Micro liquid filling device of micro centrifugal pipe

A micro-liquid and filling device technology, applied in liquid processing, packaging, bottle filling, etc., can solve the problems of long time-consuming, unfavorable large-scale operation, etc., and achieve the effect of preventing pollution and benefiting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

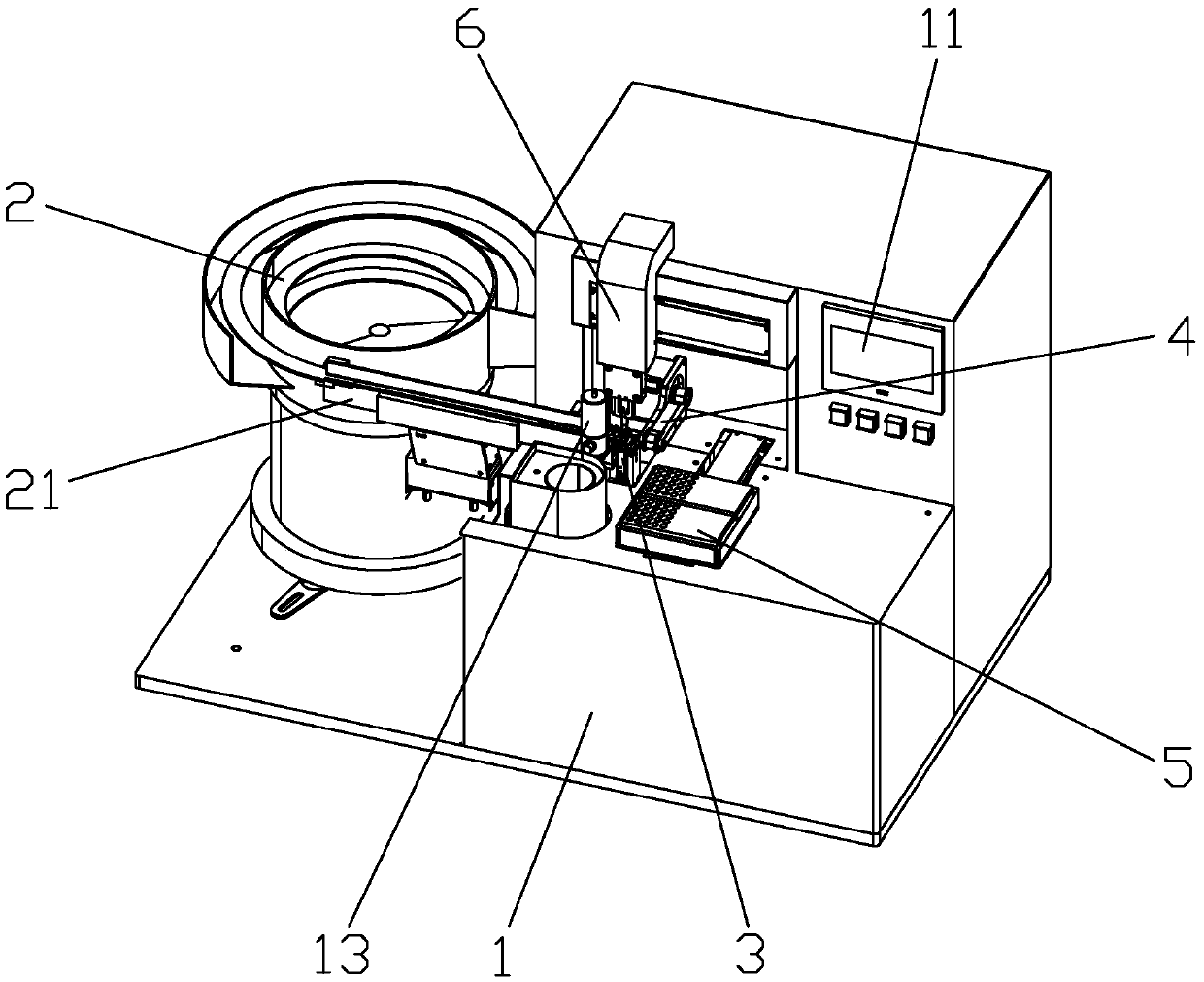

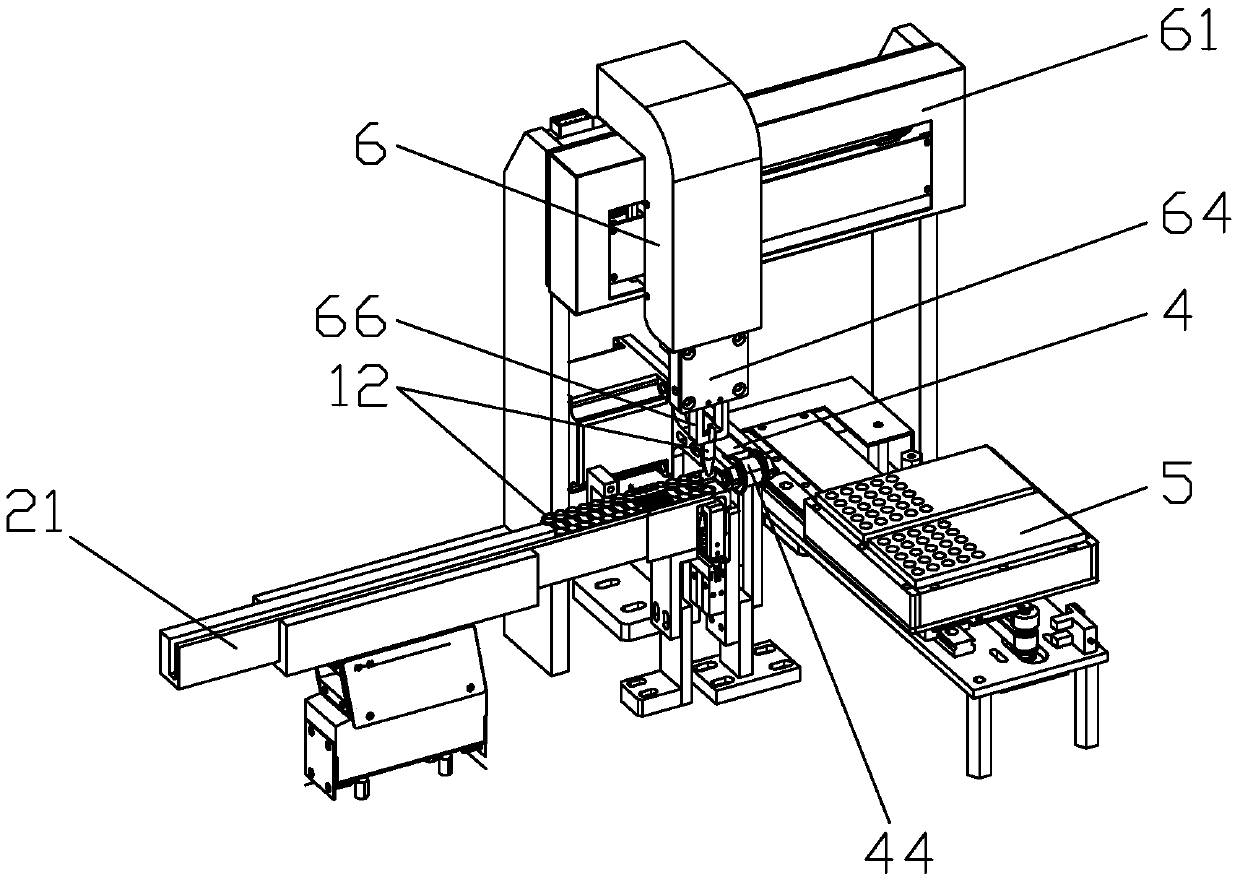

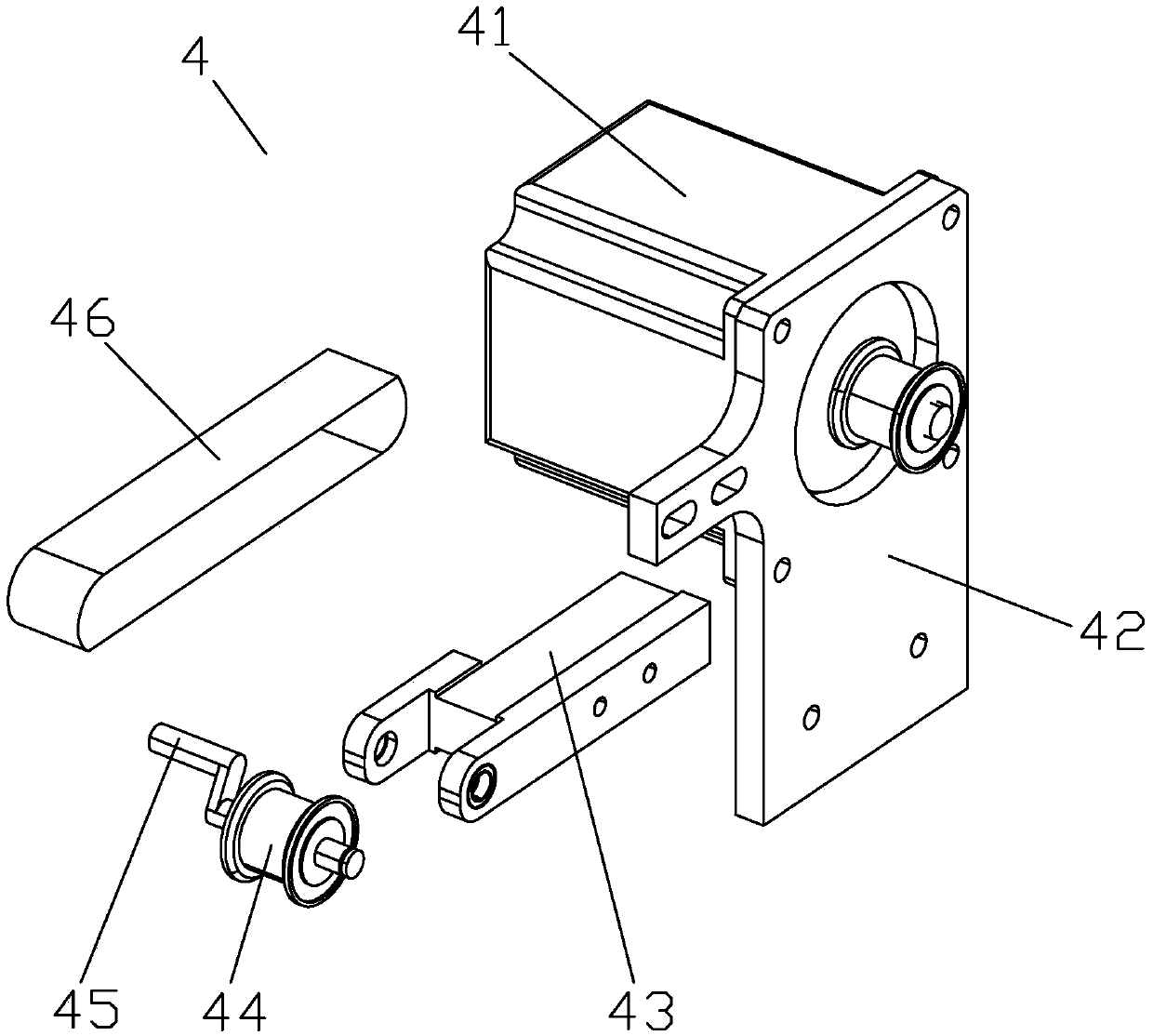

[0017] In order to make the purpose, technical solution and advantages of the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In the ensuing description some specific details are referred to for a thorough understanding of the present invention. While the present invention may still be practiced without these specific details, the descriptions and representations herein are used by those skilled in the art to effectively convey the substance of their work to others skilled in the art. In addition, it should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and " "Outside" refers to the direction toward or away from the geometric center of a specific component, and those skilled in the art who make simple and creative adjustments to the above direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com