Sprayer cover positioning, taking and assembling device

A nozzle cover and limit device technology, which is applied in the direction of transportation and packaging, bottle/container caps, conveyor objects, etc., can solve the problems of no pre-positioning device, the cap cannot be lowered, and the cap falls out of the bottle mouth, etc., to achieve ingenious design , improve efficiency, and achieve accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

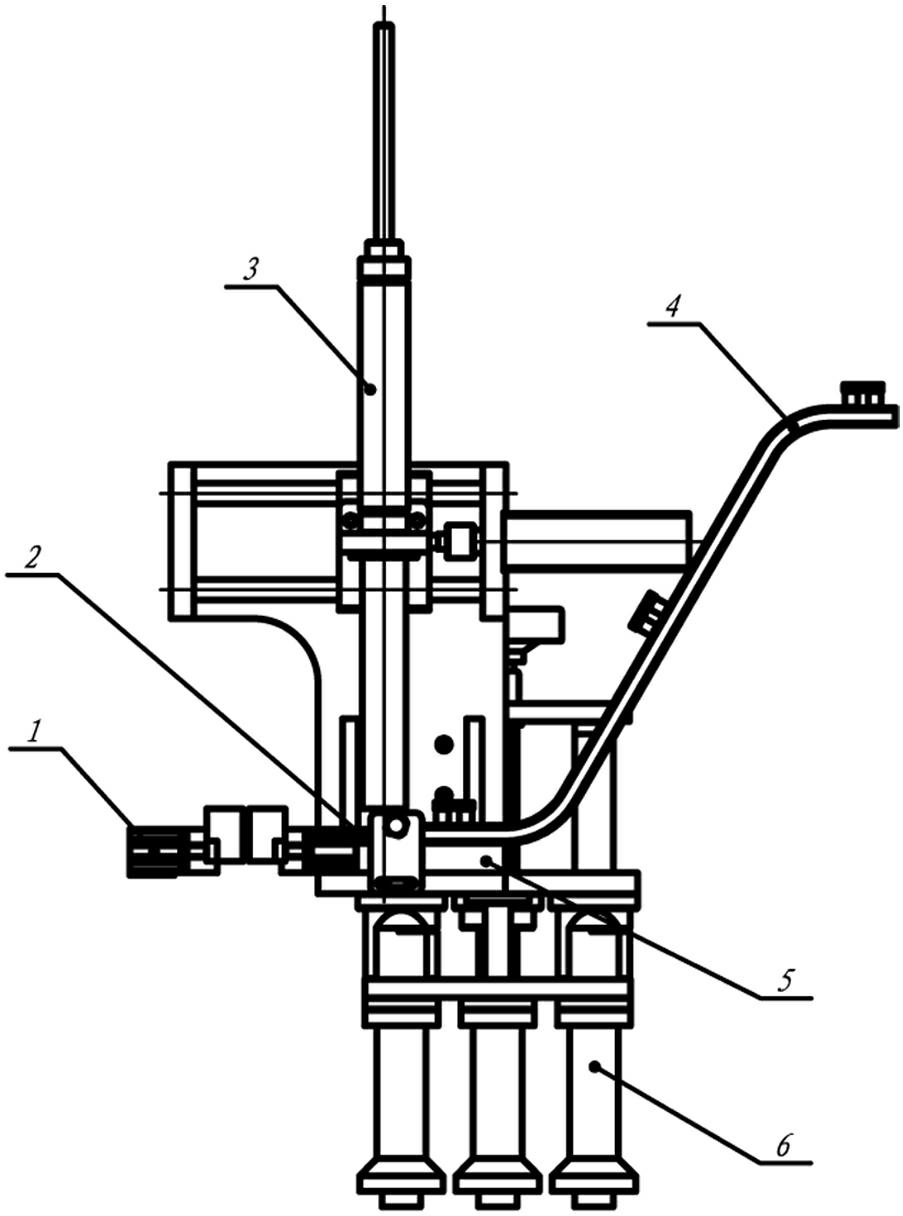

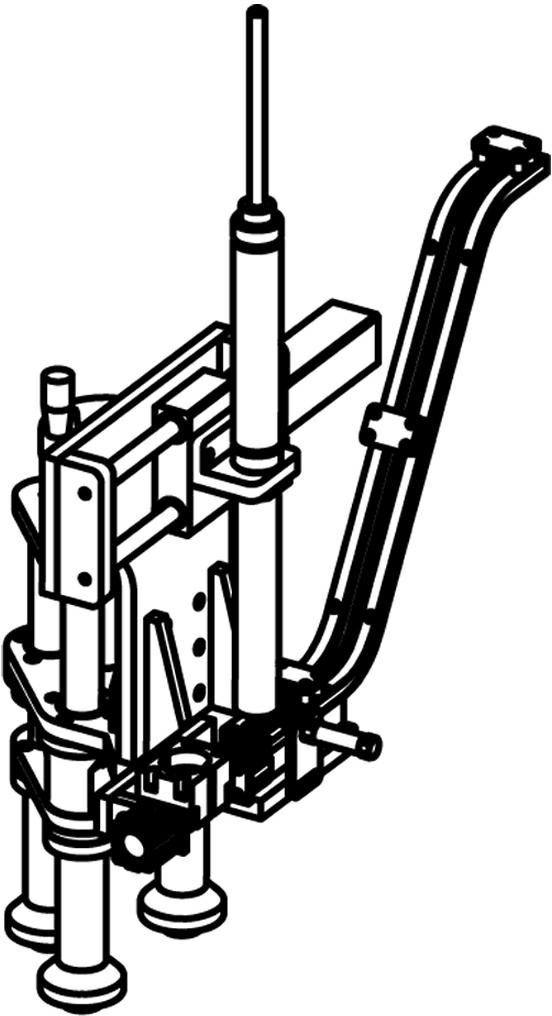

[0017] Such as figure 1 , figure 2 , image 3 In the embodiment shown, the device for positioning and removing the nozzle cover includes a cover positioning block 2, an upper cover assembly 3, a lower cover slideway 4, a slideway cushion block 5, a lifting device 6, a cylinder mounting plate 7 and a cover cylinder 8. The upper cover assembly 3 is fixedly installed on the lifting device 6, the lower cover slideway 4 and the cover positioning block 2 are installed on the lifting device 6 through the slideway pad 5, and the upper cover assembly 3 is provided with a bottle mouth and a drop Cover limiter 1, sub-cover cylinder 8 is fixed on the lifting device 6 next to lower cover slideway 4 by cylinder mounting plate 7.

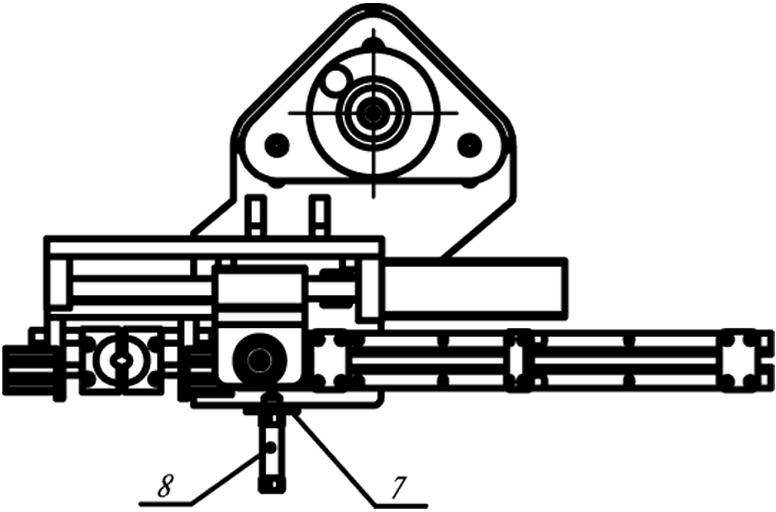

[0018] Such as Figure 4 , Figure 5 As shown, the limiting device 1 is composed of a limiting block mounting plate 11, a first limiting block 12, a guide rod 13, a cylinder mounting plate 14, a cylinder support plate 15, a second limiting block 16, a guide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com