Rotary disk type cosmetics package bottle packaging integrated machine and production method thereof

A technology for packaging bottles and cosmetics, which is applied in the field of turntable cosmetic packaging bottle packaging machine, which can solve the problems of large space occupation, large number of workers, and low efficiency, and achieve the effects of small footprint, easy maintenance, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

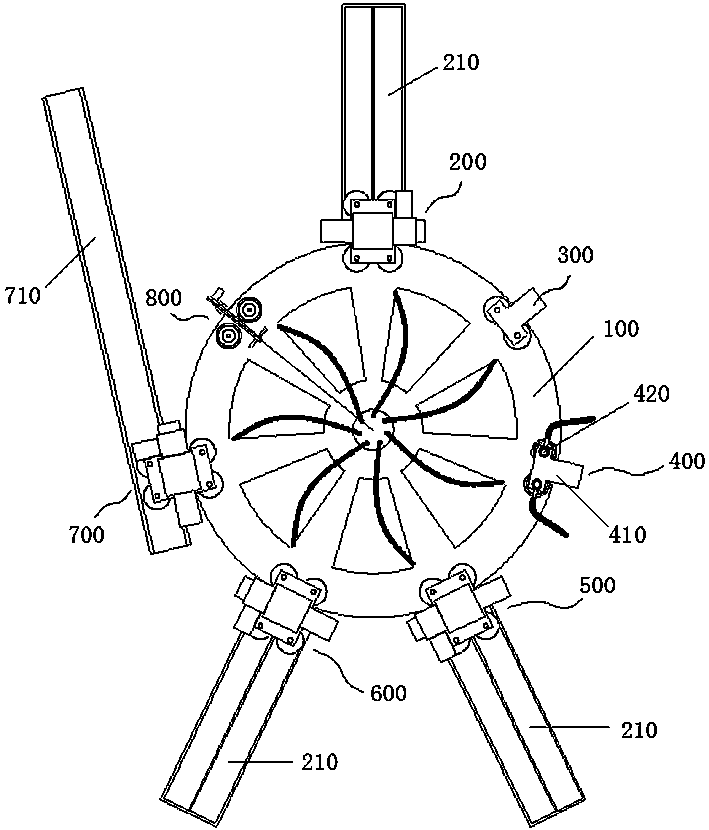

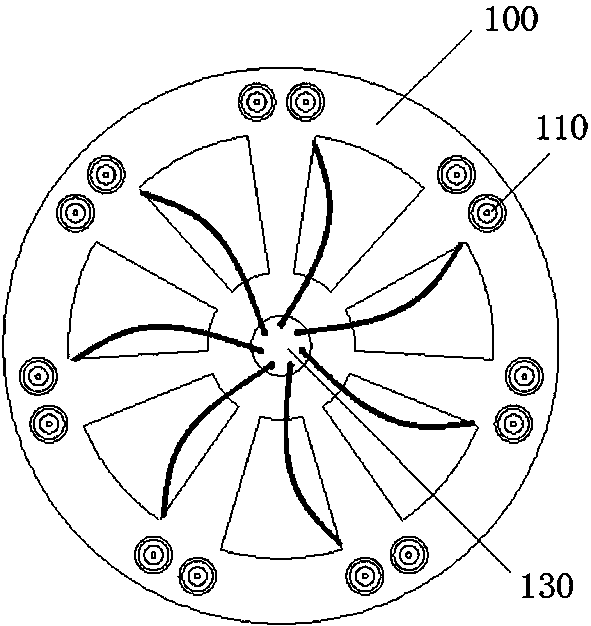

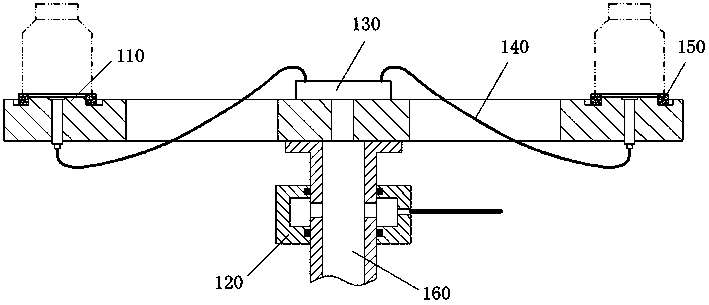

[0024] Such as Figure 1~8 As shown, a turntable type cosmetic bottle packaging machine includes a turntable 100, and the periphery of the turntable is provided with a bottle loading station 200, a cleaning station 300, a filling station 400, and a film feeding station 500. , the upper cover station 600 and the offline station 700; the turntable 100 is provided with a suction table 110 for absorbing the packaging bottle at intervals along the circumferential direction, and is located at the bottle upper station, the upper diaphragm station and the upper cover station There are conveying channels 210 located on the outer side of the turntable and arranged radially, the conveying channel of the bottle loading station is used to convey the bottle body, the conveying channel of the upper mold station is used to convey the diaphragm, and the conveying channel of the upper cover station is used to convey the bottle body. The conveying channel is used to transport bottle caps, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com