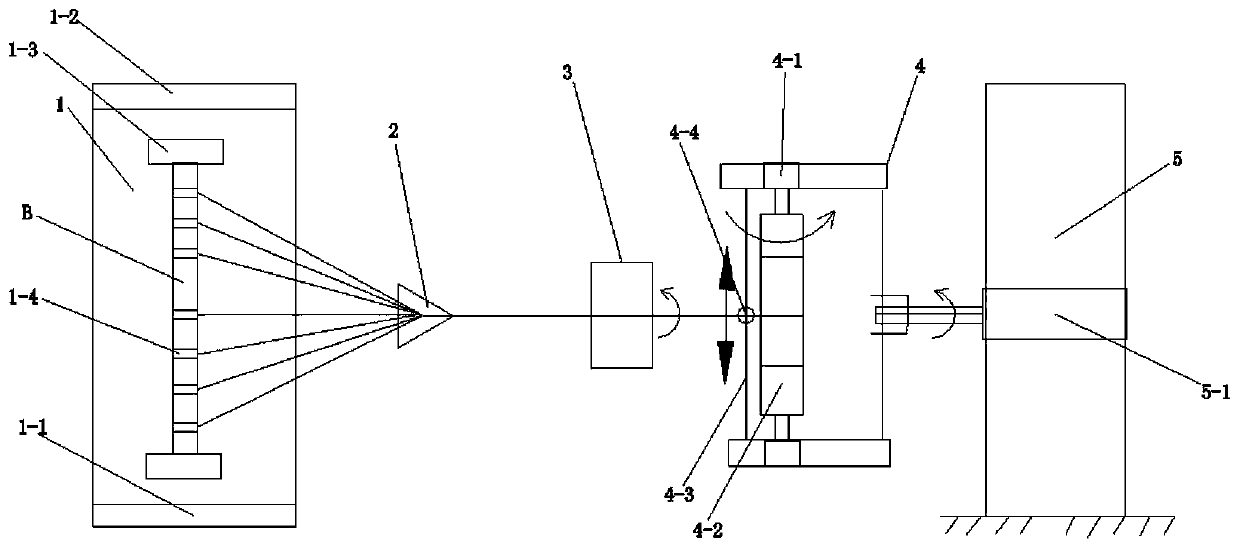

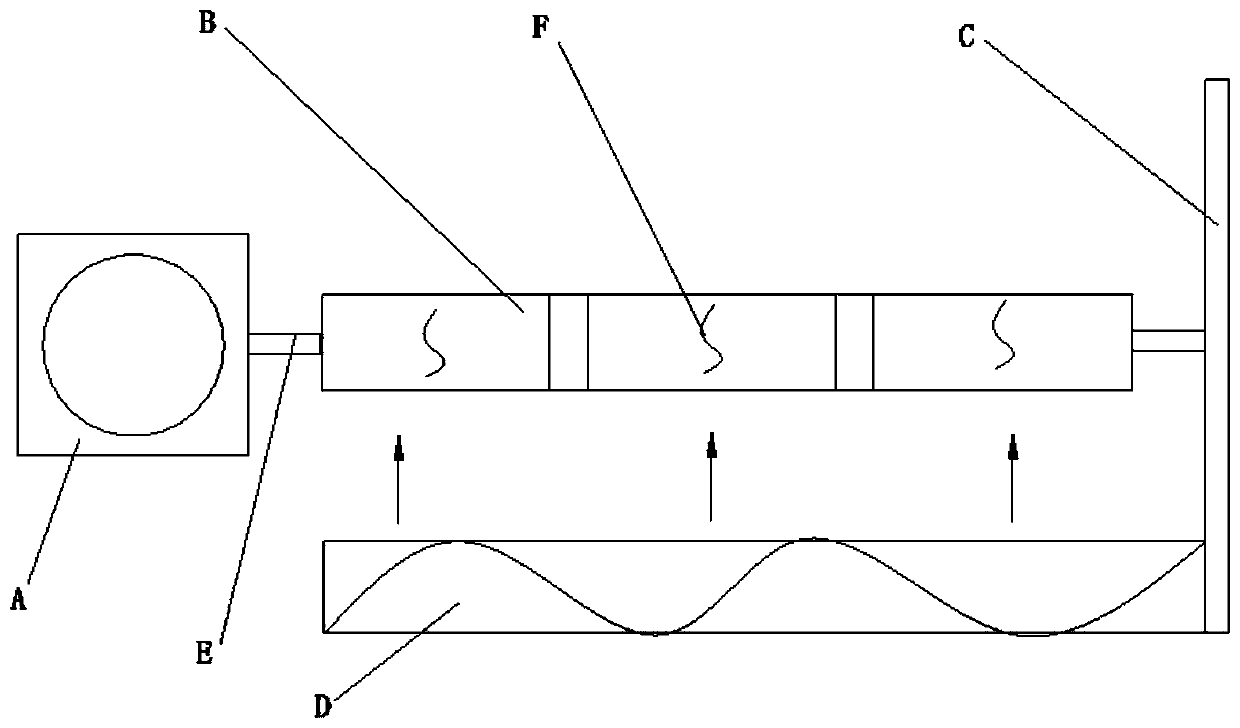

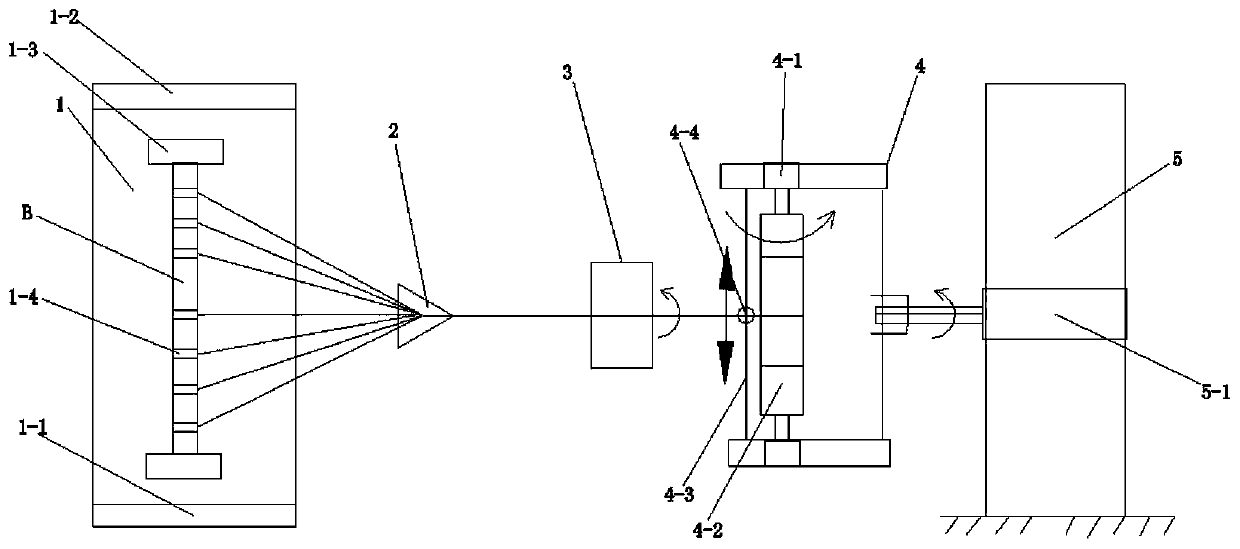

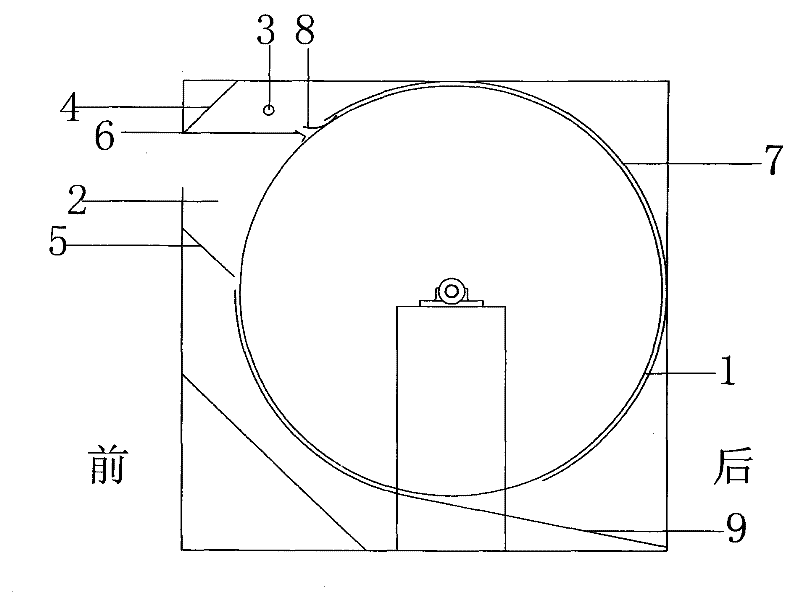

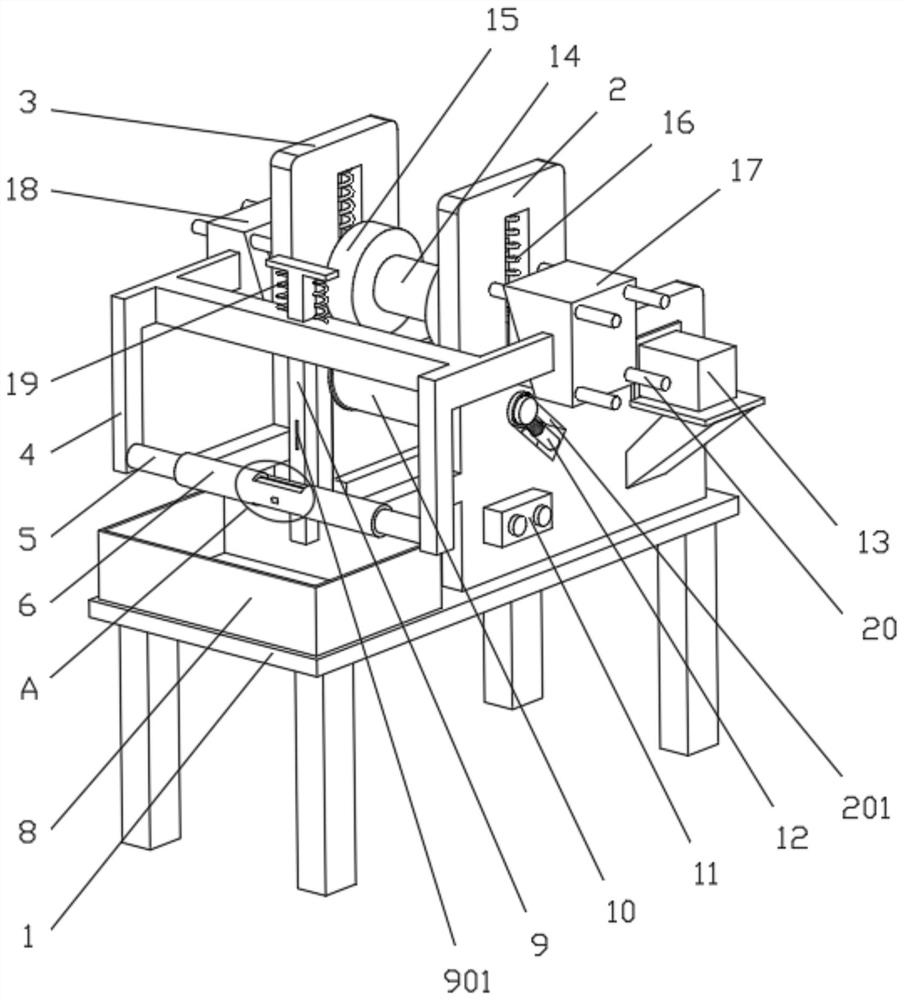

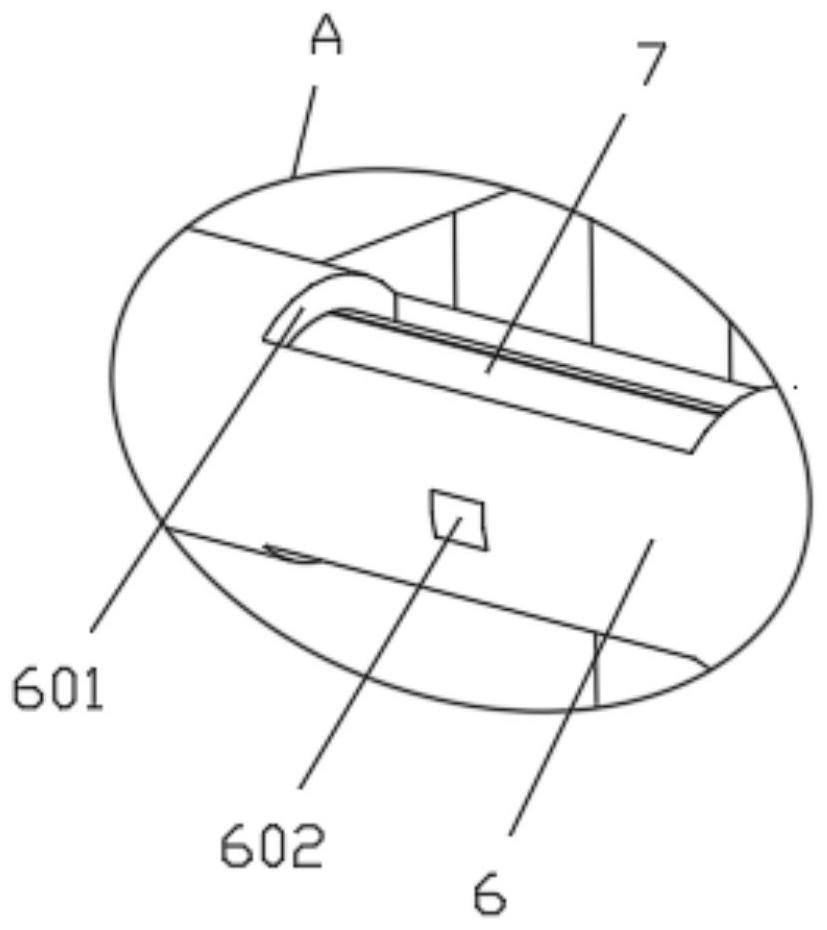

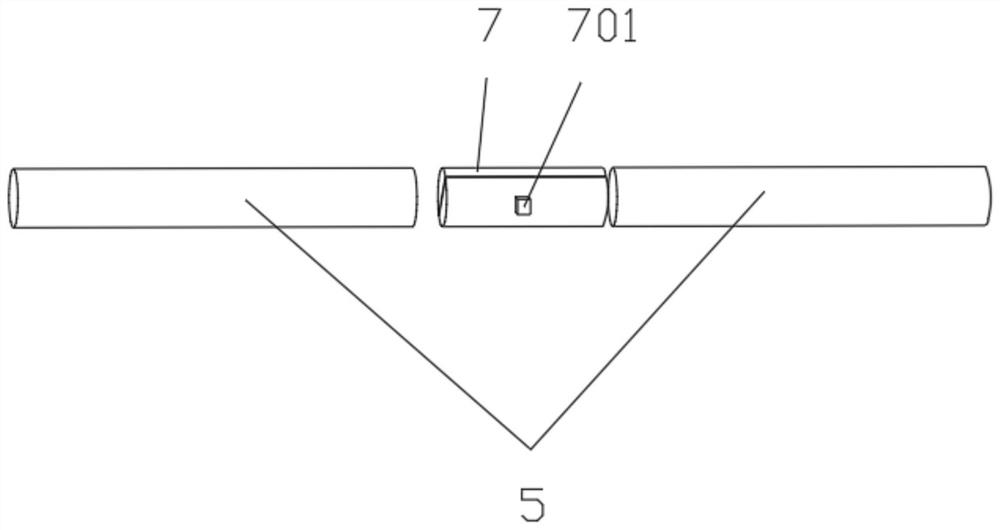

Equipment for performing drawing and bundling by using annular single-silkworm silk

PendingCN111155176ANovel structureEasy to controlFilament handlingTextile/flexible product manufactureElectric machineryEngineering

The present invention relates to equipment for performing drawing and bundling by using annular single-silkworm silk. The equipment comprises an annular silk reeling device, a silk collecting hole, aninfrared dryer, a rotary silk winding device and a vehicle head. An ultrasonic oscillator and a heater are fixedly mounted at the two ends of the annular silk reeling device, and an annular silk generation roller is arranged on an annular silk generation roller fixing seat. The vehicle head is fixedly provided with a variable frequency motor, the rotary silk winding device can be driven to rotateby the variable frequency motor, the rotary silk winding device is fixedly provided with a micro motor, a micro motor shaft is connected with a silk winding roller, the rotary silk winding device isprovided with a guide rod, and the guide rod is provided with a movable silk guide hook. The annular single-silkworm silk is formed by an annular silk generation device, the annular silk generation device comprises the micro motor, the annular silk generation roller, a support, a light source and a rotating shaft, the micro motor is connected with the annular silk generation roller through the rotating shaft, the annular silk generation roller is arranged on the support, and the light source is arranged at the bottom of the annular silk generation device.

Owner:YANCHENG INST OF IND TECH

Method for bleaching silkworm cocoons at low quality into quality ones

A bleaching poor cocoons process is achieved by: putting 13,000 cocoons into a tank with 135-160L water at 21-22 deg.C for 7-8 minutes, adding oxydol 60-80kg, pure alkali 1.8-2.5kg, sodium selenate 2-3 kg to bleach for 60-80 minutes. The products are qualified by removing oily stains and wax to have relaxing degree like the cocoons at the first grade. It increases yields of high-grade products and use ratio of raw materials.

Owner:王长清

Process for reeling hollow cocoons, dry cocoons or living cocoons

InactiveCN1584134APlay the role of turning waste into treasureSave energySilk obtainingSodium silicateBorax

A silk reeling technology for non-flesh cocoons, dried cocoons and alive pupa cocoons is achieved by: vacuumizing ,dipping non-flesh cocoons and dried cocoons in hot water, or alive pupa Immersing in water at atmosphere, processing in a relaxing liquid containing sodium silicate, sodium carbonate, red oil, borax, hydrogen peroxide, and water, reeling, and settling to make silk. The advantage of this technology is not only full use of wastes from traditional process, but also reeling the alive pupa cocoon beneficially.

Owner:韩翠英

silk cotton machine

The invention relates to a silk cotton machine for manufacturing silk cotton. The machine comprises a frame, a transmission device, a roller, a material groove, a water spray pipe, an upper baffle plate, a lower baffle plate and a scraping knife, wherein an arc-shaped fling-proof plate, an arc-shaped silk pasting plate and a fling-proof chrysalis-removing plate are arranged on the periphery of the roller. Due to the action of the arc-shaped silk pasting plate, silk after passing through the scraping knife can be closely attached on the outer surface of the roller; furthermore, once the silk attached on the roller is flung away from the roller, due to the blocking effects of the arc-shaped fling-proof plate and the fling-proof chrysalis-removing plate, the silk which is flung away can be rapidly returned onto the roller and be prevented from entangling and shedding, and the quality and the finished product rate of the machine processed silk cotton can be further improved; simultaneously, the diameter of the roller of the silk cotton machine can be increased so as to facilitate the manufacturing of an extra-width breadth silk cotton quilt with good uniformity, thereby solving the non-uniformity caused by splicing and the increased process steps during the traditional manufacturing of the extra-width breadth silk cotton quilt.

Owner:JIANGXI XIUSHUI YIJIA IND

Method of rejecting secondary cocoon during silk reeling and using secondary cocoon produce silk floss

A technology for rejecting the secondary cocoons in the silk reeling procedure includes such steps as boiling cocoons, drawing silk, brushing including the step of rejecting the dropping end cocoons, and reeling. Said dropping end cocoons can be used to prepare soft silk floss through loosening, boiling degluing, water washing, baking and carding.

Owner:汤池

Processing method of silk tops

ActiveCN104278430AImprove qualityReduce manufacturing costSilk obtainingNon-woven fabricsUltraviolet irradiationComputer science

Owner:广西中丝成丝绸科技有限公司

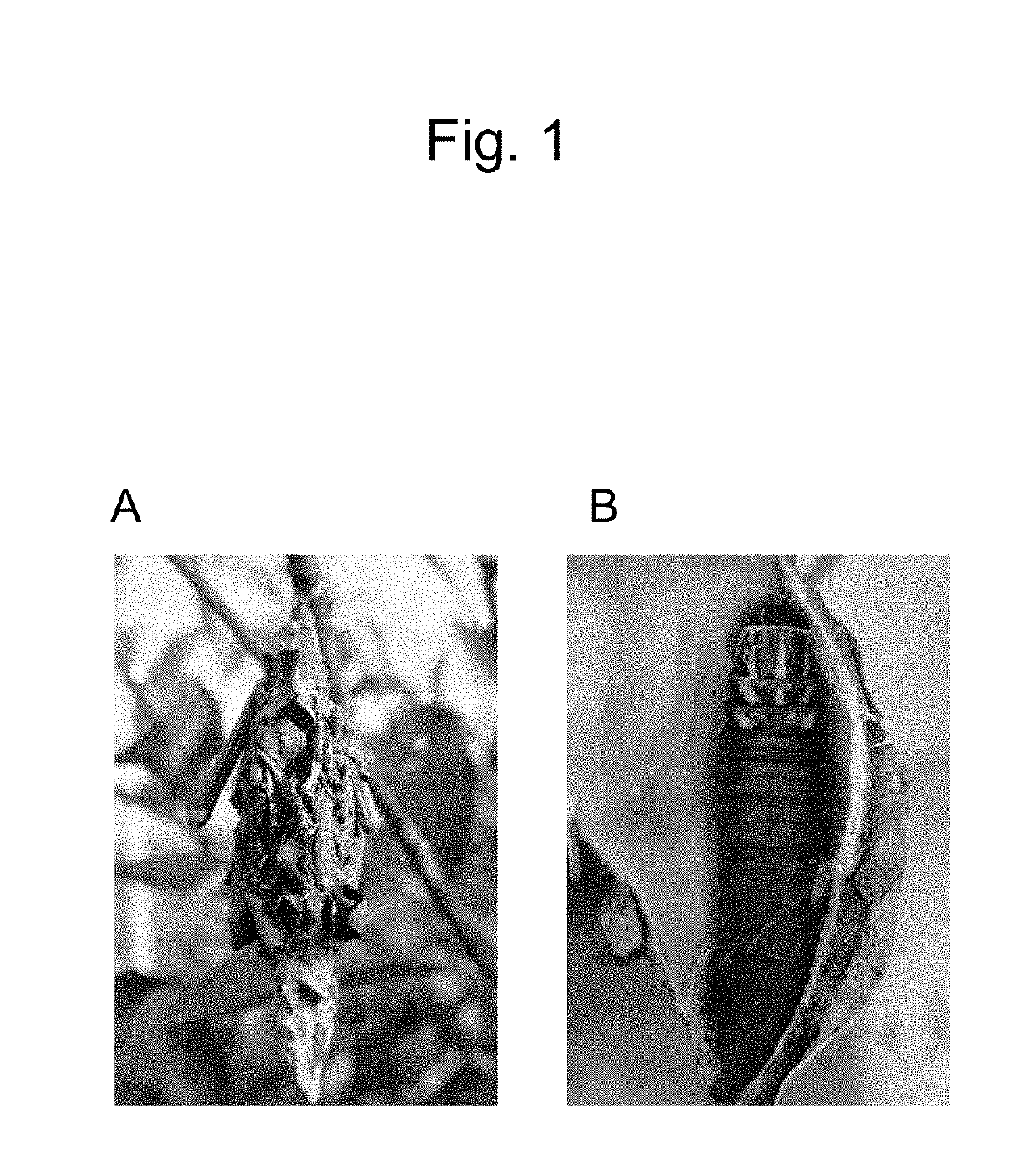

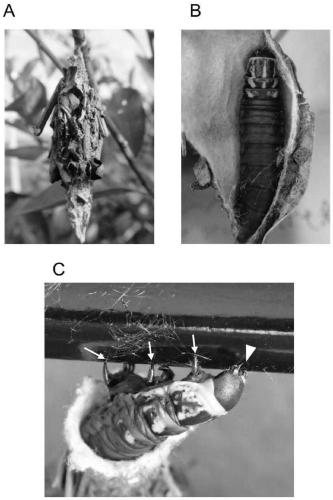

Bagworm silk thread collecting method

ActiveCN111566263AImprove qualityMonocomponent protein artificial filamentFood processingPolymer scienceOrganic chemistry

Owner:NAT AGRI & FOOD RES ORG +1

Health-care silk quilt making method

InactiveCN108425183AReduce adhesive forceEnhanced ability to absorb Chinese medicinal liquidSilk cocoons cleaning/classifyingAnimal materialMedicineSoftening

The invention discloses a health-care silk quilt making method and belongs to the technical field of processing of beddings. The health-care silk quilt making method comprises the working procedures of cocoon selection, drying, softening, soaking with traditional Chinese medicine liquid and the like. Softened silkworm cocoons are soaked with the traditional Chinese medicine liquid and then are made into silk pockets, the silk pockets are pulled into rectangular silk screens, the silk screens are stacked layer by layer, silk is pulled from four corners of each silk screen and a middle point ofeach side, the silk pulled out of the adjacent silk screens is twisted and connected, then the silk pulled out from the silk screens located on the upmost layer and the bottommost layer is twisted andconnected to obtain silk layers, and finally health-care silk quilts are obtained through soft pressing and sleeving. The health-care silk quilt making method is simple in process, also has very goodfatigue relieving, calming and sleep promoting effects while it is ensured that the health-care silk quilts are comfortable and breathable and keep warm, and the sleep quality of people is greatly improved.

Owner:河池市宜州区壮之都丝绸家纺有限公司

Silk cotton pull-weaving method

InactiveCN102337636AFree from harmSimple preparation processSilk obtainingNon-woven fabricsWarm waterEngineering

The invention discloses a silk cotton pull-weaving method, which comprises: bending a bamboo sheet into a bow shape, fixing the bamboo sheet on a bottom plate with the bow height being about 25-28cm, placing degummed cocoons into warm water of 45-50 DEG C for silk cotton pull-weaving, spreading the openings of the cocoons with both hands, making the cocoons to be sleeved on the bow part, pulling the cocoons to the bottom plate, removing bag-shaped silk cotton from the bamboo bow part, twisting to remove water and drying to obtain the finished silk cotton product. The invention has the advantages that the manufacturing process is simple, no irritation or damage can be caused to human bodies, no environmental pollution can be caused, and water can be saved.

Owner:吴佑林

Method for separating and refining silk reeling leftovers

InactiveCN102206875BAvoid it happening againReduce processing timeSilk obtainingCooking & bakingDecomposition

The invention discloses a method for separating and refining silk reeling leftovers, which is characterized by comprising the following steps: (a) artificially sorting and removing impurities; (b) separating pupae and cotton; (c) preimpregnating at low temperature; (d) dehydrating; (e) refining and blanching; (f) taking out the material, and flushing; (g) dehydrating; (h) softening; (i) dehydrating; and (j) baking. Since the pupae / cotton separation is firstly adopted and the decomposition step in the original technique is removed, the invention avoids massive wastewater and peculiar smell generated in the pupae decomposition process, and pupa powder which can be used as precious animal albumen is obtained. The experiment indicates that one ton of waste leftovers can be used for obtaining 650 kilograms of pupa powder and about 300 kilograms of silk cotton by using the method disclosed by the invention. The processing time is shortened from eight days to one day. Thus, the invention completely achieves the goals of short processing cycle, less wastewater, no influence on air and environmental hygiene and low processing cost.

Owner:NANCHONG YINHAI SILK

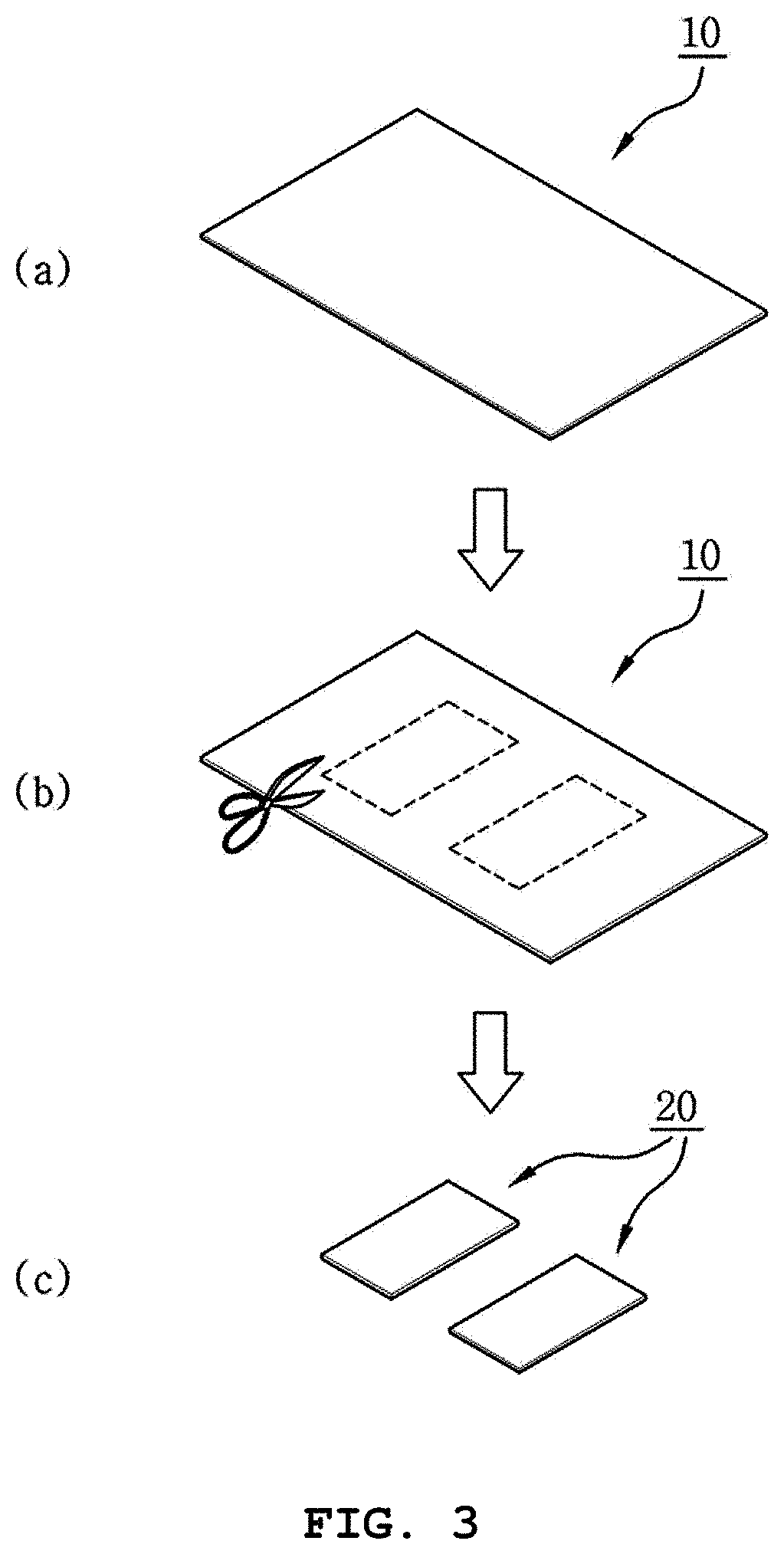

Dental barrier membrane using silk matrix and method of manufacturing the same

ActiveUS10786335B2Simple manufacturing processReduce manufacturing costDental implantsSilk cocoons cleaning/classifyingBarrier membraneBiocompatibility

Disclosed are a dental barrier membrane for guided bone regeneration using a silk matrix and a method of manufacturing the same, wherein the dental barrier membrane is configured such that a silk matrix having a cross-section with a first thickness, produced from silkworms, is subjected to planar division into two or more silk matrix pieces having a predetermined shape with the first thickness. This dental barrier membrane is biocompatible, has superior tensile strength and porosity, and promotes the formation of new bone in bone defects, unlike existing dental barrier membranes.

Owner:REPUBLIC OF KOREA (MANAGEMENT RURAL DEV ADMINISTRATION)

Manufacturing process of silk quilt and silk quilt

InactiveCN111139586AGood skin affinityHas antibacterial propertiesBlanketBed linenPolymer scienceEngineering

The invention discloses a manufacturing process of a silk quilt and the silk quilt and relates to the field of home textiles. The manufacturing method comprises the following steps of manufacturing ecological mulberry silk; manufacturing a mulberry silk quilt batt; and manufacturing a mulberry silk quilt, wherein the manufacturing steps of the mulberry silk quilt comprise the following steps of additionally putting anti-silk-out gauze on the upper and lower surfaces of the mulberry silk quilt batt first to prevent silk-out; then selecting a quilt cover made from a brocade made from ecologicalpure mulberry silk; and finally, sleeving the mulberry silk quilt batt in a selected batt cover. Hemming is carried out first in manual positioning and positioning is then carried out by adopting a nine-stitch or 12-stitch positioning method. The mulberry silk quilt is manufactured by the manufacturing process. The mulberry silk quilt is good in skin-friendliness, has anti-bacterial and antiallergic actions, can prevent skin diseases such as pruritus, and is quite good for skin health.

Owner:何银春

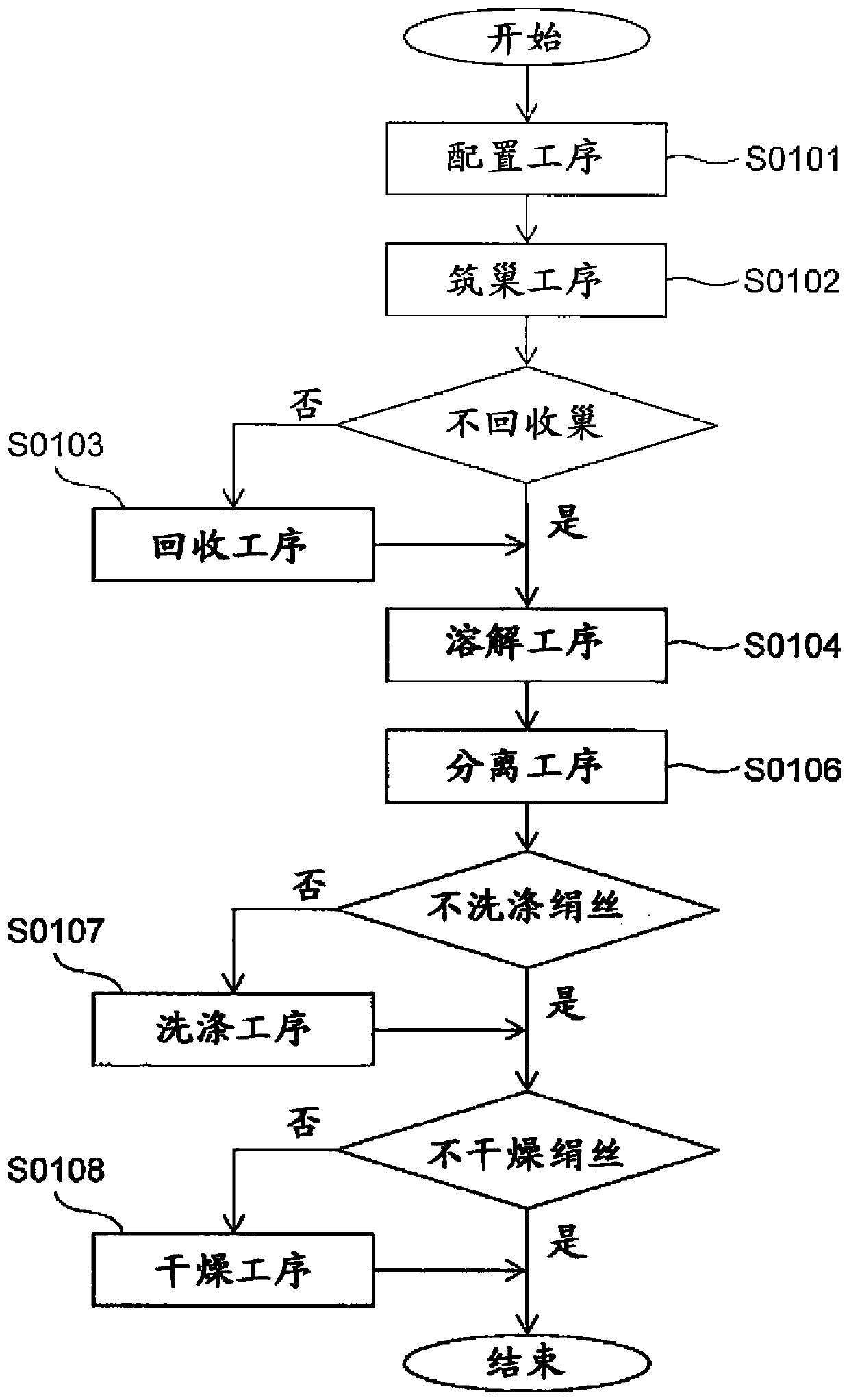

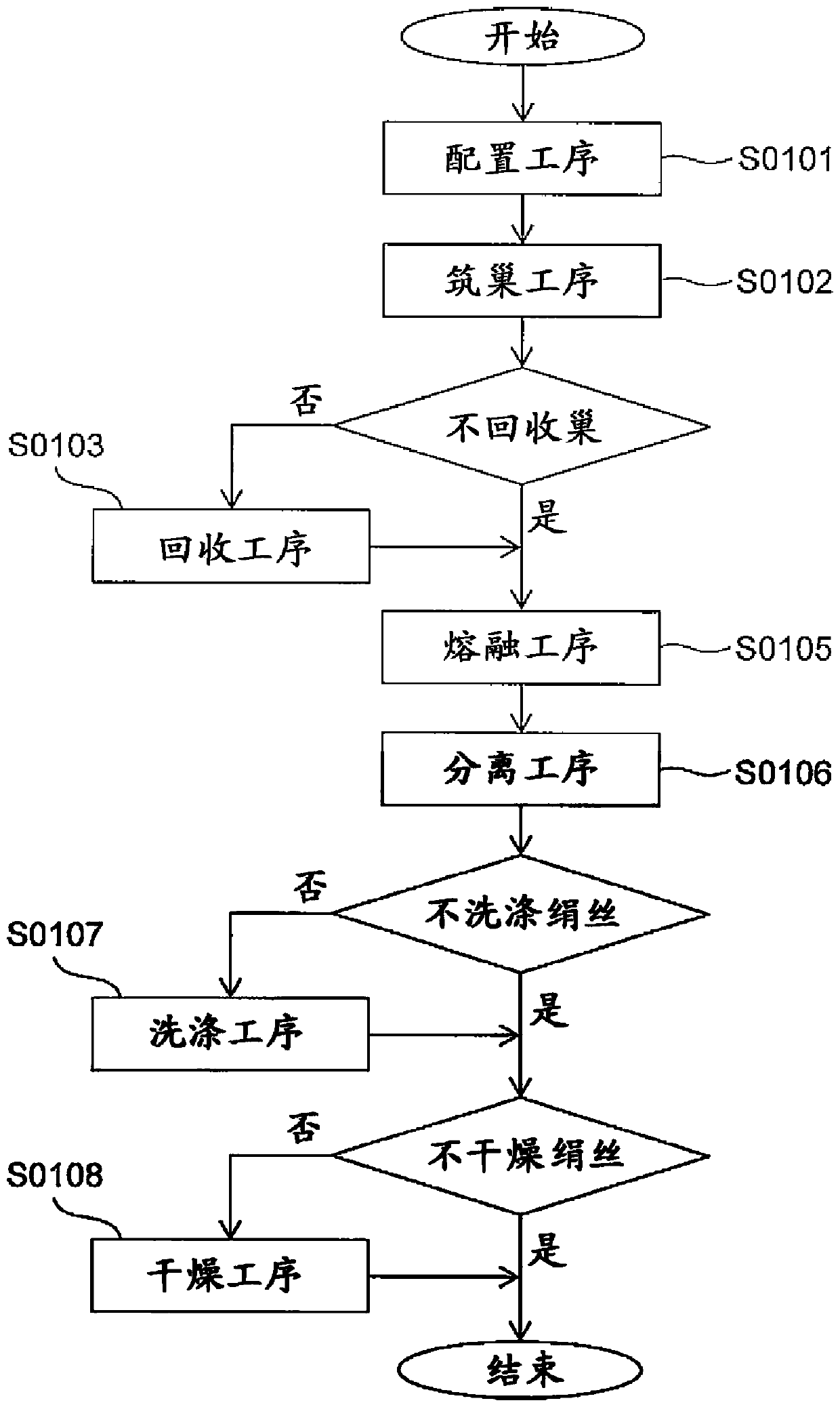

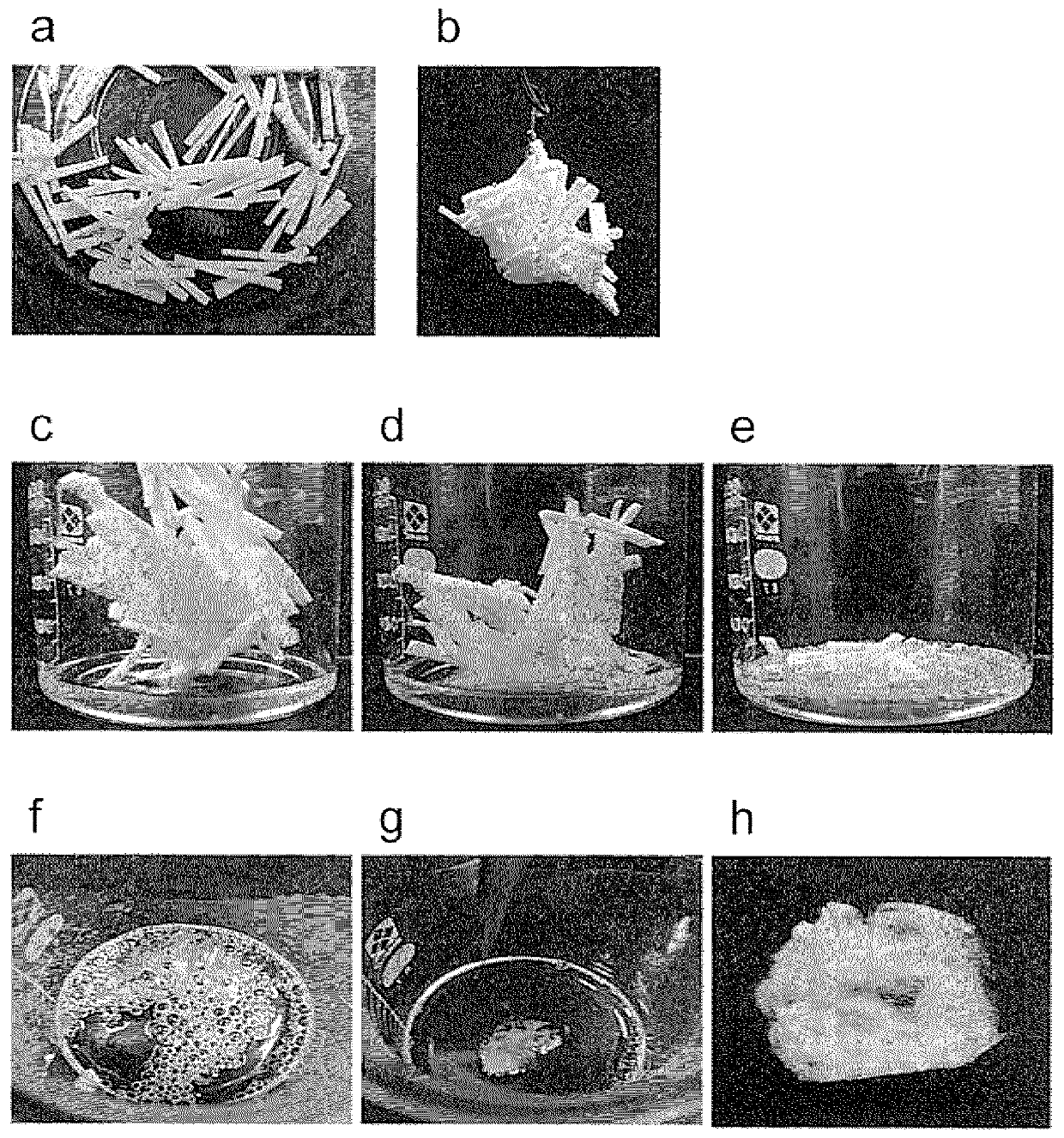

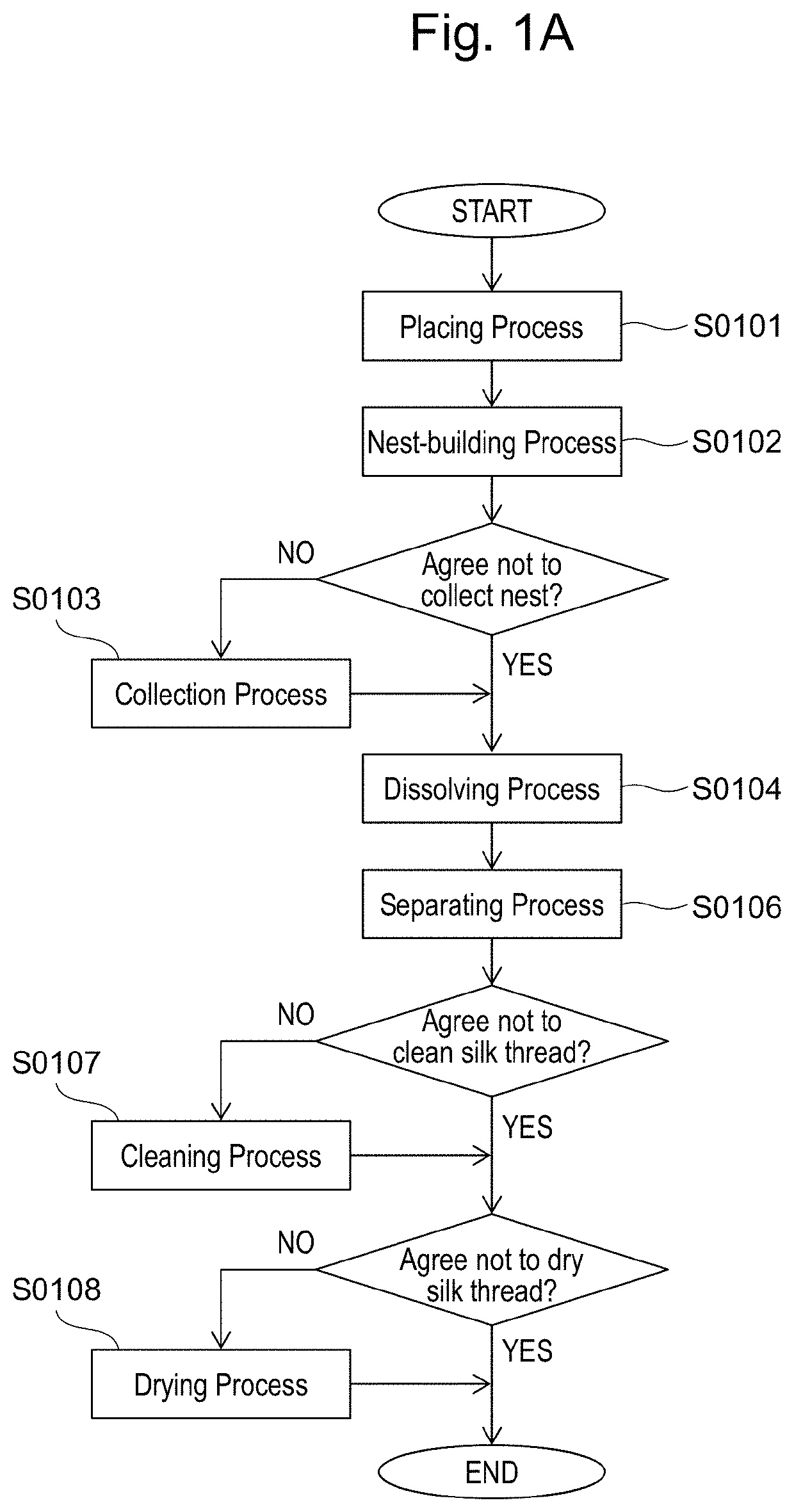

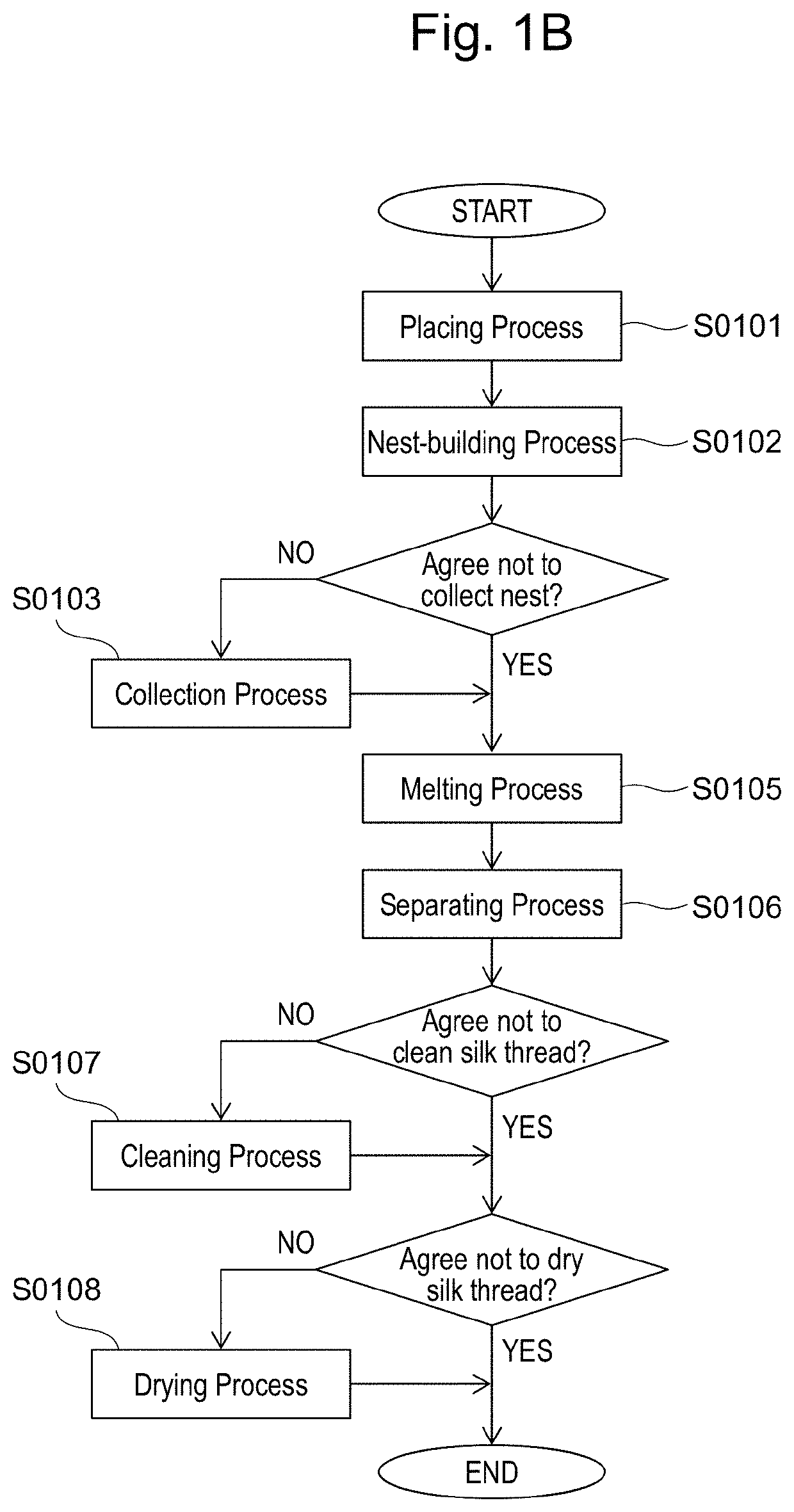

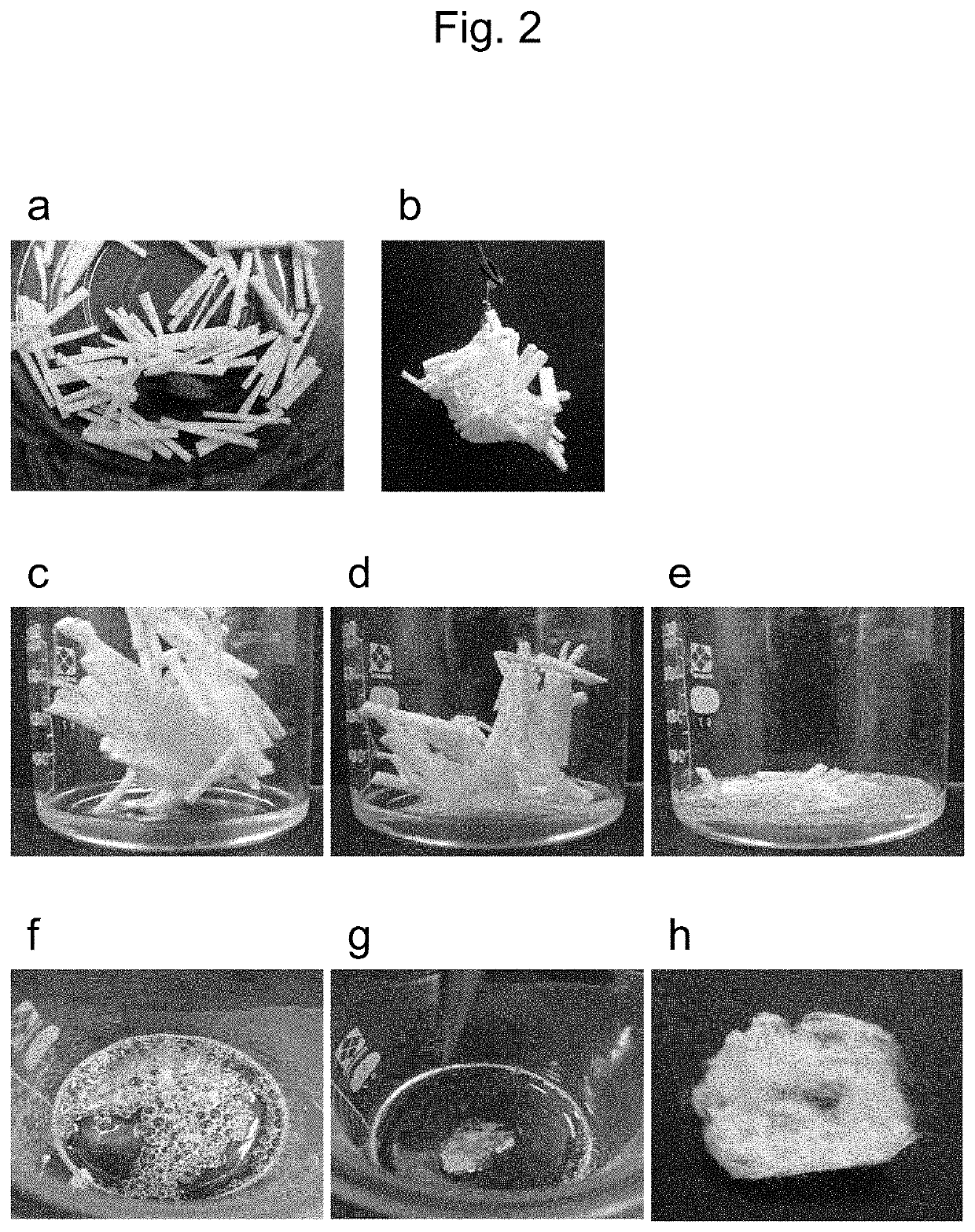

Bagworm silk thread collecting method

PendingUS20210372007A1Short timeMonocomponent protein artificial filamentFood processingPolymer scienceOrganic chemistry

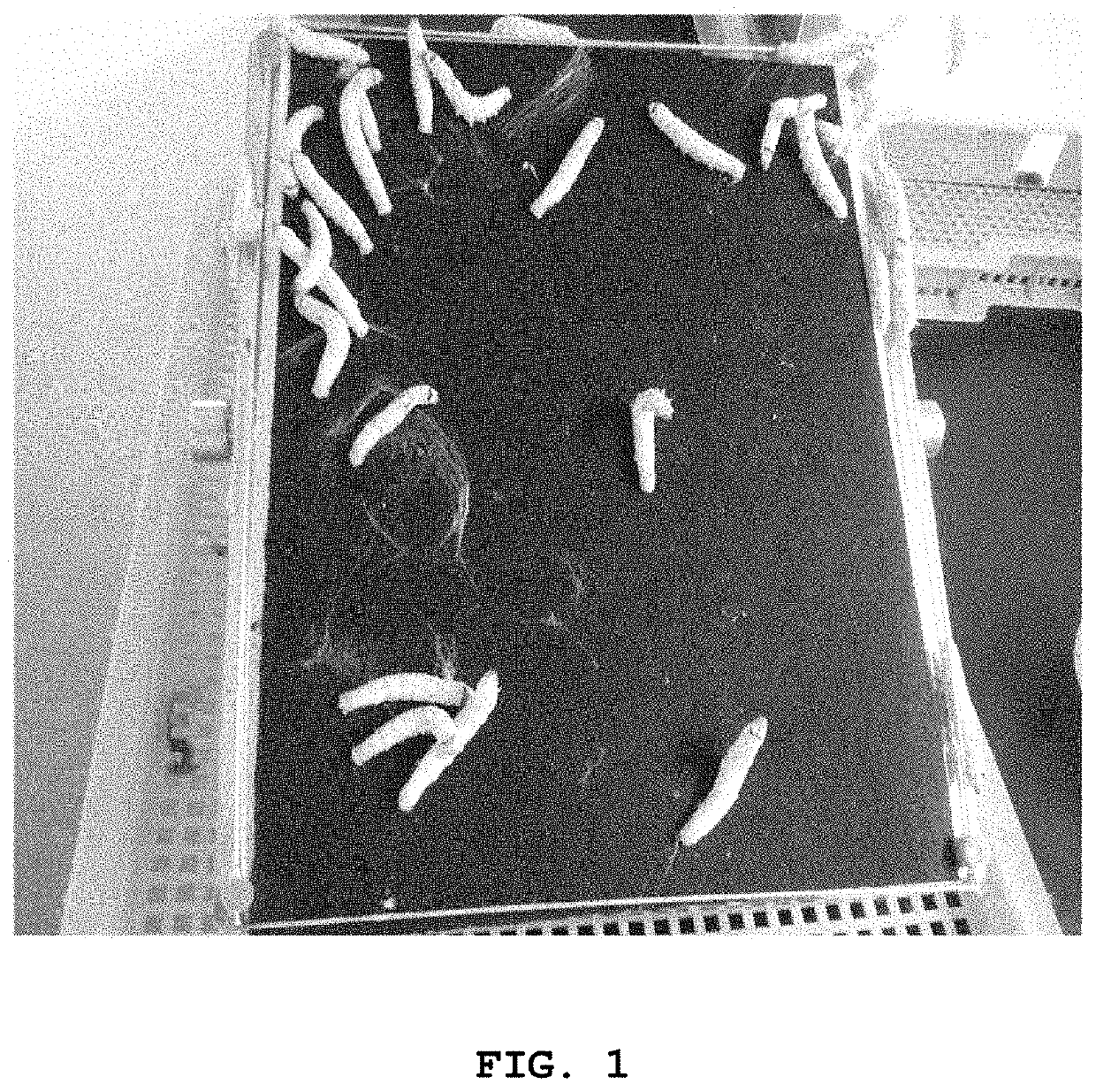

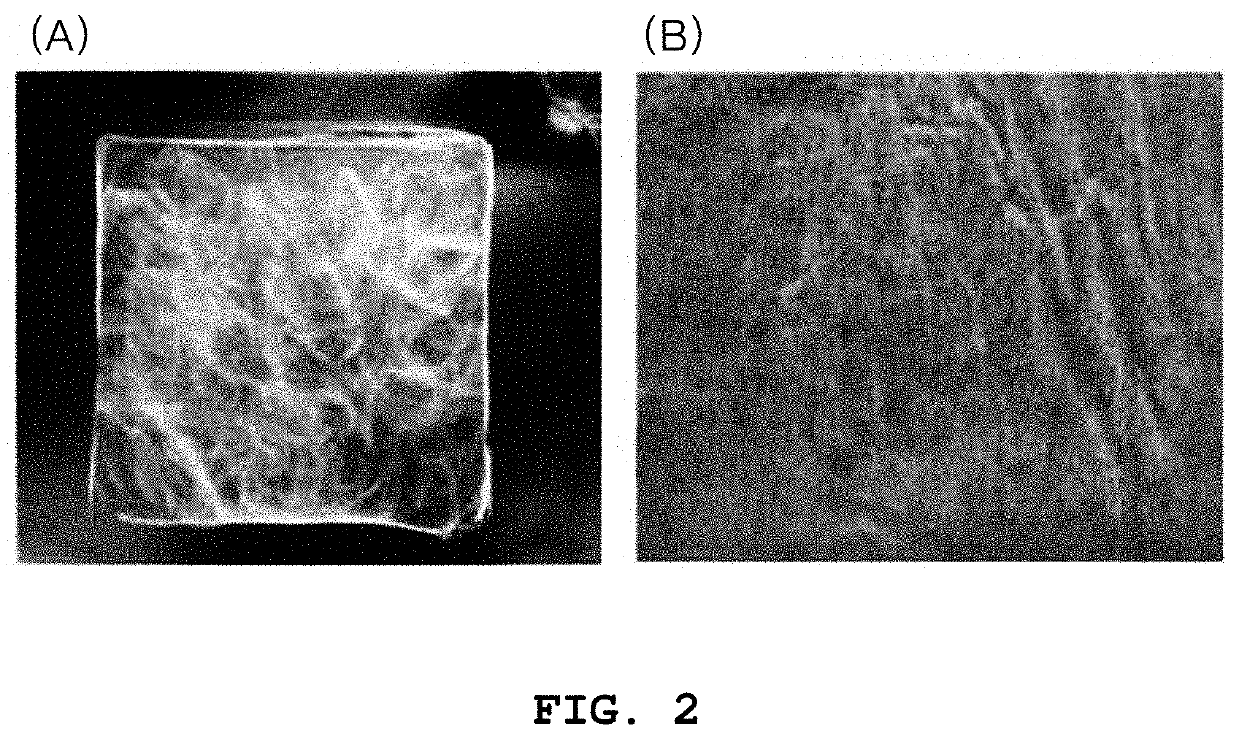

Developed and provided is a method of collecting a large amount of high-quality bagworm silk threads having no contaminant from bagworm nests in a convenient manner and at low cost. The habit of bagworms is utilized to allow a bagworm to build a nest using solvent-soluble substances or thermally meltable substances as nest materials, followed by dissolving or melting the nest materials to separate the nest material from the bagworm silk threads, whereby only pure bagworm silk threads constituting the bagworm nest can be obtained.

Owner:NAT AGRI & FOOD RES ORG +1

Auxiliary device applied to silk drawing

The invention discloses an auxiliary device applied to silk drawing. The auxiliary device comprises a base, stand columns are arranged at the two ends of the top of the base, conveying rollers are arranged at the tops of the stand columns, and a silk sorting box is arranged in the middle of the top end of the base; silk velvet adsorption rollers are symmetrically arranged on one side in the silk sorting box, a first gear is arranged at one end of each silk velvet adsorption roller, and an air suction pipe is arranged in each silk velvet adsorption roller, an air suction hole is formed in one end of each air suction pipe and connected with an air suction pump; and extrusion rollers are symmetrically arranged on the other side in each silk velvet adsorption roller, second gears are arranged at one ends of the extrusion rollers, a motor is arranged on the back face of the silk sorting box, a driving gear is arranged at the output end of the motor, and the driving gear is meshed with one first gear and one second gear at the same time. Through the overall structure, silk velvet on silk can be adsorbed, cleaned and collected, and secondary pollution or silk quality reduction caused during next silk drawing is avoided.

Owner:江西金铭丝绸有限公司

A kind of processing method of silk cotton ball

ActiveCN104278430BImprove qualityReduce manufacturing costSilk obtainingNon-woven fabricsUltraviolet irradiationComputer science

The invention discloses a processing method of silk tops. The processing method comprises the following steps: (1) finishing raw materials; (2) selecting and checking; (3) combining into consuming refined products; (4) opening cocoons; (5) performing ultraviolet irradiation; (6) performing medium biling; and (7) performing circular carding processing. The silk tops processed by utilizing the processing method have the characteristics of being good in quality and reasonable in cost.

Owner:广西中丝成丝绸科技有限公司

Sheet for mask containing partially refined colored silk, and mask by using the same

PendingCN110857483AReduce stimulationGood moisturizing effectCosmetic preparationsToilet preparationsPolymer scienceSilk cloth

The present invention relates to a sheet for a mask containing partially refined colored silk, and a mask by using the same. The present invention relates to a mask sheet, a mask produced using the mask sheet, and a method for producing the mask, the mask sheet comprising colored silk in which the raw silk portion of colored silk is refined to have a color difference of 45 or less. The facial masksheet containing colored silk according to the present invention has little irritation to the skin, is stable, has excellent moisturizing power, and can be used as a novel cosmetic facial mask sheetparticularly due to high favor brought by excellent colors.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

Silk reeling technology for hollow cocoon, dry solid cocoon and live pupa cocoon

InactiveCN100359049CPlay the role of turning waste into treasureSave energySilk obtainingPulp and paper industrySurface-active agents

Owner:郑丽玮

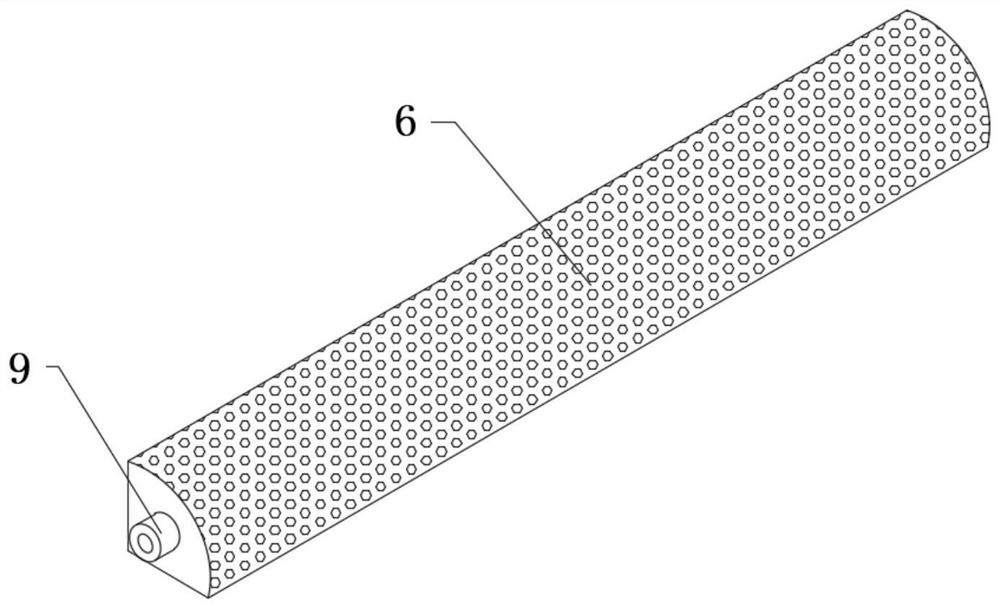

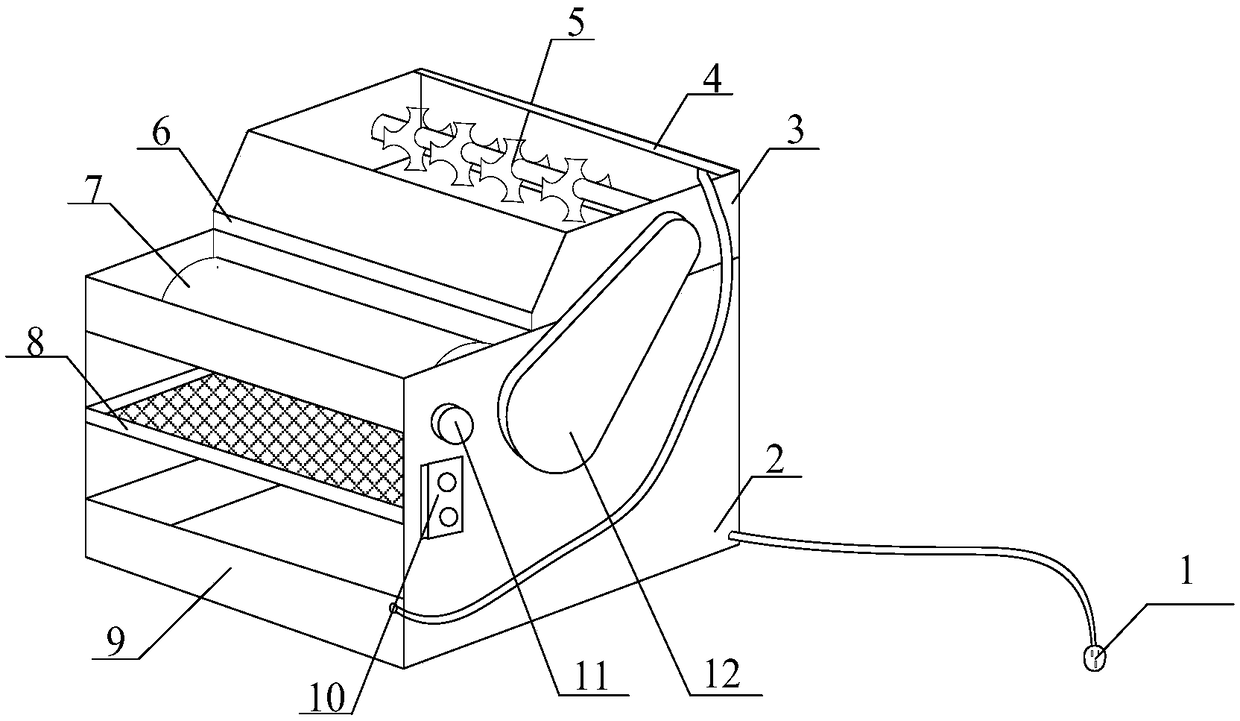

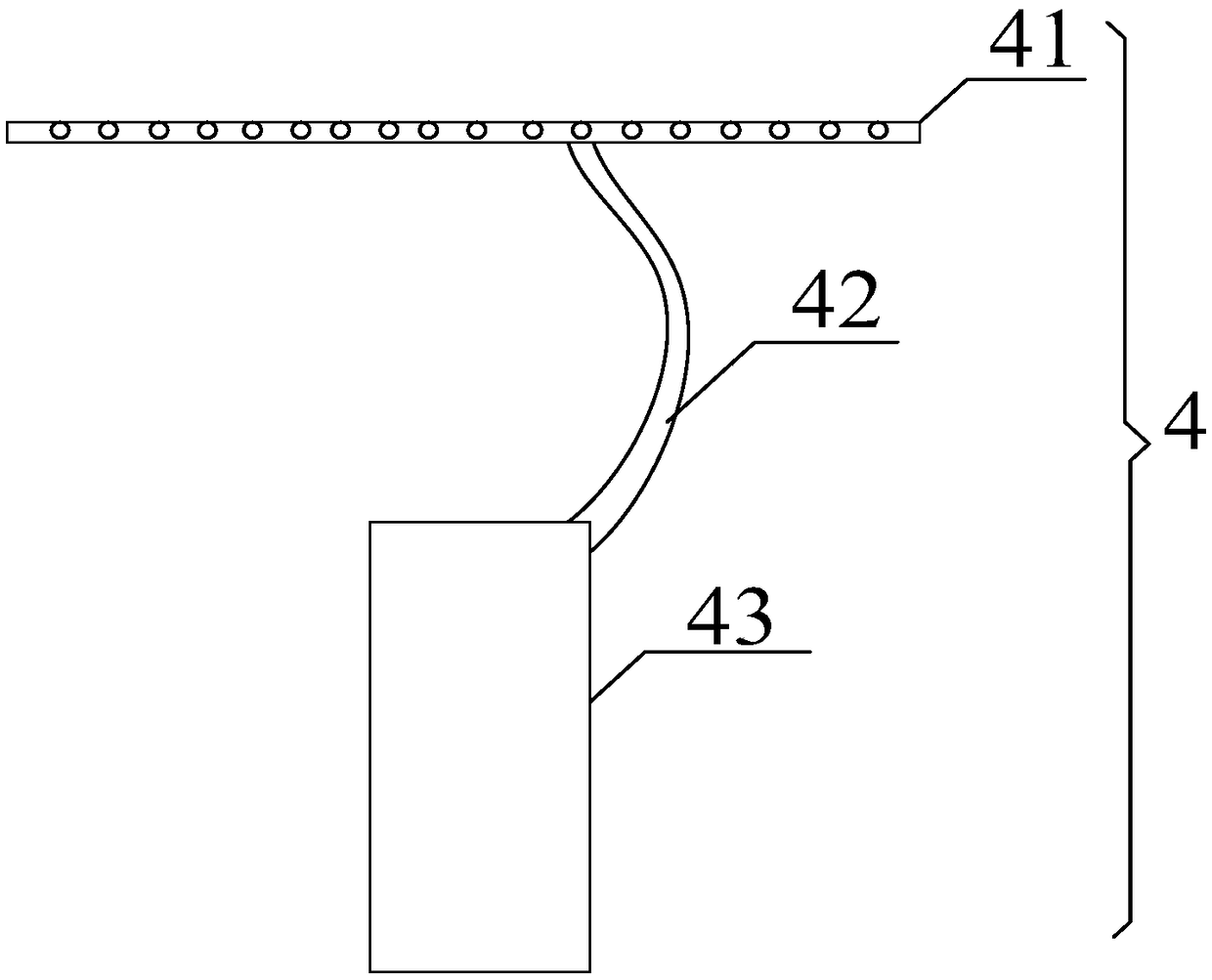

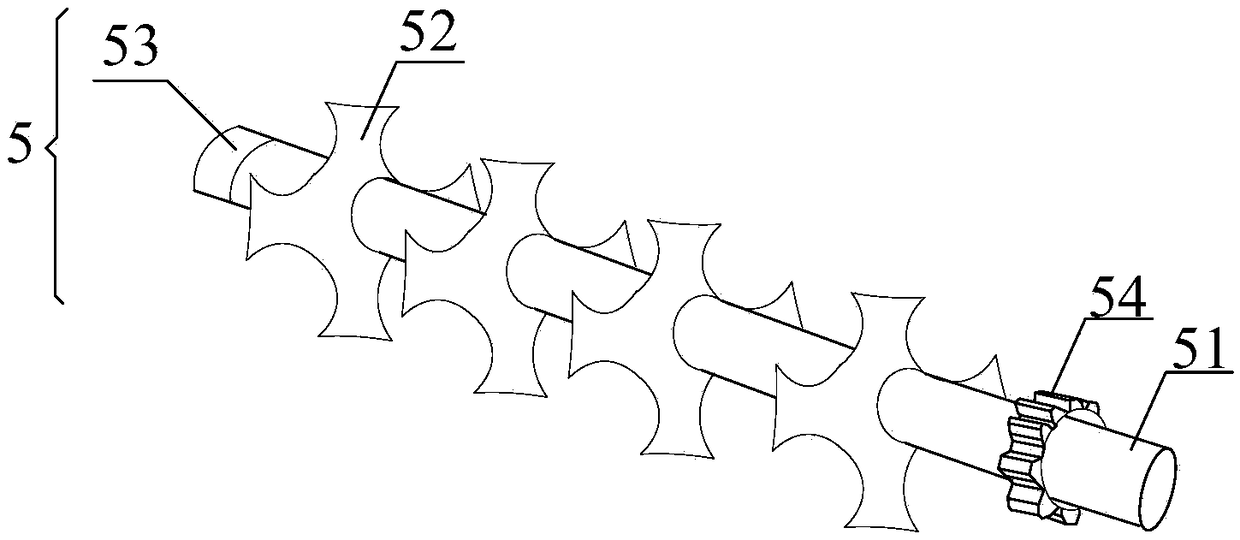

Novel water silk floss machine

The invention provides a novel water silk floss machine. The novel water silk floss machine comprises a power plug, a machine body, a stirring tank, a water spraying device, a stirring device, a discharge port, a licker-in, a filter net, a heating water tank device, a switch, an emergency stop device and a transmission mechanism. The power plug is connected with the switch through a power line andconnected with the emergency stop device in series. The stirring tank is installed on the top of the machine body in a welded mode. Through the arrangement of the stirring device and the transmissiondevice, a gear III and a gear I are driven through transmission of a motor in the transmission device, an optical shaft drives a cross screwdriver to rotate, stripping and laddering of silkworm cocoons are better achieved, and silkworm chrysalises and silk are also separated more conveniently. Through the arrangement of a resistance heater and a temperature sensor, the water temperature in a water tank can be monitored, when the water temperature is smaller than a set minimum value, the temperature sensor senses power-on, the resistance heater is switched on for heating, and when the water temperature rises to the maximum value set by the temperature senor, heating work is stopped.

Owner:杭州金利丝业有限公司

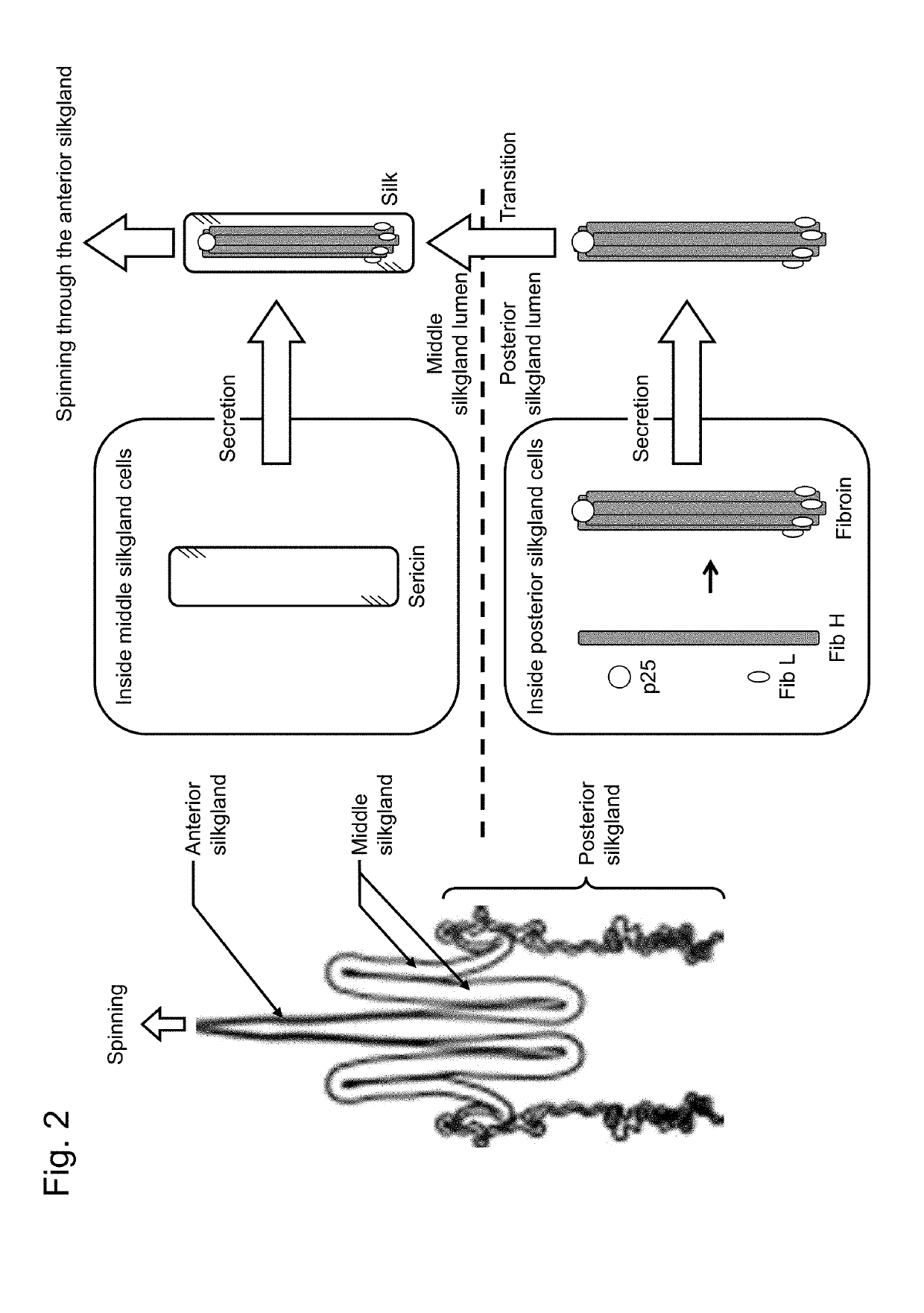

Recombinant bagworm silk (as amended)

A method of producing a transgenic silkworm that spins bagworm silks and producing a large quantity of bagworm silks by transgenic technology is developed and provided. A gene encoding a modified bagworm Fib H and a transgenic silkworm in which the gene is introduced, wherein the gene is obtained by cloning a gene fragment encoding a bagworm Fib H-like polypeptide comprising a partial amino acid sequence of bagworm Fib H, and fusing the gene fragment to a gene fragment encoding silkworm-derived Fib H, are provided.

Owner:NAT AGRI & FOOD RES ORG

Recombinant bagworm silk

A method of producing a transgenic silkworm that spins bagworm silks and producing a large quantity of bagworm silks by transgenic technology is developed and provided. A gene encoding a modified bagworm Fib H and a transgenic silkworm in which the gene is introduced, wherein the gene is obtained by cloning a gene fragment encoding a bagworm Fib H-like polypeptide comprising a partial amino acid sequence of bagworm Fib H, and fusing the gene fragment to a gene fragment encoding silkworm-derived Fib H, are provided.

Owner:NAT AGRI & FOOD RES ORG

Silkworm cocoon reeling-off device for spinning

ActiveCN114717665AWon't breakAdjustable distanceTextile/flexible product manufactureSilk obtainingSpinningAgricultural engineering

The invention relates to the technical field of agricultural product processing, and discloses a spinning silkworm cocoon drawing device which comprises a supporting plate, a driving roller and a driven roller are rotationally arranged on the supporting plate and are in transmission connection through a conveying belt used for collecting silk, and the silk is wound on the outer surface of the conveying belt. A fixing mechanism used for adjusting the position of the driven roller is arranged between the driven roller and the supporting plate, and the fixing mechanism is acted to drive the driven roller to move towards the driving roller so that the conveying belt can be loosened, and then silk can be separated from the outer surface of the conveying belt. According to the silk collecting device, the conveying belt is used for replacing a take-up wheel in the prior art to collect silk, the soft characteristic of the conveying belt is utilized, the silk can be easily taken down when the conveying belt is loose, and silk breakage cannot be caused.

Owner:云南省农业科学院蚕桑蜜蜂研究所

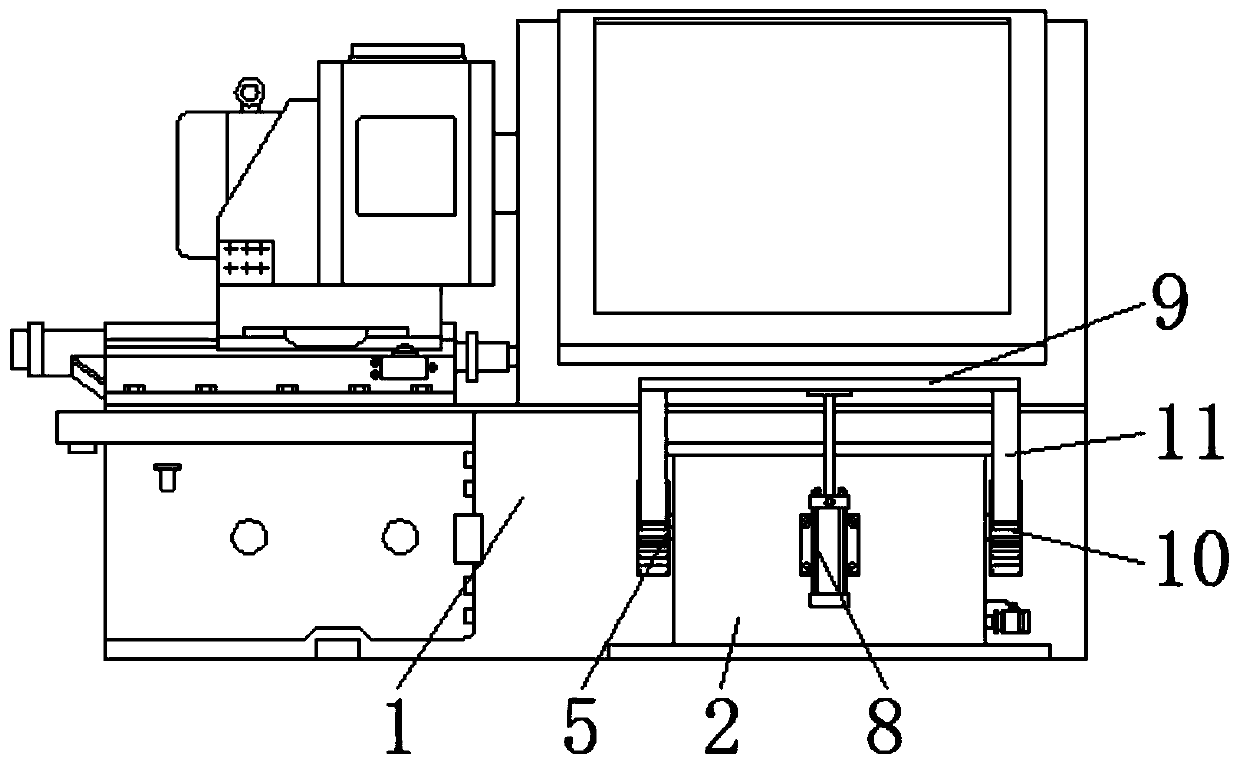

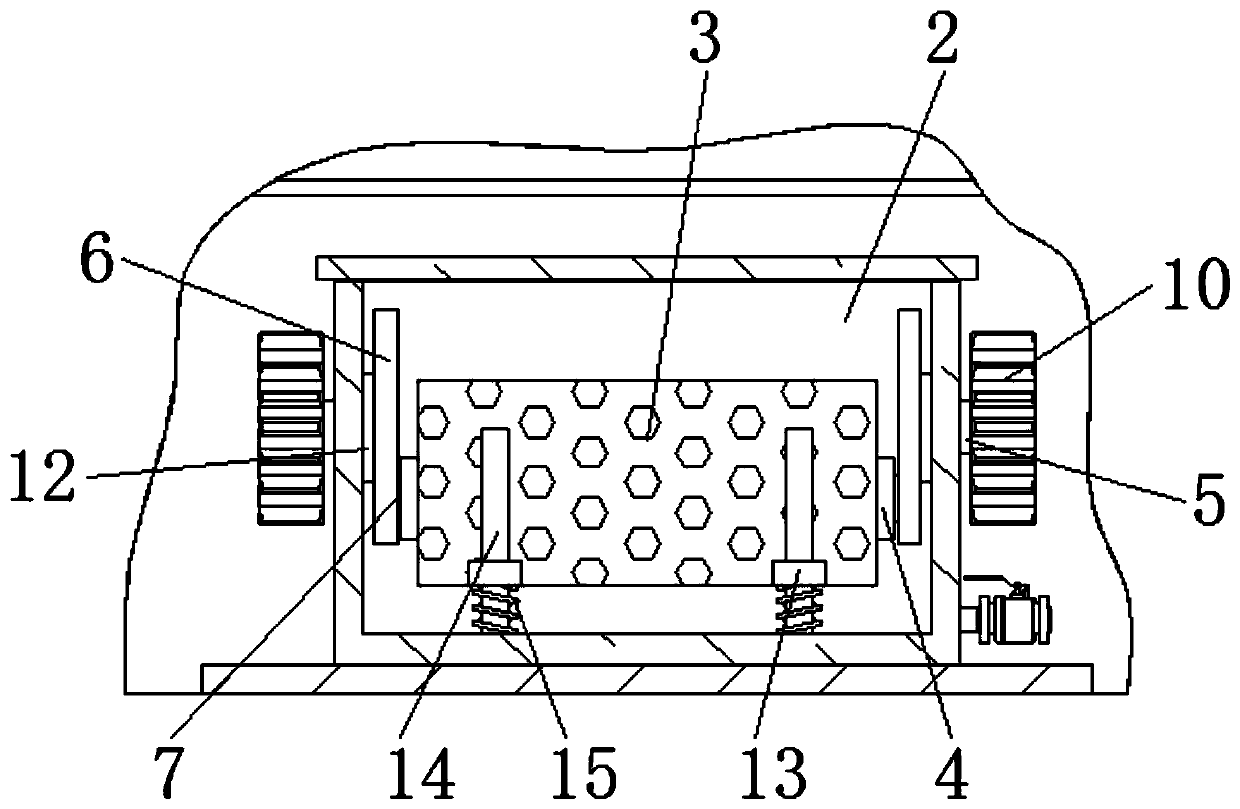

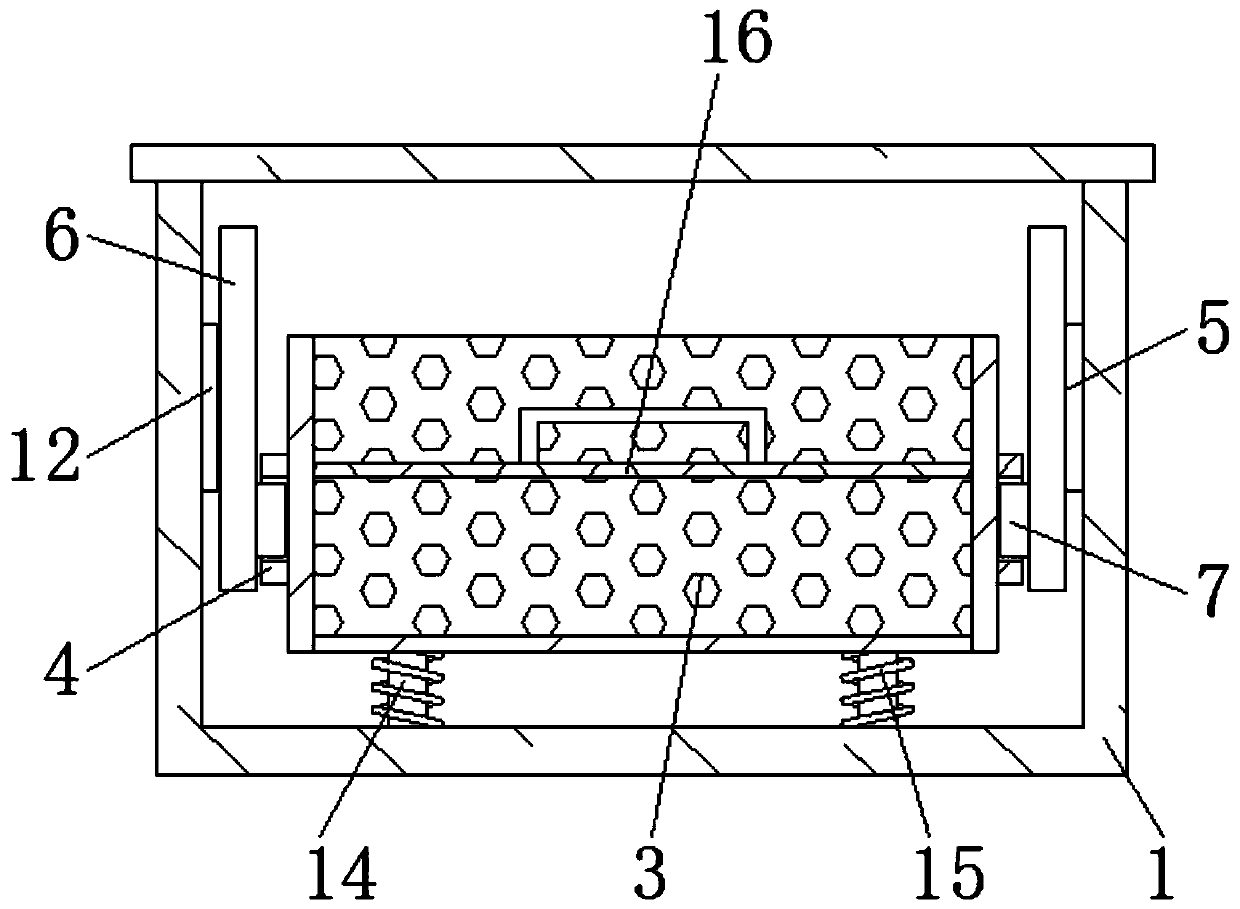

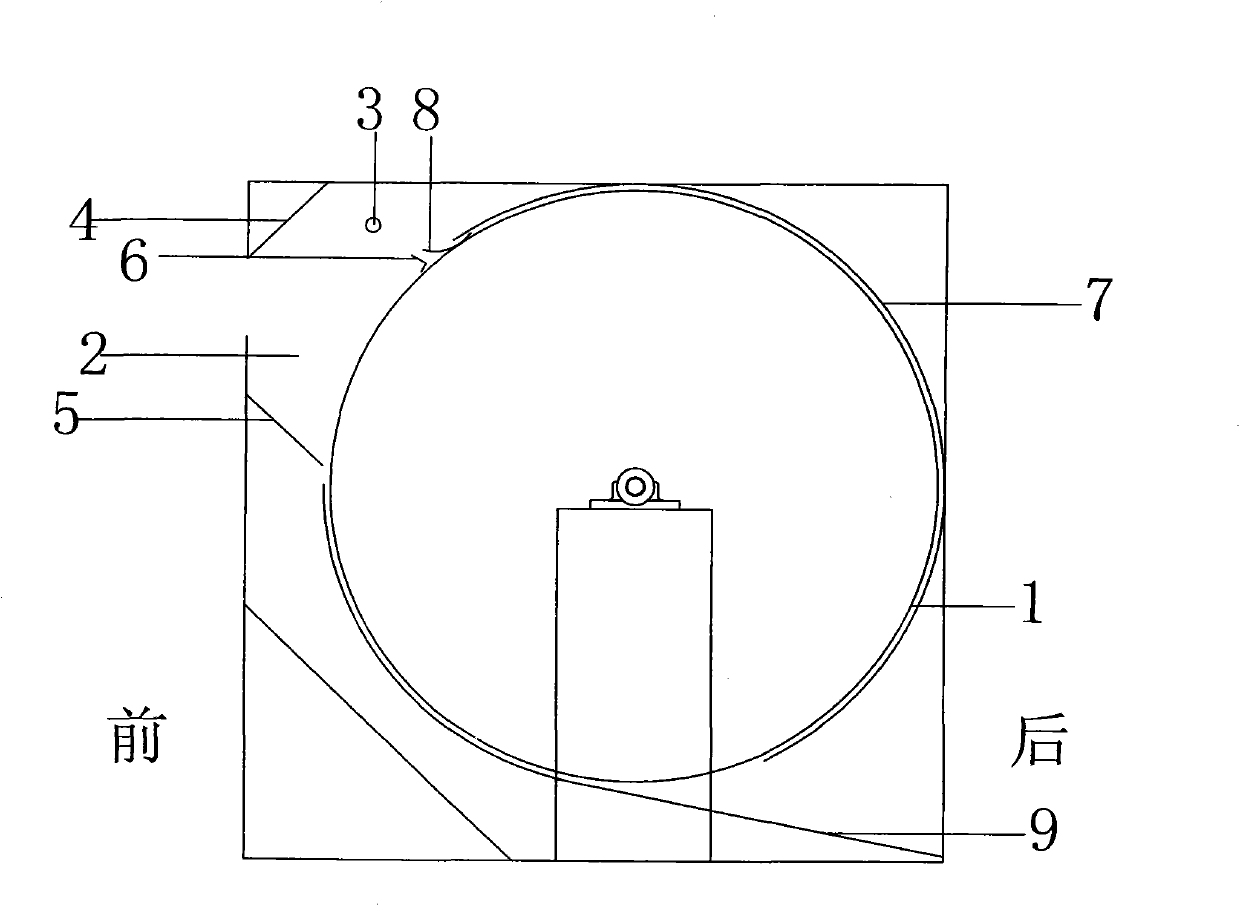

Spinning device for textile production

InactiveCN110318101APrevent easy scalding by hot waterAvoid burnsNon-rotating vibration suppressionSilk obtainingEngineeringTextile production

The invention discloses a spinning device for textile production. The spinning equipment includes a spinning device body, the front side of the spinning device body is fixedly connected with a heatingbox, the interior of the heating box is movably connected with a net box, the left and right sides of the net box are both fixedly connected with sleeving plates, the left and right sides of the interior of the heating box are both movably connected with transmission rods through bearings, and the end, away from the heating box, of each transmission rod is fixedly connected with a rotating wheel.According to the spinning equipment for textile production, the rotating wheels are driven by the transmission rods to rotate and drive forced rods to slide inside the sleeving plates to push the sleeving plates to move upwards, the sleeving plates drive the net box to move upwards to make the net box separated from hot water inside the heating box, therefore, the effect of preventing a user frombeing easily scalded by the hot water when the user fishing silkworm chrysalises is achieved, and the problems are solved that an existing spinning device is not convenient for fishing silkworm chrysalises, the user is easily scalded when the water temperature is too high during soaking, and the safety of the tapping device is reduced; the spinning device for textile production has the advantageof being convenient in silk fishing.

Owner:郭宝岭

Silk cotton machine

The invention relates to a silk cotton machine for manufacturing silk cotton. The machine comprises a frame, a transmission device, a roller, a material groove, a water spray pipe, an upper baffle plate, a lower baffle plate and a scraping knife, wherein an arc-shaped fling-proof plate, an arc-shaped silk pasting plate and a fling-proof chrysalis-removing plate are arranged on the periphery of the roller. Due to the action of the arc-shaped silk pasting plate, silk after passing through the scraping knife can be closely attached on the outer surface of the roller; furthermore, once the silk attached on the roller is flung away from the roller, due to the blocking effects of the arc-shaped fling-proof plate and the fling-proof chrysalis-removing plate, the silk which is flung away can be rapidly returned onto the roller and be prevented from entangling and shedding, and the quality and the finished product rate of the machine processed silk cotton can be further improved; simultaneously, the diameter of the roller of the silk cotton machine can be increased so as to facilitate the manufacturing of an extra-width breadth silk cotton quilt with good uniformity, thereby solving the non-uniformity caused by splicing and the increased process steps during the traditional manufacturing of the extra-width breadth silk cotton quilt.

Owner:JIANGXI XIUSHUI YIJIA IND

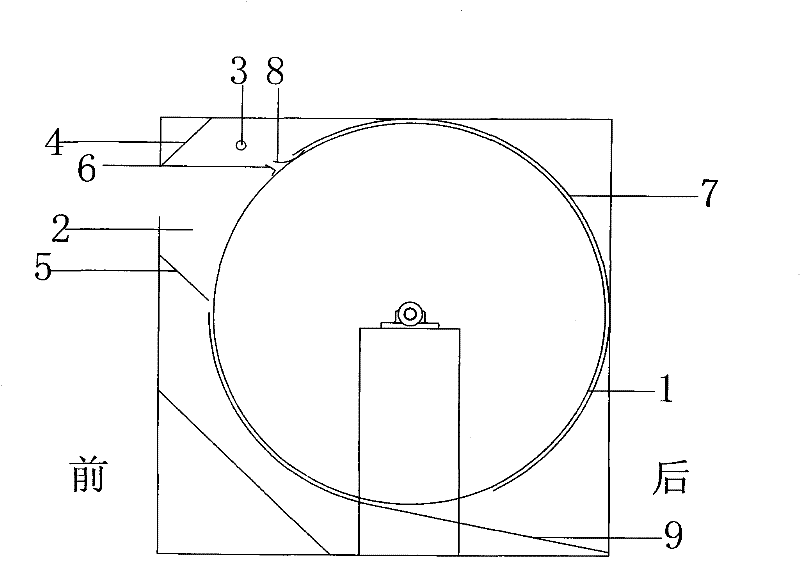

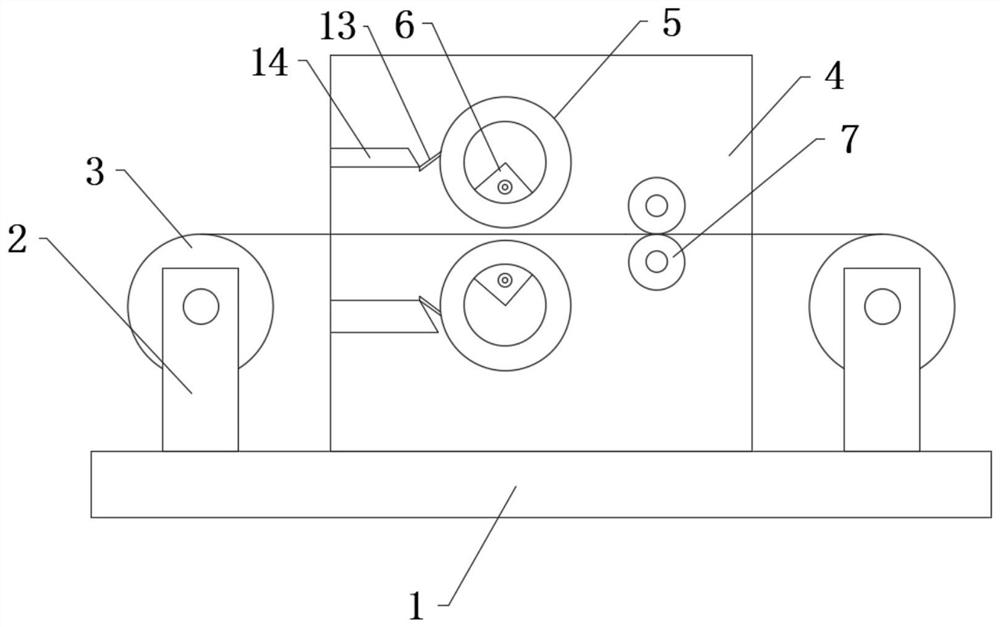

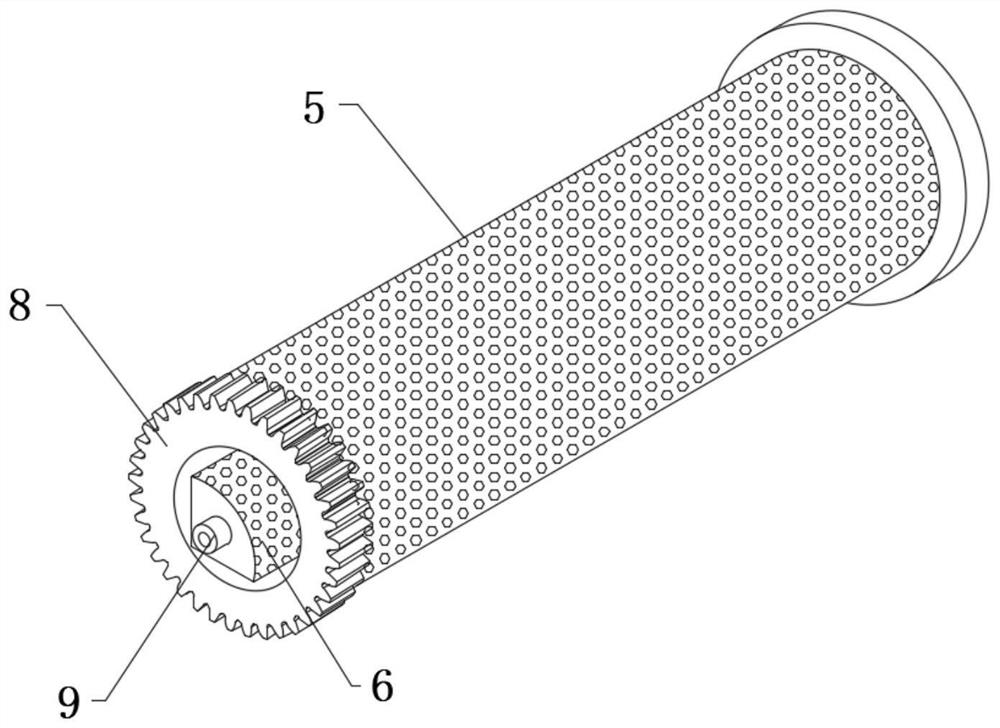

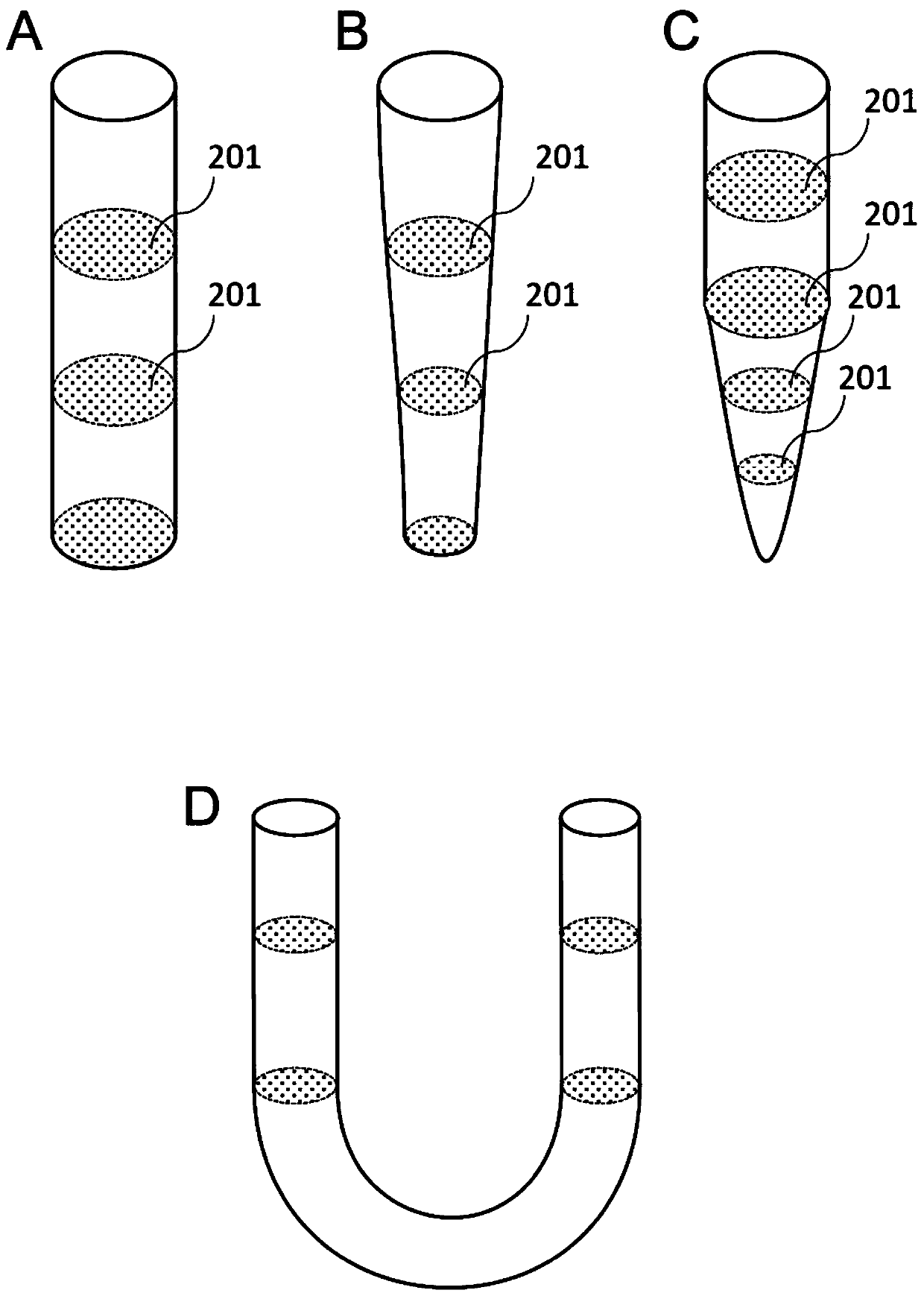

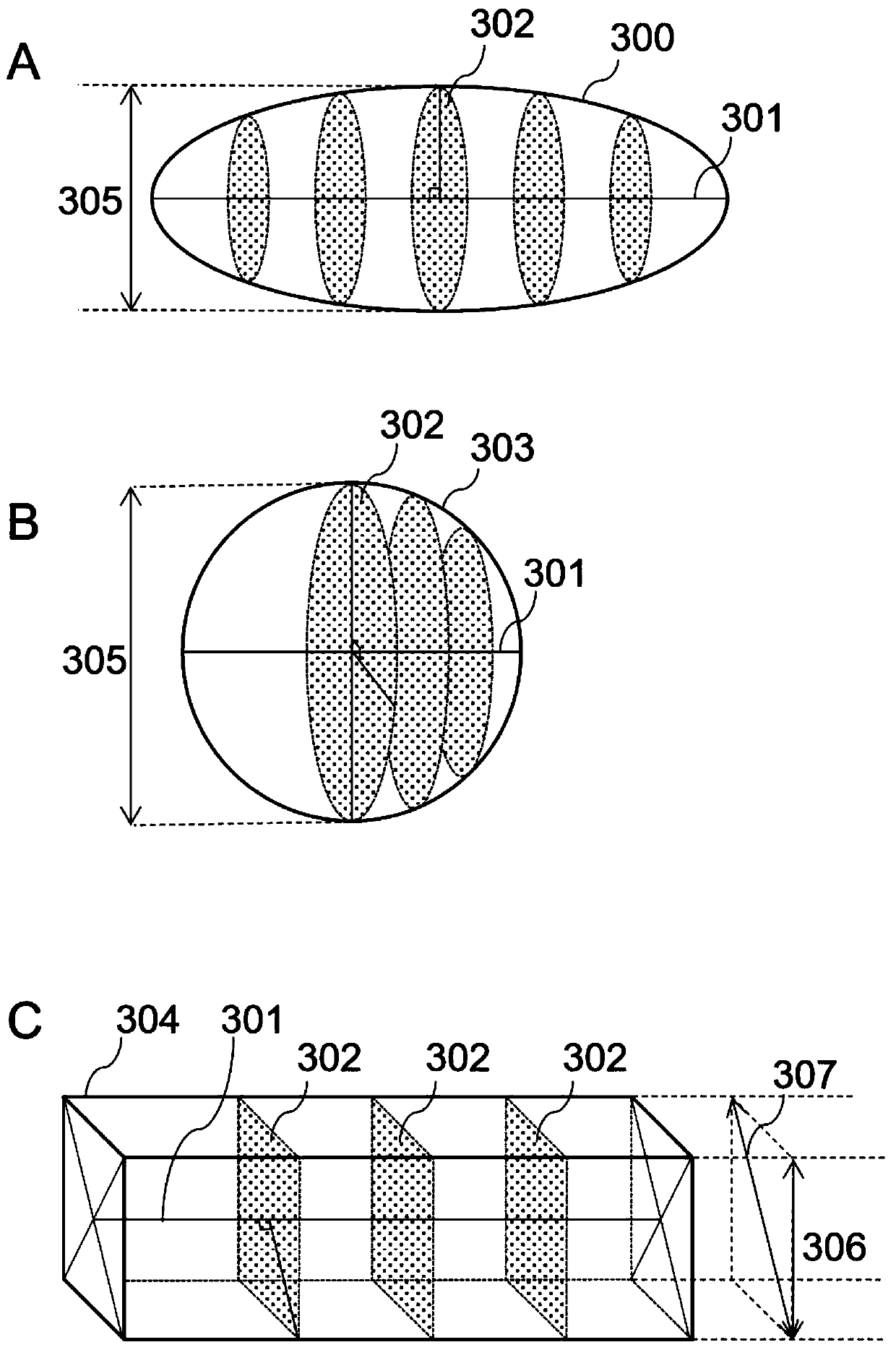

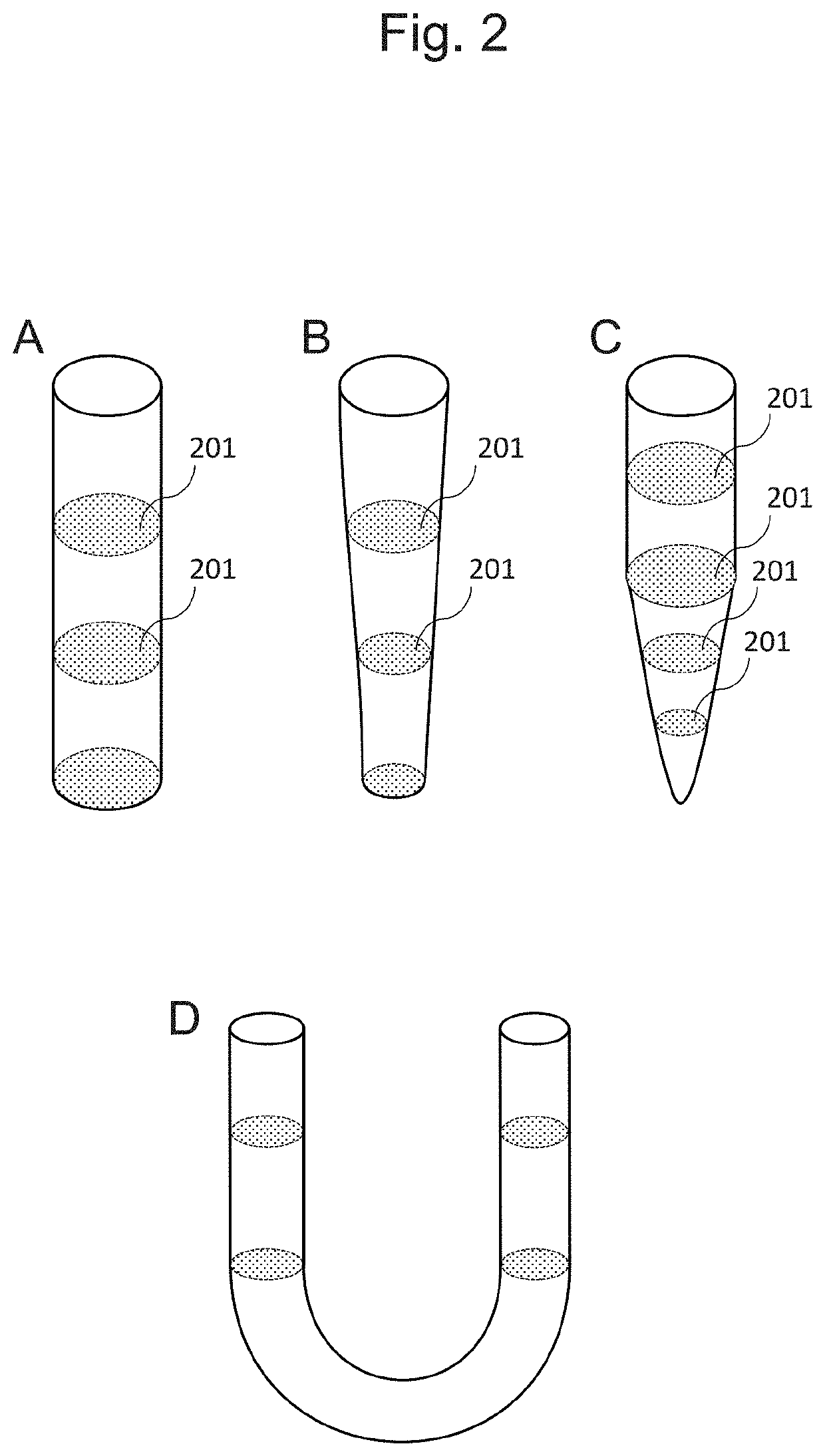

Thread collection device

PendingCN111133136AImplement the method of picking silkSilk obtainingAnimal husbandryComputer hardwareInterior space

Owner:NAT AGRI & FOOD RES ORG

Thread collecting device

PendingUS20200277710A1Easily and simply collectingSilk obtainingAnimal husbandrySoftware engineeringMechanical engineering

A thread collecting method for easily and simply collecting a bagworm-derived pure silk thread from a bagworm with a small number of processes and a thread collecting device for implementing the thread collecting method are developed and provided. A device that collects a silk thread from a bagworm is provided, the device including: a container that accommodates the bagworm; and an in-and-out hole through which the bagworm is put in and taken out of the container. A width of a maximum short axis cross section of an inner space of the container is in a range from 1.2 times or more to less than 3.1 times relative to a maximum body width of the bagworm being accommodated.

Owner:NAT AGRI & FOOD RES ORG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com