PCT/TLCP resin composition for 5G antenna oscillator base material as well as preparation method and application thereof

A technology of resin composition and antenna vibrator, which is applied in the field of PCT/TLCP resin composition for 5G antenna vibrator base material and its preparation, which can solve the problems of low dielectric constant and dielectric loss, low dielectric constant, high equipment requirements, etc. , achieve good dimensional stability and creep resistance, good chemical resistance and dielectric properties, and improve modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

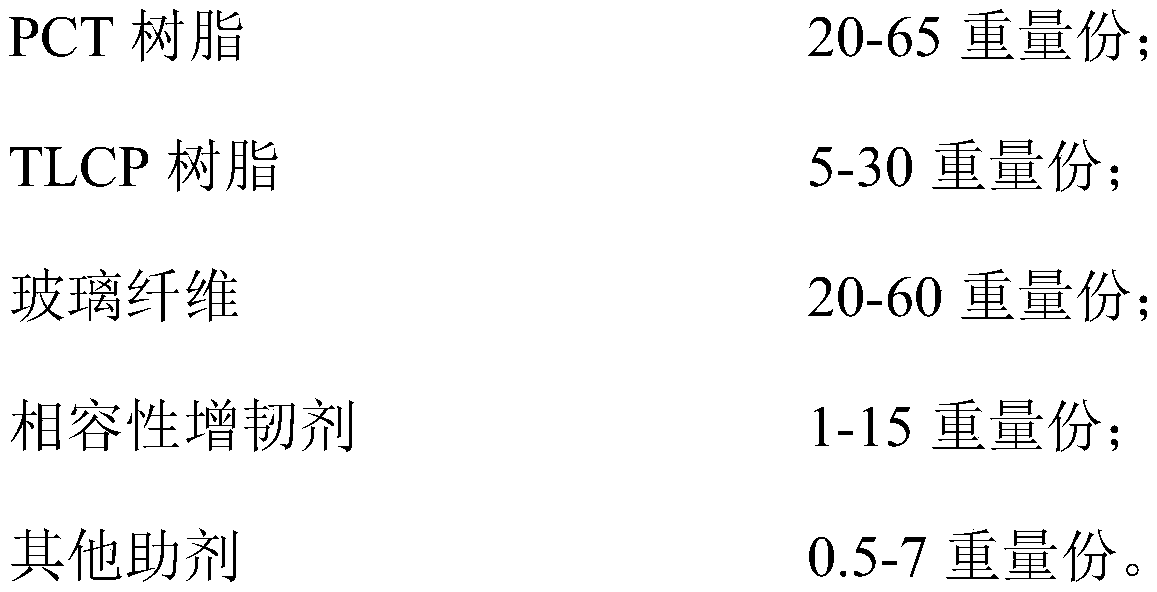

[0067] A PCT / TLCP resin composition for a 5G antenna vibrator base material, based on 100 parts of the total weight of the resin composition, consists of the following components:

[0068]

[0069] Among them, the intrinsic viscosity of PCT resin is 0.75dL / g, and the melting point is 282±2°C; the melting point of TLCP resin is 330-340°C (T3300, Nantong Haidi); the glass fiber is round cross-section glass fiber (diameter 9μm); Compatibility toughening agent is G1652 (SEBS) and 1901GT (SEBS-g-MAH), mass ratio 1:1; Dispersant is silicone powder; Nucleating agent is Nav101; Antioxidant is 1010 and 619 (mass ratio 2:3).

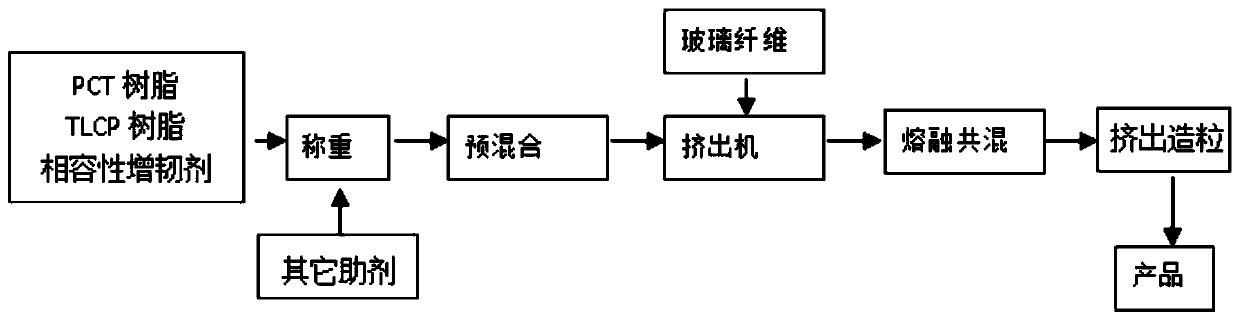

[0070] The preparation method is as follows:

[0071] (1) Mix PCT resin, TLCP resin and compatible toughening agent, and then pre-mix with dispersant, nucleating agent and antioxidant;

[0072] (2) melt extruding and granulating the mixture and glass fibers of step (1) in a twin-screw extruder to obtain a PCT / TLCP resin composition for a 5G antenna vibrator s...

Embodiment 2

[0076] A PCT / TLCP resin composition for a 5G antenna vibrator base material, based on 100 parts of the total weight of the resin composition, consists of the following components:

[0077]

[0078] Among them, the intrinsic viscosity of PCT resin is 0.75dL / g, and the melting point is 285±2°C; the melting point of TLCP resin is 330-340°C (T3300, Nantong Haidi); the glass fiber is round cross-section glass fiber (11μm in diameter); Compatibility toughening agent is KH-R172 (TPEE) and G1702 (SEBS), mass ratio 4:3; Dispersant is Hyper 100; Nucleating agent is Nav101; Antioxidant is 1010 and 619 (mass ratio 2:3 ).

[0079] The preparation method is as follows:

[0080] (1) Mix PCT resin, TLCP resin and compatible toughening agent, and then pre-mix with dispersant, nucleating agent and antioxidant;

[0081] (2) melt extruding and granulating the mixture and glass fibers of step (1) in a twin-screw extruder to obtain a PCT / TLCP resin composition for a 5G antenna vibrator substra...

Embodiment 3

[0085] A PCT / TLCP resin composition for a 5G antenna vibrator base material, based on 100 parts of the total weight of the resin composition, consists of the following components:

[0086]

[0087] Among them, the intrinsic viscosity of PCT resin is 0.75dL / g, and the melting point is 285±2°C; the melting point of TLCP resin is 330-340°C (T3300, Nantong Haidi); the glass fiber is flat glass fiber ECS301HFPA; compatibility and toughening The agent is E920 (MBS) and KH-R163 (TPEE), the mass ratio is 1:1; the dispersant is CBT100100; the nucleating agent is Nav101; the antioxidant is 1010 and 619 (mass ratio 2:3).

[0088] The preparation method is as follows:

[0089] (1) Mix PCT resin, TLCP resin and compatible toughening agent, and then pre-mix with dispersant, nucleating agent and antioxidant;

[0090] (2) melt extruding and granulating the mixture and glass fibers of step (1) in a twin-screw extruder to obtain a PCT / TLCP resin composition for a 5G antenna vibrator substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com