Jet-steam compound engine with spray liquid evaporating on hot wall

A jet engine and engine technology, applied in steam engine devices, engine components, combustion engines, etc., can solve the problems of low thermal efficiency and high fuel consumption of jet engines, and achieve the effects of high thermal efficiency, low vibration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

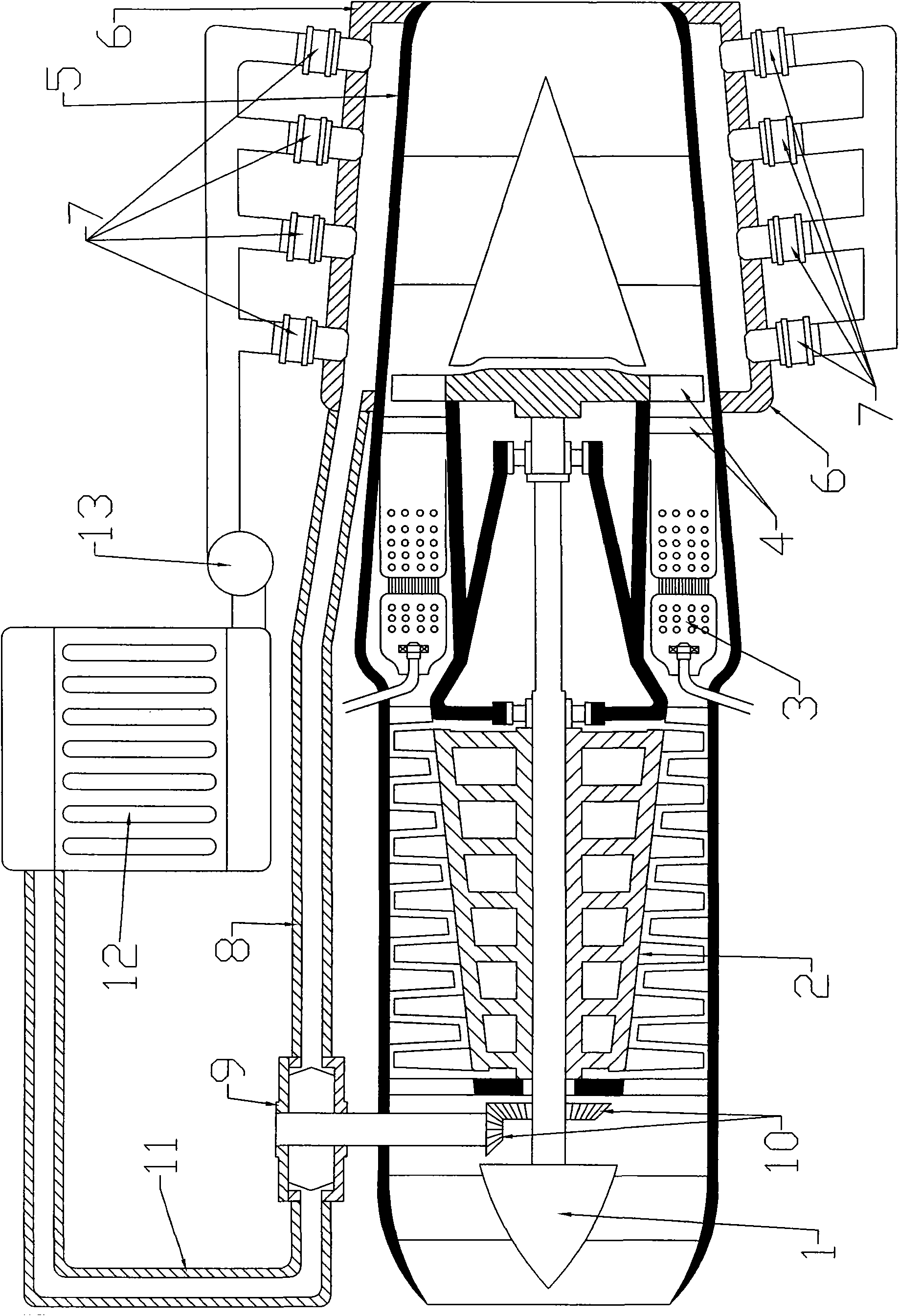

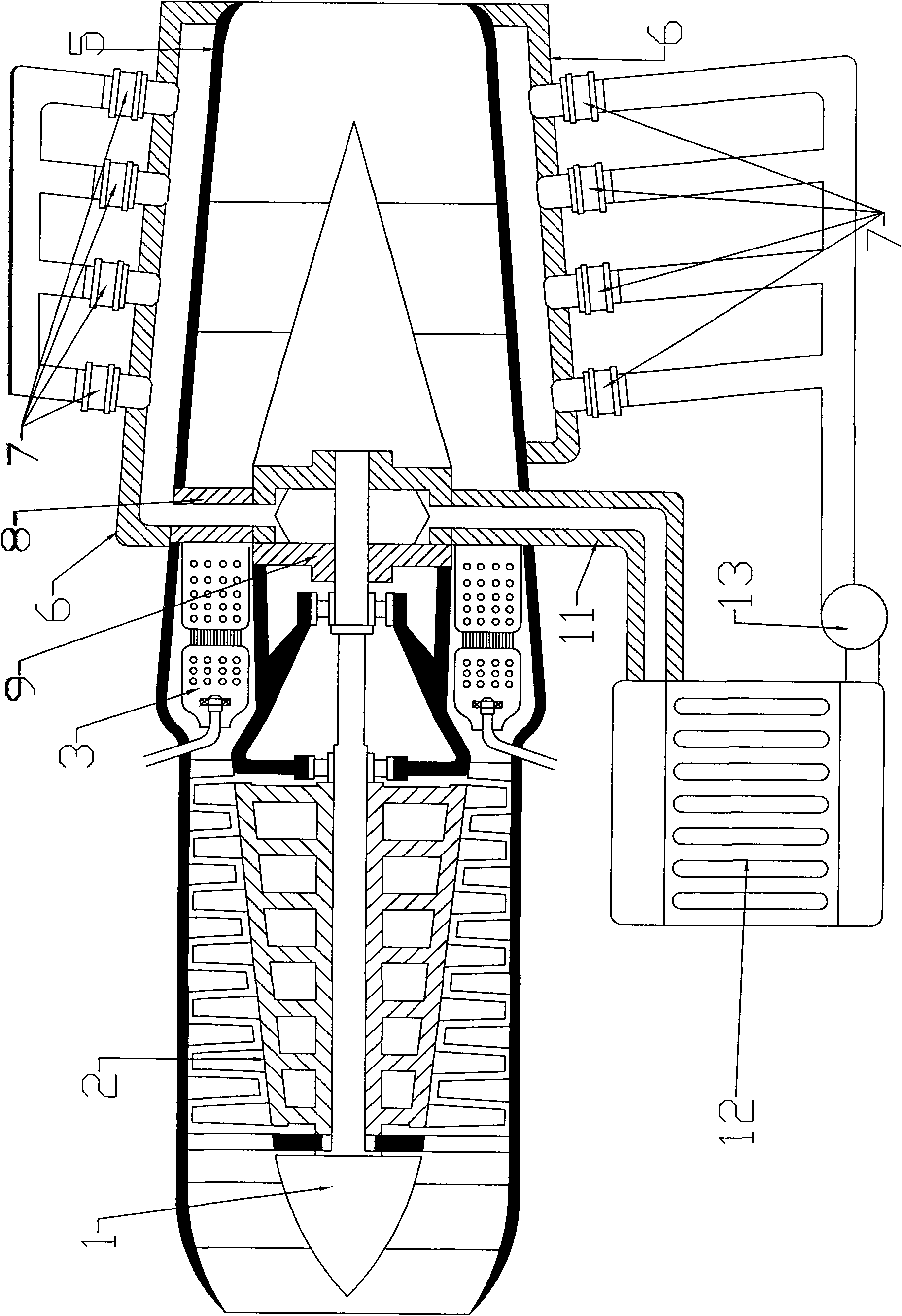

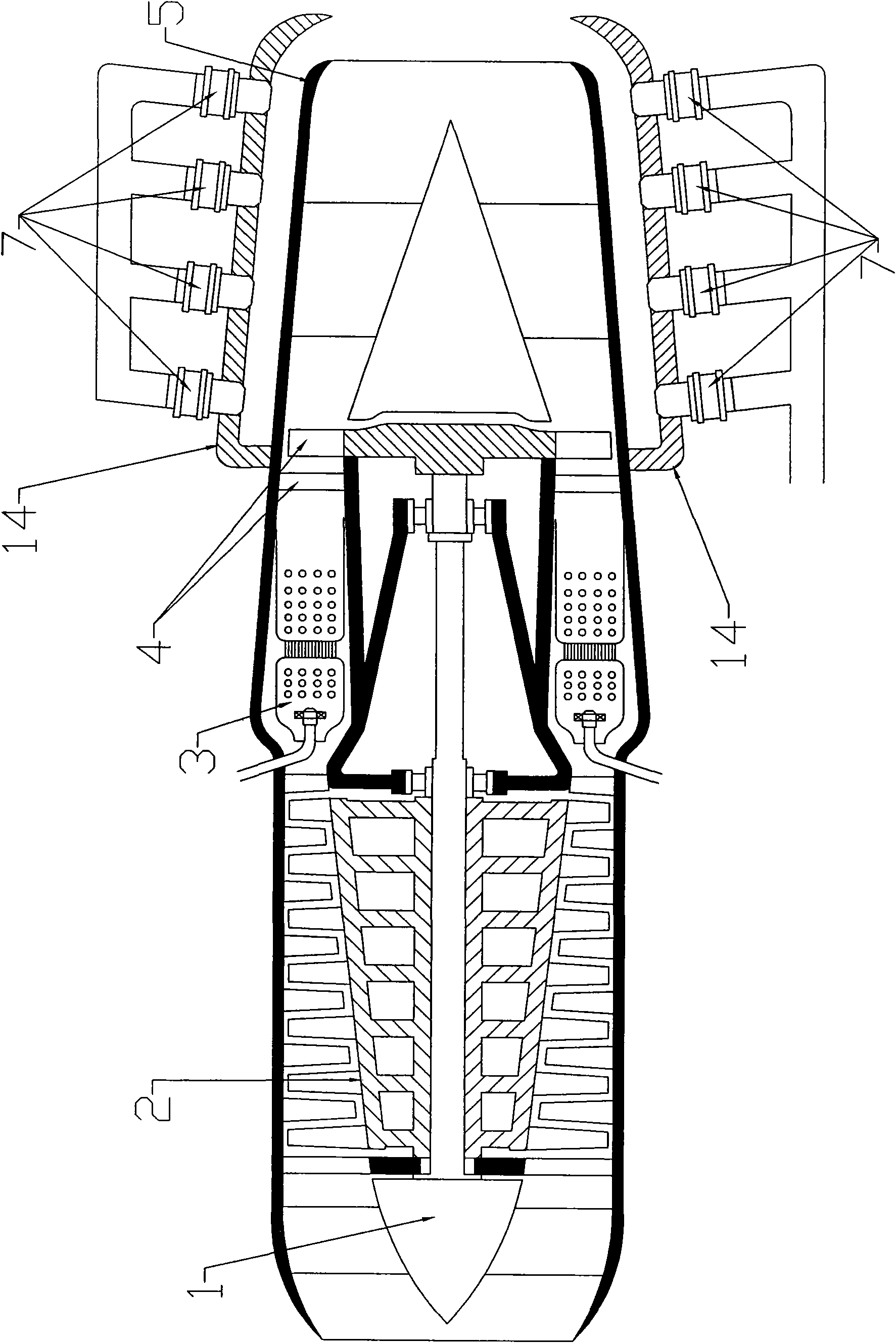

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: the present invention example has five embodiment examples;

[0021] figure 1 The first embodiment shown is that the airtight interlayer casing 6 is sheathed on the outer circumference of the exhaust nozzle casing 5 of the air jet engine 1, and it forms an evaporation chamber with the exhaust nozzle casing 5, and the airtight interlayer casing 6 is from the turbine 4 to the Exhaust nozzle ends at 5 ports. Several spray nozzles 7 are arranged on the outer periphery of the airtight sandwich casing 6, and extend into the evaporation chamber. Inlet connection. The steam turbine 9 is arranged outside the shell of the air jet engine 1, and the power shaft of the steam turbine 9 extends into the air jet engine 1 shell, and is connected to the front end of the compressor 2 of the air jet engine 1 through a bevel gear 10. The exhaust pipe 11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com