Auxiliary device applied to silk drawing

An auxiliary device and silk technology, which is applied in the production of silk from silkworm cocoons, silk fiber production, textiles and papermaking, etc., can solve the problems of secondary pollution, silk quality decline, etc., and achieve the effect of avoiding secondary pollution and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

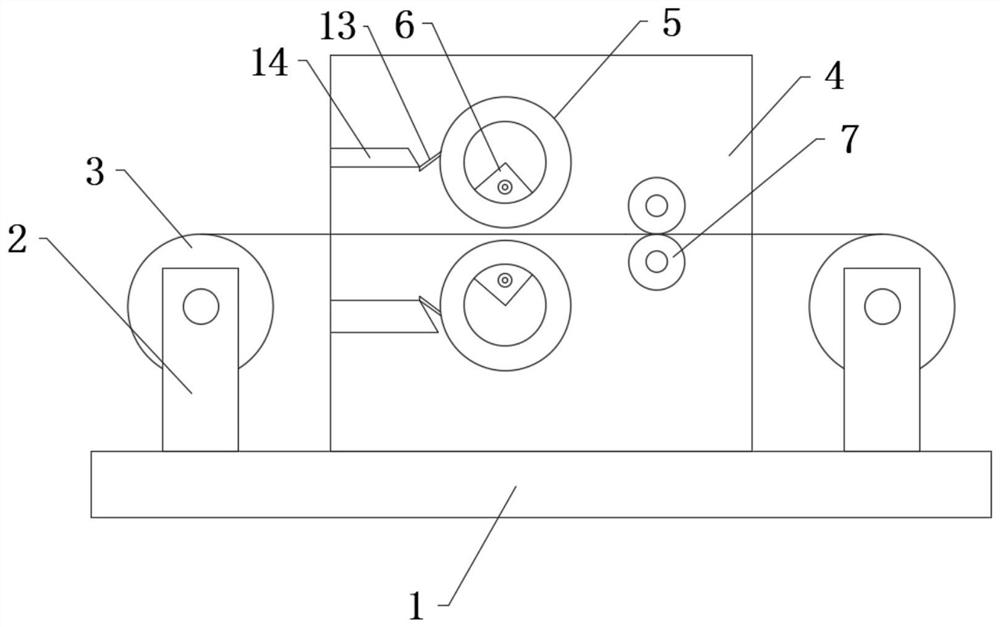

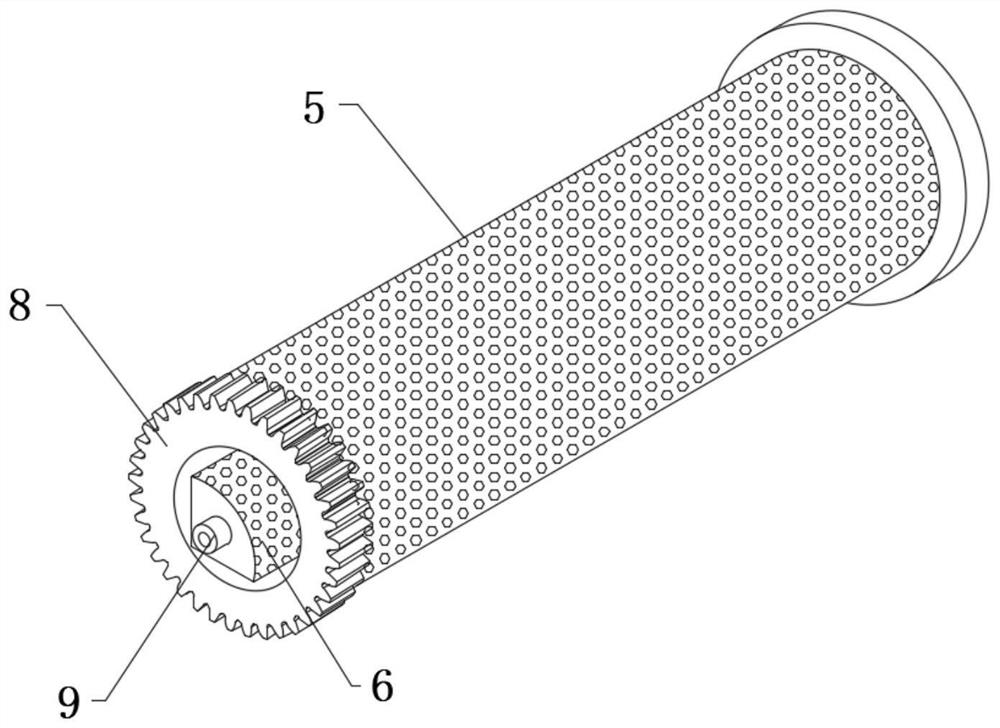

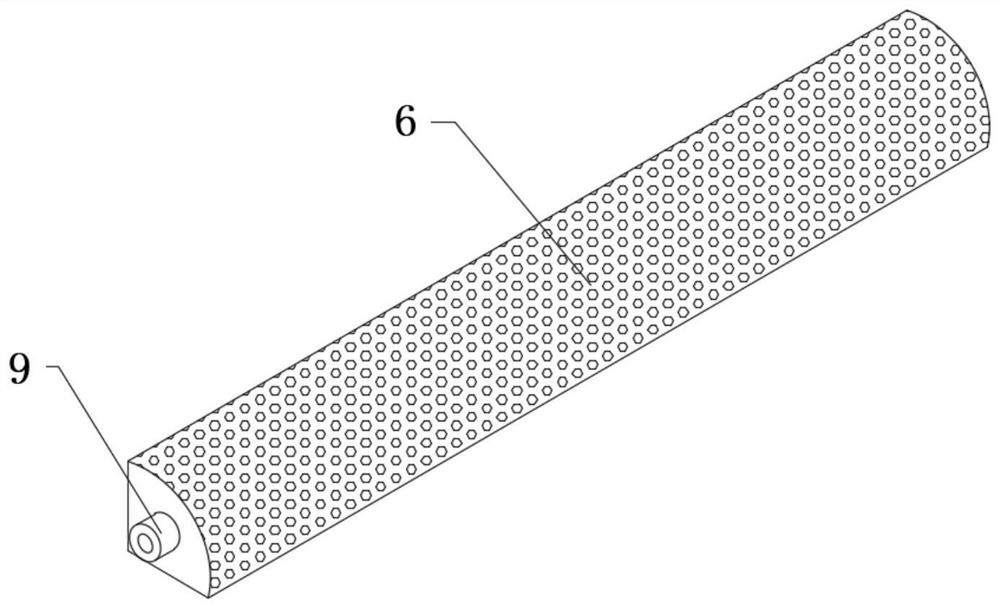

[0020] Example: such as figure 1 As shown, the present invention is an auxiliary device applied to silk drawing, which includes a base 1, a column 2 is provided at both ends of the top of the base 1, a conveying roller 3 is provided on the top of the column 2, and a silk finishing is provided at the middle of the top of the base 1. Box 4. One side in the described silk finishing case 4 is symmetrically provided with silk velvet adsorption roller 5, as Figure 2-3 As shown, one end of the silk velvet adsorption roller 5 is provided with a first gear 8, and the inside of the silk velvet adsorption roller 5 is provided with an air extraction pipe 6, and the air extraction pipe 6 is fixedly connected with the silk finishing box 4, and one end of the air extraction pipe 6 is provided with an air extraction hole 9, the suction hole 9 is connected with the suction pump, and the other side in the silk velvet adsorption roller 5 is symmetrically provided with a squeeze roller 7, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com