Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Fresh gas flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh gas flow refers to the mixture of medical gases and volatile anaesthetic agents which is produced by an anaesthetic machine. The flow rate and composition of the fresh gas flow is determined by the anaesthetist.

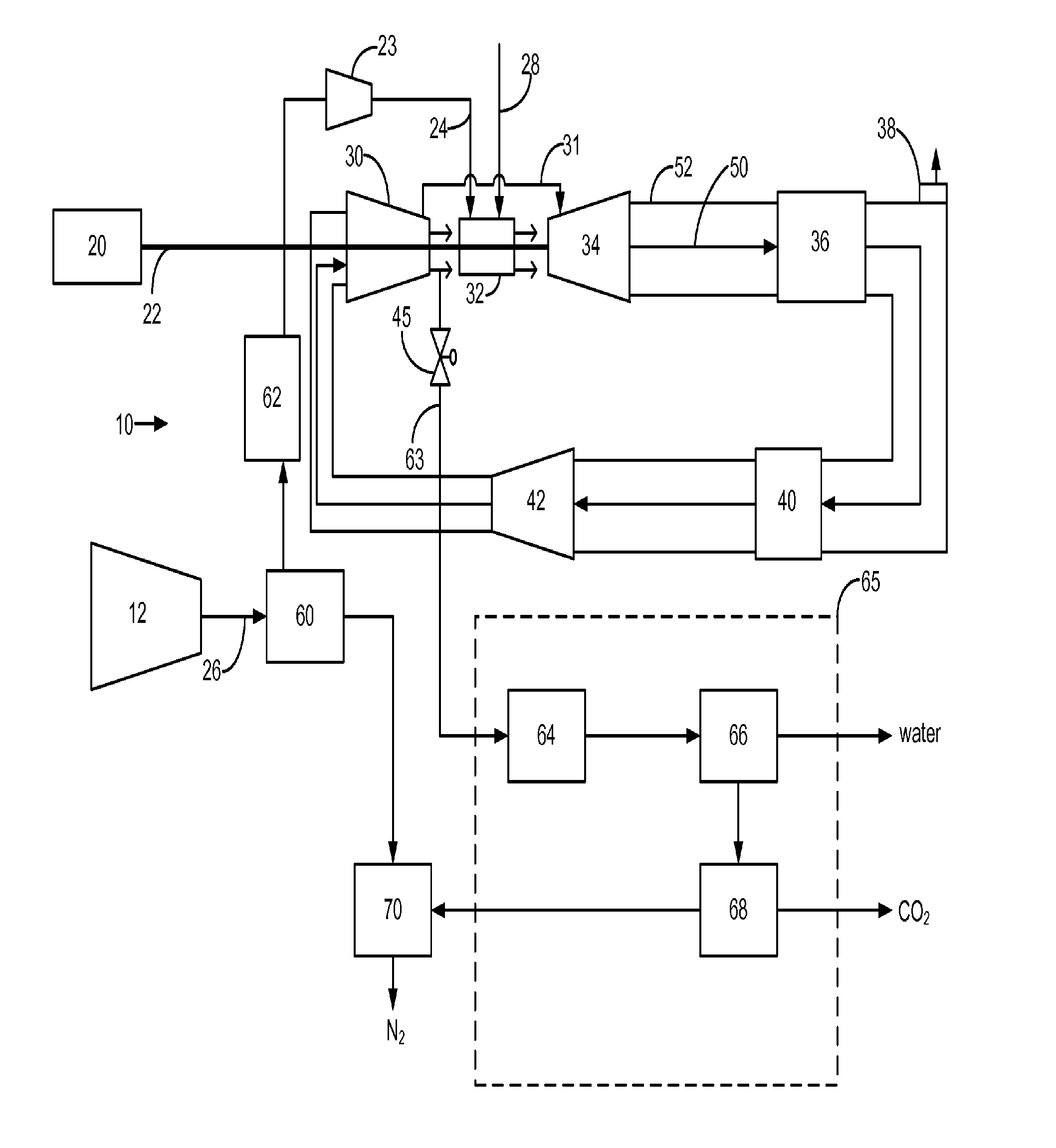

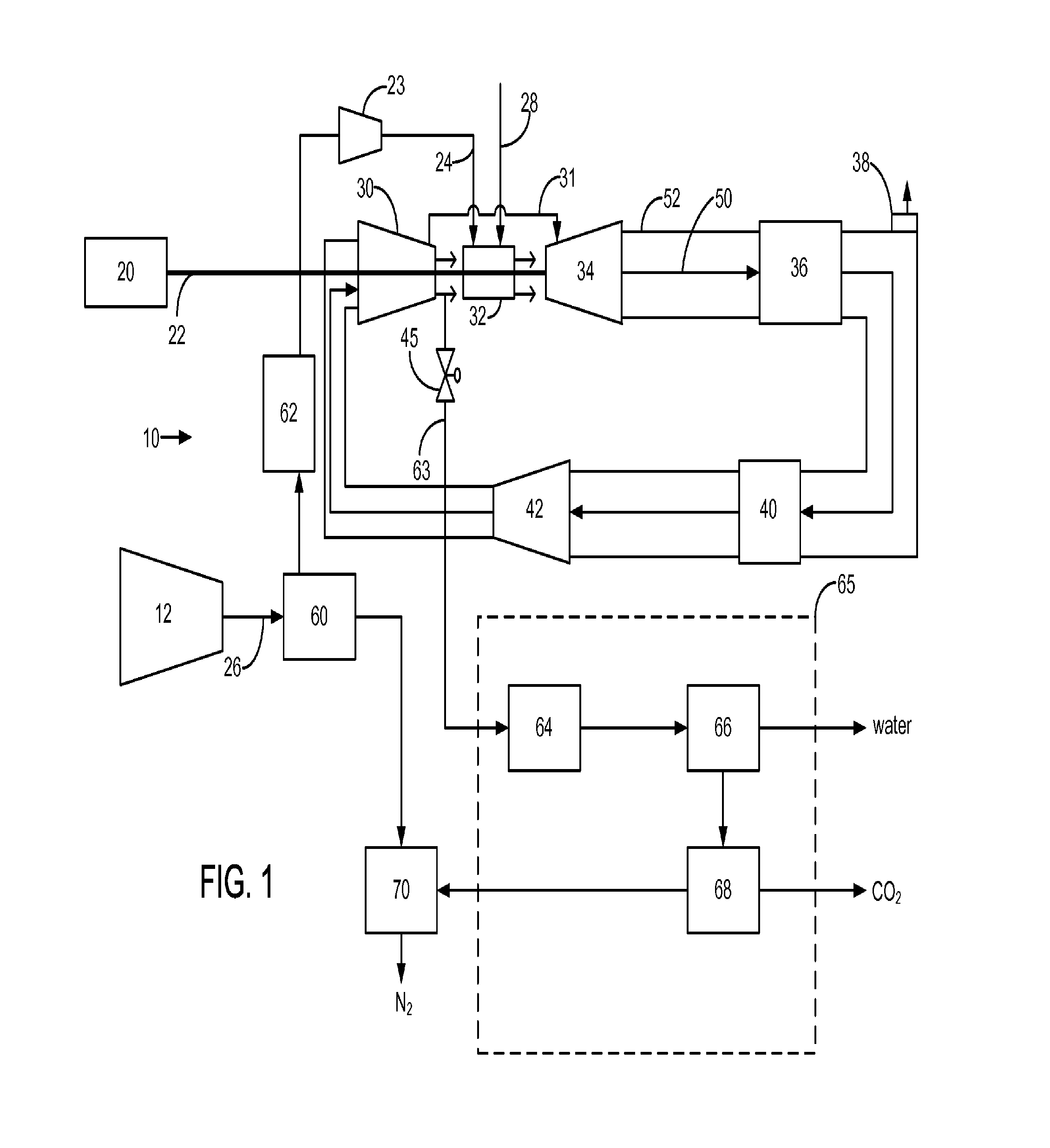

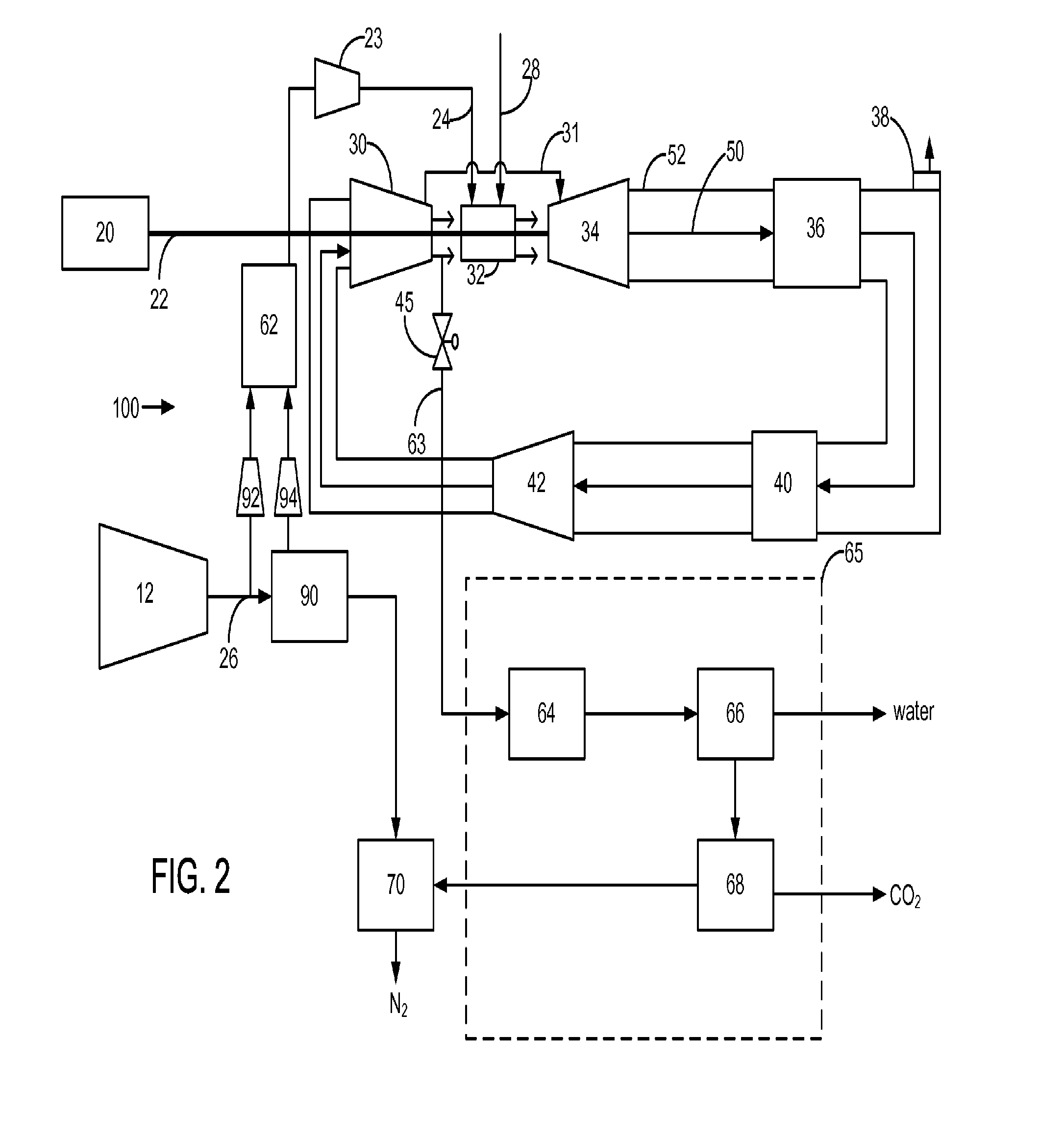

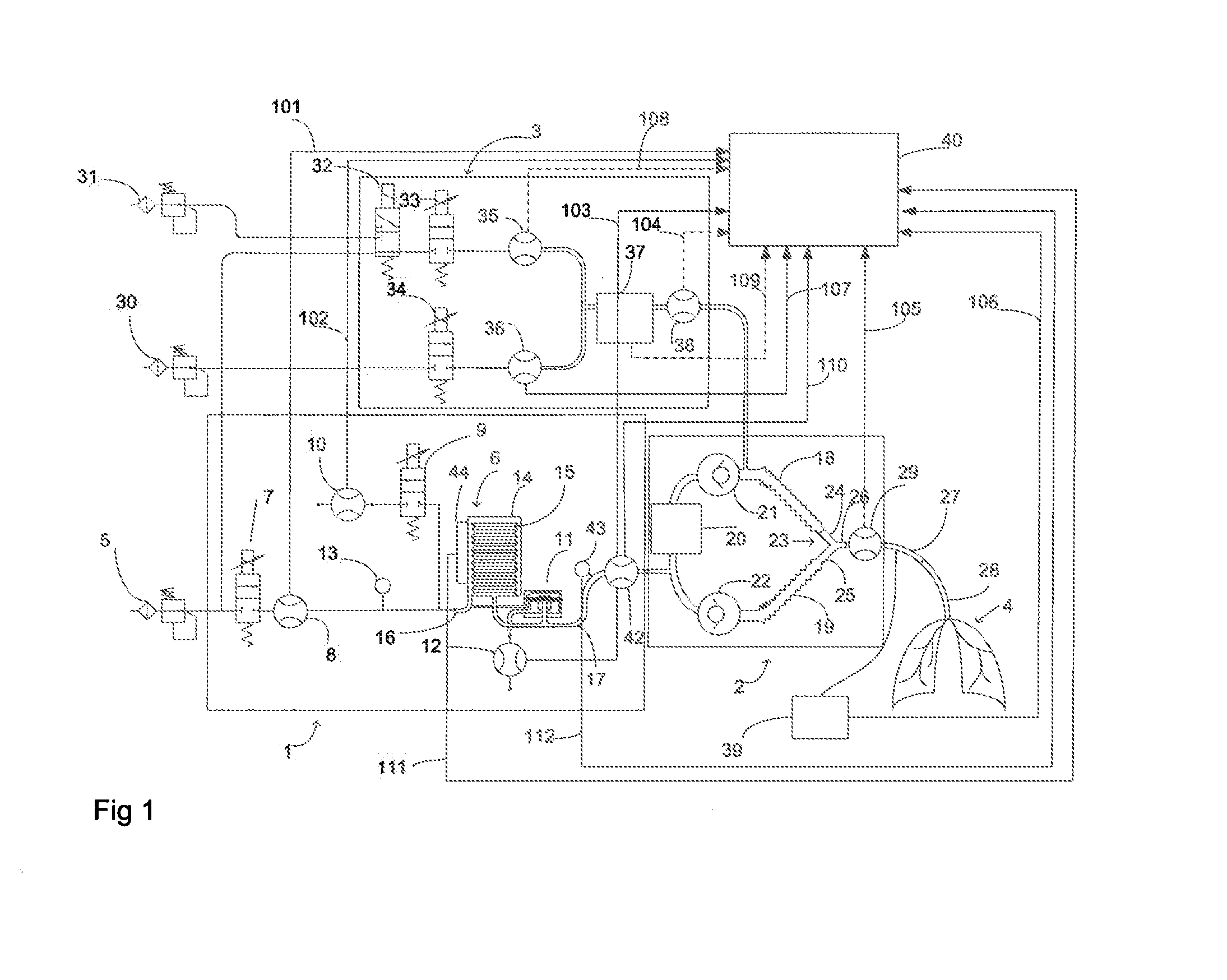

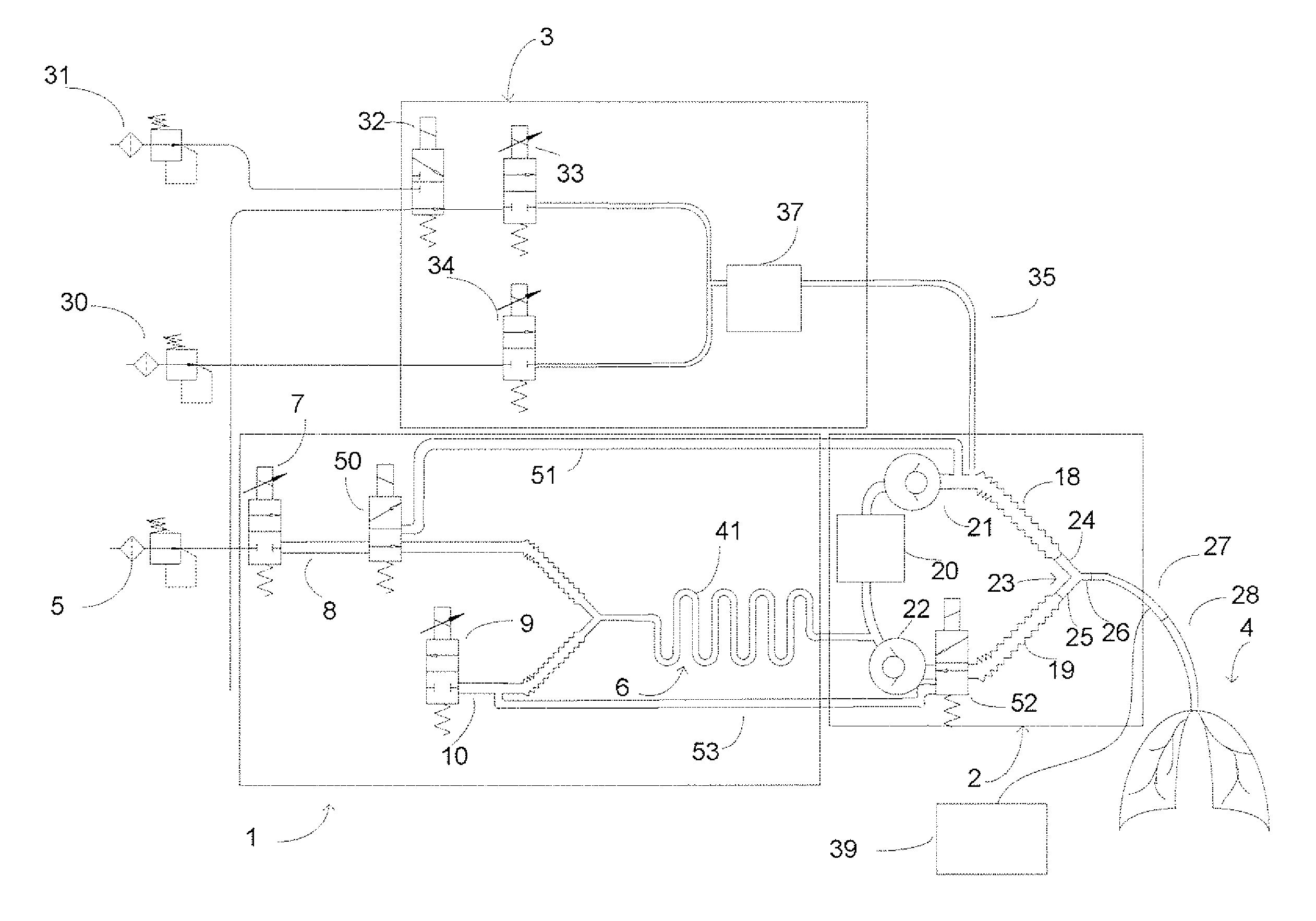

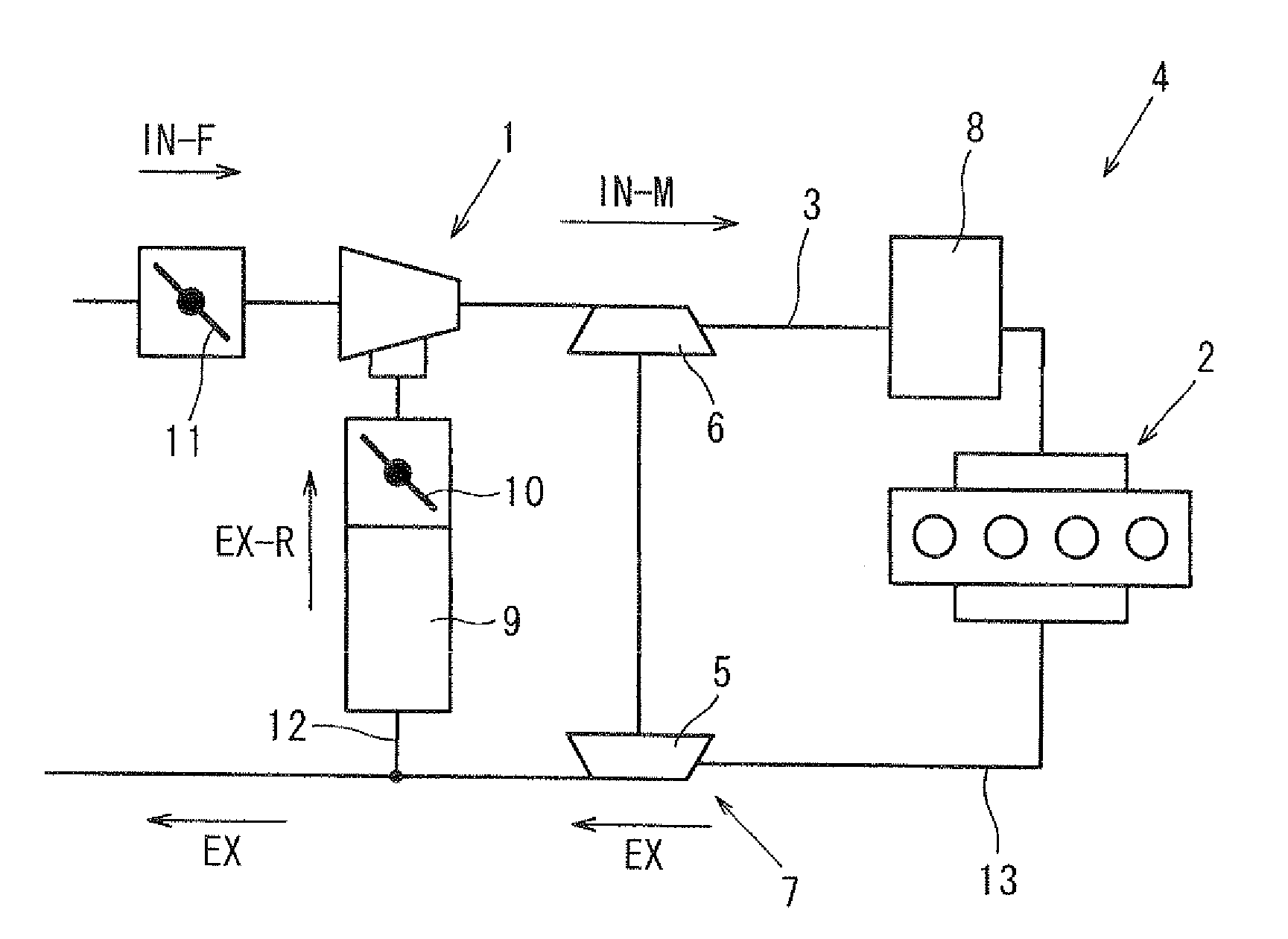

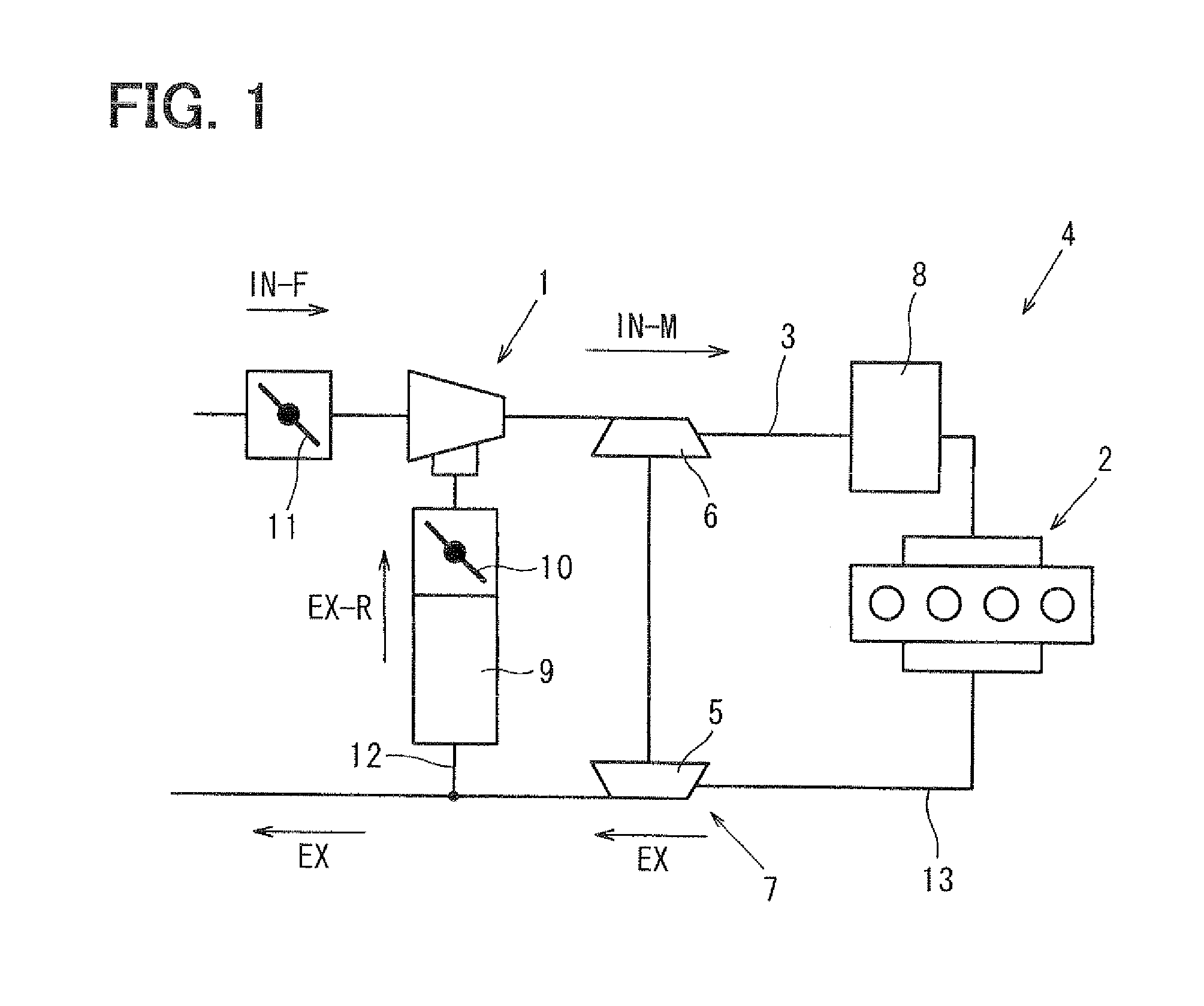

Power plant and method of operation

A power plant and method of operation is provided. The power plant comprises at least one main air compressor, an oxidizer unit configured to deliver a compressed oxygen-rich gas flow to at least one gas turbine assembly. Each assembly comprises a turbine combustor for mixing the compressed oxygen-rich gas flow with a recirculated gas flow and a fuel stream to burn a combustible mixture and form the recirculated gas flow. The assembly also comprises a recirculation loop for recirculating the recirculated gas flow from a turbine to a turbine compressor. The assembly further comprises a recirculated gas flow extraction path for extracting a portion of the recirculated gas flow from the assembly and delivering this to a gas separation system. The gas separation system separates the portion of the recirculated gas flow into a nitrogen portion and a carbon dioxide portion.

Owner:GENERAL ELECTRIC CO

Method and arrangement for detecting a leak in anesthesia system

A method and arrangement for detecting a leak in an anesthesia system. The method includes controlling respiratory movements by means of ventilator gas flows and measuring the ventilator gas flow added for an inspiration and removed for an expiration. The method also includes supplying a fresh gas flow for a respiration and measuring the fresh gas flow added for the respiration. The method further includes receiving information indicative of the measured gas flows, determining based on said received information both the gas volume added and the gas volume removed and comparing these determined gas volumes to each other. The method also includes determining based on comparing the anesthesia system leakage.

Owner:GENERAL ELECTRIC CO

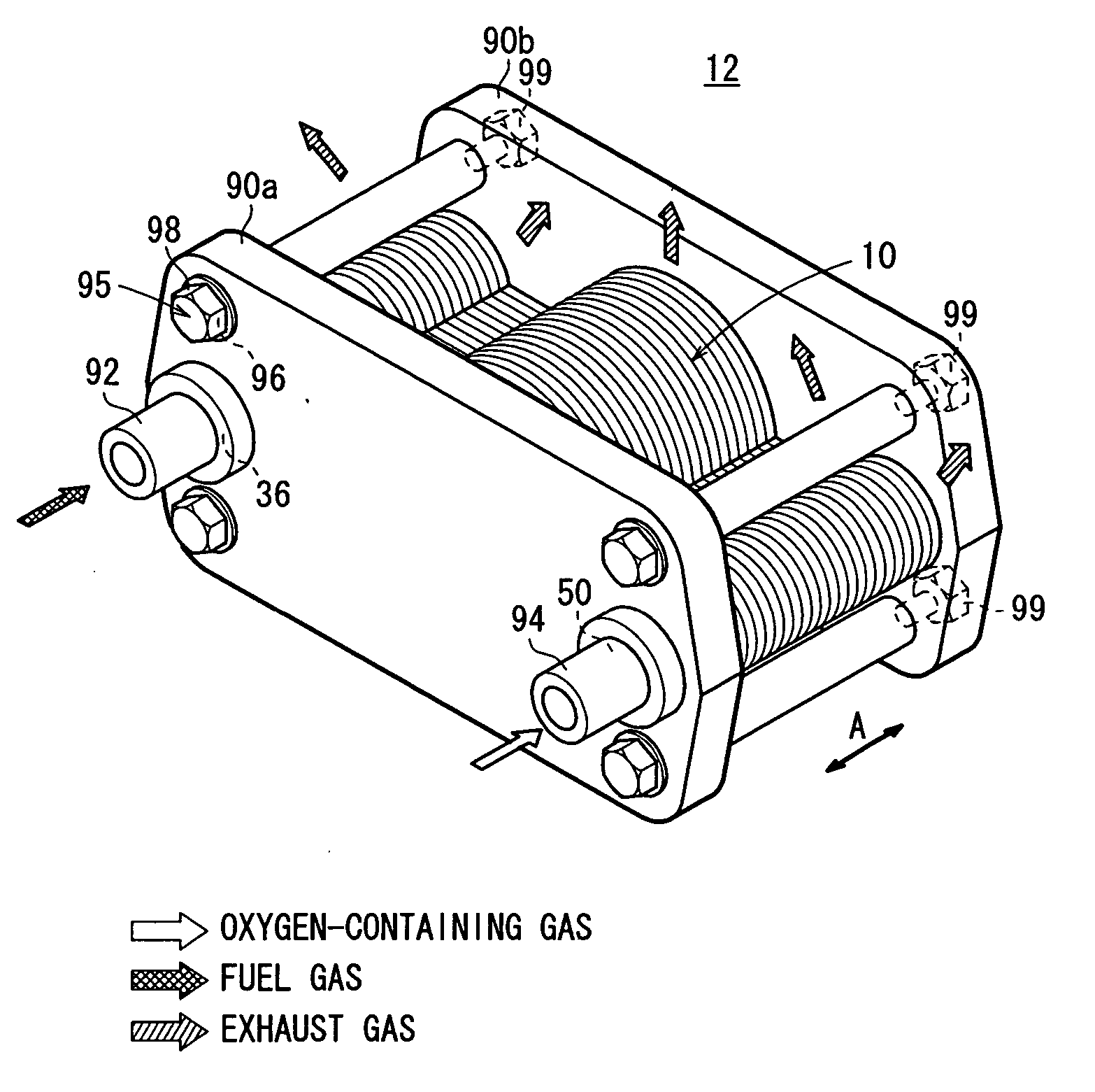

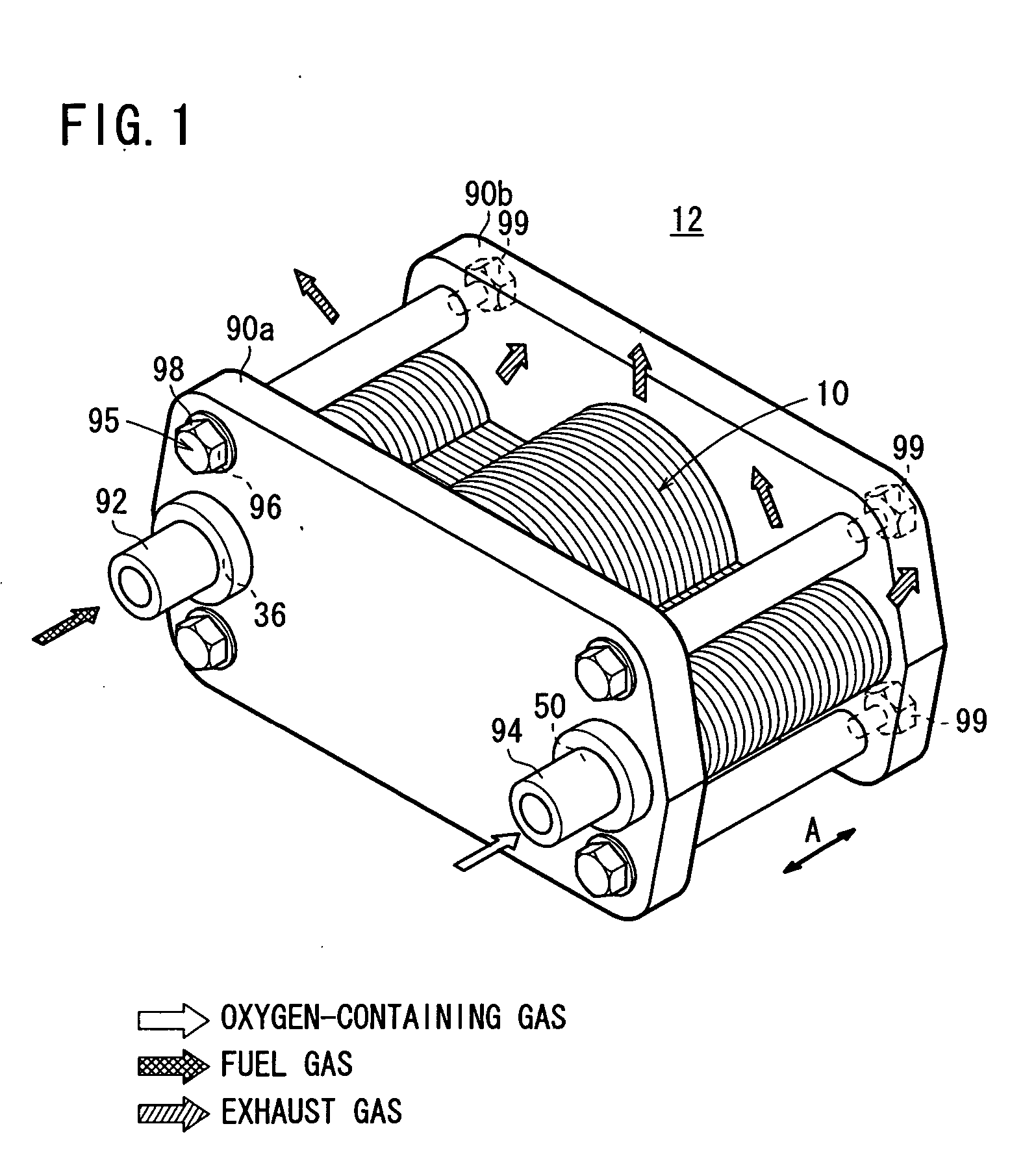

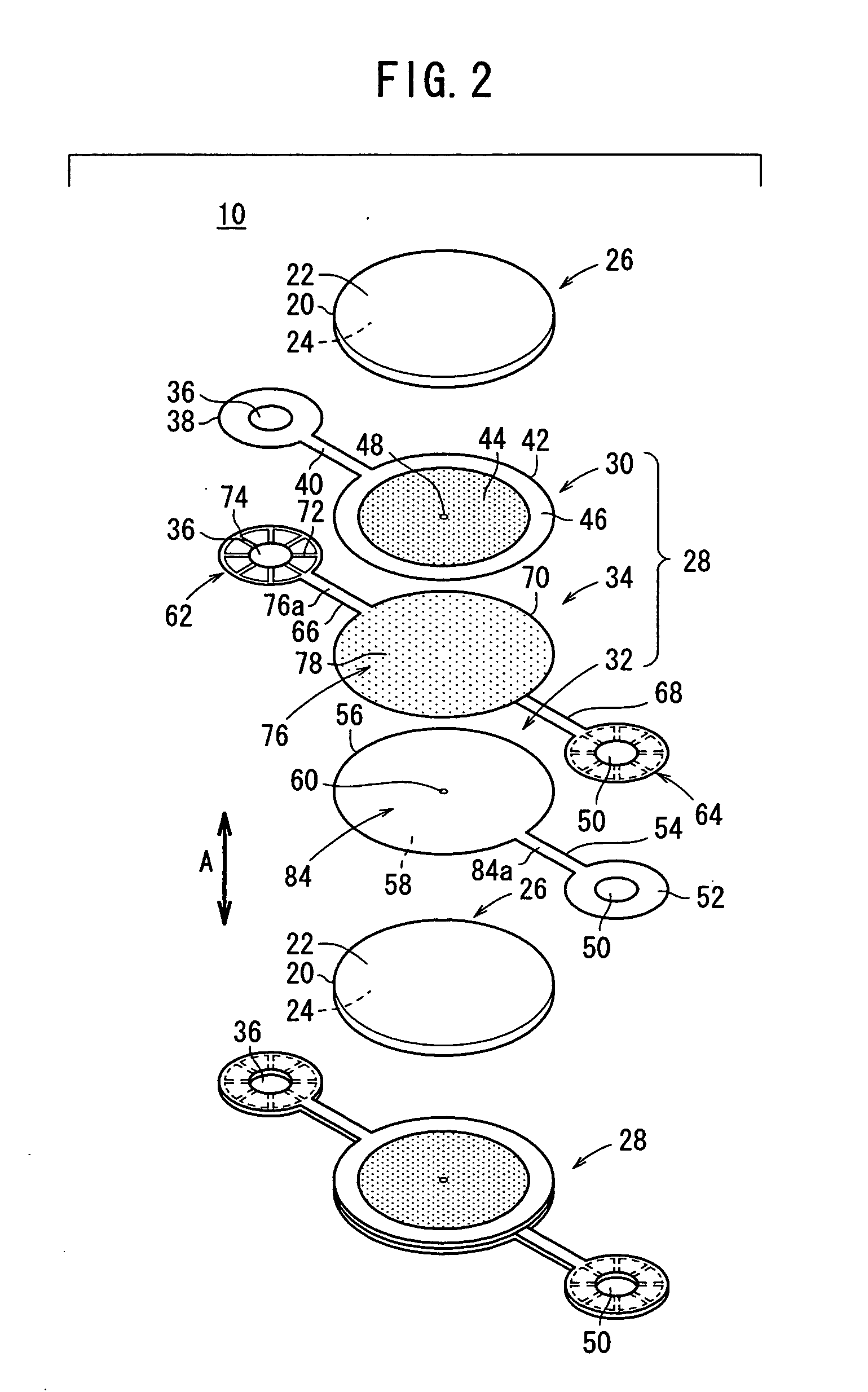

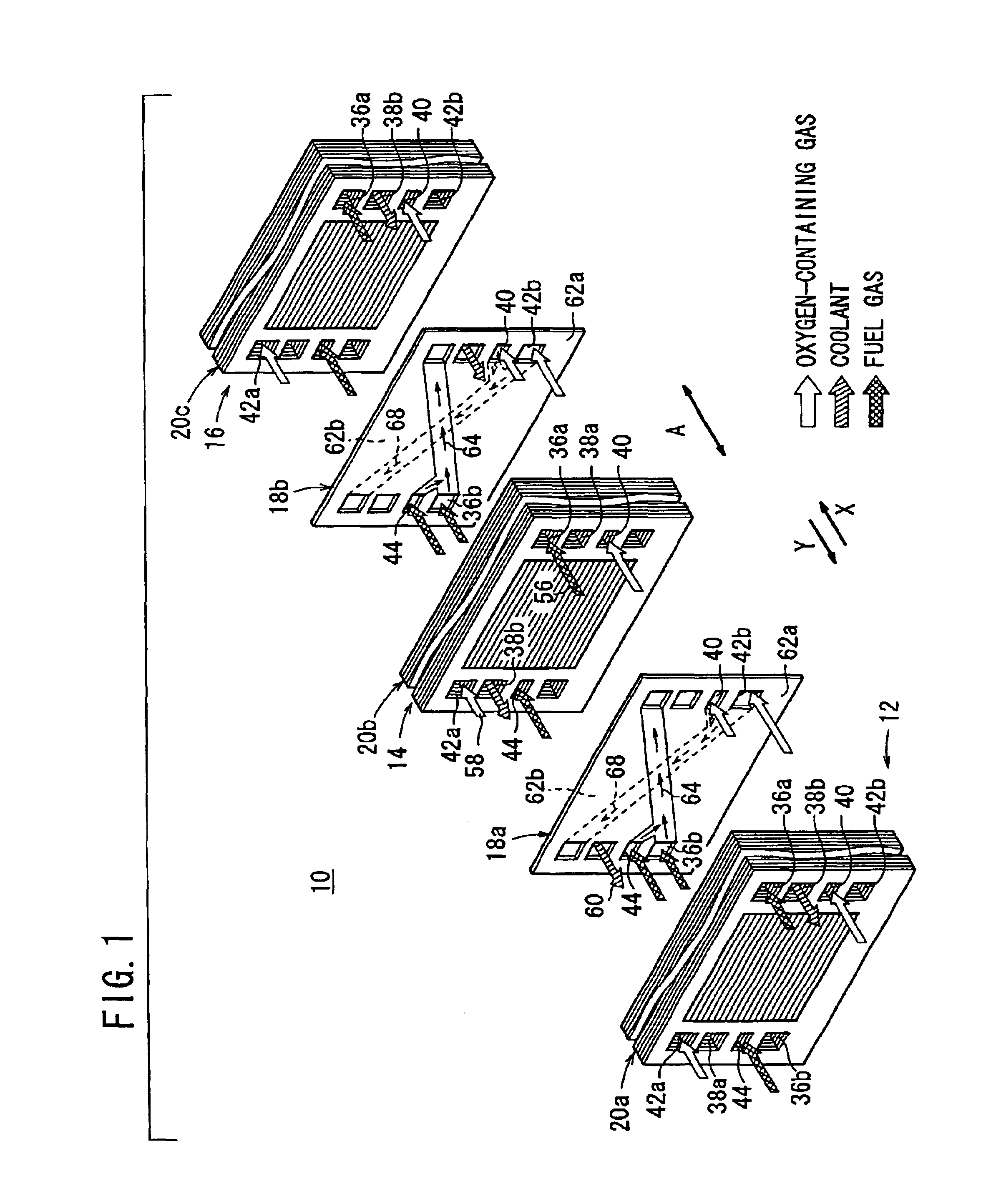

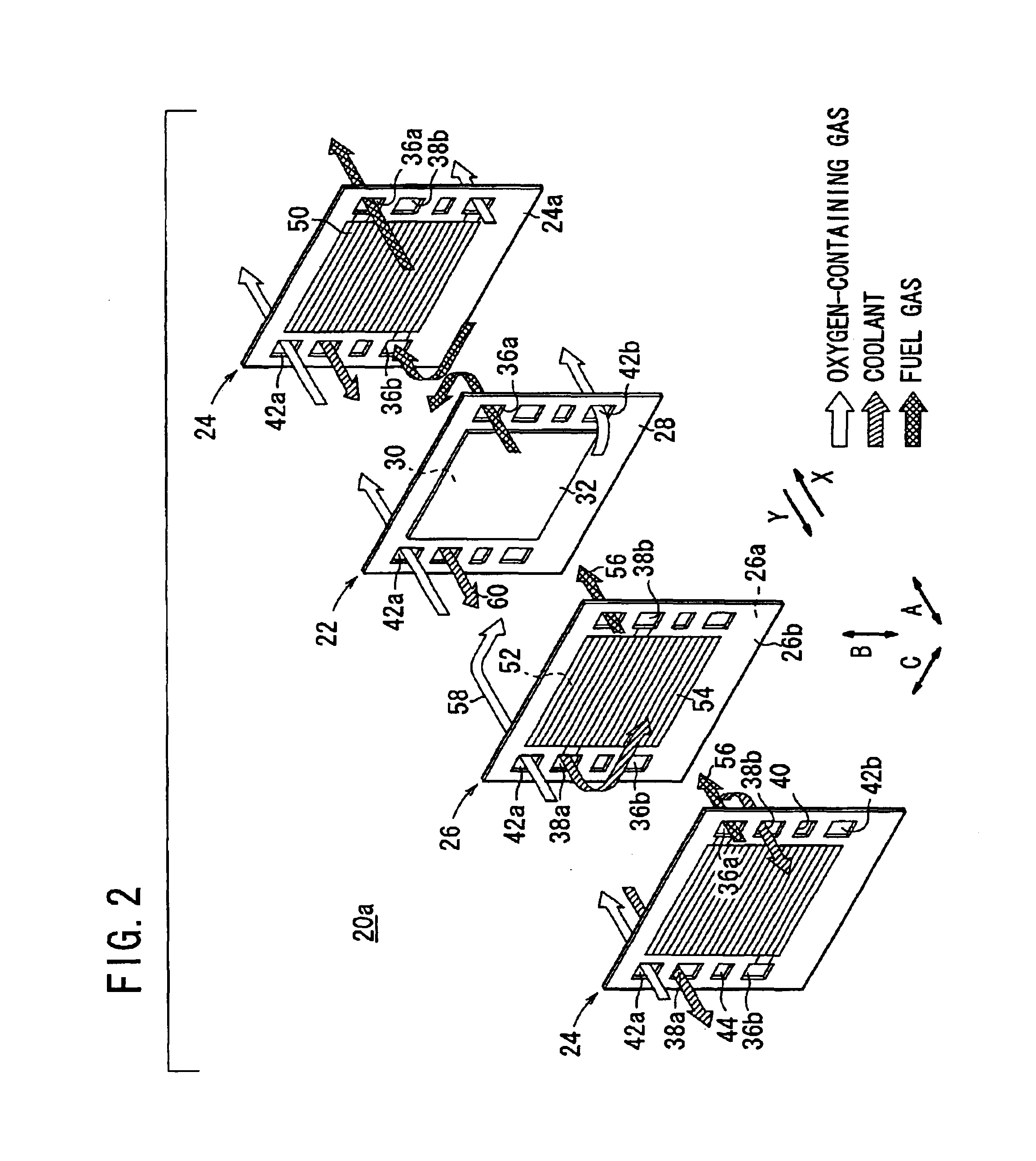

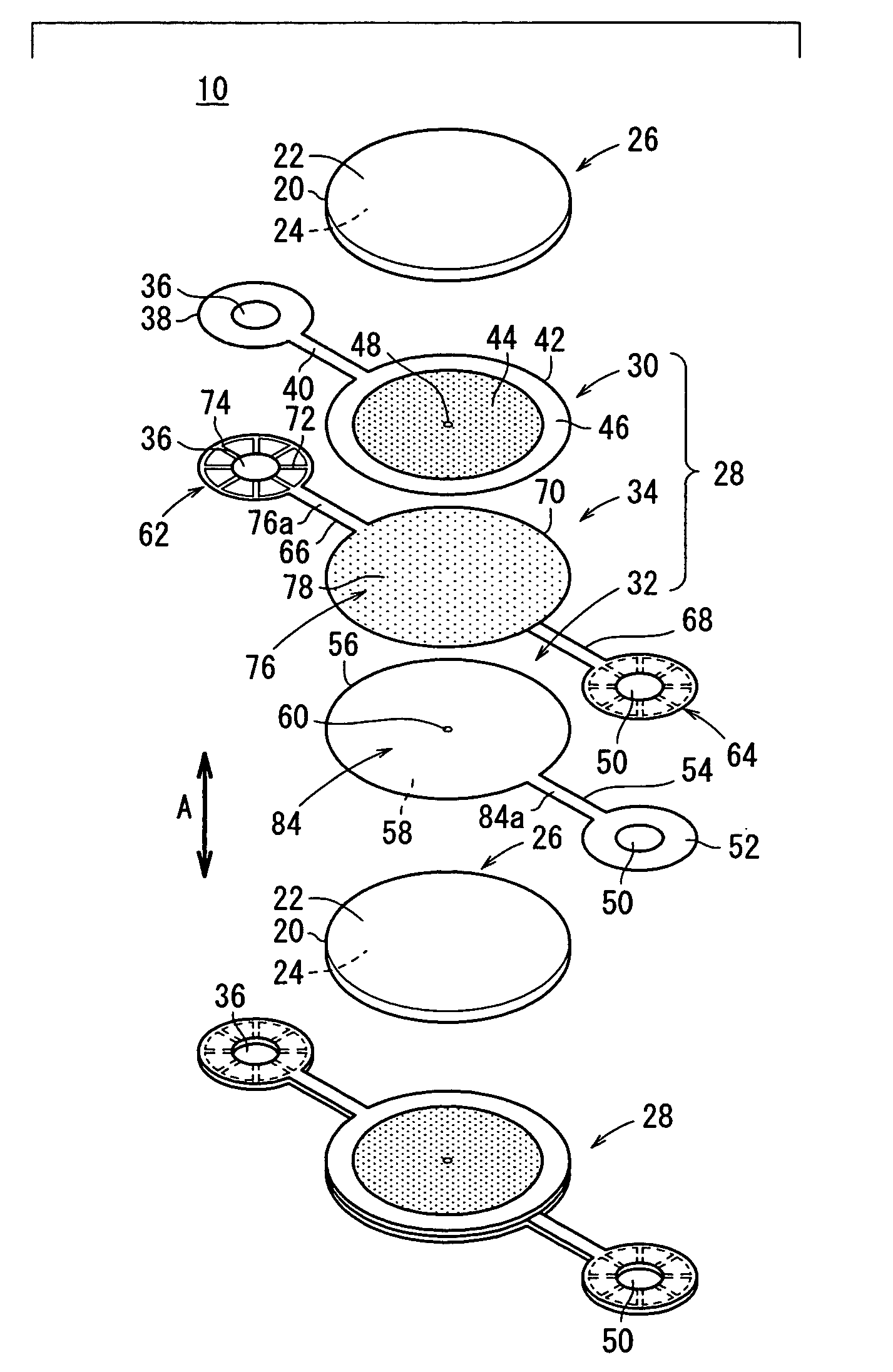

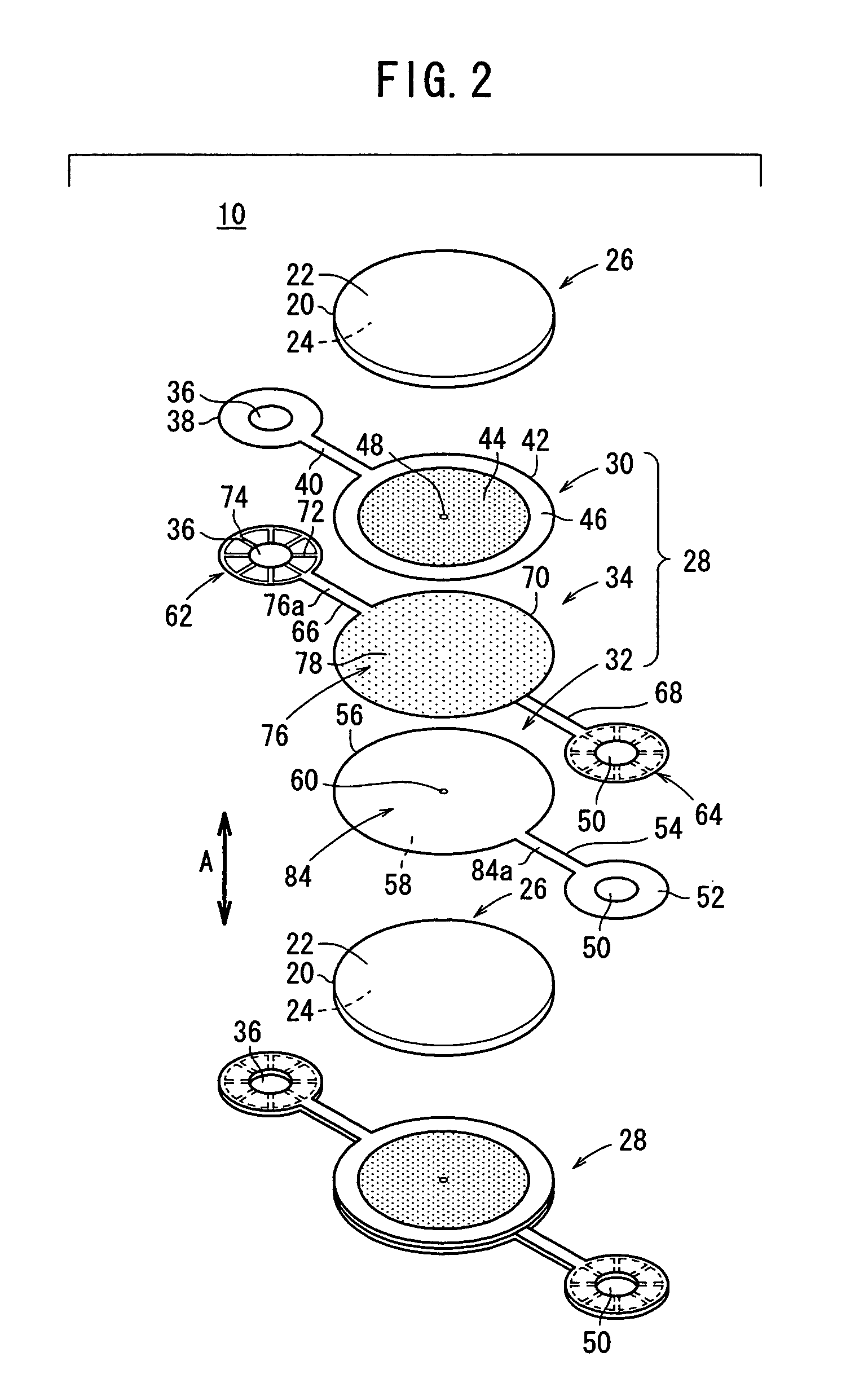

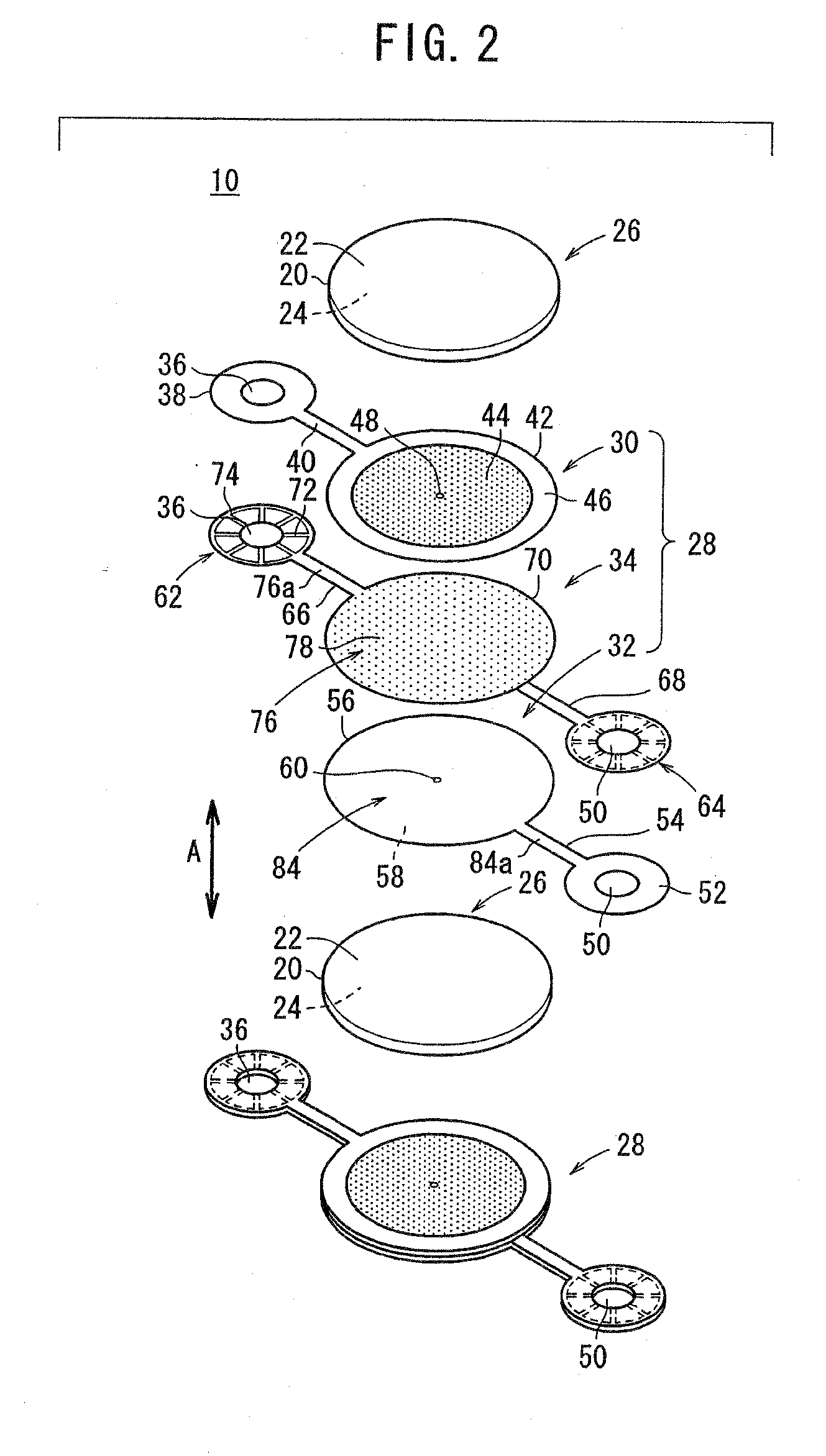

Fuel cell and fuel cell stack

InactiveUS20050136316A1Simple and economical structureImprove sealingFuel cells groupingElectrode carriers/collectorsFuel cellsProcess engineering

A fuel cell includes an electrolyte electrode assembly and separators. The separator has a fuel gas supply passage, a fuel gas distribution passage, an oxygen-containing gas supply passage, and an oxygen-containing gas distribution passage. The fuel gas flows through the fuel gas supply passage into the separator. The fuel gas distribution passage connects the fuel gas channel and the fuel gas supply passage. The oxygen-containing gas flows through the oxygen-containing gas supply passage into the separator. The oxygen-containing gas distribution passage connects the oxygen-containing gas channel and the oxygen-containing gas supply passage.

Owner:HONDA MOTOR CO LTD

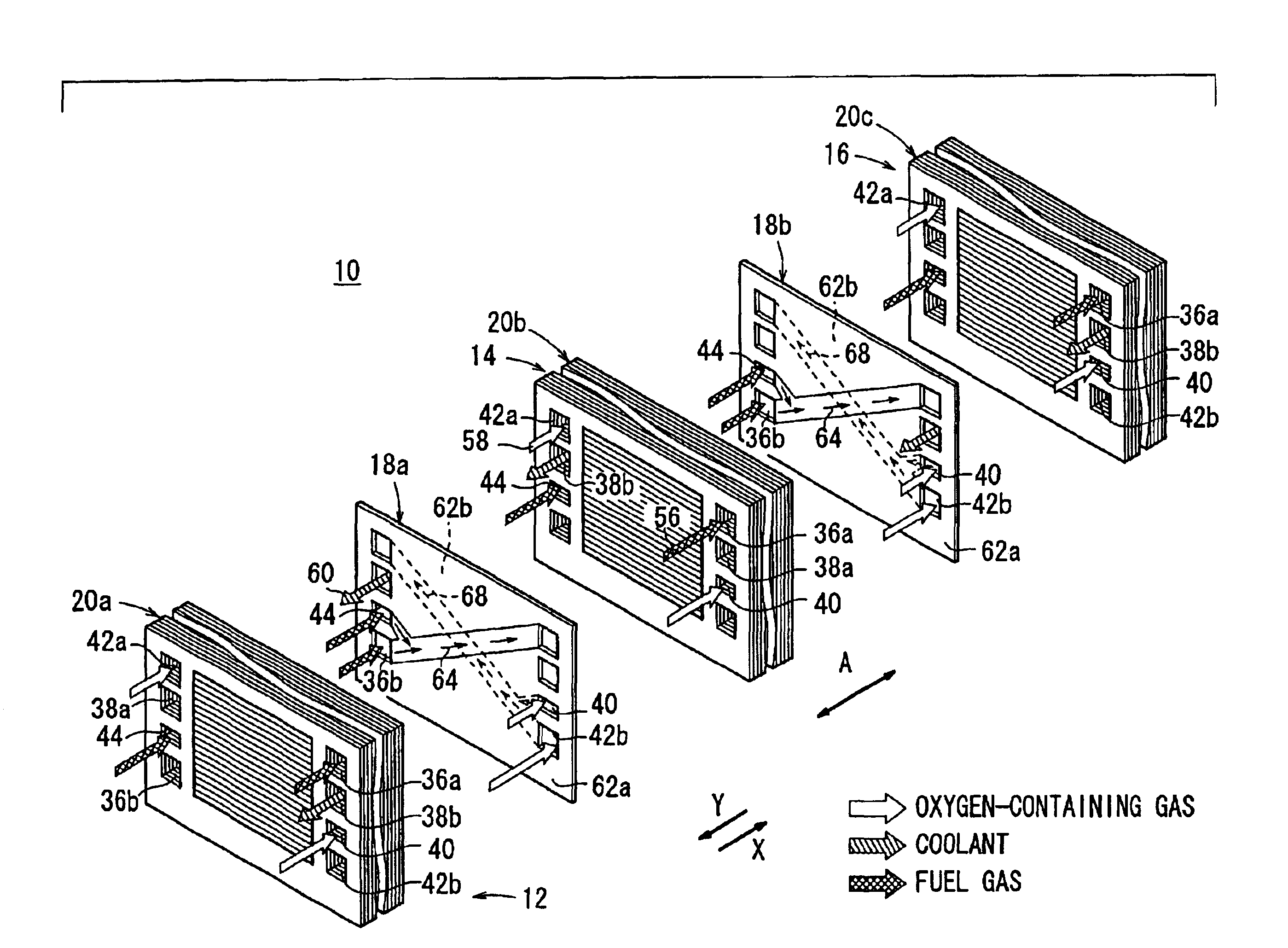

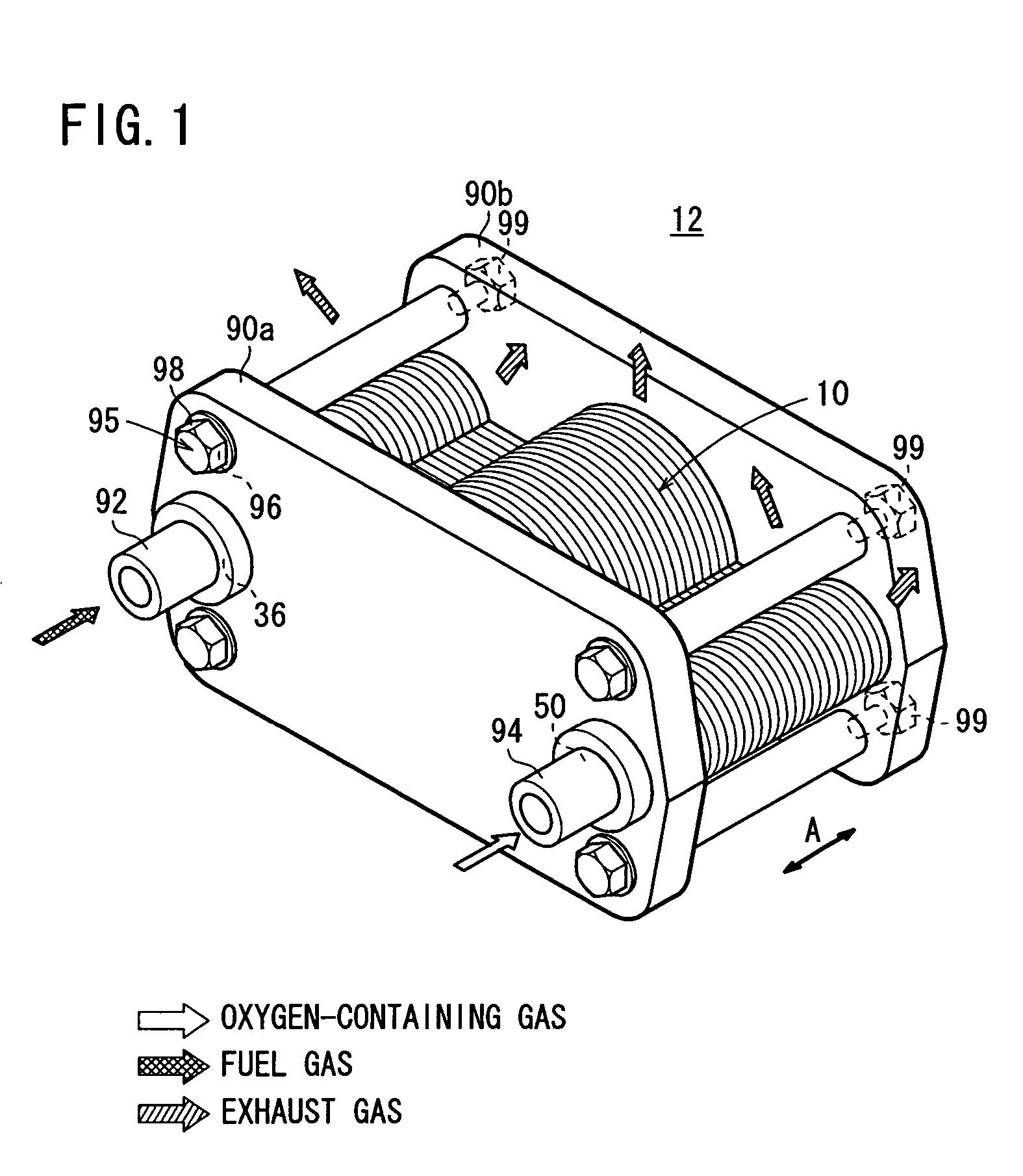

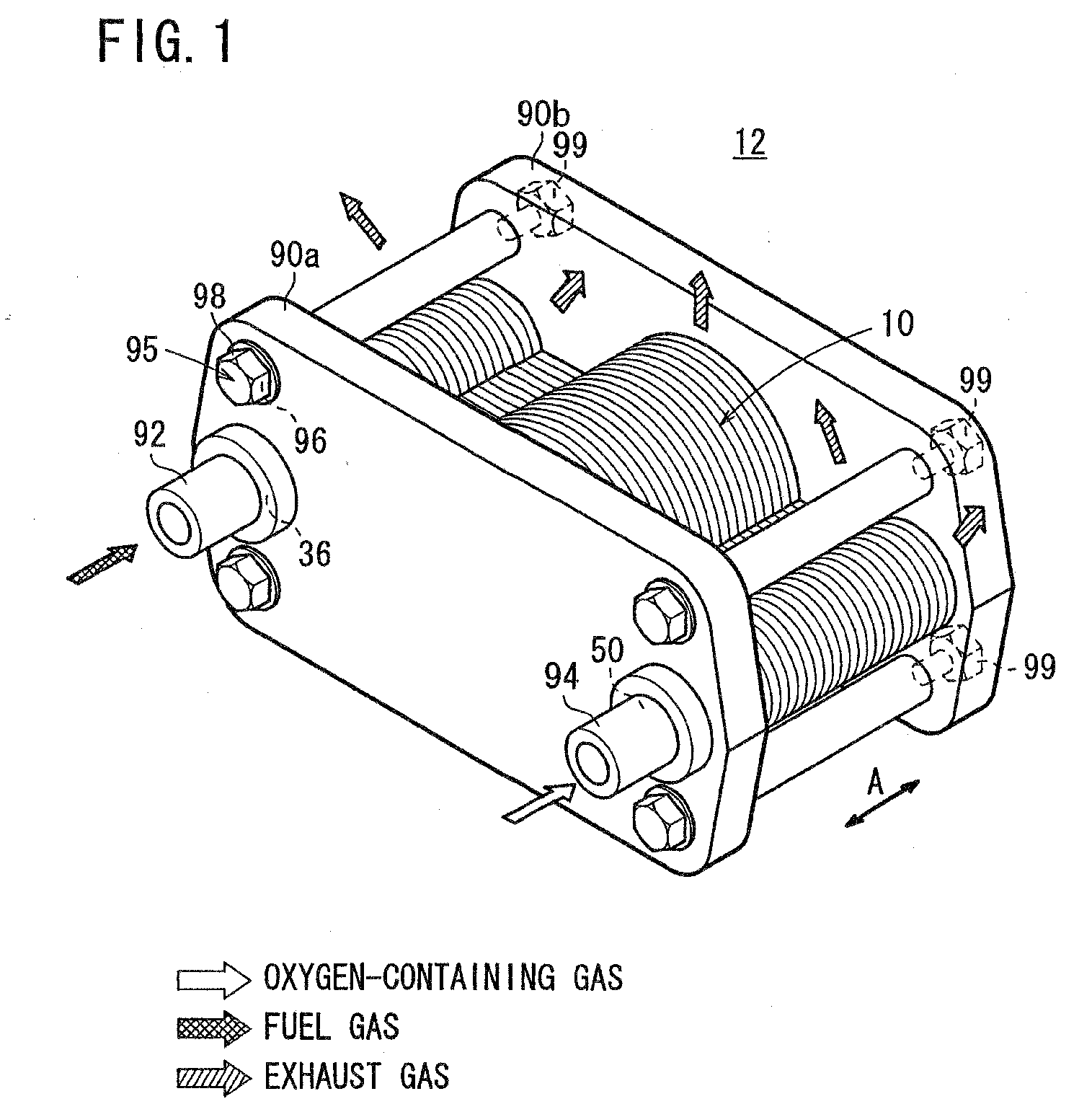

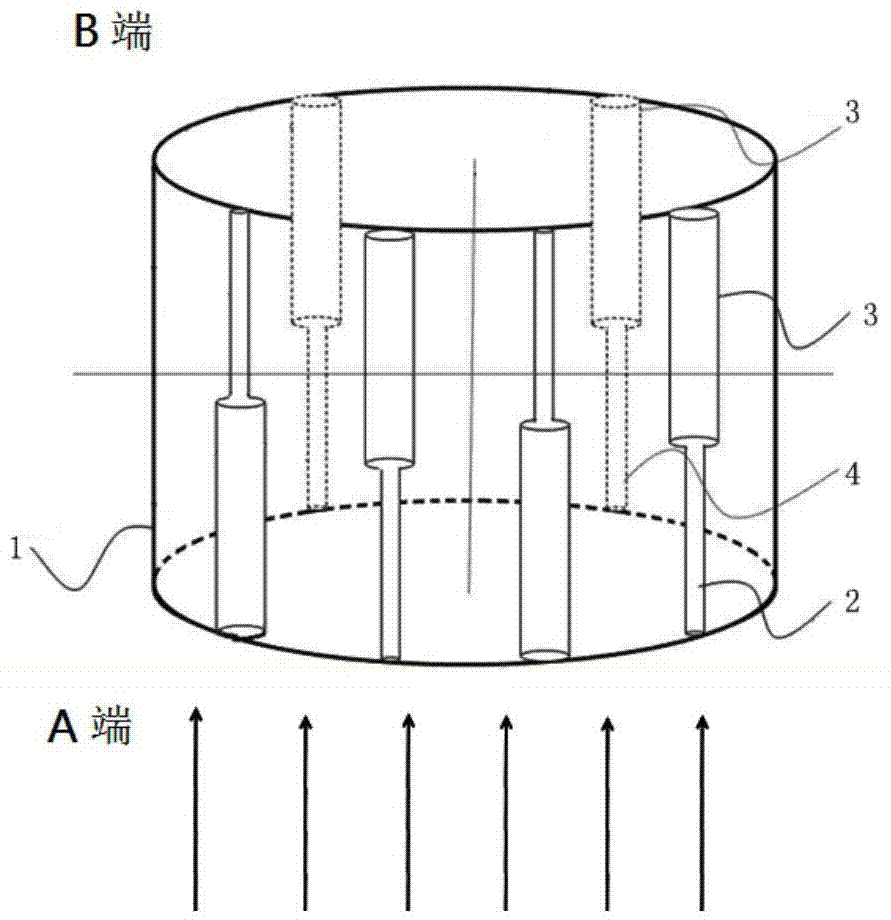

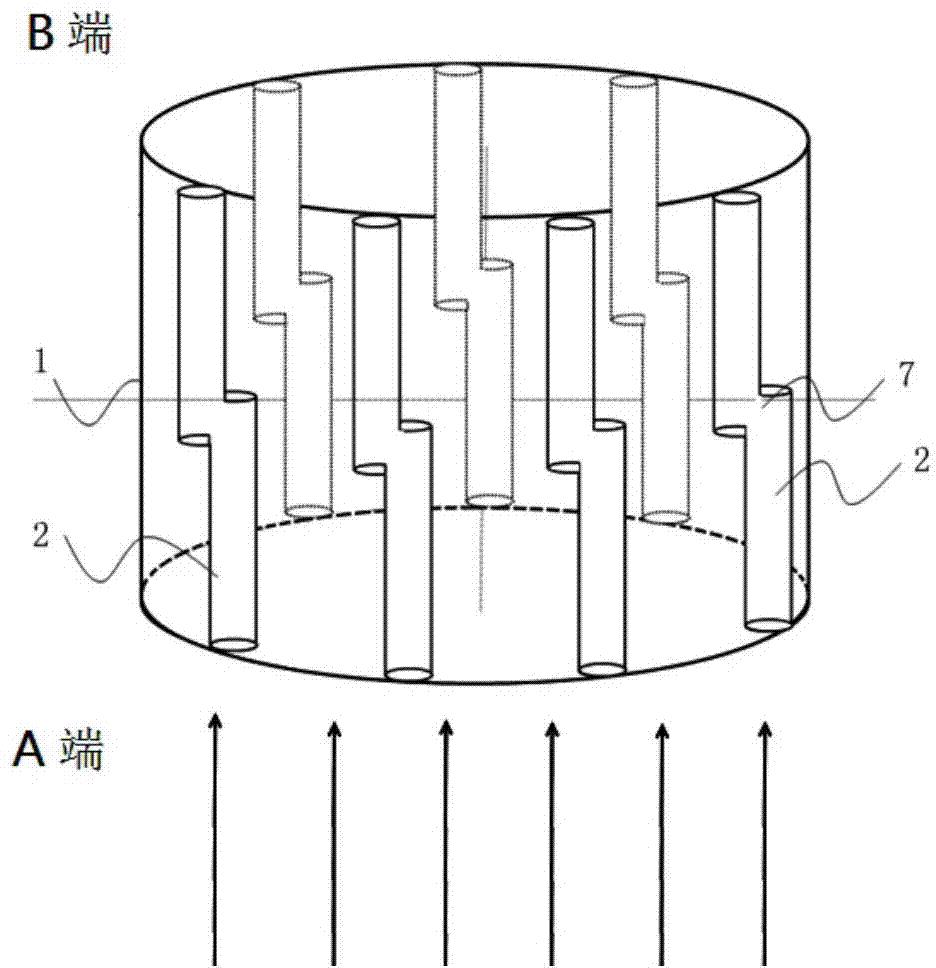

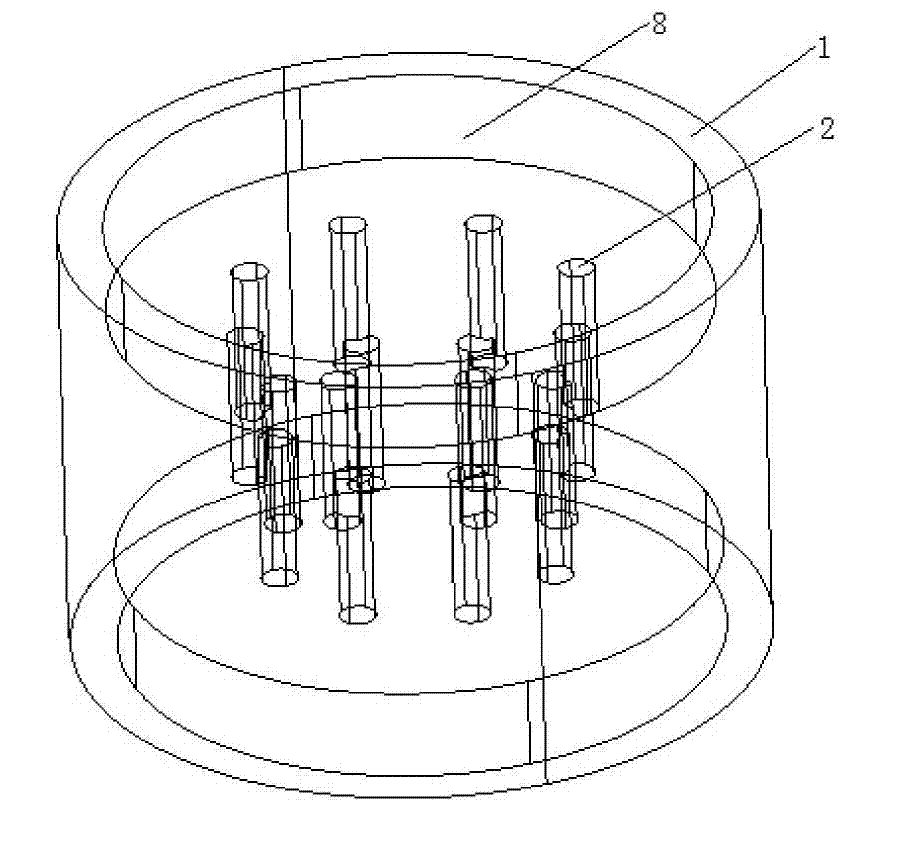

Fuel cell stack

InactiveUS6926985B2Simple structureMaintain powerFuel cell heat exchangeFuel cells groupingFuel cellsCoolant flow

A fuel gas passage, an oxygen-containing gas passage, and a coolant passage extend through a fuel cell stack. Each of the fuel gas passage and the oxygen-containing gas passage is formed by serially connecting passages between the first through third fuel cell modules. The fuel gas flows through the fuel gas passage, and the oxygen-containing gas flows through the oxygen-containing gas passage from the first fuel cell module toward the third fuel cell module. The coolant passage is formed by serially connecting passages between the first through third fuel modules. The coolant flows through the coolant passage from the third fuel cell module toward the first fuel cell module. The direction of the flow of the coolant is opposite to the direction of the flows of the fuel gas and the oxygen-containing gas.

Owner:HONDA MOTOR CO LTD

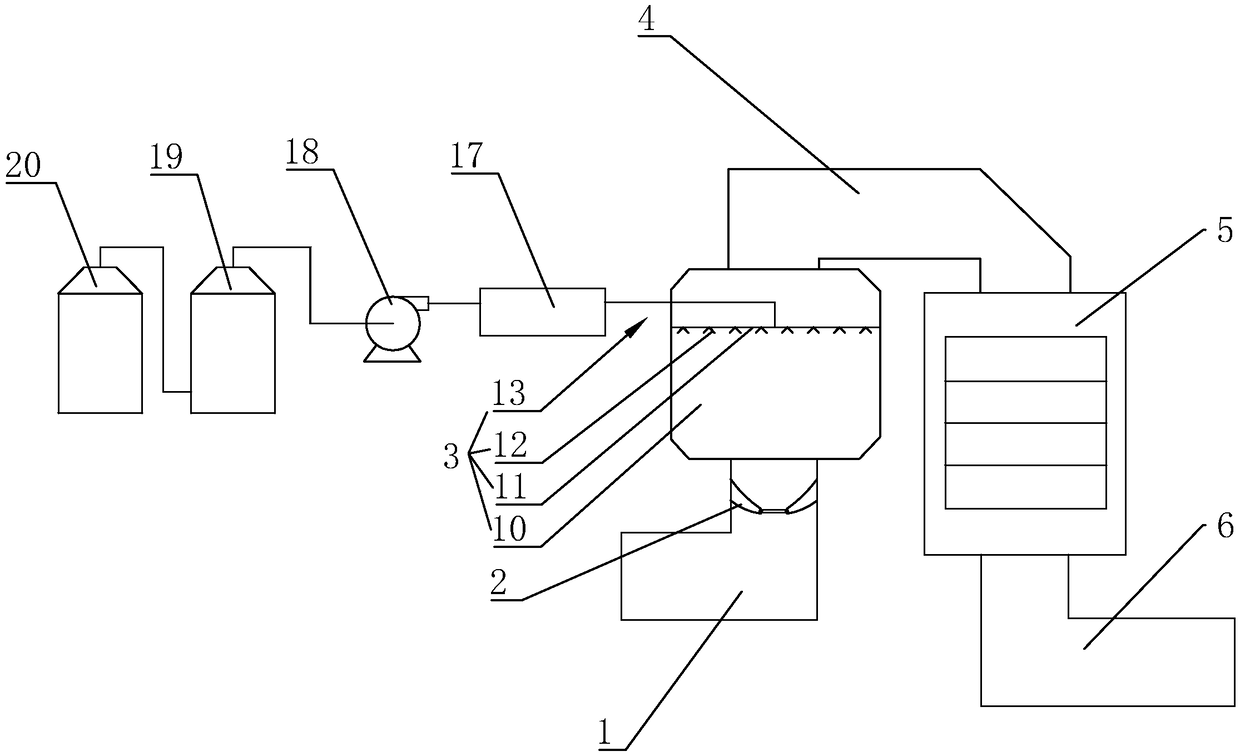

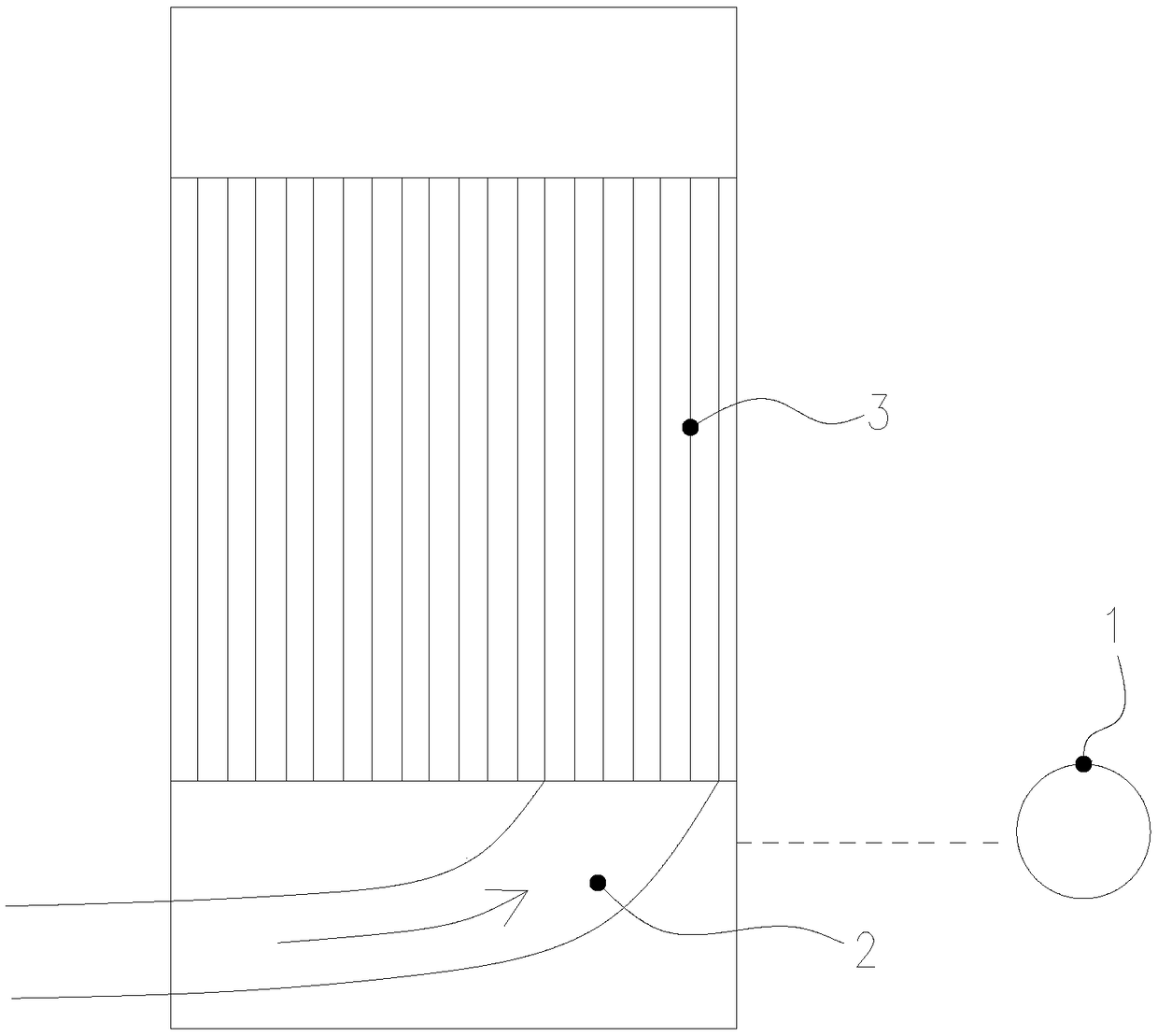

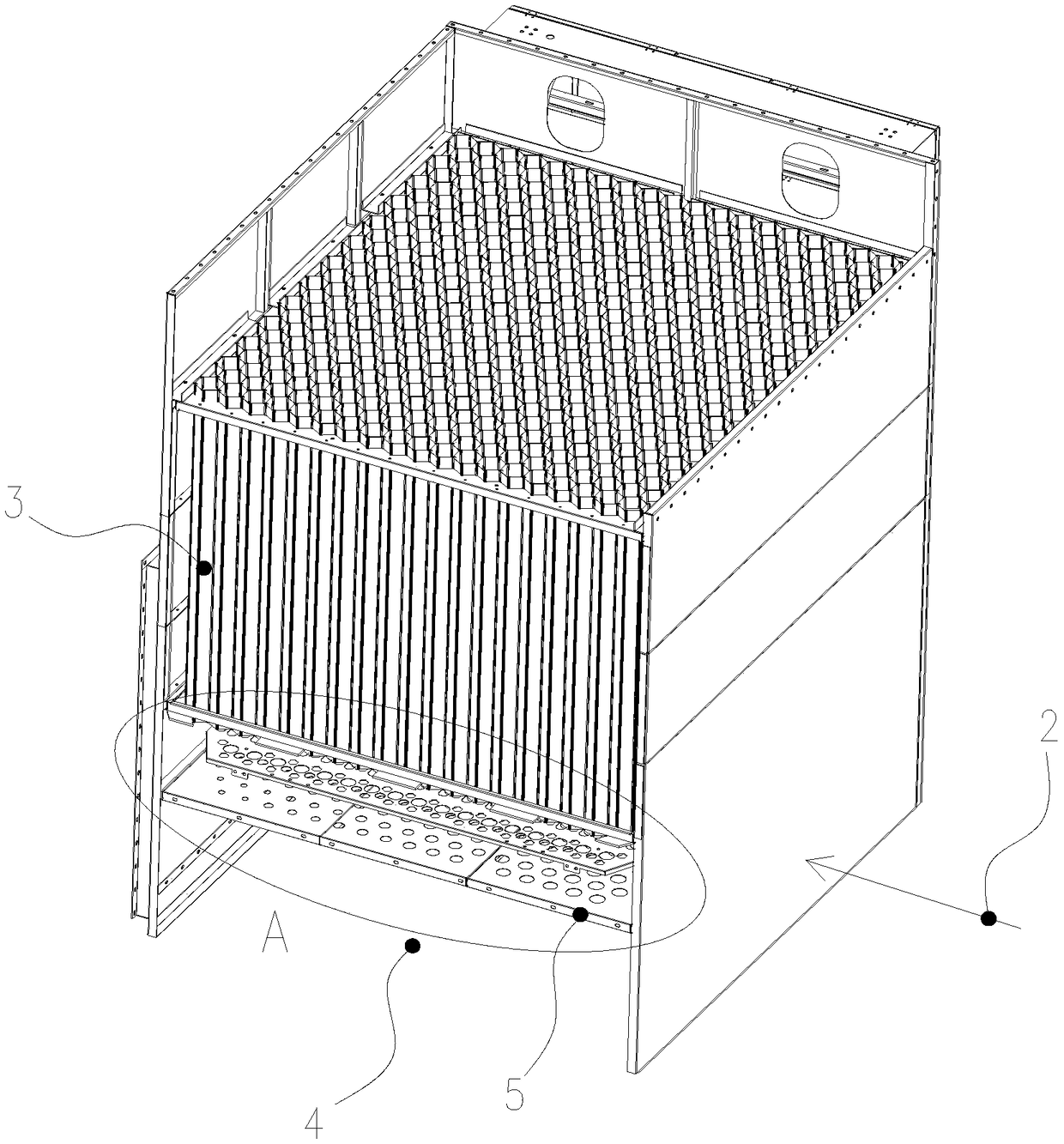

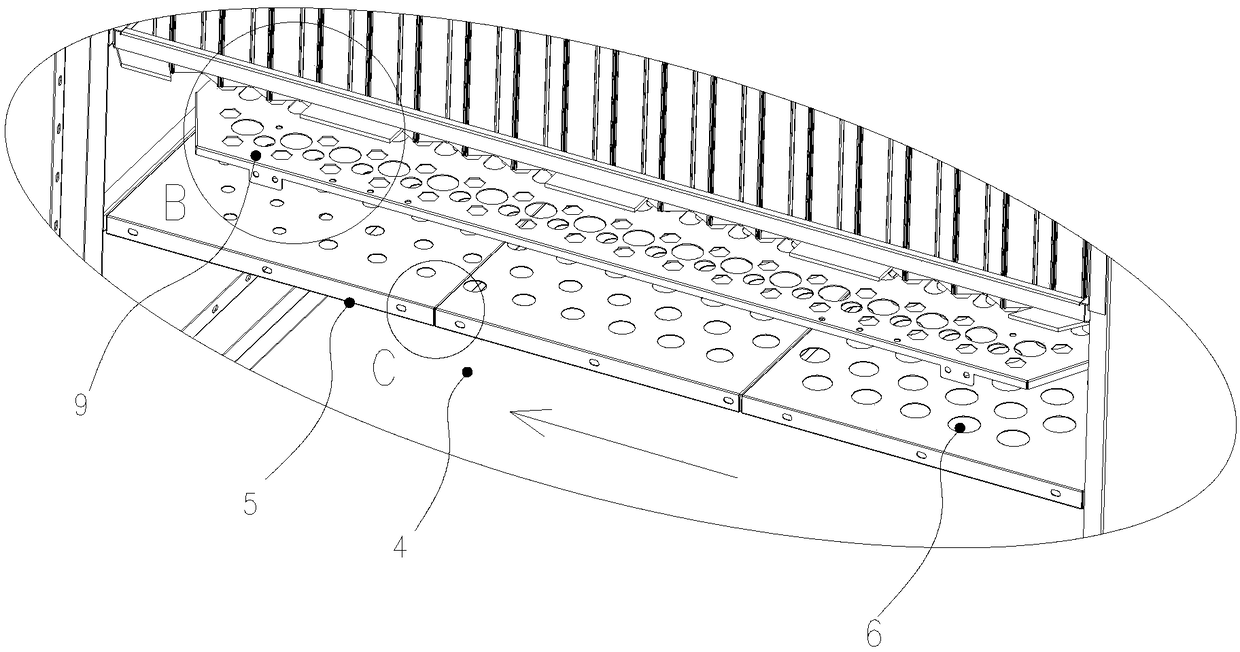

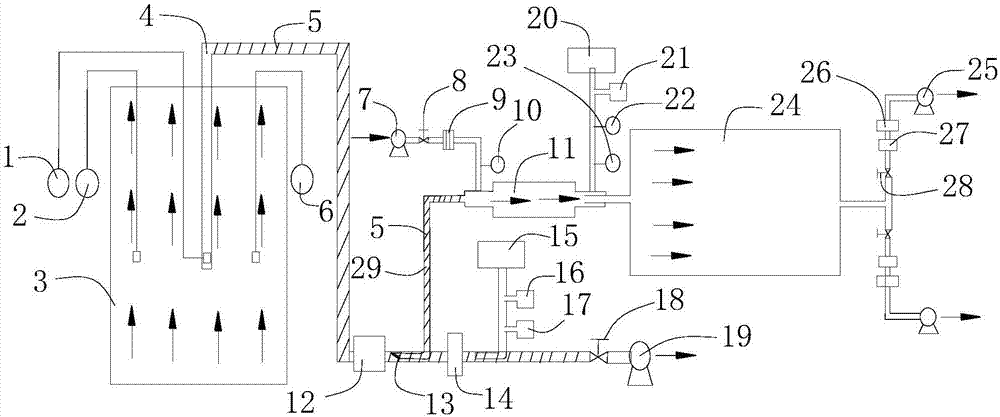

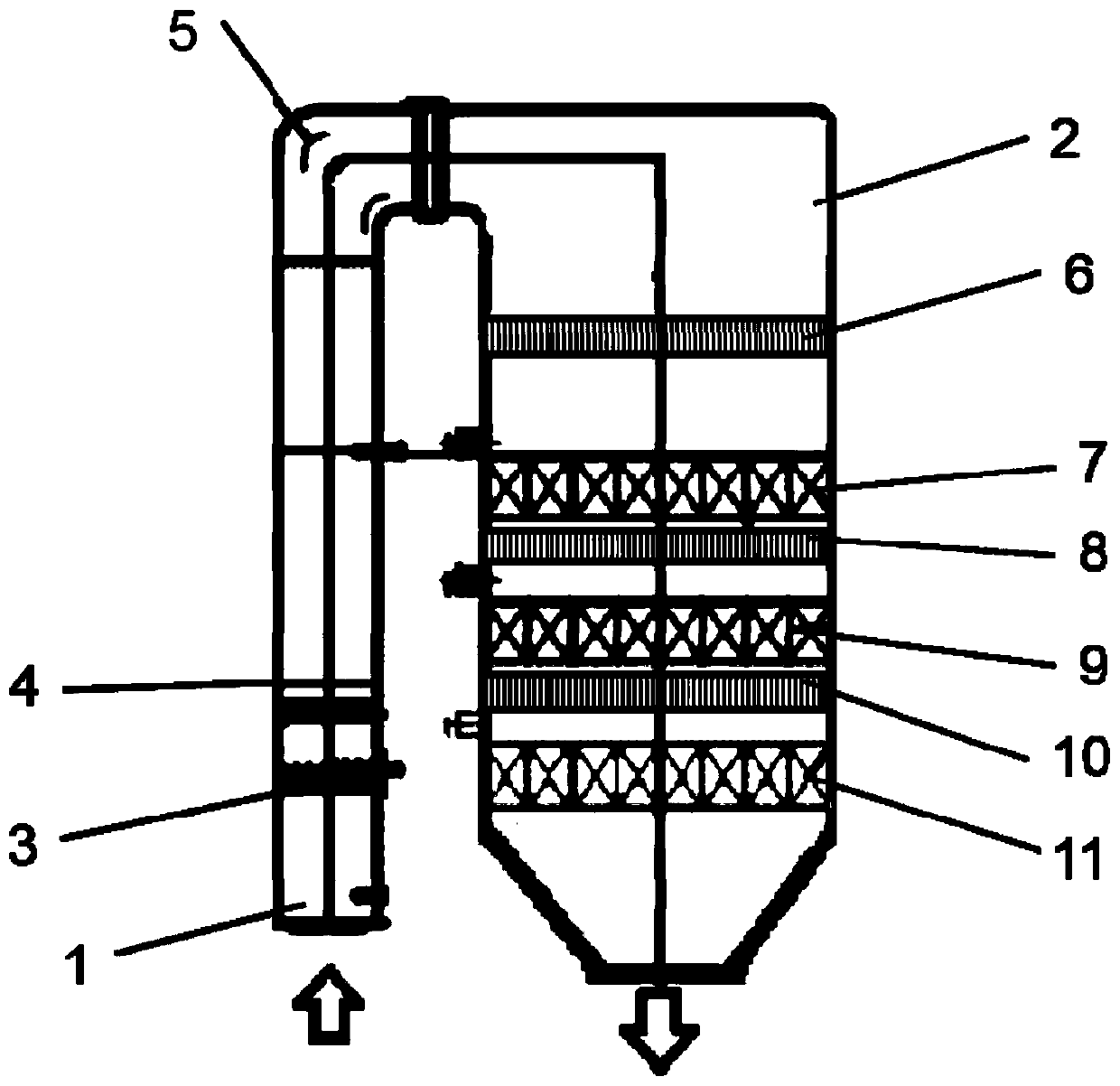

Fluidized bed technology and fluidized bed system for directly capturing CO2 in mineralized flue gas

ActiveCN104759203ASimple processReduce usageDispersed particle separationAir quality improvementSlagFresh gas flow

The invention discloses a fluidized bed technology for directly capturing CO2 in mineralized flue gas. In the technology, a high-calcium waste, such as fly ash, carbide slag, steel slag, waste cement and the like, as a raw material. A by-pass is formed on a flue gas discharge pipeline to feed a flue gas flow of which the humidity and the temperature are regulated by a temperature and humidity regulator. In a fluidized bed reactor, the flue gas flow, of which the humidity and the temperature are regulated, is contacted with the high-calcium waste in a co-current flow manner to generate calcium carbonate. After the reaction, a dust-containing gas flow discharged out from the fluidized bed reactor is fed into a cyclone separator for gas-solid separation to obtain a gas flow, wherein the gas flow is fed into the original flue gas discharge pipeline and then is fed into the chimney for being discharged. The invention also provides a fluidized bed system for directly capturing CO2 in the mineralized flue gas. The technology can not only effectively increase the utilization rate of fly ash but also reduce CO2 emission of a power plant, is simple in processes, is convenient to continuously operate, is high in device processing capacity, is small in size and less in occupied area and can be combined with the existing system conveniently. Meanwhile, the decarbonized fly ash does not influence the original use approach of the fly ash from the power plant, thereby achieving a lower decarbonization cost.

Owner:HUANENG POWER INTERNATIONAL +1

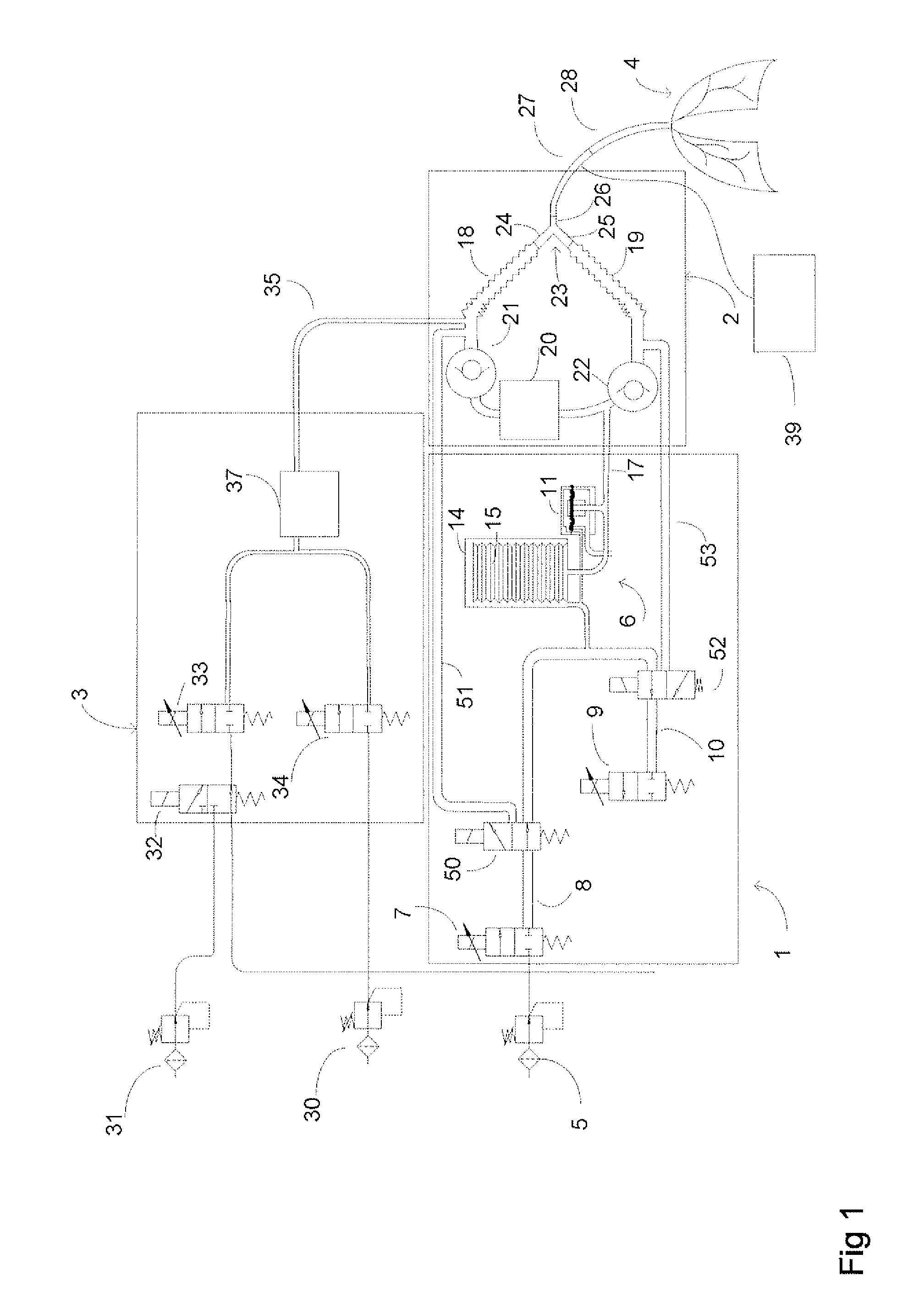

Arrangement and method for supplying breathing gas for respiration

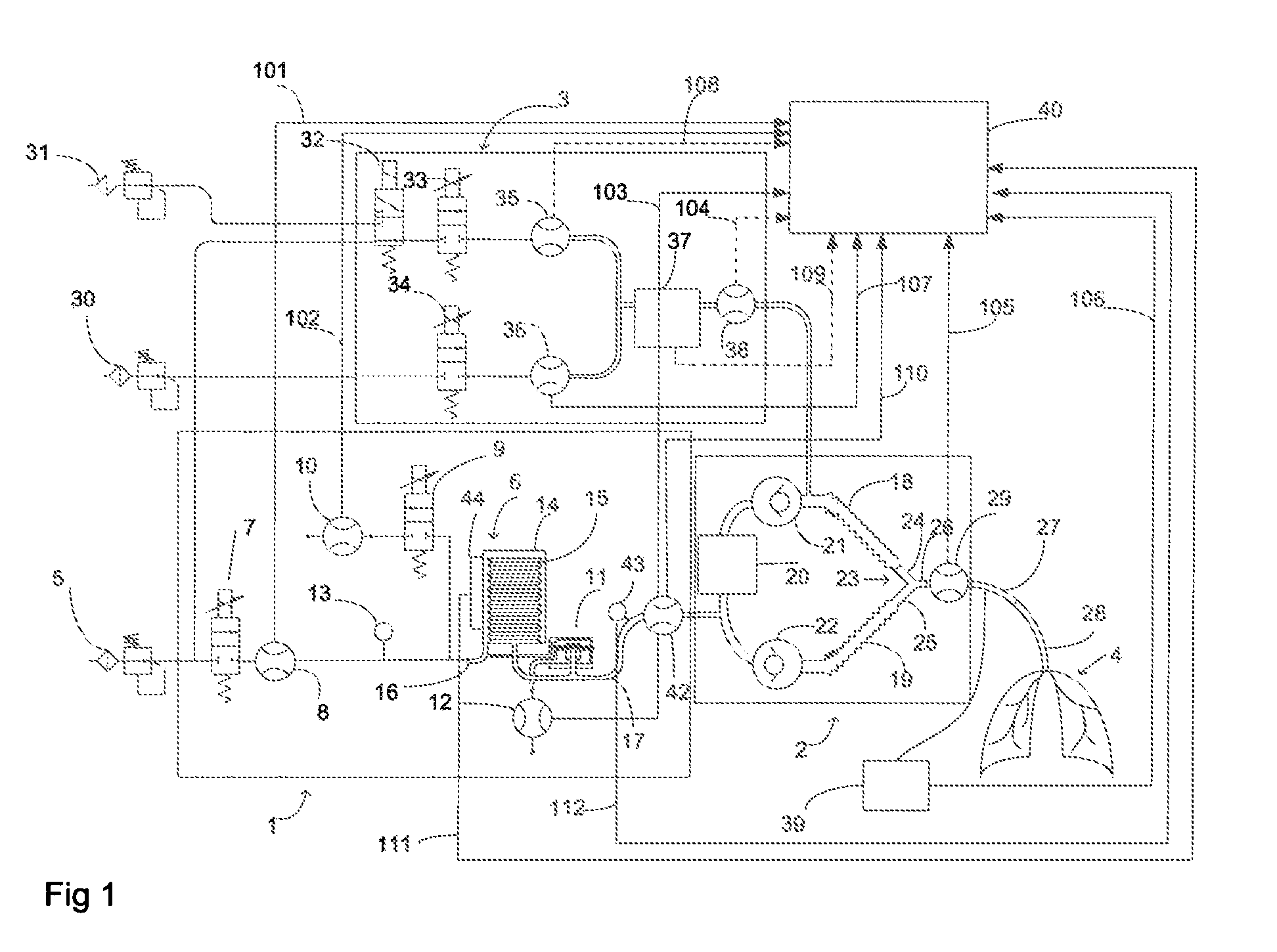

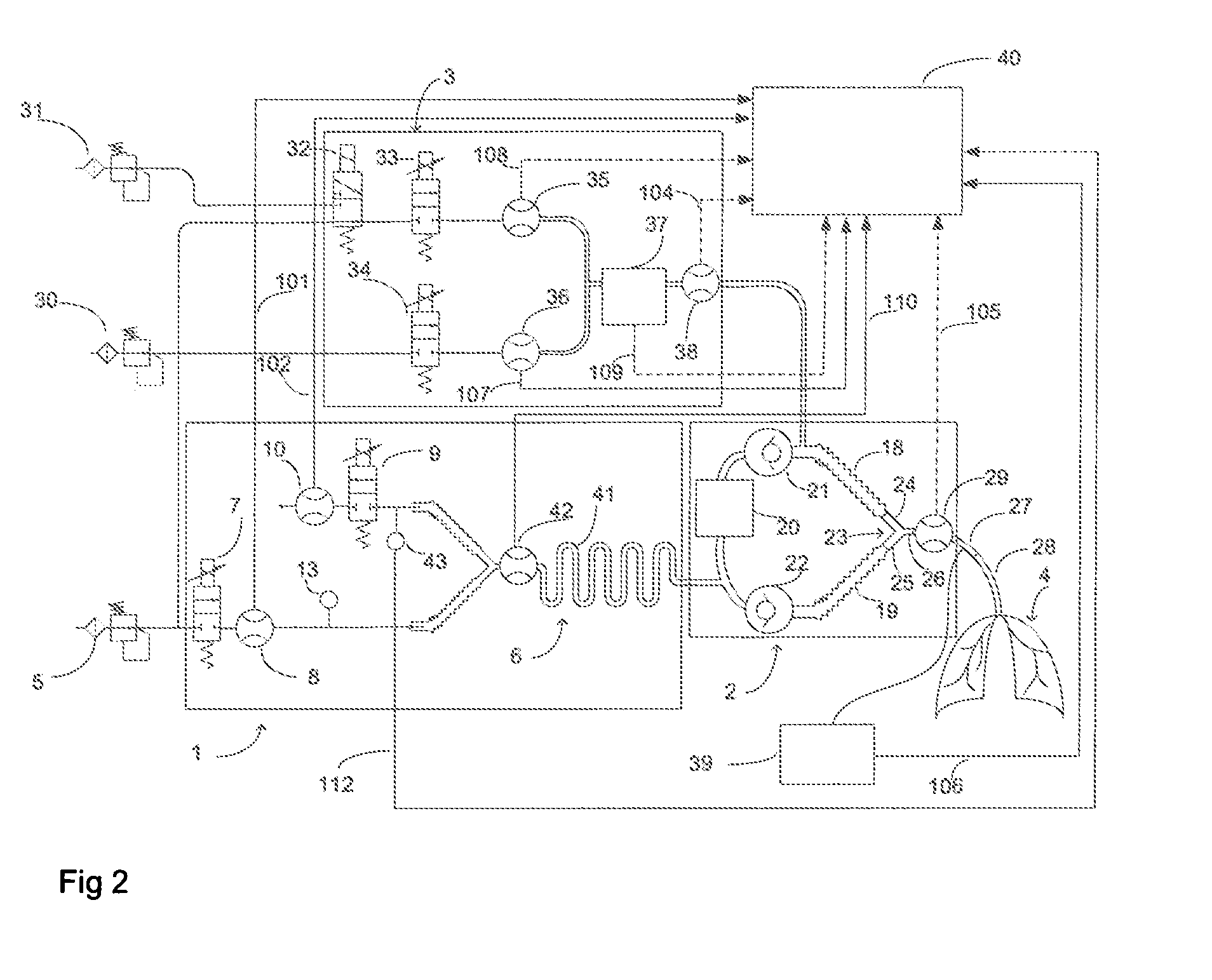

InactiveUS20110197889A1RespiratorsOperating means/releasing devices for valvesRESPIRATORY MOVEMENTSBreathing gas

An apparatus and method for supplying a breathing gas for a respiration. The apparatus includes a reciprocating unit configured to receive an inspiration gas flow and adapted to control respiratory movements. The apparatus also includes a gas mixer for supplying a fresh gas flow. The apparatus also includes a breathing circuit configured to conduct an expiration gas flow to the reciprocating unit and to conduct the fresh gas flow from the gas mixer for the respiration and to conduct the gas flow from the reciprocating unit for an inspiration, the breathing circuit comprising a CO2 remover configured to remove carbon dioxide from the gas. The apparatus also includes a first bypass passage configured to permit bypassing the reciprocating unit and connecting the breathing circuit to the inspiration gas flow upstream from the reciprocating unit.

Owner:GENERAL ELECTRIC CO

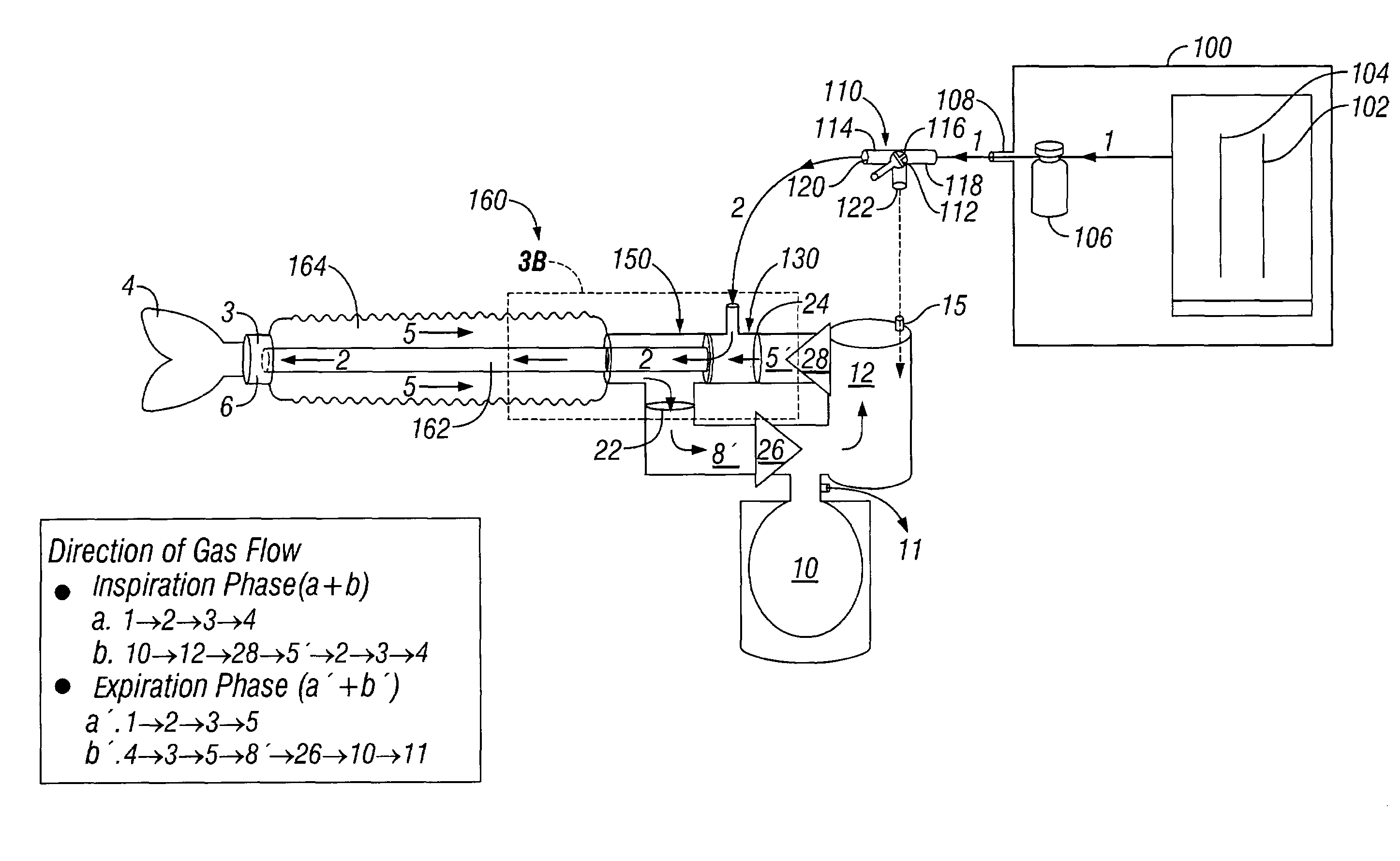

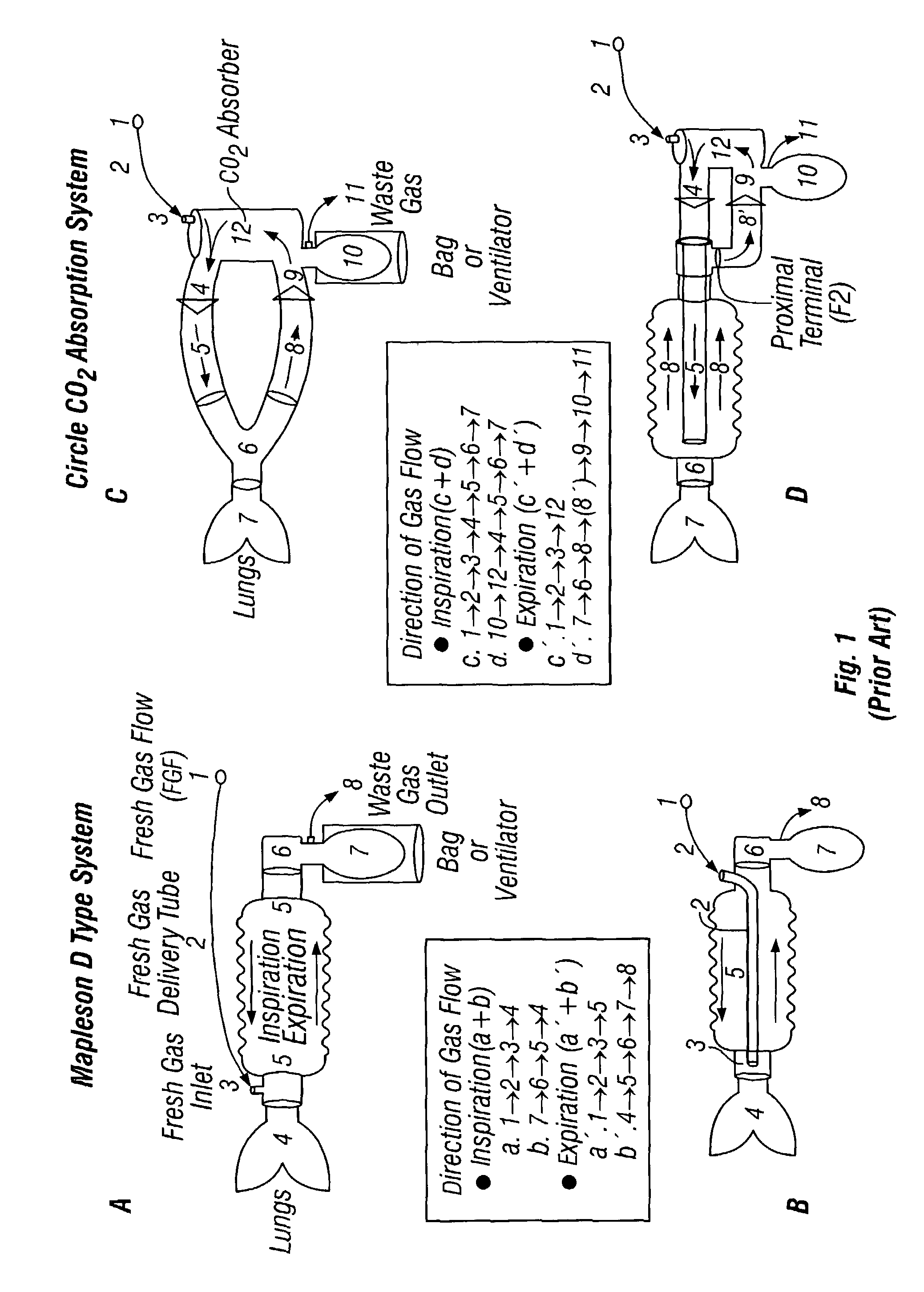

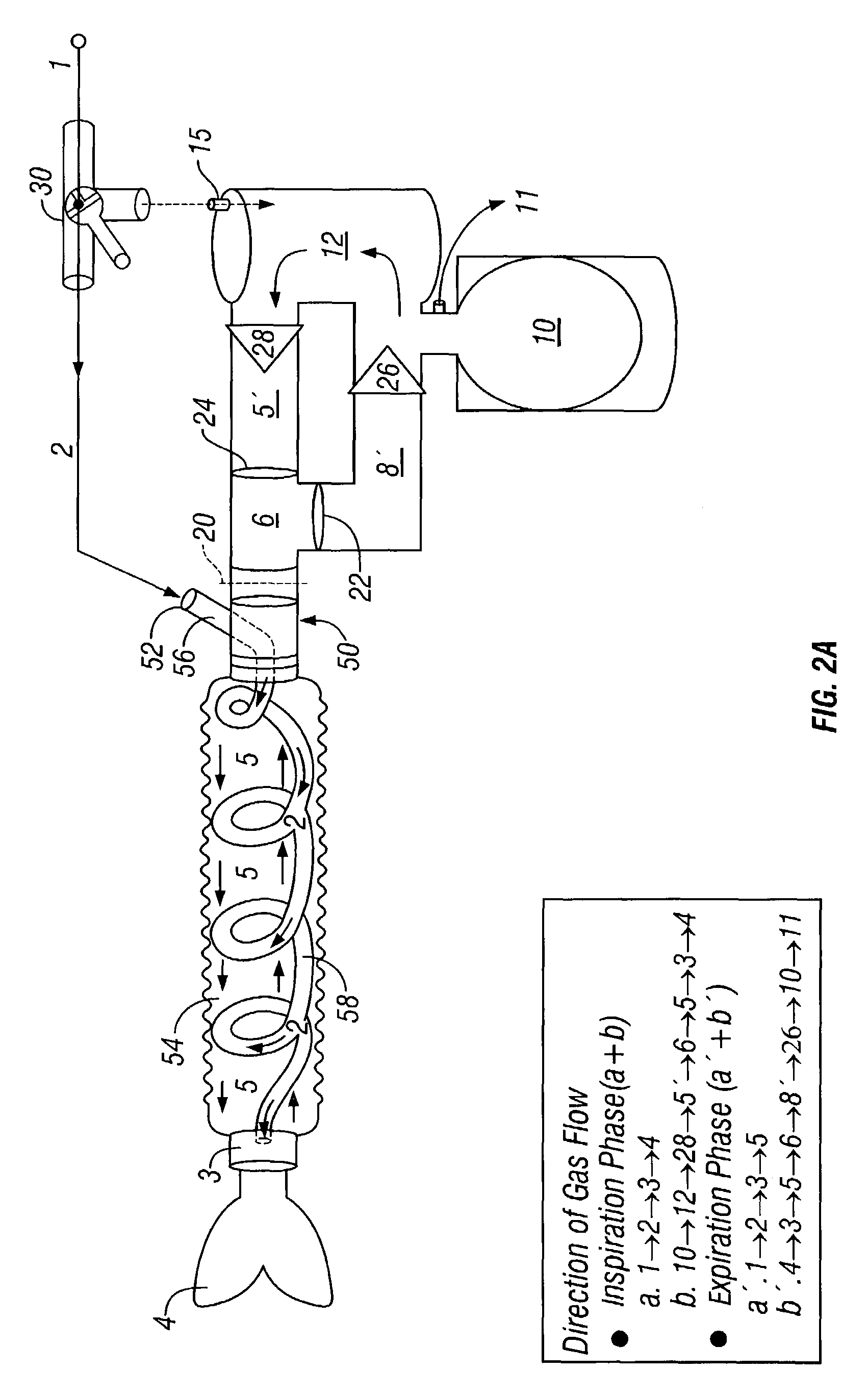

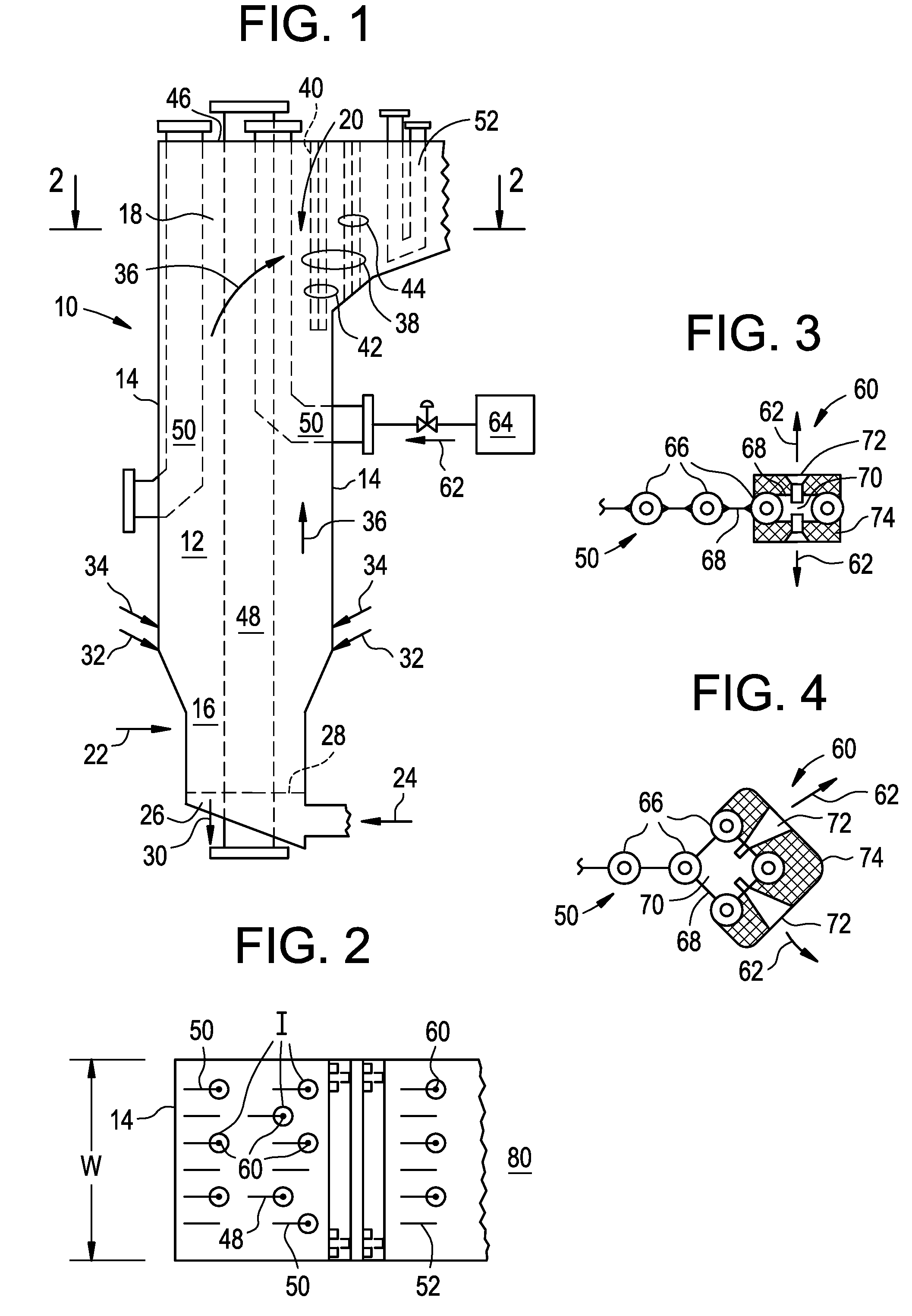

Breathing systems with post-inspiratory valve fresh gas flow input, components for implementing same, and methods of use

InactiveUS7717109B2Simple and safe processUtilization of fresh gases is optimizedRespiratorsOperating means/releasing devices for valvesAssisted ventilationBreathing circuit component

A system for providing anesthesia or assisted ventilation that has a post-inspiratory valve fresh gas flow input is disclosed. In a preferred embodiment, a fresh gas flow diverter valve is provided to permit an operator to provide fresh gas flow proximally or distally of the inspiratory valve. Also disclosed is an adaptor and other breathing circuit components for forming a system of the present invention. A method of providing anesthesia or assisted ventilation using low flow fresh gas is disclosed.

Owner:AMBU AS

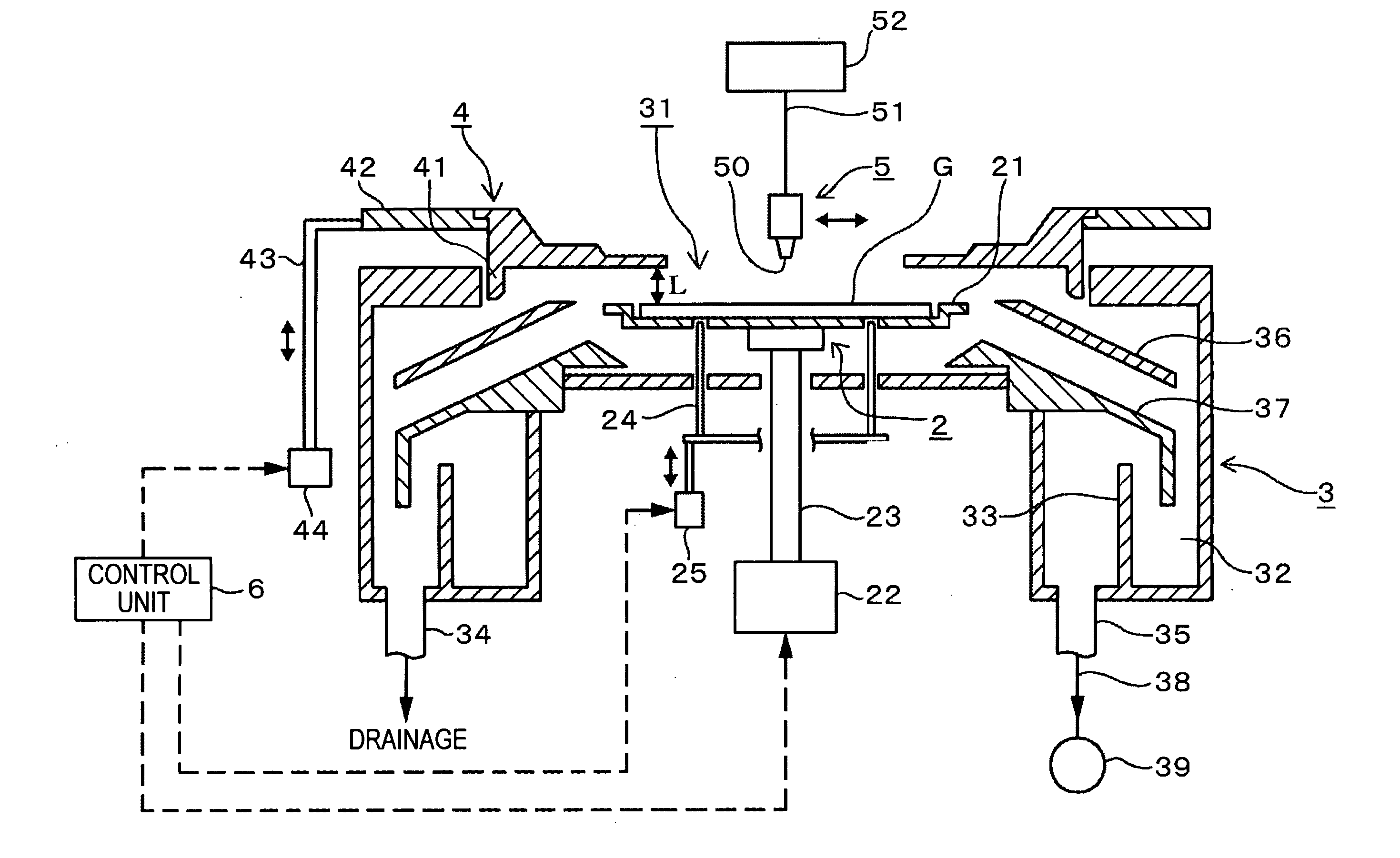

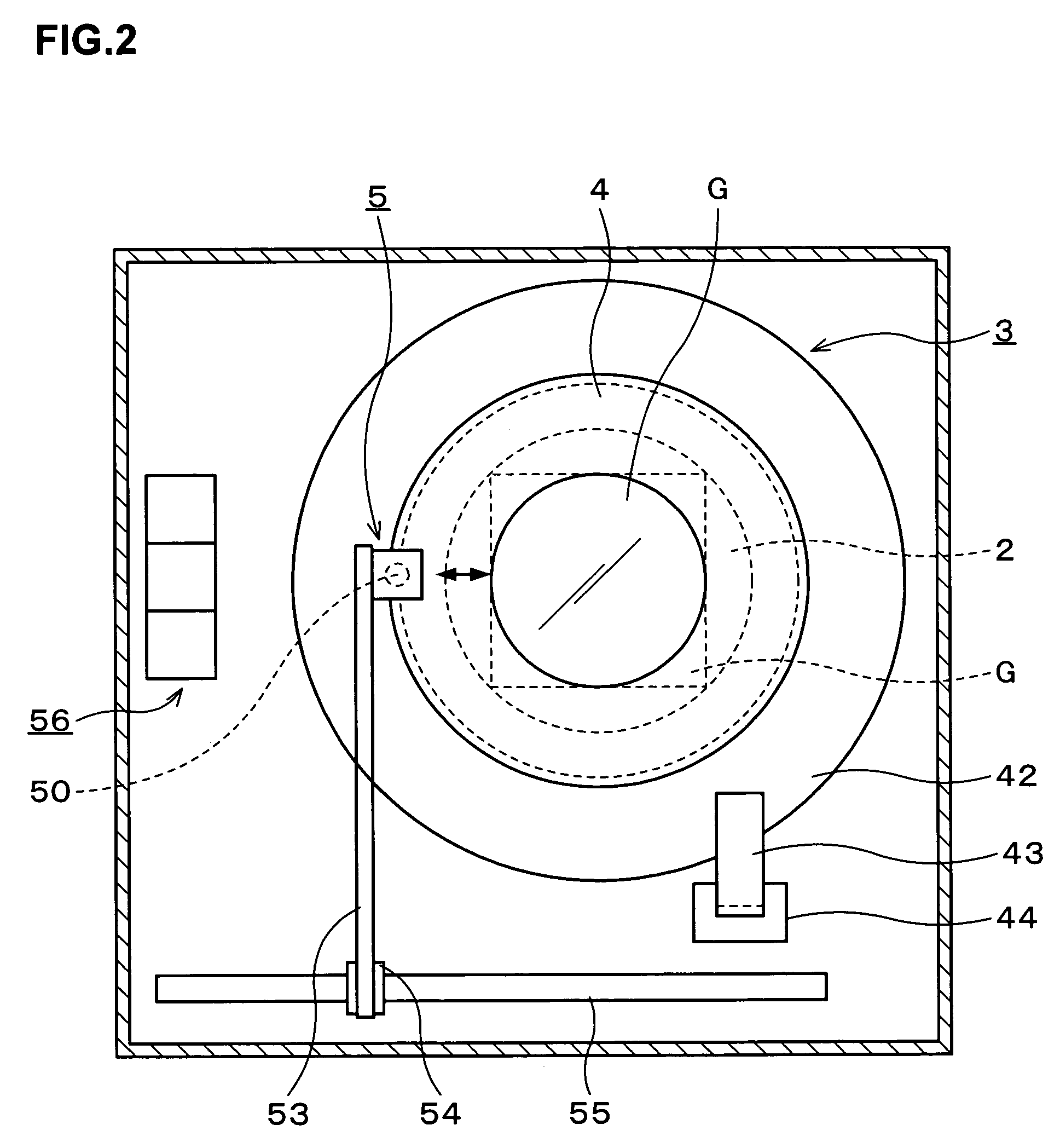

Coating treatment apparatus and coating treatment method

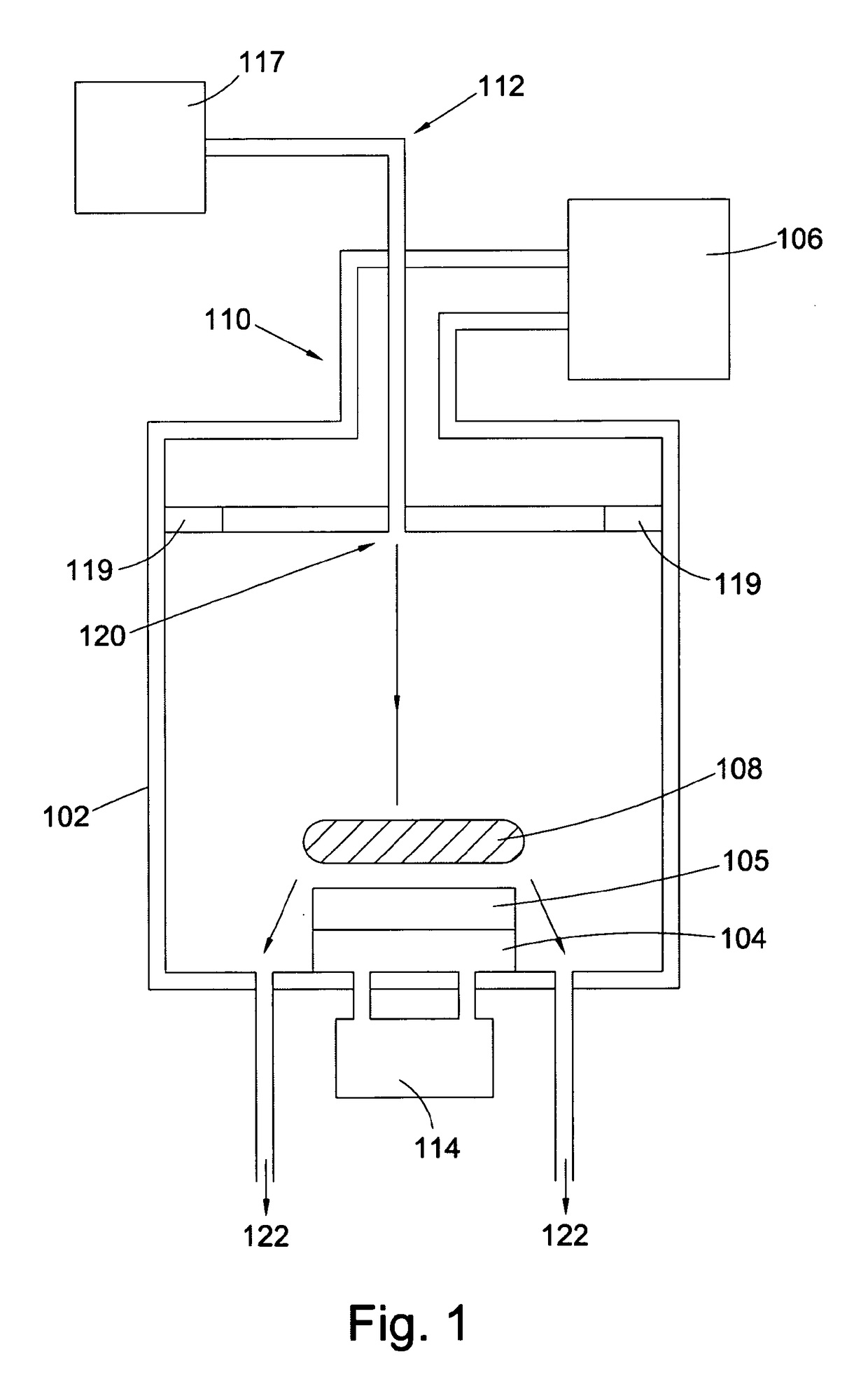

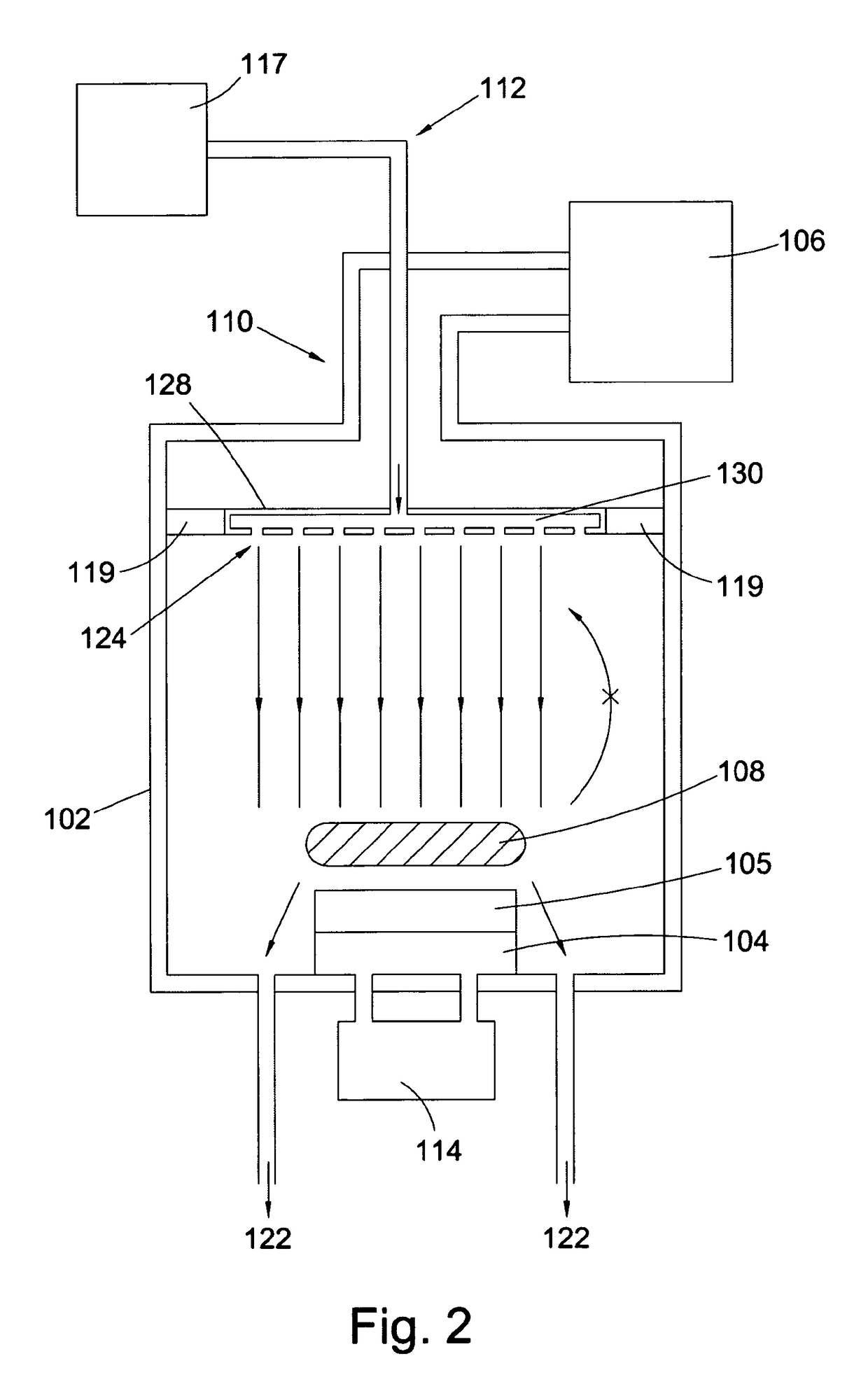

InactiveUS20050181127A1Suppresses rate of coating solutionUniform evaporation rateSemiconductor/solid-state device manufacturingPretreated surfacesEngineeringSolvent

In the present invention, a gas flow restraining ring facing corner portions of the front face of a substrate horizontally held on a substrate holding unit and movable up and down, is set to a predetermined height in accordance with a coating treatment. Then, a coating solution containing a coating film forming component and a solvent is applied to the front face of the substrate and spread into a thin film state by a so-called spin coating method, and thereafter the substrate is rotated at a high speed so that the coating solution is dried. In this case, it is possible to control fresh gas flow from above the substrate to decrease the difference in evaporation rate of the solvent between the coating solution on the corner portions of the substrate and the coating solution inside them, thus enabling the coating treatment uniform within a plane on the substrate.

Owner:TOKYO ELECTRON LTD

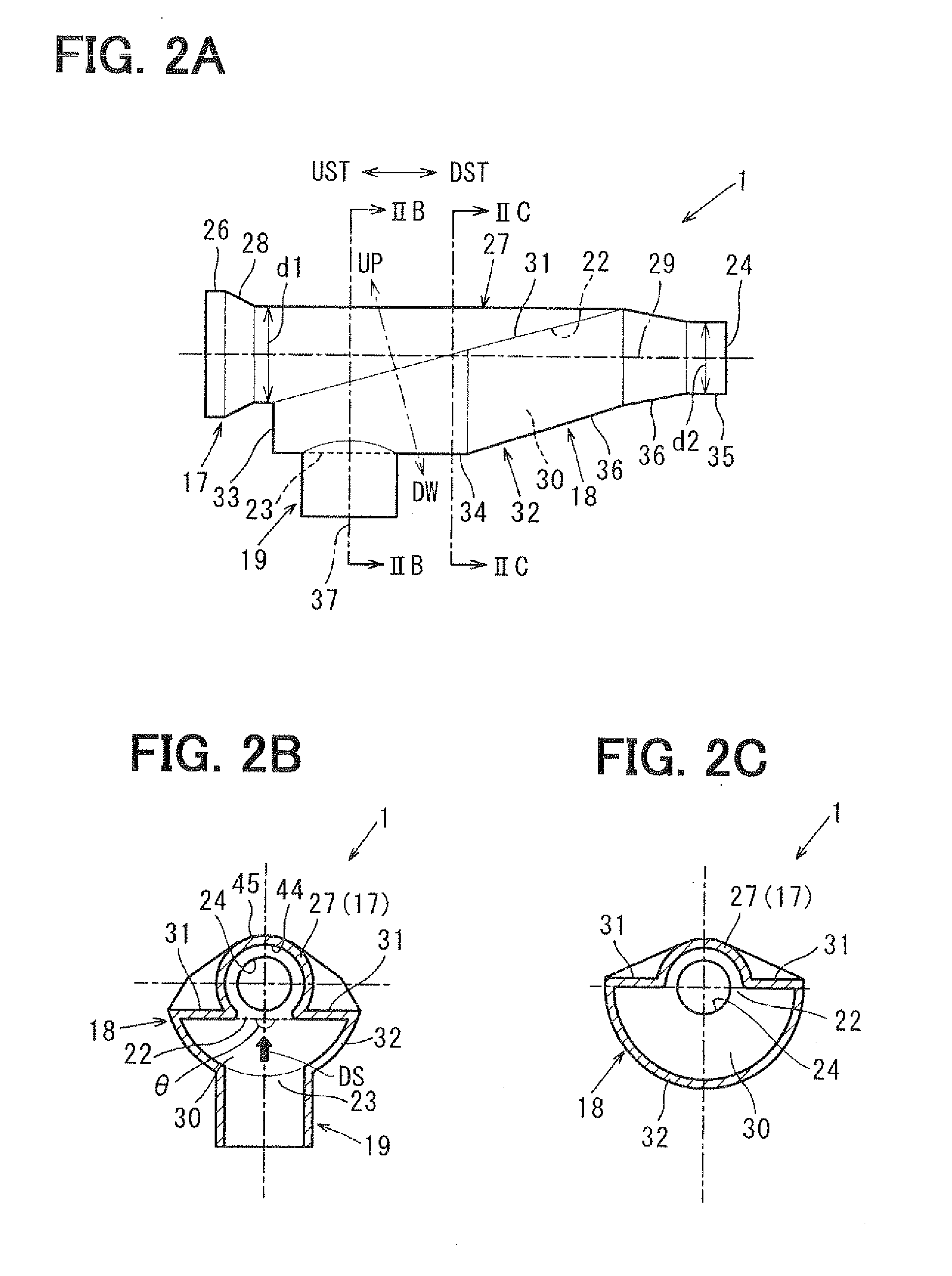

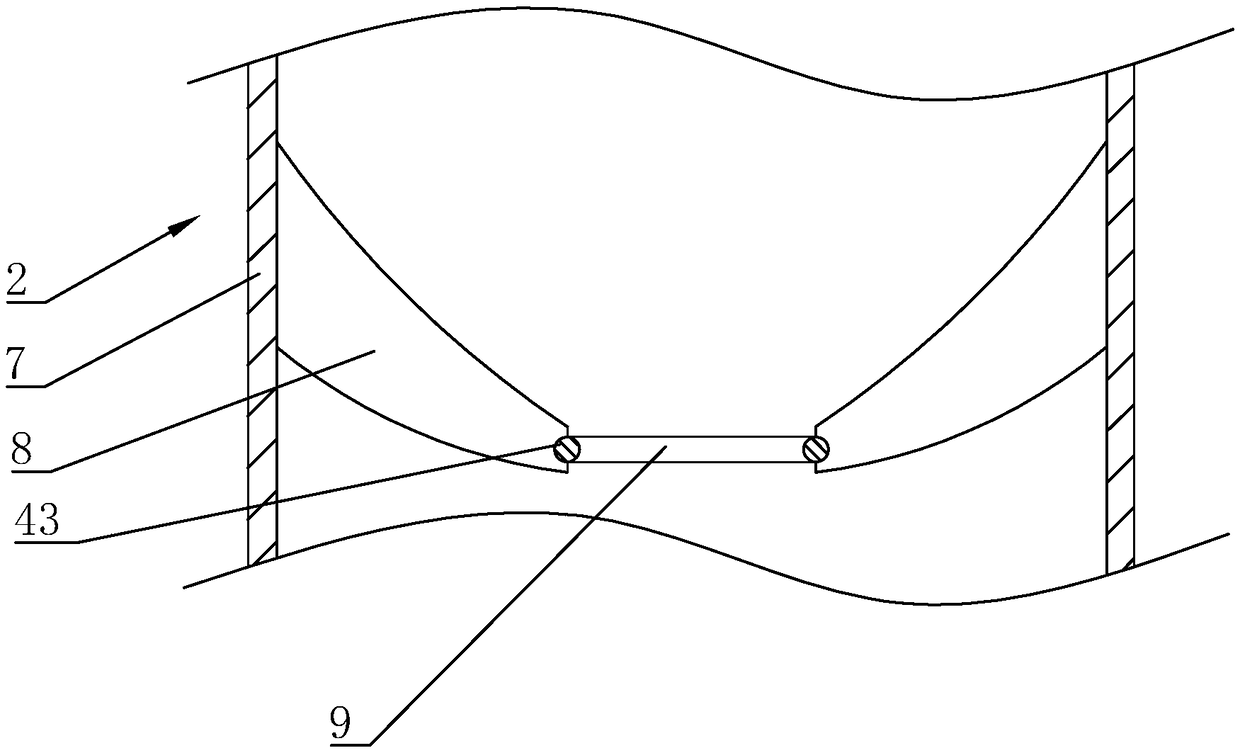

Egr mixer

InactiveUS20120048246A1Effective limitIncrease vacuumInternal combustion piston enginesNon-fuel substance addition to fuelMechanical engineeringFresh gas flow

An EGR mixer has a mixing shell which defines a mixing cavity only on the down side, and does not define the mixing cavity on the up side. The EGR mixer has a primary internal opening for fresh air, which is formed so that an opening plane is inclined to a side so that the opening plane faces a secondary internal opening for exhaust gas. The primary internal opening and the secondary internal opening are arranged to allow exhaust gas to enter into the primary internal opening. The exhaust gas restricts a fresh air flow so that the fresh air flow creates increased vacuum. It is possible to suppress pressure loss and to increase an amount of exhaust gas.

Owner:DENSO CORP

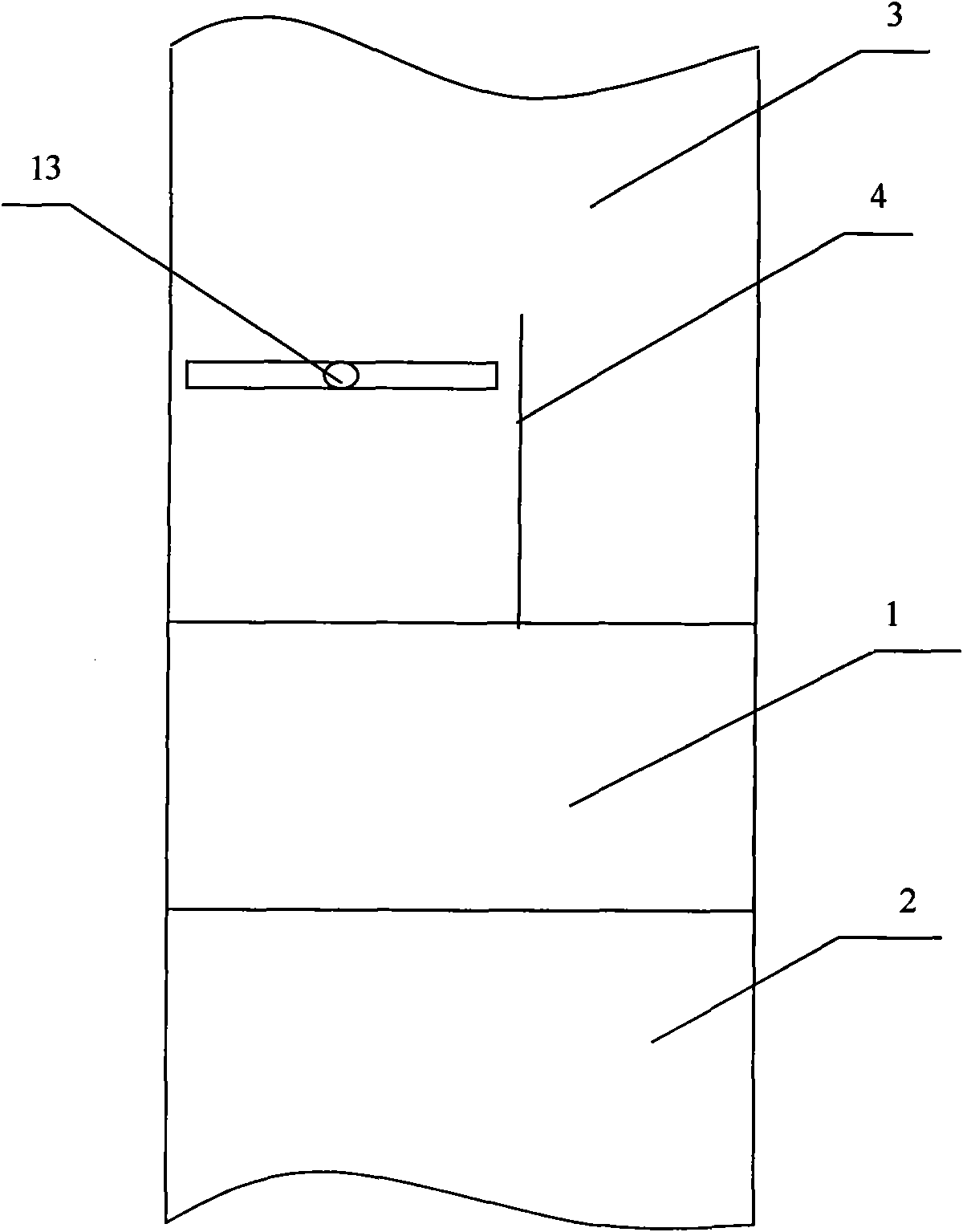

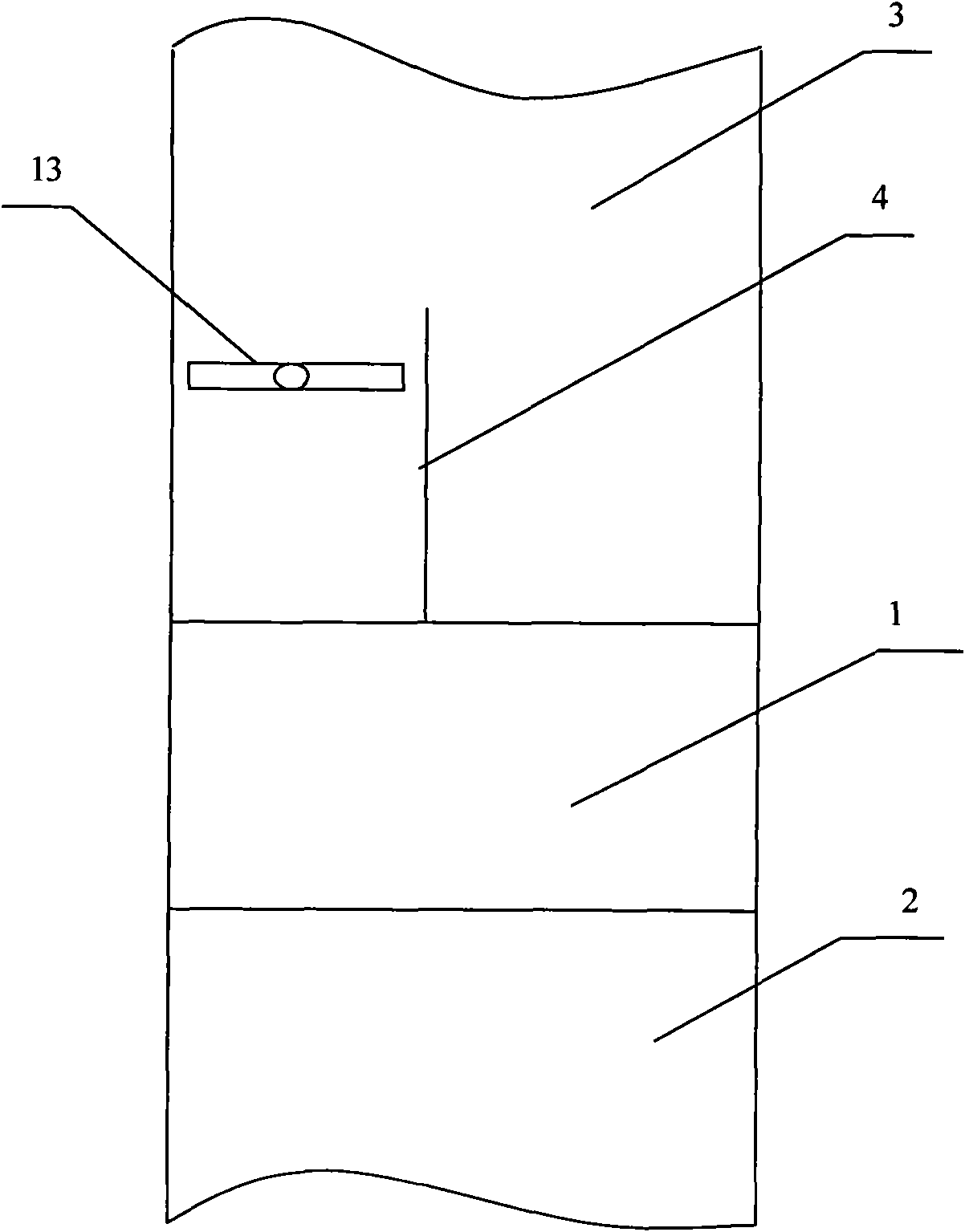

Fruit and vegetable mildew-proof storage device

ActiveCN102823642AAvoid harmResidue reductionFruit and vegetables preservationPreservativeEngineering

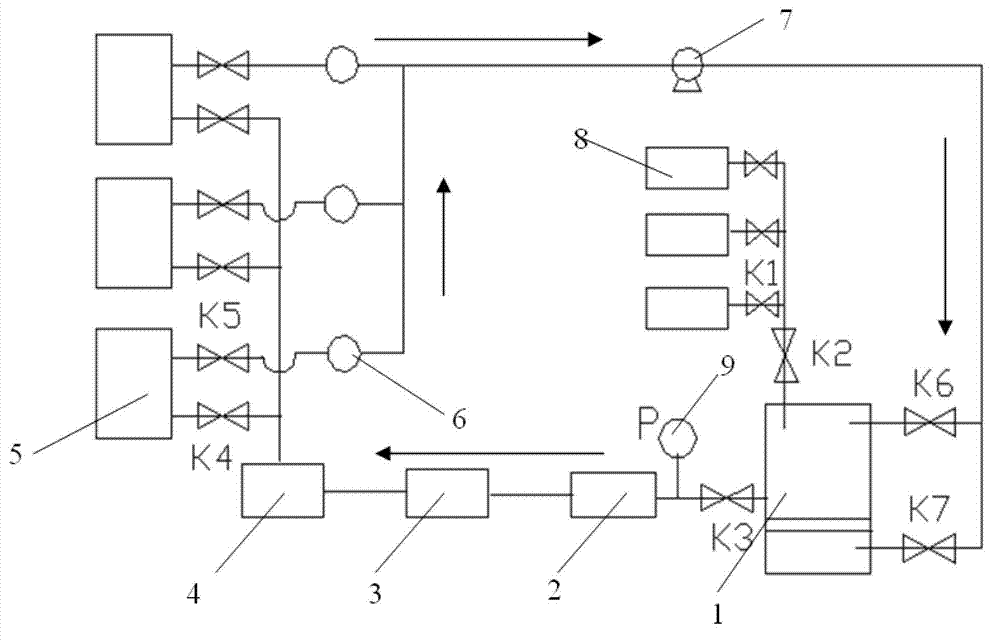

The invention discloses a fruit and vegetable mildew-proof storage device. The storage device comprises a storage jar, a total flow controller for controlling the total fresh gas flow, a cooling device, a distributor for distributing the fresh gas into a plurality of parallel fruit and vegetable storage devices as required, a gas detection device for detecting the concentration of each component in the gas discharged from each fruit and vegetable storage device at the real time, and a pump for providing a cycle power for the fresh gas, which are sequentially communicated by pipelines, wherein the pump is respectively communicated with the upper part and the lower part of the storage jar by the pipeline to form a cycle loop; the storage jar is selectively communicated with a plurality of gas generators by the pipeline. The fruit and vegetable is kept at low-concentration antibacterial state for a long time, so as to achieve the antibacterial effect, and also reduce the medicament residues, and different fruits and vegetables are processed by various preservatives and physiological regulators.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

Coating treatment apparatus and coating treatment method

InactiveUS7553374B2Increase the number ofIncrease volumePretreated surfacesSemiconductor/solid-state device manufacturingEngineeringSolvent

In the present invention, a gas flow restraining ring facing corner portions of the front face of a substrate horizontally held on a substrate holding unit and movable up and down, is set to a predetermined height in accordance with a coating treatment. Then, a coating solution containing a coating film forming component and a solvent is applied to the front face of the substrate and spread into a thin film state by a so-called spin coating method, and thereafter the substrate is rotated at a high speed so that the coating solution is dried. In this case, it is possible to control fresh gas flow from above the substrate to decrease the difference in evaporation rate of the solvent between the coating solution on the corner portions of the substrate and the coating solution inside them, thus enabling the coating treatment uniform within a plane on the substrate.

Owner:TOKYO ELECTRON LTD

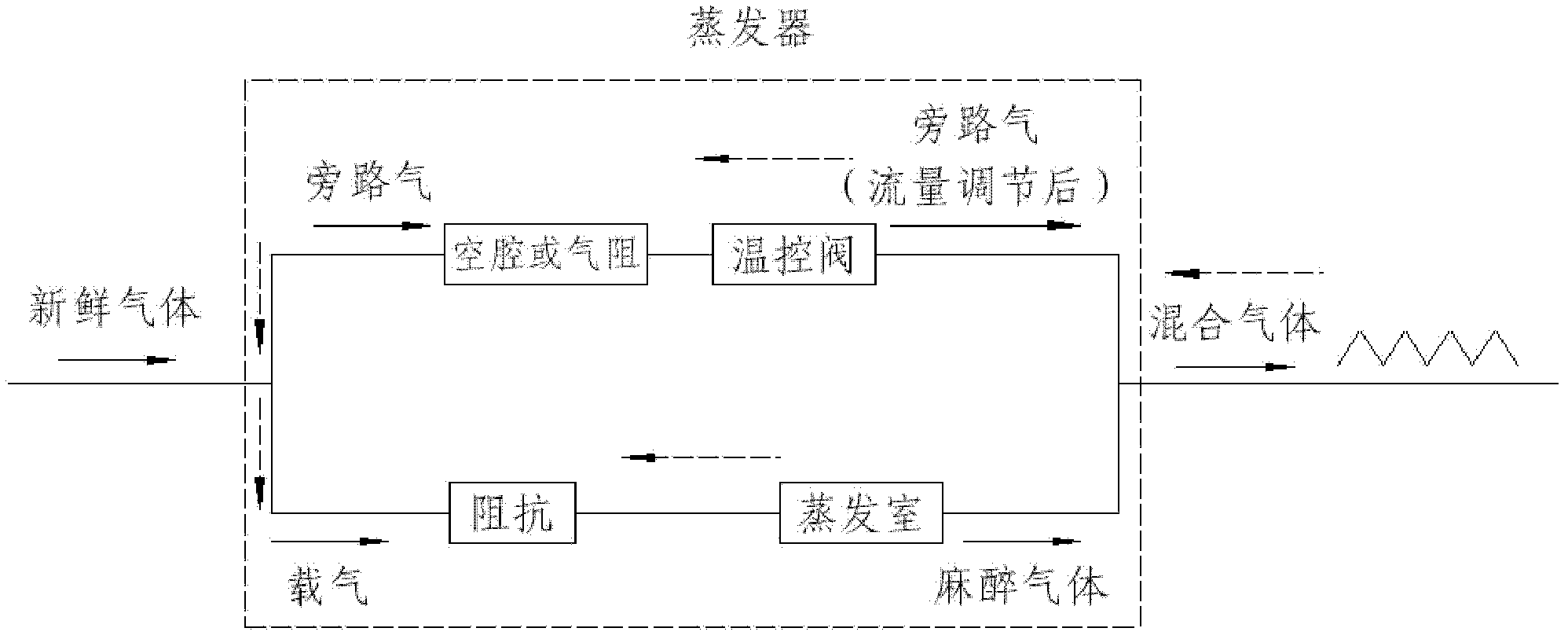

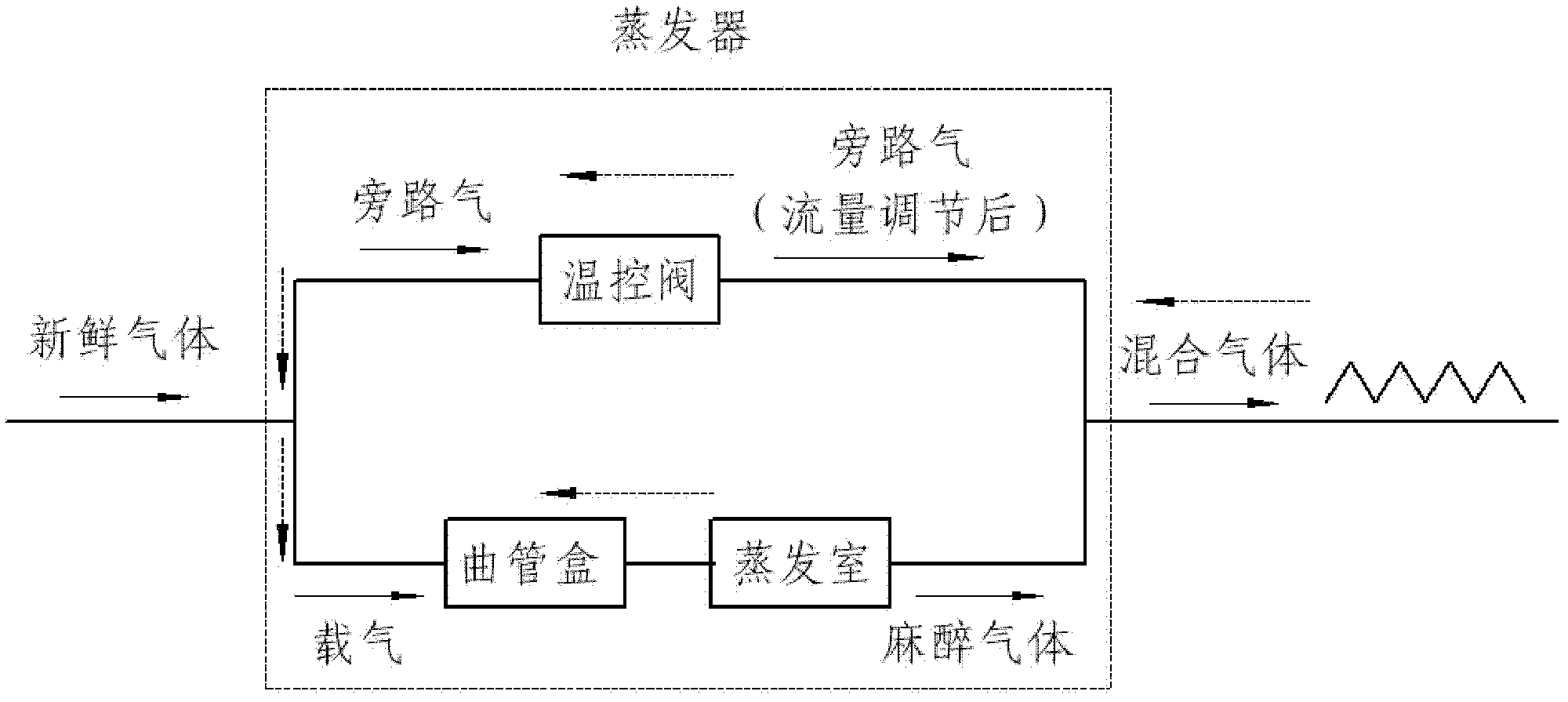

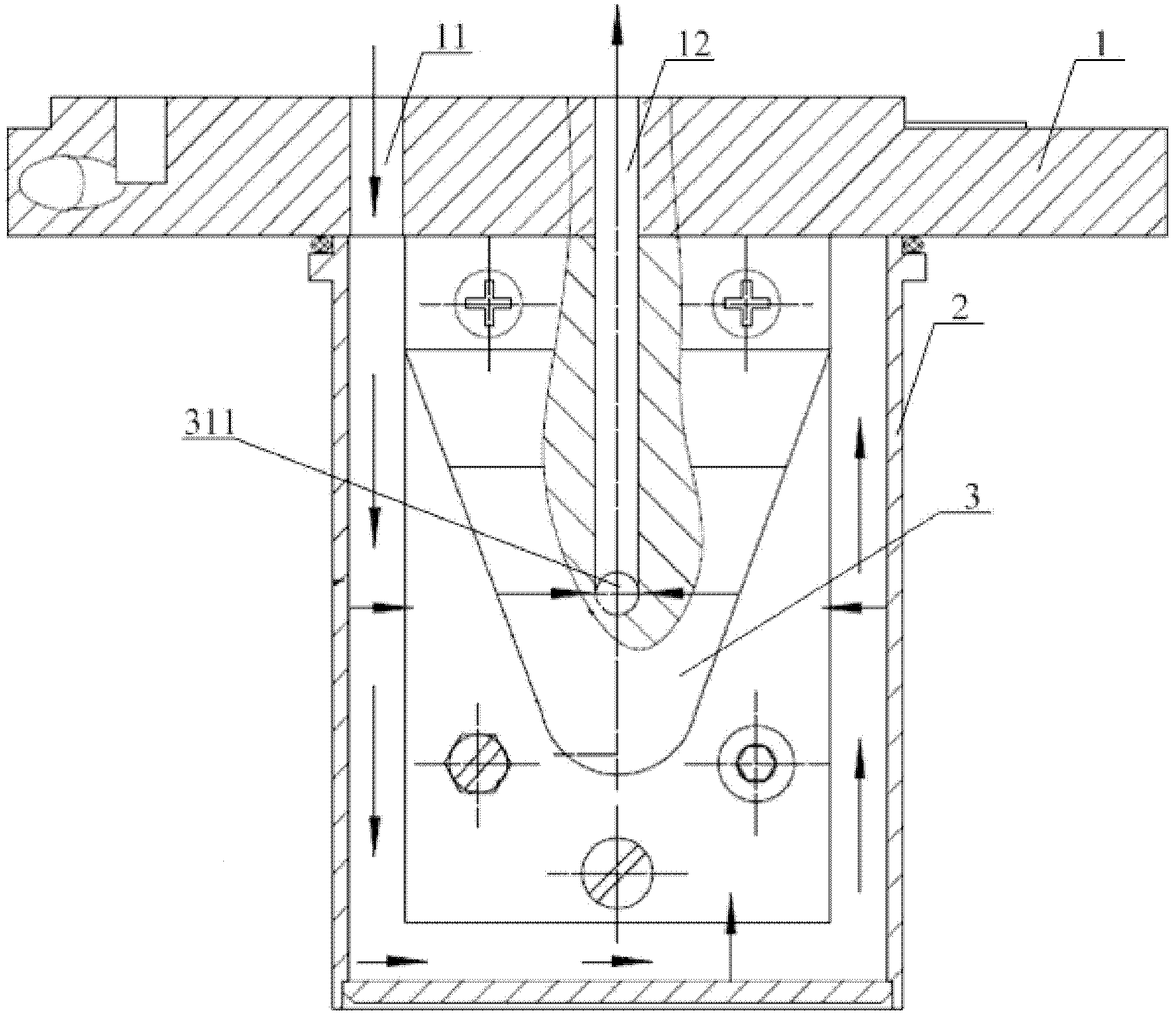

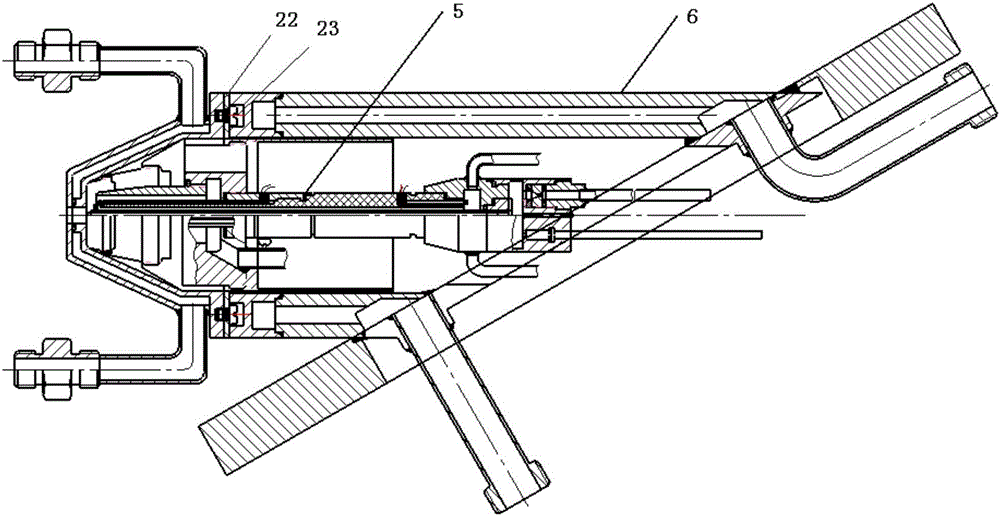

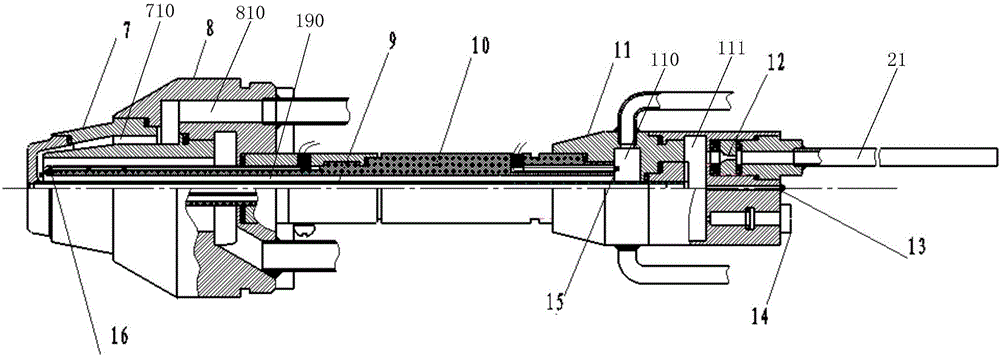

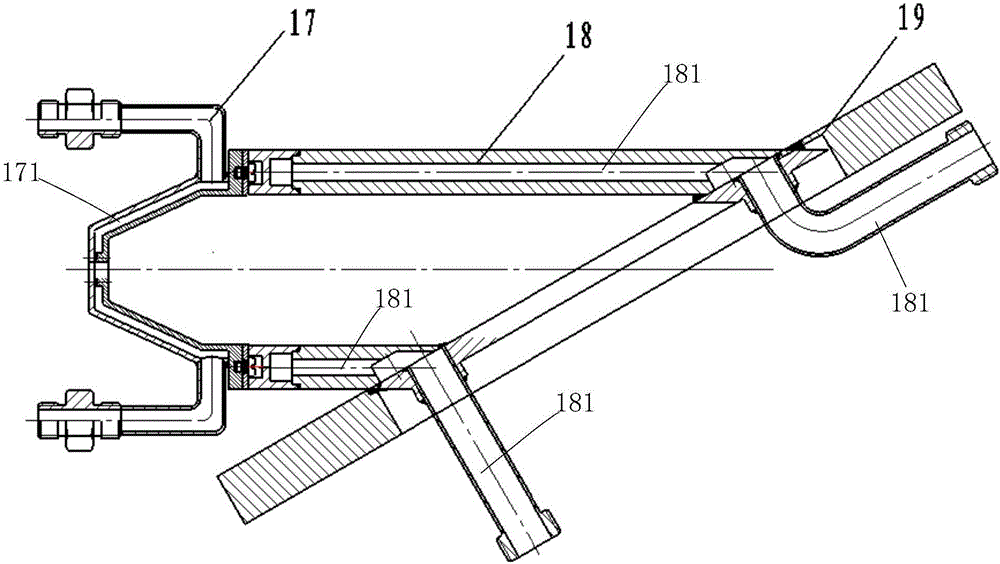

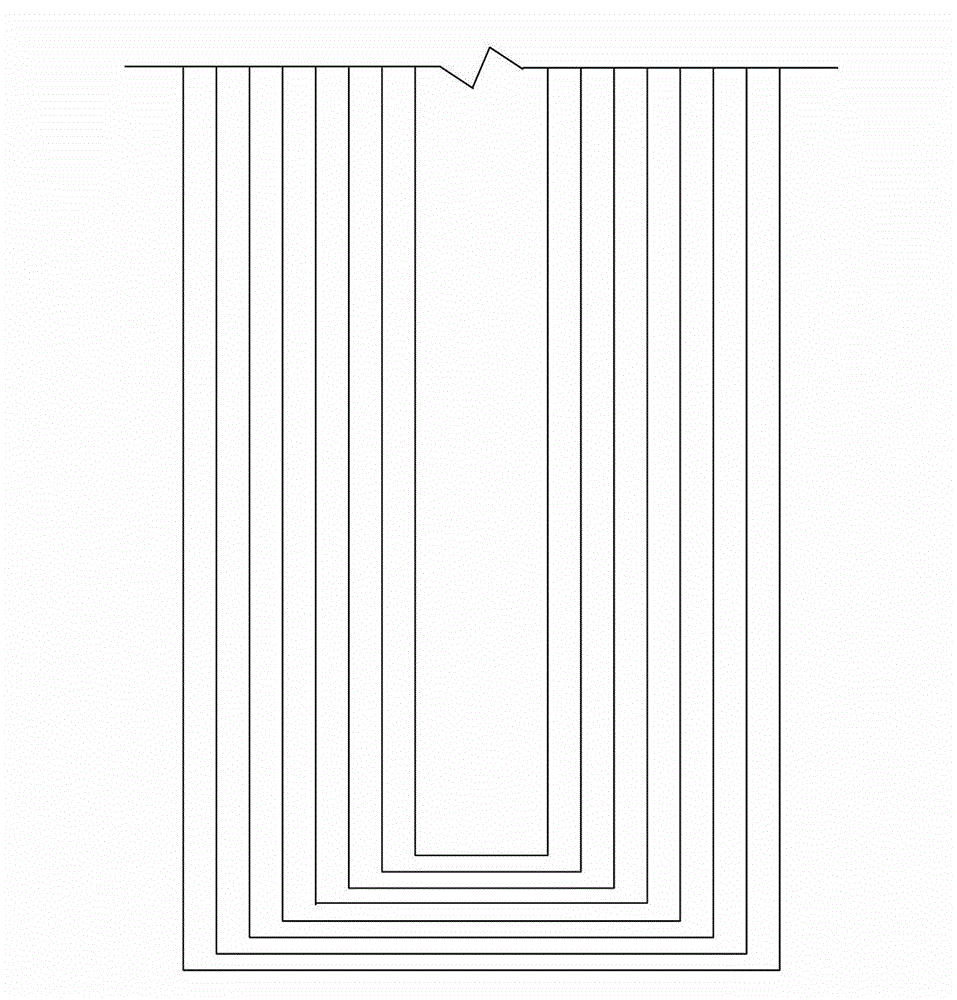

Anesthetic vaporizer with flow and pressure fluctuation compensation function

The invention discloses an anesthetic vaporizer with the flow and pressure fluctuation compensation function. The anesthetic vaporizer comprises a fresh gas inlet, a mixed gas outlet, a bypass gas circuit and a carrier gas circuit; a temperature control valve is arranged on the bypass gas circuit; an anesthetic vaporization chamber is arranged on the carrier gas circuit; a curved tube box is also arranged on the carrier gas circuit; a tortuous cavity is formed inside the curved tube box; an inlet of the tortuous cavity is respectively communicated with the fresh gas inlet and an inlet of the temperature control valve; an outlet of the tortuous cavity is communicated with an inlet of the vaporization chamber; an airflow gap for allowing gas to flow into is arranged on the temperature control valve; when flow at the fresh gas inlet increases, the airflow gap becomes small to enable the flow of the fresh gas flowing into the temperature control valve to decrease; and when flow at the fresh gas inlet decreases, the air flow gap becomes large to enable the flow of the fresh gas flowing into the temperature control valve to decrease. The anesthetic vaporizer has the advantages of simple structure, easiness in processing, and convenience in dismantling.

Owner:BEIJING AEONMED

Carbon dioxide catching device and method

Owner:JG ENVIRONMENTAL TECH +1

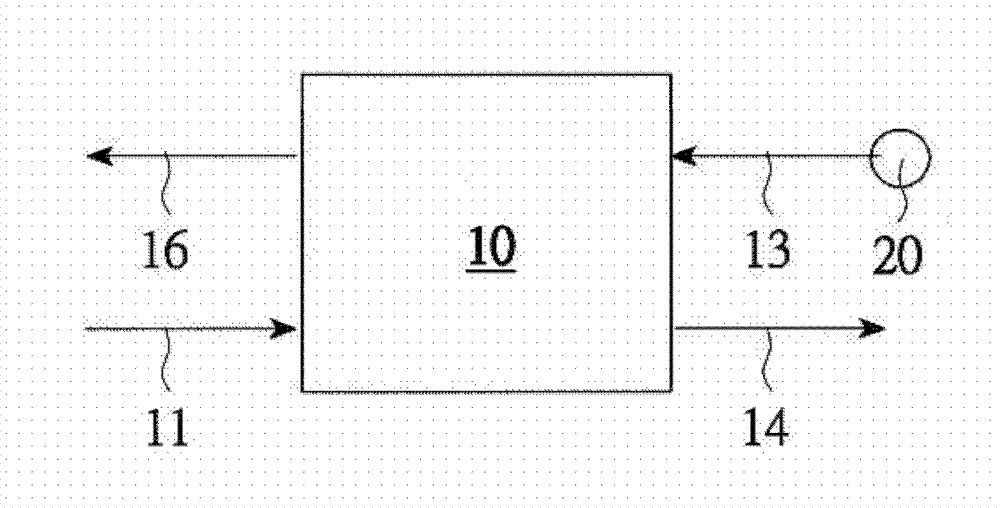

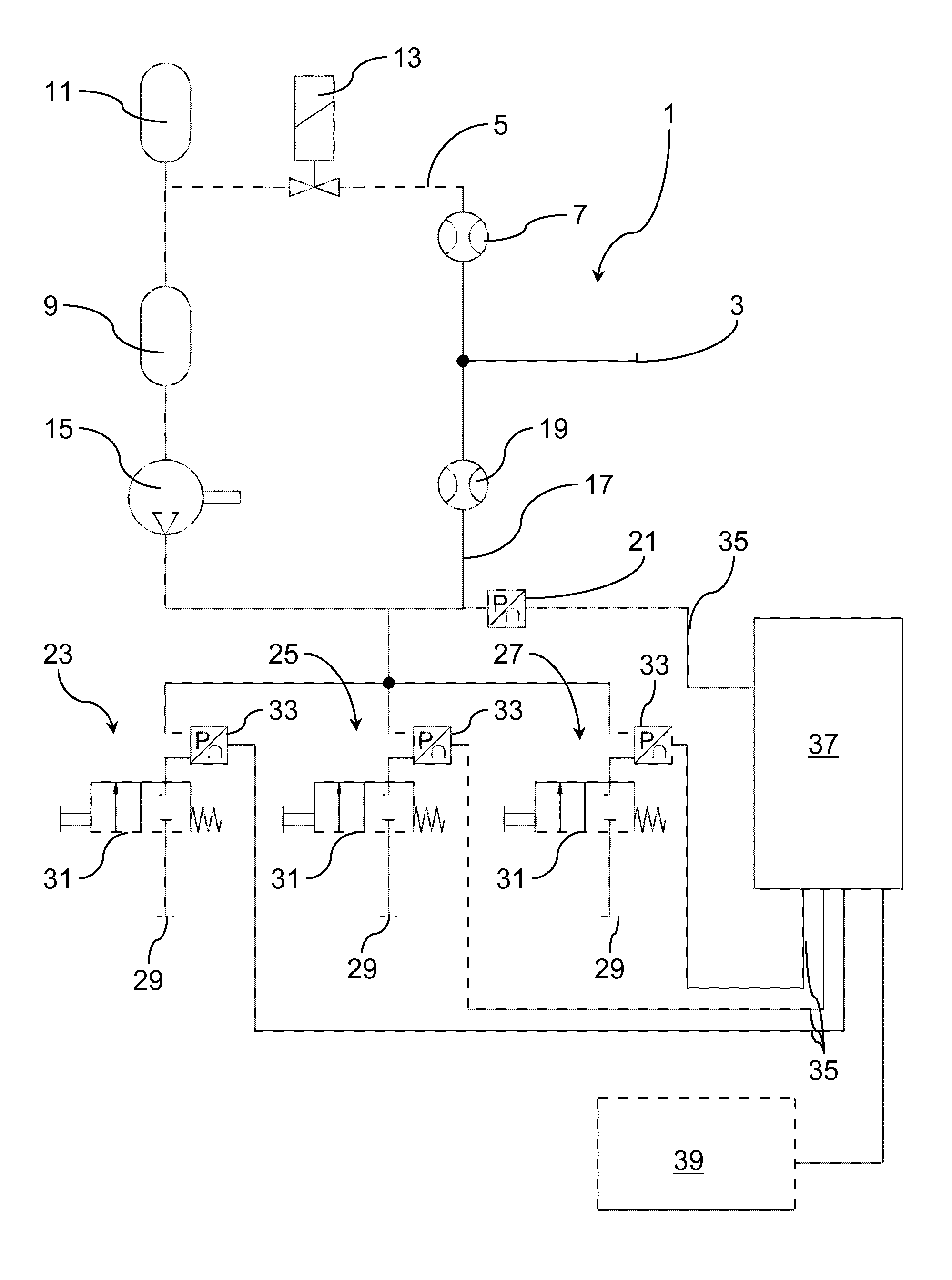

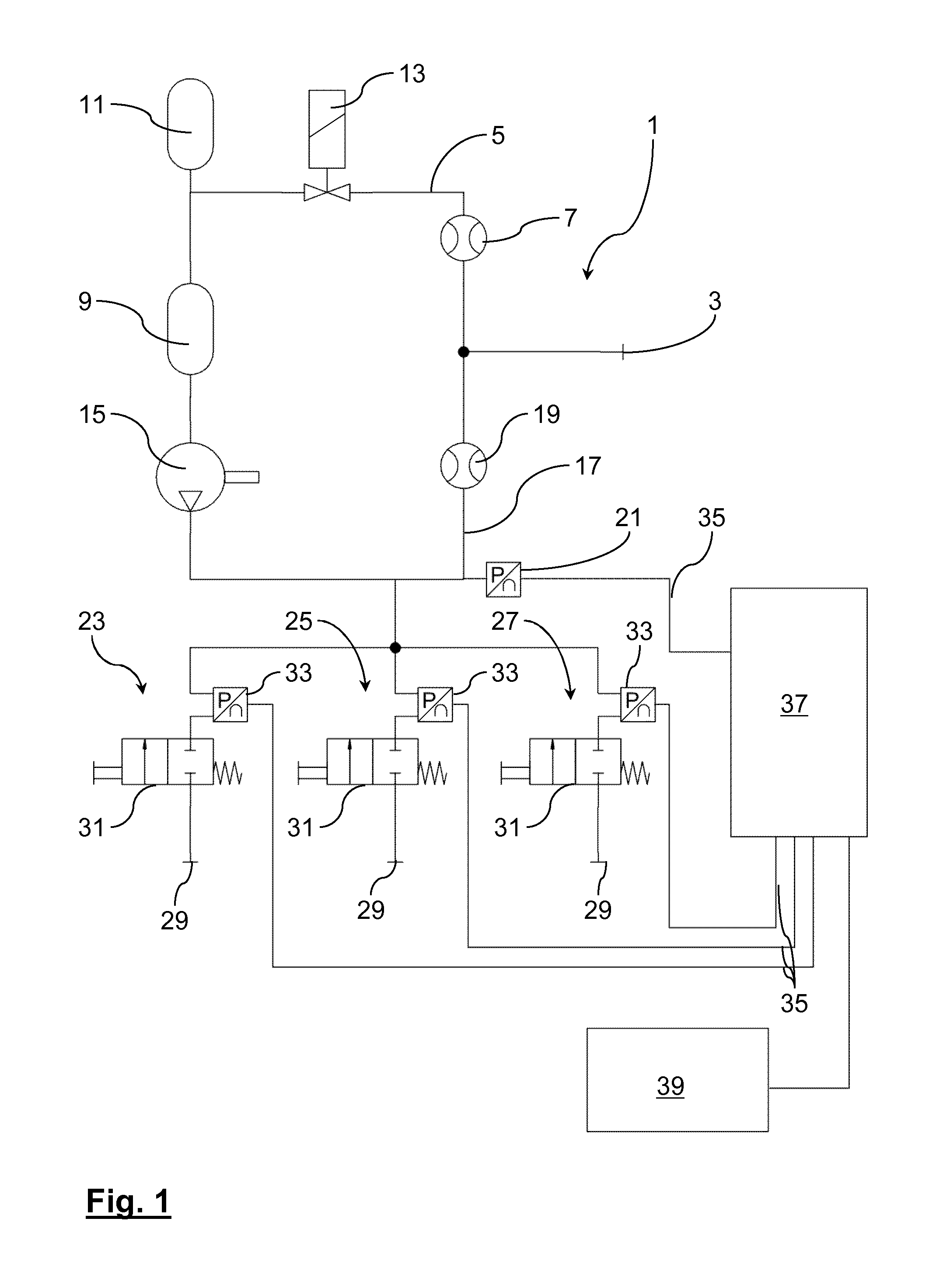

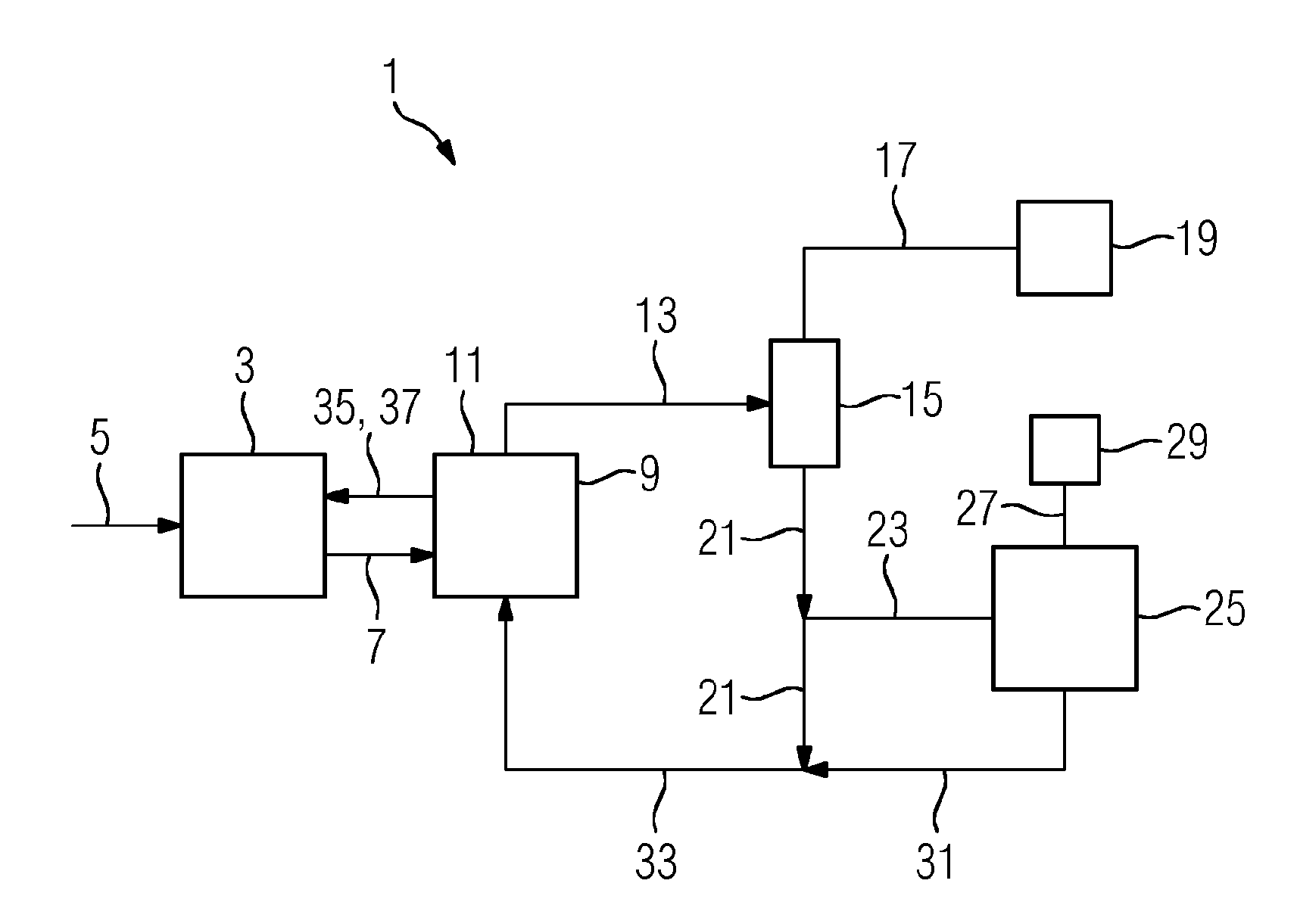

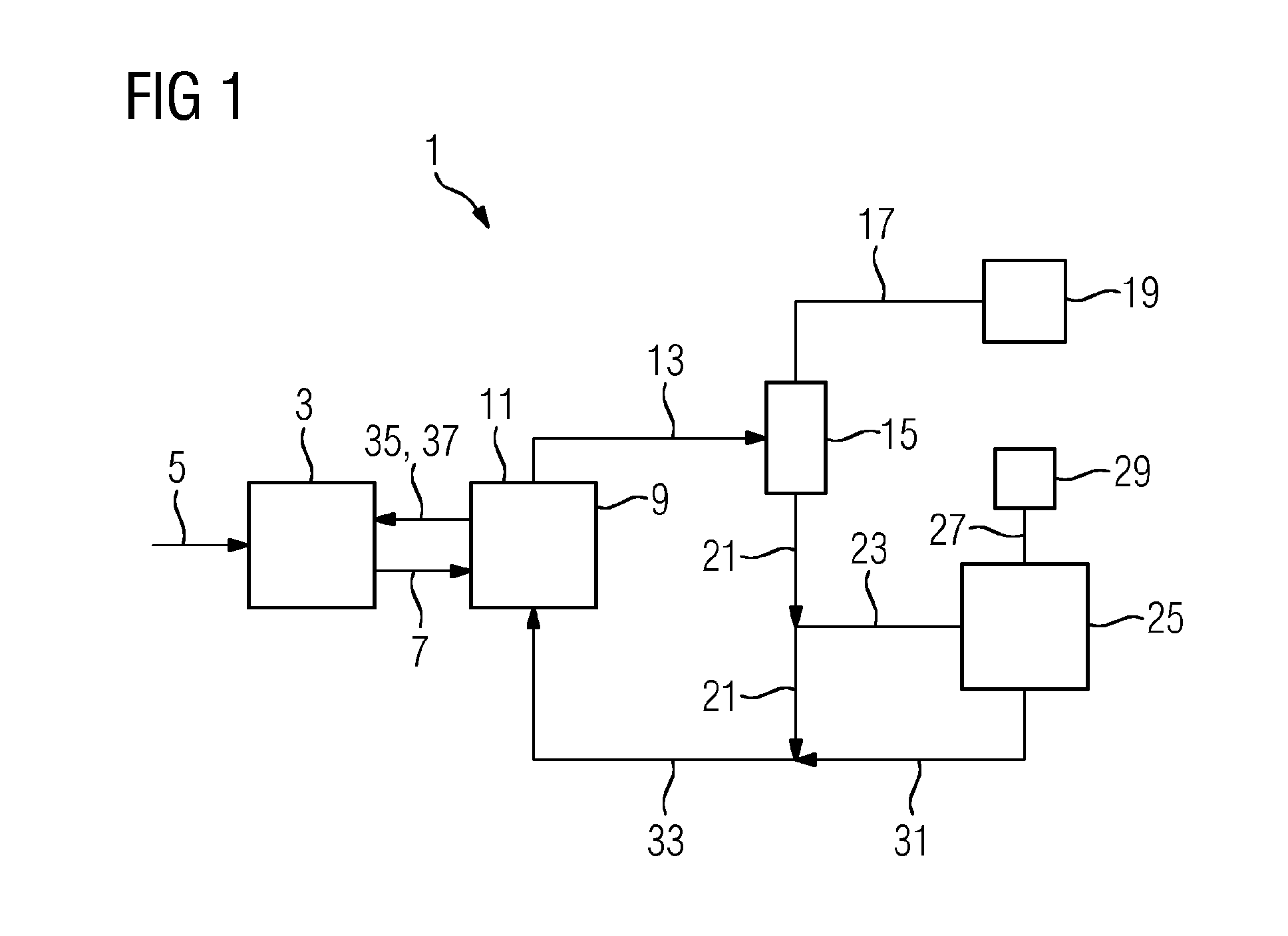

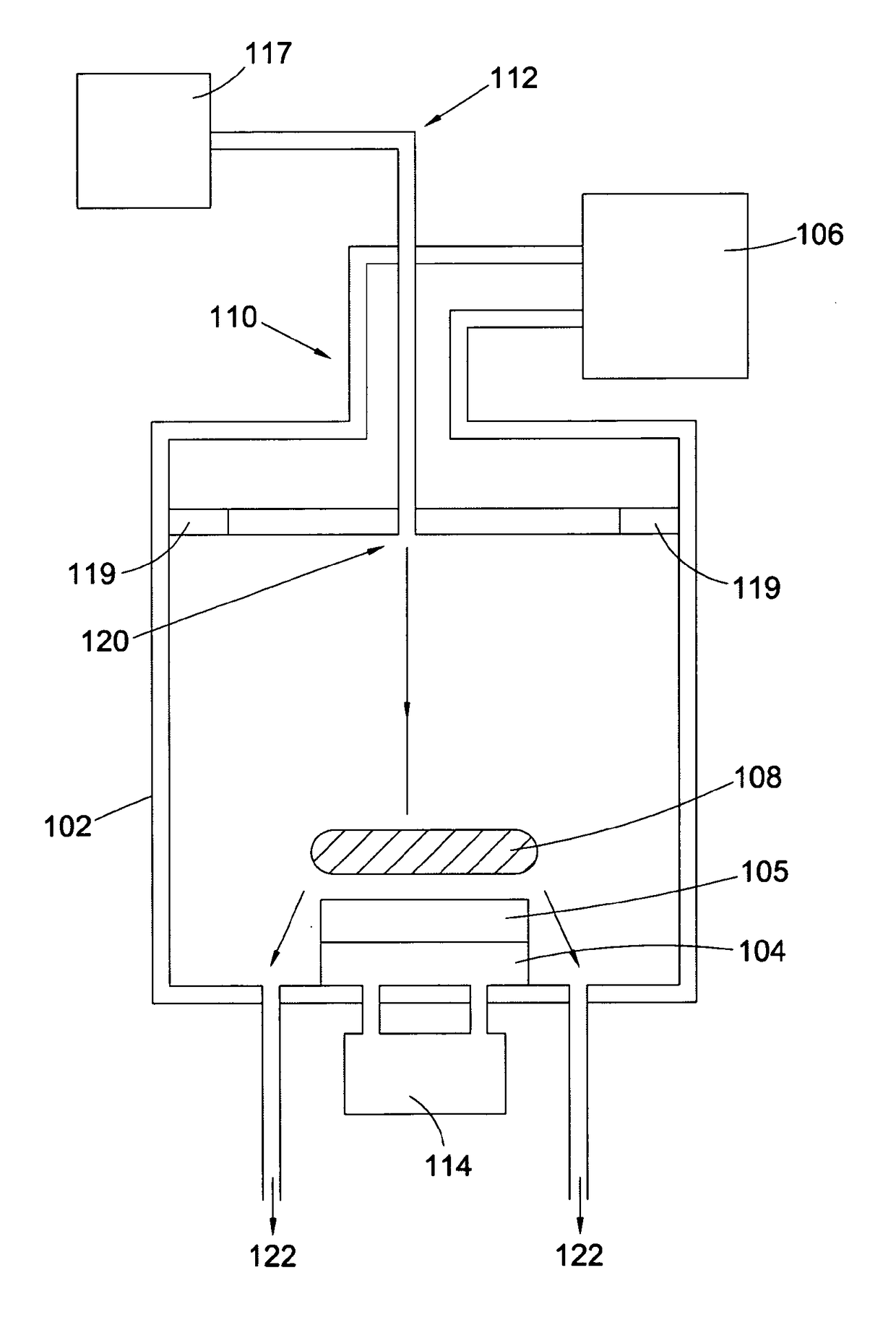

Respirator and method for determining a fresh gas flow

ActiveUS20150320950A1Improve accuracyAdjust in timeRespiratory masksMedical devicesDifferential pressureEngineering

A respirator (1) includes a fresh gas port (23, 25, 27) for connecting a fresh gas supply, a gas outlet (3) for connecting a supply line for a patient, an absolute pressure sensor (21) and a data processor (37). The gas outlet and the fresh gas port are fluidically connected via an inhalation branch (17) that is connected to the absolute pressure sensor. The fresh gas port has an adjusting valve (31), to set gas flow from the fresh gas supply to the inhalation branch, and a differential pressure sensor (33). The differential pressure sensor determines a differential pressure in the fresh gas port between the inhalation branch and the adjusting valve. The data processor receives and records the absolute pressure measured and the differential pressure to determine a fresh gas flow through the fresh gas port. A method for determining a fresh gas flow is also shown and described.

Owner:DRAGERWERK AG

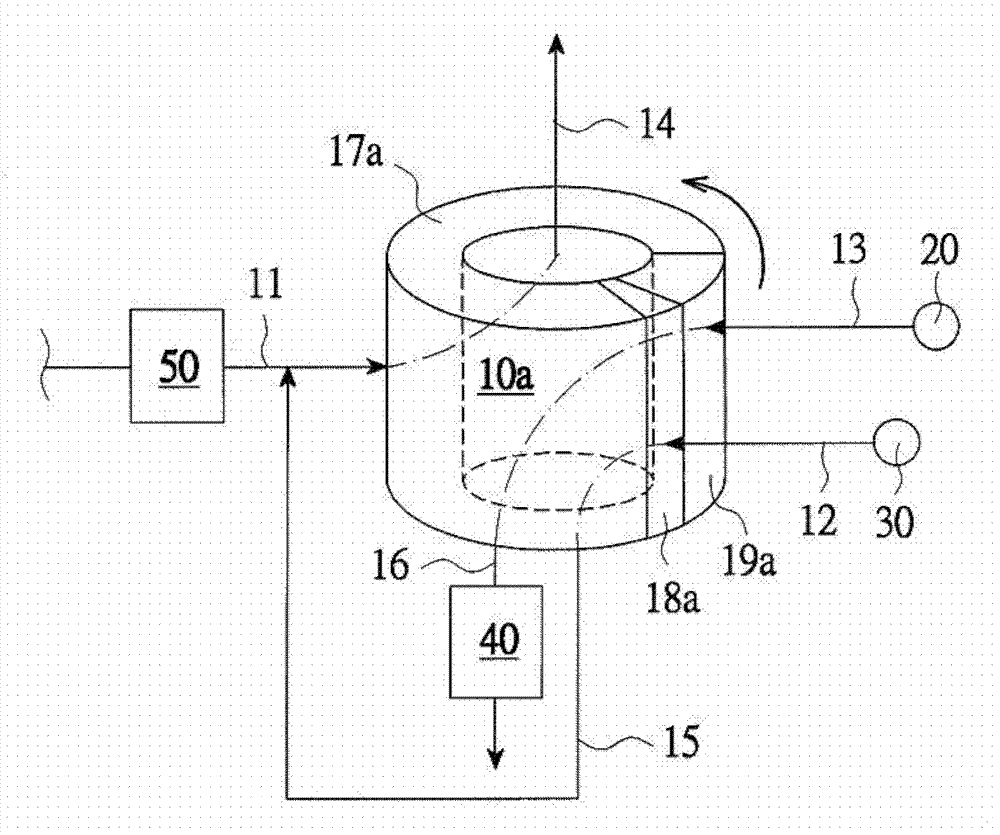

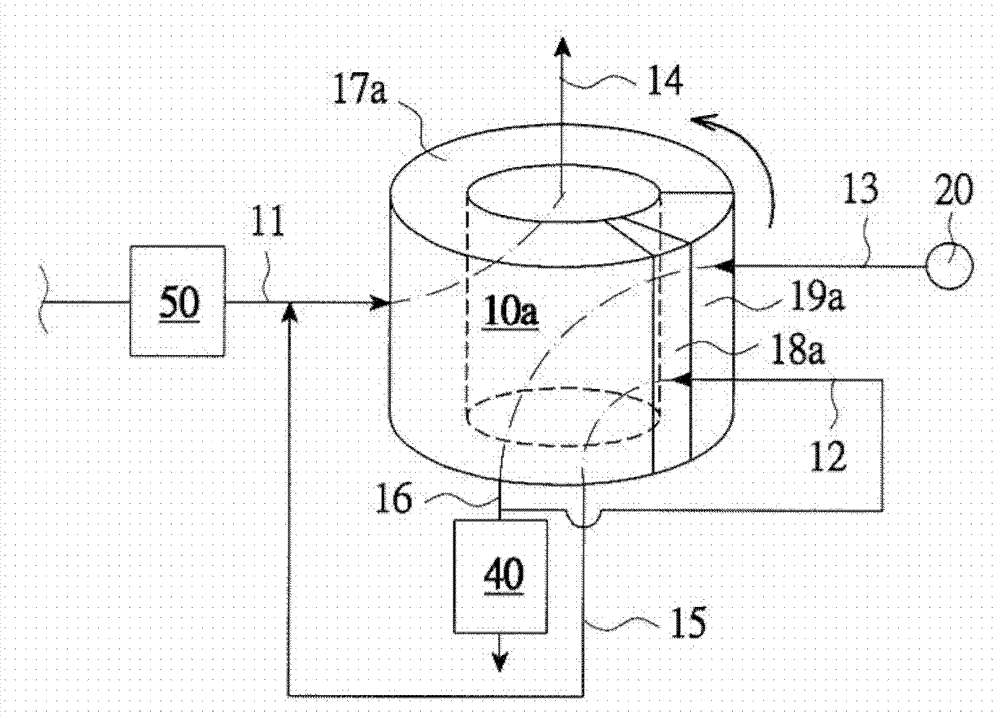

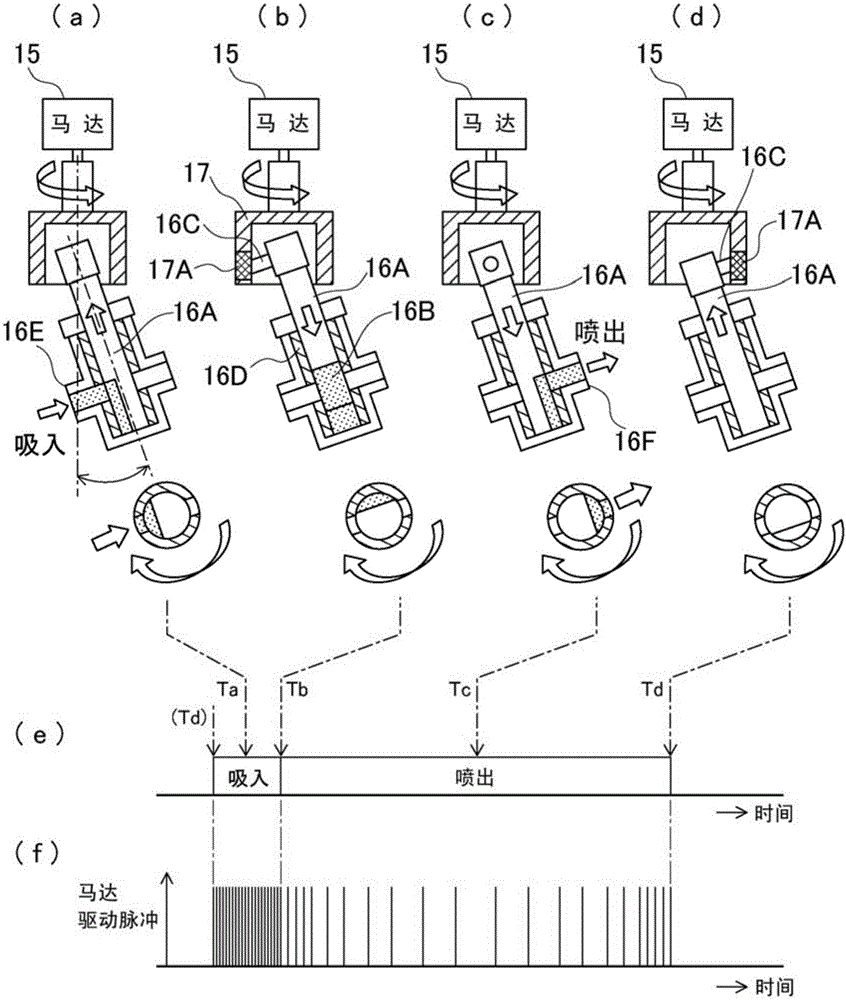

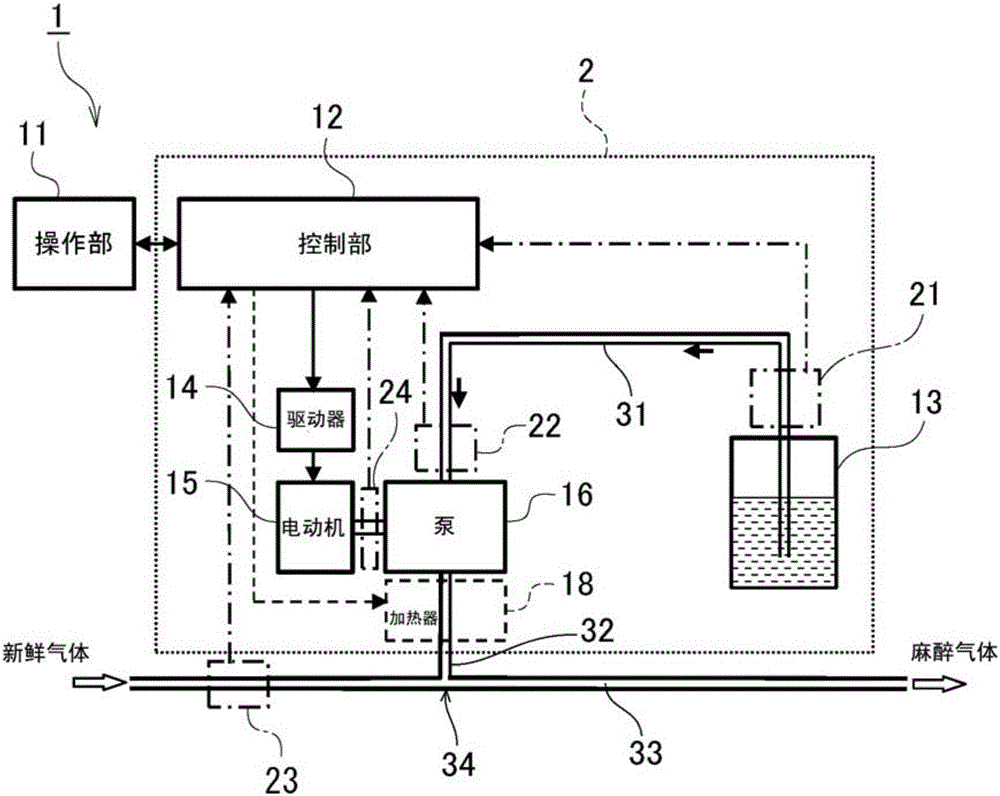

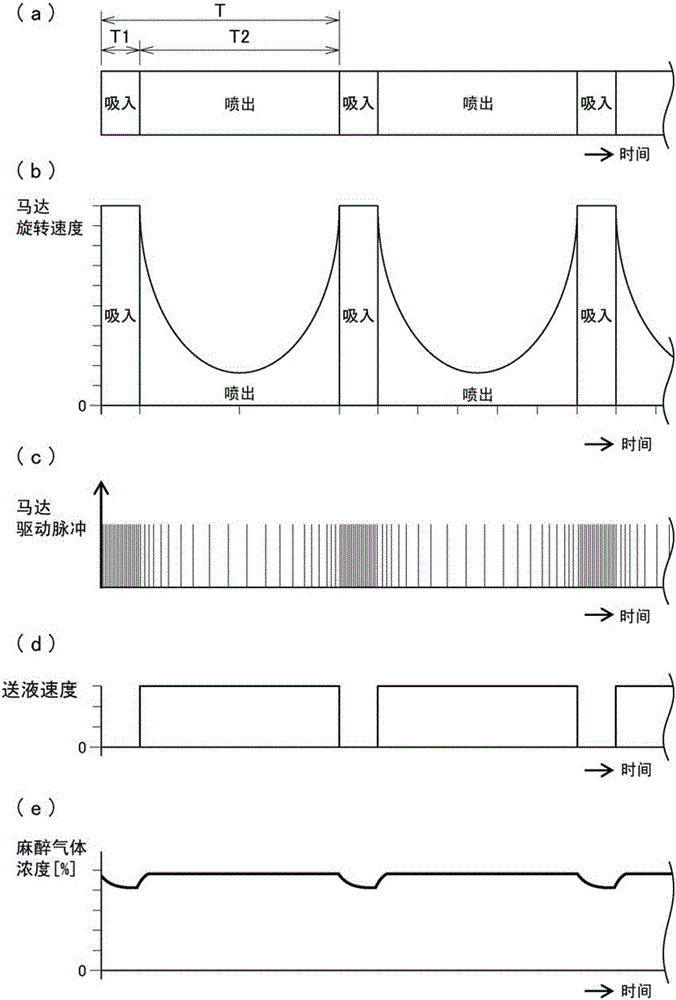

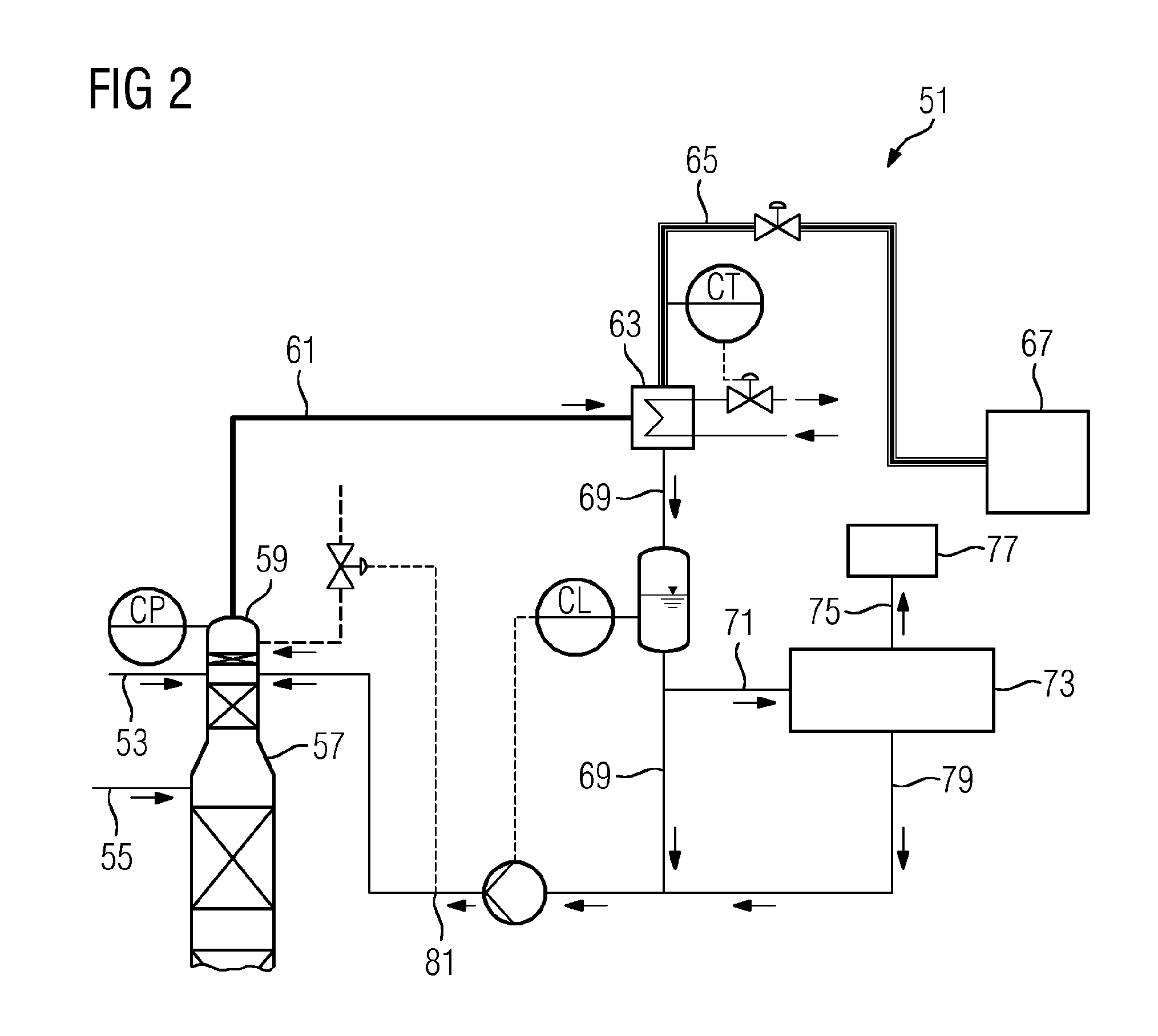

Method of driving constant volume pump, device for driving constant volume pump, vaporizer and anesthesia device

ActiveCN106170627AReduce ejectionThe ejection period is shortenedTransportation and packagingMedical devicesVolume variationReciprocating motion

To provide a method of driving a constant volume pump, a device for driving a constant volume pump, a vaporizer and an anesthesia device with which it is possible to reduce pulsations of the constant volume pump, reduce the cost of the device, and reduce the size of the device. This device for driving a constant volume pump is provided with a constant volume pump 16 which is coupled to a stepping motor 15, includes an eccentric mechanism for changing a rotating motion of the motor 15 into a reciprocating motion of a plunger 16A, and performs constant volume feed of anesthetic by means of intake and discharge thereof resulting from a volumetric change within a cylinder 16D, due to the reciprocating motion of the plunger 16A. A control unit 12 calculates an intake and discharge period T of the constant volume pump 16 on the basis of a set anesthetic gas concentration and a set fresh gas flow rate, and sets a discharge period T2 in said period T to be longer than an intake period T1. Further, by controlling the speed of rotation of the stepping motor 15, the movement speed of the plunger 16A during the discharge period is maintained to be constant.

Owner:ACOMA MEDICAL IND CO LTD

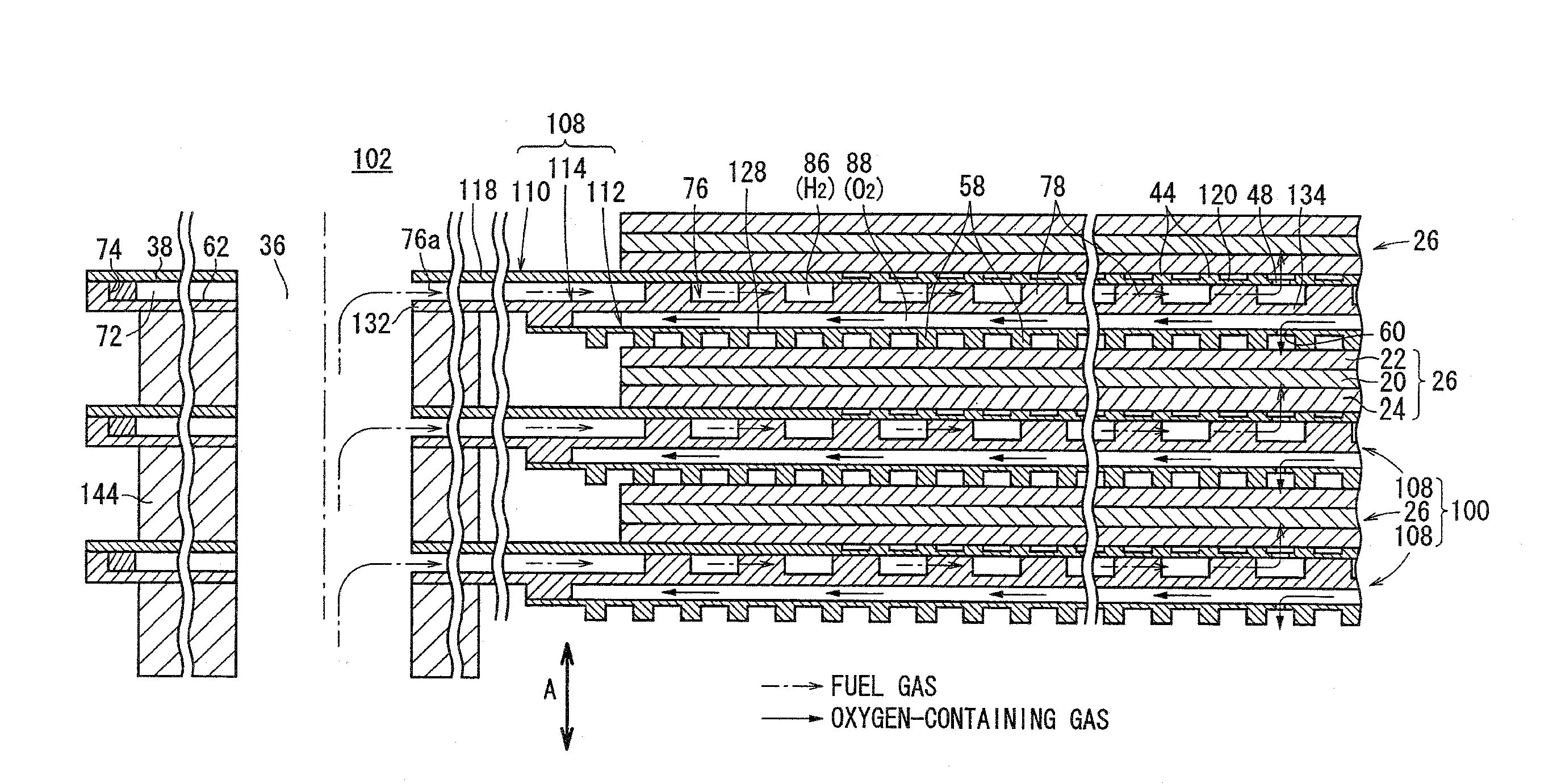

Fuel cell and fuel cell stack

InactiveUS7625657B2Simple and economical structureImprove sealingFuel cells groupingFuel cell auxillariesFuel cellsProcess engineering

A fuel cell includes an electrolyte electrode assembly and separators. The separator has a fuel gas supply passage, a fuel gas distribution passage, an oxygen-containing gas supply passage, and an oxygen-containing gas distribution passage. The fuel gas flows through the fuel gas supply passage into the separator. The fuel gas distribution passage connects the fuel gas channel and the fuel gas supply passage. The oxygen-containing gas flows through the oxygen-containing gas supply passage into the separator. The oxygen-containing gas distribution passage connects the oxygen-containing gas channel and the oxygen-containing gas supply passage.

Owner:HONDA MOTOR CO LTD

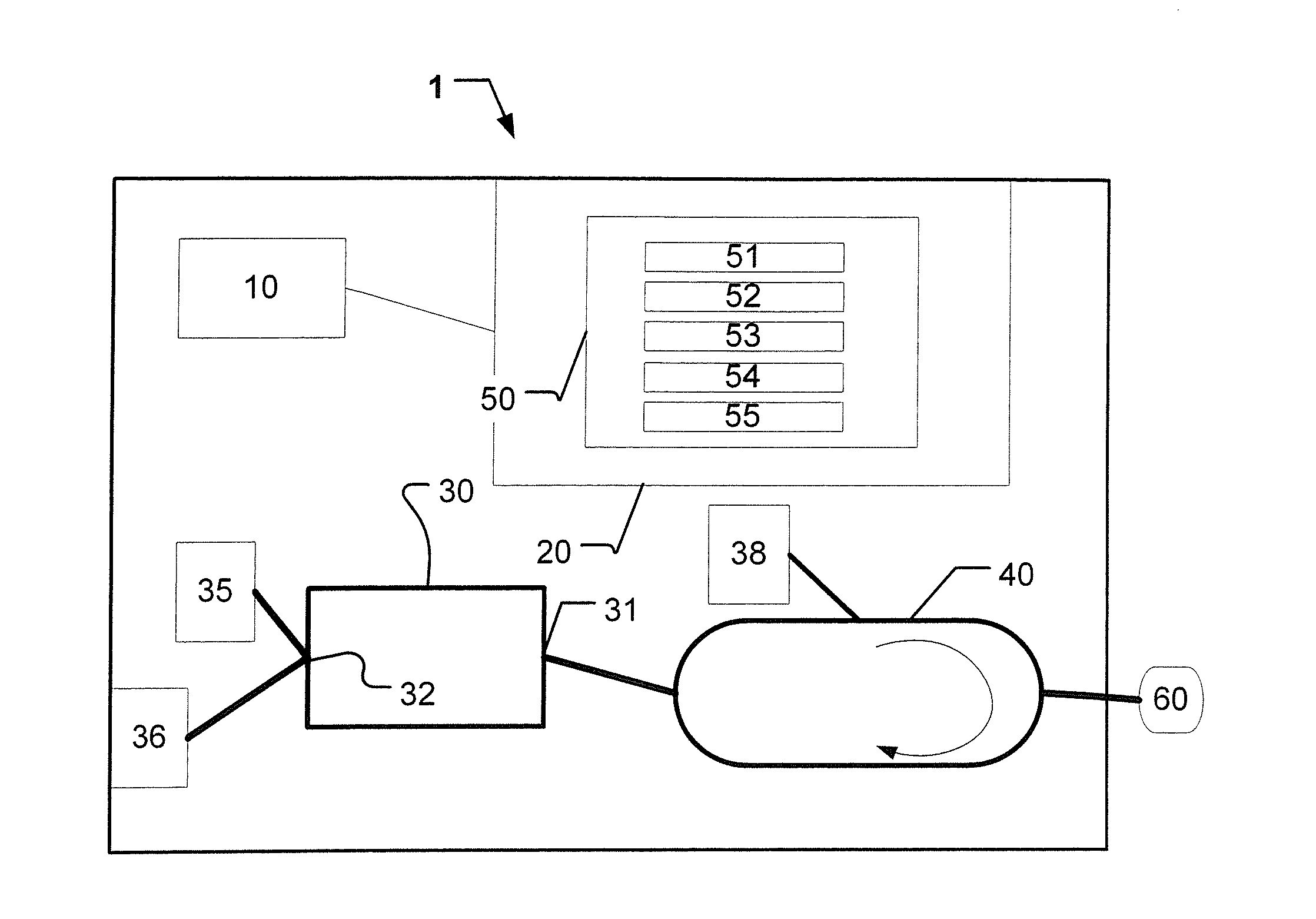

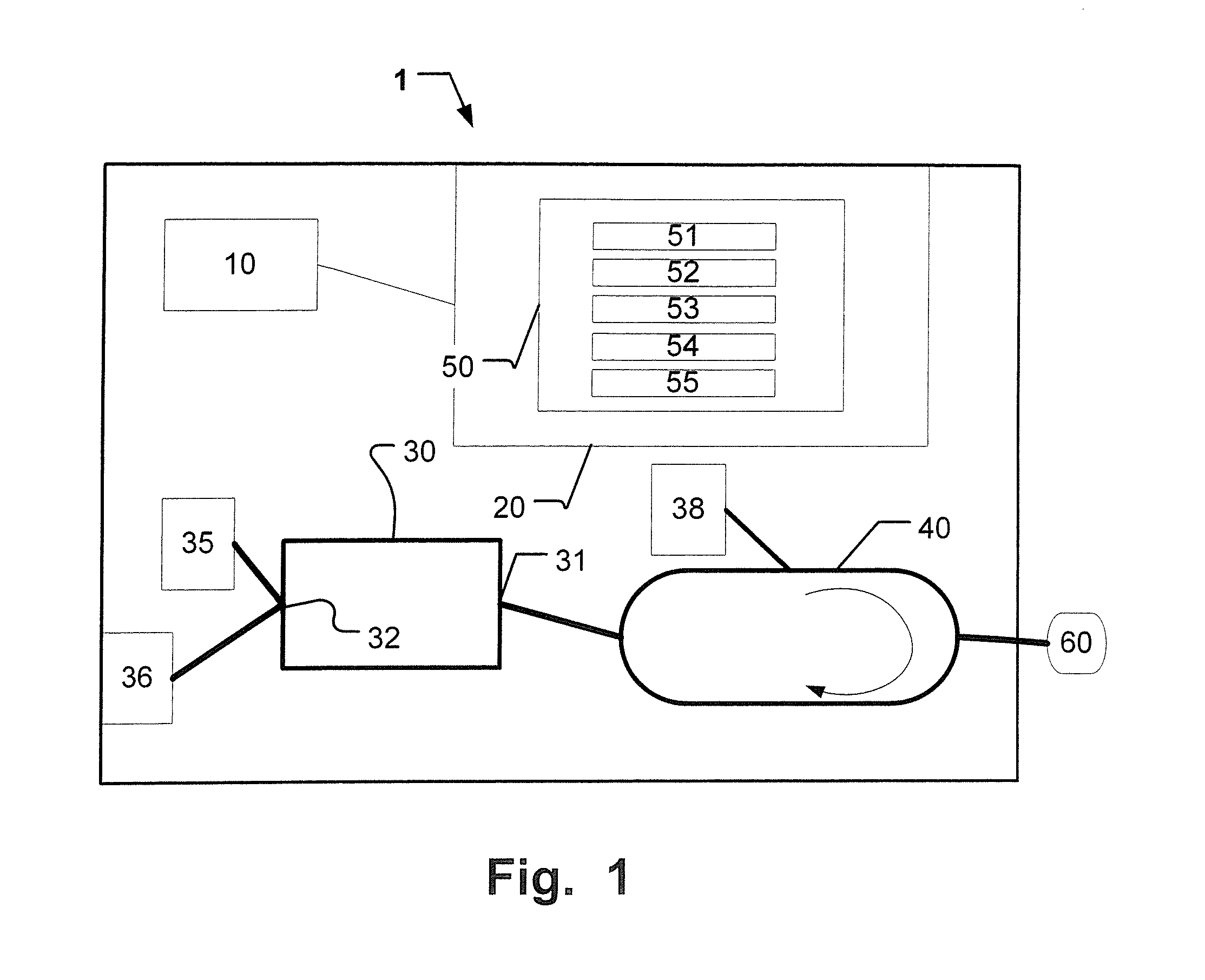

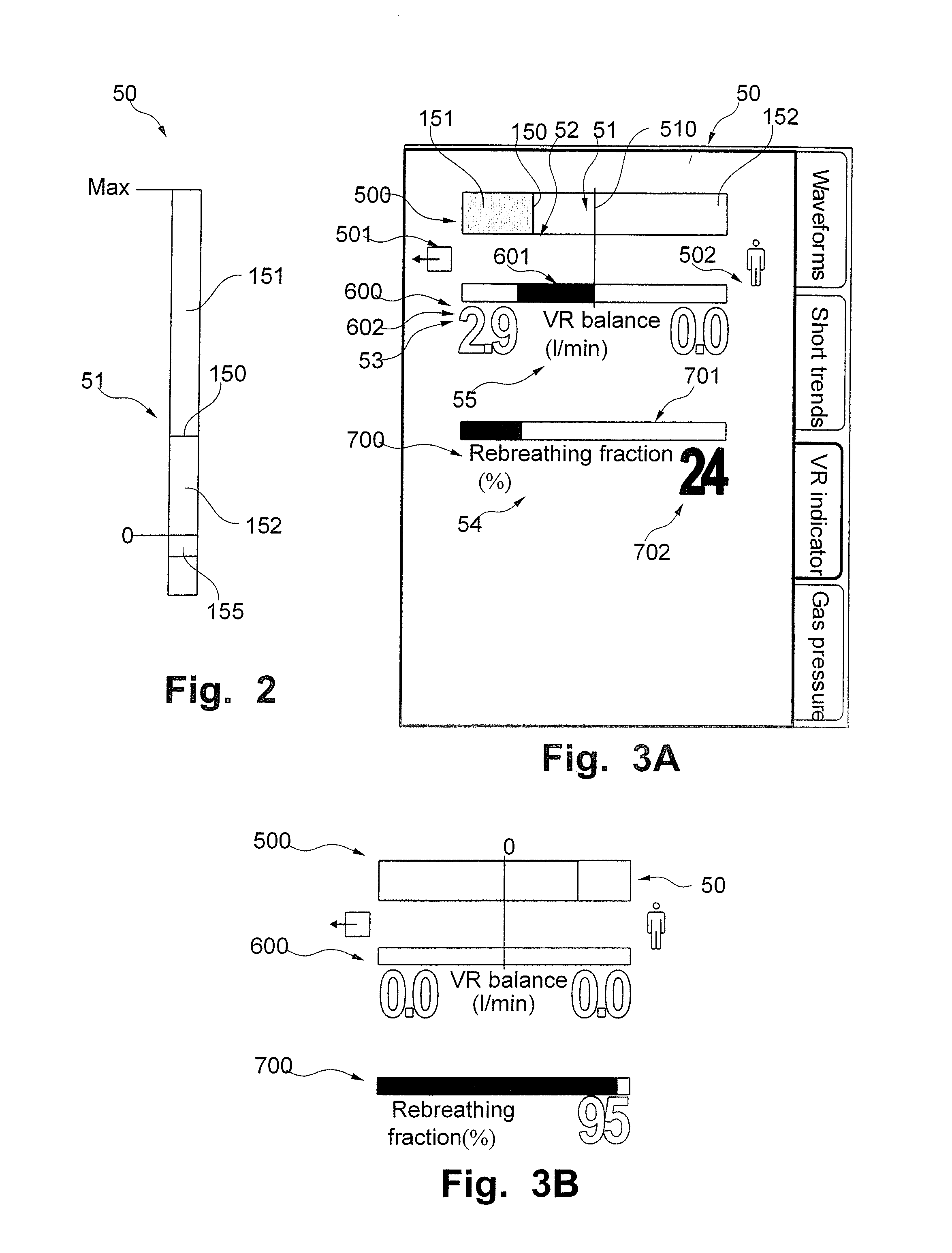

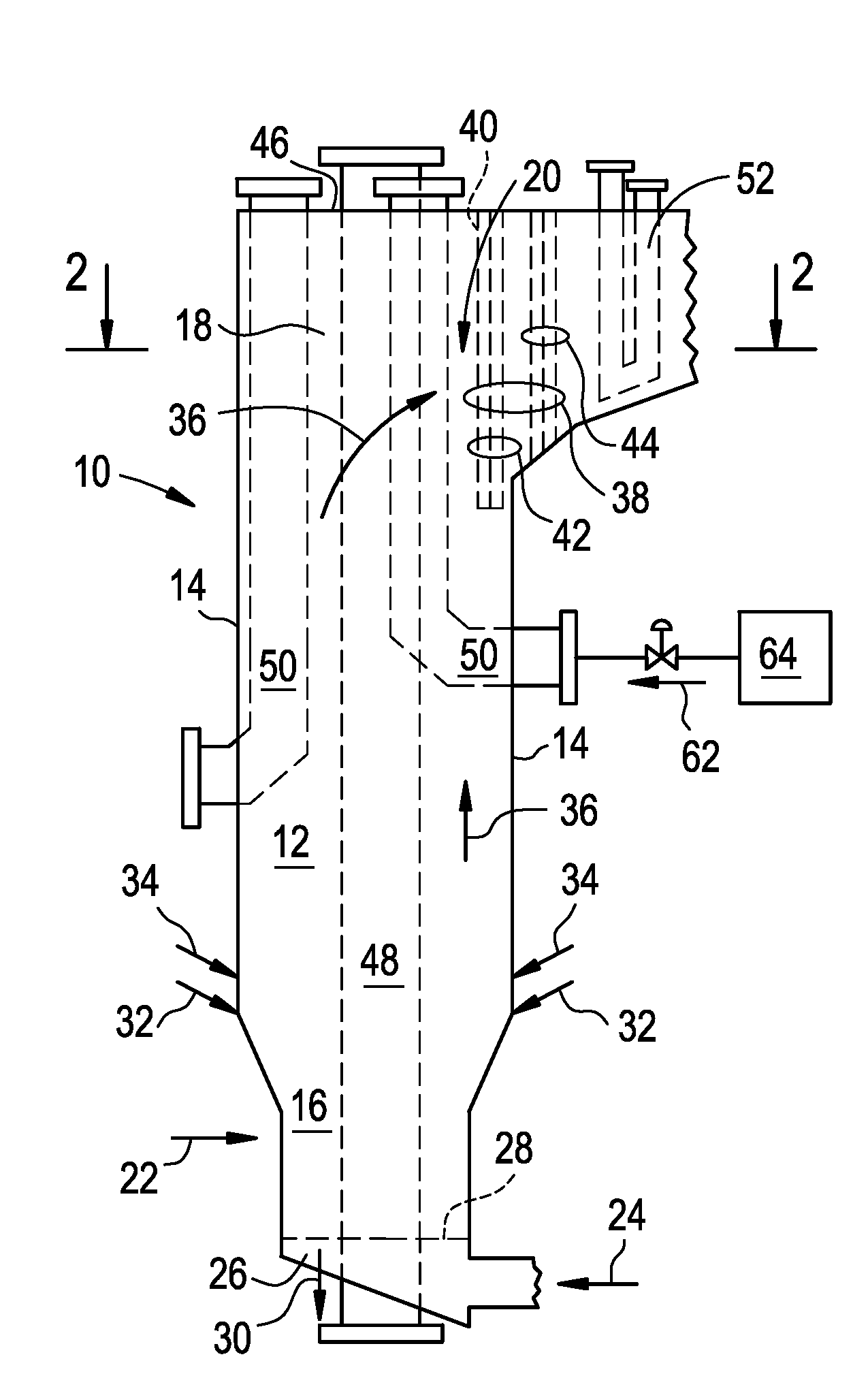

Volume reflector status indicator for anesthesia system

ActiveUS20150250960A1Improve securityReduced training of operatorRespiratorsMechanical/radiation/invasive therapiesDisplay deviceIntensive care medicine

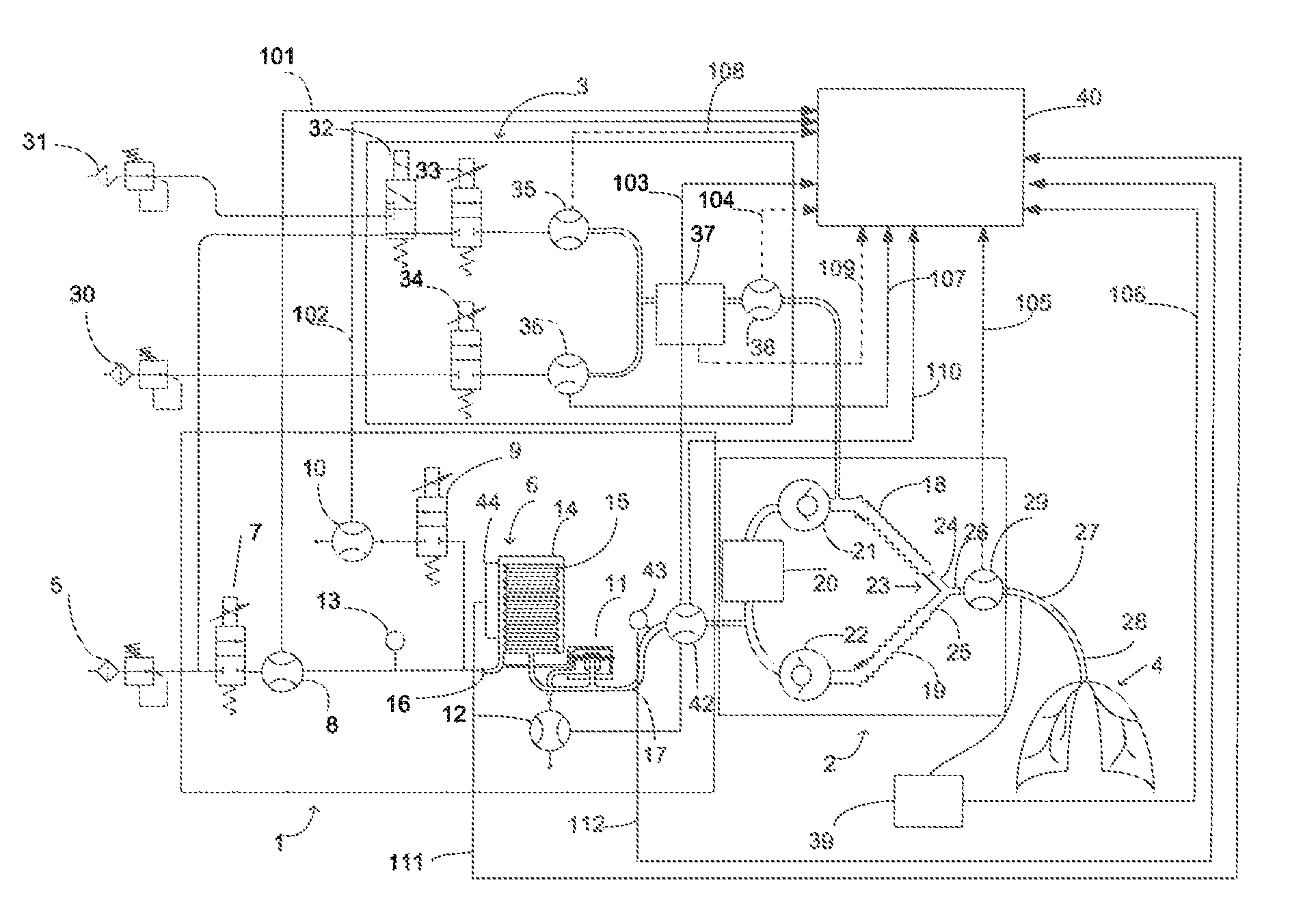

A Volume Reflector indicator for an anesthesia system is disclosed. The anesthesia system includes a volume reflector (30), a breathing circuit (40), a processing unit (10), and a display (20) operatively connected to said processing unit (10), wherein said processing unit (10) is configured to provide a status indicator (50) on said display (20) for gas in said volume reflector (30), said status indicator (50) including a graphical representation of (51) an extent of a driving gas of said volume reflector (30) and / or a patient gas in said volume reflector (30), and / or (52) a flow of gas and a direction of said flow in said volume reflector (30), and / or (53) a waste gas flow out of said volume reflector (30) relative a fresh gas flow in said system (1), and / or (54) a re-breathing fraction (RBF), and / or (55) a balance between said fresh gas flow and patient uptake and / or leakage of gas from said breathing circuit.

Owner:MAQUET CRITICAL CARE

Method and arrangement for detecting a leak in anesthesia system

A method and arrangement for detecting a leak in an anesthesia system. The method includes controlling respiratory movements by means of ventilator gas flows and measuring the ventilator gas flow added for an inspiration and removed for an expiration. The method also includes supplying a fresh gas flow for a respiration and measuring the fresh gas flow added for the respiration. The method further includes receiving information indicative of the measured gas flows, determining based on said received information both the gas volume added and the gas volume removed and comparing these determined gas volumes to each other. The method also includes determining based on comparing the anesthesia system leakage.

Owner:GENERAL ELECTRIC CO

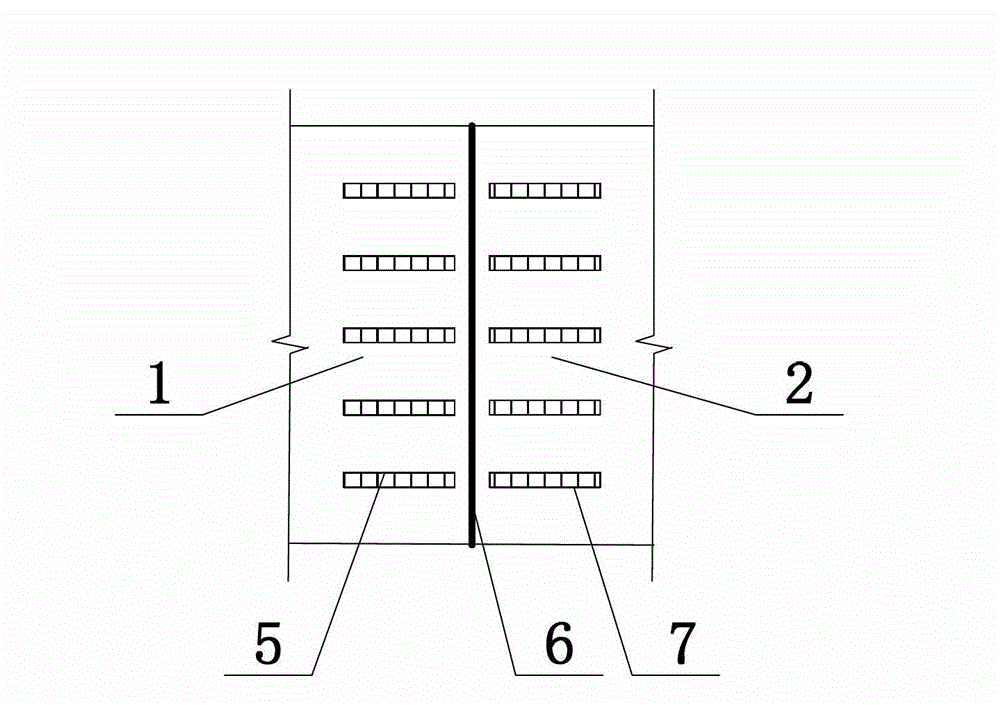

Flue gas system for unbalance control of flue gas flow

InactiveCN101566351ASolve corrosiveSolve the cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention relates to a flue gas system for unbalance control of flue gas flow, which comprises an air preheater, an air preheater outlet flue and an air preheater inlet flue which are communicated with the air preheater. N partition boards are arranged in the air preheater inlet flue to partition the air preheater inlet flue into N+1 small flue gas passages in which N adjusting doors are arranged. By adjusting the flue gas flow through the adjusting doors, the flue gas flow flowing through the air preheater forms certain deviation according to the metal temperature variation of a heat storage plate, namely when the metal temperature of the heat storage plate is lower, the heat transfer temperature pressure with the flue gas is larger, and the flue gas flow flowing through the surface of the air preheater is relatively large; and when the metal temperature of the heat storage plate is raised in the flue gas passage along with the rotation of the air preheater, the flue gas flow flowing through the surface of the air preheater is relatively reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Free jet type supersonic flue gas flow enthalpy value steady state measurement apparatus

ActiveCN106568802AImprove survivabilityShield interferenceMaterial heat developmentHeat flowFlue gas

The invention discloses a free jet type supersonic flue gas flow enthalpy value steady state measurement apparatus, which includes: a measurement apparatus and a protective sleeve which are connected to each other. The measurement apparatus is used for measuring enthalpy value of flue gas flow and the protective sleeve is used for protecting the measurement apparatus. The measurement apparatus can work in a severe heat environment with incoming flow total temperature being higher than 3000 K and heat flow density being higher than 20 MW / m<2> for long time.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

Sncr distribution grid

An SNCR distribution grid for introducing a NOx reducing reactant into a flue gas flow. The grid is made of one or more elements which are formed by fluid-cooled tubes to which membrane pieces are attached, preferably by welding, to form conduits in between the tubes. The fluid-cooled tubes may be cooled by water and / or steam and the distribution grid is disposed in the flue gas flow. To admit the reactant into the flue gas, nozzles are provided in the membrane and the reactant is conveyed from a location external of the furnace or combustor enclosure, into the conduits so formed, and thence out into the Flue gas flow via the nozzles.

Owner:THE BABCOCK & WILCOX CO

Method for separating carbon dioxide from a gas flow, in particular from a flue gas flow, and separating device for separating carbon dioxide from a gas flow, in particular from a flue gas flow

InactiveUS20160206991A1Controlled and inexpensively achievable removalEmission reductionLiquid degasificationCation exchanger materialsFlue gasIon exchange

A method for separating carbon dioxide from a gas flow, in particular from a flue gas flow, where a gas flow is brought in contact with a scrubbing medium in an absorber of a separating device and carbon dioxide contained in the gas flow is separated, the loaded scrubbing medium is fed to a desorber of the separating device in order to release the carbon dioxide, a vapor flow is drawn from the desorber and is fed to a cooling device in order to form condensate, and the condensate formed in the cooling device is at least partially fed to a purifying device, in which degradation products contained in the condensate are removed by reverse osmosis and / or by an ion exchanger. A separating device is adapted for separating carbon dioxide from a gas flow.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

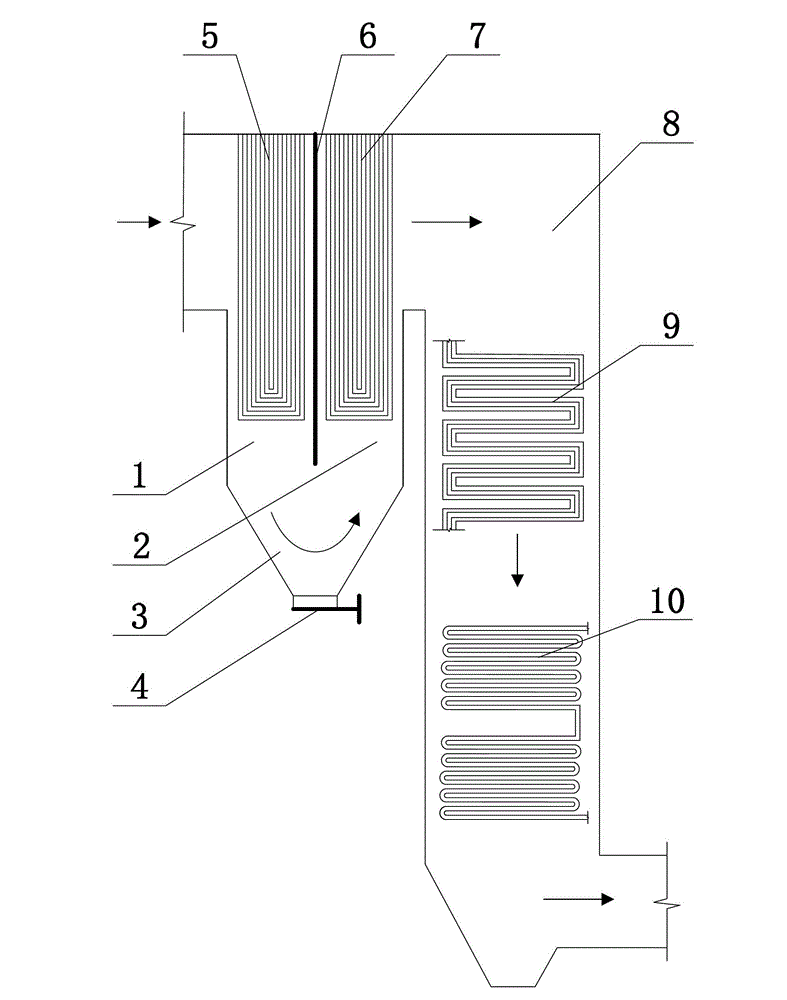

Cyclone redistribution denitration reactor for flue gas

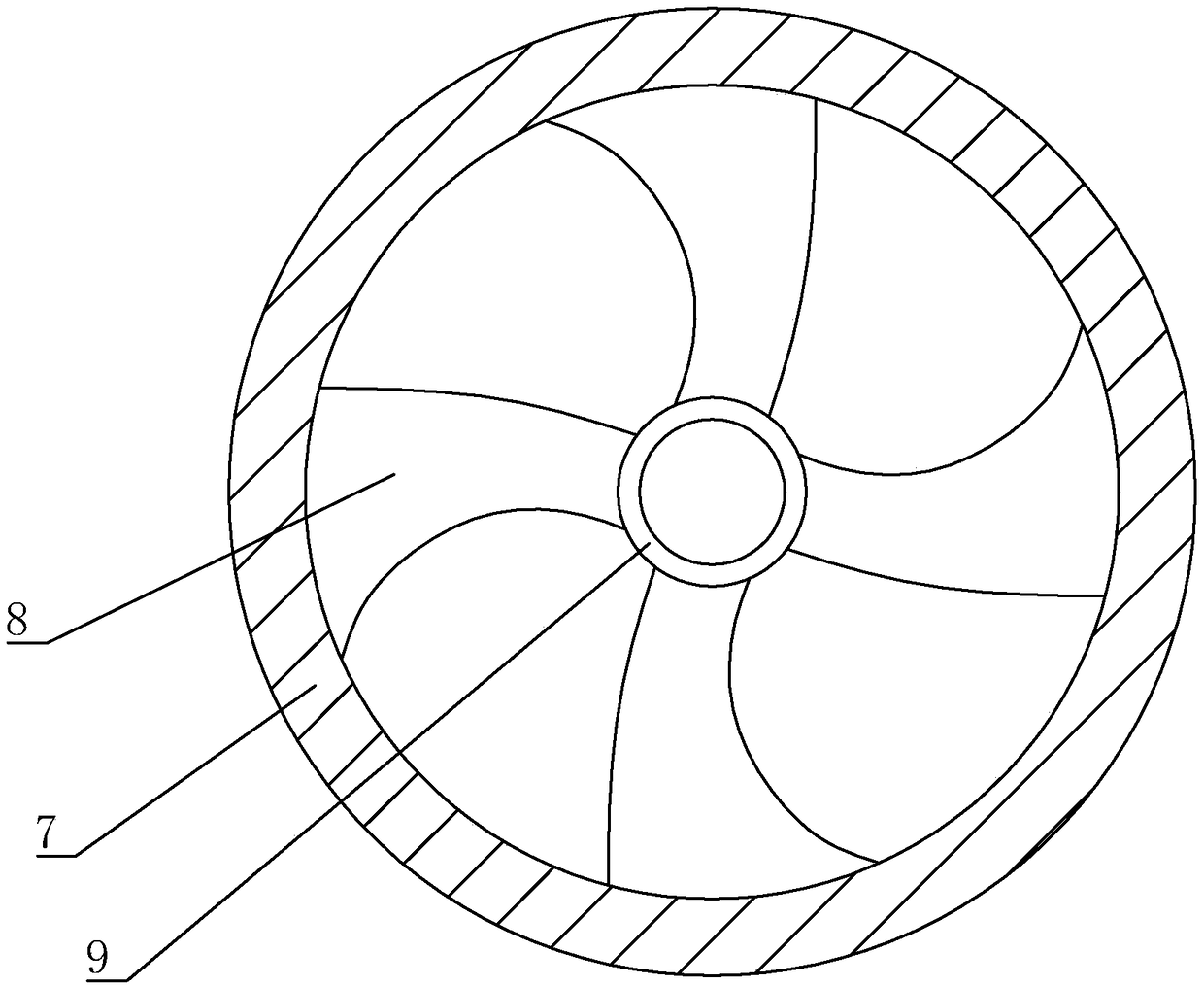

ActiveCN109173720AEvenly distributedFacilitated contact responseGas treatmentDispersed particle separationCycloneFlue gas

The invention relates to the field of environmental protection devices, and concretely discloses a cyclone redistribution denitration reactor for flue gas. The cyclone redistribution denitration reactor comprises a flue gas inlet tube, a cyclone assembly for guiding flue gas, an ammonia spraying and mixing device, a connecting flue gas tube, a catalytic reaction device and a flue gas outlet tube which are sequentially interconnected, the cyclone assembly comprises a first shell, the flow guiding plates and a mounting plate, the flow guiding plates have a spiral fan blade shape, the flow guiding plates are connected to the inner wall of the first shell, and are arranged along the circumferential direction of the first shell, the quantity of the flow guiding plates is more than one, the rotating directions of all the flow guiding plates are same to each other, the mounting plate is positioned among all the flow guiding plates, and the mounting plate is fixedly connected to one ends, facing the center of the first shell, of all the flow guiding plates. Flue gas enters the cyclone assembly through the flue gas inlet tube, and moves along the flow guiding plates to form a uniform-rotating flue gas flow, so the flue gas is in a uniformly distributed state when moving to the ammonia spraying and mixing device, thereby the flue gas is well contacted and reacted with a reaction solutionsprayed by the ammonia spraying and mixing device, dead angles are reduced, and the denitration efficiency is improved.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

Fuel cell and fuel cell stack

InactiveUS20090004523A1Simple and economical structureImprove sealingFuel cells groupingFuel cell auxillariesFuel cellsEngineering

Owner:HONDA MOTOR CO LTD

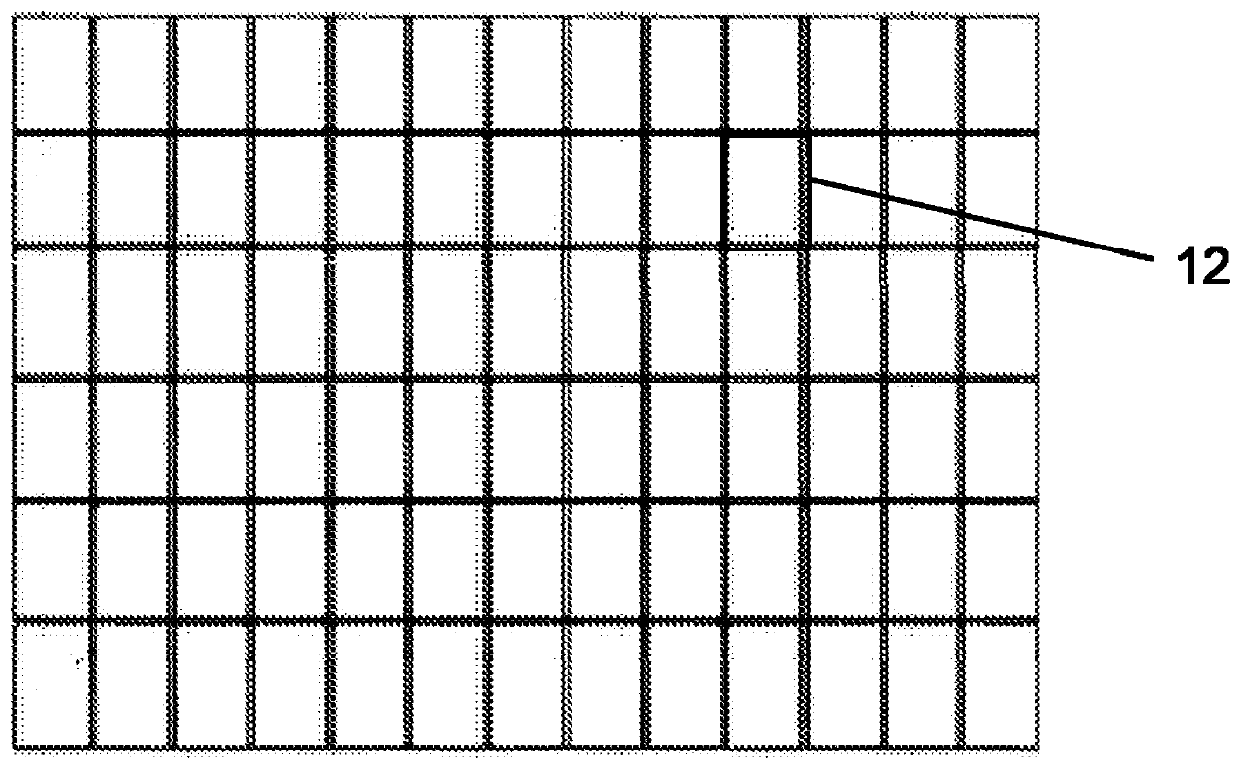

Flow gas equilibrating device

PendingCN108816520AWell mixedGuaranteed dust removal performanceVapor flow controlFlue gasProcess engineering

Belonging to the technical field of dust removers, the invention specifically relates to a flow gas equilibrating device applicable to dust removers. The flow gas equilibrating device at least comprises a cavity, flue gas enters the cavity through a cavity inlet, and circulates into an electrostatic field from the cavity. Specifically, the inlet circulation area of the cavity is larger than the flue gas circulation area of the electrostatic field. According to the invention, through the arrangement, transient accumulation and collision can occur to the flue gas flowing into the cavity while the flue gas tries to enter the electrostatic field due to decrease of the circulation area, the situation can enable quick and uniform mixing of the flue gas in the cavity, specifically, congestion canoccur to electrostatic channels in which a lot of flue gas circulates originally, and the congestion can cause conveying of redundant flue gas to electrostatic channels with little flow volume originally, so that the actual circulation area in the electrostatic field can be the designed circulation area, the flow rate and dust removal time can be set according to the requirements, and the dust removal effect can be guaranteed.

Owner:江苏蓝博环保机械有限公司

Methods of manufacturing synthetic diamond material by microwave plasma enhanced chemical vapor deposition from a microwave generator and gas inlet(s) disposed opposite the growth surface area

ActiveUS9637838B2Raise the level of dopingPromote growth ratePolycrystalline material growthElectric discharge tubesMicrowaveGas phase

Disclosed herein are methods of manufacturing synthetic CVD diamond material including orienting and controlling process gas flow in a microwave plasma reactor to improve performance. The microwave plasma reactor includes a gas flow system with a gas inlet comprising one or more gas inlet nozzles disposed opposite the growth surface area and configured to inject process gases towards the growth surface area. The method comprises injecting process gases towards the growth surface area at a total gas flow rate equal to or greater than 500 standard cm3 per minute wherein the process gases are injected into the plasma chamber through the one or more gas inlet nozzles with a Reynolds number in a range 1 to 100.

Owner:ELEMENT SIX LTD

Ship exhaust gas particulate matter dilution sampling system

ActiveCN106918475AEasy to installEasy to disassembleWithdrawing sample devicesParticulatesAtmospheric air

The invention discloses a ship exhaust gas particulate matter dilution sampling system including: a flue gas flow guiding apparatus, a flue gas diluting apparatus, a retention chamber for aging the flue gas, and a sampling apparatus. The flue gas flow guiding apparatus is connected to a chimney on a ship; the flue gas diluting apparatus is respectively connected to the flue gas flow guiding apparatus and the retention chamber; the sampling apparatus is connected to the retention chamber; the flue gas flow guiding apparatus is provided with a constant speed control mechanism, which enables the flow speed of flue gas at the position, whereat the flue gas flow guiding apparatus is connected to the chimney, to tend to be equal to the flow speed of surrounding flue gas. In the system, clean air is used for diluting the ship exhaust gas, so that a physical and chemical progress that the ship exhaust gas is emitted into atmosphere is simulated, thereby collecting and analyzing a particulate matter sample. The system can achieve constant-speed sampling to the flue gas, and can perform particulate matter dilution sampling to a chimney, on which a sampling hole is not reserved, of a ship. The system is convenient to install and detach and easy to operate and can complete sampling in a narrow space. The system has small size, is convenient to carry, is simple in operations and is suitable for in-situ application.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Boiler flue structure

InactiveCN102913891AReduce dust accumulationReduce the effect of flow resistanceSteam boilersChimneysSlagEngineering

The invention relates to a boiler flue structure which belongs to the technical field of combustion equipment. The boiler flue structure comprises a first flue, a second flue and a tail flue, wherein a boiler hearth outlet flue is partitioned into a U-shaped flue by a water-cooled wall partition, and the first flue and the second flue are sequentially arranged along a flue gas flow, and the first flue and the second flue are communicated through an ash bucket; a high-temperature reheater is arranged in the first flue, and a final stage superheater is arranged in the second flue; convection heating surfaces of a low-temperature reheater and a coal economizer are arranged in the tail flue; the bottom of the U-shaped channel is provided with the ash bucket which not only is a reversing chamber of the flue gas flow, but also can be used for ash deposition; the bottom of the ash bucket is provided with a gas lock which is convenient for regularly clearing ash deposition; and heating surfaces arranged in the U-shaped channels are all of slag coagulation structure in a large-pitch arrangement mode. By adopting the boiler flue structure provided by the invention, the problem of severe pollution of boiler high-temperature convection heating surfaces.

Owner:TSINGHUA UNIV

SCR denitration system

PendingCN110465193AReduce spillageAvoid dischargeGas treatmentDispersed particle separationFlue gasNitrogen

The invention provides an SCR denitration system. According to the invention, a first mixing unit, a first catalyst layer, a second mixing unit and a second catalyst layer are arranged in a main bodyand successively arranged along the flowing direction of flue gas. In the above-mentioned system, the flue gas is mixed by the first mixing unit; mixed flue gas flows through the first catalyst layerfor a reaction; unreacted NOx and NH3 flow out of the first catalyst layer and are in non-uniform flow-field distribution and concentration distribution; through arrangement of the second mixing unit,the flue gas is mixed again, so a nitrogen-ammonia mixture has more uniform velocity field and concentration field before flowing through the second catalyst layer, and can fully react when flowing through the second catalyst layer; thus, a large amount of an unreacted nitrogen-ammonia mixture is avoided from being discharged, and denitration efficiency of the whole SCR denitration system is improved.

Owner:CHINA HUADIAN ENG +1

One-step injection-molded smoke filter

ActiveCN103431518BSpeed up the flowChange flow stateTobacco smoke filtersHazardous substanceFlue gas

Owner:GUANGDONG GOLDEN LEAF TECHNOLOGY DEVELOPMENT CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com