Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Lambda-Carrageenan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carrageenans are a family of hydrocolloids used to thicken, stabilize and gel solutions. They are vegetarian and particularly effective with proteins so they are commonly used with dairy products. There are three basic types: Iota Carrageenan, Kappa Carrageenan and Lambda Carrageenan.

Stabilizer System For Food And Beverage Products

A stabilizer system comprising blends of cellulose, lambda-carrageenan, and guar gum. Food products and beverages, such as energy drinks, are prepared with the stabilizer blends.

Owner:PEPSICO INC

Stabilizer System For Food And Beverage Products

A stabilizer system comprising blends of cellulose, lambda-carrageenan, and guar gum. Food products and beverages, such as energy drinks, are prepared with the stabilizer blends.

Owner:PEPSICO INC

Antiallergic marine biopolymers

ActiveCN102065869ABreathe easier and more easilyOrganic active ingredientsSenses disorderDiseaseAllergic condition

The present invention relates to pharmaceutical compositions based on carrageenan as an active ingredient, for use as a medicament in the prophylactic or therapeutic treatment of allergic conditions or diseases, with the proviso that the carrageenan comprises iota- and / or kappa-carrageenan and is substantially free of lambda carrageenan. Typically, the invention relates to liquid formulations, gels and dry powder compositions comprising iota- and / or kappa-carrageenan and, optionally, one or more non-carrageenan therapeutic agents for administration to the respiratory tract, the gastrointestinal tract or the eyes. The compositions of the invention have been found to be efficacious in the prevention and treatment of type I allergies and additionally, may exert an adjuvant function upon combined mucosal administration with non-carrageenan therapeutic agents.

Owner:MARINOMED BIOTECHNOLOGIE GMBH

Dentifrice composition

ActiveCN1988876AGood dispersionAppropriate grinding forceCosmetic preparationsToilet preparationsXanthomonas campestrisKappa-Carrageenan

A dentifrice composition which comprises (A) heavy calcium carbonate having a mean particle diameter of 5 to 15 m, (B) water-insoluble inorganic granules having a collapse strength of 10 to 200g / granule, a mean particle diameter of 50 to 150 m, and a difference of 100 m or below between 90% particle diameter and mean particle diameter, and (C) a water-soluble polymeric material comprising at least one member selected from Group (a) and at least one member selected from Group (b) at a (b) / (a) mass ratio of 0.25 to 3, Group (a): sodium alginate, sodium carboxymethylcellulose, methylcellulose, hydroxyethylcellulose, Xanthomonas campestris, lambda-carrageenan, and straight-chain sodium polyacrylate, and Group (b): gellan gum, agar, kappa-carrageenan, iota-carrageenan, gelatin, pectin, and crosslinked sodium polyacrylate, and which has a total content of (a) and (b) of 0.5 to 1.5% by mass based on the whole of the composition.

Owner:LION CORP

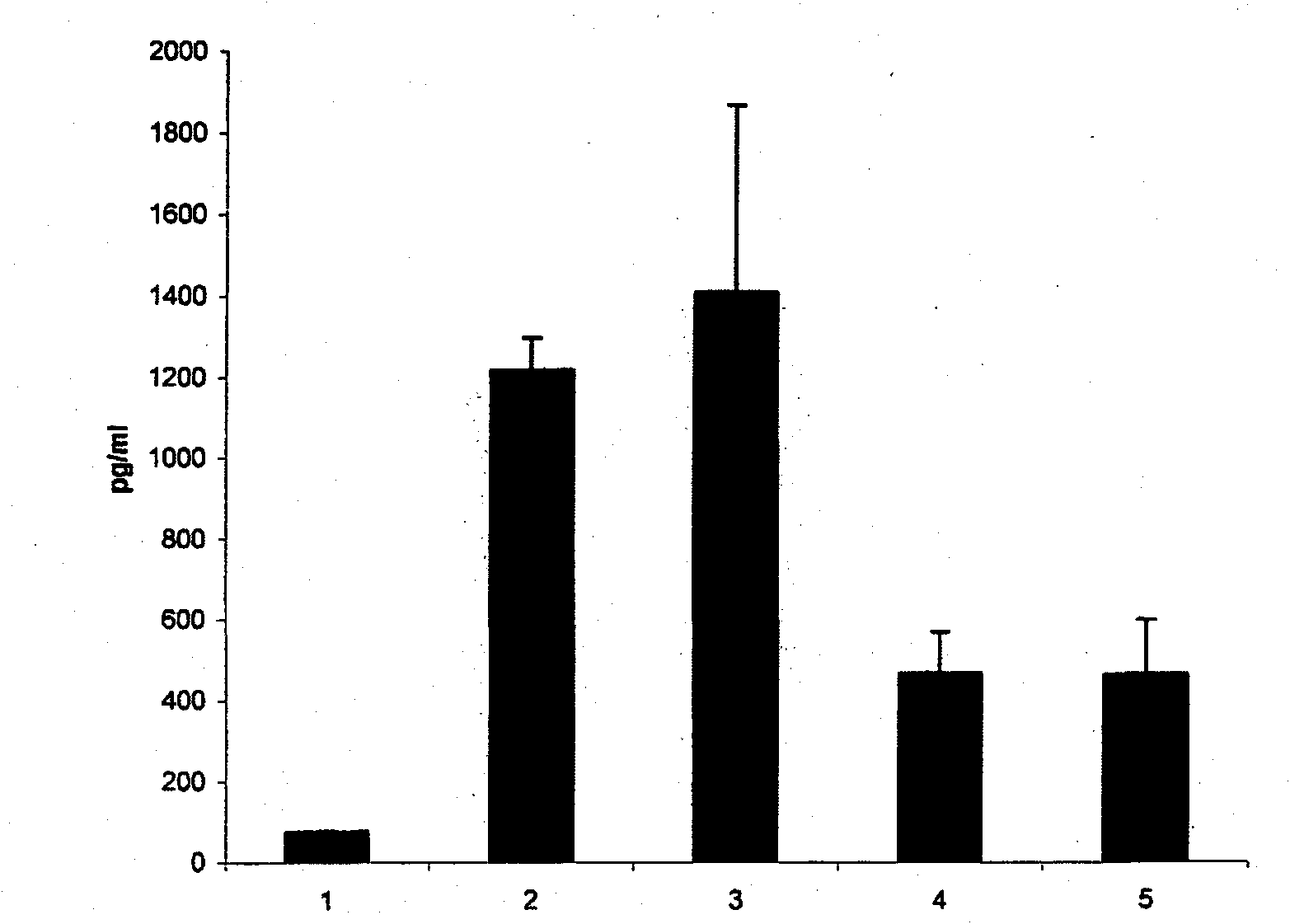

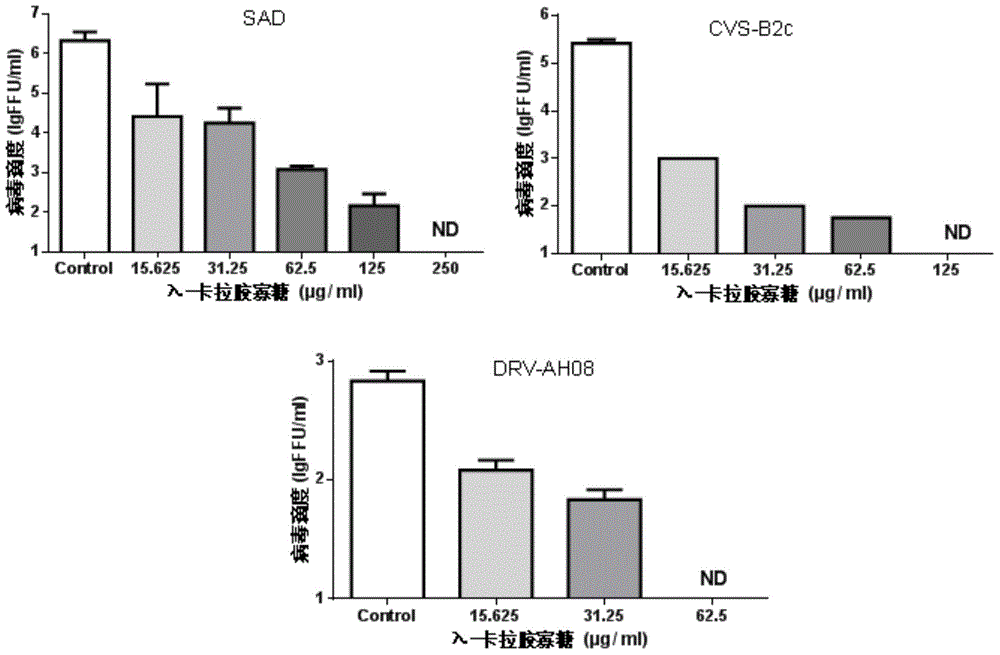

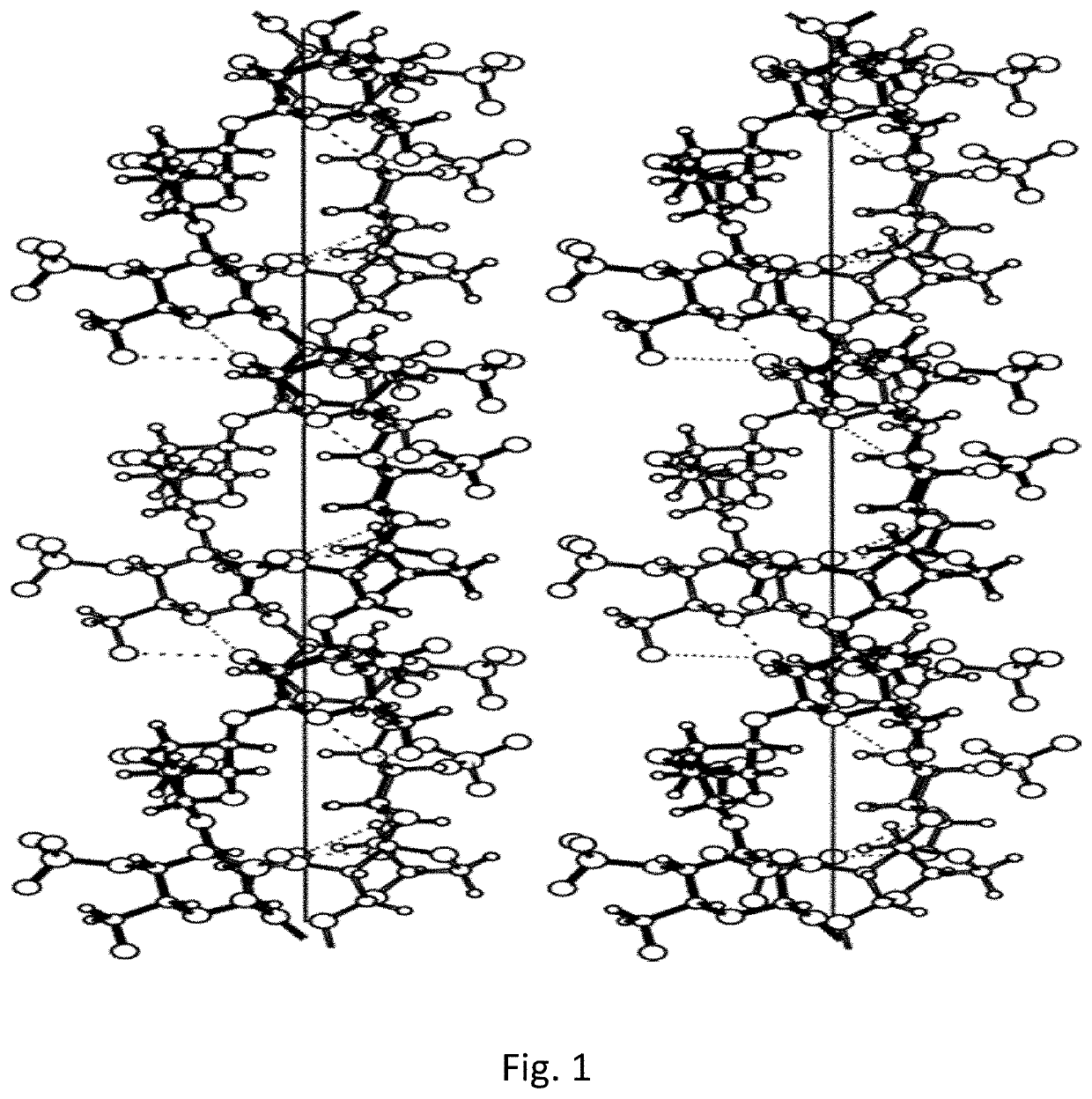

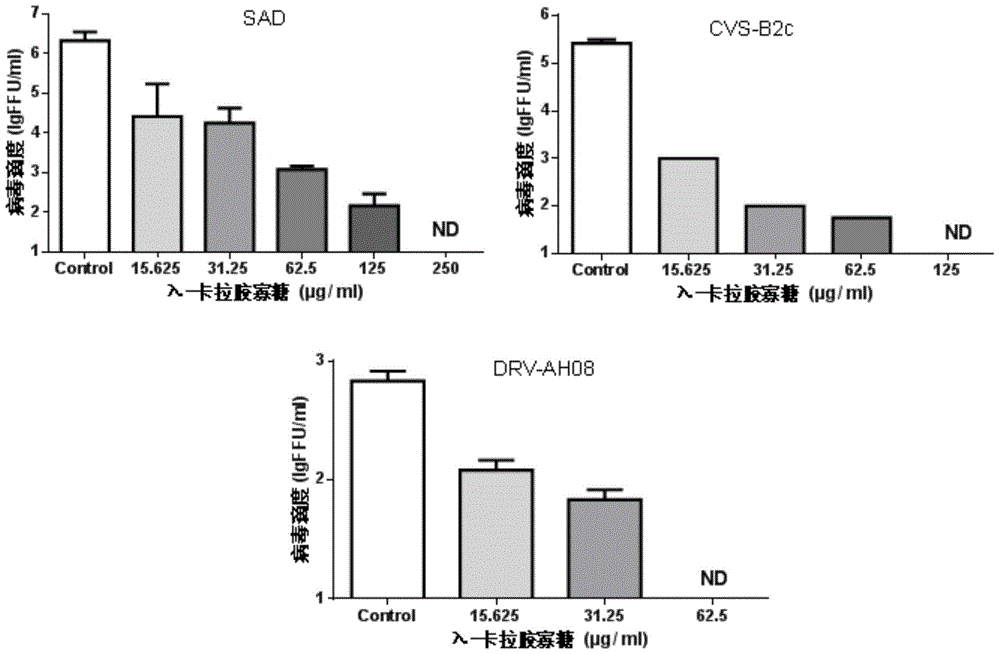

Application of lambda-carrageenan oligosaccharide to preparation of anti-rabies virus drug

ActiveCN104546895AInhibit RABVProlong the effective timeOrganic active ingredientsAntiviralsCytotoxicityPhases of clinical research

The invention discloses an application of lambda-carrageenan oligosaccharide to preparation of an anti-rabies virus drug. Experiments prove that the lambda-carrageenan oligosaccharide is low in cytotoxicity so that rabies viruses of various strains can be inhibited on various types of cells and inhibition effect is provided to each stage of the rabies viruses invading the cells; and particularly in the stage after virus adsorption, namely, 12 hours after the cells are infected by the viruses, the lambda-carrageenan oligosaccharide is still capable of remarkably decreasing the rabies virus amount in the cells. According to above discovery, the lambda-carrageenan oligosaccharide can be used as a low-cost effective wound treating agent to replace the anti-rabies virus immune globulin, and has the advantages of decreasing the viruses at the wound part to the greatest extent and reducing the rabies morbidity.

Owner:HUAZHONG AGRI UNIV

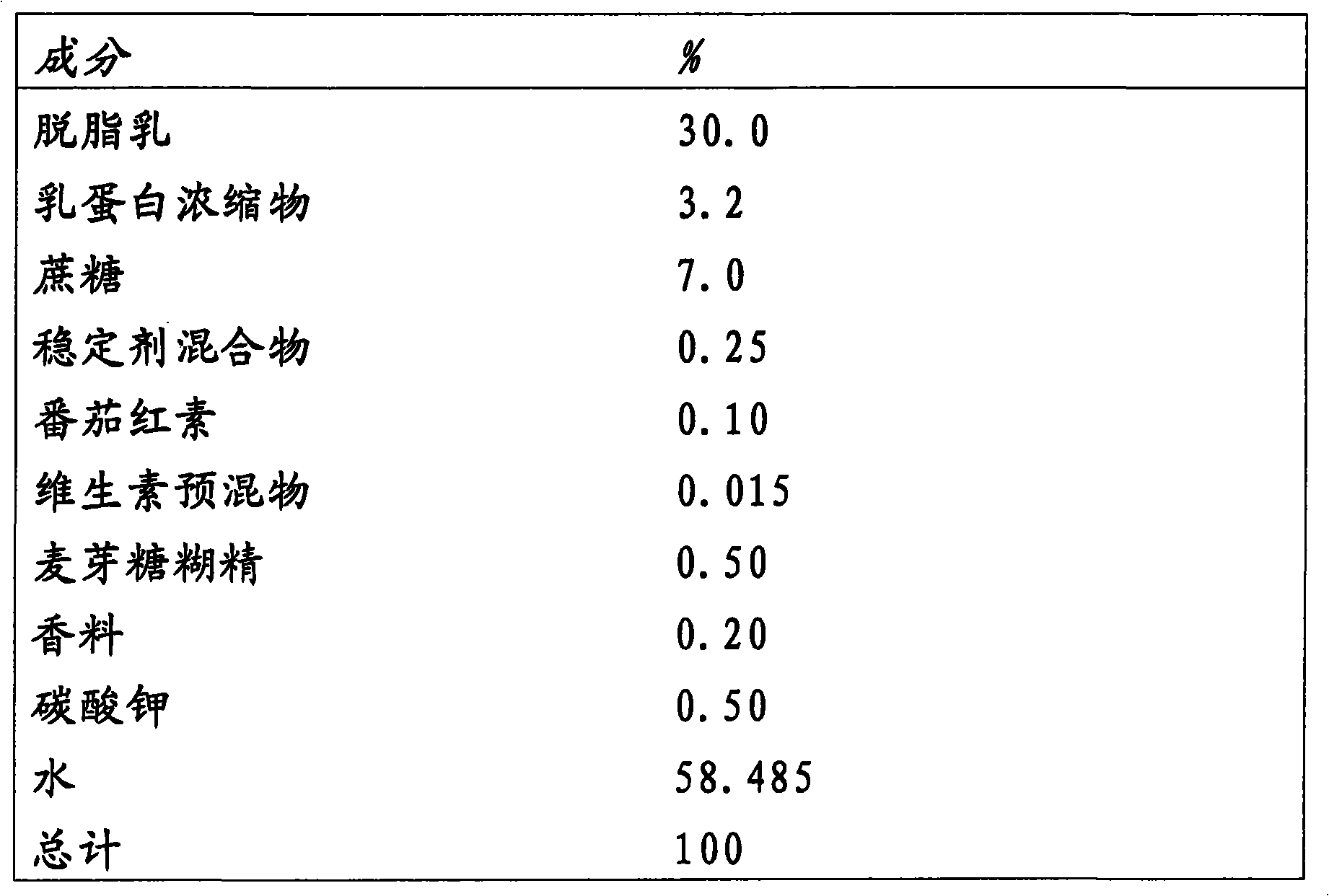

Insect diet formulations and methods for rearing insects

A composition suitable for the preparation of insect diet formulations, containing proteins, carbohydrates, vitamins, salts, and lambda carrageenan; the composition contains maltodextrin and no agar. An insect diet formulation, containing the composition described herein and water (room temperature). A method for rearing insects from eggs, involving providing the insect diet formulation described herein and culturing the insects with the insect diet formulation.

Owner:US SEC AGRI

Preparation method of lambda-carrageenan oligosaccharide

ActiveCN103290079ASkip the manufacturing processReduce and optimize process stepsMicroorganism based processesFermentationActivated carbonExtracellular

The invention discloses a method for preparing lambda-carrageenan oligosaccharide by carrying out bacterial degradation on lambda-carrageenan degrading bacteria. The method is characterized by comprising the following steps of: firstly, cultivating the lambda-carrageenan degrading bacteria which can generate extracellular lambda-carrageenan degrading enzymes, subsequently directly adding the bacterium liquid into a reaction liquid which contains 0.5-2.0% by weight of the lambda-carrageenan according to a volume ratio of 1:(0.8-1.2), reacting for 1-5 days at 20-30 DEG C under 100-150rpm, centrifuging so as to obtain supernate-containing oligosaccharide, adsorbing the oligosaccharide by using an activated carbon column, desorbing by using 20-40(v)% ethanol, concentrating, freezing and drying so as to obtain the lambda-carrageenan oligosaccharide of which the polymerization degree ranges from 2 to 8. The method has the advantages of being high in preparation process, high in yield, high in stability, and applicable to industrial production, and lambda-carrageenan oligosaccharide of which the polymerization degree ranges from 2 to 8 can be rapidly produced in large scale, so that the method has large application prospects in production of lambda-carrageenan oligosaccharide.

Owner:广西格新赛致生物科技有限公司

Liquid formulation containing protein and lambda carrageenan from halymeniales

InactiveUS20120156353A1Restore mouthfeelWider of stabilityMilk preparationFrozen sweetsMedicineLambda-Carrageenan

A liquid formulation comprising protein and lambda carrageenan, wherein the lambda carrageenan comprises lambda carrageenan from at least one seaweed of the taxonomic order Halymeniales.

Owner:FMC CORP

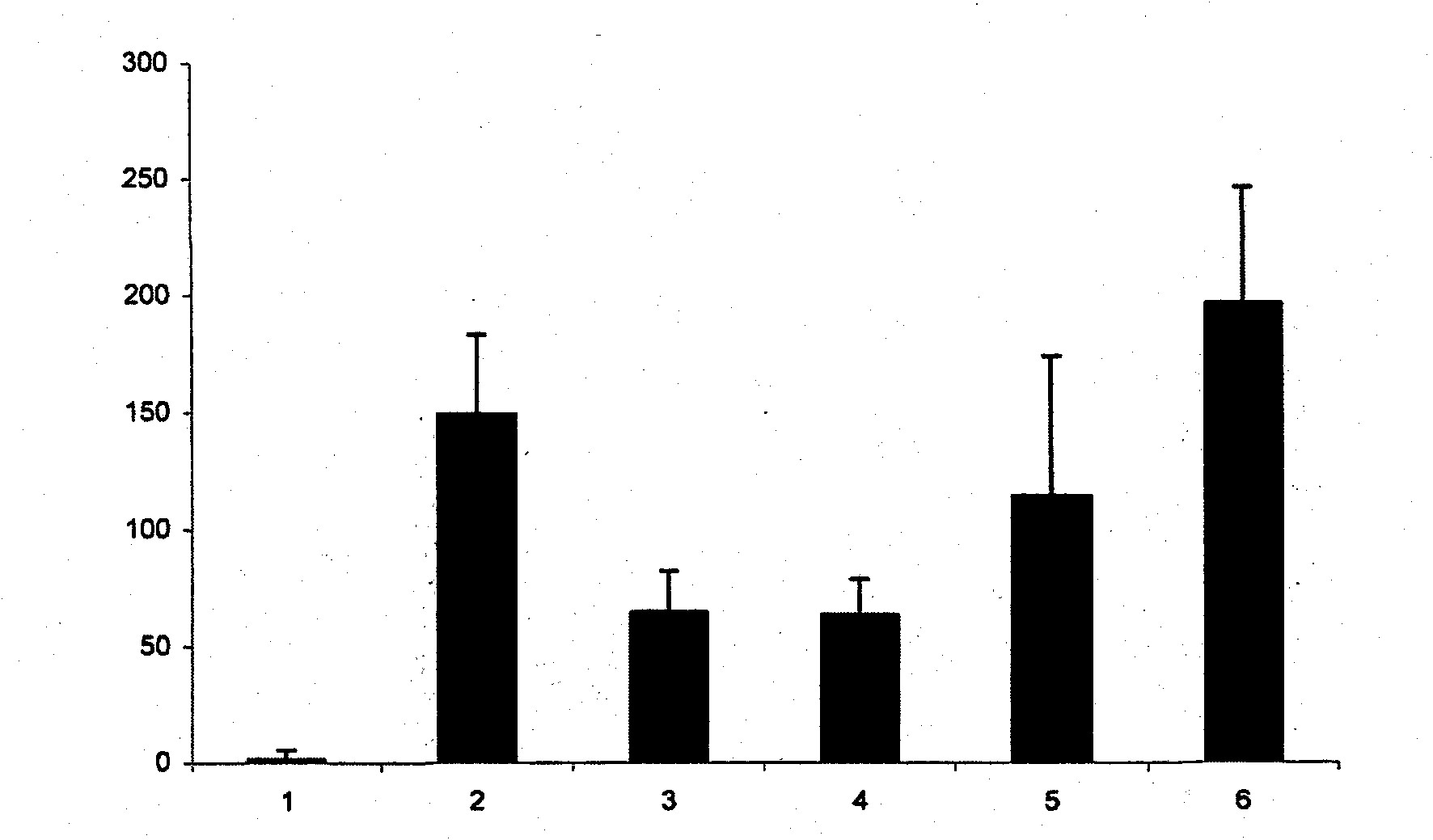

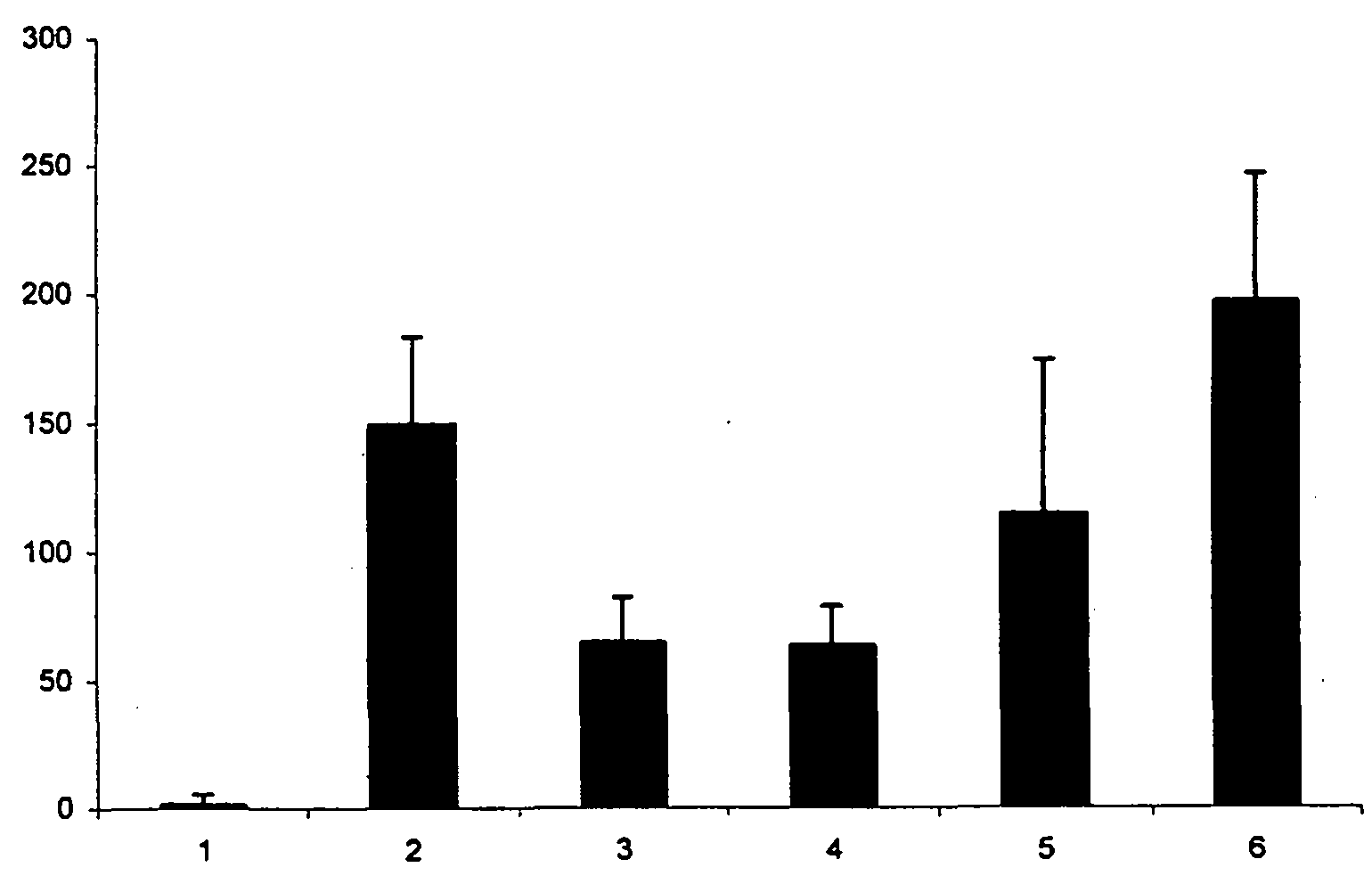

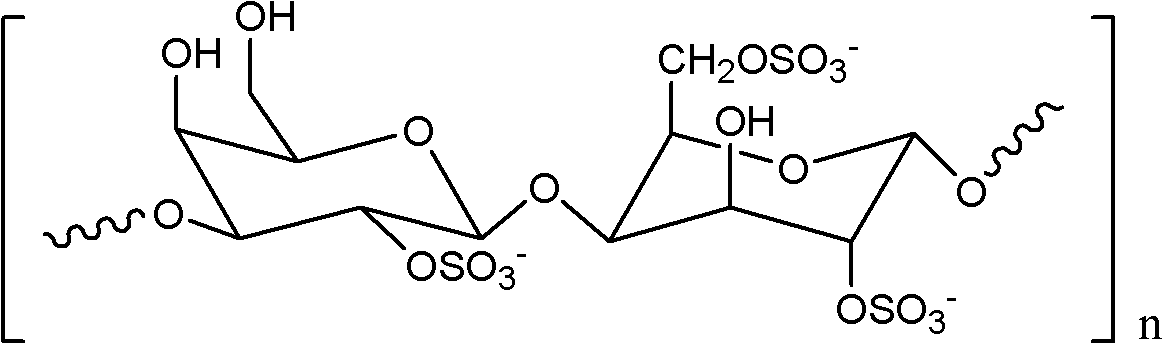

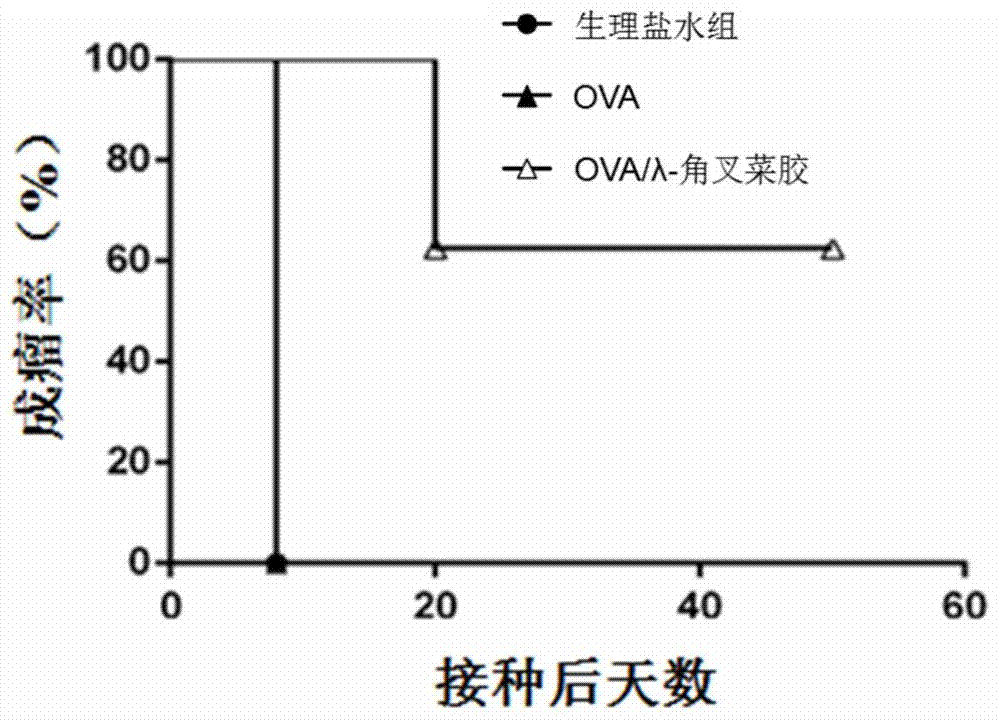

Application of Lambda-carrageenan to preparation of immunologic adjuvant and antigen-adjuvant compound

InactiveCN104840956AGood effectHas an immunomodulatory effectDigestive systemAntiviralsWilms' tumorLambda-Carrageenan

The invention belongs to the field of biological medicine, and relates to application of algal polysaccharides to a vaccine adjuvant. The invention aims at solving the technical problem that the ideal adjuvant for vaccine preparation, particularly for tumor vaccine preparation is difficult to obtain. In order to solve the technical scheme, the invention provides a new purpose of Lambda-carrageenans to preparation of an immunologic adjuvant. The Lambda-carrageenans are disaccharide units formed by connecting 2-sulfated galactose and 2, 6-sulfated galactose through beta-1, 4 keys, and each disaccharide unit is provided with polysaccharides of three sulfating sites. The tumor vaccine prepared by using the Lambda-carrageenans as the adjuvant can obviously enhance the serum antibody titers of the antigen, and can reduce the tumor formation rate of mice, the obvious anti-tumor effect is achieved, and the new selection is provided for the development and the application of the vaccine.

Owner:SICHUAN UNIV

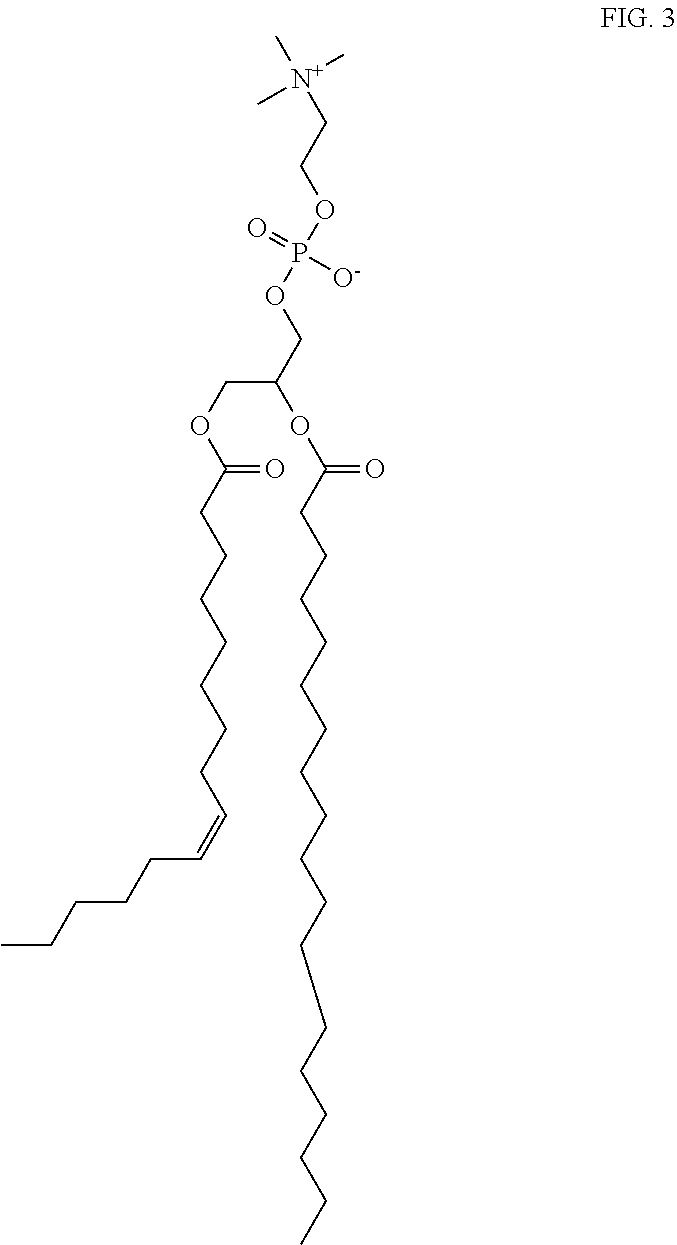

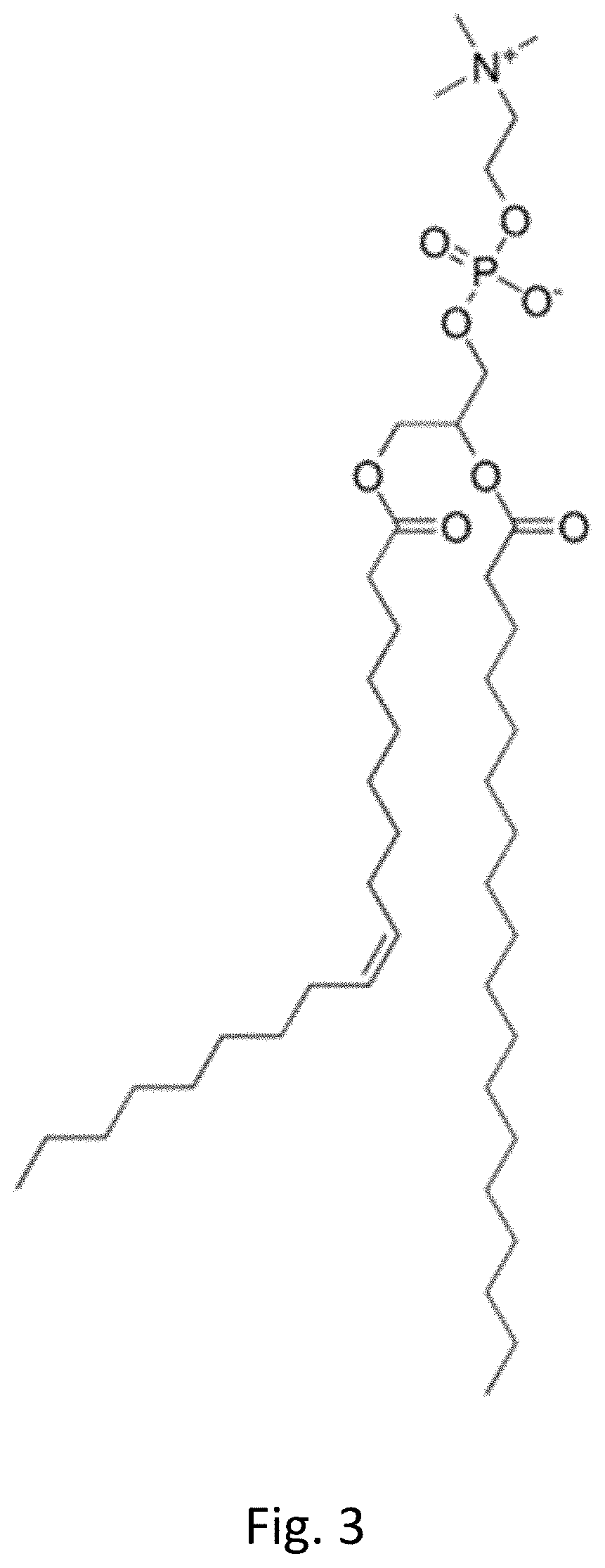

Pasty Bio-Adhesive Sustained Release Compositions

The present invention provides pasty or liquid compositions for applications on mucous membranes of cavities easily reached by hand, having a bio-adhesive prolonged effect or release. The composition includes a polysaccharide matrix agent selected from the group constituting of lambda carrageenan and iota carrageenan. The matrix allows the in situ formation of a matrix film with a reinforced bio-adhesive capacity due to complexation reactions between the polysaccharide matrix agent and the components of the local secretions of the mucous membranes. The compositions can also include a lecithin compound as a reinforcing agent of the intrinsic bio-adhesive properties of the polysaccharide matrix agent. The composition can further include at least one of (a) a hydration medium for the polysaccharide matrix agent, (b) a lecithin co-solvent allowing the dispersion of the micellar lecithin solution in the hydration medium, (c) an additive or additives, and (d) at least one active ingredient.

Owner:CARE & PHARMA PERSPECTIVES

Preparation method of stable nanogel polyferose

InactiveCN109172541AGood dispersionImprove bioavailabilityHeavy metal active ingredientsMetabolism disorderDispersion stabilityMicrosphere

The invention discloses a preparation method of stable nanogel polyferose and belongs to the field of preparation of polyferose. According to the preparation method, a novel nanoscale gel microsphereis prepared based on specific binding of lambda-carrageenan iron and ferric ion, the polyferose nanogel microsphere prepared through a stirring-dripping method shows good dispersion stability and significantly reduces the cytotoxicity of the iron ions; meanwhile, surface hydrophobic modification is further performed on the gel microsphere to improve the storage stability of polyferose powder, anddue to hydrolytic stability of the gel microsphere for a gastrointestinal tract, a theoretical support and a technical guidance are provided for development of a novel iron reinforcing agent; and theprepared lambda-car-Fe3+ complex can isolate moisture and inhibit browning, thus the storage stability and the hydrolytic stability for the gastrointestinal tract are greatly improved, and the stablenanogel polyferose as a safe iron reinforcing agent has great application potentials.

Owner:HUBEI UNIV OF TECH

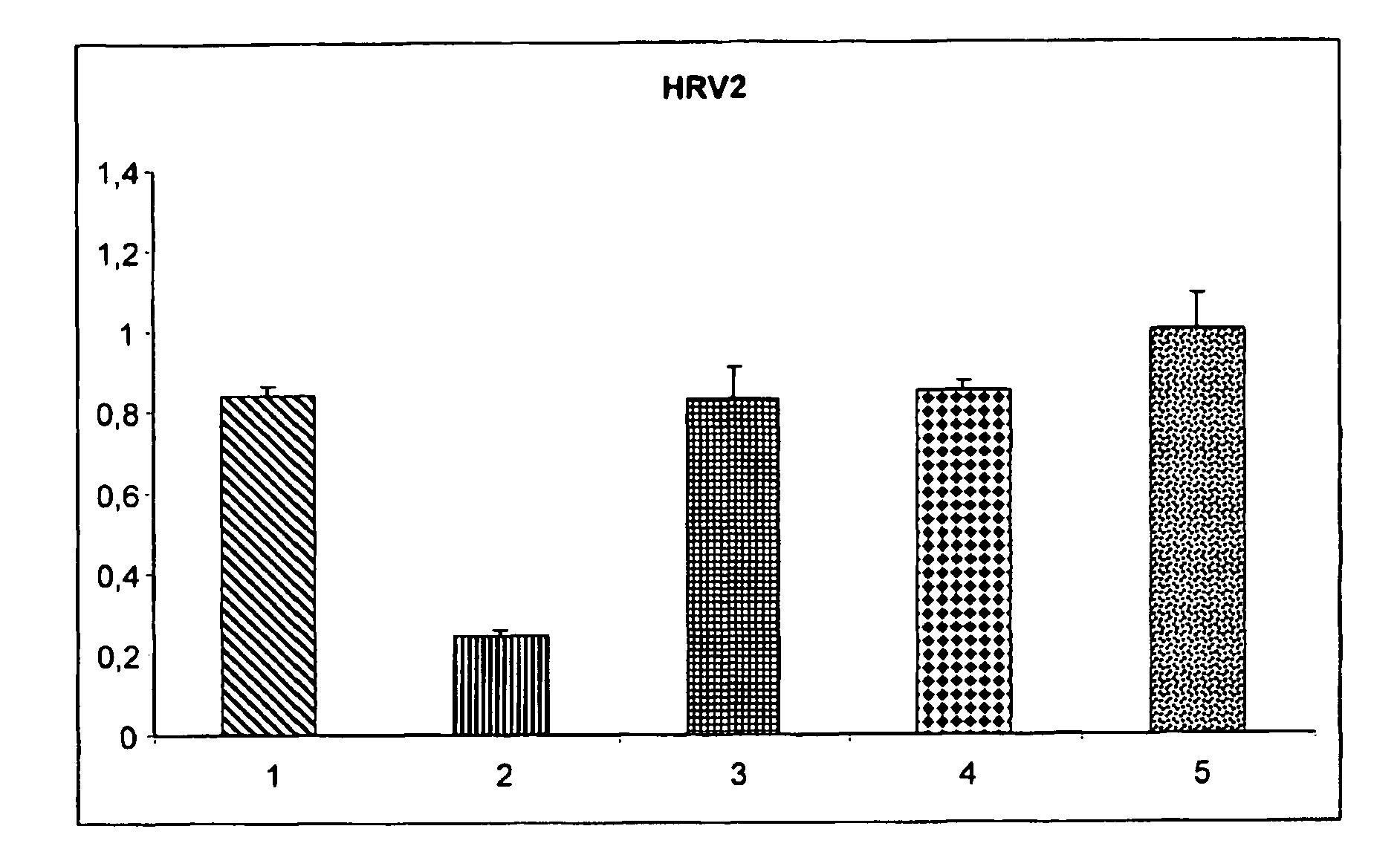

Antiviral composition and method of use

ActiveUS20100040658A1Reduce the possibilityLower Level RequirementsBiocideOrganic active ingredientsAntiviral drugRhinovirus infection

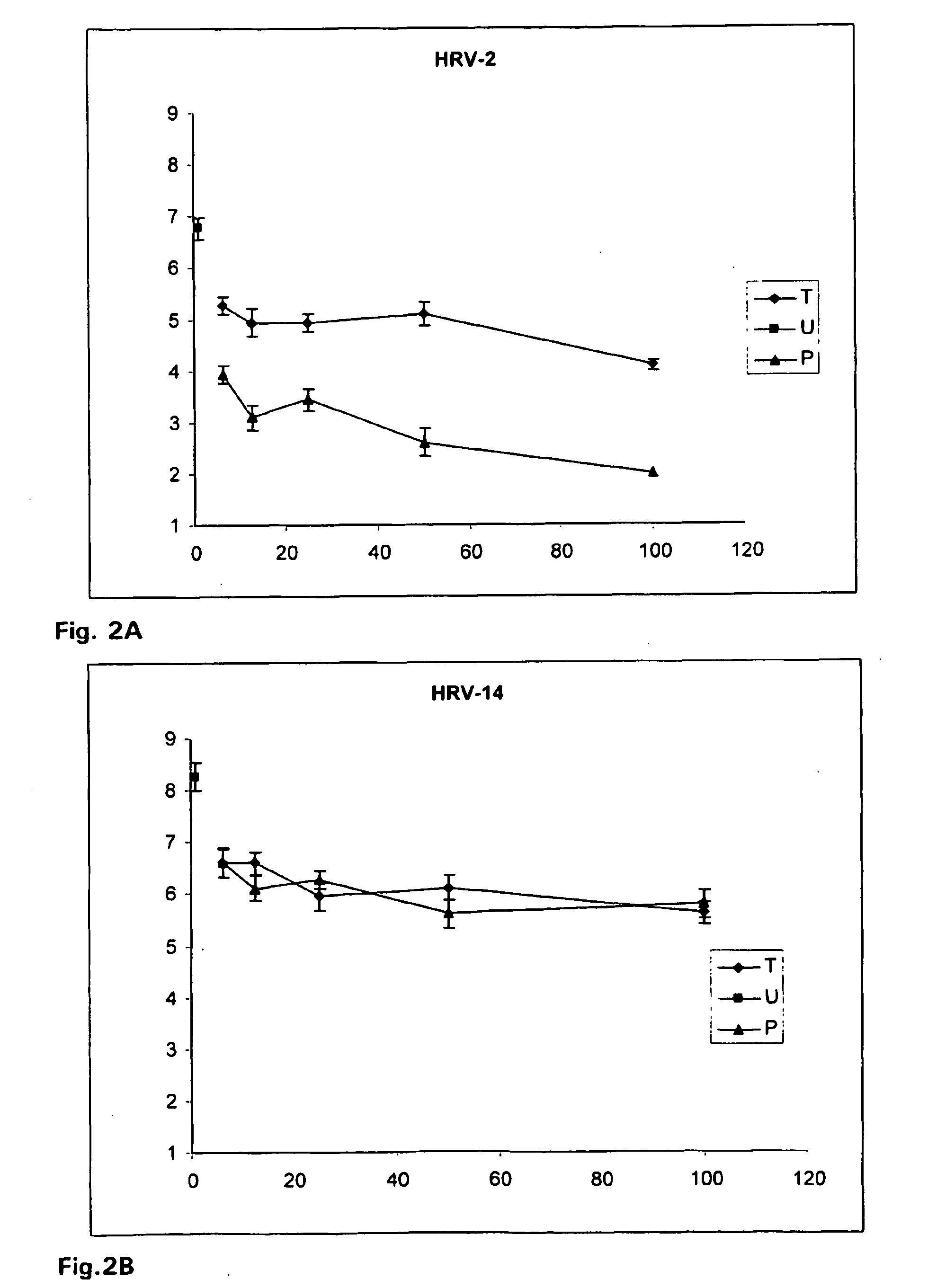

A method for manufacturing an antiviral pharmaceutical composition for the prophylaxis or treatment of a rhinovirus infection that includes the utilization of iota-, kappa- or lambda-carrageenan or mixtures thereof.

Owner:MARINOMED BIOTECH AG

Carrageenan mixtures useful as cosmetic ingredients and hair styling gels comprising them

ActiveUS20120183484A1Desirable propertyCosmetic preparationsHair cosmeticsCosmetic ingredientLambda-Carrageenan

This invention provides a carrageenan mixture comprising about 60% to about 95% by weight of iota-carrageenans and about 5% to about 25% by weight of lambda-carrageenans, which is useful as an ingredient of a cosmetic formulation such as a fully natural hair styling gel being free from synthetic polymers.

Owner:CARGILL INC

Creamers with improved texture/mouthfeel and method of making thereof

InactiveUS20180177215A1Enhanced and improved organoleptic propertyComposition is stableCream substitutesMilk substitutesCarboxymethyl celluloseGellan gum

The present invention relates to beverage products, in particular a liquid non-dairy creamer composition comprising unsaturated high oleic oils; caseinate salts; emulsifiers; and wherein further characterized in that the creamer comprises hydrocolloids comprising lambda-carrageenan, high acyl gellan gum and carboxymethyl cellulose wherein the lambda-carrageenan ranges from 0.02 to 0.1 wt / wt %, high acyl gellan gum ranges from 0.23 to 0.28 wt / wt %, and carboxymethyl cellulose ranges from 0.04 to 0.12 wt / wt % of the creamer.

Owner:SOC DES PROD NESTLE SA

Electrical Nutritional Supplement

InactiveUS20070292457A1Easy to manageEasy to operateBiocideMetabolism disorderKappa-CarrageenanAdhesive

A object of the present invention is to provide a novel system whereby an enteral nutrient or an enriched liquid food can be solidified so that it can be easily administered within a short period of time without liguefying in the body to thereby lighten a care-giver's burden in tube feeding such as gastrostomic feeding. As the results of studies, it is found out that such a nutrient or an enriched liquid food can be quickly thickened or solidified at a temperature of 40° C. or below by using a starch adhesive, which contains as the main component sodium iota-carrageenan, sodium kappa-carrageenan, sodium lambda-carrageenan or a mixture thereof, without dissolving the starch adhesive by heating. Further, it was confirmed that it is an administration method almost free from water liberation when the solidified product was administered from a syringe, thus the present invention was completed. That is, the use of the above carrageenan as a starch adhesive (a semi-solidifying agent) makes it possible to produce the desired semi-solidified enteral nutrient as described above.

Owner:MEIJI CO LTD

Enteric nutritional supplement

ActiveCN101039656AEasy to operateHigh in nutrientsMetabolism disorderDigestive systemKappa-CarrageenanAdhesive

It is intended to provide a novel system whereby an enteric nutritional supplement or a thickened liquid food can be solidified so that it can be easily administered within a short period of time without liquefying in the body to thereby lighten a care-giver's burden in tube feeding such as gastrostomic feeding. As the results of studies, it is found out that such a nutritional supplement or a thickened liquid food can be quickly thickened or solidified at a temperature of 40 DEG C or below by using a starch adhesive, which contains as the main component sodium iota-carrageenan, sodium kappa-carrageenan, sodium lambda-carrageenan or a mixture thereof, without melting the starch adhesive by heating. Further, it is confirmed that the product is almost free from water liberation when administered from a syringe. That is, use of the above-described carrageenan as a starch adhesive (a semi-solidifying agent) makes it possible to produce the desired semi-solidified enteric nutritional supplement as described above.

Owner:MEIJI CO LTD

Fluid loss control in viscoelastic surfactant fracturing fluids using water soluble polymers

Water soluble uncrosslinked polysaccharides may be fluid loss control agents for viscoelastic surfactant (VES) fluids used for stimulation (e.g. fracturing) or well completion in hydrocarbon recovery operations. The VES fluid may further include proppant or gravel, if it is intended for use as a fracturing fluid or a gravel packing fluid, although such uses do not require that the fluid contain proppant or gravel. The water soluble uncrosslinked polysac not charide fluid loss control agents may include, but not be limited to guar gum and derivatives thereof; cellulose and derivatives thereof; propylene glycol alginate; salts (e.g. sodium, potassium, and calcium salts) of iota, kappa, and lambda carrageenan; agar-agar; xanthan gum; and the like; and / or mixtures thereof. The fluid loss control agent may be added to the aqueous viscoelastic treating fluid prior to VES addition, and / or at the same time and / or after the VES is added.

Owner:BAKER HUGHES INC

Plant capsule composition of seaweed colloid and preparation method thereof

ActiveCN103768608APrevent dehydrationReduce moisture contentPharmaceutical non-active ingredientsCapsule deliveryBiotechnologyCellulose

The invention discloses a plant capsule composition of seaweed colloid and a preparation method thereof. The composition comprises the following components in parts by weight: 1-30 parts of lambda carrageenan, 50-120 parts of plant cellulose, 1-15 parts of alcohols, 0.5-10 parts of starch, and 30-90 parts of water. The plant capsule can be used as auxiliary materials of medicines and functional foods, and the raw materials are from plants and safe to use, so that potential pathogenic risks of animal source materials can be avoided; the plant capsule composition is good in stability, does not deform in high-temperature high-humidity environment, and is not fragile in a cold and dry environment; the plant capsule is wider in application range, and is suitable for Muslim, Judaism areas and vegetarians.

Owner:漳州市新明生物科技有限公司

Povidone-iodine solution as well as preparation method and application thereof

InactiveCN107410354APH and other conditions are not highLong duration of actionBiocideDead animal preservationAquatic productDrugs preparations

Owner:XINGHUA HENGWEI BIOTECH

High-performance aerated block and preparation method thereof

The invention discloses a high-performance aerated block which is characterized by comprising the following components in parts by weight: 15-20 parts of lime, 15-20 parts of cement, 60-65 parts of tailing powder, 2-3 parts of gypsum, 0.5-0.6 part of aluminum powder and 0.03-0.05 part of additive. The additive is prepared from the following components in parts by weight: 2-5 parts of rosin-based hyperbranched epoxy resin, 4-8 parts of volcanic ash, 0.5-1.5 parts of carbon fiber and 0.3-0.6 part of lambda carrageenan. The invention further provides a preparation method of the high-performance aerated block. The high-performance aerated block disclosed by the invention is excellent in comprehensive performance, more excellent in mechanical property, higher in performance stability and waterseepage prevention performance, lower in drying shrinkage value and safer and more environment-friendly to use.

Owner:苏州良浦天路新型建材有限公司

Stabilizer system for food and beverage products

A stabilizer system comprises blends of cellulose, lambda-carrageenan, and guar gum. Food products and beverages, such as energy drinks, are prepared with the stabilizer blends.

Owner:PEPSICO INC

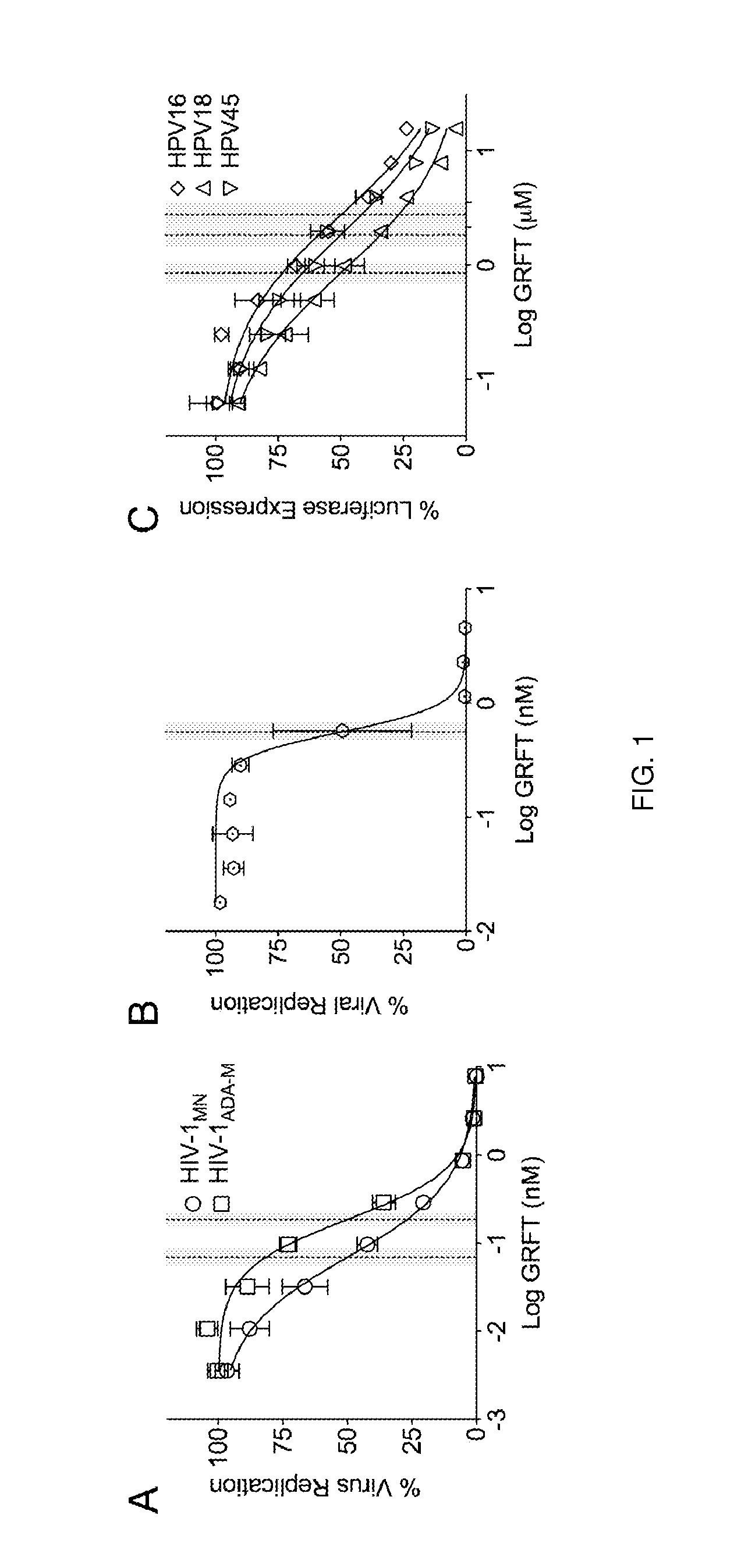

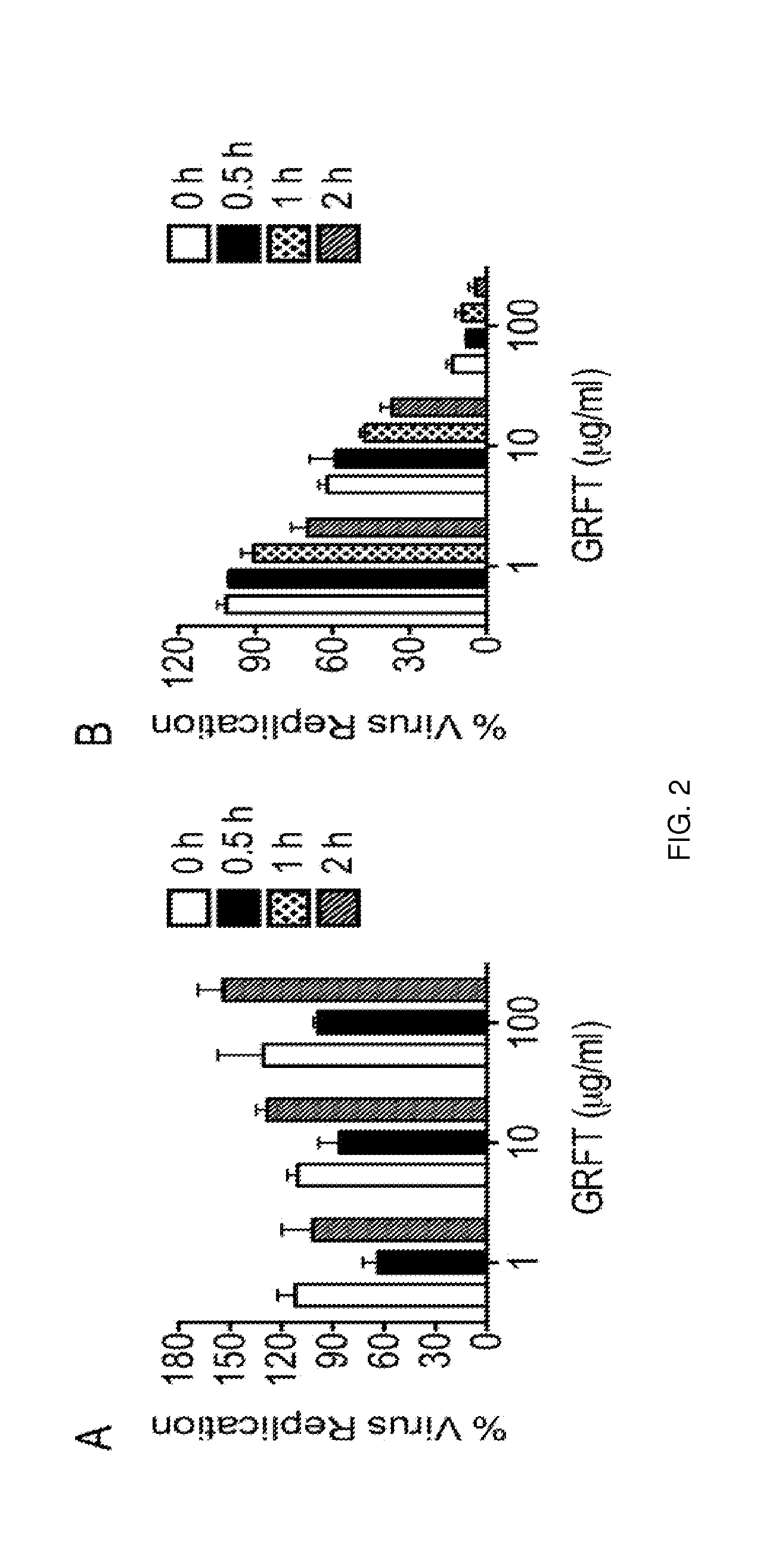

Combination product for the prevention of sexually transmitted infections

ActiveUS20160339076A1Reduce deliveryPrevent vaginal and rectal transmissionOrganic active ingredientsPeptide/protein ingredientsMedicineWater soluble

Disclosed are compositions for inhibiting transmission of a sexually transmitted infection that contain one or more polyanionic microbicides, such as carrageenans, including lambda carrageenan, as well as water-soluble metal salts and specified lectins. Also disclosed are methods for making and using the compositions.

Owner:UNITED STATES OF AMERICA +1

Combination product for the prevention of sexually transmitted infections

ActiveUS10143721B2Prevent vaginal and rectal transmissionReduce deliveryOrganic active ingredientsBiocideMedicineMicrobial agent

Disclosed are compositions for inhibiting transmission of a sexually transmitted infection that contain one or more polyanionic microbicides, such as carrageenans, including lambda carrageenan, as well as water-soluble metal salts and specified lectins. Also disclosed are methods for making and using the compositions.

Owner:UNITED STATES OF AMERICA +1

Pasty bio-adhesive sustained release compositions

The present invention provides pasty or liquid compositions for applications on mucous membranes of cavities easily reached by hand, having a bio-adhesive prolonged effect or release. The composition includes a polysaccharide matrix agent selected from the group constituting of lambda carrageenan and iota carrageenan. The matrix allows the in situ formation of a matrix film with a reinforced bio-adhesive capacity due to complexation reactions between the polysaccharide matrix agent and the components of the local secretions of the mucous membranes. The compositions can also include a lecithin compound as a reinforcing agent of the intrinsic bio-adhesive properties of the polysaccharide matrix agent. The composition can further include at least one of (a) a hydration medium for the polysaccharide matrix agent, (b) a lecithin co-solvent allowing the dispersion of the micellar lecithin solution in the hydration medium, (c) an additive or additives, and (d) at least one active ingredient.

Owner:CARE & PHARMA PERSPECTIVES

Carrageenan mixtures useful as cosmetic ingredients and hair styling gels comprising them

This invention provides a carrageenan mixture comprising about 60% to about 95% by weight of iota-carrageenans and about 5% to about 25% by weight of lambda-carrageenans, which is useful as an ingredient of a cosmetic formulation such as a fully natural hair styling gel being free from synthetic polymers.

Owner:CARGILL INC

Liquid formulation containing protein and lambda carrageenan from halymeniales

A liquid formulation comprising protein and lambda carrageenan, wherein the lambda carrageenan comprises lambda carrageenan from at least one seaweed of the taxonomic order Halymeniales.

Owner:FMC CORP

Cheese and preparation method thereof

ActiveCN103999947AImprove featuresImproved rheological propertiesCheese manufactureHardnessSoluble nitrogen

The invention discloses a preparation method of cheese, wherein the method comprises the steps: contacting raw milk with carrageenan, to obtain a material after contact; and then successively adding a leavening agent and chymosin into the material after contact, to obtain a lactoprotein clot, wherein the carrageenan is iota-carrageenan and / or lambda-carrageenan. The invention also provides the cheese prepared by the method. The cheese is prepared by the method, the cheese textural and rheological properties can be effectively improved, moreover, the moisture content in the cheese is increased, and thus the hardness is reduced, the non-fat solid content in the cheese, the cheese yield, the soluble nitrogen content, the squeezable whey content and the like are also increased, the cheese quality is effectively improved, the production cost is reduced, and the commercial value is increased.

Owner:CHINA AGRI UNIV

A kind of preparation method of λ-carrageenan oligosaccharide

ActiveCN103290079BSkip the manufacturing processReduce and optimize process stepsMicroorganism based processesFermentationActivated carbonExtracellular

The invention discloses a method for preparing lambda-carrageenan oligosaccharide by carrying out bacterial degradation on lambda-carrageenan degrading bacteria. The method is characterized by comprising the following steps of: firstly, cultivating the lambda-carrageenan degrading bacteria which can generate extracellular lambda-carrageenan degrading enzymes, subsequently directly adding the bacterium liquid into a reaction liquid which contains 0.5-2.0% by weight of the lambda-carrageenan according to a volume ratio of 1:(0.8-1.2), reacting for 1-5 days at 20-30 DEG C under 100-150rpm, centrifuging so as to obtain supernate-containing oligosaccharide, adsorbing the oligosaccharide by using an activated carbon column, desorbing by using 20-40(v)% ethanol, concentrating, freezing and drying so as to obtain the lambda-carrageenan oligosaccharide of which the polymerization degree ranges from 2 to 8. The method has the advantages of being high in preparation process, high in yield, high in stability, and applicable to industrial production, and lambda-carrageenan oligosaccharide of which the polymerization degree ranges from 2 to 8 can be rapidly produced in large scale, so that the method has large application prospects in production of lambda-carrageenan oligosaccharide.

Owner:广西格新赛致生物科技有限公司

Dentifrice composition

A dentifrice composition which comprises (A) heavy calcium carbonate having a mean particle diameter of 5 to 15 m, (B) water-insoluble inorganic granules having a collapse strength of 10 to 200g / granule, a mean particle diameter of 50 to 150 m, and a difference of 100 m or below between 90% particle diameter and mean particle diameter, and (C) a water-soluble polymeric material comprising at least one member selected from Group (a) and at least one member selected from Group (b) at a (b) / (a) mass ratio of 0.25 to 3, Group (a): sodium alginate, sodium carboxymethylcellulose, methylcellulose, hydroxyethylcellulose, Xanthomonas campestris, lambda-carrageenan, and straight-chain sodium polyacrylate, and Group (b): gellan gum, agar, kappa-carrageenan, iota-carrageenan, gelatin, pectin, and crosslinked sodium polyacrylate, and which has a total content of (a) and (b) of 0.5 to 1.5% by mass based on the whole of the composition.

Owner:LION CORP

Use of λ-carrageenan oligosaccharides in the preparation of anti-rabies virus drugs

ActiveCN104546895BPrevent proliferationNon-toxicOrganic active ingredientsAntiviralsCytotoxicityAscochyta rabiei

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com