Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Compound engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reciprocating devices

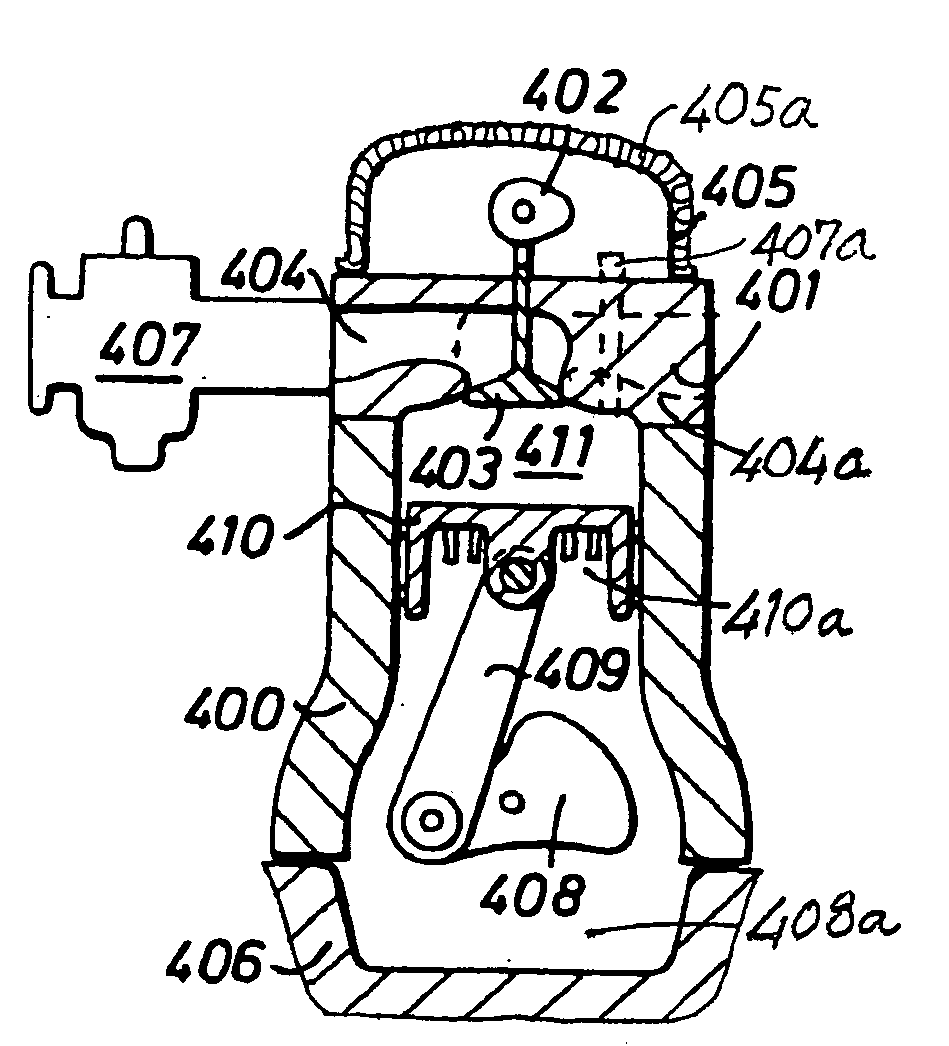

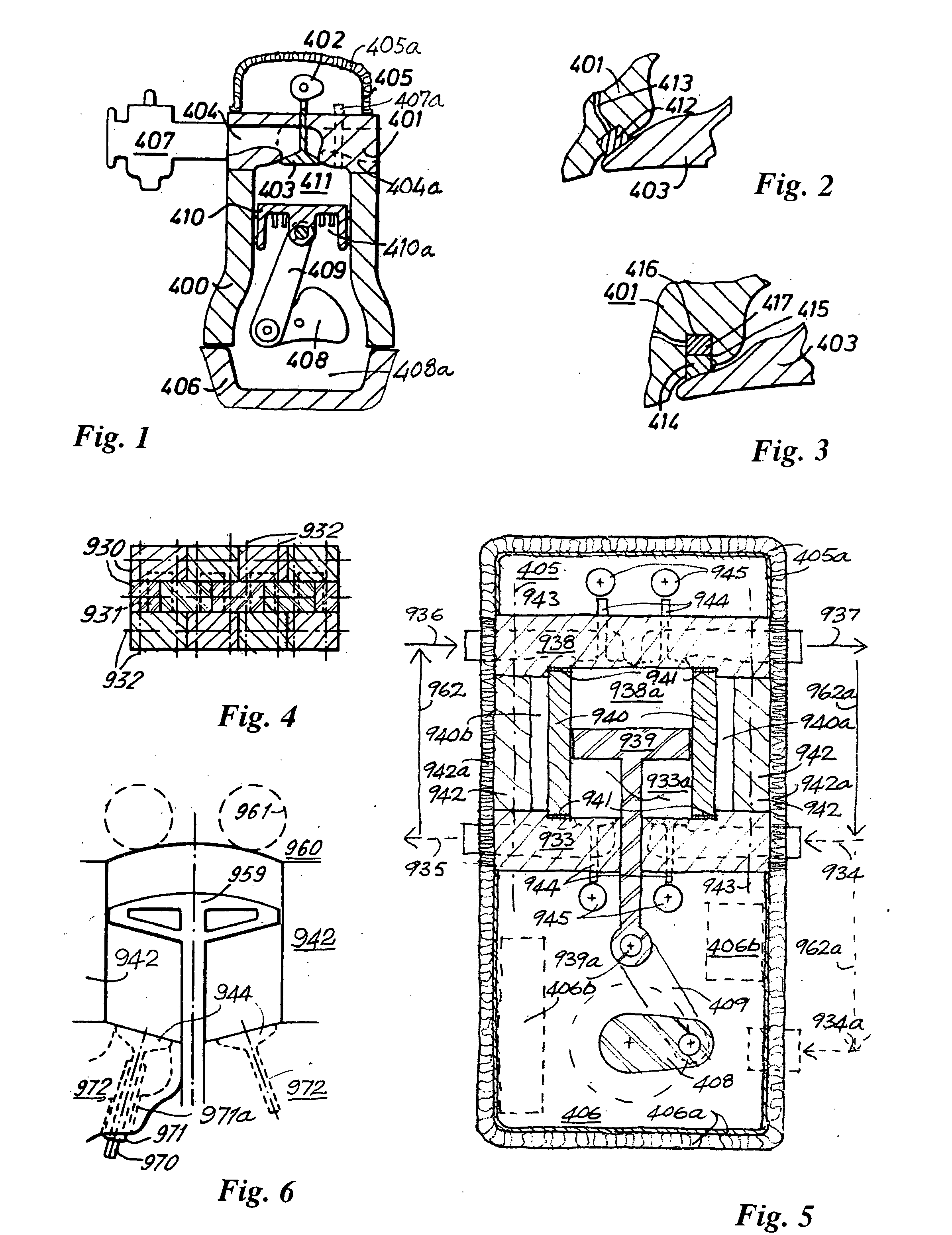

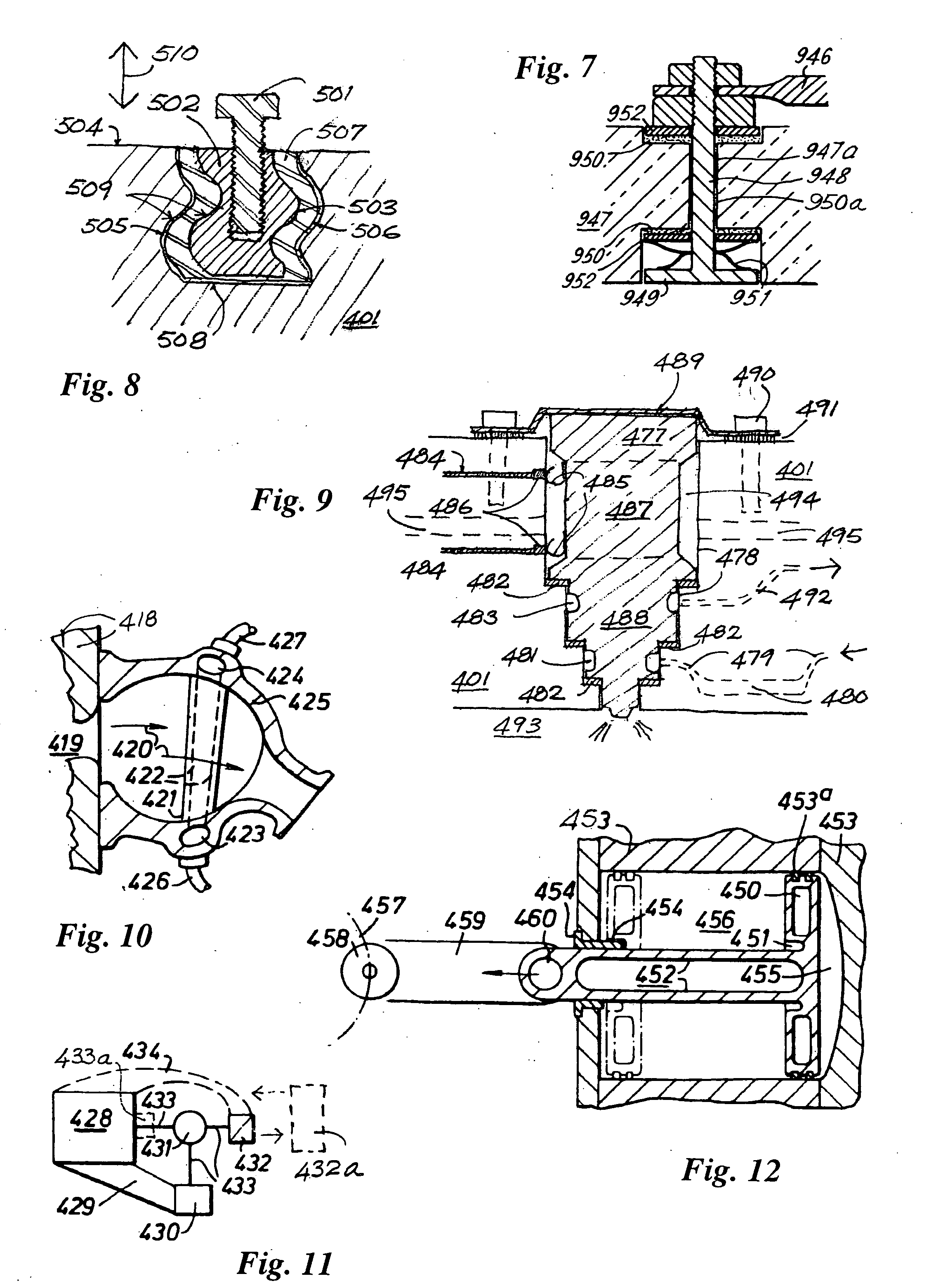

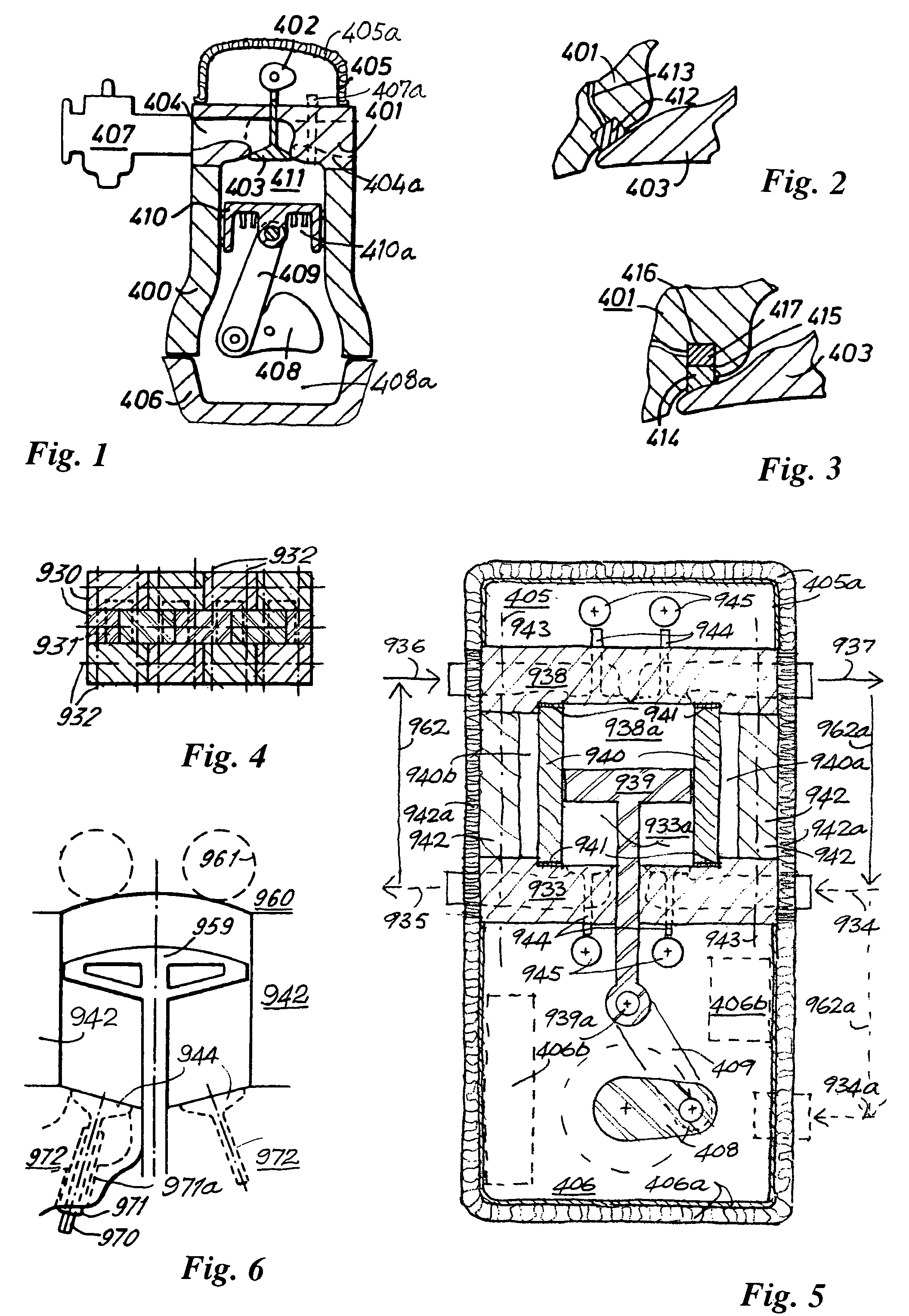

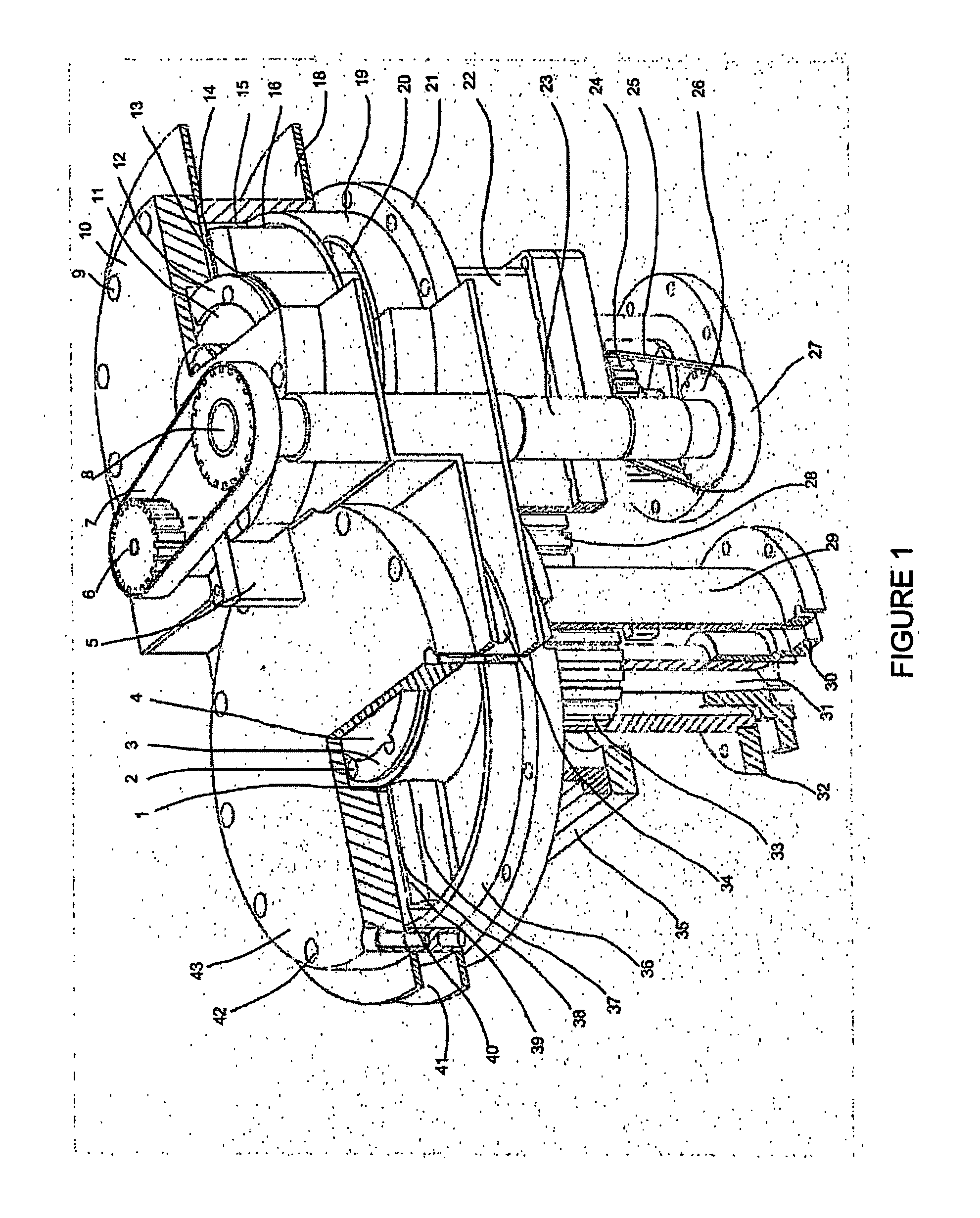

ActiveUS20080141921A1Improve power densityImprove efficiencyHybrid vehiclesInternal combustion piston enginesExternal combustion engineEnergy absorption

The disclosure relates to fluid working devices including reciprocating internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in reciprocating internal combustion IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, pistons reciprocating between pairs of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Compound engines having the new engines as a reciprocating stage are described. Improved vehicles, aircraft, marine craft and transmissions adapted to receive or be linked to the improved IV engines are also disclosed.

Owner:HINDERKS MITJA VICTOR

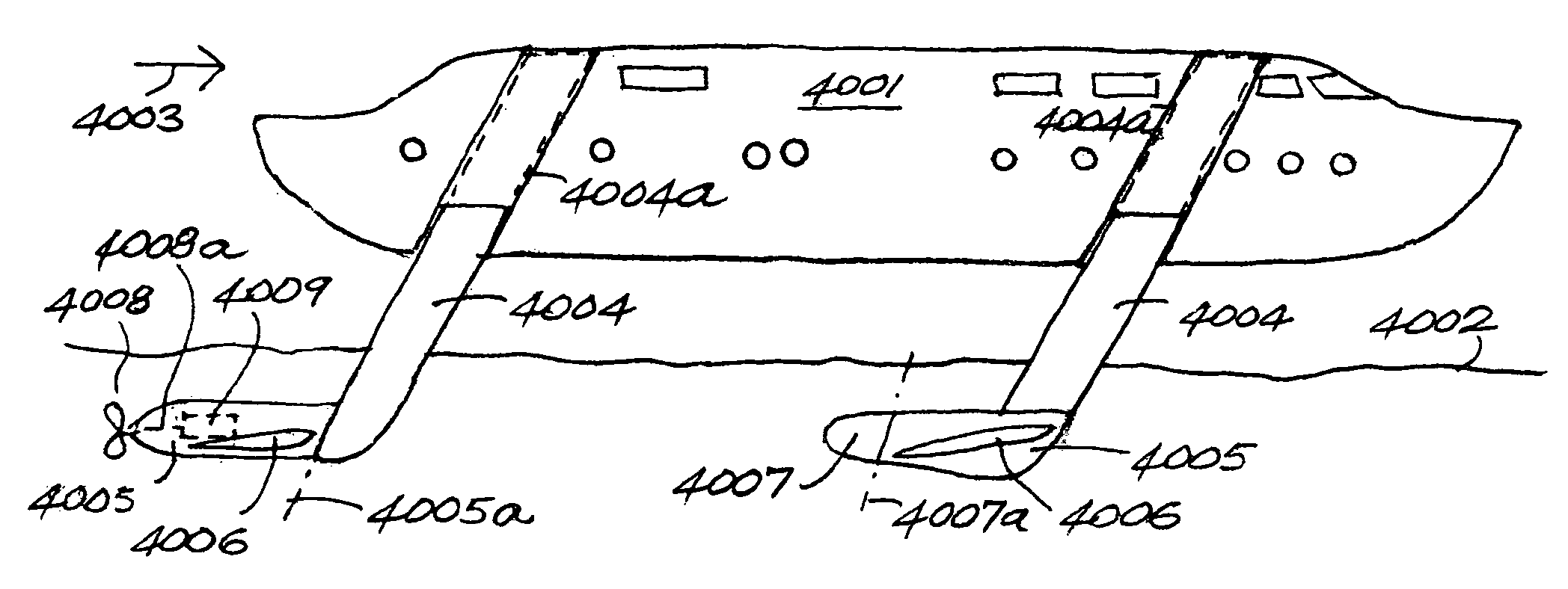

Marine hulls and drives

InactiveUS7984684B2Improve power densityNo coolingHybrid vehiclesInternal combustion piston enginesTravel modeCombustion

Owner:HINDERKS MITJA VICTOR

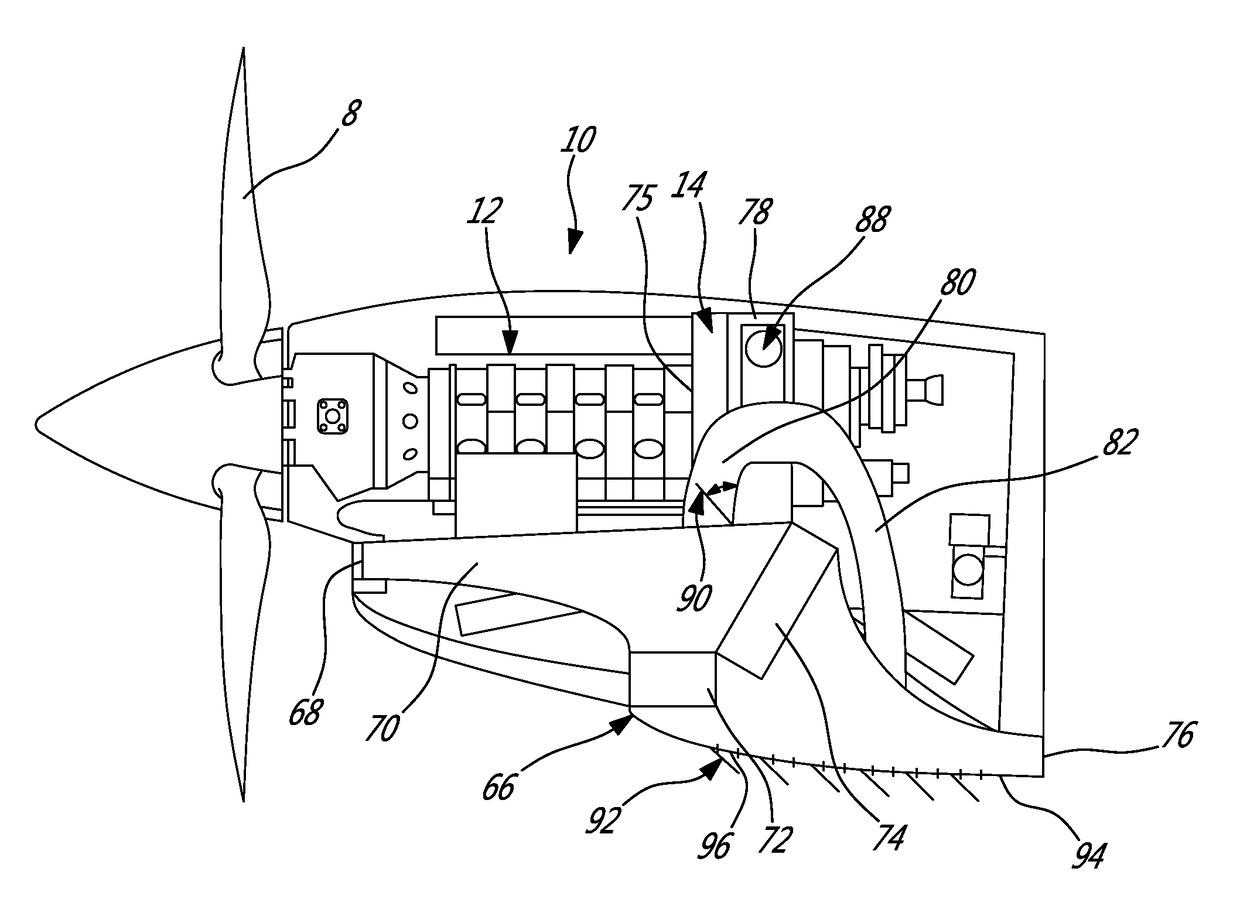

Compound engine assembly with bleed air

ActiveUS20160376981A1Power installationsInternal combustion piston enginesBleed airAuxiliary power unit

A compound engine assembly for use as an auxiliary power unit for an aircraft and including an engine core with internal combustion engine(s), a compressor having an outlet in fluid communication with an engine core inlet, a bleed conduit in fluid communication with the compressor outlet through a bleed air valve, and a turbine section having an inlet in fluid communication with the engine core outlet and configured to compound power with the engine core. The turbine section may include a first stage turbine having an inlet in fluid communication with the engine core outlet and a second stage turbine having an inlet in fluid communication the first stage turbine outlet. A method of providing compressed air and electrical power to an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

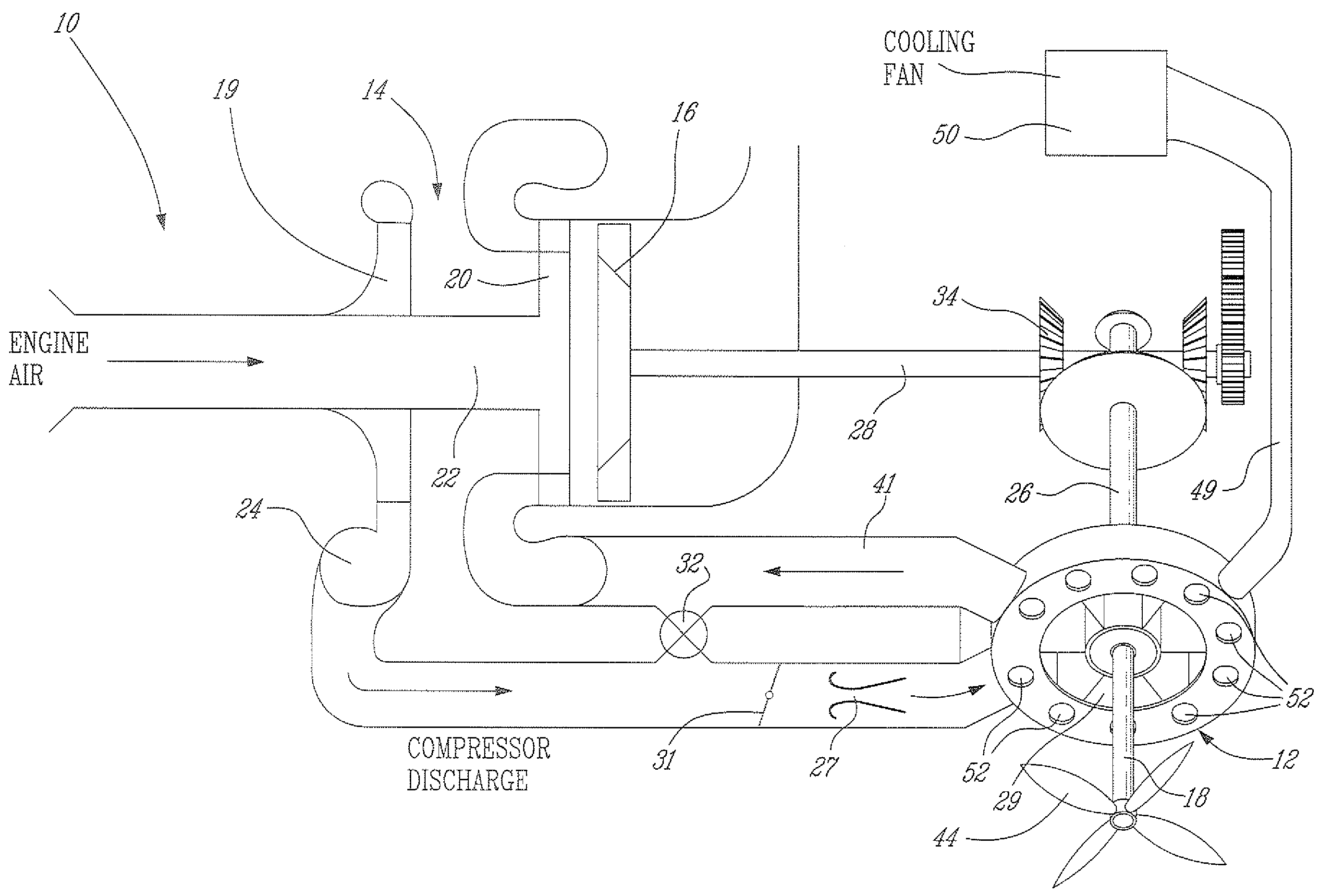

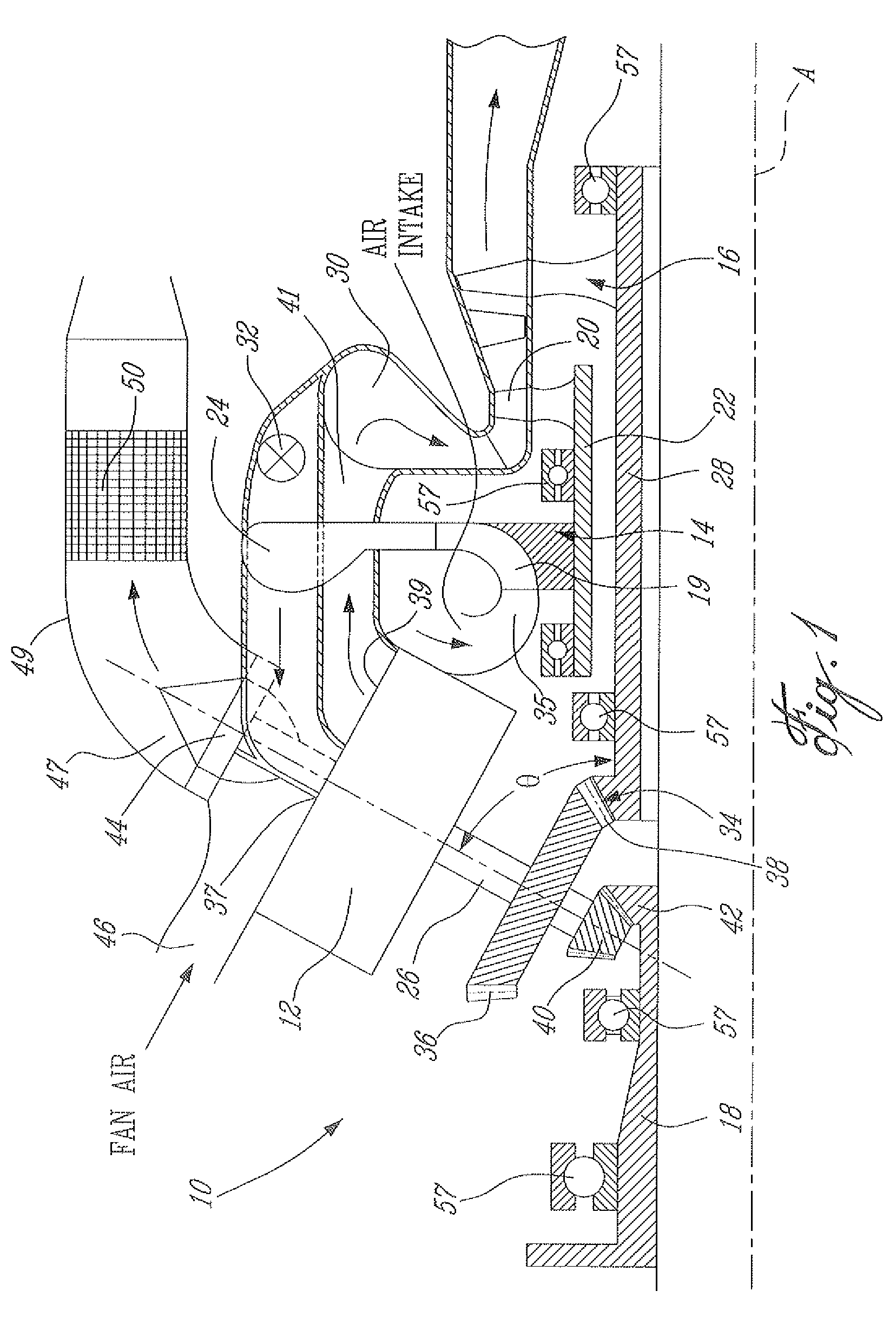

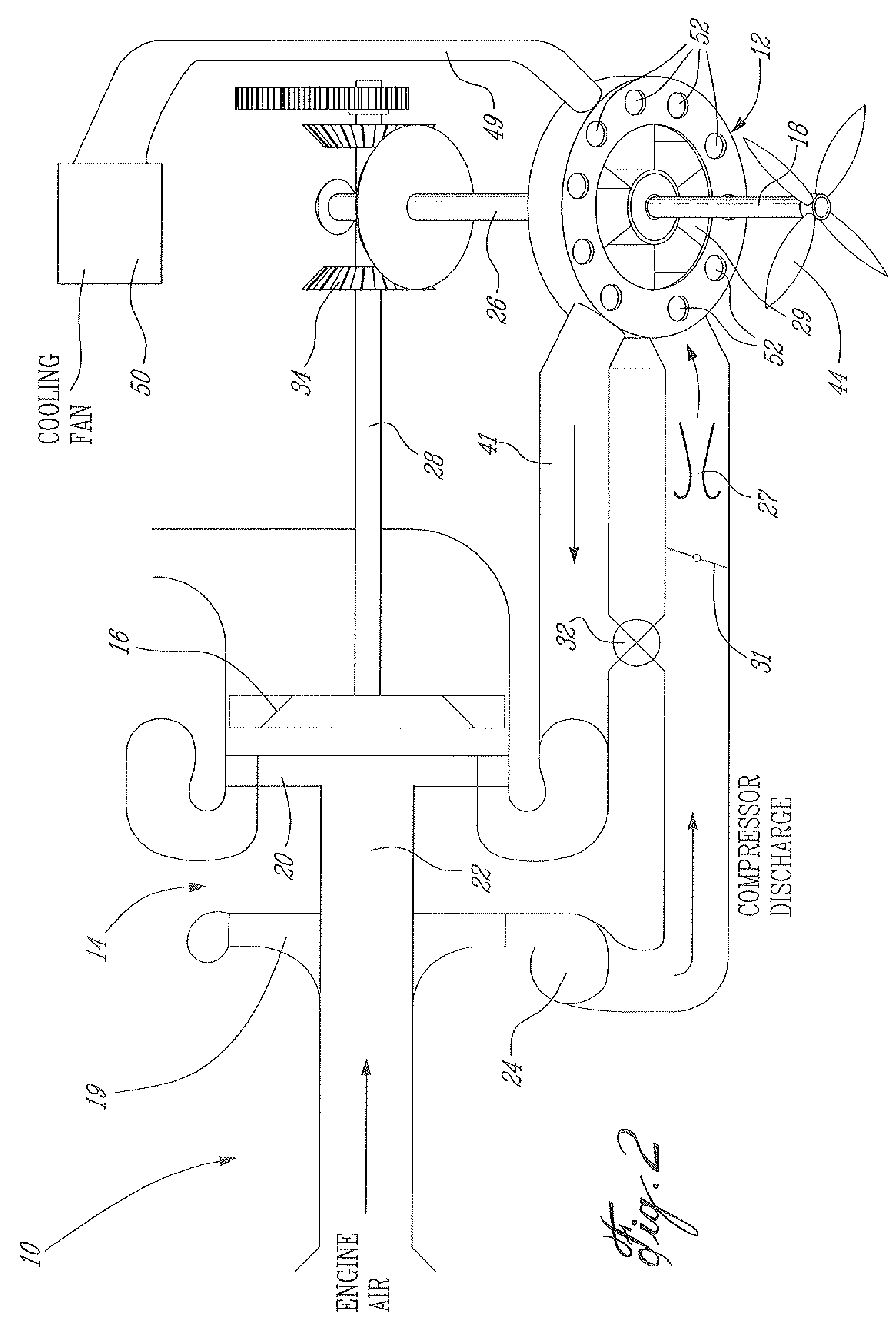

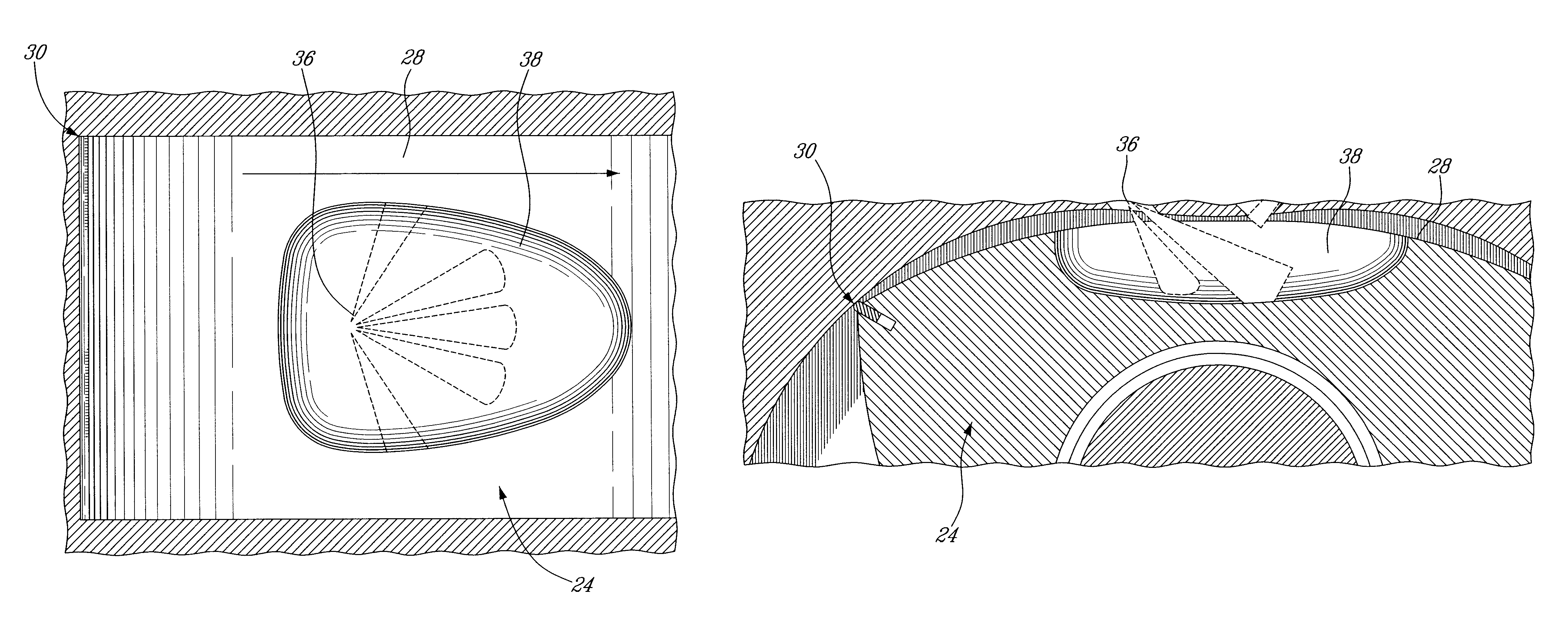

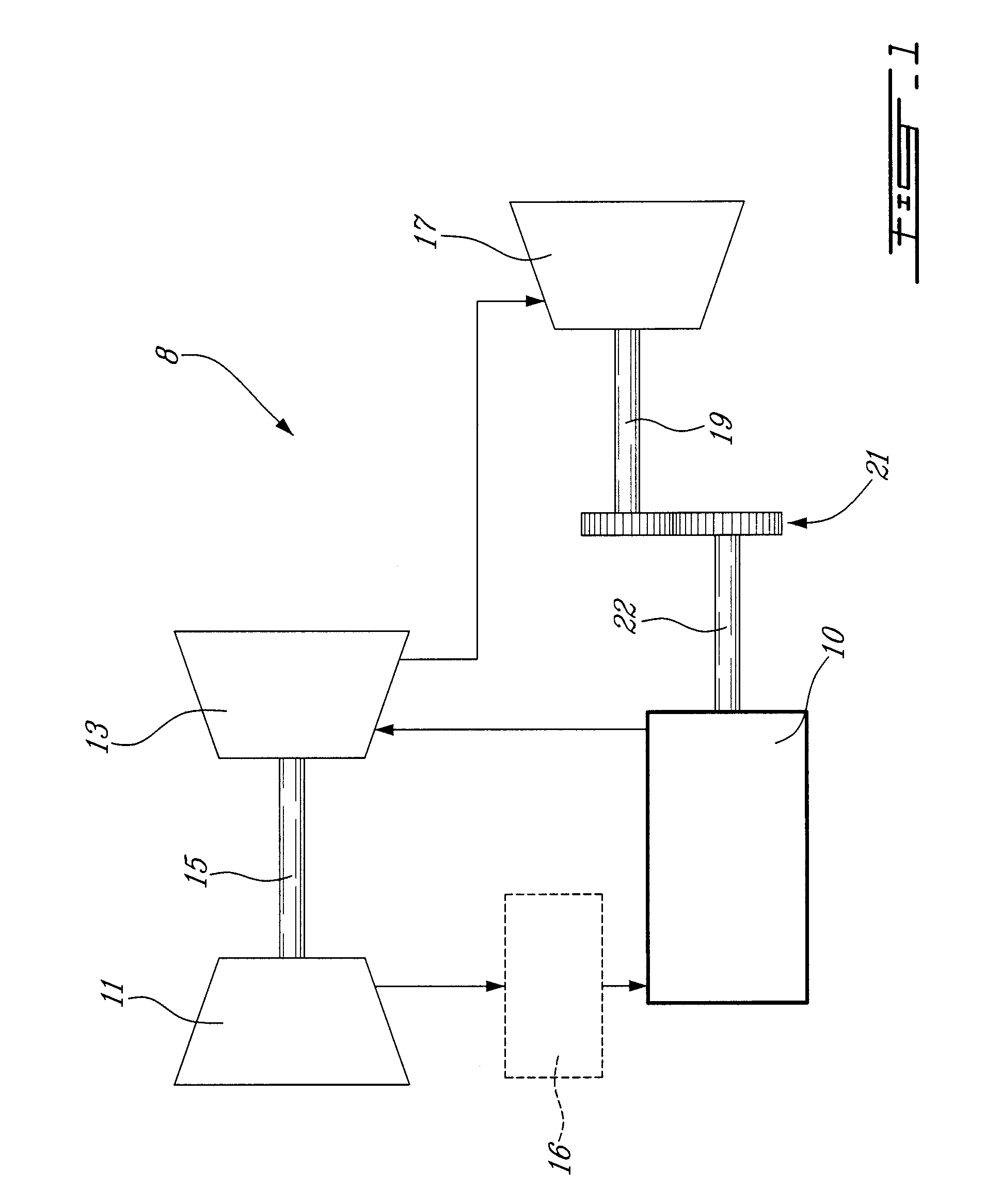

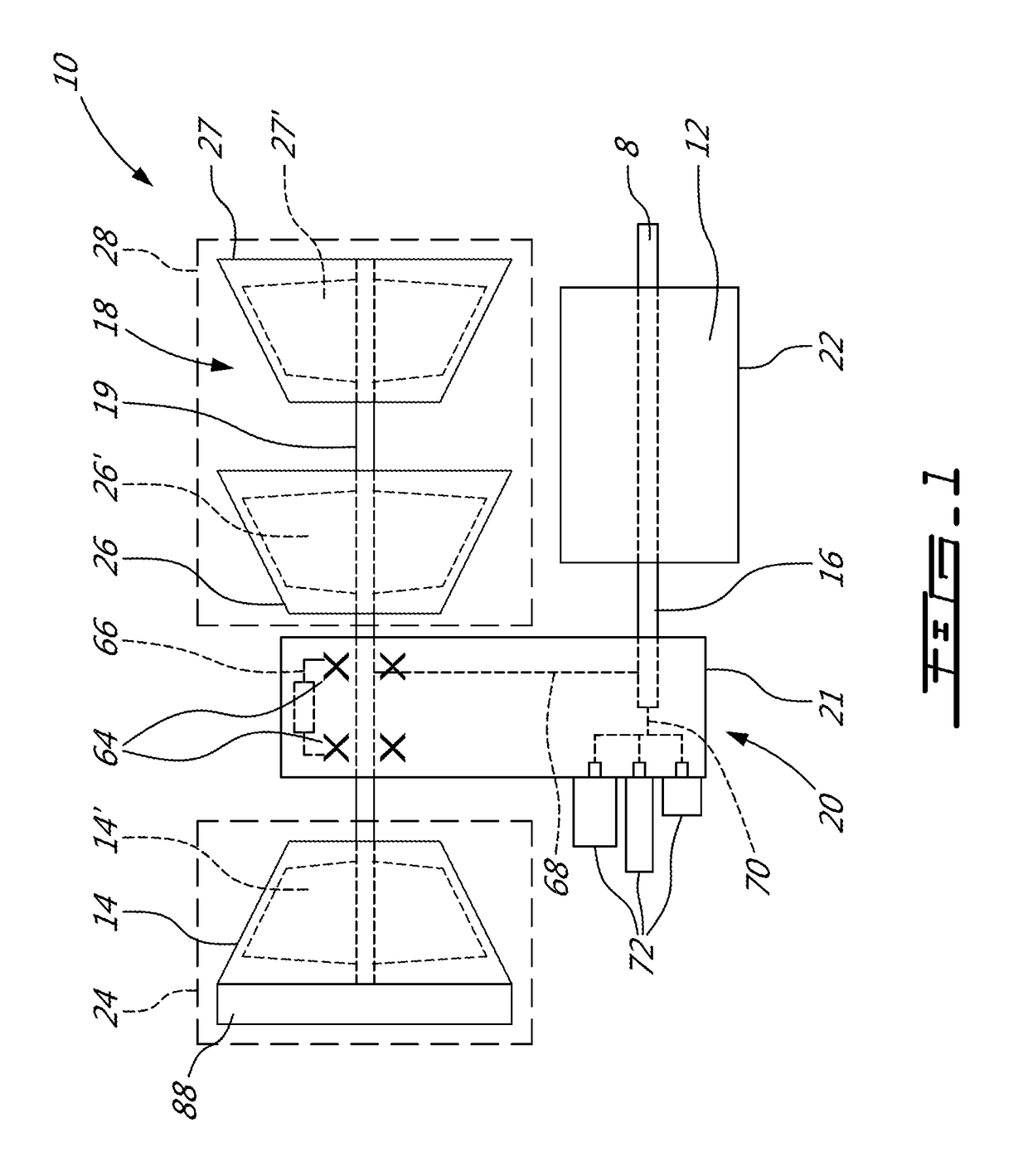

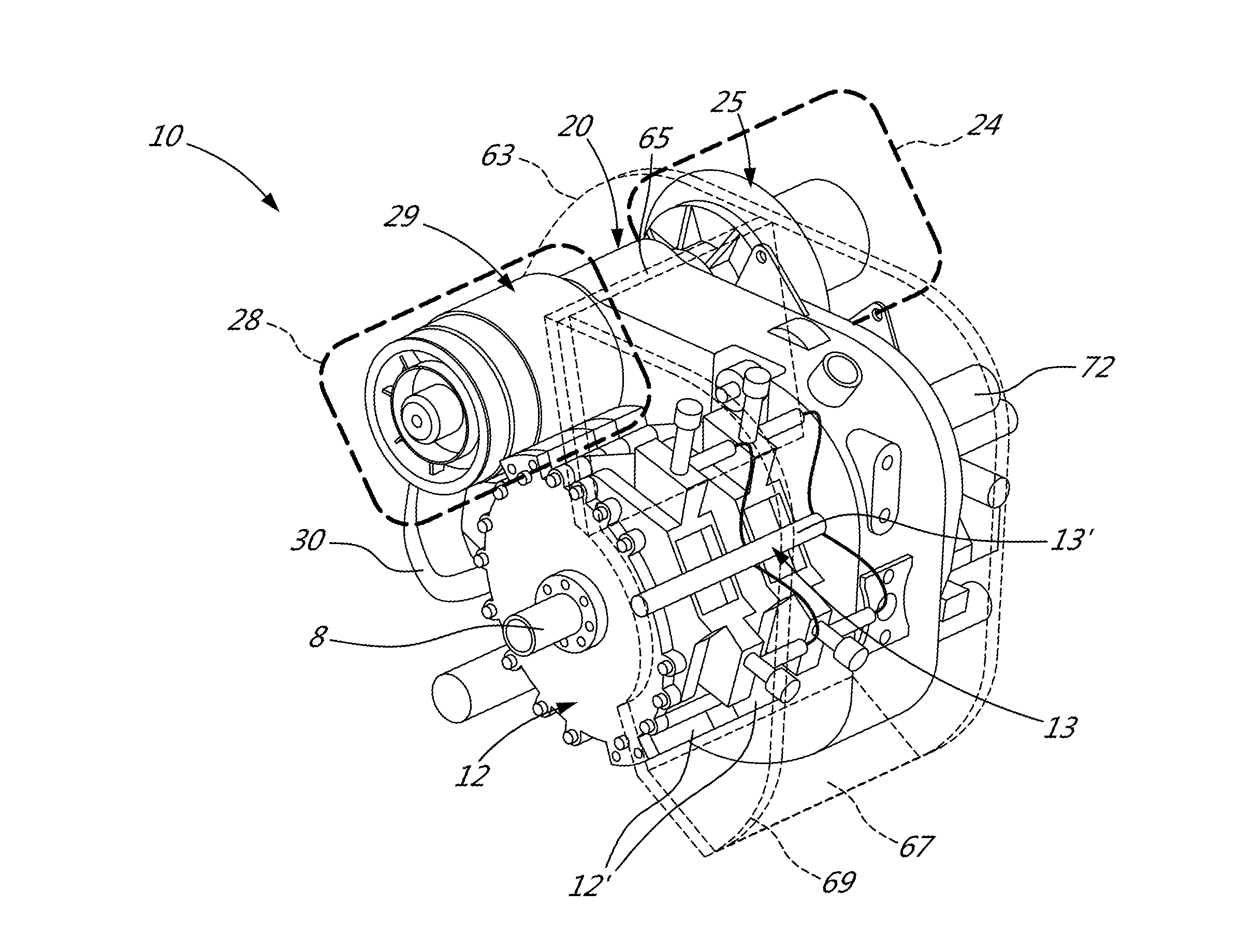

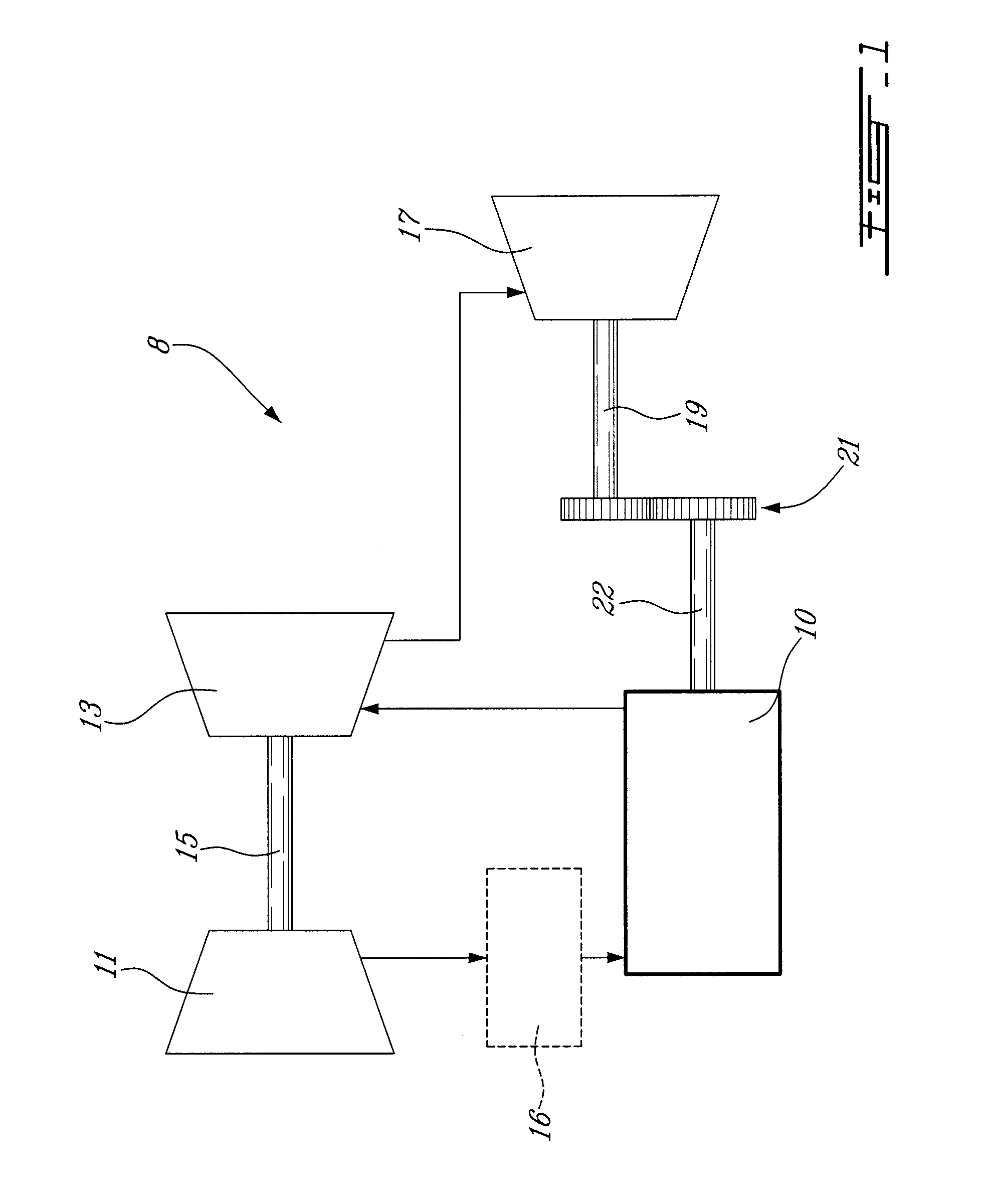

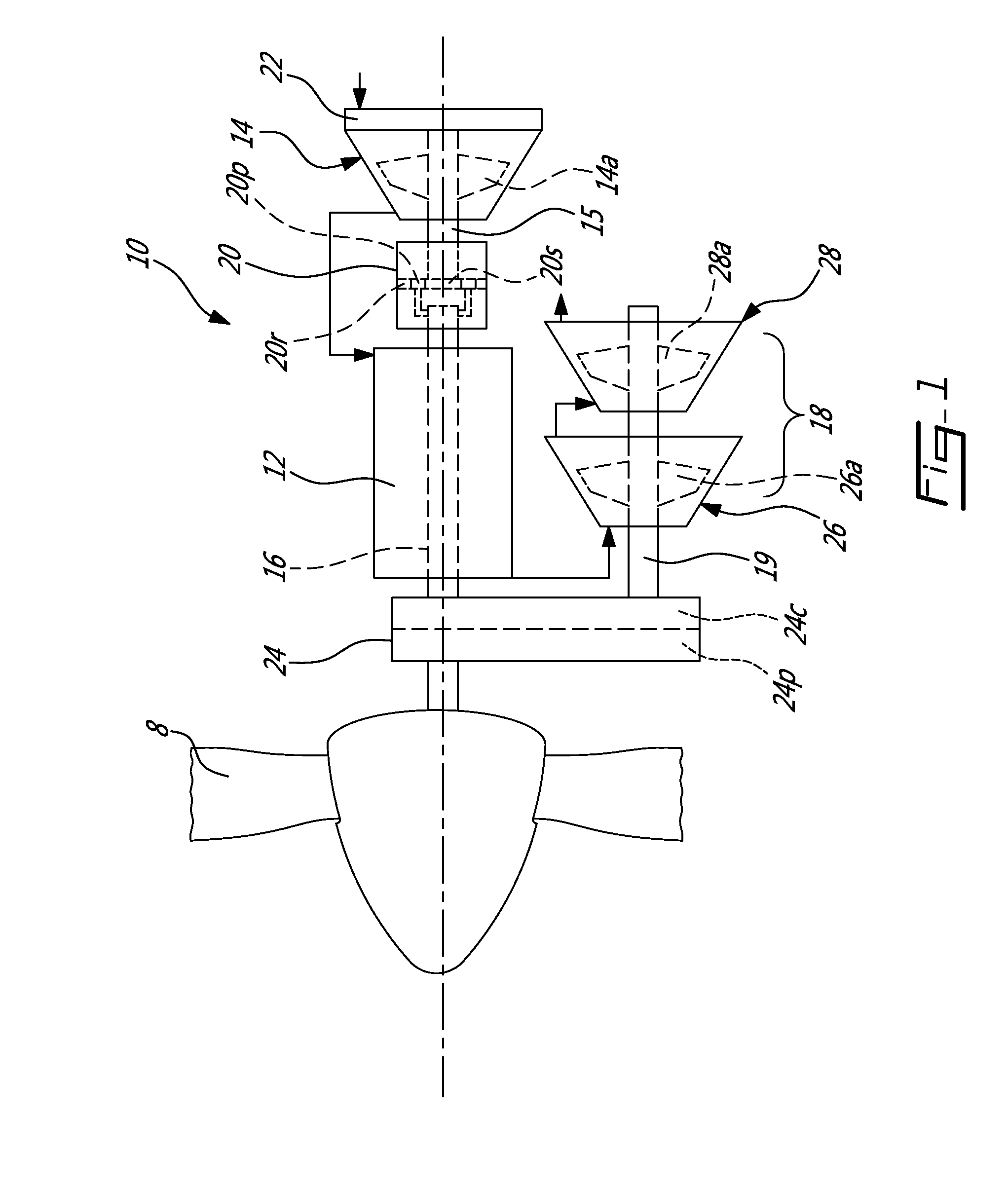

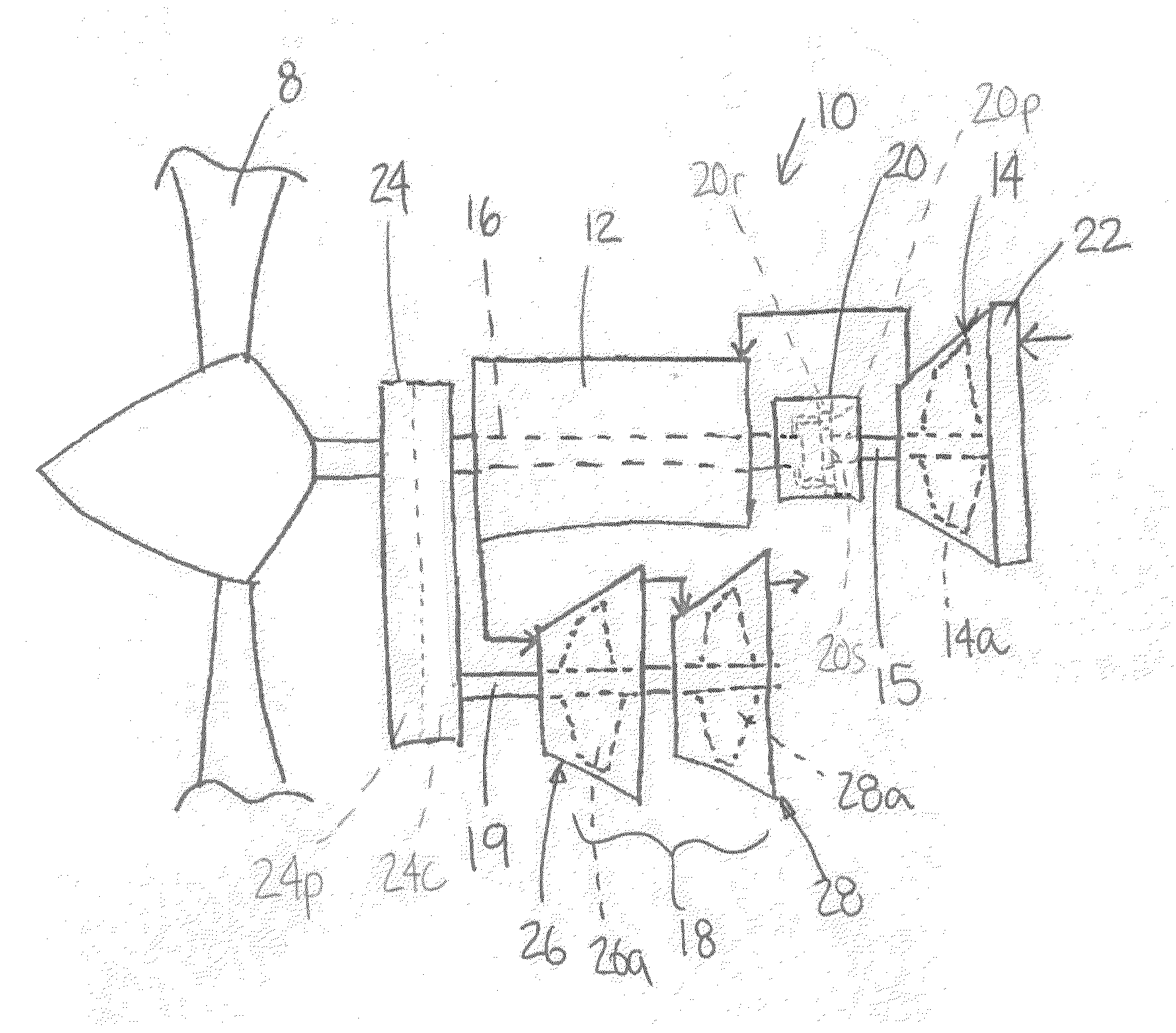

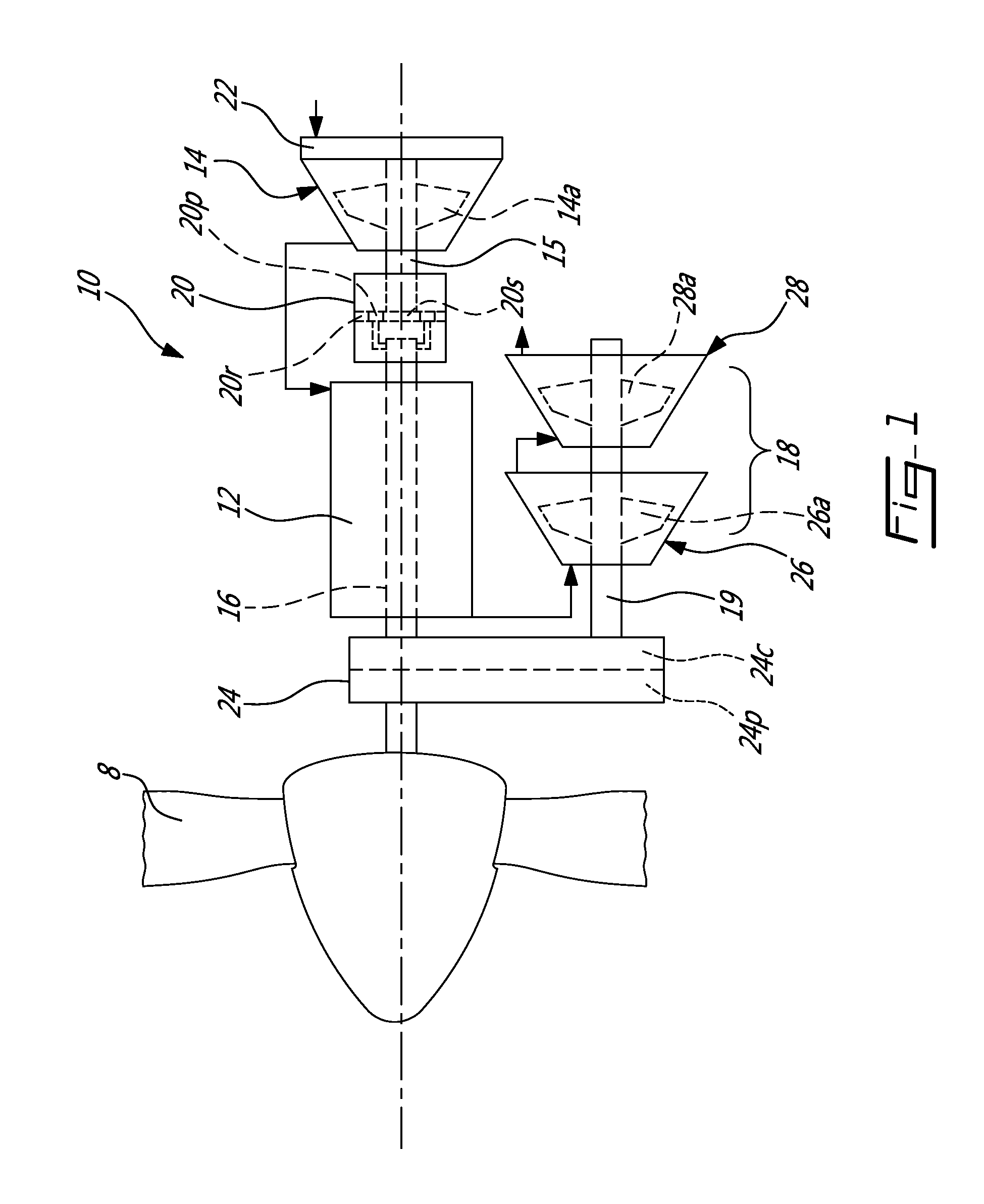

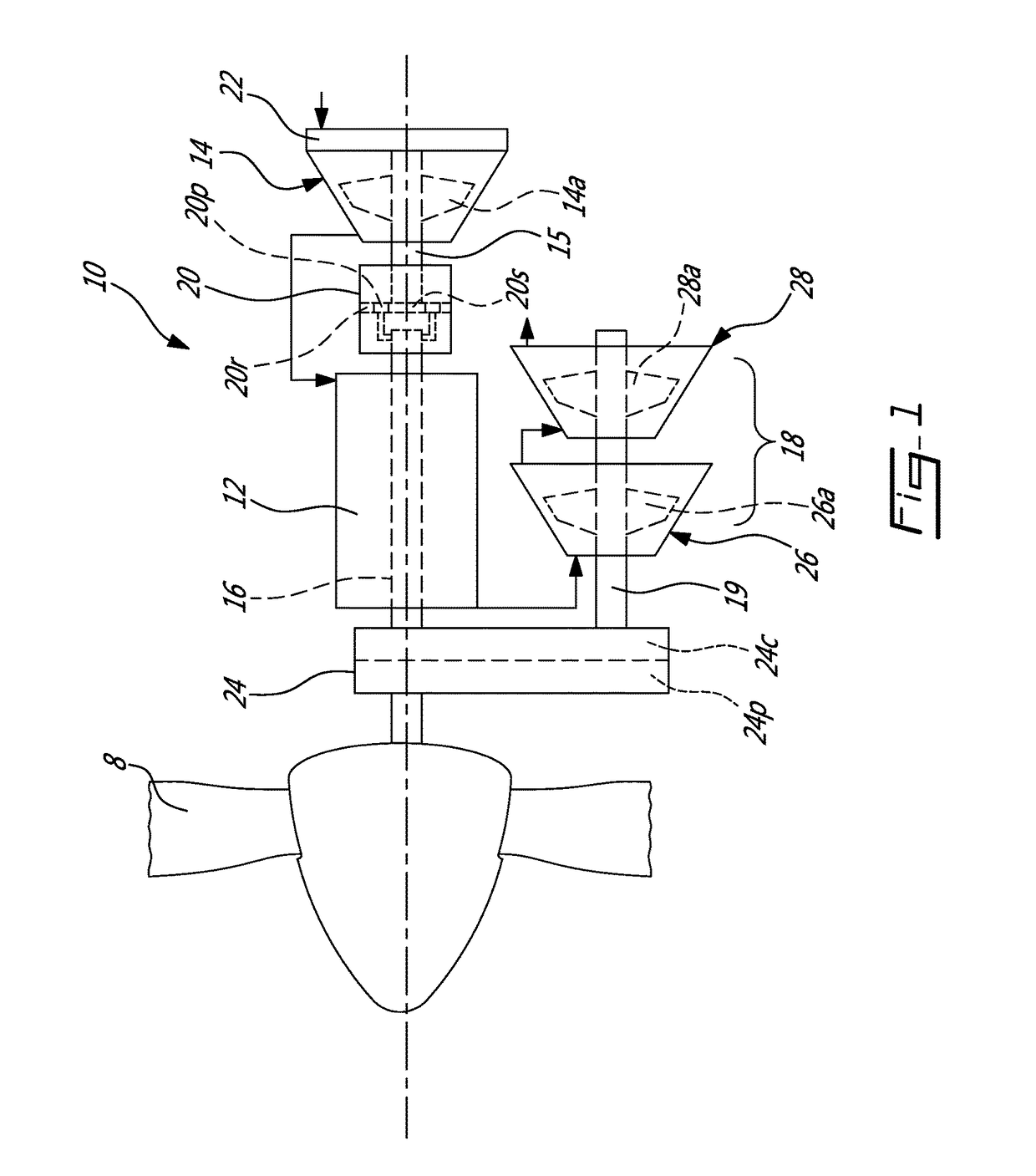

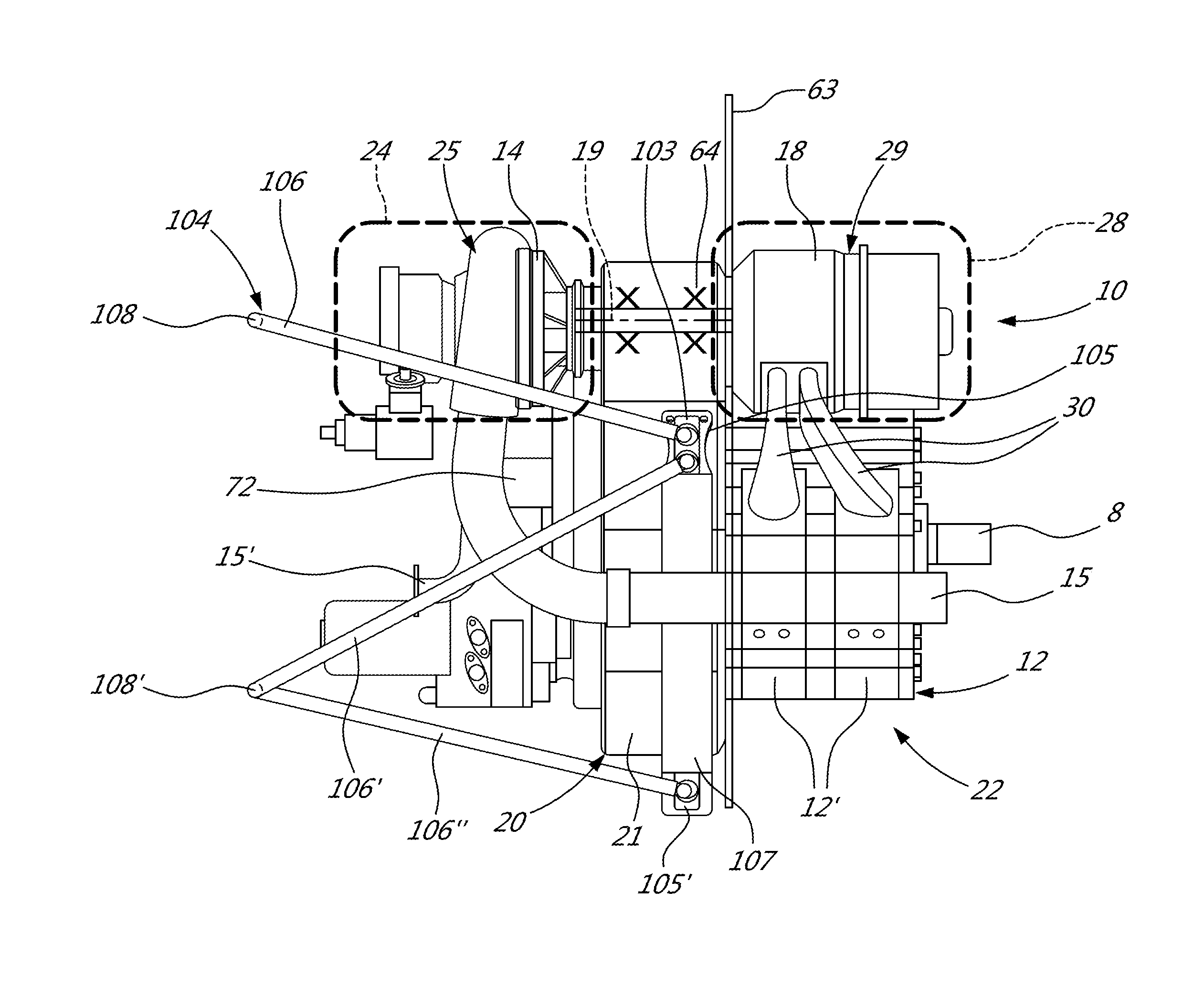

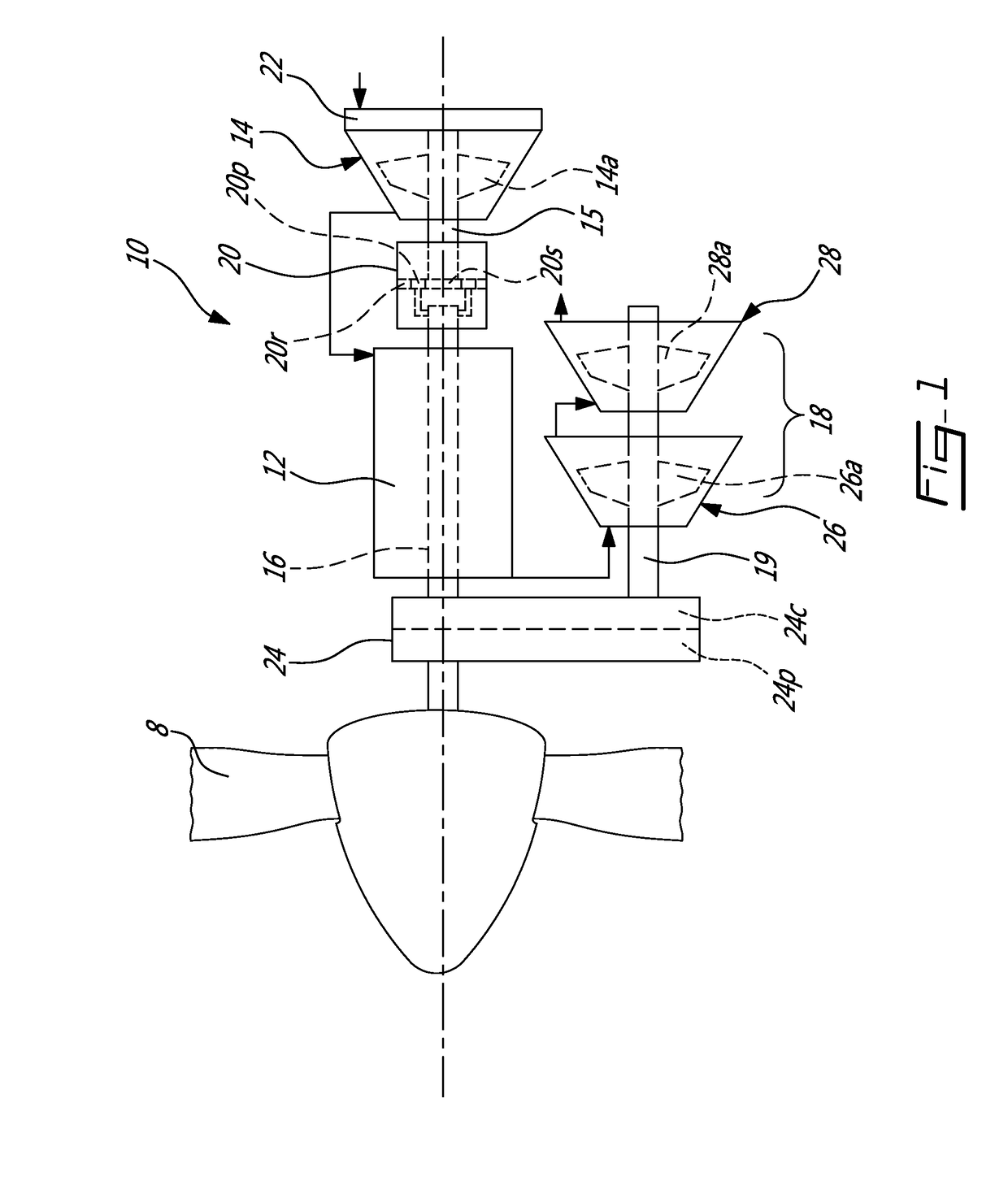

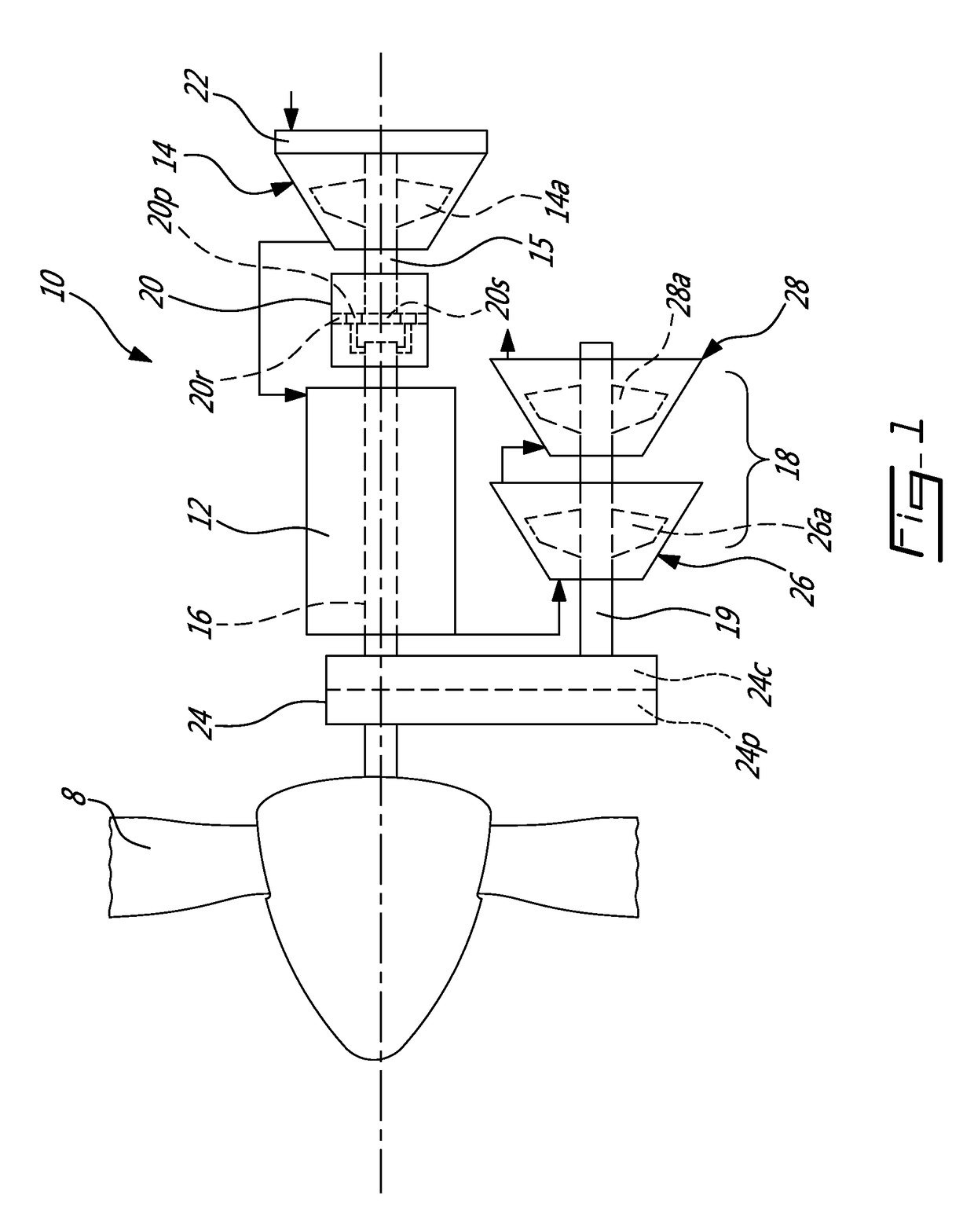

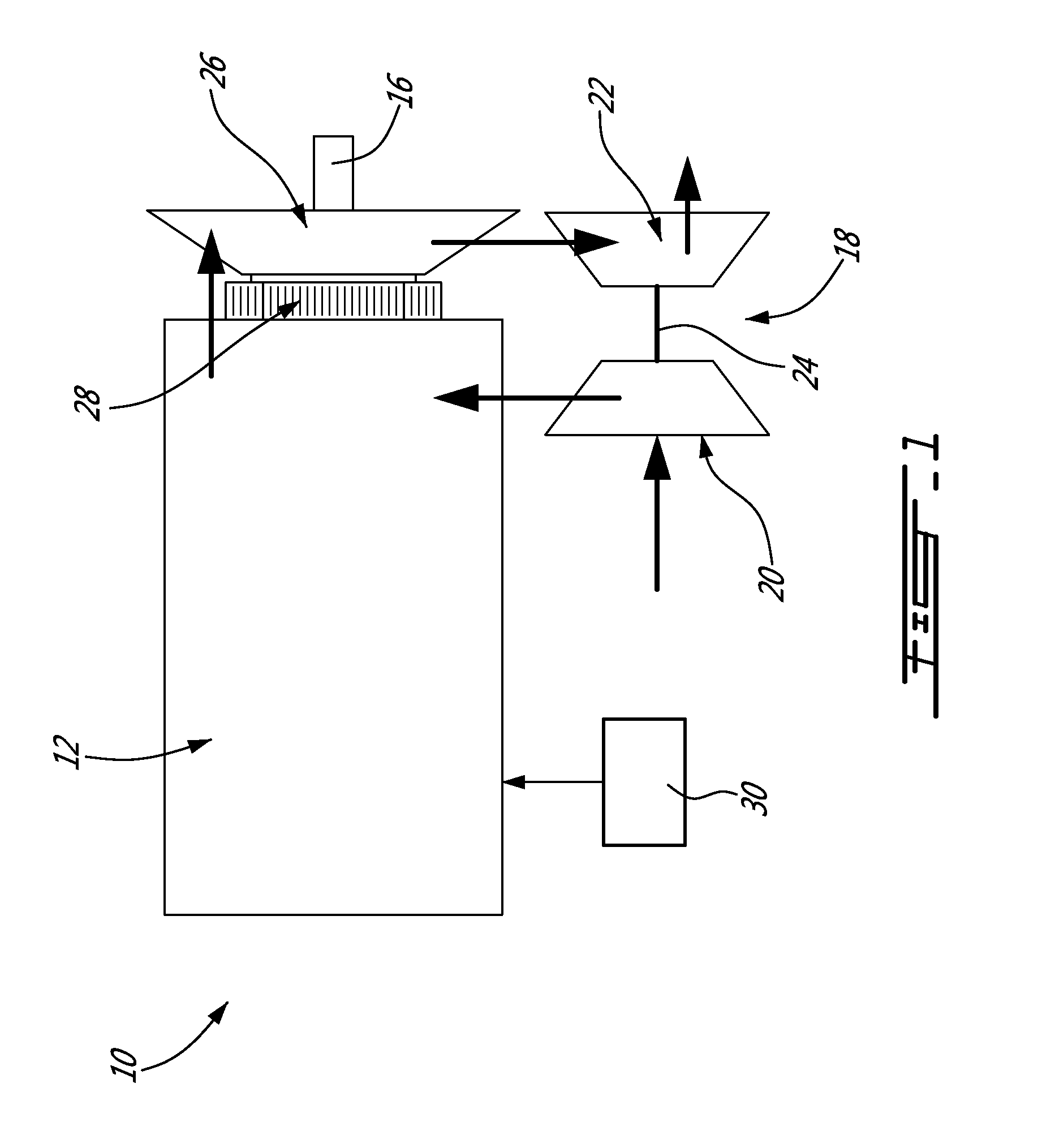

Compact compound engine package

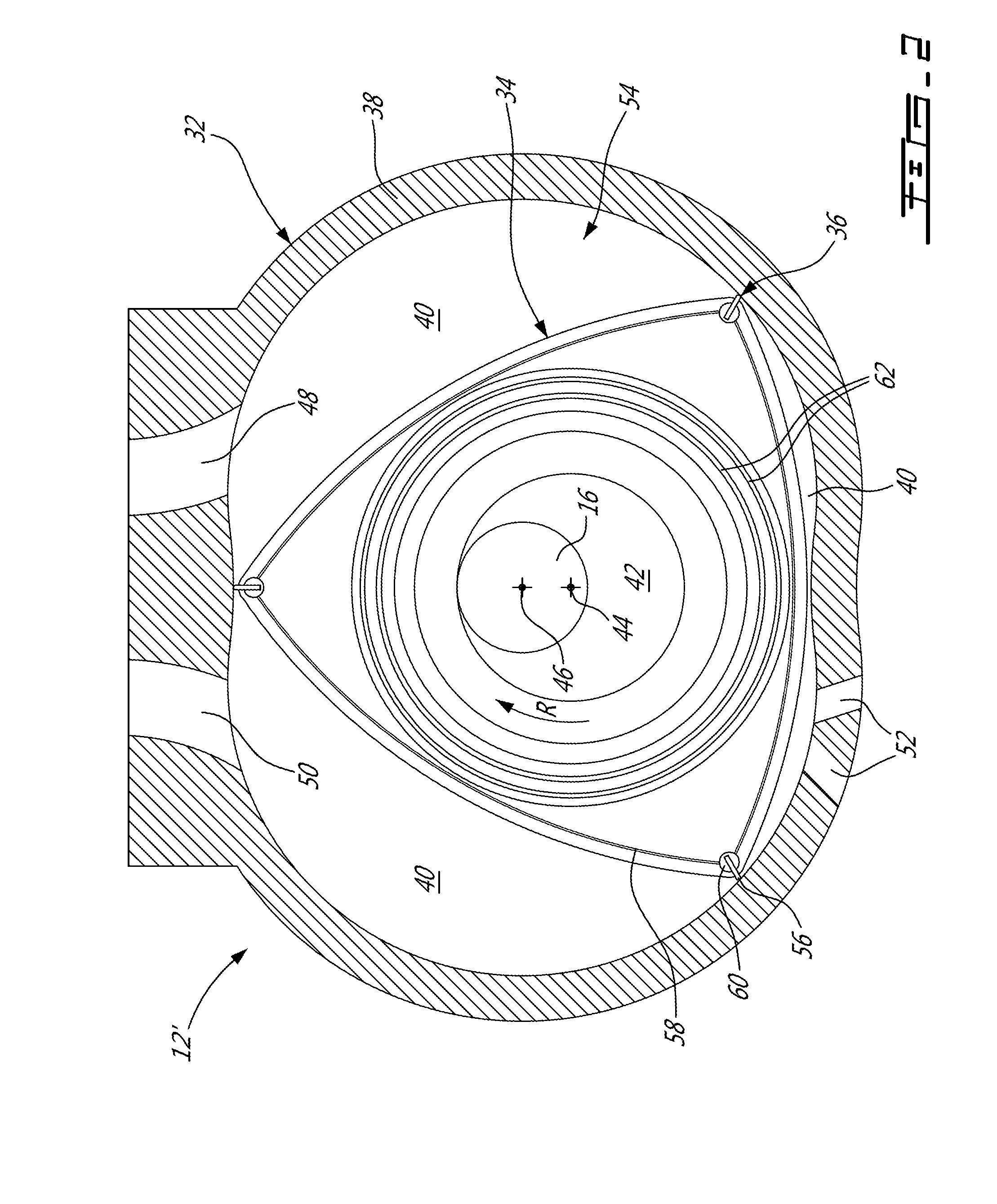

A compound cycle engine (10) comprises a compressor (19) and a turbine section (16&20), and at least one cycle topping device (12) cooperating with the turbine section (16&20) to provide power. The cycle topping device (12) has an output shaft (26) extending at an angle to the turbine shaft (28). Angled gearing (34) is provided for connecting the gas turbine shaft (28) and the cycle topping device (12).

Owner:PRATT & WHITNEY CANADA CORP

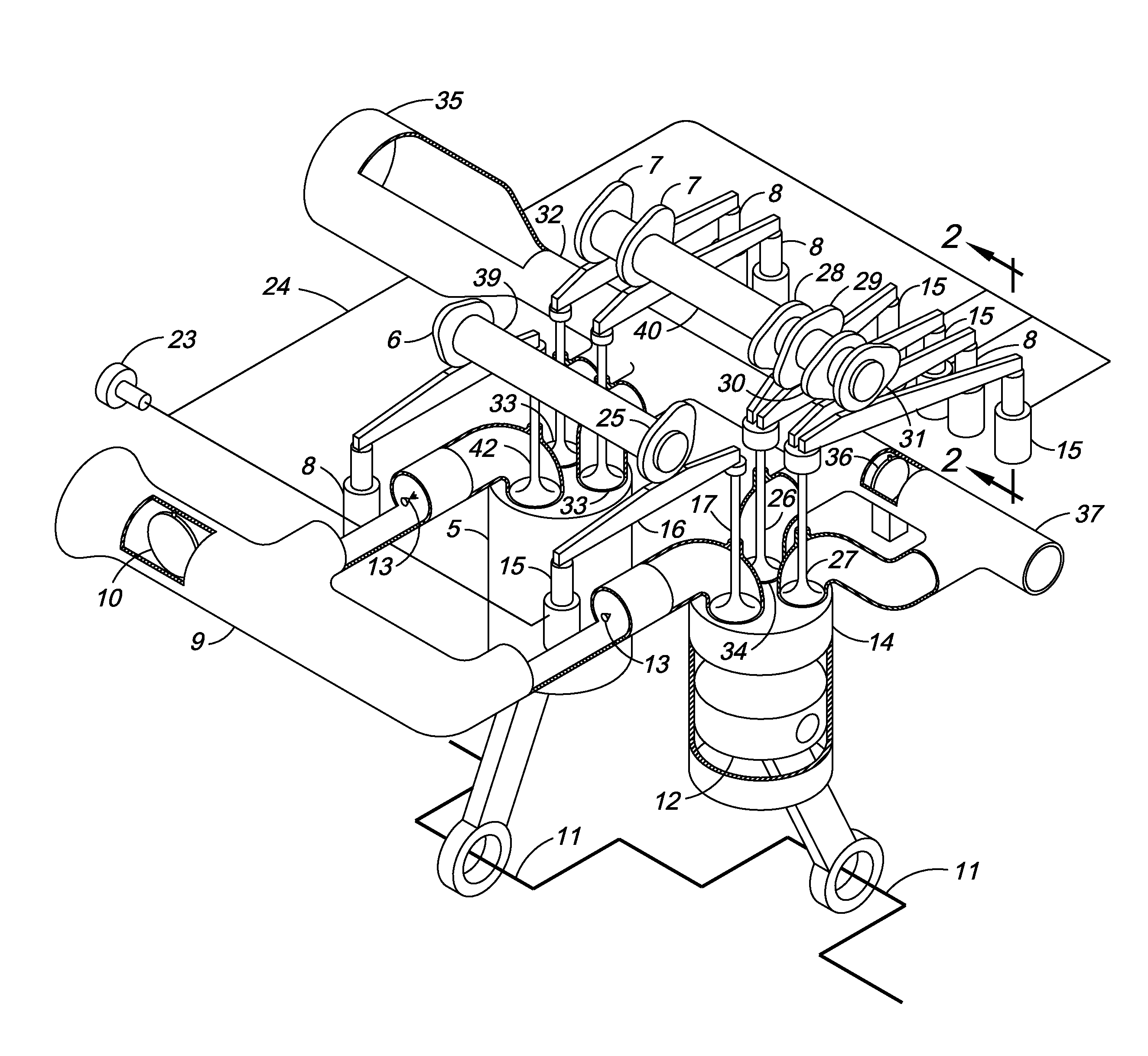

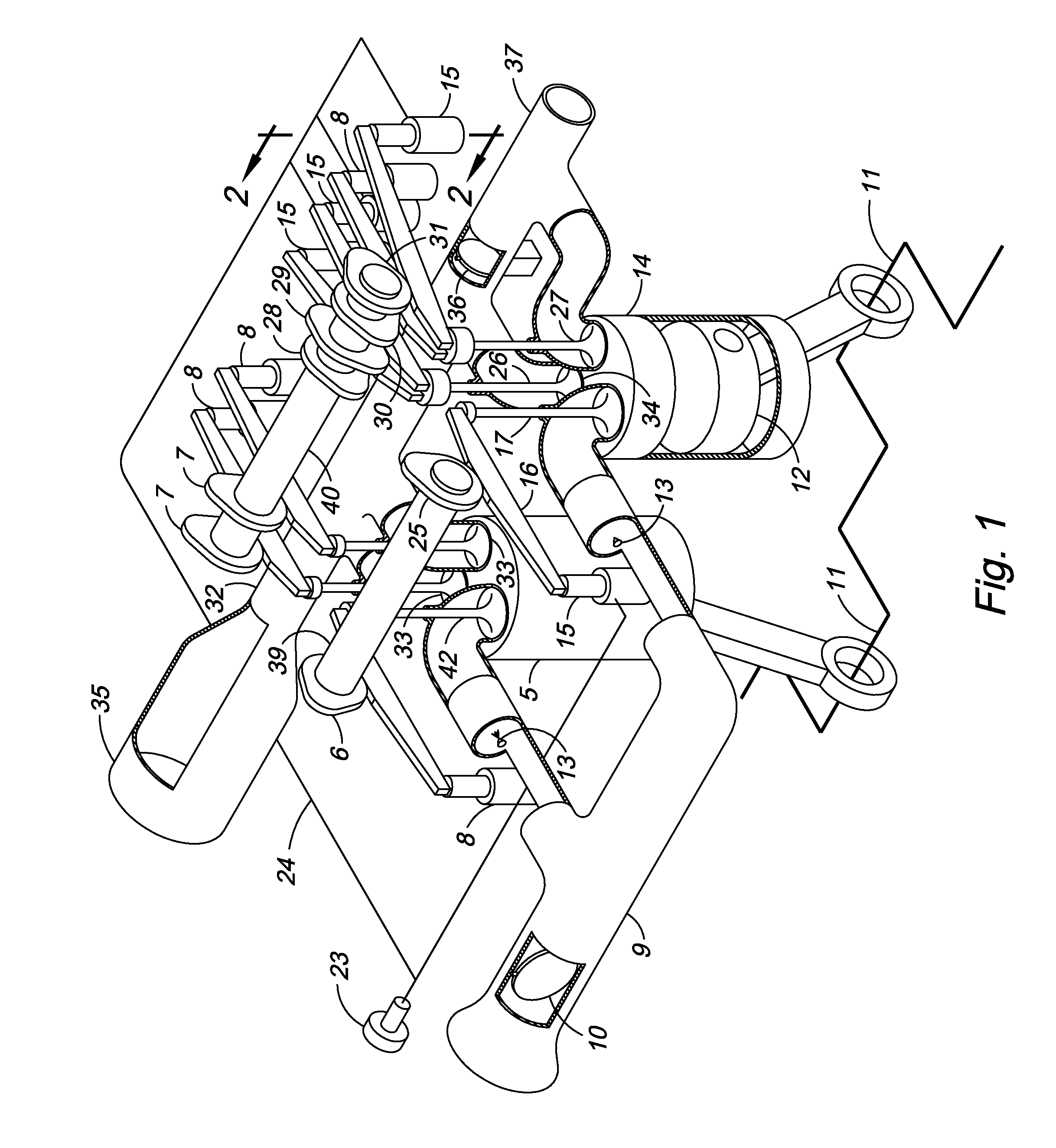

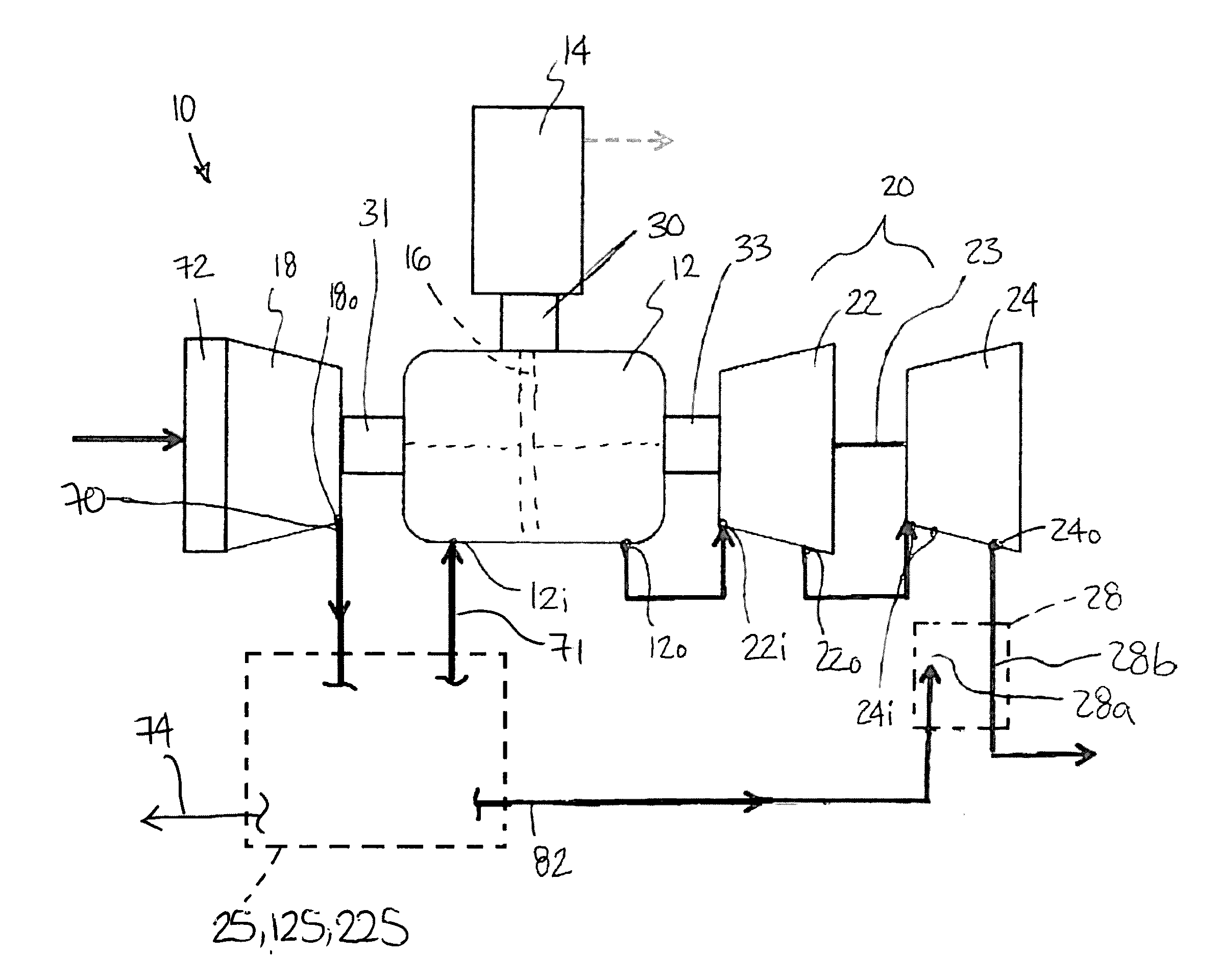

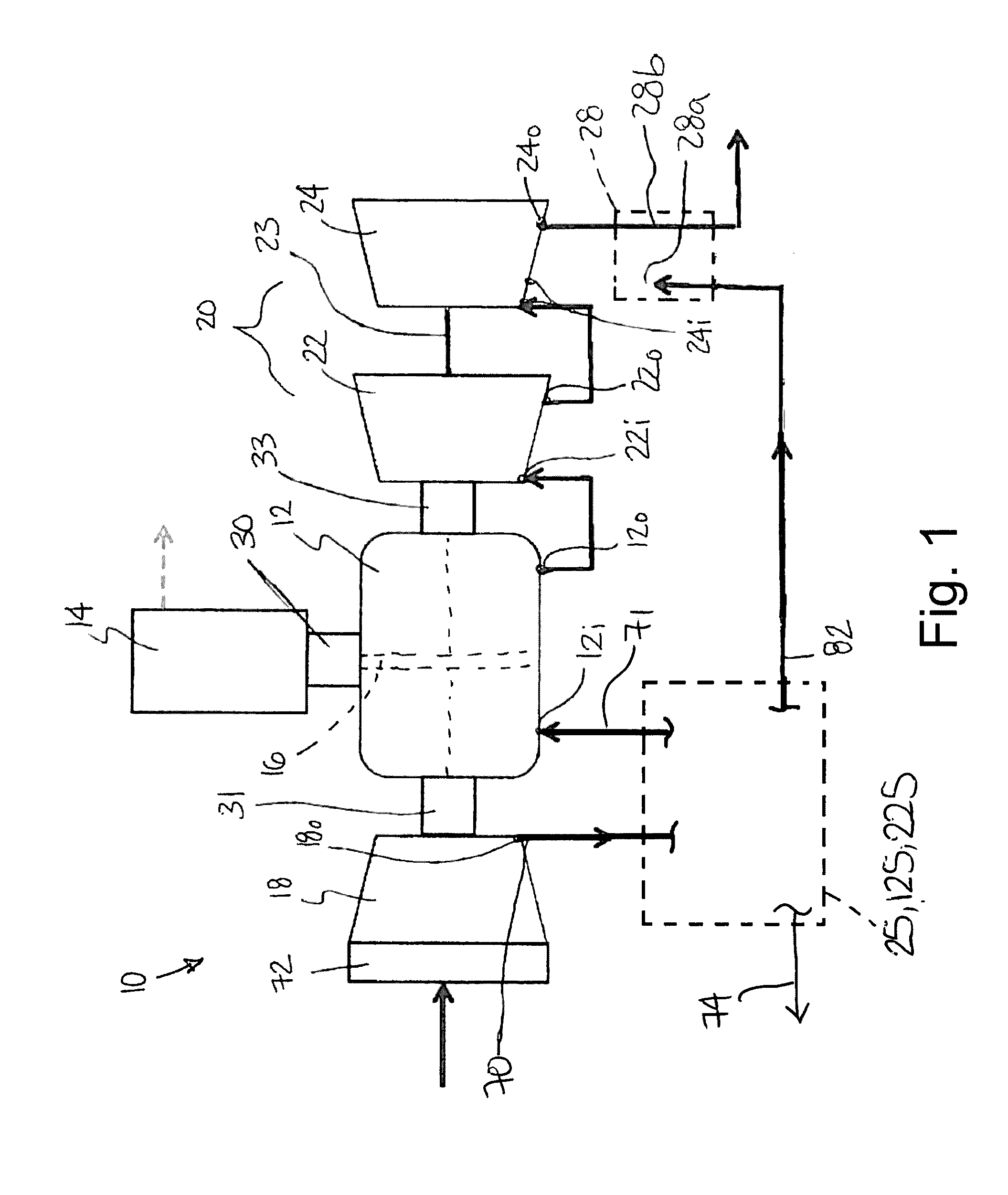

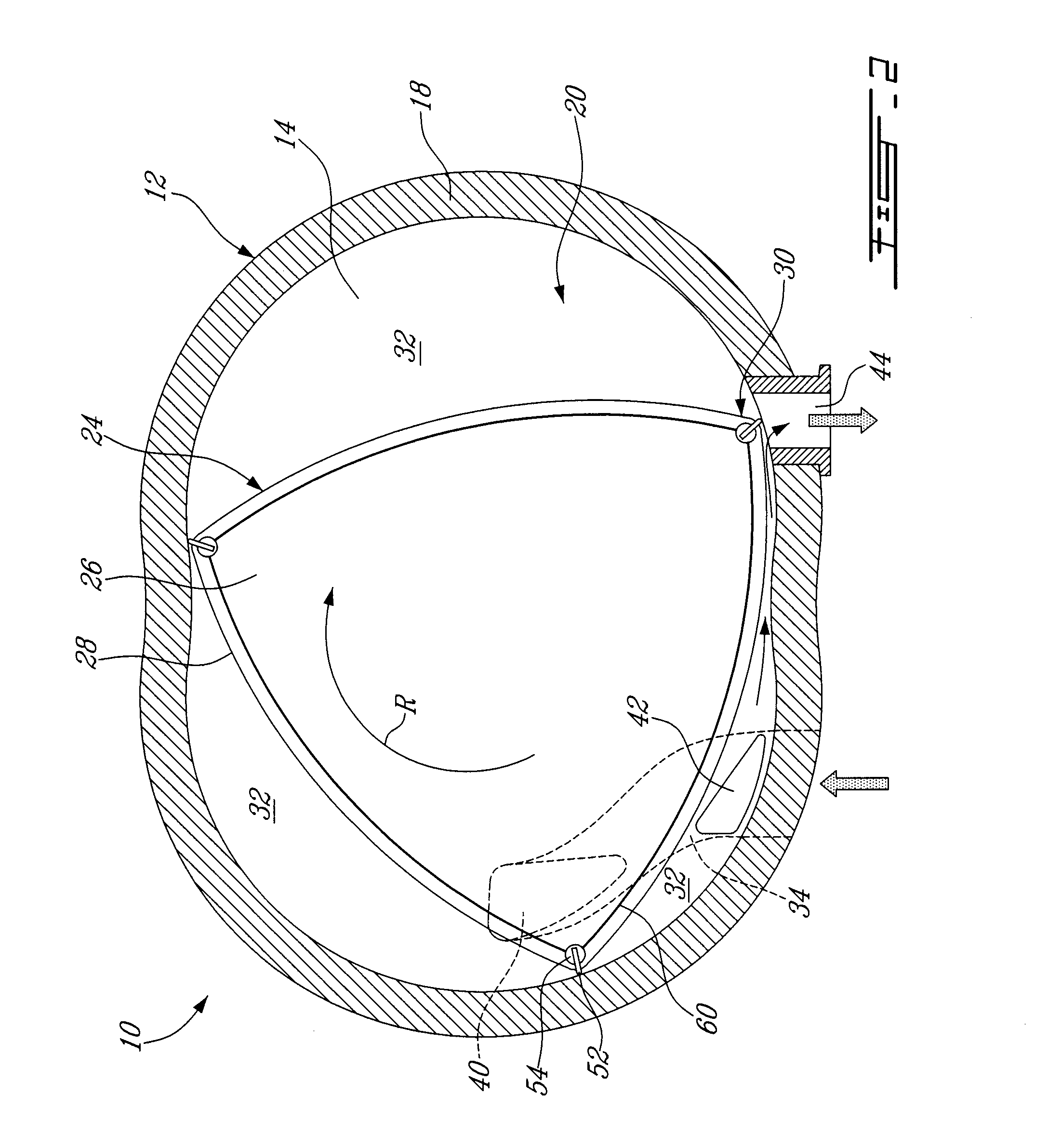

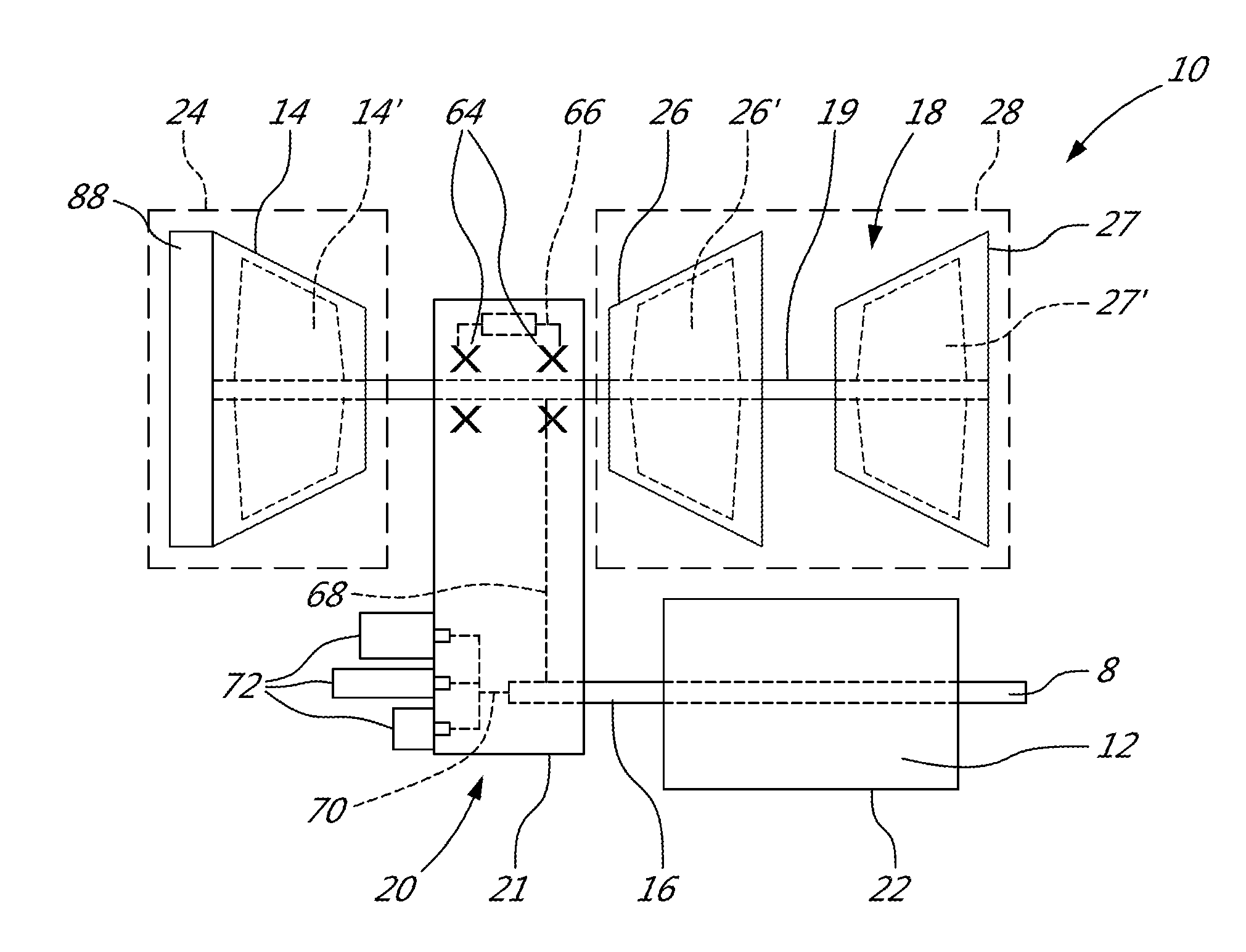

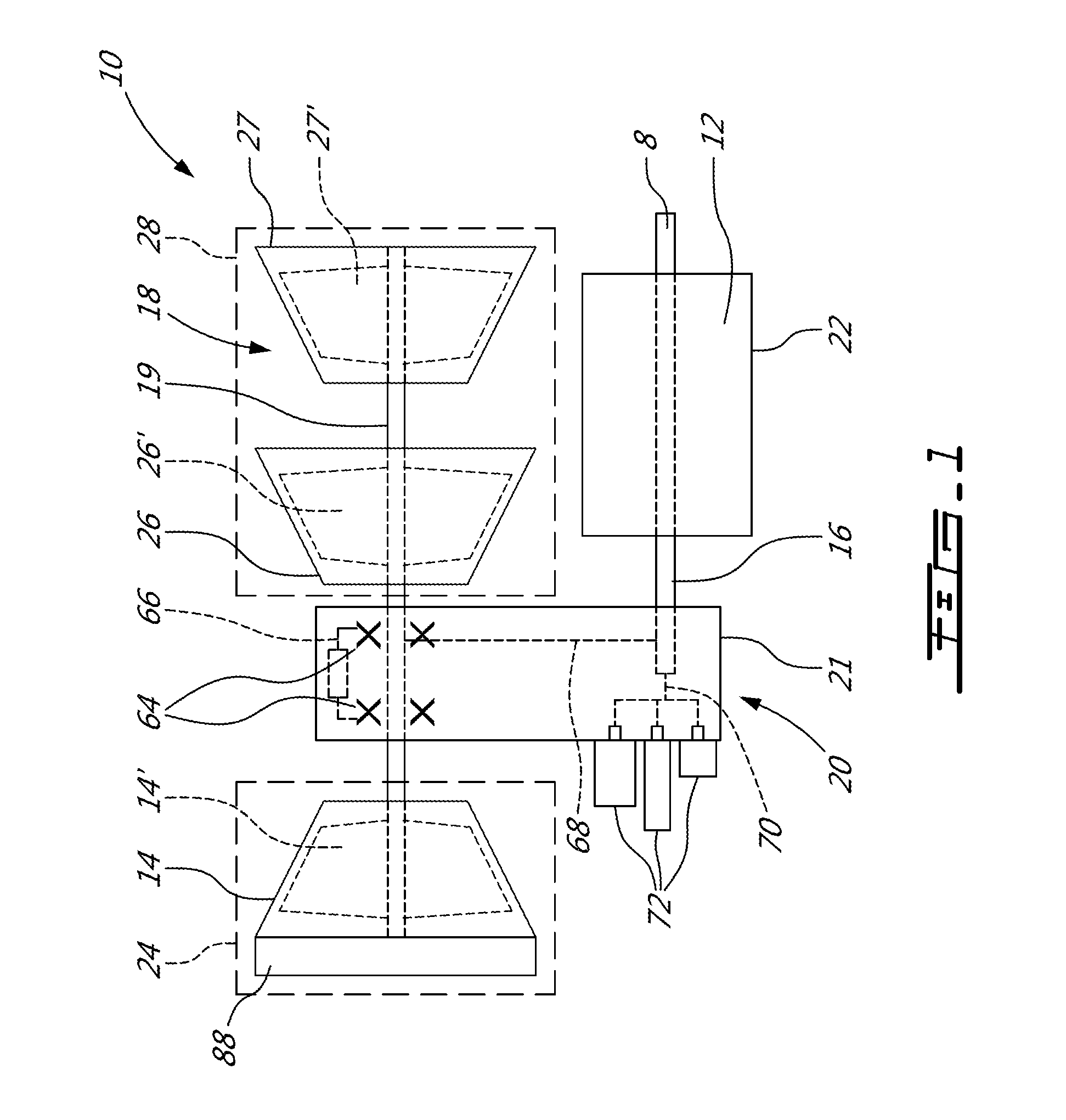

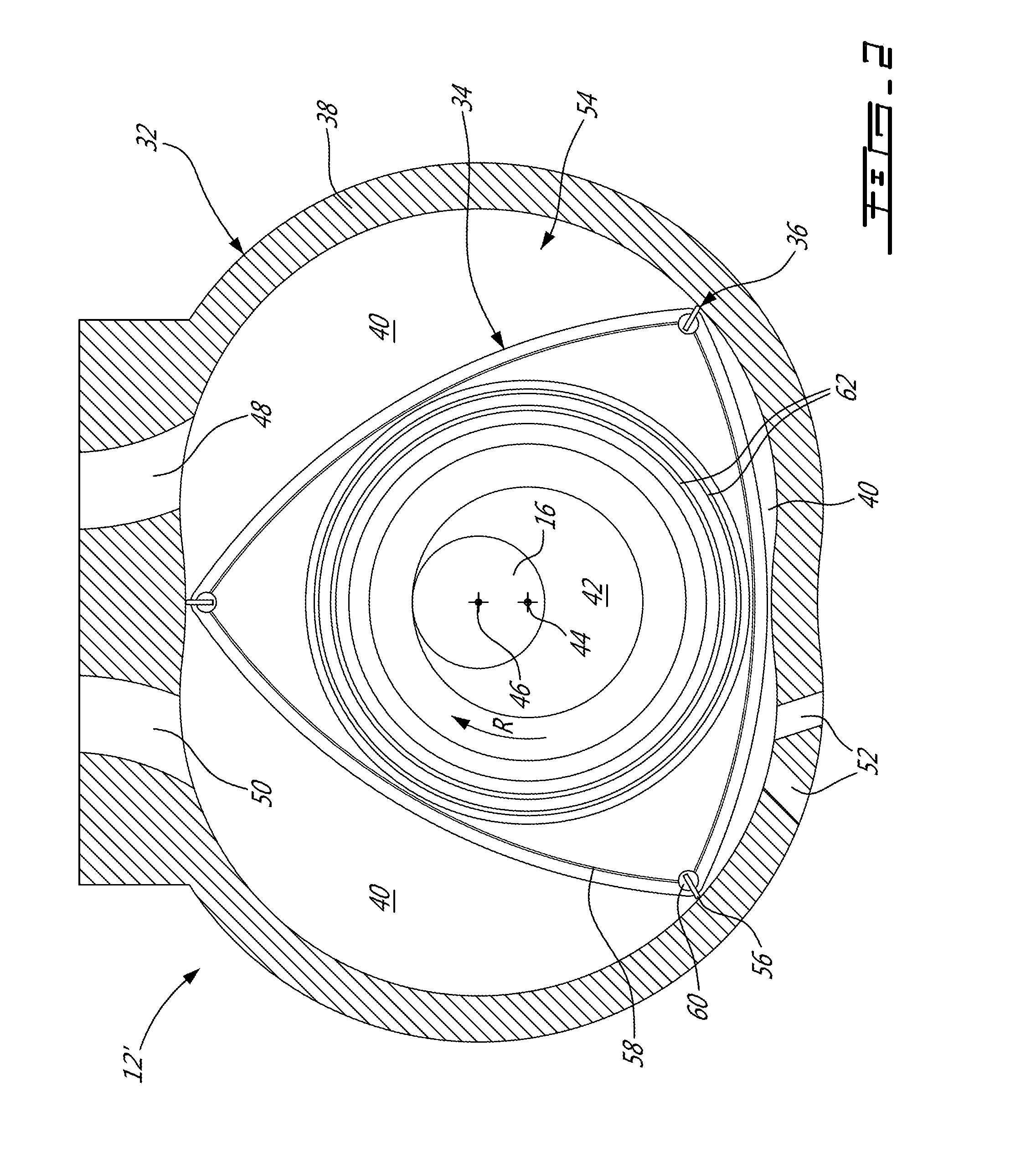

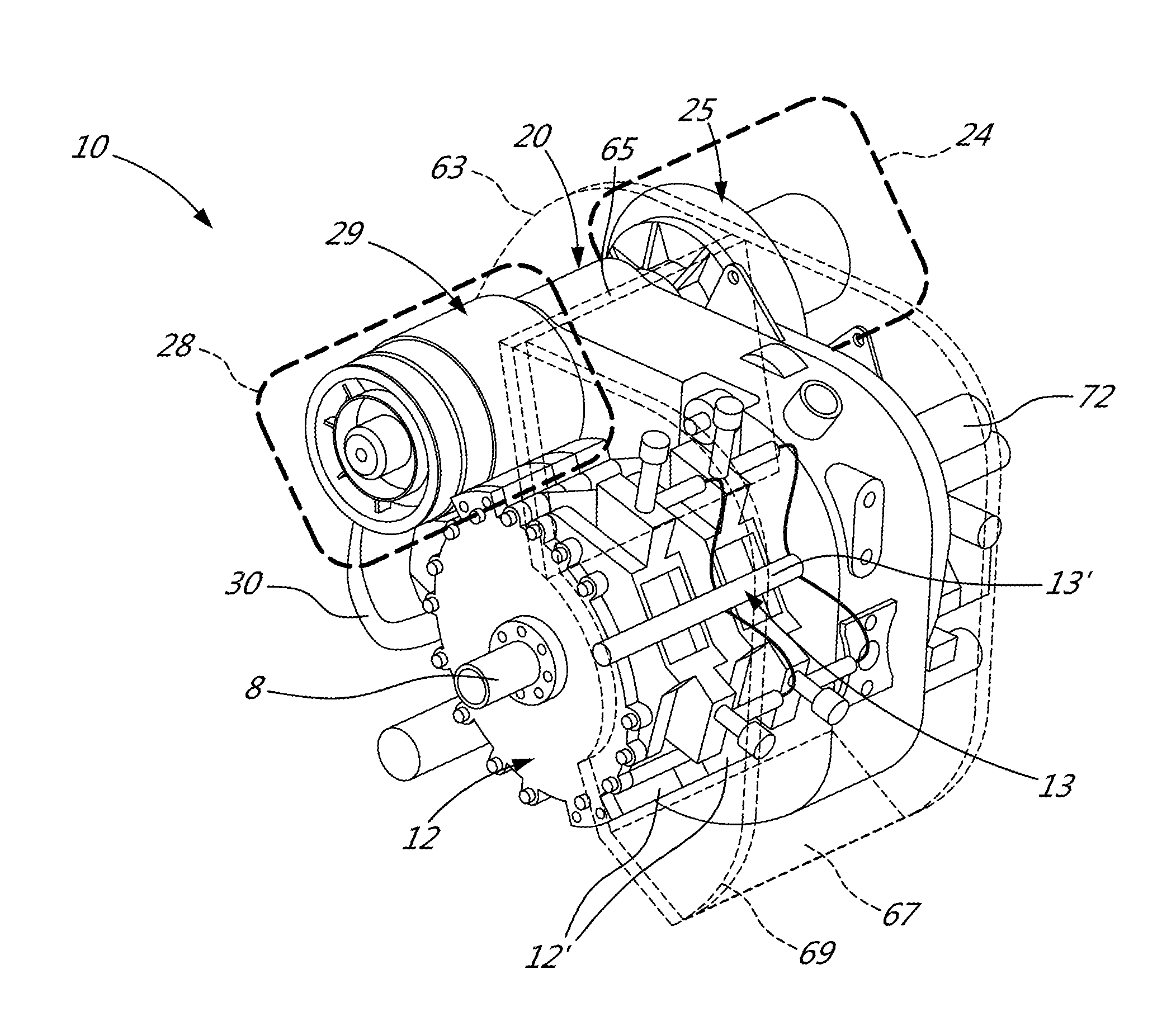

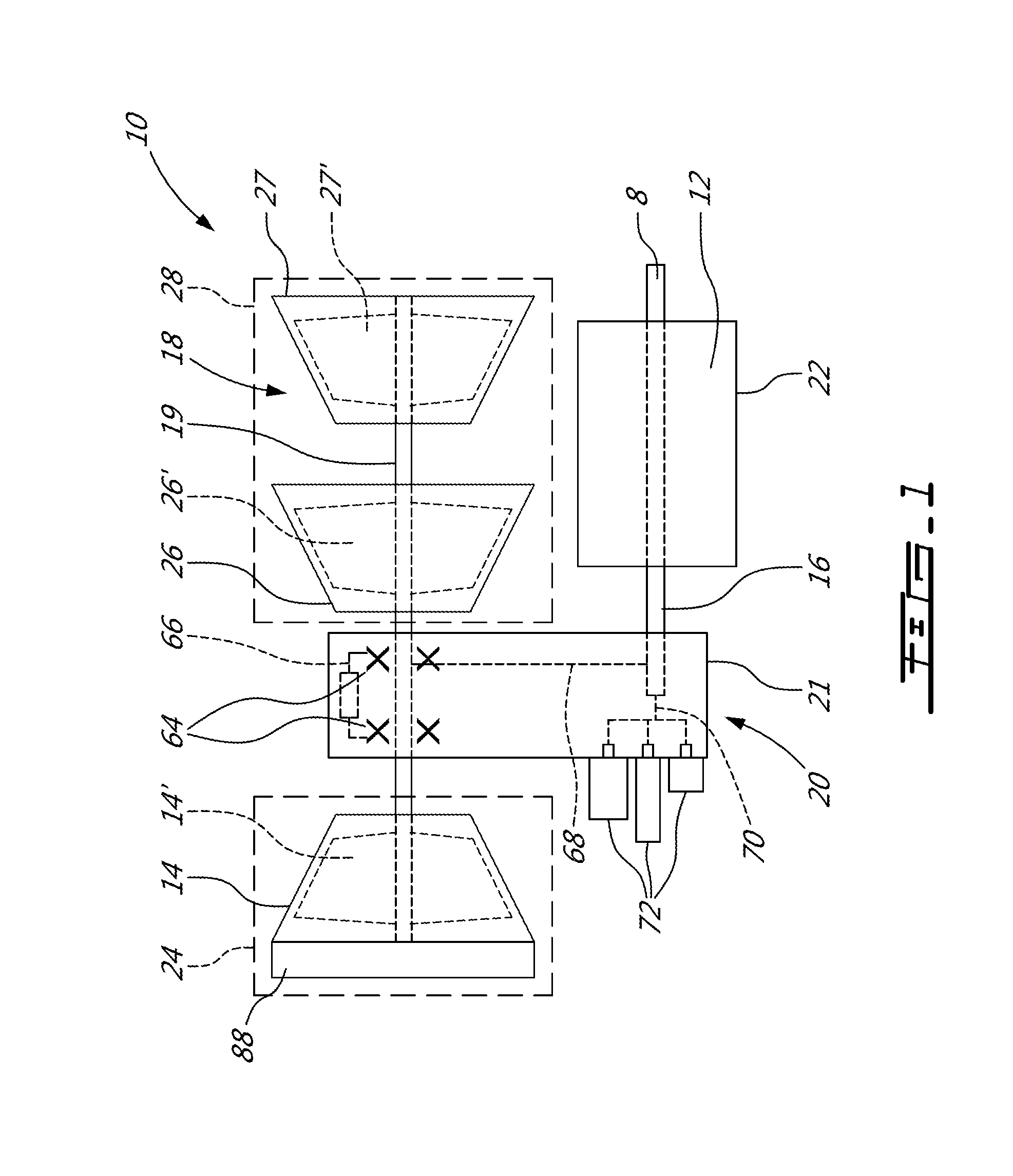

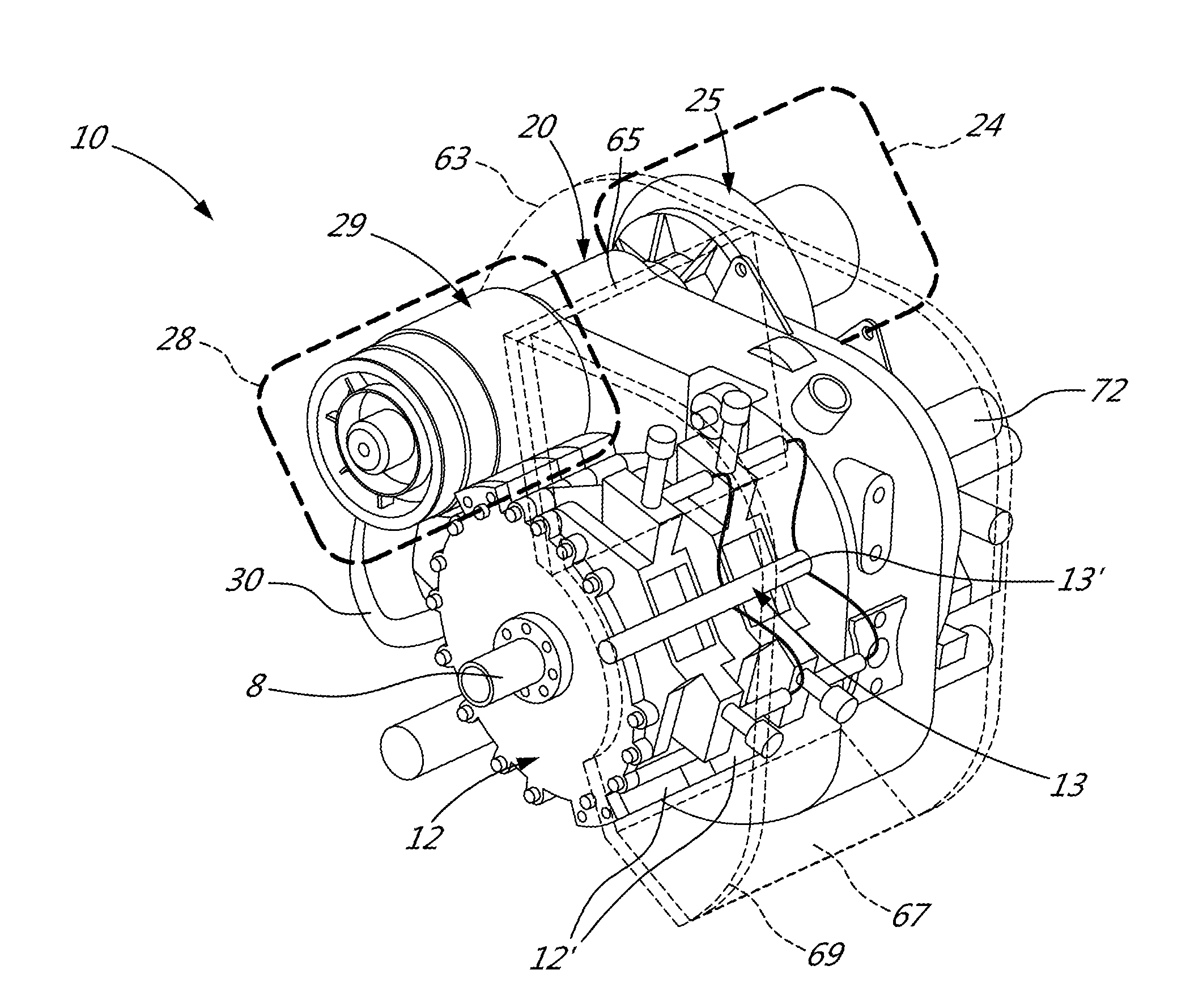

Compound engine system with rotary engine

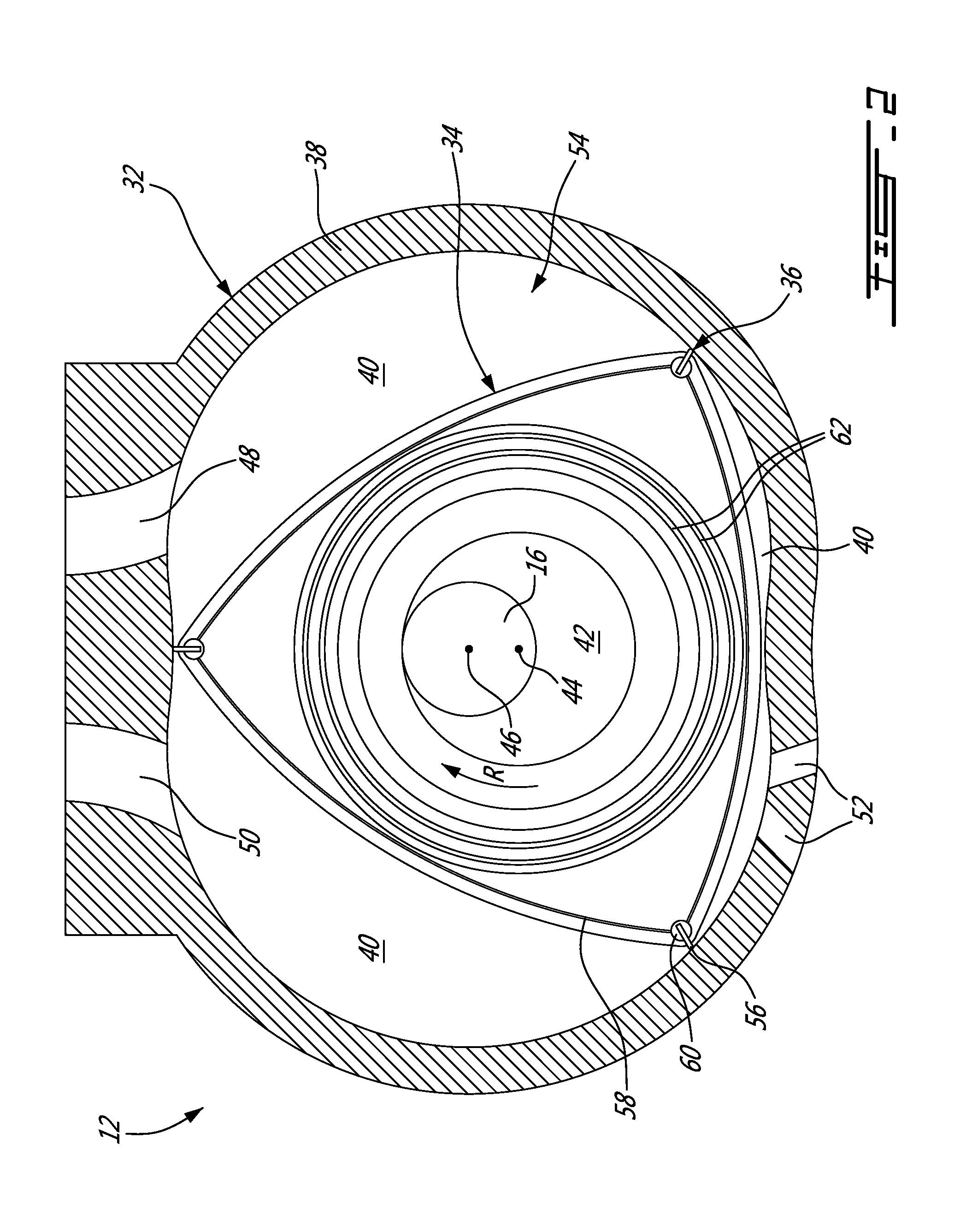

ActiveUS9027345B2Improve combustion stabilityInternal combustion piston enginesEngine of arcuate-engagement typeRotary engineTurbine

Owner:PRATT & WHITNEY CANADA CORP

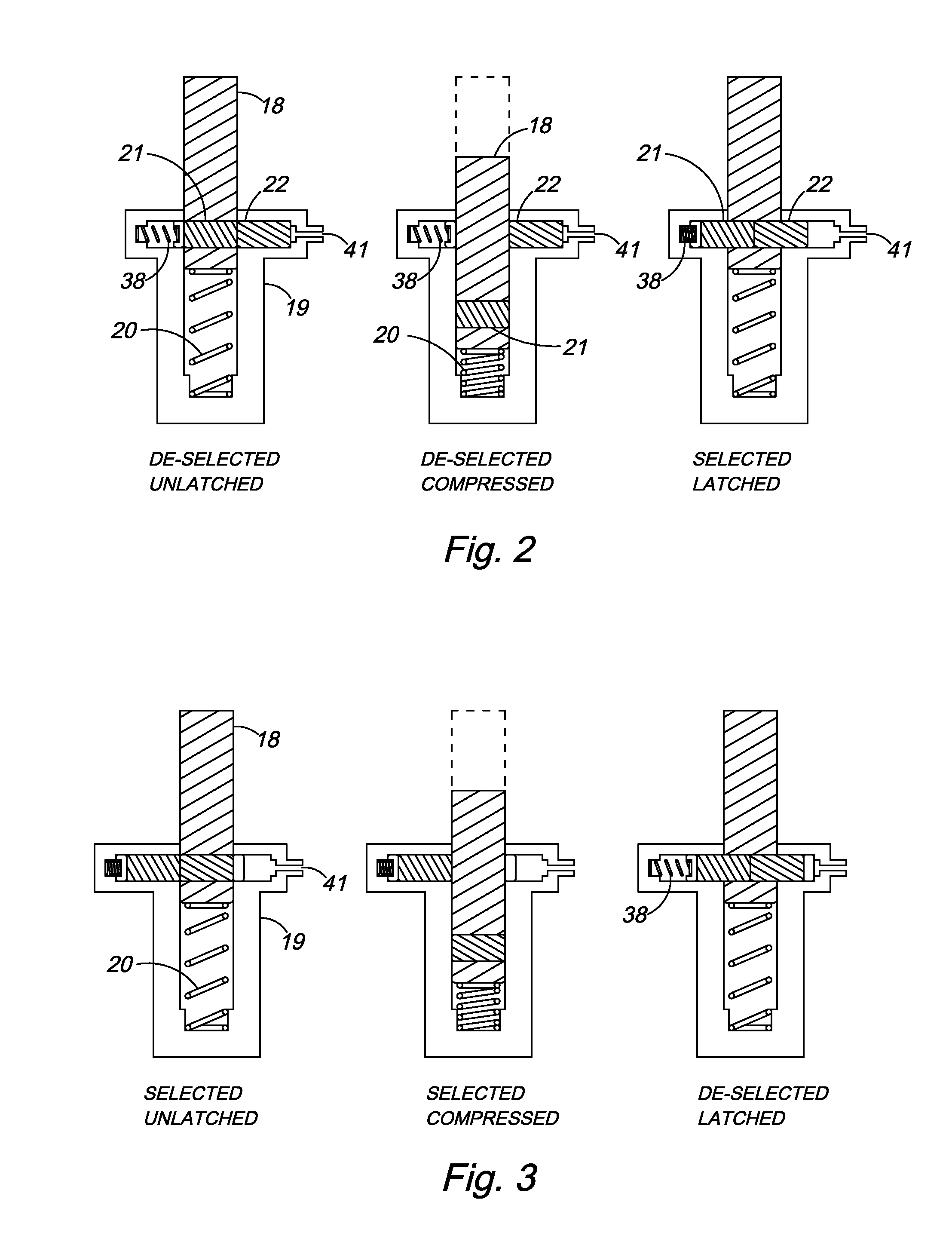

Selective Compound Engine

InactiveUS20090301086A1Improve fuel efficiencyReduce cylinder compression ratioCombustion enginesHot gas positive displacement engine plantsExhaust valveFuel efficiency

The fuel efficiency of an internal combustion reciprocating piston engine may be increased through selective secondary expansion of exhaust gas in the engine cylinders in order to recover exhaust gas energy which is otherwise wasted by cylinder blow-down at the end of the power stroke. Exhaust valve cam switching, intake valve deactivation, multiple exhaust valves, a specialized exhaust manifold arrangement and an exhaust gas diverter valve can be configured to enable a reciprocating engine to selectively operate in efficient eight stroke cycle compound mode when moderate engine power is demanded, then revert to conventional four stroke cycle non-compound mode operation when high engine power is demanded, without stopping the engine. For a road vehicle application, the benefit is substantially reduced highway cruising fuel consumption, while incurring minimal impact on engine weight, minimal impact on engine manufacturing cost, and no adverse impact on vehicle acceleration performance, hill climbing performance or trailer towing performance.

Owner:RALSTON MARK DIXON

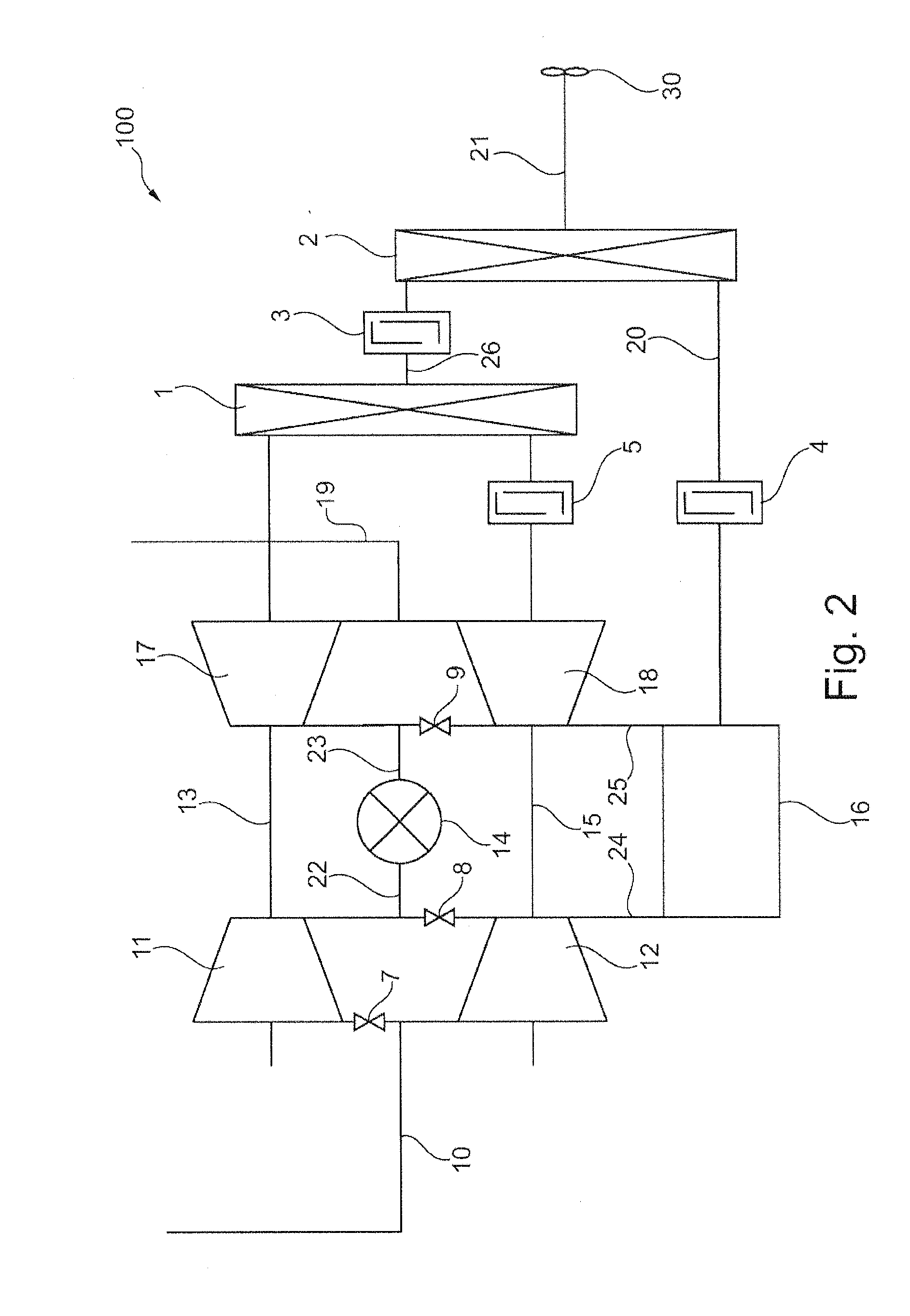

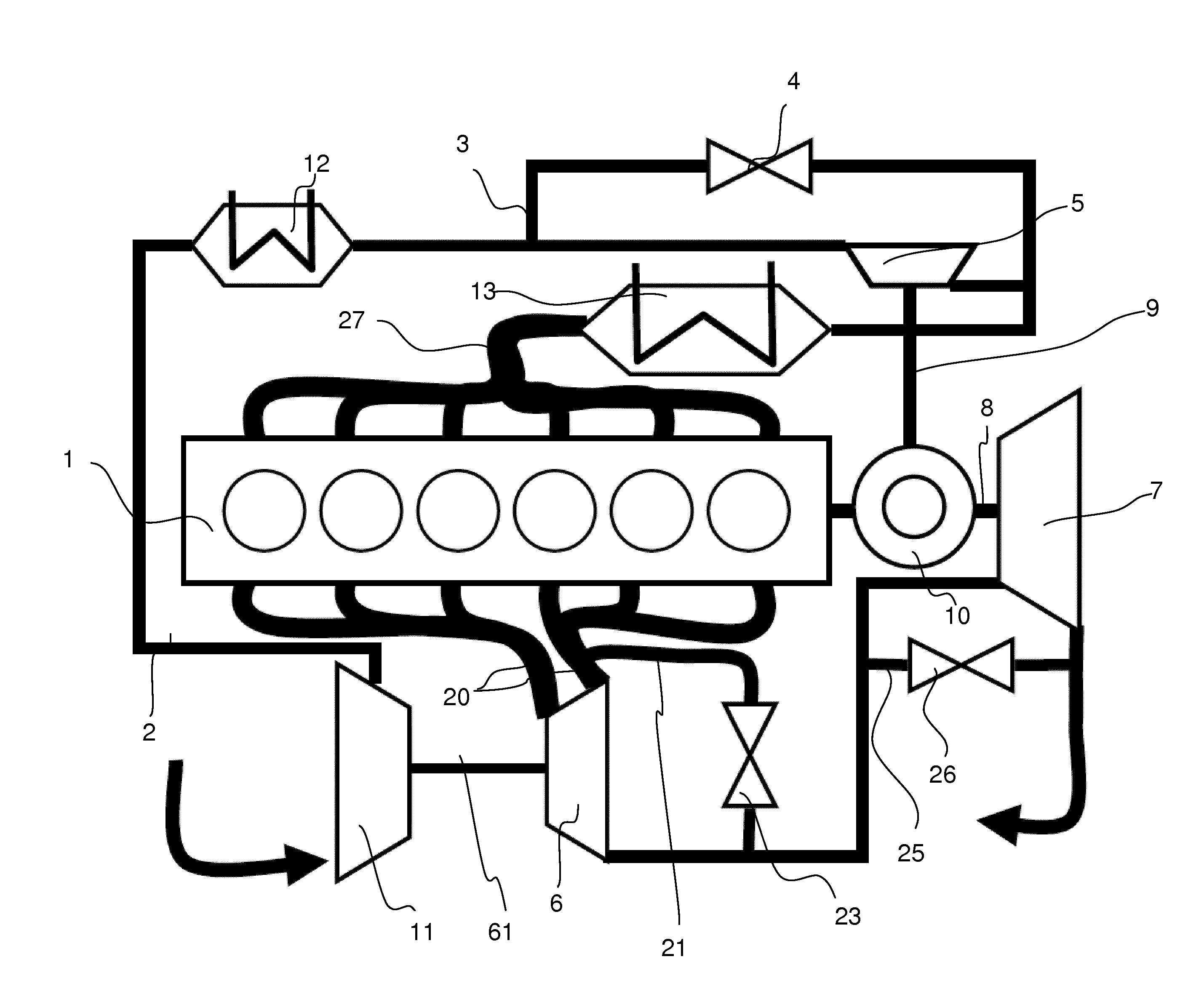

Diesel engine/gas turbine compound engine for a means of transport

InactiveUS20130213048A1Low air mass flow rateSmall dimensionInternal combustion piston enginesGas turbine type power plantsTurbochargerDiesel engine

A compound engine for a means of transportation, includes a diesel engine and a gas turbine with at least one compressor and with at least one turbine. The diesel engine and the gas turbine are interconnected in such a manner that during continuous duty operation the compound engine is configured to be operated only by way of the diesel engine, and the diesel engine is optionally operated on its own or together with a compressor and a turbine of the gas turbine as a turbocharger for the diesel engine. The compound engine is configured to be operated by way of the diesel engine or the gas turbine.

Owner:AIRBUS OPERATIONS GMBH

Selective compound engine

InactiveUS8028665B2Unrestricted power capacityEngine expansion ratio is doubledCombustion enginesHot gas positive displacement engine plantsExhaust valveInlet valve

The fuel efficiency of an internal combustion reciprocating piston engine may be increased through selective secondary expansion of exhaust gas in the engine cylinders in order to recover exhaust gas energy which is otherwise wasted by cylinder blow-down at the end of the power stroke. Exhaust valve cam switching, intake valve deactivation, multiple exhaust valves, a specialized exhaust manifold arrangement and an exhaust gas diverter valve can be configured to enable a reciprocating engine to selectively operate in efficient eight stroke cycle compound mode when moderate engine power is demanded, then revert to conventional four stroke cycle non-compound mode operation when high engine power is demanded, without stopping the engine. For a road vehicle application, the benefit is substantially reduced highway cruising fuel consumption, while incurring minimal impact on engine weight, minimal impact on engine manufacturing cost, and no adverse impact on vehicle acceleration performance, hill climbing performance or trailer towing performance.

Owner:RALSTON MARK DIXON

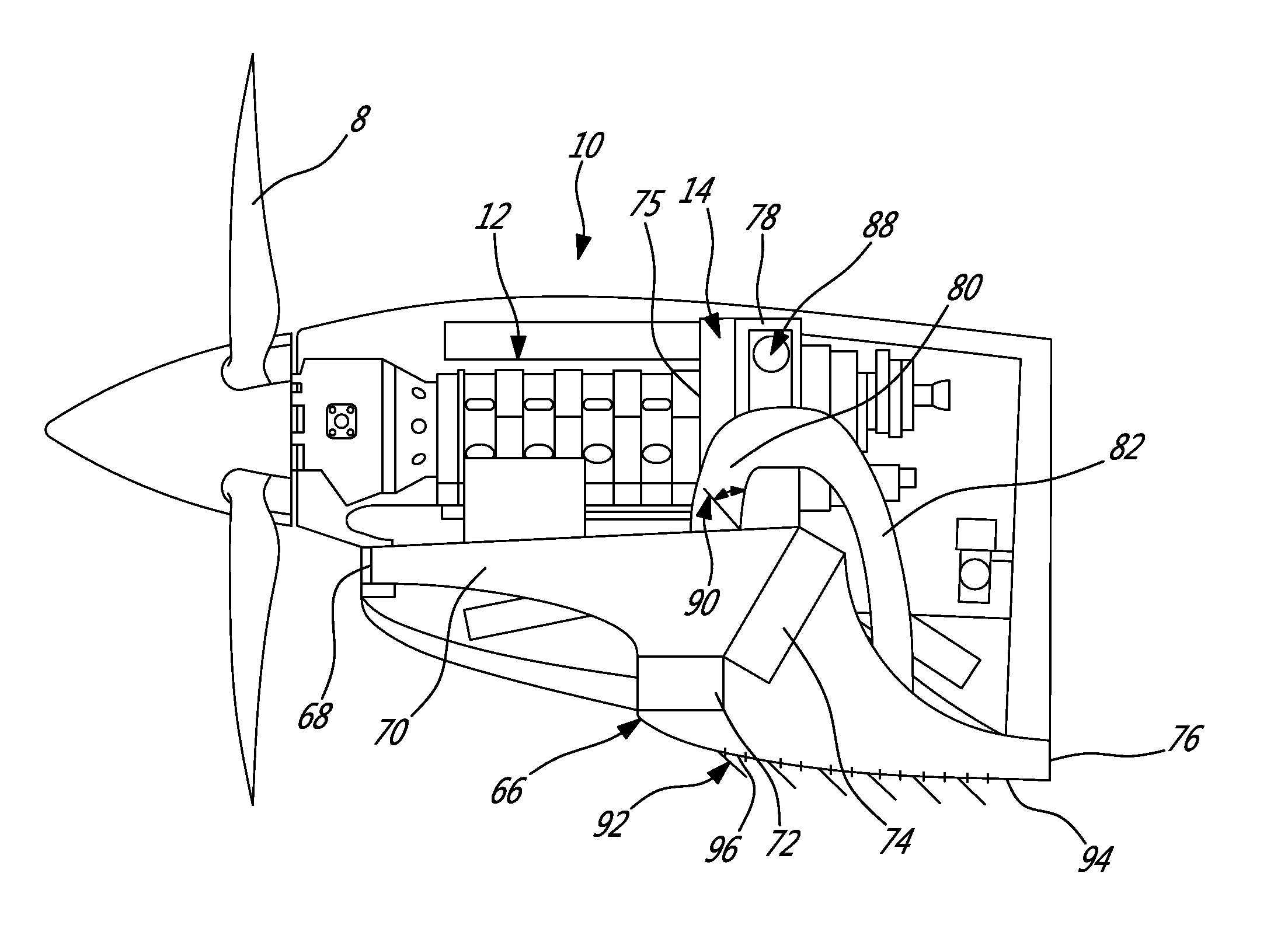

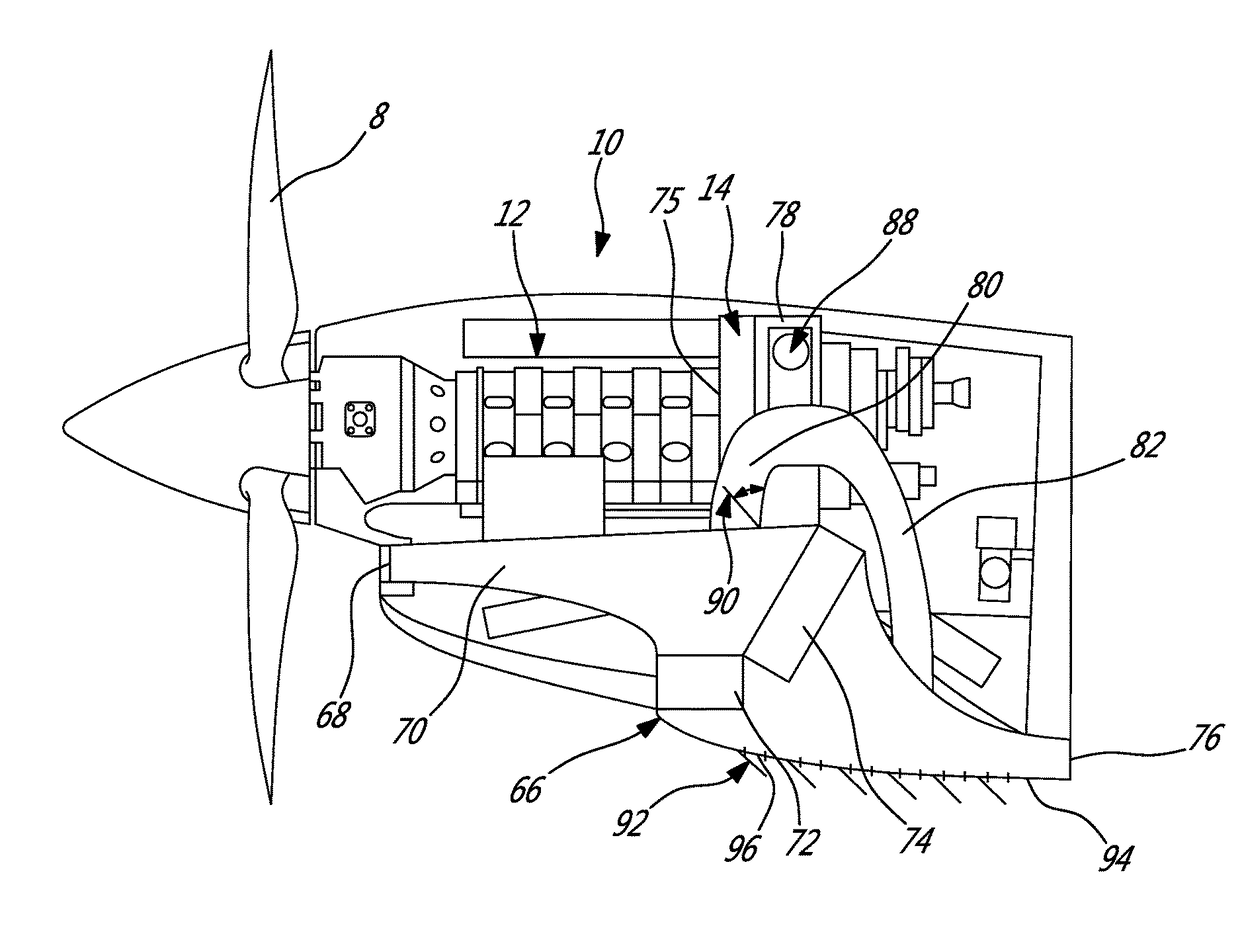

Compound engine assembly with cantilevered compressor and turbine

ActiveUS9869240B2Internal combustion piston enginesEngine fuctionsInternal combustion engineCompound engine

A compound engine assembly with an engine core including at least one internal combustion engine, a compressor, and a turbine section where the turbine shaft is configured to compound power with the engine shaft. The turbine section may include a first stage turbine and a second stage turbine. The turbine shaft is rotationally supported by a plurality of bearings all located on a same side of the compressor rotor(s) and all located on a same side of the turbine rotor(s), for example all located between the compressor rotor(s) and the turbine rotor(s), such that the compressor rotor(s) and the turbine rotor(s) are cantilevered. A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

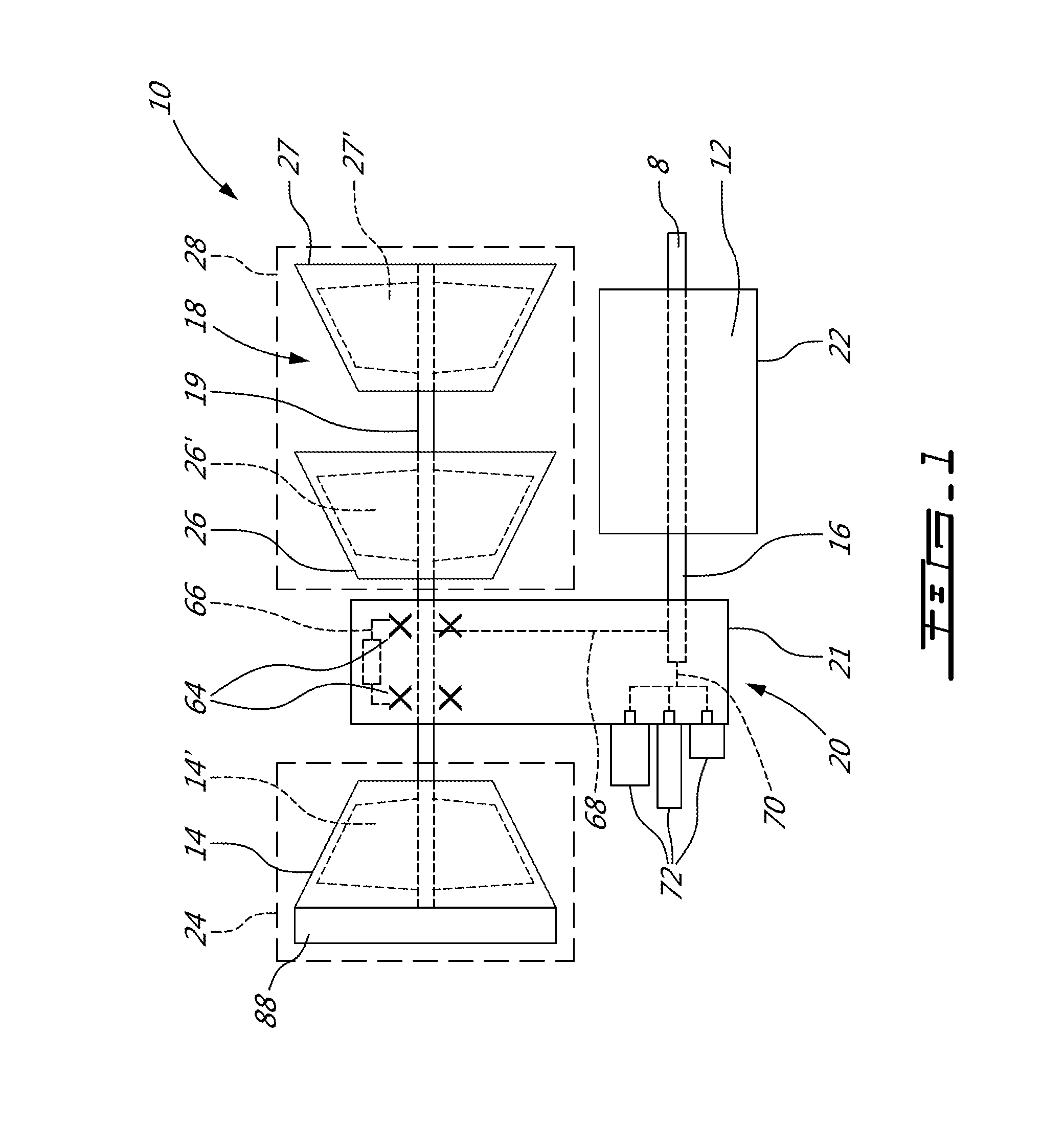

Compound engine assembly with direct drive of generator

ActiveUS20160376023A1Power installationsAir-treatment apparatus arrangementsEngineeringAuxiliary power unit

A compound engine assembly for use as an aircraft auxiliary power unit, having an engine core including internal combustion engine(s) in driving engagement with an engine shaft, a generator having a generator shaft directly engaged to the engine shaft such as to be rotatable at a same speed, a compressor having an outlet in communication with the engine core inlet, and a turbine section having an inlet in communication with the engine core outlet and configured to compound power with the engine core. The turbine section may include a first stage turbine having an inlet in communication with the engine core outlet, and a second stage turbine having an inlet in communication with the first stage turbine outlet. A method of providing electrical power to an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with mount cage

ActiveUS20160245170A1Internal combustion piston enginesCombination enginesHot zoneExternal combustion engine

A compound engine assembly with an engine core including at least one internal combustion engine, a turbine section, and a compressor having an outlet in fluid communication with an inlet of the engine core. A casing is connected to the turbine section, the compressor and the engine core. A mount cage is connected to mounts attached to the casing between the compressor and a hot zone including the turbine section and the engine core. The mount cage includes a plurality of struts all extending from the mounts away from the turbine section and engine core. The casing may be a gearbox module casing through which the turbine shaft in engaged with the engine shaft. The mount cage may be completely contained within an axial space with the turbine section and engine core being located outside of the axial space.

Owner:PRATT & WHITNEY CANADA CORP

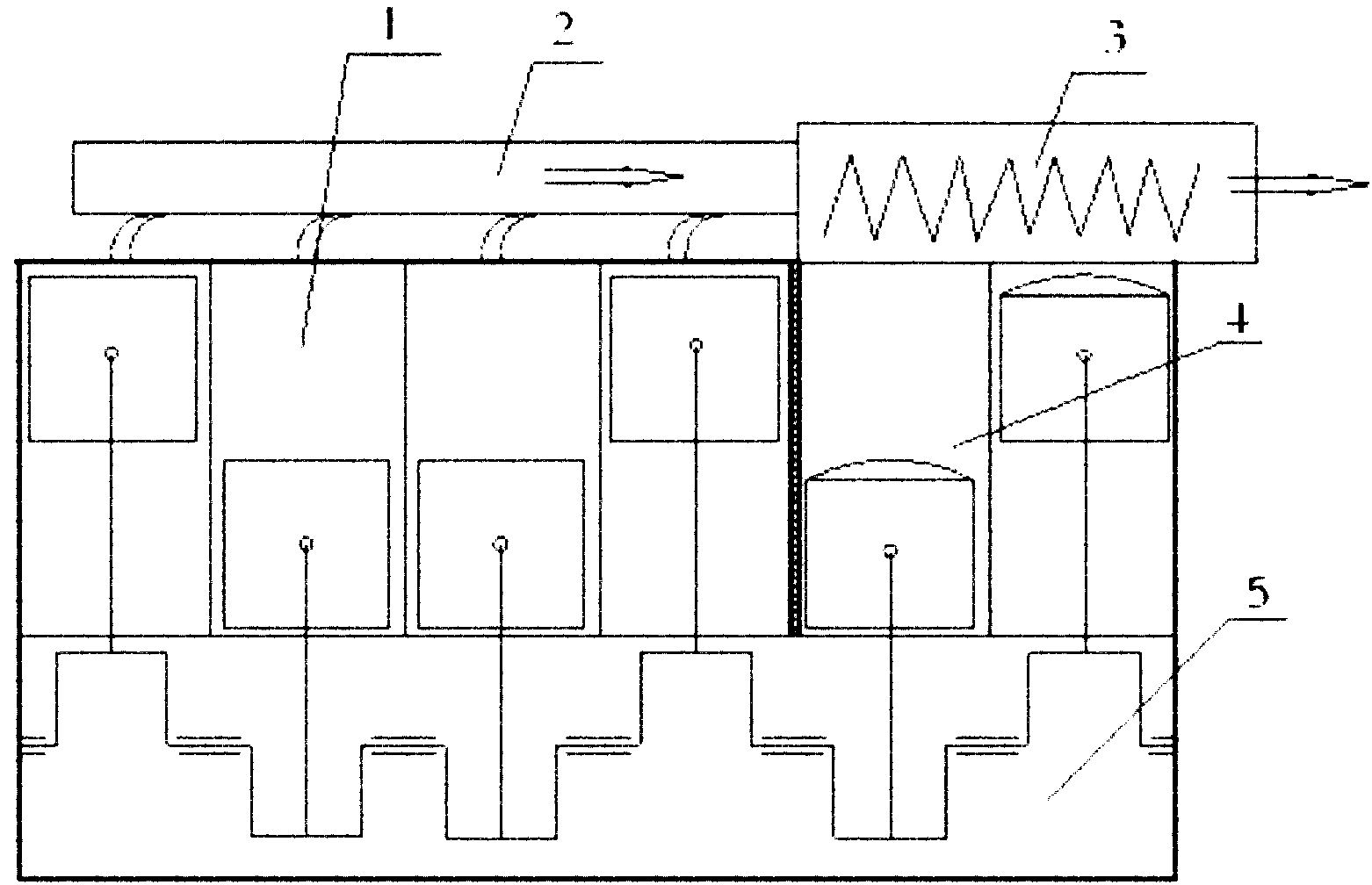

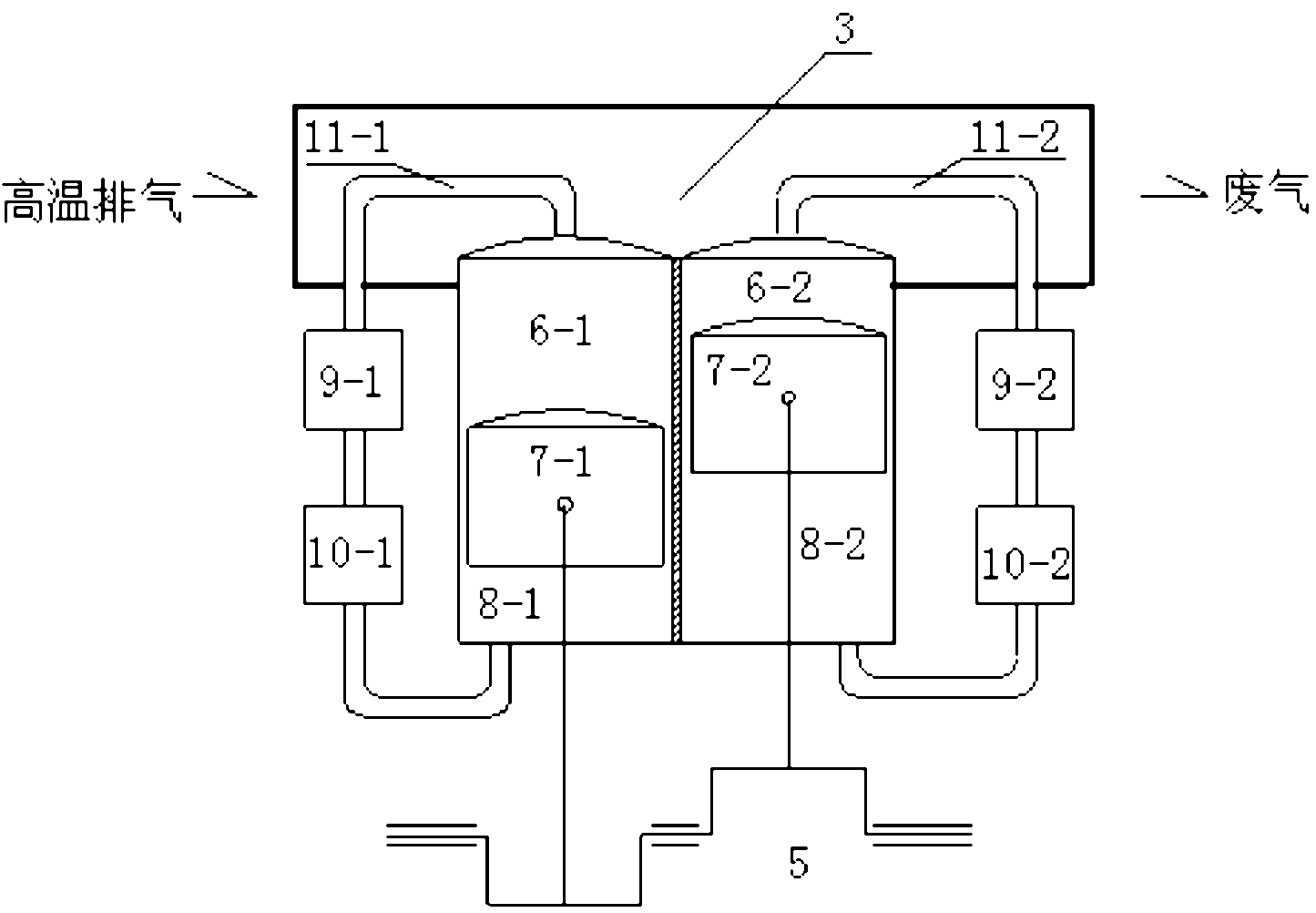

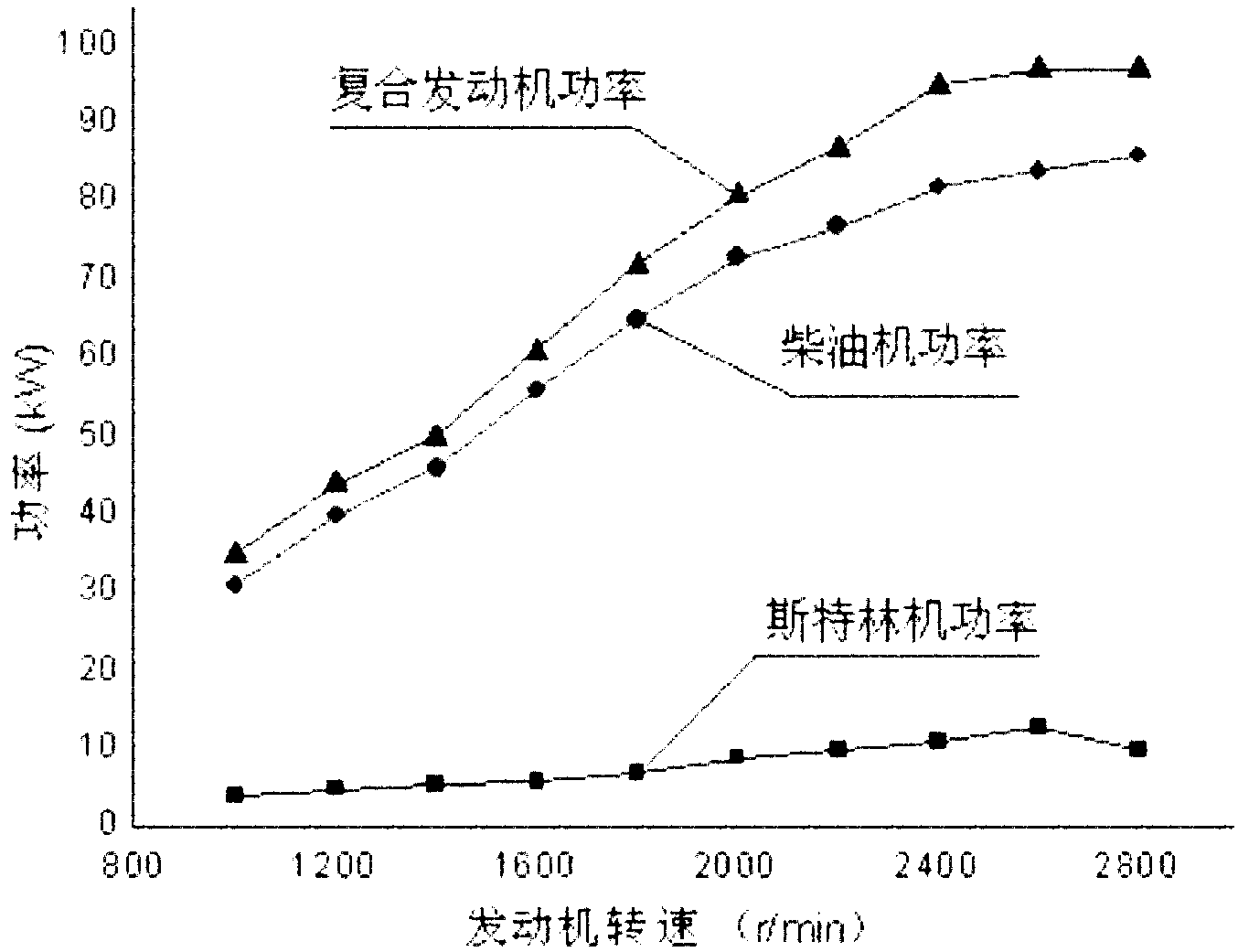

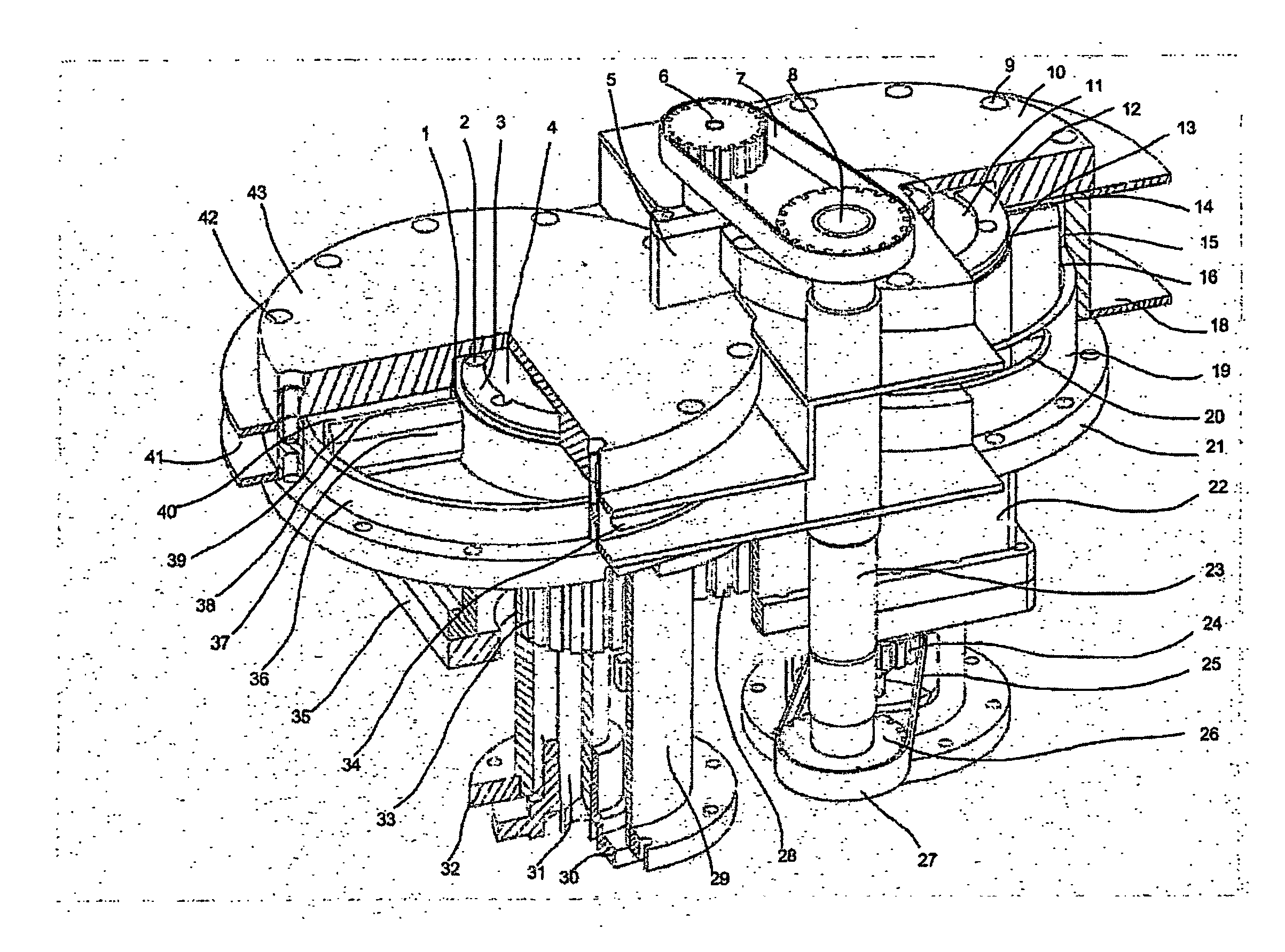

Combustion motor and stirling compound engine

InactiveCN101915147AIncrease powerReduce volumeInternal combustion piston enginesExhaust apparatusEffective powerTurbo-compound engine

The invention relates to an engine compounded by combustion motor and stirling engine. Combustion motor and stirling engine are in the same machine body, the exhaust pipe of the combustion motor is connected with the heater of the stirling enging in series, exhaust of the combustion motor is taken as high temperature heat source of the stirling engine, and power produced by the two engines is used for driving the same crankshaft. Working medium in the stirling engine passes through closed circulation loops, each loop is composed of an expanding cavity, a piston, a compression cavity, a heat regenerator, a cooler and a group of heating tubes which are sequentially connected. The processes of working medium when doing work in the circulation loop are the same, namely the working medium absorbs heat of exhaust of the combustion motor and then is expanded in the expanding cavity, the piston is driven to move downward, and the crankshaft is driven to do work. The invention has the characteristic that stirling engine can absorb waste heat of exhaust of combustion motor to the utmost extent. Compared with the traditional combustion motor waste heat recycling device, the invention can cause mean effective power of diesel engine to be increased by 10% under the same fuel consumption condition.

Owner:TIANJIN UNIV

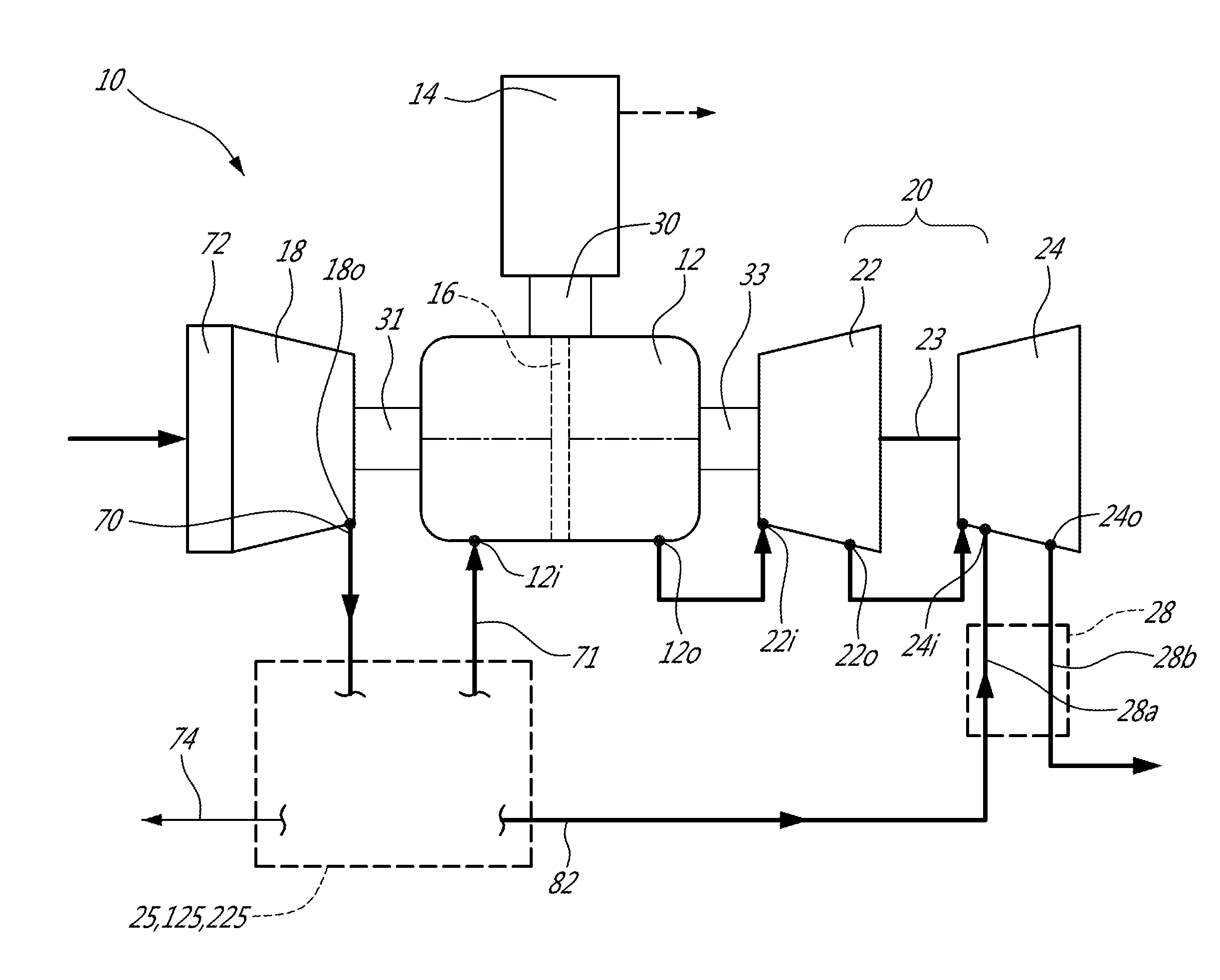

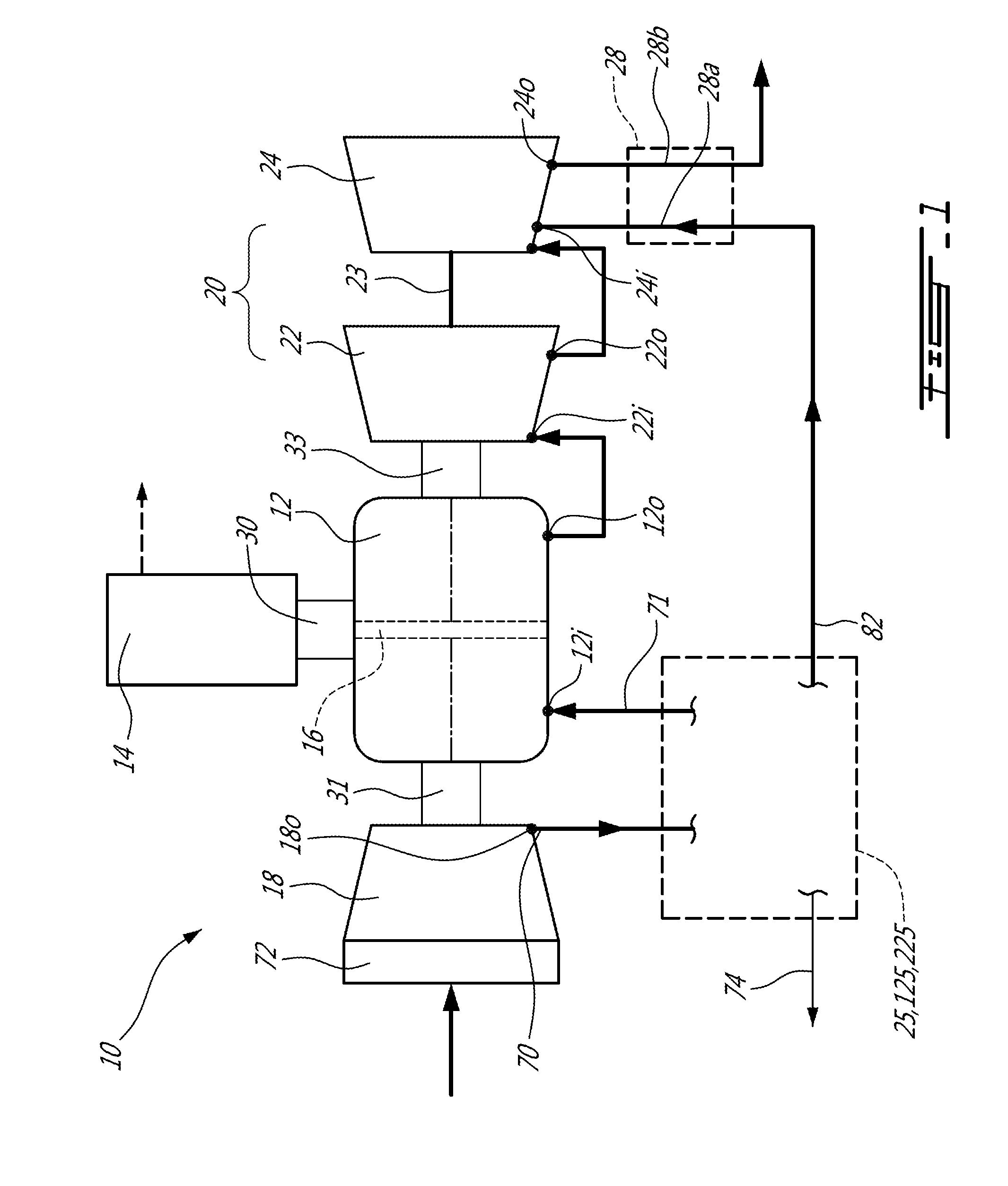

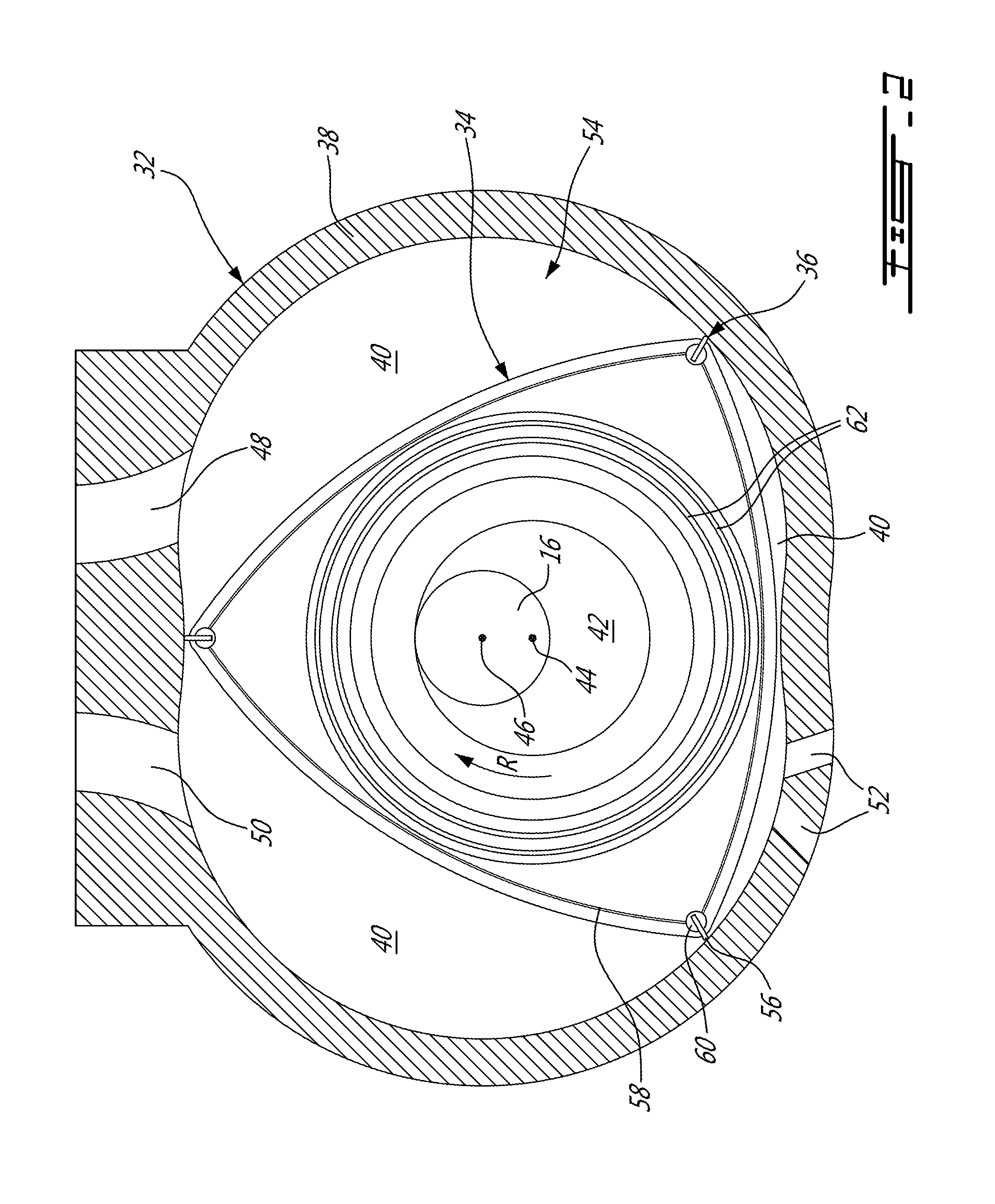

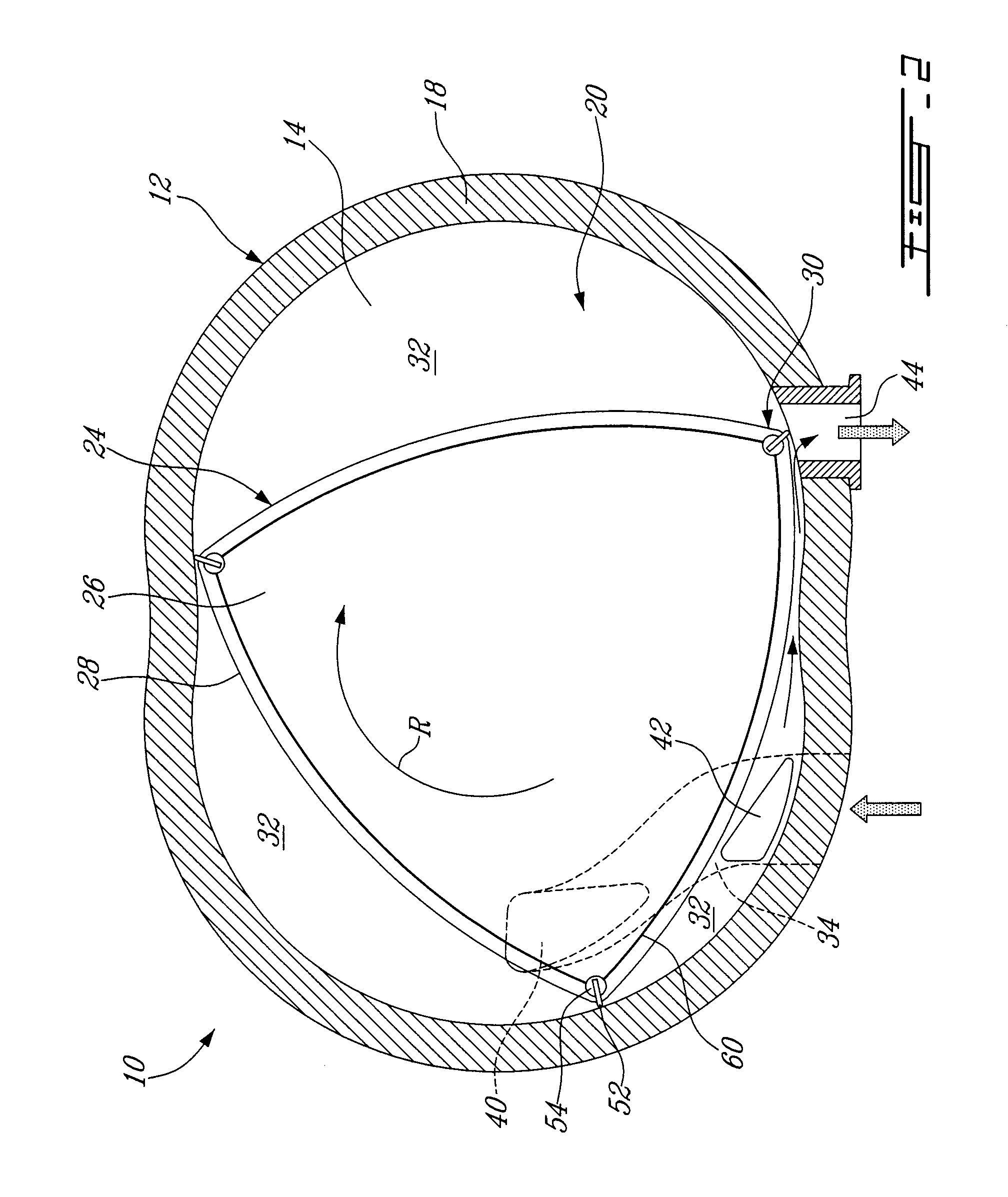

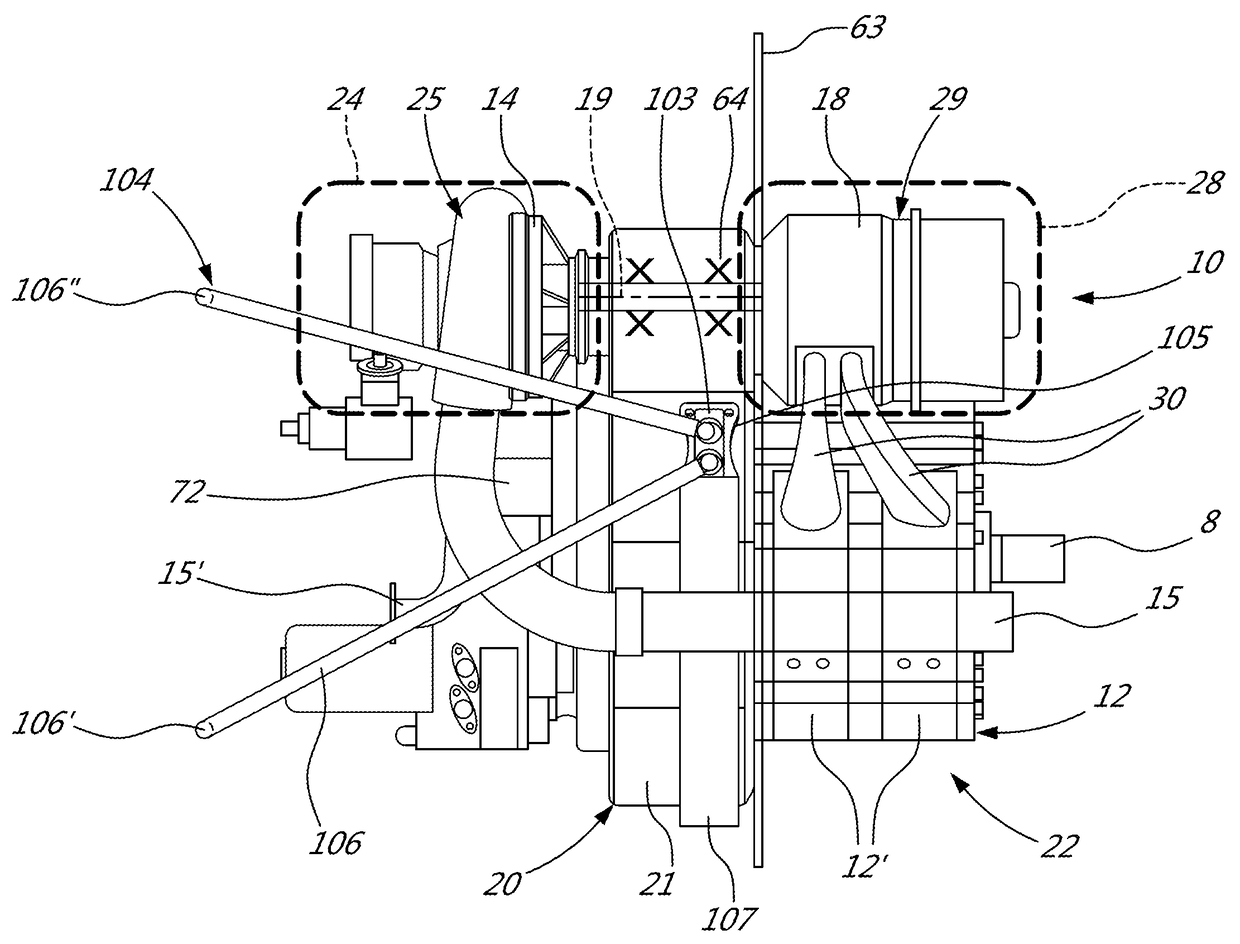

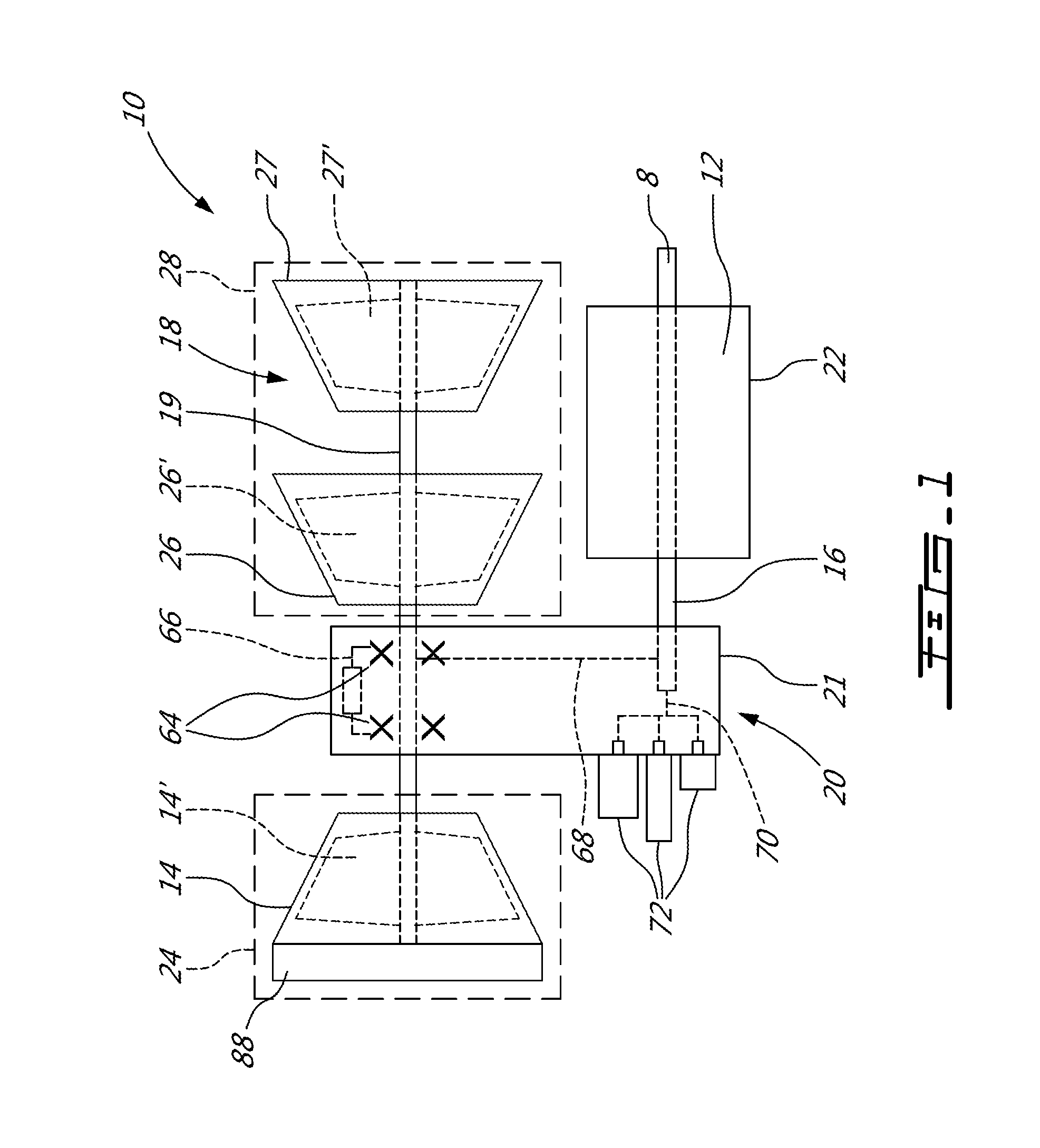

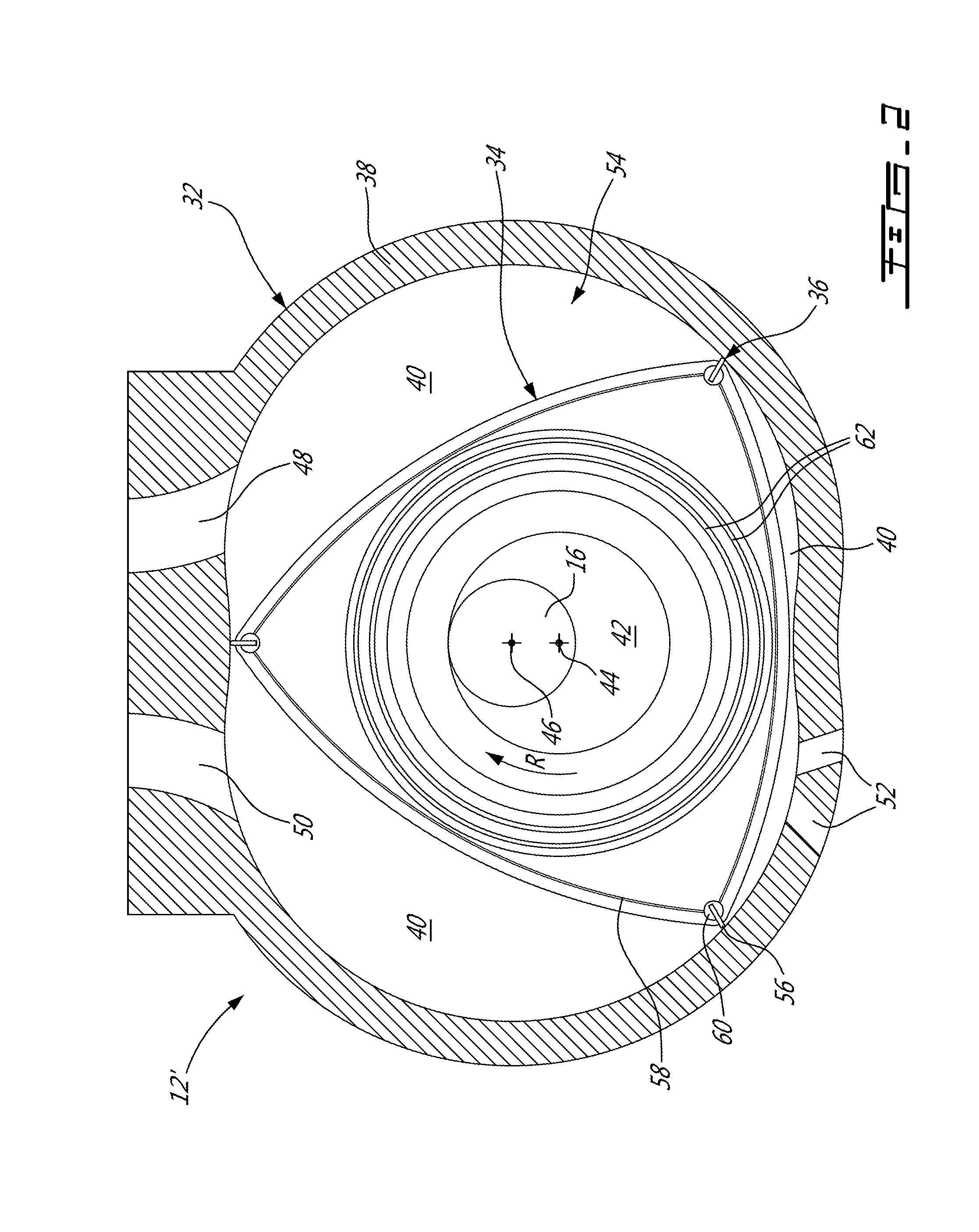

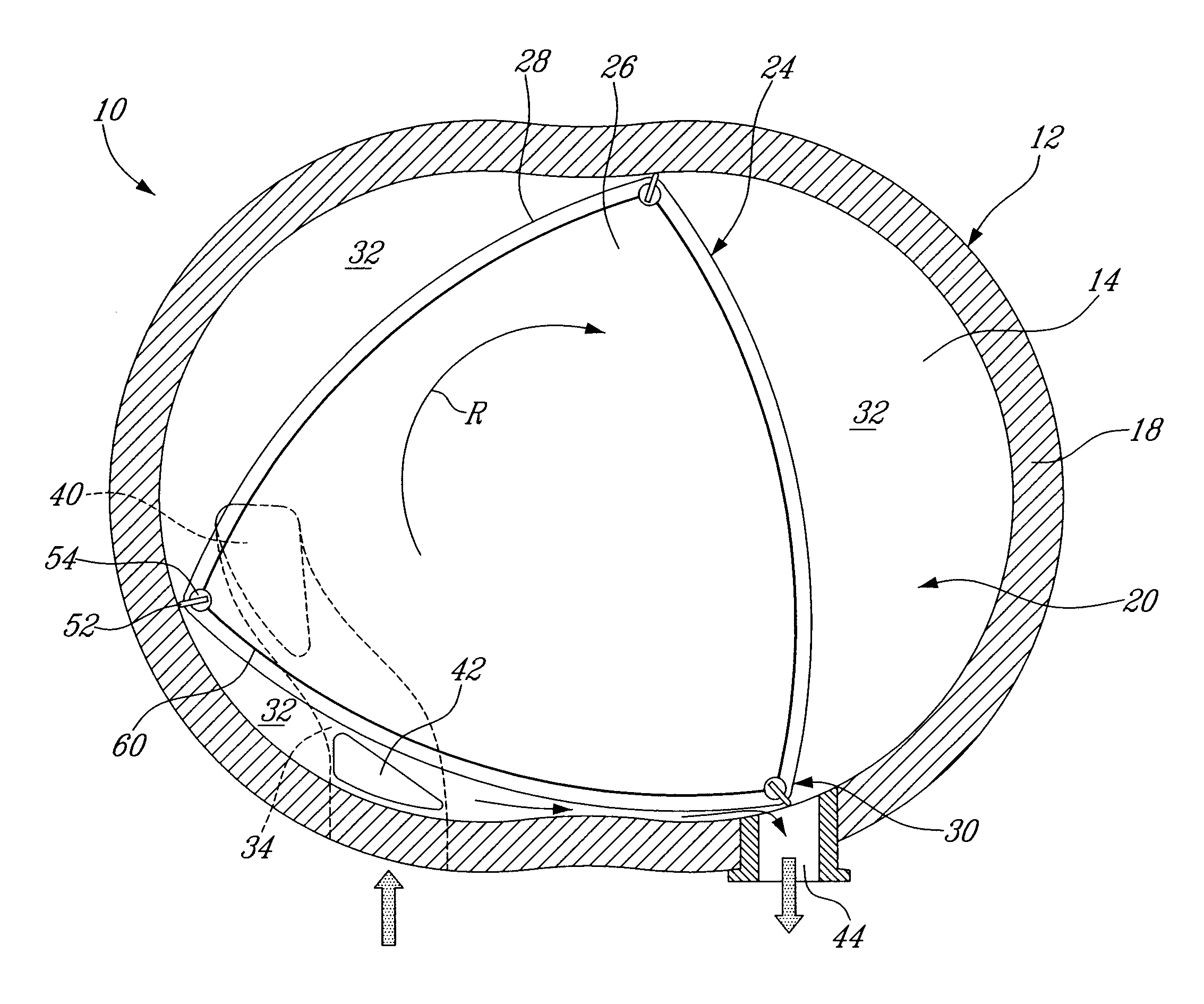

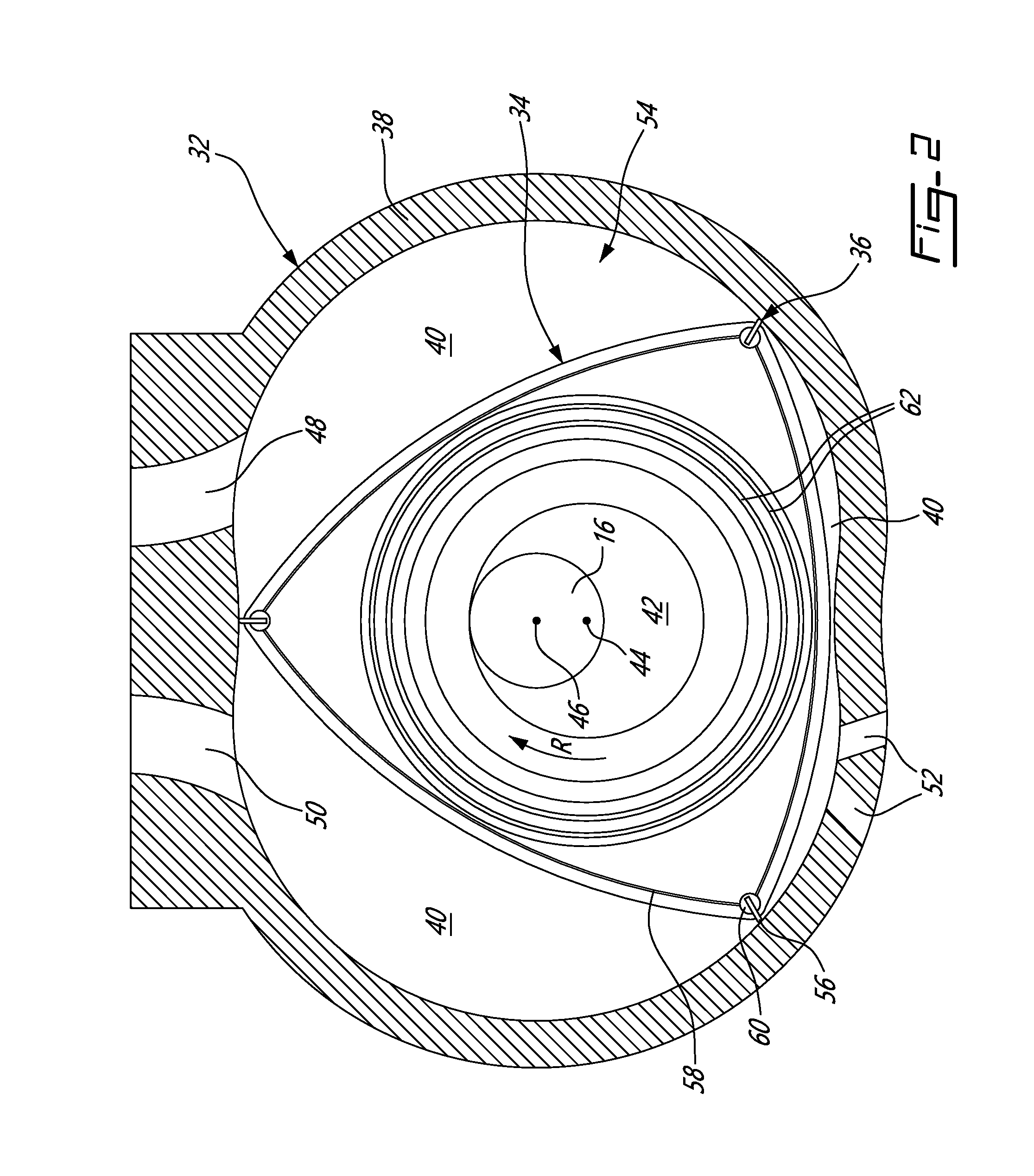

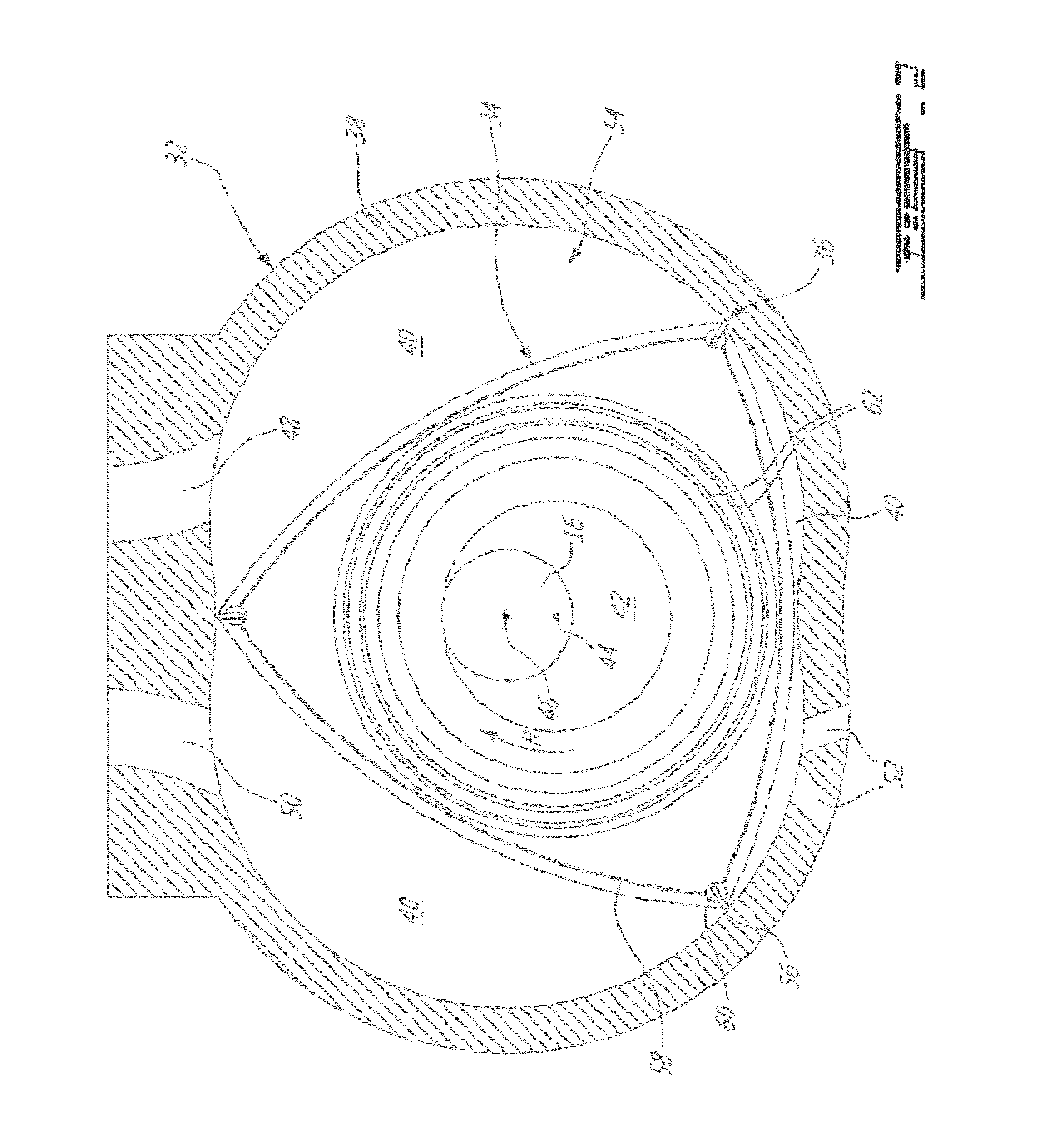

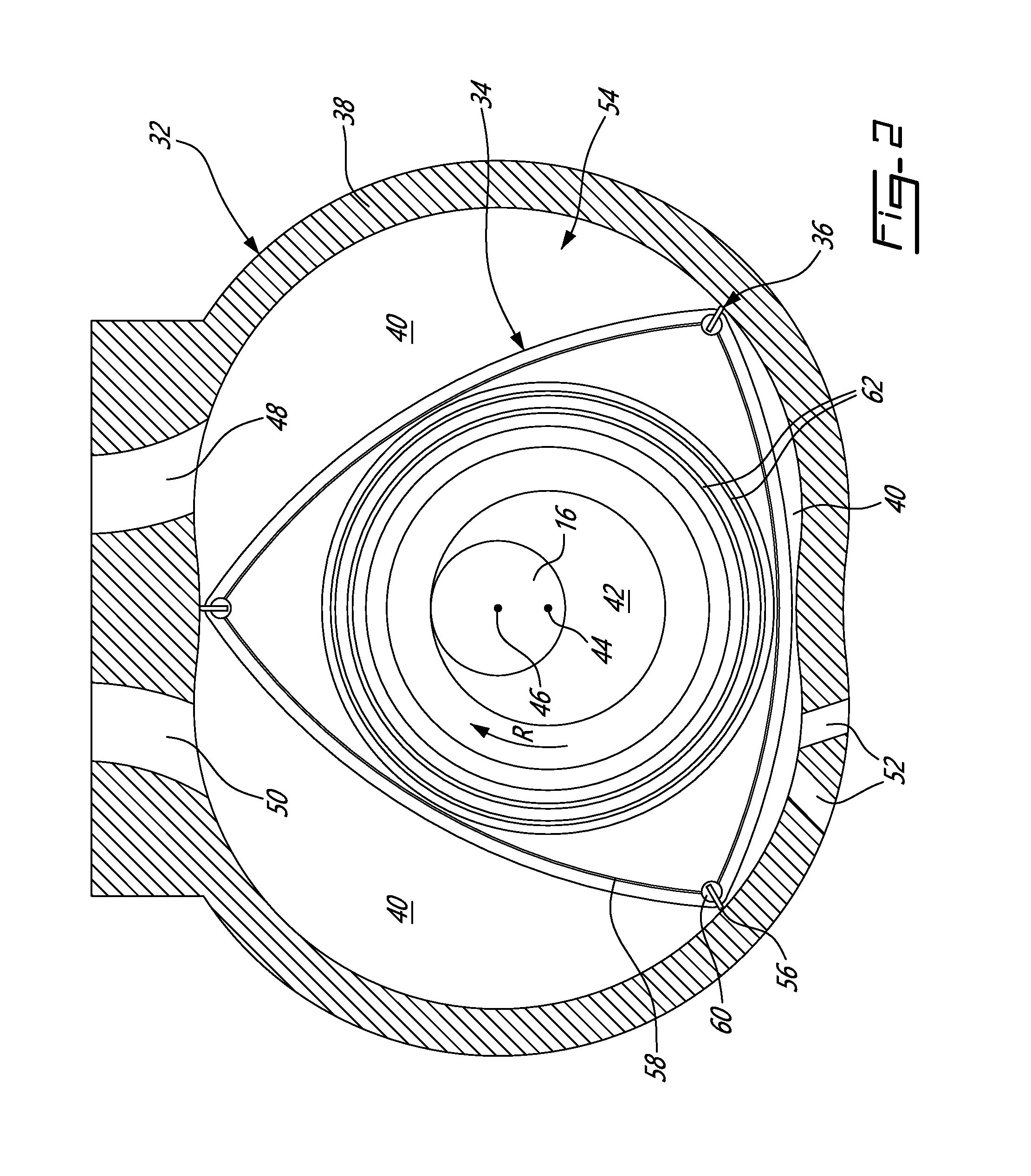

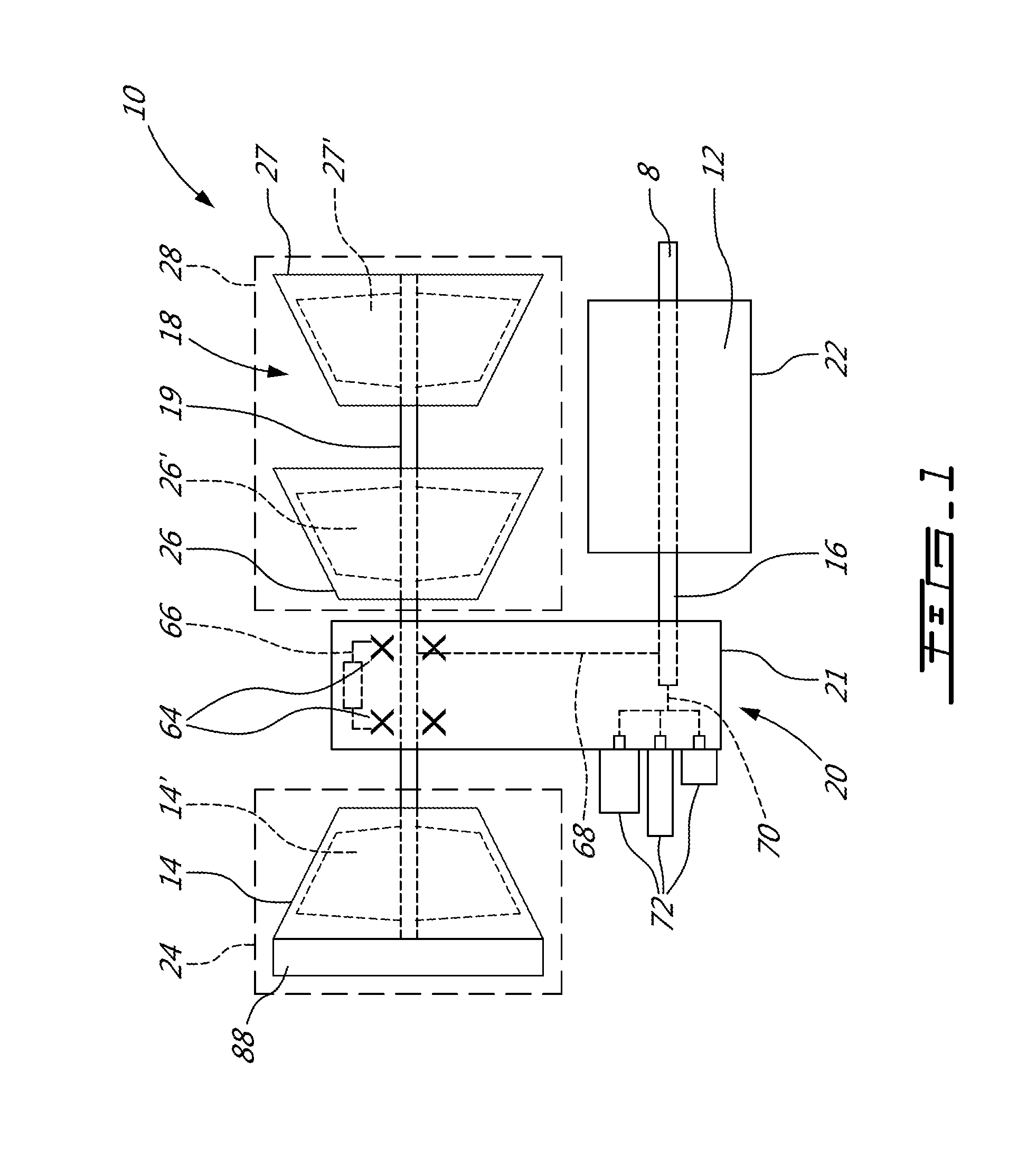

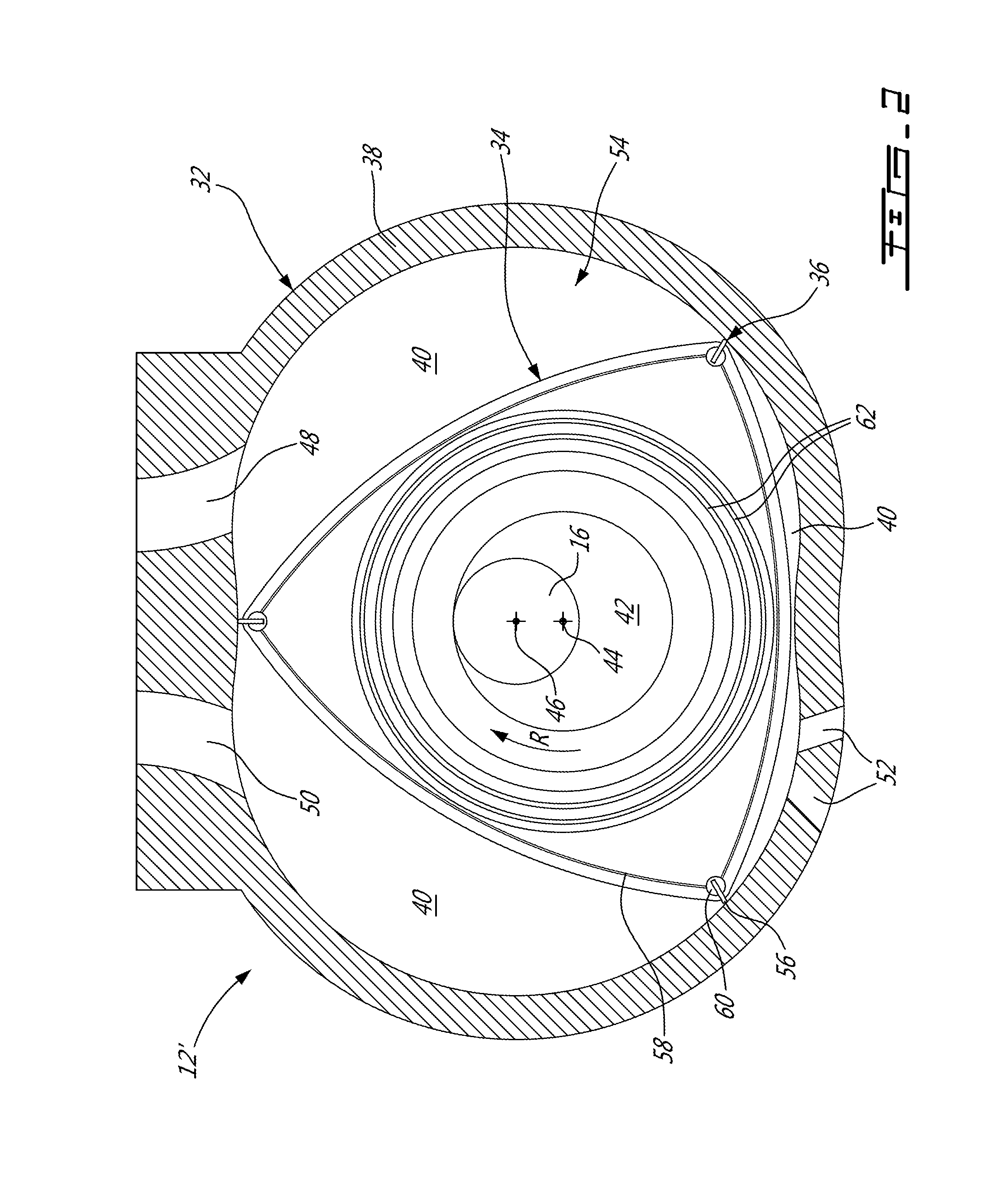

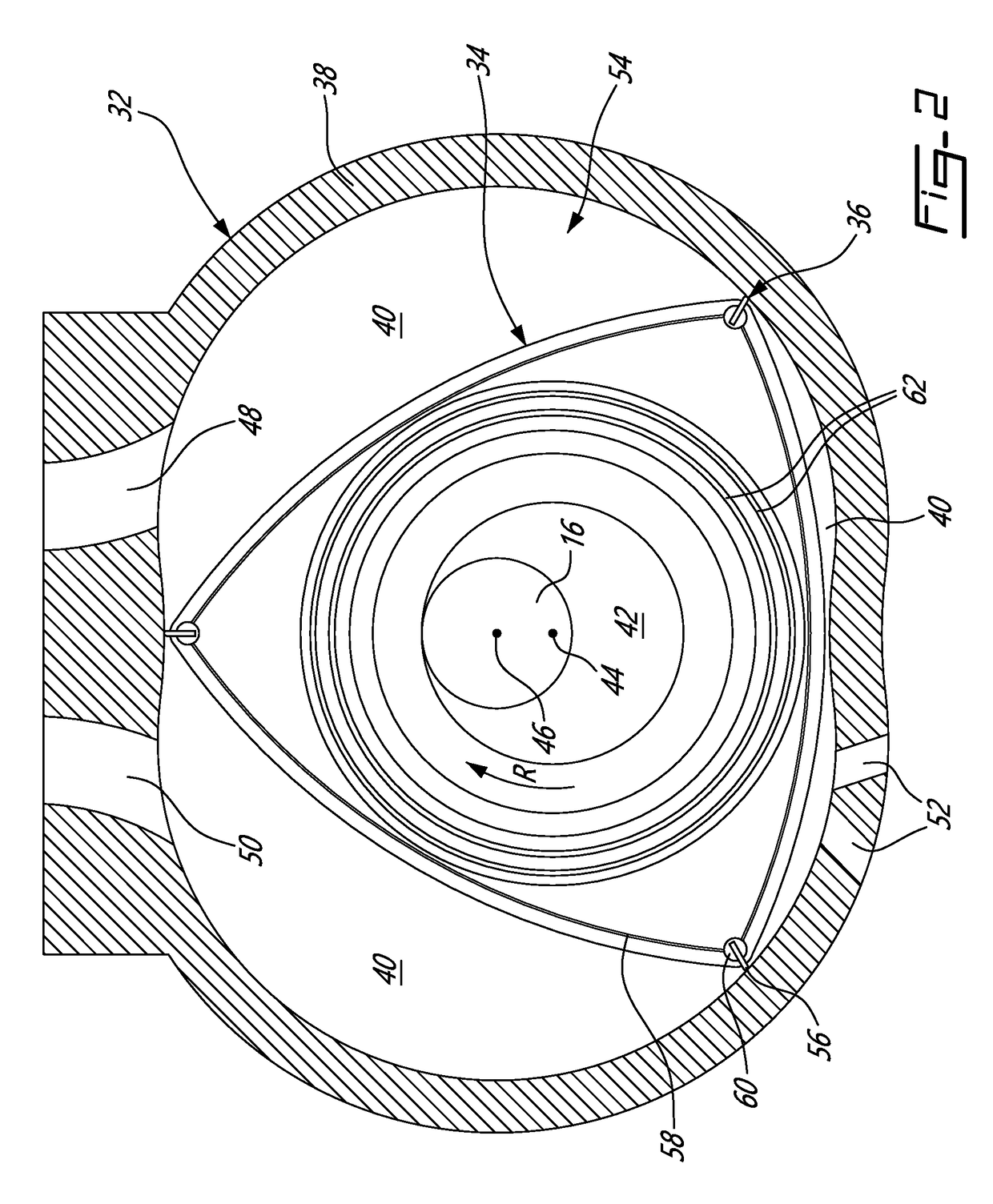

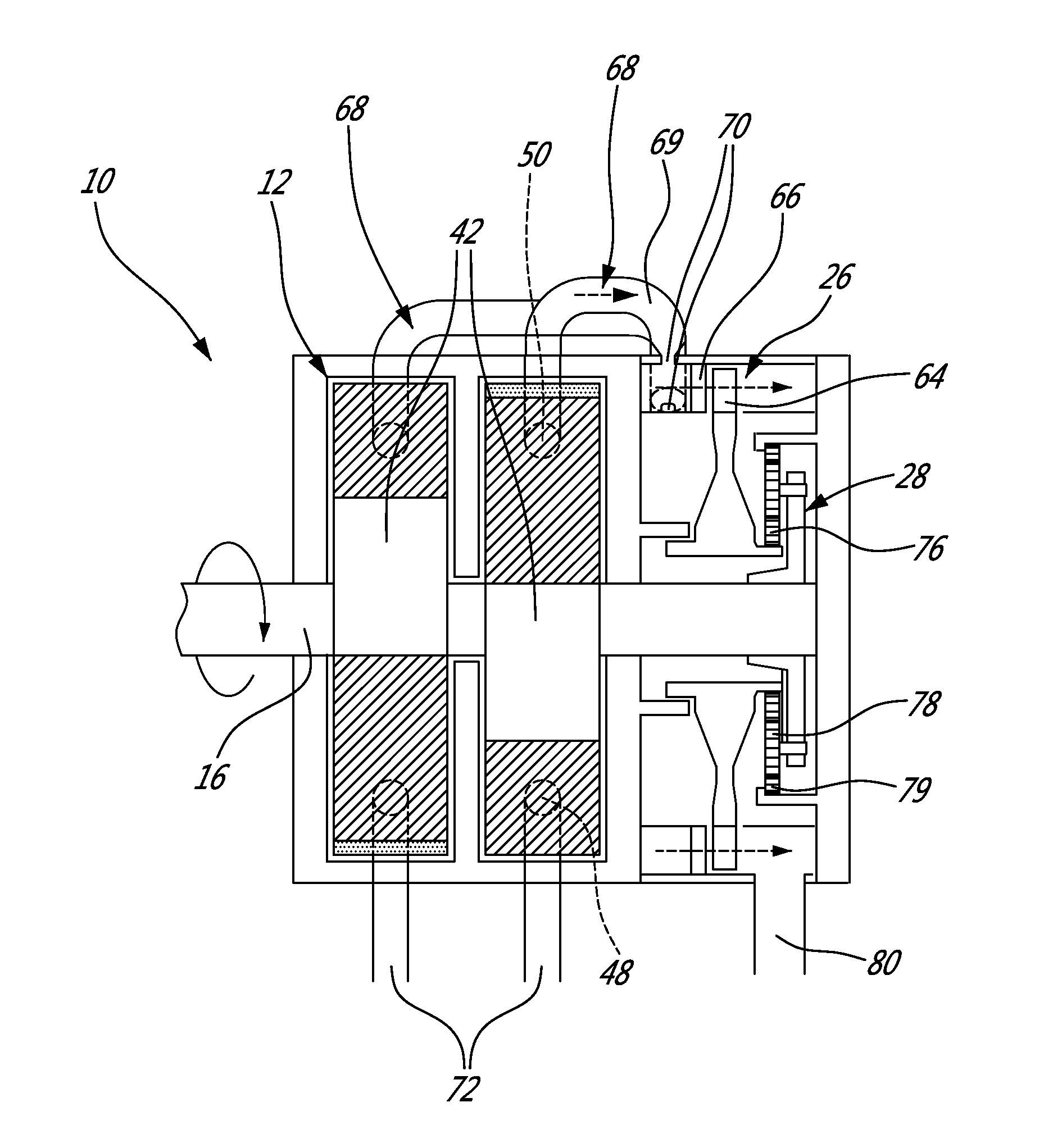

Compound engine system with rotary engine

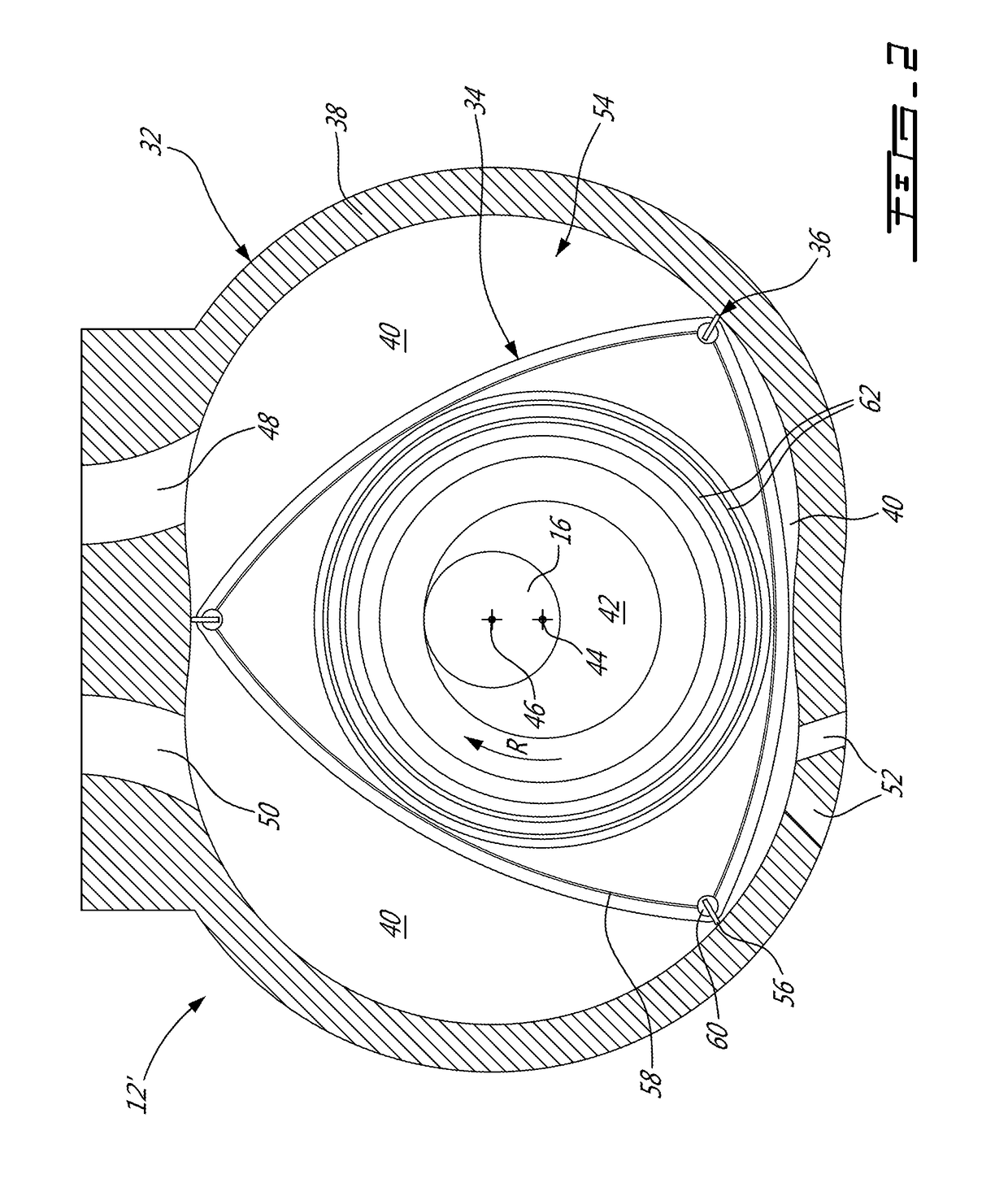

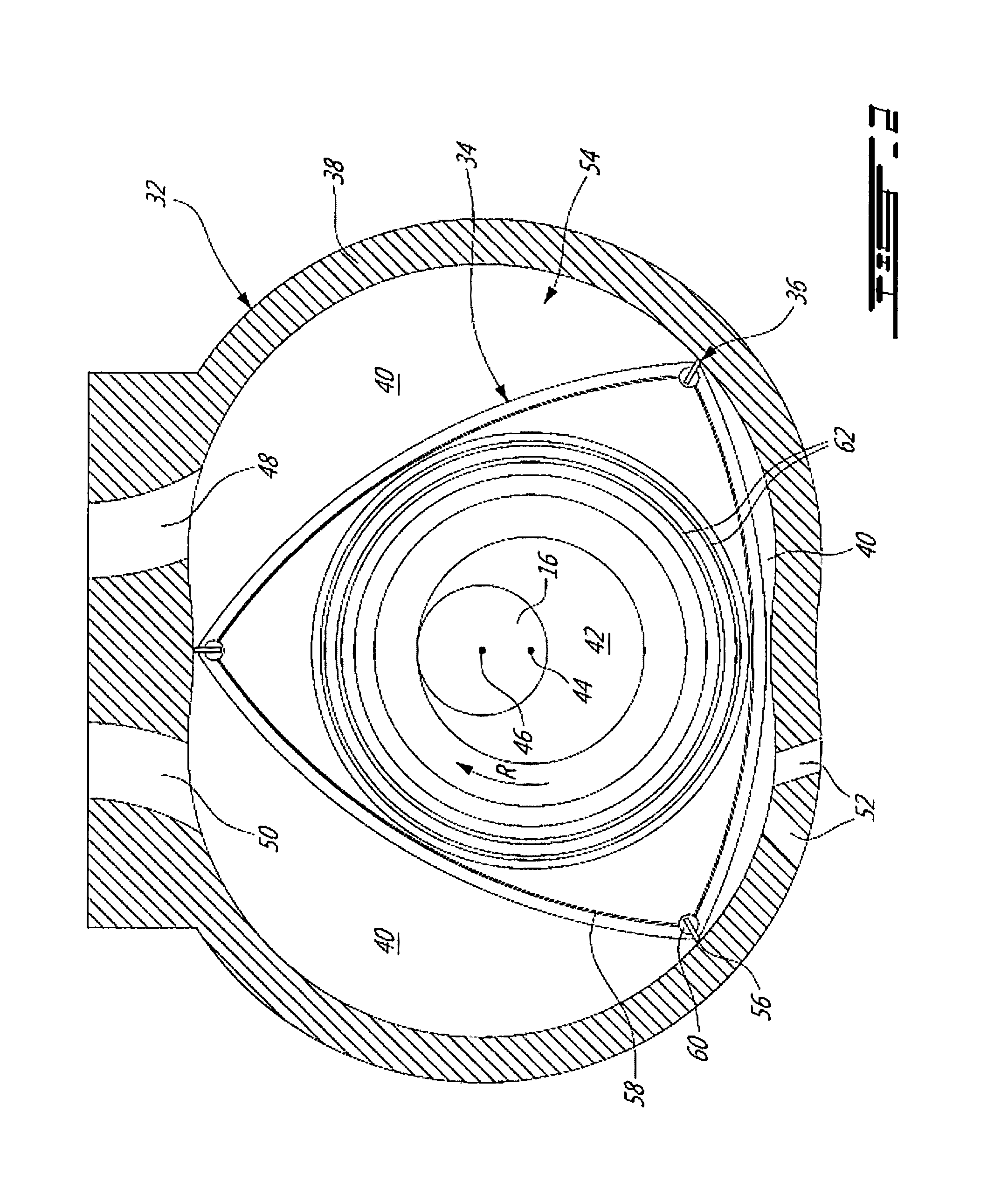

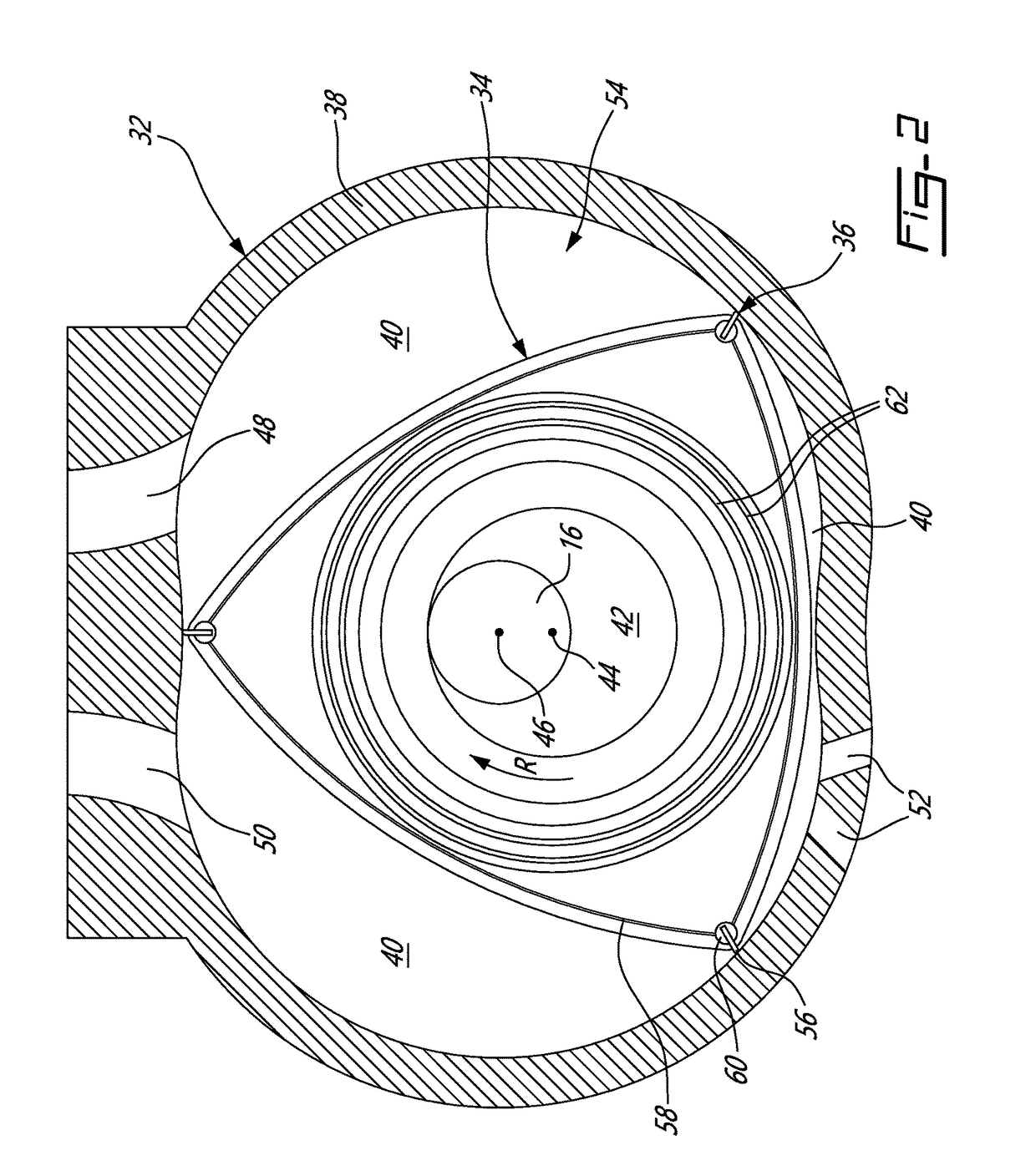

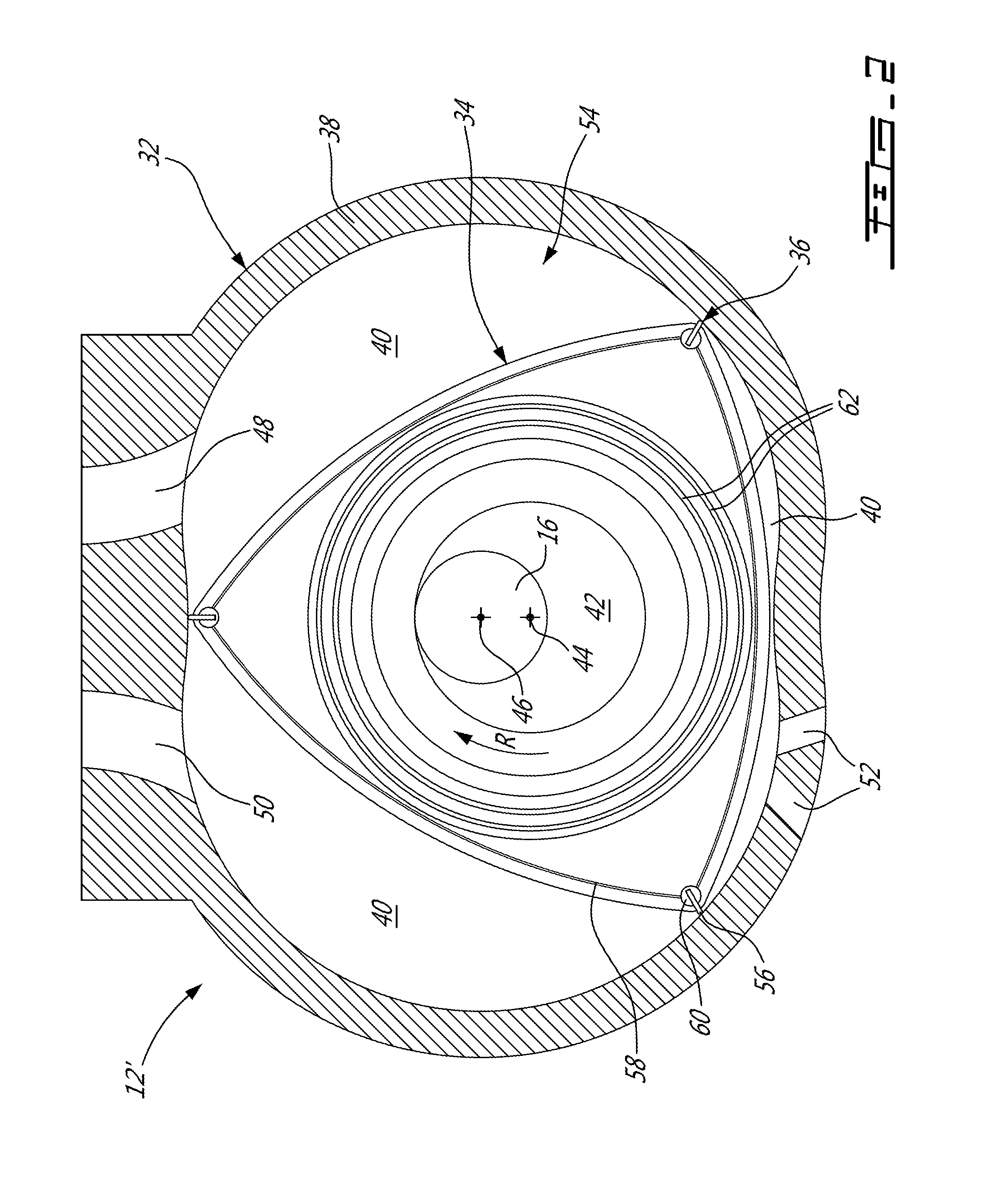

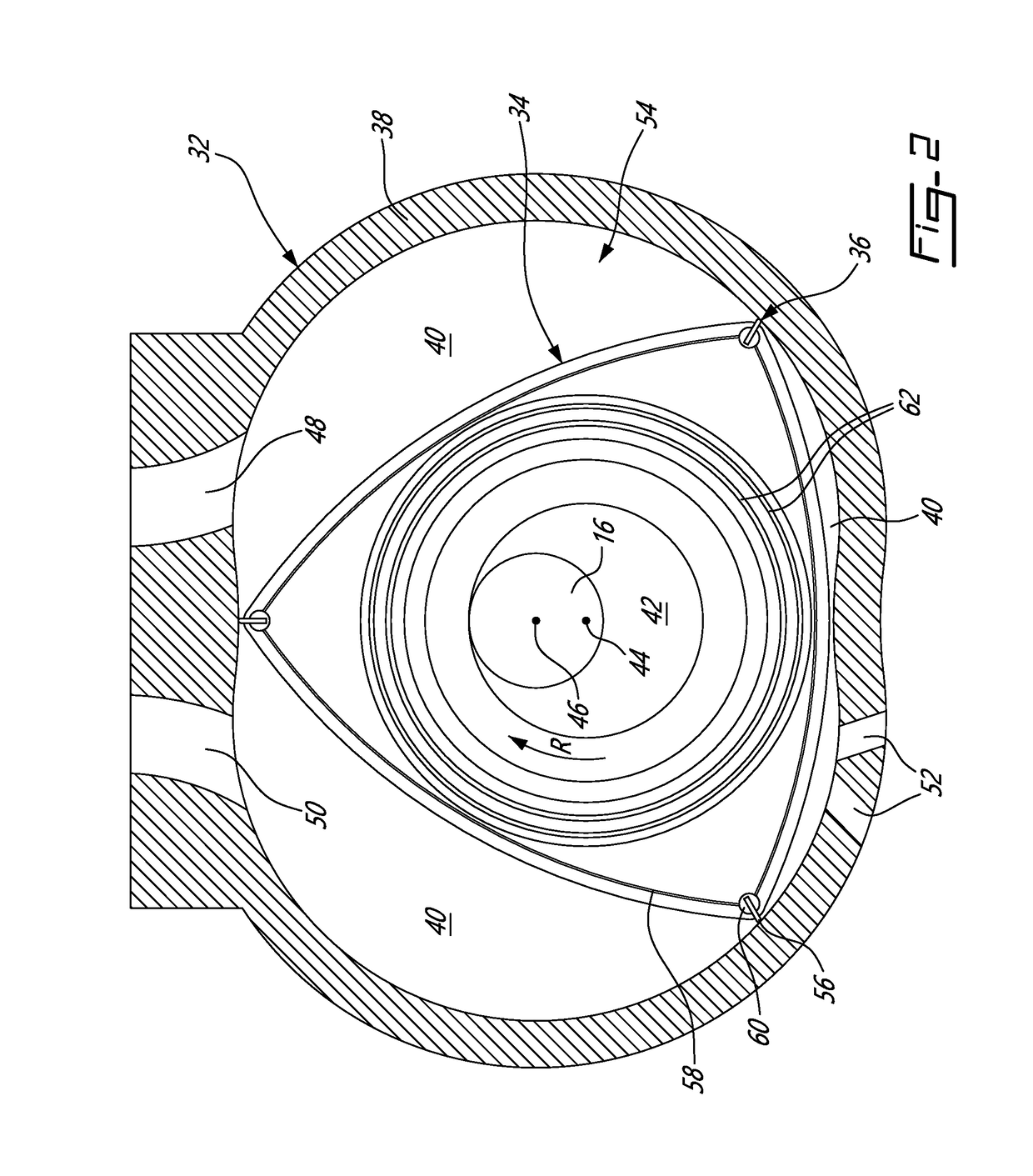

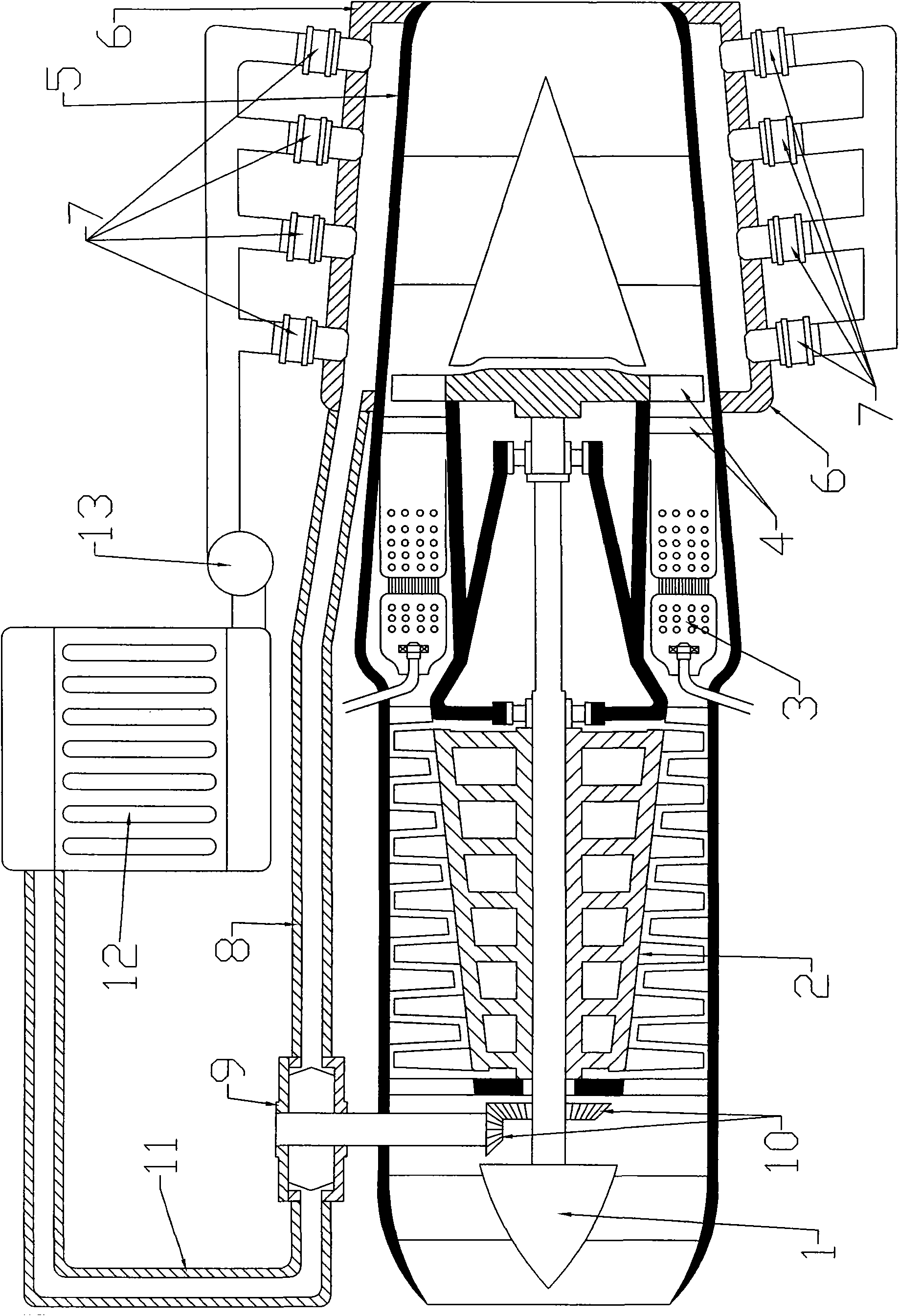

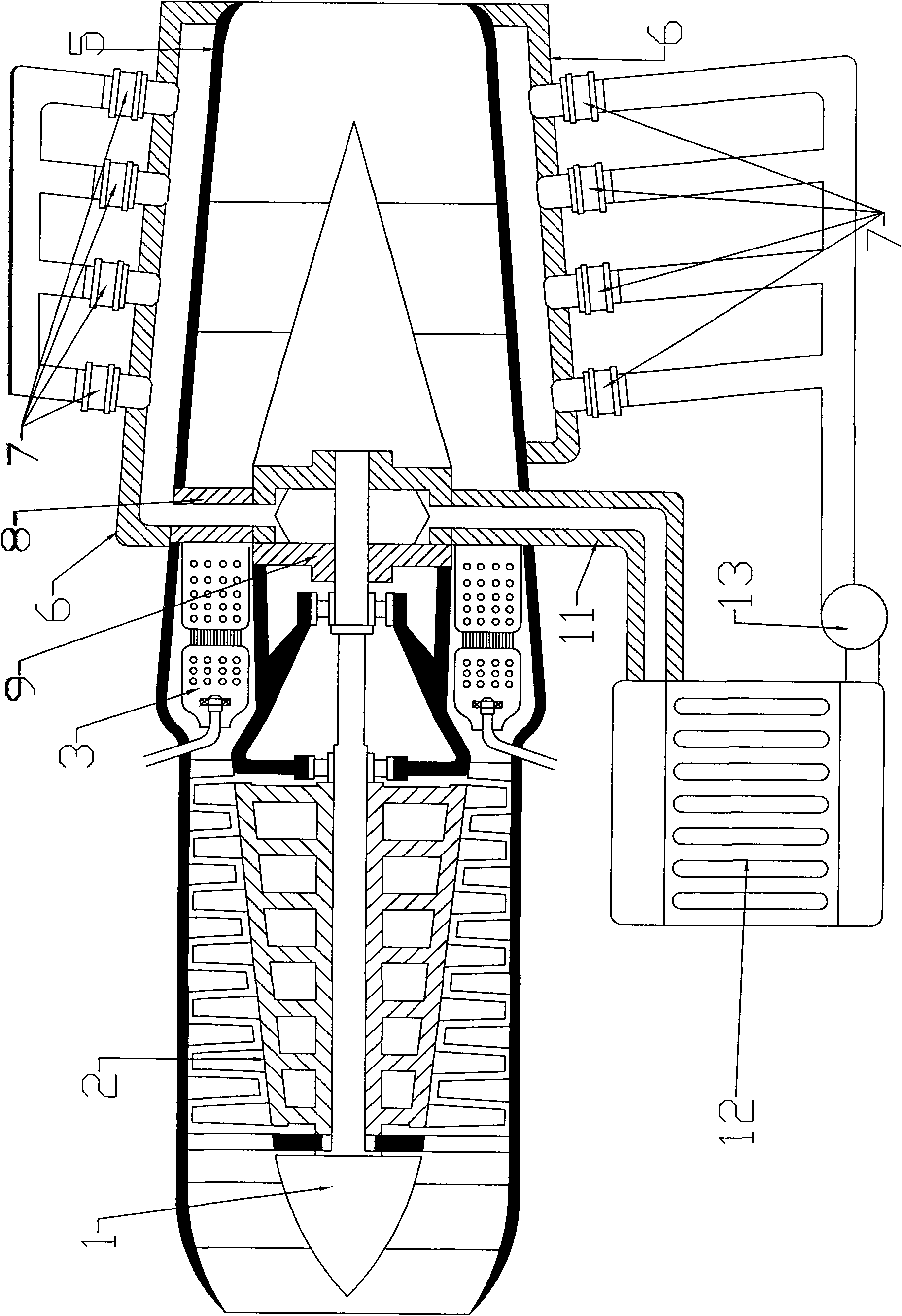

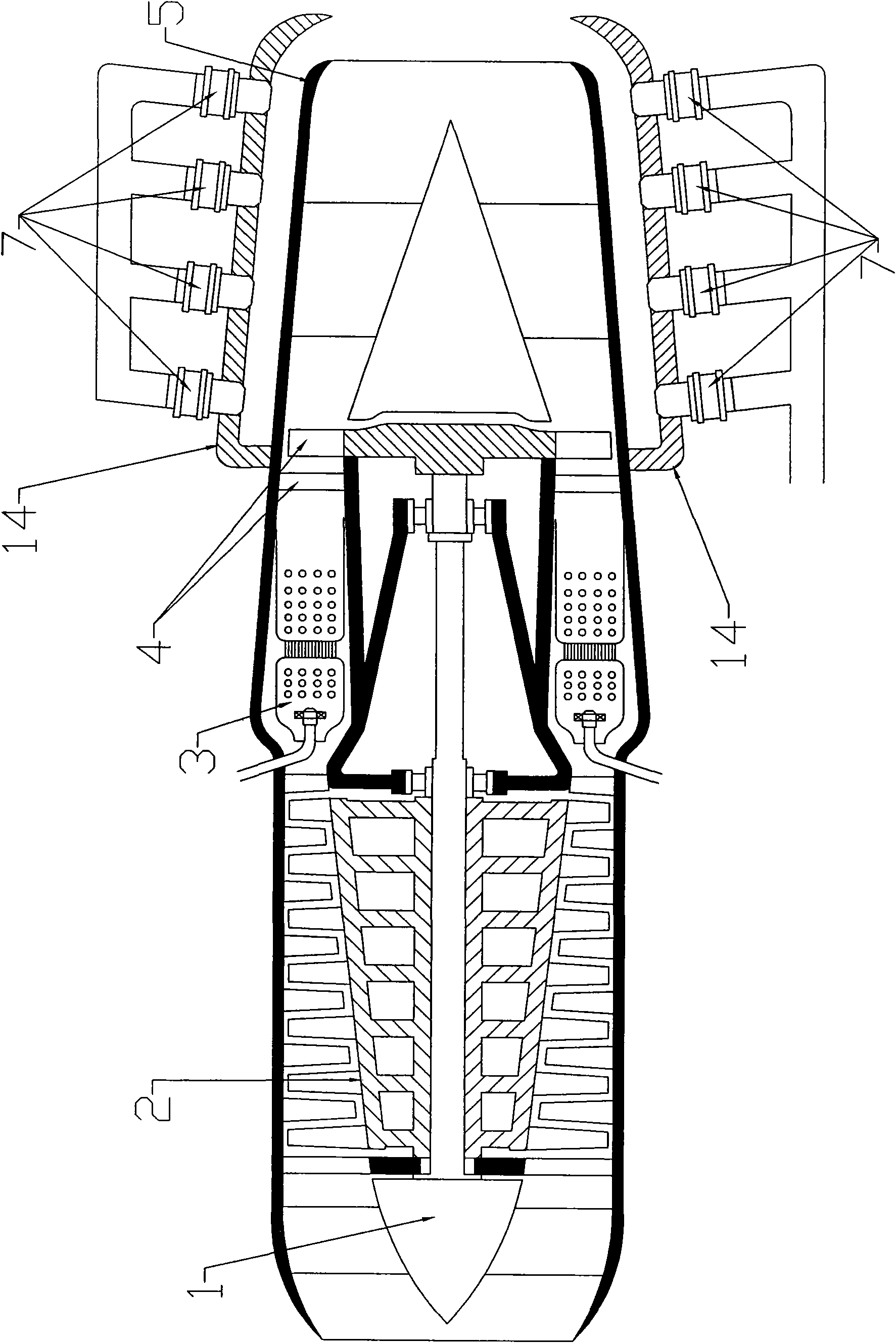

ActiveUS20130028772A1Reduce the compression ratioImprove combustion stabilityInternal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

A compound engine system comprising a rotary engine having a volumetric compression ratio lower than its volumetric expansion ratio, and a recess defined in the peripheral wall of the rotor in each of the chambers having a volume of more than 5% of the displacement volume of the chamber. The expansion in the turbine section compensates for the relatively low expansion ratio of the rotary engine.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with cantilevered compressor and turbine

ActiveUS20160245163A1Internal combustion piston enginesEngine fuctionsInternal combustion engineCompound engine

A compound engine assembly with an engine core including at least one internal combustion engine, a compressor, and a turbine section where the turbine shaft is configured to compound power with the engine shaft. The turbine section may include a first stage turbine and a second stage turbine. The turbine shaft is rotationally supported by a plurality of bearings all located on a same side of the compressor rotor(s) and all located on a same side of the turbine rotor(s), for example all located between the compressor rotor(s) and the turbine rotor(s), such that the compressor rotor(s) and the turbine rotor(s) are cantilevered. A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

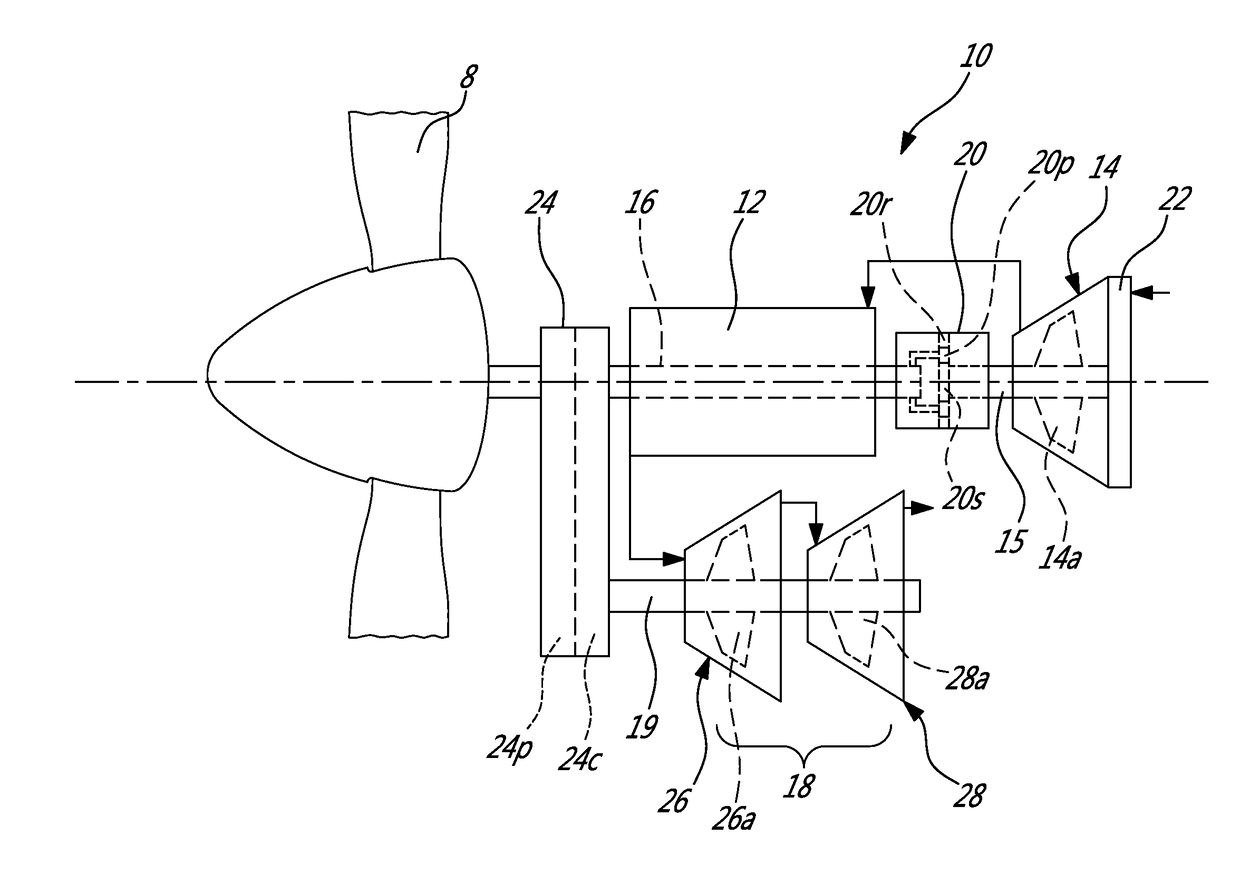

Compound engine assembly with coaxial compressor and offset turbine section

ActiveUS20160245166A1Engine manufactureInternal combustion piston enginesInternal combustion engineTurbine

A compound engine assembly having an engine core including at least one internal combustion engine in driving engagement with an engine shaft, a compressor having an outlet in fluid communication with an inlet of the engine core and including at least one rotor rotatable about an axis coaxial with the engine shaft, the engine shaft in driving engagement with the compressor rotor, and a turbine section having an inlet in fluid communication with an outlet of the engine core and including at least one rotor engaged on a rotatable turbine shaft, the turbine shaft configured to compound power with the engine shaft. The turbine and engine shafts are parallel to and radially offset from one another, and the turbine shaft and the axis of the compressor rotor are parallel to and radially offset from one another. A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with common inlet

ActiveUS20160245154A1Internal combustion piston enginesTurbine/propulsion engine coolingInternal combustion engineHeat exchanger

A compound engine assembly including an air conduit having an inlet in fluid communication with ambient air around the compound engine assembly, a compressor having an inlet in fluid communication with the air conduit, an engine core including at least one rotary internal combustion engine and having an inlet in fluid communication with an outlet of the compressor, a turbine section having an inlet in fluid communication with an outlet of the engine core and configured to compound power with the engine core; and at least one heat exchanger in fluid communication with the air conduit, each heat exchanger configured to circulate a fluid of the engine assembly in heat exchange relationship with an airflow from the air conduit circulating therethrough. A method of supplying air to a compound engine assembly is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

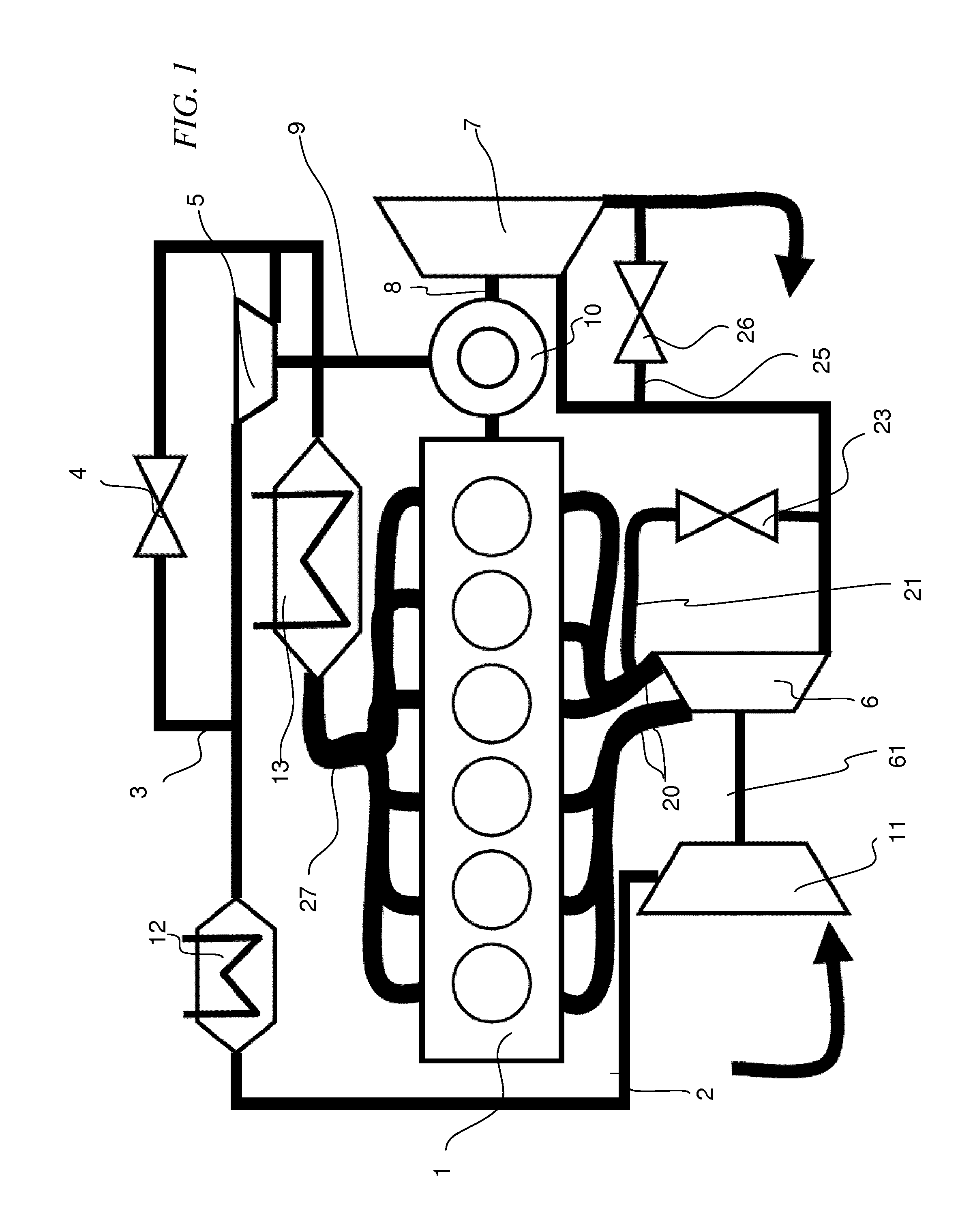

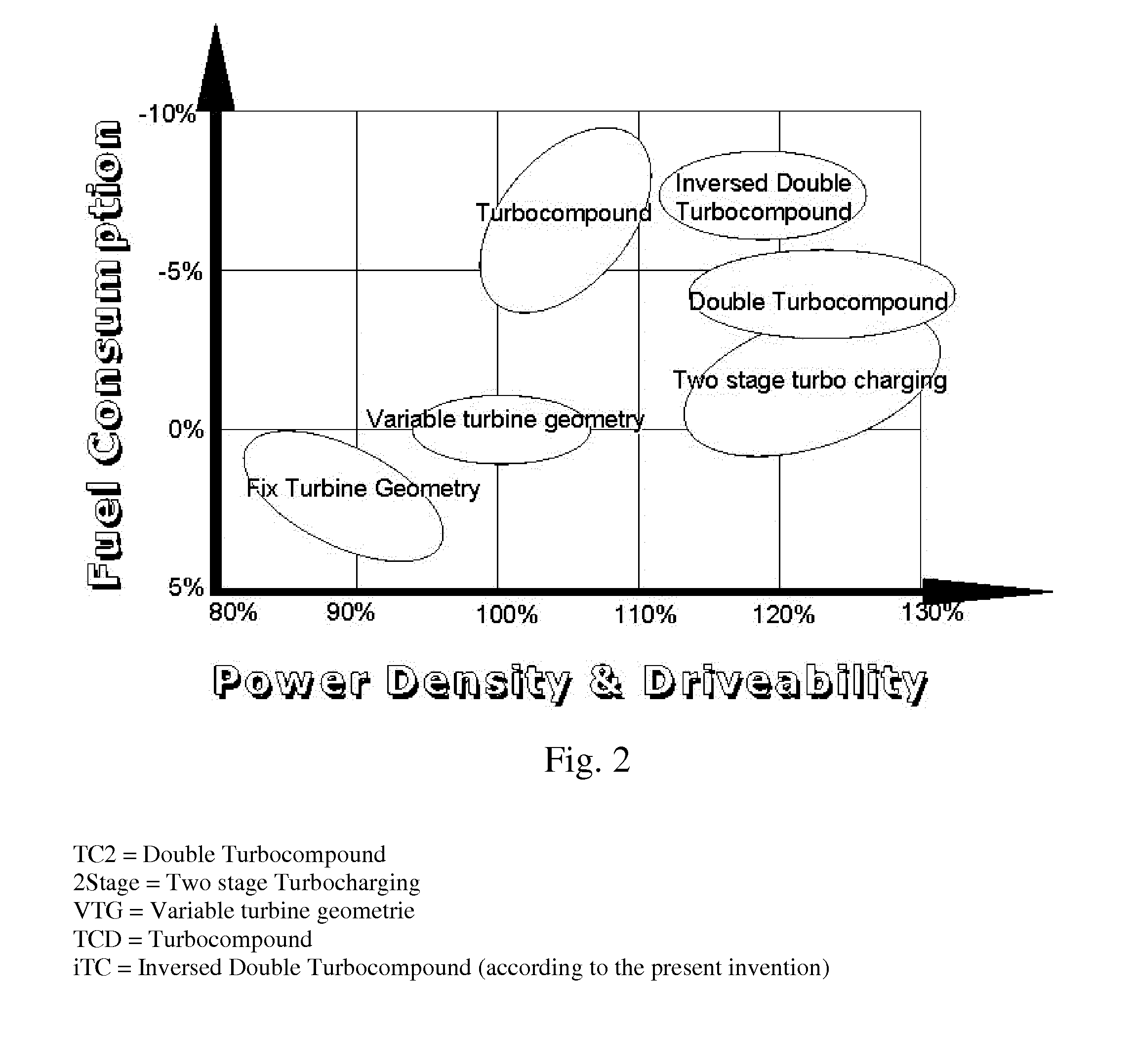

Supercharged turbocompound hybrid engine apparatus

ActiveUS20140190163A1Reduce fuel consumptionImprove power densityHybrid vehiclesInternal combustion piston enginesTurbo-compound engineEngineering

The present invention is relative to a control method of a turbo-compound engine apparatus wherein said apparatus comprises a low pressure compressor connected to the high pressure turbine and a low pressure turbine connected to a high pressure compressor by means of a coupling unit. The apparatus also comprises first bypassing means of said high pressure compressor. The method according to the invention comprises the step of deactivating said first bypassing means when at least a specific condition occurs.

Owner:FPT MOTORENFORSCHUNG

Compound engine assembly with modulated flow

ActiveUS20160245161A1Power plant cooling arrangmentsInternal combustion piston enginesEngineeringInternal combustion engine

A compound engine assembly including a compressor, an engine core including at least one rotary internal combustion engine and having an inlet in fluid communication with an outlet of the compressor, a turbine section having an inlet in fluid communication with an outlet of the engine core and configured to compound power with the engine core, and an air conduit having at least one heat exchanger extending thereacross. An outer wall of the air conduit has a plurality of openings defined therethrough downstream of the heat exchanger(s), each selectively closable by a pivotable flap movable between a retracted position where the opening is obstructed and an extended position away from the opening. Each opening defines a fluid communication between the air conduit and the ambient air when the respective flap is in the extended position. A method of directing flow through a compound engine assembly is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with common inlet

ActiveUS9797297B2Internal combustion piston enginesCombination enginesExternal combustion engineEngineering

A compound engine assembly including an air conduit having an inlet in fluid communication with ambient air around the compound engine assembly, a compressor having an inlet in fluid communication with the air conduit, an engine core including at least one rotary internal combustion engine and having an inlet in fluid communication with an outlet of the compressor, a turbine section having an inlet in fluid communication with an outlet of the engine core and configured to compound power with the engine core; and at least one heat exchanger in fluid communication with the air conduit, each heat exchanger configured to circulate a fluid of the engine assembly in heat exchange relationship with an airflow from the air conduit circulating therethrough. A method of supplying air to a compound engine assembly is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with inlet lip Anti-icing

ActiveUS20160245174A1Engine manufactureInternal combustion piston enginesFlight vehicleRotary engine

A compound engine assembly with an inlet duct having an inlet surrounded by an inlet lip including at least one conduit extending therethrough, a compressor, an engine core including at least one internal combustion engine, a turbine section having a turbine shaft in driving engagement with the engine shaft, and an exhaust conduit providing a fluid communication between the outlet of the turbine section and the conduit(s) of the inlet lip. An exhaust duct and ant exhaust conduit providing a fluid communication between the outlet of the turbine section and the exhaust duct may also be provided. The internal combustion engine(s) may be rotary engine(s). A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with mount cage

ActiveUS20160245171A1Internal combustion piston enginesPiston type power plantsInternal combustion engineTurbine

A compound engine assembly with an engine core including at least one internal combustion engine, a turbine section, and a compressor having an outlet in fluid communication with an inlet of the engine core. A casing is connected to the turbine section, compressor and engine core. A mount cage is connected to mounts attached to the casing between the compressor and a hot zone including the turbine section and exhaust pipe(s). The struts are separated from the hot zone by at least one firewall. The mount cage may include a plurality of struts all extending from the mounts away from the turbine section and engine core. The casing may be a gearbox module casing through which the turbine shaft in engaged with the engine shaft. The mount cage may be completely contained within an axial space with the turbine section and exhaust pipe(s) being located outside of the axial space.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with coaxial compressor and offset turbine section

ActiveUS9932892B2Engine manufactureInternal combustion piston enginesInternal combustion engineTurbine

A compound engine assembly having an engine core including at least one internal combustion engine in driving engagement with an engine shaft, a compressor having an outlet in fluid communication with an inlet of the engine core and including at least one rotor rotatable about an axis coaxial with the engine shaft, the engine shaft in driving engagement with the compressor rotor, and a turbine section having an inlet in fluid communication with an outlet of the engine core and including at least one rotor engaged on a rotatable turbine shaft, the turbine shaft configured to compound power with the engine shaft. The turbine and engine shafts are parallel to and radially offset from one another, and the turbine shaft and the axis of the compressor rotor are parallel to and radially offset from one another. A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Compound engine assembly with offset turbine shaft, engine shaft and inlet duct

InactiveUS20160245162A1Internal combustion piston enginesEngine manufactureInternal combustion engineTurbine

A compound engine assembly with an inlet duct, a compressor, an engine core including at least one internal combustion engine, and a turbine section including a turbine shaft configured to compound power with the engine shaft. The turbine section may include a first stage turbine and a second stage turbine. The turbine shaft and the engine shaft are parallel to each other. The turbine shaft, the engine shaft and at least part of the inlet duct are all radially offset from one another. A method of driving a rotatable load of an aircraft is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Low-cost oil-based annulus protection fluid applicable to CO2 flooding well and preparation method thereof

InactiveCN107603579AReduce corrosionImprove protectionBorehole/well accessoriesHydantoin derivativesMorpholine

The invention provides low-cost oil-based annulus protection fluid applicable to a CO2 flooding well and a preparation method thereof and belongs to the technical field of corrosion protection of an oil and gas well. A low-cost oil-based annulus protection fluid system applicable to the CO2 flooding well is prepared by compounding engine oil, a corrosion inhibitor, a bactericide, an oxygen removing agent, a density regulator and a surfactant. The annulus protection fluid is prepared from the following components in percentage by mass: 1 percent to 3 percent of a morpholine derivative compoundcorrosion inhibitor, 0.8 percent to 1.6 percent of halogenated hydantoin bactericide, 3 percent to 5 percent of the oxygen removing agent, 5 percent to 30 percent of an organic acid salt density regulator, 3 percent to 5 percent of a non-ionic type polyoxyethylene type surfactant and the balance of the engine oil. The oil-based annulus protection fluid provided by the invention has a very good protection effect on a shaft tubular column of the CO2 flooding well and has the advantages of good high-temperature stability, good low-temperature freezing resistance and long-period stability; meanwhile, the refrigeration engine oil is used as a dispersant, so that the low-cost oil-based annulus protection fluid has the advantages of low cost and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Jet-steam compound engine with spray liquid evaporating on hot wall

InactiveCN101539066AImprove thermal efficiencyReduce vibrationInternal combustion piston enginesGas turbine plantsCombustion chamberGas compressor

The invention relates to a jet-steam compound engine with spray liquid evaporating on a hot wall. The compound engine mainly consists of an aerojet engine, a gas compressor, a combustion chamber, a turbine, an exhaust cone, a closed interlayer shell, a spraying nozzle, a steam conduit, a steam turbine, a cone gear, a steam discharge pipe, a condensation radiator, a water pump, a tail opening interlayer shell, a turboprop, a circular surrounding fixed housing, a steel pipe, a propeller, a turbo propeller fan engine, a petal type spray pipe, a circular tube housing, a steam turbine and other parts. The compound engine is high in heat efficiency, energy-saving, small in vibration, low in noise, simple in structure, mature in the technology and the like and can be widely applied to various airplanes and power generation plants.

Owner:王鑫弘

Compound engine assembly with modulated flow

ActiveUS9896998B2Internal combustion piston enginesCombination enginesExternal combustion engineEngineering

A compound engine assembly including a compressor, an engine core including at least one rotary internal combustion engine and having an inlet in fluid communication with an outlet of the compressor, a turbine section having an inlet in fluid communication with an outlet of the engine core and configured to compound power with the engine core, and an air conduit having at least one heat exchanger extending thereacross. An outer wall of the air conduit has a plurality of openings defined therethrough downstream of the heat exchanger(s), each selectively closable by a pivotable flap movable between a retracted position where the opening is obstructed and an extended position away from the opening. Each opening defines a fluid communication between the air conduit and the ambient air when the respective flap is in the extended position. A method of directing flow through a compound engine assembly is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

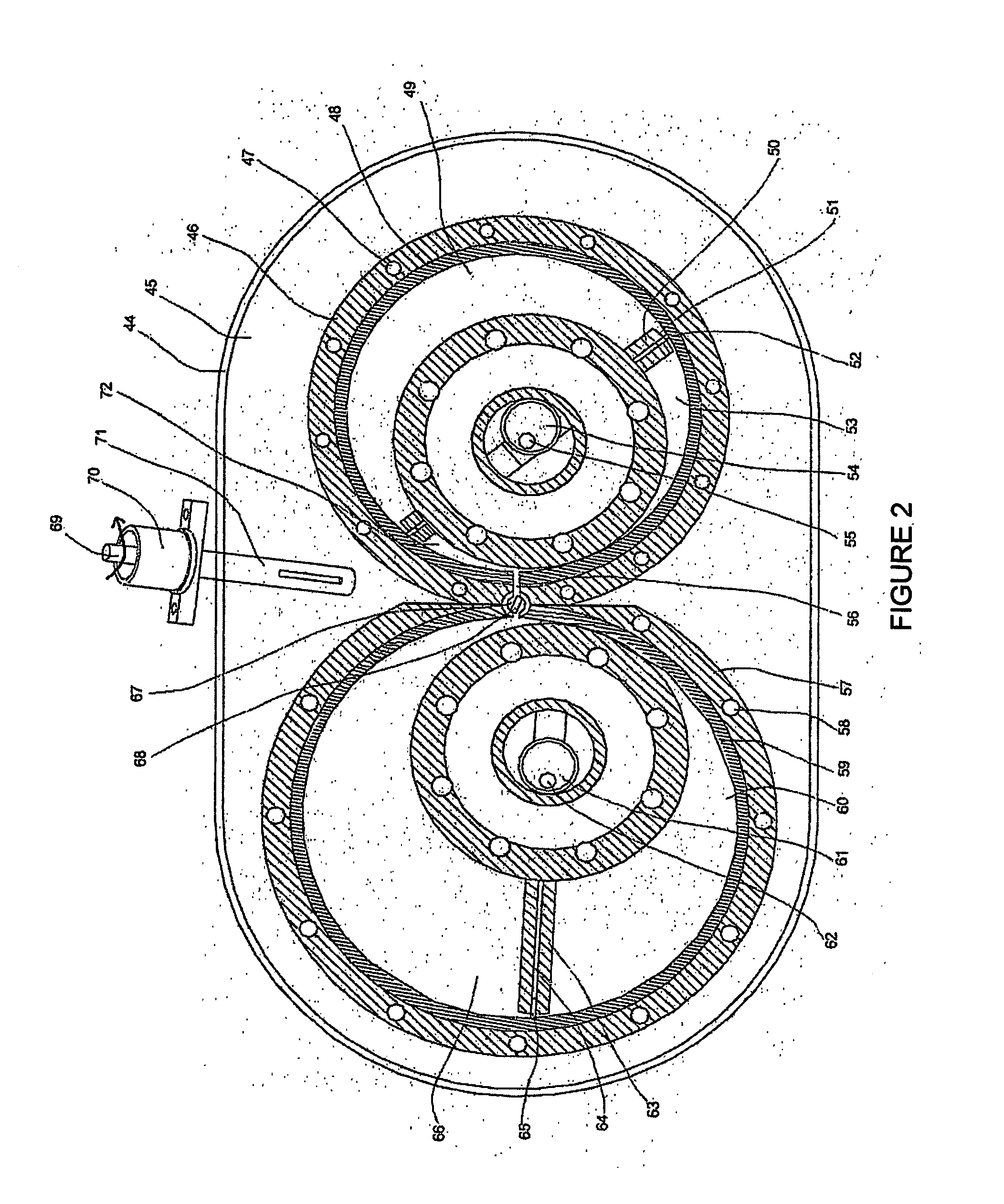

Rotary vane engine and thermodynamic cycle

InactiveUS20060124101A1Improve thermal efficiencyIncrease the compression ratioInternal combustion piston enginesPump componentsRotary enginePropeller

For low mass flow, the solo use of the turbo-rotary engine overcomes the limitations of conventional internal combustion engines and enable significant improvement in power, torque and efficiency. The solo configurations (FIG. 1, 2, 3, 4) of the invention comprise compressor (48) and turbine housings (59), each housing receiving an eccentrically placed rotor (135), equipped by a single sliding vane (50, 63). Contact wear of the sliding vane tips (86, 109) with the chamber non-circular cycloidal peripheral (88, 97), is eliminated by a pivot axle vane retention mechanism (139, 150). For high mass flow rate, a compound configuration (FIGS. 8, 9, 10) of rotary compressors and turbines with conventional gas turbine engine components. Allows an improvement in efficiency and performance. Conventional long and heavy concentric main shafts are eliminated. In this invention, rotary turbines drive compressors (158), fans (153), propellers and rotary wings (186). In return, the conventional turbines (171) drives a plurality or rotary compressors (164, 166, 168). The compound engine of the invention combines the thermal efficiency of the rotary internal engine cycle (151) and the high mass flow, high power, compact size and light weight of the gas turbine engines.

Owner:AKMANDOR IBRAHIM SINAN +1

Compound engine assembly with exhaust pipe nozzle

ActiveUS20160369693A1Valve arrangementsInternal combustion piston enginesExternal combustion engineRotary engine

A compound engine assembly with at least one rotary internal combustion engine, an impulse turbine, and an exhaust pipe for each internal combustion engine providing fluid communication between the exhaust port of the respective internal combustion engine and the flow path of the turbine. Each exhaust pipe terminates in a nozzle. For each exhaust pipe, a ratio Vp / Vd between the pipe volume Vp and the displacement volume Vd of the respective internal combustion engine is at most 1.5. A minimum value of a cross-sectional area of each exhaust pipe is defined at the nozzle. In one embodiment, a ratio An / Ae between the minimum cross-sectional area An and the cross-sectional area Ae of the exhaust port of the respective internal combustion engine is at least 0.2. A method of compounding at least one rotary engine is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

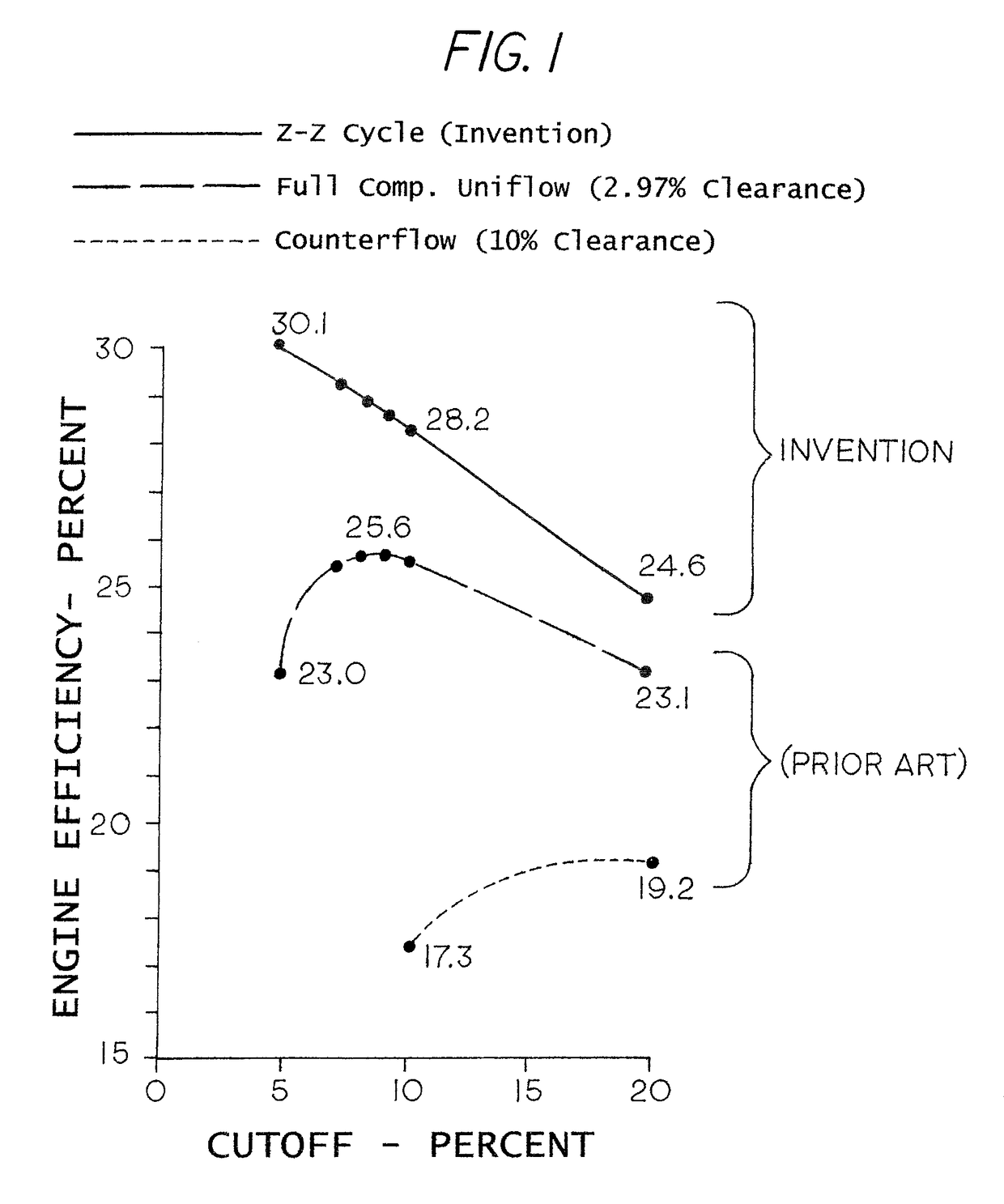

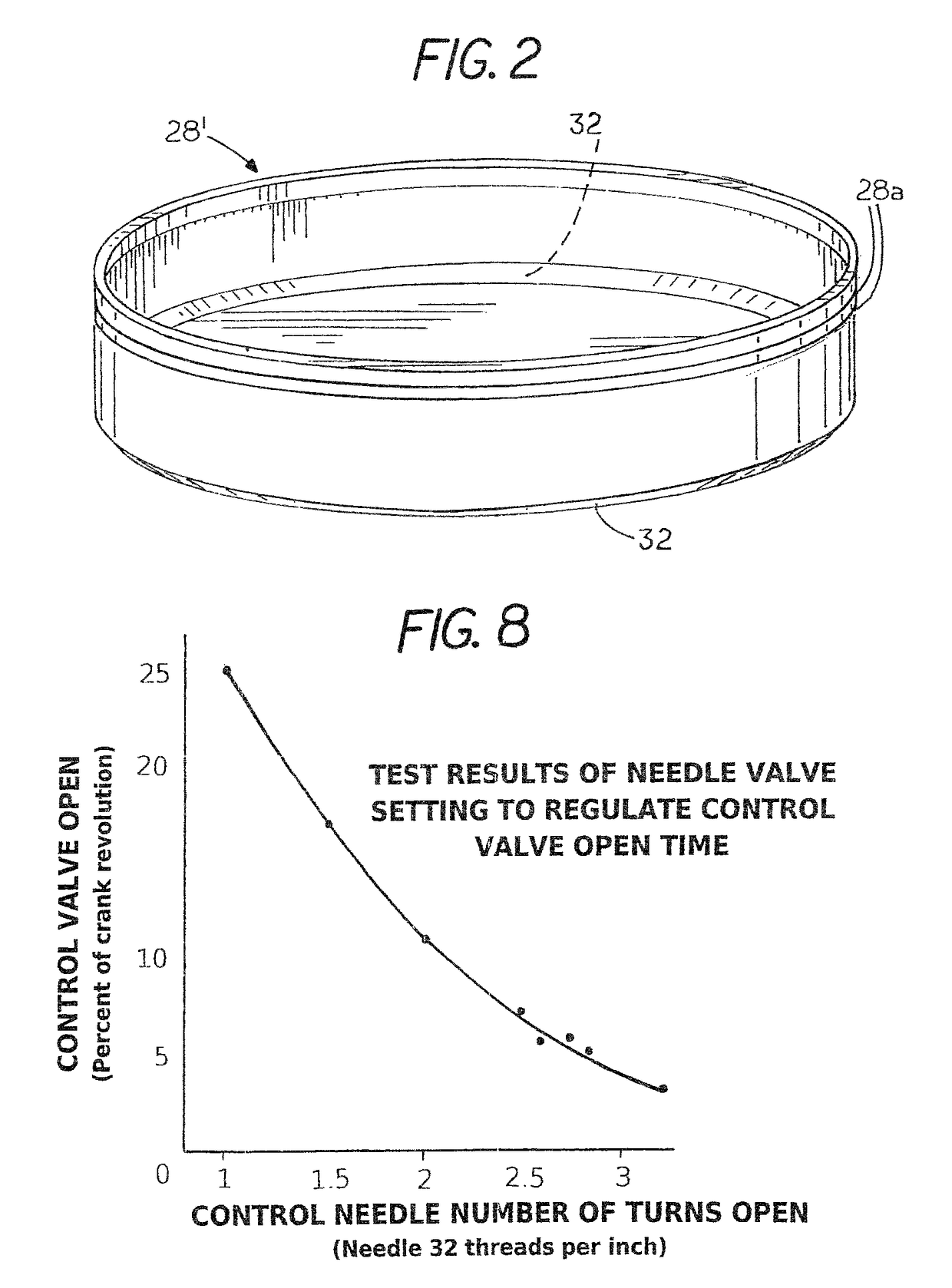

High efficiency steam engine and steam expander

ActiveUS9828886B1Reciprocating combination enginesInternal combustion piston enginesExhaust valveCylinder head

A high efficiency steam engine or steam expander includes a cylinder, cylinder head and piston in which cylinder clearance volume is zero or nearly zero together with a negligible amount of compression such that any pressure in the cylinder clearance volume just before the power stroke is as low as ambient pressure or condenser pressure to provide superior thermal efficiency in a compact compound engine having a high pressure expansion chamber within the piston and low pressure chamber in the cylinder. The inlet valve is opened slightly by piston movement and a steam assist force then drives it to its fully open position. Steam passes from the high pressure chamber to the low pressure chamber through a transfer valve located in the head of the piston and steam is released through an automatic exhaust valve in the cylinder head.

Owner:THERMAL POWER RECOVERY

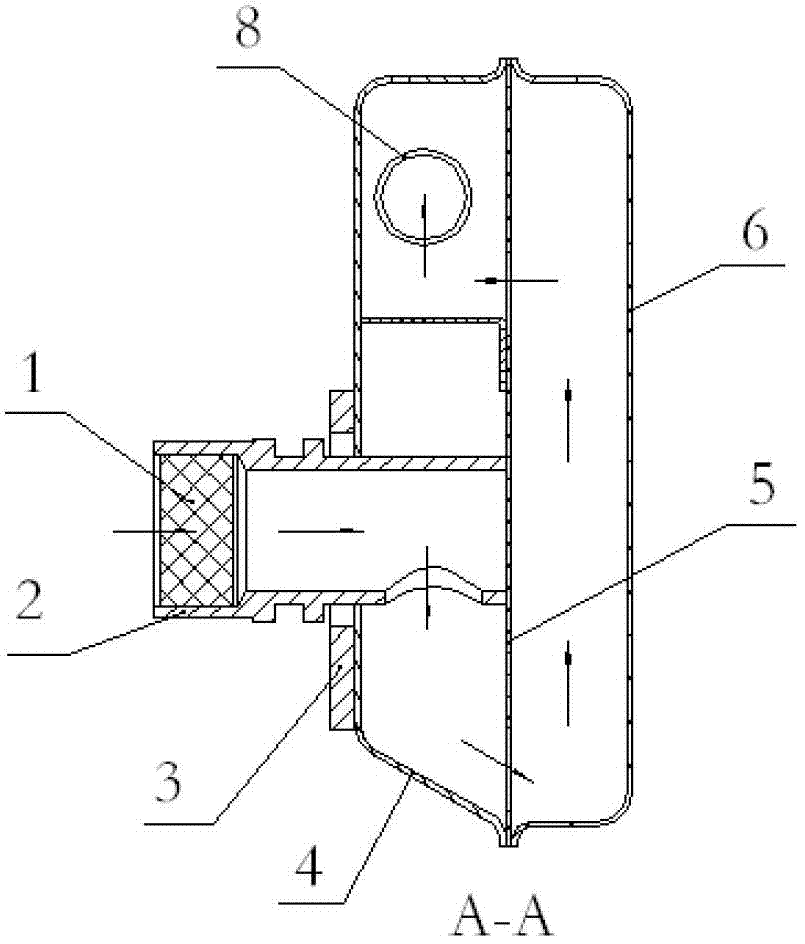

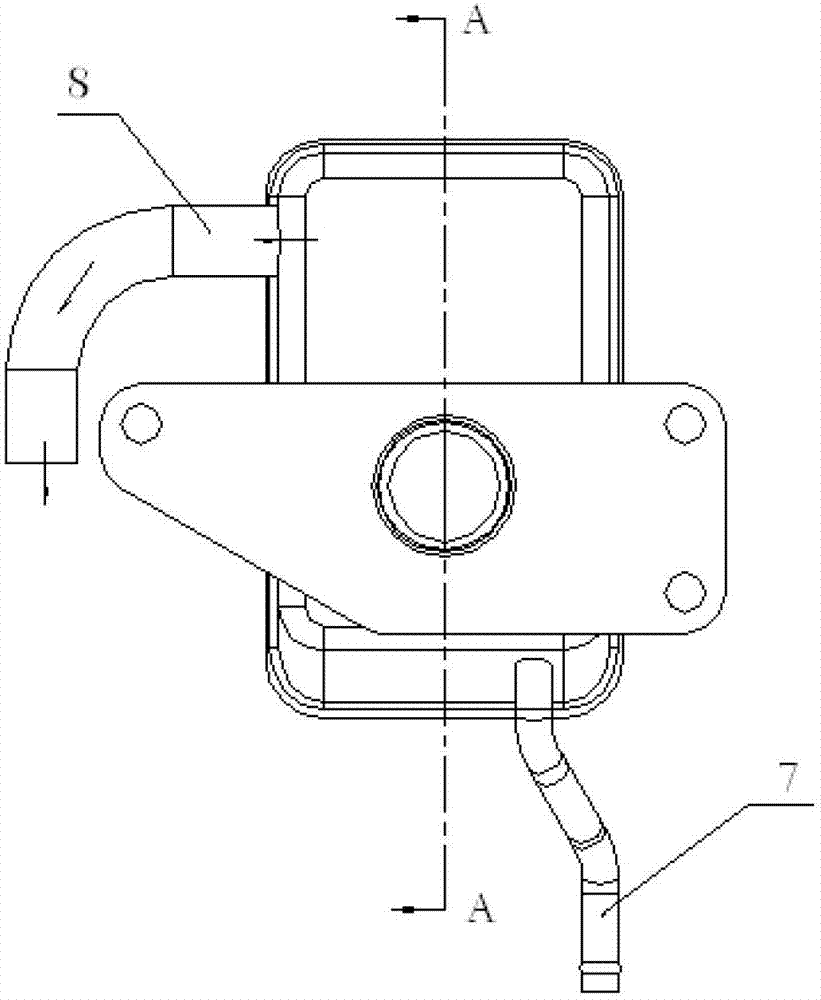

Compound engine crankcase ventilation device

InactiveCN102733889AEffective filteringReduce fuel consumptionMachines/enginesCrankcase ventillationRespiratorAtmospheric air

The invention discloses a compound engine crankcase ventilation device. A filter screen is arranged in a respirator joint seat; the respirator joint seat is fixed on a respirator inner cover through a connecting flange, so that a first-stage oil filtering cavity is formed; a middle baffle plate is arranged between the respirator inner cover and a respirator outer cover; a second-stage oil filtering cavity consists of the respirator inner cover, the middle baffle plate and the respirator outer cover; the filter screen and the joint seat construct a filtering cavity; and a maze type condensing cavity is formed by inner and outer shells and the baffle plate. Two types of respirators are combined skillfully, and a reasonable design is adopted, so that residual engine oil mist can be effectively filtered on the basis of ensuring pressure balance in a crankcase, oil consumption of lubricating oil is lowered, and the pollution on the atmospheric environment is lowered remarkably. Due to the adoption of the design, the requirement of pressure balance of an engine crankcase cavity under any load of the engine can be met, engine oil is prevented from flowing outwards, and the phenomenon of burning of lubricating oil is reduced remarkably. Moreover, the compound engine crankcase ventilation device has the characteristics of small size, simple structure and remarkable engine oil recovering effect.

Owner:东风朝阳朝柴动力有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com