Drawing device and drawing method

A wire drawing and wire drawing wheel technology, applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as poor wire drawing efficiency and inability to perform wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

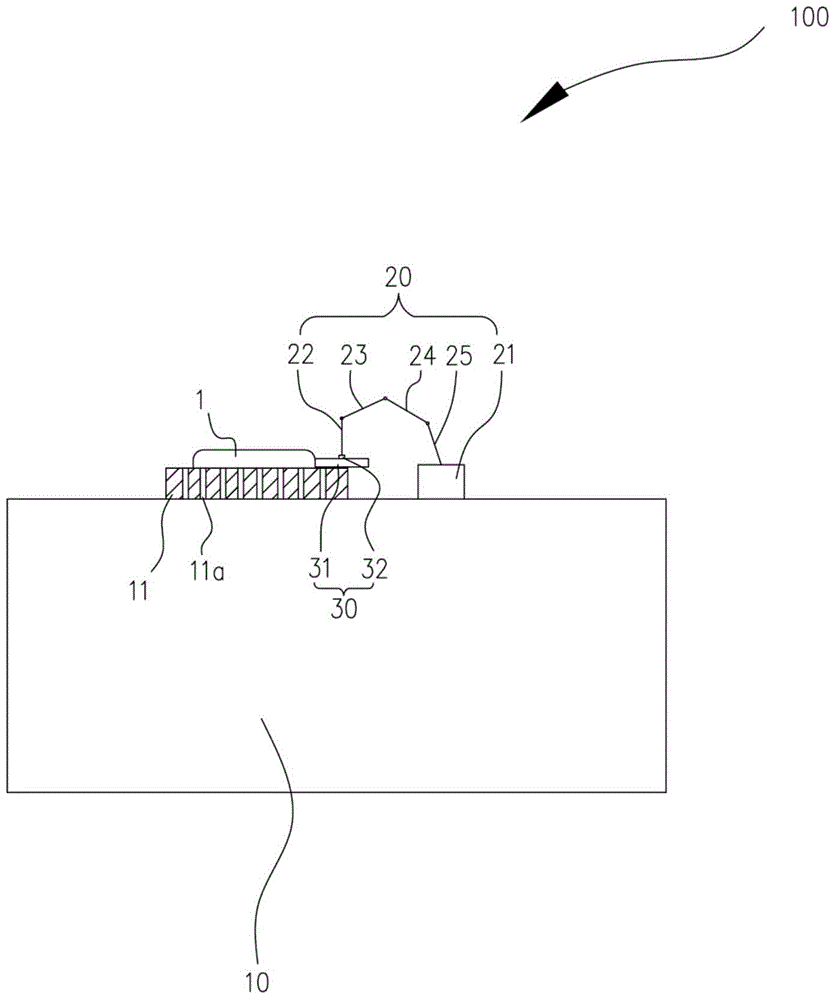

[0023] see figure 1 with figure 2 , a wire drawing device 100 provided by the present invention is used for wire drawing the surface of a metal workpiece 1 . The wire drawing device 100 includes a base 10 , a mechanical arm 20 and a processing assembly 30 . The base 10 is provided with a parallel and horizontal working platform 11 for fixing the metal workpiece 1 . The mechanical arm 20 includes a base 21 and a first link 22, the base 21 is fixed on the base 10, one end of the first link 22 is rotatably connected to the base 21, the first link The rotation direction of the rod is perpendicular to the working platform 11 . The processing assembly 30 includes a drawing wheel 31 and a working shaft 32, the working shaft 32 is rotatably connected to the end of the first connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com