Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about "Oven coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

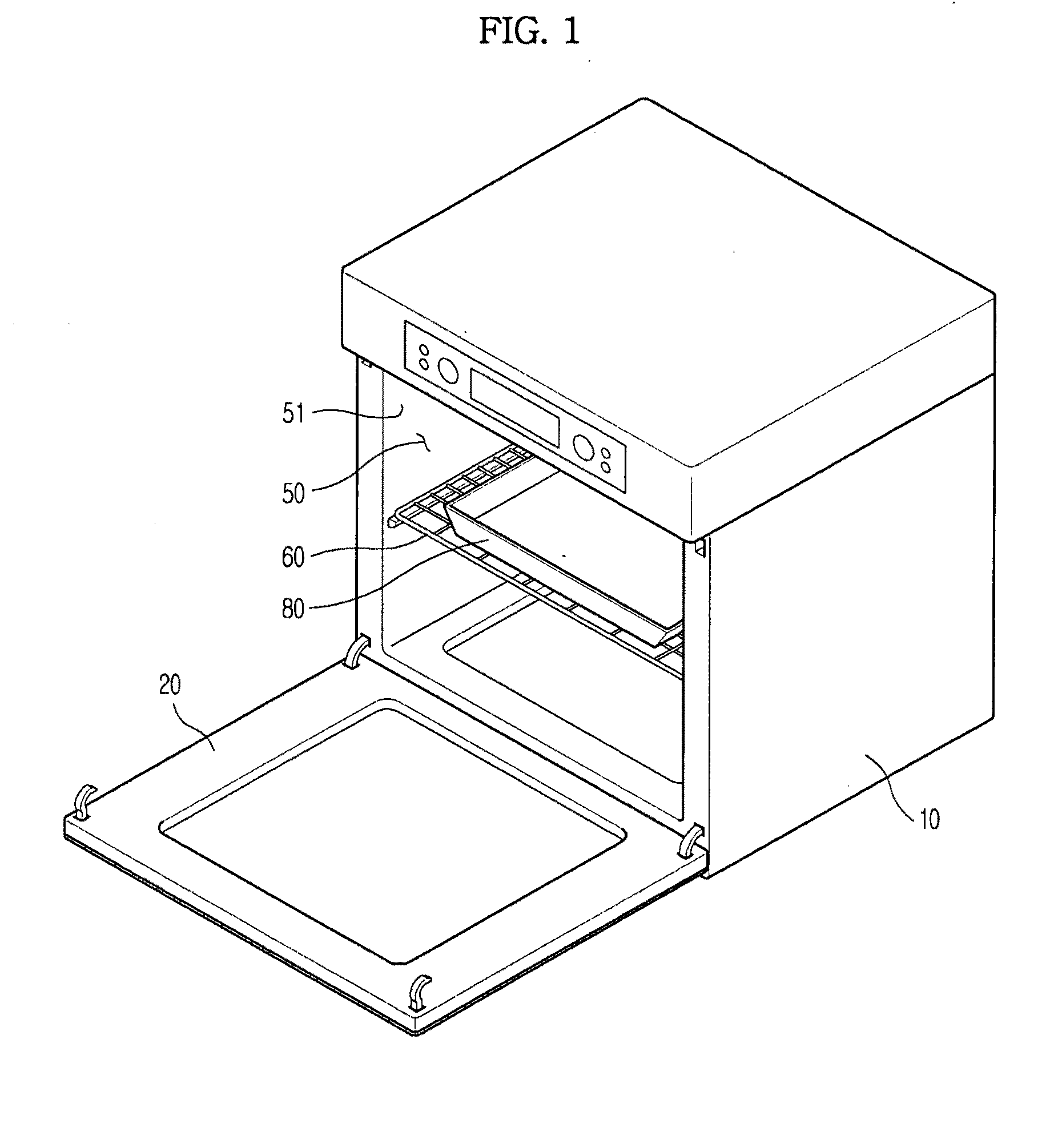

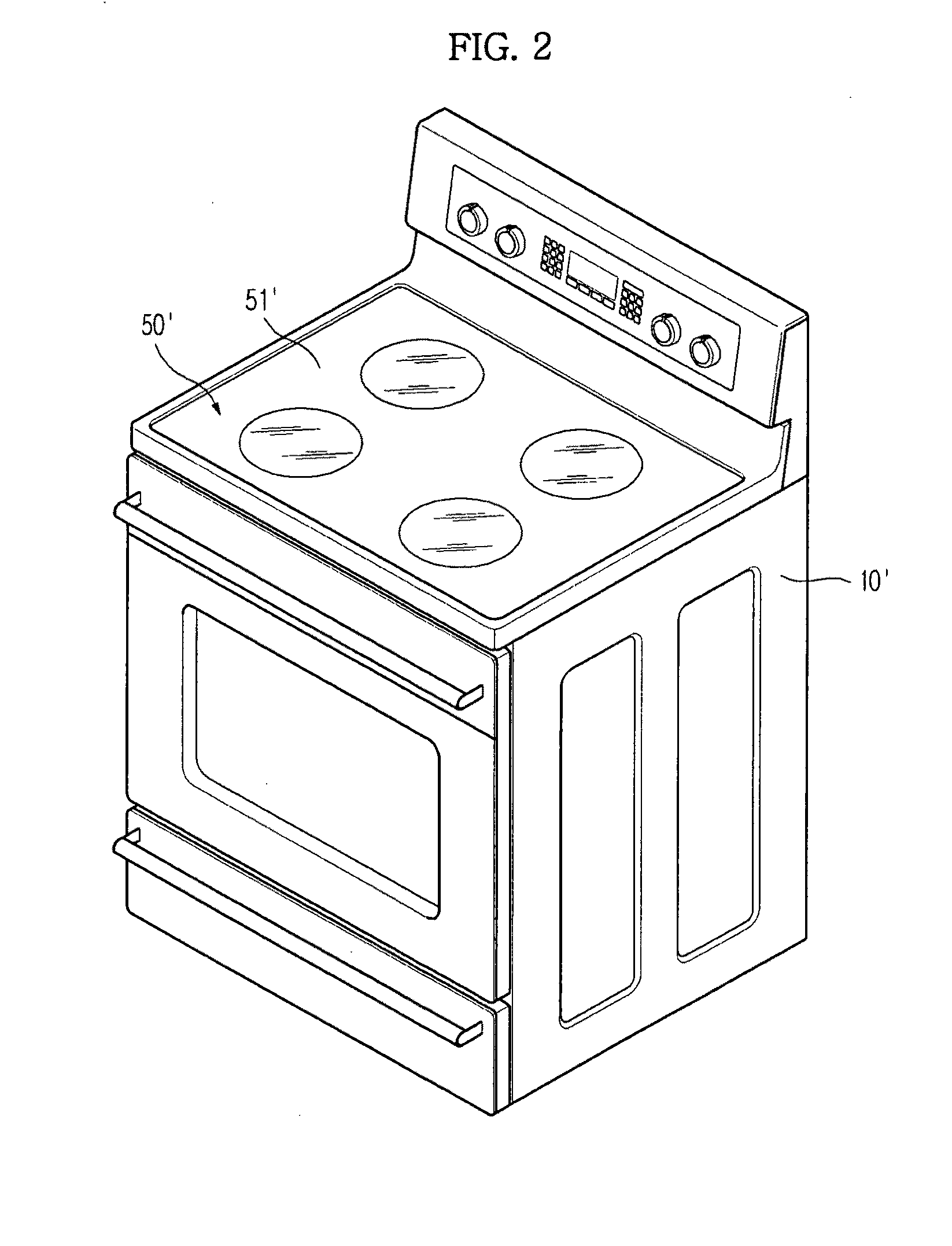

Cooking Appliance

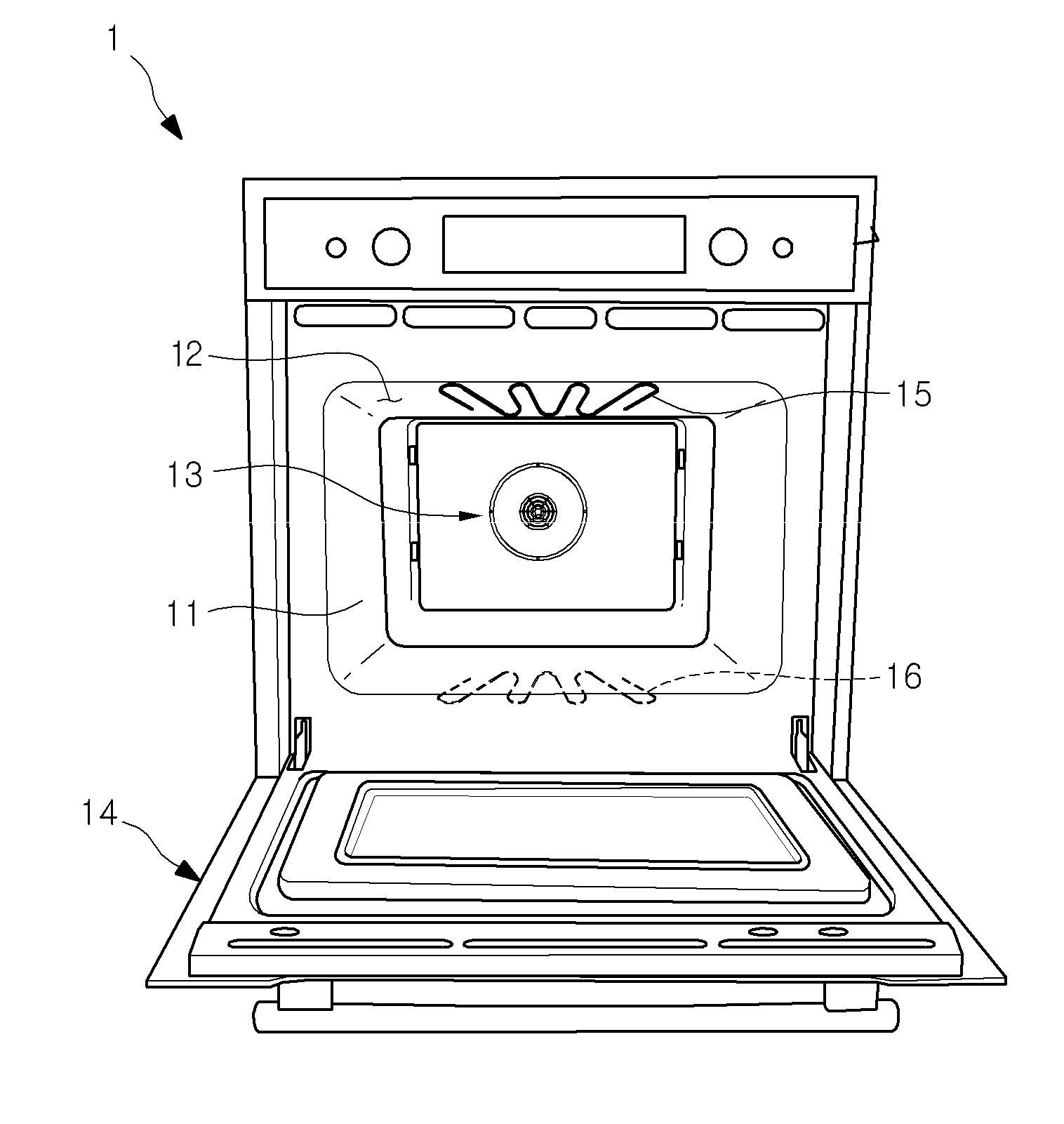

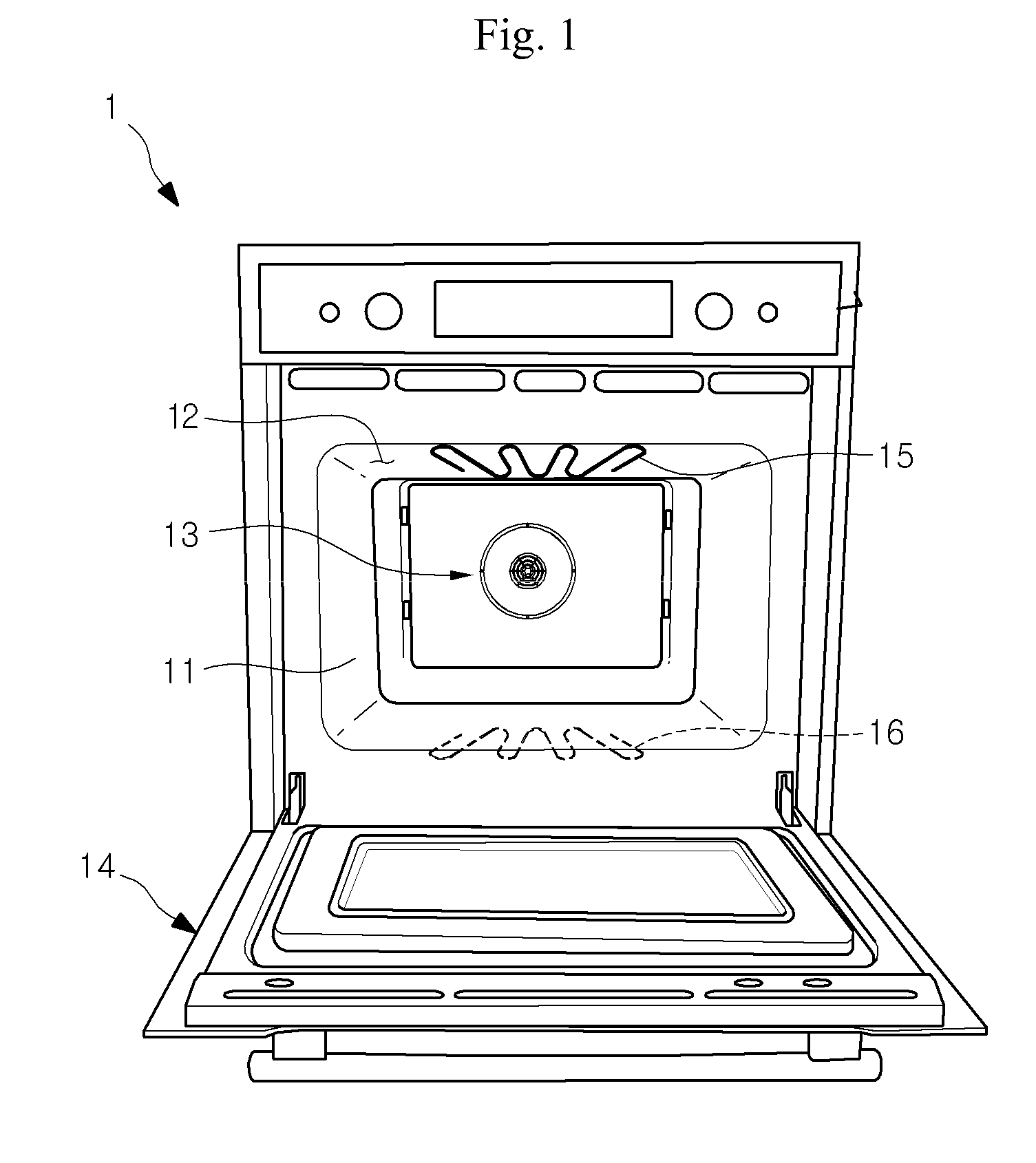

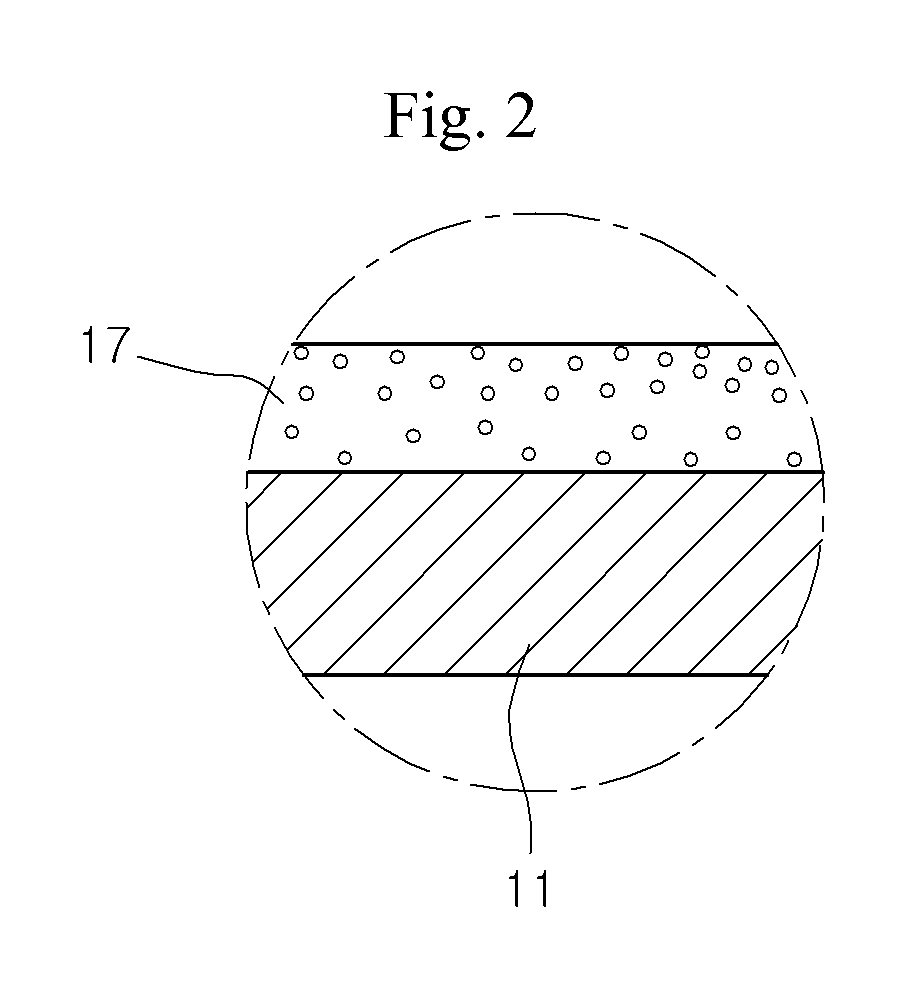

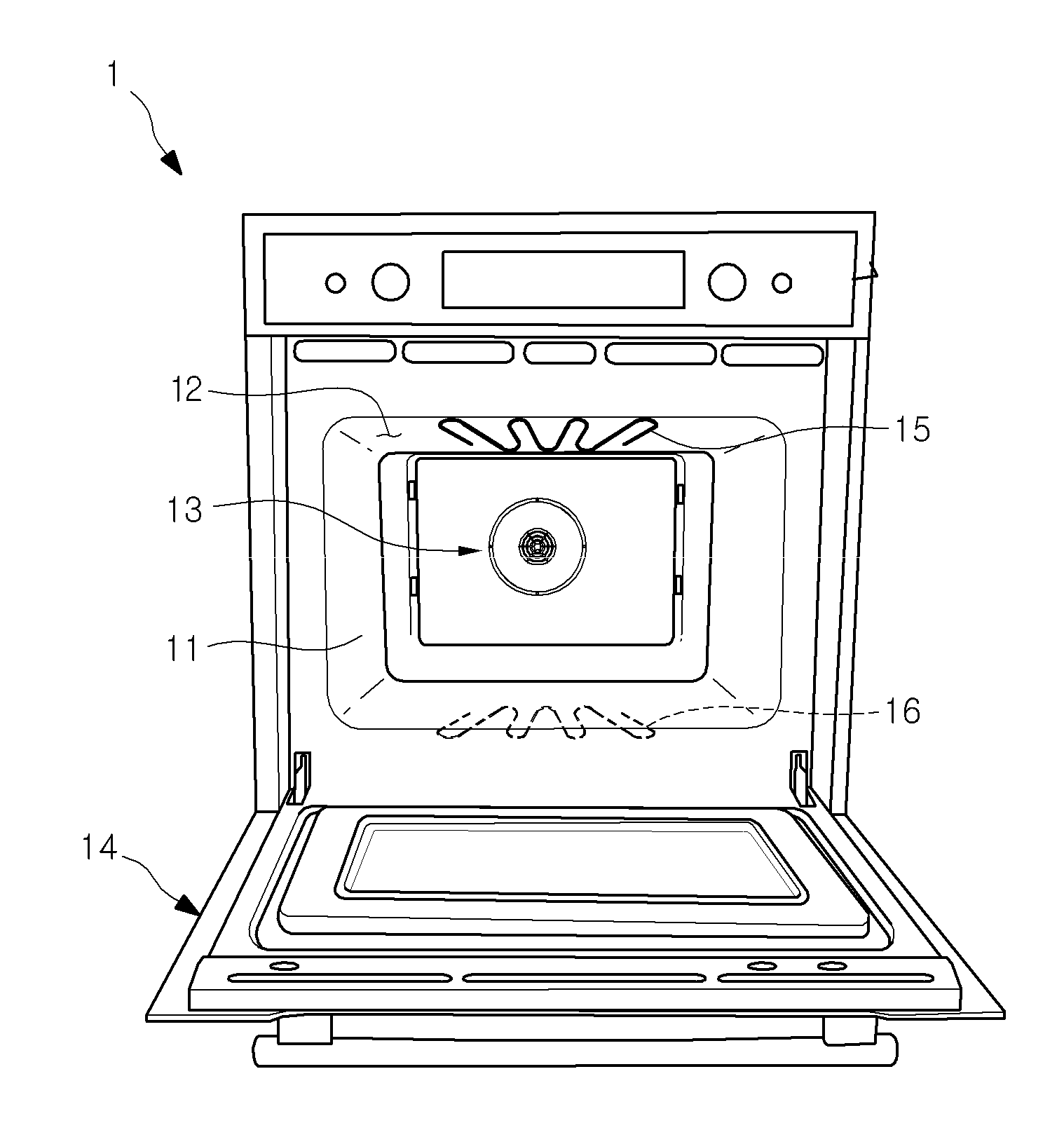

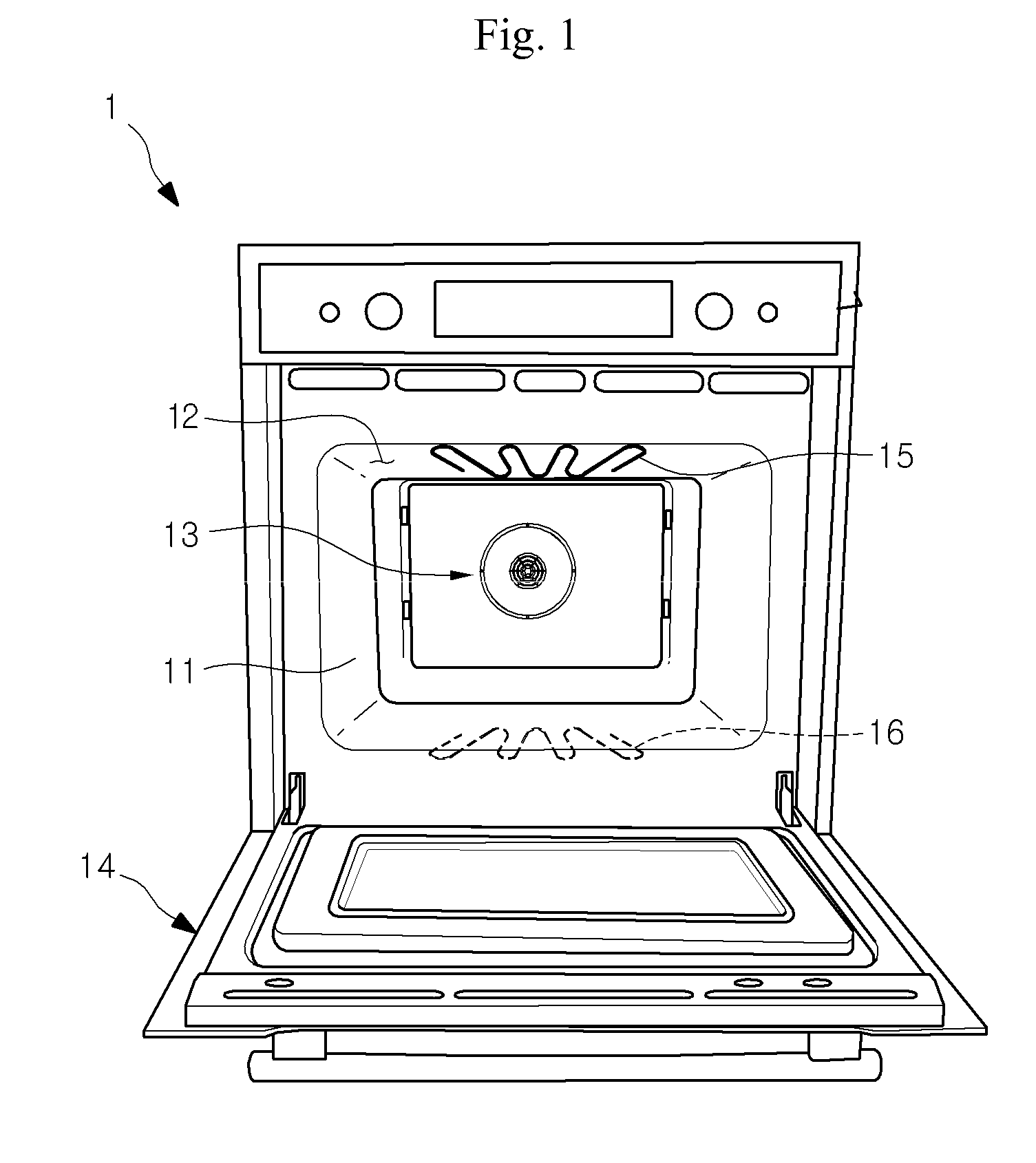

ActiveUS20110049122A1Improve heat resistanceGood chemical resistanceElectric heating for furnacesElectric/magnetic/electromagnetic heatingHeat resistanceWear resistance

The present invention includes a cooking appliance with an enamel composition. The enamel composition includes a heat resistance, chemical resistance, wear resistance, and pollution resistance, such that the cooking appliance withstands high temperature, acid or alkali and is readily cleaned.

Owner:LG ELECTRONICS INC

Coating composition, and cooking device or cooking receptacle coated with the same

ActiveUS20090311514A1Increase thermal resistanceImprove acid resistanceCeramic layered productsGlass/slag layered productsHeat resistanceMechanical property

A coating composition and a cooking device and / or cooking receptacle coated with the coating composition are described. The coating composition includes 10 to 30 wt. % of SiO2, 10 to 30 wt. % of P2O5, 10 to 30 wt. % of Al2O3, 1 to 20 wt. % of TiO2, 7 to 15 wt. % of Na2O, 7 to 15 wt. % of K2O, 5 to 10 wt. % of ZrO2, 2 to 5 wt. % of BaO, 2 to 5 wt. % of B2O3, 1 to 2 wt. % of MnO2, and an adhesion enhancer. The coating composition provides favorable thermal resistance, acid resistance and mechanical properties, such that a cooking device and / or receptacle coated with the coating composition may be easily cleaned at a relatively low temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

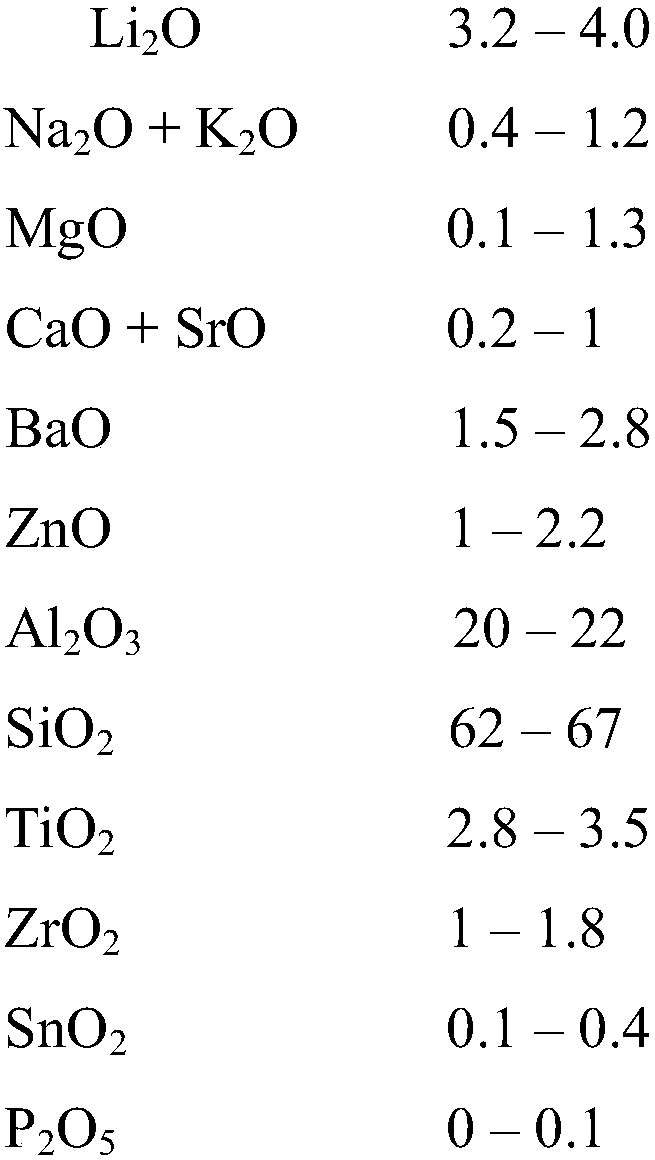

Enamel and ground coat compositions

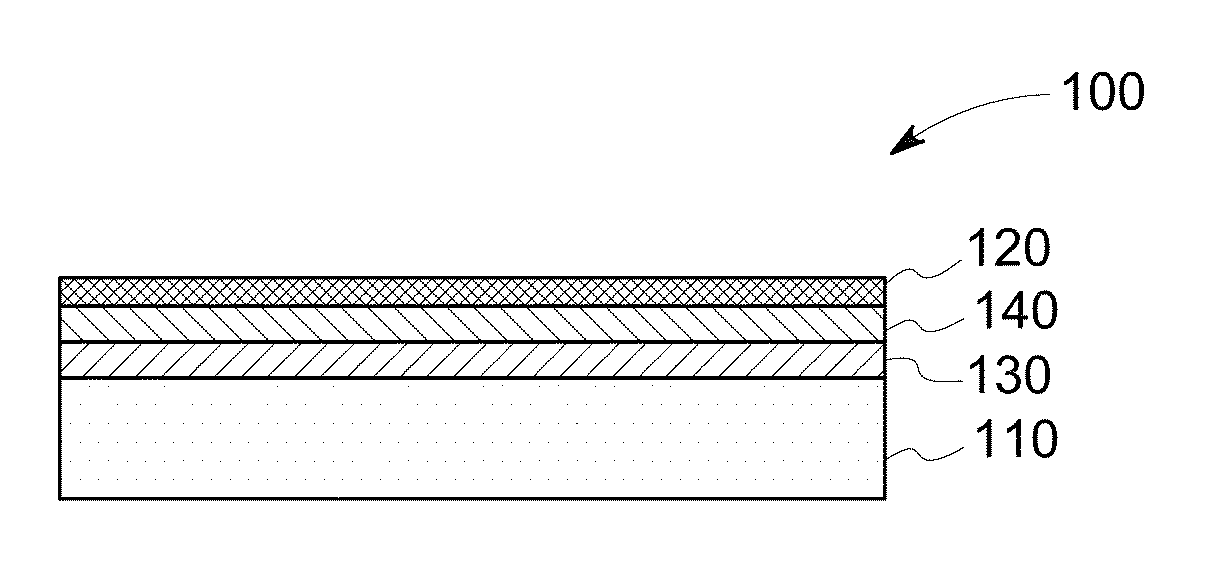

A composition that upon firing, forms a non-stick enamel layer is disclosed. The composition can be applied to a metal substrate to provide a non-stick, durable coating for cooking surfaces. Also disclosed are methods of forming enamel layers and corresponding coated substrates. Various ground coats and related methods are also described. Furthermore, various multilayer coatings and structures are disclosed that include an enamel layer and a ground coat layer.

Owner:FERRO CORP

Enamel composition

The present invention provides a composition for use in forming an enamel cover coat from which baked-on foods can be removed without the need for pyrolysis or highly alkaline cleaners. The enamel cover coat preferably exhibits no chipping or other surface defects subsequent to a 2.0 mm Plum Jam Test and an acid resistance of A or better according to ISO 2722. The composition according to the invention includes a glass component including at least a first glass frit comprising a low SiO2 glass frit. Preferably, the glass component includes a blend of the first glass frit and at least a second glass frit. Preferably, the first glass frit includes by weight from about 30% to about 45% P2O5, from about 20% to about 40% Al2O3, from about 15% to about 35% Li2O+Na2O+K2O, up to about 15% B2O3, up to about 15% MgO+CaO+SrO+BaO+ZnO, up to about 10% TiO2+ZrO2, and up to about 10% SiO2.

Owner:FERRO FRANCE S A R L

Catalytic porcelain enamel coating composition

The present invention provides a new and improved porcelain enamel coating composition for use in forming a self-cleanable coating upon aluminized steel. The coating composition comprises a glass component having a composition comprising from about 30% to about 55% SiO2, from about 11% to about 20% TiO2, from about 0% to about 10% B2O3, from about 20% to about 40% alkali metal oxides, less than about 5% rare earth metal oxides, from about 0% to about 10% CaO, from about 0% to about 10% BaO, from about 0% to about 10% MnO, from about 2% to about 12% CuO, from about 0% to about 10% Sb2O3, from about 1.5% to about 10% Fe2O3, from about 0% to about 10% SnO2, from about 0% to about 10% P2O5, less than about 2% MoO3, and less than about 5% V2O5.

Owner:FERRO FRANCE S A R L

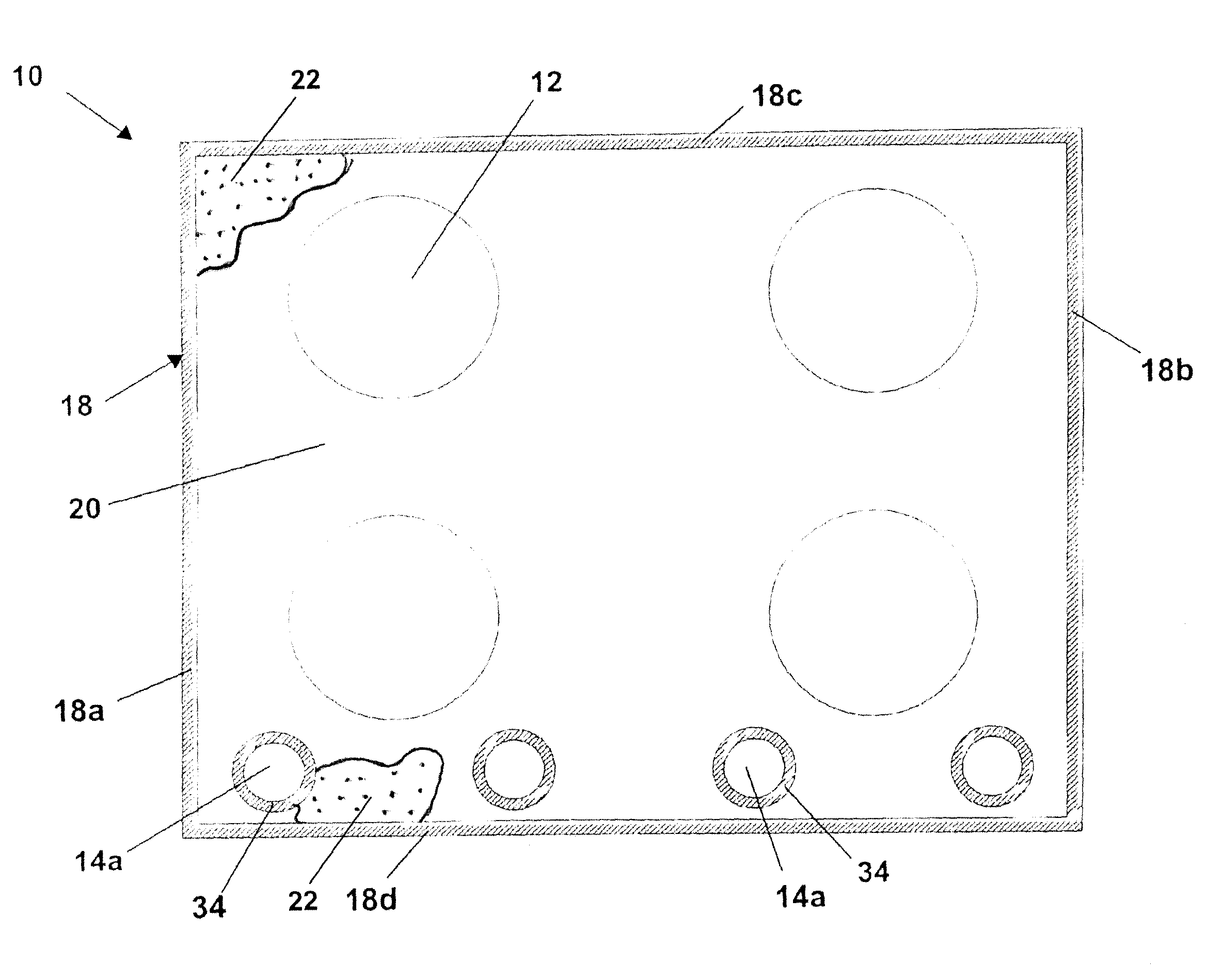

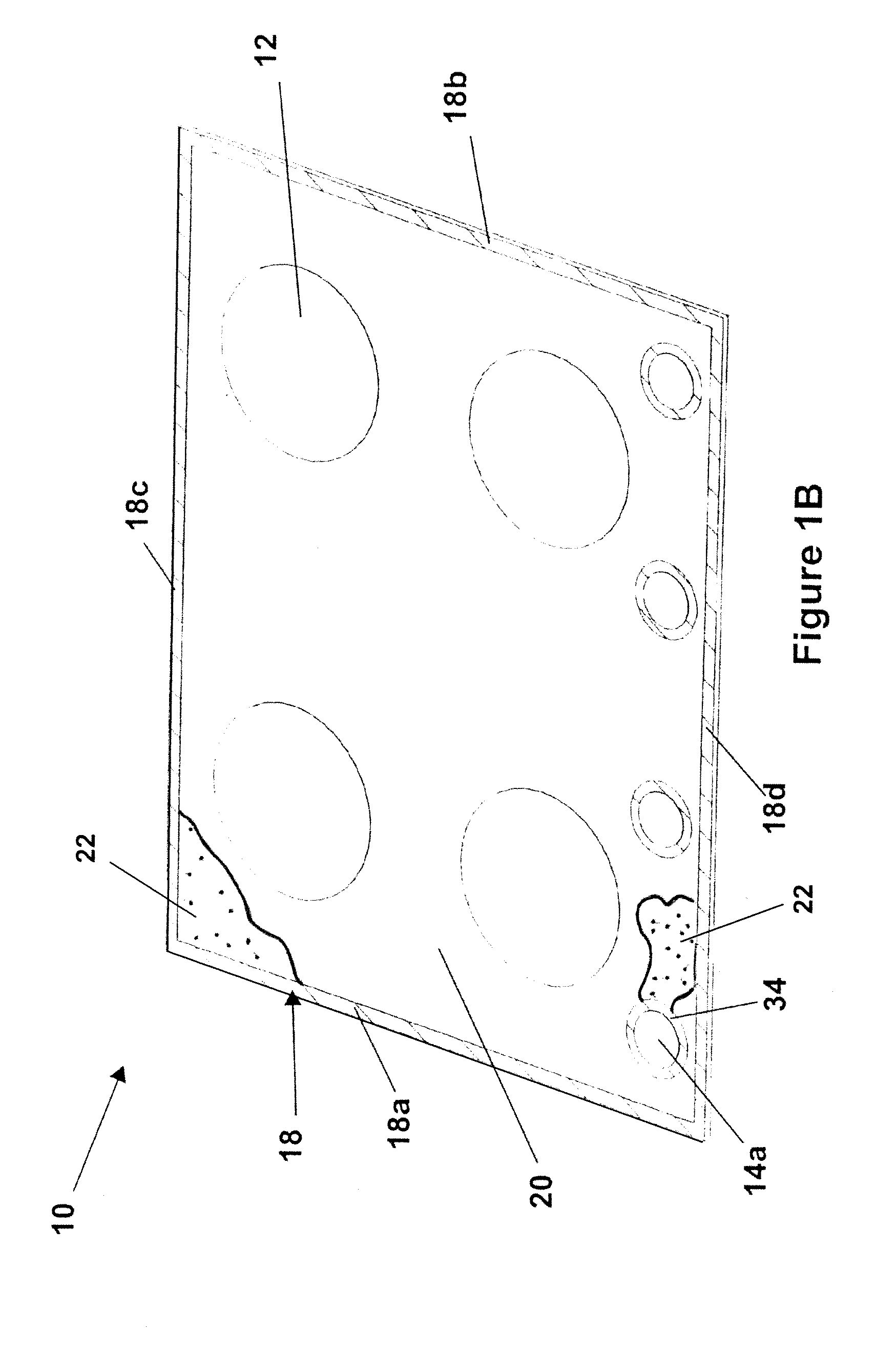

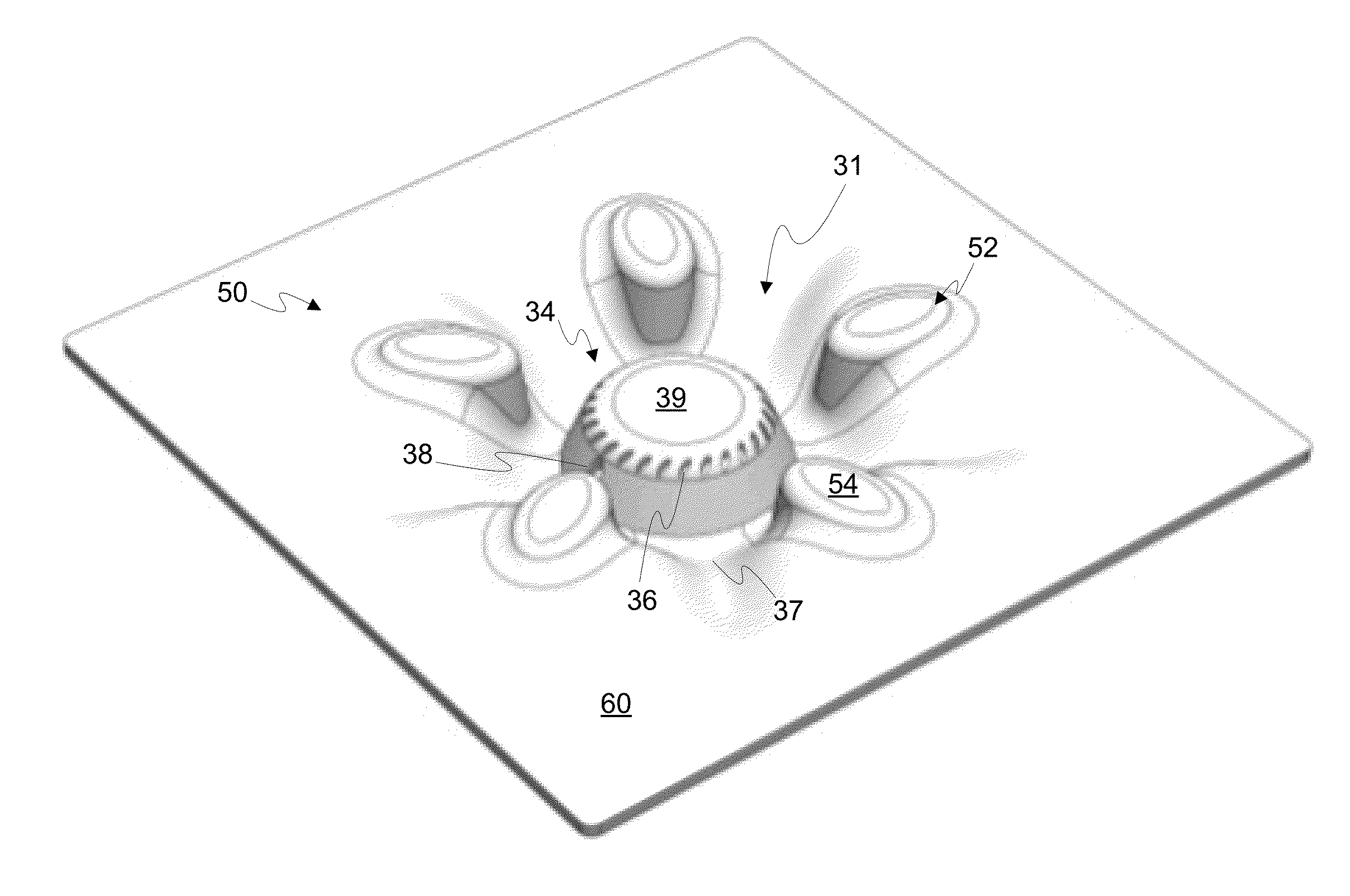

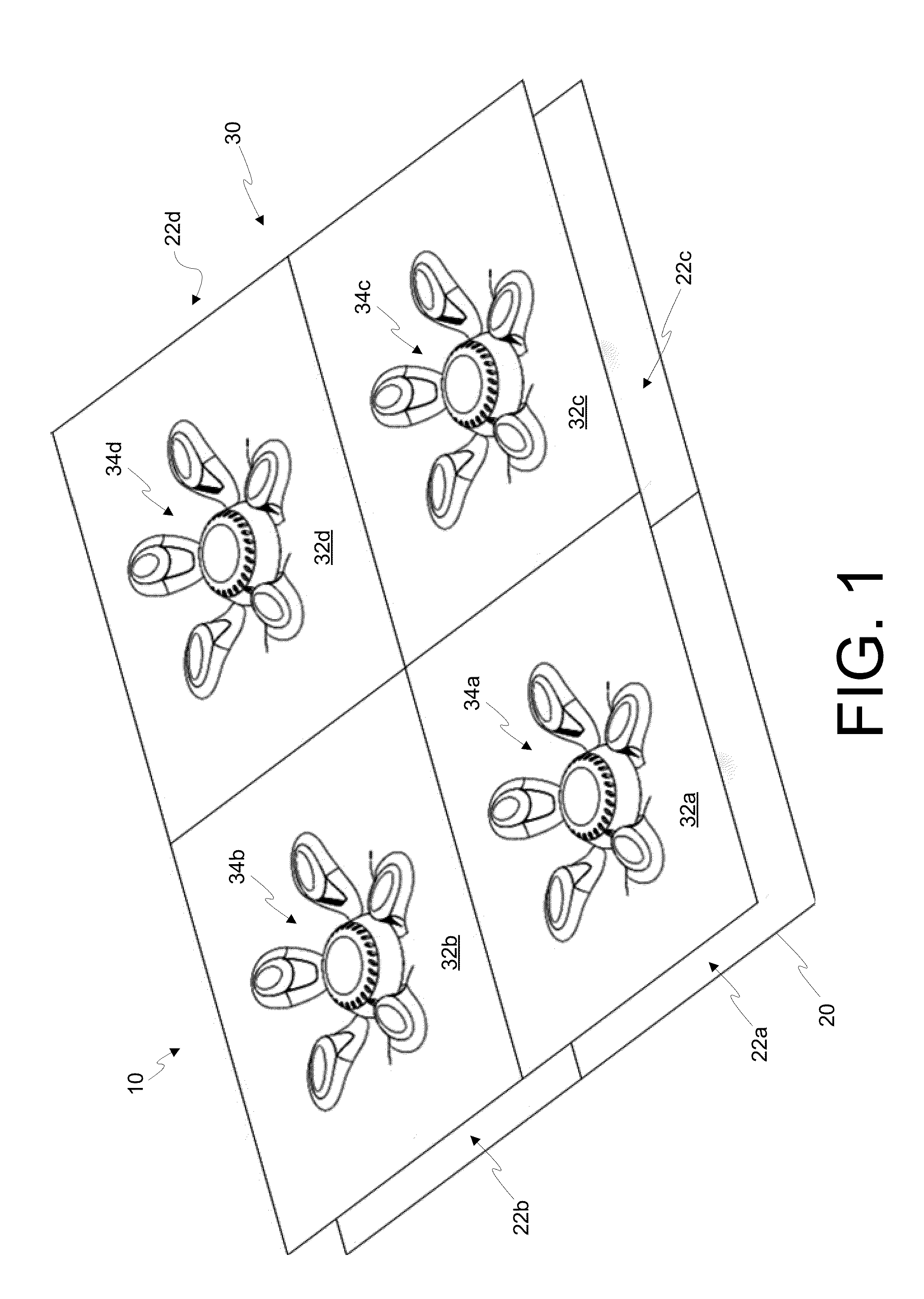

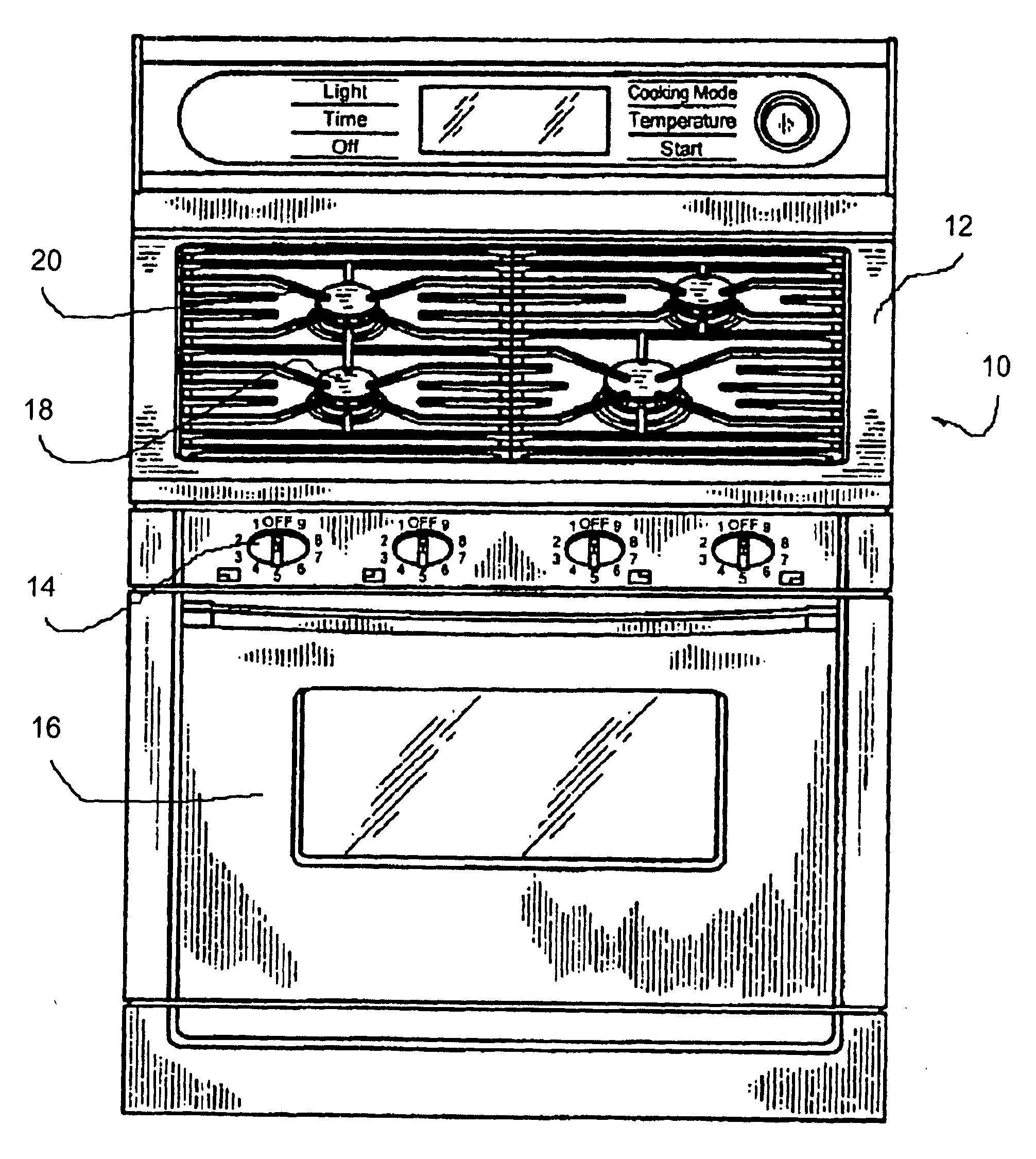

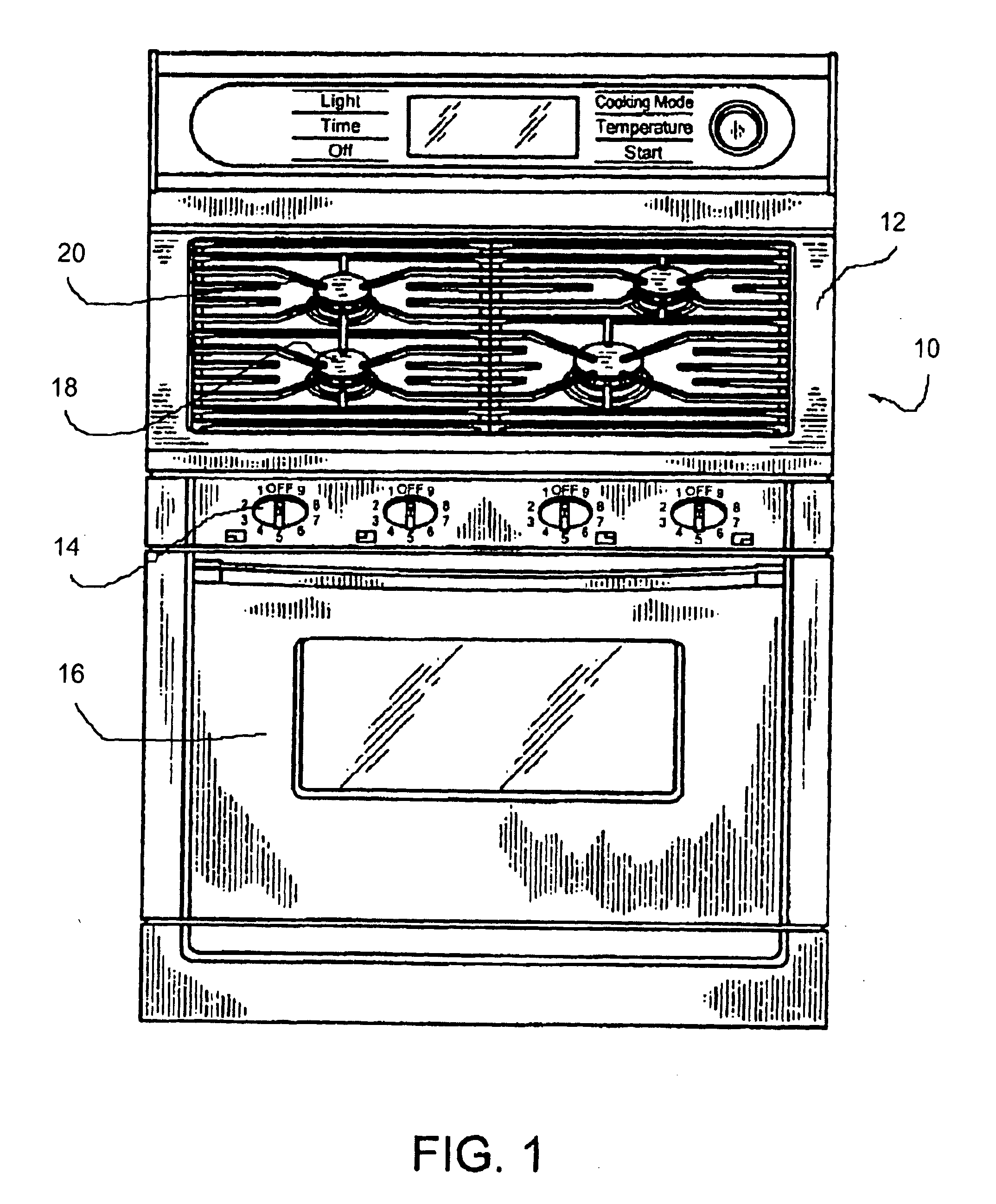

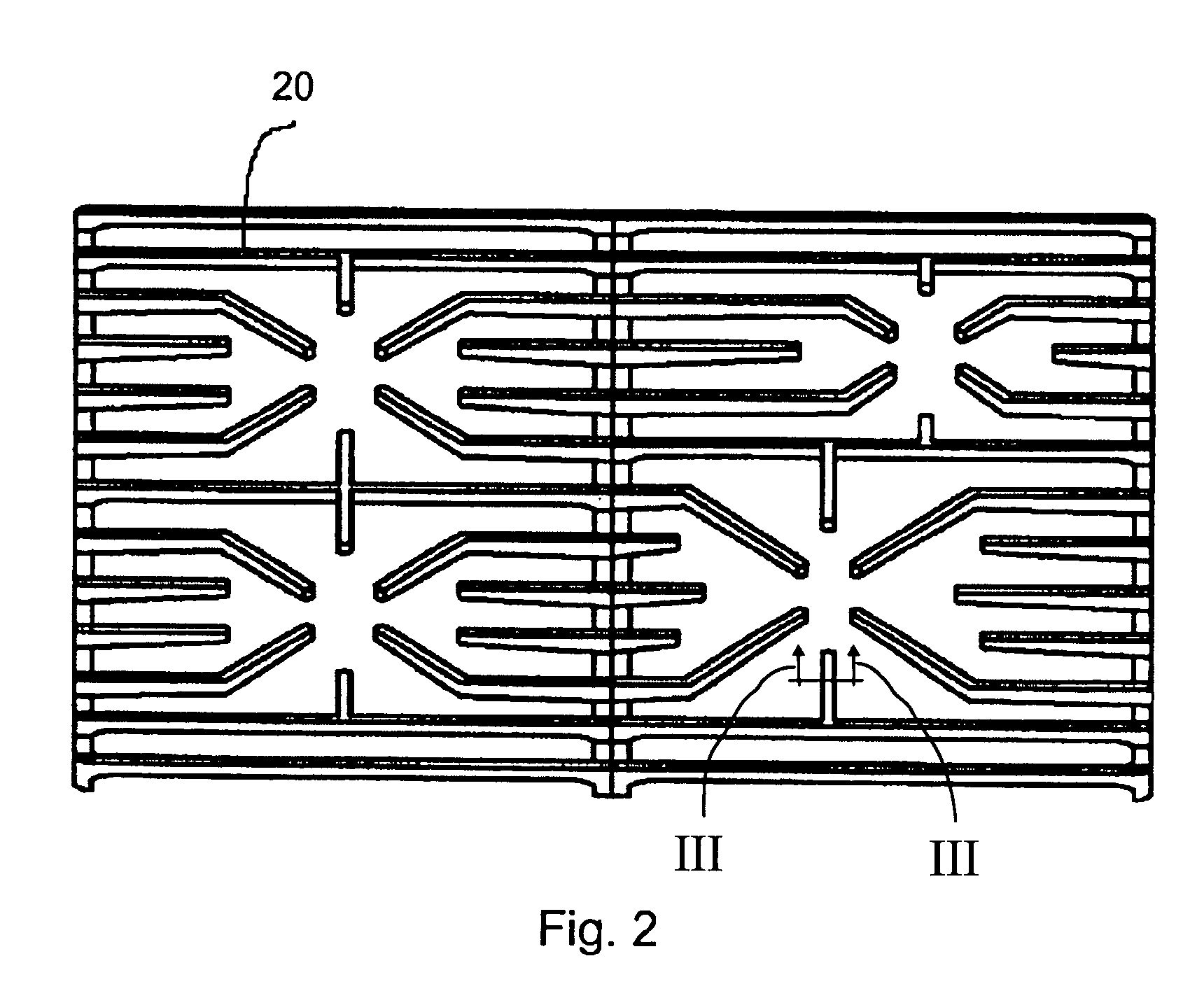

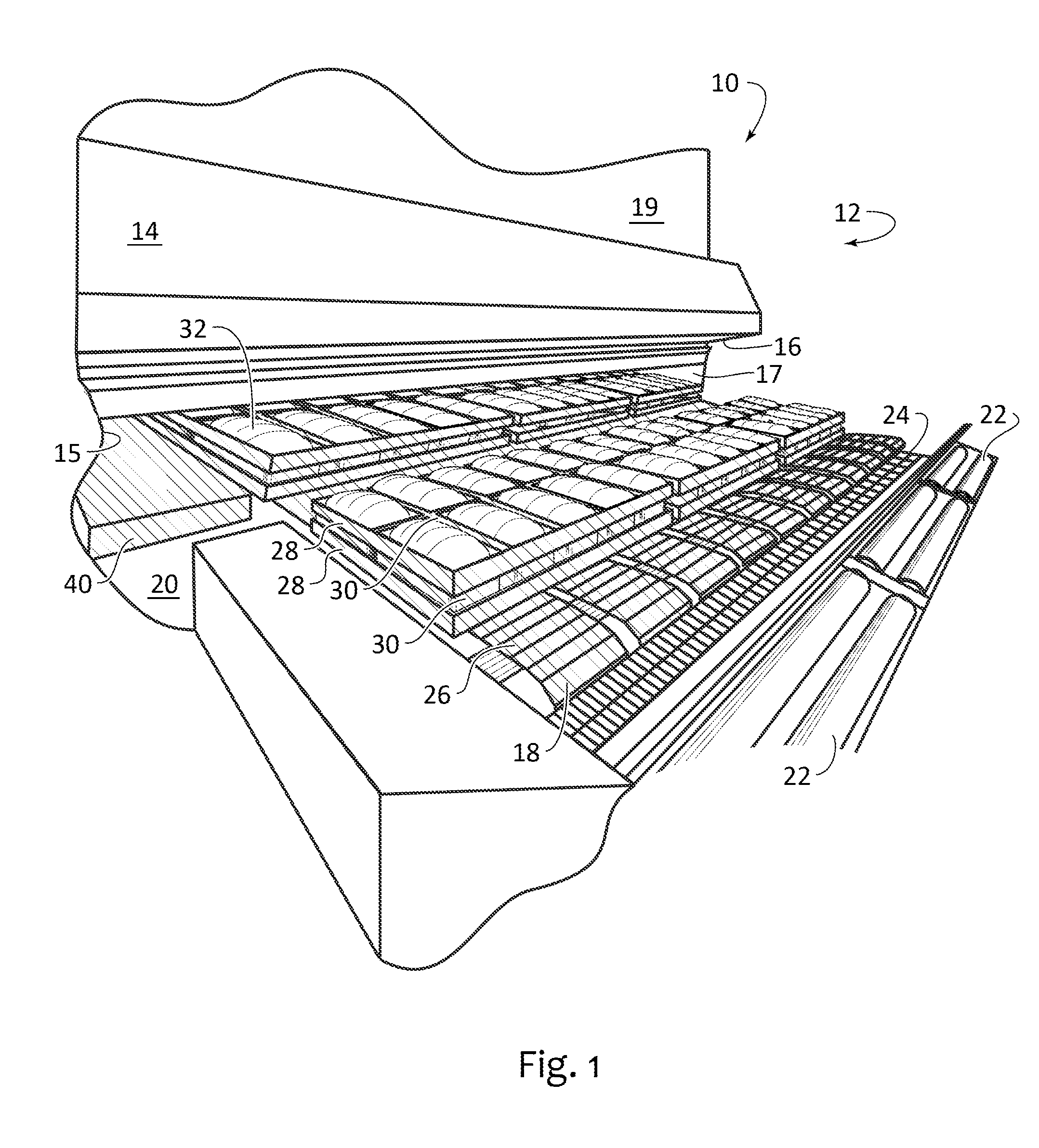

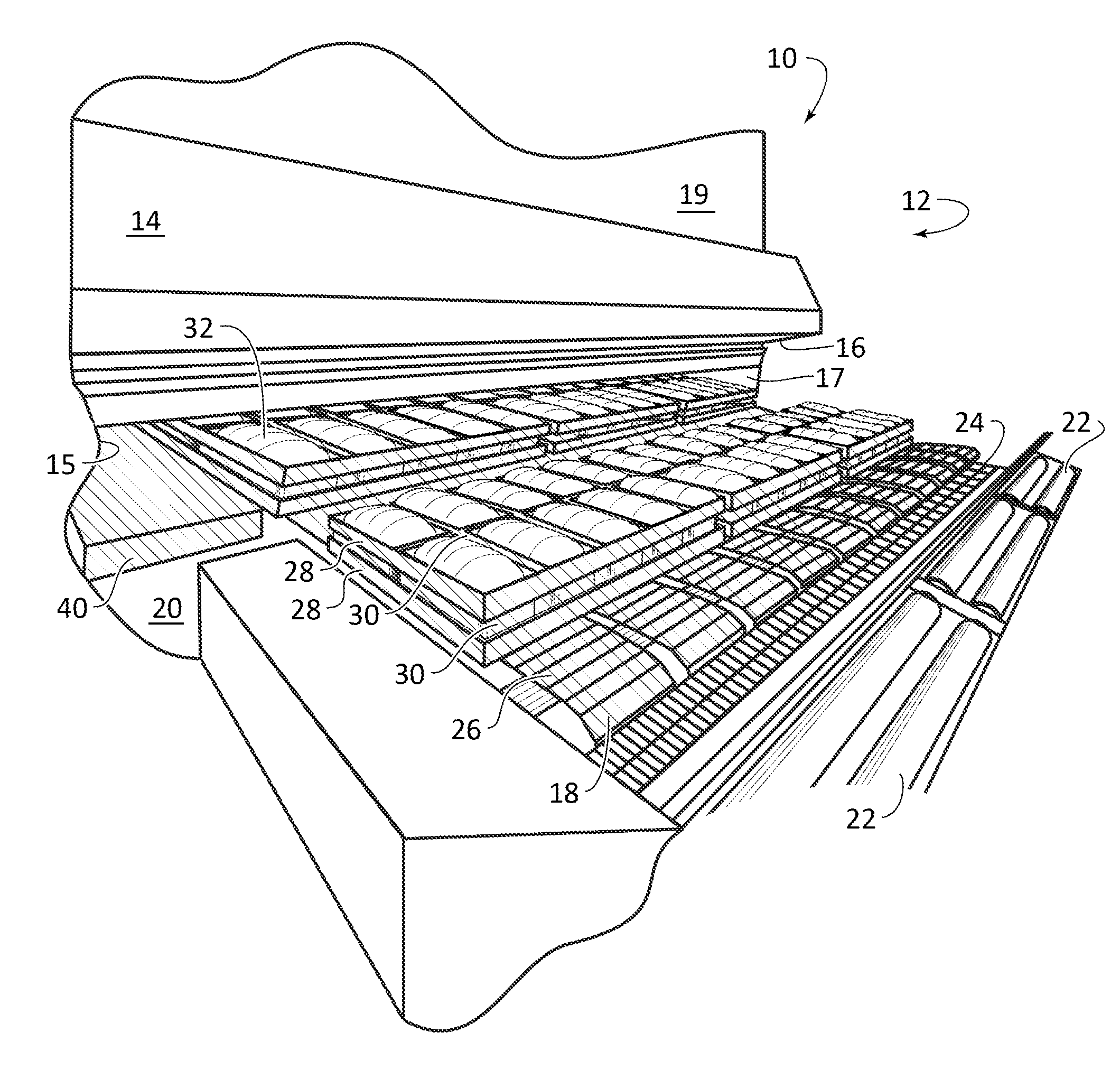

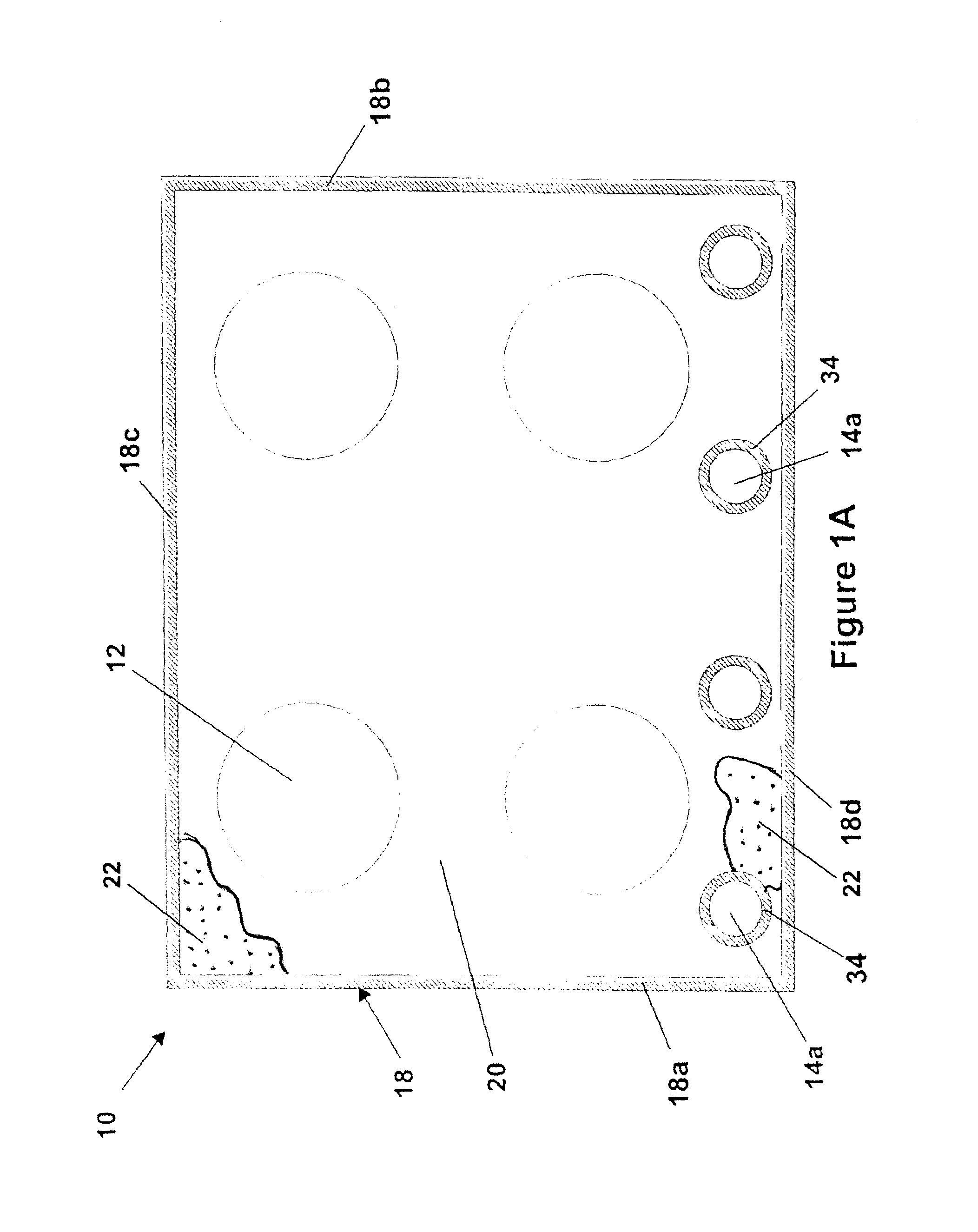

Cooking appliance surfaces having spill containment pattern and methods of making the same

A pattern of high temperature hydrophobic surfaces for use with cooking and baking appliances, such as kitchen cooktops, stoves and oven interior walls. The pattern of hydrophobic surfaces confines overflowed liquids to the enclosed non-hydrophobic surface areas and away from protected areas, such as around burner control knobs, burner surfaces, cal rods, fan and vent openings, countertops, and the like. The hydrophobic materials used are able to withstand and effectively repel liquids at high operating temperatures.

Owner:SSW ADVANCED TECH LLC

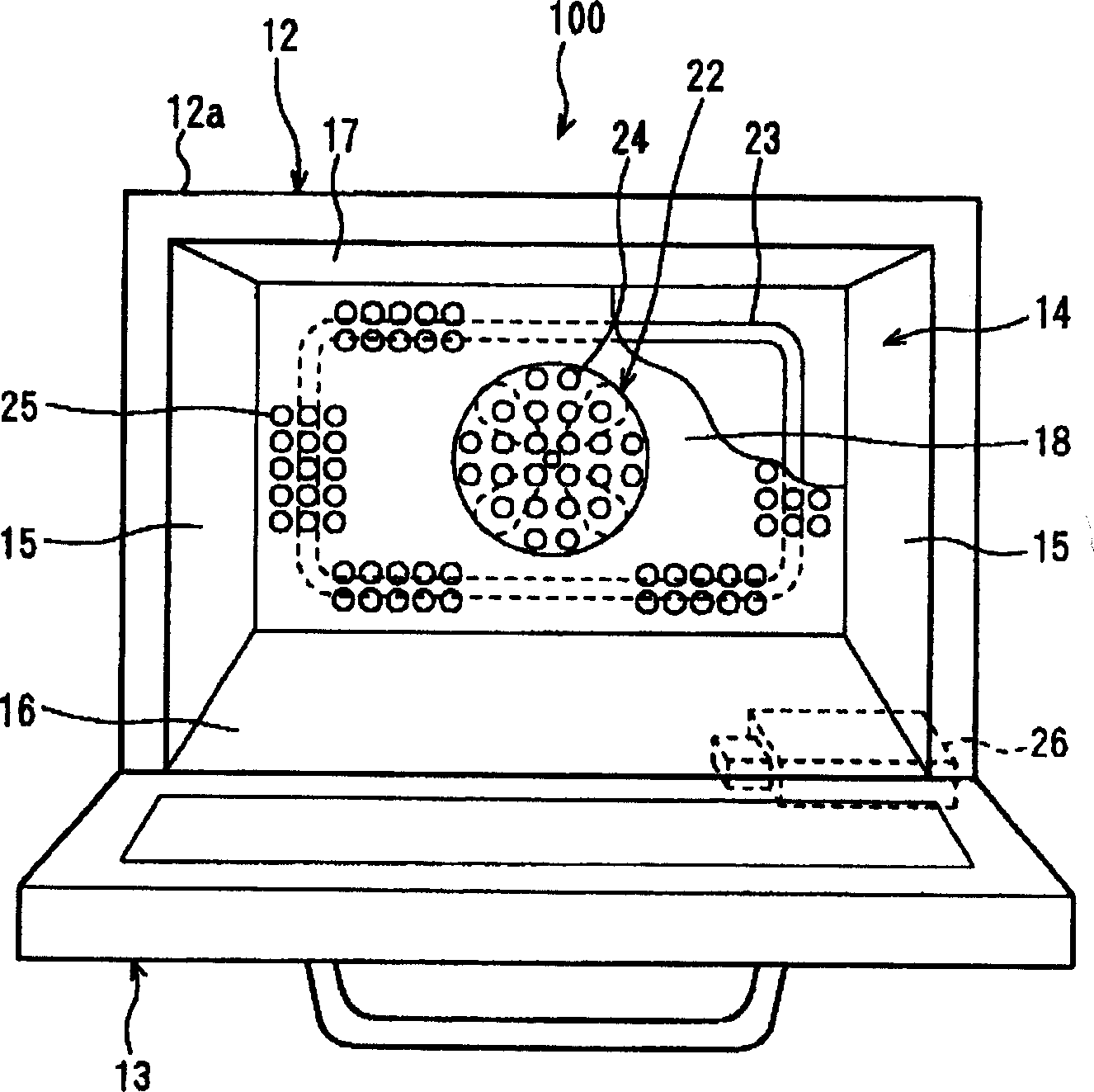

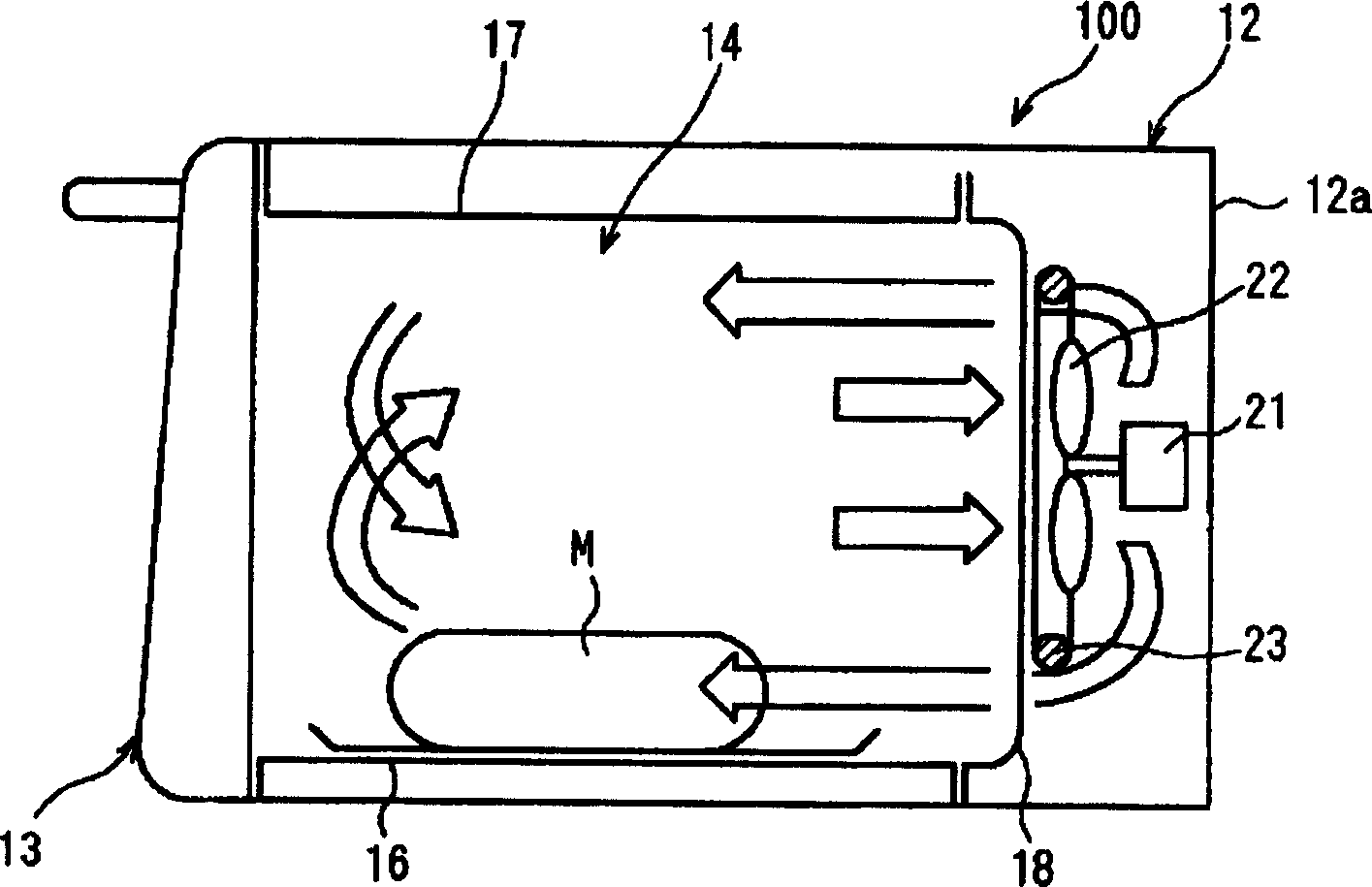

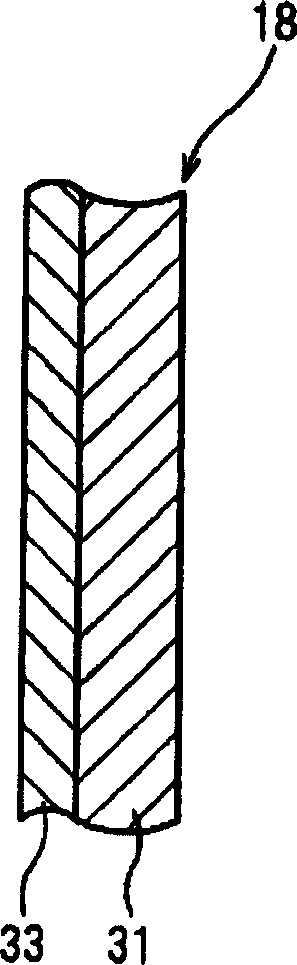

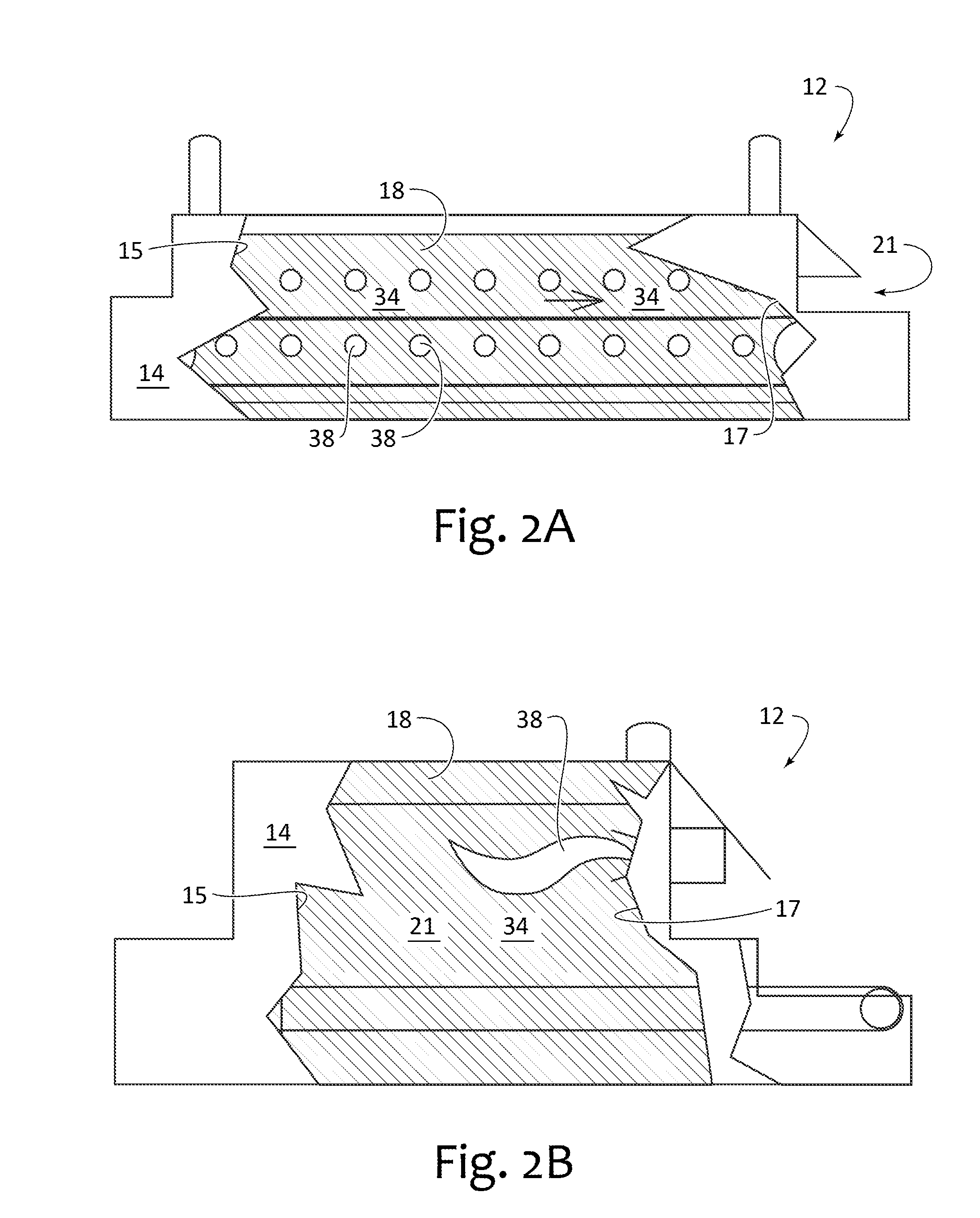

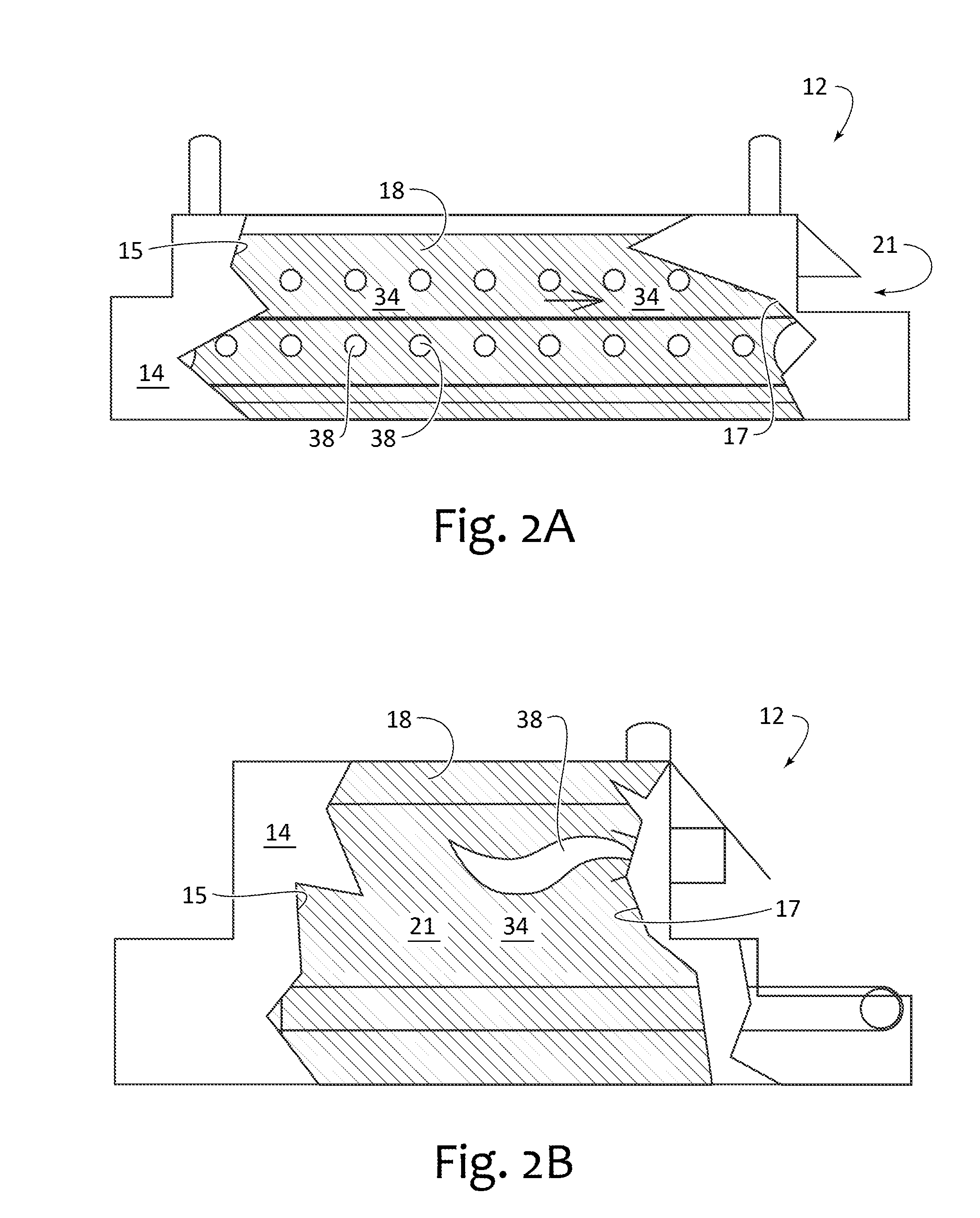

Heat cooking apparatus and self-cleaning material and producing method thereof

InactiveCN1487240AReduce capacityReduce consumptionSelf-cleaning stoves/rangesLighting and heating apparatusConvection heaterMethods of production

A convection heater (23) is disposed along a back surface of a rear face plate (18) which is comprised of a stainless steel plate that forms a heating chamber (14). On a back side of the rear face plate (18), disposed is a circulation fan (22) by which, air in the heating chamber (14) is sucked from air intake use through-holes into the back side, and after it is heated by the convection heater (23), it is returned from air blowing use through-holes to the heating chamber. On a surface of an inner side of the heating chamber (14) of the rear face plate (18), a self-cleaning layer is formed by dissolving a self-cleaning material which oxide-decomposes and removes accreted dirt at high temperature into a porcelain enamel glaze and by applying and bake-sticking.

Owner:PANASONIC CORP

Cleanability of ovens and cooktops

An oven cavity for an oven or range appliance includes a heat-stable base substrate, and a hard ceramic coating disposed on the base substrate. The hard ceramic coating is a poly-condensated silicone, polymeric silazane or poly-ceramic coating composition. A method of forming a surface for an oven or range appliance is also disclosed.

Owner:GENERAL ELECTRIC CO

Non-stick, pyrolytic coatings for heating devices

ActiveUS20140238379A1Stoves/ranges foundationsSelf-cleaning stoves/rangesSilanesCrystalline materials

In accordance with one aspect of the present invention, a heating device is presented. The heating device includes a pyrocatalytic, non-stick coating disposed on at least one surface. The pyrocatalytic non-stick coating includes (i) a binder derived from a silane, a polysiloxane, a polysilazane, or combinations thereof; and (ii) a catalyst dispersed within the binder, wherein the catalyst comprises a pervoskite crystalline material, a pyrochlore crystalline material, a spinel crystalline material, an ilmenite crystalline material, or combinations hereof.

Owner:HAIER US APPLIANCE SOLUTIONS INC

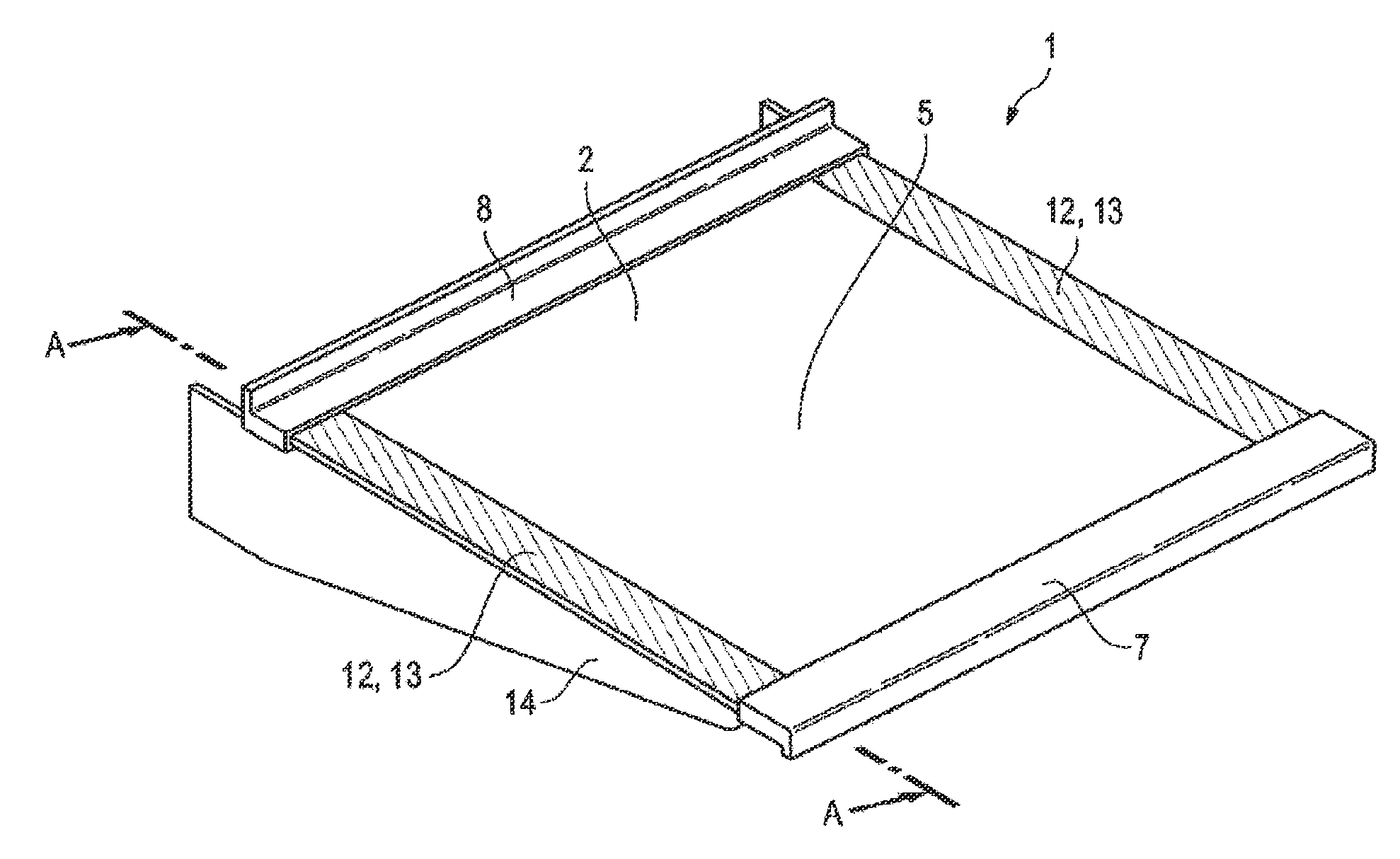

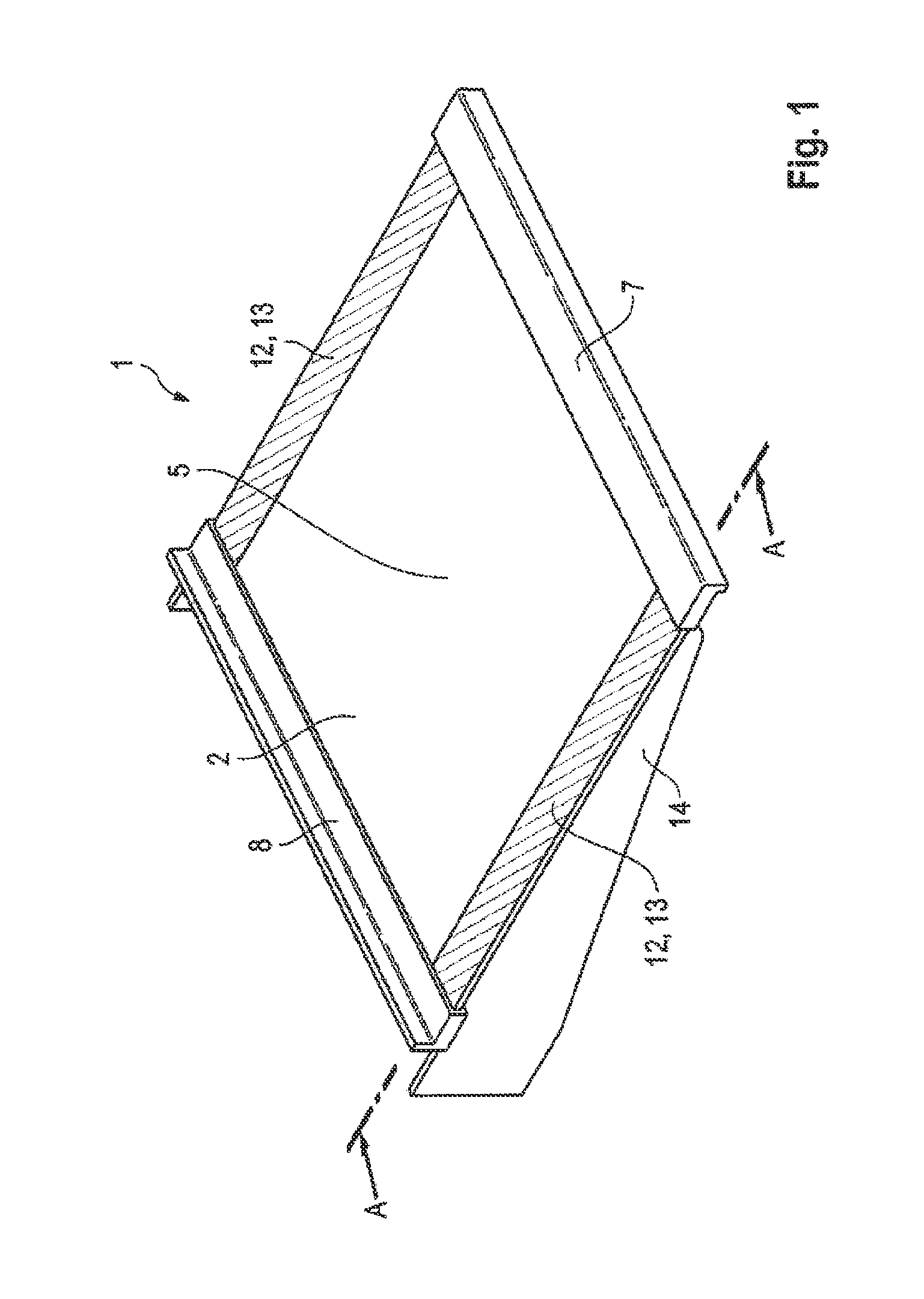

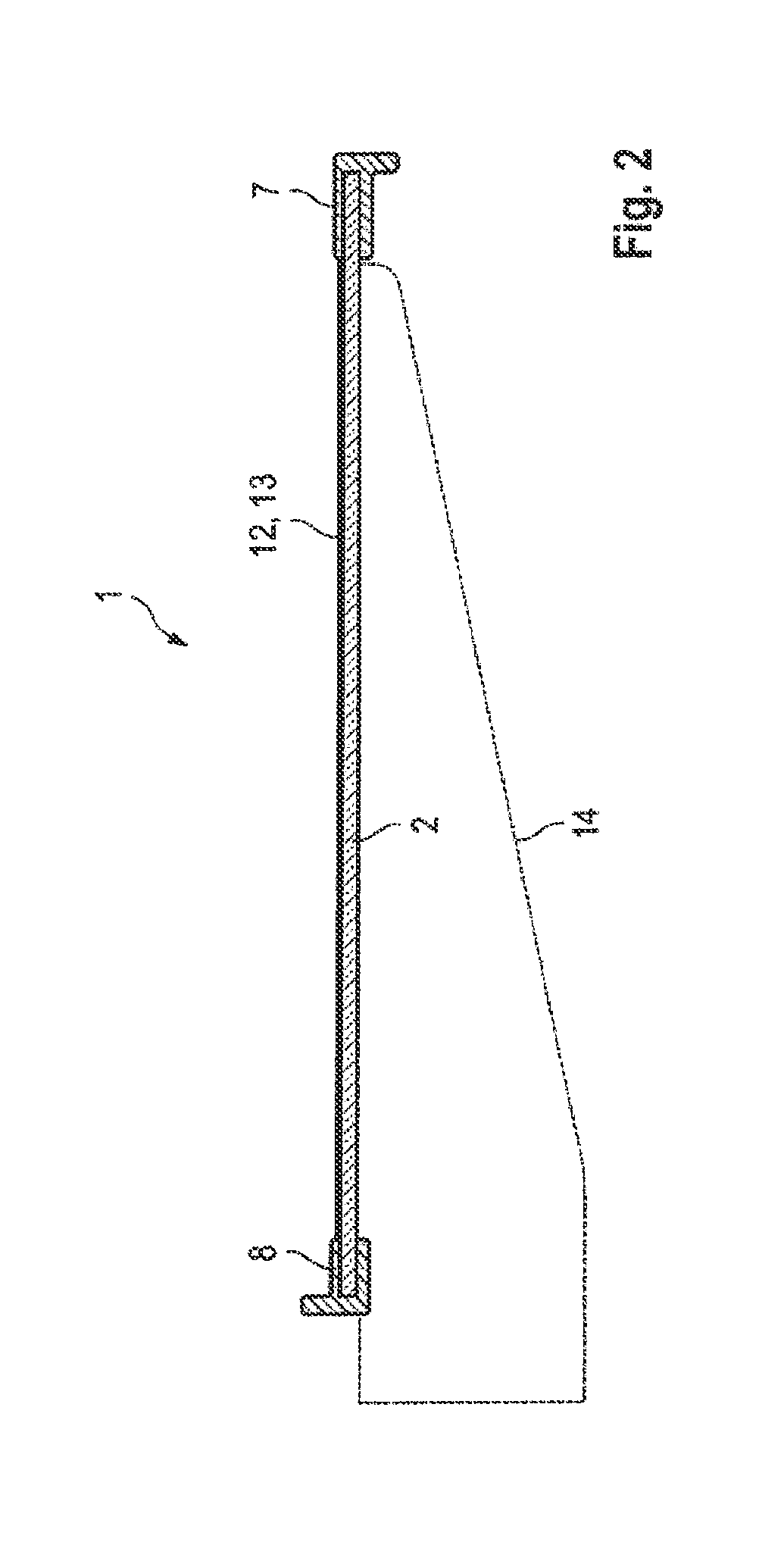

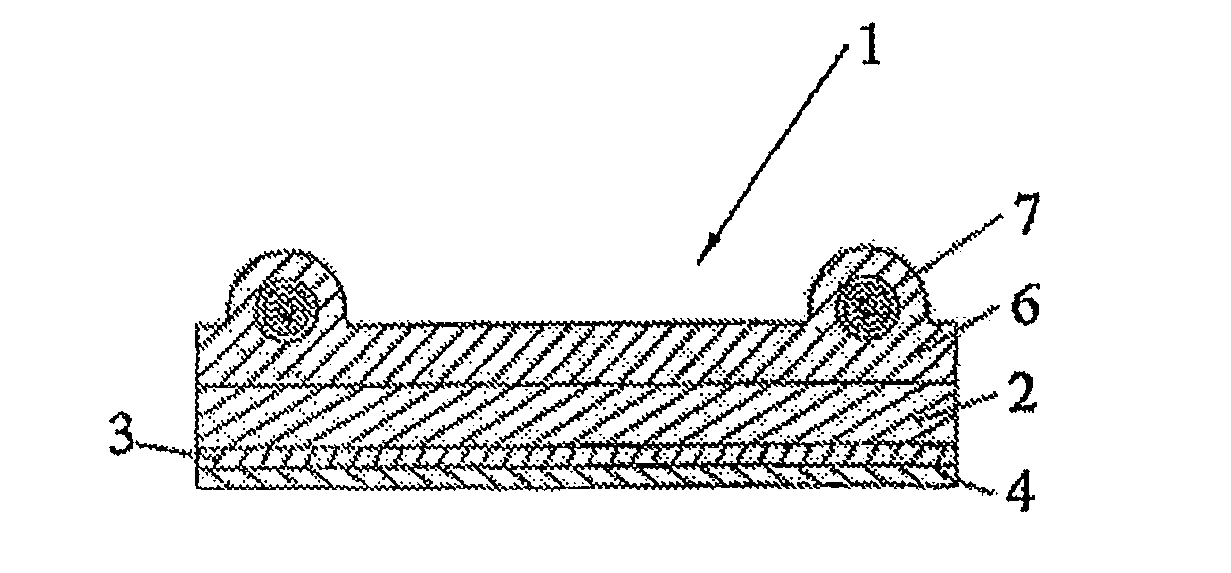

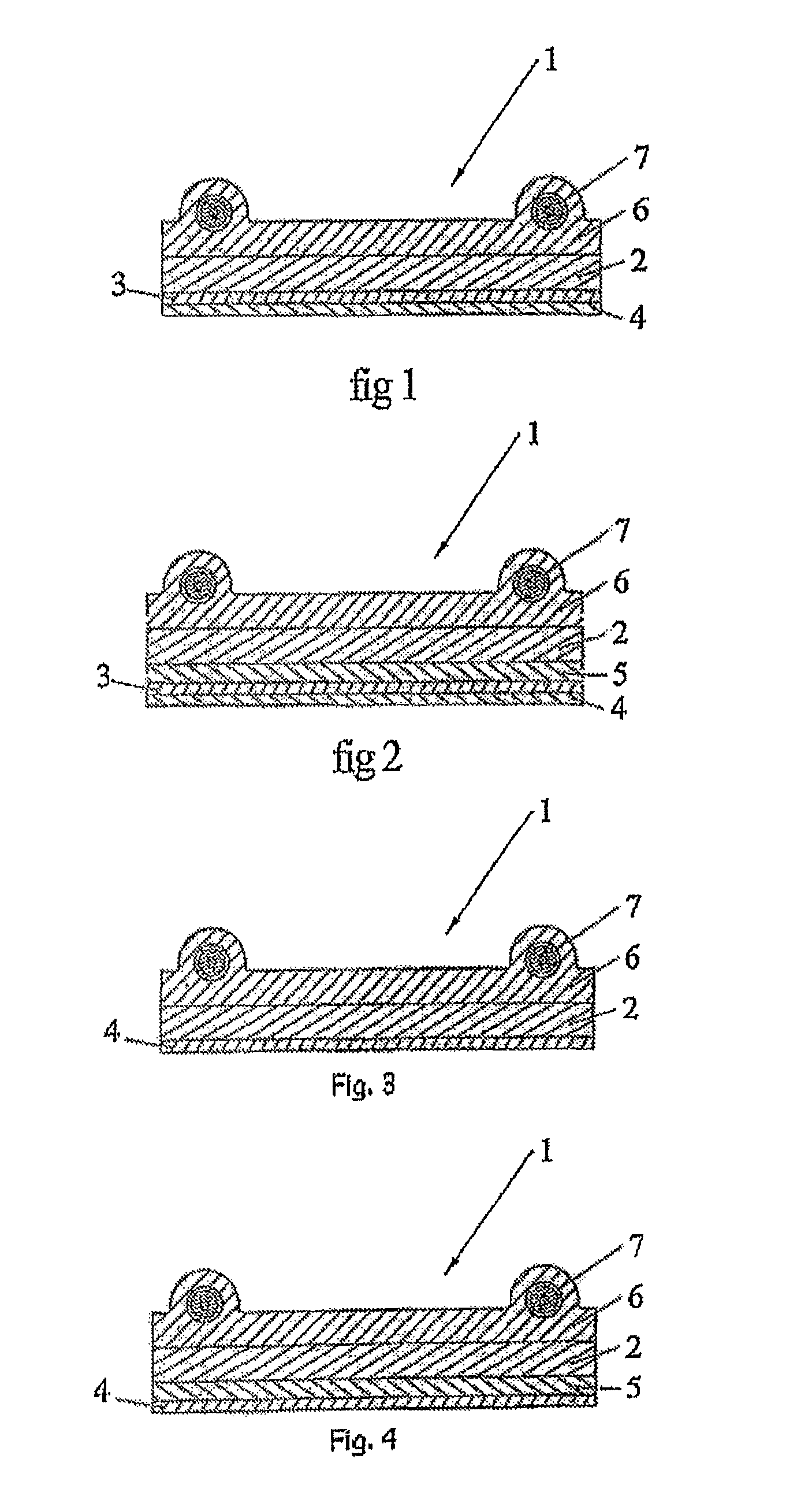

Einlegeboden

ActiveUS20140138337A1Simple methodStoves/ranges shelves or racksLighting and heating apparatusEngineeringMechanical engineering

Owner:SCHOTT AG

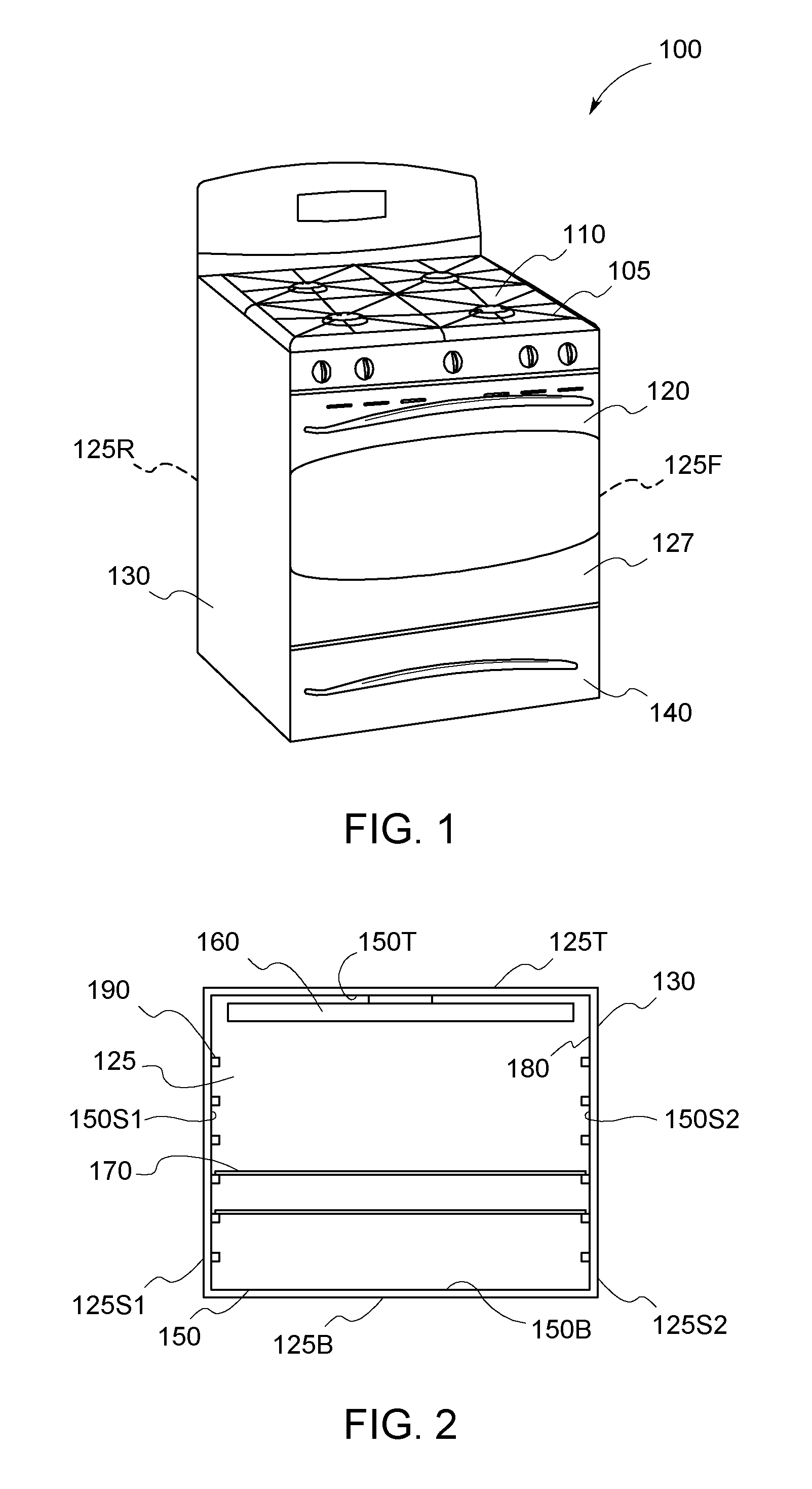

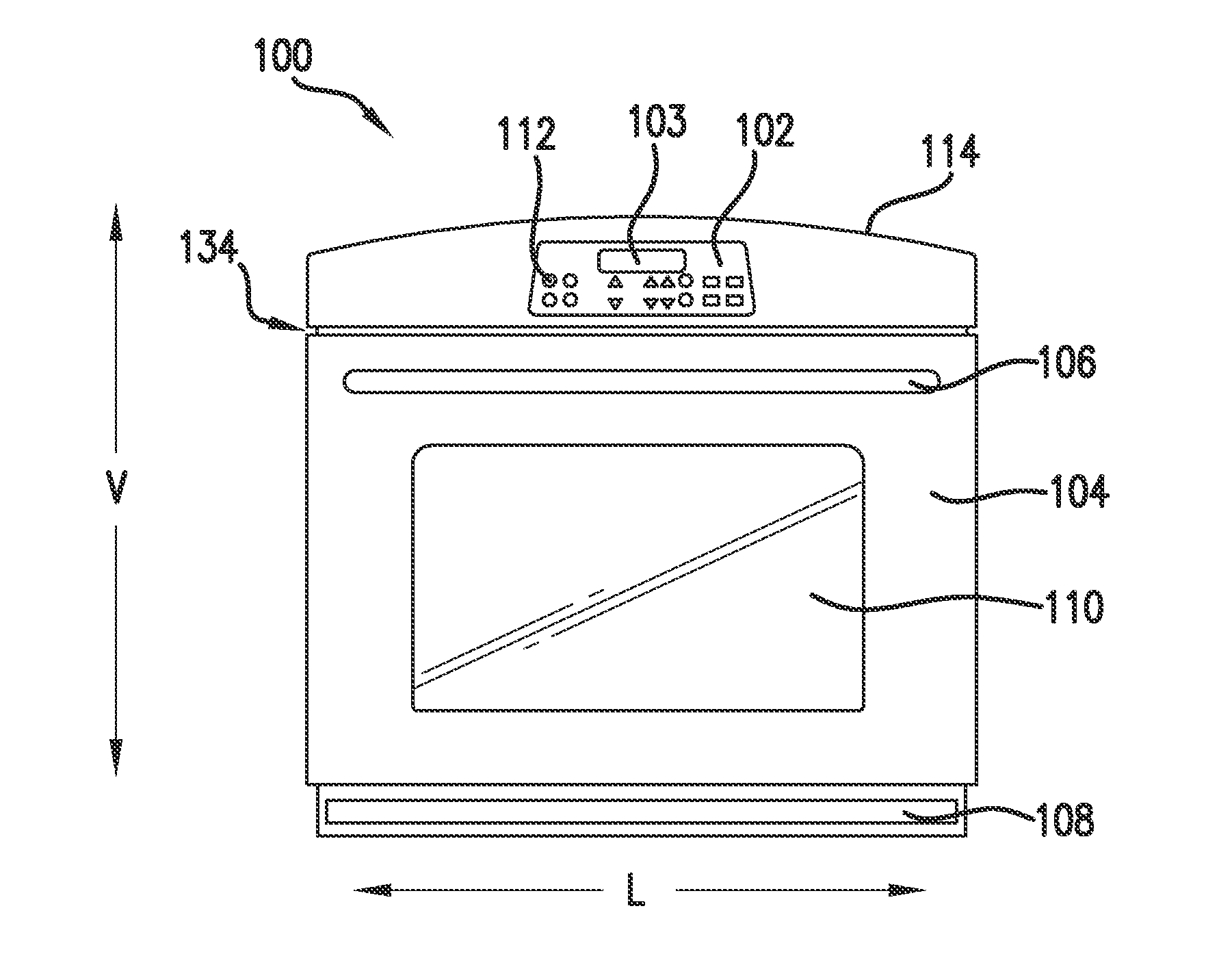

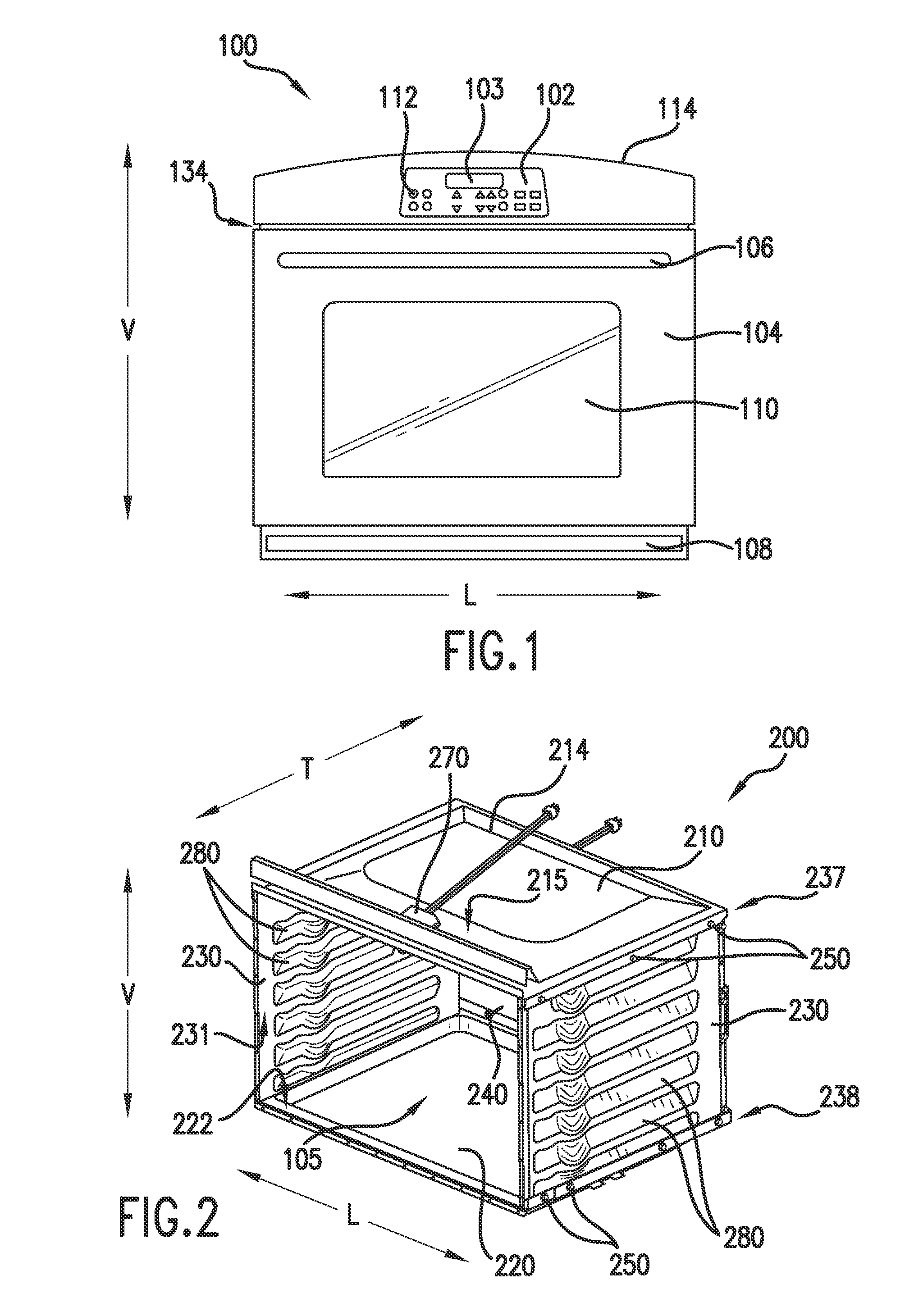

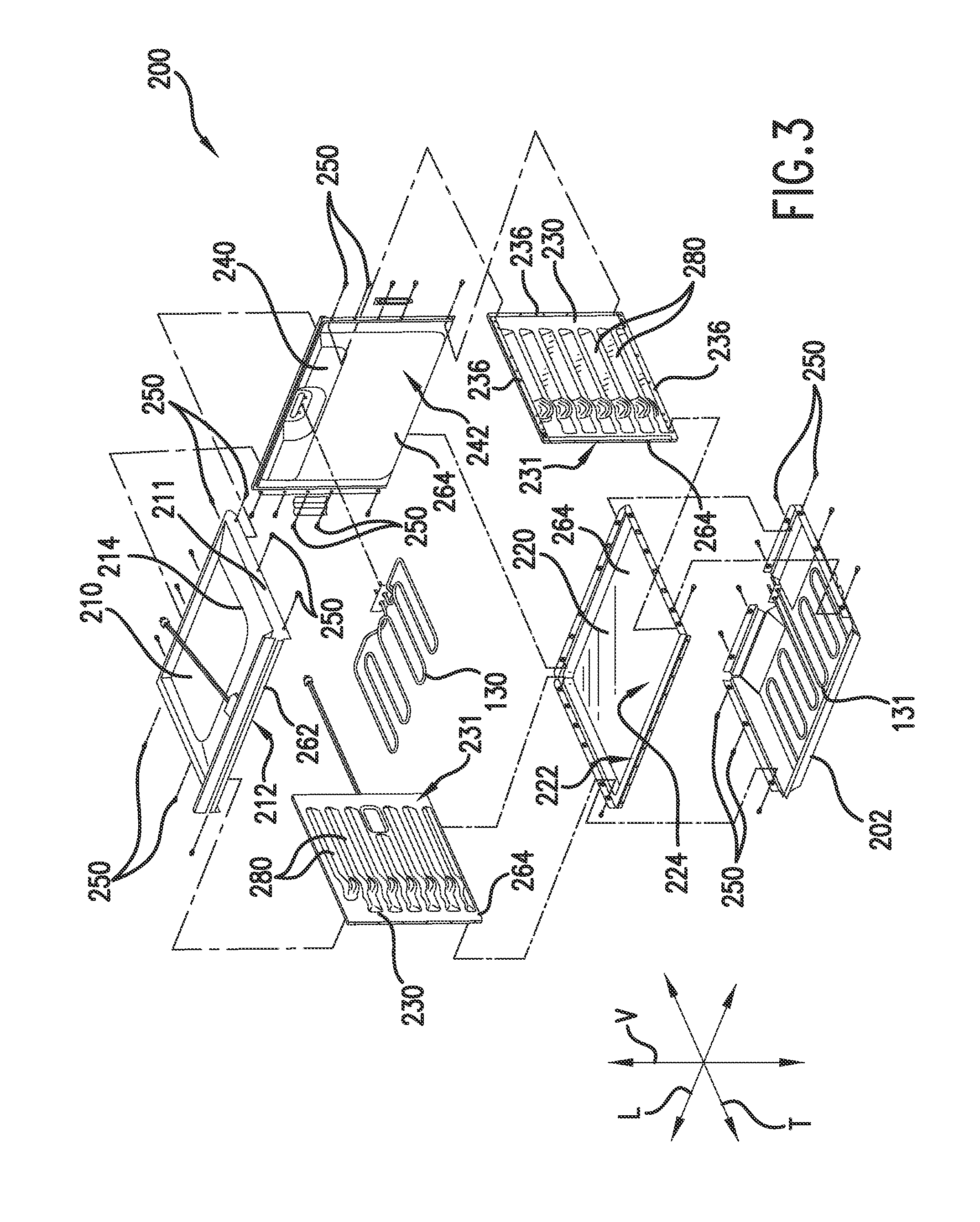

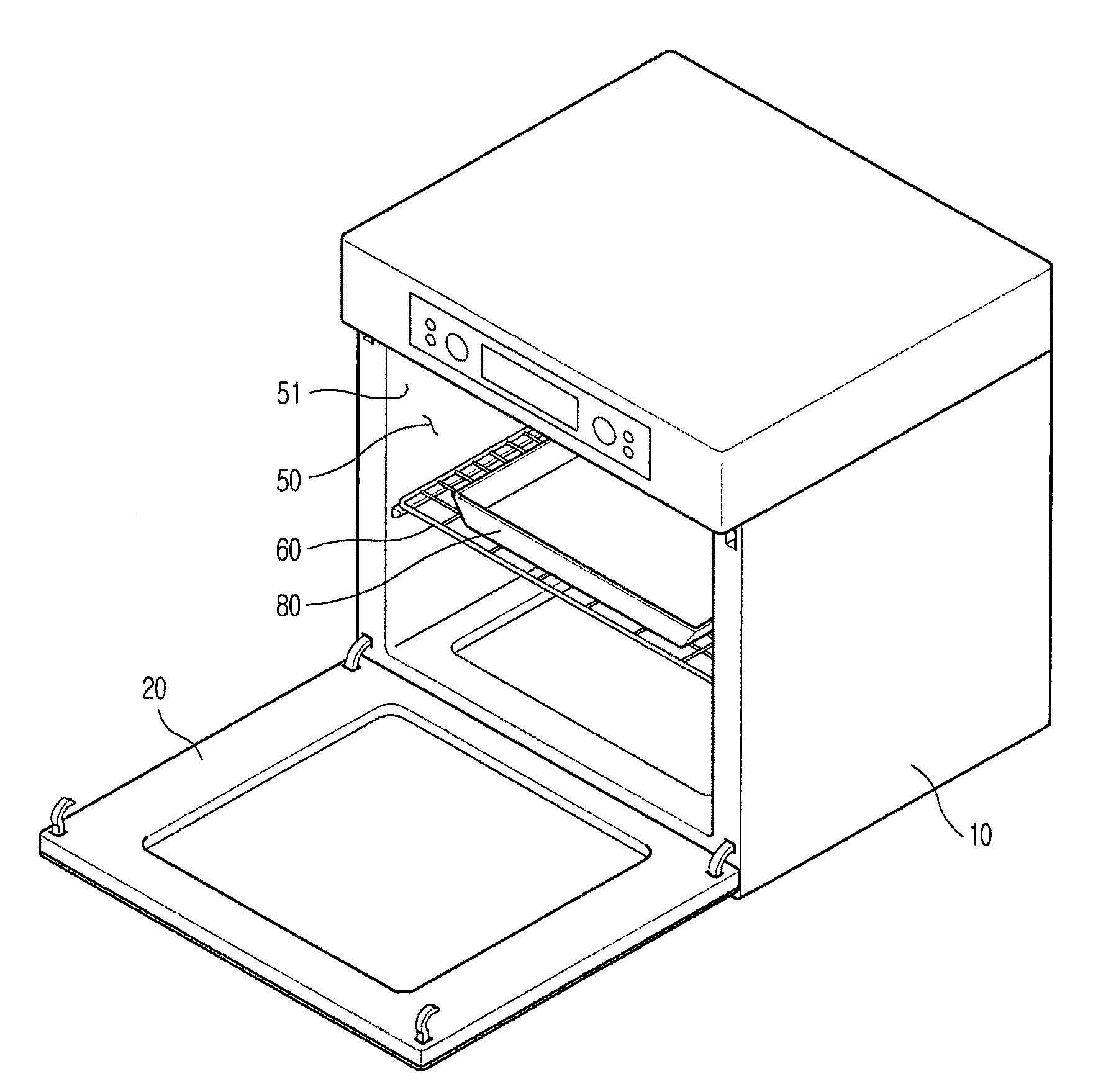

Oven Appliance and a Method for Manufacturing a Cooking Chamber of an Oven Appliance

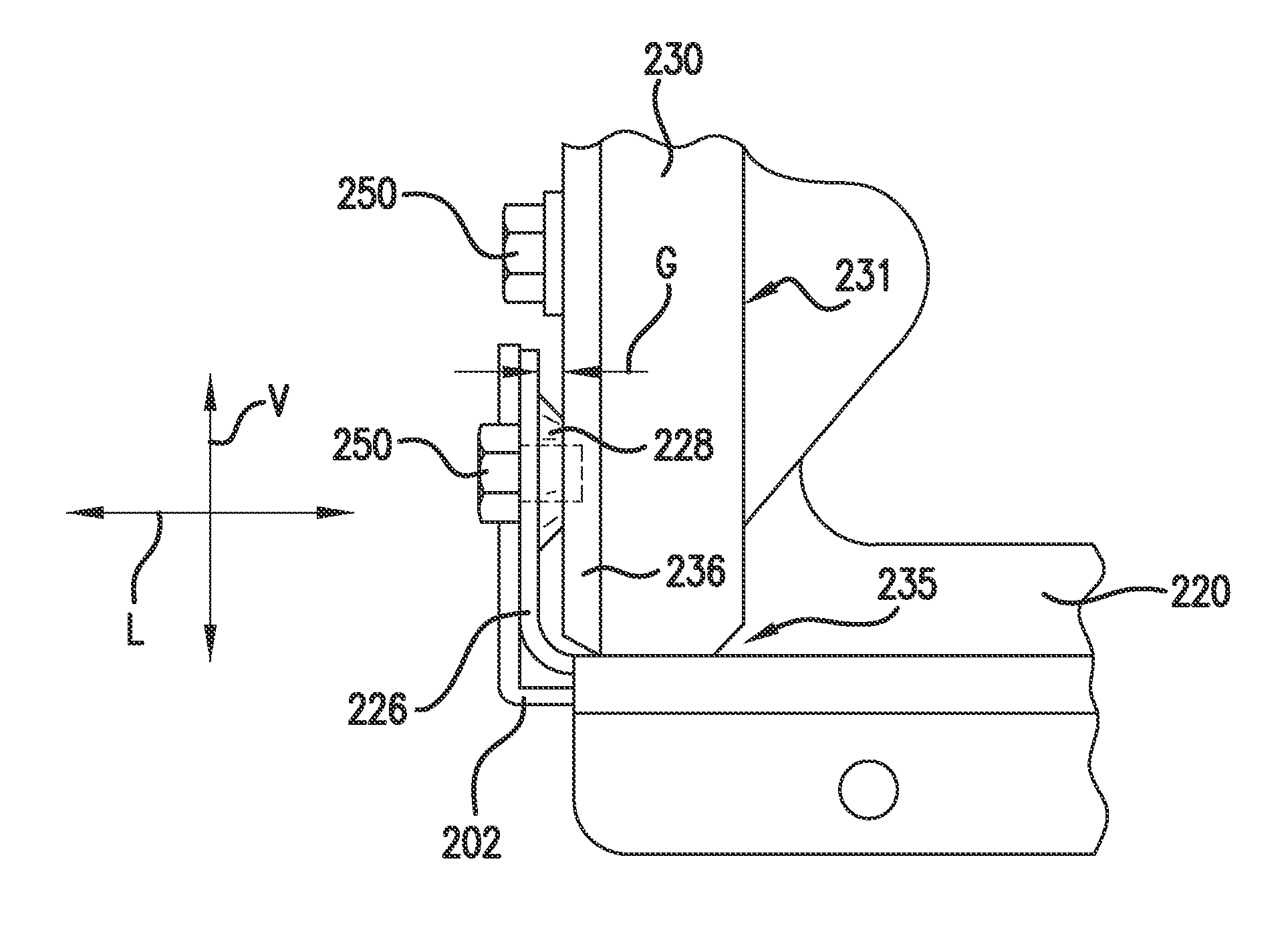

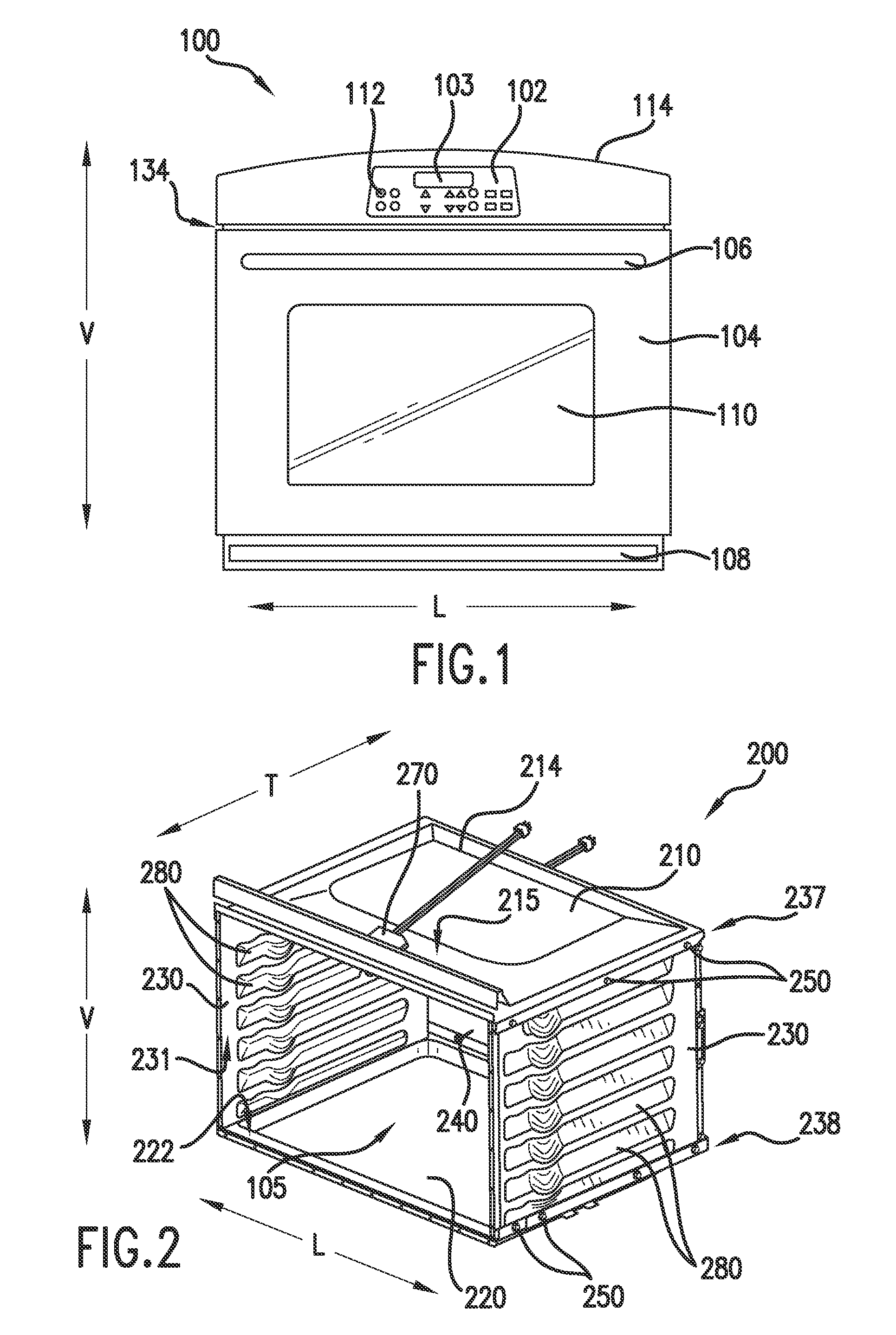

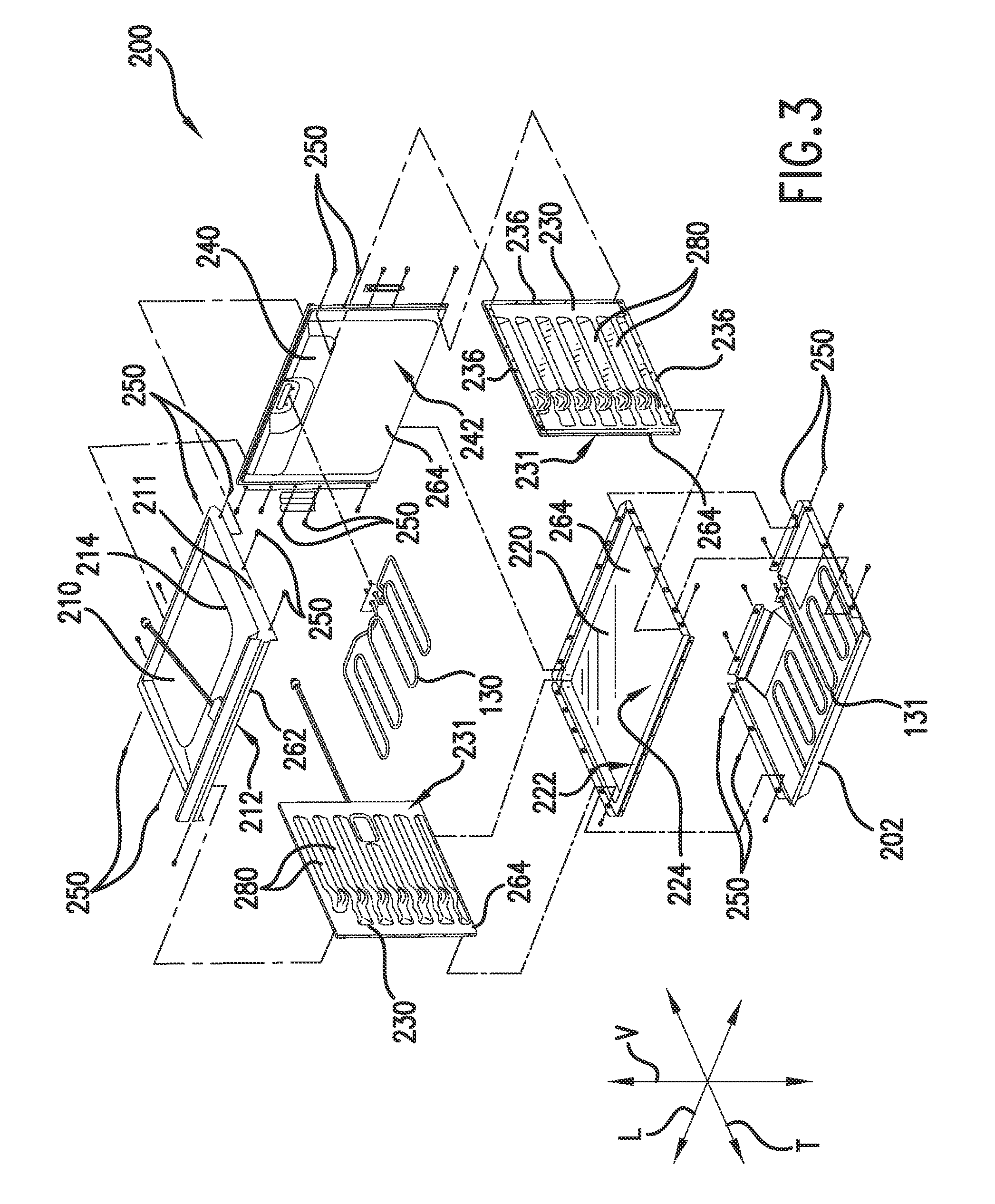

ActiveUS20150047623A1Stoves/ranges foundationsDoors for stoves/rangesFastenerElectrical and Electronics engineering

Owner:HAIER US APPLIANCE SOLUTIONS INC

Enamel And Ground Coat Compositions

Owner:FERRO CORP

Treated structural components for a cooking appliance

InactiveUS20090127246A1Domestic stoves or rangesLighting and heating apparatusPlasma electrolytic oxidationMaterials science

A structural component for a cooking appliance includes a core structure formed from metal in a general configuration of the structural component for a cooking appliance; and an outer coating defining a ceramic layer formed by a plasma electrolytic oxidation treatment applied to the core structure of the structural component.

Owner:BSH HOME APPLIANCES CORP

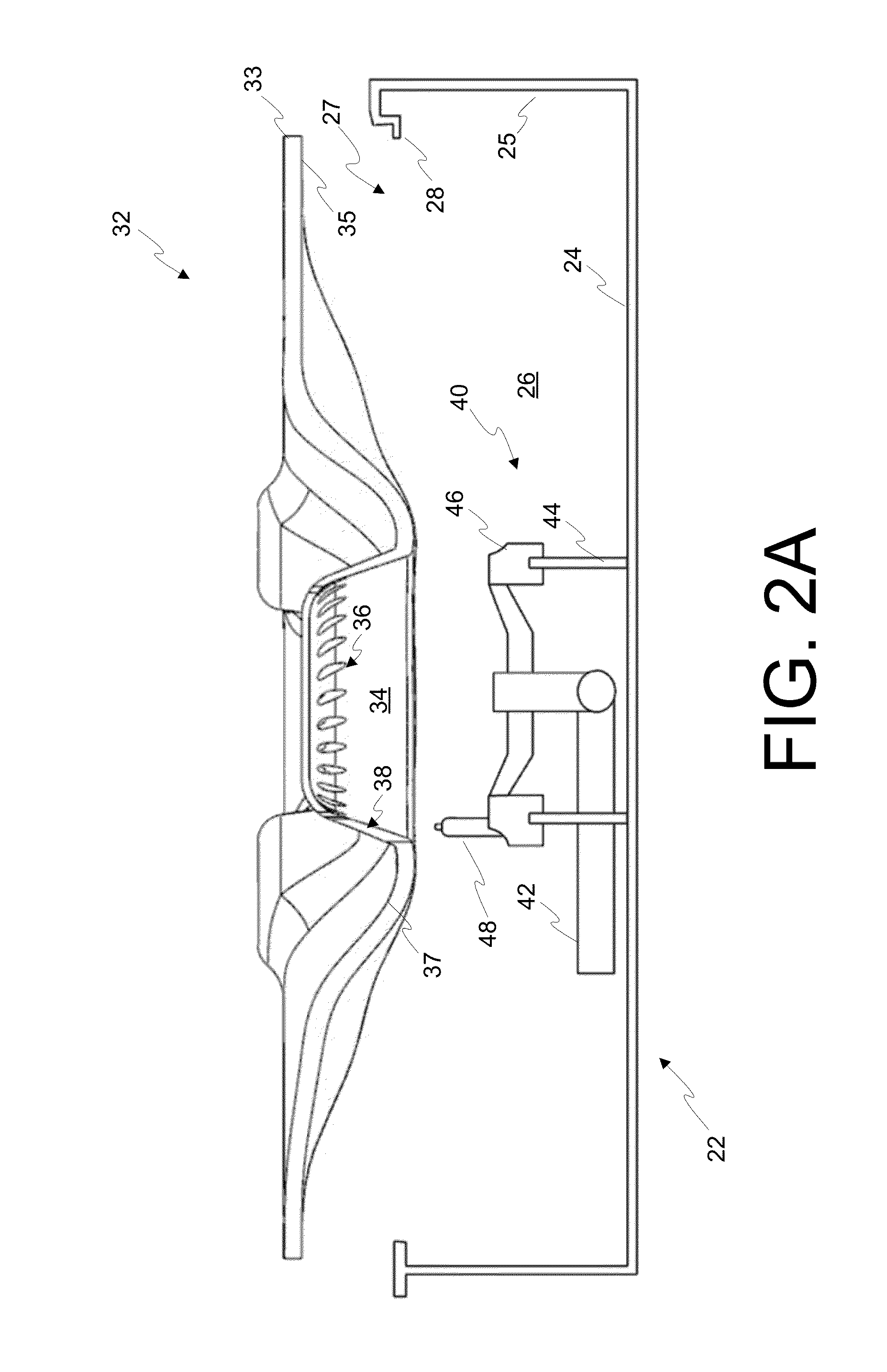

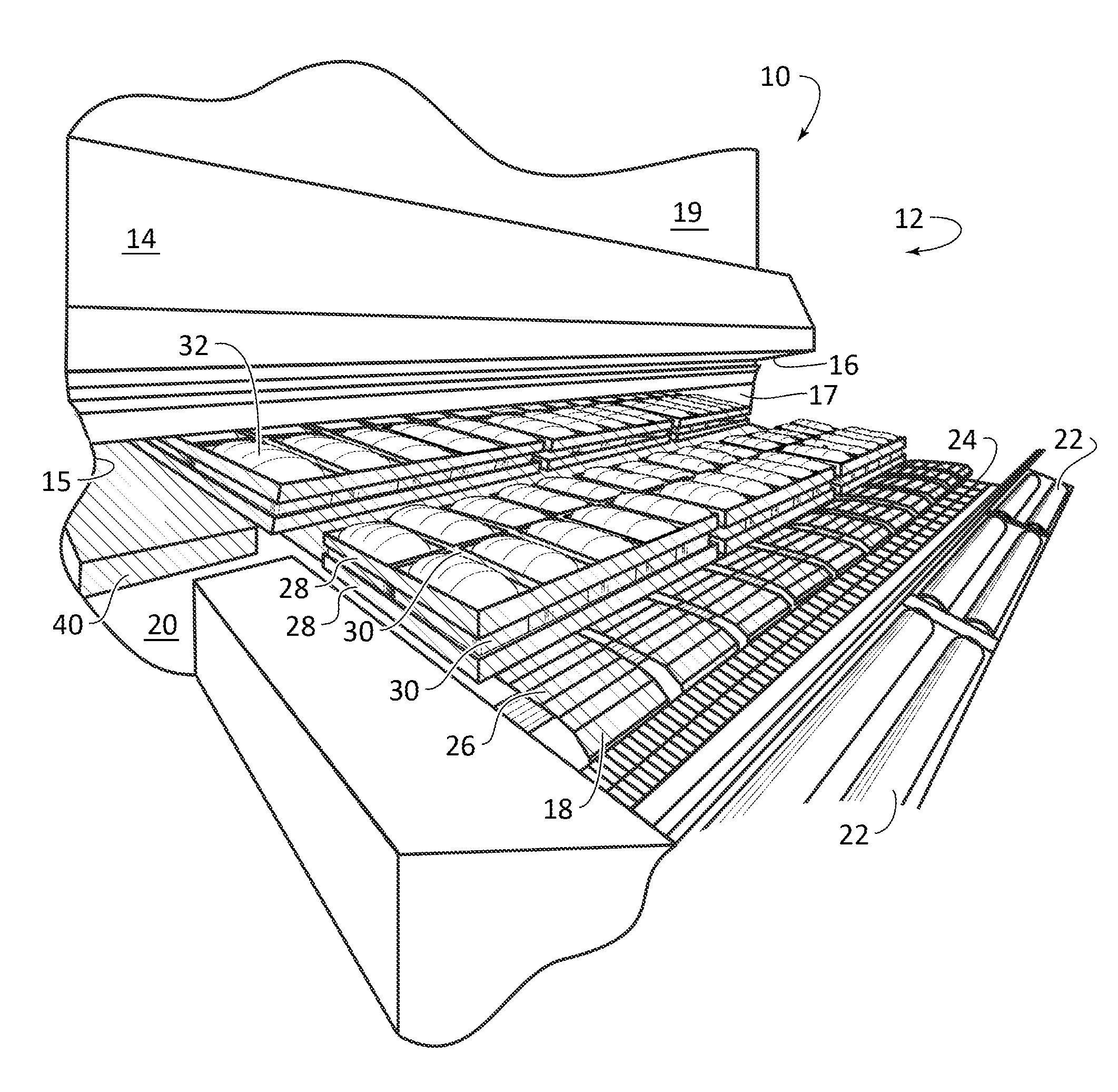

Food product and method and apparatus for baking

ActiveUS20120074122A1Less timeLess energyEnvelopes/bags making machineryCharge supportsColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

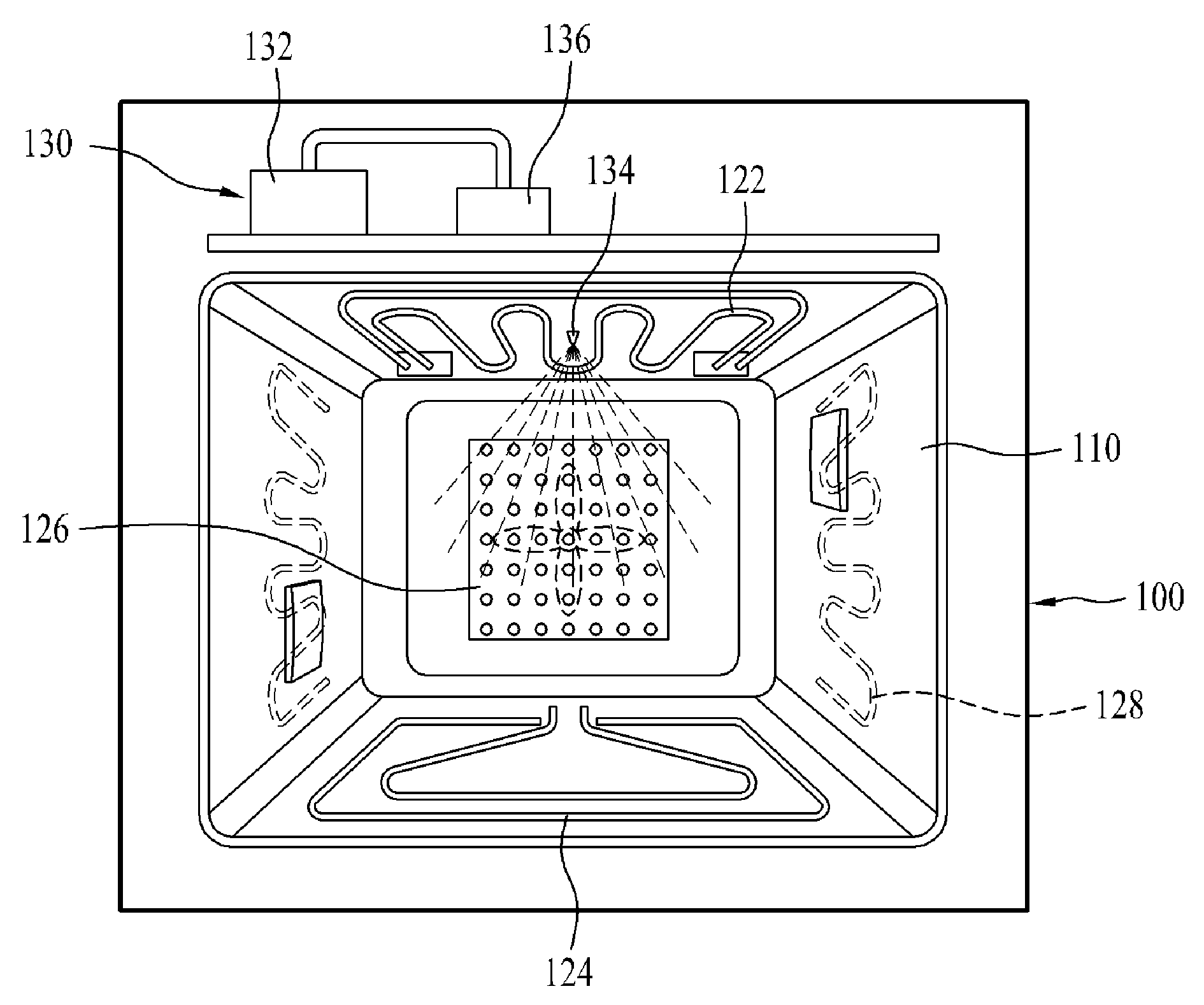

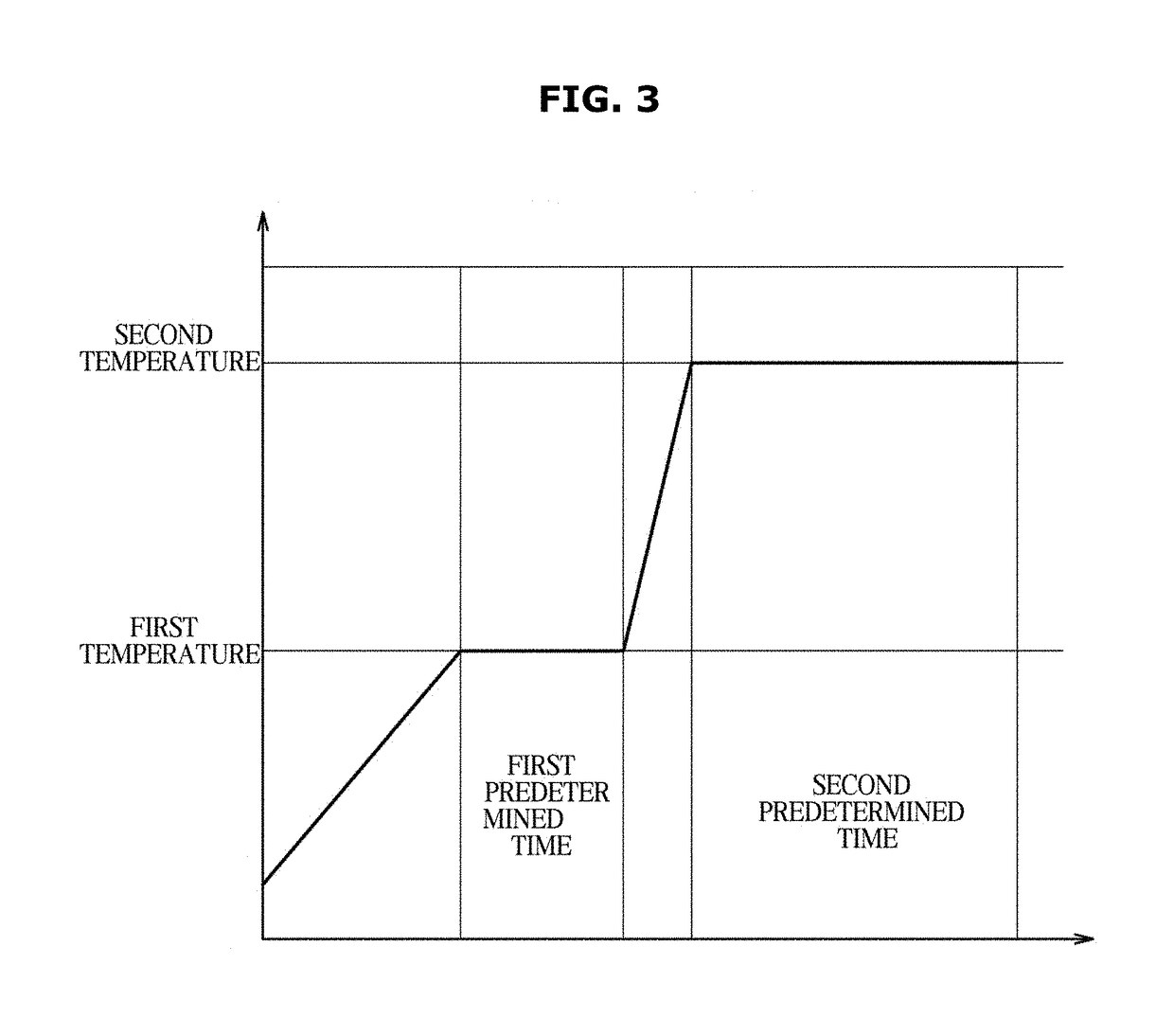

Cooking apparatus and cleaning method for the same

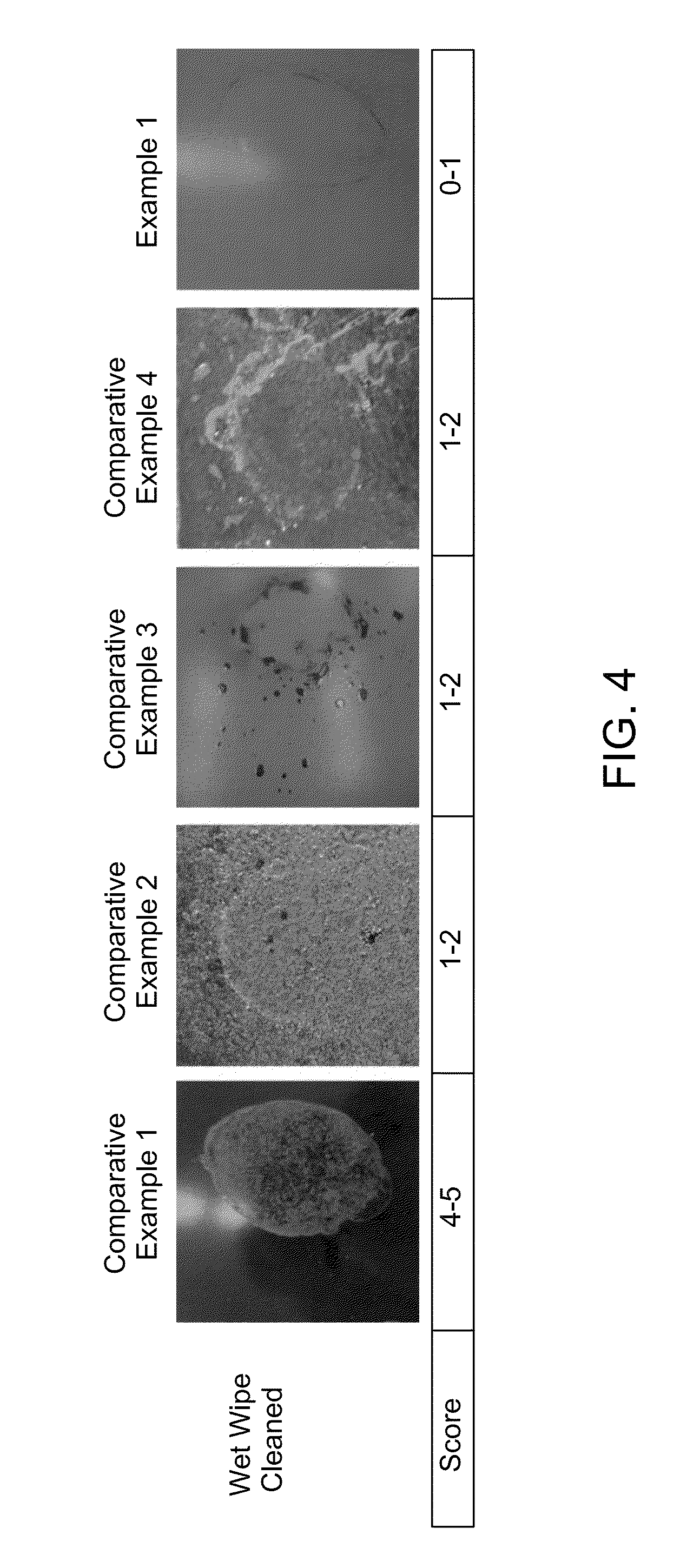

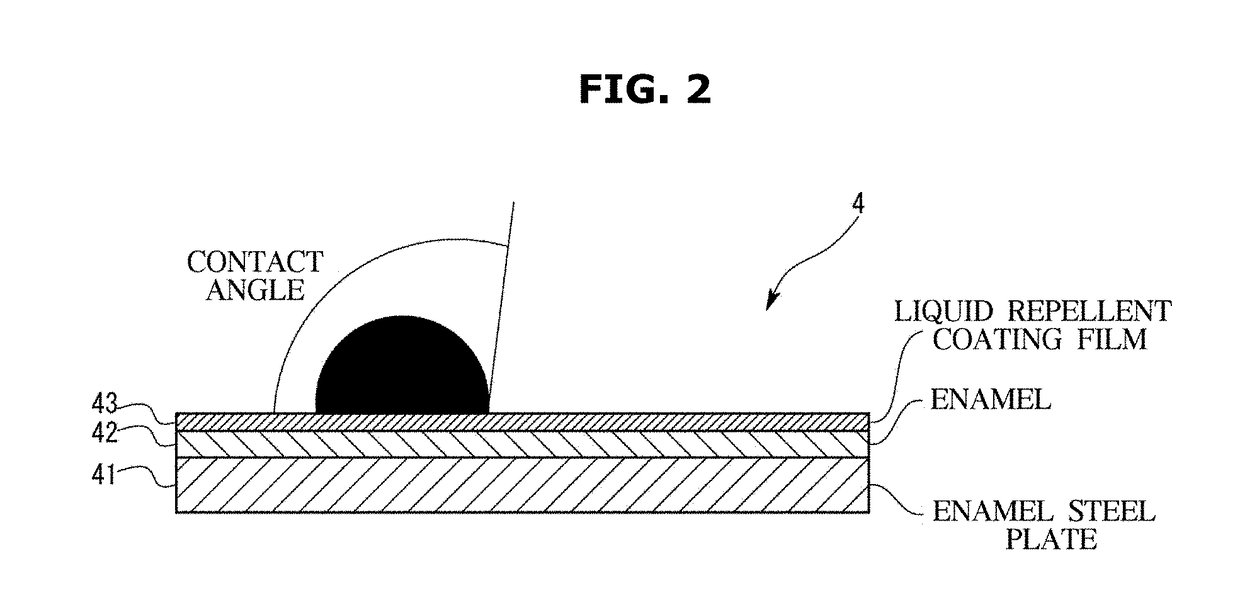

ActiveUS20090266243A1Avoid problemsReduce adhesionGrain huskingSelf-cleaning stoves/rangesCleaning methodsProcess engineering

A cooking apparatus for assuring easier cleaning of contaminants, such as food residue, attached to the wall surface of a cavity in the cooking apparatus is disclosed. The cooking apparatus includes a body defining the outer appearance of the cooking apparatus, and a cavity defining a space for heating and cooking an object and having an inner surface to form an oil-repellent surface by being heated. In a cleaning method for the cooking apparatus, the inner surface of the cavity is heated prior to cooking food, to have an oil-repellency. The inner surface makes it difficult for the contaminants to be attached thereto. Even if the contaminants are attached, the contaminants have a very low adhesive power and thus are easy to clean.

Owner:LG ELECTRONICS INC

Enamel and ground coat compositions

A composition that upon firing, forms a non-stick enamel layer is disclosed. The composition can be applied to a metal substrate to provide a non-stick, durable coating for cooking surfaces. Also disclosed are methods of forming enamel layers and corresponding coated substrates. Various ground coats and related methods are also described. Furthermore, various multilayer coatings and structures are disclosed that include an enamel layer and a ground coat layer.

Owner:FERRO CORP

Coating composition, and cooking device or cooking receptacle coated with the same

ActiveUS7695831B2Favorable thermal resistance and acid resistance and mechanical strengthEasy to cleanCeramic layered productsGlass/slag layered productsHeat resistanceMechanical property

A coating composition and a cooking device and / or cooking receptacle coated with the coating composition are described. The coating composition includes 10 to 30 wt. % of SiO2, 10 to 30 wt. % of P2O5, 10 to 30 wt. % of Al2O3, 1 to 20 wt. % of TiO2, 7 to 15 wt. % of Na2O, 7 to 15 wt. % of K2O, 5 to 10 wt. % of ZrO2, 2 to 5 wt. % of BaO, 2 to 5 wt. % of B2O3, 1 to 2 wt. % of MnO2, and an adhesion enhancer. The coating composition provides favorable thermal resistance, acid resistance and mechanical properties, such that a cooking device and / or receptacle coated with the coating composition may be easily cleaned at a relatively low temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

Food product and method and apparatus for baking

ActiveUS8840942B2Less timeLess energyEnvelopes/bags making machineryDough treatmentColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

Heating appliance covered with a self-cleaning coating and production method thereof

A heating appliance including a metal substrate, at least a part of which is covered with a self-cleaning coating including at least one oxidation catalyst selected from the platinoid oxides, and at least one dopant of said oxidation catalyst selected from the rare-earth oxides. The self-cleaning coating is a bilayer coating including: an inner layer at least partially covering the metal substrate and including the dopant; and an outer layer in contact with the ambient air and including the oxidation catalyst. Also provided is a method for producing such a heating appliance.

Owner:SEB SA

Oven appliance and a method for manufacturing a cooking chamber of an oven appliance

ActiveUS9395088B2Stoves/ranges foundationsDomestic stoves or rangesFastenerElectrical and Electronics engineering

Owner:HAIER US APPLIANCE SOLUTIONS INC

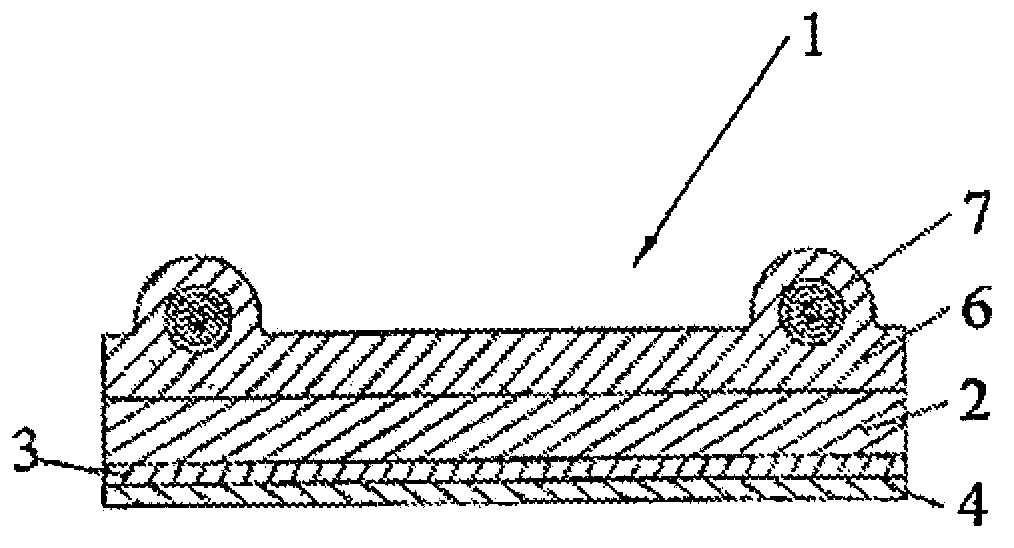

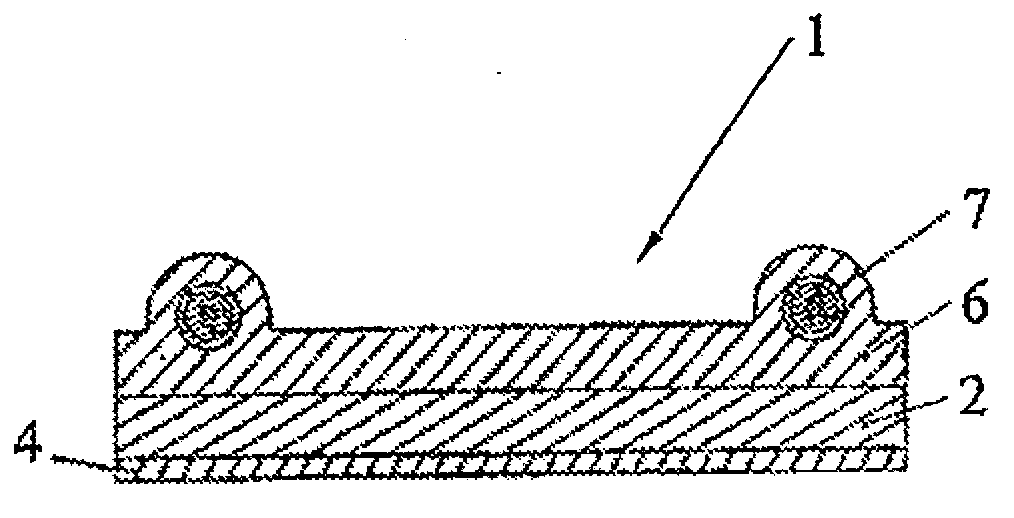

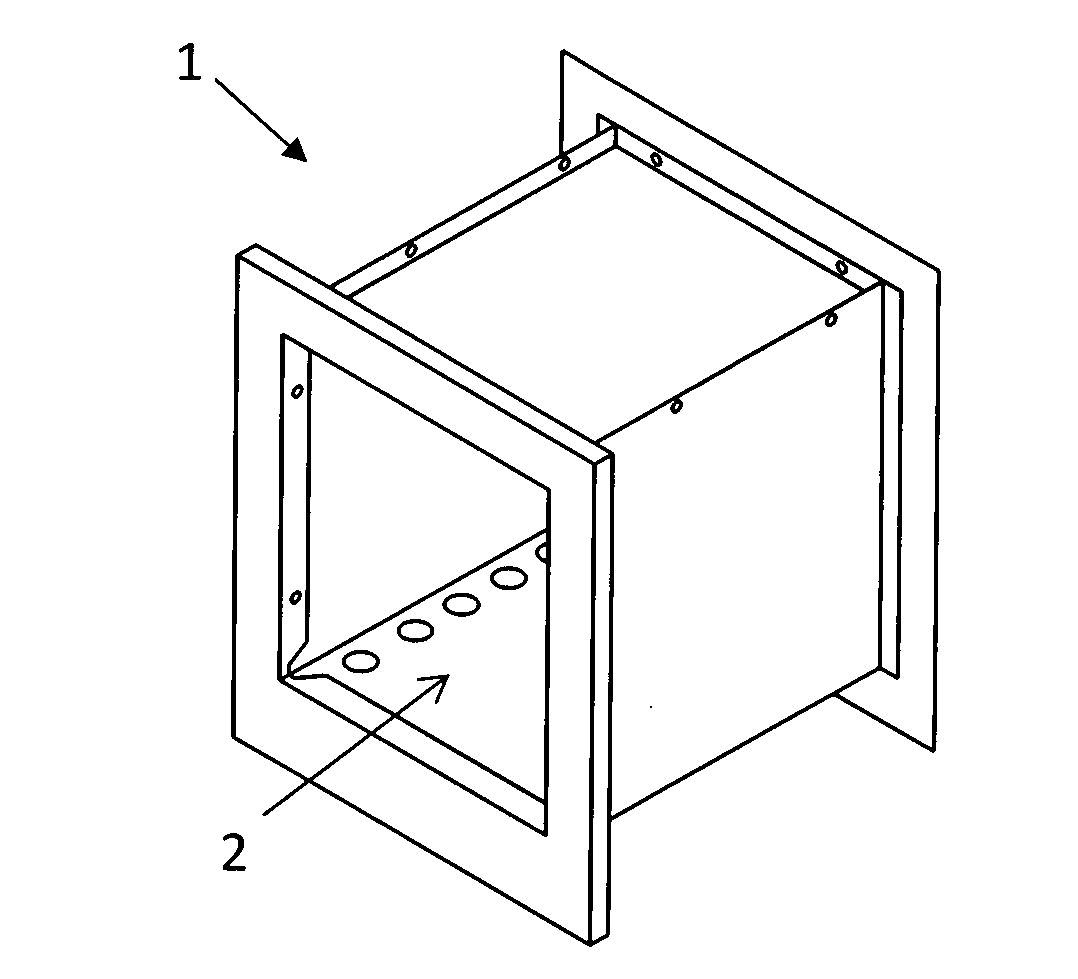

Kitchen oven and cooking range

InactiveUS20150059730A1Eliminating orTechnology is limitedSelf-cleaning stoves/rangesLighting and heating apparatusCombustorPolymer science

An oven (1) for cooking / heating up miscellaneous foods. The oven (1) has at least one internal cavity (2) with a set of walls (3, 4, 5, 6, 7) and at least one wall of the internal cavity (2) is made of carbon steel coated by an alloy made of Zinc, Aluminum and Silicon. A kitchen oven includes a set of burners and at least one domestic oven (1) as described above, and the domestic oven (1) is disposed under the set of burners.

Owner:ELECTROLUX DO BRASIL

Cooking appliance

ActiveUS8410404B2Improved heat resistance and chemical resistance and wear resistance and pollution resistanceBetter withstand a high temperatureElectric heating for furnacesElectric/magnetic/electromagnetic heatingHeat resistanceWear resistance

The present invention includes a cooking appliance with an enamel composition. The enamel composition includes a heat resistance, chemical resistance, wear resistance, and pollution resistance, such that the cooking appliance withstands high temperature, acid or alkali and is readily cleaned.

Owner:LG ELECTRONICS INC

Exterior material of home appliance, home appliance including the exterior material, and manufacturing method thereof

ActiveUS20190071347A1Increase resistanceCooking-vessel materialsBeverage vesselsRare earthEngineering

A cooking apparatus including an enamel coating layer having an improved cleaning efficiency and a manufacturing method therefor are provided. The cooking apparatus includes a cooking compartment configured to accommodate a cooking object, a door configured to open and close the cooking compartment, and an enamel coating layer provided on a surface of the cooking compartment. The enamel coating layer includes, in percent (%) by weight of the entire composition, 5% or less (excluding 0%) of a silicon dioxide (SiO2), 10% to 20% of an aluminum oxide (Al2O3), 10% to 20% of a phosphorous pentoxide (P2O5), 5% to 15% of a rare earth oxide, and 5% to 10% of a ferric oxide (Fe2O3).

Owner:SAMSUNG ELECTRONICS CO LTD

Heating appliance covered with a self-cleaning coating and production method thereof

InactiveUS8745904B2Reduce the amount requiredEffectively its catalytic activityCharge supportsVacuum evaporation coatingDopantRare earth

Owner:SEB SA

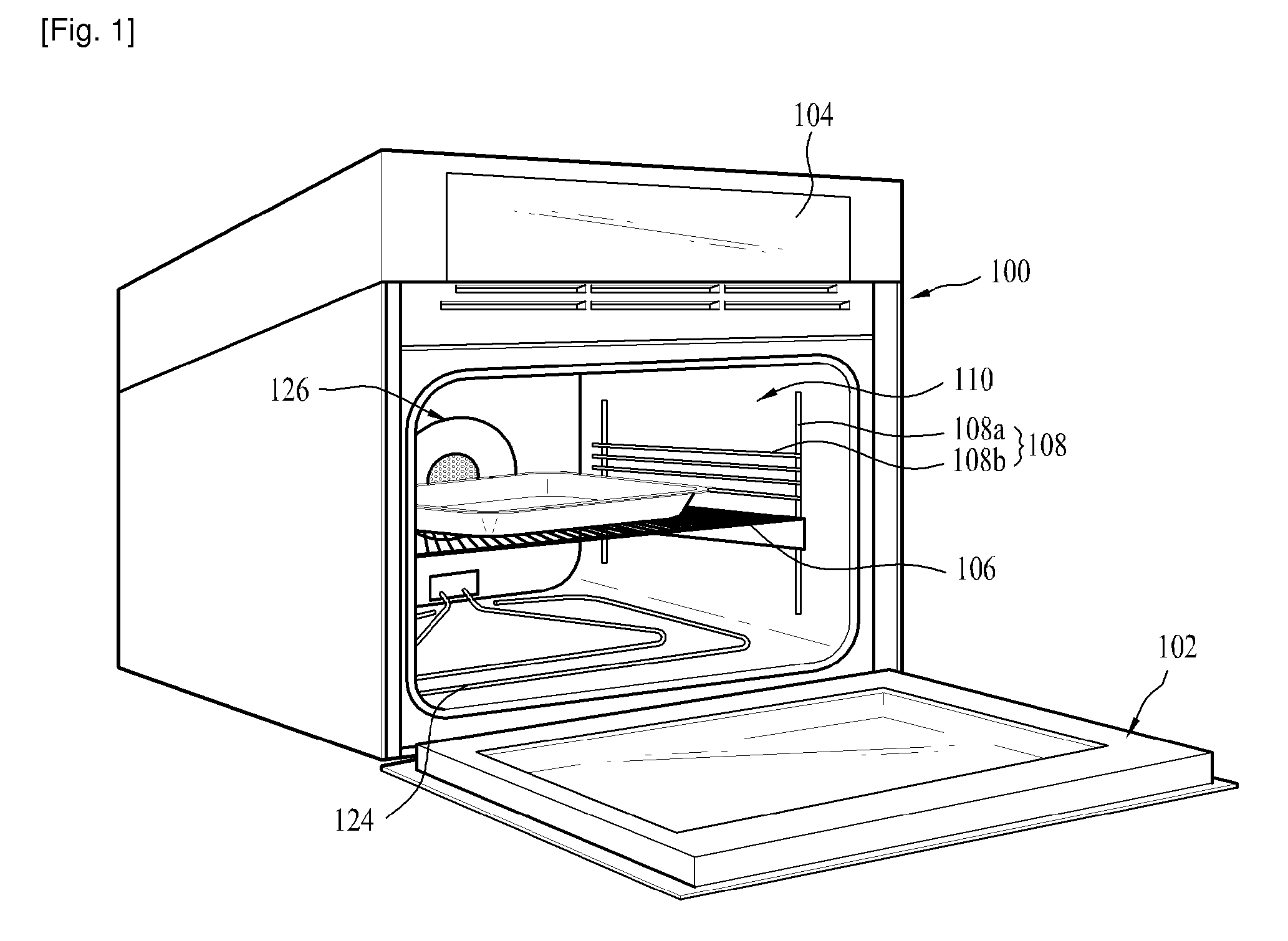

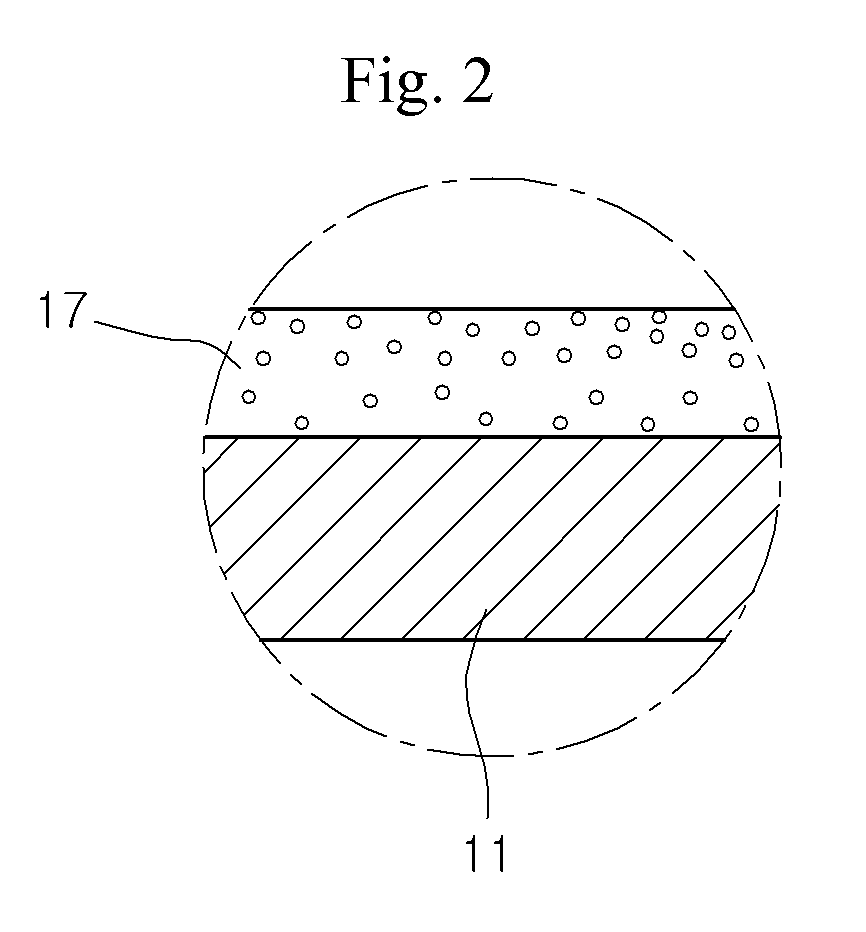

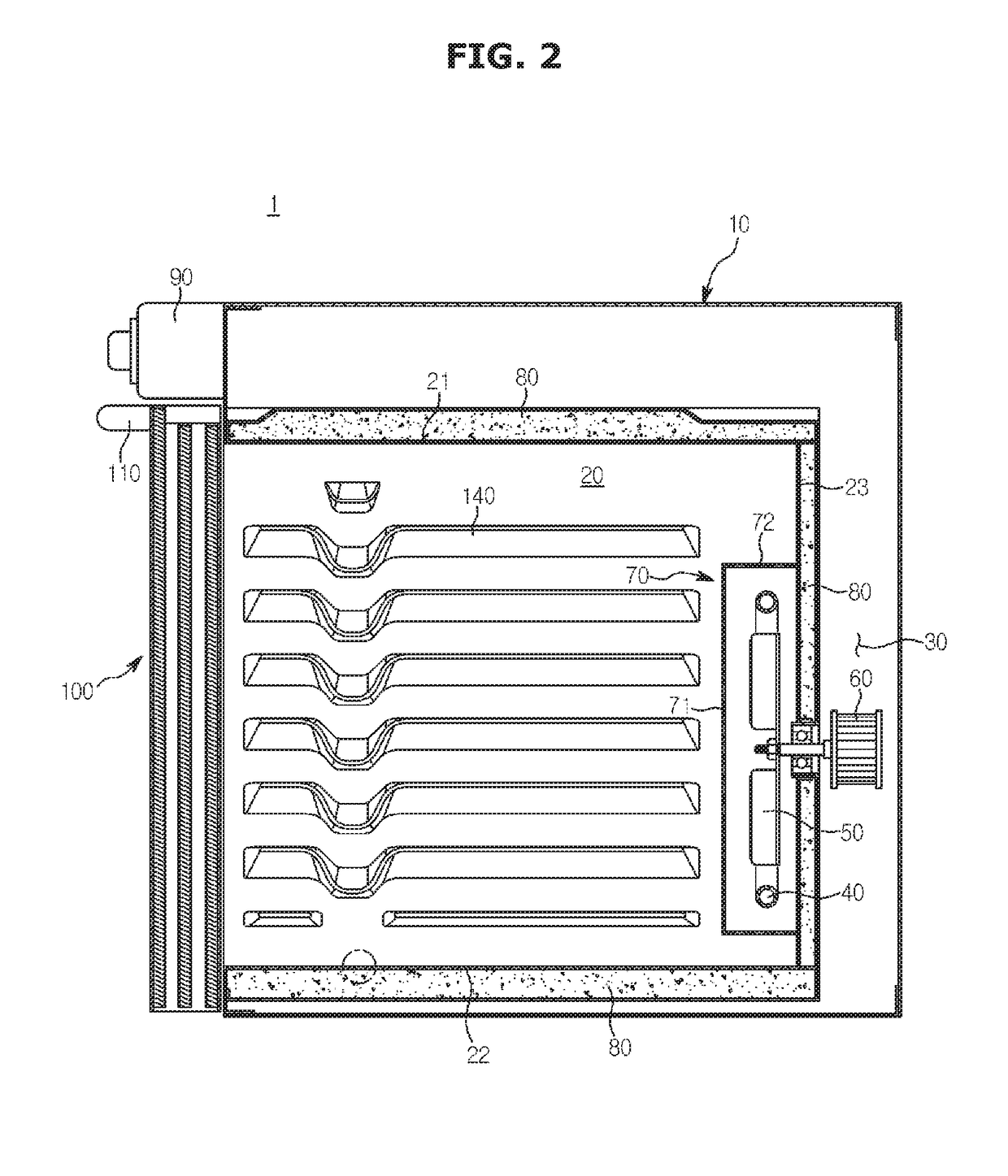

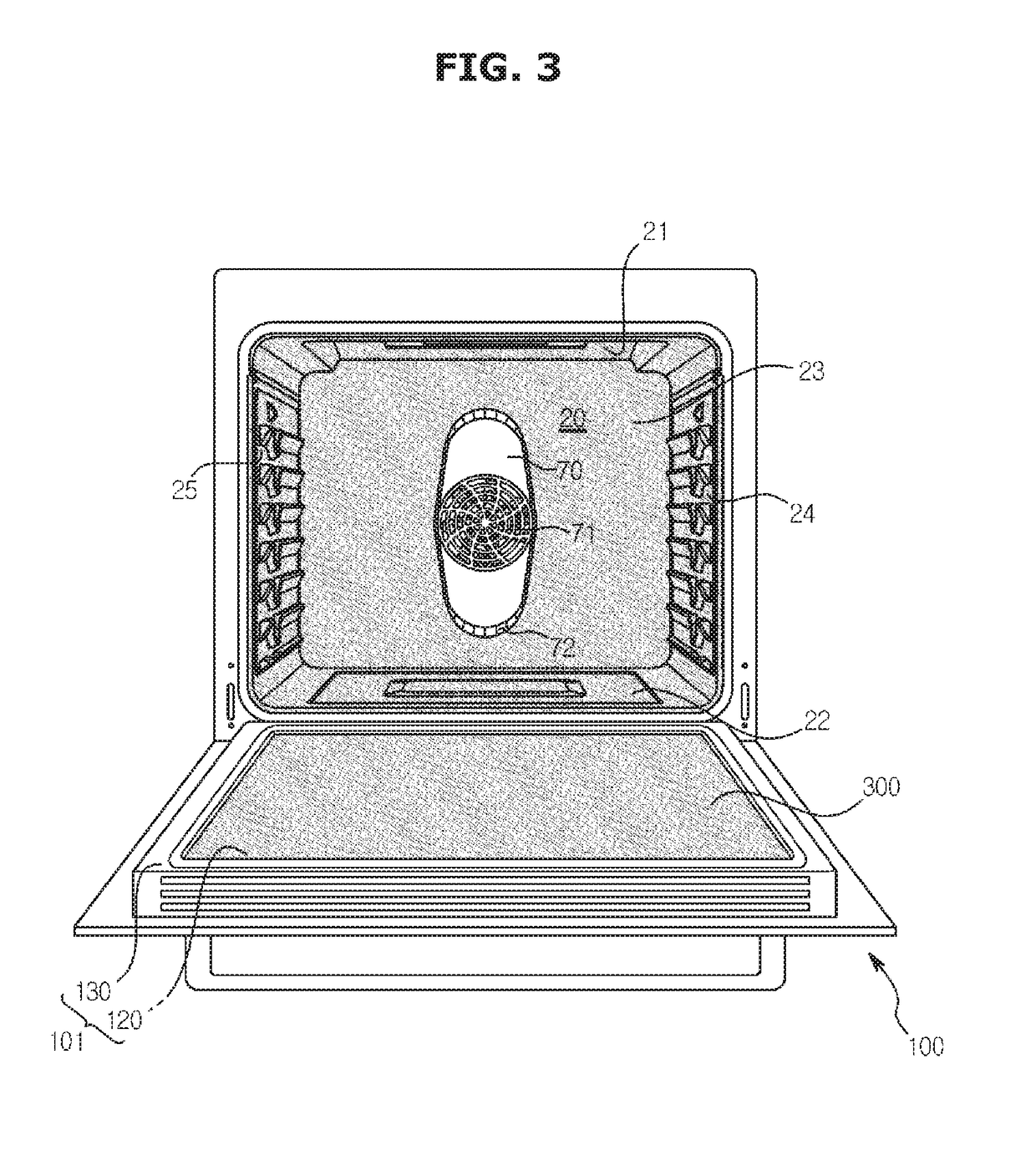

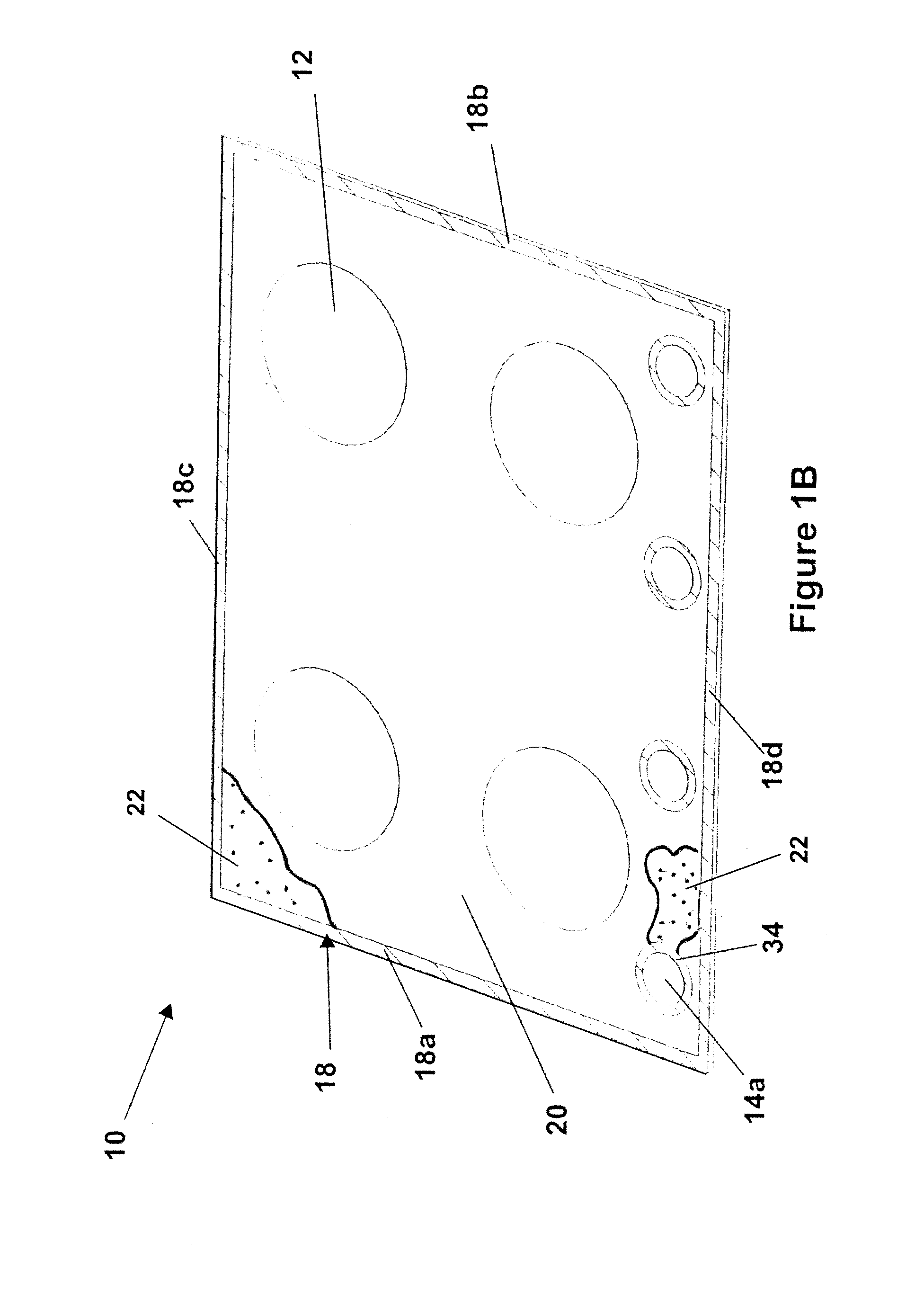

Oven

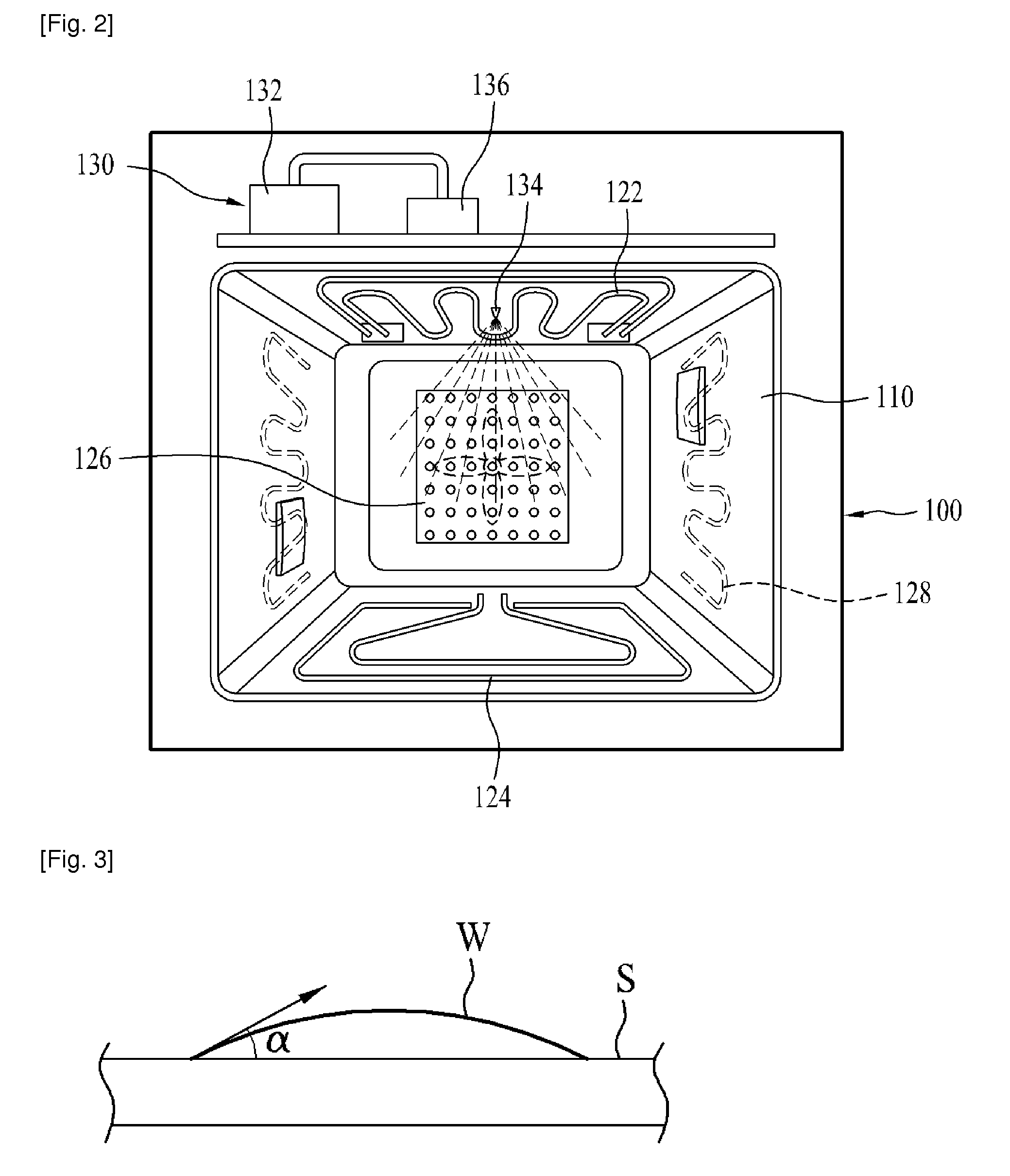

ActiveUS10914473B2Easy to cleanEasy to burnSelf-cleaning stoves/rangesElectrical heating fuelThermodynamicsEngineering

An oven includes a collision area in which air circulating inside a cooking compartment is collided to reduce the pollution inside of the cooking compartment. A collision area may collectively collect an oil mist condensed by the collision of the air. The collision area is disposed on the side where the flow of air is changed to induce air collision and guide the air to the front side of the cooking compartment to increase air circulation and increase ease of cleaning inside the cooking compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

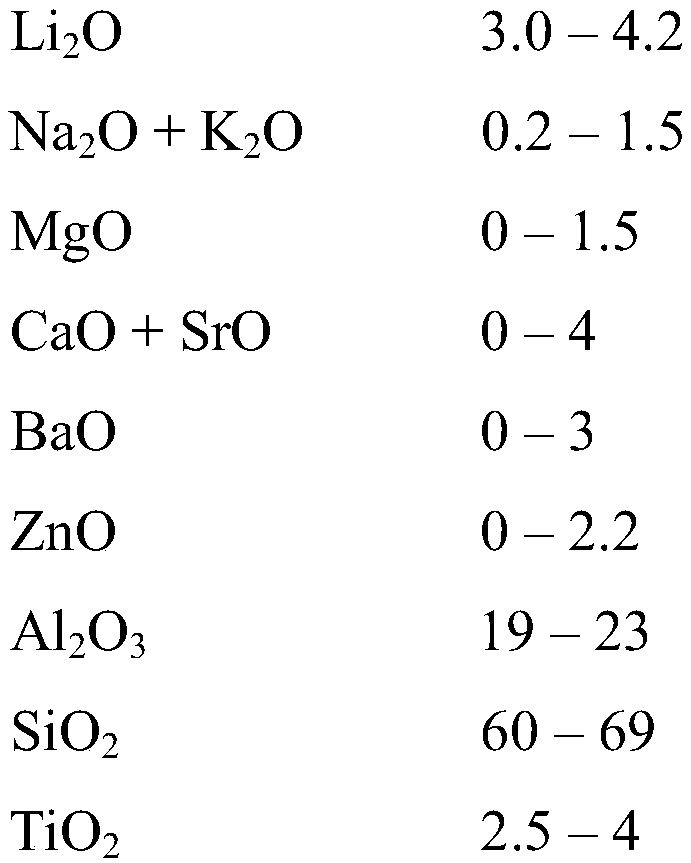

Coloured transparent lithium aluminium silicate glass-ceramic and use thereof

A description is given of a coloured, transparent, lithium aluminium silicate glass-ceramic and also of the use thereof, said glass-ceramic possessing a light transmission Y of 2.5% to 10% and a spectral transmission [tau](at 465 nm) of more than 1.0%.

Owner:SCHOTT AG

Cooking appliance surfaces having spill containment pattern

A pattern of high temperature hydrophobic surfaces for use with cooking and baking appliances, such as kitchen cooktops, stoves and oven interior walls. The pattern of hydrophobic surfaces confines overflowed liquids to the enclosed non-hydrophobic surface areas and away from protected areas, such as around burner control knobs, burner surfaces, cal rods, fan and vent openings, countertops, and the like. The hydrophobic materials used are able to withstand and effectively repel liquids at high operating temperatures.

Owner:SSW ADVANCED TECH LLC

Forming method for microwave oven cavity or oven cavity

ActiveCN106793232AGuaranteed not to deformReduce energy consumptionDomestic stoves or rangesLighting and heating apparatusCeramic coatingHigh energy

The invention discloses a forming method for a microwave oven cavity or an oven cavity. The forming method comprises the following steps of preparing sheet materials; performing surface treatment on the sheet materials; performing welding and shaping, and powder ceramic coating spraying. According to the forming method, the rough sand finish surfaces of the sheet materials are prepared firstly; then a welding and forming way is adopted, and next, the ceramic coating is sprayed, so that it is ensured that the cavity is not deformed, and the ceramic coating which is low in energy consumption, high in strength, resistant to high temperature, non-viscous and easy to clean can be obtained; the sheet materials are subjected to sand blasting treatment firstly and then the powder ceramic coating is sprayed, so that the conditions of high energy consumption, high-temperature solidification and deformation, or toxic fluorine-containing gas decomposition at a high temperature of the conventional enamel coating or Teflon coating can be avoided; and in addition, the cavity forming method disclosed by the invention achieves the beneficial effects of simple process, easy operation, high use safety, and strong high-temperature resistance.

Owner:深芏(中山)科技实业有限公司

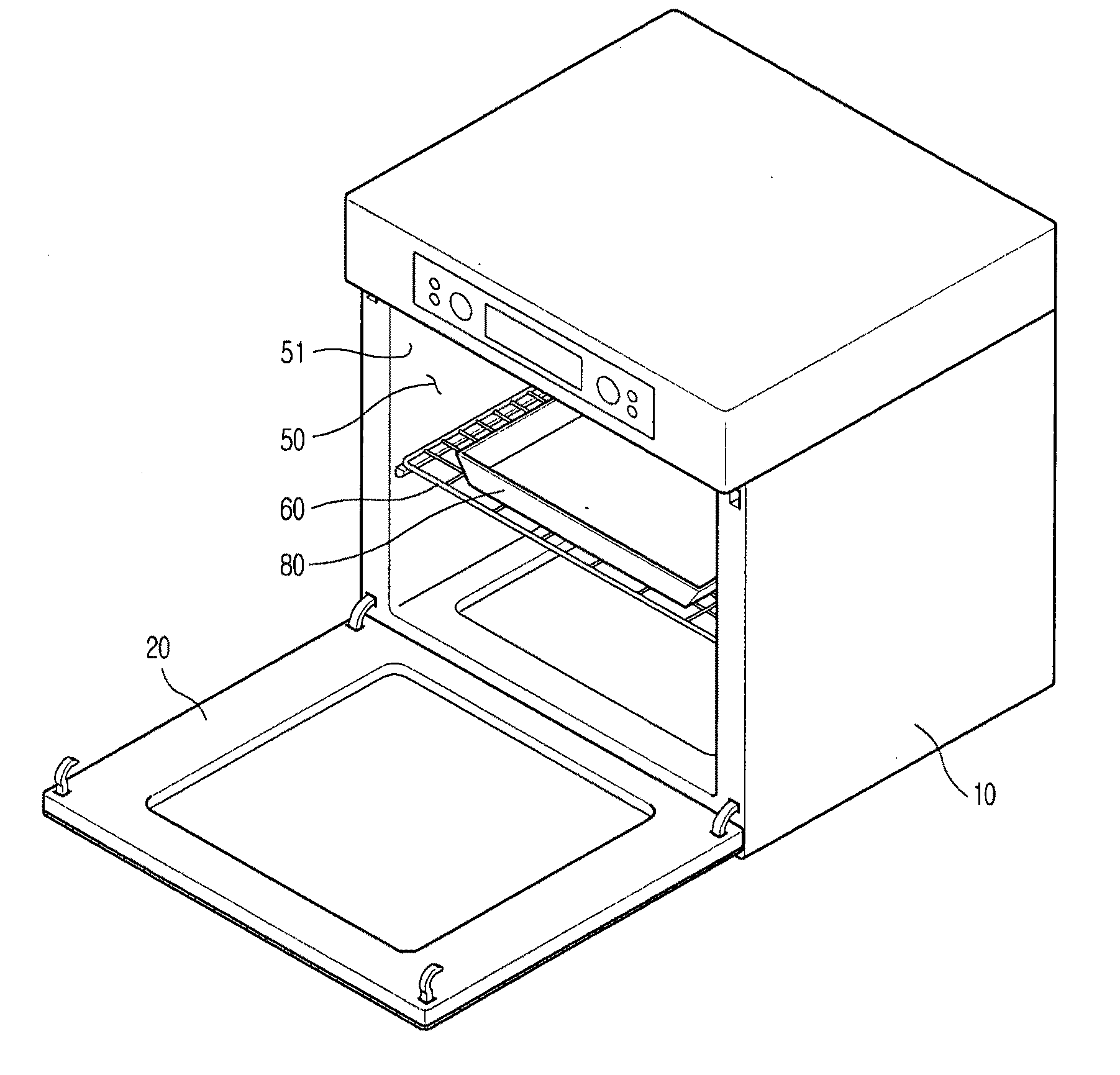

Oven

ActiveUS20190049119A1Avoid pollutionAvoid stickingSelf-cleaning stoves/rangesAntifouling/underwater paintsEngineeringCoating

Provided is an oven having an improved structure for keeping a cooking chamber clean. The oven includes a main body, a cooking chamber provided inside the main body, a main heater disposed inside the cooking chamber, a fan disposed inside the cooking chamber to circulate air heated by the main heater, a coating film formed on at least a part of a cooking chamber inner wall and having a liquid repellency, and a contaminant collecting portion having a liquid repellency smaller than that of the coating film and provided on the cooking chamber inner wall with which air circulated by the fan collides.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com