Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Engineering drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An engineering drawing, a type of technical drawing, is used to fully and clearly define requirements for engineered items. Engineering drawing (the activity) produces engineering drawings (the documents). More than merely the drawing of pictures, it is also a language—a graphical language that communicates ideas and information from one mind to another.

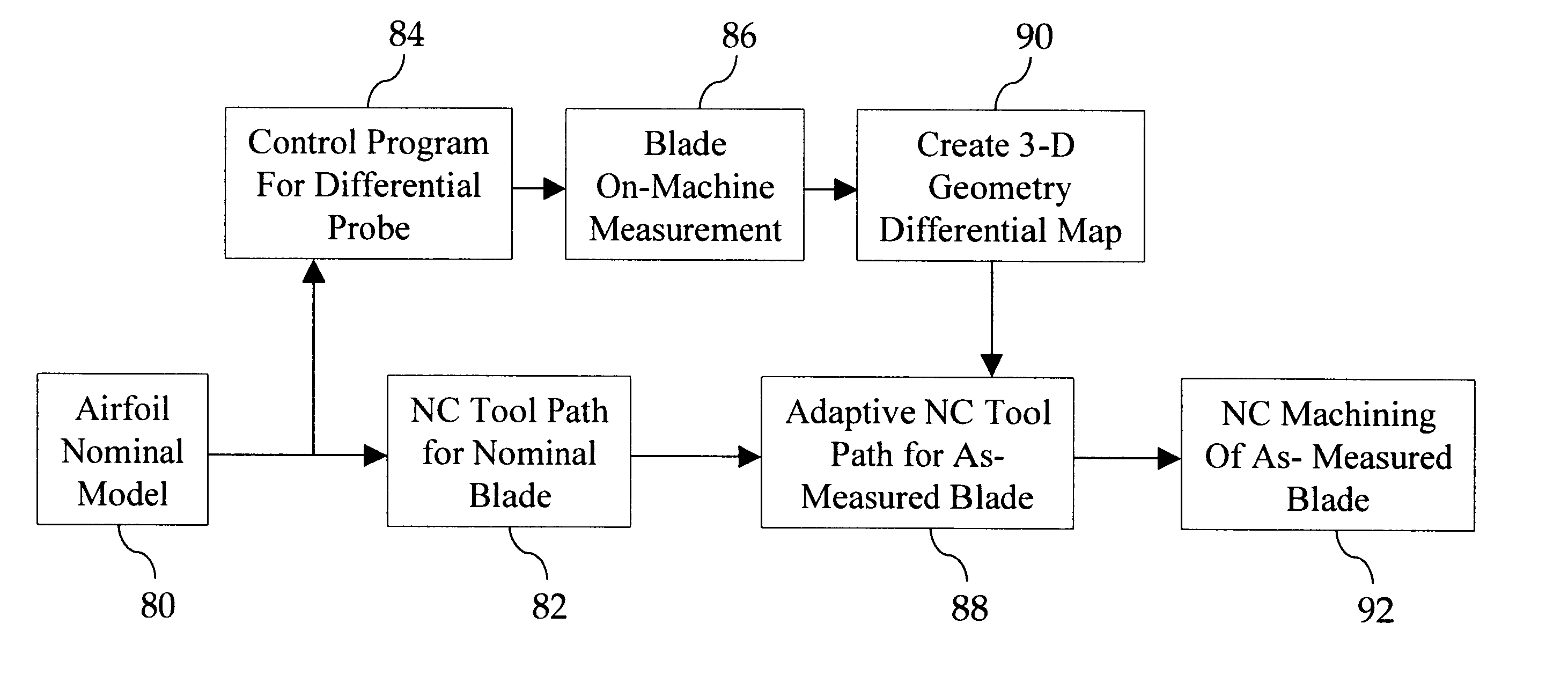

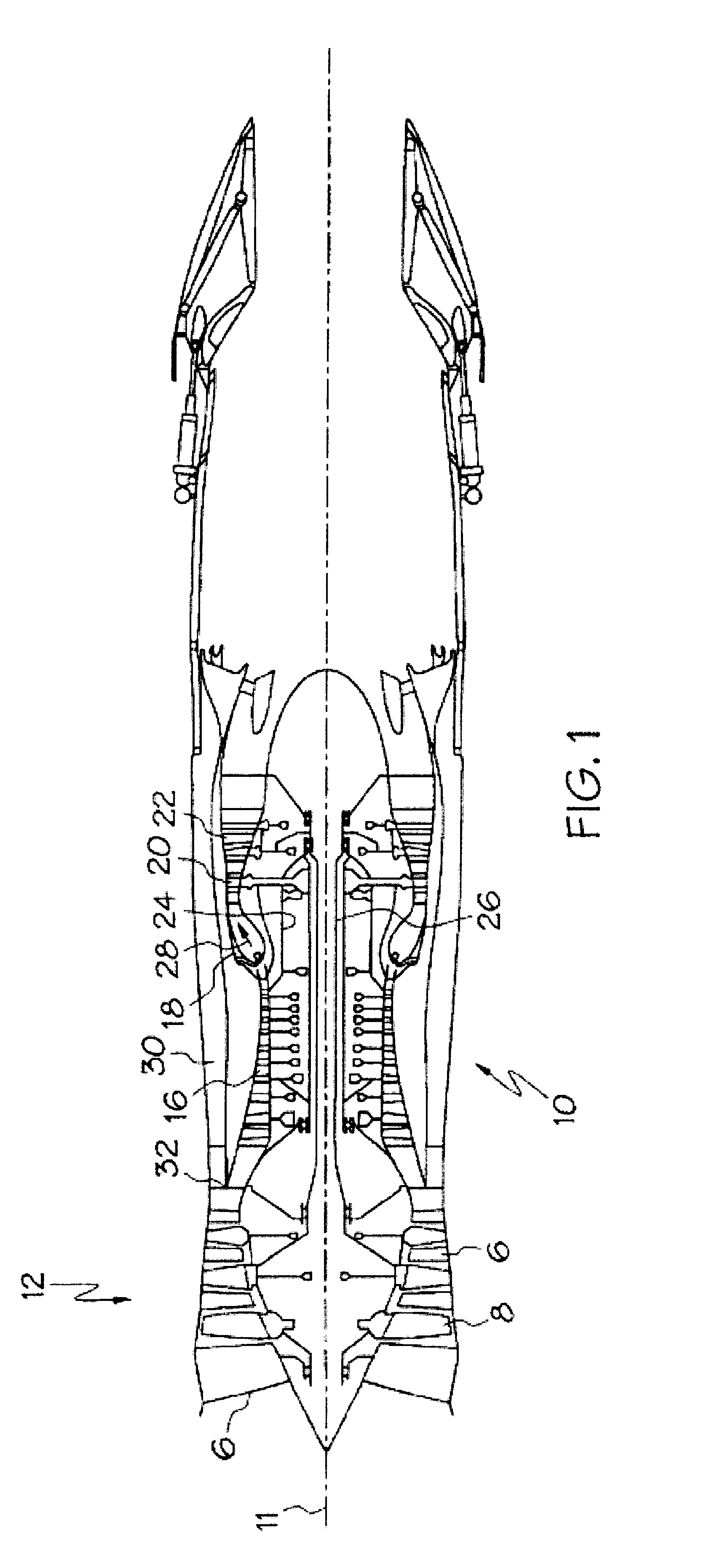

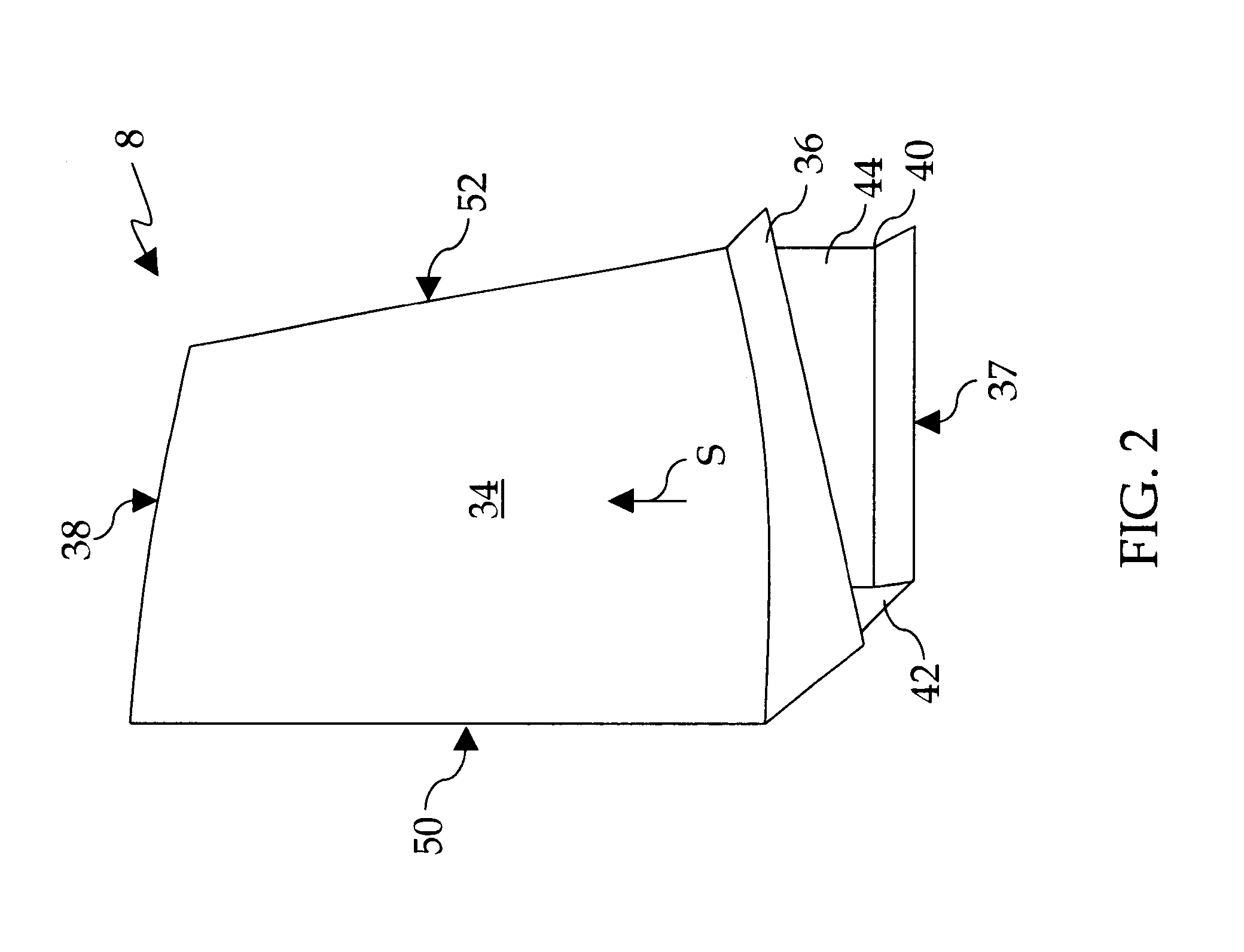

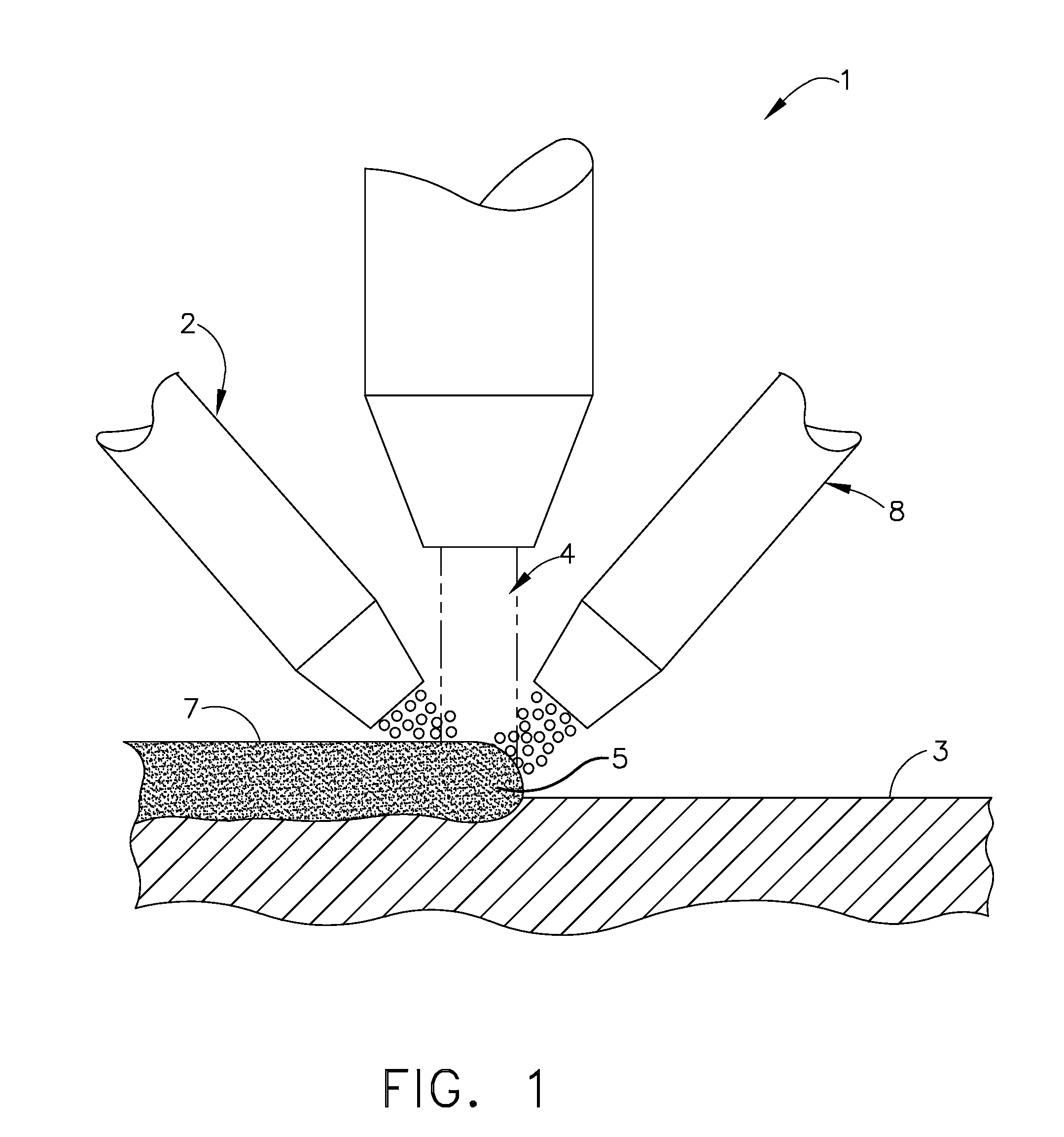

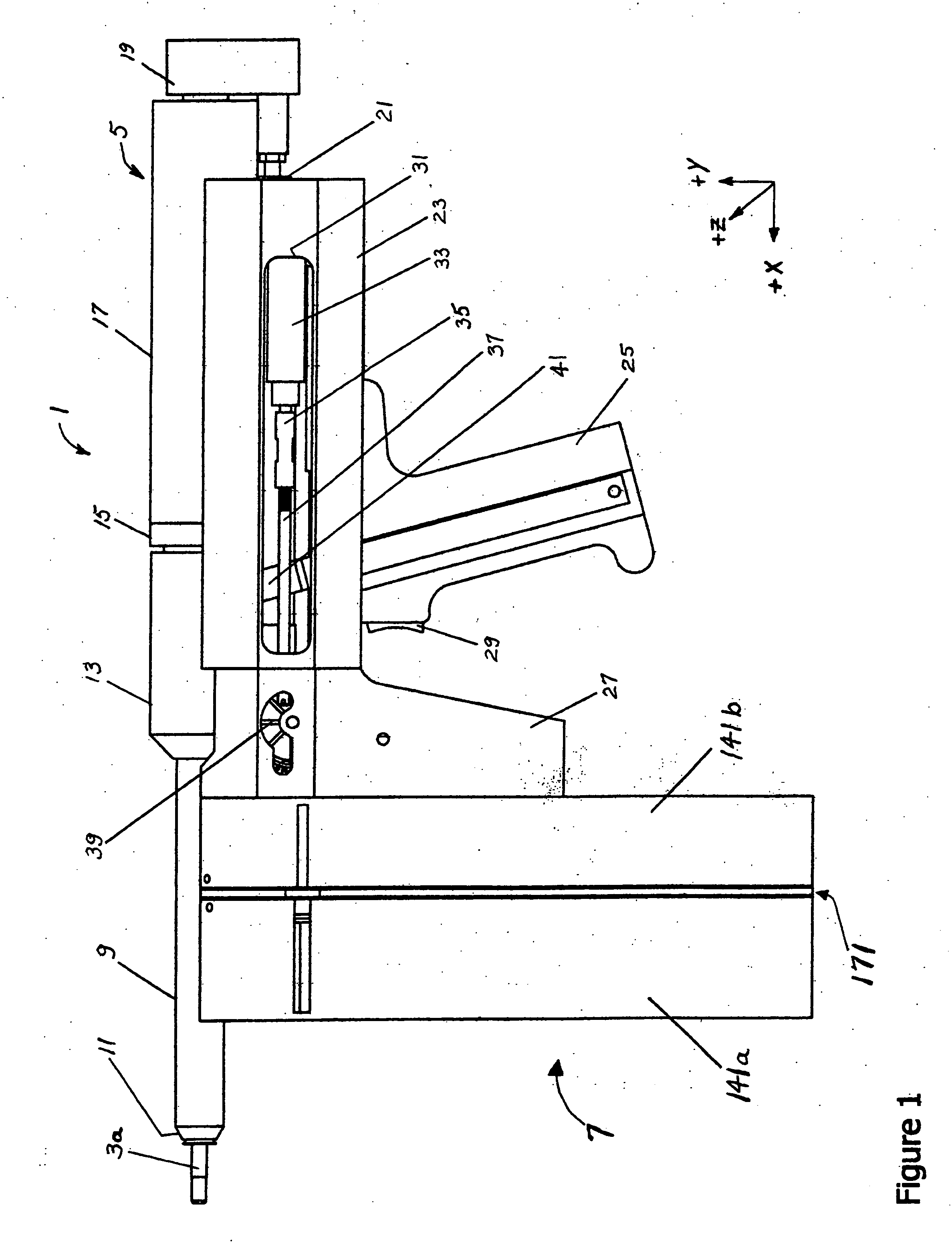

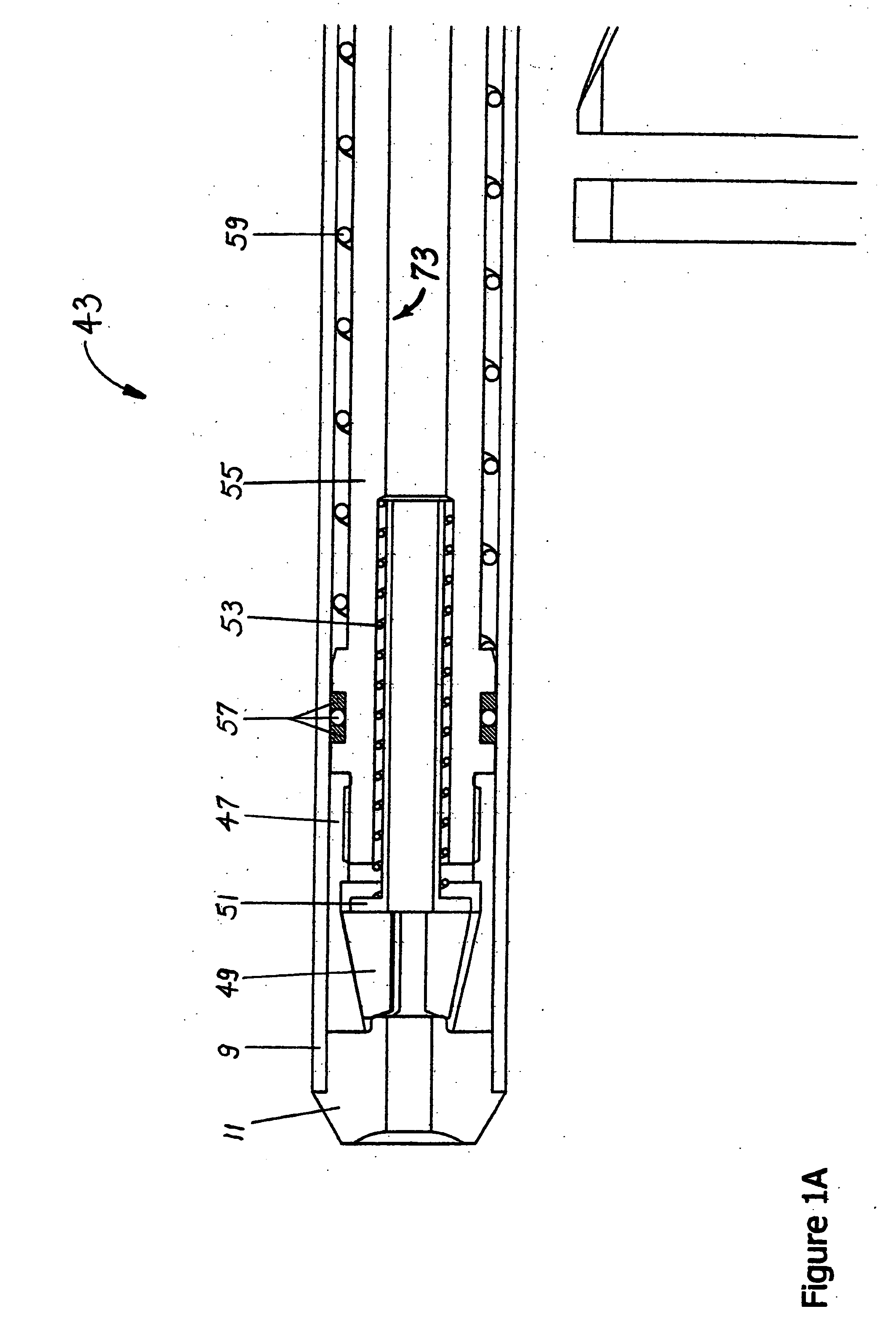

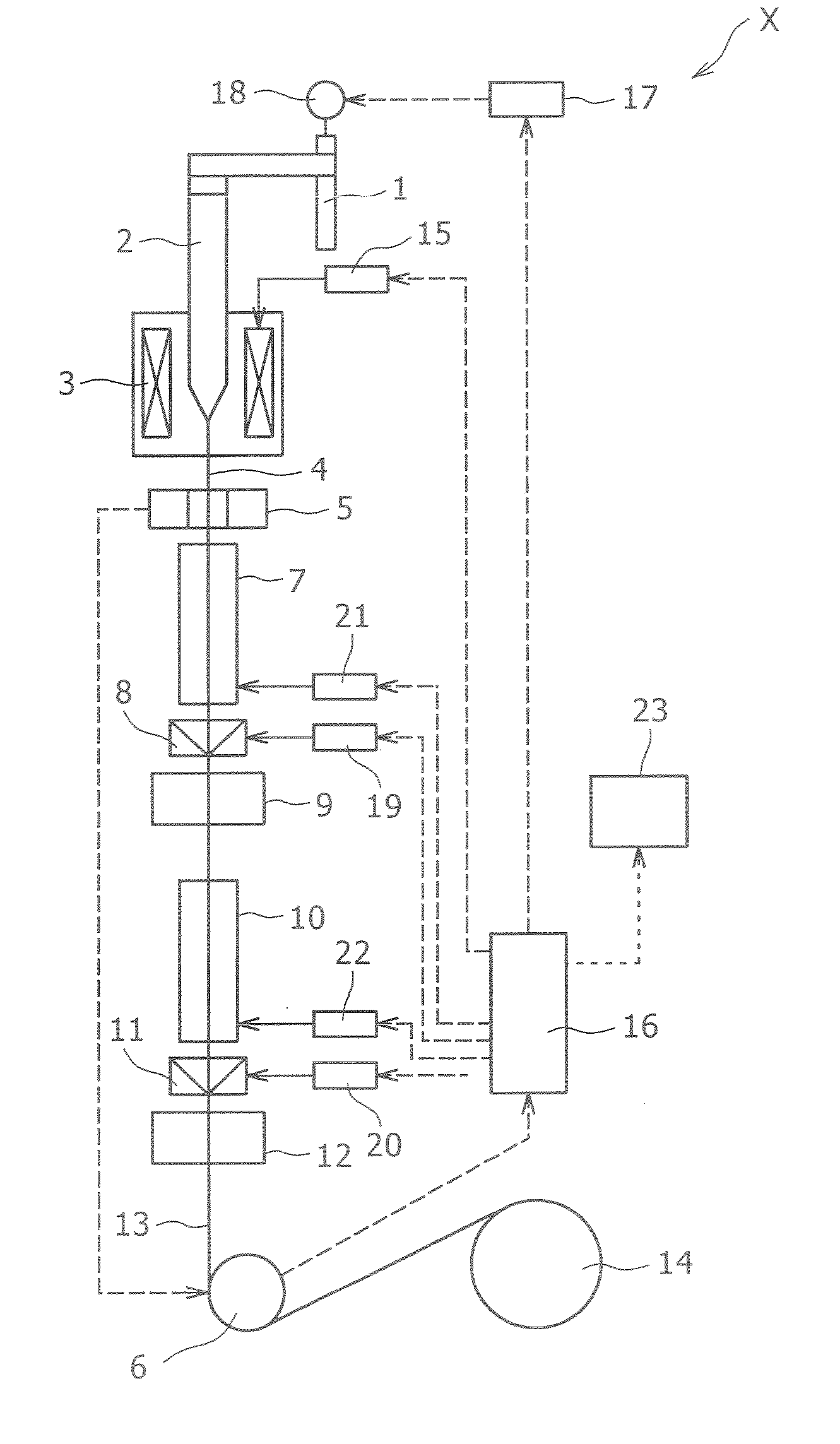

Systems and methods for automated sensing and machining for repairing airfoils of blades

InactiveUS6912446B2AdaptableEasy maintenanceProgramme controlTurbinesNumerical controlData acquisition

A method for repairing an airfoil comprising creating a nominal numerically-controlled tool path based on a nominal shape of the airfoil, measuring the airfoil using a displacement sensor, capturing differences in the airfoil shape as compared to the nominal shape, creating a three-dimensional map by synchronizing x, y and z coordinates and readings from the sensor, modifying the tool path based on the three-dimensional map, and machining the airfoil. A system for measuring and machining an airfoil comprising a computer operable for data acquisition and numerically-controlled tool path generation, a numerically-controlled machine, a cutting tool holder comprising a plurality of cutting tools, and a displacement-sensing probe.

Owner:GENERAL ELECTRIC CO

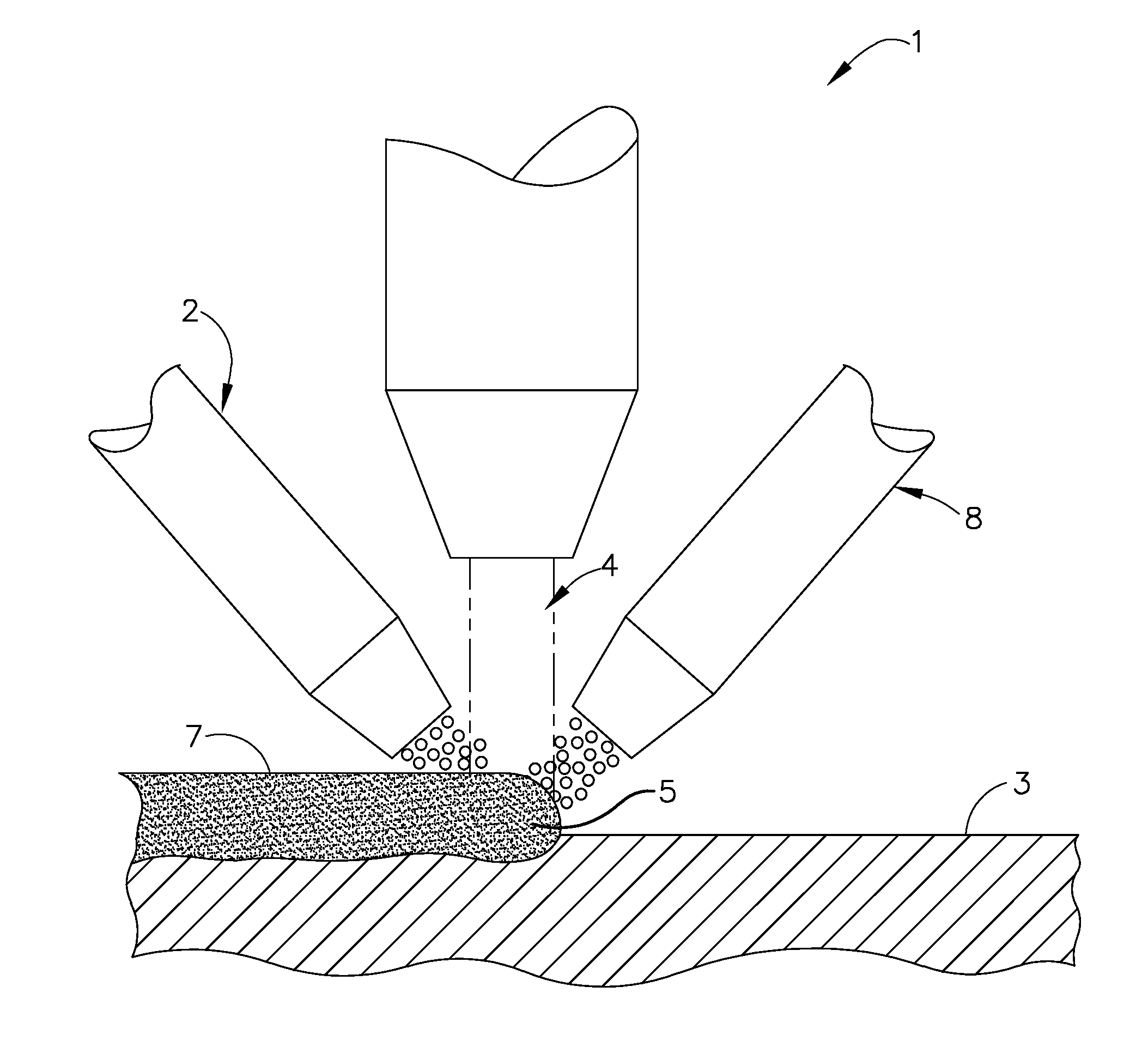

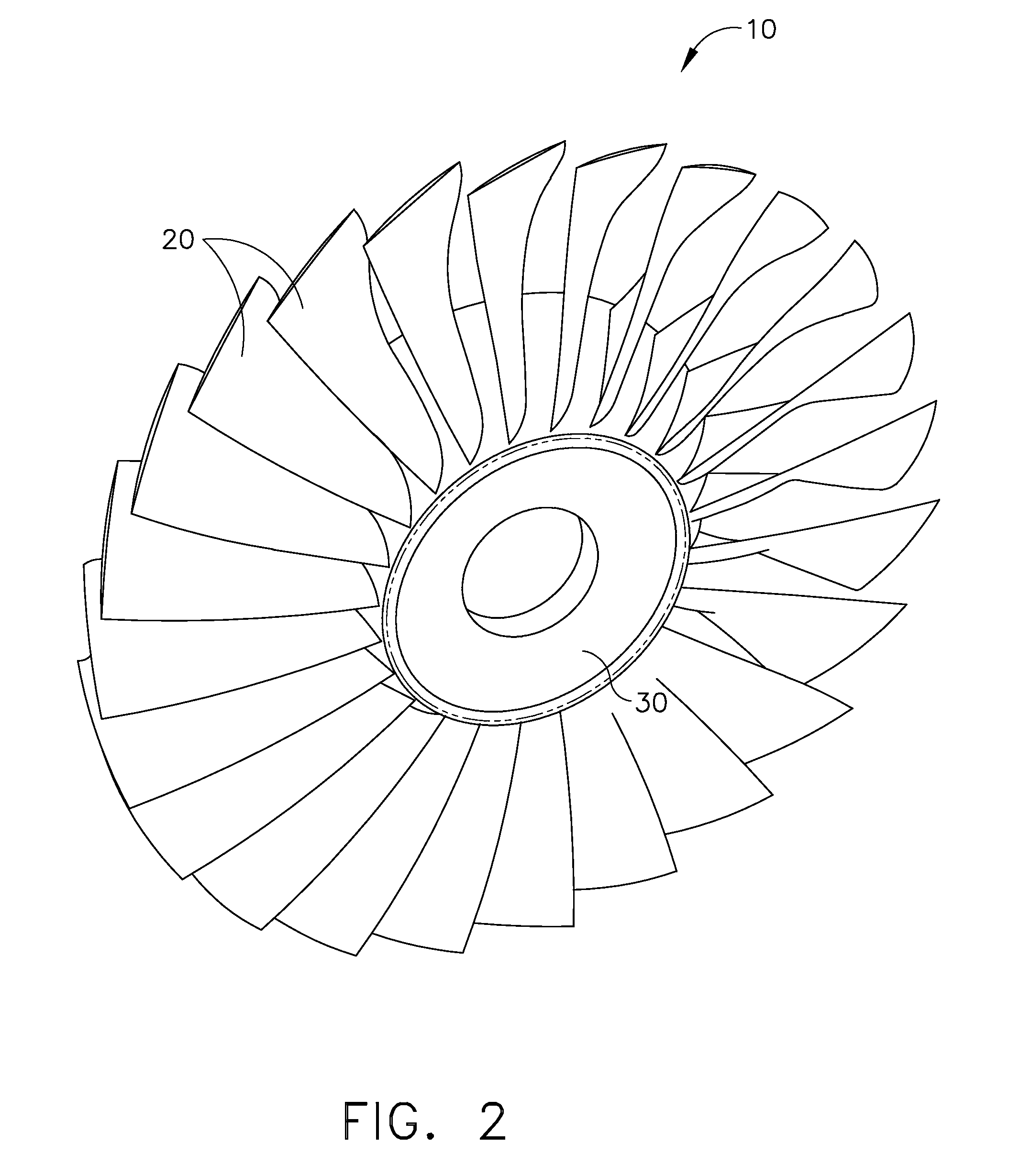

Laser net shape manufacturing and repair using a medial axis toolpath deposition method

InactiveUS20080182017A1Eliminate and reduce numberAdditive manufacturingTurbinesMedial axisNet shape

A method is disclosed for laser net shape manufacturing a part or repairing an area of a part comprising providing a CAD model of the part to be manufactured or repaired, digitally slicing the CAD model into a plurality of deposition layers, determining a medial axis for each of the deposition layers of the part or repair area; and depositing a bead of a material in a pattern centered upon the medial axis of each of the deposition layers so as to build-up the material by each of the deposition layer until the part is manufactured or repaired.

Owner:GENERAL ELECTRIC CO

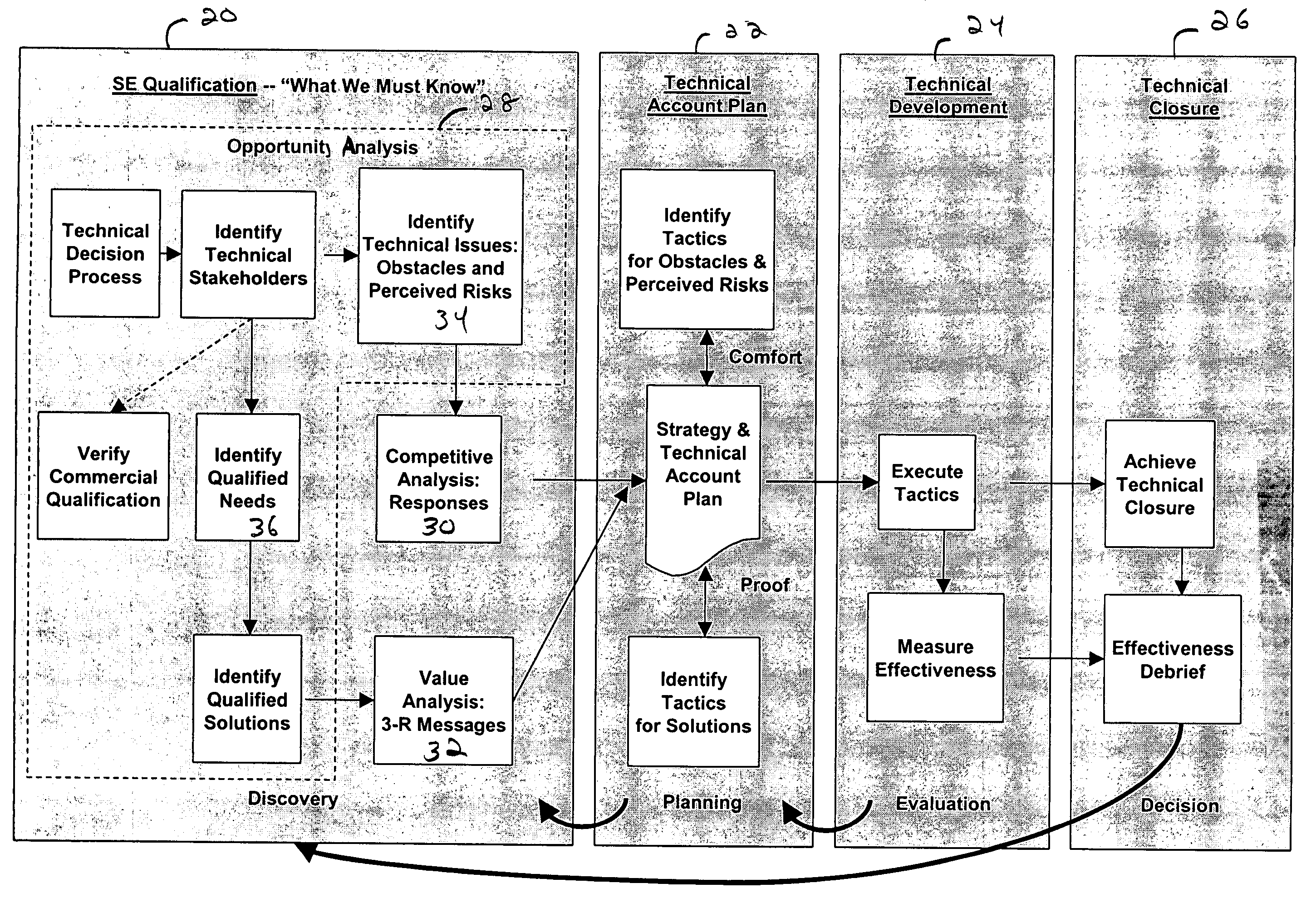

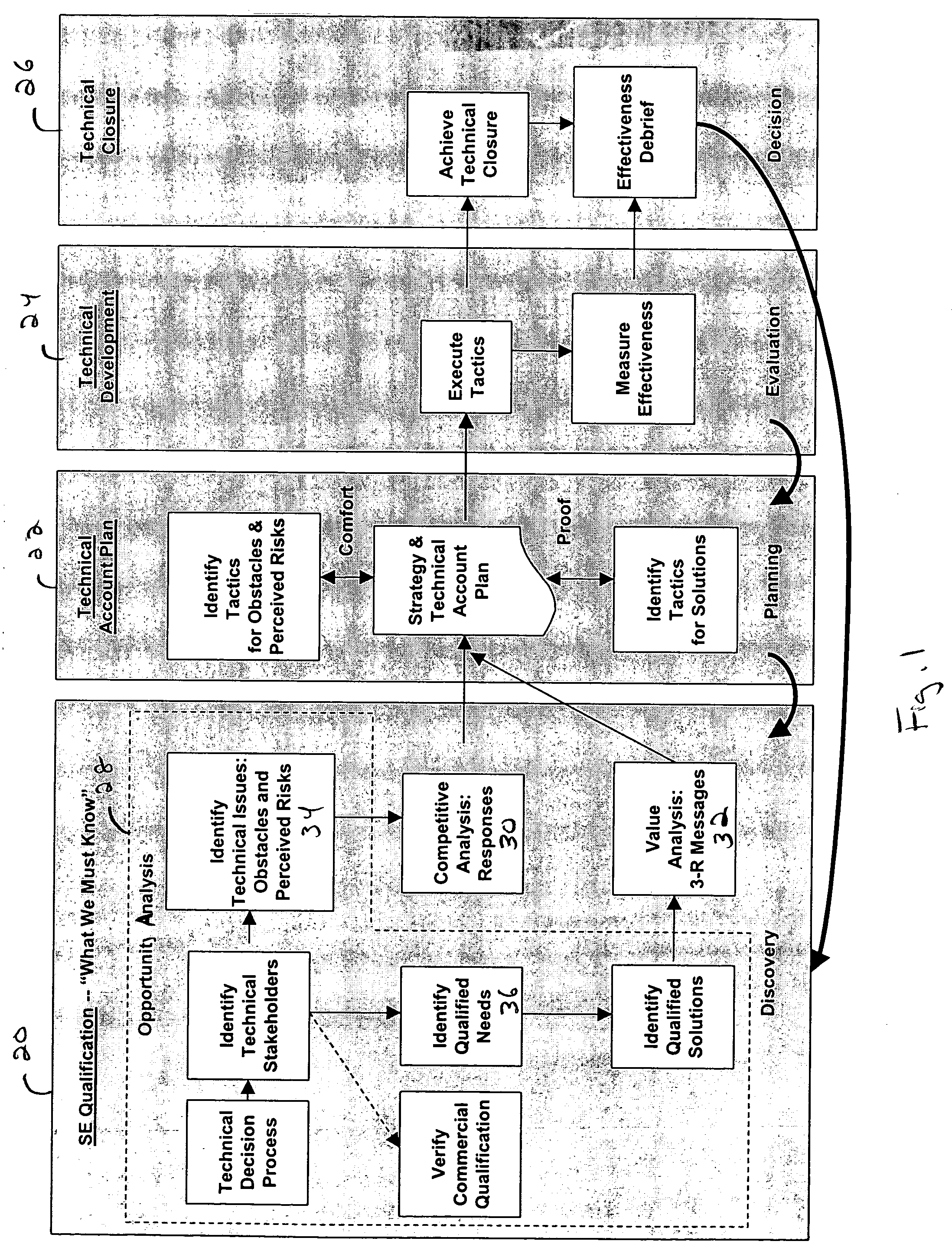

Technical sales systems and methods

InactiveUS20050038693A1Long and costlyEasy to identifyCommerceSpecial data processing applicationsEngineering drawing

The present invention relates to systems and methods for managing a sales engineering process and to methods for training a sales engineer.

Owner:TECHSELLENTS

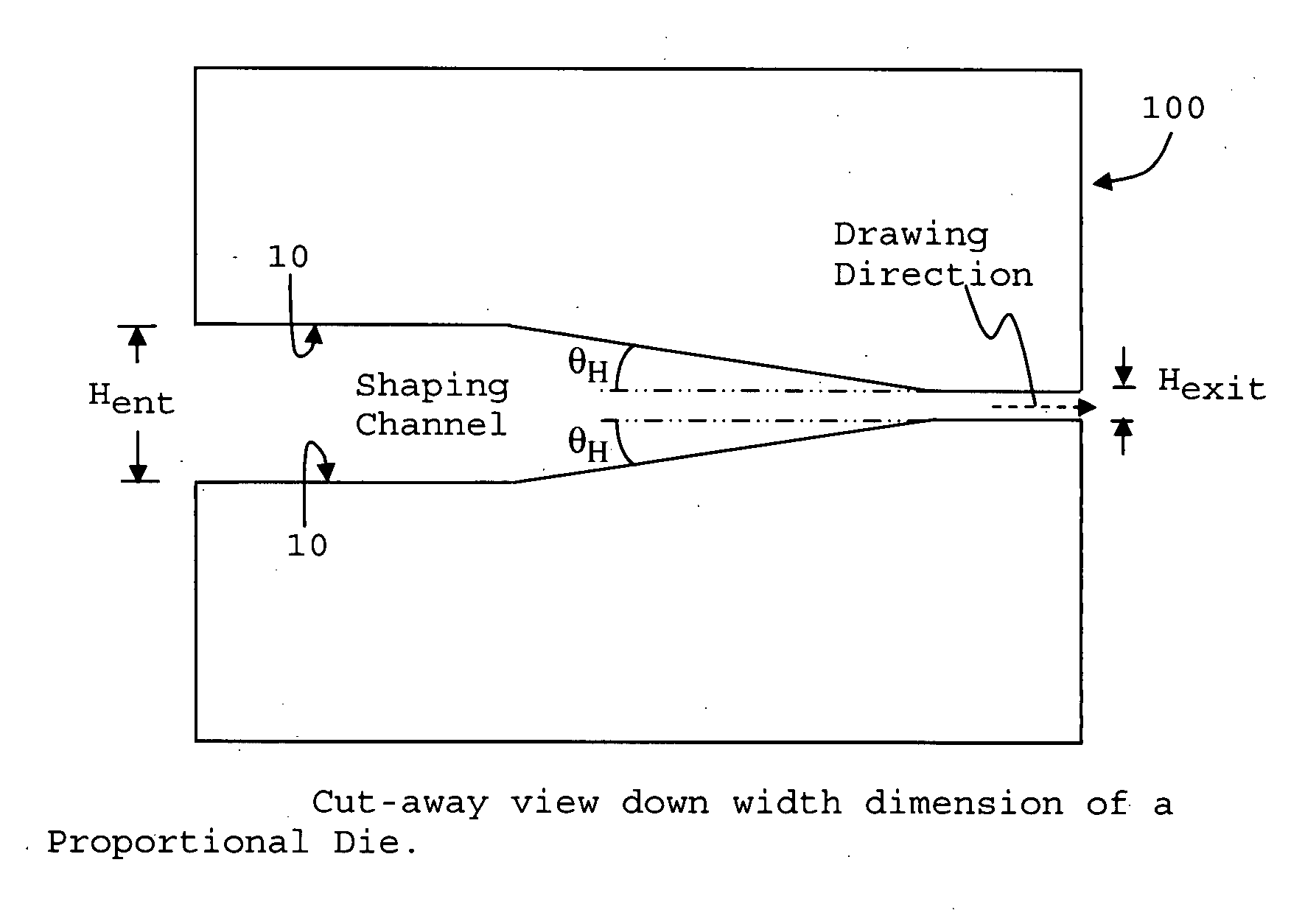

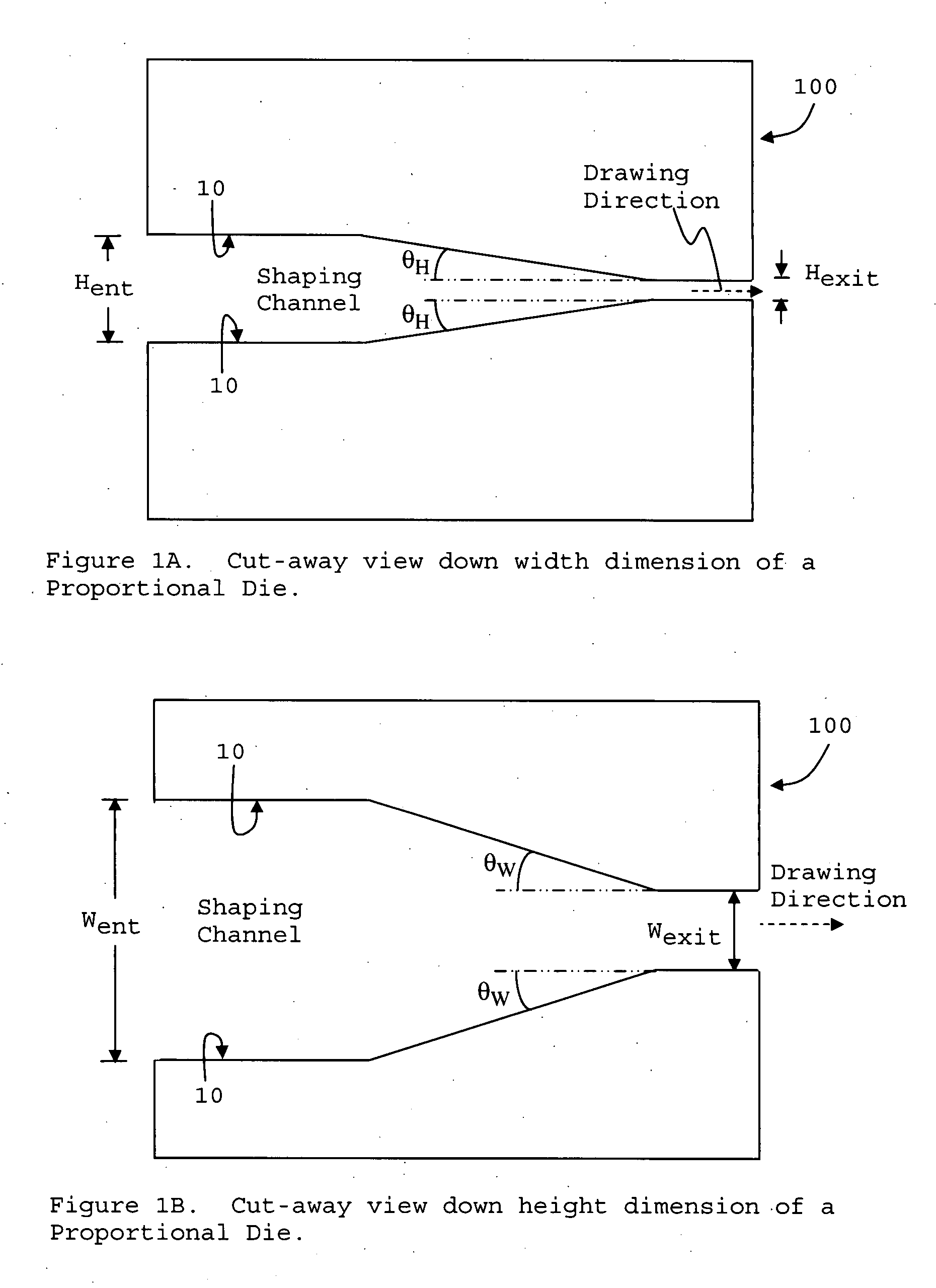

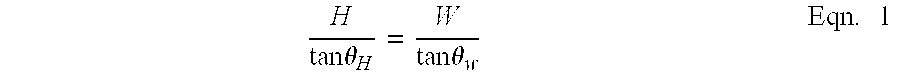

Substantially proportional drawing die for polymer compositions

An inventive solid state drawing die has shaping walls that define a shaping channel and that, in the course of solid state drawing, direct polymer composition along a drawing path. Each cross section of the drawing path (and, hence, polymer composition in the drawing path) is non-circular, substantially proportional to one another, contains a centroid that lies on a substantially straight line parallel to the drawing direction and all cross sectional dimensions are 1.5 millimeters or more.

Owner:EOVATIONS

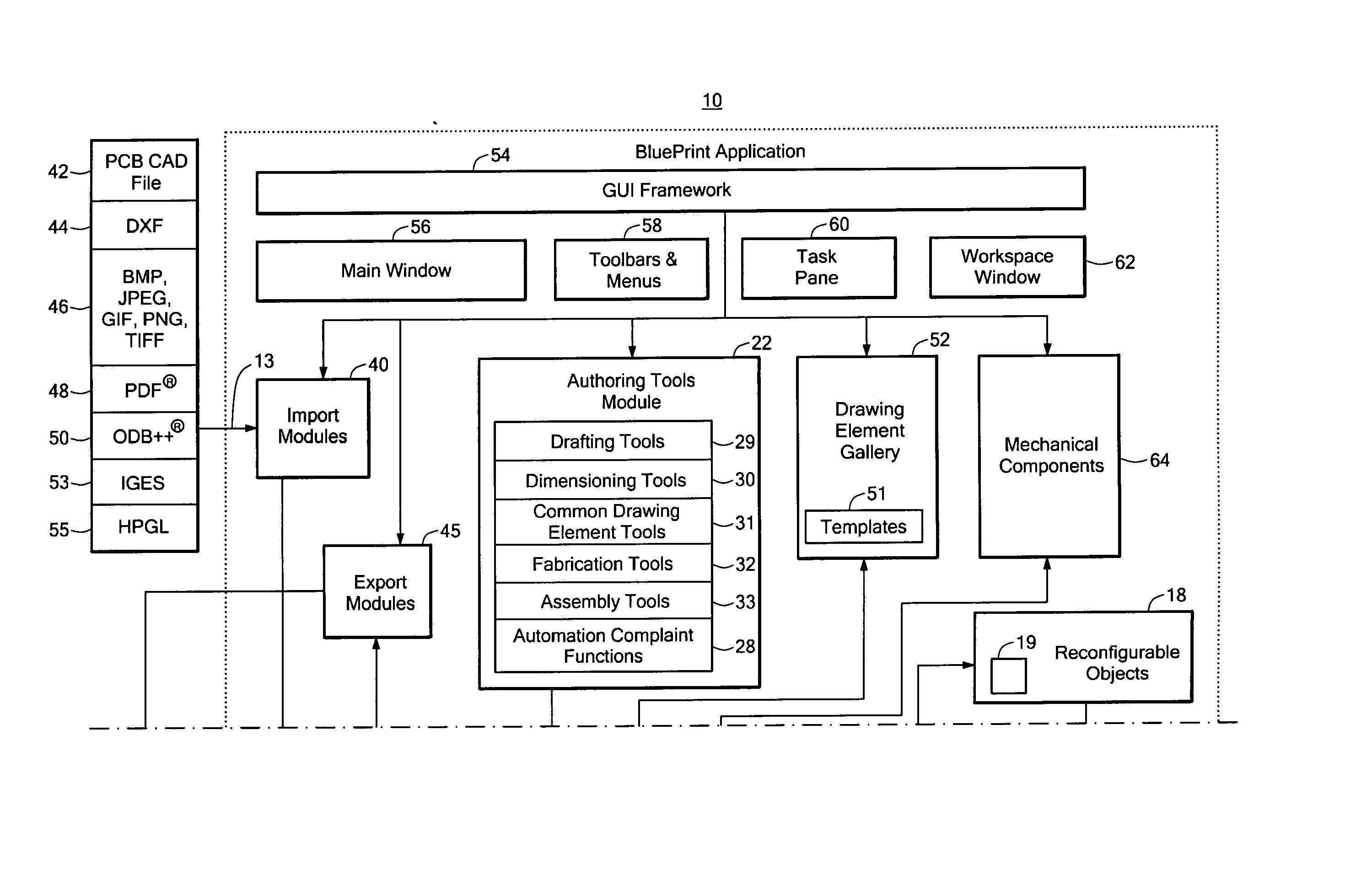

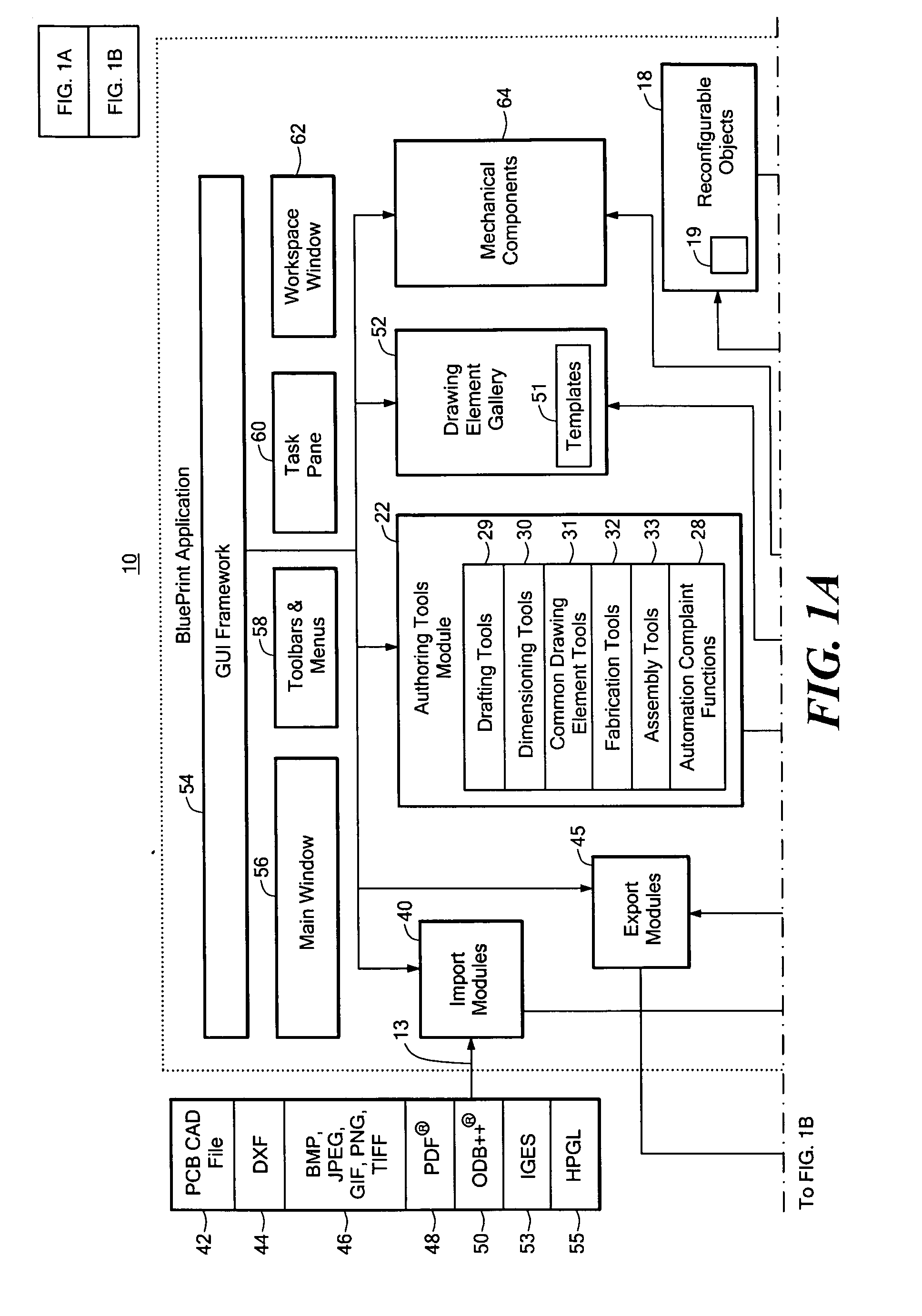

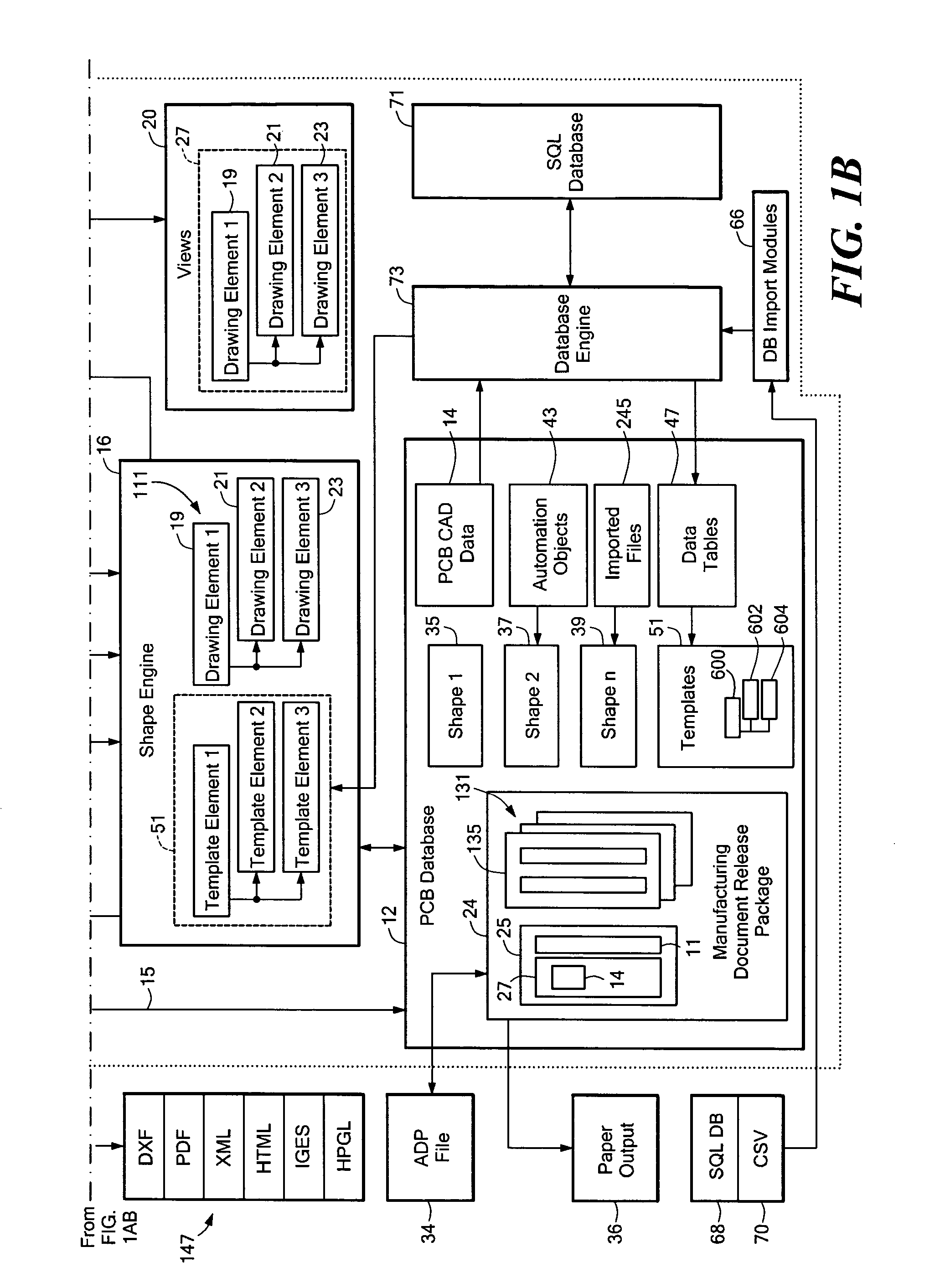

Automated PCB manufacturing documentation release package system and method

ActiveUS20060190116A1Easy to useShorten the timeCAD circuit designSpecial data processing applicationsDocumentation procedureEngineering drawing

An automated PCB manufacturing documentation release package system including a PCB database including PCB CAD data associated with a CAD file of a PCB design, and a shape engine configured to display simultaneous views of a given PCB from the PCB database including different views of the PCB and configured to retrieve the data in the PCB database and create reconfigurable objects displayable simultaneously in the forms of different views of the PCB such that any change in the design of the PCB is reflected in the different views.

Owner:DOWNSTREAM TECH

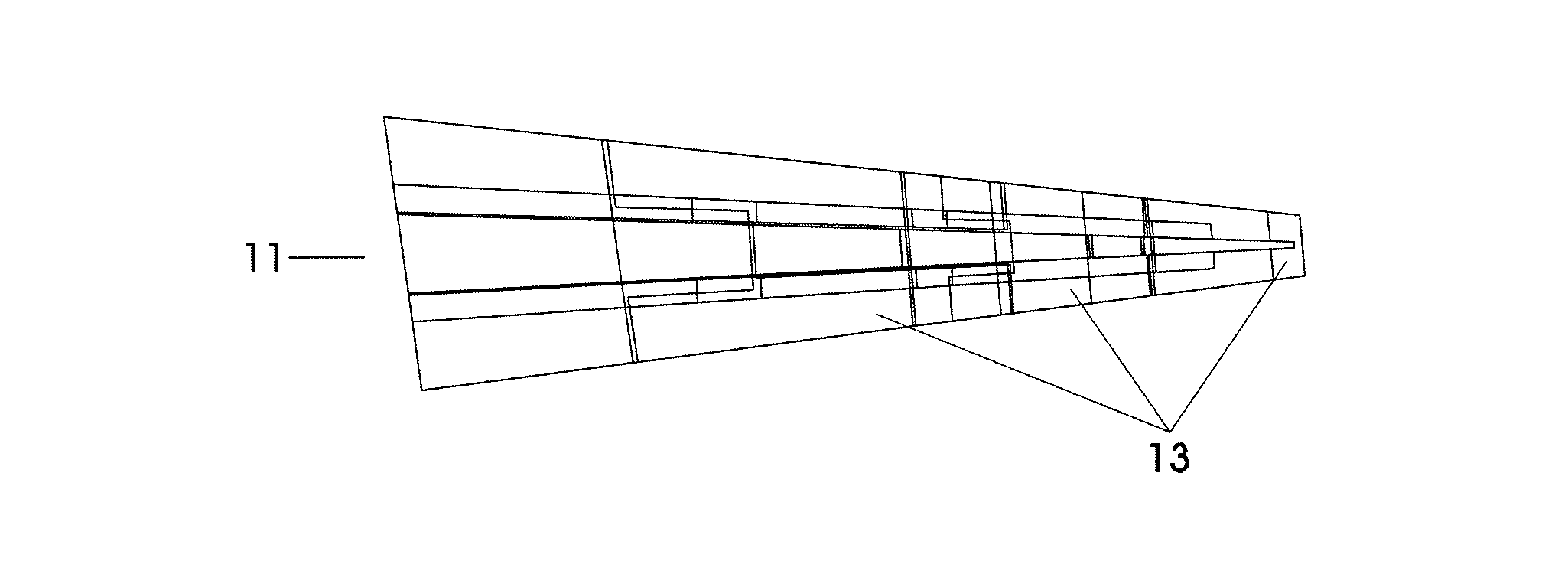

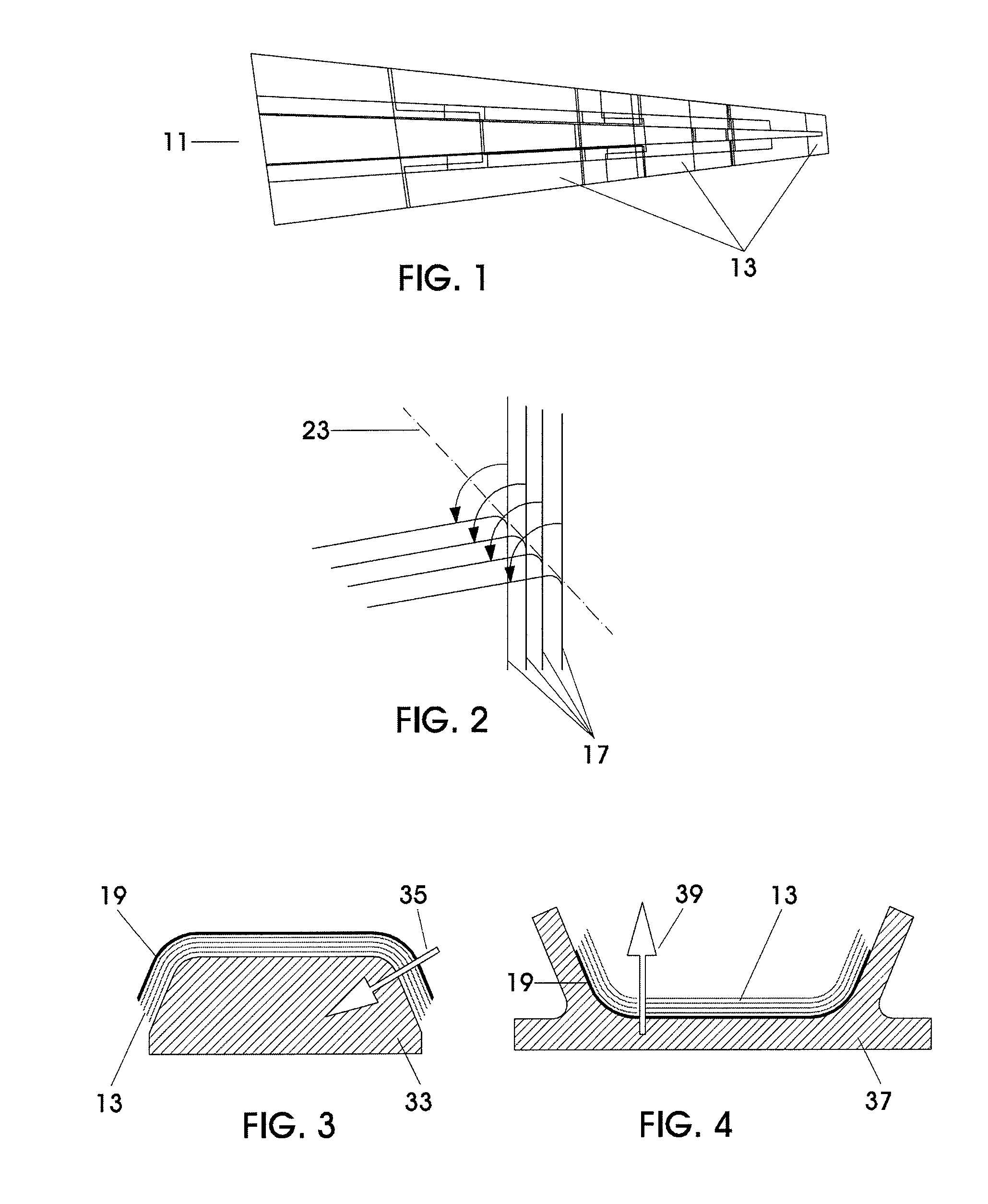

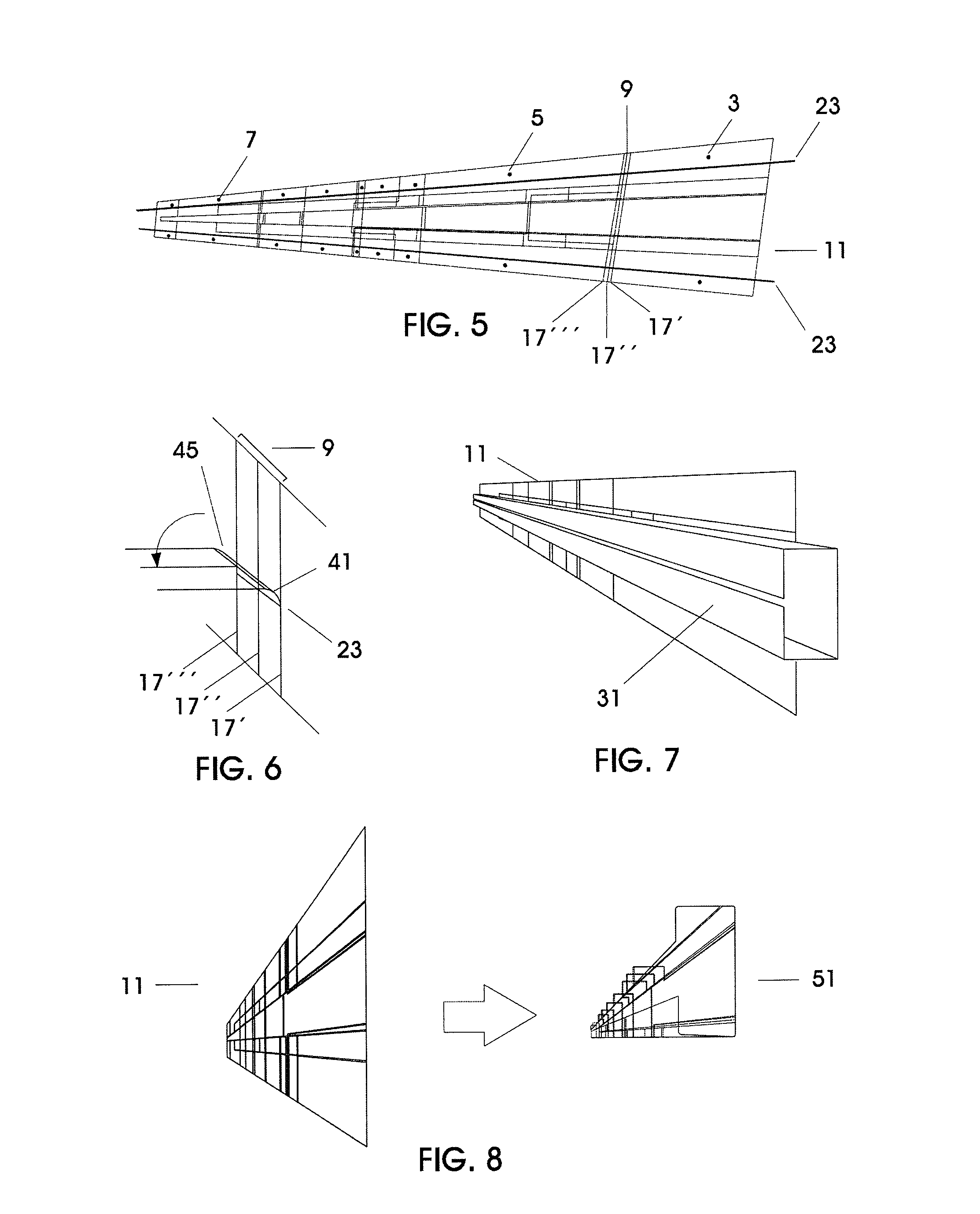

Computer assisted method for the advanced design of bent parts of composite material

InactiveUS8165703B2Computation using non-denominational number representationDesign optimisation/simulationComputer-aidedCad system

Computer assisted method for the advanced design of bent parts of composite material using a computer assisted CAD system comprising the following stages: a) Supplying the 2D mesh model (11) of the part; b) Generating the 3D outer surface (19) of the part; c) Obtaining the 3D mesh model (51) by adapting the 2D mesh model (11) to the geometry of the 3D outer surface (19) by bending the contour lines (17) of the patterns (13) of the 2D model (11) with respect to some bending lines (23) set up in relation to a bending surface (31) similar to that of the tool provided for bending the part; d) Generating the solid model (53) of the bent part. The invention also relates to a computer program that when it is executed on a computer together with a CAD system it causes the execution of the method.

Owner:AIRBUS OPERATIONS SL

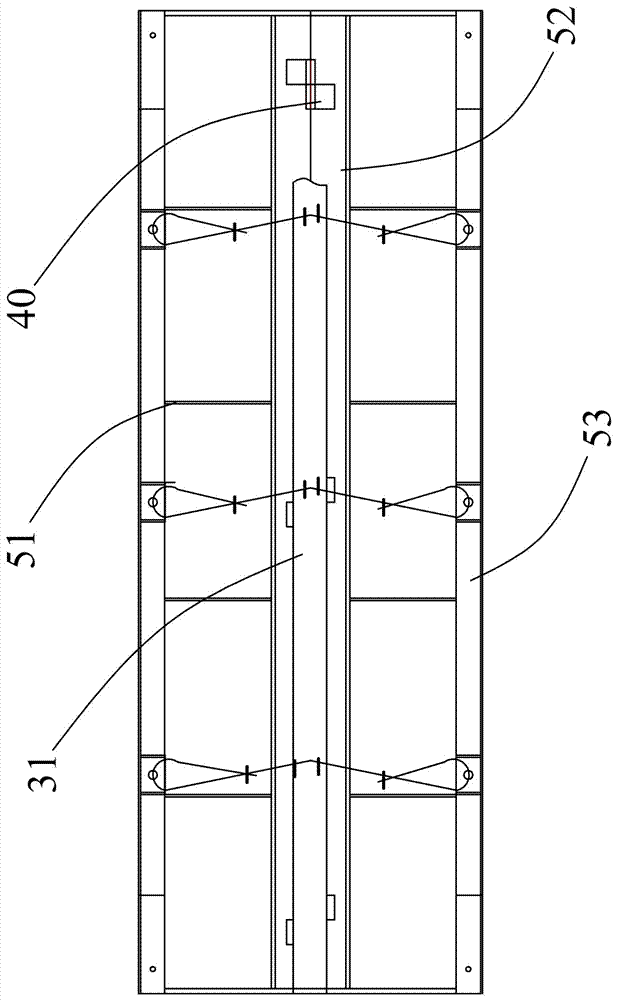

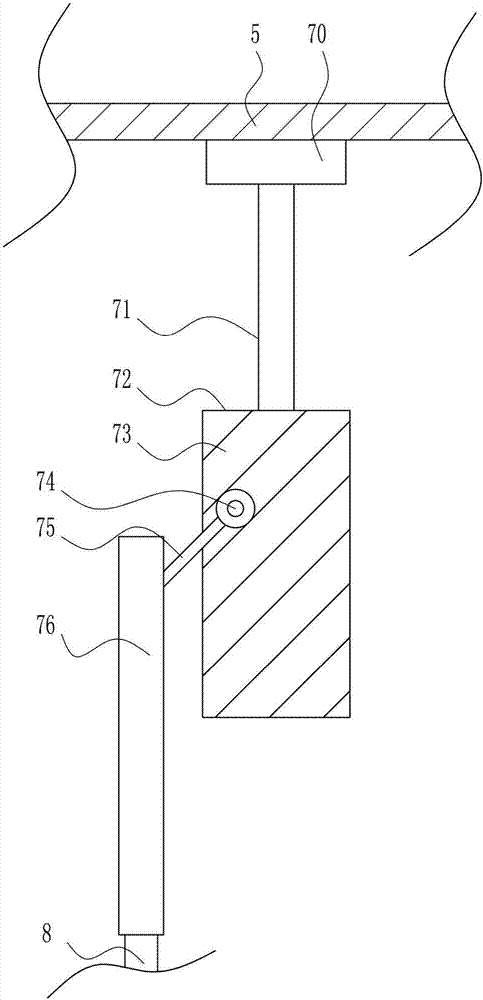

Structure for detecting post-grouted inserting type sleeve and steel bar connector through endoscope method and method applying structure

PendingCN107288268AAccurate judgmentSimple and fast operationMaterial analysis by optical meansUsing optical meansRebarEndoscope

The invention discloses a structure for detecting a post-grouted inserting type sleeve and steel bar connector through an endoscope method and a method applying the structure and belongs to the technical field of detection. Whether the position of a steel bar in a sleeve is in place or not is observed through an industrial endoscope. According to the method, operation is easy and convenient, the result is visual and reliable, the applicable working condition is wide, and the influence of the site construction condition on themethod is less; and meanwhile, whether a grouting channel and an overflowing channel are unobstructed or not can be inspected, and the guarantee is provided for the quality of subsequent grouting construction.

Owner:ZHEJIANG UNIV

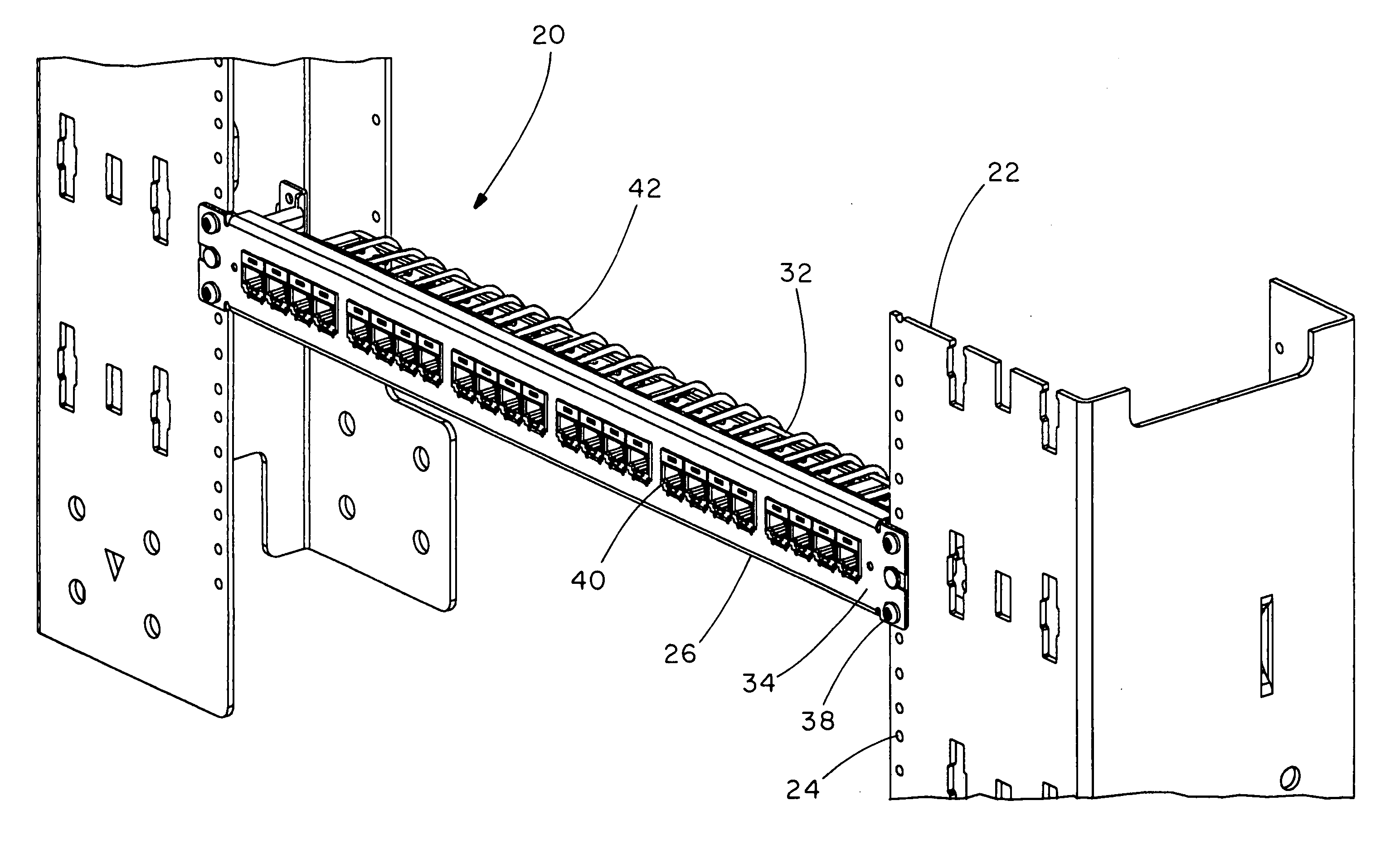

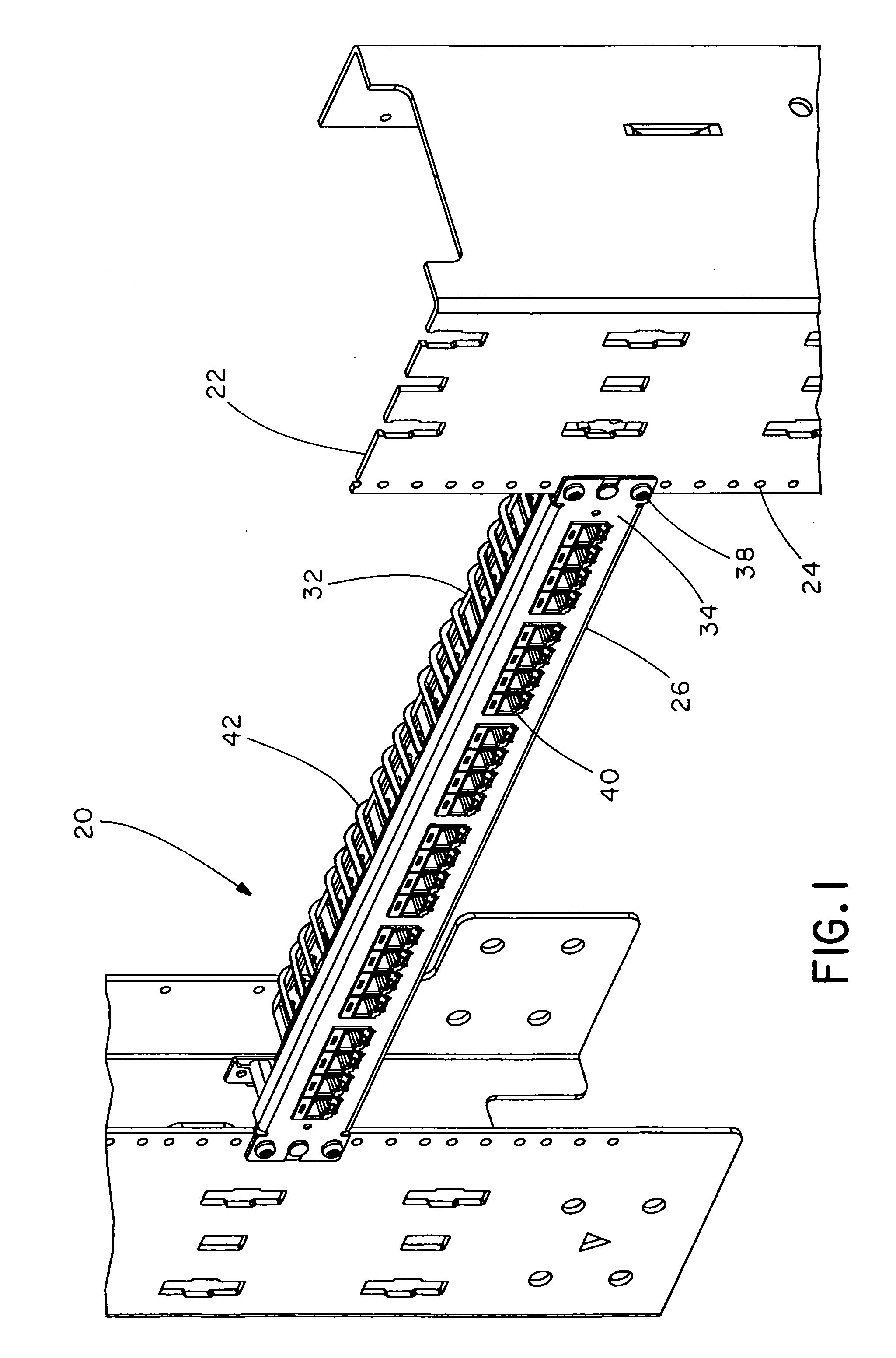

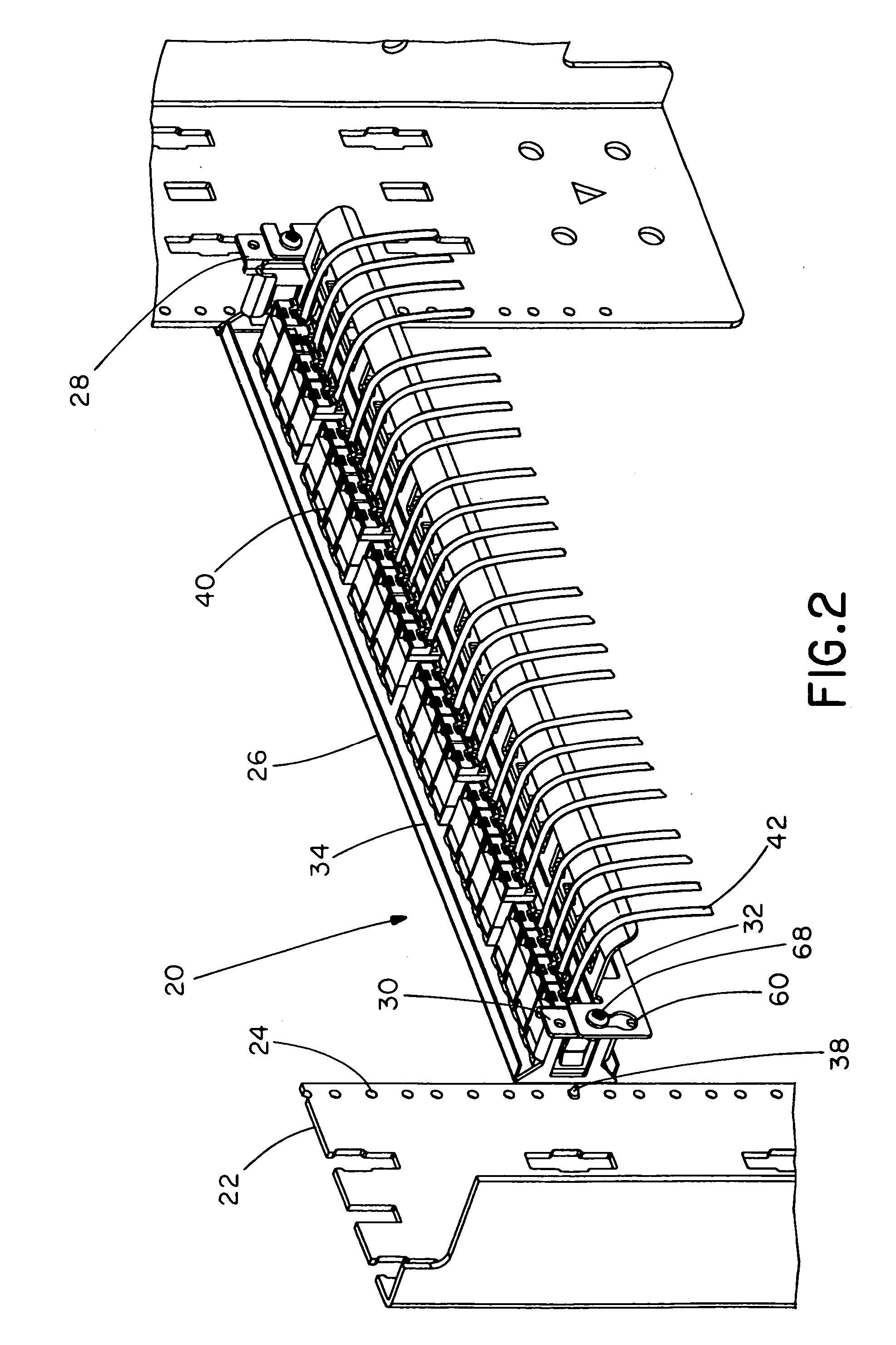

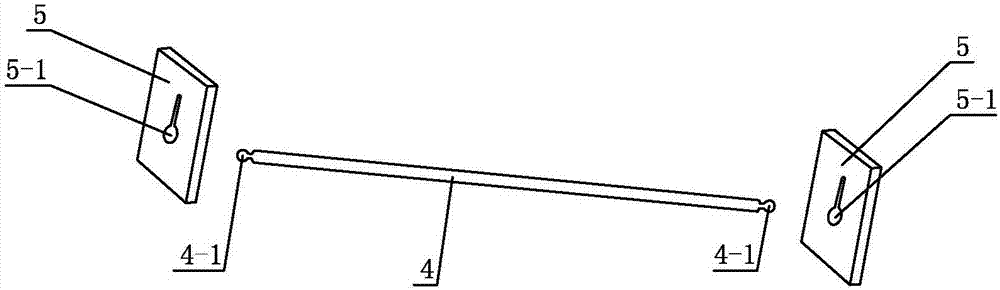

Patch panel and strain relief bar assembly

ActiveUS20060160431A1Quick releaseElectrically conductive connectionsSubstation/switching arrangement detailsPatch panelRollover

A patch panel and strain relief bar assembly includes a patch panel, two bracket assemblies connected to the patch panel and a strain relief bar connected to the bracket assemblies. Each bracket assembly includes a first bracket and a second bracket removably secured to the first bracket. The first bracket is connected to the patch panel, and the first bracket has a tab including a cantilever that secures the first bracket to the second bracket. The first bracket also includes two rollover edges connected to the tab. The second bracket is connected to the strain relief bar, and the second bracket has a tab including an aperture that receives a portion of the first bracket therein.

Owner:PANDUIT

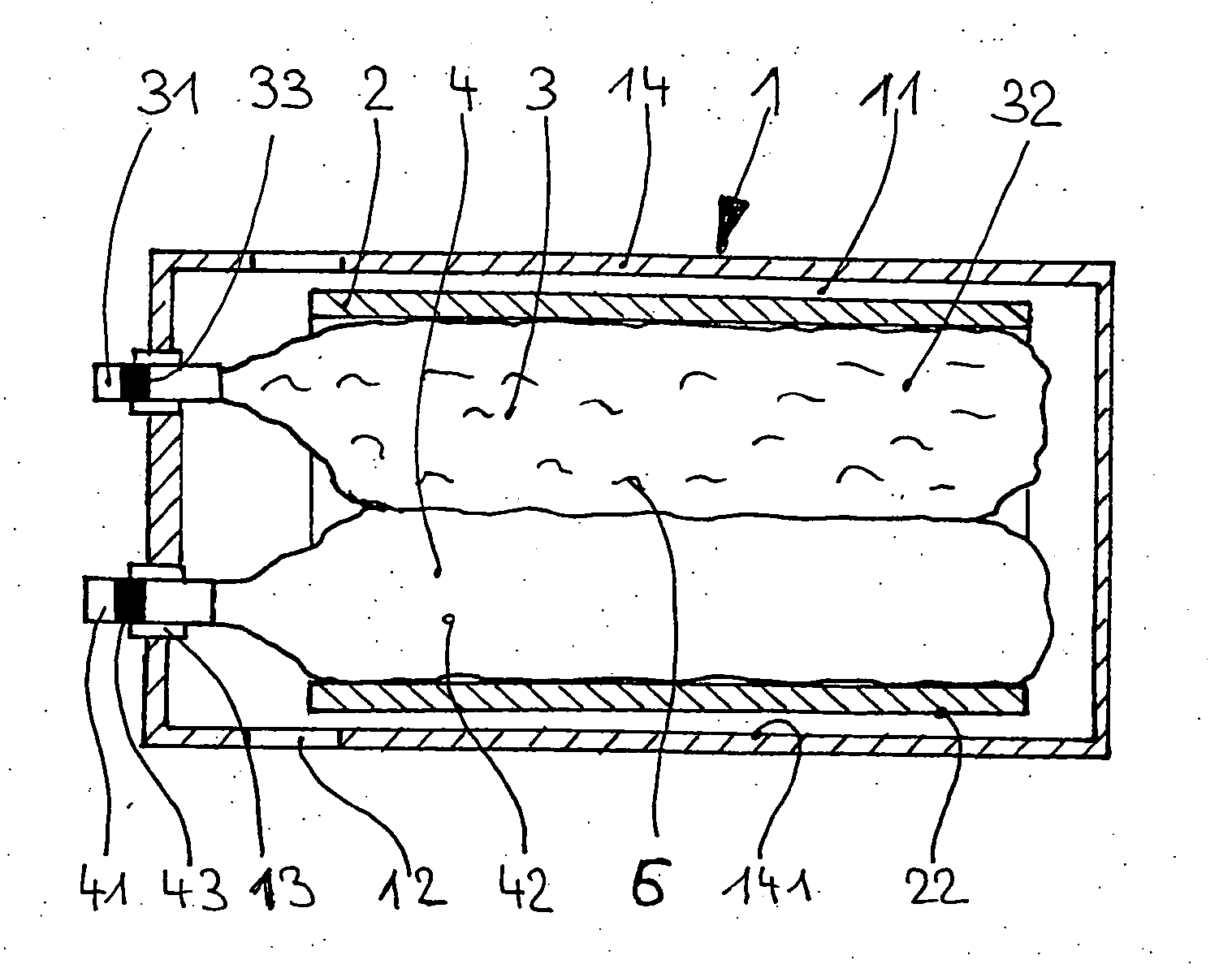

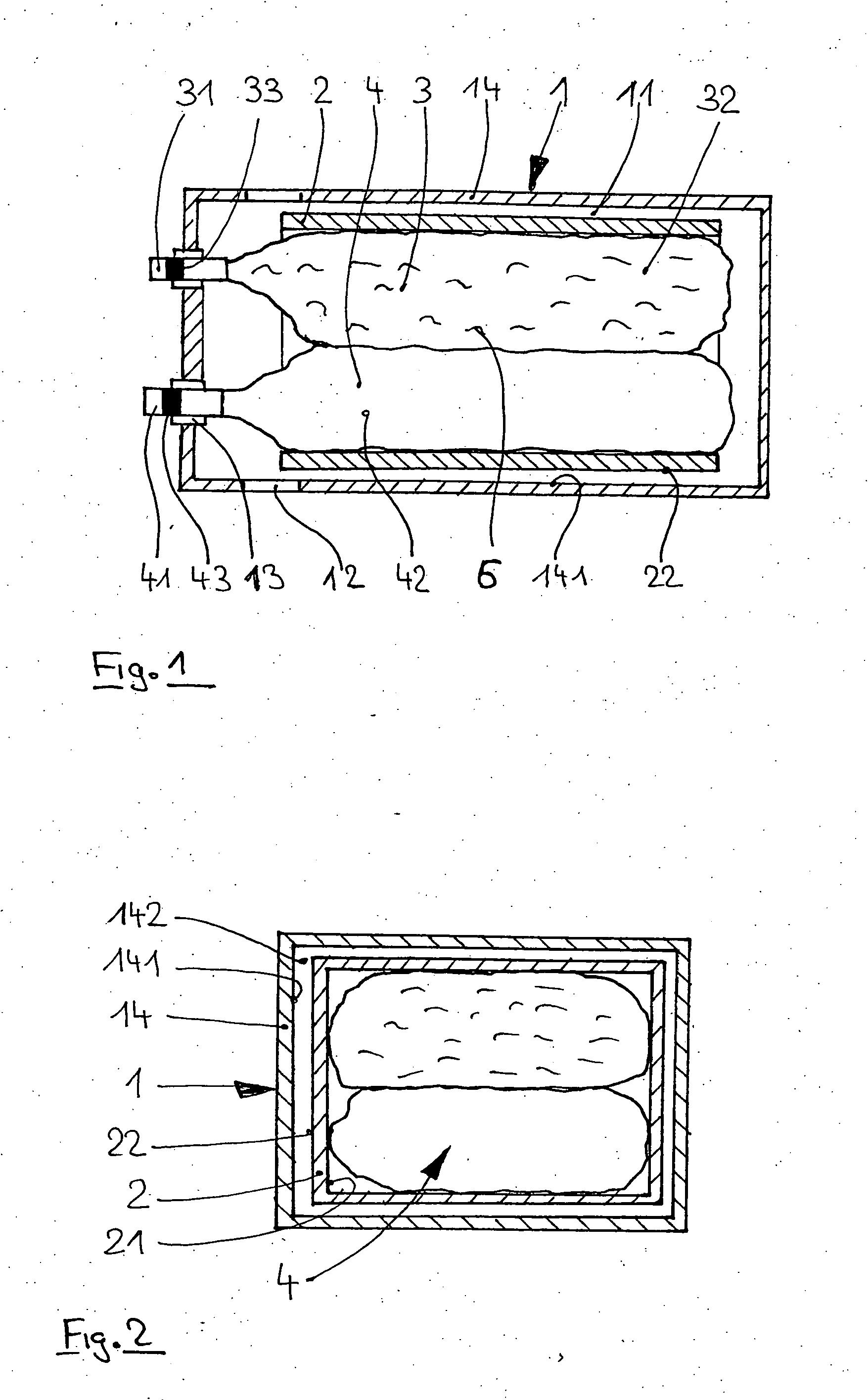

Ink reservoir for automatic recording, writing, and drawing devices

An ink reservoir or tank for automatic recording, writing, and drawing devices, particularly ink-jet systems, such as printers and plotters, wherein a sleeve or bandage is arranged within the ink reservoir. The ink pouch and the printing device are entirely or partially surrounded by the sleeve or bandage. In addition, the sleeve or bandage is constructed with respect to shape and dimensions in such a way that a free space exists between the outer wall of the sleeve or bandage and the inner side of the housing wall of the ink reservoir.

Owner:J S STAEDTLER

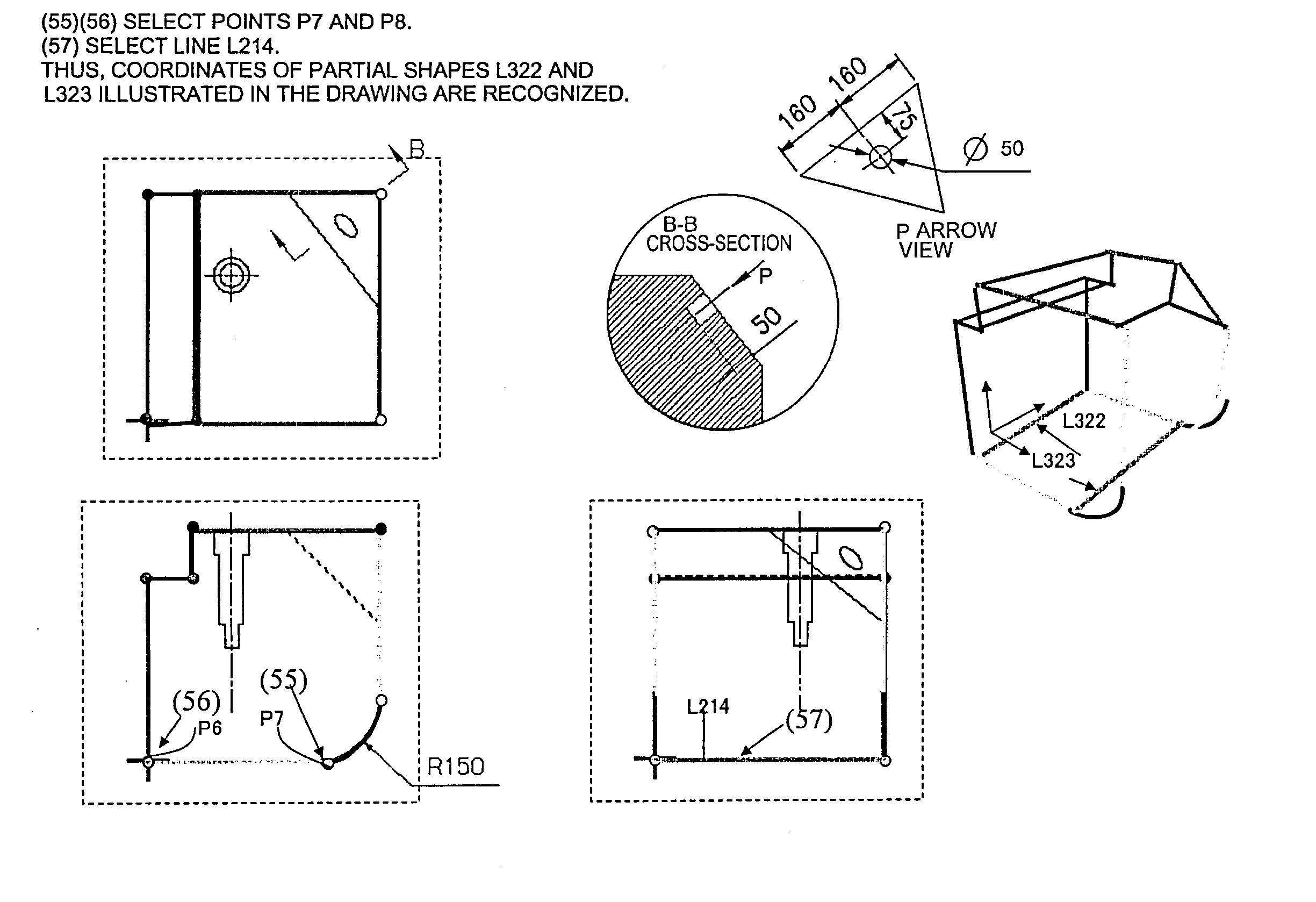

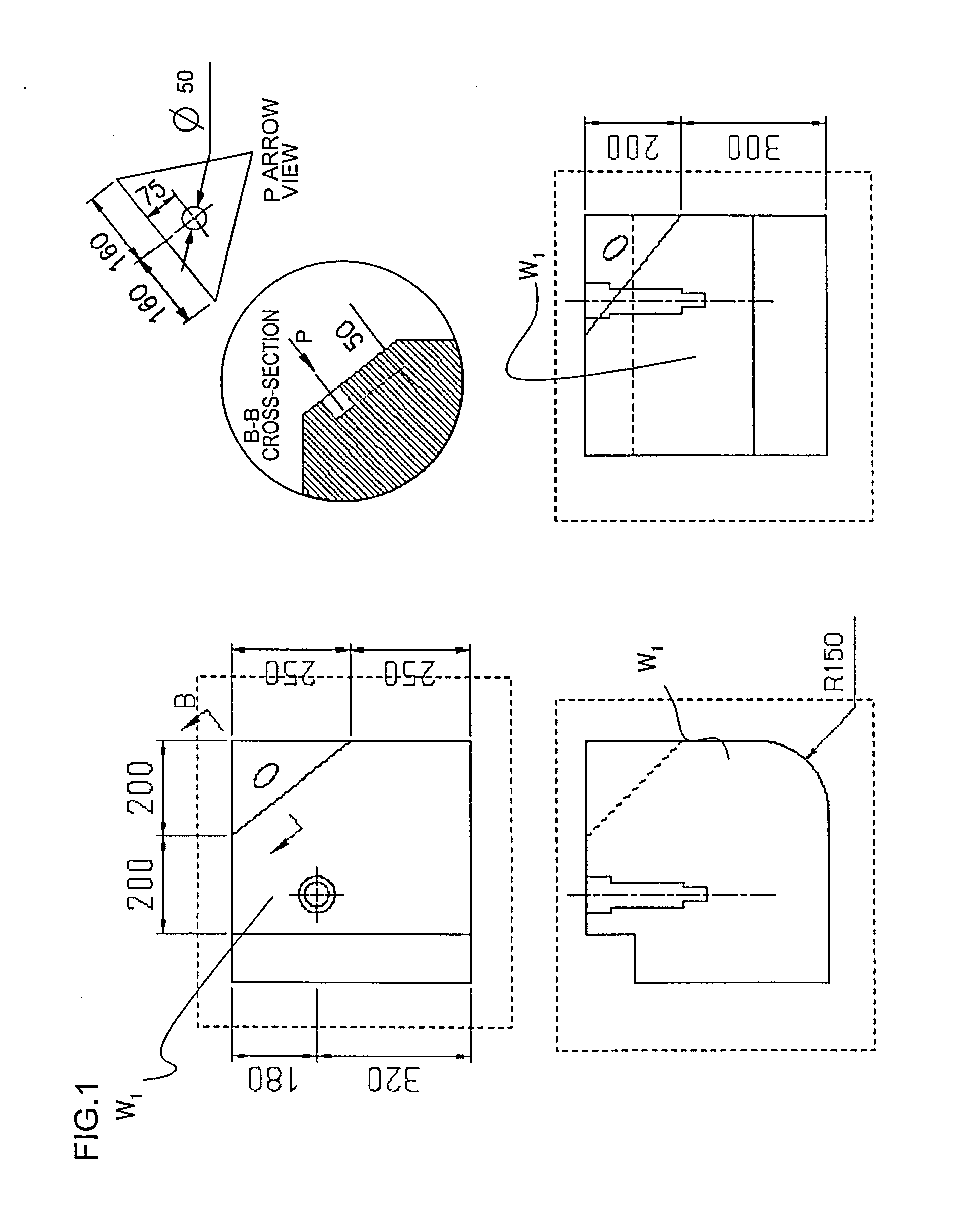

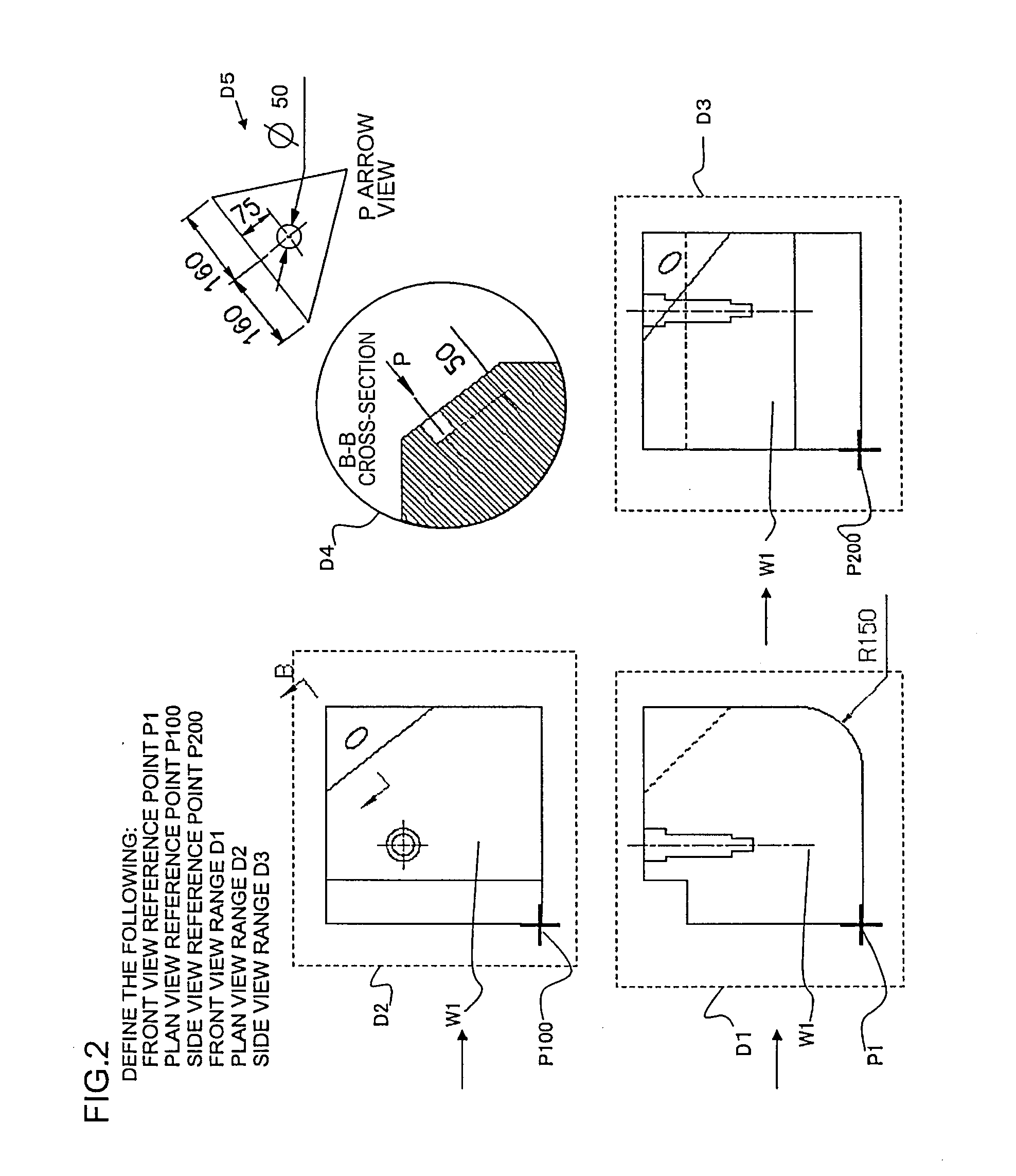

Method for converting two-dimensional drawing into three-dimensional solid model and method for converting attribute

InactiveUS20080100616A1Easy to createEasy to convertData acquisition and loggingThree-dimensional object recognitionEngineering drawing

The invention provides a method for creating a three-dimensional solid model from a two-dimensional projection drawing created on a CAD screen via a simple operation. Reference points P1, P100 and P200 are respectively selected on a front view, a plan view and a right side view of a CAD screen. Line L1 is selected in step (1), and points P100 and P101 are selected in steps (2) and (3). By selecting lines L200 and L201 in steps (4) and (5), the coordinates of three-dimensional elements L300 and L301 are recognized. Thereafter, the procedure is repeated sequentially to recognize the whole shape of the product via points and lines. By recognizing closed shapes surrounded by lines as surfaces, it becomes possible to create a three-dimensional solid model via a simple method.

Owner:YAMAZAKI MAZAK KK

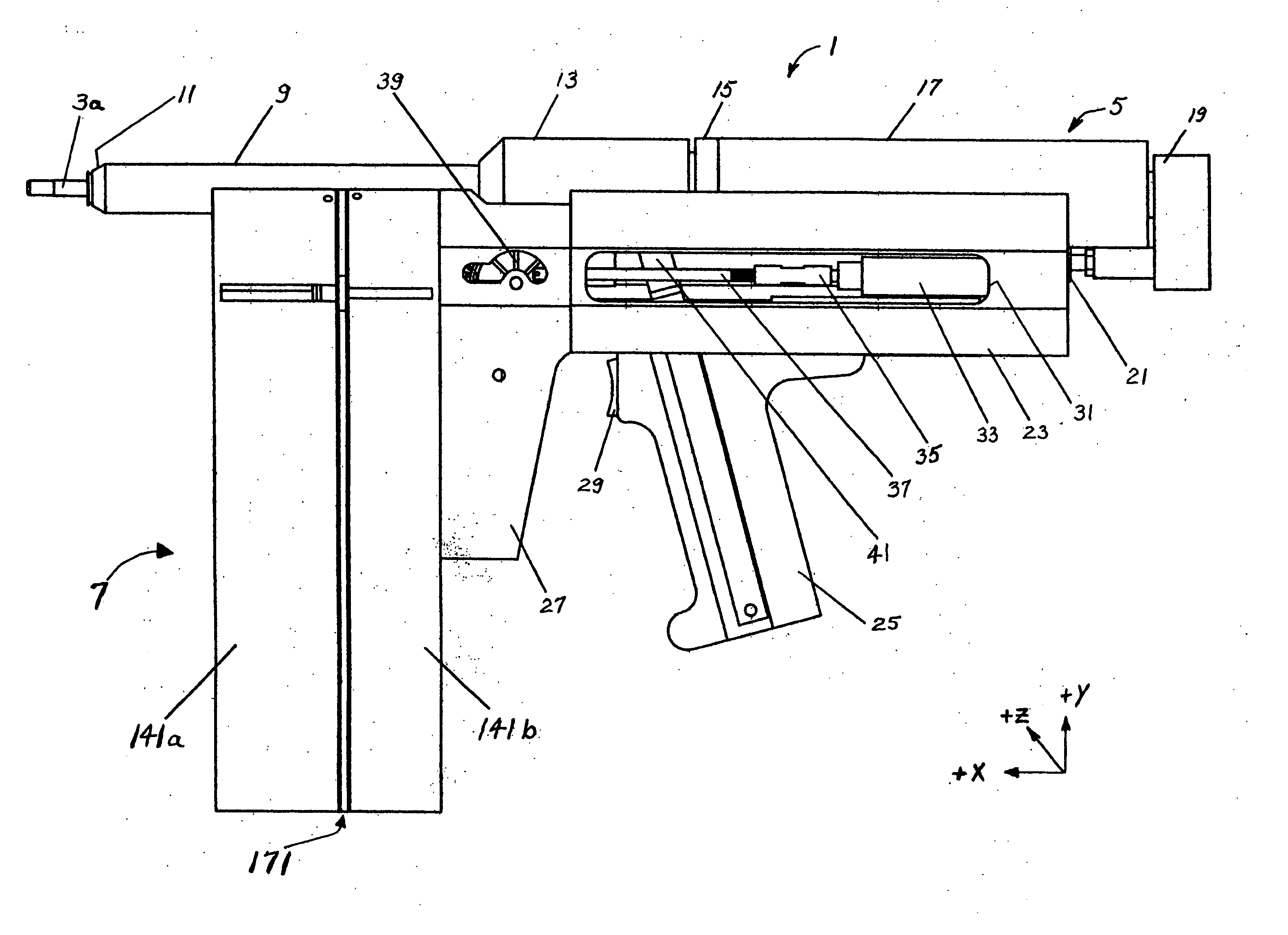

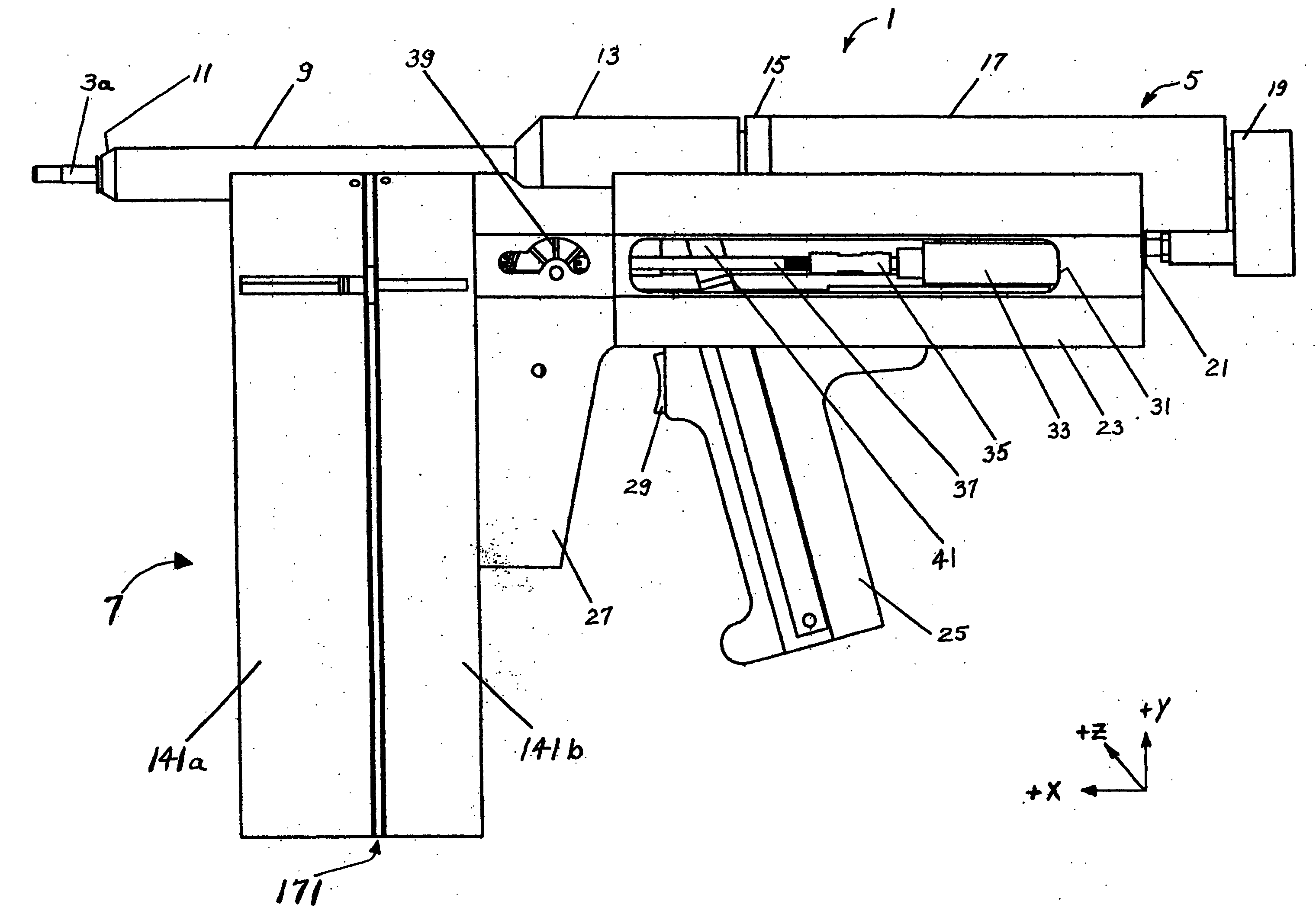

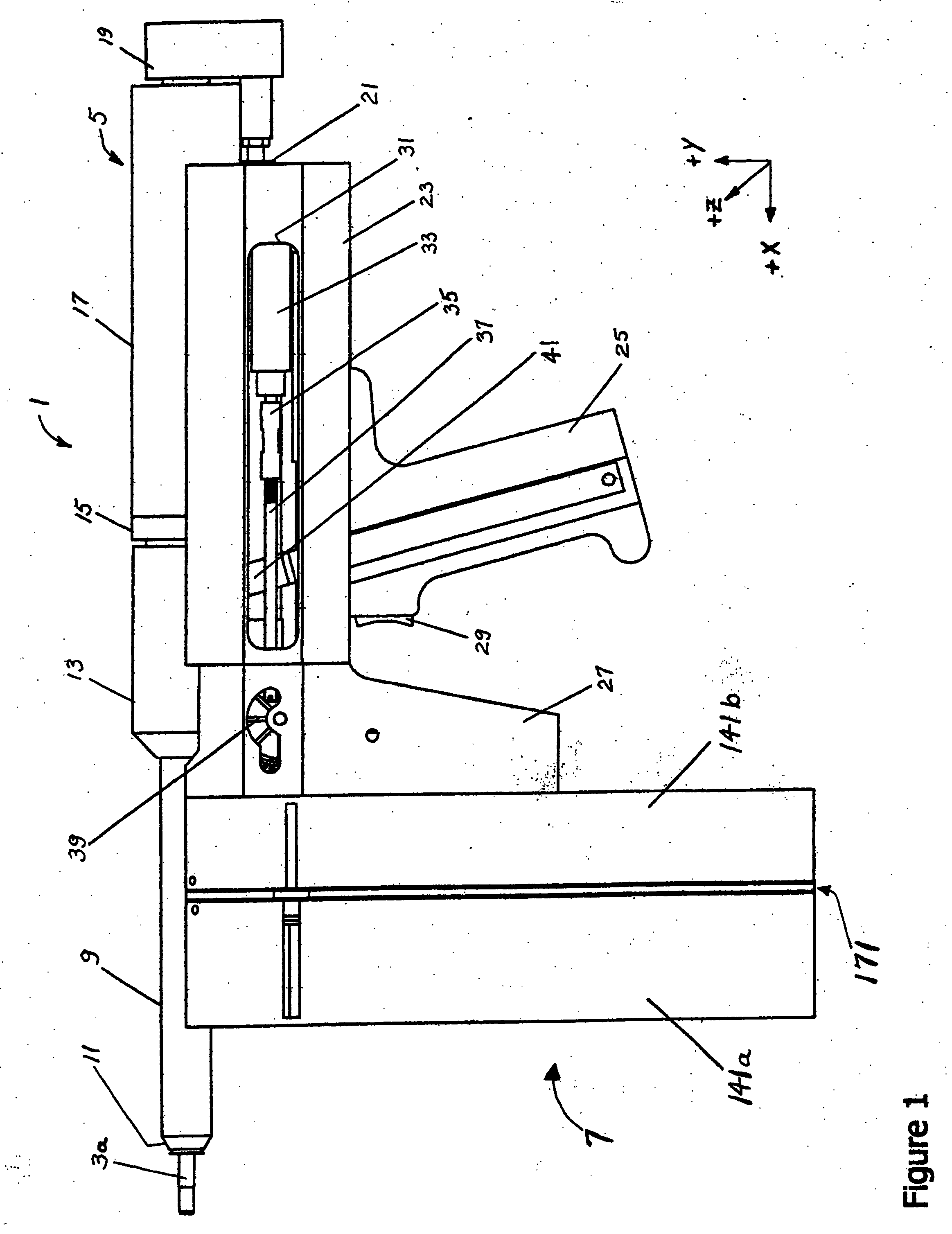

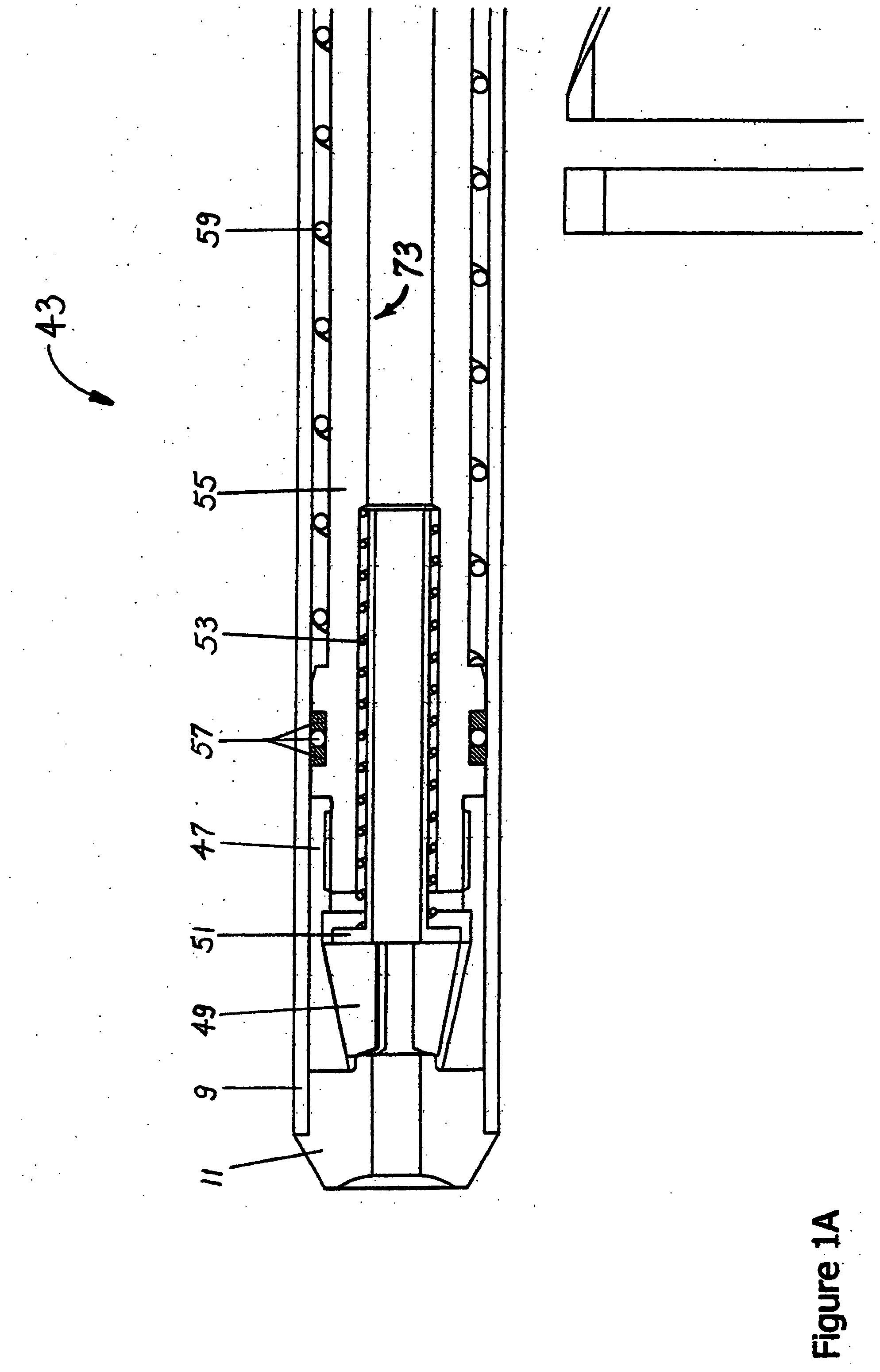

Fastener installation system

A blind fastener installation tool which accomplishes the blind installation of a series of fasteners is described in detail in this specification. The blind fastener installation tool comprises a structural housing which features a means for securing a fastener installation assembly in position relative to said structural housing during the blind installation of a fastener; and a means for reciprocating said fastener installation assembly relative to said structural housing at the conclusion of a cyclic blowline-fed or clip-fed blind installation of a fastener. The blind fastener installation tool also comprises a fastener installation assembly comprising (1) a pull rod assembly comprising means for pulling a first portion of a fastener; (2) an annular, piston-actuated, piston-decoupled pull rod actuation assembly to translate the pull rod assembly relative to said fastener installation assembly when said fastener installation assembly is secured at a fastener installation assembly fastener installation position, thereby pulling said first portion of said fastener until blind installation of said fastener is complete; and (3) a nose assembly comprising (3a) a fastener receptacle for securing the position of a fastener relative to said nose assembly during blind installation of said fastener; and (3b) one or more optional pull rod translation dampening assemblies to smoothly and effectually dampen the sudden translation of said pull rod assembly after pintail break during blind installation of a pintail-break-type fastener. The blind fastener installation tool also comprises an optional fastener delivery assembly, said optional fastener delivery assembly constituting: (1) a clip-fed fastener delivery system; or (2) a blowline-fed fastener delivery system.

Owner:FULBRIGHT DAVID J

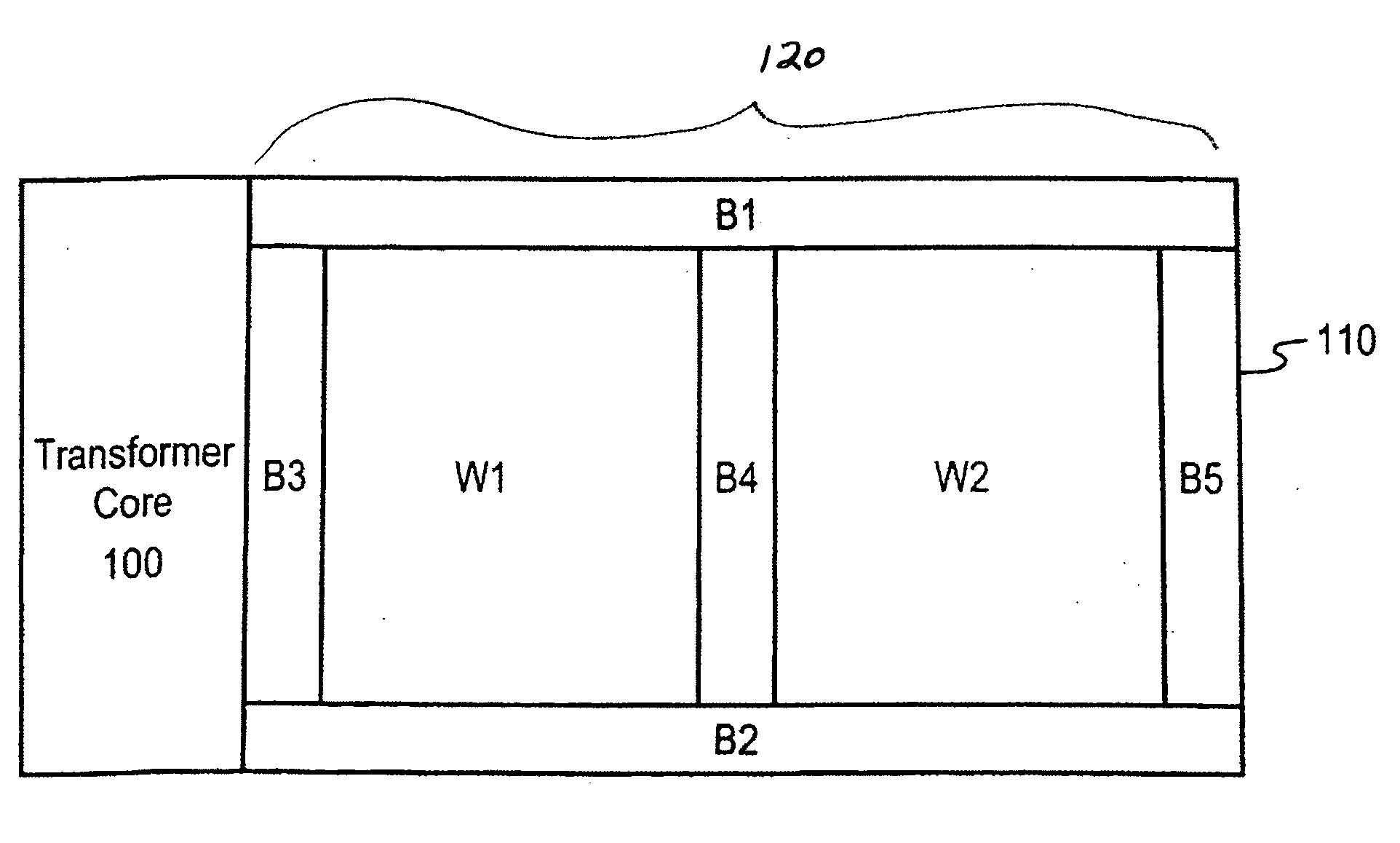

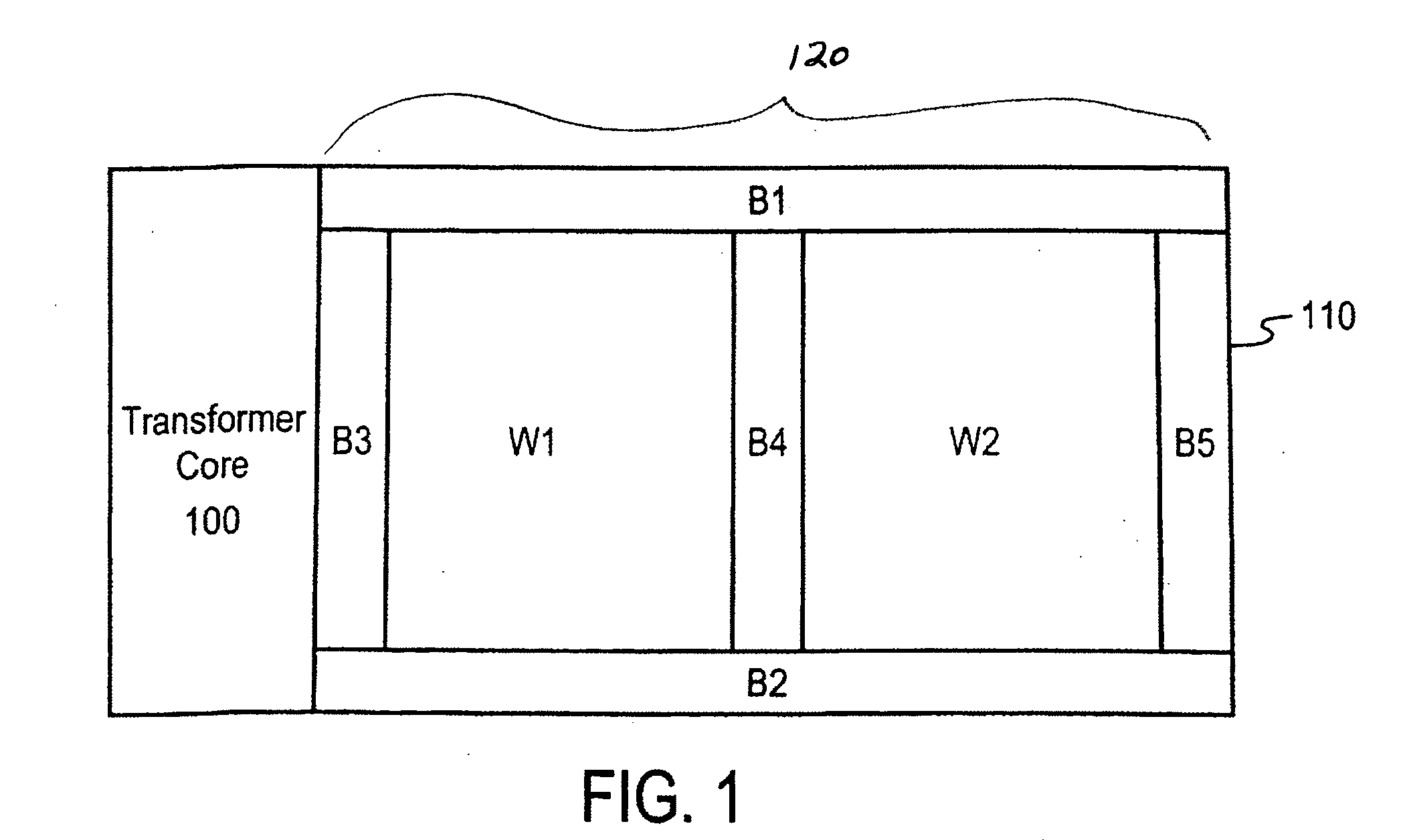

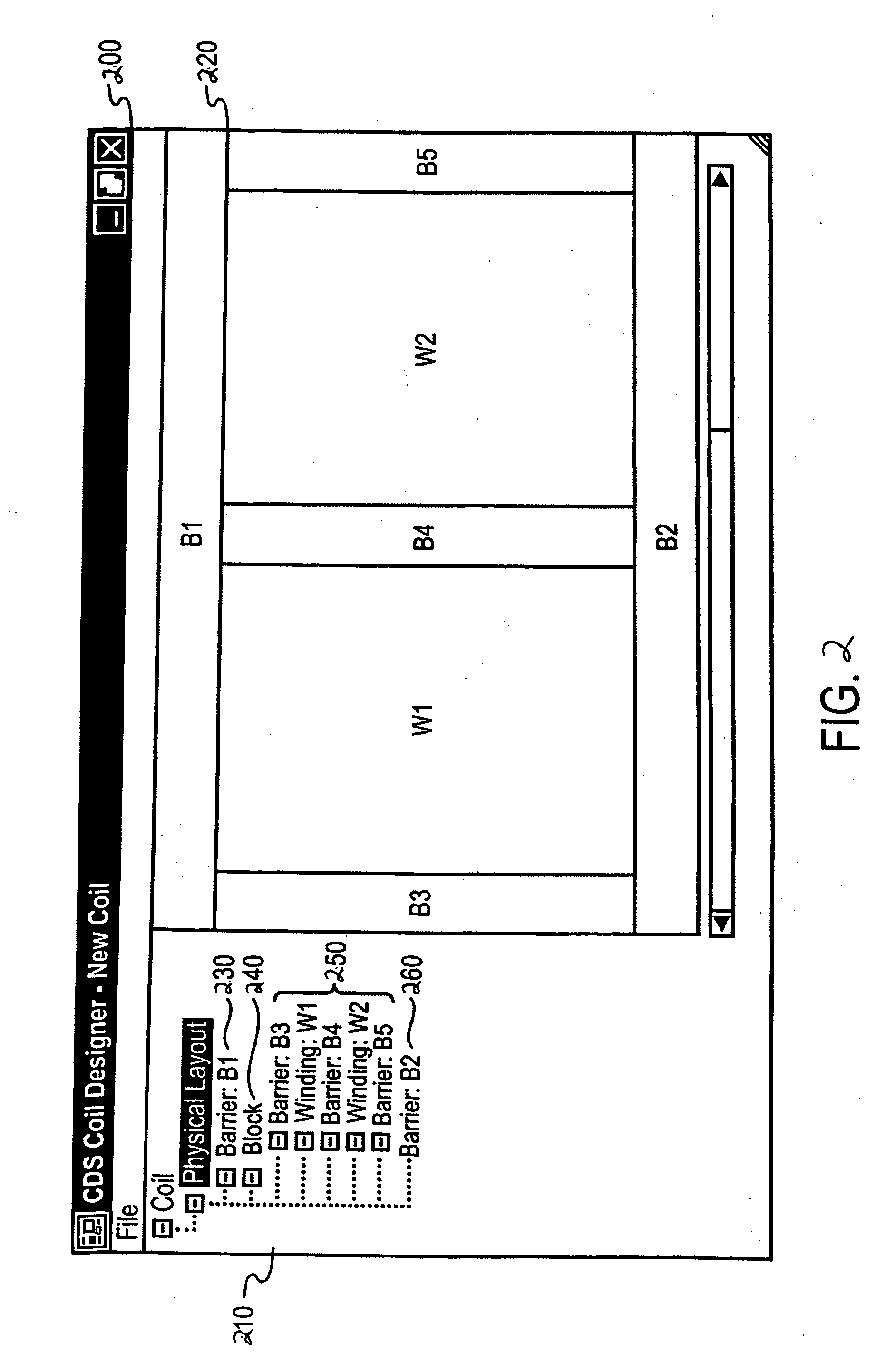

Automated method and tool for documenting a transformer design

InactiveUS20070027883A1TransformersDigital data processing detailsDocumentation procedureTransformer

A method and tool for creating documentation for a transformer design uses design files created during the transformer design process to generate drawings and other information necessary to populate documentation. The design files contain information relating to the physical layout of all of the components of the coil as well as the electrical connectivity of the windings. The method and tool retrieve the design information, construct the associated drawings, format the drawings to the appropriate sizes, and display any associated text.

Owner:ABB RES LTD

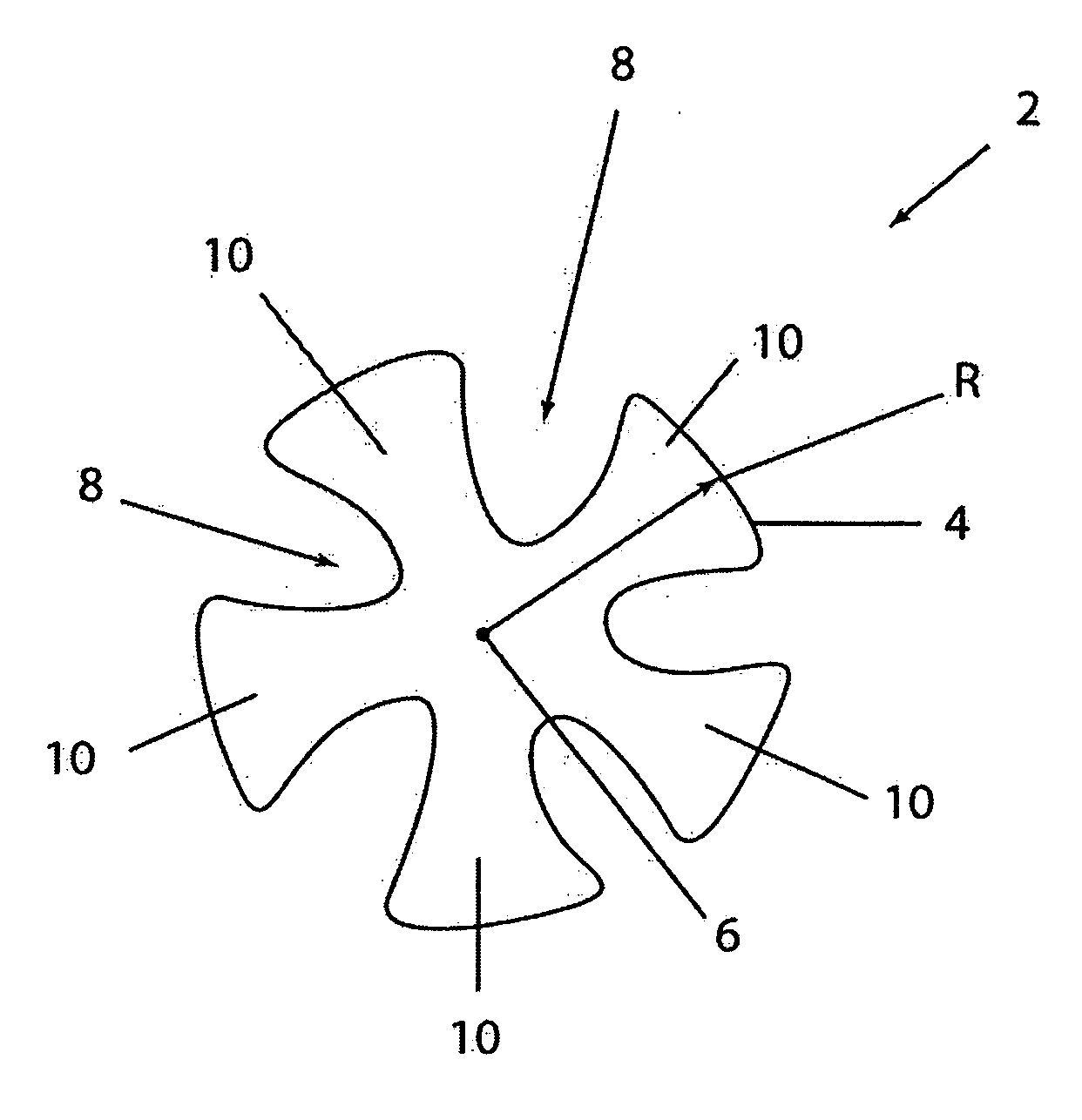

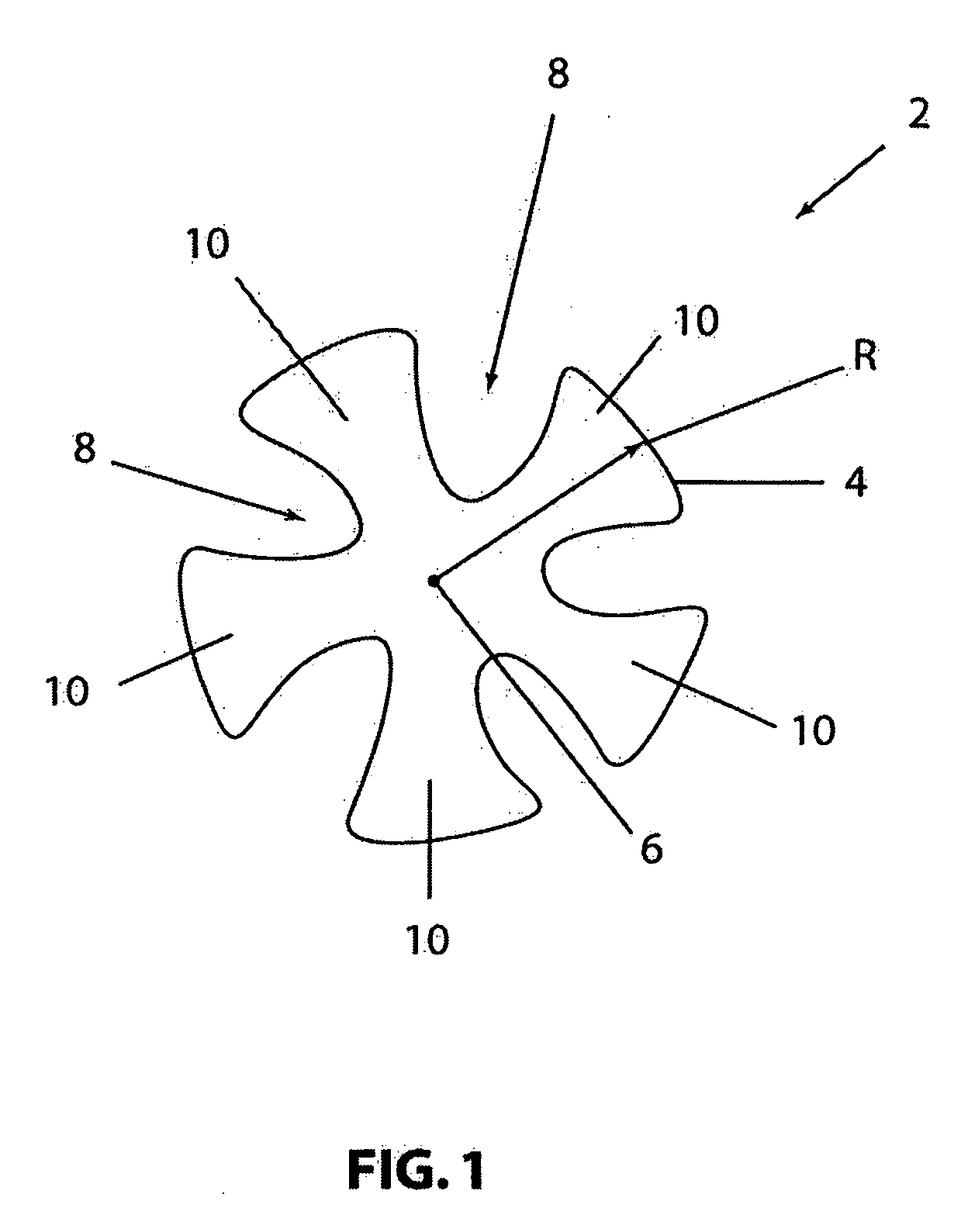

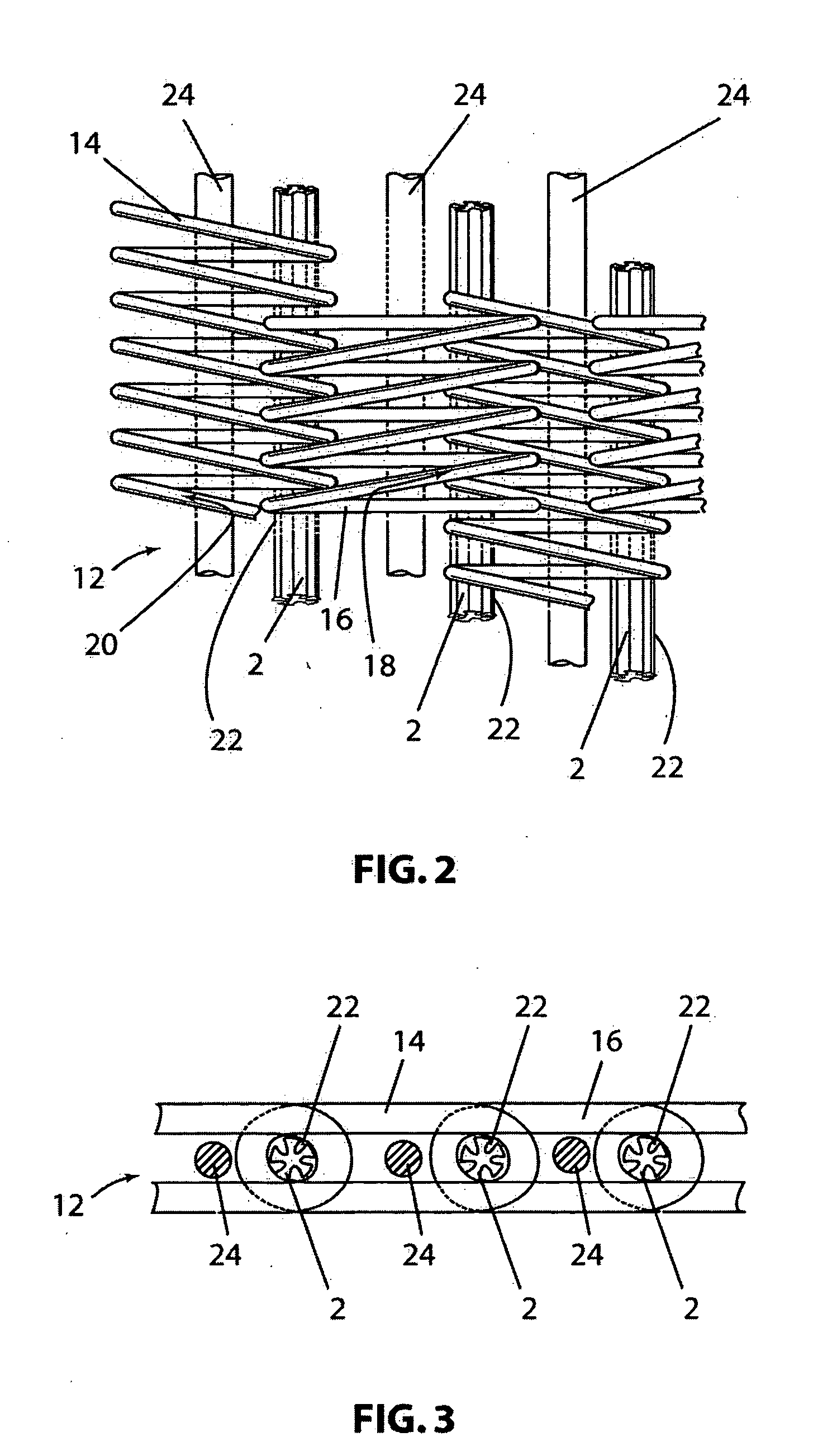

Pintle for spiral fabrics

ActiveUS20060005936A1Thinner fabricReduce penetrationMachine wet endPress sectionEngineering drawing

Owner:ALBANY INT CORP

Fastener installation system

A blind fastener installation tool which accomplishes the blind installation of a series of fasteners is described in detail in this specification. The blind fastener installation tool comprises a structural housing which features a means for securing a fastener installation assembly in position relative to said structural housing during the blind installation of a fastener; and a means for reciprocating said fastener installation assembly relative to said structural housing at the conclusion of a cyclic blowline-fed or clip-fed blind installation of a fastener. The blind fastener installation tool also comprises a fastener installation assembly comprising (1) a pull rod assembly comprising means for pulling a first portion of a fastener; (2) an annular, piston-actuated, direct action, piston-decoupled pull rod actuation assembly to translate the pull rod assembly relative to said fastener installation assembly when said fastener installation assembly is secured at a fastener installation assembly fastener installation position, thereby pulling said first portion of said fastener until blind installation of said fastener is complete; and (3) a nose assembly comprising (3a) a fastener receptacle for securing the position of a fastener relative to said nose assembly during blind installation of said fastener; and (3b) one or more optional pull rod translation dampening assemblies to smoothly and effectually dampen the sudden translation of said pull rod assembly after pintail break during blind installation of a pintail-break—type fastener. The blind fastener installation tool also comprises an optional fastener delivery assembly, said optional fastener delivery assembly constituting: (1) a clip-fed fastener delivery system; or (2) a blowline-fed fastener delivery system.

Owner:FULBRIGHT DAVID J

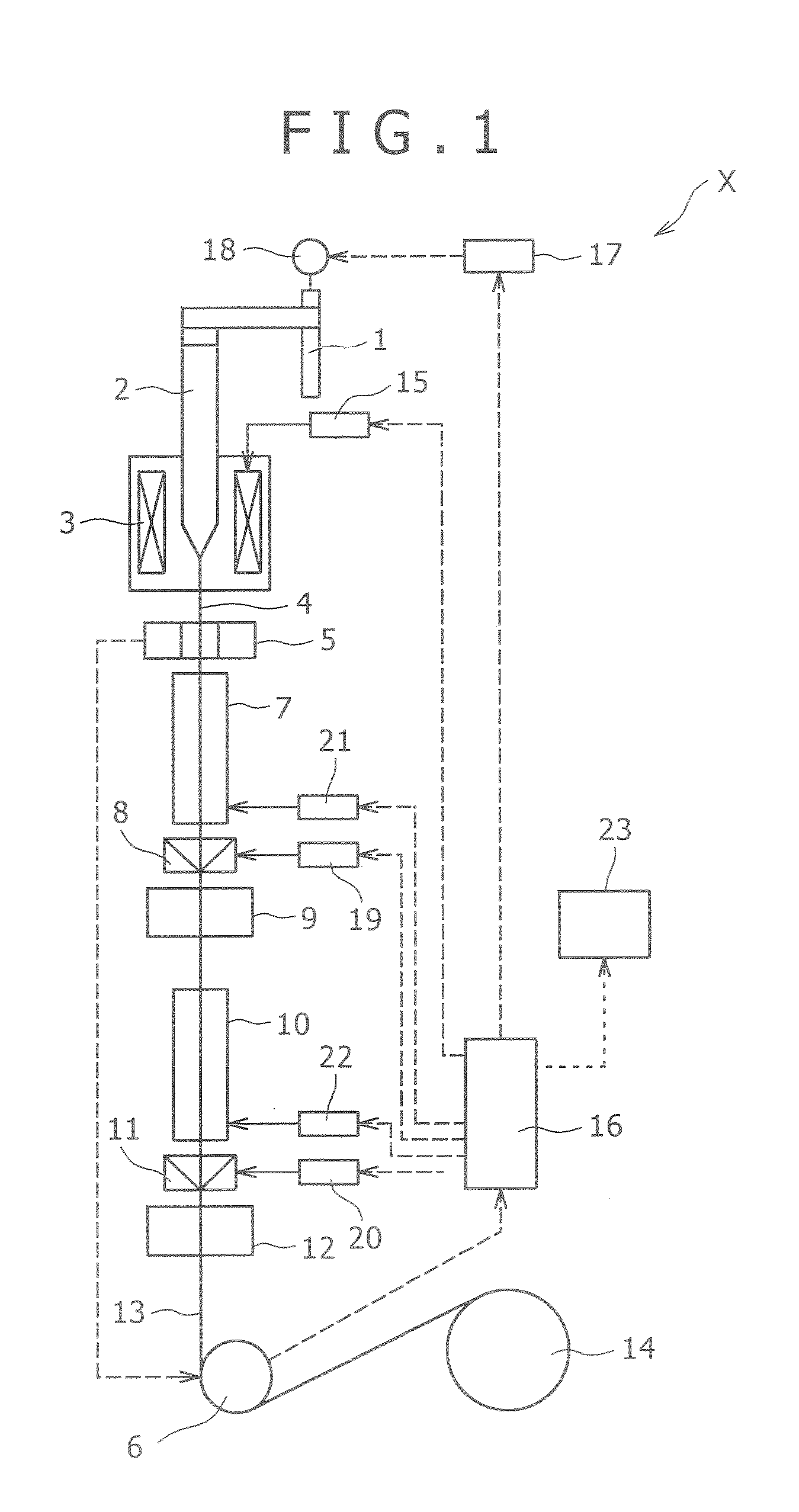

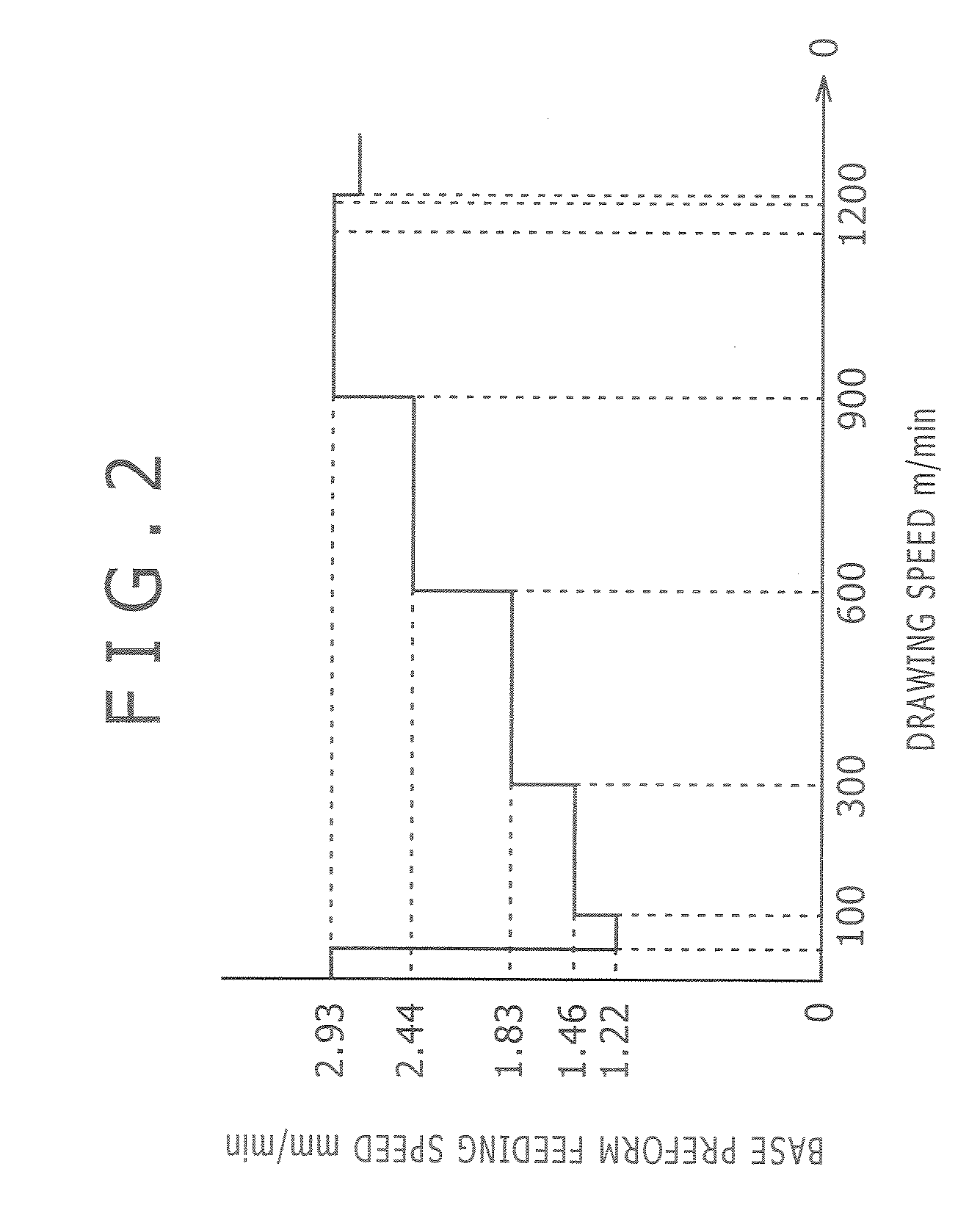

Optical Fiber Drawing Apparatus

ActiveUS20080016917A1Stable drawing controlShorten fiber lengthGlass furnace apparatusGlass fibre drawing apparatusFiberFurnace temperature

In an optical fiber drawing device of the present invention, as an operational parameters corresponding to the real drawing speed in the duration from the moment of starting the operation of the optical fiber drawing device till the moment of reaching the target drawing speed are extracted from operational parameters stored in a operational parameter storage unit and applied to the optical fiber drawing device. The operational parameters include a base preform feeding speed, a target variation of real drawing speed, a gain multiplied by the speed element related with the variation of the real drawing speed, an operation cycle, a drawing furnace temperature, a coating resin pressure to coat the optical fiber, and flow of cooling gaseous helium, etc. The optical fiber drawing device of the present invention capable of a stable drawing control that does not generate hunting or overshoot or the like, while reducing the start-up fiber length (or speed increasing time) in the unsteady state (transient state) operation of the optical fiber drawing device.

Owner:KOBE STEEL LTD

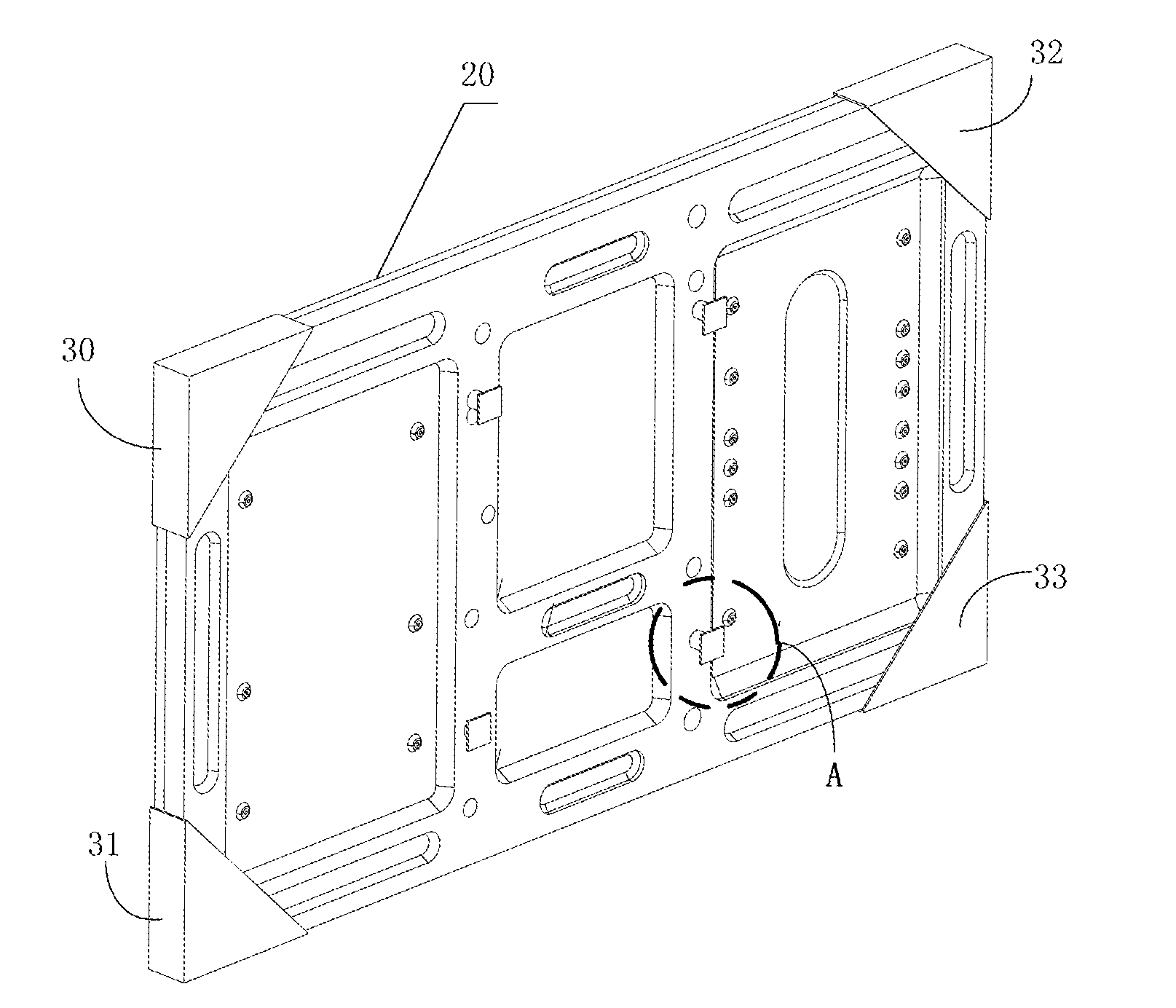

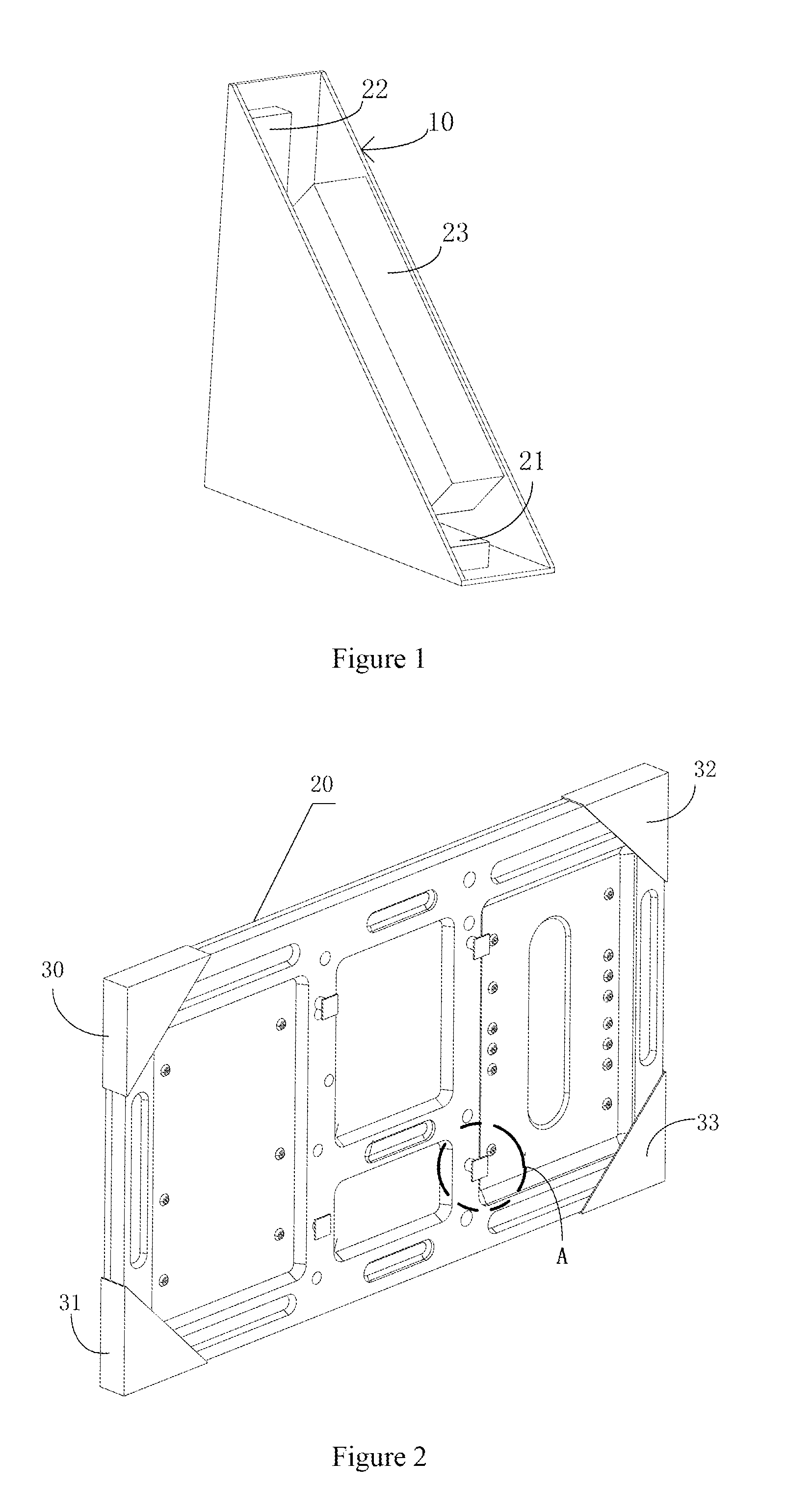

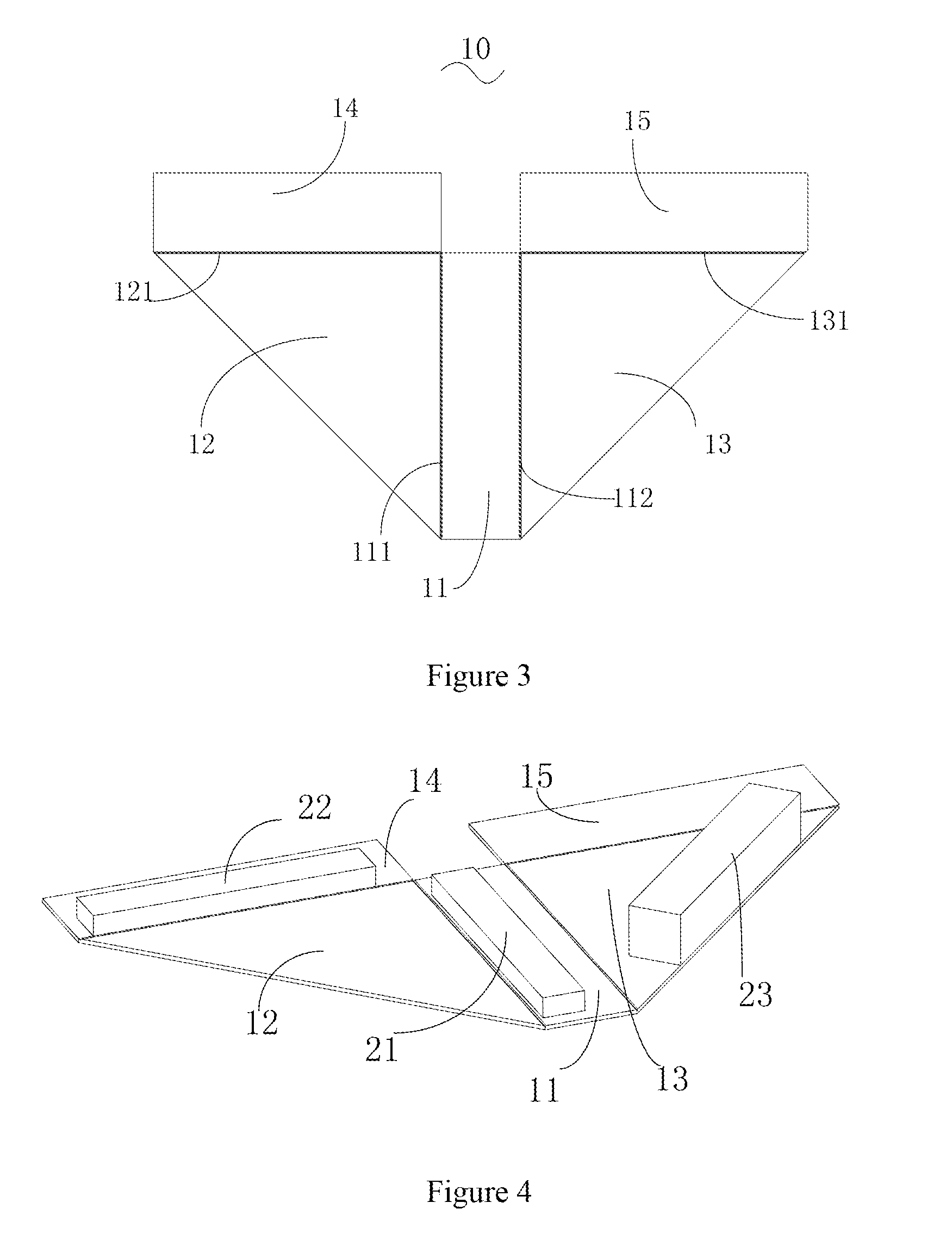

Packaging Device for Panel

InactiveUS20140014549A1Low costMaterial efficiencyOther accessoriesContainer/bottle contructionEngineering drawingSurface plate

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

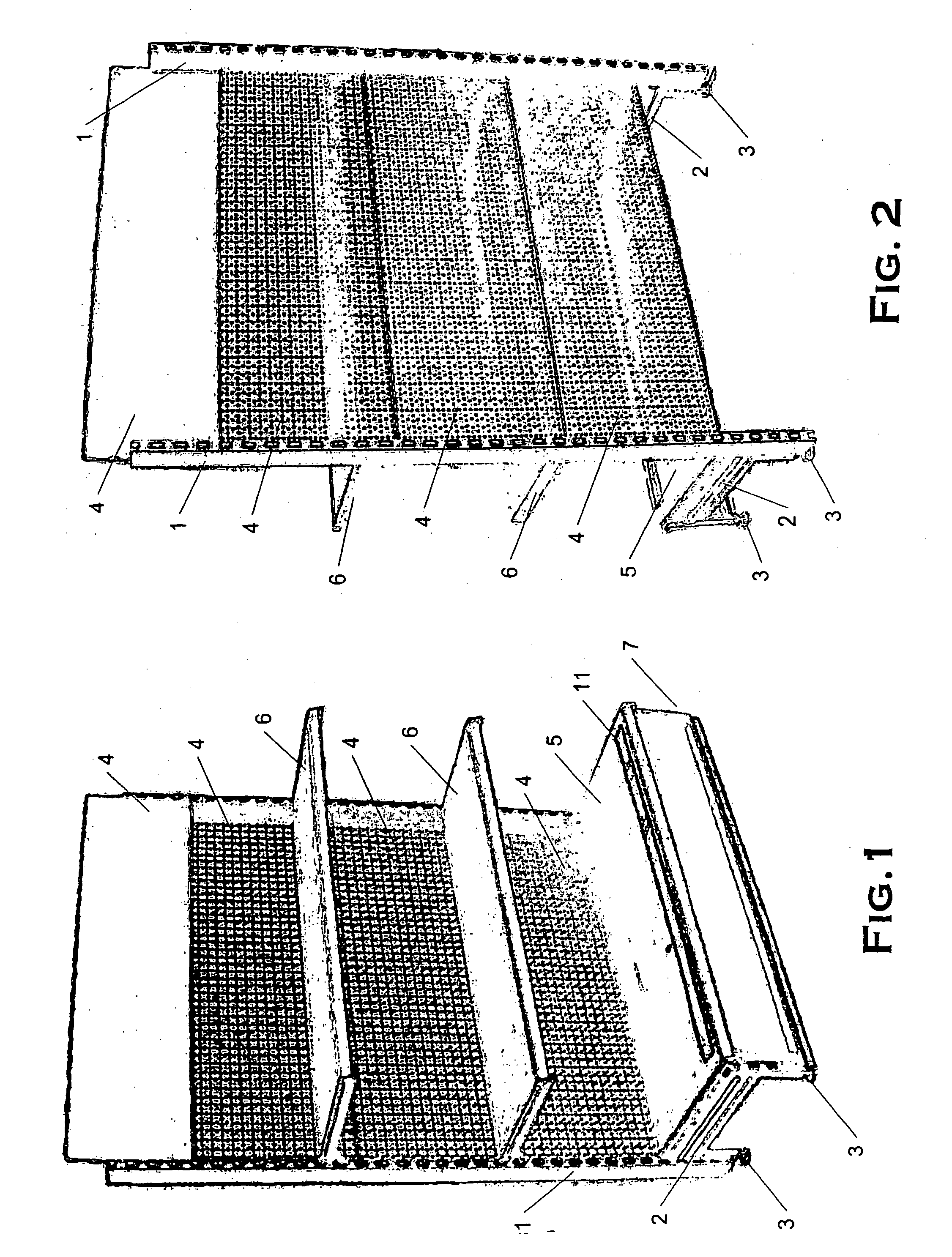

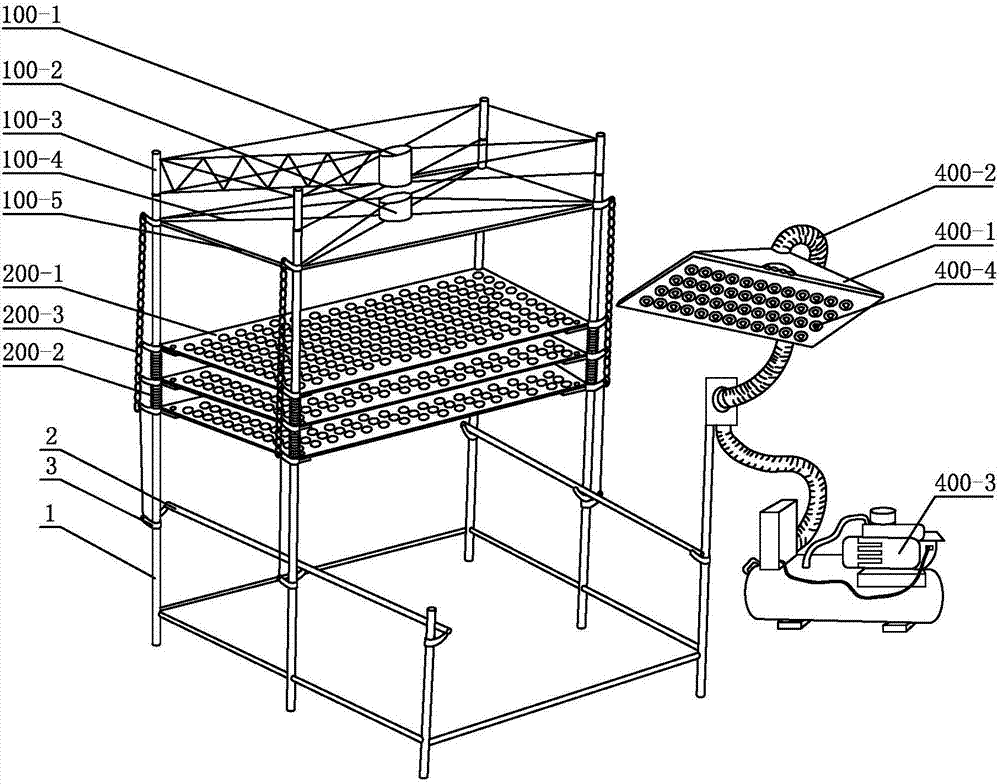

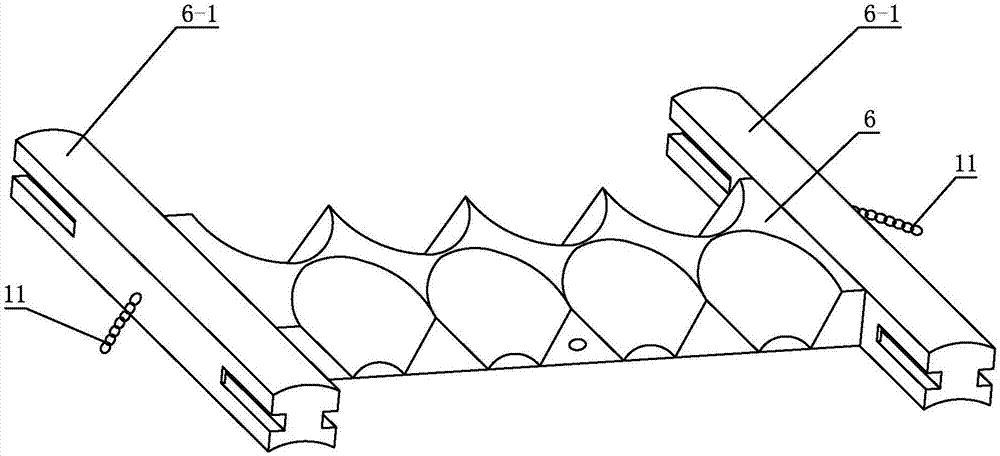

Drawing type steel inner die and construction method of prefabricated hollow slab girder

PendingCN107471414AAvoid risk of damageReduce maintenance costsDischarging arrangementCeramic shaping mandrelsFour componentEngineering drawing

The invention discloses a drawing type steel inner die. The drawing type steel inner die comprises a first die plate and a second die plate. The first die plate comprises a first component and a second component which are symmetrically arranged in the vertical direction and are hinged to each other. The second die plate comprises a third component and a fourth component which are symmetrically arranged in the vertical direction and are hinged to each other. The four components jointly form a hollow cylindrical structure. The first die plate and the second die plate are each provided with a drawing unit. Each drawing unit comprises a main shaft pull rod and at least one steel wire rope, wherein the middle portion of each steel wire rope is fixedly connected with the main shaft pull rod, and the two ends of the steel wire rope are fixedly connected with the upper component and the lower component. The invention further discloses a construction method used for a prefabricated hollow slab girder and achieved through the drawing type steel inner die. According to the technical scheme, the drawing units which are composed of the steel wire ropes and the main shaft pull rods are adopted to carry out drawing die dismounting, connection can be achieved without hinges, the risks that the hinges and the components are damaged in the drawing process of the steel inner die are eradicated, the clamping problem is solved, the maintaining cost is low, repeated using is facilitated, and the production efficiency is improved.

Owner:中铁二十二局集团第三工程有限公司 +1

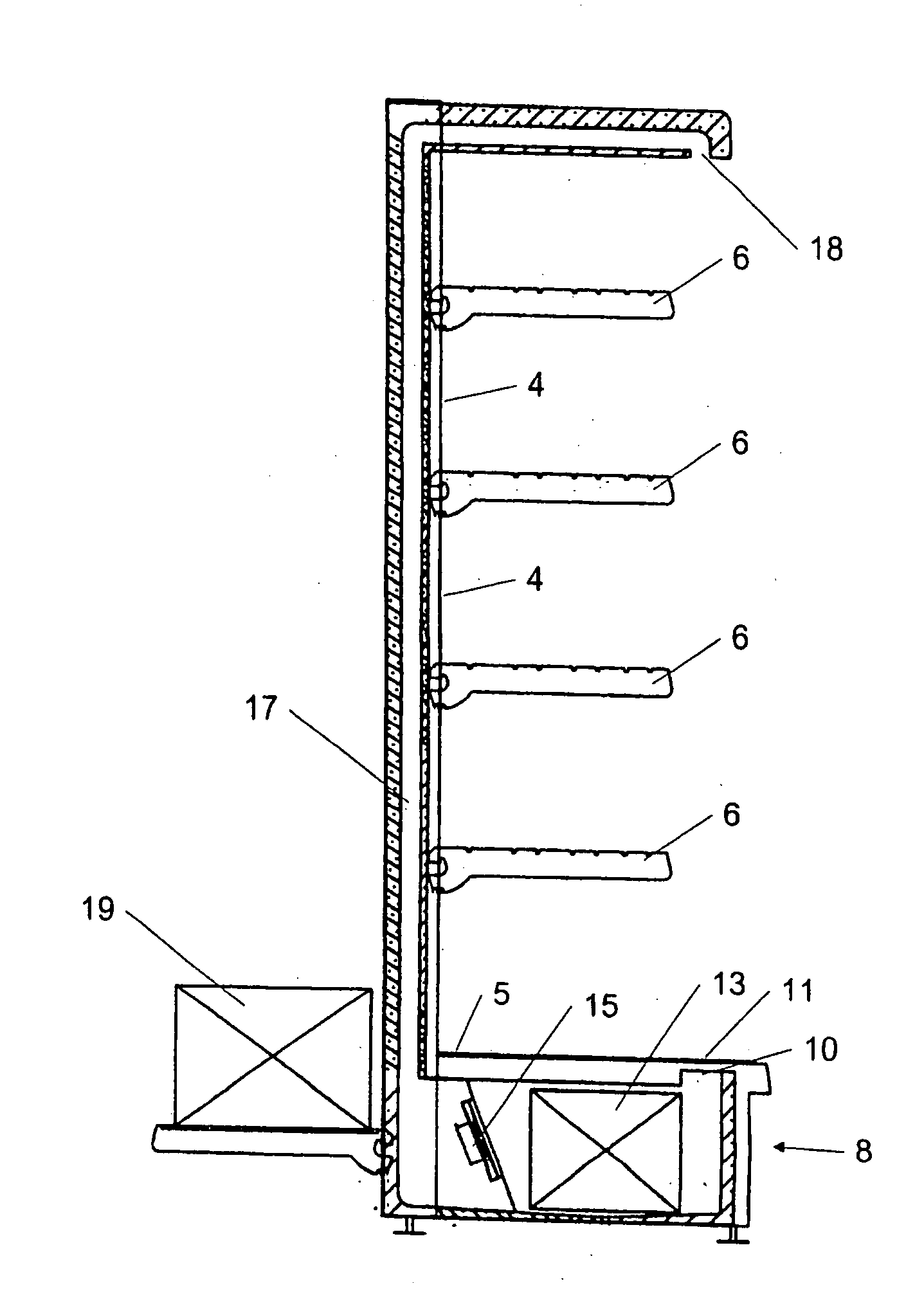

Cabinet for the storage of goods requiring refrigeration

A cabinet for the storage of goods requiring refrigeration, includes a modular frame structure, space-delimiting elements and shelves (6) bearing the goods, and equipped with a caloric heat exchanger (8) generating an air flow of a temperature selected to suit the goods, and an air channel system (17) communicating with it. Thus a refrigerated cabinet of any size and design can be transformed from an existing cabinet or a mass-manufactured cabinet product range, without altering the module structure of the non-refrigerated cabinet, incorporating all advantageous characteristics of a modular assembly option. The transformation implies no permanent change in structural design, basic parameters or external dimensions of the original cabinet, so it can be transformed back into a non-refrigerated cabinet at any time, by replacing certain elements and the installation and fitting of further units.

Owner:FOCKTER VILMOS

Drawing apparatus and drawing control method thereof

Owner:CASIO COMPUTER CO LTD

Quickly-stabilized type line drawing device of traffic road marking line

InactiveCN107090766AStable jobLimit slide distanceRoads maintainenceElectric machineryEngineering drawing

Owner:浙江聚业科技有限公司

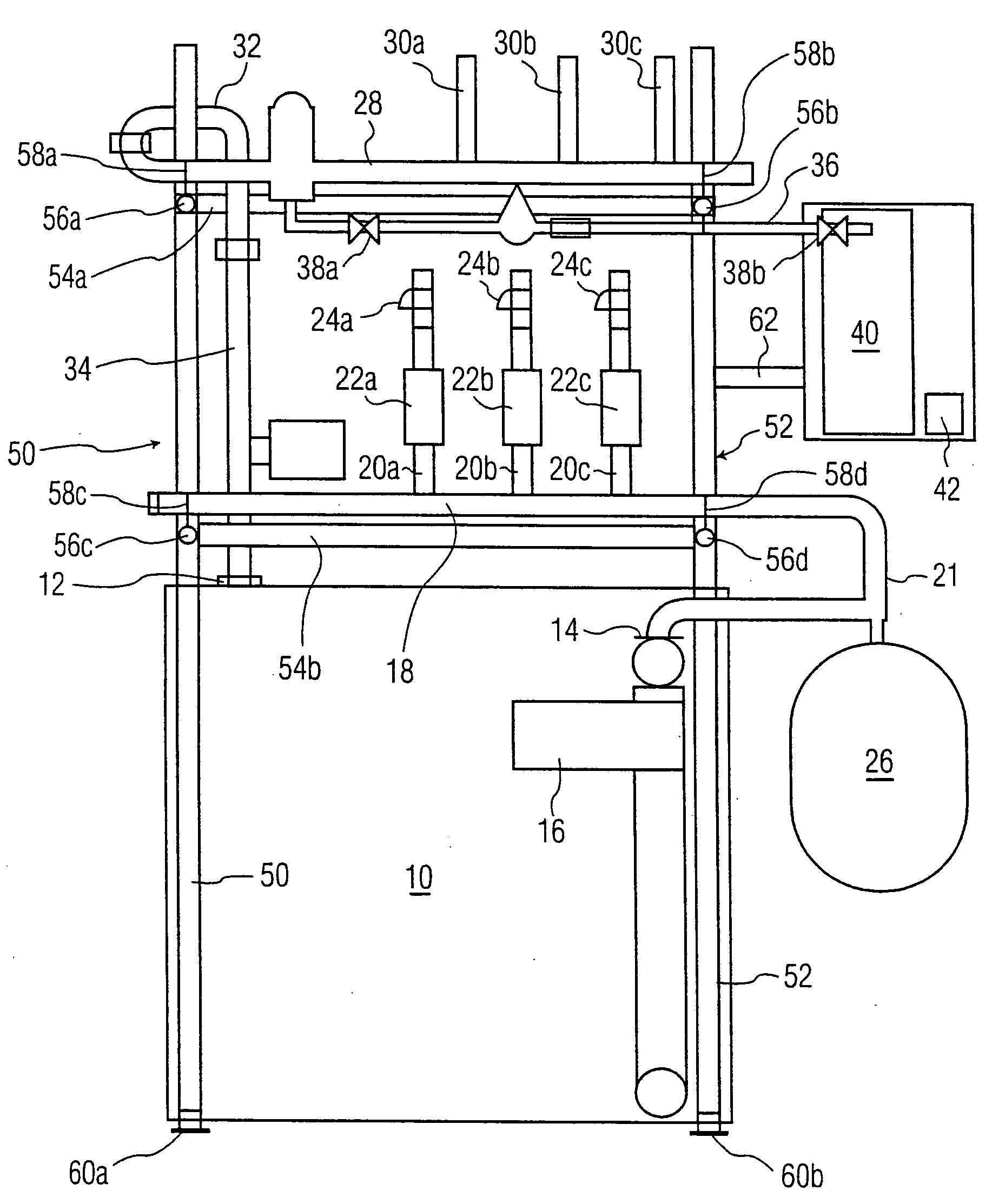

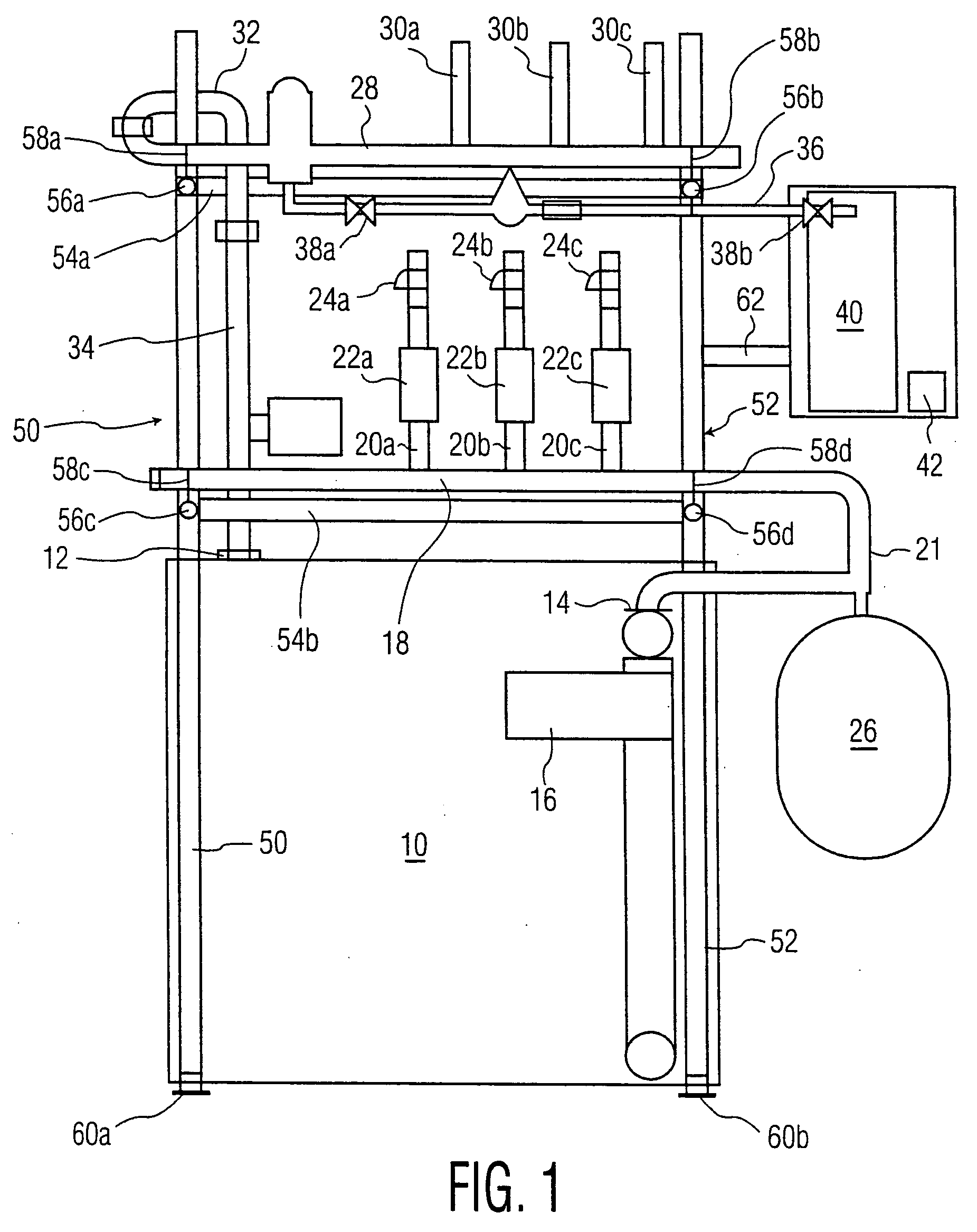

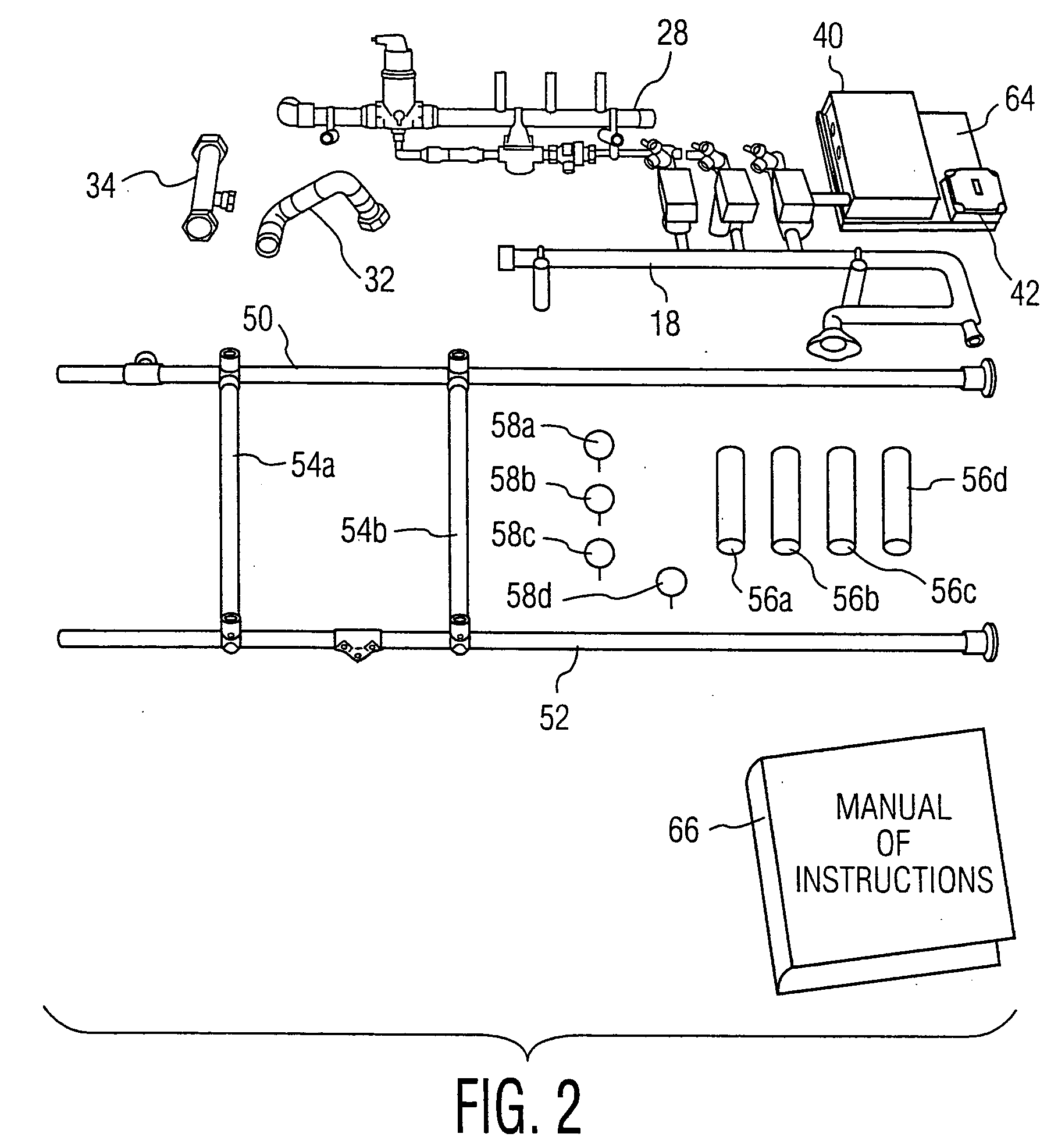

Apparatus and method for installing a heating system in a building

InactiveUS20060283966A1Easy to installReduce complexityMechanical apparatusHot-air central heatingHeating systemEngineering drawing

A kit of component parts, and a method for using this kit, are disclosed for installing a boiler for a heating system in a building. The kit comprises prefabricated inlet and outlet manifolds for multiple heating circuits and parts to construct a framework, attachable to the boiler, for holding the manifolds and other parts of the boiler and heating system.

Owner:ONEILL TIMOTHY

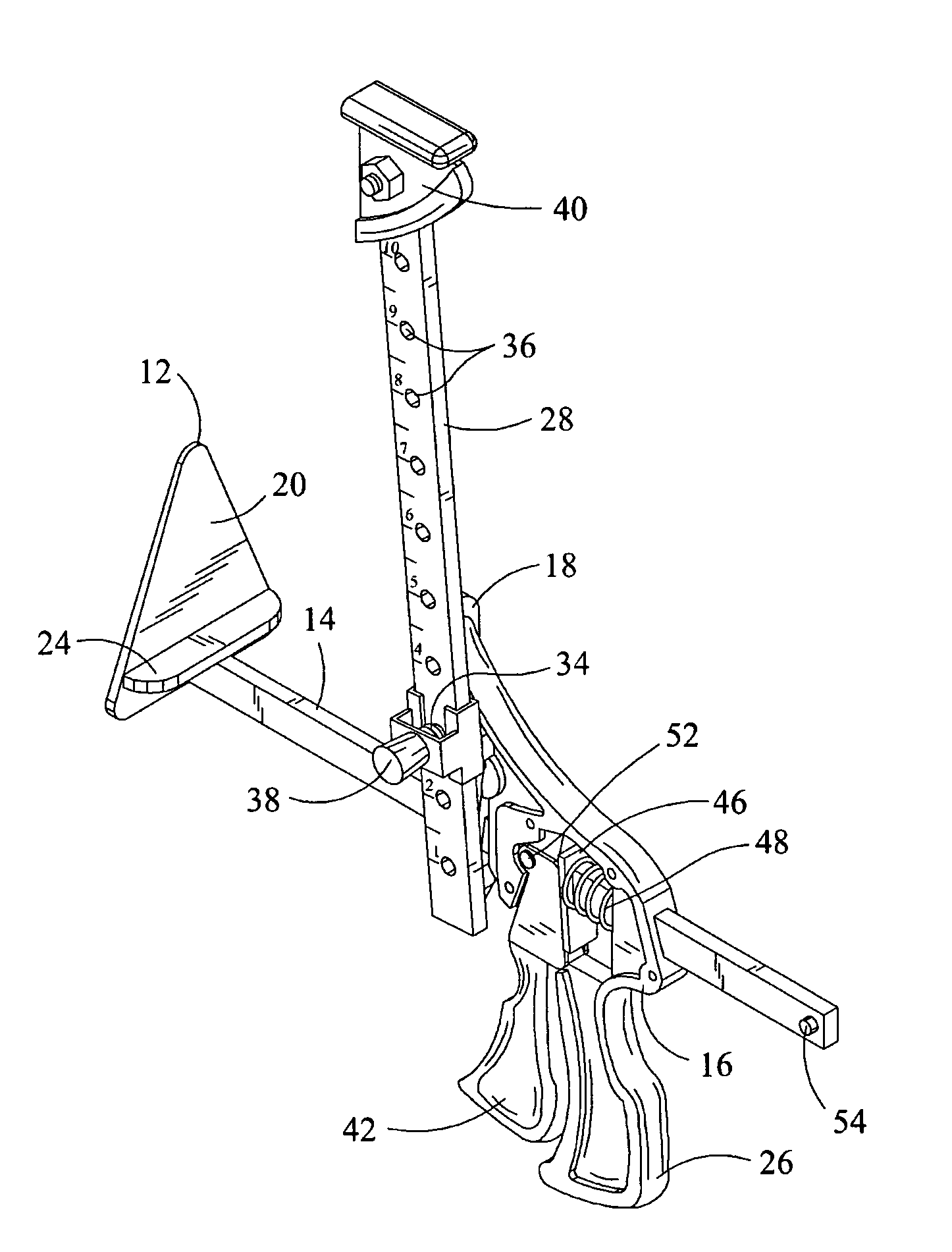

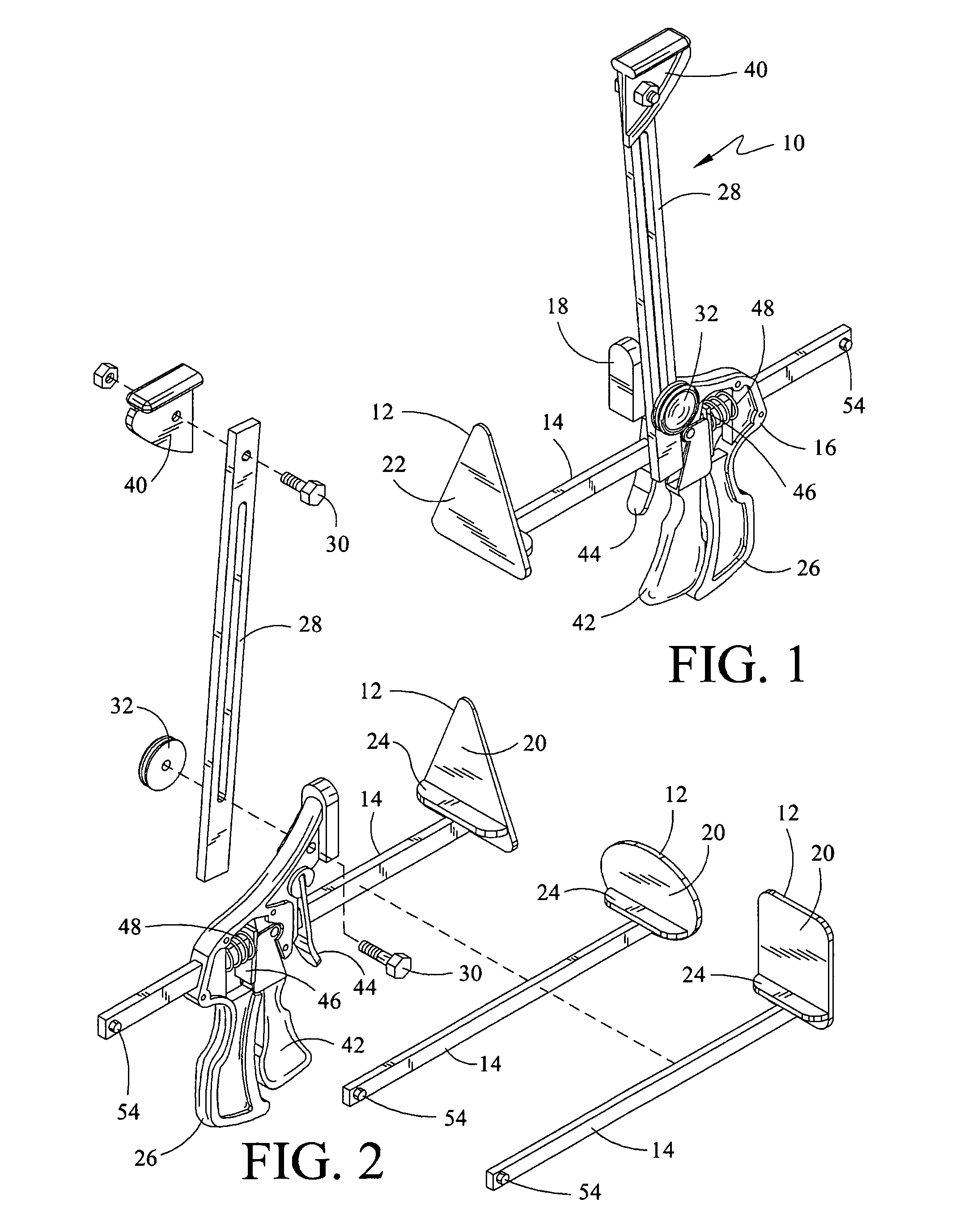

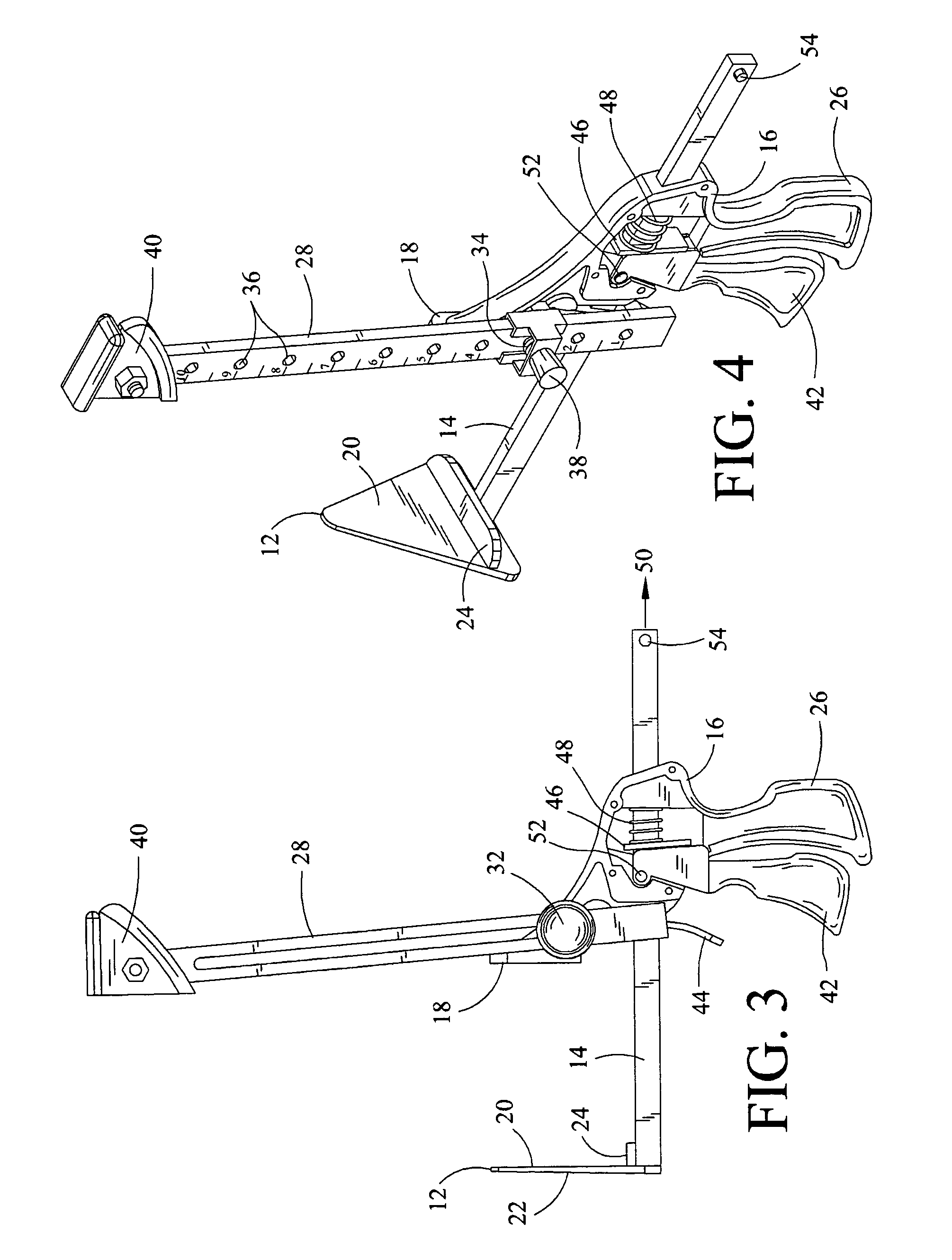

Hand tool apparatus and method

InactiveUS20060196070A1Avoid manipulationWorkpiece holdersMeasurement devicesHand toolEngineering drawing

The present invention comprises a hand tool for the installation of elongated horizontally overlapping siding on a vertical framework.

Owner:WALCHAK NORMAN J

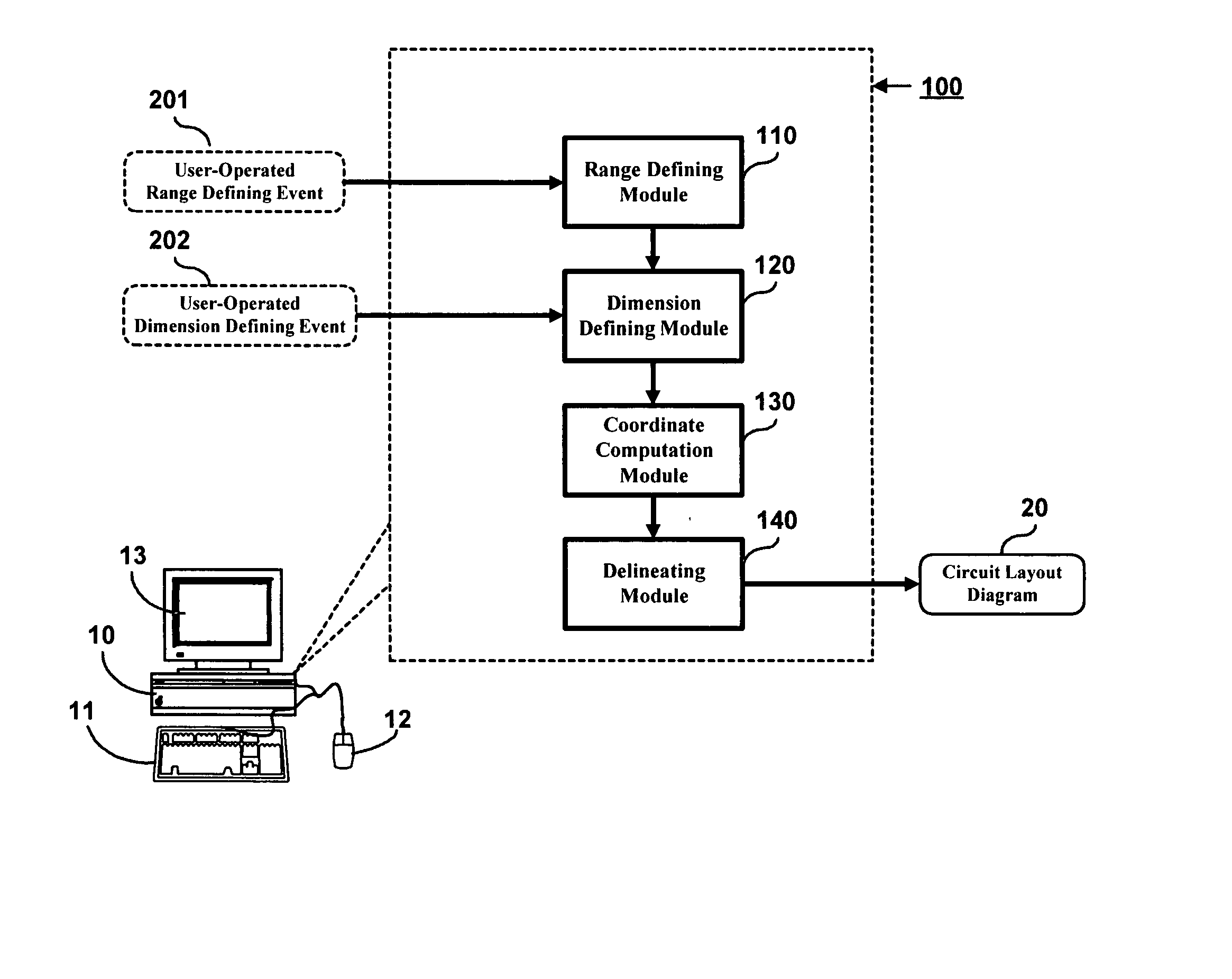

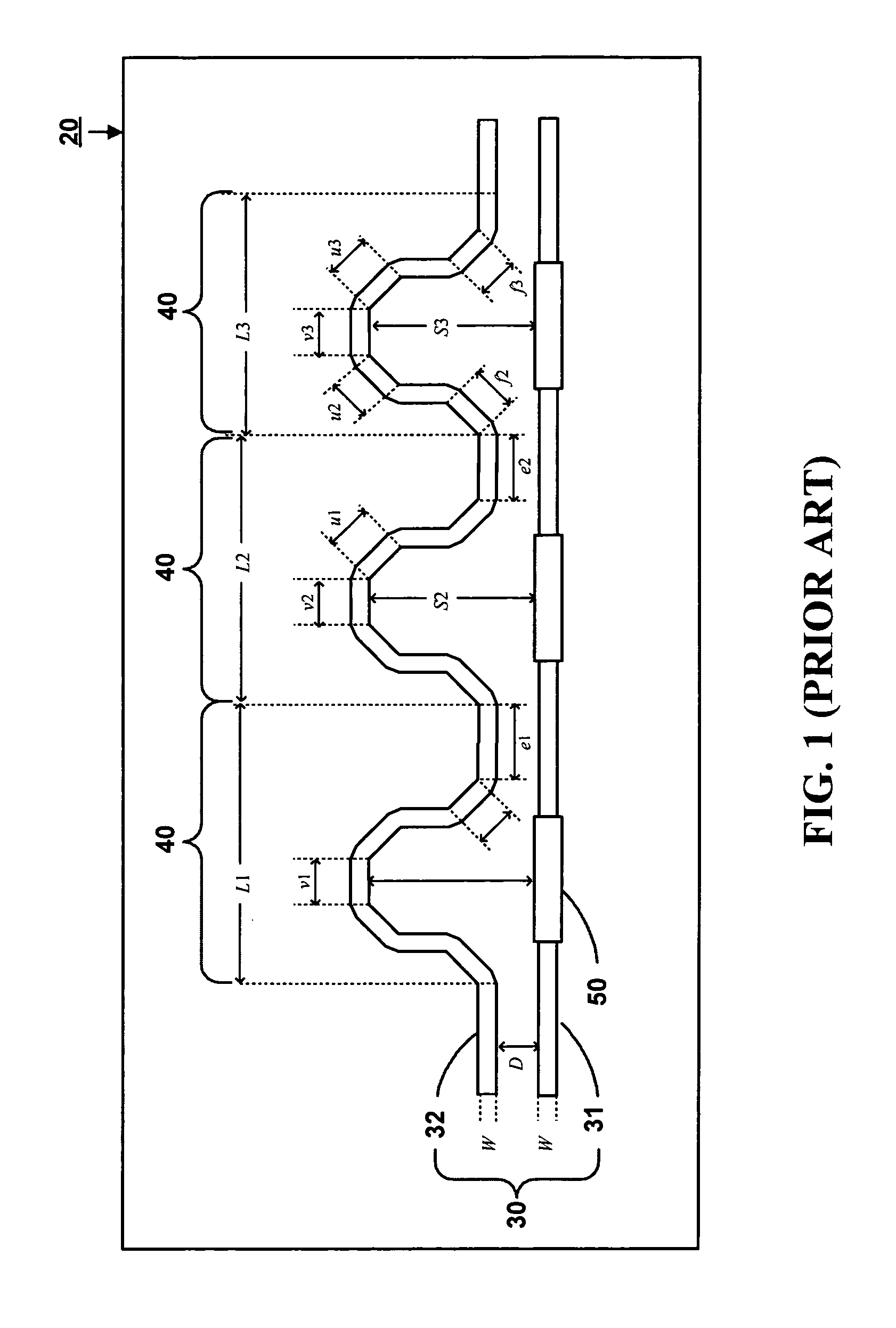

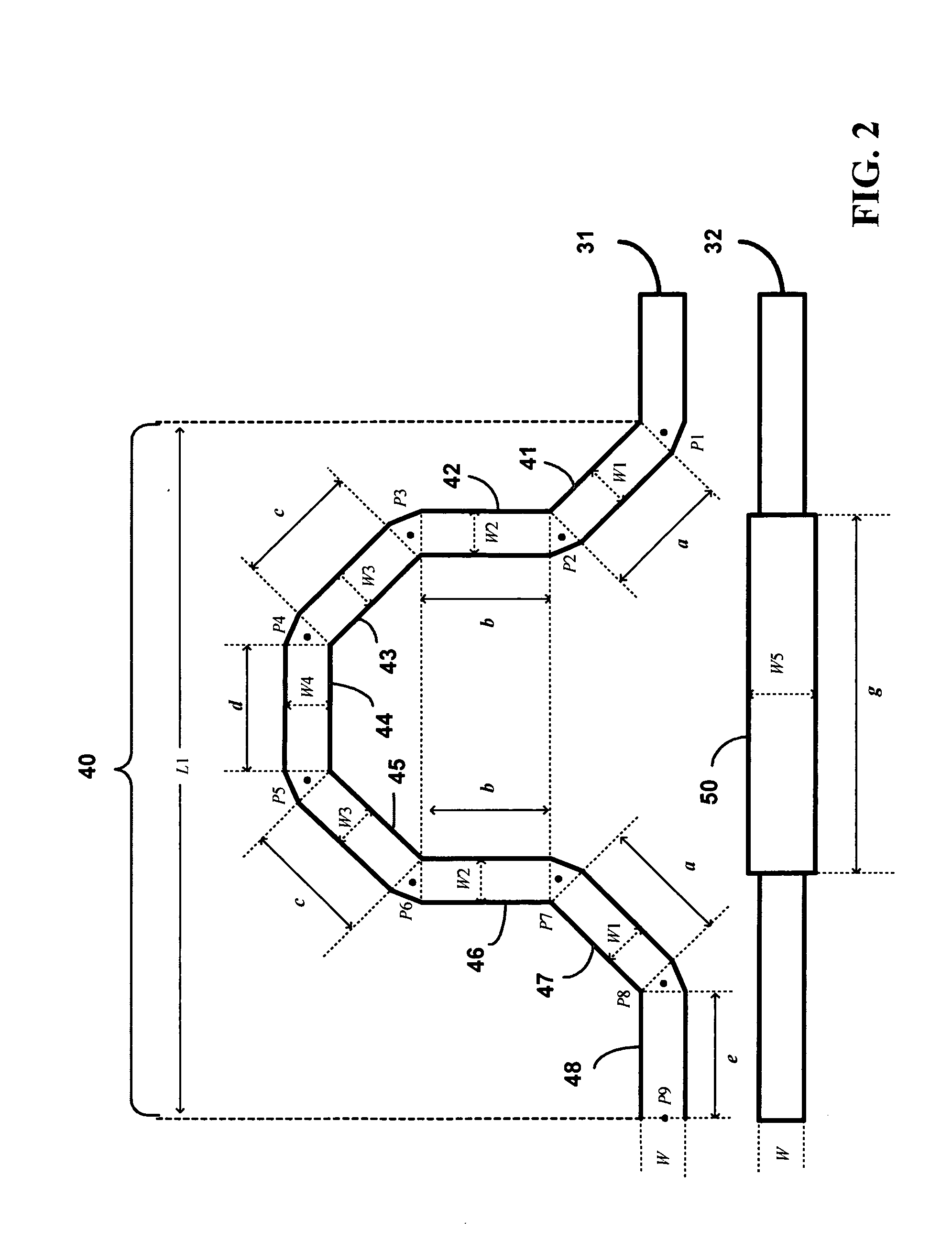

Computer aided wave-shaped circuit line drawing method and system

InactiveUS20070220472A1Drawn preciselyHigh frequency circuit adaptationsComputer programmed simultaneously with data introductionSystems designComputer-aided

A computer aided wave-shaped circuit line drawing method and system is proposed, which is designed for use with a computer platform for providing a user-operated wave-shaped circuit line drawing function, and which is characterized by the utilization of computer-aided graphic drawing technology to allow a user to define a set of dimensional attributes for a wave-shaped microstrip line, and whereby the shape of the wave-shaped microstrip line will be automatically drawn on a circuit layout diagram. Compared to the prior art, since the invention allows the dimensional attributes and locations of each constituent portions (i.e., segments and turning points) in the wave-shaped microstrip to be precisely drawn on the circuit layout diagram, it allows the realization of a microwave digital circuit board from the circuit layout diagram to have precise characteristic impedance and thus precise electrical performance in actual operation.

Owner:INVENTEC CORP

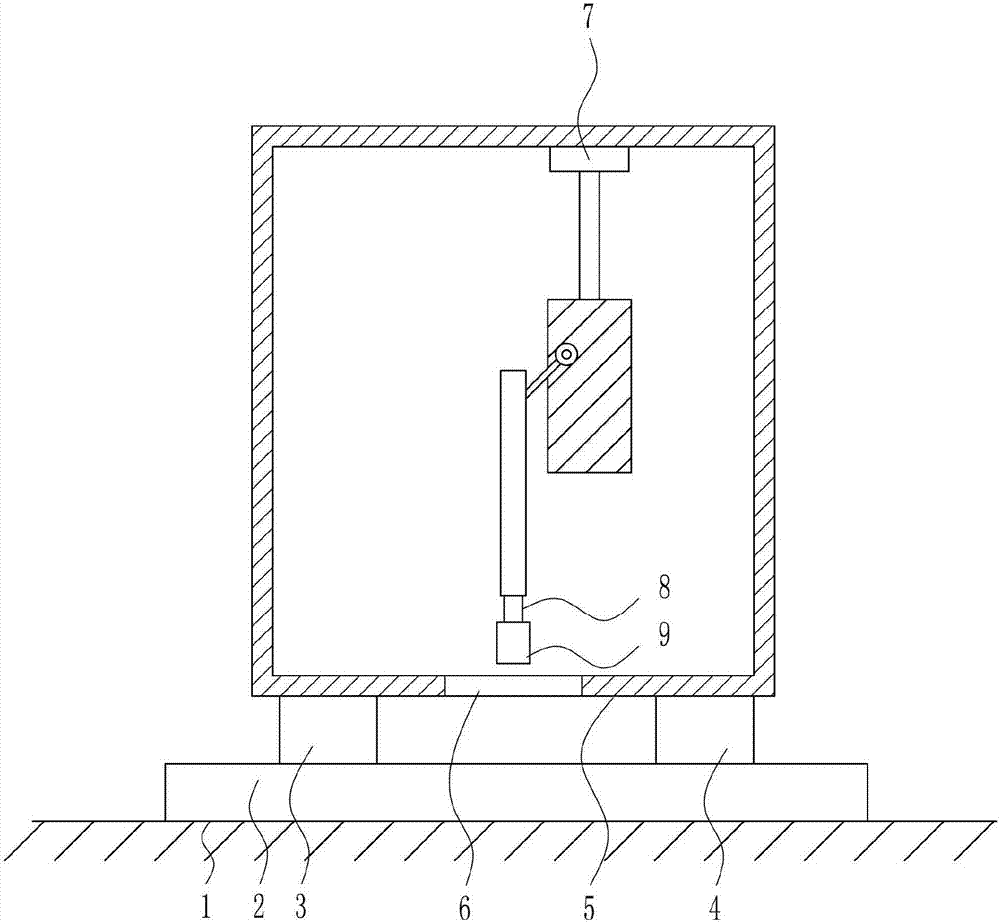

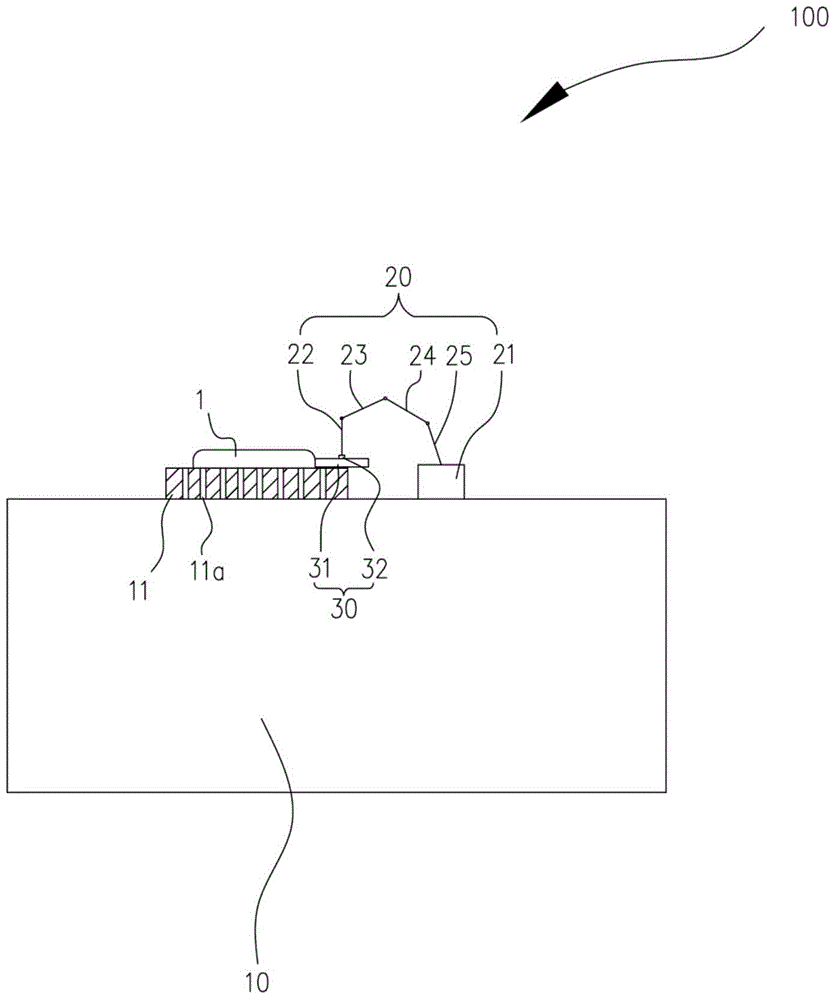

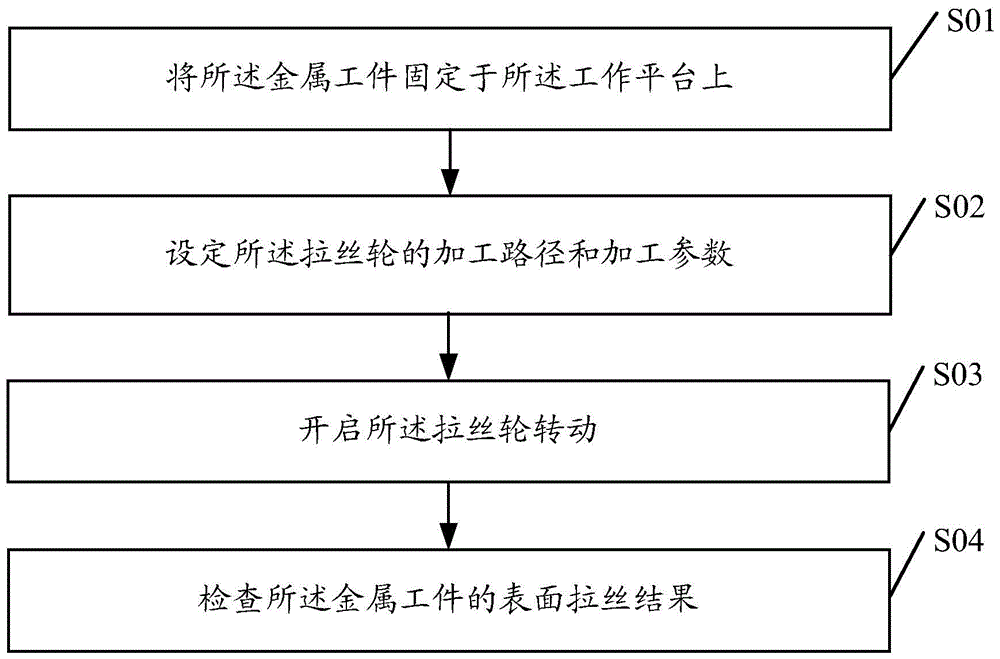

Drawing device and drawing method

InactiveCN105690186AImprove drawing efficiencyBrushed to achieveGrinding carriagesBelt grinding machinesEngineering drawingWire drawing

The invention relates to a drawing method and a drawing device. The drawing device comprises a substrate, a mechanical arm and a processing assembly, wherein a working platform is arranged on the substrate, and the working platform is used for fixing a metal workpiece; the mechanical arm comprises a base and a first connecting rod, the base is fixed to the substrate, and one end of the first connecting rod is rotatably connected to the base; the processing assembly comprises a drawing wheel and a working rotating shaft, the working rotating shaft is rotatably connected to one end, which is far from the base, of the first connecting rod, and the drawing wheel is rotatably connected to the working rotating shaft; when the working rotating shaft is driven to beaxially in the vertical direction by the first connecting rod, the side wall of the metal workpiece is drawn by the drawing wheel; when the working rotating shaft is driven to be axially in the horizontal direction by the first connecting rod, the top surface of the metal workpiece is drawn by the drawing wheel, so that the drawing efficiency of the drawing device is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

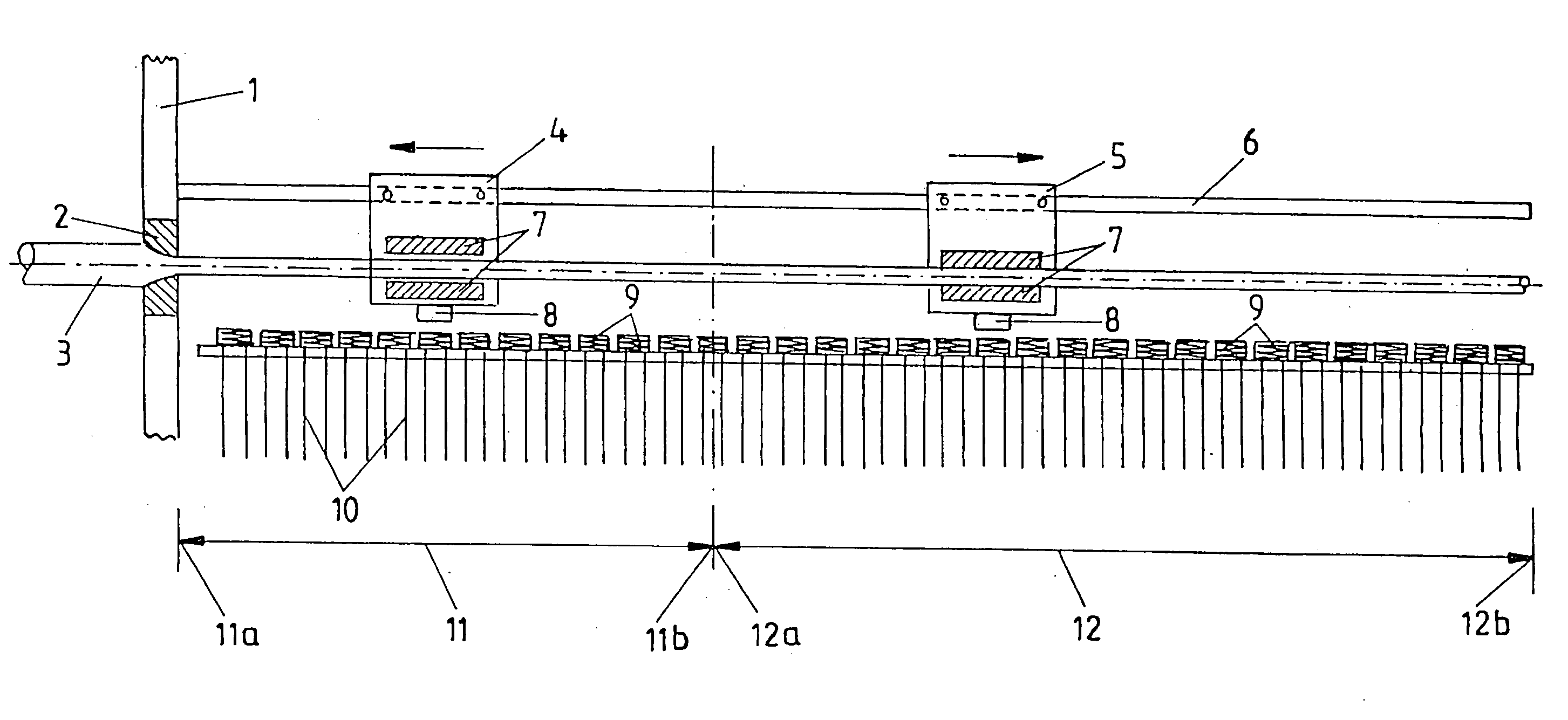

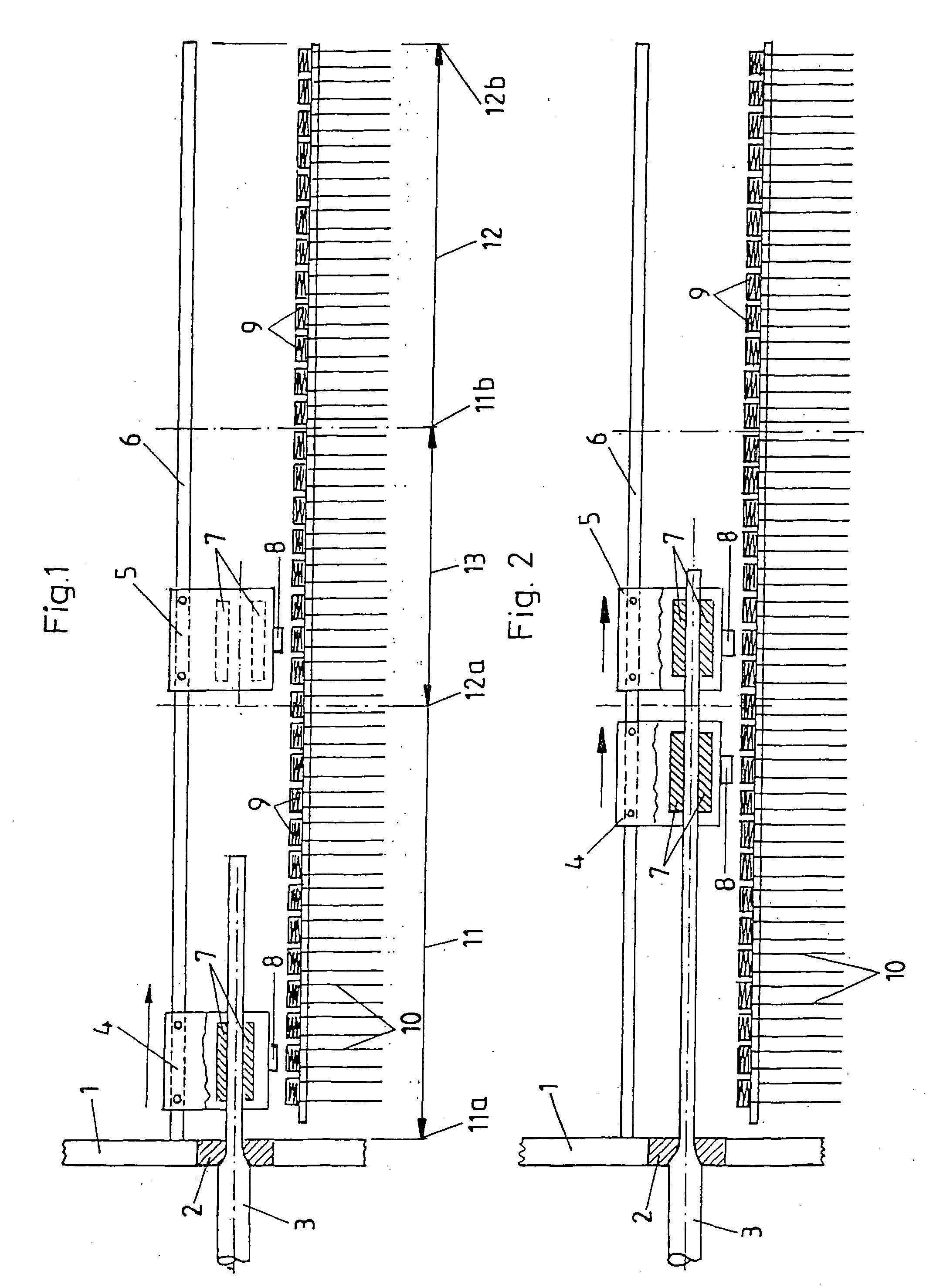

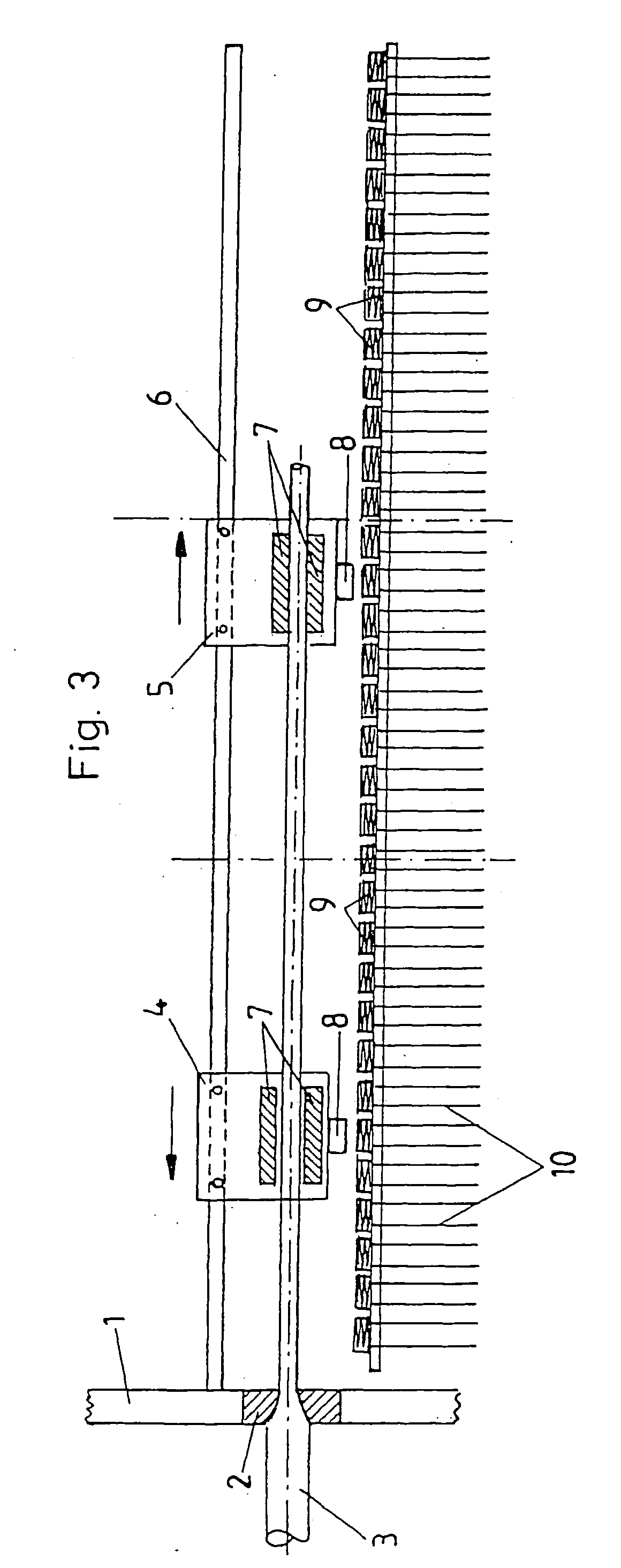

Straight drawing machine

Rectilinear drawing machine for drawing material, especially bars, pipes or sections, with at least two movable drawing cars which are driven on a path, one run being assigned to each drawing car, and the runs can be fixed in a variable manner.

Owner:BL CHEM

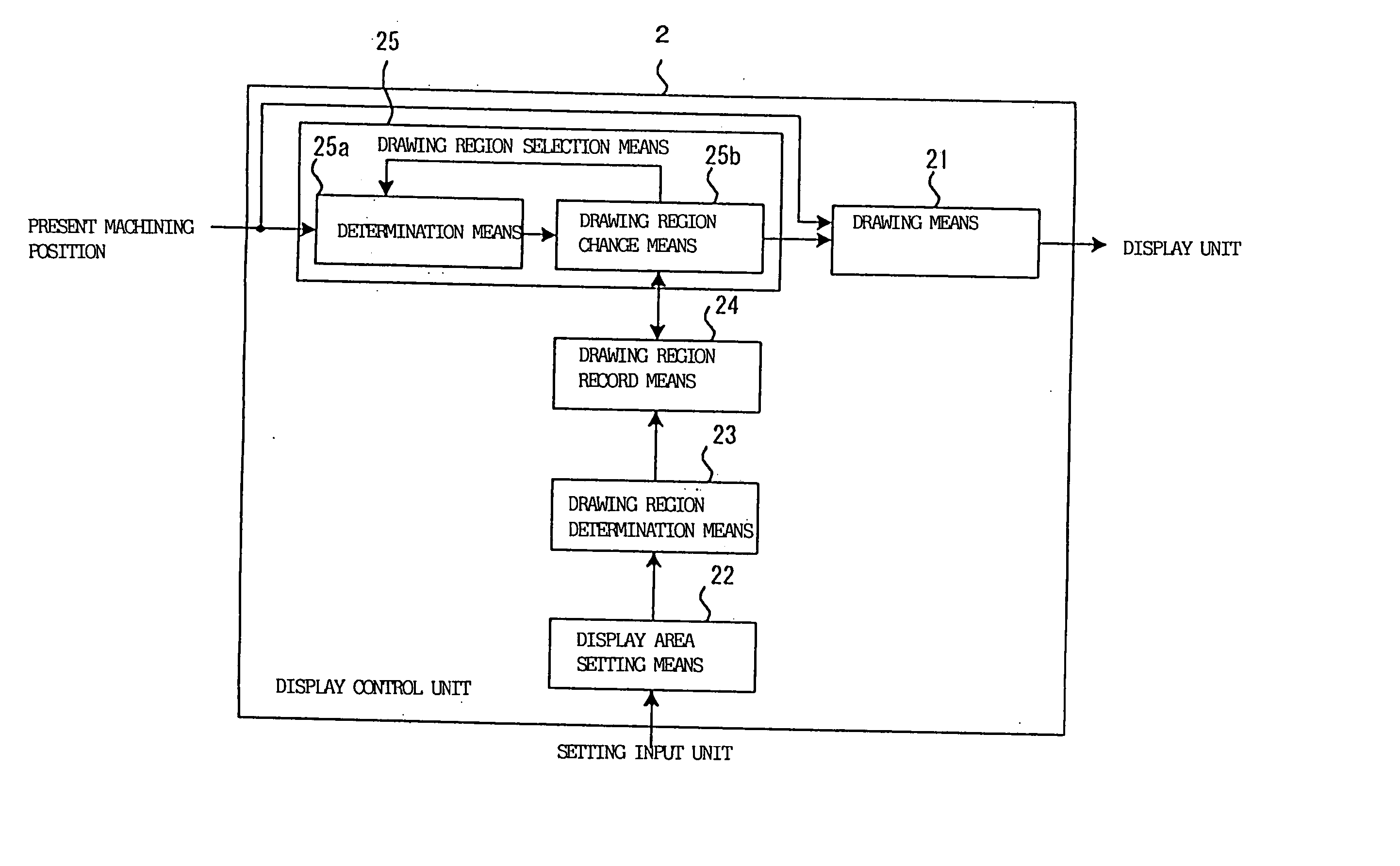

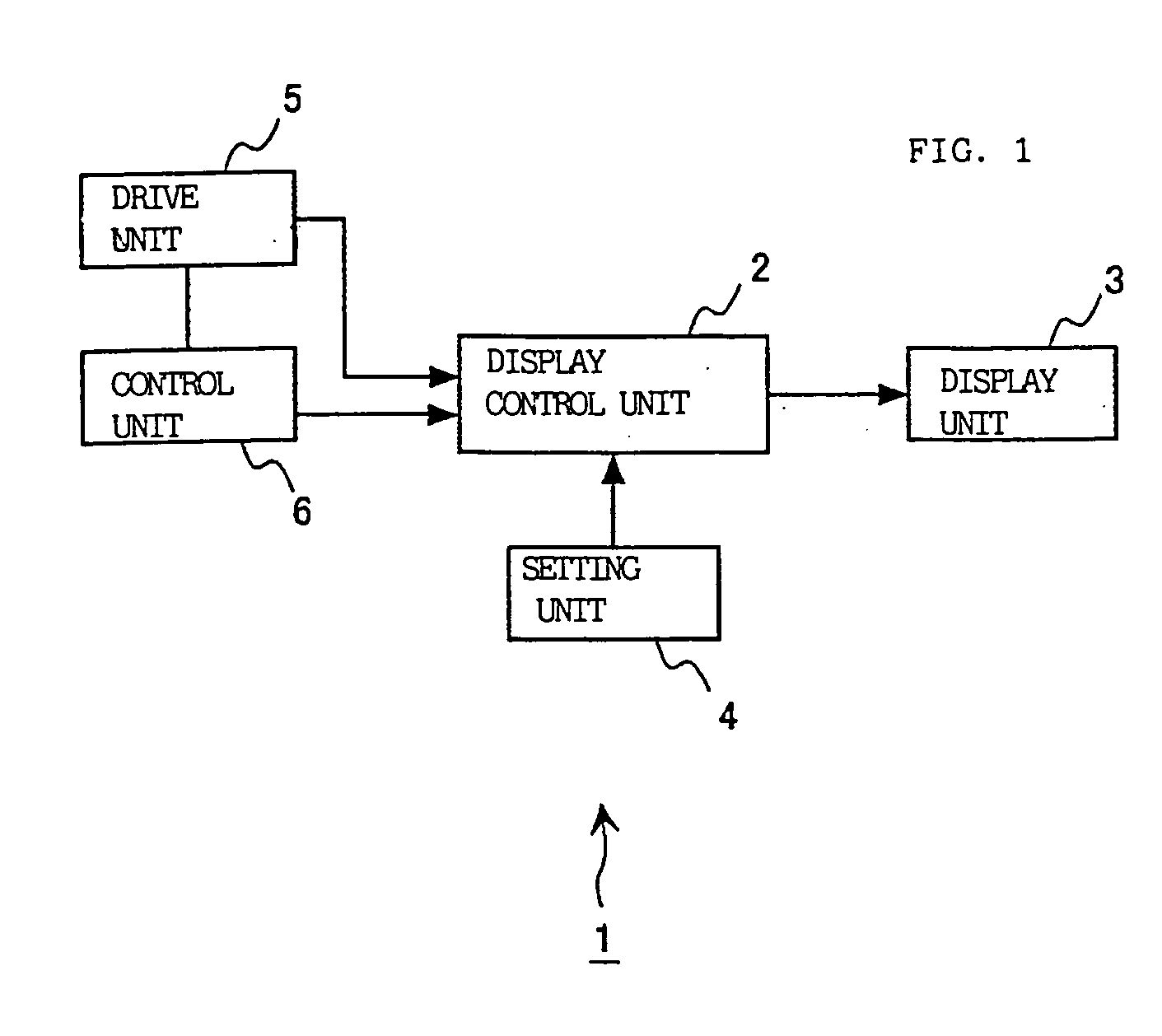

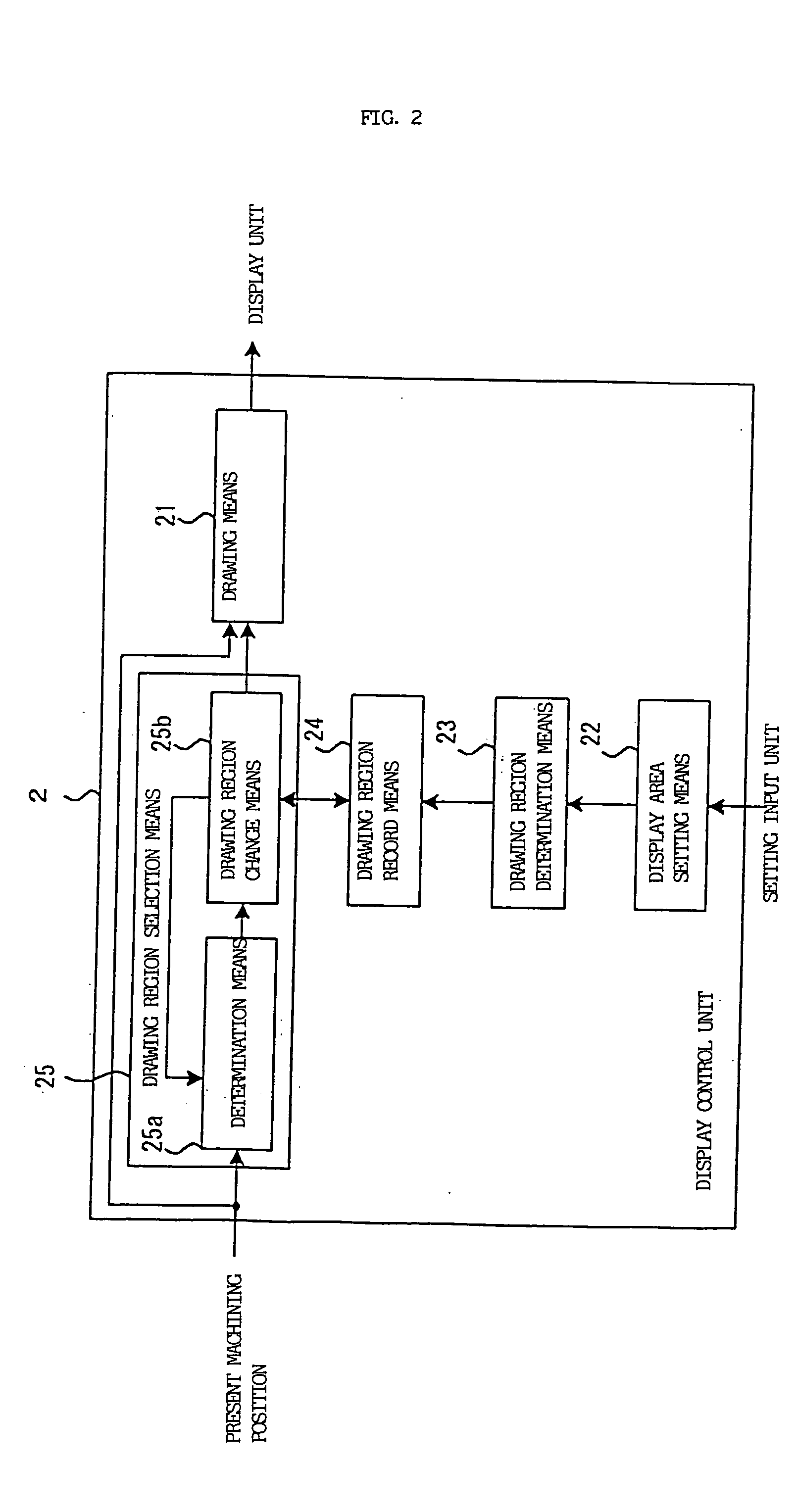

Machining configuration drawing apparatus and machining configuration drawing method

ActiveUS20050209728A1Processing amount of operationReduce settingsProgramme controlAutomatic control devicesRegion selectionMachining

A machining configuration drawing apparatus includes a drawing unit for drawing a machining configuration and a present machining position, a setting unit for setting a display area in an overall drawing area, a division unit for dividing the overall drawing area into a plurality of display areas based on the set display area, and a selection unit for selecting a drawing region drawn by the drawing unit from a plurality of drawing regions. The selection unit selects a drawing region in which the present machining position exists. Further, the drawing unit draws a machining configuration and a present machining position of the selected drawing region.

Owner:FANUC LTD

Automatic batch skewering machine

InactiveCN107372755AEnsure hygiene and safetyImprove processing efficiencyPutting meat on skewersHydraulic cylinderTime cost

The invention discloses an automatic batch skewering machine, relates to the field of food processing and aims at solving the problems of low processing efficiency, high human cost, high time cost, large labor intensity and difficulty in ensuring sanitary safety of string products in the existing skewering process of the string products. A prod pushing device, a prod limiting device and a plurality of groups of material placing templates are sequentially arranged on a bracket from top to bottom; a material sucking device is installed on an upright column on the side surface of the bracket; four bushings of an upper chamber bracket sleeve the upper ends of four vertical rods of the bracket respectively; a lower chamber bracket is in sliding connection with the bracket; prod pushing plates are fixedly connected with the lower end of the lower chamber bracket; a hydraulic cylinder is installed in an oil cylinder upper chamber; a piston rod of the hydraulic cylinder is fixedly connected with an oil cylinder lower chamber; the prod limiting device is connected with the four vertical rods of the bracket in a sliding manner; two template slideways are fixedly connected with the lower part of the bracket through a plurality of bent arms respectively; and a plurality of groups of material placing templates are installed on the two template slideways in the sliding manner. The automatic batch skewering machine is used for skewering string products of meat strings, sugar-coated haws and the like.

Owner:王海石

Drawing apparatus, and method of manufacturing article

Owner:CANON KK

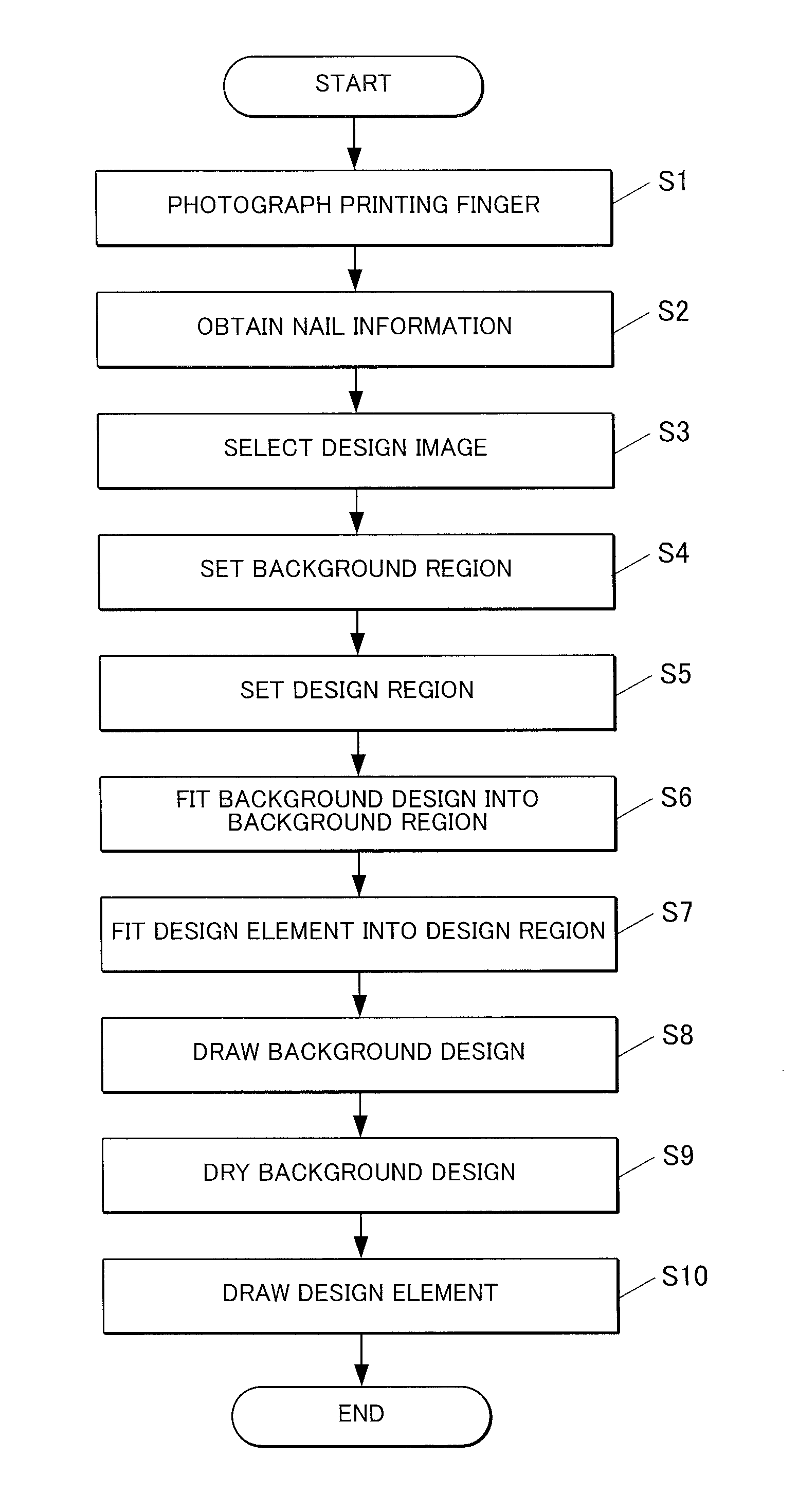

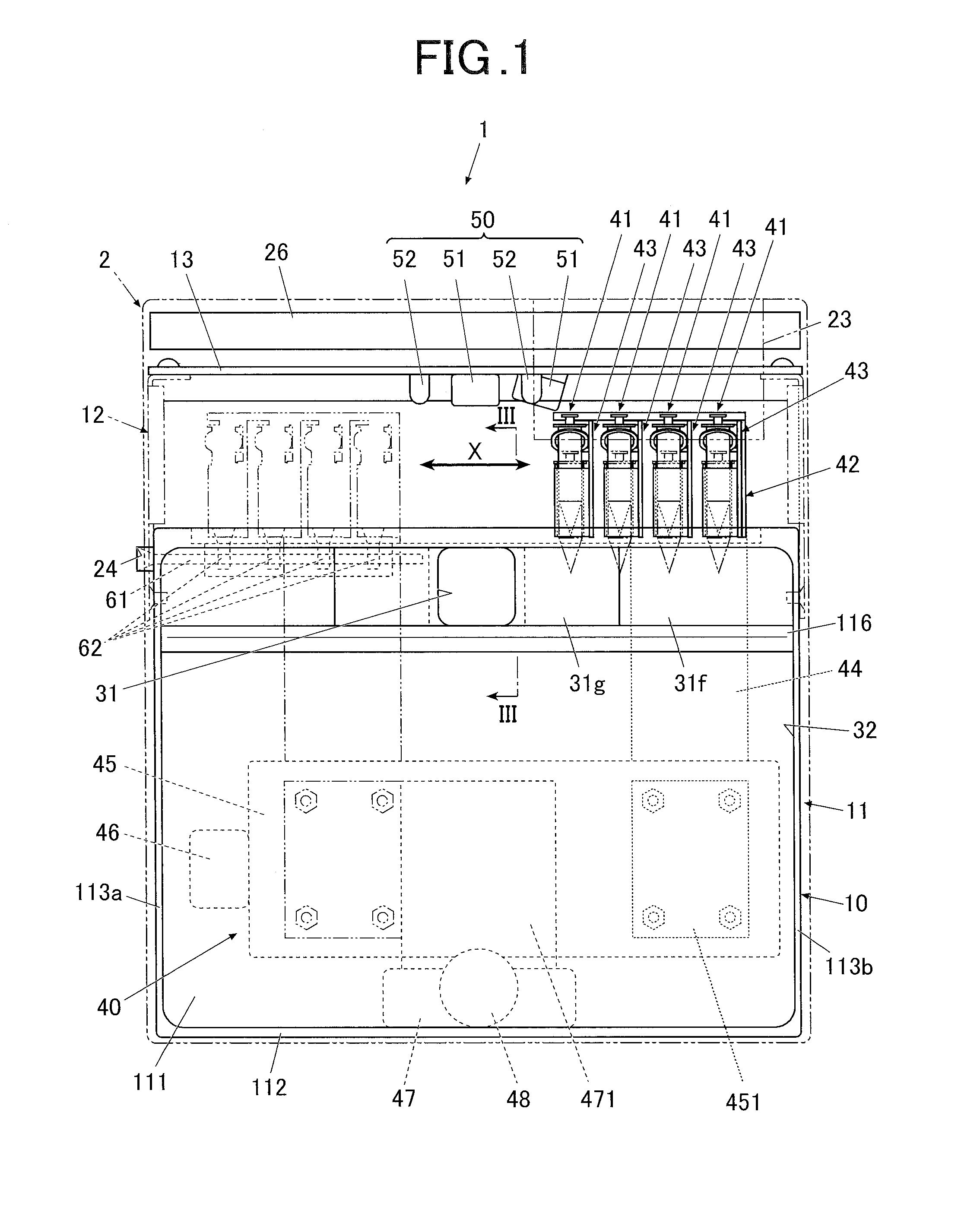

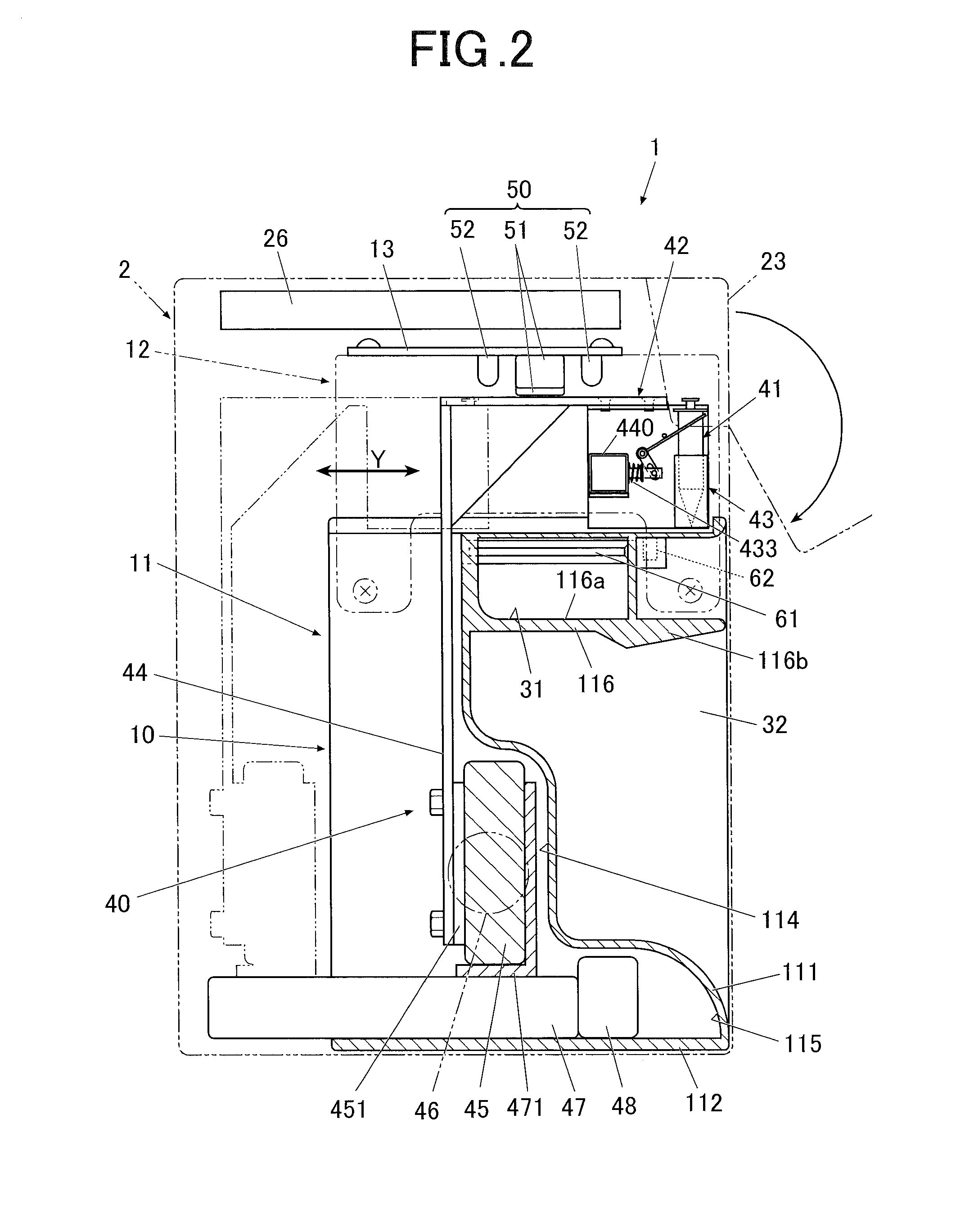

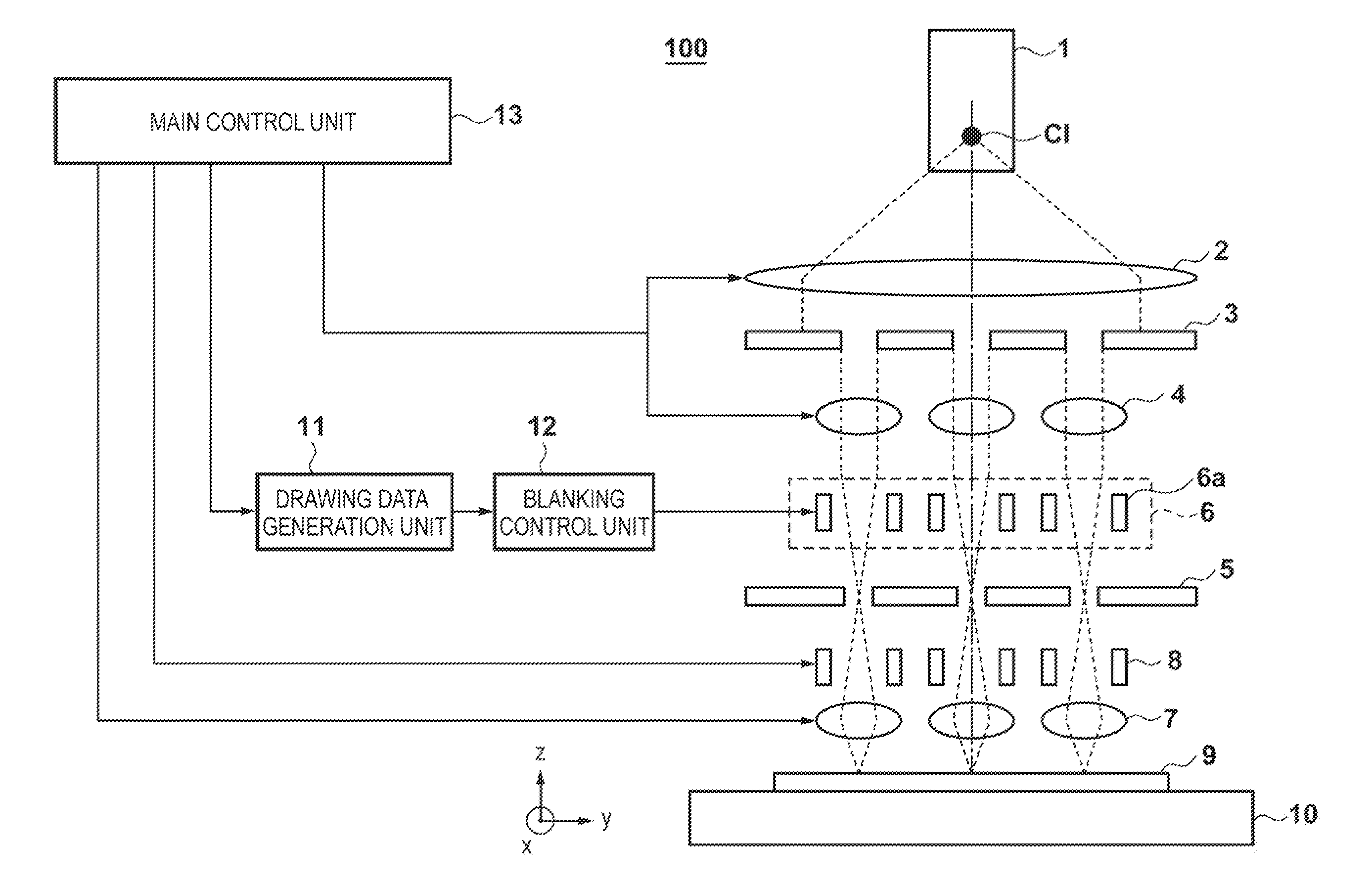

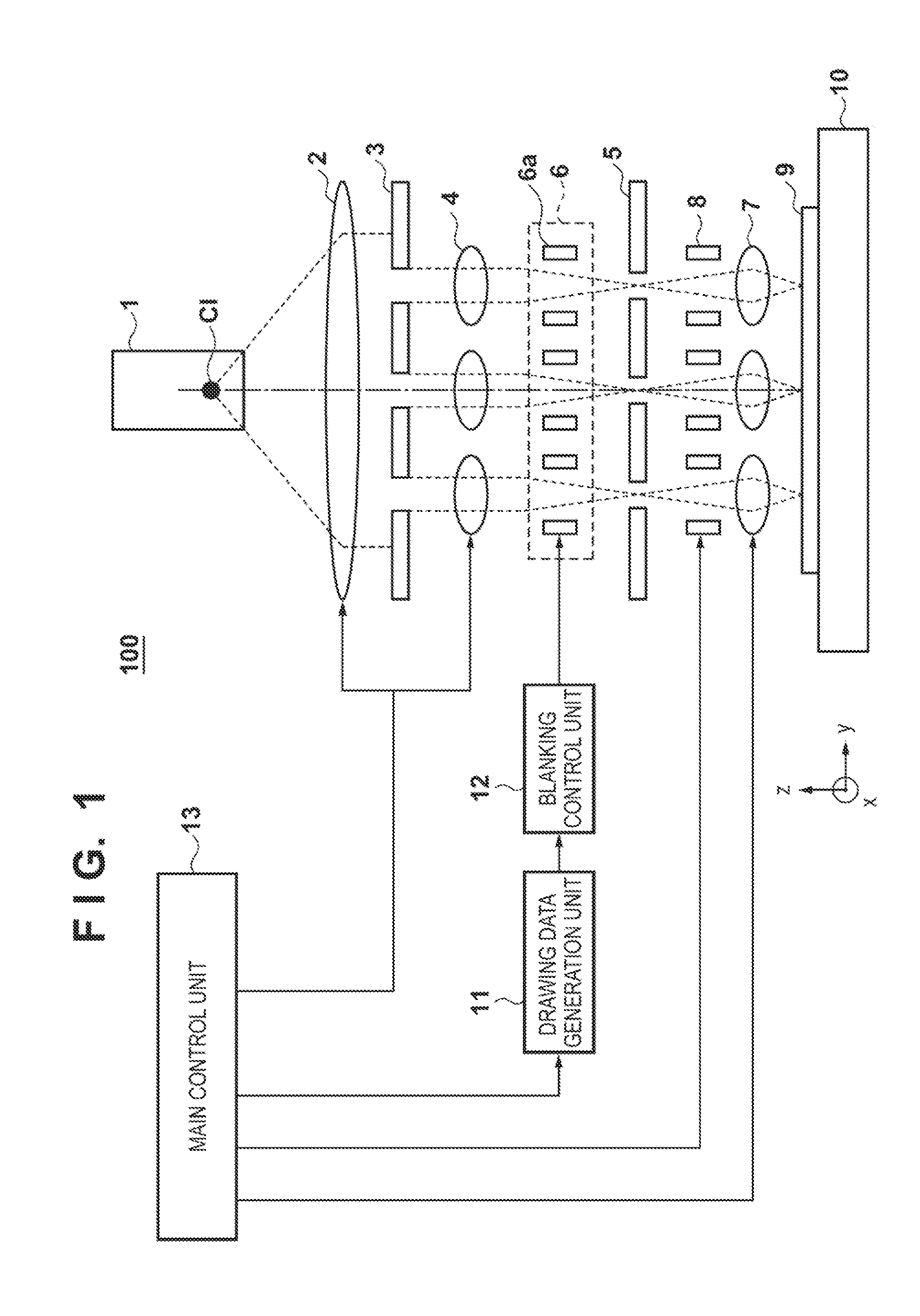

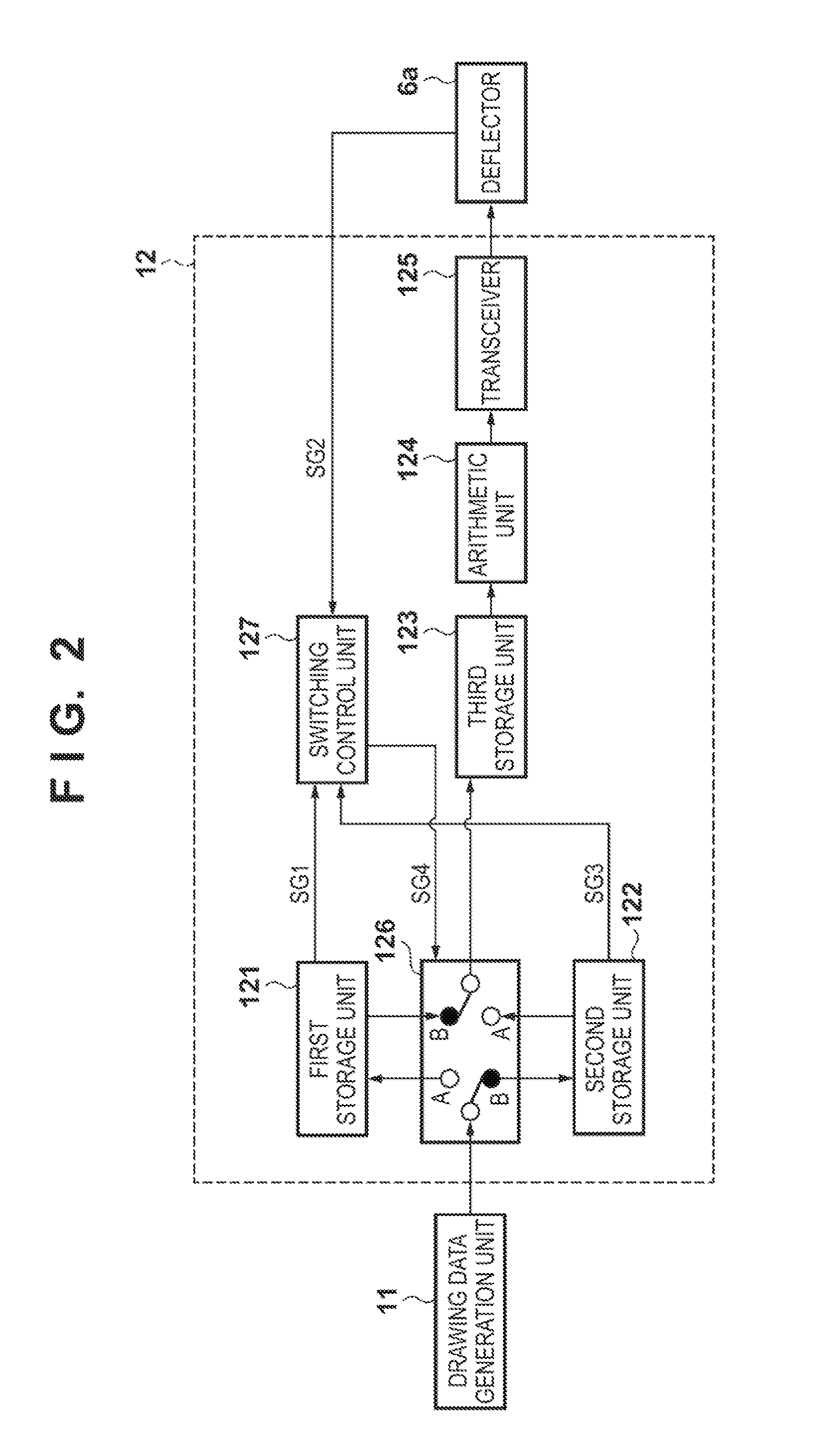

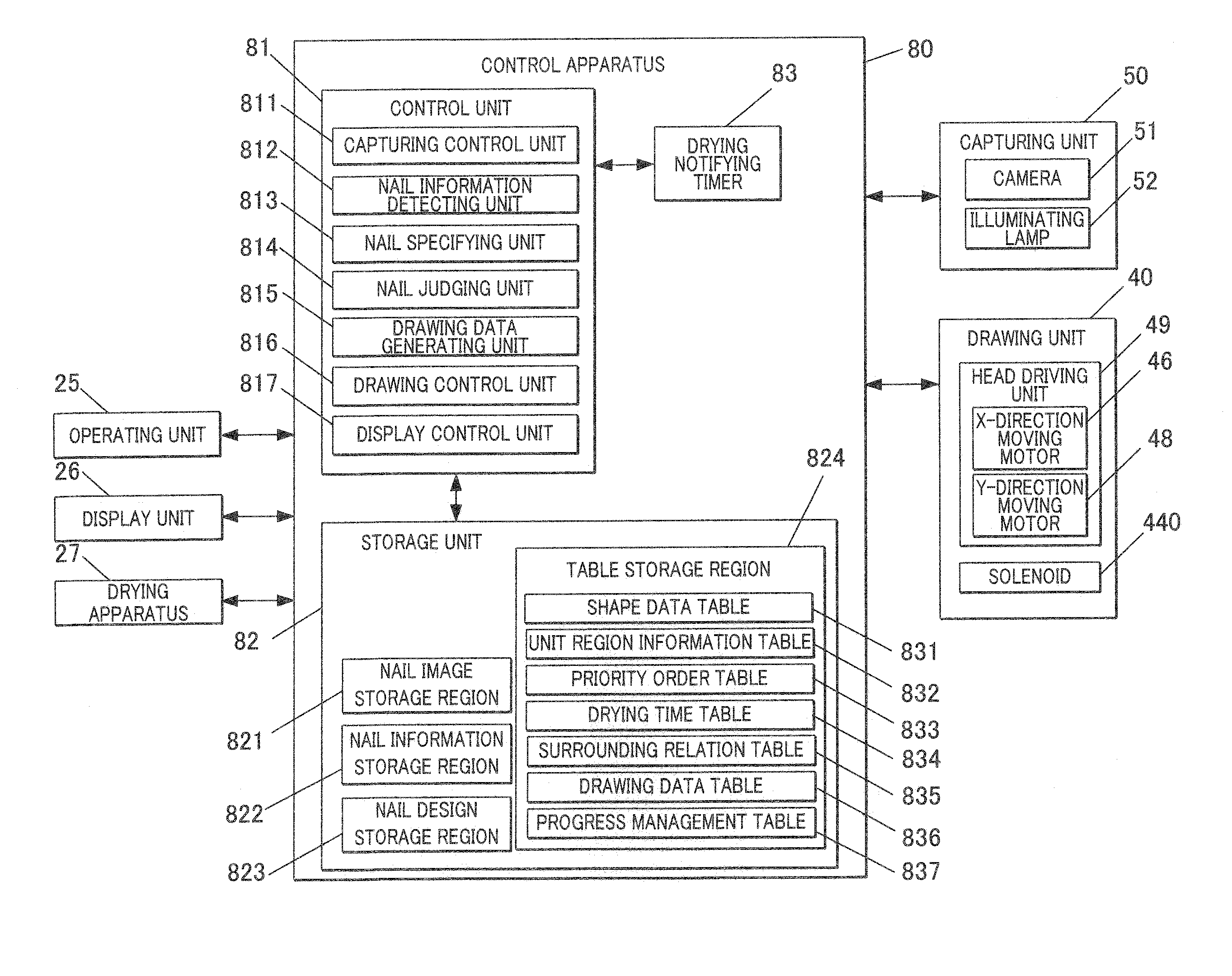

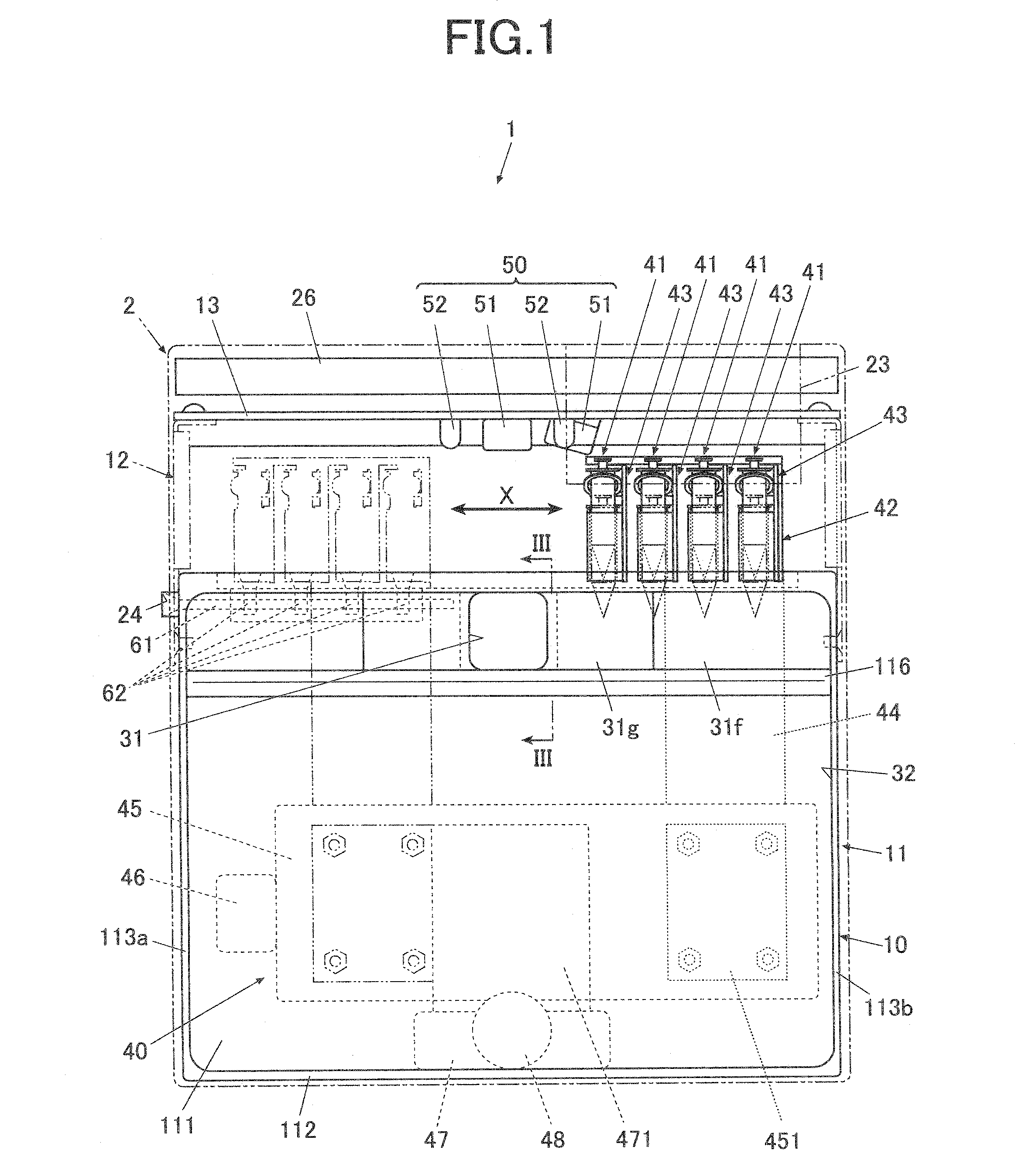

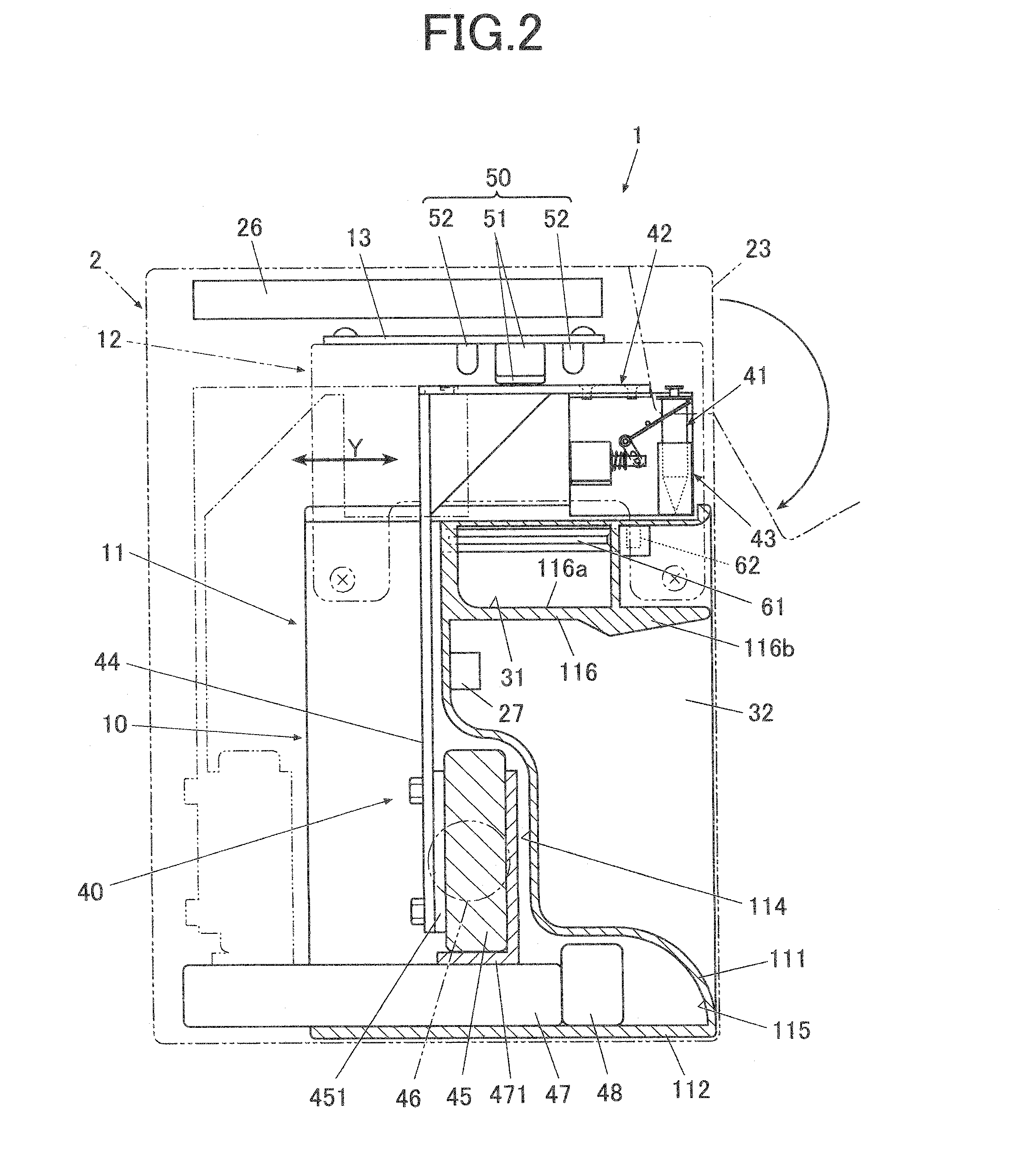

Drawing apparatus and drawing method of drawing apparatus

ActiveUS20150375525A1Avoid image blurAmount of timeTypewritersOther printing apparatusEngineering drawingControl unit

A drawing apparatus and drawing method to perform drawing on a drawing target region are shown. The drawing apparatus includes a drawing unit and a control unit. The drawing target region is a surface of a plurality of nails and the nails include unit regions in contact with each other to be drawn with ink in different colors. The control unit includes a nail specifying unit which judges whether each of the unit regions is a dried unit region, a non-dried unit region, and a non-drawn unit region. Then, the nail specifying unit extracts the non-drawn unit region which is not in contact with the non-dried unit region as a specific unit region. The control unit also includes a drawing control unit which controls the drawing unit to perform the drawing on the specific unit region.

Owner:CASIO COMPUTER CO LTD

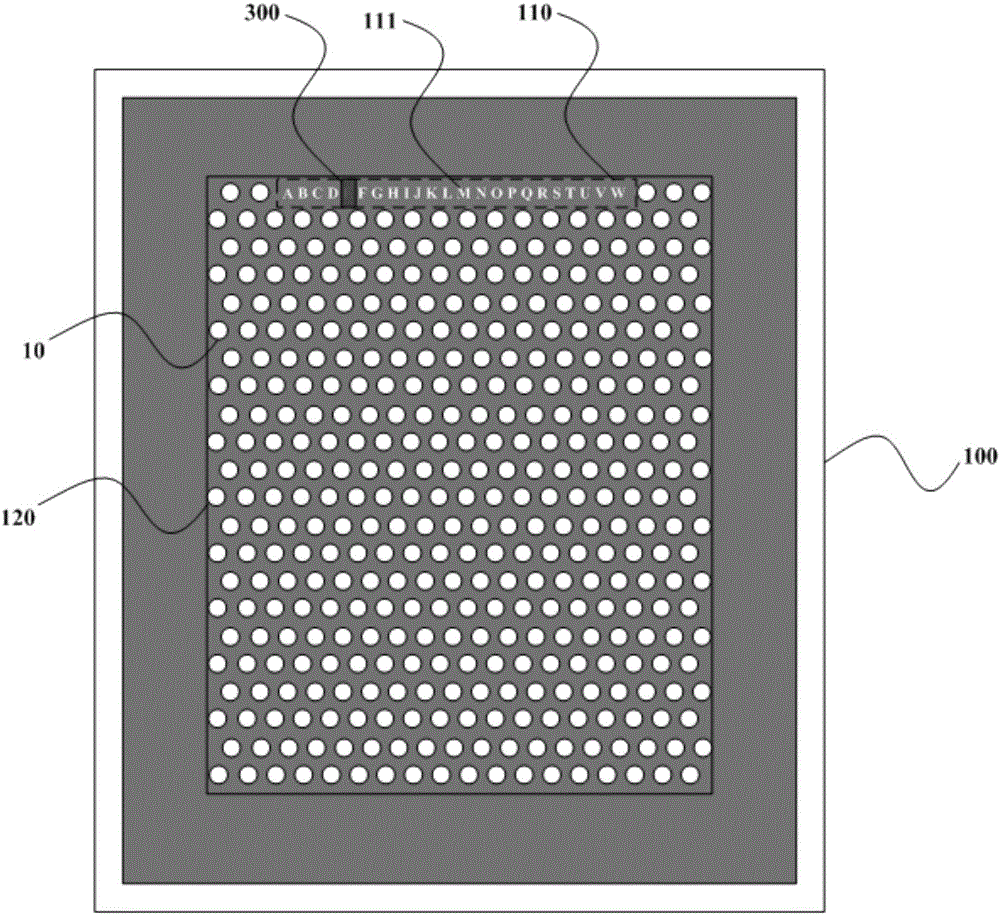

Screen printing plate, light guide plate, display equipment and manufacturing method of light guide plate

InactiveCN105856816AReduce the difficulty of production controlRealize TrackingScreen printersPlanar/plate-like light guidesScreen printingLight guide

The embodiment of the invention relates to the technical field of display and discloses a screen printing plate, a light guide plate, display equipment and a manufacturing method of the light guide plate. By the adoption of the screen printing plate, the light guide plate, the display equipment and the manufacturing method of the light guide plate, tracing of the production information of the light guide plate can be achieved, and accordingly the production control difficulty of the light guide plate is lowered. The screen printing plate comprises a screen printing plate body. The screen printing plate body comprises a screen point printing part corresponding to the light guide plate to be printed. The screen point printing part comprises at least one production information mark printing area, and each production information mark printing area comprises a plurality of printing marks. A covering piece is arranged for each production information mark printing area, and the covering pieces are detachably connected with the screen printing plate body and cover selected printing marks in the production information mark printing areas.

Owner:LETV HLDG BEIJING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com