Integrating rock ductility with fracture propagation mechanics for hydraulic fracture design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

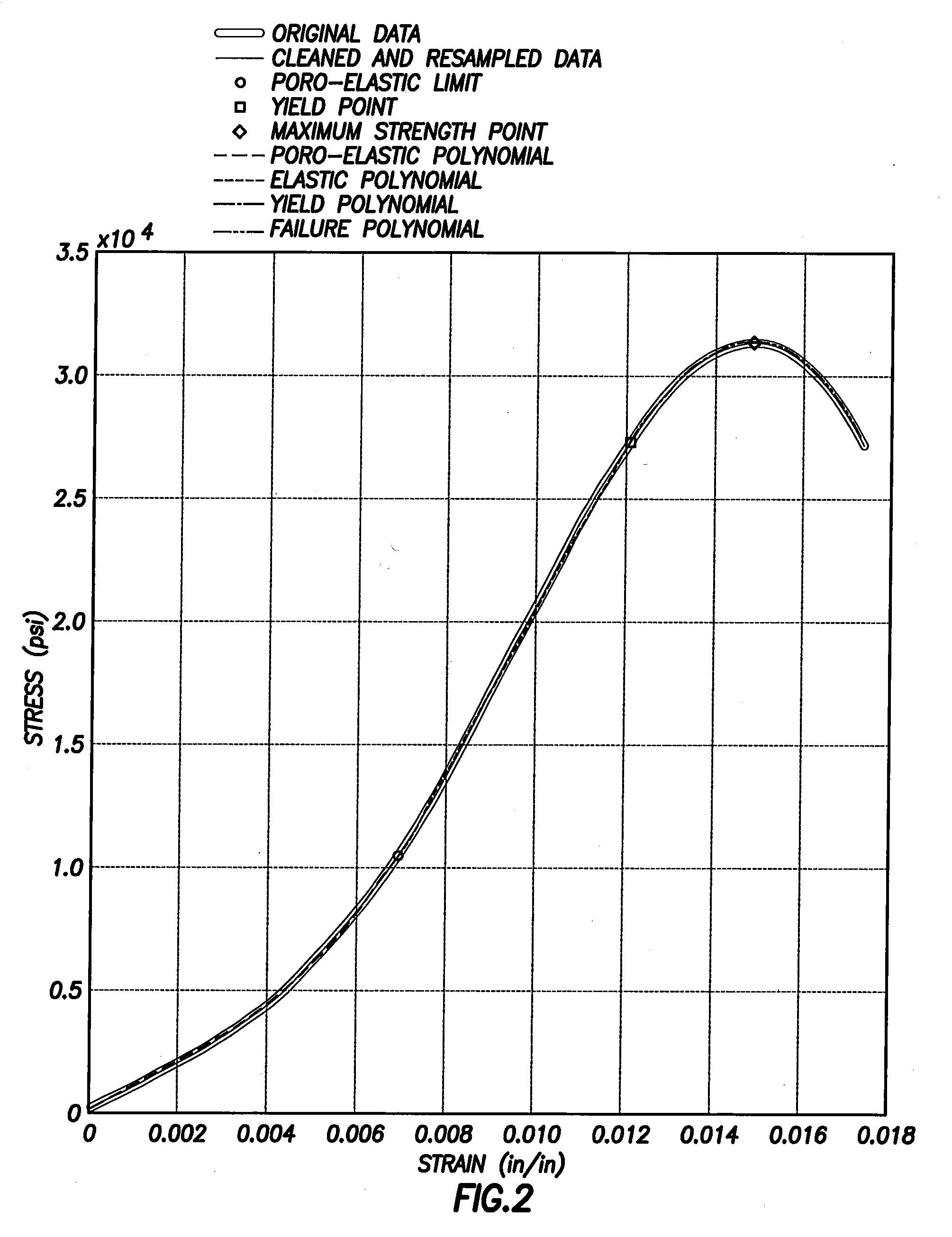

[0100]FIGS. 2 and 3 show cleaned and re-sampled data with the original data from laboratory triaxial testing from couple of core samples. As is usual with this type of testing, the data has erroneous points and inconsistent sampling. The script performs statistical analysis to clean the erroneous points and do quality checks (step 1 above). Once the data is cleaned, the script defines the poro-elastic limit, yield point and failure point (step 2) and these points are shown on FIG. 2. The elastic index (EI) parameter is then calculated. In this example:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com