Bagworm silk thread collecting method

A moth larvae and silk technology, applied in the field of nest raw materials, can solve the problems of huge labor time, no collection, low-quality products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187]

[0188] (Purpose)

[0189] Using a low-polarity solvent-soluble nest raw material for naked bag moth larvae, a bag moth larvae nest is produced, and further, bag moth larvae silk is collected from the nest.

[0190] (method and results)

[0191] As the bag moth larvae, the last instar larvae of the tea bag moth collected at a fruit tree farm in Tsukuba City, Ibaraki Prefecture were used. The collected bag moth larvae were fed with leaves of a sufficient amount of broad-leaved trees for 3 days. After defecating in a fasted state for one day, the bag moth larvae in the nest were picked out from the bag moth larvae nest using scissors.

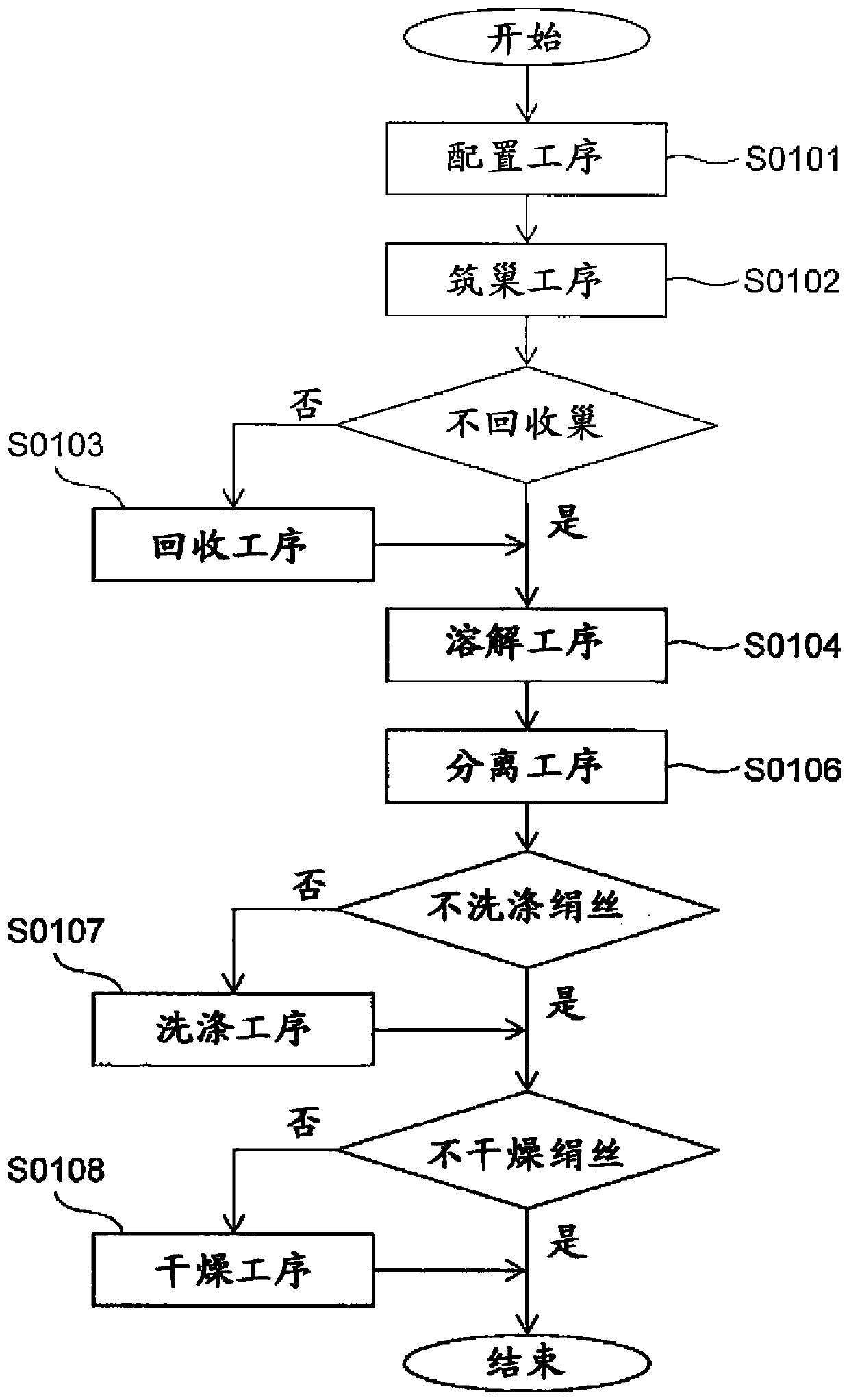

[0192] exist figure 2The silk picking method of the present invention is illustrated in the figure. On the bottom of a 100mL glass beaker, thin rod-shaped styrofoam (polystyrene) flakes adjusted to a length of 20 mm to 25 mm were covered as a low-polarity solvent-soluble nest material, and the beaker was set on a transparent plasti...

Embodiment 2

[0195]

[0196] (Purpose)

[0197] The larvae of the naked bag moth were made into a nest of the bag moth larvae using a water-soluble nest material, and the silk silk of the bag moth larvae was collected from the nest.

[0198] (method and results)

[0199] As for the bag moth larvae, in the same manner as in Example 1, the last instar larvae of the bag moth were collected at a fruit tree farm in Fuji City, Shizuoka Prefecture. The basic operation follows Example 1.

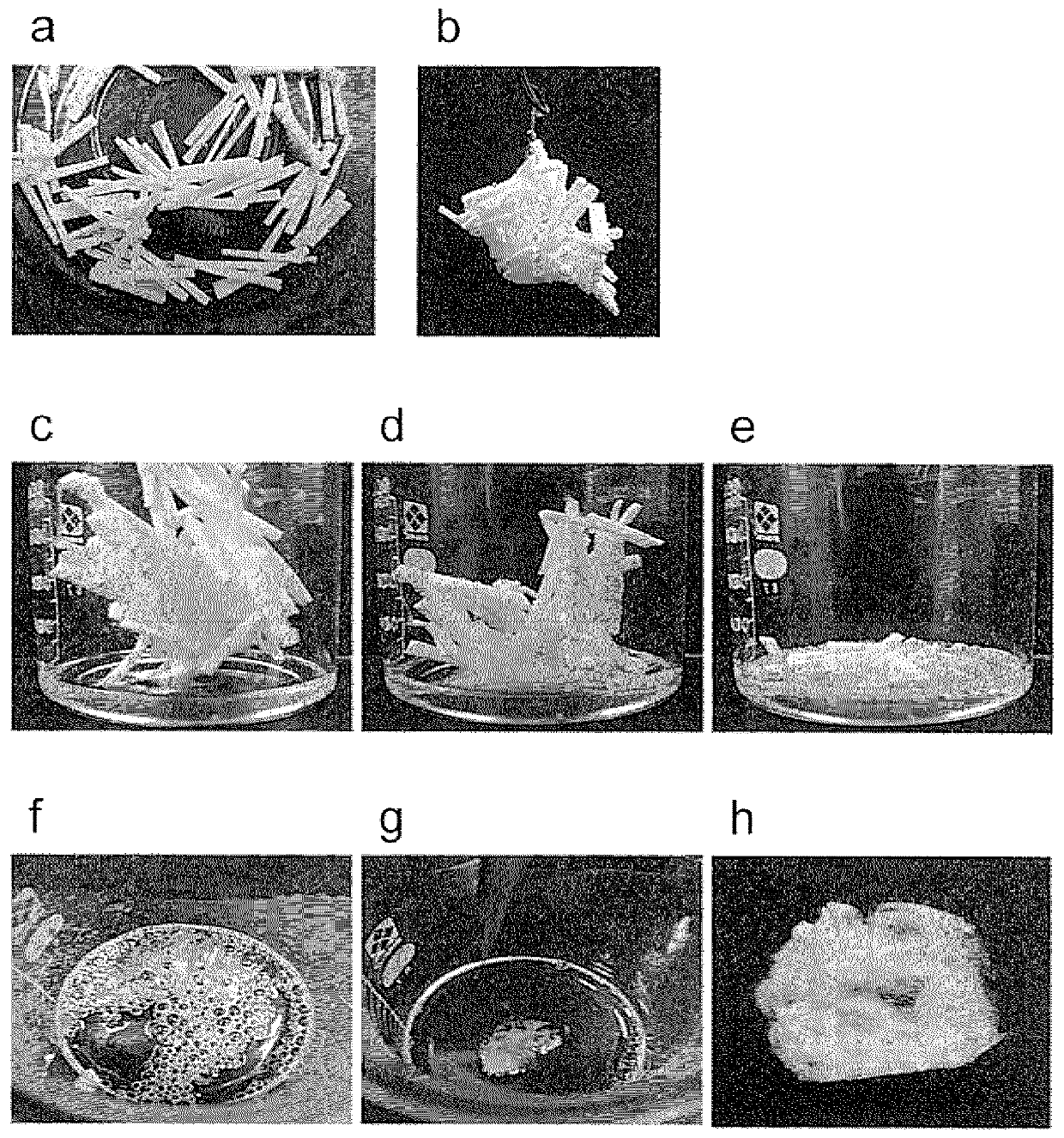

[0200] exist image 3 The silk picking method of the present invention is illustrated in the figure. On the bottom of a 500 mL glass beaker, gelatin hard capsules (TORPAC: experimental gelatin capsules) cut into 9 mm to 20 mm laminar pieces were spread as water-soluble nest materials. The larvae (full length: 20 mm) taken out from the nest were placed on gelatin chips in a beaker, and left at 25° C. under atmospheric pressure (a). Three days later, the bag moth larval nest (b) newly produced using the gel...

Embodiment 3

[0203]

[0204] (Purpose)

[0205] The larvae of the naked bag moth were made into a nest of the bag moth larvae using a thermofusible nest material, and the silk thread of the bag moth larvae was collected from the nest.

[0206] (method and results)

[0207] As for the bag moth larvae, the last instar larvae of the bag moth were collected from a fruit tree farm in Tsukuba City, Ibaraki Prefecture in the same manner as in Example 1. The basic operation of preparing naked bag moth larvae is according to Example 1.

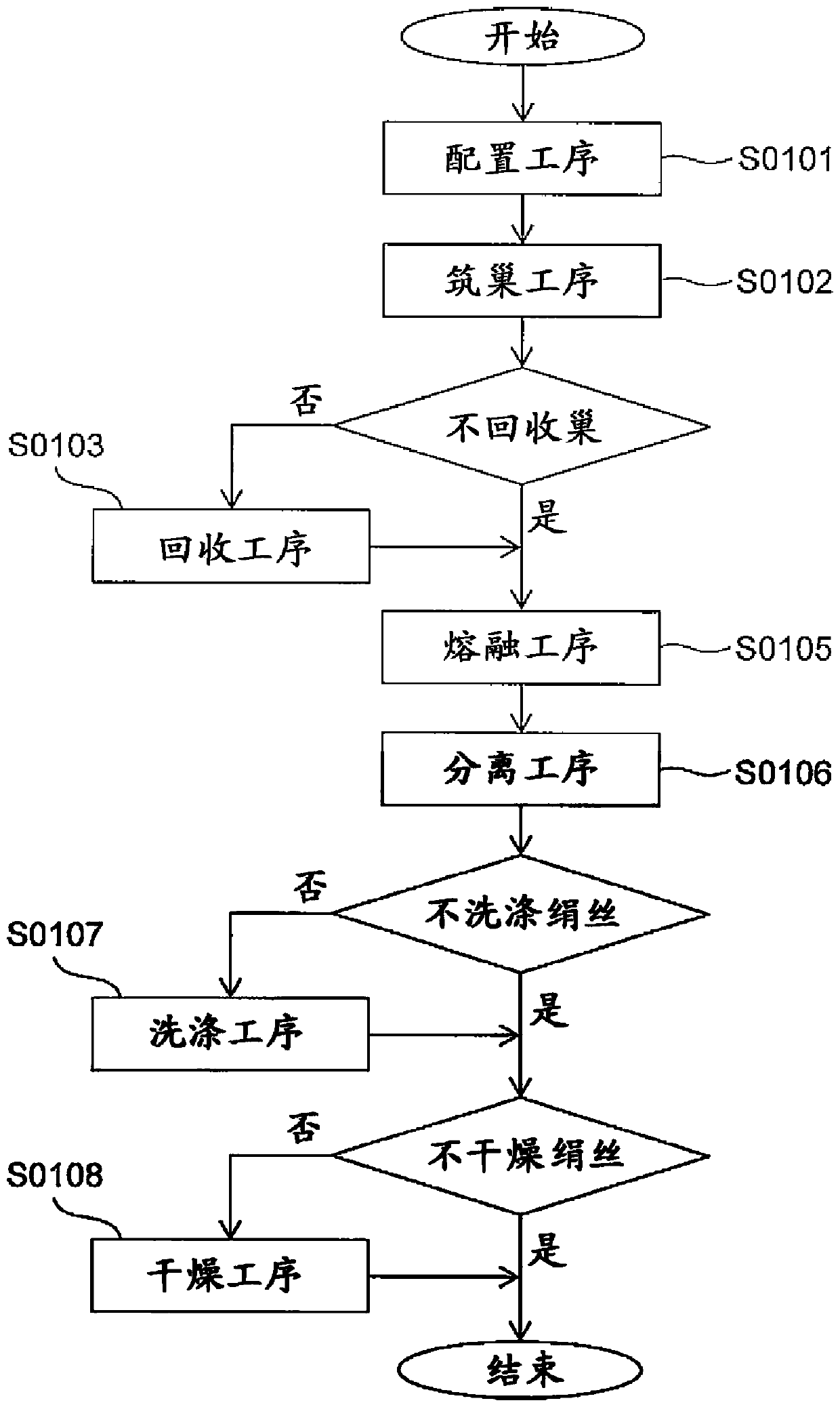

[0208] exist Figure 4 The silk picking method of the present invention is illustrated in the figure. At the bottom of a 100mL glass beaker, spread beeswax (manufactured by Yamada Bee Farm) prepared in the shape of a thin layer of 10-20mm in length and a thin rod of 10mm-20mm as a heat-fusible nest material, so that The beaker is set on the clear plastic housing in such a way that the bottom edge also lets in the light. The larvae (full length: 25 mm) taken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com