Masonry bracket, system and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

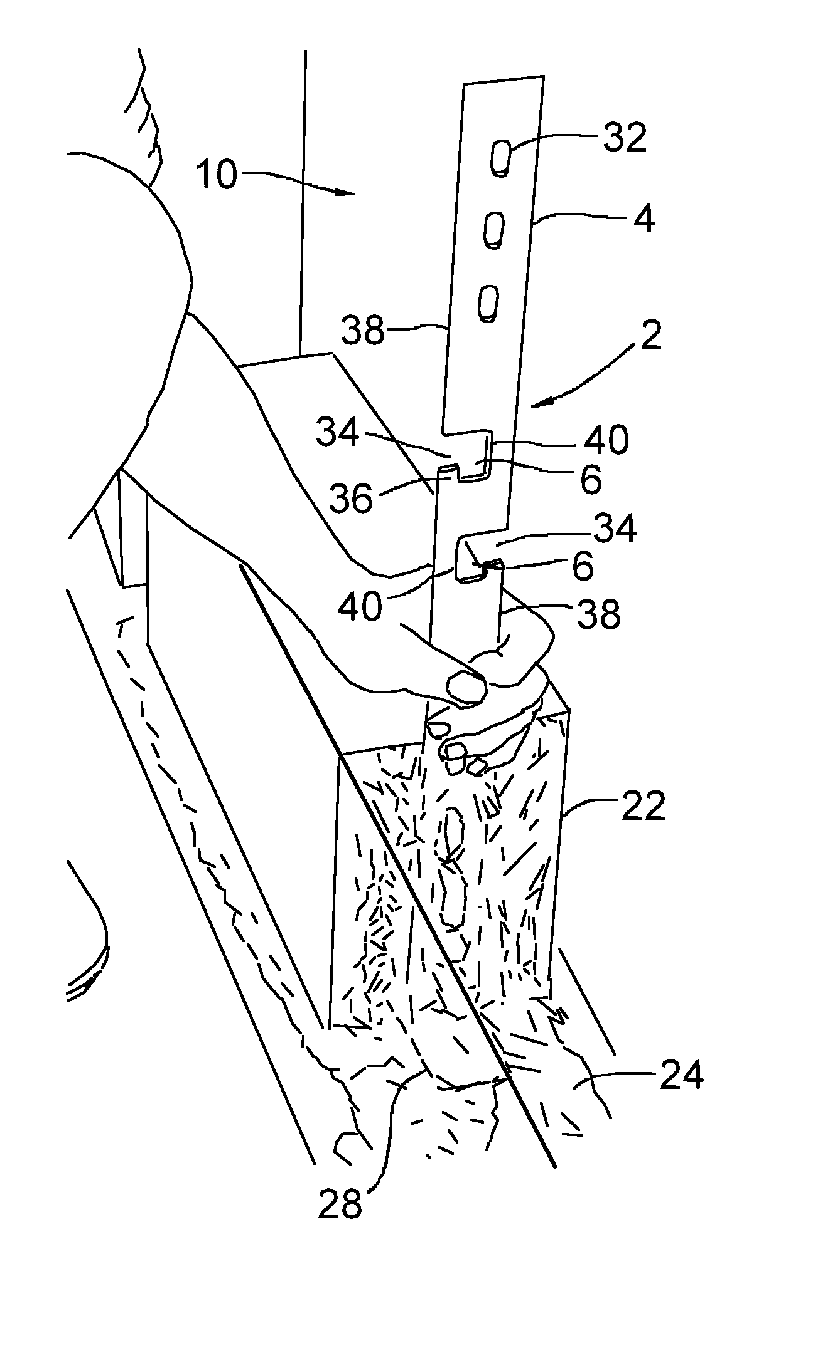

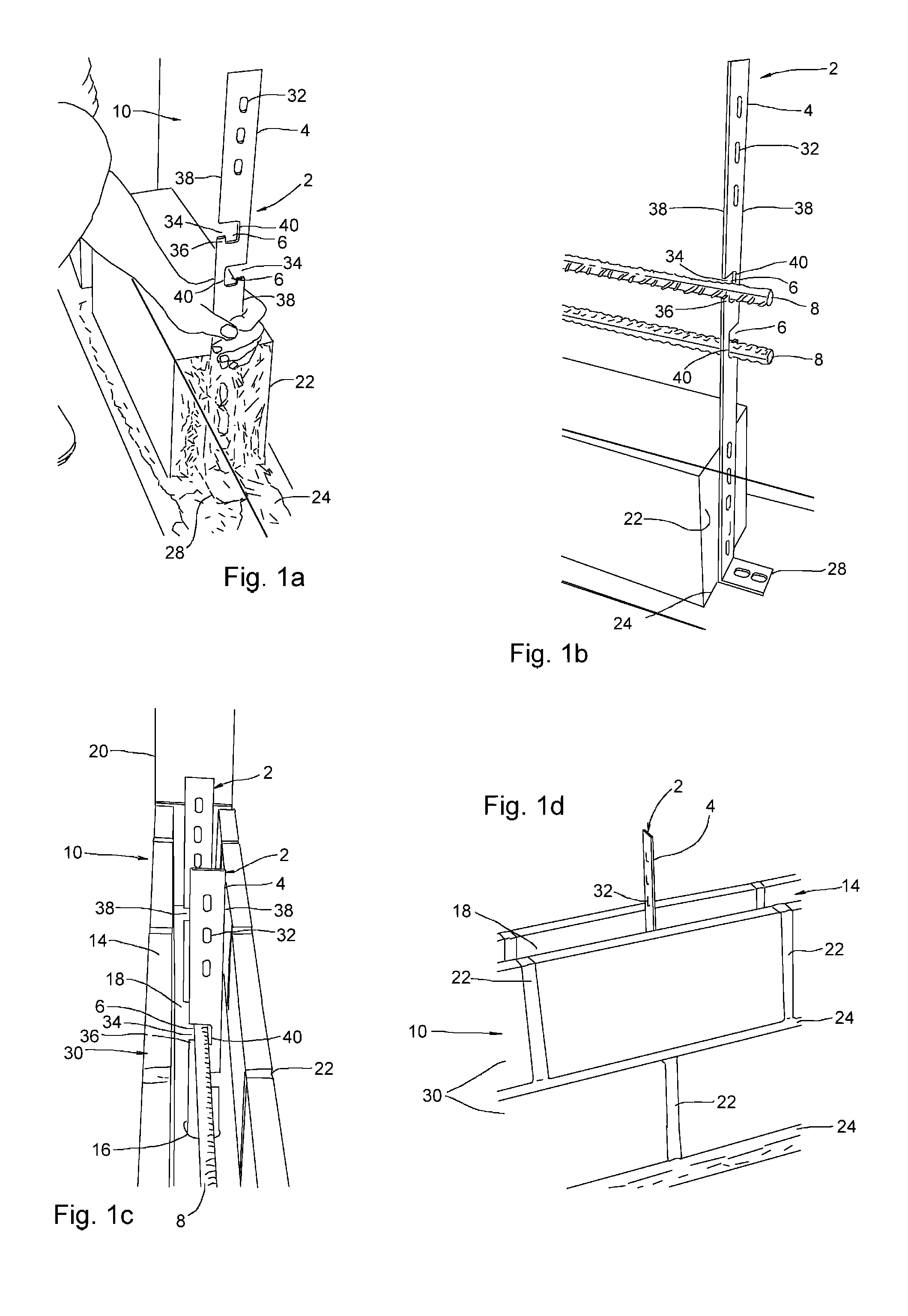

[0024]Referring to FIGS. 1a-1e, the present invention provides a masonry wall reinforcing bracket 2 comprising an elongate stress transfer member 4 adapted and configured to extend between at least two courses 30 of masonry in use. The stress transfer member 4 further comprises one or more rebar cradling features 6. The cradling feature 6 is operative to support and locate a rebar 8 within a masonry wall 10, e.g. to allow it to be cast into a bond beam 12 formed within a course of hollowed masonry units 14. The bracket 2 is formed from a material that is stronger in tension and shear compared to the bond beam matrix material (i.e. concrete, usually) and mortar. Such a bracket 2 material could be steel or another metal, or a metallic or non metallic composite material.

[0025]As shown, the stress transfer member 4 extends between at least two immediately adjacent masonry courses 30, but it may in principle extend through any number of masonry courses 30. In use the stress transfer memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com