Medicinal iodine solution filling production line

A production line and iodine solution technology, which is applied to liquid bottling, safety devices of perfusion devices, packaging, etc., can solve the problems of large floor space, complex structure and high purchase cost, and achieve space saving, simple structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

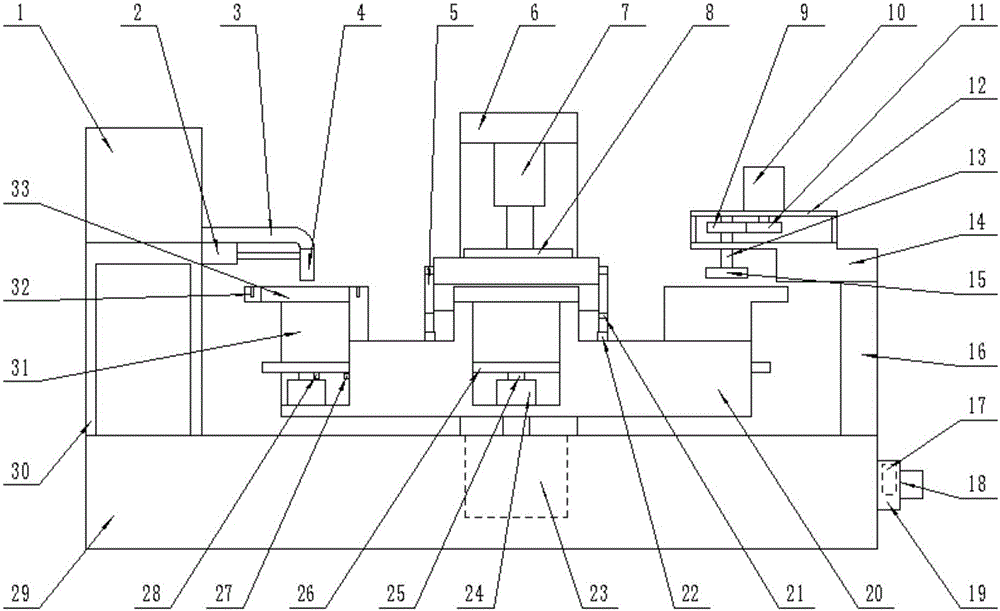

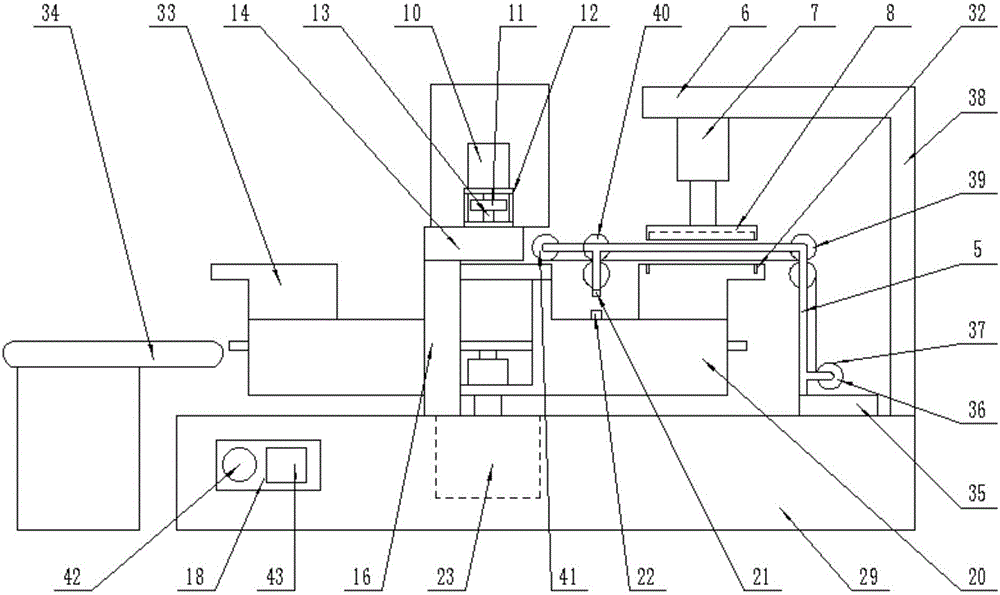

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 Shown, a kind of medical iodine liquid filling production line comprises workbench (29) and is arranged on the conveyer belt (34) that one end of workbench (29) docks with workbench (29), on described workbench (29) The surface is provided with a rotary feeding unit, and the upper surface of the workbench (29) is sequentially provided with a disinfection unit, an iodine solution filling unit, a packaging unit and an outer cover screw-in unit along the circumferential direction of the rotary feeding unit, and the outer cover is screwed in. One side of the input unit is provided with a manipulator in order to transfer the iodine solution bottle, and the iodine solution filling unit is composed of a support frame (30) arranged on the workbench (29), a barrel body arranged on the support frame (30) (1), the driving mechanism (2) arranged on the support frame (30), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com