Bond beam and block joist

a technology of bonding beams and joists, which is applied in the direction of building roofs, building components, constructions, etc., can solve the problems of high construction cost, high carpentry skill level,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

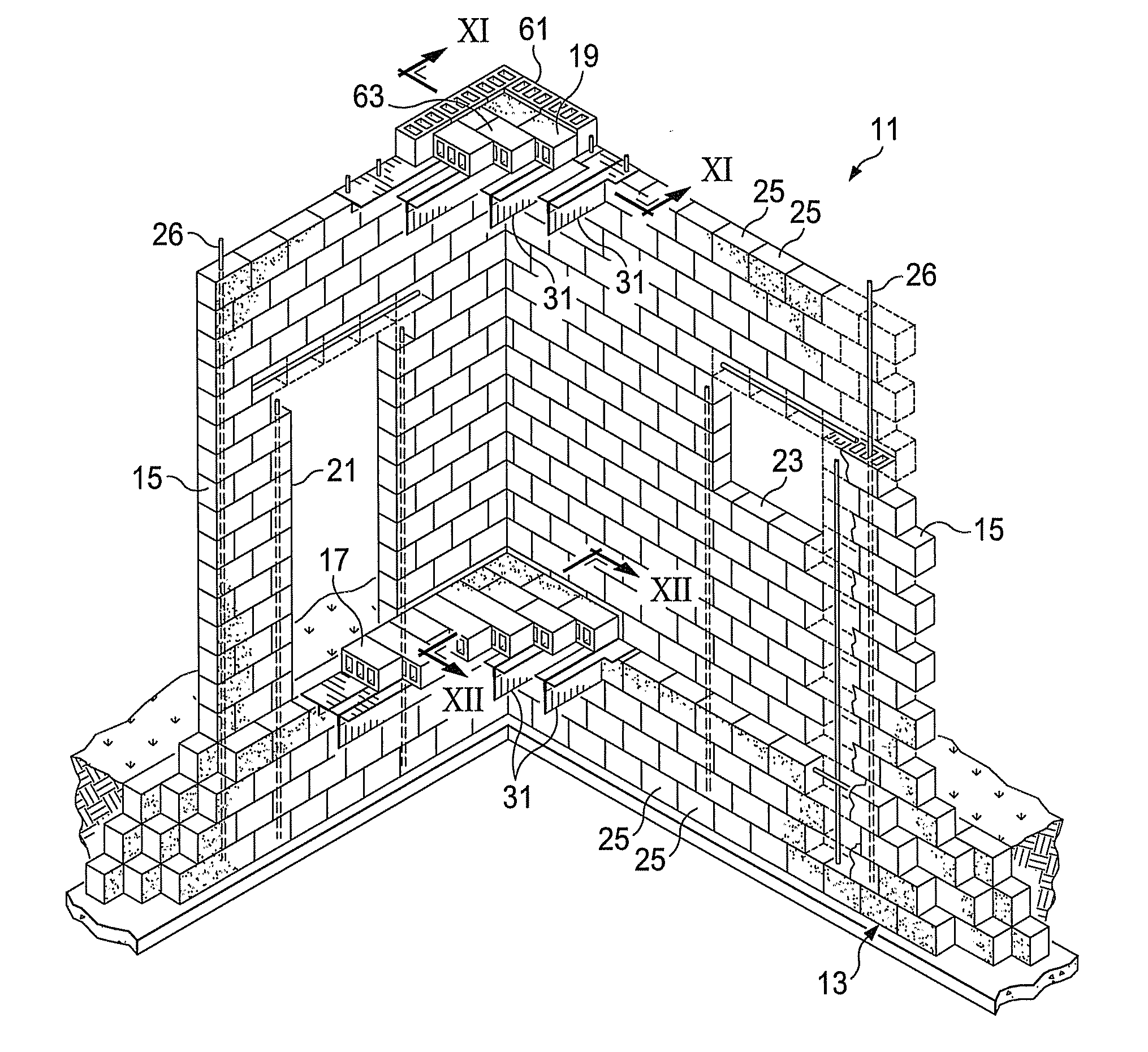

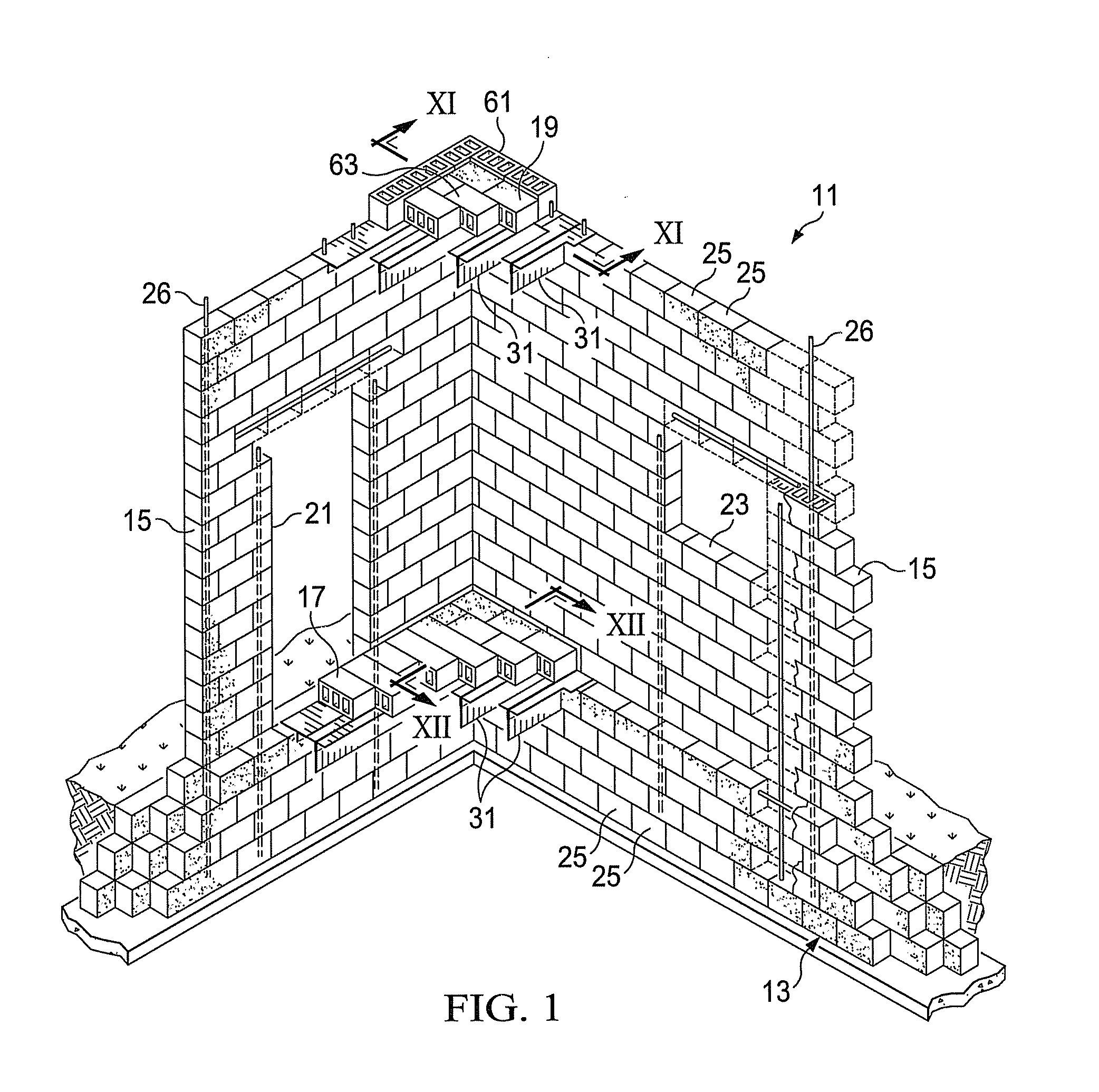

[0031]In FIG. 1, part of a building 11 is shown. The building has a foundation 13, walls 15, a floor 17 and a roof 19. The interior of the building can have one or more rooms. The walls 15 have doorways 21 and window openings 23. The walls 15 and foundation 13 are formed from concrete or cement blocks 25. Such blocks 25 are typically rectangular with holes or cavities 27 (see FIG. 11) therethrough. When building the walls 15 with the blocks, the cavities 27 are vertically oriented so that the cavities of one block align with the cavities located above and below adjacent blocks. Typically vertical bars 26 are inserted into the walls so as to extend into the cavities of plural rows of blocks. The blocks 25 can be the type that are conventional and commercially available, which blocks can be mortared together to build the walls. Alternatively, the blocks 25 could be mortarless as described in my previous patent application Publication No. 2008 / 0060313, the complete disclosure which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com