silk cotton machine

A silk-cotton machine and silk-cotton technology, which is applied in the production of silk from cocoons, etc., can solve the problems of uneven silk-cotton quilts, lower yields of finished products, and small width of silk-cotton sheets, and solve the problems of unevenness and increase in processes, Improve quality and yield, avoid tangling and shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

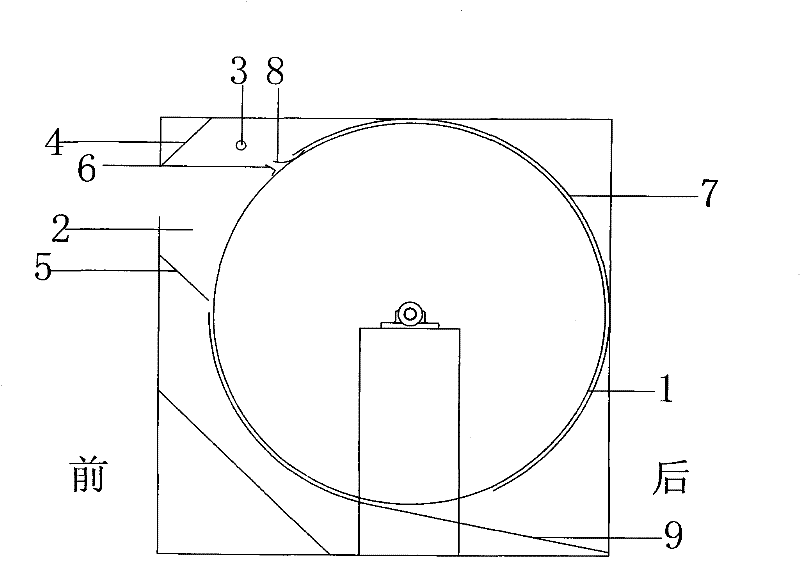

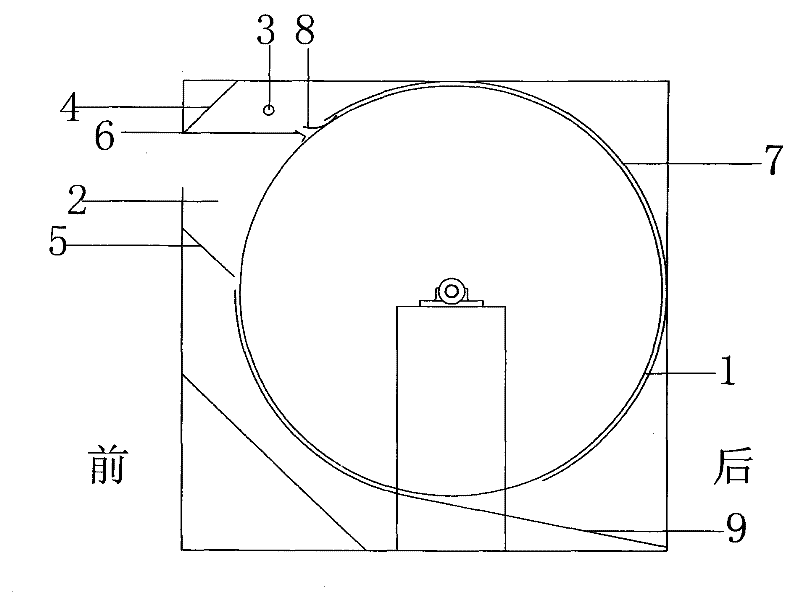

[0010] A silk cotton machine for making silk cotton, comprising a frame, a transmission device and a drum (1), a trough (2), a water spray pipe (3), an upper baffle (4), a lower baffle (5), and a scraper (6), it is characterized in that: the outer periphery of cylinder has an arc-shaped anti-swing board (7), arc-shaped paste silk board (8), and anti-swing off pupal plate (9). The arc-shaped anti-shake plate (7) is 1 to 5 centimeters apart from the outer surface of the drum (1), and the arc-shaped anti-shake plate extends from the upper front of the drum to below the center line of the drum. The arc-shaped pasted silk board (8) is located at the rear upper part of the scraper (6), and extends from the front side of the drum to the bottom of the arc-shaped anti-swing plate (7); the front end of the arc-shaped pasted silk board is fixed, and the rear end It can move up and down between the arc-shaped anti-shake plate (7) and the drum (1). Due to the force of gravity, the arc-shap...

Embodiment 2

[0012] 1 centimeter is changed into 2 centimeters with the arc-shaped anti-shake plate (7) and the outer surface of the cylinder (1) in embodiment 1, and all the other are the same as embodiment 1.

Embodiment 3

[0014] 1 centimeter is changed into 3 centimeters with the arc-shaped anti-shake plate (7) and the outer surface of the cylinder (1) in embodiment 1, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com