Compound engine crankcase ventilation device

A crankcase ventilation and engine technology, which is applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of large space occupation and insufficient short-distance labyrinth effect, and achieve the goals of reducing fuel consumption, simple structure, and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

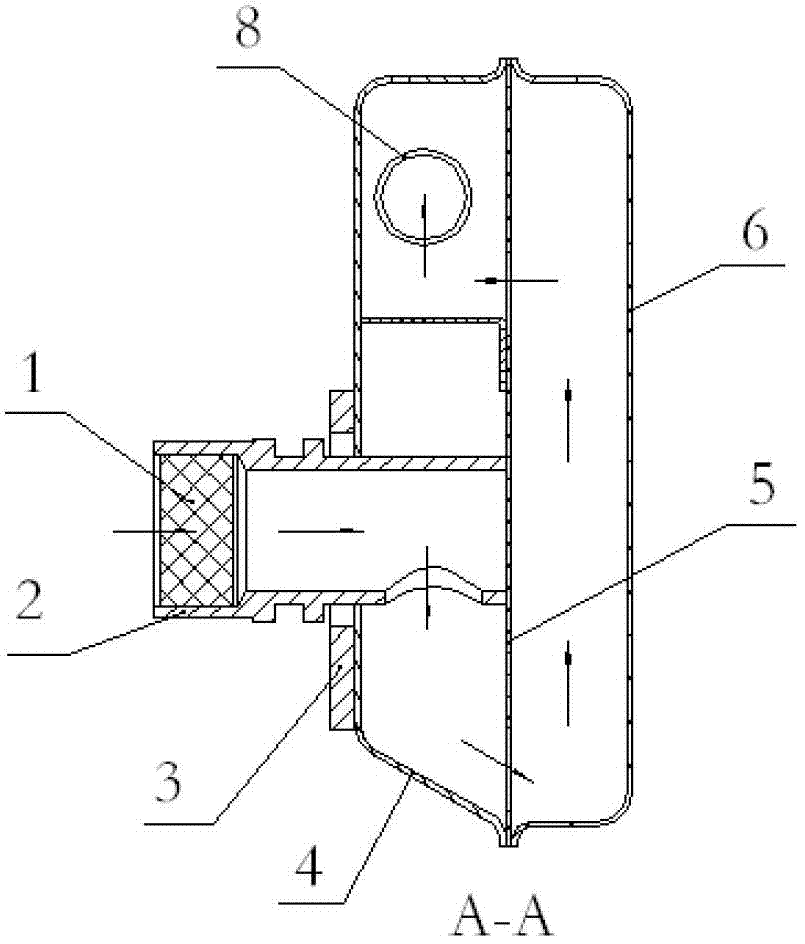

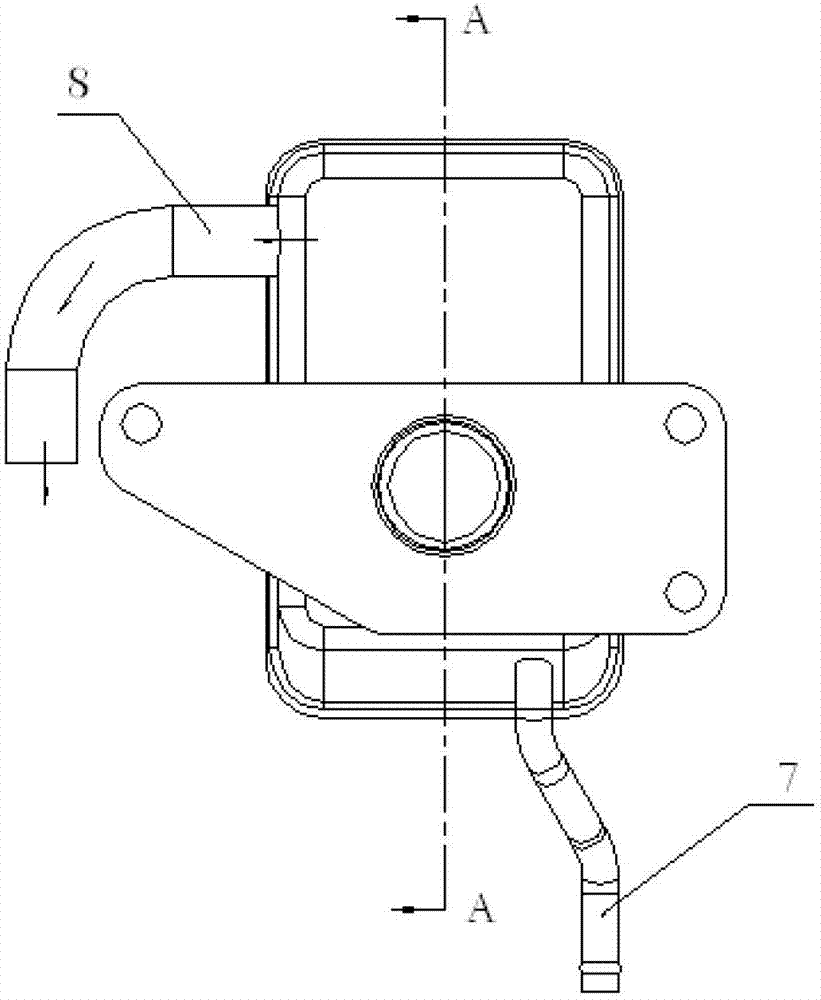

[0011] The composite engine crankcase ventilation device has the structure that the filter screen 1 is placed in the respirator socket 2, and the respirator socket is fixed to the respirator inner cover 4 through the connecting flange 3 to form the first stage oil filter chamber. An intermediate baffle 5 is arranged between the respirator inner cover and the respirator outer cover 6, and the respirator inner cover, the intermediate baffle, and the respirator outer cover form the second-stage oil filter chamber. The separation of oil and gas is completed through two-stage filtration. An oil return pipe 7 is arranged at the lower end of the cavity formed by the respirator inner cover and the intermediate baffle, and an air outlet pipe 8 is arranged at the upper end of the cavity formed by the intermediate ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com