Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "PCB attached/integrated components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

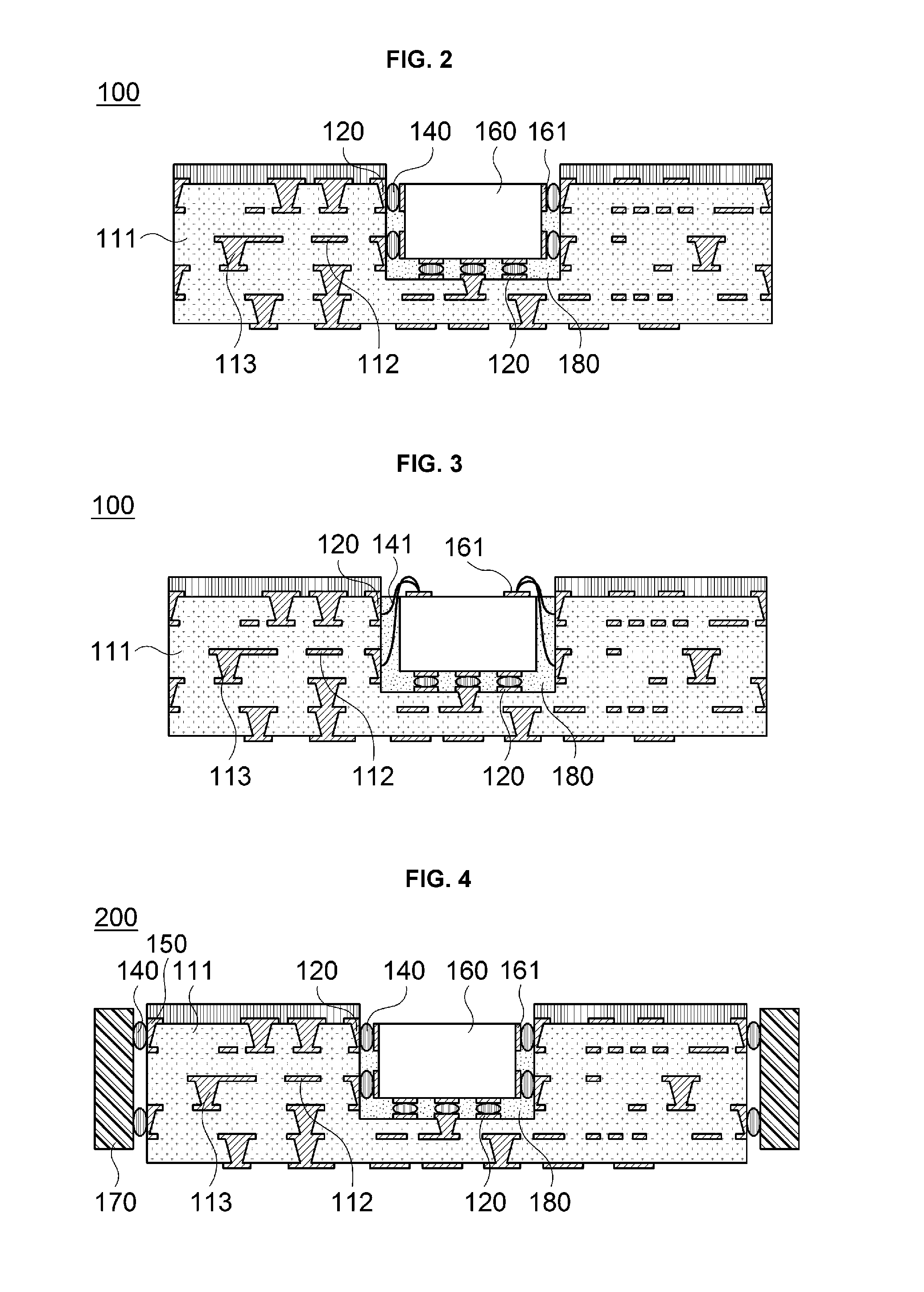

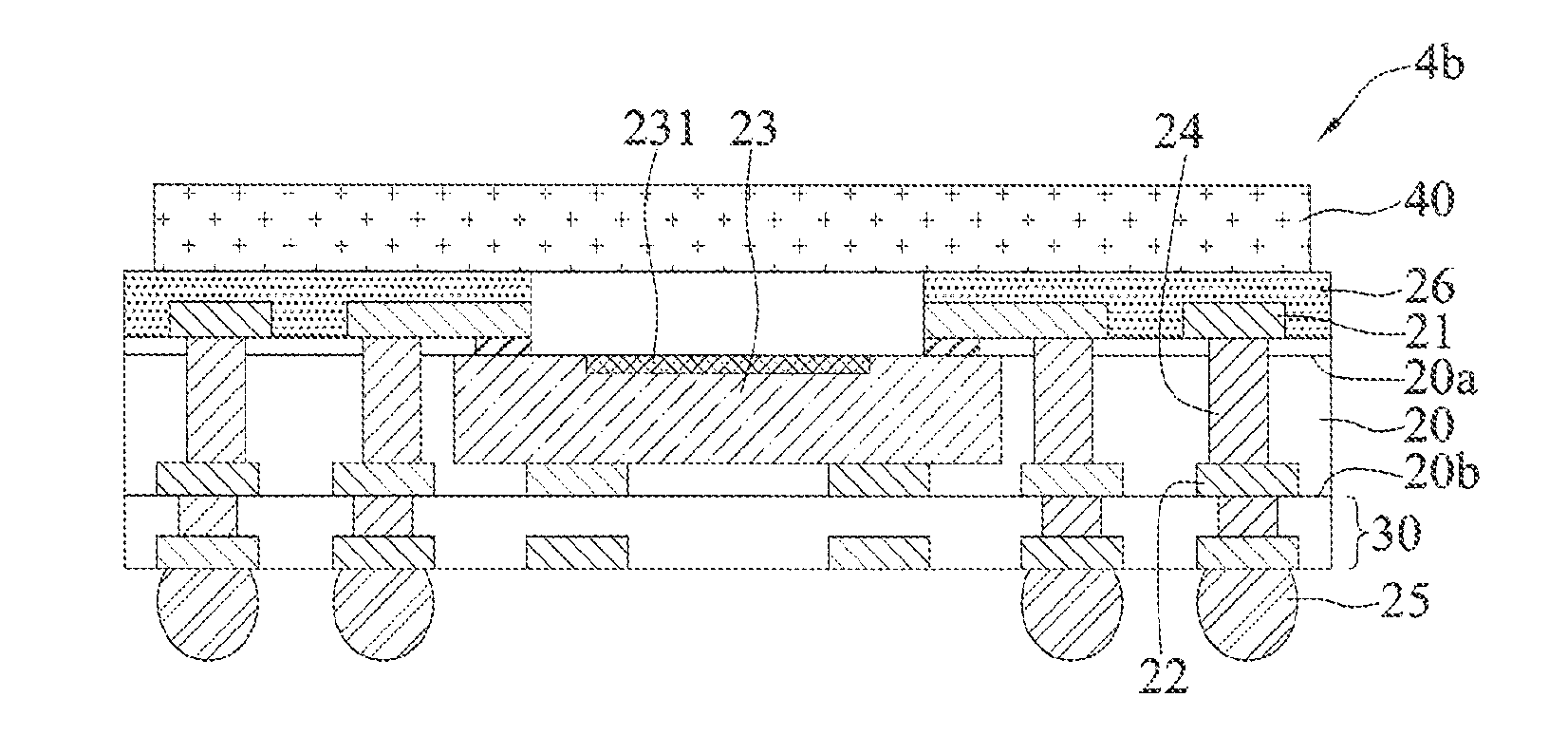

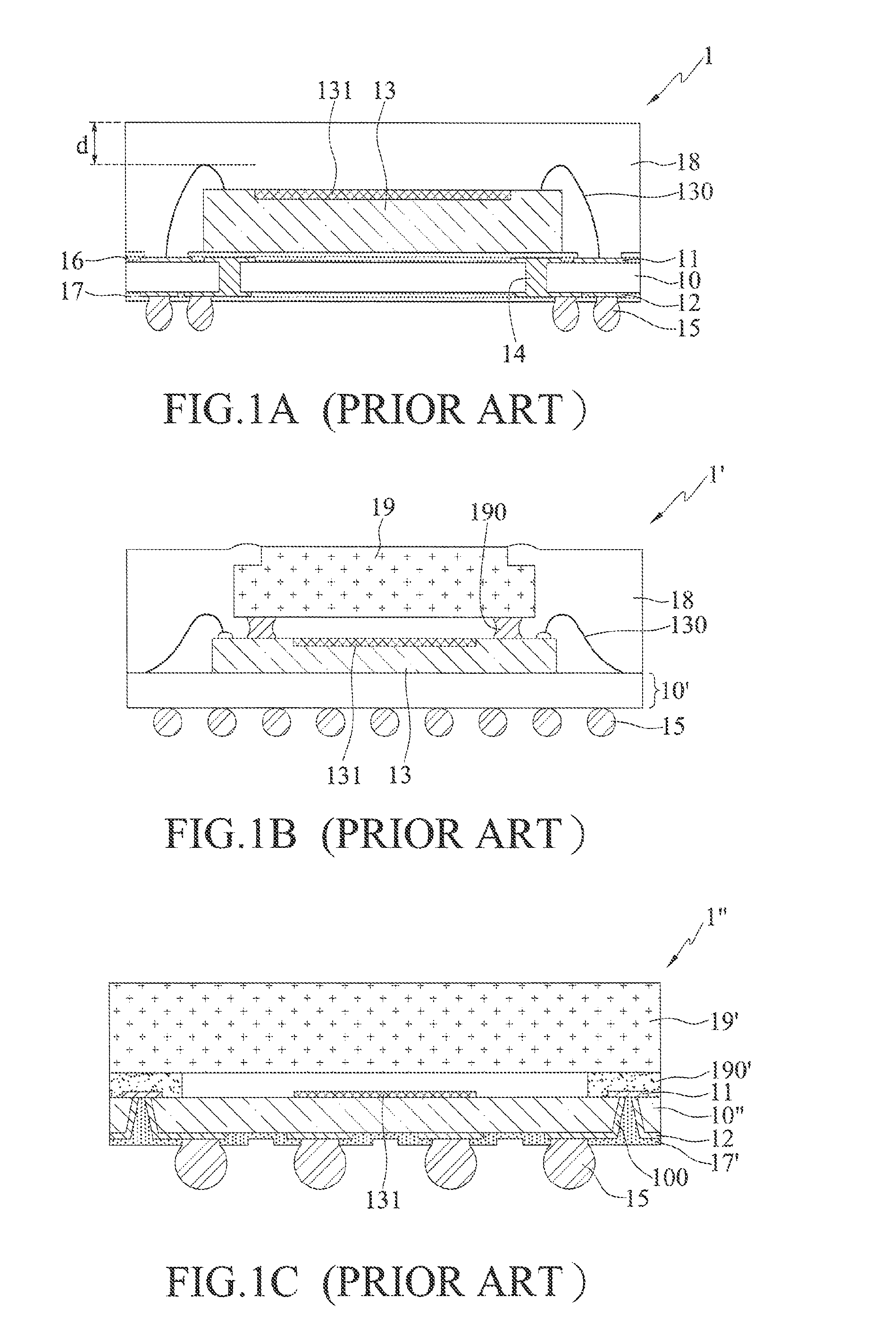

Printed circuit board with embedded electronic component and manufacturing method thereof

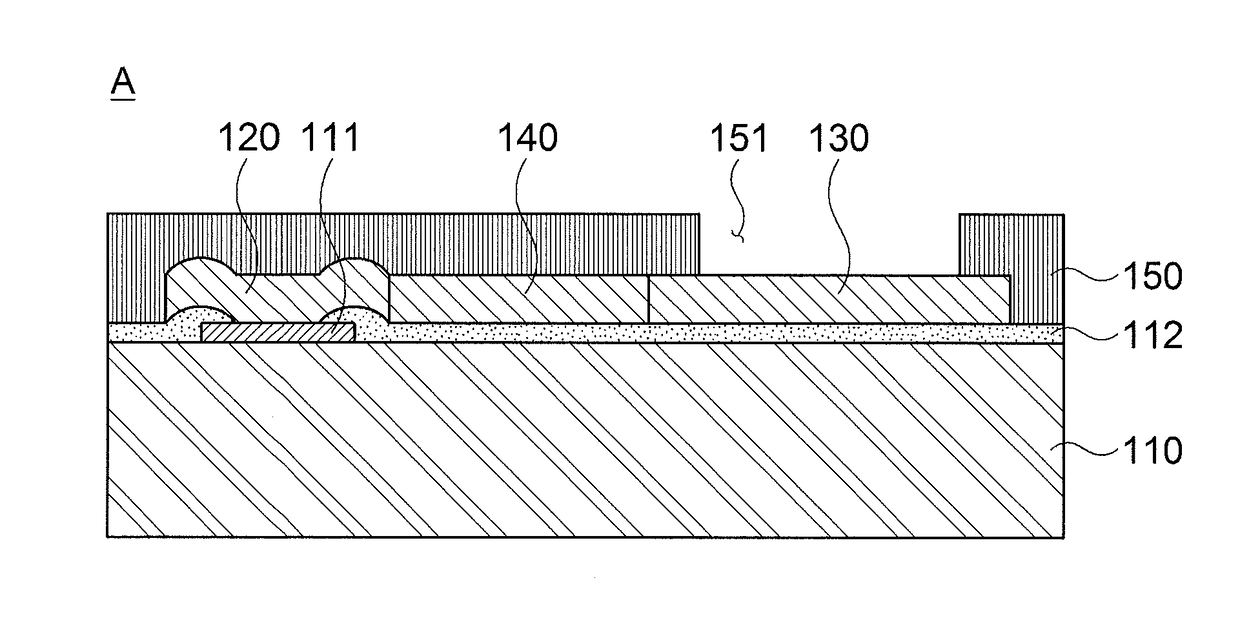

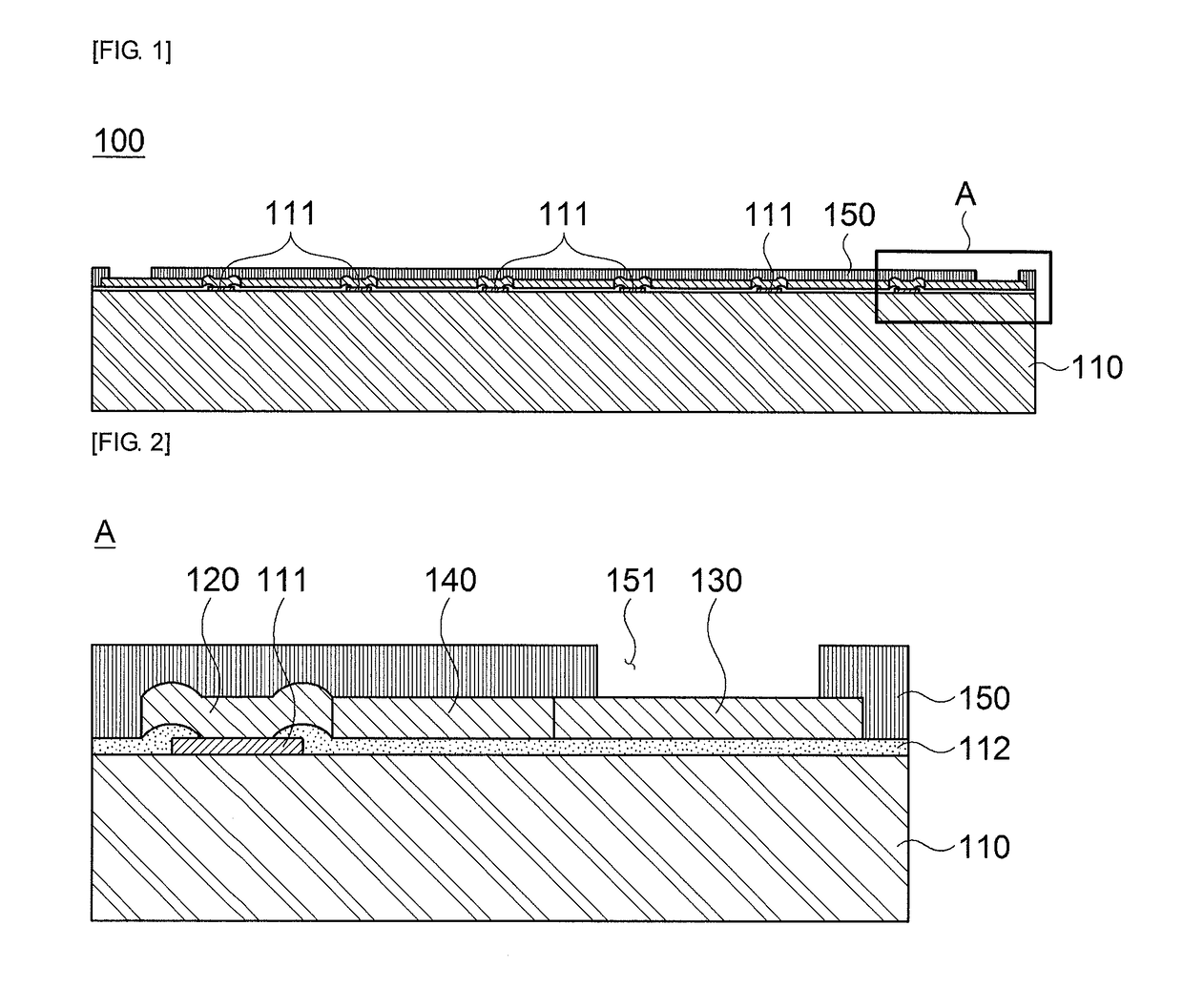

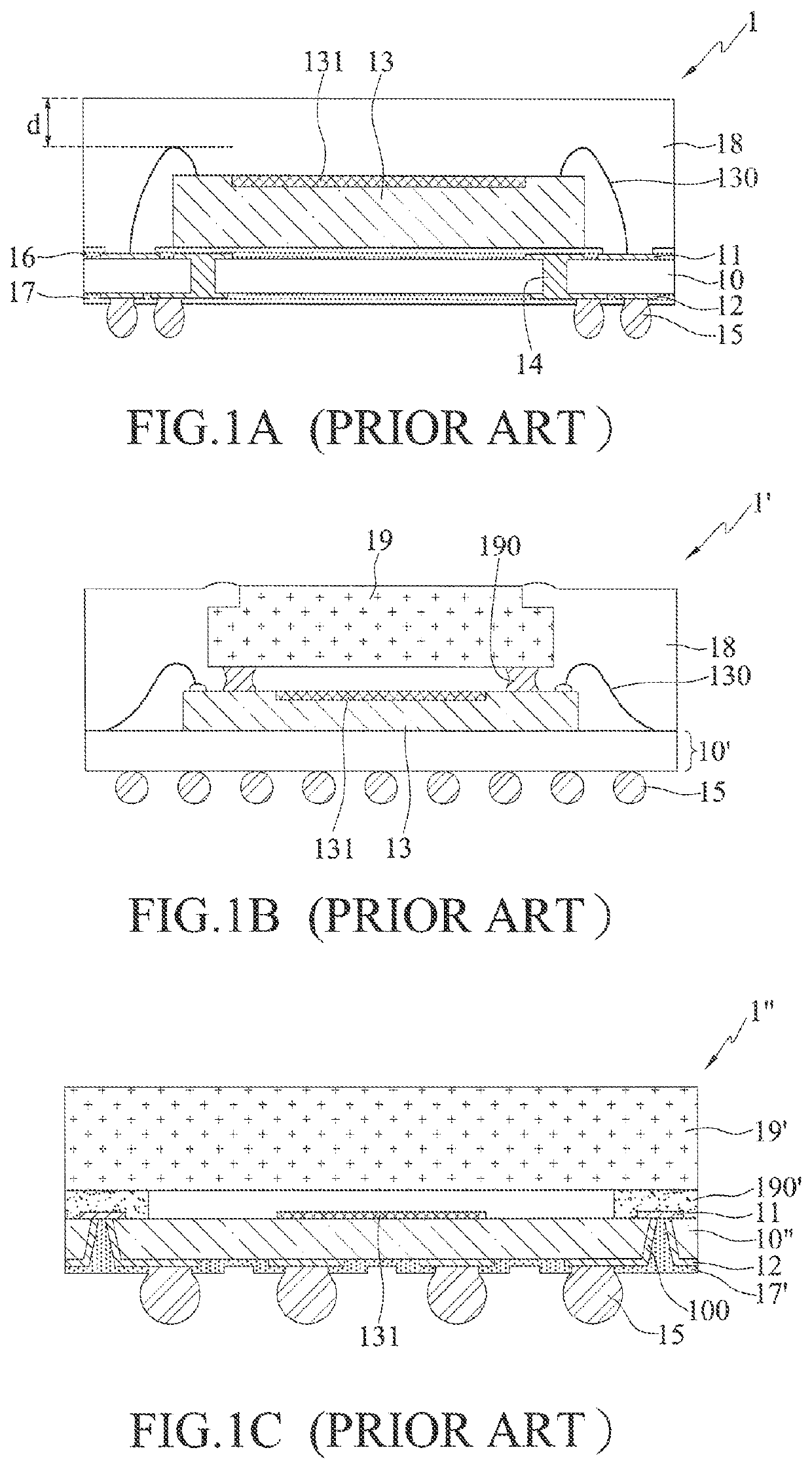

ActiveUS20160219712A1Well formedPrinted circuit assemblingSemiconductor/solid-state device detailsInsulation layerEngineering

A printed circuit board including an electronic component and a method of producing the same are provided. The printed circuit board includes a multilayered substrate including an insulation layer and an inner circuit layer laminated therein, a cavity disposed in the multilayered substrate, a via disposed in the insulation layer and configured to electrically connect the inner circuit layer with another inner circuit layer, a first electronic component inserted in the cavity, and a bump pad disposed on a surface of the cavity facing the first electronic component, and the bump pad is formed by having the insulation layer and the via exposed to a lateral side of the cavity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

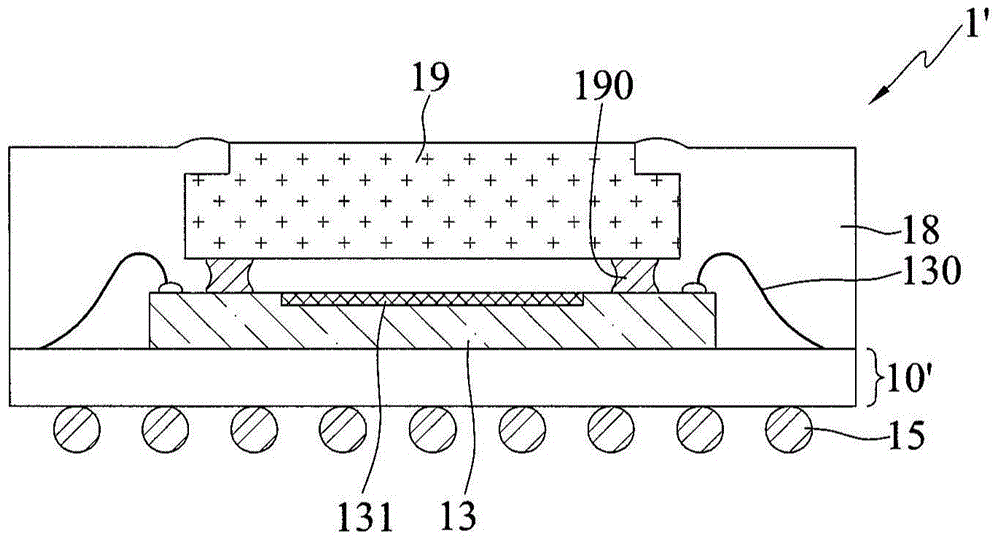

Electronic encapsulation structure

ActiveCN105845635AThickness is easy to controlThe overall thickness is thinSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

An electronic encapsulation structure comprises an insulating layer, an electronic component which is embedded in the insulating layer and has an induction area exposed to the insulator, and a first circuit layer which is arranged on the insulating layer and electrically connected with the electronic component. Thus, the thickness of the whole encapsulation structure is reduced.

Owner:PHOENIX PIONEER TECH

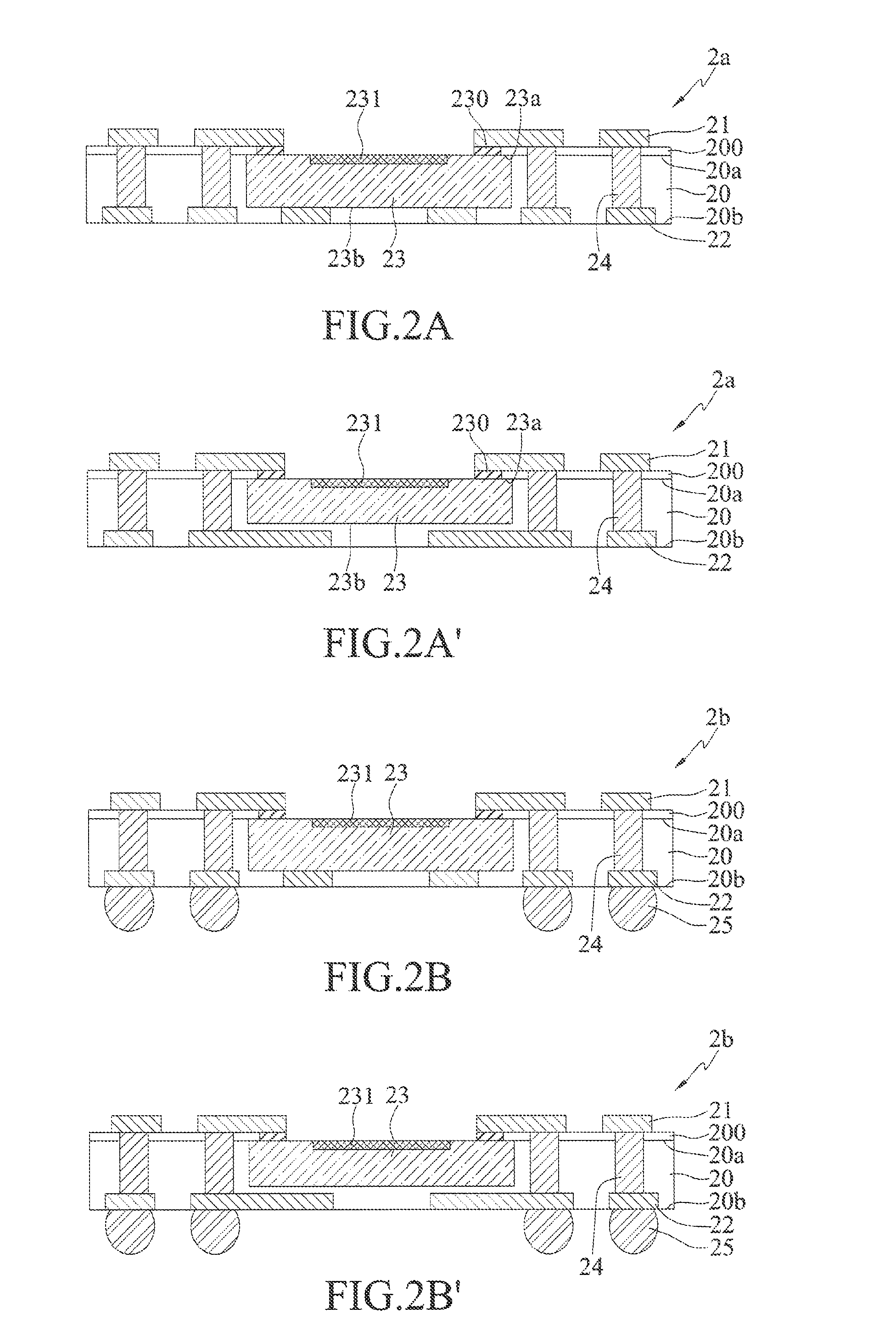

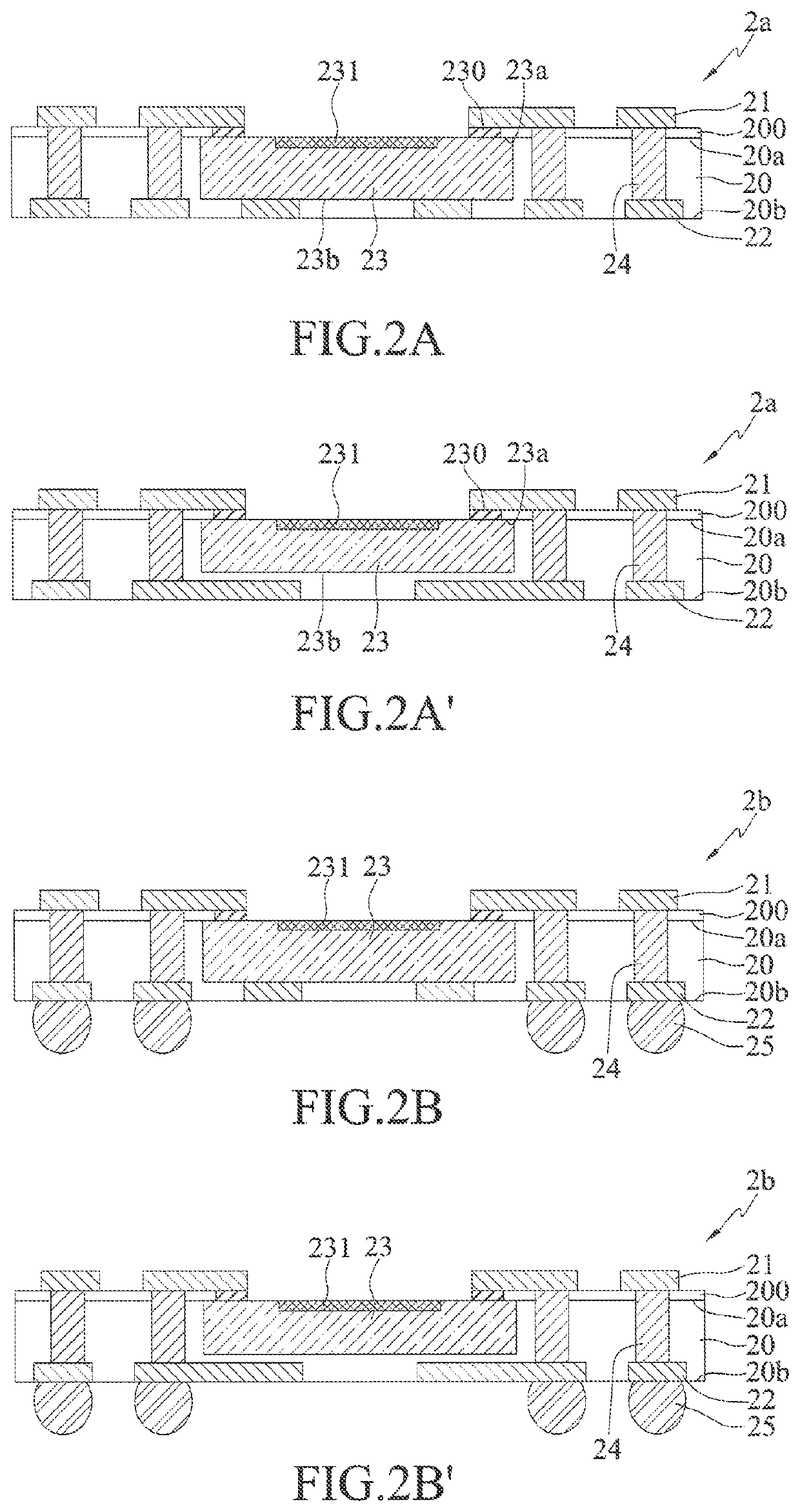

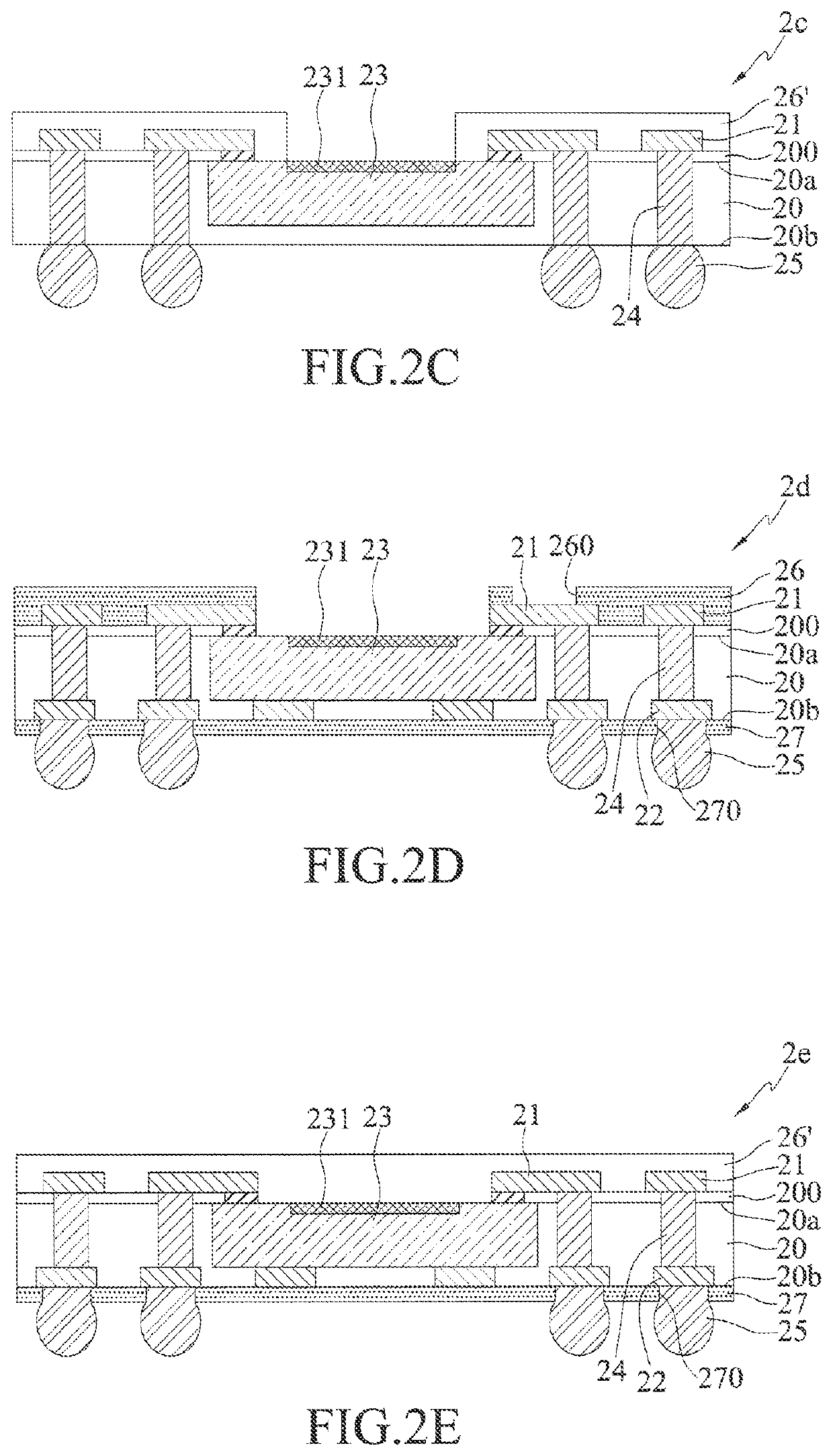

Electronic package

ActiveUS20160212852A1Easy to controlImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesElectronic packagesElectrical and Electronics engineering

An electronic package is provided, which includes: an insulating layer; an electronic element embedded in the insulating layer and having a sensing area exposed from the insulating layer; and a circuit layer formed on the insulating layer and electrically connected to the electronic element, thereby reducing the thickness of the overall package structure.

Owner:PHOENIX PIONEER TECH

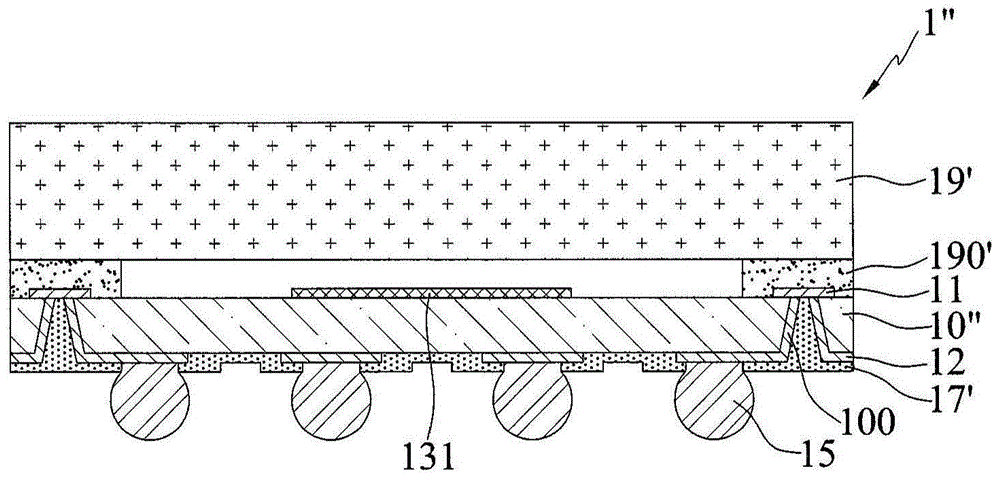

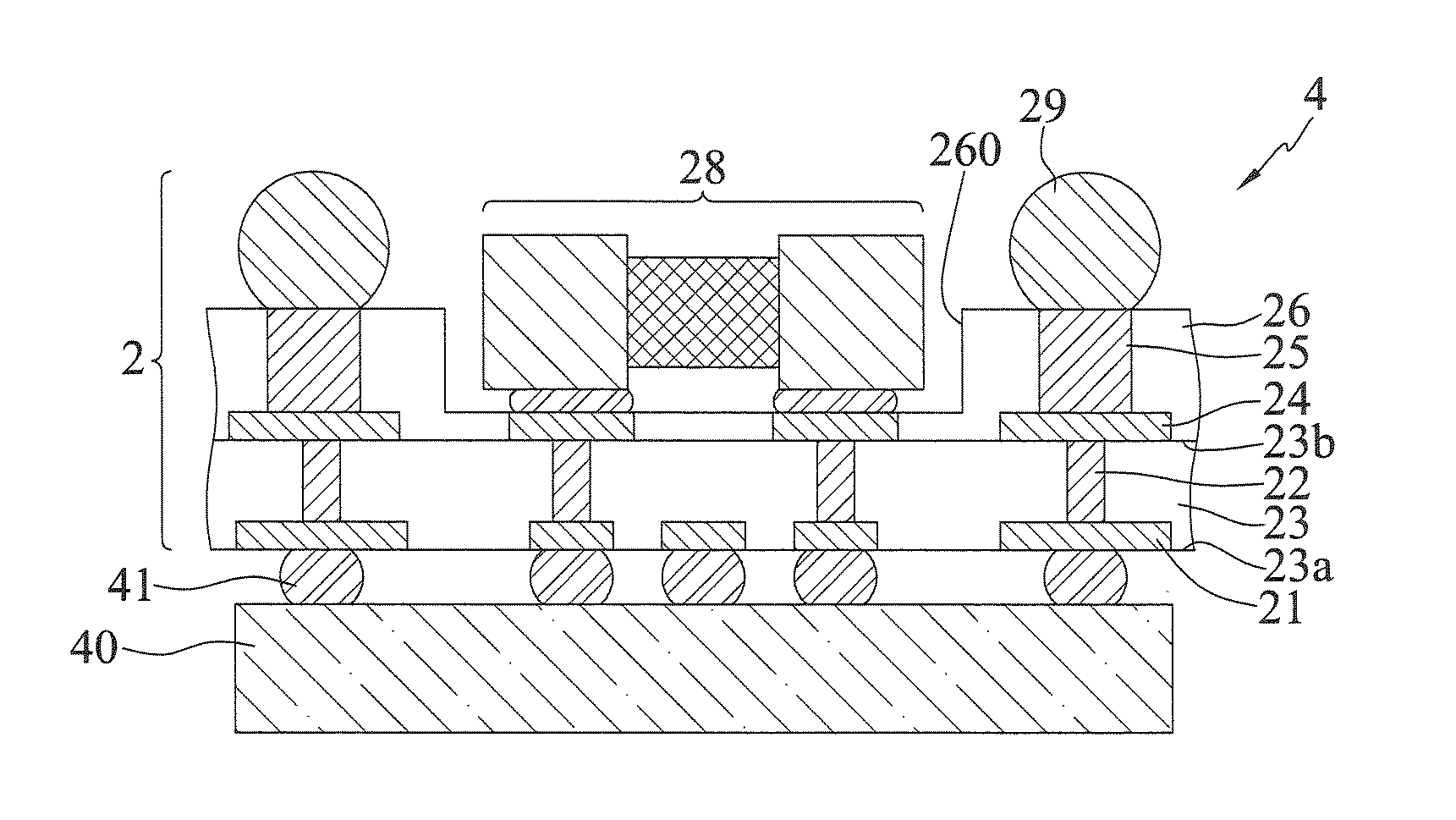

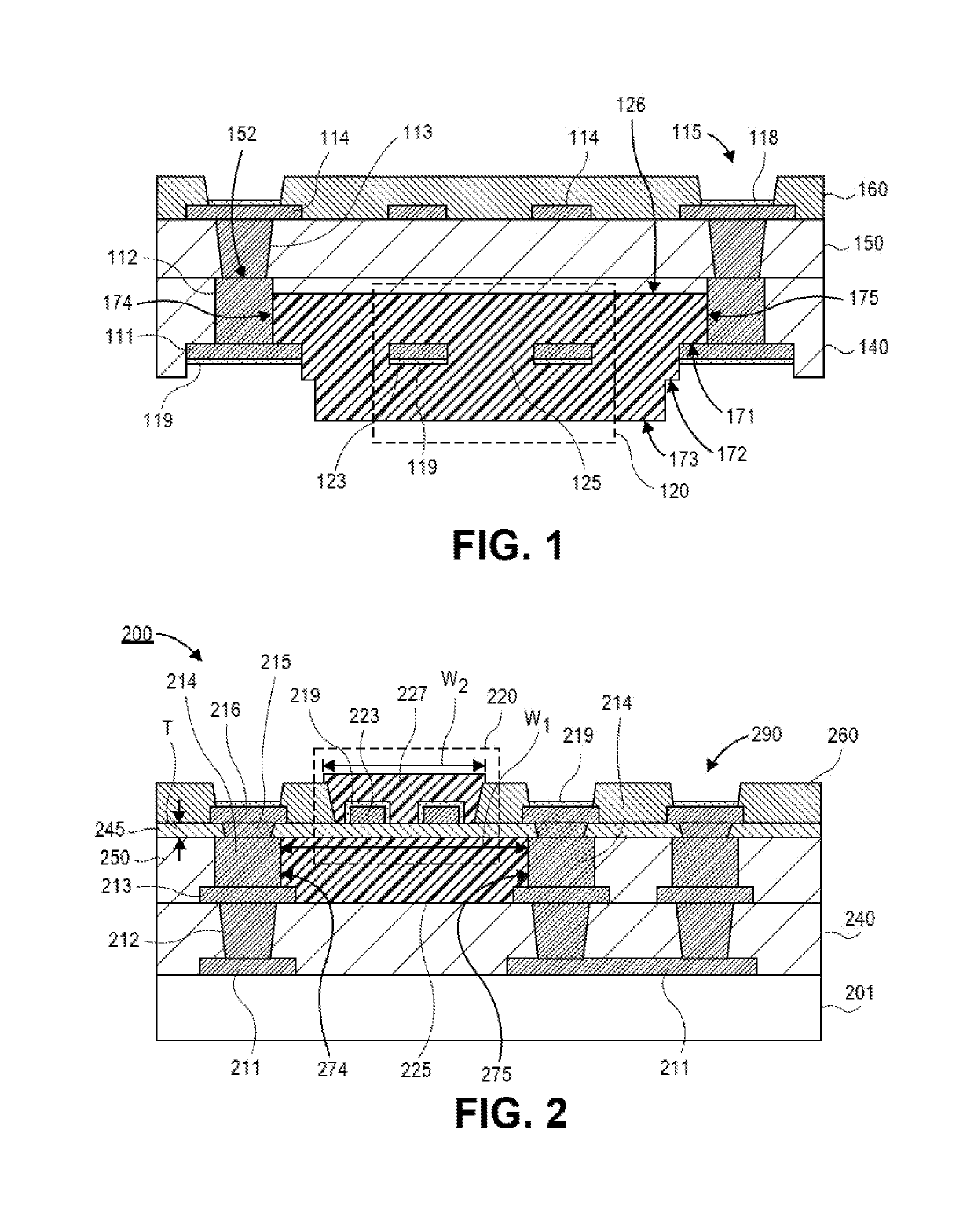

Package structure and method of manufacturing the same

ActiveUS20150359096A1Improve electrical performanceImprove performance stabilityPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorEngineering

A method of manufacturing a package structure is provided, including forming a first wiring layer on a carrier board, forming up plurality of first conductors on the first wiring layer, forming a first insulating layer that encapsulates the first wiring layer and the first conductors, forming a second wiring layer on the first insulating layer, forming a plurality of second conductors on the second wiring layer, forming a second insulating layer that encapsulates the second wiring layer and the second conductors, and forming at least an opening on the second insulating layer for at least one electronic component to be disposed therein. Since the first and second insulating layers are formed before the opening, there is no need of stacking or laminating a substrate that already has an opening, and the electronic component will not be laminated and make a displacement. Therefore, the package structure thus manufactured has a high yield rate. The present invention further provides the package structure.

Owner:PHOENIX PIONEER TECH

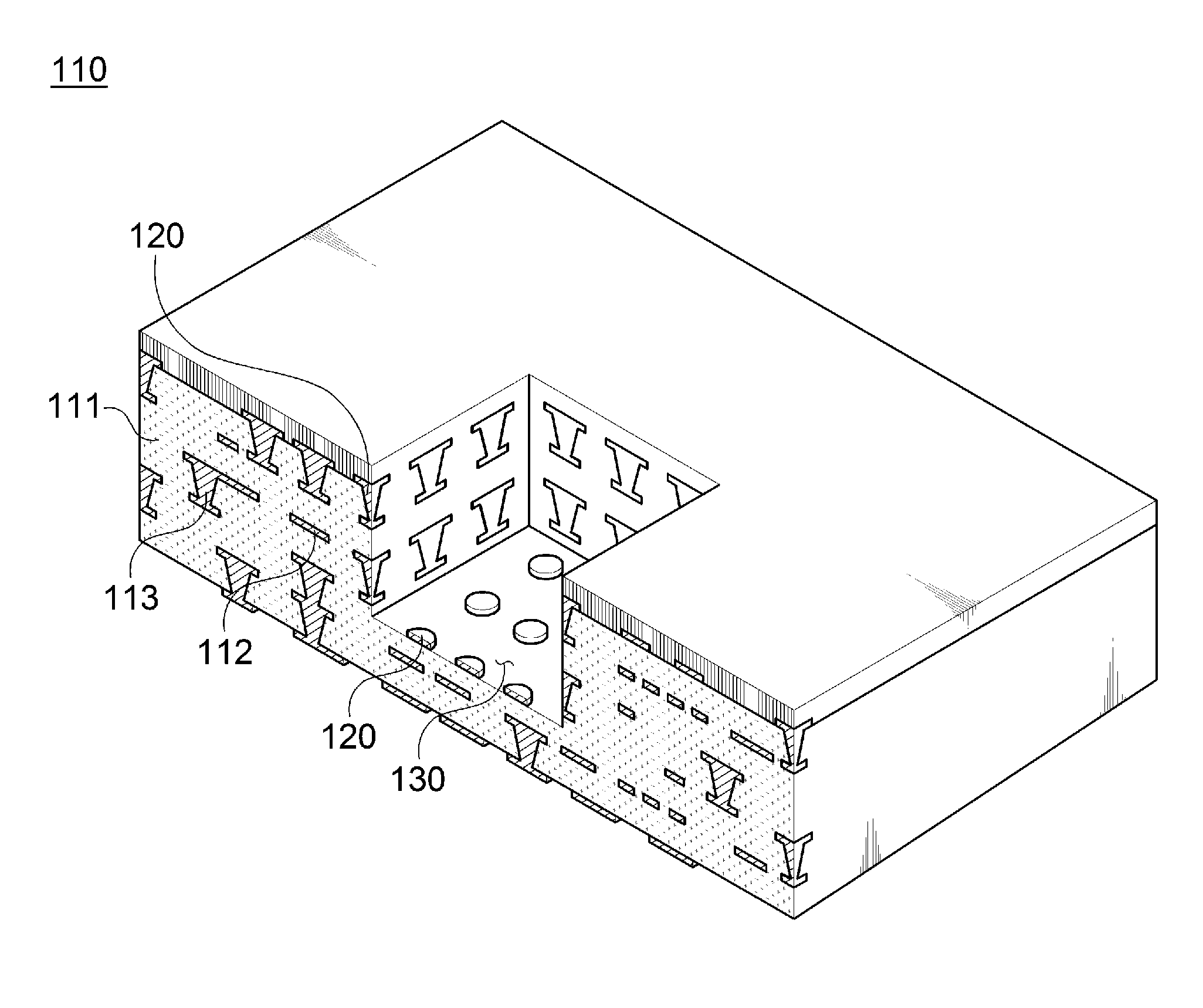

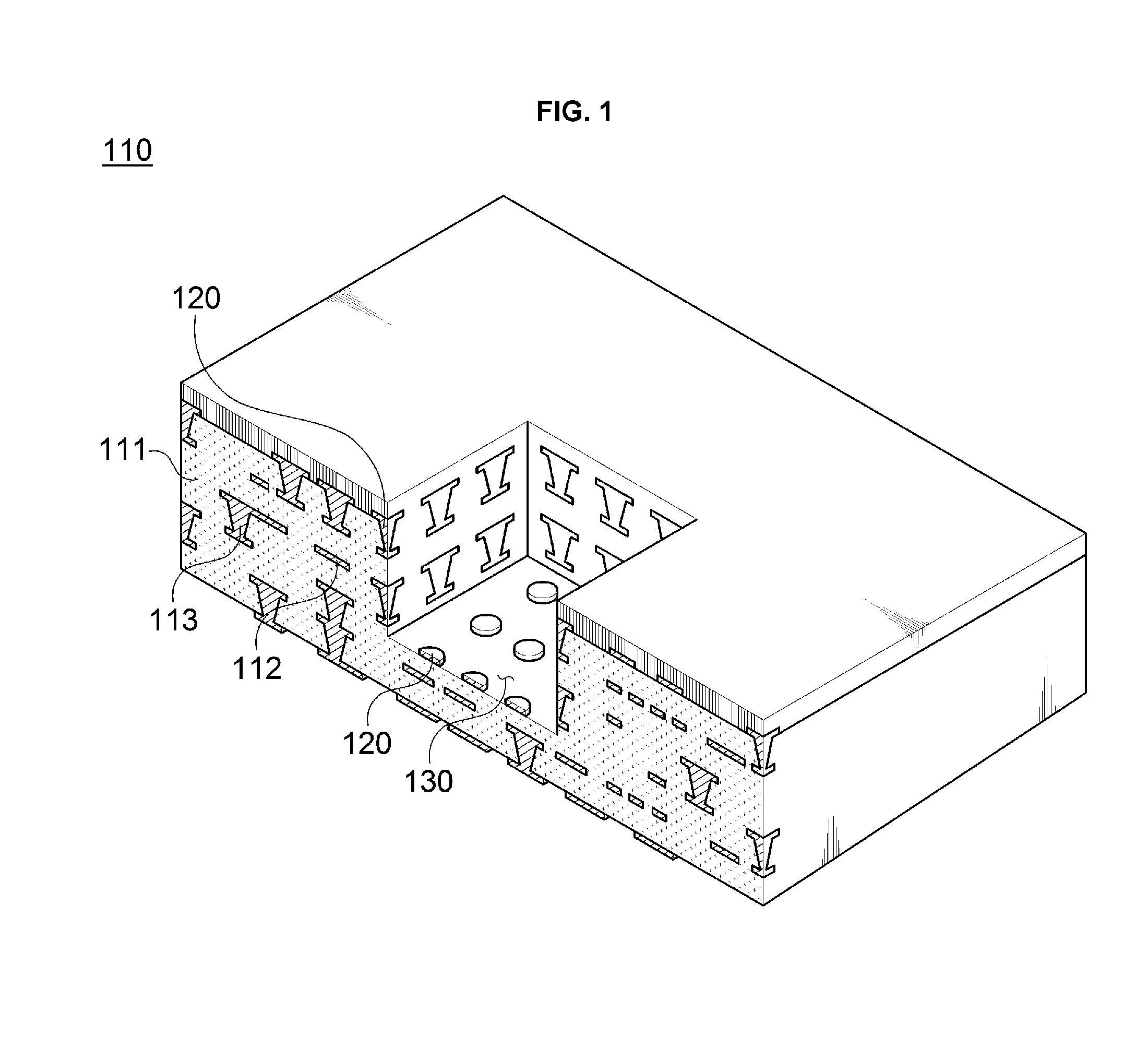

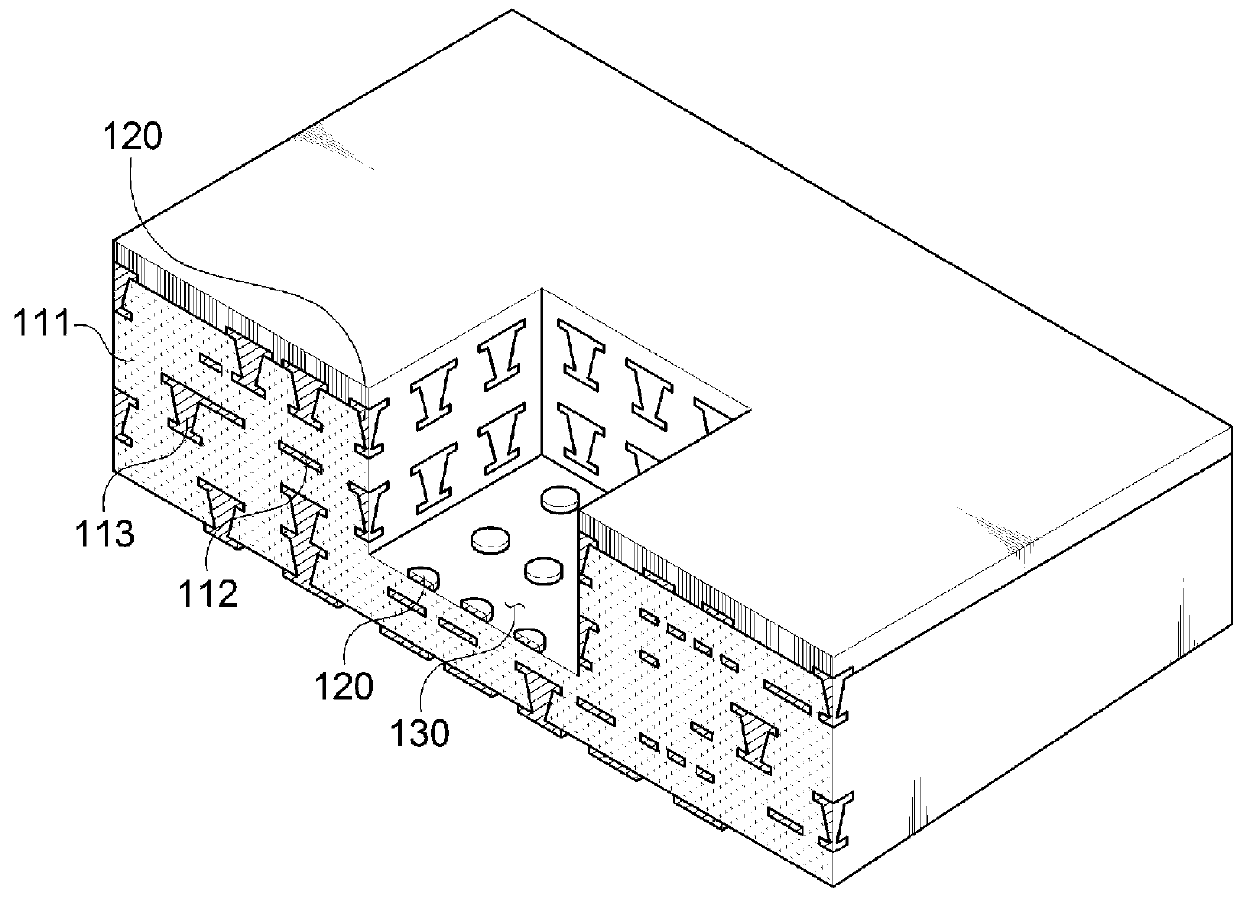

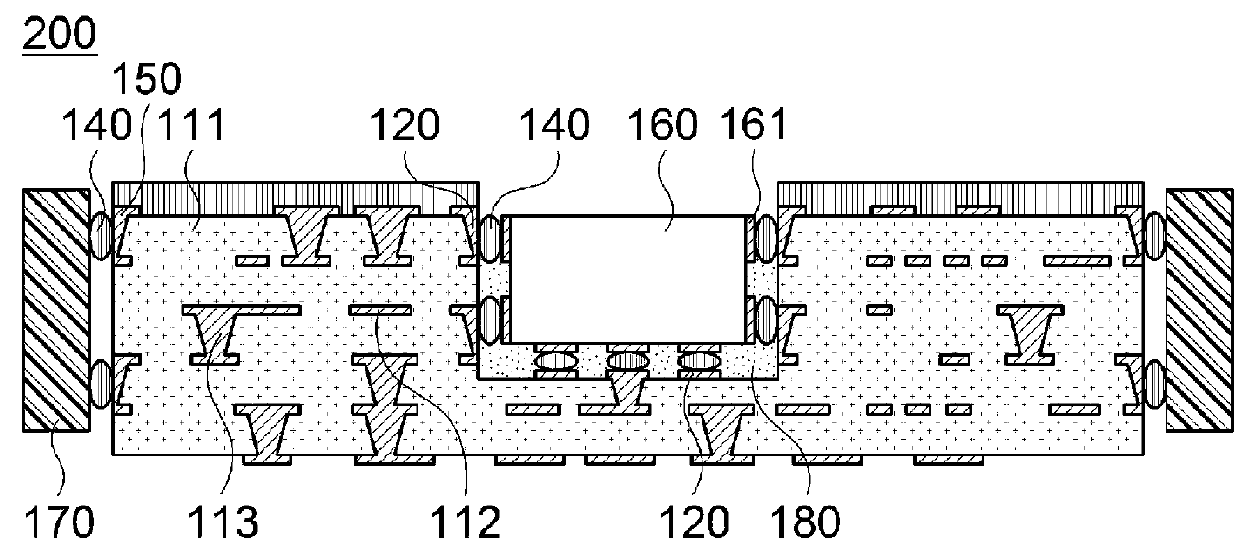

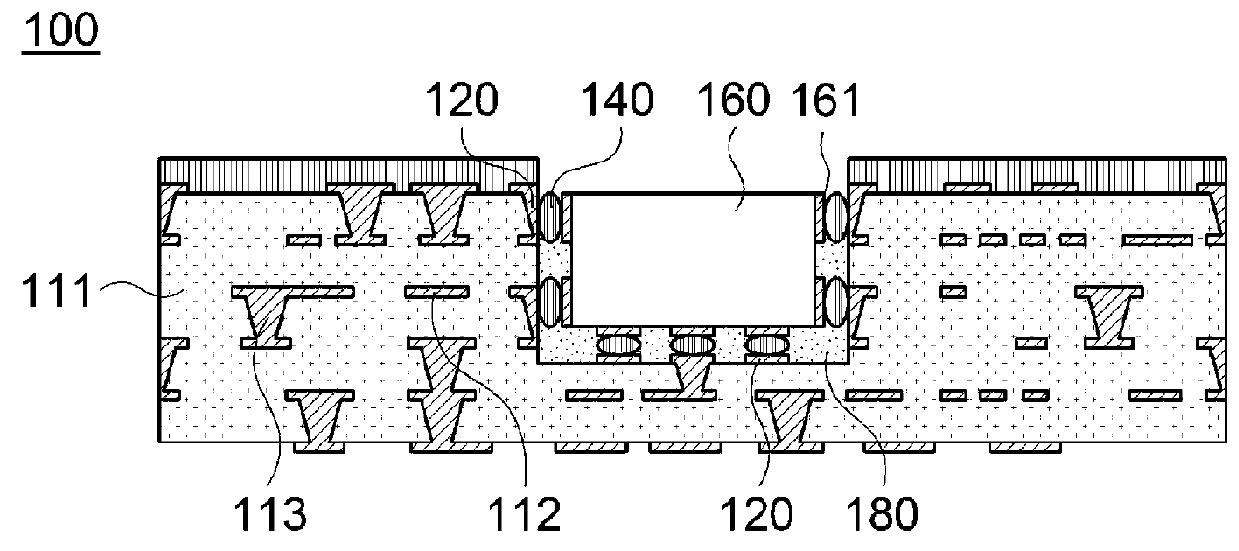

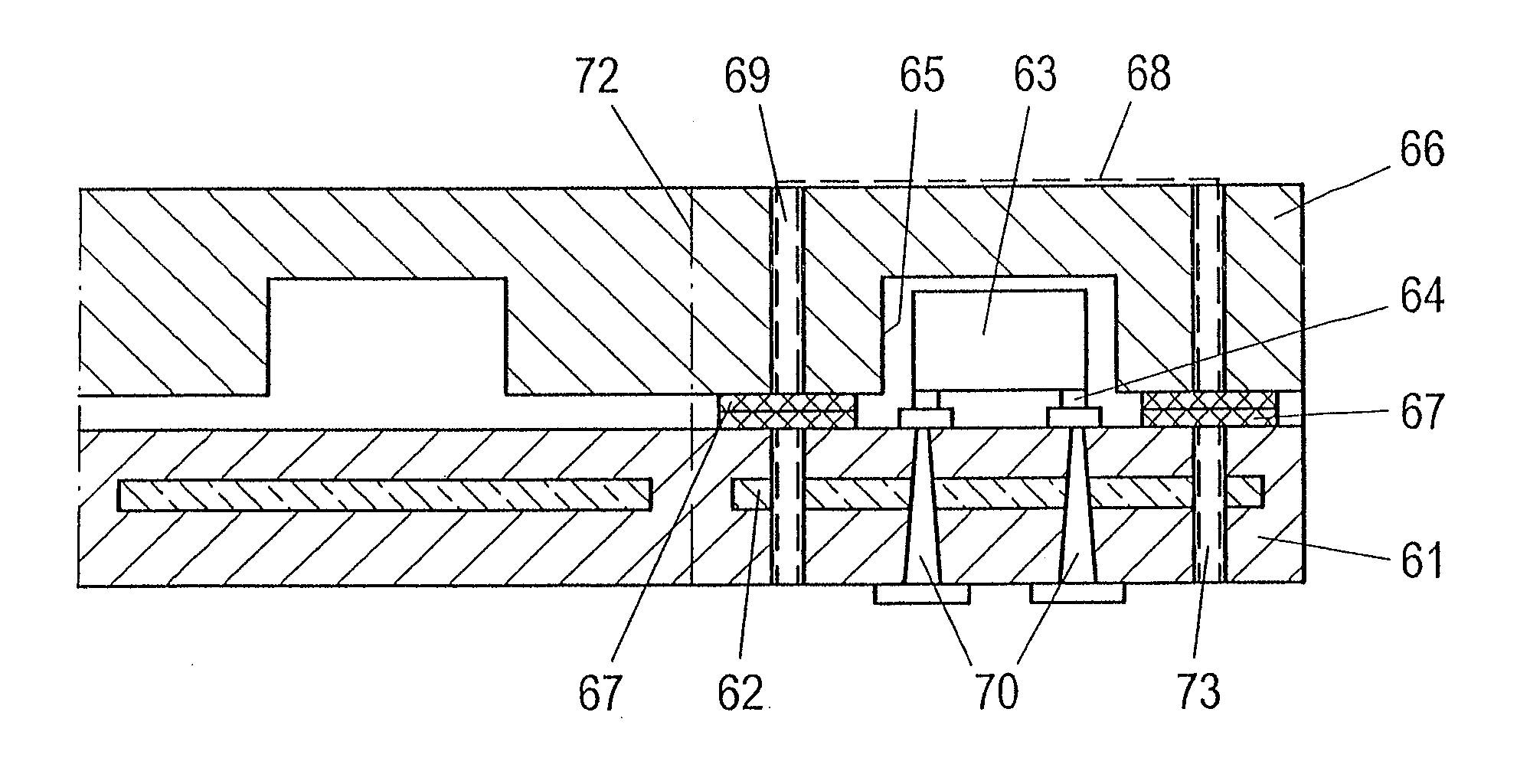

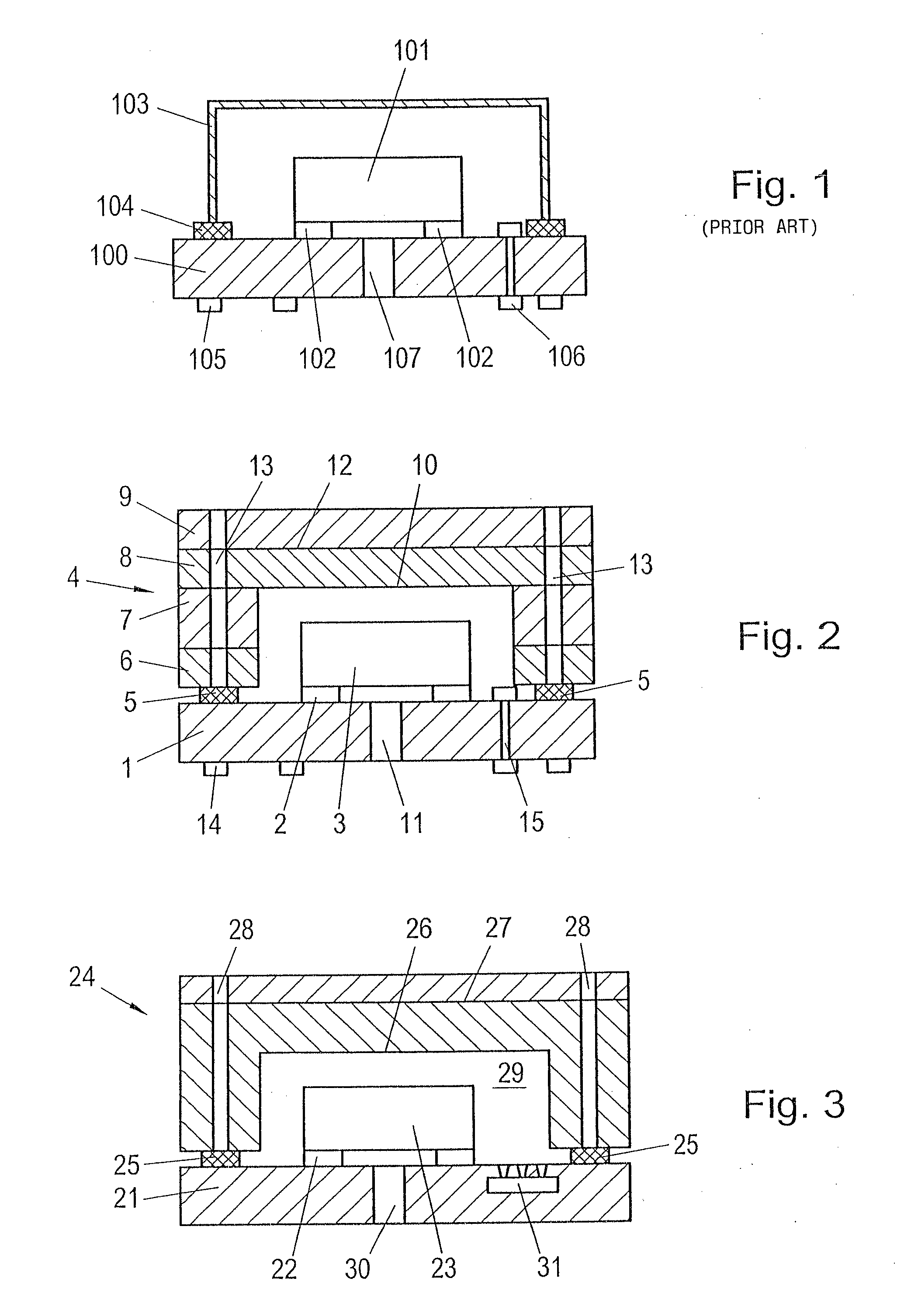

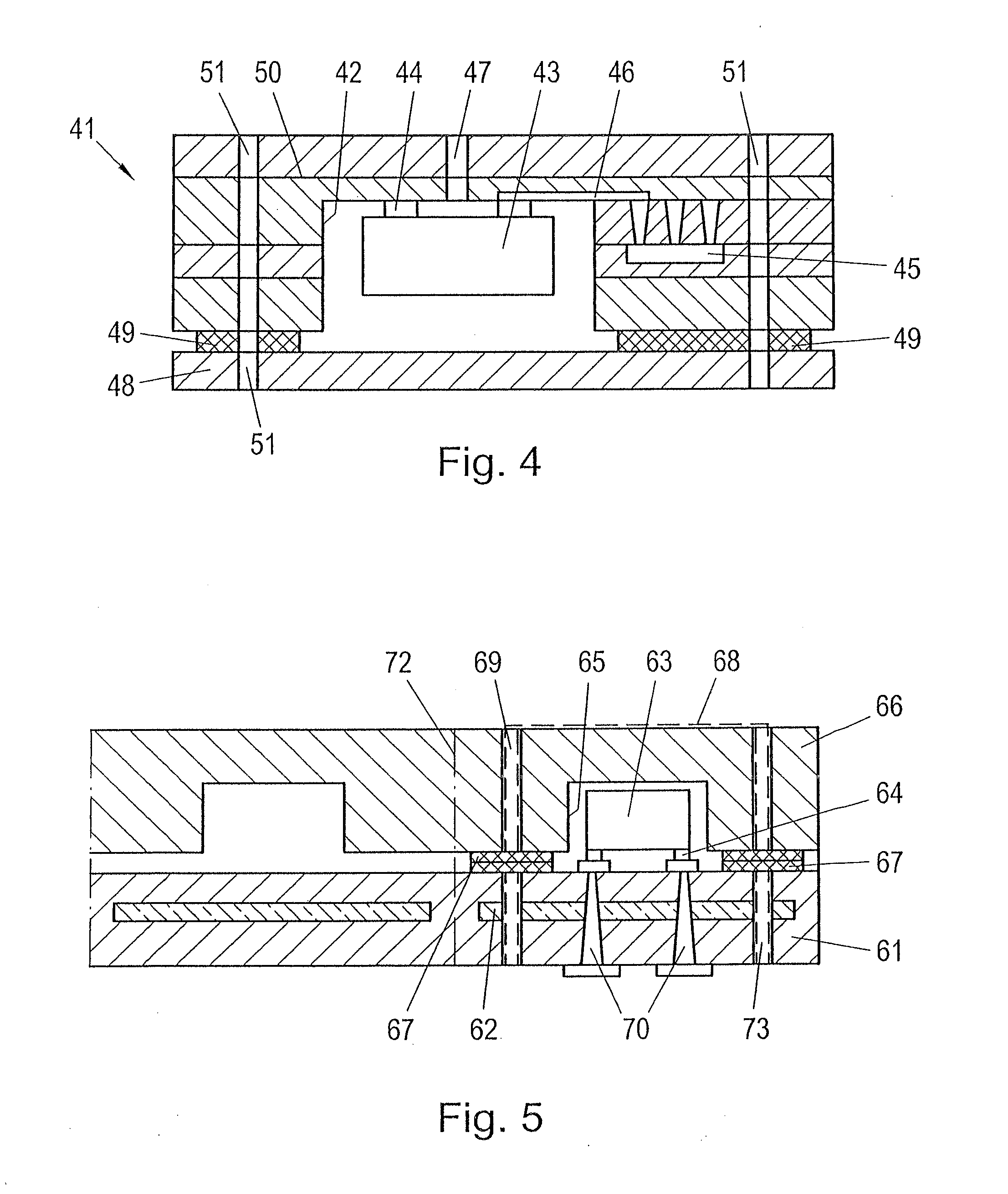

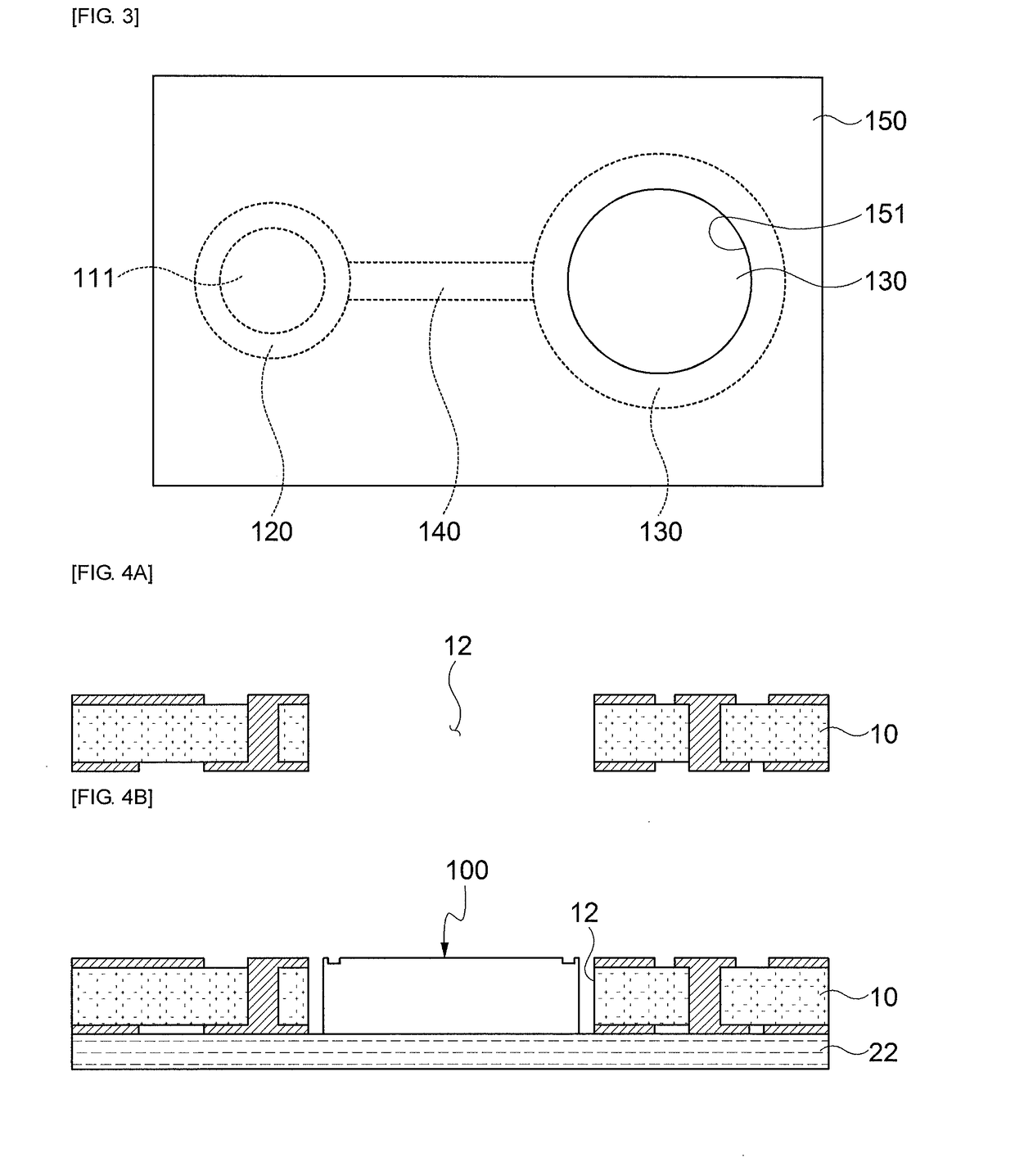

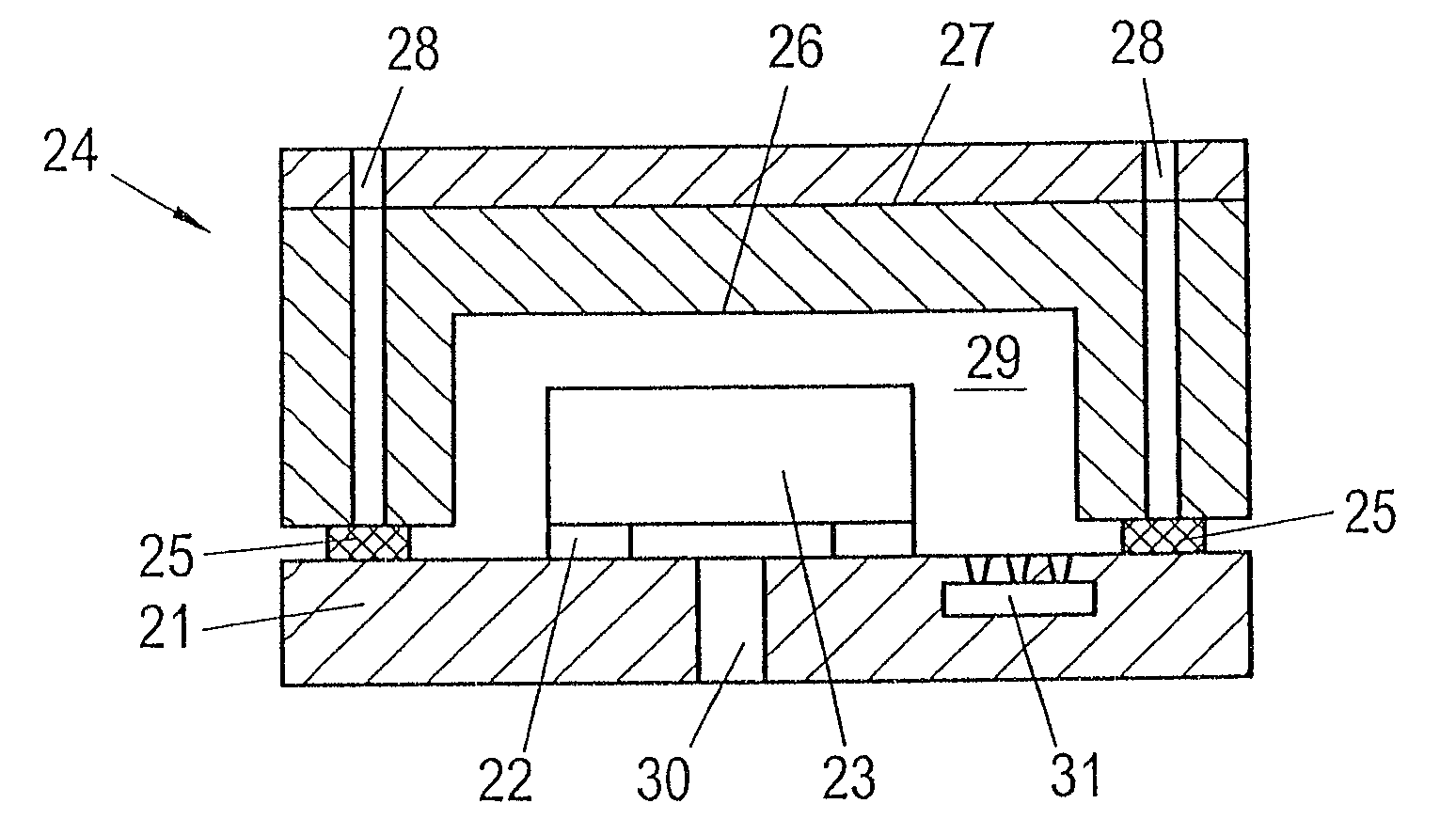

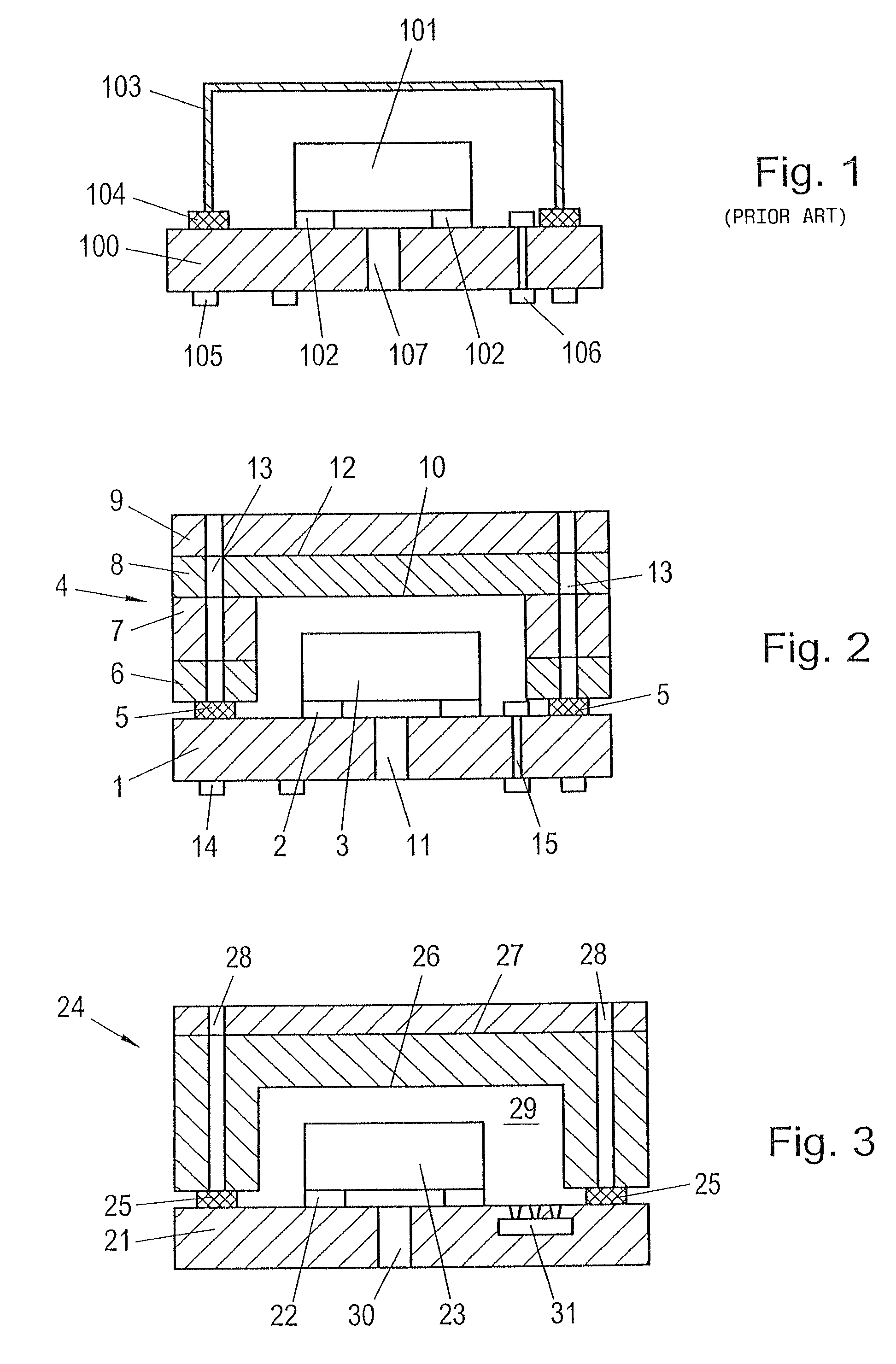

Printed circuit board comprising an electronic component integrated therein

ActiveUS20150237733A1Avoid connectionCross-talk/noise/interference reductionStacked PCBsElectronic componentPrinted circuit board

A printed circuit board having two completed printed circuit board elements which consists of a plurality of interconnected plies or layers, wherein at least one printed circuit board element has a cutout or depression containing the component to be integrated on one of the printed circuit board elements or in the cutout of the at least one printed circuit board element, and the printed circuit board elements are connected with the component being accommodated in the cutout, as a result of which it is possible to obtain secure and reliable accommodation of the component in the printed circuit board. Furthermore, a printed circuit board of this type also contains an electronic component integrated therein.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Three-dimensional integrated wafer-level package structure and package method for high-frequency IPD (Integrated Passive Device) module

ActiveCN104486907AReduce areaMiniaturizationPrinted circuit assemblingSemiconductor/solid-state device detailsHigh resistanceElectrical resistance and conductance

The invention relates to a three-dimensional integrated wafer-level package structure and a package method for a high-frequency IPD (Integrated Passive Device) module. The three-dimensional integrated wafer-level package structure comprises an PCB (Printed Circuit Board) system board and is characterized in that a low-frequency IPD package body is piled on the PCB system board, and a radio-frequency IPD package body is piled on the low-frequency IPD package body; the PCB system board is connected with the front surface of the low-frequency IPD package body through a solder ball; the low-frequency IPD package body is electrically connected with the outside through a solder ball; the low-frequency IPD package body is connected with the radio-frequency IPD package body through a first metal soldering pad and a second metal soldering pad. According to the package structure and the package method, the functions of the radio-frequency IPD module are partitioned, and an IPD chip is partitioned into two parts including a lower-frequency circuit and a radio-frequency circuit; the packaging of the radio-frequency IPD module with a three-dimensional structure is realized by adopting wafer-level planar machining and TSV (Through Silicon Via) three-dimensional integrated wafer technologies based on a high-resistance silicon material, and the interference of the radio-frequency IPD module on a signal circuit on the PCB system board is reduced. In the meantime, the area of occupying the PCB system board is correspondingly reduced, and device and system minimization is facilitated.

Owner:NAT CENT FOR ADVANCED PACKAGING

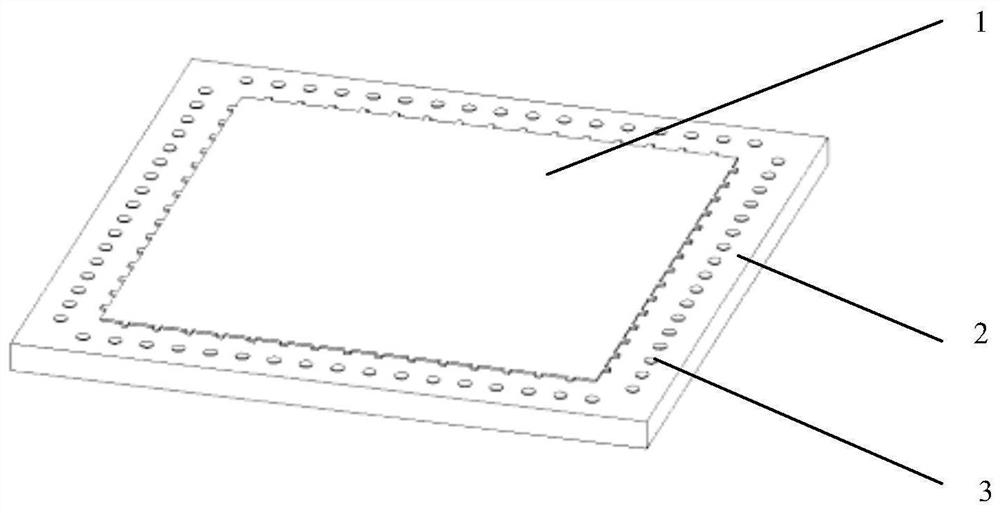

Base Substrate Which Prevents Burrs Generated During the Cutting Process and Method for Manufacturing the Same

ActiveUS20150049447A1Generation of burr can be minimized and eliminatedSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

A base substrate which prevents burrs generated during the cutting process includes: multiple conductive layers stacked in one direction with respect to the base substrate; at least one insulation layer being alternately stacked with said conductive layers and electrically separating said conductive layers; and a through-hole penetrating said base substrate covering said insulation layer at the contact region where said cut surface and said insulation layer meet during the cutting of said base substrate in accordance with a predetermined region of the chip substrate. A method of manufacturing the base substrate includes alternately stacking conductive layers and insulation layers and forming a through-hole.

Owner:POINT ENG

Printed circuit board with embedded electronic component and manufacturing method thereof

ActiveUS9999131B2Semiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

A printed circuit board including an electronic component and a method of producing the same are provided. The printed circuit board includes a multilayered substrate including an insulation layer and an inner circuit layer laminated therein, a cavity disposed in the multilayered substrate, a via disposed in the insulation layer and configured to electrically connect the inner circuit layer with another inner circuit layer, a first electronic component inserted in the cavity, and a bump pad disposed on a surface of the cavity facing the first electronic component, and the bump pad is formed by having the insulation layer and the via exposed to a lateral side of the cavity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

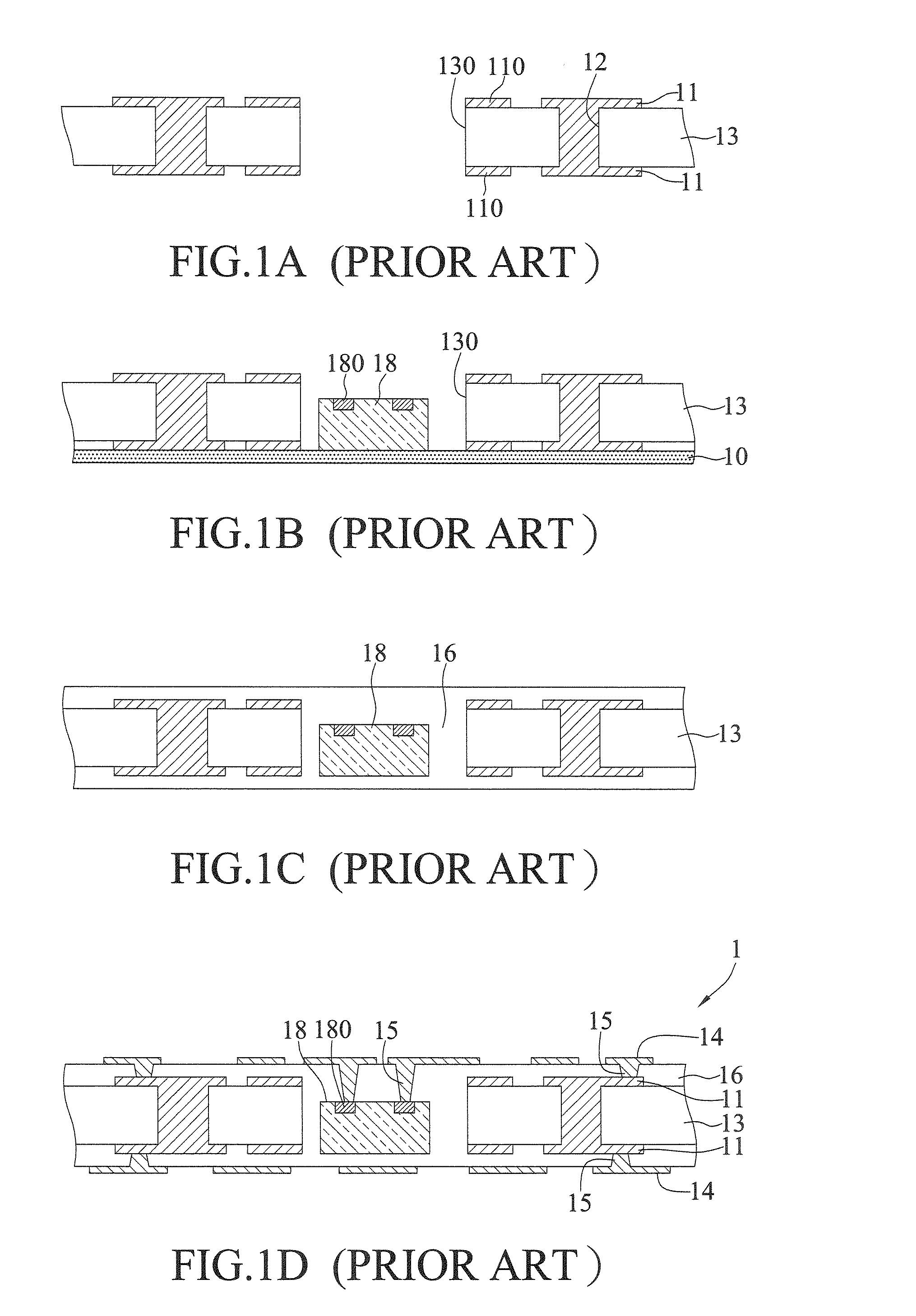

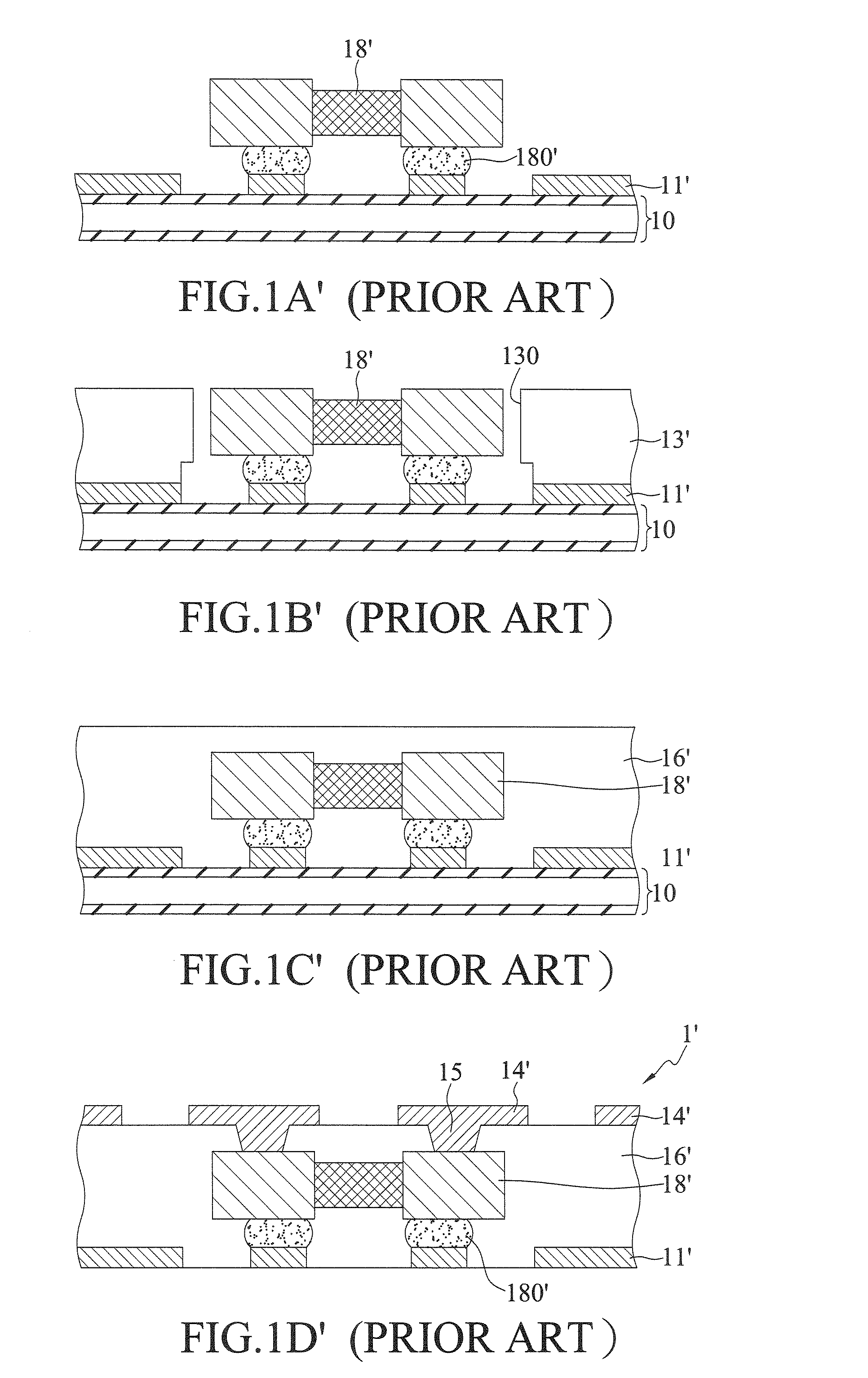

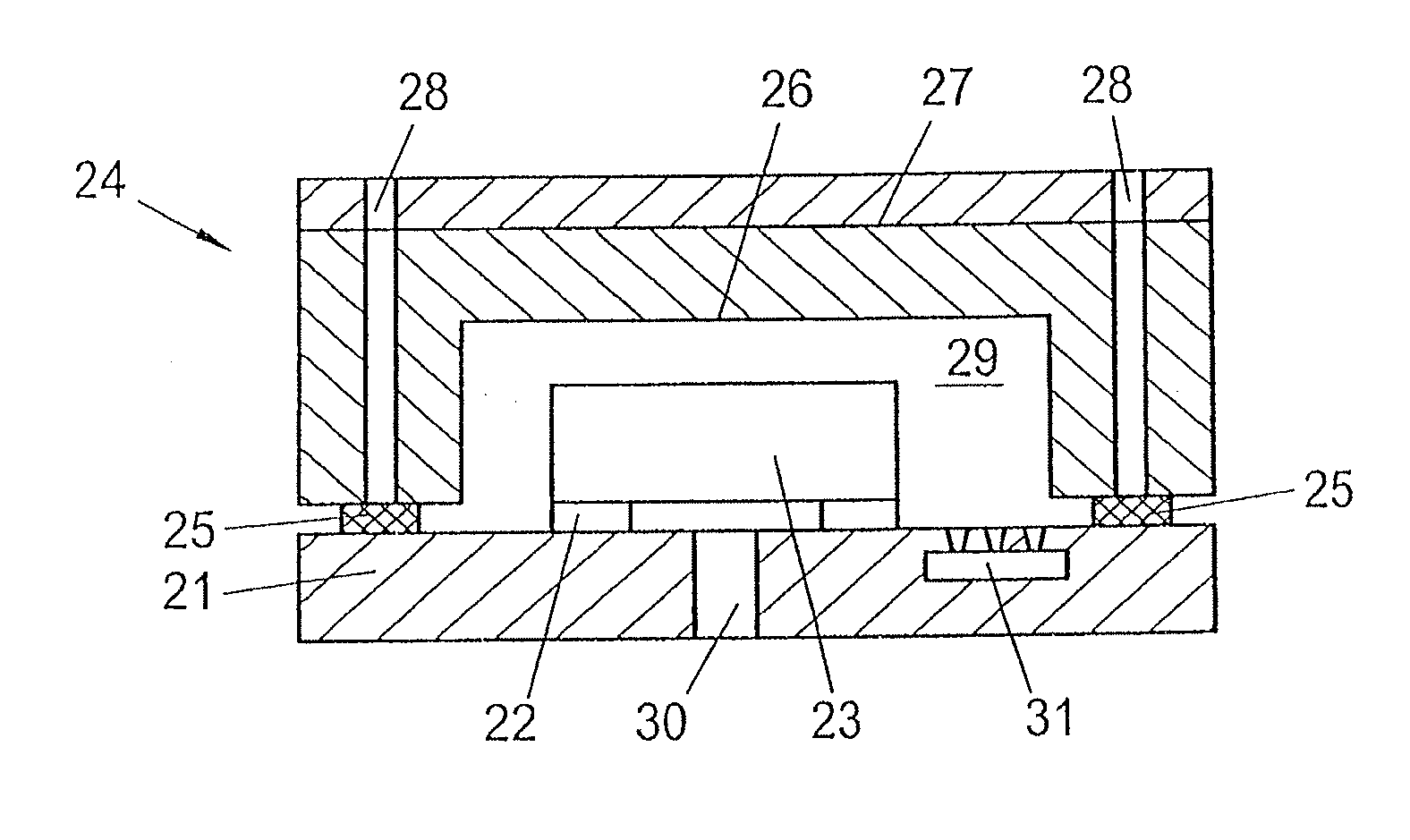

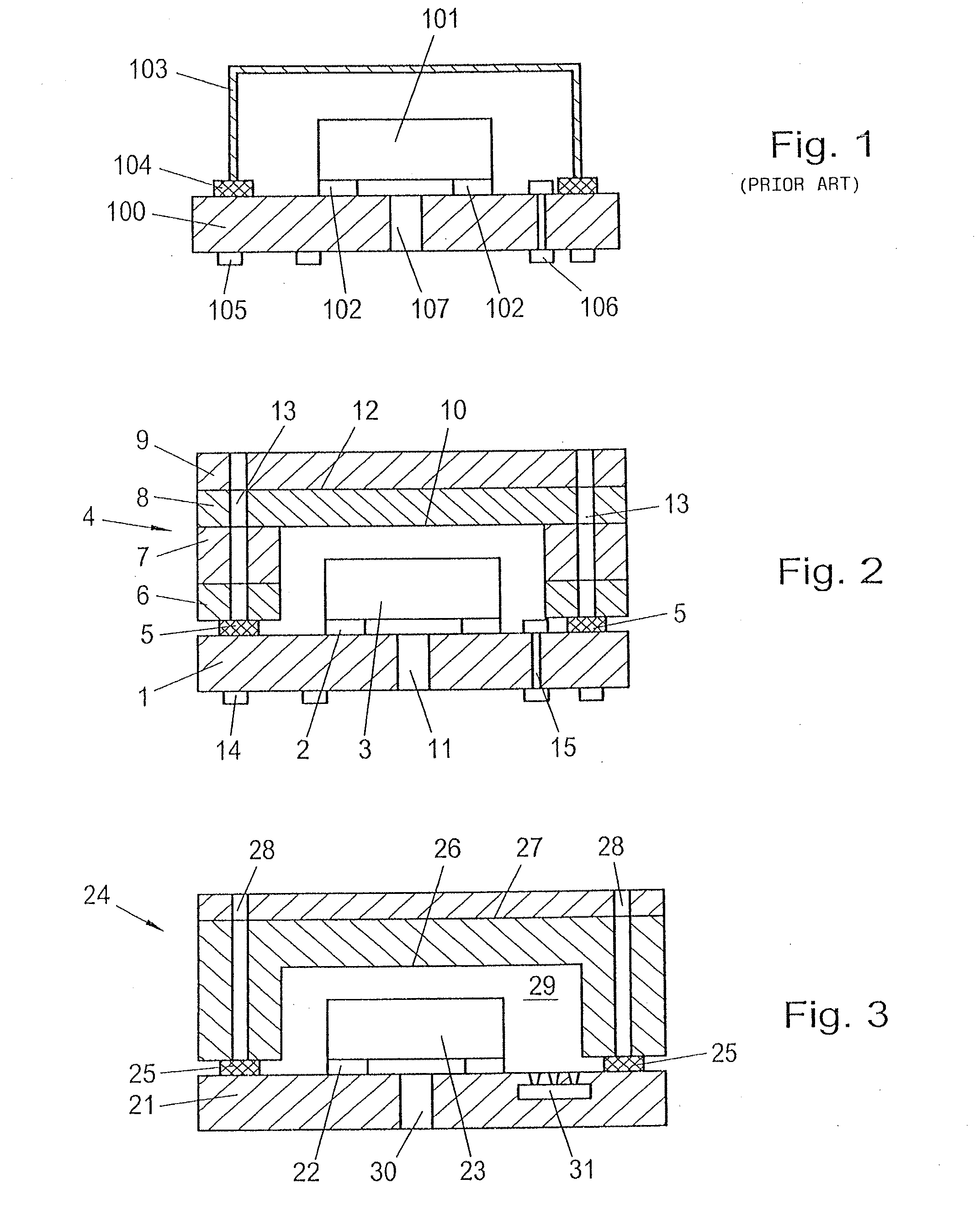

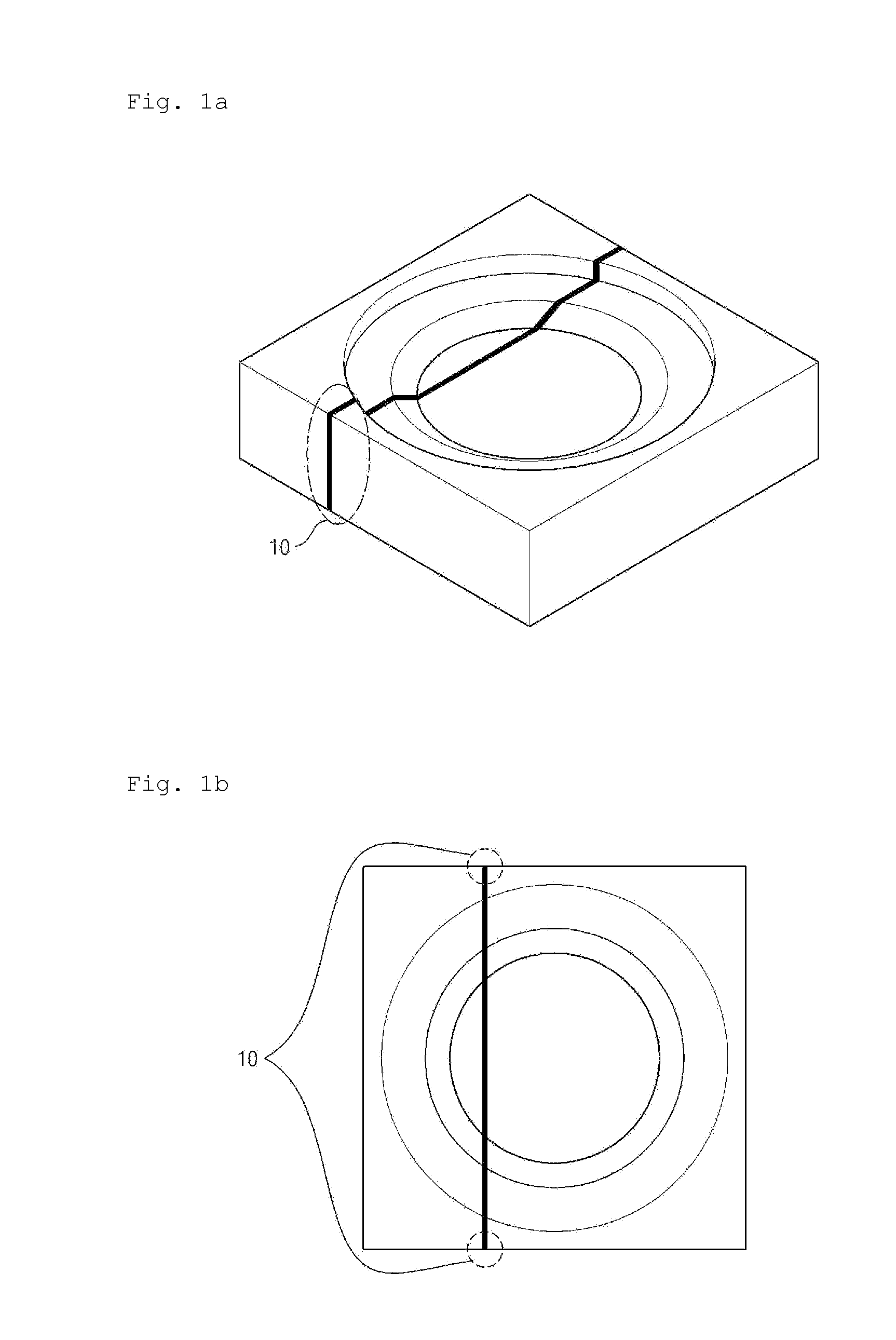

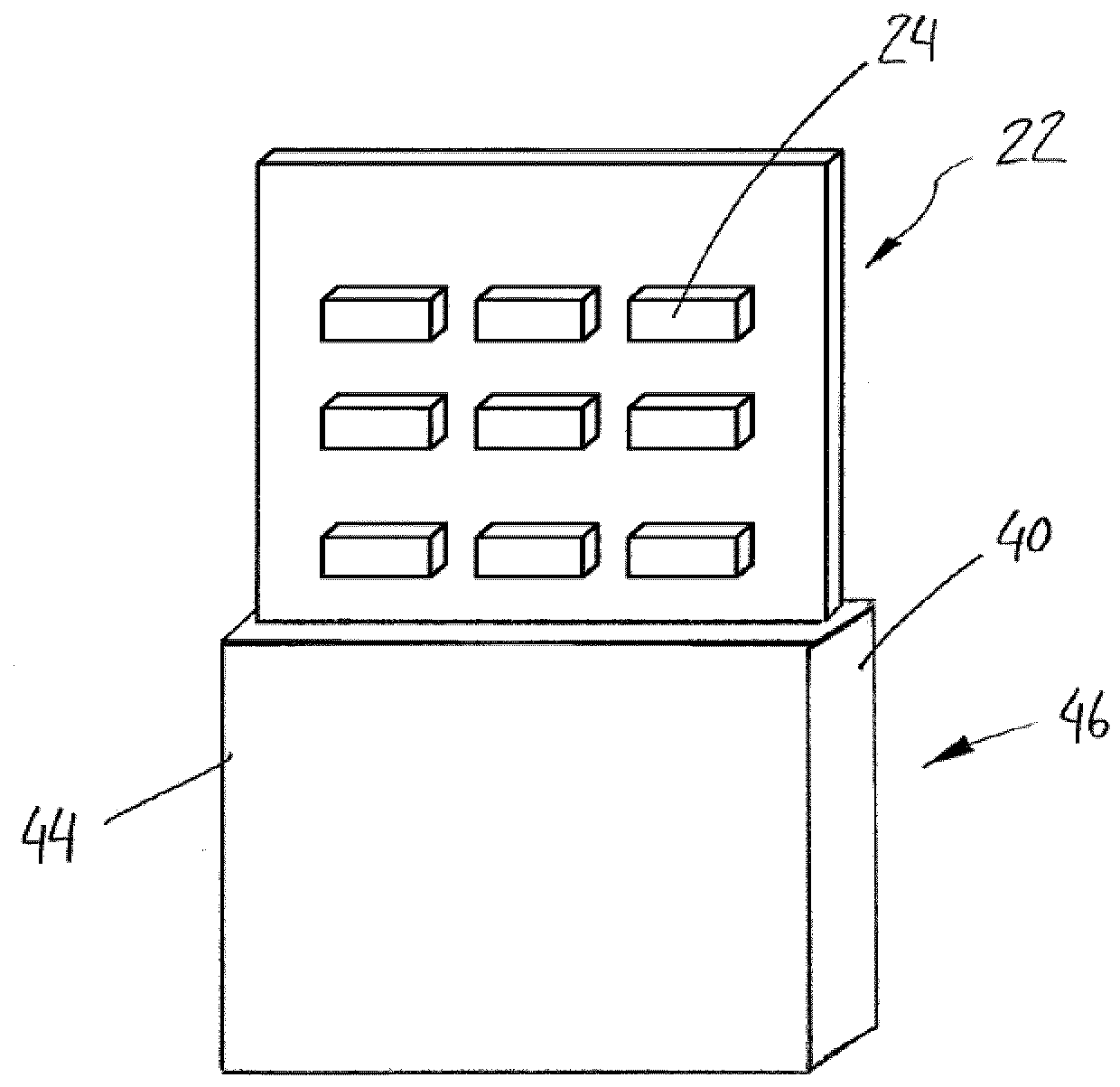

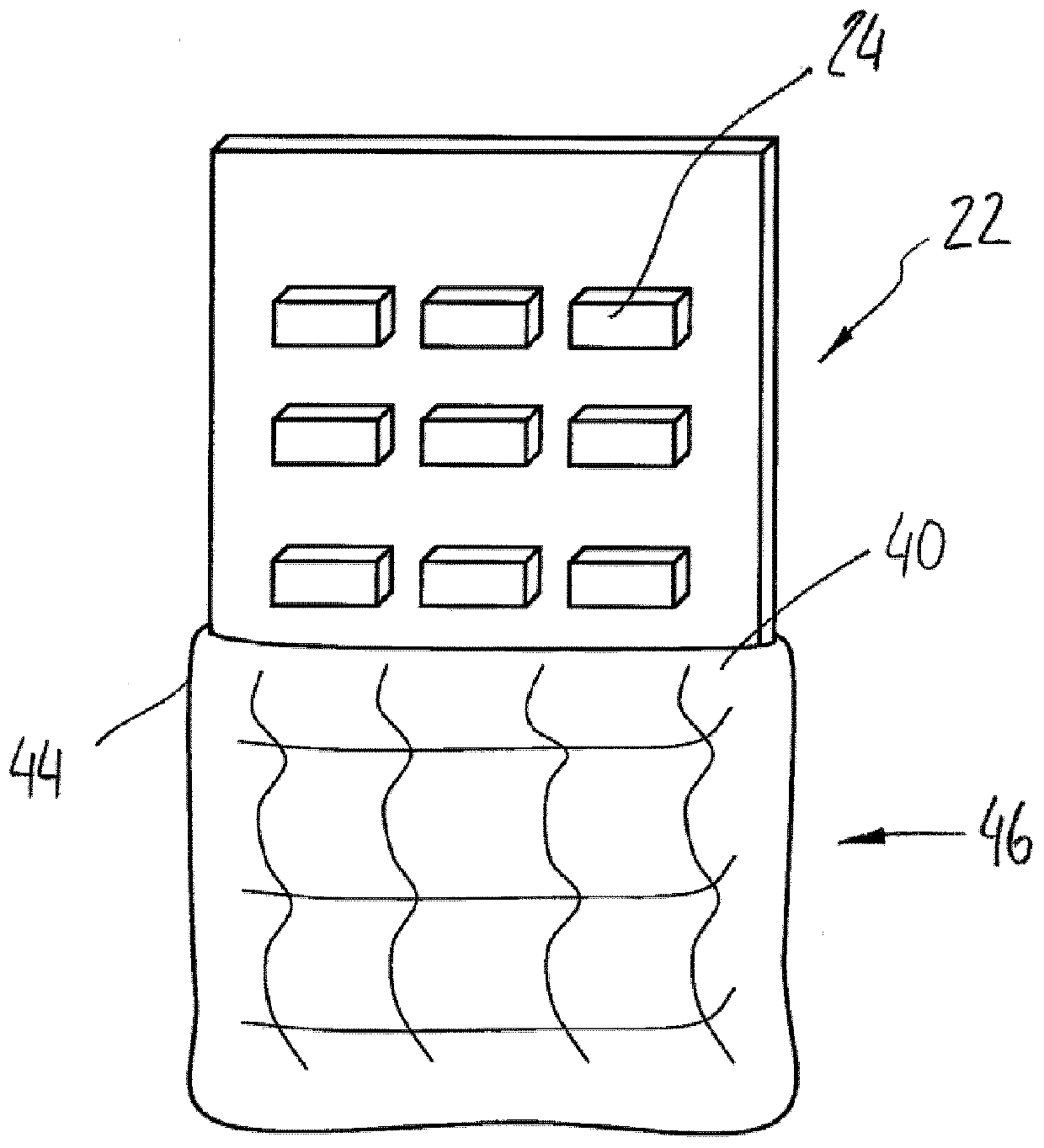

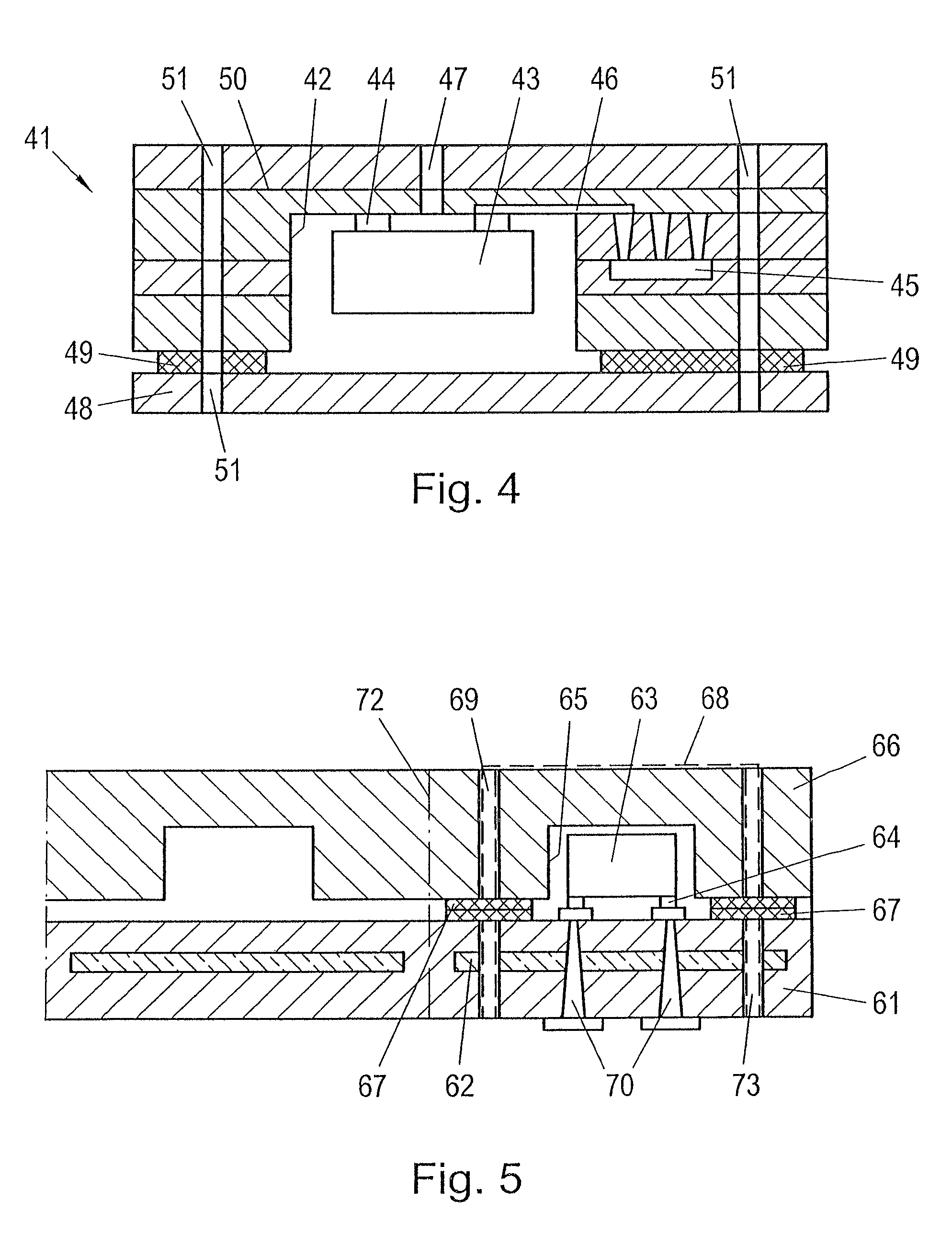

Method for integrating an electronic component into a printed circuit board, and printed circuit board comprising an electronic component integrated therein

ActiveUS20130008703A1Avoid connectionPrinted circuit assemblingCross-talk/noise/interference reductionElectronic componentPrinted circuit board

In a method for integrating a component (3) into a printed circuit board, the following steps are provided:providing two completed printed circuit board elements (1, 4), which more particularly consist of a plurality of interconnected plies or layers (6, 7, 8), wherein at least one printed circuit board element (4) has a cutout or depression (10),arranging the component (3) to be integrated on one of the printed circuit board elements (1) or in the cutout of the at least one printed circuit board element, andconnecting the printed circuit board elements (1, 4) with the component (3) being accommodated in the cutout (10), as a result of which it is possible to obtain secure and reliable accommodation of a component or sensor (3) in a printed circuit board.Furthermore, a printed circuit board of this type comprising an electronic component (3) integrated therein is provided.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

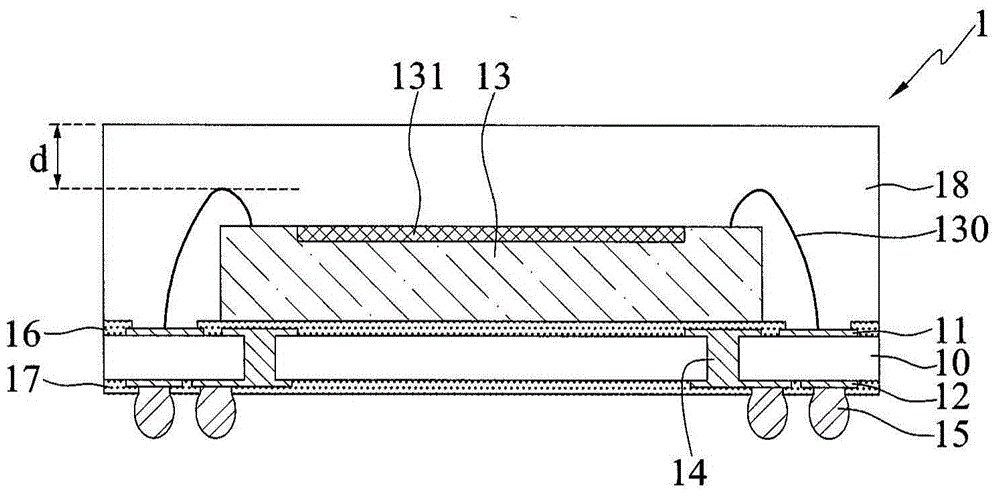

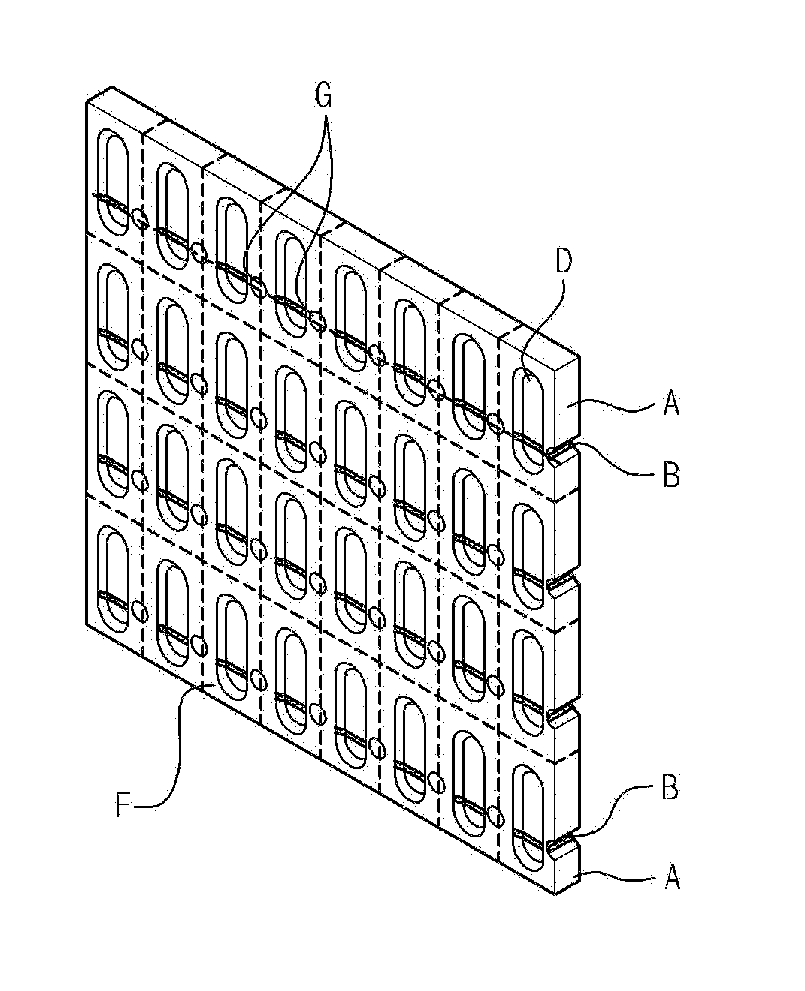

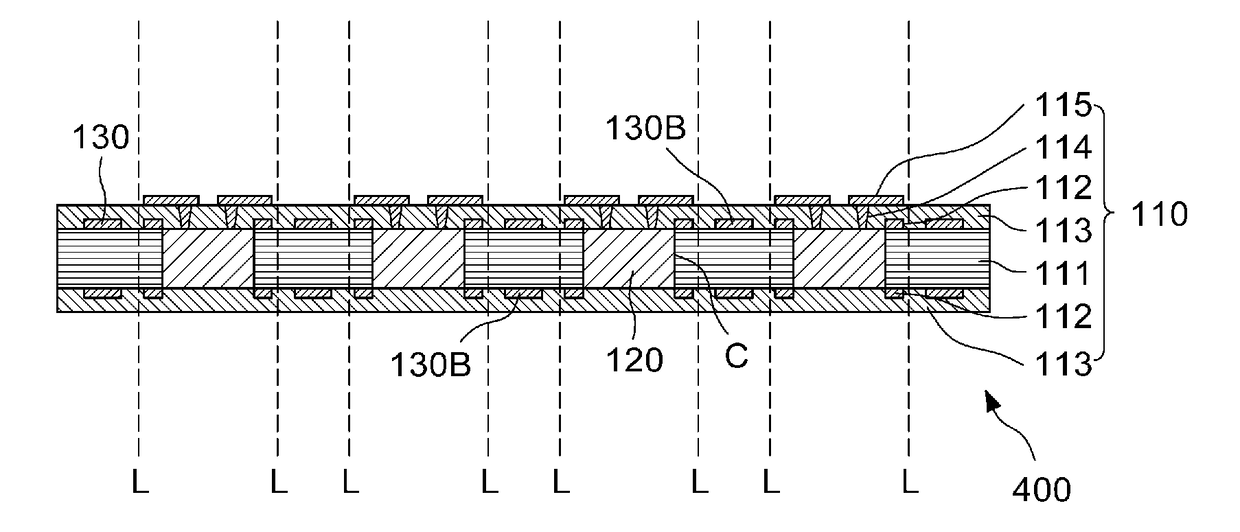

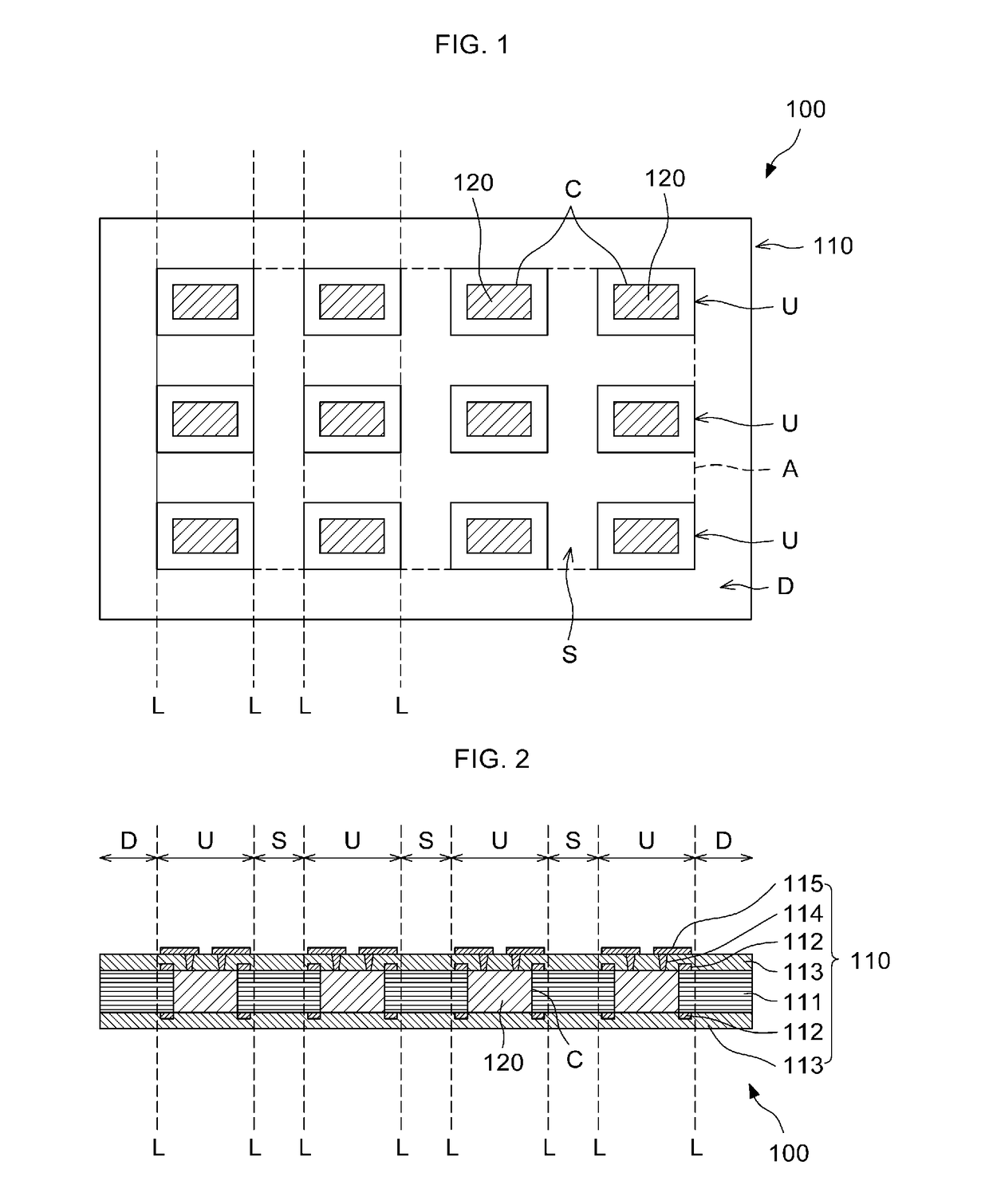

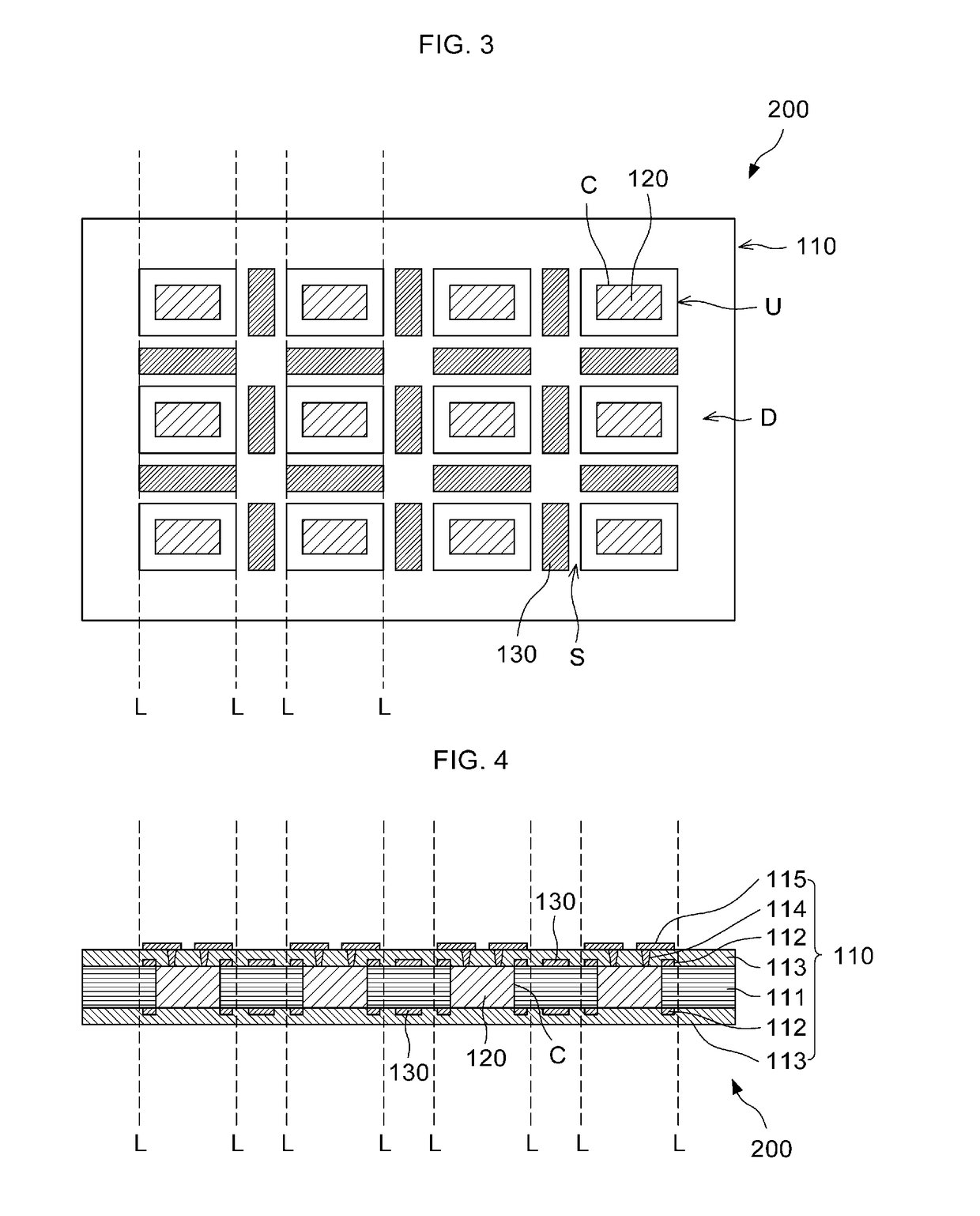

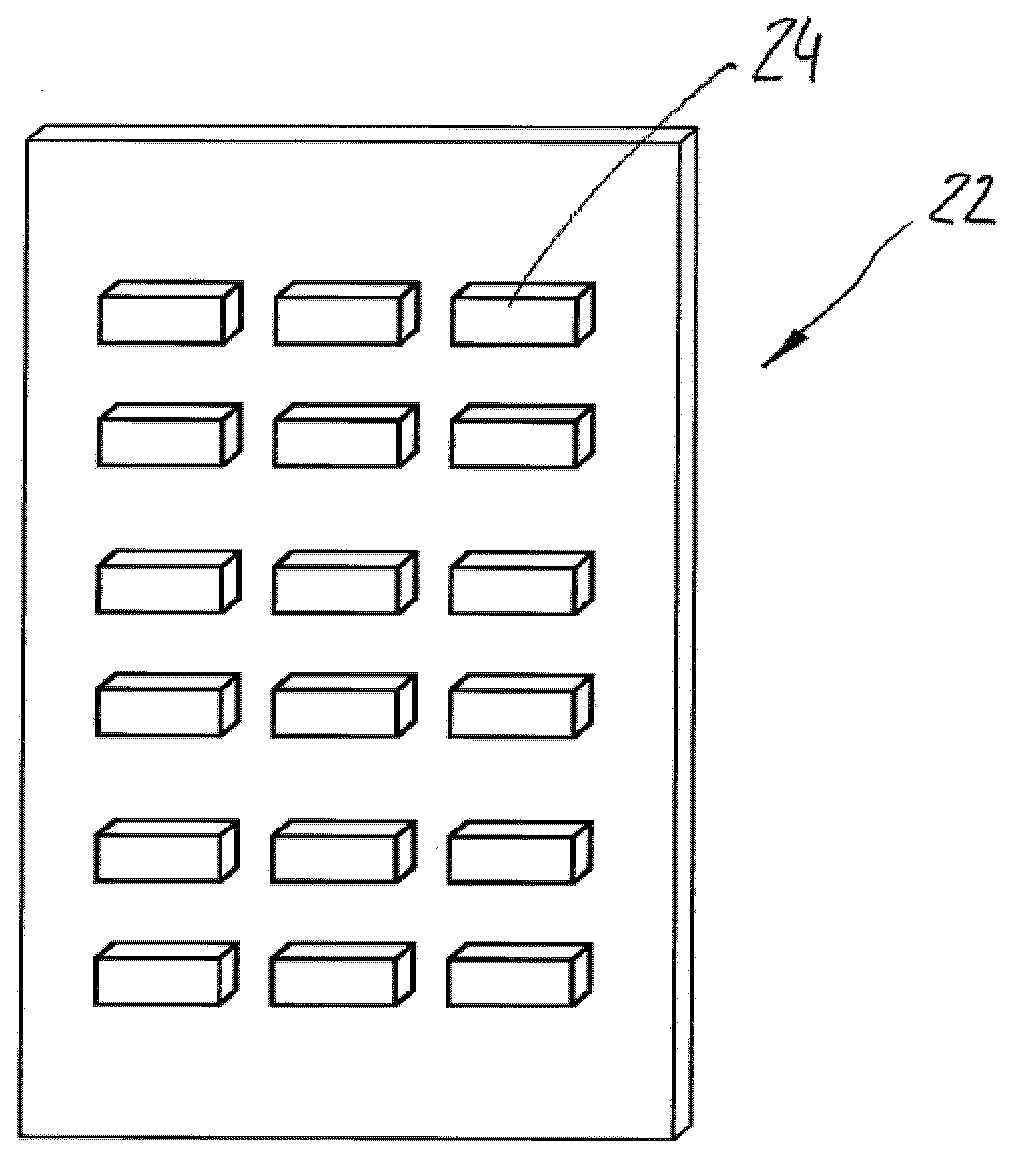

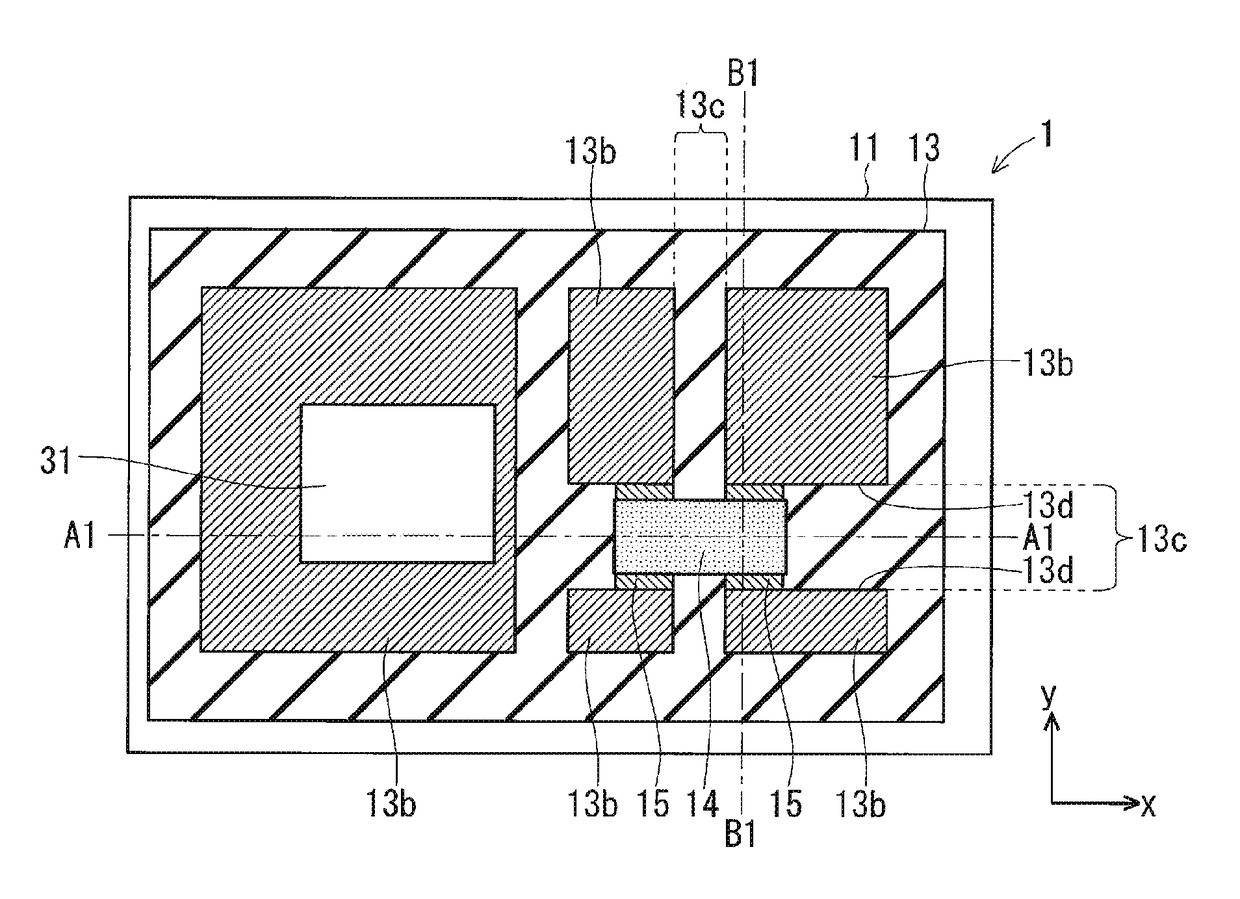

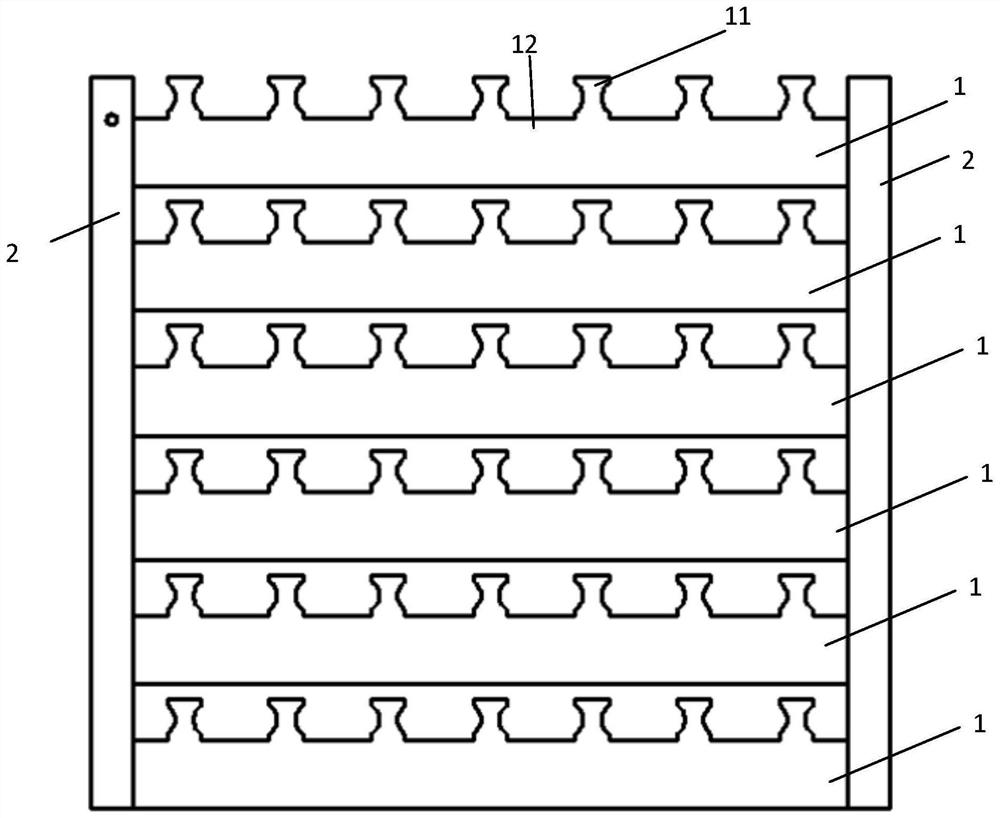

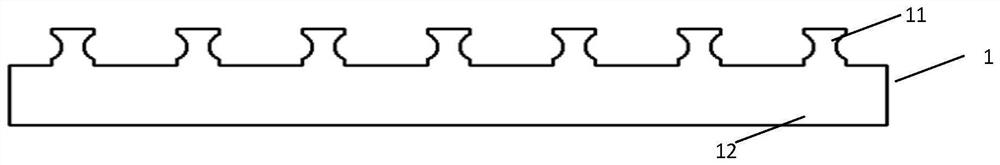

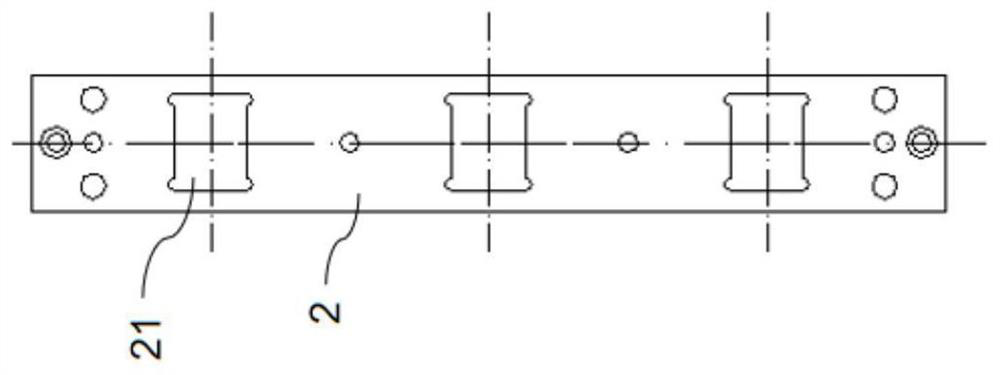

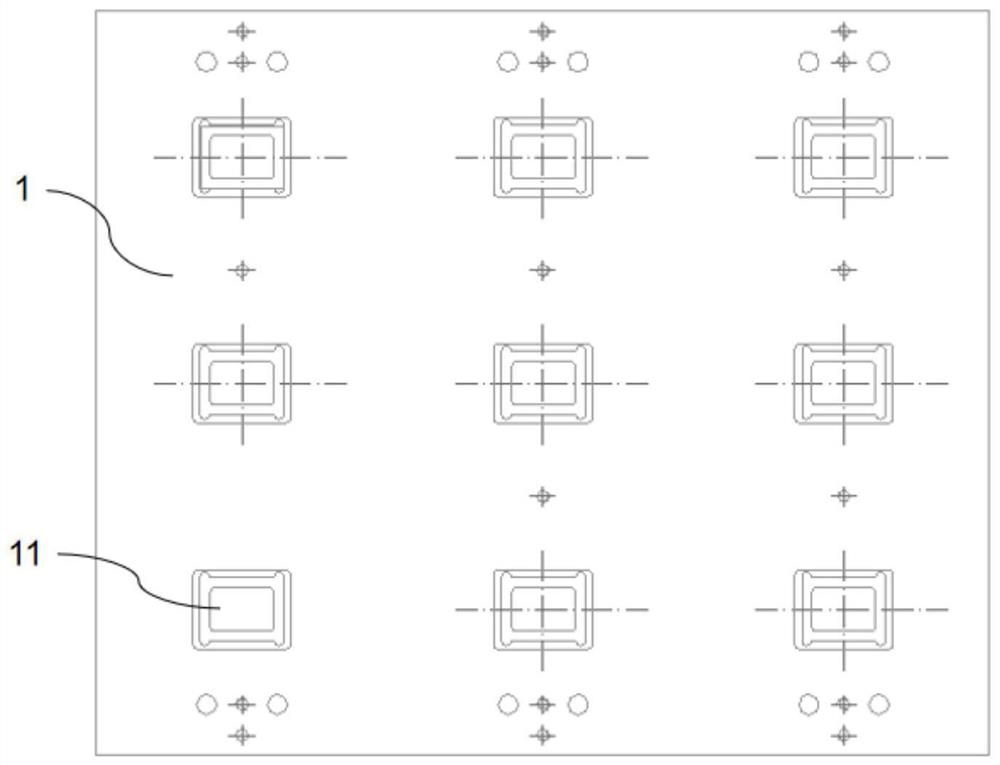

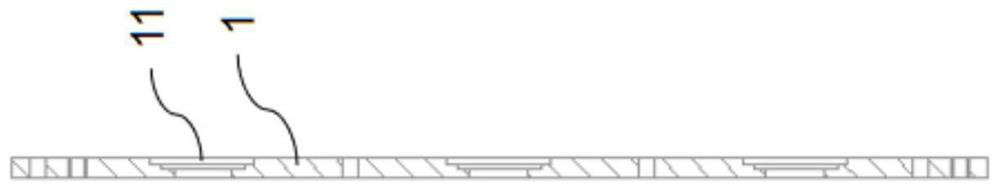

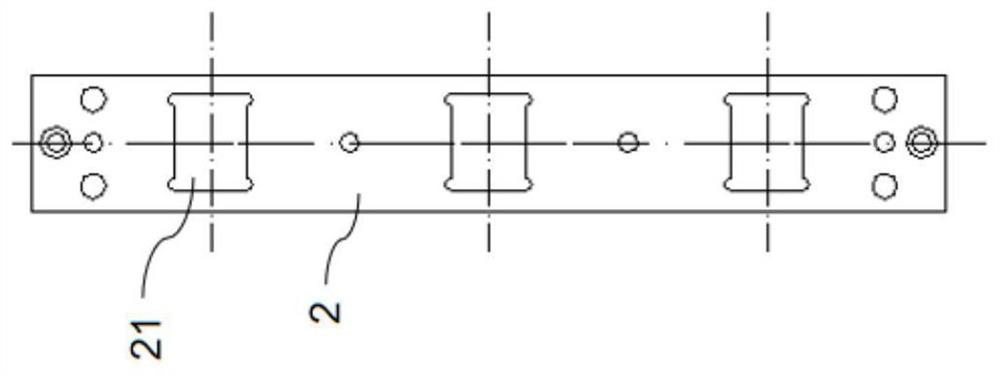

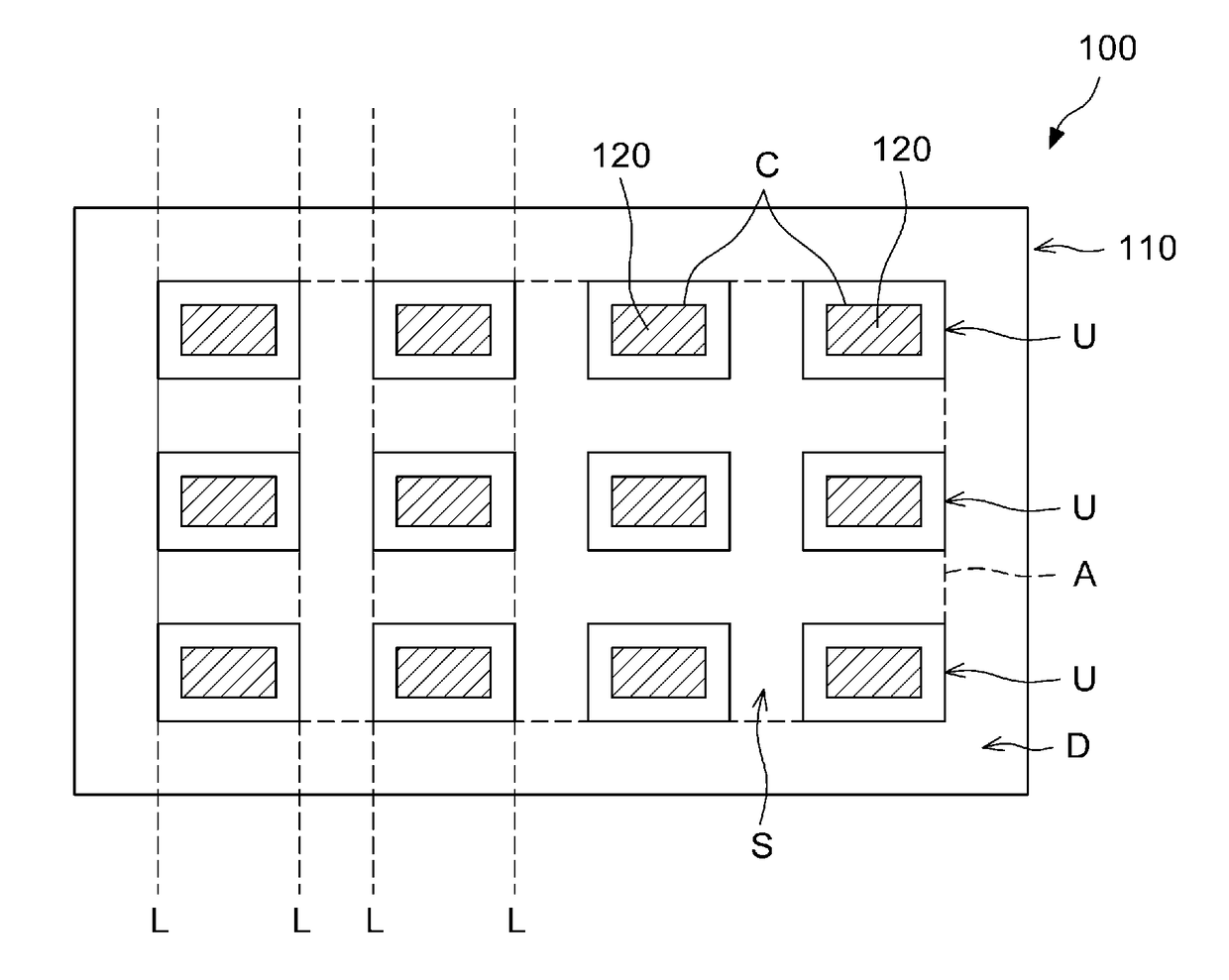

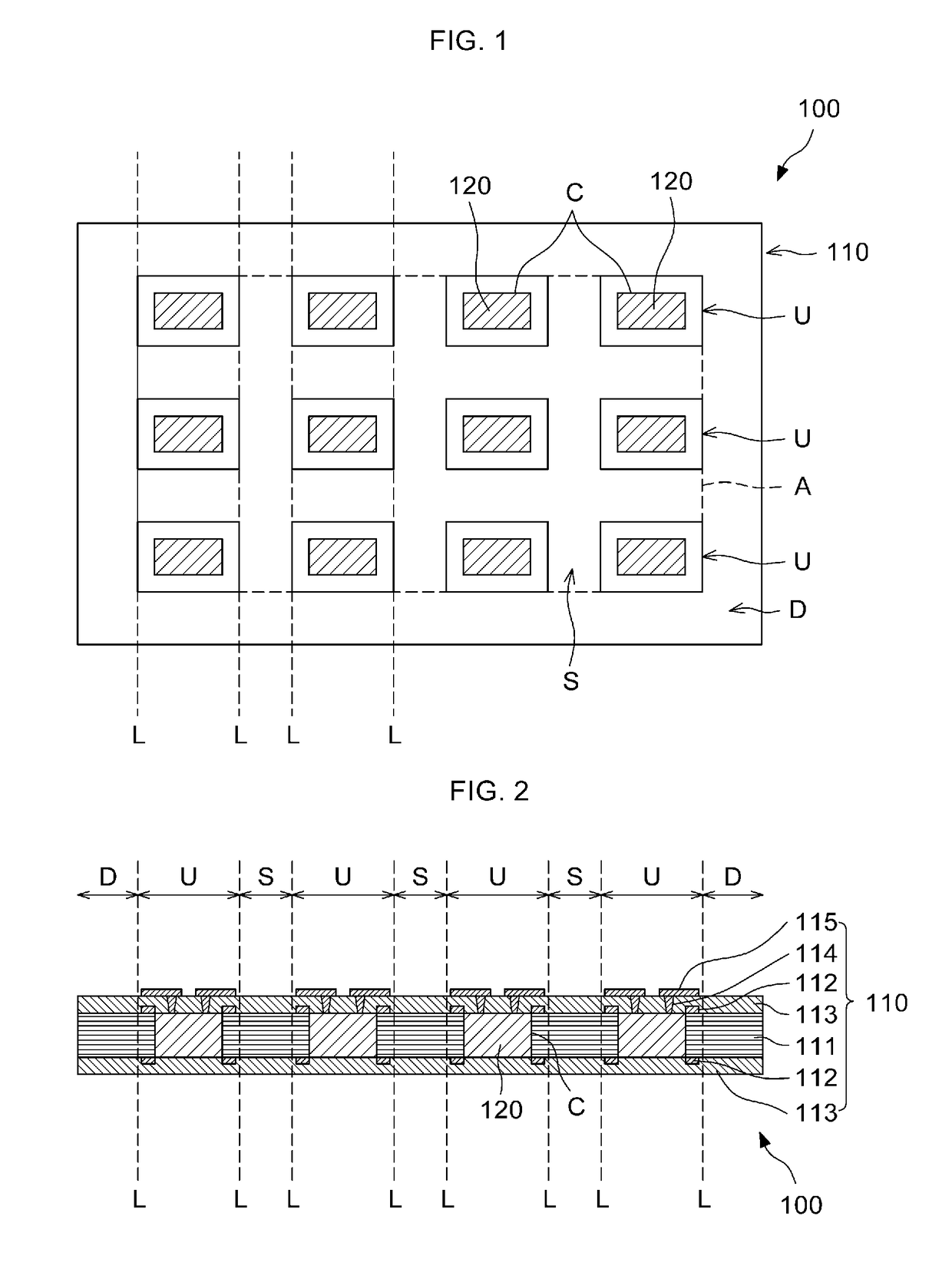

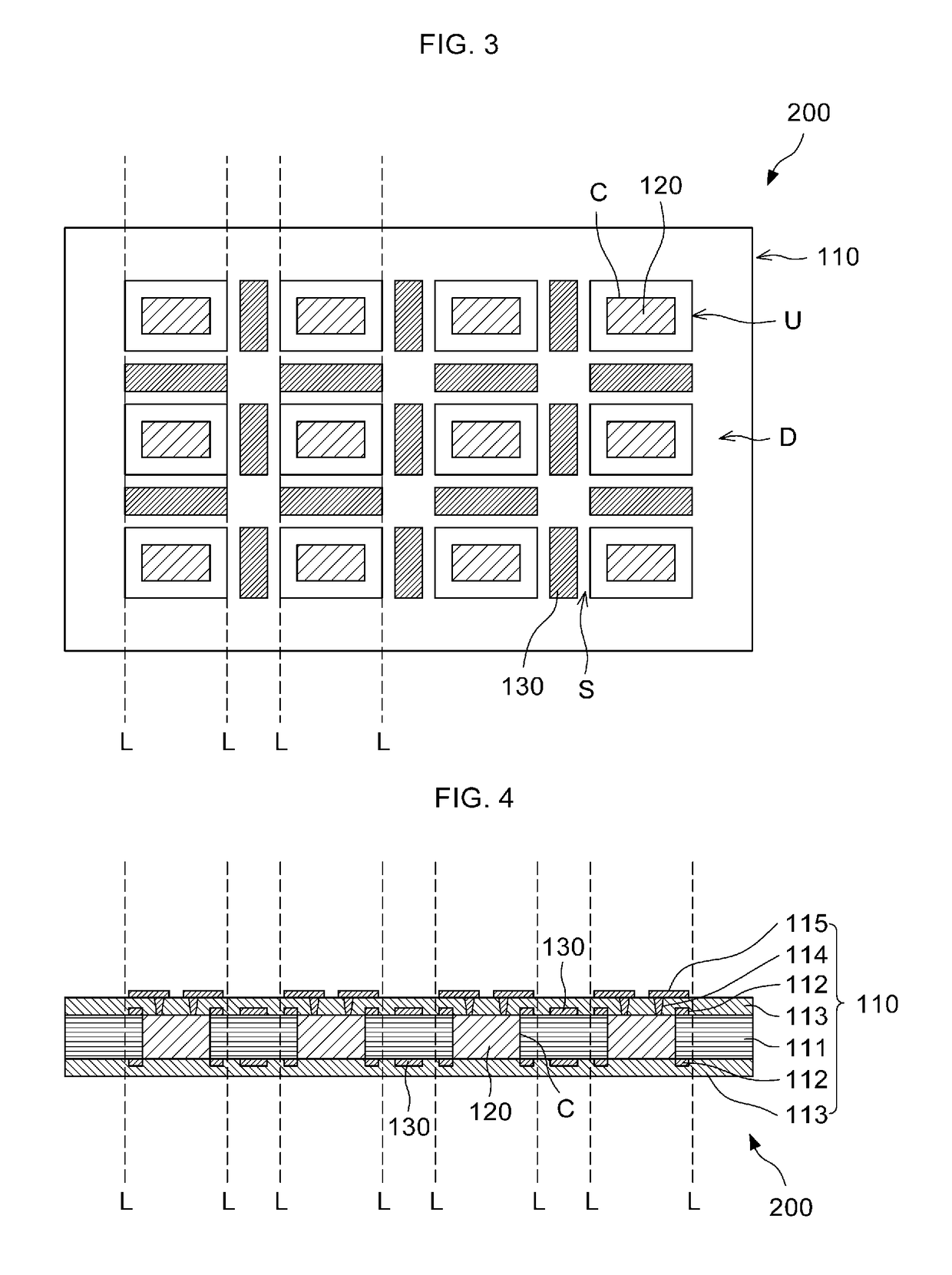

Printed circuit board

ActiveUS20170079143A1Well formedPrinted circuits stress/warp reductionInsulating layers/substrates workingElectronic componentPrinted circuit board

A printed circuit board includes: a strip substrate sectioned into unit areas; electronic components respectively installed in each of the unit areas; and a separation space disposed between the unit areas.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

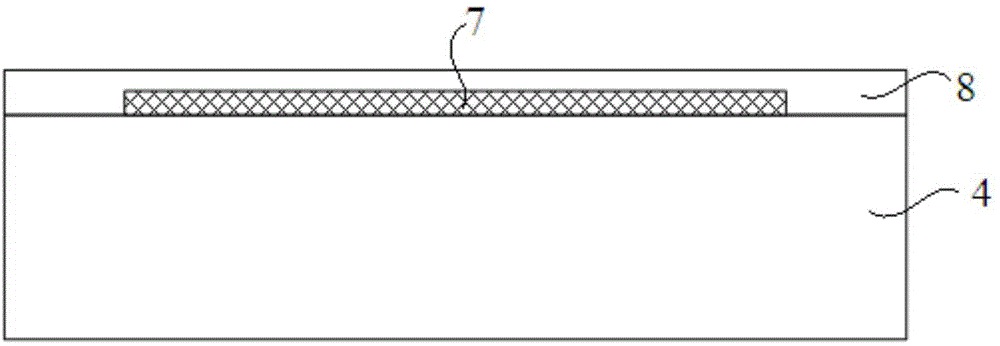

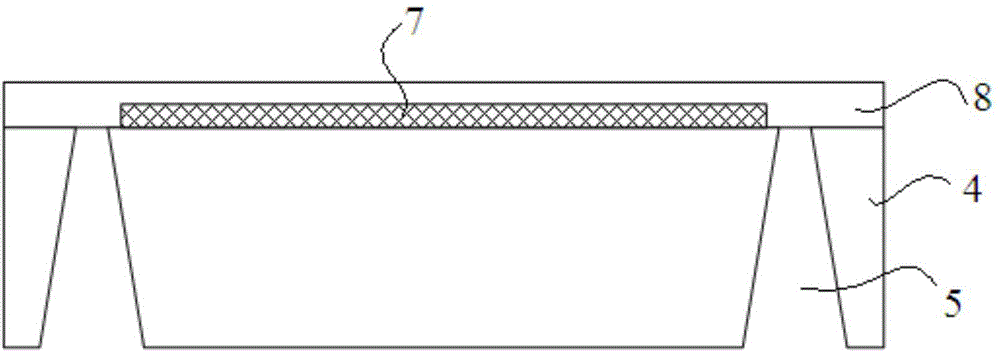

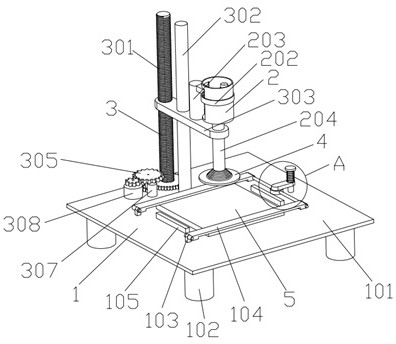

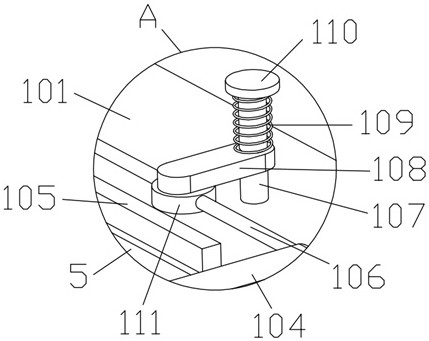

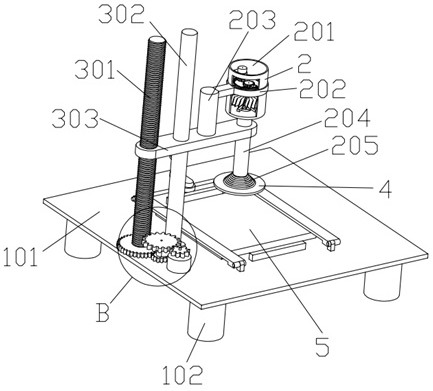

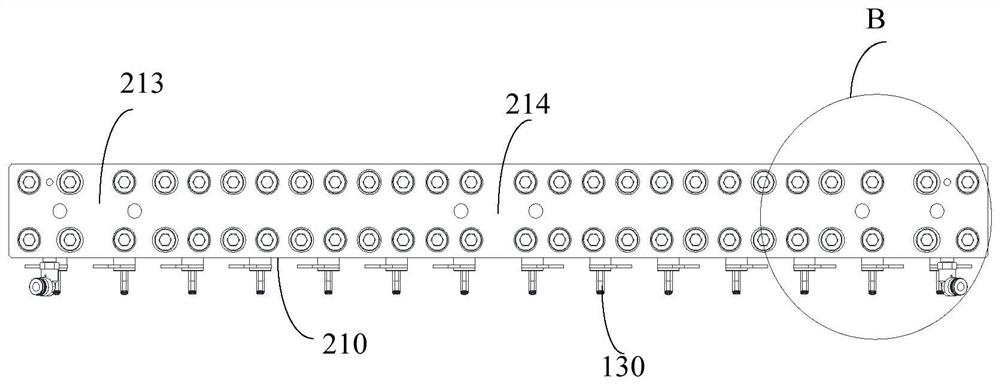

Vacuum fixed installation system for integrated circuit

InactiveCN111970855AAvoid burnsSolve the problem of easy scratches on the surface of silicon wafersPrinted circuit assemblingPCB attached/integrated componentsWaferingEngineering

The invention discloses a vacuum fixed installation system for an integrated circuit. The vacuum fixed installation system comprises a fixing module, an adsorption module, a positioning module, a silicon wafer and a PCB. By arranging the fixing module, not only can the PCB be fixed on the upper surface of the heating table, but also the PCB can be heated, so that mutual pressing of the PCB is replaced, the phenomenon that an operator is scalded is avoided, the adsorption module is arranged to replace a clamp in an adsorption manner, and the problem that the clamp is easy to scratch the surfaceof the silicon wafer in the process of clamping the silicon wafer is solved.

Owner:隋心怡

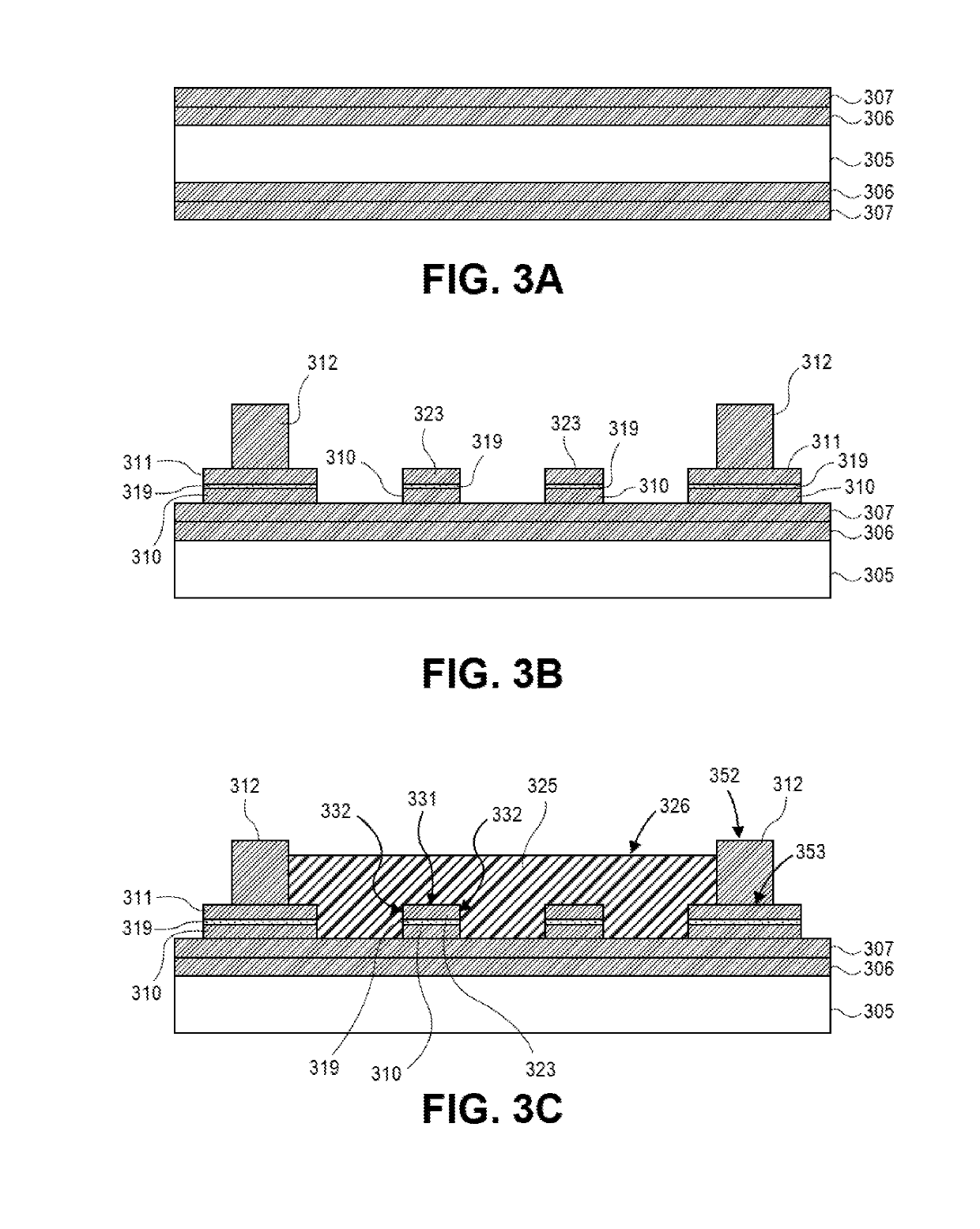

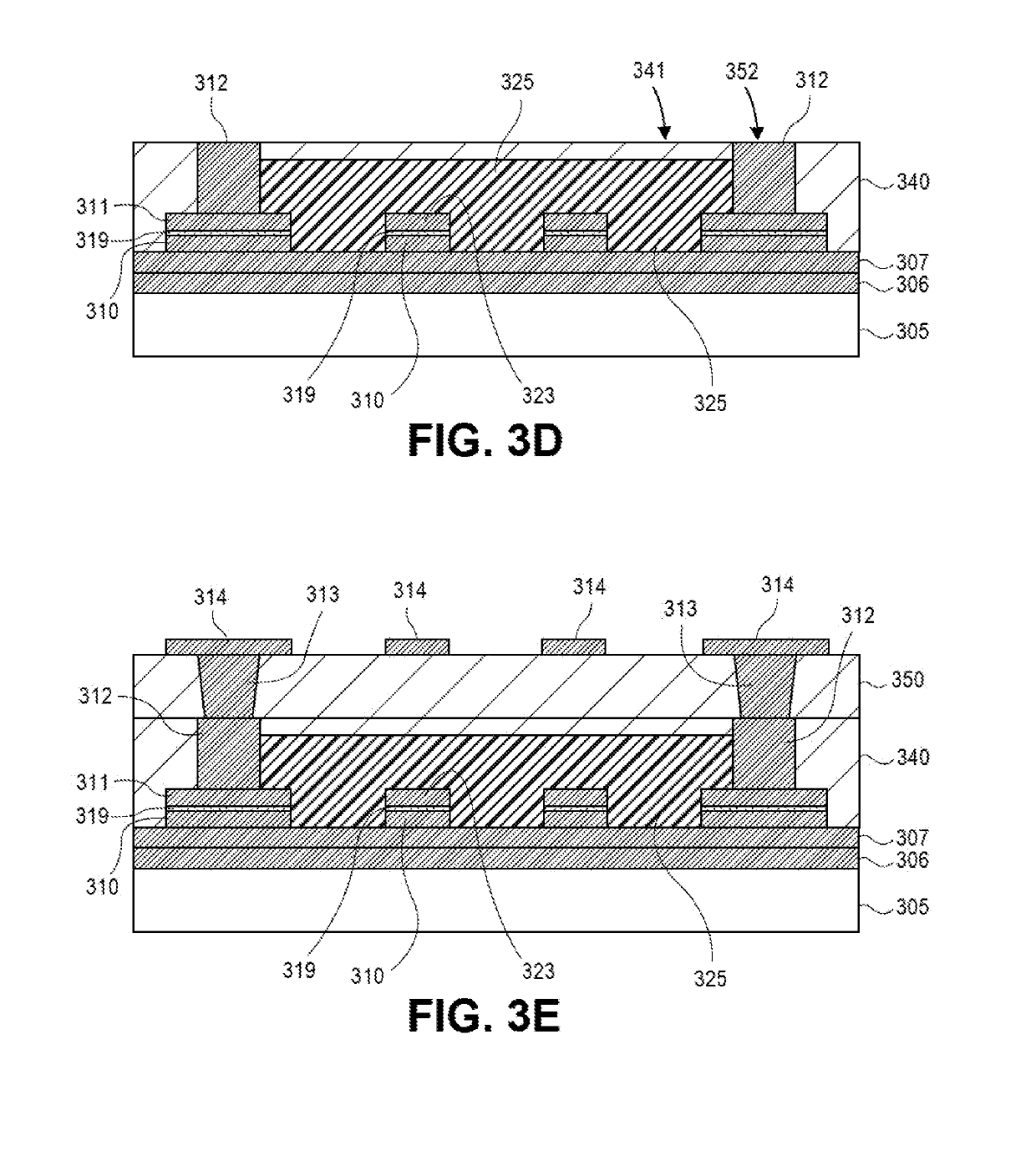

Methods to selectively embed magnetic materials in substrate and corresponding structures

ActiveUS20190304661A1Transformers/inductances casingsSemiconductor/solid-state device detailsInductorEngineering

Embodiments include an inductor that comprises an inductor trace and a magnetic body surrounding the inductor trace. In an embodiment, the magnetic body comprises a first step surface and a second step surface. Additional embodiments include an inductor that includes a barrier layer. In an embodiment, an inductor trace is formed over a first surface of the barrier layer. Embodiments include a first magnetic body over the inductor trace and the first surface of the barrier layer, and a second magnetic body over a second surface of the barrier layer opposite the first surface. In an embodiment, a width of the second magnetic body is greater than a width of the first magnetic body.

Owner:INTEL CORP

Chip pin expansion device

InactiveCN112492752AIncrease the number ofMeet functional requirementsPCB attached/integrated componentsPrinted circuit non-printed electric components associationMechanical engineeringEmbedded system

The invention provides a chip pin expansion device which comprises an expansion board, a plurality of regularly arranged pins are arranged on the expansion board, the expansion board is welded to theedge of a main chip, and the number of the pins of the main chip is increased. According to the invention, the I / O quantity can be expanded in BGA packaging of the same size. By changing the structureof the chip and increasing the number of the pins, the function requirement is met, meanwhile, the occupied space of a PCB can be saved, the PCB design time is shortened, and the chip is suitable forapplication and popularization.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

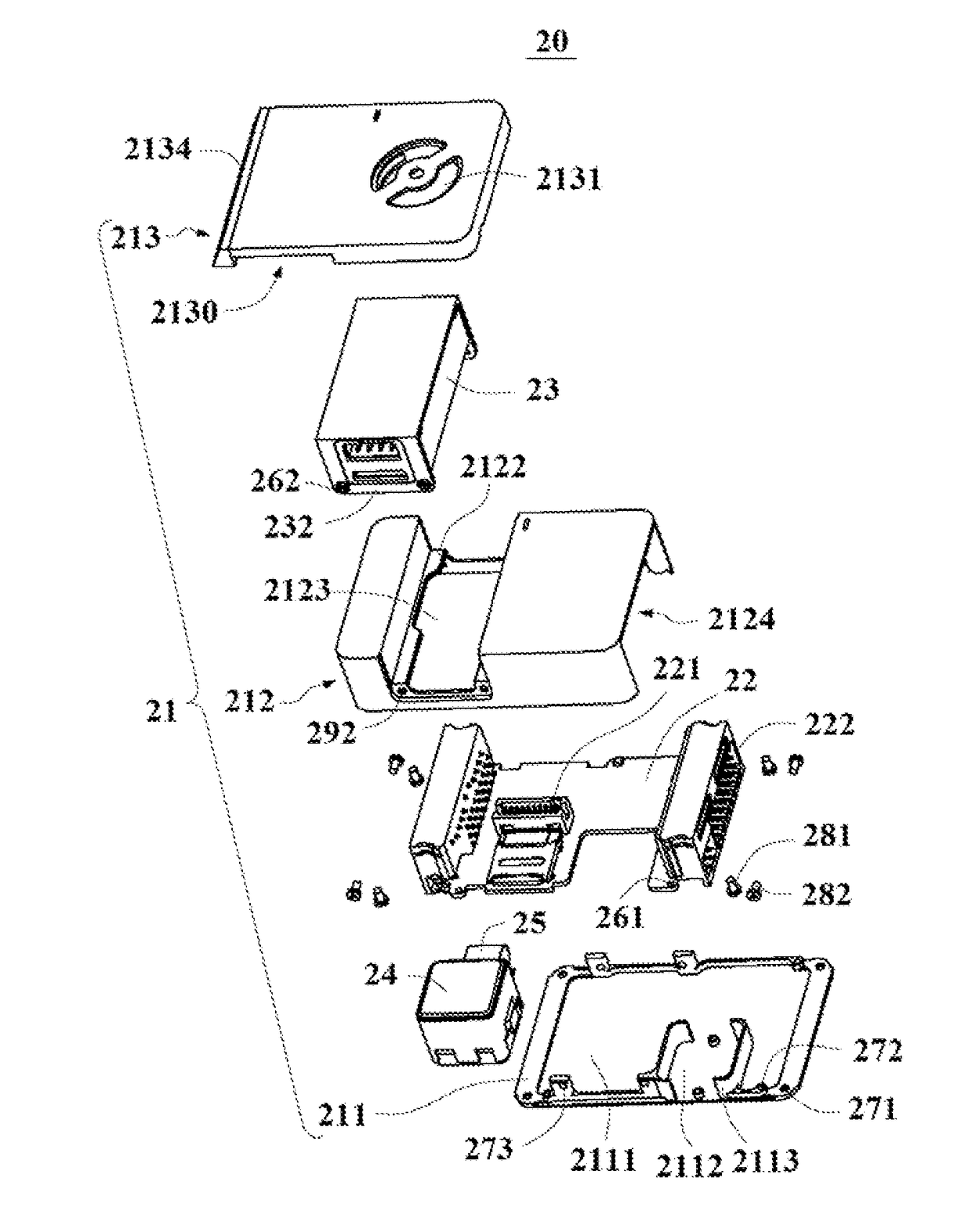

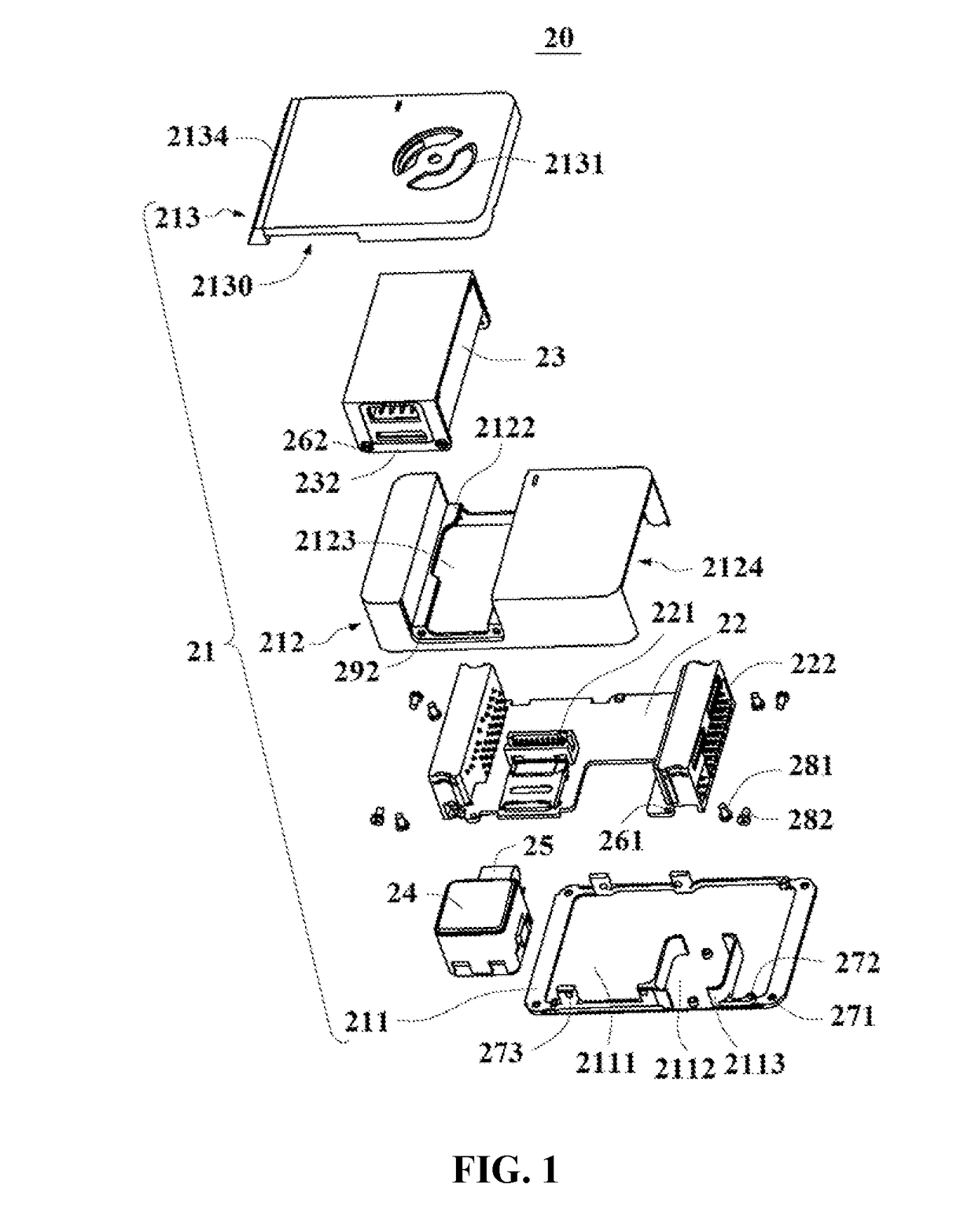

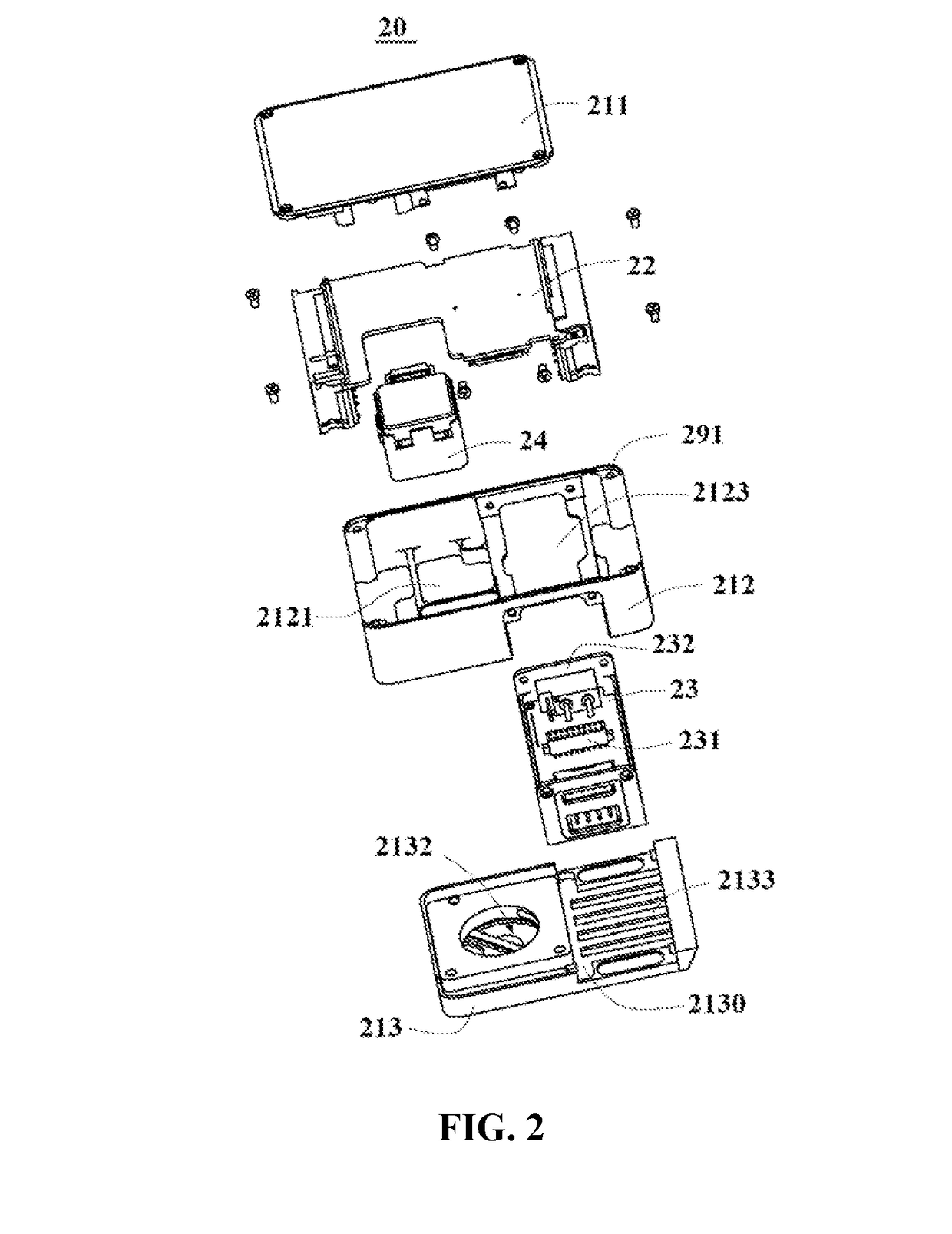

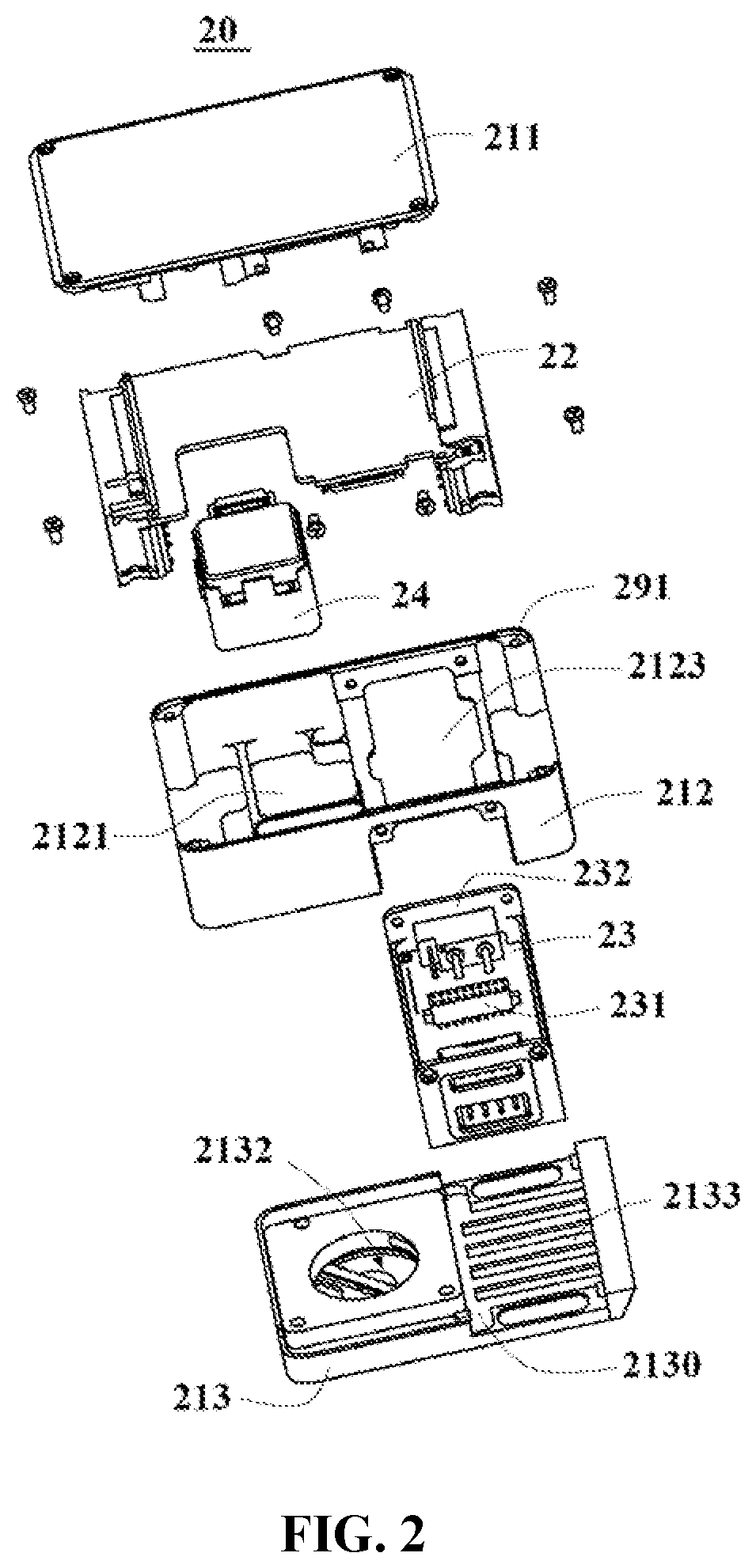

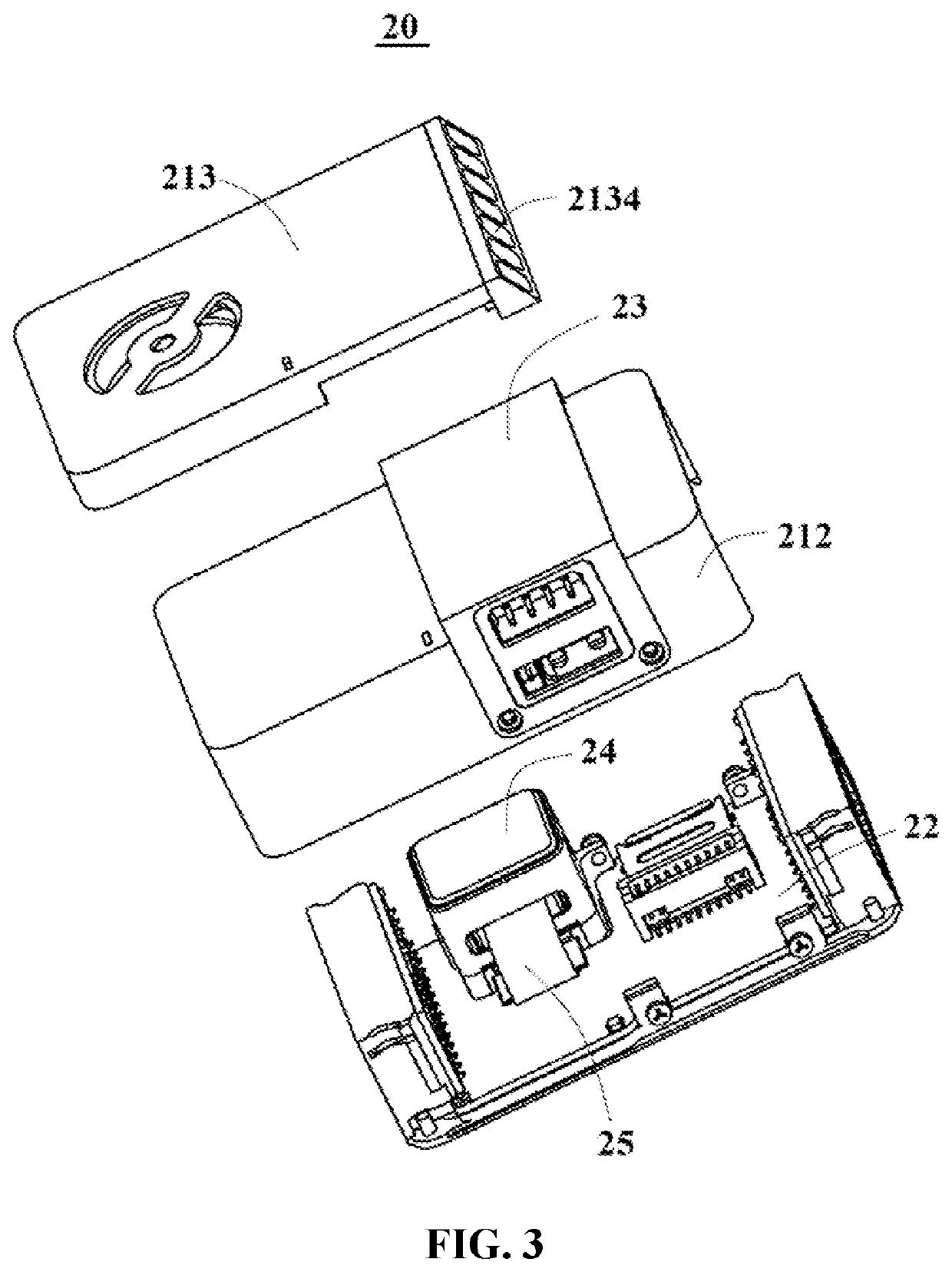

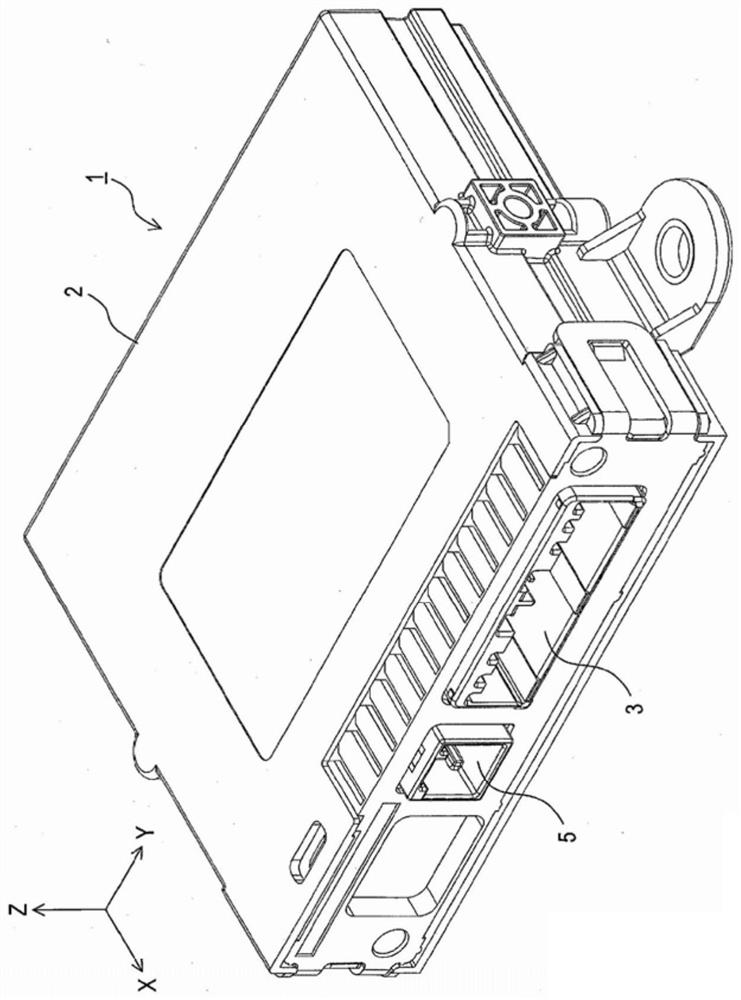

Flight control device and unmanned aerial vehicle having the same

ActiveUS20180244388A1High system integrationCompact configurationUnmanned aerial vehiclesCasings/cabinets/drawers detailsFlight control modesMarine engineering

A flight control device includes a housing, a main control board provided in the housing, an inertial measurement unit provided in the housing and electrically connected to the main control board, and a power management unit provided at the housing and electrically connected to the main control board. The main control board, the inertial measurement unit, and the power management unit are fixedly connected to and integrated with the housing as a whole.

Owner:SZ DJI TECH CO LTD

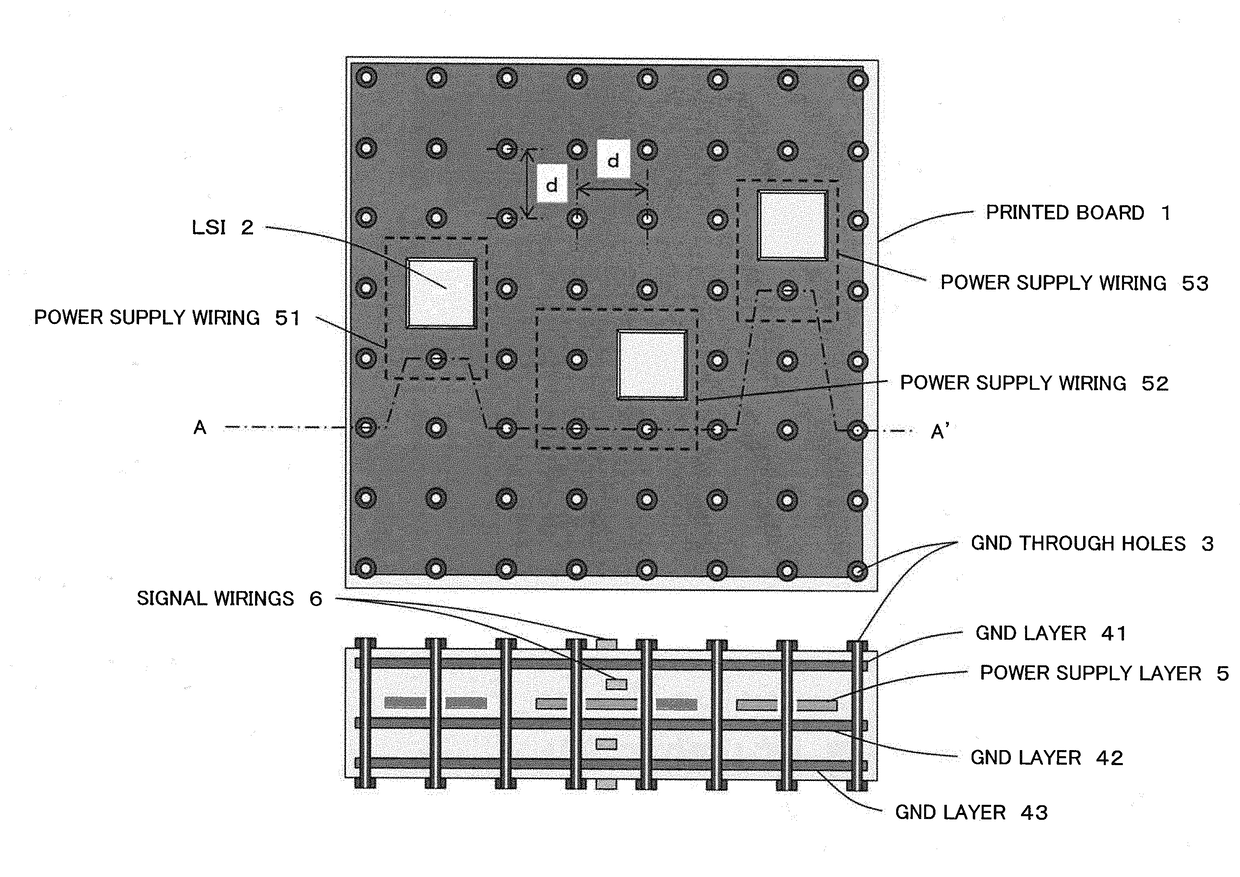

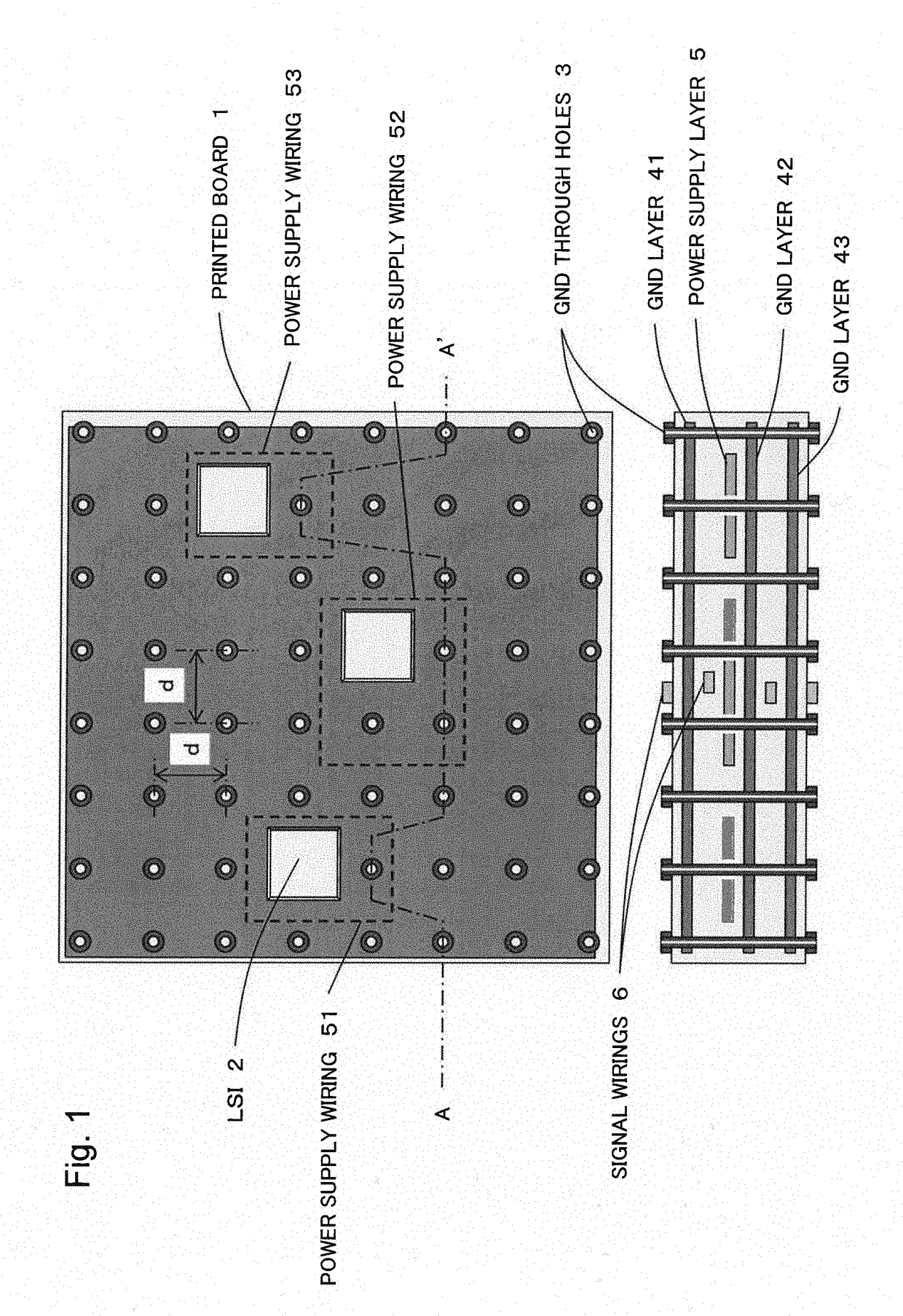

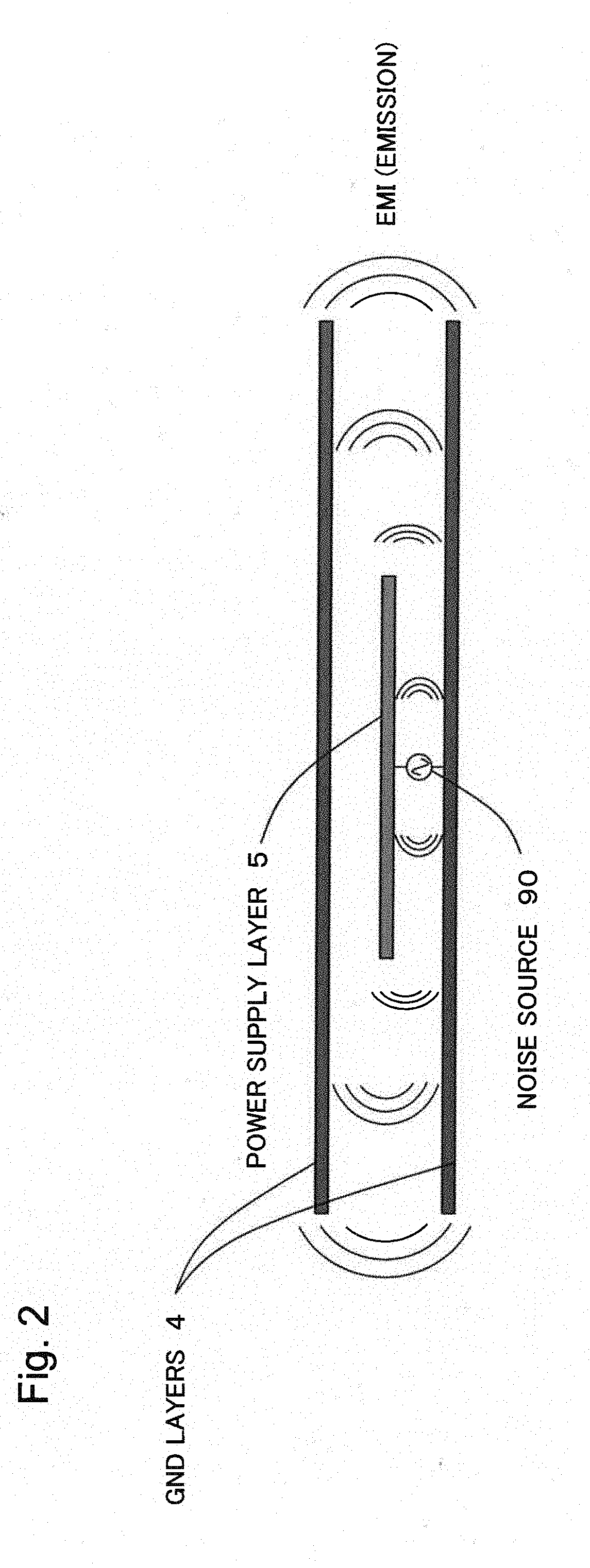

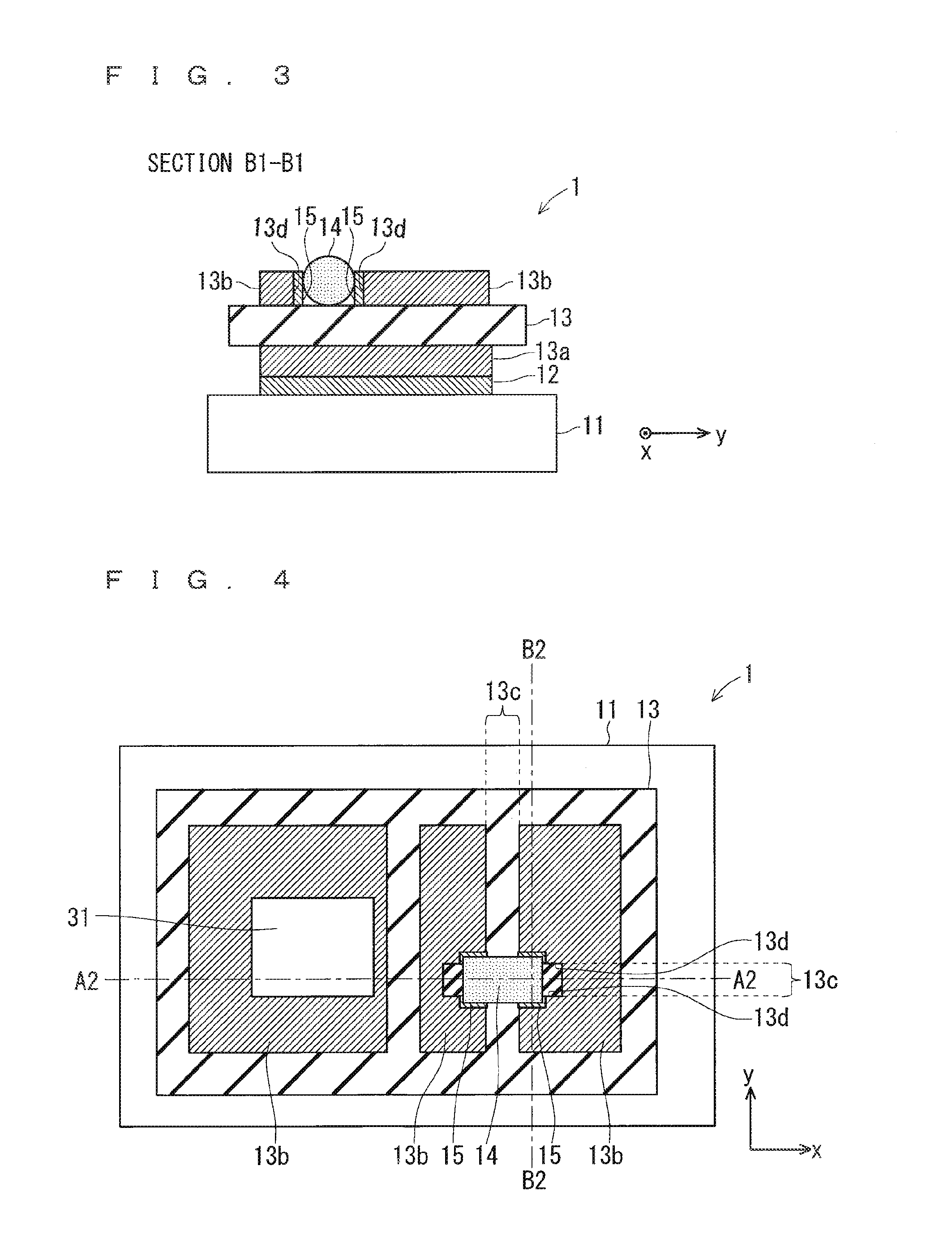

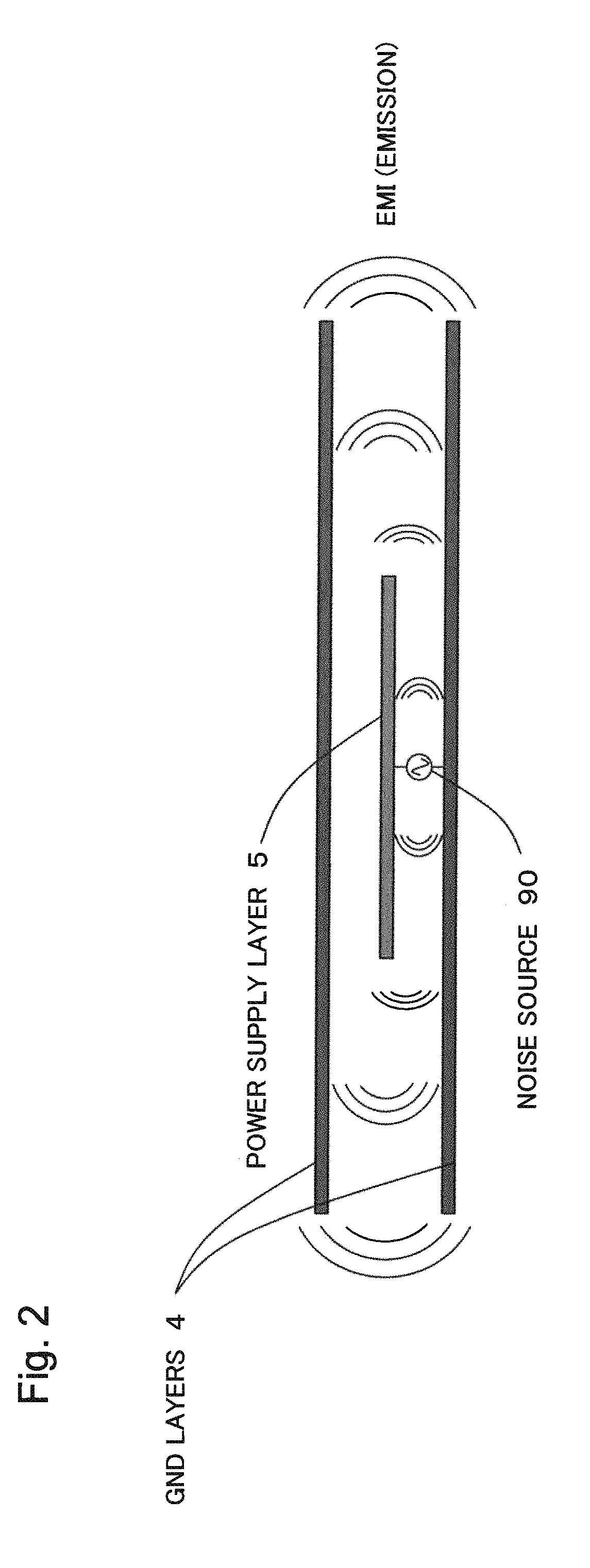

Printed board

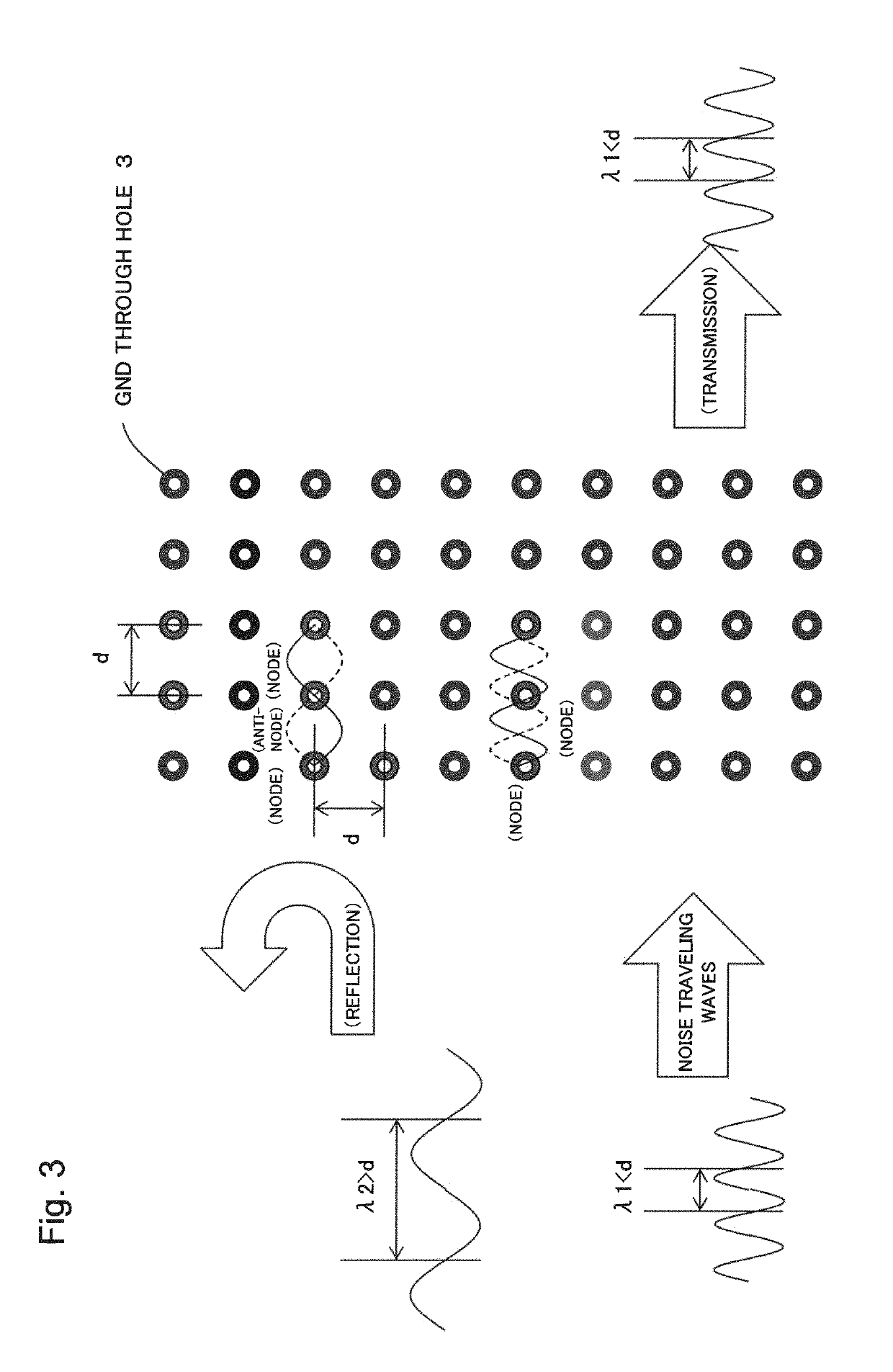

ActiveUS20180235076A1Suppressing EMI emissionCross-talk/noise/interference reductionElectrical connection printed elementsWavelengthElectrical and Electronics engineering

An objective of the present invention is to provide a printed board being capable of suppressing EMI emissions from power supply wirings. To accomplish the objective, a printed board of the present invention includes a plurality of ground layers disposed in a printed board, a power supply layer put between the plurality of the ground layers, and through holes disposed along at least periphery of the printed board and connecting the plurality of the ground layers, wherein the through holes are disposed at intervals according to a wavelength corresponding to a maximum frequency of electromagnetic waves to be suppressed.Further, a printed board of the present invention includes a power supply layer disposed in a printed board and put between ground layers above and below the power supply layers, and a plurality of through holes connecting the ground layers above and below the power supply layers, wherein the plurality of the through holes are disposed at and near the power supply layer and are spaced apart at intervals according to a wavelength corresponding to a maximum frequency of electromagnetic waves to be suppressed.

Owner:NEC CORP

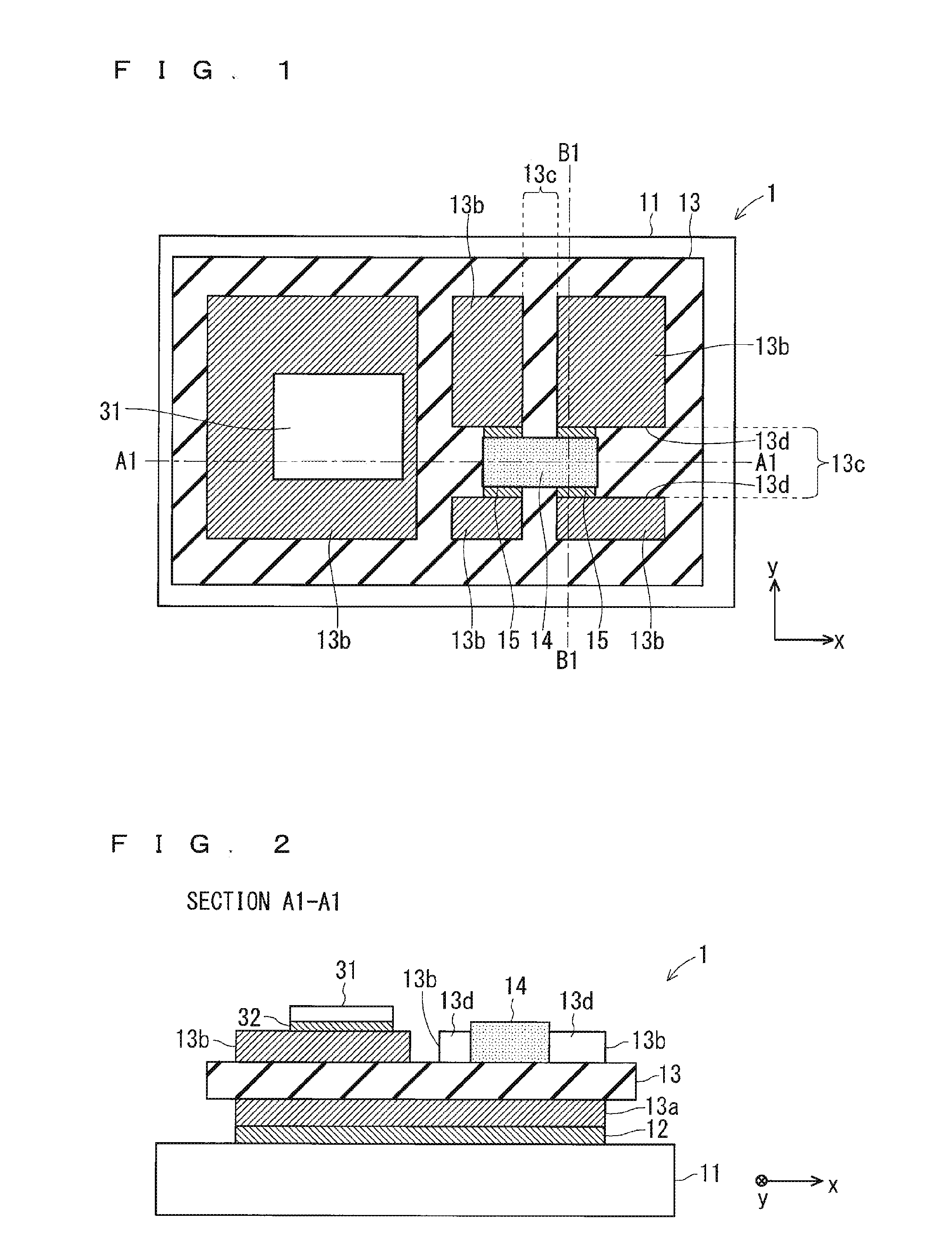

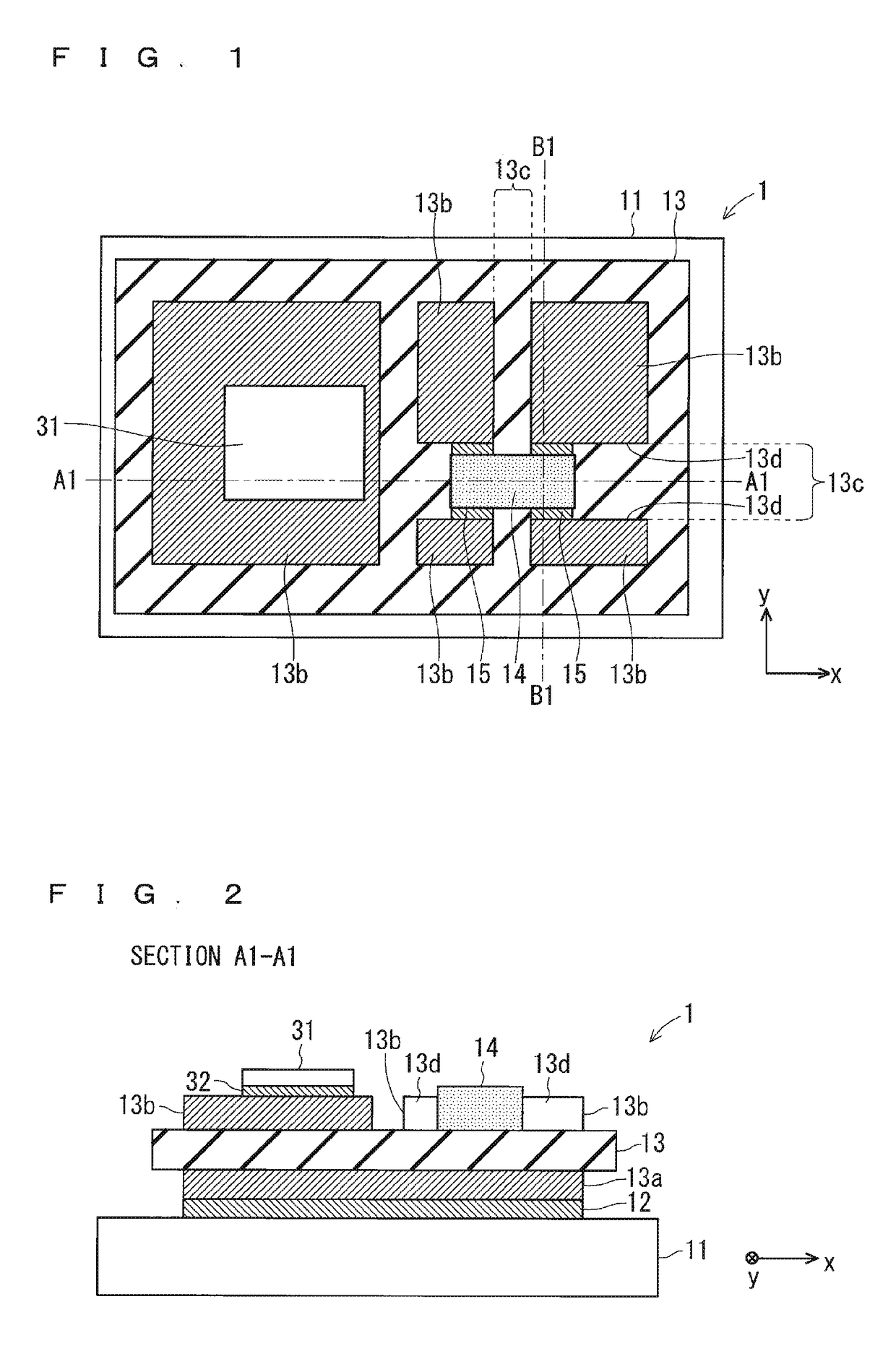

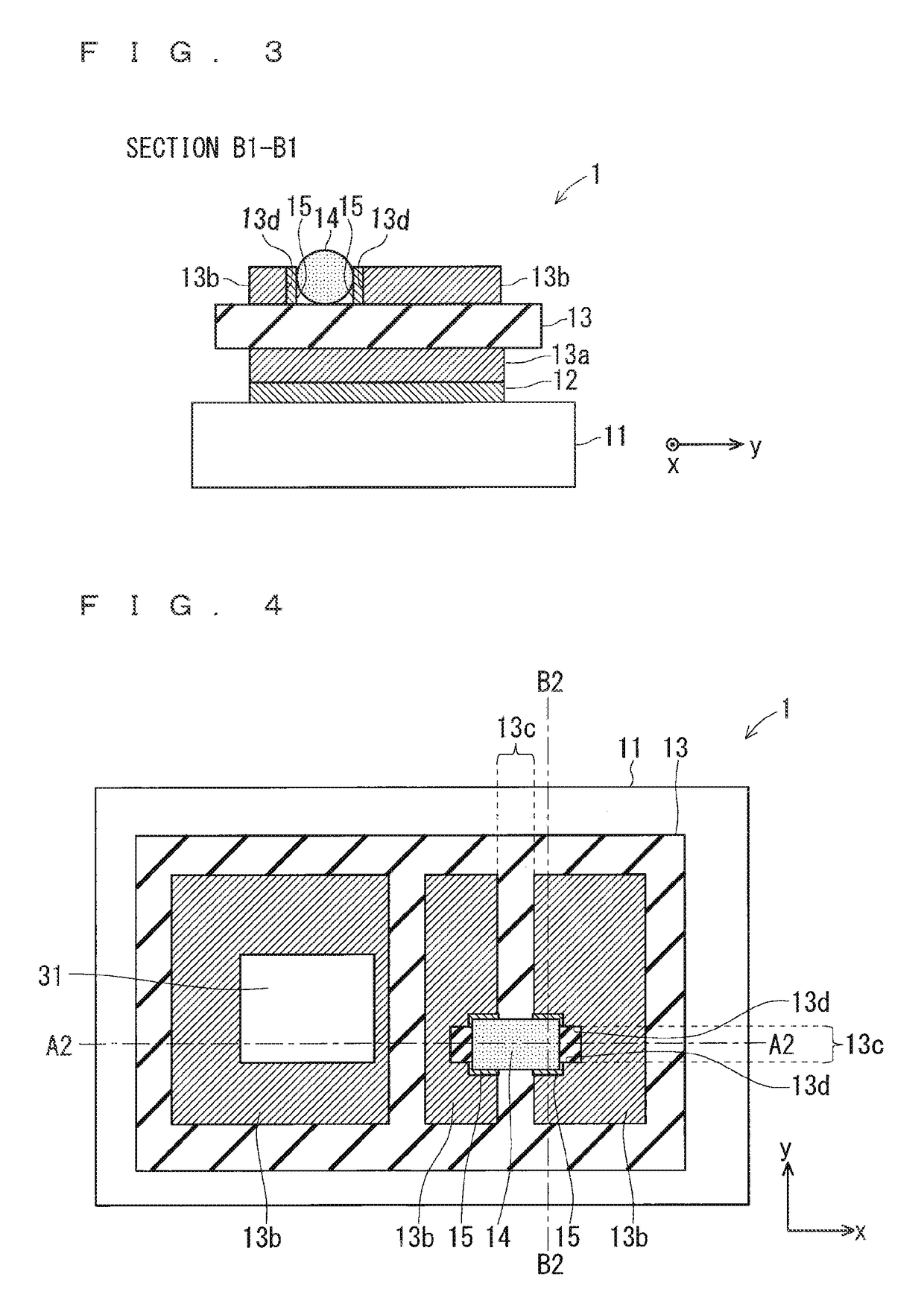

Electronic component mounting device and semiconductor device including the same

ActiveUS20150163916A1Avoid displacementReduce thermal stressInsulating substrate metal adhesion improvementFinal product manufactureEngineeringElectronic component

An electronic component mounting device includes an insulating substrate having a metal pattern formed thereon and a MELF electronic component. The MELF electronic component is fitted into a first receiving portion configured with the metal pattern and the insulating substrate exposed from a lacking portion of the metal pattern. The electronic component mounting device further includes a conductive member formed between the MELF electronic component and the metal pattern, and the conductive member is not formed between the MELF electronic component and the insulating substrate.

Owner:MITSUBISHI ELECTRIC CORP

Printed board

InactiveUS10375818B2Suppressing EMI emissionCross-talk/noise/interference reductionElectrical connection printed elementsEngineeringWavelength

An objective of the present invention is to provide a printed board being capable of suppressing EMI emissions from power supply wirings. To accomplish the objective, a printed board of the present invention includes a plurality of ground layers disposed in a printed board, a power supply layer put between the plurality of the ground layers, and through holes disposed along at least periphery of the printed board and connecting the plurality of the ground layers, wherein the through holes are disposed at intervals according to a wavelength corresponding to a maximum frequency of electromagnetic waves to be suppressed.Further, a printed board of the present invention includes a power supply layer disposed in a printed board and put between ground layers above and below the power supply layers, and a plurality of through holes connecting the ground layers above and below the power supply layers, wherein the plurality of the through holes are disposed at and near the power supply layer and are spaced apart at intervals according to a wavelength corresponding to a maximum frequency of electromagnetic waves to be suppressed.

Owner:NEC CORP

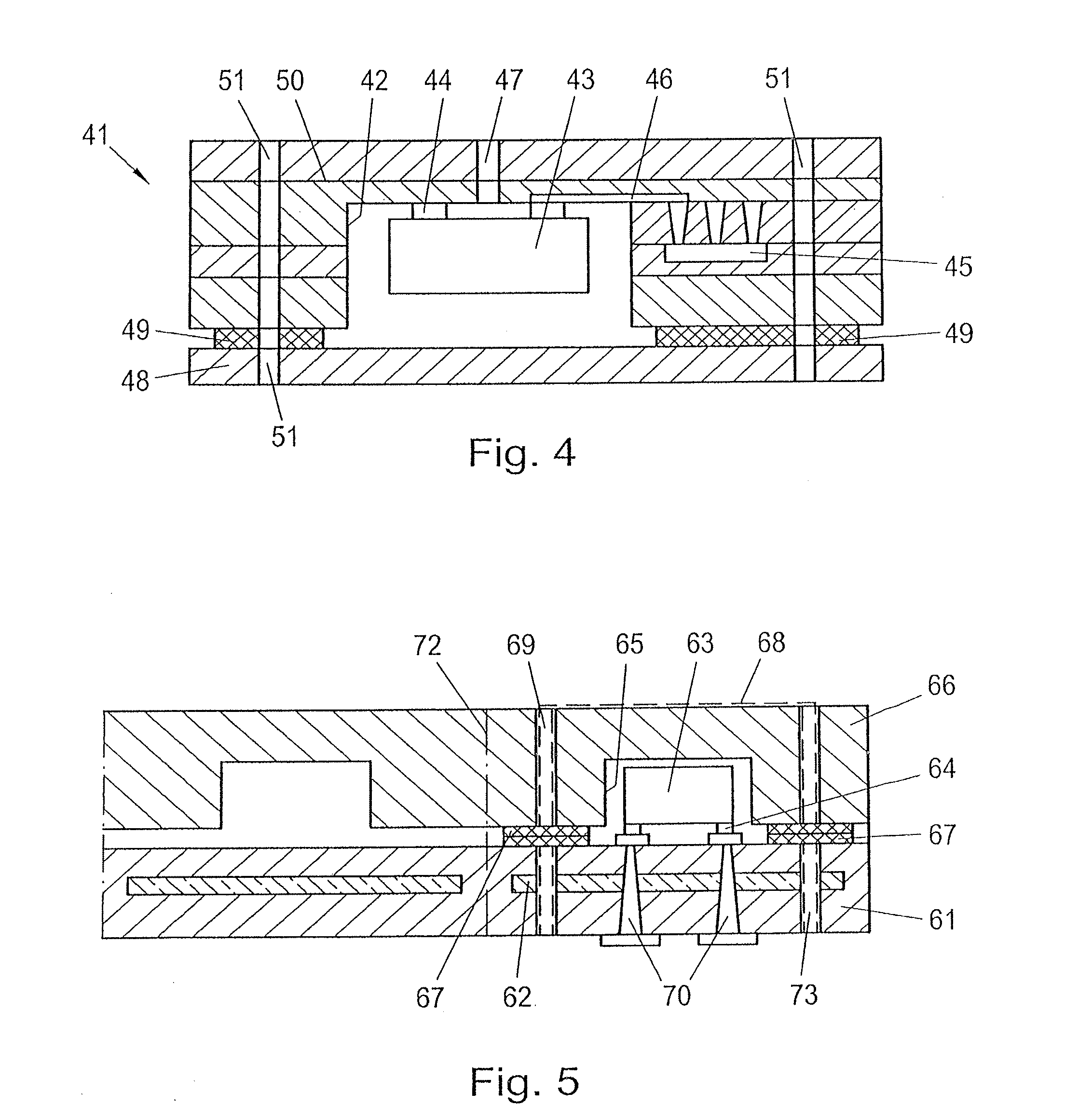

Embedded electronic component and method of manufacturing electronic component embedded substrate

ActiveUS9894770B2Improve efficiencyImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingContact padEngineering

Disclosed is an embedded electronic component which can improve reliability of connection with external wiring and efficiency of an embedding process by including: a contact pad provided on at least one surface of a body portion and made of a conductive material; a first insulating layer for covering the at least one surface of the body portion; a first pad in contact with a surface of the contact pad and made of a conductive material; a rearrangement portion provided on a surface of the first insulating layer to be in contact with the first pad; a second pad provided on the surface of the first insulating layer to be in contact with the rearrangement portion; and a second insulating layer having an opening to expose a portion of the second pad while covering the first insulating layer, the first pad, the rearrangement portion, and the second pad.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Electronic package

ActiveUS10784205B2Easy to controlImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesElectronic componentEngineering physics

An electronic package is provided, which includes: an insulating layer; an electronic element embedded in the insulating layer and having a sensing area exposed from the insulating layer; and a circuit layer formed on the insulating layer and electrically connected to the electronic element, thereby reducing the thickness of the overall package structure.

Owner:PHOENIX PIONEER TECH

Flight control device and unmanned aerial vehicle having the same

ActiveUS11142313B2High system integrationCompact configurationUnmanned aerial vehiclesCasings/cabinets/drawers detailsUncrewed vehiclePower Management Unit

A flight control device includes a housing, a main control board provided in the housing, an inertial measurement unit provided in the housing and electrically connected to the main control board, and a power management unit provided at the housing and electrically connected to the main control board. The main control board, the inertial measurement unit, and the power management unit are fixedly connected to and integrated with the housing as a whole.

Owner:SZ DJI TECH CO LTD

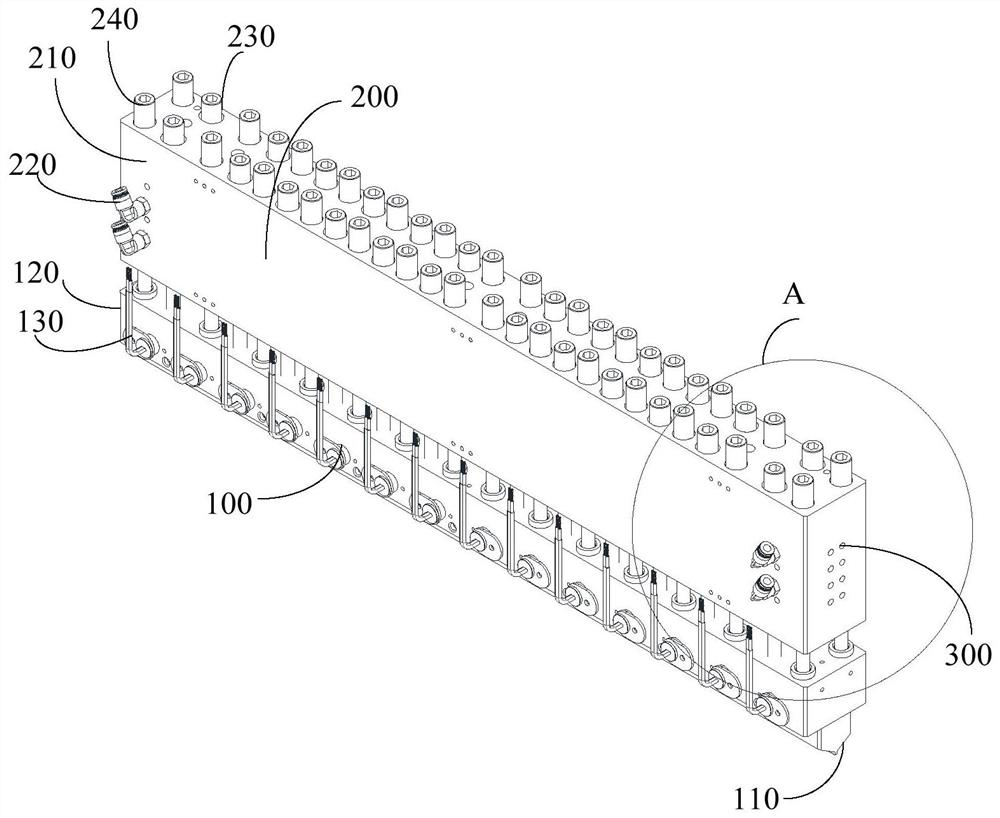

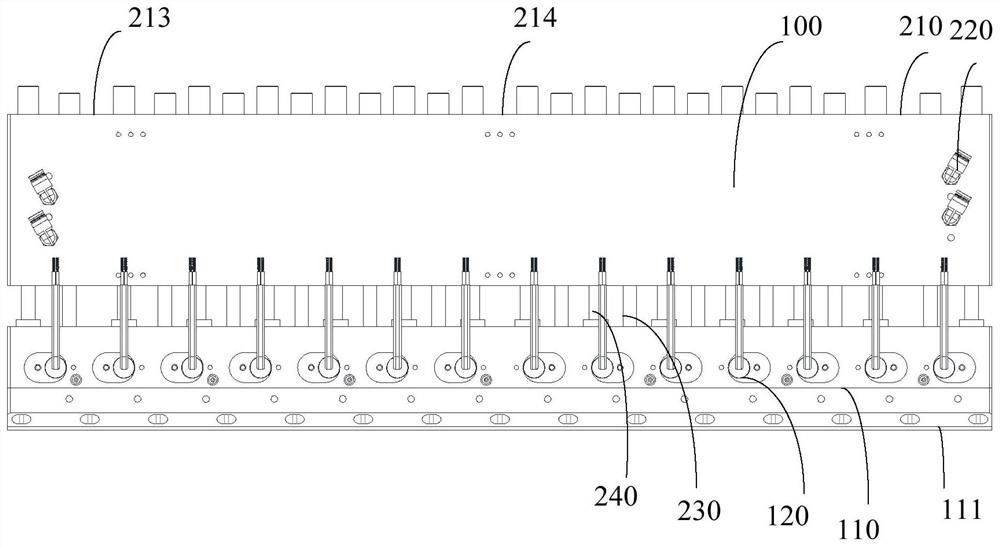

Bonding head, bonding device, and forming method of cooling channel

ActiveCN113329563AAvoid deformationWarranty requirementsPrinted circuit assemblingLighting and heating apparatusCold airTool bit

The invention relates to a bonding head, a bonding device, and a forming method of a cooling channel. The bonding head comprises a tool bit assembly and an adjusting assembly, the tool bit assembly comprises a pressing head and a heating block, the pressing head is connected to the heating block, and the pressing head is used for hot-pressing a conducting medium to a circuit board; and the adjusting assembly is connected to the end, away from the pressing head, of the heating block and comprises a balance block and an air pipe connector, the air pipe connector is connected to the surface of the balance block, a cooling loop is arranged in the balance block and provided with an air inlet and an air outlet which are communicated, and at least one of the air inlet and the air outlet is communicated with the air pipe connector. The cooling loop is arranged in the balance block, and cold air entering from the air pipe joint can be used for cooling the balance block, so that the pressure head is cooled, the pressure head is prevented from being deformed in a high-temperature state, and the flatness requirement and the stability process requirement of the pressing surface of the pressure head are ensured.

Owner:东莞联鹏智能装备有限公司

Sterilization unit for packaging material

Power supply unit, in particular for a sterilization device, comprising at least one electric component, wherein, at least one of the electric components is at least partly covered with a solid insulation layer, wherein the solid insulation layer is adapted to provide an electric insulation.

Owner:TETRA LAVAL HLDG & FINANCE SA

Method for integrating an electronic component into a printed circuit board

ActiveUS9055706B2Avoid connectionPrinted circuit assemblingCross-talk/noise/interference reductionElectronic componentPrinted circuit board

A method for integrating a component into a printed circuit board includes the following steps: providing two completed printed circuit board elements, which more particularly consist of a plurality of interconnected plies or layers, wherein at least one printed circuit board element has a cutout or depression, arranging the component to be integrated on one of the printed circuit board elements or in the cutout of the at least one printed circuit board element, and connecting the printed circuit board elements with the component being accommodated in the cutout, as a result of which it is possible to obtain secure and reliable accommodation of a component or sensor in a printed circuit board. Furthermore, a printed circuit board of this type comprising an electronic component integrated therein is provided.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Electronic component mounting device and semiconductor device including the same

ActiveUS9723718B2Avoid displacementReduce thermal stressPrinted circuit assemblingInsulating substrate metal adhesion improvementPower semiconductor deviceElectronic component

Owner:MITSUBISHI ELECTRIC CORP

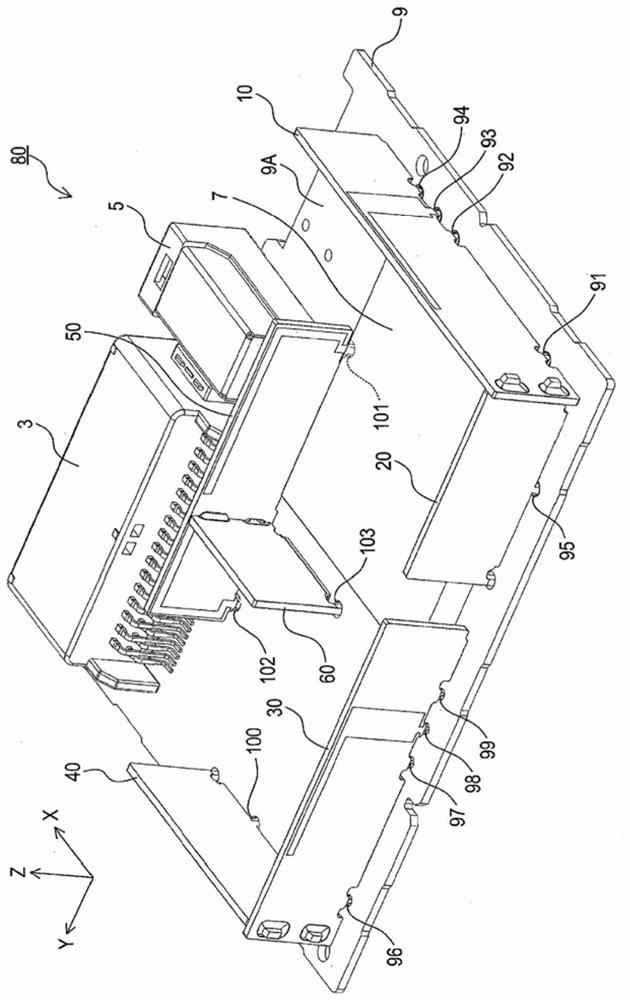

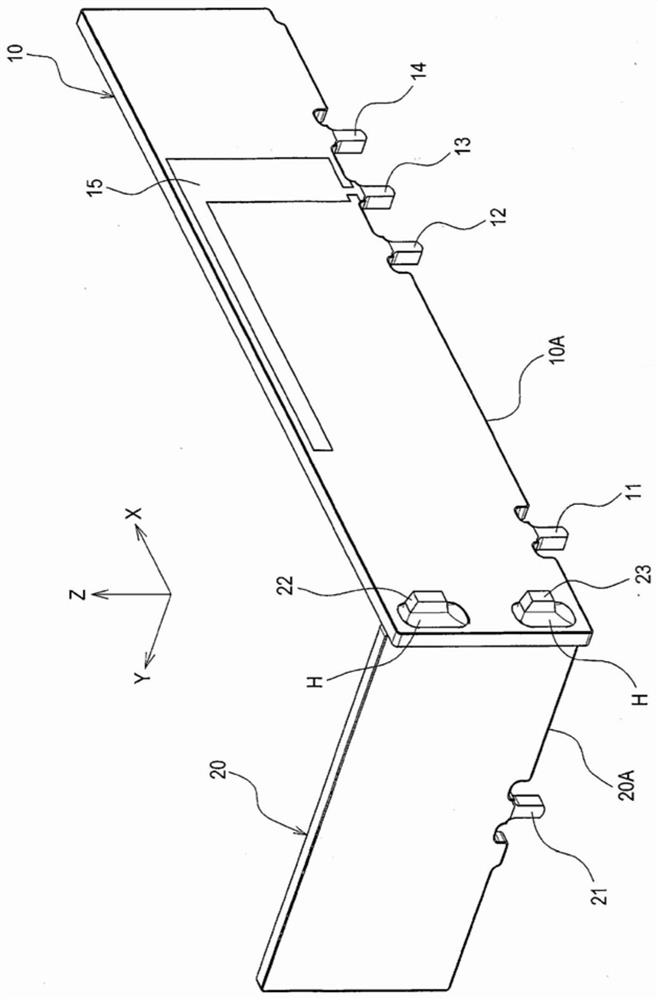

Electronic circuit

ActiveCN111656872AProhibition of usePrinted circuit assemblingAntenna supports/mountingsMechanical engineeringElectronic circuit

This electronic circuit comprises: a first printed wiring board (9); second printed wiring boards (10, 30, 50); and third printed wiring boards (20, 40, 60). The second printed wiring boards are mounted so that one edge (10A, 30A, 50A) thereof abuts a part mounting surface (9A) of the first printed wiring board, i.e. abuts a surface of the first printed wiring board on which parts (3, 5, 7) are mounted. The third printed wiring boards are mounted so that one edge (20A, 40A, 60A) thereof abuts the part mounting surface. The second printed wiring boards and the third printed wiring boards are connected to each other in a state in which the board thickness direction of the second printed wiring boards is oriented in a different direction, around a normal line rising from the part mounting surface, from that of the third printed wiring boards. Further, an antenna pattern is formed on the second printed wiring boards and / or the third printed wiring boards.

Owner:DENSO CORP +1

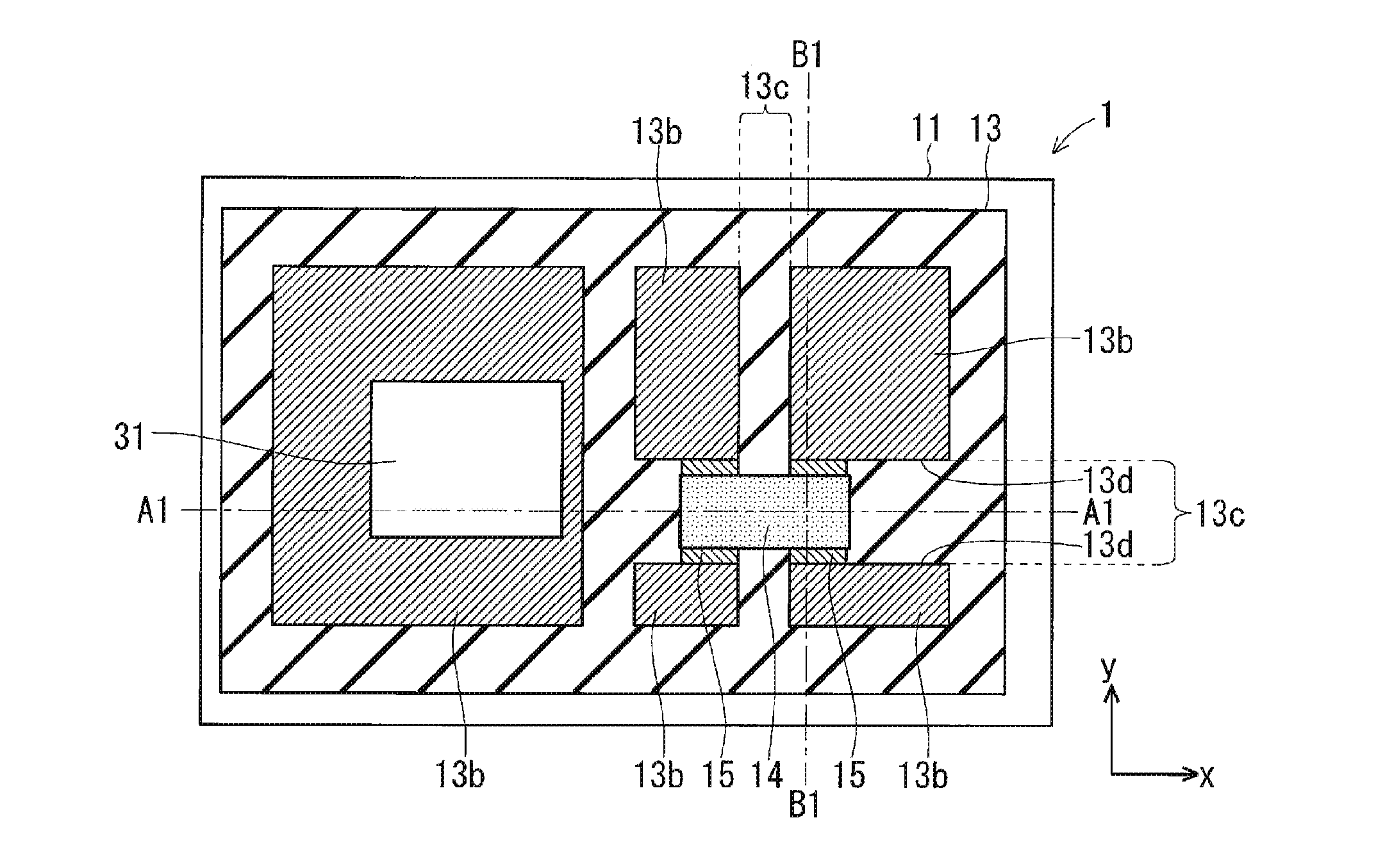

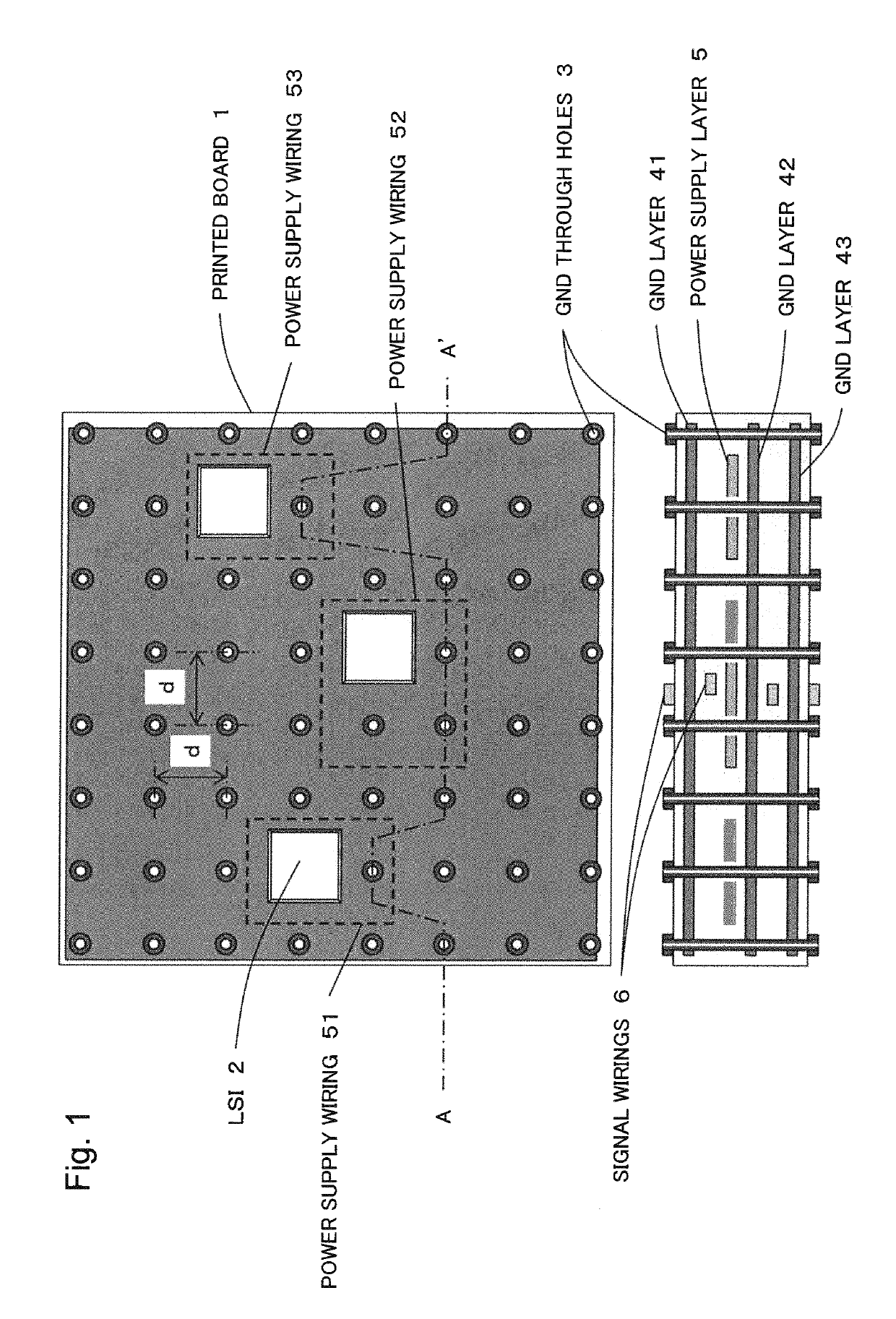

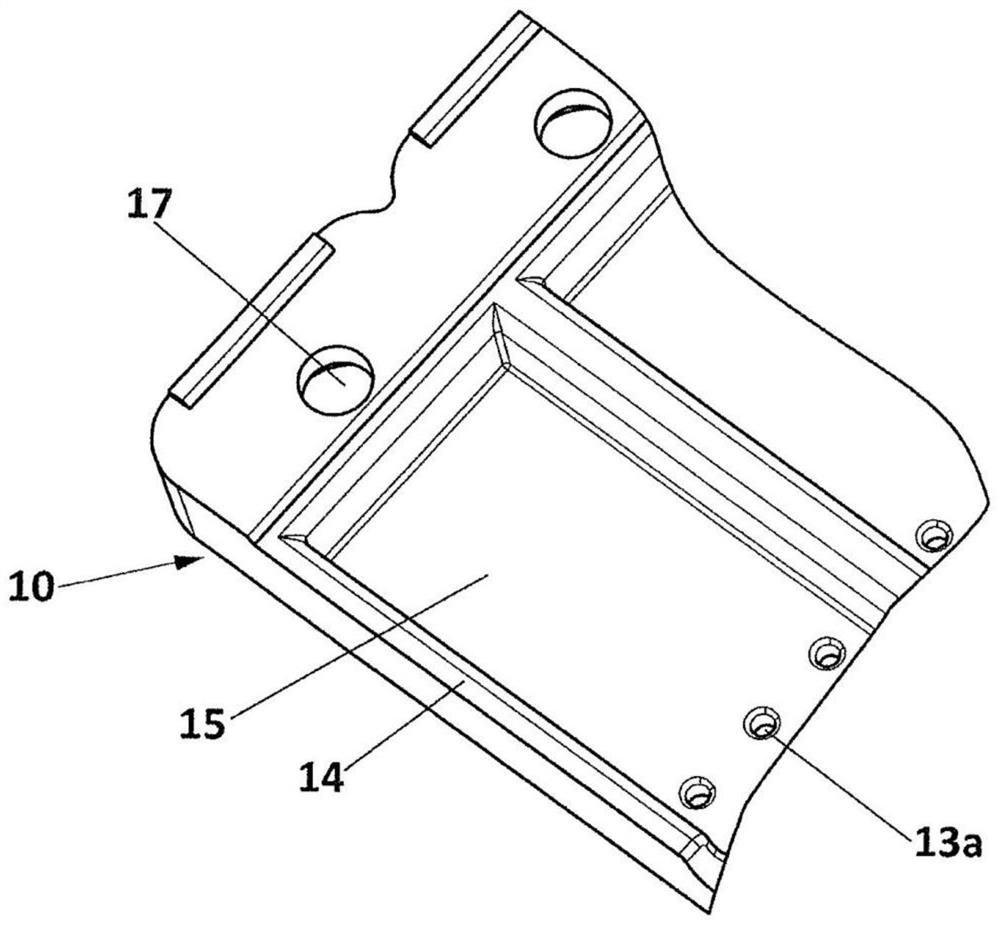

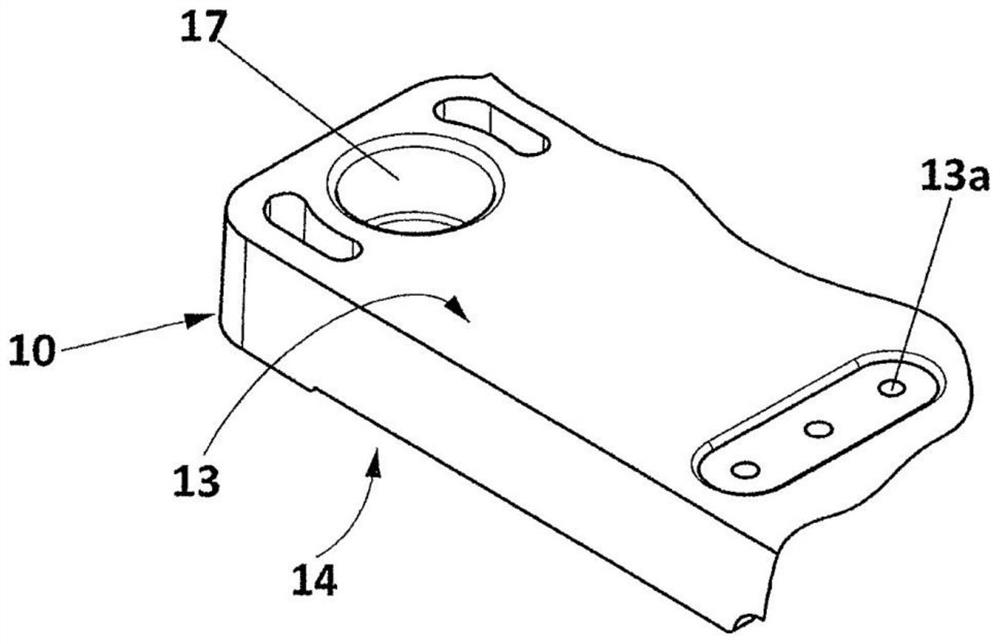

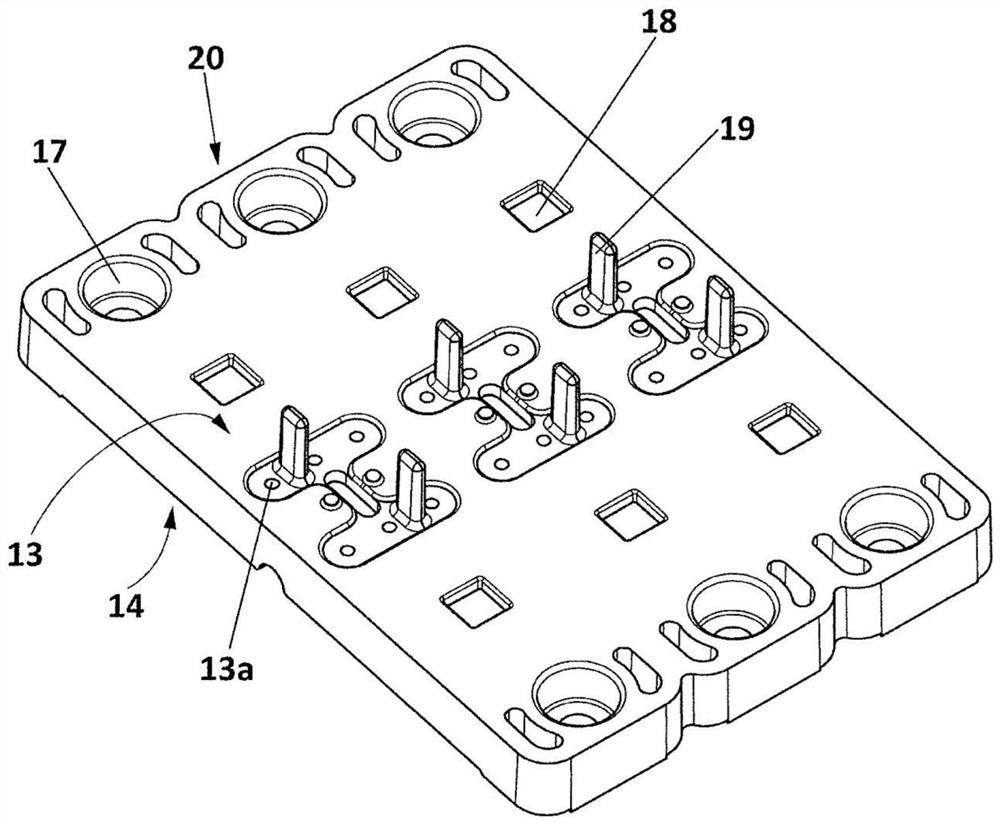

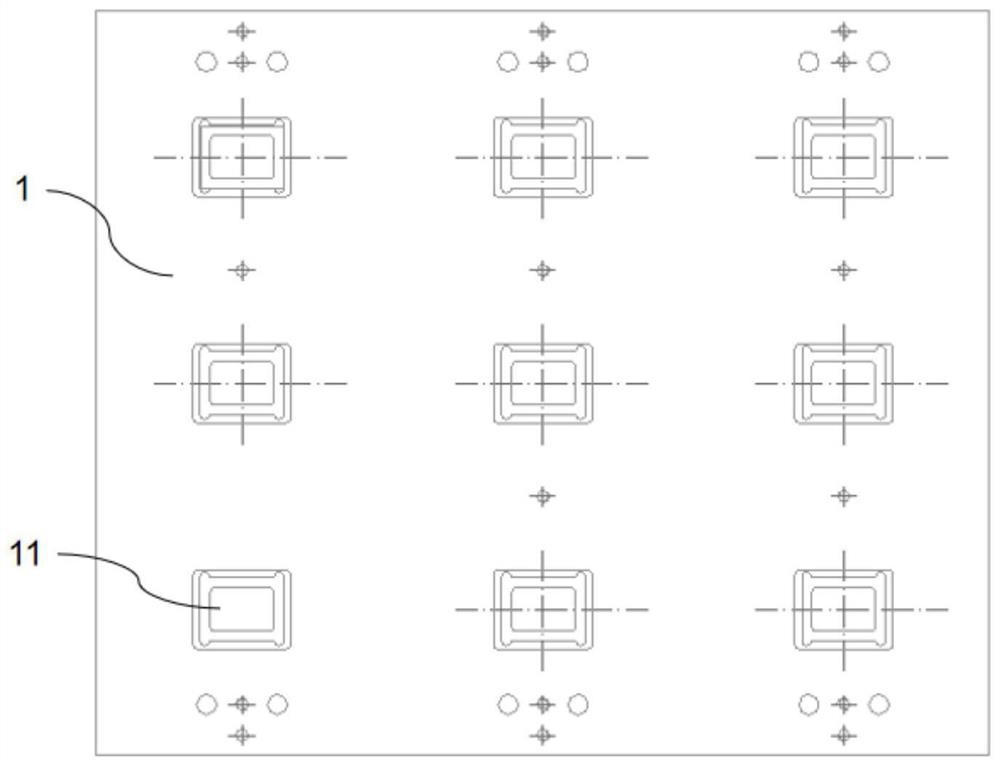

Mounting devices for semiconductor packages

ActiveCN111668176APermanent holding forceImproved gap distanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering physics

Mounting device (10) for semiconductor packages (11), the device (10) comprising a bottom side (14) comprising one or more cavities (15) to house semiconductor packages (11); a top side (13) comprising a plurality of holes (13a) extending from the bottom side (14) to the top side (13) for accommodating contact pins (12) of the semiconductor package (11); and fixation means to fix the device (10) housing the semiconductor packages (11) to a heat dissipation structure.

Owner:MAHLE INT GMBH

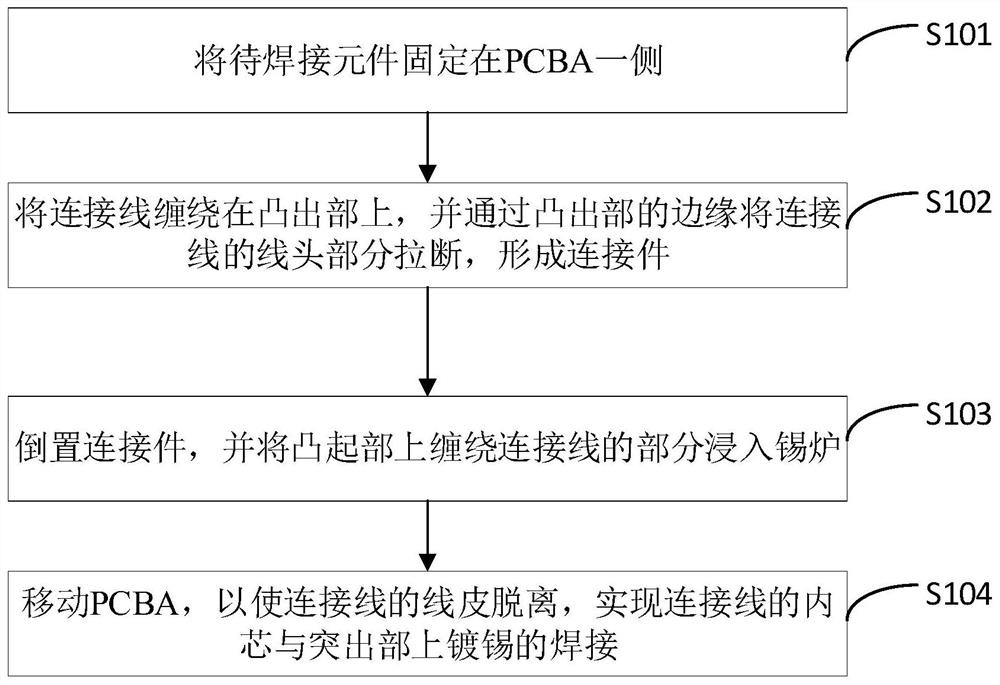

Welding method

ActiveCN113068325AReduce processImprove welding strengthPrinted circuit assemblingMetallurgical bondingTinningElectrical resistance and conductance

The embodiment of the invention discloses a welding method. The method comprises the steps that a to-be-welded element is fixed to one side of a PCBA board; a connecting line is wound on a protruding part, the line end part of the connecting line is snapped through the edge of the protruding part, and a connecting piece is formed; the connecting piece is inverted, and the part, wound with the connecting wire, of the protruding part is immersed in the tin liquid; and the PCBA board is moved, so that the wire skin of the connecting wire is separated, and the welding of the inner core of the connecting wire and the tinned part on the protruding part is realized. Compared with an existing scheme, the scheme does not need manual patent leather breaking and thread end cutting, the working procedures are saved, workers do not need high-requirement training and the method is easy to master; the welding area is large, the contact resistance is small, and the product performance is more stable; and the welding strength is high, falling is not prone to occurring, and the reject ratio is reduced.

Owner:重庆炬特电子有限公司

A kind of preparation method of sealed surface mount emi filter and its welding tool

ActiveCN112437539BEasy to excludeMeet air tightness requirementsPrinted circuit assemblingMetallurgical bondingEngineeringAir tightness

The invention relates to a method for preparing a sealed surface-mounted EMI filter and welding tooling thereof, wherein the welding tooling used for preparing a sealed surface-mounted EMI filter includes: a bottom pallet, a middle pallet and a top pallet; There is a groove for placing the substrate. The middle pallet can be detachably connected with the bottom pallet. The middle pallet is provided with a through hole matching the frame. When the middle pallet is connected with the bottom pallet, the through hole and the groove Correspondingly, the top supporting plate is detachably connected with the bottom supporting plate, and the top supporting plate is used for compressing and fixing the surrounding frame. The EMI filter is made by welding tooling, which can ensure that the frame is placed exactly in the middle of the corresponding pad on the substrate during welding, avoiding horizontal or inclined offsets that affect the quality and appearance of the weld; at the same time, through the top support The plate exerts pressure on the frame and presses the frame and the LTCC substrate tightly, which is conducive to the removal of gas inside the weld during welding, ensuring that the weld is dense and free of pores, and meets the airtightness requirements of the finished product.

Owner:北京航天微电科技有限公司

Preparation method of sealed surface-mounted EMI filter and welding tool thereof

ActiveCN112437539AEasy to excludeMeet air tightness requirementsPrinted circuit assemblingMetallurgical bondingEngineeringWeld seam

The invention relates to a preparation method of a sealed surface-mounted EMI filter and a welding tool thereof. The welding tool for preparing the sealed surface-mounted EMI filter comprises a bottomlayer supporting plate, a middle layer supporting plate and a top layer supporting plate, wherein a groove for accommodating a substrate is formed in the bottom layer supporting plate, the middle layer supporting plate is detachably connected with the bottom layer supporting plate, a through hole matched with the enclosure frame is formed in the middle layer supporting plate , when the middle layer supporting plate is connected with the bottom layer supporting plate, the through hole corresponds to the groove, the top layer supporting plate is detachably connected with the bottom layer supporting plate, and the top layer supporting plate is used for pressing and fixing the enclosure frame. The EMI filter is manufactured by means of the welding tool, thereby guaranteeing that the enclosureframe is just placed in the middle of a corresponding bonding pad on the substrate in the welding process, and avoiding the situation that the quality and attractiveness of a weld joint are affecteddue to horizontal deviation or inclined deviation; meanwhile, pressure is applied to the enclosure frame through using the top layer supporting plate, and the enclosure frame and the LTCC substrate are pressed tightly, thereby being conductive to exhausting gas in a weld joint during welding, guaranteeing that the weld joint is dense and free of pores and satisfying the air tightness requirement of a finished product.

Owner:北京航天微电科技有限公司

Printed circuit board

ActiveUS10104767B2Printed circuits stress/warp reductionInsulating layers/substrates workingElectronic componentPrinted circuit board

A printed circuit board includes: a strip substrate sectioned into unit areas; electronic components respectively installed in each of the unit areas; and a separation space disposed between the unit areas.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com