Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

191results about "Closure members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

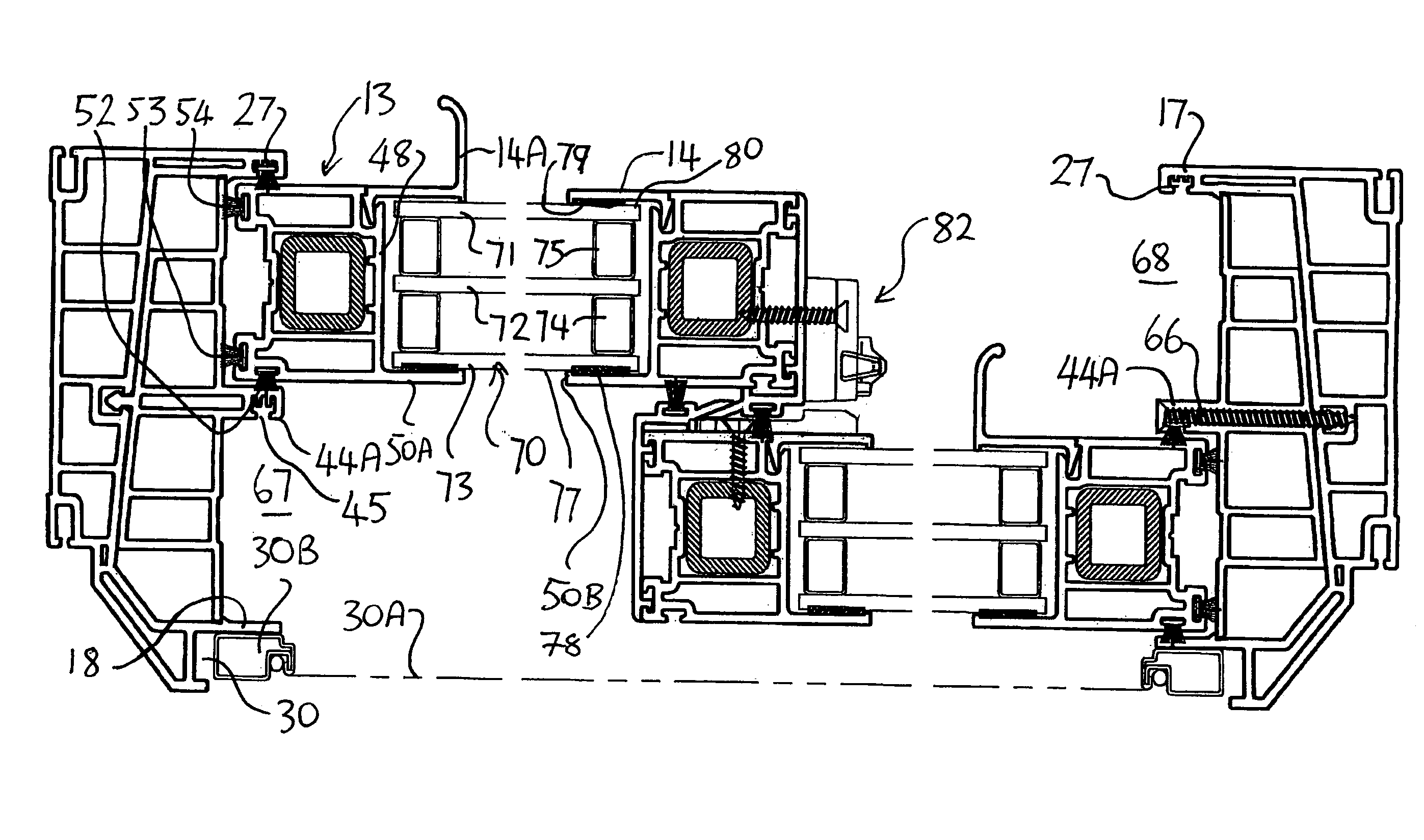

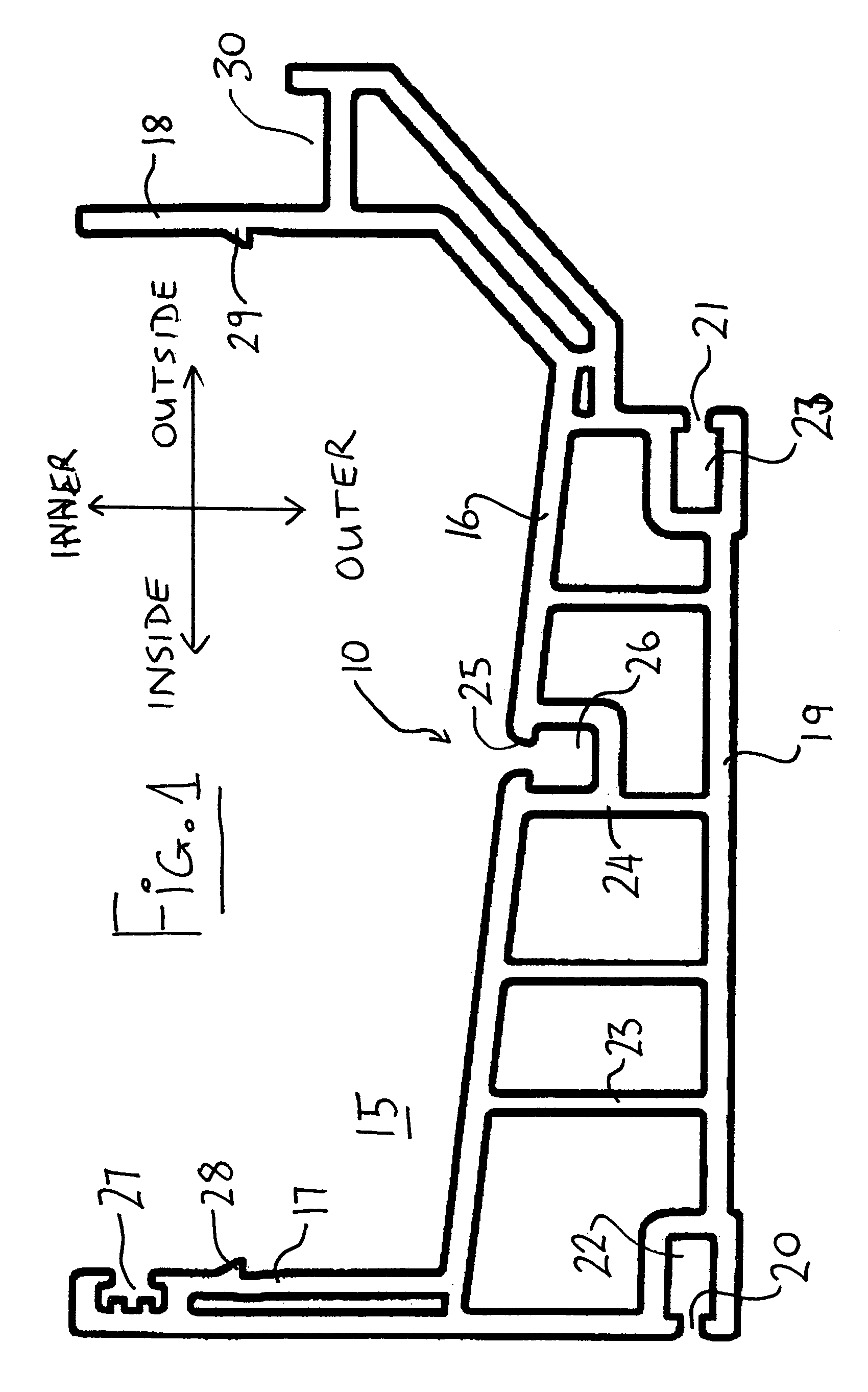

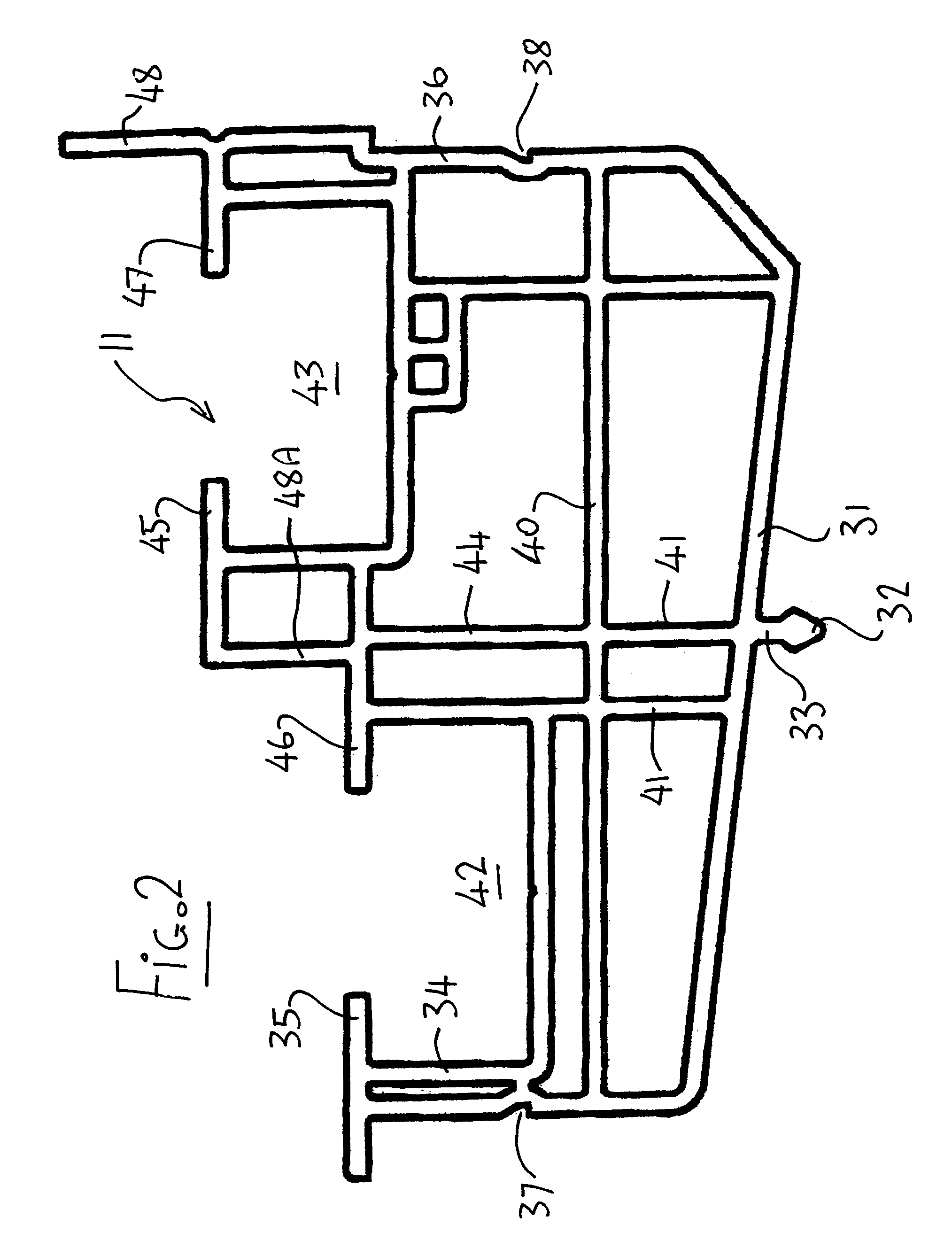

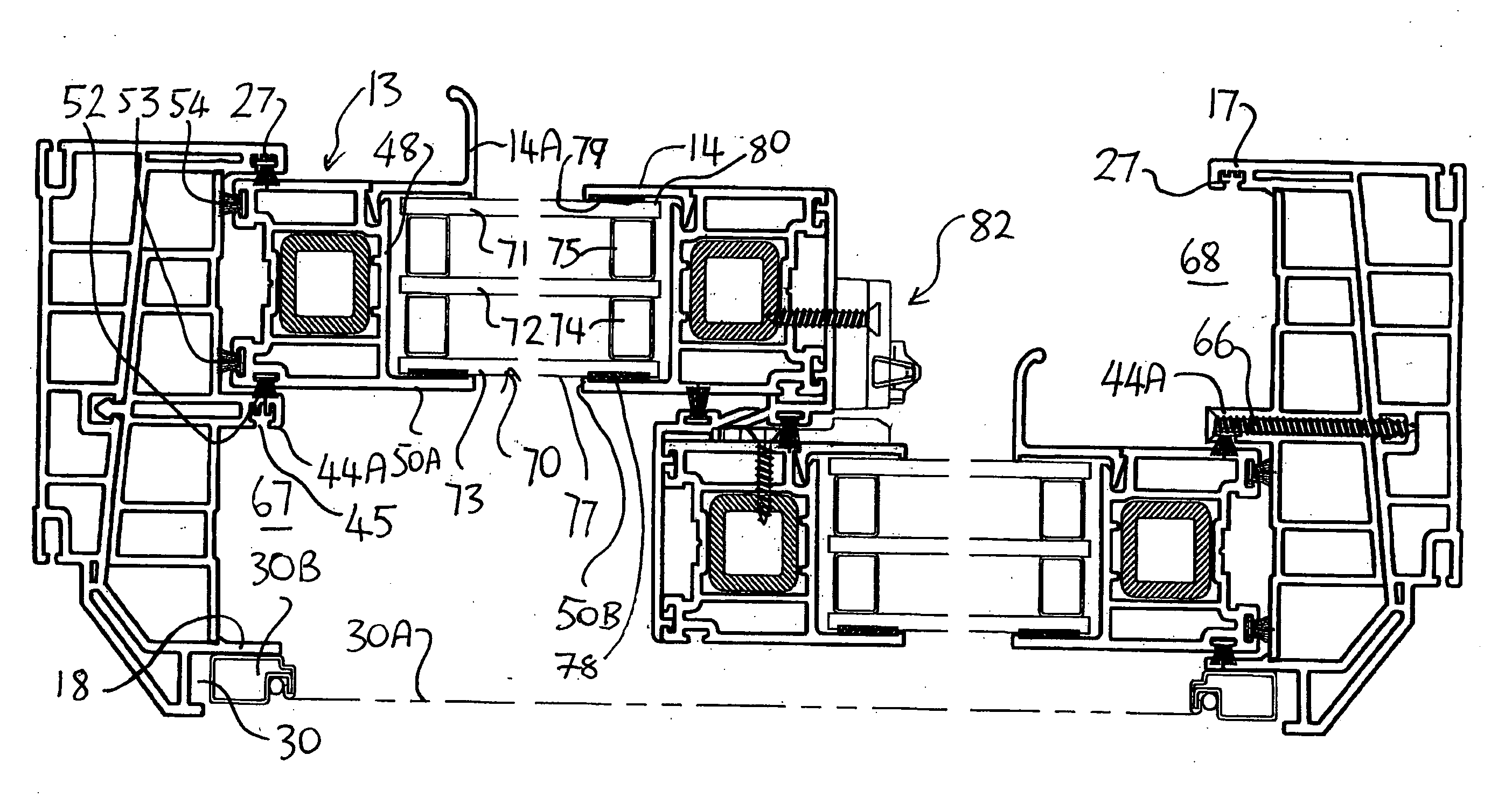

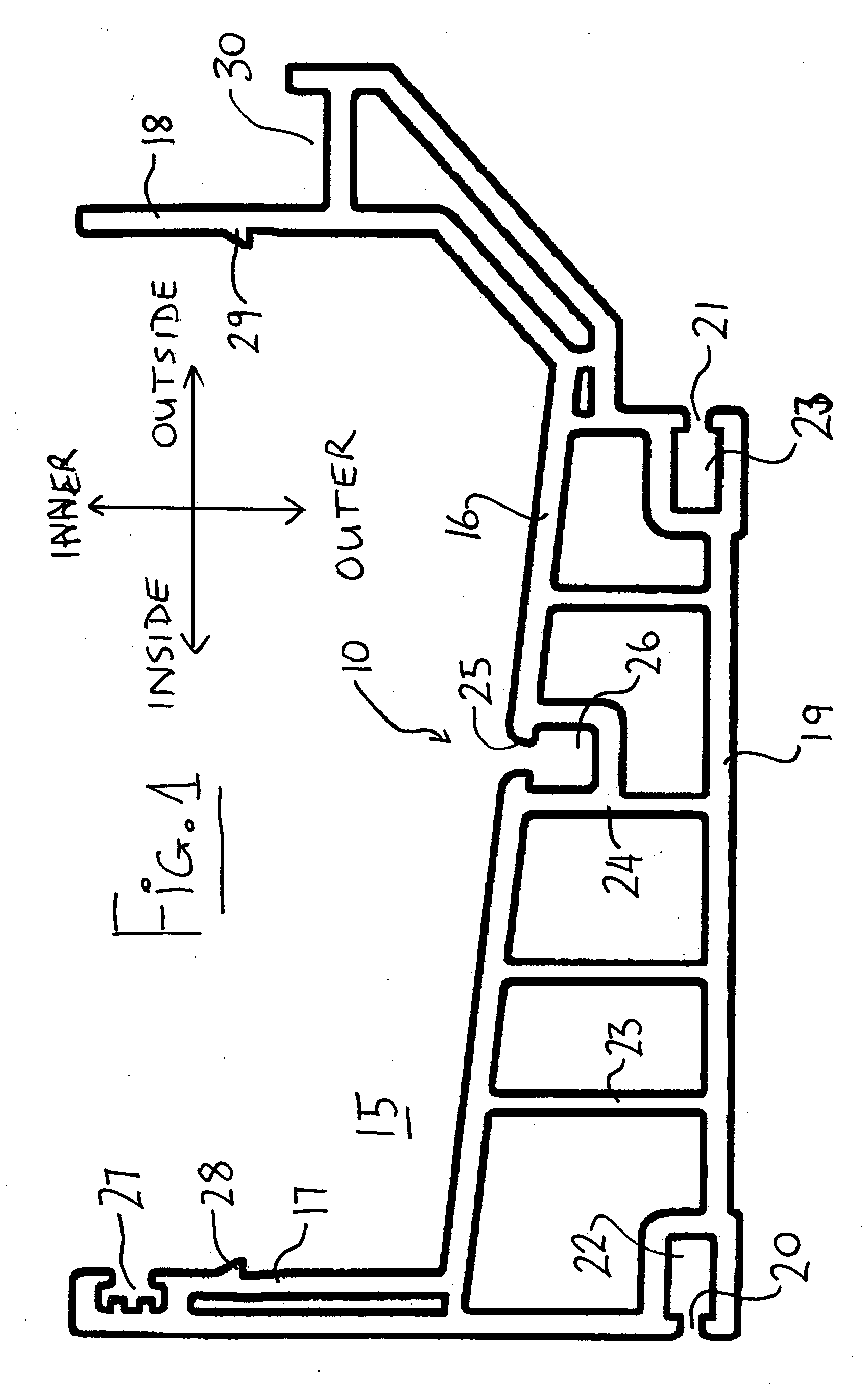

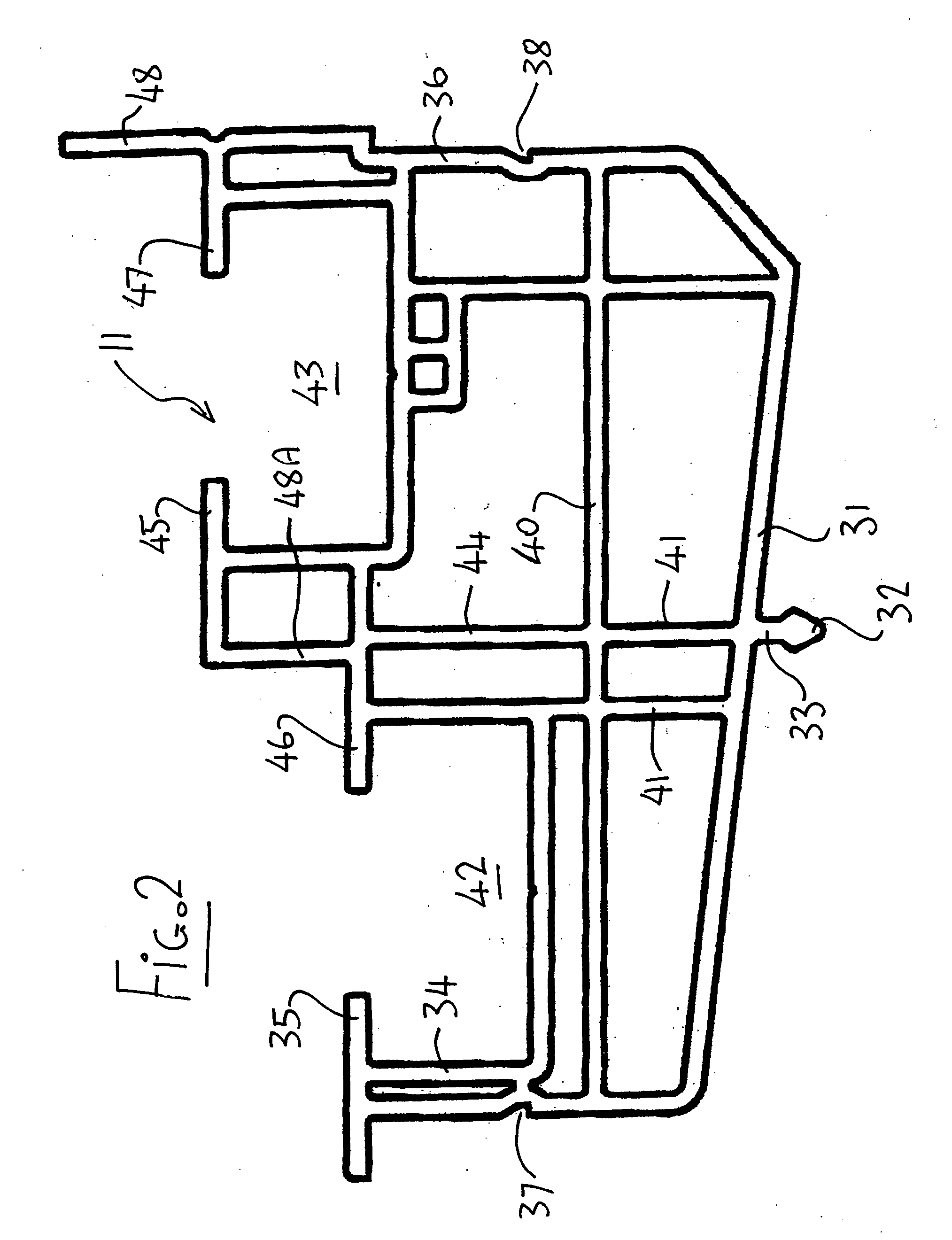

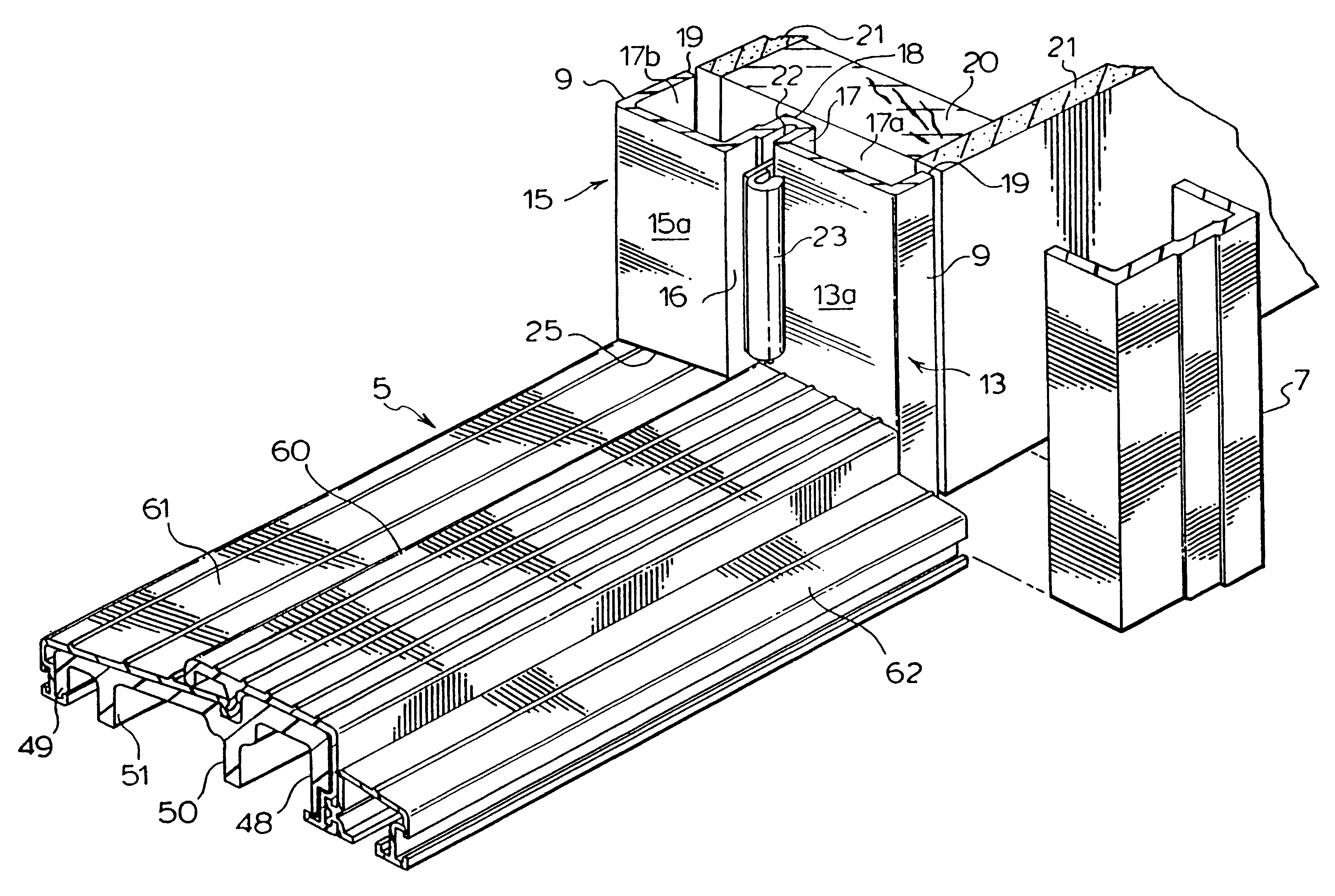

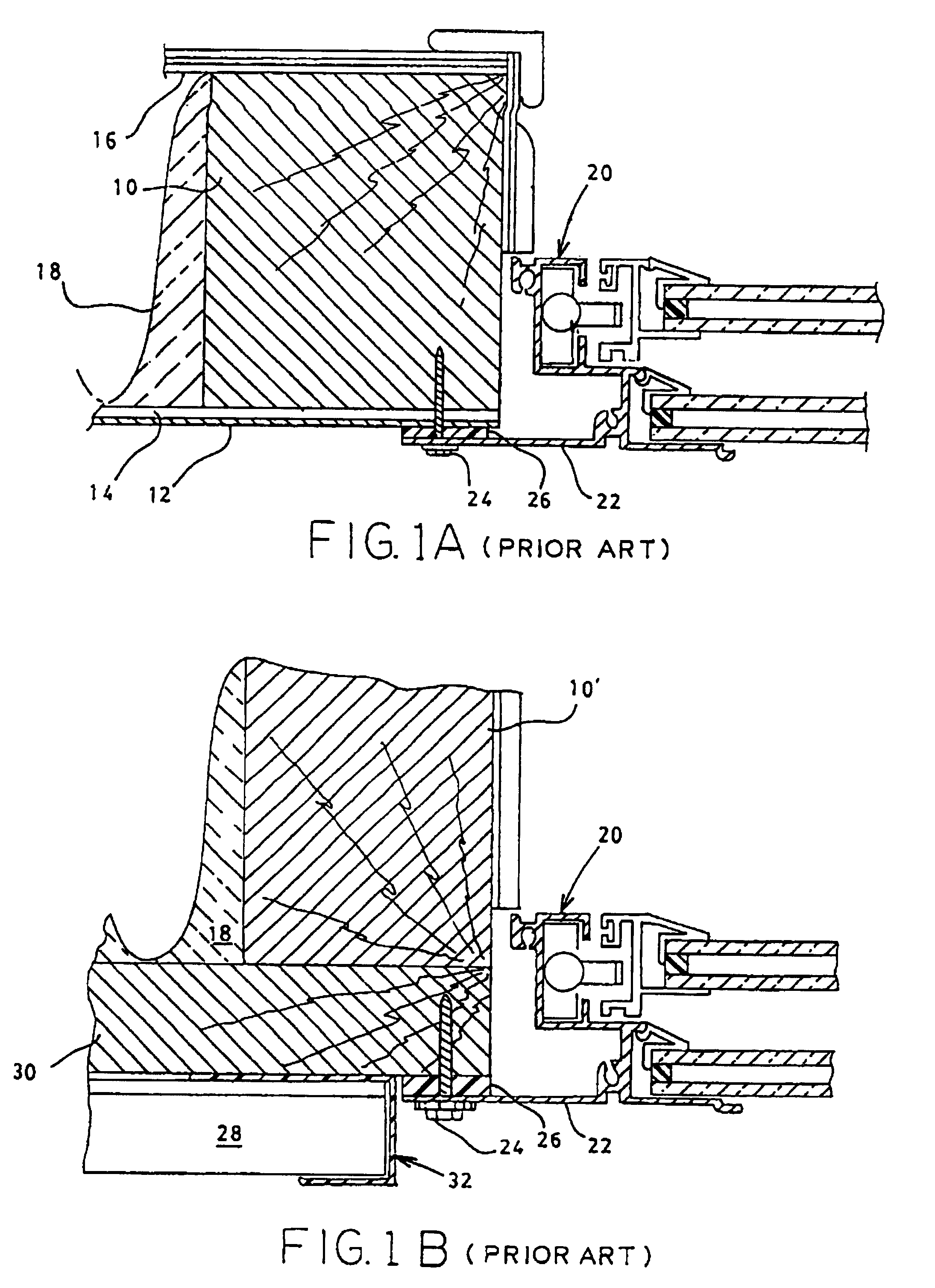

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

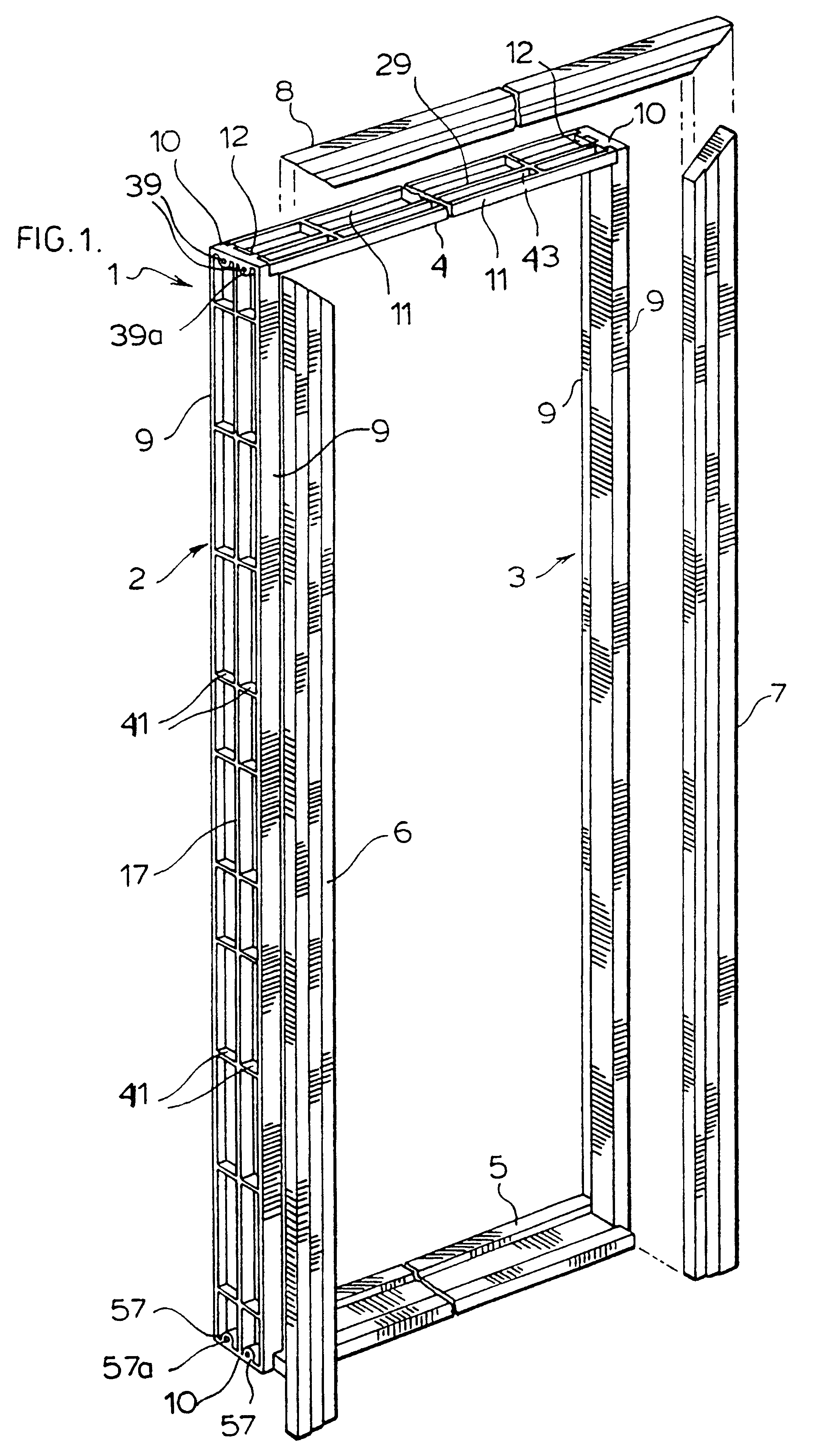

Composite door frames

InactiveUS6412227B1Quickly and easily and accurately assembledMinimal materialCorner/edge jointsWindow/door framesCompression moldingEngineering

A frame assembly (1) for mounting doors and the like comprising a pair of jambs (2, 3) and a header (4) for connecting said jambs, and, where required, a sill, each said jambs and header and sill (5) where required being a compression molding of filler, waste, or recycled particulate material bound together by a thermoplastic binder, each said jambs (2, 3) and header (4) presenting when assembled an inwardly facing planar surface of a width to receive a door to be mounted in said frame assembly and an inwardly projecting door stop shoulder formation projecting inwardly of said planar surface.

Owner:ROYAL GRP TECH LTD

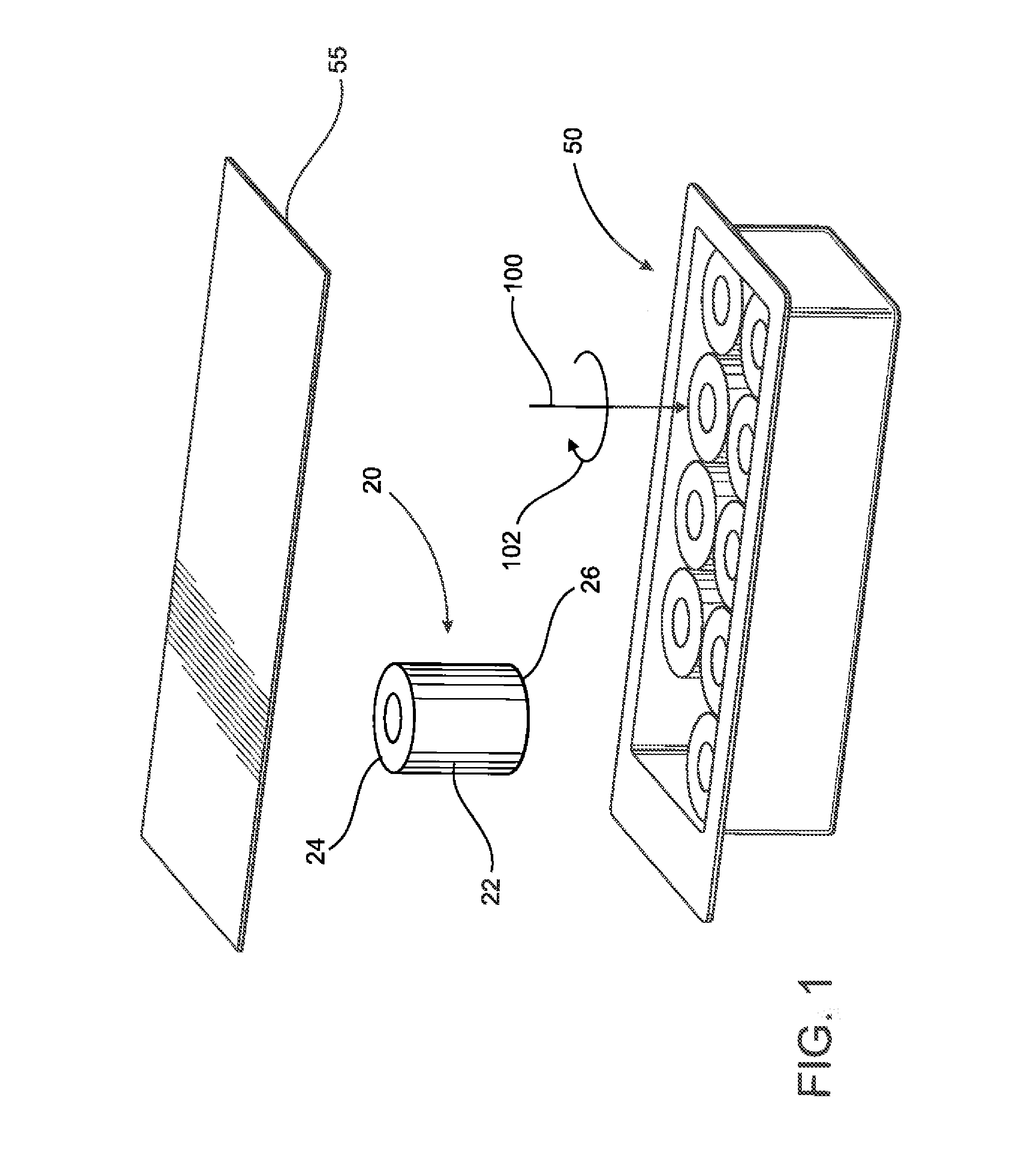

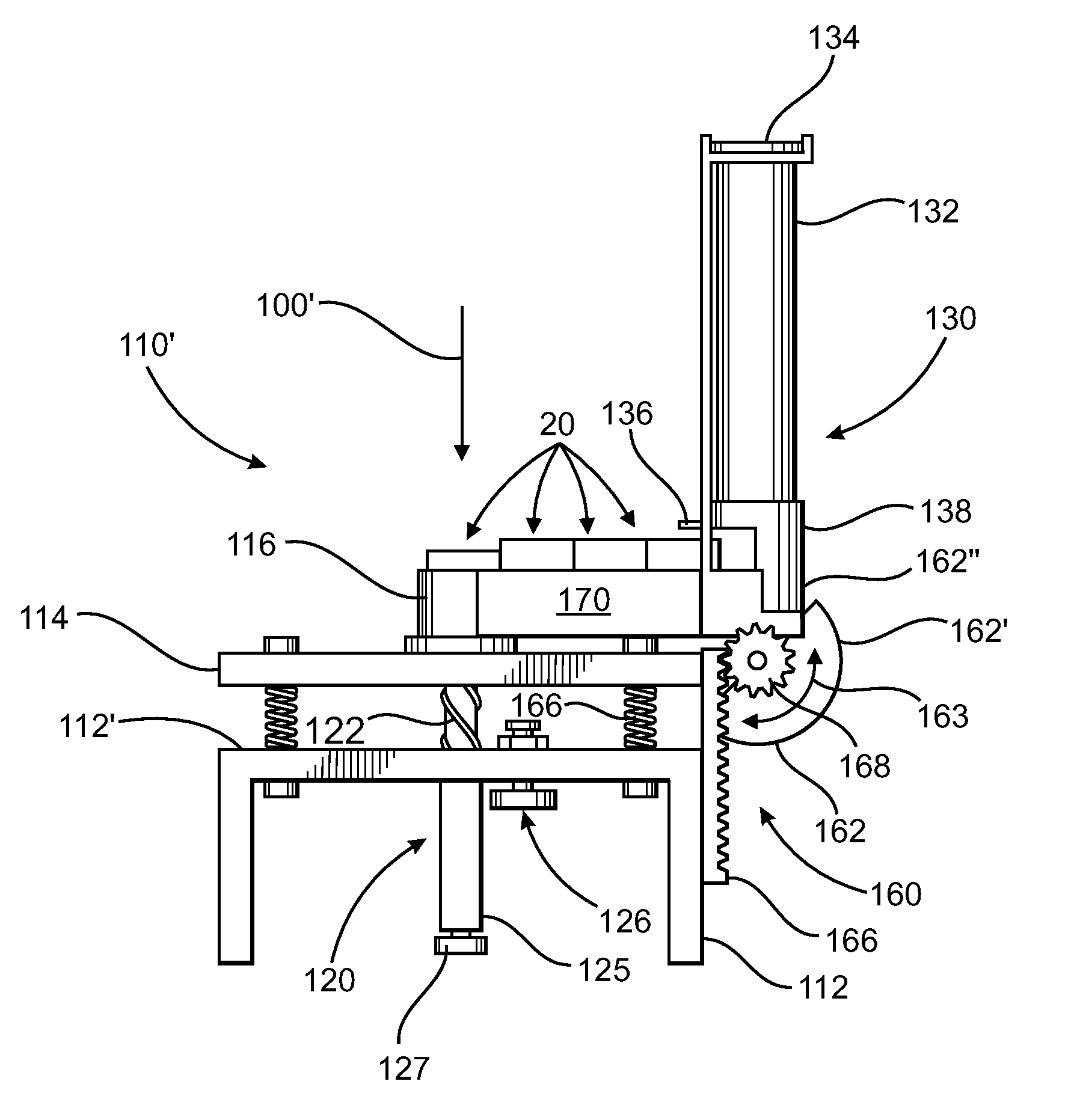

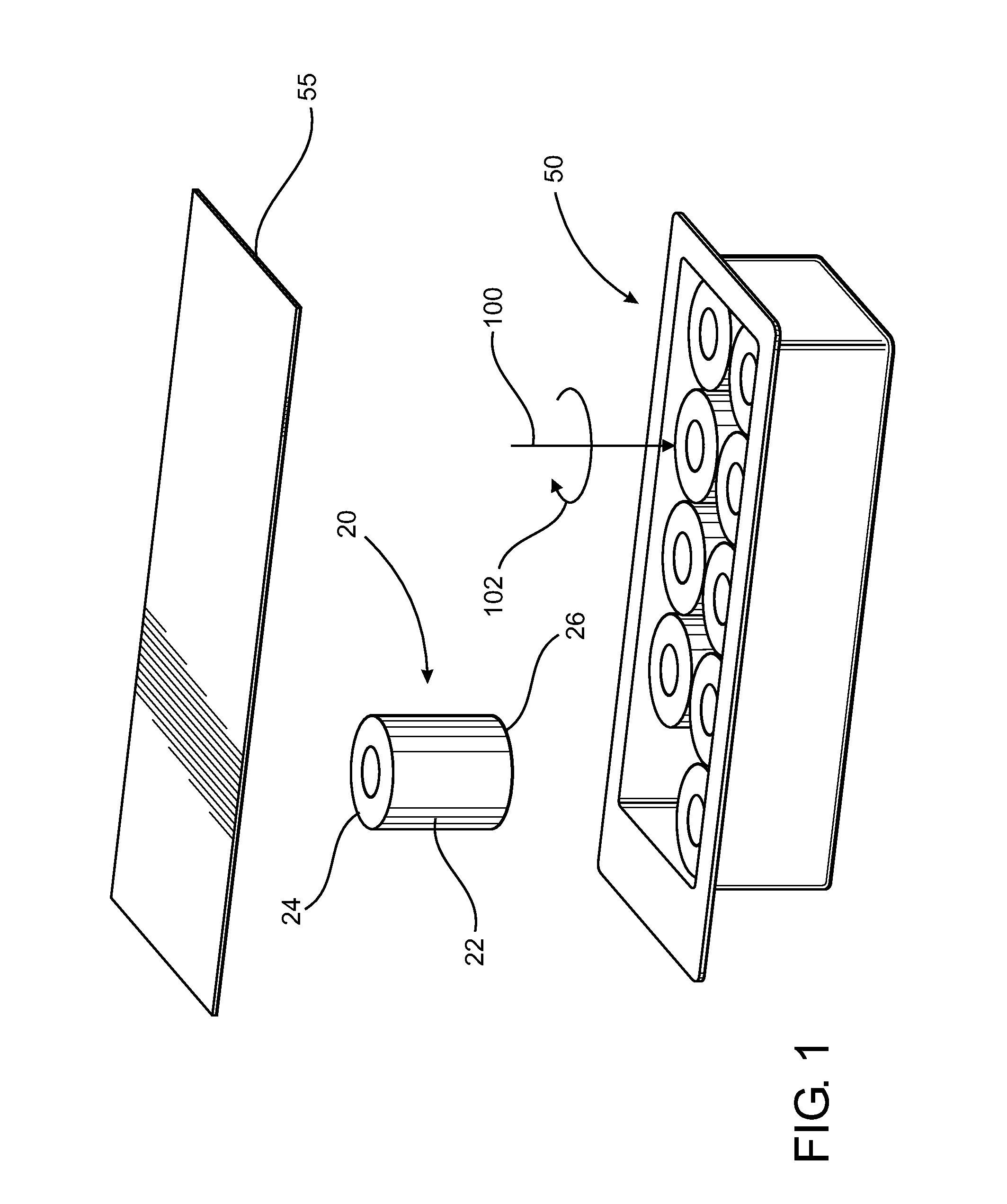

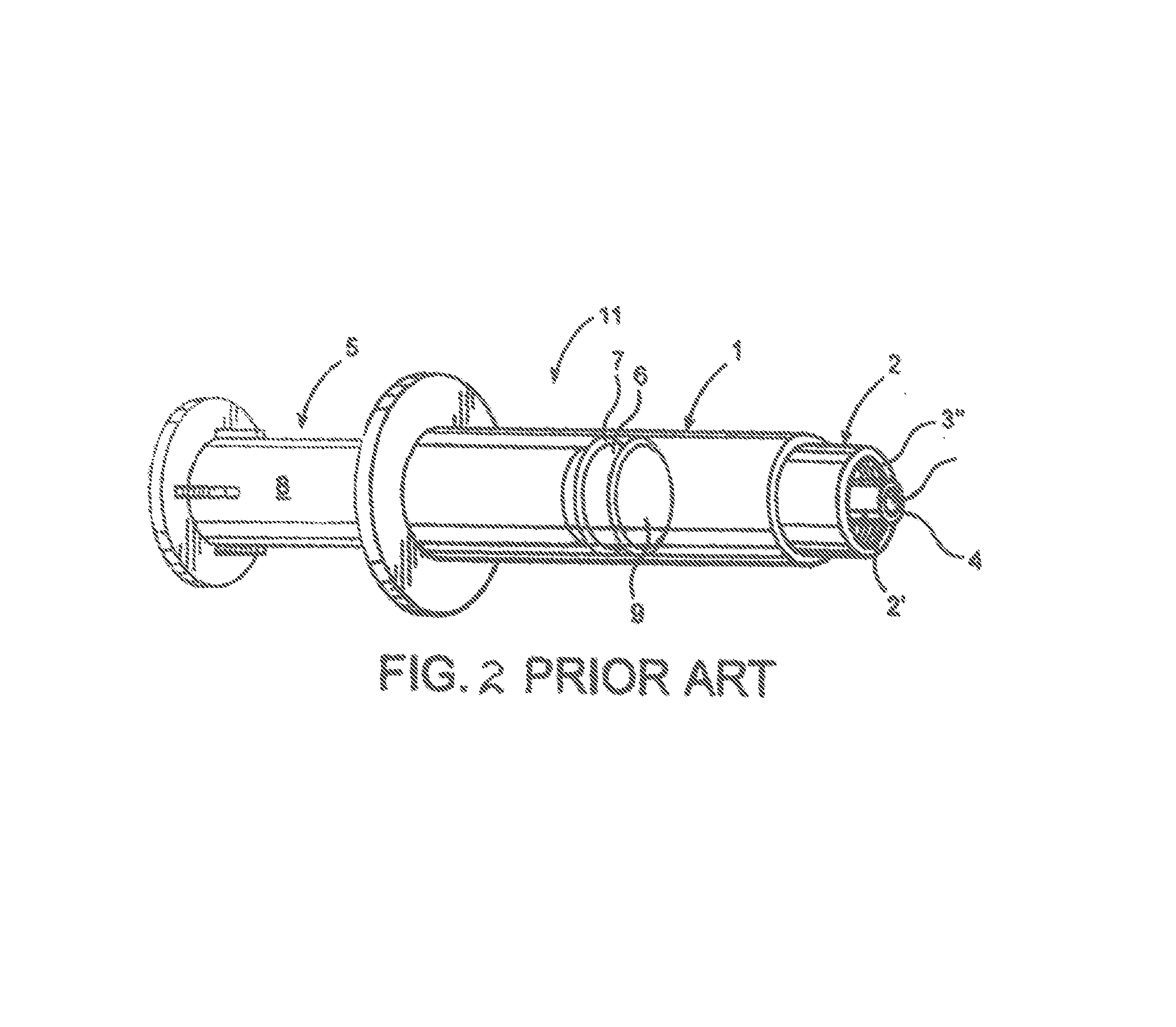

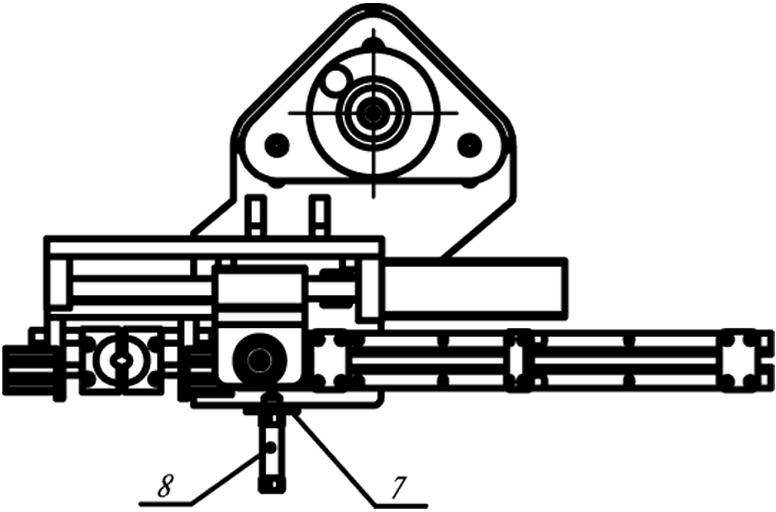

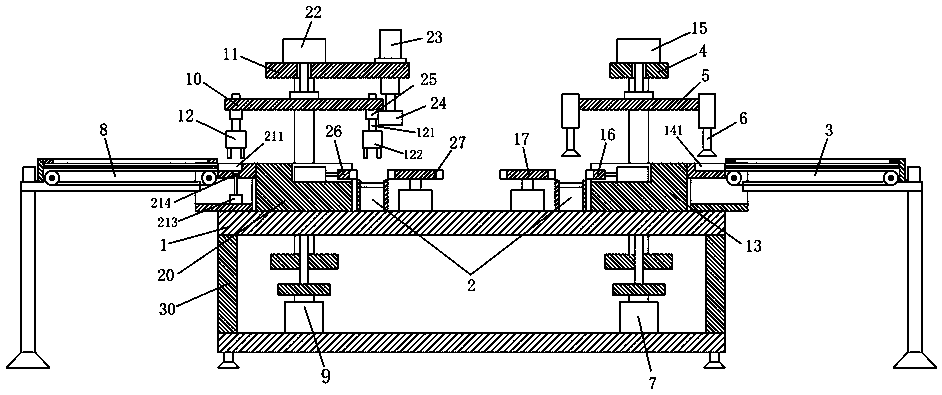

Assembly and system for connecting a closure to a syringe

ActiveUS8591462B1Facilitate gravitational feedEasy to exportClosing machinesInfusion syringesEngineeringNozzle

An assembly for closing the discharge nozzle of a syringe which is pre-filled with a drug or medication. A syringe in combination with a connecting structure removably maintain and support the closure in an operative orientation, which facilitates the rotational attachment of the syringe and the closure when the closure is in mating engagement with the connecting structure. A subsequent removal of the syringe and connected closure from the container or other type of connecting structure is thereby facilitated. The need for an individual to directly handle or touch the closure during its attachment to the syringe is restricted or eliminated. The closure assembly preferably also includes a tamper evident structure which reduces the chances of tampering with the syringe in order to access its contents.

Owner:MEDICAL DEVICE ENG

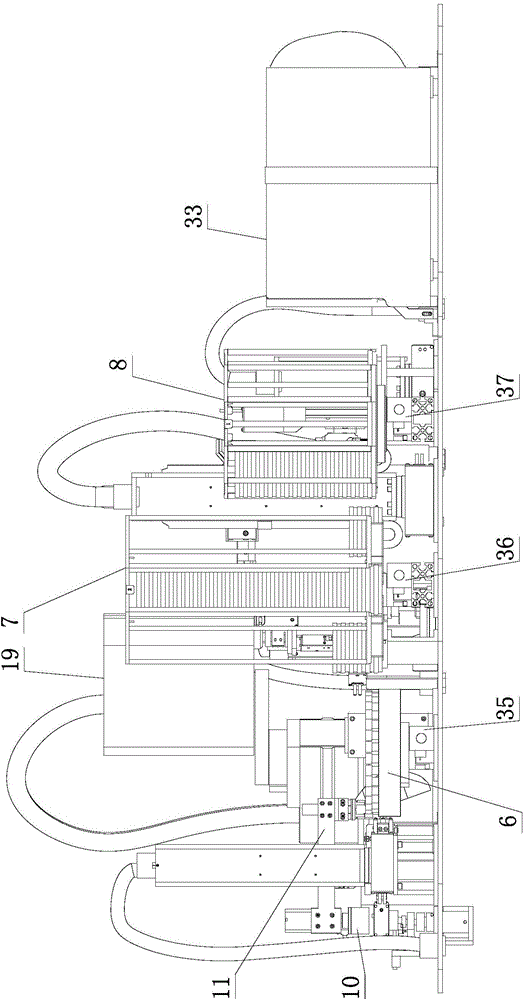

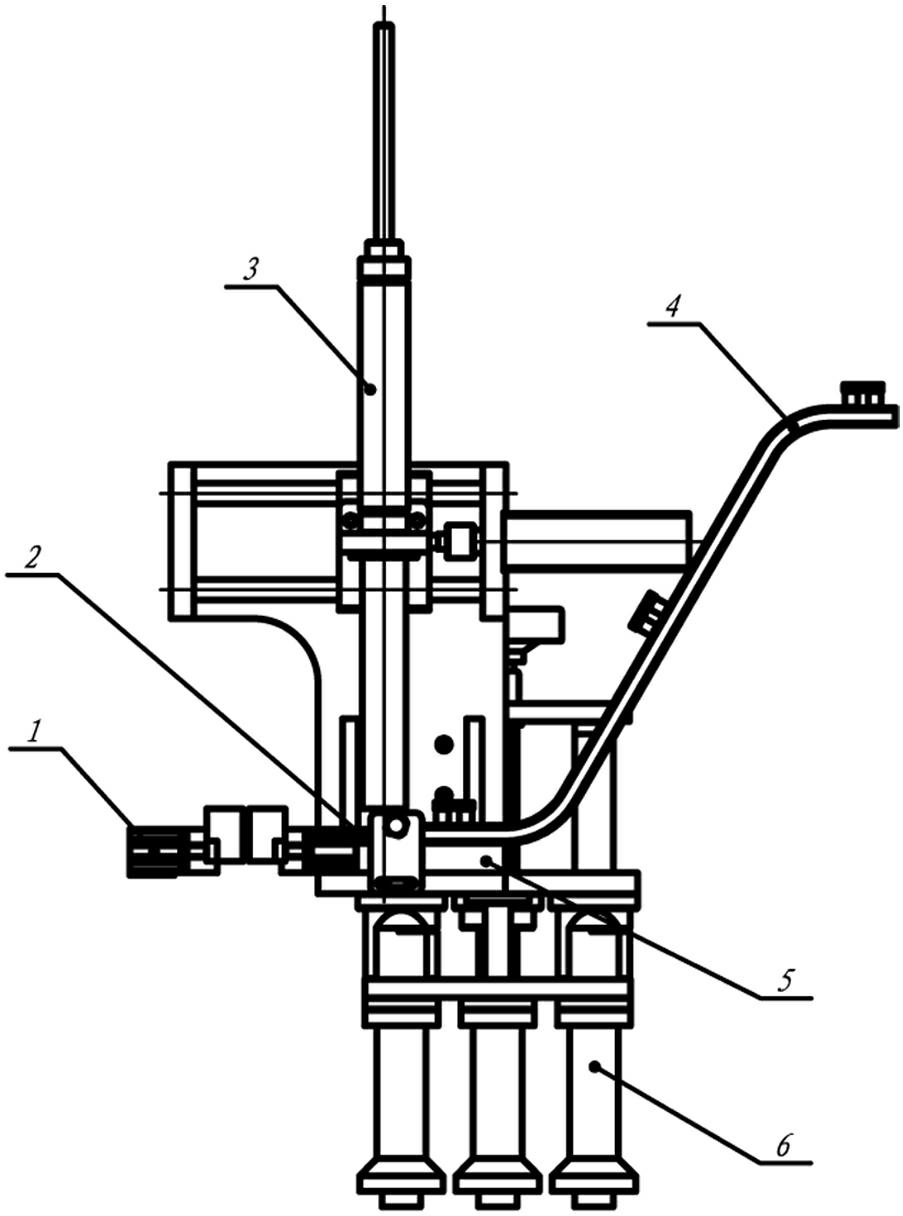

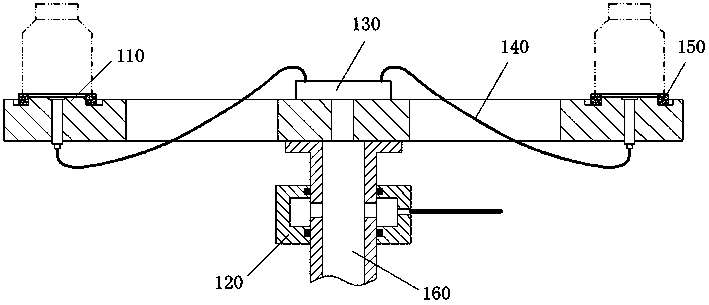

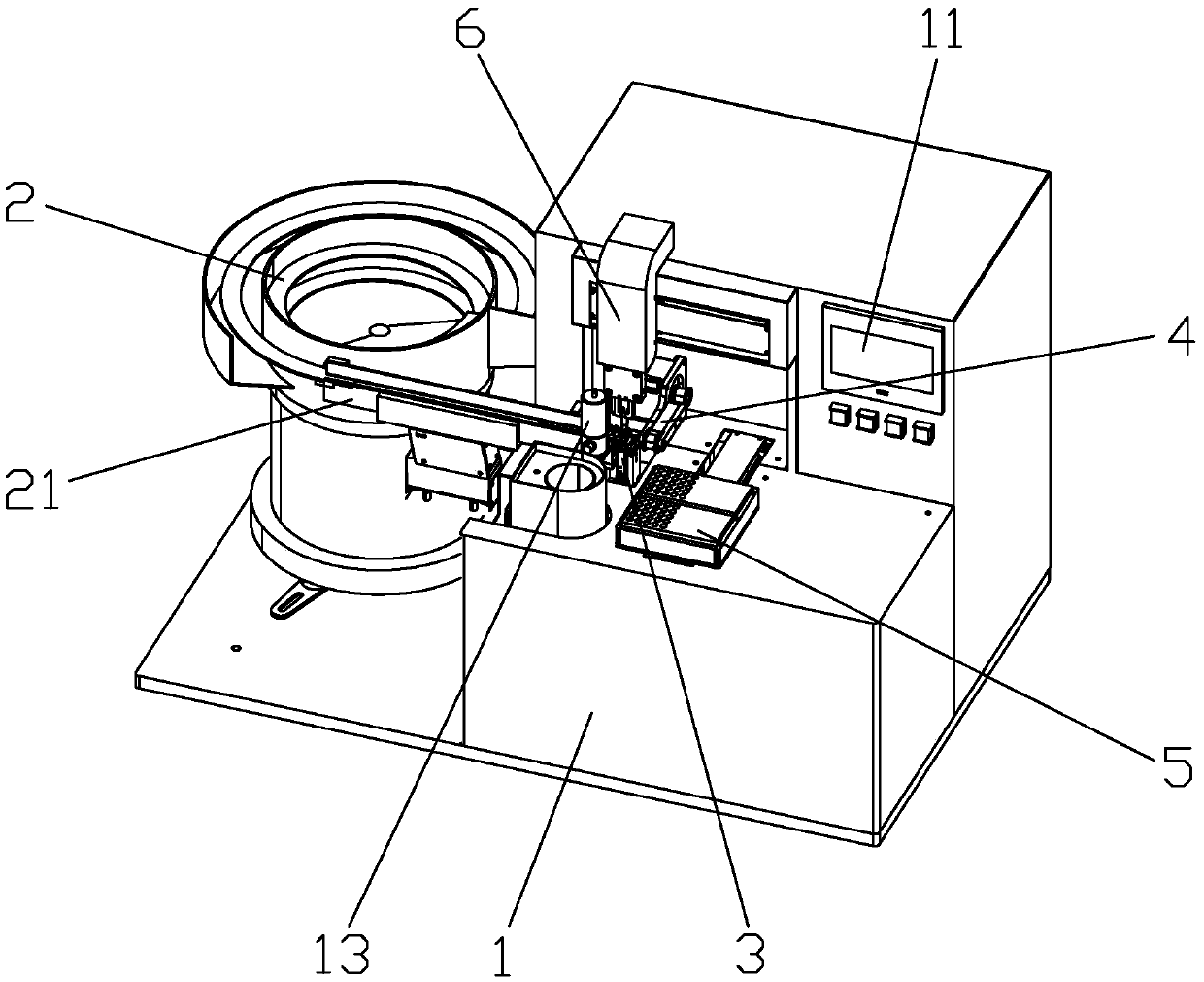

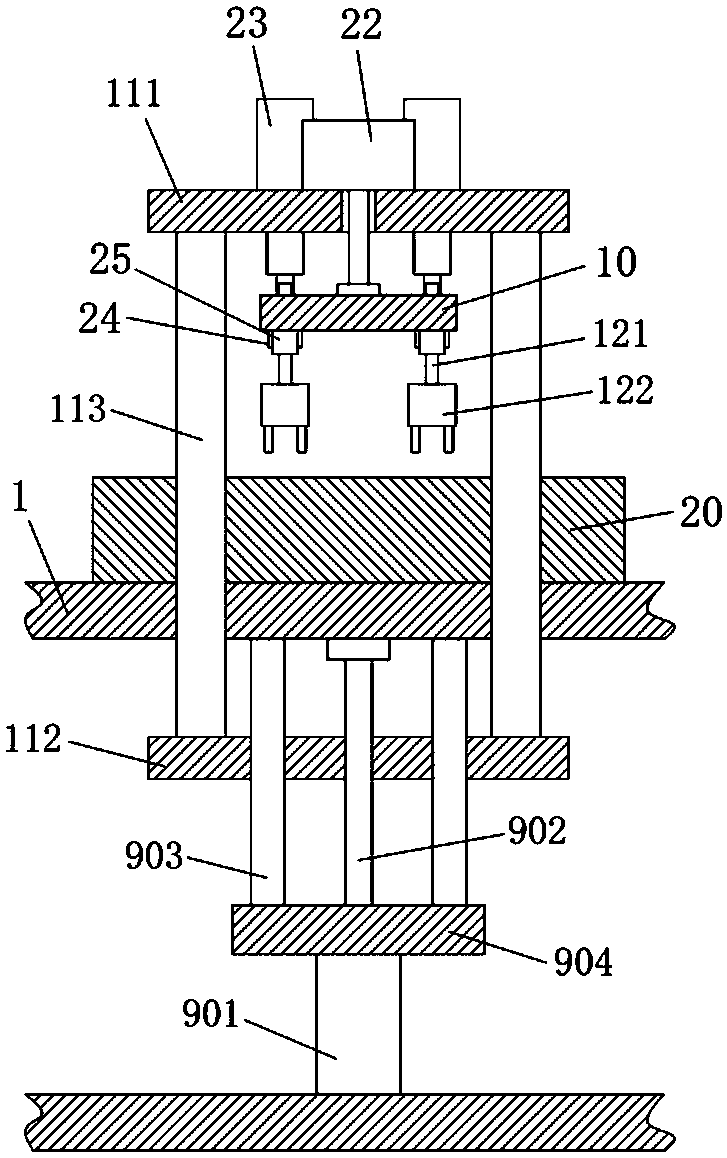

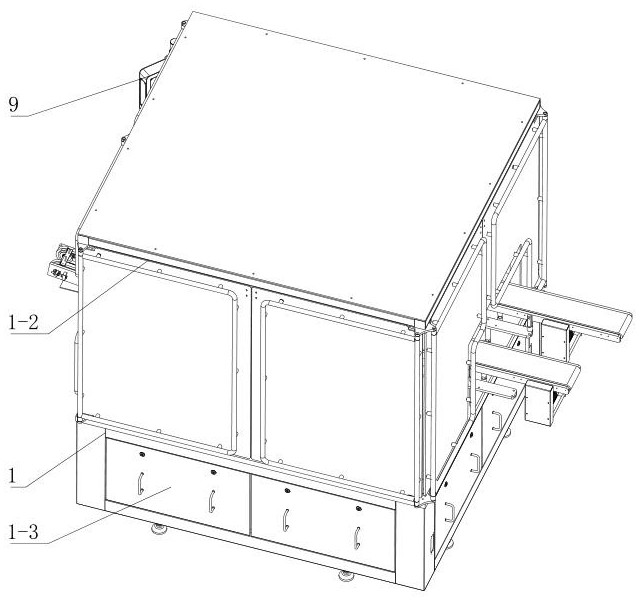

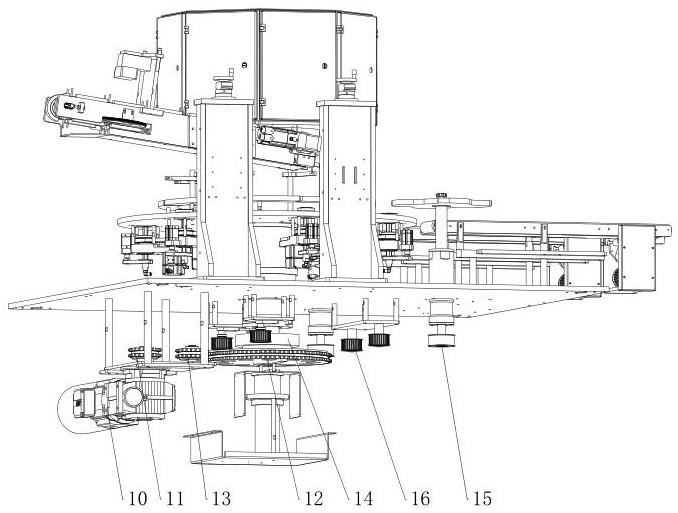

Automatic cover opening or closing and carrying device for sample test tube

ActiveCN104444983AImprove work efficiencyLow costClosing machinesThreaded caps applicationMicrobial inoculationElectric machinery

The invention relates to an automatic cover opening or closing and carrying device for a sample test tube, and solves the technical problems of low efficiency, high cost, easy bacterial infection of operators and negative influence caused by artificial and environmental factors during manual operation of an existing microorganism sample test tube. The device comprises a machine table, a test tube clamping vertical movement electric cylinder, a test tube top rotary motor, a test tube clamping bottom rotary electric cylinder, a test tube clamping electric cylinder and a test tube cover opening clamping electric cylinder, wherein the test tube clamping bottom rotary electric cylinder is connected with the machine table; the test tube clamping vertical movement electric cylinder is connected with the test tube clamping bottom rotary electric cylinder; the test tube clamping electric cylinder and the test tube top rotary motor are connected with the test tube clamping vertical movement electric cylinder respectively; the test tube clamping electric cylinder is provided with two clamping jaws; the test tube top rotary motor is connected with a cover screwer; the test tube cover opening clamping electric cylinder is connected with the machine table and provided with two clamping jaws. The device is widely applied to the technical fields of microorganism inoculation, clinics, chemicals, environments and the like.

Owner:WEIHAI SHILI ELECTRONICS TECH

Assembly and system for connecting a closure to a syringe

Owner:MEDICAL DEVICE ENG

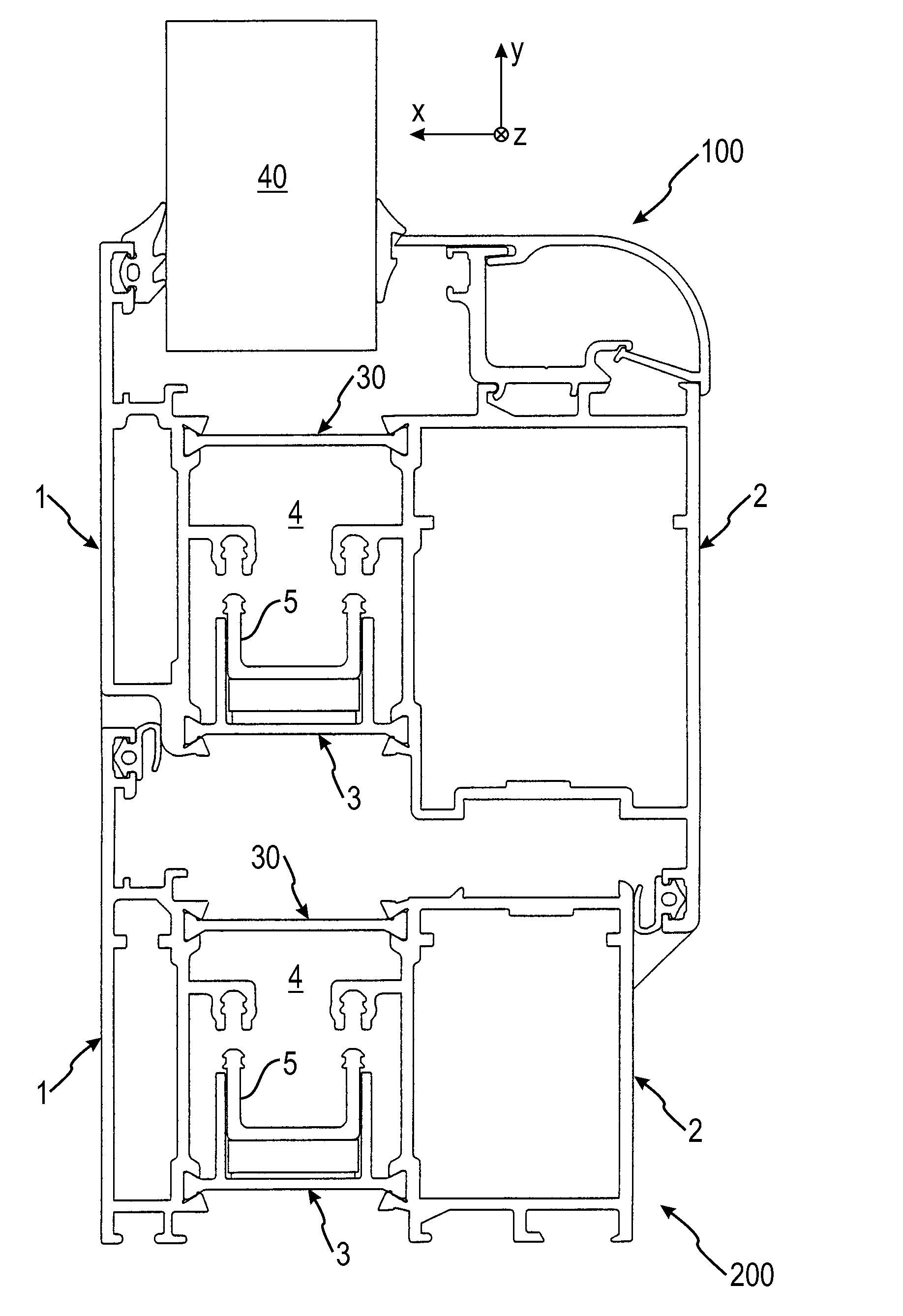

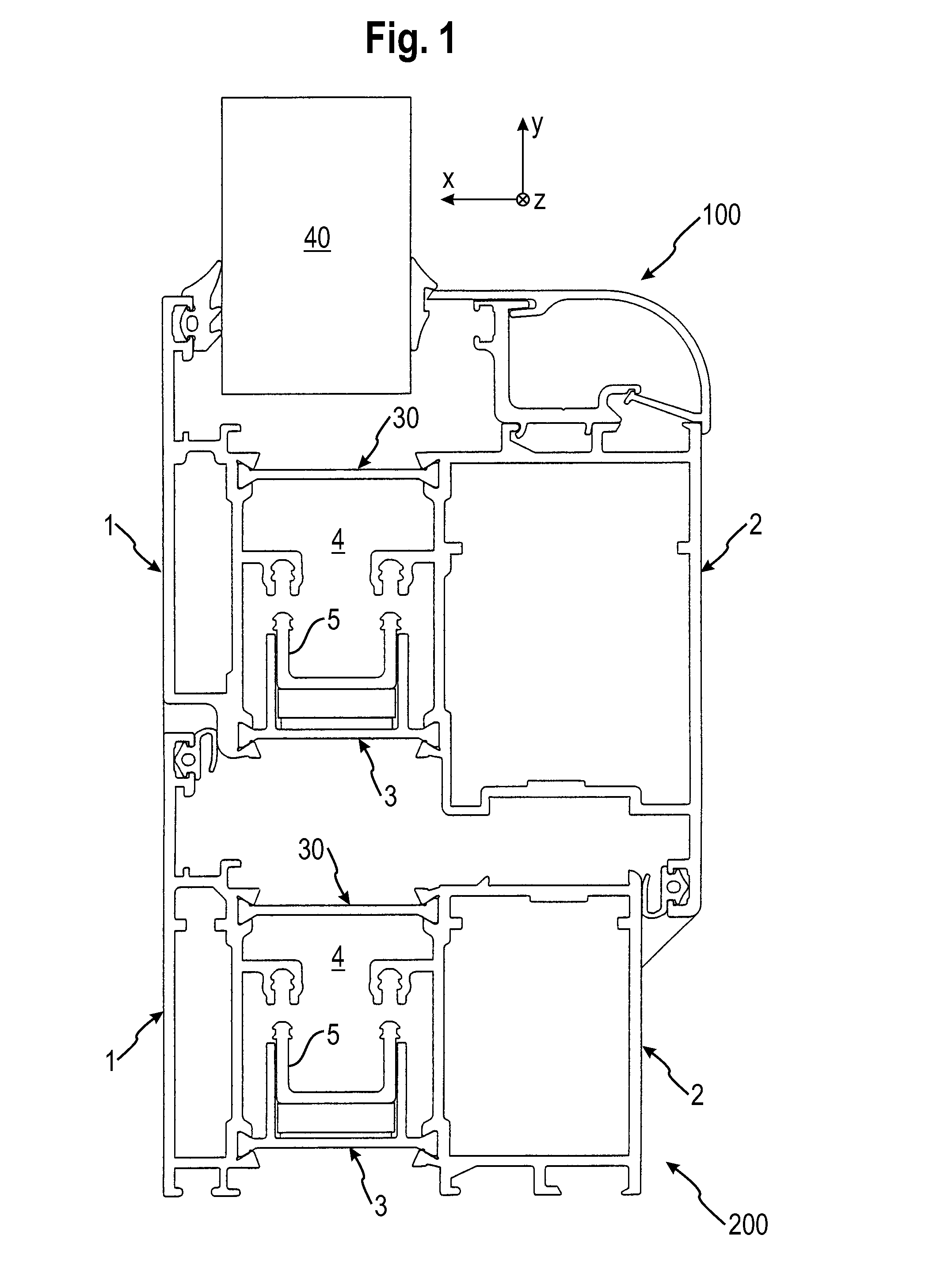

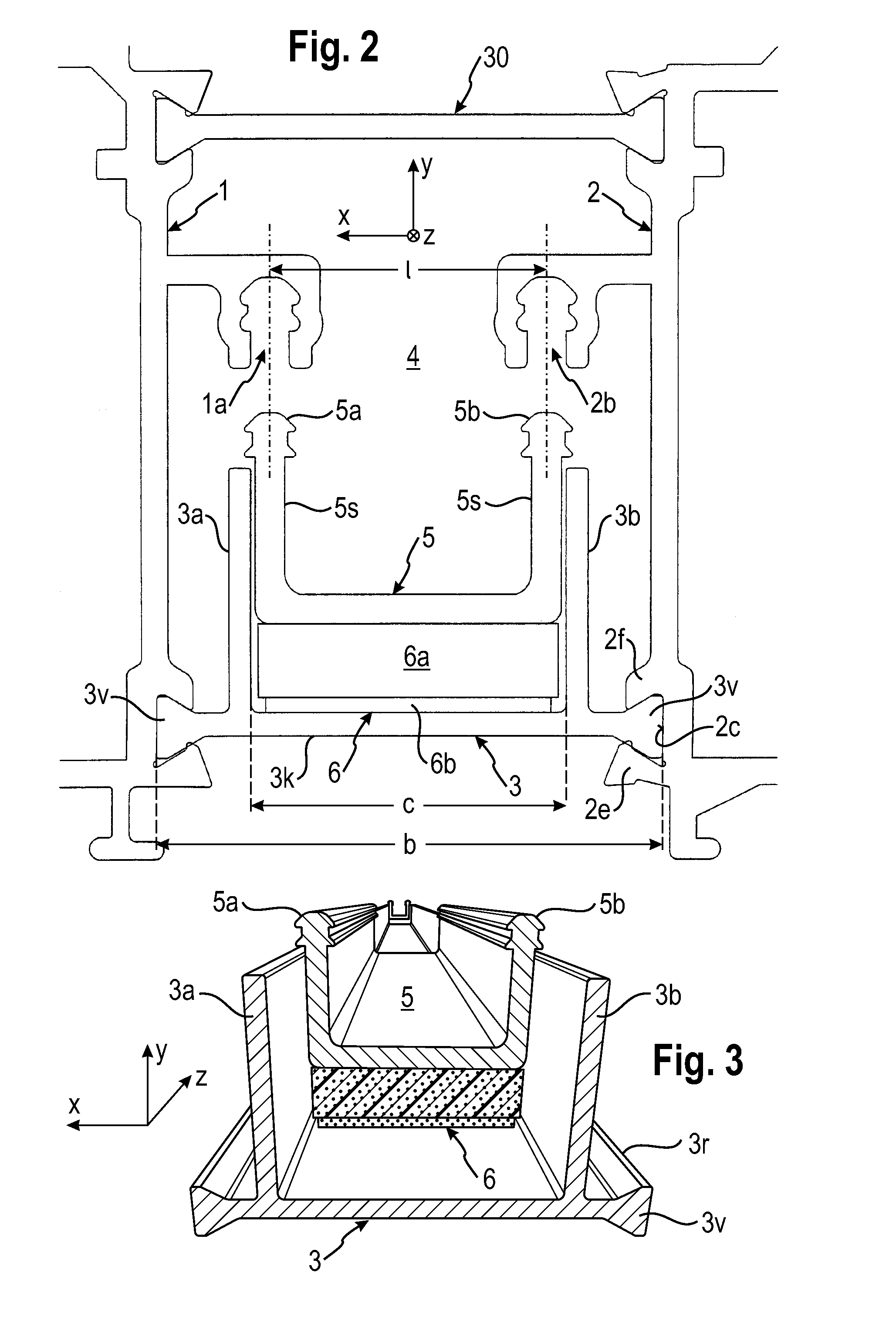

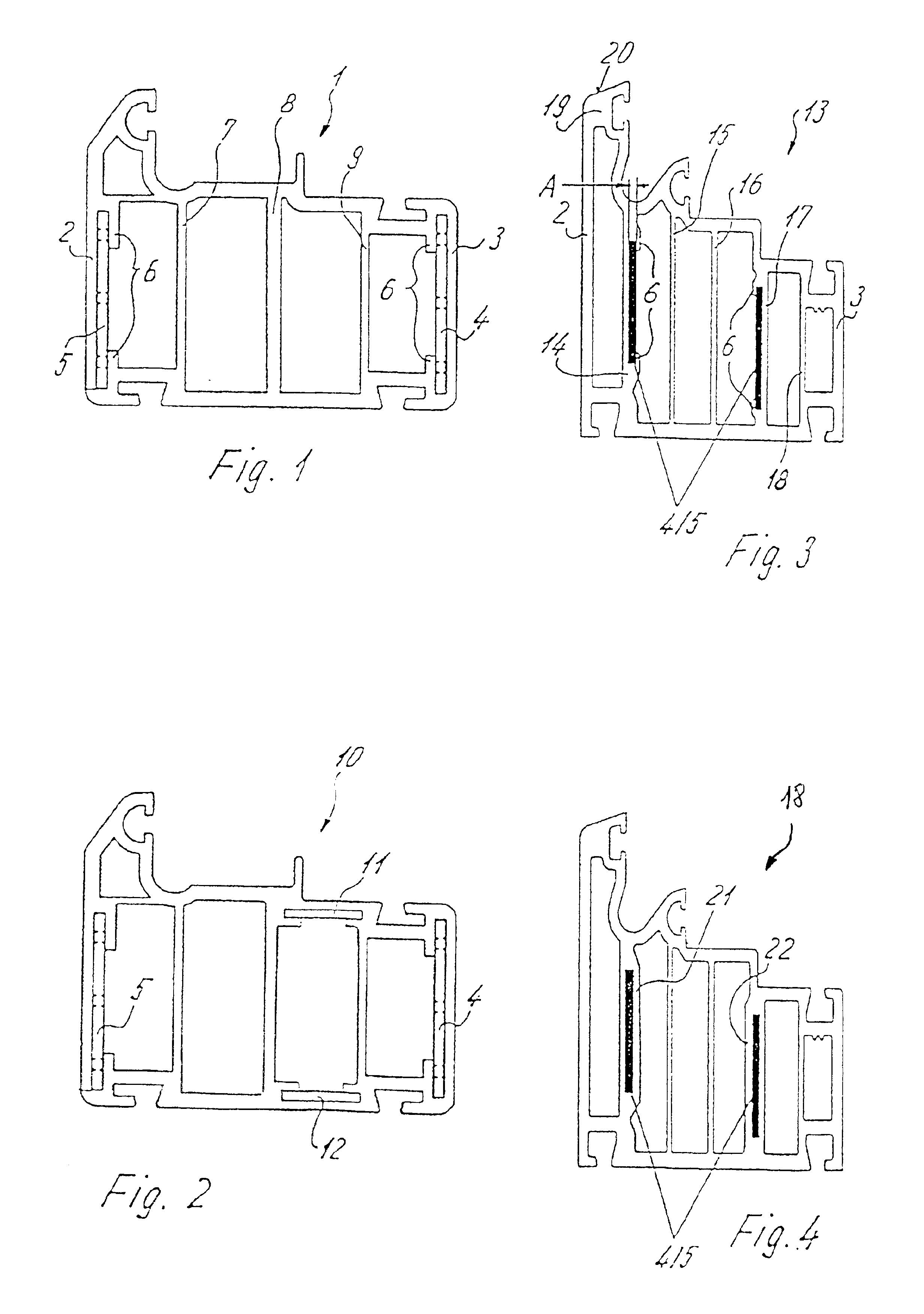

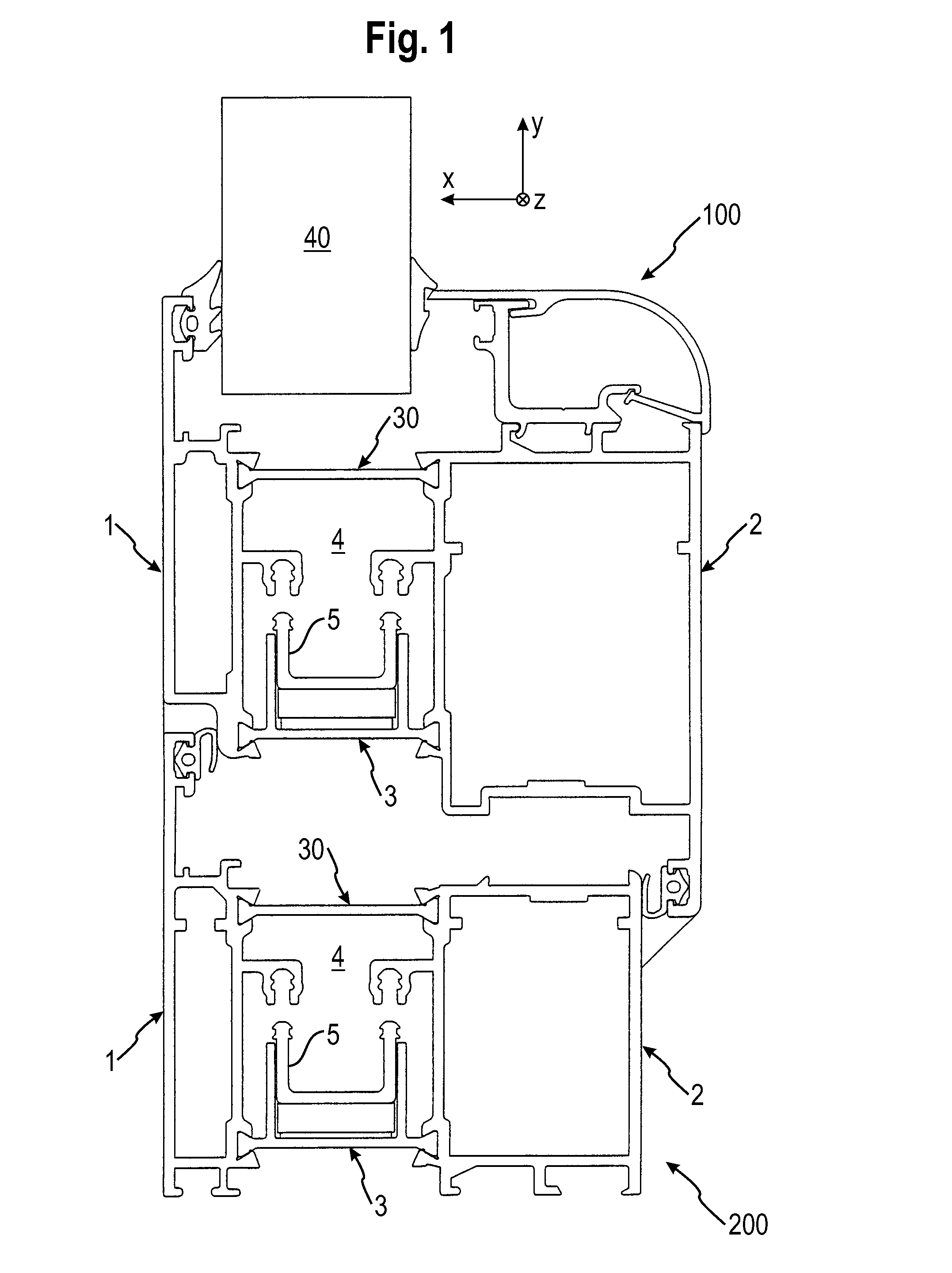

Composite profile for window, door or facade element

InactiveUS20090313941A1Improving thermal separationEnhance the imageDoors/windowsPower-operated mechanismEngineeringMechanical engineering

A composite profile for a window, door or façade element includes first and second outer profile parts and at least one insulating strip connecting the first and second outer profile parts with an intermediate space defined between them for thermal separation. At least one outer profile part connecting element is disposed in the intermediate space so that it is normally not in contact with the first and second outer profile parts. An actuating element is disposed so that, upon being activated by heat, it moves the outer profile part connecting element into engagement with the first and second outer profile parts, so that the outer profile part connecting element connects the first and second outer profile parts.

Owner:TECHNOFORM BAUTEC HLDG

Hollow plastic section

A hollow plastic section, includes a frame section defining a longitudinal axis and having an interior subdivided in several inner chambers by a plurality of partition walls extending in a direction of the longitudinal axis, Received in the interior is a plurality of stiffening elements arranged separate from one another, without interconnection, for realizing a reinforcement of the frame section. The stiffening elements may be made of metal or may be configured as bands or strips of fiber-reinforced plastic.

Owner:SCHUCO INT KG

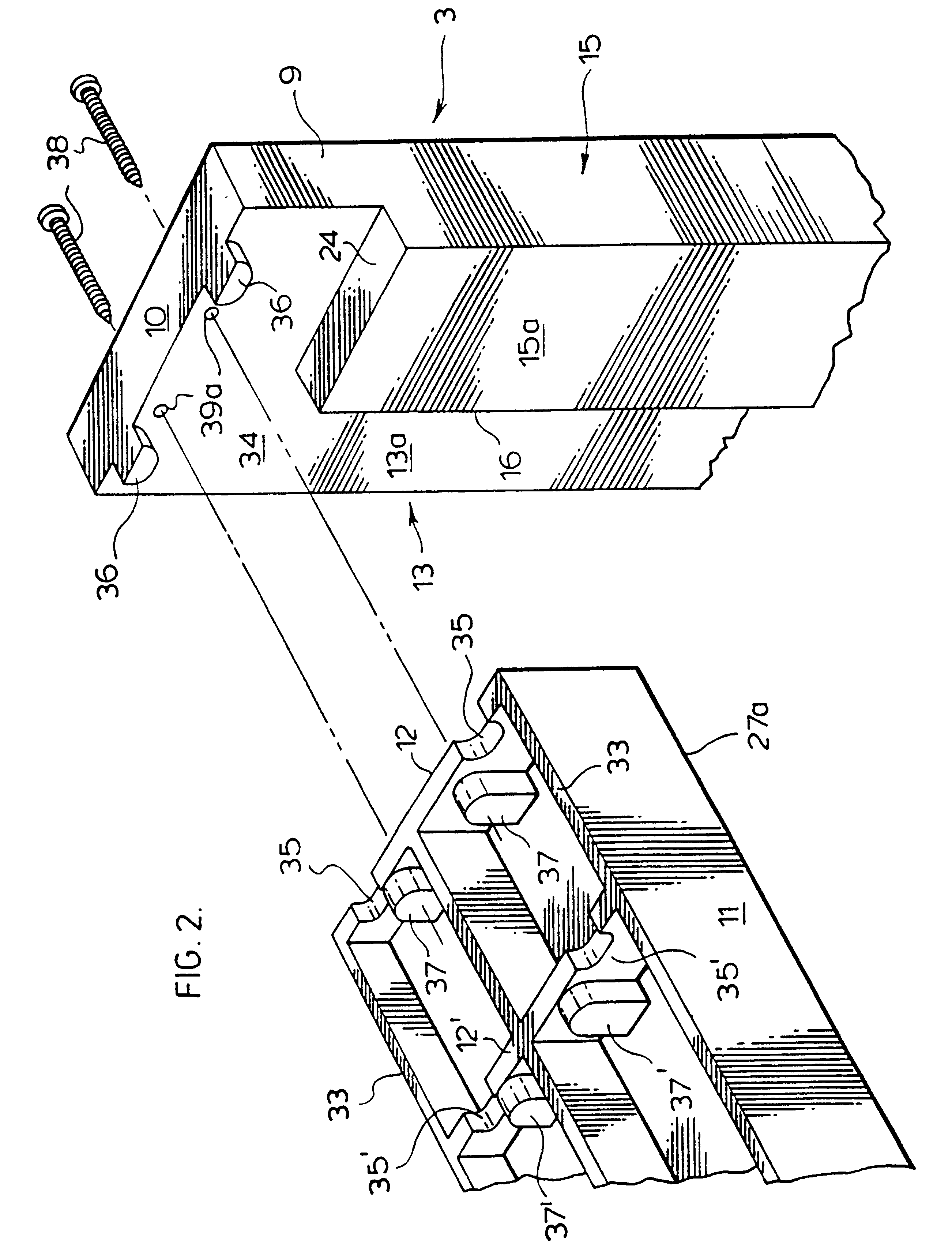

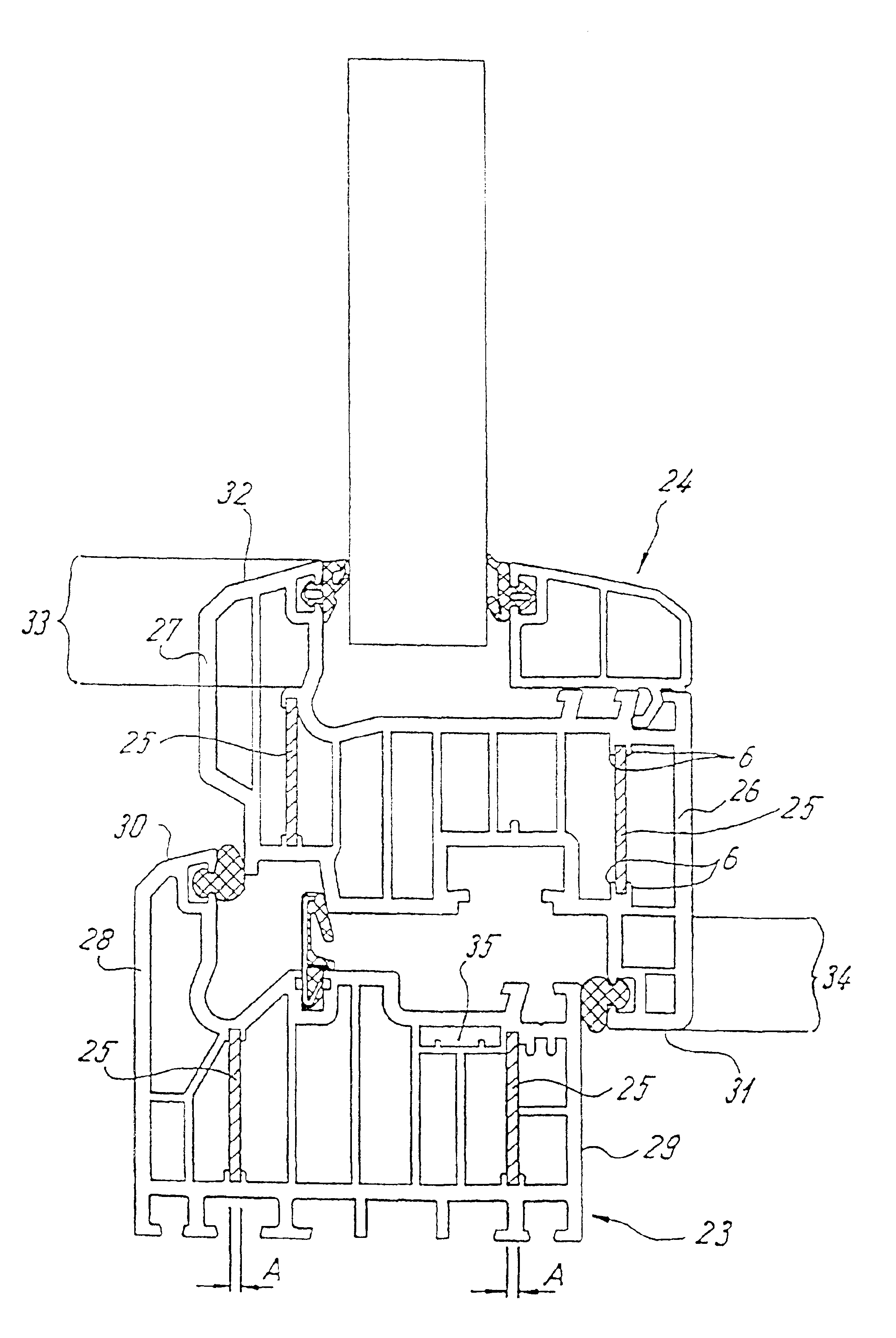

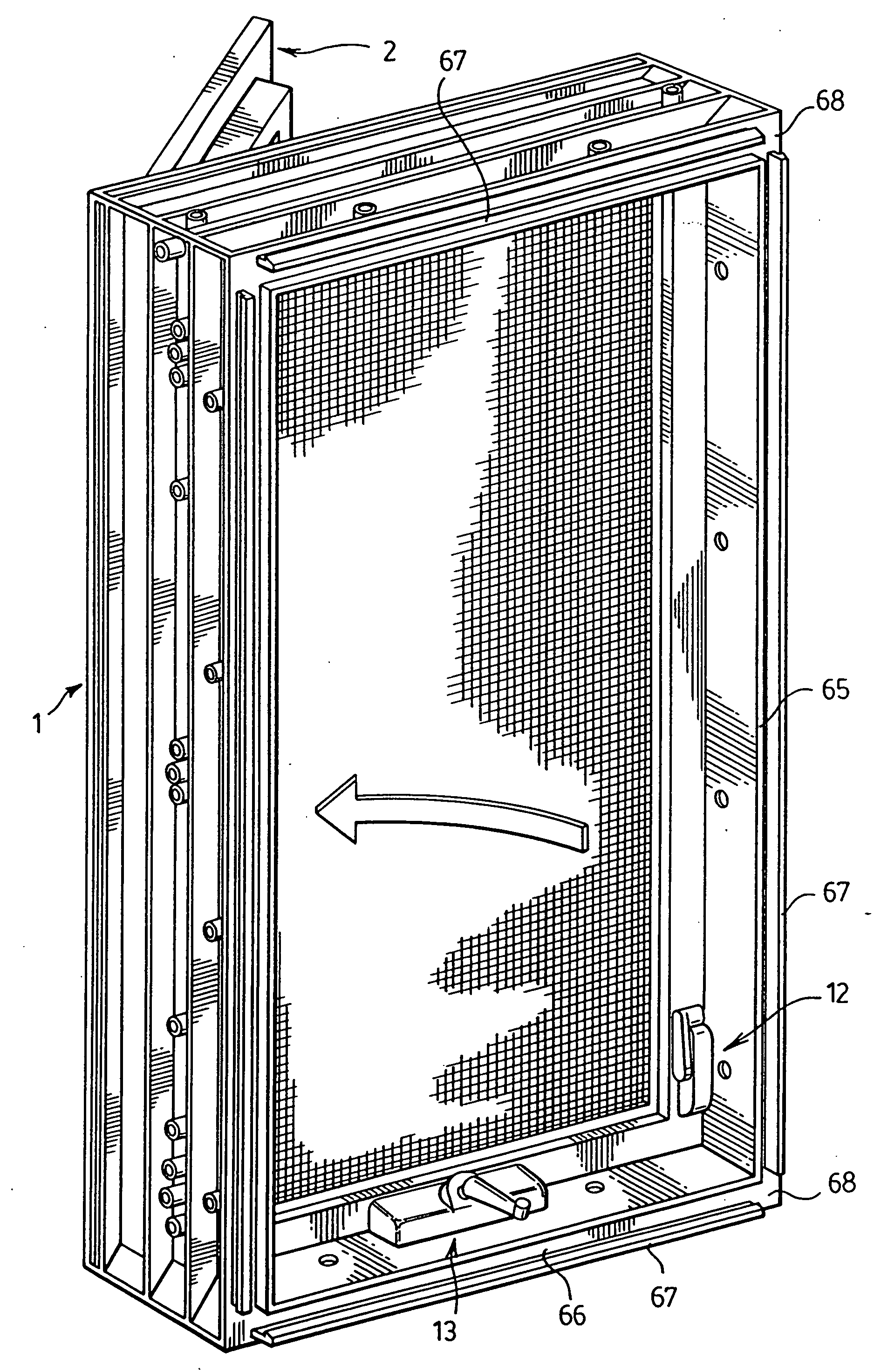

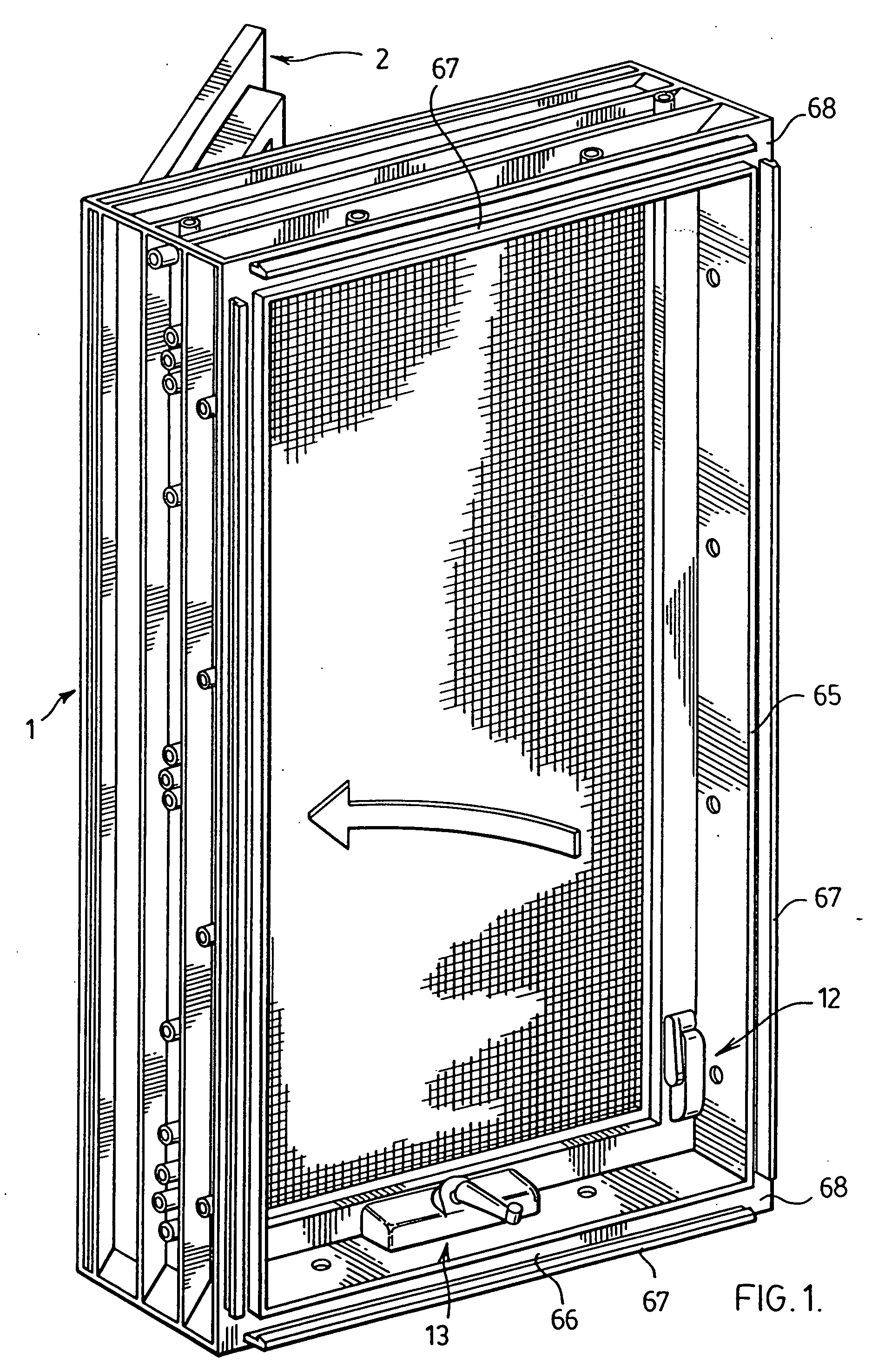

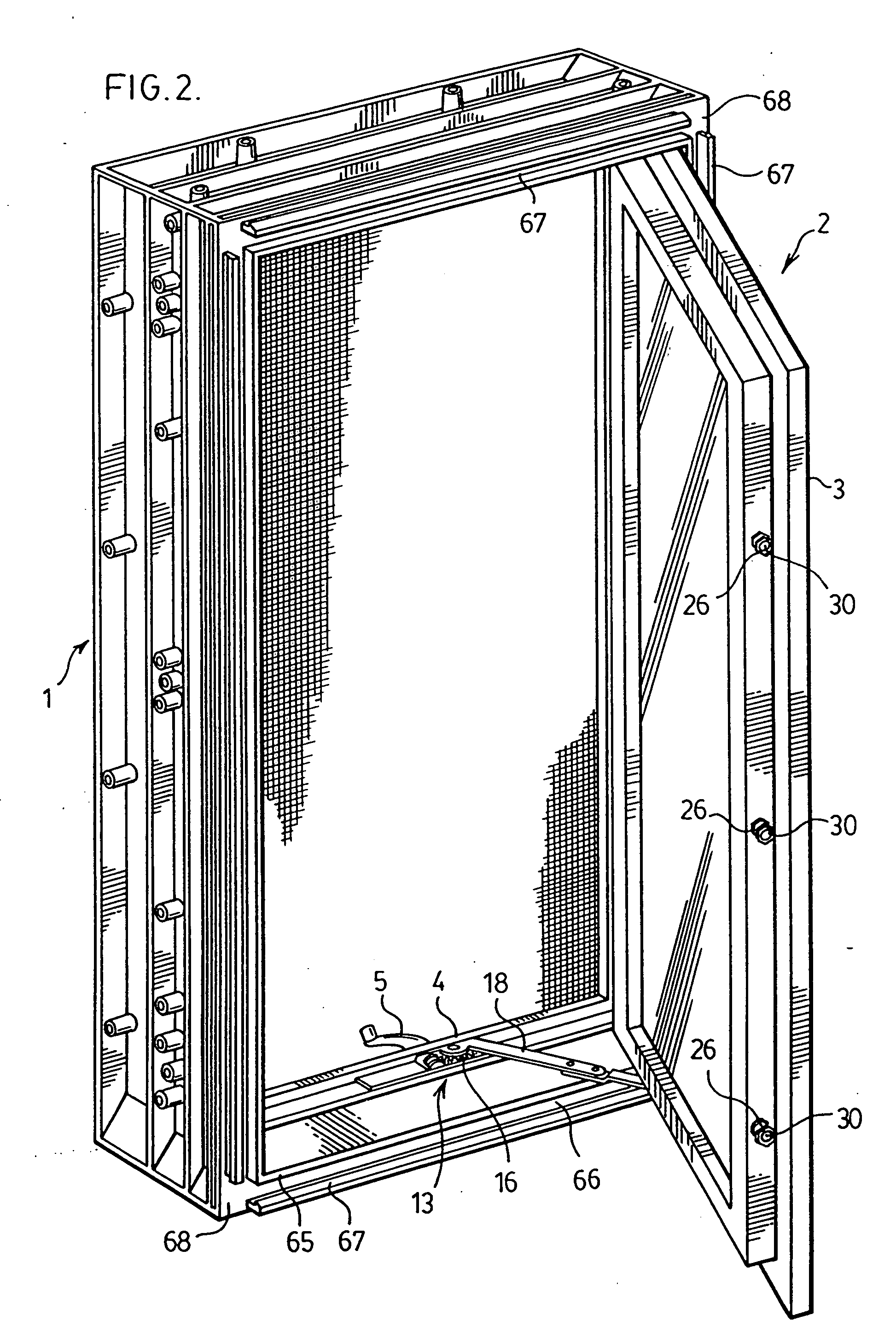

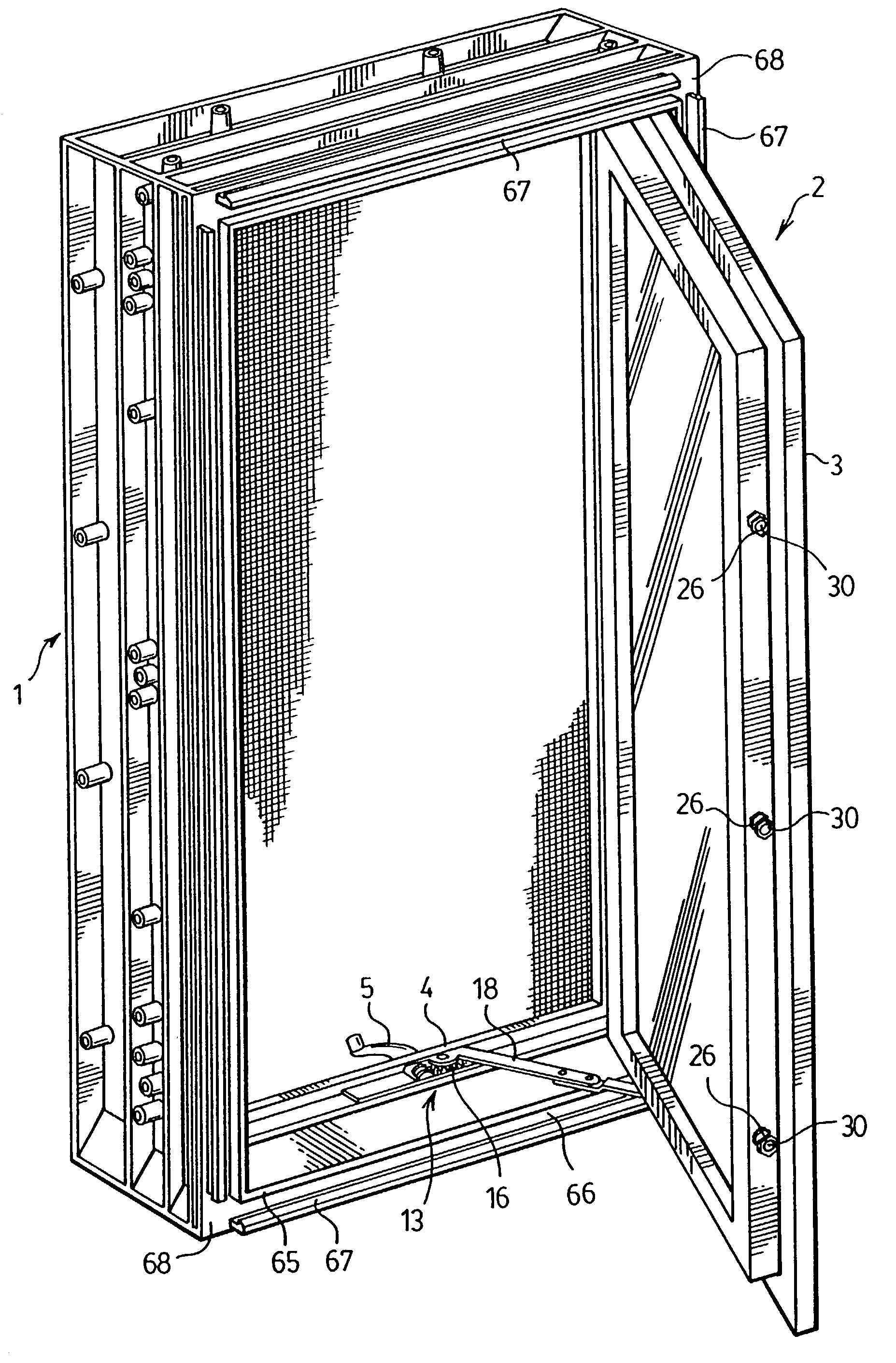

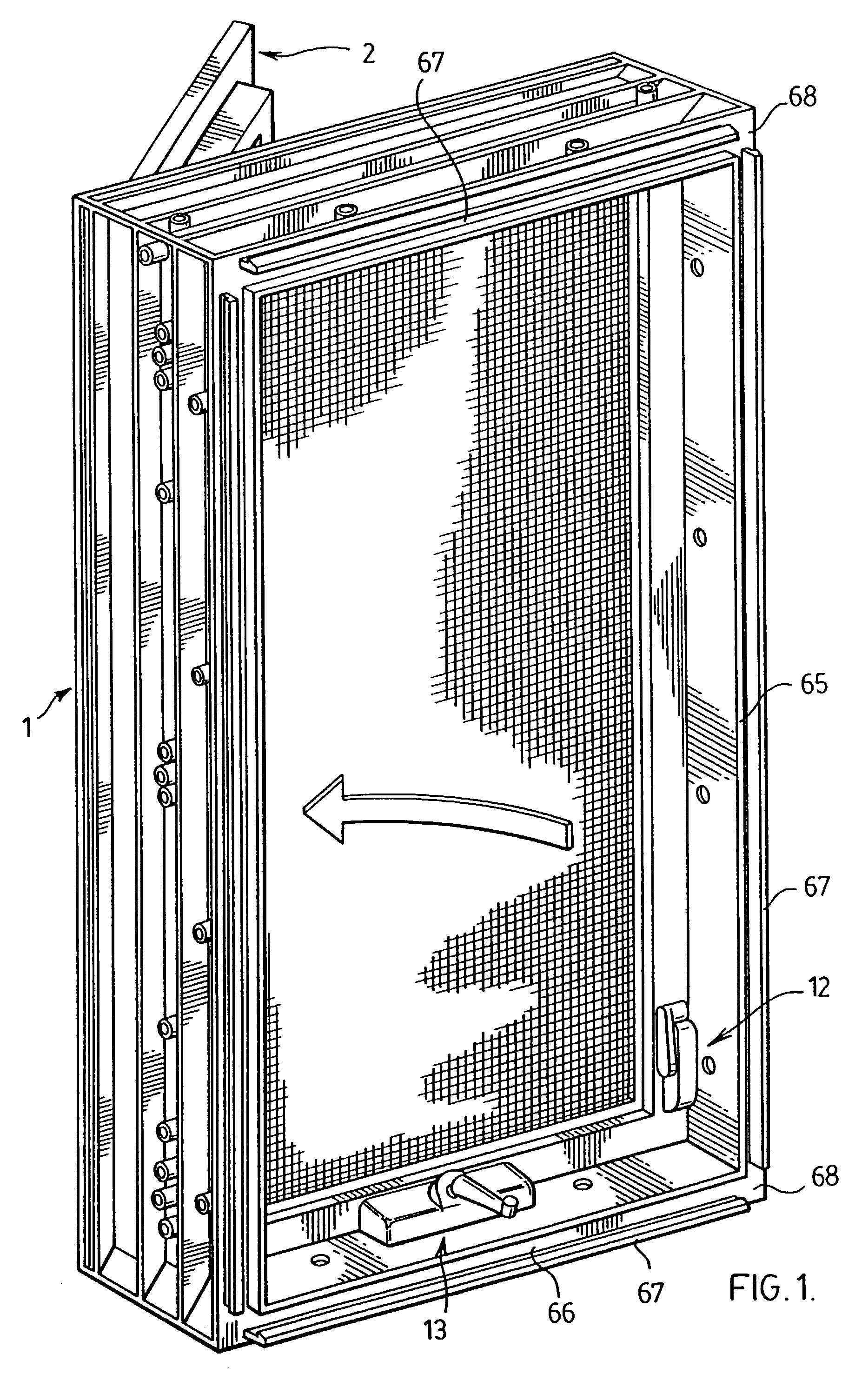

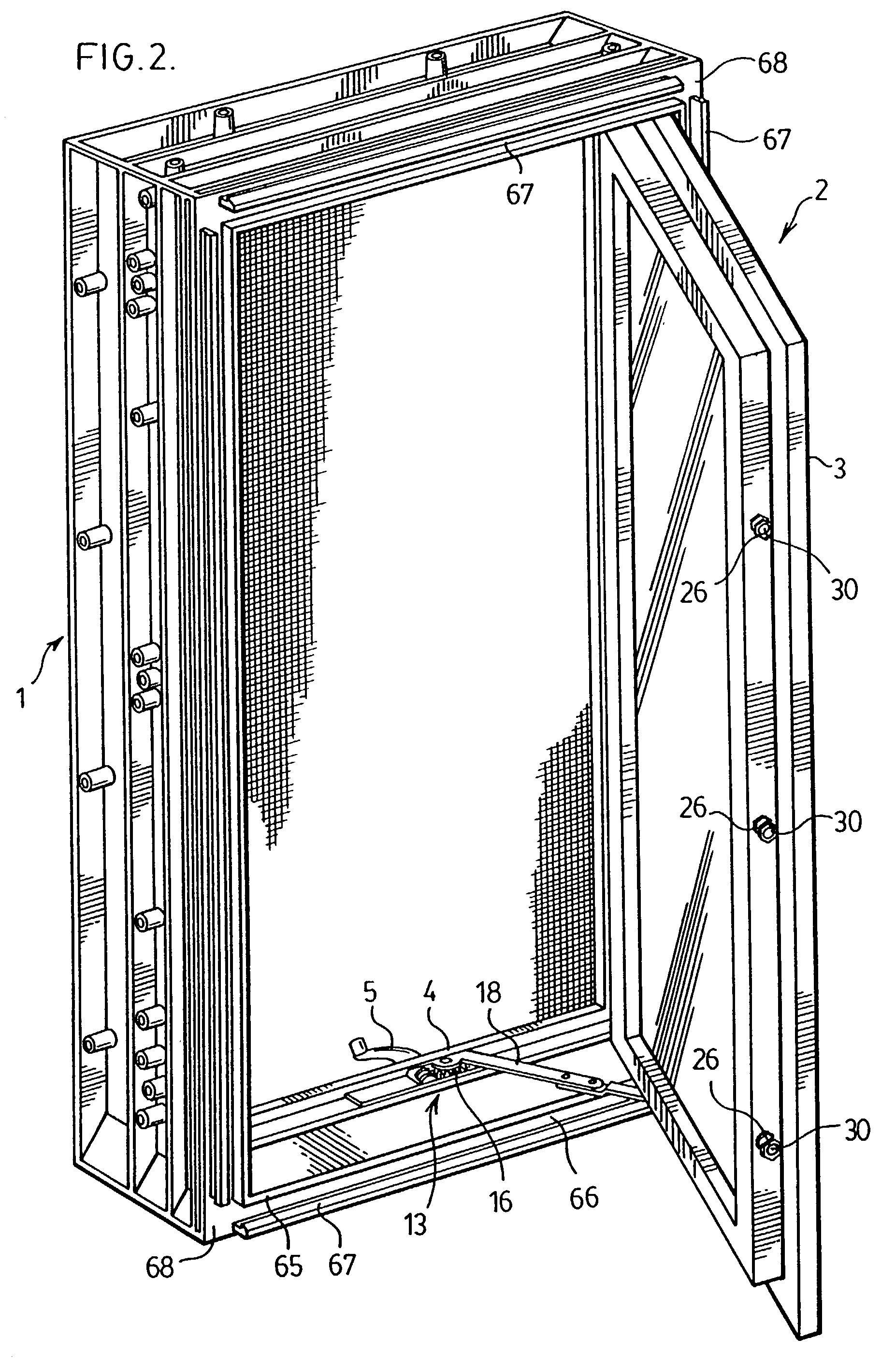

Casement window system and components and hardware therefor

InactiveUS20070011948A1Eliminate useQuick and easy and correct attachmentBuilding locksMan-operated mechanismEngineeringCasement window

Injection molded casement window frames completely ready for assembly into windows with the frames for swinging sash windows formed for mounting of all necessary hardware. Also hardware which mates with such frames and casement window assembled with such frames and hardware.

Owner:ROYAL GROUP

Casement window system and components and hardware therefor

InactiveUS7100327B2Eliminate useQuick and easy and correct attachmentBuilding locksMan-operated mechanismEngineeringInjection moulding

Injection molded casement window frames completely ready for assembly into windows with the frames for swinging sash windows formed for mounting of all necessary hardware. Also hardware which mates with such frames and casement window assembled with such frames and hardware.

Owner:ROYAL GROUP

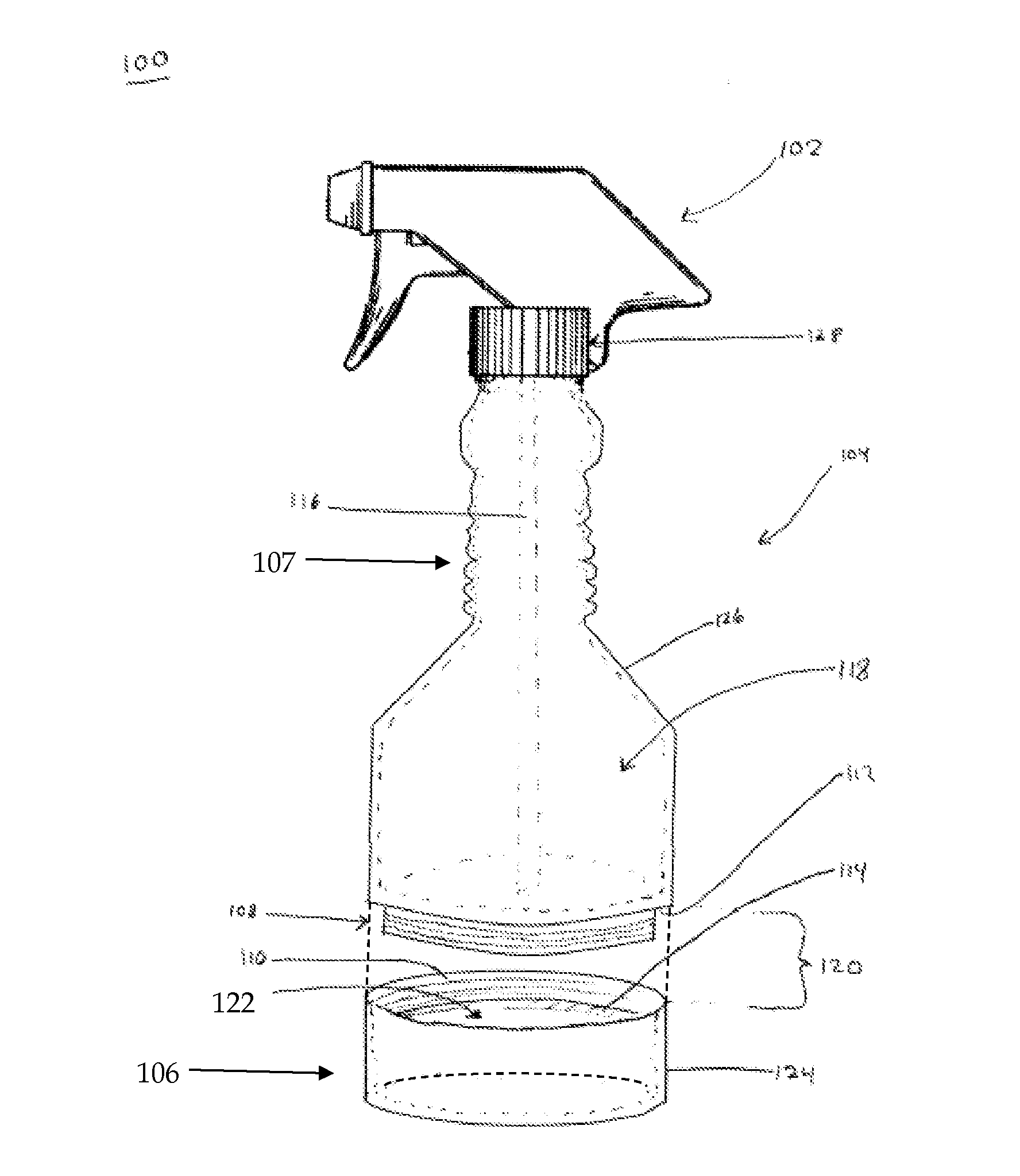

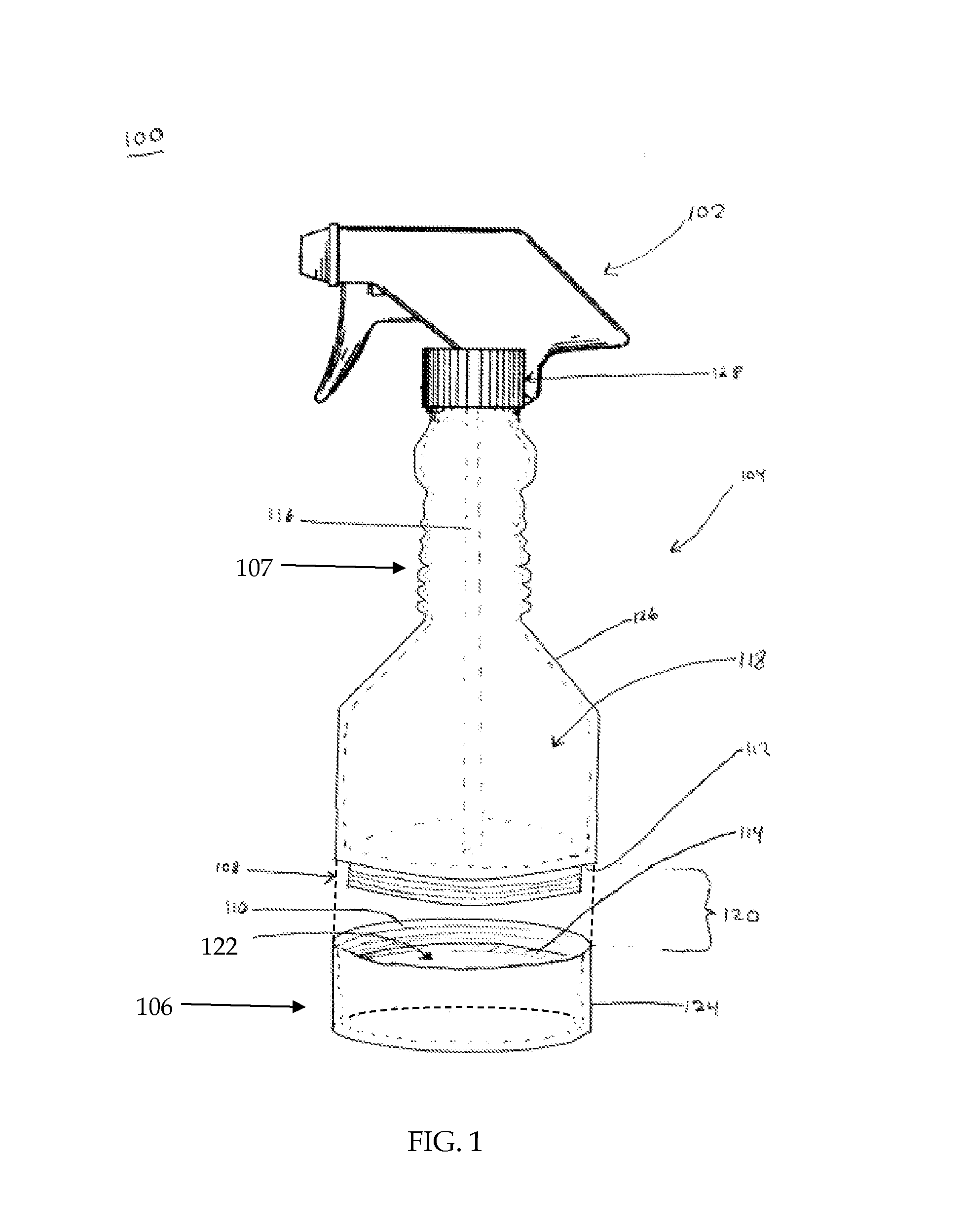

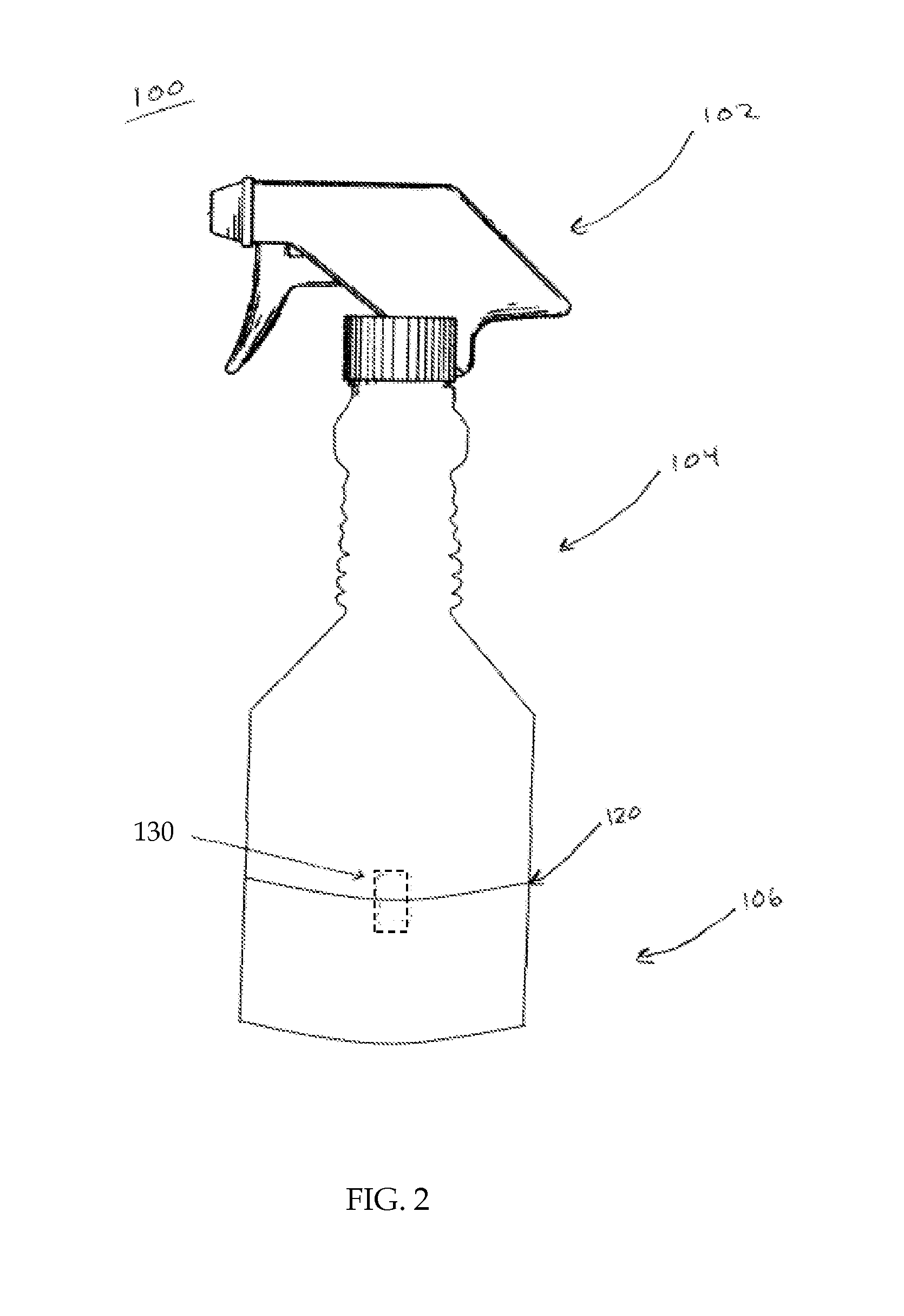

Spray bottle with storage area and methods thereof

A spray bottle is provided that may comprise a spray head for spraying liquid contained within the spray bottle; a bottle for storing the liquid, the bottle comprising a bottle attachment; a compartment for storing items, the compartment comprising a storage attachment adapted to detachably attach to the bottle attachment. In some embodiments the spray bottle apparatus may comprise a spray head for spraying liquid contained within the spray bottle; a bottle for storing the liquid, the bottle comprising a bottle attachment; a compartment for storing items, the compartment comprising a storage attachment adapted to detachably attach to the bottle attachment; and wherein the bottle attachment and the storage attachment comprise inversely threaded portions adapted to couple with each other.

Owner:STERNBERG ERIC +1

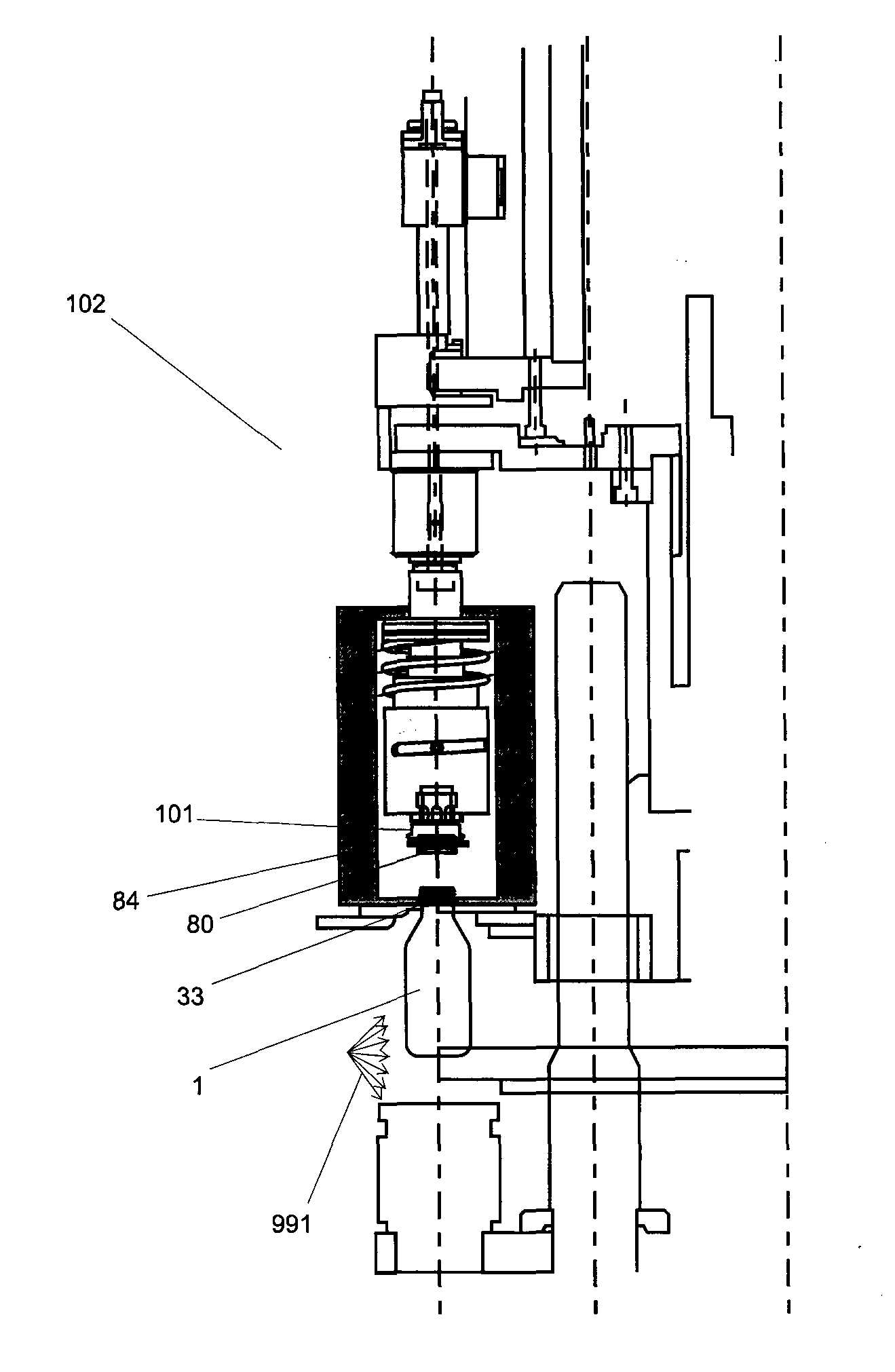

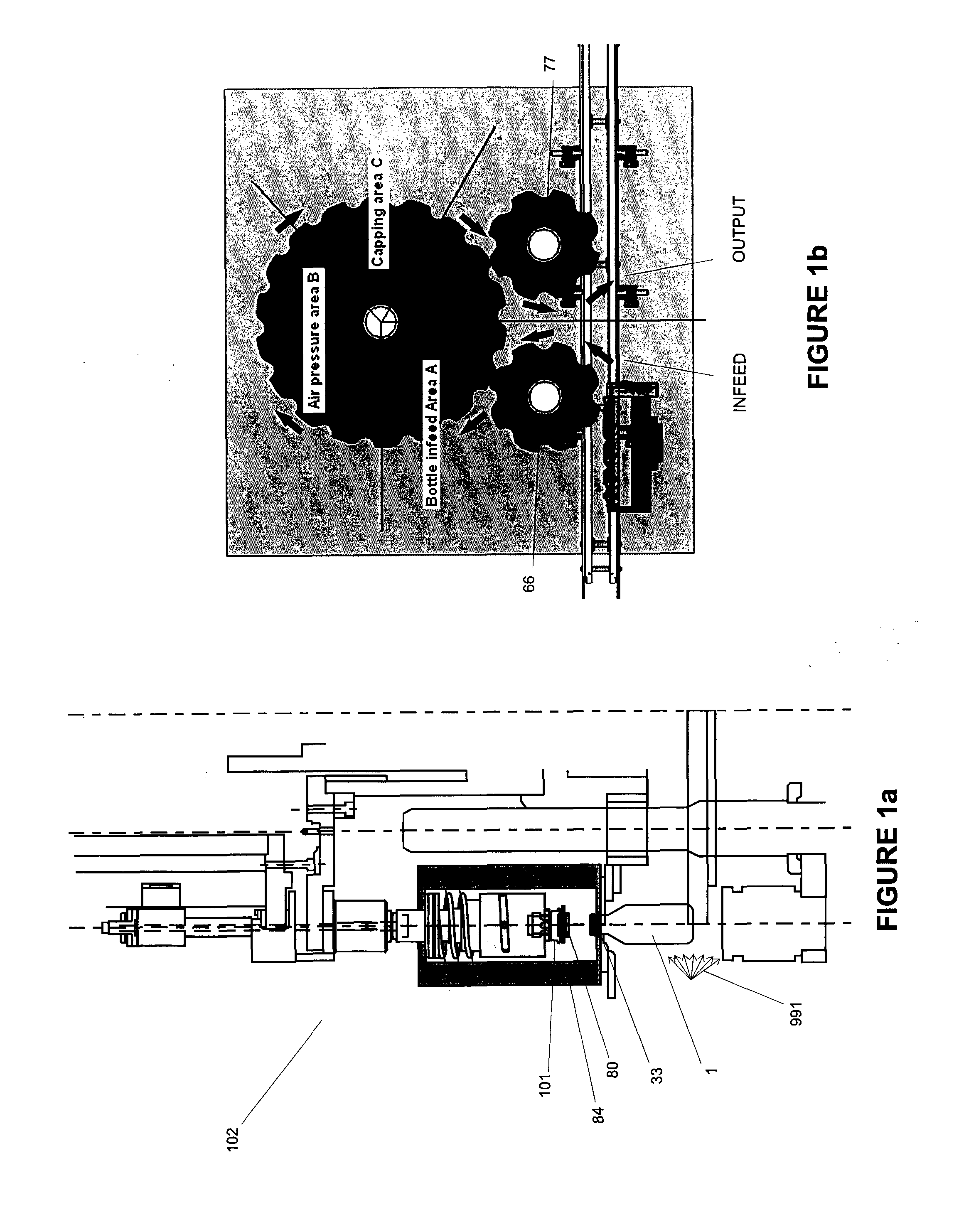

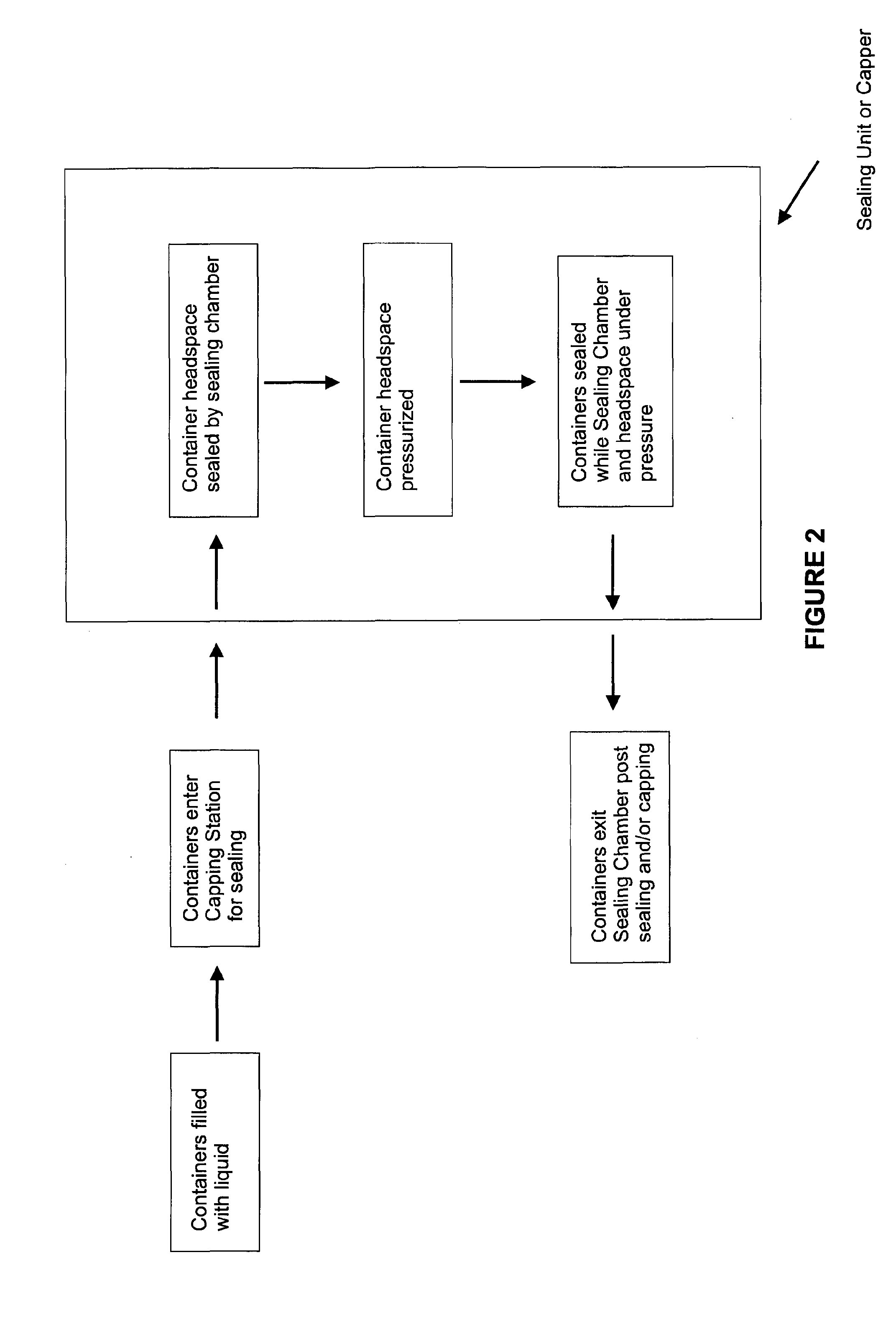

Controlled container headspace adjustment and apparatus therefor

InactiveUS20130239522A1Minimal coolingGreat control over structureClosing machinesSterilising/aseptic filling operationsEngineeringMechanical engineering

A sealing and pressure dosing apparatus, and container filling method, including a capping machine (102) which receives containers (1). Closures (80) are applied to the containers (1) immediately following the raising of pressure within the containers (1) by a pressure dosing system in a pressure sealing changer (84). Preferably a cooling system is integrated with the capping machine.

Owner:MELROSE DAVID MURRAY

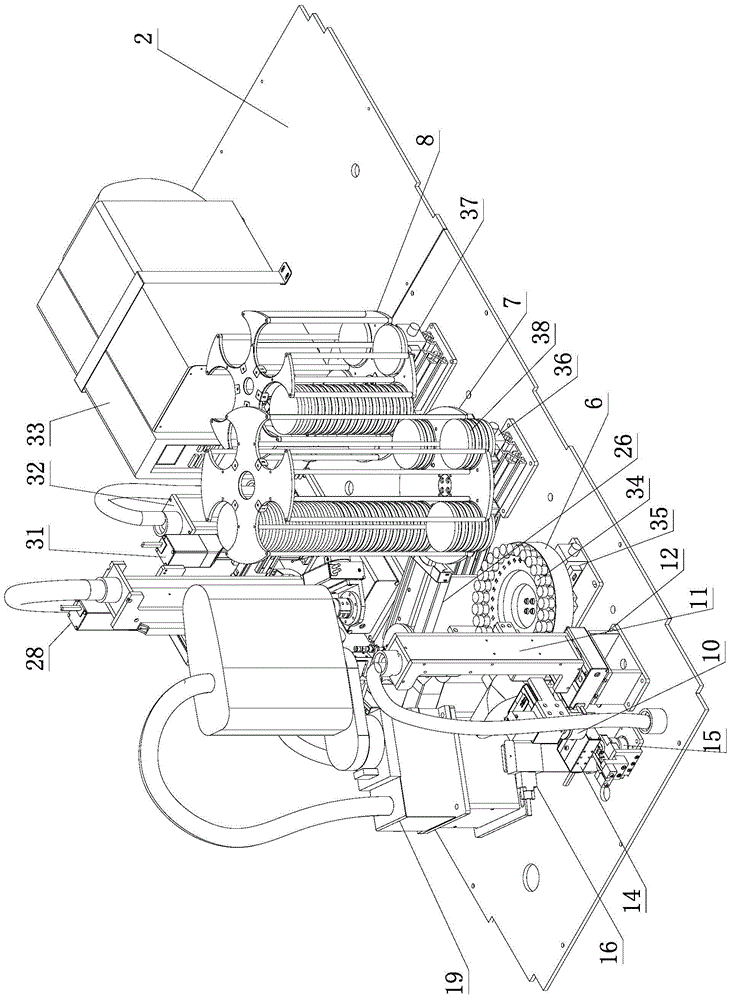

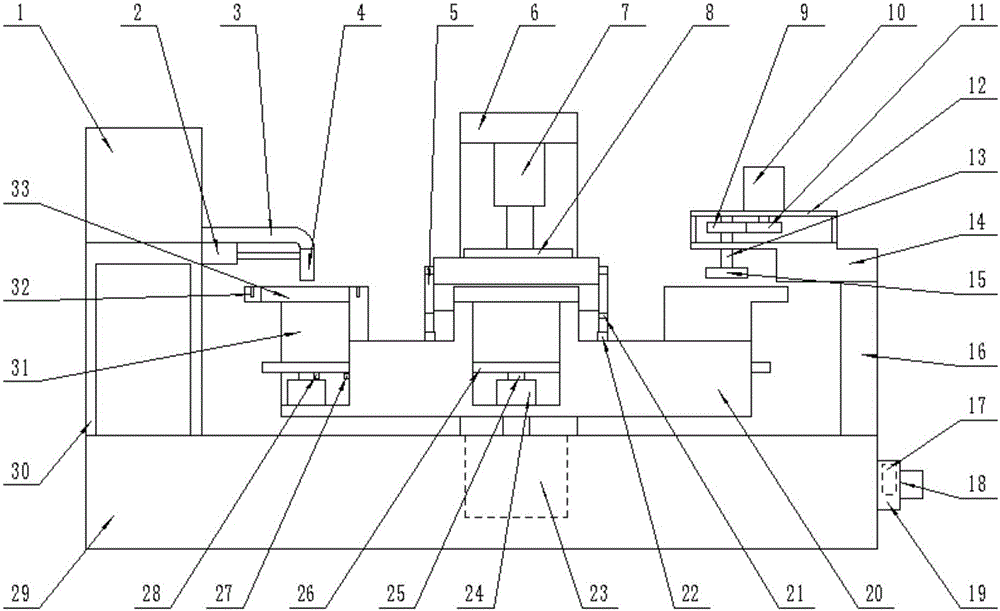

Medicinal iodine solution filling production line

ActiveCN106006521ASimple structureLow costThreaded caps applicationSynchronising machinesProduction lineBiochemical engineering

The invention discloses a medicinal iodine solution filling production line which comprises a workbench and a conveyer belt which is arranged at one end of the workbench and is in butt joint with the workbench. A rotary feeding unit is arranged on the upper surface of the workbench; a disinfection unit, an iodine solution filling unit, a packaging unit and an outer cover screwing unit are sequentially on the upper surface of the workbench in the circumferential direction of the rotary feeding unit; a manipulator used for transferring iodine solution bottles is arranged on one side of the outer cover screwing unit; and the iodine solution filling unit is composed of a supporting frame arranged on the workbench, a barrel arranged on the supporting frame, a drive mechanism arranged on the supporting frame, a butt joint filling head communicating with the interior of the barrel and fixedly connected with a piston rod of the drive mechanism, and a limiting sleeve installed at the discharging end of the butt joint filling head in a sleeving mode. The medicinal iodine solution filling production line has the beneficial effects of being simple in structure and high in practicability.

Owner:江西草珊瑚消毒用品股份有限公司

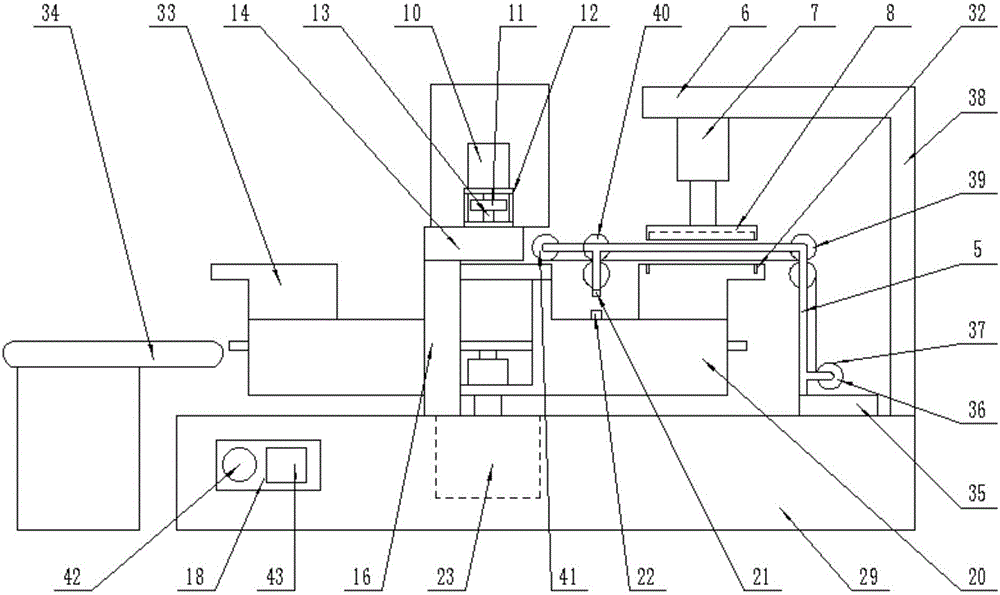

Bottle cap tightening machine

InactiveCN107792821ATighten to achieveRealize automatic tighteningClosing machinesThreaded caps applicationDrive shaftEngineering

The invention relates to the field of automation equipment, in particular to a bottle cap tightening machine, comprising a conveyor belt, a material rail, a feeding mechanism and a tightening mechanism, the conveying direction of the conveyor belt is perpendicular to the guide of the material rail, and the discharge end of the conveyor belt It is connected with the feeding end of the material rail, and the side of the discharge end of the conveyor belt is provided with a pushing device matched with the material rail. The feeding mechanism and the tightening mechanism are distributed along the guiding interval of the material rail. One side of the material rail A positioning device arranged opposite to the tightening mechanism is provided. The invention can realize the automatic tightening of bottle caps. The tightening mechanism adopts a rotatable rotating shaft installed inside the lifting screw rod, and a tightening head is installed at the bottom of the rotation. The lifting of the screw rod drives the rotating shaft to go up and down synchronously, and the rotation drives the tightening. The head rotates to tighten the bottle cap. The mechanism for driving the screw rod up and down and the mechanism for driving the rotating shaft are independent of each other, so that the structure is simpler, the cost is lower, and the maintenance is easier.

Owner:乔合祥

Window frame for manufactured housing

InactiveUSRE40041E1Avoid insufficient lengthCorner/edge jointsWindow/door framesEngineeringVinyl siding

A window frame construction particularly useful in a manufactured housing unit to provide a structure for receiving and supporting at least one window and to provide coverage of ends of siding applied to the exterior of the housing unit. The window frame includes a window body member to generally circumscribe an opening in the housing unit, with a J-rail return member integrally formed therewith to provide a flange member for attachment of the window frame to the housing unit and to cover and secure ends of the siding in a slot formed between the flange member and the return member of the J-rail return. The return member has sufficient width to cover the siding ends even when the siding contracts during lowered temperatures. The window frame, in the preferred form, is constructed from extruded vinyl, and it is used principally for vinyl siding.

Owner:SEALMASTER

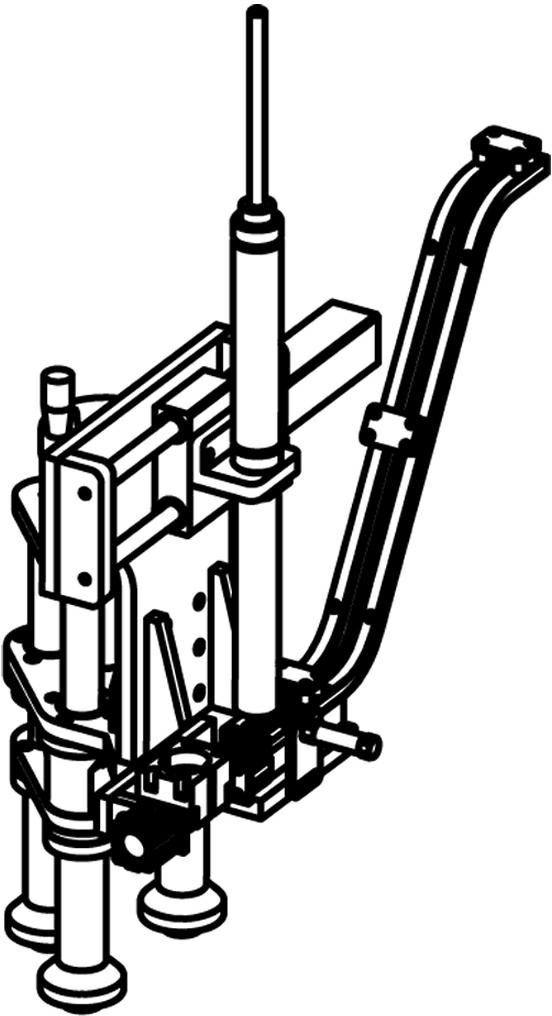

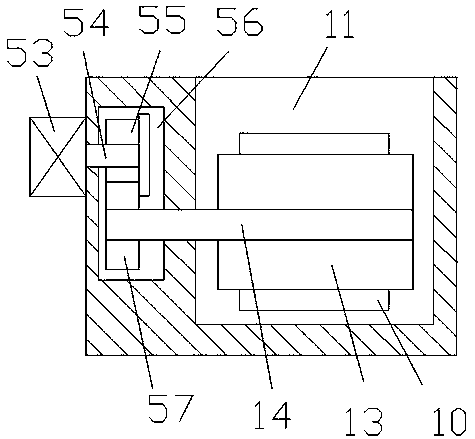

Sprayer cover positioning, taking and assembling device

InactiveCN102431942AAccurate placementImprove automatic cappingBottle/container closureClosure membersEngineeringBottle neck

A sprayer cover positioning, taking and assembling device comprises a cover positioning block, a cover feeding assembly, a cover assembling slide, a slide cushion block, a lifting device, a cylinder mounting plate and a cover distributing cylinder. The cover feeding assembly is fixedly mounted on the lifting device, the cover assembling slide and the cover positioning block are mounted on the lifting device, a bottle neck and falling cover limiting device is arranged in front of the cover feeding assembly, and the cover distributing cylinder is fixed on the lifting device beside the cover assembling slide. A sprayer cover is sucked by the cover feeding assembly from the cover positioning block on the cover assembling slide, is taken by the cylinder, enters a glass tube of the cover feeding assembly, is driven to slide to a limit position and is placed in a bottle neck from the glass tube through the limiting device, and accordingly cover positioning, taking and assembling are completed.

Owner:ZHEJIANG RIGAO MACHINERY CORP LTD

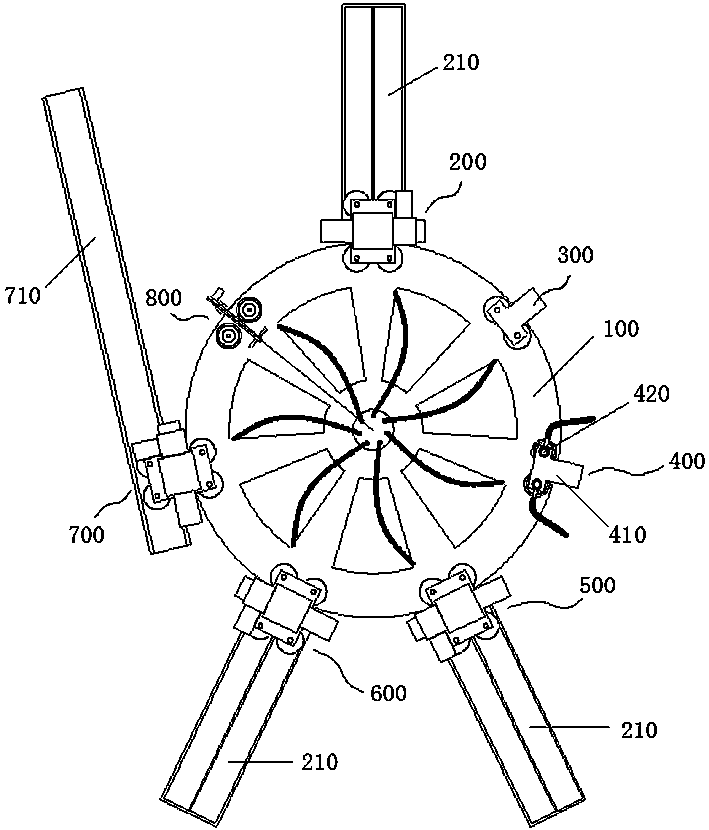

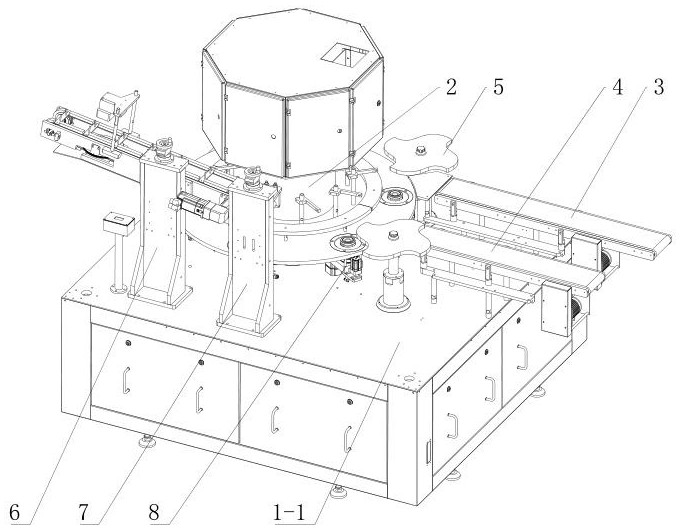

Rotary disk type cosmetics package bottle packaging integrated machine and production method thereof

PendingCN107697878ACompact structureSmall footprintThreaded caps applicationSynchronising machinesEngineeringSmall footprint

The invention relates to a rotary disk type cosmetics package bottle packaging integrated machine and a production method thereof. The rotary disk type cosmetics package bottle packaging integrated machine comprises a rotary disk. The peripheral side of the rotary disk is provided with a bottle feeding position, a cleaning position, a filling position, a membrane feeding position, a cap feeding position and an offline position in sequence. Adsorption platforms used for adsorbing packaging bottles are arranged on the rotary disk at intervals in the circumferential direction. Conveying channelsare located on the outer side of the rotary disk in the bottle feeding position, the membrane feeding position and the cap feeding position correspondingly and arranged in the radial direction. A bottle output conveyor belt arranged in the tangential direction of the rotary disk is located on the outer side of the rotary disk in the offline position. Double-head suction mechanisms used for grabbing articles and conducting 180-degree exchange are arranged in the bottle feeding position, the membrane feeding position, the cap feeding position and the offline position correspondingly. The rotarydisk type cosmetics package bottle packaging integrated machine is compact in structure, small in occupied area, convenient to adjust, stable in operation, easy to maintain and high in production efficiency.

Owner:FUJIAN PIENTZEHUANG COSMETICS CO LTD +1

Automatic wine jar sealing device

InactiveCN110980612AAvoid churnDosage controlClosure membersThreadless stopper insertionAqua vitaeElectric machinery

The invention discloses an automatic wine jar sealing device which comprises a conveying box. A conveying cavity opened upward is formed in the conveying box, a first motor is fixedly connected to theback end surface of the conveying box, a sealing box is fixedly connected to the upper end surface of the conveying box, a sealing cavity communicating to the conveying cavity downward and penetrating left and right sides is formed in the sealing box, a wood plug through port communicates to the upper side of the sealing cavity, and a wood plug storage cavity opened upward communicates to the left side of the wood plug through port. Automatic feeding and automatic sealing are finished by matching two scored pulleys, so that the automatic wine jar sealing device is simple to operate. A wood plug is discharged automatically by reciprocating a rack. The wood plug is compacted by reciprocating a pressing plate up and down. The wood plug is compacted fully by a machine, so that alcohol volatilization and loss caused by a gap is prevented. Meanwhile, the dosage of beewax is controlled while full sealing is guaranteed by pouring liquid beewax quantatively at a fixed trajectory, so that the waste is prevented and the cost is lowered.

Owner:慈溪市纵深包装有限公司

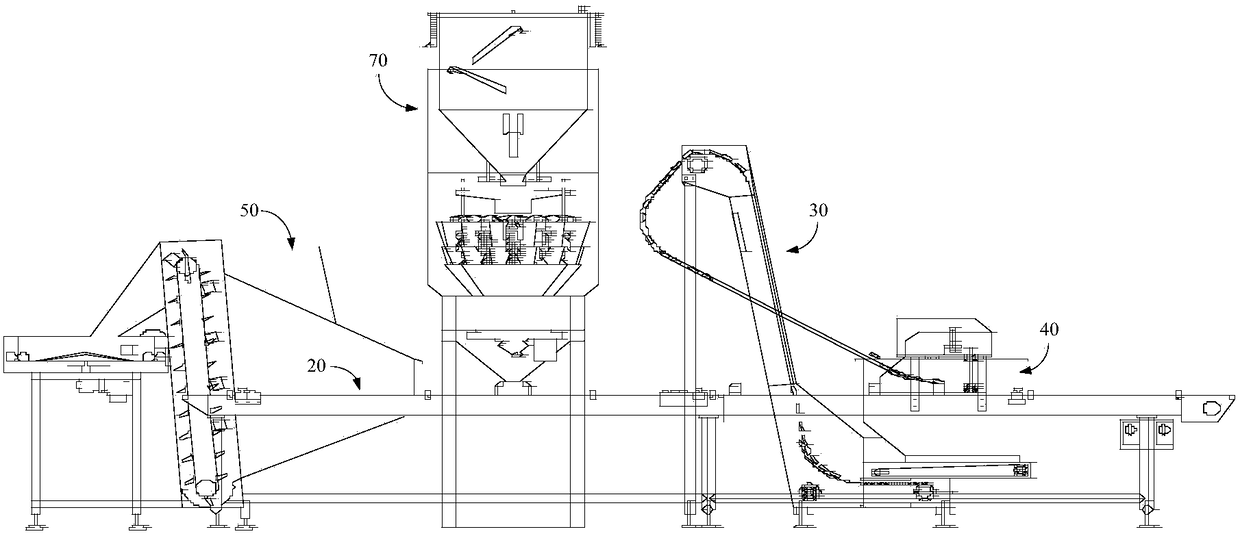

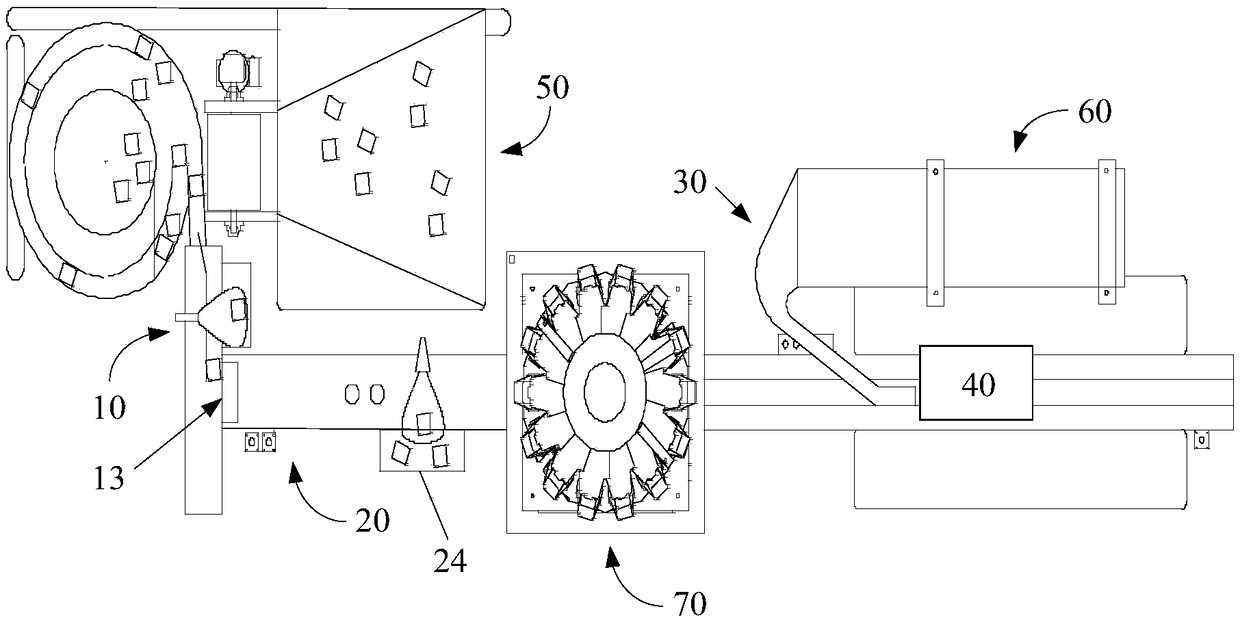

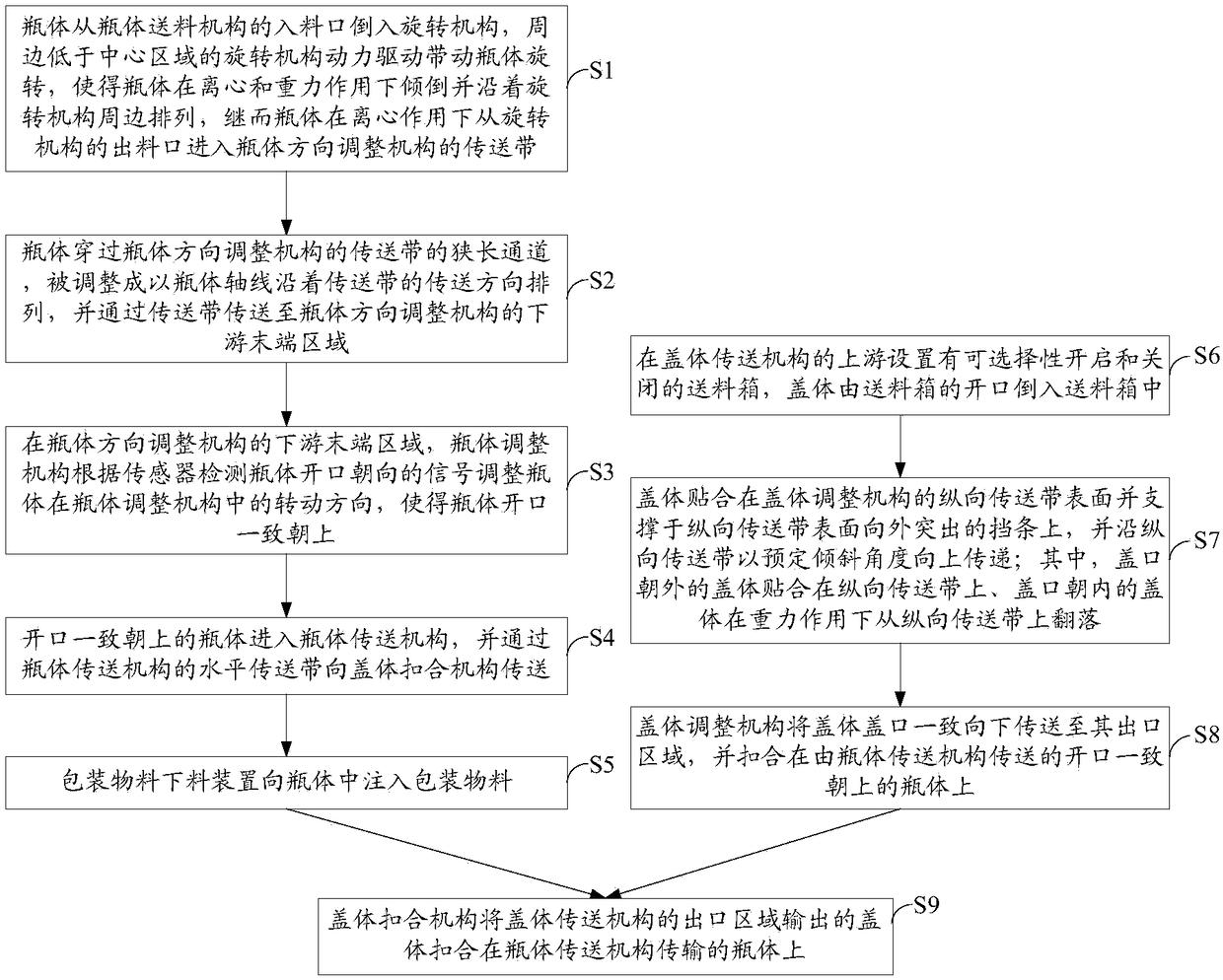

Packaging device and packaging method for automatic fastening of bottle body and cover body

ActiveCN108264003AHigh degree of automationImprove efficiencyClosing machinesConveyorsEngineeringBottle

The invention discloses a packaging device and a packaging method for automatic fastening of a bottle body and a cover body. A sensor and a bottle adjusting mechanism are cooperated, to automaticallyadjust orientations of openings of bottle bodies to be consistent, a barrier strip which protrudes outward and a conveyor belt in a preset inclination angle are collaboratively arranged, to automatically adjust orientations of cover mouths of cover bodies to be consistent, that is, pile-up of the bottle bodies and cover bodies is automatically completed by the device, and manual pile-up is not needed. The device is advantaged by high automation degree, high pile-up accuracy, high packaging efficiency, and low labor cost.

Owner:WM WRIGLEY JR CO

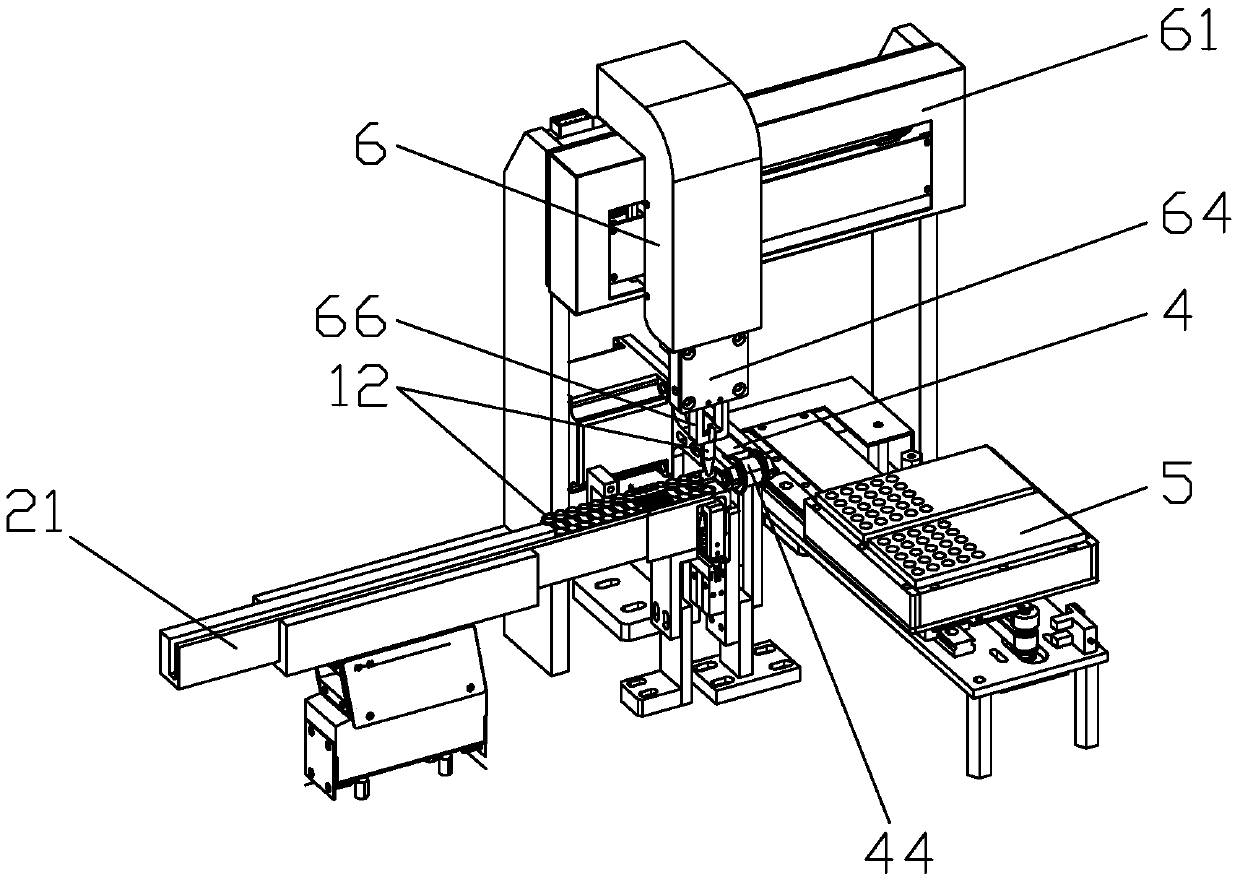

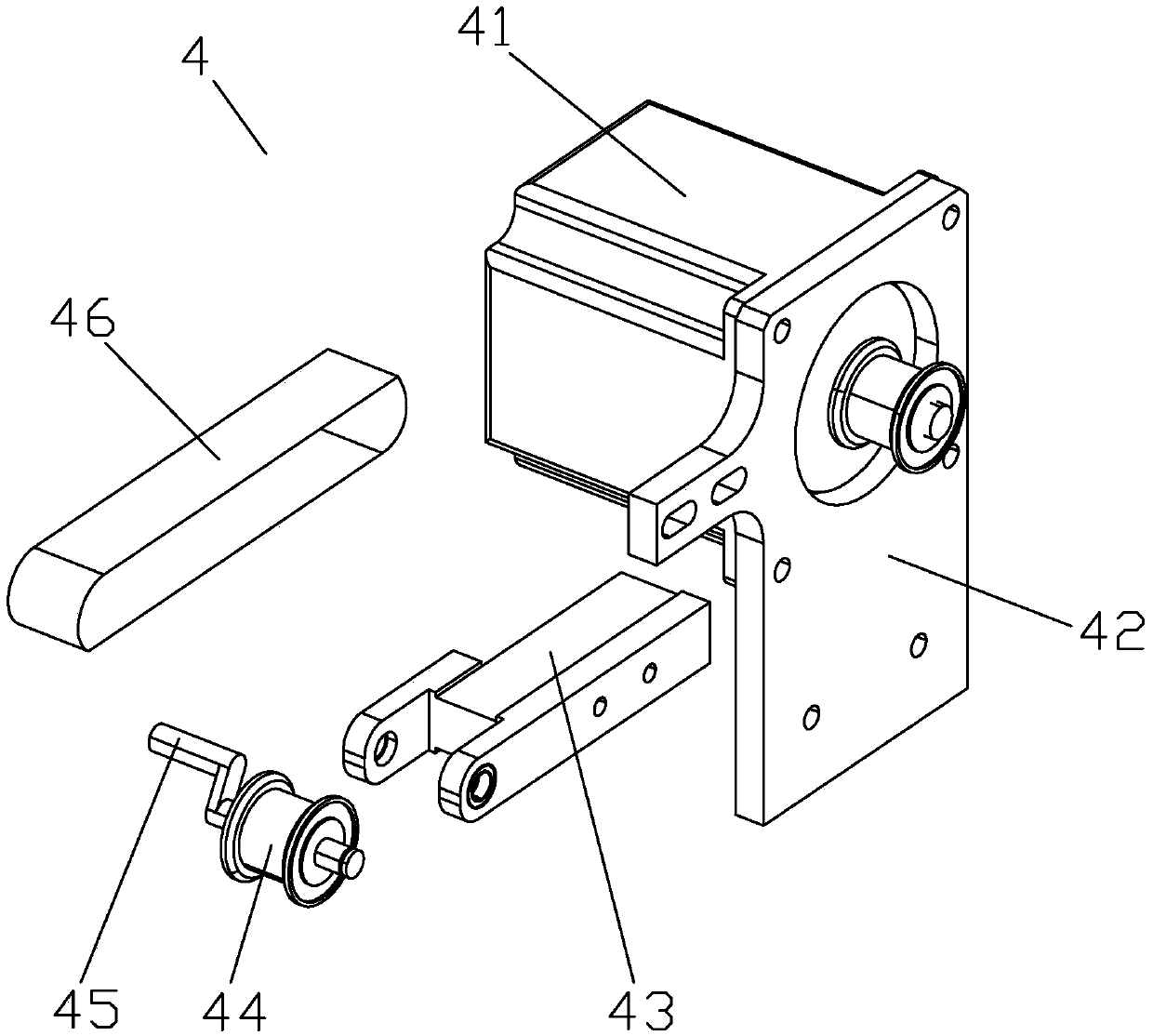

Micro liquid filling device of micro centrifugal pipe

ActiveCN105502245AGood precisionAvoid it happening againClosing machinesFlanged caps applicationElectric machineryEngineering

The invention discloses a micro liquid filling device of a micro centrifugal pipe. The micro liquid filling device comprises a stand; the stand includes a vibration disc, a pushing channel, a taking module, a cover turning module and an arrangement disc module in sequence from left to right; a gripper module is arranged above the taking module; the cover turning module includes a motor connected with the stand and a motor base; a cover turning arm is arranged at the front end of the motor base; and a cover turning transmission wheel and a cover turning crank connected with the cover turning transmission wheel are arranged at the end part of the cover turning arm. The device combines with the requirement of performing micro liquid filling work for the centrifugal pipe, and enables the centrifugal pipe, filled with micro liquid, to be timely covered and automatically transferred to the arrangement disc module through reasonable structure improvement, and in particular through mutual matching of the taking module, the cover turning module and the gripper module, so that the micro liquid filling precision is facilitated, labors are saved, the efficiency is high, and micro centrifugal pipe liquid separation and covering devices for preventing staff from generating pollution replace operators to operate.

Owner:ZHUHAI SINOCHIPS BIOSCIENCE CO LTD

Automatic gasket installation and cap installation device for cosmetic packaging bottles, and working method thereof

ActiveCN107673293ACompact structureReasonable designClosing machinesThreaded caps applicationEngineeringBottle cap

The invention relates to an automatic gasket installation and cap installation device for cosmetic packaging bottles, and a working method thereof. The automatic gasket installation and cap installation device comprises a rotary conveying mechanism, wherein a gasket installation device and a cap installation device are arranged at the input end and the output end of the rotary conveying mechanismseparately; the gasket installation device comprises a gasket installation conveying mechanism, a gasket installation support frame, a gasket installation reversing plate, and gasket installation suction discs arranged at the two ends of the gasket installation reversing plate, and the gasket installation suction discs suck hand gaskets and then rotate to achieve the space above the rotary conveying mechanism under the driving of the gasket installation reversing plate, and place the hand gaskets on bottle bodies; and the cap installation device comprises a cap installation conveying mechanism, a cap installation support frame, a cap installation reversing plate, cap grabbing heads arranged at the two ends of the cap installation reversing plate, and a cap rotation mechanism, the cap grabbing heads grab bottle caps and then rotate to achieve the space above the rotary conveying mechanism under the driving of the cap installation reversing plate, and place the bottle caps on the bottlebodies, and the cap rotation mechanism drives the cap grabbing heads to carry out cap rotation. The automatic gasket installation and cap installation device disclosed by the invention is compact in structure, reasonable in design, capable of realizing automatic gasket installation and cap installation for the packaging bottles, high in production efficiency, low in manual labor intensity, and capable of realizing large batch production.

Owner:FUJIAN PIENTZEHUANG COSMETICS CO LTD +1

Composite profile for window, door or facade element

InactiveUS8176709B2Easy to separateConnection securityDoors/windowsPower-operated mechanismEngineeringMechanical engineering

Owner:TECHNOFORM BAUTEC HLDG

Automatic filling process

ActiveCN112320740AEasy to fillEasy to detectBottle/container closureBottle-handling machinesEngineeringHeat conservation

The invention relates to an automatic filling process. A filling sleeve, an inner cover and an outer cover are included, and the inner cover and the outer cover are used in cooperation with the filling sleeve. A first contact piece and a second contact piece are fixedly connected to the two sides of the filling sleeve, a dispensing pipe, a vacuumizing pipe and a filling pipe are inserted into a shell in a sealed mode, a vacuum degree detection head is installed on the vacuumizing pipe, an electric push rod is fixedly connected to the upper end of a heat preservation cylinder through a second connecting rod, and an injection plug is installed in the heat preservation cylinder in a sealed and sliding mode. An air bag is installed in the inner cover, a movable ejector rod is fixedly connectedto the upper portion of a piston, a second contact head is fixedly connected to the upper end of the movable ejector rod, and a rubber sheet is fixedly connected to the top of a conical groove. According to the process, sealing performance detection is facilitated before and after filling. Automatic filling operation is conveniently achieved, vacuumizing, filling and sealing are all concentratedon the filling head, the operation process is saved, the working efficiency is improved, the occupied space of other devices is reduced, and the cost is saved.

Owner:福州幽力克生物科技有限公司

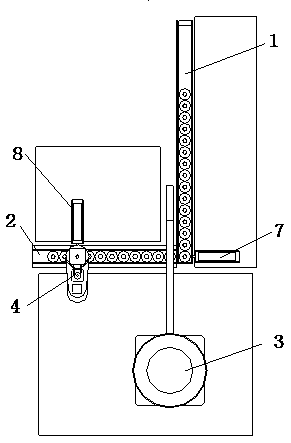

Milk bottle cover conveying device

PendingCN107777637AImprove blow forceImprove work efficiencyClosing machinesThreaded caps applicationEngineeringBottle

The invention discloses a milk bottle cover conveying device which comprises a conveying device and a push device, wherein the conveying device is used for conveying a milk bottle cover to a milk bottle cover screwing device; the discharge end of the conveying device and the cover inlet hole of the milk bottle cover screwing device are arranged oppositely; and the push device is arranged at the discharge end of the conveying device and is used for pushing milk bottle covers at the discharge end of the conveying device to the cover inlet hole of the milk bottle cover screwing device in sequence. As the milk bottle covers are continuously conveyed to the discharge end from the feeding end of the conveying device and are sequentially pushed into the cover inlet hole of the milk bottle cover screwing device one by one in a correct direction through the push device, the overall working efficiency of the milk bottle cover screwing device is improved.

Owner:湖北酷我乳业股份有限公司

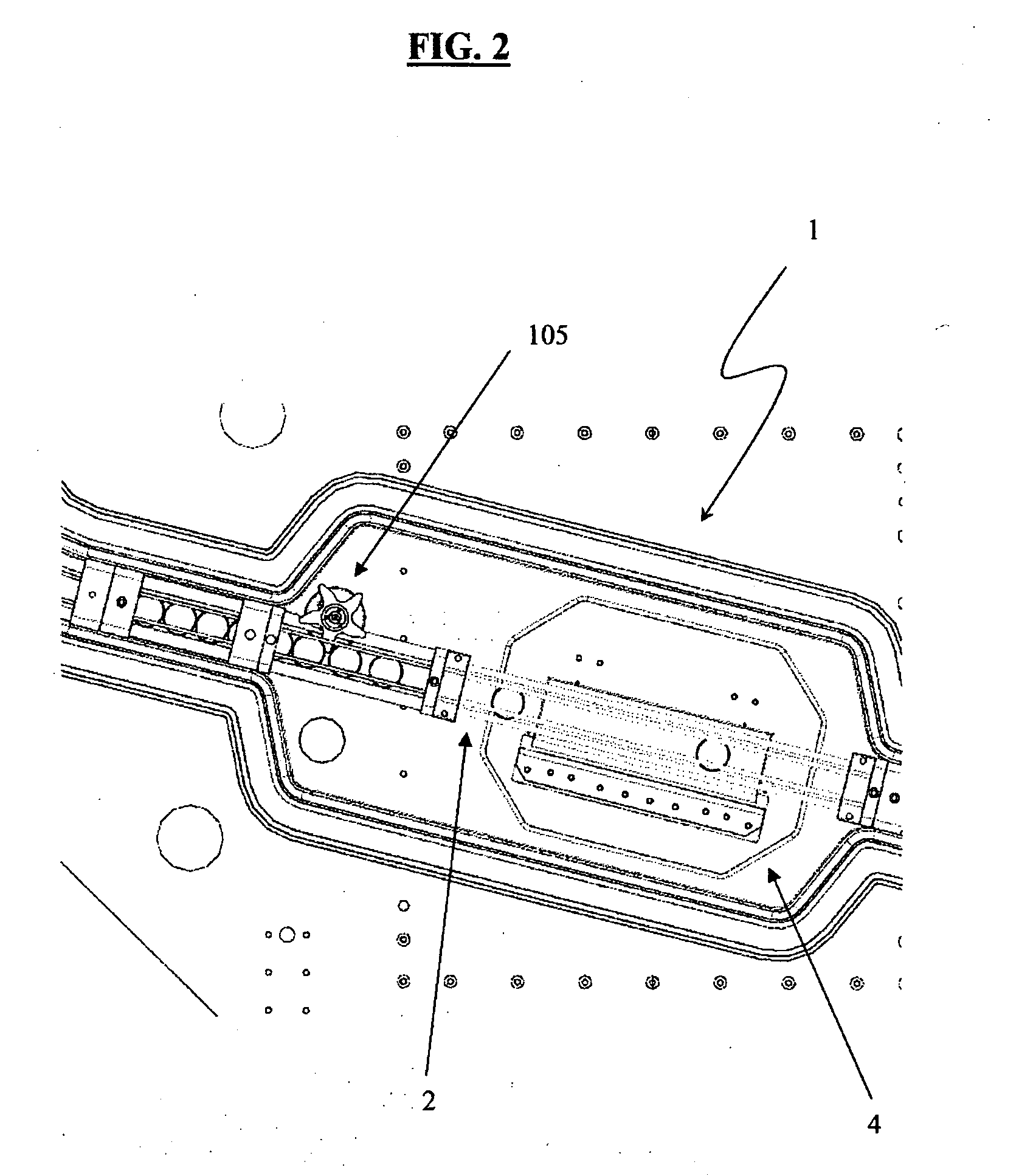

High-speed capping machine for high caps

ActiveCN113548614AImprove capping efficiencyMeet the needs of modern productionClosing machinesFlanged caps applicationMachineIndustrial engineering

The invention relates to the technical field of canning equipment, in particular to a high-speed capping machine for high caps. The high-speed capping machine is provided with a rack, a rotating part, an inlet net chain part, an outlet net chain part, a star wheel part, a cap feeding part, a cap pressing part, a tank body positioning part and a control part, and the control part is arranged on the rack and electrically connected with the rotating part, the inlet net chain part, the outlet net chain part, the star wheel part, the cap feeding part, the cap pressing part and the tank body positioning part, so that an integral control effect is achieved. The cap pressing efficiency is improved, the cap pressing speed reaches 100 pieces or above per minute, and the requirement of modern production is met. Cap feeding operation can be conducted on tank bodies with different heights through the cap feeding lifting part, the efficiency is high, and full automation is achieved. A visual camera can monitor whether the cap feeding work is normally carried out or not in real time, cap neglected loading is prevented, and it is ensured that the positions of the caps are correct when the caps are conveyed to the next procedure.

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

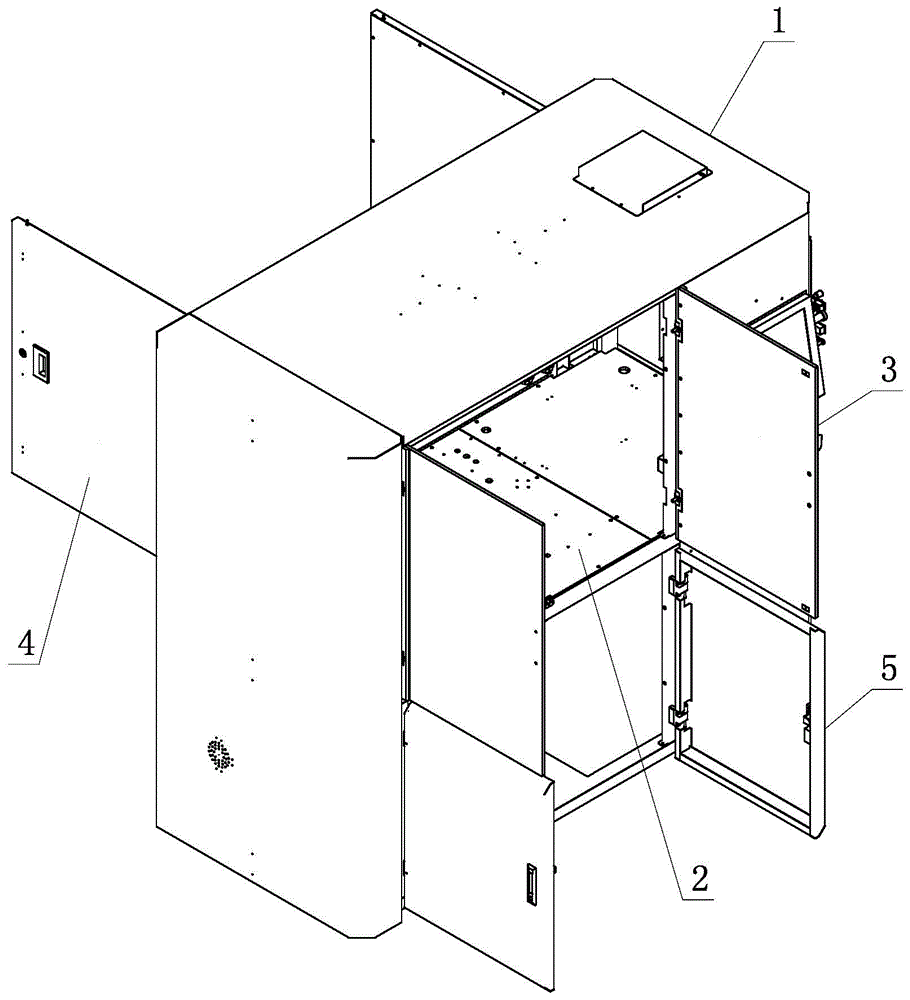

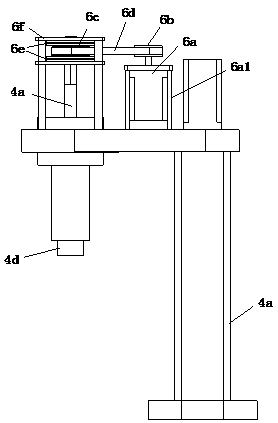

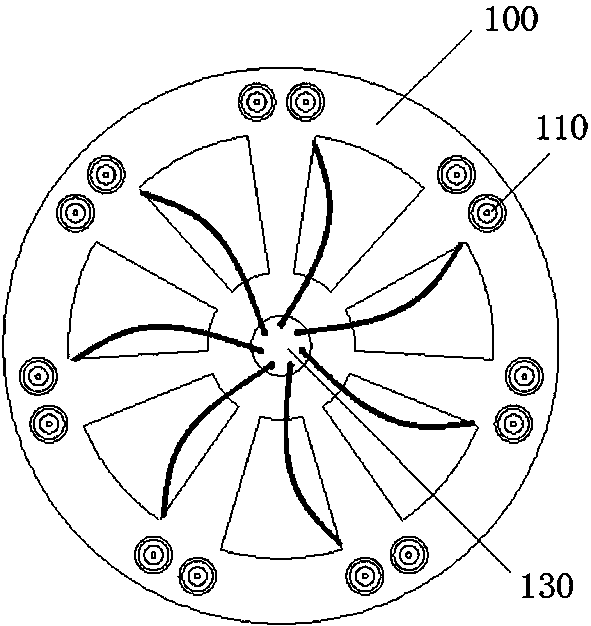

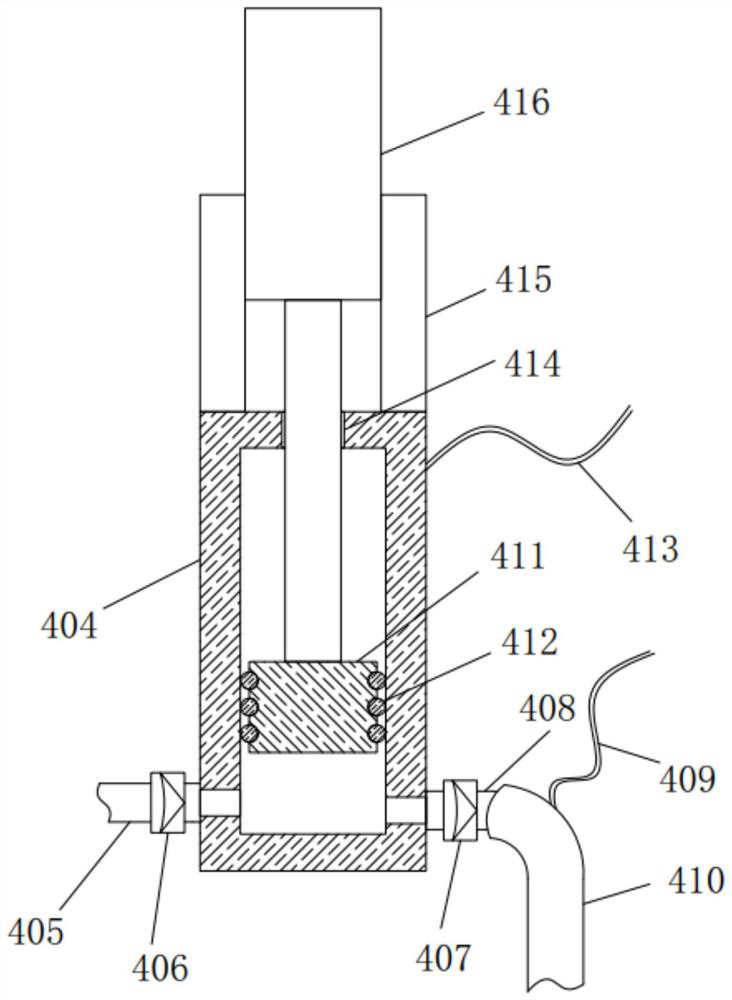

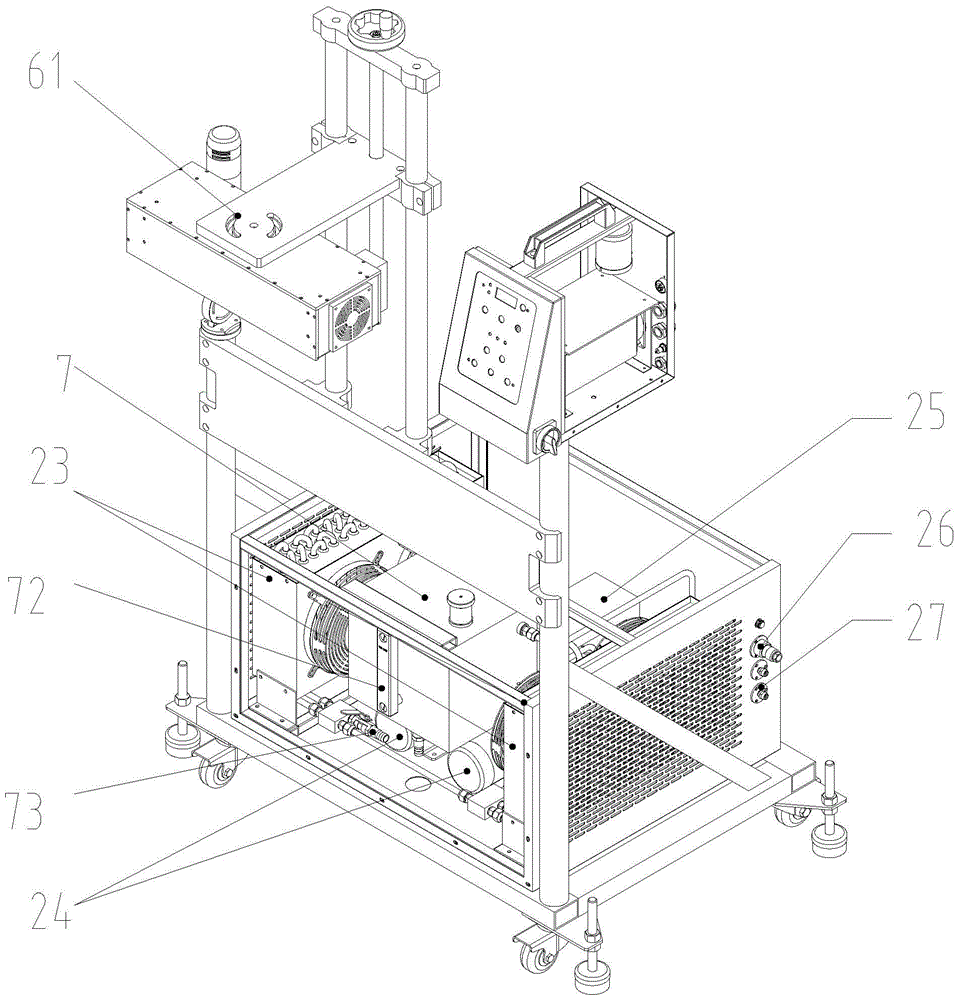

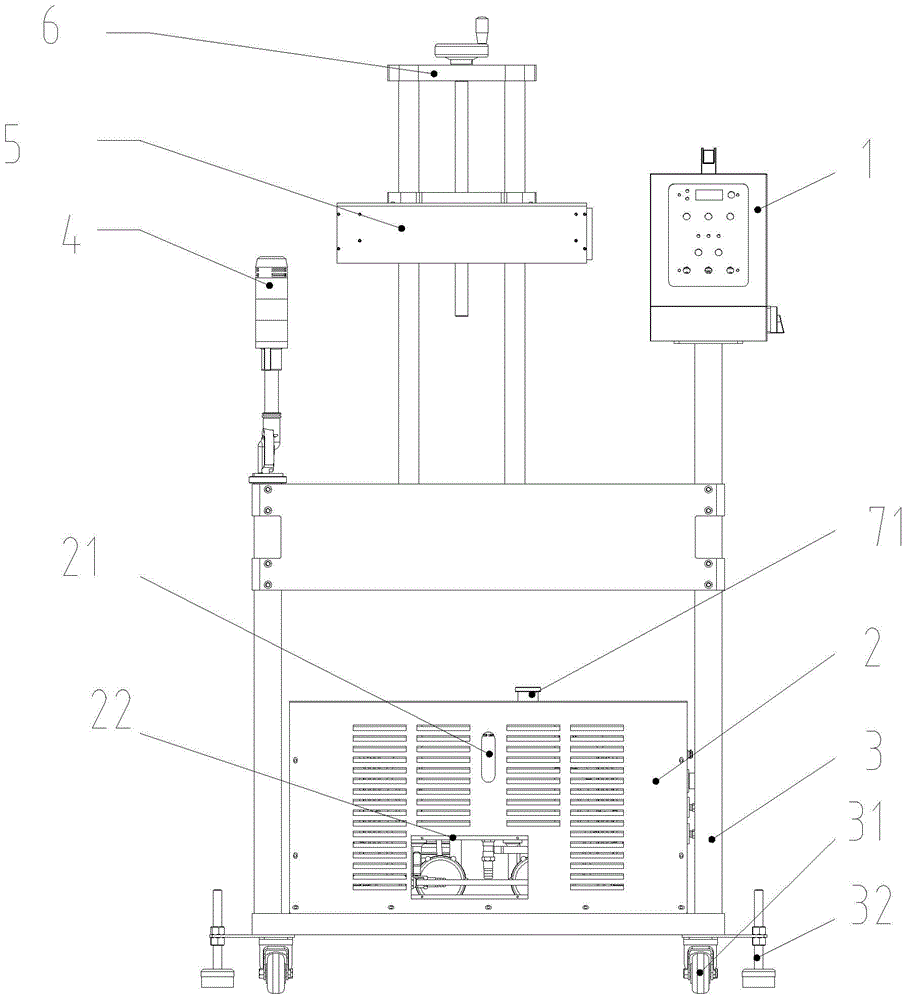

Water-cooling type electromagnetic induction aluminum foil sealing machine

ActiveCN106082060AFast sealing speedImprove cooling effectBottle/container closureClosure membersWater storage tankRadiation mode

The invention provides a water-cooling type electromagnetic induction aluminum foil sealing machine. The water-cooling type electromagnetic induction aluminum foil sealing machine comprises a control box, a main machine box, a whole machine frame, an alarm lamp, a water-cooling sealing head, a lifting adjustment device and a water storage tank, wherein the main machine box is fixed to a platform surface at the lower end of the whole machine frame; the water storage tank is fixed inside the main machine box; the control box and the alarm lamp are fixed to stand columns at the left end and the right end of the whole machine frame correspondingly; a pair of stand columns are fixed to a platform surface at the upper end of the whole machine frame; the lifting adjustment device is fixed to the pair of stand columns and connected with the water-cooling sealing head through a rotary sealing fixing plate; the water-cooling sealing head communicates with the water storage tank through a passage; and a pair of water pumps are arranged in the passage. The sealing speed of the water-cooling type electromagnetic induction aluminum foil sealing machine is far higher than that in the prior art, a cooling water circular heat radiation mode is adopted, and the whole machine is kept in a low-temperature, stable and reliable work state.

Owner:GUANGZHOU XUEBA SPECIAL EQUIP CO LTD

Sterile automatic filling line

InactiveCN106553988AEfficient fillingReliable fillingThreaded caps applicationBottle-handling machinesWine bottleEngineering

The invention discloses a sterile automatic filling line. The sterile automatic filling line comprises a wine bottle conveying device and a filling cabinet. The filling cabinet is arranged in the middle of a conveying frame. The conveying frame passes through two sides of the filling cabinet. The filling cabinet is orderly provided with a filling station, a sealing station and a capping station. A filling system is arranged at the filling station. A sealing device is arranged at the sealing station. A capping system is arranged at the capping station. A position sensor is arranged on the conveying frame on the filling cabinet. The conveying frame is provided with a sterilization box. A microwave sterilizer is arranged in the sterilization box. The sterilization box is close to a wine bottle inlet of the filling cabinet. The sterile automatic filling line can realize efficient and reliable liquid filling, has a high metering precision and is especially suitable for filling of various liquors.

Owner:CHONGQING ANTAO WINE IND

System for filling liquid containing bottles

InactiveUS20170029261A1Filled quickly and efficientlyReduce necessityClosing machinesSynchronising machinesEngineeringBottle

A system for efficiently filling liquid containing bottles having removable and replaceable threaded screw tops. The system includes a bottle spindle mechanism having a bottle receiving receptacle, and a liquid dispensing head movable between a raised position for enabling placement and removal of bottles into and from the receptacle with the screw tops in place and lowered liquid dispensing position. With a bottle in the receptacle, the receptacle and bottle are rotatable in one rotary direction while the screw top is manually retained against rotation for unscrewing and removing the screw top; the dispensing head is then lowered to the liquid dispensing position for filling the bottle; the dispensing head then is raised and the screw top repositioned on the bottle; and the receptacle and bottle are rotated in an opposite direction while the screw top is retained for rescrewing the screw top on the bottle.

Owner:SPRAYING SYST

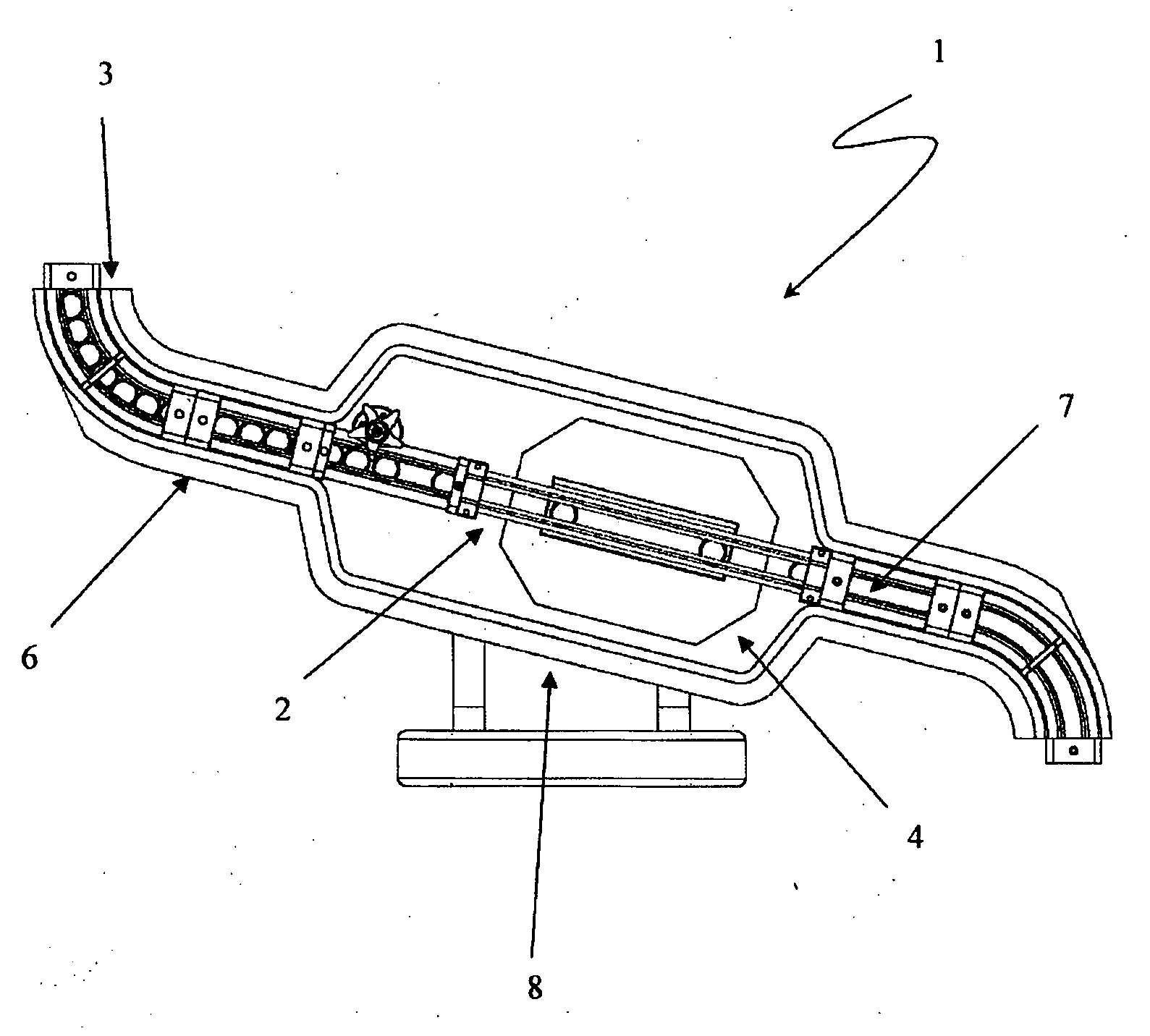

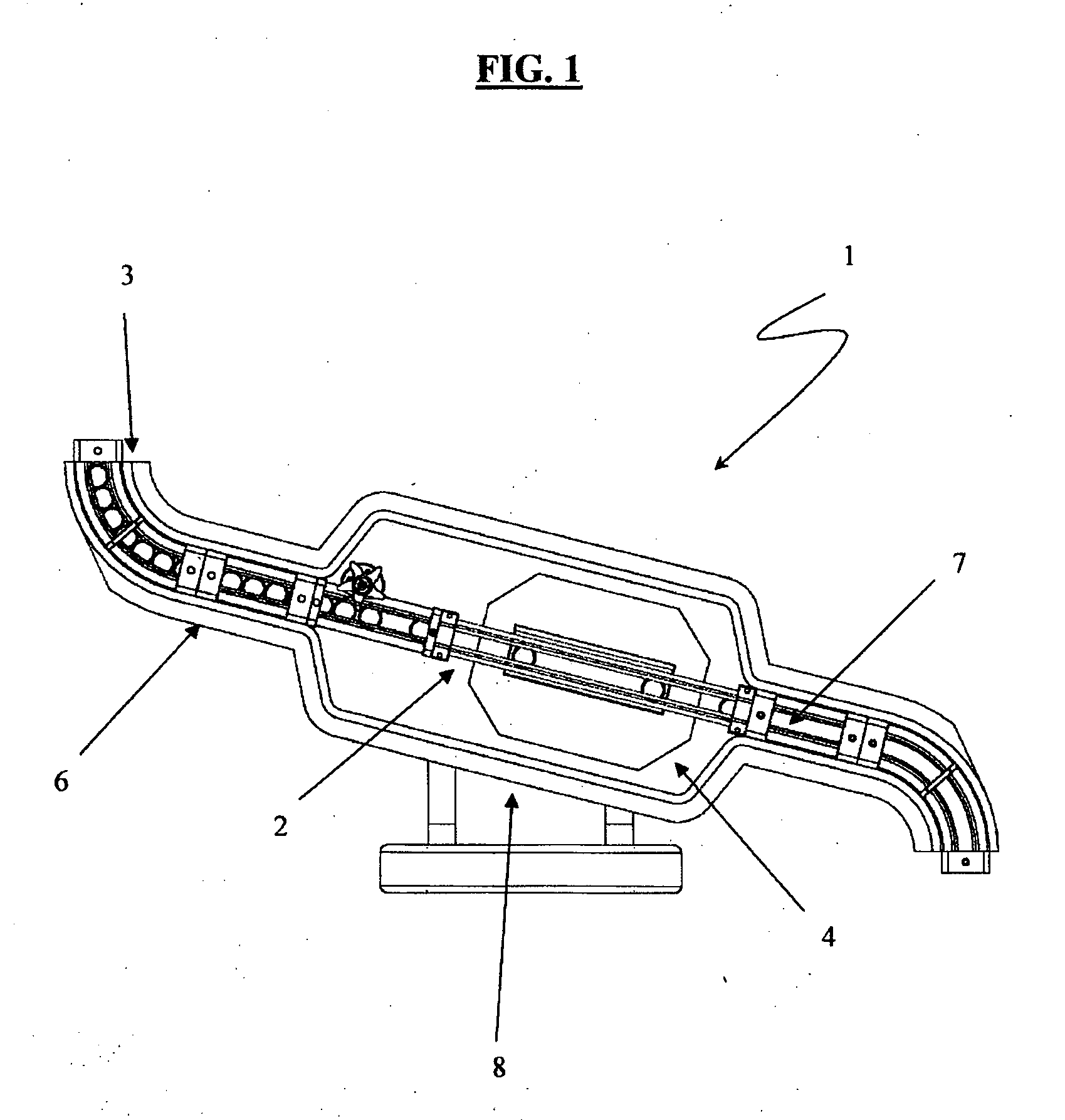

Apparatus for sterilising container closures

InactiveUS20110057115A1Inhibition formationSimple and reliable processClosing machinesMaterial analysis using wave/particle radiationEngineeringMechanical engineering

Device (1) for feeding container closures, comprising guiding means (2) for conveying the closures (100) to a treatment station associable with said device. The device (1) comprises spacer means (5, 105) to deliver the closures to the treatment station at evenly spaced time intervals, said spacer means being operatively associated with said guiding means (2) and positioned upstream from said treatment station. Apparatus for sterilising container closures equipped with a sterilisation station and comprising such a device (1) for feeding container closures to said sterilisation station.

Owner:GEA PROCOMAC

Drop pill filling production line

PendingCN110116831AHigh degree of automationImprove work efficiencyClosing machinesFlanged caps applicationFailure rateProduction line

The invention provides a drop pill filling production line, and belongs to the field of filling equipment. The drop pill filling production line comprises a bottle arrangement part, a bottle loading part, a transfer part, a filling part and a cover loading part arranged in sequence to form a production line; bottle body conveying rails for realizing transfer of bottle bodies are arranged at the lower ends of the transfer part, the filling part and the cover loading part; the bottle body transfer rails are chain or belt conveying rails; separation pieces for separating the bottle bodies are vertically arranged at the upper ends of the bottle body conveying rails; and the bottle body conveying rails are connected with an external control center to realize positioning stop and operation actions. The drop pill filling production line is high in automation degree, low in failure rate and high in working efficiency.

Owner:天津市润比特斯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com