Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Vacuum fryer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum fryer is a deep-frying device housed inside a vacuum chamber. Vacuum fryers are fit to process low-quality potatoes that contain higher sugar levels than normal, as they frequently have to be processed in spring and early summer before the potatoes from the new harvest become available. With vacuum frying it is easier to maintain natural colors and flavours of the finished product. Due to the lower temperatures applied (approximately 130 °C (266 °F)), the formation of suspected carcinogen acrylamide is significantly lower than in standard atmospheric fryers, where the frying temperature is approximately 170 °C (338 °F). The fat absorption of the products is also reported to be lower than in atmospheric fryers. In South East Asia (mainly Philippines, Thailand, China and Indonesia) batch type vacuum fryers are mainly used for the production of fruit chips. However, these machines are only appropriate for relatively small production companies.

Processing method of vacuum low-temperature fried okra

The invention discloses a processing method of vacuum low-temperature fried okra. The processing method comprises the following steps of: blanching okra after being cleaned in hot water; after cooling, quickly freezing in an instant freezer; placing the frozen okra in maltose solution for vacuum impregnation; after leaching, putting the mixture in the instant freezer for quick freezing; placing the frozen okra in a vacuum fryer for frying; and rotating a centrifugal deoiling machine for deoiling. The processing method has the characteristics that vacuum low-temperature frying technique is adopted for processing, the original color, flavor, taste and nutritional ingredients of okra are kept, the okra is crispy in mouthfeel, and secondary cooking is not required.

Owner:LAIYANG HENGRUN FOODSTUFF

Method for quick pretreatment of raw materials of lentinan and ultrasonic assisted extraction of lentinan

The invention relates to a method for quick pretreatment of raw materials of lentinan and ultrasonic assisted extraction of lentinan. The method comprises the following steps: (1) pretreatment, namely cleaning fresh mushrooms, dicing, putting the diced mushrooms into a microwave oven for low-fire batch treatment, next, feeding the sample into a vacuum fryer, drying, and grinding after oil removal; (2) degreasing; (3) water extraction, namely extracting the degreased dried mushroom powder under the conditions that the material-liquid ratio is 1:20, the ultrasonic operating power is 150W, the extraction temperature is 80 DEG C and the extraction time is 2.5 hours; (4) alcohol precipitation; (5) deproteinization; and (6) micromolecule removal, thereby finally obtaining the purified lentinan. According to the method for quick pretreatment of the raw materials of the lentinan and the ultrasonic assisted extraction of the lentinan, the pretreatment operation is simple and easy to industrially popularize, and the pretreated mushrooms have the water activity lower than 0.6 and can be preserved for a long time at a normal temperature; the extraction conditions are mild and do not cause damage to the structure and the configuration of the lentinan, the extraction rate is high and the cost is low.

Owner:SICHUAN AGRI UNIV

Method for preparing crispy dried sweet potatoes

The invention relates to a method for preparing crispy dried sweet potatoes and belongs to the technical field of agricultural product processing. According to the method, fresh white sweet potatoes which are free of worm damage, large in size, smooth in surface and easy to clean are adopted as the raw material, pretreatment including cleaning, peeling and slitting is conducted, then the sweet potatoes are cooked in a pot to be medium-well, transferred to an oven to be baked till surfaces become crispy, soaked with baijiu till the sweet potatoes become wet and soft, taken out, dried, placed in a vacuum fryer to be fried, subjected to centrifugation with a deoiling centrifuge, cooled and subjected to nitrogen-filled packing, and finally the crispy dried sweet potatoes which taste delicious, strong and pure and have a durable aftertaste are obtained.

Owner:刘楚玲

Processing technology of crisp, fragrant and sweet zea mays kernels

The invention relates to a crisp, fragrant and sweet zea mays kernel leisure food which takes zea mays kernels as raw materials and is eatable directly. A processing technology of crisp, fragrant and sweet zea mays kernels comprises the following steps of: removing impurities in zea mays, cleaning up, and performing stewing on zea mays kernels at 100 DEG C by steaming equipment until the zea mays kernels are thoroughly cooked; pre-cooling the zea mays kernels, and then slowly freezing the pre-cooled zea mays kernels at a temperature lower than 0 DEG C by a freezer; unfreezing at room temperature, blow-drying moisture on the surfaces of the zea mays kernels, and frying in a vacuum fryer until the moisture content of the zea mays kernels is 10-15%; and evenly mixing weighted star anise, pepper, Chinese cinnamon, clove, ginger and other spiceries, chilli powder, table salt, white granulated sugar and other accessories, cyclodextrin, antioxidant and other food additives, and the fired zea mays kernels in a mixing pot, weighting and performing gas packing to obtain the crisp, fragrant and sweet and delicious zea mays kernel leisure food.

Owner:杨大伟

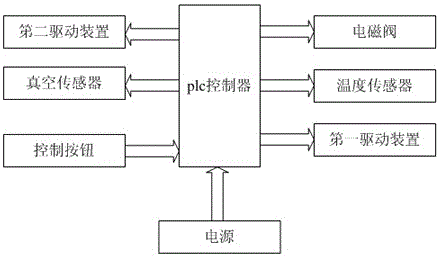

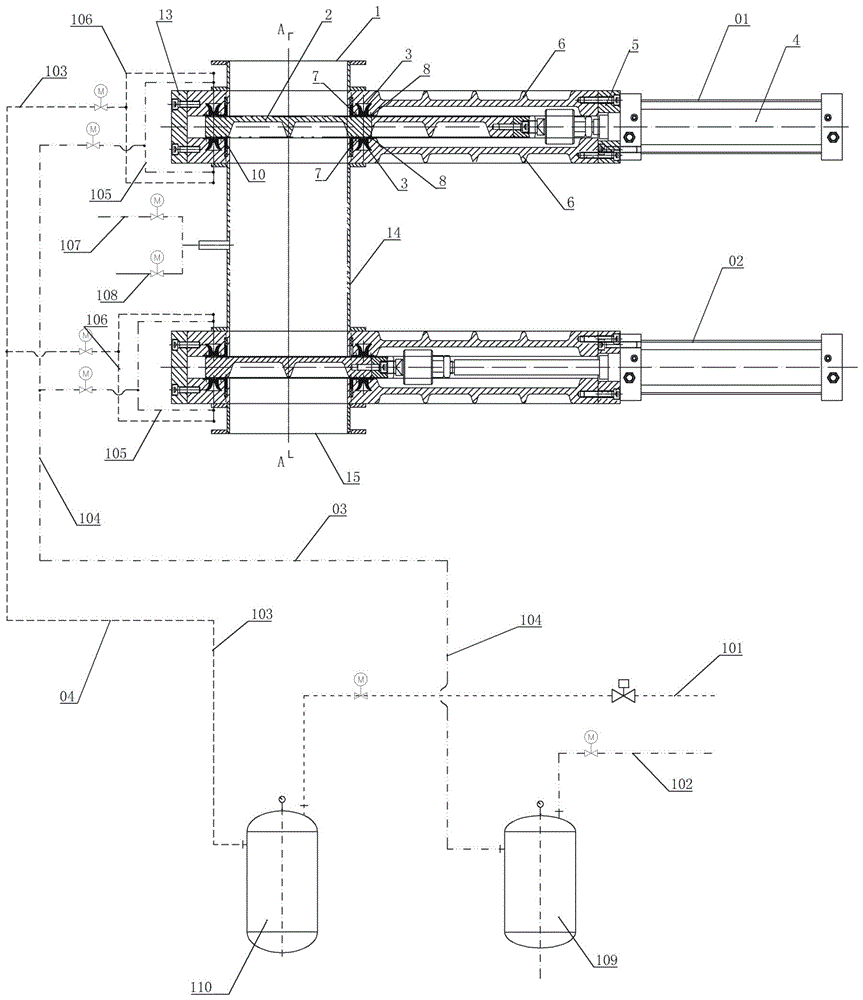

Efficient vacuum fryer and control method thereof

ActiveCN103907651AGuaranteed low temperature frying effectEvenly heatedOil/fat bakingProgramme control in sequence/logic controllersProgrammable logic controllerElectromagnetic valve

The invention discloses an efficient vacuum fryer and a control method thereof. The efficient vacuum fryer comprises an outer fryer body, an inner pot and a processing pot, the outer fryer body is a sealed box, the inner pot is arranged in the outer fryer body and used for loading oil, steam heating tubes are arranged in the inner pot, a steam intake tube is arranged on one side of the outer fryer body and communicated with a steam inlet of each steam heating tube, and an electromagnetic valve is arranged on the steam intake tube. A temperature sensor is arranged on the inner wall of the inner pot. The processing pot is arranged in the inner pot, a first driving device is arranged on the inner wall of the outer fryer body on one side of the processing pot, and the first driving device is connected to one side of the processing pot through a driving arm. A fryer door capable of sliding up and down is arranged on one end face of the outer fryer body, a second driving device is arranged on the outer side wall of the outer fryer body and connected with the fryer door through a driving arm, and lifting and swinging of the processing pot are controlled via a PLC (programmable logic controller) according to data detected and returned by the temperature sensor of the processing pot and a displacement sensor. The efficient vacuum fryer is simple in structure, and low-temperature frying effect of food is guaranteed.

Owner:LAIYANG HENGRUN FOODSTUFF

Processing method of nuts capable of being peeled by hand

InactiveCN107616466AProcessing method realizationReduce nutrient lossFood scienceFreeze-dryingAtmospheric pressure

The invention discloses a processing method of nuts capable of being peeled by hand. The processing method comprises the following steps: screening nuts, cleaning and airing the screened nuts, and freezing the aired nuts at -20 to 4 DEG C for 2-6 hours; putting the frozen nuts into a vacuum pot, heating the nuts at the air pressure of 0.1-0.9MPa and the temperature of 80-600 DEG C, and simultaneously rotating the vacuum pot up and down at the rotation speed of 2r / min-43r / min for 3-60 minutes, wherein rotating shafts are arranged at the two ends of the pot body of the vacuum pot and the cross section of the pot body is round; charging the heated nuts into vacuum freeze drying equipment for performing quick freezing to enable the nutshells to crack at the air pressure of 1.3-13Pa for 10-30 minutes; charging the cracked nuts into a vacuum frying pot for performing air frying at 80-100 DEG C for 25-60 minutes; charging the fried nuts into a vacuum low-temperature drier for performing drying at the air pressure of 0.4-0.9MPa and the temperature of 110-150 DEG C for 30-90 minutes; and performing screening and packaging. Through the above mode, the processing method of nuts capable of being peeled by hand is realized through a vacuum low-temperature technique.

Owner:ANHUI LIREN FOOD

Preparation process of spiced beef

InactiveCN110495568AIncrease profitExtended shelf lifeFood ingredient as antioxidantFood ingredient as thickening agentSide effectVacuum fryer

The invention discloses a preparation process of spiced beef. The preparation process comprises the following steps: (1) raw materials are taken in parts by weight; (2) the materials are packed; (3) boiling out is conducted; (4) spicing is conducted; (5) air drying is conducted; and (6) fragrant frying is conducted, specifically, 300-500 parts of spiced beef strips are taken out and sliced into beef slices with the thickness being 0.3-0.6 cm, 10-30 parts of soy sauce is evenly smeared on the surfaces of the beef slices, after being pickled for 10-30 minutes, the beef slices are sent into a vacuum fryer to be fried for 5-10 minutes, and then the spiced beef can be obtained. Preparation of the sauce is based on a traditional Chinese medicine theory and an existing cooking technology, the spiced beef has perfect combination of color, aroma and taste, is balanced in nutrition, and has a health care effect on intestines and the stomach, and the spiced beef prepared from the sauce has the longer shelf life, and has no side effect on the body after being eaten for a long time.

Owner:成都市恒业生态农产品电子商务有限公司

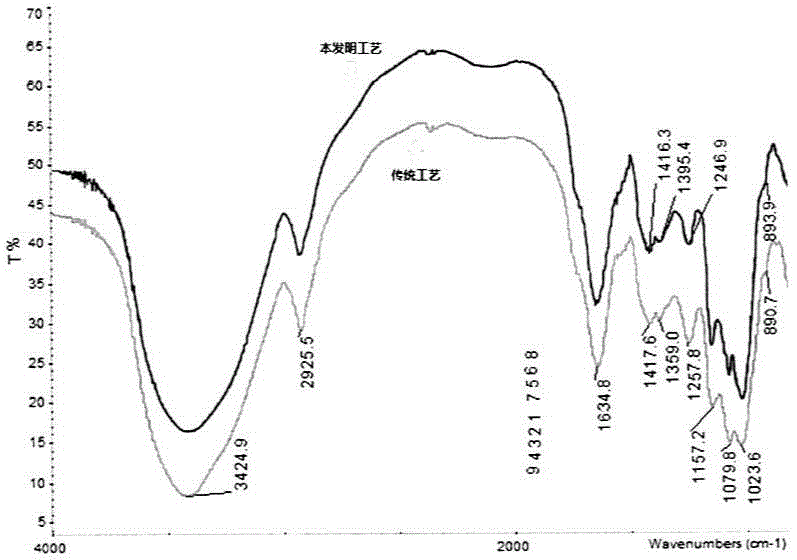

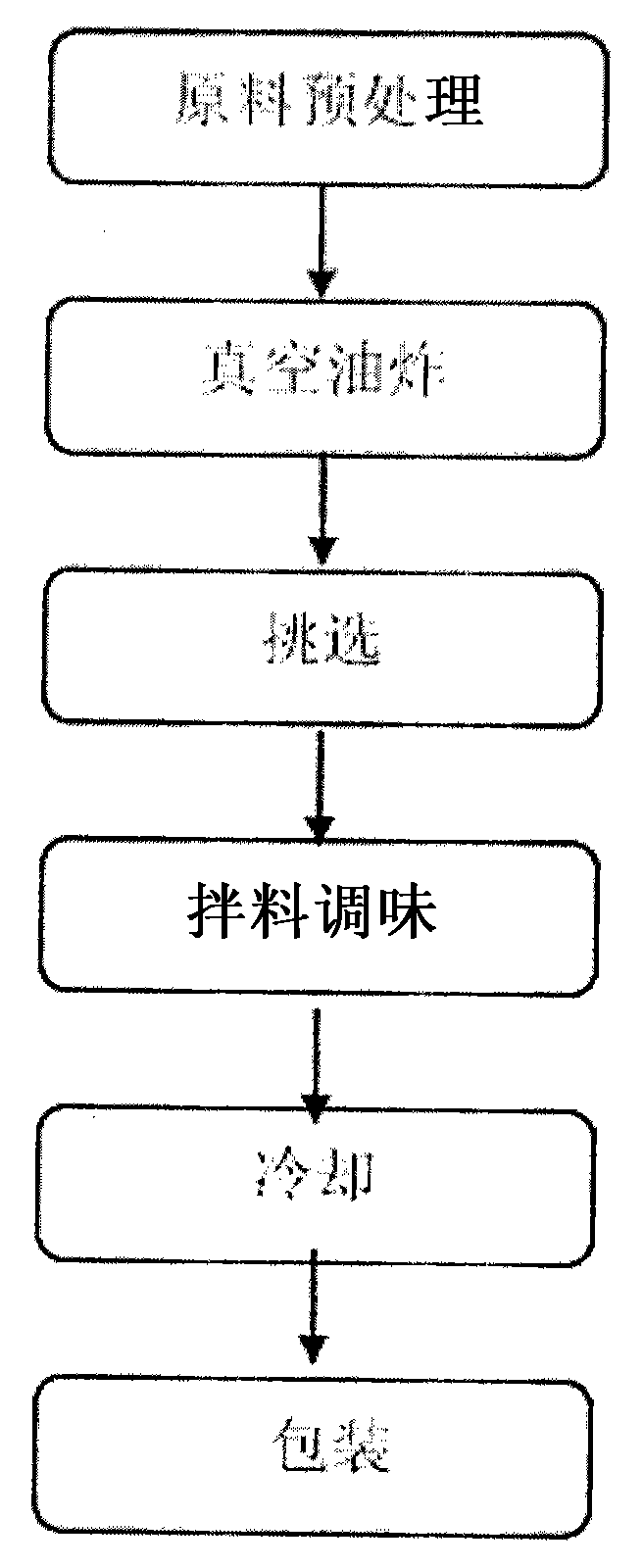

Vacuum low-temperature frying equipment and method

The invention relates to vacuum low-temperature frying equipment and method, and aims at providing vacuum low-temperature frying equipment and method with the advantages that the operation is continuous, the operation is simple and convenient, the labor cost is reduced, and the mouth feel of fried food is good. The method comprises the following steps of sending to-be-fried material into a vacuum frying pot for frying, maintaining the process temperature to 80-110 DEG C and the frying time to 30-40 minutes, automatically controlling the temperature in the frying process, and automatically removing oil after frying; putting the fried food into a collection hopper, and removing defective semi-finished products and impurities on a frying conveying line; stirring the material by a stirrer in a rolling way, and uniformly mixing the sorted fried semi-finished products and the auxiliary materials; conveying the semi-finished products to a cooling line for cooling, and maintaining the temperature to 20-30 DEG C by adjusting, increasing and reducing the number of cooling fans; conveying the seasoned fried semi-products to a package table, and packaging.

Owner:SUZHOU KOUSHUIWA FOOD

Preparation method of day lily fruit and vegetable crisp chips

The invention provides a preparation method of day lily fruit and vegetable crisp chips. The preparation method comprises the following steps: (1) carefully selecting fresh day lily, performing fixation in boiling water, performing washing with water, performing cooling and performing draining; (2) chopping the day lily after fixation, performing transferring to a high-speed shearing machine, adding water according to a ratio of 100 parts of the day lily after fixation and 25-40 parts of water, performing shearing at a high speed to obtain day lily pulp, adding 10-20 parts of starch, 0.2-1 part of edible salt and / or 1-5 parts of sucrose, continuously performing shearing, performing uniform dissolving, heating the obtained mixed pulp to 60-75 DEG C by a continuous forming pelleter, performing gelatinizing and performing cutting into slices; and (3) performing frying in a vacuum fryer to be crisp, performing spin-drying to remove oil, performing cooling, performing grading, and performing packaging in a moistureproof manner to obtain the day lily fruit and vegetable crisp chips. The day lily fruit and vegetable crisp chips obtained by the method are not greasy, crisp in mouth feel and delicious in flavor, well maintain color, appearance, flavor, taste and nutrition of the day lily, have the characteristics of low fat, low calorie, high cellulose and the like, are convenient to eat, and are suitable for people of all ages.

Owner:湖南新发食品有限公司

Processing method for improving elasticity of crayfish meat

InactiveCN109820162ALittle elasticityMitigate the loss of elasticityMeat/fish preservation using chemicalsDeep fryingAquatic product

The invention belongs to the technical field of processing of aquatic products, and particularly relates to a processing method for improving the elasticity of crayfish meat. The crayfish meat prepared by means of the method is high in elasticity and oxidation resistance, and the texture of the crayfish meat is improved. The processing method is characterized by comprising the steps of removing crayfish intestines after fresh crayfishes are brushed thoroughly with clear water; conducing microwave heating on the crayfishes; putting the crayfishes after microwave heating treatment into a fryingpan for stir-frying, putting fructus schizandrae which accounts for 0.1-0.3% of the mass of the crayfishes and tea leaves which account for 0.05-0.1% of the mass of the crayfishes into the frying fan,and conducting stir-frying for 1-2 min; putting the crayfishes into a vacuum deep-frying pan for deep-frying, conducting deep-frying for 1-2 min under the vacuum degree of 70-80 KPa, wherein the deep-drying temperature is 60-70 DEG C; fishing out the crayfishes, pouring the crayfishes into the pan, adding condiments, conducting stir-frying for 3-5 min, and then transferring the crayfish meat outof the pan.

Owner:HUNAN UNIV OF ARTS & SCI

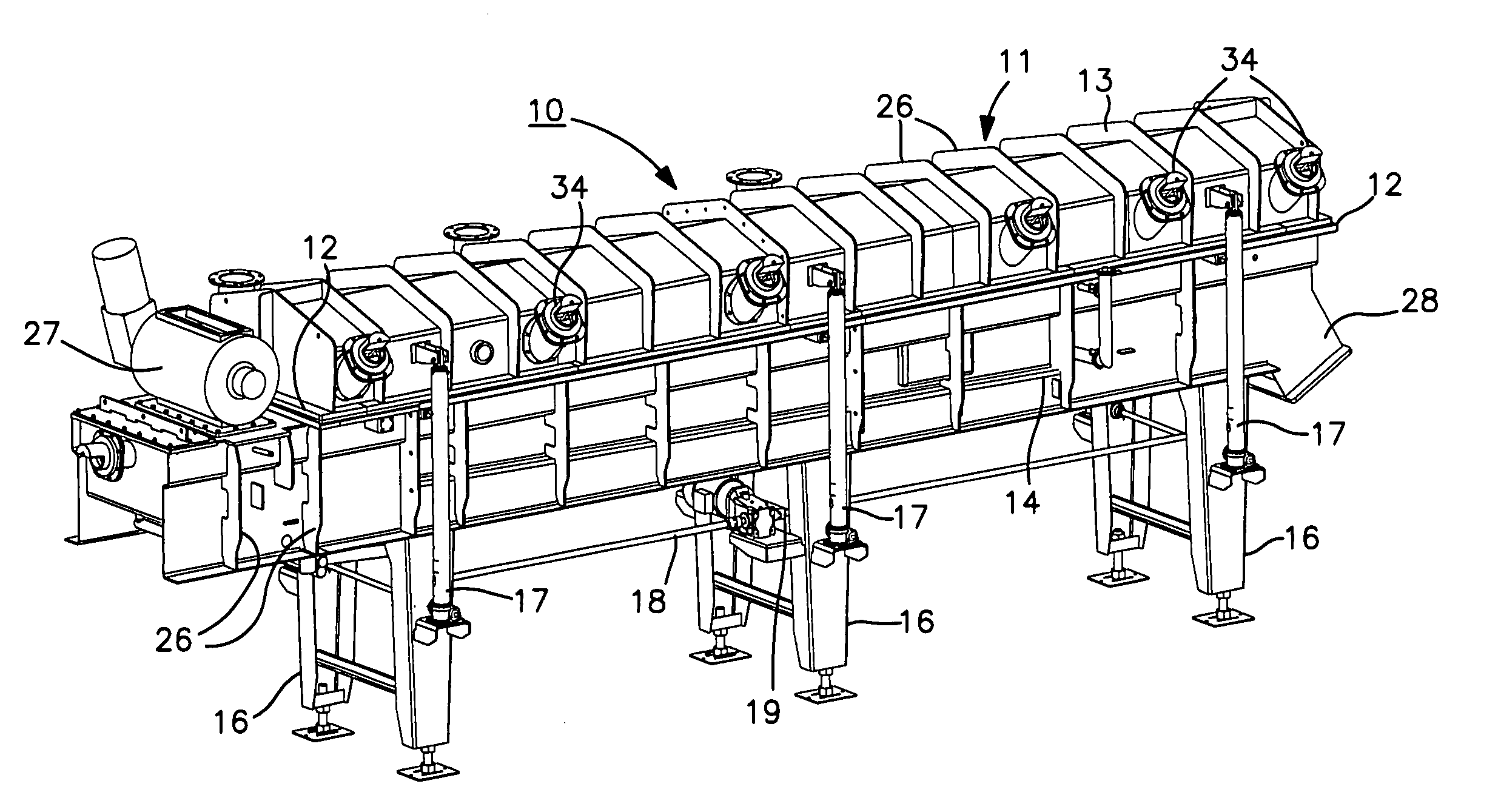

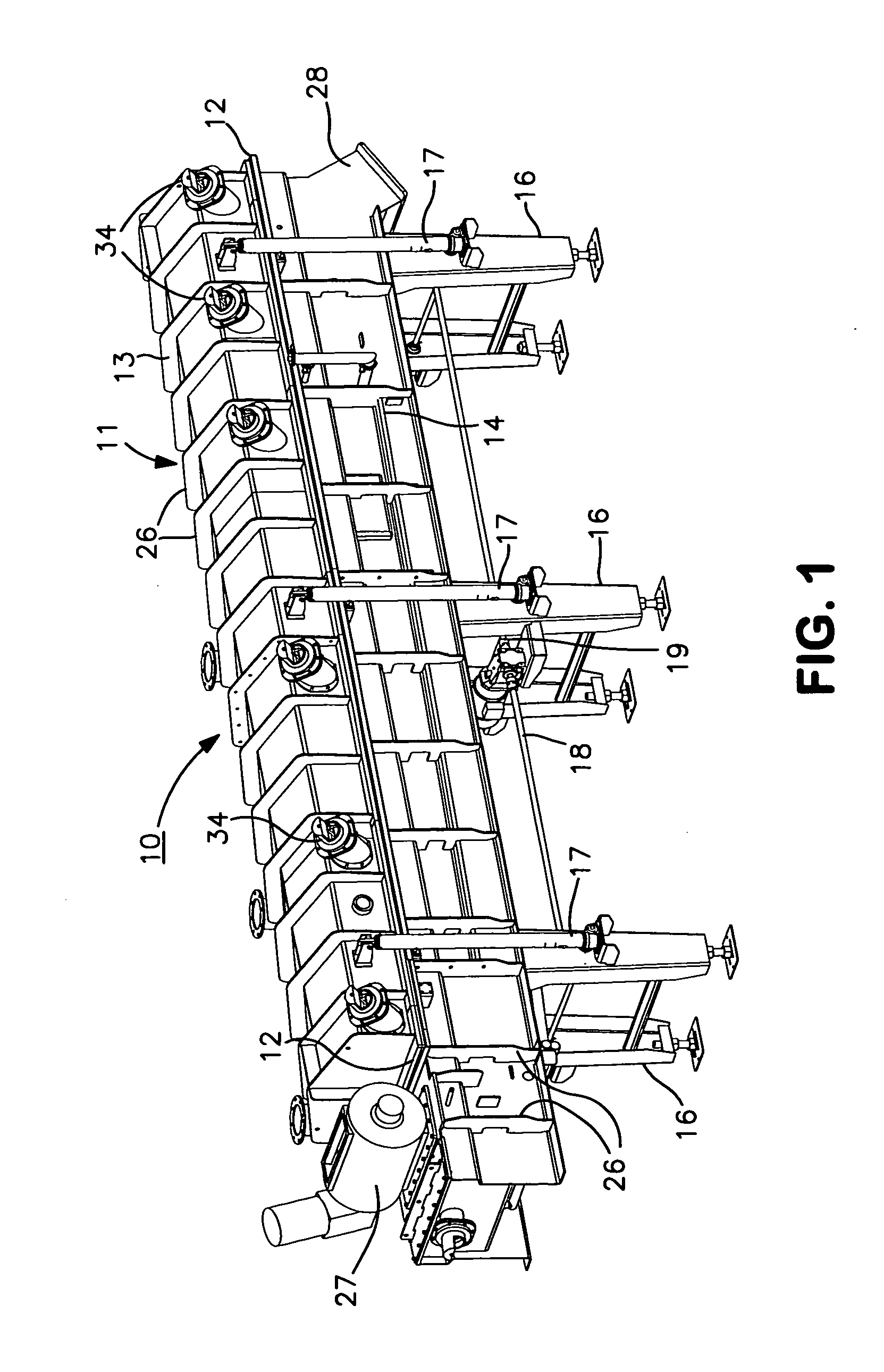

Unitized vacuum fryer

ActiveUS8651016B2Easy to openReduce manufacturing costSteam cooking vesselsDeep fat fryersEngineeringVacuum fryer

The unitized vacuum fryer is capable of low atmosphere vacuum cooking and has an elongate cooking tunnel having an upper portion separable from a base portion for cleaning and maintenance. When hermetically sealed together the two portions function to retain a high vacuum for an enclosed fry cooking system. Hermetic sealing locks at each end of the tunnel afford product entry and exit. The vacuum fryer does not require a separate enclosing pressure vessel.

Owner:HEAT & CONTROL

Preparation method of refrigerated fresh-keeping flavored crayfishes

InactiveCN109820160ARaise the pHLittle elasticityMeat/fish preservation by freezing/coolingPrawnDeep frying

The invention belongs to the technical field of aquatic product processing, and particularly relates to a preparation method of refrigerated fresh-keeping flavored crayfishes. By means of the method,the storage period of the crayfishes can be prolonged, the meat of the refrigerated crayfishes still keeps high protein content and elasticity, the good taste is maintained, and a longer crayfish storage and transportation period is provided for families or production industries. The method is characterized in that fresh crayfishes are placed in clear water for temporary breeding; the crayfishes are fished out and placed in an aqueous solution of acetic acid, semen cassiae, broad bean powder and gleditsia sinenis lam gum are added into the aqueous solution and mixed uniformly, and the crayfishes are completely submerged in water, cooled, frozen into blocks and refrigerated for storage; the refrigerated crayfish ice blocks are unfrozen, and the crayfishes are thoroughly washed and brushed with clear water; the crayfishes are put into a vacuum fryer for deep frying; the crayfishes are fished out and poured into a hot oil pot, seasonings are added, and stir frying is carried out; sauce ispoured into the pot, braising is conducted for 2-3 min, and the crayfishes can be taken out of the pot.

Owner:HUNAN UNIV OF ARTS & SCI

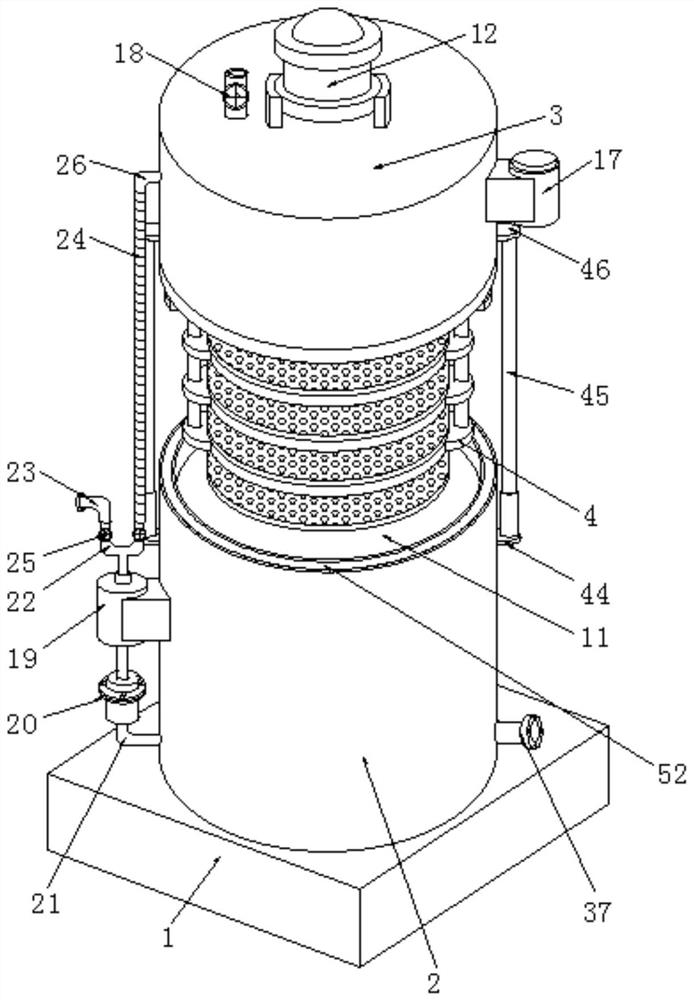

Upper driving type no-clean vacuum fryer

PendingCN111481076AGuaranteed cleanlinessSolve the retentionDeep fat fryersStructural engineeringMechanical engineering

The invention discloses an upper driving type no-clean vacuum fryer comprising a pot body, an annular pot cover pressed on the top of the pot body in a sealed mode, and a circular pot cover pressed onan opening of the annular pot cover in a sealed mode. A bracket extending into the pot body is connected to the inner wall of the annular pot cover, a frying basket with an opening in the top and located in the pot body is rotatably connected to the bracket, and a left driving mechanism capable of driving the annular pot cover to swing leftwards and upwards so as to swing the frying basket out ofthe outer side of the pot body is arranged on the outer side of the pot body; a pressing disc for driving the frying basket to rotate is mounted at the bottom of the circular pot cover; a right driving mechanism for driving the circular pot cover to lift up and down and swing towards the upper right side is arranged at the outer side part of the pot body. The vacuum fryer is simple in structure,the problems of residue retention and accumulation are solved, the residue discharging effect is improved, vacuum frying operation can be achieved, frying work and pan bottom self-cleaning work can beachieved at the same time, the cleanliness of oil in the frying process can be guaranteed, and the frying effect and the product quality are improved.

Owner:张培森

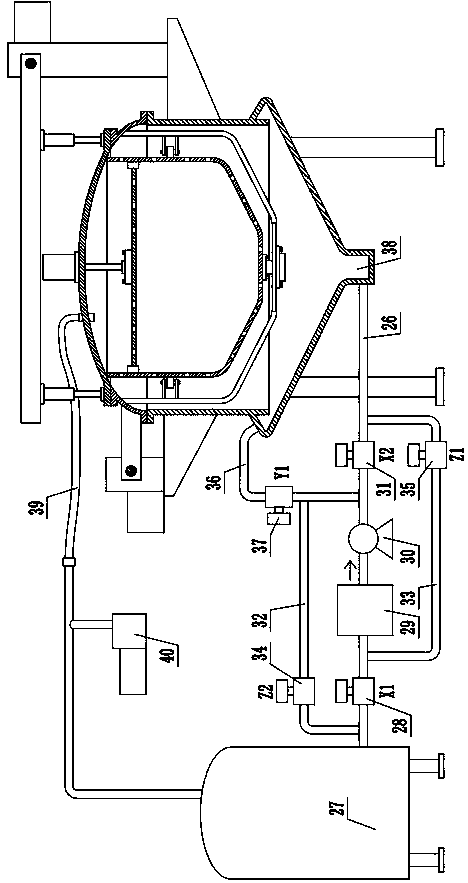

Intelligent low-temperature vacuum fryer

ActiveCN103907652AGuaranteed low temperature frying effectEvenly heatedOil/fat bakingFood safetyEngineering

The invention relates to an intelligent low-temperature vacuum fryer comprising an outer member, an inner pot, and a foodstuff pot. The outer member is a sealed box. The inner pot is disposed in the outer member and used for carrying oil. A steam heating tube is disposed in the inner pot. One side of the outer member is provided with a steam incoming tube. The steam incoming tube is communicated with a gas inlet of the steam heating tube. The steam incoming tube is provided with an electromagnetic valve. A temperature sensor is disposed on the inner wall of the inner pot. The foodstuff pot is disposed in the inner pot. A first driver is disposed on the inner wall of the outer member on one side of the foodstuff pot. The first driver is connected to one side of the foodstuff pot through a drive arm. One end face of the outer member is provided with a pot door capable of sliding up and down. The outer wall of the outer member is provided with a second driver. The second driver is connected with the pot door through another drive arm. A feed hole of the outer member is provided with a food safety detection system. The intelligent low-temperature vacuum fryer has the advantages that intelligent video control is achieved and low-temperature frying of foods is guaranteed.

Owner:LAIYANG HENGRUN FOODSTUFF

Preparation method for vacuum-fried puffing potato chips

The invention discloses a preparation method for vacuum-fried puffing potato chips. The preparation method comprises the steps of raw material selecting, chip cutting, quick freezing, vacuum frying and packaging. The vacuum frying method specifically comprises the steps that quick-frozen potato chips are put into a vacuum frying pot, and vacuumizing is performed intermittently, wherein vacuumizing is controlled to be performed at the speed that the vacuum degree is reduced by 10-20 KPa per minute, then frying is performed for 1-2 min by keeping the vacuum degree, vacuumizing and frying are repeatedly performed until the vacuum degree in the vacuum frying pot reaches 80-95 KPa, frying is continuously performed for 1-5 min by keeping the vacuum degree invariable, then vacuum frying is completed, and the frying temperature is controlled at 60 DEG C-80 DEGC in the vacuum frying process; after vacuum frying is completed, vacuum deoiling is performed by continuously keeping the vacuum degree invariable. The vacuum-fried puffing potato chips prepared through the method are good in quality and mouthfeel and stable in quality.

Owner:长沙星达知识产权服务有限公司

Processing technology of Taiwan style lotus root cake

InactiveCN106974228AThe processing technology is easy to operateNice appearanceFood coatingOil temperatureLotus root

The invention discloses a processing technology of a Taiwan style lotus root cake. The processing technology comprises the steps as follows: preparing, cleaning and slicing lotus roots; preparing minced meat; preparing crisp paste; placing lotus root sandwiches coated with the crisp paste in a vacuum fryer to be fried at the oil temperature of 150-160 DEG C for 6 min; cooling the fried lotus root sandwiches to obtain a finished product, and quick-freezing and packaging the finished product. The processing technology of the Taiwan style lotus root cake is simple to operate, the lotus root sandwiches coated with the crisp paste are placed in the vacuum fryer, and the produced lotus root sandwich product is attractive in appearance and intact in shape. The Taiwan style lotus root cake fried according to the processing technology and the formula of the Taiwan style lotus root cake tastes crisp, has lasting aftertaste, has low oil content and conforms to modern health concept because no expanding agents, crisping agents or chemical seasonings are added and frying is conducted in the vacuum fryer.

Owner:徐加将

Energy-saving vacuum fryer

The invention discloses an energy-saving vacuum fryer, which belongs to the technical field of fruit and vegetable production frying, and comprises a base, a fryer main body is arranged on the upper surface of the base, the fryer main body comprises a shell I and a shell II through a hydraulic rod, the shell II can be controlled by the hydraulic rod to extend or contract to realize up-and-down movement, the shell I is installed on the base, a containing frame is arranged in the shell I, and a driving part used for driving the containing frame to rotate so as to achieve rapid deep-frying is installed on the shell II. A plurality of placing seats are matched with connecting blocks, fixing blocks and screens to form a placing frame for placing fruits and vegetables, different fruits and vegetables can be separately placed, the screens are used for ensuring that deep-frying liquid enters the placing seats for deep-frying, and meanwhile, a motor is matched to drive a rotating shaft and a positioning plate to drive the placing frame to rotate; the product can fully operate when fruits and vegetables are fried, the vacuum fryer is simple in structure and convenient to use, and the deep-frying effect is effectively improved.

Owner:安徽东方果园生物科技有限公司

Processing technology of fragrant and sweet corn grains

InactiveCN105581088AOvercome the problems of many processes and heavy workloadIncrease profitFood preparationFood additiveAdditive ingredient

The invention discloses a processing technology of fragrant and sweet corn grains. The processing technology comprises the following steps: removing impurities from the corn grains and fully washing the corn grains; steaming the corn grains by a steaming device at high temperature until the corn grains are fully cooked; pre-cooling the corn grains and slowly freezing the corn grains by a freezing device; unfreezing the corn grains at room temperature; blowing the corn grains so as to dry the moisture on surfaces of the corn grains; frying the corn grains in oil by a vacuum frying pan; uniformly mixing the fried corn grains with weighed spices, accessory ingredients and food additives in a material-mixing pot, wherein the accessory ingredients comprise star anises, pricklyash peels, barks of Japanese cinnamon, cloves, fresh gingers and the like, the accessory ingredients comprise hot-pepper powder, table salt, white granulated sugar and the like, and the food additives comprise cyclodextrin, antioxidant and the like; and packing the corn grains in measured inflatable packages, so that a crispy, sweet and delicious corn leisure food is prepared.

Owner:吕子玉

a vacuum fryer

InactiveCN104222182BAccurate placementEasy to operateOven doors/gatesOil/fat bakingVacuum fryerOperating table

The invention discloses a novel vacuum fryer and relates to the technical field of fryers. Vertical shafts (5) are vertically arranged on upper portions of tank upper covers (2), material fences (8) are arranged in tanks (1), material fence covers (7) are arranged on upper portions of the material fences (8), the material fence covers (7) are fixed on the tank upper covers (2) through connecting shafts (6), ladders (15) are respectively arranged on front sides of two operating tables (14), and a mechanical arm (13) is arranged between the two tanks (1). The tank upper covers are opened by lifting, and when the tank upper covers are lifted, oil on inner sides of the covers flows to oil receiving trays along the inner sides of the covers and finally is recycled in the tanks with no waste. Taking out and placing of the material fences are all operated by the mechanical arm, the mechanical arm is precise in placing position, the tank upper covers and the material fence covers are integrally arranged, when the tank upper covers are opened, the material fence covers of air cylinders rise, and when the tank upper covers are closed, the air cylinders push the material fence covers to decline to cover the material fences, and therefore, novel vacuum fryer is convenient to operate.

Owner:全武

Application of rice noodle residues to simulating puffed rice bars

InactiveCN110214863AUniform humidityImprove the economic effect of usingFood processingAnimal feeding stuffHigh humidityDeep frying

The invention discloses application of rice noodle residues to simulating puffed rice bars, and belongs to the field of rice noodle residue waste recycling. The dry rice noodle residues cut from riversnails rice noodles are used as the raw material of the deep-fried simulating puffed rice bars for preparing the deep-fried puffed rice bars. The process of preparing the simulating puffed rice barsfrom the rice noodle residues specifically includes the steps of sieving the rice noodle residues with different lengths through a vibration rotary mesh cylinder, conducting high-pressure air-blowingimpurity removal on the sieved rice noodle residues through high-pressure air, putting the impurity-removed rice noodle residues into a high-pressure, high-temperature and high-humidity box for softening and wetting treatment, and putting the softened and wetted rice noodle residues into a vacuum deep-frying pot to be deep-fried. When the dry river snails rice noodles are cut for the consistent length during packaging, some rice noodle residues can be left, the rice noodle residues are cooked, heated and dried rice noodle residues and cannot have a good effect when being reused in the later period or used as a feed for pigs, and 0.5 kg of rice noodle residues can be sold for the profit of 50-70 RMB after being deep-dried.

Owner:广西三农食品有限公司

Mushroom processing method

InactiveCN109527535ASolve the problem of not being able to eat directlyFood scienceShiitake mushroomsVacuum fryer

The invention relates to a mushroom processing method, which relates to the technical field of food processing, and the method includes the following processes: decolorization, dewatering, crisping, flavoring, and drying. The decolorization step comprises the following processes: dried mushroom is selected and put into a cleaning tank, wherein the weight ratio of mushroom to water in the cleaningtank is 1:2, salt is added to the water, the mass ratio of salt to water is 1:1000-1:1500, wherein the materials are uniformly stirred during the whole process. The dewatering step comprises the following processes: the stirred mushroom is spread and placed in the environment of minus 30 DEG C to minus 24 DEG C for 6 to 8 hours. The crisping step comprises the following processes: the mushroom issent to a vacuum fryer for frying; the frying temperature is between 80 DEG C to 95 DEG C, and the frying time is 1 to 3 minutes. The flavoring step comprises the following processes: the fried mushroom is removed, and cooled to below 40 DEG C. The drying step comprises the following processes: the cooled mushroom is poured into a centrifuge for de-oiling for 3 to 4 minutes, and is rotated in a centrifuge; the processed mushroom is mixed with the seasoning, and the seasoning ratio is 1% of the weight of the mushroom, and after uniform blending, the mushroom can be bagged.

Owner:杨满辉

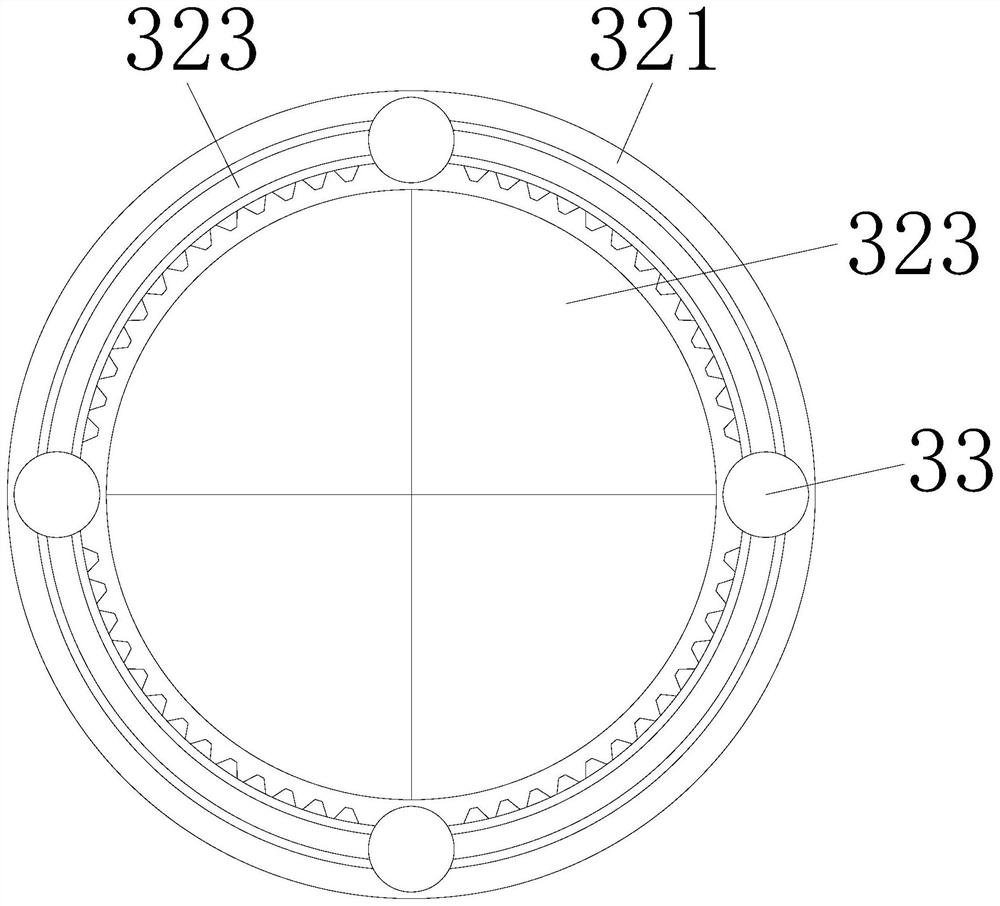

Self-cleaning full-automatic vacuum fryer

Owner:山东瑞海自动化科技有限公司

A kind of low-temperature vacuum frying equipment and processing method

The invention relates to the field of food processing equipment, in particular to a low-temperature vacuum frying equipment and processing method, comprising: a frying chamber, a water vapor heat source, an oil storage tank, a heating oil tank and a vacuum condensing device, the bottom of the frying chamber A pallet is arranged at the center, and the pallet is connected with the motor at the bottom. The low-temperature vacuum frying machine provided by the present invention can solve the problems of unstable oil temperature, excessive oil temperature, fruit and vegetable sticking, and complicated frying oil recovery. High quality, suitable for industrial production.

Owner:青岛六一机械有限公司 +1

Unitized vacuum fryer

ActiveUS20120279399A1Easy to openReduce manufacturing costSteam cooking vesselsDeep fat fryersAtmosphereVacuum fryer

The unitized vacuum fryer is capable of low atmosphere vacuum cooking and has an elongate cooking tunnel having an upper portion separable from a base portion for cleaning and maintenance. When hermetically sealed together the two portions function to retain a high vacuum for an enclosed fry cooking system. Hermetic sealing locks at each end of the tunnel afford product entry and exit. The vacuum fryer does not require a separate enclosing pressure vessel.

Owner:HEAT & CONTROL

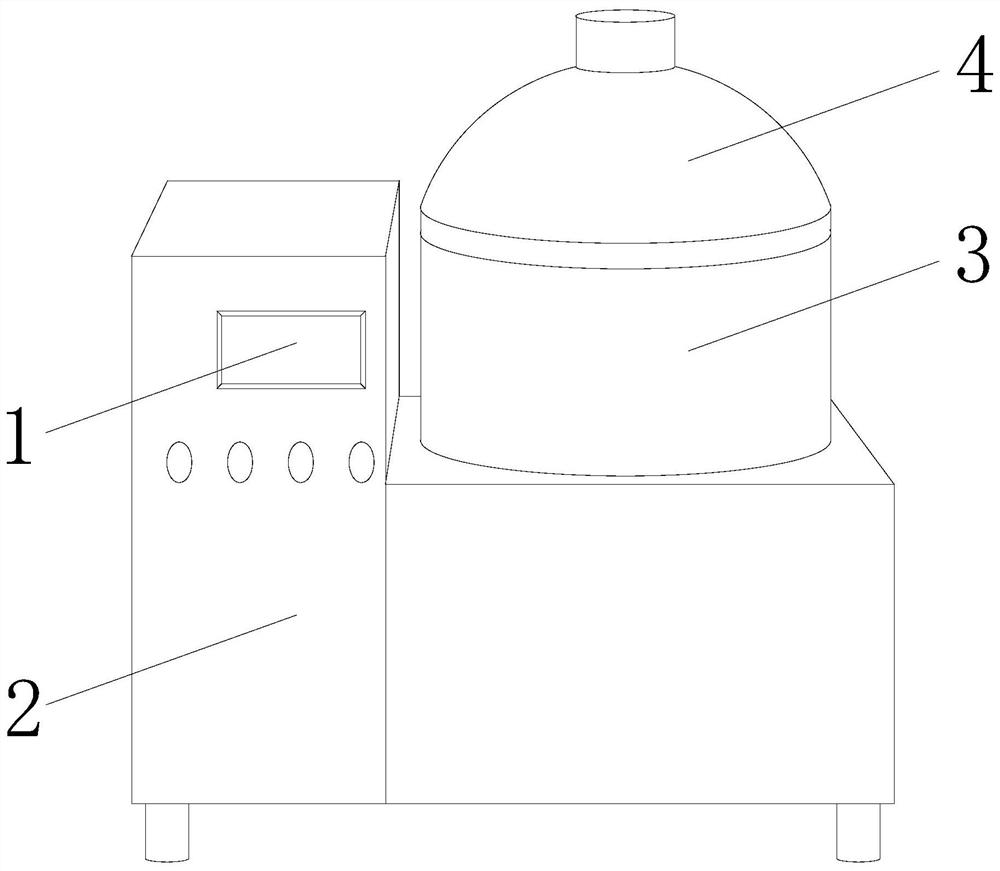

A vacuum fryer in which steam pressure moves ingredients to be heated evenly

The invention discloses a vacuum fryer in which steam pressure stirs ingredients to be evenly heated. Its structure includes a display panel, a steam heater, a steam pressure vacuum fryer, and a vacuum pot cover. Electrically connected by wires, the steam heater is installed inside the right end of the steam pressure vacuum fryer, and a vacuum cover is installed on the top of the steam pressure vacuum fryer. When the steam pressure vacuum fryer is working, steam pressure is generated inside and passes through the peak. The steam pressure collector collects the steam pressure and collects water vapor, and then transmits the pressure to the steam pressure compression tube, and compresses the pressure through the steam pressure compression tube to increase the power. The nozzle sprays the airflow, and moves the ingredients in the middle to the wall of the steam pressure vacuum fryer. The ingredients flow repeatedly from the center of the fryer to the sides of the wall, so that the ingredients are heated more evenly.

Owner:铜陵高新产业园发展有限公司

An intelligent low-temperature vacuum fryer

ActiveCN103907652BGuaranteed low temperature frying effectEvenly heatedOil/fat bakingFood safetySolenoid valve

The invention relates to an intelligent low-temperature vacuum fryer, which includes a pot outer body, an inner pot and a material pot. There is a steam heating pipe inside the pot, a steam inlet pipe is arranged on one side of the outer body of the pot, the steam inlet pipe is connected to the air inlet of the steam heating pipe, and a solenoid valve is arranged on the steam inlet pipe; a temperature sensor is arranged on the inner wall of the inner pot; The pot is arranged in the inner pot, and the inner wall of the outer body of the pot on one side of the pot is provided with a first driving device, and the first driving device is connected to one side of the pot through a driving arm; one end surface of the outer body of the pot is opened There is a pot door that can slide up and down, and a second driving device is installed on the outer wall of the outer body of the pot, and the second driving device is connected to the pot door through a driving arm; a food safety detection system is set at the feeding port of the outer pot. The invention realizes the intelligent control of the video and ensures the low-temperature frying effect of the food.

Owner:LAIYANG HENGRUN FOODSTUFF

Low-temperature and vacuum walnut kernel frying device

Disclosed is a low-temperature and vacuum walnut kernel frying device. The low-temperature and vacuum walnut kernel frying device is composed two identical vacuum fryers and a vacuum tank, wherein each vacuum fryer is in a structure with an inclined bottom, a cylindrical body and a sealing cover, the bottom side surface of the inclined bottom is provided with an oil residue discharging port and avalve, the circumference of the cylindrical body is sequentially provided with a heating layer and a heat insulating layer, one side of the upper portion of the cylindrical body is provided with a vibrating motor, and the other side opposite to the vibrating motor is provided with the support ring and the inverted L-shaped cantilever of a sealing cover opening device; the sealing cover is closed by a rotating screw fixed onto the upper portion of the outside of the wall of the cylindrical body and is provided with the lifting screw, the nut, the vacuum meter, the vacuum valve and the pipe of the sealing cover opening device; the inner bottom of each vacuum dryer is provided with a meshed support plate, on which a barrel composed of a meshed wall and a meshed bottom is arranged, and the toprim of the barrel is connected with the vibrating motor through a vibrating rod; the vacuum tank is in a barrel shape, the top of the vacuum tank is provided with a sealing plug, which is provided with an oil inlet, a vacuum valve and a pipe, and the vacuum tank is connected with the vacuum fryers through pipes on both sides.

Owner:山西谷坤农产品有限公司

Flashboard type vacuum sealing device

The invention discloses a flashboard type vacuum sealing device and relates to the sealing device capable of keeping vacuum degree under the condition that bulk material and packaging material are continuously fed and discharged, The flashboard type vacuum sealing device is composed of two groups of sealing valve banks, a forevacuum cabin, a vacuum return-flow system and a pressure gas supply system which can be combined into three different processing manners, that is, feeding and discharging manner of bulk material vertical flashboard type vacuum sealing device, feeding and discharging manner of bulk material or packaging straight-line falling flat-pushing flashboard type vacuum sealing device and feeding and discharging manner of packaging right-angle flat-pushing flashboard type vacuum sealing device; the flashboard type vacuum sealing device uses a feeding-discharging sealing device under the continuous vacuum or pressure condition, or some equipment adopts a group of sealing valve bank as a sealing valve for sealing in interstitial pressure or vacuum processing; and the feeding-discharging sealing device and the sealing valve bank are suitable for the supporting facility of a continuous feeding-discharging sealing device of a continuous vacuum dryer, a continuous vacuum fryer, a continuous vacuum precooling machine, a continuous vacuum impregnating machine and the like.

Owner:陈长清

Ultrasonic-assisted extraction of lentinan and rapid pretreatment of raw materials

The invention relates to an ultrasonic-assisted extraction of lentinan and a rapid pretreatment method for raw materials thereof. The steps are as follows: (1) pretreatment: clean and cut fresh lentinan into a microwave oven for intermittent treatment at low heat, and then put the sample into a vacuum (2) degreasing; (3) water extraction: dry the dry shiitake mushroom powder after degreasing, according to the material-liquid ratio of 1:20, the ultrasonic power is 150W, and the extraction temperature is 80°C. The extraction time is 2.5h; (4) alcohol precipitation; (5) protein removal; (6) small molecule removal to obtain purified lentinan. The pretreatment operation of the invention is simple and easy for industrial promotion, the water activity of the obtained shiitake mushrooms is lower than 0.6, and can be stored for a long time at room temperature; the extraction conditions are mild, the structure and configuration of the lentinan will not be damaged, the extraction rate is high, and the cost is low.

Owner:SICHUAN AGRI UNIV

An energy-saving vacuum fryer

ActiveCN112568247BVariety of sportsSimple structureOil/fat bakingAgricultural engineeringElectric machinery

The invention discloses an energy-saving vacuum fryer, which belongs to the technical field of fruit and vegetable production frying, and comprises a base. and the second shell, the second shell can be extended or contracted by the hydraulic rod to realize the up and down movement, the first shell is installed on the base, the inside of the first shell is provided with a shelf, the second shell There is a driving part for driving the rack to rotate to realize rapid frying; multiple racks are used to cooperate with connecting blocks, fixed blocks and screens to form a rack to place fruits and vegetables, and different fruits and vegetables can be placed separately, and the screen is used to It ensures that the frying liquid enters the inside of the storage base for frying, and at the same time cooperates with the motor to drive the rotating shaft and the positioning plate to drive the storage rack to rotate, thereby ensuring the full movement of the fruit and vegetable when frying. The structure is simple, easy to use, and the frying effect is effectively improved. .

Owner:安徽东方果园生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com