Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Reference dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reference dimension is a dimension on an engineering drawing provided for information only. Reference dimensions are provided for a variety of reasons and are often an accumulation of other dimensions that are defined elsewhere (e.g. on the drawing or other related documentation). These dimensions may also be used for convenience to identify a single dimension that is specified elsewhere (e.g. on a different drawing sheet).

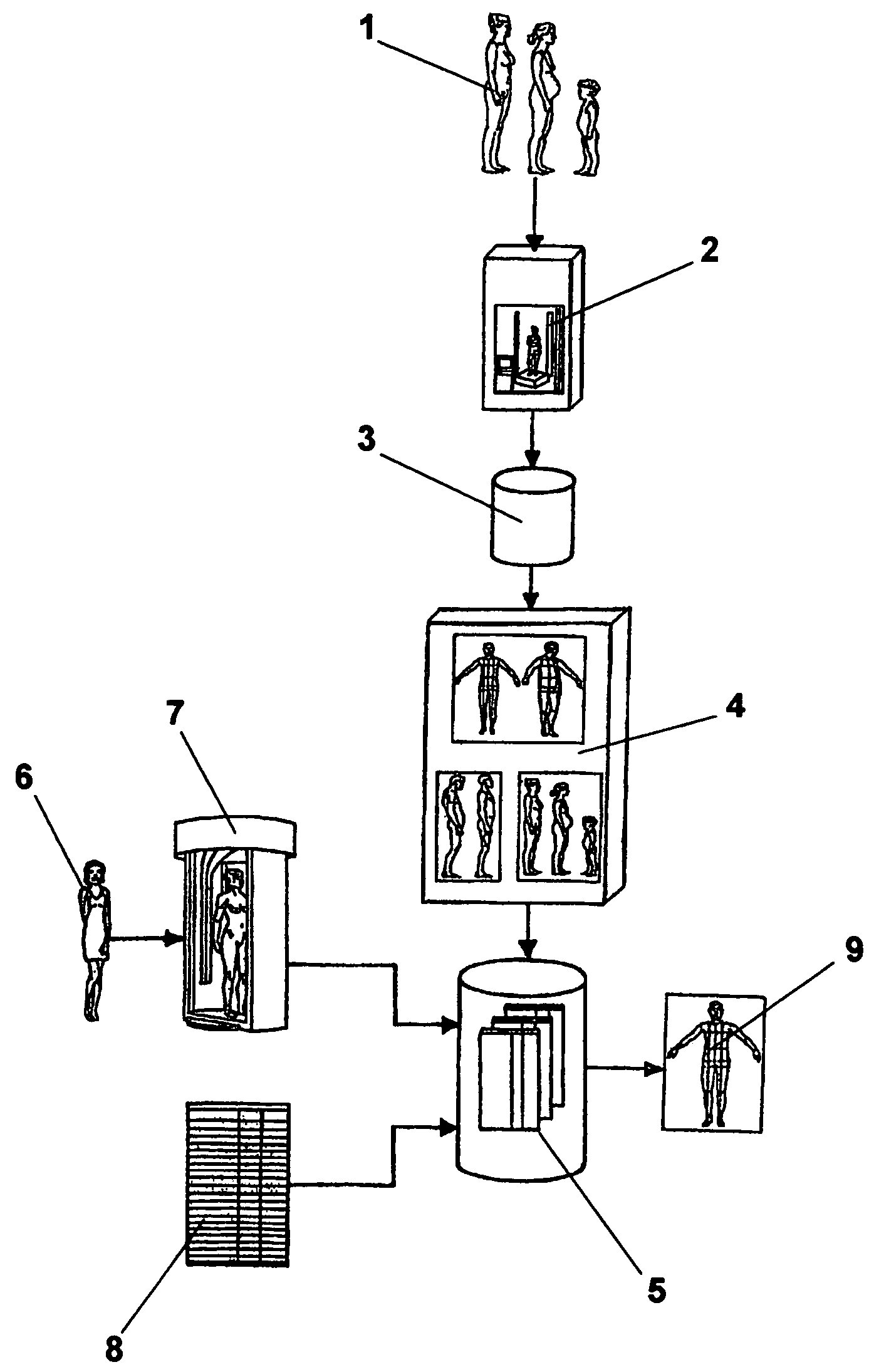

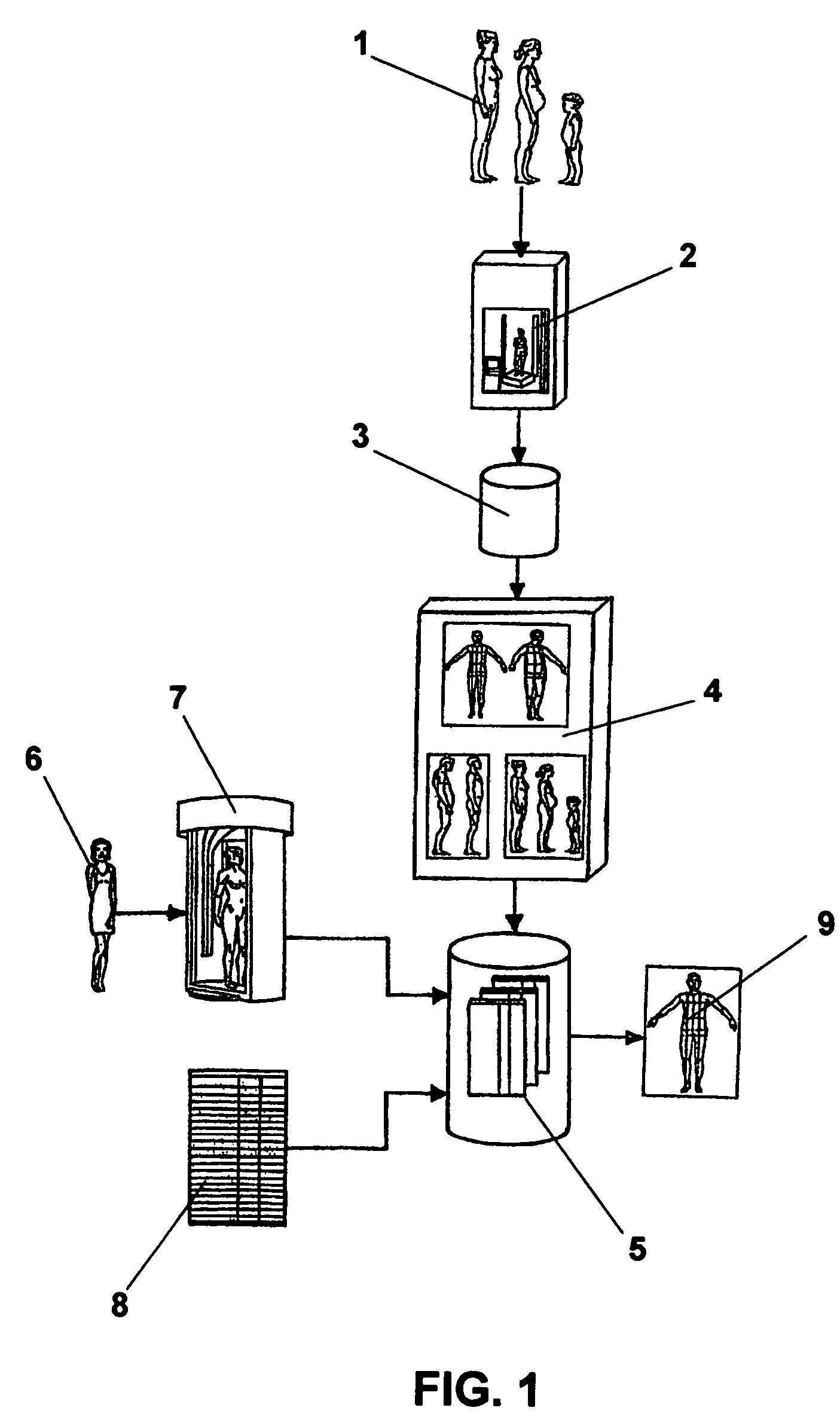

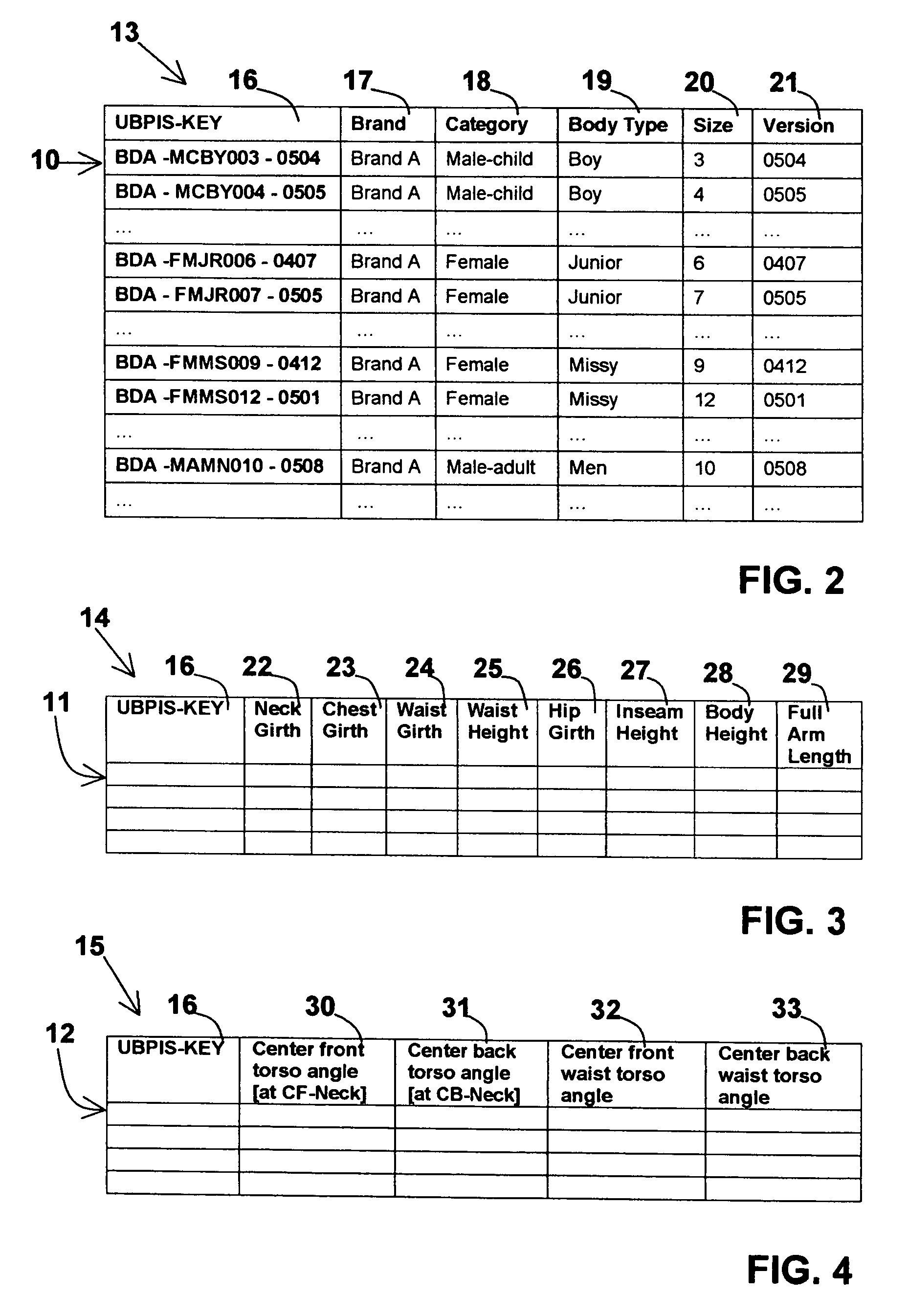

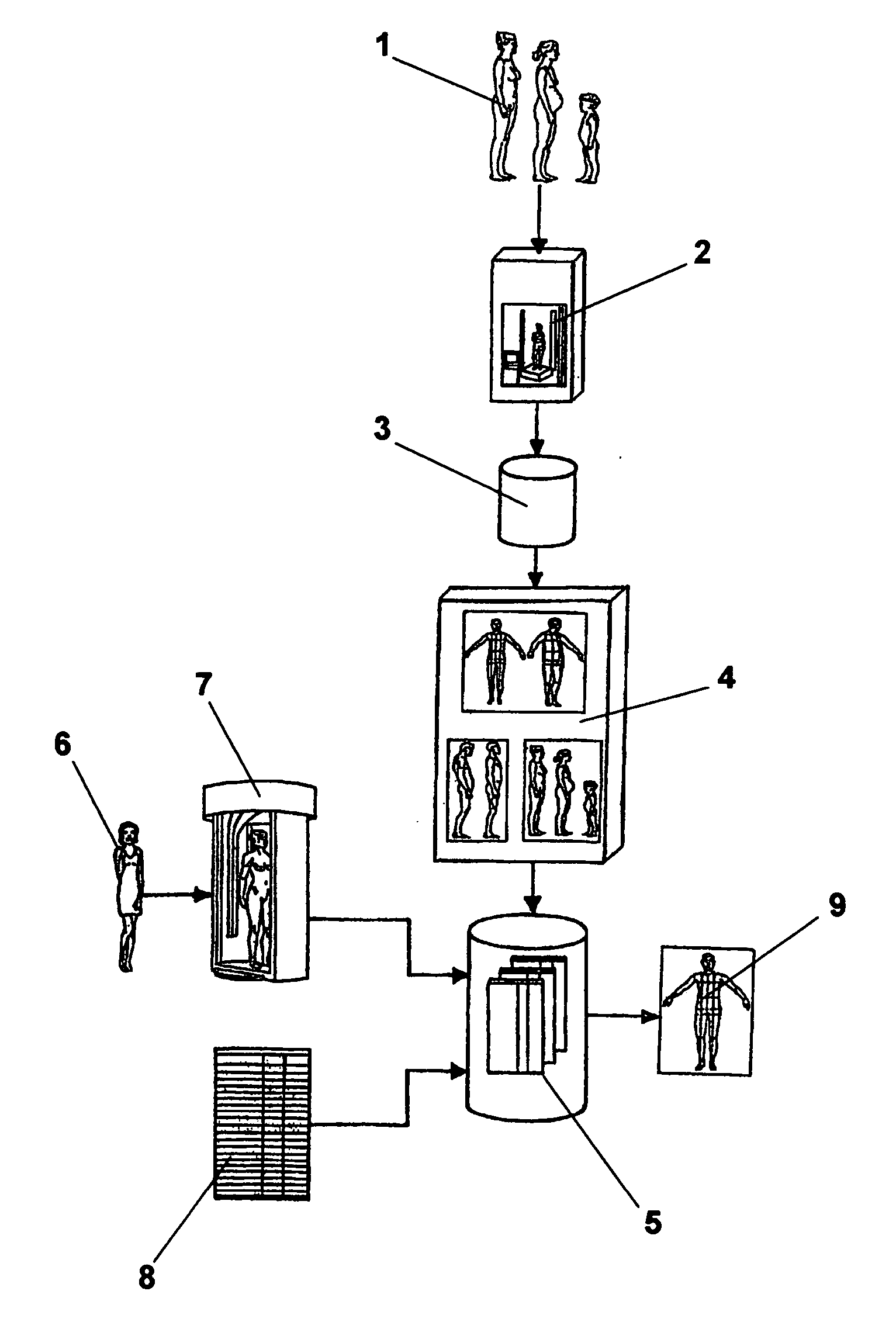

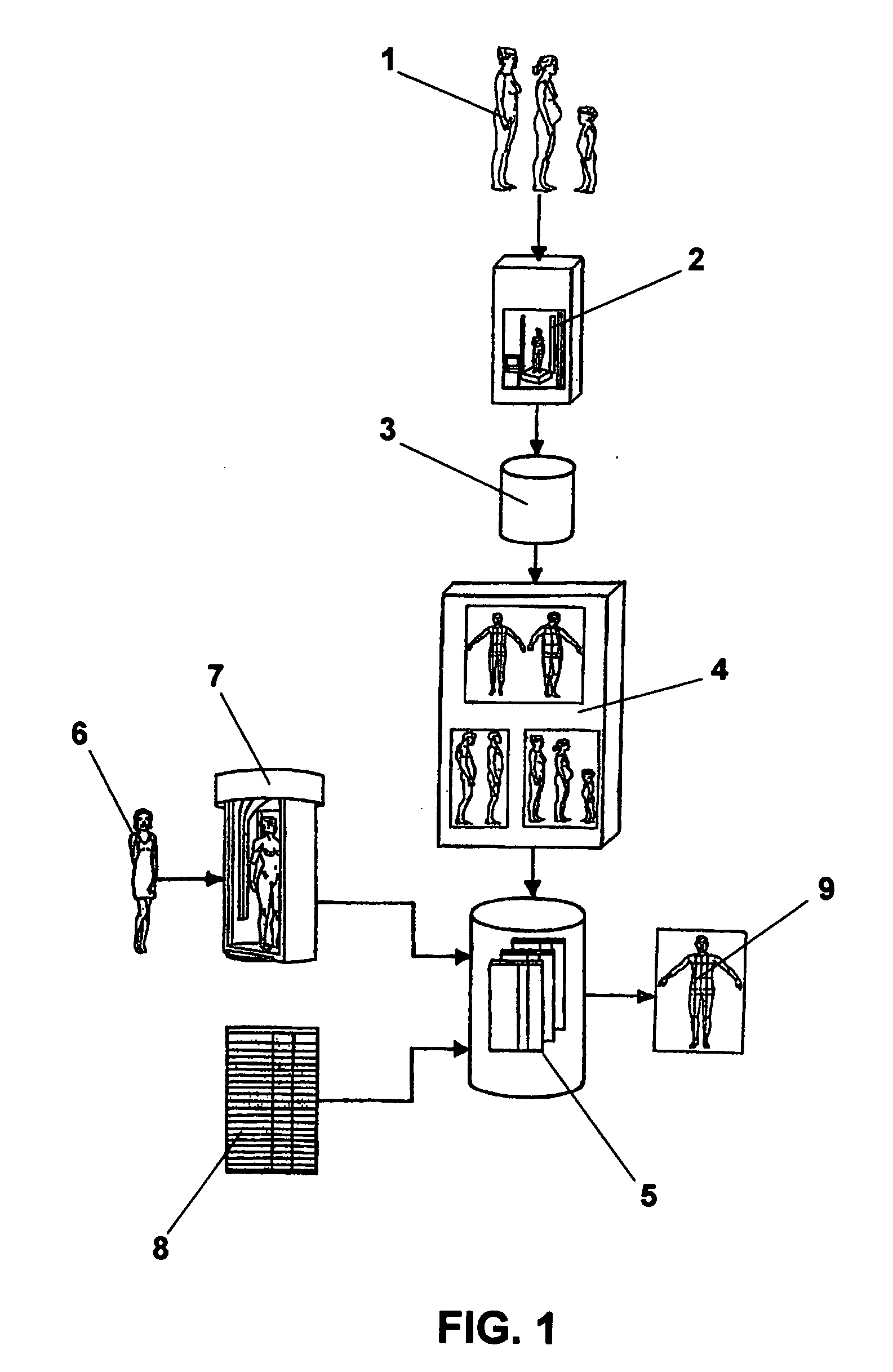

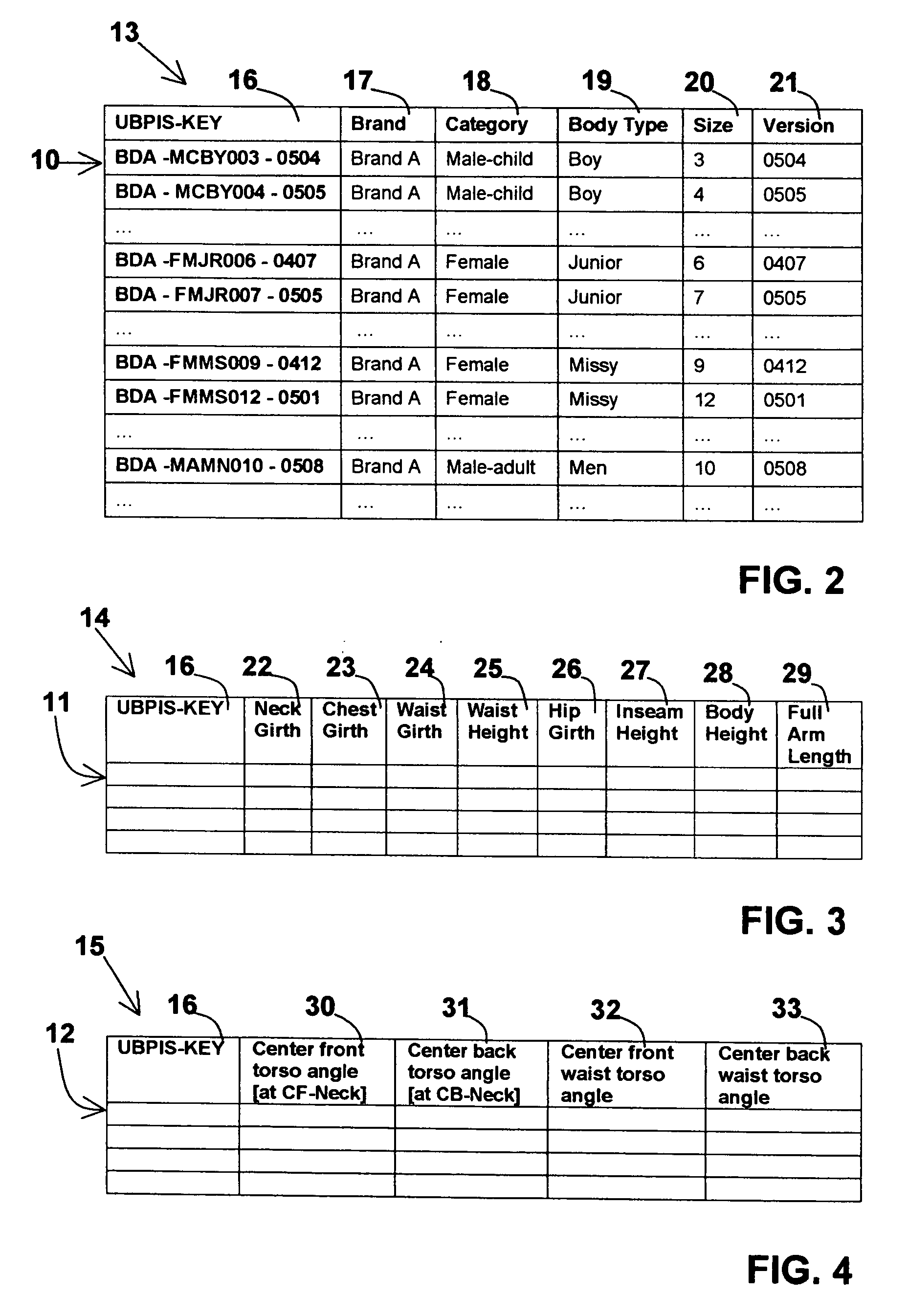

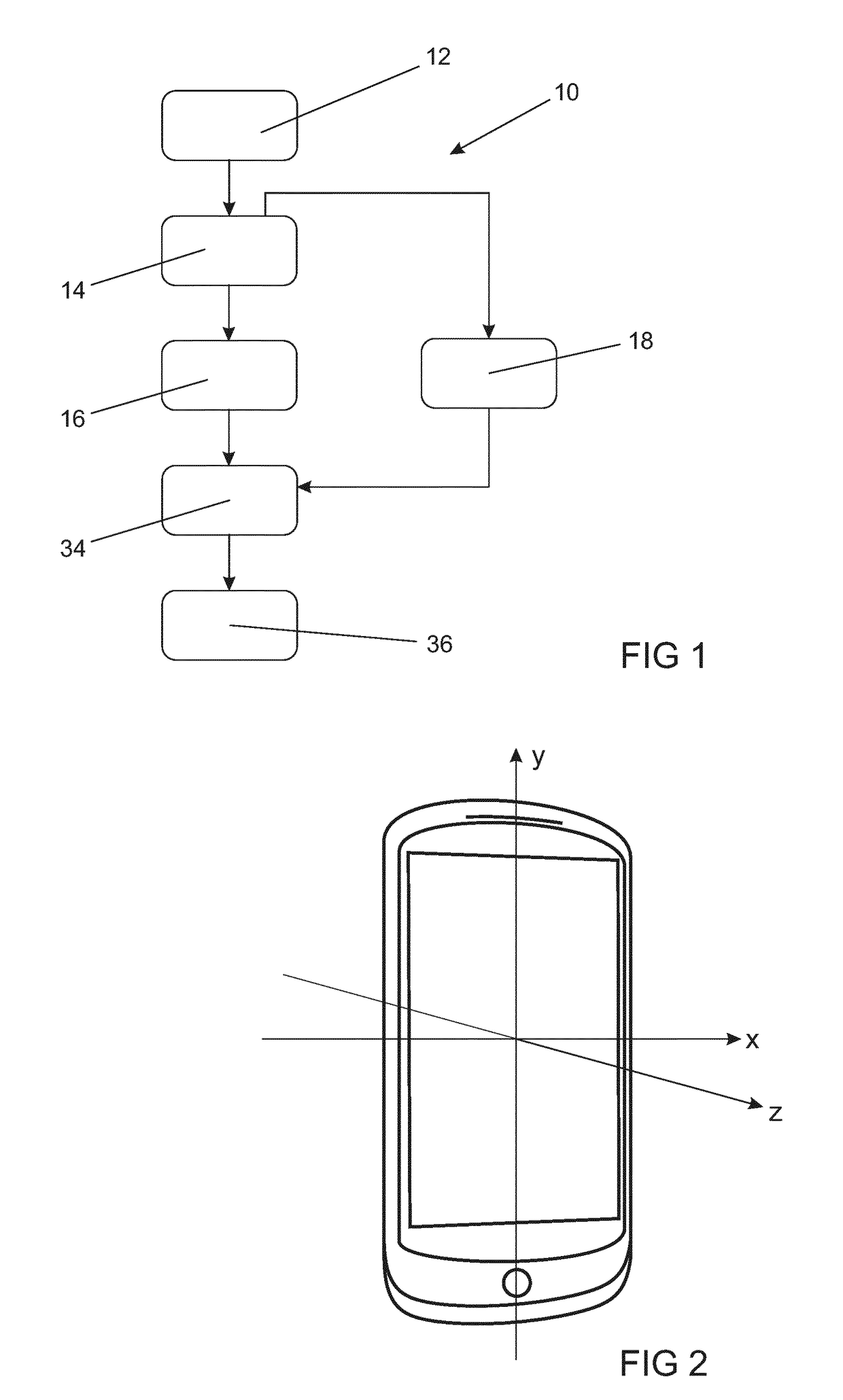

Method and apparatus for identifying virtual body profiles

InactiveUS7242999B2Buying/selling/leasing transactionsSpecial data processing applicationsHuman bodyInformation processing

3D morphological data representative of reference size models of garment brands and respective categorizing data are introduced into an information processing system. These 3D morphological data are indexed by brand names, categorizing data, and volumetric, dimensional, and angular data derived from the morphological data in order to build a database of virtual human body profiles. For selecting a suitable profile matching a consumer's body, his / her personal measurements and categorizing data are introduced into the system, either directly if they are known, or acquired by scanning only a minimum numbers of points on the customer's body in a scanning booth so as to derive these measurements. Instead of methods of the prior art defining the body profiles of the consumers per se from the general population, this method attempts to categorize the body profiles of the specific brands' reference size human models, and all offered sizes, through the brands' grading rules.

Owner:WANG KENNETH KUK KEI

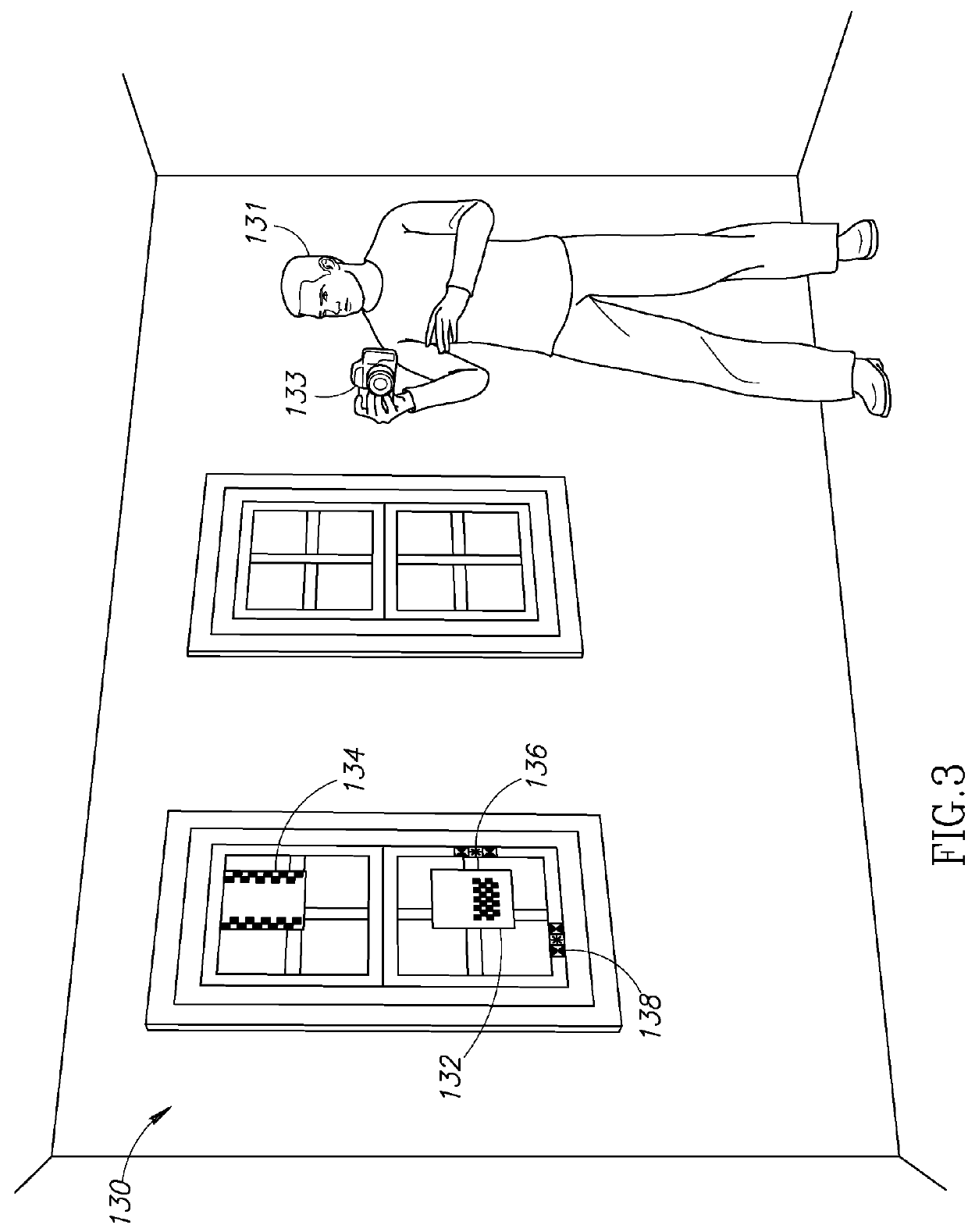

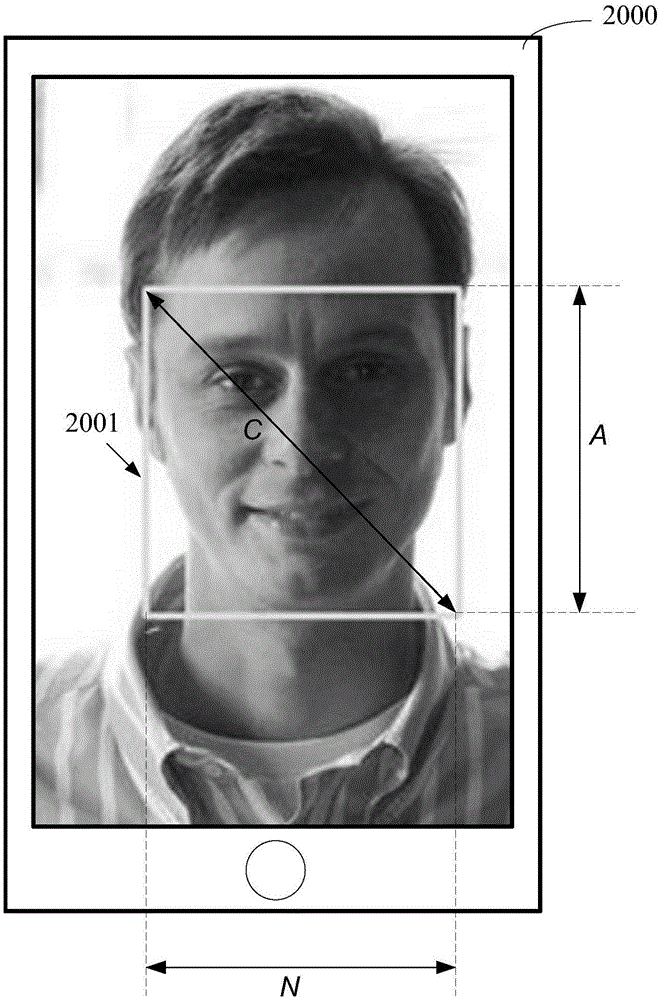

System and method of measuring distances related to an object

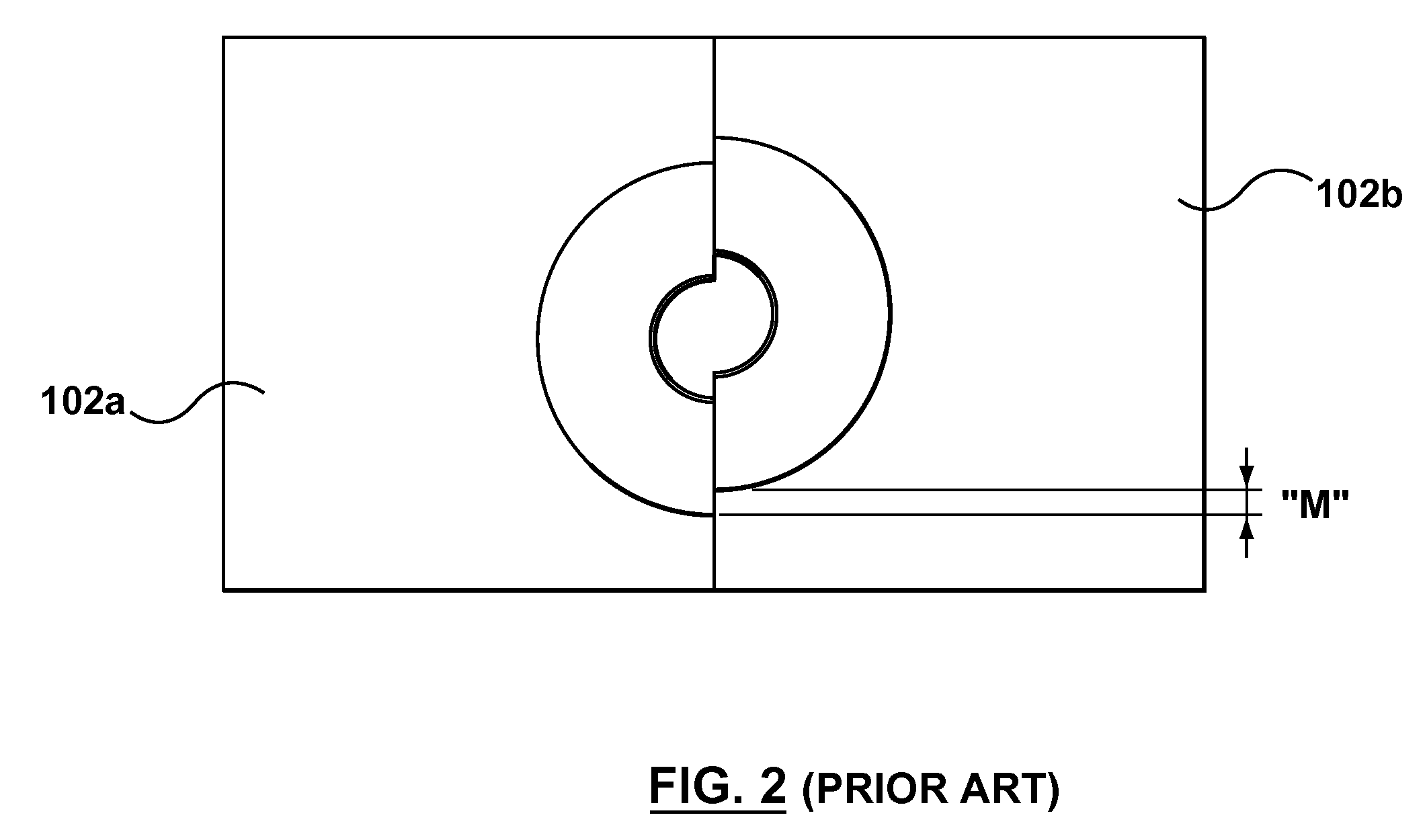

ActiveUS20140193039A1Maintain aestheticsMaintain appearanceImage enhancementImage analysisDigital imageManufacturing systems

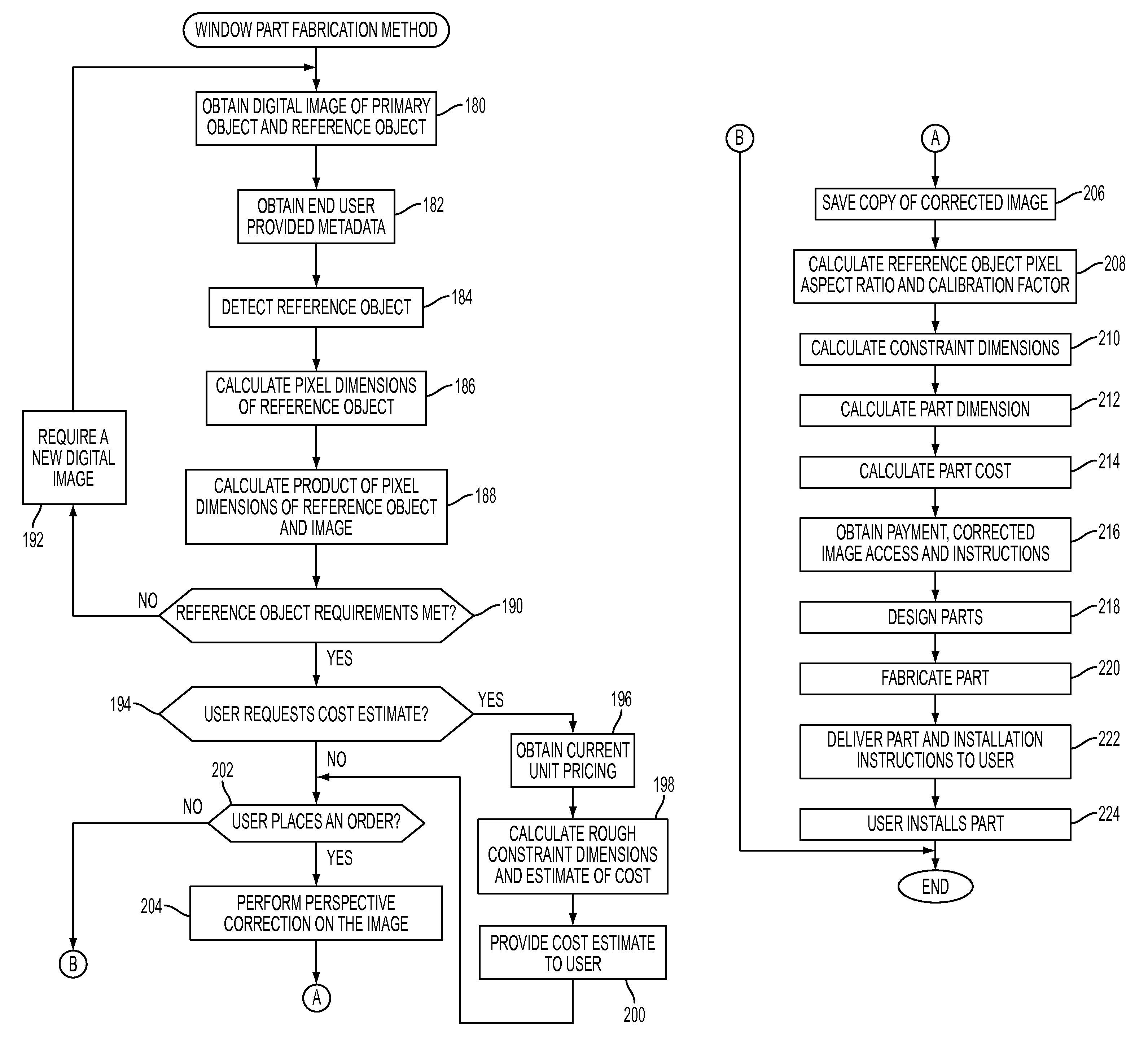

A system and method for the measurement of distances related to an object depicted in an image. One aspect including delivery of supplemental materials for fenestration and for constructing insulating materials for fenestration. A digital image containing a primary object dimension and a reference object dimension in substantially the same plane undergoes digital image processing to provide improved measurement capability. Information regarding a primary object is provided to an automated measurement process, design and manufacturing system to provide customized parts to end users. A digital image is obtained having an observable constraint dimension to which a customized part is to conform wherein the digital image contains a reference object having a reference dimension and a constraint dimension is calculated from the digital image based on a reference dimension. The custom part is designed and manufactured based on the calculated constraint dimension.

Owner:WEXENERGY INNOVATIONS

System and method of measuring distances related to an object

ActiveUS8923650B2Re-installation by the end user is simplifiedCorrect distortionImage enhancementImage analysisDigital imageManufacturing systems

Owner:WEXENERGY INNOVATIONS

Target detection method and device and computer readable storage medium

InactiveCN108875577AImprove detection rateCharacter and pattern recognitionNeural architecturesNetwork modelSmall target

The invention discloses a target detection method which comprises the following steps of: acquiring a to-be-detected image, wherein the to-be-detected image is subjected to multi-layer convolution extraction of features in a neural network to generate a feature map; loading modified structural parameters in a neural network model, and generating corresponding anchor box coordinates on the basis ofthe structural parameters, wherein the preset structural parameters comprise a reference dimension of an anchor box, an anchor box scale and a length-width ratio of the anchor box; generating candidate box coordinates on the basis of a region nomination subnet, taking a corresponding region on the feature map according to the candidate coordinates, and by pooling of a ROI (Region Of Interest), obtaining corresponding features; and on the basis of the features, determining prediction box coordinates, and on the basis of the prediction box coordinates, determining a target object position. Theinvention further discloses a target detection device and a computer readable storage medium. According to the invention, a case of generating an optimized prediction box to determine a target objectis implemented, a small target can be detected, and a detection rate for the target is improved.

Owner:SHENZHEN ECHIEV AUTONOMOUS DRIVING TECH CO LTD

Method and apparatus for identifying vitual body profiles

InactiveUS20070032898A1Buying/selling/leasing transactionsSpecial data processing applicationsInformation processingHuman body

3D morphological data representative of reference size models of garment brands and respective categorizing data are introduced into an information processing system. These 3D morphological data are indexed by brand names, categorizing data, and volumetric, dimensional, and angular data derived from the morphological data in order to build a database of virtual human body profiles. For selecting a suitable profile matching a consumer's body, his / her personal measurements and categorizing data are introduced into the system, either directly if they are known, or acquired by scanning only a minimum numbers of points on the customer's body in a scanning booth so as to derive these measurements. Instead of methods of the prior art defining the body profiles of the consumers per se from the general population, this method attempts to categorize the body profiles of the specific brands' reference size human models, and all offered sizes, through the brands' grading rules.

Owner:WANG KENNETH KUK KEI

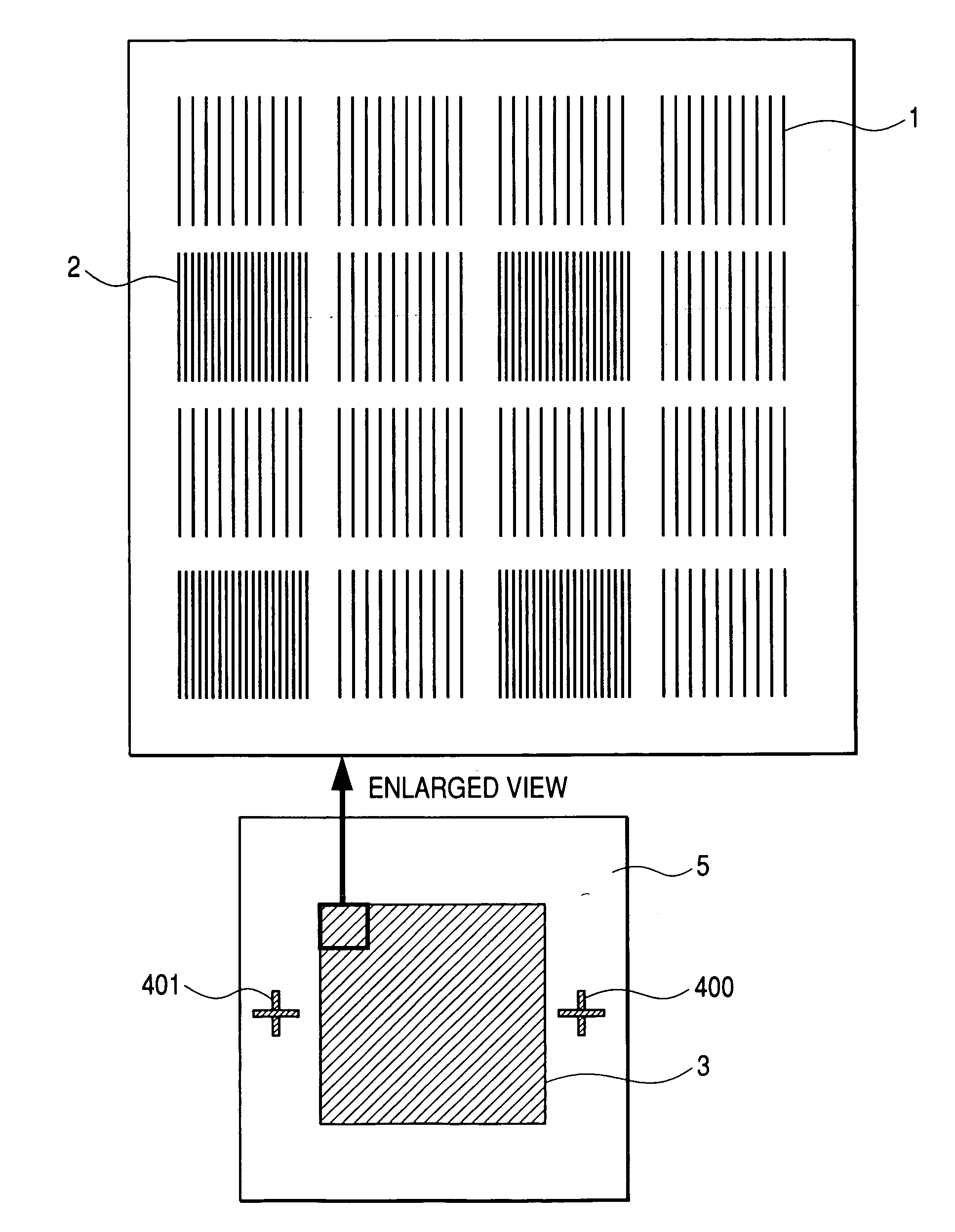

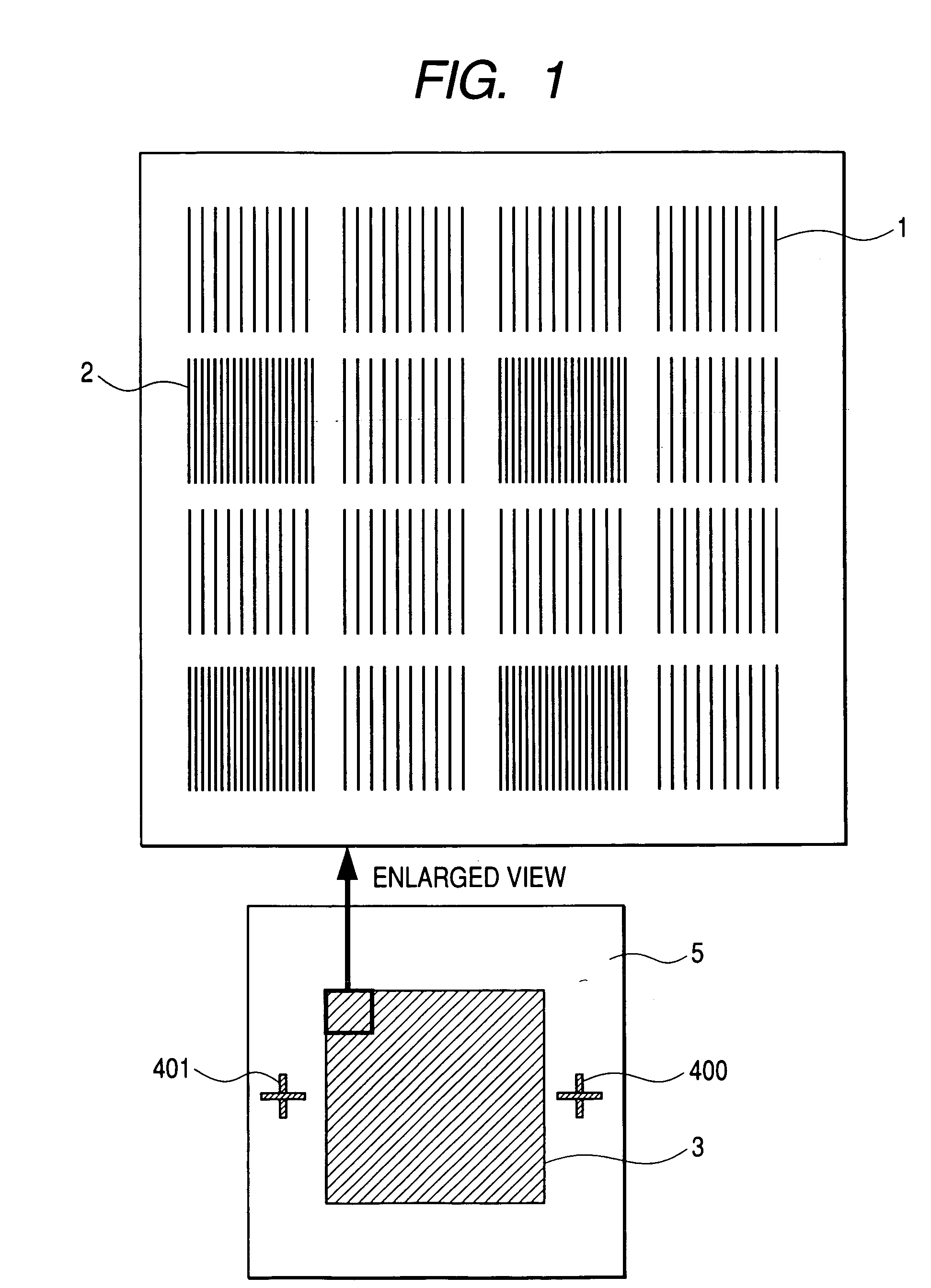

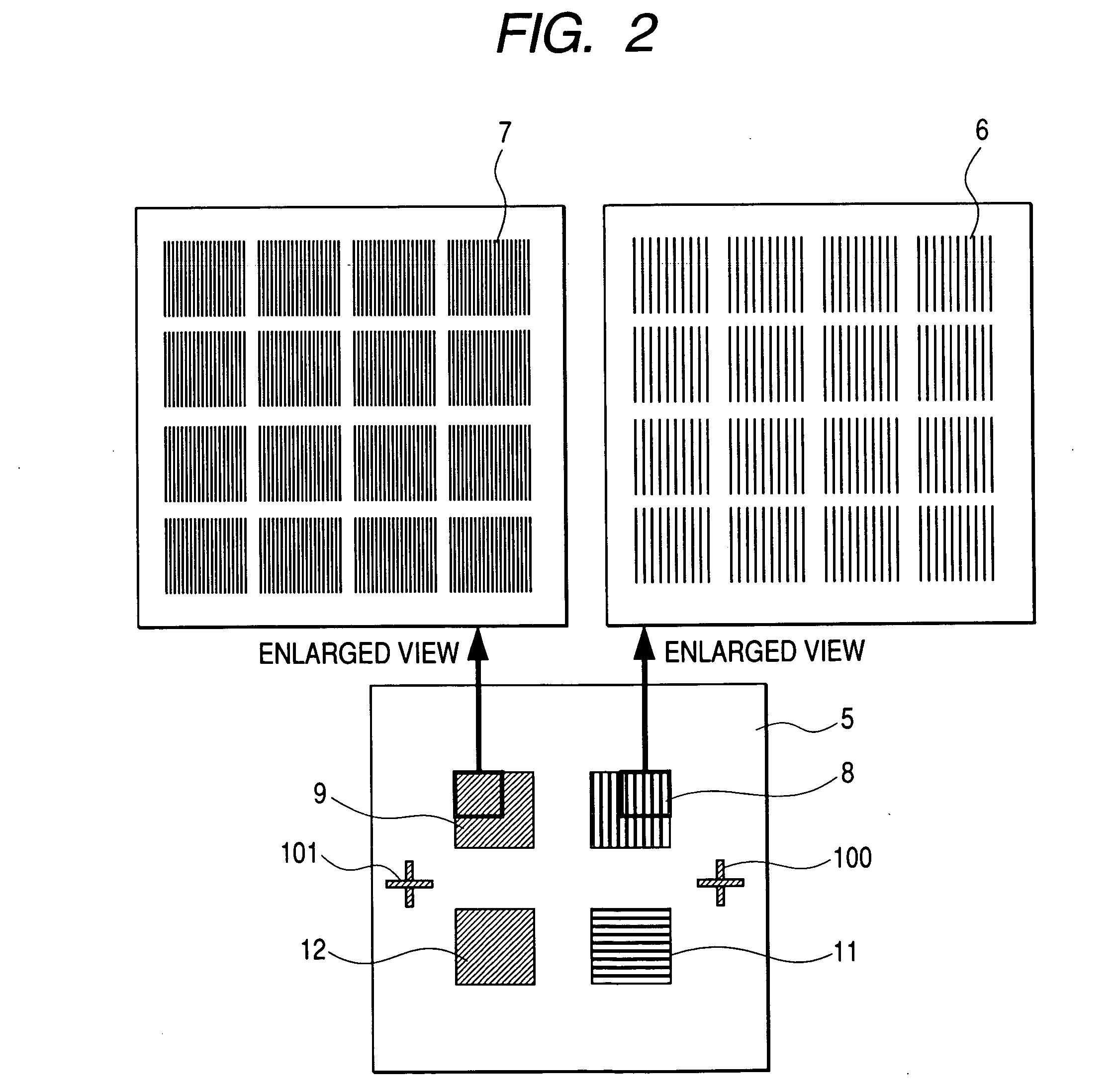

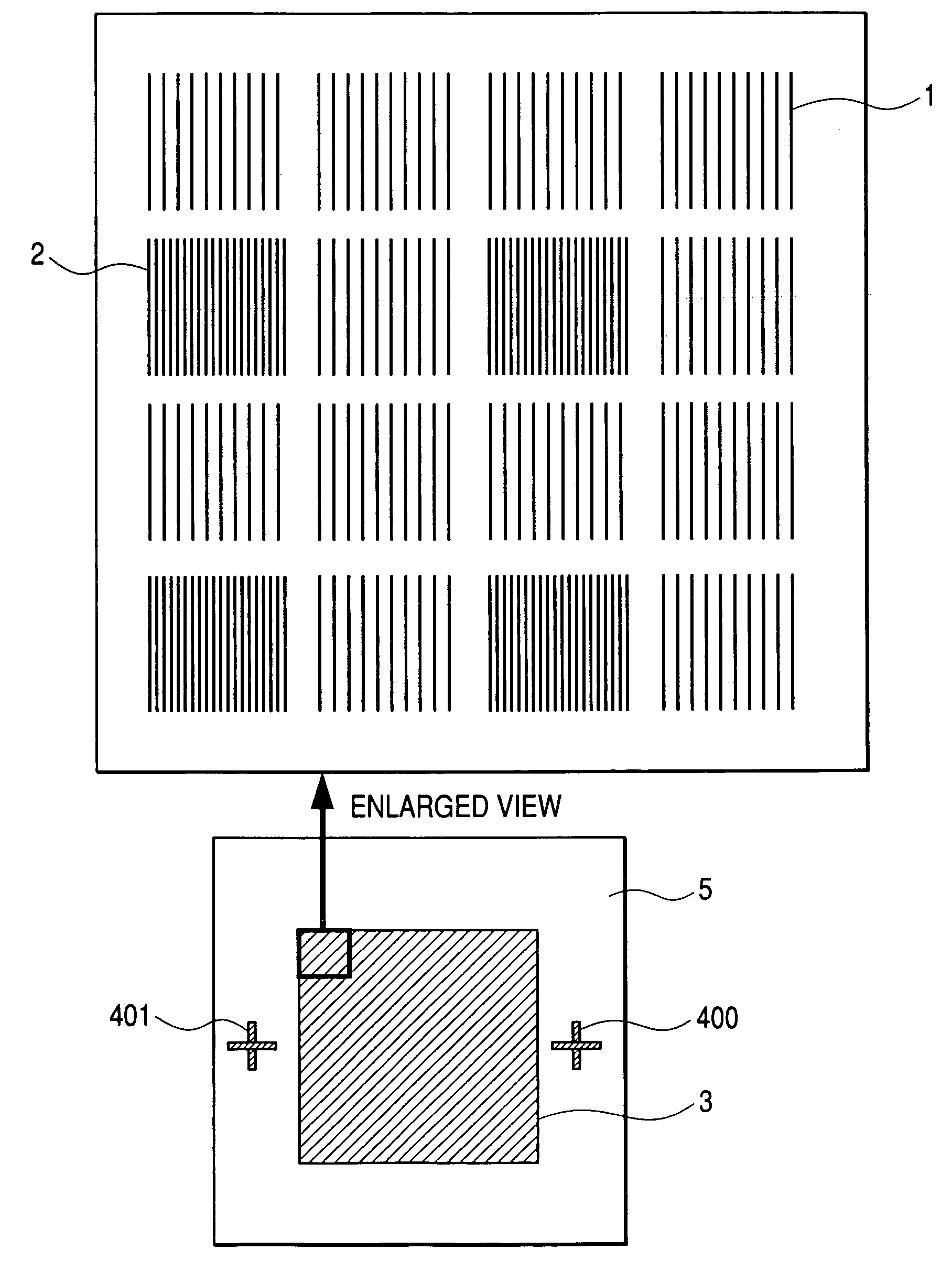

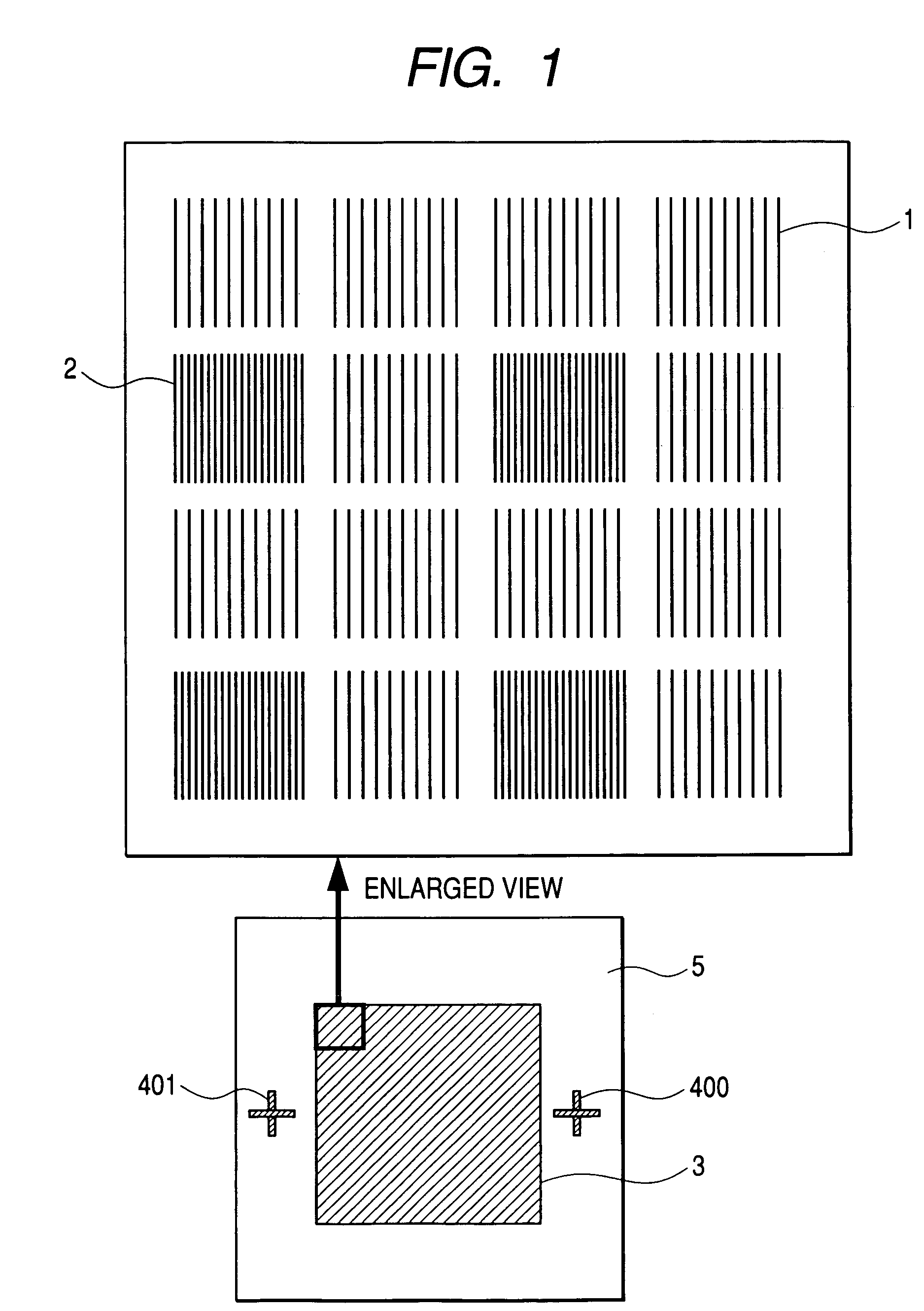

Standard reference for metrology and calibration method of electron-beam metrology system using the same

InactiveUS20050184234A1Easy to distinguishImprove accuracyMaterial analysis using wave/particle radiationElectric discharge tubesOptical diffractionMetrology

Owner:HITACHI HIGH-TECH CORP

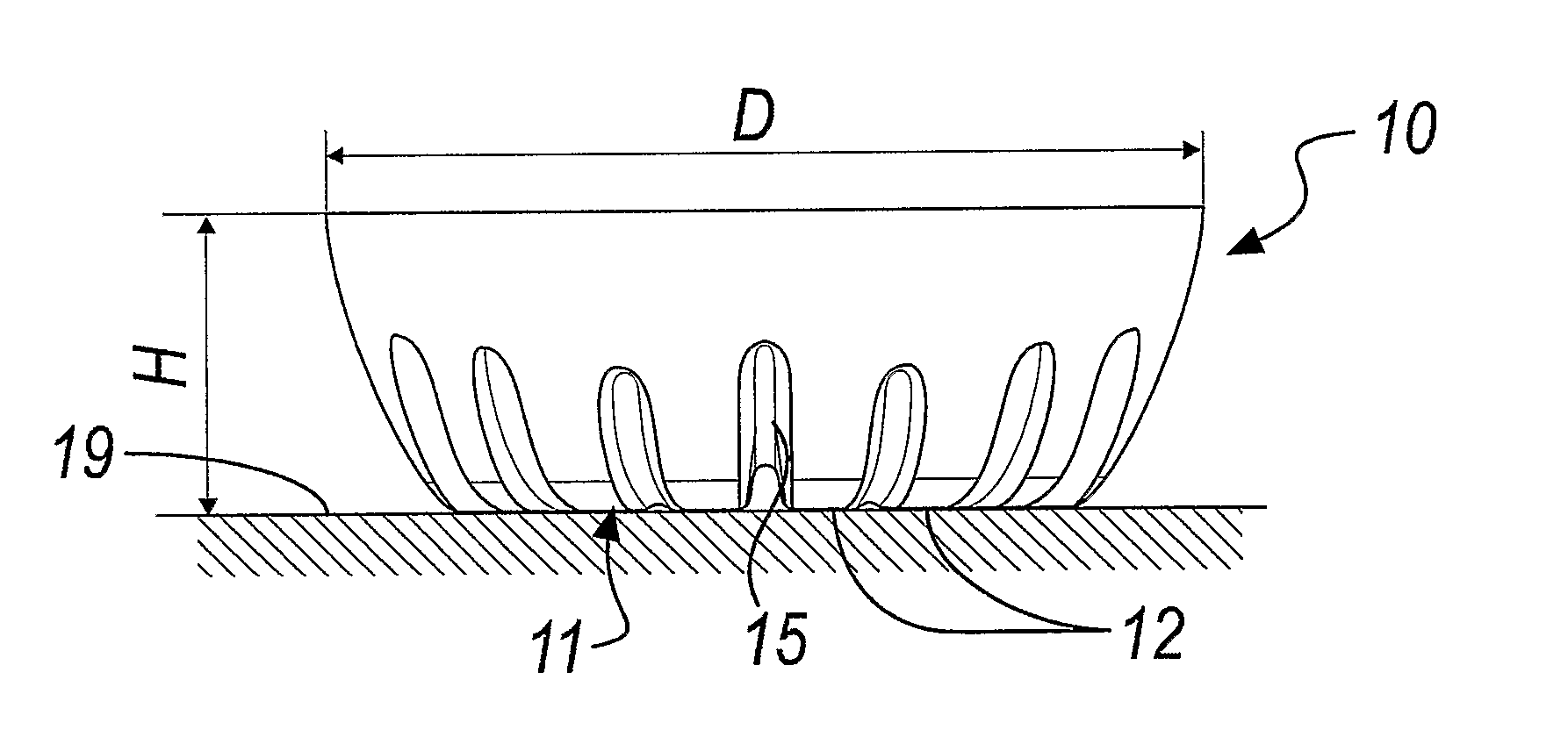

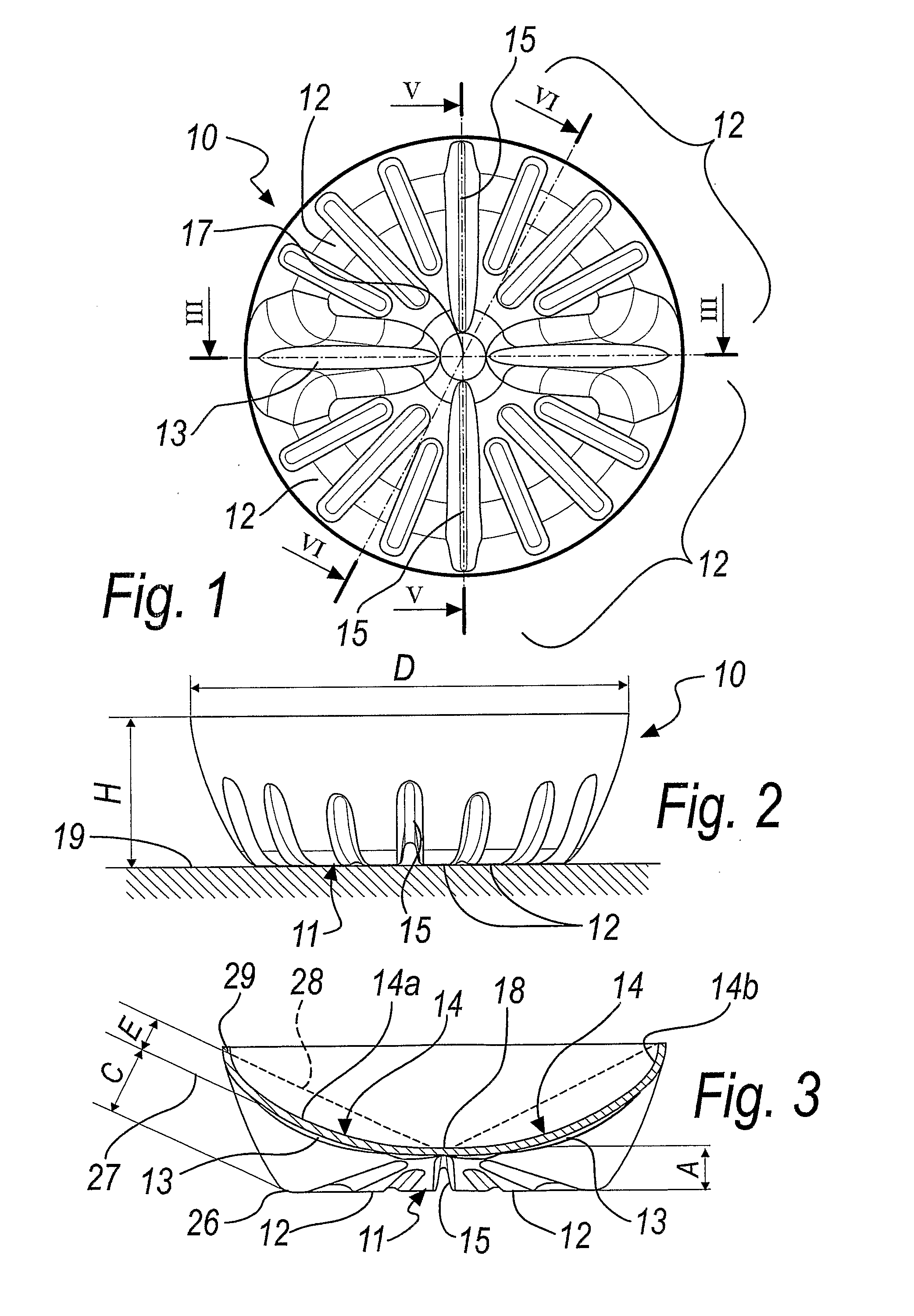

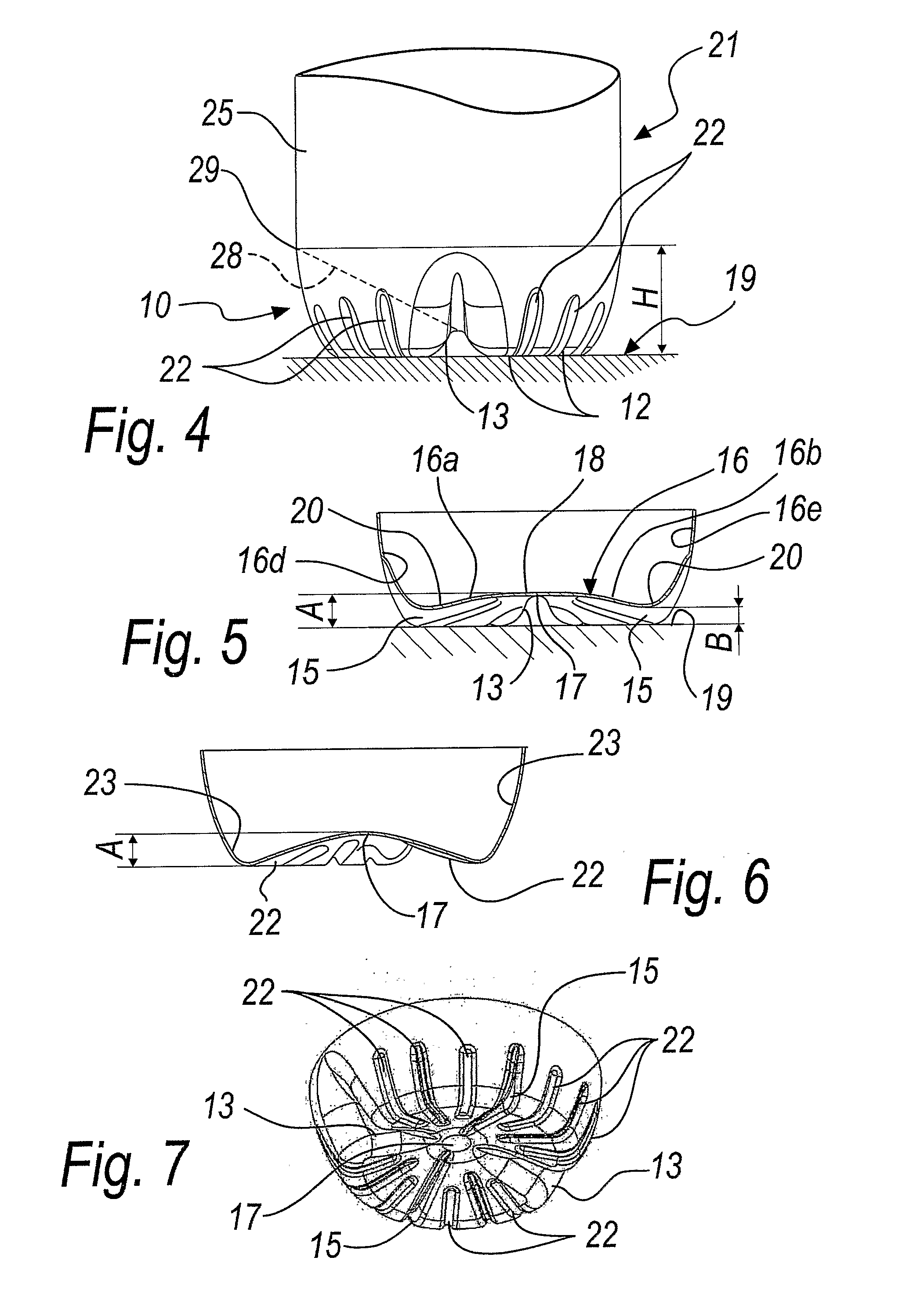

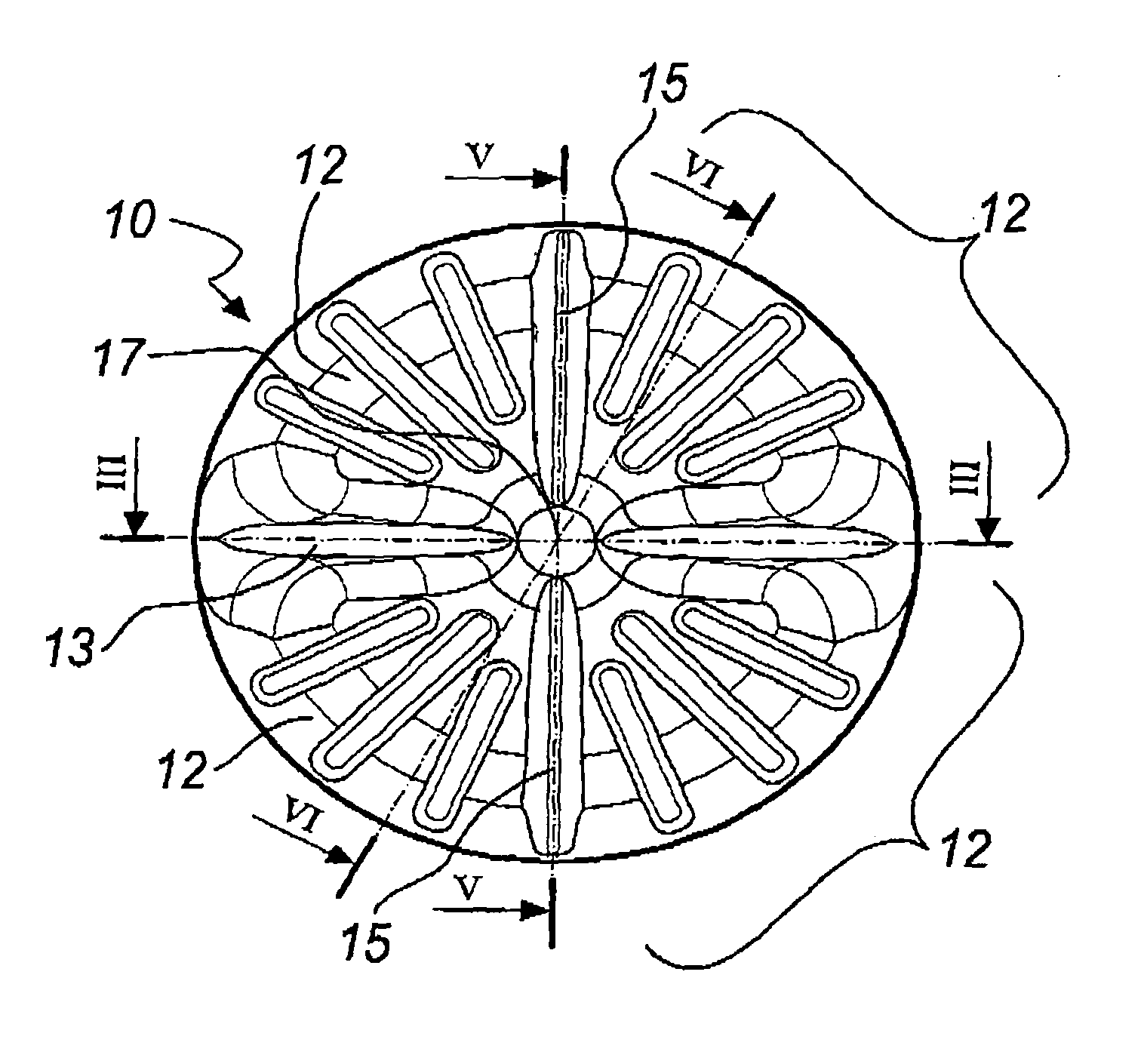

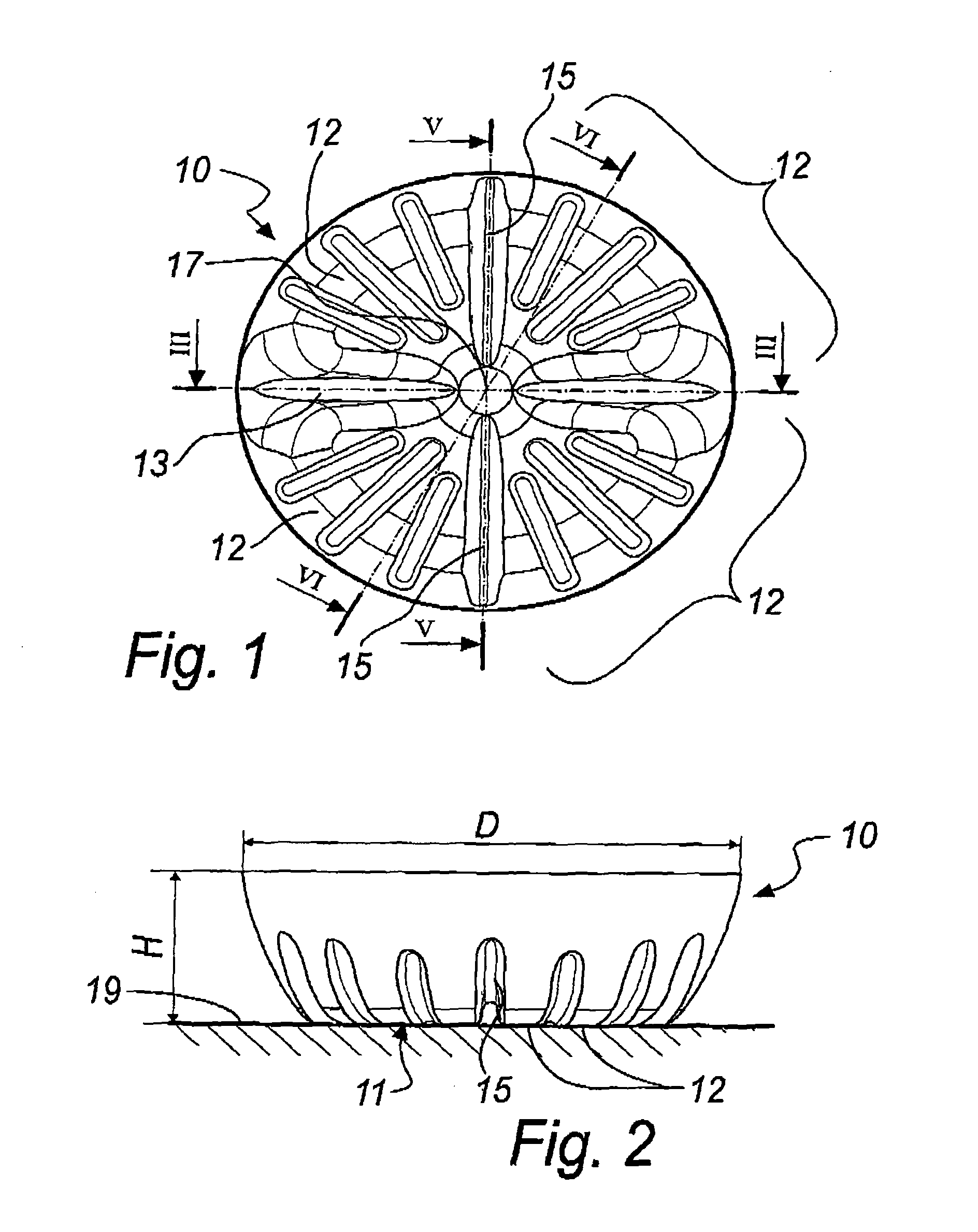

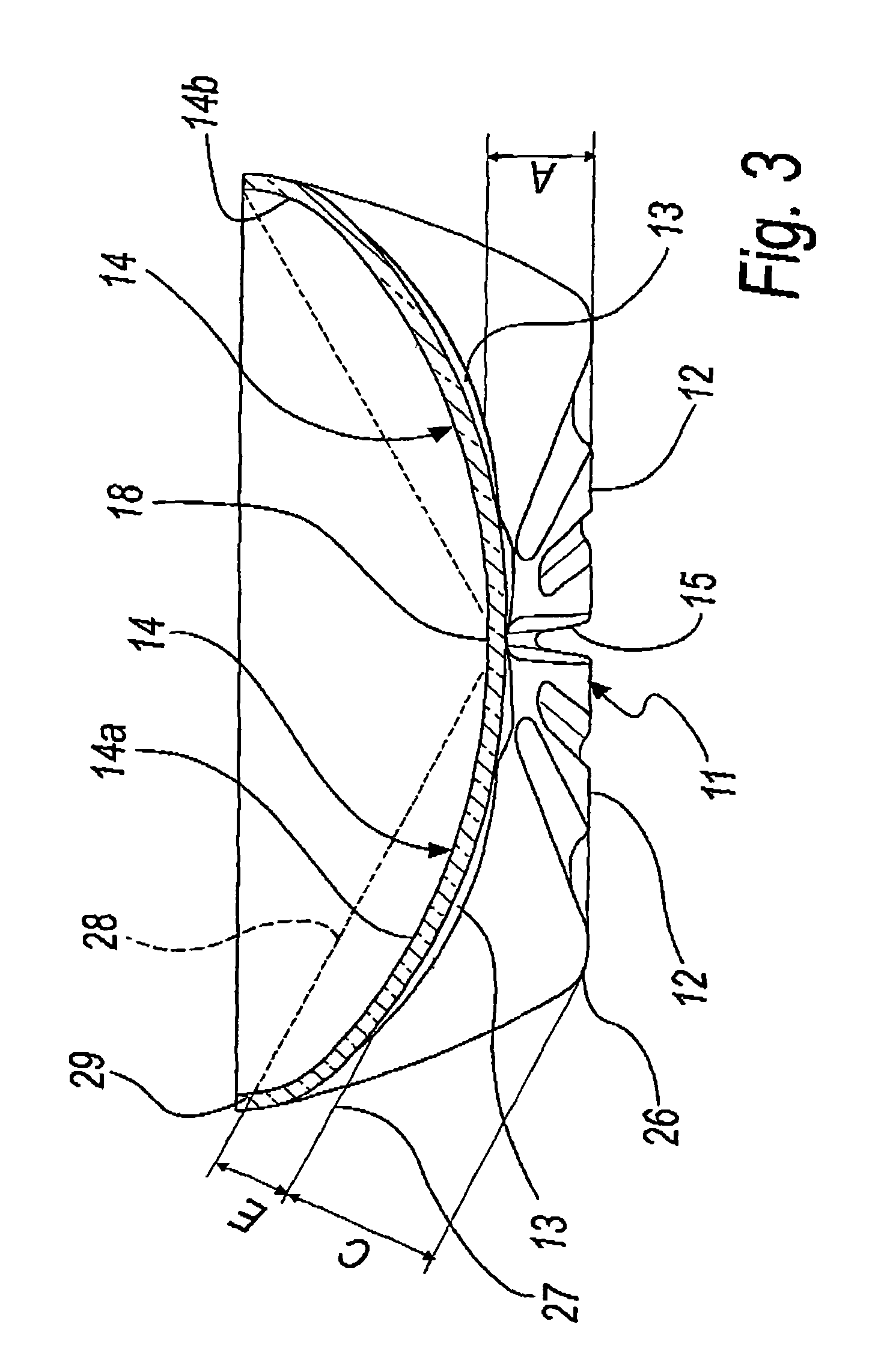

Plastic Bottle Base

InactiveUS20070262046A1Improve standing stabilityLarge containersRigid containersPlastic materialsReference dimension

A bottle base made of plastic material, particularly for beverages, of the type which has, on its bottom, reinforcement recesses. The reinforcement recesses comprise a recess which runs along a transverse reference dimension of the base; the recess forms a main rib inside the base.

Owner:ACQUA MINERALE SAN BENEDETTO SPA

Plastic bottle base

A bottle base made of plastic material, particularly for beverages, of the type which has, on its bottom, reinforcement recesses. The reinforcement recesses comprise a recess which runs along a transverse reference dimension of the base; the recess forms a main rib inside the base.

Owner:ACQUA MINERALE SAN BENEDETTO SPA

Standard reference for metrology and calibration method of electron-beam metrology system using the same

InactiveUS7078691B2Easy to distinguishImprove accuracyMaterial analysis using wave/particle radiationElectric discharge tubesOptical diffractionMetrology

The present invention is to provide a standard reference for metrology having finer reference sizes and high-precision electron-beam metrology including the same. By using a standard reference member in which a grating unit pattern of a pitch size proven by an optical diffraction angle by using a laser beam whose wavelength is absolutely guaranteed and a plurality of patterns having a finer size than that (100 nm or less) over the same substrate, fineness and correctness of calibration are made verifiable on a regular basis, and by using an electron-beam collective exposure method for pattern fabrication, fabrication of this standard reference is made possible.

Owner:HITACHI HIGH-TECH CORP

System and method of measuring distances related to an object

ActiveUS9230339B2Facilitate inventionImprove the measurement effectImage enhancementImage analysisImaging analysisManufacturing systems

A system and method for measuring distances related to a target object depicted in an image and the construction and delivery of supplemental window materials for fenestration. A digital image is obtained that contains a target object dimension and a reference object dimension in the same plane. The digital image may contain a target object dimension identified by an ancillary object and a reference object dimension in different planes. Fiducial patterns on the reference and optional ancillary objects are used that are recognized by an image analysis algorithm. Information regarding a target object and its immediate surroundings is provided to an automated or semi-automated measurement process, design and manufacturing system such that customized parts are provided to end users. The digital image contains a reference object having a reference dimension and calculating a constraint dimension from the digital image based on a reference dimension. The custom part is then designed and manufactured based on a calculated constraint dimension.

Owner:WEXENERGY INNOVATIONS

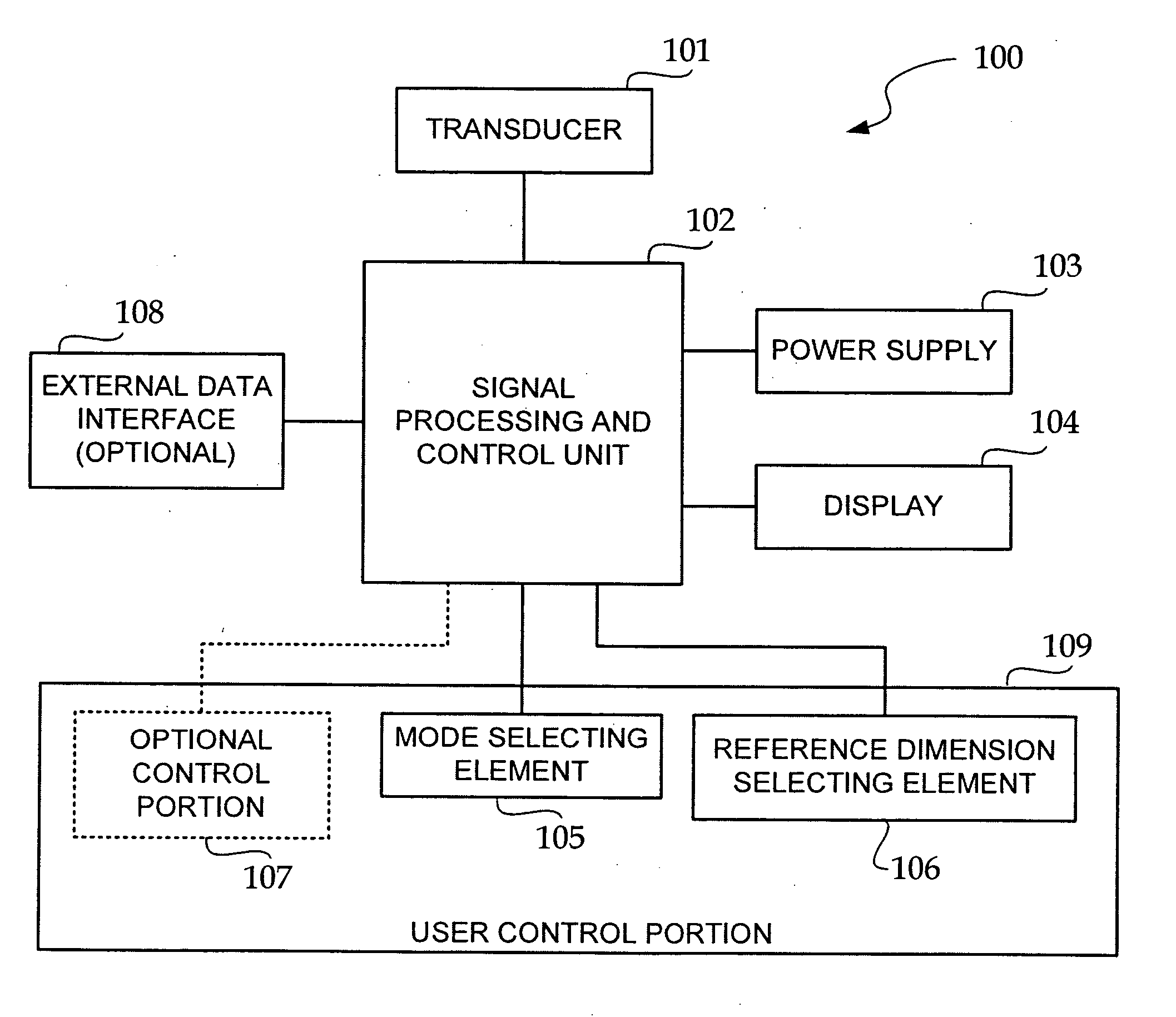

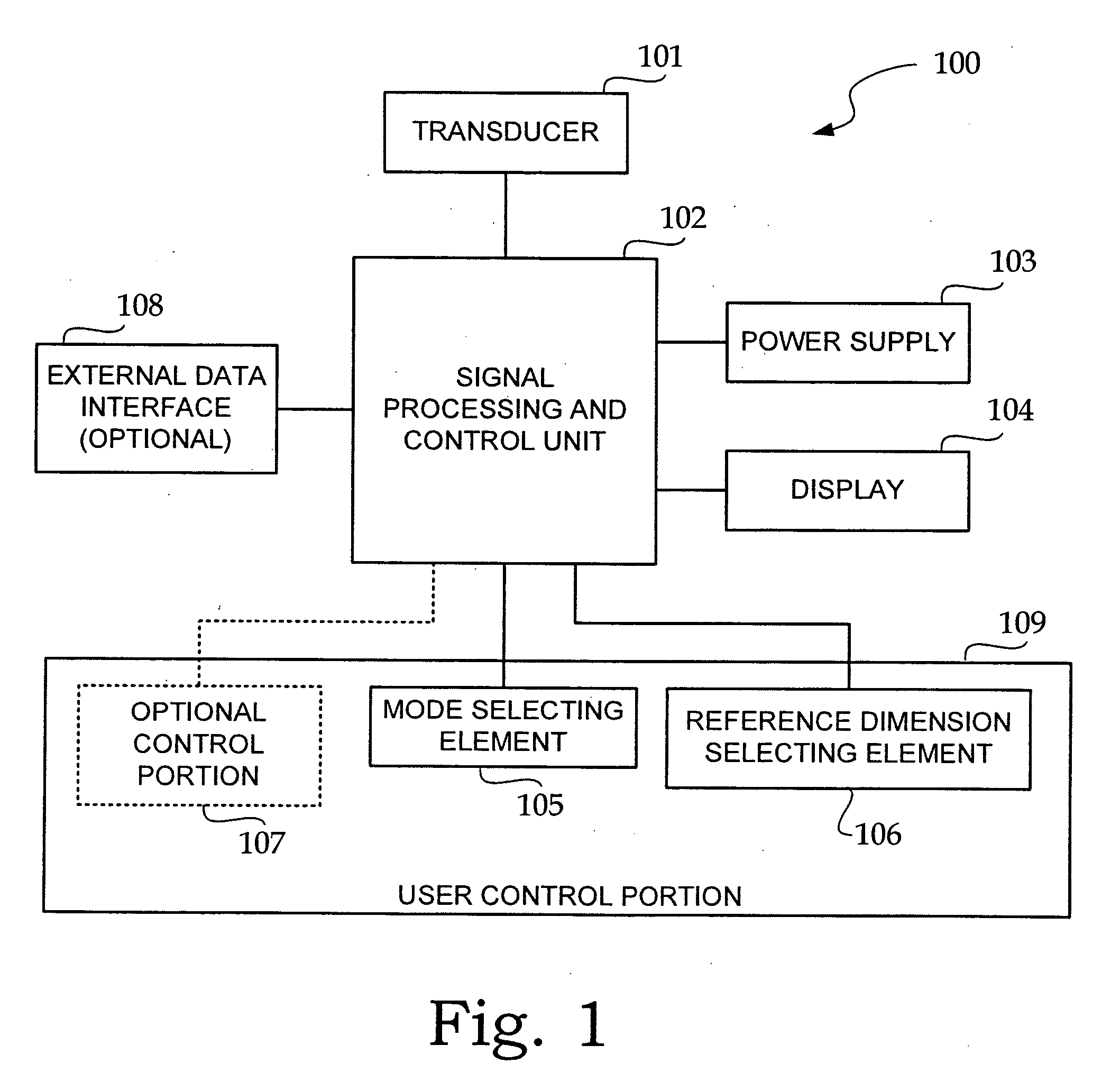

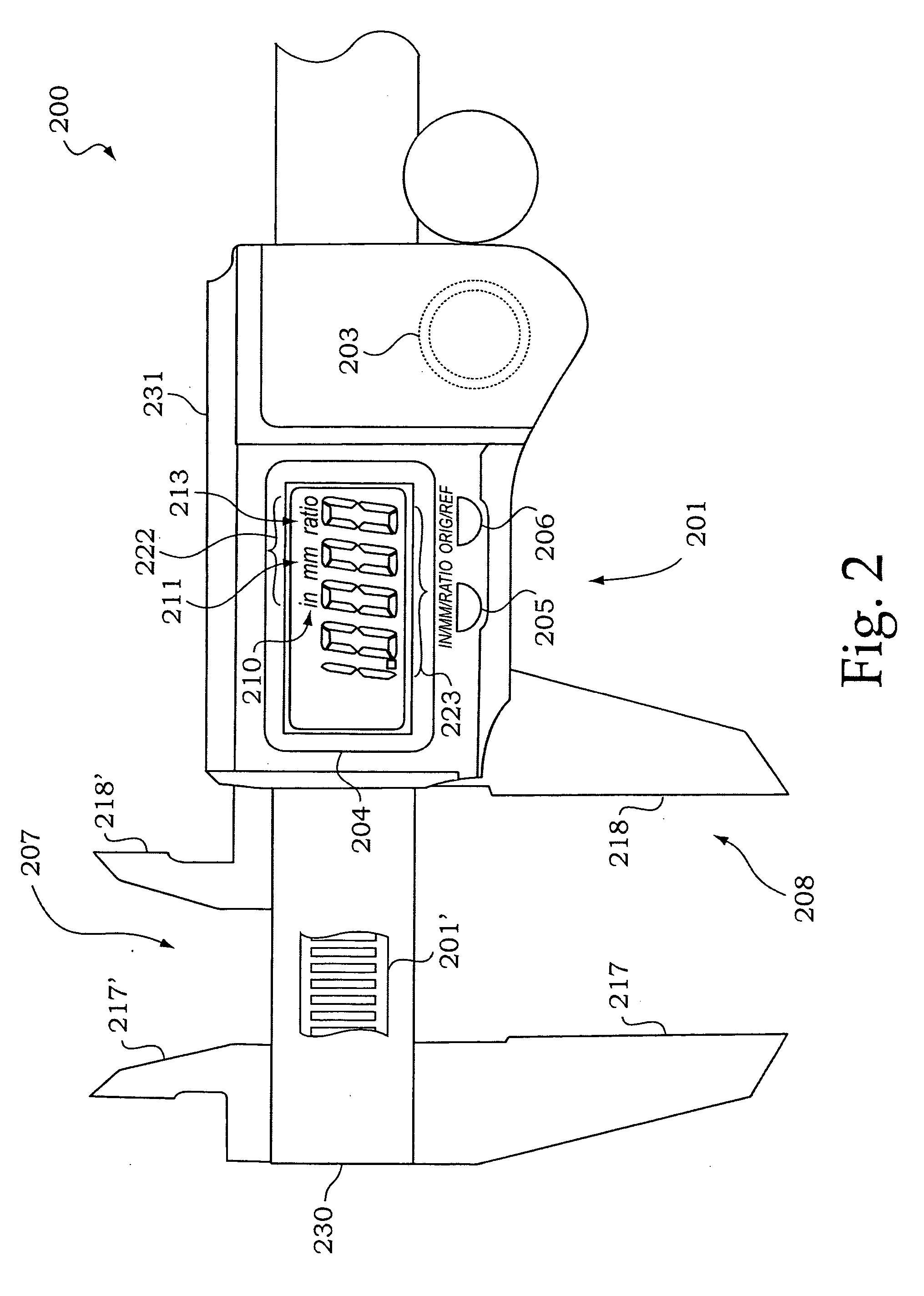

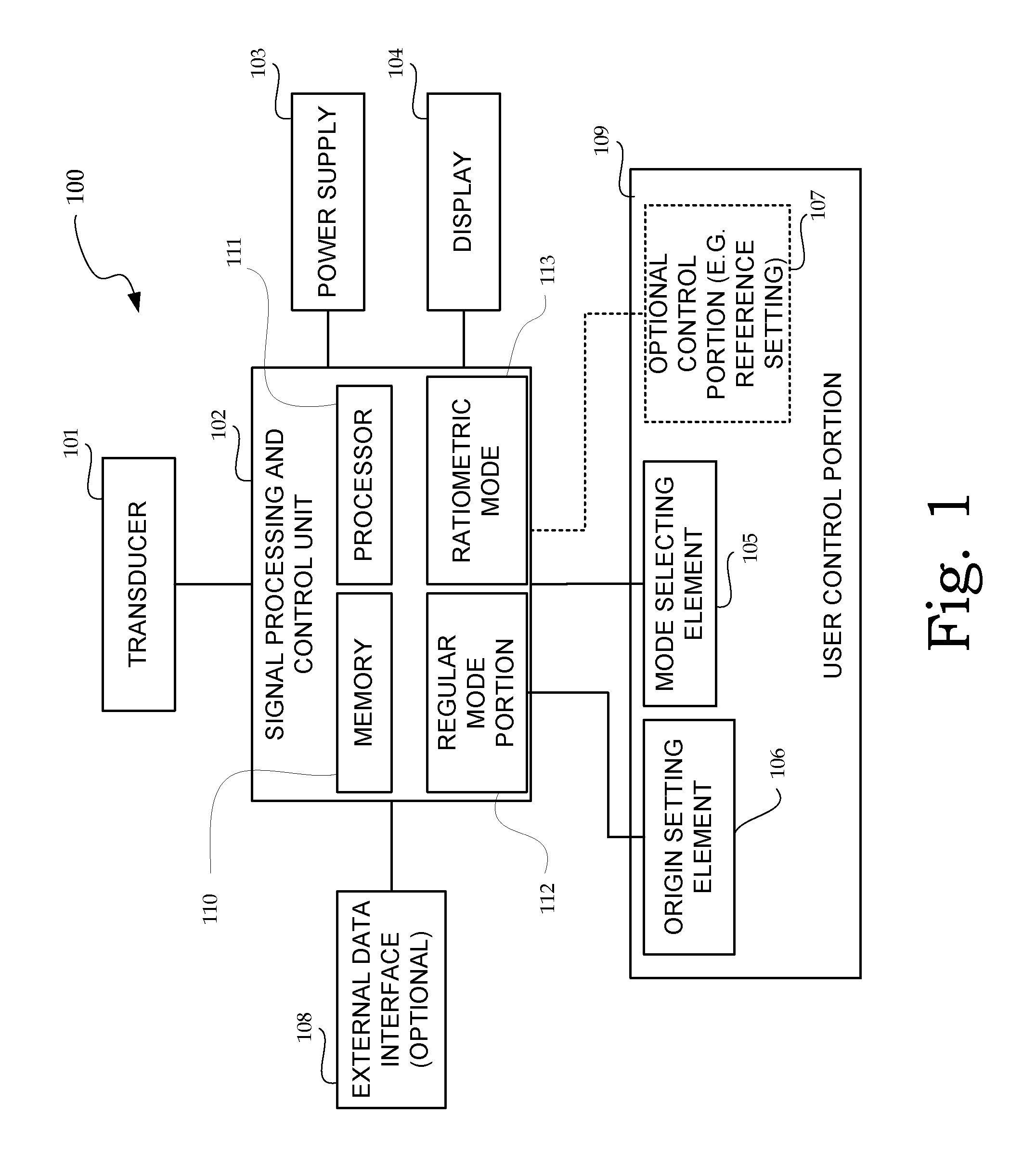

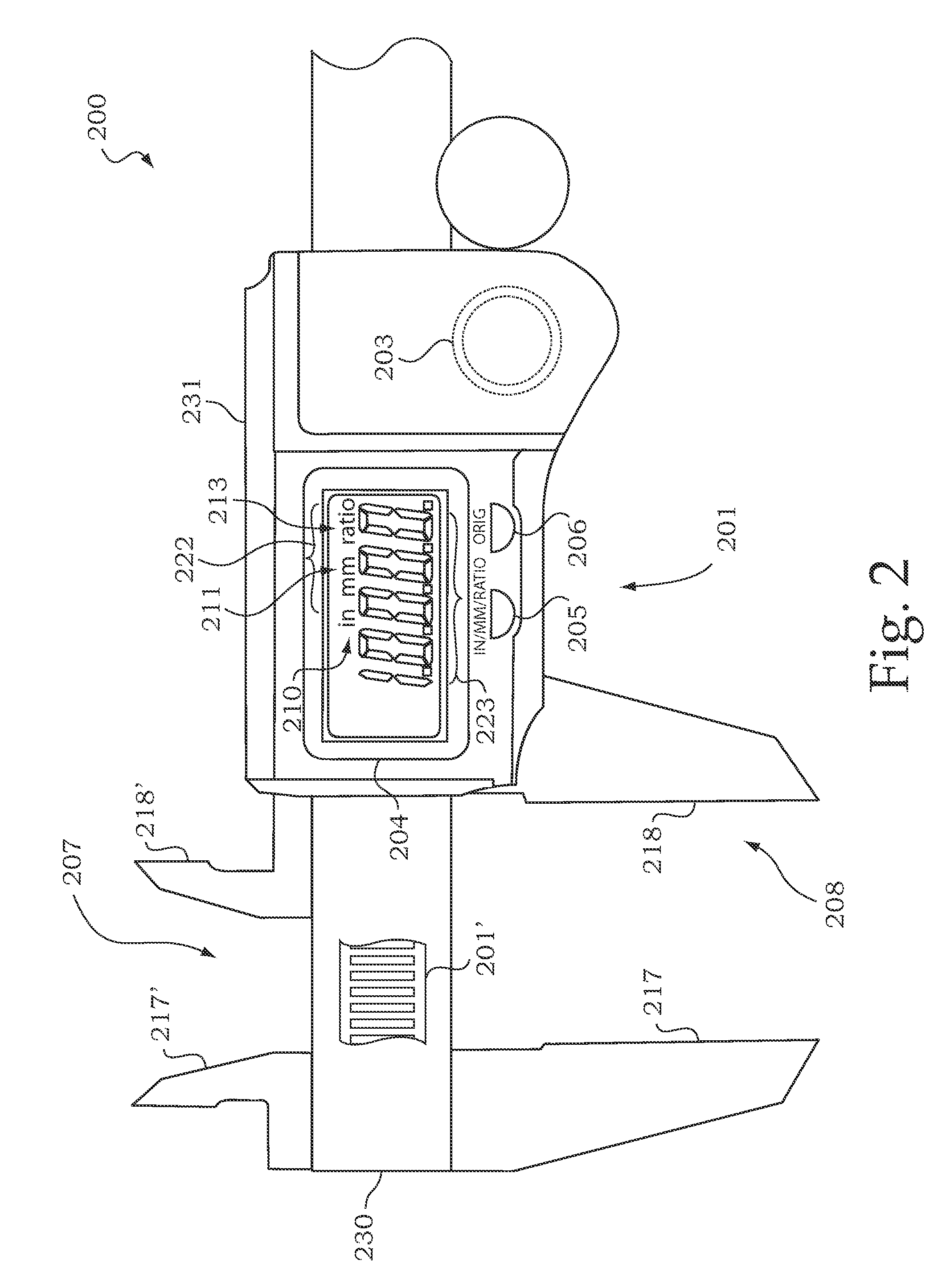

Multimode electronic calipers having ratiometric mode and simplified user interface

InactiveUS20060106568A1Simple and intuitive settingSimple and intuitive to understandDigital computer detailsMechanical clearance measurementsMeasuring instrumentOperation mode

A multimode electronic measuring instrument is provided that includes a ratiometric mode of operation. During the ratiometric mode, a desired dimension is established as a stored reference dimension “Xref”. After the reference dimension is stored in memory, subsequent ratiometric measurement readouts will equal a current measurement distance “Xcurr” divided by the reference dimension Xref. A ratiometric measurement according to this invention indicates the relationship of a current dimension to another readily changed (reference) dimension. The ratiometric mode of operation can be implemented in combination with conventional function caliper functions to provide a multimode caliper having a simple and intuitive user interface. Setting the reference dimension and interpreting the ratiometric measurement display are particularly easy, to facilitate intuitive understanding and operation.

Owner:MITUTOYO CORP

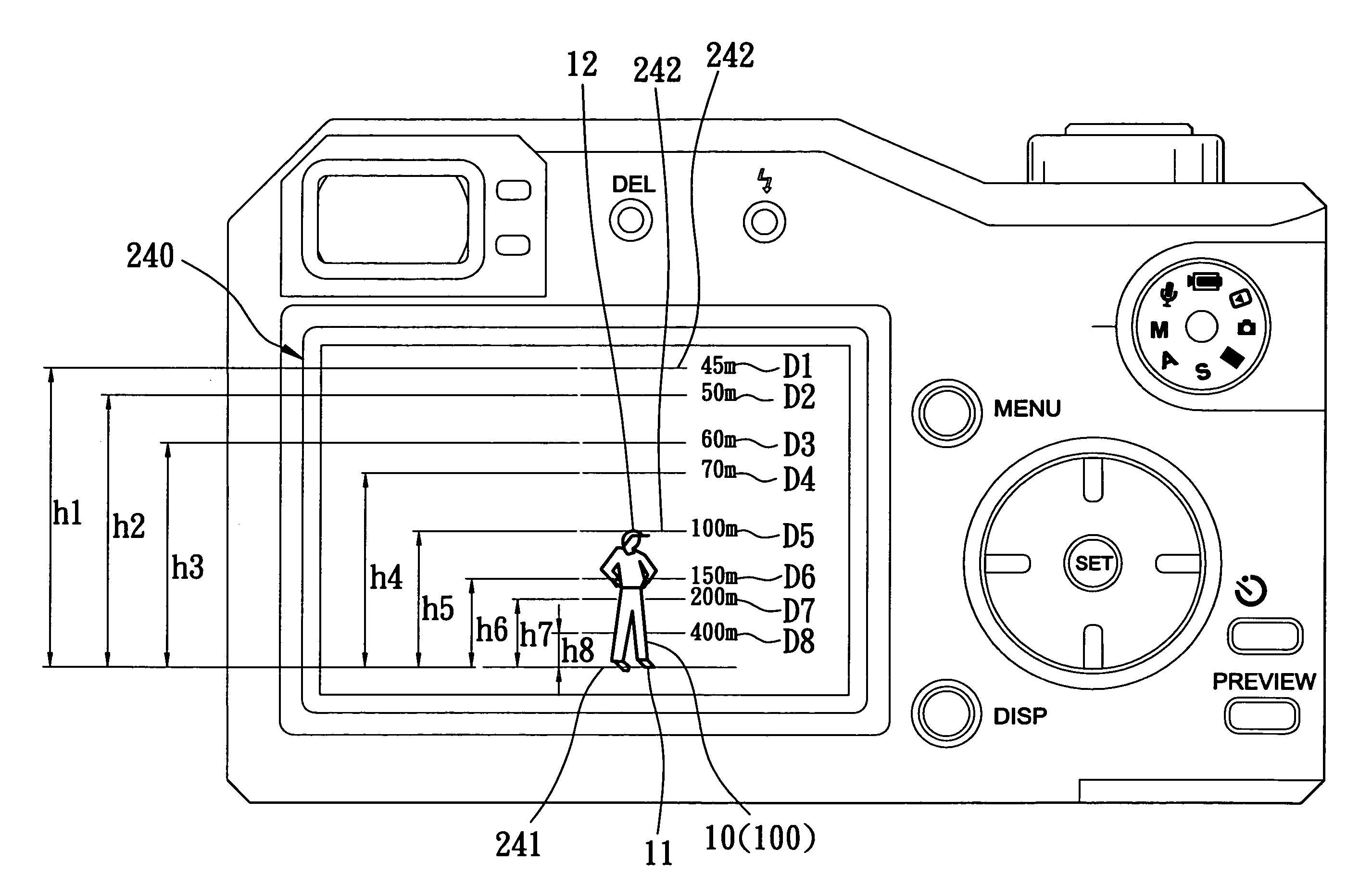

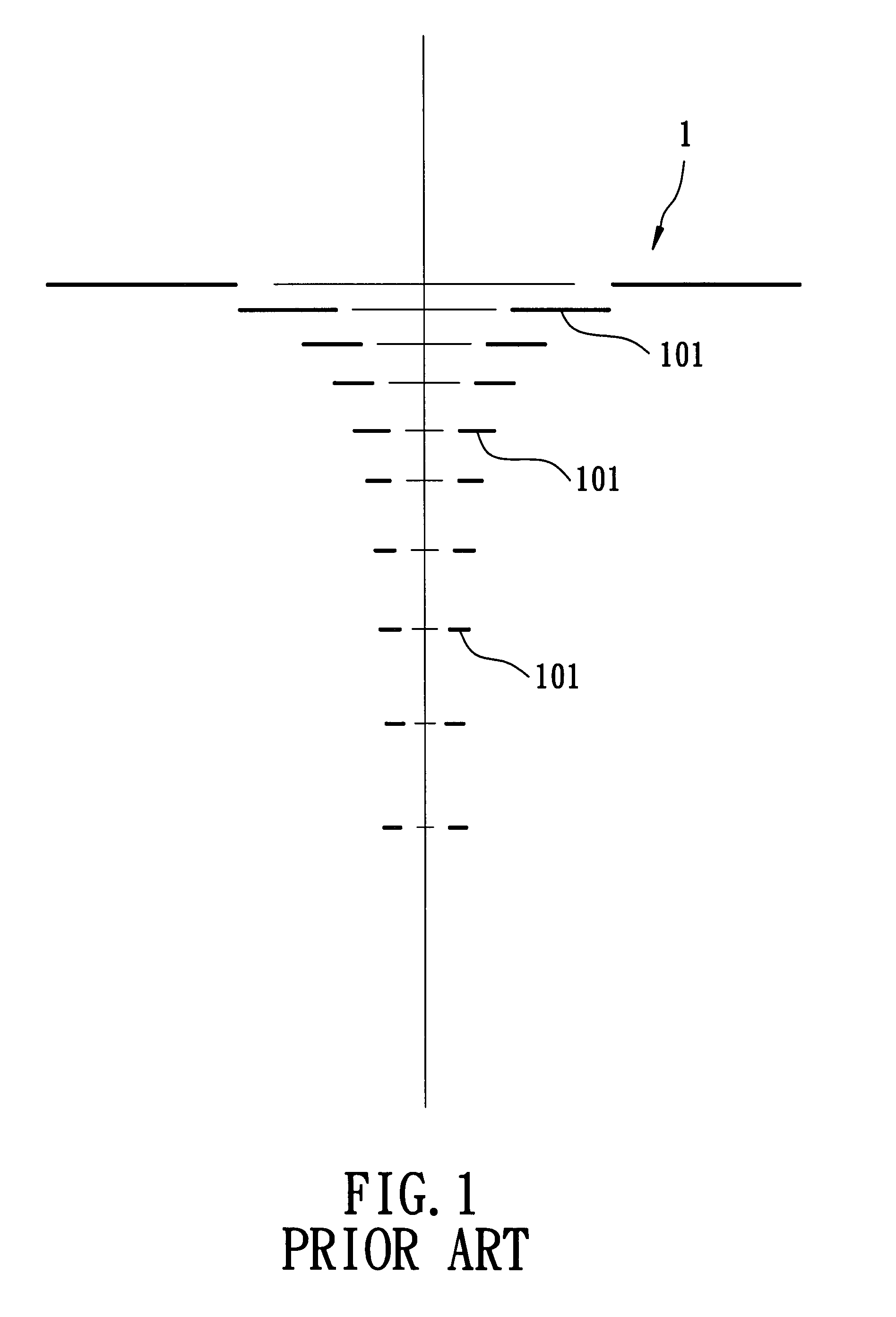

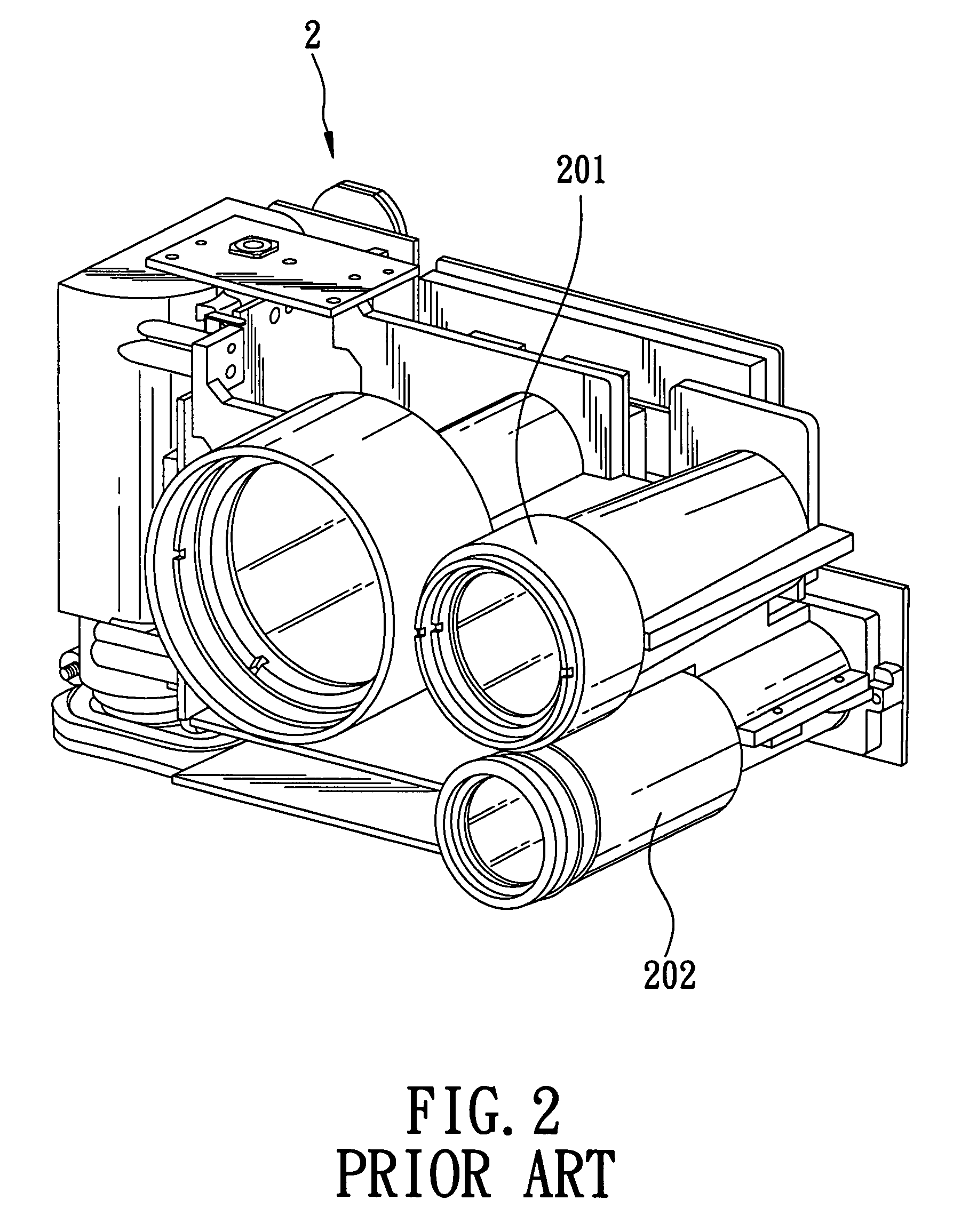

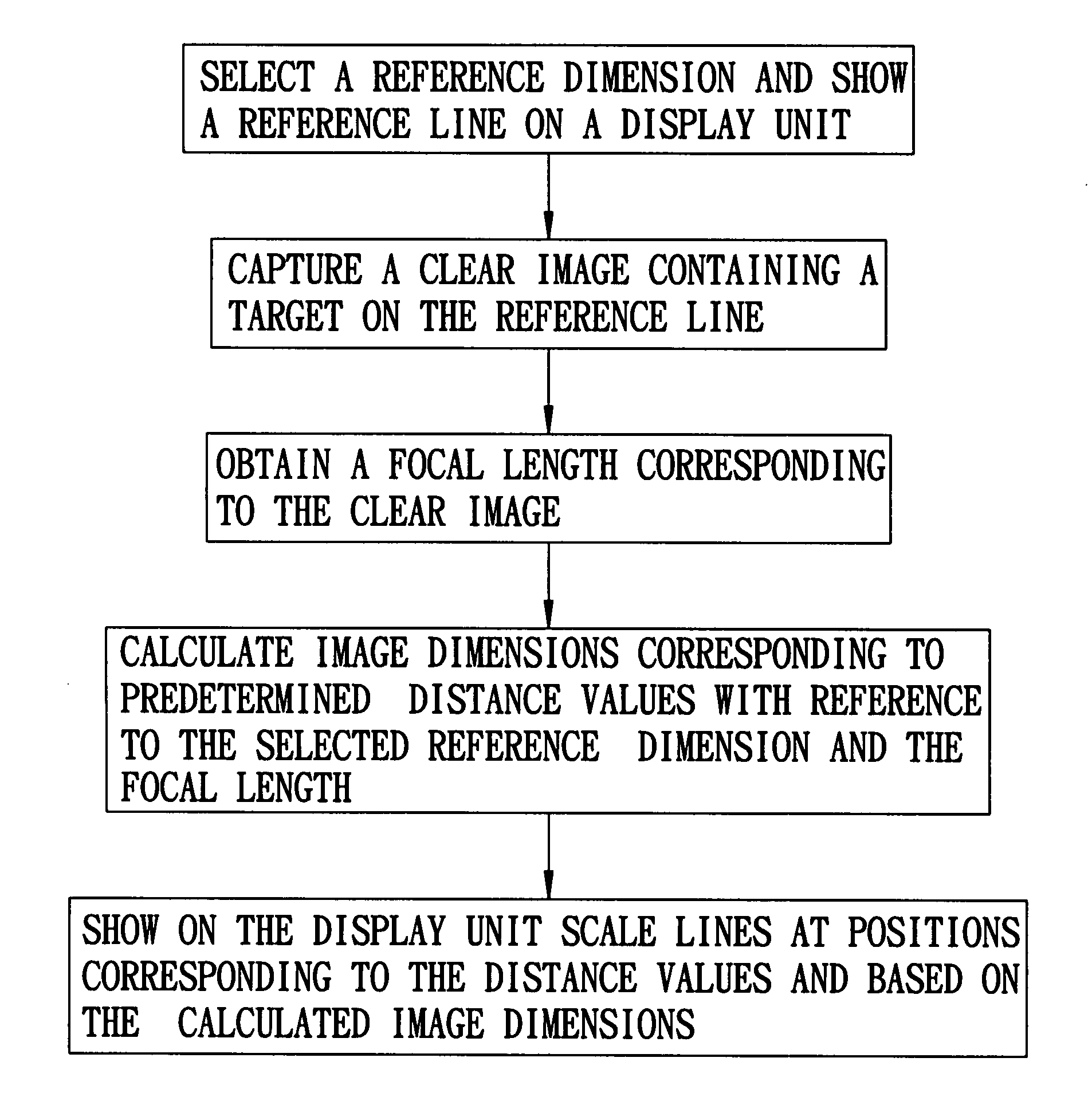

Method of distance estimation to be implemented using a digital camera

InactiveUS7683963B2Television system detailsCharacter and pattern recognitionImage estimationDigital camera

A method of distance estimation is to be implemented using a digital camera, and includes: selecting a pre-established reference dimension corresponding to a target whose distance is to be estimated; enabling operation of the digital camera to capture a clear image containing the target; obtaining a focal length corresponding to the captured clear image; calculating an image dimension for each of predetermined distance values with reference to the selected reference dimension and the focal length; and showing the distance values on a display unit at positions based on proportions of the calculated image dimensions. The distance of the target can be estimated as one of the distance values corresponding to a dimension of the target image contained in the clear image and shown on the display unit.

Owner:ASIA OPTICAL INT LTD

Method of distance estimation to be implemented using a digital camera

InactiveUS20080007627A1Television system detailsCharacter and pattern recognitionDigital cameraFocal length

A method of distance estimation is to be implemented using a digital camera, and includes: selecting a pre-established reference dimension corresponding to a target whose distance is to be estimated; enabling operation of the digital camera to capture a clear image containing the target; obtaining a focal length corresponding to the captured clear image; calculating an image dimension for each of predetermined distance values with reference to the selected reference dimension and the focal length; and showing the distance values on a display unit at positions based on proportions of the calculated image dimensions. The distance of the target can be estimated as one of the distance values corresponding to a dimension of the target image contained in the clear image and shown on the display unit.

Owner:ASIA OPTICAL INT LTD

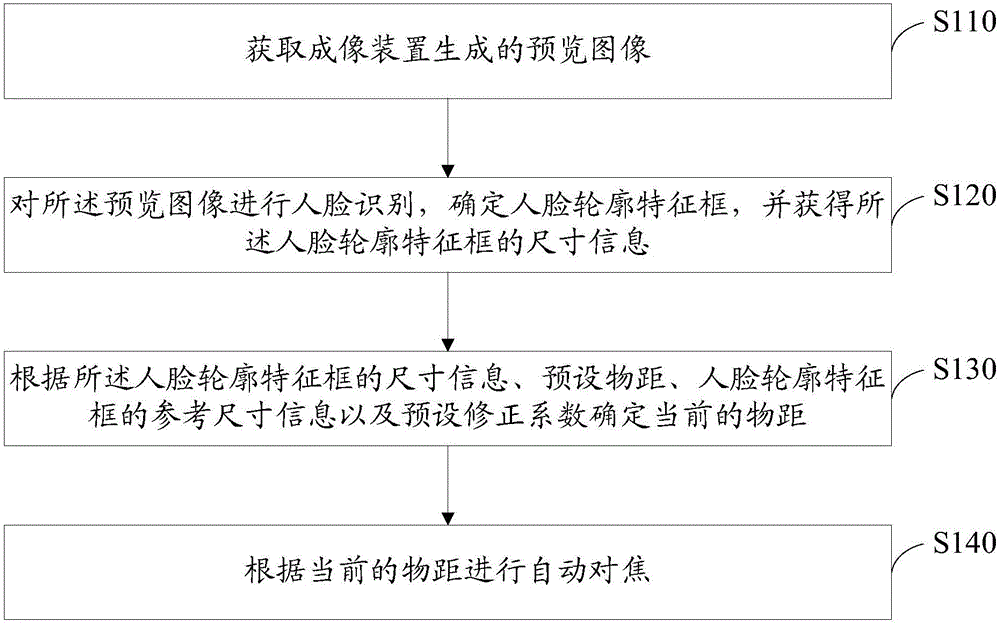

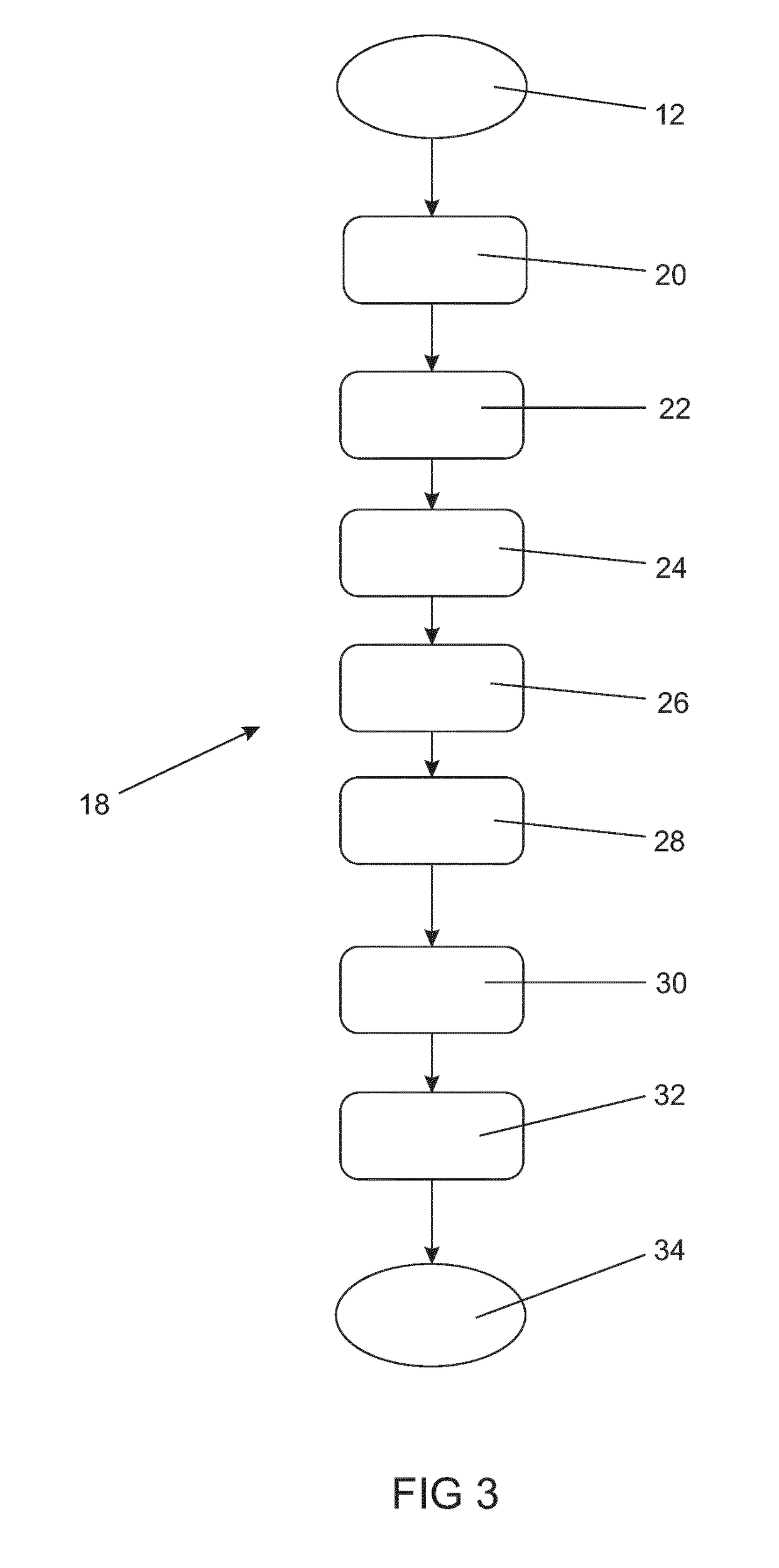

Automatic focusing method and system, and shooting device

ActiveCN106249508AMeet the use requirementsFast focusingTelevision system detailsColor television detailsComputer graphics (images)Face contour

The invention relates to an automatic focusing method and system, and a shooting device. The method comprises: a preview image generated by an imaging device is obtained; face identification is carried out on the preview image, a face contour feature frame is determined, and dimension information of the face contour feature frame is obtained; and according to the dimension information of the face contour feature frame, a preset object distance, a reference dimension information of the face contour feature frame, and a preset correction coefficient, a current object distance is determined, and automatic focusing is carried out based on the current object distance. According to the invention, an object distance can be calculated rapidly and automatic focusing is carried out; the focusing speed is fast; sacrifice of masked pixels as well as manufacturing cost increasing can be avoided; and the using requirement of the front camera is met.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

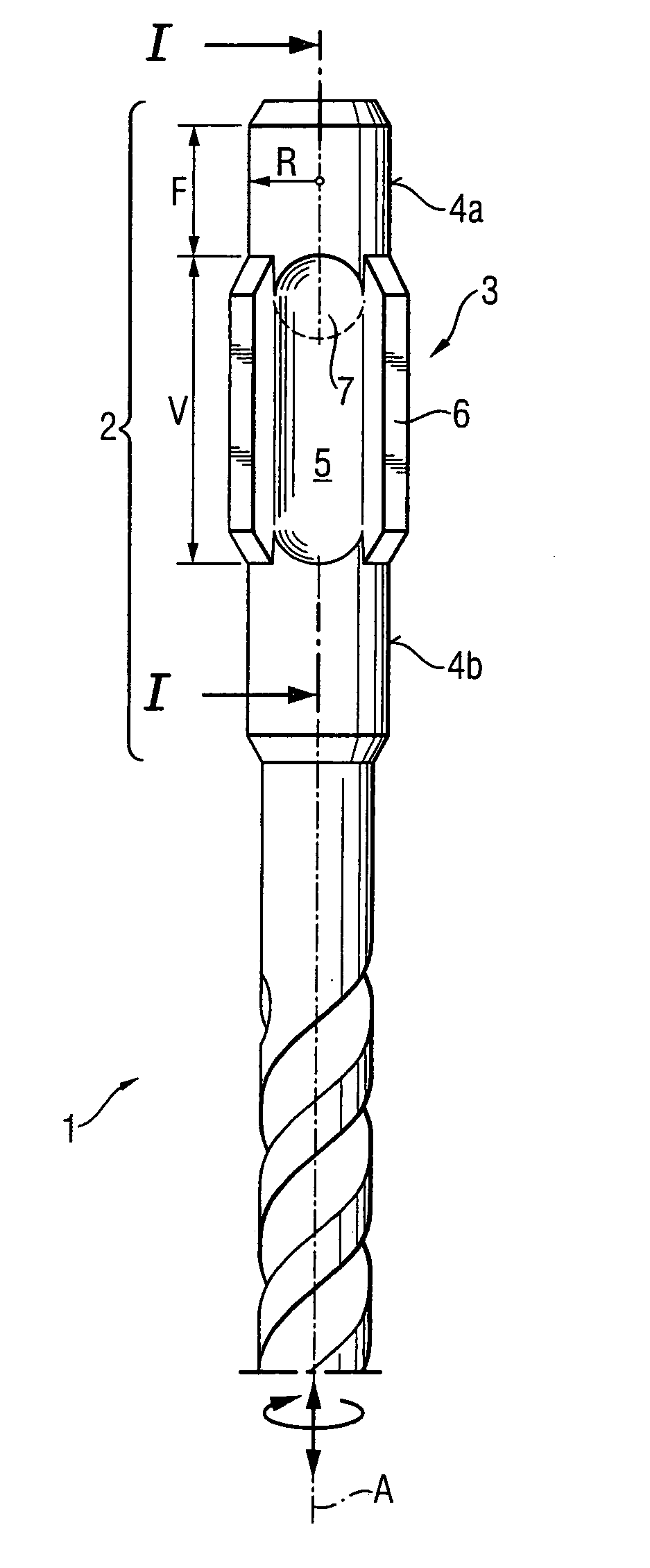

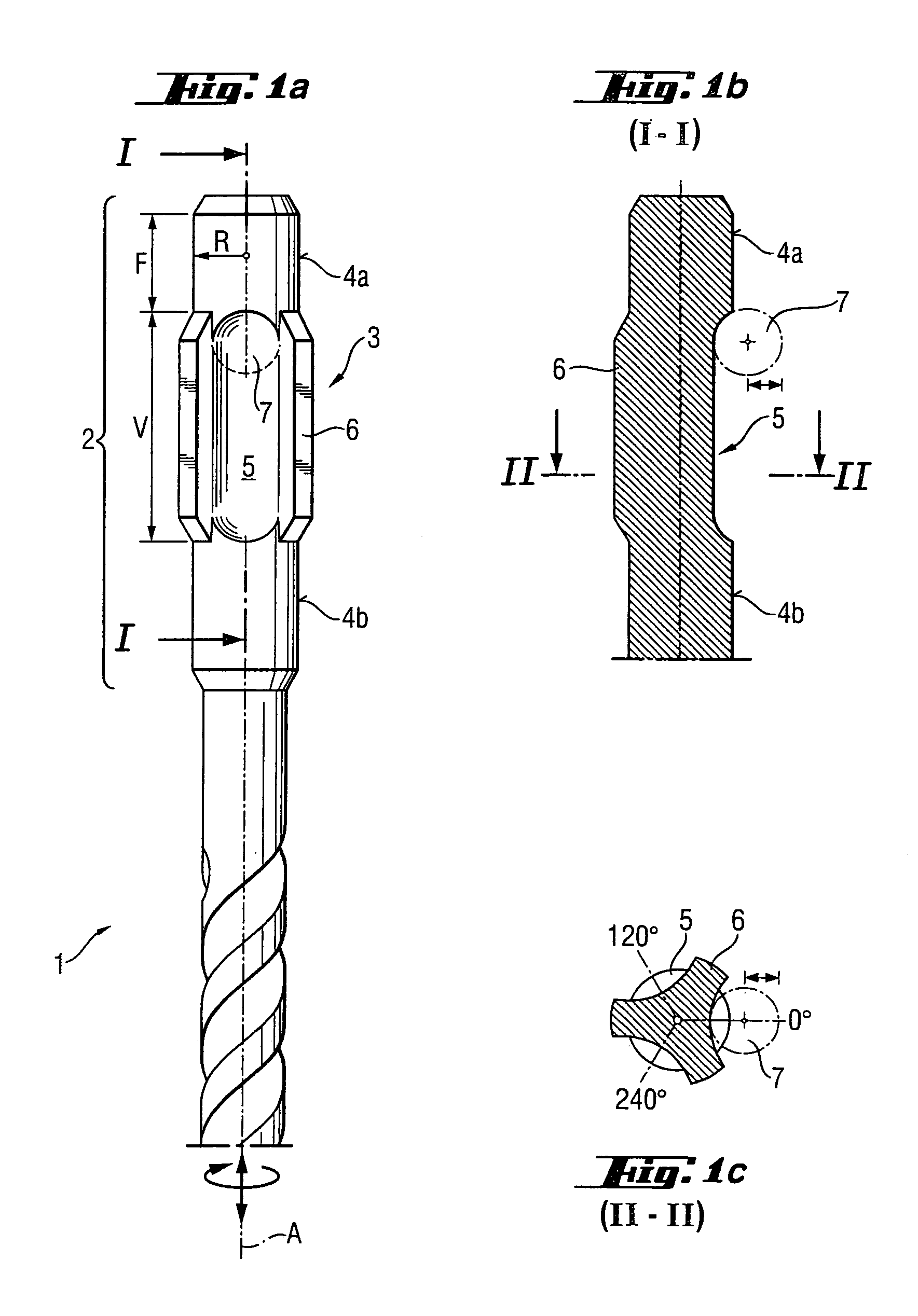

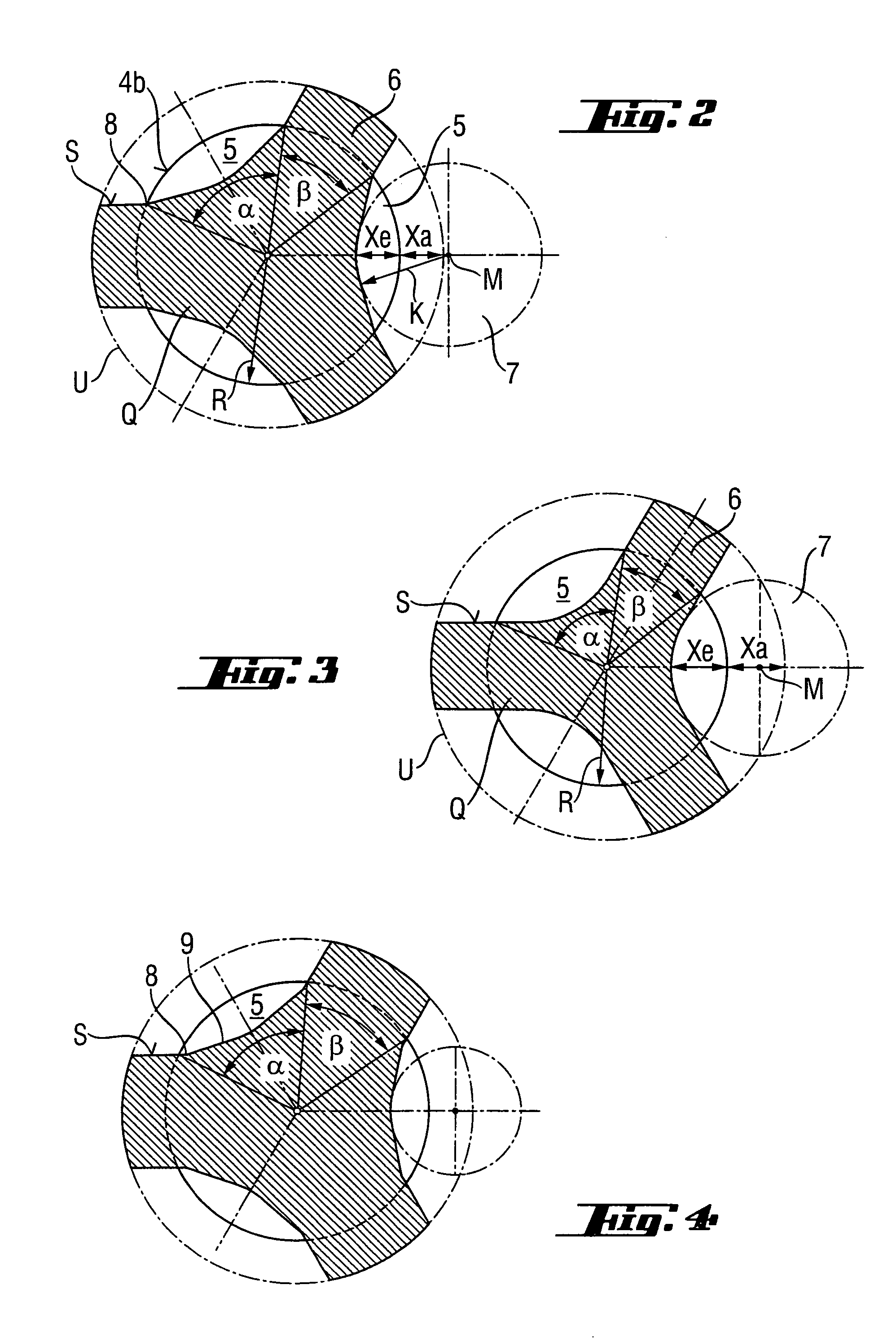

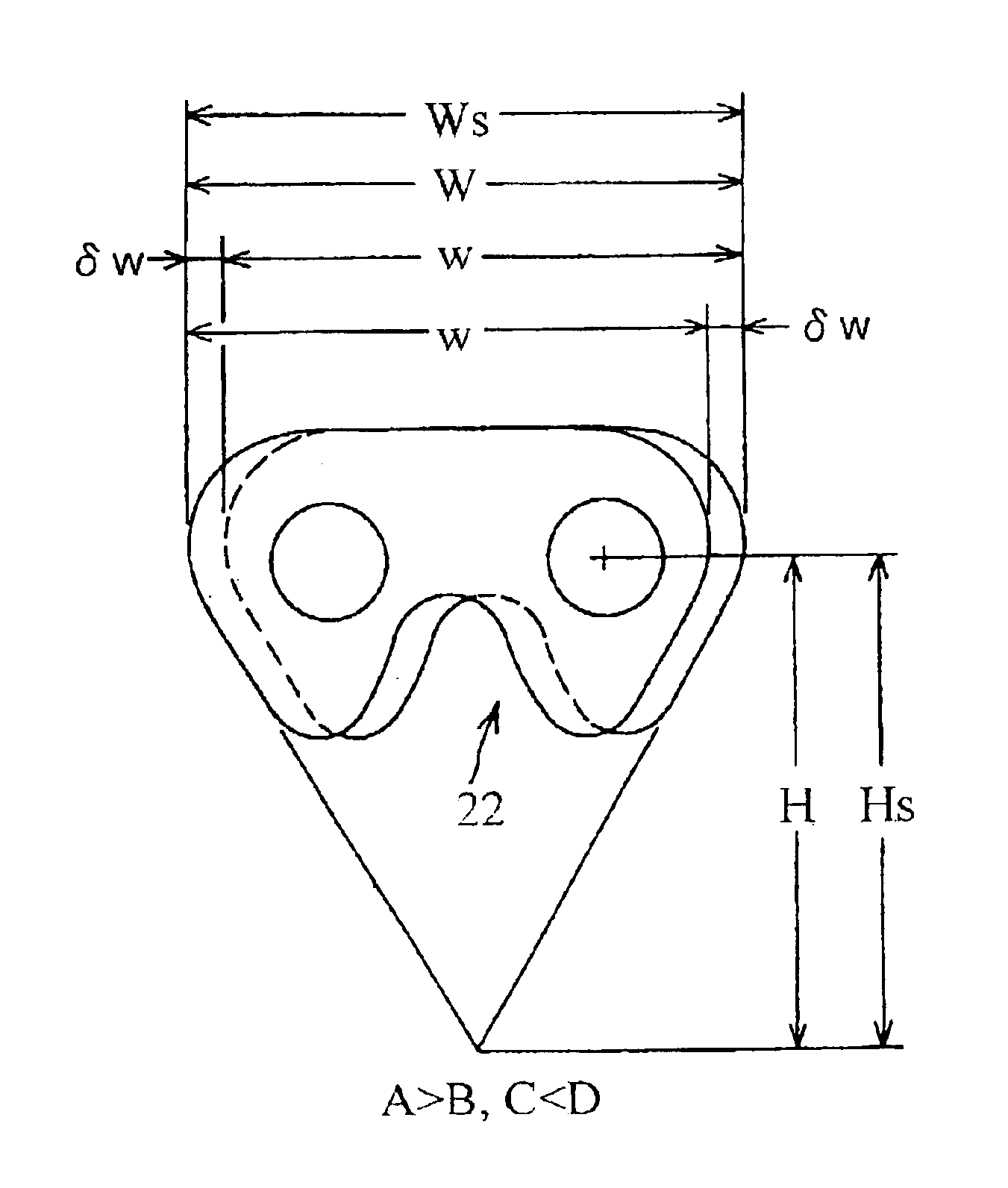

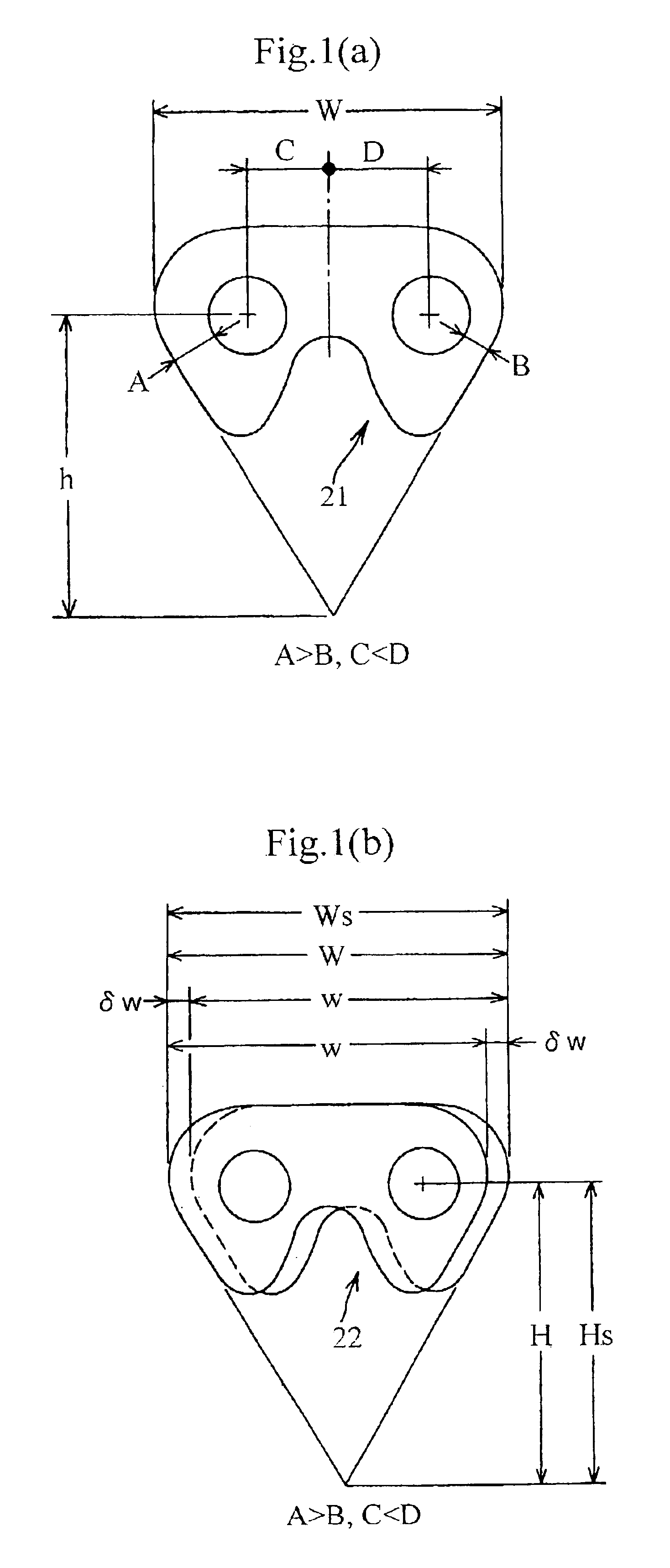

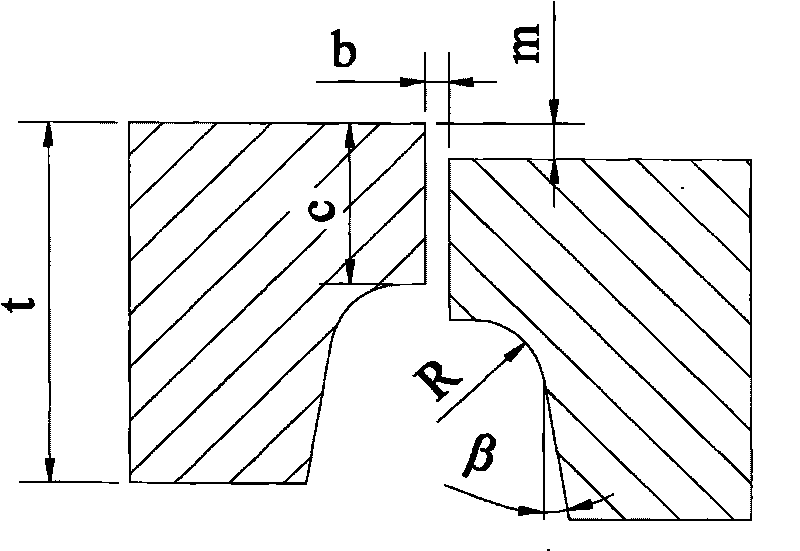

Shank for a rotary/percussion tool

ActiveUS7261169B2Small contact surface pressureLittle wearDrill bitsDrilling rodsEngineeringReference dimension

A shank for a working tool has at least three recesses (5) provided within the lockable region (3) and arranged in a cross-section (c-c) to the tool axis (A) at least at angles of 0°, 120°, and 240° within the radial reference dimension (R) of the shank, with at least one of the recesses (5) being axially closed toward a free end of the shank (1), and at least one protrusion (6) arranged circumferentially between two adjacent recesses (5) outside of the radial reference dimension, with the sum of central recess angles (α) of the recesses amounting to at least 150°, and a central protrusion angle (β) of the at least one protrusion (6) being smaller than a central recess angle (α).

Owner:HILTI AG

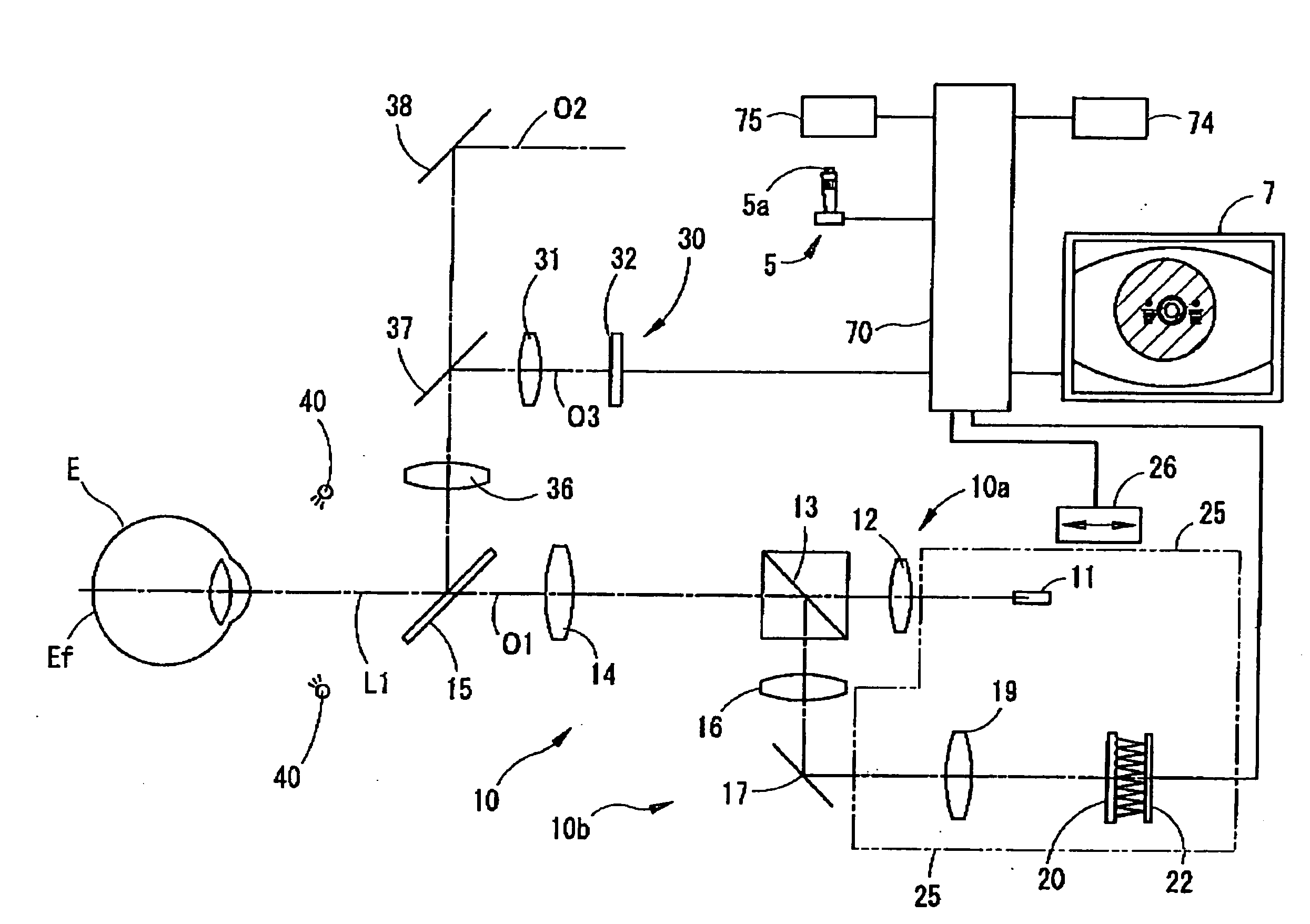

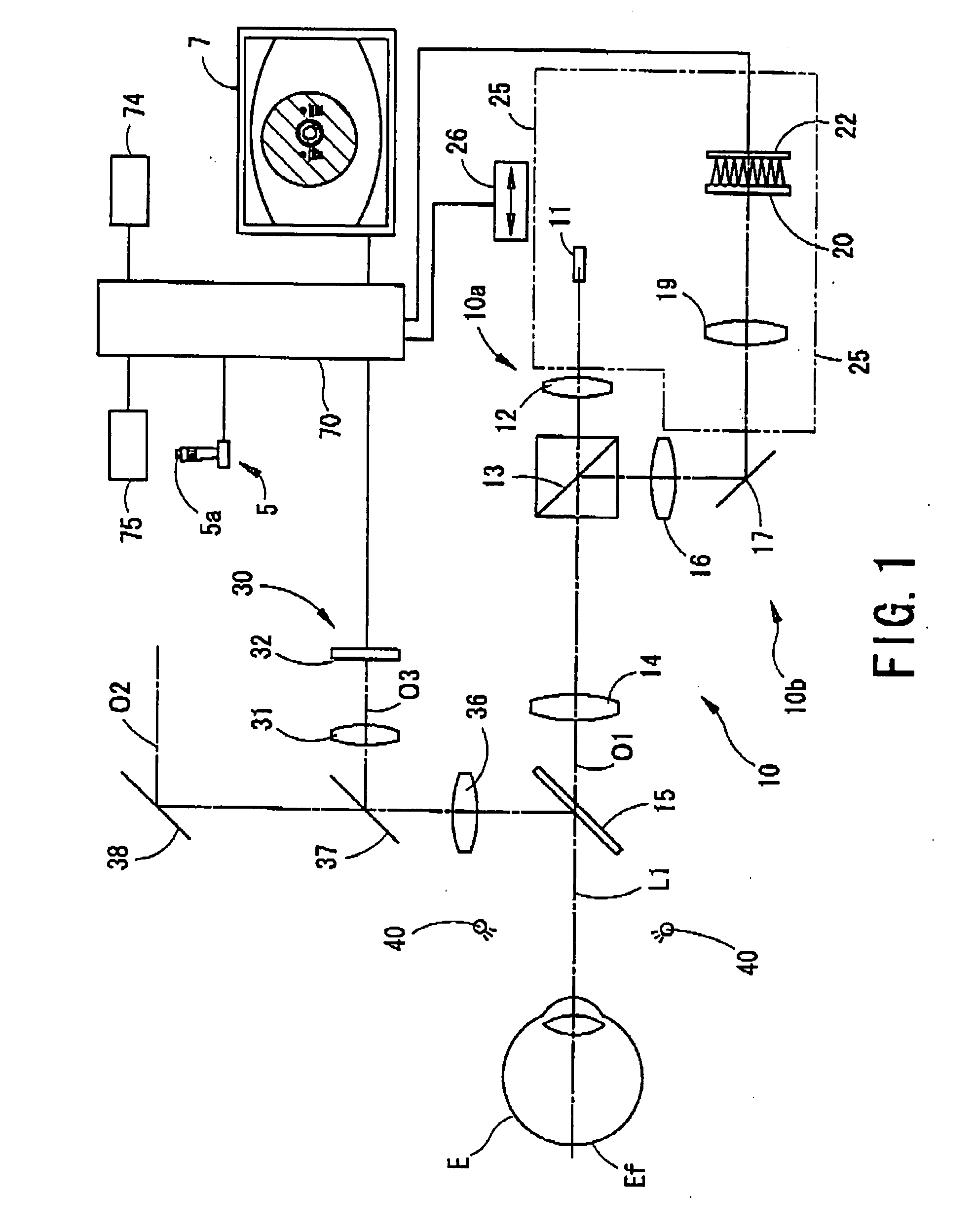

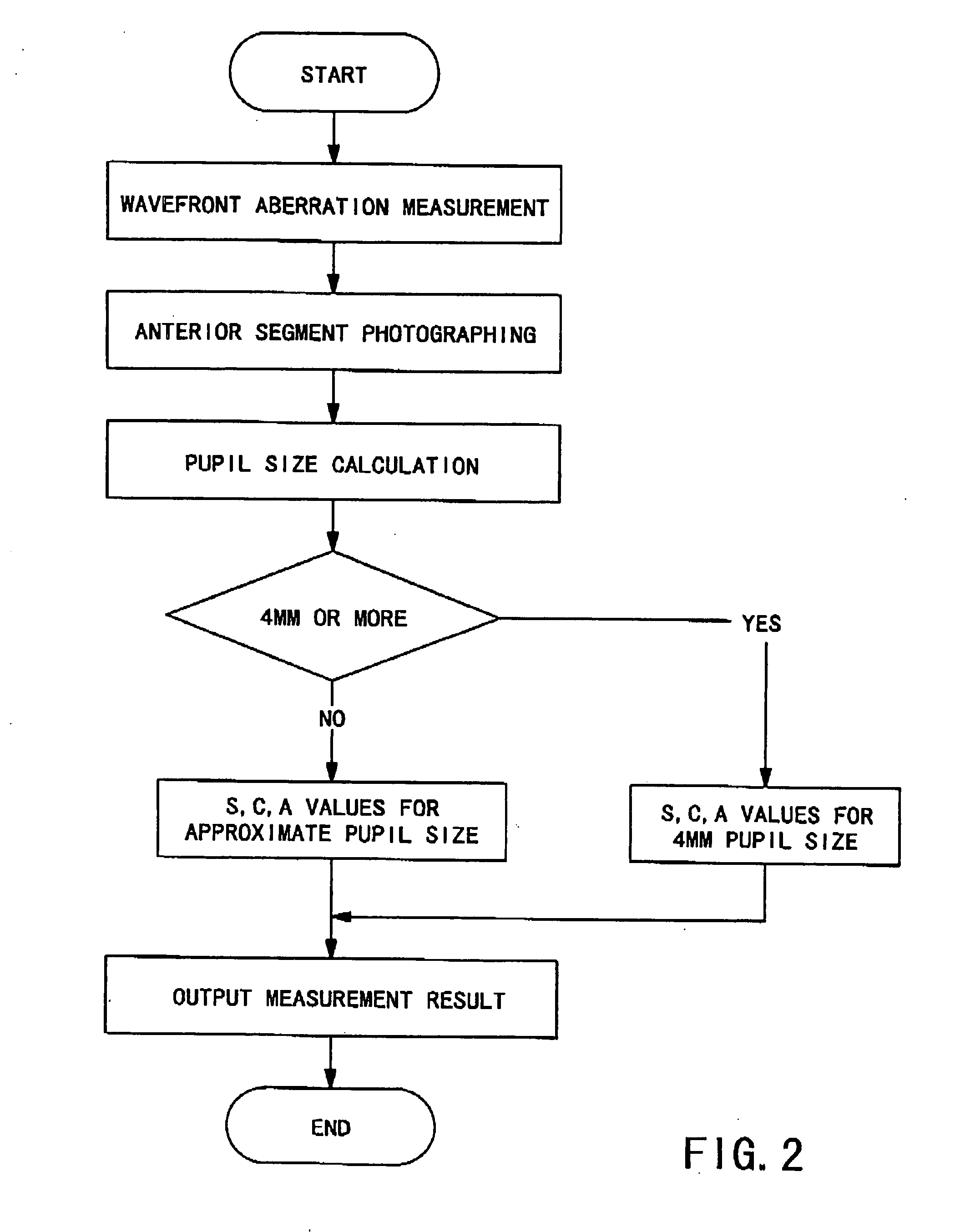

Ophthalmic measurement apparatus

An ophthalmic measurement apparatus capable of outputting correction data (objective values) for a patient's eye as approximate as possible to subjective values includes an optical system for projecting a measurement target onto a fundus and detecting an image of the target reflected therefrom using a photoelectric element so as to obtain measurement data on eye refractive power distribution or wavefront aberration, an optical system for photographing an anterior-segment including a pupil using an image-pickup element, a device which detects a size of a pupil area by image processing, and a device which obtains a spherical power, an astigmatic power, and an astigmatic axial angle based on the data within a given area smaller than the pupil area when the detected size is larger than a reference size, and obtains the three values based on the data within the pupil area when the detected size is smaller than the reference size.

Owner:NIDEK CO LTD

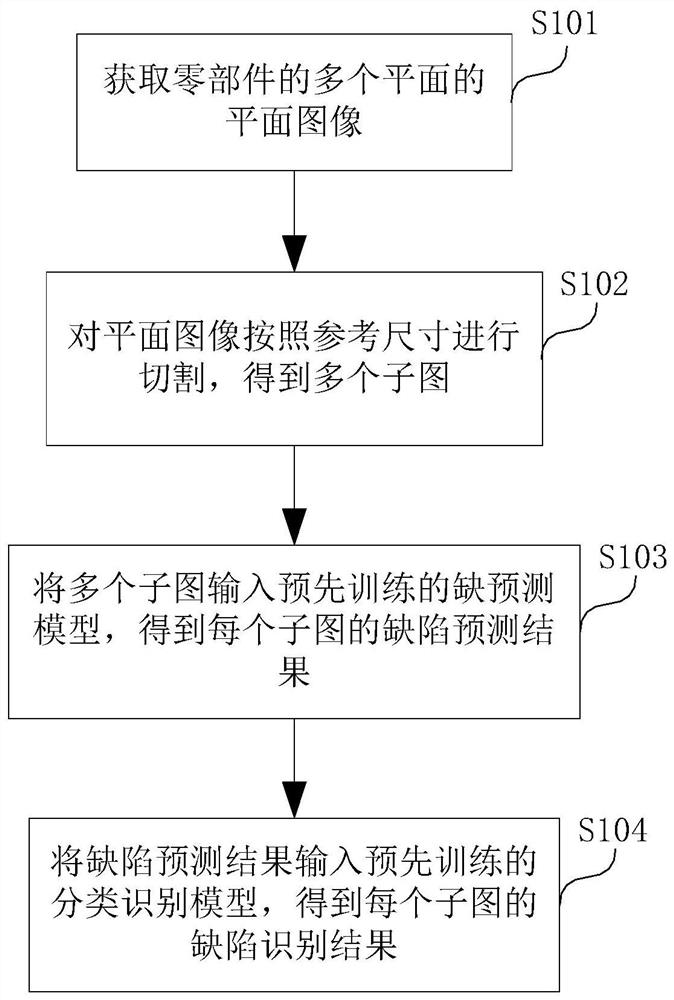

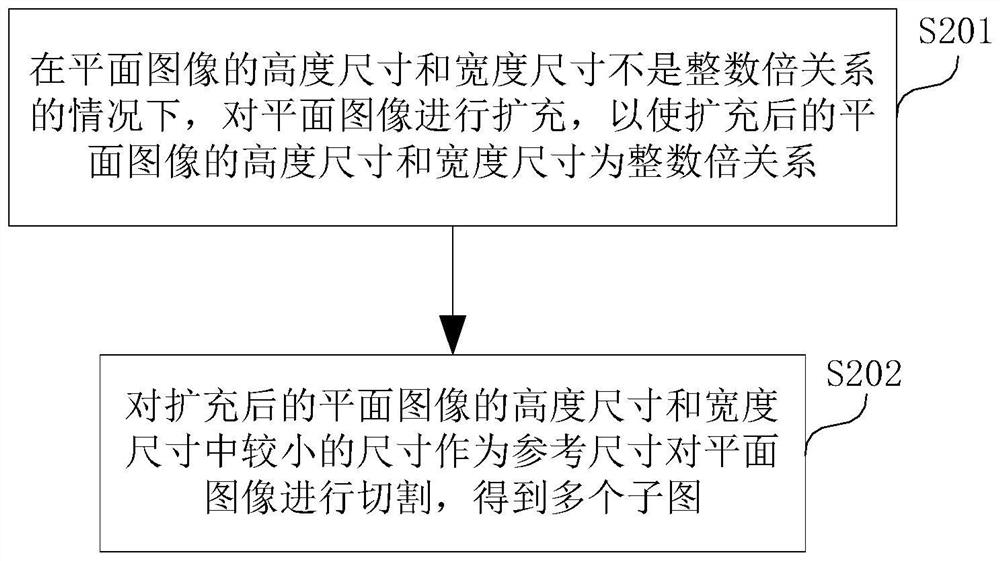

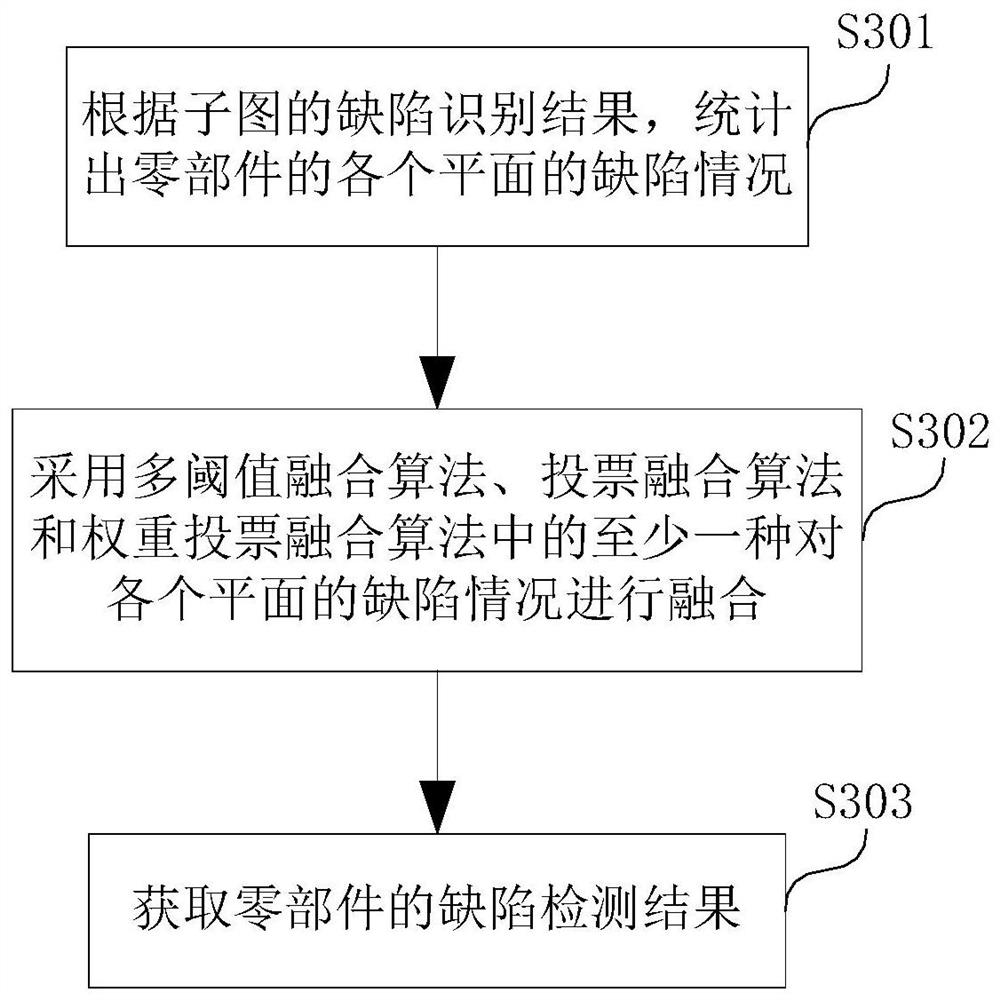

Part defect detection method and device and electronic equipment

PendingCN111768381ARealize precise identificationReduce the probability of misjudgment of defectsImage enhancementImage analysisPattern recognitionAlgorithm

The invention discloses a part defect prediction method and device and electronic equipment, and relates to the fields of artificial intelligence, deep learning, cloud computing and computer vision, in particular to the aspect of industrial quality inspection. According to the specific implementation scheme, the method includes: obtaining plane images of multiple planes of the part; cutting the plane image according to a reference size to obtain a plurality of sub-images; inputting the plurality of sub-graphs into a pre-trained defect prediction model to obtain a defect prediction result of each sub-graph; and inputting the defect prediction result into a pre-trained defect identification model to obtain a defect identification result of each sub-graph, the defect identification result comprising a defect type and a defect grade. Through the above scheme, on one hand, accurate identification of real defects of the part can be realized, so that the accuracy of a defect detection resultis improved, and the probability of misjudgment on whether the part has defects or not is reduced; and on the other hand, the input data of the defect prediction model is convenient to process, and the labor cost can be reduced.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

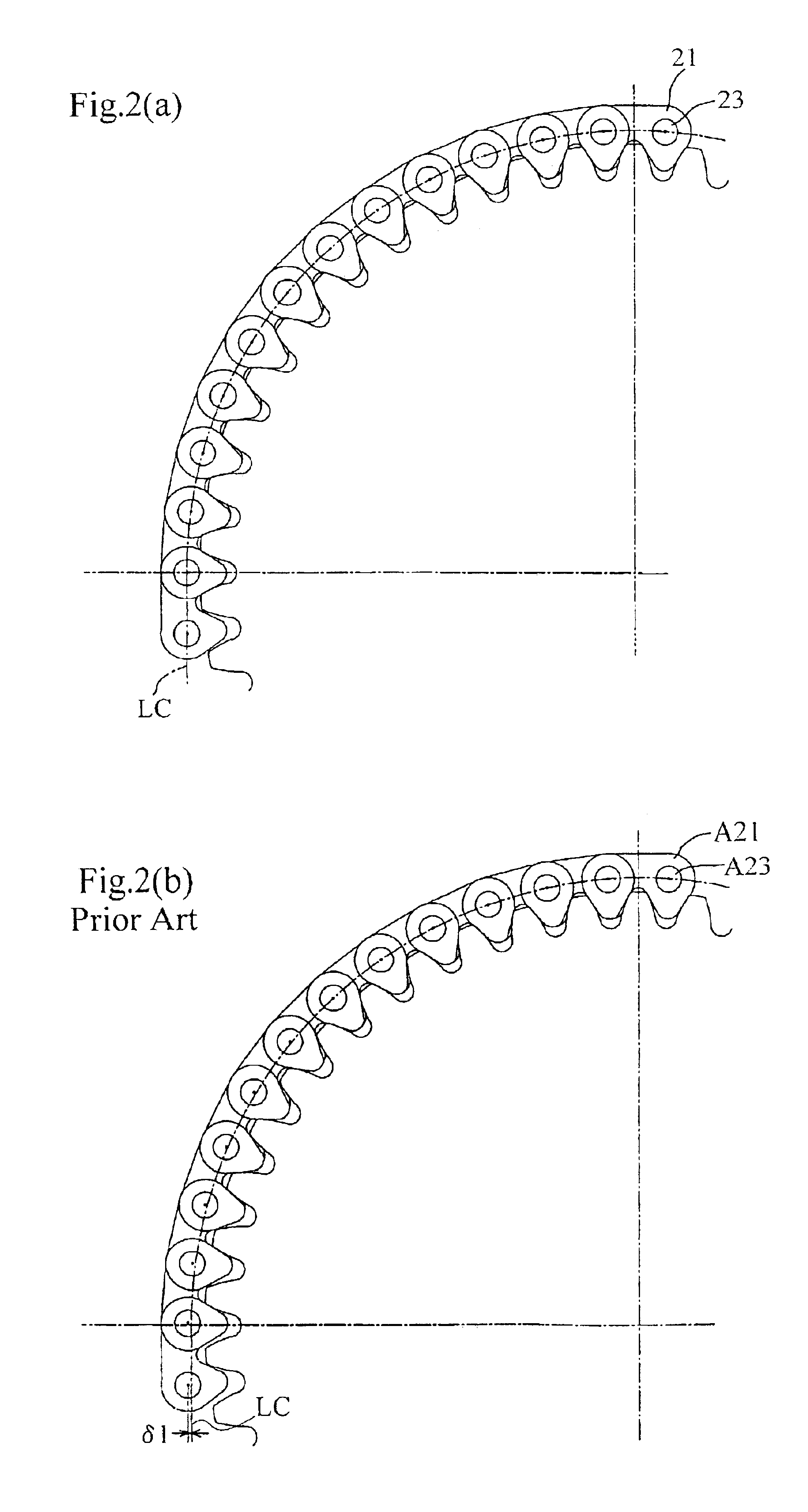

Silent chain transmission mechanism

A silent chain transmission mechanism includes a sprocket and a silent chain having link interleaved link rows each composed of plural randomly selected link plates and connected together by connecting pins. The outside dimensions of the link plate are smaller than the outside dimensions of a link, but the outside dimensions of the link match the design reference dimensions of a link plate capable of proper meshing with the sprocket. The requirement for manufacturing accuracy and the effort required for assembly of the silent chain are reduced. However, the silent chain travels on the sprocket on the chain traveling line so that improved noise, vibration and friction properties, and traveling stability are realized.

Owner:TSUBAKIMOTO CHAIN CO

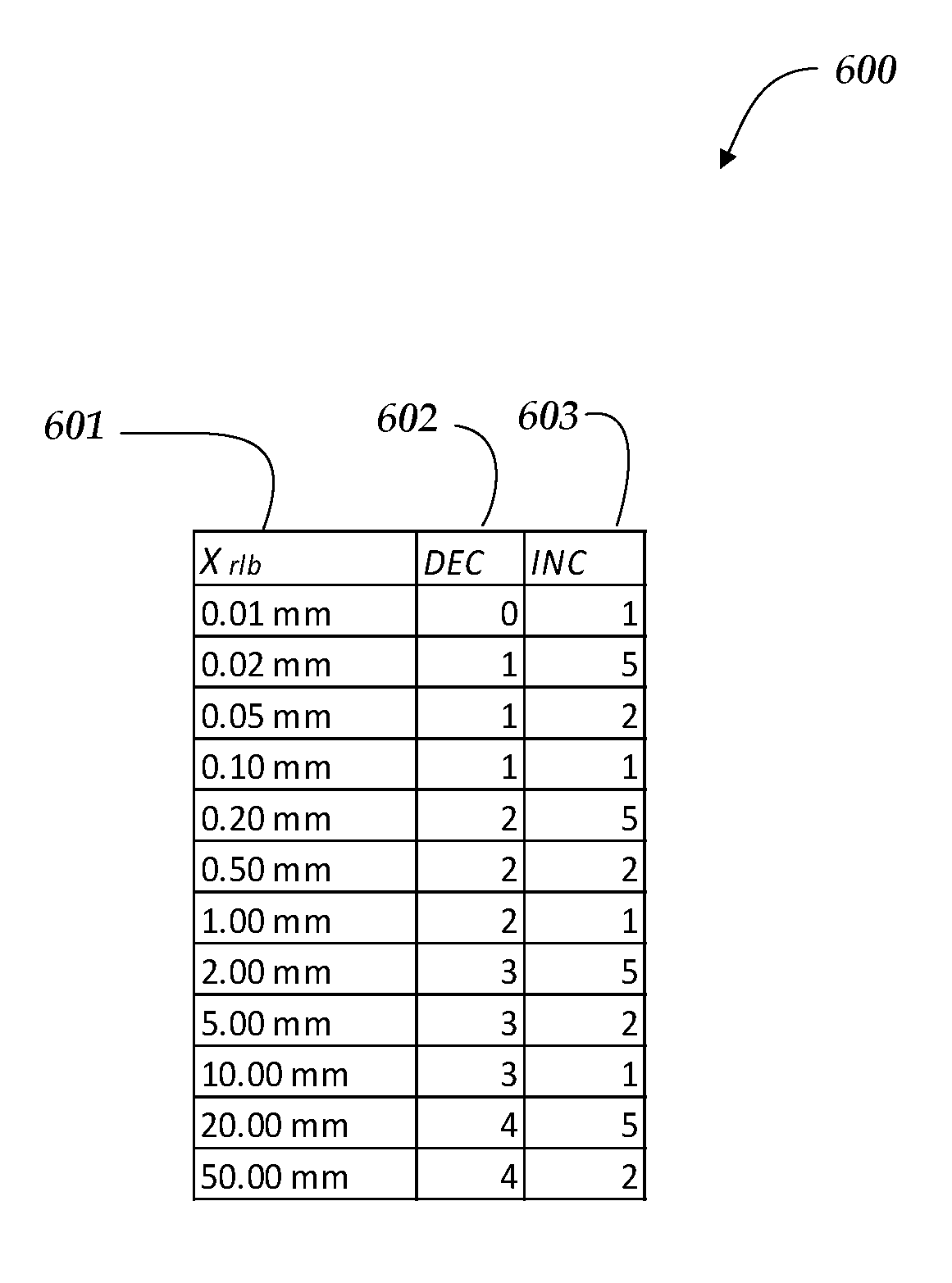

Display configuration for multimode electronic calipers having a ratiometric measurement mode

ActiveUS20110137967A1Flexible and simple and intuitively understoodImprove the display effectElectrical measurement instrument detailsElectrical testingImage resolutionMeasuring instrument

A multimode electronic measuring instrument is provided that includes a ratiometric mode of operation. During the ratiometric mode, a desired dimension is established as a stored reference dimension Xref. After the reference dimension is stored in memory, subsequent ratiometric measurement readouts will equal a current measurement distance Xcurr divided by the reference dimension Xref. A persistent number of decimal places used to the right of the decimal point as seen on a display is determined based on a current reference dimension Xref, an increment used for the least significant digit, and an internal measurement resolution of the multimode electronic measuring instrument.

Owner:MITUTOYO CORP

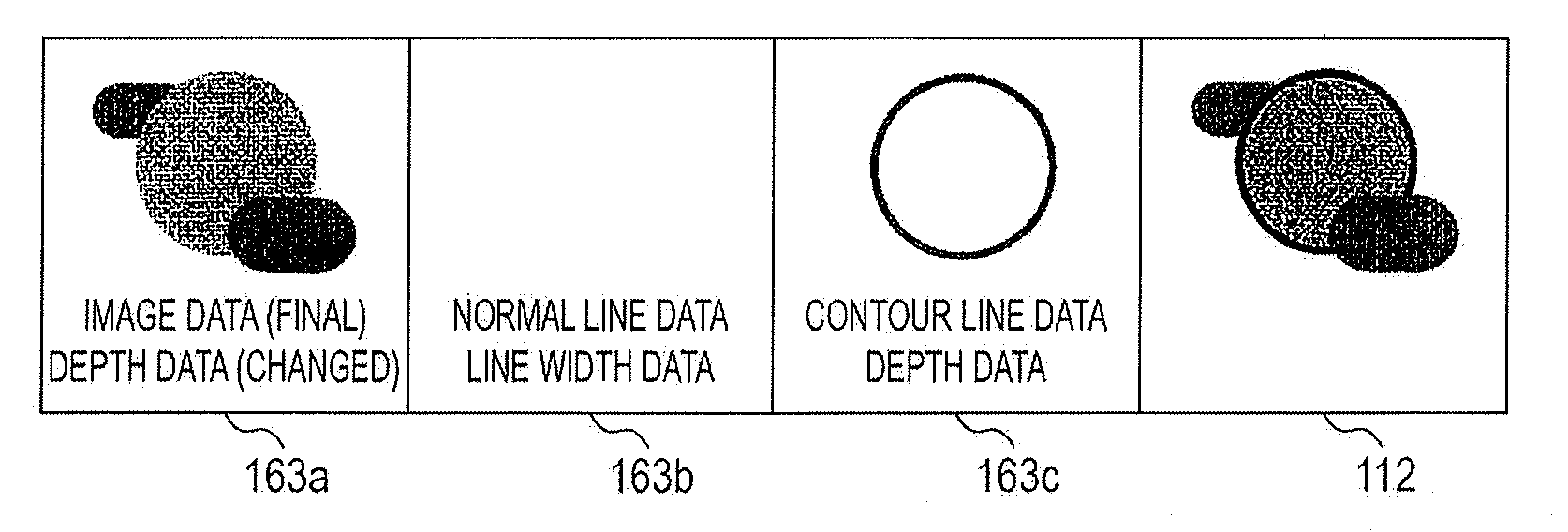

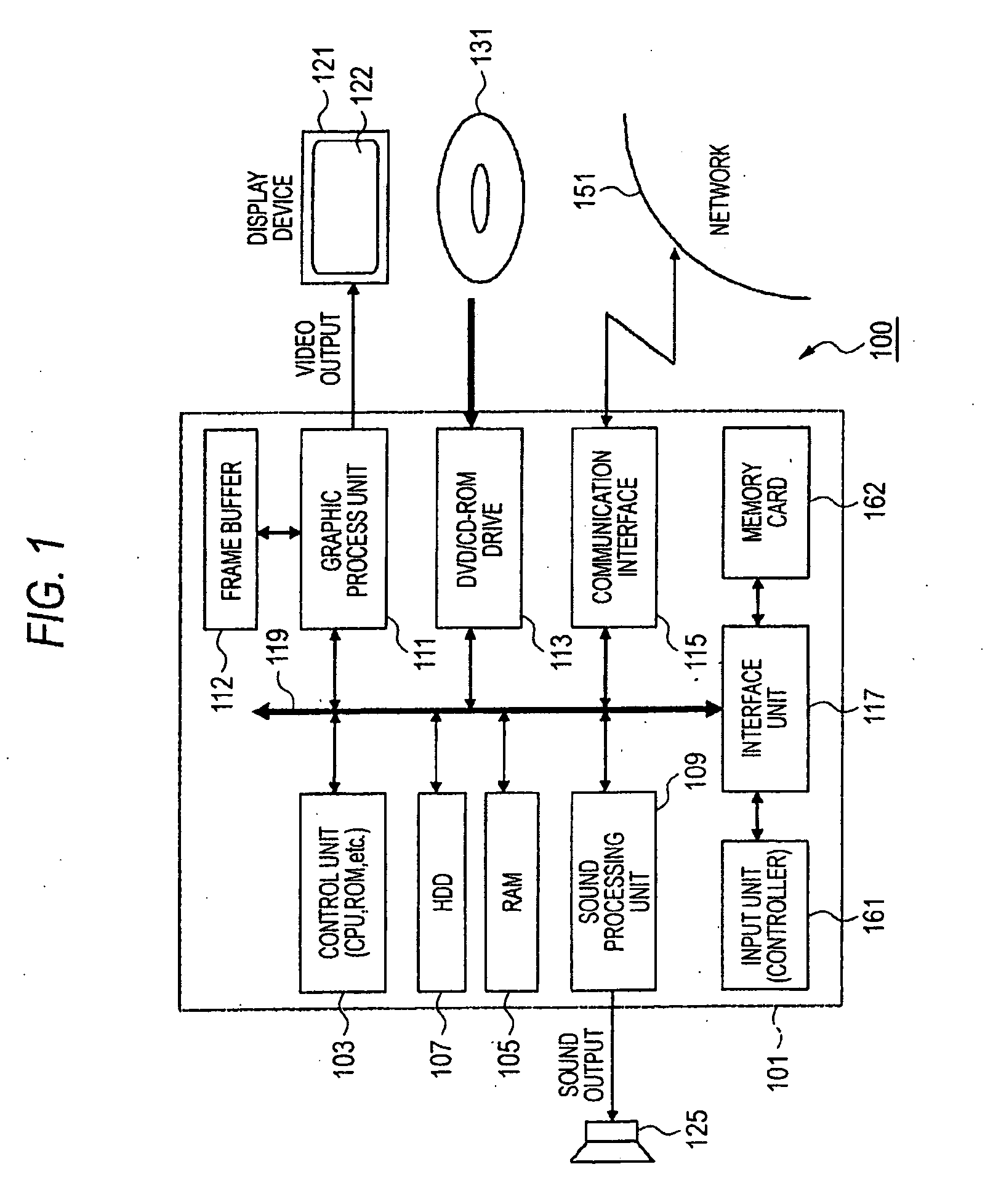

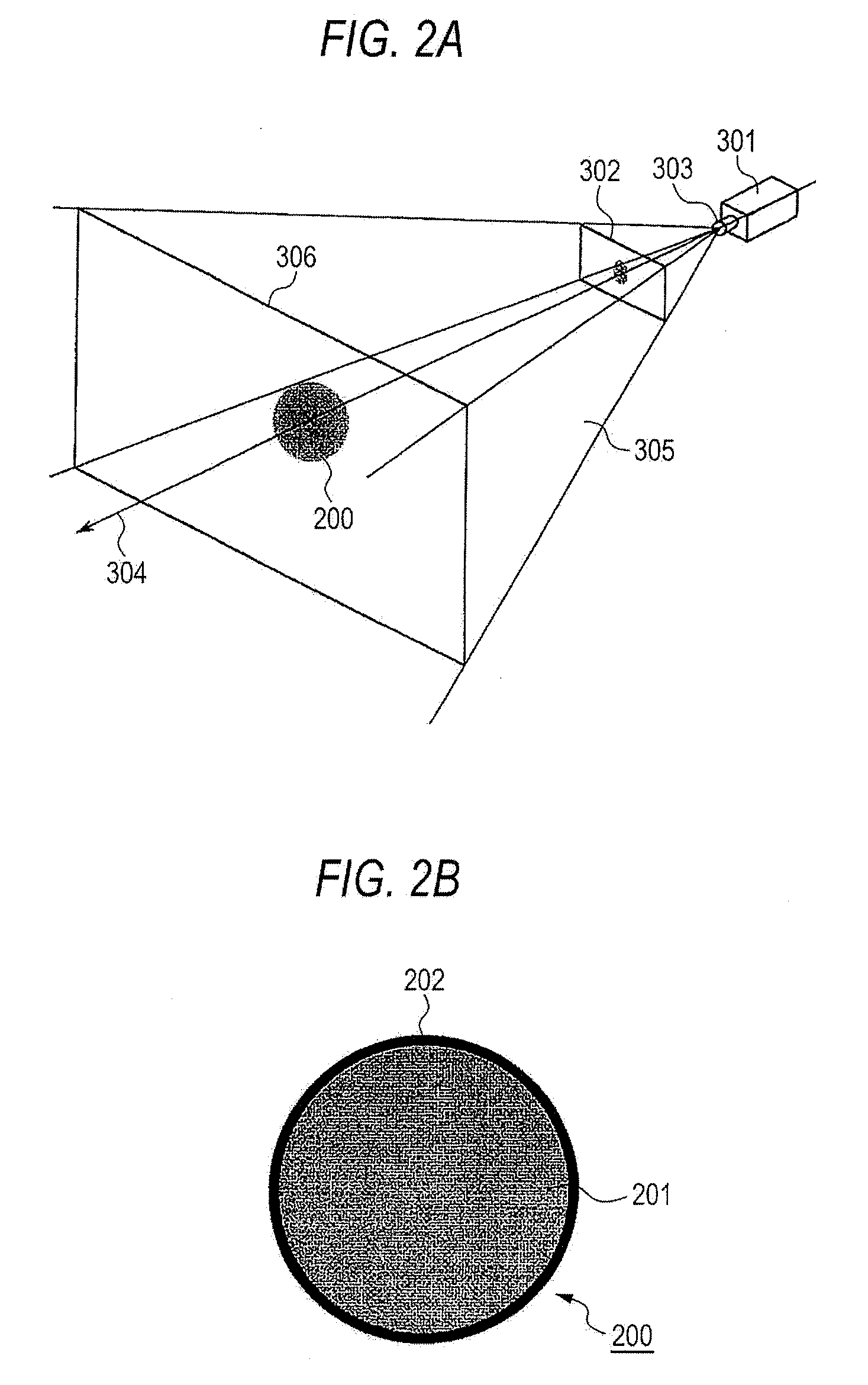

Image generating apparatus, method of generating image, program, and recording medium

ActiveUS20090027388A1Clear tune representationClear representationVideo games3D-image renderingThree-dimensional spaceVirtual screen

The object of the present invention is to draw a natural contour line in a tuned object and perform clear tuned representation. For each tuned object existing in a virtual three-dimensional space, a reference width 402 that is determined in accordance with a reference size of each tuned object projected on a virtual screen is set, assuming that a distance from a viewing point of a virtual camera (or a distance from the virtual screen) used for perspective transforming the virtual three-dimensional space is a predetermined reference distance Db. The line width W of the contour line of each tuned object is calculated by using an equation of “W=RNDUP (a×Eb×Db / D)” based on a distance D from the viewing point 303 to a reference point of each tuned object and coefficient “a” determined in accordance with the progress status of a game. Here, RNDUP is a function for rounding up the fractional part to the nearest integer.

Owner:SQUARE ENIX HLDG CO LTD

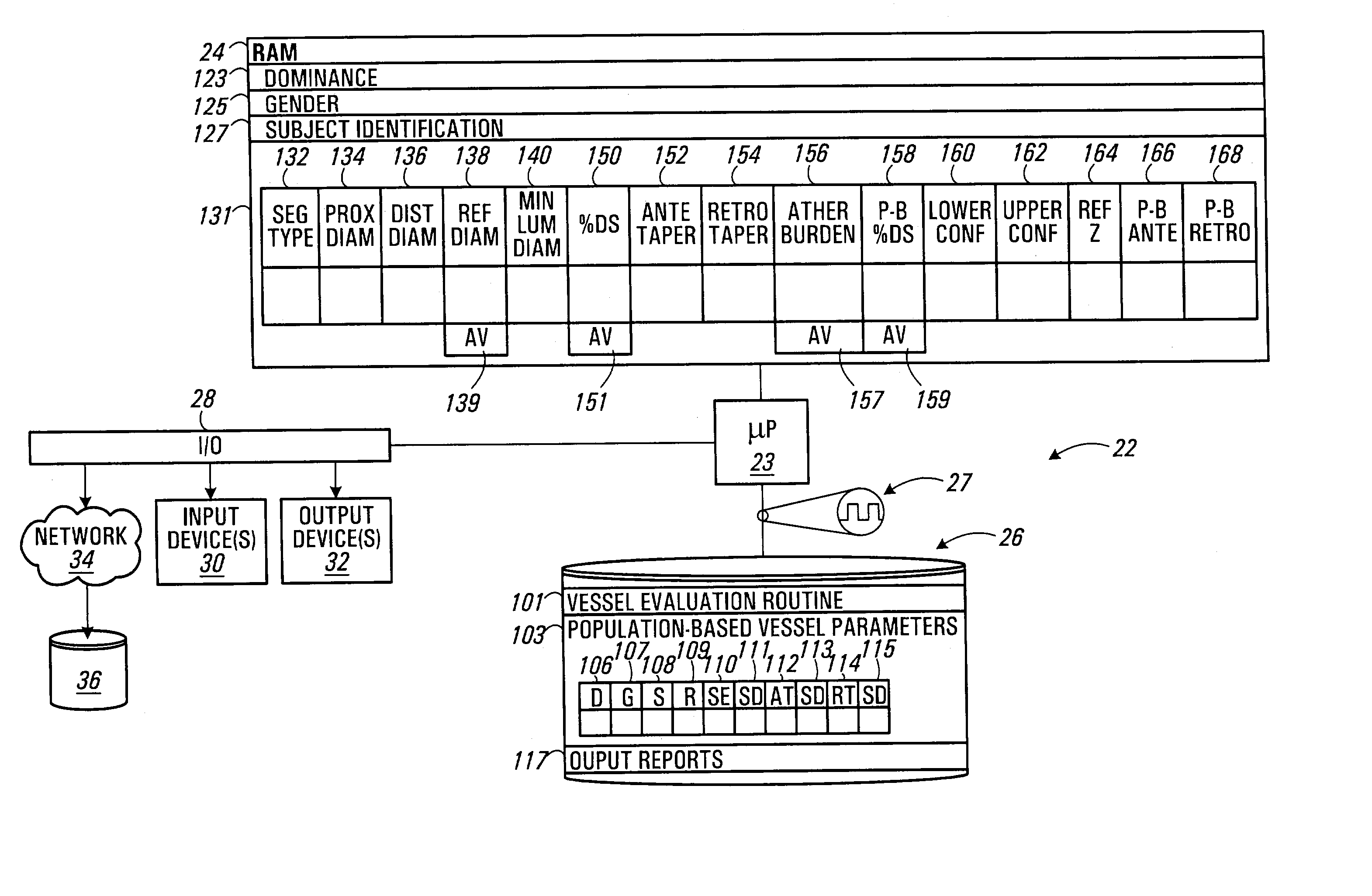

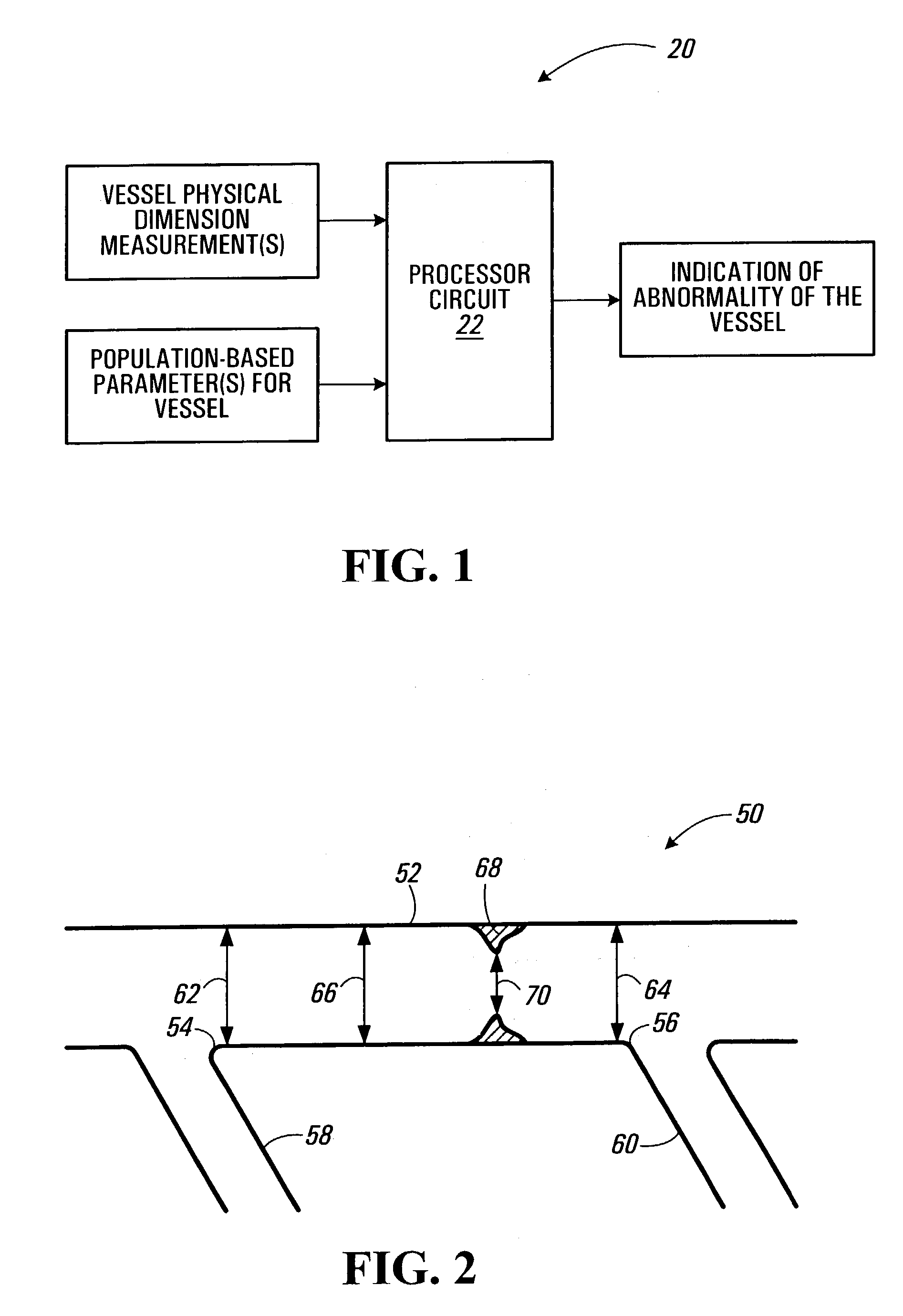

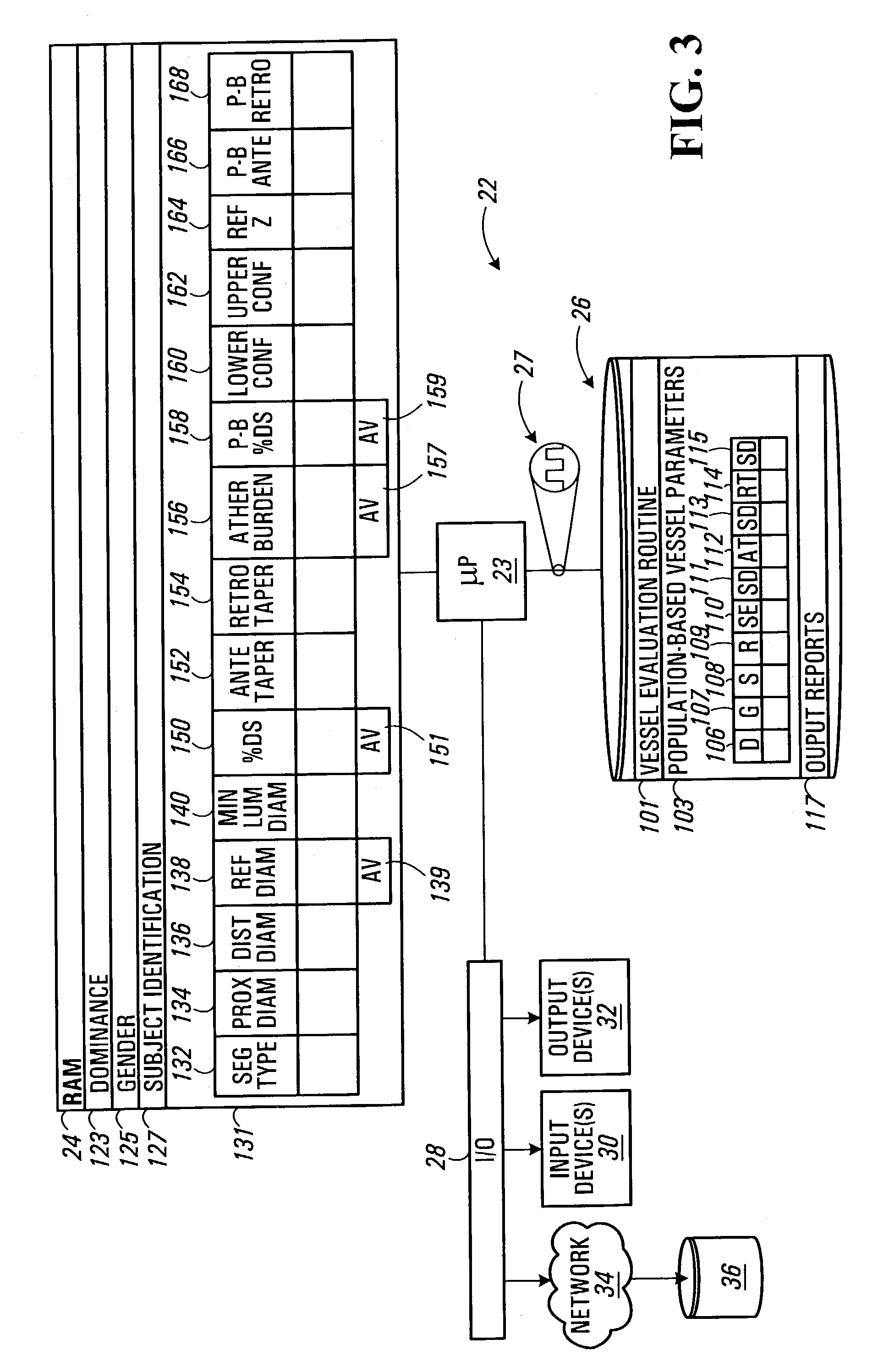

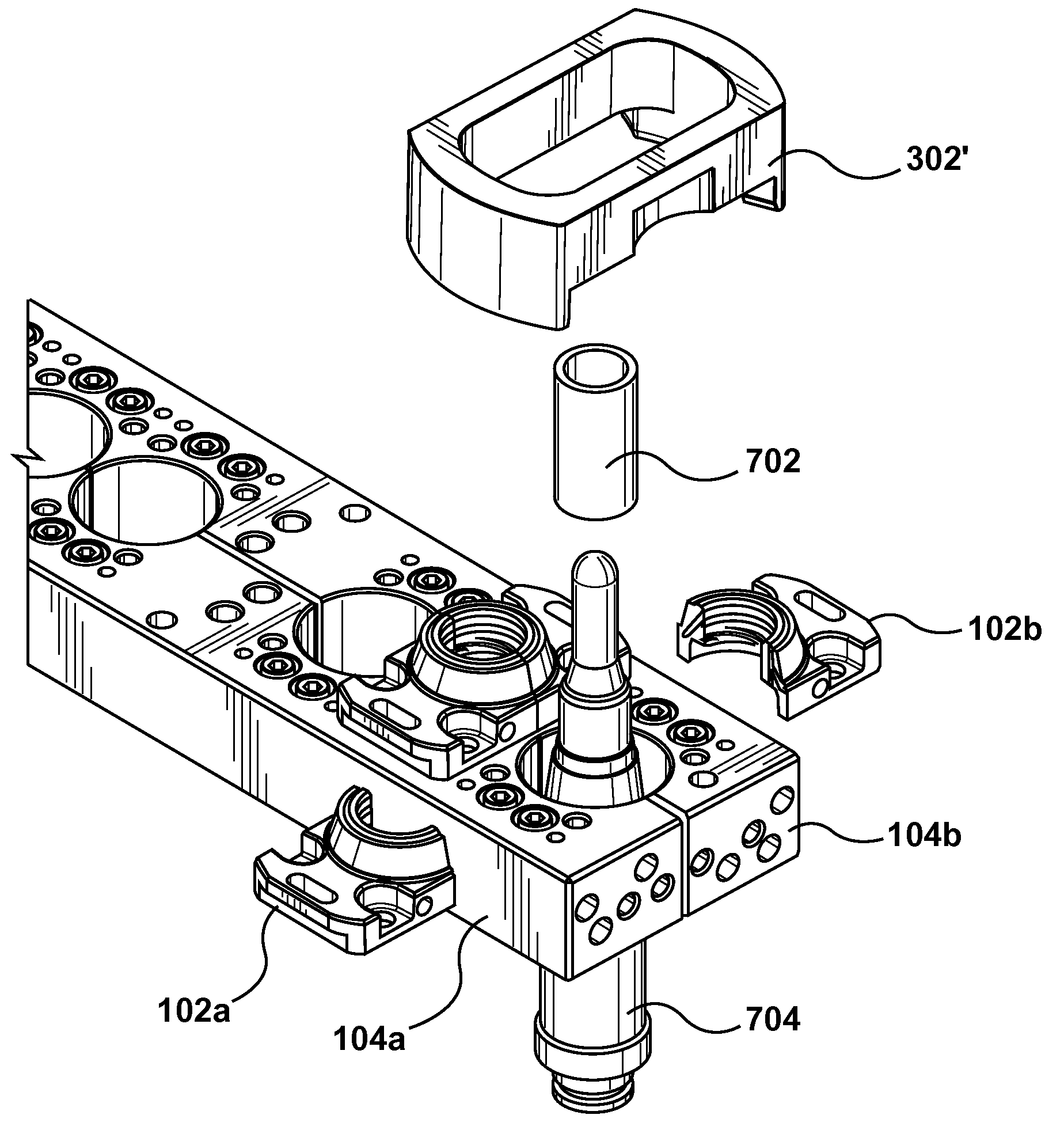

Vessel evaluation methods, apparatus, computer-readable media and signals

InactiveUS7165010B2Heart/pulse rate measurement devicesCatheterCoronary arteriesDimension measurement

Methods, apparatuses, media and signals for evaluating a vessel. One method includes receiving at least one measurement of a physical dimension of the vessel, and producing an indication of abnormality in the vessel, in response to the at least one received measurement and at least one population-based parameter for the vessel. Producing may include producing an indication of stenosis of the vessel, in response to the physical dimension measurement and a population-based reference dimension for the vessel. This may include producing a population-based percent stenosis value in response to a ratio of the physical dimension measurement to the population-based reference dimension. Producing may further include identifying a shape characteristic of the vessel, which may include producing a tapering comparison value in response to the tapering of the vessel and a population-based average tapering value. The vessel may include a coronary artery segment, for example.

Owner:THE UNIV OF BRITISH COLUMBIA

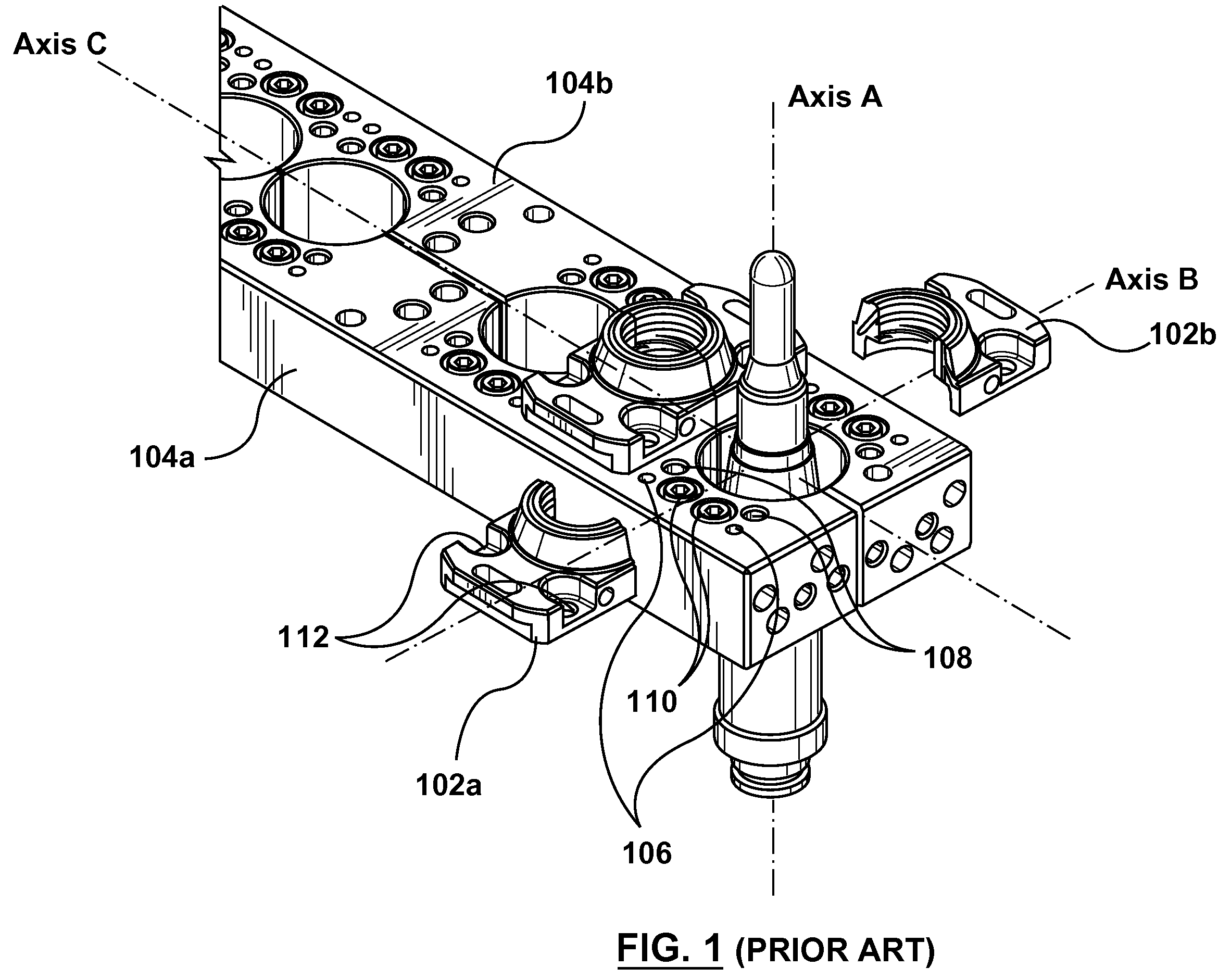

Split Mold Insert Positioning Device and a Method of Use

According to the embodiments of the present invention, there is provided a split mold insert positioning device and a method of use thereof. More specifically, a split mold insert positioning device is provided. The split mold insert positioning device comprises a split mold insert positioning interface dimensioned in a complementary arrangement to a reference dimension of a given split mold insert; and a tooling interface for providing access to the given split mold insert when the split mold insert positioning interface is positioned over the given split mold insert.

Owner:HUSKY INJECTION MOLDING SYST LTD

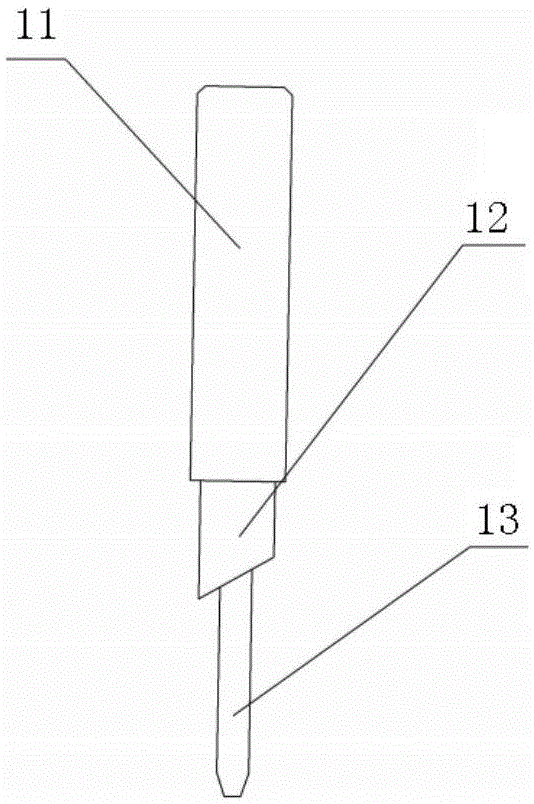

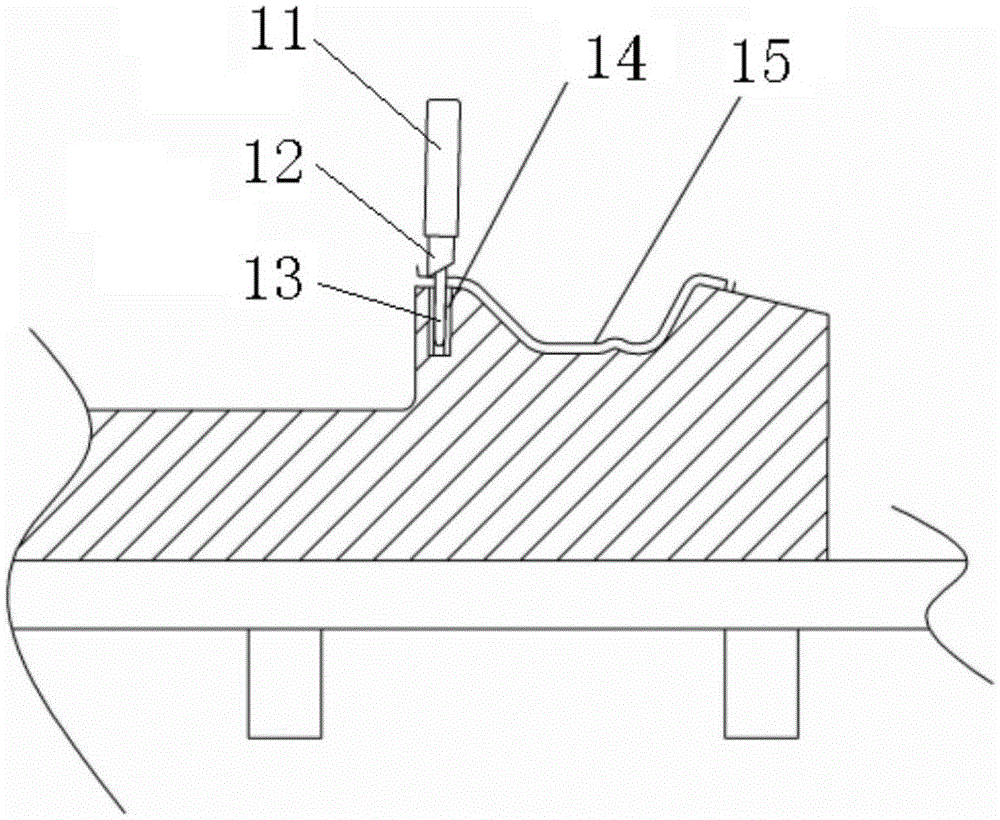

Detection equipment and stamped part non-circular hole detection pin thereof

InactiveCN105057397APrevent excessive displacementMetal working apparatusIndustrial engineeringOblique plane

The invention discloses detection equipment and a detection pin thereof. The detection pin comprises a handle, a body part and a scribing part. An oblique plane is formed at the end, facing a hole to be detected, of the scribing part, and a scribing sharp corner is formed through one end of the oblique plane. The body part sequentially comprises a connecting section, a rotating shaft section, a detection section and a guide section. The connecting section is fixedly connected with the handle. The scribing part is mounted on the rotating shaft section in circumferential rotating and axial sliding modes. The external diameter of the detection section is larger than the external diameter of the guide section, the shape of the outer contour of the detection section is the same as the reference shape of the hole to be detected, and the boundary dimension of the detection section is the same as the reference dimension of the hole to be detected. At least one anti-rotation plane is formed on the outer side wall of the guide section. In this way, hole site detection of non-circular holes is achieved. Due to the arrangement of the detection section, qualified parts can also be detected in time. Compared with the prior art, piece-by-piece scribing calculation is needless, so that the detection process is simplified, hole sites can be recognized rapidly, and working efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

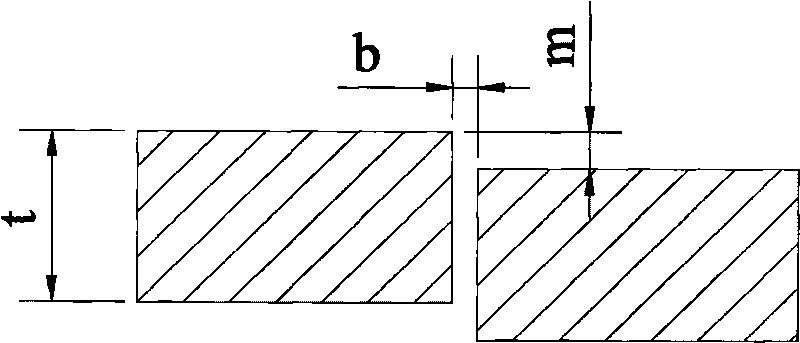

Plasma-arc welding method of cupronickel with thickness of 2-20 mm

InactiveCN101758326AImprove quality and efficiencyIncrease productivityArc welding apparatusPlasma welding apparatusCupronickelPass rate

The invention relates to a plasma-arc welding method of cupronickel with the thickness of 2-20 mm, comprising the following steps of: measuring divided edge reference dimension and adopting a welding mode; setting parameters before welding; and setting process parameters in a welding process, wherein a divided edge includes an I-shaped divided edge and a U-shaped divided edge; the welding mode includes downward welding and horizontal welding or vertical welding; the process parameters in the welding process are set by selecting different welding currents, welding voltages, welding speeds and wire feed speeds according to different thicknesses of the cupronickel plates; protective gases are all pure argon; plasma gas flow rate is not less than 3-10 L / min; and welding gun gas flow rate is not less than 15-25 L / min. The invention has the advantages of stable welding process, high welding efficiency and welding seam qualification rate and good welding seam quality and outstanding economic benefit, and can effectively enhance the welding quality and the production efficiency of cupronickel materials.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Image processing apparatus and method for determining the volume of timber in a stack of logs

InactiveUS20190003829A1Fast and easy to useData easilyUsing optical meansMechanical measuring arrangementsComputer scienceStandardization

A system for determination of the volume of a stack of logs comprises digital image acquisition of a stack end with a known reference dimension, image display and image recognition for determination of the total volume of timber. Volume is determined by image analysis routines for detecting the end of each log in the digital image and overlying circles substantially coincident with each detected log end on the digital image. An operator may manually adjust or vary the circles on an interactive screen. The areas of each overlaid circle is calculated and total volume is determined factoring in a standardized log length and stratification data entered by the operator.

Owner:TIMBETER OU

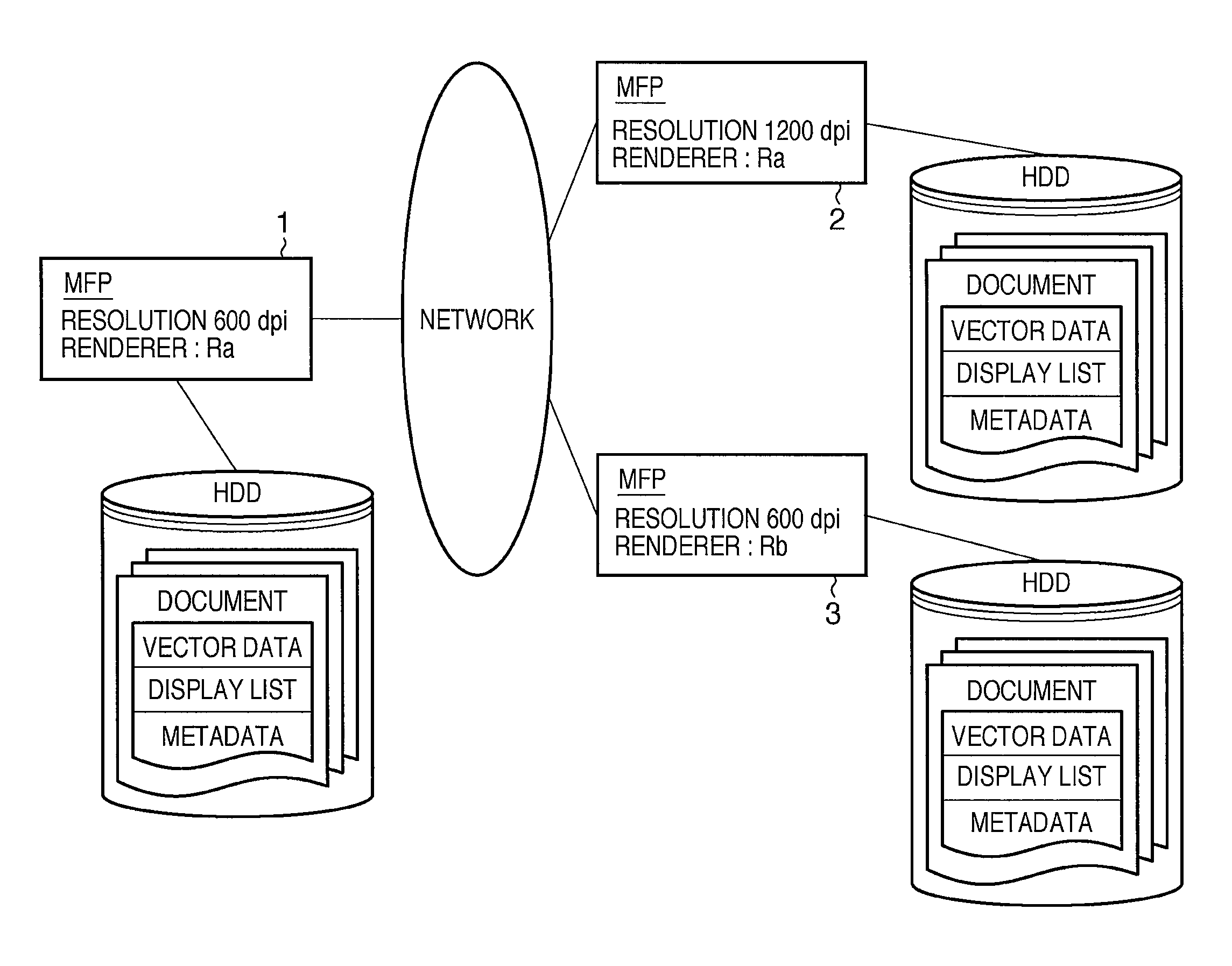

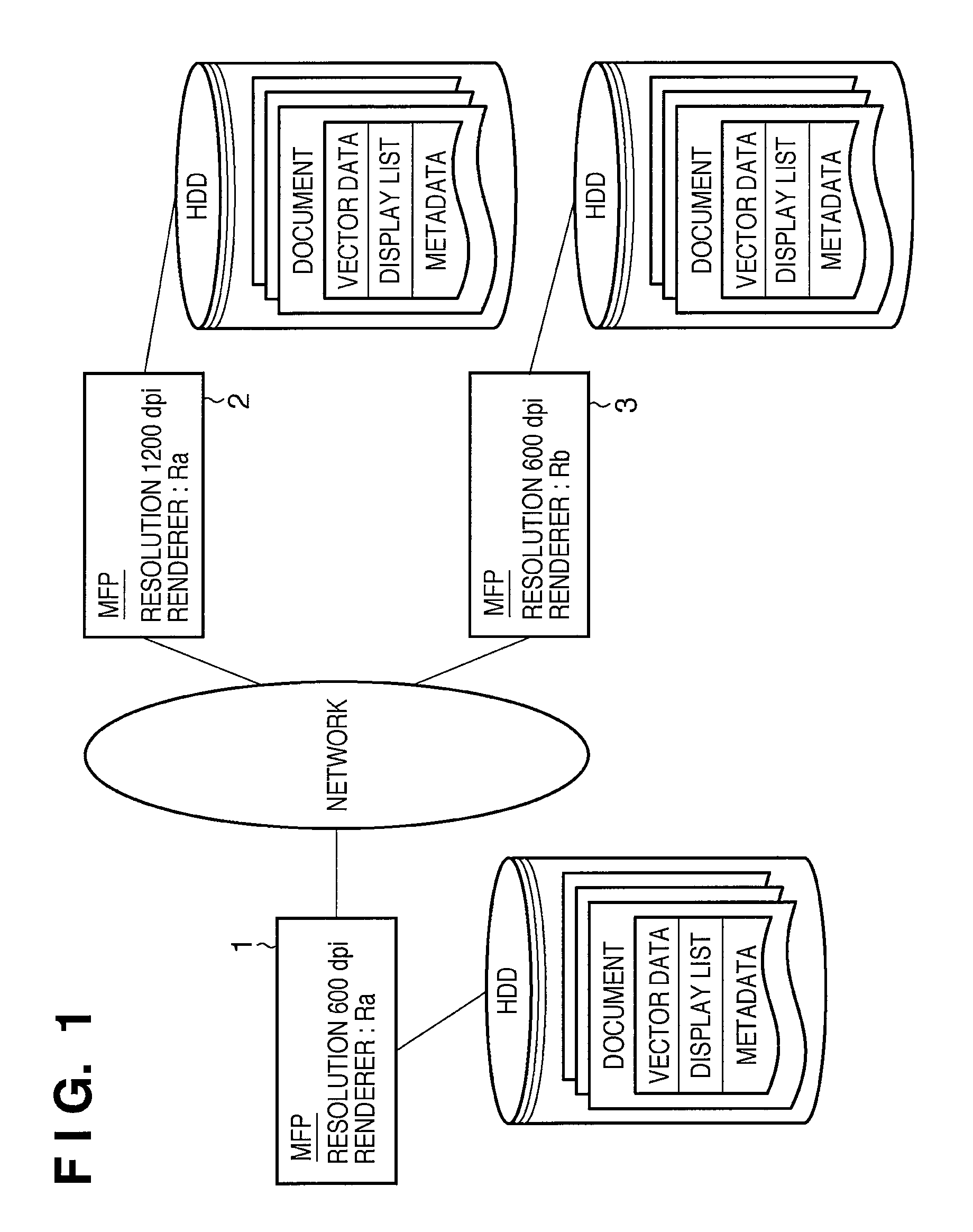

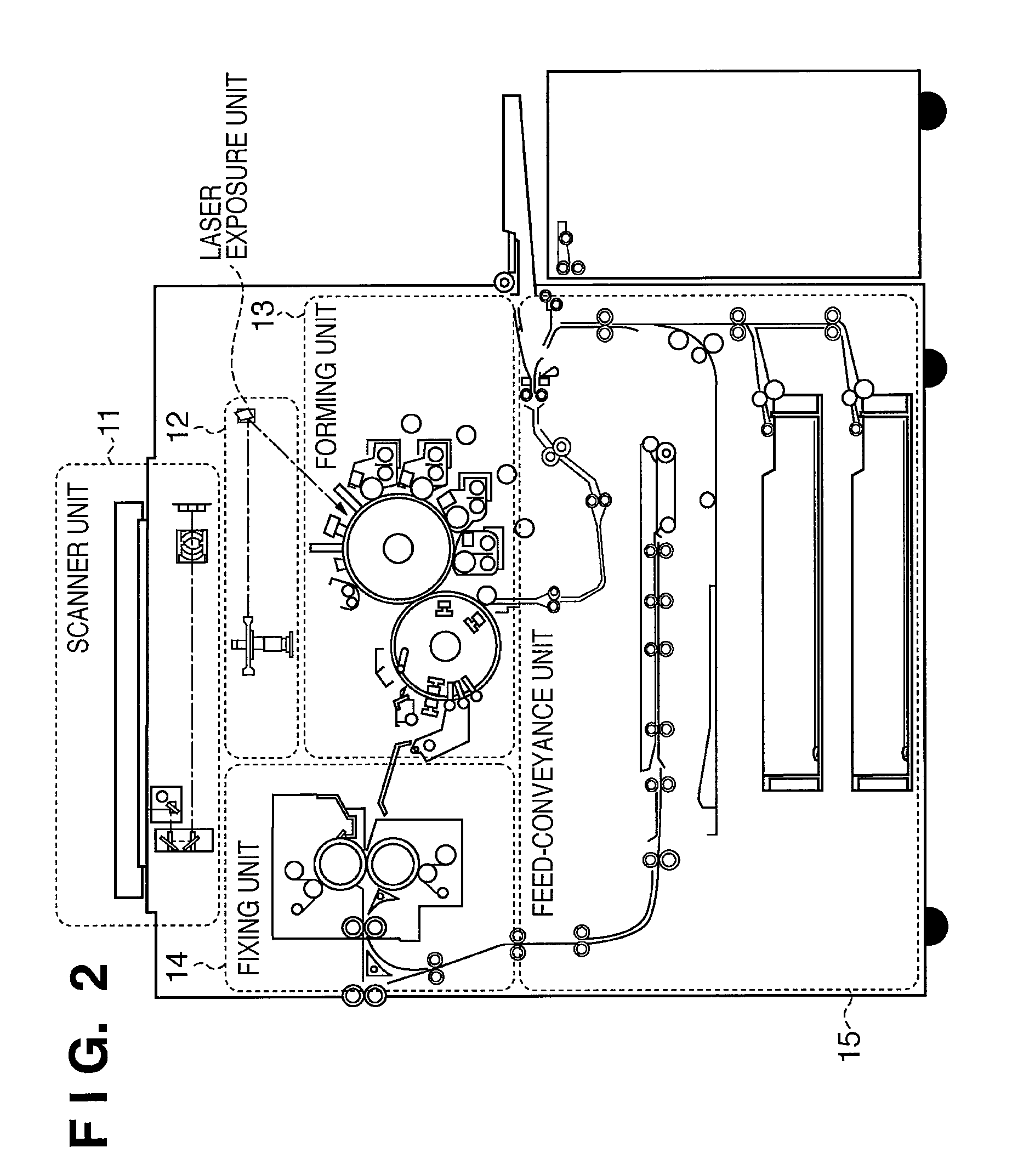

Image processing apparatus and image processing method

InactiveUS8185504B2Improve search speedDigital data processing detailsVectoral format still image dataImaging processingSize determination

Owner:CANON KK

Gear casting mold

The invention discloses a gear casting mold, which comprises a cylindrical cast seat, a toothlike casting and a gear reducer casting mold, wherein a cylindrical groove is formed in the central axis of the cylindrical cast seat; a convex cylinder is arranged in the cylindrical groove; the cylindrical groove is a stepped hole; the toothlike casting is an inner gear ring casting mold; the gear reducer casting mold is annular; teeth are arranged at two side end parts of the gear reducer casting mold; teeth at one side surface are completely meshed with inner wall teeth of the toothlike casting; teeth at the other side surface are different from the toothlike casting in dimension and shape. By virtue of the technical scheme, a reference dimension gear can be cast through the cylindrical groove in the cylindrical cast seat, the convex cylinder and the toothlike casting; if the tooth shape of the gear and the gear dimension need to be changed, only the proper gear reducer casting mold needs to be put on the inner tooth surface of the toothlike casting; one end of the gear reducer casting mold is completely meshed with the toothlike casting; and the needed toothlike casting is arranged at the other end of the gear reducer casting mold, so that another gear can be directly cast, and further waste of the cast mold is avoided.

Owner:DALIAN ORIENT METAL

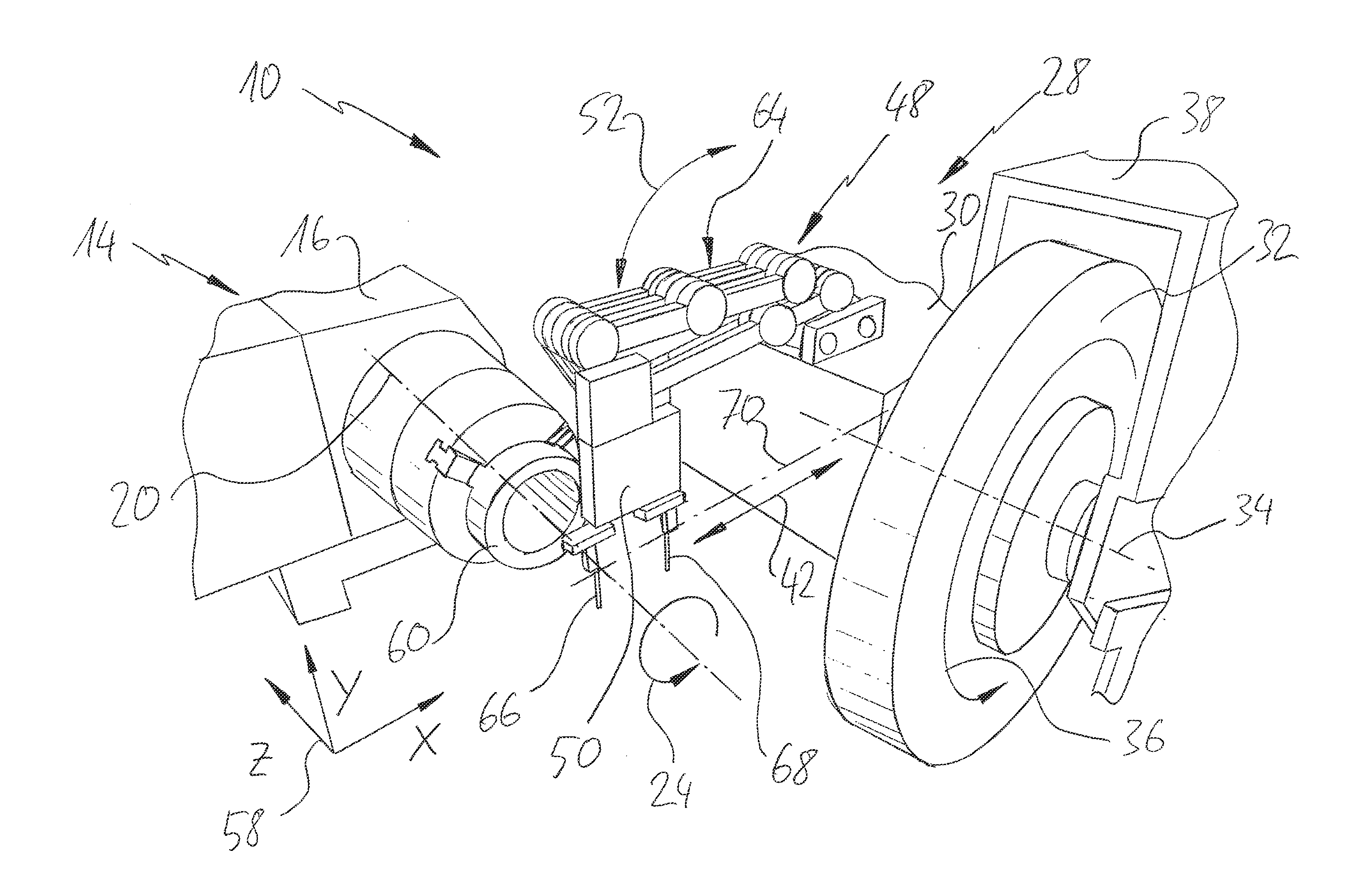

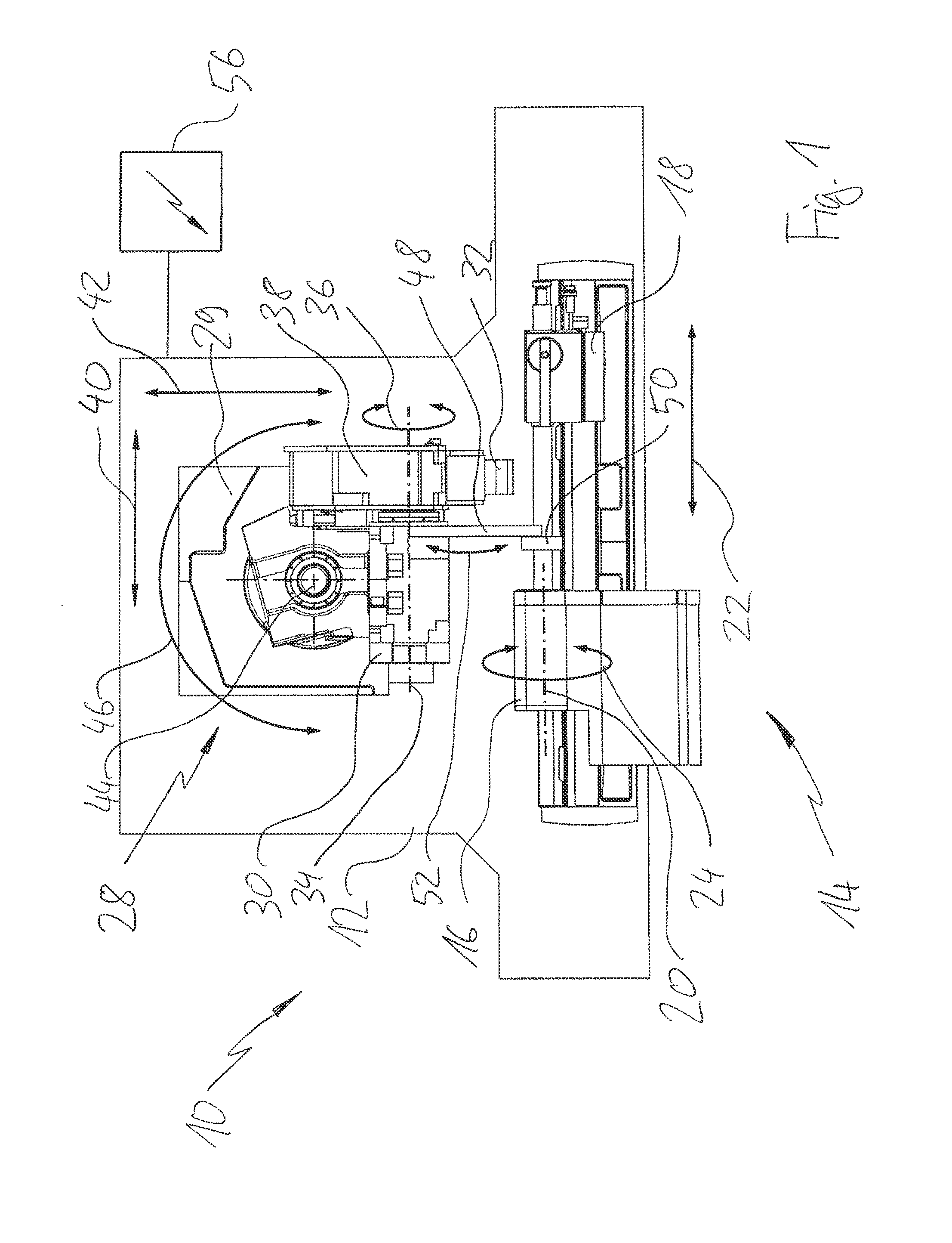

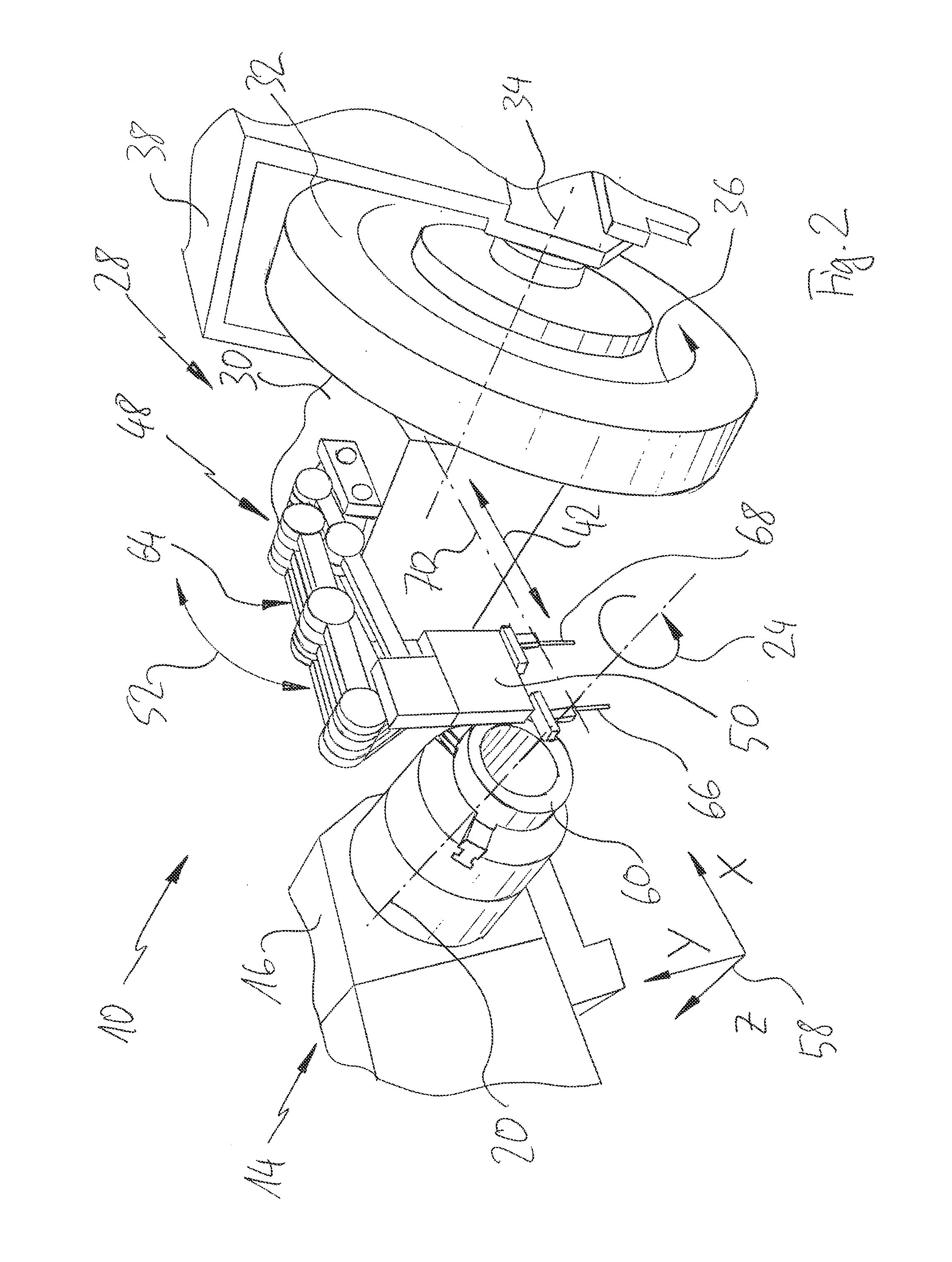

Machine tool and method for measuring a workpiece

InactiveUS20140213148A1Good flexibilityOptimizationRevolution surface grinding machinesMeasurement/indication equipmentsMachine toolElectrical and Electronics engineering

The present disclosure relates to a machine tool, in particular a grinding machine, and to a method for measuring a workpiece, in particular a workpiece diameter, in a machine tool, in particular a grinding machine, which comprises a workpiece mount, a tool unit, a measuring device and a control device which is connectable to the measuring device and the tool unit, wherein the measuring device is accommodated on the tool unit and comprises at least two measuring probes, wherein in a measuring configuration the at least two measuring probes are spaced apart by a basic spacing which defines a measurement region, wherein the basic spacing is selected to be greater than a known reference dimension, wherein the control device is configured for acquiring values detected by way of the at least two measuring probes, of detecting an actual position of the tool unit, and, on the basis of a displacement path of the tool unit when probing a workpiece which is moved into the measurement region, of determining an actual spacing, in particular an actual diameter, with consideration to the reference dimension and / or the basic spacing.

Owner:FRITZ STUDER AG

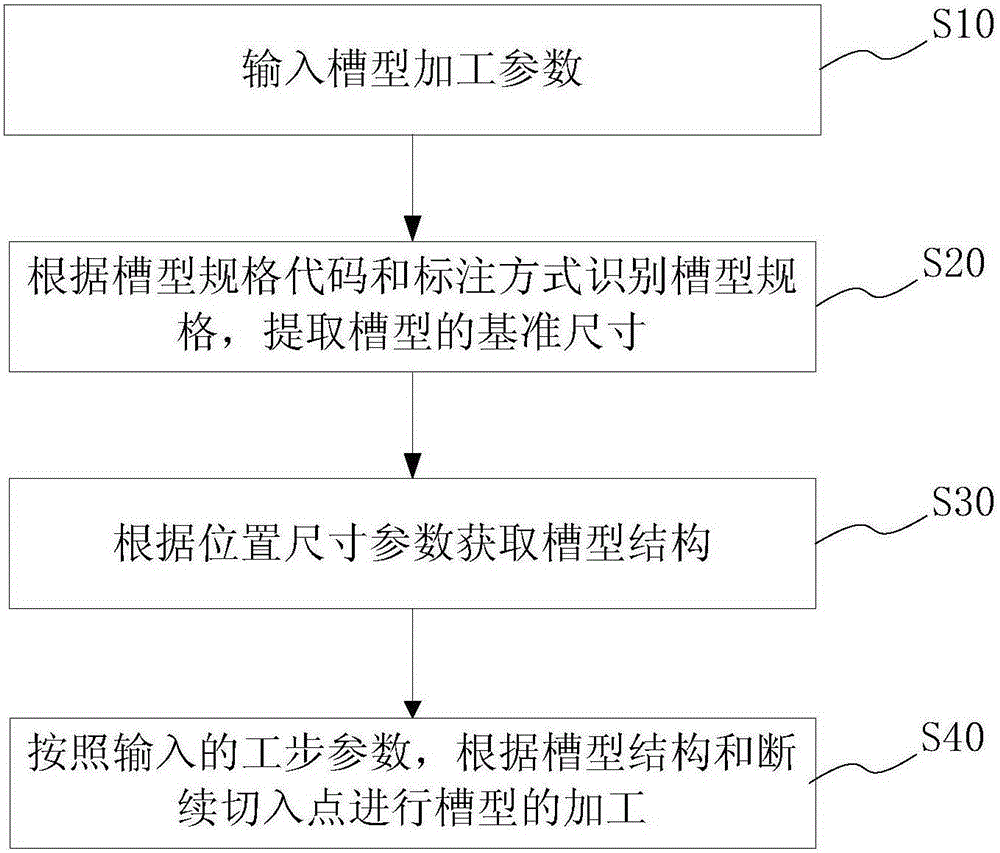

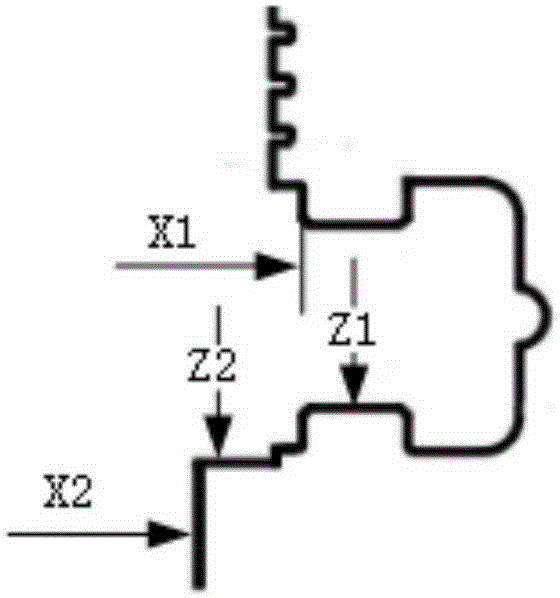

Trench type processing method and system

InactiveCN106557071AAchieve full coverageImprove programming efficiencyProgramme controlComputer controlNumerical controlEntry point

The present invention provides a trench type processing method and system. The trench type processing method and system are applied to a numerical control machine tool, and the trench type processing method comprises: inputting trough type processing parameters, wherein the trough type processing parameters include trough type specification codes, a label mode, process step parameters, position size parameters and interruption entry points; identifying the trench type specification according to the trench specification codes and the label mode, ands extracting the reference dimension of the trench type in the reference dimension bank, wherein the reference dimension in the reference dimension bank is preset according to the trench type specification; obtaining the trench type structure according to the position size parameters; and performing processing of the trench type according to the input process step parameters, the trench type structure and the interruption entry points. The trench type processing method and system greatly improve the programming efficiency, reduce the artificial programming error probability, and are high in universality, high in standardization degree, high in automation degree and high in working accuracy.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

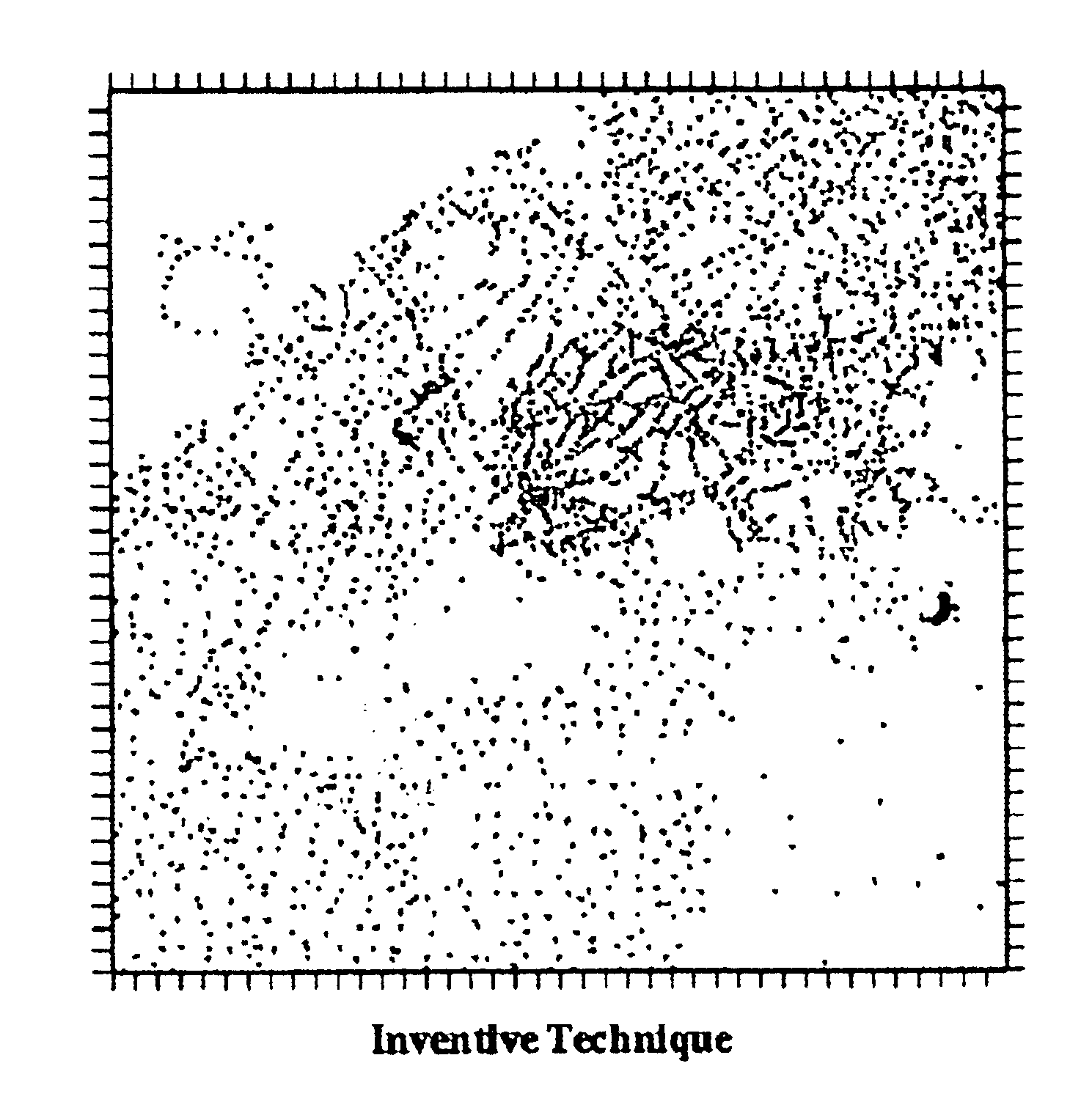

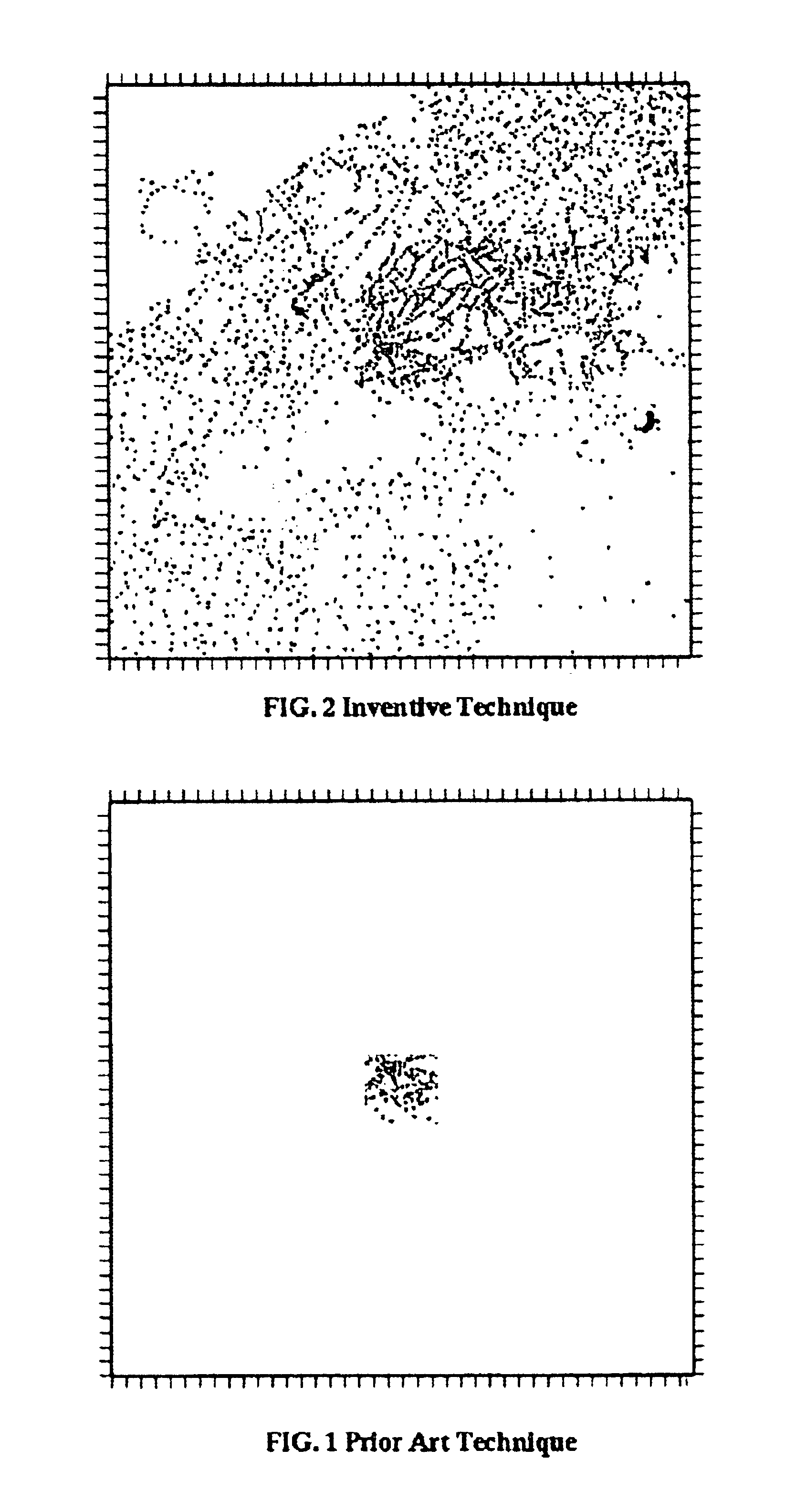

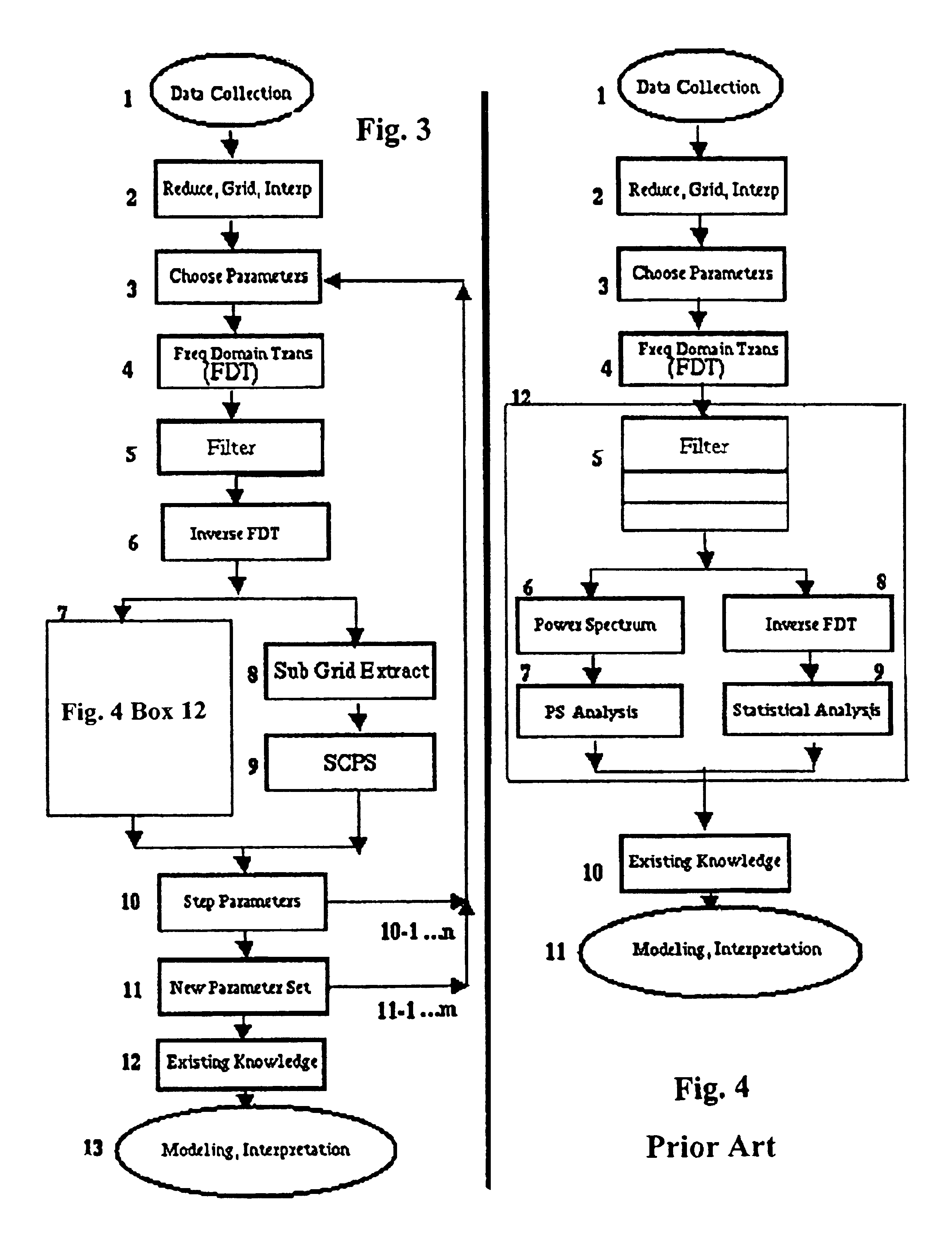

Method for enhancing depth and spatial resolution of one and two dimensional residual surfaces derived from scalar potential data

InactiveUS7043366B2Seismic signal processingElectric/magnetic detectionScalar potentialReference Region

An improved method is disclosed for collecting or assembling scalar potential data measurements that are to be subsequently prepared as a surface representation for analysis via frequency domain transform filters. Measurements are made over a geographic reference region which extends in all cardinal directions from the center of some previously determined primary region. The reference dimensions must contain the primary region and must be plural multiples of the greatest depth to be considered in analyzing the contributions to the measurements. A combined or separate improved method for delineating or defining geospatial information contributing to a scalar potential surface is disclosed. This method is implemented using traditional statistical techniques to construct an histogram from the set of values comprising a surface representation. This histogram constitutes a Spatially Correlated Potential Spectrum for the surface. These combined and separate methods improve resolution of geological structures over depths and spatial extents under consideration.

Owner:MCDERMOTT ANDREW MARTIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com