Machine learning system and data fusion for optimization of deployment conditions for detection of corrosion under insulation

A machine learning and data fusion technology, applied in machine learning, image data processing, computer components, etc., can solve problems such as unreliable and effective detection of CUI by assets, high pipeline network, and insufficient accuracy of NDT technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

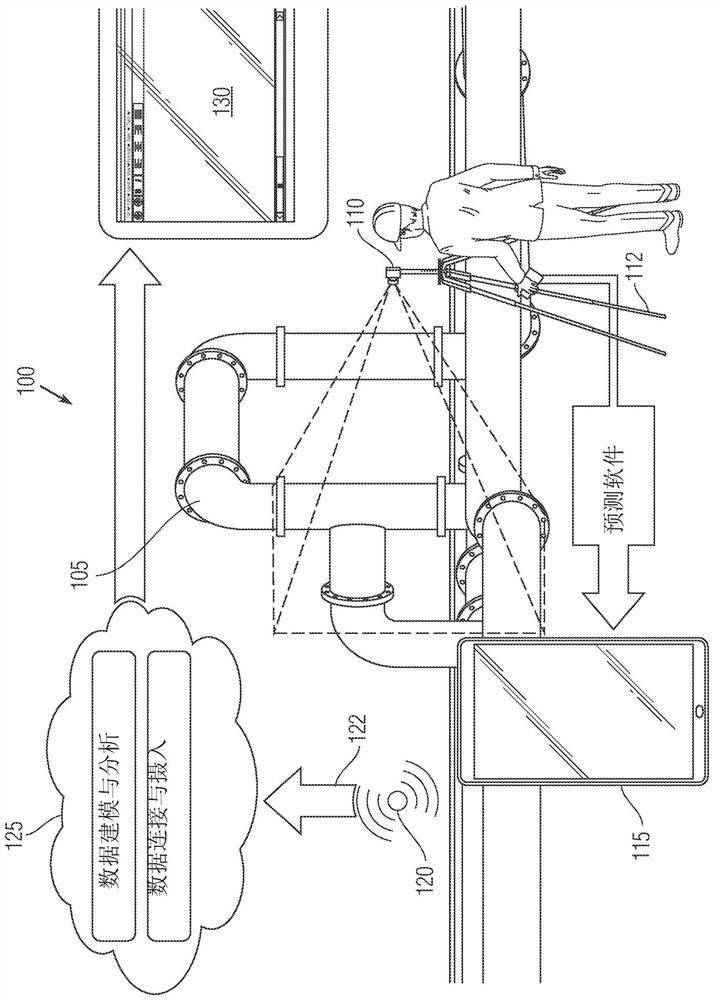

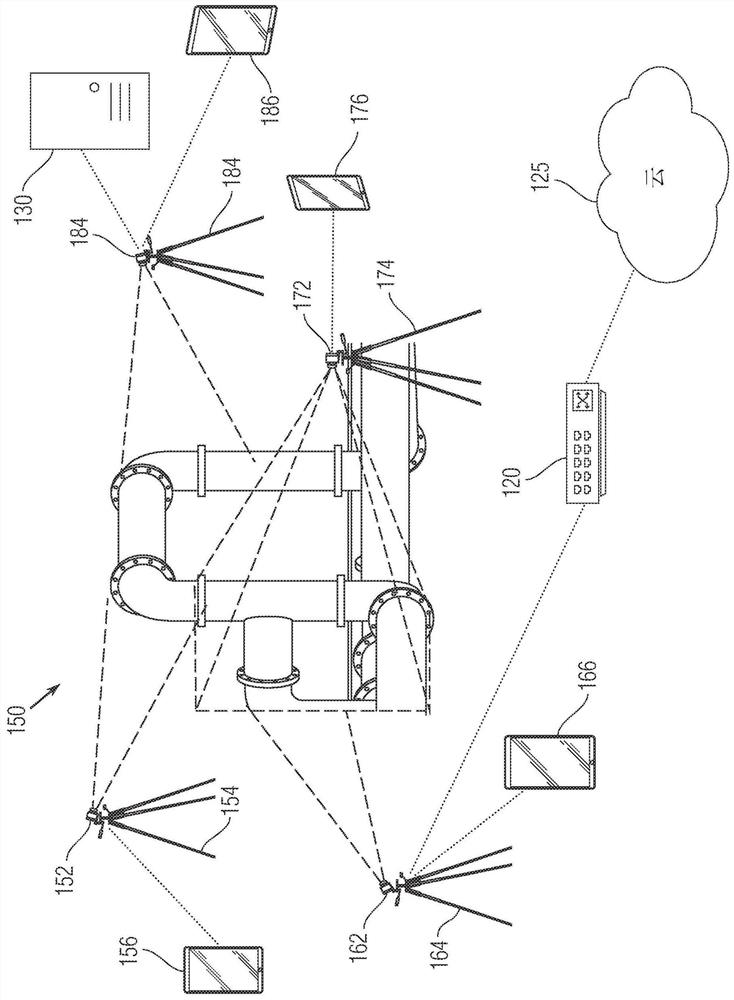

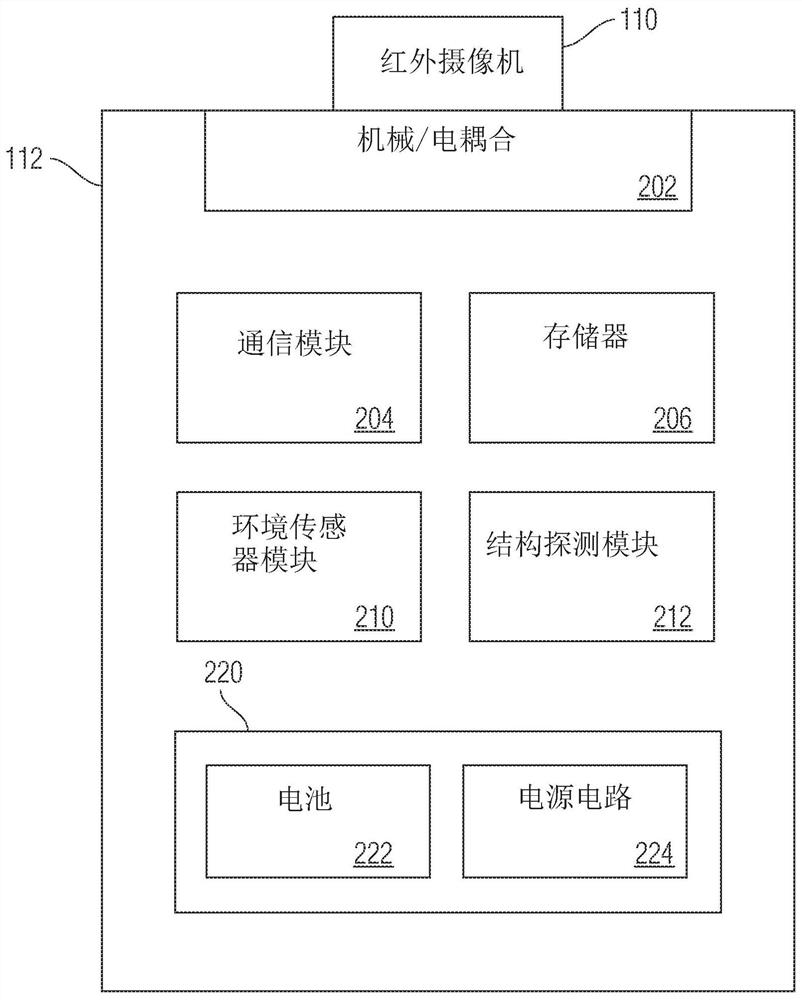

[0040]Embodiments of the present invention provide a prediction method, which takes into account the associated and independent peripheral variables to detect the corrosion of the insulation layer (Cui). The hot image of the surveyed assets is captured over time.

[0041]As a series of thermal images in the same or overlap region over time, the changes in phenomena can be easily observed, including the impact of temporary issues (such as wind). The thermal image can provide several types or sequential temperature information, which can indicate that it is susceptible to the CUI. The first stage of temperature information is a regular temperature (T) data displayed by the color displayed in the hot image. The second stage of temperature information is a temperature change (ΔT), such as the contrast display between different regions, the third stage of information is the rate of change of temperature analysis (DF (T) / DT), which is analyzed over time Image is determined. Other assessmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com