Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244results about "Heat exchange simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

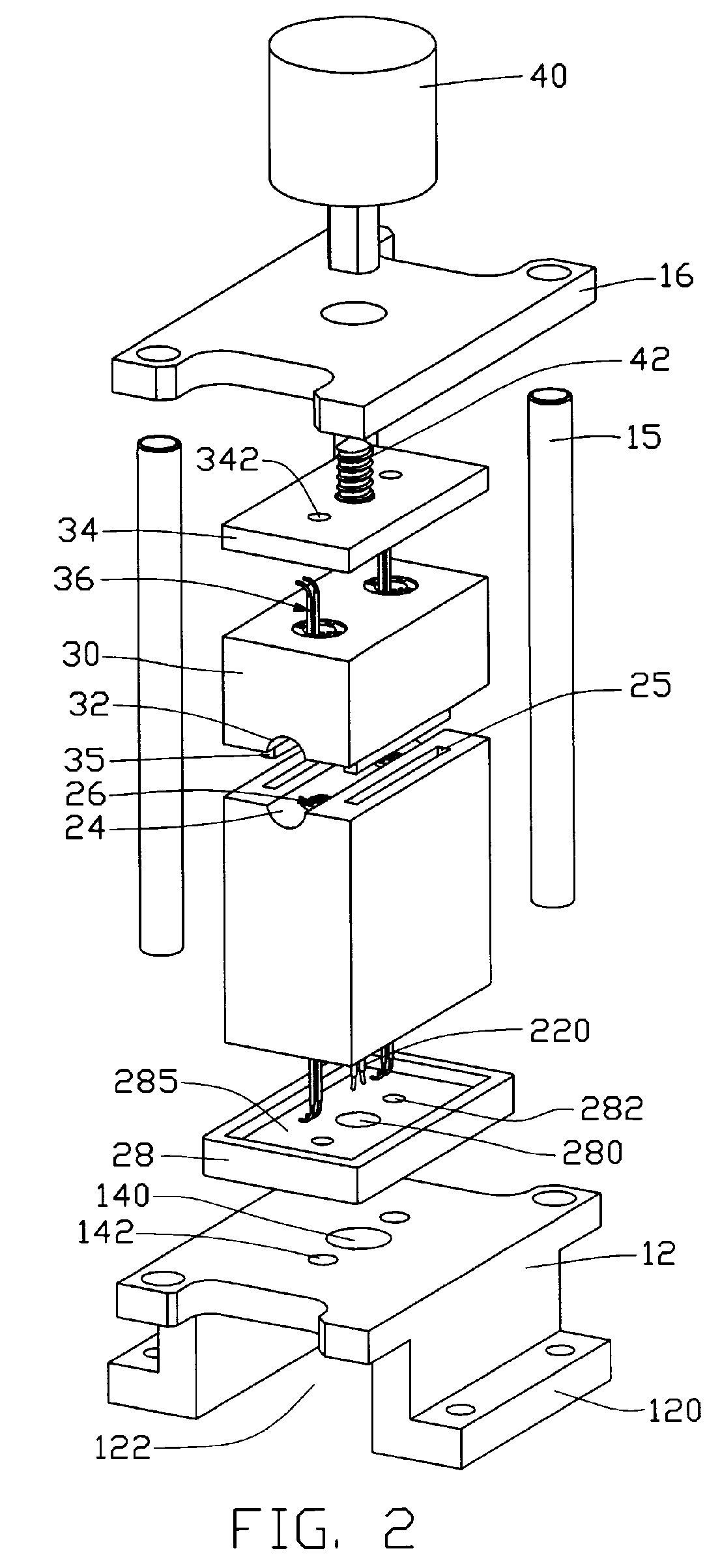

Measuring device for heat pipe

InactiveUS7147368B2Accurate transferLow thermal conductivityThermometer detailsMaterial thermal conductivityWorking fluidDesign testing

Owner:HON HAI PRECISION IND CO LTD

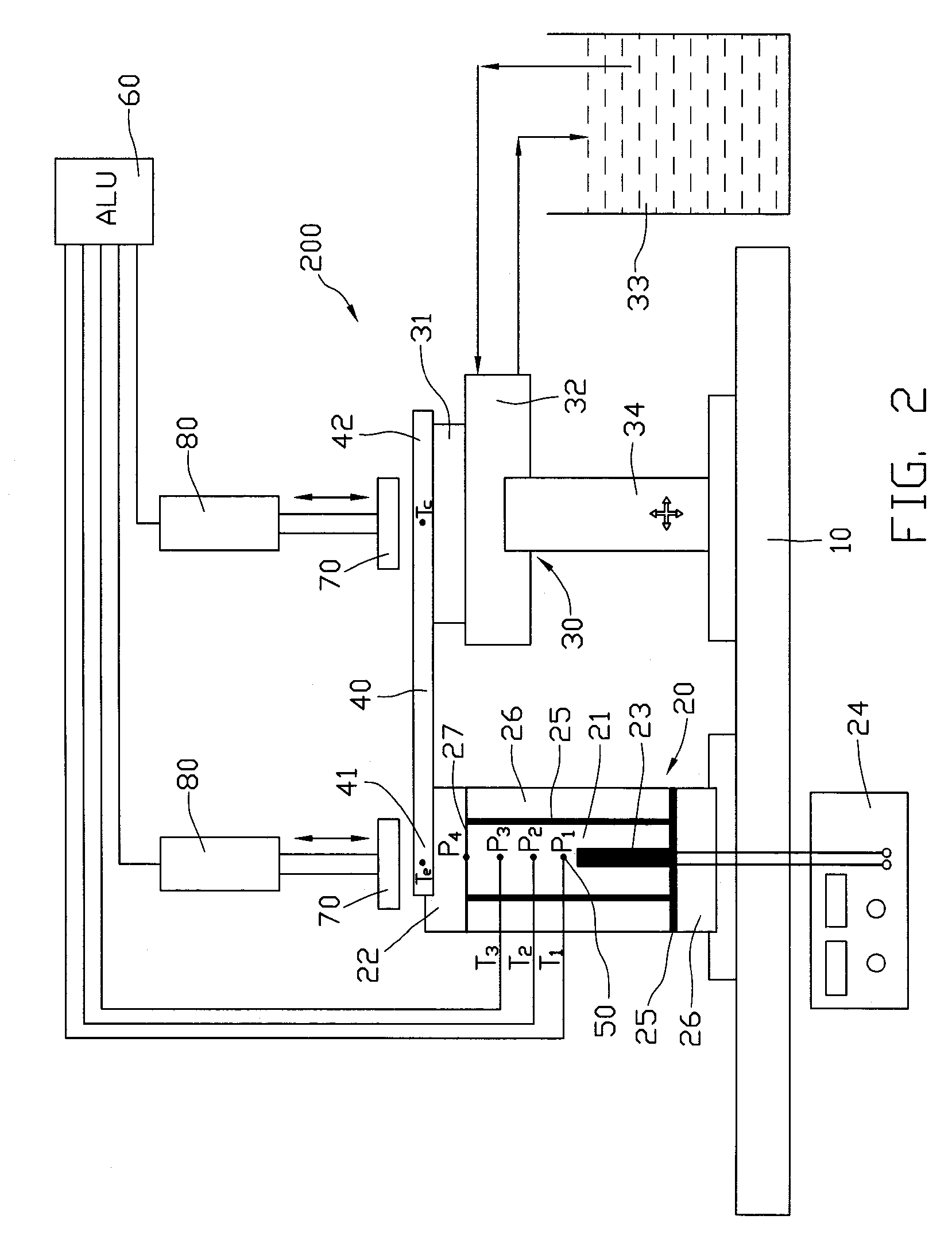

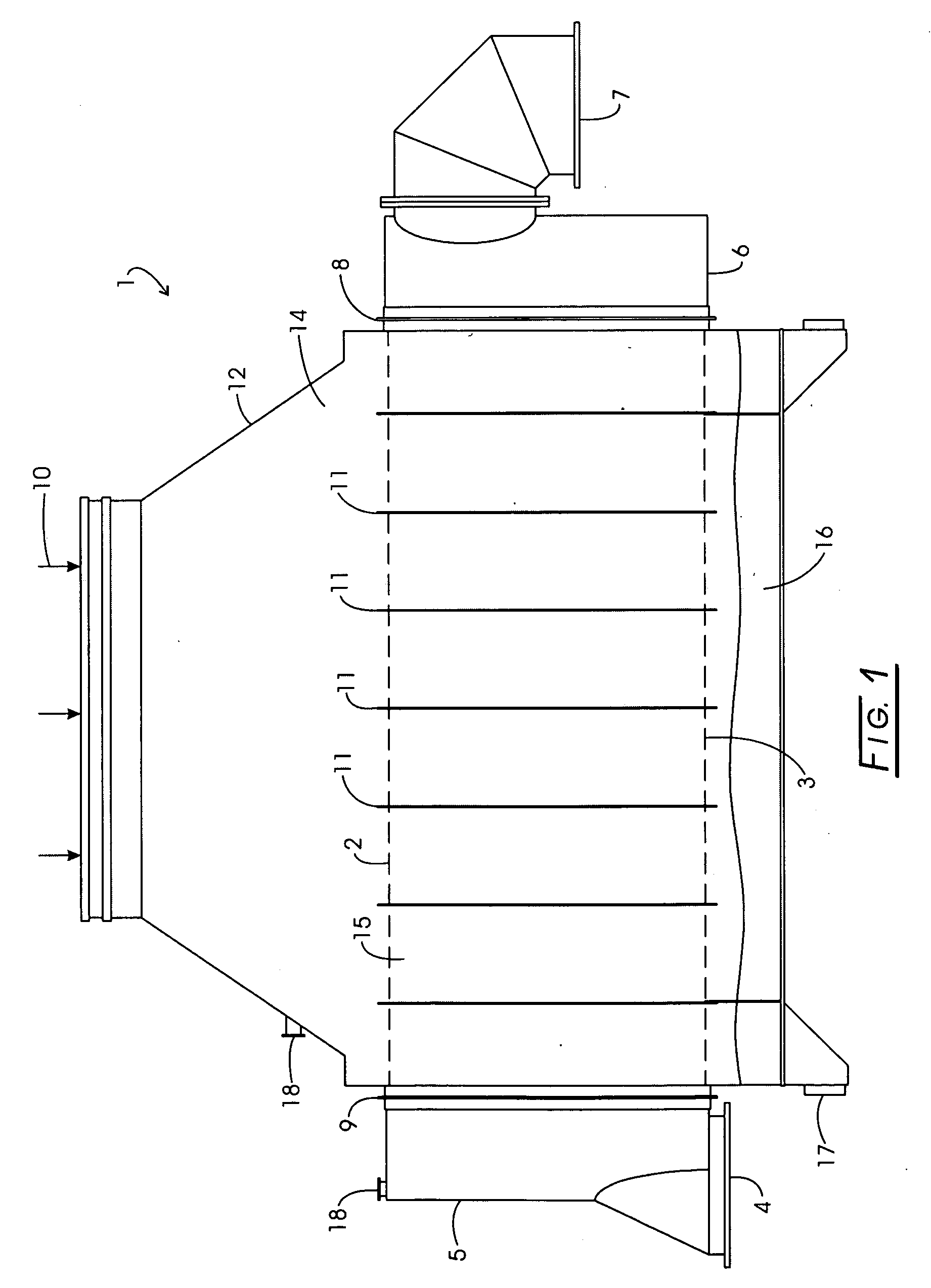

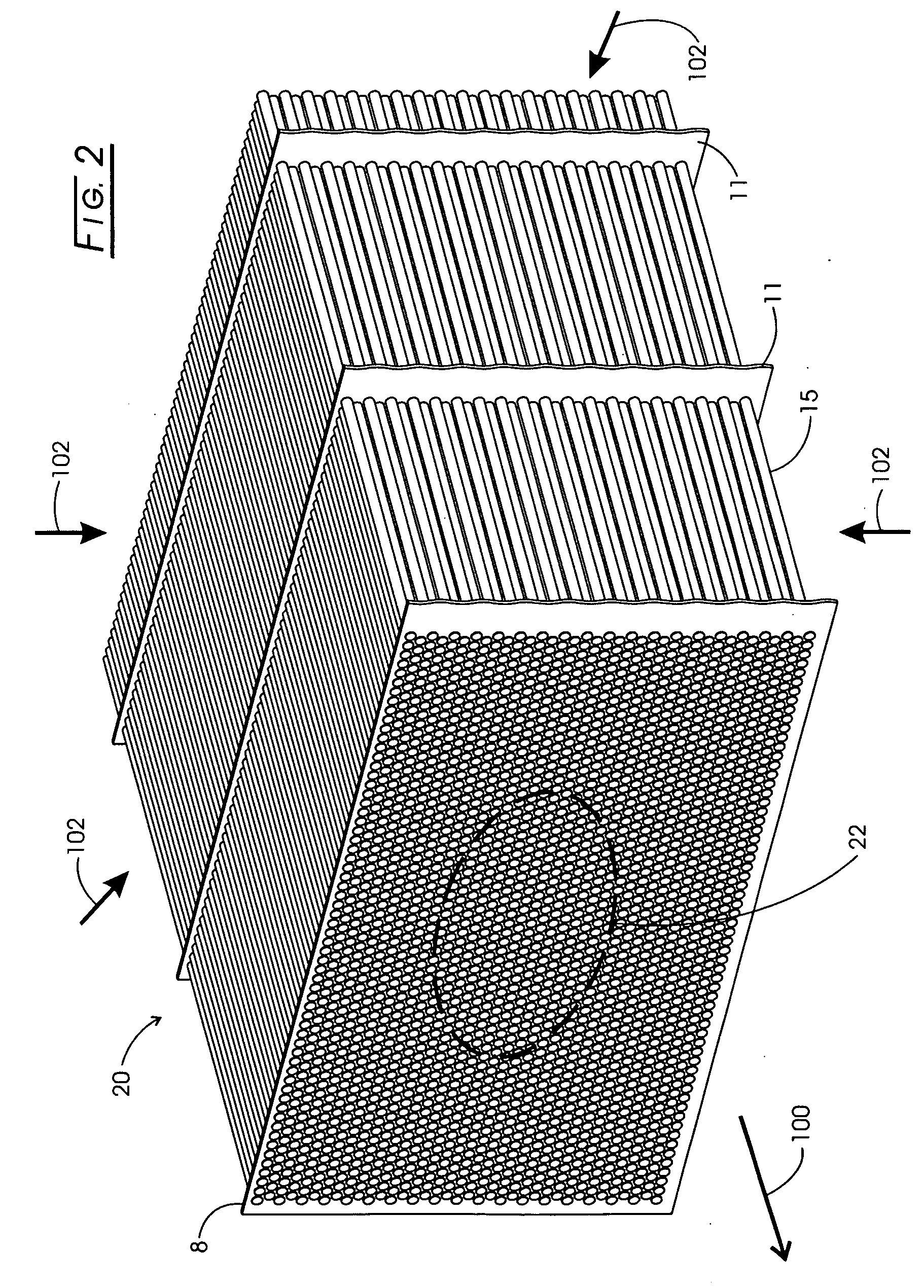

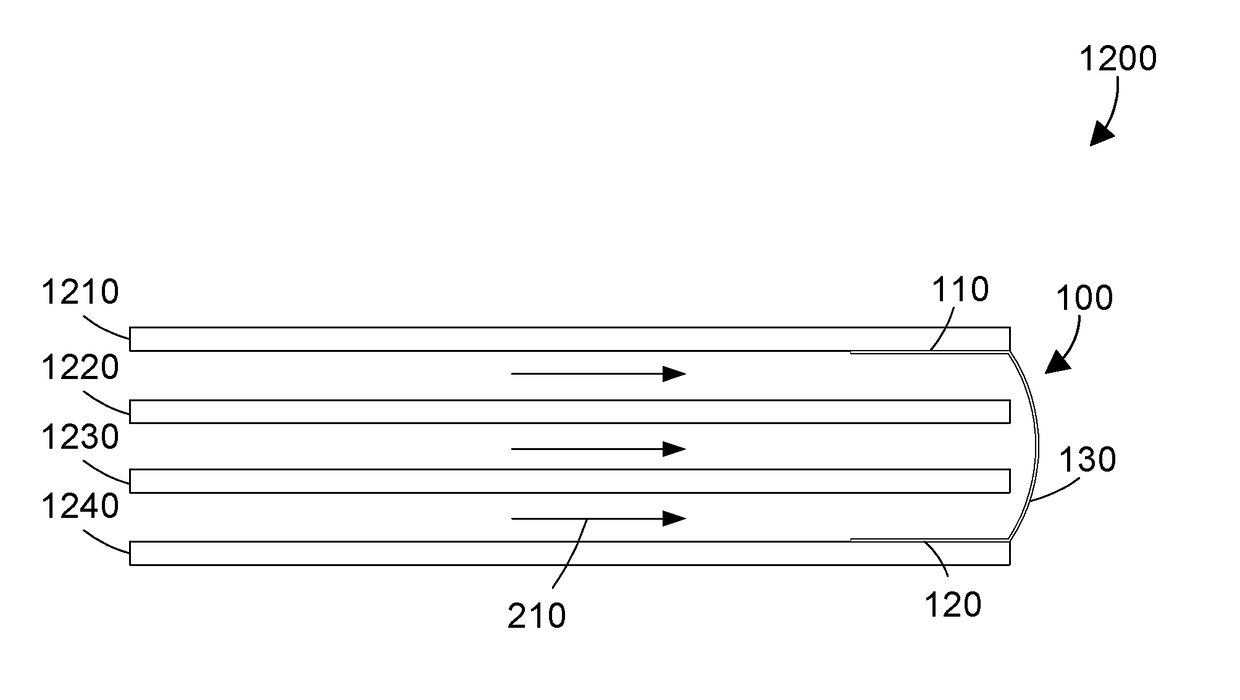

Energy chassis and energy exchange device

ActiveUS9080789B2Improve efficiencySimplifying design and constructionOther heat production devicesSpace heating and ventilationHigh energyEngineering

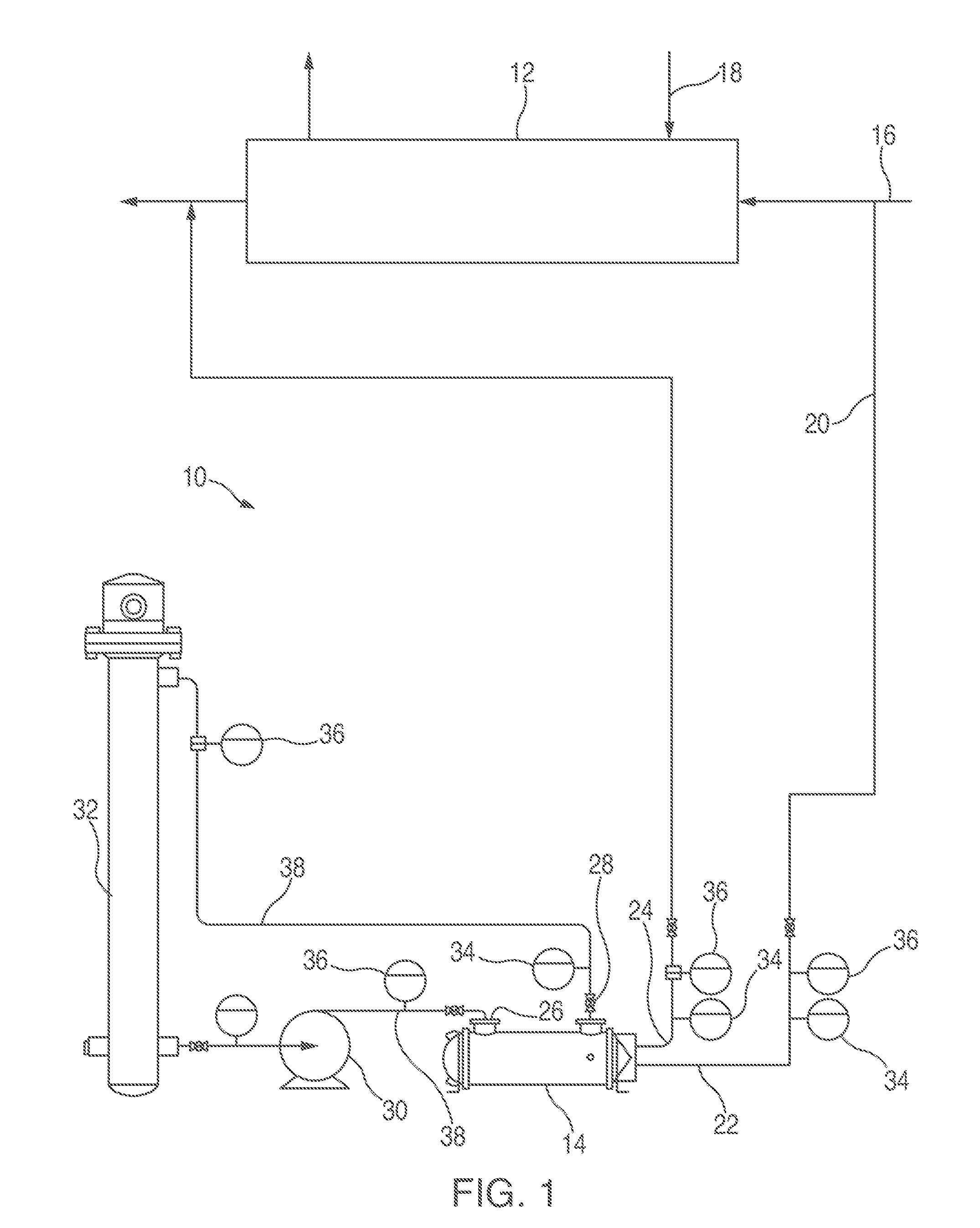

Systems, methods and devices for utilizing an energy chassis device designed to sense, collect, store and distribute energy from where it is available using devices that harvest or convert energy to locations requiring energy such as but not limited to HVAC (heating, ventilation and cooling) systems. The systems, methods and devices can also be used with a next generation geothermal heat exchanger that achieves higher energy harvesting efficiency and provides greater functionality than current geothermal exchangers.

Owner:GREENSLEEVES TECH CORP

Method and a device for detecting an abnormality of a heat exchanger and the use of such a device

InactiveUS20060032606A1Early detectionAutomatic detectionAir-treating devicesHeat exchange simulationEngineeringHeat exchanger temperature

A method and a device for detecting an abnormality of a heat exchanger exchanging heat between a first fluid flow flowing in a conduit and a second fluid flow flowing along a flow path, said conduit and said flow path each having an inlet and an outlet, whereby the method comprises the steps of establishing at least one parameter representative of the temperature conditions of the heat exchanger, establishing a second fluid inlet temperature, establishing a parameter indicative of expected heat exchange between the heat exchanger and the second fluid, processing the heat exchanger temperature, the second fluid temperature and the parameter indicative of expected heat exchange for establishing an estimated second fluid outlet temperature, and employing the estimated second fluid outlet temperature for evaluating the heat exchange between the first and second fluids by comparing the estimated second fluid outlet temperature, or a parameter derived therefrom, with a reference value.

Owner:DANFOSS AS

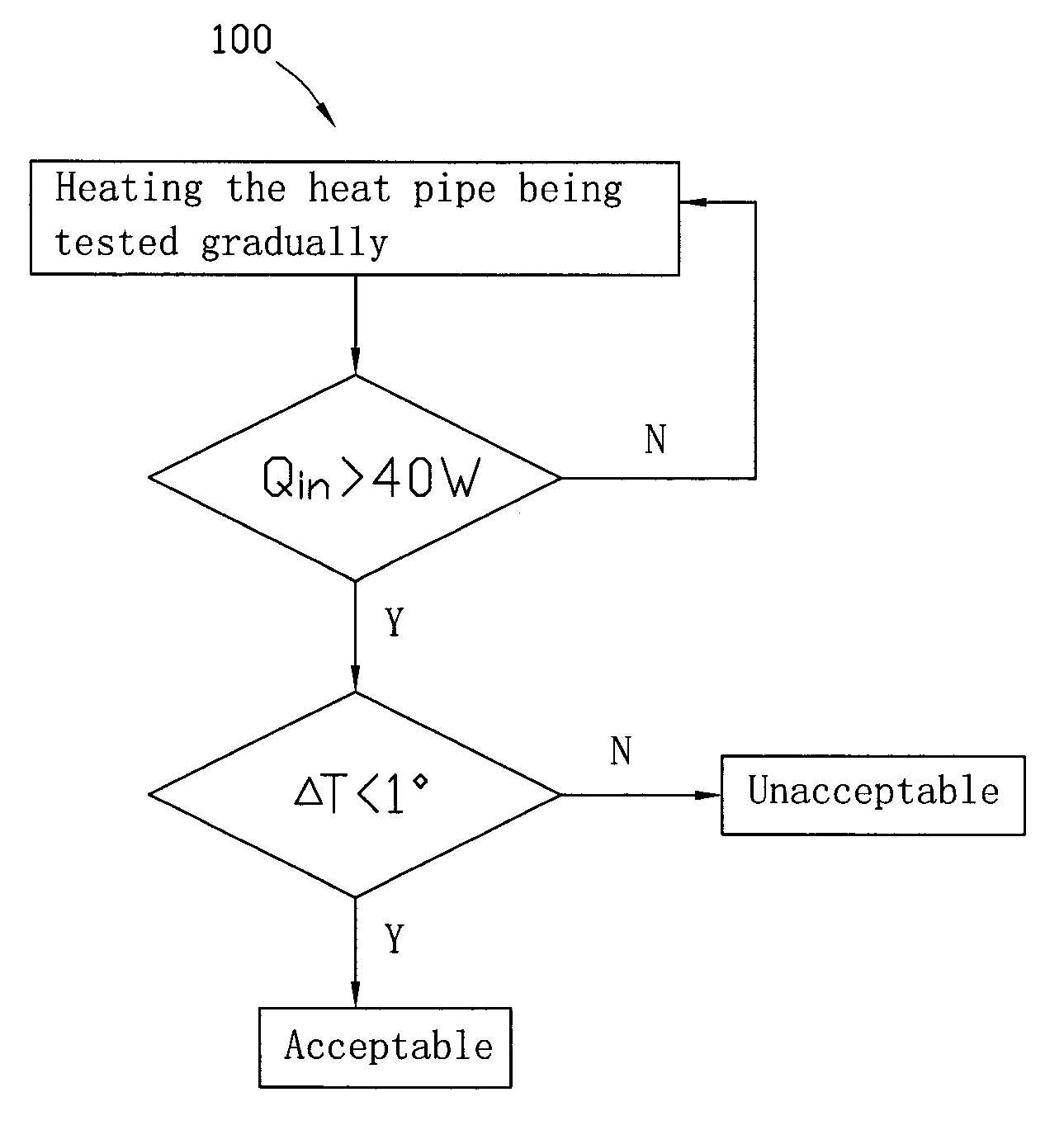

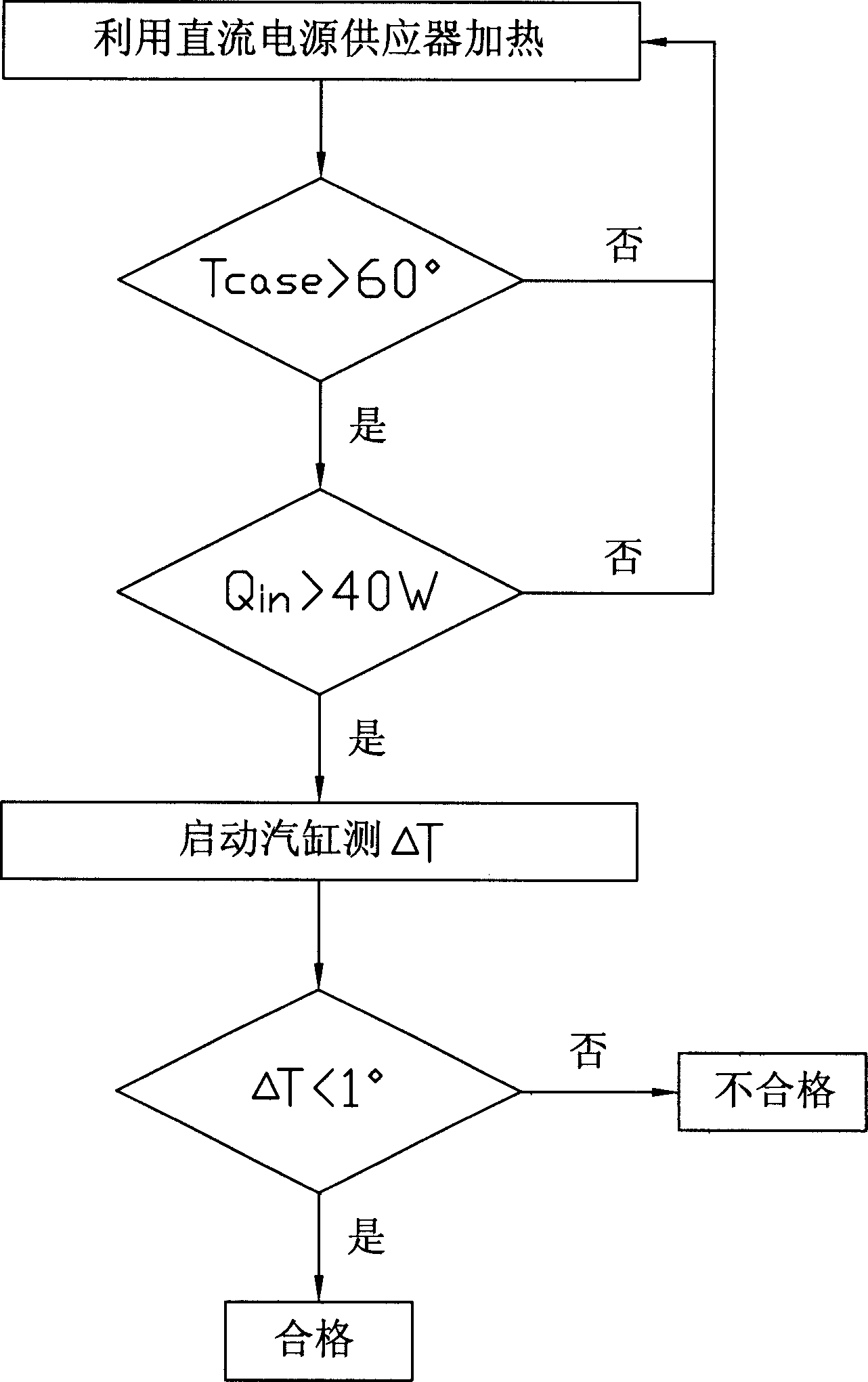

Method and apparatus for conducting performance test to heat pipe

InactiveUS20060256834A1Evaluate performanceThermometer detailsHeat exchange simulationThermal energyEngineering

Disclosed is a method for testing the performance of a heat pipe and an apparatus for conducting the performance test. The apparatus includes a heating device and a cooling device. Two ends of the heat pipe are thermally connected to the heating device and the cooling device, respectively. The heating device is applied to supply thermal energy to the heat pipe. When the quantity of thermal energy being transferred to the heat pipe reaches to a specified value, the temperatures at the two ends of the heat pipe are detected. If the temperature difference between the two ends is lower than a predetermined value, the heat pipe being tested is deemed as acceptable.

Owner:HON HAI PRECISION IND CO LTD

Process for optimizing a heat exchanger configuration

ActiveUS20130264027A1Improve performanceEasy to determineNuclear monitoringDigital computer detailsCounter flowNuclear engineering

A heat exchanger door and heat exchanger core optimization method are provided. The door resides at an air inlet or outlet side of an electronics rack, and includes an air-to-coolant heat exchanger with a heat exchanger core. The core includes a first coolant channel coupled to a coolant inlet manifold downstream from a second coolant channel, and the first channel has a shorter channel length than the second channel. Further, coolant channels of the core are coupled to provide counter-flow cooling of an airflow passing across the core. The core optimization method determines at least one combination of parameters that optimize for a particular application at least two performance metrics of the heat exchanger. This method includes obtaining performance metrics for boundary condition(s) of possible heat exchanger configurations with different variable parameters to determine a combination of parameters that optimize the performance metrics for the heat exchanger.

Owner:LENOVO GLOBAL TECH INT LTD

Battery thermal management method and system

ActiveUS20170033417A1Improve battery lifeImprove device performanceElectrical testingHeat exchange simulationElectrical batteryEngineering

A method and battery system for thermal management of a battery system includes predicting a total heat generation by a battery based on determined internal conditions of the battery, and controlling a selective adjusting of a heat transfer coefficient for the battery based on the predicted total heat generation to maintain an operating temperature of the battery at a target temperature or within a target temperature range.

Owner:SAMSUNG ELECTRONICS CO LTD

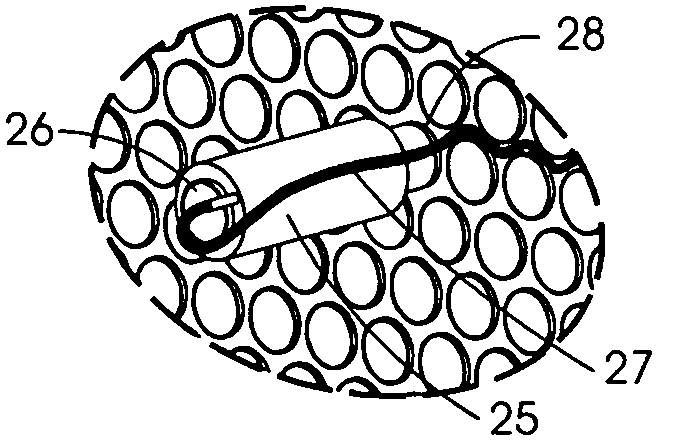

Method and apparatus for detecting heat conducting pipe performance

InactiveCN1862254AThere will be no misjudgment of qualificationThere will be no false positivesThermometer detailsMaterial thermal conductivityHeat conductingEvaporation

The present invention discloses a method for detecting thermal pipe performance and its detection equipment. It includes a heating device and a cooling device. When the thermal pipe is detected, the evaporation section and condensation section of thermal pipe to be detected are respectively placed on said heating device and cooling device, then the heating device is used to heat said evaporation section to make the thermal pipe be reached to operation temperature, and the cooling device is used to cool the condensation section to make the thermal pipe be retained in working state, then it judges that the heat quantity inputted into evaporation section of said thermal pipe by heating device is greater than some defined value or not, if it is greater than some defined value, it can detect the temperature difference of two ends of said the thermal pipe and judge that said thermal pipe is qualified or not.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Tube fouling monitor

InactiveUS20090188645A1Accurate measurementMinimizing sensor variationAir-treating devicesHeat exchange simulationEngineeringCooling fluid

A method for measuring the effects of fouling of heat transfer tubes in heat exchangers where a cooling fluid at lower temperature is removing heat from another fluid at higher temperature includes placing a nonrestrictive mass flow rate and temperature measuring tube extension sensor on a tube outlet end; obtaining the tube inlet temperature for deriving the rise in fluid temperature; analytically computing the amount of heat transferred from the hot fluid to the cold fluid; from tube length, inside and outside tube diameter, analytically deriving the tube heat transfer coefficient; and determining tube fouling factor, the value of which is the fraction of the clean tube heat transfer coefficient available for transferring heat, by dividing the heat transfer coefficient by the known heat transfer coefficient of an unfouled tube.

Owner:INTEK

Plate-type heat exchanger

InactiveCN101726202AReduce temperature gradientReduce thermal stressLiquefactionReinforcing meansPlate heat exchangerFluid layer

A plate-type heat exchanger (10), especially a soldered aluminium plate heat exchanger has a heat exchanging portion (12) which comprises two or more first channels (14a) and two or more second channels (14b); first fluid can flow through the first channels and second fluid can flow through the second channels; in this way, the first fluid exchanges heat with the second fluid. For reducing the thermal stress inside the heat exchange portion (12), the heat exchange portion (12) comprises at least one no-fluid layer (30) disposed between the two fluid channels (14a, 14b).

Owner:LINDE AG

Heat exchanger and fabrication

ActiveUS20170045313A1Additive manufacturing apparatusHeat exchange simulationProcess engineeringMetal powder

A method for making a heat exchanger assembly is described, involving generating a digital model of a heat exchanger assembly that comprises a heat exchanger core within a housing. The digital model is inputted into an additive manufacturing apparatus or system comprising an energy source. The additive manufacturing apparatus applies energy from the energy source to successively applied incremental quantities of a metal powder, which fuses the powder to form incremental portions of the heat exchanger core and housing according to the digital model. Unfused or partially fused metal powder is enclosed in a first region of the heat exchanger assembly between the heat exchanger core and the housing.

Owner:HAMILTON SUNDSTRAND CORP

Multi-segmented tube sheet

ActiveUS9581395B2Reduce thicknessHeat exchanger casingsStationary tubular conduit assembliesEngineeringControl valves

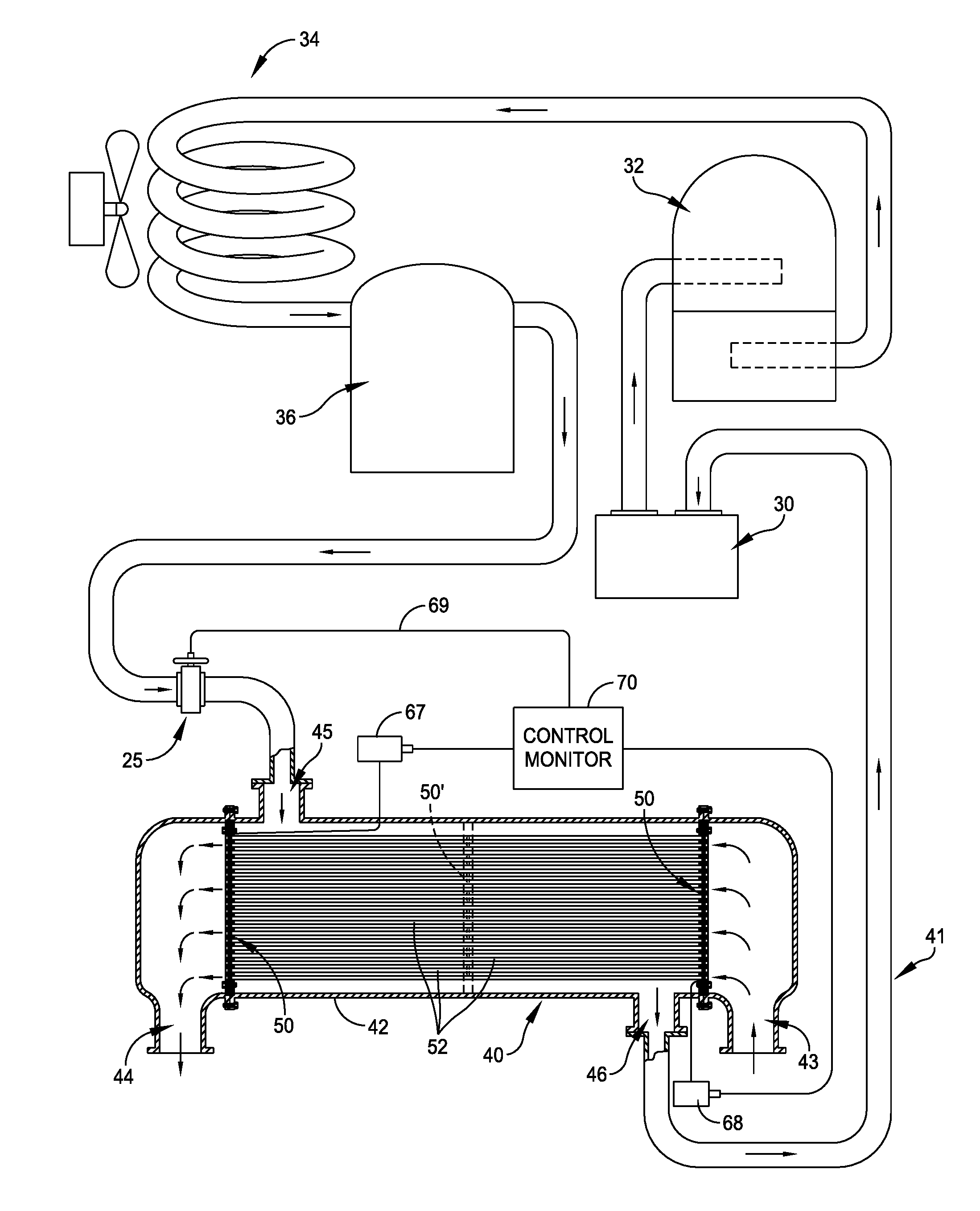

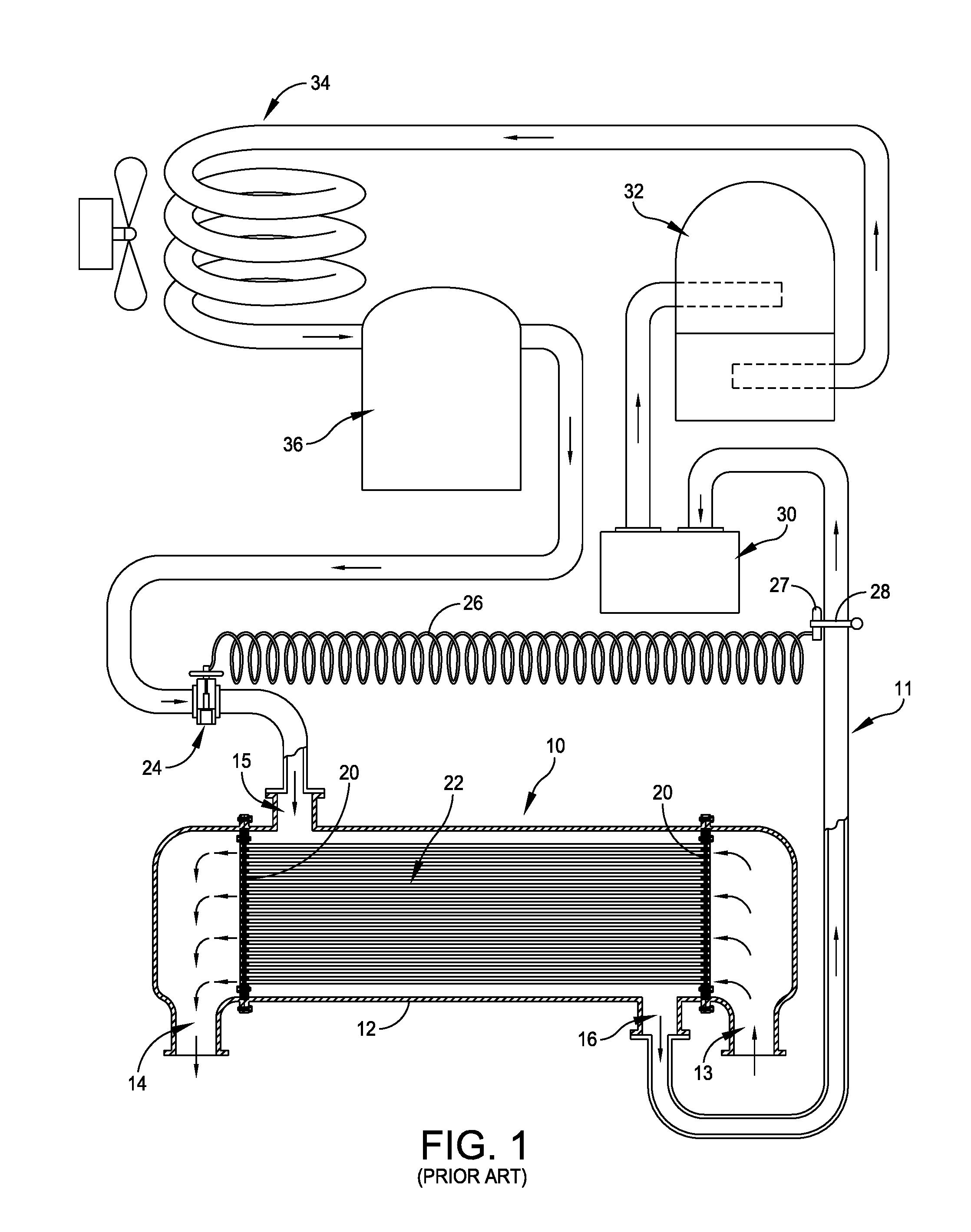

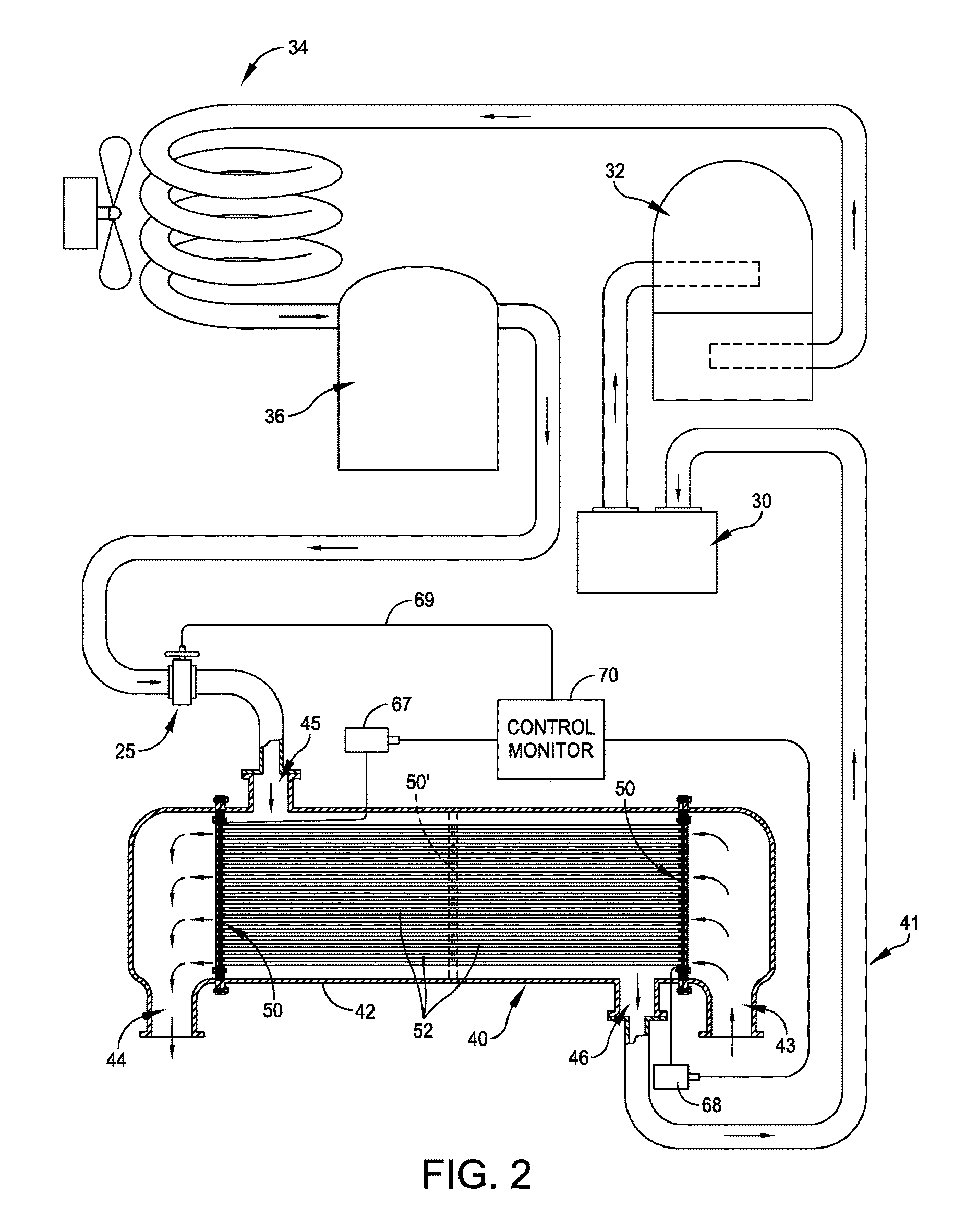

A heat exchanger that is constructed with a heat exchanger shell having inlet and outlet plenums and fluid inlet and outlet ports, and a tube sheet construction disposed in the heat exchanger shell. The tube sheet construction includes at least two separate tube sheets and a plurality of tubes that extend between the separate tube sheets. Each tube sheet includes at least two planar tube sheet segments and a interstitial layer disposed between the at least two tube sheet segments, and at least one sensor element supported by each of the interstitial layers. A control monitor controls flow through the shell by a feedback control from the sensor to an inlet control valve and / or a stimulus device excites the media layer. In an alternate embodiment opposed position sensor elements may be provided at opposite sides of the tube sheet construction.

Owner:NEPTUNE BENSON INC

Heat-pipe measuring device

InactiveCN1892206AImprove accuracyImprove reliabilityMaterial thermal conductivityMaterial heat developmentEngineeringHeat pipe

The present invention provides a heat tube measuring unit. It contains heating arrangement with one heat block; one cooling unit with one inserting port; one end part for inserting measured heat tube; wherein said heat block having one trough connected with another end of measured heat tube, said trough inner wall surface set with one heat interface material. Said heat interface material can fill miniature interstice between trough and heat tube contact interface when becomes soften by heating, thereby capable of reducing thermal resistance between heat block trough and heat tube, to make heat tube measuring unit having high metering accuracy and reliability, suitable for different kinds shape of heat tube metering.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method and system for evaluating fluid flow through a heat exchanger

InactiveUS20060021739A1Rapid and cost-effective and non-destructive evaluationRapid, cost effective, and non-destructive evaluationAir-treating devicesTemperature measurement in air-conditioning systemsStream flowEngineering

A heat exchanger evaluation system (84) includes a refrigeration subsystem (126) and a platform (94) in communication with the subsystem (126) for attachment of a heat exchanger (32). The system, (84) further includes a thermal imaging camera (168) and a monitor (100). A method (180) entails routing a fluid (38) through the heat exchanger (32) via the refrigeration subsystem (126). The camera (168) detects the temperature variation across the heat exchanger (32) as the fluid (38) flows through the heat exchanger, and provides successive thermal images representing the temperature variation responsive to the flow of the fluid (38). The thermal images are utilized to determine an efficacy of the flow through the heat exchanger (32). In particular, a determination can be made as to whether the flow deviates from a pre-determined flow path (79) of the fluid (38) through the heat exchanger.

Owner:CALSONICKANSEI NORTH AMERICA

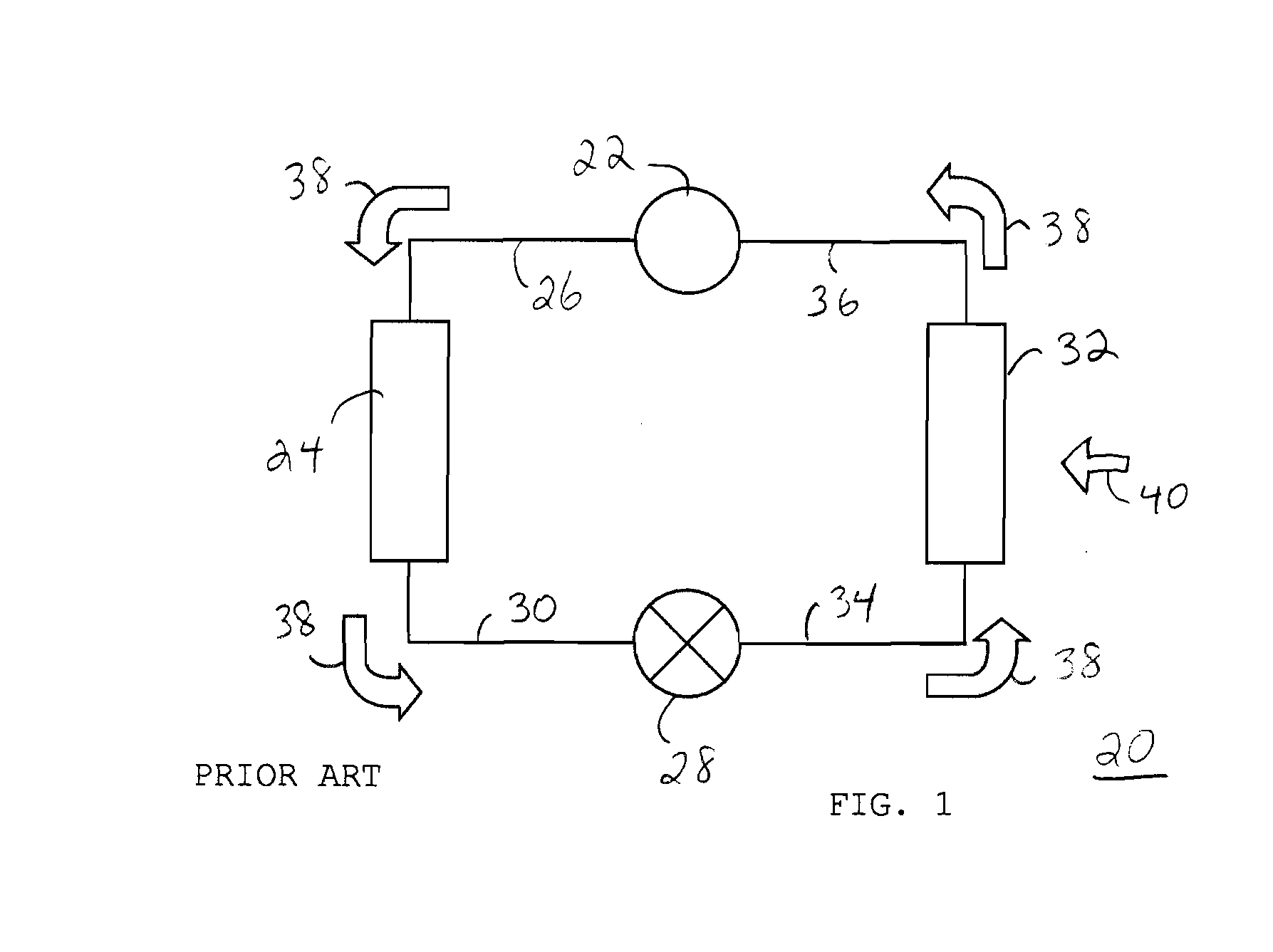

Heat exchanger testing device

ActiveUS20150003495A1Weather/light/corrosion resistanceHeat exchange simulationEngineeringProcess conditions

An apparatus and a process for testing fluid from a heat exchanger. A first fluid from a heat exchanger to be tested is passed through a test heat exchanger. A second fluid is circulated through the test heat exchanger with a pump. The second fluid is heated with a heater so that a temperature in the test heat exchanger can be controlled, for example, to so that conditions in the heat exchanger are close to the conditions in the heat exchanger. After a period of time, the test heat exchanger can be removed and inspected, tested, or both. Also, multiple test heat exchangers may be used to test various process conditions. Additionally, the test heat exchangers may include different materials to test various materials.

Owner:KNEW VALUE

Multi-segmented tube sheet

ActiveUS9303924B1Easy to optimizeHigh toleranceHeat exchanger casingsStationary tubular conduit assembliesEngineeringControl valves

A heat exchanger that is constructed with a heat exchanger shell having inlet and outlet plenums and fluid inlet and outlet ports, and a tube sheet construction disposed in the heat exchanger shell. The tube sheet construction includes at least two separate tube sheets and a plurality of tubes that extend between the separate tube sheets. Each tube sheet includes at least two planar tube sheet segments and an interstitial layer disposed between the at least two tube sheet segments, and at least one sensor element supported by each of the interstitial layers. A control monitor controls flow through the shell by a feedback control from the sensor to an inlet control valve and / or a stimulus device excites the media layer.

Owner:NEPTUNE BENSON INC

Heat pipe performance detection apparatus

InactiveCN101498677AImprove accuracyImprove convenienceMaterial thermal conductivityMaterial heat developmentEngineeringHeat pipe

The invention discloses a thermotube performance detecting device comprising a heating component, a radiating component and a bearing part. The heating component and the radiating component respectively comprise a fixed part and a movable part which can be separable and inseparable from each other; at least one measuring and accommodating part capable of accommodating a thermotube to be measured is arranged between the opposite surfaces of the heating component and the radiating component; the measuring and accommodating part is internally provided with at least one temperature sensor; the heating component is provided with at least one heating element for heating the evaporating section of the thermotube to be measured; the radiating component is provided with at least one cooling structure; the bearing part comprises one positioning seat and two clamping seats which are arranged on the positioning seat and bear the heating component and the radiating component respectively, wherein at least one clamping seat adjusts the relative angel of the measuring and accommodating part arranged between the heating component and the radiating component with respect to the preset rotation angle of the positioning seat so as to bend thermotubes to be measured differently.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

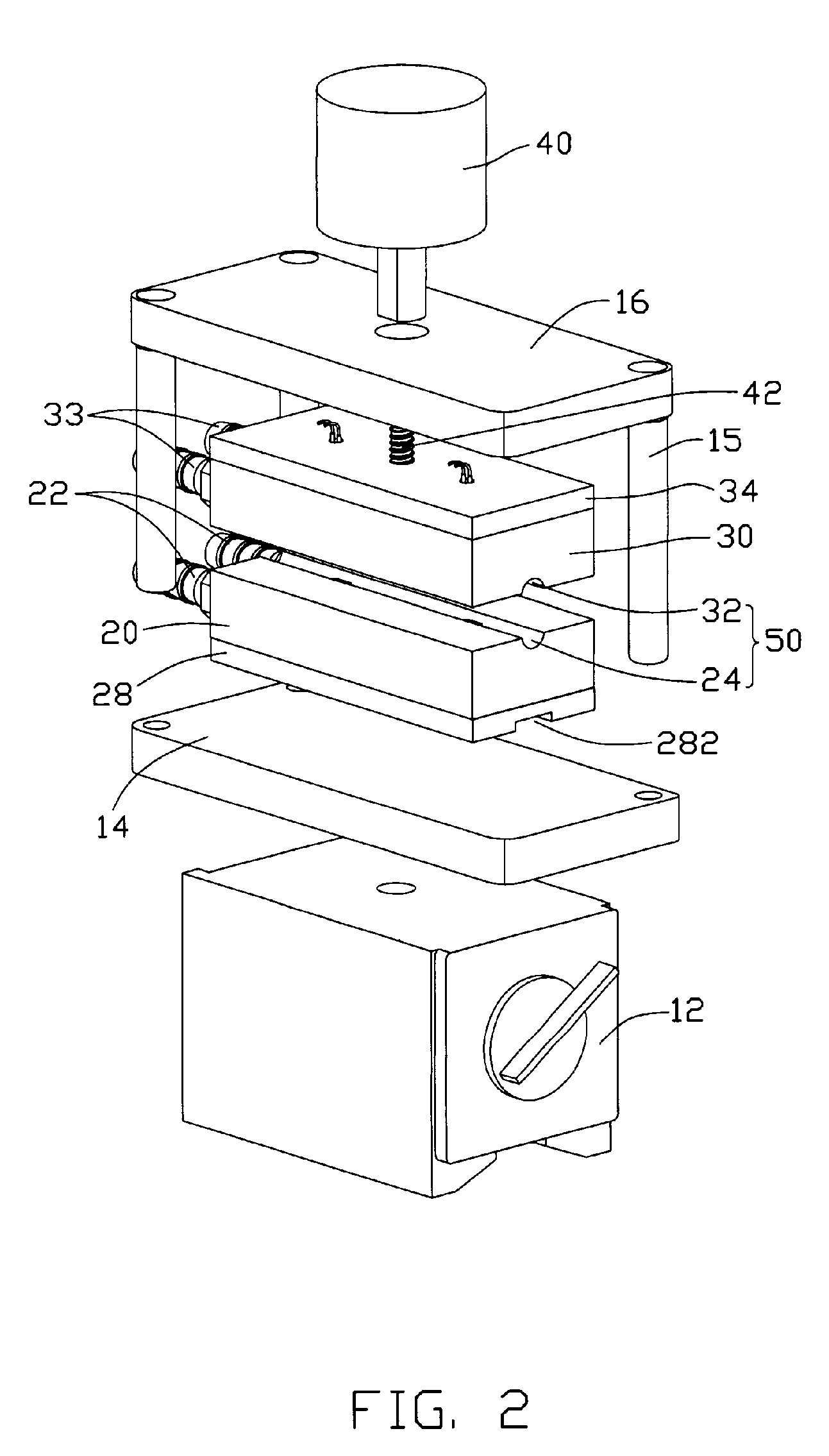

Performance testing apparatus for heat pipes

Owner:HON HAI PRECISION IND CO LTD

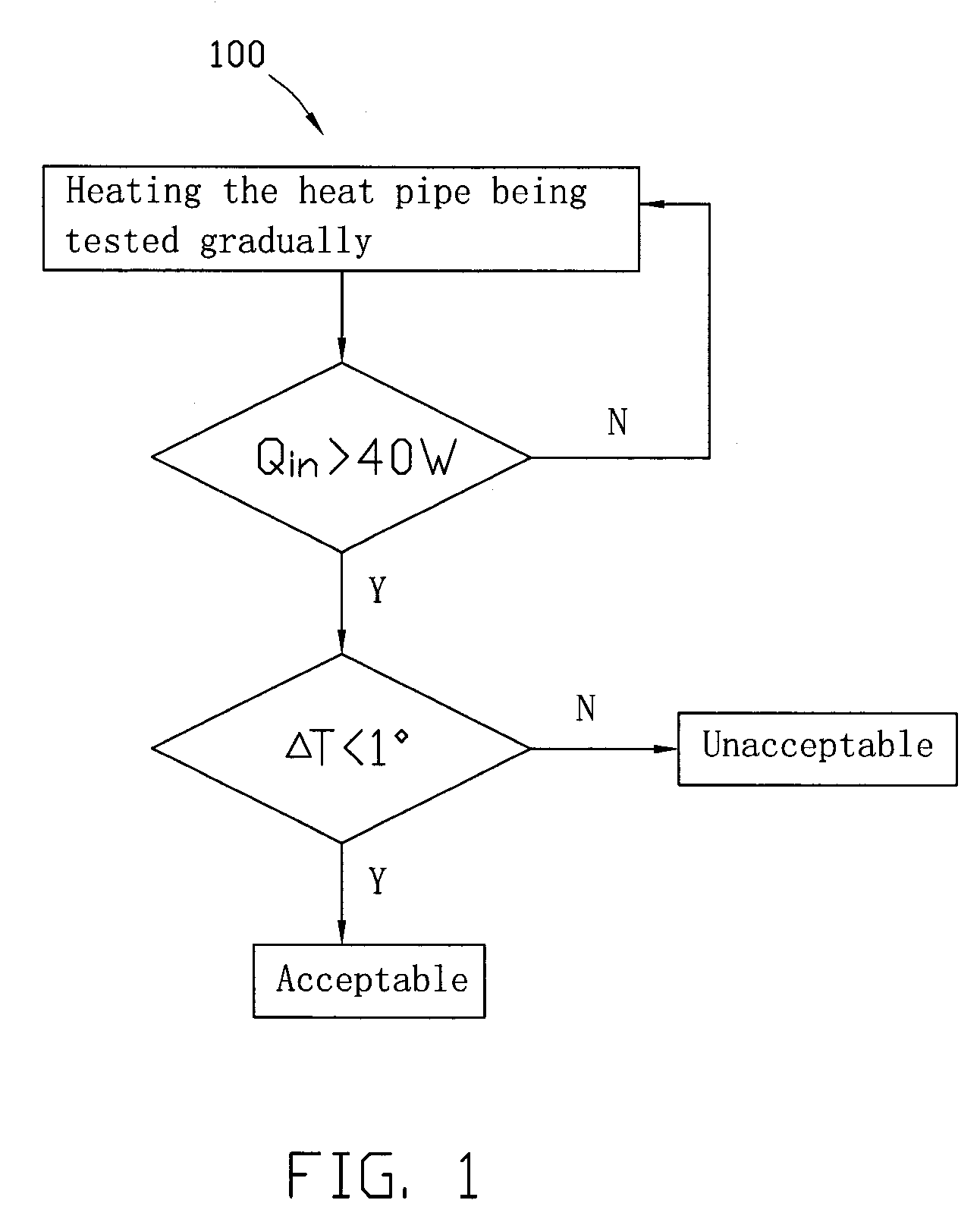

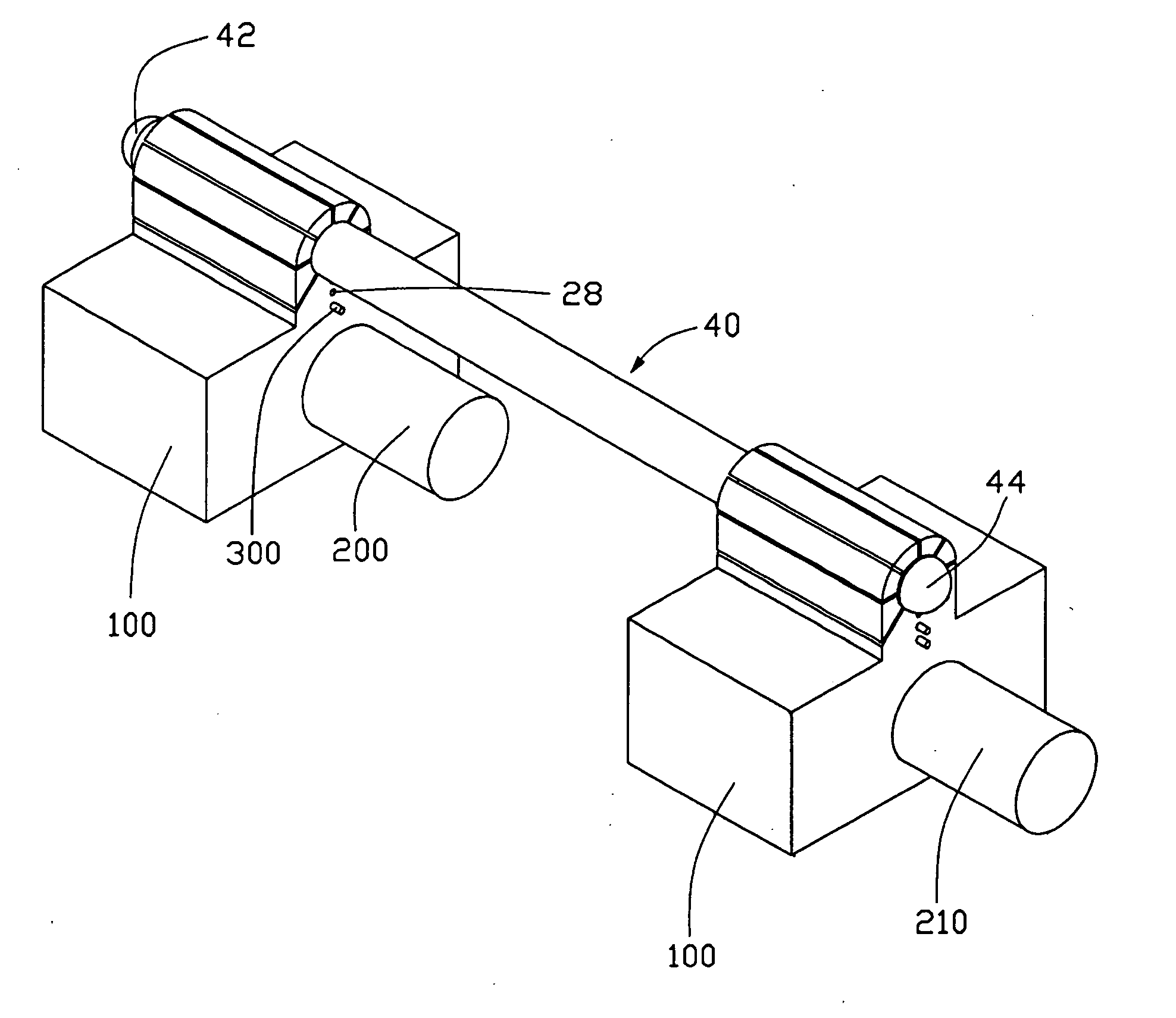

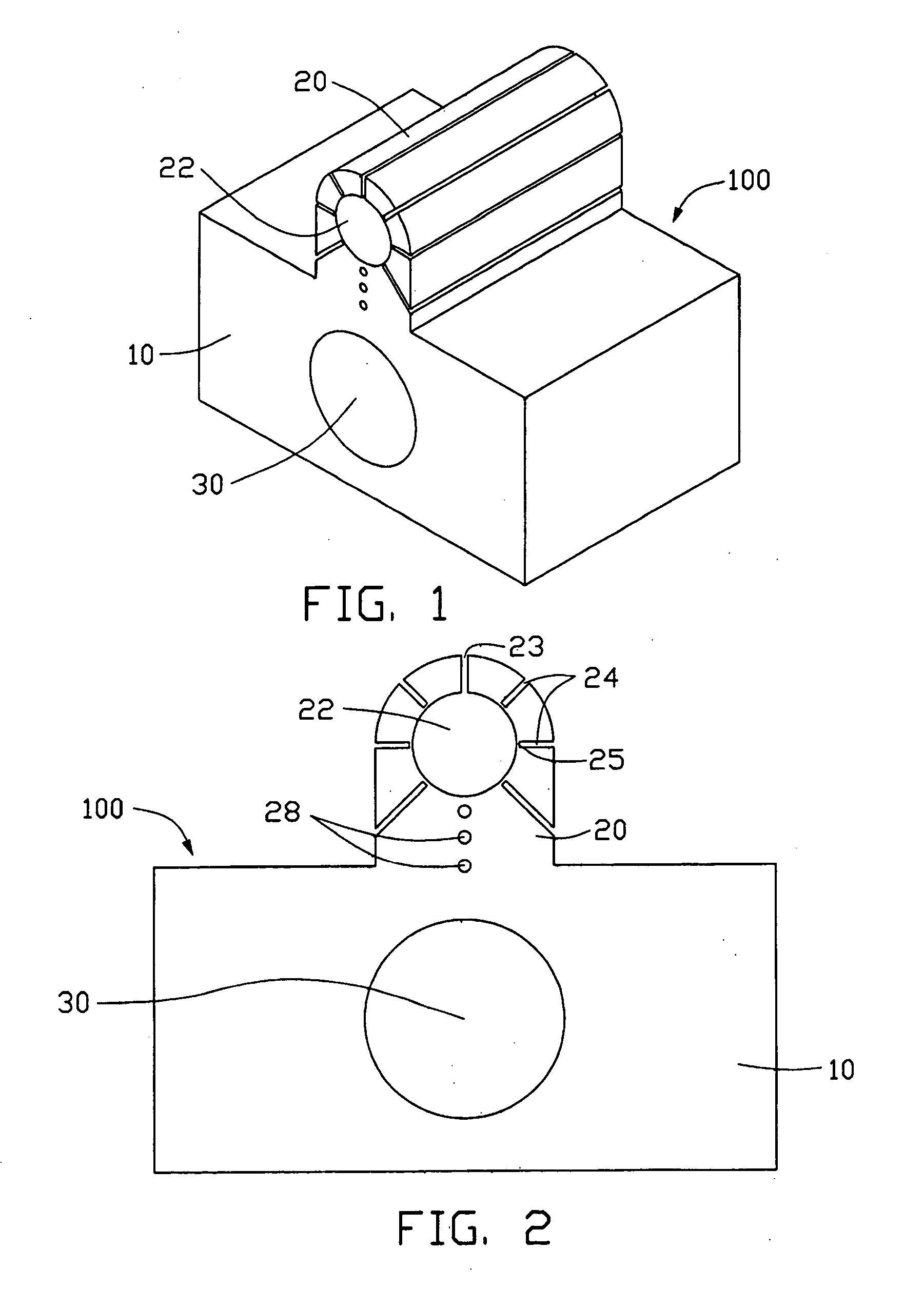

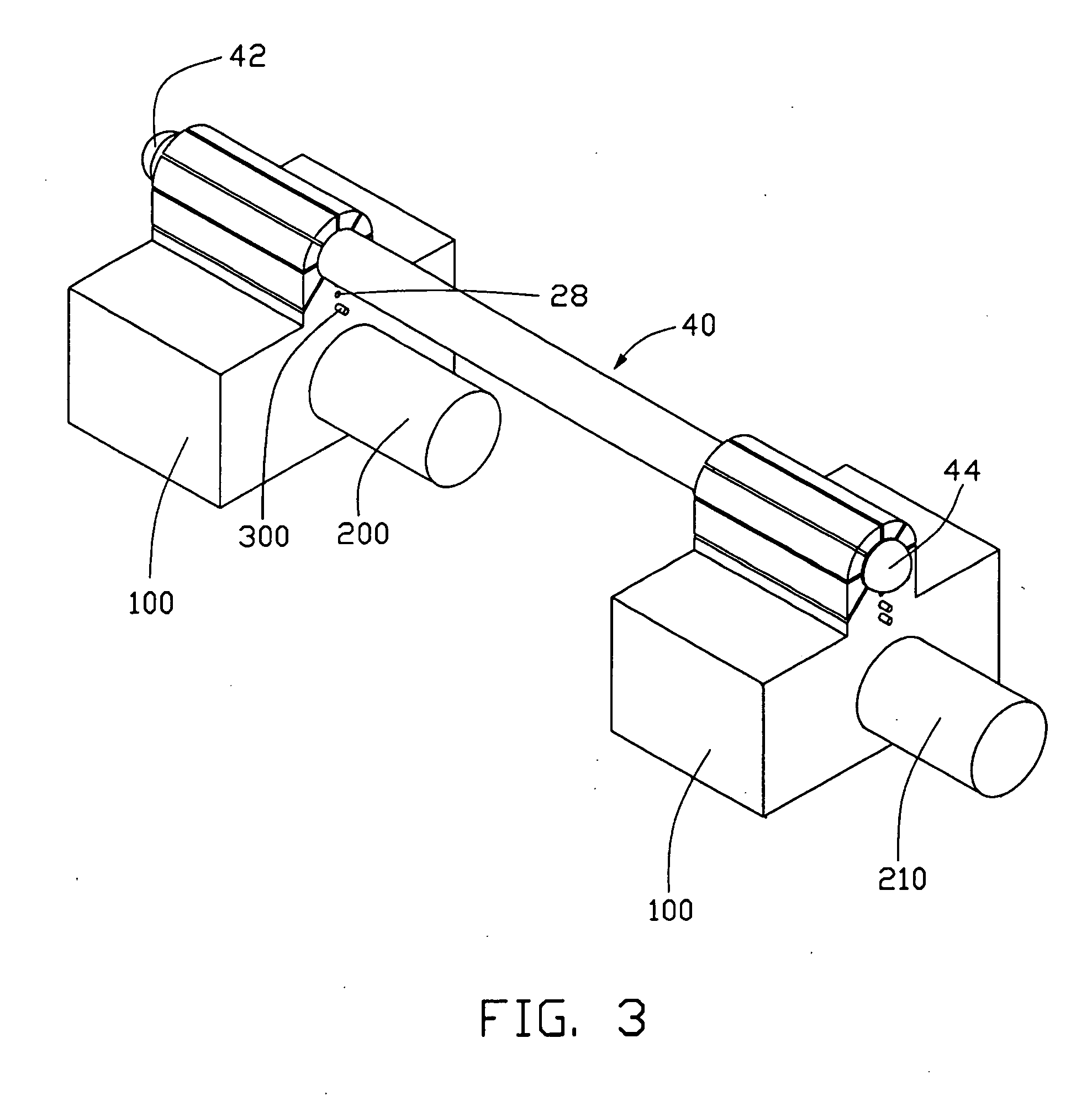

Measuring device for heat pipe

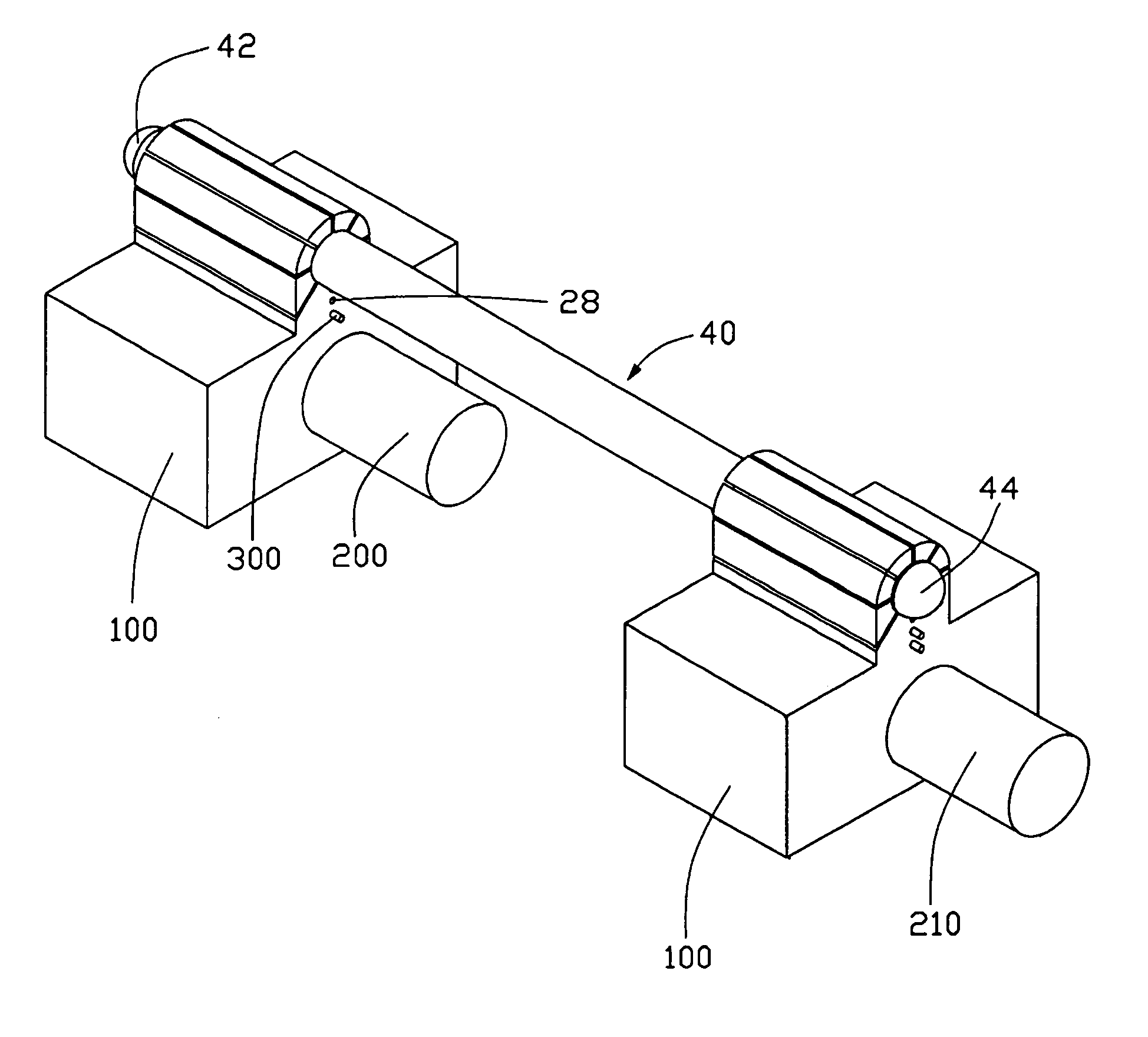

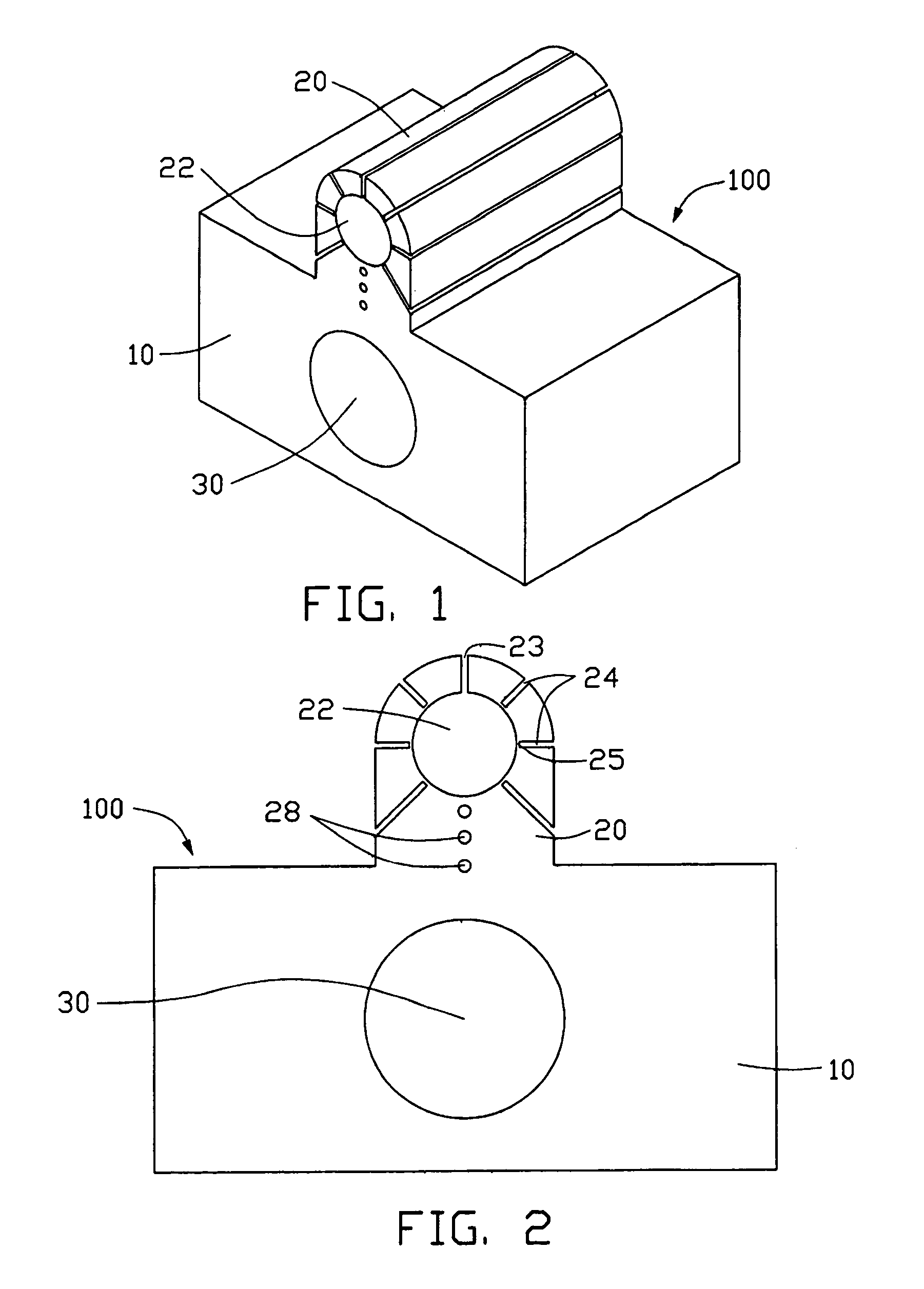

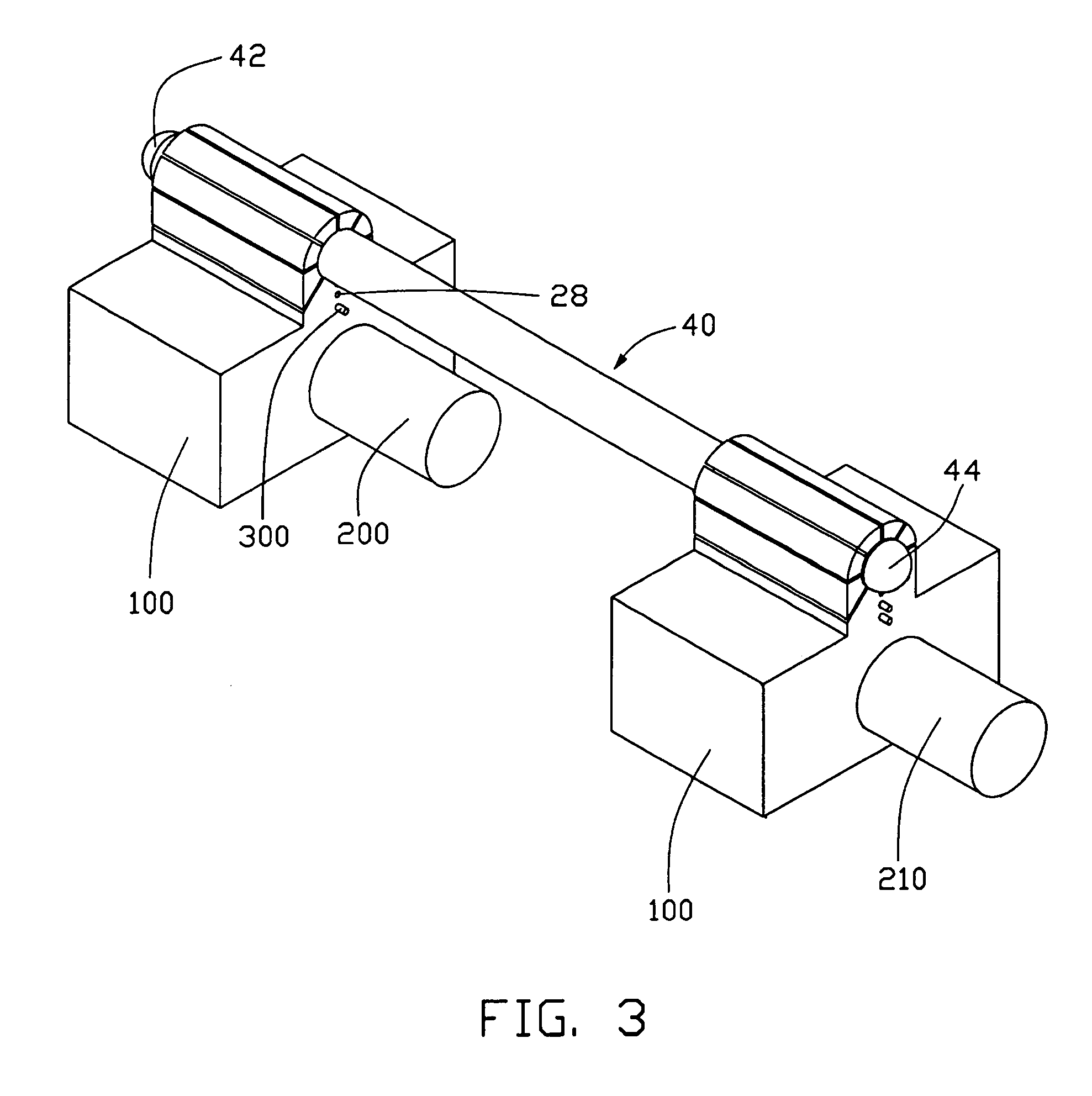

InactiveUS20050220168A1Accurately heat transfer characteristic of heatLow thermal conductivityThermometer detailsMaterial thermal conductivityThermal probeHeat pipe

A measuring device for a heat pipe (40) includes a first platform (100), a second platform (100), a heating member (200), a cooling member (210) and thermal probes (300). The heat pipe (40) includes a first end (42) and a second end (44) opposite to the first end (42). The first platform (100) flexibly receives the first end (42) of the heat pipe (40) therein and the second platform (100) flexibly receives the second end (44) of the heat pipe (40) therein. The heating member (200) is for heating the first end (42) of the heat pipe (40) and the cooling member (210) is for cooling the second end (44) of the heat pipe (40). The thermal probes (300) are received into the first platform (100) and the second platform (100) to measure the temperatures where they are positioned.

Owner:HON HAI PRECISION IND CO LTD

Airflow sensor for a heat sink

ActiveUS20170234631A1Volume/mass flow by electric/magnetic effectsHeat exchange simulationElectronic componentElectroactive materials

An airflow sensor for a heat sink has a first portion having a first electrical point of contact, a second portion have a second electrical point of contact, and a deformable portion made of an electroactive material electrically coupled to the first and second portions. The deformable portion has first electrical properties measured between the first and second electrical points of contact when there is no airflow and the deformable portion is in a first position, and has second electrical properties different than the first electrical properties when a source of airflow blows air against the deformable portion, thereby causing the deformable portion to extend to a second position farther away from the source of airflow than the first position. The airflow sensor can be incorporated into a heat sink for an electronic component.

Owner:IBM CORP

Performance testing apparatus for heat pipes

InactiveUS20070147470A1Accurate receptionThermometer detailsMaterial thermal conductivityTester deviceMechanical engineering

A performance testing apparatus for a heat pipe includes an immovable portion having a heating member located therein for heating an evaporating section of the heat pipe, and a movable portion capable of moving relative to the immovable portion. A receiving structure is defined between the immovable portion and the movable portion for receiving the evaporating section of the heat pipe therein. A positioning structure extends from the immovable portion and slideably receives the movable portion therein for avoiding the movable portion from deviating from the immovable portion during movement of the movable portion relative the immovable portion. Temperature sensors are attached to the immovable portion and the movable portion for detecting temperature of the heat pipe.

Owner:HON HAI PRECISION IND CO LTD

Process for optimizing a heat exchanger configuration

ActiveUS20130264024A1Overcomes shortcomingEnhanced advantageAir-treating devicesHeat exchange simulationCounter flowNuclear engineering

A heat exchanger core optimization method is provided for a heat exchanger door which resides at an air inlet or outlet side of an electronics rack, and includes an air-to-coolant heat exchanger with a heat exchanger core. The core includes a first coolant channel coupled to a coolant inlet manifold downstream from a second coolant channel, and the first channel has a shorter channel length than the second channel. Further, coolant channels of the core are coupled to provide counter-flow cooling of an airflow passing across the core. The core optimization method determines at least one combination of parameters that optimize for a particular application at least two performance metrics of the heat exchanger. This method includes obtaining performance metrics for boundary condition(s) of possible heat exchanger configurations with different variable parameters to determine a combination of parameters that optimize the performance metrics for the heat exchanger.

Owner:LENOVO GLOBAL TECH INT LTD

Performance testing apparatus for heat pipes

InactiveUS7674037B2Move preciselyThermometer detailsMaterial thermal conductivityTester deviceEngineering

Owner:HON HAI PRECISION IND CO LTD

Method and system for evaluating fluid flow through a heat exchanger

InactiveUS20080083526A1Rapid, cost effective, and non-destructive evaluationAir-treating devicesTemperature measurement in air-conditioning systemsStream flowEngineering

A heat exchanger evaluation system (84) includes a refrigeration subsystem (126) and a platform (94) in communication with the subsystem (126) for attachment of a heat exchanger (32). The system (84) further includes a thermal imaging camera (168) and a monitor (100). A method (180) entails routing a fluid (38) through the heat exchanger (32) via the refrigeration subsystem (126). The camera (168) detects the temperature variation across the heat exchanger (32) as the fluid (38) flows through the heat exchanger, and provides successive thermal images representing the temperature variation responsive to the flow of the fluid (38). The thermal images are utilized to determine an efficacy of the flow through the heat exchanger (32). In particular, a determination can be made as to whether the flow deviates from a pre-determined flow path (79) of the fluid (38) through the heat exchanger.

Owner:CALSONICKANSEI NORTH AMERICA

Performance testing apparatus for heat pipes

InactiveUS20070121700A1Thermometer detailsWeather/light/corrosion resistanceTester deviceEngineering

A performance testing apparatus for a heat pipe includes an immovable portion having a cooling structure defined therein for cooling a heat pipe requiring to be tested. A movable portion is capable of moving relative to the immovable portion and has a cooling structure therein for cooling the heat pipe. A receiving structure is located between the immovable portion and the movable portion for receiving the heat pipe therein. At least one temperature sensor is attached to at least one of the immovable portion and the movable portion. The least one temperature sensor has a detecting section exposed in the receiving structure for thermally contacting the heat pipe in the receiving structure to detect a temperature of the heat pipe.

Owner:HON HAI PRECISION IND CO LTD

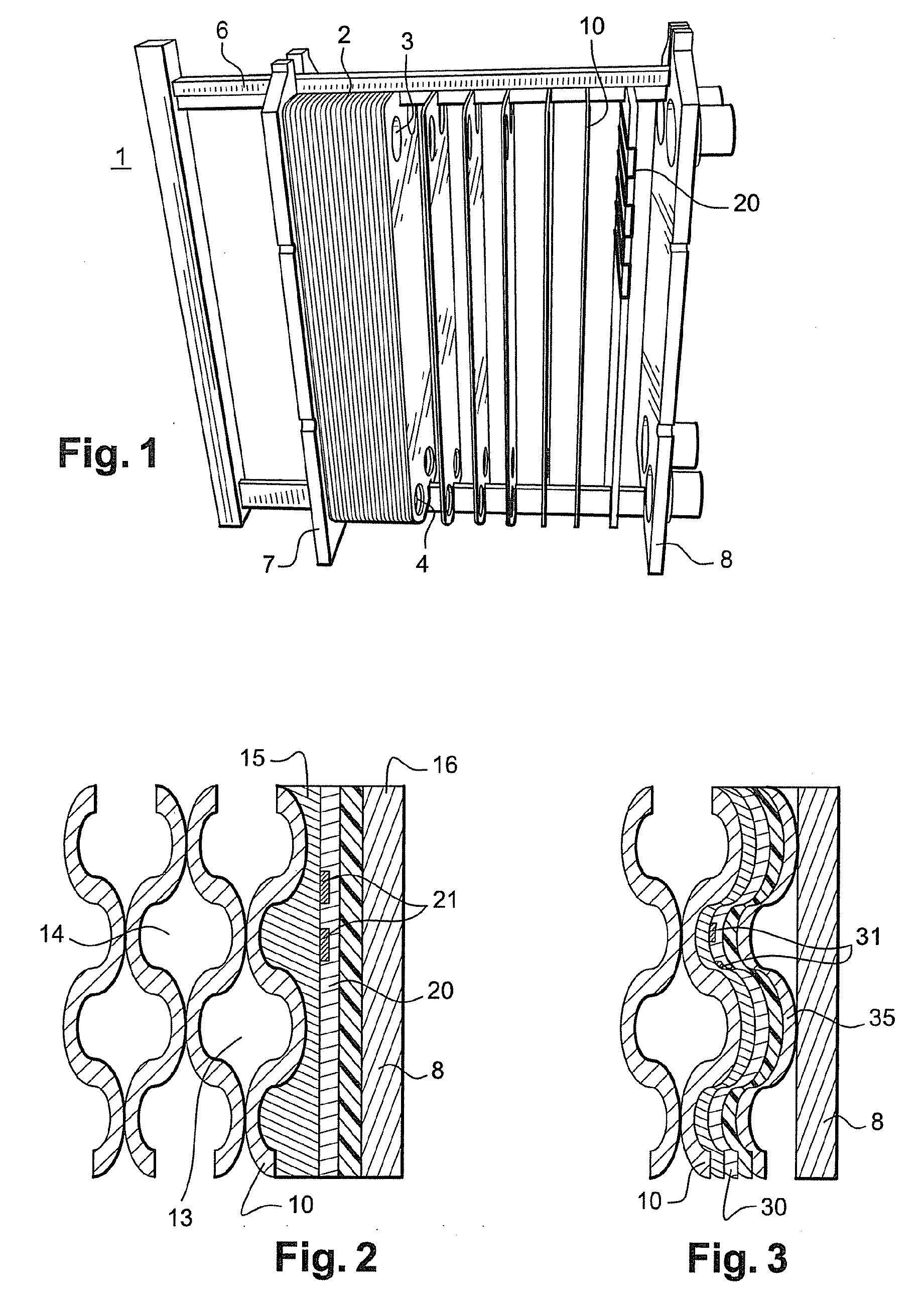

Plate-type heat exchanger including a device for evaluating the extent to which it has become coated in scale

A plate-type heat exchanger (1) comprising a plurality of stacked plates (2) and including a device (20) for evaluating the extent to which the fluid circuit(s) have become coated in scale, characterised in that the evaluating device (20) comprises an electrical resistor (21) which is thermally connected to plate (10) located at the end of the stack and means of measuring the temperature in the immediate vicinity of said resistor.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Performance testing apparatus for heat pipes

InactiveUS7632009B2Improve test accuracyAssembly precisionThermometer detailsMaterial thermal conductivityTester deviceEngineering

A performance testing apparatus for a heat pipe includes an immovable portion having a heating member located therein for heating an evaporating section of the heat pipe, and a movable portion capable of moving relative to the immovable portion. A receiving structure is defined between the immovable portion and the movable portion for receiving the evaporating section of the heat pipe therein. A concavo-convex cooperating structure is defined in the immovable portion and the movable portion for avoiding the movable portion from deviating from the immovable portion to ensure the receiving structure being capable of receiving the heat pipe precisely. At least one temperature sensor is attached to at least one of the immovable portion and the movable portion for detecting temperature of the heat pipe.

Owner:HON HAI PRECISION IND CO LTD

Monitoring of heat exchangers in process control systems

InactiveUS20100036638A1Improve accuracyEasy to getCleaning heat-transfer devicesDigital computer detailsHeat flowPlate heat exchanger

A method for monitoring the efficiency of a heat exchanger is provided. Heat flows from a first medium into a second medium and an actual heat flow is detected and compared with at least one reference heat flow corresponding to a respectively predetermined degree of soiling of the heat exchanger. Furthermore, a device for controlling a plant having at least one heat exchanger is described. The plant has a storage device storing at least one reference heat flow of the heat exchanger.

Owner:SIEMENS AG

Header for heat exchanger and method of making the same

InactiveUS20110290464A1Reduce laborLow costHeat exchange simulationStationary conduit assembliesStress concentrationPlate heat exchanger

A header box for a heat exchanger assembly and the method of manufacture. The header box has a first header component and a second header component. The first header component has a first corner portion with a first wall and a second wall extending therefrom. The second header component has a second corner portion with a third wall and a fourth wall extending therefrom. Free ends of the first wall and the third wall cooperate to form a first seam which is welded to maintain the first wall in position relative to the second wall. The free ends of the second wall and the fourth wall cooperate to form a second seam which is welded to maintain the third wall in position relative to the fourth wall. The header box, with the first corner portion and the second corner portion, will withstand the stress concentrations associated with a flow of fluid in the header box.

Owner:HARSCO CORP

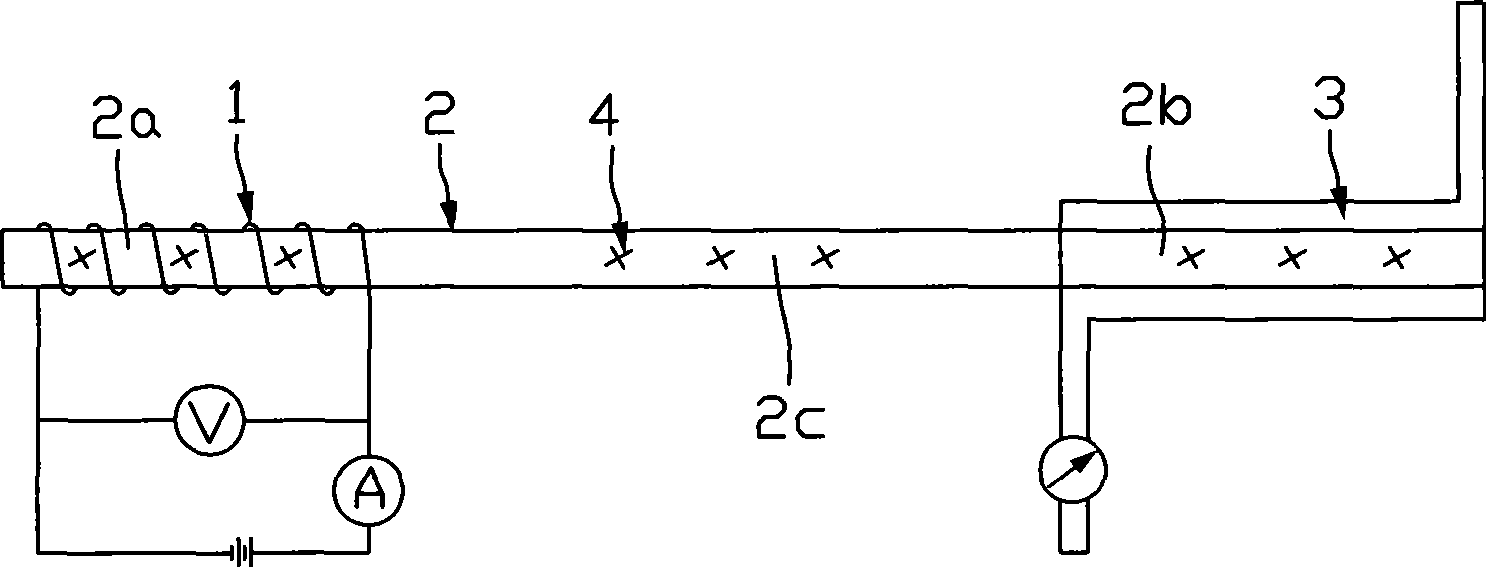

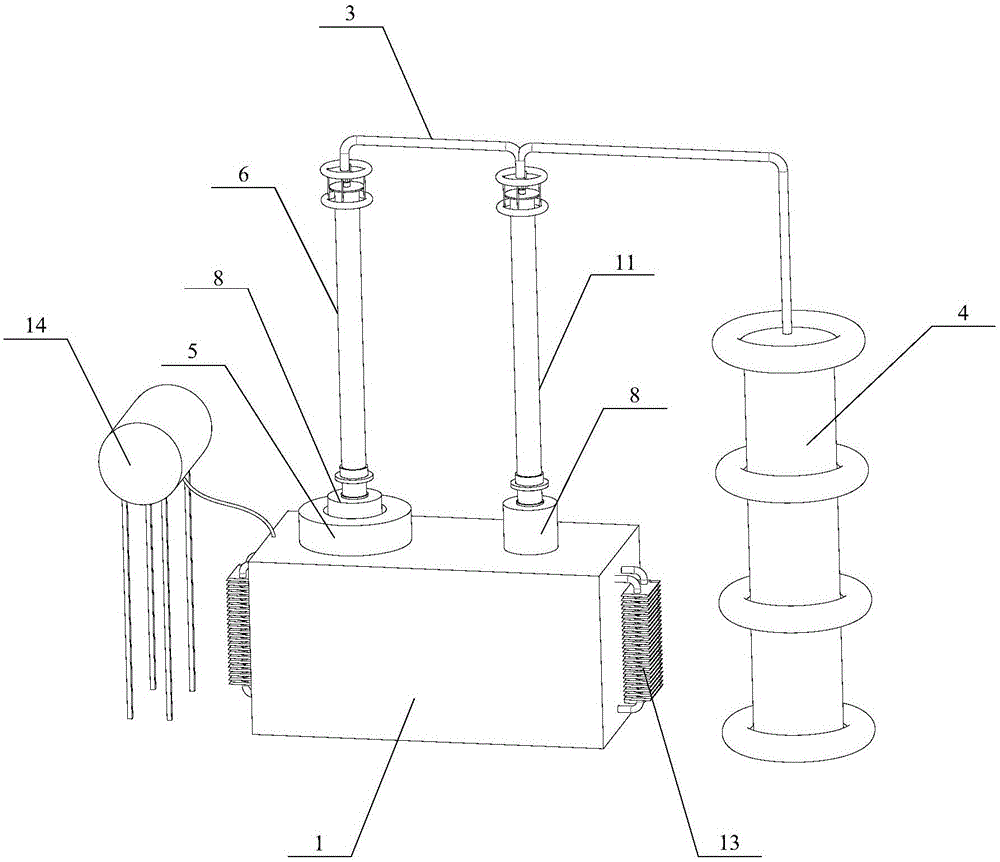

Heat pipe type insulation sleeve pipe test device

ActiveCN106226633AHigh simulationSolve the problem that the performance of the heat pipe insulation sleeve cannot be testedElectrical testingHeat exchange simulationVoltage generatorTransformer

The invention provides a heat pipe type insulation sleeve pipe test device, which comprises an oil tank, a temperature detection device, an insulation sleeve, a first conduction rod, a voltage generator, a step-down transformer and a second conduction rod, wherein the oil tank is provided with a first connecting hole and a second connecting hole; a heat pipe type insulation sleeve pipe to be tested is arranged in a penetrating way and is connected with the first connecting hole; the insulation sleeve pipe is arranged in the penetrating way and is connected with the second connecting hole; the first end of the heat pipe type insulation sleeve pipe and the first end of the insulation sleeve pipe are connected with each other in the oil tank through the first conduction rod; the second end of the heat pipe type insulation sleeve pipe and the second end of the insulation sleeve pipe are connected with each other outside the oil tank through the second conduction rod; the heat pipe type insulation sleeve pipe, the insulation sleeve pipe, the first conduction rod and the second conduction rod form a closed loop; the step-down transformer is arranged outside the heat pipe type insulation sleeve in a sleeving way; the voltage generator is connected with the heat pipe type insulation sleeve pipe; the temperature detection device is arranged in the heat pipe type insulation sleeve pipe. The heat pipe type insulation sleeve pipe test device has the advantages that the performance test of the heat pipe type insulation sleeve pipe is realized; the safety and the reliability are improved.

Owner:CHINA ELECTRIC POWER RES INST +2

Online heurisitc algorithm for combined cooling heating and power plant optimization

ActiveUS9915178B2Sampled-variable control systemsHeat storage plantsThermal energyThermal energy storage

A method of real-time optimization for a Combined Cooling, Heating and Power system, including determining a first operation sequence of a plurality of chillers and at least one thermal energy storage tank in the system over a time period (410) and determining a second operation sequence of the plurality of chillers and at least one thermal energy storage tank in the system over the time period by using the first operation sequence as input to a greedy algorithm (420).

Owner:SIEMENS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com