Controlled container headspace adjustment and apparatus therefor

a container headspace adjustment and container technology, applied in the direction of containers, liquid bottling, packaging goods, etc., can solve the problems of inexact absolute pressure control, limited process control, and high cost of nitrogen handling system, so as to reduce spoilage rate and improve control over the structure of the container.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

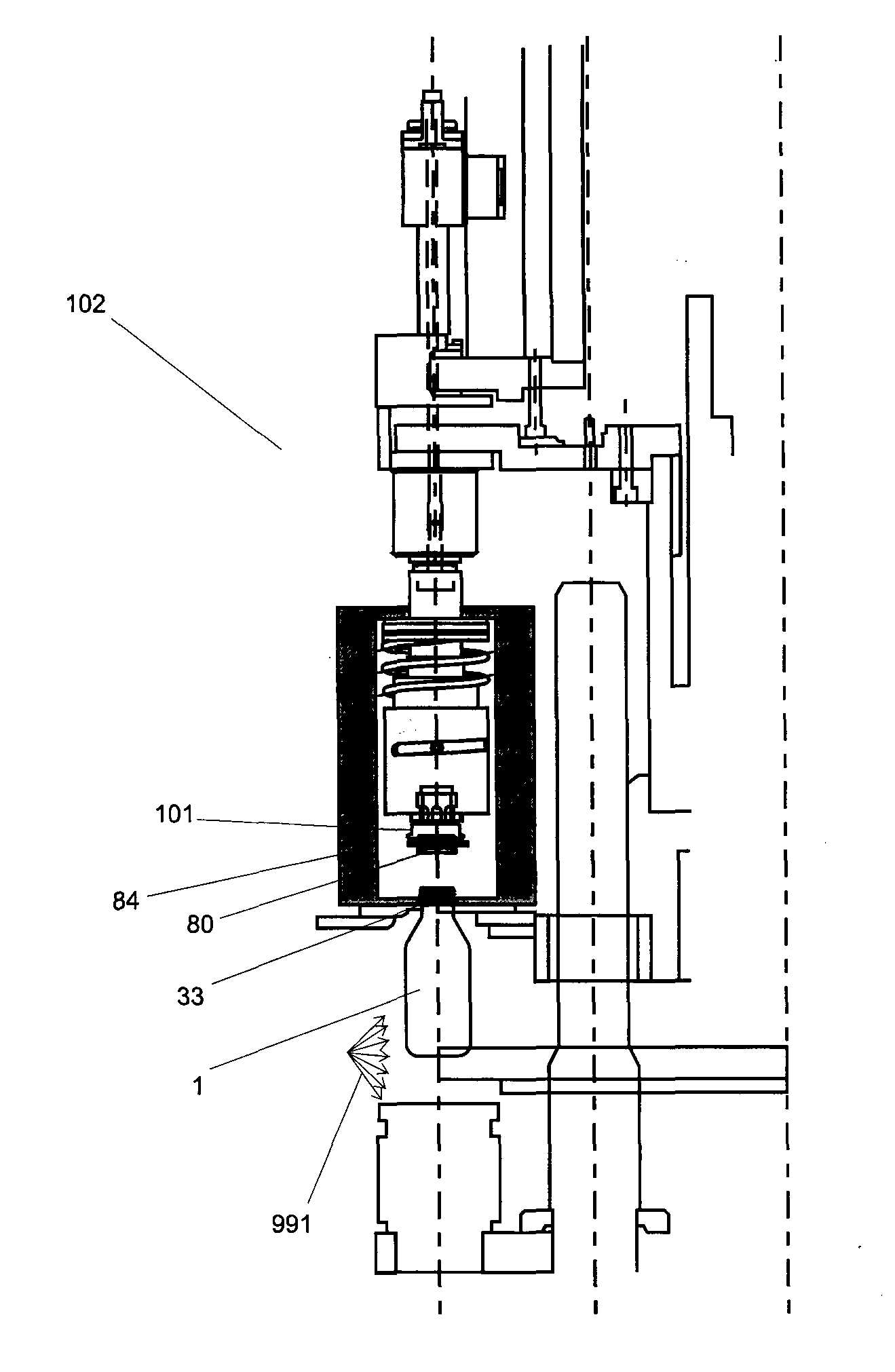

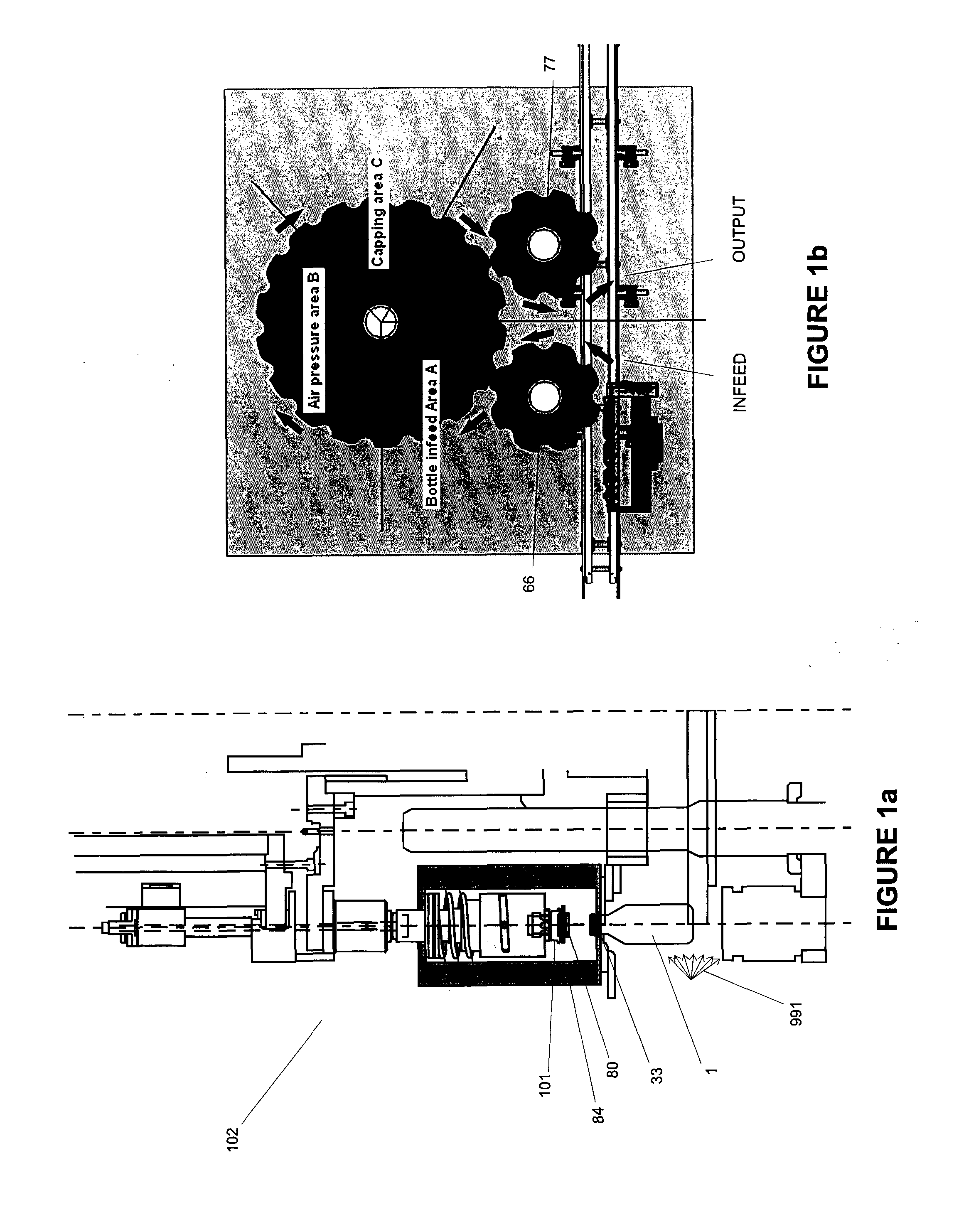

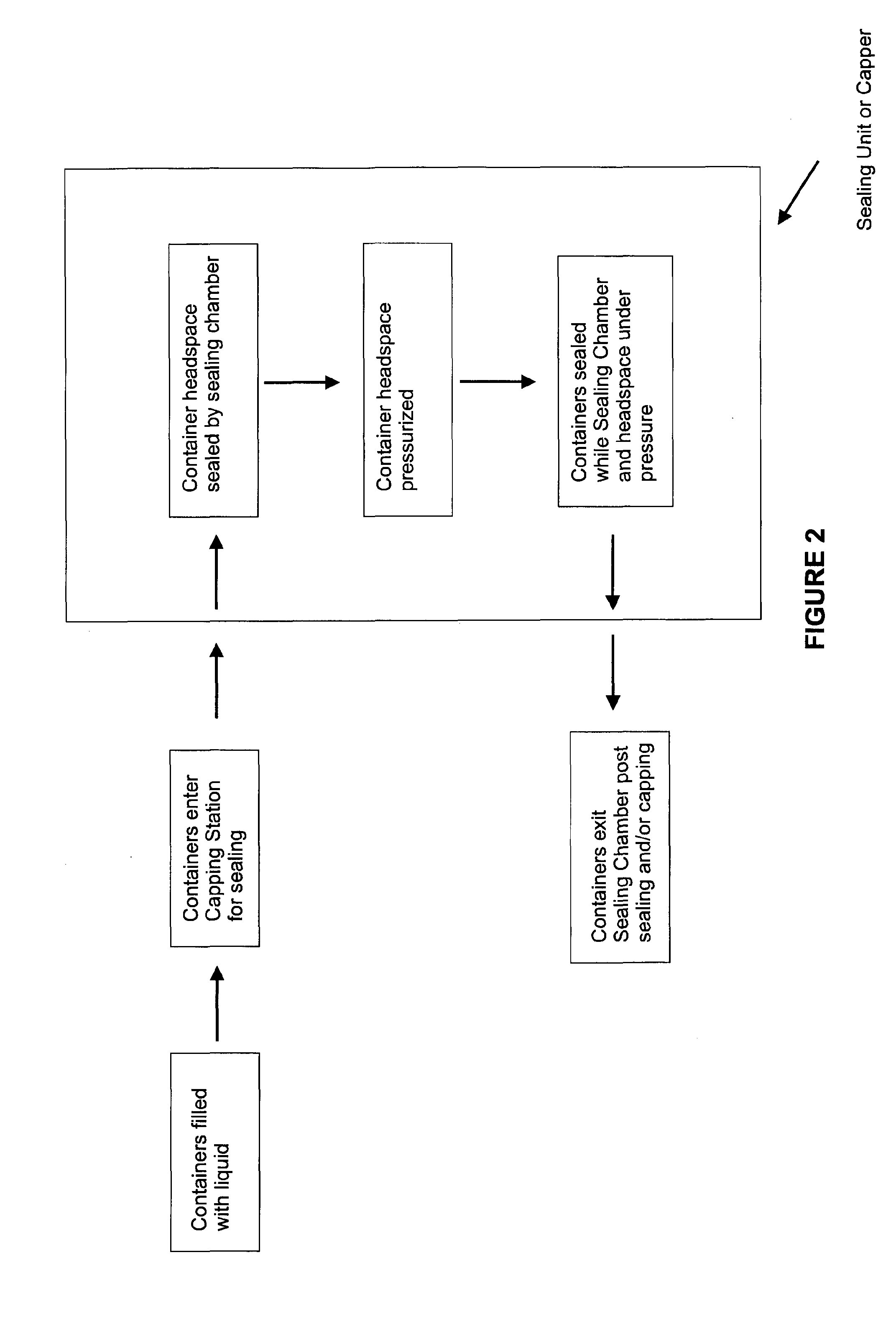

Embodiment Construction

[0091]In my further PCT specifications WO 2009 / 142510 and WO 2011 / 062512, the contents of which are herein incorporated in their entirety where appropriate, are described headspace modification methods and apparatus therefor.

[0092]However, in prior art proposals, in order to pressurize containers for both cold and hot filled beverage applications, containers must be conveyed through a nitrogen-dosing unit where nitrogen may be dripped into the unsealed bottles and shortly afterwards the bottles are sealed. The following description of preferred embodiments is merely exemplary in nature, and is in no way intended to limit the invention or its application or uses.

[0093]While the present invention is capable of various embodiments, there is shown in the drawings and specification some presently preferred embodiments, or parts of presently preferred embodiments, with the understanding that the present disclosures are to be considered as exemplifications of the invention, and are not int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com