Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Hydrometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrometer is an instrument used for measuring the relative density of liquids based on the concept of buoyancy. They are typically calibrated and graduated with one or more scales such as specific gravity.

Method for adaptively detecting and eliminating shadow in video segmentation

InactiveCN101854467AAccurate removalSmall amount of calculationTelevision system detailsColor television detailsHydrometerVertical projection

The invention discloses a method for adaptively detecting and eliminating a shadow in video segmentation. The method comprises the following steps of: firstly, roughly detecting a moving changing region by using accumulated frame differences and constructing a motion template by using a static index; secondly, performing statistics on brightness information to establish a background model, performing updating by combining the motion template, and detecting a foreground and an edge of the foreground by using a background difference and a Sobel operator; thirdly, performing horizontal projection and vertical projection on a detected edge image respectively, performing statistics on the distribution condition of edge images and roughly determining a shadow position and a search direction by combining shadow characteristics with a spatial position; and finally, precisely positioning a shadow point along the search direction in a suspected shadow region by using a hydrometer method so as to precisely eliminate the shadow. Due to the combination of the characteristics of the edge and the spatial position of the shadow, the method for adaptively detecting and eliminating the shadow disclosed by the invention has the advantages of adaptively positioning the shadow region and precisely eliminating the shadow point under the condition of invariance and availability of chrominance, along with small calculation amount and high robustness.

Owner:BEIHANG UNIV

Glass fiber screen cloth immersing glue solution for grinding wheel reinforcement and initial rinsing method

InactiveCN101139172ASolve the problem that is easy to cause scrap rateReduce pollutionHydrometerFiberglass mesh

The present invention discloses a glass fiber mesh fabric dip solution for reinforcement of grinding wheel and the dipping method, which belongs to the field of composite materials; wherein the dip solution is formed by mixing the industrial alcohol with the liquid phenolic resin, the solid content of which is larger than or equal to 65 percent. The mixing ratio between the liquid phenolic resin against the industrial alcohol ranges from 1:0.15 to 0.20. The presoaking method is realized by utilizing the conventional dipping machine and the specific operating steps are that the glass fiber mesh fabrics are delivered into a dipping groove through a fabric transportation drum and a fabric storage roller so as to be dipped by the dip solution arranged in the dipping groove; then the dipped glass fiber mesh fabrics go into the rubber pressing by a dandy roll and then are fed into an oven to be pre-cured; the dipped glass fiber mesh fabrics are pulled out by a traction device and are trimmed and rolled up after passing through a buffering fabric storage roller and a deviation-correcting device. Two kinds of raw materials are selected as the raw materials of the present invention, thus simplifying the confection process of the present invention; the hydrometer is used to measure and adjust the proportion of the dip solution, thus resulting in that the gum chicle content is effectively controlled and the quality of products is stable; the volatile quantity is lowered from originally 5 percent to 1.5 percent. The glass fiber mesh fabric dip solution for reinforcement of grinding wheel causes few contaminations to the environment, has low cost and is easy to be popularized and put into use.

Owner:北京玻钢院复合材料有限公司

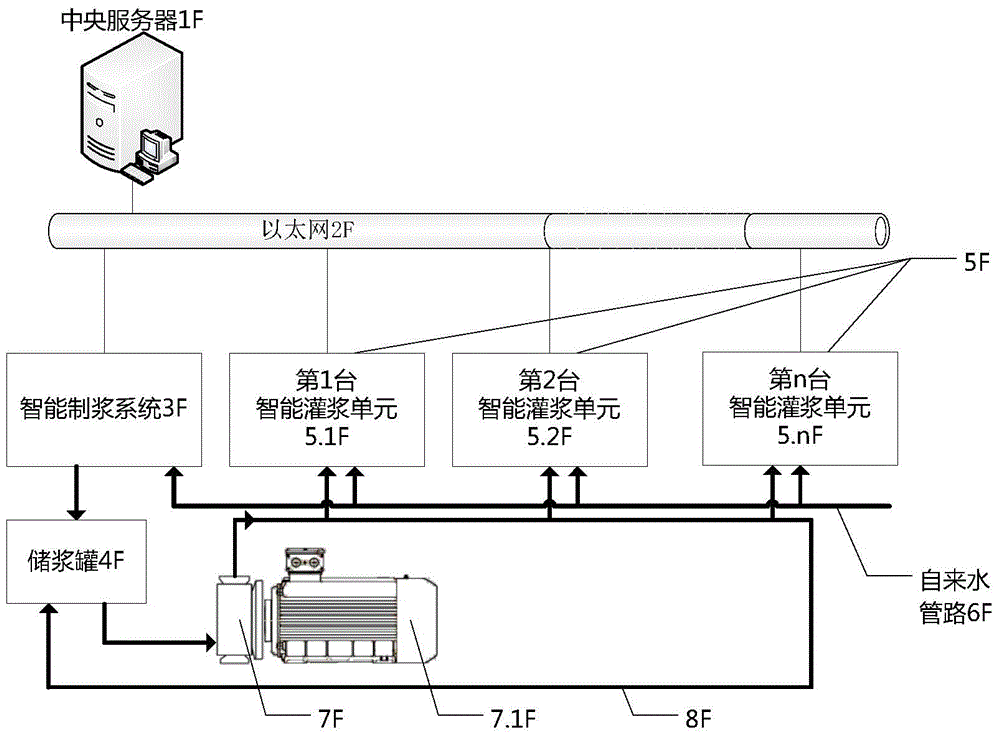

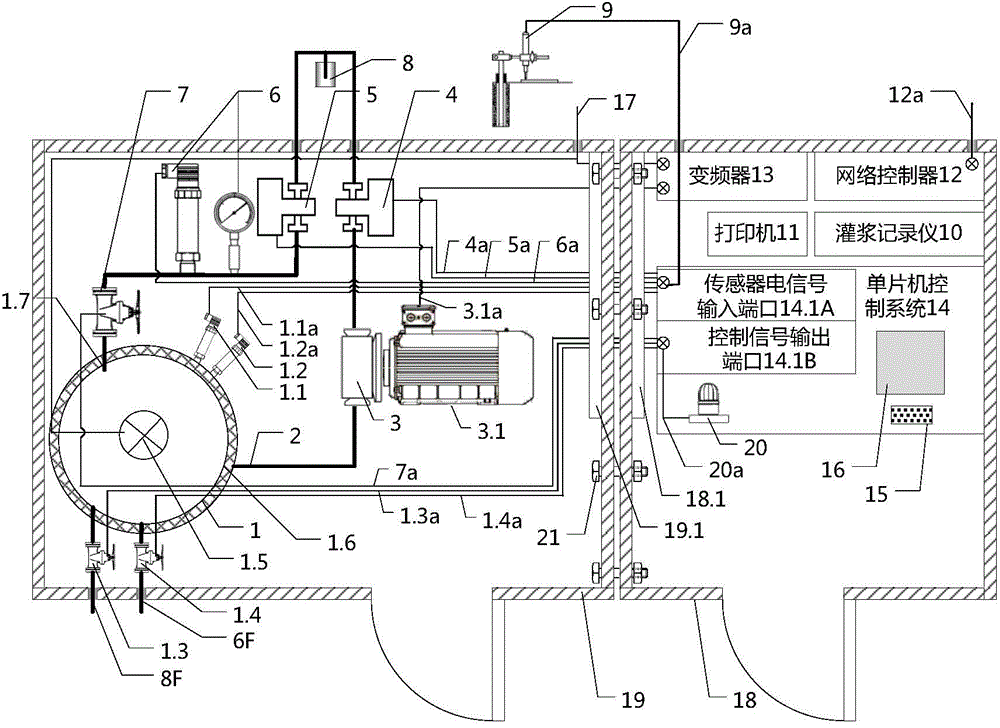

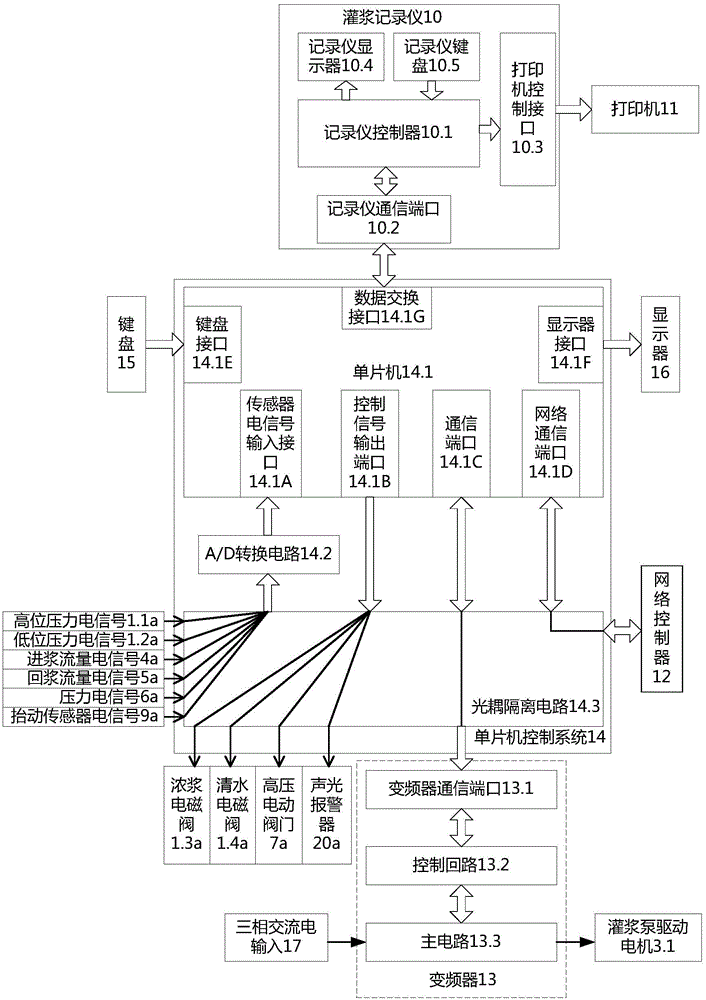

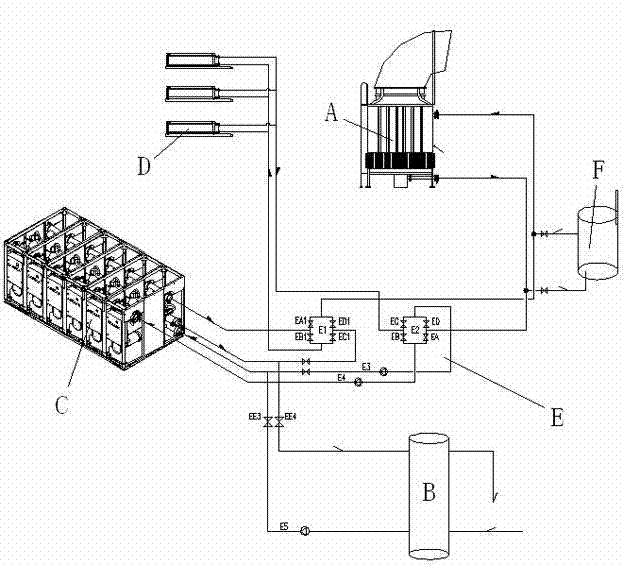

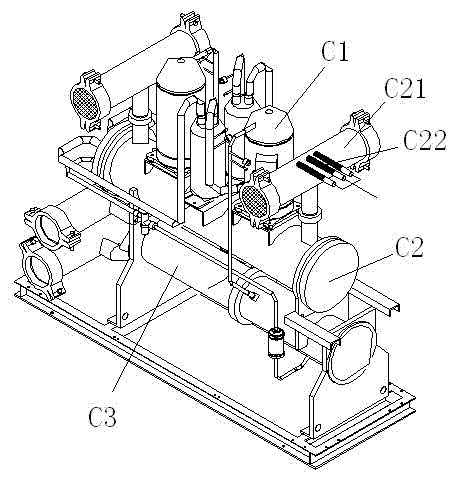

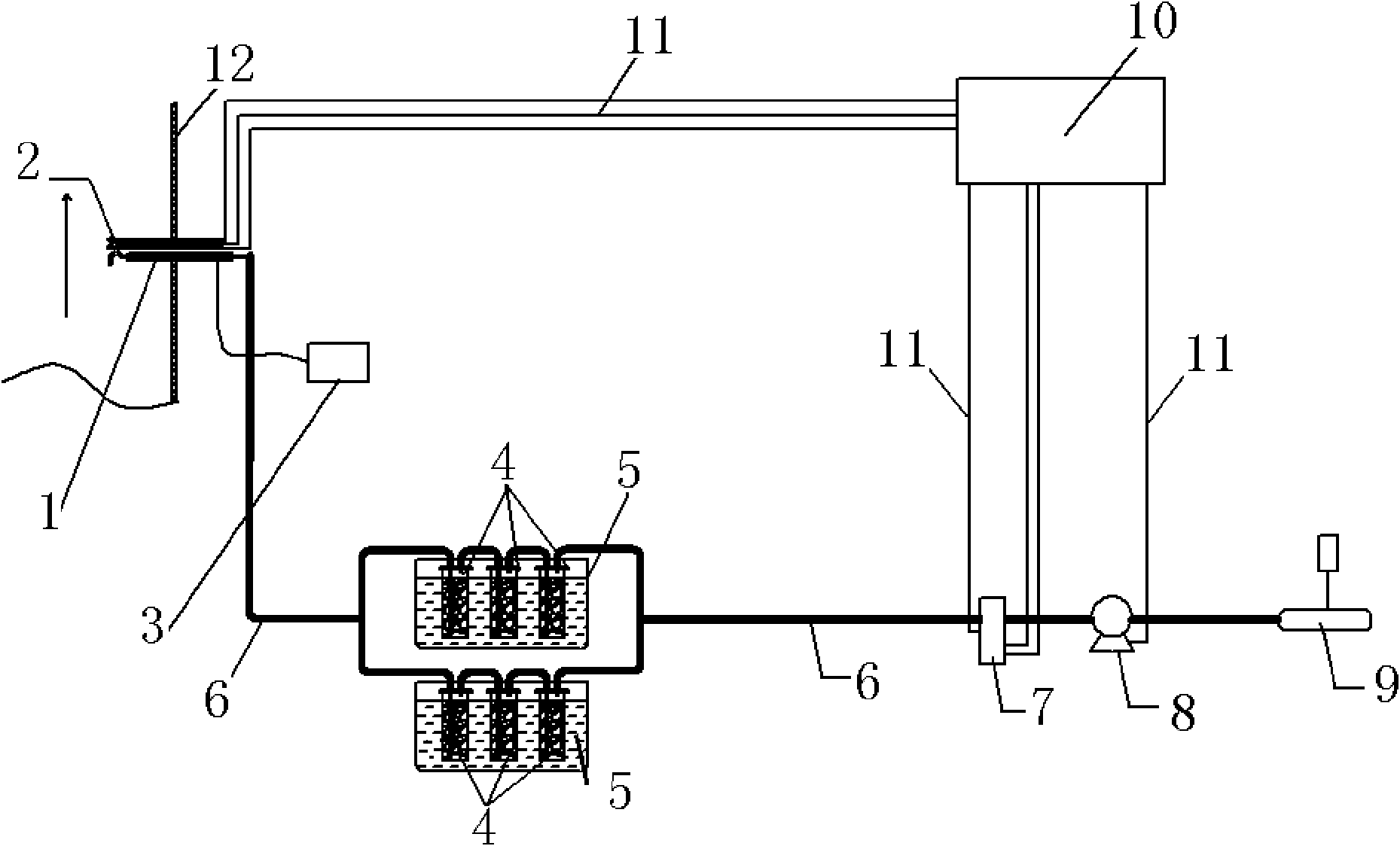

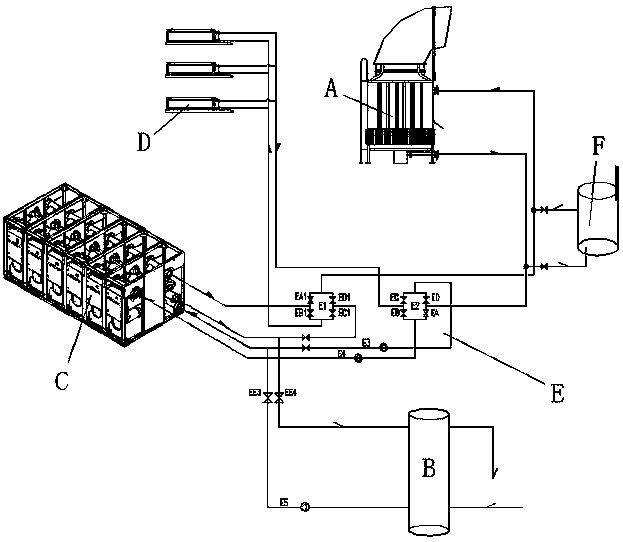

Integrated intelligent grouting system

Disclosed is an integrated intelligent grouting system. A pulp feeding pump is employed to convey a thick pulp prepared by an intelligent pulp preparing system into a pulp storage tank and n intelligent grouting units; and a network is employed to connect a central server. Automatic pulp preparing pipelines of water, cement, sand and additives, as well as an on-line pulp hydrometer, a liquid level detector and a pulp preparing single chip machine are arranged inside the pulp preparing system. Each intelligent grouting unit comprises a grouting box containing an integrated pulp distribution tank, a grouting sensor, a grouting pump, and a valve, as well as an intelligent box containing a single chip machine, a keyboard, a display, a grouting recorder, a network controller, a frequency converter, and an alarm device. The thick pulp is prepared at first, and then is diluted in the pulp distribution tanks having highly integrated interfaces, thereby measuring the concentration of the pulp inside the tanks in real time, and the concentration is constant. Moreover, the integrated intelligent grouting system has few pipelines, and thereby the integrated intelligent grouting is easy to be achieved. The programmed pulp distribution is efficient and accurate, and is monitored by the hydrometer in real time. The two boxes are integrated for changing the working surface and maintaining conveniently. The grouting pump is controllable and energy-saving; the alarm is sent out and the valve is adjusted when the pressure of the pipelines goes beyond the limits, thereby avoiding the dam displacement and the accidents. The remote monitoring is achieved by the network. The integrated intelligent grouting system is used for the grouting constructions of hydropower stations.

Owner:CHINA THREE GORGES CORPORATION +1

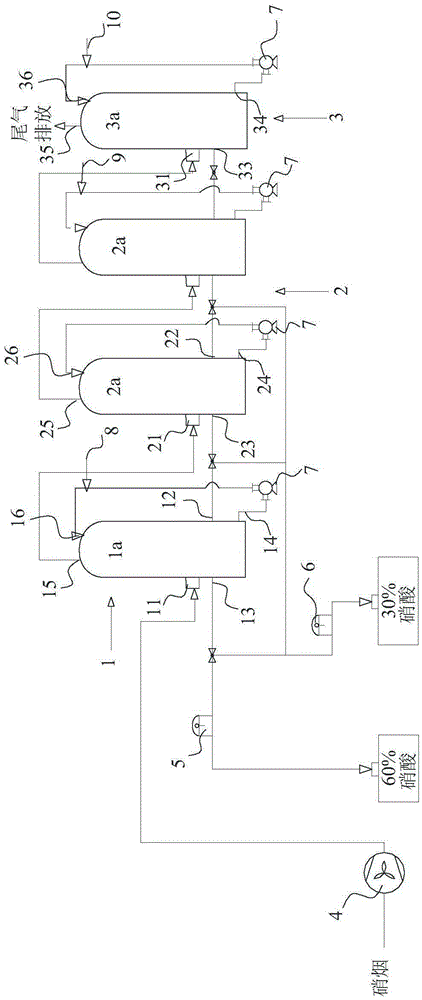

Device and method for recovering gas of nitrogen oxides in production process of nitro-cotton

InactiveCN105327608AMeet sales needsGuaranteed uptimeDispersed particle separationNitric acidHydrometerProcess engineering

The invention relates to the field of treatment of waste gas generated in the production of nitro-cotton, aims to provide a device and a method for recovering gas of nitrogen oxides in the production process of nitro-cotton. The device comprises a first absorption unit, a second absorption unit, a third absorption unit, an exhaust fan, a first hydrometer and a second hydrometer, wherein the first absorption unit comprises a water washing absorption tower; the second absorption unit comprises at least two water washing absorption towers connected in series, is arranged at a station behind the first absorption unit and is connected with the first absorption unit in series; the third absorption unit comprises at least one absorption tower with a urea and hydrogen peroxide mixed solution as an absorbent, is arranged at a station behind the second absorption unit and is connected with the second absorption unit in series; an outlet for 60% nitric acid is formed behind the first hydrometer, and an outlet for 30% nitric acid is formed behind the second hydrometer; multi-stage water washing treatment and urea and hydrogen peroxide treatment are adopted, secondary pollution cannot be caused in the whole treatment process, nitric acid with two kinds of concentration can be provided simultaneously, users of nitric acid are increased, normal operation of a recovery system for the gas of nitrogen oxides is guaranteed, and the economic efficiency of recovery of the gas of nitrogen oxides is improved.

Owner:SICHUAN NITROCELLULOSE CORP

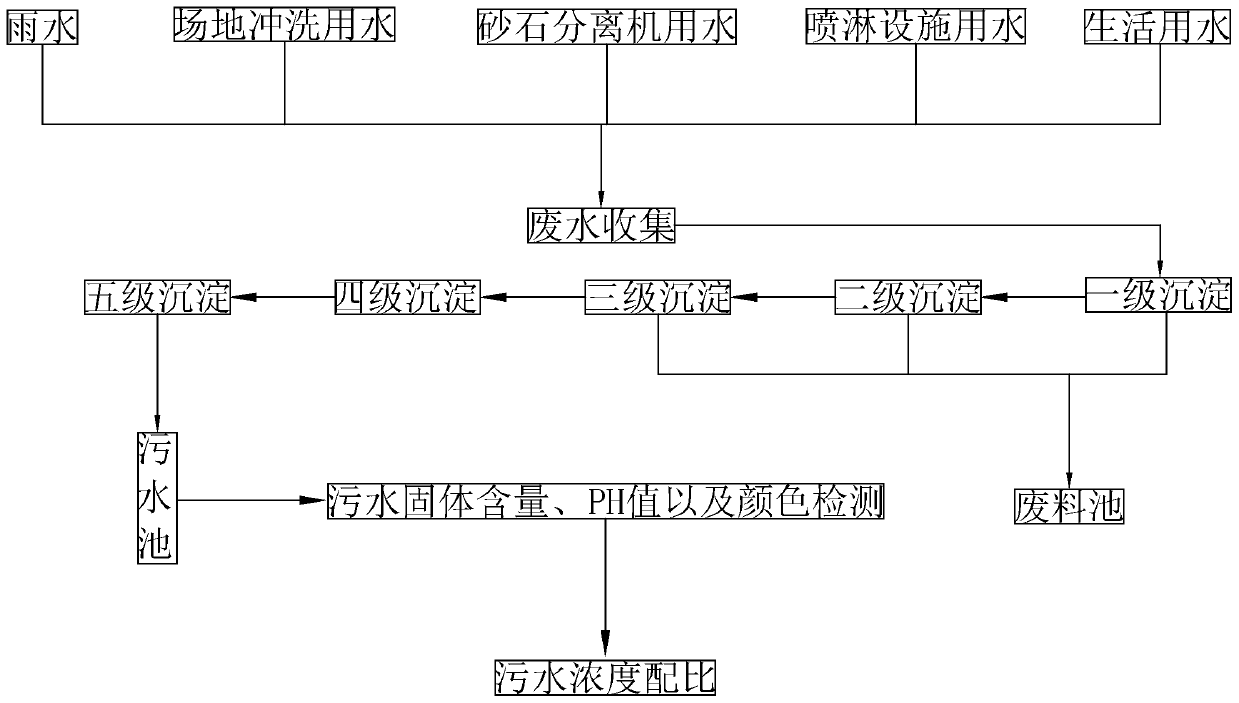

Concrete wastewater detection process

InactiveCN110568142AImprove compactnessDoes not affect appearanceColor measuring devicesTesting waterHydrometerWastewater

The invention relates to a concrete wastewater detection process and belongs to the technical field of concrete detection processes. The concrete wastewater detection process comprises the following steps of (1) wastewater collection: collecting concrete mixing plant wastewater through a water pipe arranged on the ground of a site, (2) five-stage precipitation: sequentially introducing the collected wastewater into five precipitation tanks for wastewater impurity precipitation and finally discharging the wastewater into a sewage tank for storage to obtain sewage, (3) solid content, pH value and color detection of the sewage, wherein the solid content of the sewage is measured through a mud hydrometer measuring method, the solid content is not larger than 8%, the pH value is directly measured through an acidometer, the pH value ranges from 6 to 8, the color of the sewage is observed through naked eyes, and the sewage is colorless, and (4) proportioning sewage concentration, wherein thetotal concentration does not exceed 5%. The concrete wastewater detection process has the advantage that the content of the wastewater is effectively and quickly detected before the wastewater is recycled so that the wastewater meets a recycling requirement.

Owner:成都精准混凝土有限公司

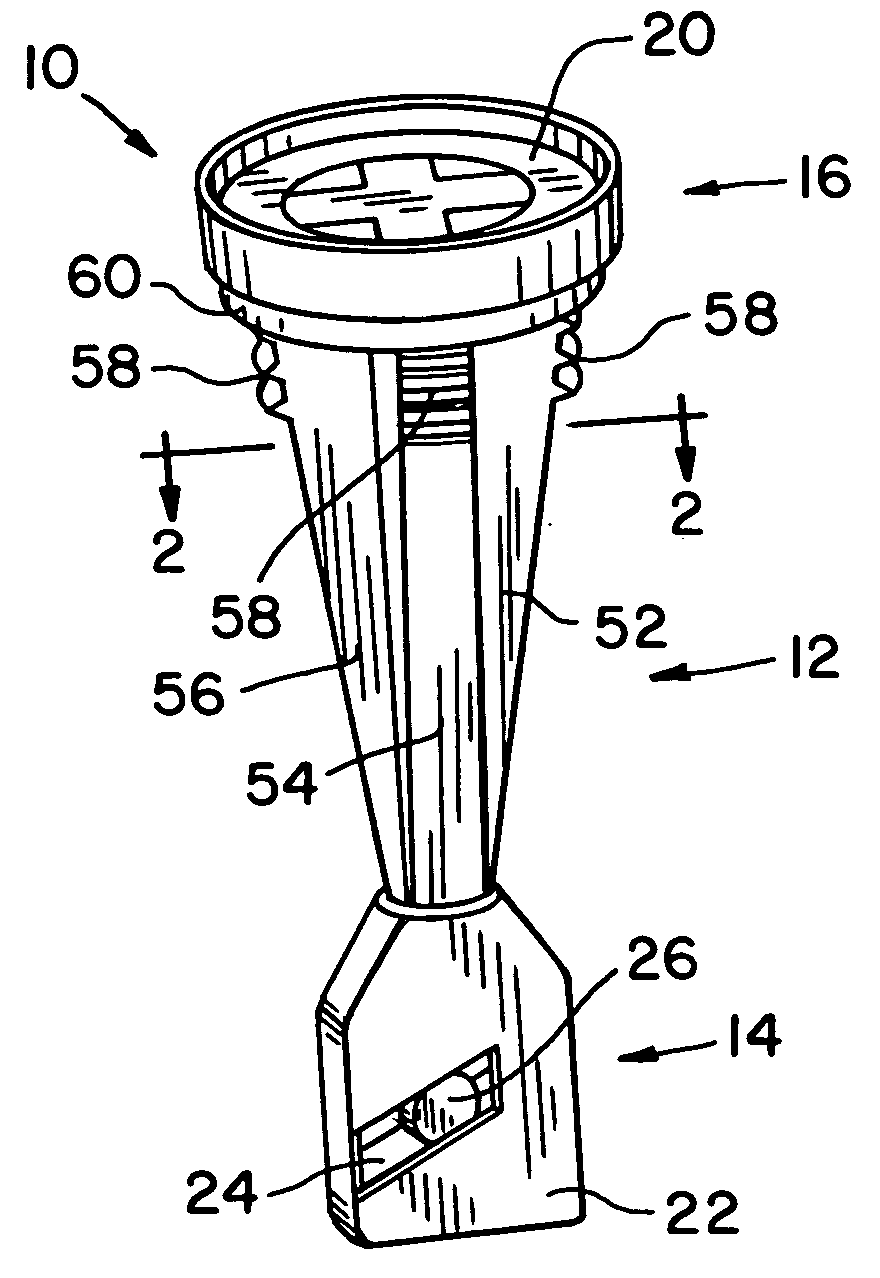

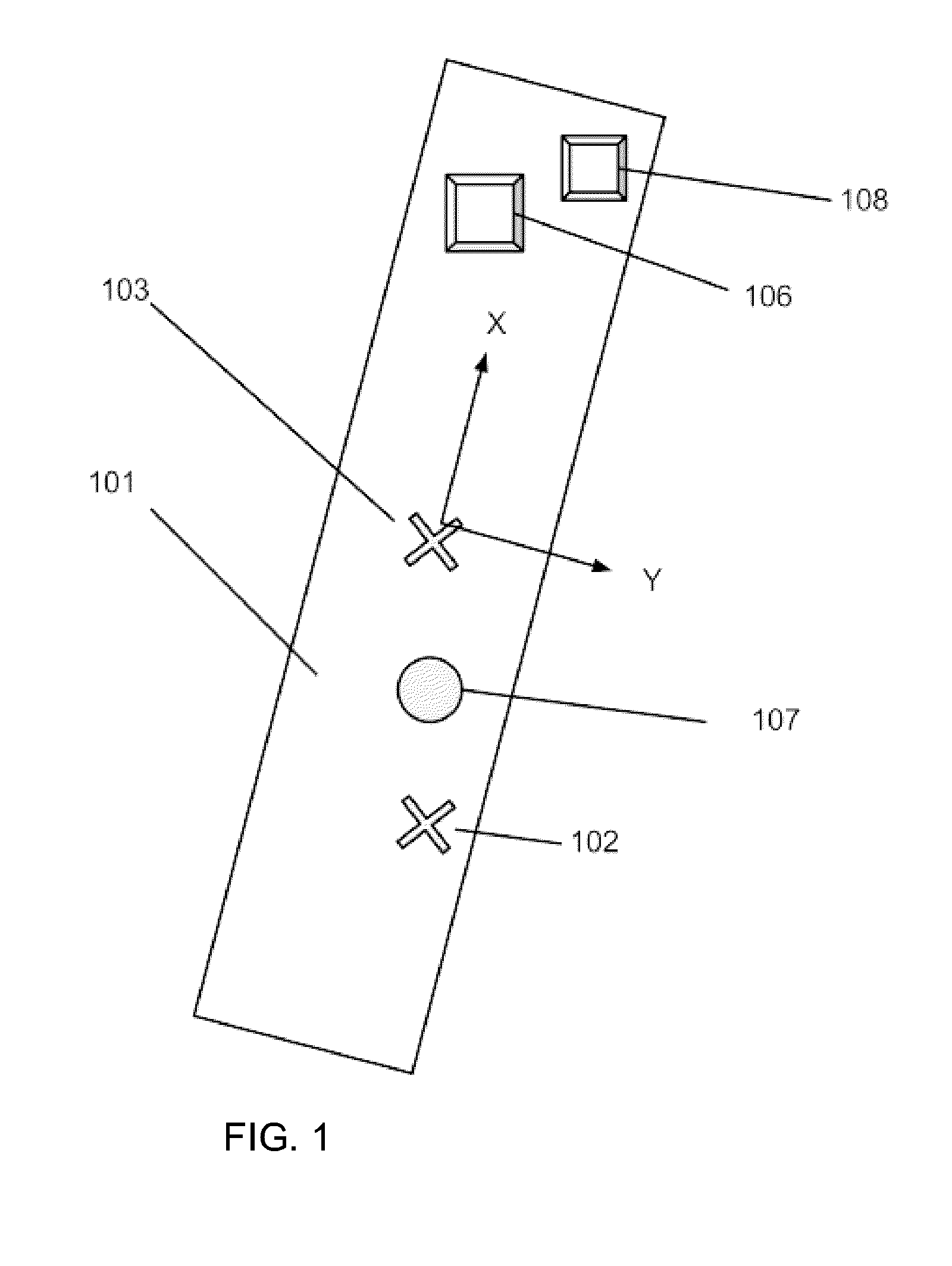

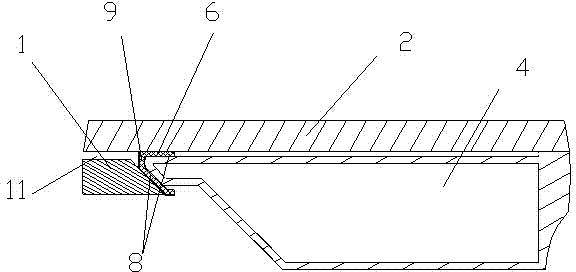

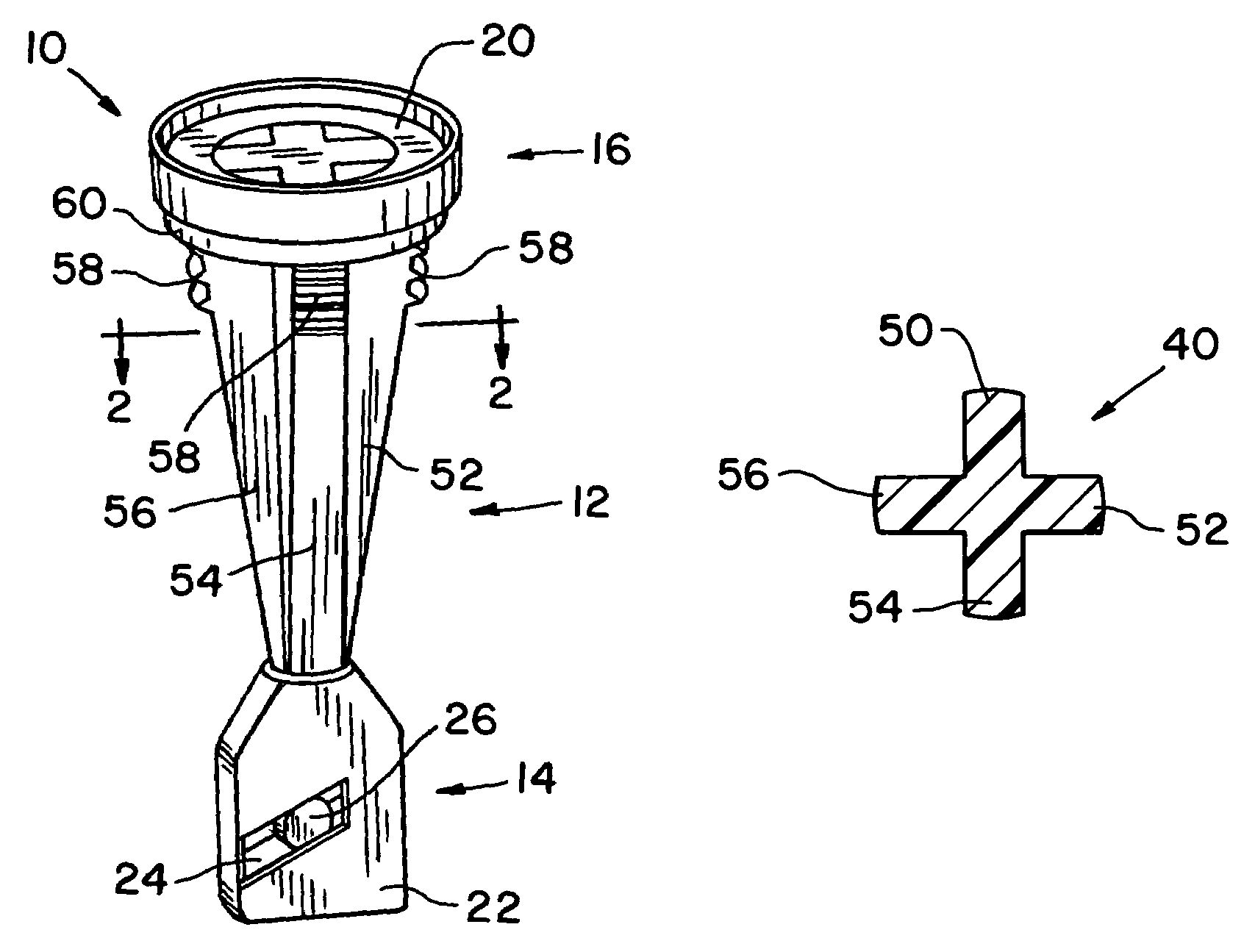

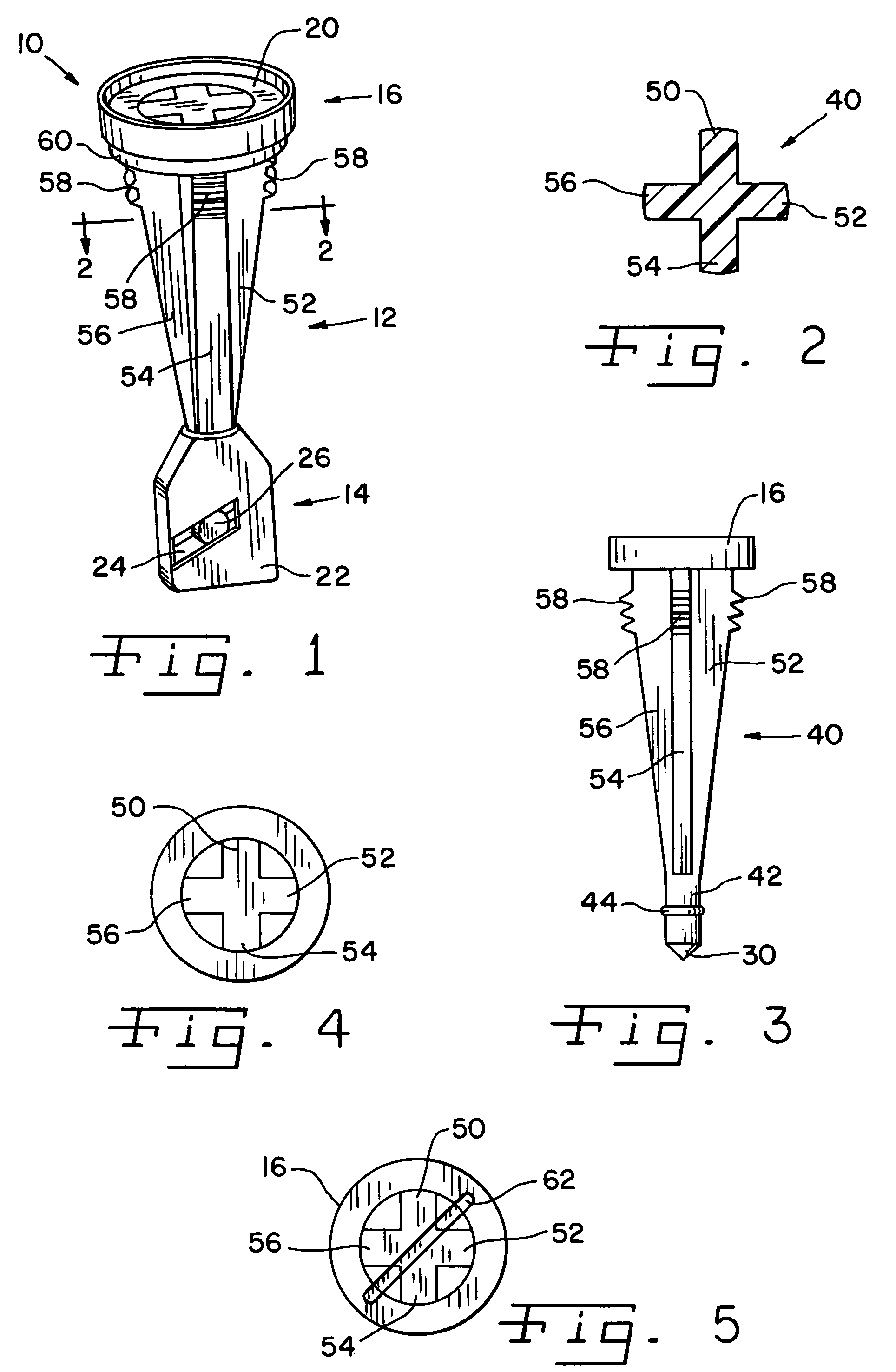

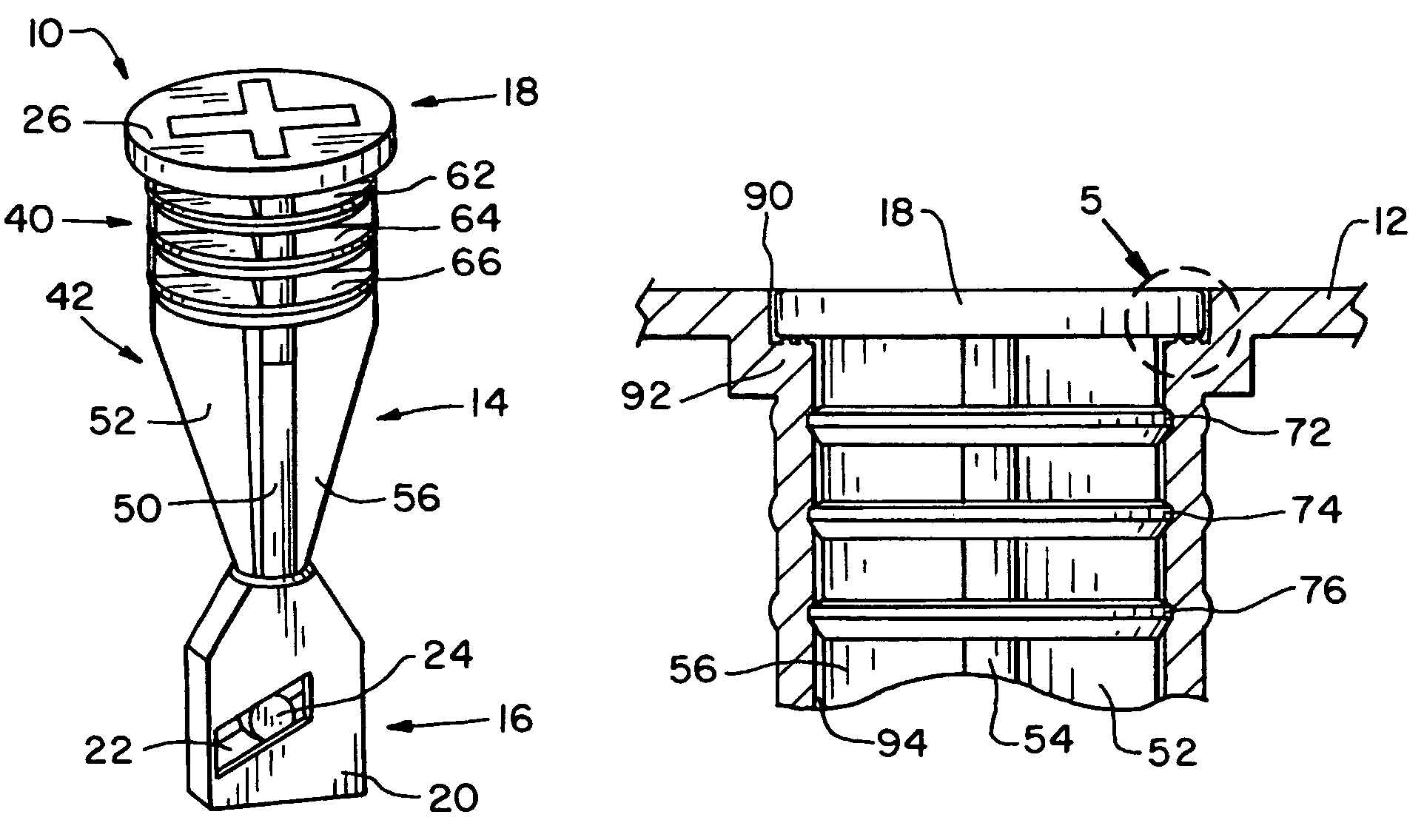

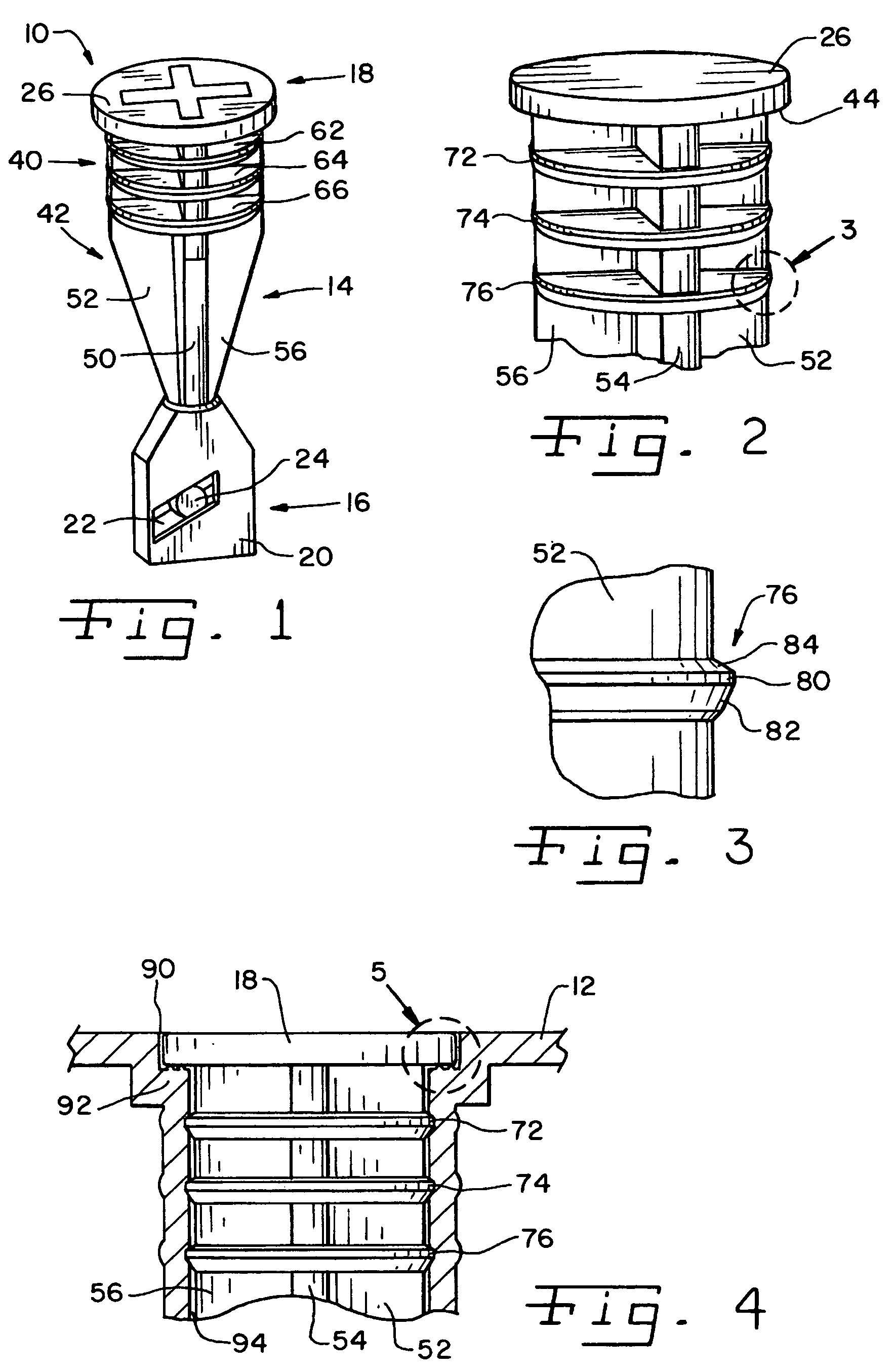

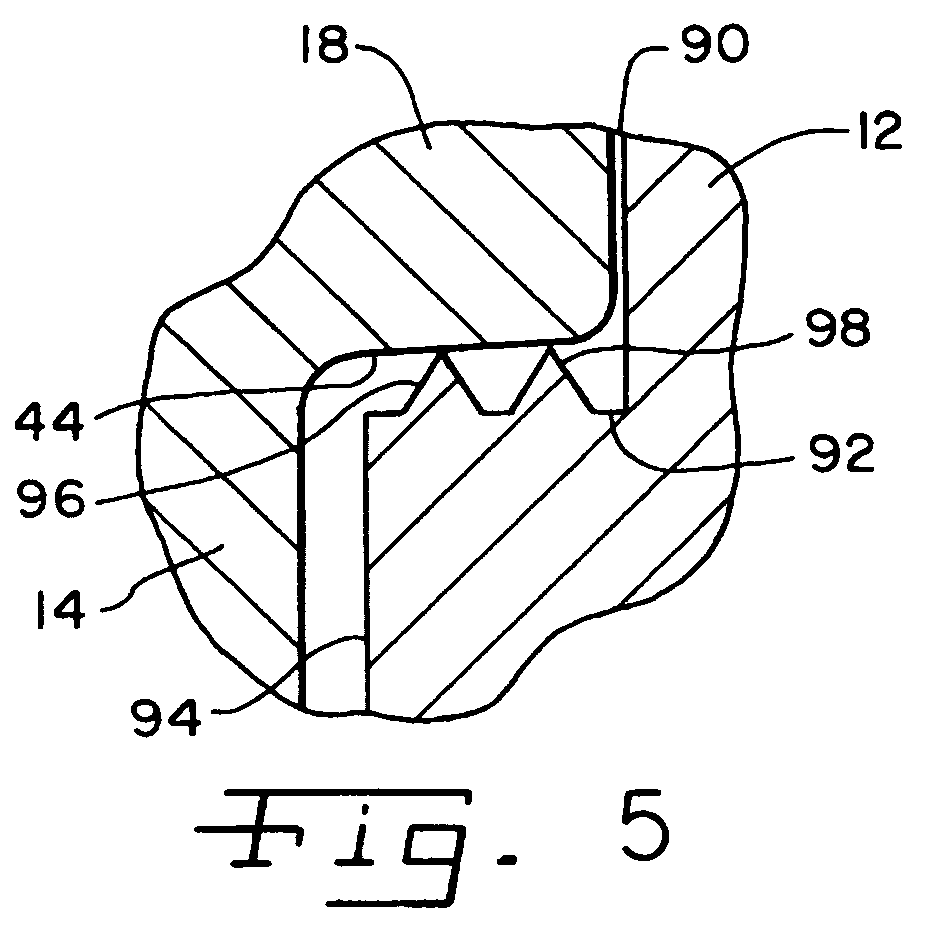

Hydrometer/fluid level sensor

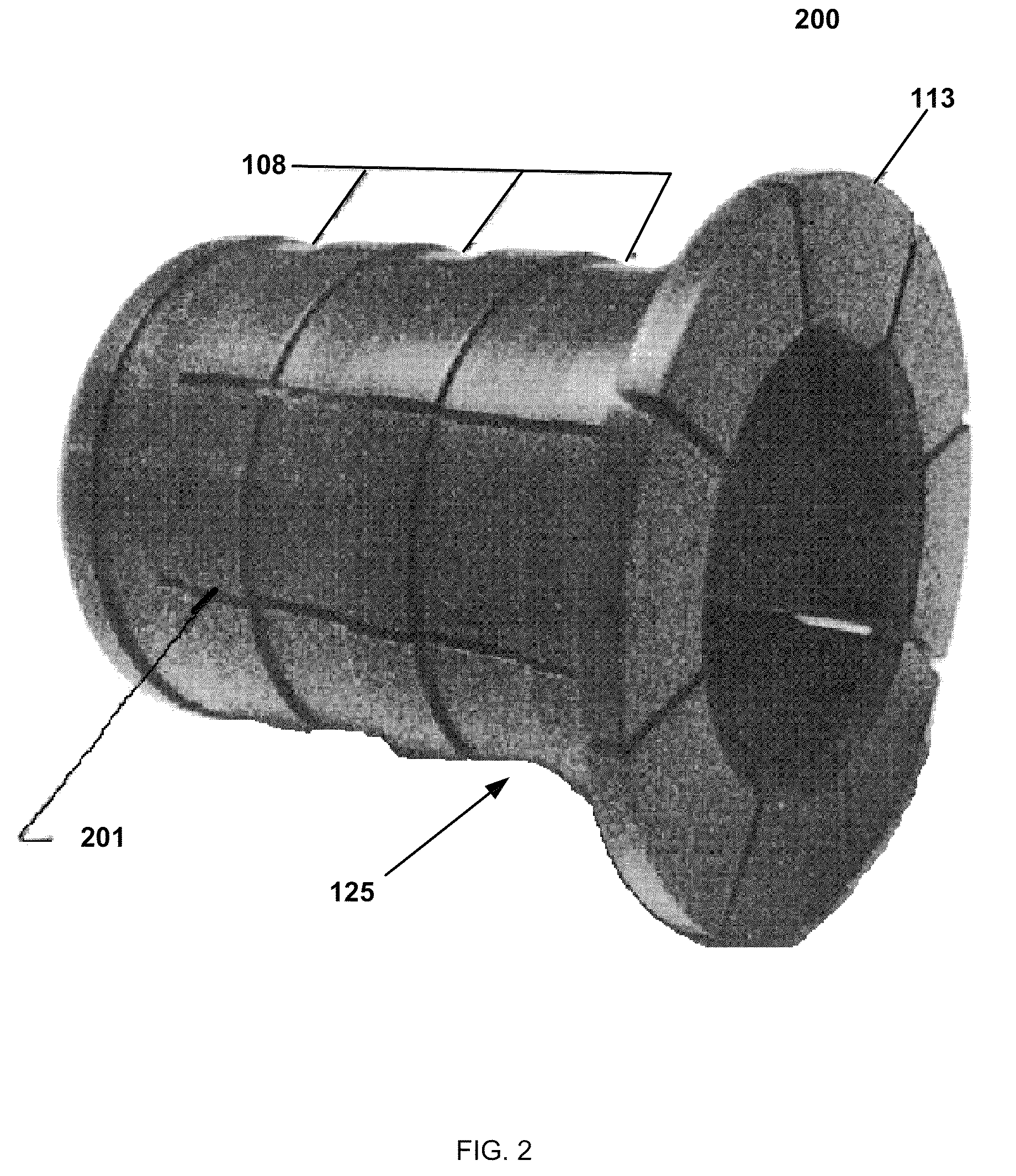

InactiveUS20060027018A1OptimizationEasy to failLead-acid accumulatorsMachines/enginesCruciformHydrometer

A light transmissive body for a fluid condition indicator has a substantial length shaped as a cruciform in transverse cross-section.

Owner:ILLINOIS TOOL WORKS INC

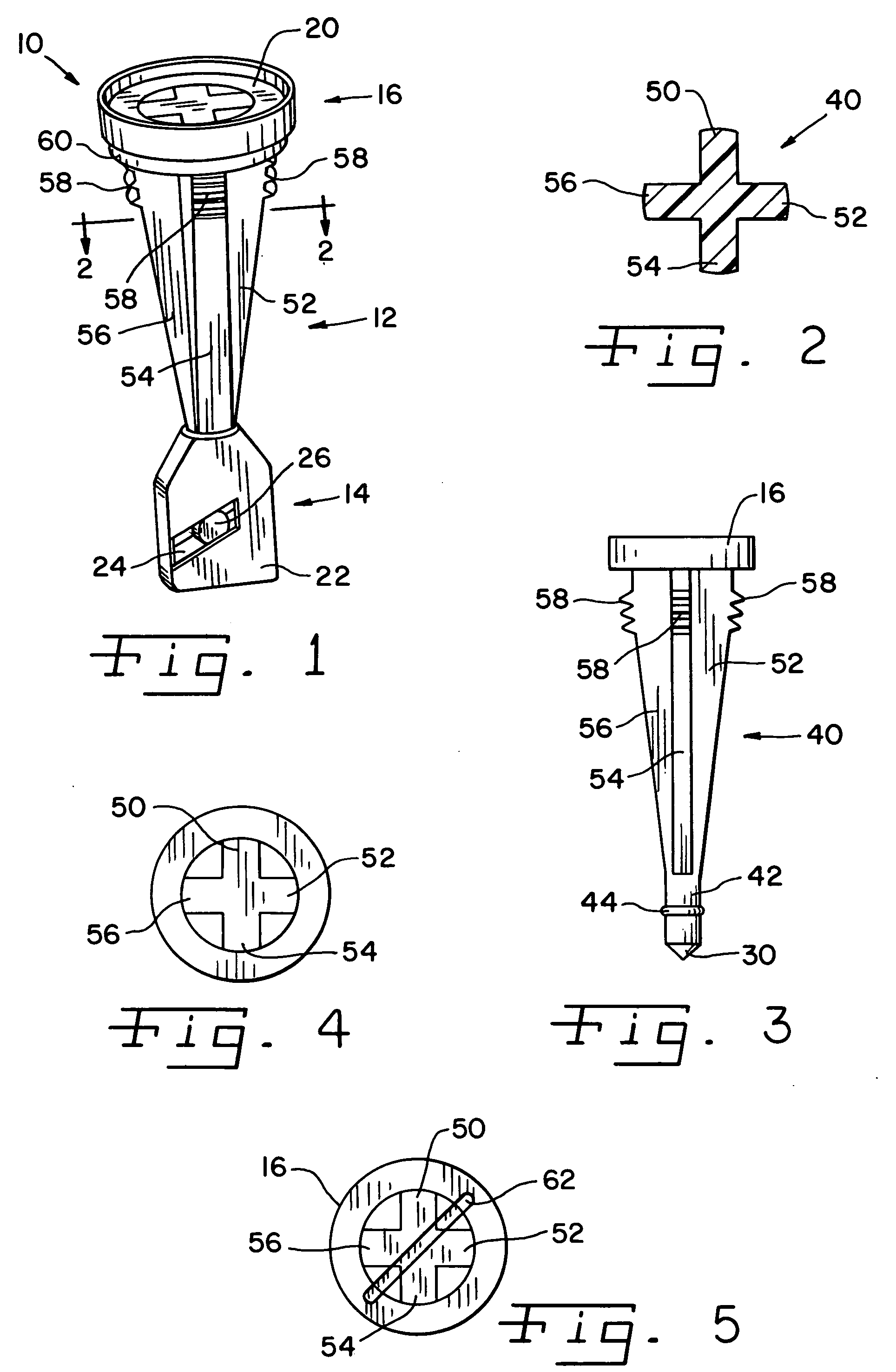

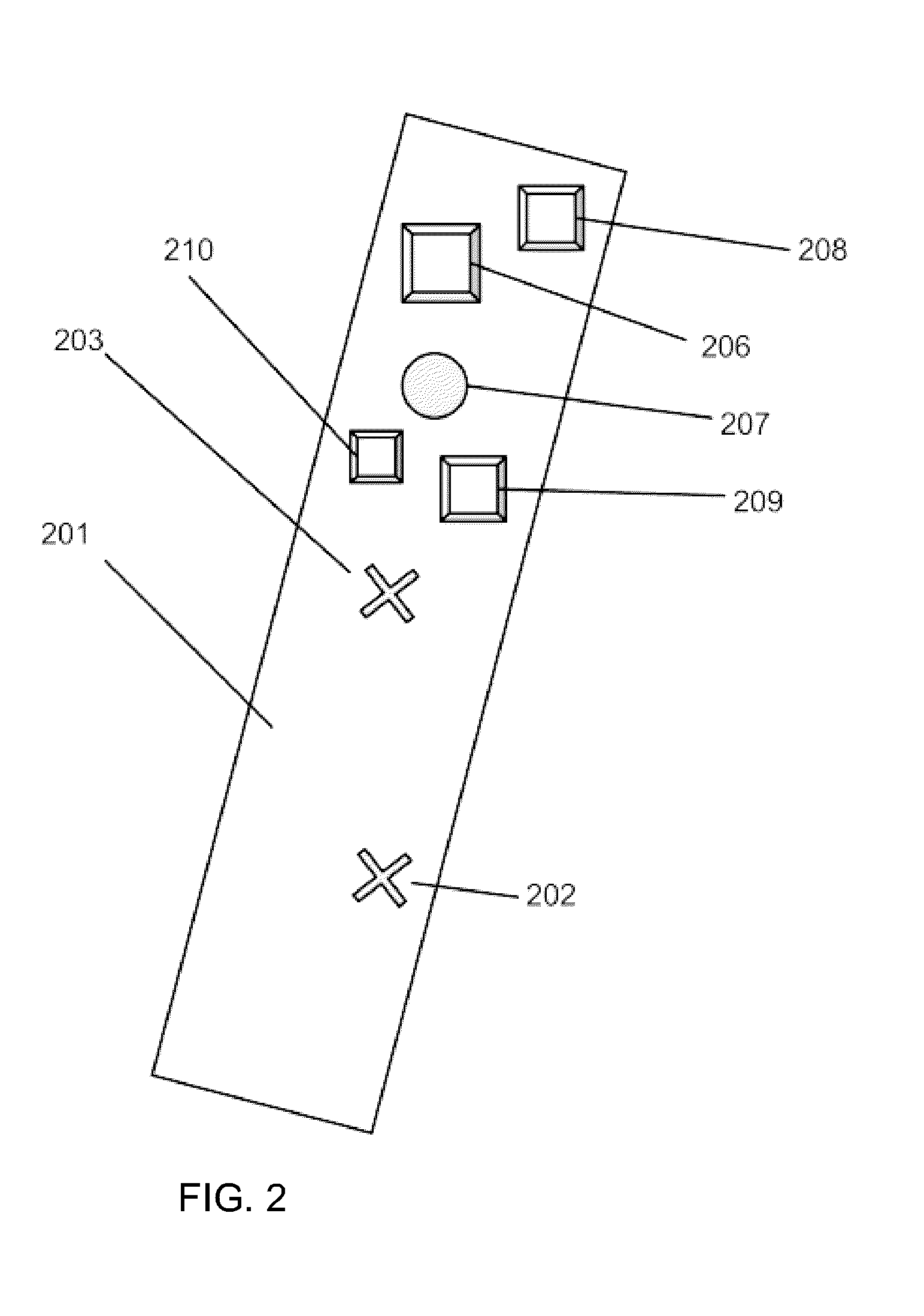

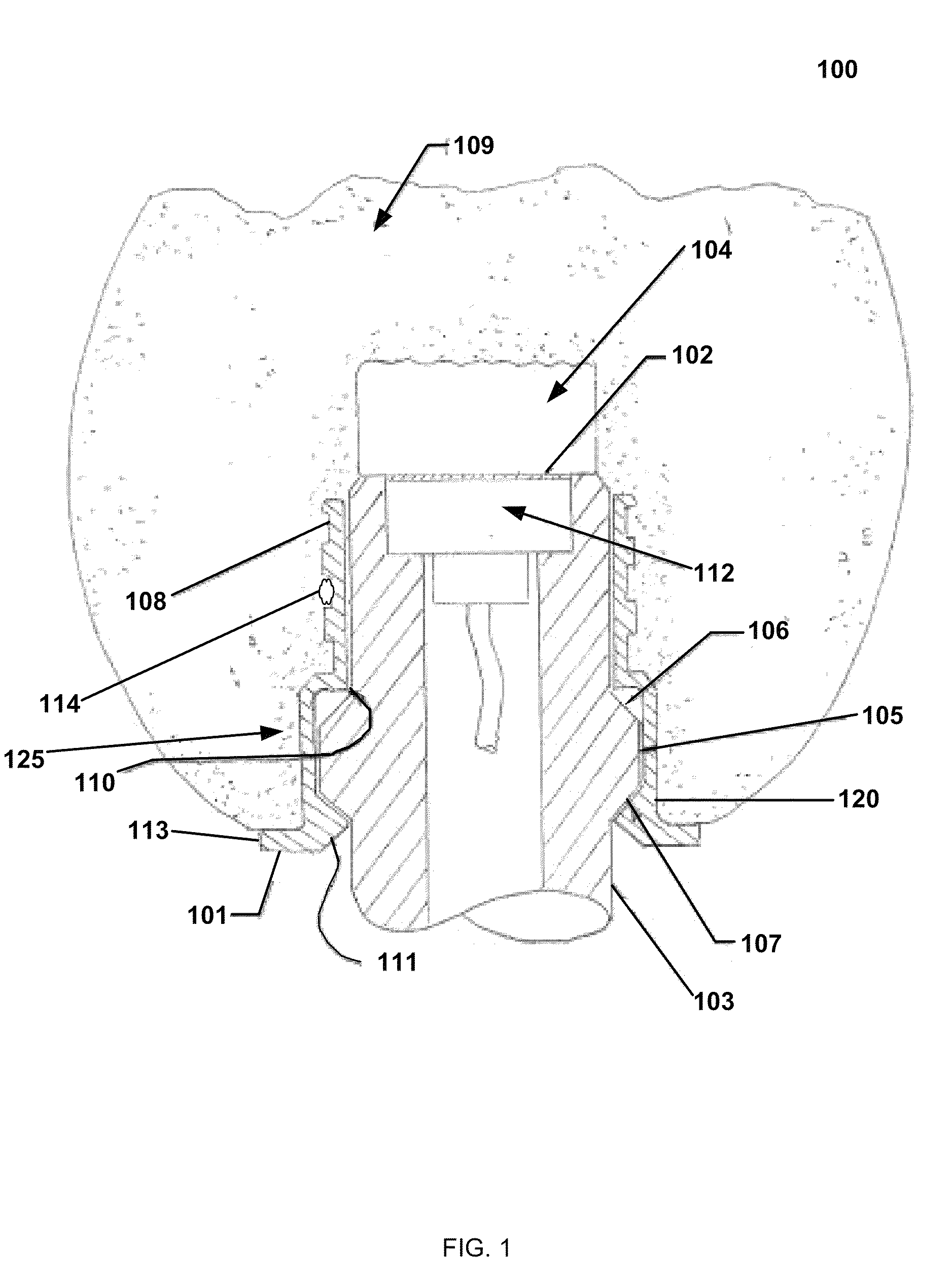

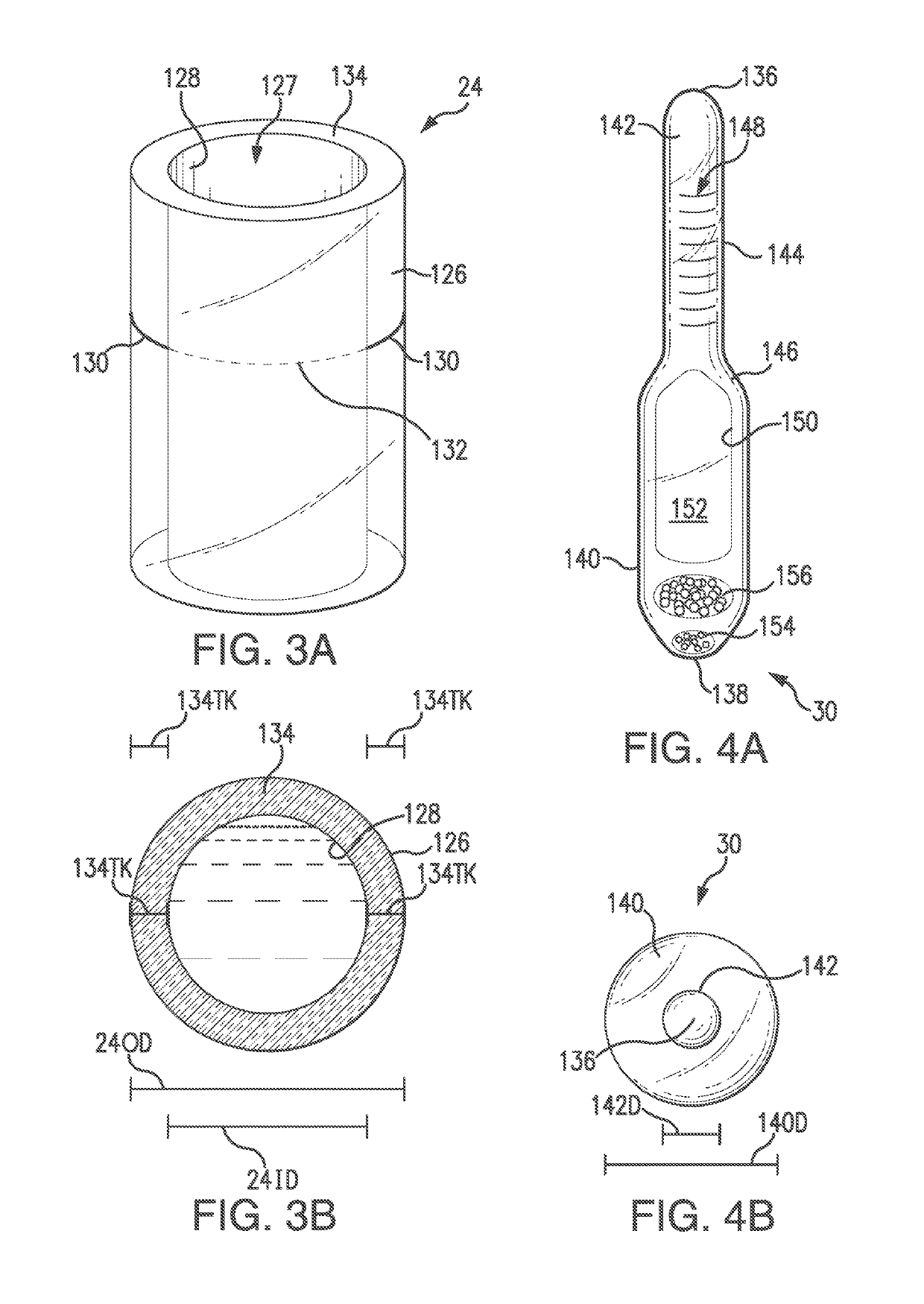

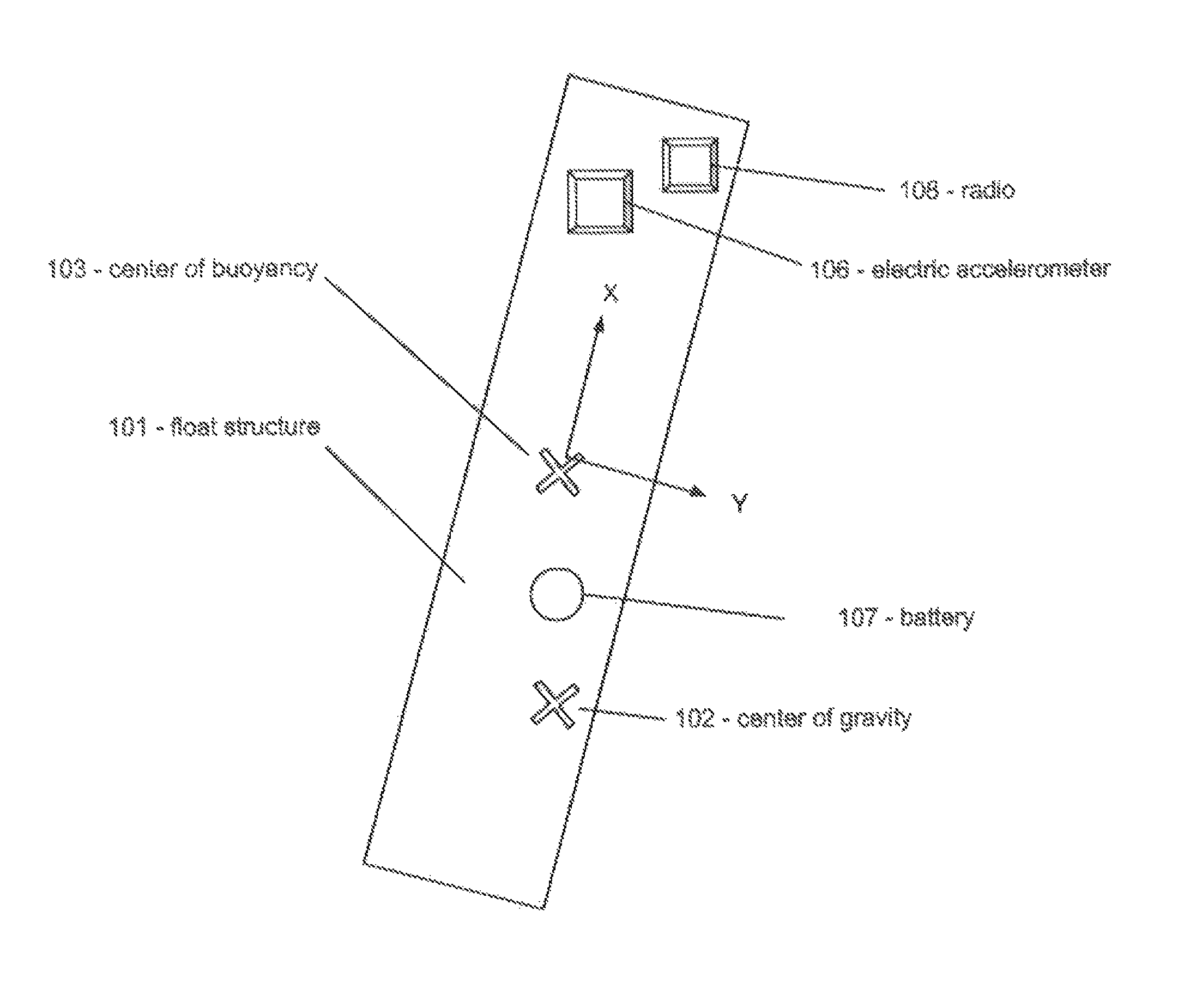

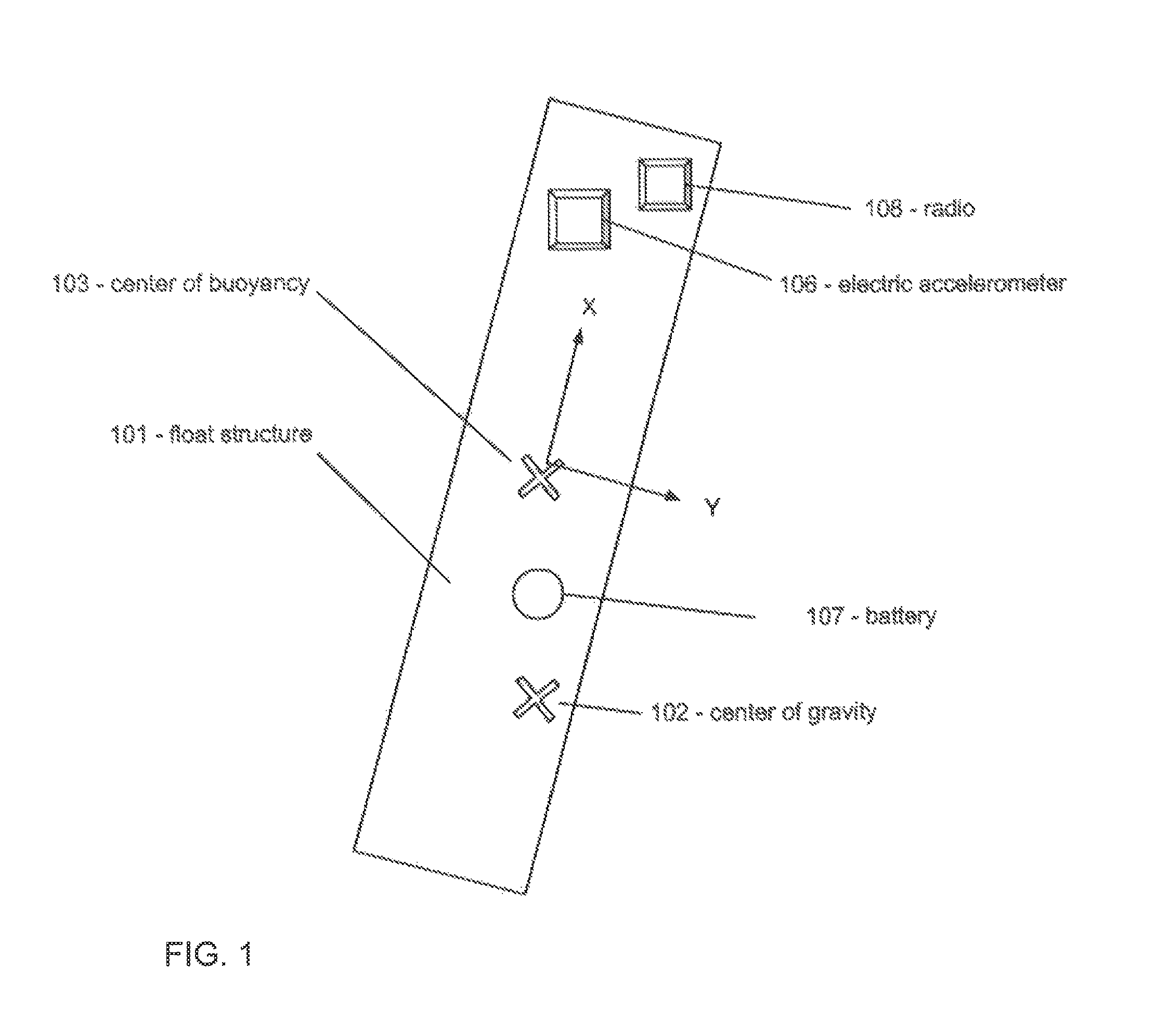

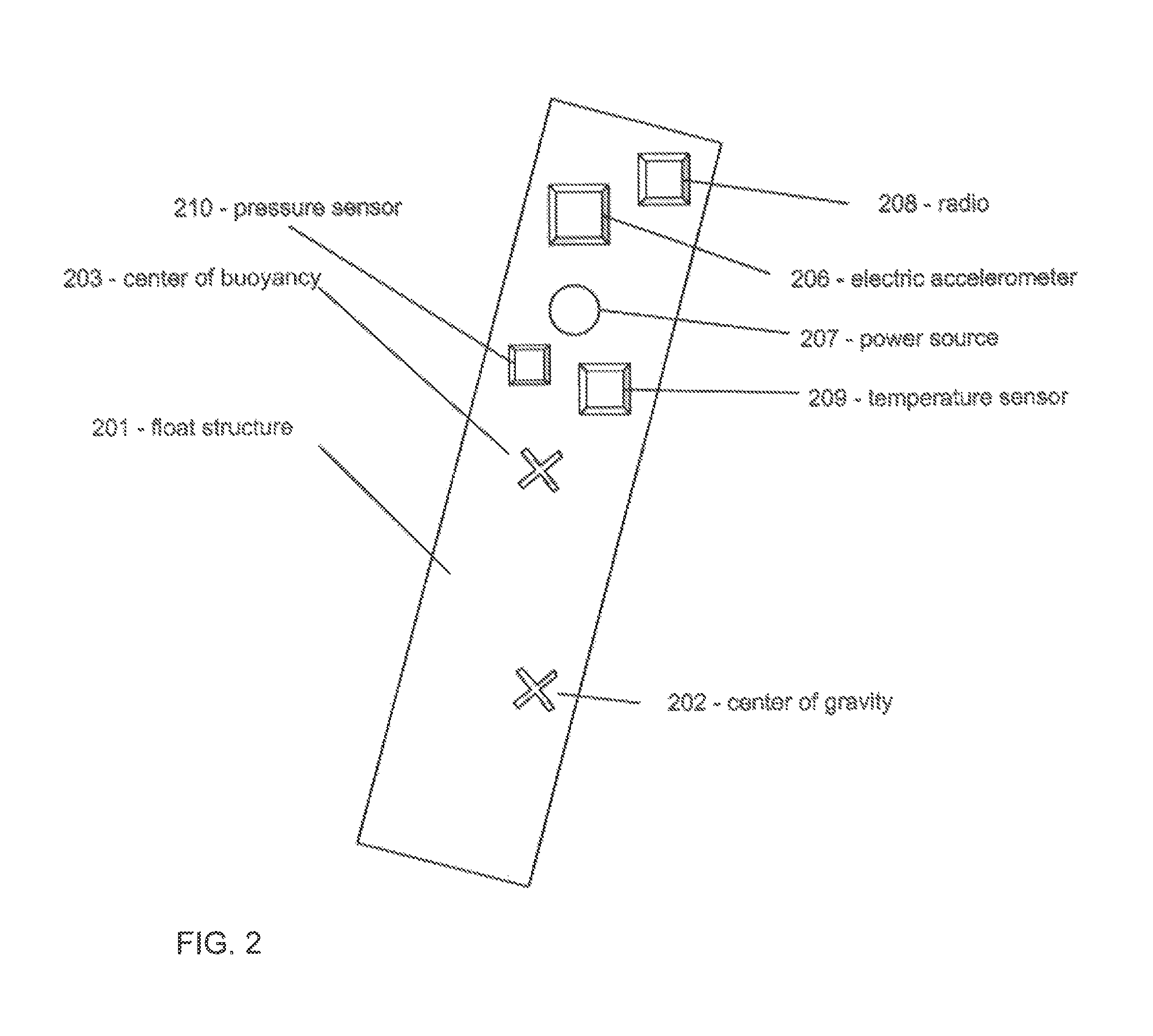

Free Floating Tilt Hydrometer

ActiveUS20140260607A1Improve transmission distanceEliminate needMaterial analysis by observing immersed bodiesHydrometerAccelerometer

A hydrometer embodied as self-contained buoyant structure that reacts to the buoyant force of a fluid by equilibrating at a tilt. The tilt of the structure can then be used to calculate the specific gravity of the fluid. In one embodiment, an accelerometer for measuring the inclination of the buoyant structure, a radio for transmitting the data wirelessly and a battery is contained within the buoyant structure, which allows for a convenient, and efficient automated process for monitoring the specific gravity of a liquid.

Owner:BARON BREW EQUIP

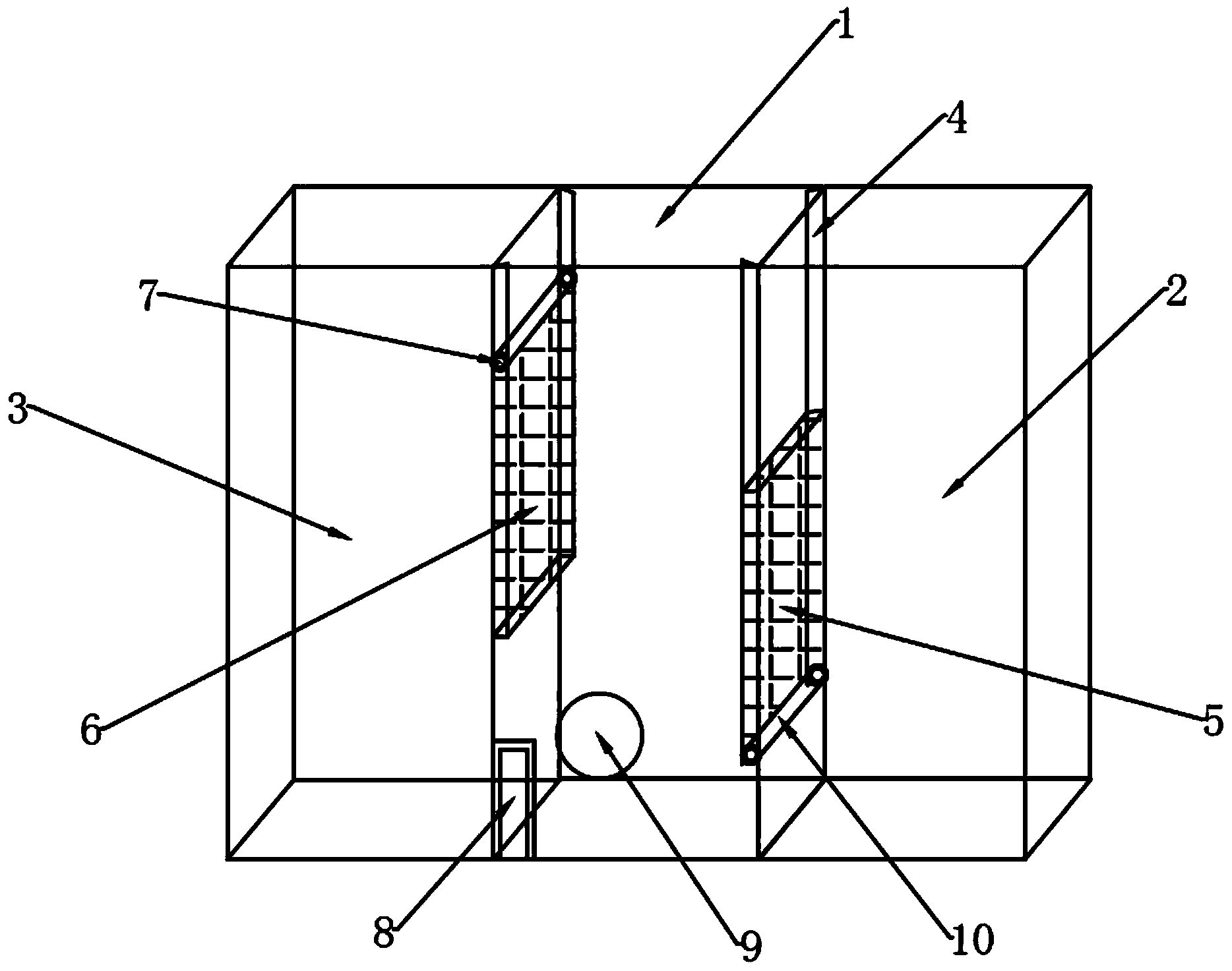

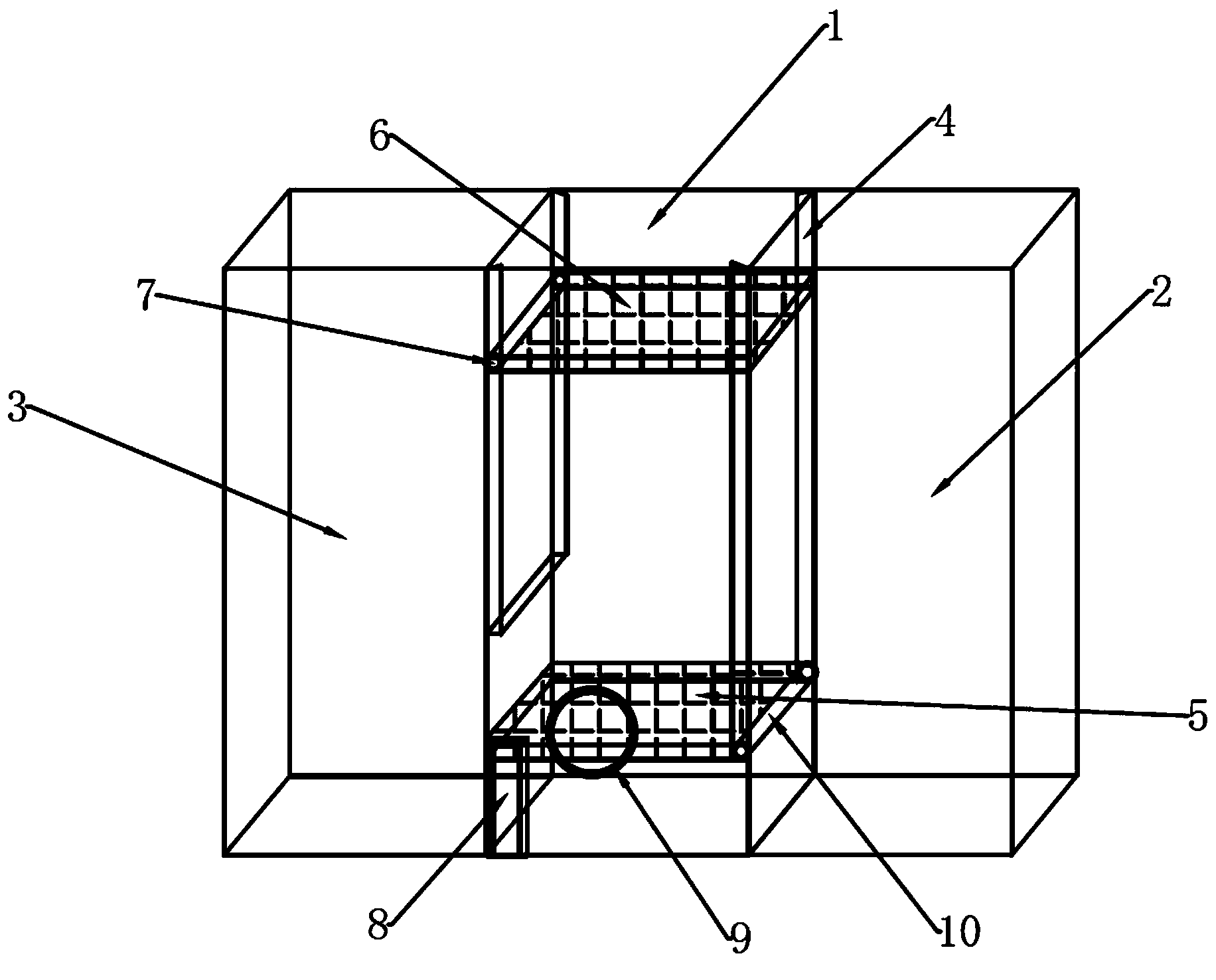

Glass hydrometer detecting/calibrating device

ActiveCN104237067AAchieve calibrationHigh degree of automationSpecific gravity measurementHydrometerGraduated cylinder

Owner:HENAN PROVINCE INST OF METROLOGY

Method for producing high-efficiency purifying agent magnesium ferrous sulfate from titanium dioxide waste acid by using sulphuric acid method

InactiveCN101774650AIncrease the amount of controlSimple processMagnesium sulfatesIron sulfatesHydrometerFiltration

The invention discloses a method for producing a high-efficiency purifying agent magnesium ferrous sulfate from titanium dioxide waste acid by using a sulphuric acid method, aims to overcome the defect of the commonly used purifying agent at present, solves the problem of waste acid pollution in a titanium dioxide plant and provides a method for producing the purifying agent. The method comprises the following steps: putting mother liquor into a reaction pool; adding magnesia with the MgO content of more than or equal to 85 percent into the mother liquor; mixing with a stirrer; controlling the adding amount of the magnesia by using a method of measuring the specific gravity of mixed liquor with a Baume hydrometer; controlling the adding amount of waste sulphuric acid by using a method of detecting the pH value of the mixed liquor; controlling the reaction temperature not to exceed 95 DEG C; performing pressure filtration on a reacted mixed liquor with a pressure filter after the reaction is performed for 1.5 to 2.5 hours; delivering filtrate to a cooling bath for initial cooling and then delivering the filtrate to a cooling tank with a pump; further cooling the filtrate through stirring; discharging when the temperature is reduced to 10 to 30 DEG C; putting the cooled filtrate to a crystallizing pool to crystallize and precipitate naturally; and drying a precipitated product to obtain a granular product.

Owner:孙宝钦 +1

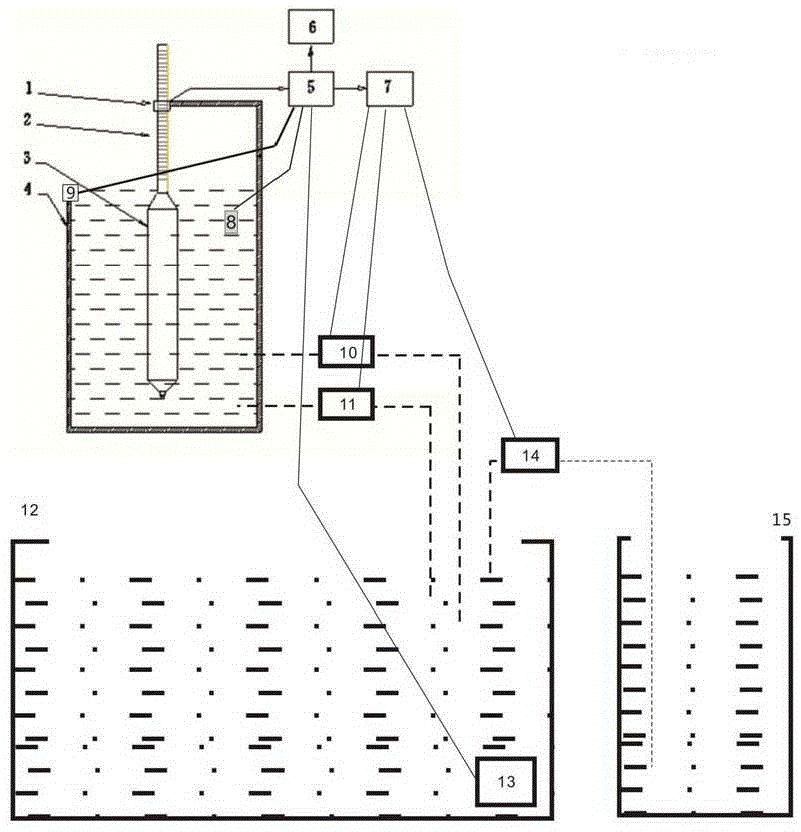

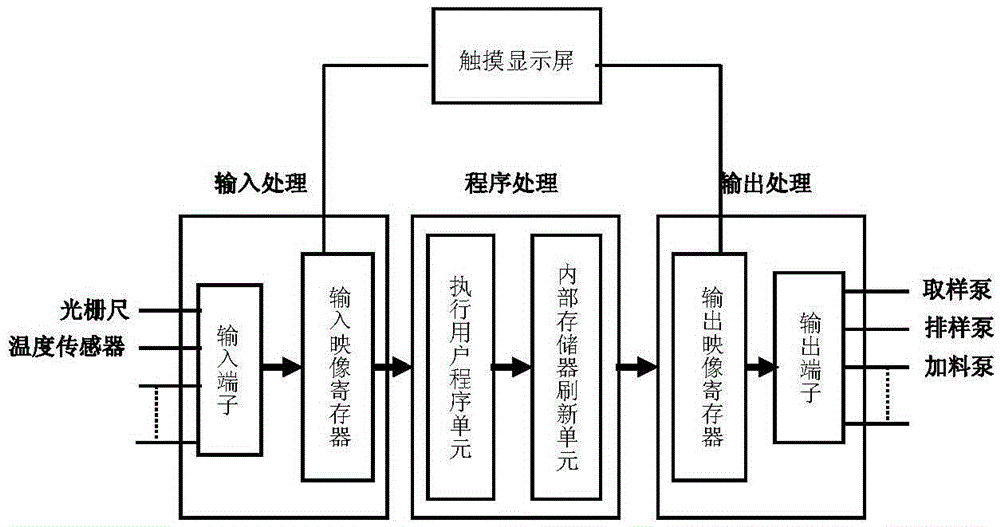

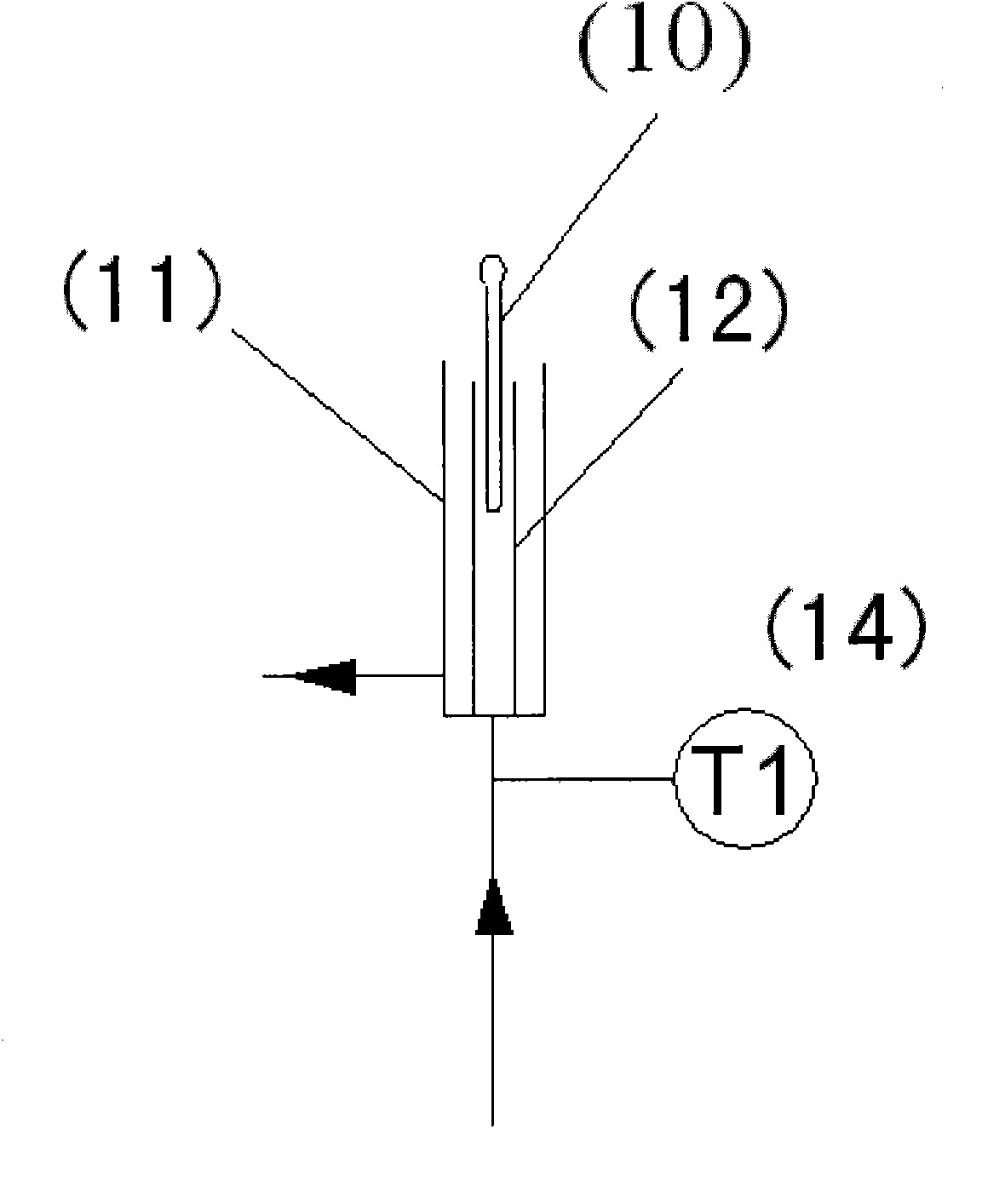

Alcohol specific gravity measuring device

InactiveCN105372152AControlling ratio of multiple fluid flowsMaterial analysis by observing immersed bodiesHydrometerLiquid density

The invention discloses an alcohol specific gravity measuring device. The alcohol specific gravity measuring device comprises a glass hydrometer, a grating ruler sensor used for measuring up and down floating distance of the glass hydrometer in a liquid to be measured, and a measuring and controlling system connected with the grating ruler sensor; and the measuring and controlling system is used for measuring and controlling the concentration of alcohol or isopropanol in the liquid to be measured. The alcohol specific gravity measuring device can be applied to high grade printing to control alcohol specific gravity to be 3 to 5%, and 3% preferably, and can be applied to liquid density measuring in a plurality of industries.

Owner:QUFU NORMAL UNIV

Method for improving washed soil

InactiveCN103240269AImprove water retentionHigh organic contentContaminated soil reclamationHydrometerSoil science

The invention discloses a method for improving washed soil, and relates to a method for improving soil. The method for improving washed soil comprises the following process: determining the proportion of sand granules of 0.025mm of washed soil according to a hydrometer method, when the proportion of sand granules greater than 0.025mm of the washed soil is 60%-80%, the additive amount of mushroom residue composite additives is 8wt%-10wt%; when the proportion of sand granules greater than 0.025mm of the washed soil is 40%-60%, the additive amount of mushroom residue composite additives is 3wt%-5wt%, and when the proportion of sand granules greater than 0.025mm of the washed soil is below 40%, the additive amount of mushroom residue composite additives is 1.5wt%-2.5wt%; and mushroom residue composite additive is formed by uniformly mixing mushroom residue after decomposition treatment, biogas residue and fulvic acid according to the mass ratio of 355:97:38. The method not only can be used for increasing the water retaining capacity of the washed soil, but also can replenish nutritional ingredients of the washed soil, meanwhile, is low in cost, has no engineering modification, and is high in feasibility in actual applications.

Owner:SHENYANG UNIV

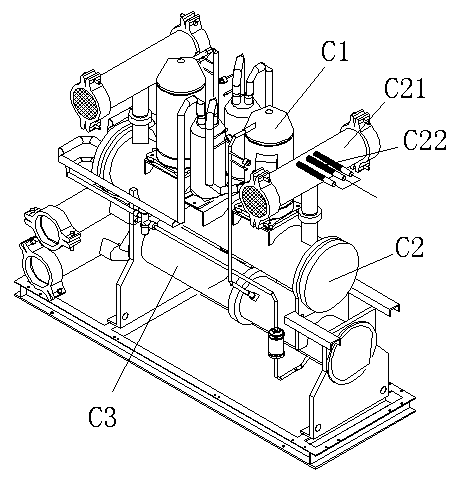

Air energy-collecting tower heat pump unit

The invention relates to an air energy-collecting tower heat pump unit which comprises an air energy-collecting tower, an energy storage thermostatic water tank, a vortex main engine, an air conditioner end, a unit pipeline and an antifreezing liquid concentration system, wherein the antifreezing liquid concentration system comprises a charging barrel, a generating barrel, a condenser, a water bucket and a vacuum pump; the generating barrel is respectively communicated with the charging barrel and the condenser, the condenser is also communicated with the water bucket and the water bucket is also communicated with the vacuum pump; the generating barrel is also communicated with a liquid inlet pump and a liquid outlet pump, an electrical bar is installed in the generating barrel, a hydrometer is installed on the generating barrel; the liquid inlet pump is respectively communicated with a liquid outlet of air energy-collecting tower and the unit pipeline, the liquid outlet pump is respectively connected with an liquid inlet of the air energy-collecting tower and the unit pipeline; an electric heating pipe is installed in a liquid inlet pipe of an evaporator; and a rain holding and rain proofing device is installed on the air energy-collecting tower. The invention can concentrate the antifreezing liquid, can realize rain proofing and rain-holding functions and can improve the temperature of the solution entering into the evaporator of the vortex main engine.

Owner:杭州联投能源科技有限公司

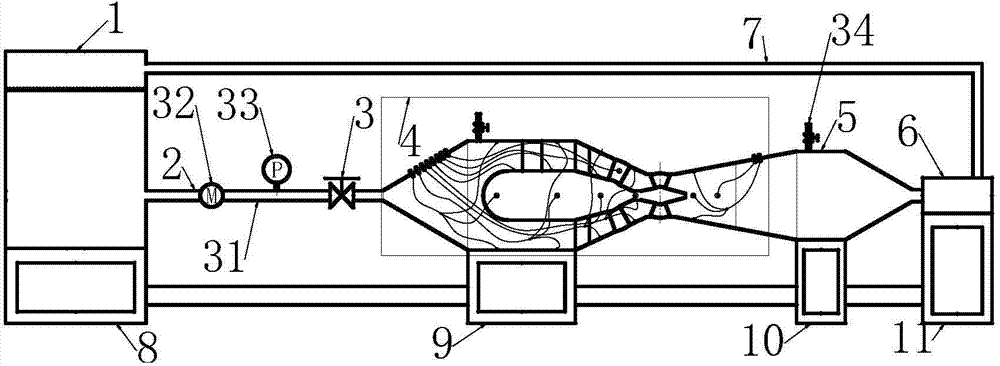

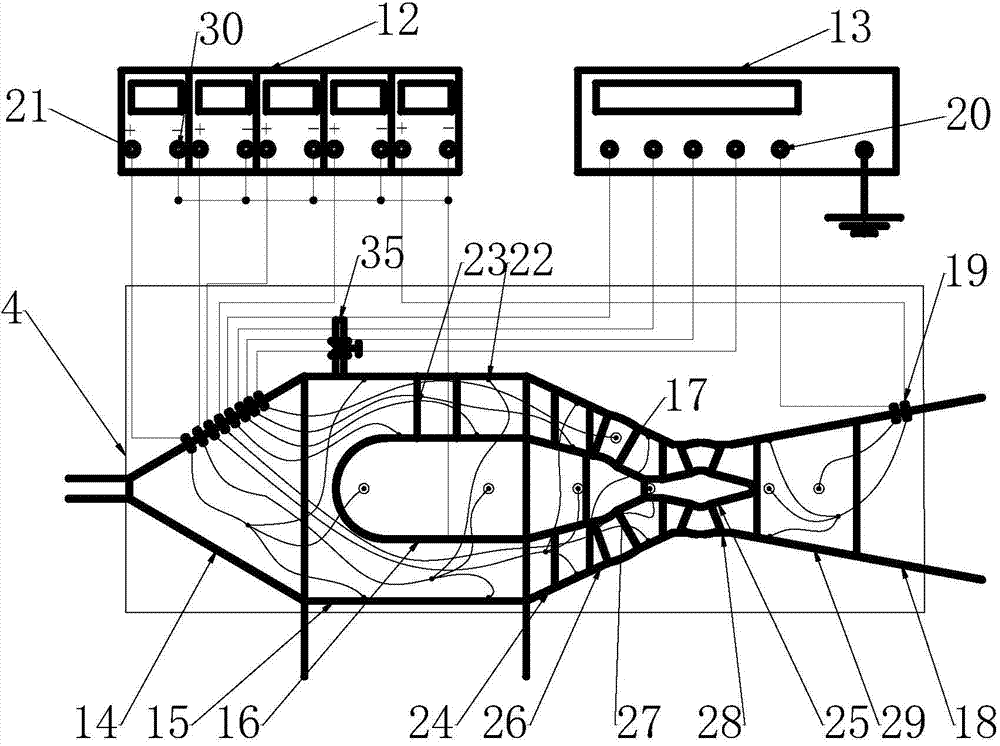

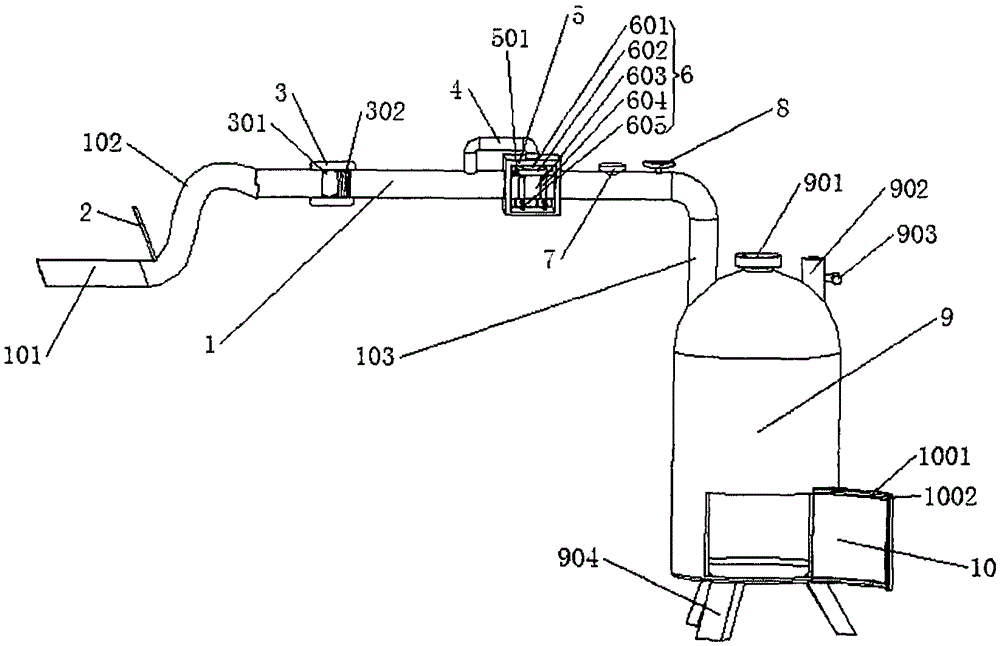

Through-flow turbine corrosion test model device

InactiveCN104122197AImprove liquidityAchieving tightnessWeather/light/corrosion resistanceHydrometerExhaust valve

The invention discloses a through-flow turbine corrosion prevention model device which consists of a water tank, a water inlet pipe, a hydrometer, a pressure gauge, a valve, a through-flow turbine model, a drain tank, a water pump, a wet return pipe, a water tank support seat, a model support seat, a drain tank support seat, a water pump support seat, a potentiostat, a digital multimeter, a conductive electrode with an insulating shell, an electrode and an exhaust valve. The through-flow turbine corrosion prevention model device can be used for guiding the electrochemical protection scheme design of a real machine. Furthermore, the through-flow turbine corrosion prevention model device is also capable of evaluating and prejudging the potential problems such as uniform corrosion, spot corrosion, crevice corrosion and galvanic corrosion in the through-flow turbine model by a model test, thus providing reference basis for design and manufacture of the real unit.

Owner:HARBIN ELECTRIC MASCH CO LTD

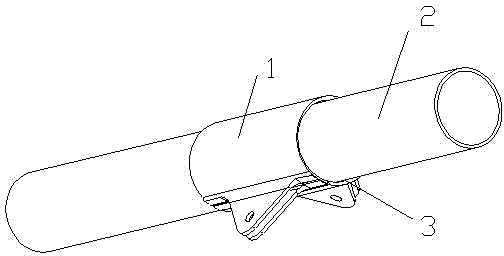

Glue joining device capable of carrying out glue joining in tiny space and application method thereof

ActiveCN104747551ASolve the problem of uncontrollable bonding qualityLight structureMaterial gluingRod connectionsHydrometerPipe fitting

The invention discloses a glue joining device capable of carrying out glue joining in a tiny space and an application method thereof. A glue solution enters the glue joining device through a glue solution groove pipe and flows into a glue solution filling cavity through a glue solution injection connector assembly and an air sealing gasket; air in the glue solution filling cavity is sucked out of a vacuum pump pipe through an air filtering gasket. The application method comprises the steps that after a standard pipe fitting and a connector are preassembled up to standard, the air filtering gasket and the air sealing gasket penetrate through the two sides of the connector respectively, and a vacuum suction connector assembly and the glue solution injection connector assembly are installed at the two sides respectively; the vacuum suction connector assembly is connected to the vacuum pump pipe, the glue solution injection connector assembly is connected to the glue solution groove pipe, a vacuum pump is started, a glue solution hydrometer is observed until the hydrometer does not change, and then glue solution injection is finished. By means of the mode, the problem that the glue joining quality cannot be controlled in the tiny space can be solved, the glue joining device is light in structure, easy to operate and high in glue joining efficiency, and meanwhile all the structural assemblies of the technique device can be standardized.

Owner:NEW UNITED GROUP

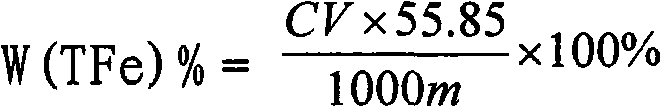

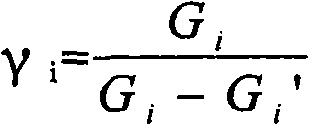

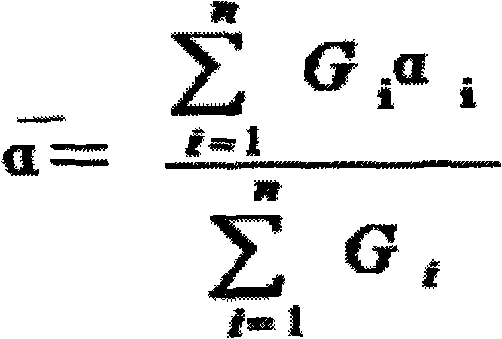

Method for measuring ore grade by hydrometer method

InactiveCN101929925AReduce consumptionEasy to operateMaterial analysis by measuring buoyant forcesWithdrawing sample devicesHydrometerEnergy conservation

The invention relates to a method for measuring ore grade, in particular to a method for measuring ore grade by a hydrometer method. The method comprises the following steps: sampling and specific gravity measurement: putting each sample ore into a cage, weighing weight G of each sample ore in the air and weight G' of each sample ore in the water with a weighing machine one by one, inputting the weight data into a spreadsheet document set by a computer, working out specific gravity gamma of each sample ore, checking a specific gravity-ore grade curve by utilizing the worked out ore specific gravity so as to obtain the grade of the sample ore, working out grade mean value of the ore sample by the weighting method, comparing the average ore grade with the planned ore grade, finally making judgments on ore grade to indicate whether the sample ore is qualified product or not. The method of the invention has simple operation, environment friendliness, energy conservation, less consumption of materials and devices, safe, fast and accurate measurement of ore grade.

Owner:ANSTEEL GRP MINING CO LTD

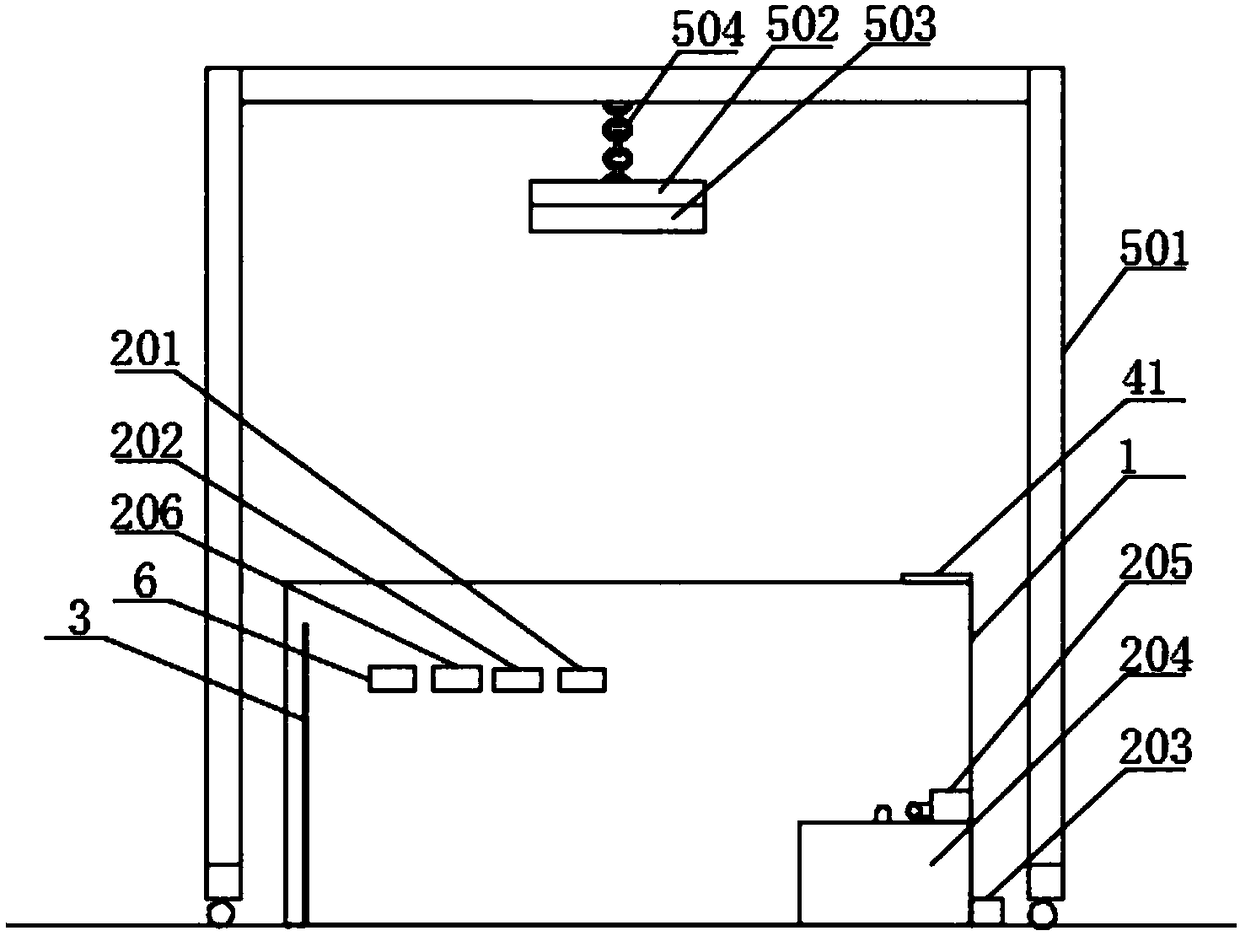

System and method used for seawater immersion test of power battery pack

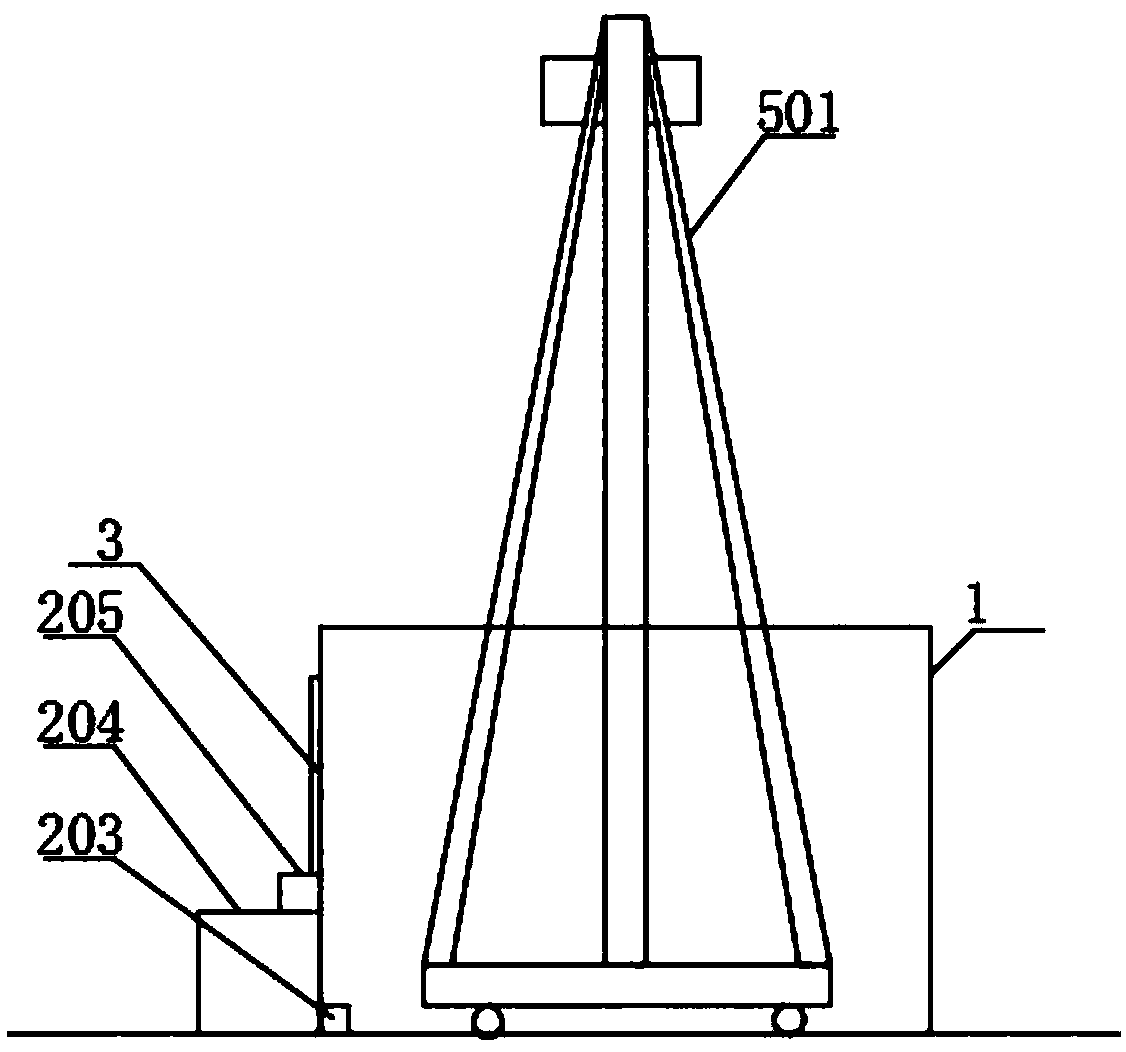

PendingCN109443647AImprove accuracyImprove reliabilityWeather/light/corrosion resistanceFluid-tightness measurement using fluid/vacuumHydrometerPower battery

The invention relates to the technical field of battery tests, in particular to a system and method used for a seawater immersion test of a power battery pack. The system comprises an immersion box, and a hydrometer and a pH tester are mounted on the immersion box and placed under a liquid surface of a test solution; the system further comprises a thermostat, a circulation pump, a movable hoistingframe and a lifting hoisting head; the pH value and specific gravity value of the test solution are adjusted before the test by the hydrometer and the PH tester so as to be more proximate to those ofseawater; at the same time, the temperature of the test solution in the immersion box is adjusted by the thermostat and the circulation pump so that the temperature of the test solution in the immersion box can be stabilized, the test solution can also stay in a flowing state, a seawater flowing state is further simulated, and the sealing performance of the power battery pack in the state that the power battery pack is driven by flowing liquid is tested to enhance the accuracy and reliability of a test result.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

Sensor shield retention device and system

ActiveUS8256287B2Fluid pressure measurementSpeed/acceleration/shock instrument detailsHydrometerVisibility

A system and device that provides for the retention of a sensor shield for a sensor such as a microphone, hydrometer, chemical sensor, or other detector. This invention provides for the quick attachment and release of a reduced visibility and reduced bulk shield retention assembly. In a battlefield environment, a smaller profile sensor shield presents less visibility as a prospective target of interest to enemy forces. Also, the sensor shield may be readily replaced without the use of any tools. The snap-lock feature provides a positive means for holding, for example, a windscreen in its respective position, requiring reasonable, but yet not objectionable force to install and remove the windscreen from the sensor's mounting shaft. Furthermore, the snap-lock feature, when engaged, may provide positive location of the sensor shield's sweet spot by maintaining a slight air space between the sensor shield and the sensor, and thereby precluding direct physical contact.

Owner:AIRPORTS AUTHORITY OF INDIA

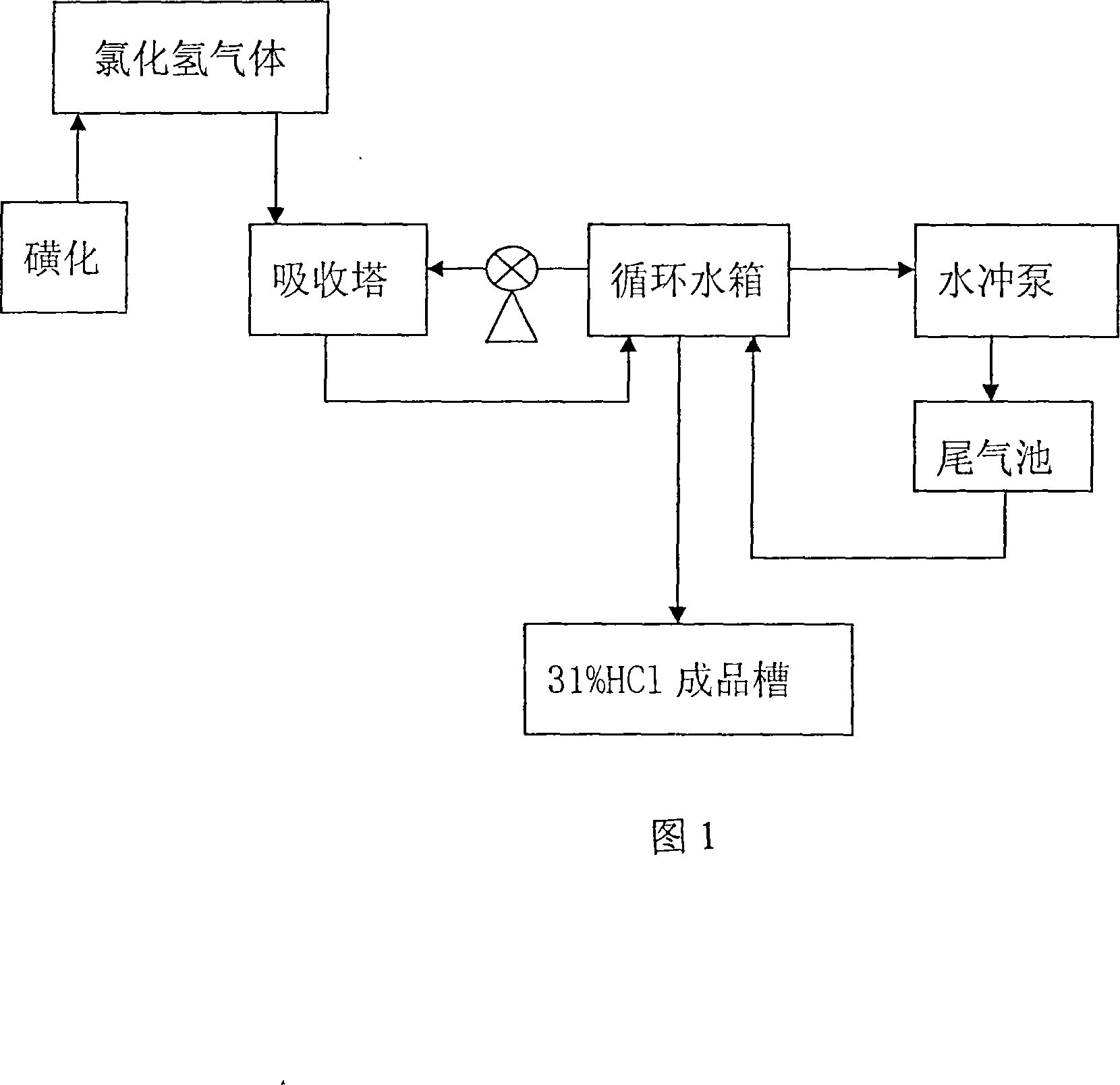

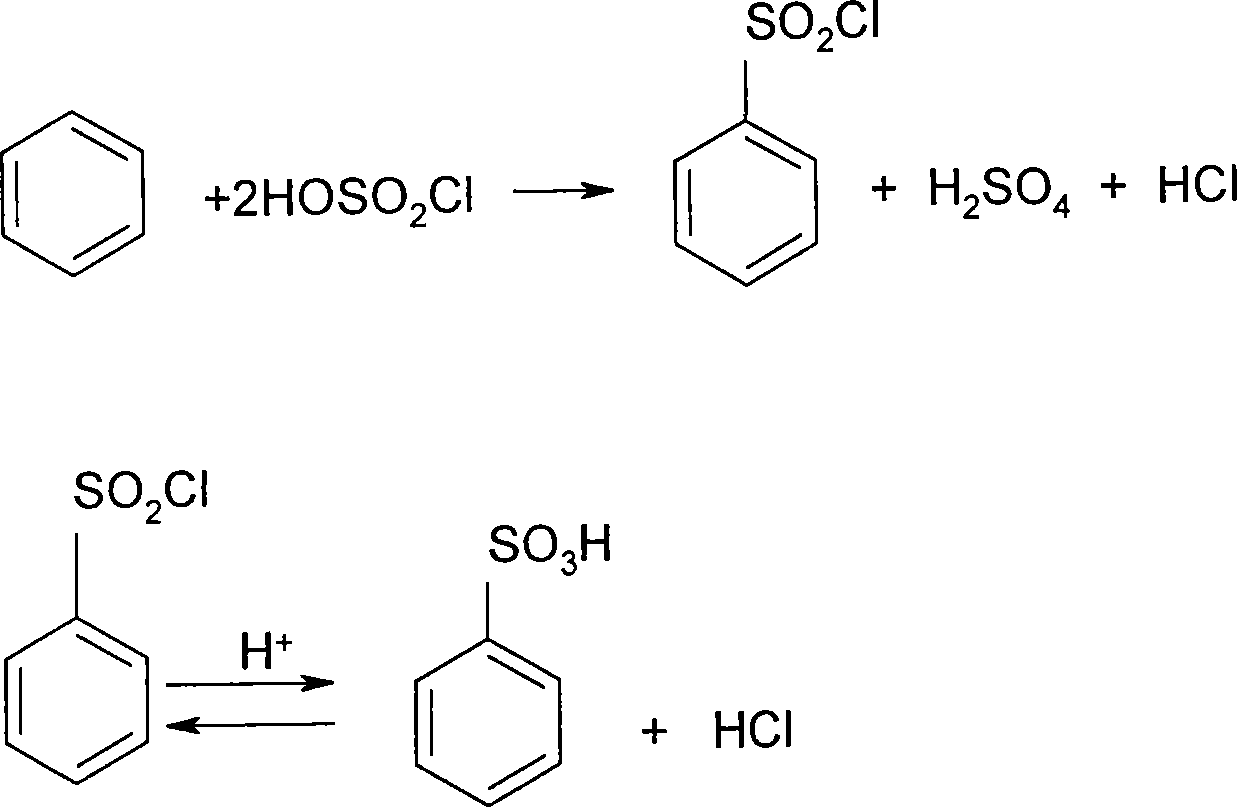

Method for recovering hydrochloric acid from HCL gas during the production process of benzene sulfochloride

ActiveCN101177242ARelieve pressureIncrease repeated cycle absorptionChlorine/hydrogen-chlorideHydrometerPositive pressure

The invention relates to a method for HCI hydrochloric acid gas recovery in the process of producing benzene sulfone chloride; based on the planar absorption apparatus, the prior positive pressure chlorosulfonation is changed into a bleed chlorosulfonation by adding a water pump and a circulation water tank at the end of tail gas, so that the pressure inside a reaction kettle and a pipeline can be reduced; the unabsorbed HCI tail gas is completely absorbed by the water pump cyclically through implementing a circulation absorption technology in the state of negative pressure. The invention has the advantages that the HCI gas which is generated in the process of sulphonation can be absorbed cyclically by adopting the negative pressure reactivity, so the smoky HCI gas in the air is removed; based on the planar absorption apparatus, the water pump and the circulation tank are added for implementing the circulation absorption under the state of negative pressure, when the absorbed concentration reaches 31% (the specific gravity is up to 1.155 which is measured by a hydrometer), the reclamation can be implemented; the invention can be used in manufacturing the products of rubber strengthening agent white black carbon so as to improve the economic benefit; the invention also can be better to solve the problem in environmental protection.

Owner:镇江惠隆化工有限公司

Constant speed mechanical water sampling device and sampling method

ActiveCN102103045ASimple structureEasy assembly and applicationWithdrawing sample devicesWeighing by absorbing componentMicrocontrollerHydrometer

The invention discloses a constant speed mechanical water sampling device and a sampling method. The constant speed mechanical water sampling device comprises a flue, an electric heating sampling gun, an electric heating controller, an absorption bottle group, a cooling water tank, a flow meter, a sucking pump, a hygrometer and a singlechip, wherein the electric heating sampling gun is arranged at the position of the section of the flue, is provided with an S-shaped pitot tube and a thermocouple, and is connected with the inlet of the absorption bottle group through a flue gas hose; the absorption bottle group is arranged in the cooling water tank; the electric heating sampling gun is connected with the electric heating controller; one side of the flow meter is connected with the outlet of the absorption bottle group through the flue gas hose, and the other side of the flow meter is connected with one side of the sucking pump through the flue gas hose; the hydrometer is connected with the other side of the sucking pump through the flue gas hose; and the electric heating sampling gun, the flow meter and the sucking pump are connected with the singlechip through a signal connecting line. The sampling method by using the constant speed mechanical water sampling device comprises four steps. By the device and the method, the requirement of accurately measuring the content of mechanical water in a supersaturated state can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

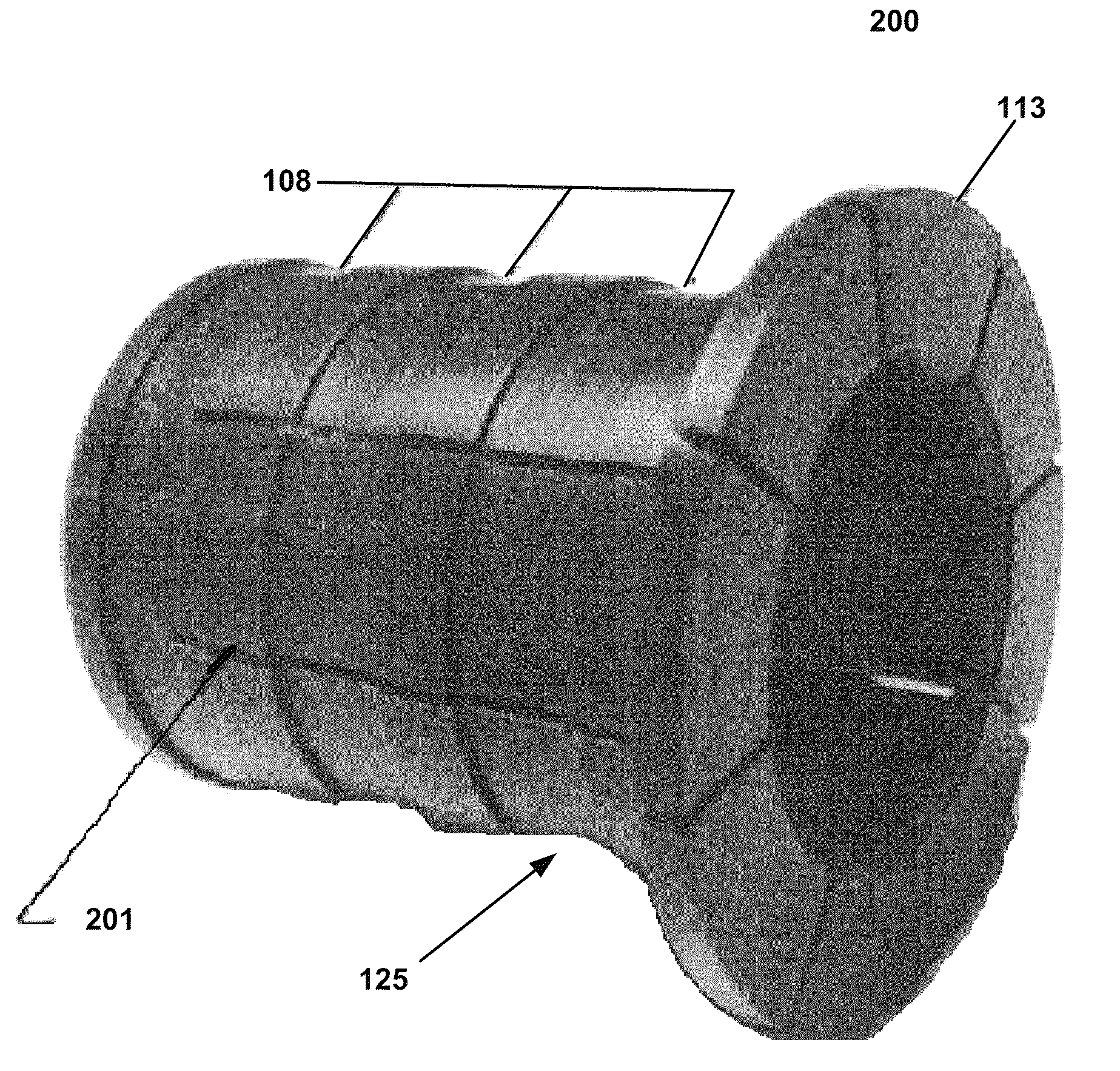

Hydrometer/fluid level sensor

InactiveUS7228737B2More discernable visual queueOptimizationLead-acid accumulatorsMachines/enginesCruciformHydrometer

A light transmissive body for a fluid condition indicator has a substantial length shaped as a cruciform in transverse cross-section.

Owner:ILLINOIS TOOL WORKS INC

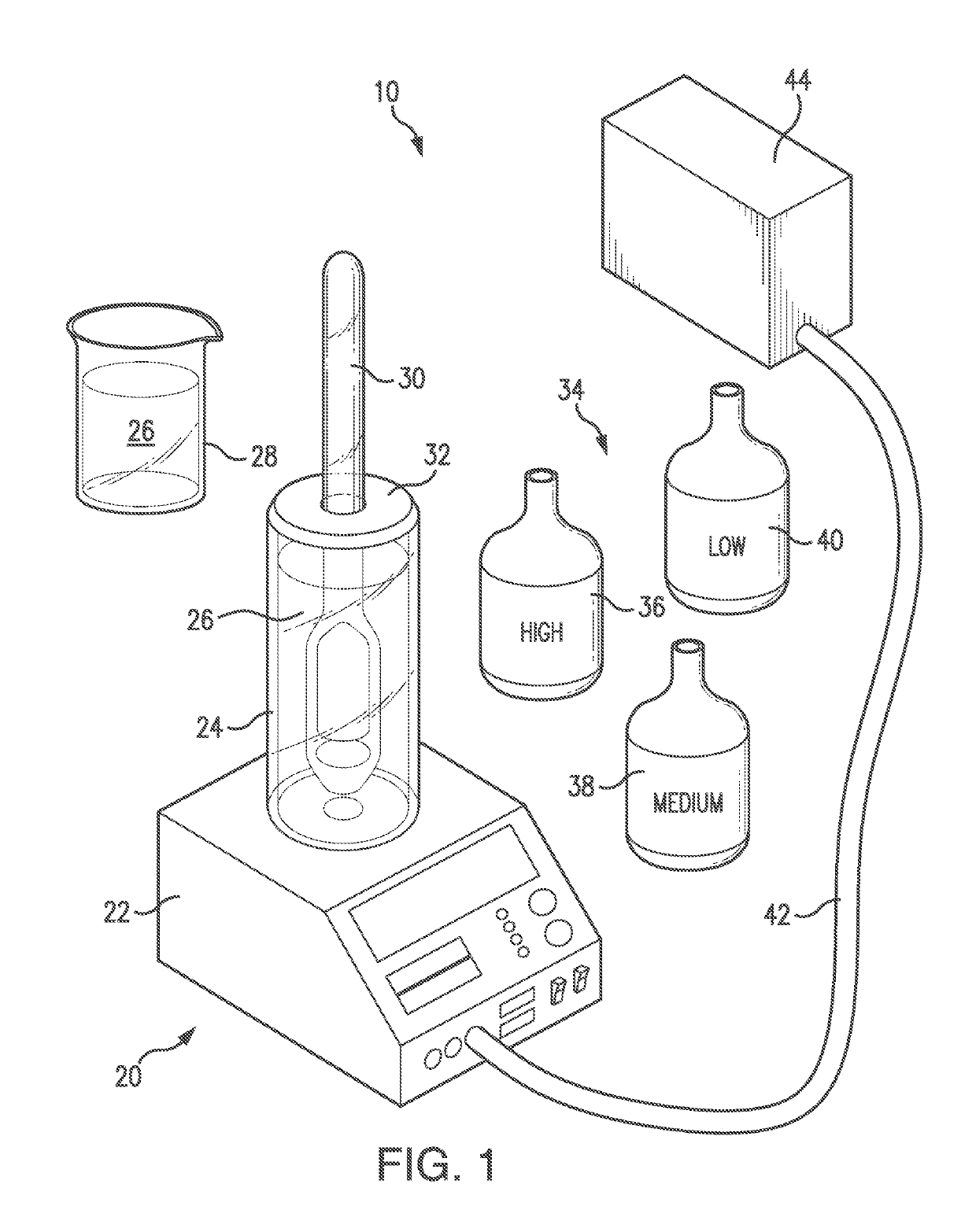

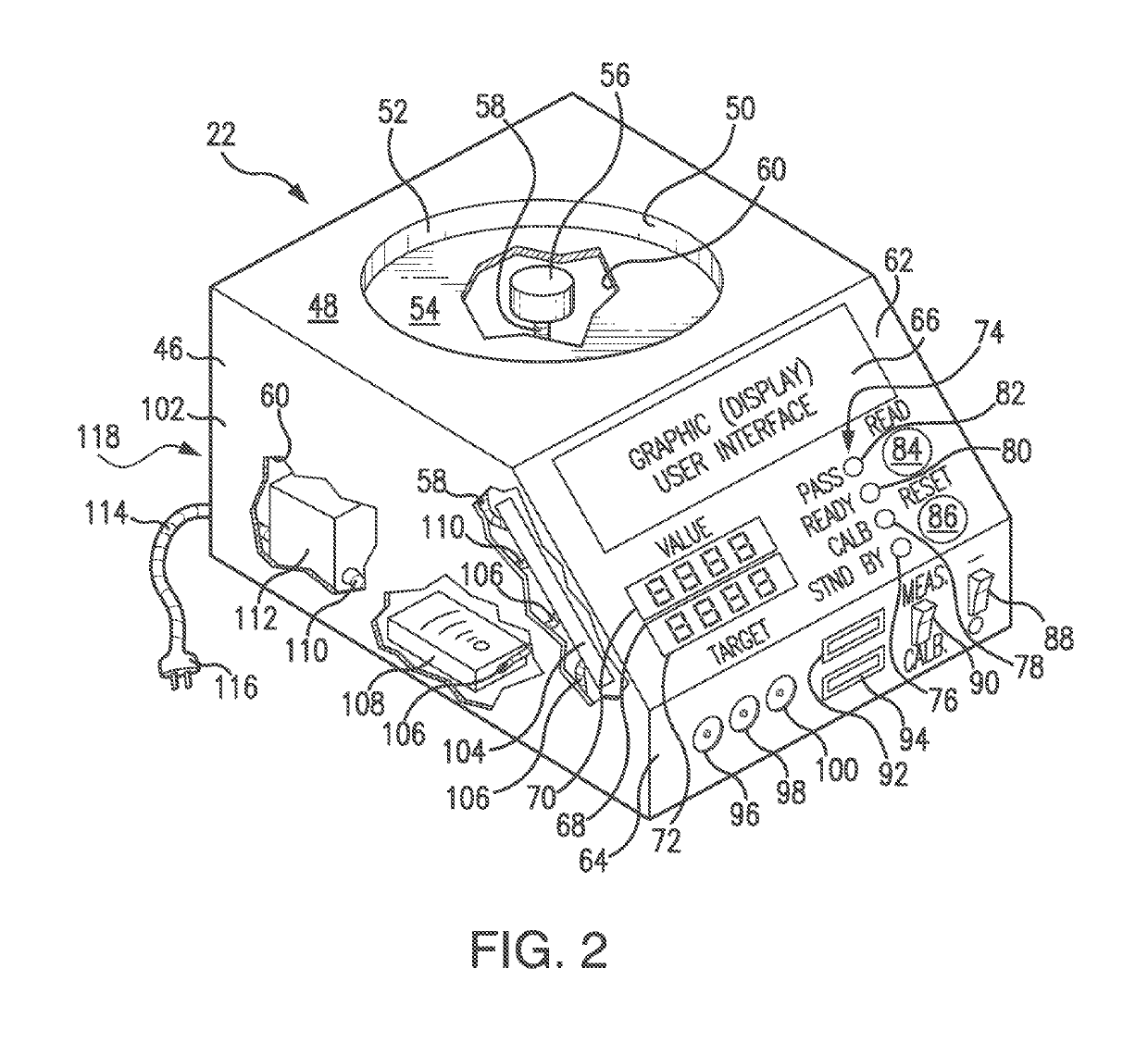

Digital hydrometer assistant reader

ActiveUS10379023B2Accurate and preciseMaterial analysis by observing immersed bodiesHydrometerElectricity

A digital hydrometer and methods of digitally displaying a specific gravity measured by a hydrometer are provided. The digital hydrometer can comprise a base, a displacement vessel, an inductive distance sensor, an output circuit, and a hydrometer float. The displacement vessel and inductive distance sensor can be mounted in or on the base. The displacement vessel can hold a displacement fluid. The hydrometer float can float in the displacement fluid. The output circuit can be in electrical communication with the inductive distance sensor and comprise a digital display device configured to display a digital value that is commensurate with a change in impedance attributable to the proximity of a metallic object, in the hydrometer float, to the sensor or its inductor. The digital value can be a specific gravity of the displacement fluid.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Free floating tilt hydrometer

ActiveUS9234828B2Improve transmission distanceEliminate needMaterial analysis by observing immersed bodiesHydrometerAccelerometer

Owner:BARON BREW EQUIP

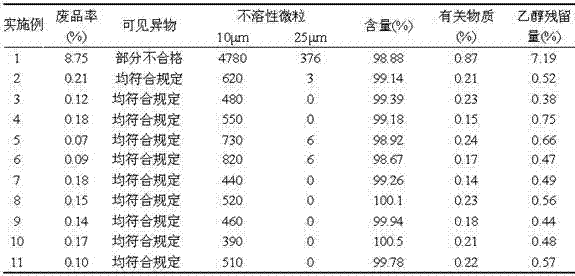

Docetaxel combination for injection and preparation method thereof

ActiveCN101862319BLow content of related substancesStable and uniform qualityOrganic active ingredientsLyophilised deliveryHydrometerDocetaxel

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Hydrometer/fluid level sensor

ActiveUS7430907B2Simple to assemble and installPrecise positioningSecondary cellsCell component detailsHydrometerElectrical battery

Owner:ILLINOIS TOOL WORKS INC

Anhydrous noiseless chest closed drainage device

InactiveCN105664273AAvoid frequent replacementPrevent backflowMedical devicesIntravenous devicesSaline waterHydrometer

The invention discloses an anhydrous noiseless chest closed drainage device which comprises a drainage pipe, wherein a fixing rubber belt is arranged at the left end of the drainage pipe; the right end of the drainage pipe is connected with a vacuum liquid storage tank through a drainage opening; a one-way valve is arranged on the drainage pipe; a pressure adjusting valve is arranged at the right end of the one-way valve; a hydrometer is arranged at the right end of the pressure adjusting valve; a switch knob is arranged at the right end of the hydrometer; a vacuum air exhausting pipe is arranged at the right end of the vacuum liquid storage tank; a closing switch is arranged on the vacuum air exhausting pipe; a liquid outlet door is hinged to the lower end of the vacuum liquid storage tank through a hinge. The chest closed drainage device adopts the anhydrous drainage device, the condition that frequent replacement is needed in traditional saline water or cold water drainage is avoided, the drainage speed can be automatically adjusted according to feedback pressure difference in a pressure adjusting pipe by a current-limiting device, and when the pressure difference is zero, the drainage can be automatically stopped, so that the nursing workload can be relieved, the use convenience of the drainage device is improved, and the popularization and generalization are facilitated.

Owner:THE THIRD PEOPLES HOSPITAL OF QINGDAO

Indoor fresh ginger germination-accelerating device and using method thereof

The invention discloses an indoor fresh ginger germination-accelerating device. The device comprises mud tanks used for stacking fresh gingers, the mud tanks are formed by piling up bricks and stones, steel plates are arranged at the bottoms of the mud tanks, water tanks are formed below the steel plates, the steel plates are erected above the water tanks, two through long water pipes with small holes are arranged inside the water tanks below the steel plates and connected with external water pipes, the other ends of the external water pipes are connected with a steam boiler, the tops of the mud tanks are covered with seal cloth with small ventilation holes, and a thermometer and a hydrometer are arranged at the portions, on the two steel plates of the water tanks, inside the mud tanks respectively. The thermometer and the hydrometer master germination acceleration of the fresh gingers through the device, in this way, the temperature difference inside the mud tanks is small, the temperature inside the mud tanks is basically kept balanced, then germination acceleration of the fresh gingers succeeds in a one-off mode, and the germination rate of the fresh gingers is increased.

Owner:铜陵南门姜业专业合作社

Air energy-collecting tower heat pump unit

The invention relates to an air energy-collecting tower heat pump unit which comprises an air energy-collecting tower, an energy storage thermostatic water tank, a vortex main engine, an air conditioner end, a unit pipeline and an antifreezing liquid concentration system, wherein the antifreezing liquid concentration system comprises a charging barrel, a generating barrel, a condenser, a water bucket and a vacuum pump; the generating barrel is respectively communicated with the charging barrel and the condenser, the condenser is also communicated with the water bucket and the water bucket is also communicated with the vacuum pump; the generating barrel is also communicated with a liquid inlet pump and a liquid outlet pump, an electrical bar is installed in the generating barrel, a hydrometer is installed on the generating barrel; the liquid inlet pump is respectively communicated with a liquid outlet of air energy-collecting tower and the unit pipeline, the liquid outlet pump is respectively connected with an liquid inlet of the air energy-collecting tower and the unit pipeline; an electric heating pipe is installed in a liquid inlet pipe of an evaporator; and a rain holding and rain proofing device is installed on the air energy-collecting tower. The invention can concentrate the antifreezing liquid, can realize rain proofing and rain-holding functions and can improve the temperature of the solution entering into the evaporator of the vortex main engine.

Owner:杭州联投能源科技有限公司

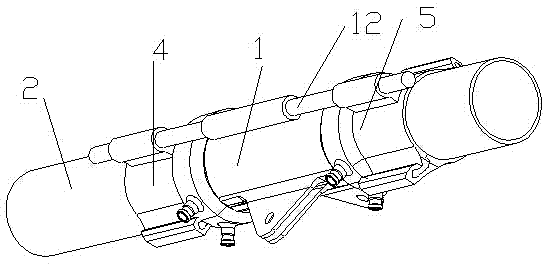

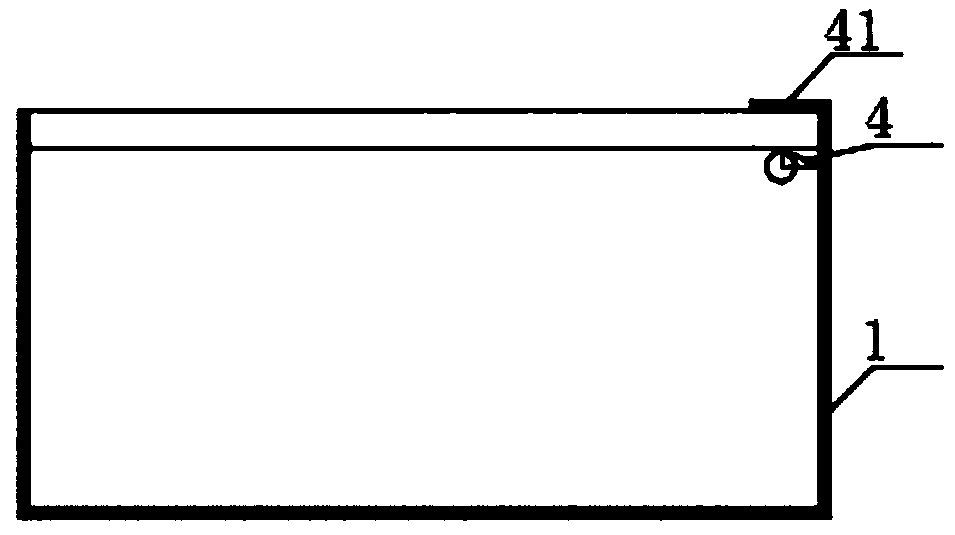

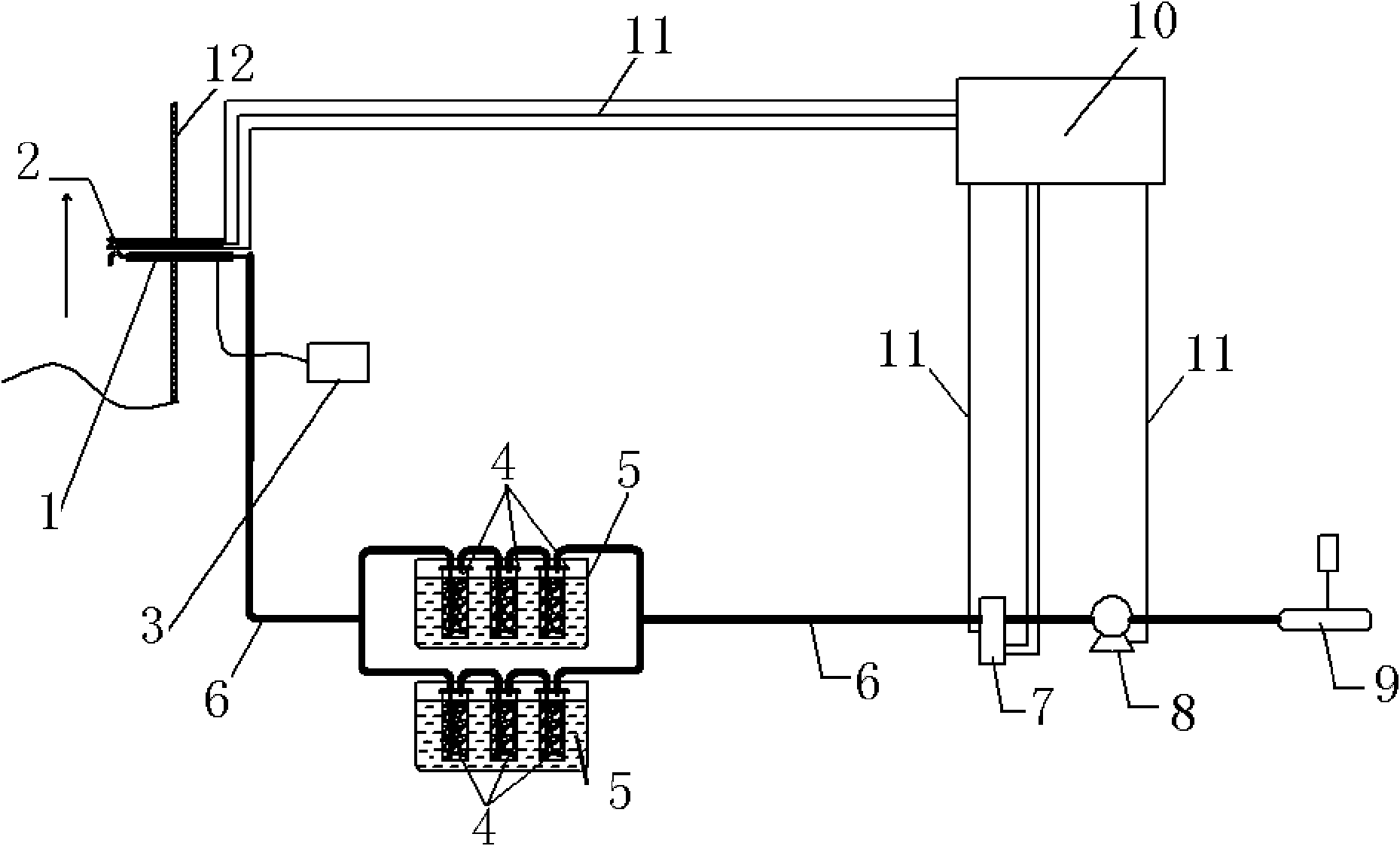

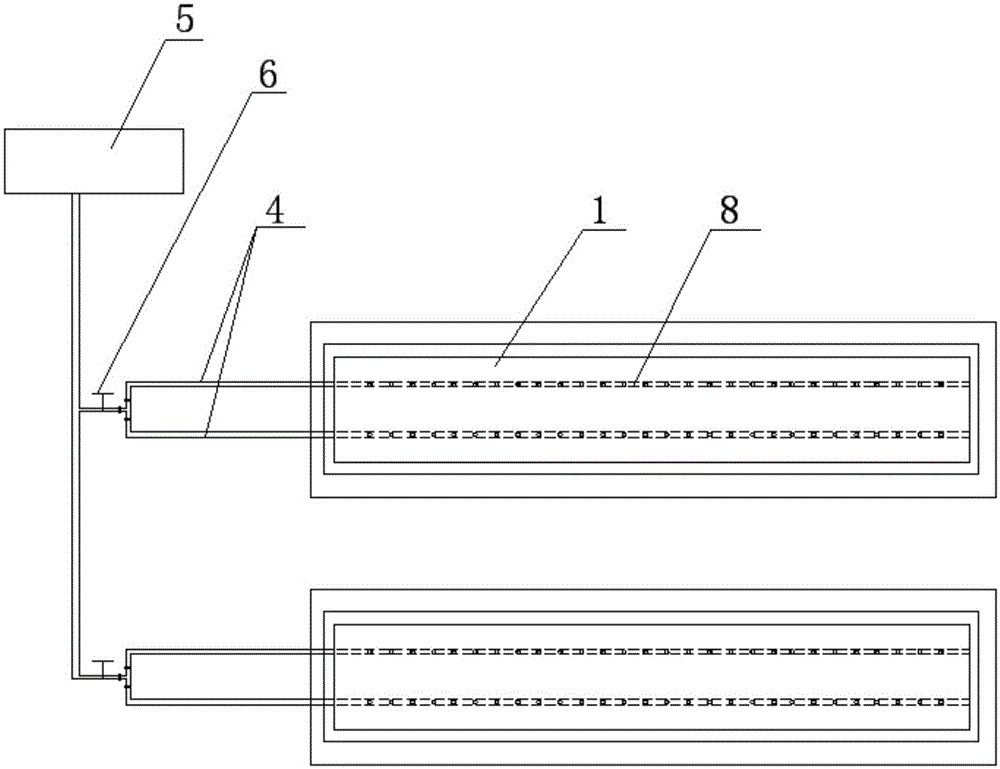

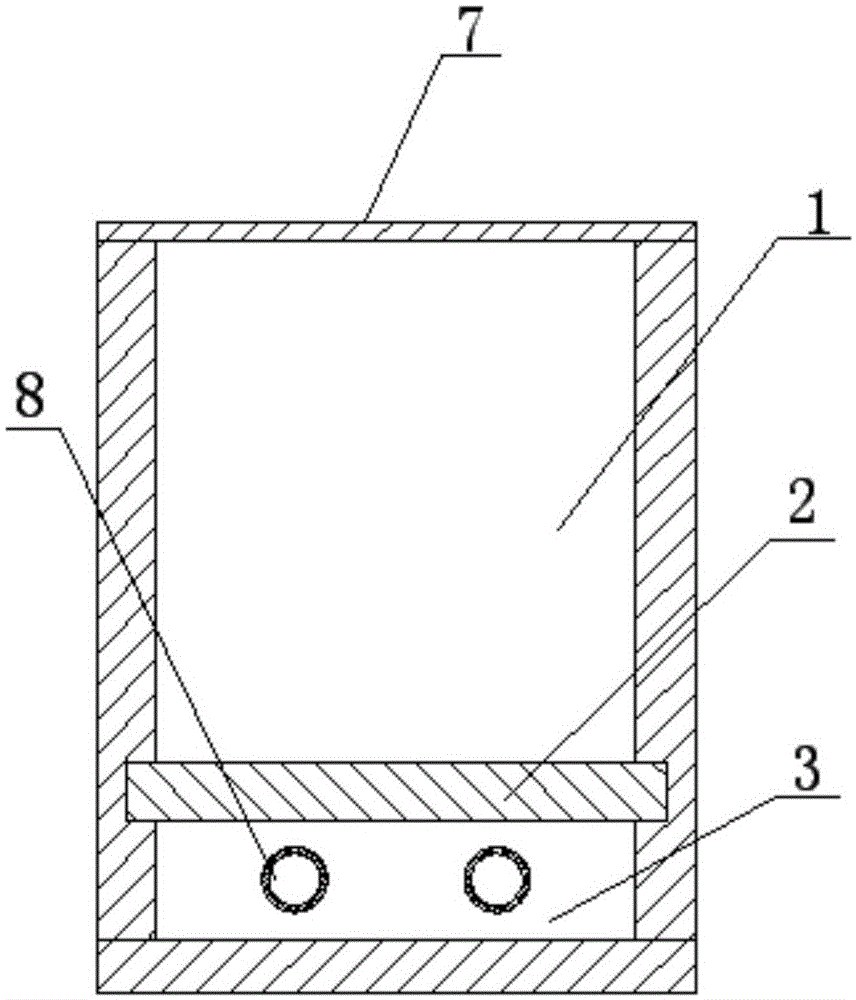

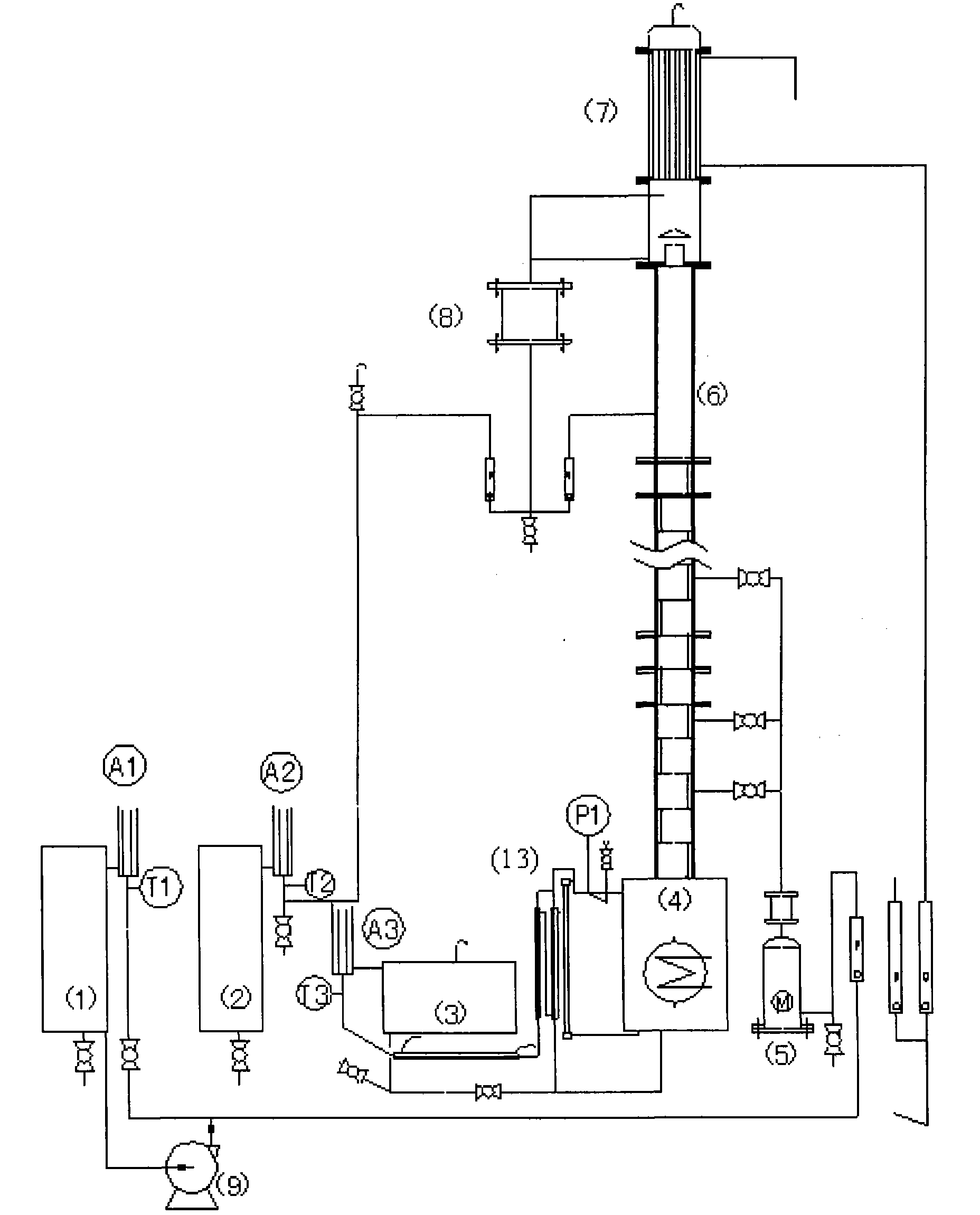

On-line rectification product concentration detecting device

InactiveCN103471962AConcentration real-time monitoringEnables intuitive online readingSpecific gravity measurementHydrometerLiquid temperature

The invention discloses an on-line rectification product concentration detecting device. On the structural basis of an existing device mainly comprising a raw material tank (1), a tower top product tank (2), a tower kettle product tank (3), a tower kettle (4), a pre-heater (5), a sieve plate rectifying tower (6), a total condenser (7), a fractionator (8), a charging pump (9) and a plurality of sections of stainless steel pipelines, a measuring device capable of detecting the concentration of a product on line is arranged near liquid inlets of the raw material tank (1), the tower top product tank (2) and the tower kettle product tank (3). The device is of a double-sleeve structure; an inner pipe (12) is lower than an outer pipe (11) and is vertically arranged; detected liquid flows into the inner pipe from bottom to top, overflows into a jacket of the inner pipe (12) and the outer pipe (11) and flows down into a corresponding tank body from the inner part of the bottom end of the jacket. Meanwhile, the liquid with a stable liquid surface is accumulated in the inner pipe (12), a hydrometer (10) floats in the inner pipe (12), and a temperature sensor (14) is arranged in a pipeline, into which the liquid flows, in front of the device; the temperature of the liquid can be synchronously measured, and the reading of the hydrometer can be corrected auxiliarily.

Owner:莱帕克(北京)科技有限公司

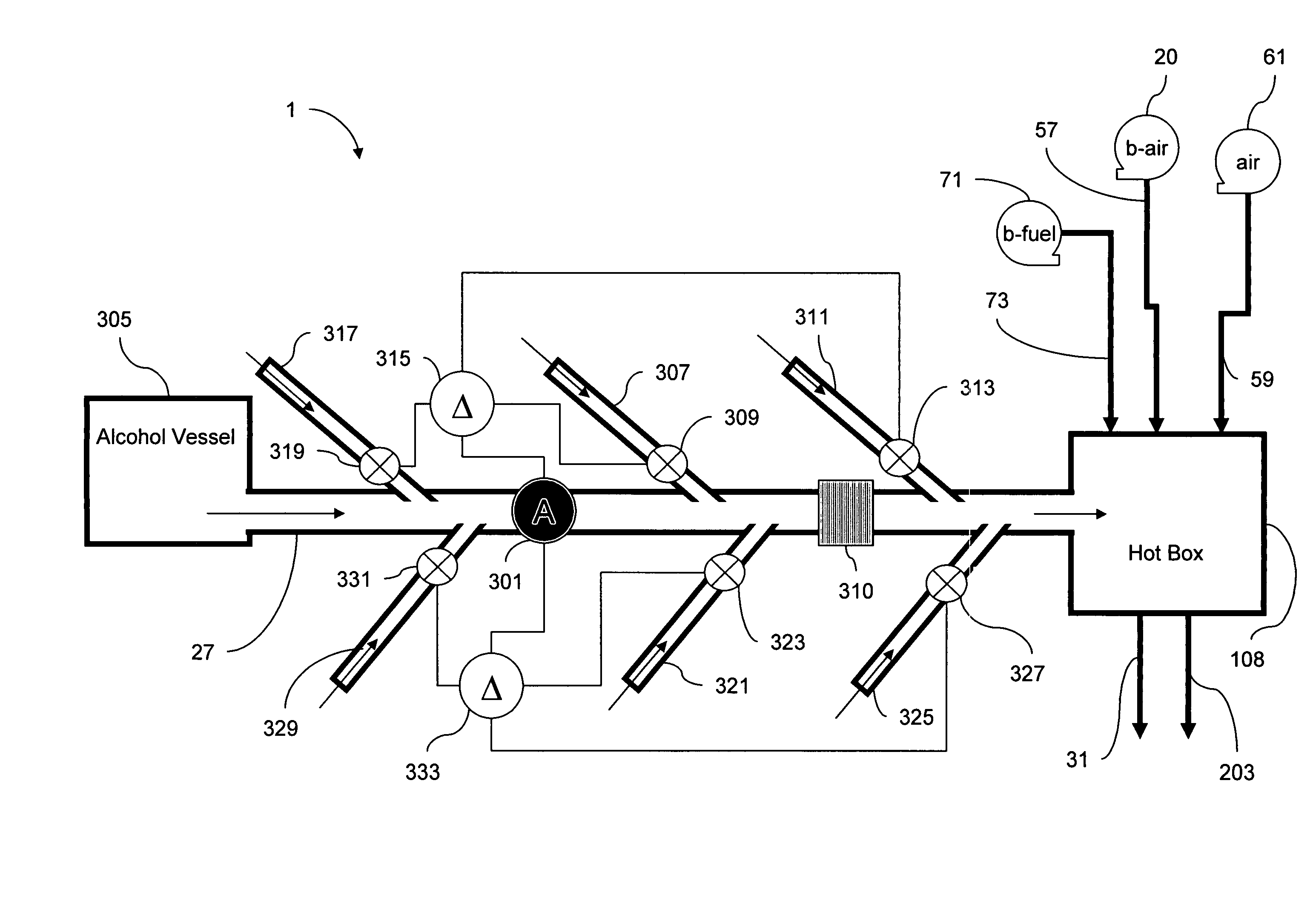

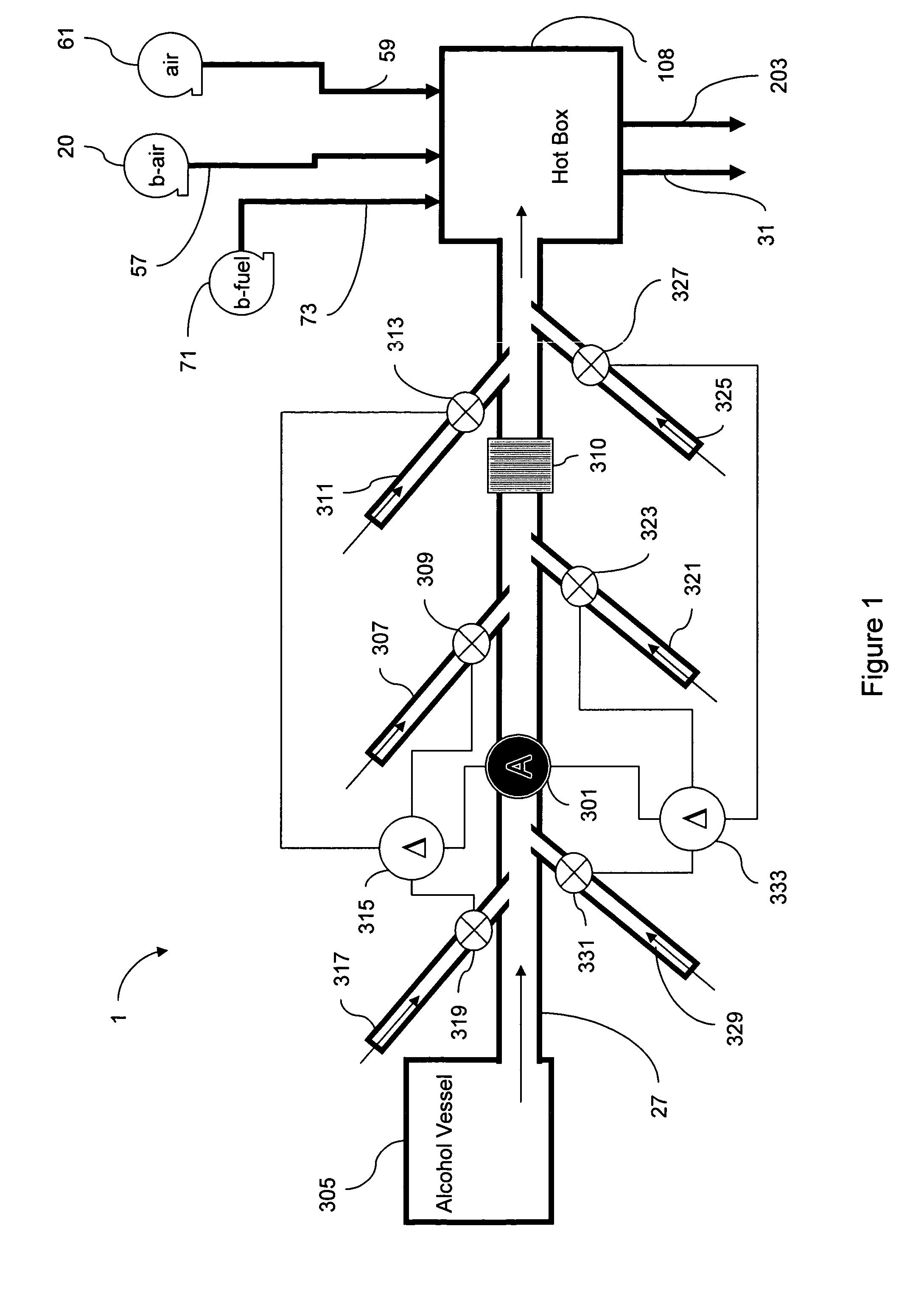

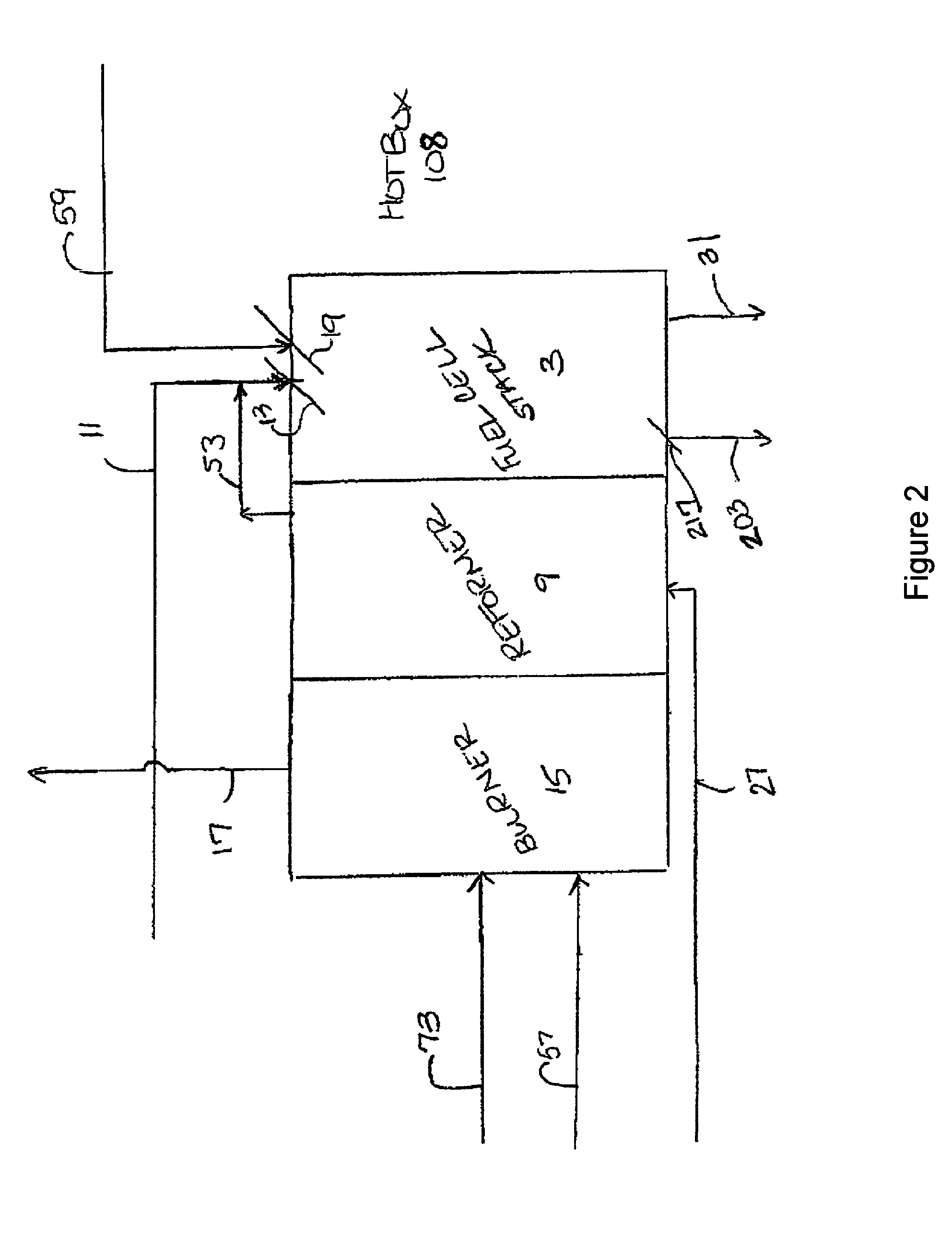

Structure and method for optimizing system efficiency when operating an SOFC system with alcohol fuels

A fuel cell system includes a fuel cell stack, a fuel inlet conduit, a water inlet conduit, and a hydrometer, such as an alcoholometer. The hydrometer is adapted to provide a measurement of a water-to-fuel ratio of a fuel inlet stream within the fuel inlet conduit. The water inlet conduit is adapted to provide a quantity of water to the fuel inlet conduit in order to achieve a desired water-to-ratio being provided to the fuel cell stack.

Owner:BLOOM ENERGY CORP

Salt water seed sorting machine

InactiveCN104226459AHarm reductionDensity is accurateCleaning using liquidsWet separationSaline waterDisease

The invention provides a salt water seed sorting machine comprising a seed-water separation tank, a superior seed tank and an inferior seed tank. The seed-water separation tank is of a cuboid structure, and the height of the cuboid is larger than the length of the cuboid. Sliding rails are mounted at edges, perpendicular to the ground, of the cuboid seed-water separation tank. The cuboid seed-water separation tank comprises a superior seed filter plate and an inferior seed filter plate which slide on the slide rails of the seed-water separation tank through motors respectively. The seed-water separation tank further comprises a hydrometer and a water outlet. The salt water seed sorting machine has the advantages that pathogen spore attached to the surfaces of seeds can be removed, harm caused by disease development of the seeds is reduced, the density of salt water is more accurate, the superior seeds and the inferior seeds can be placed in different tanks, and seed sorting efficiency is improved greatly.

Owner:TIANJIN BAOTIAN AGRI MACHINERY SALES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com