Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Bond beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bond beam is a horizontal structural element, usually found as an embedded part of a masonry wall assembly. The bond beam serves to impart horizontal strength to a wall where it may not otherwise be braced by floor or roof structure. Bond beams encase steel reinforcing in grout or concrete, binding the structure together horizontally, and often interlocking with additional vertical reinforcement. A bond beam is typically found near the top of a freestanding wall. A bond beam may also be used to provide a consistent anchorage for floor or roof structure. Bond beam assemblies are most commonly used in construction using concrete masonry units, where special shapes allow the beam to blend with the wall construction, but may also be built using brick or may be formed in concrete.

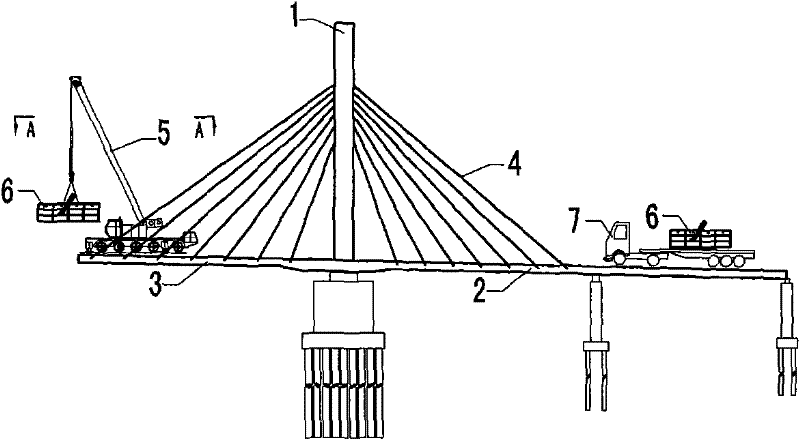

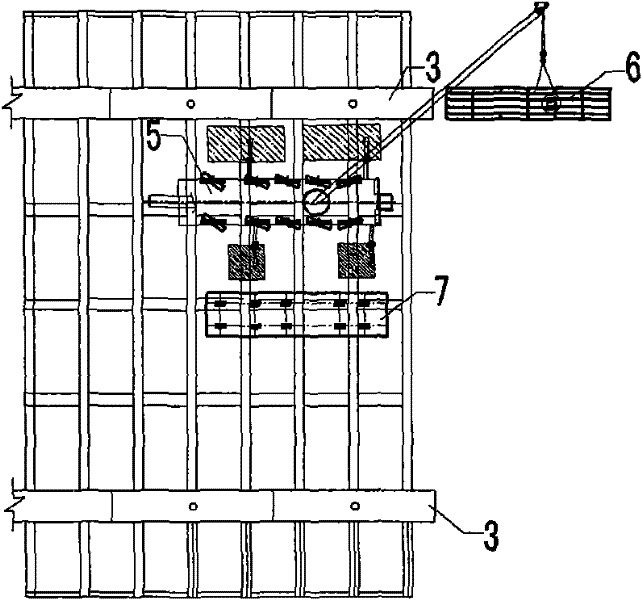

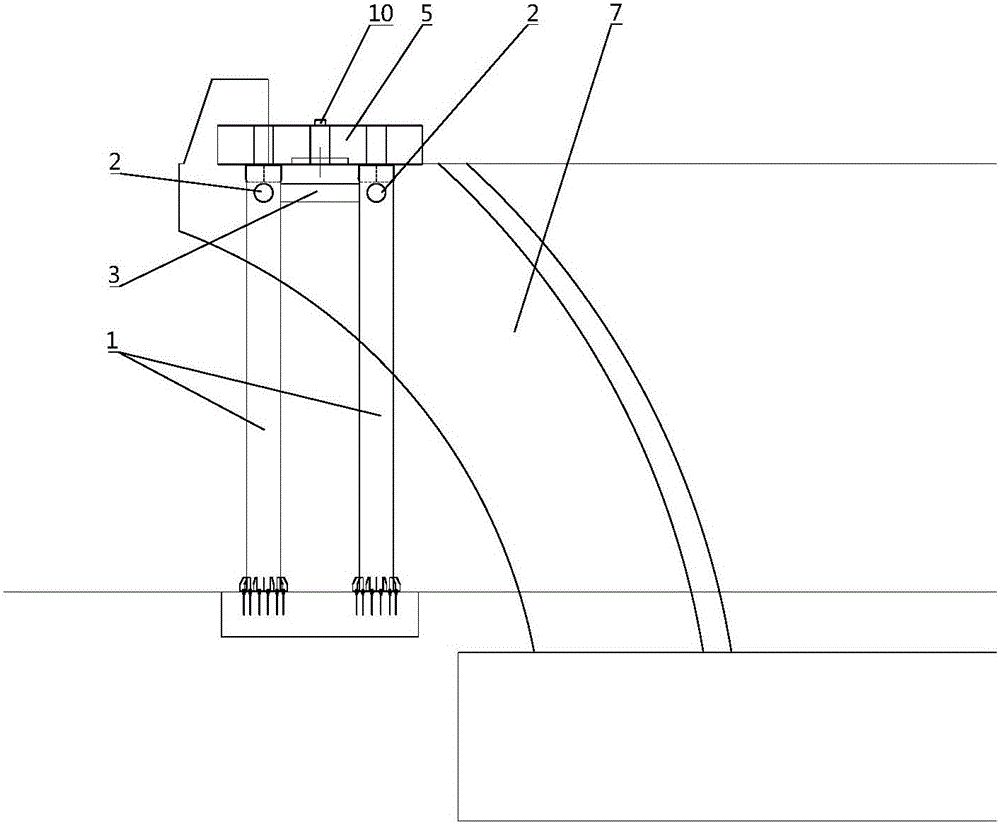

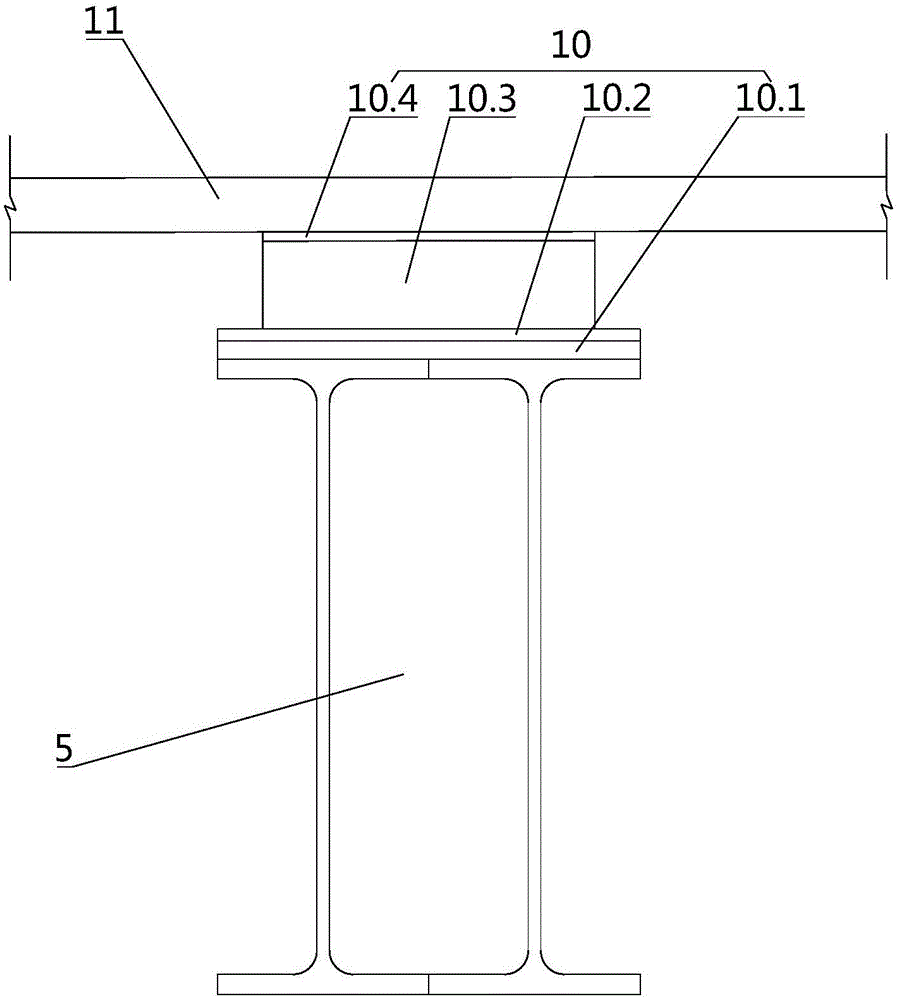

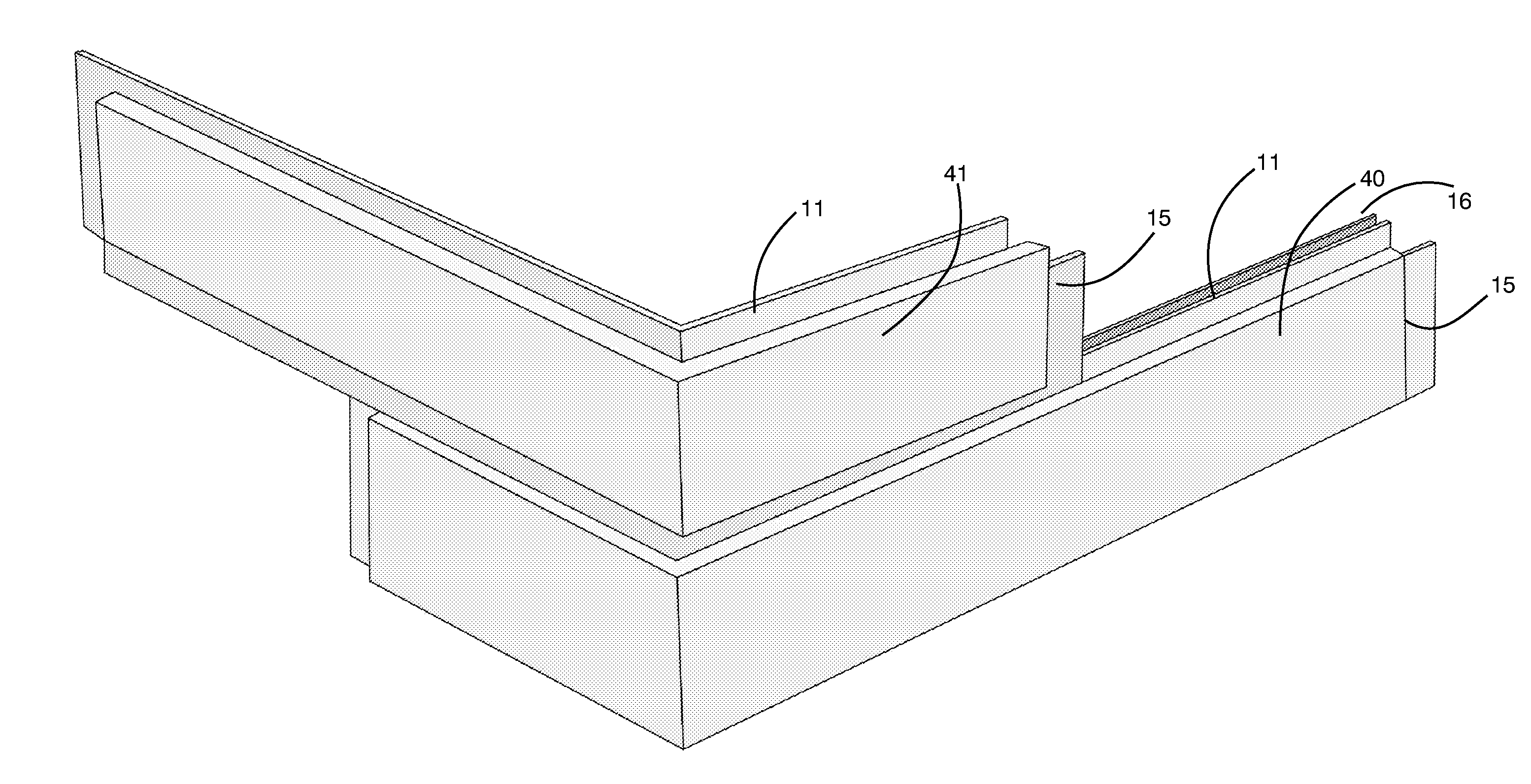

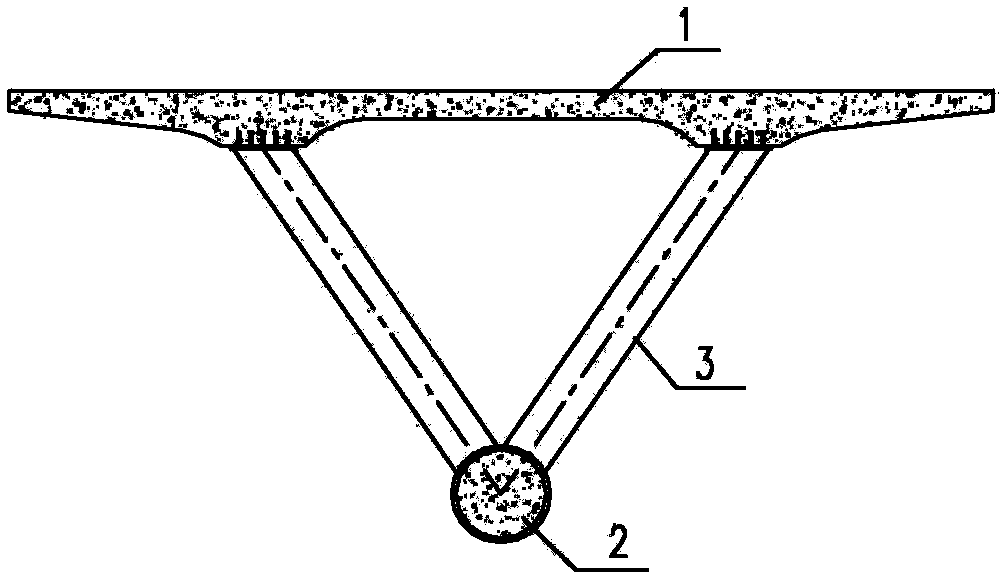

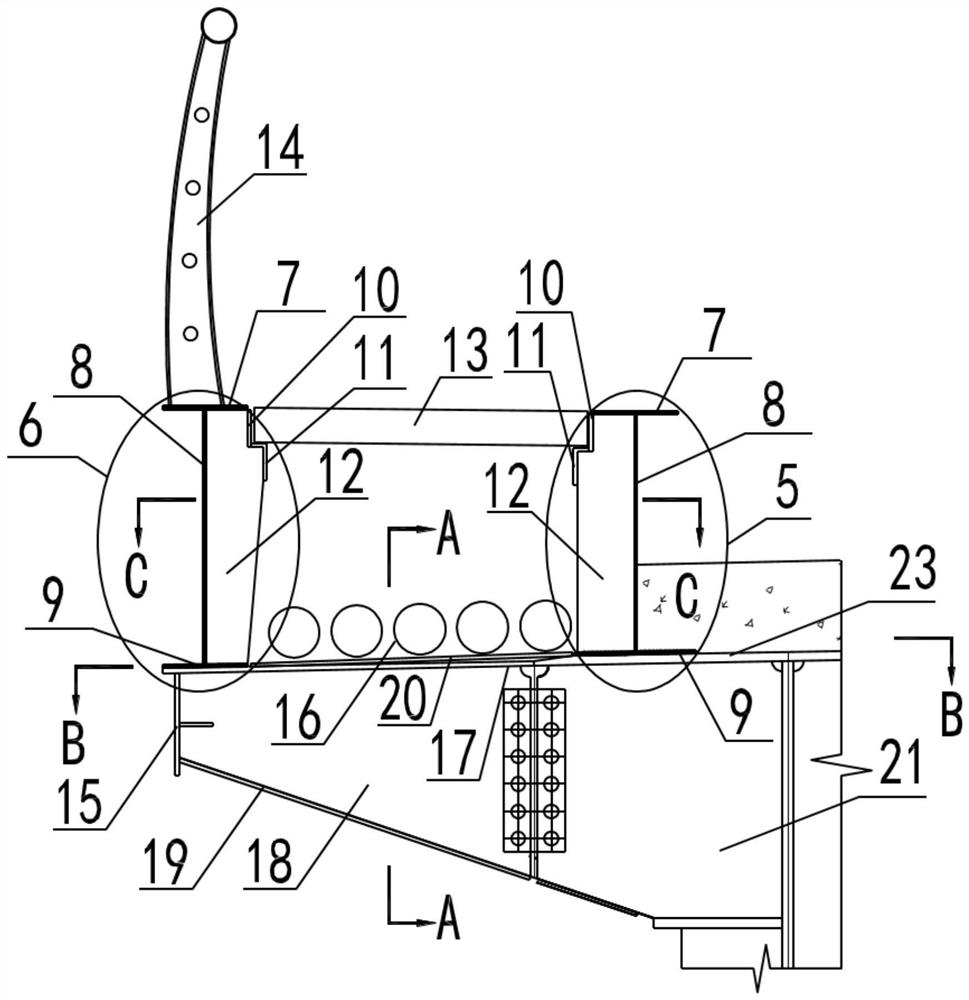

A new construction method of hybrid combined beam cable-stayed bridge

InactiveCN102286935AEliminate assemblyEliminate the hassle of disassemblyBridge erection/assemblyCable stayedBridge deck

The invention relates to a brand-new construction method of a mixed combined girder cable-stayed bridge. After the construction of the main tower, auxiliary piers, side piers, main bridge side span concrete beams and approach bridges, the mid-span steel girder members and prefabricated concrete decks of the cable-stayed bridges are transported from the ground via the approach bridges and main bridge side spans to Midspan. The truck crane also moves from the ground through the approach bridge and the side span of the main bridge to the front end of the completed combined beam in the mid-span, and lifts the components on the girder truck for cantilever construction. The bridge is hung with stay cables and tensioned for the first time. Construct the wet joints of the bridge deck, form the mid-span combined beam of this section, and repeat the construction until the main structure of the cable-stayed bridge is completed, and the bridge deck and the auxiliary structure of the main tower are constructed. The invention adopts the automobile crane, which can adapt to the construction of the wide bridge, and is convenient and flexible in use, and saves labor;

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

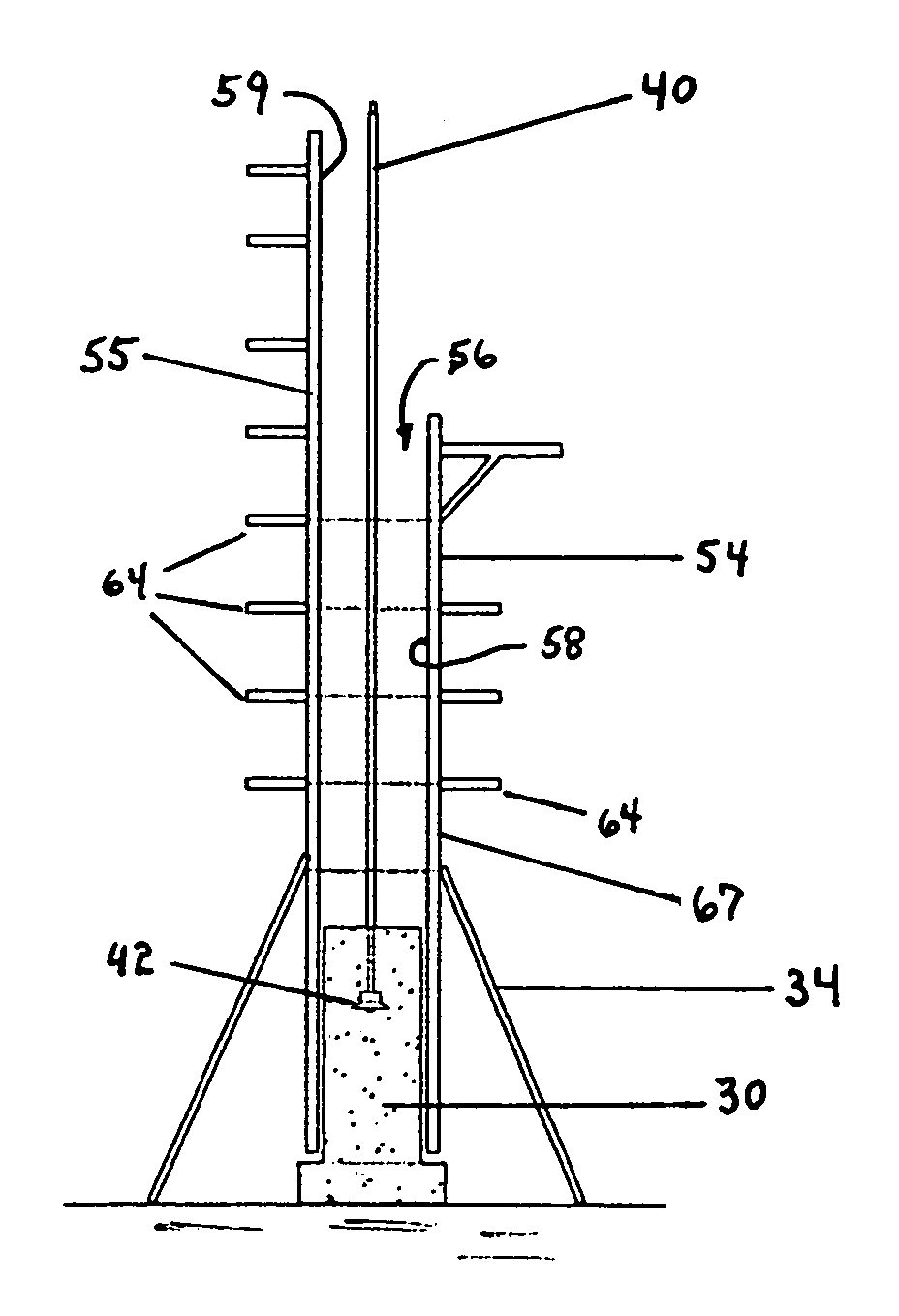

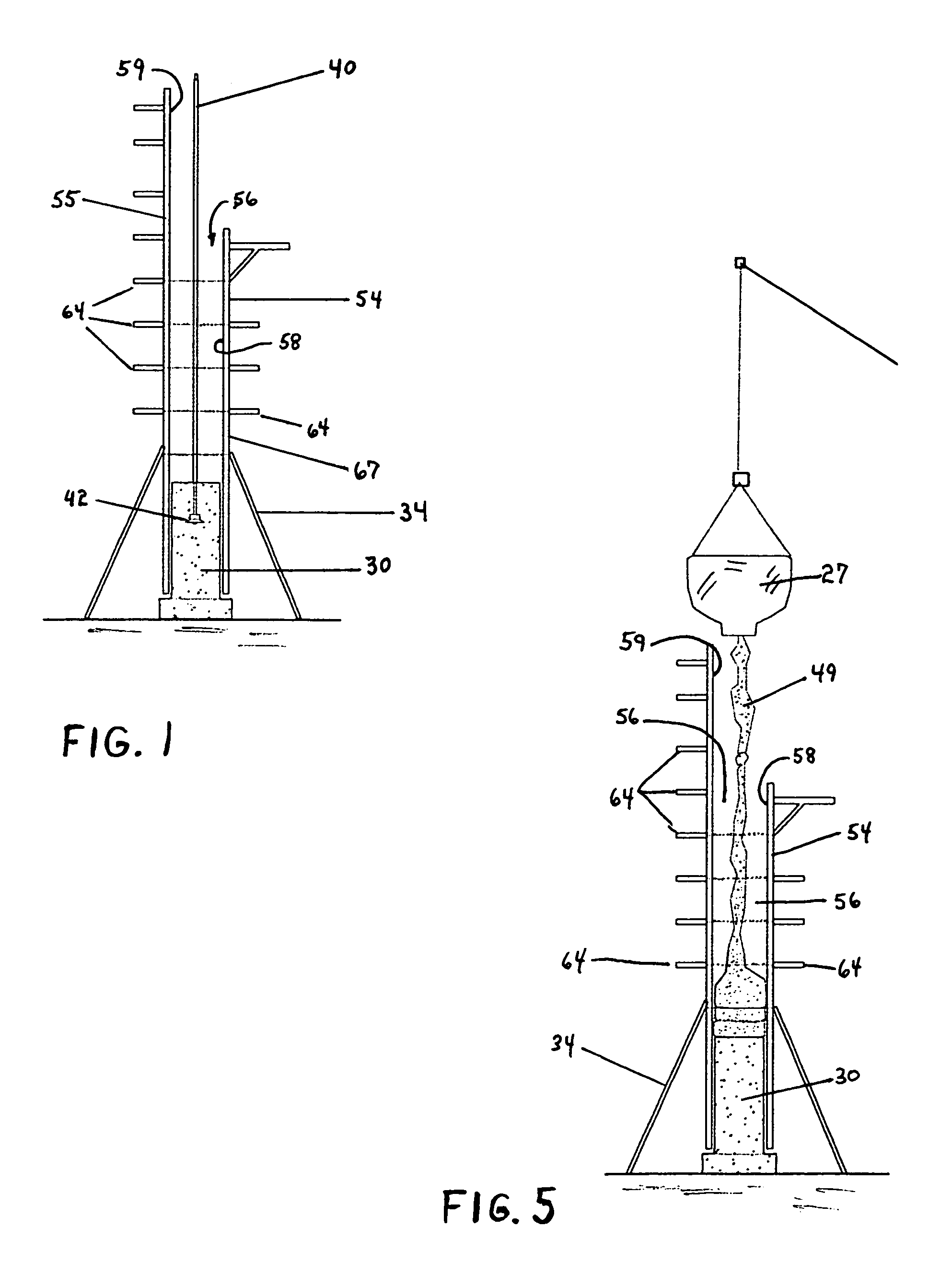

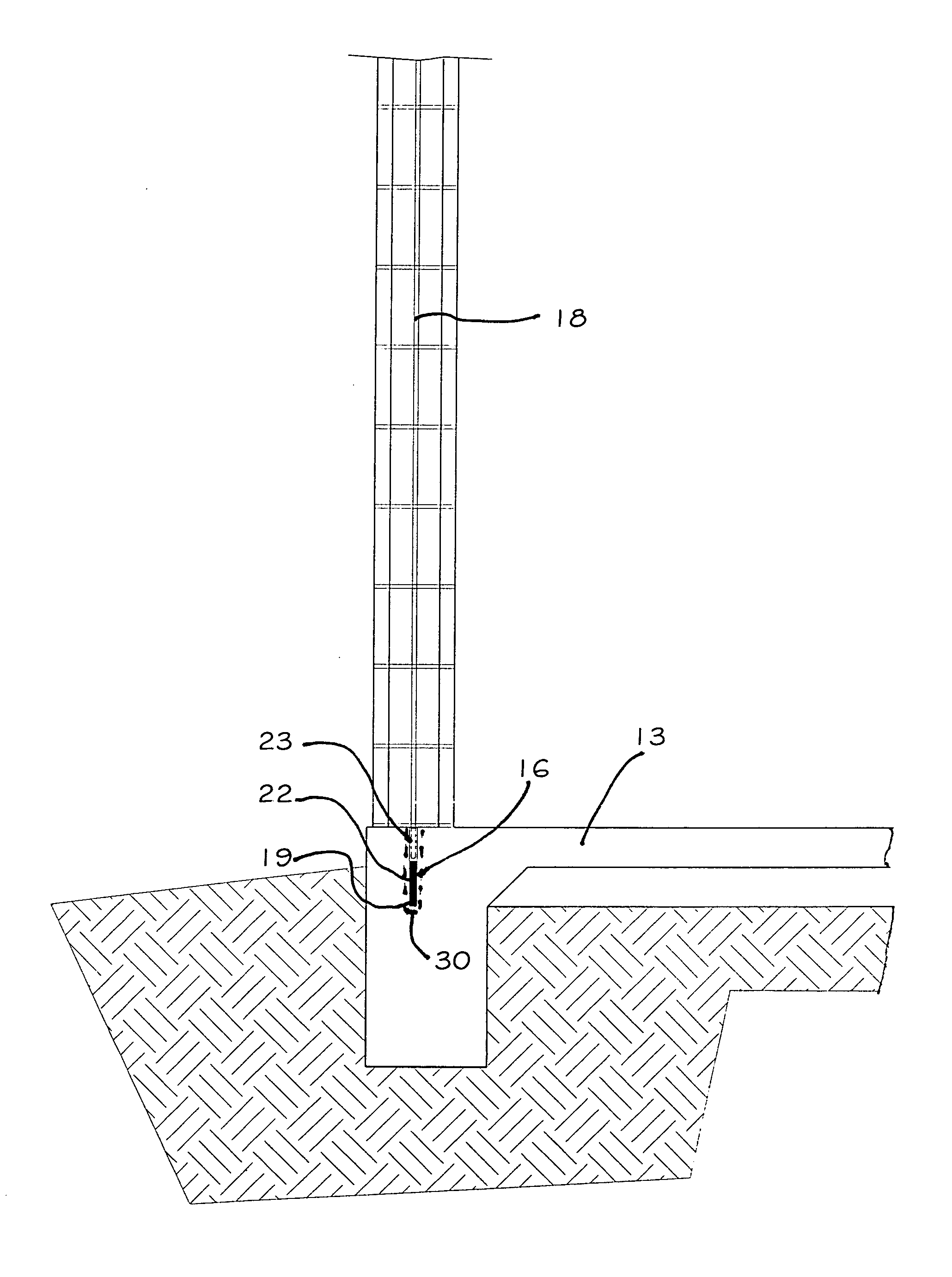

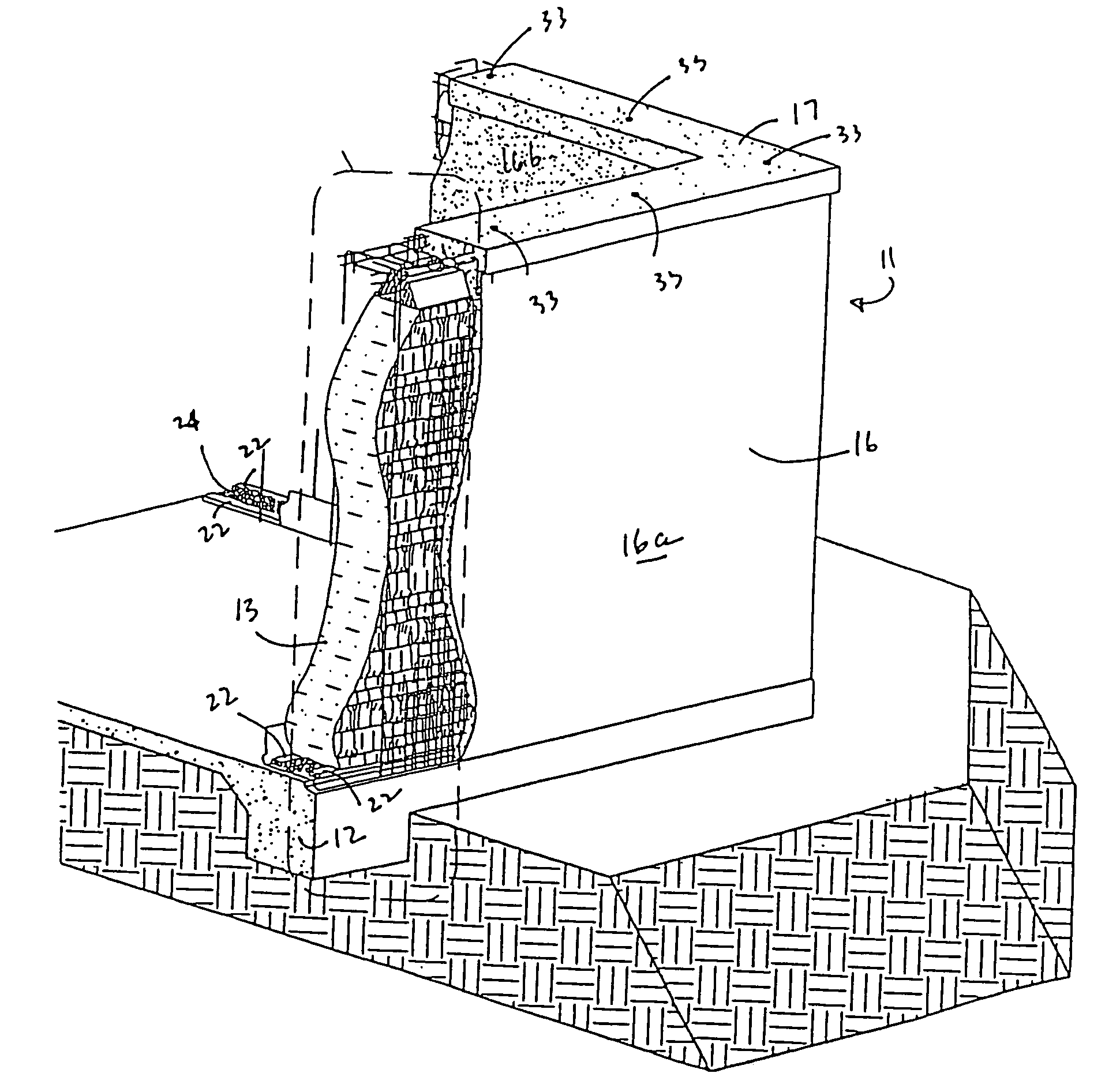

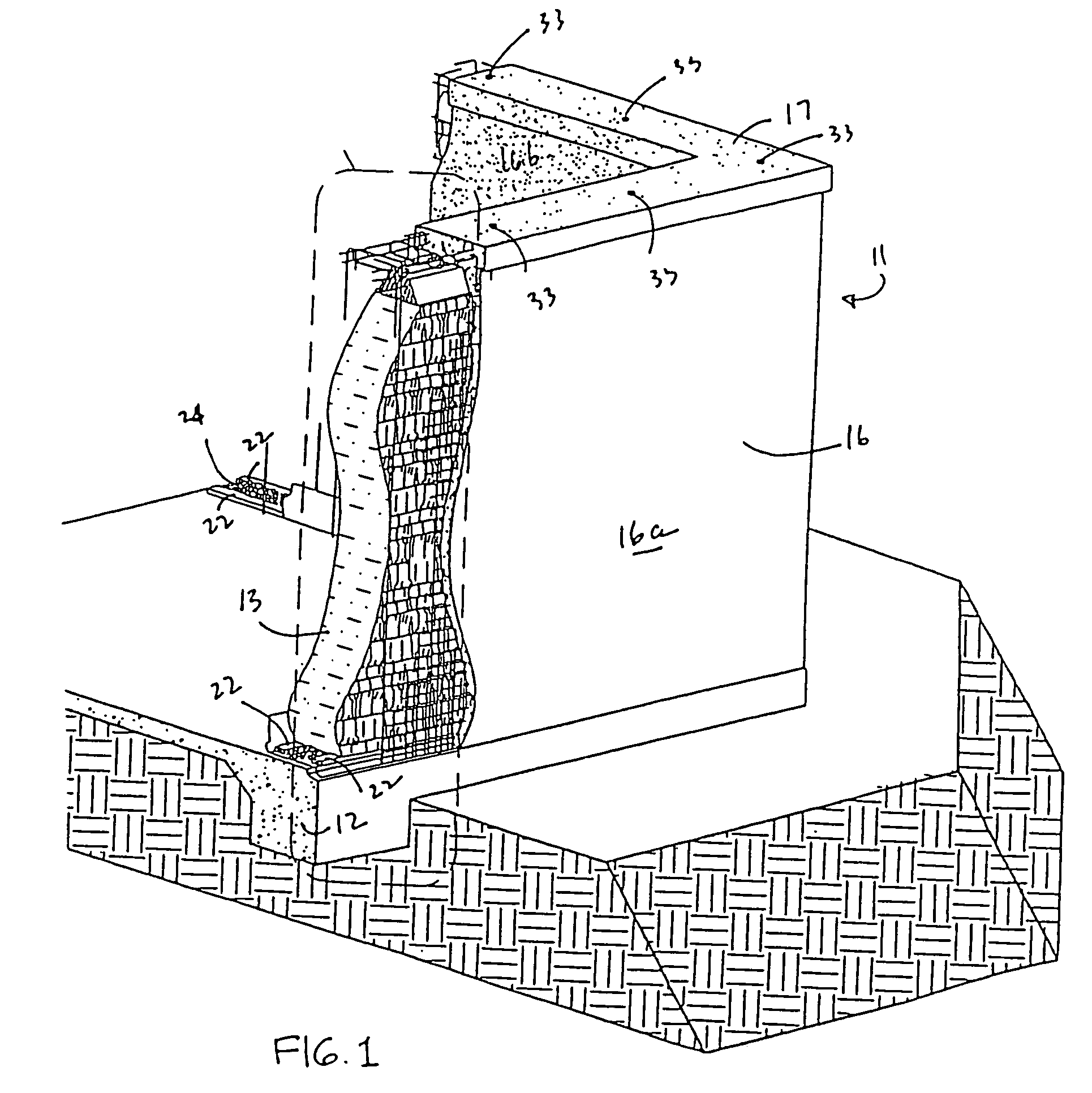

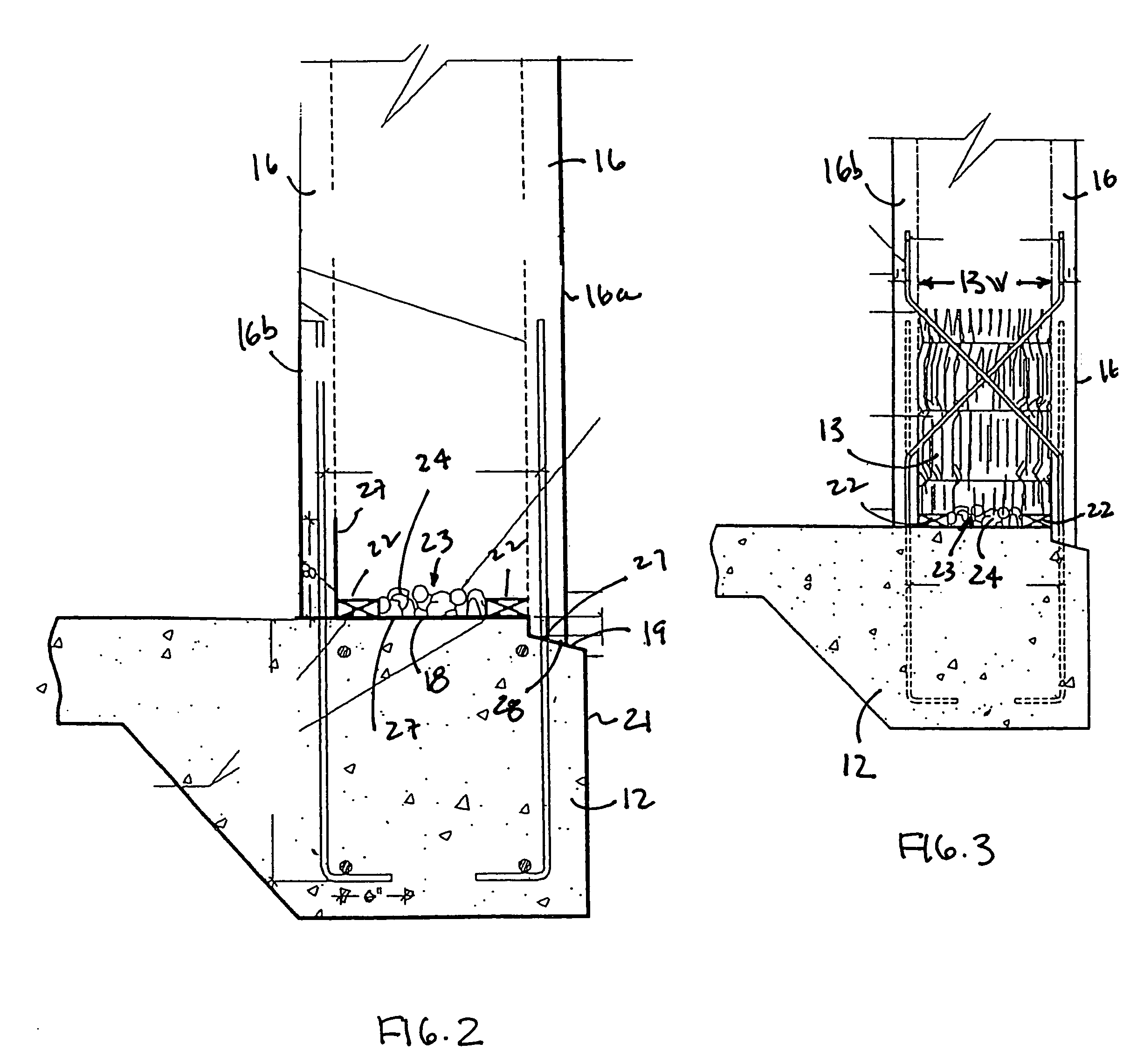

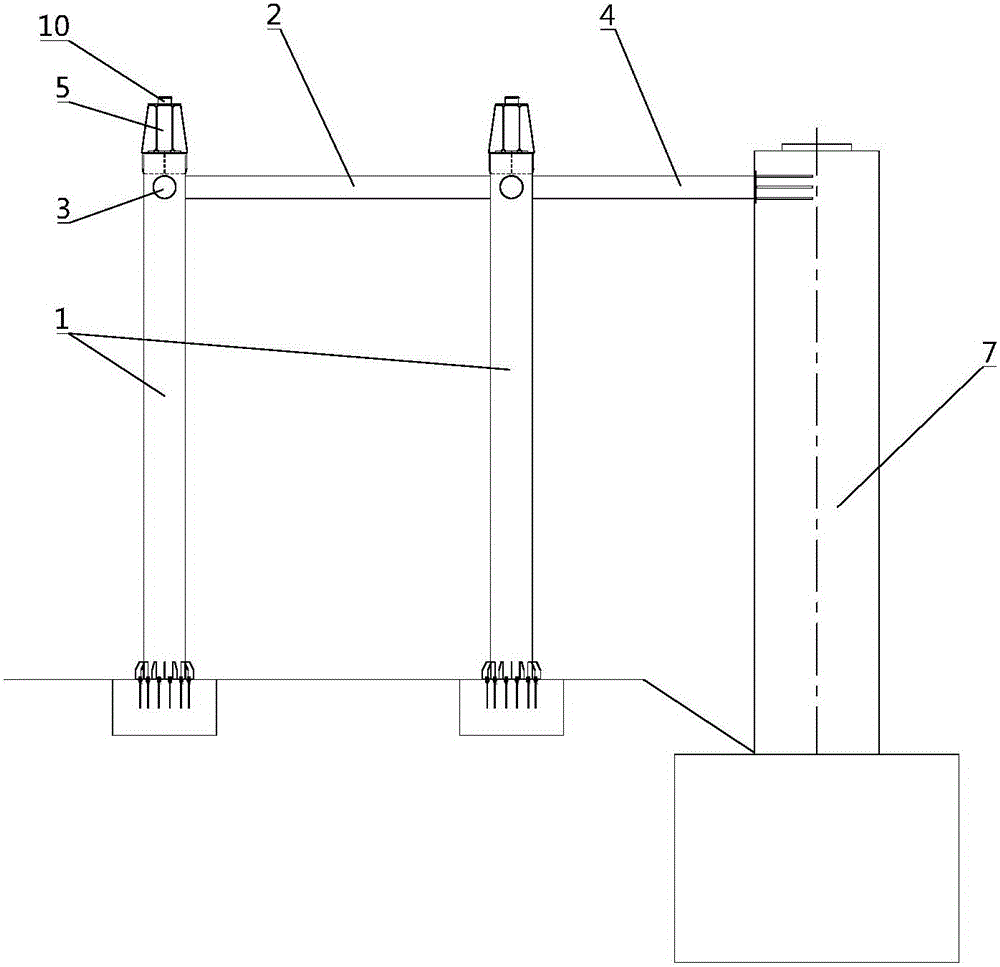

Post-tensioned rammed earth construction

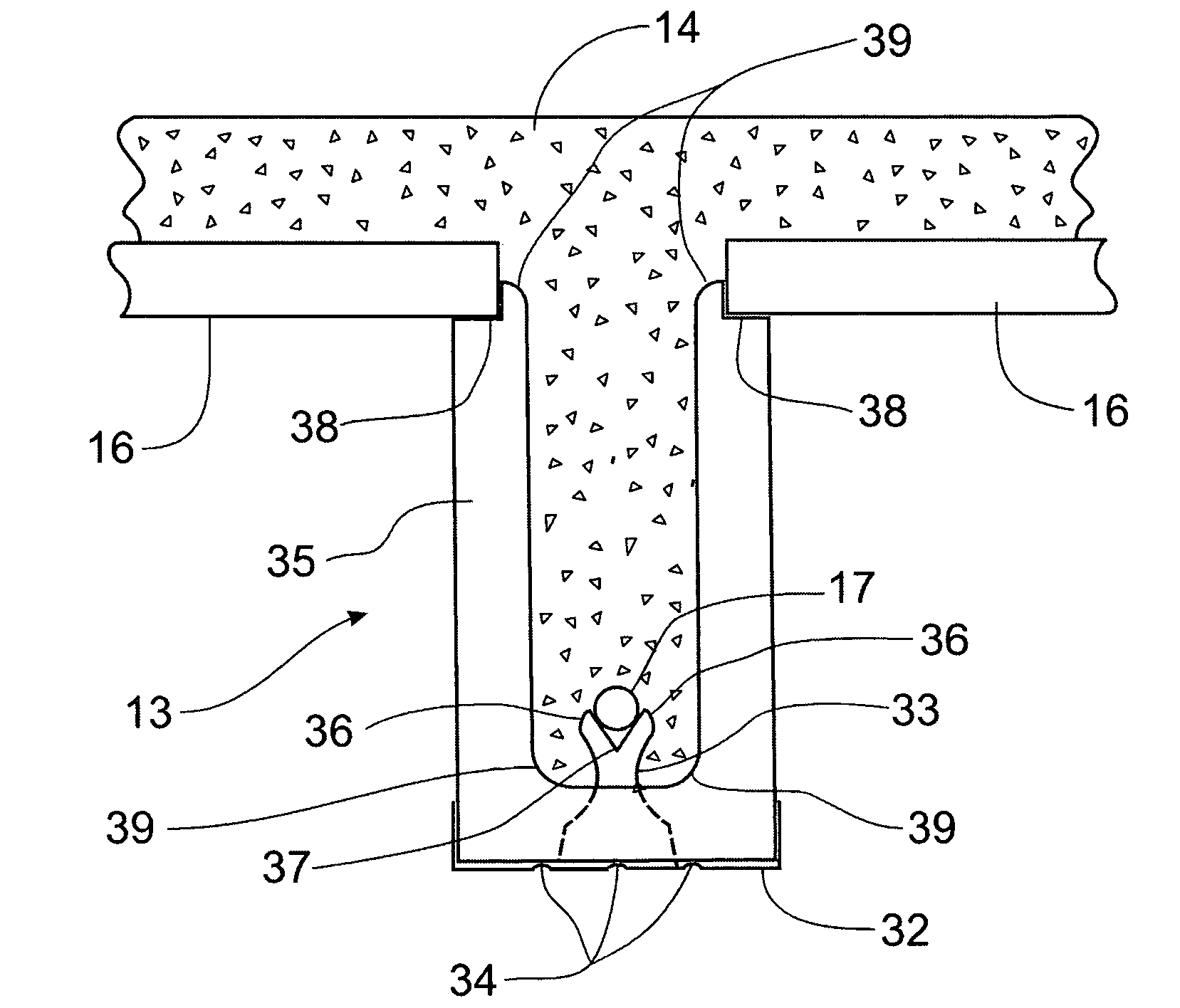

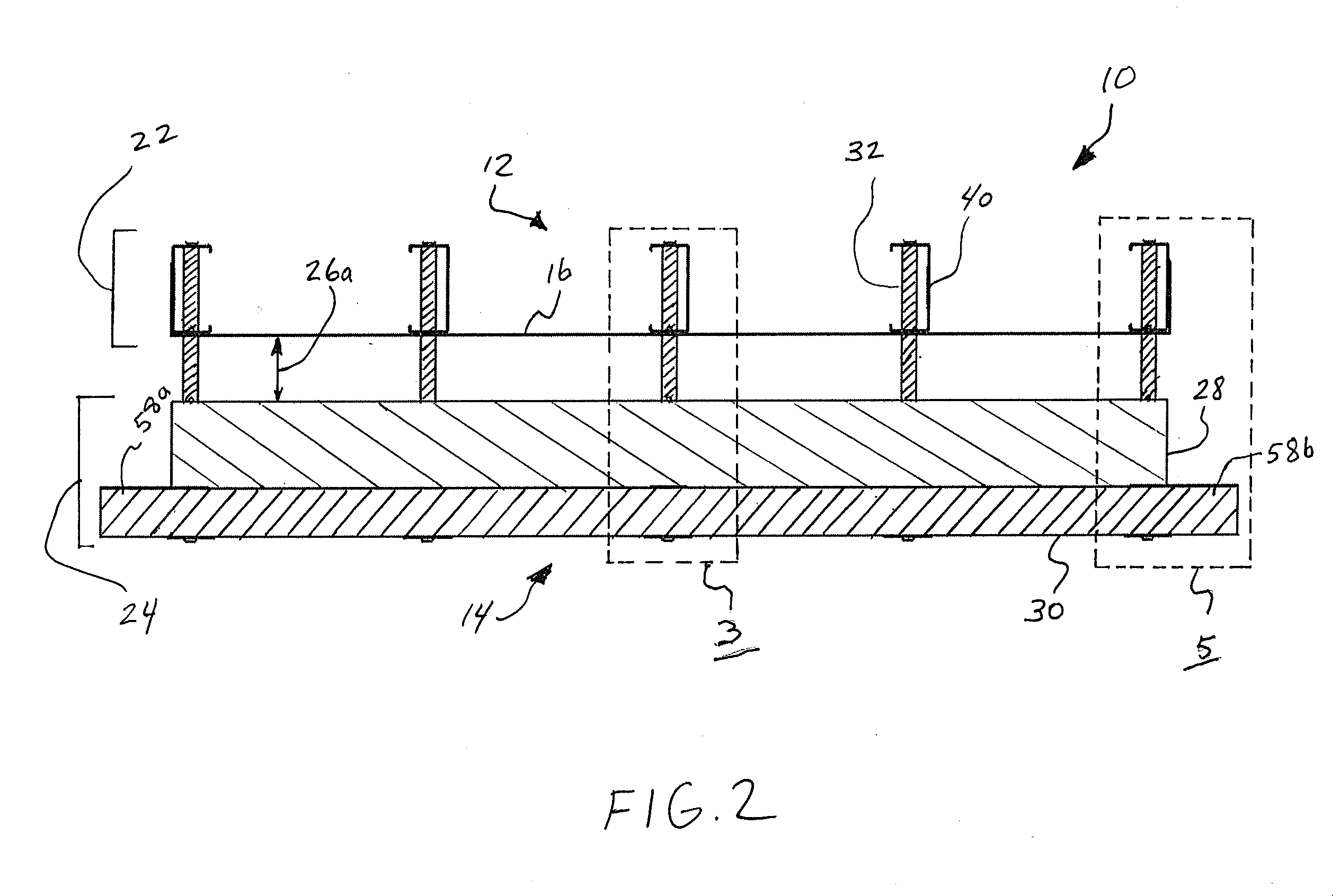

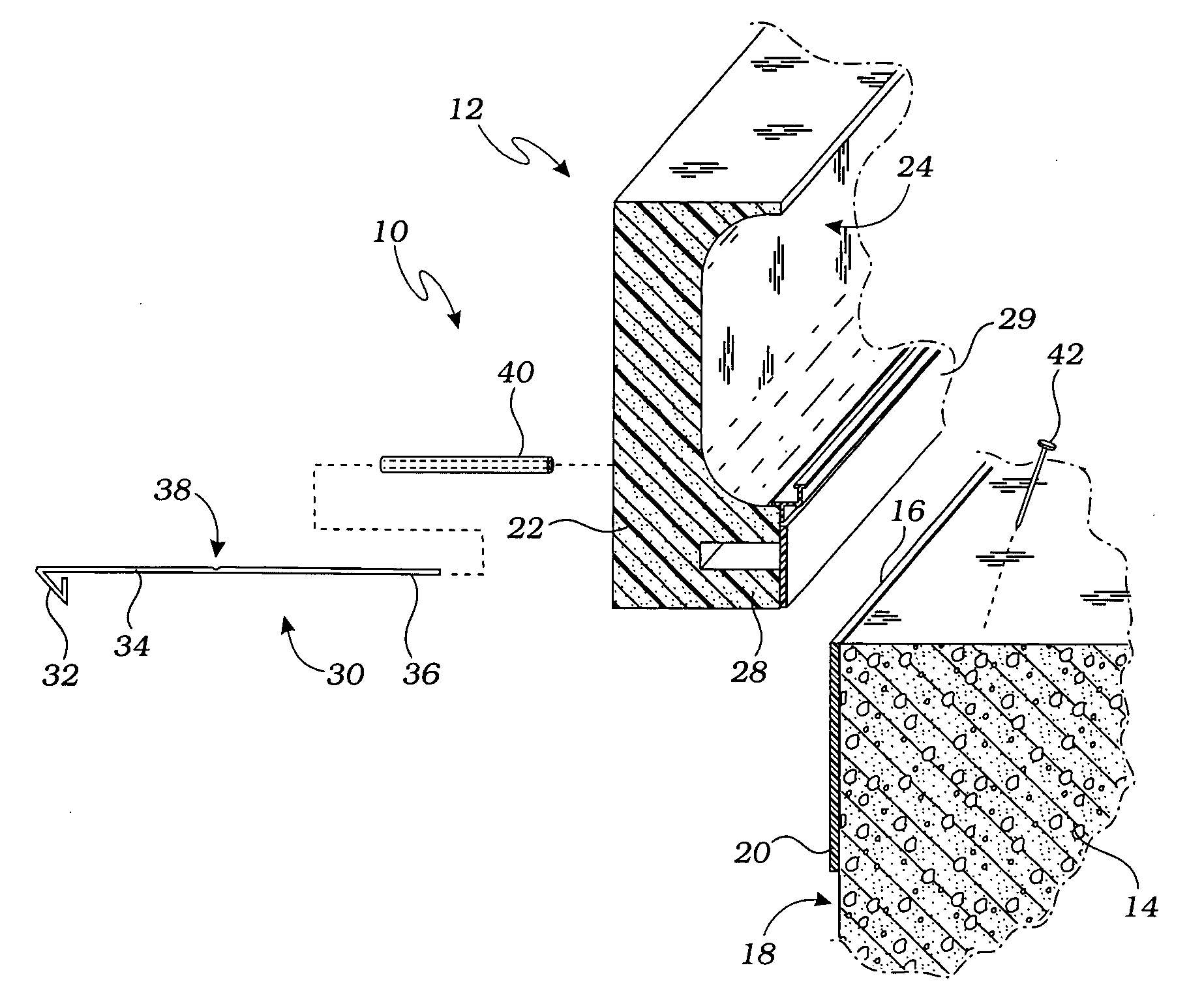

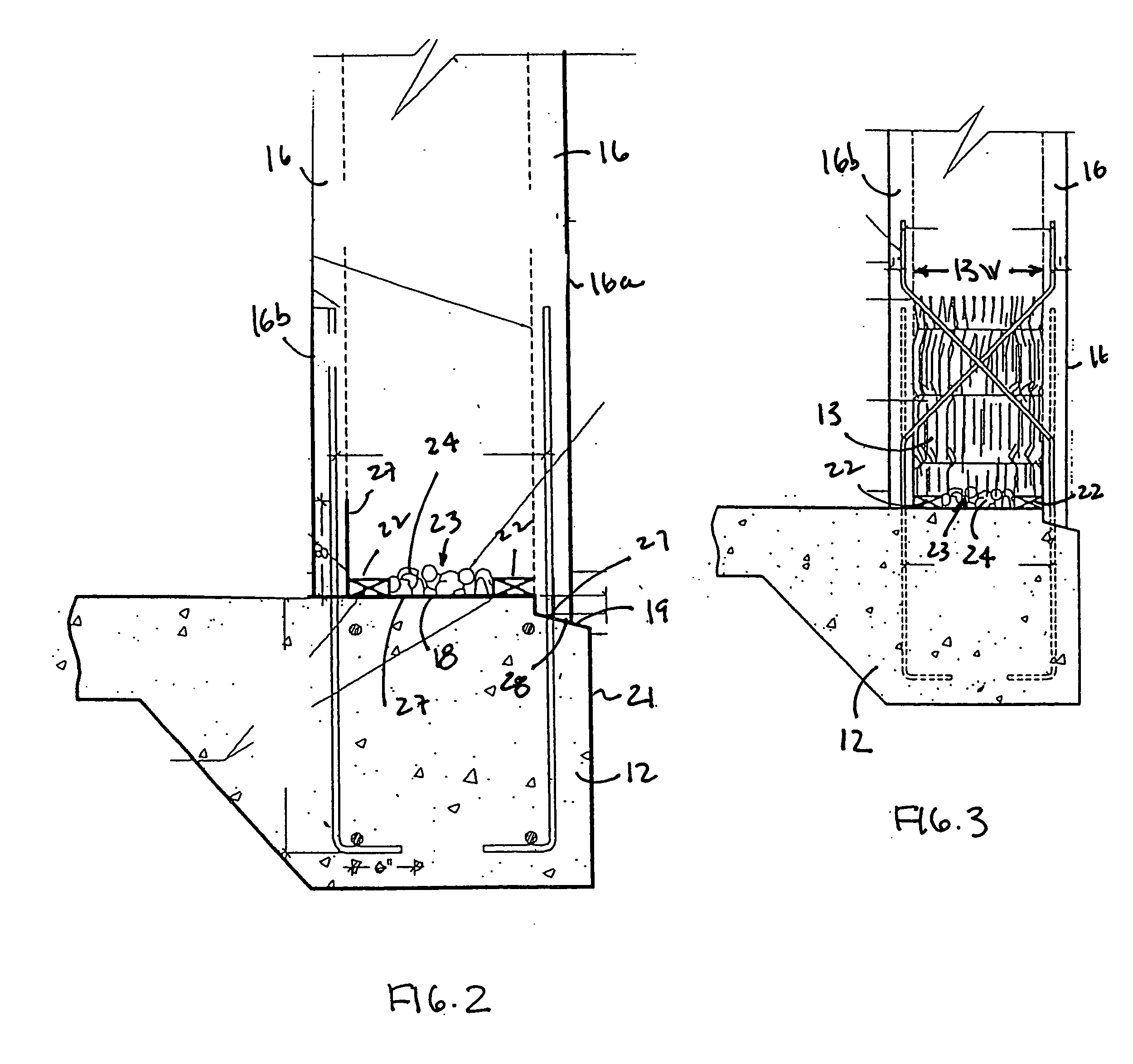

A method for erecting structures composed of rammed-earth. A method of rammed-earth building construction is disclosed wherein walls are post-tensioned to enhance the ability of the wall to receive lateral loading without failing in tension.Post-tensioning rods are anchored to a concrete footing, and temporary forms erected alongside the footing. A protective sleeve is disposed around each post-tensioning rod. An earthen mixture is placed between the forms and around the sleeves, and rammed by compaction in a series of stacked courses. When the rammed-earth wall has obtained the desired height, it is topped with a concrete bond beam through which the post-tensioning rods extend. Using the bond beam as a brace against which a retaining plate may push, retaining plates are disposed upon the bond beam and around the threaded upper ends of each rod. A nut is threaded upon each rod and tightened against the retaining plate to draw the rod into tension. The torque applied to the nut thus loads the wall in compression via the plates and bond beam. Thus compressed, the rammed-earth wall is less susceptible to tension failure.

Owner:WARD THOMAS +1

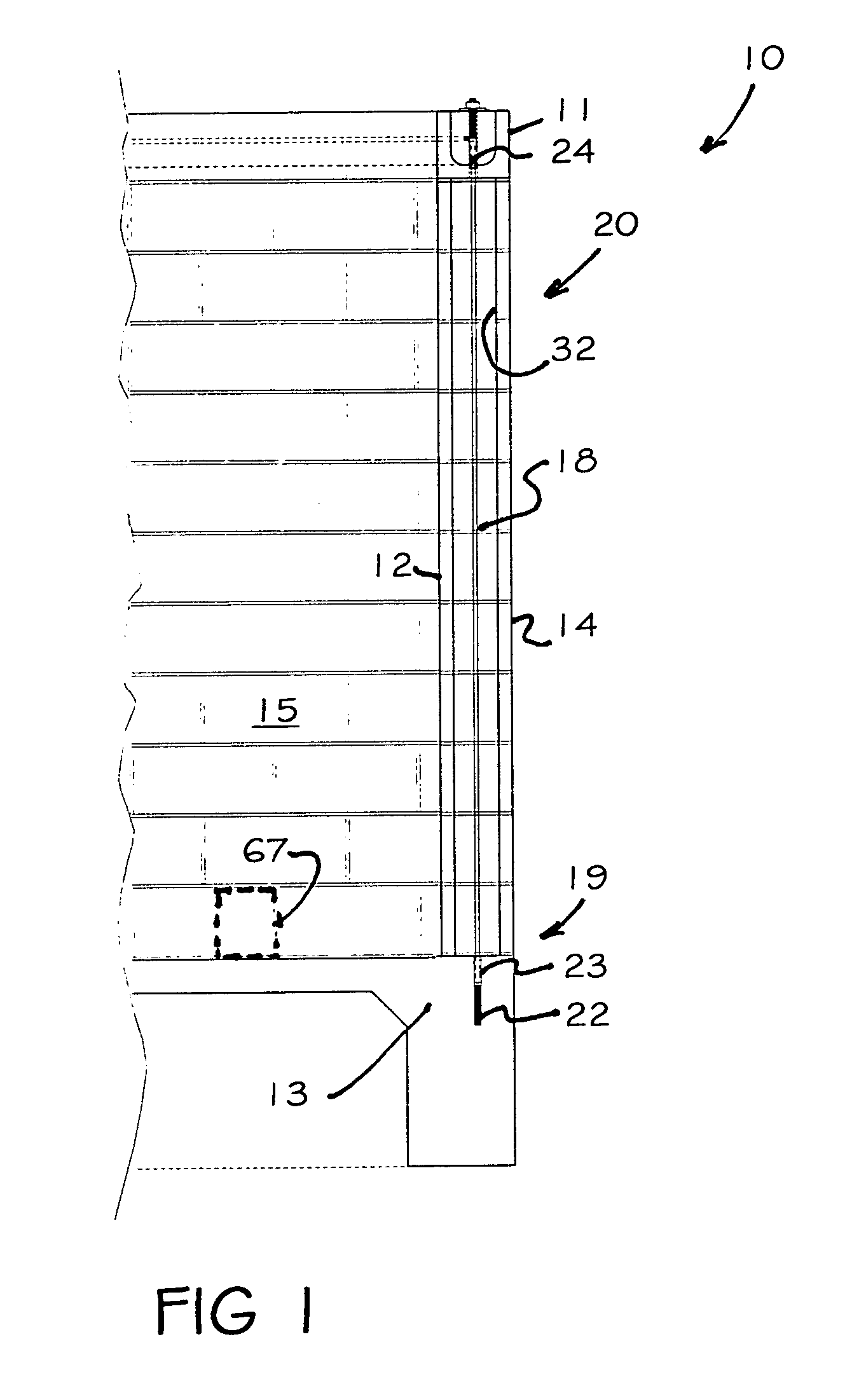

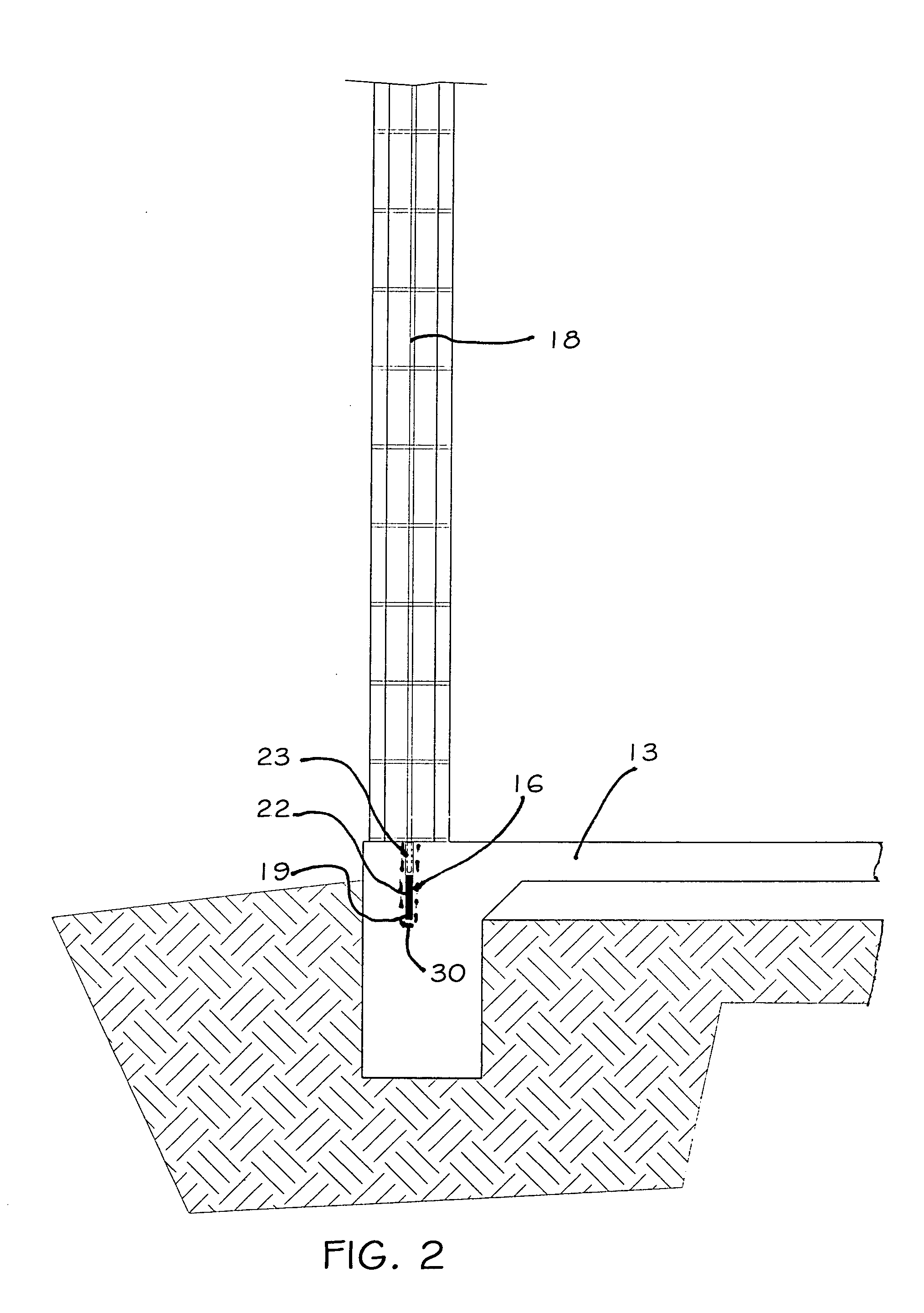

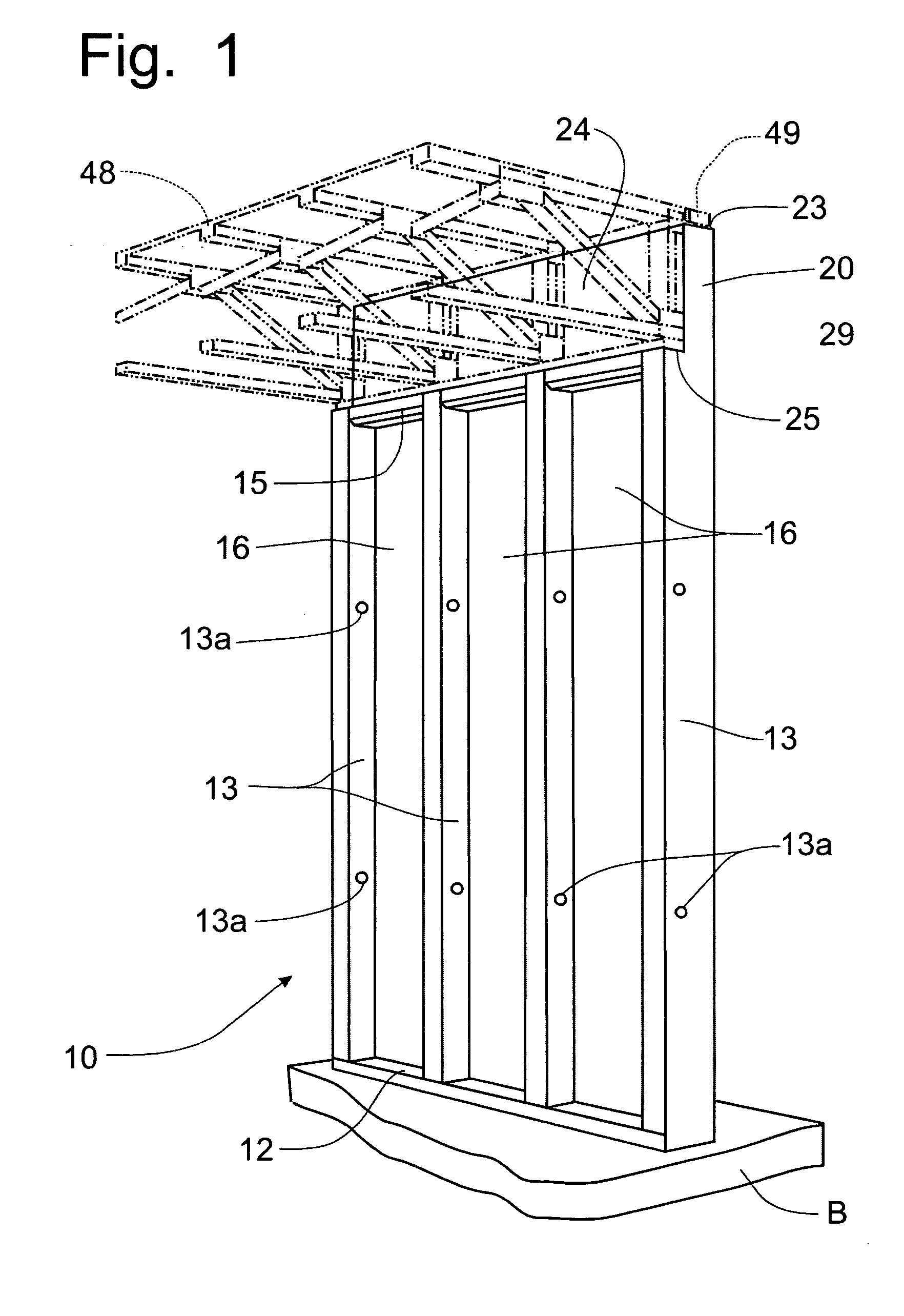

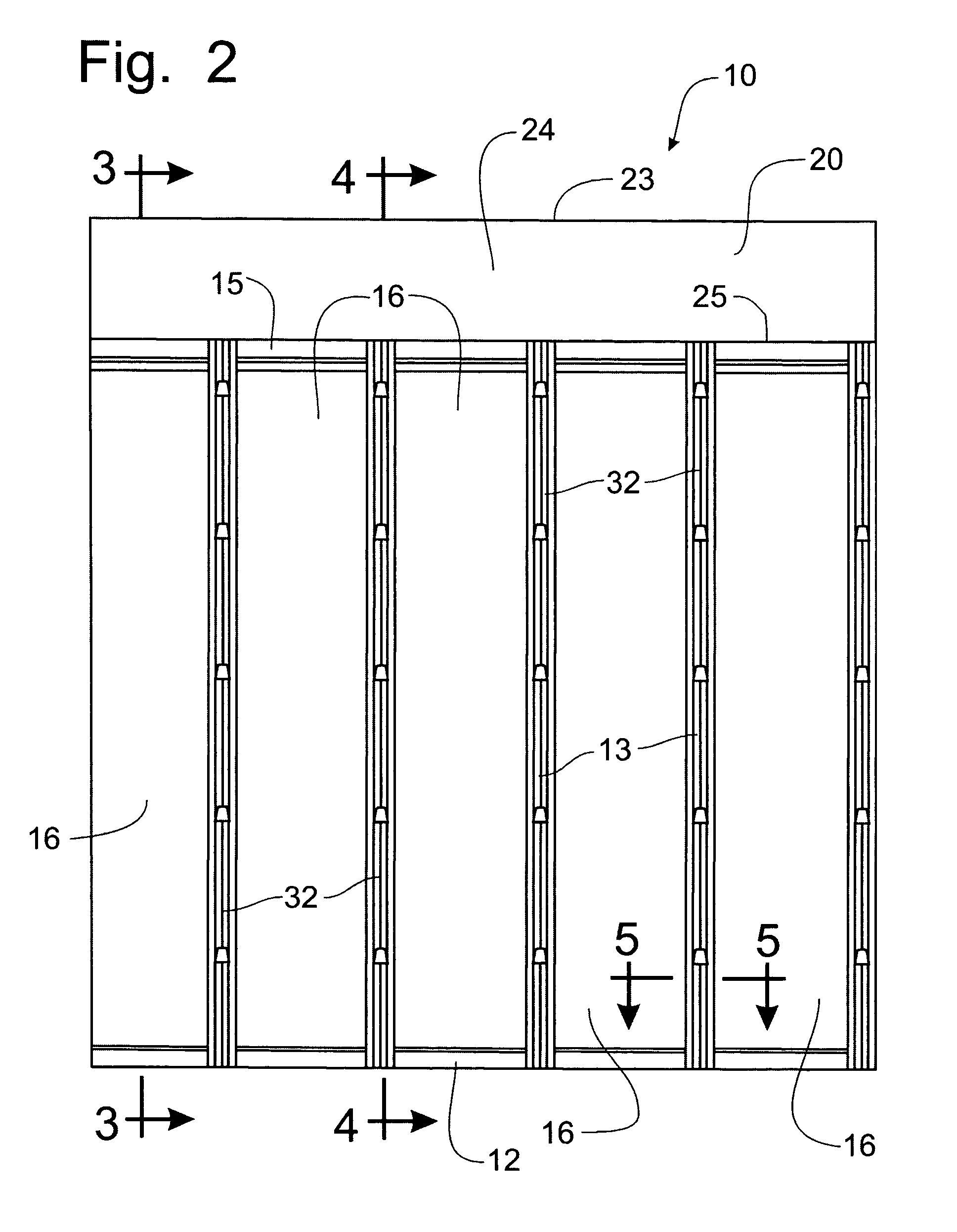

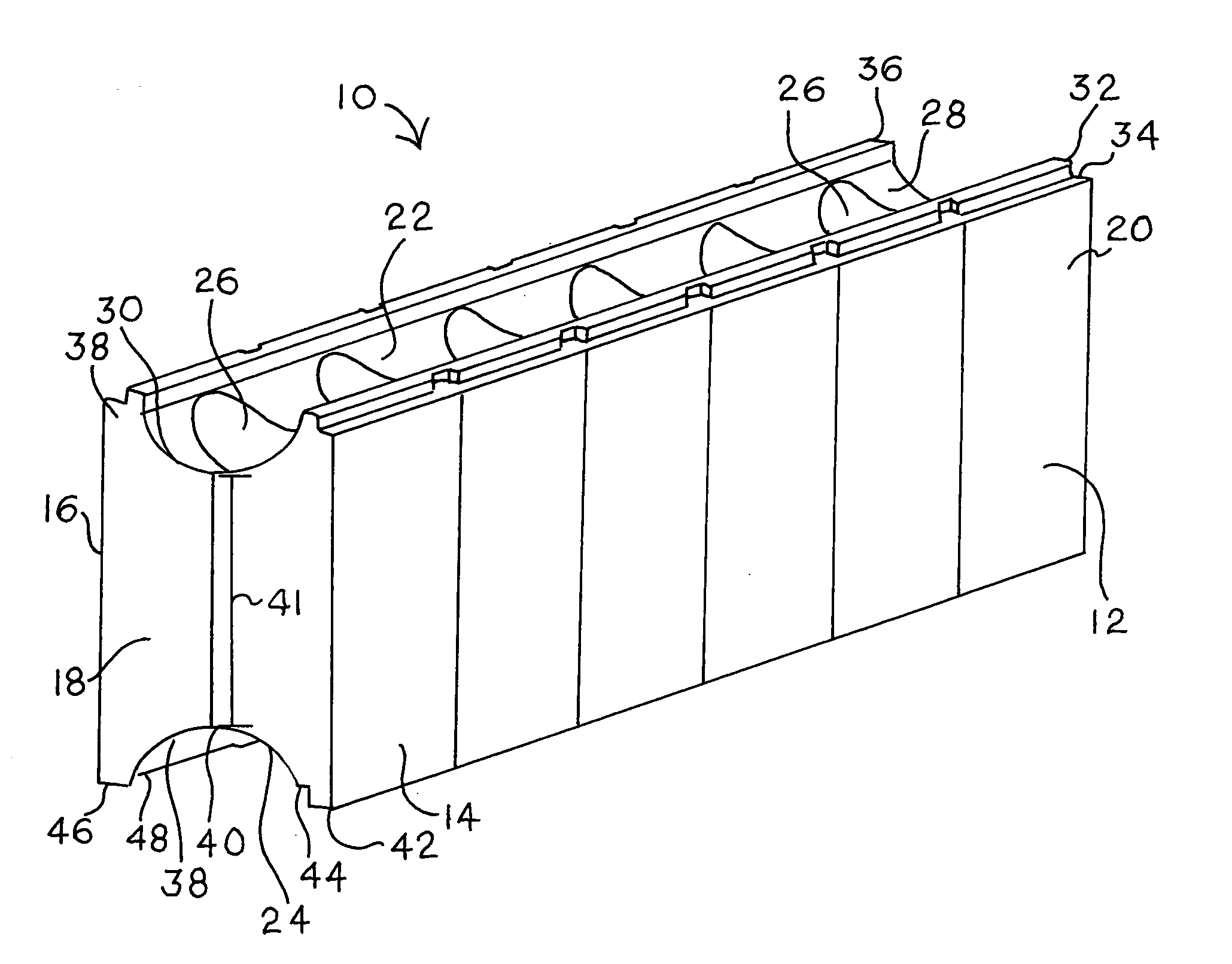

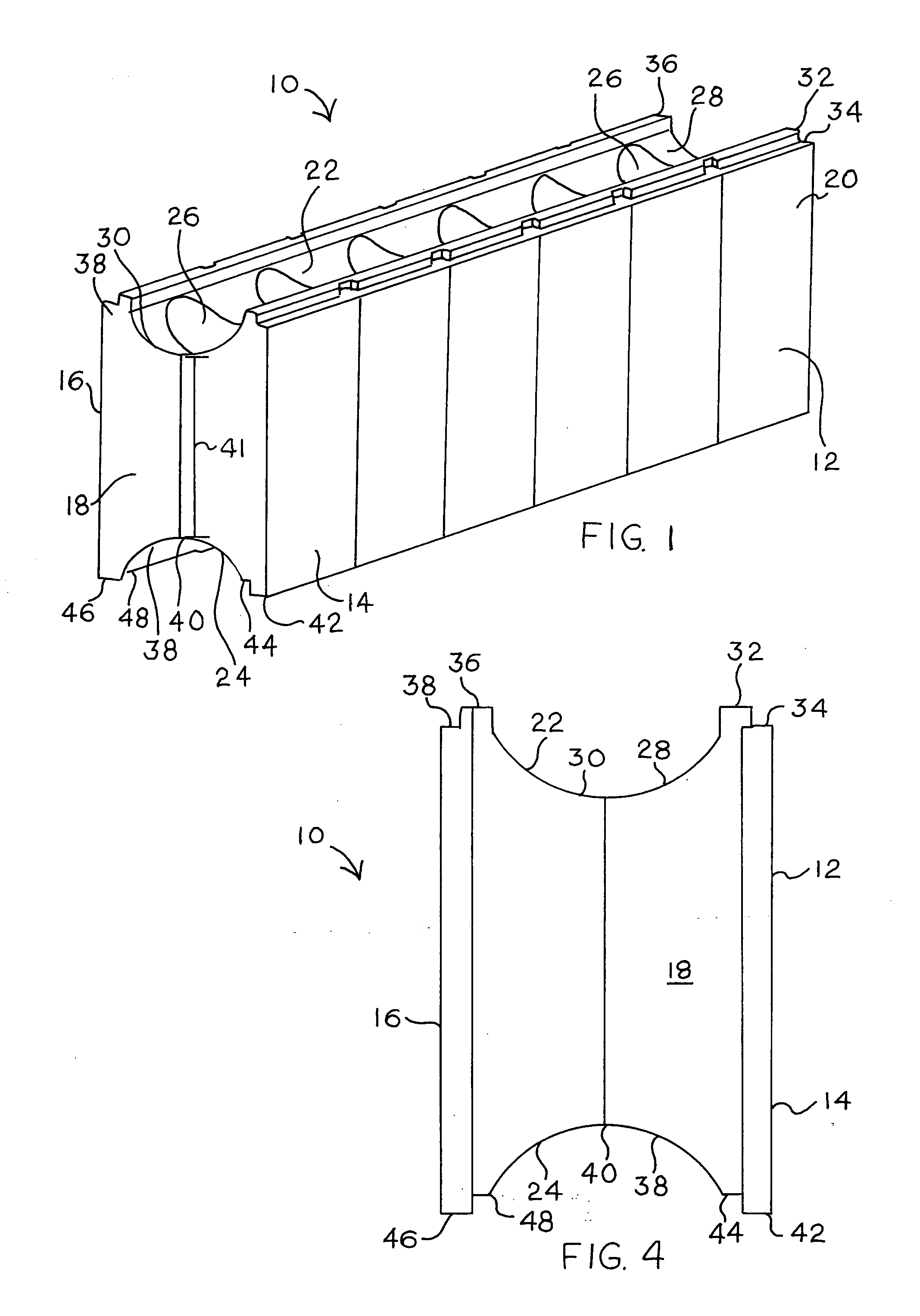

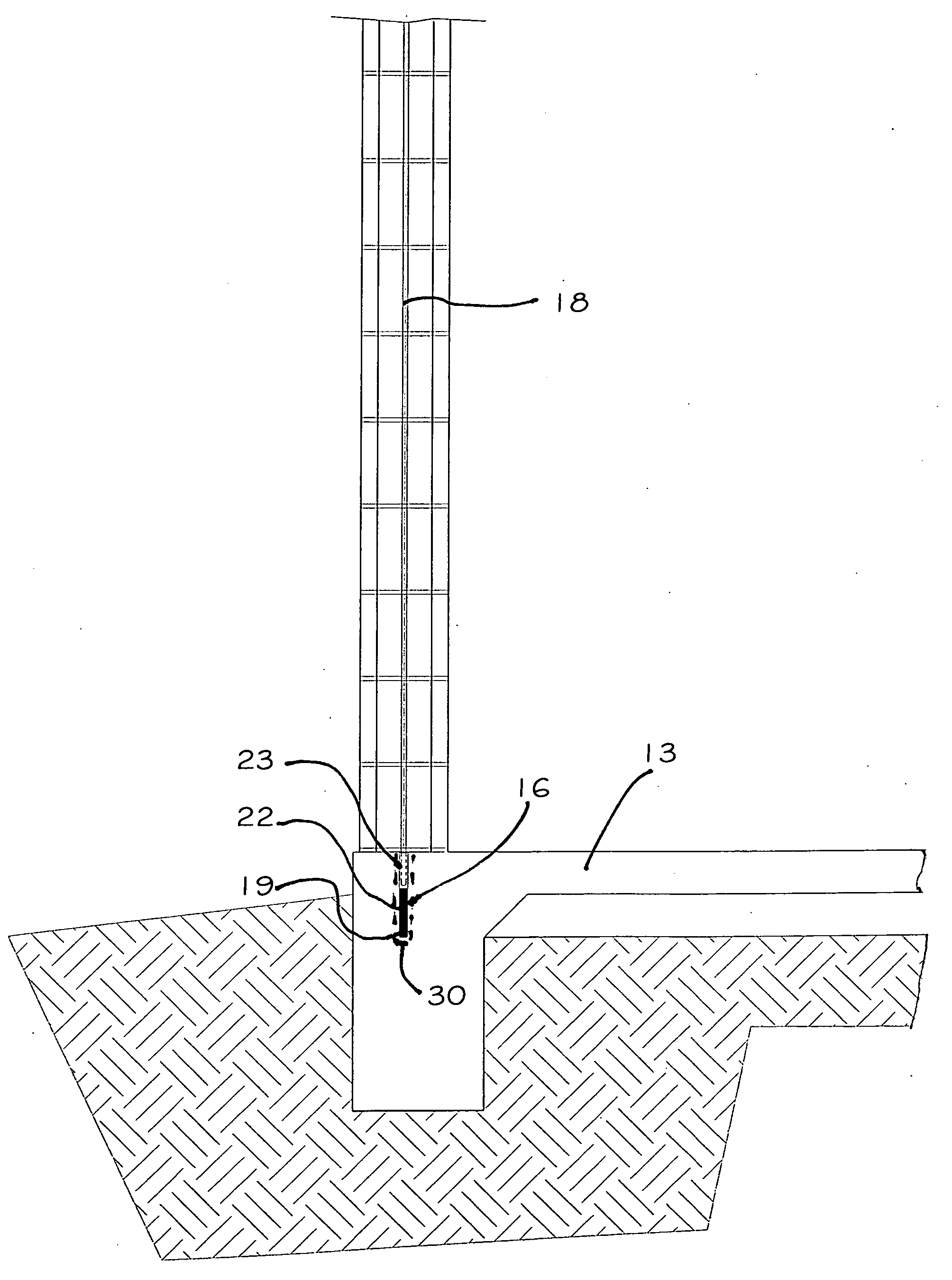

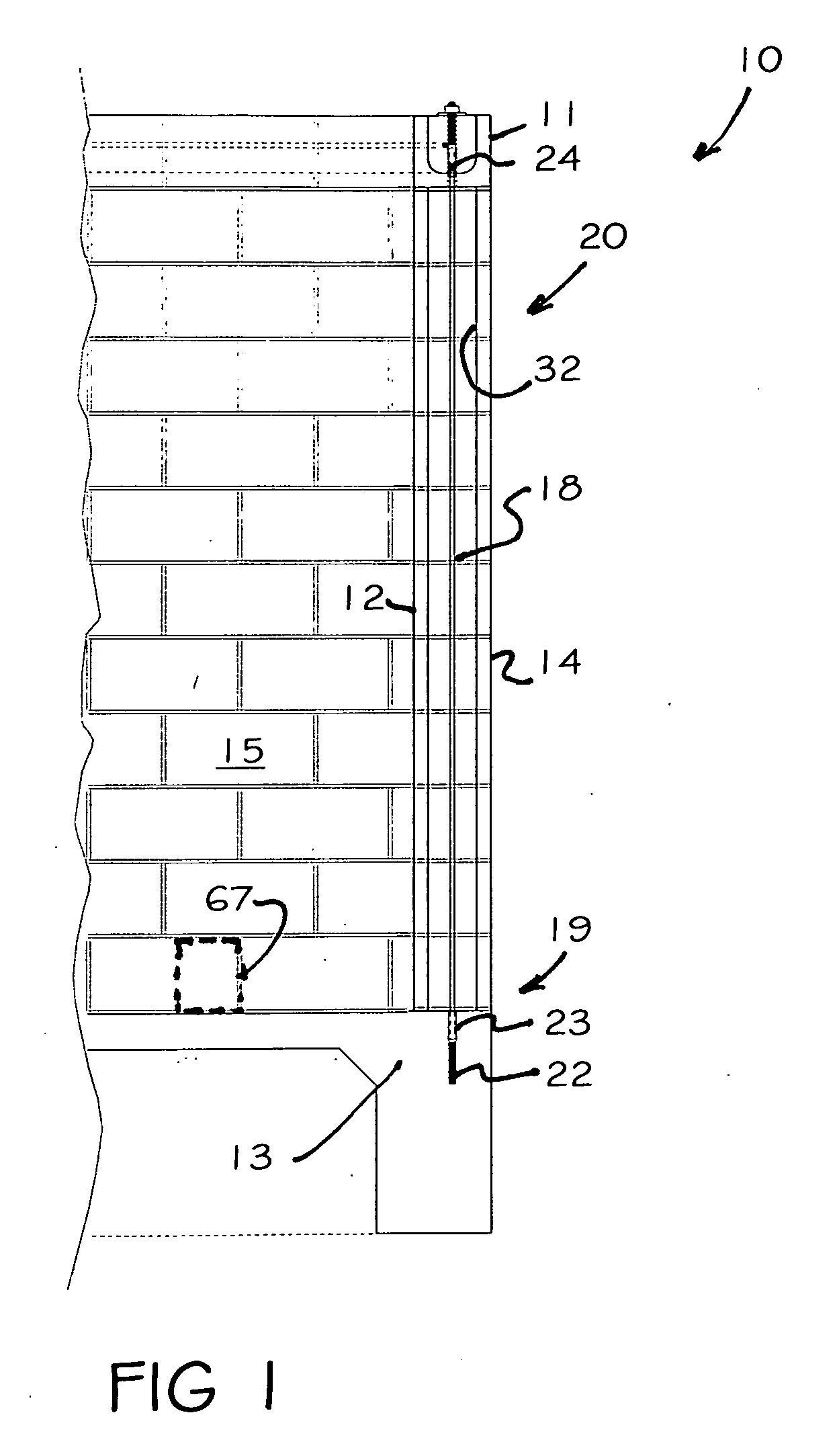

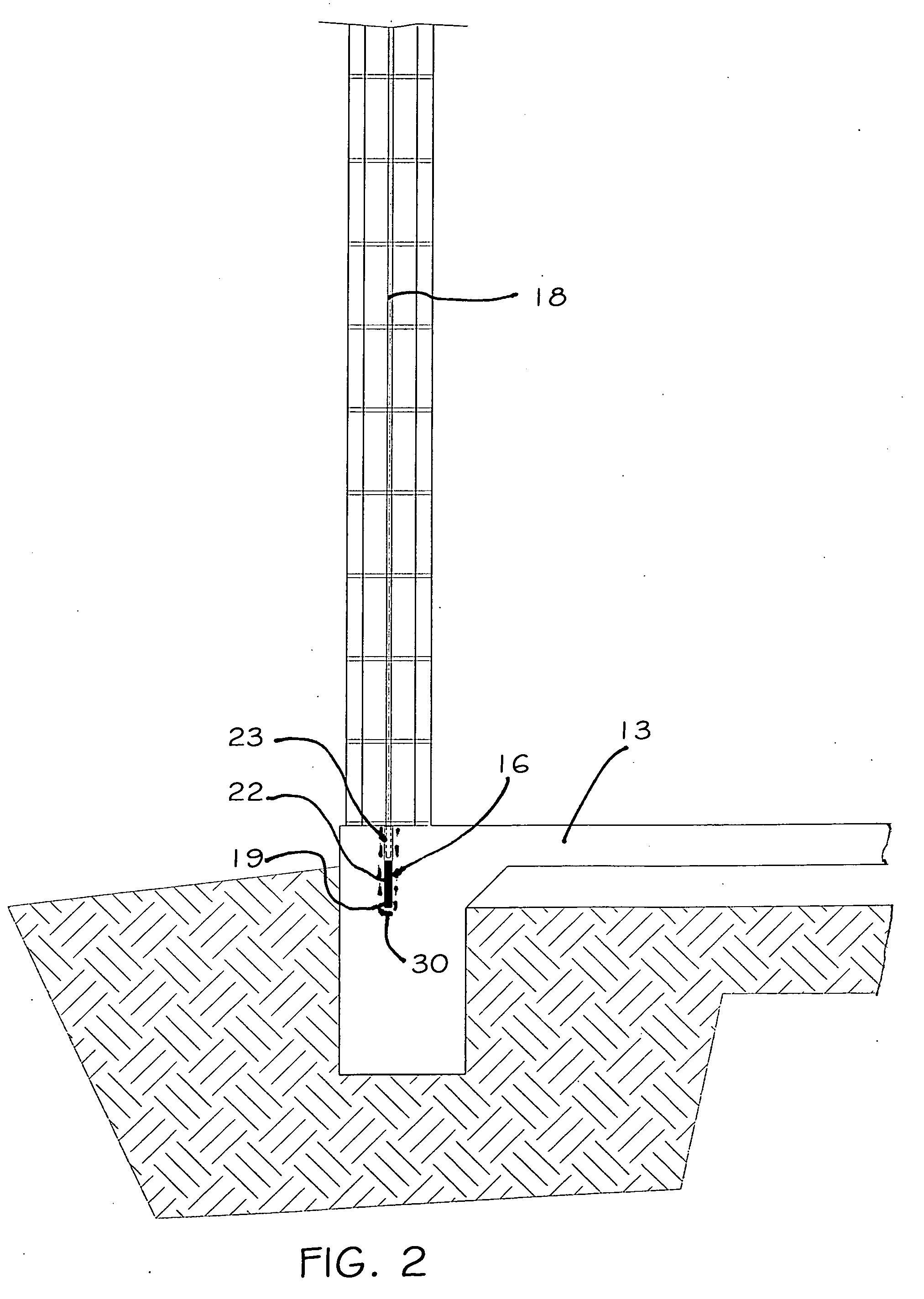

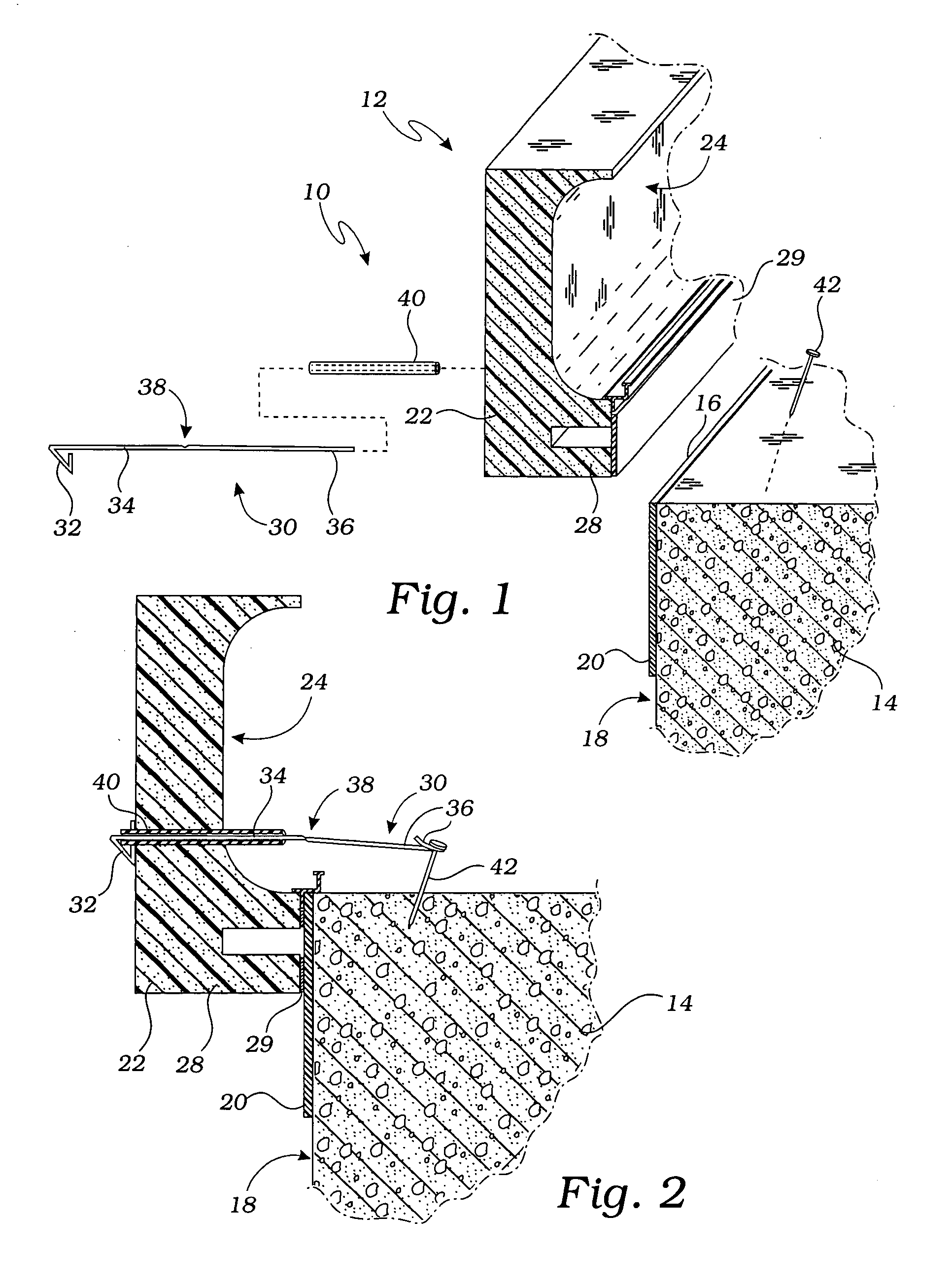

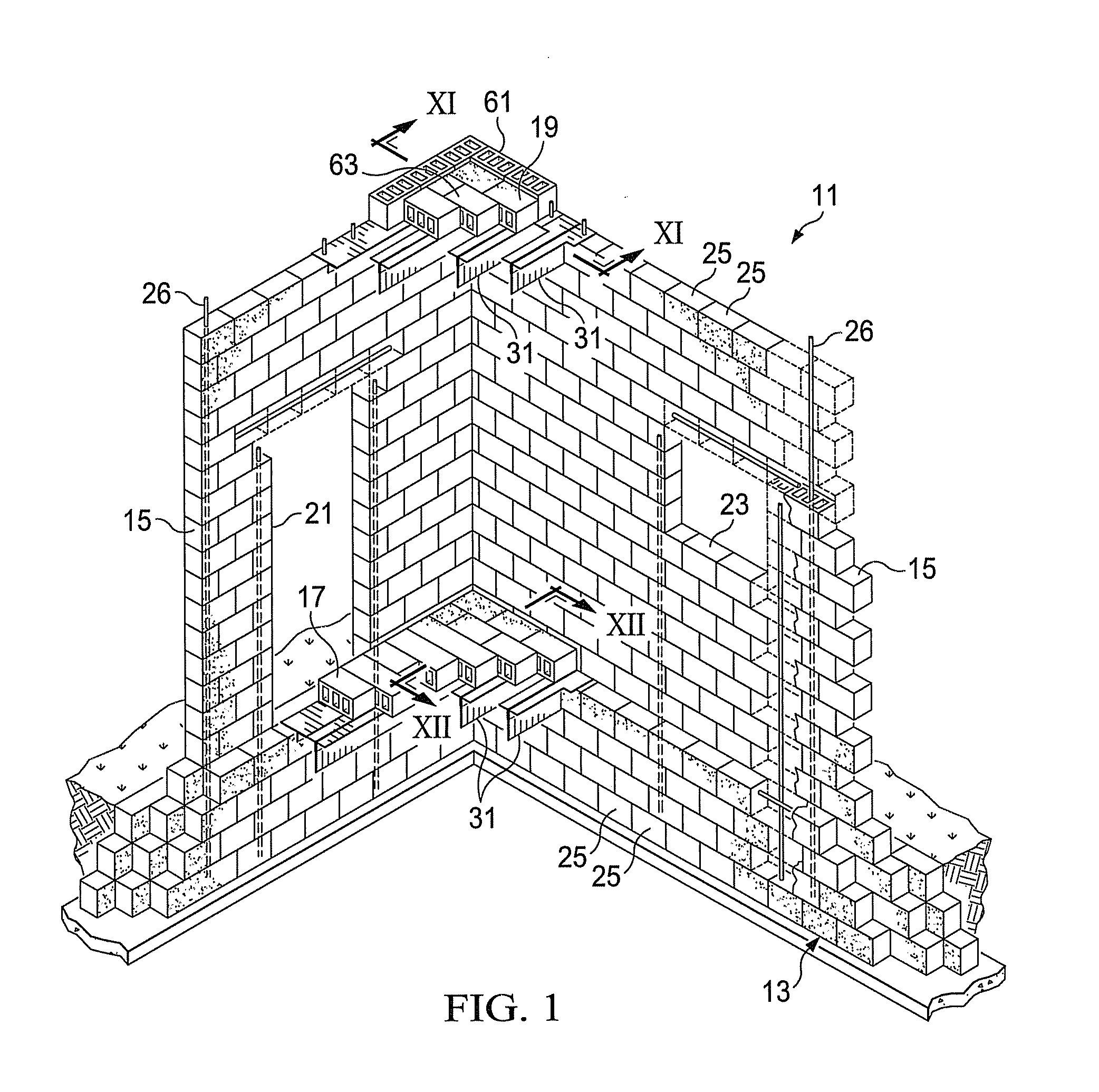

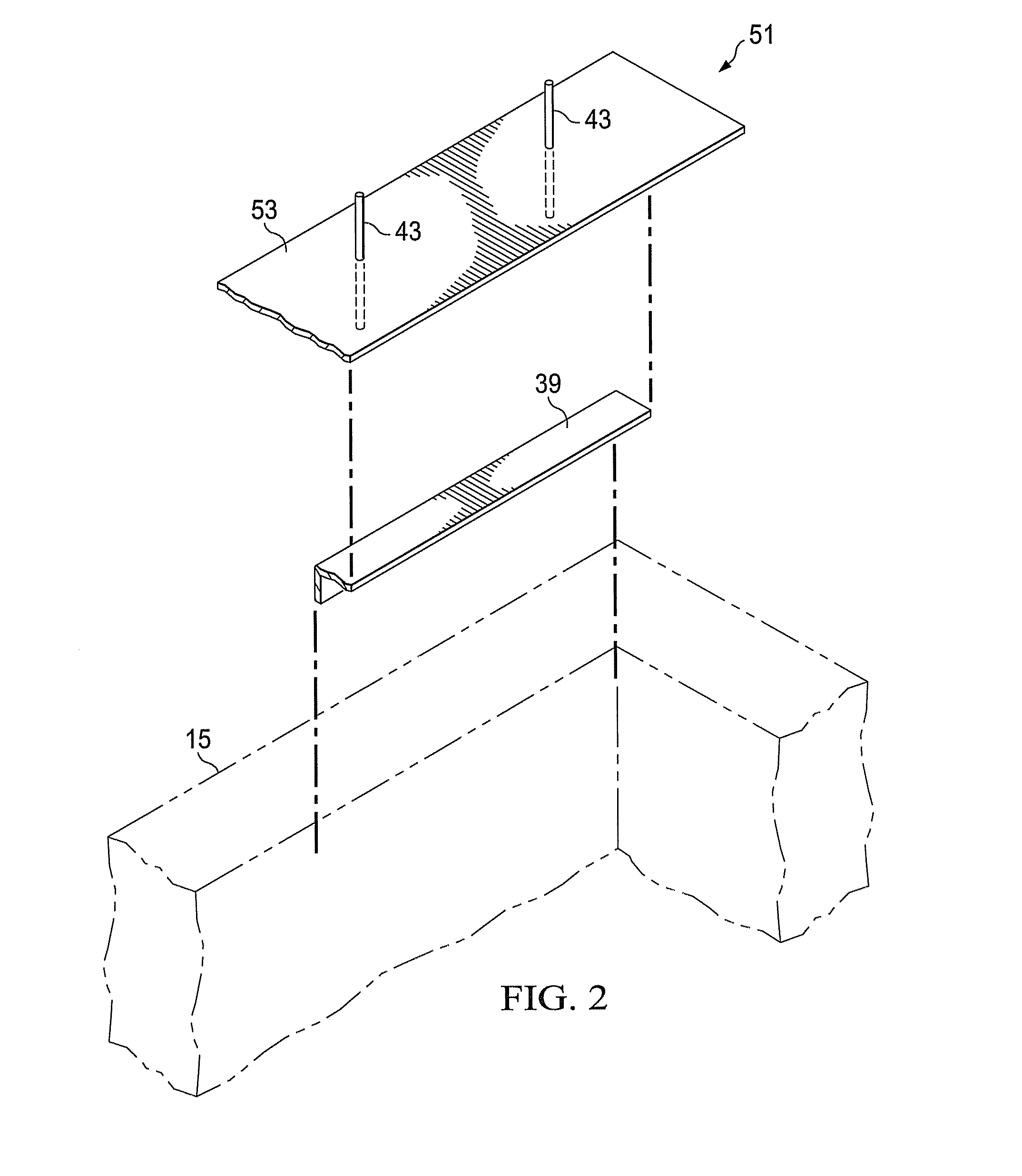

Masonry wall tension device and method for installing same

Masonry walls of buildings supported on concrete foundations are strengthened against destructive wind and seismic forces by spaced elongated members inserted inside the hollow masonry walls. The spaced elongated members are secured to the continuous masonry bond beam and the foundation. Tension means at the top of the masonry wall make the elongated members taut creating a continuous tension load path from bond beam to the foundation.

Owner:CRUMLEY HARVEL K

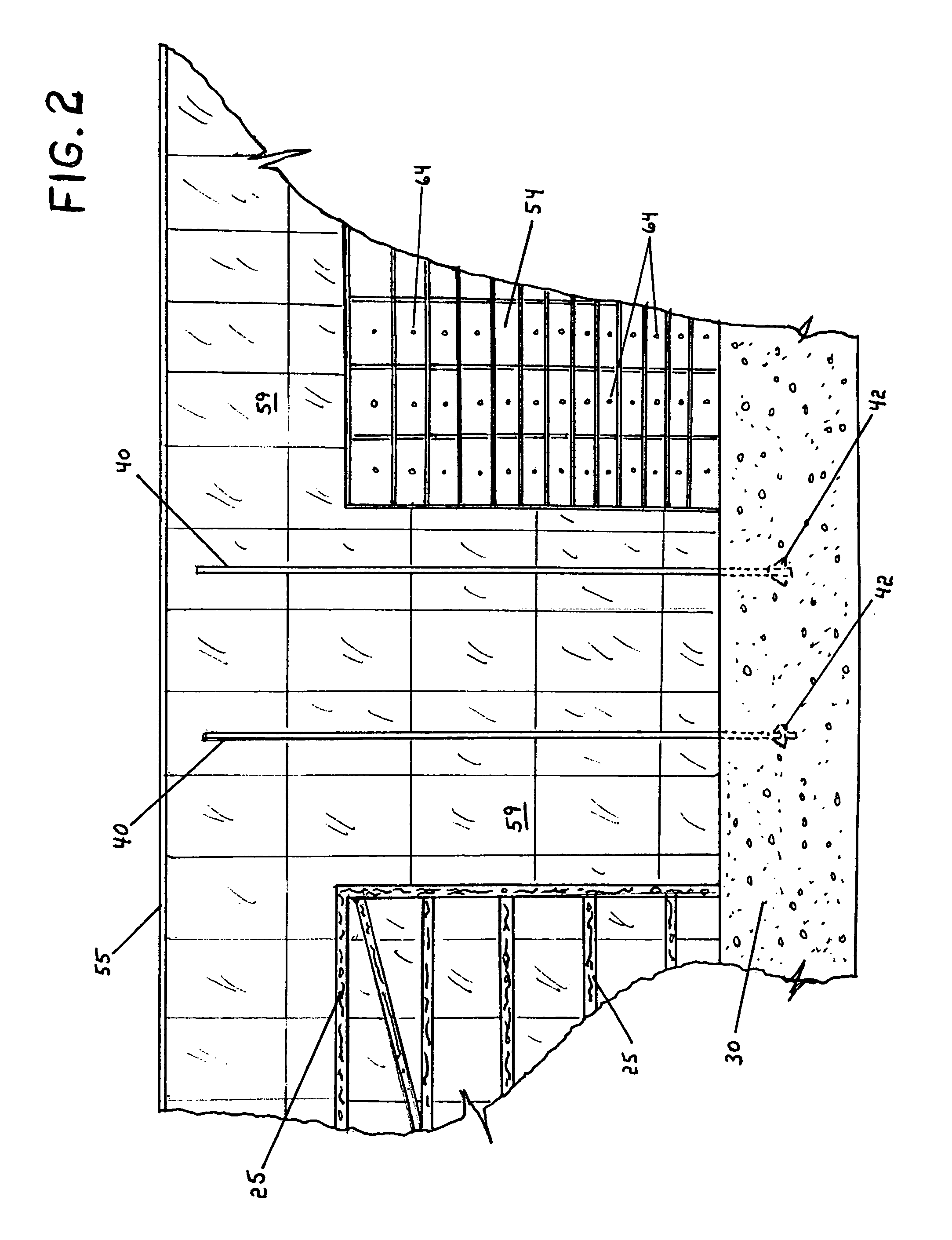

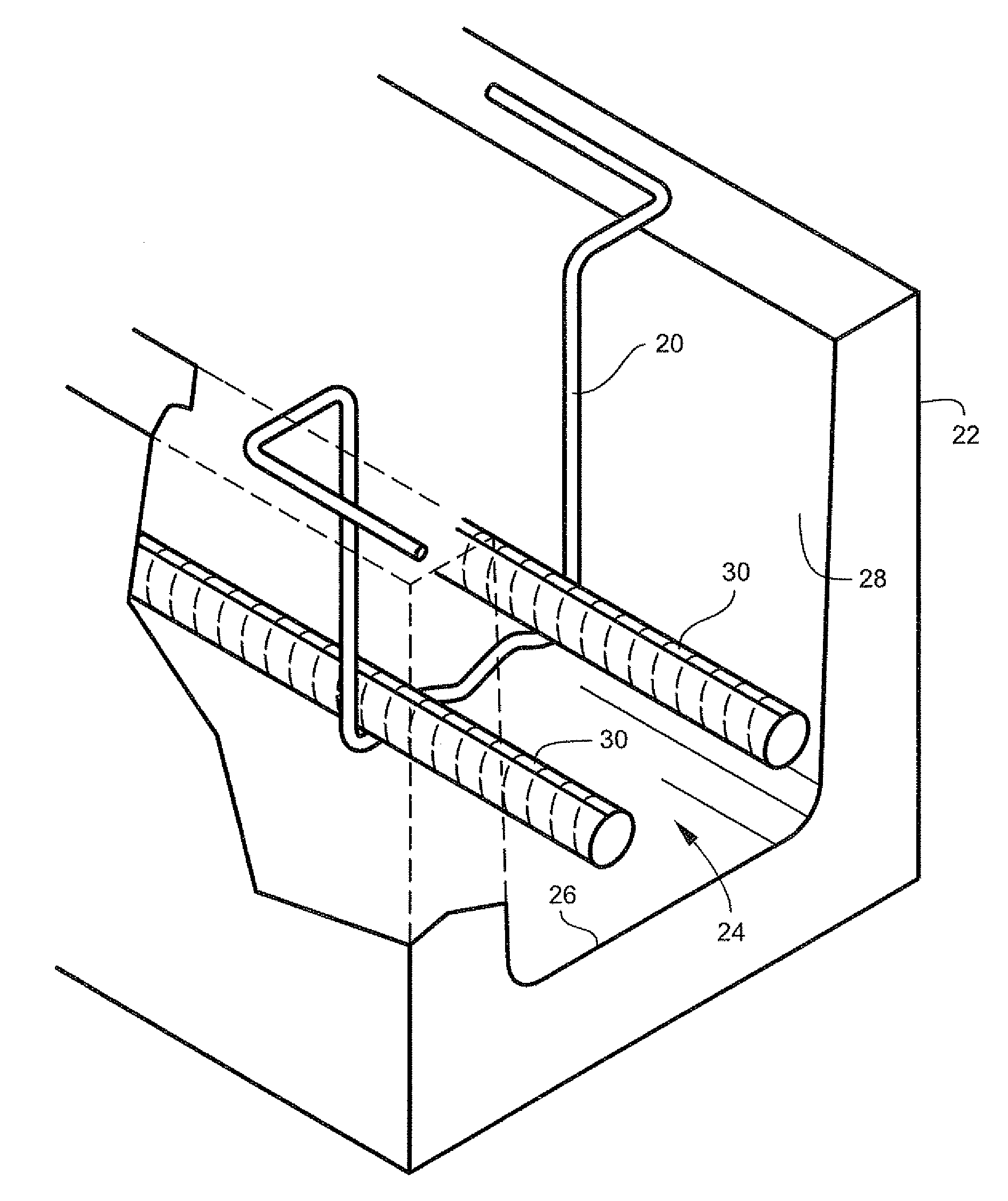

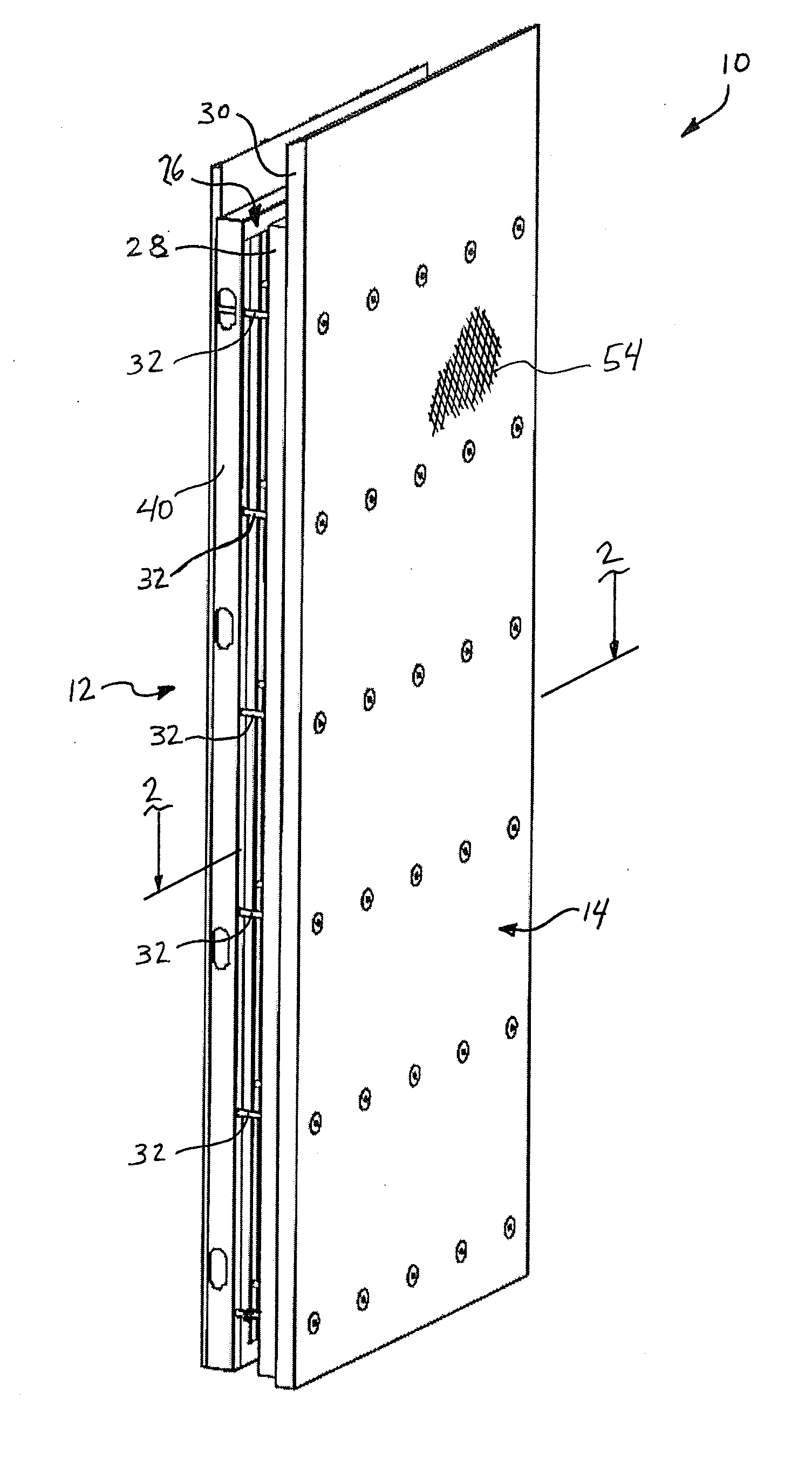

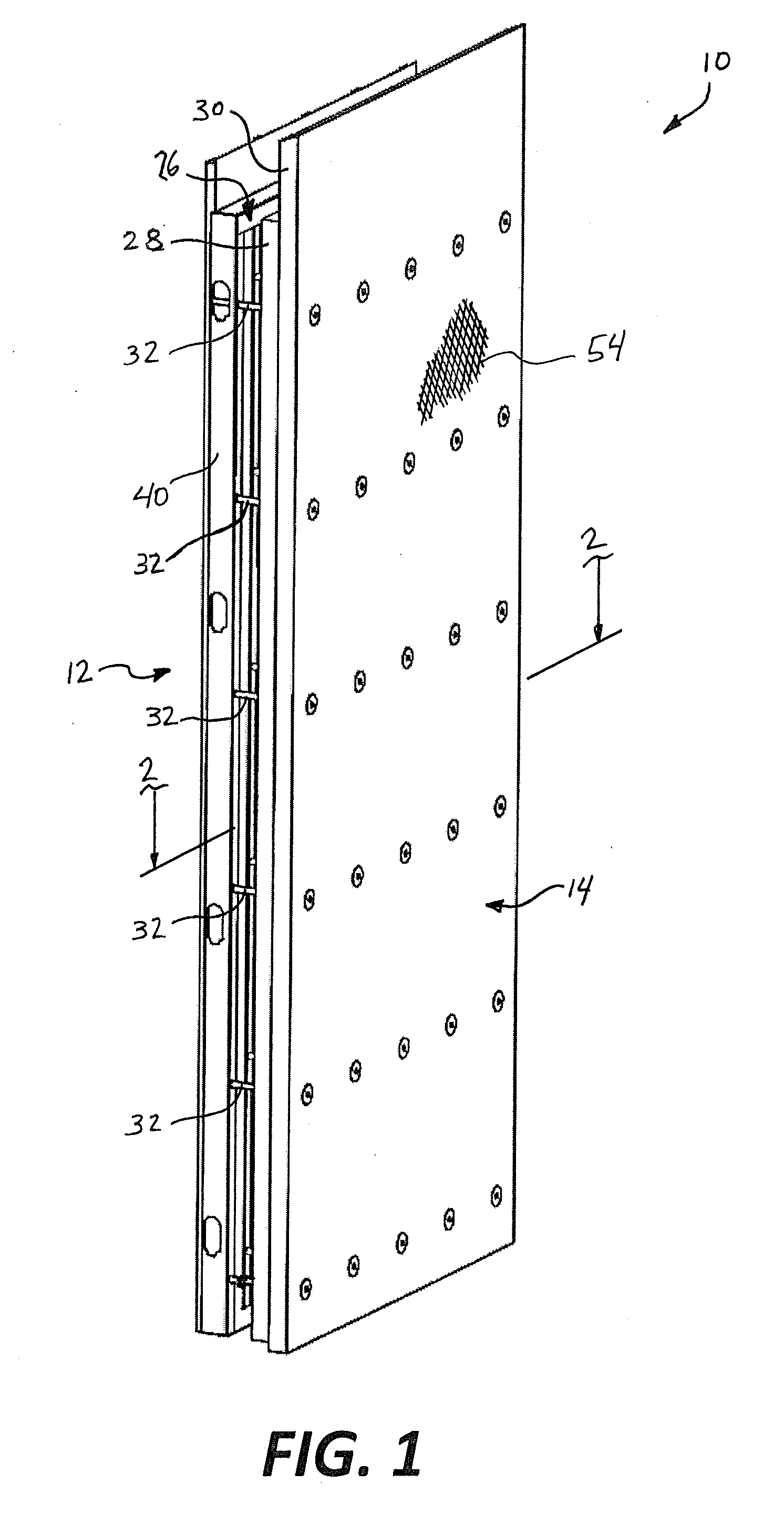

Pre-cast concrete wall with truss ledge

ActiveUS7530203B1High strengthReliable constructionBuilding constructionsSurface layering apparatusEngineeringRebar

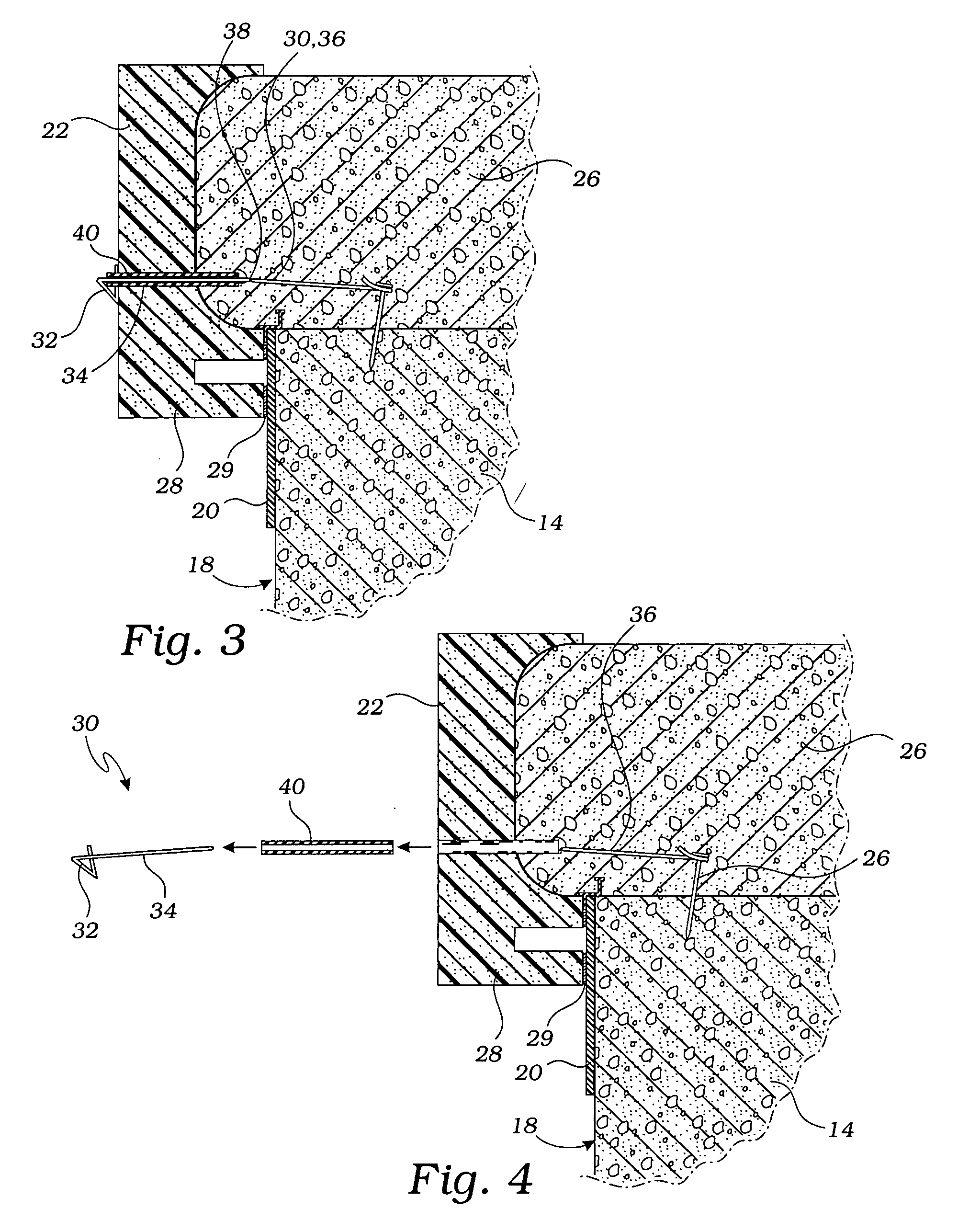

A pre-cast concrete wall system that incorporates a truss ledge for positioning a building floor system at a below-grade location. The truss ledge is defined by a vertical wall formed as a continuation of the exterior wall of the wall panel extending from the footer beam to the upper bond beam and projecting vertically above the upper bond beam to provide a support surface for the building floor members. A floor truss system can be supported on the upper bond beam with the truss ledge forming a concrete below-grade surface externally of the floor trusses. Galvanized steel stud facings incorporating fold-up reinforcing bar supports are used on the interior surface of the vertical wall beams. Insulated access holes are formed through the vertical beams for the passage of wiring and plumbing behind the wall finish to be fastened to the stud facings.

Owner:SUPERIOR WALLS OF AMERICA

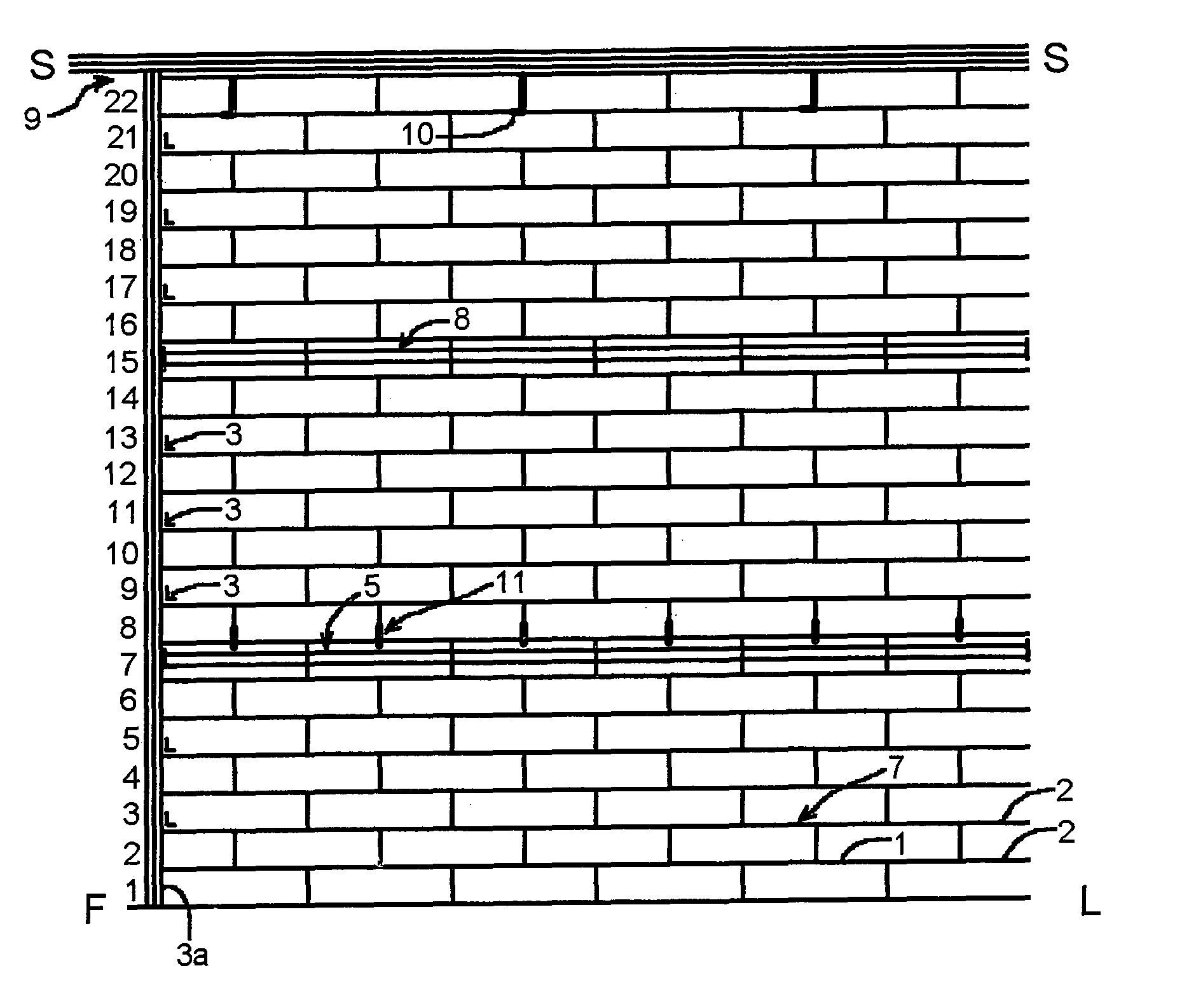

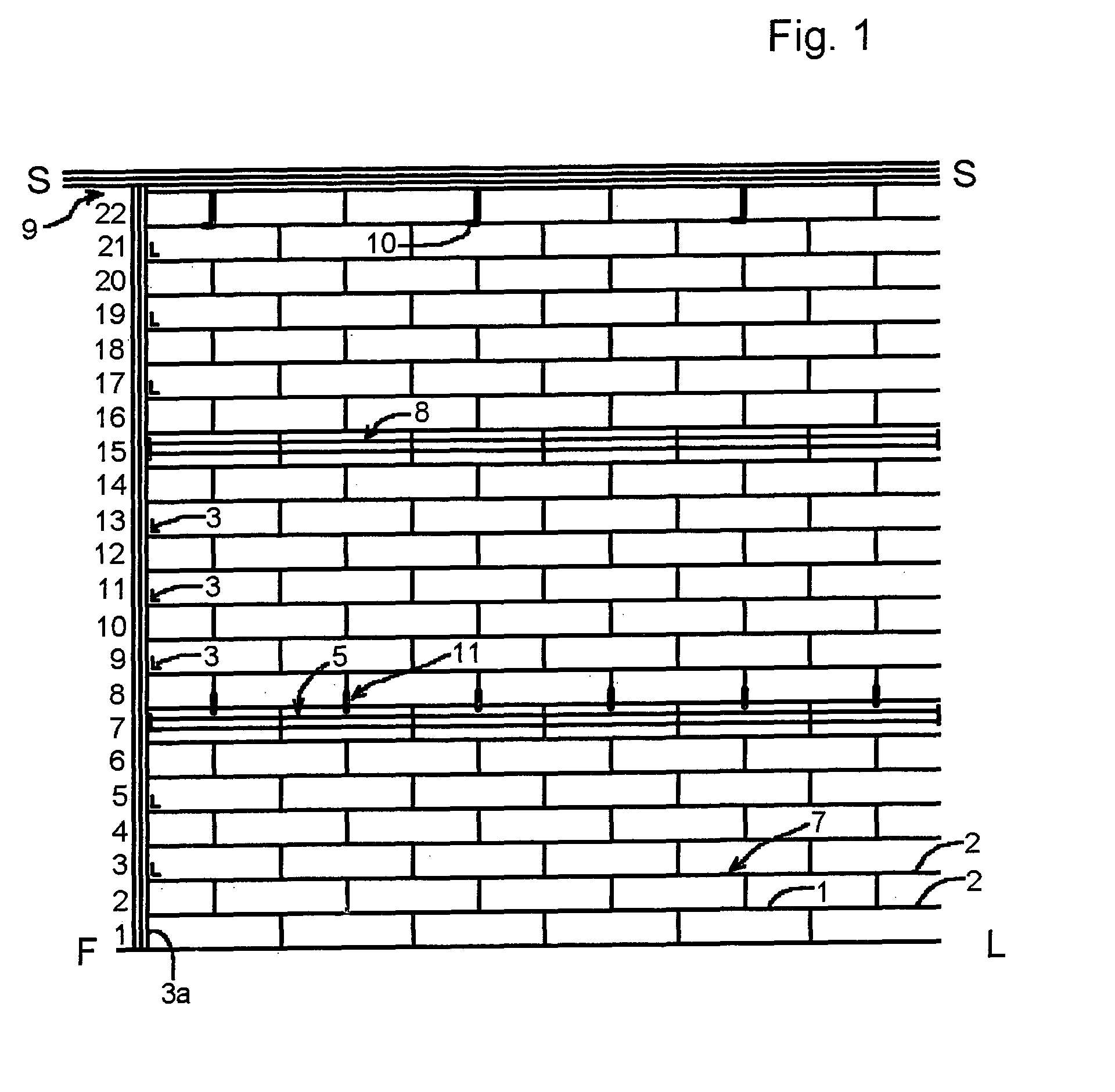

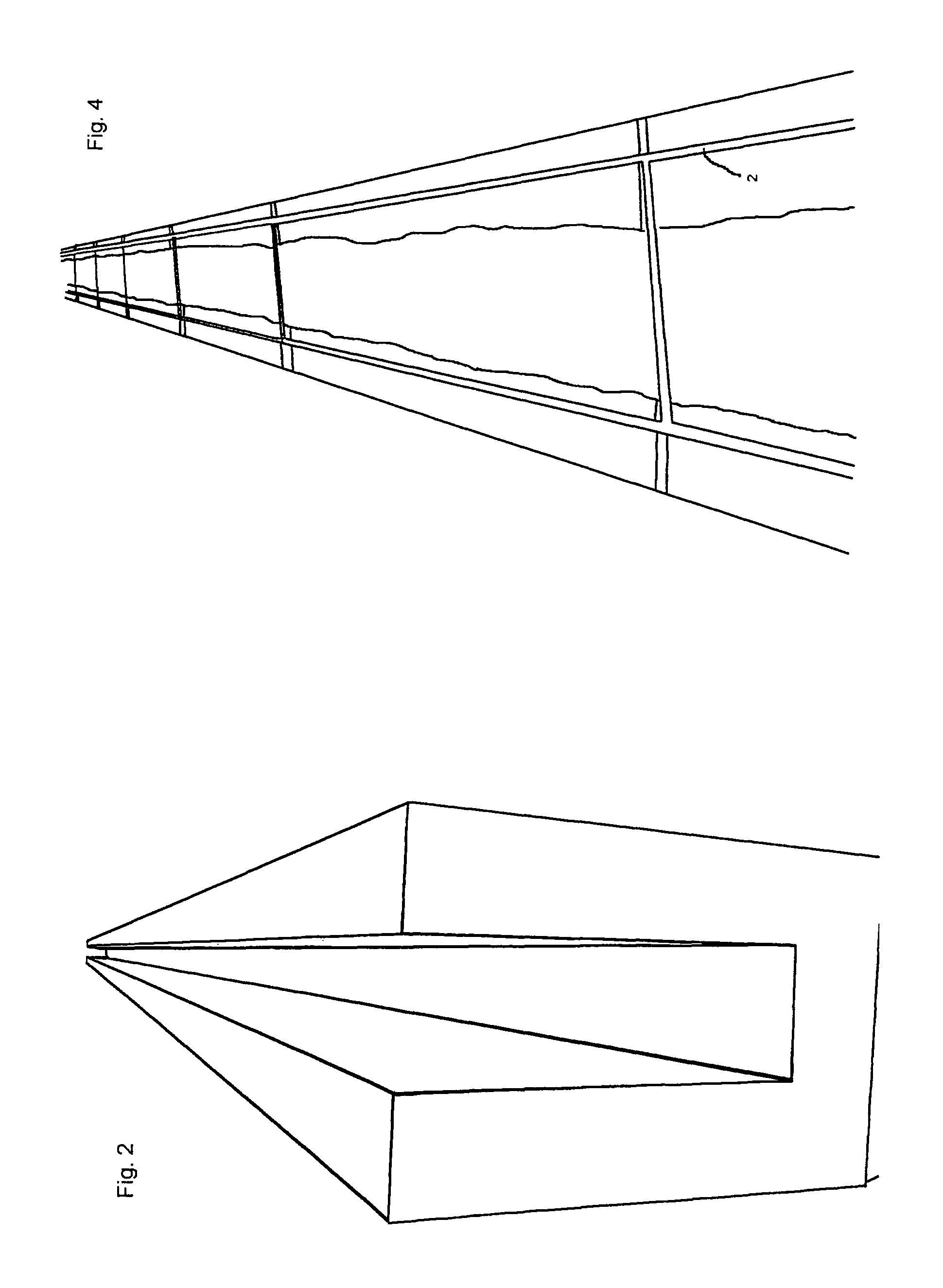

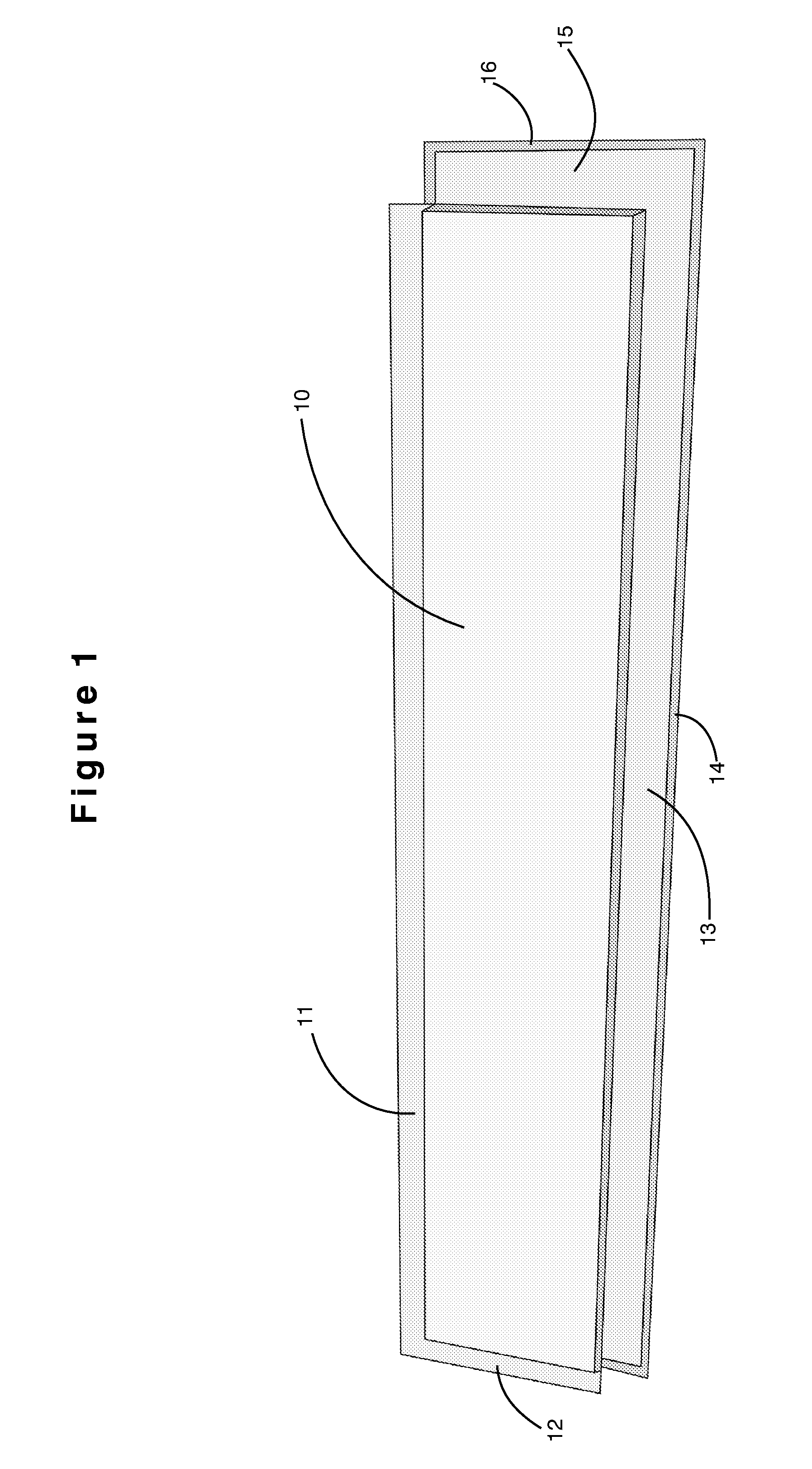

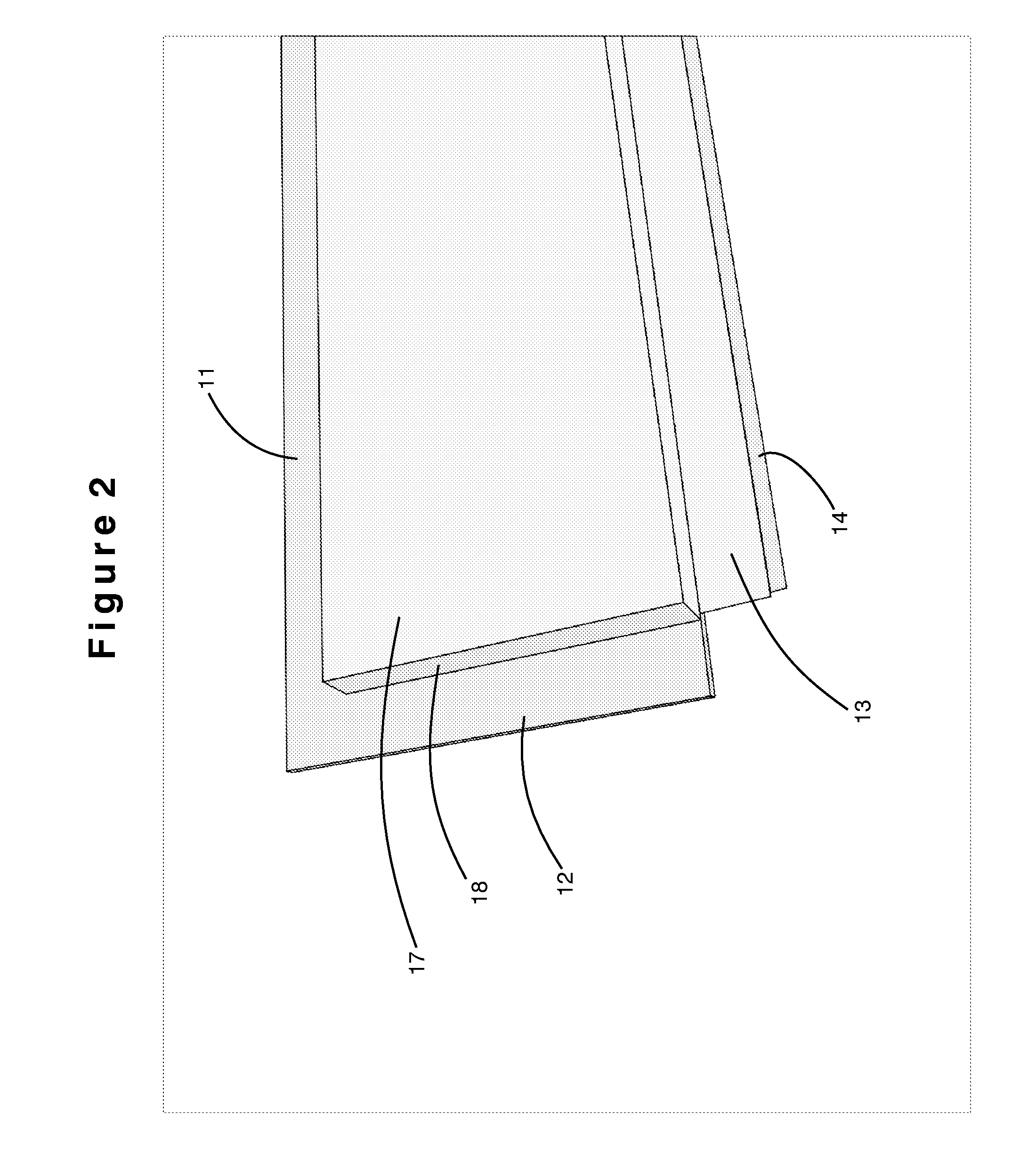

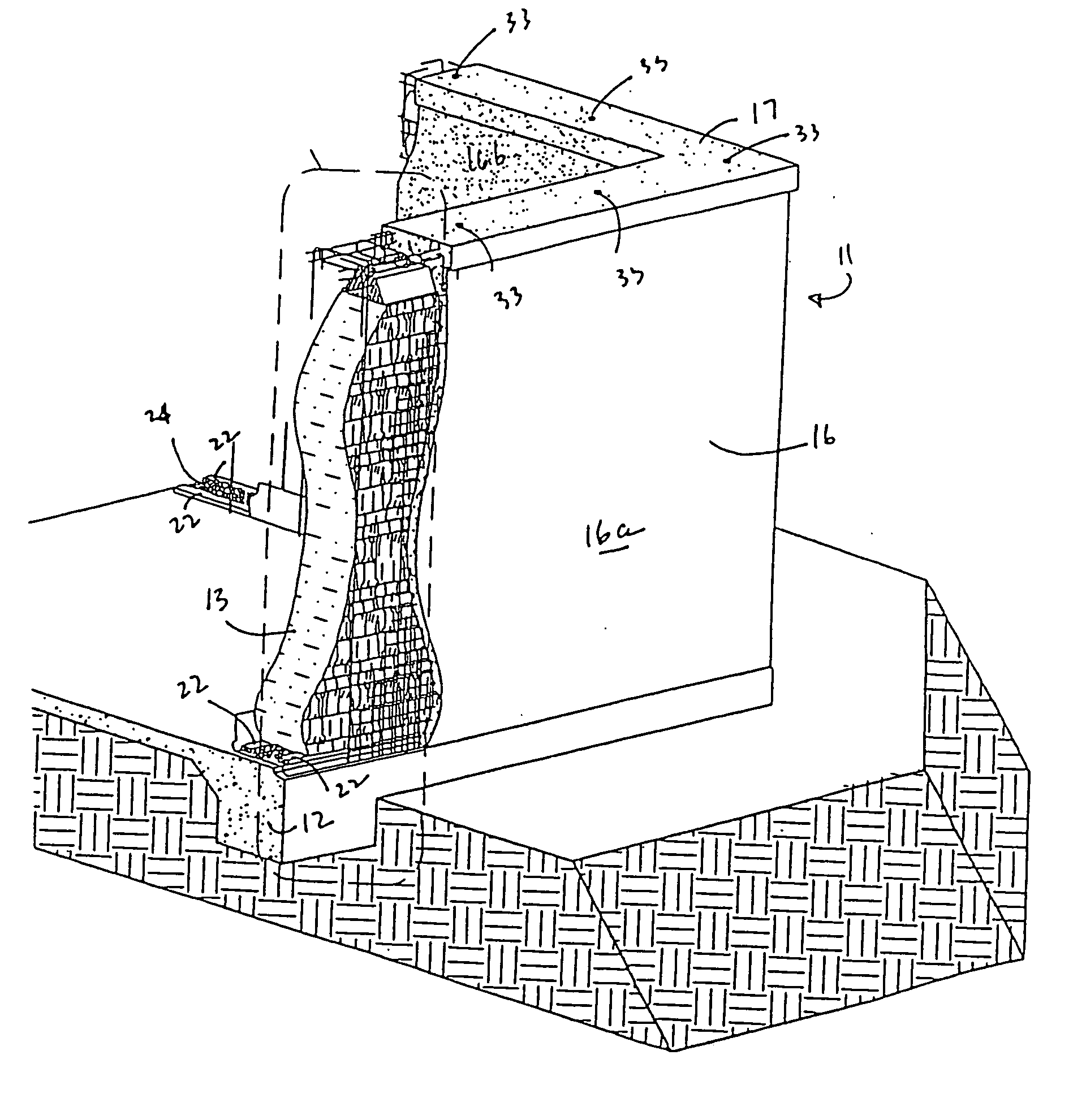

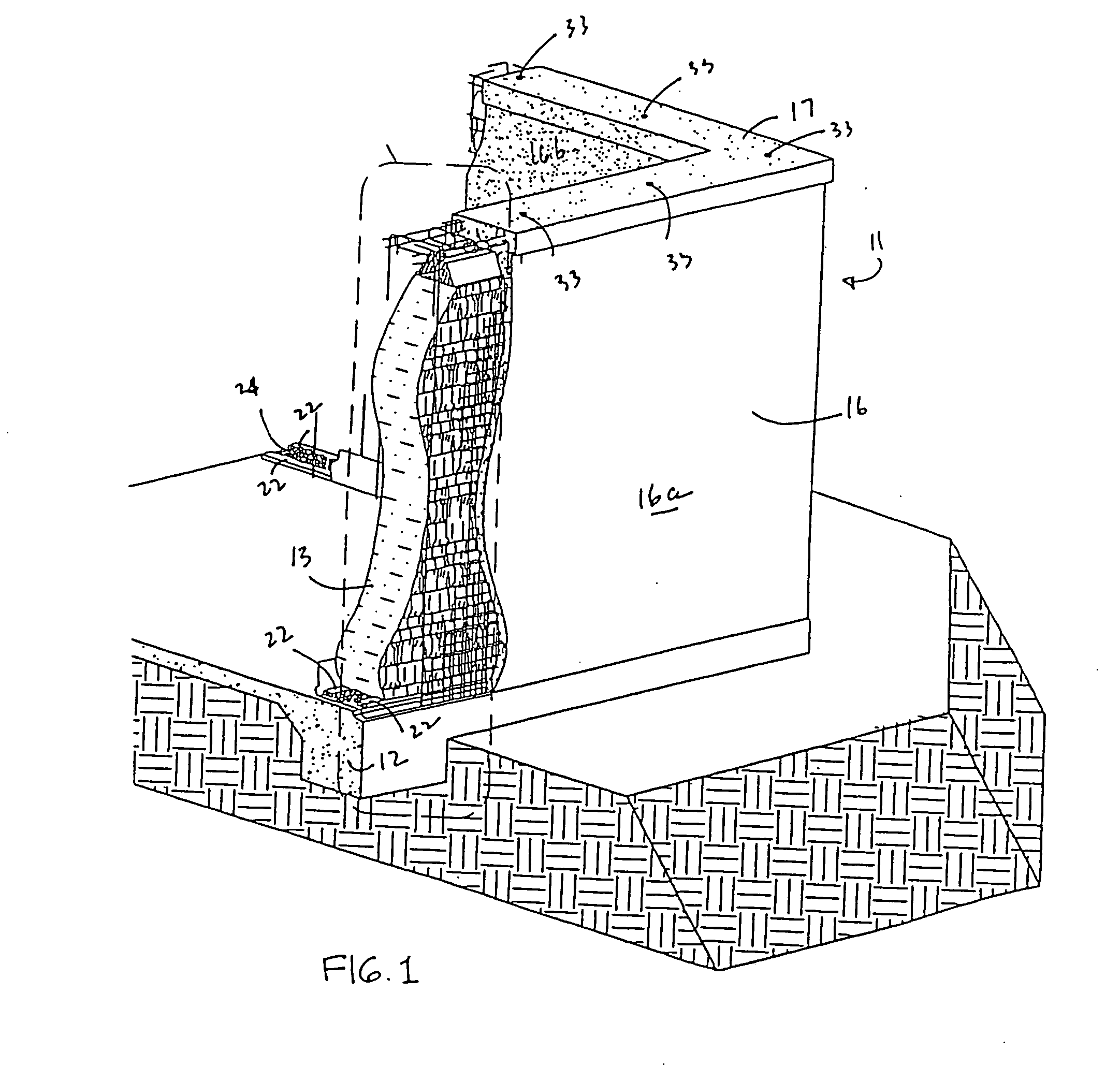

Reinforced masonry panel structures

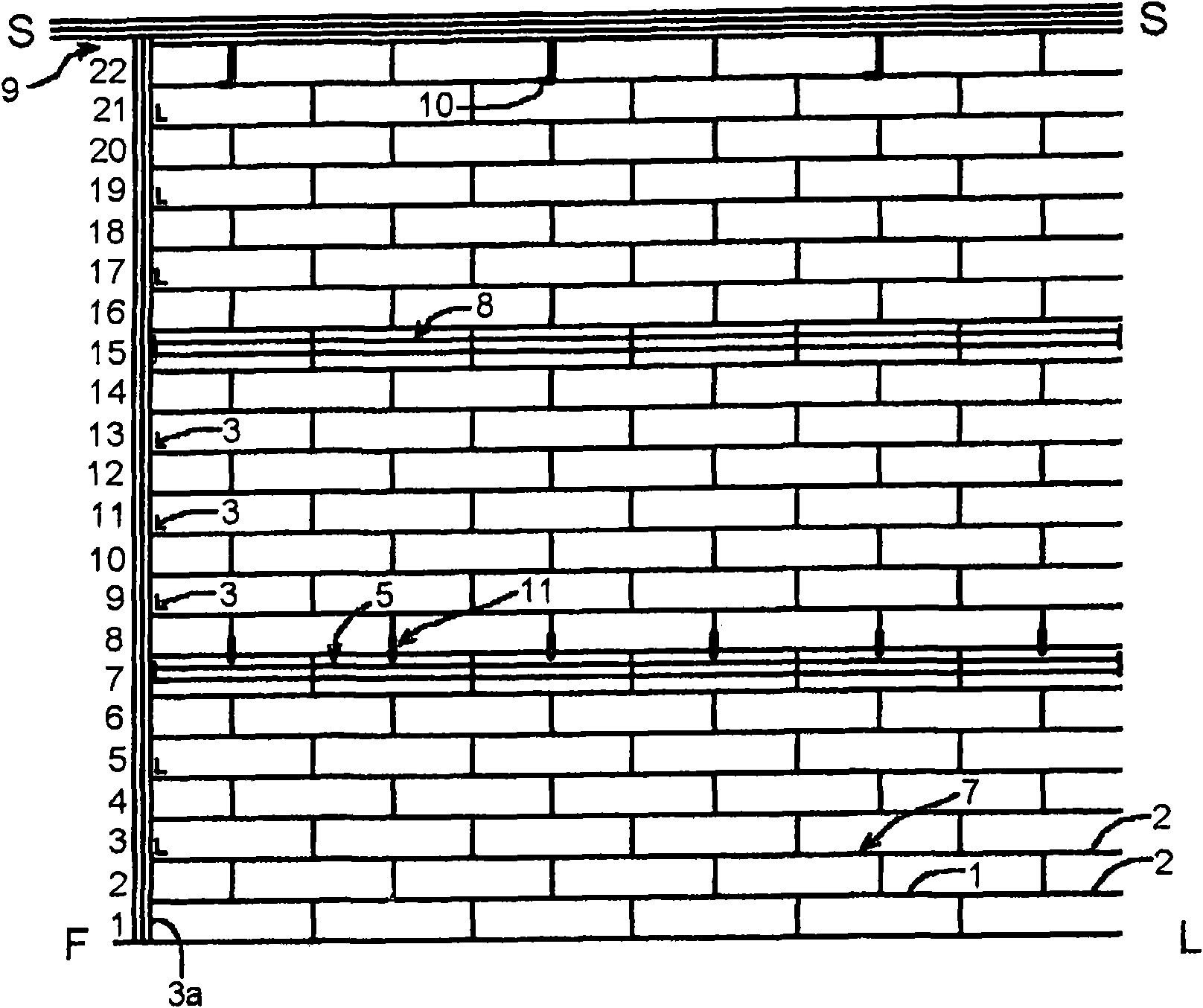

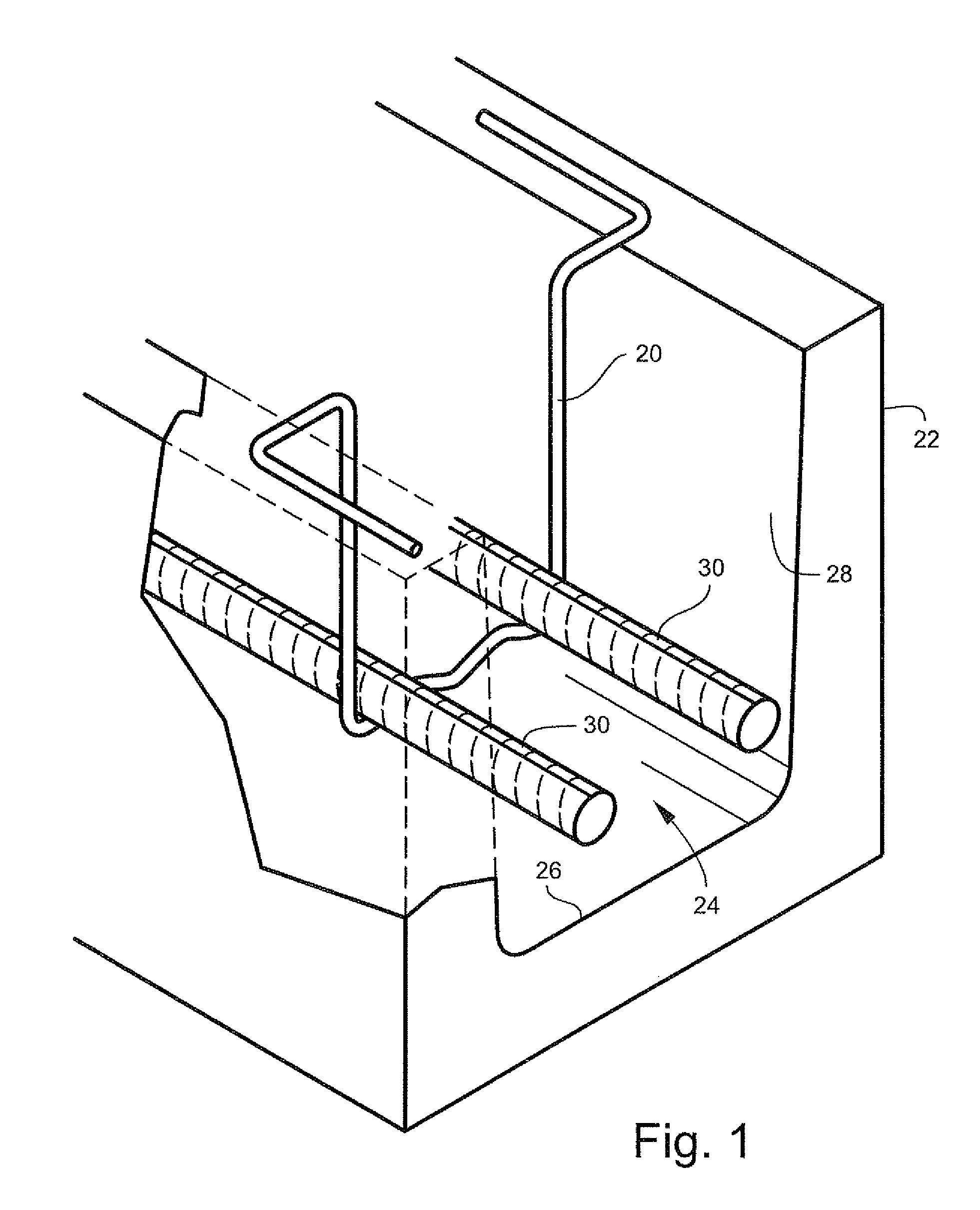

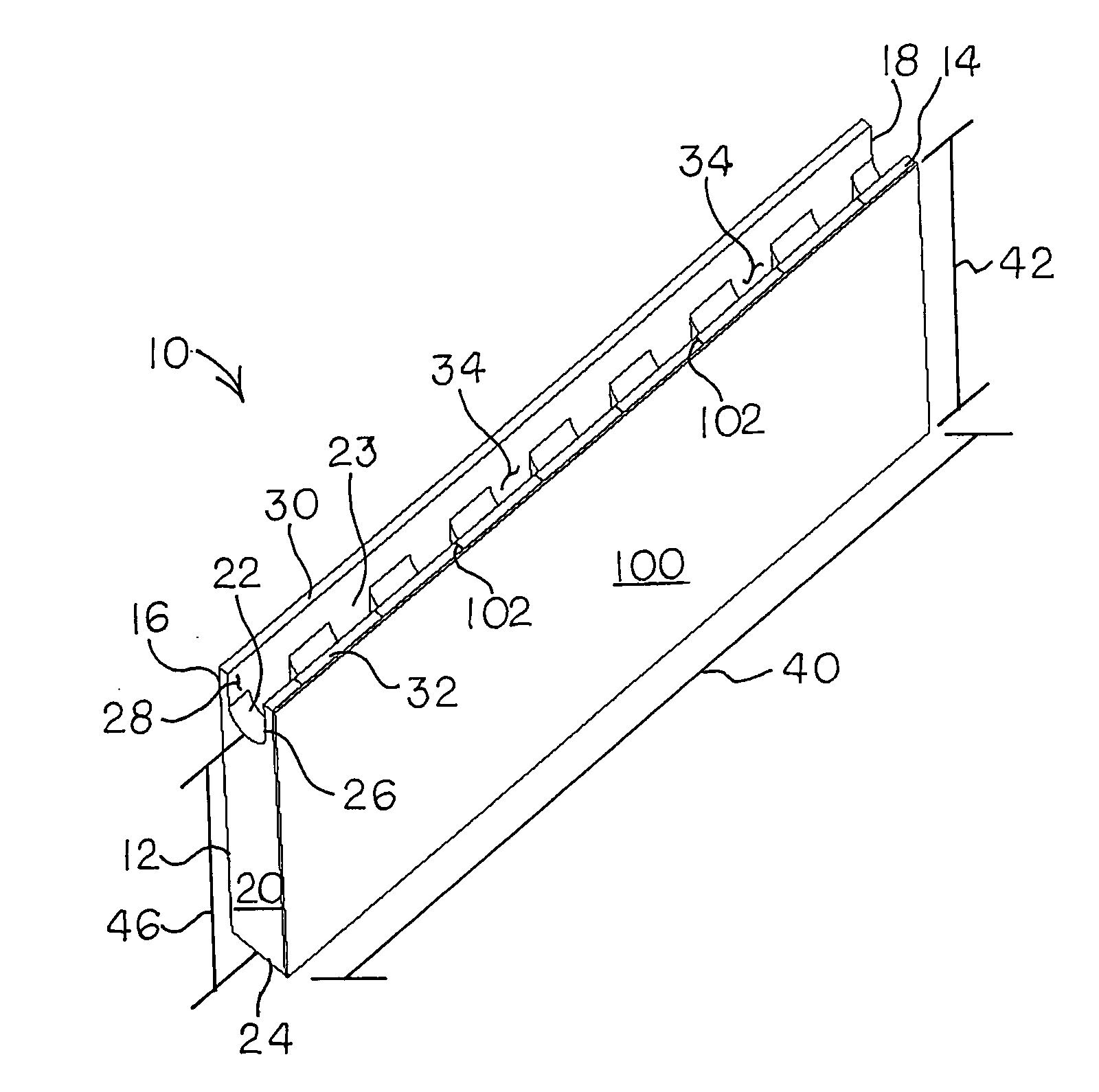

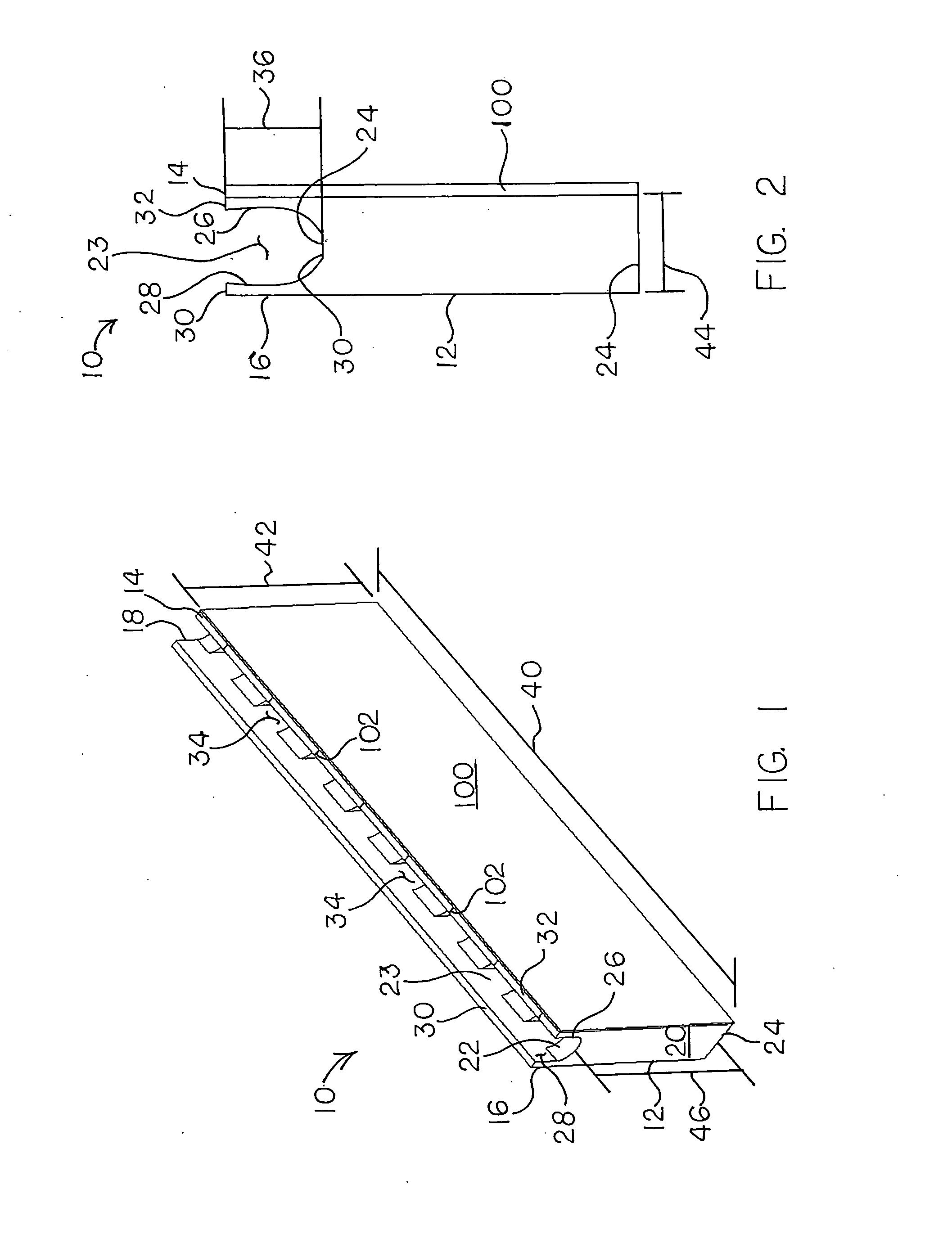

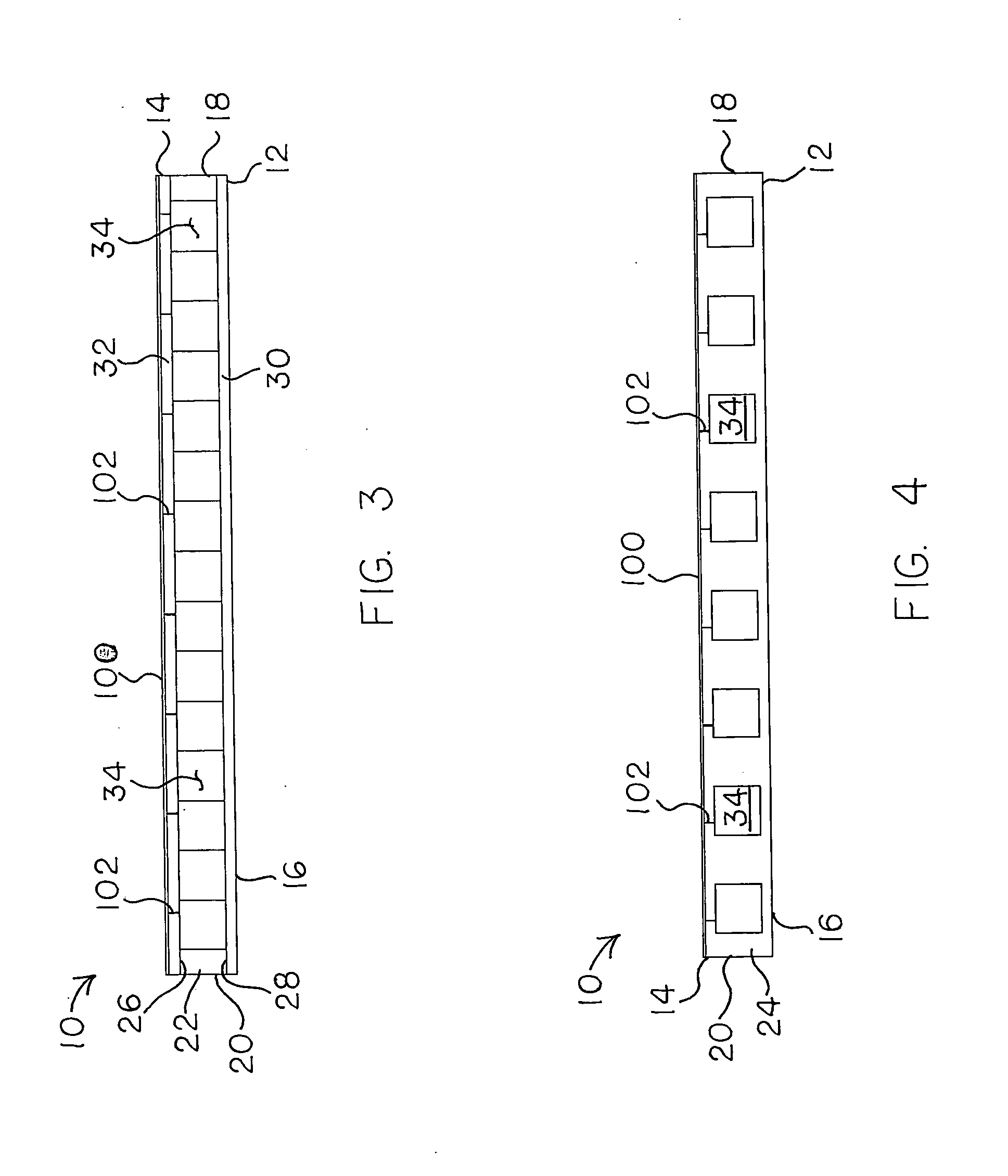

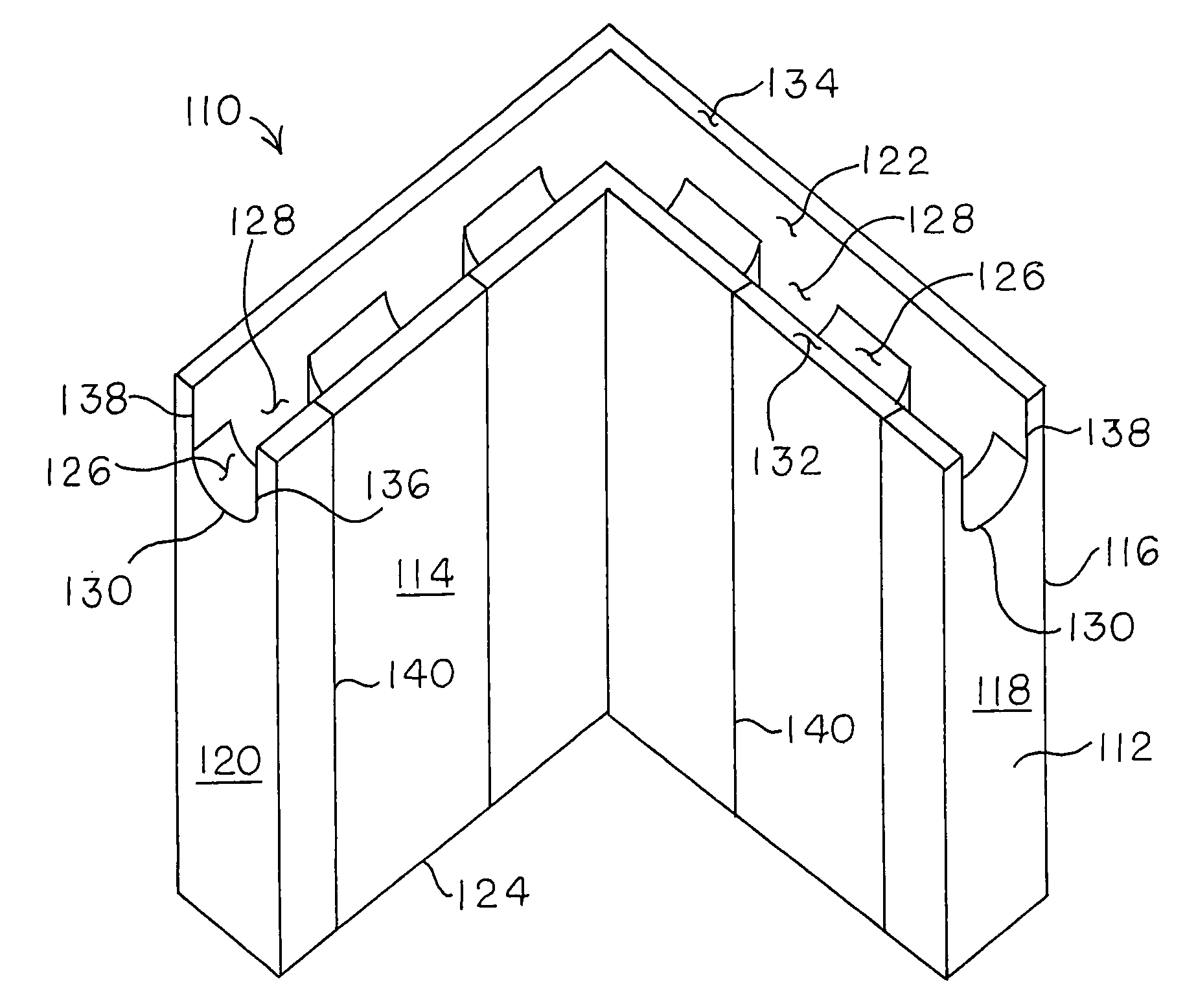

A method of constructing a masonry infill in a load bearing structure comprises the steps of: laying one or more courses of masonry (7) in the infill space; partitioning off a casting space having as its base the then uppermost course of masonry (22); the casting space extending from one side of the infill space to the other; positioning reinforcing material (14) in the casting space; securing an end of the reinforcing material to the load bearing structure; filling the casting space with concrete (20), and laying one or more further courses of masonry on top of the filled casting space. The reinforced concrete forms a bond beam which strengthens the masonry. The reinforcing material may be rebar, secured to a load-bearing frame of the building by a cleat (16) having pockets (12) for reception of the rebar ends. Optionally the reinforcement may be tensioned, to pre-stress the bond beam. The bond beam may also be used to strengthen bonded, load-bearing masonry panels in bending, without being secured to an adjacent load-bearing structure.

Owner:WEMBLEY INNOVATION

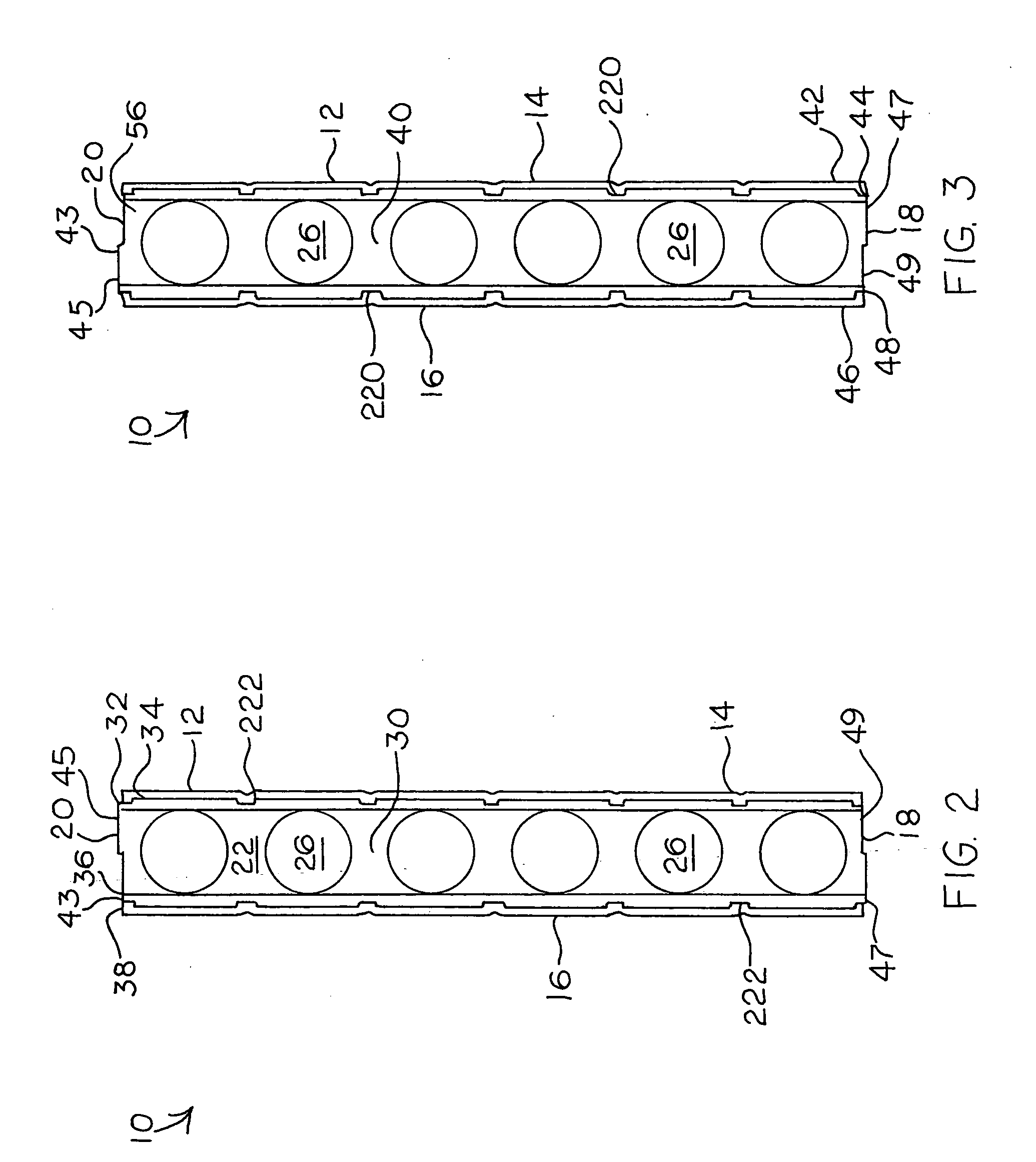

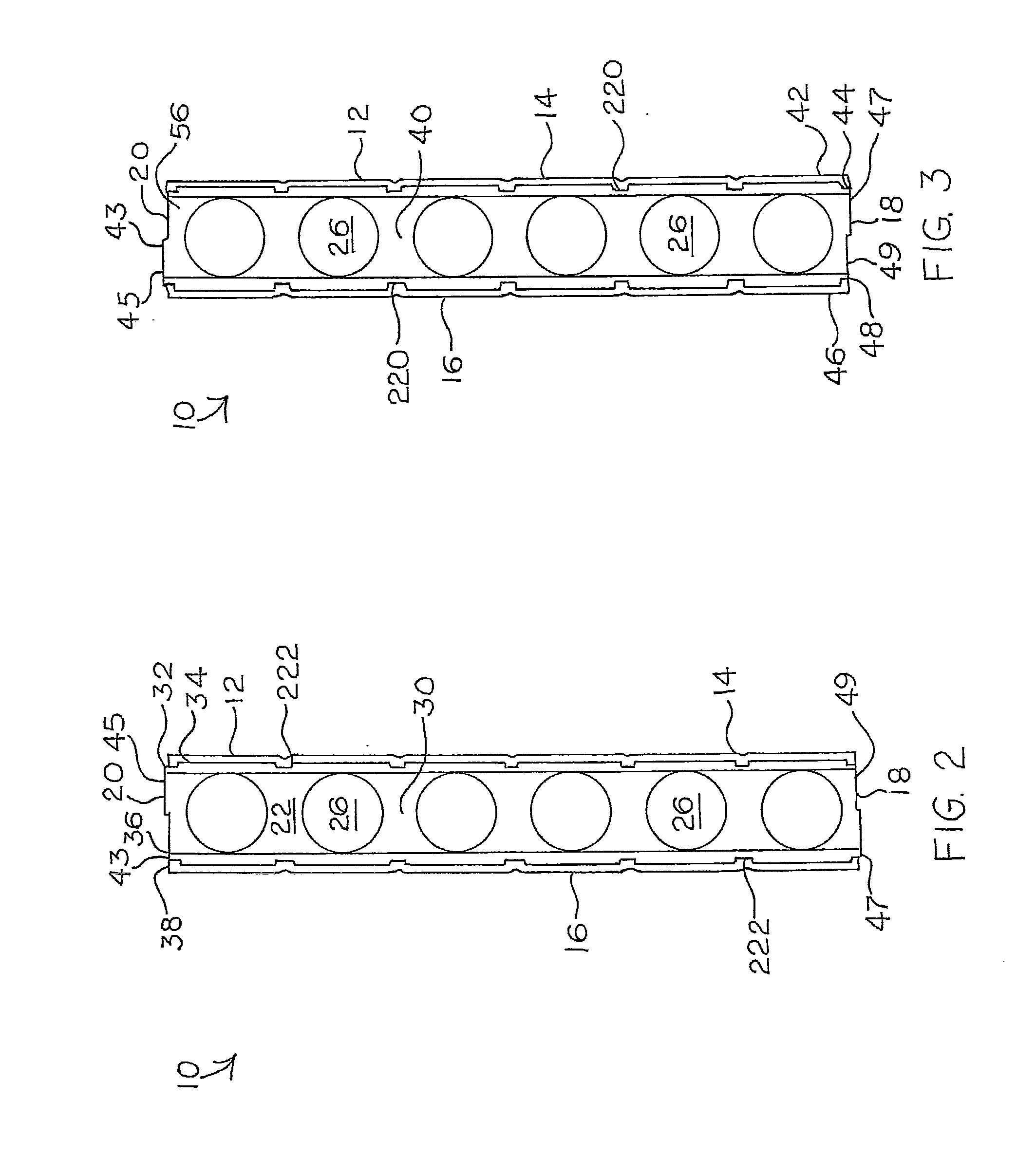

Insulated concrete form

A concrete wall forming system including interconnected mold units that include a top surface containing a first portion bond beam form, a first top ledge, a first top lip seal portion, a second top ledge, and a second top lip seal portion; a bottom surface containing a second portion bond beam form, a first bottom ledge, a first bottom lip seal portion, a second bottom ledge, and a second bottom lip seal portion; and two or more column forms extending from the top depression to the bottom depression. The first top lip seal portion and first bottom lip seal portion and second top lip seal portion and second bottom lip seal portion are adapted to form a seal between two mold units such that the bond beam form portions are combined to form a bond beam form. The system can be used to form an insulated concrete wall.

Owner:NOVA CHEM INC

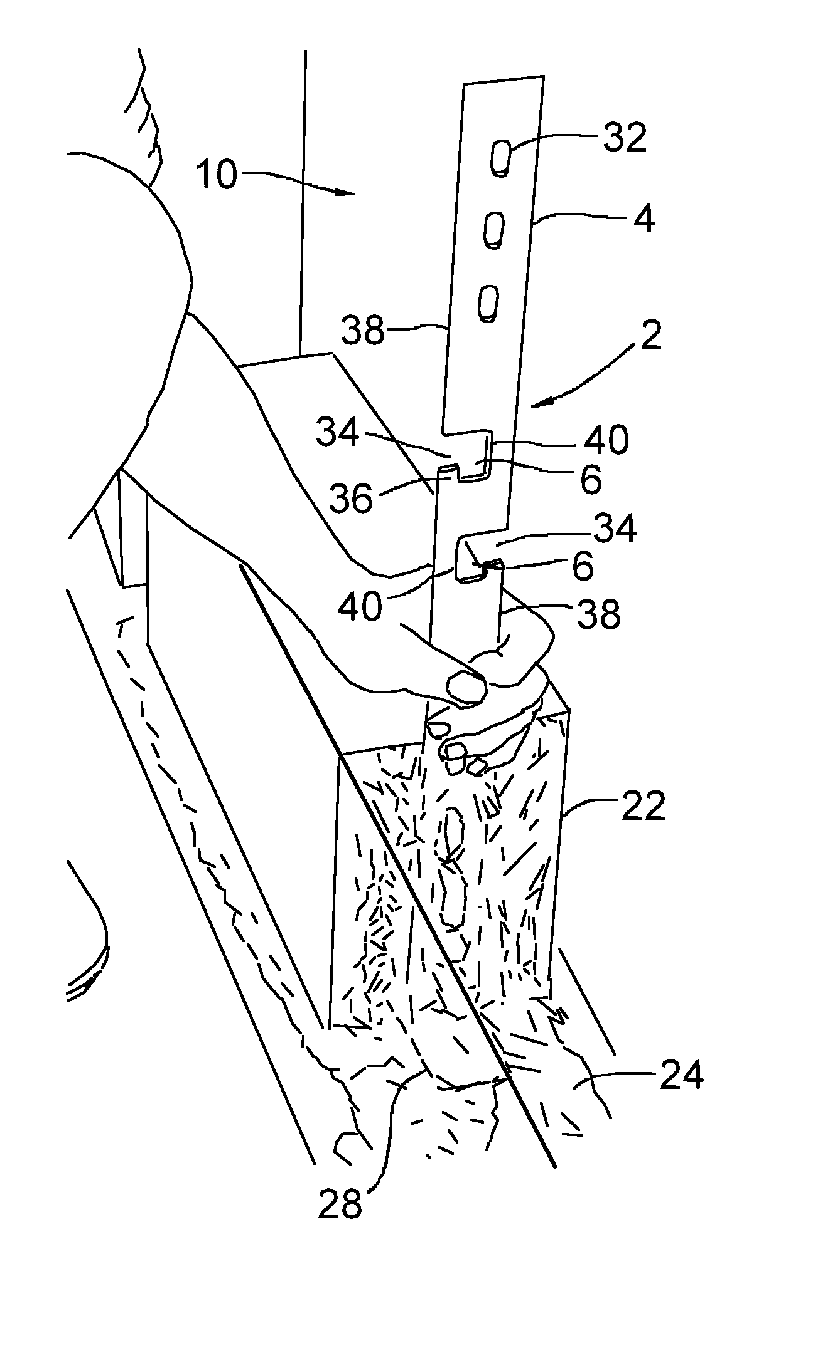

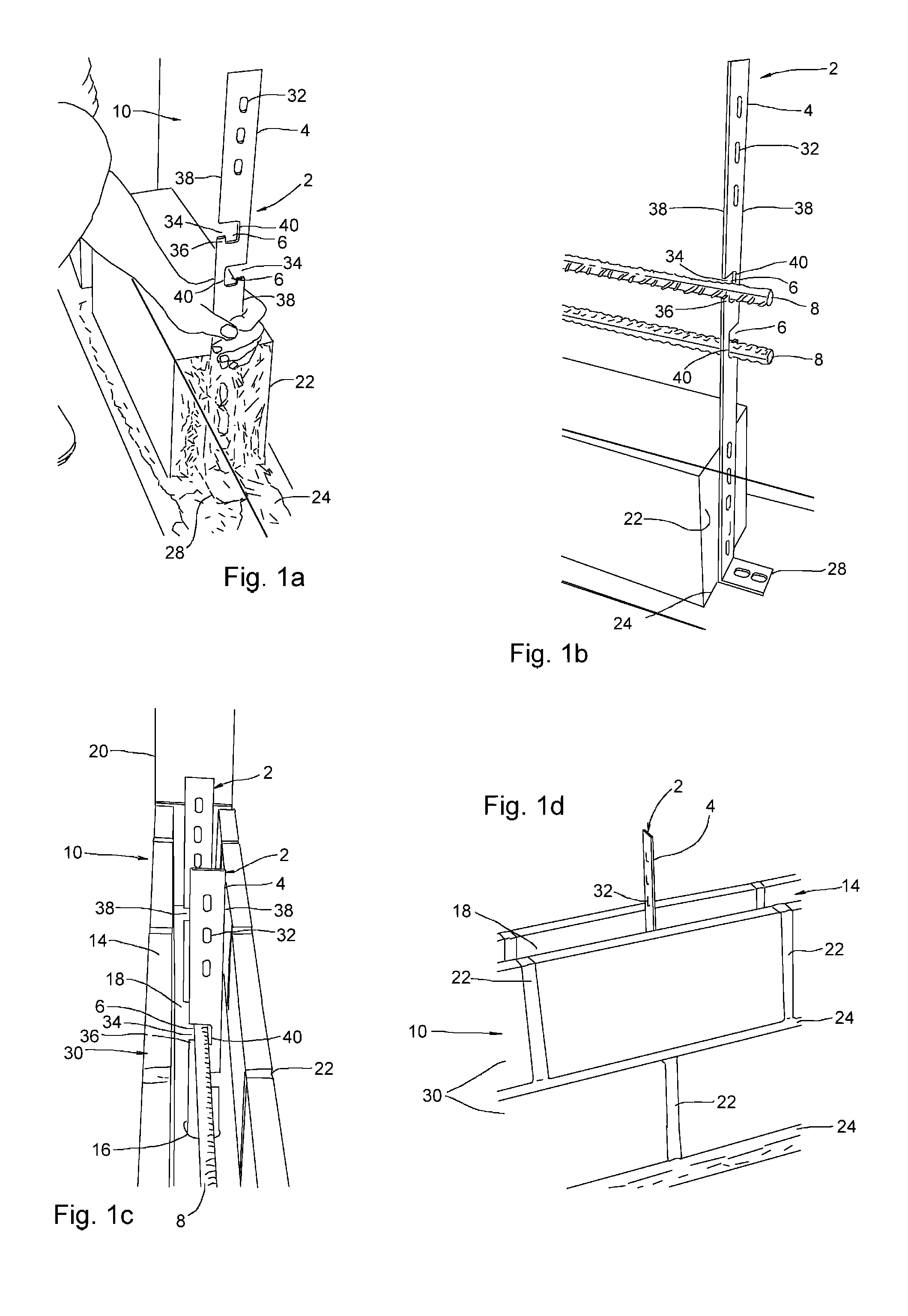

Masonry bracket, system and construction method

The present invention provides a masonry wall reinforcing bracket (2) comprising an elongate inter-course shear transfer member (4), the shear transfer member (4) comprising a rebar cradling feature (6). The shear transfer member (4) may further comprise a plate (5) operative to be located within at least a perpend (22) of a masonry wall (10). The bracket may further comprise a supporting member (28) that protrudes perpendicularly from the length of the shear transfer member (4). The supporting member (28) may comprises a plate operative to be located within a bed joint (24) of the masonry wall (10). The supporting member (28) may be a stabilising foot. The rebars and brackets are used in a bond beam (10) system incorporated within the wall (10).

Owner:WEMBLEY INNOVATION

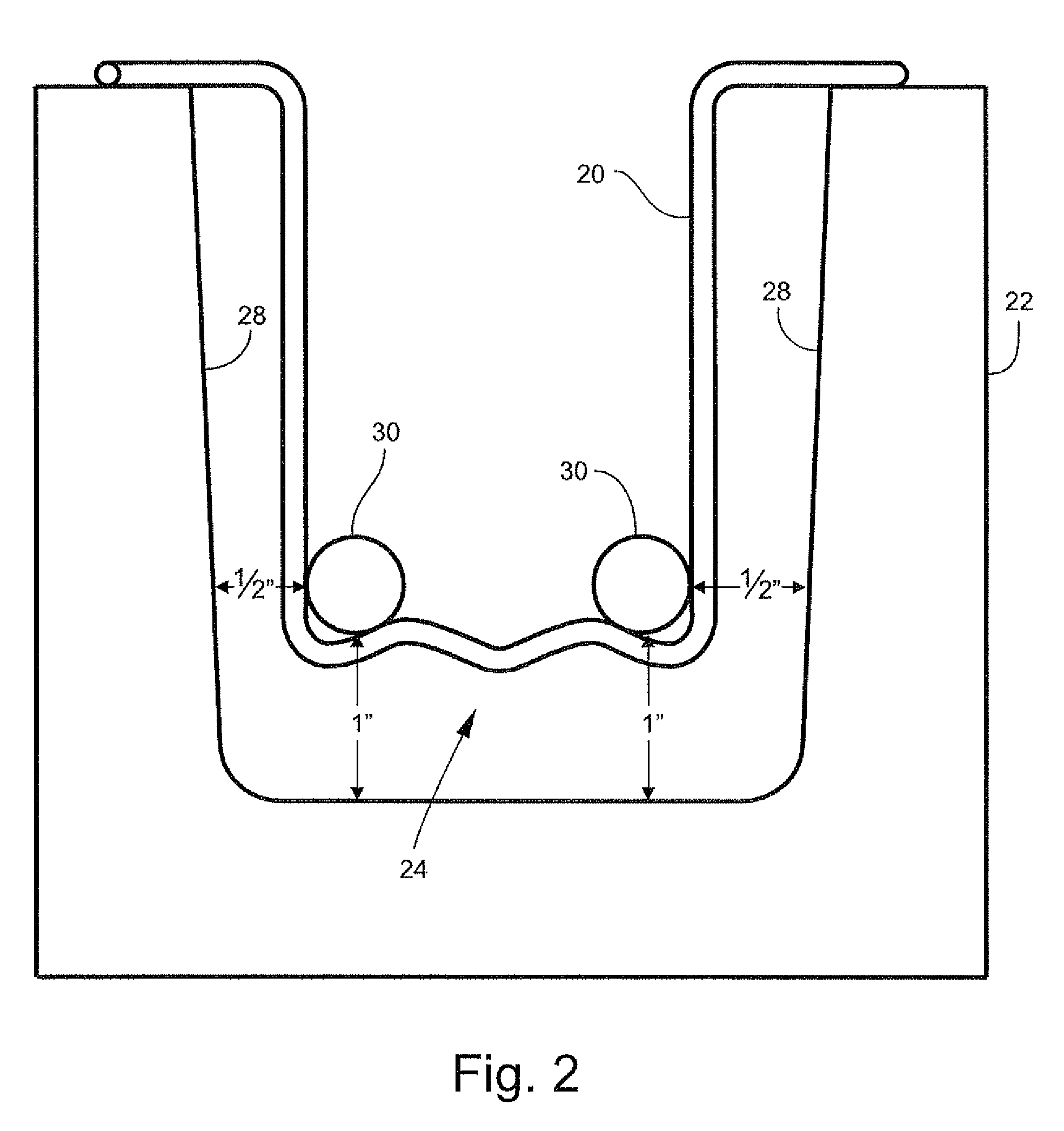

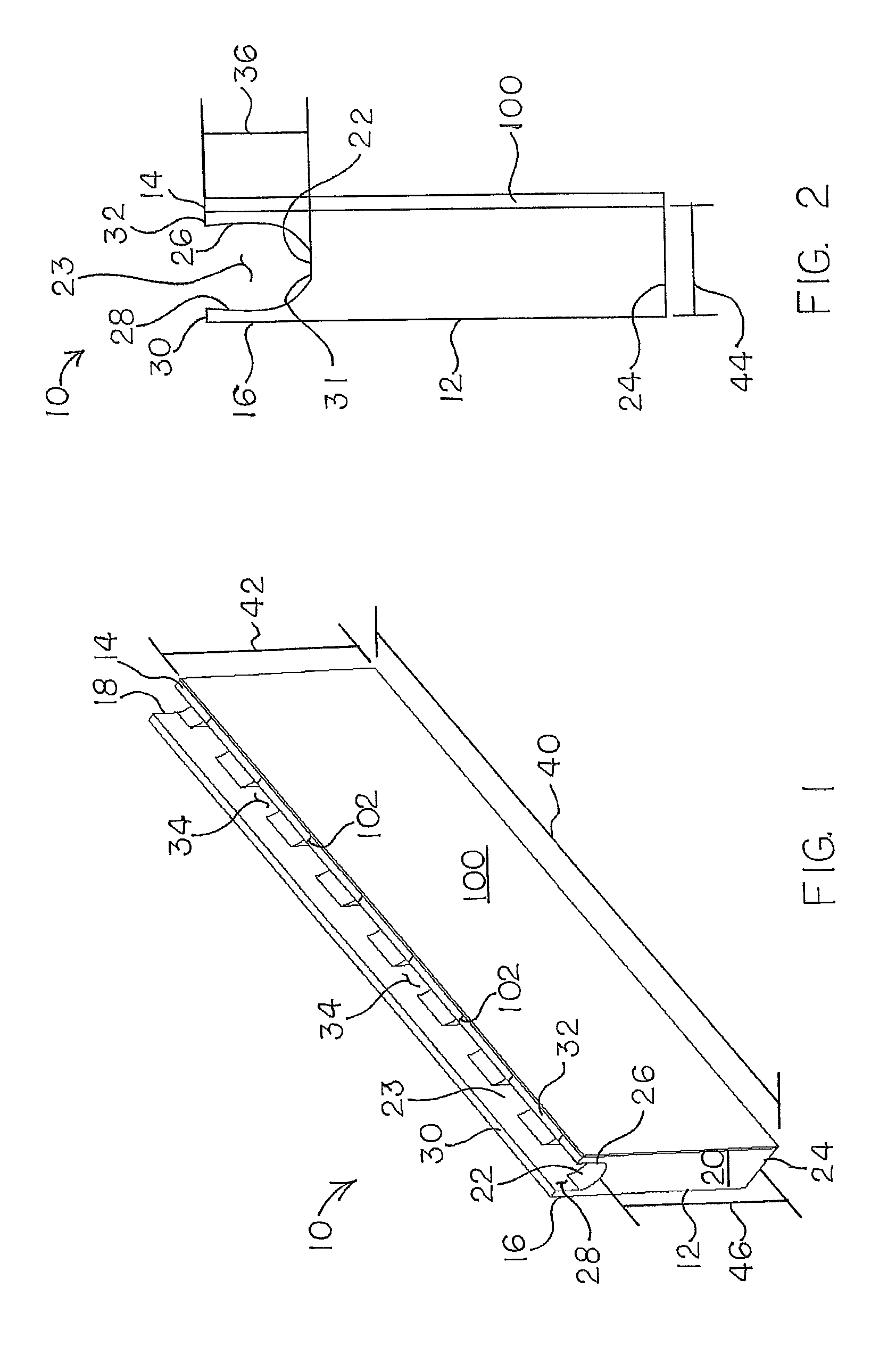

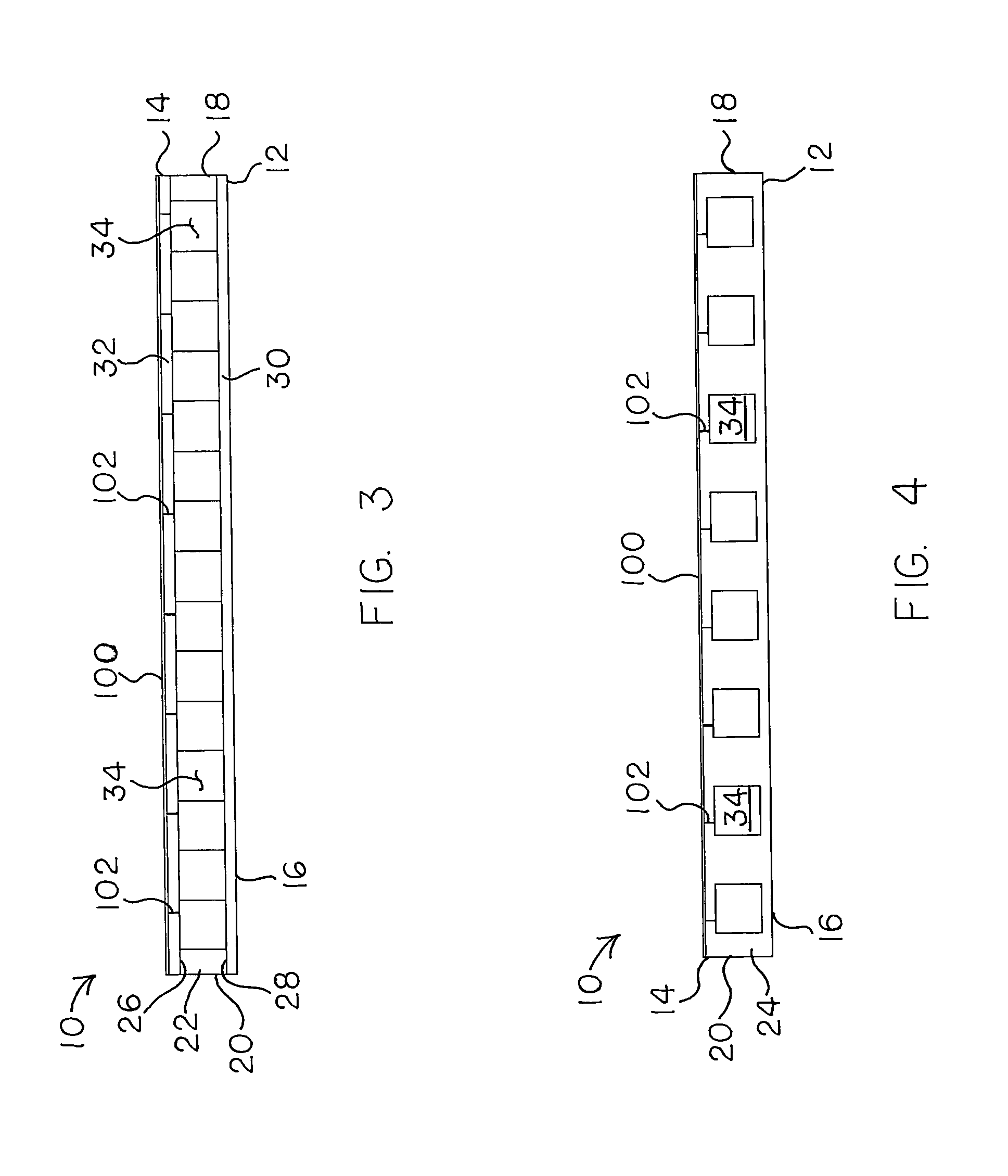

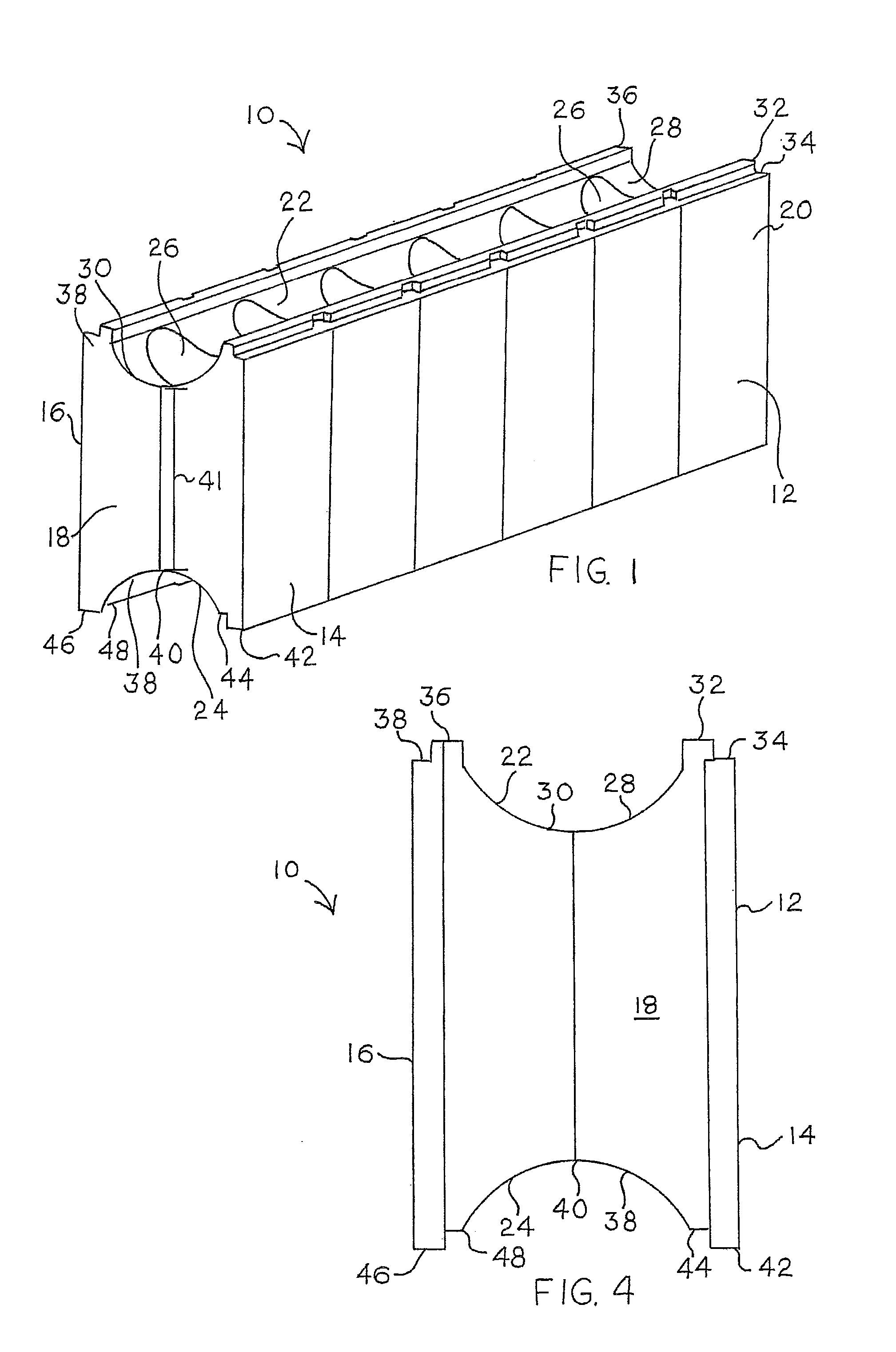

Bond beam rebar positioner

A bond beam rebar positioner including a center segment having an undulating form positioned between first and second legs, each of the legs including a first segment arranged perpendicular to a notional straight line longitudinally bisecting the curves of the center segment, a second segment perpendicular to the first segment, parallel to the straight line, and in a direction away from the center segment, and a third segment perpendicular to the second segment, coplanar with the second segment, and perpendicular to a common plane of the center, first and second segments.

Owner:MASONRY REINFORCING OF AMERICA

Modular concrete form panel

A modular form panel for assembling a cast-in-place concrete structure includes an inner panel section and an outer panel section. A filling gap is defined between the inner and outer panel sections. The filling gap is configured to receive concrete poured on-site to form a concrete wall or roof section. One or more tie members span the filling gap interconnecting the inner and outer panel sections. The panel includes an integral side flange in some embodiments. When multiple panels are positioned adjacent one another, the adjacent side flanges form an end gap on each lateral side of the panel. The end gap has a thickness greater than the filling gap thickness. Concrete disposed in each end gap forms an integrated support column on each side of the panel. A bond beam gap is defined along the top edge of the panel having a greater thickness than the filling gap.

Owner:GADDES SHANE

Insulated concrete form

A concrete wall forming system including a plurality of mold units for forming a wall of concrete. The mold units include a bond beam form extending into the body lengthwise, defined by a first wall, a second wall, a bond beam form bottom, a first end and a second end where the first wall and second wall extend a depth defined by a portion of the distance from the top surface to the bottom surface and where the bond beam form does not touch the first side or the second side. First and second ledges extend lengthwise along the body from the first and second sides respectively to the first and second walls respectively of the bond beam form. The bond beam form bottom extends from the first wall to the second wall. At least two column forms extend from the bond beam form bottom to a bottom surface.

Owner:SYNTHEON

Masonry wall tension device and method for installing same

Owner:CRUMLEY HARVEL K

Form support for supporting a disposable mold form

InactiveUS20050001139A1Avoid stickingForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringBond beam

A form support for supporting a disposable mold form. The disposable mold form is adapted to be mounted on a bond beam for forming a cement coping. The form support includes a tie wire and an elongate tube. The tie wire has a head, an elongate midsection, and an end portion. The elongate midsection and the end portion are separated by a weakened portion. The tie wire is adapted to be positioned through the disposable form mold such that the head abuts the disposable mold form, the elongate midsection extends through the disposable mold form, and the end portion extends over the bond beam. The elongate tube is shaped to fit around the tie wire such that the elongate tube extends from the head to the vicinity of the weakened portion.

Owner:STEGMEIER

Insulated concrete form

A concrete wall forming system including a plurality of mold units for forming a wall of concrete. The mold units include a bond beam form extending into the body lengthwise, defined by a first wall, a second wall, a bond beam form bottom, a first end and a second end where the first wall and second wall extend a depth defined by a portion of the distance from the top surface to the bottom surface and where the bond beam form does not touch the first side or the second side. First and second ledges extend lengthwise along the body from the first and second sides respectively to the first and second walls respectively of the bond beam form. The bond beam form bottom extends from the first wall to the second wall. At least two column forms extend from the bond beam form bottom to a bottom surface.

Owner:SYNTHEON

Methods and apparatus for controlling moisture in straw bale core walls

InactiveUS7631466B2Prevent moistureAvoid cavitiesBuilding repairsBuilding material handlingControl systemStructural engineering

A moisture control system for a straw bale core wall having an air pathway from the foundation of the wall to its bond beam permitting air to be pumped into the wall at the foundation level and up through the core of the wall into a plenum space at the top of the wall and out through one or more vents into the atmosphere.

Owner:INTEGRATED STRUCTURES

Insulated Concrete Form

Owner:SYNTHEON

Main beam side-span closure construction method for bond beam cable-stayed bridge

Owner:CCCC SECOND HARBOR ENG

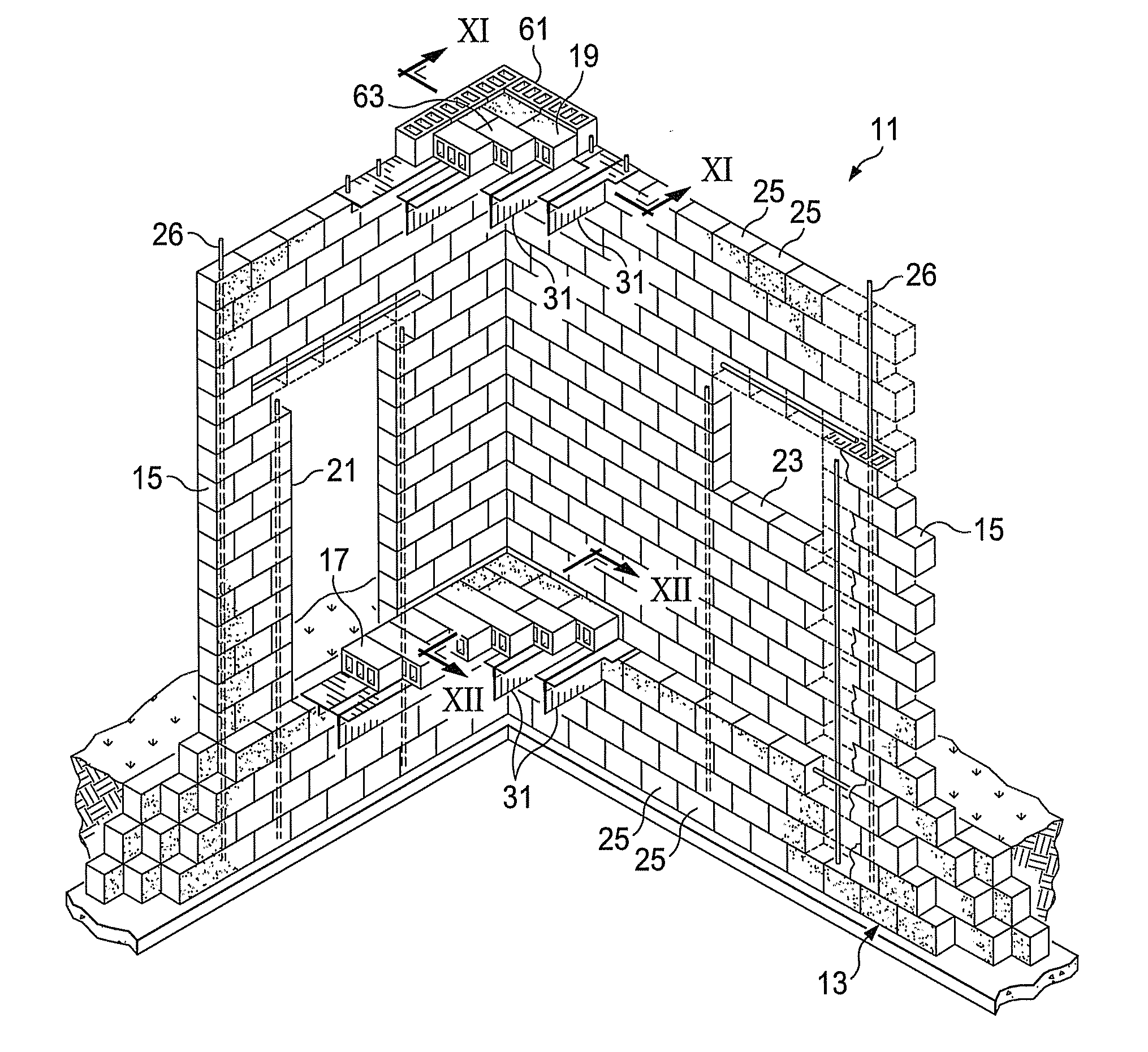

Reinforced masonry panel structures

A method of constructing a masonry infill in a load bearing structure comprises the steps of: laying one or more courses of masonry (7) in the infill space; partitioning off a casting space having as its base the then uppermost course of masonry (22); the casting space extending from one side of the infill space to the other; positioning reinforcing material (14) in the casting space; securing an end of the reinforcing material to the load bearing structure; filling the casting space with concrete (20), and laying one or more further courses of masonry on top of the filled casting space. The reinforced concrete forms a bond beam which strengthens the masonry. The reinforcing material may be rebar, secured to a load-bearing frame of the building by a cleat (16) having pockets (12) for reception of the rebar ends. Optionally the reinforcement may be tensioned, to pre-stress the bond beam. The bond beam may also be used to strengthen bonded, load-bearing masonry panels in bending, without being secured to an adjacent load-bearing structure.

Owner:WEMBLEY INNOVATION

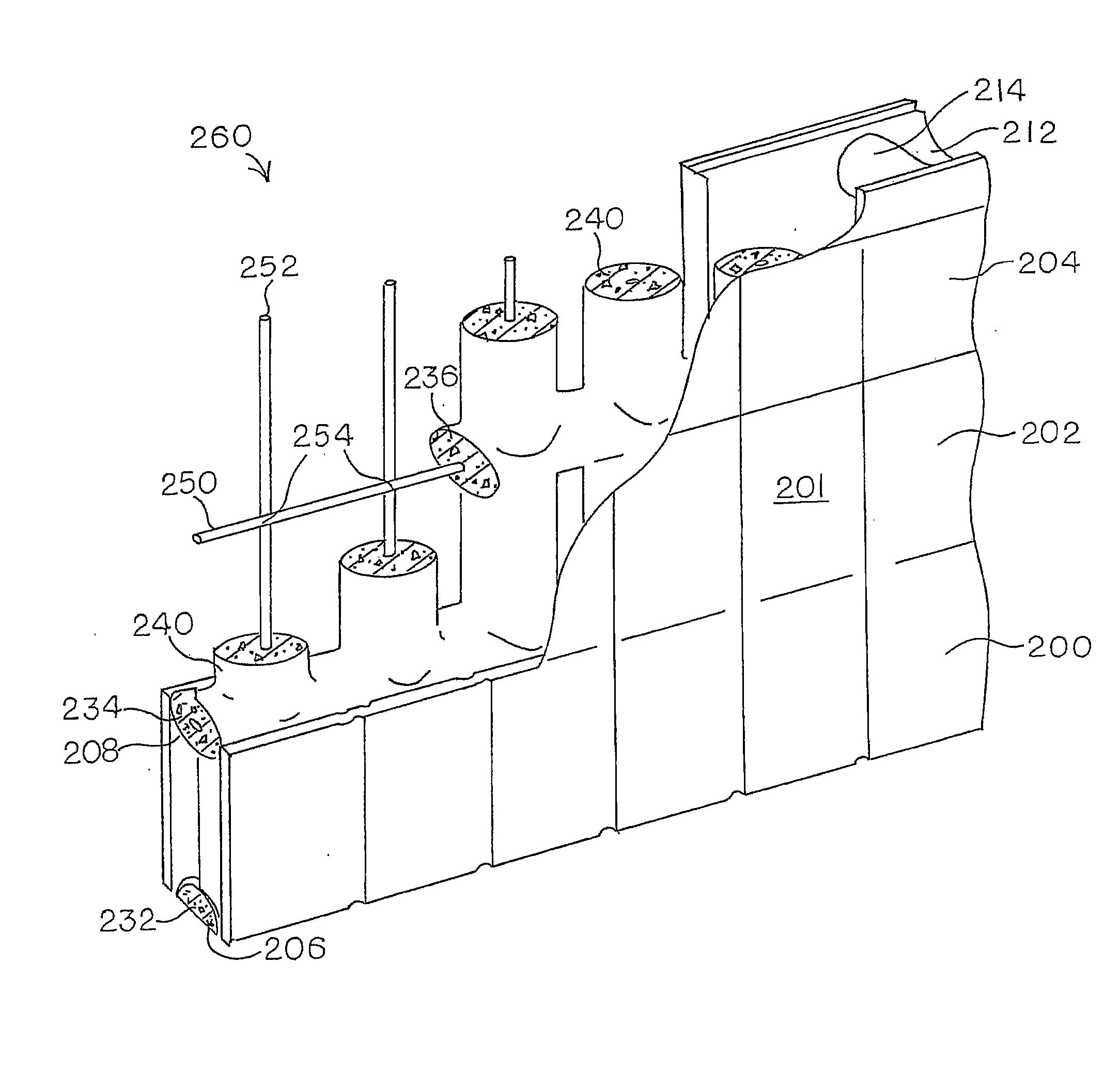

Modular Concrete Wall System

Disclosed is a modular poured concrete wall system that addresses the needs not optimally met by the prior art, where inexpensive small light interlocking forms are quickly and readily assembled, to produce the desired aesthetically pleasing appearance of a brick wall system. The forms remain in place as part of the final structure and finished surface of the walls. Thus, a footer track assembly is affixed to a standard concrete footer or foundation. Then the modular forms are assembled upon the footer track, stacked together to produce the appearance of a brick wall. As each row or two of forms are assembled, the forms are filled with concrete. Following the concrete pour, additional forms are assembled on the top of the prior forms, to produce additional rows. By repeating this process, the full height of the wall can be quickly reached. The method may include steel rebar, such as for horizontal bond beams and for vertical strength. In an alternative embodiment, curved modular forms may be assembled to produce a circular column, where the exterior surface is finished as a decorative brick appearance.

Owner:BANOVA ALDO

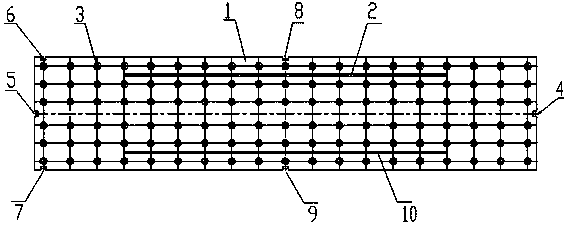

Girder drilled template tooling and steel box bond beam drilling method

The invention discloses a girder drilled template tooling. The tooling comprises a rectangular overlay panel. Drilling sleeves arranged in rectangular arrays are arranged on the surface of the overlaypanel. A first reinforcing plate and a second reinforcing plate are fixed to the surface of the overlay panel. A first alignment groove, a second alignment groove, a third alignment groove, a fourthalignment groove, a fifth alignment groove, a sixth alignment groove and the second reinforcing plate are formed in or arranged on the four sides of the overlay panel correspondingly. The first alignment groove is located in a width side of the overlay panel. The second alignment groove is located in the other width side of the overlay panel. The third alignment groove and the fifth alignment groove are located in one length side of the overlay panel. The fourth alignment groove and the sixth alignment groove are located in the other length side of the overlay panel. By means of the girder drilled template tooling, requirements for manufacturing precision, hole group connecting precision and the like of curved steel bridges can be met.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

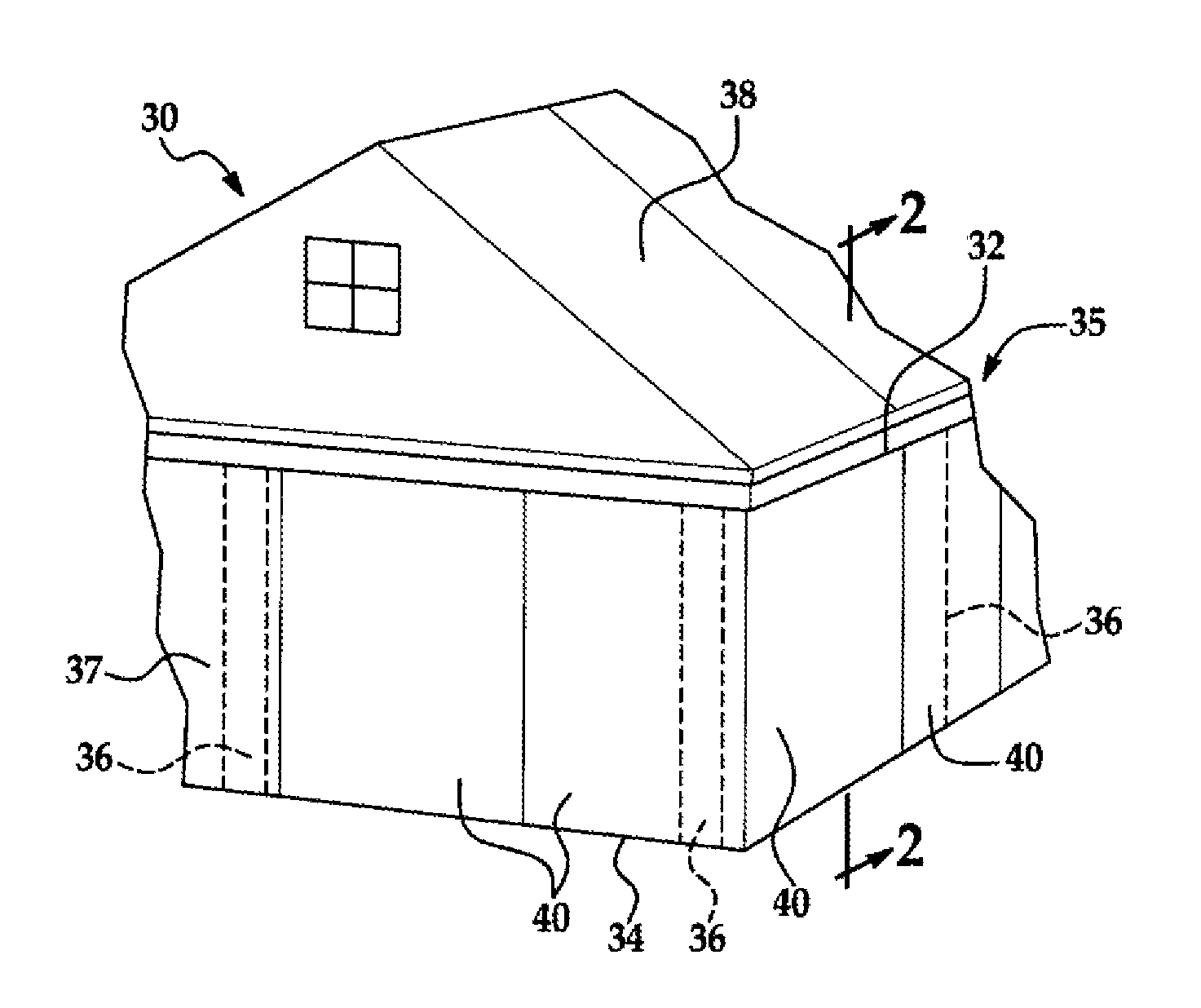

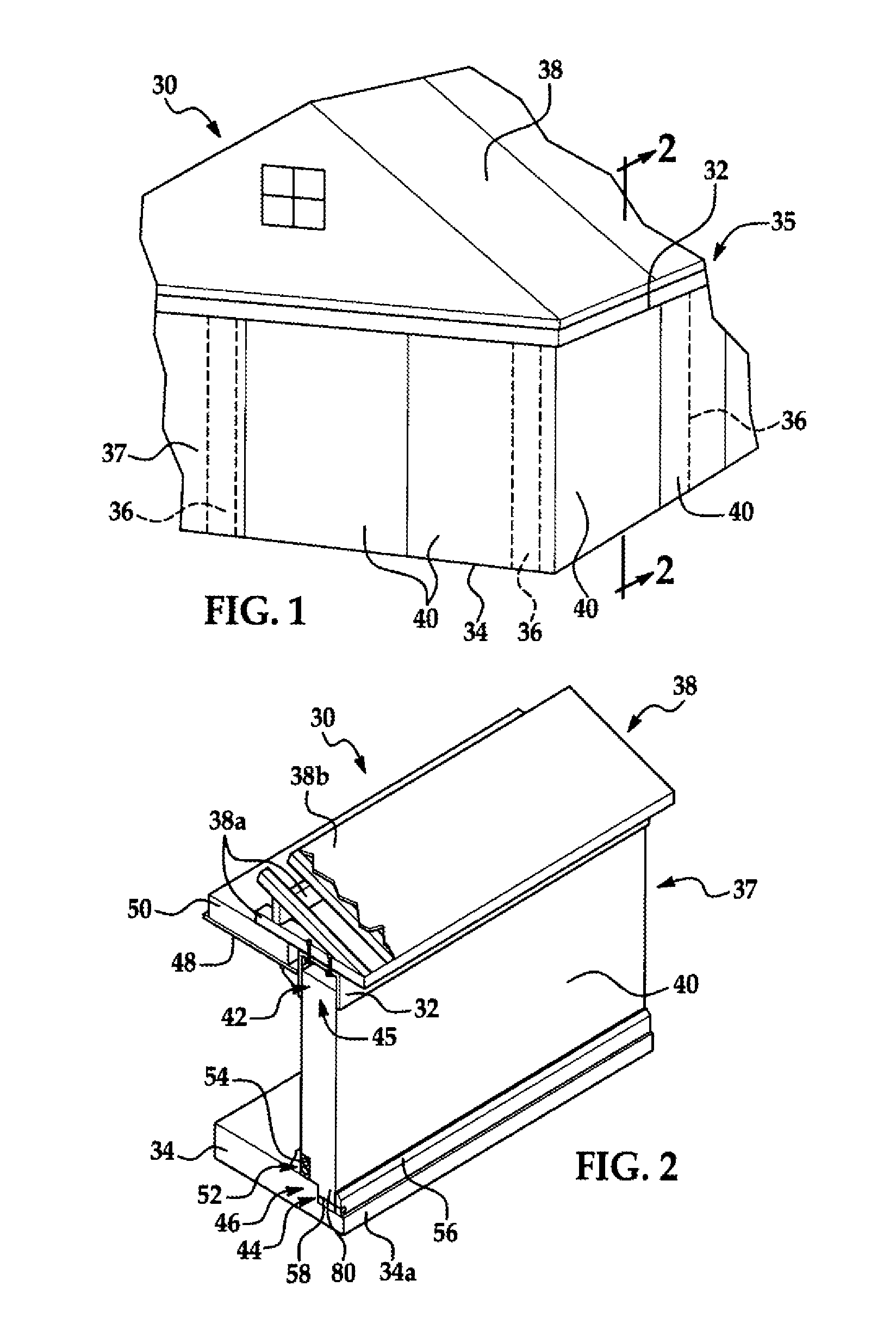

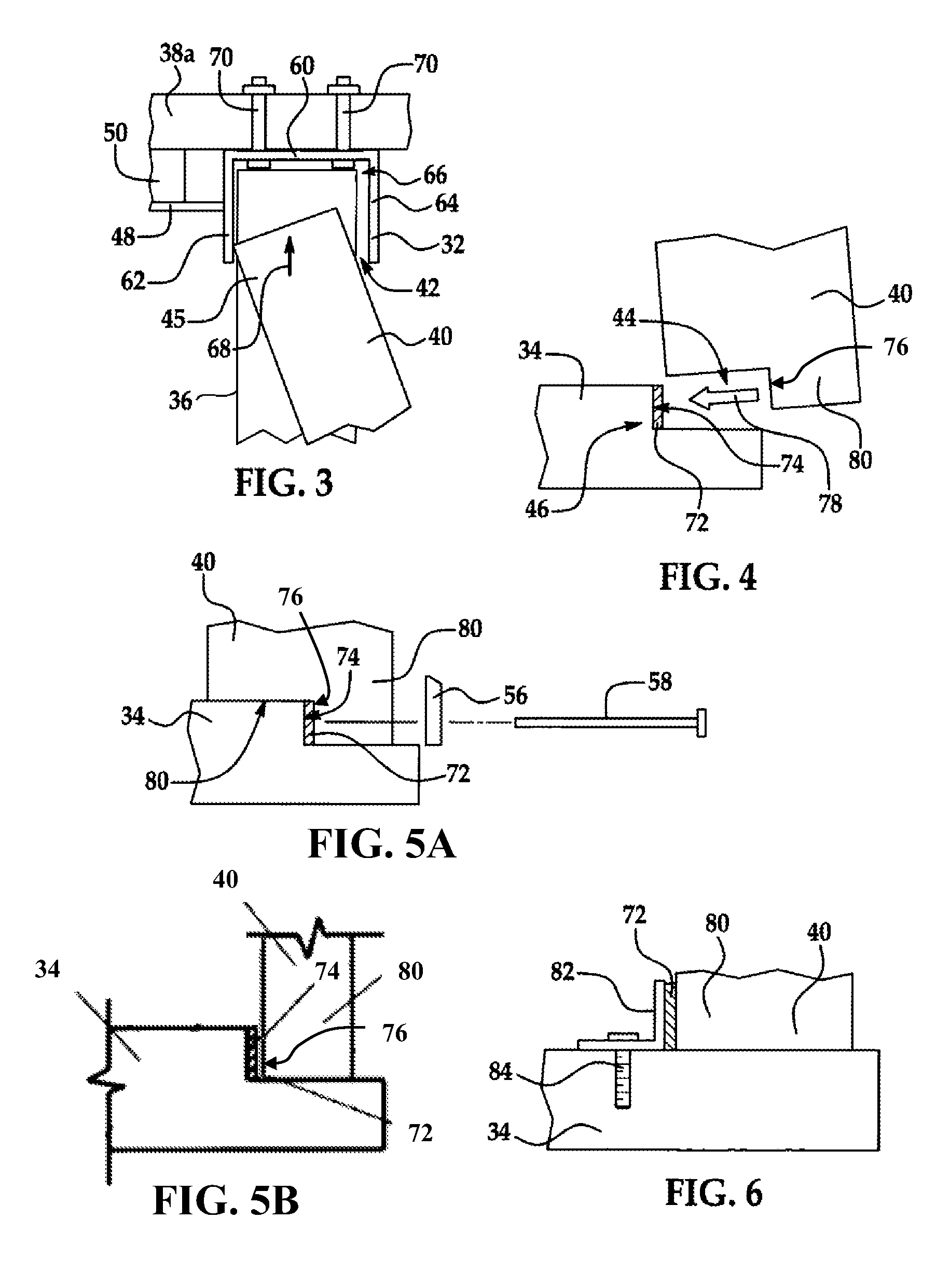

Modular building system

A modular building system uses a perimeter bond beam and prefabricated wall panels to form an exterior curtain wall. The wall panels are captured within, and may move vertically inside a channel formed in the bond beam. The wall panels are quickly erected by inserting an upper edge of each panel into the channel and swinging the panel onto the foundation where it is claimed in place on the foundation.

Owner:PALMERI RICHARD

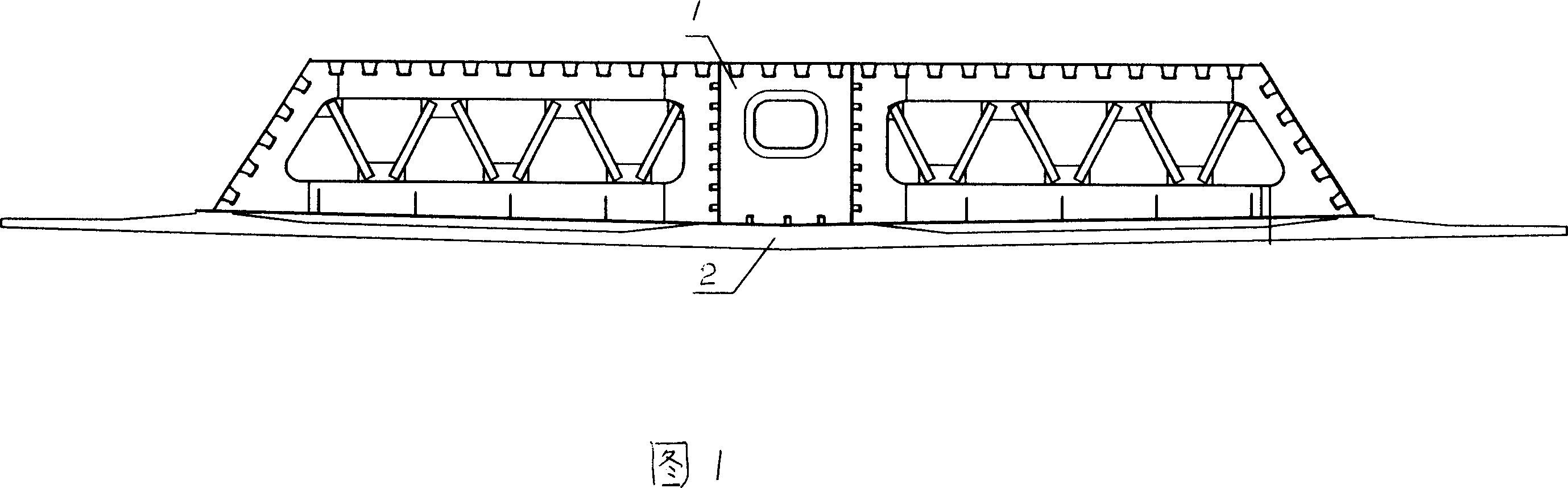

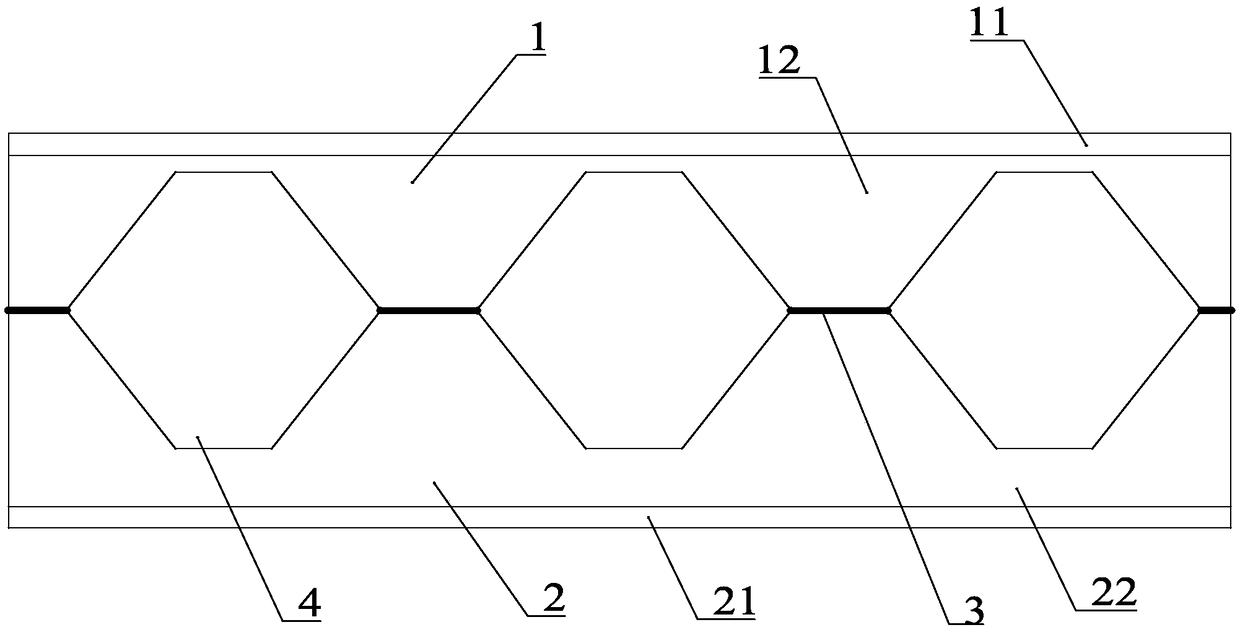

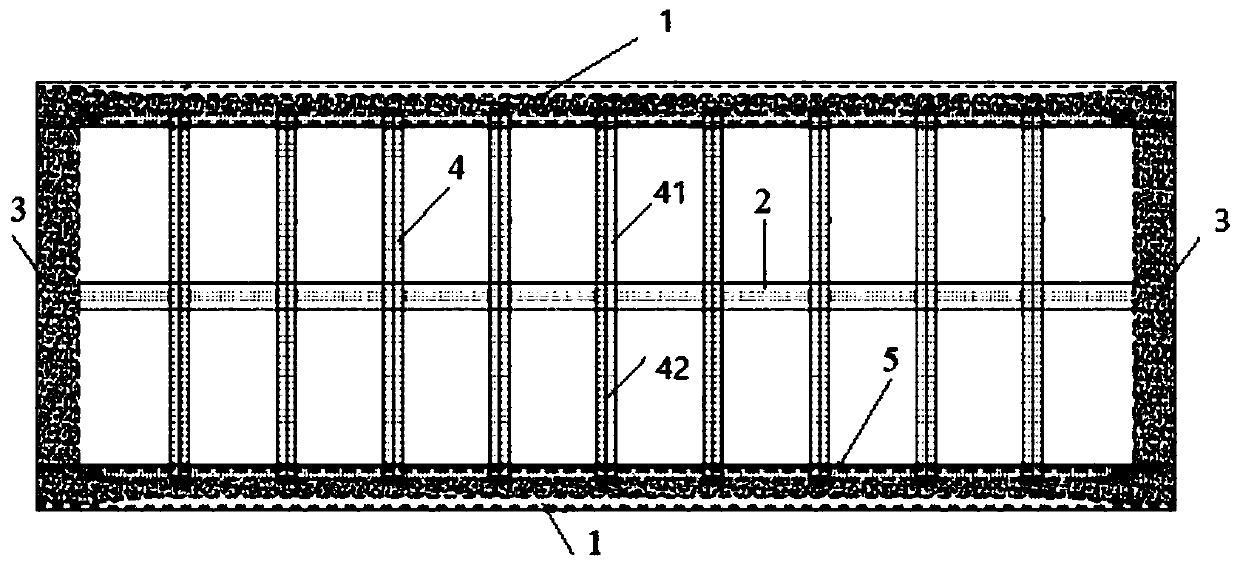

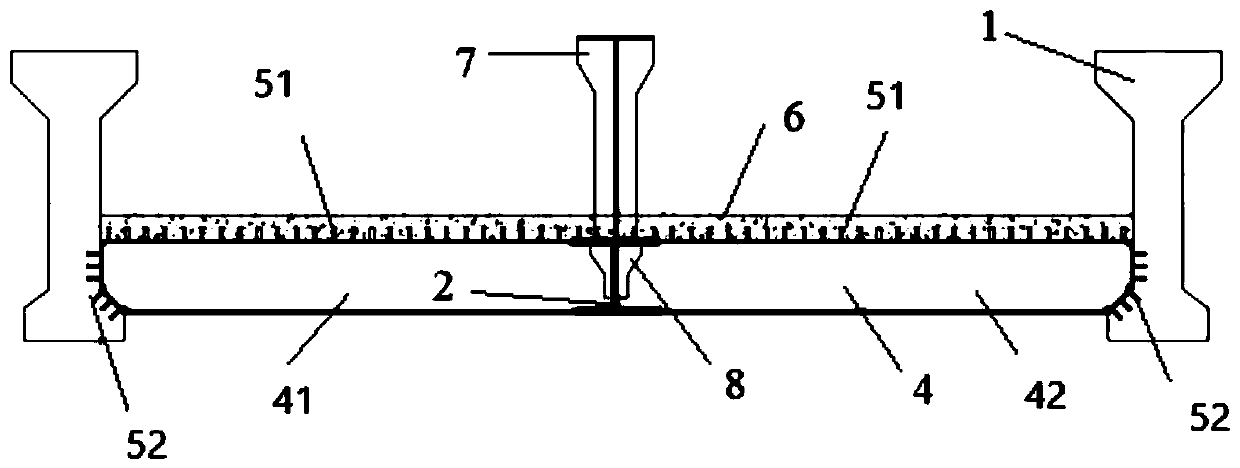

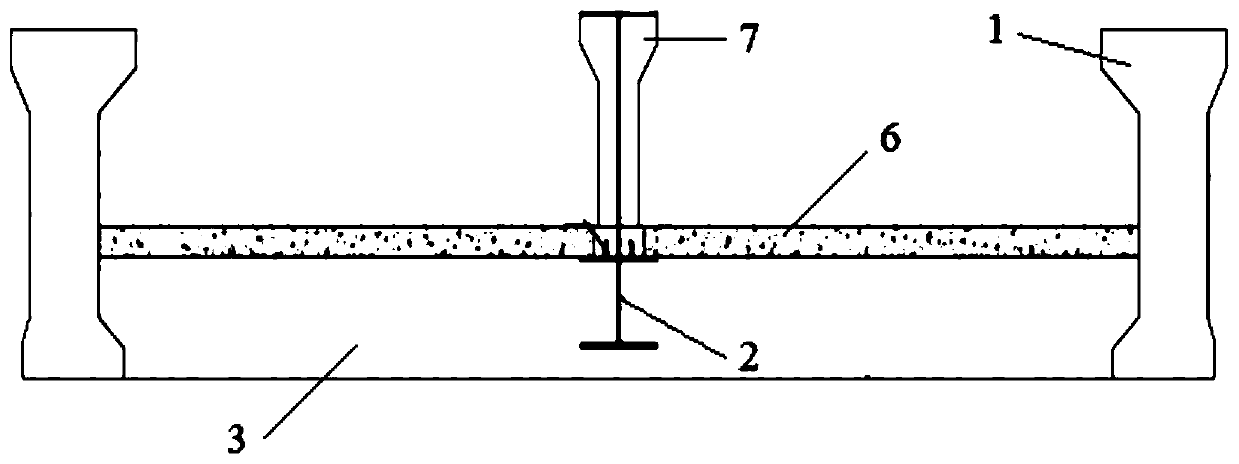

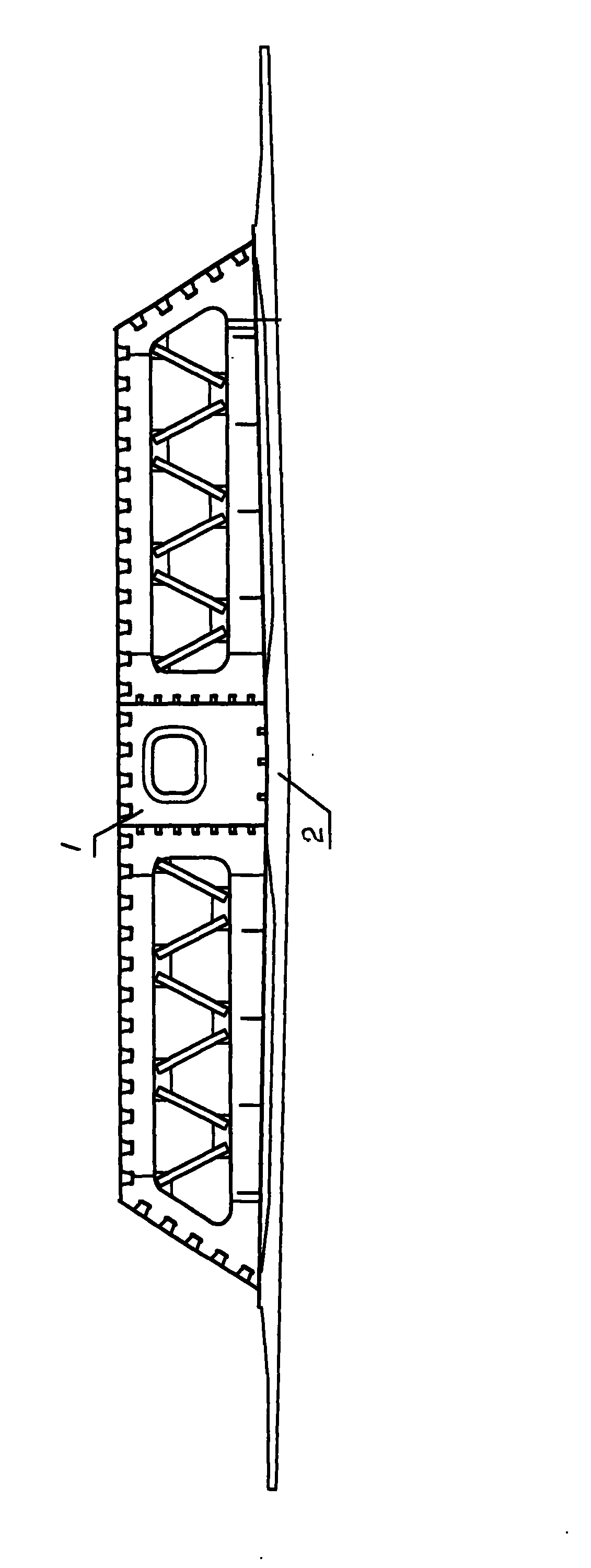

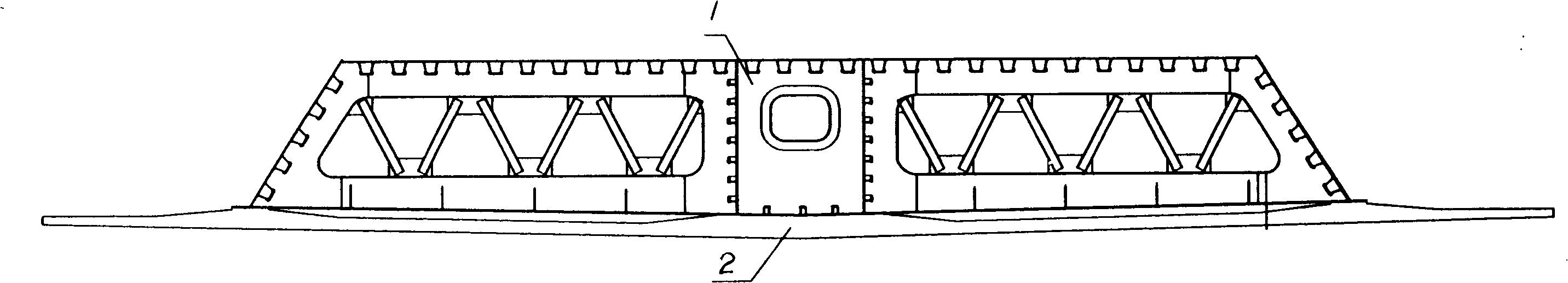

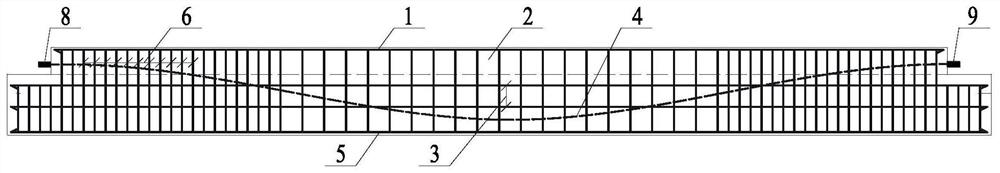

Deck-type triangular truss steel joist bond beam

InactiveCN103541299AImprove the state of stressImprove economyTruss-type bridgeGusset plateBridge deck

The invention relates to a deck-type triangular truss steel joist bond beam which is composed of lower chords, web members and a bridge deck slab, wherein the lower chords are connected with the web members through gusset plates, and the web members are connected with the bridge deck slab. The deck-type triangular truss steel joist bond beam is of a novel structure, triangular trusses are adopted in cross sections, single steel pipes are adopted in main beams to be connected with bridge deck concrete plates through the web members to form a stress system, the state of stress on the structure is improved, rod pieces of upper chords, flat links and the like are omitted, the structure can be lighter, stress is simpler, and economical efficiency and attractiveness of the structure are enhanced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

Technique of producing steel-concrete connecting beam

ActiveCN101032830AAvoid deformationPrevent displacement and deformationMouldsPre stressPre stressing

The process of manufacturing bond beam includes the following steps: 1. cutting steel plate; 2. forming steel structure plate unit with steel plates; 3. assembling steel structure beam section with steel structure plate units; 4. regulating the line profile of the beam section, pre-assembling and correcting errors; 4. setting formwork on steel structure beam section, depositing concrete and curing to form concrete panel and bond beam; 6. pre-stress stretching the concrete panel; 7. trial assembling the steel structures of adjacent bond beam; and 8. disassembling the pre-assembled steel structures, painting, transporting to site and site assembling. The said process can prevent deformation of bolt holes caused by stretching after drilling holes.

Owner:SHANGHAI FOUND ENG GRP

Methods and apparatus for controlling moisture in straw bale core walls

InactiveUS20090031654A1Prevent moistureAvoid cavitiesBuilding repairsBuilding material handlingControl systemEngineering

A moisture control system for a straw bale core wall having an air pathway from the foundation of the wall to its bond beam permitting air to be pumped into the wall at the foundation level and up through the core of the wall into a plenum space at the top of the wall and out through one or more vents into the atmosphere.

Owner:INTEGRATED STRUCTURES

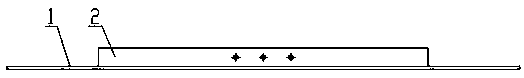

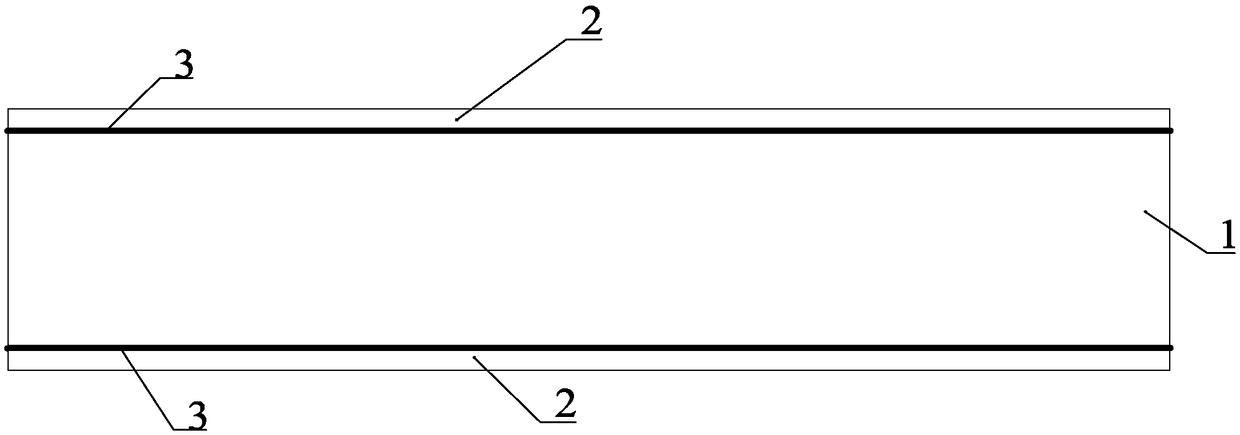

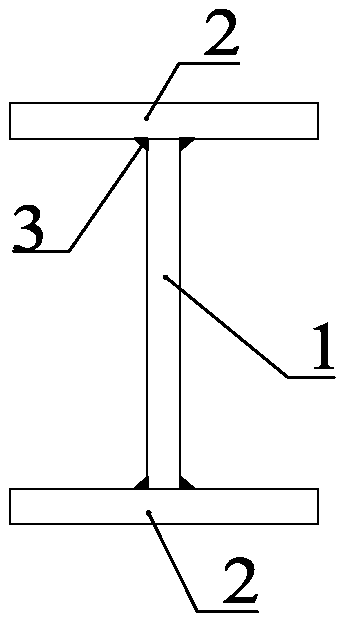

Novel steel plate beam and steel-concrete bond beam

The invention discloses a novel steel plate beam and a steel-concrete bond beam. The novel steel plate beam comprises a first splicing part and a second splicing part. The first splicing part comprises a frange plate I and a web plate II which are integrally rolled and formed; the second splicing part comprises a frange plate II and a web plate II which are integrally rolled and formed, and the web plate I and the web plate II are connected by means of a butt weld. The steel-concrete bond beam comprises any one novel steel plate beam and a concrete plate covering the novel steel plate beam. Aconnecting part is connected between the novel steel plate beam and the concrete plate. The novel steel plate beam is formed by splicing the first splicing part and the second splicing part, so that the height of the steel plate beam can be improved greatly. The first splicing part and the second splicing part are rolled and formed, and the web plates and the frange plates are connected tightly, so that no fillet welds are available and the force transfer property is excellent. Furthermore, the first splicing part and the second splicing part are connected through the butt weld, so that the novel steel plate beam is convenient to process and manufacture, and the welding quality of the butt weld is easily guaranteed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

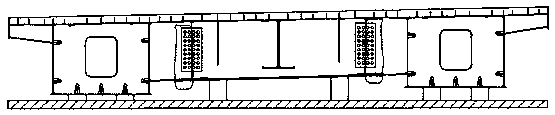

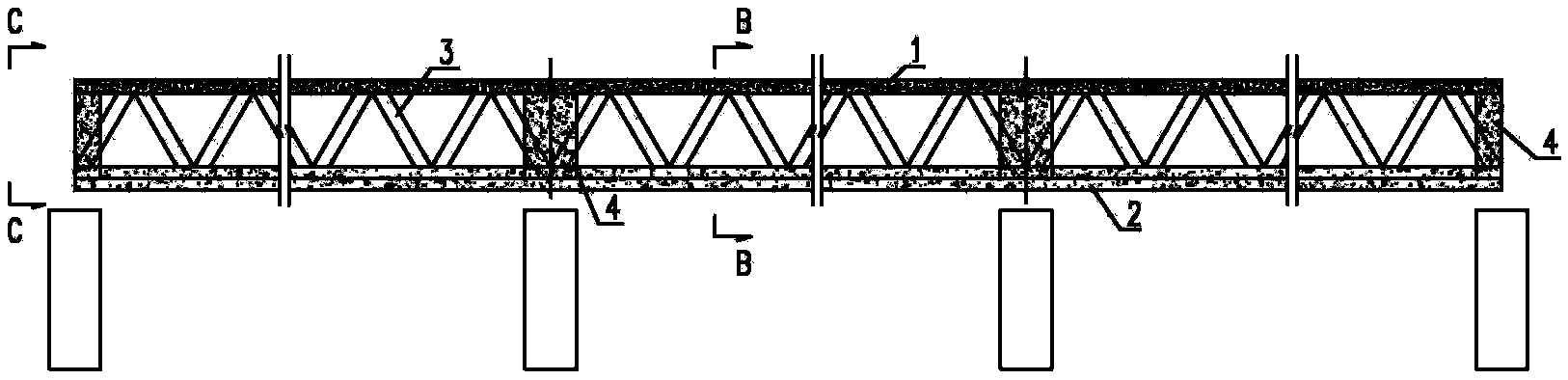

Urban rail transit bond beam and construction method thereof

PendingCN110331647ASimple processImprove construction efficiencyBridge erection/assemblyBridge materialsBridge deckBond beam

The invention discloses an urban rail transit bond beam and a construction method thereof and belongs to the technical field of urban rail transit. The urban rail transit bond beam comprises two concrete edge longitudinal beams, two concrete cross beams, a steel longitudinal beam, a plurality of steel cross beams, and a concrete bridge deck slab; the two concrete cross beams are arranged at the two ends of the two concrete edge longitudinal beams respectively, and the two ends of the steel longitudinal beam are connected with the two concrete cross beams respectively; each steel cross beam comprises a first cross beam and a second cross beam, the two sides of the first transverse beam and the two sides of the second transverse beam are respectively connected with the steel longitudinal beam and the concrete edge longitudinal beams, and the first transverse beam, the second transverse beam and the steel longitudinal beam form a supporting surface; and the concrete bridge deck slab is arranged on the supporting surface formed by the first transverse beam, the second transverse beam and the steel longitudinal beam. According to the urban rail transit bond beam provided by the invention, the transverse stress of the beam body is improved, the weight of the beam body component is reduced, and the installation efficiency is improved.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Bond beam and block joist

A building has walls built from blocks with cavities. Roofs and floors are formed from joists extending between walls. Each joist has a vertical plate, an angle piece located on each side of the vertical plate and end plates. The end plates bear on the wall blocks. Pins extend from the end plates into cavities of the wall blocks. Bond beams can be positioned on walls parallel to the joist. Horizontal blocks are laid across the joists to form a roof or floor.

Owner:EDWARDS DOUGLAS

A structure and construction method of a combined girder bridge with external support girder type maintenance road

ActiveCN110747749BHigh strengthImprove space utilizationBridge erection/assemblyArchitectural engineeringStringer

The invention discloses an externally supported girder type inspection road structure and a construction method of a combined girder bridge, and relates to the technical field of bridge construction. It includes: support beams, the support beams are fixedly connected on both sides of the combined beam bridge, there are multiple support beams, and the multiple support beams are arranged at intervals along the longitudinal direction of the combined beam bridge; the first longitudinal beam and the second longitudinal beam, the first The first longitudinal beam and the second longitudinal beam are fixedly arranged above the support beam at intervals, the first longitudinal beam is located on the side close to the combined beam bridge, and the second longitudinal beam is located on the side away from the combined beam bridge; Laying on the top of the first longitudinal girder and the second longitudinal girder, there are multiple access slabs, and the multiple access slabs extend along the longitudinal bridge direction of the combined girder bridge. The supporting beams, the first longitudinal beam and the second longitudinal beam of the external support beam type inspection road of the present invention are all made of steel structure materials, and the inspection road board adopts prefabricated slabs made of concrete materials, which can significantly reduce the structure The self-weight is lower, the cost of materials is reduced, and the construction is convenient.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Technique of producing steel-concrete connecting beam

The invention relates to a process of manufacturing novel bond beam, which includes the following steps: 1. cutting steel plate; 2. forming steel structure plate unit with steel plates; 3. assembling steel structure beam section with steel structure plate units; 4. regulating the line profile of the beam section, pre-assembling and correcting errors; 5. setting formwork on steel structure beam section, depositing concrete and curing to form concrete panel and bond beam; 6. pre-stress stretching the concrete panel; 7. boring and trial assembling the steel structure beam sections at the lower part of adjacent bond beams; and 8. disassembling the pre-assembled steel structures, painting, transporting to site and site assembling. The said process can prevent deformation of bolt holes caused by stretching after drilling holes.

Owner:SHANGHAI FOUND ENG GRP

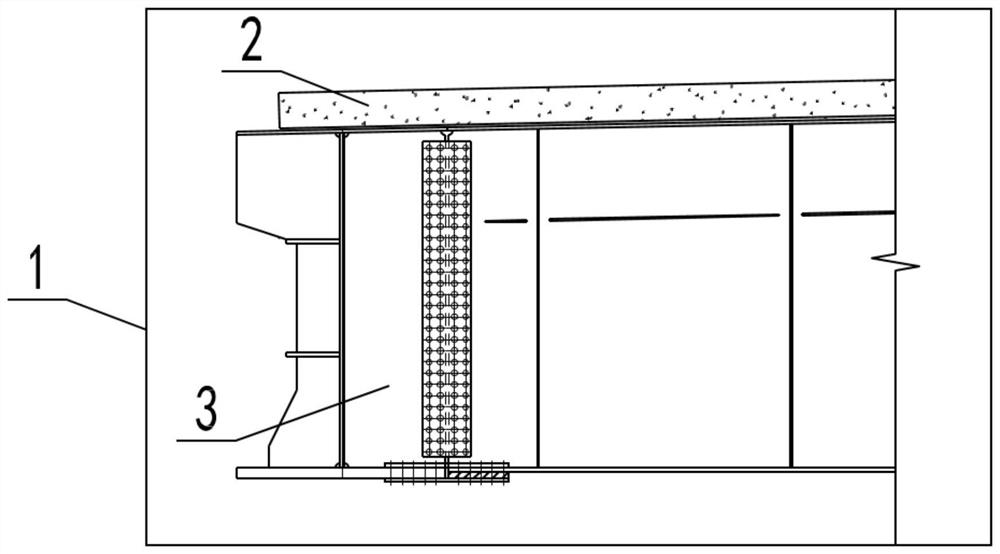

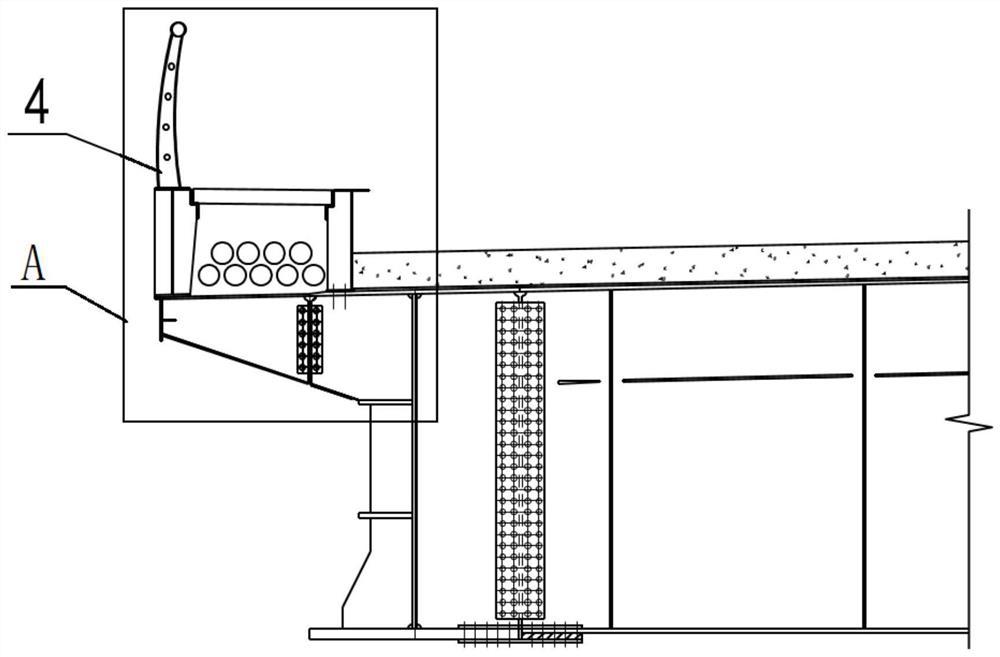

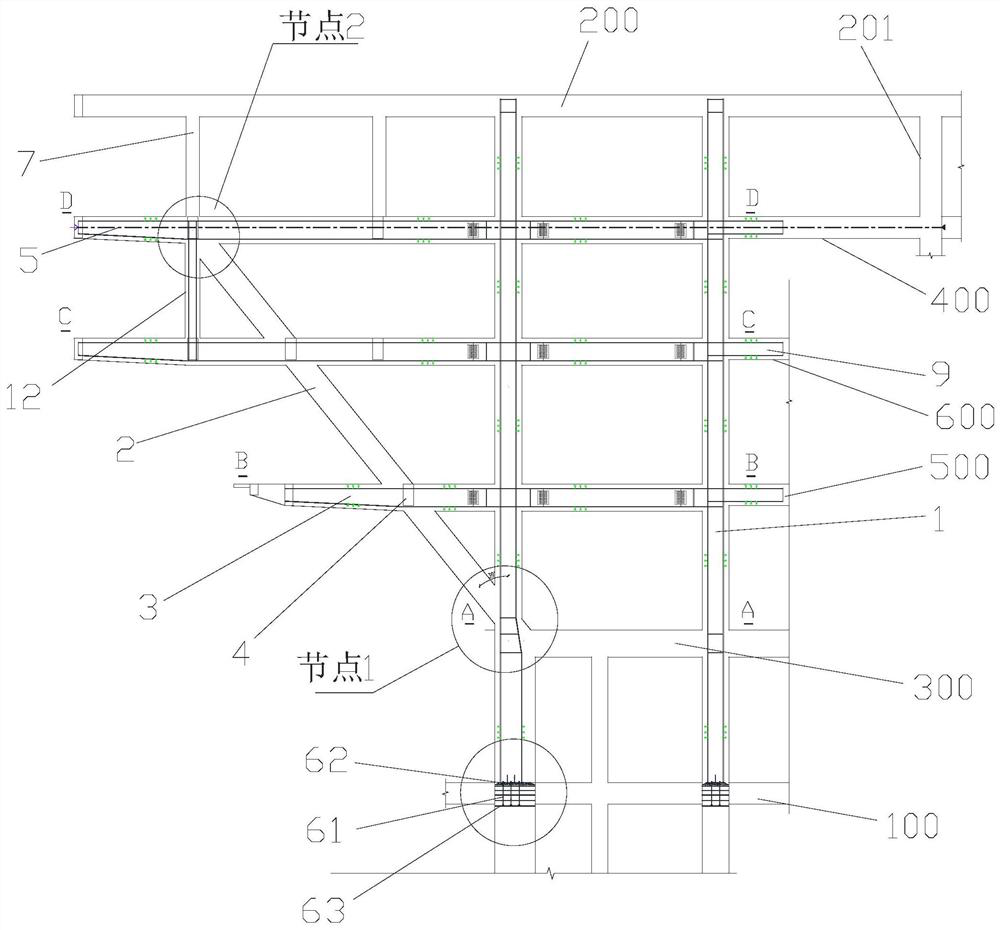

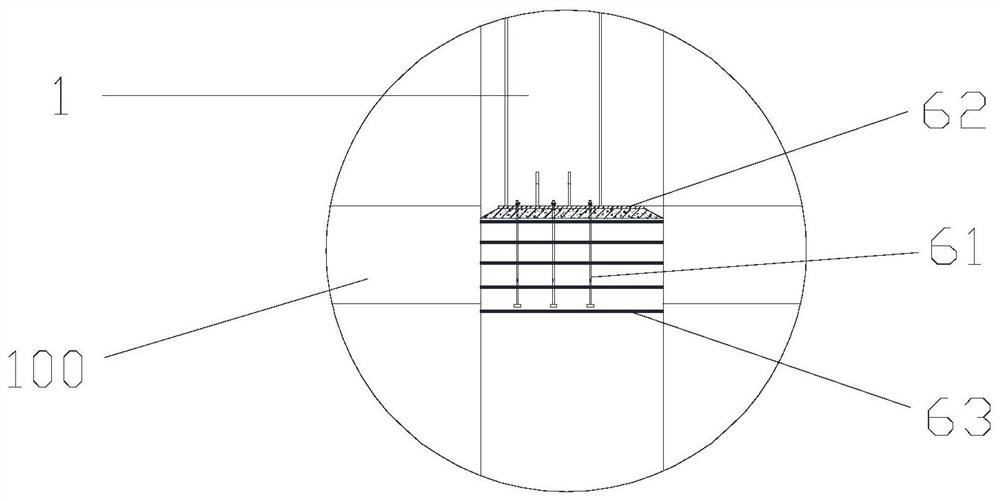

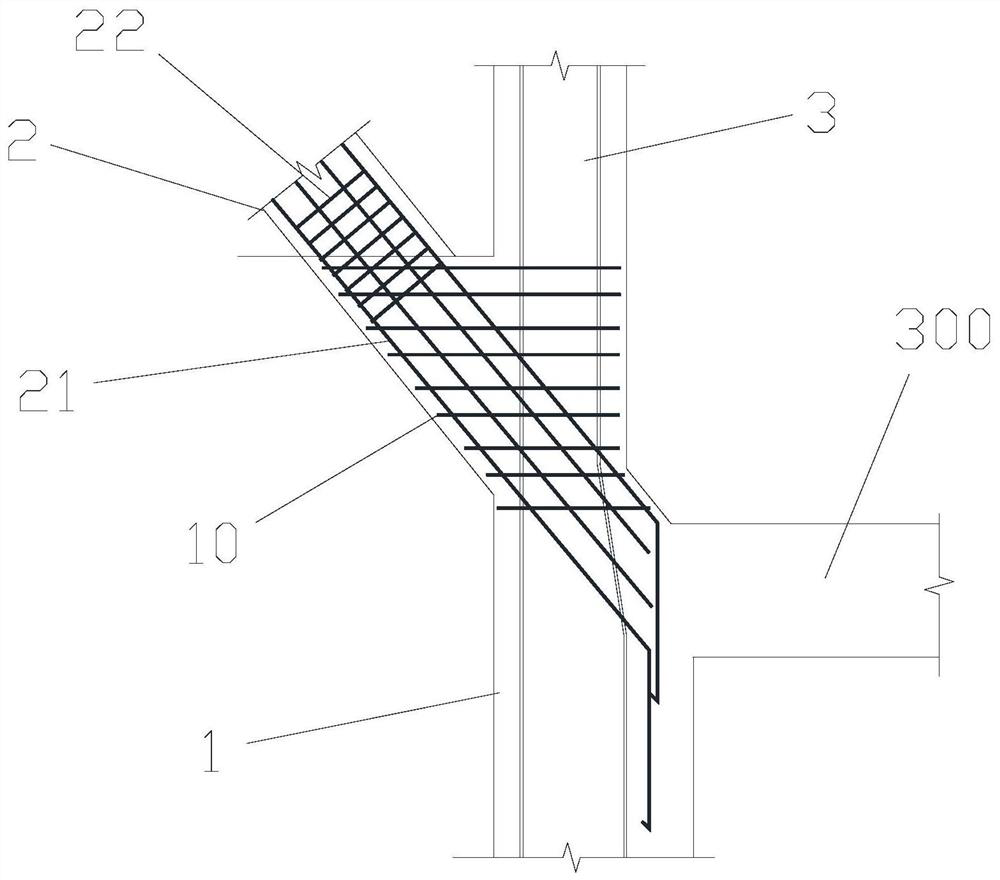

Large-span step-by-step cantilevered diagonal bracing structure and its construction method based on pull-up and bottom-embedded structures

ActiveCN110107075BGuaranteed styling needsTo achieve the purpose of beautiful imageScaffold accessoriesPre stressArchitectural engineering

The invention discloses a large-span step-by-step cantilevered diagonal bracing structure based on an upper pull-down and lower embedded structure and a construction method thereof. , tie beams (4) and prestressed tendons (5); the bottom of the load steel frame column is fixed in the negative layer (100), and the top of the load steel frame column is fixed on the roof layer (200); On the load steel frame column (1) of the first floor (300), the eccentric angle of the diagonal brace and the load steel frame column is formed between the diagonal brace and the load steel frame column; the steel frame beams are connected by tie beams and set on the load steel frame columns to form the structure of the building. For several levels, the diagonal braces extend upwards to the top floor and are fixed with the steel beams of each level through tie beams to form a step-by-step cantilever structure; the prestressed tendons are anchored on the fixed structural columns (201), and the prestressed tendons are set Steel beams and anchored. The invention can meet the architectural requirements of the oblique shape of the large-span cantilevered step by step in the building structure through the construction technology of pulling up and inserting diagonal braces.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

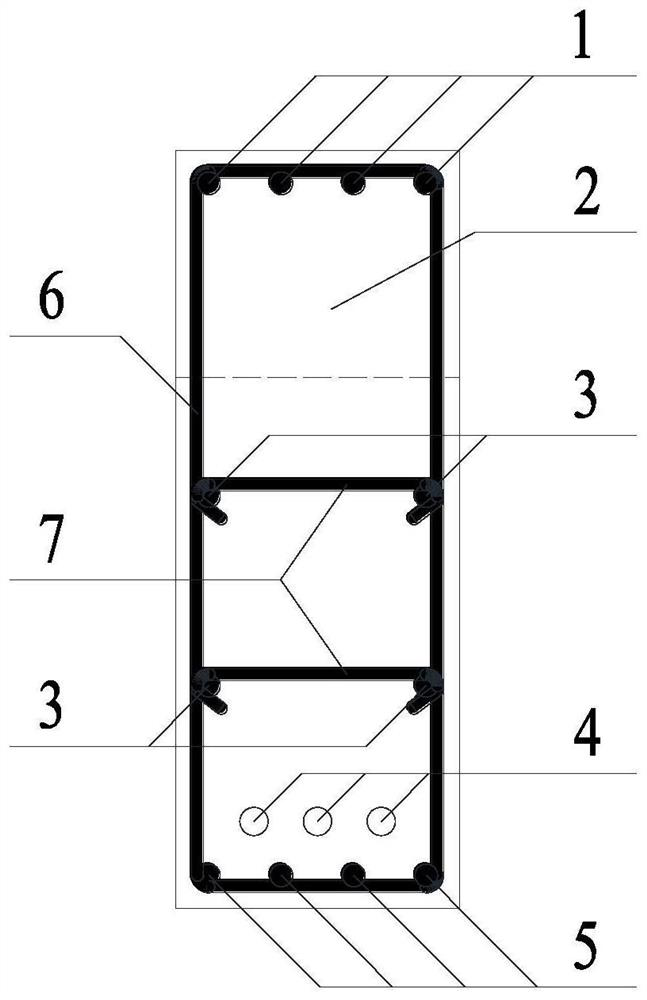

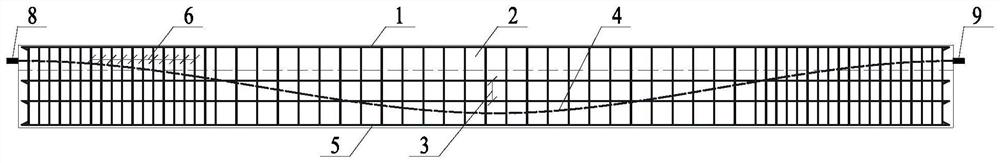

Post-tensioned unbonded prestressed concrete composite beam and its design and construction method

ActiveCN109868937BImprove crack resistanceImprove bending abilityGirdersJoistsPre stressArchitectural engineering

The invention relates to a post-tensioned non-bonded prestressed concrete composite beam and a construction method thereof. The composite beam is a kind of post-tensioned non-bonded beam applied to the entire beam after the composite beam is laminated and formed to meet the requirements of use. Bonded prestress. Compared with the traditional composite beam, it adopts post-tensioning unbonded prestressing technology, which not only inherits the characteristics of high prefabrication and convenient construction of the lower composite structure, but also improves the crack resistance and bending resistance of the components. Because it can apply post-tensioned prestress after the overall construction, it is especially suitable for structures with high performance requirements such as large spans and heavy loads that require high deformation control and bearing capacity, and can also reflect the design requirements while meeting the design requirements. Advantages of prefabricated structures.

Owner:上海同吉建筑工程设计有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com