Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Time marching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosion Simulation in Finite Element Analysis

ActiveUS20100256957A1Reduce computing timeImprove userComputation using non-denominational number representationDesign optimisation/simulationProduction rateElement analysis

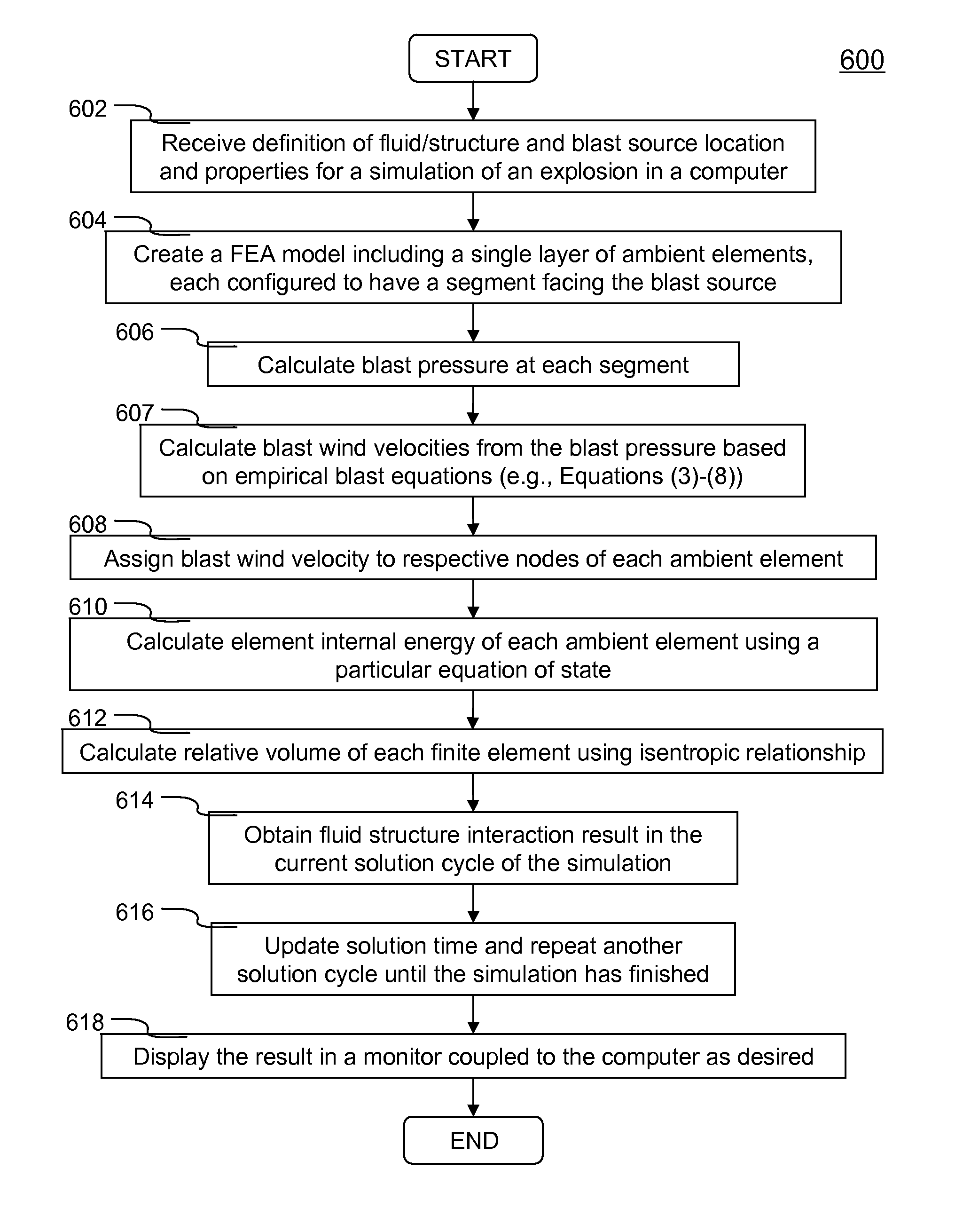

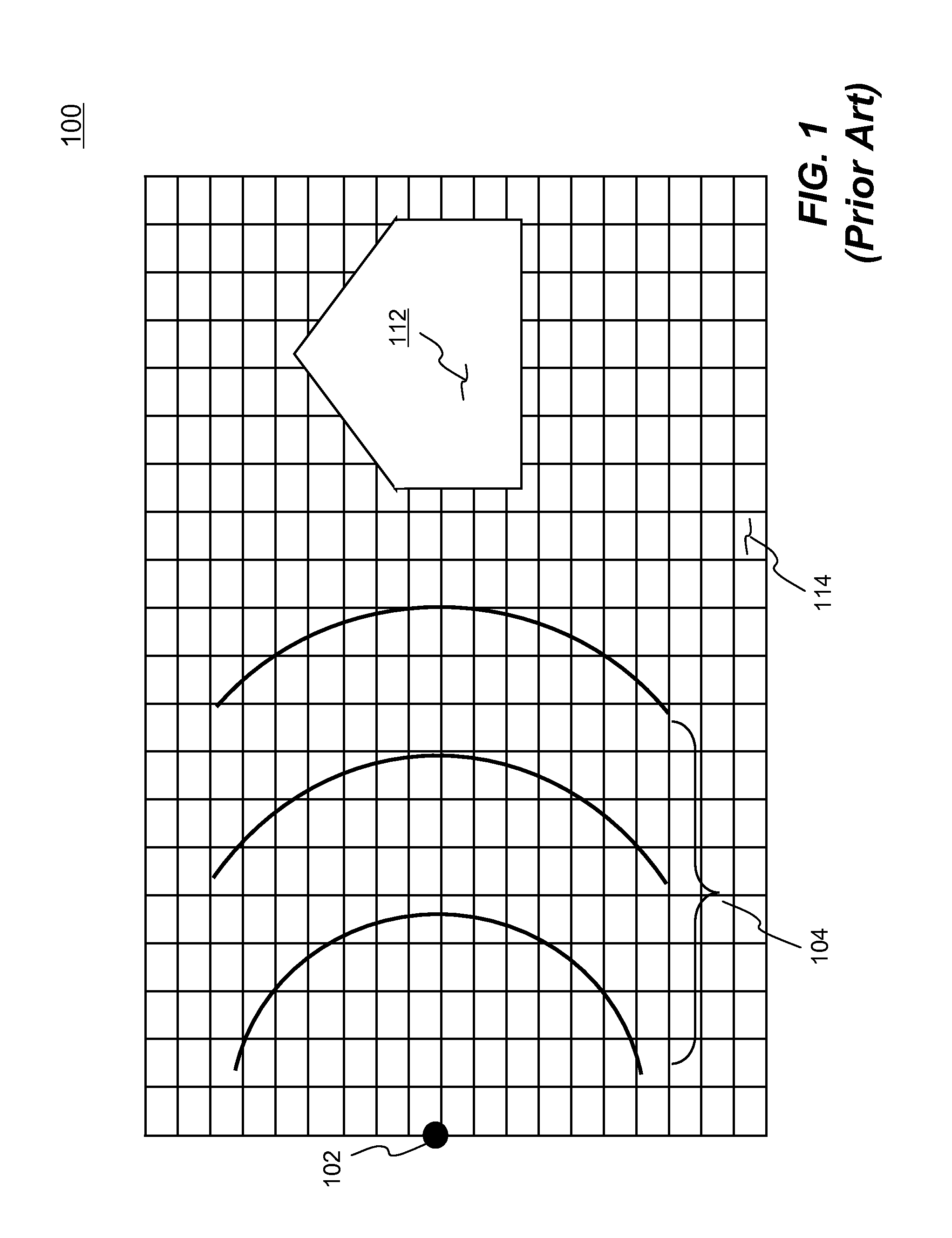

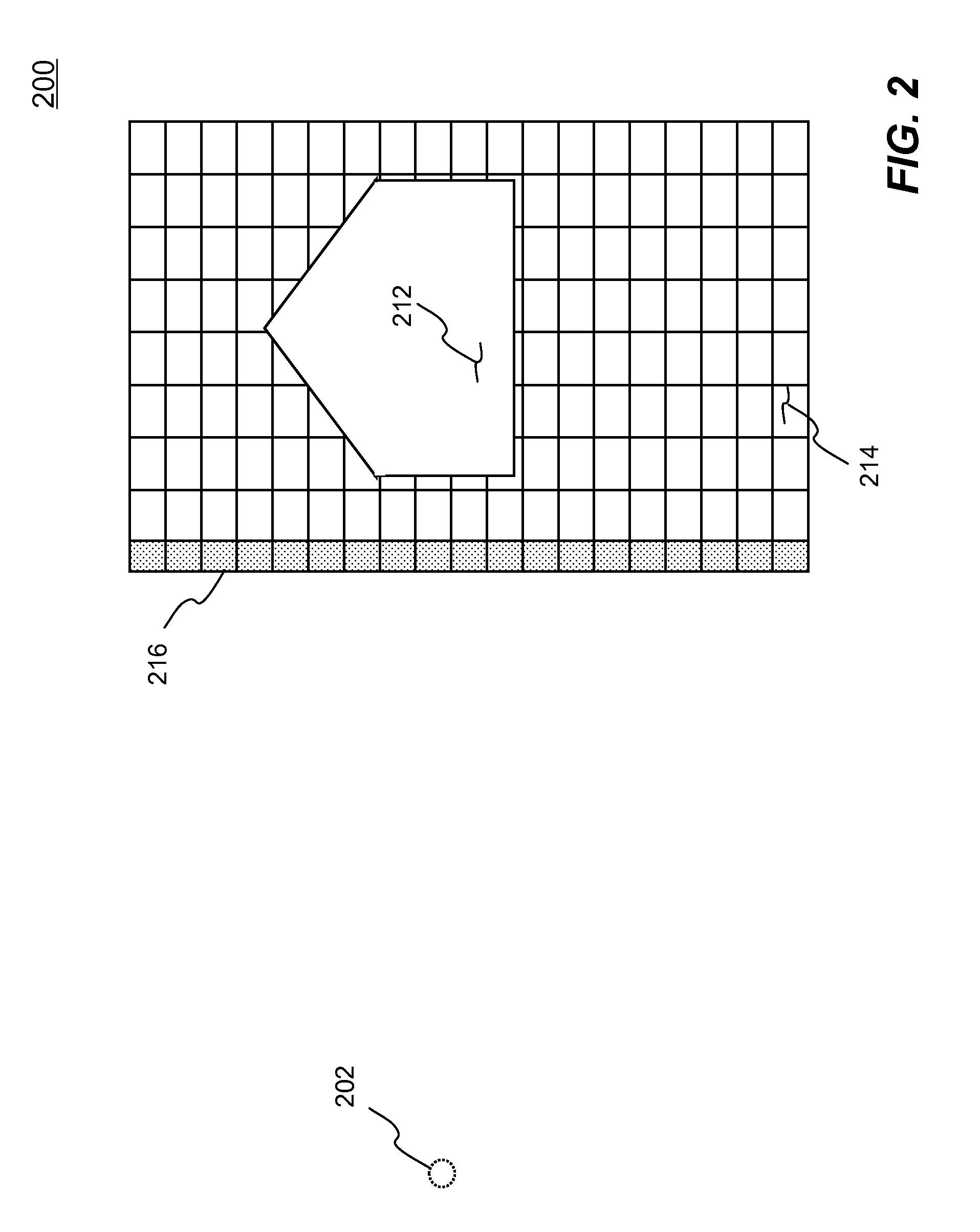

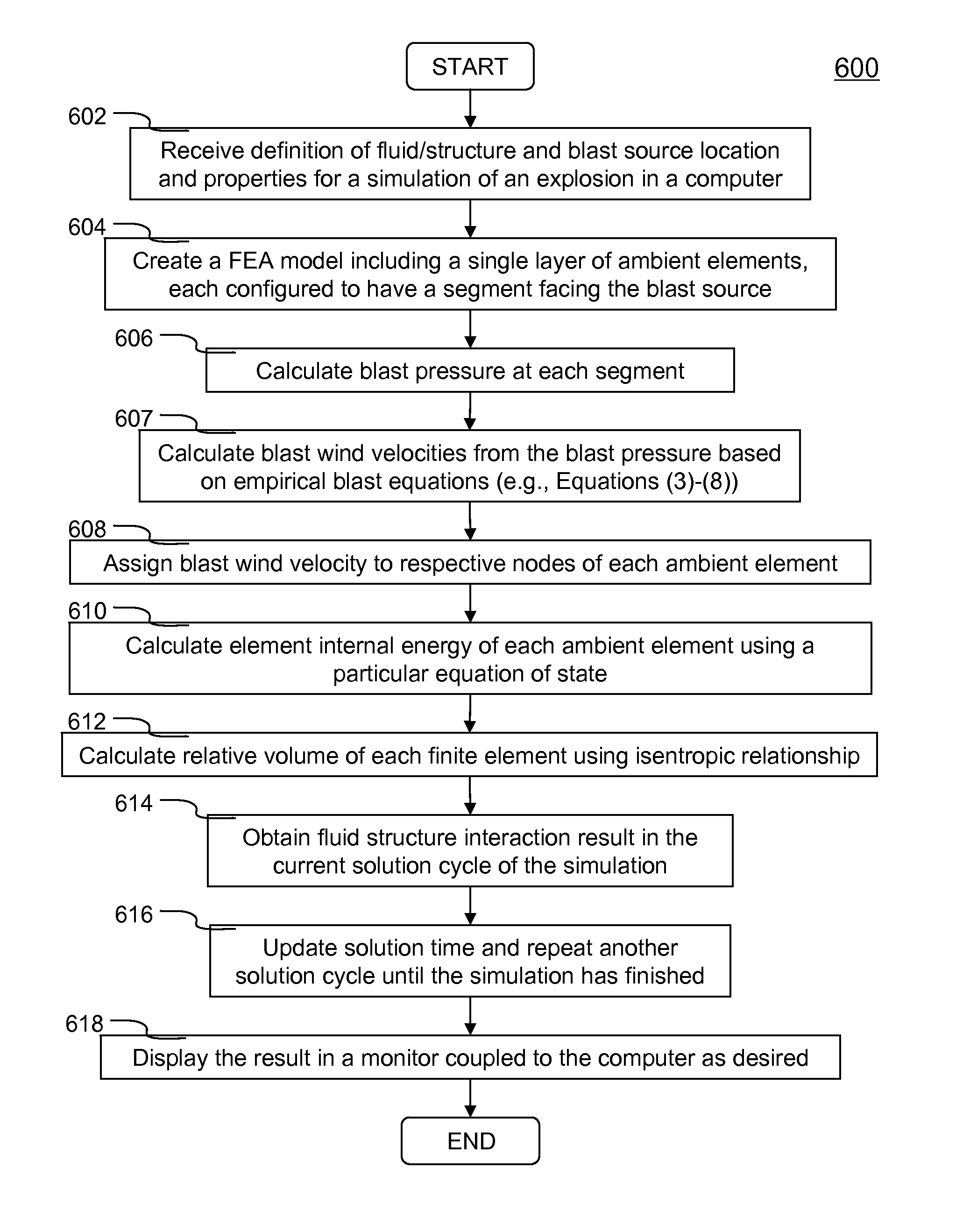

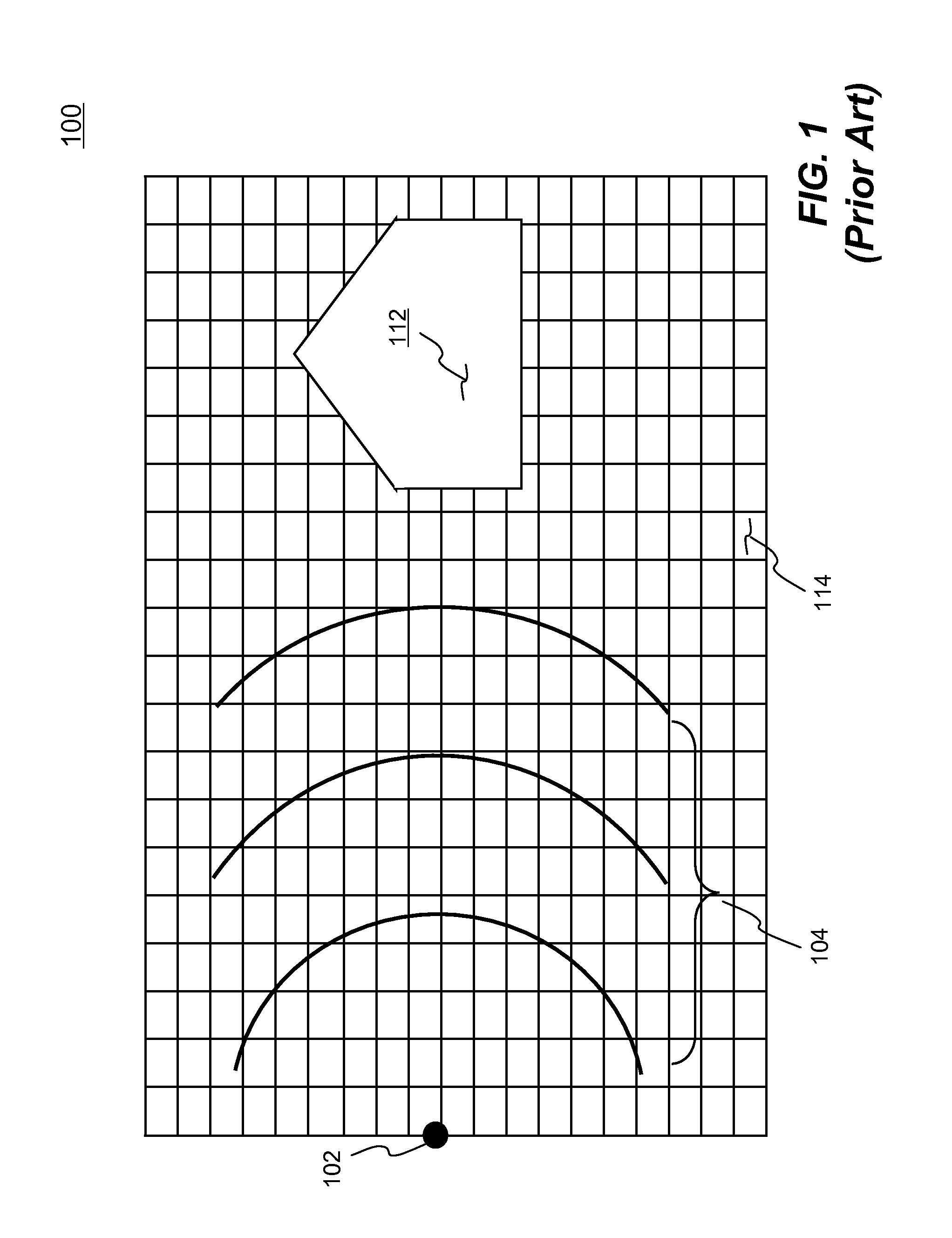

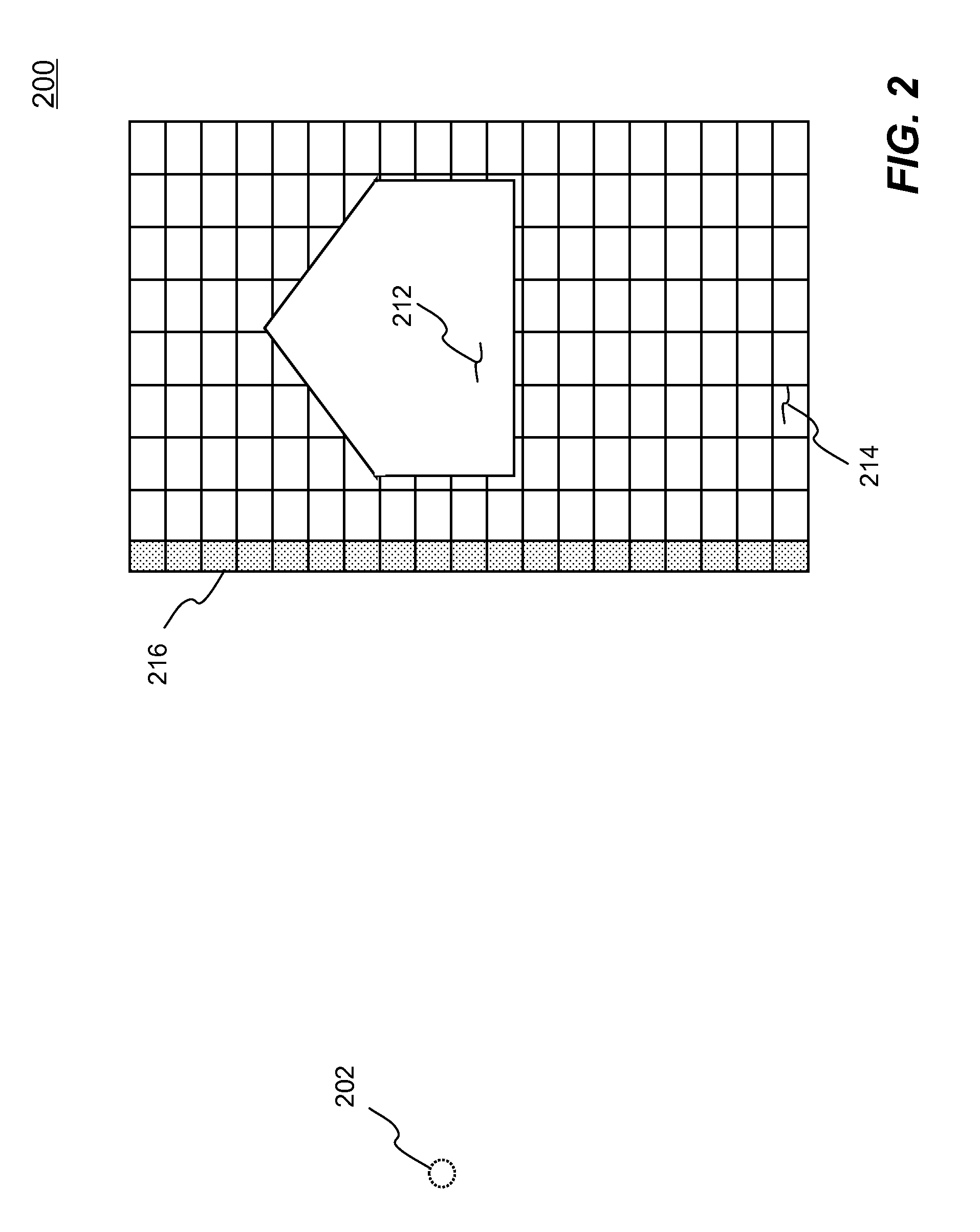

Systems and methods of simulating an explosion in time-marching finite element analysis are disclosed in the present invention. According to one aspect, a method is configured for increasing user (e.g., engineer or scientist) productivity by reducing computation time of simulating fluid-structure interaction due to an explosion. The method comprises a creation of a finite element analysis model that includes structure, surrounding fluid, a blast source of the explosion and a single layer of ambient elements each having a segment representing a boundary of the fluid facing the blast source. Each ambient element is associated with a particular finite element representing the fluid at the boundary. The ambient elements are configured to be situated between the blast source and the structure such that the simulation can be carried on a set of boundary conditions specified thereon. The boundary conditions comprise a set of nodal velocities that are determined from the empirical formula (e.g., Friedlander equation).

Owner:ANSYS

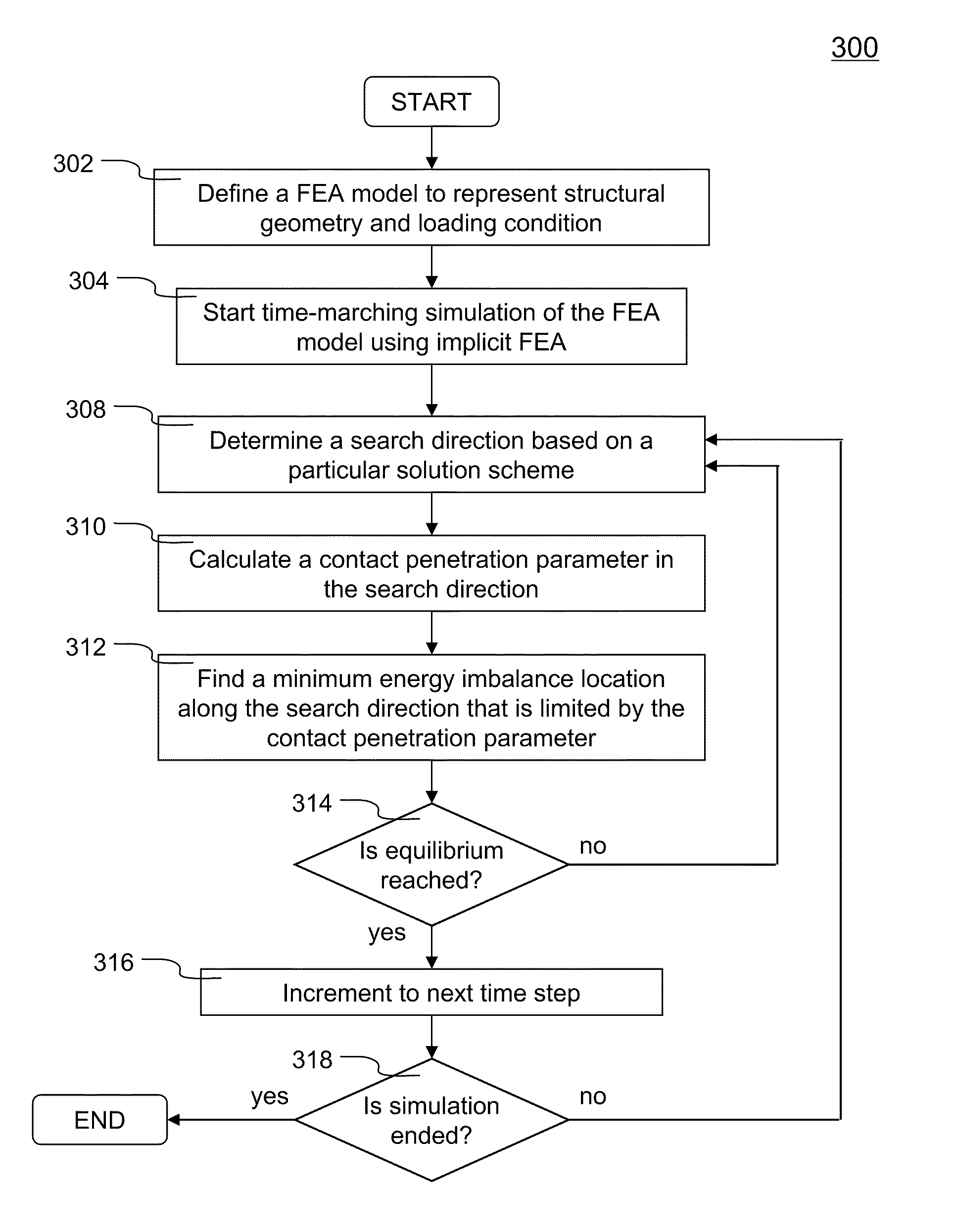

Systems and Methods of Limiting Contact Penetration in Numerical Simulation of Non-linear Structure Response

ActiveUS20090299702A1Analogue computers for chemical processesComputation using non-denominational number representationElement analysisNonlinear structure

Systems and methods of limiting contact penetration in numerical simulation of non-linear structure response using implicit finite element analysis are described. According to one aspect, a finite element analysis (FEA) model of a structure is defined as a number of nodes and elements based on geometry and material properties of the structure. A time-marching analysis of the FEA model is then performed. The time-marching analysis results contain a number of solutions of non-linear structure response at respective time steps. Solution at each time step requires at least one iteration to compute. Non-linear structure response is determined in the following manner: 1) determining a search direction; 2) calculating a contact penetration parameter in the search direction; and 3) finding a minimum energy imbalance location along the search direction as a solution which is further restricted by the CPP such that contact penetration of the structure is substantially limited.

Owner:ANSYS

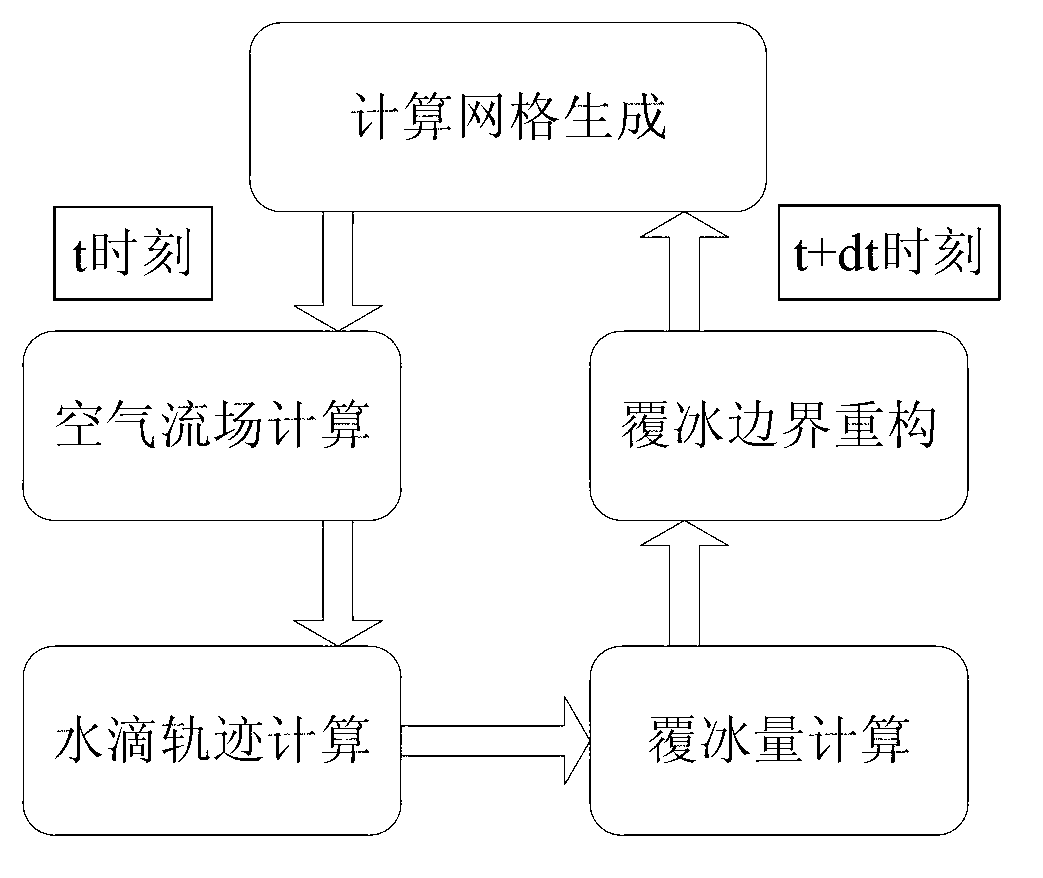

Two-dimensional numerical simulation method for icing process of power transmission line

The invention belongs to the field of electric power systems and relates to a two-dimensional numerical simulation method for an icing process of a power transmission line. Based on the lagrangian method, the invention provides the two-dimensional numerical simulation method for a surface rime icing process of the power transmission line. A Reynolds-averaged Navier-Stokes (RANS) equation and shear-stress-transport-k-omega (SST-k-omega) turbulence model of non-steady incompressible flow is solved by adopting a semi-implicit method for pressure linked equations (SIMPLE) algorithm on a staggered grid so as to obtain an air flow field; movement tracks of super-cooled water droplets in the flow field are tracked by adopting the lagrangian method to obtain the transient local collision rate of all control volumes on the surface of the power transmission line; solving is performed based on an icing thermodynamic equation established by a Messinger control volume method so as to obtain the rime icing temperature of all the control volumes, and the icing process is simulated by combining an icing time marching method. Indicated by results, predicted ice shapes are better fitted with test measurement data in literature, and therefore, the two-dimensional numerical simulation method for the icing process of the power transmission line is feasible and effective.

Owner:STATE GRID CORP OF CHINA +2

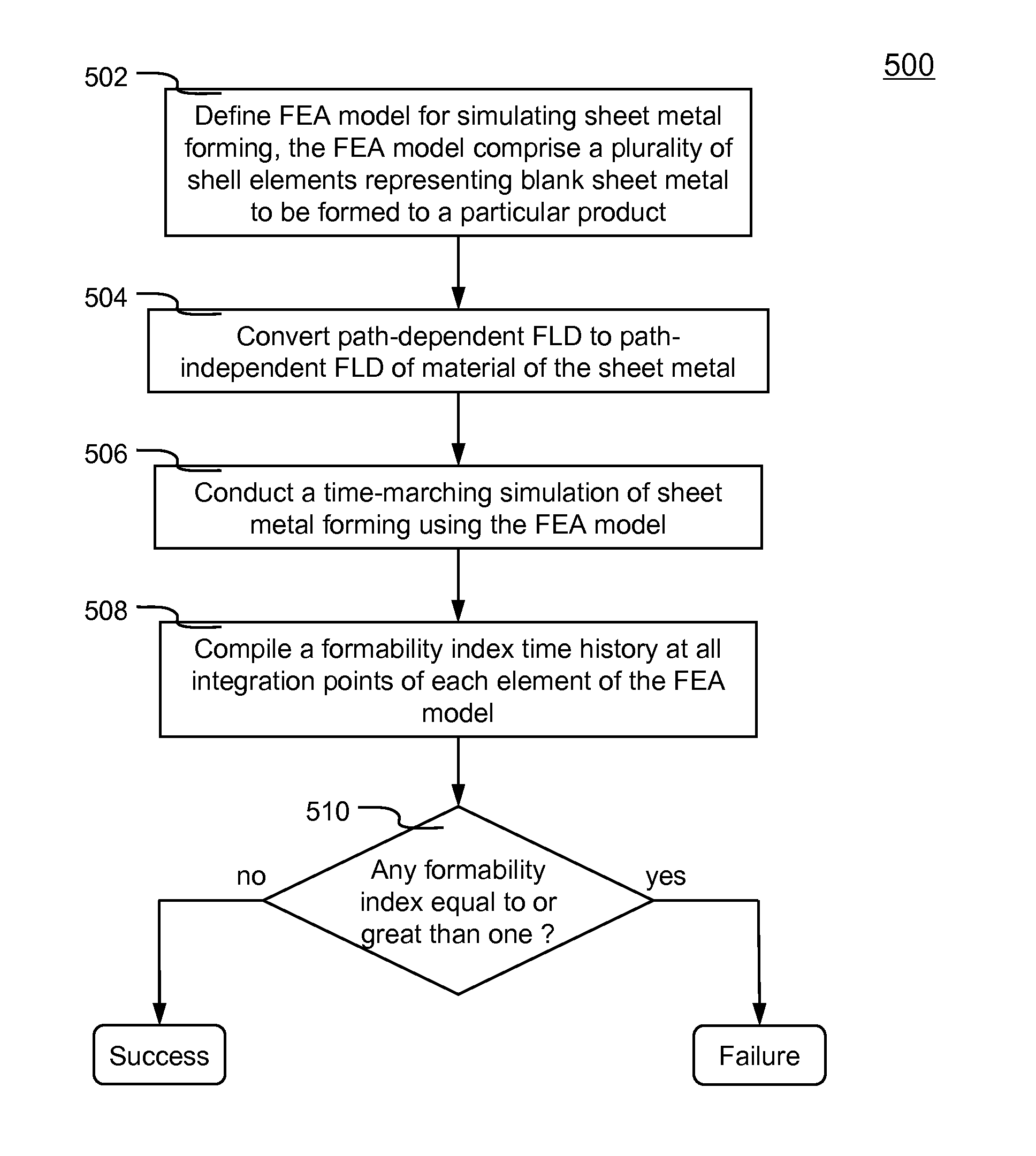

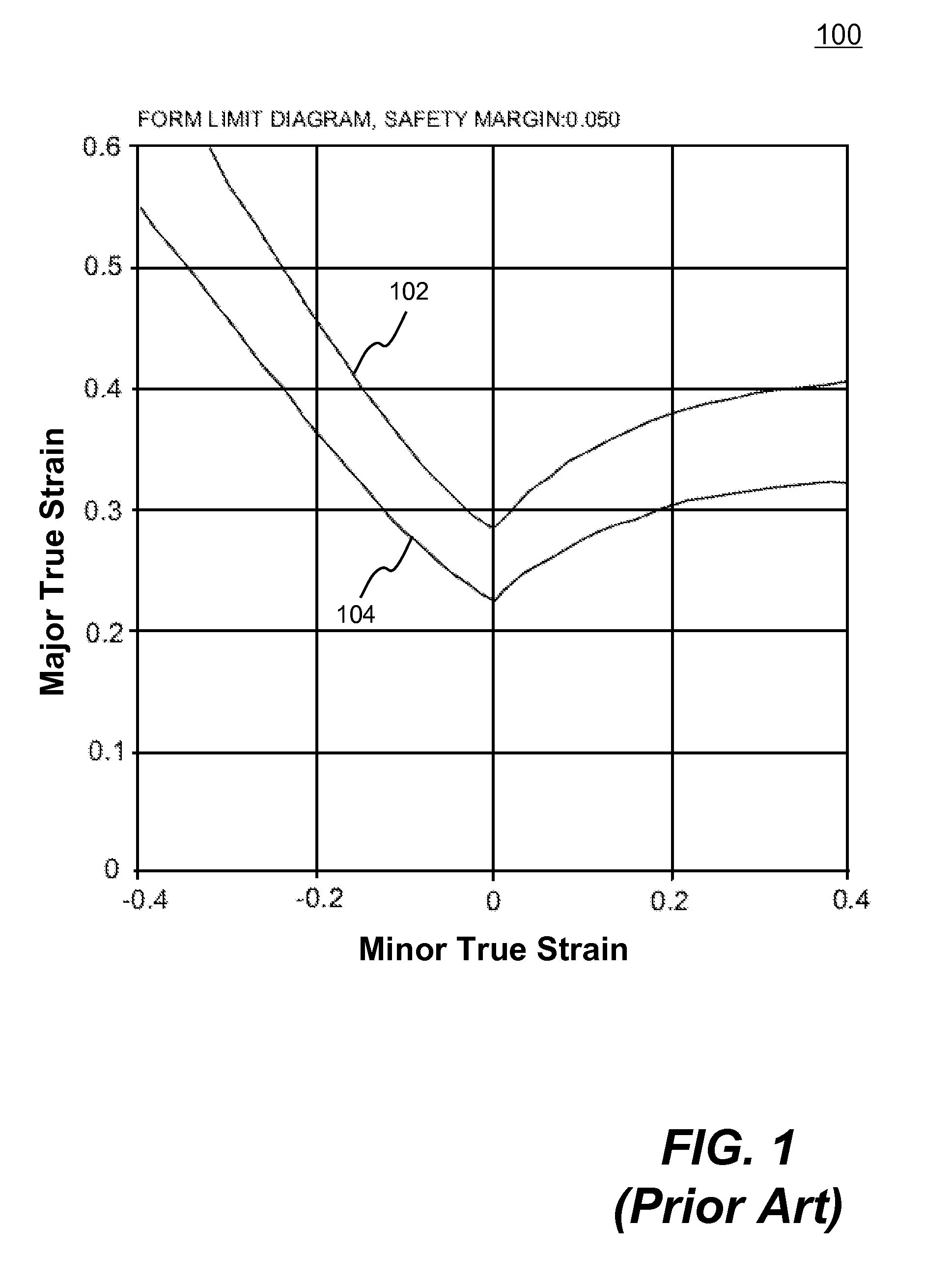

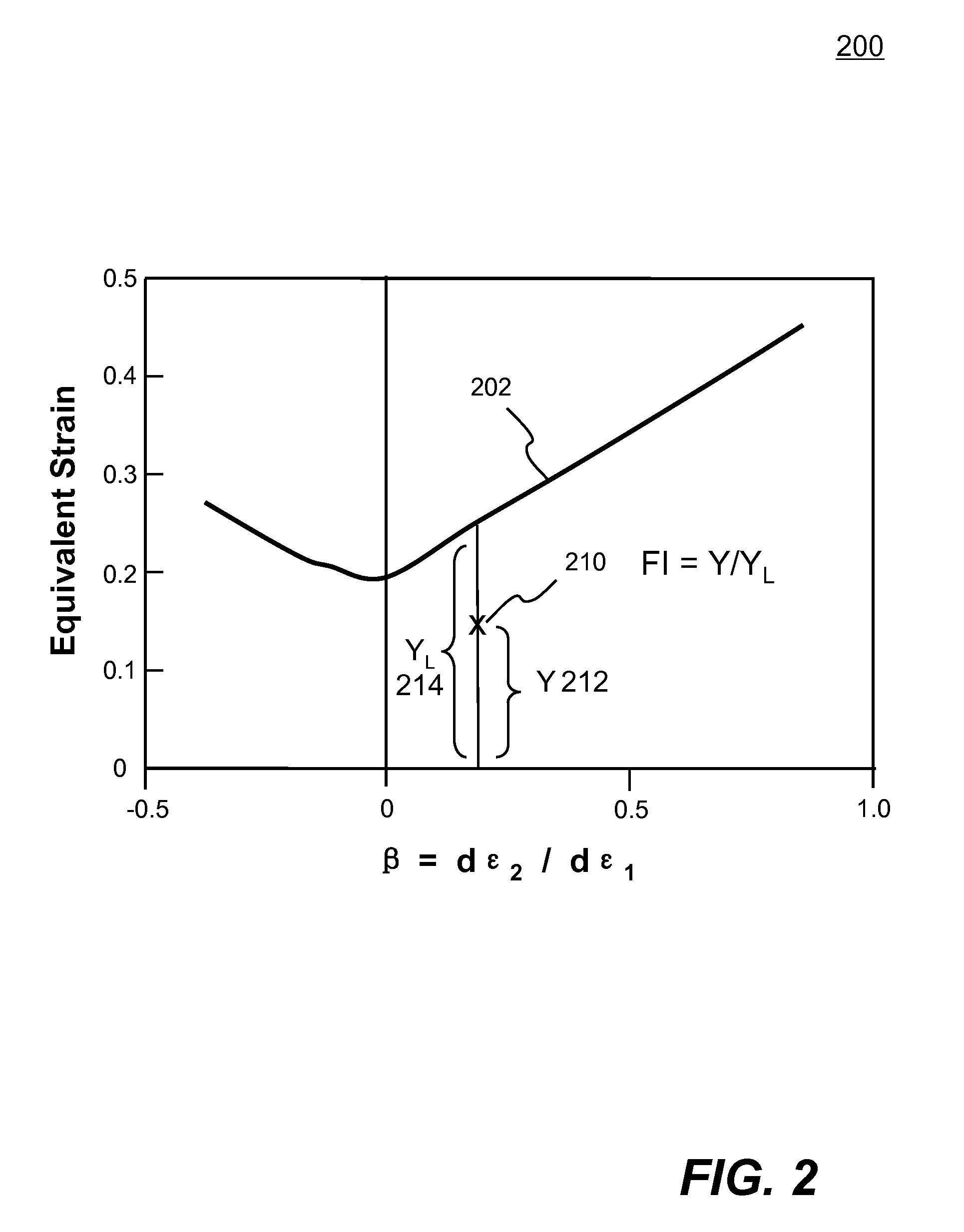

Method and system for numerically simulating and predicting necking failure in sheet metal forming

InactiveCN102262688AEasy to useEasy to observeDesign optimisation/simulationAerodynamics improvementForming limit diagramElement analysis

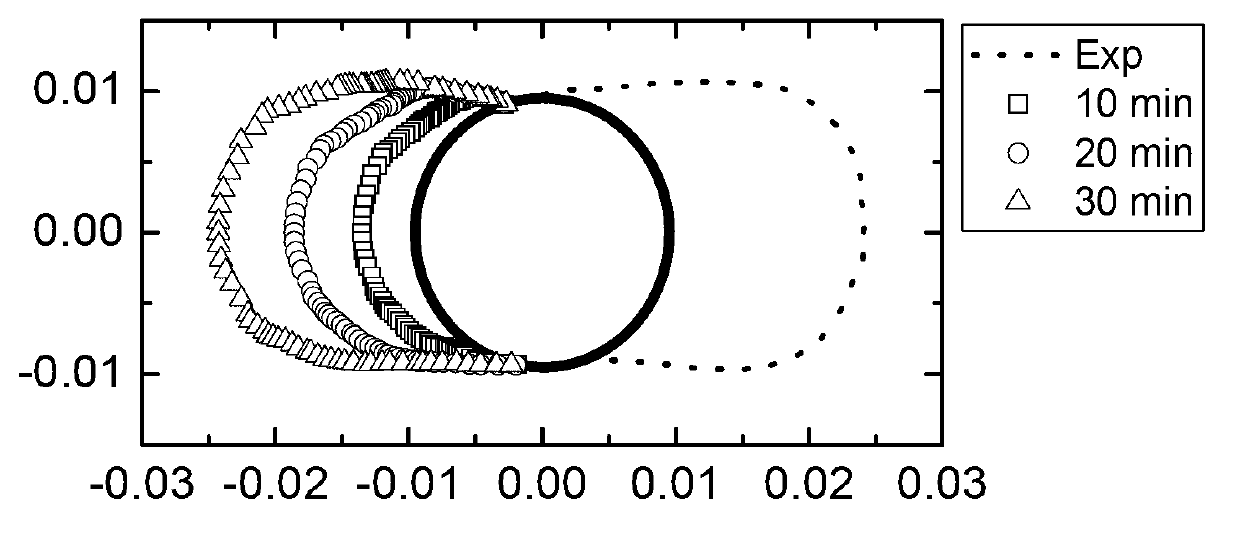

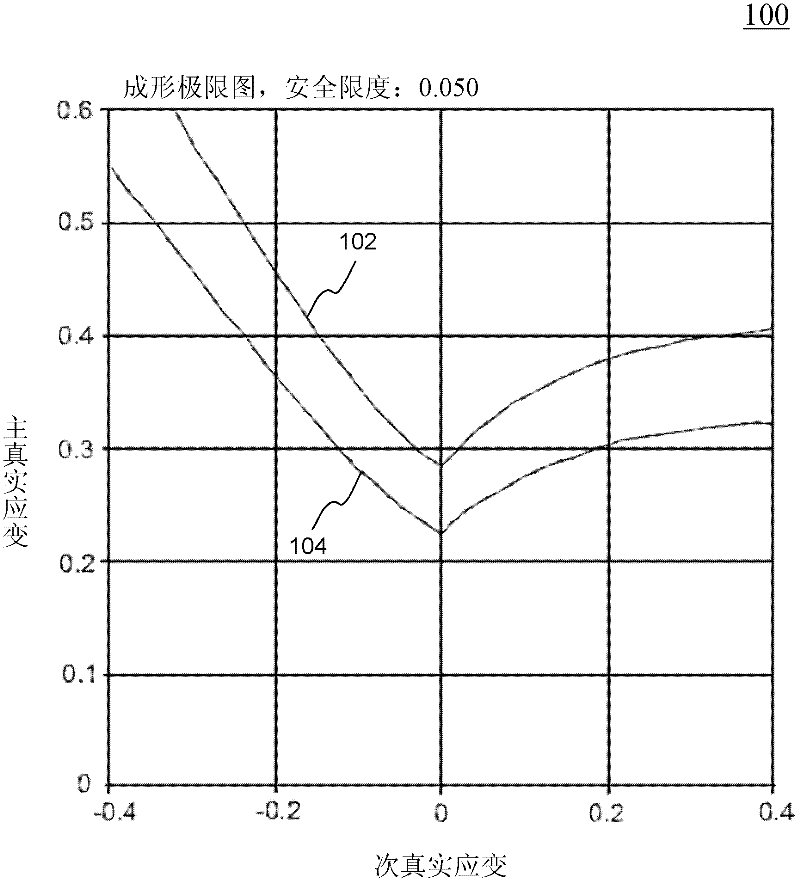

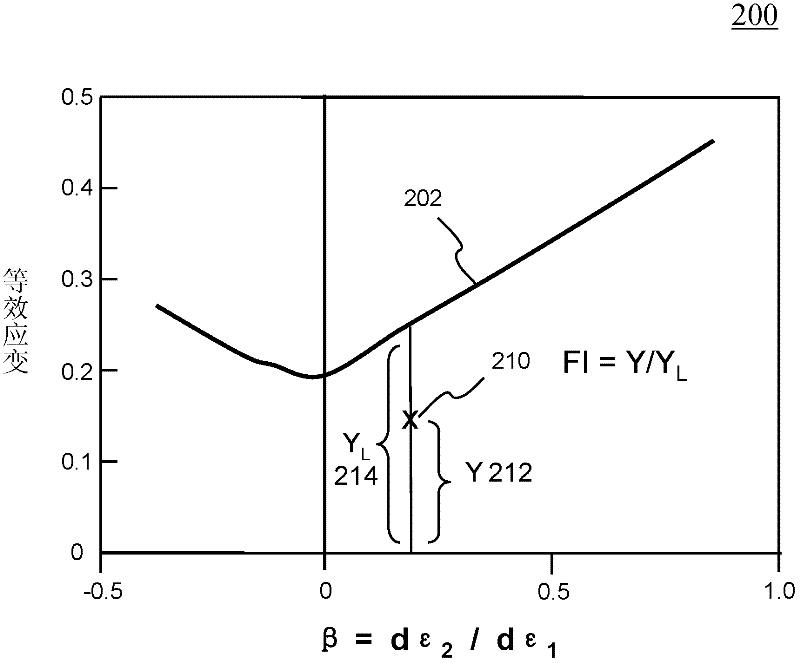

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

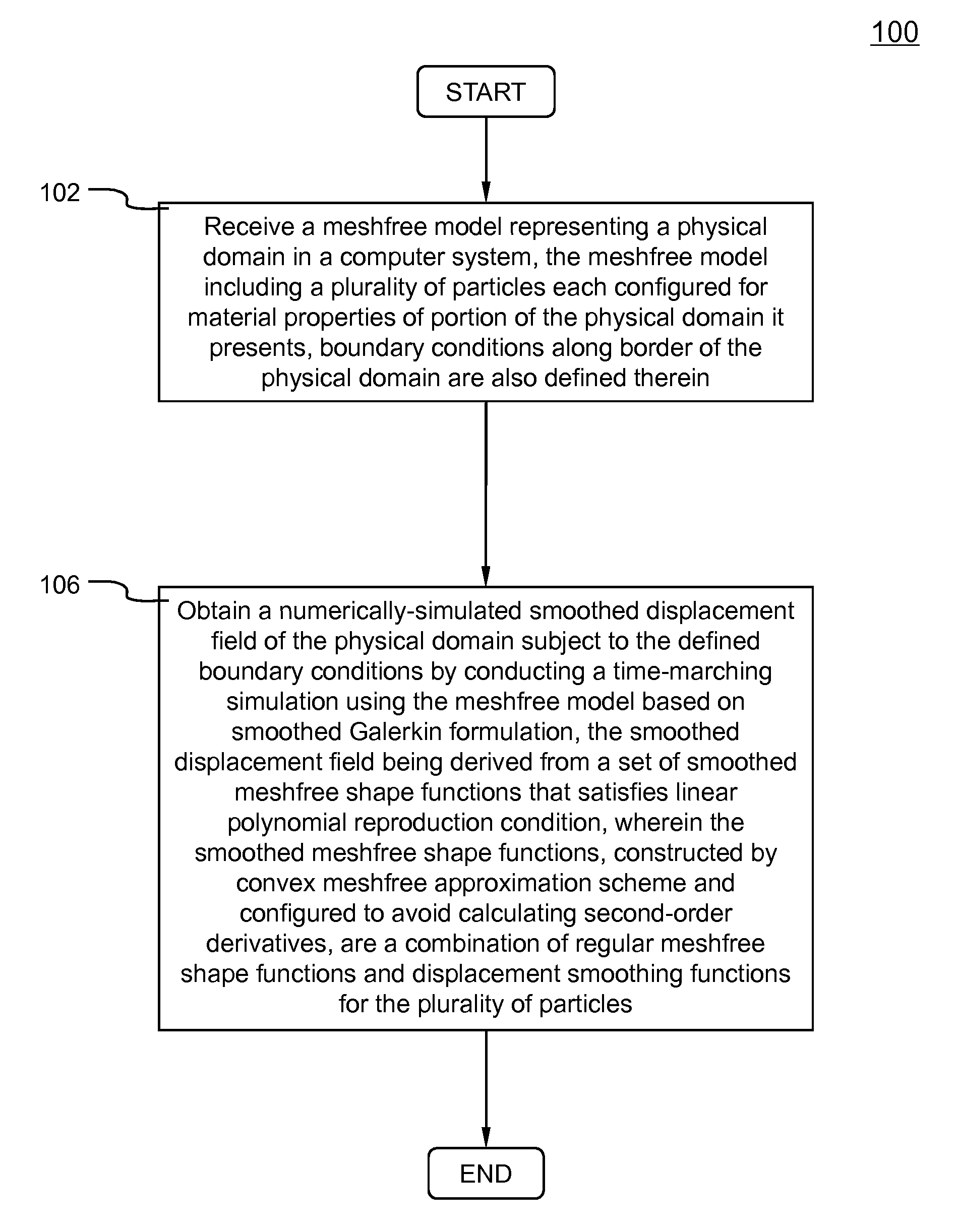

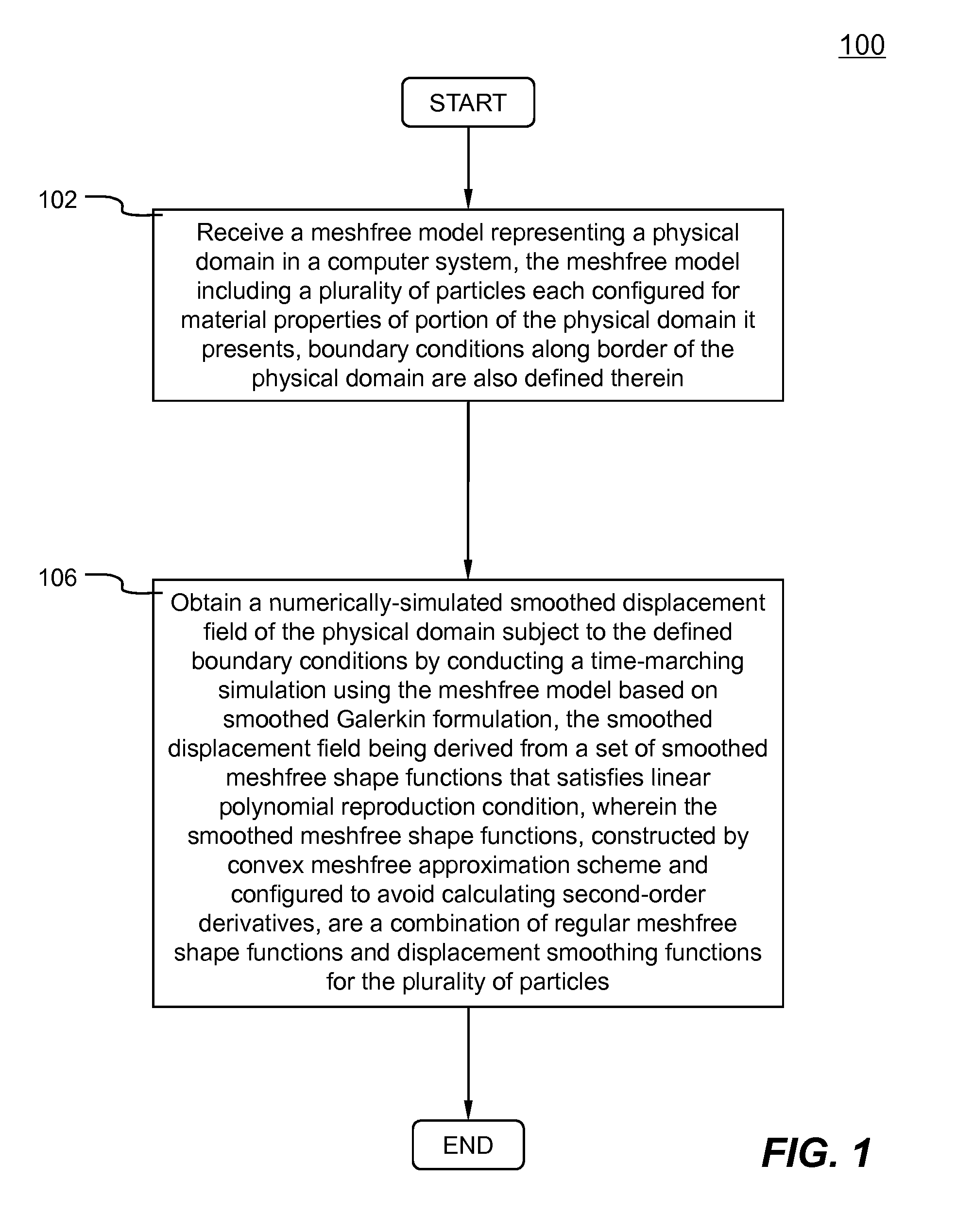

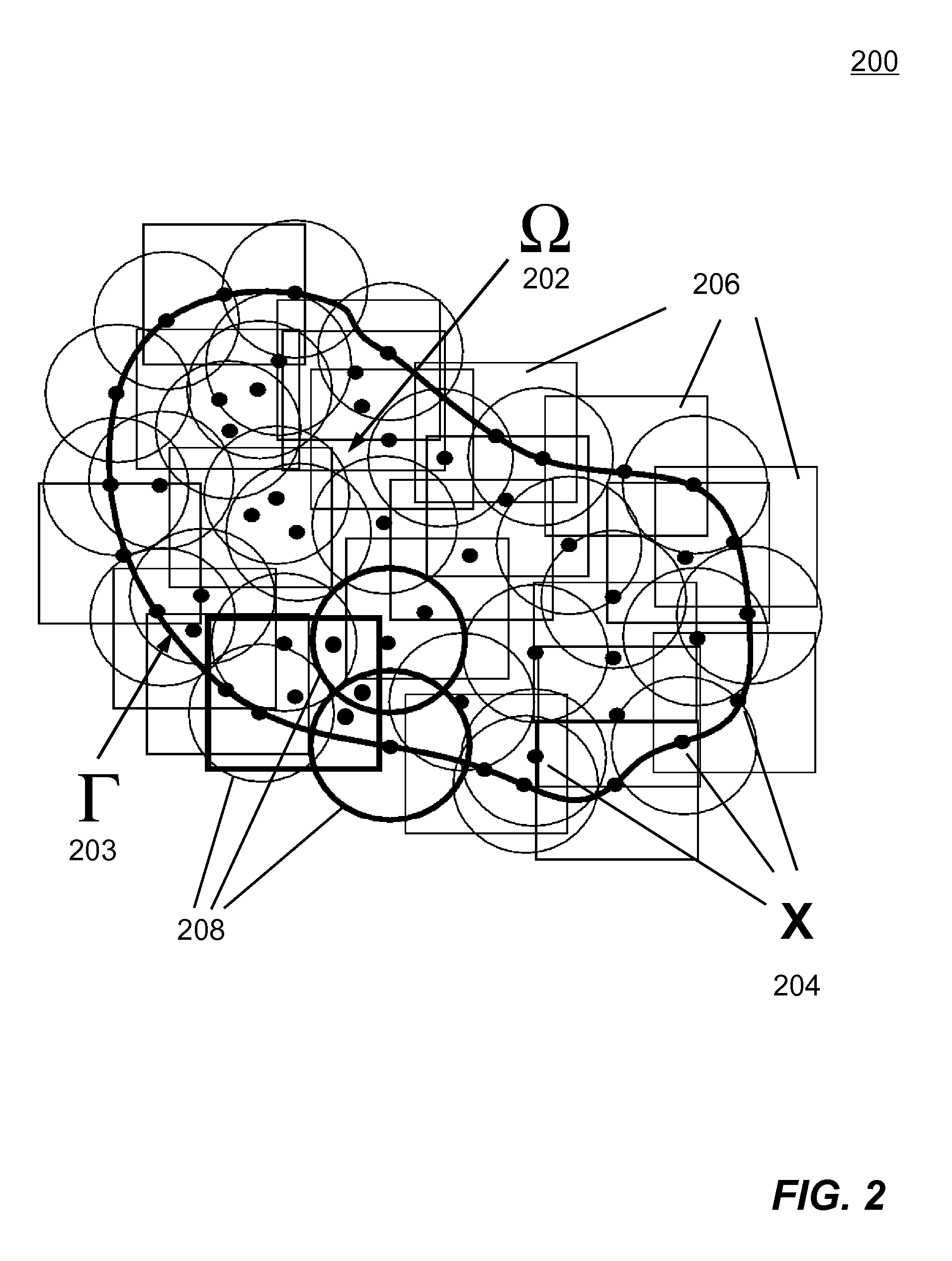

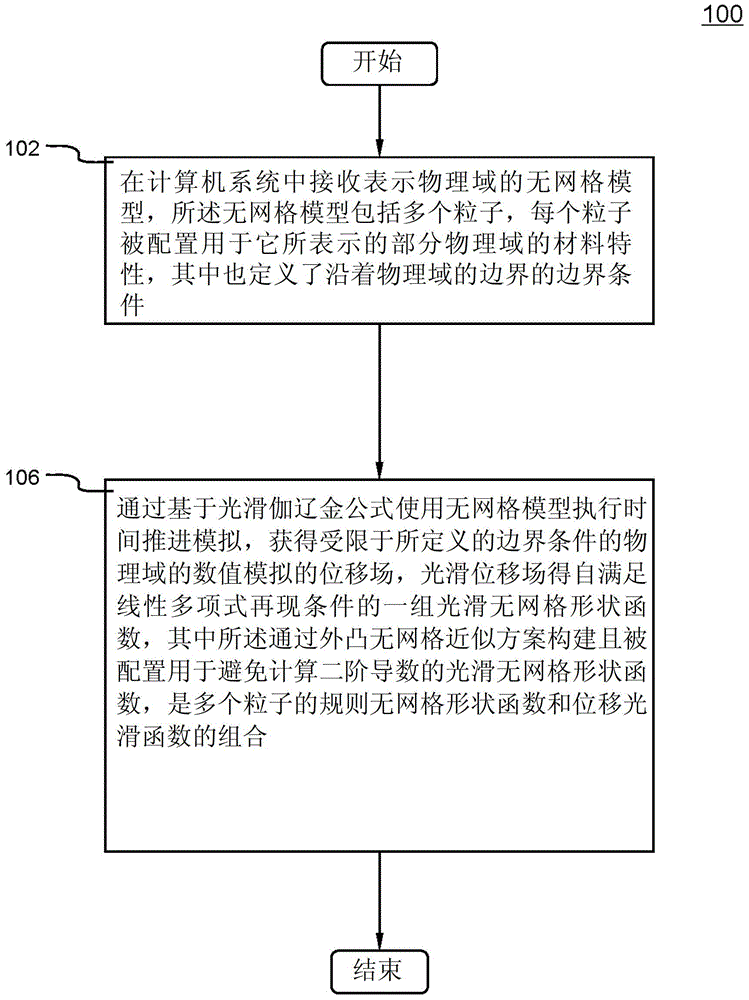

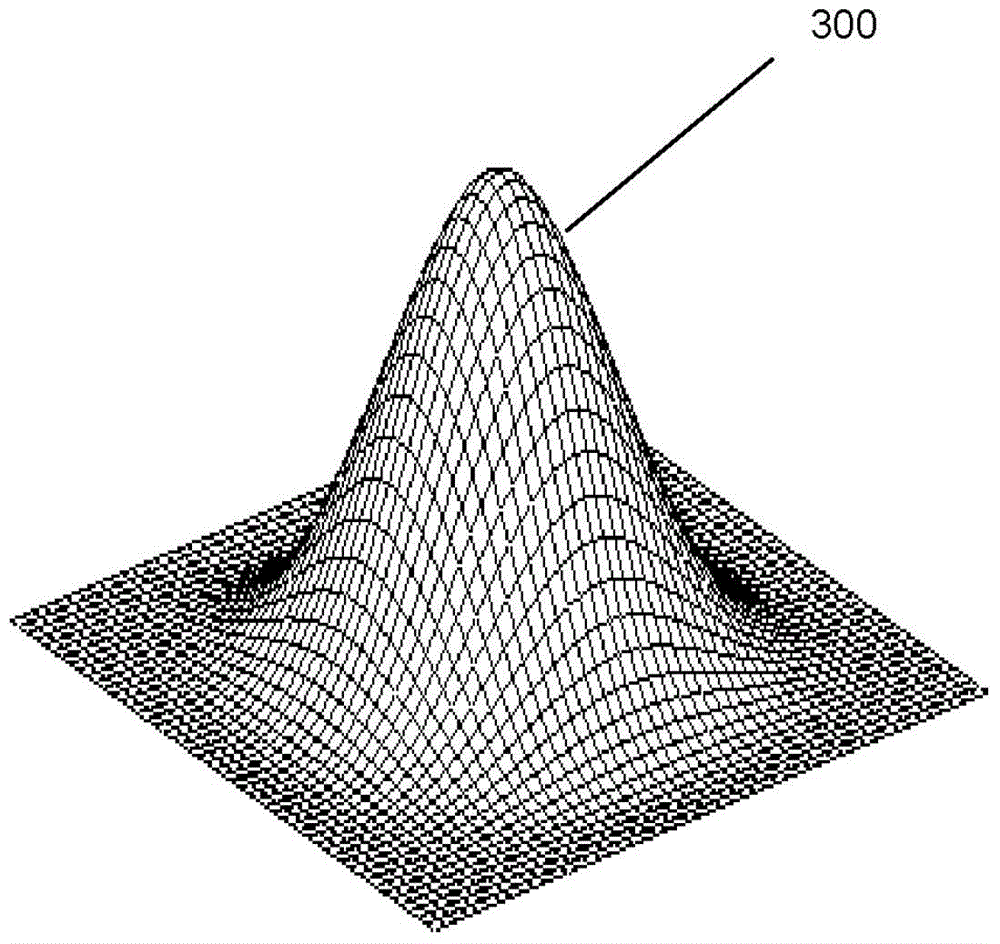

Smoothed Particle Galerkin Formulation for Simulating Physical Behaviors in Solids Mechanics

InactiveUS20150112653A1Computation using non-denominational number representationDesign optimisation/simulationComputerized systemComputational physics

Methods and systems for conducting numerical simulation of structural behaviors in solid mechanics using smoothed particle Galerkin formulation are disclosed. A meshfree model representing a physical domain defined by a plurality of particles is received in a computer system. Each particle is configured for material properties of portion of the physical domain it represents. A smoothed displacement field of the physical domain subject to defined boundary condition is obtained by conducting a time-marching simulation using the meshfree model based on smoothed particle Galerkin formulation. The smoothed displacement field is derived from a set of smoothed meshfree shape functions that satisfies linear polynomial reproduction condition. The set of smoothed meshfree shape functions is constructed by convex meshfree approximation scheme and configured to avoid calculation second order derivatives. The set of smoothed meshfree shape functions is a combination of regular meshfree shape function and a displacement smoothing function for the particles.

Owner:LIVERMORE SOFTWARE TECH

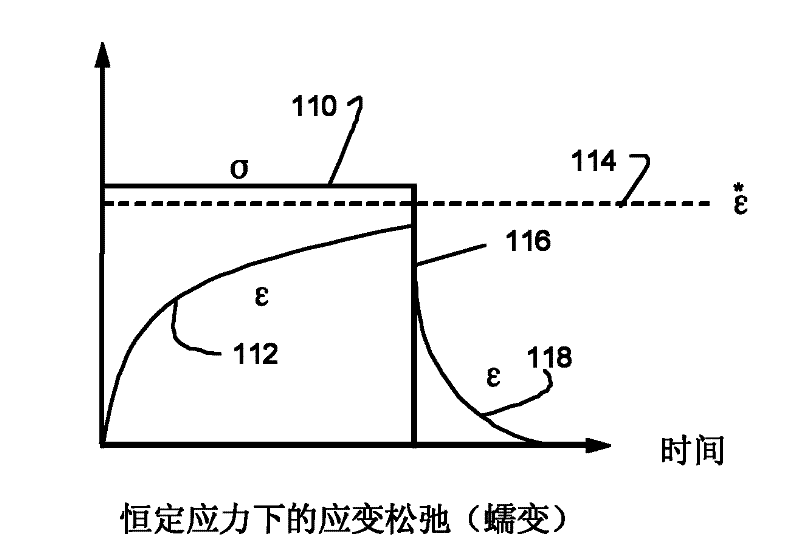

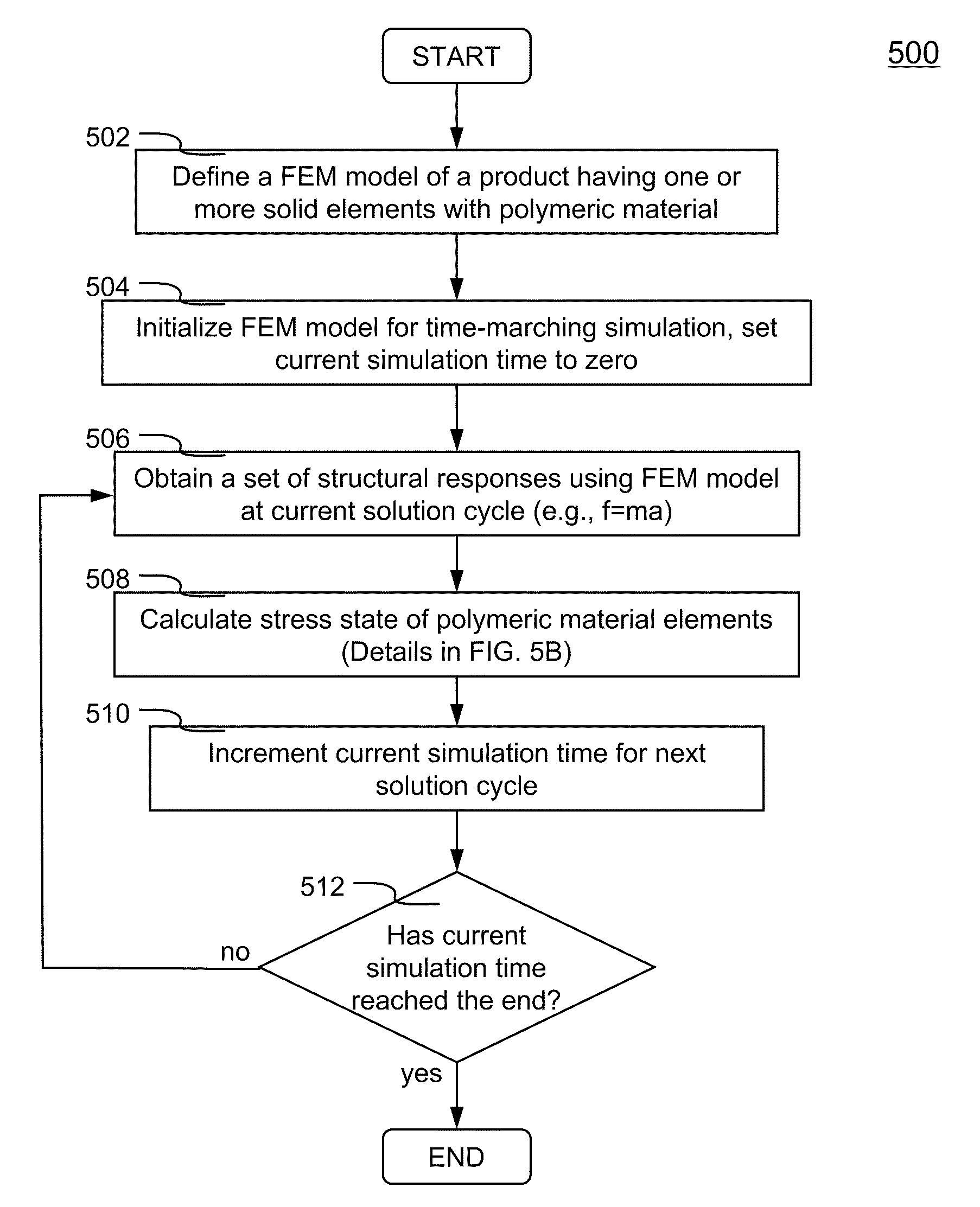

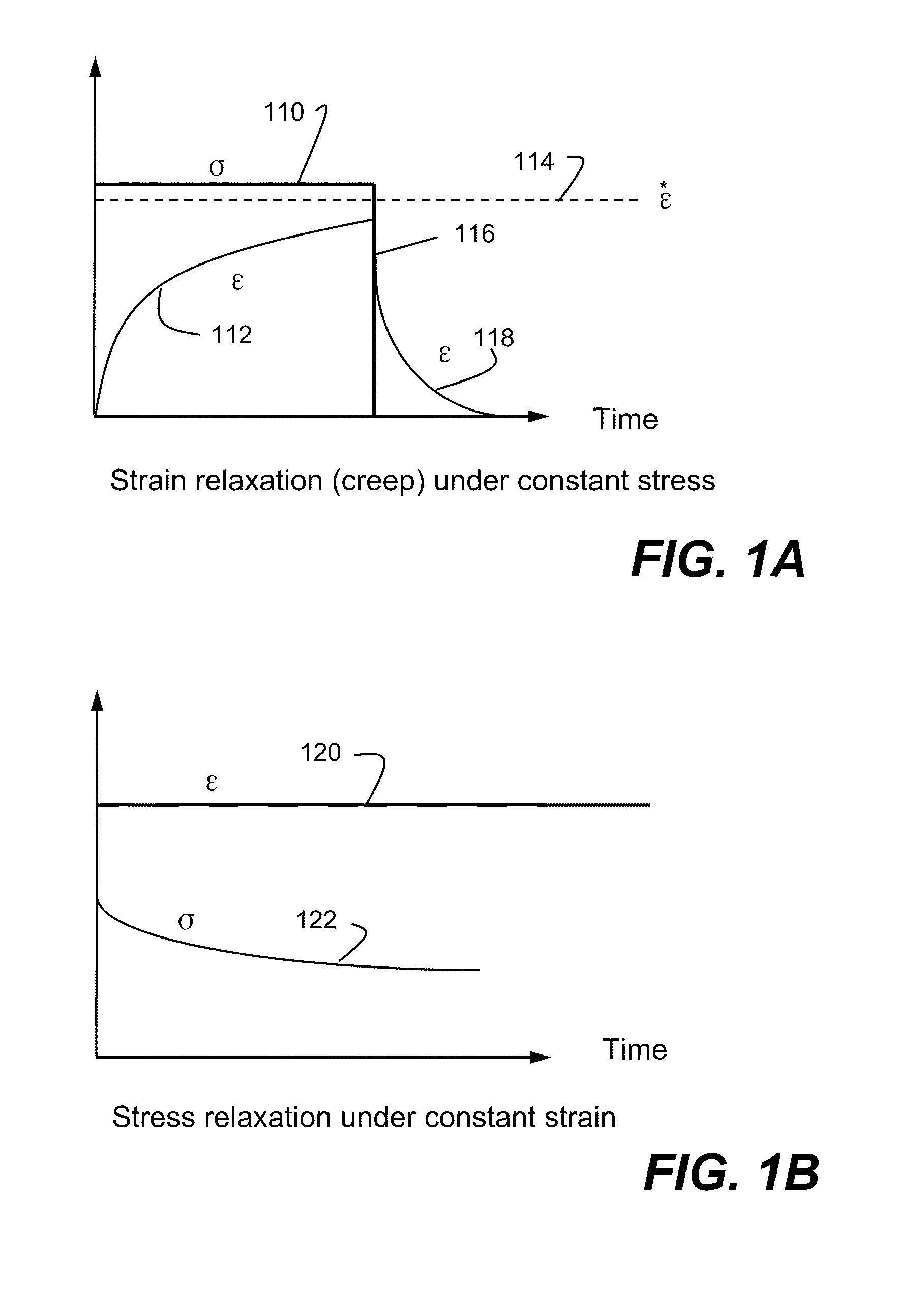

Methods and systems using a numerical model to describe polymeric material properties

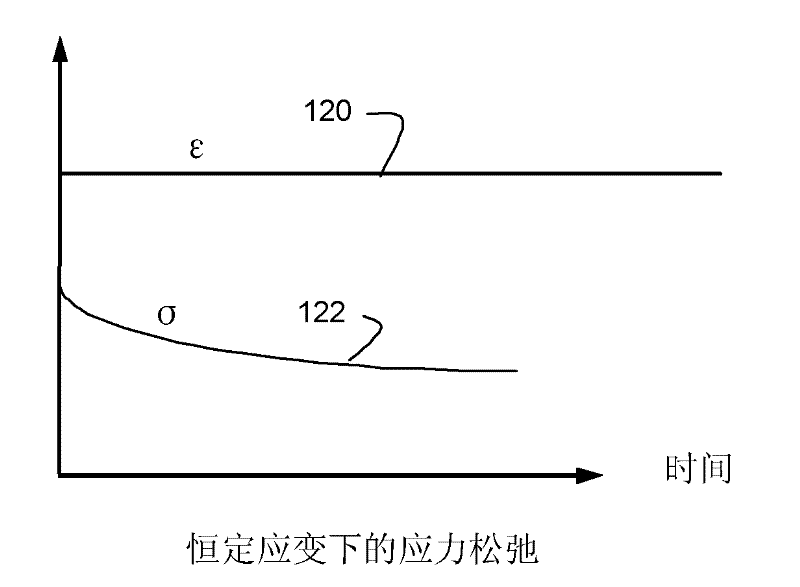

InactiveCN102254060ADesign optimisation/simulationSpecial data processing applicationsMathematical modelNumerical models

Methods and systems using a numerical model to describe polymeric material properties are disclosed. FEM model of a product is defined. FEM model includes one or more solid elements of polymeric material. In a time-marching simulation of the product under loads, stress state of the solid elements is calculated from deformation gradient tensors. Stress state incorporates the Mullins effect and strain hardening effect, also includes elastic stress, viscoelastic stress and back stress. A yield surface is defined to determine whether the elements are under plastic deformation. Plastic strain is obtained to update the deformation gradient tensor, which is then used to recalculate the stress state. Calculations continue until updated stress state is within a tolerance of the yield surface, at which time the results of polymeric material elements are obtained. The numerical model takes into account all characteristics of a polymeric material.

Owner:LIVERMORE SOFTWARE TECH

Sheet Metal Forming Failure Prediction Using Numerical Simulations

InactiveUS20110295570A1Computation using non-denominational number representationDesign optimisation/simulationForming limit diagramElement analysis

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

Numerical simulation of airflow within porous materials

InactiveUS20110010137A1Realistic simulation of structural behavior of porous materialsComputation using non-denominational number representationDesign optimisation/simulationVolume variationElement analysis

Systems and methods of numerically simulating airflow within porous materials are disclosed. According to one aspect of the present invention, engineering product represented by a finite element analysis model containing in part porous material with permeability. In each solution cycle of a time-marching simulation, each of the elements of porous material is evaluated with airflow in conjunction with the traditional mechanical response. Each element's volume change results into different air-pore pressure hence a pressure gradient, which in turn is used for airflow calculated in accordance with a fluid seepage law that depends upon permeability of the porous material. Therefore, a more realistic simulation of structural behavior of porous materials can be achieved. The volume change and pressure of each element of porous material is evaluated using ideal gas law. A general form of Darcy's law includes user control parameters is used for evaluating airflow based on the pressure gradient and permeability.

Owner:LIVERMORE SOFTWARE TECH

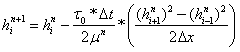

Method of measuring friction stress on interference surface of oil film

InactiveCN104697705AAccurately get the friction stressAerodynamic testingFluid pressure measurement by optical meansTime changesTime marching

The invention discloses a method of measuring friction stress on an interference surface of an oil film. The method comprises the following specific steps: step 1, obtaining a variable relationship of a viscosity coefficient [mu] of the oil film when time changes between a time t1 and a time t2, and measuring the thicknesses of the oil film at the time t1 and the time t2; step 2, setting an initial friction stress t0, calculating a thin oil film equation according to the variable relationship of the viscosity coefficient [mu] of the oil film when time changes, the thickness of the oil film at the time t1 and a numerical value, and adopting explicit time-marching to arrive at the time t2, so as to calculate the thickness of the oil film at the time t2; step 3, comparing the thickness of the oil film calculated at the time t2 with the thickness of the oil film measured at the time t2, correcting the friction stress t0 according to a comparison result, and carrying out explicit time-marching to the time t2 from the beginning of the time t1 again, wherein the t0 is the solved friction stress t after the circulation when the thickness of the oil film calculated is consistent to the thickness of the oil film measured. According to the method provided by the invention, the friction stress on the interference surface of the oil film can be obtained.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

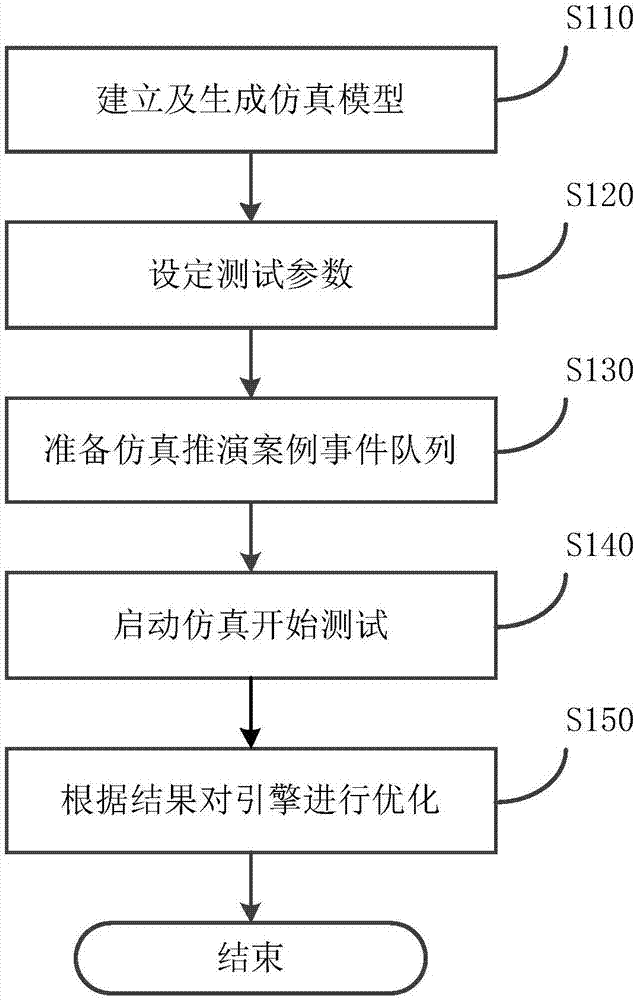

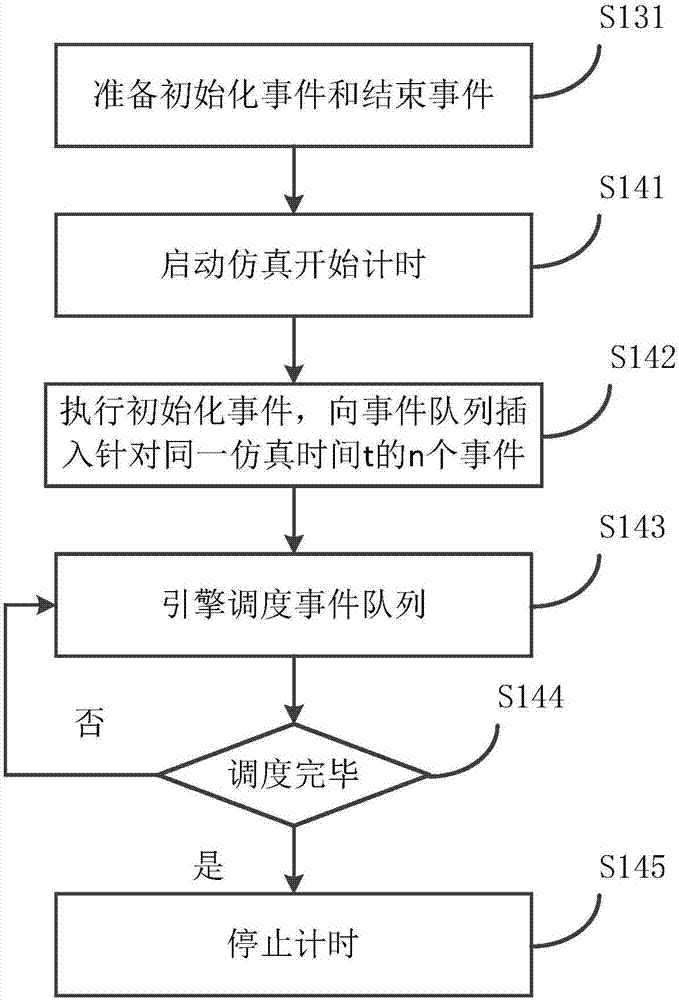

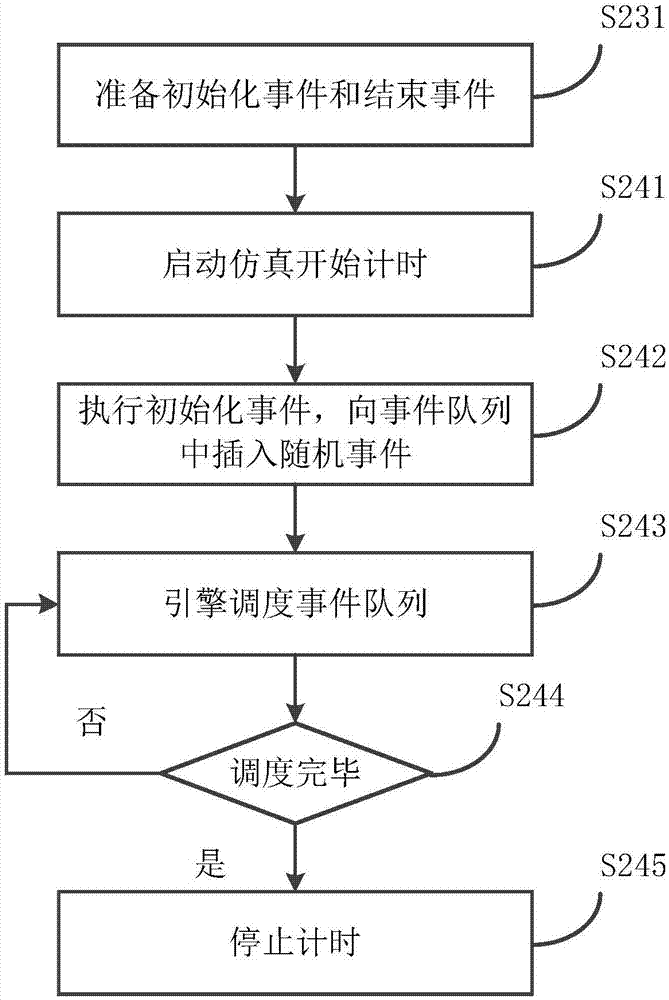

Performance testing method of simulation engine and storage medium

ActiveCN107315889AReduce logic complexityEliminate the effects ofHardware monitoringDesign optimisation/simulationLogic complexityParallel computing

The invention provides a performance testing method of a simulation engine and a storage medium, and is applied to simulation of parallel discrete events. The method performance testing method of the simulation engine includes the steps of establishing and generating a simulation model, using information needed by application managing for configuring the simulation model, using synchronous-event scheduling performance, random-event scheduling performance, event queue managing performance and time marching efficiency to test the simulation model, according to selected performance indexes, preparing simulation event queues separately, and according to the selected performance indexes, starting simulation to start testing till treatment is completed or timing is completed. According to the performance testing method of the simulation engine, a parallel mode and a serial mode are compatible and can be switched; model logic participating in performance testing is extremely low in complexity, and the influence of simulation-model performance on engine performance testing is excluded; testing indexes mainly aims at time coordination of simulation engine event scheduling, can represent basic performance of the engine and has objectivity. An index testing method can be implemented on different simulation engines and has implementation feasibility.

Owner:BEIJING HUARU TECH

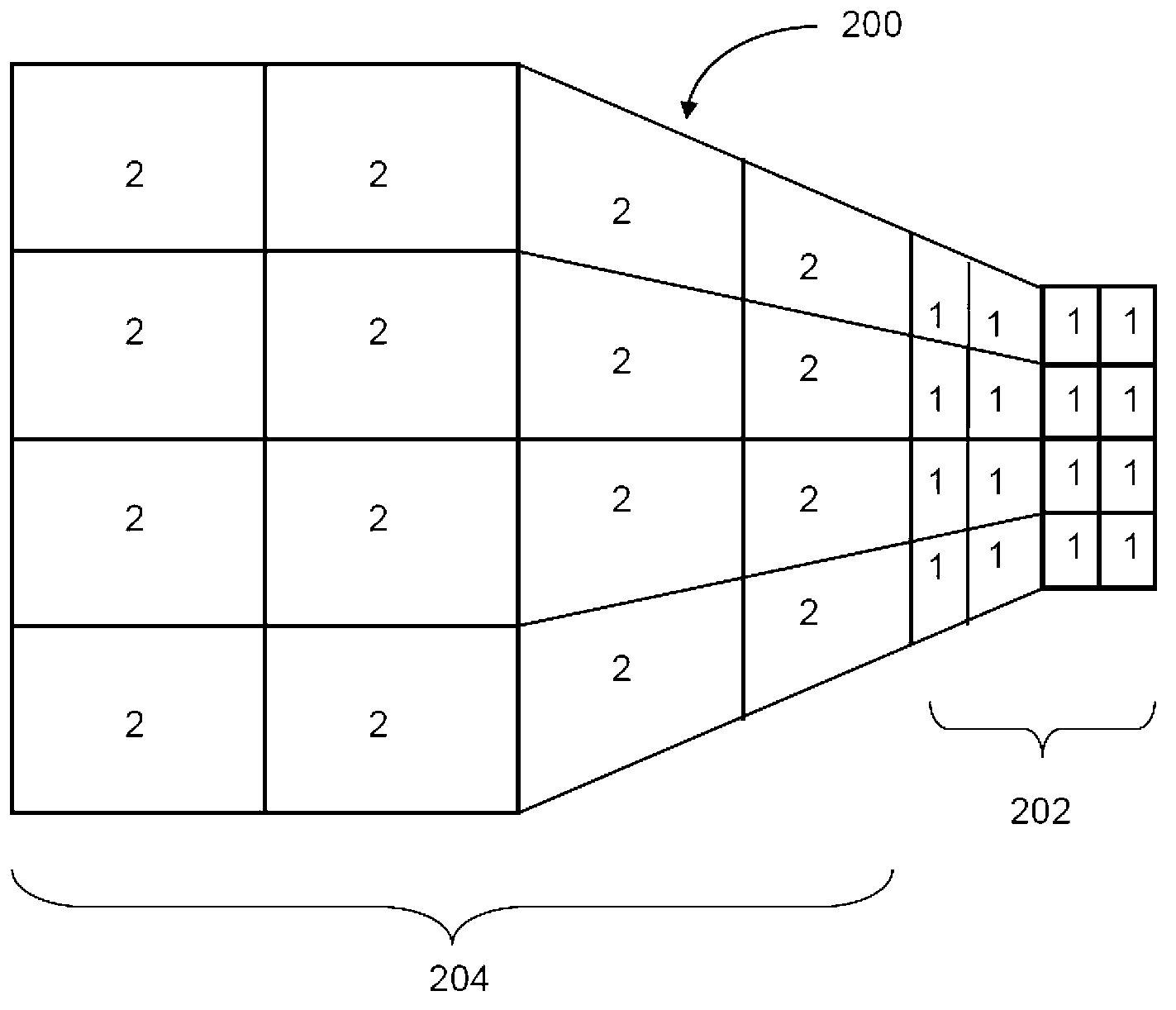

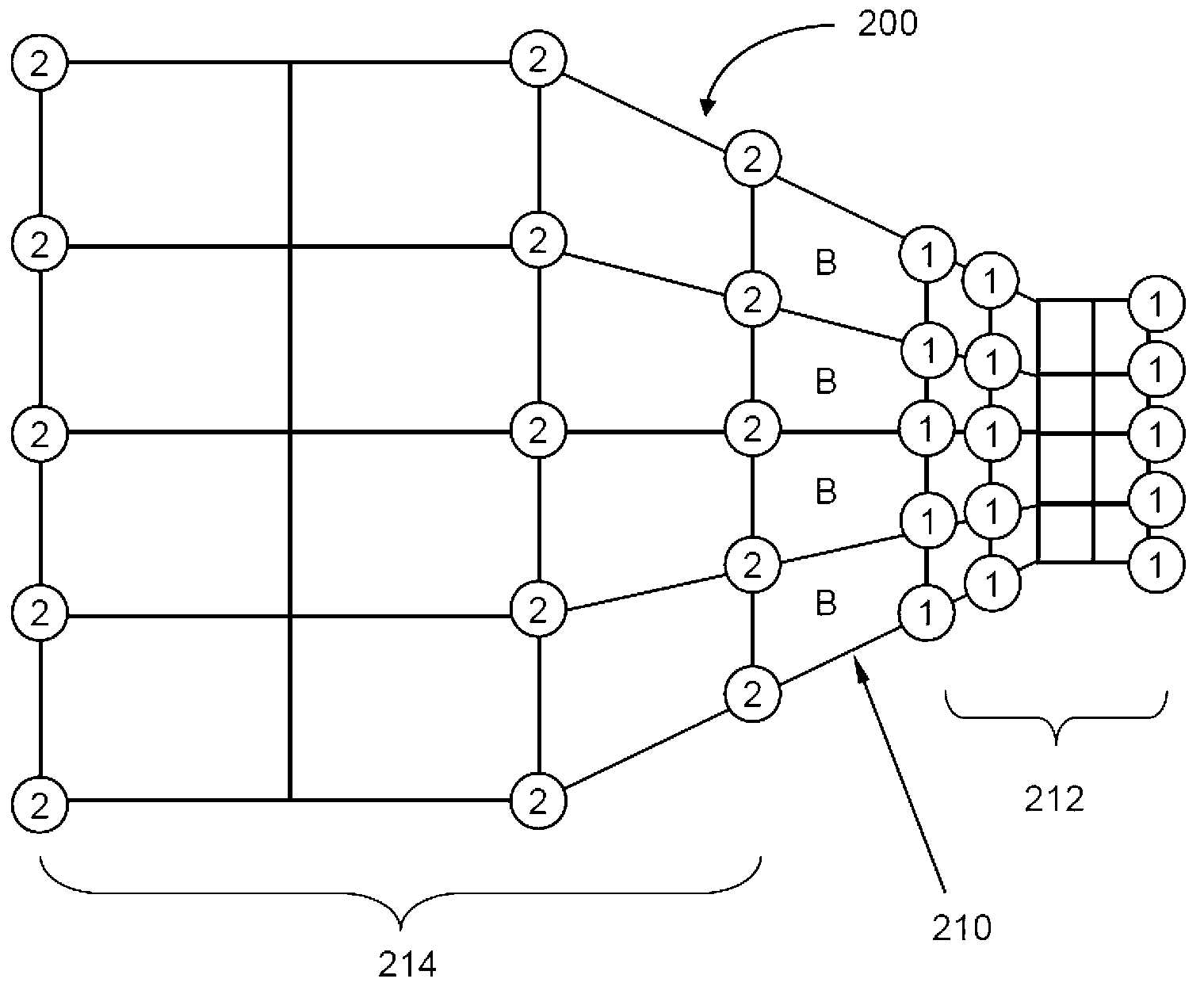

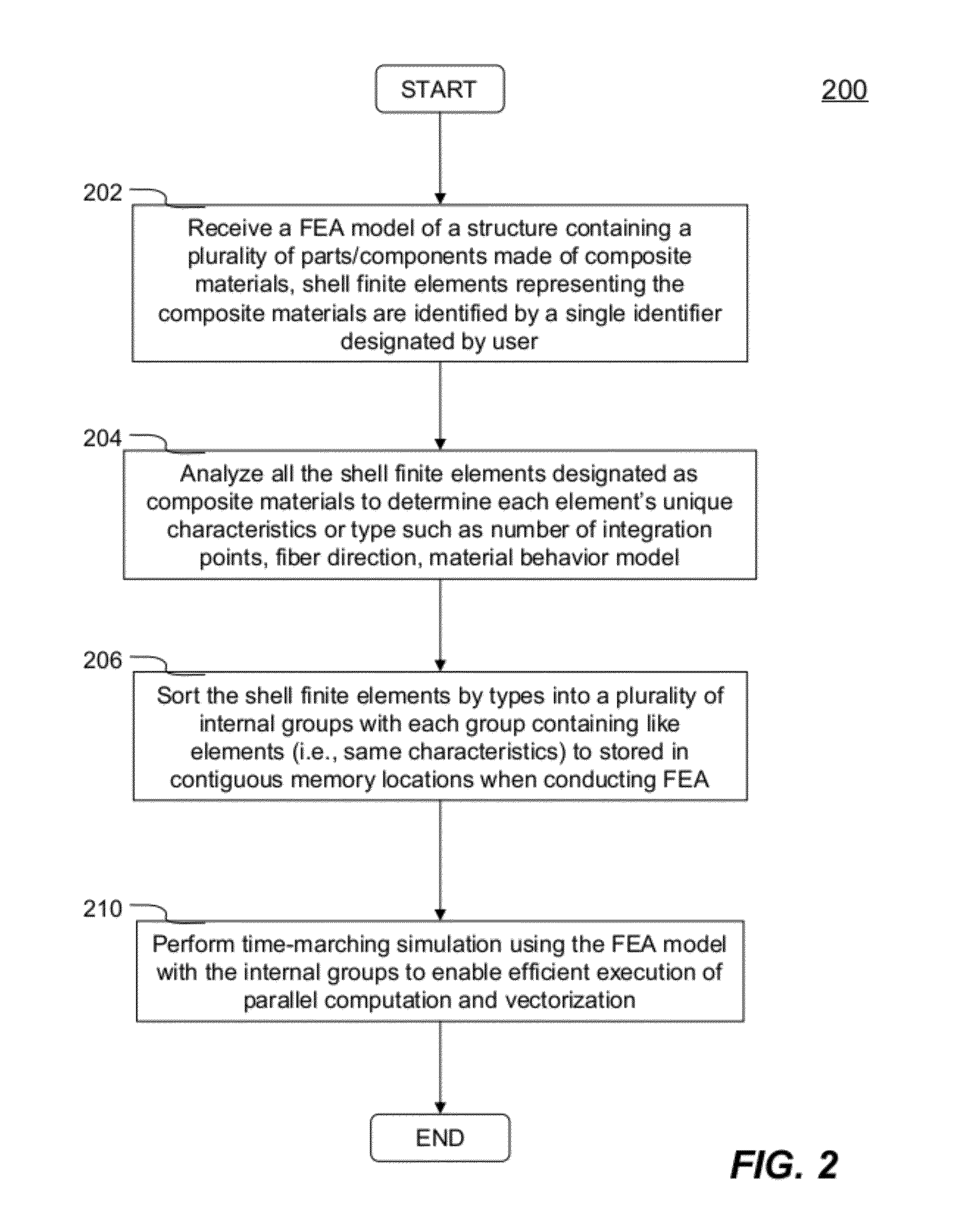

Efficient Data Management For Shell Finite Elements Representing Layered Composite Materials

ActiveUS20120053907A1Geometric CADComputation using non-denominational number representationDecompositionIntegration point

Methods and systems for obtaining numerically simulated structural behaviors of layered composite materials within a structure in a time-marching simulation using finite element analysis (FEA) are disclosed. A single identifier is used for designating all shell finite elements representing parts or components made of layered composite materials in a FEA model of a structure by user. Layered composite materials may have arbitrary number of layers. Each layer may have different material orientation / angle or fiber direction, thickness, and structural material behaviors. Each shell element representing composite material includes a set of through-thickness integration points with each corresponding to one layer of the layered composite materials. The shell elements are sorted by types into a number of internal groups to facilitate vectorization and / or more optimal domain decomposition in massive parallel processing. The internal groups are configured to be hidden from the user and stored in contiguous memory locations when conducting a FEA.

Owner:ANSYS

Systems and methods of limiting contact penetration in numerical simulation of non-linear structure response

ActiveUS7953578B2Analogue computers for chemical processesComputation using non-denominational number representationNODALElement analysis

Owner:ANSYS

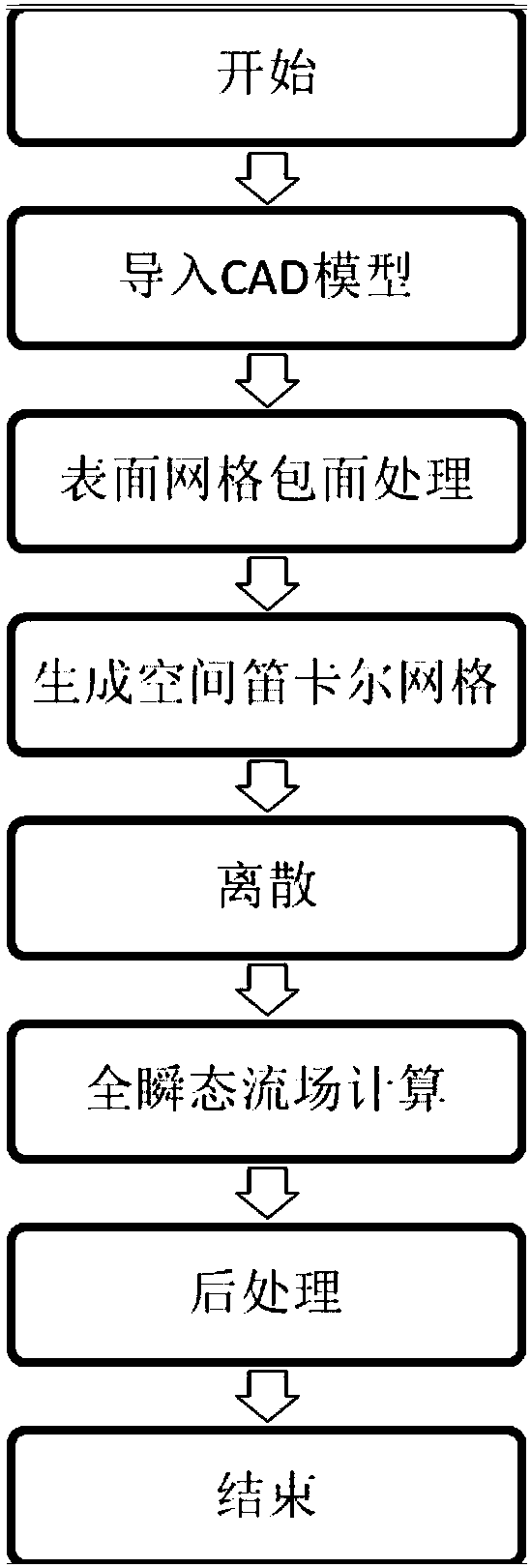

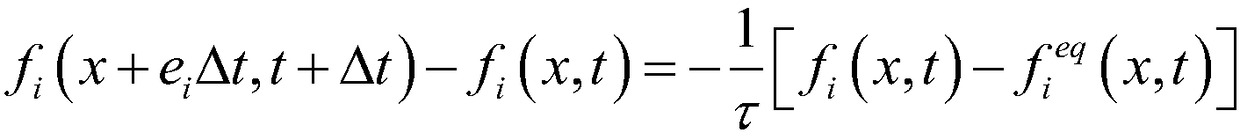

Method for fluid simulation by using Boltzmann equation

PendingCN109408836AGuarantee authenticityGuaranteed accuracyDesign optimisation/simulationSpecial data processing applicationsBoltzmann equationMolecular cluster

The invention discloses a method and a system for fluid simulation by using Boltzmann equation. The method for fluid simulation by using Boltzmann equation comprises the following steps: surface meshenvelope treatment; generating spatial Cartesian grids; full transient flow field calculation. This method calculates the molecular cluster density function of each point in the flow field at different time. The particle distribution function satisfies the lattice Boltzmann equation. The method for simulating a fluid by using the Boltzmann equation adopts a full-detail geometric model, does not need to be simplified, and ensures the authenticity and accuracy of the simulation result; full transient algorithm, accurate calculation of the real transient aerodynamic force; accurate solution of separated flow at hgh angle of attack (or stall state); time-marching explicit algorithm, so that there is no divergence problem in the solution process; high-precision automatic solution, so that no manual intervention is needed and high stability is achieved.

Owner:上海索辰信息科技股份有限公司

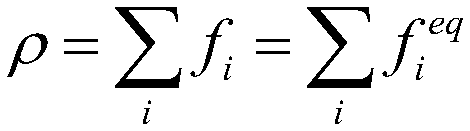

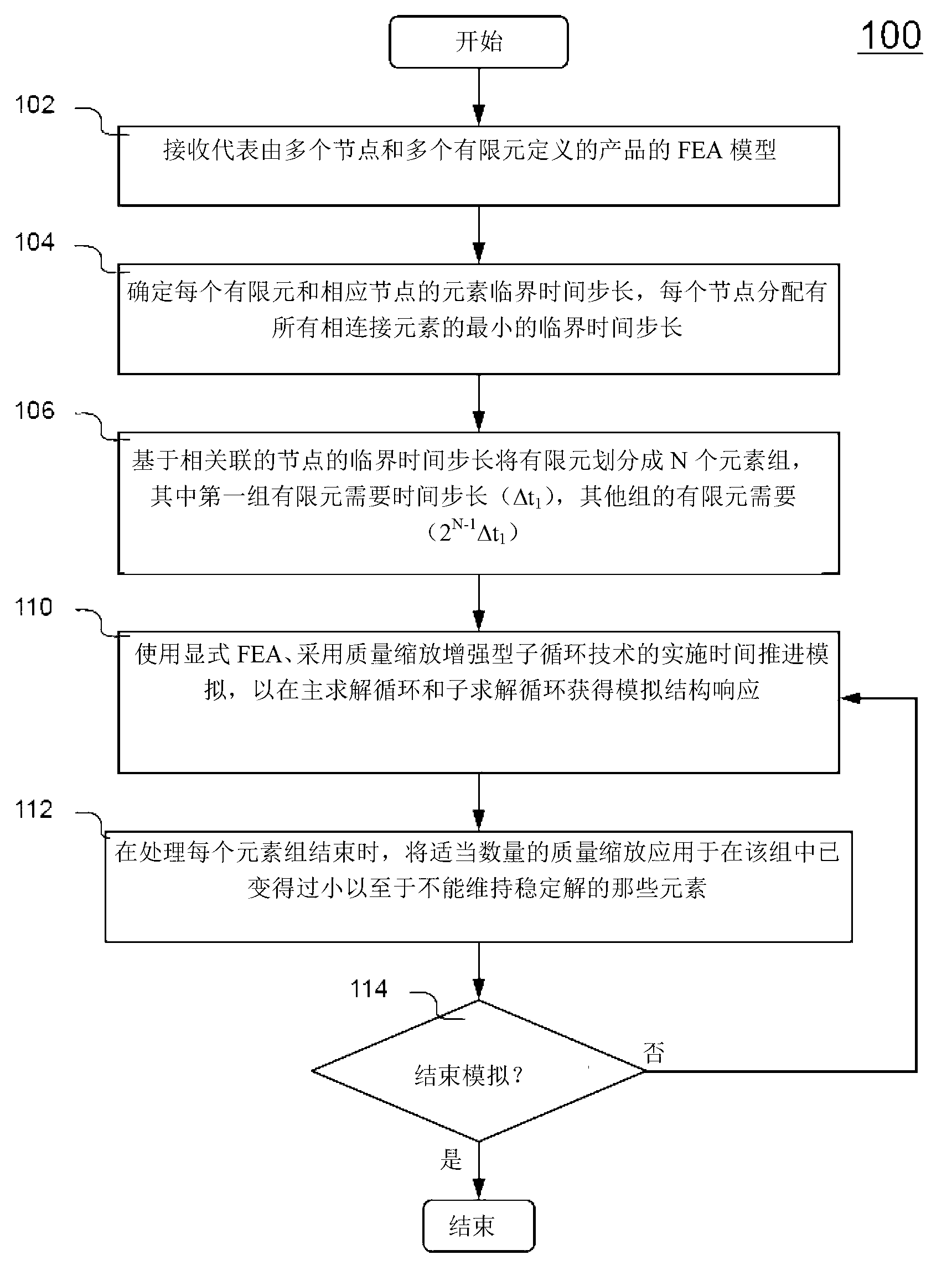

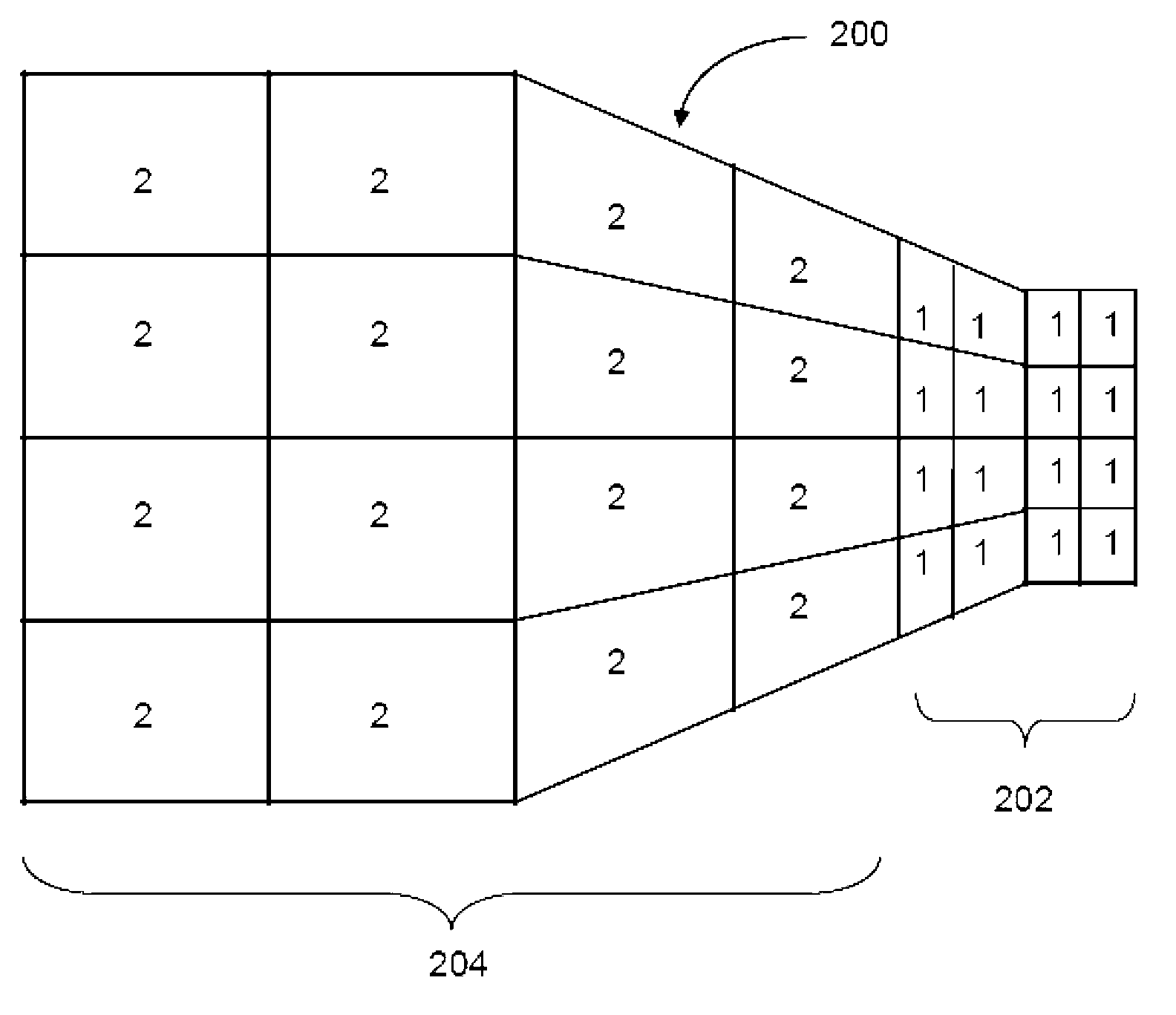

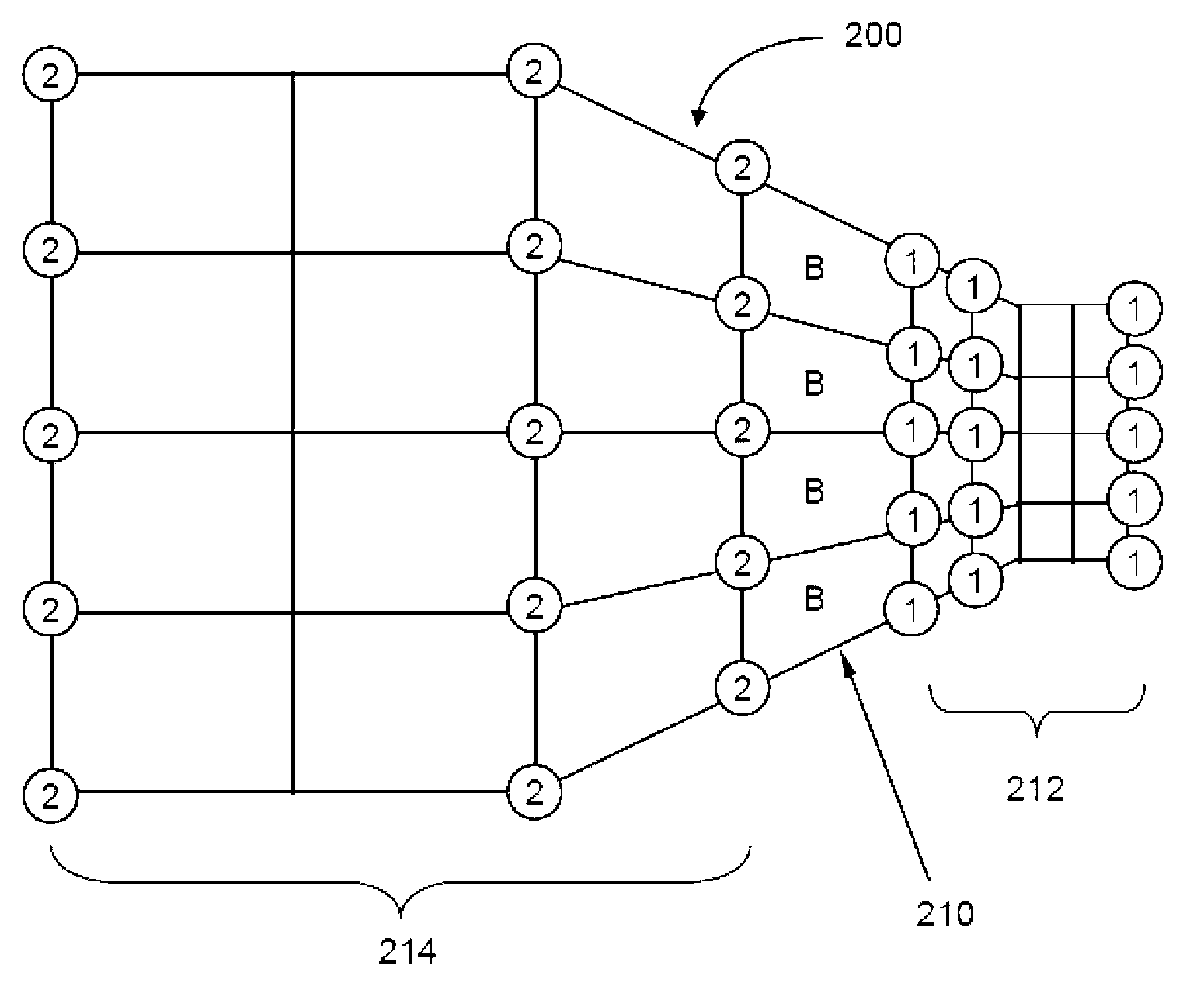

Numerically simulating structural behaviors of a product by using explicit finite element analysis with a combined technique of mass scaling and subcycling

Methods and systems for numerically simulating structural behaviors of a product by using explicit FEA with a combined technique of subcycling and mass scaling are disclosed. A FEA model representing a product and a minimum time step size ([Delta]tmin) for a time-marching simulation of the product are specified. N element groups is established with the first element group associated with [Delta]tmin as required minimum time step size, while other element groups with integer multiples of [Delta]tmin according to formula [Delta]ti=2i-1[Delta]tmin, n=1, 2, . . . , N. Finite elements are periodically resorted into N element groups based on their new respective [Delta]tcr. To ensure all finite elements in the FEA model are processed at the user specified minimum time step size, proper amount of mass scaling is applied to those finite elements that are or have become too small to maintain a stable solution in the first element group.

Owner:LIVERMORE SOFTWARE TECH

Numerical simulation of airflow within porous materials

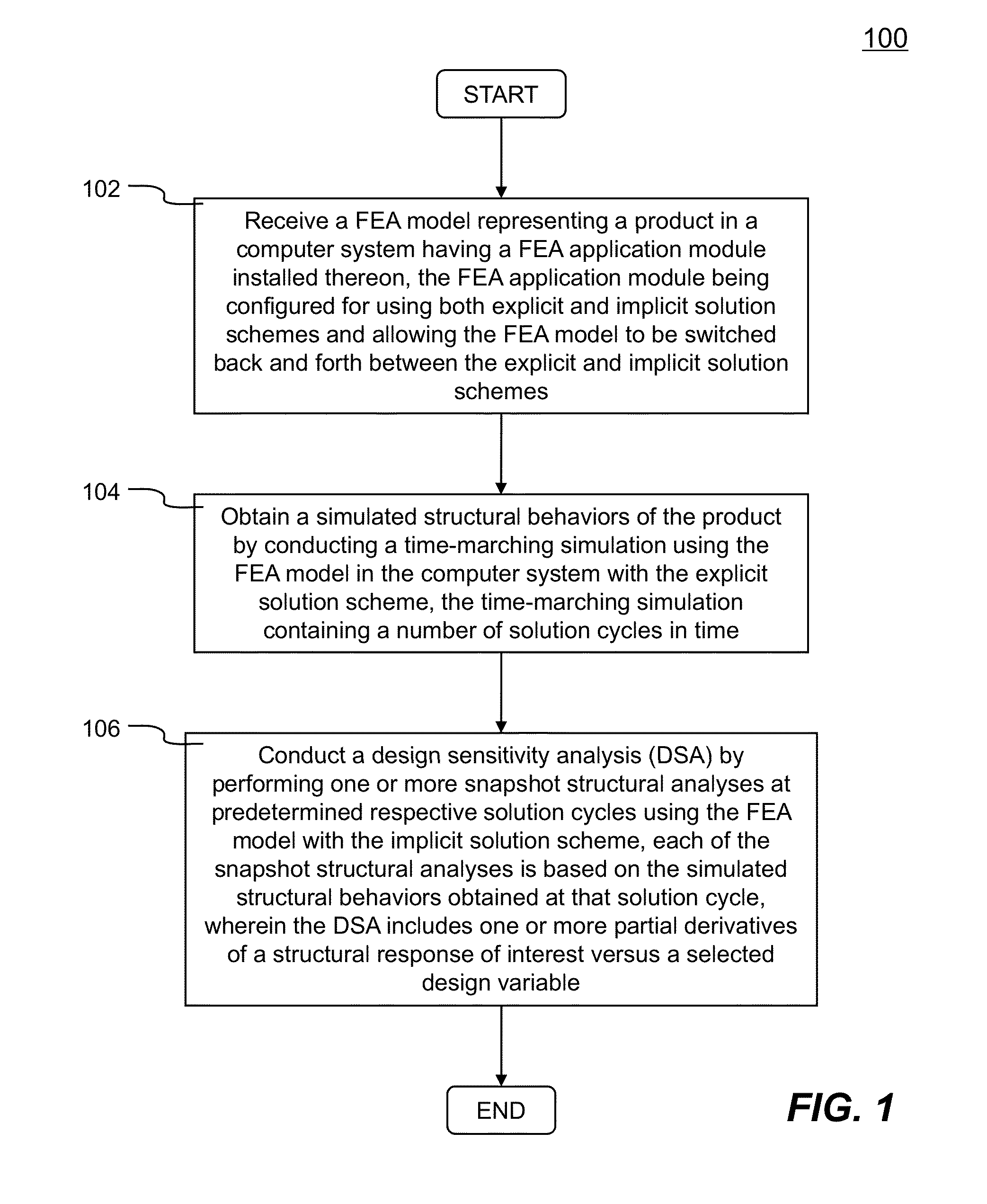

InactiveUS20110282637A1Reduce needFeasible solutionGeometric CADComputation using non-denominational number representationCar seatElement analysis

Systems and methods of numerically simulating airflow within porous materials are disclosed. Engineering product (e.g., car seat) represented by a finite element analysis model containing in part porous material with permeability. In each solution cycle of a time-marching simulation, each of the elements of porous material is evaluated with airflow in conjunction with the traditional mechanical response. Each element's volume change results into different pore air pressure hence a pressure gradient, which in turn is used for airflow calculated in accordance with a fluid seepage law that depends upon permeability of the porous material. Therefore, a more realistic simulation of structural behavior of porous materials can be achieved. The volume change and pressure of each element of porous material is evaluated using ideal gas law. A general form of Darcy's law includes user control parameters is used for evaluating airflow based on the pressure gradient and permeability.

Owner:LIVERMORE SOFTWARE TECH

Efficient data management for shell finite elements representing layered composite materials

ActiveUS8494819B2Geometric CADComputation using non-denominational number representationMassively parallelElement analysis

Owner:ANSYS

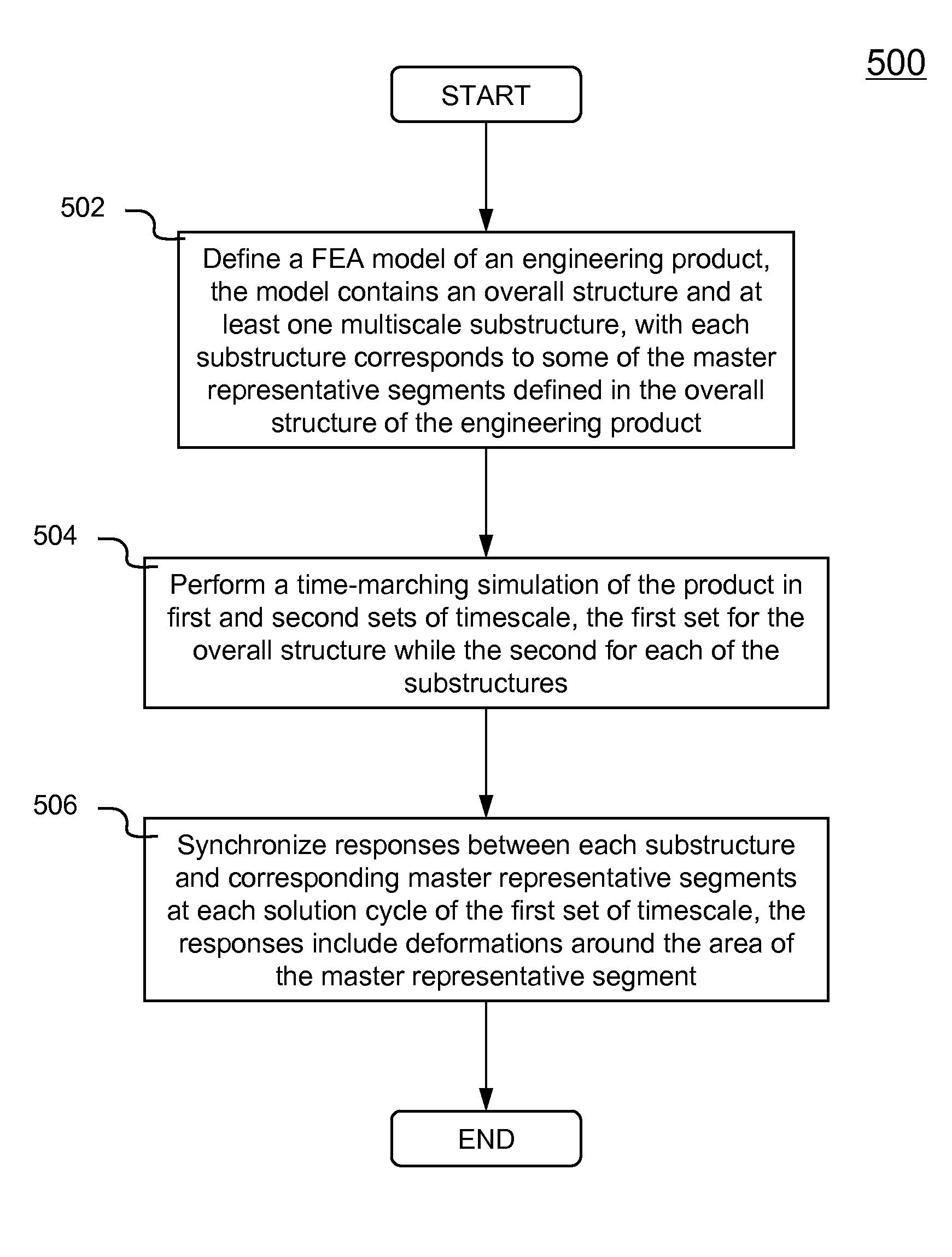

Multiscale substructures in finite element analysis

InactiveUS20110191068A1Design optimisation/simulationSpecial data processing applicationsElement analysisEngineering

Methods and systems for conducting a time-marching simulation of a product using a finite element analysis model including at least one multiscale substructure are disclosed. According to one aspect, a FEA model of a product is defined for a time-marching simulation. The FEA model comprises an overall structure, and at least one multiscale substructure. Each substructure corresponds to some of the master representative segments defined in the overall structure. Time-marching simulation of the product is conducted with first and second sets of timescale due to significantly different characteristic dimension of the FEA model. The first set is configured for the overall structure or master group, while the second set for the substructures or slave group. The first set is run at a time step significantly larger than the second set. Synchronization of the responses is at the end of each solution cycle corresponds to the first set of timescale.

Owner:LIVERMORE SOFTWARE TECH

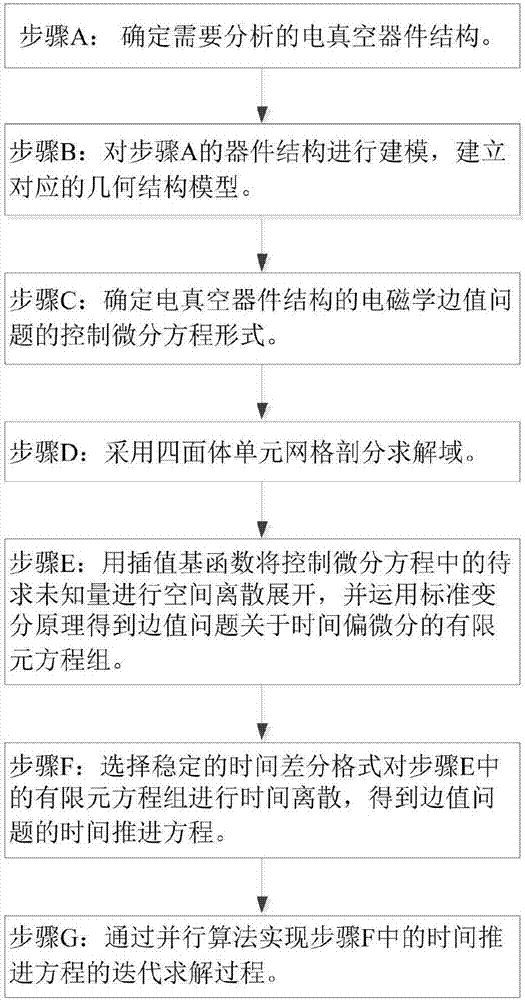

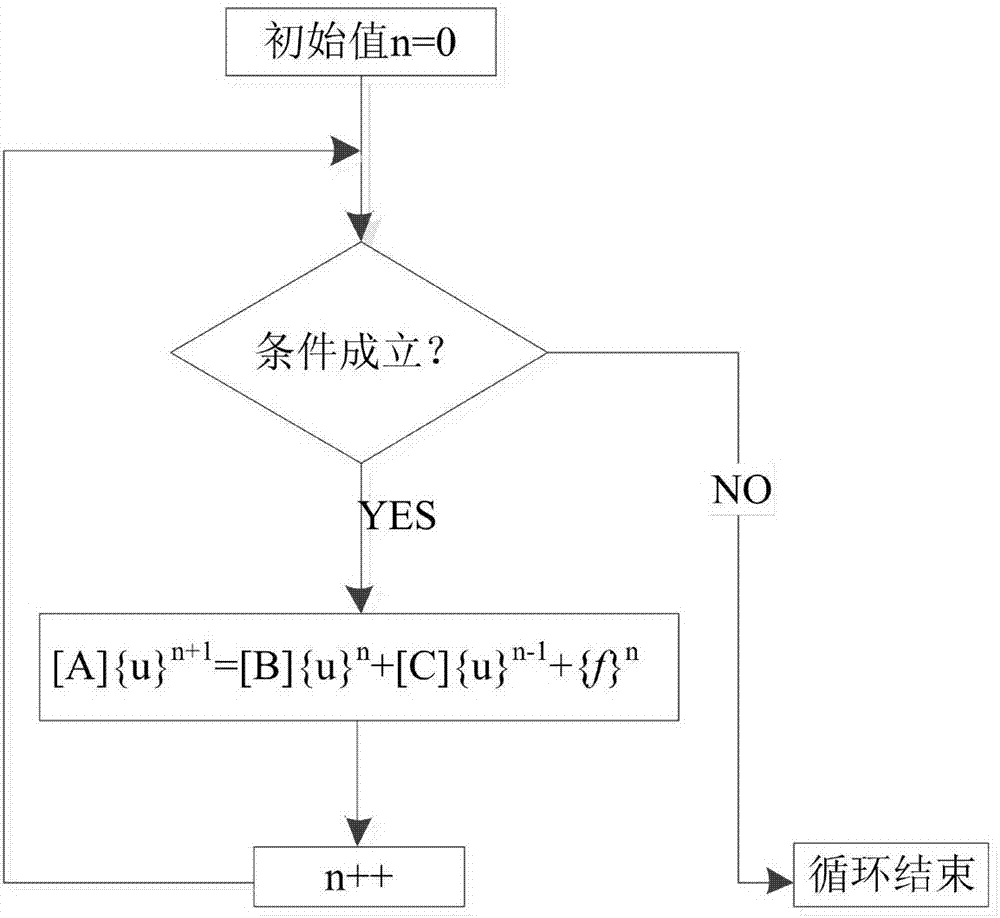

FETD (finite-element time-domain) Analog simulation method based on parallel algorithm

ActiveCN107247686AGuaranteed calculation accuracyImprove computing efficiencyDesign optimisation/simulationCAD numerical modellingParallel algorithmFinite element time domain

The invention discloses an FETD (finite-element time-domain) analog simulation method based on a parallel algorithm and belongs to the field of computational electromagnetics. According to the method, loop iteration solving of an equation is achieved by replacing conventional serial computation by parallel computation based on existing algorithms; in the parallel solving process, a matrix is introduced to convert an equation set in order to overcome dependent relationship of three adjacent moment unknown quantities in a time marching equation, so that paralleling is made feasible. The method enables the problem of low loop iteration solving efficiency of a time marching equation in FETD to be solved at the premise of ensuring computation precision.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

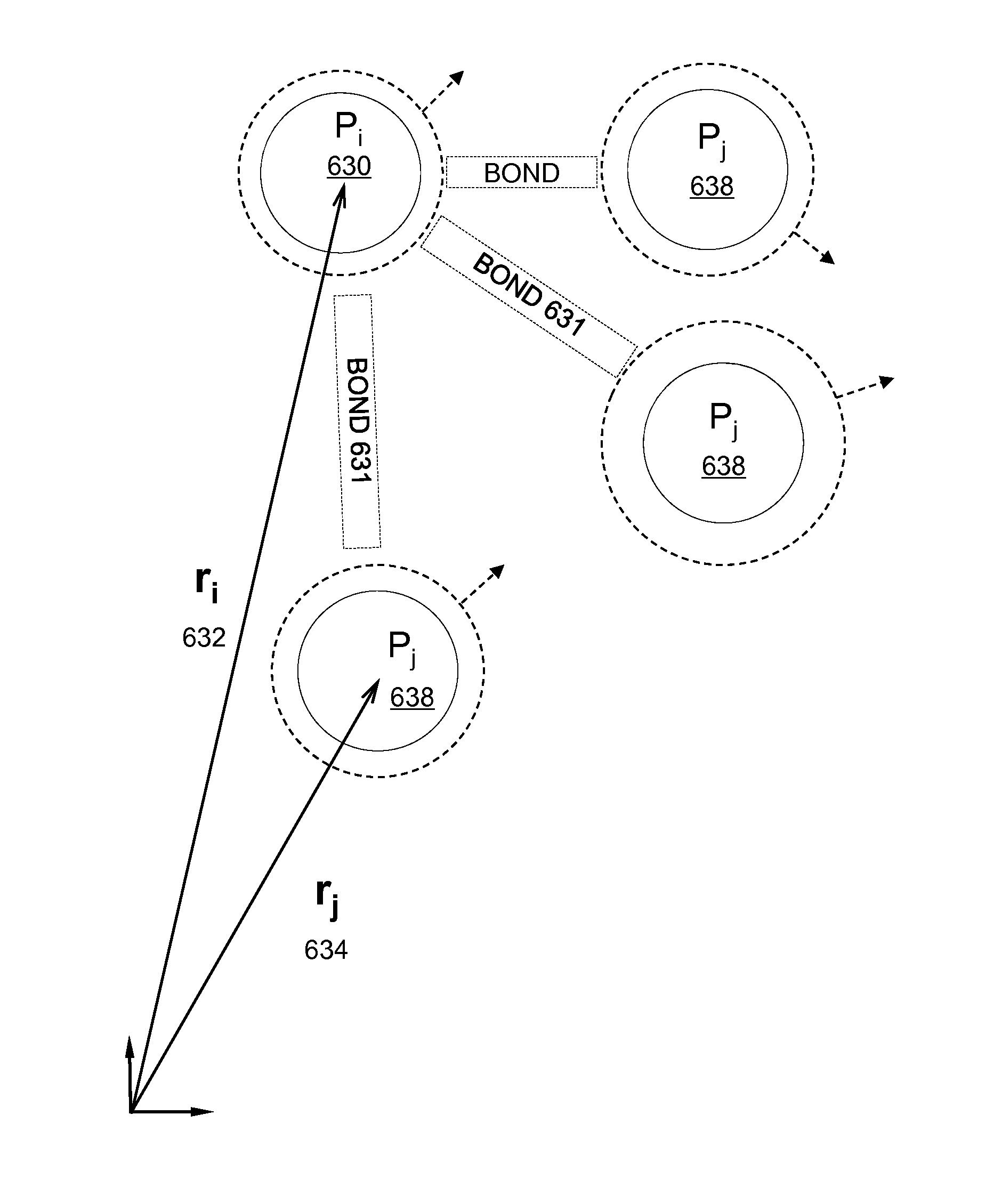

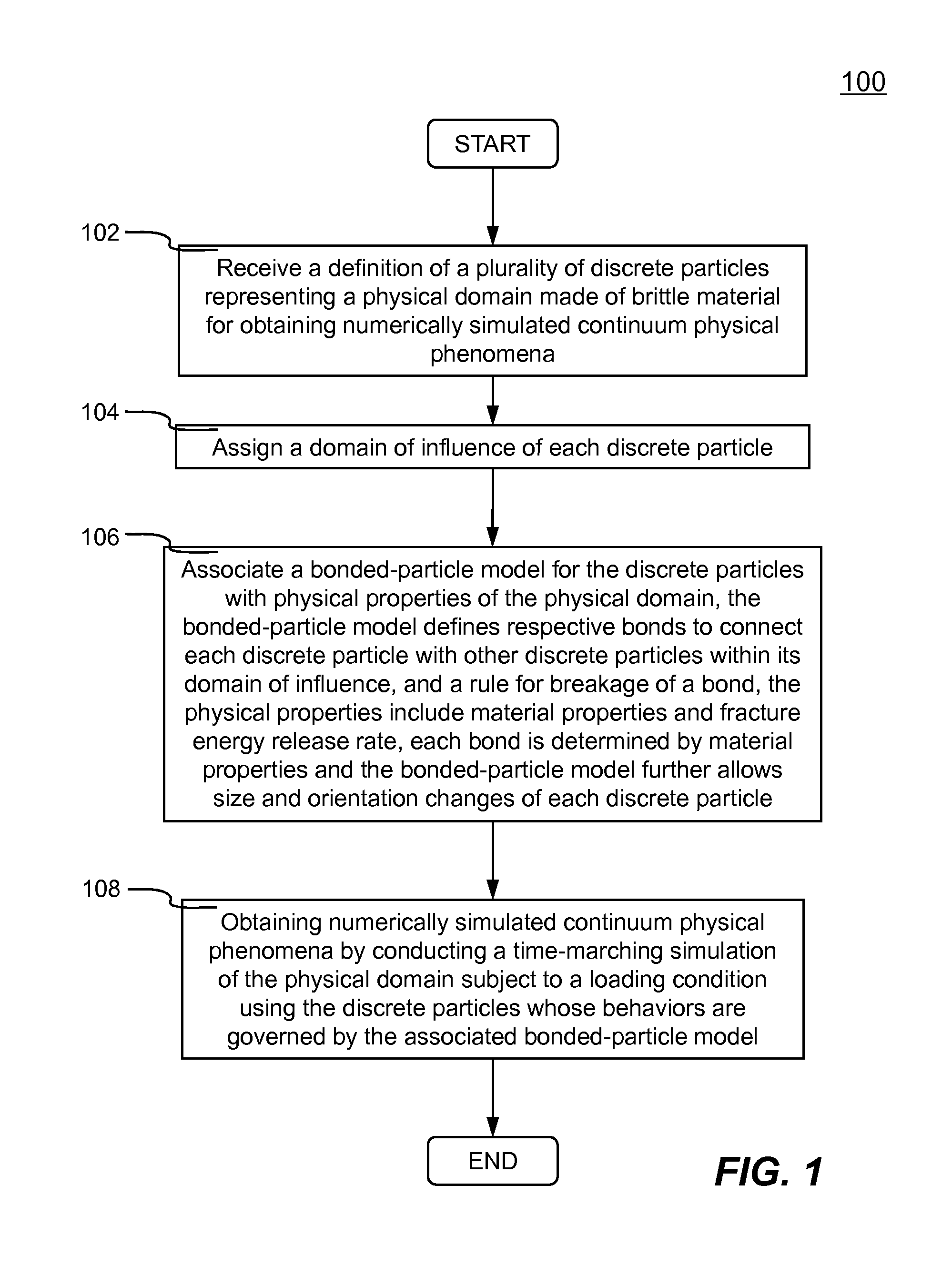

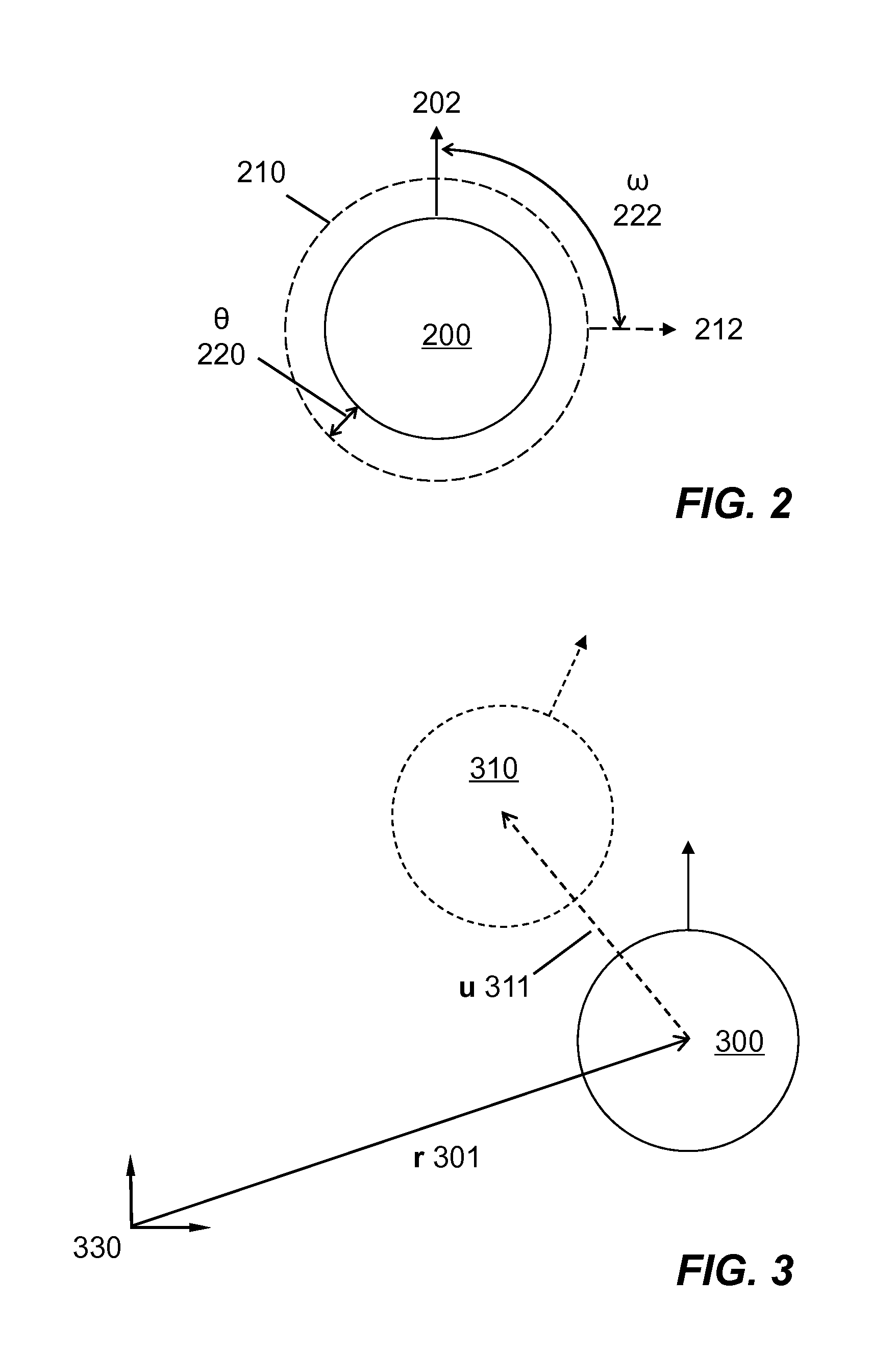

Methods For Providing A Bonded-Particle Model In Computer Aided Engineering System

ActiveUS20130289957A1Design optimisation/simulationComputational theoretical chemistryA domainComputer science

Systems and methods of providing bonded-particle model amongst a plurality of discrete particles representing a physical domain made of brittle material in a time-marching simulation to obtain numerically simulated continuum physical phenomena are disclosed. A physical domain is represented by a plurality of discrete particles. A domain of influence is assigned to each discrete particle and a bonded-particle model is created for the discrete particles. Respective bonds are established to connect each discrete particle to all other discrete particles within its domain of influence. The bonded-particle model further defines a rule for breakage of a bond. Continuum physical phenomena of the physical domain are numerically represented through a set of formula such that a time-marching simulation of the physical domain can be conducted. Physical properties include material properties and fracture energy release rate. Finally, the bonded-particle model allows size and orientation changes of each discrete particle.

Owner:ANSYS

An explicit R-K time marching acceleration method based on MIC coprocessor

ActiveCN109408867AImprove portabilityReduce workloadDesign optimisation/simulationSpecial data processing applicationsMarch algorithmCoprocessor

Owner:XI AN JIAOTONG UNIV

Explosion simulation in finite element analysis

ActiveUS8200464B2Reduce computing timeImprove userComputation using non-denominational number representationDesign optimisation/simulationNODALElement analysis

Systems and methods of simulating an explosion in time-marching finite element analysis are disclosed in the present invention. A method is configured for increasing user (e.g., engineer or scientist) productivity by reducing computation time of simulating fluid-structure interaction due to an explosion. The method comprises a creation of a finite element analysis model that includes structure, surrounding fluid, a blast source of the explosion and a single layer of ambient elements each having a segment representing a boundary of the fluid facing the blast source. Each ambient element is associated with a particular finite element representing the fluid at the boundary. The ambient elements are configured to be situated between the blast source and the structure such that the simulation can be carried on a set of boundary conditions specified thereon. The boundary conditions comprise a set of nodal velocities that are determined from the empirical formula (e.g., Friedlander equation).

Owner:ANSYS

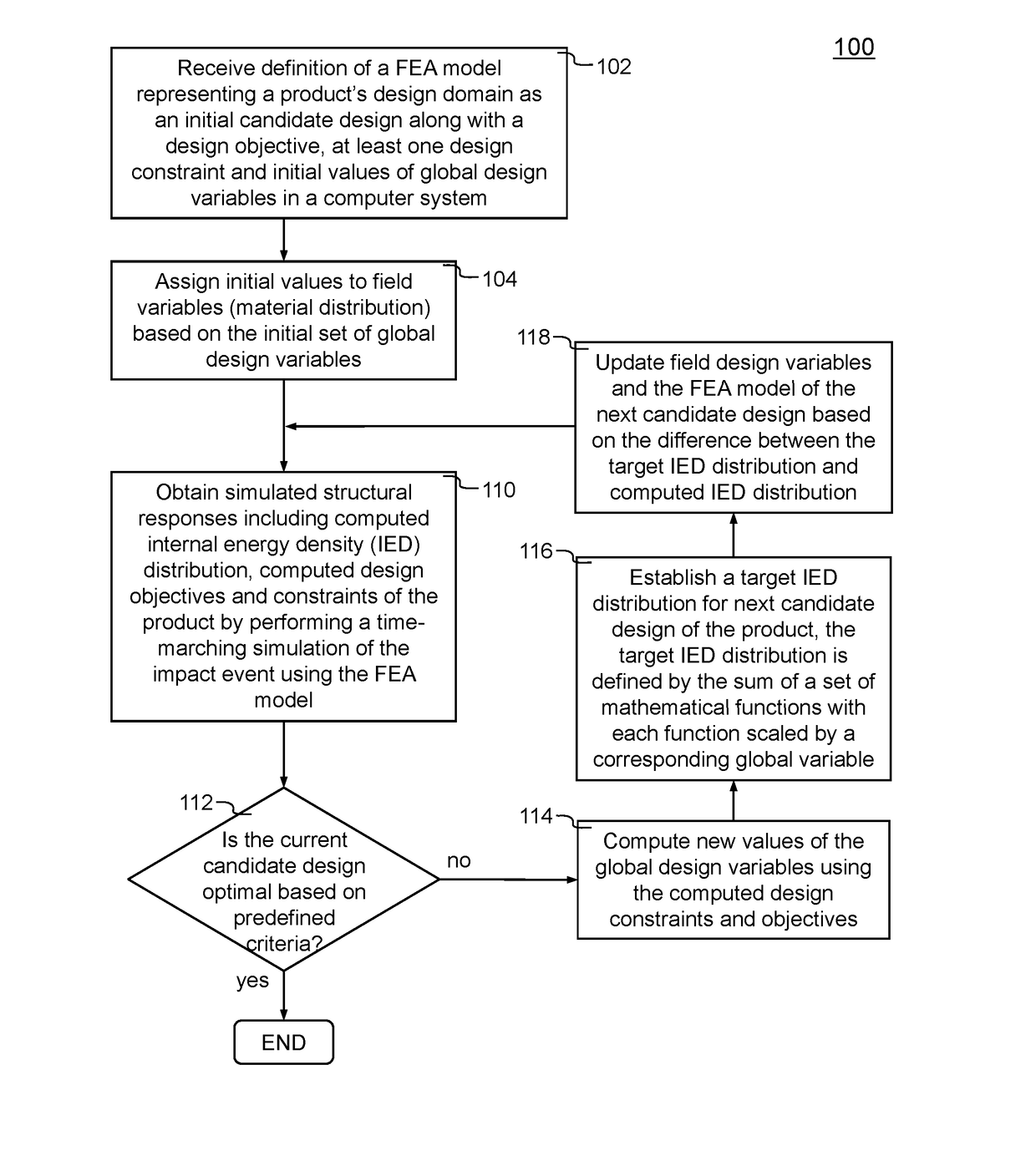

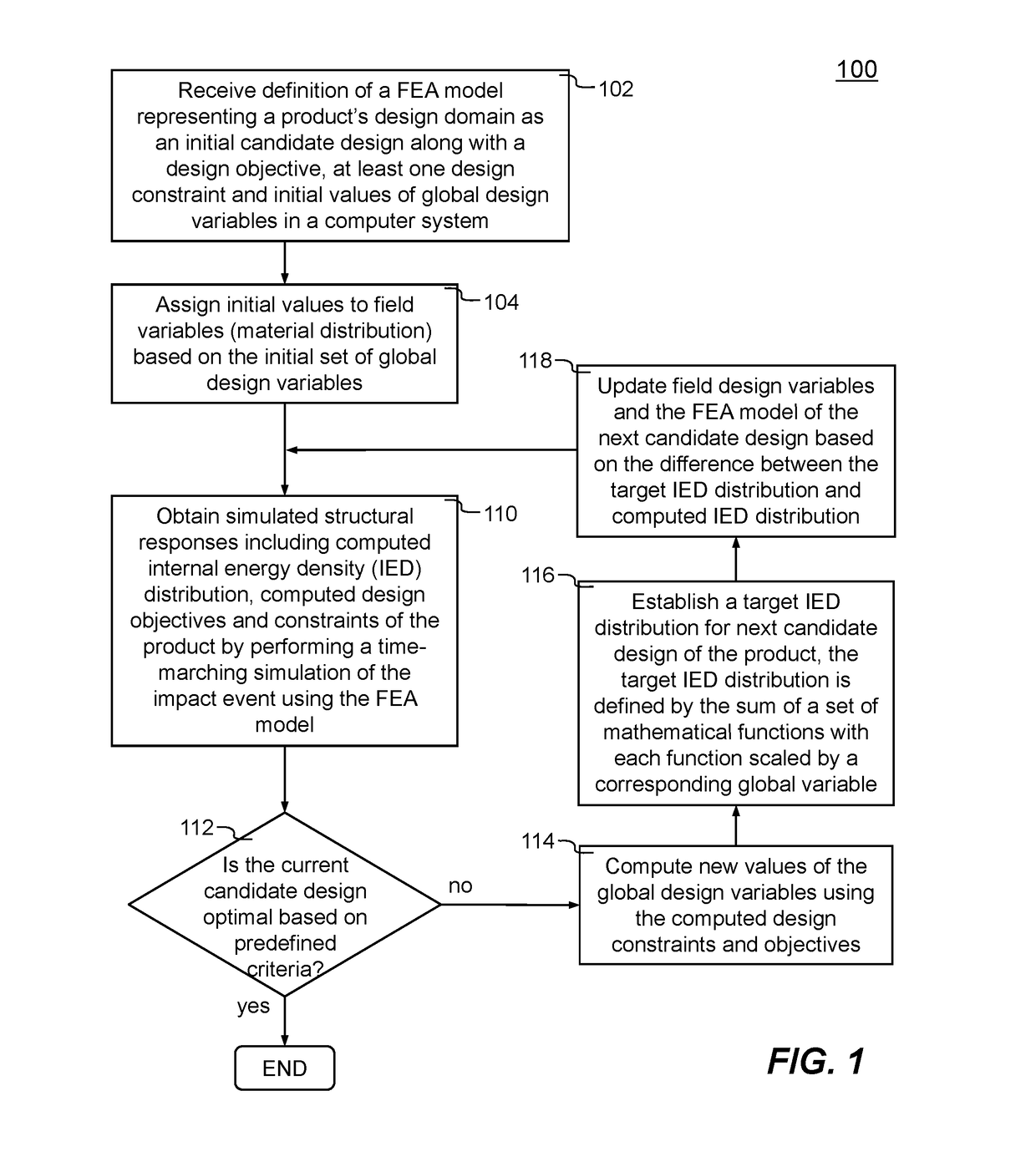

Enhanced Global Design Variables Used In Structural Topology Optimization Of A Product In An Impact Event

Enhanced global design variables used in structural topology optimization are disclosed. FEA model of a product's initial candidate design along with design objective and constraint, and initial global design variables are received. Field design variables are then initialized. Simulated structural responses including computed IED distribution and design constraints and objectives of the product are obtained by performing a time-marching simulation of the impact event using the FEA model. New values of global design variables are computed based on computed design constraints and objectives, A target IED distribution defined by the sum of a set of mathematical functions with each function scaled by a corresponding global design variable for next candidate design is established. Field design variables are then updated using the differences of the target IED distribution and the computed IED distribution. Simulated structural responses are obtained until the current candidate design is deemed to be optimal.

Owner:LIVERMORE SOFTWARE TECH

Numerically simulating structural behaviors of a product by using explicit finite element analysis with a mass scaling enhanced subcycling technique

Methods and systems for numerically simulating structural behaviors of a product by using explicit FEA with a mass scaling enhanced subcycling technique are disclosed. A FEA model of the product defined by a plurality of nodes and finite elements is received. A critical time step size is calculated for each finite element and then assigned to associated nodes. Elements are partitioned into N element groups with first group requiring minimum time step size [Delta]t1 and other element groups requiring respective time step sizes ([Delta]tN=2N-1[Delta]t1). In order not to resort or repartition the finite elements and still obtain a stable solution, respective proper amounts of mass scaling are applied to those elements that have become too small to maintain a stable solution in their respective element groups. A time-marching simulation using explicit FEA with the mass scaling enhanced subcycling technique is then conducted with such a FEA model.

Owner:LIVERMORE SOFTWARE TECH

Numerical Model For Simulating Polymeric Material Properties

InactiveUS20110288827A1Computation using non-denominational number representationDesign optimisation/simulationBack stressNumerical models

Owner:LIVERMORE SOFTWARE TECH

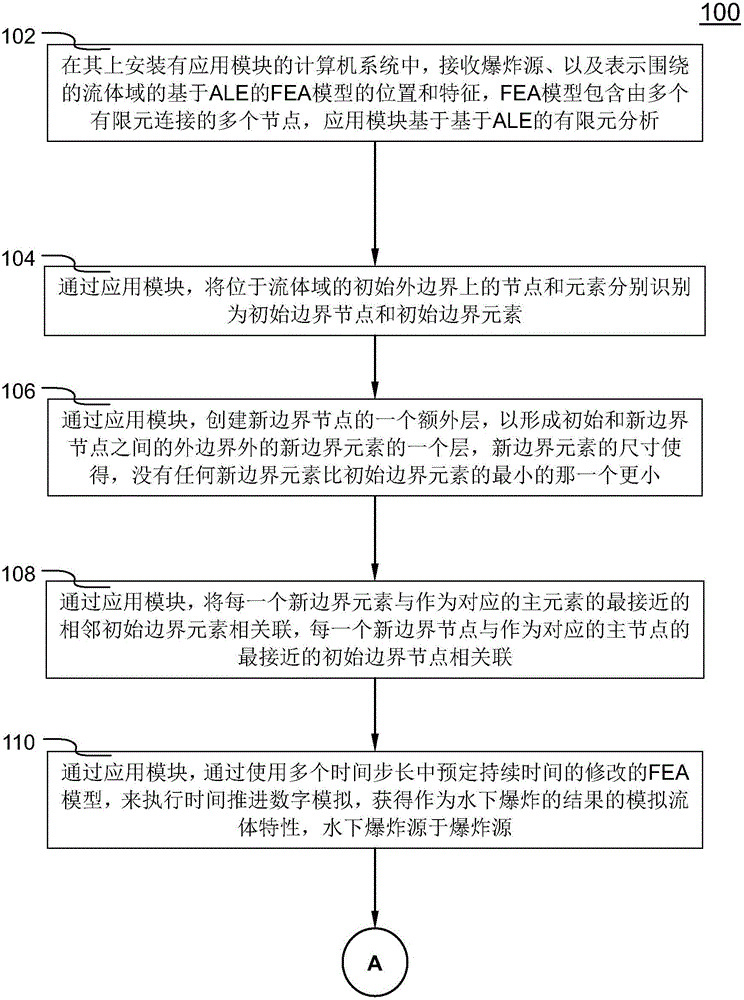

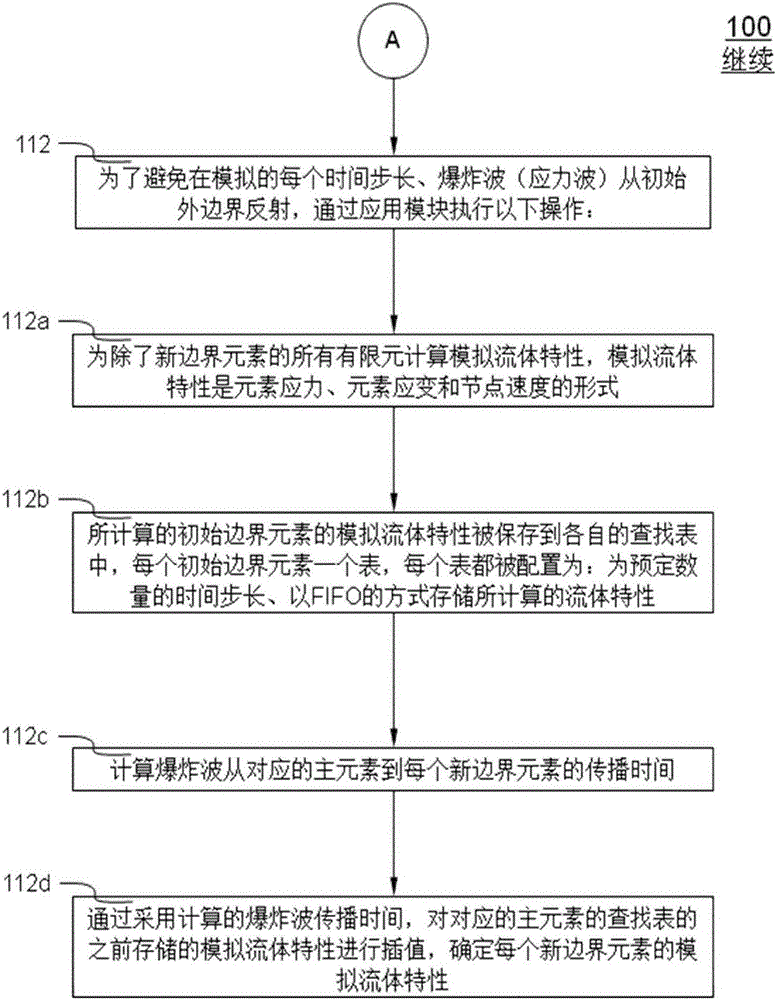

Systems and methods of conducting numerical simulation of an underwater explosion

ActiveCN106528903ADesign optimisation/simulationSpecial data processing applicationsUnderwater explosionPropagation time

The invention discloses systems and methods of conducting numerical simulation of an underwater explosion. Characteristics of a blast source and a FEA model representing a surrounding fluid domain are defined. One layer of new border nodes and elements are created outside of the fluid domain's original outer boundary formed by the original border elements. Each new border elementde is associated with one of the original border elementsdes as corresponding master elementde. At each time step of a time-marching simulation of an underwater explosion, simulated fluid behaviors are computed for all but the new border elements. The computed fluid behaviors of each original border element are saved into a corresponding lookup table configured to store the computed fluid behaviors for a predefined number of time steps in a first-in-first-out manner. Simulated fluid behaviors of each new border element are determined by interpolating, with the calculated blast wave propagation time from the master element, the stored fluid behaviors in the corresponding master element s lookup table.

Owner:LIVERMORE SOFTWARE TECH

Smoothed particle galerkin formulation for simulating physical behaviors in solids mechanics

InactiveCN104573166ADesign optimisation/simulationSpecial data processing applicationsComputerized systemComputational physics

Owner:LIVERMORE SOFTWARE TECH

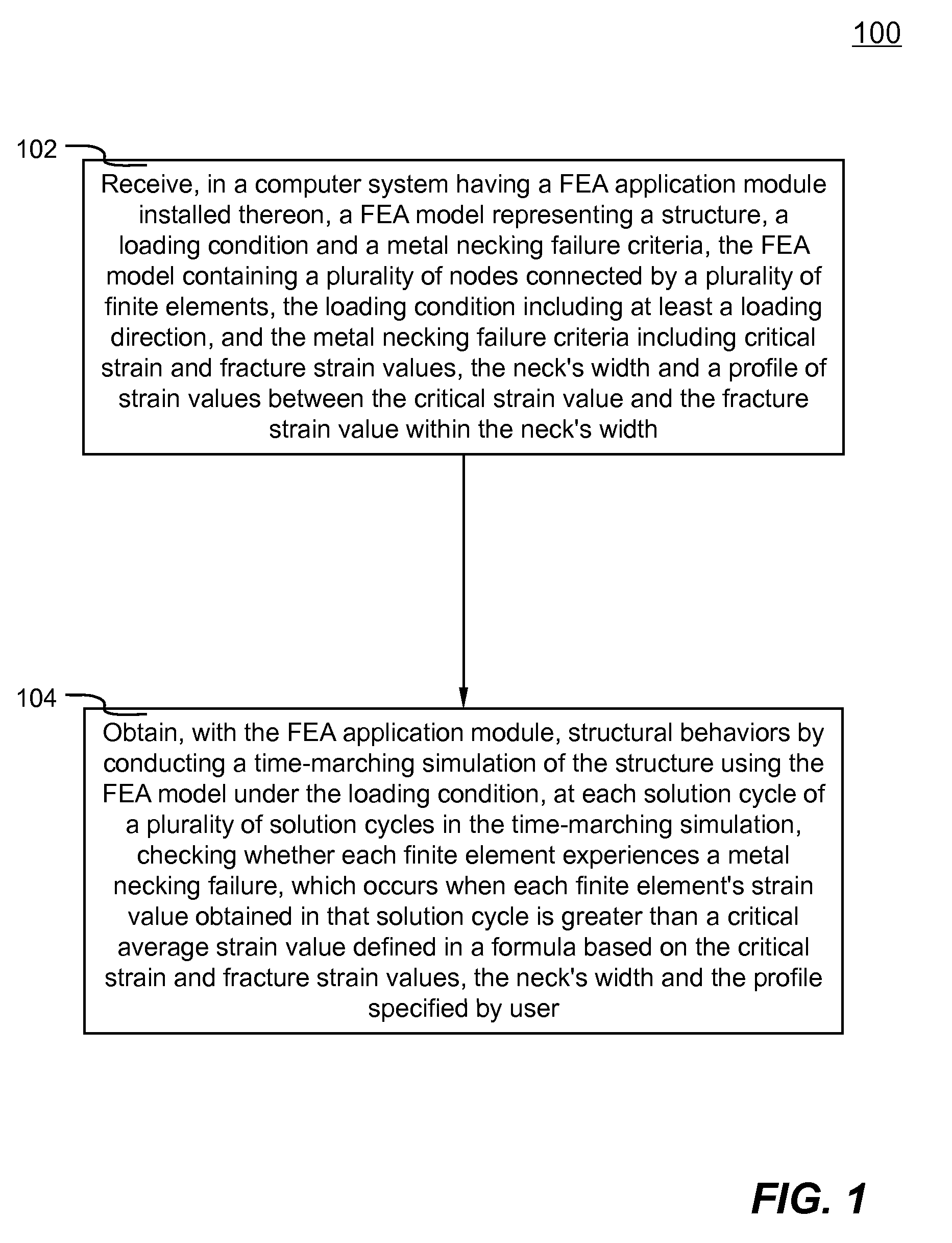

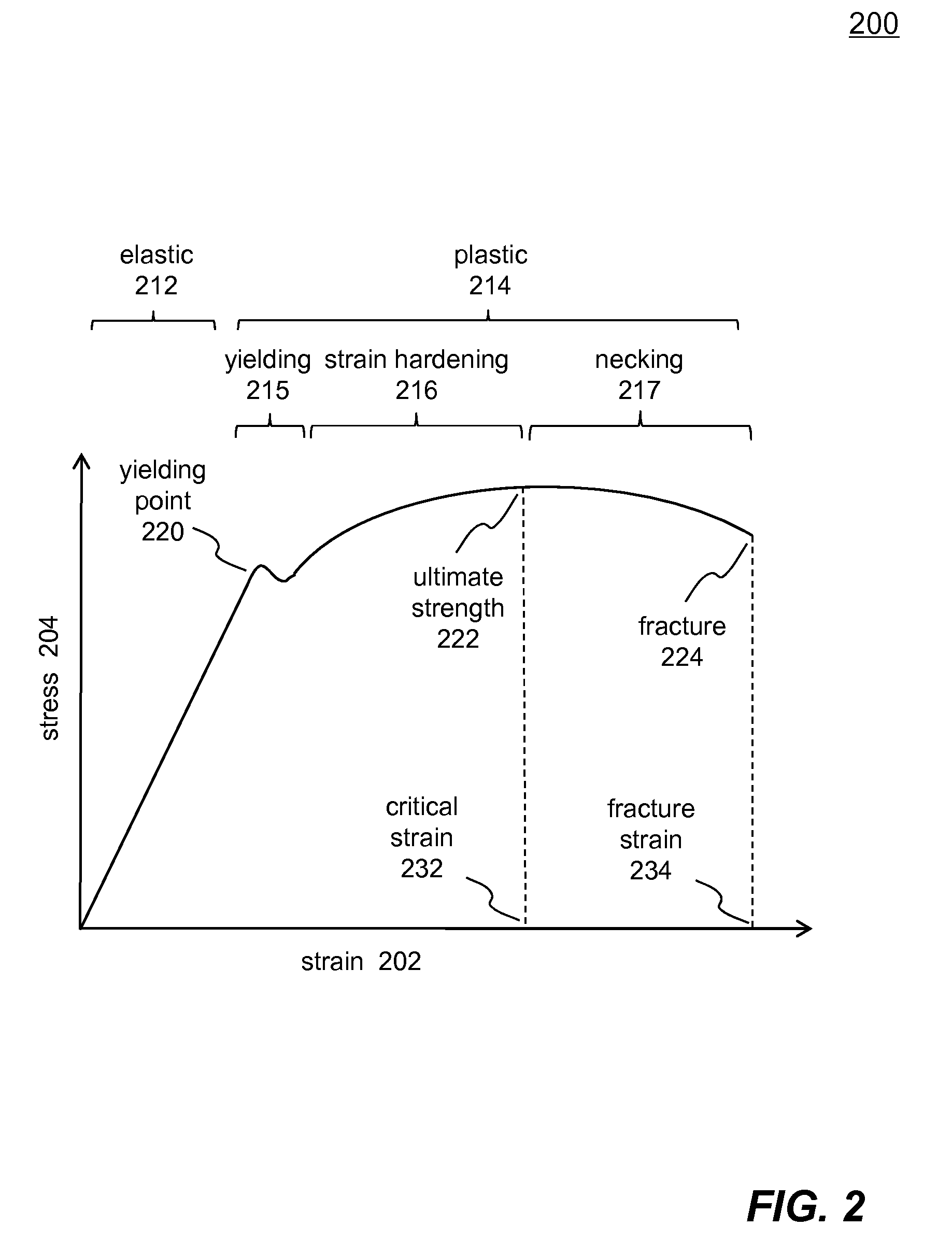

Methods And Systems For Specifying Metal Necking Failure Criteria In Finite Element Analysis

ActiveUS20160328502A1Avoid obscuring purposeDesign optimisation/simulationSpecial data processing applicationsElement analysisComputerized system

Methods and systems for specifying metal necking failure criteria in FEA are disclosed. FEA model contains many finite elements representing a structure, a loading condition and a metal necking failure criteria are received in a computer system. The loading condition includes a loading direction. The metal necking failure criteria includes critical strain and fracture strain values, the neck's width, and a profile of strain values between the critical strain value and the fracture strain value within the neck's width. At each solution cycle in the time-marching simulation of the structure, each finite element is check to determine whether it experiences a metal necking failure, which occurs when each finite element's strain obtained in that solution cycle is greater than an average strain value defined in a formula according to the critical strain and fracture strain values, the neck's width and the profile of the metal necking failure criteria.

Owner:ANSYS

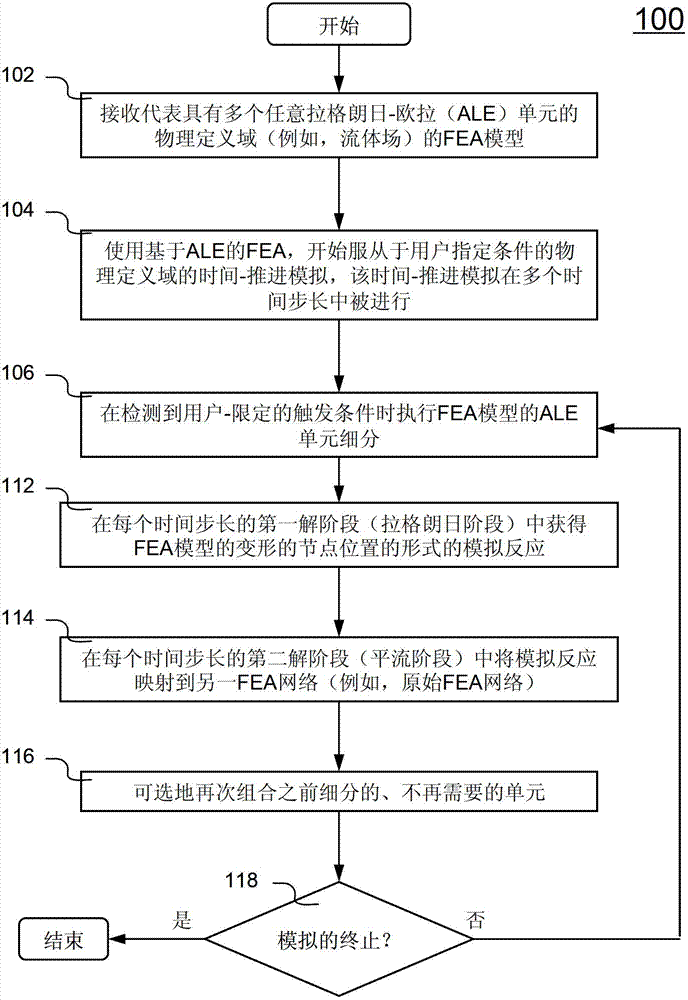

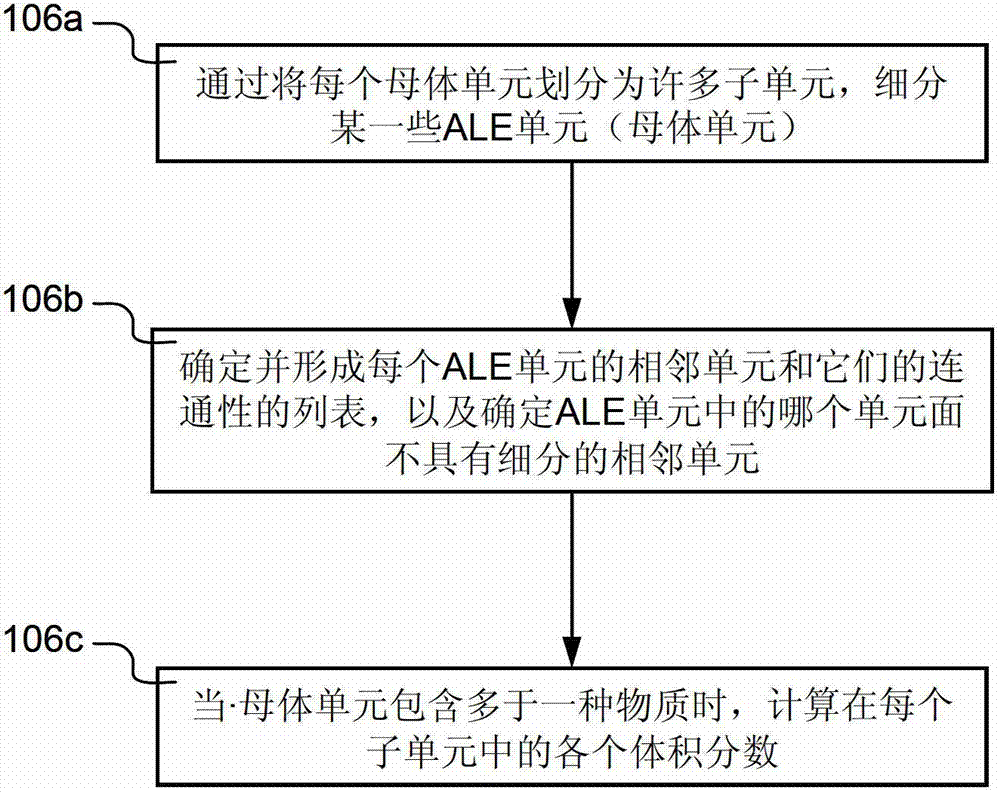

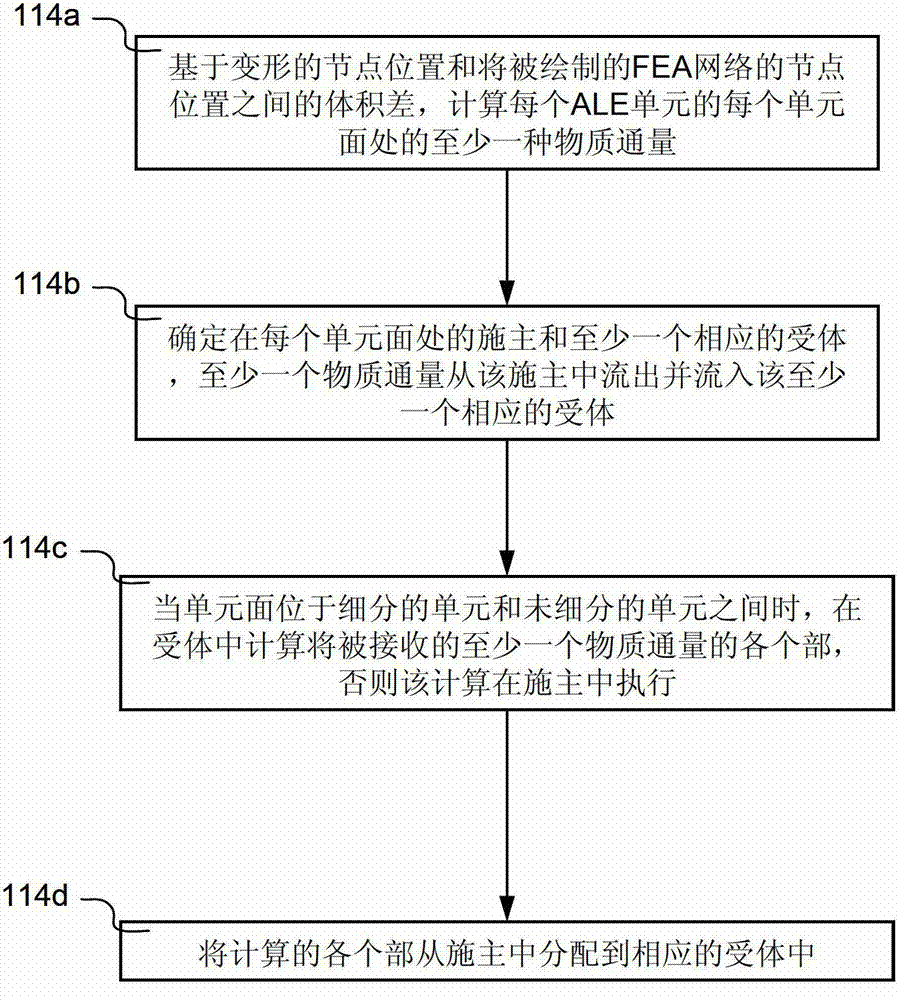

Element refinement methods and systems in arbitrary Lagrangian-Eulerian (ALE) based finite element analysis

ActiveCN103246755AComputation using non-denominational number representationDesign optimisation/simulationElement analysisFinite element method analysis

Systems and methods for refining ALE elements in a time-marching simulation are disclosed. A FEA model representing a physical domain is defined and used in a time-marching simulation that simulates physical phenomena of the physical domain. Certain ones of the ALE elements are refined upon detecting a user-defined triggering condition. Each of said certain ones of the ALE elements is refined into a number of child elements. When an ALE element contains more than one material, volume fractions representing respective materials are calculated in each of the child elements right after each refinement. At each advection phase, each donor maps its flux to one or more receptors. When a donor maps its flux to multiple receptors, each receptor calculates its own share of the flux from the donor. When the donor contains more than one material, each receptor must account for such situation.

Owner:LIVERMORE SOFTWARE TECH

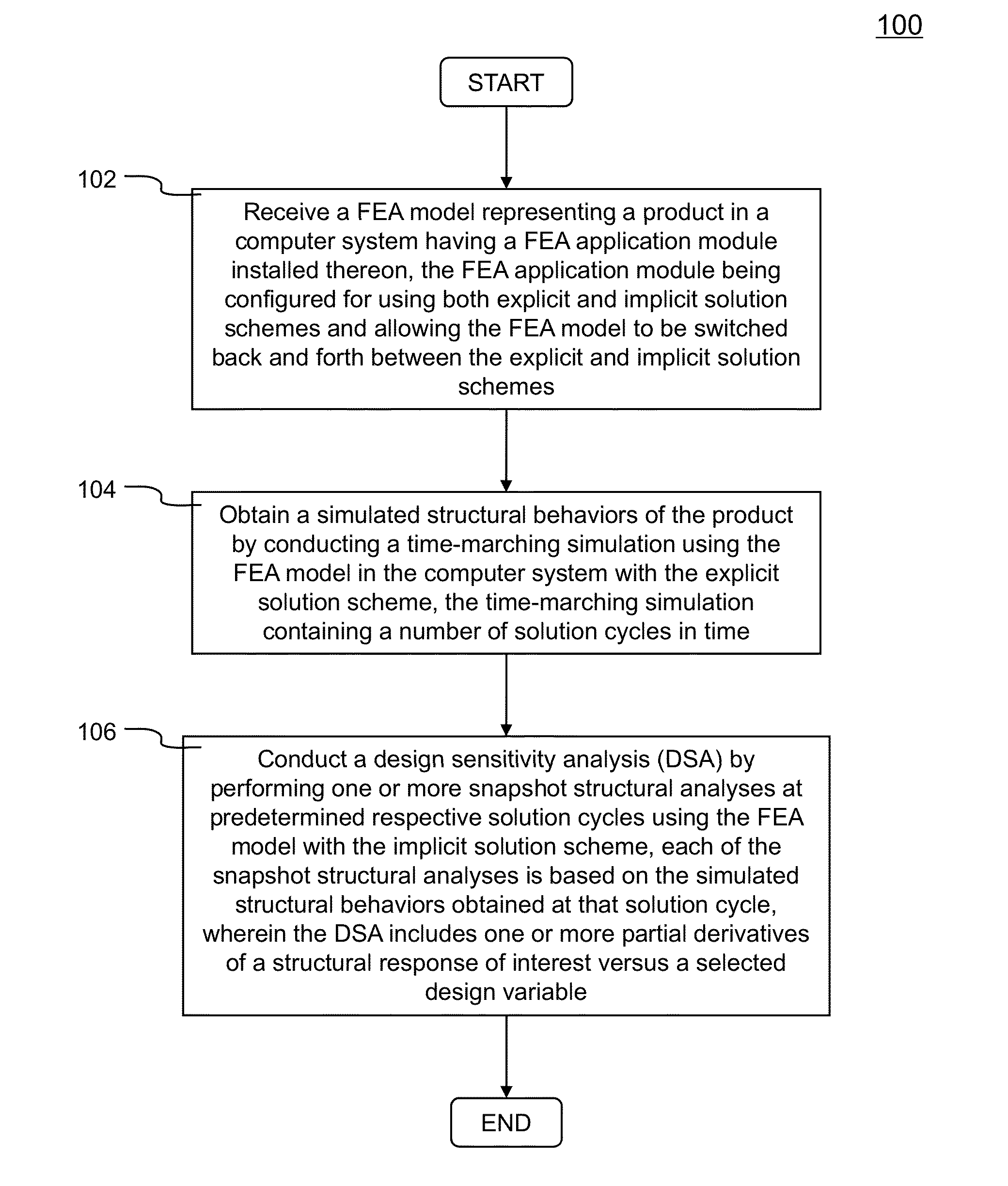

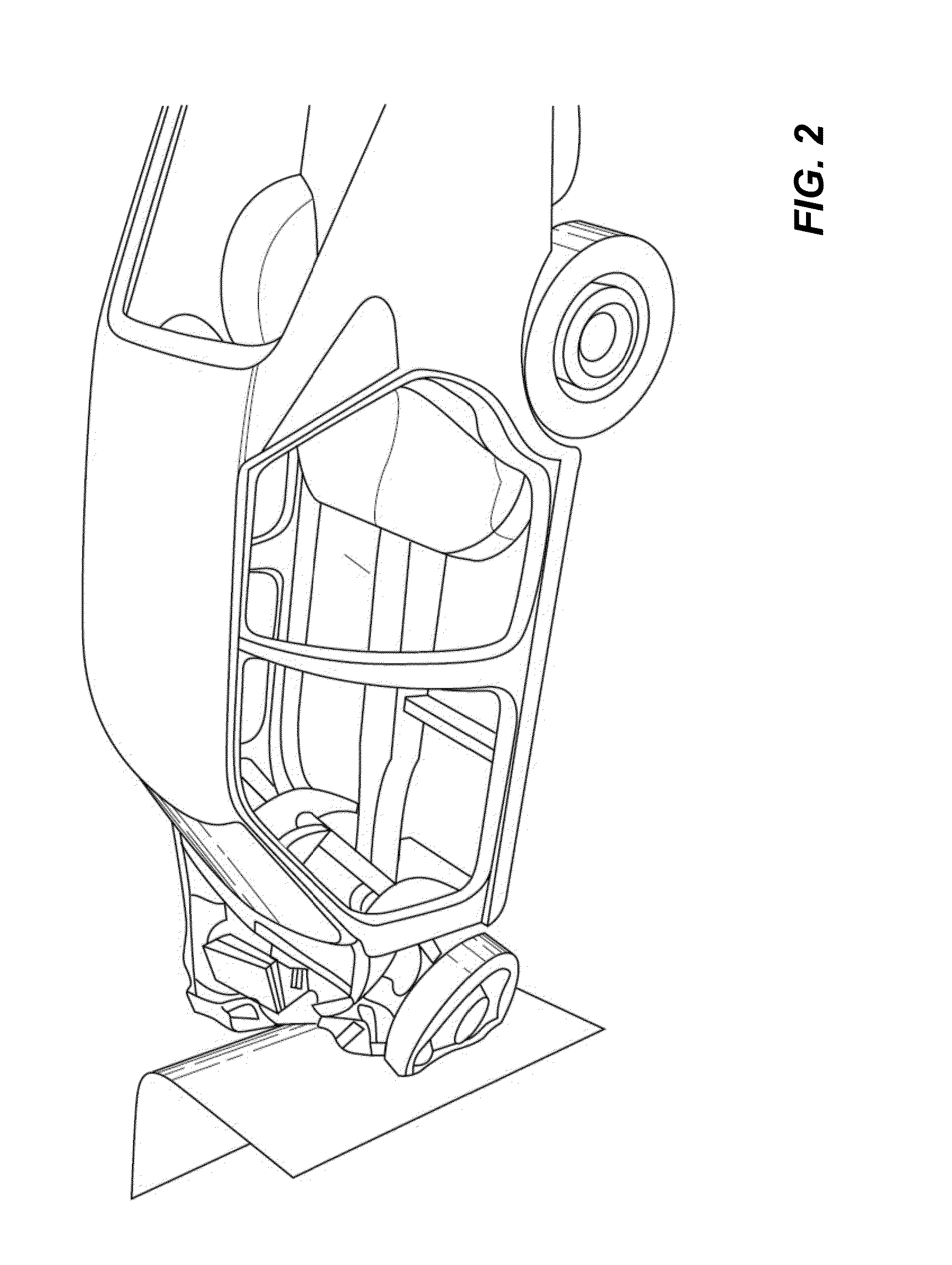

Methods And Systems For Conducting Design Sensitivity Analysis

InactiveUS20150213165A1Simple designGeometric CADSustainable transportationComputerized systemEngineering

Methods and systems for conducting design sensitivity analysis of a product are disclosed. FEA model representing a product is received in a computer system having a FEA software installed thereon. The FEA software is configured for using both explicit and implicit solution schemes and allowing the FEA model to be switched back and forth between said explicit and said implicit solution schemes. Numerically simulated structural behaviors are then obtained by conducting a time-marching simulation using the FEA model in the computer system with the explicit solution scheme. Then, DSA is conducted by performing one or more snapshot structural analyses at respective predetermined solution cycles using the same FEA model with the implicit solution scheme. Each snapshot structural analysis is based on the simulated structural behaviors obtained at that solution cycle. The DSA includes one or more partial derivatives of a structural response of interest versus a selected design variable.

Owner:LIVERMORE SOFTWARE TECH

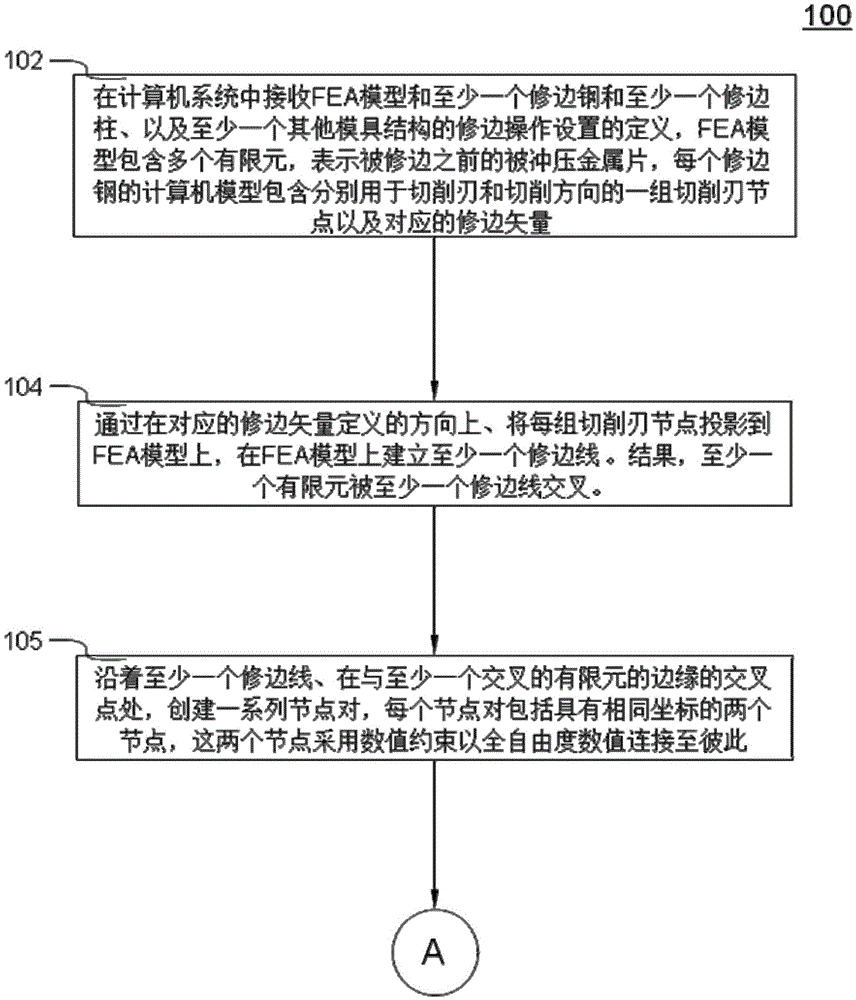

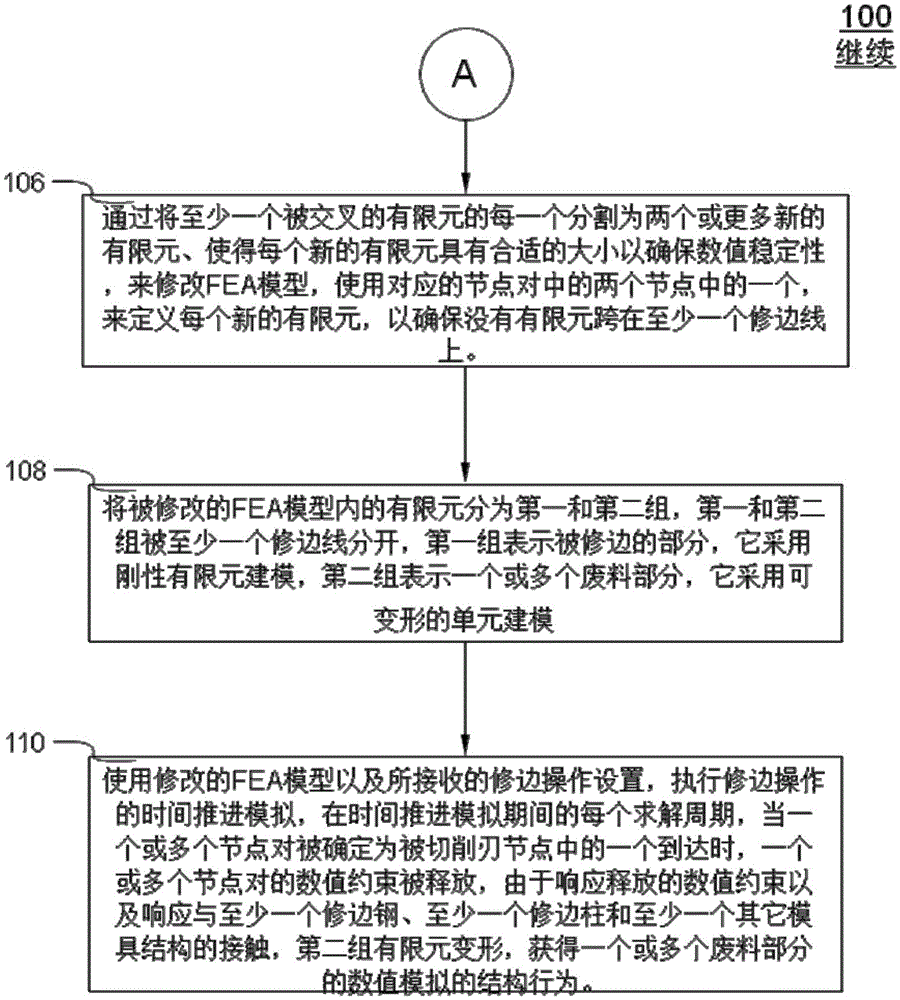

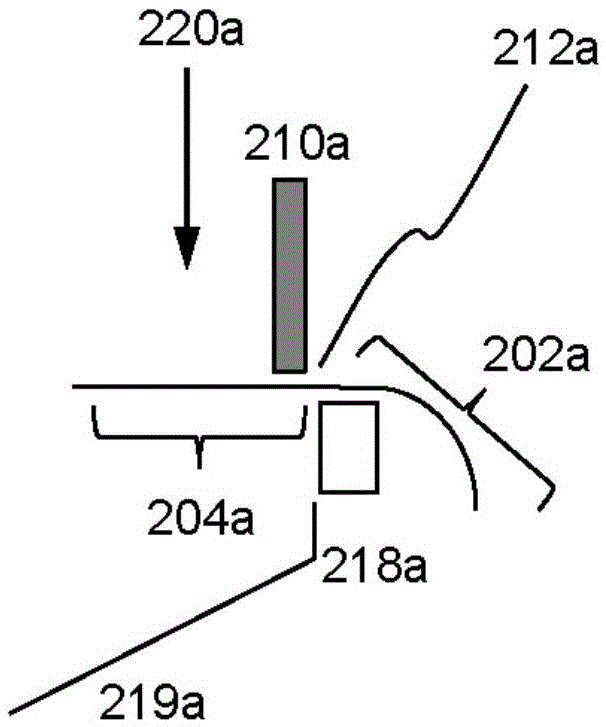

Numerical simulation of scrap trimming operations in sheet metal forming

ActiveCN105808809ADesign optimisation/simulationSpecial data processing applicationsNumerical stabilityMetal forming

FEA model representing a stamped sheet metal before trimming and a trimming operation setup are received. Each trim steel contains a set of cutting-edge nodes associated with a trim vector. At least one trim line is established by projecting cutting-edge nodes onto the FEA model according to the trim vector. Numerically-constrained node-pairs along the trim line are created at intersections with edges of crossed finite elements. The FEA model is modified by splitting crossed finite elements to preserve the original geometry and to ensure numerical stability. New finite elements are defined using one of the nodes in corresponding node-pairs such that no finite element straddles the trim line. At each solution cycle of a time-marching simulation of trimming operations, the numerical constraint is released for each node-pair determined to be reached by one of the cutting-edge nodes. Simulated structural behaviors are obtained as the scrap portion(s) deforms and falls accordingly.

Owner:LIVERMORE SOFTWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com