Automatic filling process

An automatic filling and process technology, used in packaging, bottling machines, bottle filling and other directions, can solve the problems of difficult to detect the tightness of the bottle, splashing liquid, and difficult to clean, etc., to facilitate detection and production management, improve work Efficiency, saving the effect of operating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

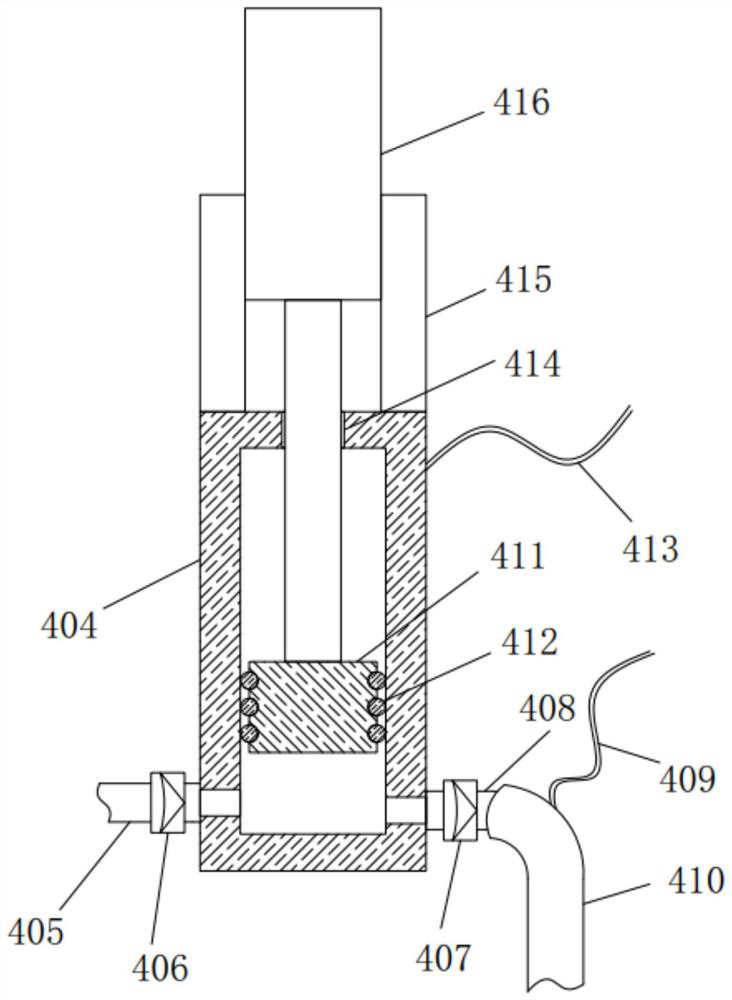

[0040] Attached below Figure 1-3 The present invention is further described with embodiment:

[0041]An automatic filling process, including a filling sleeve 3 and an inner cover 1 and an outer cover 2 used in conjunction with the filling sleeve 3; the two sides of the filling sleeve 3 are respectively fixedly connected with a first contact piece 305 and a second contact piece 301, the upper end of the filling sleeve 3 is fixedly connected with the housing 4, and the inside of the housing 4 is sealed and plugged with a little rubber tube 302, a vacuum tube 306 and a filling tube 307, and an air valve 402 is installed on the upper end of the vacuum tube 306, and the vacuum tube A vacuum detection head 417 is also installed on the front of the air valve 402 on the 306, a filling valve 403 is installed on the upper end of the filling pipe 307, and an insulating tube 404 is connected to the upper end of the dispensing tube 302, and the lower side of the insulating tube 404 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com