Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

233 results about "Fracture propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The fracture propagation is driven by injection of an incompressible Newtonian fluid at a constant rate. The fracture opening and the fluid pressure are related through an elastic singular integral equation, and the flow of fluid within the fracture is modeled using lubrication theory.

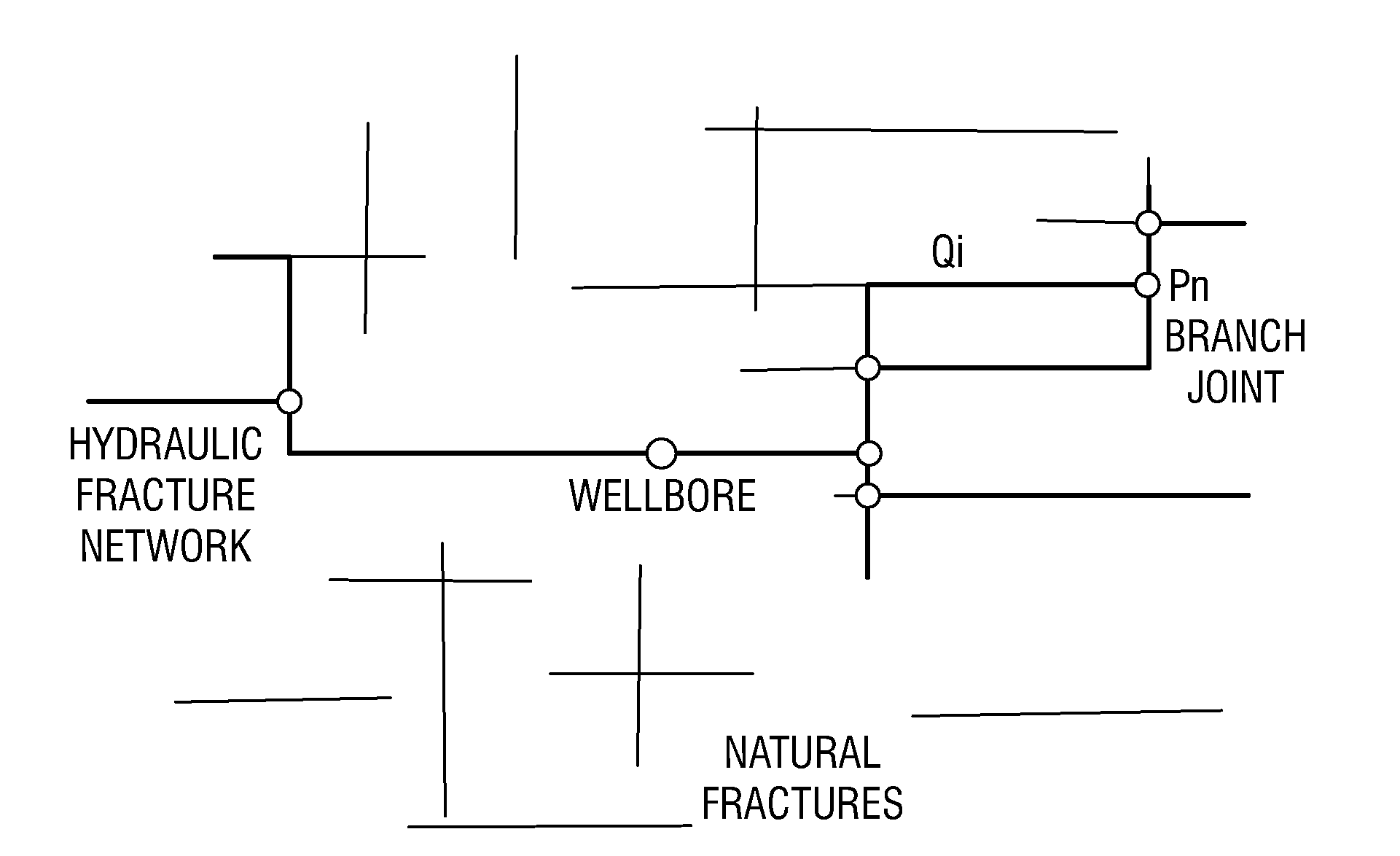

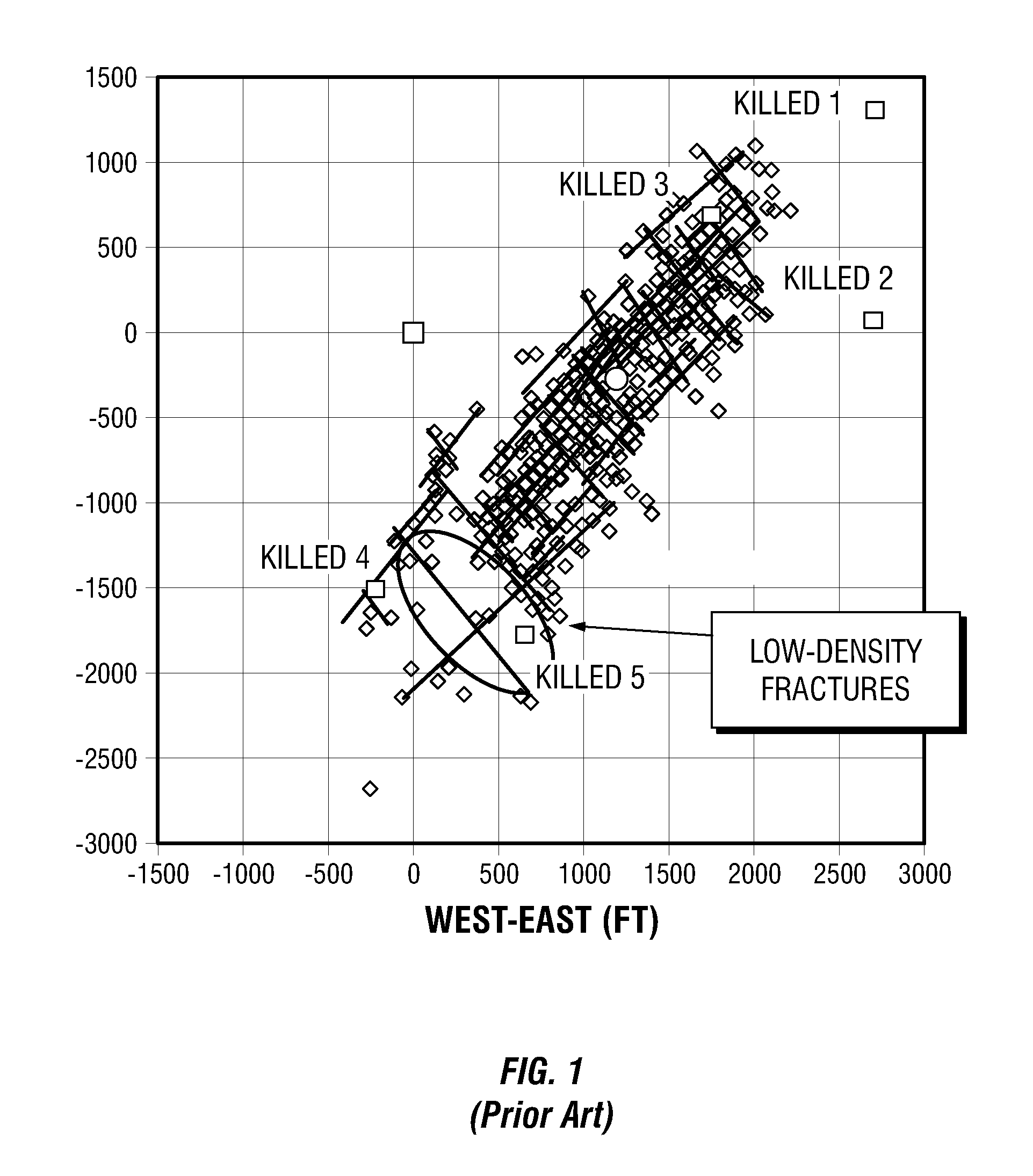

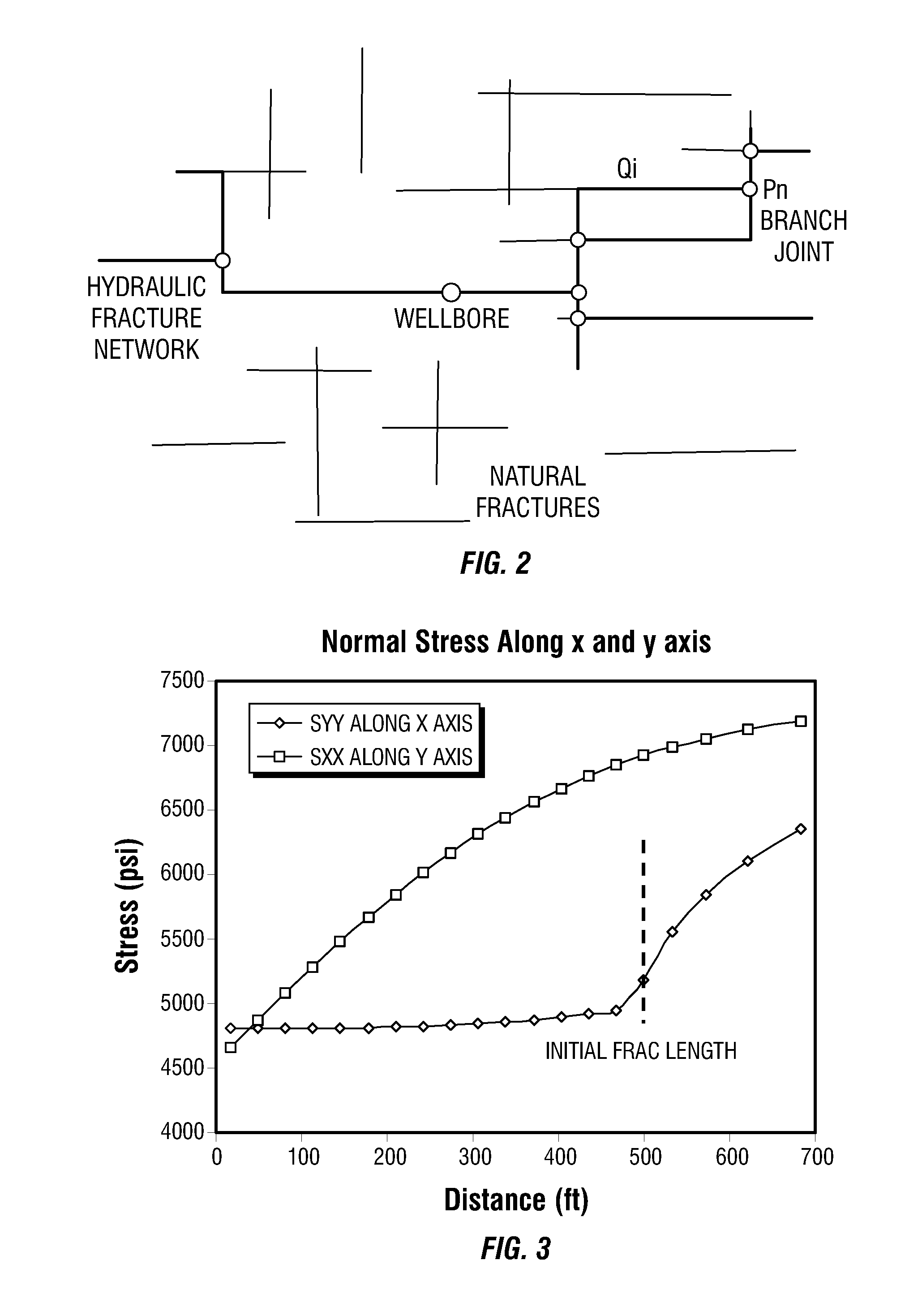

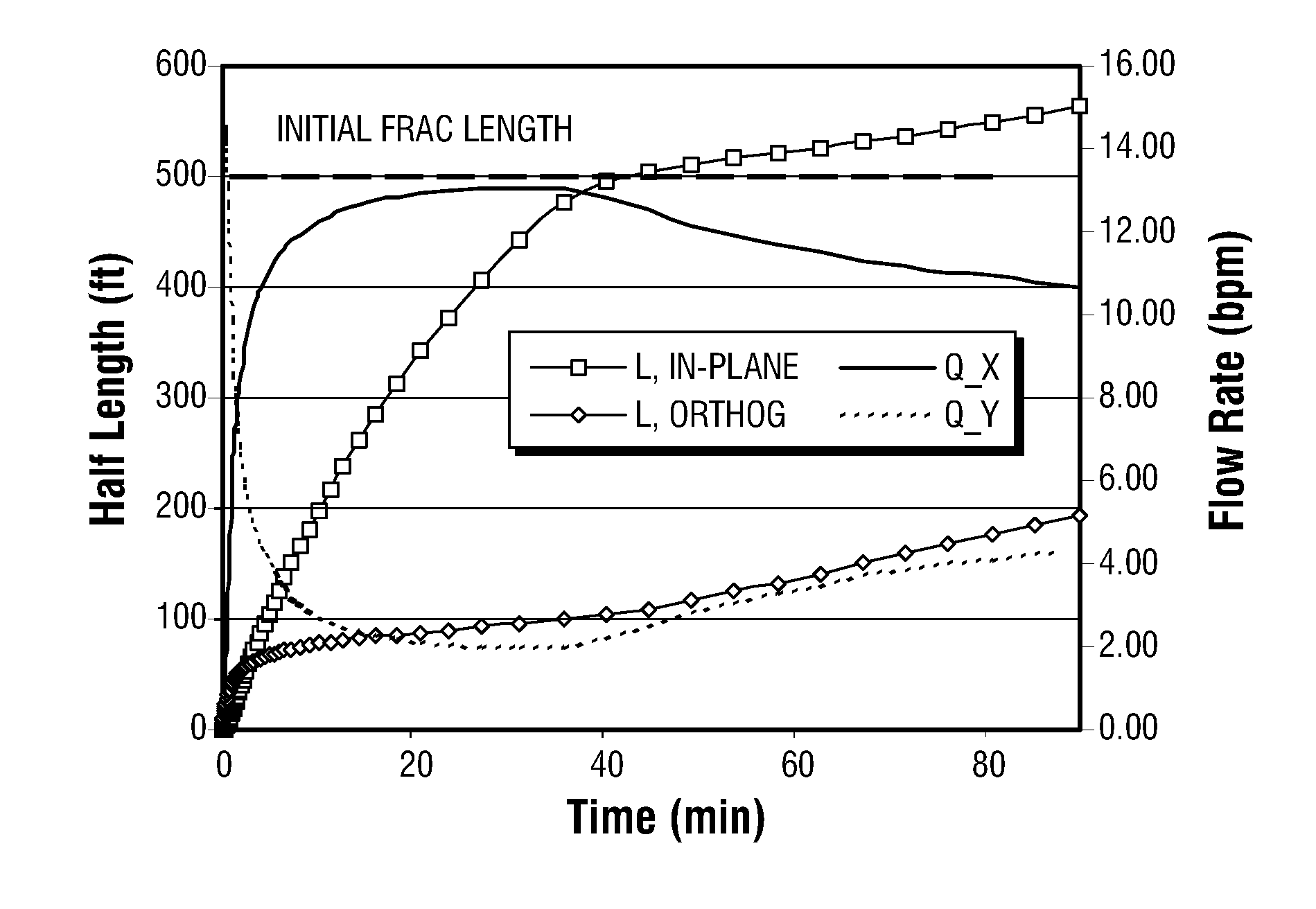

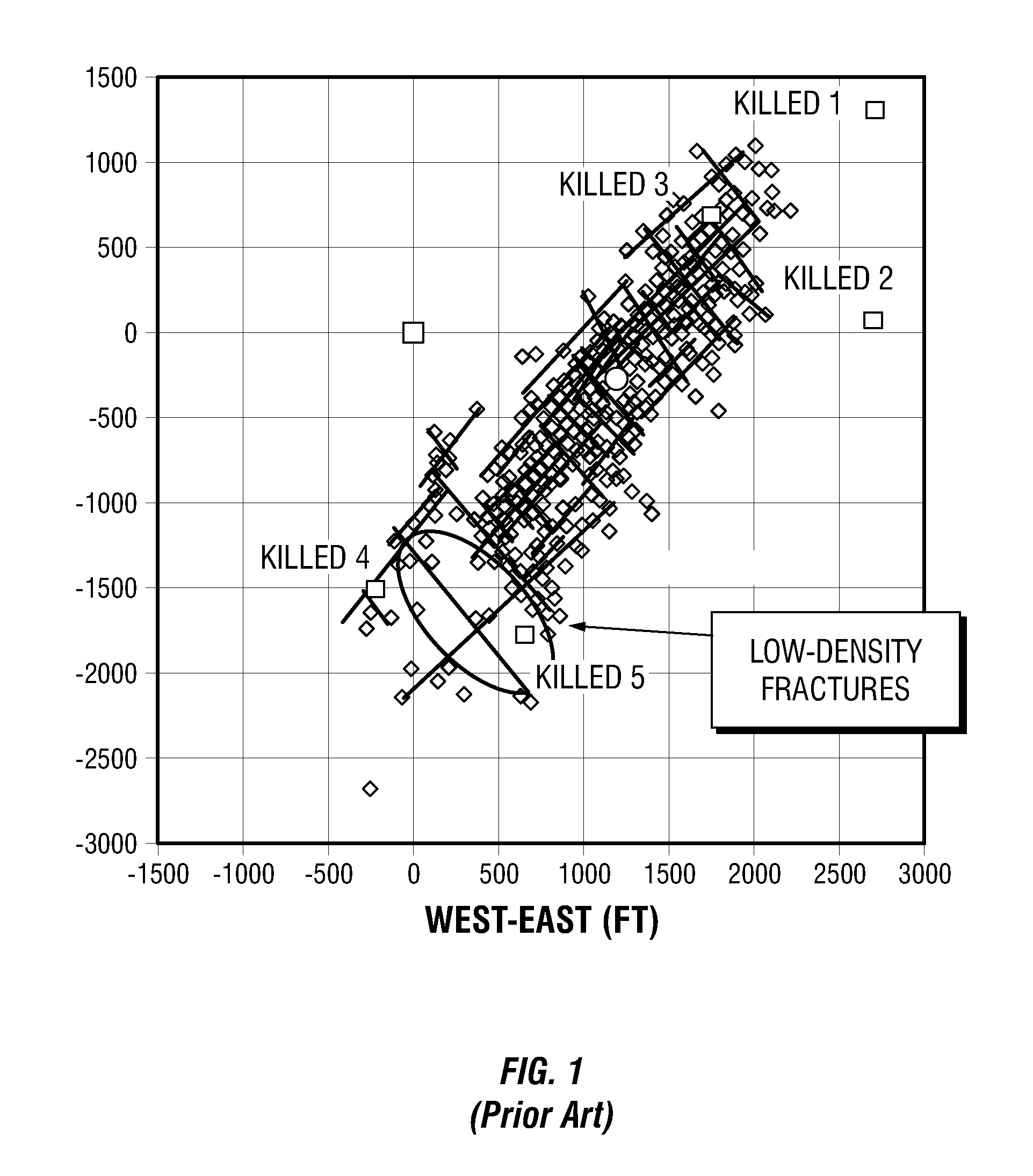

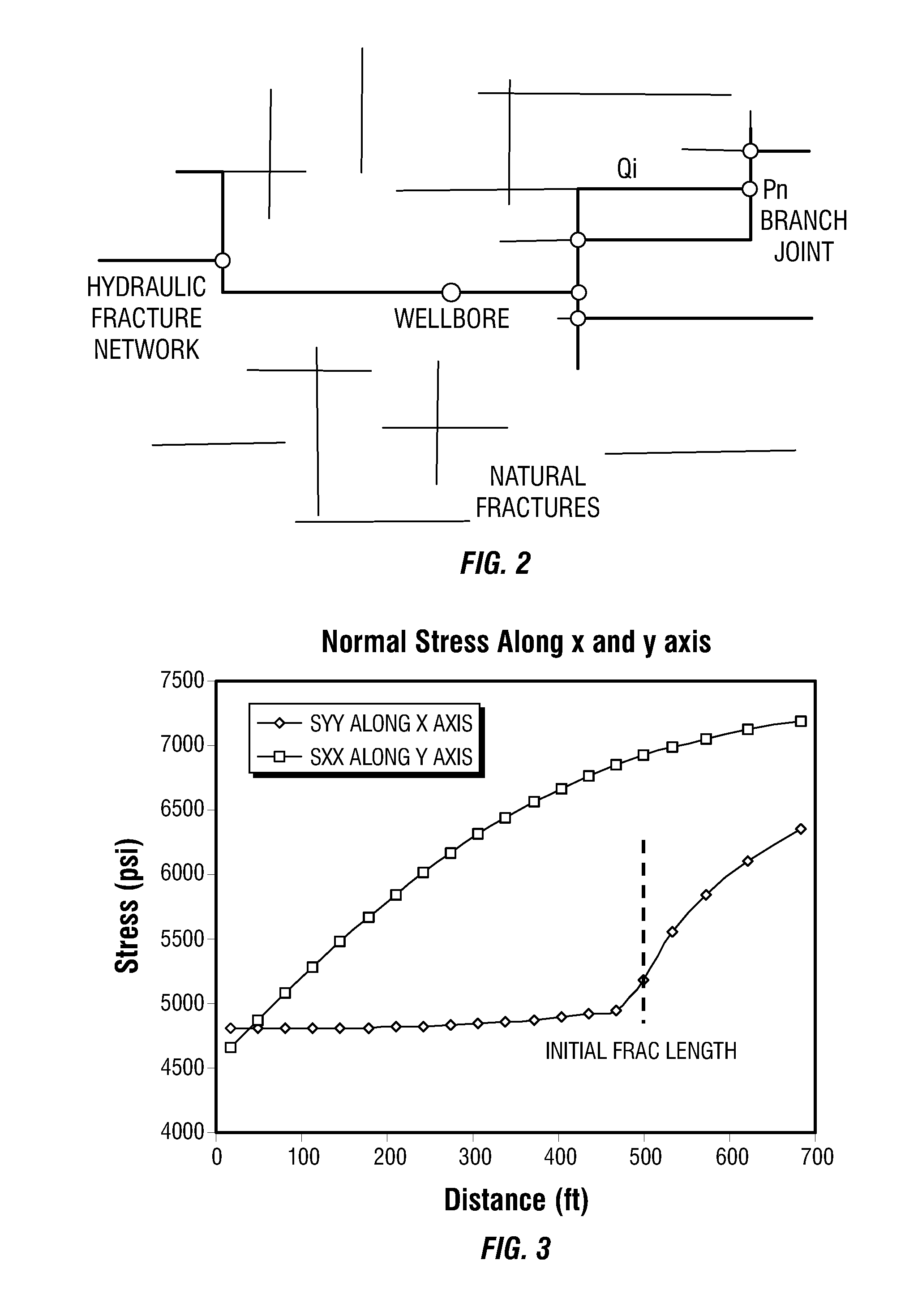

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

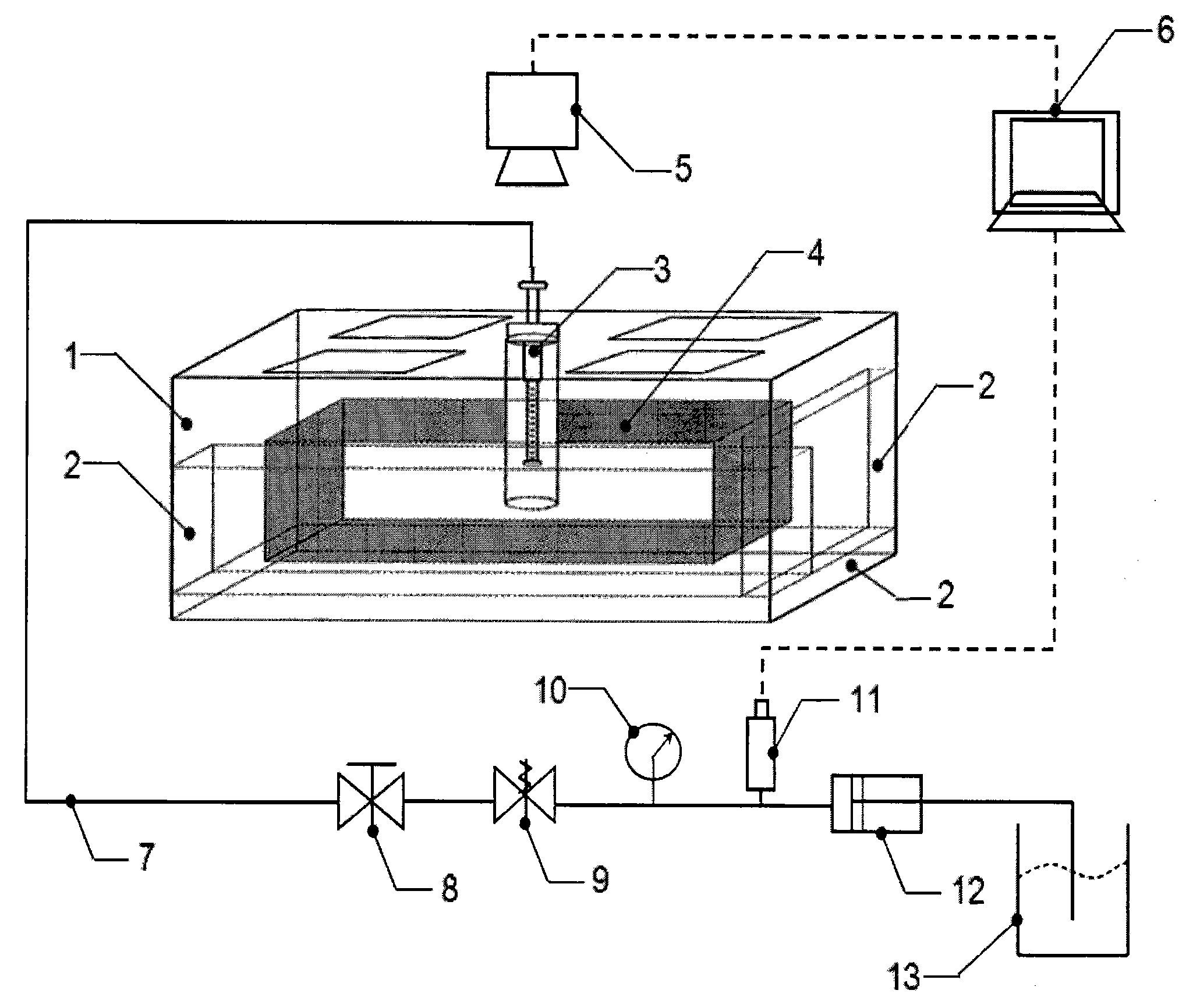

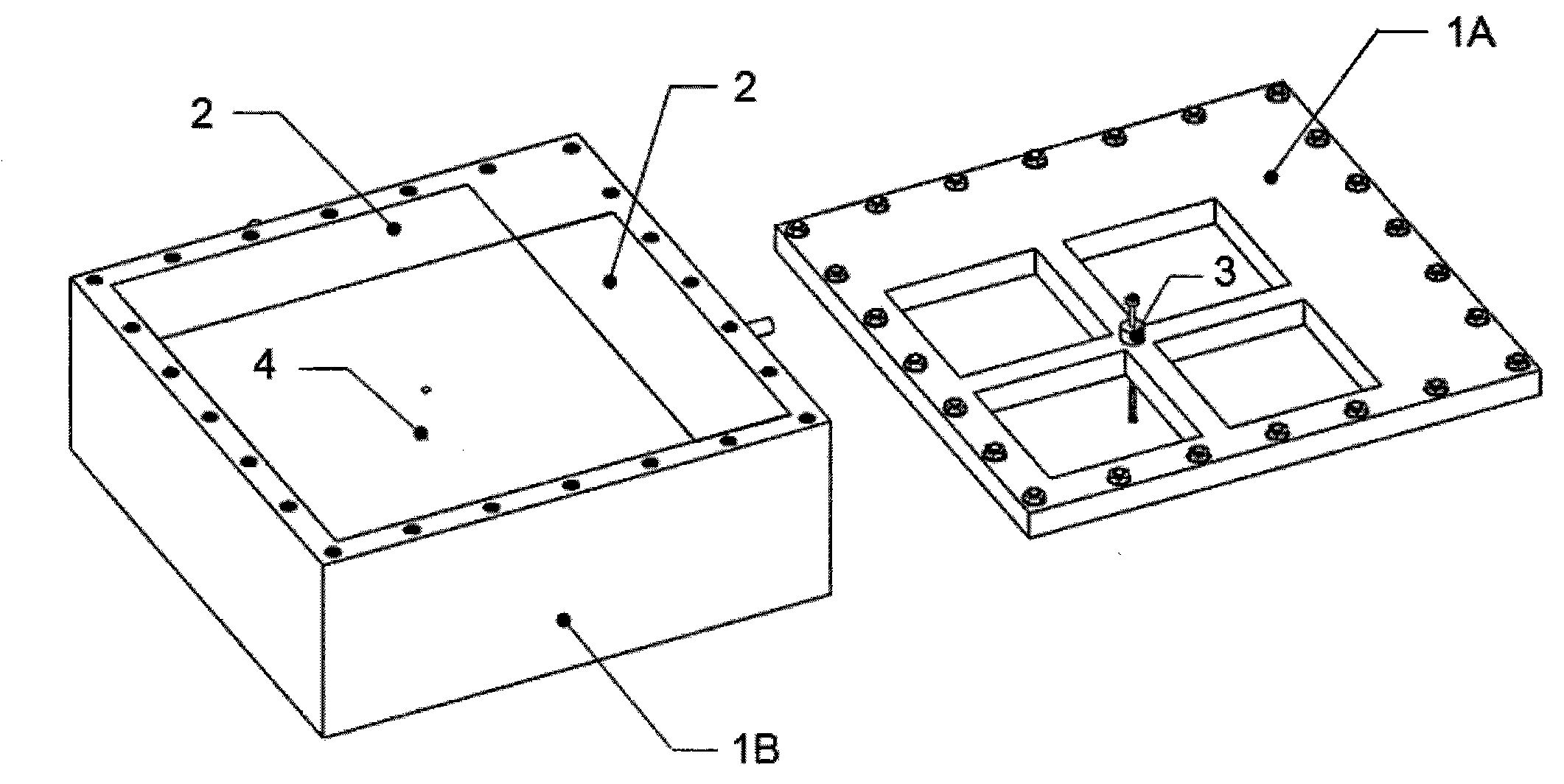

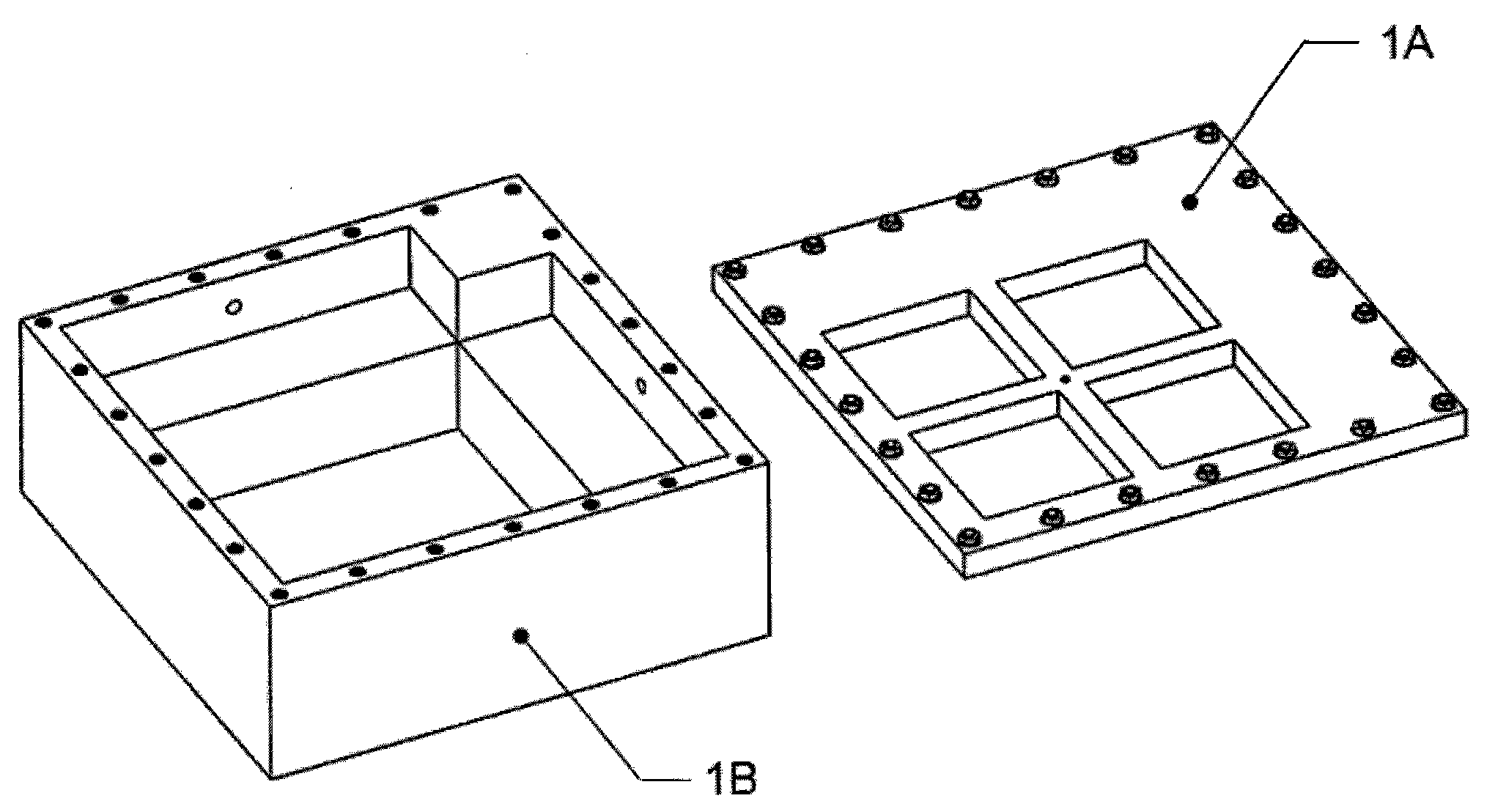

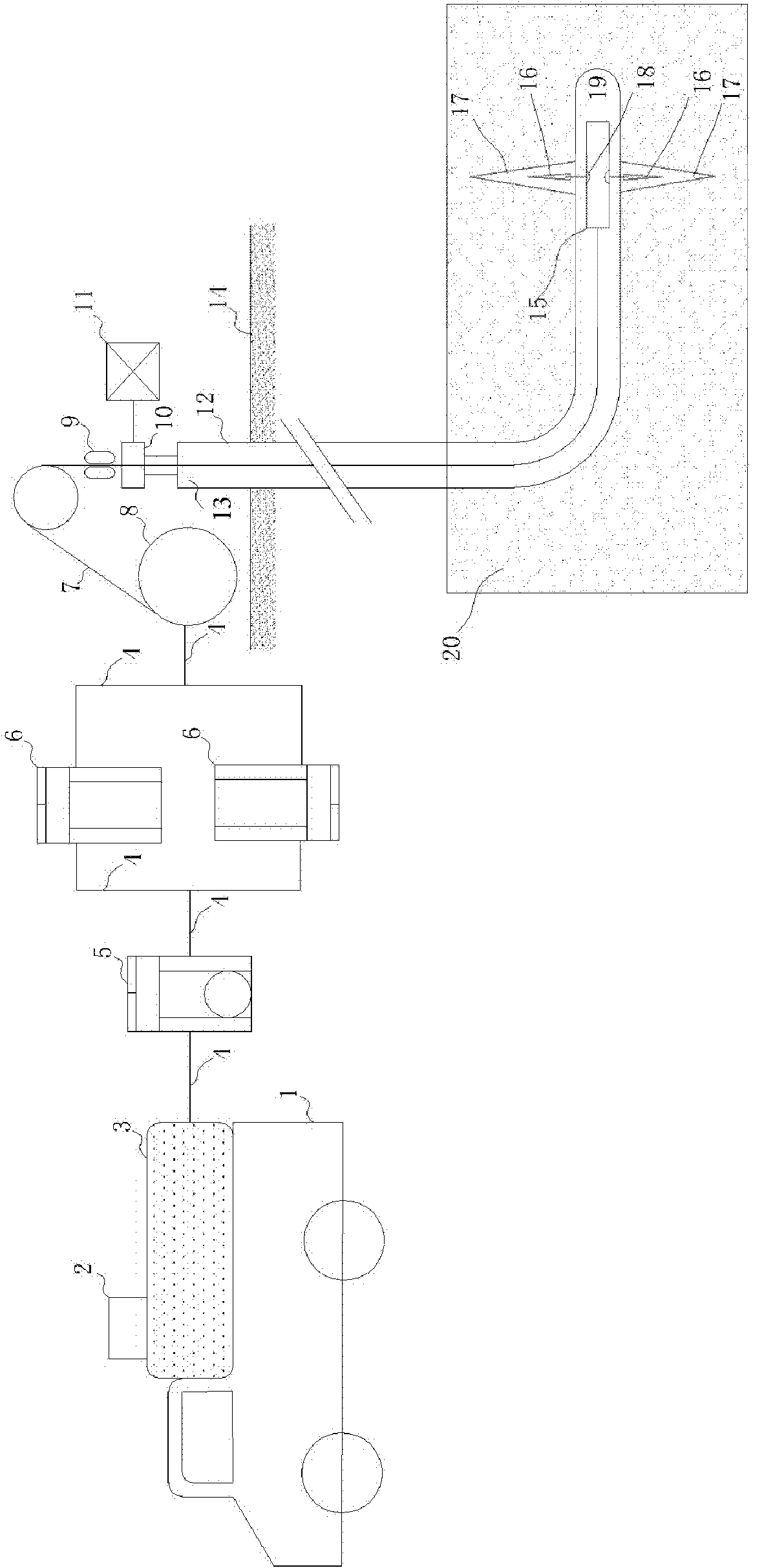

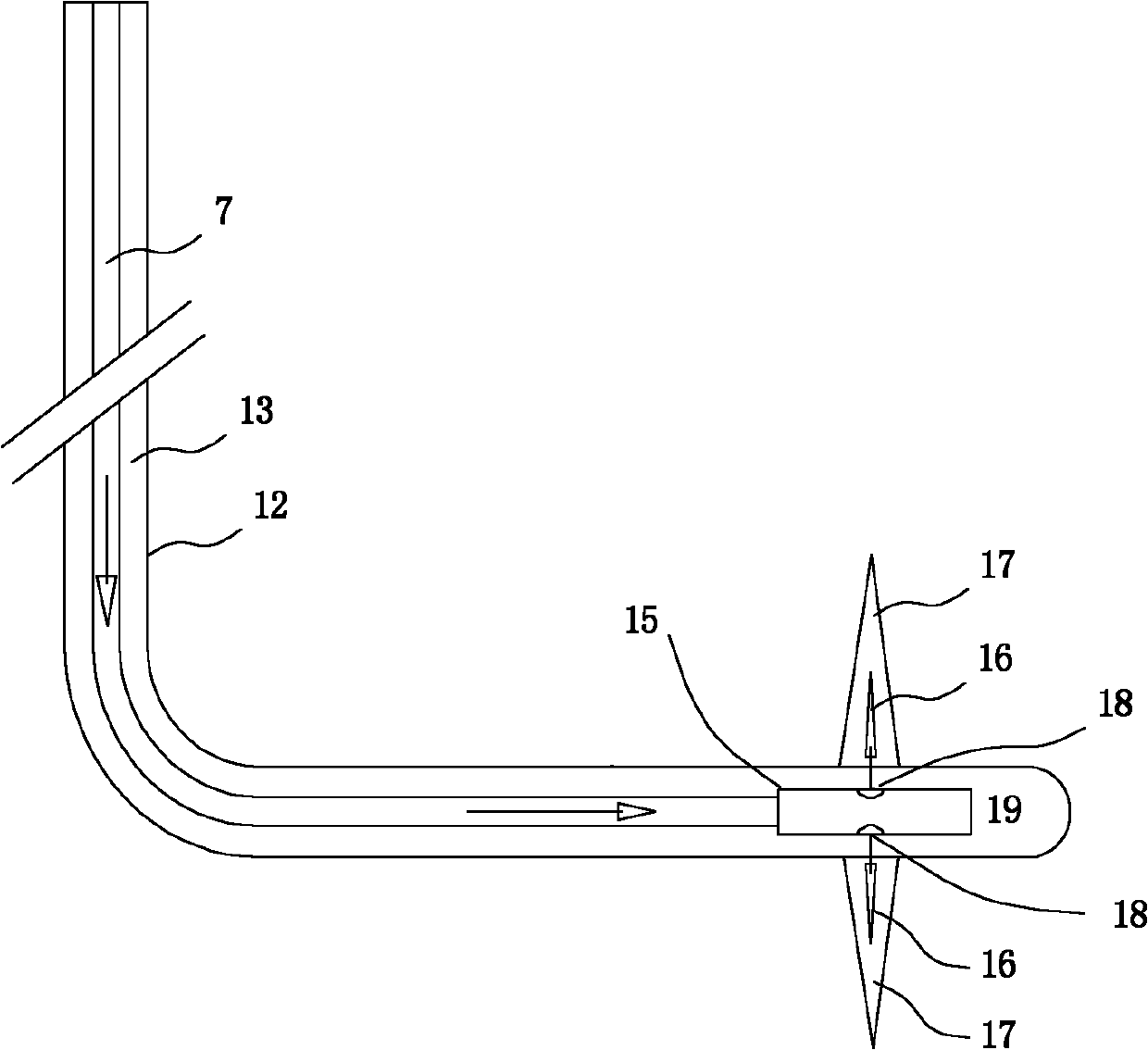

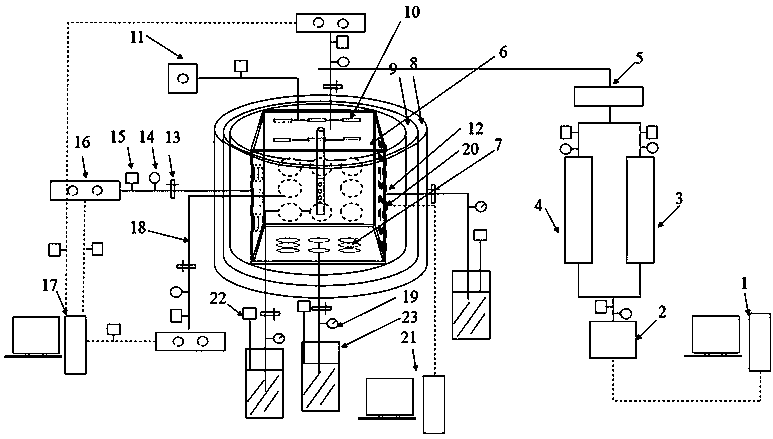

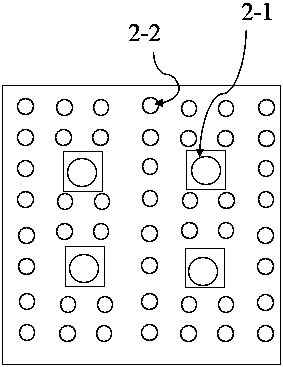

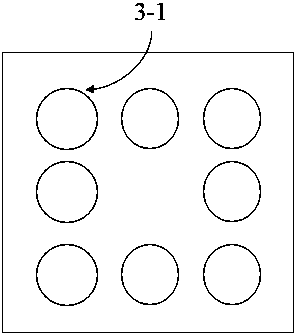

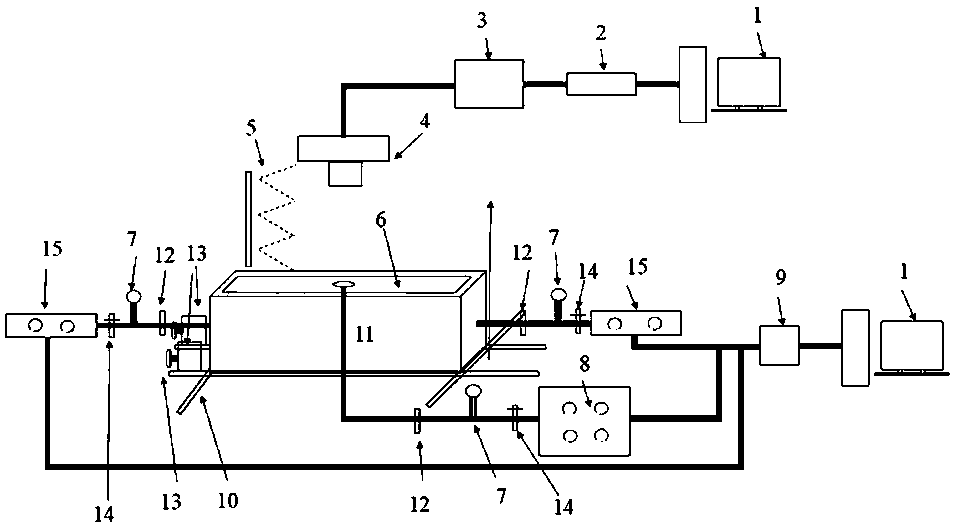

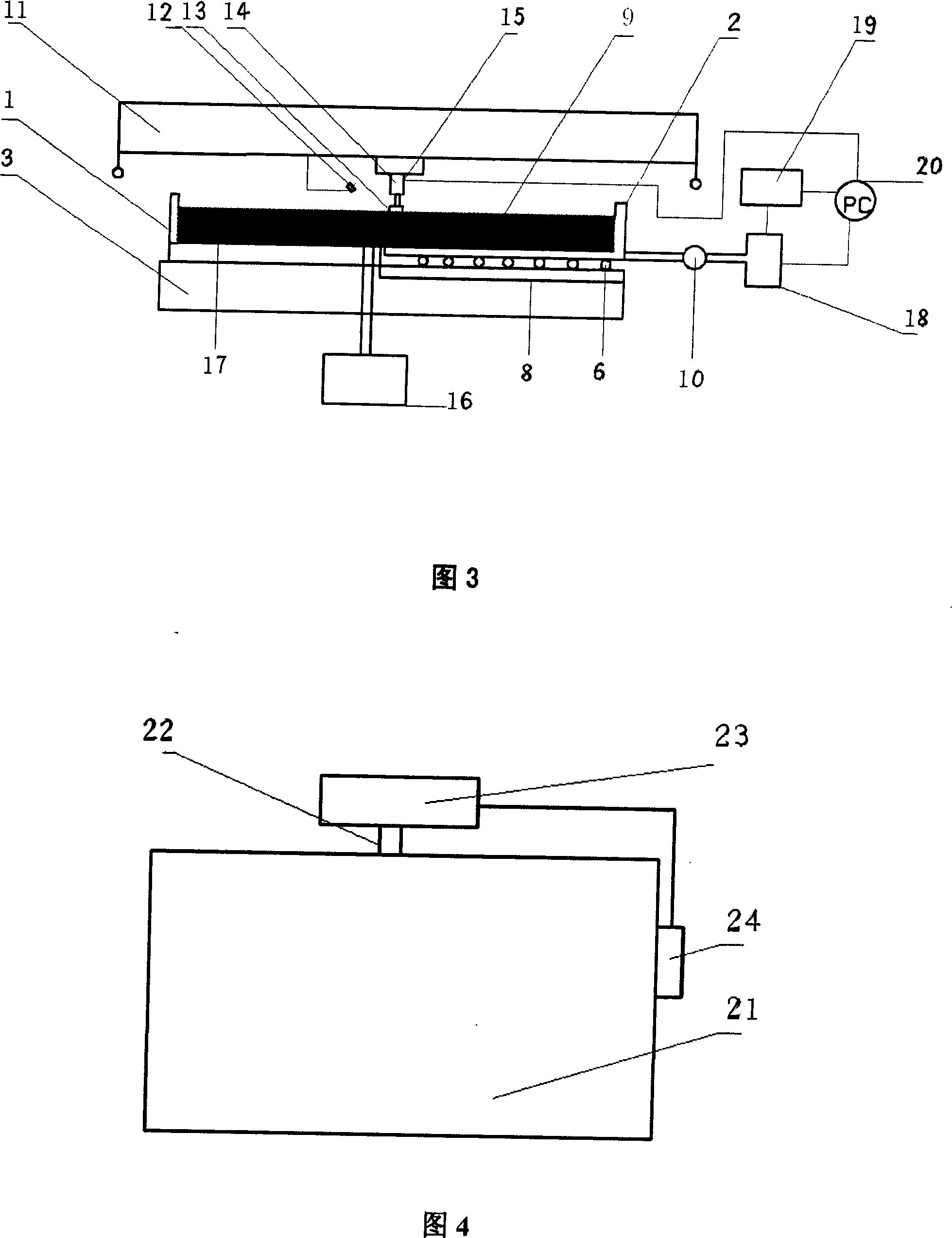

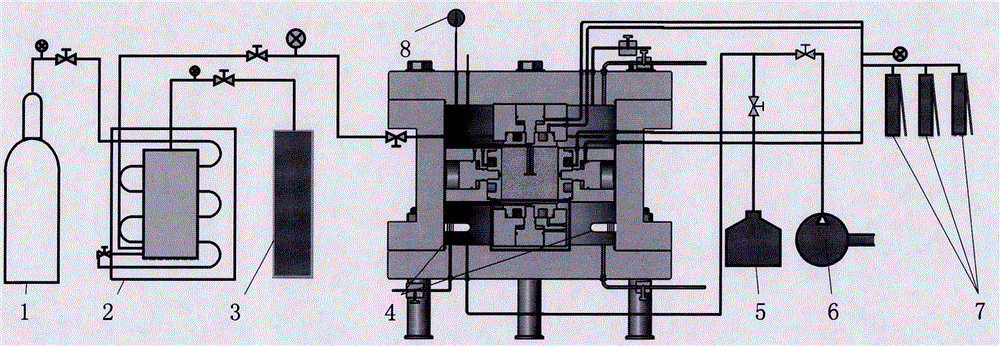

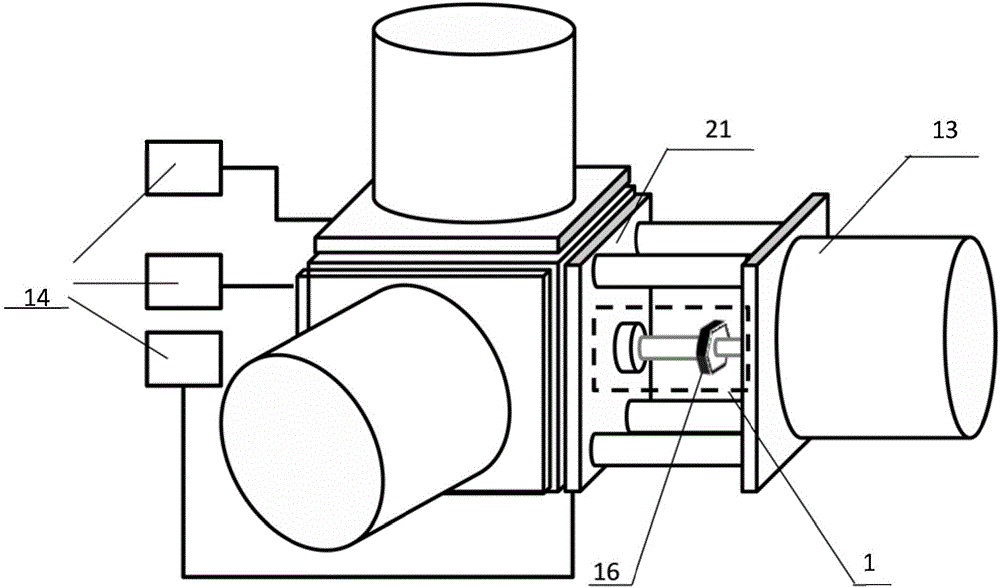

Oil-gas well hydraulically-created-fracture expansion visualization experiment method and oil-gas well hydraulically-created-fracture expansion visualization experiment device

ActiveCN103485759AFor the purpose of visualizationSurveyEarth material testingEpoxyHigh pressure water

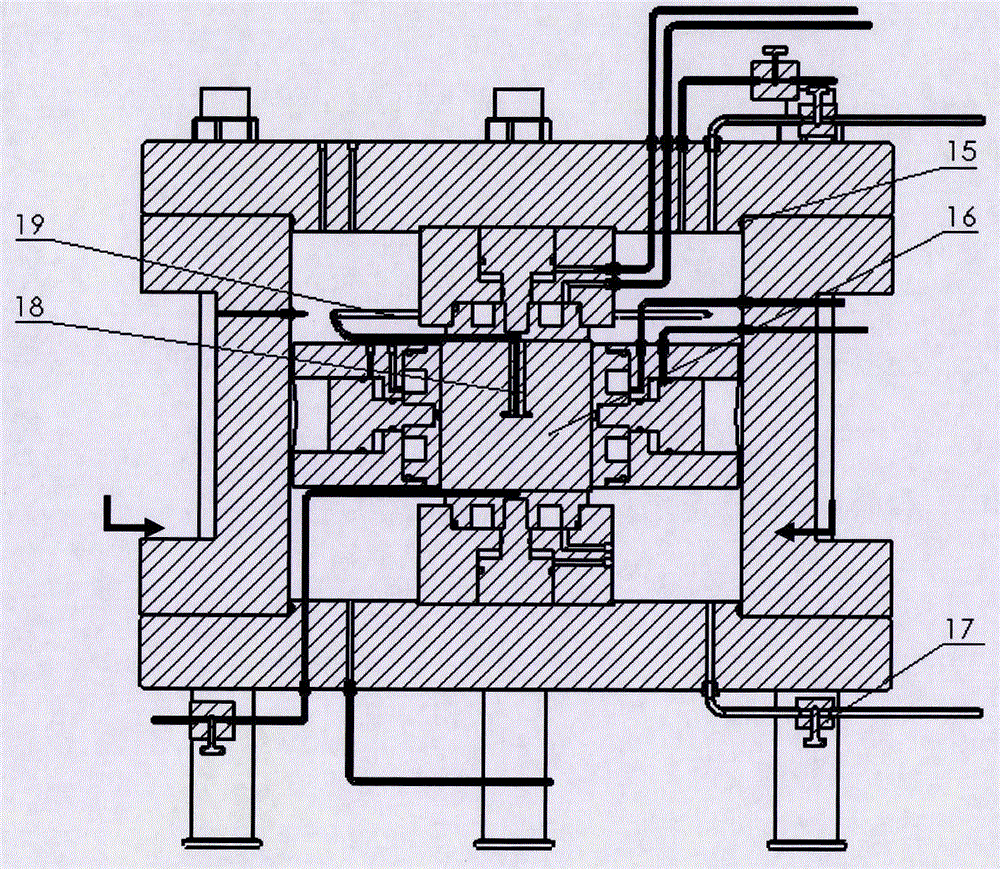

The invention relates to an oil-gas well hydraulically-created-fracture expansion visualization experiment method and an oil-gas well hydraulically-created-fracture expansion visualization experiment device. The device is composed of a rock sample chamber, a crustal loading unit, a simulation fracturing string, a high-speed camera, a high-pressure pumping unit, a data measuring and collecting unit and the like, and four transparent observation ports are formed on a top cover of the rock sample chamber. The method includes firstly, preparing a flat-plate-type rock sample, performing high-pressure-water cutting to preform a natural fracture, and filling the natural fracture with epoxy resin to form a filled-type fracture; secondly, performing water saturation on the rock sample for 3-5 days, and using epoxy resin to wrap the rock sample after water saturation; thirdly, loading three-axis stress on the rock sample, drilling a borehole under the condition that the three-axis stress is applied on the rock sample, and mounting the simulation fracturing string; finally, connecting a high-pressure pipeline with a constant-flux pump, pumping fracturing liquid, recording a fracture expansion path by the high-speed camera, and measuring pumping pressure changes by a pressure transmitter. By the method and the device, the hydraulically-created-fracture expansion path can be visualized on a plane, and a novel experiment method is provided for studying on a hydraulically-created-fracture expansion mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

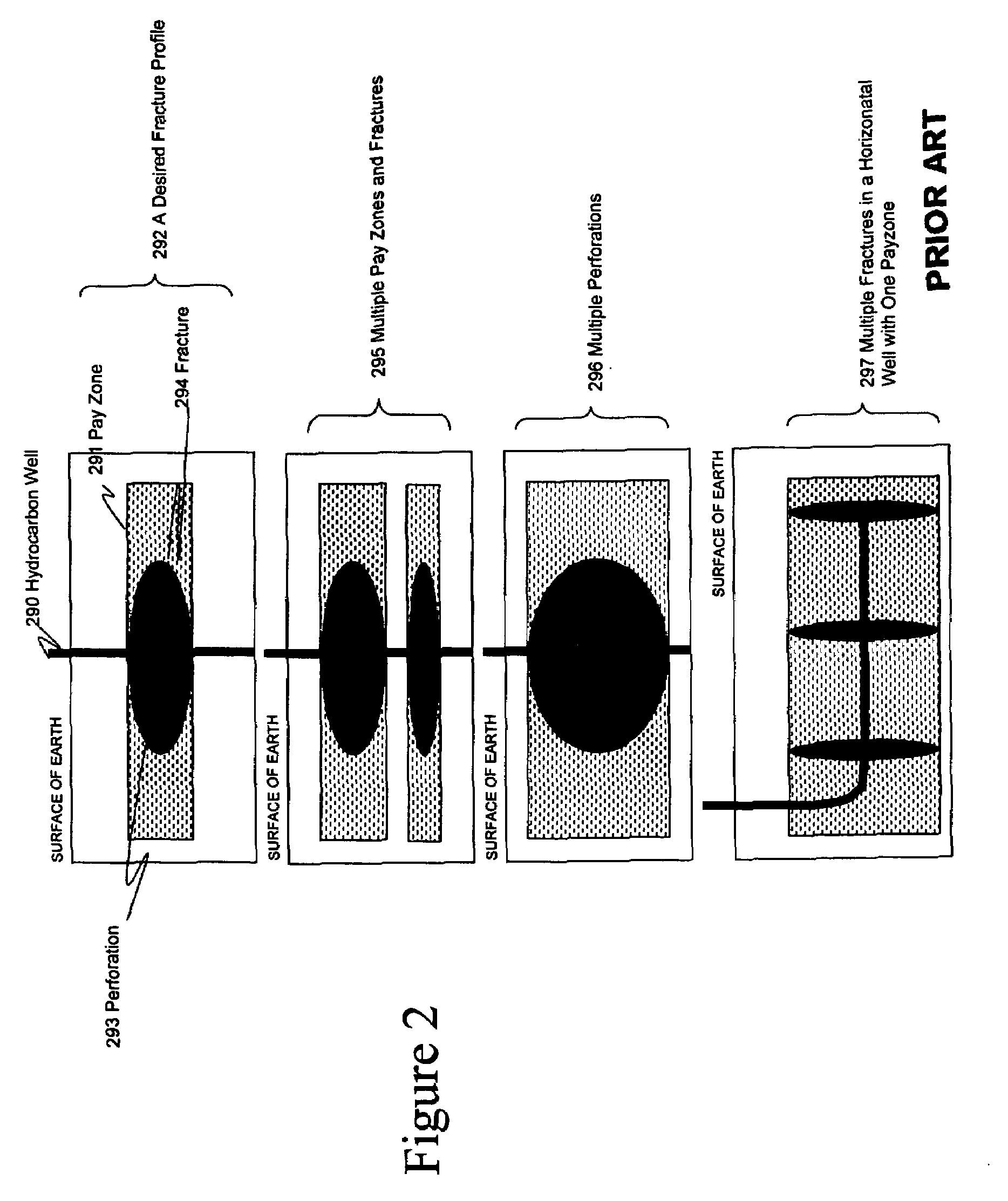

Techniques for hydraulic fracturing combining oriented perforating and low viscosity fluids

The present invention relates to novel methods to stimulate a hydrocarbon-bearing formation; in particular, techniques are disclosed for shooting perforations aligned with the direction of probable fracture propagation; this is followed by fracturing using a low viscosity fluid, preferably a viscoelastic surfactant-based fluid; the combination yields surprising results with respect to optimized fracture efficiency (i.e., ideal height, and half-length more closely approaches the true fracture length due to superior clean up properties of the fluids).

Owner:SCHLUMBERGER TECH CORP

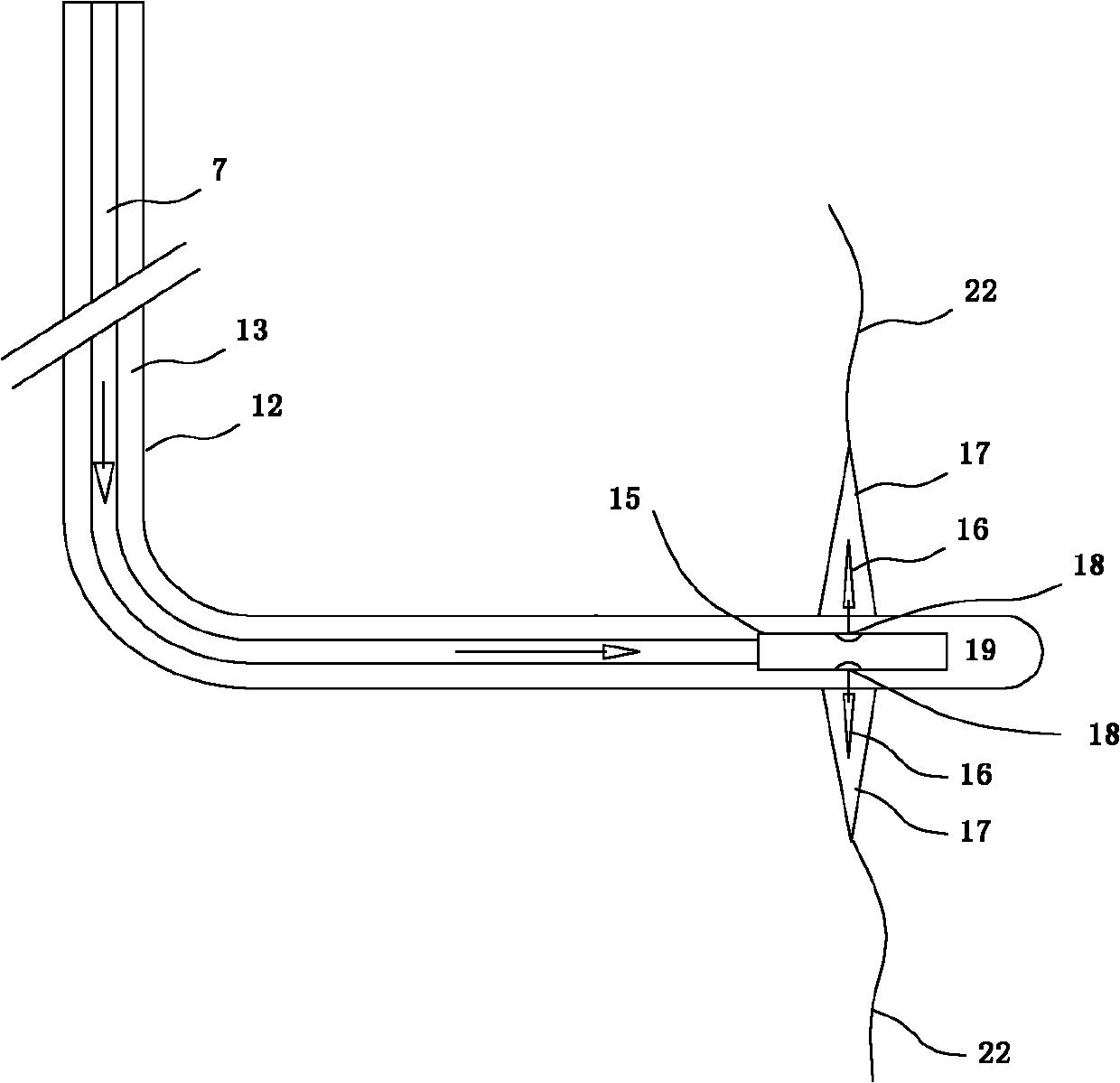

Coiled tubing supercritical CO2 jet fracturing method

ActiveCN102168545AJet rock breaking efficiency is highRock breaking threshold pressure is lowLiquid/gas jet drillingFluid removalWater basedFracturing fluid

The invention relates to a coiled tubing supercritical CO2 jet fracturing method. The method is used for performing jet fracturing on oil well reservoirs by taking supercritical CO2 as fracturing fluid. By the method, a supercritical CO2 fluid is used as the fracturing fluid to perform the jet fracturing; a supercritical CO2 sand jet perforating hole can reduce system pressure; the pressure needed by fissure extension can be further reduced by the characteristics of low viscosity and high dispersion performance of the supercritical CO2 fluid; most importantly, the supercritical CO2 jet fracturing does not pollute the reservoirs, but the supercritical CO2 can further improve the oil and gas recovery ratio after entering the reservoirs; the return discharge is not needed after the fracturing is completed; when the stage-by-stage jet fracturing is performed by using the coiled tubing, a tube pillar can be lifted or put down without mineshaft pressure relieving, the operation process is reduced and the operation cost is reduced, so that the method is extremely suitable for fracturing modification of unconventional oil-gas reservoirs such as thick oil reservoirs, low permeability and super-low permeability oil-gas reservoirs, shale gas reservoirs, coal bed methane reservoirs and the like of which the effects are low by using the conventional water-based fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

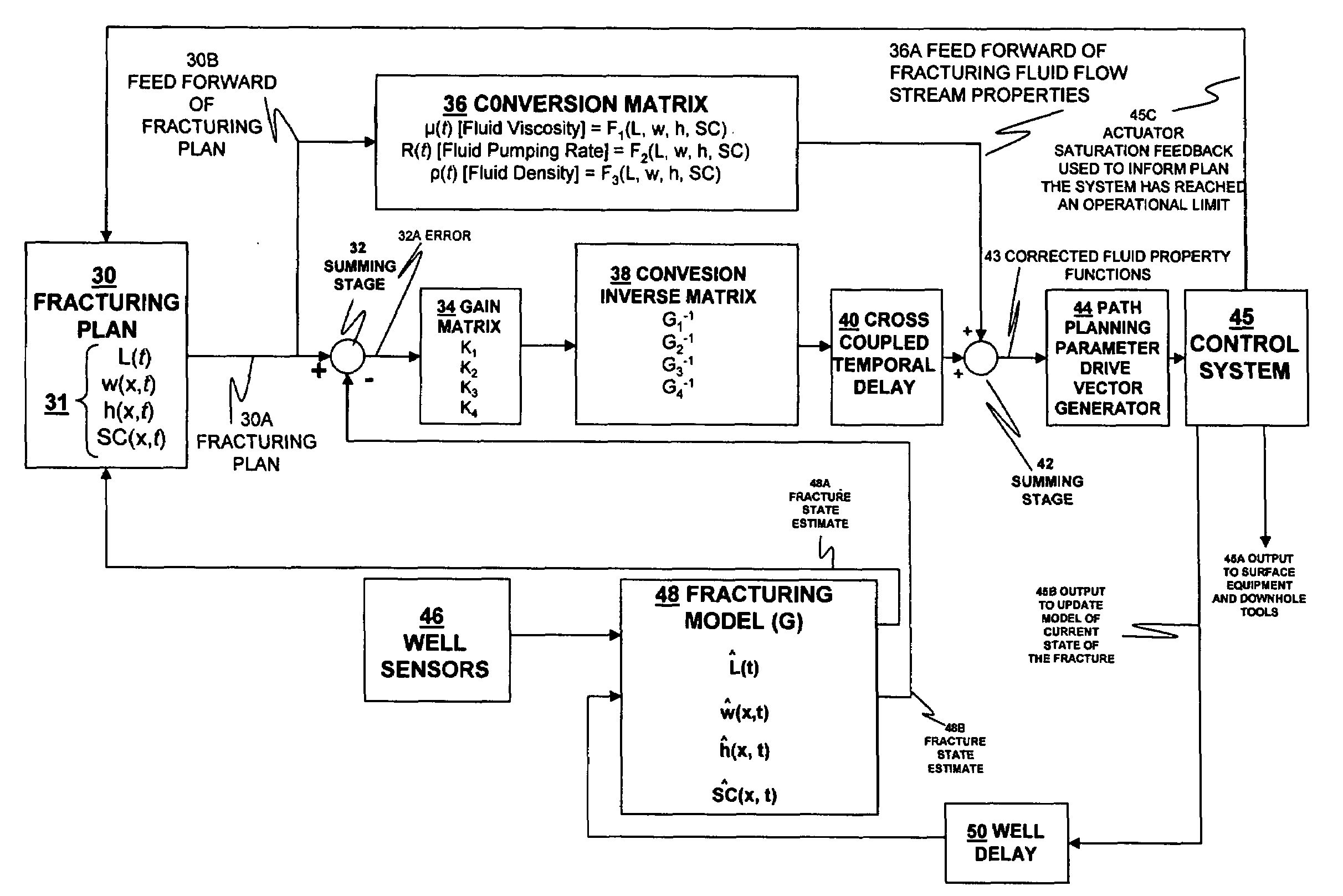

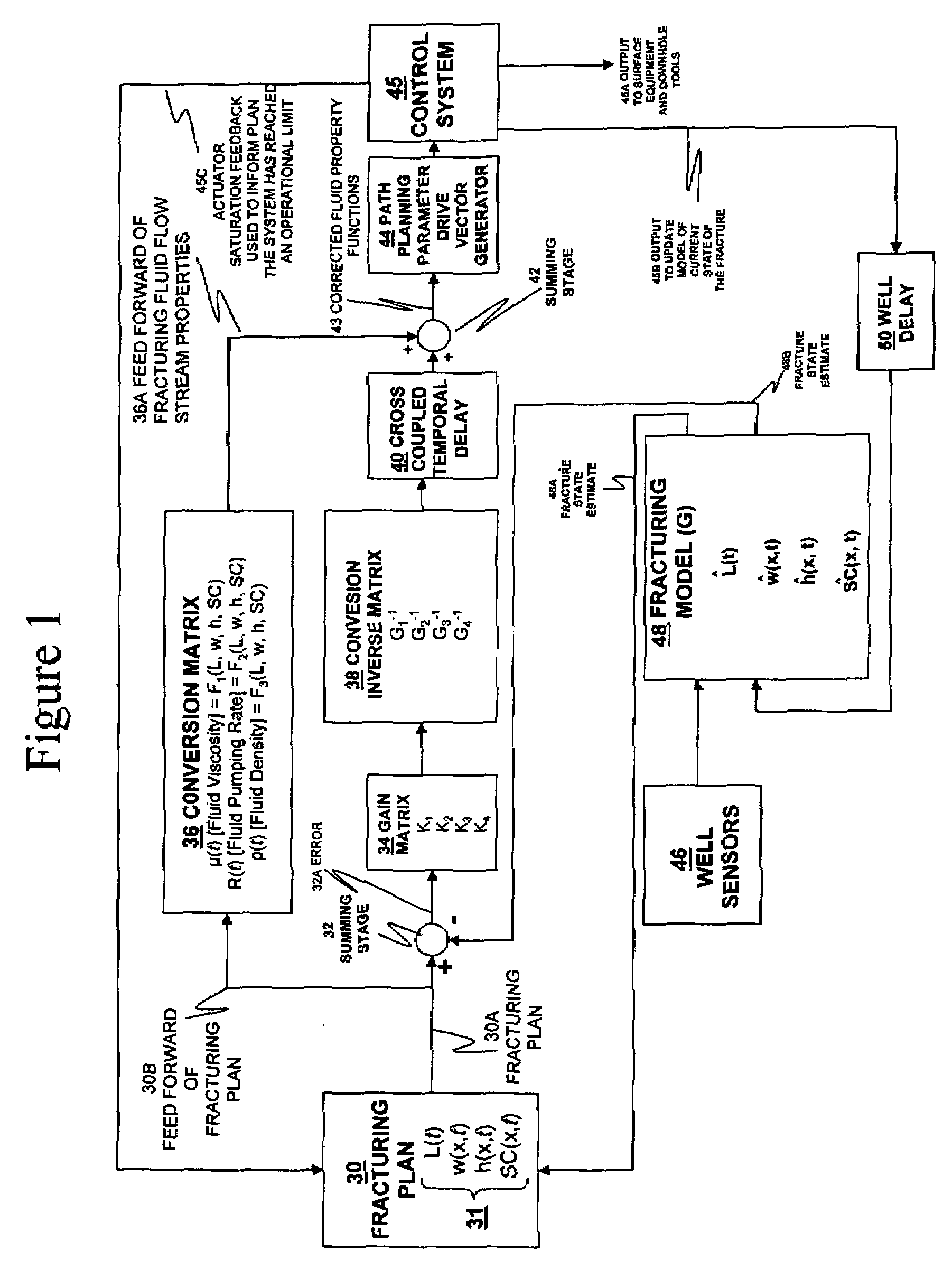

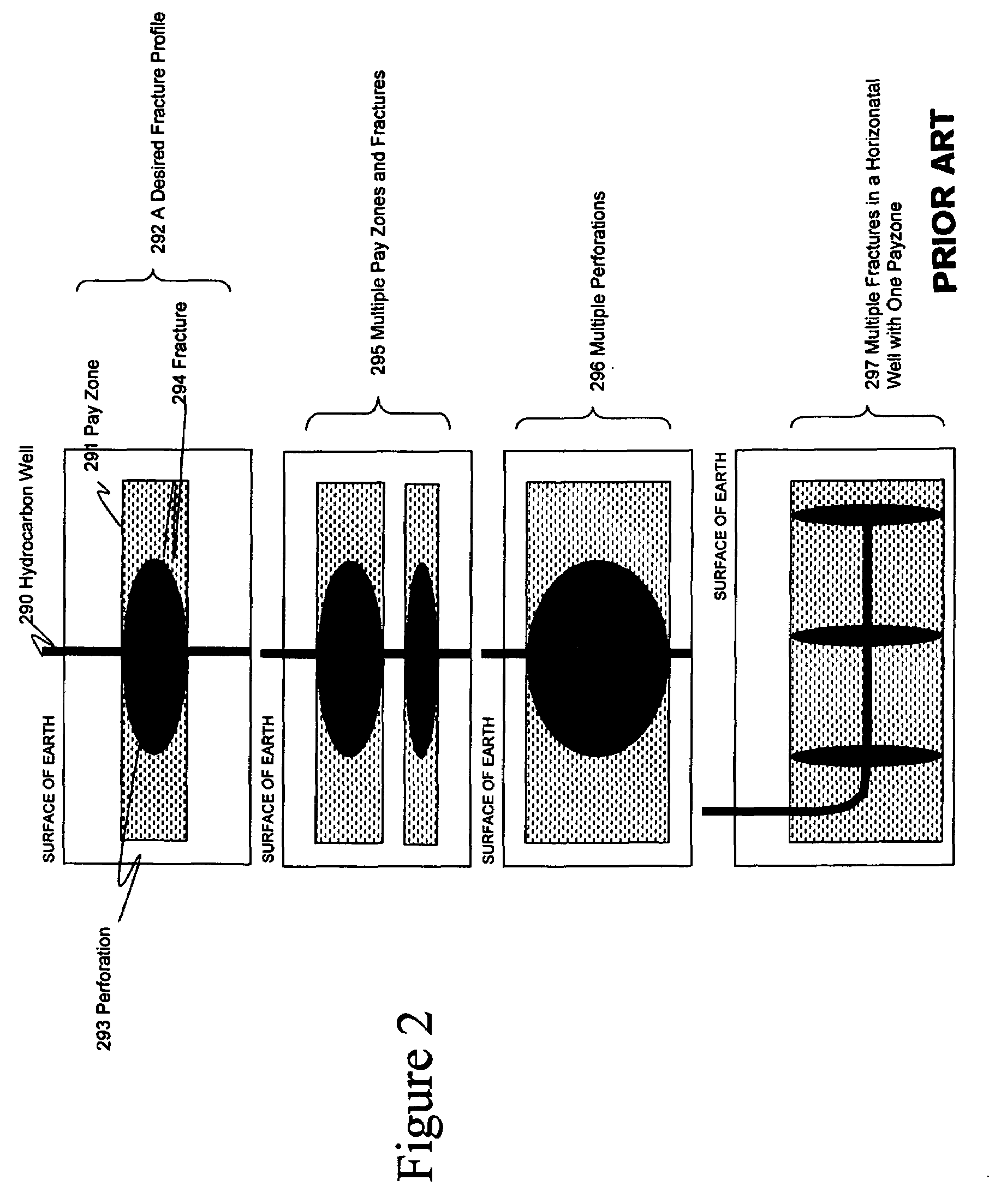

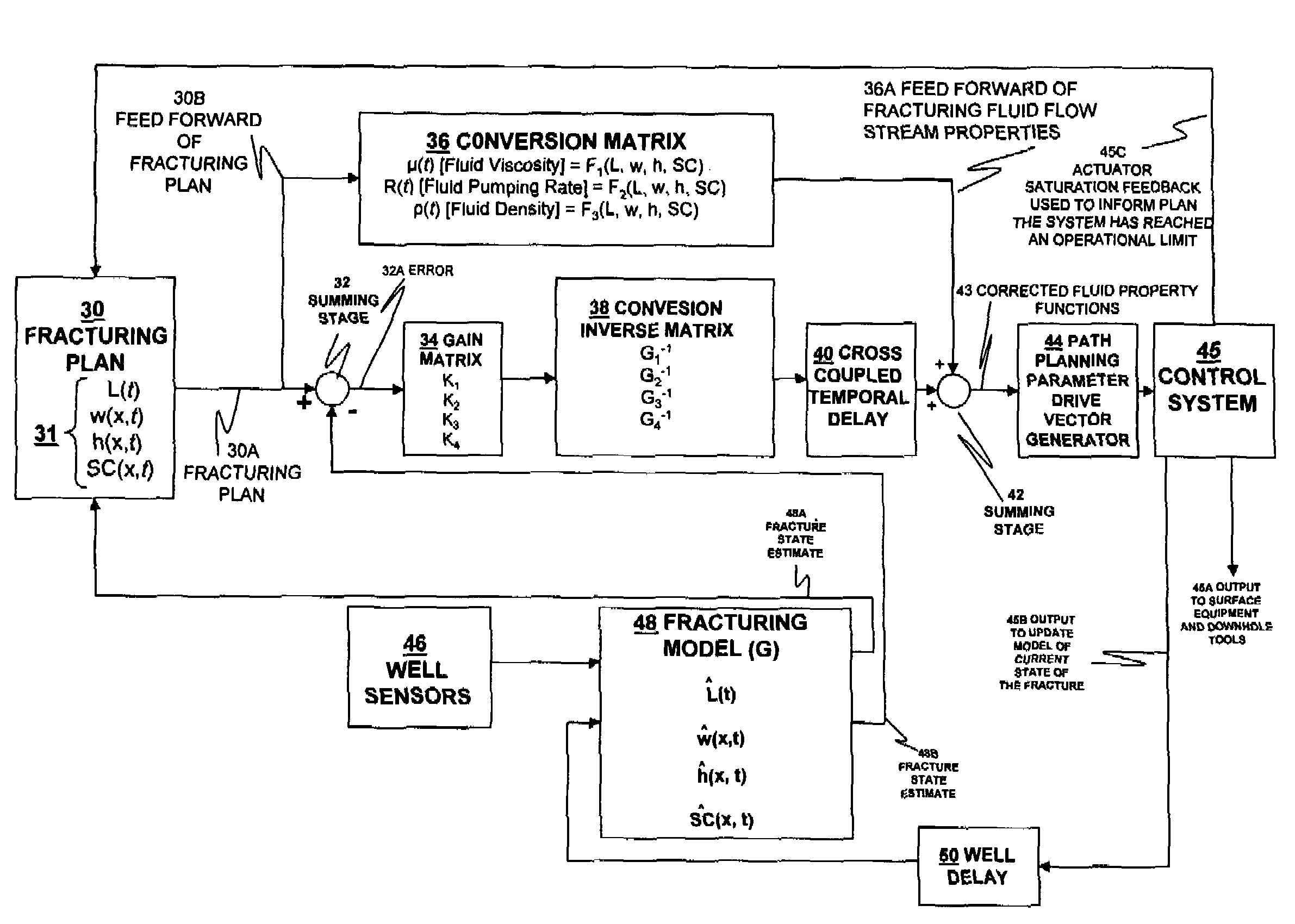

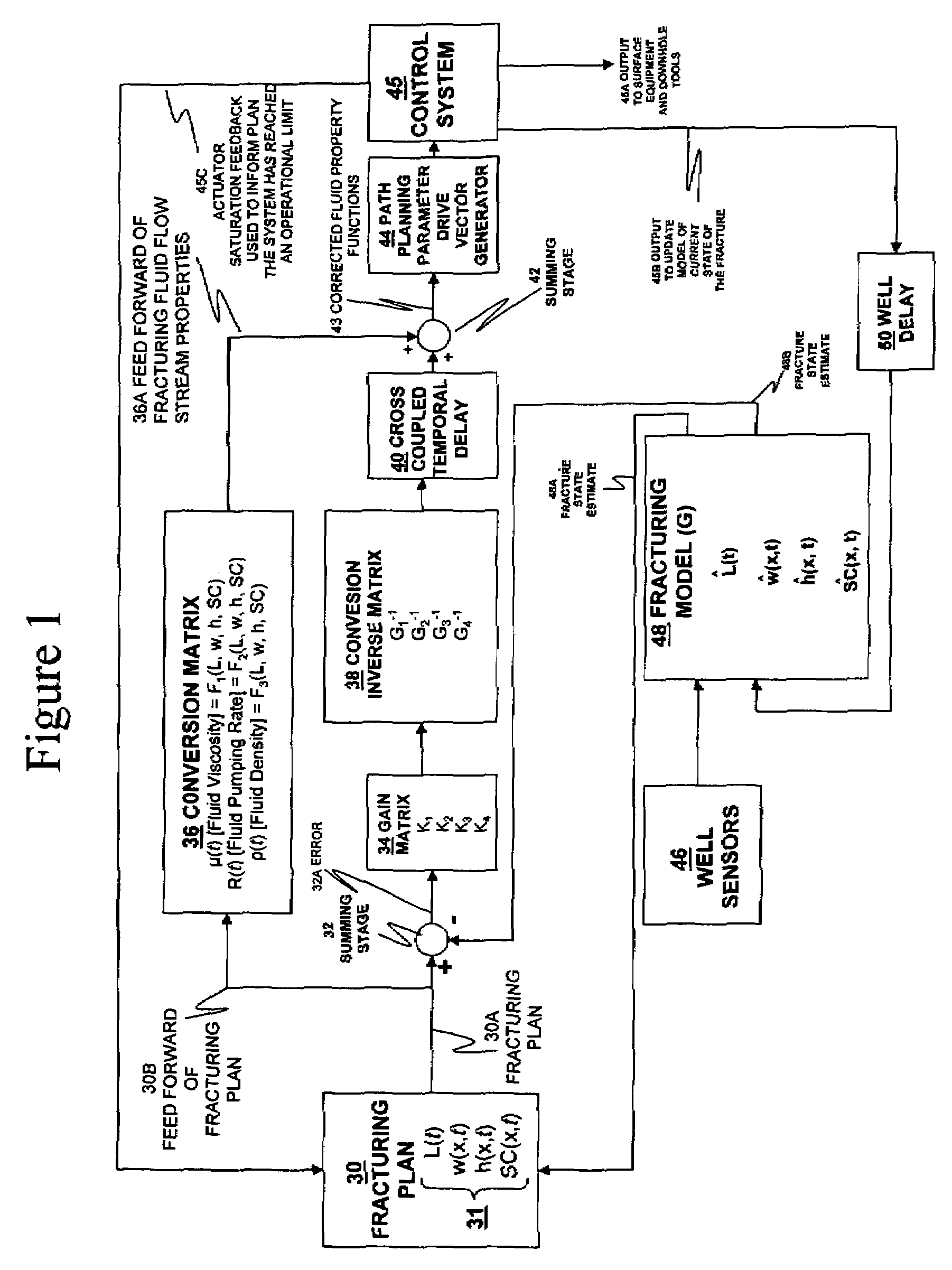

Methods and systems for fracturing subterranean wells

ActiveUS20080164021A1Reduce riskImprove permeabilitySurveyFluid removalControl flowAutomatic control

New methods and systems for subterranean fracturing for hydrocarbon wells. A plan of the fracture propagation and in-fracture proppant distribution is used with a real-time model of the status of the fracture dimensions and in-fracture proppant concentration to automatically control flow rates and properties of a fracturing fluid flow stream being used to induce and prop the fracture. Real-time measurements of the status of the fracture are made using surface and / or down-hole sensors. Real-time control over the flow rate and properties of a fracturing fluid flow stream are made by manipulating the fracturing fluid supply equipment. Real-time modifications of the fracturing model are made by comparing fracture sensor measurements of actual fracture dimensions to the predicted dimensions, and then adjusting the model for inaccuracies. Real-time updates to the fracturing plan are made by comparing actual fracture and propping results to desired results, and then adjusting to achieve optimal results.

Owner:HALLIBURTON ENERGY SERVICES INC

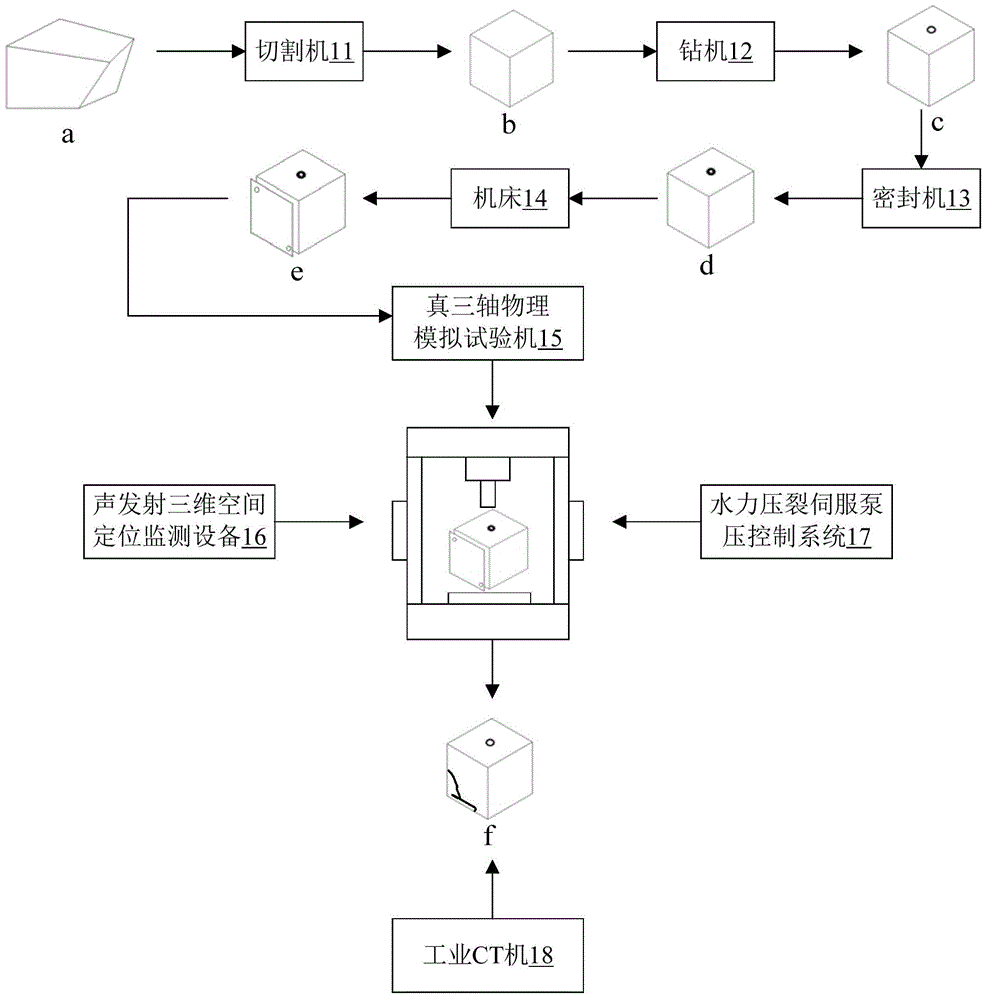

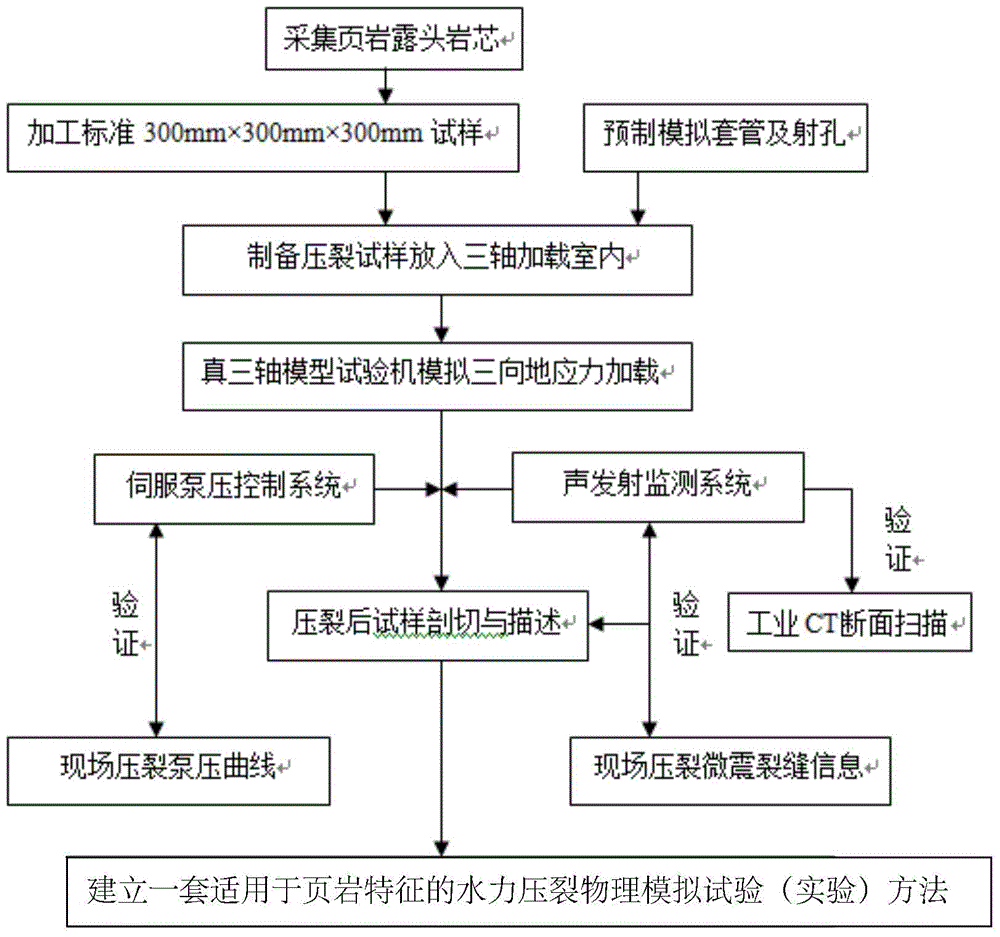

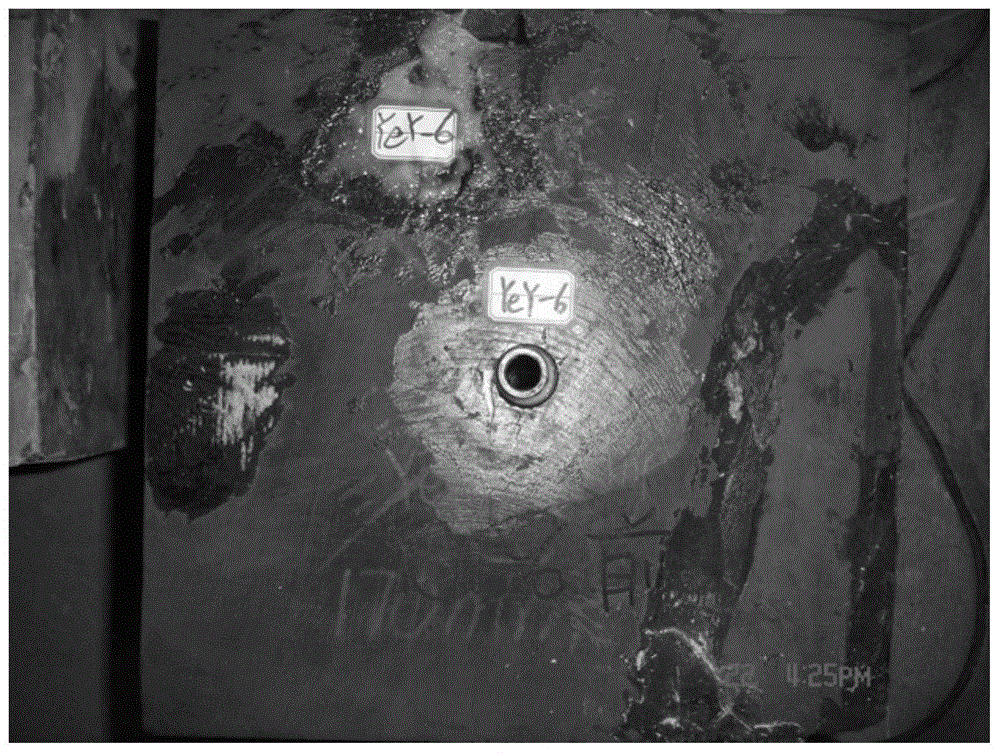

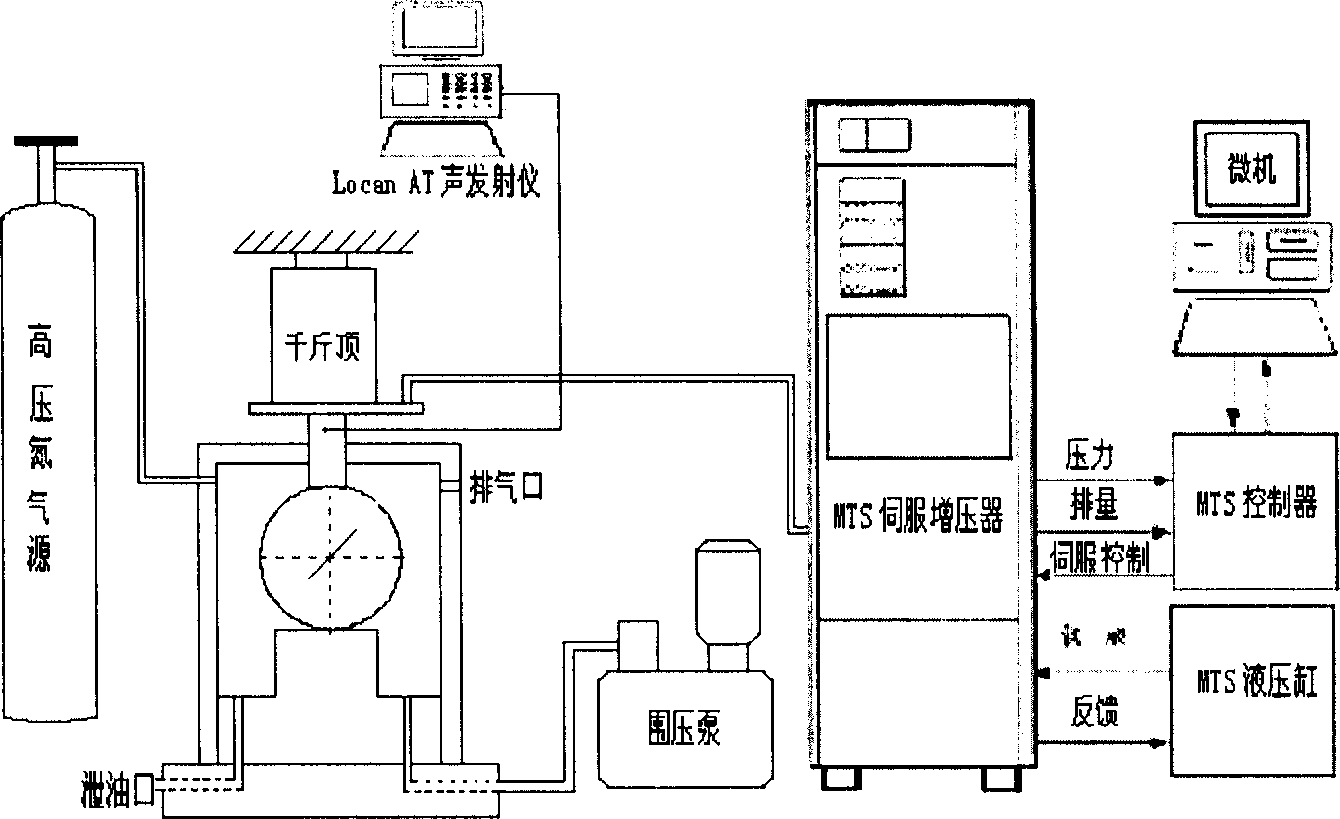

Physical simulation system and method for fracture propagation in shale

InactiveCN105756645AAccurate discriminationTo achieve the purpose of increasing productionFluid removalFracturing fluidHydraulic fracturing

The invention discloses a physical simulation system and method for fracture propagation in shale. The system comprises a drilling rig, a sealing machine, a machine tool, a true triaxial physical simulation testing machine, a hydraulic fracturing servo pump pressure control system, acoustic emission three-dimensional space location monitoring equipment and an industrial CT (computed tomography) machine, wherein the drilling rig, the sealing machine and the machine tool are jointly used for processing acquired shale into a fracturing sample; the true triaxial physical simulation testing machine is used for loading simulated three-dimensional ground stress to the fracturing sample; the hydraulic fracturing servo pump pressure control system is used for providing a fracturing fluid for the fracturing sample, so that a hydraulic fracturing process can be simulated; the acoustic emission three-dimensional space location monitoring equipment is used for monitoring the simulated hydraulic fracturing process in real time; the industrial CT machine is used for preforming tomography scanning on the fracturing sample before and after hydraulic fracturing. The physical simulation system for fracture propagation in the shale can be used for researching fracture initiation, expansion and extension laws of anisotropic shale in the hydraulic fracturing process, so that fracture information can be distinguished more accurately, high-precision basic data are provided for fracturing construction design, technical support is provided for site fracturing construction, and the yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

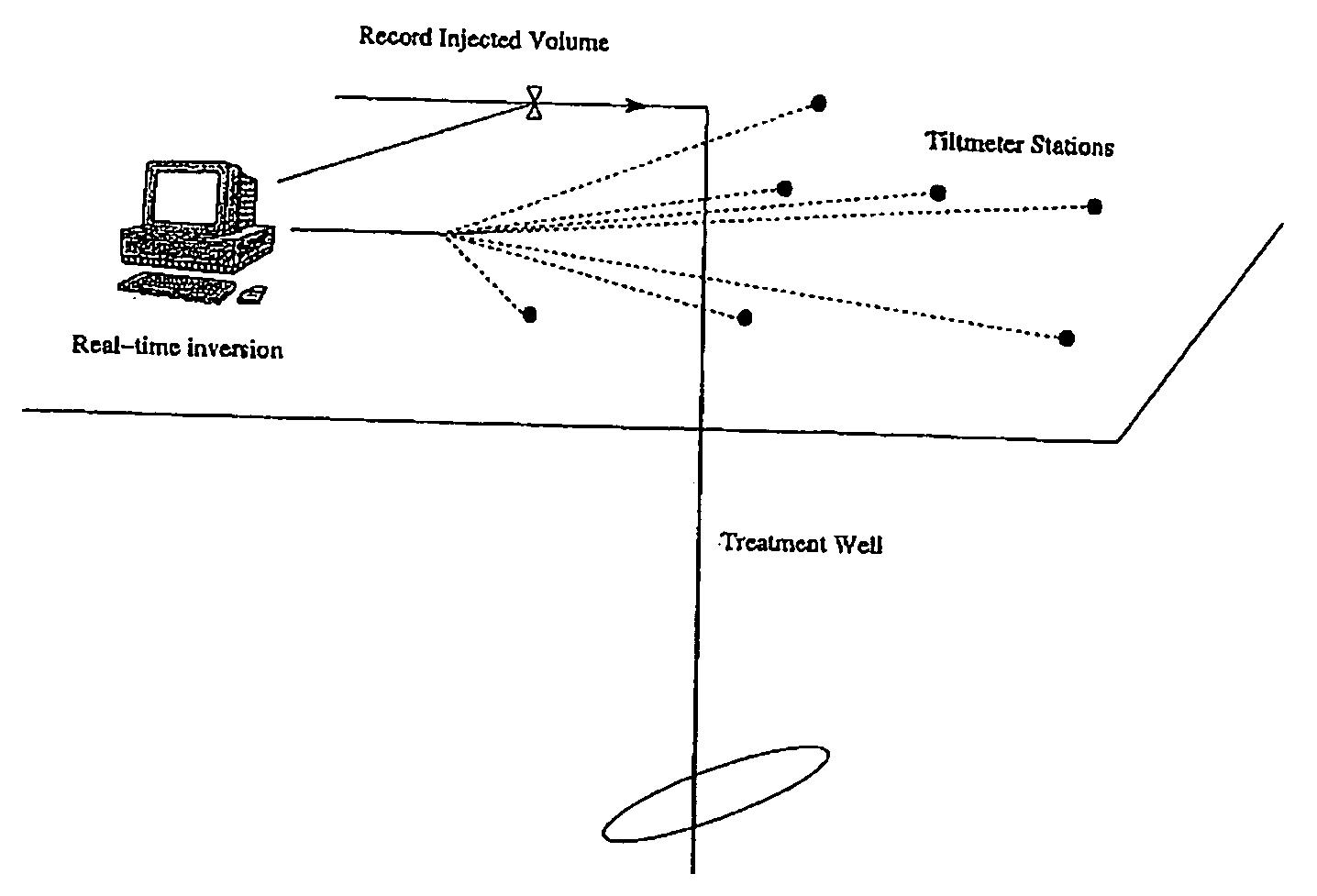

Hydraulic fracturing

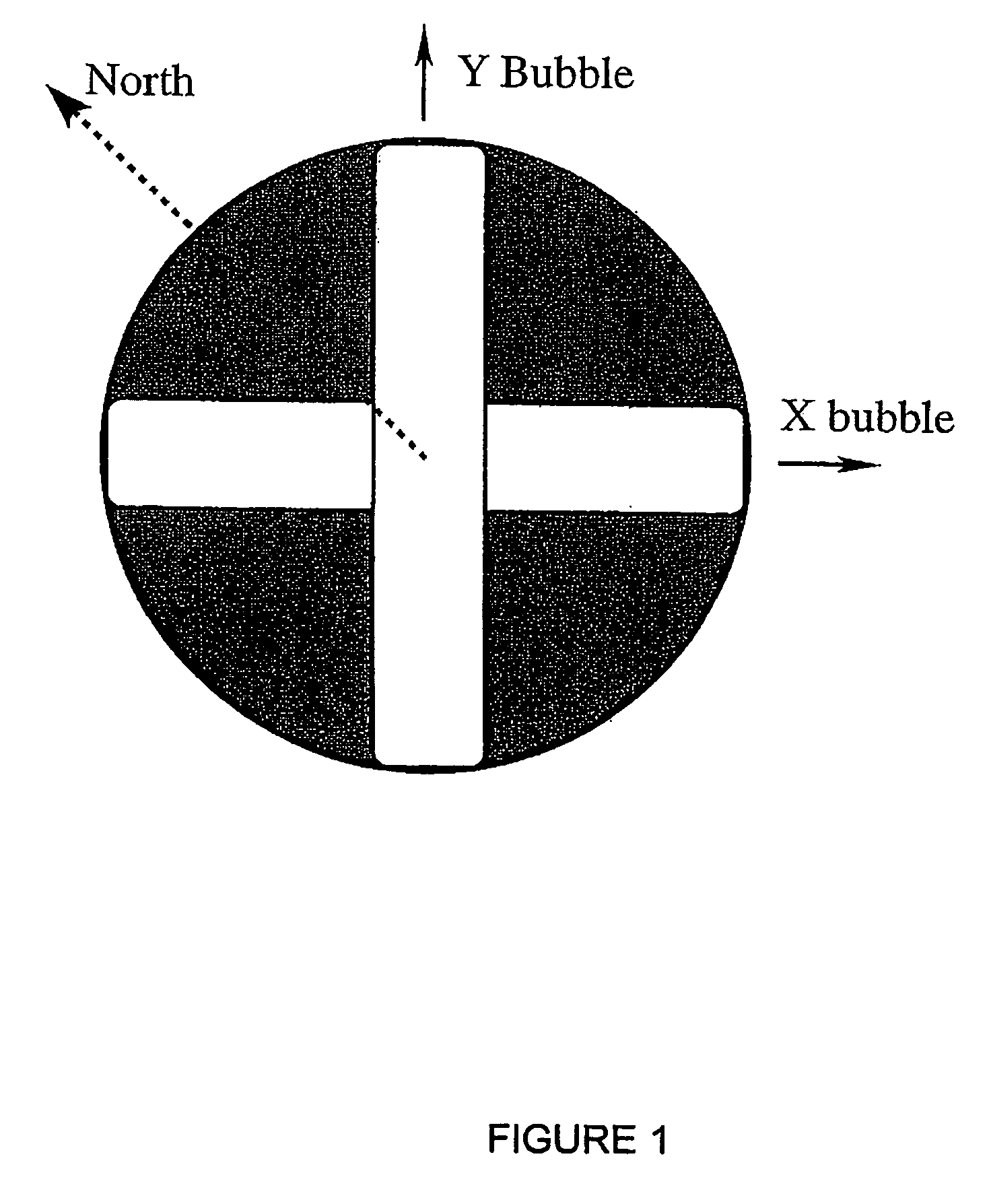

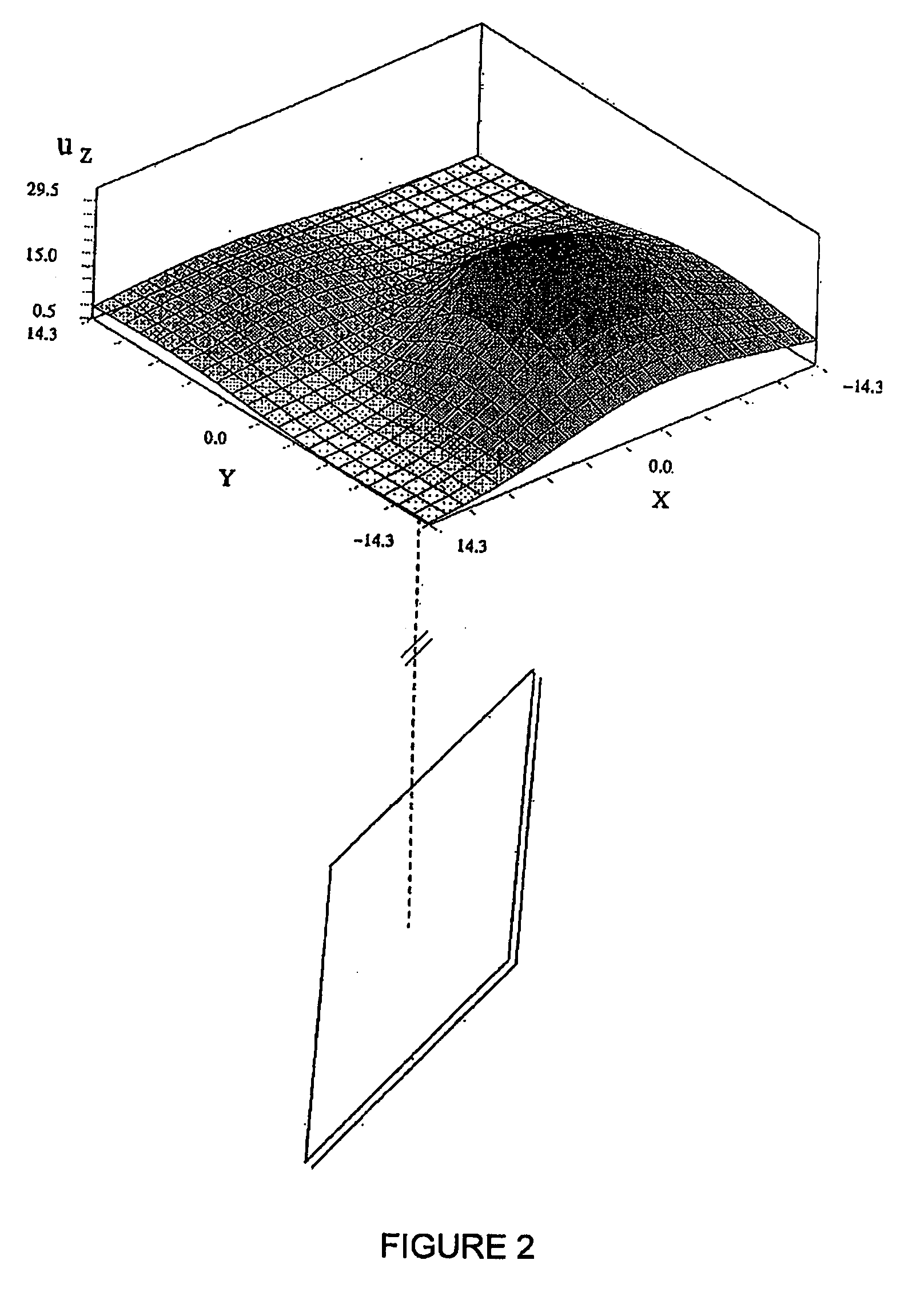

Method and apparatus for monitoring growth of fracture during hydraulic fracturing treatment of a ground formation. A series of tiltmeters are positioned at spaced apart tiltmeter stations at which tilt changes due to hydraulic fracturing treatment are measurable by those tiltmeters. Tilt measurements obtained from the tiltmeters at progressive times during the fracture treatment are compared with estimated tilt changes estimated from an assumed hydraulic fracturing propagation. Useful values for initially undetermined values of parameters of the model are derived using an inverse procedure. The data analysis may be performed in real time as the hydraulic treatment progresses using differing propagation models to determine a most probable model.

Owner:COMMONWEALTH SCI & IND RES ORG

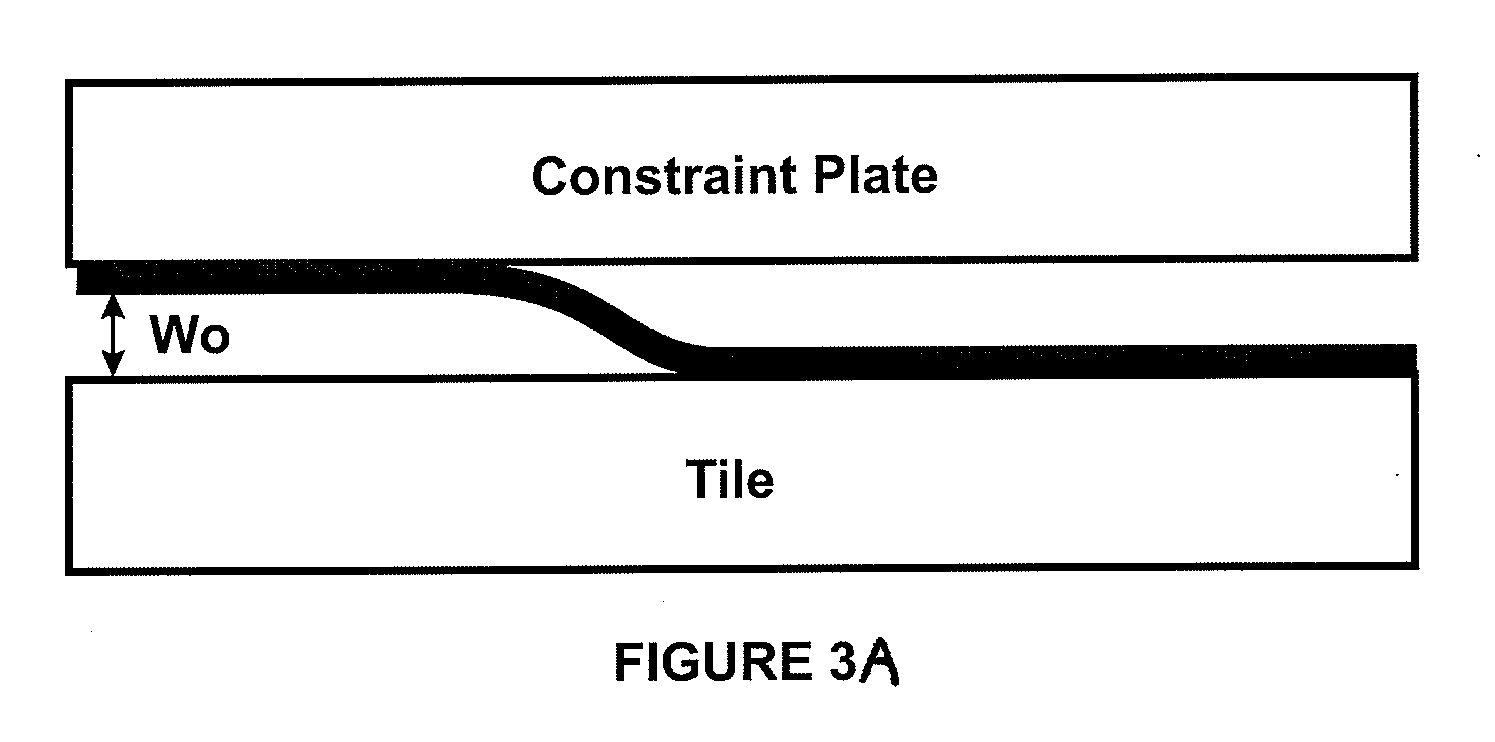

Layer transfer of films utilizing controlled shear region

ActiveUS20090277314A1Quality improvementImprove efficiencySemiconductor/solid-state device manufacturingMetal working apparatusEngineeringThermal treatment

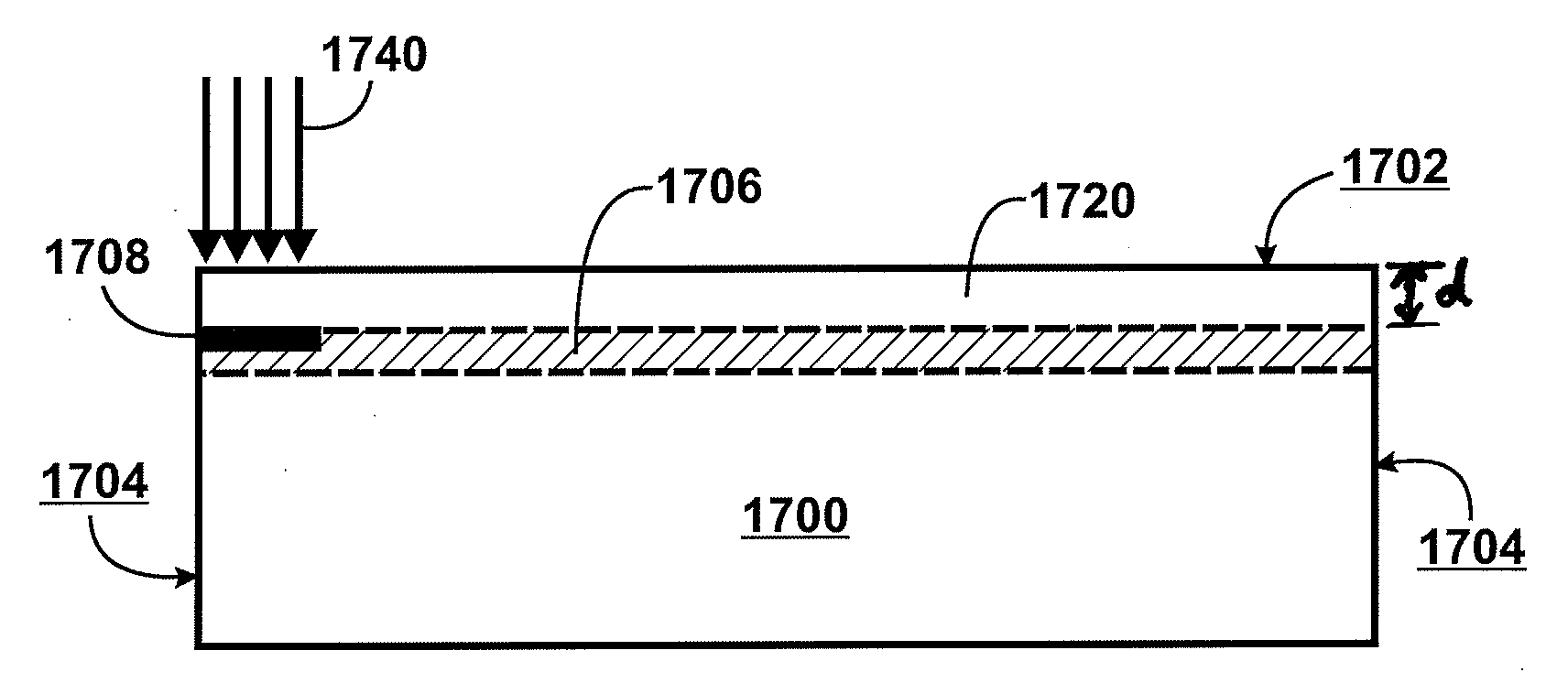

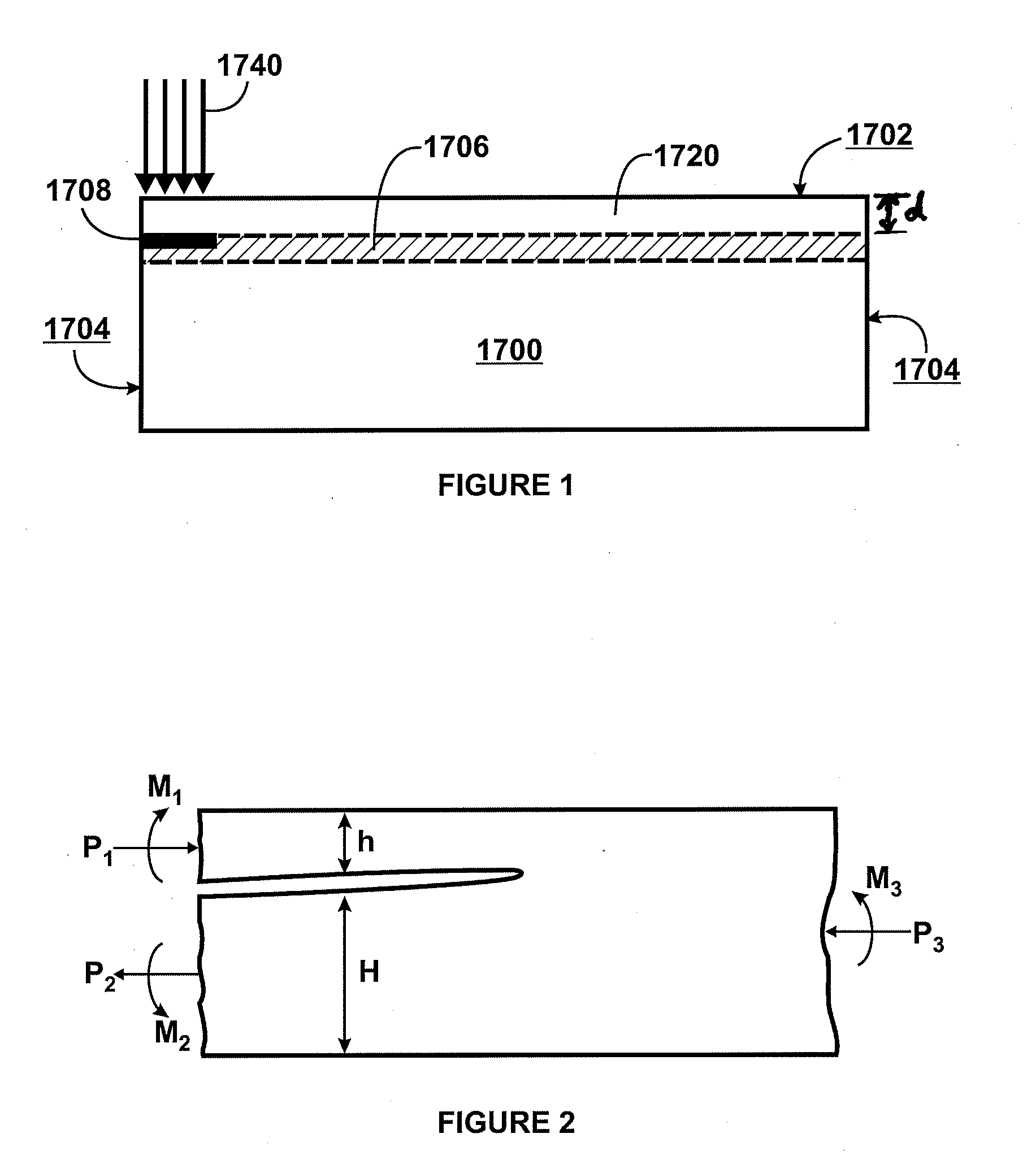

A film of material may be formed by providing a semiconductor substrate having a surface region and a cleave region located at a predetermined depth beneath the surface region. During a process of cleaving the film from the substrate, shear in the cleave region is carefully controlled. According to certain embodiments, an in-plane shear component (KII) is maintained near zero, sandwiched between a tensile region and a compressive region. In one embodiment, cleaving can be accomplished using a plate positioned over the substrate surface. The plate serves to constrain movement of the film during cleaving, and together with a localized thermal treatment reduces shear developed during the cleaving process. According to other embodiments, the KII component is purposefully maintained at a high level and serves to guide and drive fracture propagation through the cleave sequence. In one embodiment, the high KII component is achieved by adiabatic heating of silicon through exposure to E-beam radiation, which imparts a highly abrupt thermal gradient and resulting stress at a precisely defined depth in the silicon.

Owner:SILICON GENERAL CORPORATION

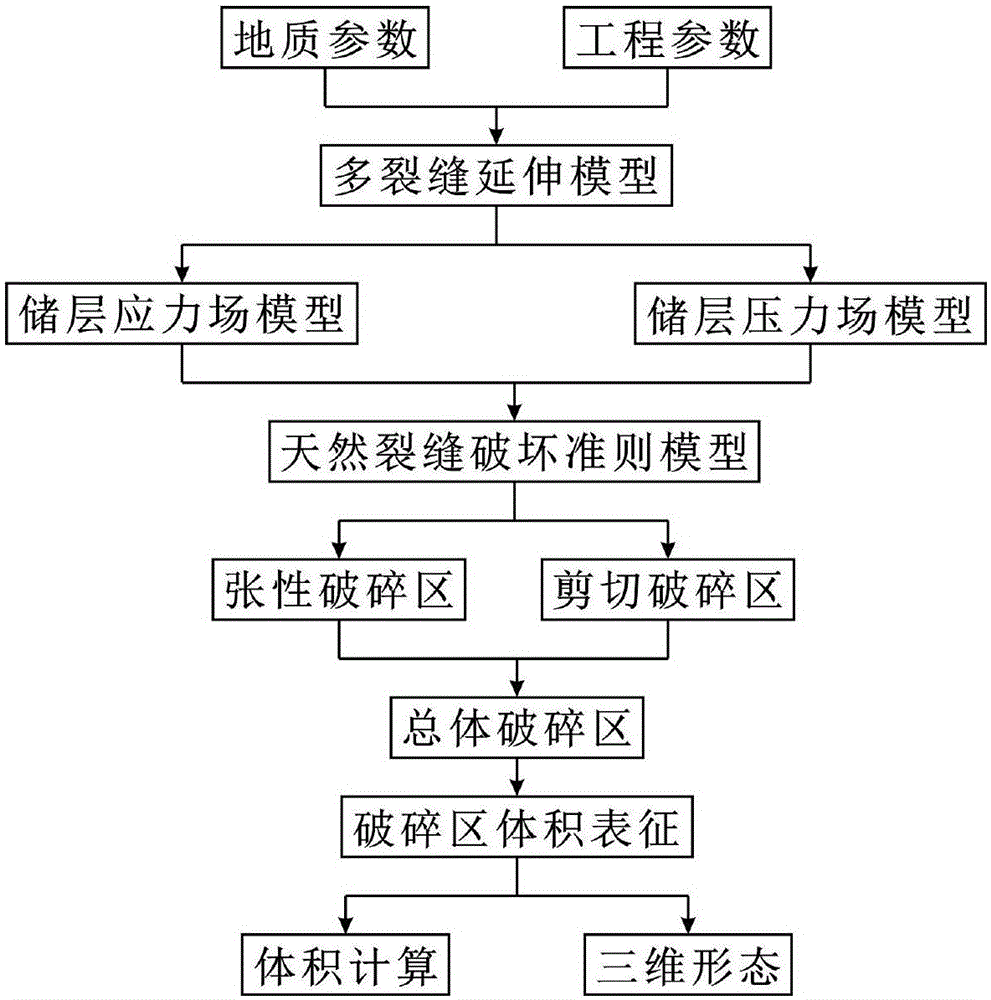

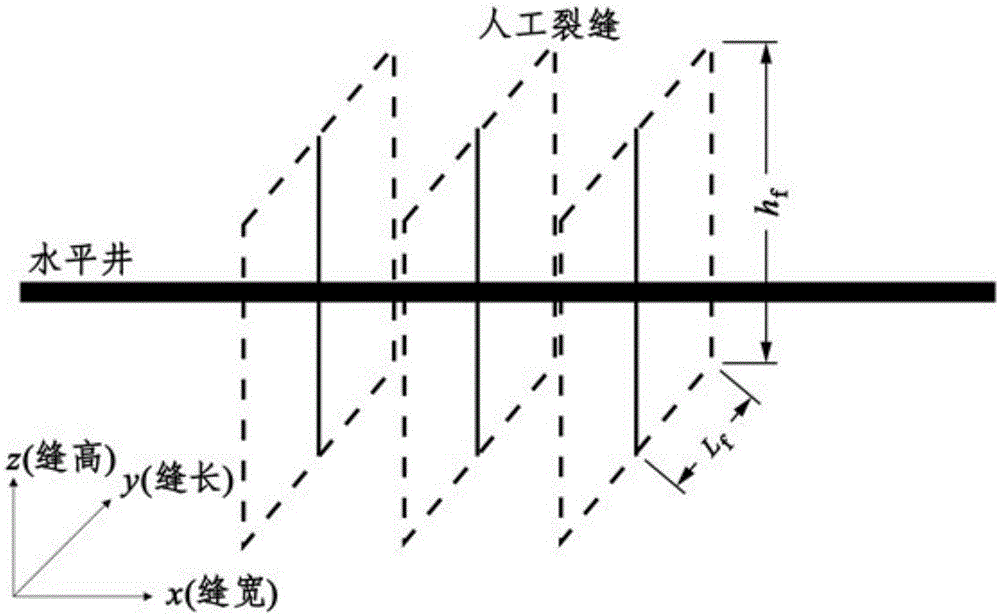

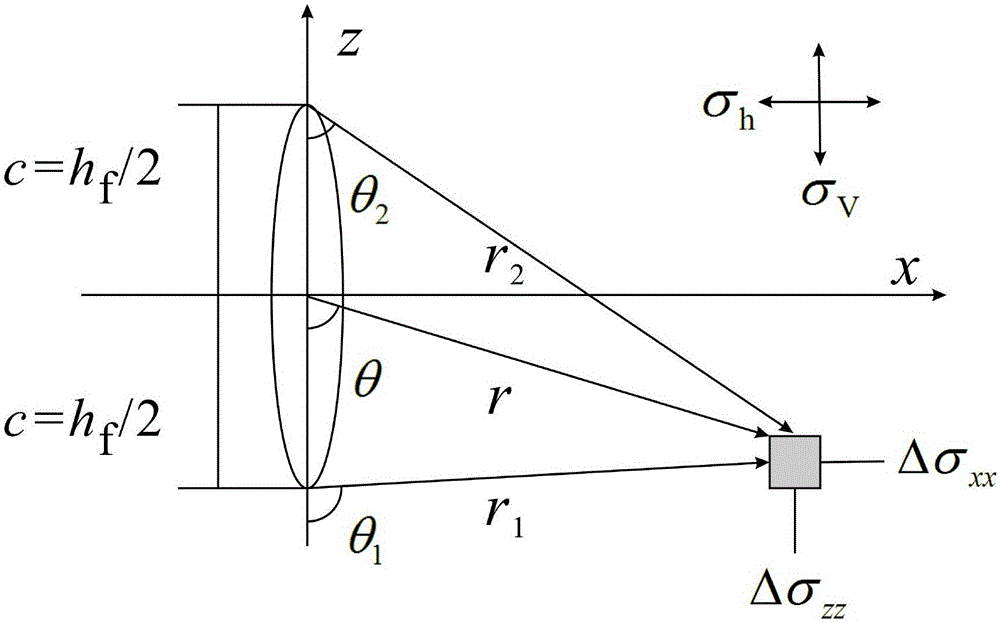

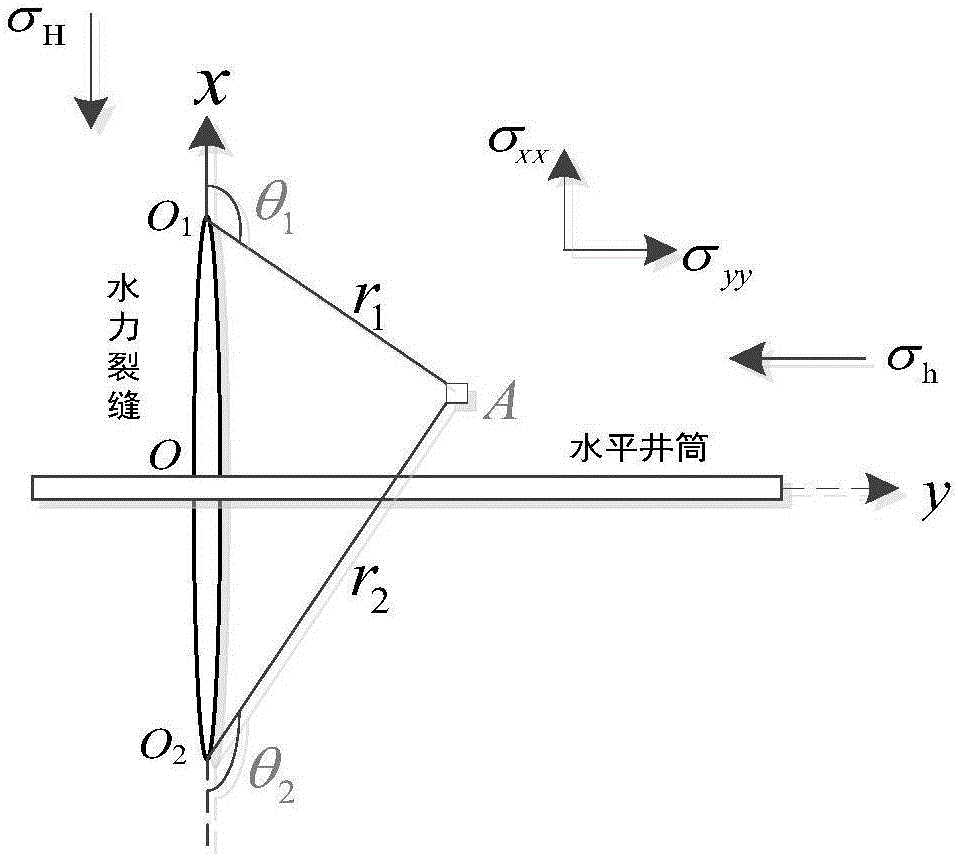

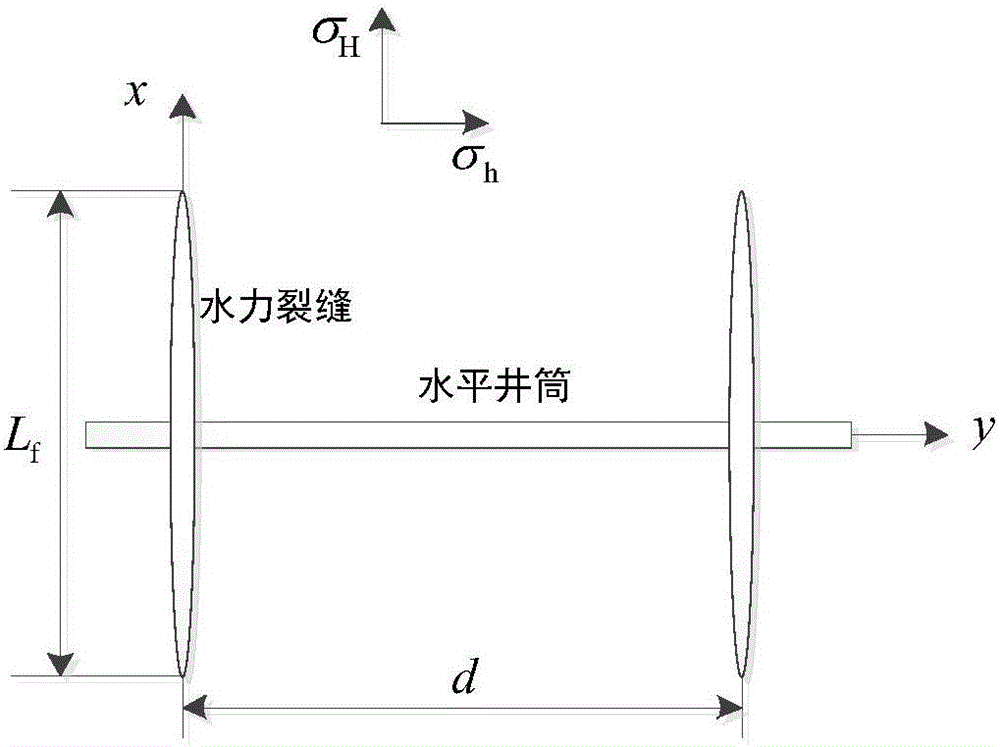

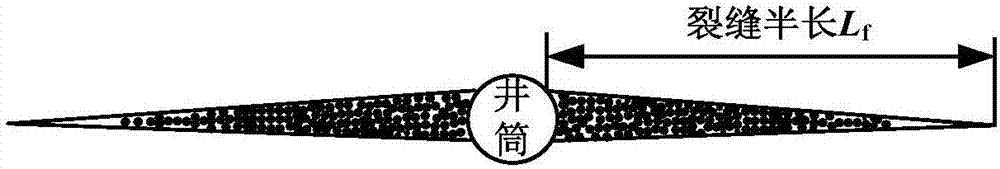

Calculating method for size of fracturing and broken region of horizontal well for shale

ActiveCN105019877AAccurate quantitative evaluationSolve problems that cannot be widely promoted and appliedFluid removalCalculation methodsPoromechanics

The invention discloses a calculating method for the size of a fracturing and broken region of a horizontal well for shale. The calculating method comprises following steps of: A, utilizing the theory of crack propagation available to establish a hydraulic fracture extension model during a shale fracturing process; B, utilizing the theory of rock mechanics available to establish a model for stress field variation during a shale fracturing process; C, utilizing the theory of seepage mechanics available to establish a model for pressure field variation during a shale fracturing process; D, utilizing the rock breaking theory available to establish a rule model for natural fractures; E, combining the above four steps to calculate and represent the size of the fracturing and broken region by means of a calculation flow. The calculating method for the size of the fracturing and broken region of the horizontal well for shale has following beneficial effects: time and money spent on calculating the size of the broken region during fracture of the horizontal well for shale are saved so that the valuation of the size of the fracturing and broken region can be extensively prompted and applied.

Owner:SOUTHWEST PETROLEUM UNIV

Methods and systems for fracturing subterranean wells

ActiveUS7516793B2Improve permeabilityIncrease fluid velocitySurveyFluid removalControl flowAutomatic control

Owner:HALLIBURTON ENERGY SERVICES INC

Hydraulic fracturing simulation experimental device and method of hot dry rock enhanced type geothermal system

InactiveCN107893652AAccurate calculation of hydraulic fracturing heat transfer efficiencySimulation is accurateSurveyFluid removalHydraulic fracturingHigh pressure

The invention relates to a hydraulic fracturing simulation experimental device and method of a hot dry rock enhanced type geothermal system. A hot dry rock high-pressure and high-temperature generating environment is simulated, precise stress is applied to a rock core by designing a multistage piston, the permeability of hot dry rock fluid is maintained by adopting a pressureproof and temperature-resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collection chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embedded into a true-triaxial high-pressure axe to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process, integrated collection of information of rock hydraulic fracturing, sound emission, heat energy recovery efficiency and the like under the triaxial confining pressure condition can be achieved by utilizing the device, and therefore the fracture initiation andexpanding situations of the hot dry rock hydraulic fracture can be studied. The hydraulic fracturing simulation experimental device and method have the beneficial effects that warming and heat preservation effects are good, a sealed part is simple to replace and convenient to maintain, a sound emission embedded part can be adjusted according to the requirements for the probe sizes, in addition, the whole device further has the characteristics that operation is convenient, and the protection and maintenance period is short, and the device is an important technological innovation at the aspect of dry hot rock enhanced type geothermal system hydraulic fracturing testing device detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

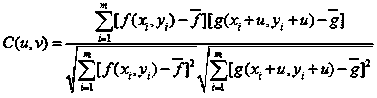

Experimental device and method for simulating extension influence of hydraulic fracturing cracks and natural cracks

ActiveCN107701160ADisadvantages such as high cost of customer service experiments and limited accuracySimple structureSurveyFluid removalHydraulic fracturingRock sample

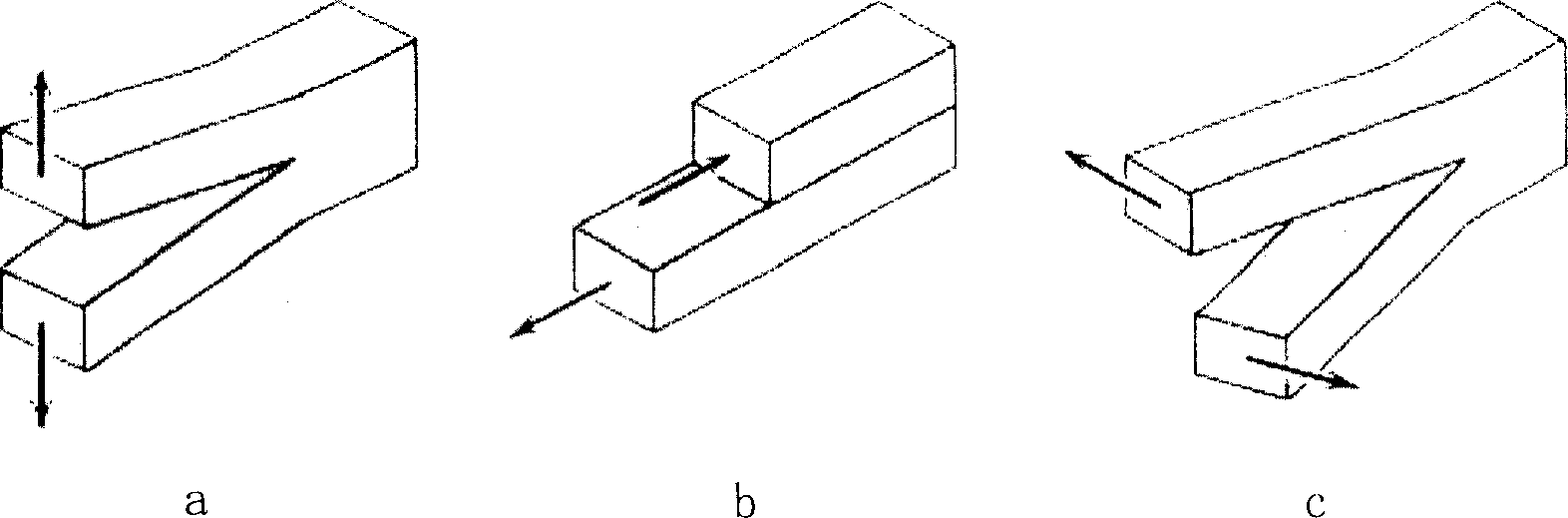

The invention relates to an experimental device and method for simulating the extension influence of hydraulic fracturing cracks and natural cracks. Fracturing pipe columns are simulated through steelpipes, planar rock samples are formed through pouring and cured, and then rock samples with random spots are prepared; then the samples are placed into adjustable hydraulic fracturing cavities, unequal ground stress is applied to the two sides of the samples, and then fracturing liquid is injected through the fracturing pipe columns; and meanwhile a high-speed camera is utilized to shoot the crack extension condition in the hydraulic fracturing process, the rock body deformation condition in the hydraulic fracturing process is collected through a deformeter, and the pumping-in pressure and strain change are detected. According to the experimental device and method for simulating the extension influence of the hydraulic fracturing cracks and the natural cracks, the interplaying mechanicalrelation between the hydraulic fracturing cracks and the natural cracks can be intuitively analyzed, the distribution problem after a flow makes contact with the natural cracks can be accurately researched, and meanwhile the complex mechanical behavior such as cracking rules of hydraulic fracturing, rock body deformation caused by hydraulic crack extension and opening, re-starting or dislocation of the natural cracks at different strength is intuitively observed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

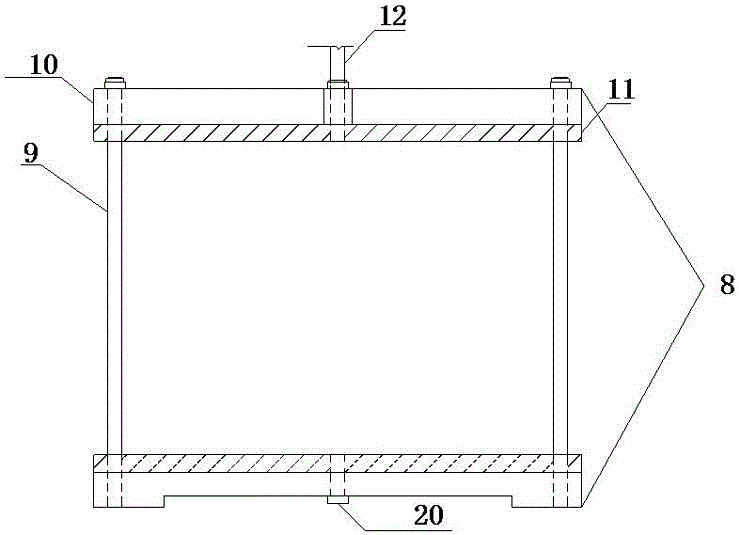

Asphalt pavement reflection crack propagation analog experiment device

InactiveCN101178340AGuaranteed molding effectEasy to study crack resistanceMaterial testing goodsStrength propertiesMicrocomputerTester device

The invention discloses a blacktop reflecting crack propagation analog experiment device which includes an environment box and a blacktop simulative platform and a reflecting crack propagation tester arranged in the environment box. The reflecting crack propagation tester includes a horizontal pulling fatigue test part, a vertical cutting fatigue test part and a data collecting part controlled by a microcomputer. The blacktop simulative platform includes a fixed testing vehicle (1) and a skip car frame (3) welded as a whole, and an active testing skip car (2) that can move horizontally on the skip car frame (3). The device can carry through pulling type and cutting type reflecting crack propagation expanding large scale dimension road structure experiment, analyze and compare the anti-crack effects of different blacktop structures or materials, acquire relevant calculating parameters and verify a theoretical calculating result, and provide a reliable testing basis for the blacktop structure design.

Owner:CHANGAN UNIV

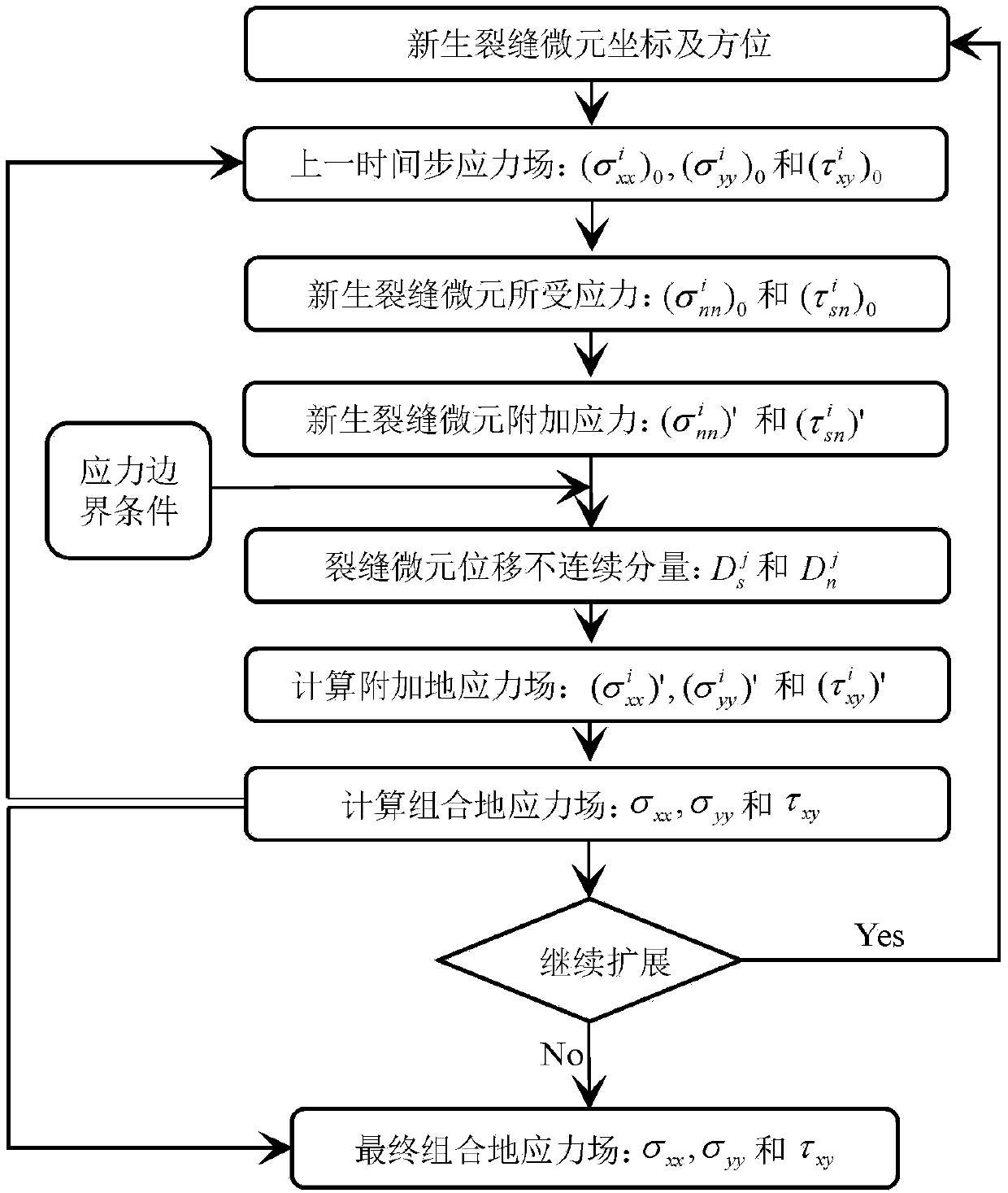

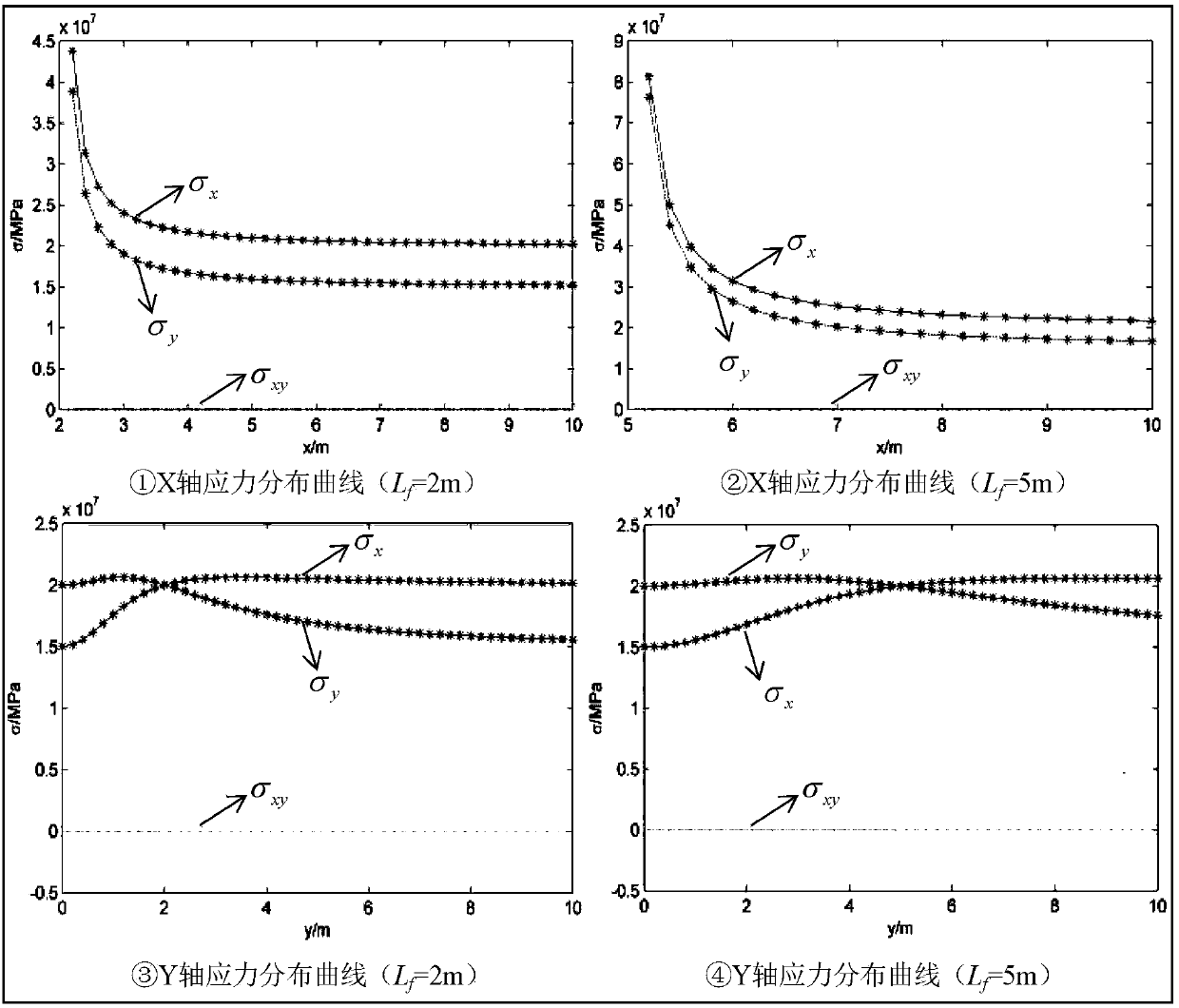

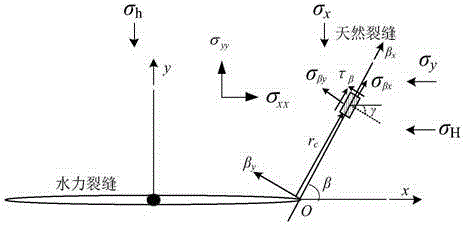

Tight reservoir volume pressure crack network extension simulation and representation method

ActiveCN108319756AMake up for the shortcomings of incomplete considerationDesign optimisation/simulationSpecial data processing applicationsNetwork structureFracturing fluid

The invention discloses a tight reservoir volume pressure crack network extension simulation and representation method. The method comprises the following steps of: firstly establishing a multi-crackstress interference-considered tight reservoir combined ground stress field calculation model by utilizing a displacement discontinuity method, mechanical mechanism analysis and crack initiation and extension criterions; aiming at a stress interference problem in volume pressure crack multi-crack extension process, establishing flow pressure drop distribution models, in primary and secondary cracks, of a fracturing fluid, so as to form a tight reservoir volume pressure crack horizontal well crack network extension theoretical model; and finally comprehensively analyzing influences, on volume pressure crack network structural morphology, of different factors, and defining a plurality of feature parameters to represent crack network structure morphology and attribute features. At last, the tight reservoir volume pressure crack network extension simulation and representation method is established. The tight reservoir volume pressure crack network extension simulation and representation method has the advantages of being comprehensive in model factor consideration, high in simulation effect and visual in result, and has a certain guiding significance for optimum design and efficient development of tight reservoir cracks.

Owner:XI'AN PETROLEUM UNIVERSITY

Layer transfer of films utilizing controlled propagation

ActiveUS20100055874A1Quality improvementImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSilicon

A film of material may be formed by providing a semiconductor substrate having a surface region and a cleave region located at a predetermined depth beneath the surface region. During a process of cleaving the film from the substrate, shear in the cleave region is carefully controlled to achieve controlled propagation by either KII or energy propagation control. According to certain embodiments, an in-plane shear component (KII) is maintained near zero by adiabatic heating of silicon through exposure to E-beam radiation. According to other embodiments, a surface heating source in combination with an implanted layer serves to guide fracture propagation through the cleave sequence.

Owner:SILICON GENERAL CORPORATION

Volume alternating fracturing method of horizontal well in experimental shale reservoir

The invention discloses a volume alternating fracturing method of a horizontal well in an experimental shale reservoir. The method comprises the following steps: collecting the stratum parameter, the natural fracture parameter and the hydraulic fracture basic parameter of a reservoir; establishing stretching, shearing and pass through failure criterions of a natural fracture when a hydraulic fracture and the natural fracture are interacted, and quantitatively analyzing the influence on the natural fracture failure by a horizontal principal stress difference; establishing a hydraulic fracture induced stress calculation model, and computing the influence on the induced stress of a middle perforation cluster fracture elongated area by gaps among different perforation cluster fractures and fracture extended lengths; optimally selecting a shale reservoir horizontal well volume fracturing perforation cluster gap and perforation cluster extended lengths at the two ends, so as to promote a middle perforation cluster hydraulic fracturing fracture to be extended and interactively produce stretching, shearing and pass through failure modes with the natural fracture at the same time to form a complex fracture. According to the method, induced stress field produced through the extension of the hydraulic fracture, perforation gaps within the same fracturing section and the extended fracture lengths are organically combined, and the horizontal well volume fracturing technology is properly perfected.

Owner:SOUTHWEST PETROLEUM UNIV

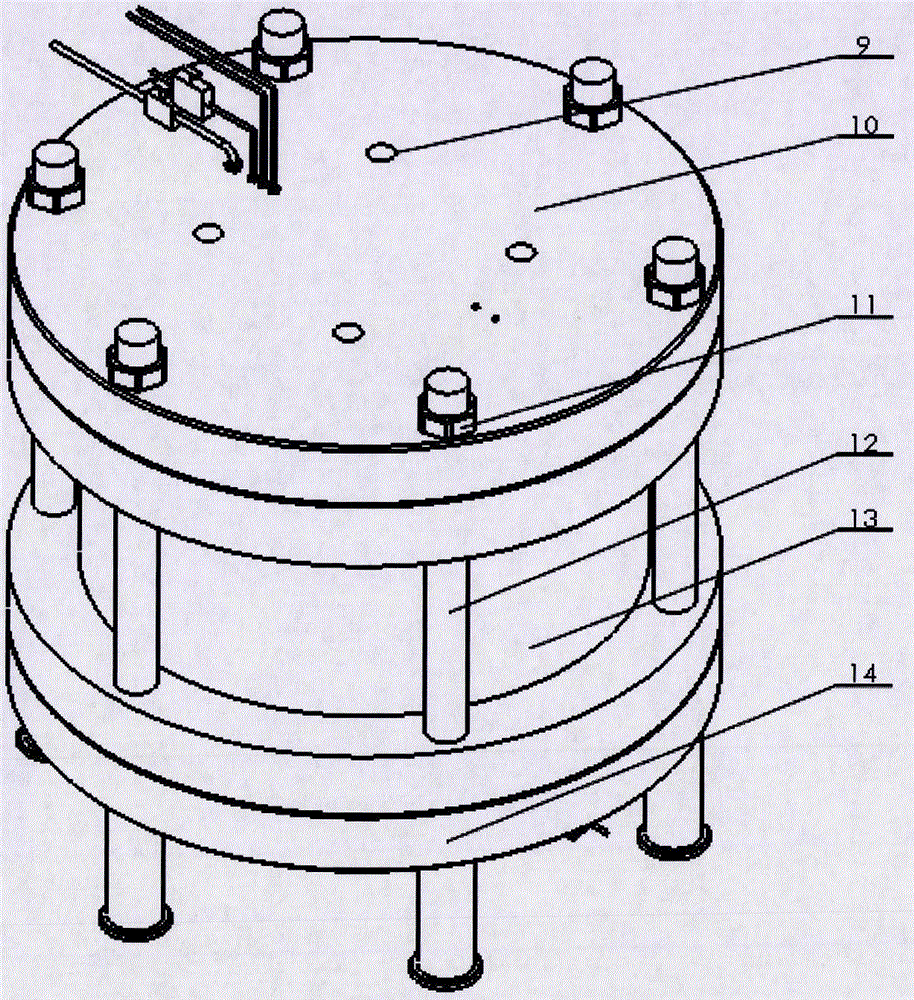

Supercritical carbon dioxide fracturing simulation experiment device

ActiveCN106404549AFully infiltratedSimulate the realMaterial strength using tensile/compressive forcesInjection pressureFracturing fluid

The invention discloses a supercritical carbon dioxide fracturing simulation experiment device. The device is characterized in that a pressure chamber, a vacuum saturation system and a carbon dioxide phase state transformation system are included; the pressure chamber comprises a closed cavity, flat jacks and heating rods, wherein the closed cavity is composed of an upper cover plate, a confining pressure barrel and a pressure chamber base which are sealed through a seal ring, the four flat jacks are evenly distributed on the side wall of the confining pressure barrel, the upper cover plate and the pressure chamber base are each fixedly provided with one flat jack, and the heating rods are fixed to the pressure chamber base; the vacuum saturation system comprises a vacuum pump and a saturation hydraulic station; the carbon dioxide phase state transformation system comprises a carbon dioxide gas source, a cooling device and an injection pump, and carbon dioxide is liquefied by lowering the temperature and then transformed to be in a supercritical state through pressurizing and temperature increasing. According to the supercritical carbon dioxide fracturing simulation experiment device, a supercritical carbon dioxide fracturing simulation experiment is conducted on rock and an artificial test piece under the saturated pore pressure condition, the parameters such as the injection pressure, the temperature and the output volume of fracturing fluid in the fracturing process are monitored in real time, a fracture extension rule is acquired, and the device is an experimental platform for researching the supercritical carbon dioxide fracturing mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Simulations for hydraulic fracturing treatments and methods of fracturing naturally fractured formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

Supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method

InactiveCN107905778AAccurate calculation of effectivenessSurveyConstructionsRock coreHydraulic fracturing

The invention relates to a supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method. Supercritical CO2 is injected through a gas source supply system and gas source supercharging equipment, accurate stress is applied to a rock core by designing a piston device, the permeability of hot dry rock fluid is maintained by adopting a pressure-proof and temperature resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collecting chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embeddedinto the fluid collecting chamber to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process. The supercritical CO2 fluid fracturing enhancement type geothermal system experimental device and method have the beneficial effects that integrated collection of information of hydraulic fracturing, strain, sound emission, permeability, heat energy recovery efficiency and the like of rock can be achieved under a confining pressure condition by utilizing the device, and the fracture initiation and expanding situations of a hydraulic fracture of the hot dryrock are researched; and a fracture initiation behavior and an expansion state of the hydraulic fracture under the high-temperature and high-pressure environmental conditions can be monitored in realtime, and meanwhile the heat energy mining rate can be calculated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

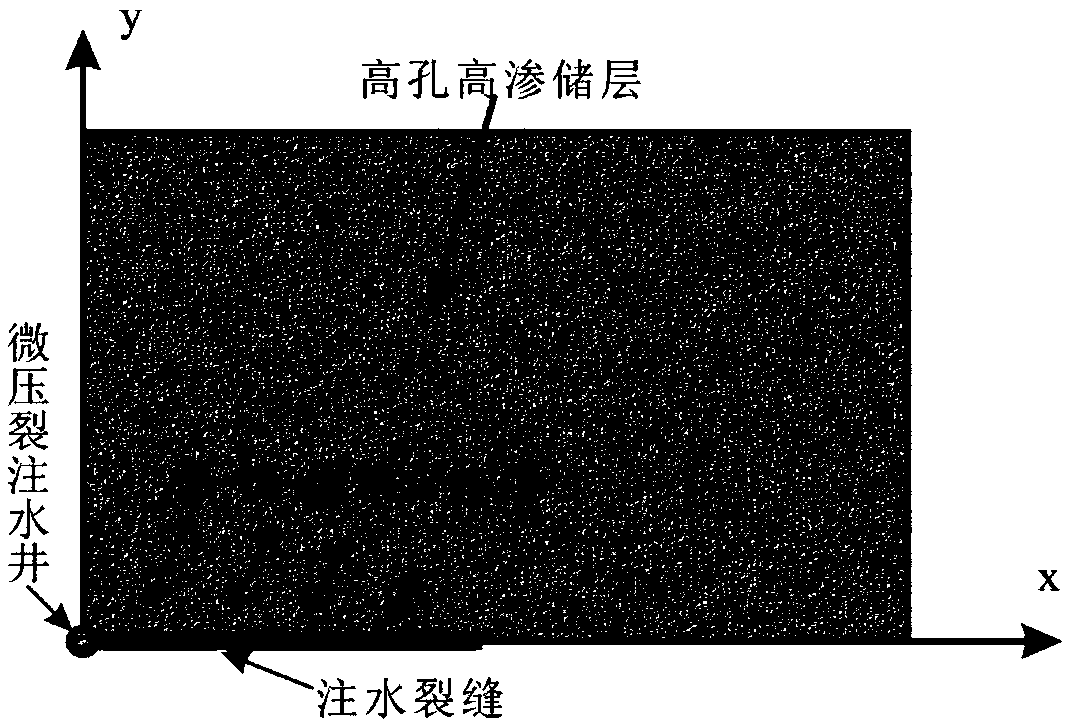

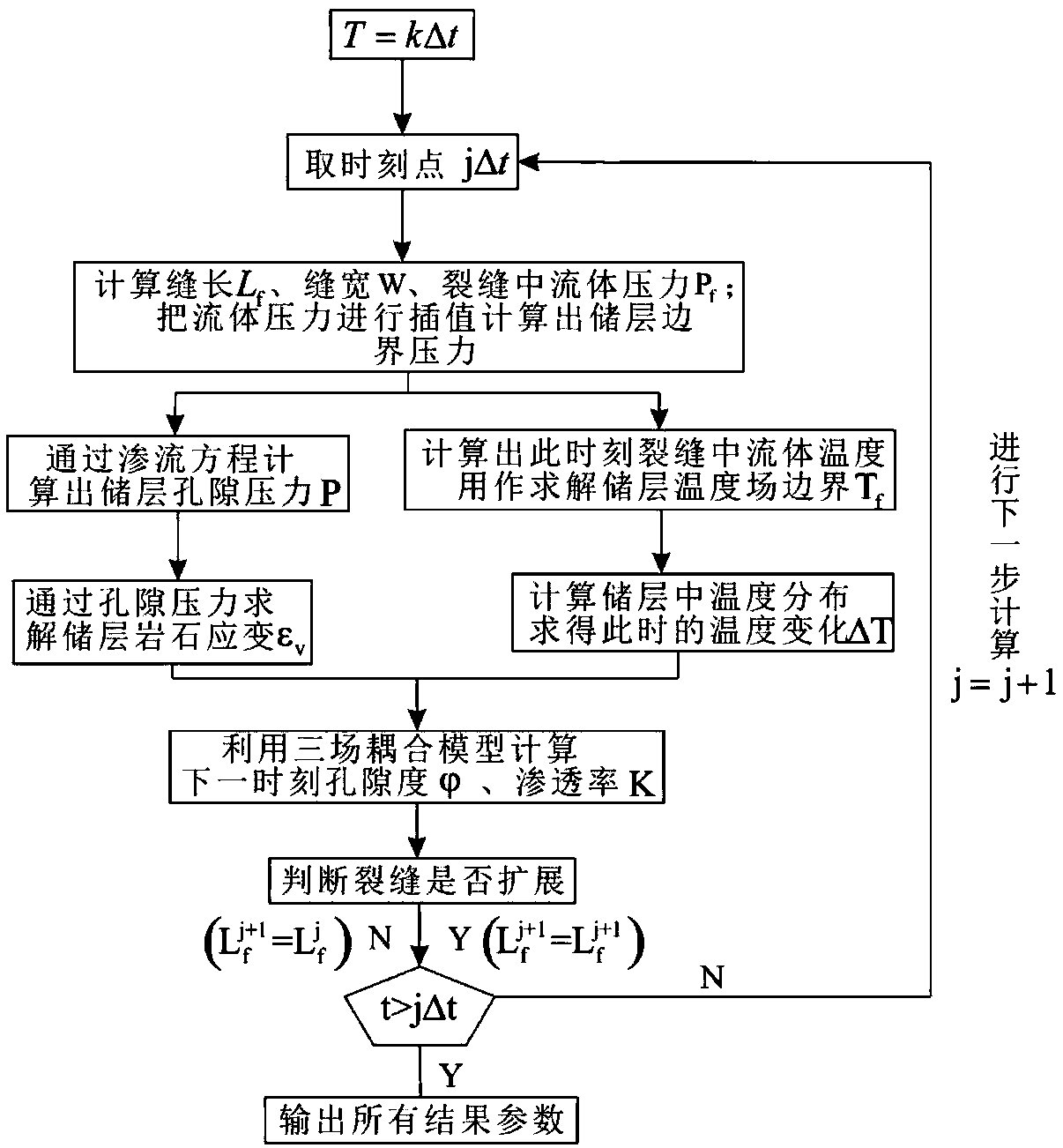

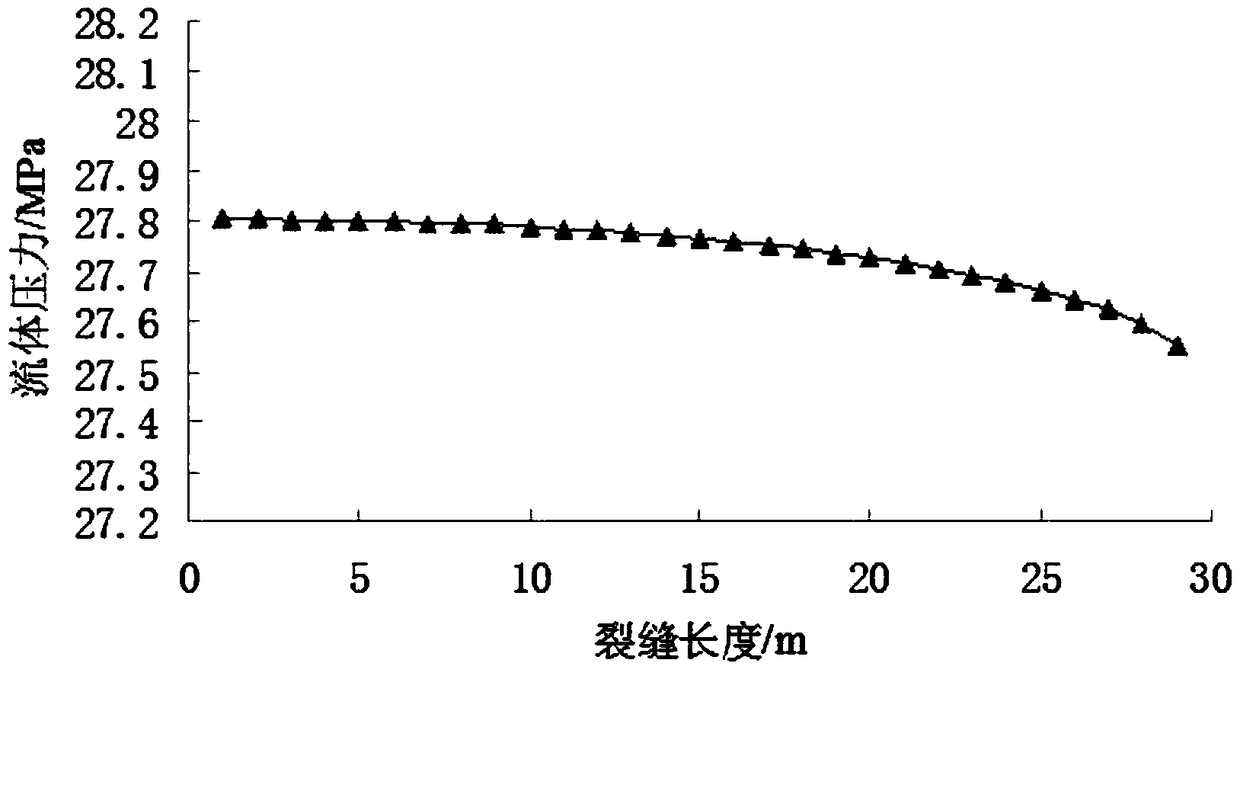

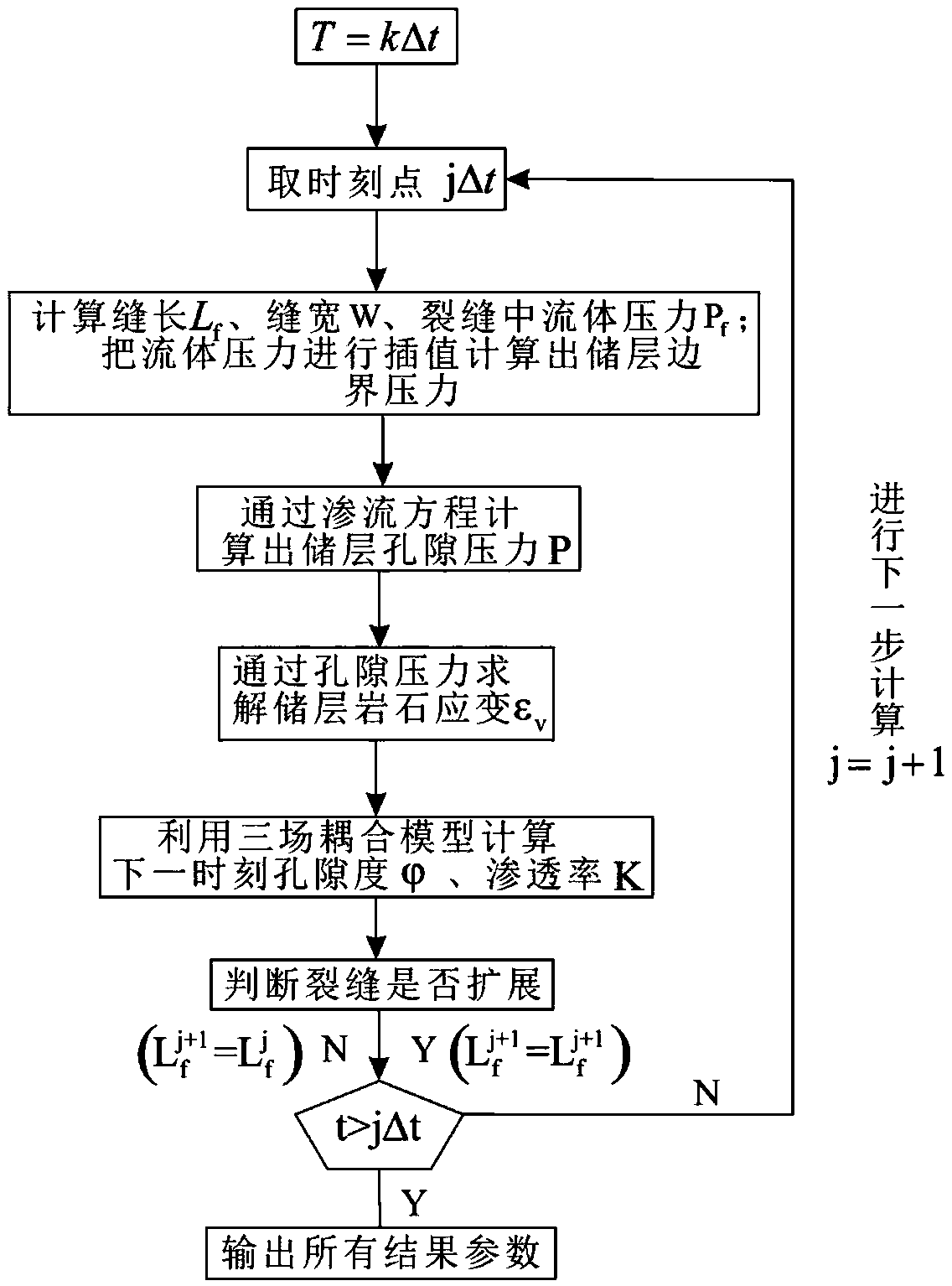

Method for simulating offshore oilfield micro fracturing injection increase crack propagation on basis of fluid-solid-heat coupling theory

ActiveCN108830020AInjection speed is smallReliable Analytical Research MethodsDesign optimisation/simulationSpecial data processing applicationsPorosityFiltration

The invention discloses a method for simulating offshore oilfield micro fracturing injection increase crack propagation on the basis of fluid-solid-heat coupling theory. The method comprises the following steps that geological characteristic parameters are obtained on the basis of offshore micro fracturing well geological data; a hydraulic crack propagation model is built, and fluid pressure and filter loss in a crack are obtained; on the basis of a reservoir matrix model, dynamically changing pore pressure in a reservoir is worked out; on the basis of elastic mechanics and permeation fluid mechanics, a pore elastic deformation relation between fluid and rock is built, that is to say, a fluid-solid coupling model is built, and by means of the calculated pore pressure, rock strain caused bythe fluid can be obtained; a heat effect relation between the temperature and the rock is built, a strain, porosity, permeability and temperature fluid-solid-heat coupling model is built, the permeability and porosity after coupling change are obtained, the pore pressure after three-field coupling change is obtained, the changed pore pressure reacts on a Darcy filtration model, and the crack extension dynamic of the next moment is obtained. According to construction and geological parameters, the dynamic extension situation of the hydraulic crack and real-time change situation of the reservoir parameters in the offshore micro fracturing well long-term injection increase process can be predicted according to the construction and geological parameters.

Owner:SOUTHWEST PETROLEUM UNIV

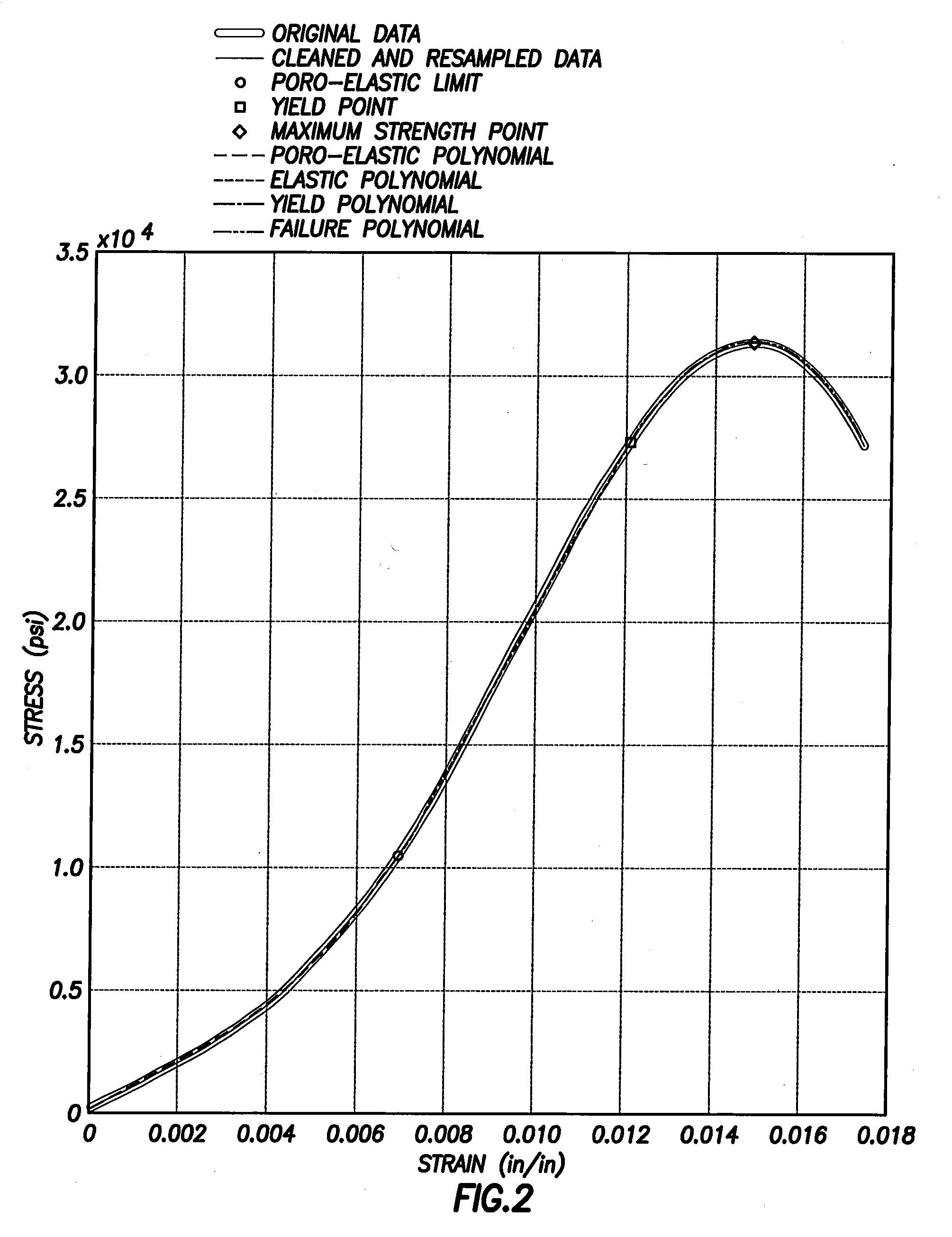

Integrating rock ductility with fracture propagation mechanics for hydraulic fracture design

InactiveUS20140352949A1Significant plasticitySignificant ductilitySurveyConstructionsGeomorphologyLinear region

The invention relates to the calculation of parameters to inform hydraulic stimulation of non-conventional hydrocarbon-bearing rock formations, such as shales. Unlike conventional formations, non-conventional formations tend to display elastic-plastic behavior and have stress-strain characteristics which with substantial non-linear regions. A parameter which has been termed Elastic Index (EI) is proposed, together with a demonstration of how this parameter, when coupled with principles of fracture mechanics, may be used to extract meaningful calculated or estimated values for e.g.; total required volume of fracturing fluid; treating pressure; fracturing fluid viscosity; proppant size; and proppant concentration.

Owner:CONOCOPHILLIPS CO

Evaluation method for low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential

ActiveCN107044277AIn line with the actual production dynamicsImprove accuracySurveyFluid removalRepeated fracturesEclipse

The invention discloses an evaluation method for low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential. The evaluation method sequentially comprises the following steps that (1), a crack expansion model is built by utilizing Meyer software, and inversion of first-time fracturing hydraulic crack parameters is conducted; (2), an oil reservoir heterogeneous geological model is built by utilizing oil reservoir numerical value simulation software Eclipse, the first-time fracturing hydraulic crack parameters are planted into the heterogeneous geological model to conduct production dynamic history fitting, and remaining oil saturation field and stratum pressure field distribution is obtained; and (3), quantitative evaluation is conducted on the horizontal well repeated fracturing yield increasing potential according to the remaining oil saturation field and stratum pressure field distribution, first-time fracturing hydraulic cracks are classified, and pertinence repeated fracturing modes are proposed. The problems of the stress sensitivity phenomenon and poor pertinence of the repeated fracturing modes and the like existing in evaluation of the low permeability heterogeneous oil reservoir horizontal well repeated fracturing yield increasing potential are effectively solved, the effect of repeated fracturing transformation is improved, the risk of engineering construction is reduced, and the evaluation method has wide market application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

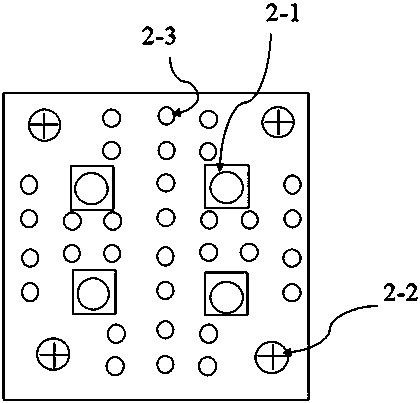

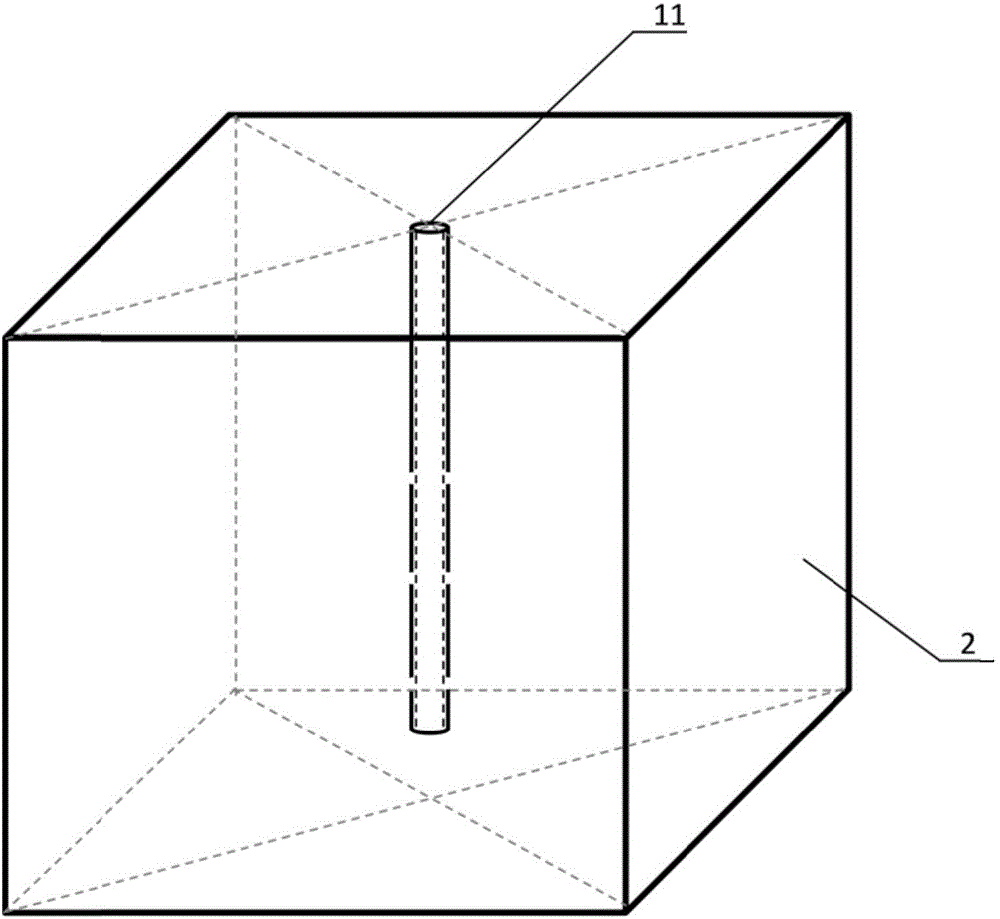

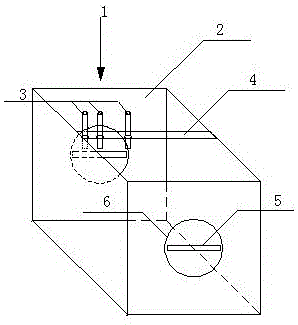

Simulation experiment system for staged fracturing or simultaneous fracturing of horizontal wells

InactiveCN106401551ASave spaceEffective guidanceFluid removalExperimental methodsInterference phenomenon

The invention provides a simulation experiment system for staged fracturing or simultaneous fracturing of horizontal wells. The system is used for performing fracturing simulation on a cubic artificial rock sample and comprises fracturing simulation assemblies, stress loading devices and fracture monitoring devices; each fracturing simulation assembly comprises a simulation wellbore, a liquid injection pipe and a position adjusting device; the simulation wellbores are located inside the artificial rock sample; the liquid injection pipes are located in the simulation wellbores; and at least two simulation perforations which are equal in number and different in position are formed in each simulation wellbore and each liquid injection pipe. Positions of the liquid injection pipes are controlled by the position adjusting devices, the communicating sequence of the simulation perforations in different fracturing sections is realized, and the different fracturing sections are fractured respectively. The simultaneous fracturing process of the two horizontal wells can be simulated by the two fracturing simulation assemblies. The simulation experiment system can simulate interference phenomena among fractures during staged fracturing of the horizontal wells or simultaneous fracturing of the two horizontal wells, and an experimental method is provided for understanding of hydraulic fracture propagation rules and fracture shapes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method

The invention discloses a three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method. The experimental system comprises a core test specimen, acore clamping device, a fully-three-dimensional multilayered stress loading device, a fracturing pumping-in device, a crack expansion real-time monitoring device and a control device. The invention provides the three-dimensional multilayered multi-well fracturing prop crack real-time monitoring experimental system and method, under the conditions that three-directional stress is applied, and twohorizontal directions are layered stresses, the core specimen which includes a plurality of shafts simulates hydraulic fracturing and sand supporting, by crack initiation on fracturing cracks and real-time and quantitative monitoring and later interpretation on crack induction stress of an expansion process, crack initiation of three-dimensional multilayered multi-well fracturing prop cracks and quantified description of the expansion process are realized, and the laying state of a propping agent in the cracks can be obtained.

Owner:唐山合众启航科技有限公司

Method for gasification fracturing of liquid nitrogen in hydrocarbon reservoirs

InactiveCN102493795ANo pollution in the processNo clay hydration swelling problemConstructionsFluid removalWater resourcesFracturing fluid

A method for gasification fracturing of liquid nitrogen in hydrocarbon reservoirs is mainly characterized in that a heat-insulation oil pipe is inserted in a casing punctured in an underground hydrocarbon reservoir, openings are respectively arranged on the left and the right of the middles of two packers in the heat-insulation oil pipe, a plurality of holes are drilled on the casing by a perforating gun, and the liquid nitrogen which is used as fracturing liquid is pumped into cracks of a stratum via the heat-insulation oil pipe and the perforated holes. Shut-in and soaking are realized on the ground or under the ground. The liquid nitrogen absorbs heat and is gasified in the stratum, the pressure of fluid in the cracks is increased, the temperature and the volume of rocks are reduced, and the cracks are expanded until the temperature of the stratum recovers to the original temperature. The problem of hydration and expansion of clay is avoided, air outlet holes are not easy to be blocked, the method is not limited by water resources, environmental pollution is avoided, and large-scale fracturing can be realized. The method is most suitable for development of shale gas, coal bed gas, tight sandstone gas and low-permeability reservoirs.

Owner:YANSHAN UNIV

Method for simulating water injection well water pressure drive fracture extension dynamic

ActiveCN108952660AReliable Analytical Research MethodsFluid removalFluid solid couplingFeature parameter

The invention discloses a method for simulating water injection well water pressure drive fracture extension dynamic. The method comprises the following steps that an oil reservoir geological characteristic parameter of a target water injection well with fractures is obtained according to the oil reservoir geological study; a water injection well water pressure drive hydraulic fracture extended model is established with the integration of a Darcy leak-off model, a continuity equation, a matter balance equation and an initial condition; fluid volume filtered into a stratum is used as a source item based on an oil-water two-phrase seepage model of a seepage mechanics theory, the boundary condition is established by combining the fluid pressure in the fracture, a hole elastic deformation relationship between a fluid body and a rock is established by being combined with a boundary condition established by the fluid pressure in the fracture, that is, a fluid-solid coupling model is established, and the formation pore pressure is calculated and strain and a pore penetration change which are caused by a change in the fluid pressure are obtained; and then the fracture extension dynamic after the action of the fluid-solid coupling is obtained, then the obtained new parameter is used as an initial condition to be repeated, and finally the fracture extension dynamic is obtained. Accordingto the method for simulating the water injection well water pressure drive fracture extension dynamic, the dynamic extension condition of the fracture in a water injection well and the dynamic changecondition of the parameter in a reservoir can be forecasted according to the construction and geological parameters.

Owner:SOUTHWEST PETROLEUM UNIV

Hydraulic fracturing simulation experiment system for oil shale and manufacturing method of experiment sample

InactiveCN104330310AGuarantee authenticityPreparing sample for investigationMaterial strength using tensile/compressive forcesData acquisitionOil shale gas

The invention discloses two parts namely a hydraulic fracturing simulation experiment device for oil shale and a manufacturing method of an experiment sample. The hydraulic fracturing simulation experiment device for the oil shale is composed of a hydraulic fracturing pressurization and data acquisition part and an experiment sample triaxial pressurization part. The crack initiation pressure and the crack propagation situation of the oil shale under different stress situations and different perforation conditions can be tested by utilizing a true oil shale test block. By virtue of the manufacturing method of an oil shale sample, an experiment can be performed by utilizing the true oil shale test block, stresses in three directions can be fully transferred to the oil shale test block, and the oil shale test block can be truly stressed.

Owner:JILIN UNIV

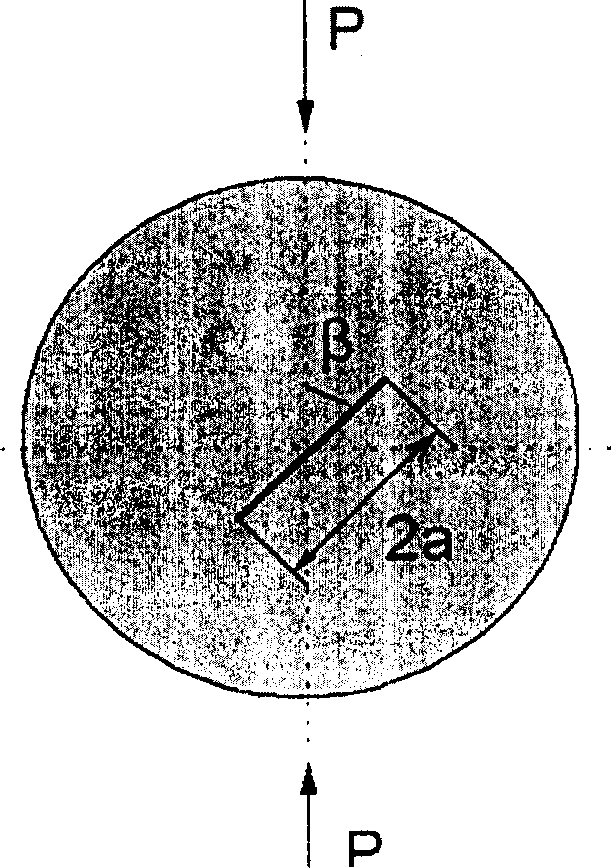

Method for computing rock II-type fracture toughness

InactiveCN1818608AImprove forecast accuracyEffective distributionPreparing sample for investigationInvestigating material hardnessType fractureHydraulic fracturing

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Testing device and testing method for simulating hydraulic fracture characteristic of concrete bedrock contact surface

ActiveCN106442154AImprove sealingThe process is simple and fastPreparing sample for investigationMaterial strength using tensile/compressive forcesBedrockEngineering

The invention discloses a testing device and testing method for simulating the hydraulic fracture characteristic of a concrete bedrock contact surface. The testing device mainly comprises a mold, a steel sheet, pressure measuring guide pipes, a water seal fixture, a water pressure loading system, strain gauges, a clip gauge, a computer and the like. A pair of discs are cut in the mold in a central symmetry mode, can rotate and are used for allowing the steel sheet to be inserted into preformed initial cracks with different thicknesses, widths, roughness and angles; the water seal fixture clamps a test piece in a screwing mode through a screw to seal the water pressure, a high-pressure-resistant water guide pipe is connected with a fixture thread center hole formed in the center of a water seal device through a thread connector, the strain gauges are arranged in the development direction of the cracks, and a coloring agent is added into a water tank connected with the high-pressure-resistant water guide pipe to track the propagation trajectory of the hydraulic fracture cracks. The testing device can be used for studying the hydraulic fracture characteristic of the concrete bedrock contact surface, is simple and convenient to operate and can truly reflect the crack propagation characteristic among contact surfaces of different materials.

Owner:HOHAI UNIV

Optimal drilling trajectory prediction method of lateral well

PendingCN108442922ADetermine reliabilityVerify reliabilitySurveyData processing applicationsAcoustic emissionAcoustic wave

The invention relates to the technical field of exploration and development of oil and gas fields, in particular to an optimal drilling trajectory prediction method of a lateral well. The method includes the steps of acquiring a rock three-dimensional dynamics parameter field through conversion of dynamic static rock dynamics; determining natural fracture systems and occurrence distribution through core palaeomagnetic orientation, imaging logging and array acoustic logging; conducting present stress field simulation utilizing the rock three-dimensional dynamics parameter field; determining development probability of fractures of different periods utilizing acoustic emission experiments to simulate ancient stress field of different periods; simulating and determining present crustal stressvertical distribution through stress field simulation of well areas; and predicting fracturing fracture spreading directions utilizing crustal stress, fractures and vertical distribution of rock dynamics to establish an equivalent extending vertical zonation model of fracturing fractures. The optimal drilling trajectory prediction method of the lateral well verifies the reliability of fracturing fracture spreading directions by combining the drilling direction of the lateral well and dynamic materials of the lateral well, and realizes direction prediction of fracturing fractures of different blocks and optimal drilling trajectory design of the lateral well.

Owner:刘敬寿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com