Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Corrosion under insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

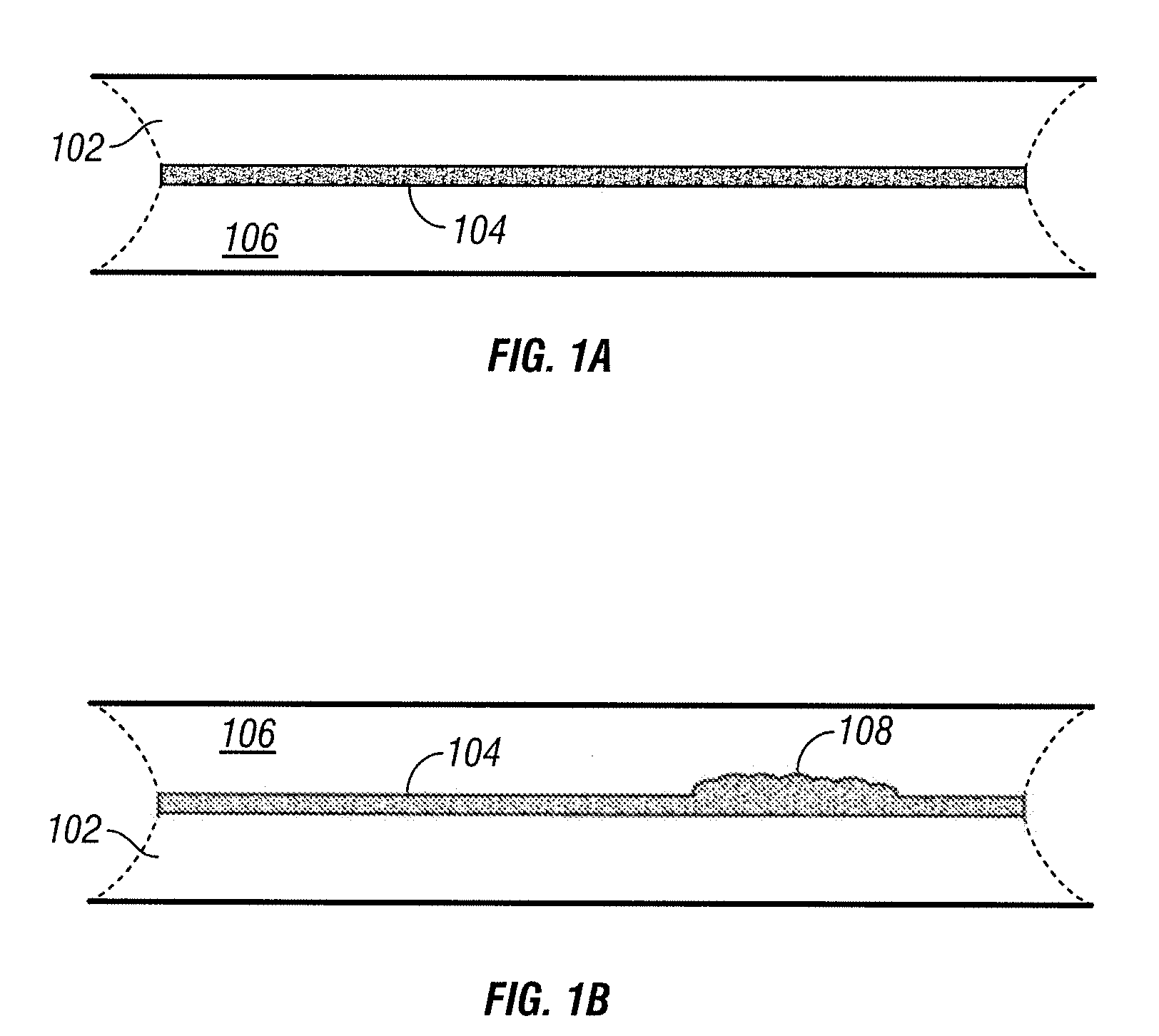

Corrosion under insulation (CUI) is a severe form of localized external corrosion that occurs in carbon and low alloy steel equipment that has been insulated. This form of corrosion occurs when water is absorbed by or collected in the insulation. The equipment begins to corrode as it is exposed to water and oxygen. CUI is common in refineries and process plants that typically operate equipment at high temperatures.

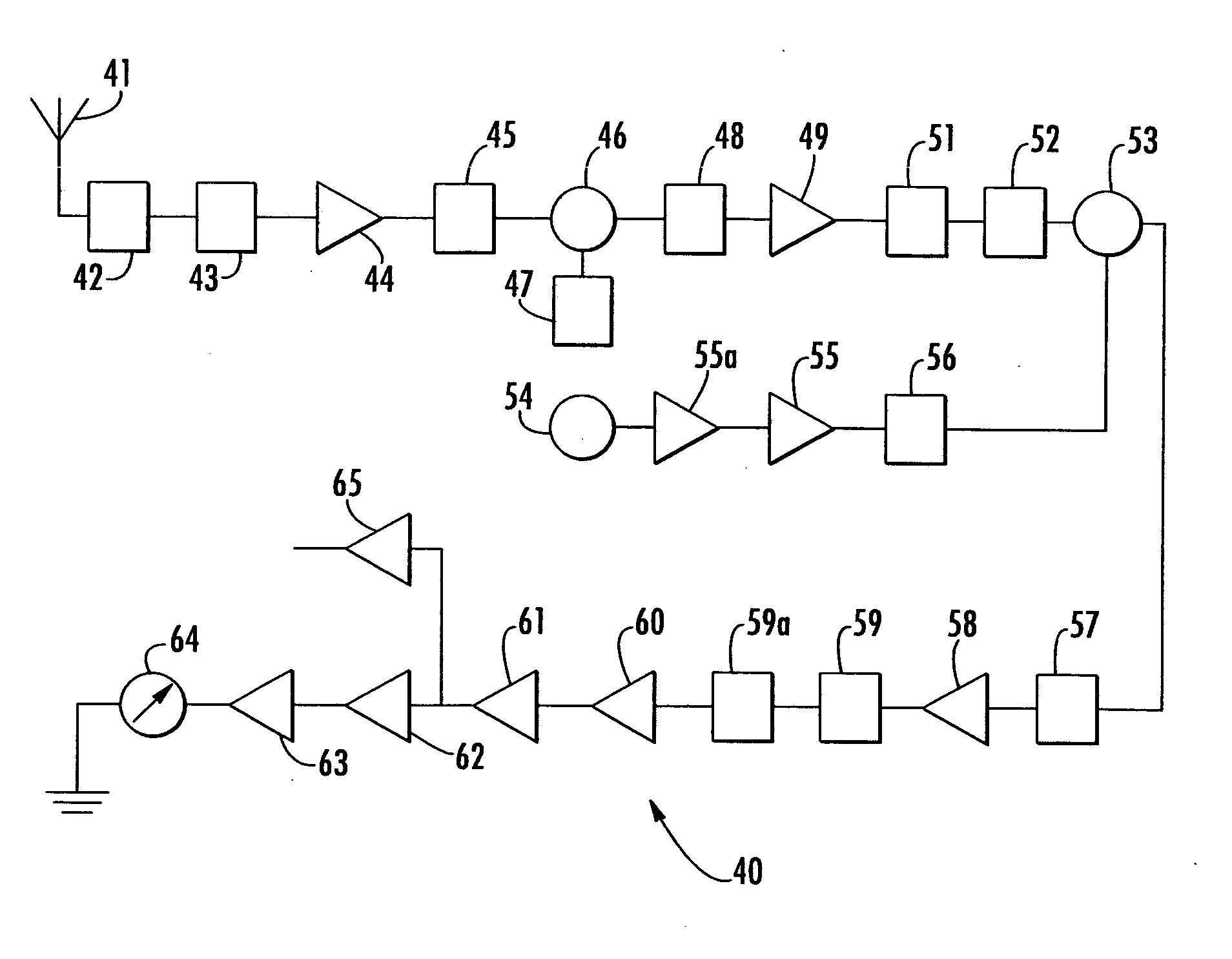

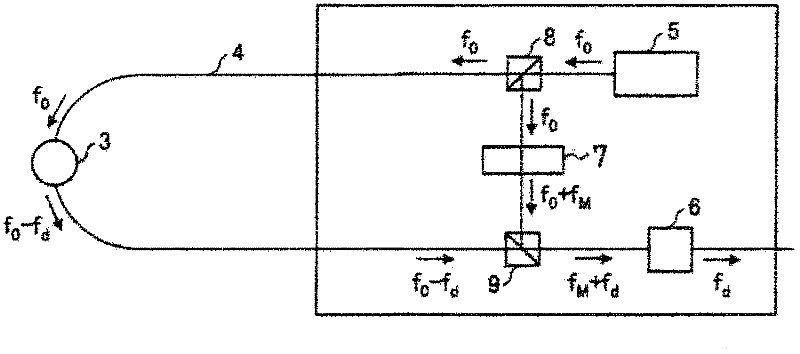

Harmonic wireless transponder sensor and method

ActiveUS7145453B2Telemetry/telecontrol selection arrangementsRecord carriers used with machinesEnvironmental effectHarmonic

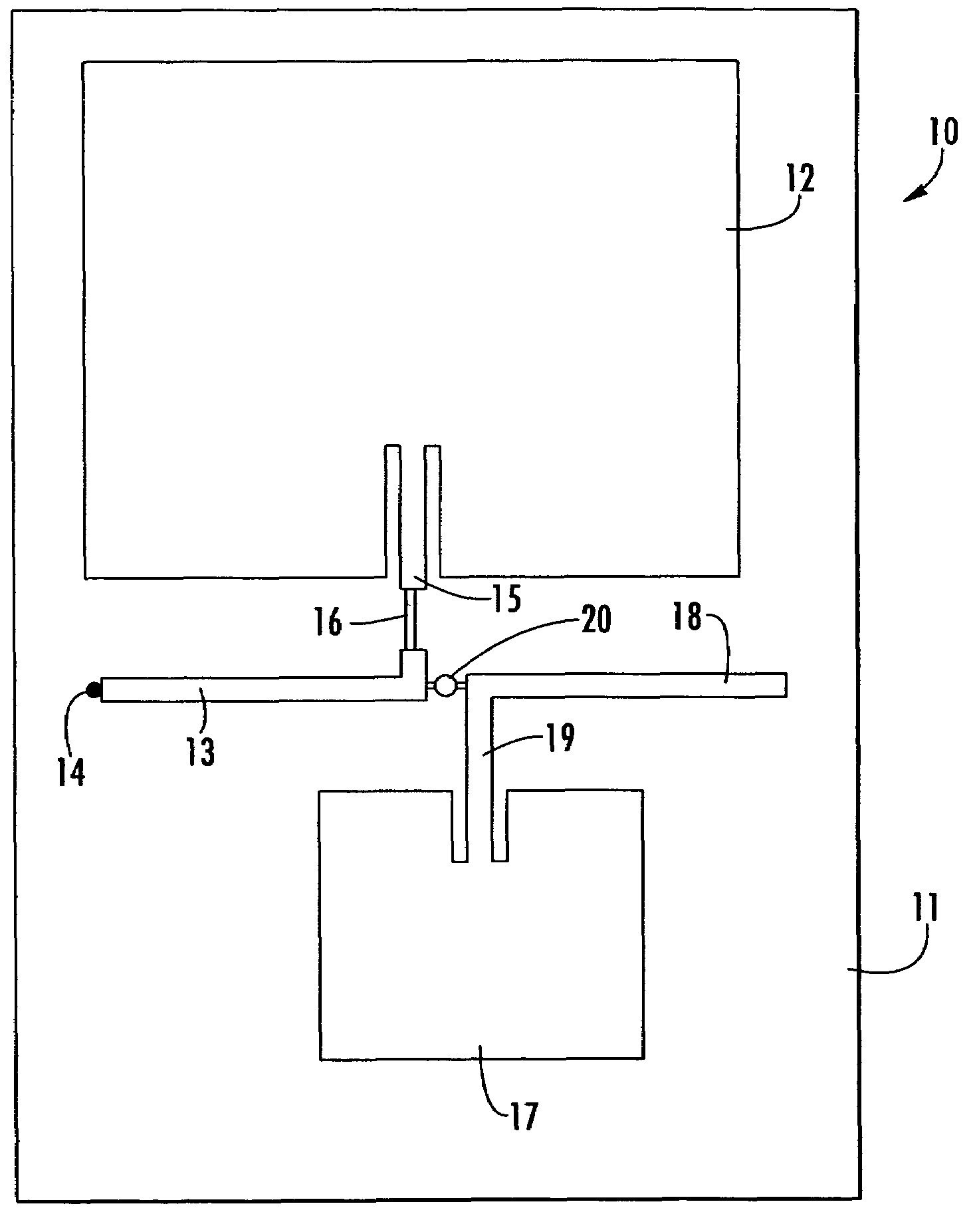

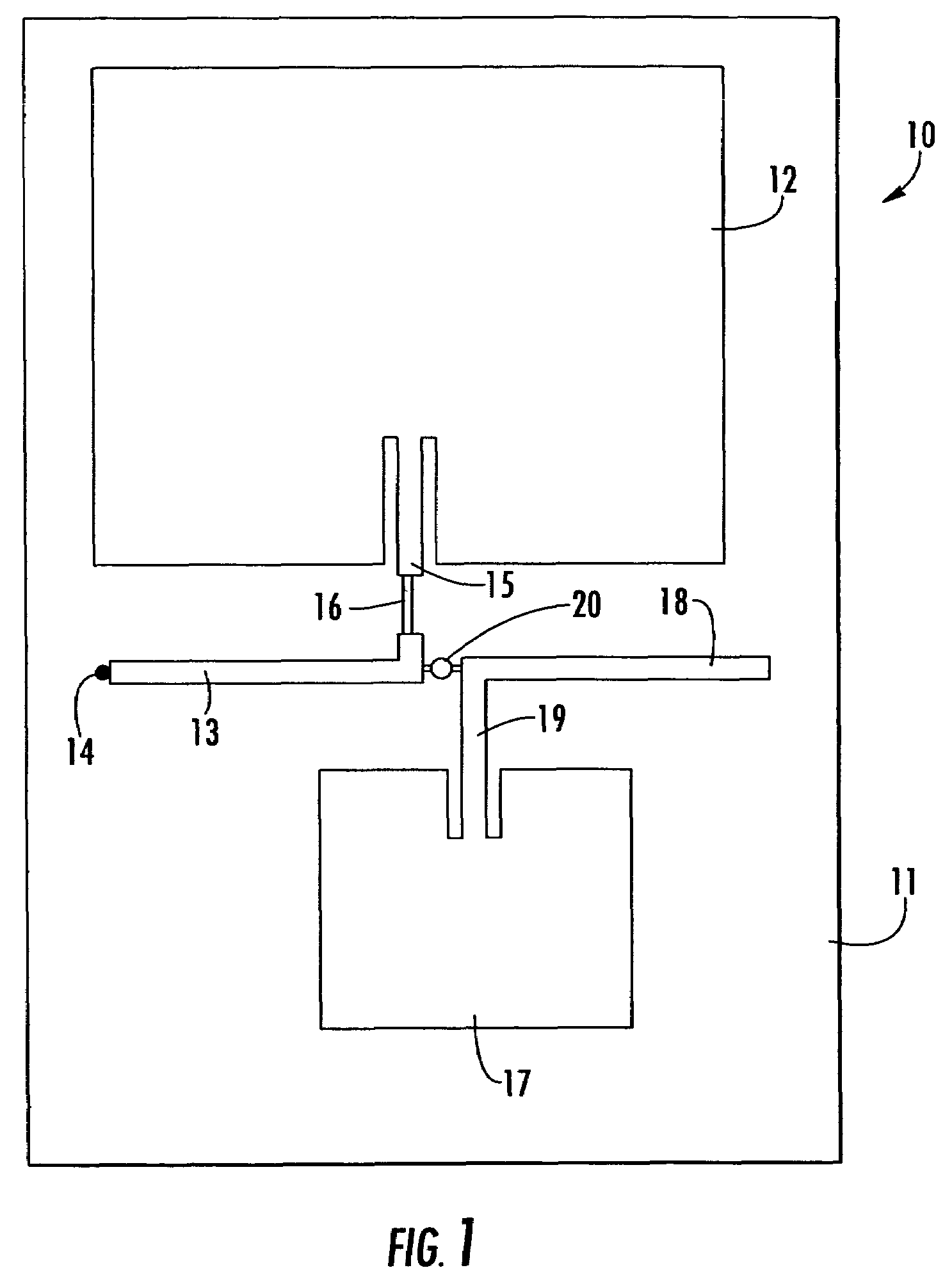

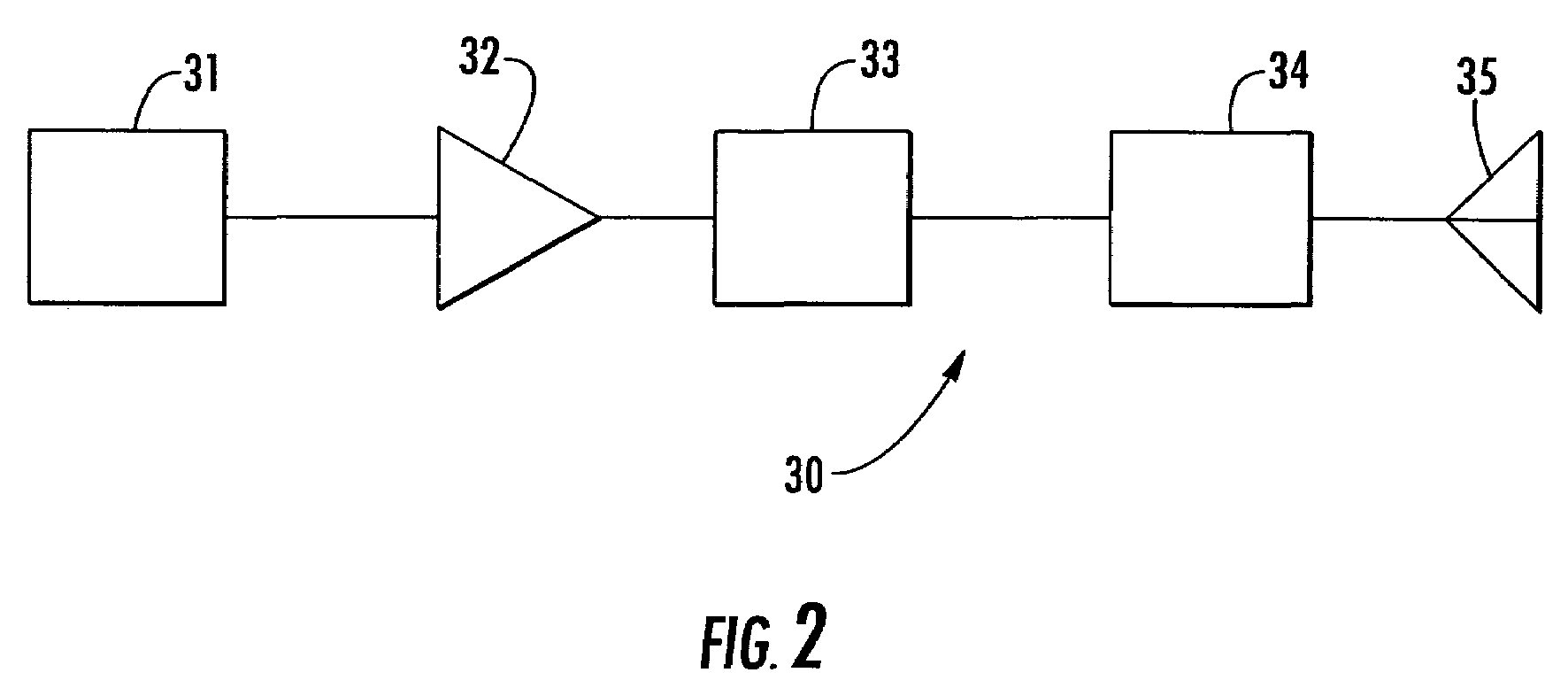

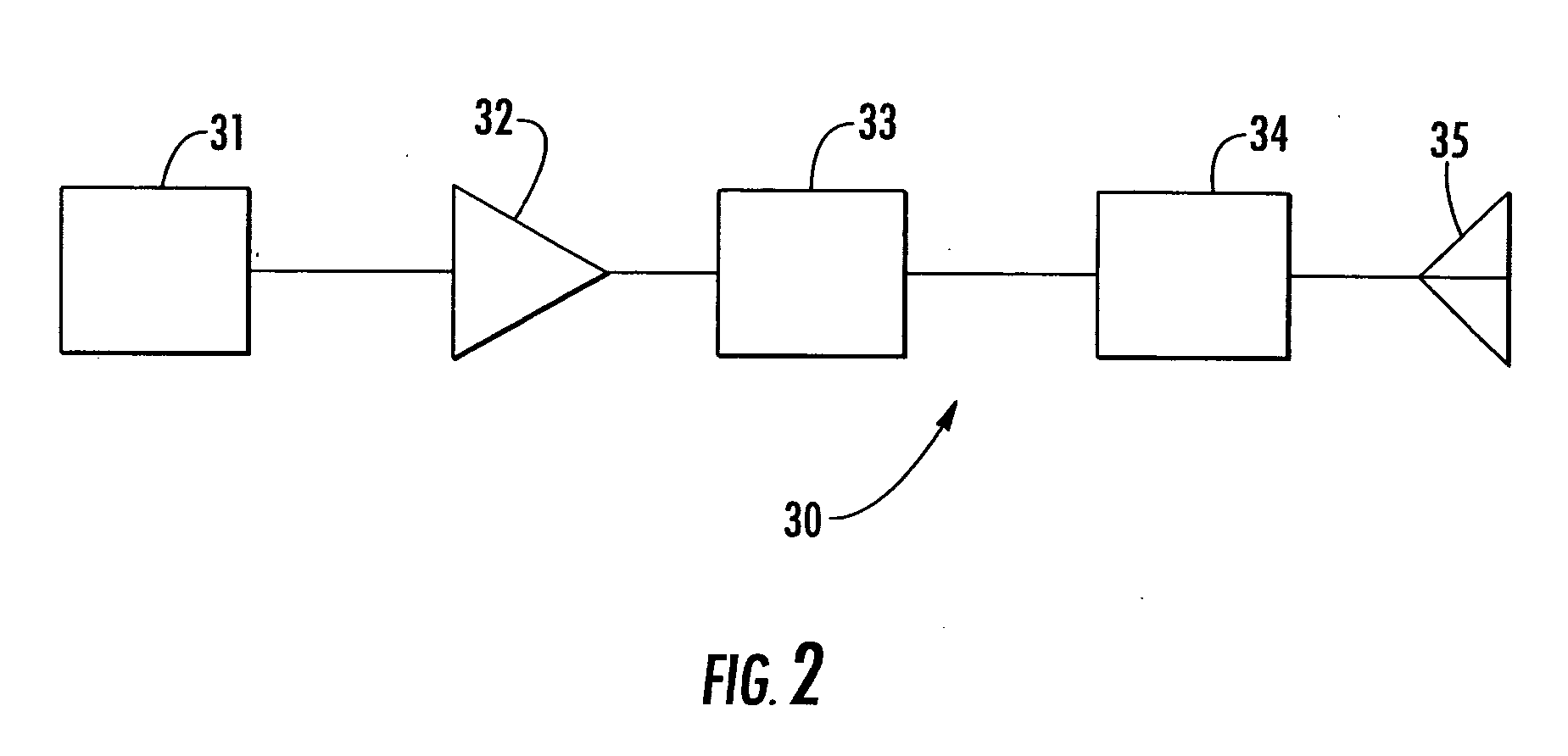

A method for detecting a latent environmental effect (such as a corrosive environment under insulation) or a latent structural change (such as a crack in a concealed structural member) at a known remote concealed location. The method of the instant invention includes three steps. The first step is to use a harmonic electromagnetic transponder at the known remote concealed location of the latent environmental effect or the latent structural change, the harmonic electromagnetic transponder having a reactive portion which reacts to the latent environmental effect or latent structural change to modify the harmonic emission of the transponder. The second step is to remotely interrogate the transponder by directing electromagnetic radiation at the transponder. The third step is to use the harmonic emission of the transponder to remotely determine the latent environmental effect or the latent structural change.

Owner:MICHIGAN STATE UNIV +1

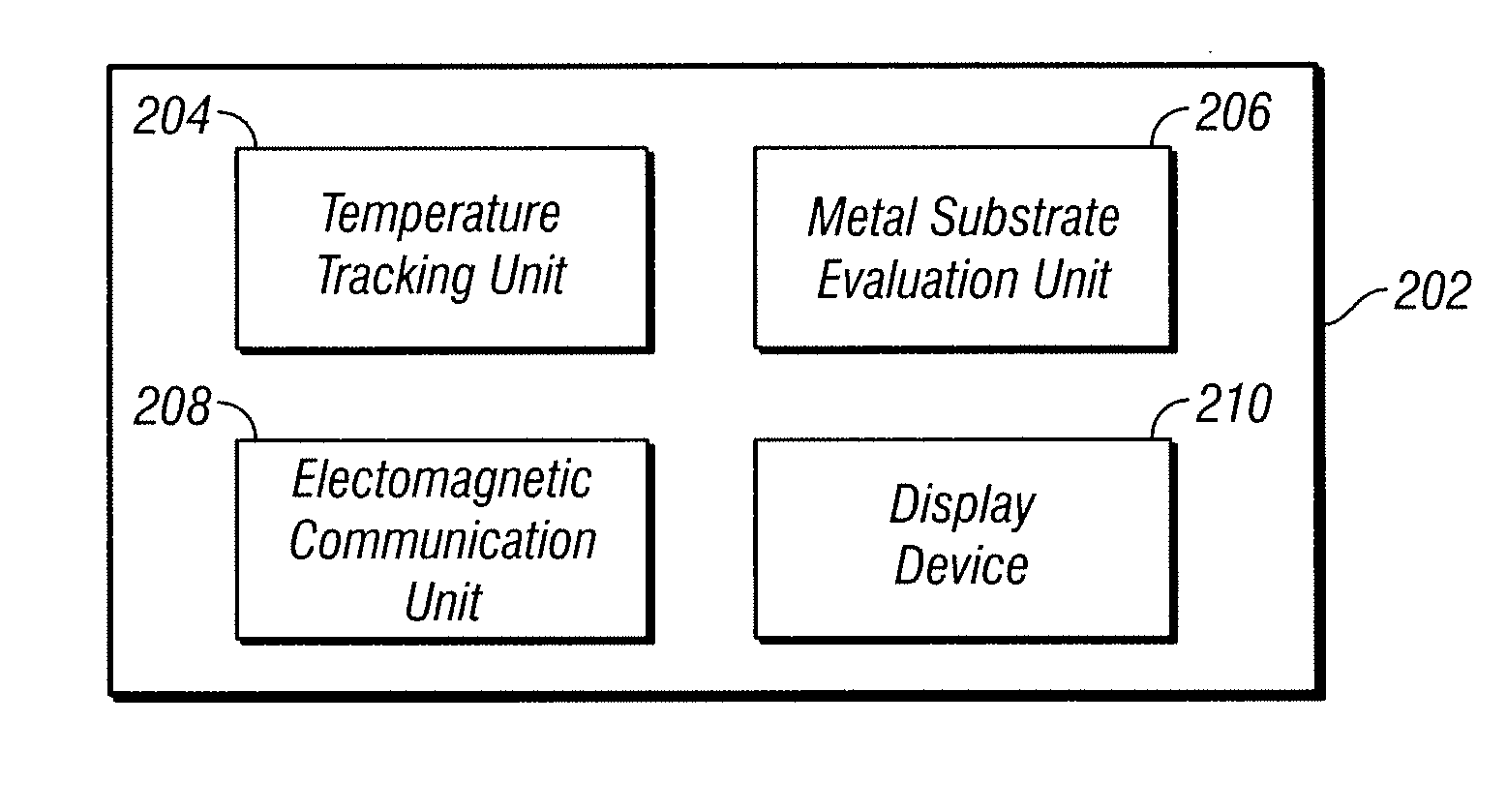

Method and System for Detecting Corrosion Under Insulation

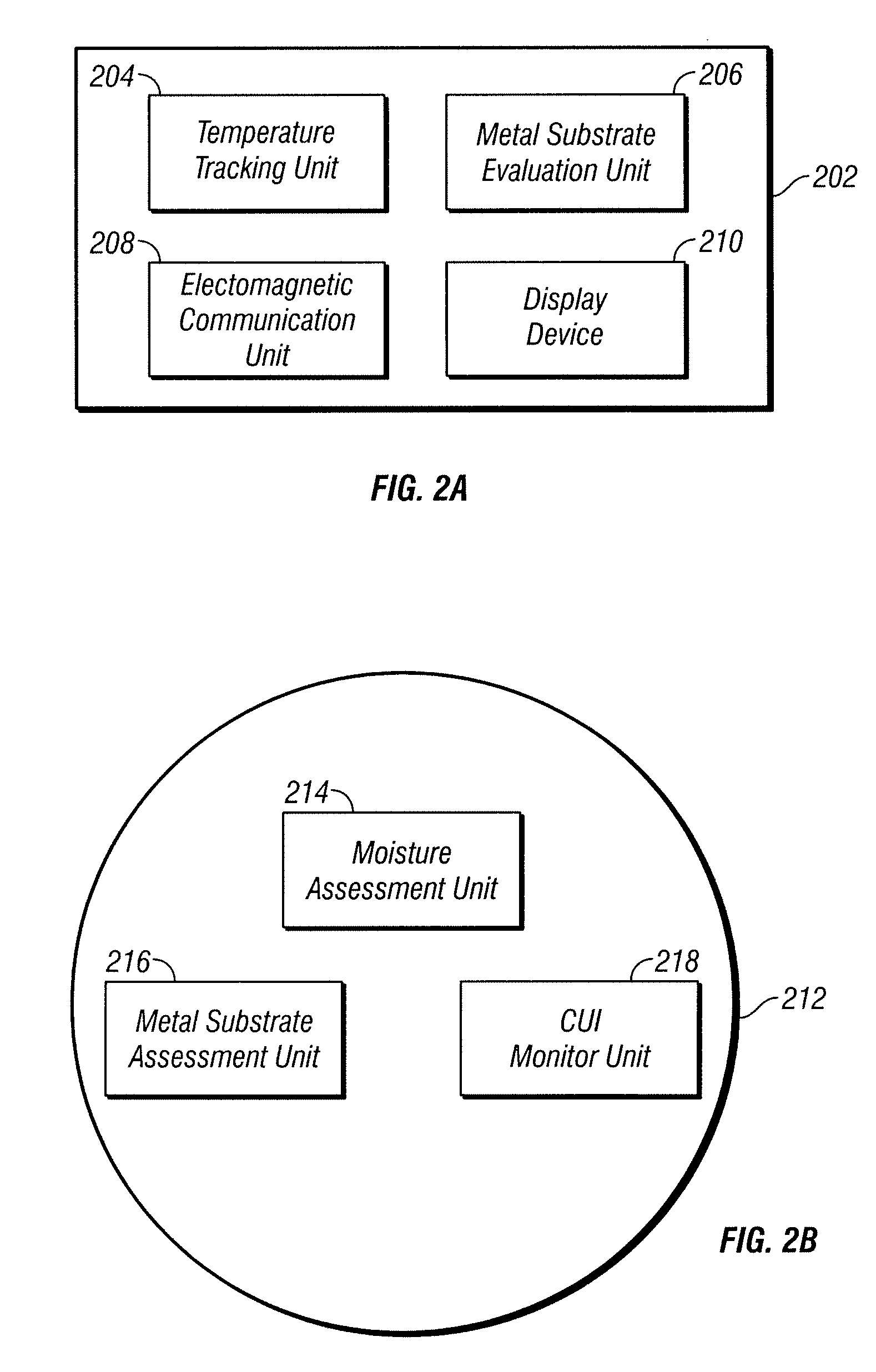

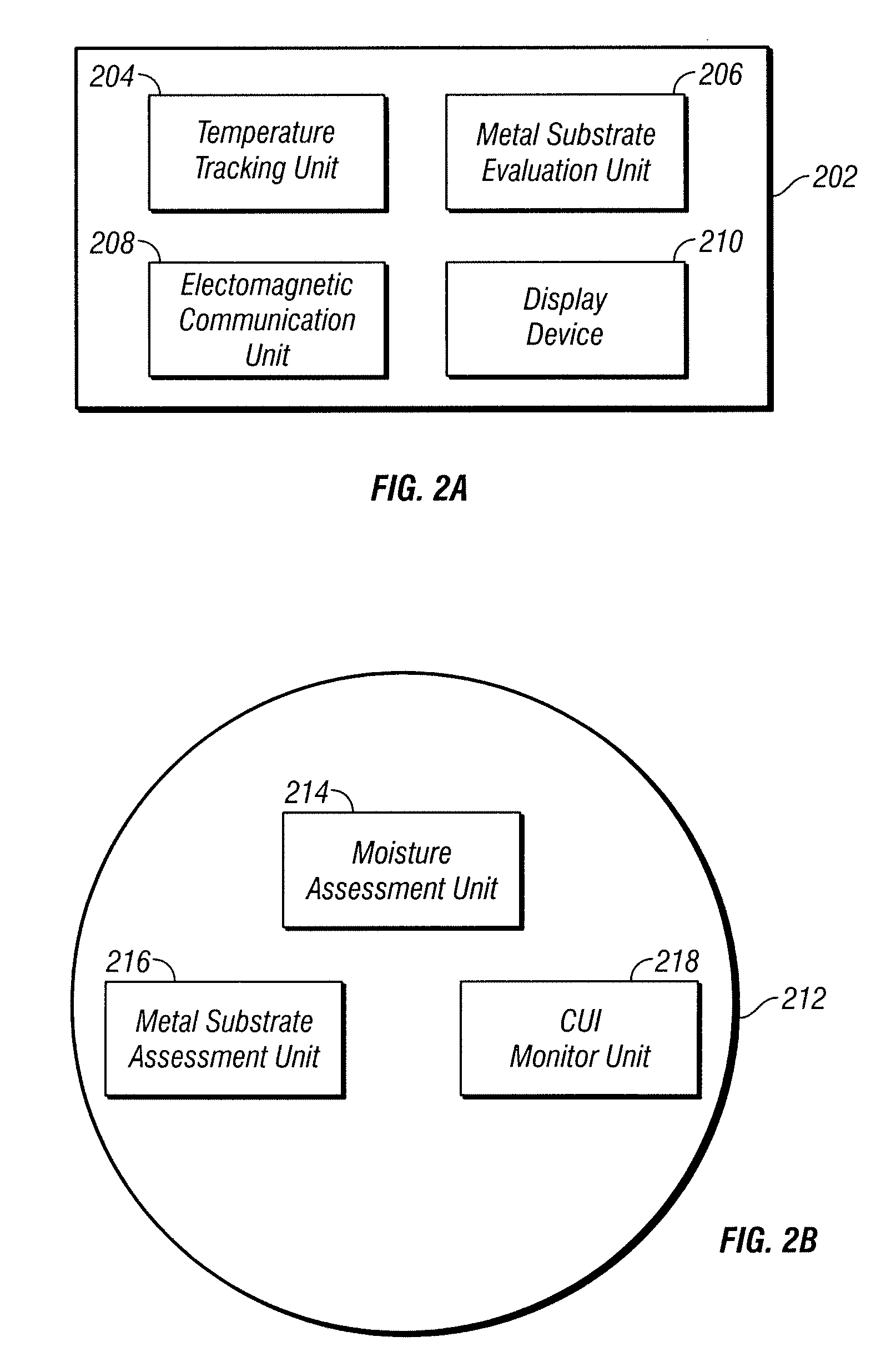

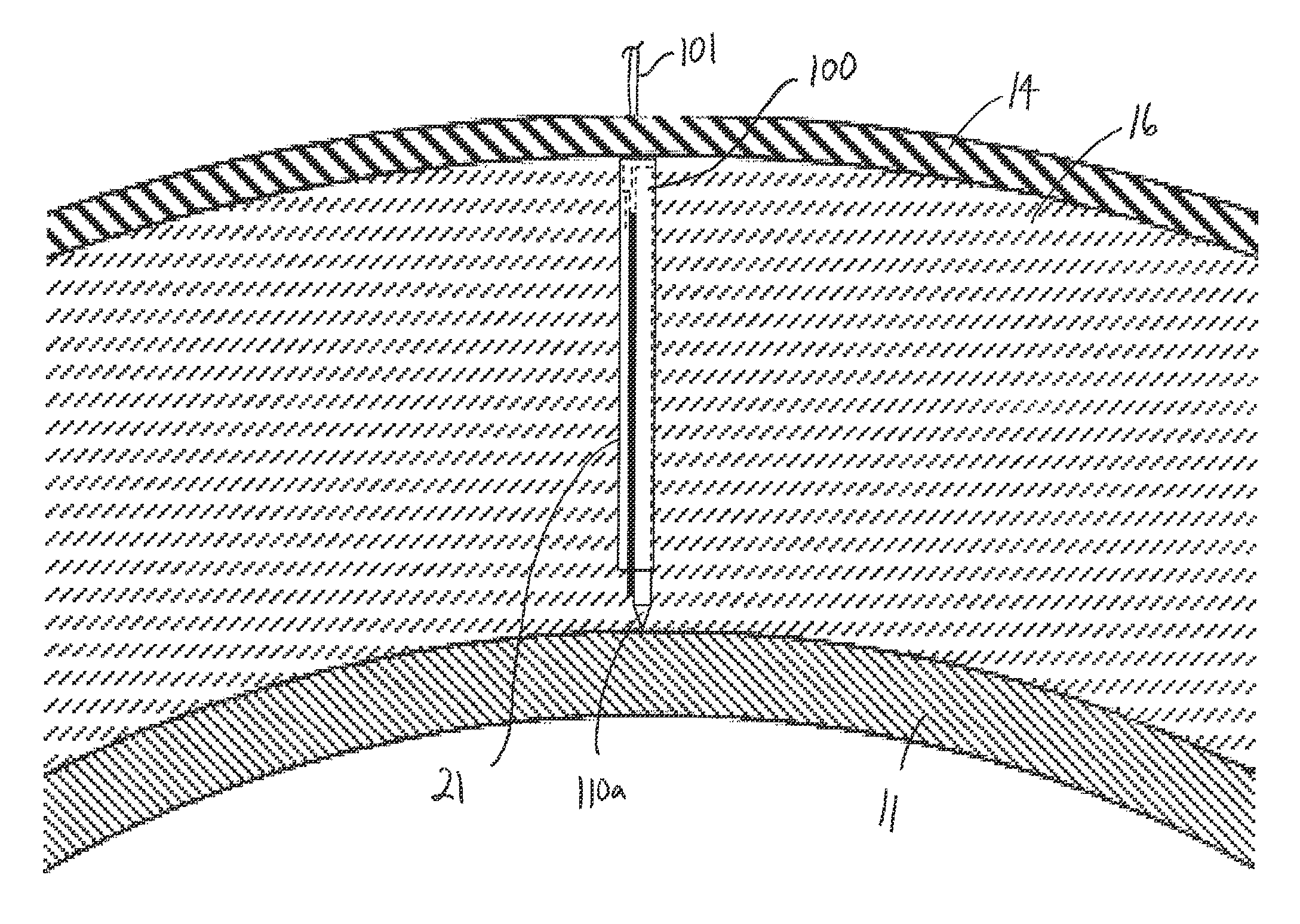

ActiveUS20100107767A1Thermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesProcess equipmentThermal insulation

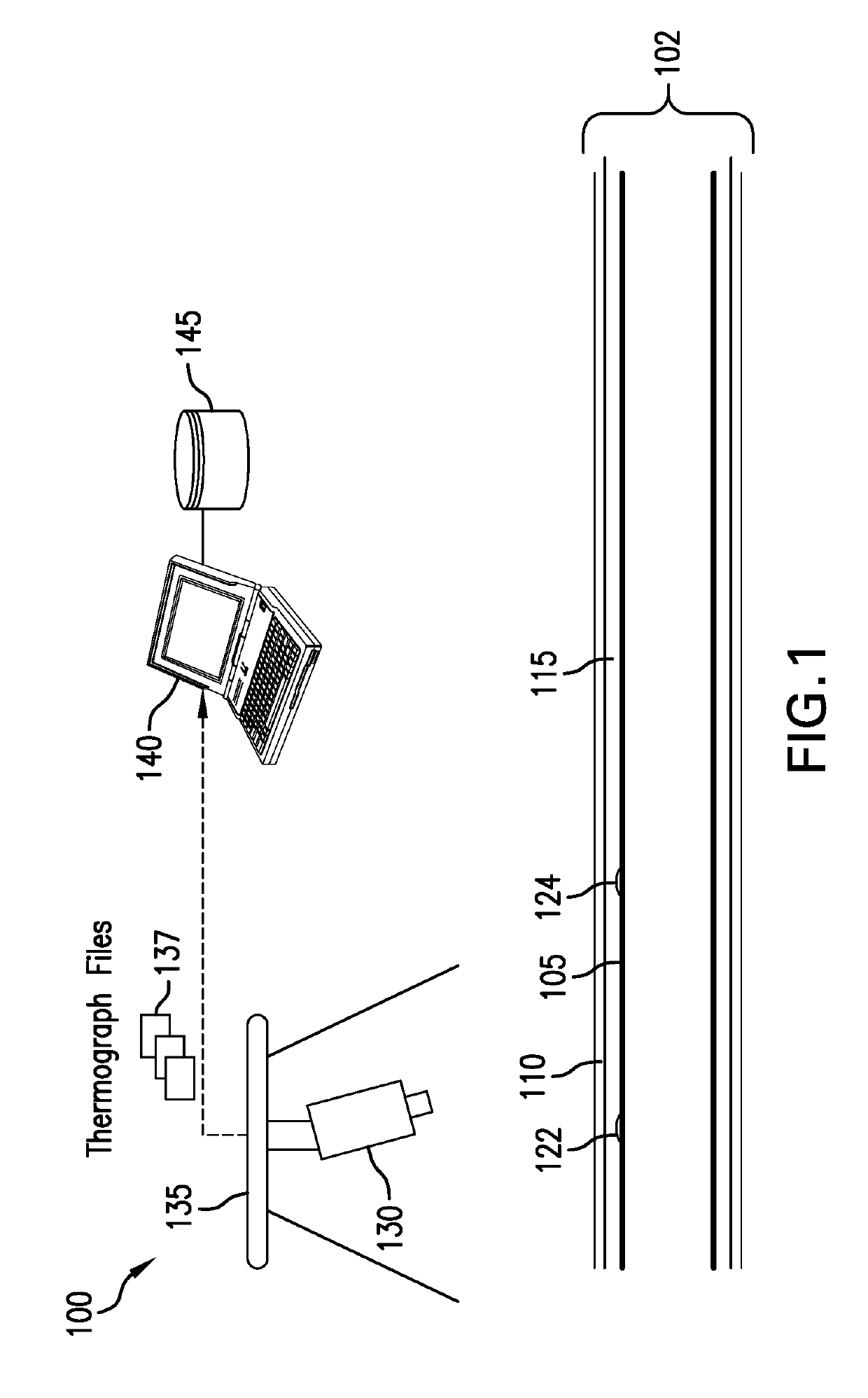

The present invention relates generally to thermal imaging systems and methods and uses therefor, and in a particular though non-limiting embodiment, to a method of detecting corrosion under insulation, as well as corrosion-related material data associated therewith. The system utilizes advanced infrared imaging video cameras to detect characteristic signatures of wet thermal traits on process equipment. Various embodiments of the invention integrate equipment, automation, and algorithms to form a method for identifying wet thermal insulation by scanning multiple locations along insulated piping, tanks, or other manufacturing equipment. Such scans can occur individually, sequentially, or simultaneously, with the results then being stored and comparatively analyzed. Further embodiments comprise tracking the approximate time of exposure to moisture, prediction of the corrosion rates for underlying insulated metal substrates, and measuring wall thicknesses along either predetermined random portions of the metal substrate.

Owner:HONEYWELL INT INC

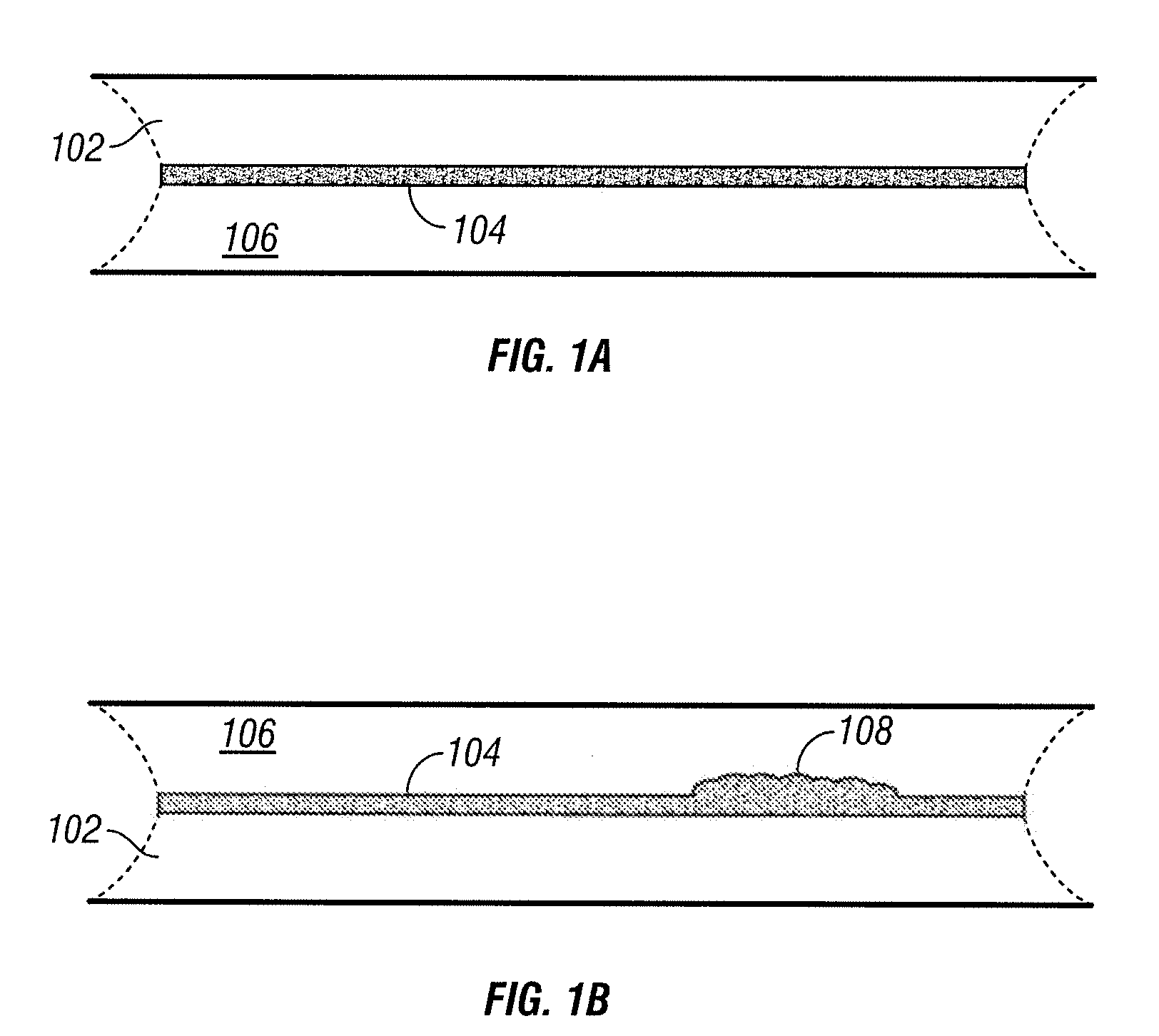

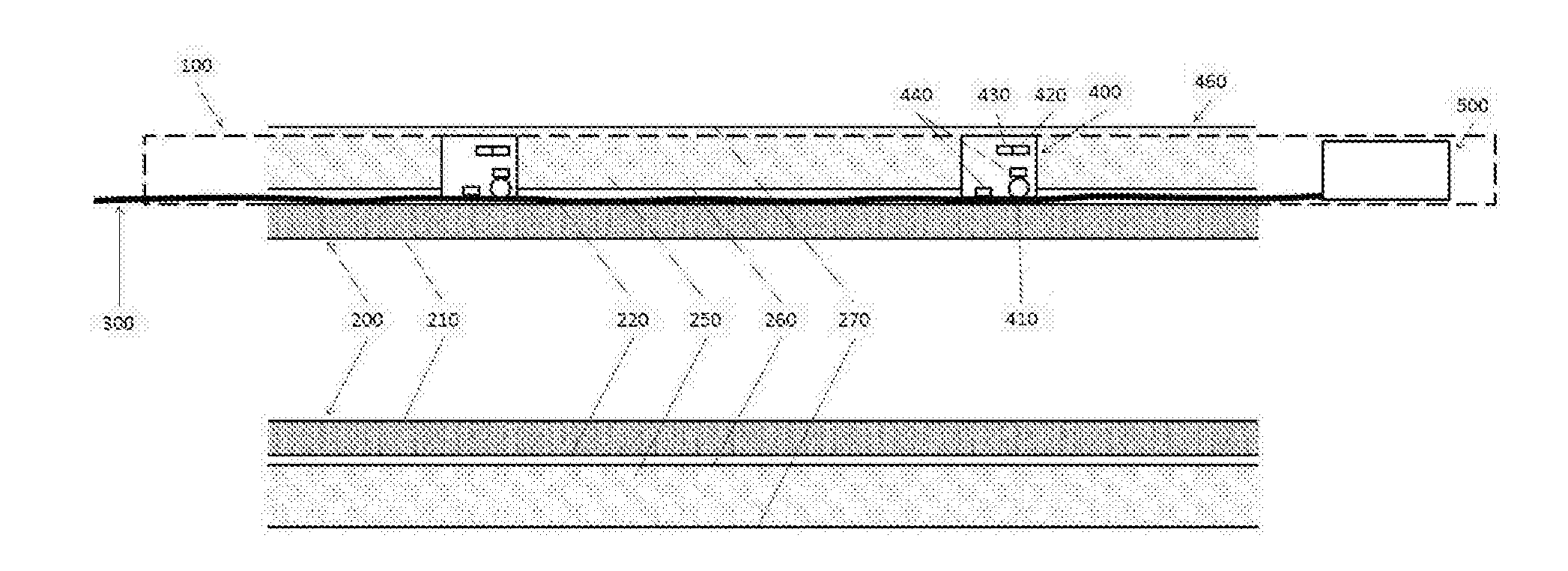

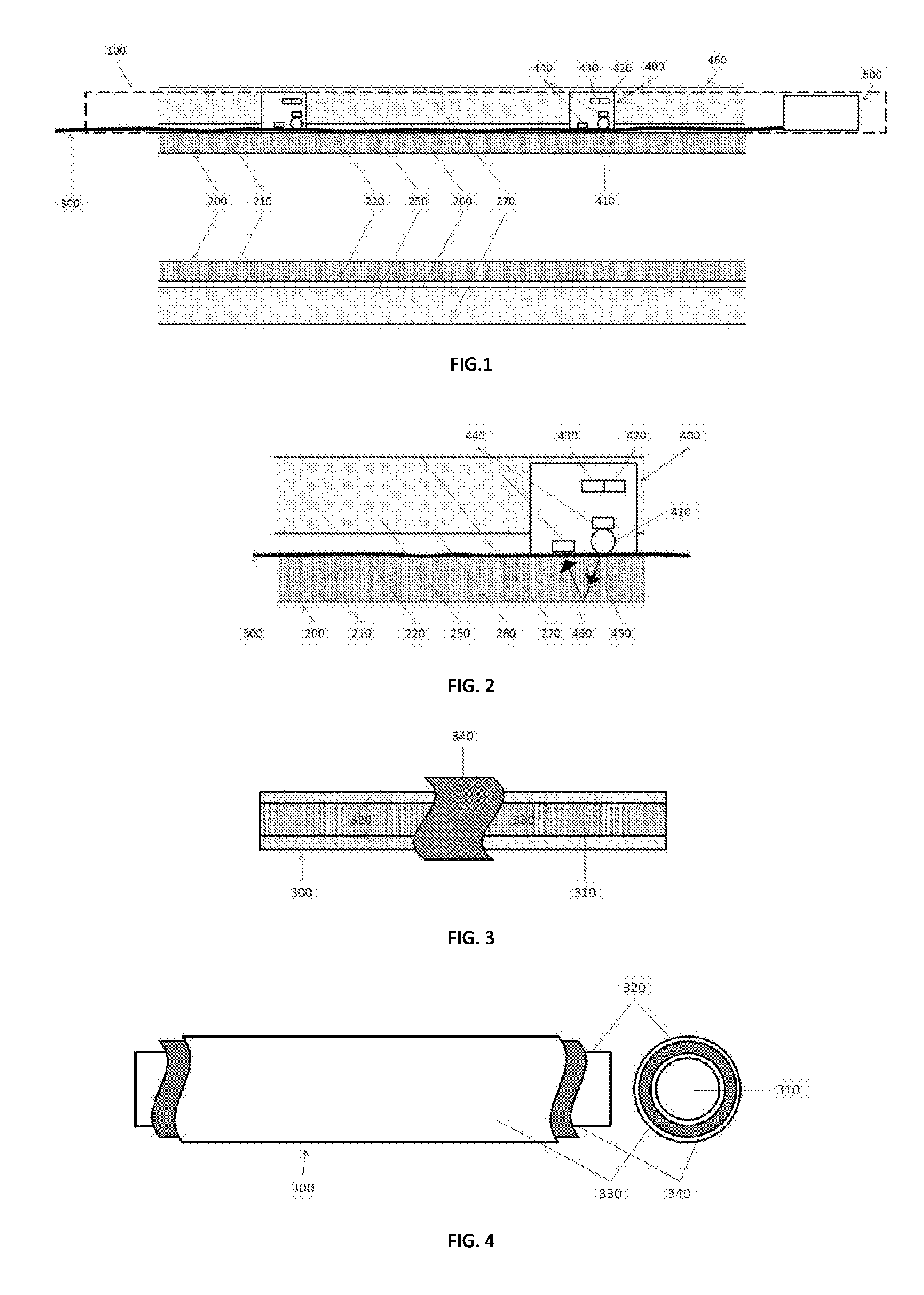

Methods and devices for sensing corrosion under insulation (CUI)

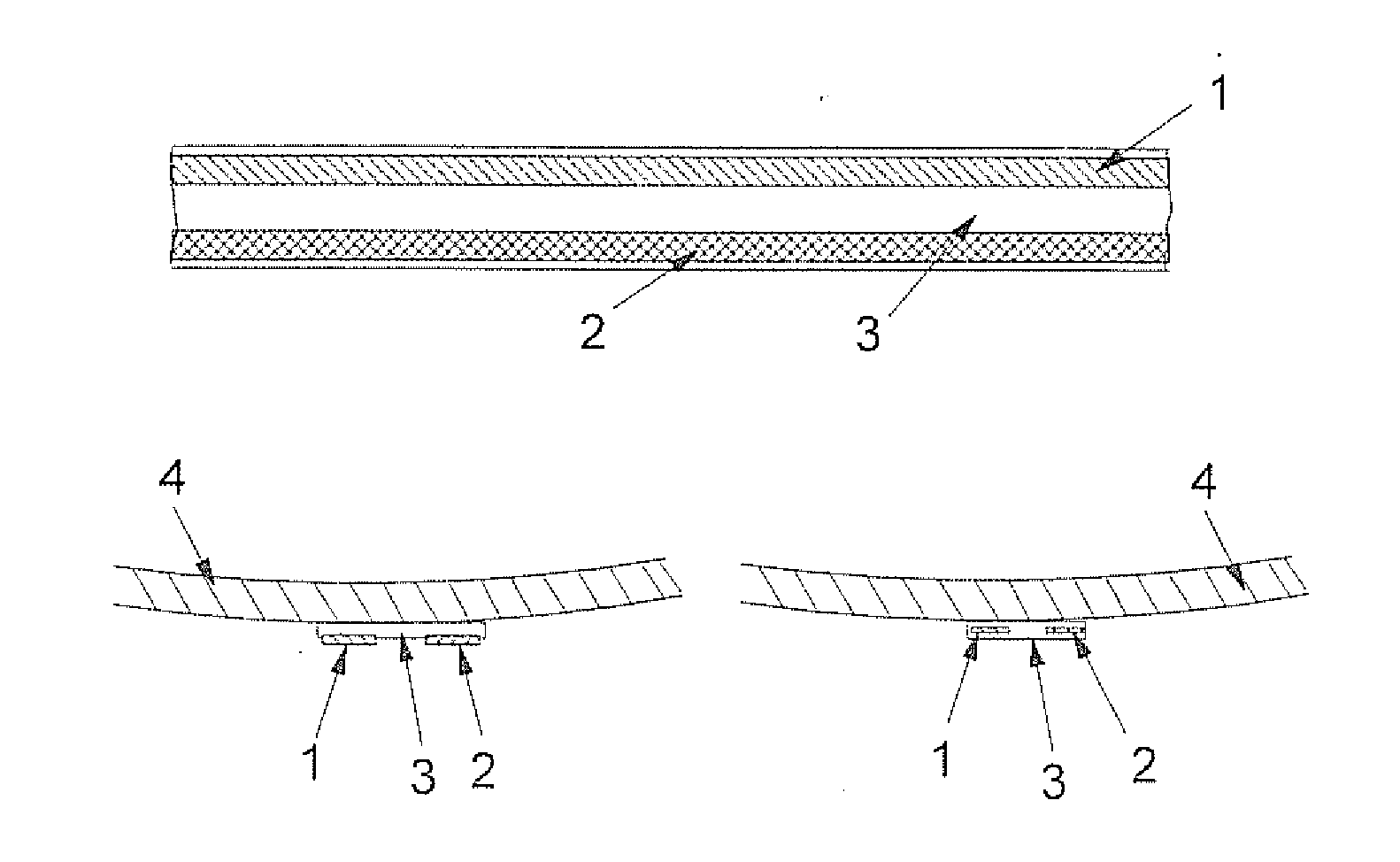

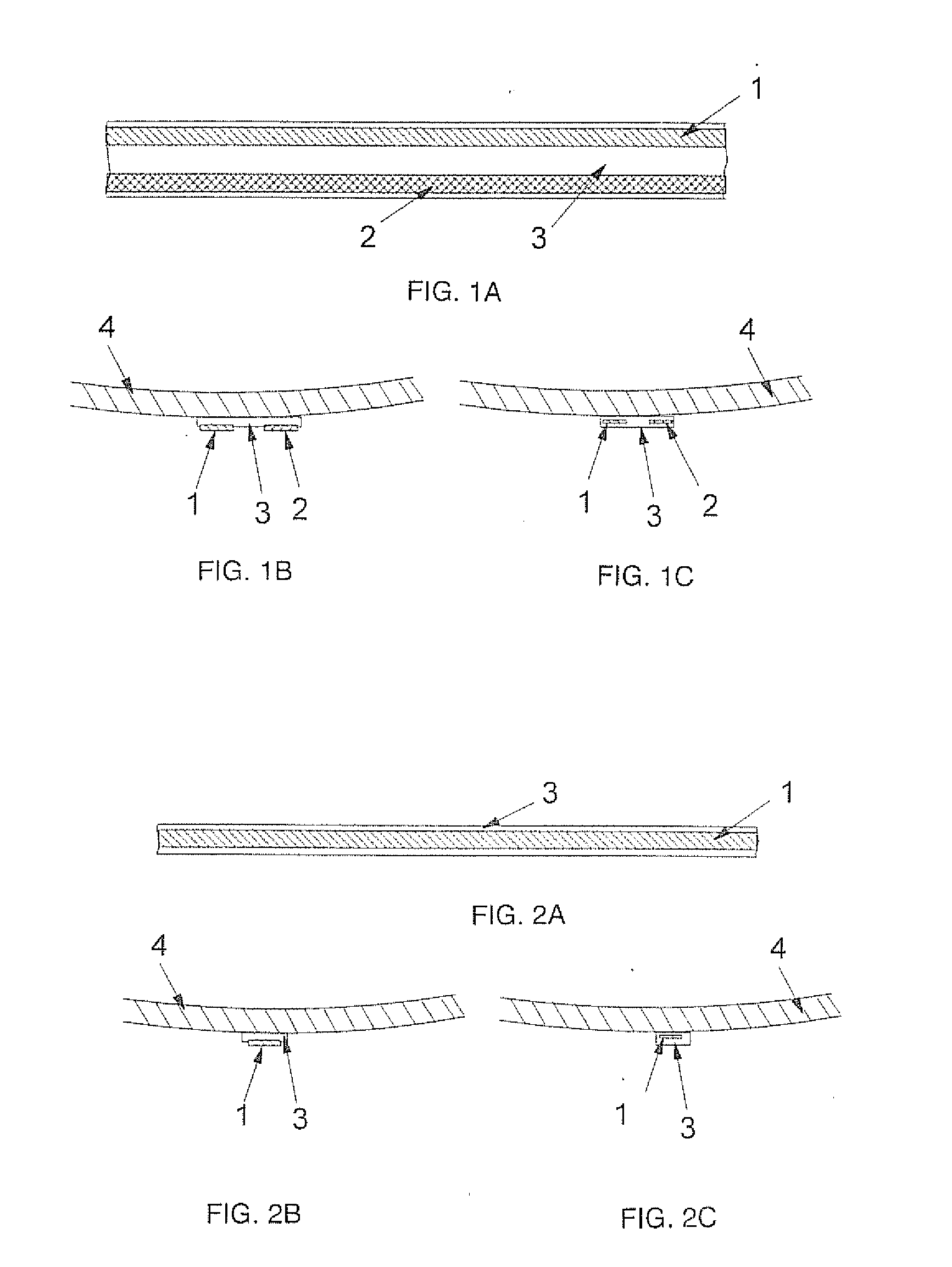

InactiveUS20120056634A1Readily apparentWeather/light/corrosion resistanceResistance/reactance/impedenceElectrical conductorCorrosion under insulation

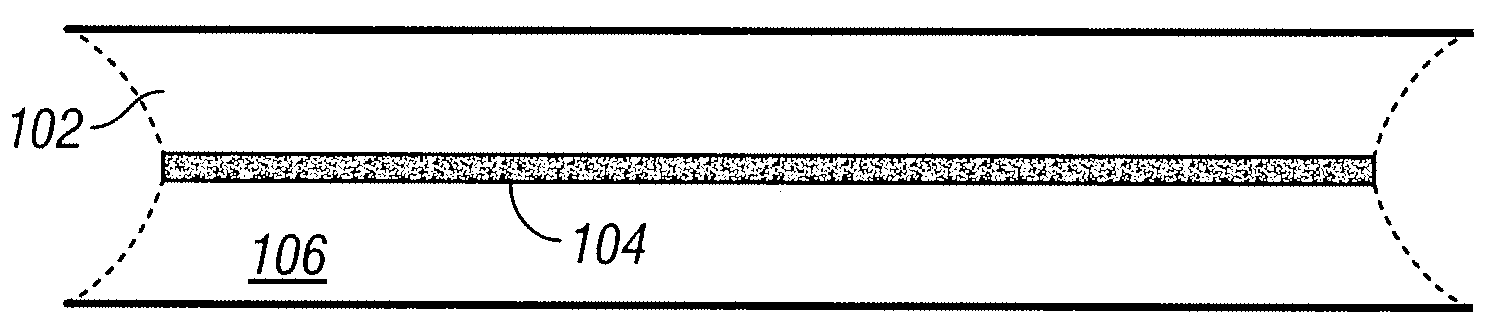

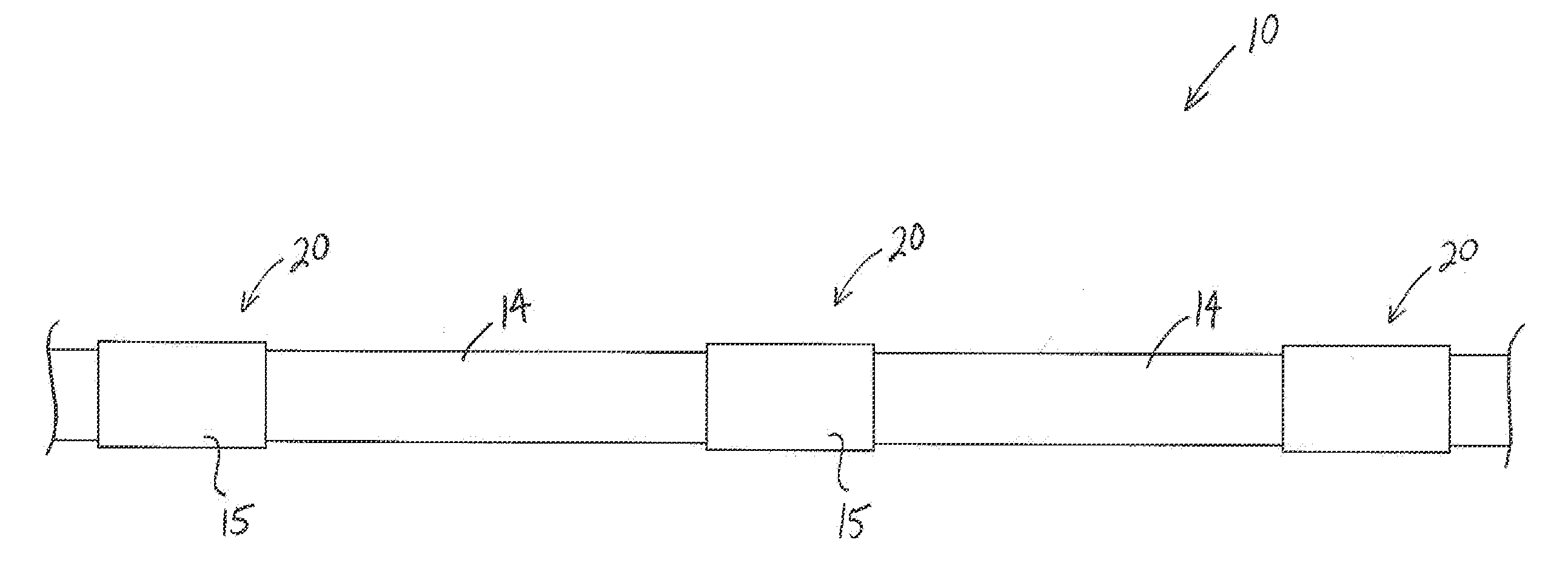

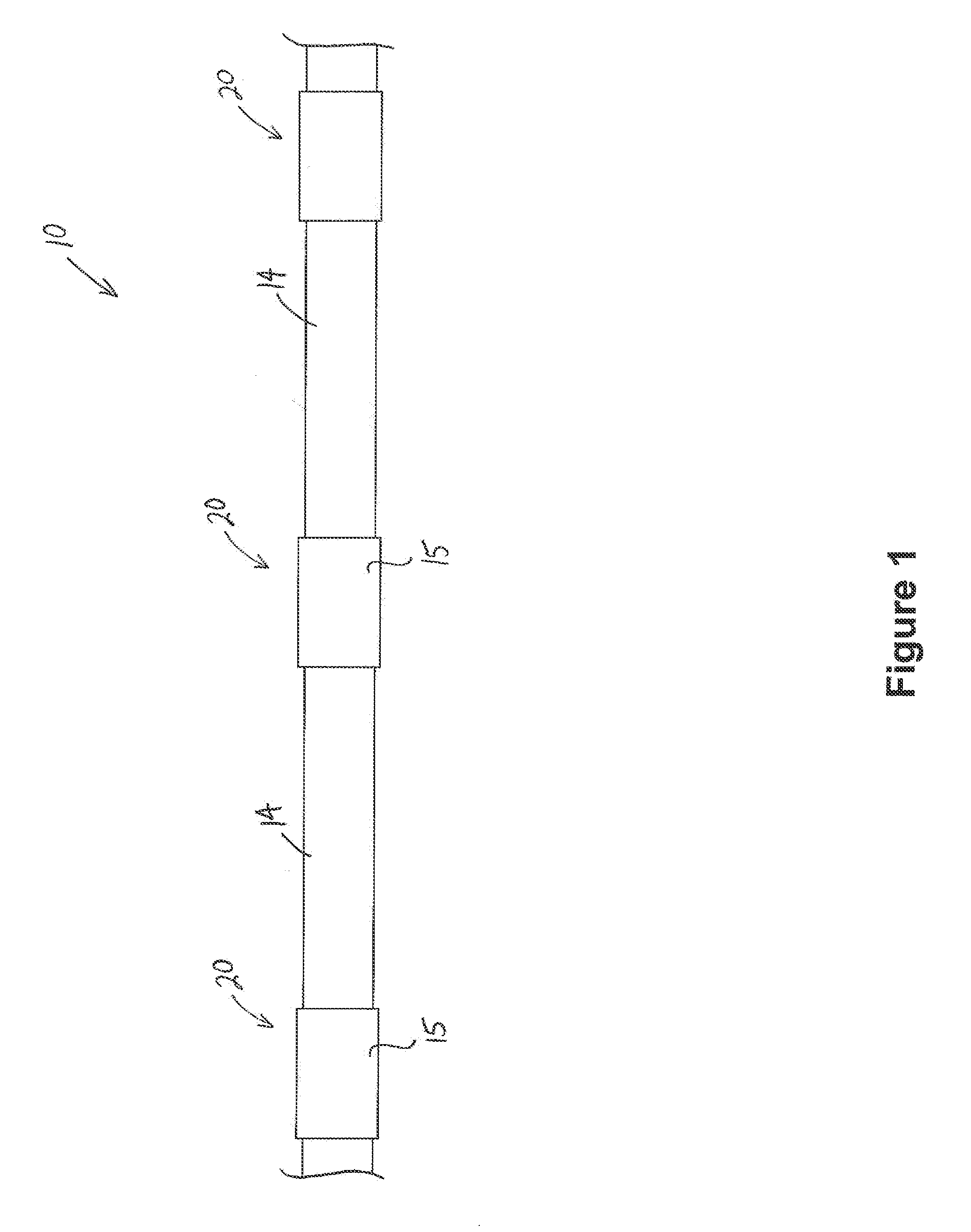

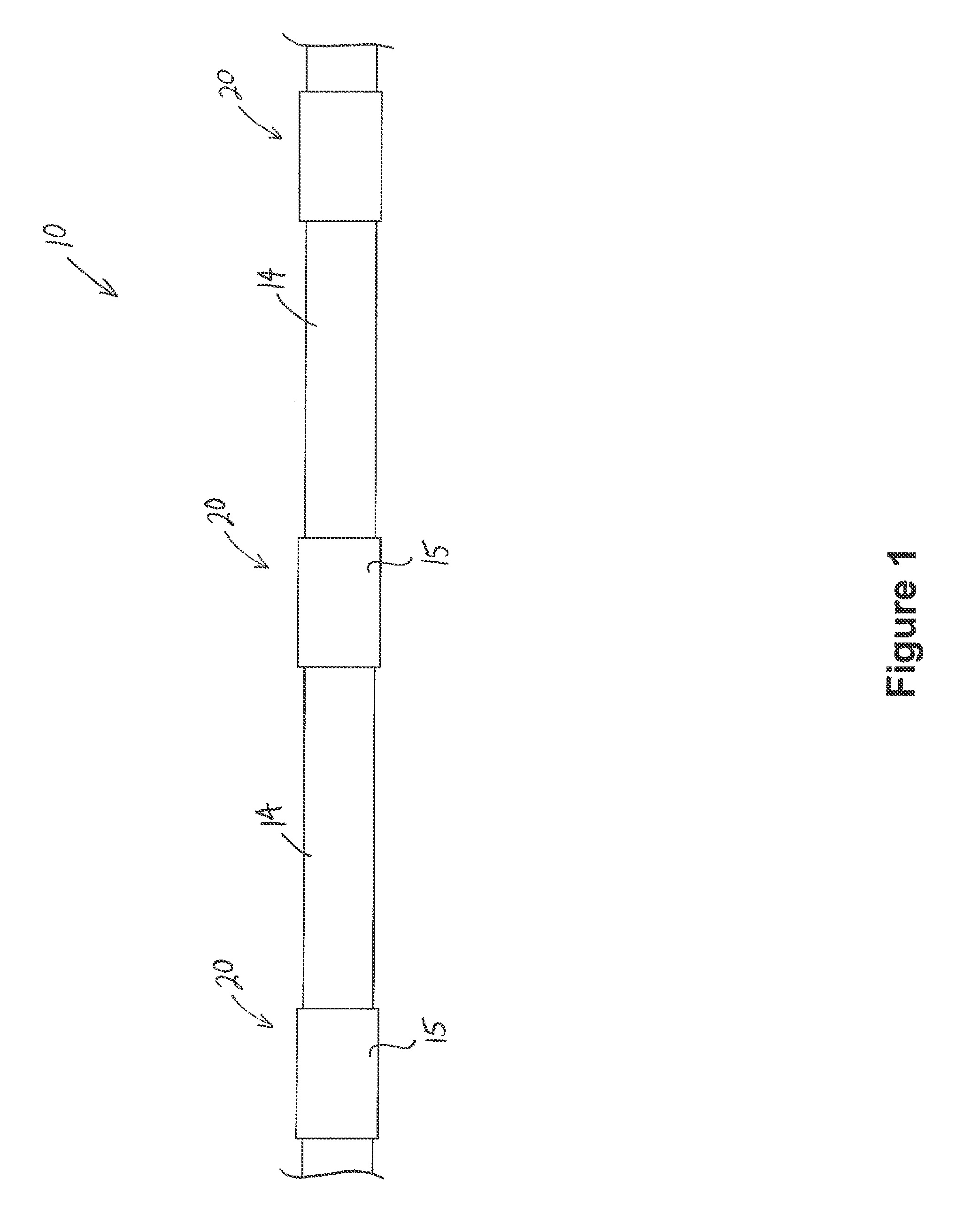

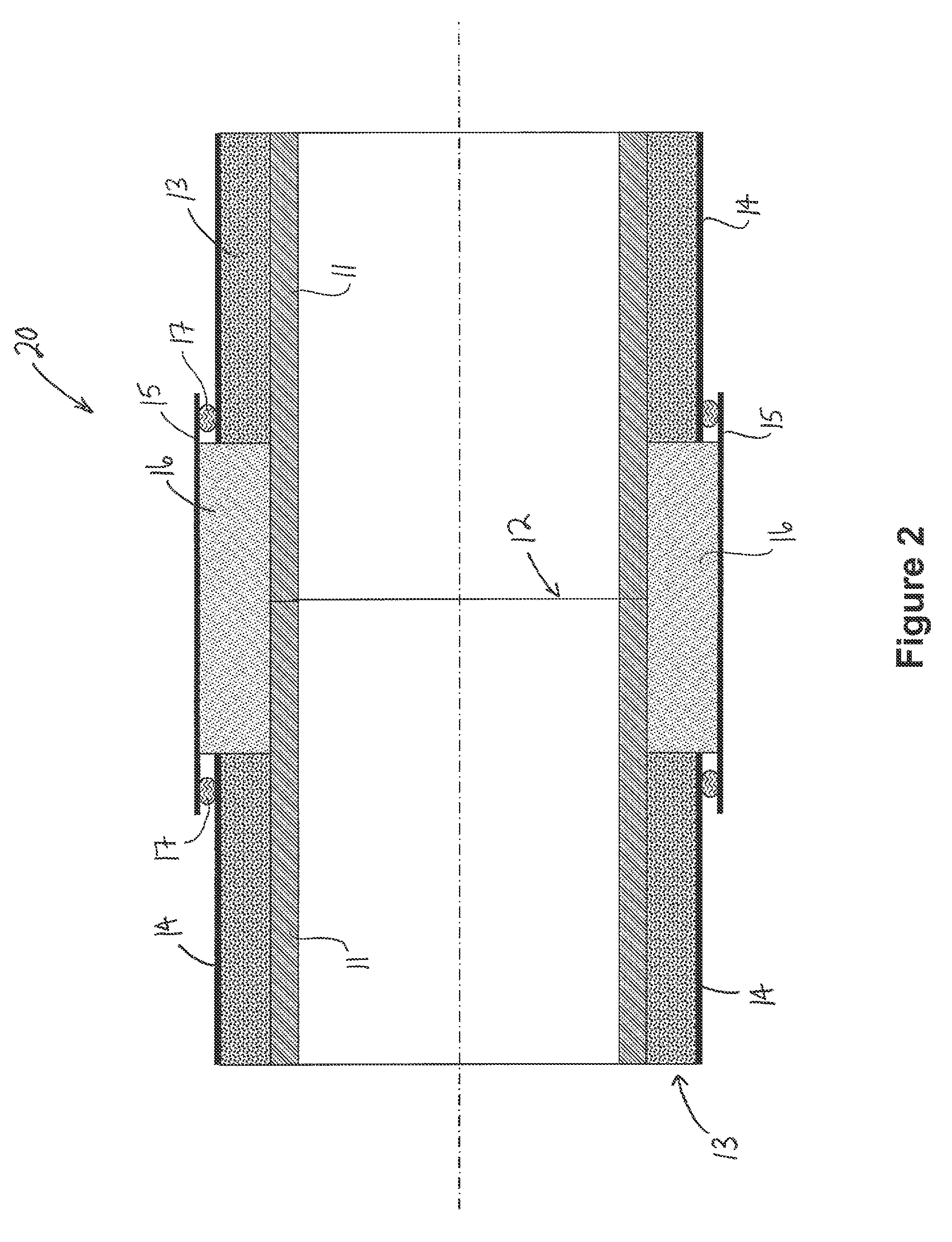

A method of sensing corrosion of a pipe covered by a layer of insulation comprises positioning a CUI sensor radially adjacent an outer surface of the pipe. The CUI sensor comprises a non-conductive base having a first end and a second end opposite the first end. In addition, the CUI sensor comprises a first test circuit mounted to the base. The first test circuit includes a first conductor, a second conductor, and a first testing element extending between the first conductor and the second conductor. Further, the method comprises exposing the first testing element to the same environment as the outer surface of the pipe. Still further, the method comprises determining whether the first testing element has corroded through. Moreover, the method comprises assessing whether corrosion of the pipe has occurred based on the determination of whether the first testing element has corroded through.

Owner:BP CORP NORTH AMERICA INC

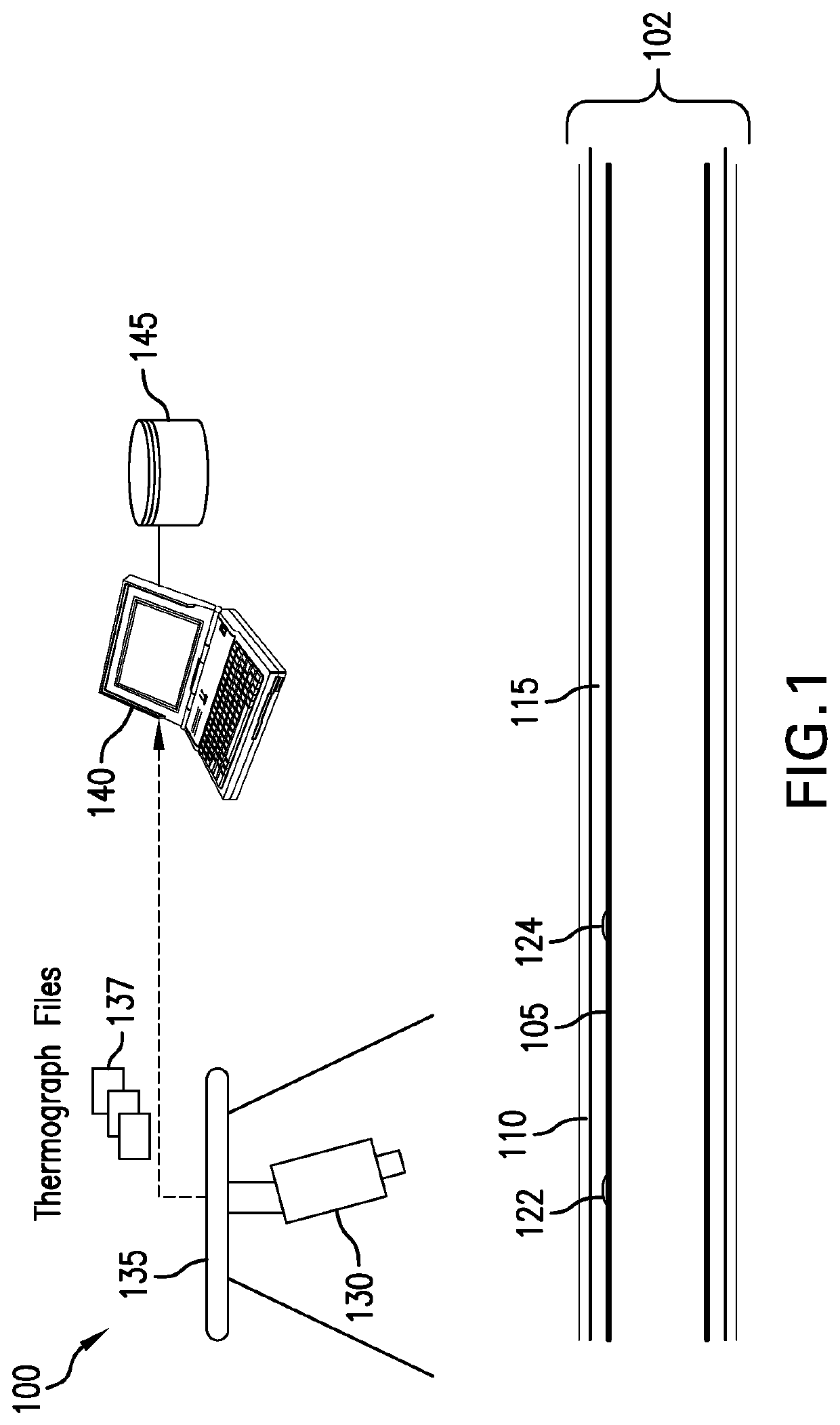

Thermography image processing with neural networks to identify corrosion under insulation (CUI)

ActiveUS20190094124A1Accurate detectionKeep dryThermometer detailsWeather/light/corrosion resistanceImaging processingImage manipulation

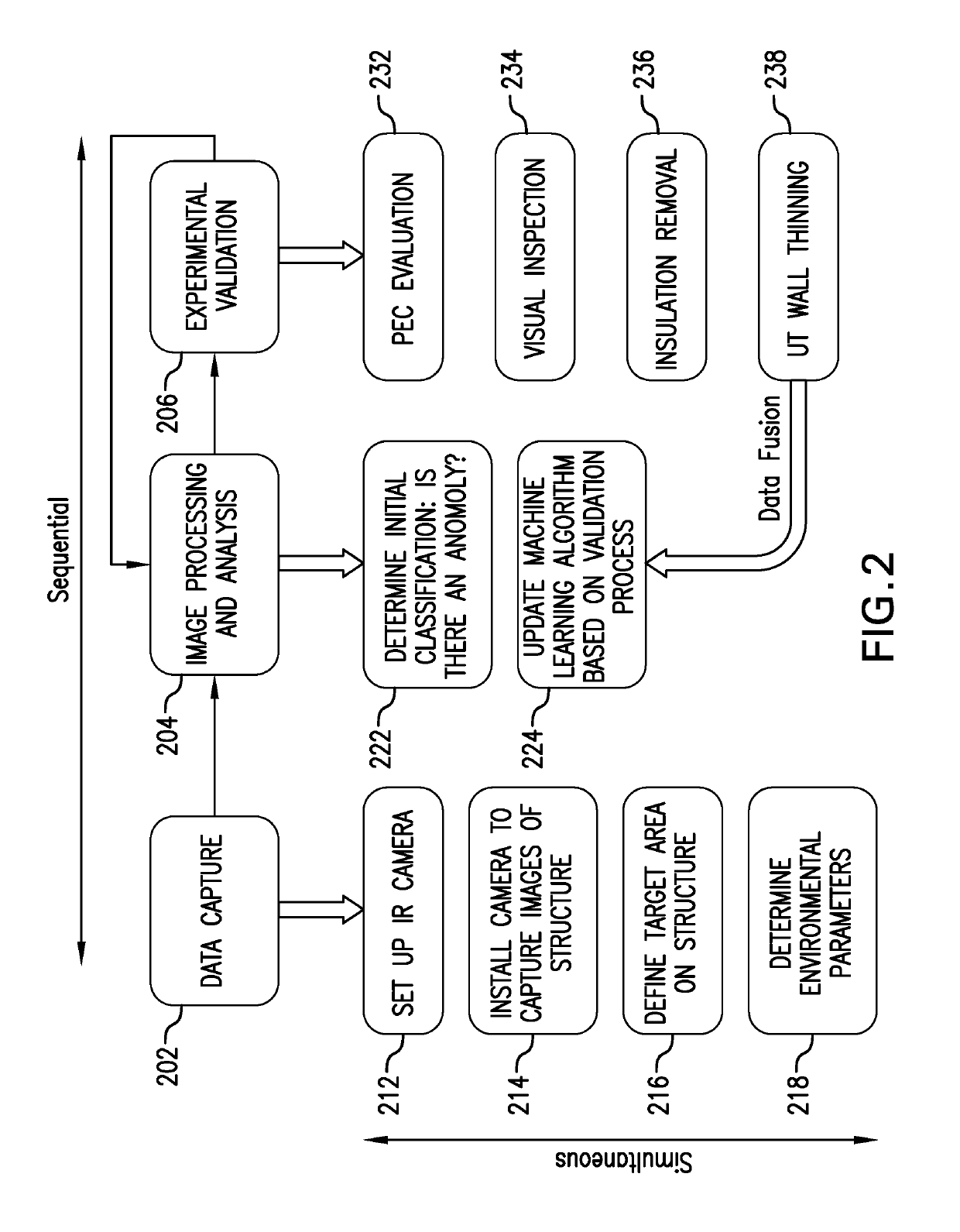

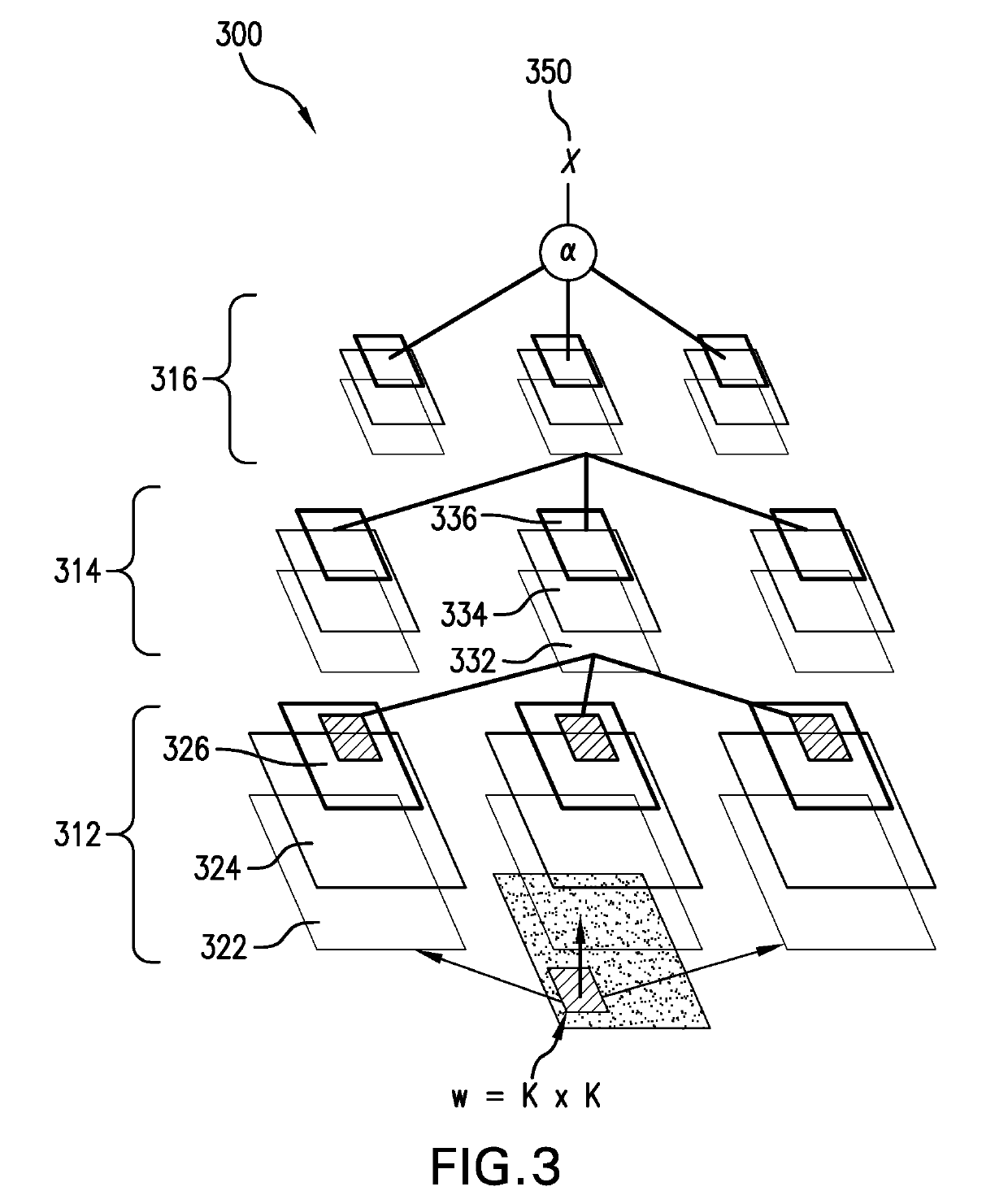

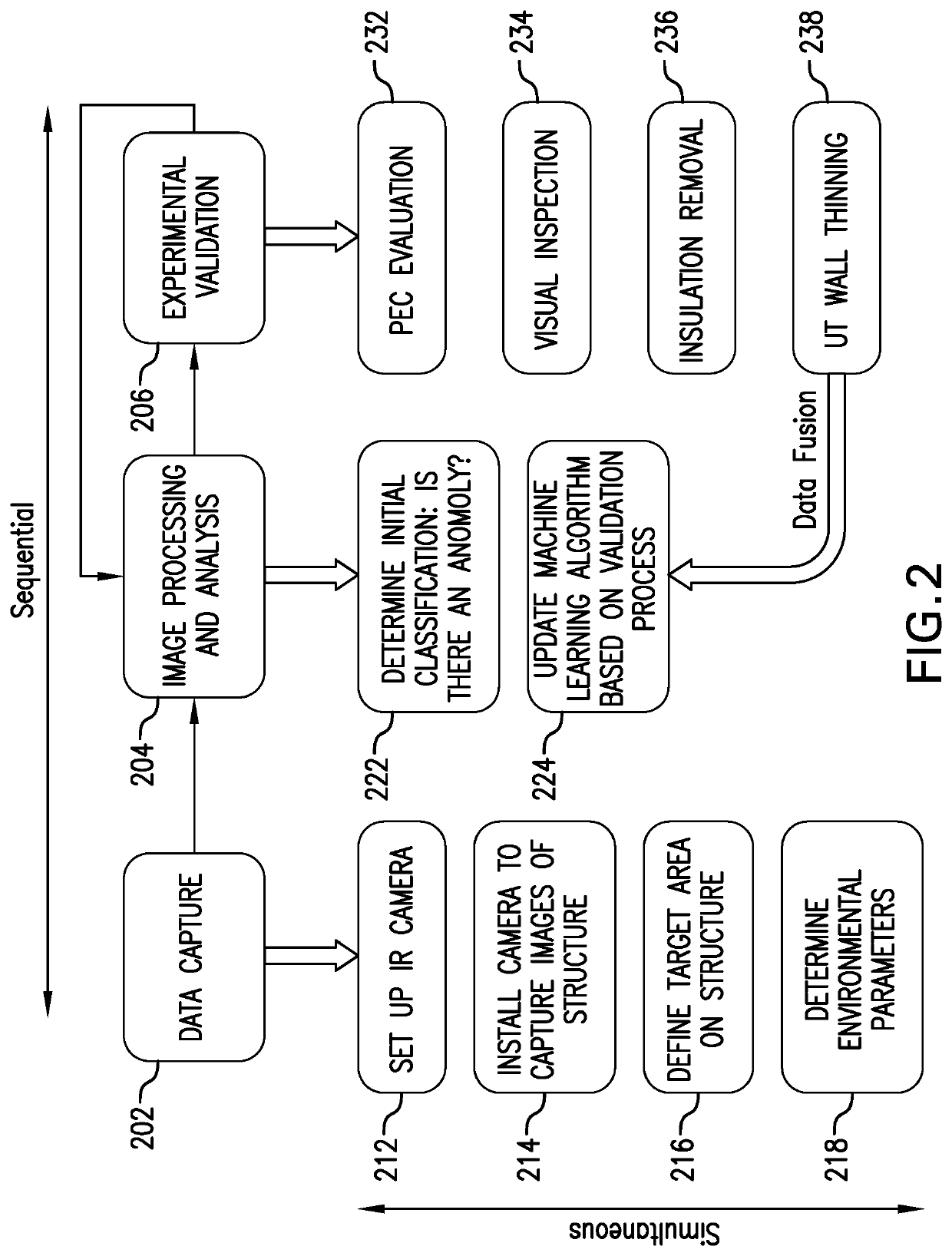

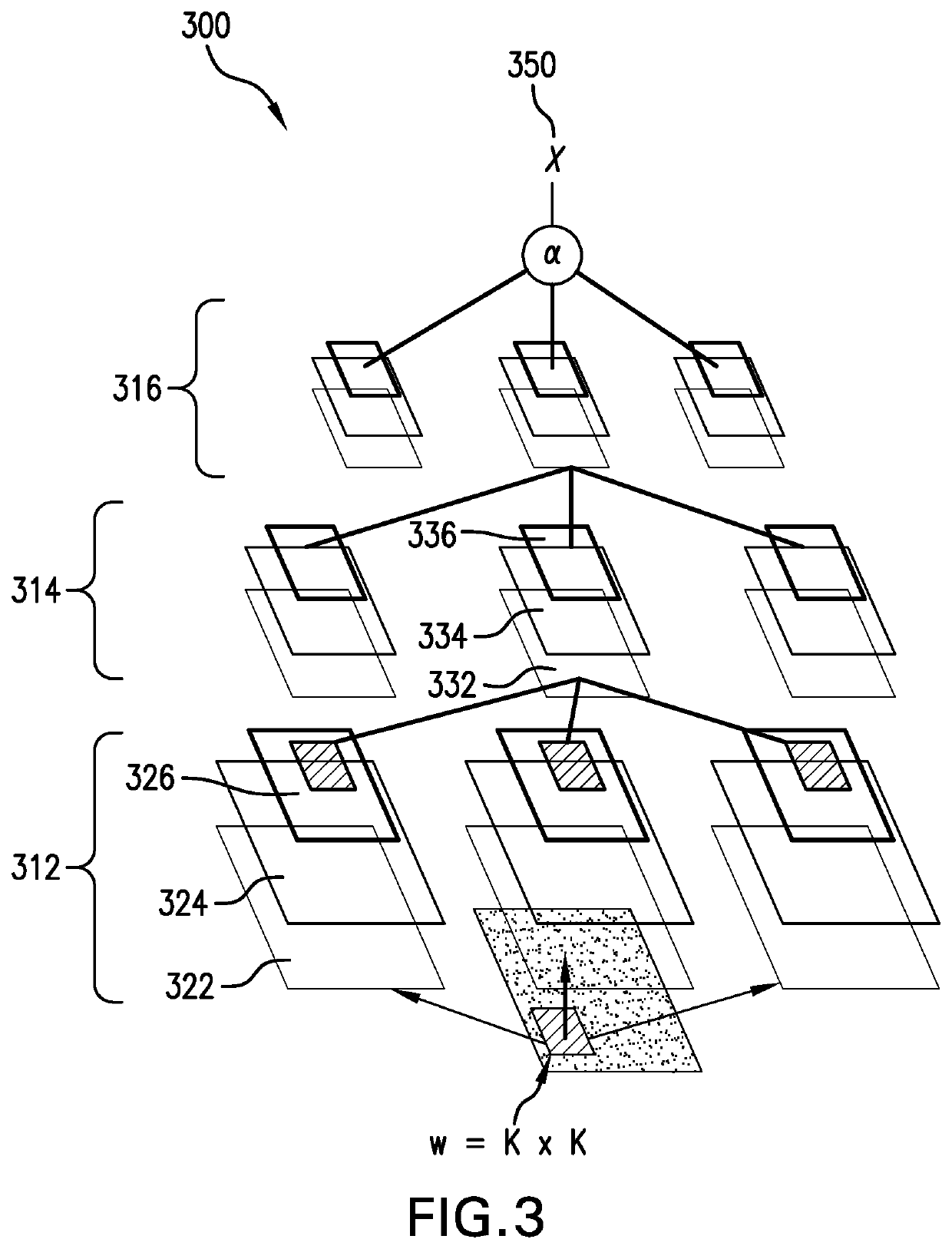

A method for identifying corrosion under insulation (CUI) in a structure comprises receiving thermographs from the structure using an infrared camera, applying filters to the thermograph using a first machine learning system, initially determining a CUI classification based on output from the filters, and validating the initial CUI classification by an inspection of the structure. The first machine learning system is trained using results of the validation. Outputs of the first machine learning system and additional structural and environmental data are fed into a second machine learning system that incorporates information from earlier states into current states. The second machine learning system is trained to identify CUI according to changes in the outputs of the first machine learning system and the additional data over time until a second threshold for CUI classification accuracy is reached. CUI is thereafter identified using the first and second machine learning systems in coordination.

Owner:SAUDI ARABIAN OIL CO

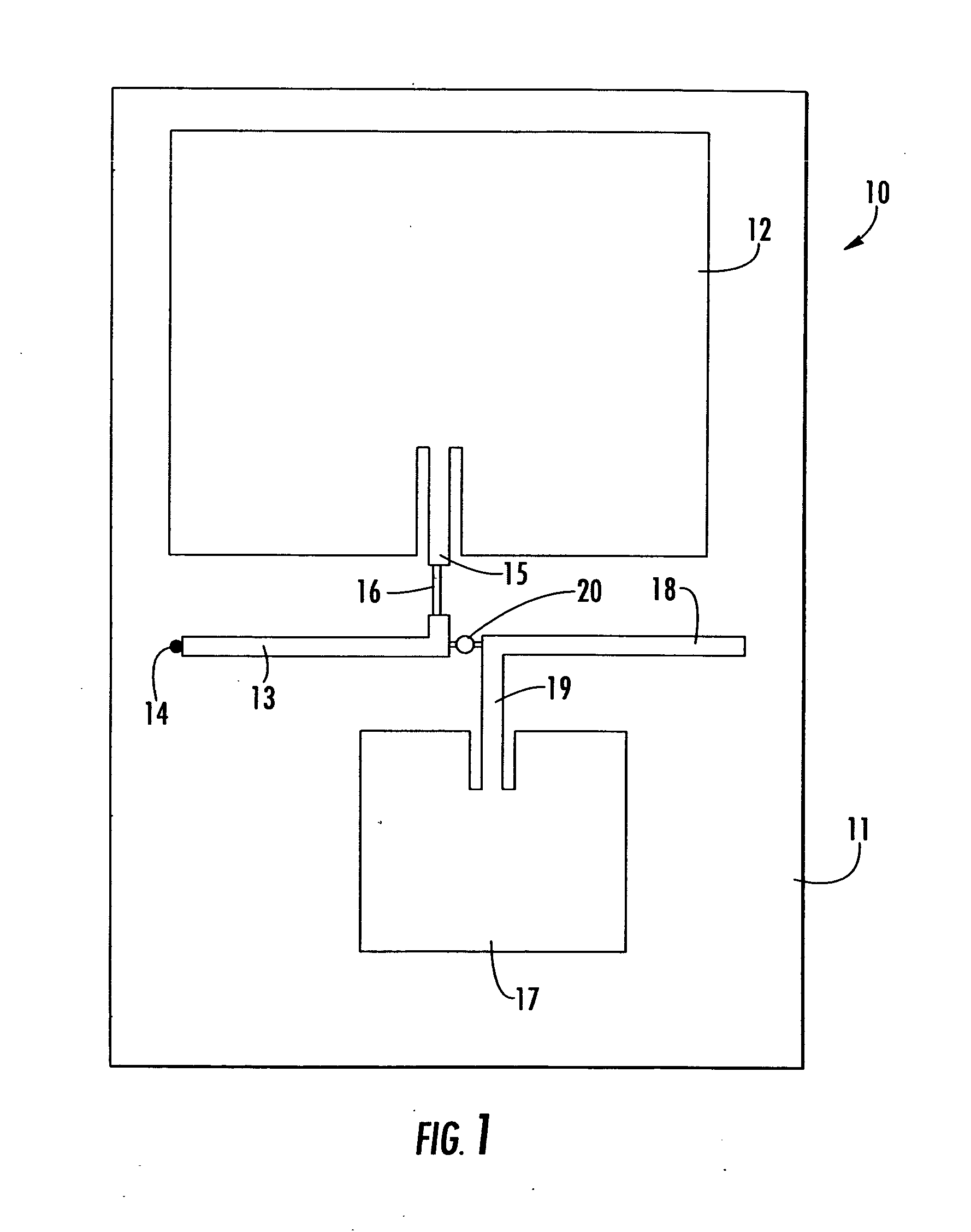

Method and apparatus for detecting moisture on metal and other surfaces, including surfaces under thermal insulation

InactiveUS20130037420A1Reduce inspectionLow costWeather/light/corrosion resistanceVolume/mass flow measurementThermal insulationPotential difference

Systems and methods are disclosed for detecting the presence of water on or in pipelines, tanks, equipment and other structures, including insulated structures which may be subject to corrosion under insulation, or CUI. Two dissimilar, spaced-apart metals are coupled at least indirectly to a structure to be monitored, and apparatus for detecting a potential difference between the two dissimilar metals, thereby indicating that water is present as an electrolyte. In CUI applications, at least one of the dissimilar metals is attached to, or embedded within, a water-absorbing insulator or other material coupled to or surrounding the structure. The water-absorbing material may be provided in the form of a tape attached to the surface of a metal component fanning the structure. In some embodiments, the structure to be monitored may itself incorporate a ferrous metal component which is used as one of the dissimilar metals.

Owner:FUNAHASHI MIKI

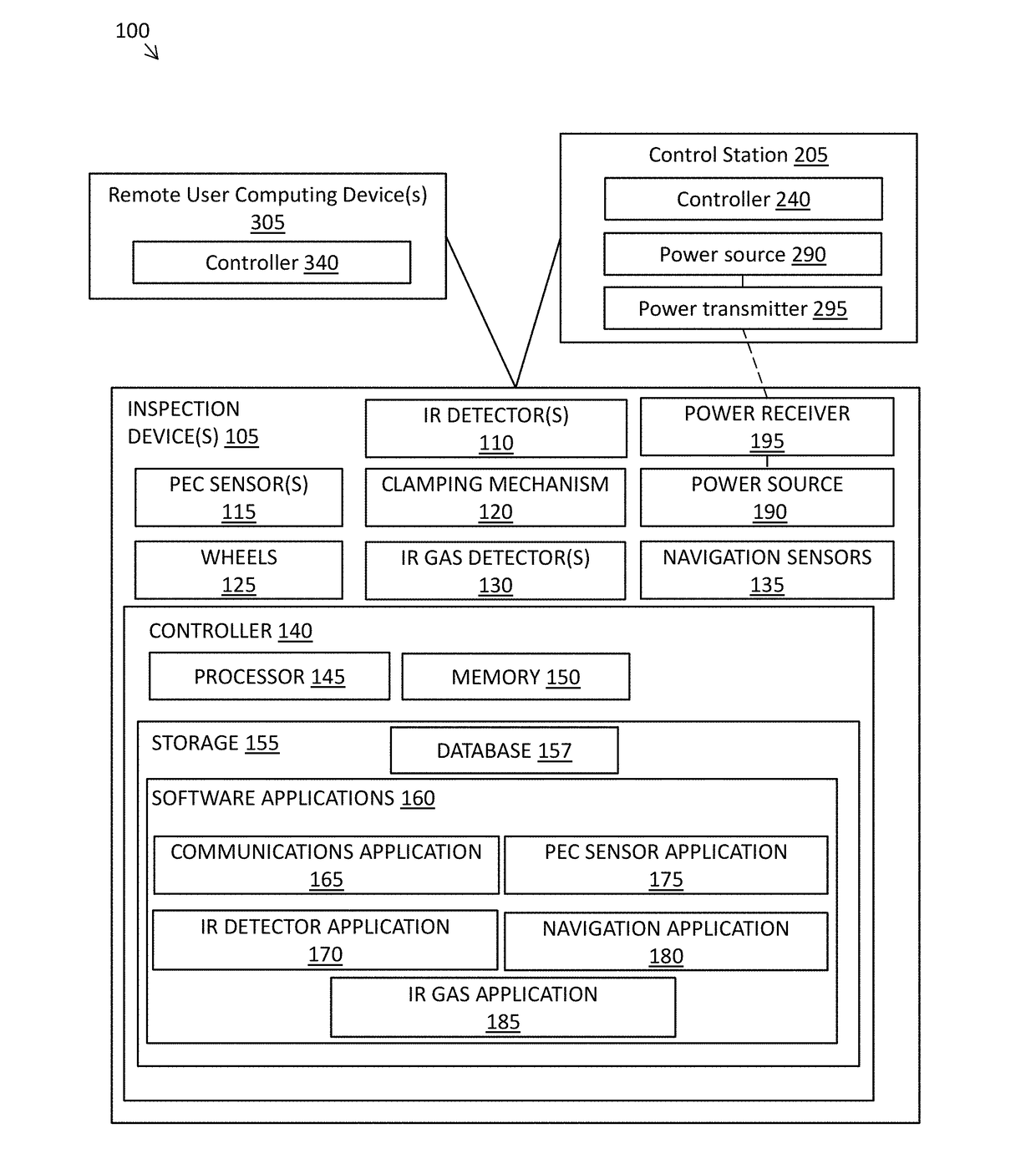

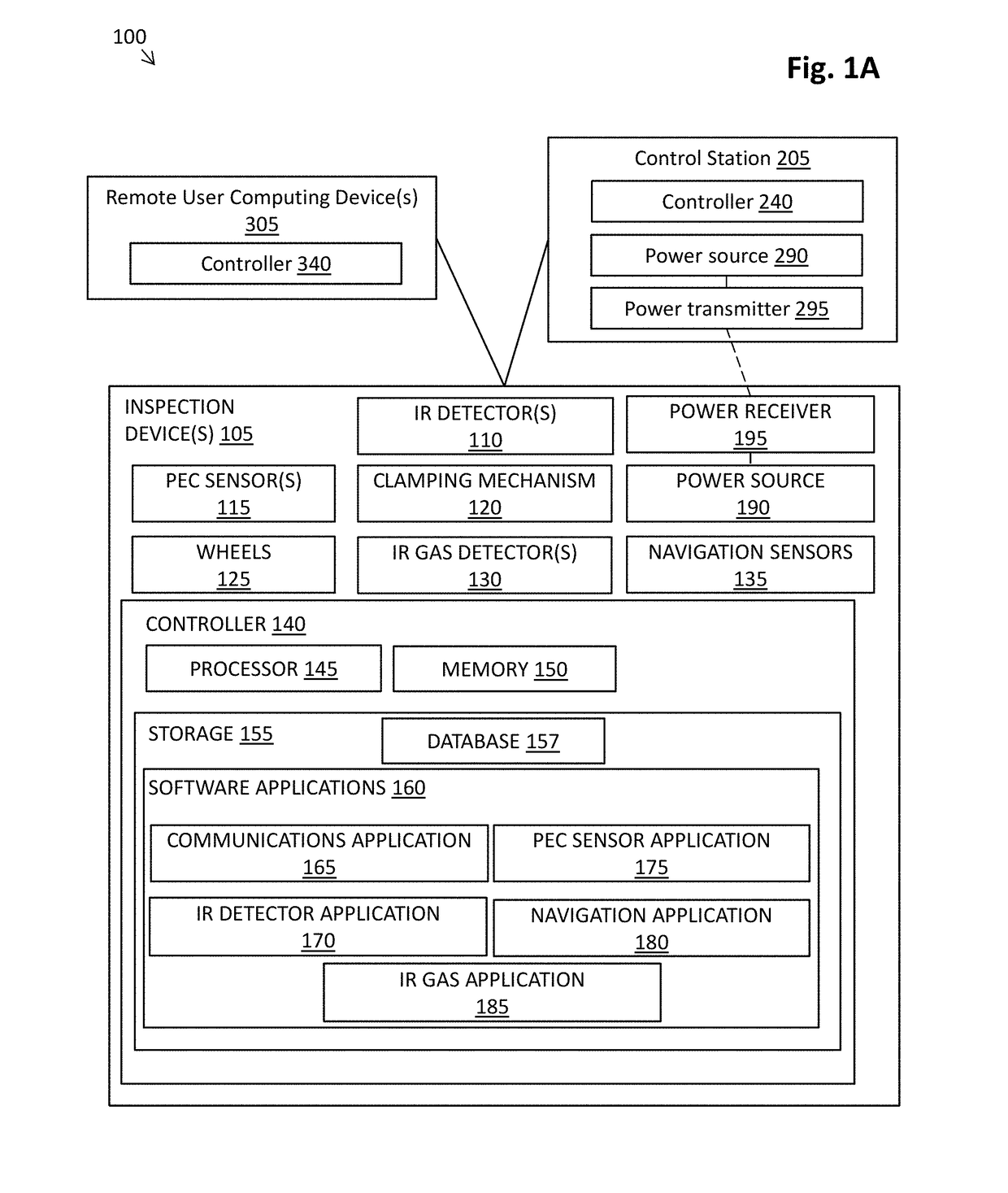

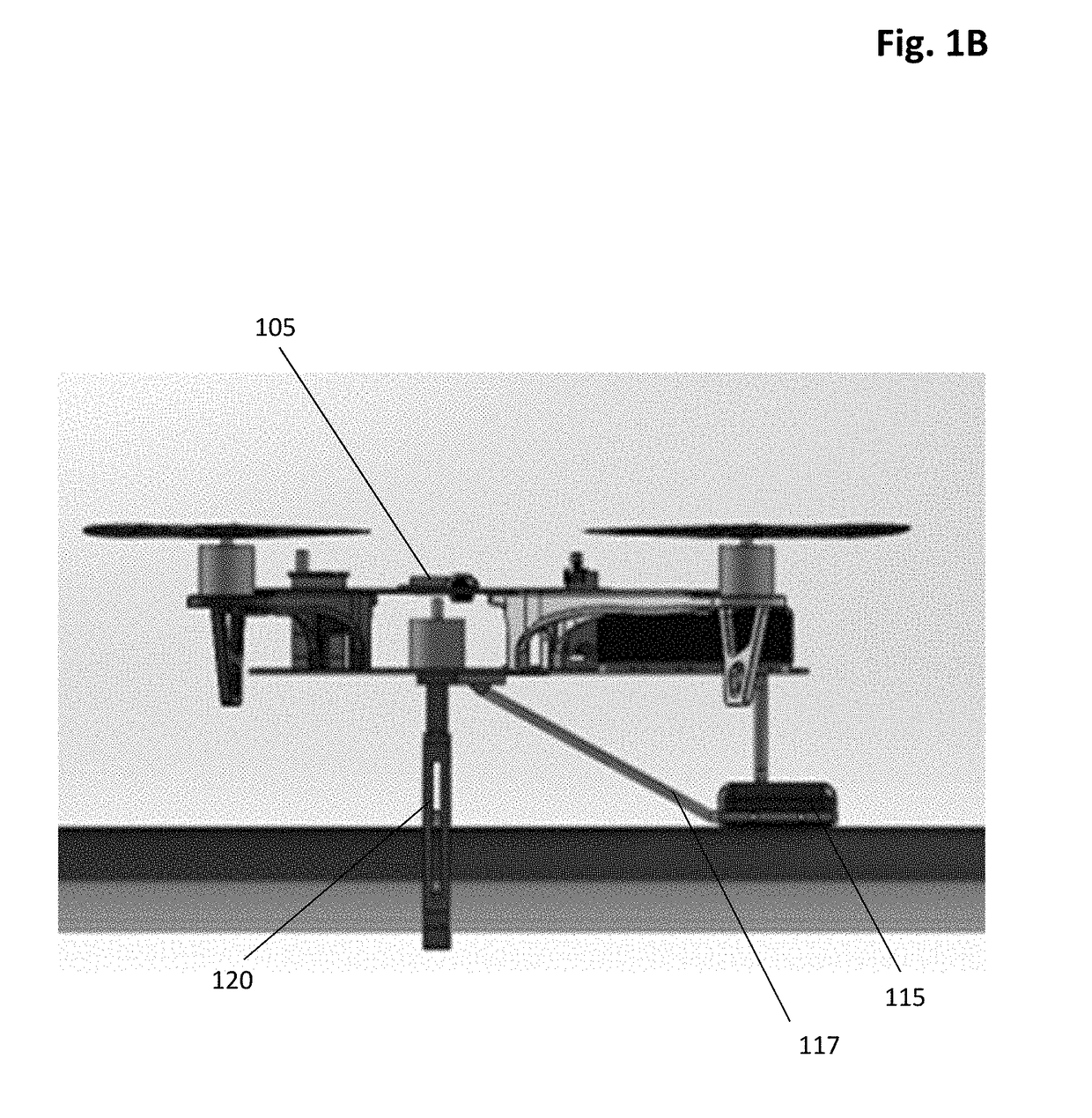

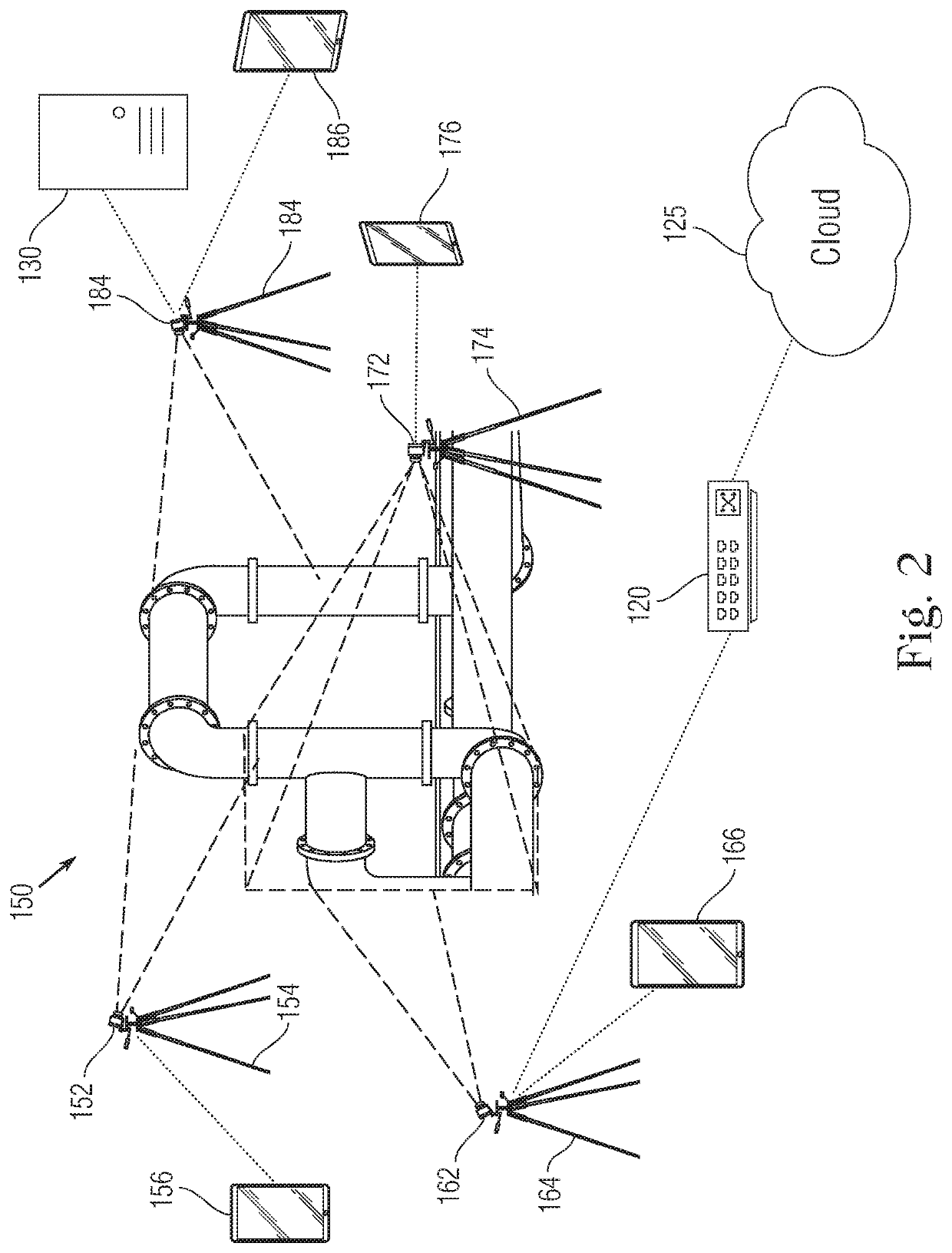

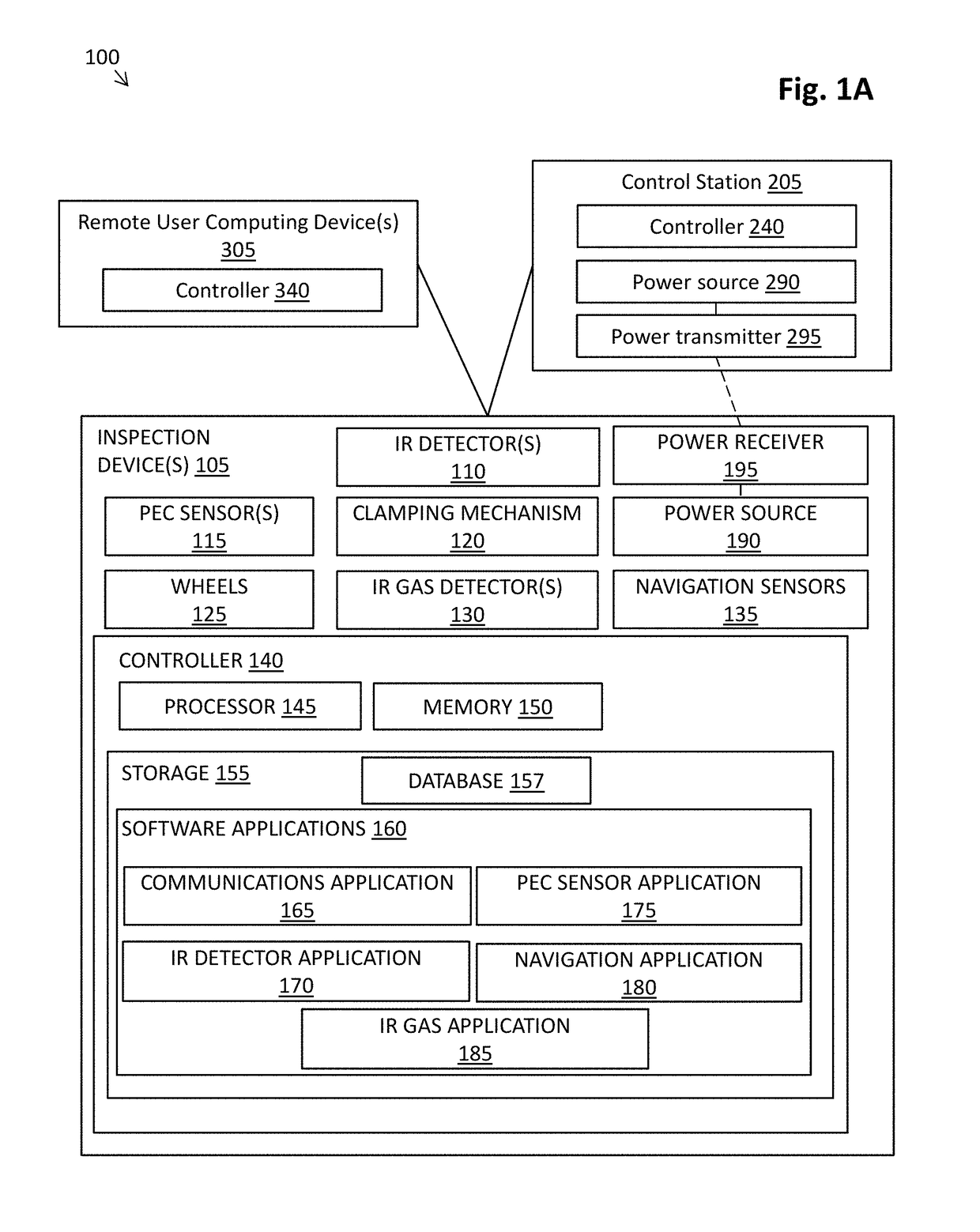

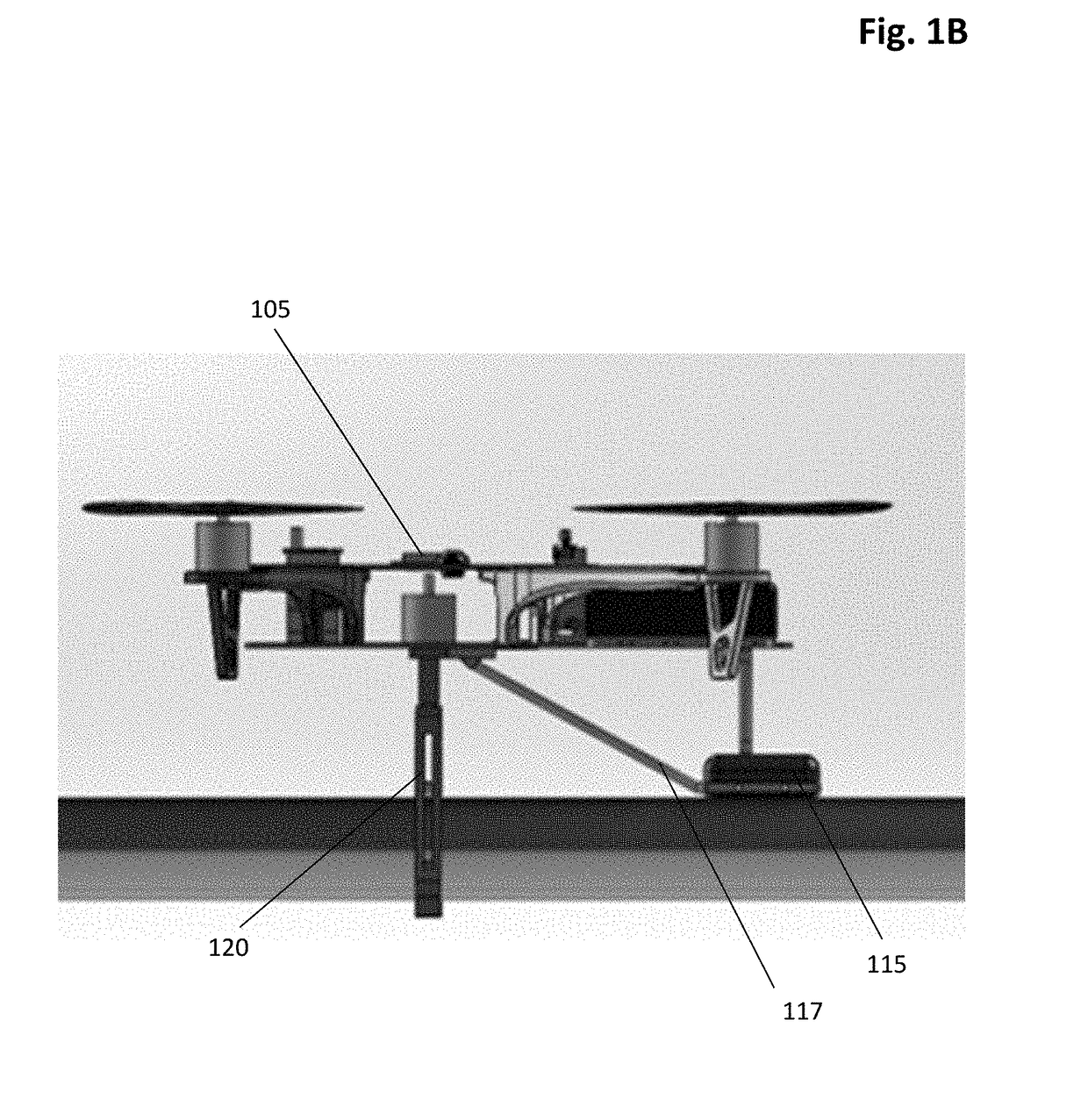

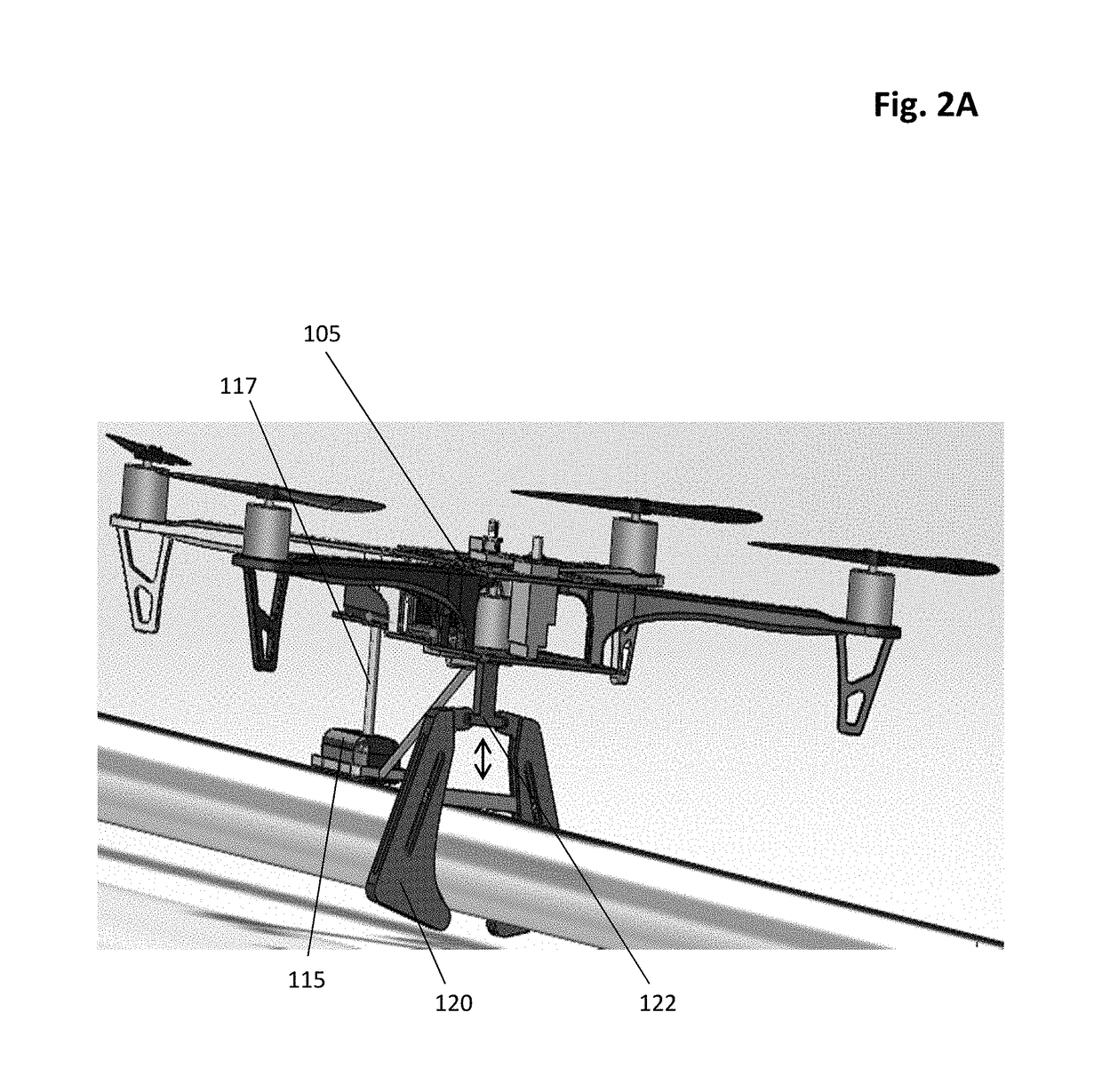

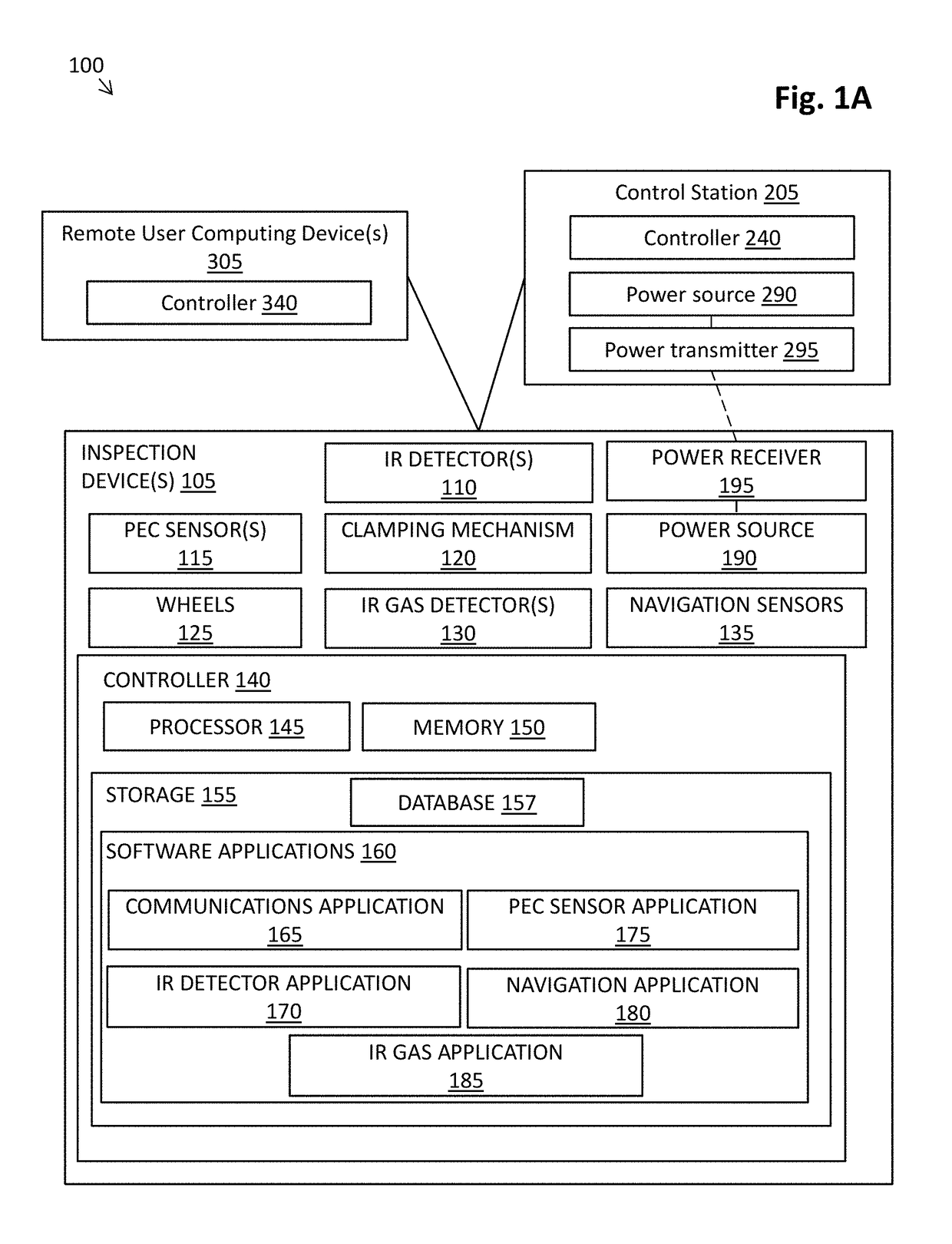

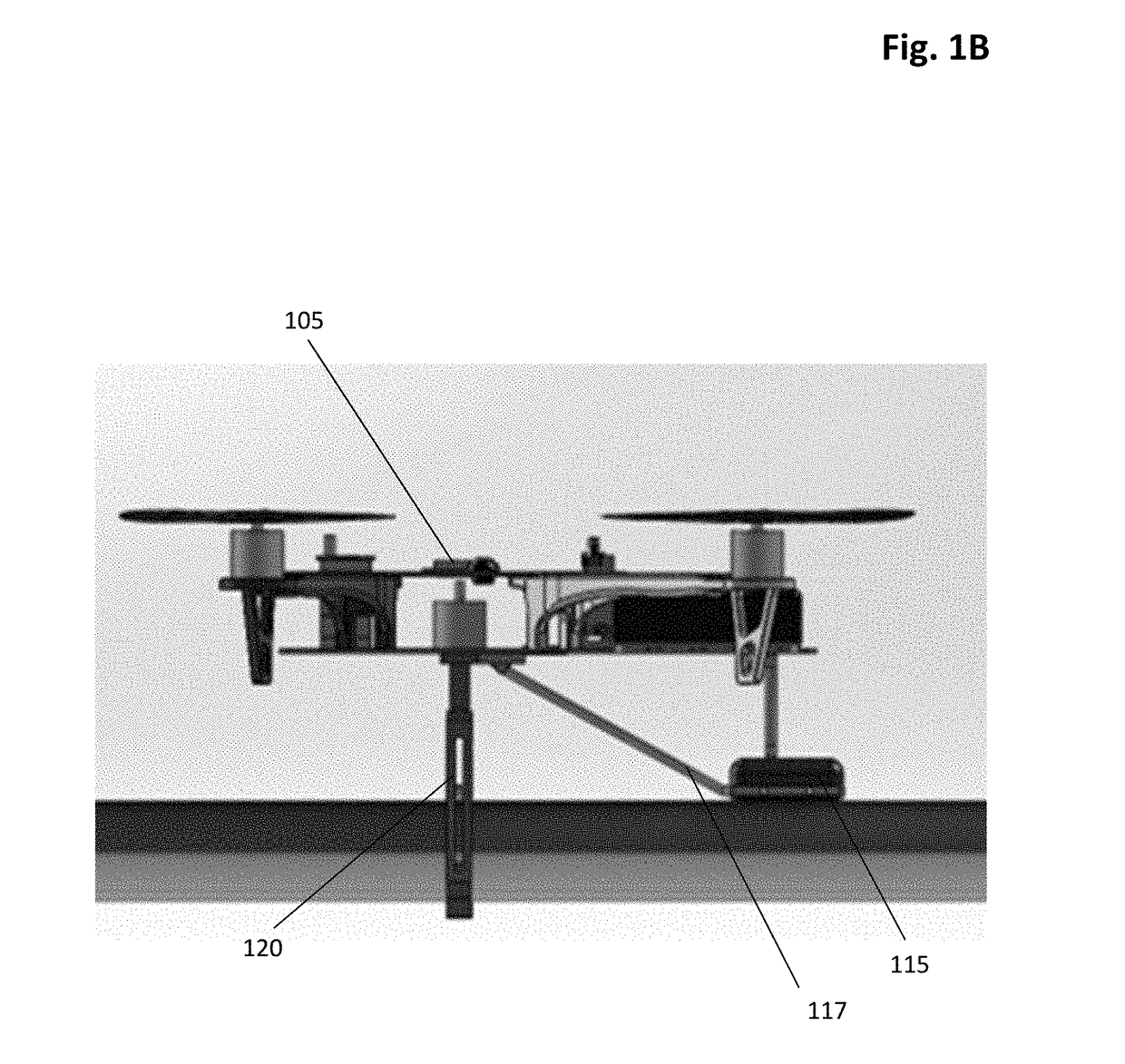

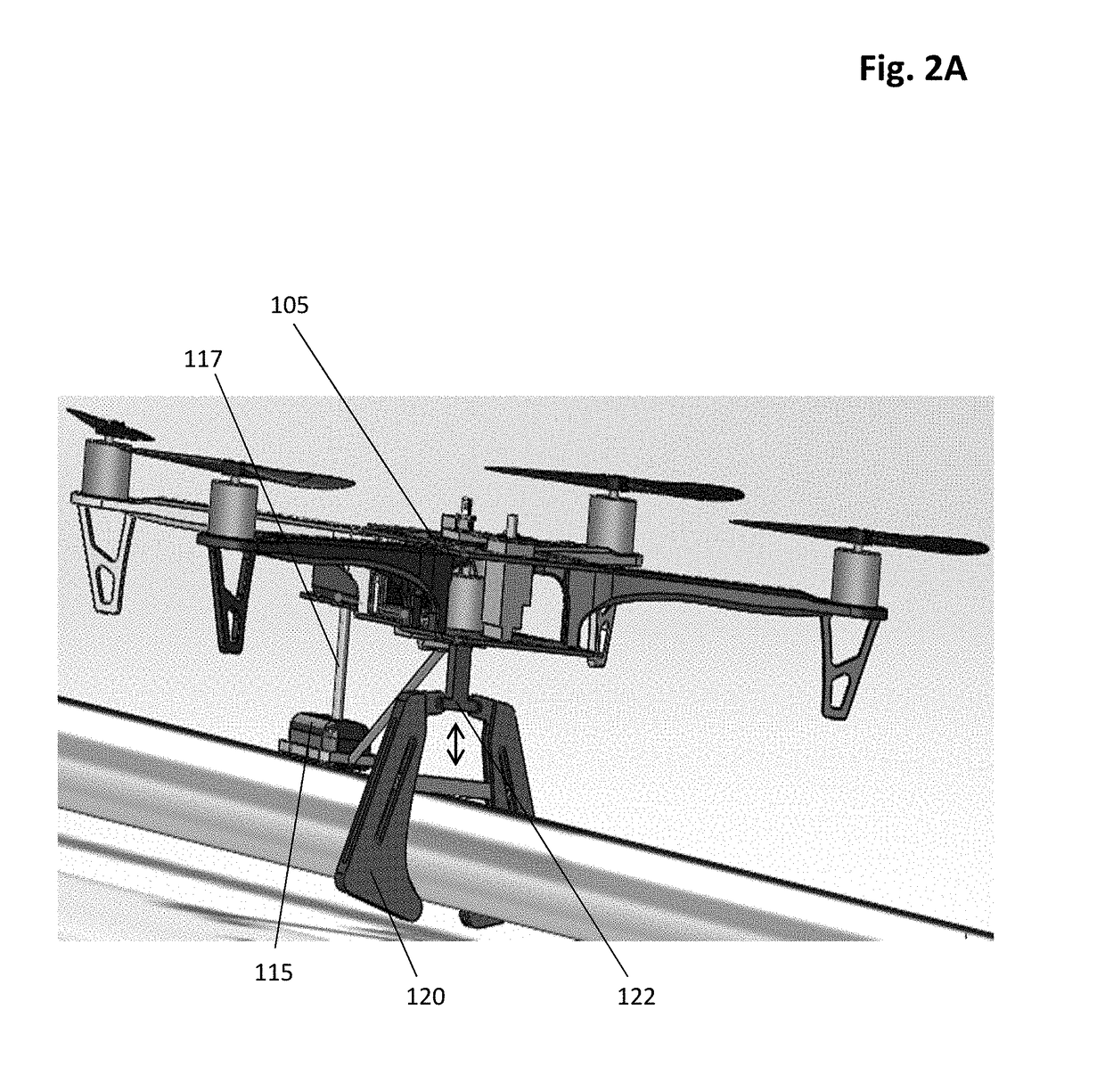

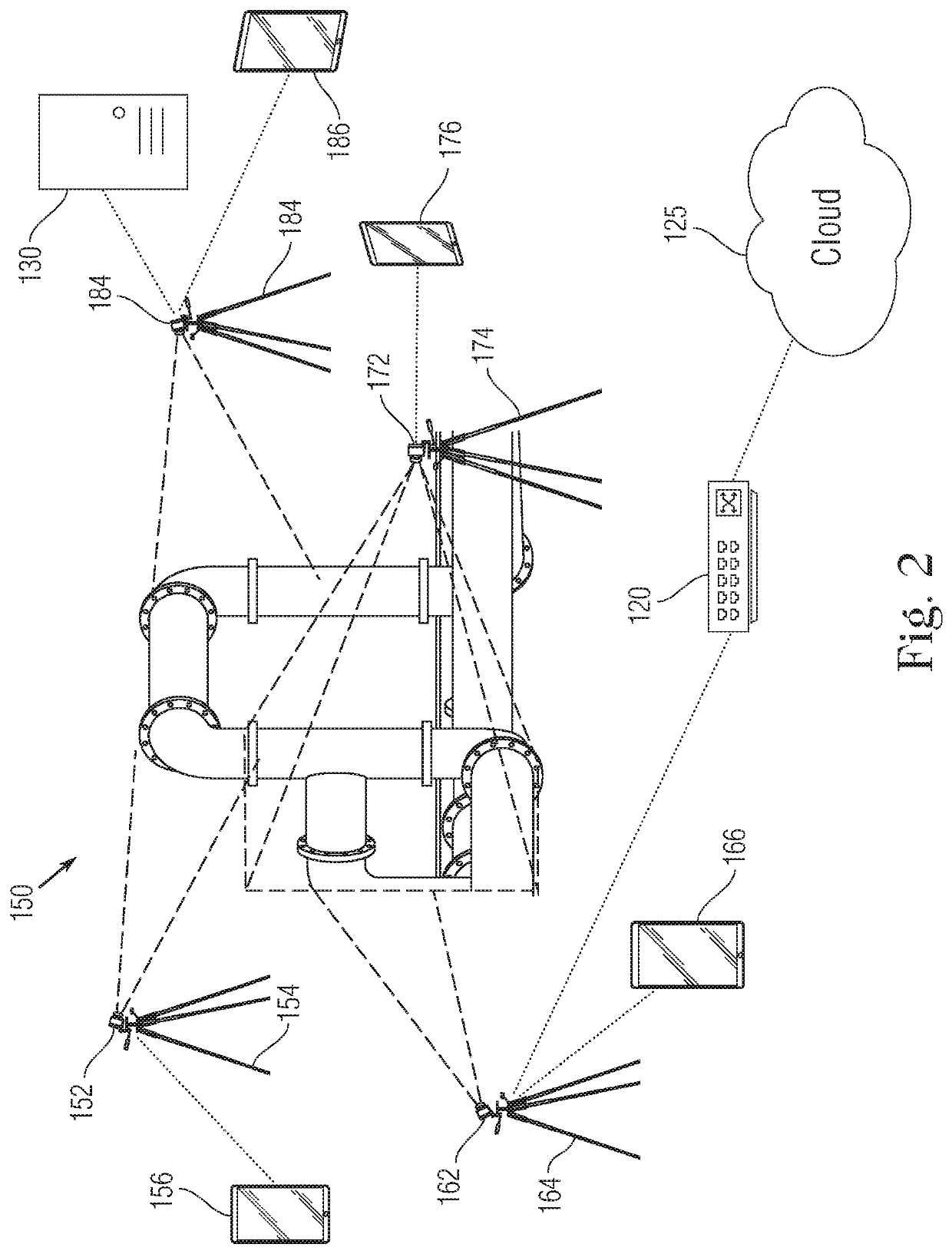

Two-Stage Corrosion Under Insulation Detection Methodology and Modular Vehicle with Dual Locomotion Sensory Systems

ActiveUS20180335404A1Weather/light/corrosion resistanceUnmanned aerial vehiclesModularityCorrosion under insulation

Methods and systems for inspecting insulated equipment for corrosion under insulation are provided. The system includes an autonomous unmanned vehicle having aerial and ground locomotive capabilities. The vehicle includes an infrared detector and a pulsed eddy current sensor. In the method, infrared waves emitted from the equipment are detected along the equipment with the infrared detector. Using the infrared detector, at least one image of an inner surface of the equipment is developed based on the detected infrared waves. At least one area that is susceptible to corrosion is determined based on the at least one image. The susceptible area is inspected with the pulsed eddy current sensor, which induces an eddy current in the inner wall of the equipment. Based on a rate of the decay in strength of the eddy current, it is determined whether corrosion exists at the susceptible area using a processor configured by code.

Owner:SAUDI ARABIAN OIL CO

Method and system for detecting corrosion under insulation

The present invention relates generally to thermal imaging systems and methods and uses therefor, and in a particular though non-limiting embodiment, to a method of detecting corrosion under insulation, as well as corrosion-related material data associated therewith. The system utilizes advanced infrared imaging video cameras to detect characteristic signatures of wet thermal traits on process equipment. Various embodiments of the invention integrate equipment, automation, and algorithms to form a method for identifying wet thermal insulation by scanning multiple locations along insulated piping, tanks, or other manufacturing equipment. Such scans can occur individually, sequentially, or simultaneously, with the results then being stored and comparatively analyzed. Further embodiments comprise tracking the approximate time of exposure to moisture, prediction of the corrosion rates for underlying insulated metal substrates, and measuring wall thicknesses along either predetermined random portions of the metal substrate.

Owner:HONEYWELL INT INC

Methods and devices for sensing corrosion under insulation (CUI)

InactiveUS8810264B2Weather/light/corrosion resistanceResistance/reactance/impedenceElectrical conductorCorrosion under insulation

A method of sensing corrosion of a pipe covered by a layer of insulation comprises positioning a CUI sensor radially adjacent an outer surface of the pipe. The CUI sensor comprises a non-conductive base having a first end and a second end opposite the first end. In addition, the CUI sensor comprises a first test circuit mounted to the base. The first test circuit includes a first conductor, a second conductor, and a first testing element extending between the first conductor and the second conductor. Further, the method comprises exposing the first testing element to the same environment as the outer surface of the pipe. Still further, the method comprises determining whether the first testing element has corroded through. Moreover, the method comprises assessing whether corrosion of the pipe has occurred based on the determination of whether the first testing element has corroded through.

Owner:BP CORP NORTH AMERICA INC

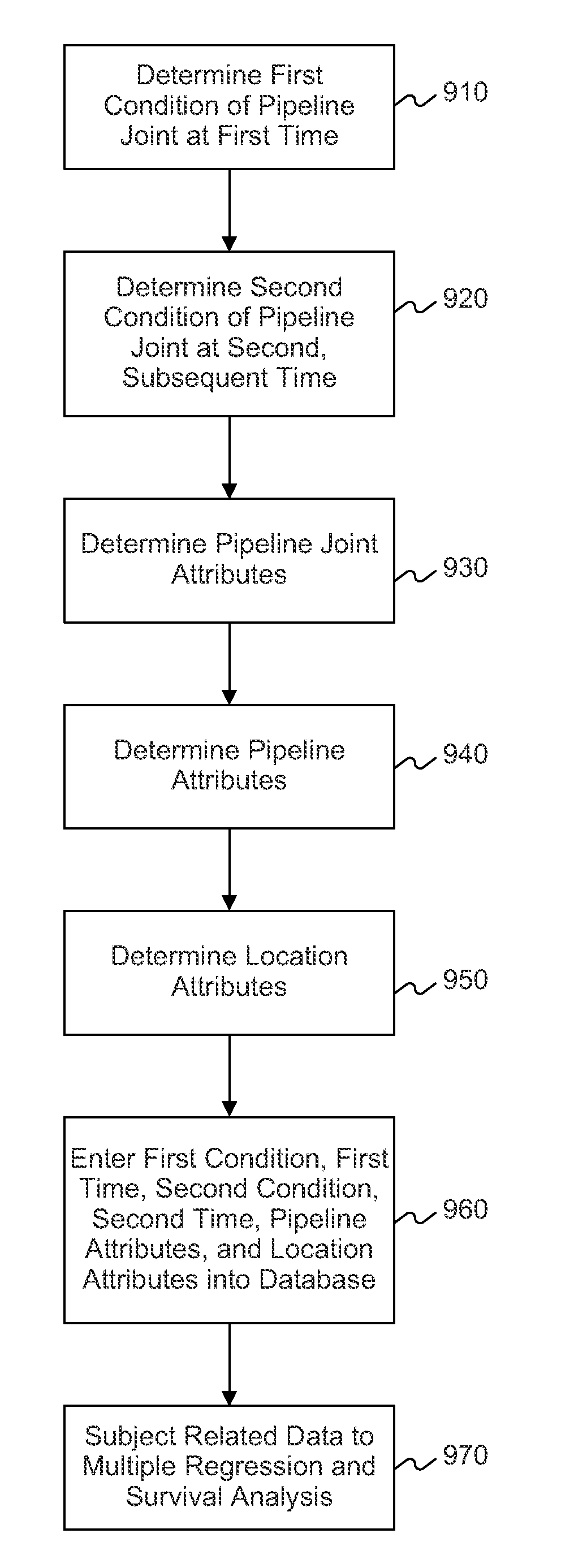

Use of survival modeling methods with pipeline inspection data for determining causal factors for corrosion under insulation

InactiveUS20130304438A1Computer aided designSpecial data processing applicationsCorrosion under insulationEngineering

Owner:BP CORP NORTH AMERICA INC +1

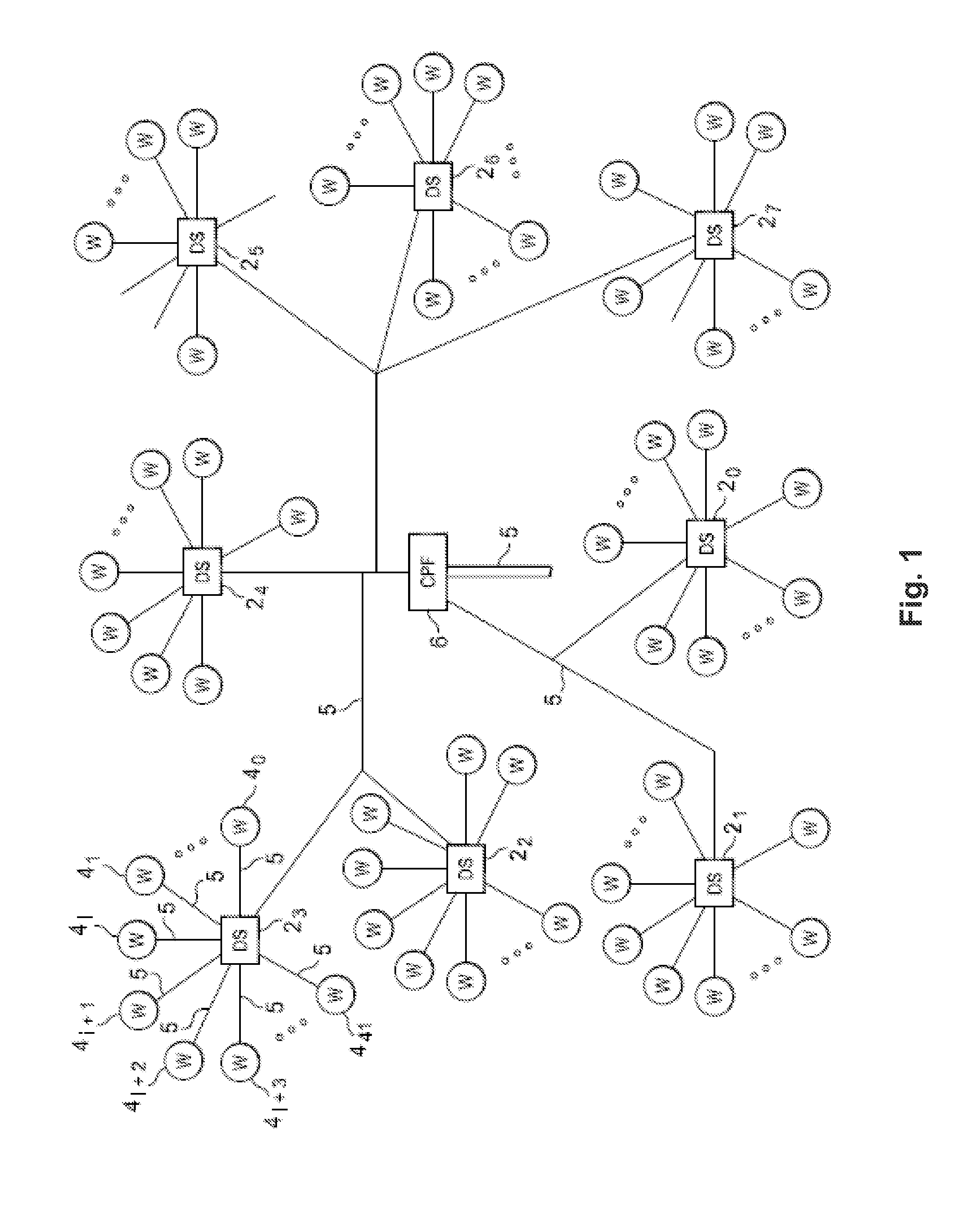

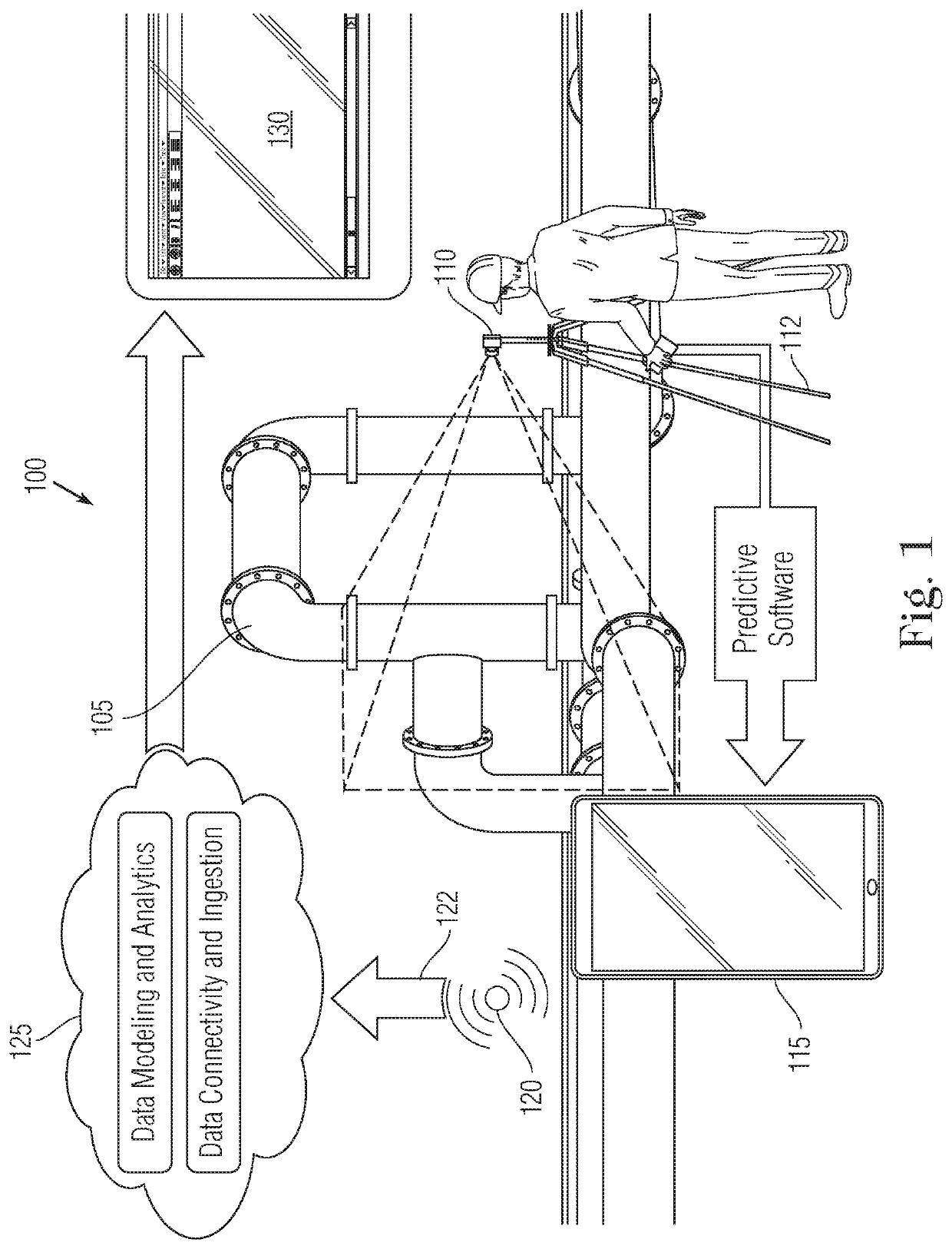

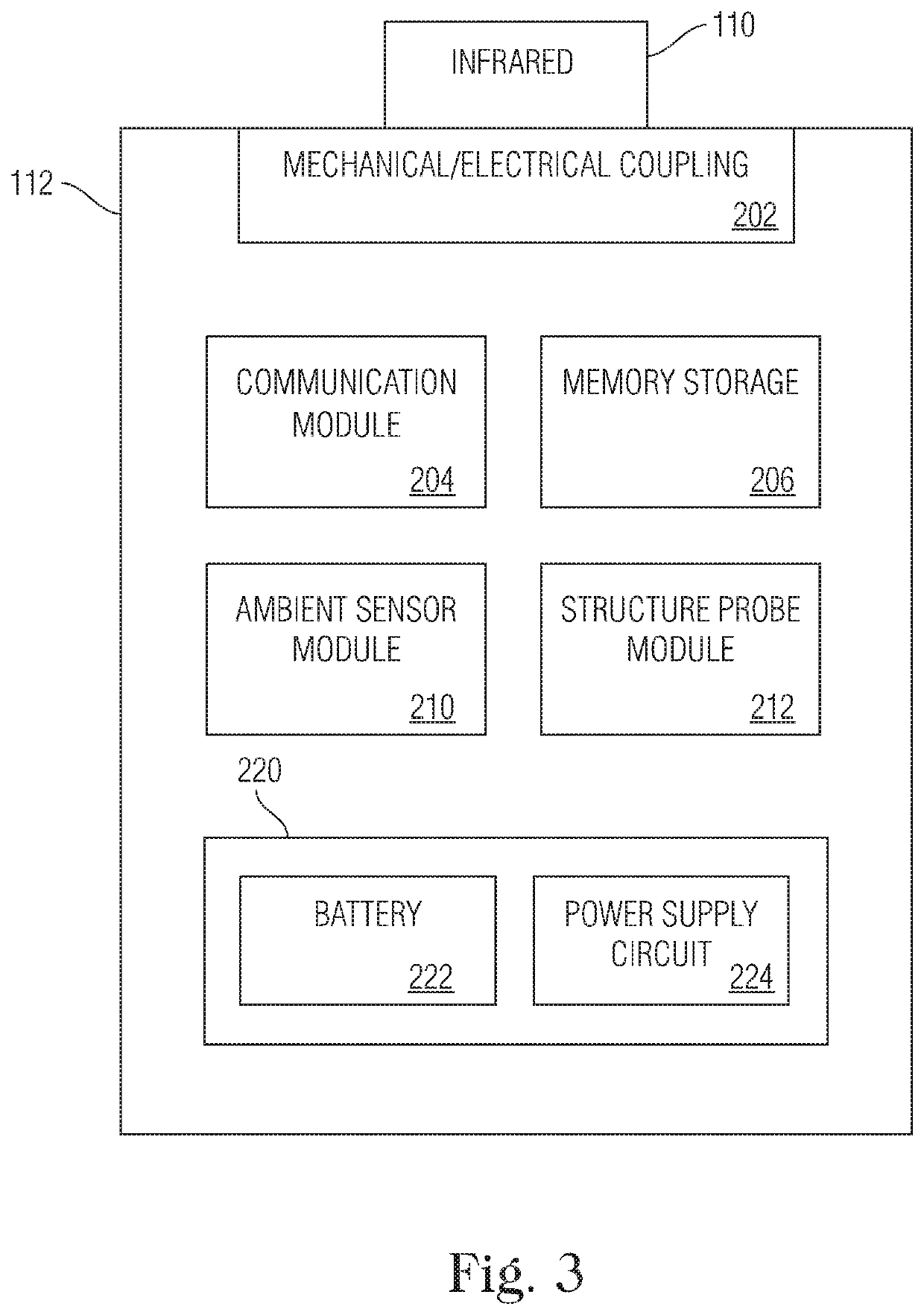

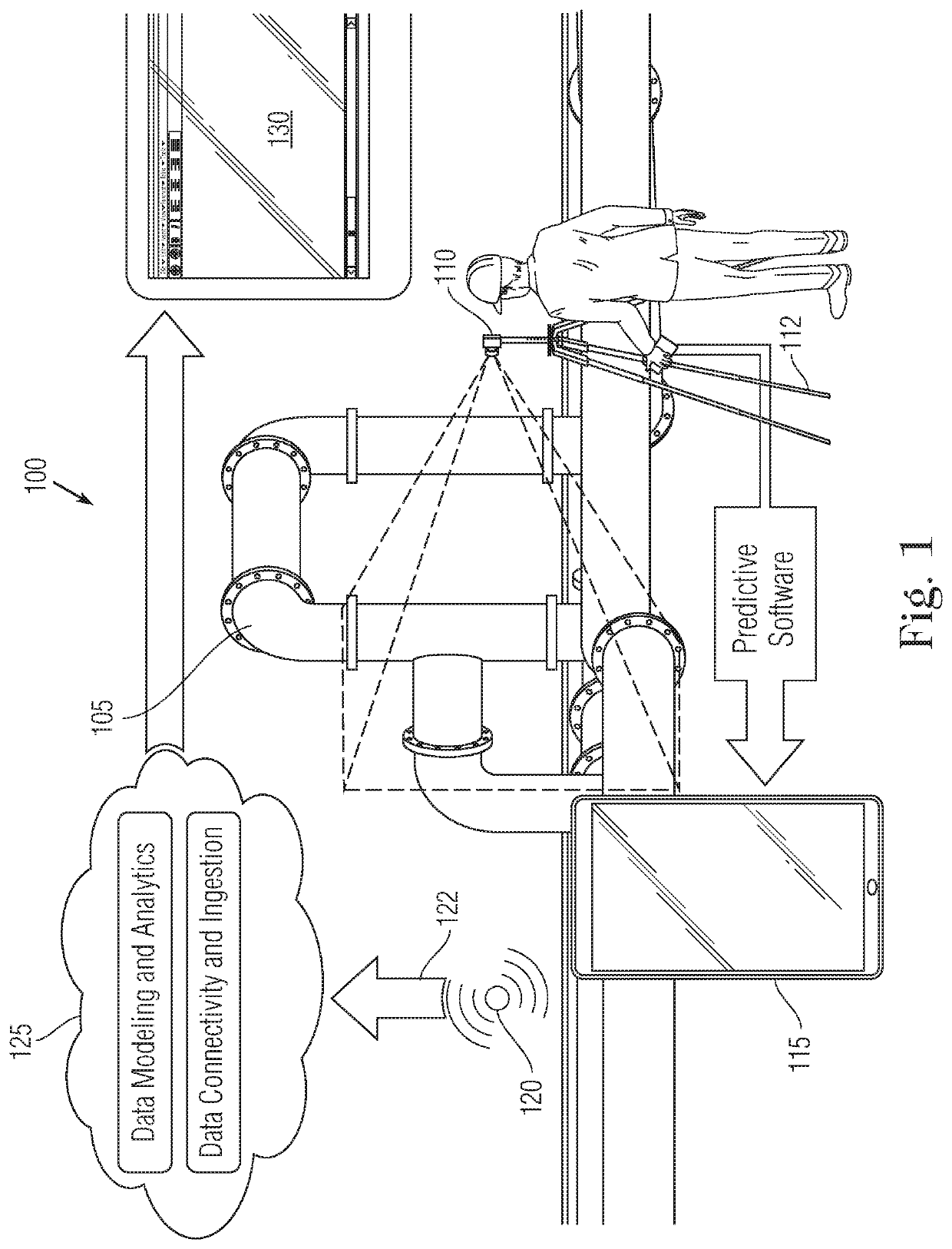

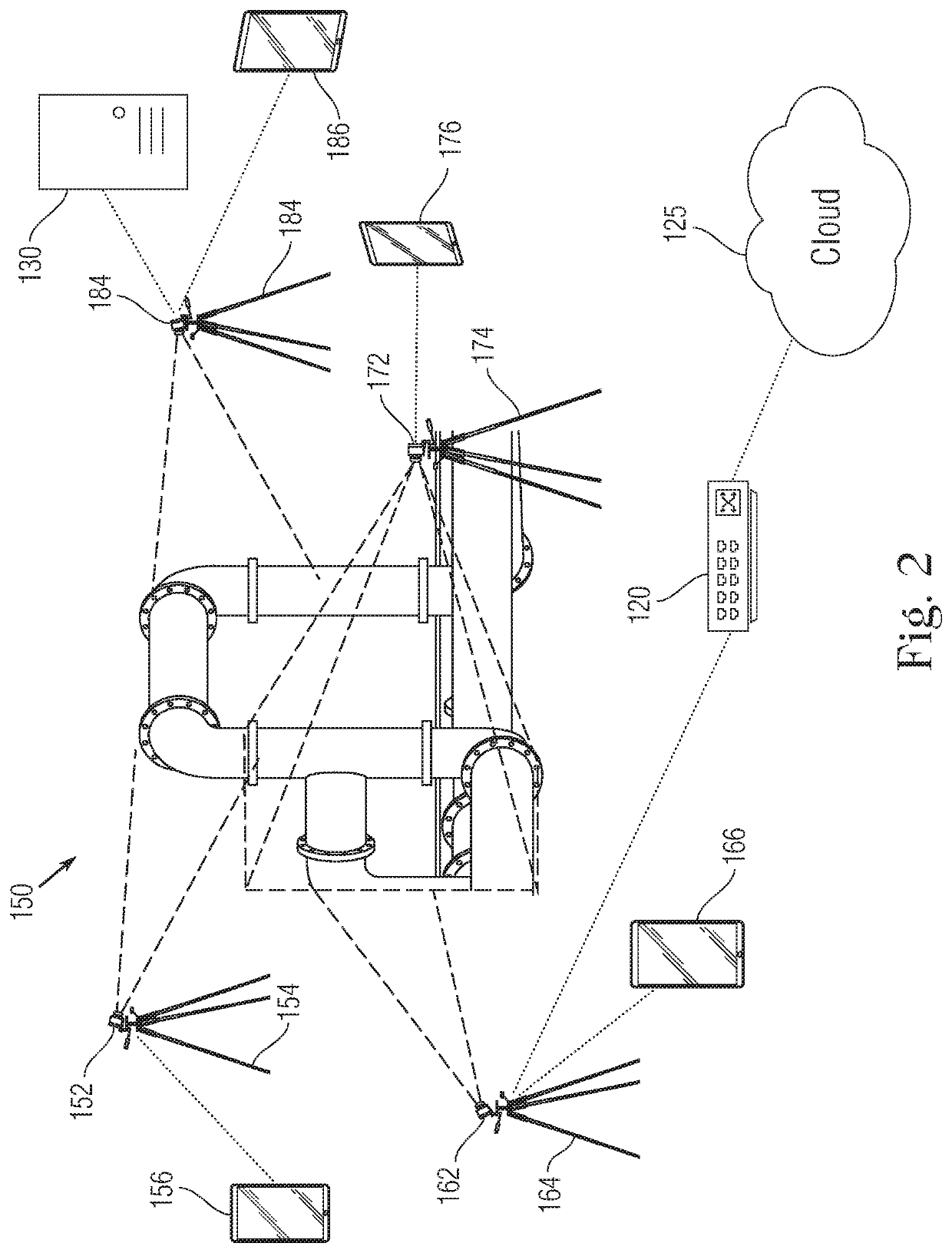

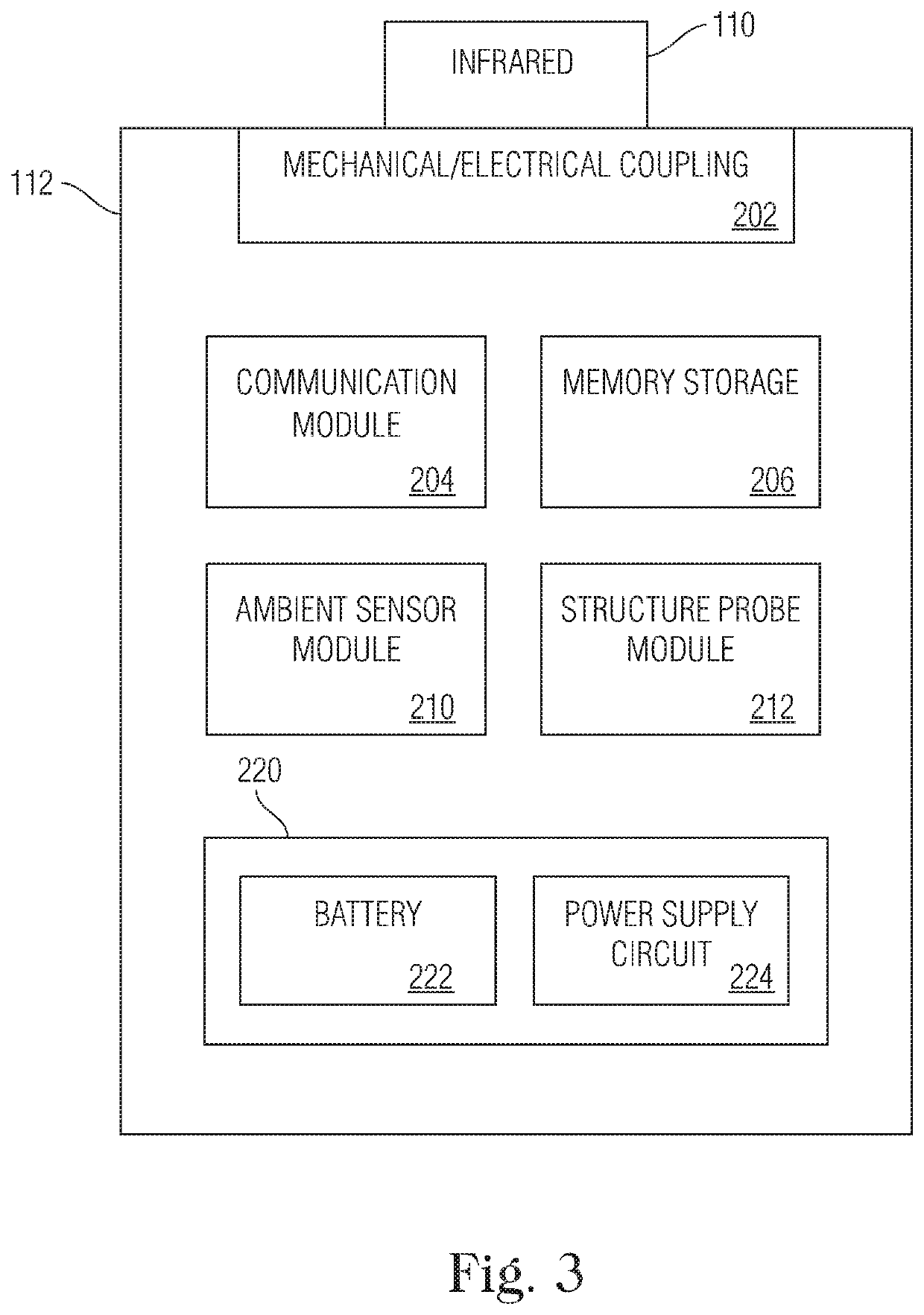

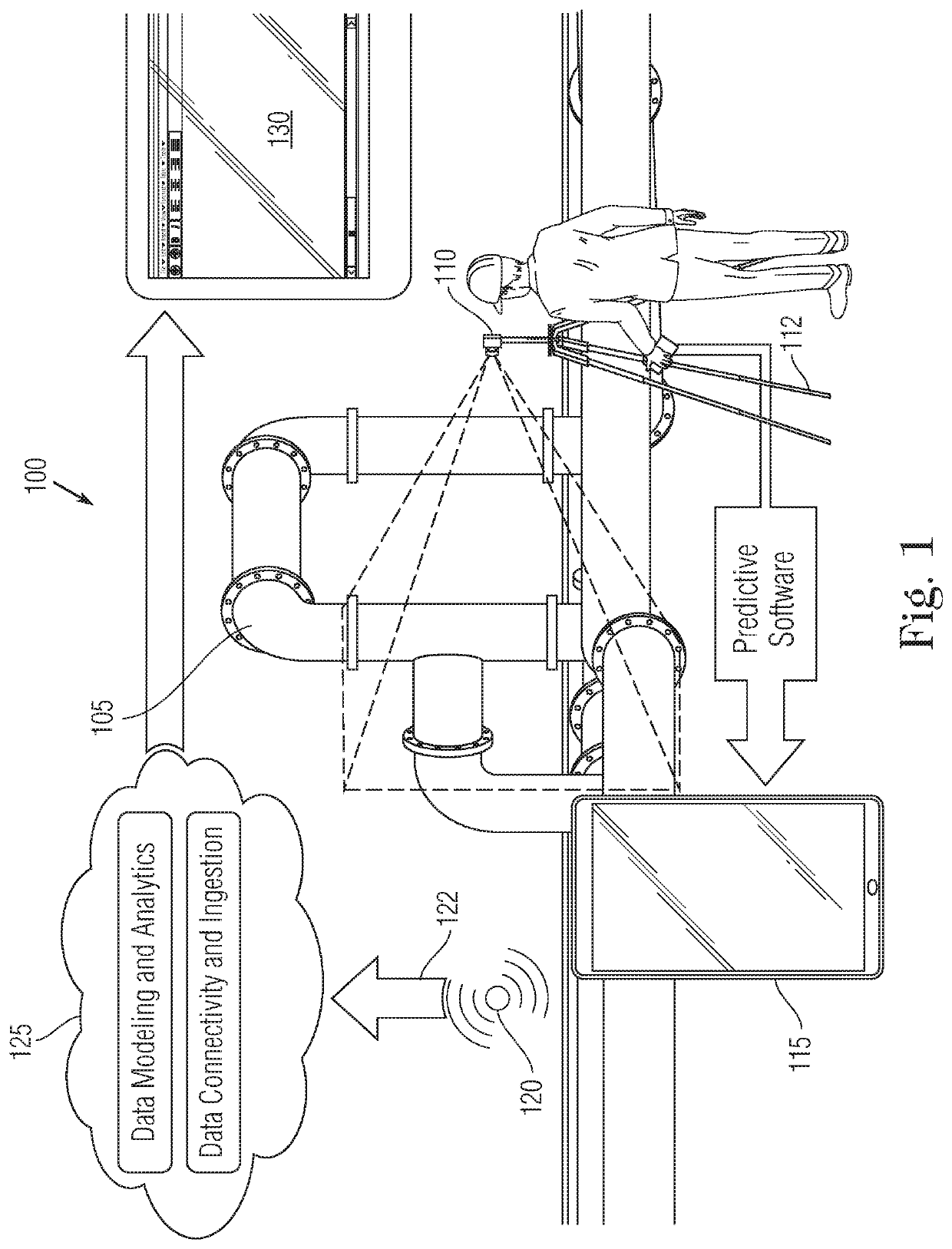

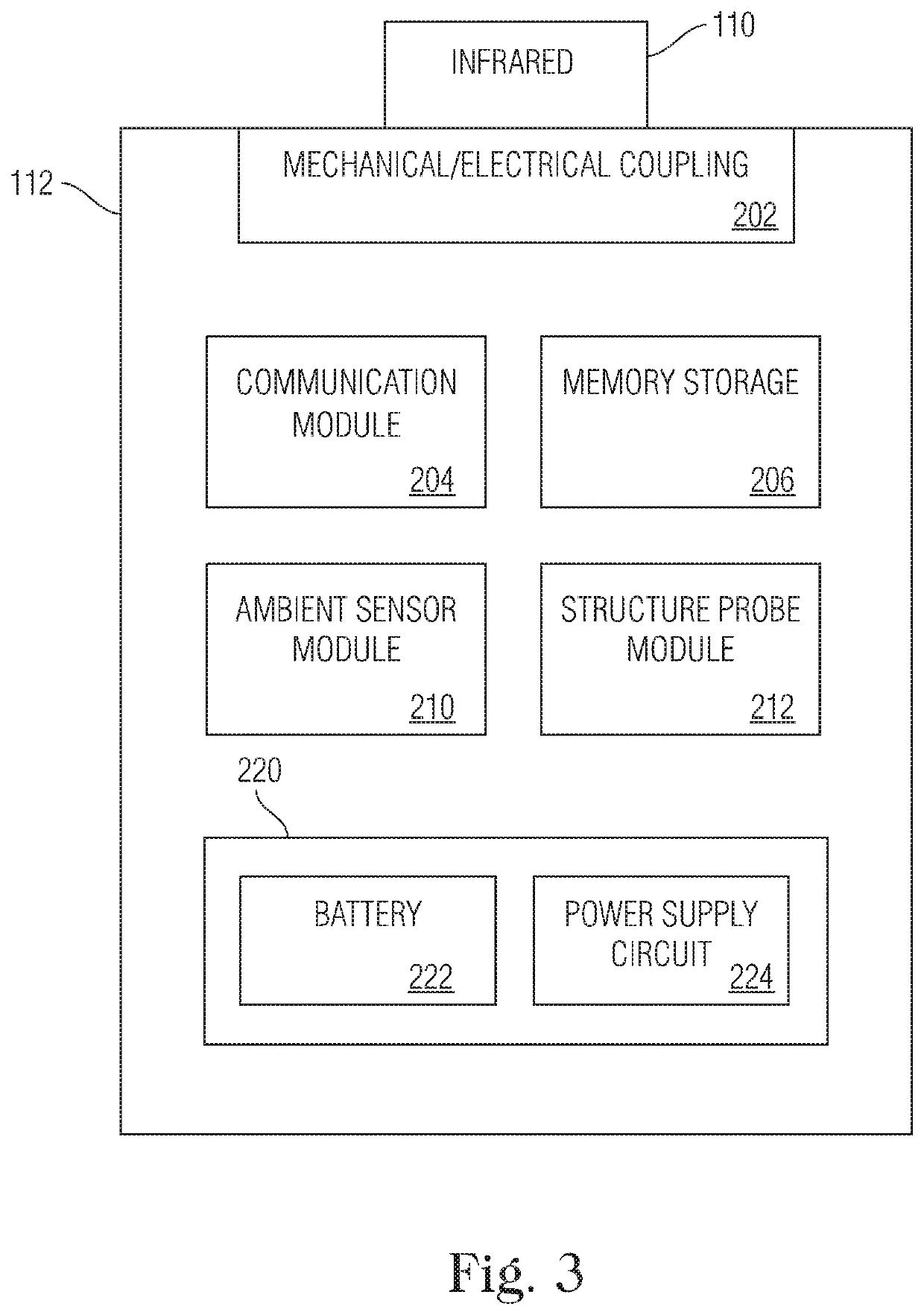

Cloud-based machine learning system and data fusion for the prediction and detection of corrosion under insulation

ActiveUS10533937B1Reduce noiseWeather/light/corrosion resistanceMaterial analysis by optical meansSimulationCorrosion under insulation

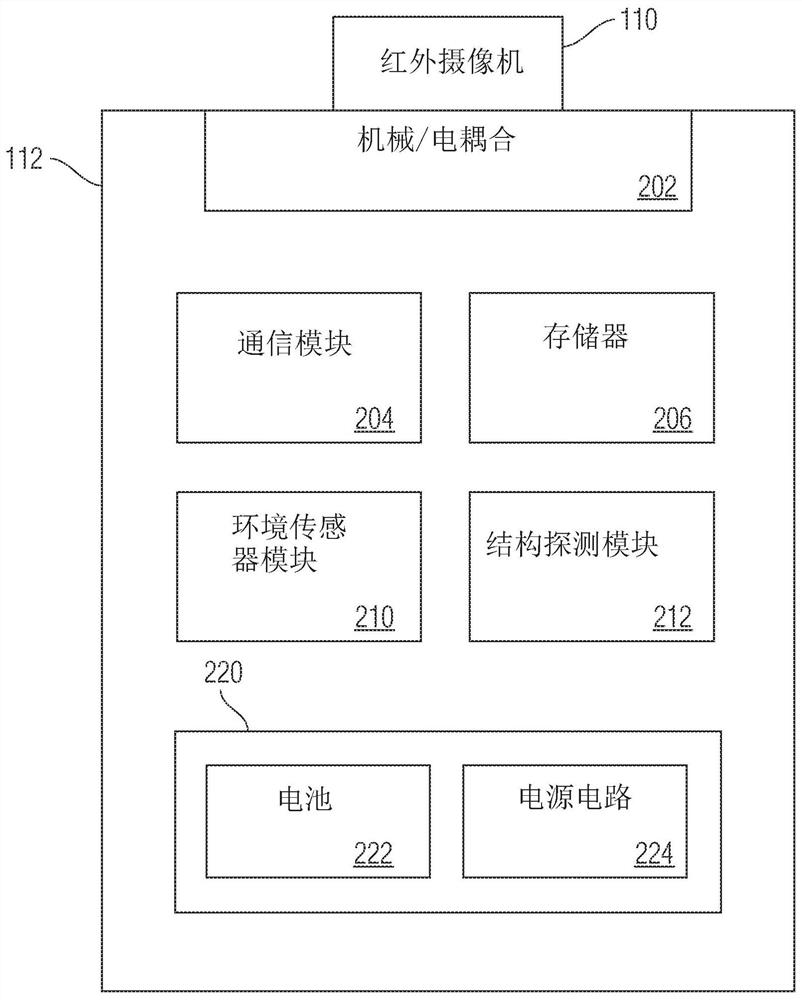

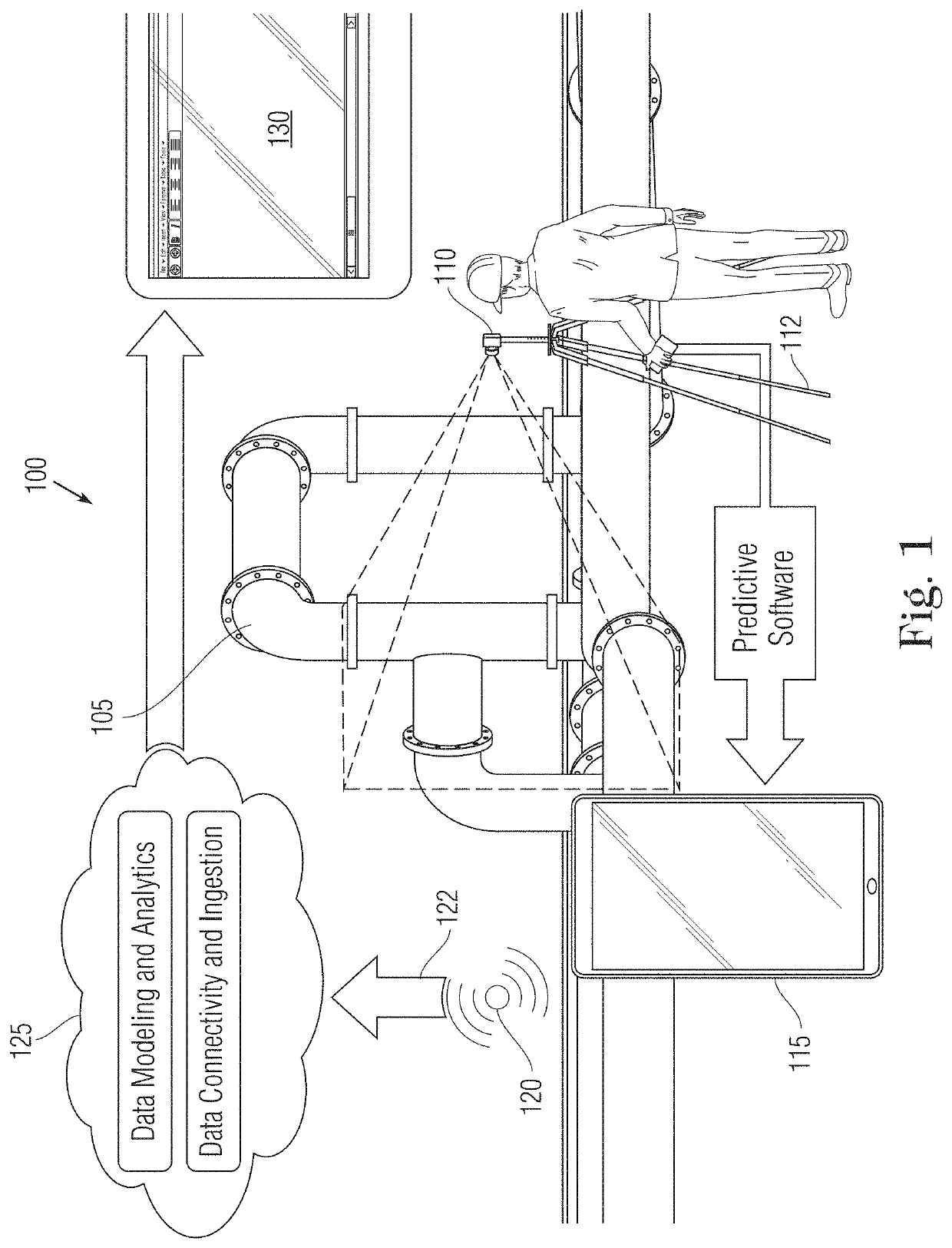

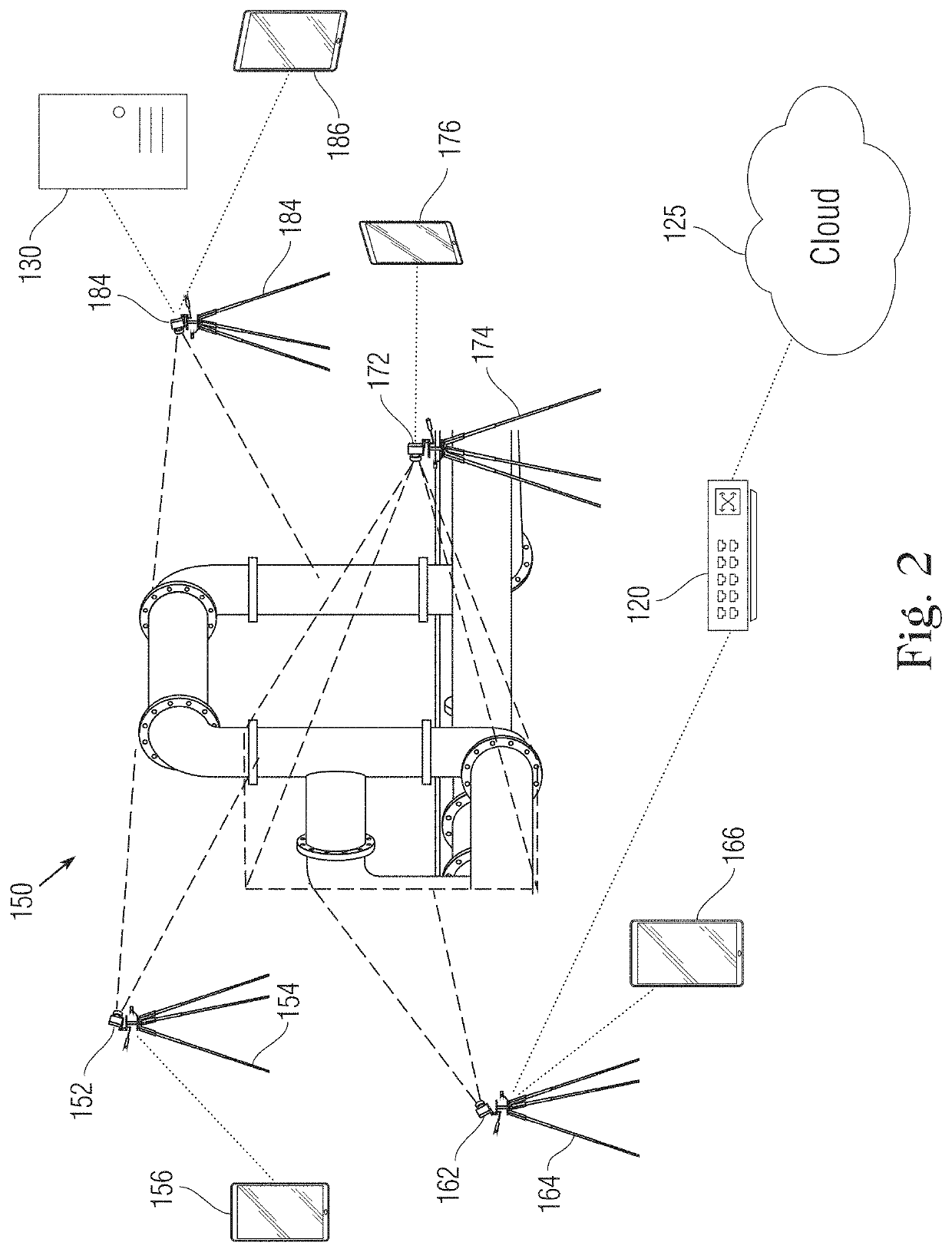

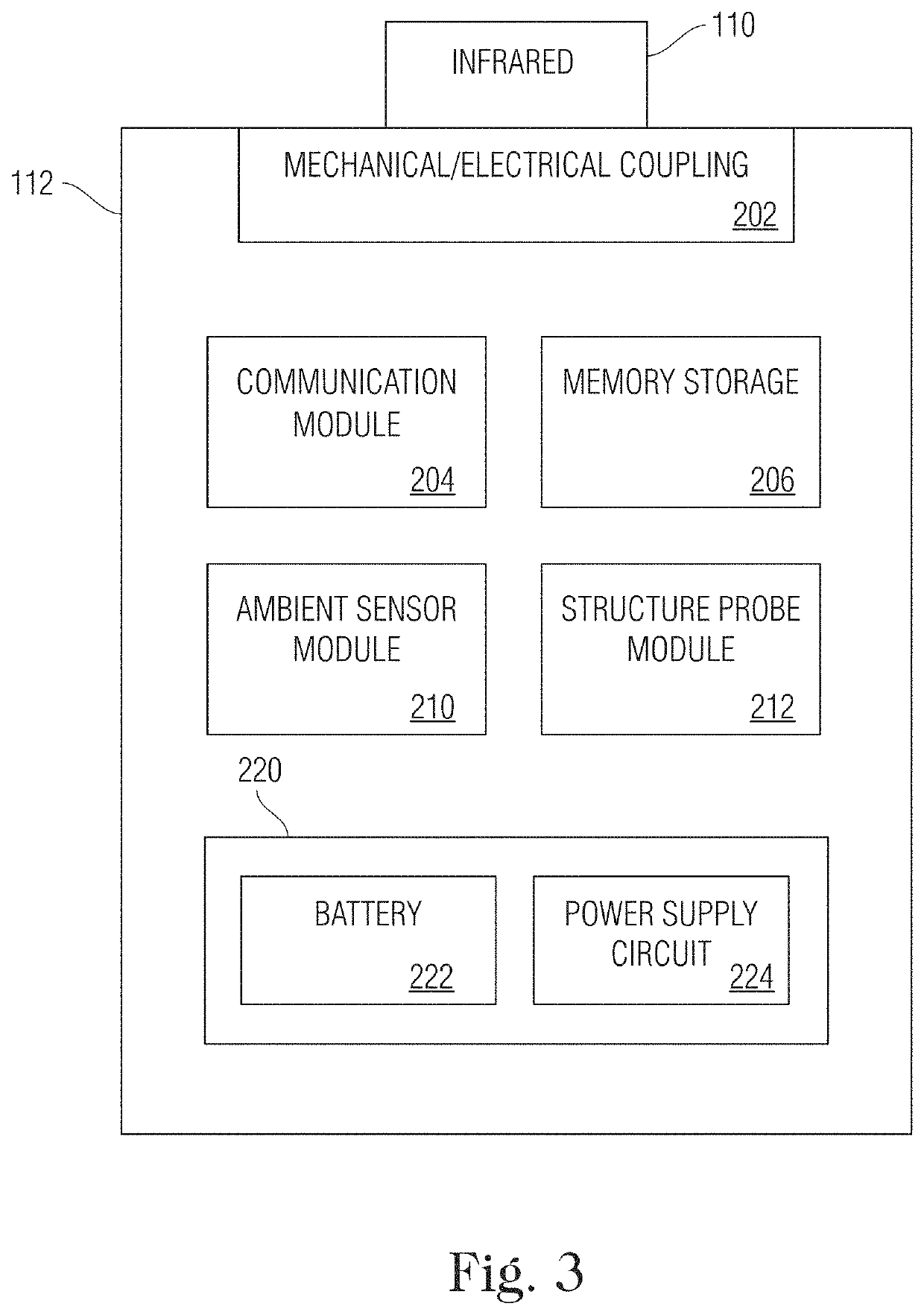

A system for predicting corrosion under insulation (CUI) in an infrastructure asset includes at least one infrared camera positioned to capture thermal images of the asset, at least one smart mount supporting and electrically coupled to the at least one infrared camera and including a wireless communication module, memory storage, a battery module operative to recharge the at least one infrared camera, an ambient sensor module adapted to obtain ambient condition data and a structural probe sensor to obtain CUI-related data from the asset. At least one computing device has a wireless communication module that communicates with the at least one smart mount and is configured with a machine learning algorithm that outputs a CUI prediction regarding the asset. A cloud computing platform receive and stores the received data and the prediction output and to receive verification data for updating the machine learning algorithm stored on the computing device.

Owner:SAUDI ARABIAN OIL CO +1

Phenolic aldehyde epoxy coating with CUI (corrosion under insulation) resistance

ActiveCN105524545AGood high temperature resistance (250°C) performanceImprove crack resistanceAnti-corrosive paintsPolyamide coatingsCrack resistanceMicrosphere

The invention discloses a phenolic aldehyde epoxy coating with CUI (corrosion under insulation) resistance. The phenolic aldehyde epoxy coating comprises a component A and a component B, wherein the component A comprises raw materials in percentage by weight as follows: 20%-30% of phenolic aldehyde epoxy resin, 16%-19% of a solvent, 0.5%-0.6% of a thixotropic agent, 0.4%-0.6% of a defoaming agent, 15%-22% of flaky iron oxide red, 5%-8% of hollow glass microspheres, 27%-34% of barite and 0.5%-1% of a silane coupling agent; the component B is 100% modified polyamide resin; before coating, the component A and the component B are mixed in a weight ratio of A to B being (88-92): (8-12) for use. According to the phenolic aldehyde epoxy coating with CUI resistance, a high-temperature-resistant film can be combined with flaky iron oxide red and the hollow glass microspheres, and an acquired coating layer has good high-temperature resistance, high-temperature cracking resistance and good long-term corrosion resistance, and can effectively resist metal surface corrosion caused by rainwater, mist and electrolyte ion infiltration under insulation; the phenolic aldehyde epoxy coating is easy to prepare and simple, facilitates construction and can be widely applied to the fields of petrochemical industry and thermal pipeline application.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL +1

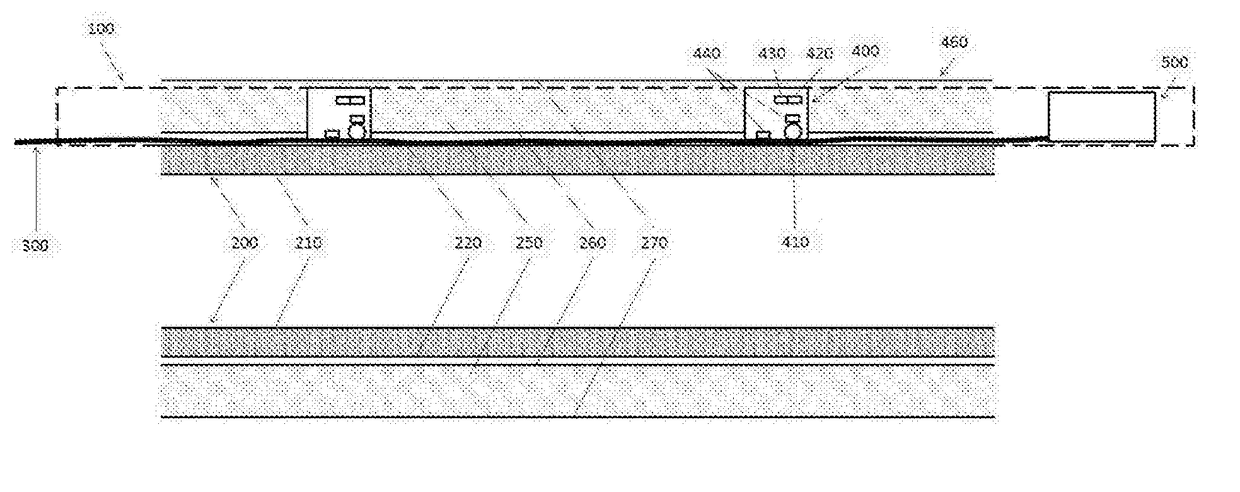

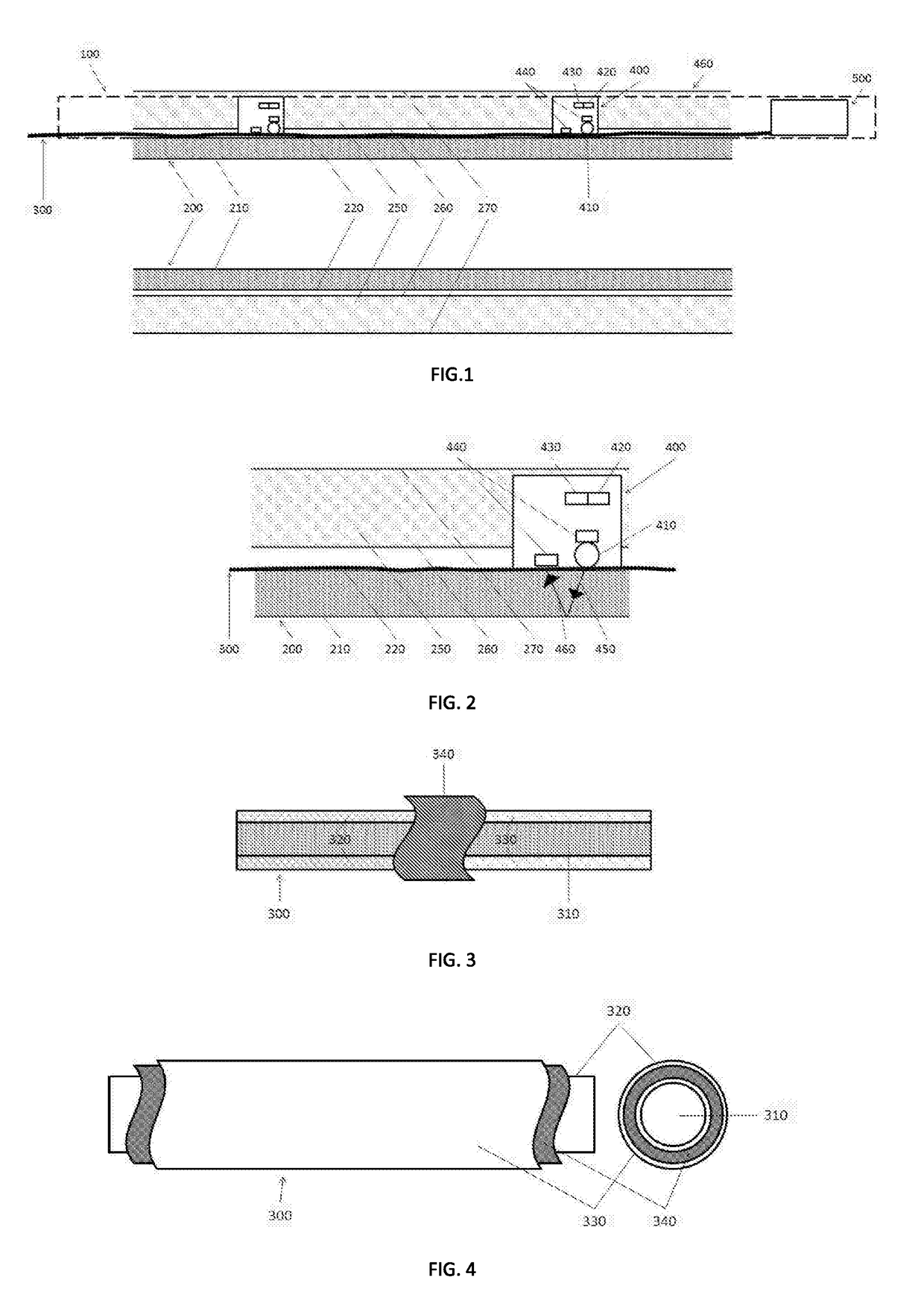

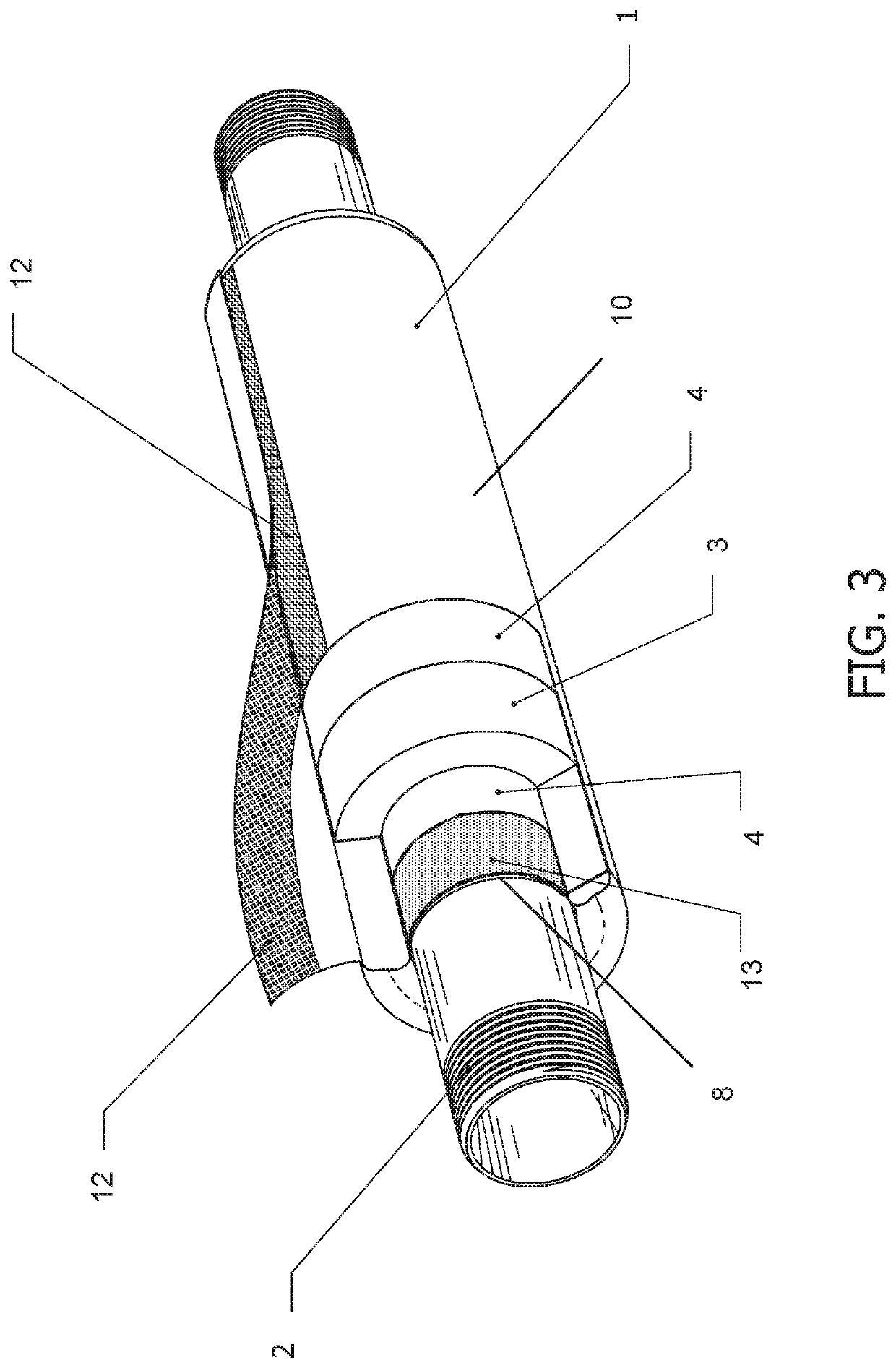

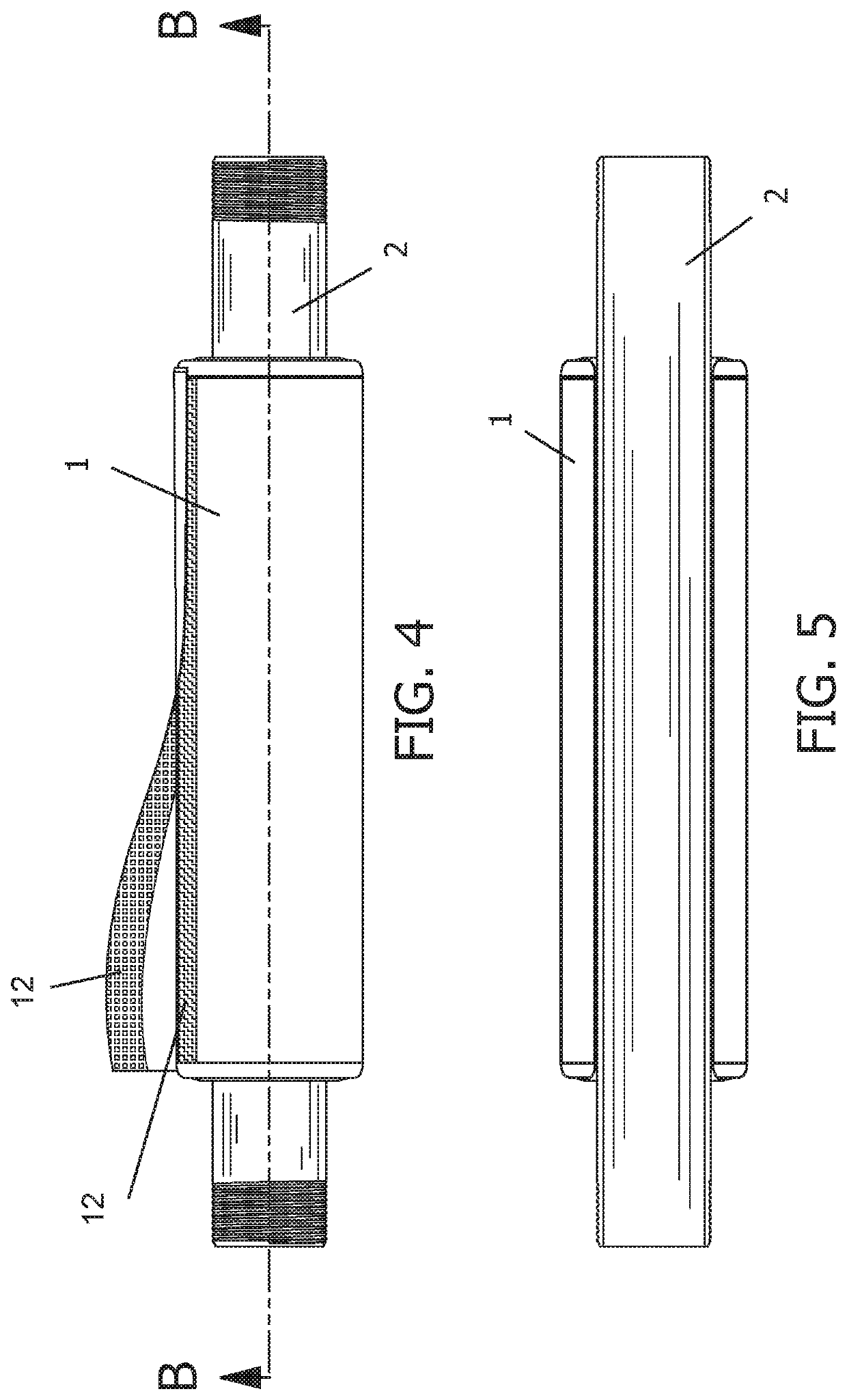

Sensor system for corrosion monitoring

ActiveUS20150346159A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberMonitoring system

A permanently installed monitoring system for corrosion under insulation (PIMSCUI) and a method for performing the monitoring of said system are provided. The present invention attains the objective of the invention by a fibre optic cable permanently mounted between walls of a pipeline and pipeline insulation surrounding the pipeline and placement of acoustic emitters along the length of the pipeline in mechanical contact with the optical fibre. The acoustic emitters send a pulsed acoustic signal towards the pipeline which is received by the optical fibre, the acoustic signal subsequently travels through the pipeline wall, reflecting from the inner diameter of the pipeline before the reflected pulse is received at the optical fibre.

Owner:NORCE INNOVATION AS

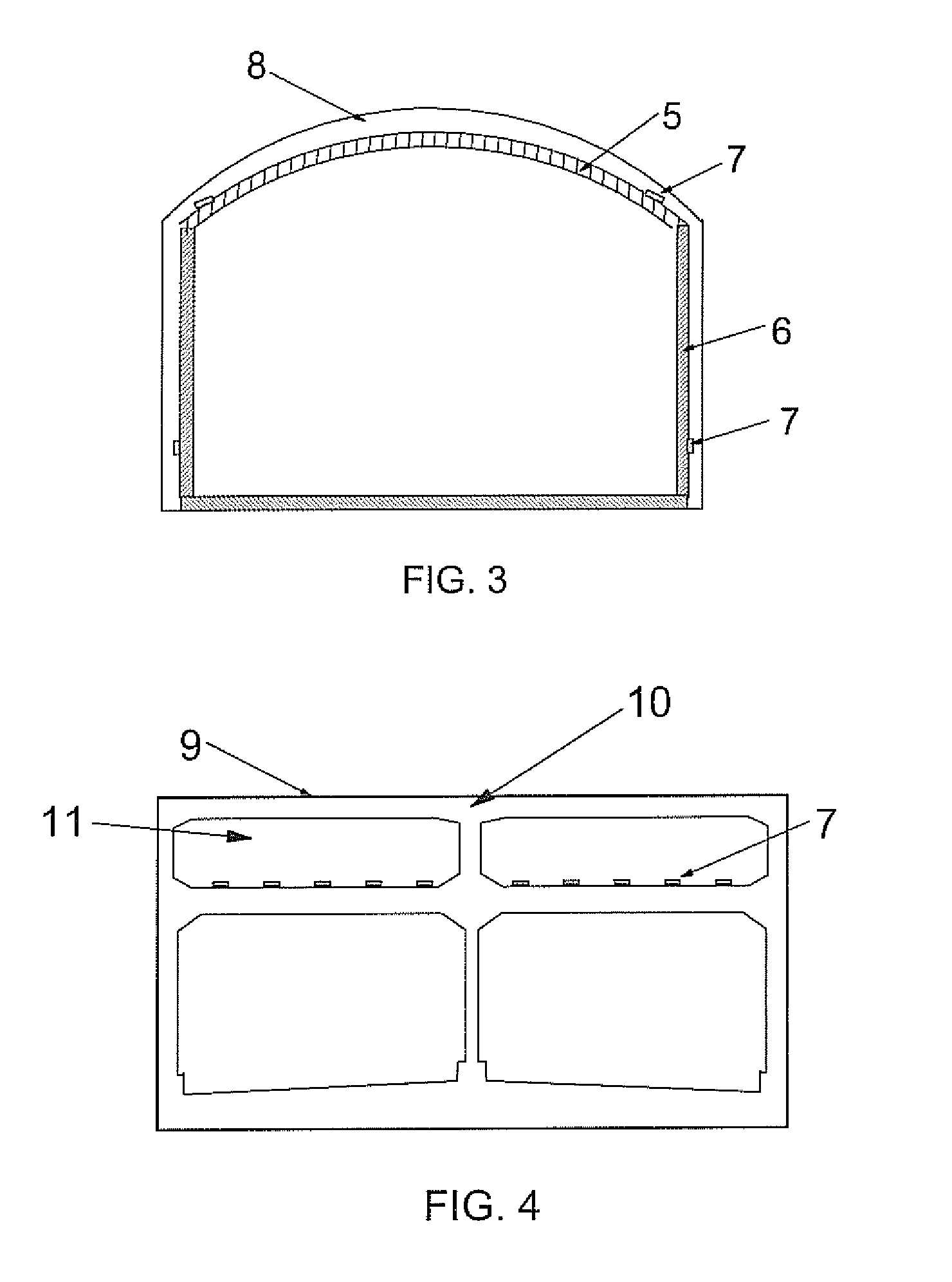

Two-stage corrosion under insulation detection methodology and modular vehicle with dual locomotion sensory systems

ActiveUS20190086365A1Weather/light/corrosion resistanceUnmanned aerial vehiclesCurrent sensorModularity

Methods and systems for inspecting insulated equipment for corrosion under insulation are provided. The system includes an autonomous unmanned vehicle having aerial and ground locomotive capabilities. The vehicle includes an infrared detector and a pulsed eddy current sensor. In the method, infrared waves emitted from the equipment are detected along the equipment with the infrared detector. Using the infrared detector, at least one image of an inner surface of the equipment is developed based on the detected infrared waves. At least one area that is susceptible to corrosion is determined based on the at least one image. The susceptible area is inspected with the pulsed eddy current sensor, which induces an eddy current in the inner wall of the equipment. Based on a rate of the decay in strength of the eddy current, it is determined whether corrosion exists at the susceptible area using a processor configured by code.

Owner:SAUDI ARABIAN OIL CO

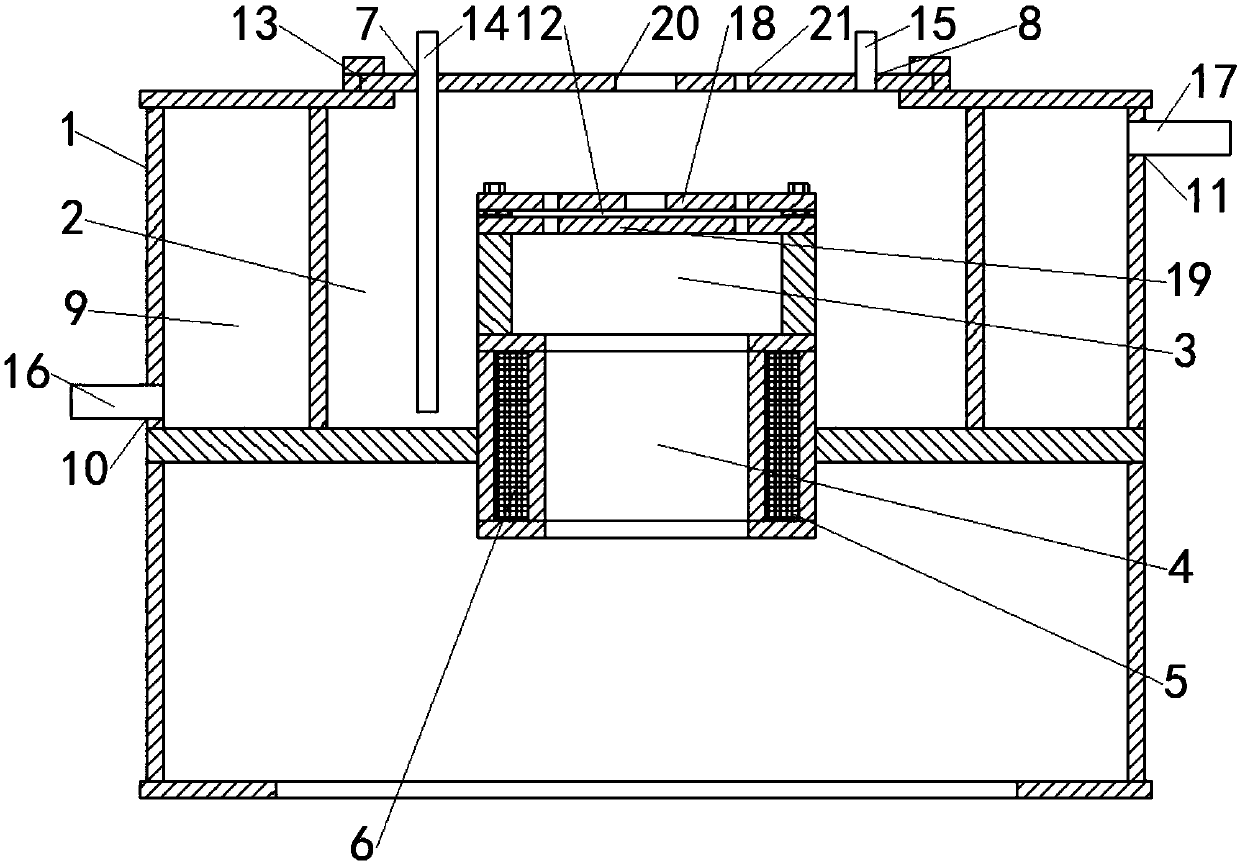

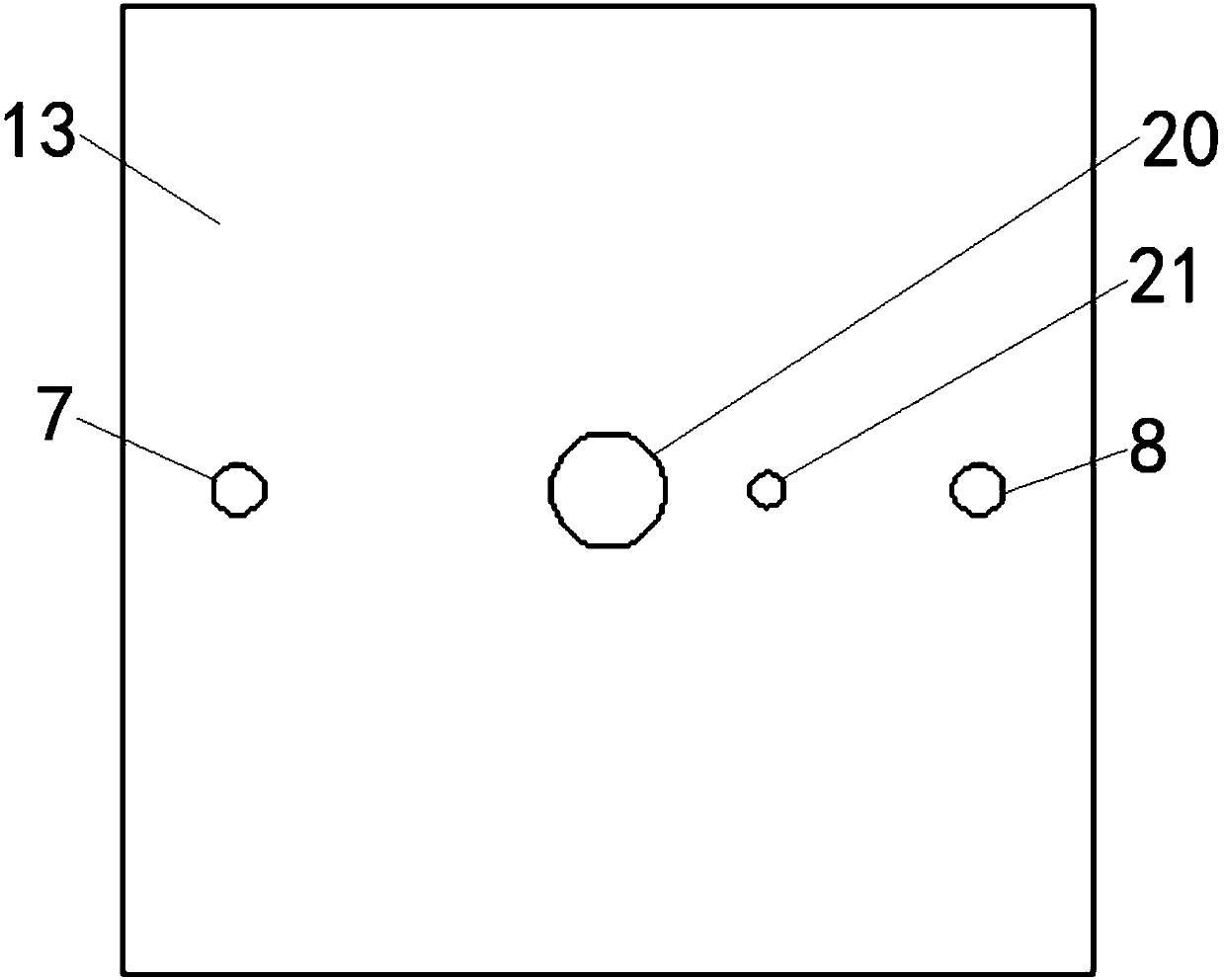

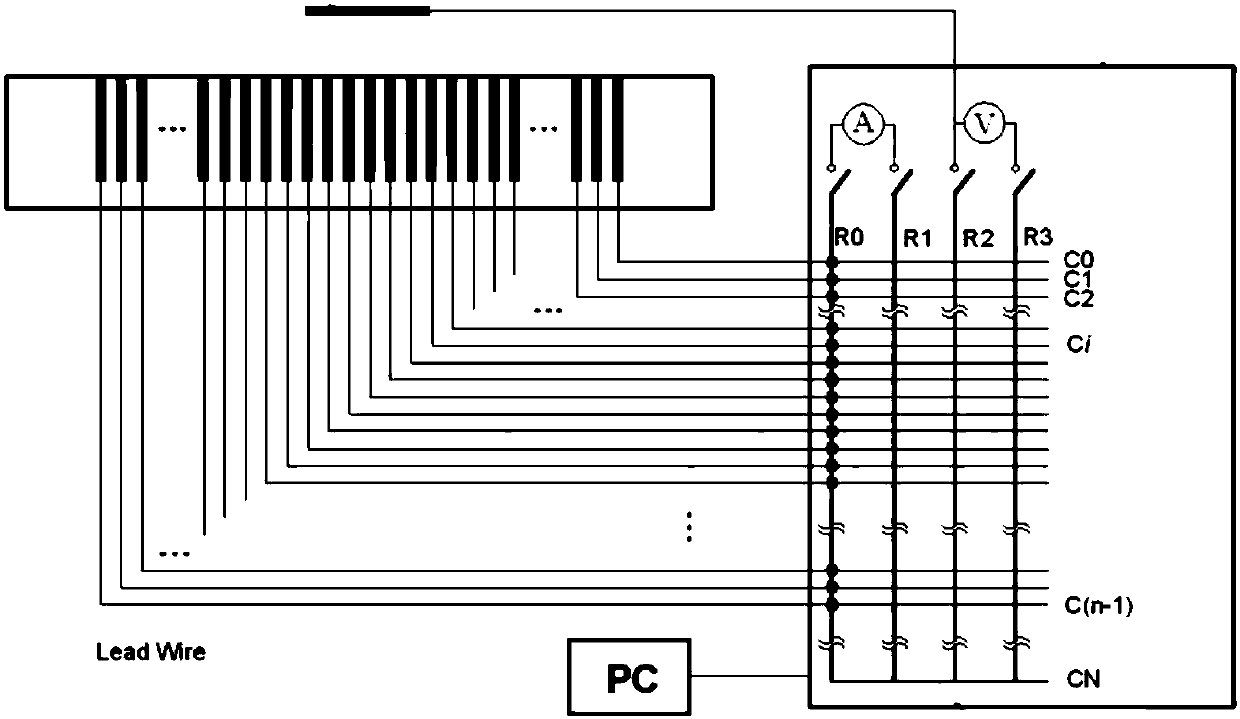

Test device and test method for CUI (corrosion under insulation)

PendingCN107677593AAccurate Laws in Corrosion ProcessesExact lawWeather/light/corrosion resistanceProcess efficiency improvementCorrosion under insulationWorking electrode

The invention provides a test device and a test method for CUI (corrosion under insulation). The test device for CUI comprises a tank body, wherein sealed chambers are formed in the tank body and comprise an immersion chamber capable of being filled with a leaching agent, a first filling chamber capable of being filled with a water immersion insulating material, a second filling chamber capable ofbeing filled with a dry insulating material as well as a first mounting chamber; the immersion chamber is communicated with the first filling chamber; the first filling chamber is formed between thesecond filling chamber and the immersion chamber to isolate the second filling chamber from the immersion chamber; the second filling chamber is formed between the first filling chamber and the firstmounting chamber to isolate the first filling chamber from the first mounting chamber; a working electrode is mounted in the first mounting chamber. An accurate basis can be provided by the test device for occurrence of CUI.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Harmonic wireless transponder sensor and method

ActiveUS20060044178A1Telemetry/telecontrol selection arrangementsRecord carriers used with machinesEnvironmental effectHarmonic

A method for detecting a latent environmental effect (such as a corrosive environment under insulation) or a latent structural change (such as a crack in a concealed structural member) at a known remote concealed location. The method of the instant invention includes three steps. The first step is to use a harmonic electromagnetic transponder at the known remote concealed location of the latent environmental effect or the latent structural change, the harmonic electromagnetic transponder having a reactive portion which reacts to the latent environmental effect or latent structural change to modify the harmonic emission of the transponder. The second step is to remotely interrogate the transponder by directing electromagnetic radiation at the transponder. The third step is to use the harmonic emission of the transponder to remotely determine the latent environmental effect or the latent structural change.

Owner:MICHIGAN STATE UNIV +1

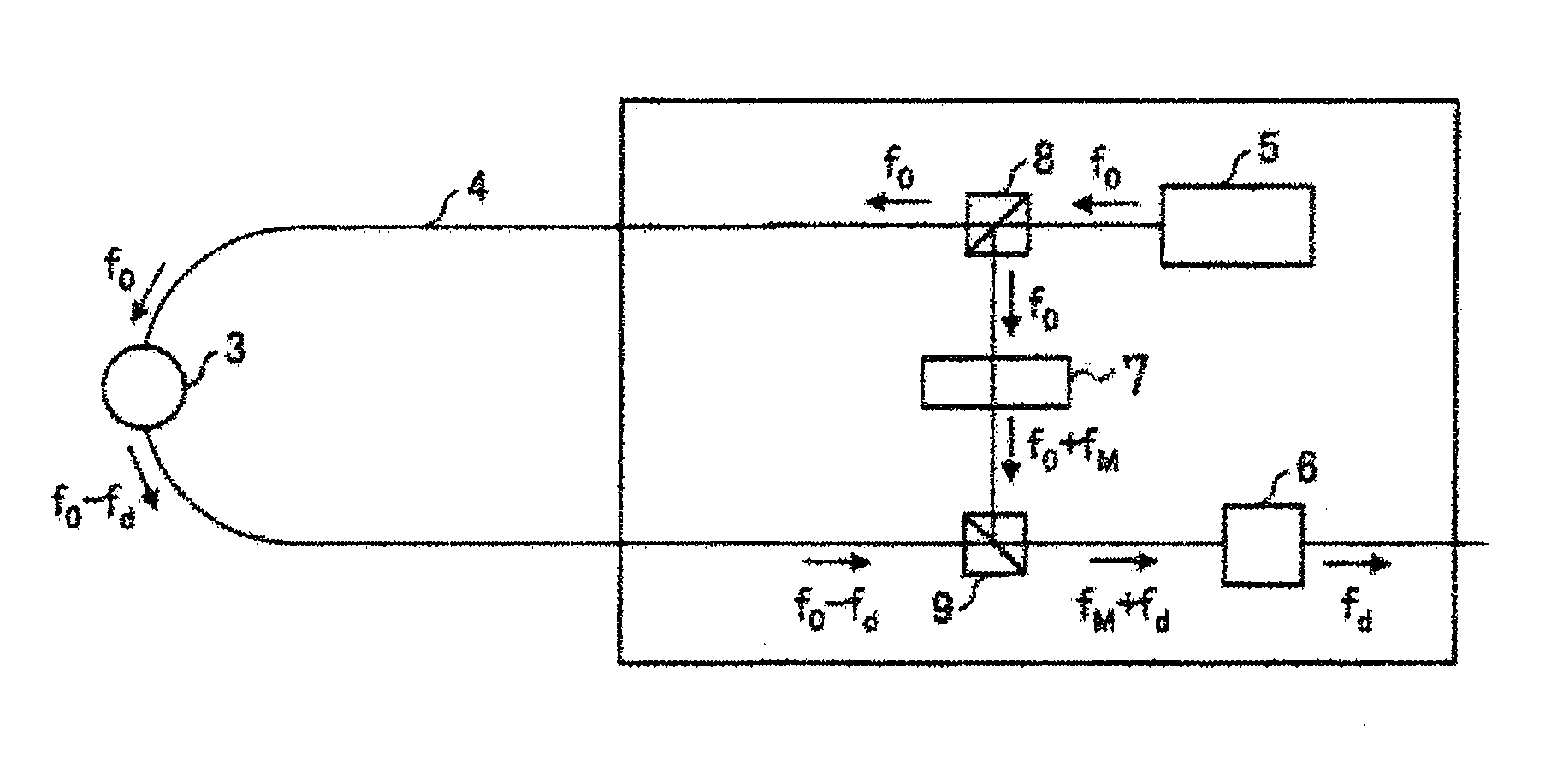

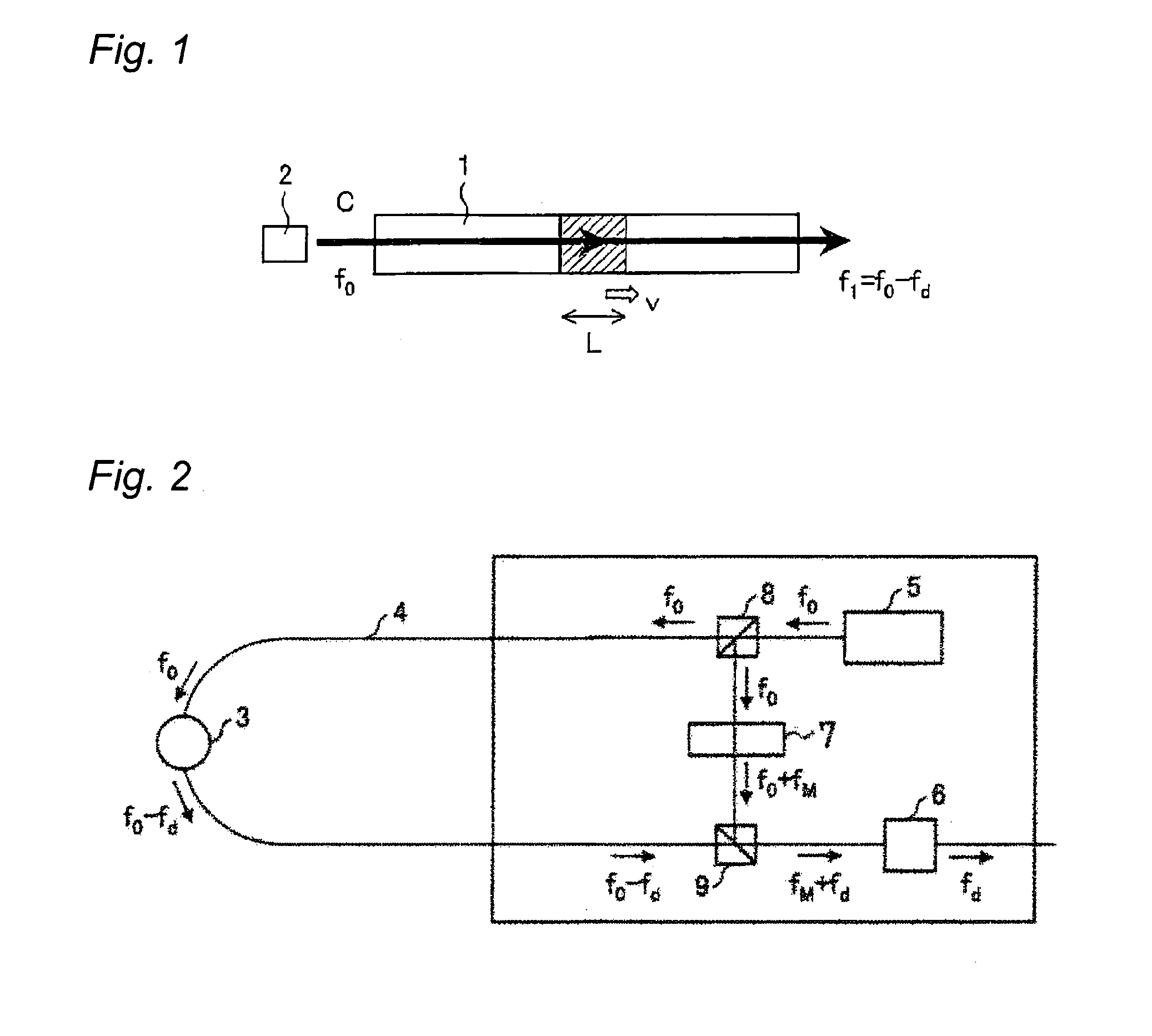

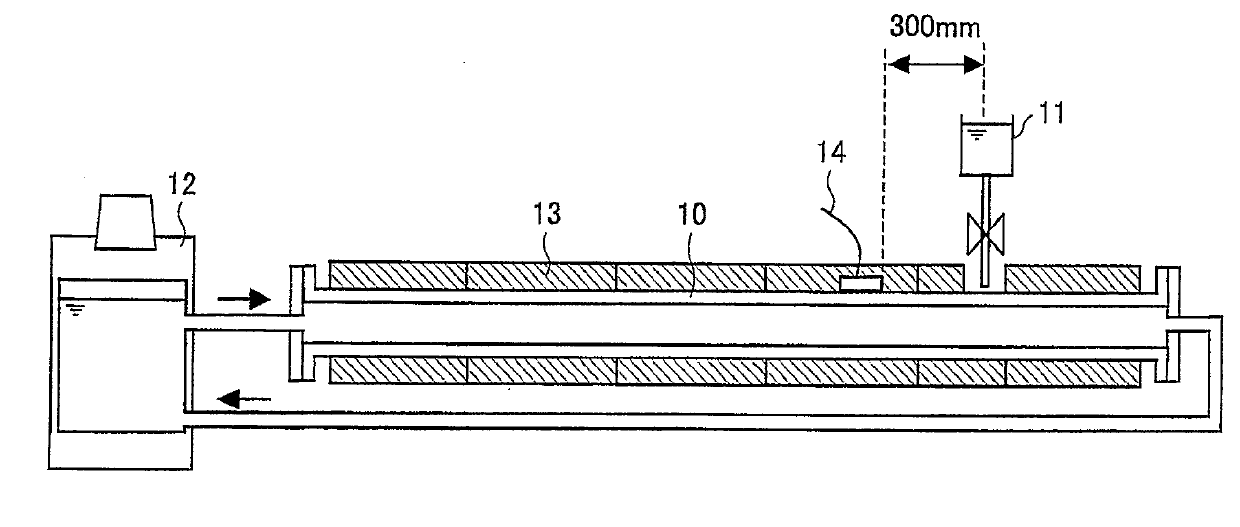

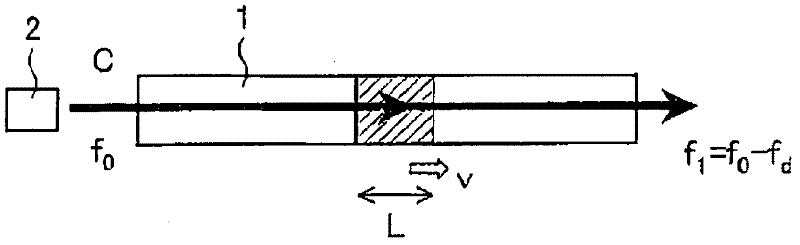

Inspection method for inspecting corrosion under insulation

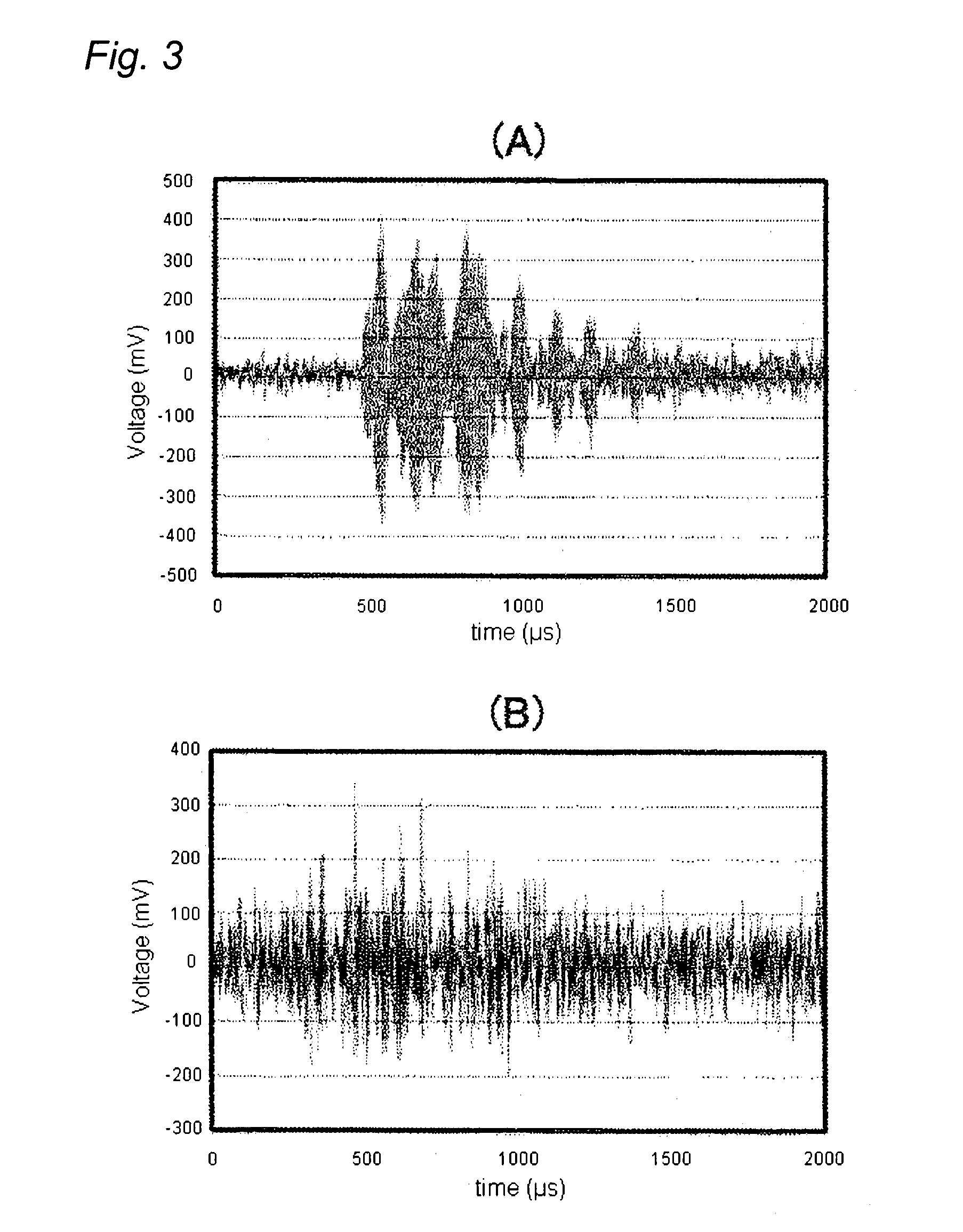

InactiveUS20110205532A1Weather/light/corrosion resistanceMaterial analysis using acoustic emission techniquesFiberCorrosion under insulation

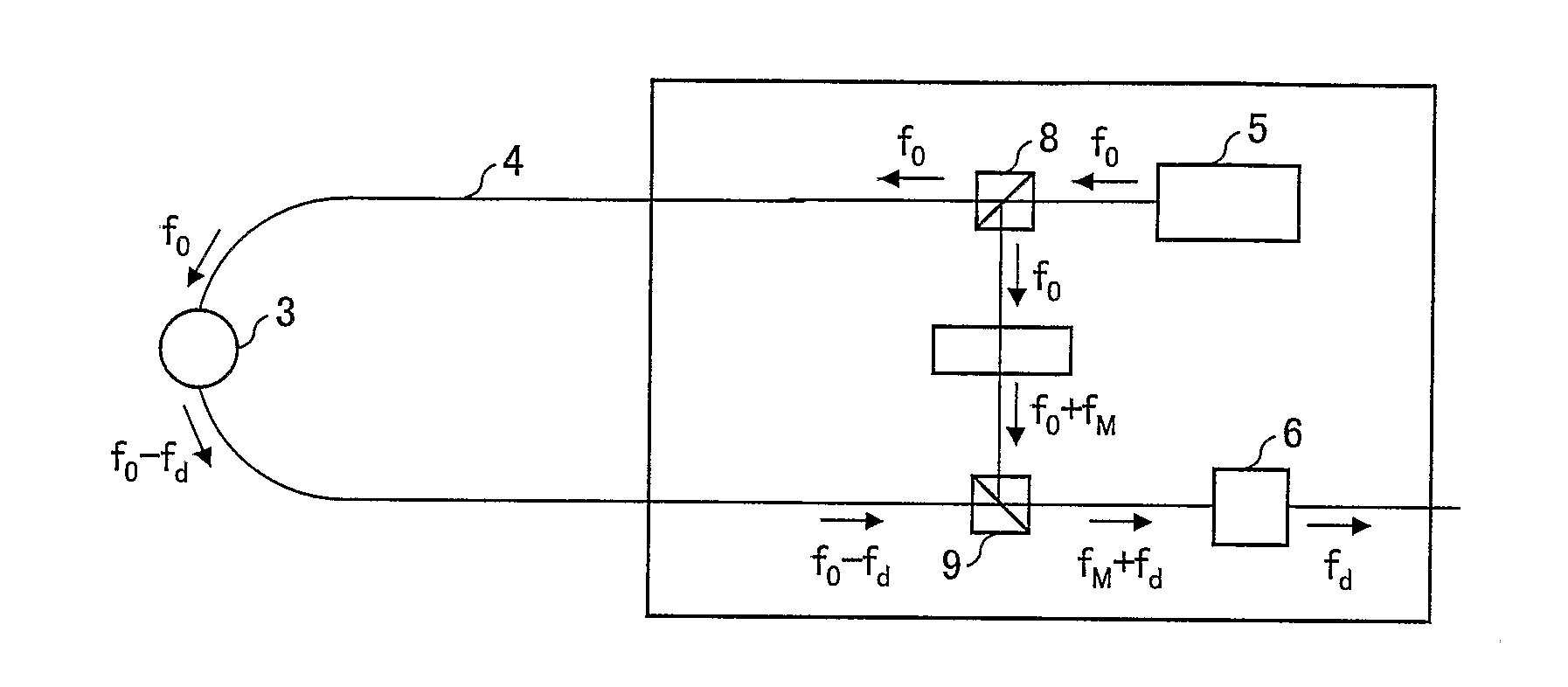

The present invention realizes an inspection method for inspecting corrosion under insulation. This inspection method according to the present invention makes it possible to inspect corrosion easily and economically in piping furnished with heat insulators. The inspection method is an inspection method for inspecting corrosion under insulation, in piping to which an heat insulator is provided, and includes providing a fiber optical Doppler sensor to the piping; and inspecting the corrosion in the piping by using the fiber optical Doppler sensor.

Owner:SUMITOMO CHEM CO LTD

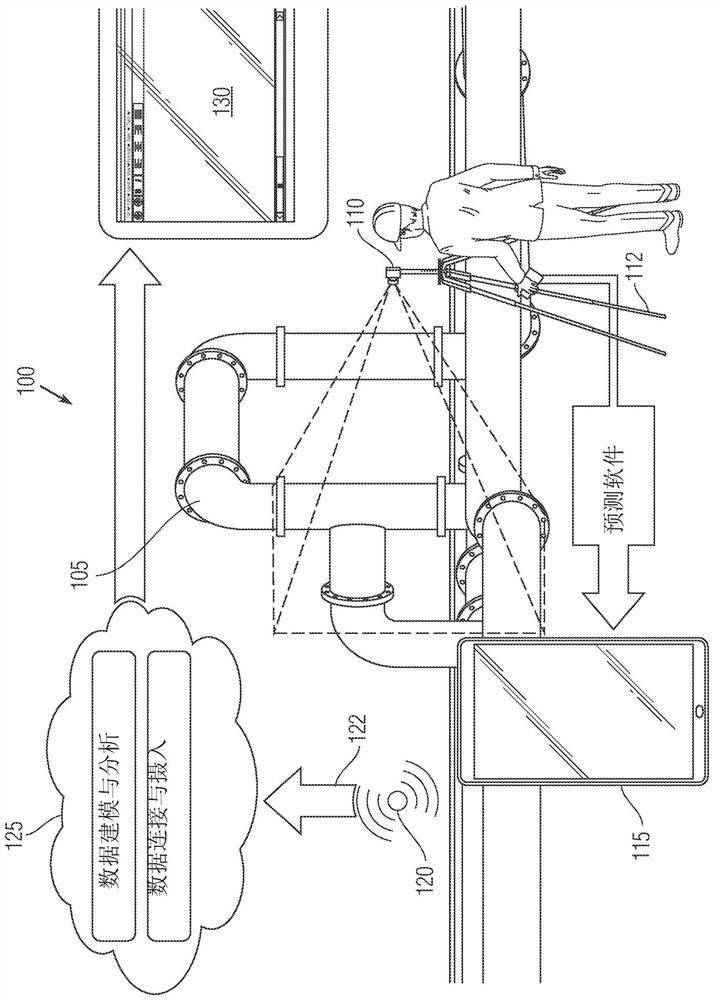

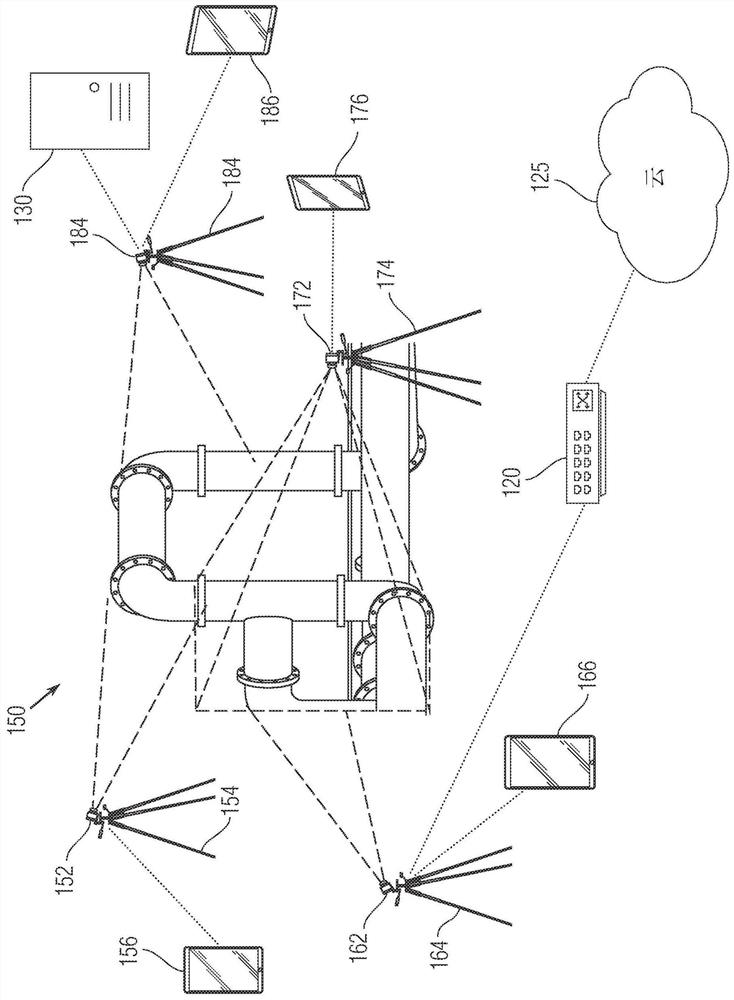

Machine Learning System and Data Fusion for Optimization of Deployment Conditions for Detection of Corrosion Under Insulation

A system for predicting corrosion under insulation (CUI) in an infrastructure asset includes at least one infrared camera positioned to capture thermal images of the asset, at least one smart mount supporting and electrically coupled to the at least one infrared camera and including a wireless communication module, memory storage, a battery module operative to recharge the at least one infrared camera, an ambient sensor module adapted to obtain ambient condition data and a structural probe sensor to obtain CUI-related data from the asset. At least one computing device has a wireless communication module that communicates with the at least one smart mount and is configured with a machine learning algorithm that outputs a CUI prediction regarding the asset. A cloud computing platform receive and stores the received data and the prediction output and to receive verification data for updating the machine learning algorithm stored on the computing device.

Owner:SAUDI ARABIAN OIL CO +1

Thermography image processing with neural networks to identify corrosion under insulation (CUI)

ActiveUS10551297B2Accurate detectionKeep dryThermometer detailsWeather/light/corrosion resistanceImaging processingImage manipulation

A method for identifying corrosion under insulation (CUI) in a structure comprises receiving thermographs from the structure using an infrared camera, applying filters to the thermograph using a first machine learning system, initially determining a CUI classification based on output from the filters, and validating the initial CUI classification by an inspection of the structure. The first machine learning system is trained using results of the validation. Outputs of the first machine learning system and additional structural and environmental data are fed into a second machine learning system that incorporates information from earlier states into current states. The second machine learning system is trained to identify CUI according to changes in the outputs of the first machine learning system and the additional data over time until a second threshold for CUI classification accuracy is reached. CUI is thereafter identified using the first and second machine learning systems in coordination.

Owner:SAUDI ARABIAN OIL CO

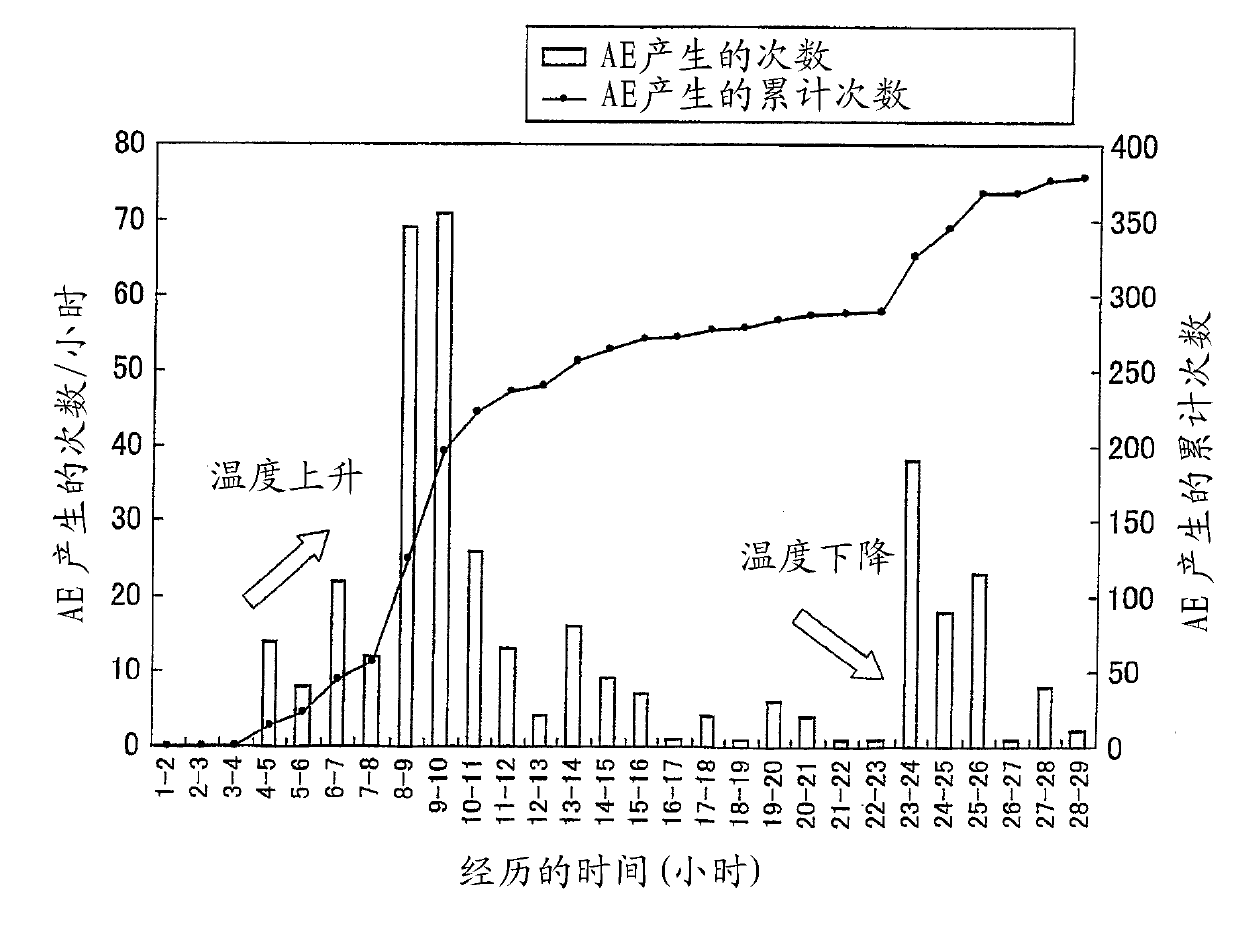

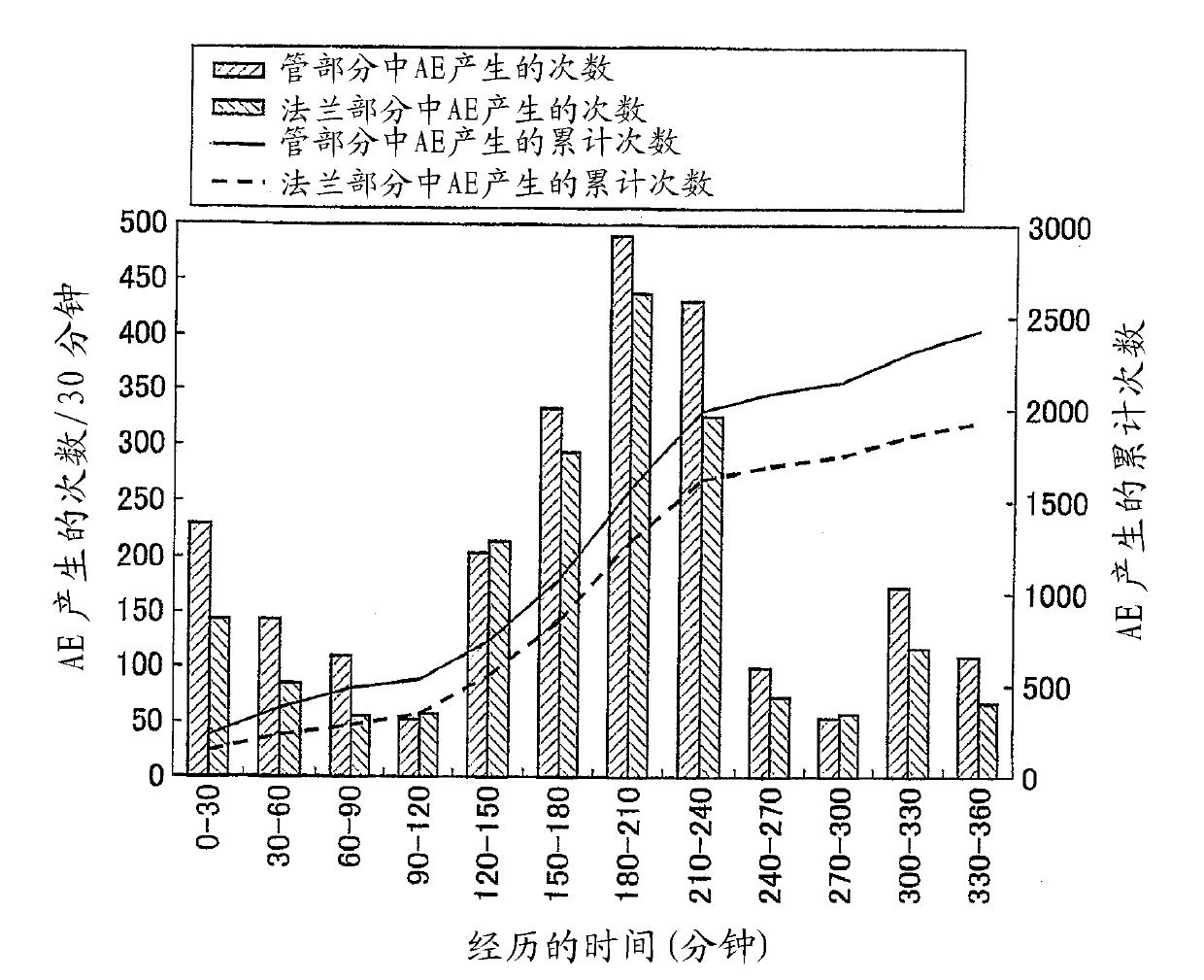

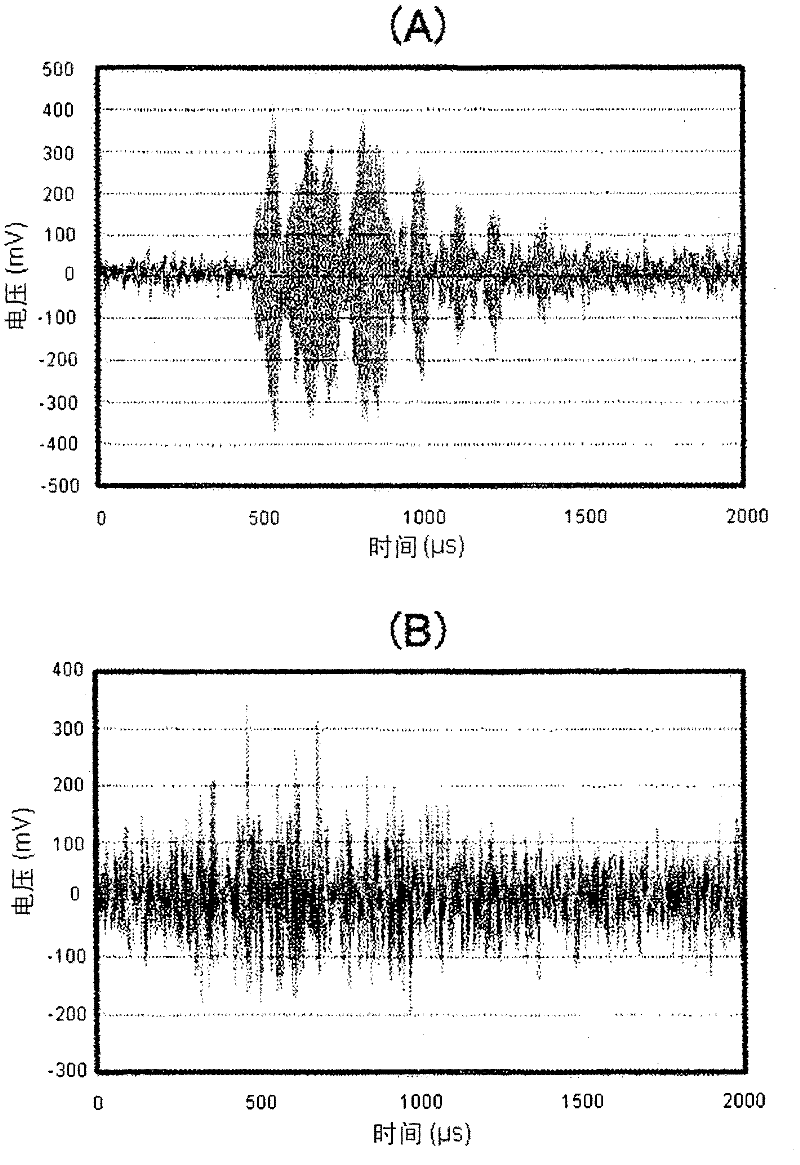

Method for inspecting corrosion under insulation

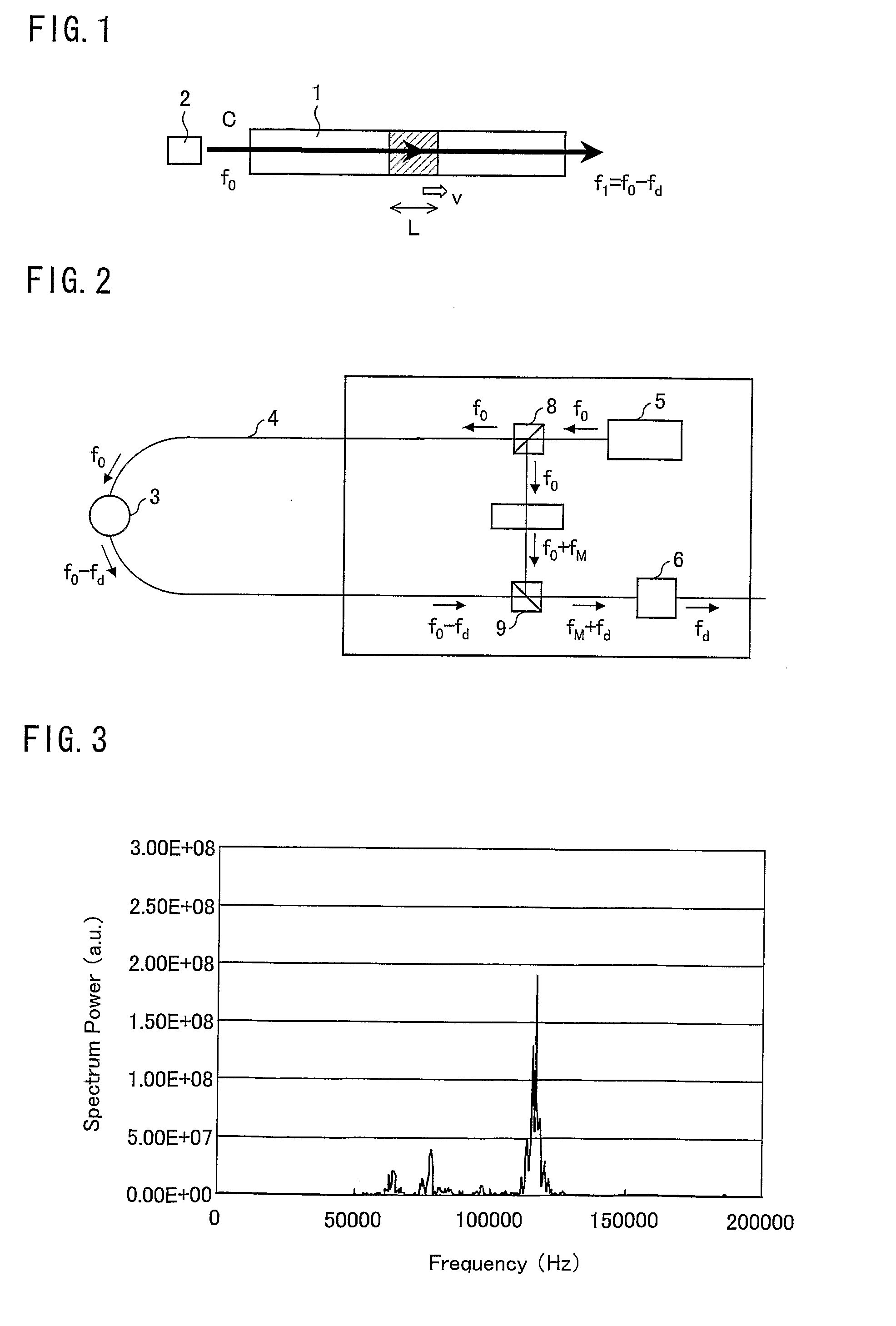

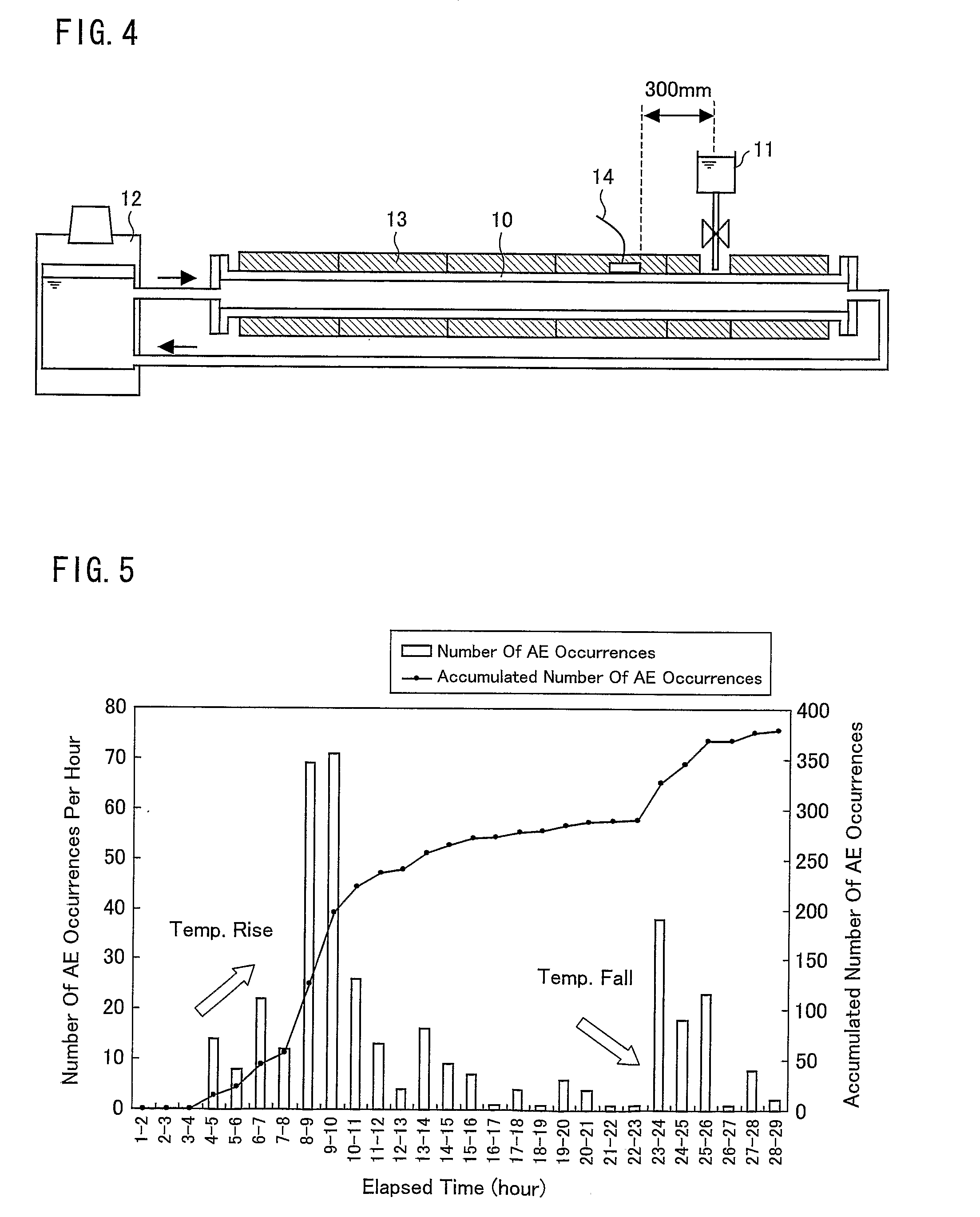

InactiveUS20120265450A1Low costPlug gaugesAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberAcoustic emission

A method for inspecting corrosion under insulation simply and precisely at a low cost is provided. The method for inspecting CUI is characterized by obtaining signals from a fiber optical Doppler sensor attached to equipment and counting a waveform for a predetermined time before and after a point where an amplitude is over a threshold value as one acoustic emission (AE) signal, recording the AE signals and the maximum amplitudes thereof, subjecting the AE signals to a filtering process to remove noise signals, determining a frequency distribution of the AE signal hits relative to various maximum amplitude values, determining a regression line of the number of the AE hits relative to the maximum amplitudes from a scattering diagram which is obtained by double logarithmic expression of the frequency distribution, and judging existence or nonexistence of the corrosion based on a gradient of the regression line.

Owner:SUMITOMO CHEM CO LTD

Inspection method for inspecting corrosion under insulation

InactiveCN102203585AValid checkEasy to checkMaterial analysis using acoustic emission techniquesWeather/light/corrosion resistanceFiberCorrosion under insulation

Owner:SUMITOMO CHEM CO LTD

Two-stage corrosion under insulation detection methodology and modular vehicle with dual locomotion sensory systems

ActiveUS10139372B1Weather/light/corrosion resistanceUnmanned aerial vehiclesModularityCorrosion under insulation

Methods and systems for inspecting insulated equipment for corrosion under insulation are provided. The system includes an autonomous unmanned vehicle having aerial and ground locomotive capabilities. The vehicle includes an infrared detector and a pulsed eddy current sensor. In the method, infrared waves emitted from the equipment are detected along the equipment with the infrared detector. Using the infrared detector, at least one image of an inner surface of the equipment is developed based on the detected infrared waves. At least one area that is susceptible to corrosion is determined based on the at least one image. The susceptible area is inspected with the pulsed eddy current sensor, which induces an eddy current in the inner wall of the equipment. Based on a rate of the decay in strength of the eddy current, it is determined whether corrosion exists at the susceptible area using a processor configured by code.

Owner:SAUDI ARABIAN OIL CO

Machine learning system and data fusion for optimization of deployment conditions for detection of corrosion under insulation

A system for predicting corrosion under insulation (CUI) in an infrastructure asset includes at least one infrared camera positioned to capture thermal images of the asset, at least one smart mount supporting and electrically coupled to the at least one infrared camera and including a wireless communication module, memory storage, a battery module operative to recharge the at least one infrared camera, an ambient sensor module adapted to obtain ambient condition data and a structural probe sensor to obtain CUI-related data from the asset. At least one computing device has a wireless communication module that communicates with the at least one smart mount and is configured with a machine learning algorithm that outputs a CUI prediction regarding the asset. A cloud computing platform receive and stores the received data and the prediction output and to receive verification data for updating the machine learning algorithm stored on the computing device.

Owner:SAUDI ARABIAN OIL CO +1

Method for inspecting corrosion under insulation

InactiveCN102549420AChecking is simple and preciseAccurate checkAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesAcoustic emissionCorrosion under insulation

A method for inspecting corrosion under insulation simply and precisely at a low cost is provided. The method for inspecting CUI is characterized by obtaining signals from a fiber optical Doppler sensor attached to equipment and counting a waveform for a predetermined time before and after a point where an amplitude is over a threshold value as one acoustic emission (AE) signal, recording the AE signals and the maximum amplitudes thereof, subjecting the AE signals to a filtering process to remove noise signals, determining a frequency distribution of the AE signal hits relative to various maximum amplitude values, determining a regression line of the number of the AE hits relative to the maximum amplitudes from a scattering diagram which is obtained by double logarithmic expression of the frequency distribution, and judging existence or nonexistence of the corrosion based on a gradient of the regression line.

Owner:SUMITOMO CHEM CO LTD

Sensor system for corrosion monitoring

ActiveUS9841368B2Confirm the likelihood that corrosion has taken placeAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceAcoustic emissionCorrosion under insulation

Owner:NORCE INNOVATION AS

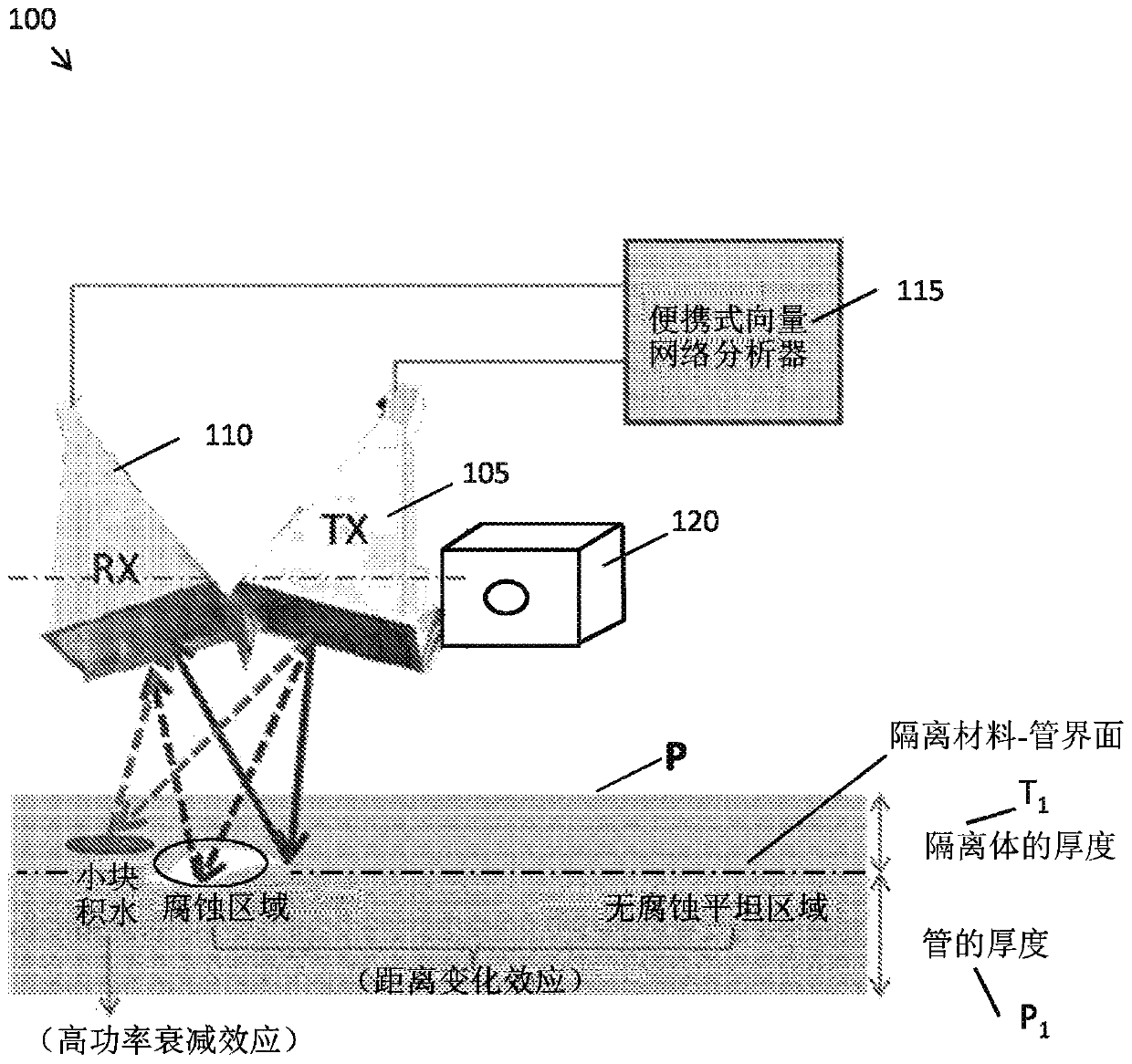

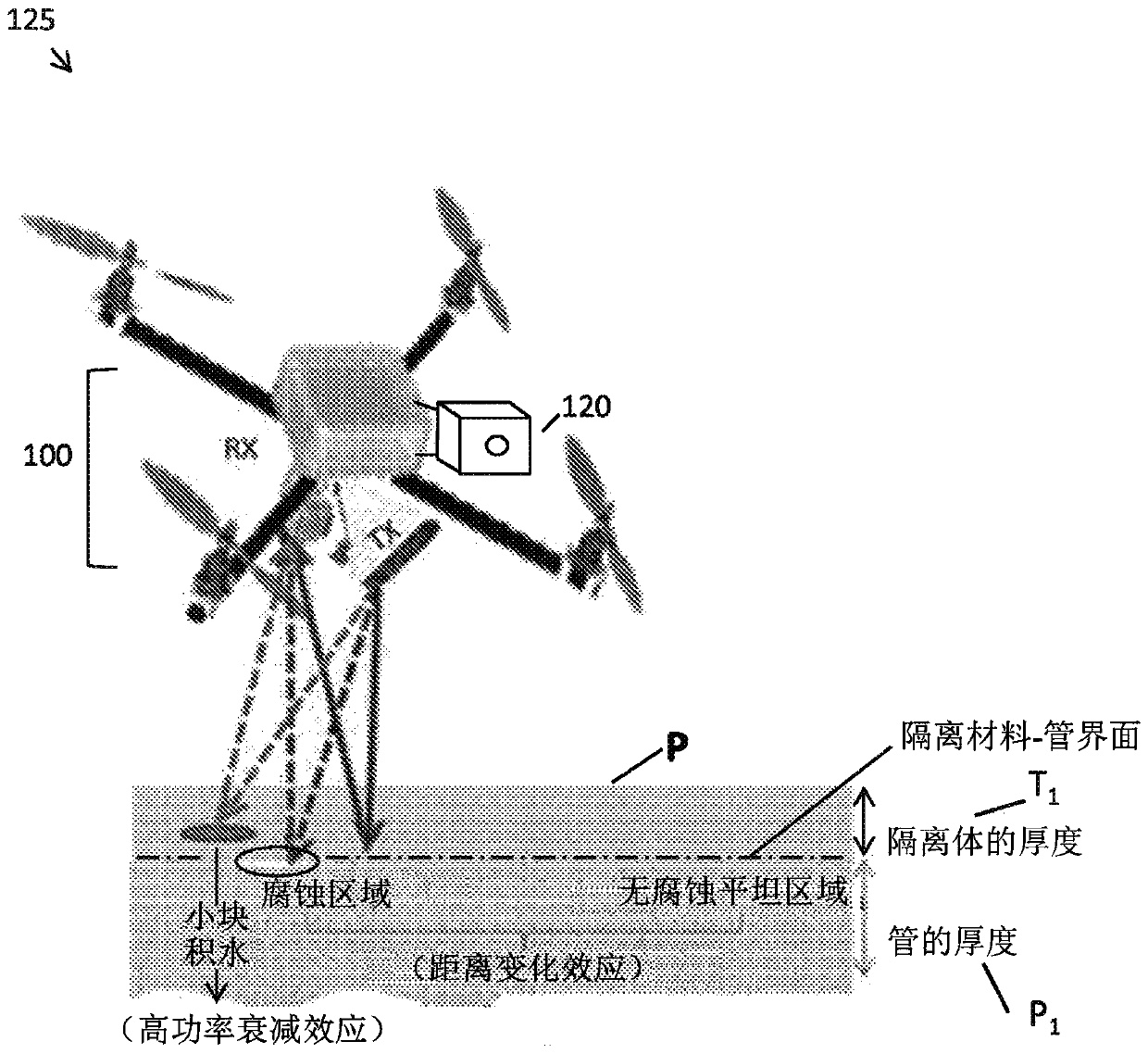

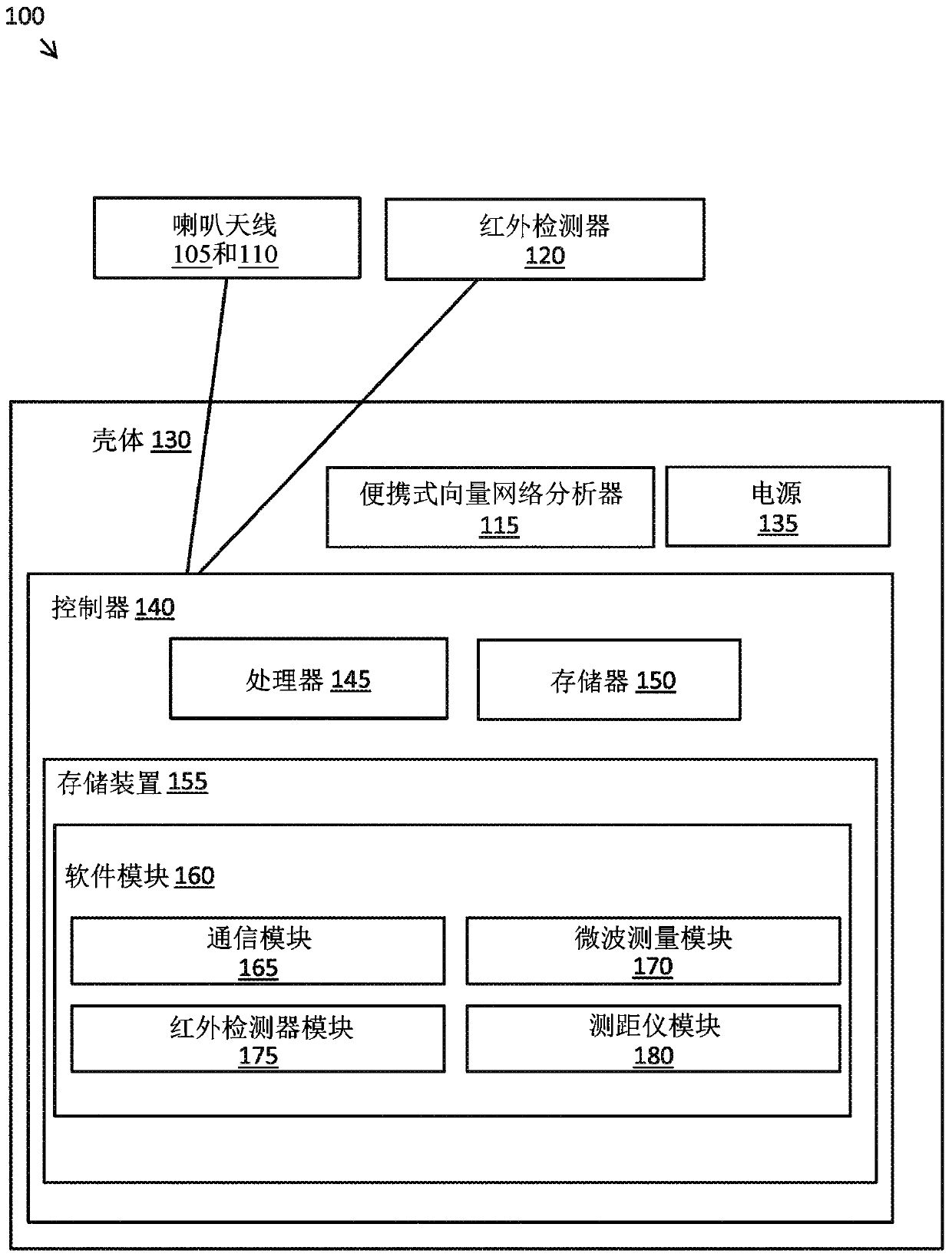

Microwave horn antennas-based transducer system for CUI inspection without removing insulation

InactiveCN110678735AWeather/light/corrosion resistanceResistance/reactance/impedenceMicrowaveCorrosion under insulation

The present disclosure is directed to methods and systems for inspecting insulated equipment for any corrosion under insulation (CUI). The system includes a device comprising transmitter and receiverhorn antennas, a vector network analyzer operatively connected to the antennas, and an infrared detector. In the method, a location for inspection of the equipment is identified. A metal jacket surrounding the location is removed without stripping the insulation. Microwaves are transmitted by the transmitted horn antenna at the location, and provide heating at the location. The microwaves are received by the receiver horn antenna after reflection off the equipment. The vector network analyzer analyzes the microwaves. The infrared detector detects infrared waves emitted from the location and develops an infrared image of the inner surface of the equipment. Based on the analysis of the microwaves and the developed image, a programmed processor determines whether CUI exists at the location.

Owner:SAUDI ARABIAN OIL CO

Machine learning system and data fusion for optimization of deployment conditions for detection of corrosion under insulation

A system for predicting corrosion under insulation (CUI) in an infrastructure asset includes at least one infrared camera positioned to capture thermal images of the asset, at least one smart mount supporting and electrically coupled to the at least one infrared camera and including a wireless communication module, memory storage, a battery module operative to recharge the at least one infrared camera, an ambient sensor module adapted to obtain ambient condition data and a structural probe sensor to obtain CUI-related data from the asset. At least one computing device has a wireless communication module that communicates with the at least one smart mount and is configured with a machine learning algorithm that outputs a CUI prediction regarding the asset. A cloud computing platform receive and stores the received data and the prediction output and to receive verification data for updating the machine learning algorithm stored on the computing device.

Owner:SAUDI ARABIAN OIL CO +1

Corrosion-resistant phenolic epoxy coating under insulation

ActiveCN105524545BGood high temperature resistance (250°C) performanceImprove crack resistanceAnti-corrosive paintsPolyamide coatingsCrack resistanceMicrosphere

The invention discloses a phenolic aldehyde epoxy coating with CUI (corrosion under insulation) resistance. The phenolic aldehyde epoxy coating comprises a component A and a component B, wherein the component A comprises raw materials in percentage by weight as follows: 20%-30% of phenolic aldehyde epoxy resin, 16%-19% of a solvent, 0.5%-0.6% of a thixotropic agent, 0.4%-0.6% of a defoaming agent, 15%-22% of flaky iron oxide red, 5%-8% of hollow glass microspheres, 27%-34% of barite and 0.5%-1% of a silane coupling agent; the component B is 100% modified polyamide resin; before coating, the component A and the component B are mixed in a weight ratio of A to B being (88-92): (8-12) for use. According to the phenolic aldehyde epoxy coating with CUI resistance, a high-temperature-resistant film can be combined with flaky iron oxide red and the hollow glass microspheres, and an acquired coating layer has good high-temperature resistance, high-temperature cracking resistance and good long-term corrosion resistance, and can effectively resist metal surface corrosion caused by rainwater, mist and electrolyte ion infiltration under insulation; the phenolic aldehyde epoxy coating is easy to prepare and simple, facilitates construction and can be widely applied to the fields of petrochemical industry and thermal pipeline application.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL +1

Cloud-based machine learning system and data fusion for the prediction and detection of corrosion under insulation

ActiveUS20200217777A1Weather/light/corrosion resistanceMaterial analysis by optical meansSimulationCorrosion under insulation

A system for predicting corrosion under insulation (CUI) in an infrastructure asset includes at least one infrared camera positioned to capture thermal images of the asset, at least one smart mount supporting and electrically coupled to the at least one infrared camera and including a wireless communication module, memory storage, a battery module operative to recharge the at least one infrared camera, an ambient sensor module adapted to obtain ambient condition data and a structural probe sensor to obtain CUI-related data from the asset. At least one computing device has a wireless communication module that communicates with the at least one smart mount and is configured with a machine learning algorithm that outputs a CUI prediction regarding the asset. A cloud computing platform receive and stores the received data and the prediction output and to receive verification data for updating the machine learning algorithm stored on the computing device.

Owner:AVITAS SYST INC +1

Superabsorbent Polymer Capsules and Bio-Mineralization Process for the Mitigation of Corrosion Under Insulation as smart packaging materials

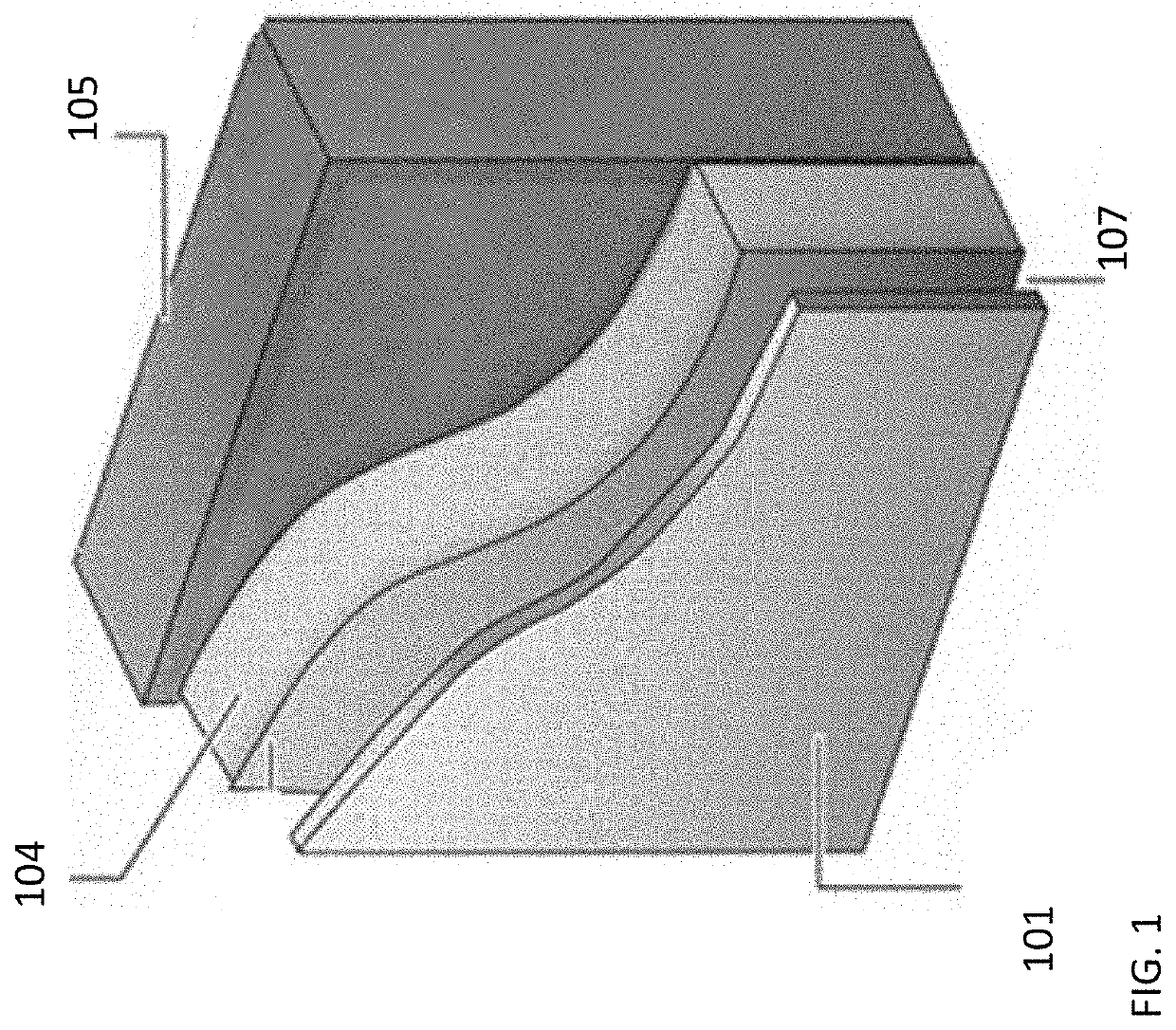

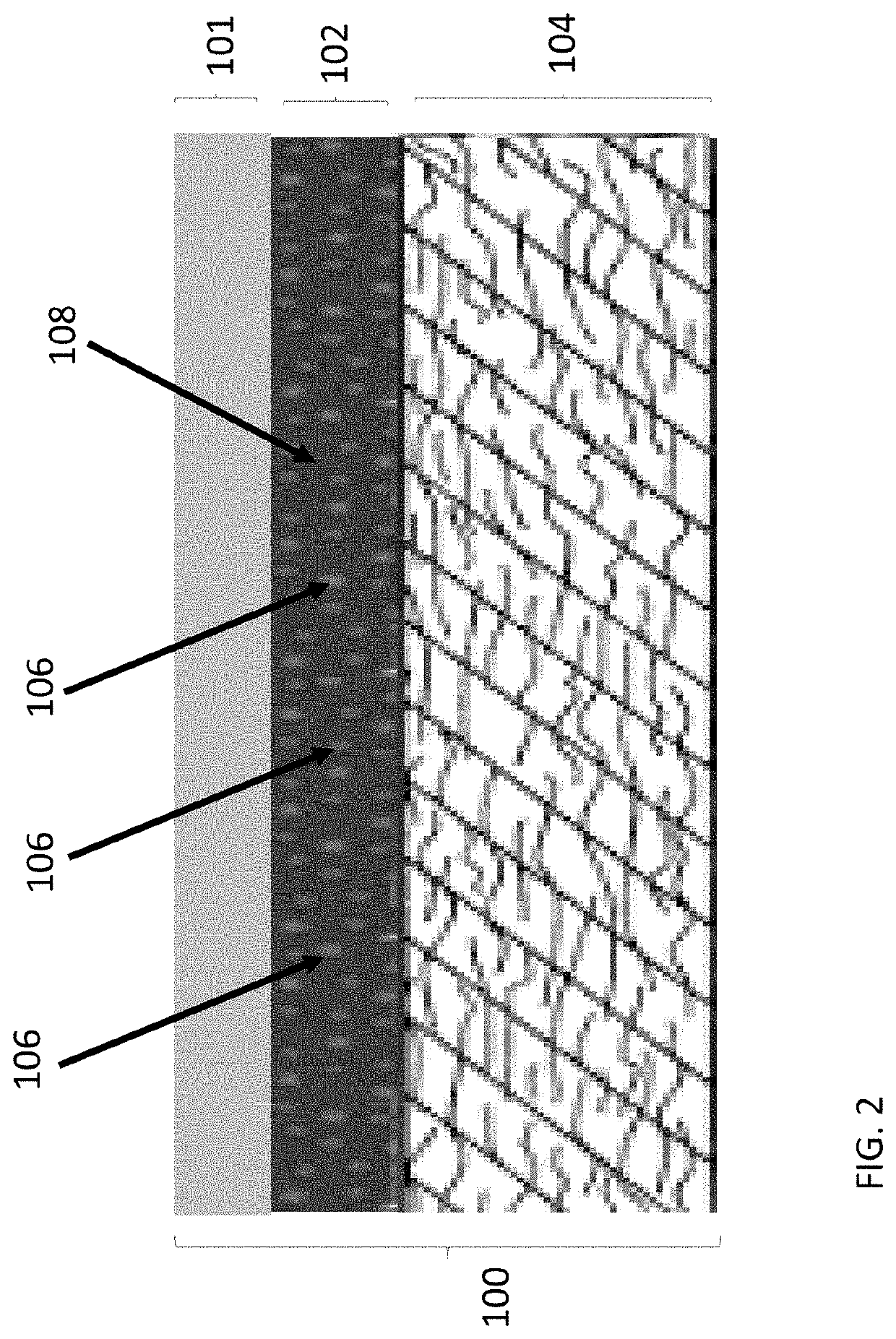

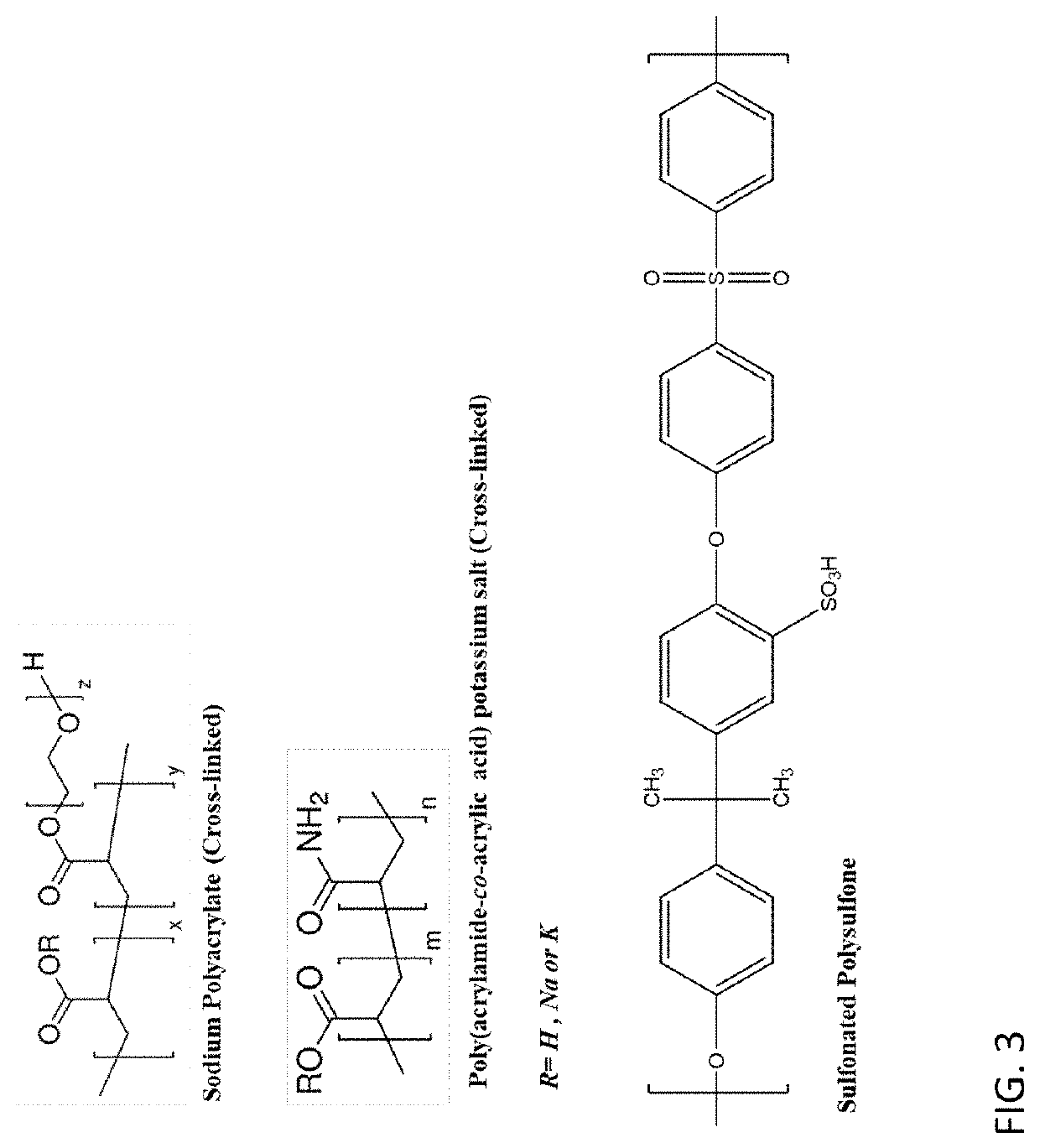

ActiveUS20210060899A1Reduce corrosionSynthetic resin layered productsConstructions elementsPolymer scienceCorrosion under insulation

A composite insulating material is provided. In one or more configurations the composite insulating material includes one or more active or responsive elements that mitigate corrosion under insulation (CUI). In a further aspect of the present invention, one or more active components of a composite insulation material are provided that dynamically generate an insoluble barrier within an insulating material through a bio-mineralization process.

Owner:SAUDI ARABIAN OIL CO

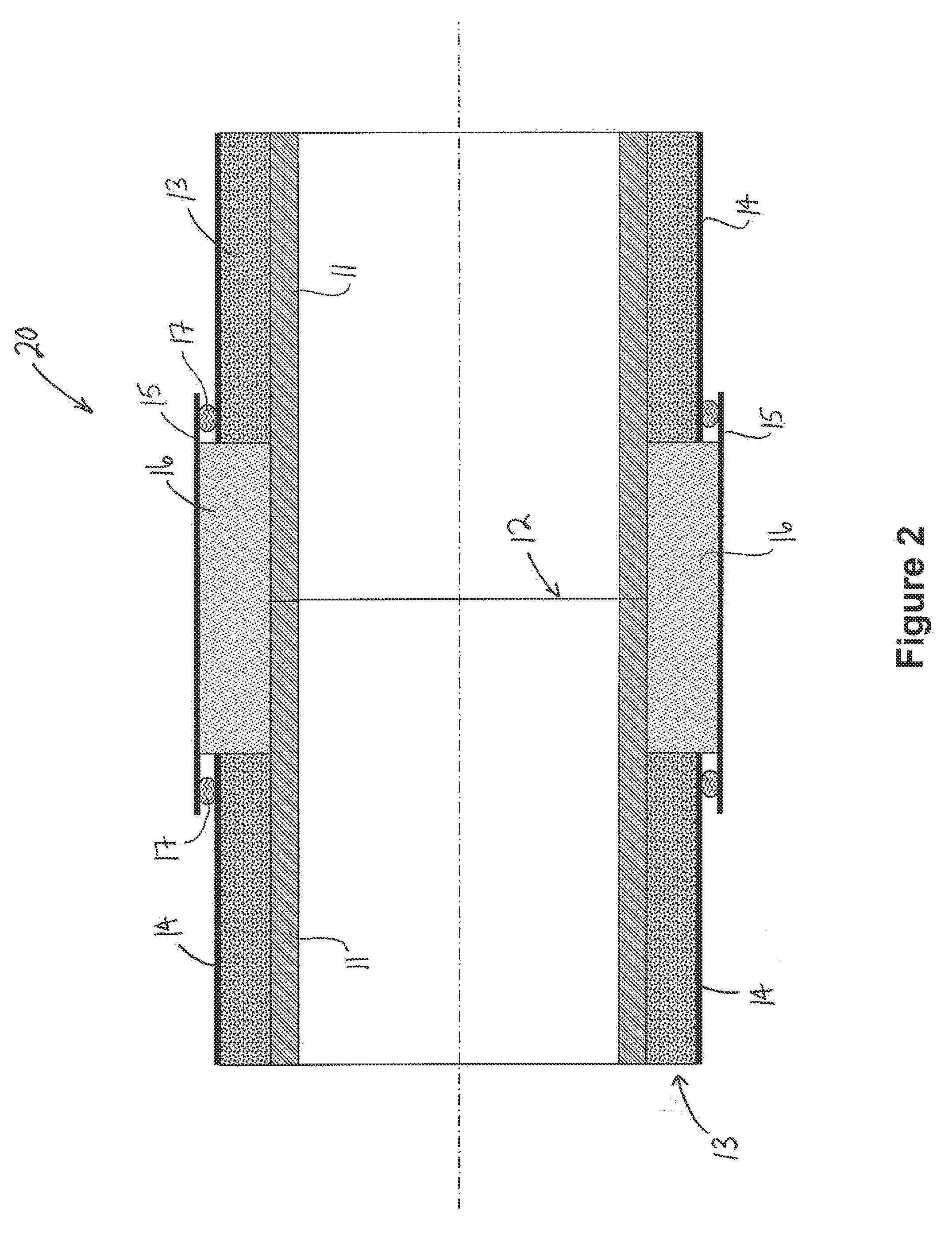

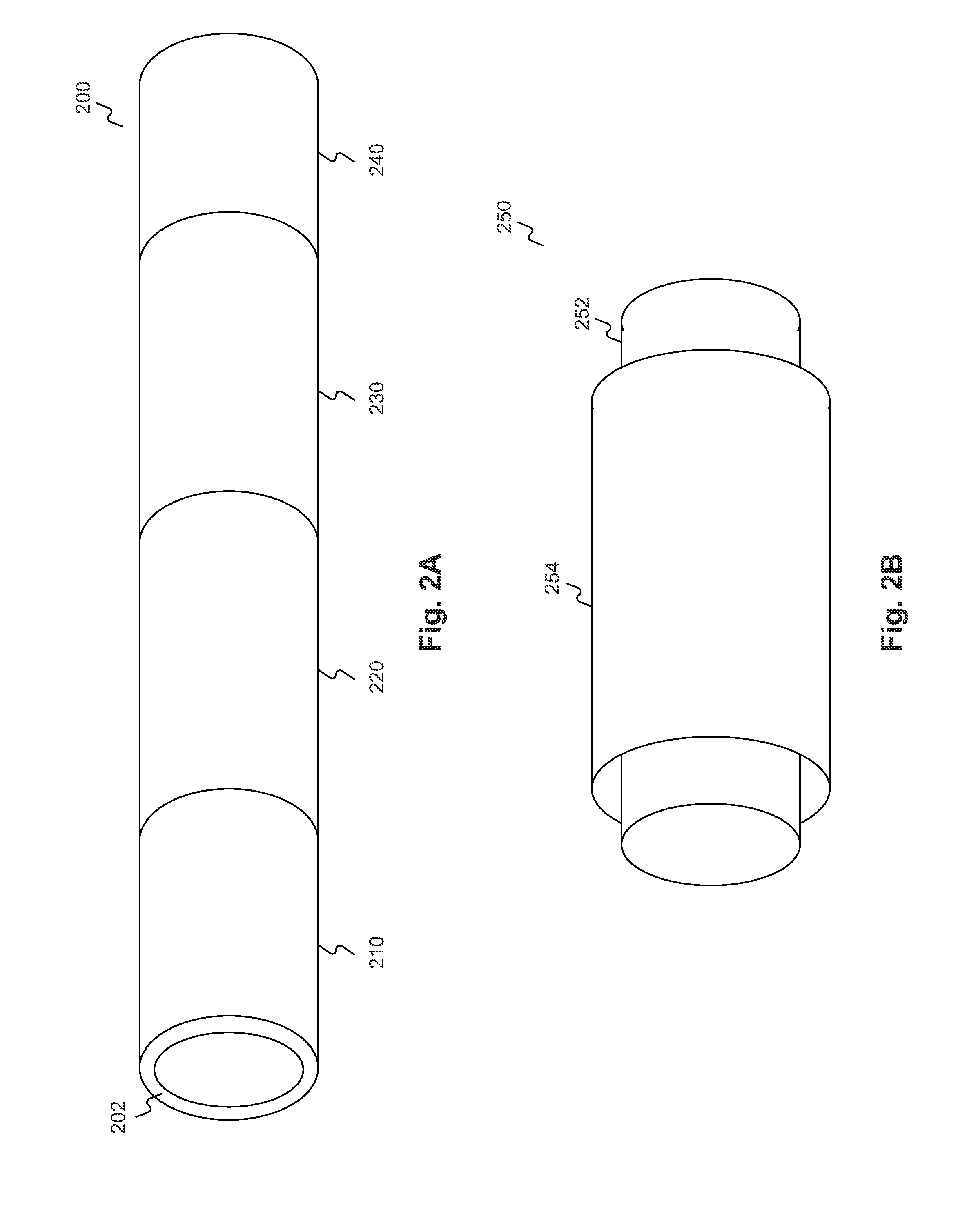

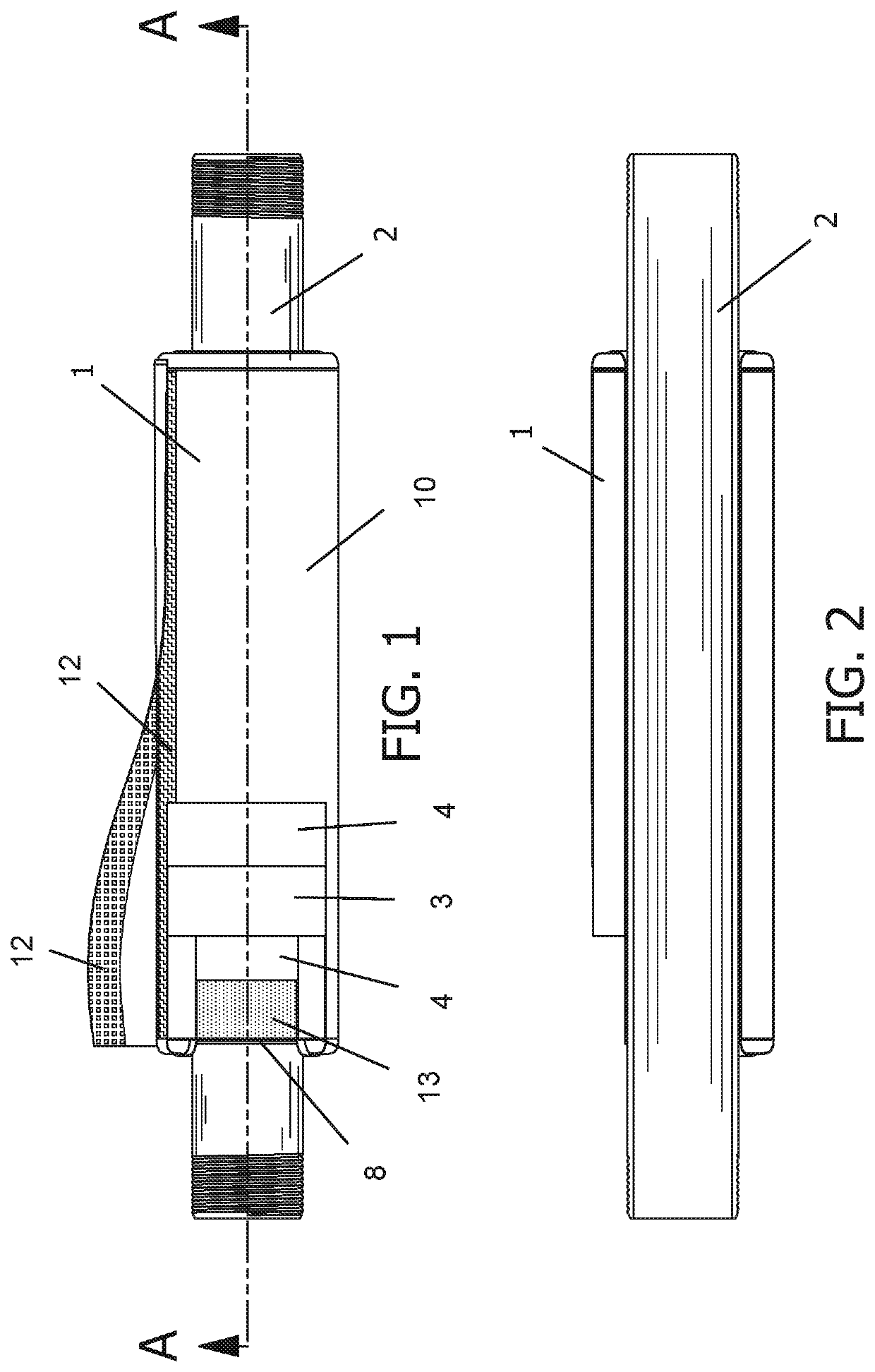

Removable pipe insulation system

A removable pipe insulation system comprising one or more components, each component comprising insulation in a waterproof covering with at least one opening for air to exit the covering during use. The insulation in the covering may be surrounded by an inside skin with a plurality of holes formed through hot micro perforation. The inside skin may be surrounded by an outside cover, which may be edged in elastic binding and which may attach to itself by hook and loop fastener. The component may be wrapped around a pipe element and secured to provide insulation to the pipe element while protecting the insulation from moisture and protecting the pipe element from corrosion under insulation.

Owner:BOND BRETT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com