Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Will not interfere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

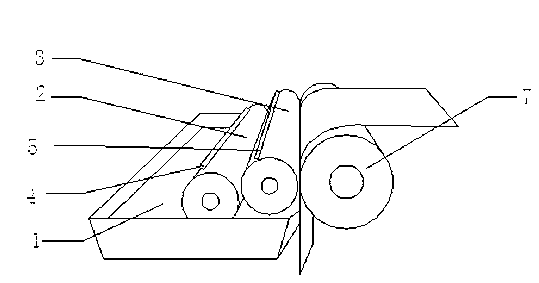

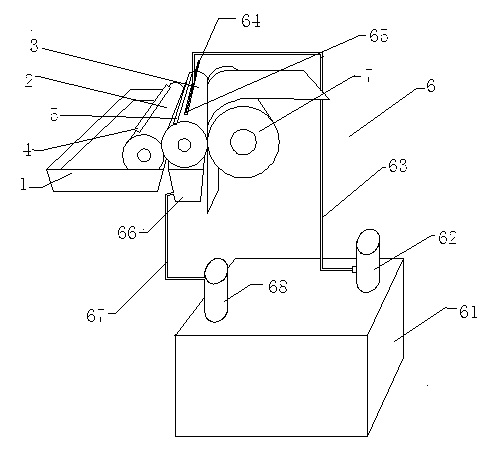

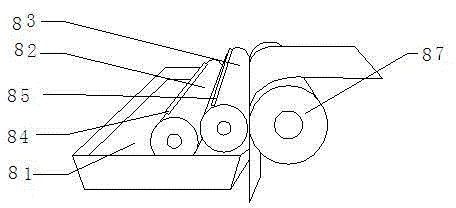

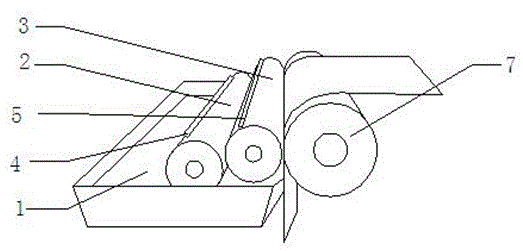

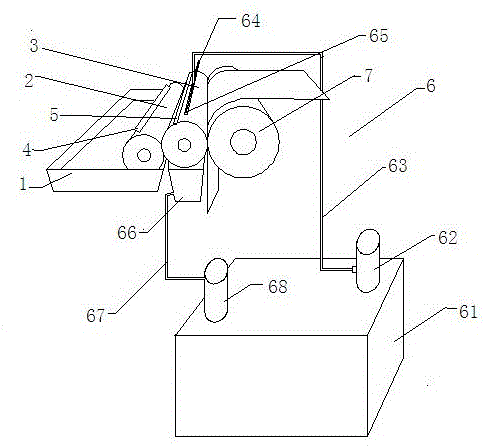

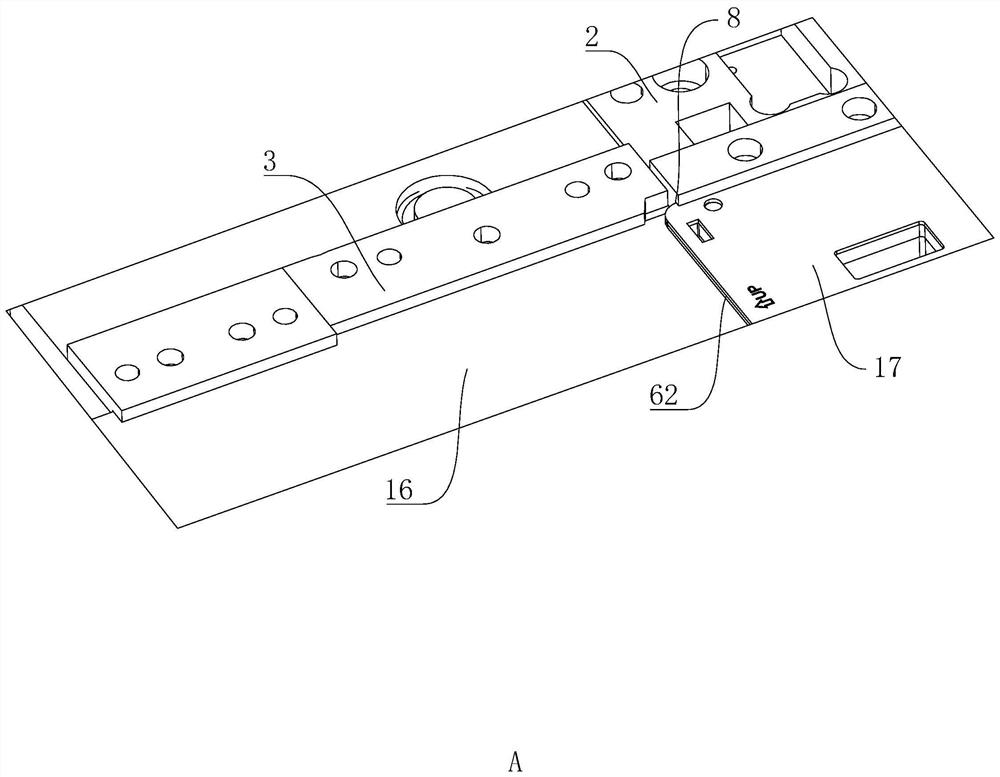

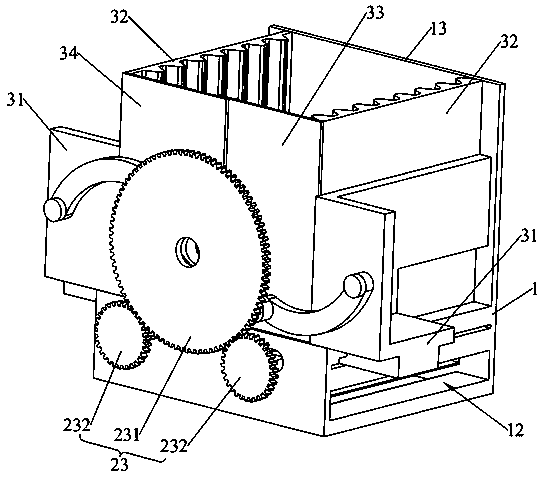

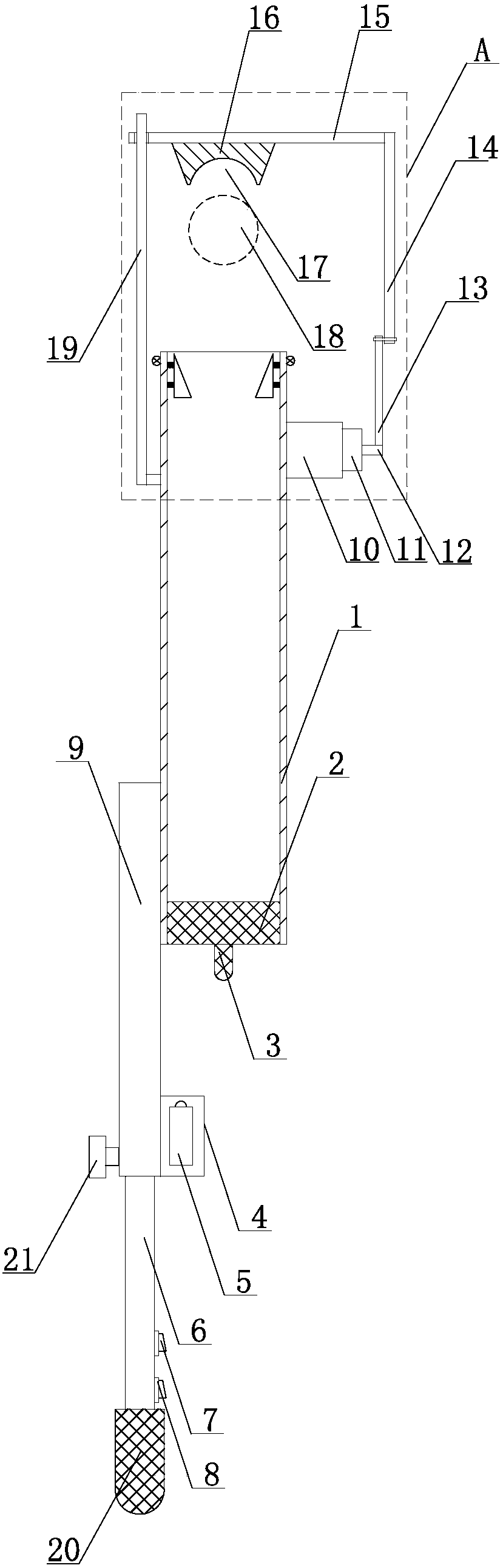

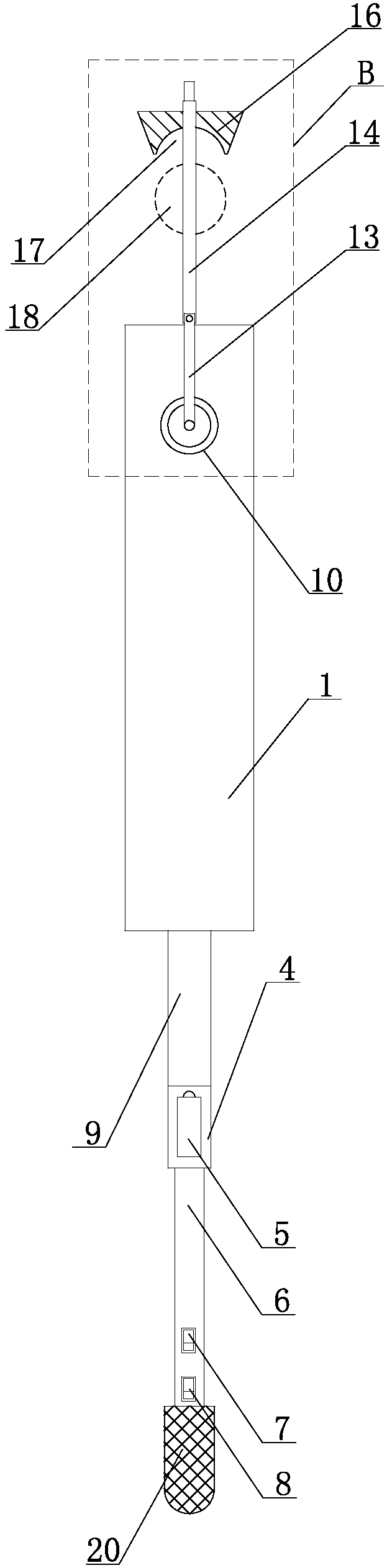

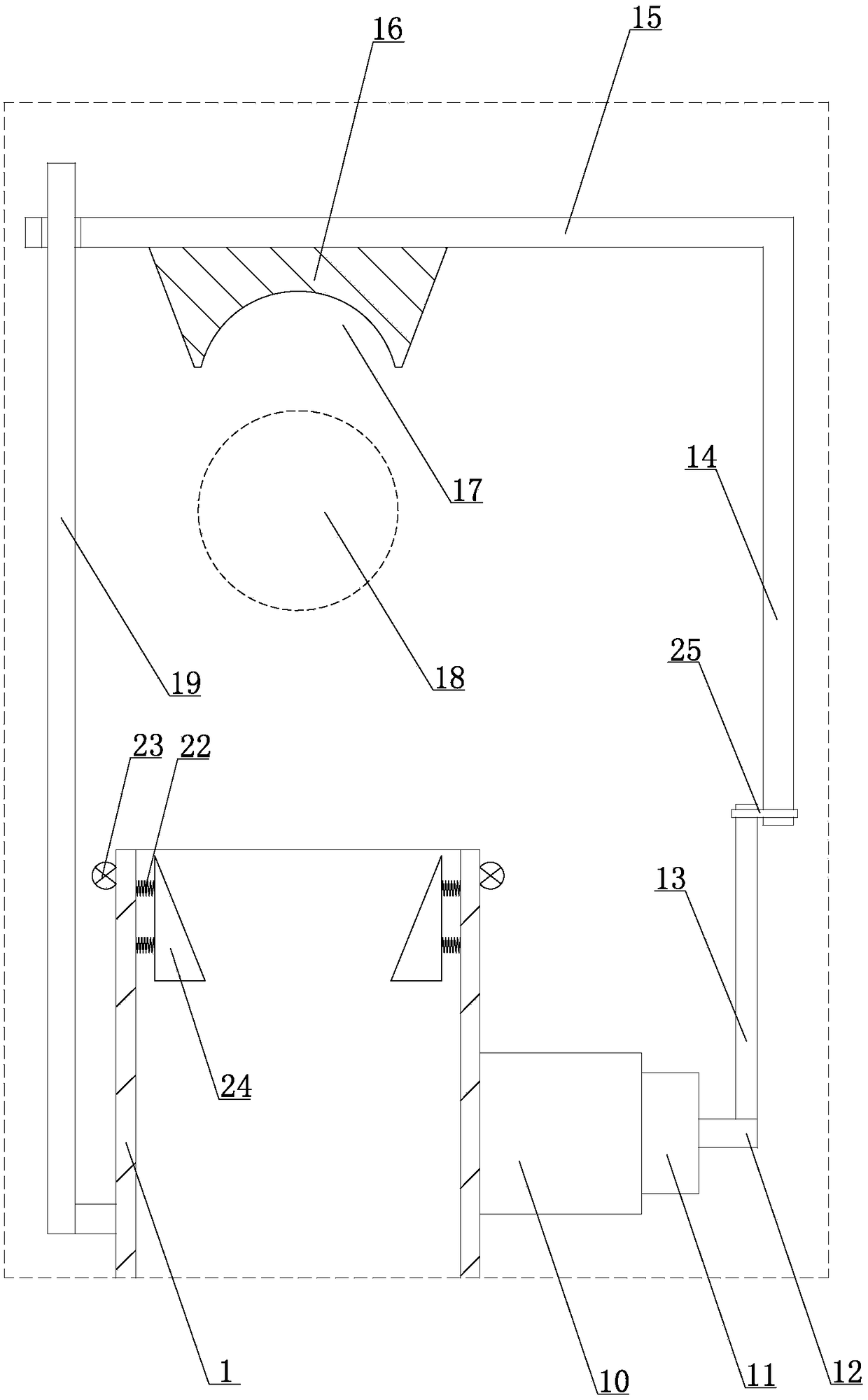

Photogravure press

InactiveCN102991097AExtended service lifeAvoid the defects of low labor efficiencyRotary intaglio printing pressPrinting press partsPhotogravureEngineering

The invention provides a photogravure press, a coating roller of which is made of rubber to ensure that the coating roller is respectively in flexible contact with an absorbing roller and a to-be-printed steel plate, and thus the tightness of the contact is ensured, a pattern region on the absorbing roller can be completely transferred on the coating roller, and a pattern region on the coating roller also can be completely transferred to the to-be-printed steel plate, therefore a complete pattern region is formed. In addition, the photogravure press provided by the invention comprises a first scraper and a second scraper, wherein the first scraper is used for scraping a coating on the absorbing roller, except for a pit for forming an image region, the second scraper is used for removing residual coating on a rubber roller after transferring, therefore, the defects of lower labor efficiency and poor control precision caused by manual removal of the coating are avoided, and thus the labor productivity is increased and the product quality is ensured. In addition, the first scraper and the second scraper are respectively in contact with the absorbing roller and the coating roller by a specific angle, and thus a better scraping effect can be ensured.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

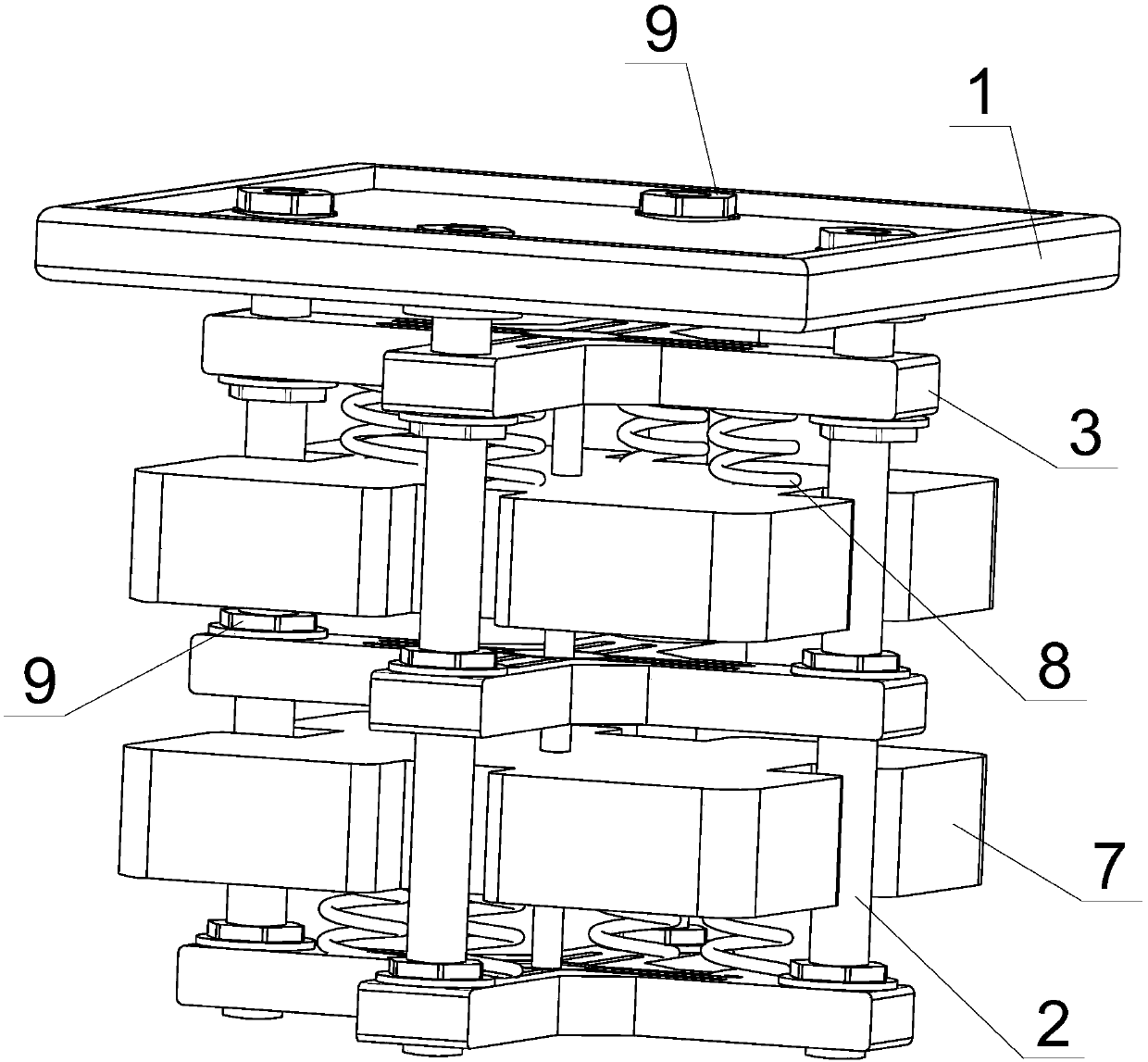

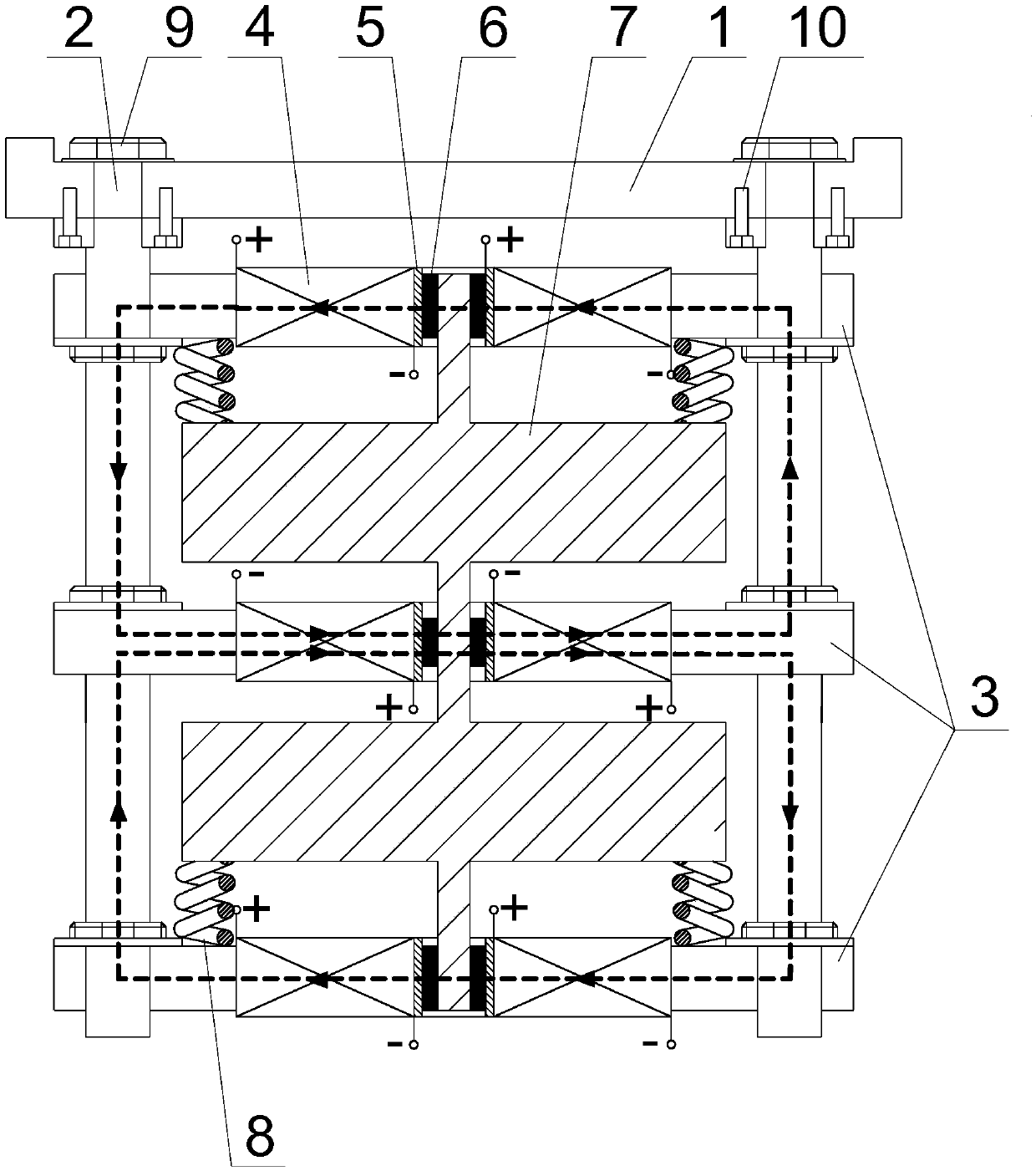

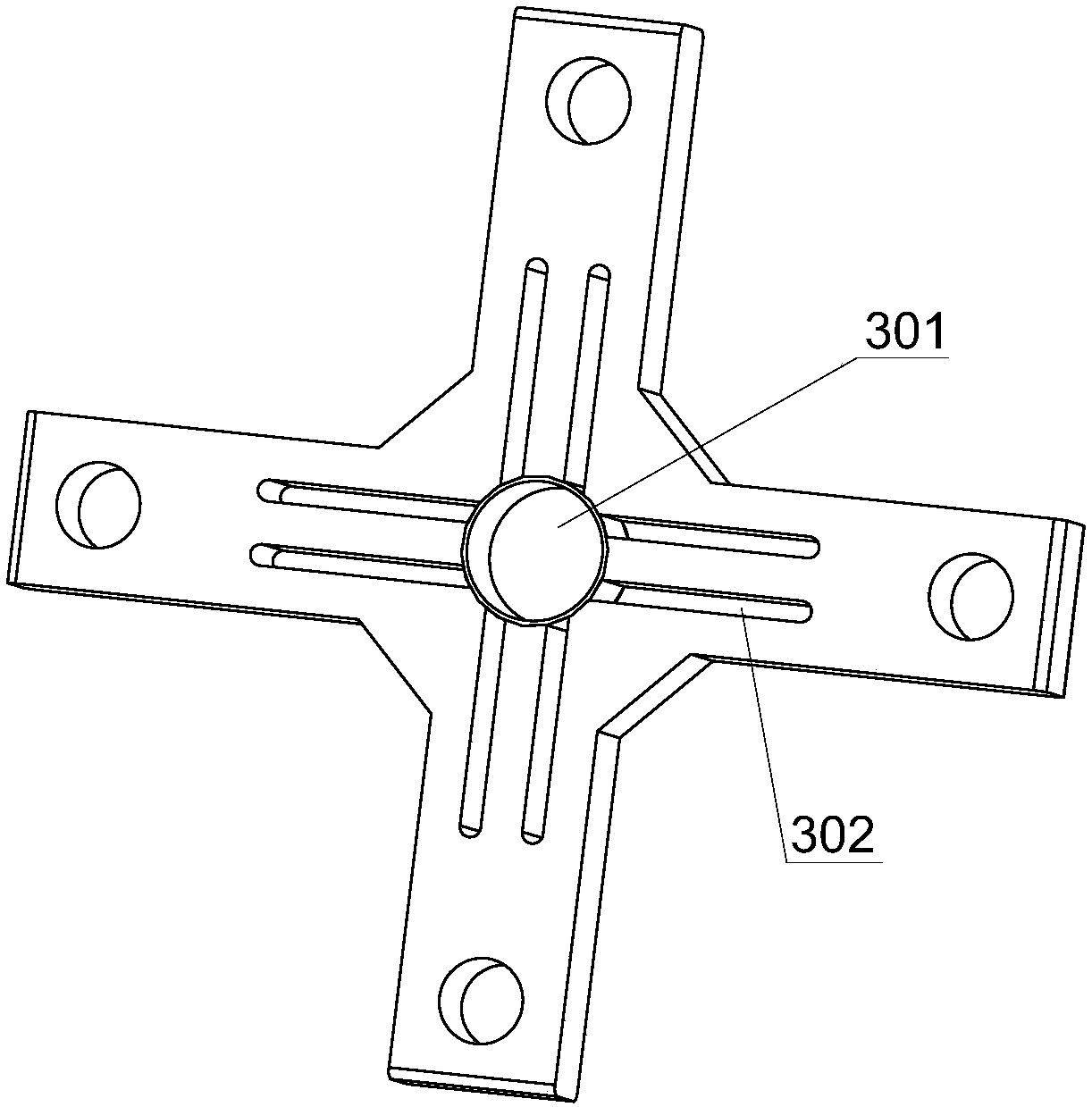

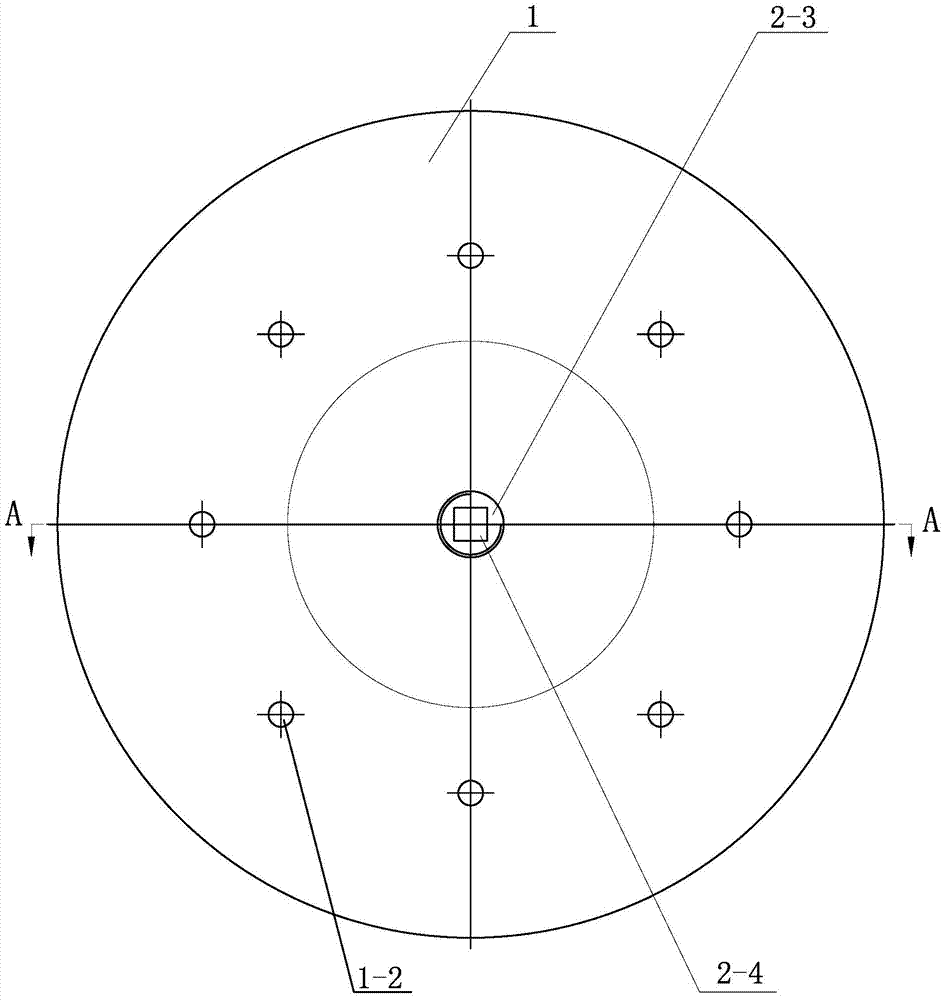

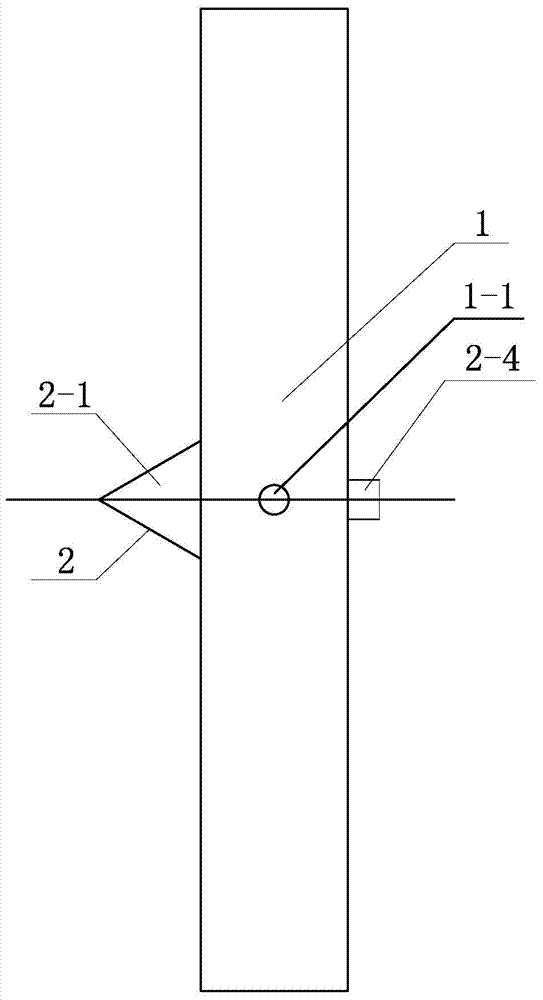

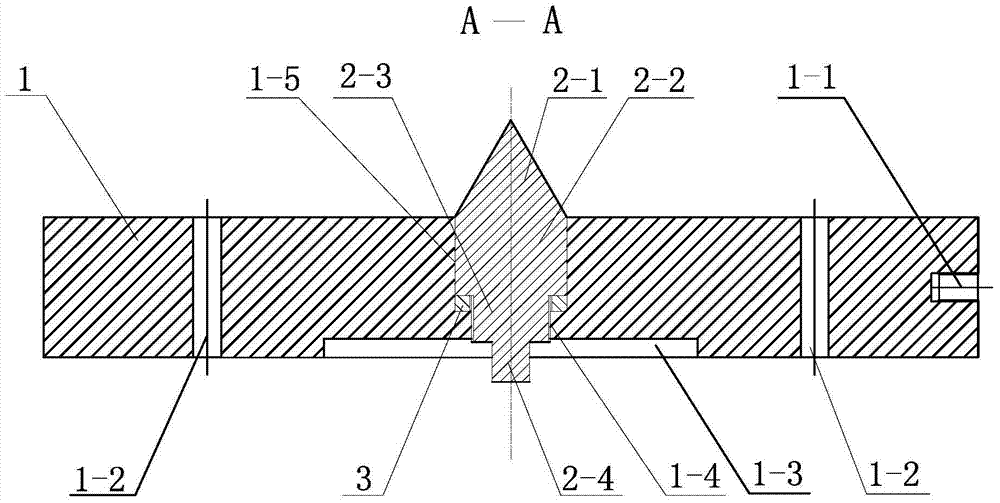

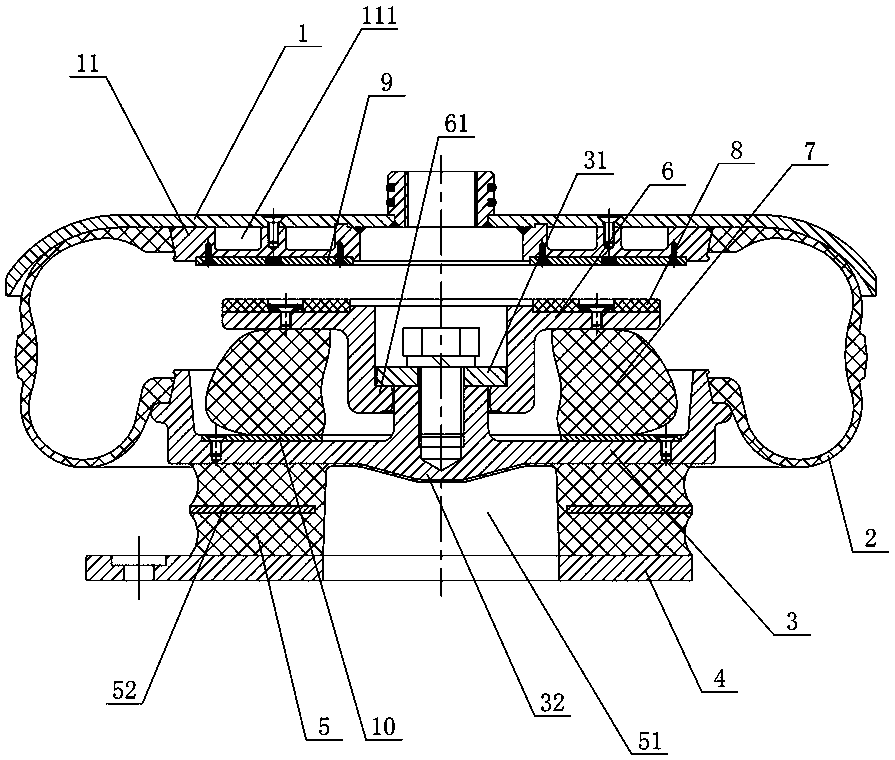

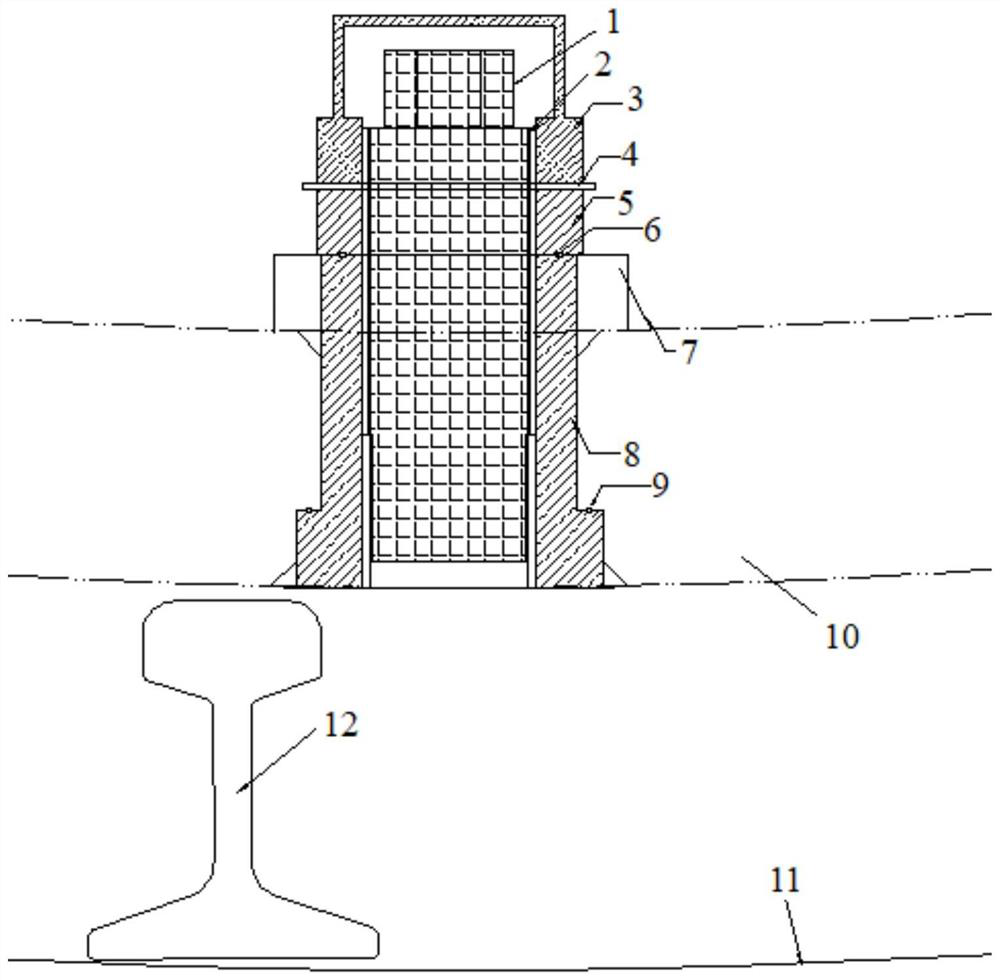

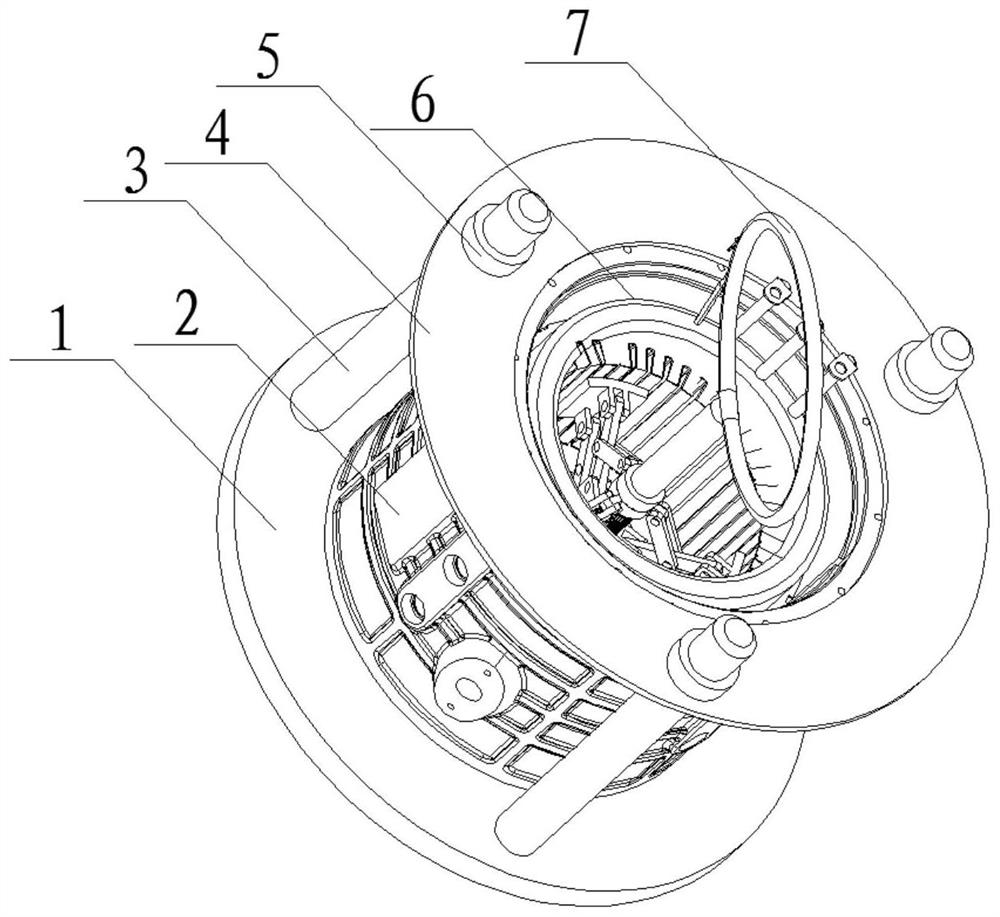

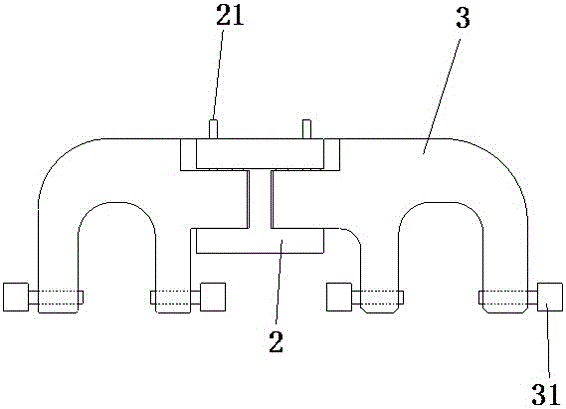

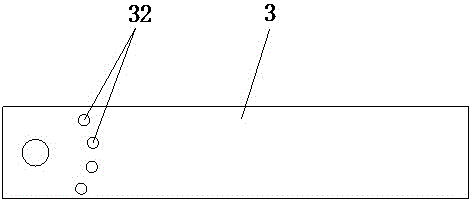

Semi-active dynamic vibration absorber for magneto-rheological elastomers and selection and installation method

ActiveCN107939901ASuppress vertical vibrationAchieve broadband vibration reductionSpringsNon-rotating vibration suppressionElastomerSemi active

The invention discloses a semi-active dynamic vibration absorber for magneto-rheological elastomers and a selection and installation method. According to the semi-active dynamic vibration absorber andthe selection and installation method, multiple layers of cross-shaped cross beams arranged in parallel are fixed to the positions below a bottom frame base located at the bottom of a railway vehiclein a suspended mode through four vertical magnetic conductive rods arranged vertically and penetrating through the four end parts of cross-shaped beam arms; multiple layers of stacked structures which are spaced from each other are formed between multiple layers of grooving vibrators and the cross-shaped cross beams; vertical mounting through holes are formed in the centers of the cross-shaped cross beams; the annular magneto-rheological elastomers are arranged between the mounting through holes and a connecting shaft of the multiple layers of grooving vibrators; the multiple layers of grooving vibrators can vibrate up and down relative to the bottom frame base in the axial direction of the mounting through holes; winding grooves are formed in the beam arms of the cross-shaped cross beams; and excitation coils are wound in the winding grooves. The semi-active dynamic vibration absorber has the advantages that the vibration absorption effect is good, the energy consumption is small, the structure is simple and compact, the installation is easy, the safety and the reliability are high, the utilization of the residual space under the railway vehicle is reasonable, and vertical wide-frequency vibration reduction can be carried out on a railway vehicle body which suffers form an abnormal vibration problem due to the fact that a railway is unsmooth.

Owner:SHANGHAI UNIV OF ENG SCI

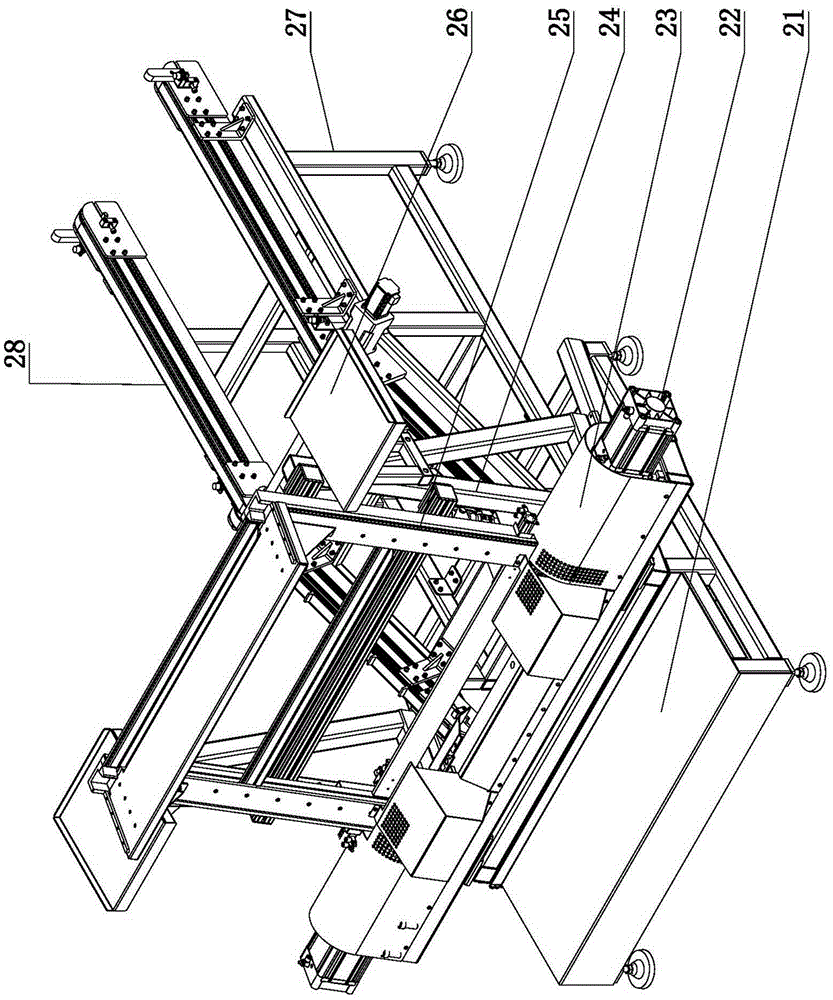

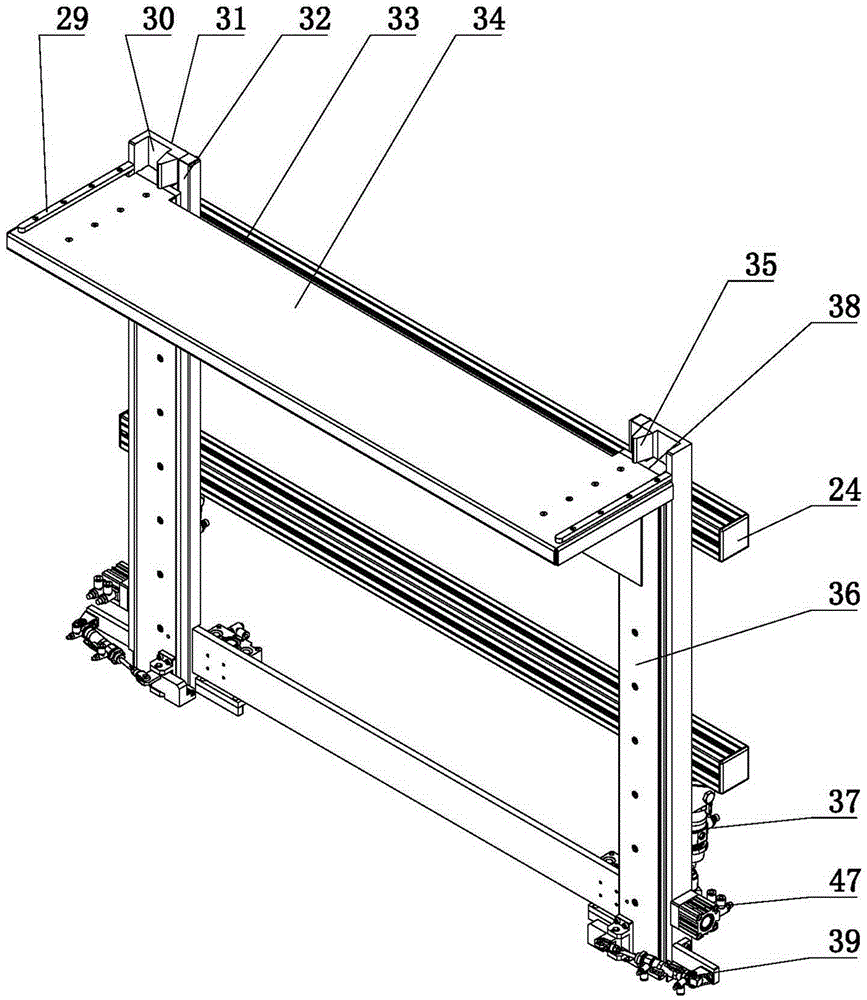

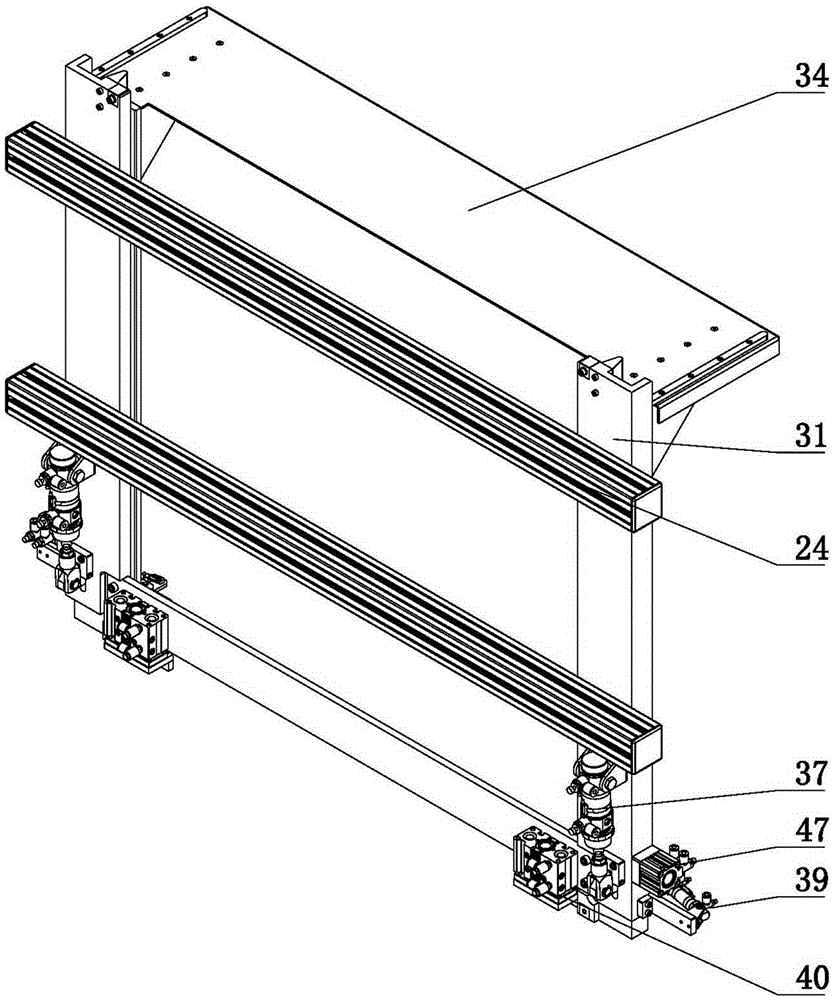

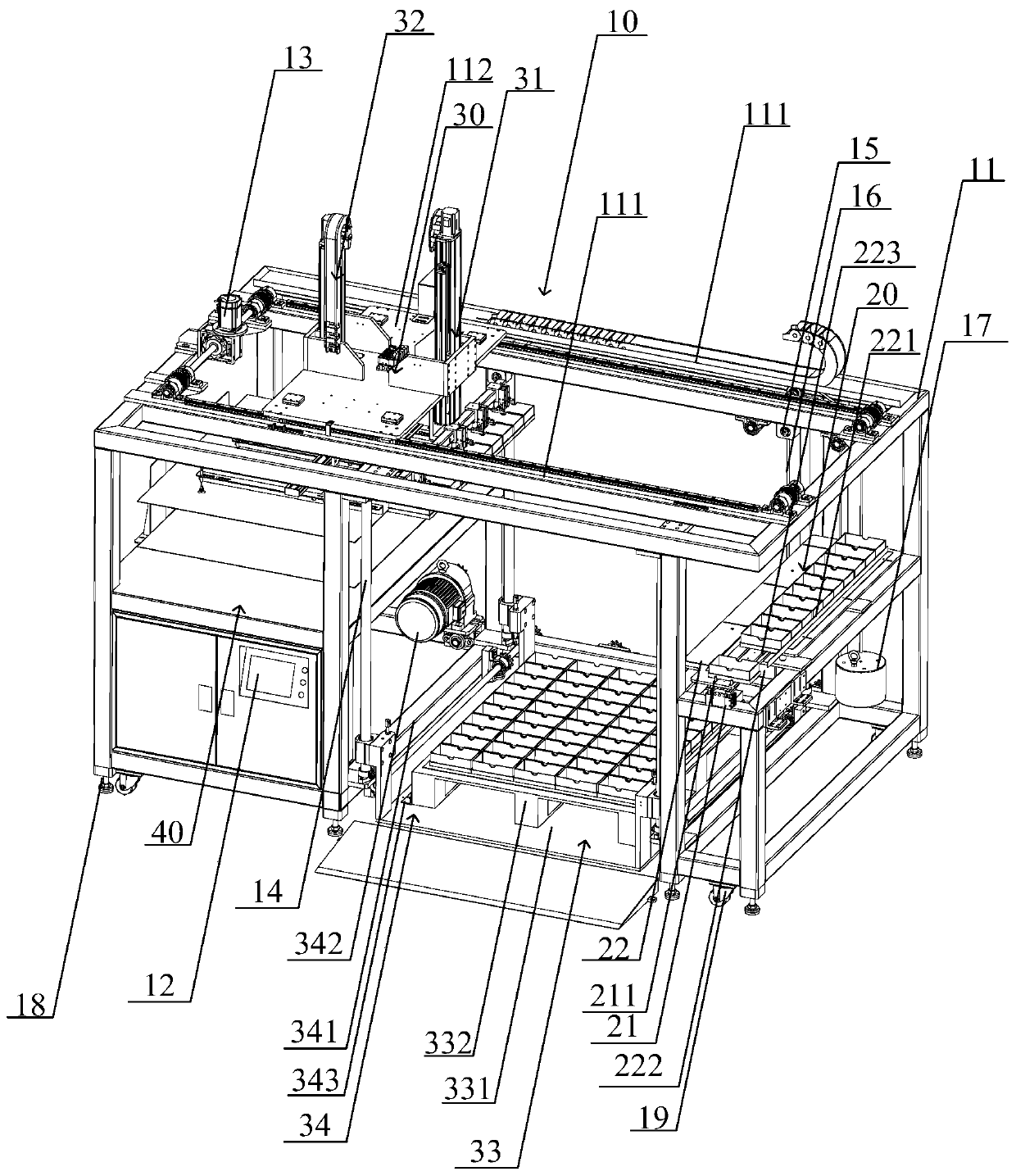

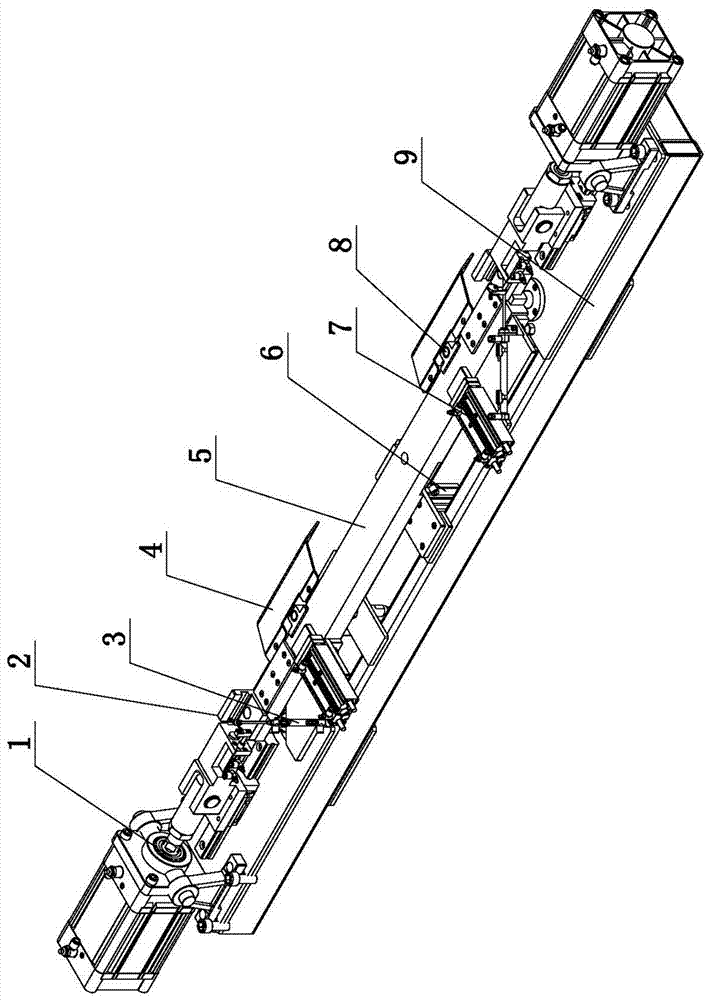

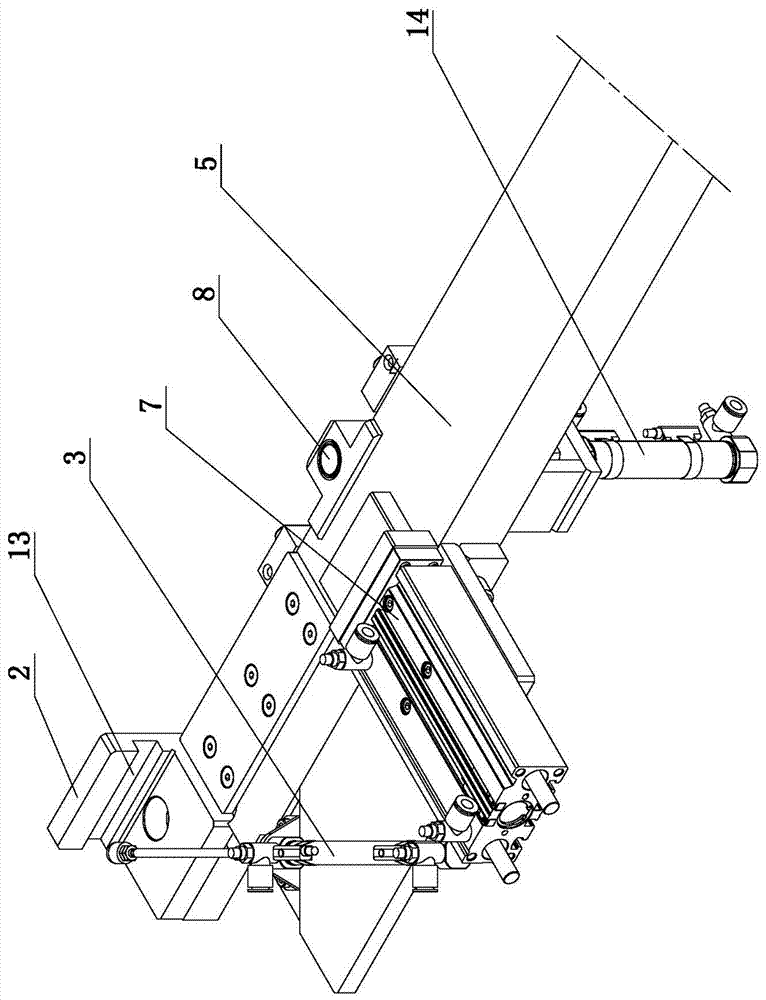

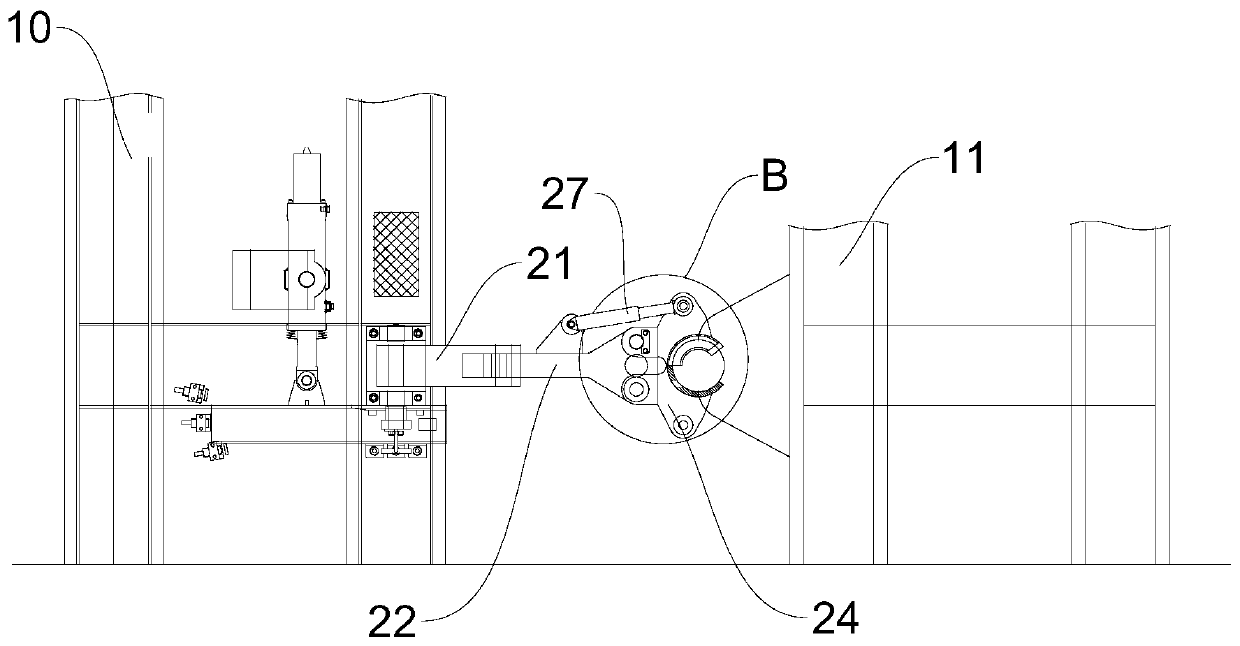

Automatic mounting machine for aluminum profile border corners

ActiveCN105345440ARealize automatic feedingSave human effortMetal working apparatusStructural engineeringMachine

The invention relates to the technical field of automated production equipment of aluminum profiles, in particular to an automatic mounting machine for aluminum profile border corners. The automatic mounting machine for the aluminum profile border corners saves manpower, improves the production efficiency and improves product quality. The automatic mounting machine for the aluminum profile border corners is characterized in that a feeding device comprises a rack, wherein two bin stand columns are arranged on the rack; a loading plate is arranged between upper ends of the two bin stand columns; a border discharging trough is formed between the two bin stand columns and on the loading plate, and border slides are arranged on the bin stand columns and correspond to the border discharging trough; corner slides are arranged on the bin stand columns and correspond to two ends of the loading plate, and a corner discharging trough is formed in the loading plate and correspond to the corner slides; a border unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding border slide; a corner unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding corner slide; a corner pressing mechanism corresponds to the lower ends of the bin stand columns.

Owner:YINGKOU JINCHEN MACHINERY

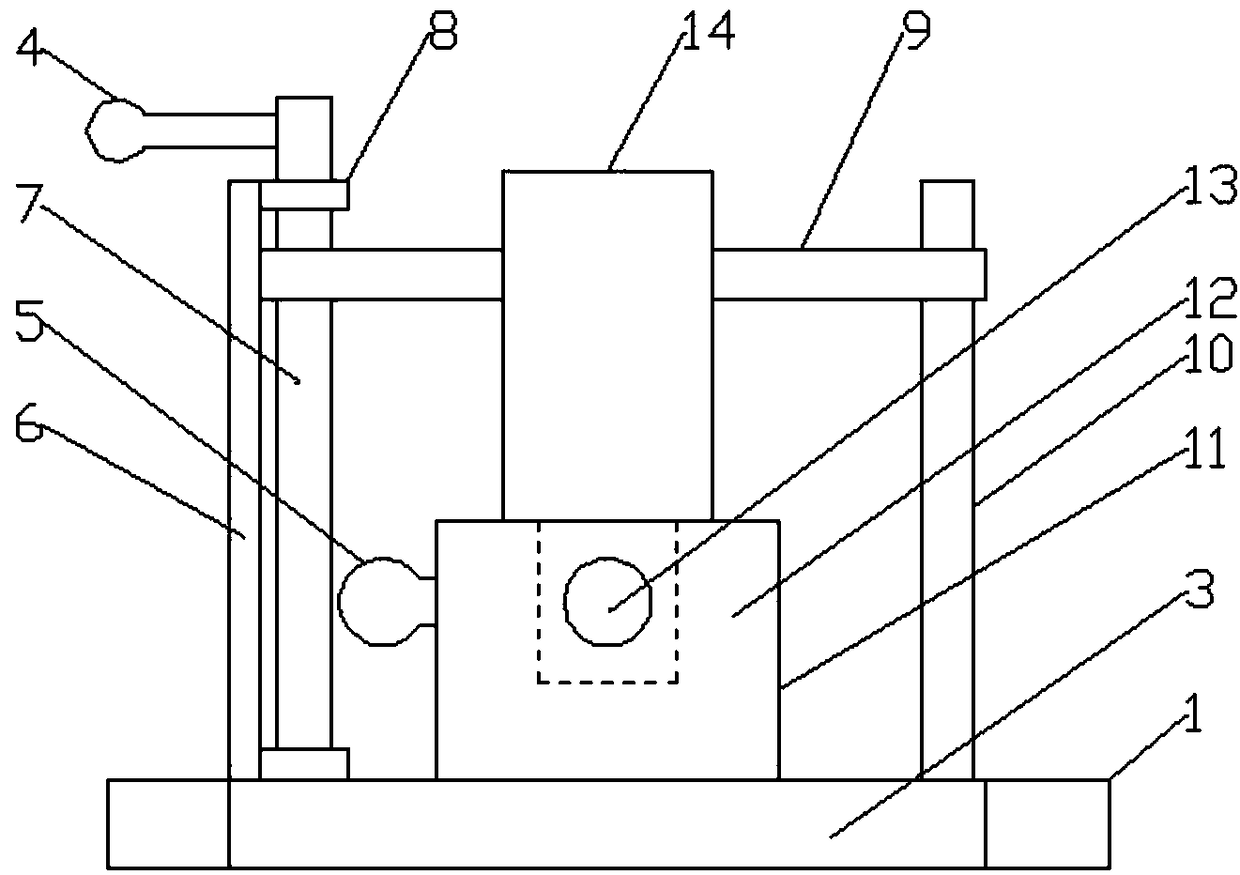

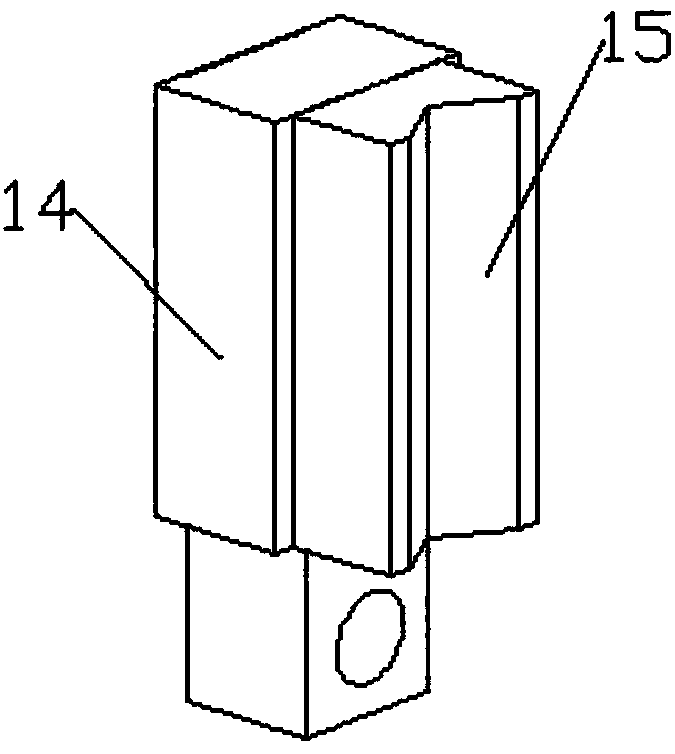

Auxiliary clamping device with two positioning modes for turning process of steam turbine rotors

InactiveCN103586706AEasy to processWill not interfereTailstocks/centresPositioning apparatusEngineeringScrew thread

The invention provides an auxiliary clamping device with two positioning modes for turning process of steam turbine rotors, and relates to an auxiliary clamping device for turning process of steam turbine rotors, aiming to solve problems that in the holding-type turning process of high and middle pressure rotors, the high and middle pressure rotors cannot be clamped well by chucks of horizontal lathes due to the fact that no flanges are arranged at adjusting ends of the high and middle pressure rotors and the adjusting ends have small diameters; if the electric ends are clamped for processing the other portions of the rotors, portions, clamped by the chucks, of the electric ends of the rotors, cannot be processed, and the electric ends are easy to deform to influence run-out due to thin outer circumference and groove walls of flanges at the electric ends. A stop recess, a first threaded hole and a pin hole are coaxially arranged at the center of one end face of a disc, a plurality of through holes running thorough the disc are uniformly machined in the disc on the same circumference, second threaded holes are radially processed on the outer circumference of the disc, a sleeve is arranged in the pin hole, a rectangular portion of a positioning part extends out of the stop recess from one side of the pin hole, and a second column of the positioning part is in threaded connection with the first threaded hole. The auxiliary clamping device is used for auxiliary clamp positioning in the turning process of the steam turbine rotors.

Owner:HARBIN TURBINE

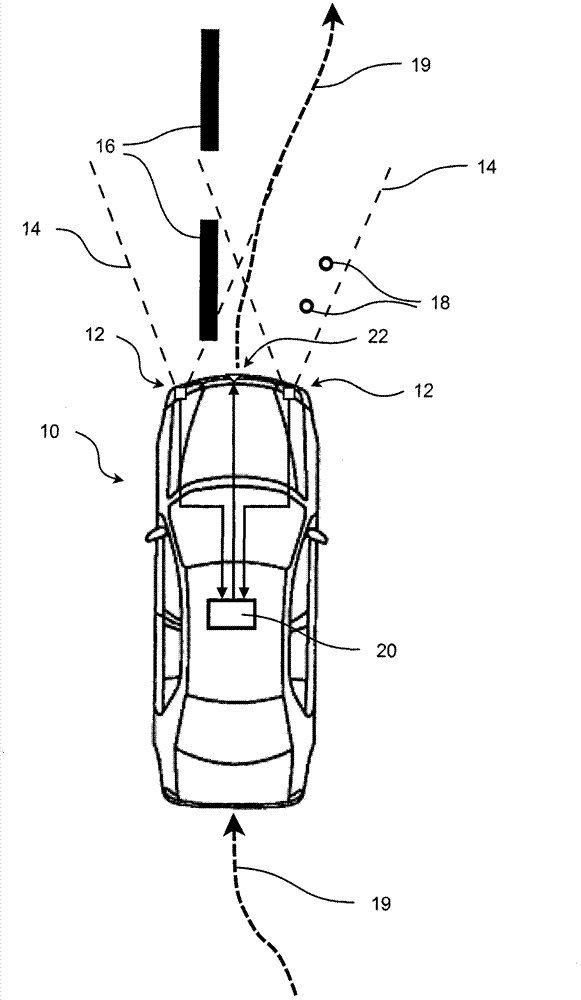

Parking control device

Owner:GM GLOBAL TECH OPERATIONS LLC

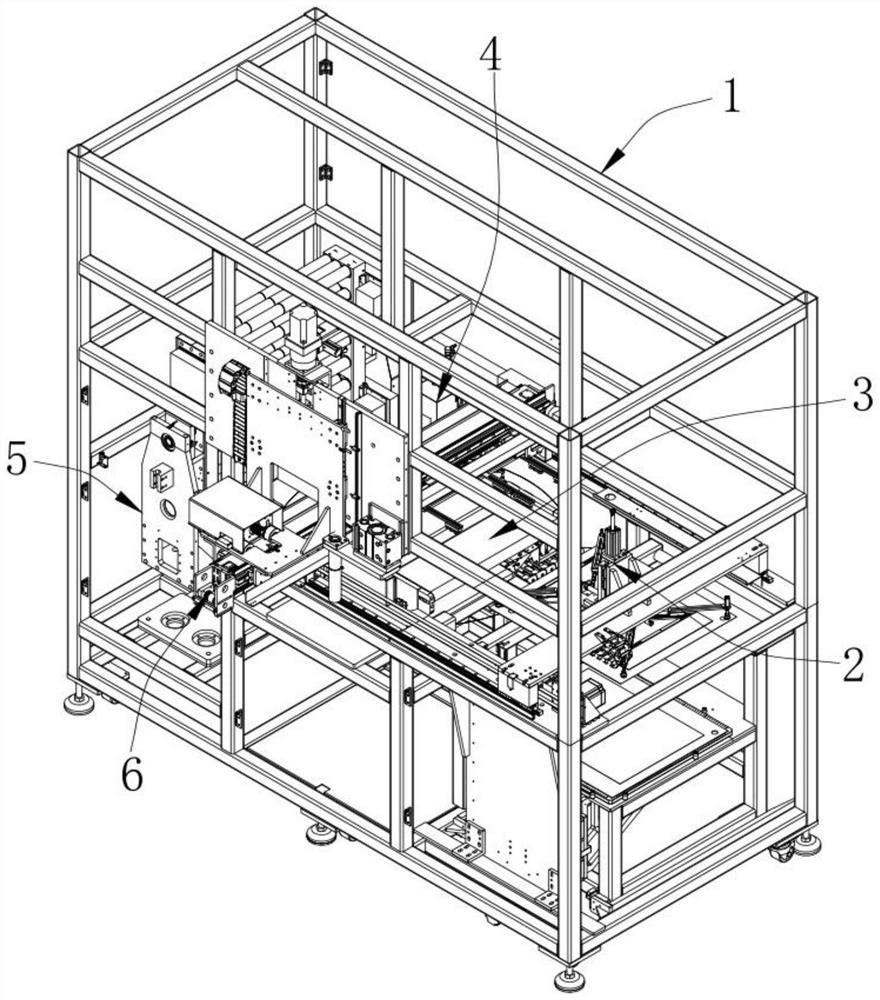

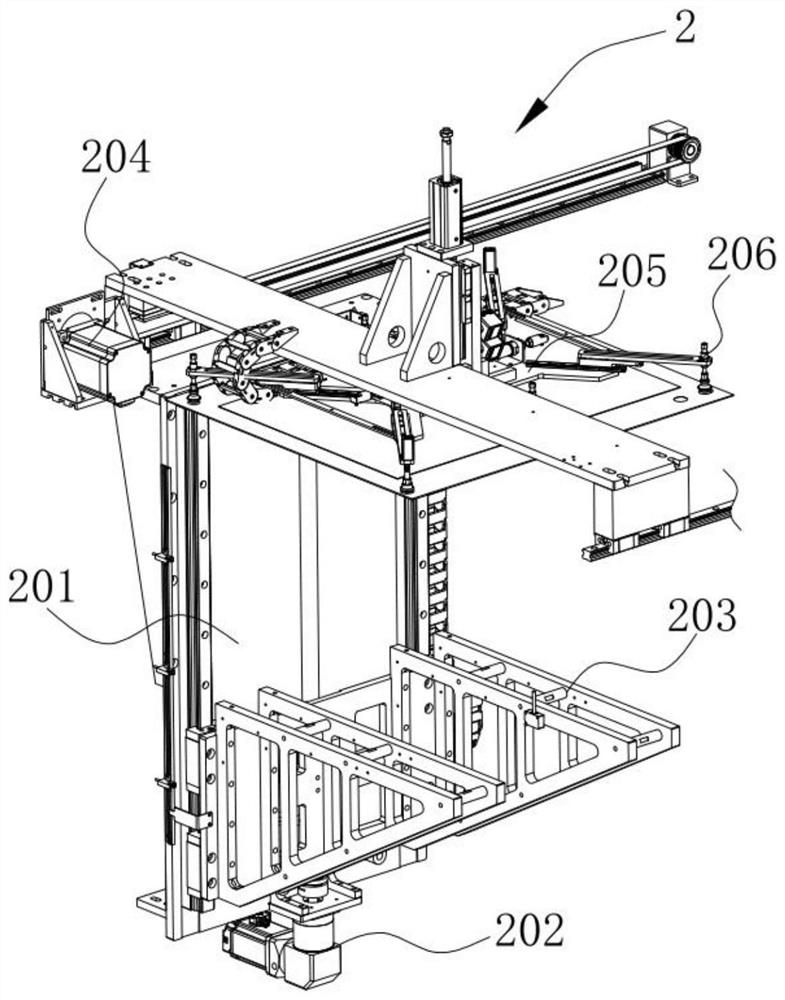

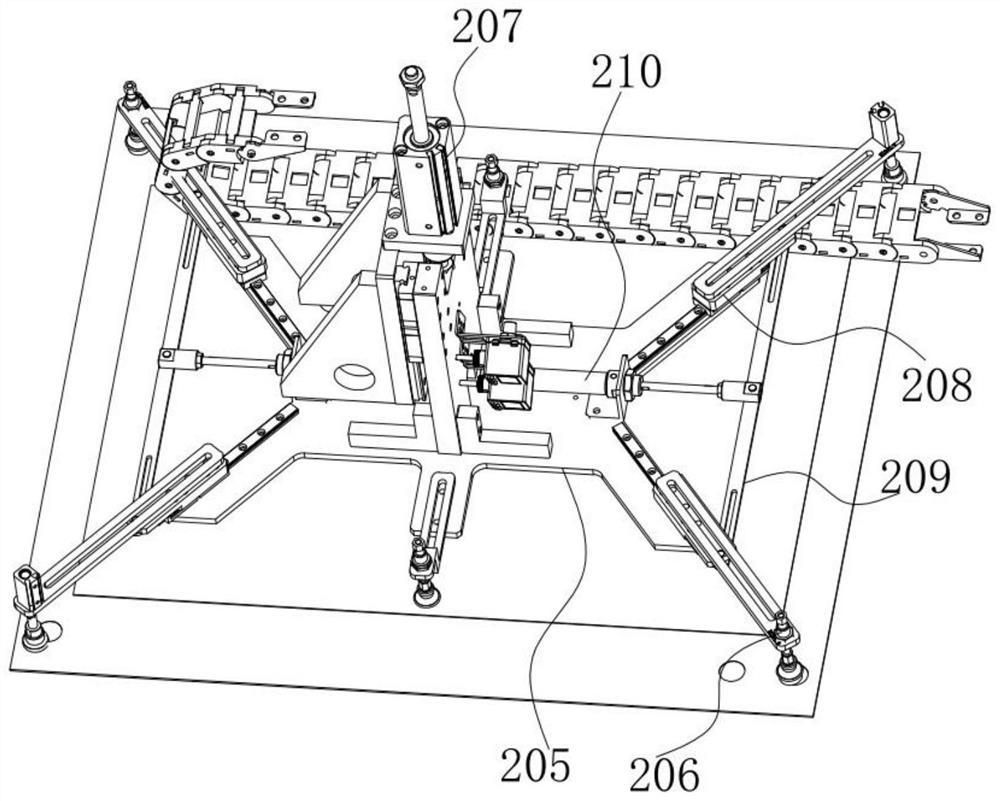

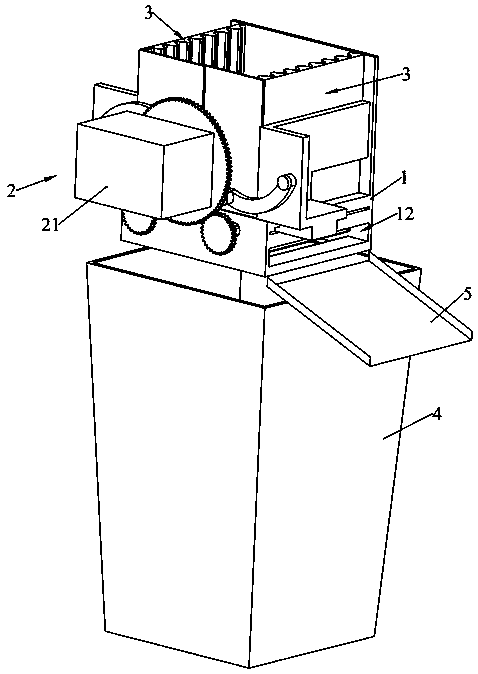

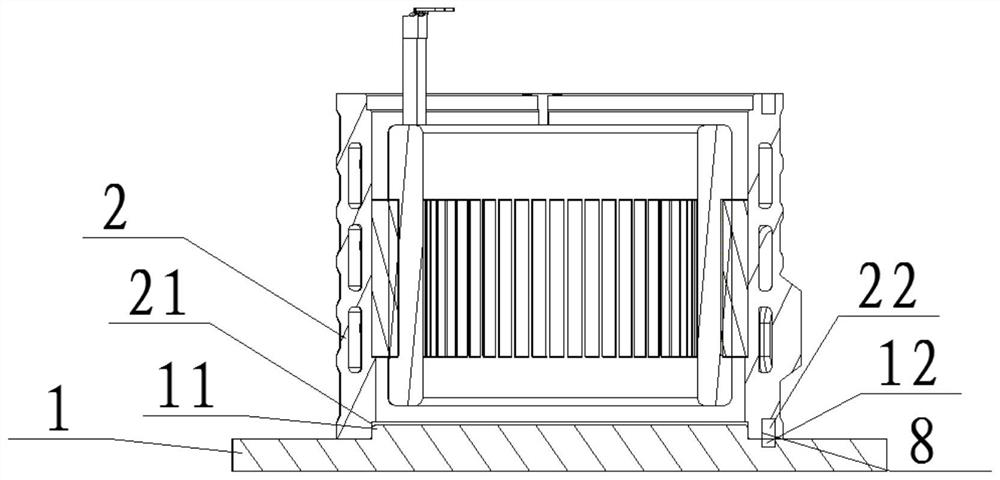

Palletizer

InactiveCN111453439AImprove stabilityRealize automatic palletizingConveyorsStacking articlesRobot handPalletizer

The invention discloses a palletizer. The palletizer comprises a rack; a master control unit; an arrangement mechanism arranged on the rack and used for placing and arranging boxes to be palletized; apalletizing mechanism arranged on the rack and used for palletizing the arranged boxes to be palletized; a paper separating bin arranged on the rack and used for placing and storing separating paperneeded for palletizing; the palletizing mechanism comprises a first mechanical hand, a second mechanical hand and a palletizing station; the palletizing station comprises a lifting platform; a first pallet is arranged on the lifting platform; the first mechanical hand is used for palletizing the arranged boxes to be palletized on the first pallet into a layer; the second mechanical hand takes outa piece of separating paper from the paper separating bin and puts the separating paper on the palletized layer; and the first mechanical hand and the second mechanical hand alternately work to palletize the boxes to be palletized to a stack. The palletizer provided by the invention realizes automatic palletizing of the boxes, reduces the labor cost, and further improves the palletizing efficiency.

Owner:深圳市安耐节科技有限公司

Pre-compaction type air spring system

ActiveCN108105324AWon't breakAvoid destructionSpringsSprings/dampers functional characteristicsElastomerAir spring

The invention discloses a pre-compaction type air spring system. The pre-compaction type air spring system comprises an upper cover plate, a gasbag, an upper end plate and a lower end plate, wherein the periphery of the upper cover plate is connected with the periphery of the upper end plate through the gasbag; a lower elastomer is connected between the upper end plate and the lower end plate; a pre-compaction plate is arranged on the top of the upper end plate; a higher ring-shaped elastomer is arranged between the pre-compaction plate and the upper end plate; and a first stop part which is positioned in the higher ring-shaped elastomer is arranged on the middle position of the pre-compaction plate. The air spring system has the advantages of being simple in structure, convenient to mount, low in gas-leakage heavy-load perpendicular rigidity and high in comfort and stability.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Corner pressing mechanism for corner connectors of aluminum profile frame

ActiveCN105583616ARealize automatic pressure angle functionSave human effortAssembly machinesEngineeringMechanical engineering

Owner:YINGKOU JINCHEN MACHINERY

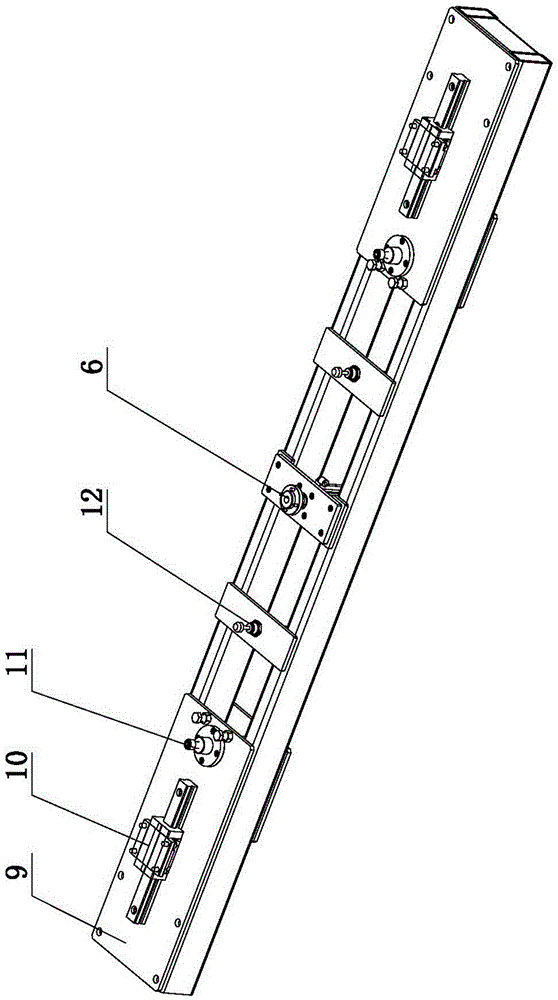

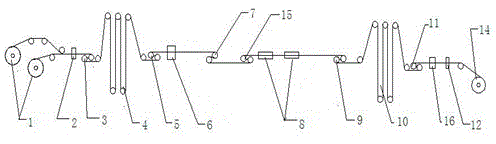

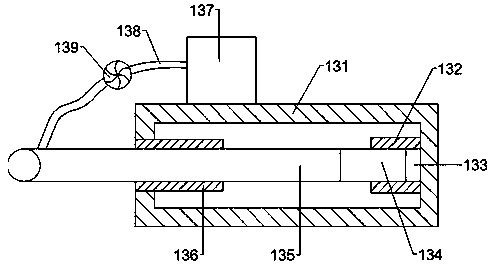

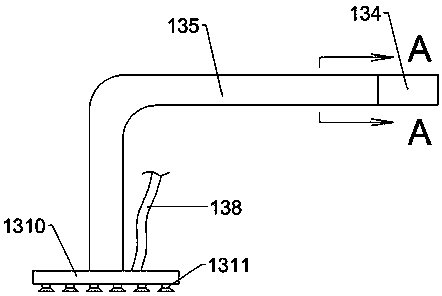

Production line for roller-coated color steel plate

InactiveCN102975019AGuaranteed uptimeGood molding effectOther manufacturing equipments/toolsRotary pressesProduction lineSurface roughness

The invention provides a production line for roller-coated color steel plates. Steel bands at all process sections are flattened through a plurality of tension rollers and stable and constant tension is particularly provided for a roller coating section. Moreover, since corona treatment is conducted to the surfaces of the steel bands before the steel bands enter the roller coating section to form a plurality of pits on the surfaces of the steel bands, the surface roughness of the steel bands is improved, the adhering force between the surfaces of the steel bands and color pattern layers is improved, the color pattern layers are not apt to peel off and the formability of the steel bands is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

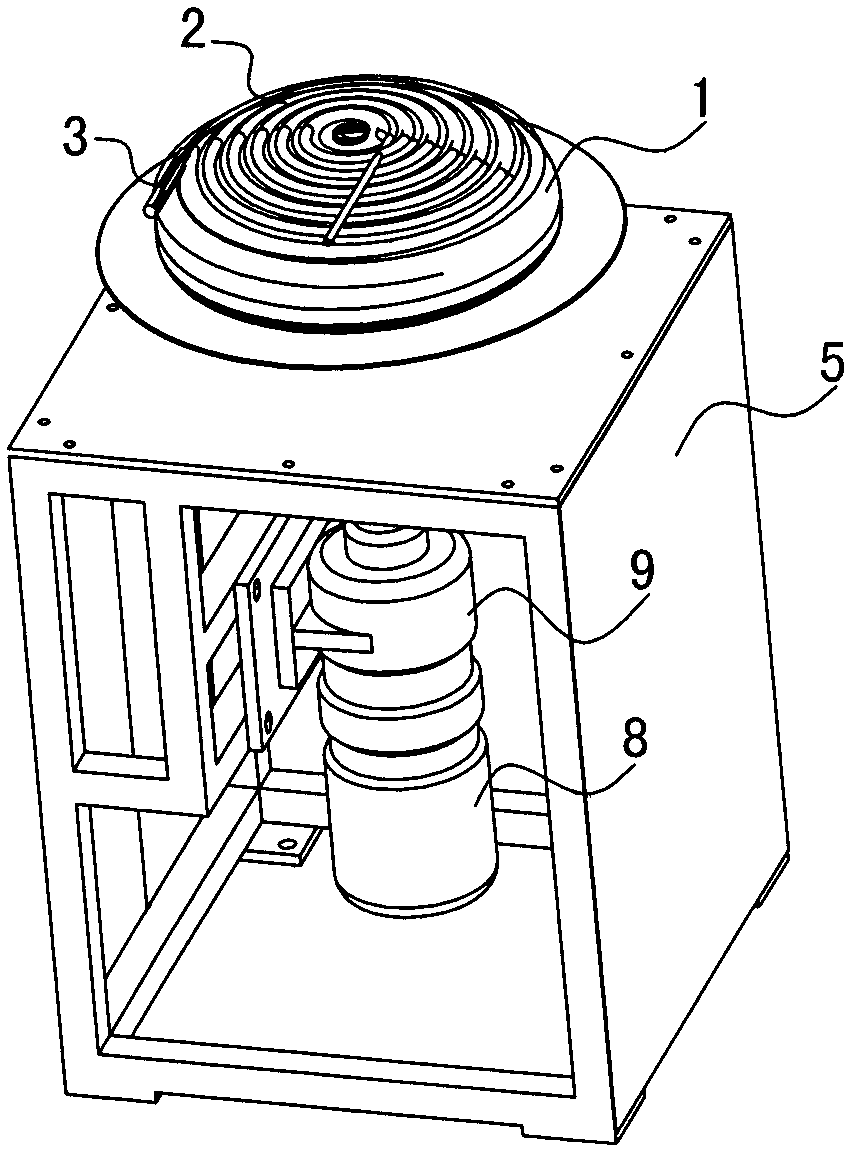

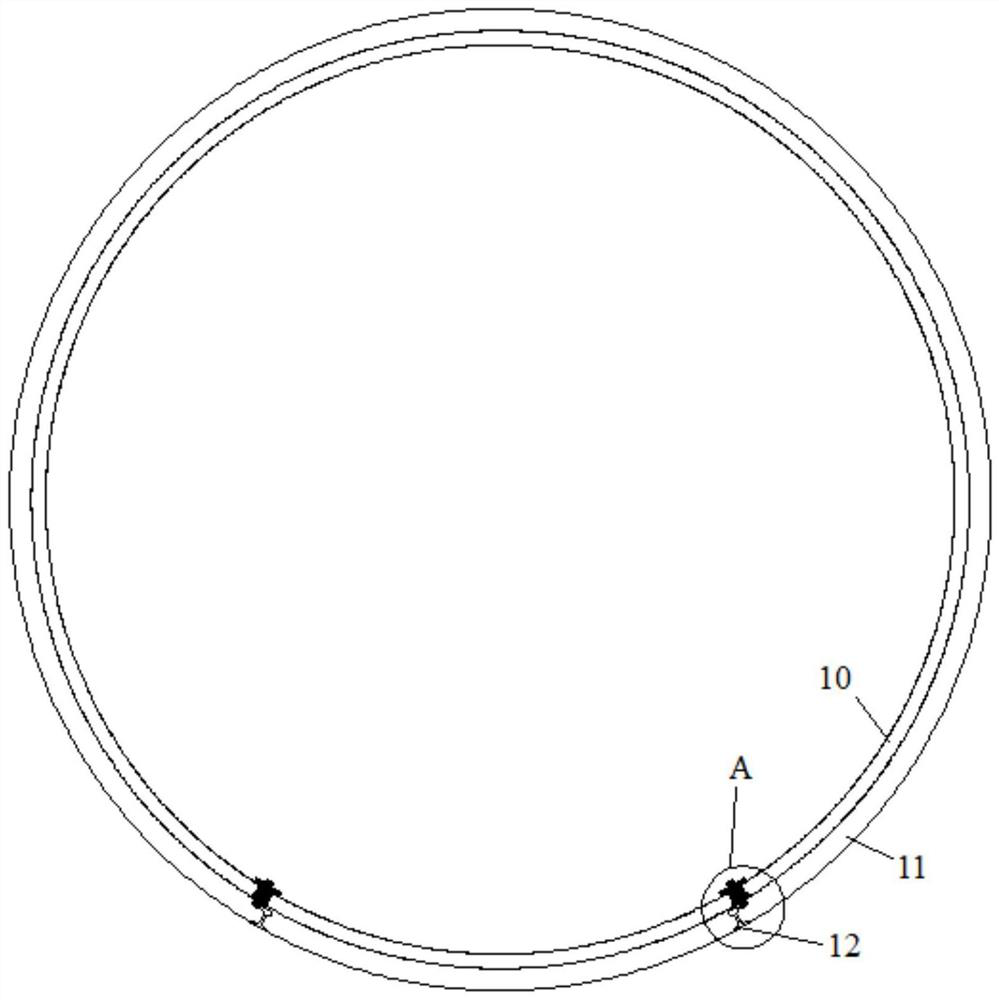

Die, device and method for forming heat exchange coil pipe

ActiveCN102463297AReduce manufacturing costReduce machining errorsShaping toolsSpiral coilElectrical and Electronics engineering

The invention discloses a die, a device and a method for forming a heat exchange coil pipe. The die comprises a die holder and a formed spiral coil pipe which is arranged on the die holder and is fixed with the die holder, wherein the middle part of the die holder is bulged upwards, and the height of the die holder at a position farther away from a central position is lower; and the formed spiral coil pipe is in a spiral shape, the center of the formed spiral coil pipe is positioned on the middle part of the die holder, and the formed spiral coil pipe forms a formed surface of the heat exchange coil pipe. The die comprises the die holder and the formed spiral coil pipe which is arranged on the die holder and is fixed with the die holder; the die holder is in a circular shape, the middle part of the die holder is bulged upwards, and the height of the die holder at a position farther away from the central position is lower;; and the formed spiral coil pipe is in a spiral shape, is adaptive with the outline of the die holder and forms the formed surface of the heat exchange coil pipe. According to the die, the manufacturing cost of the heat exchange coil pipe is lower, and the machining efficiency is higher.

Owner:GREE ELECTRIC APPLIANCES INC

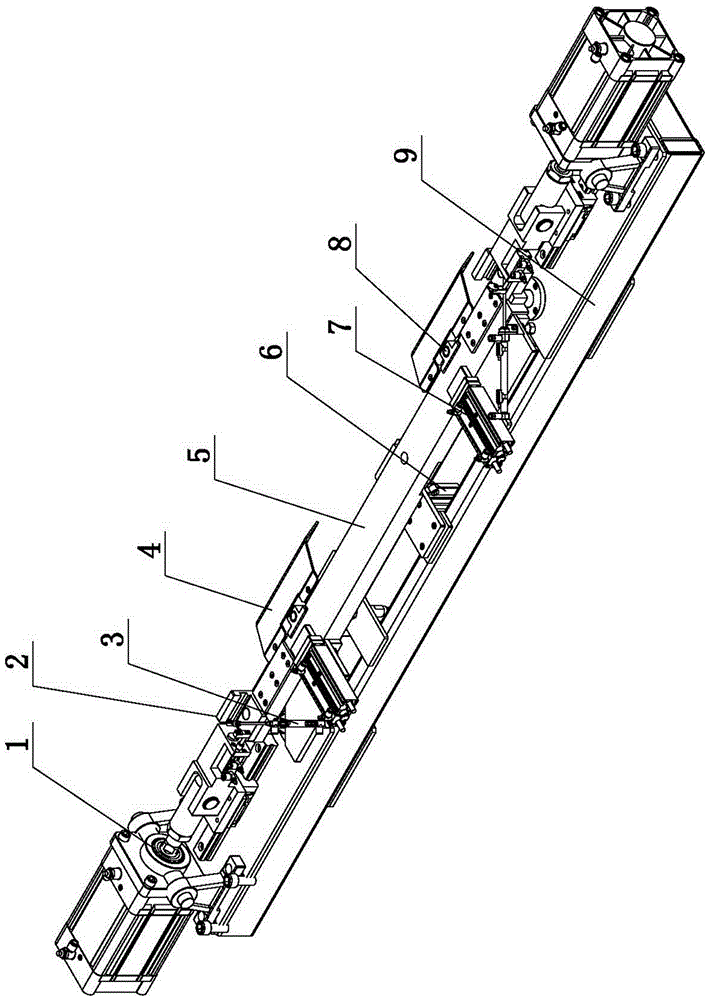

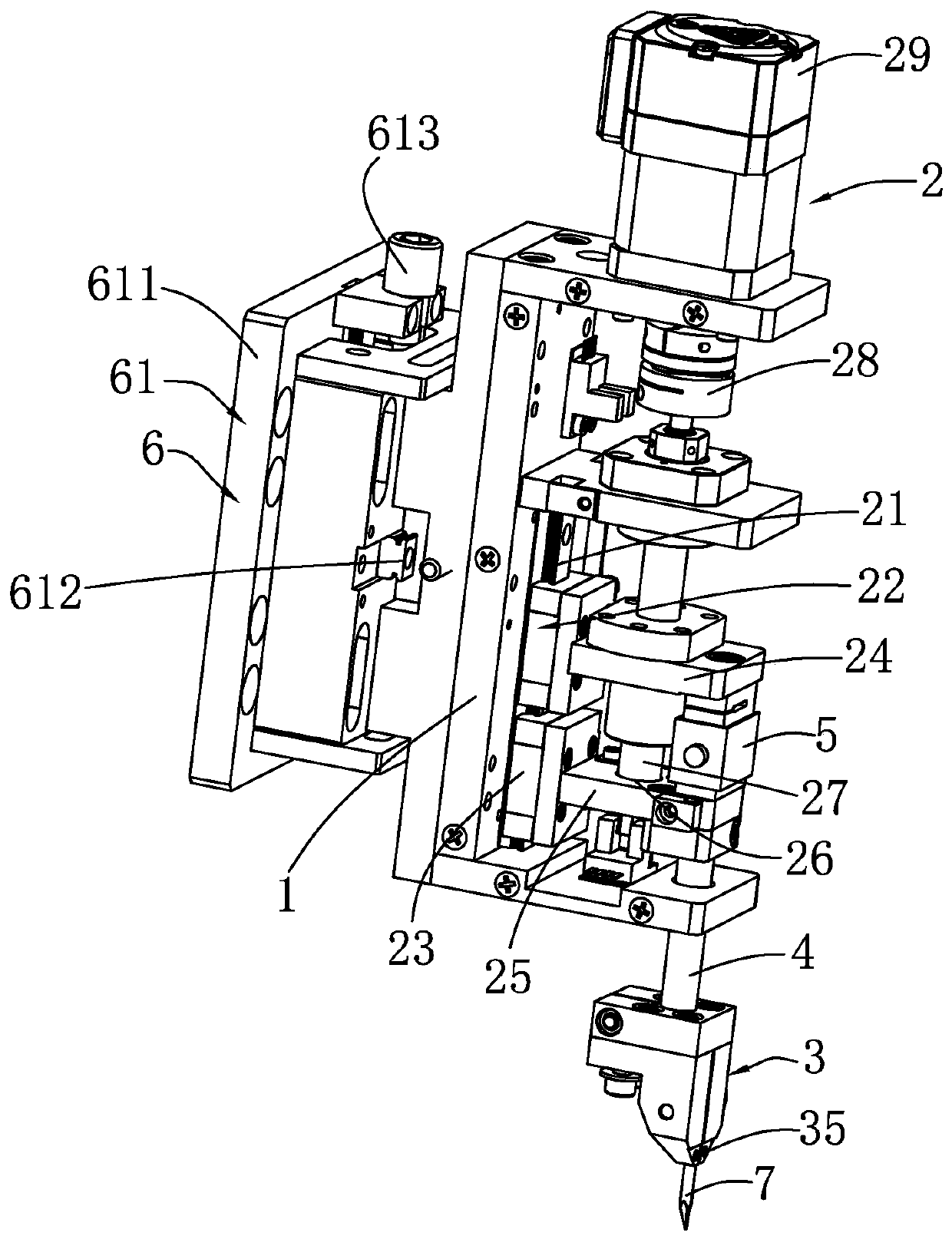

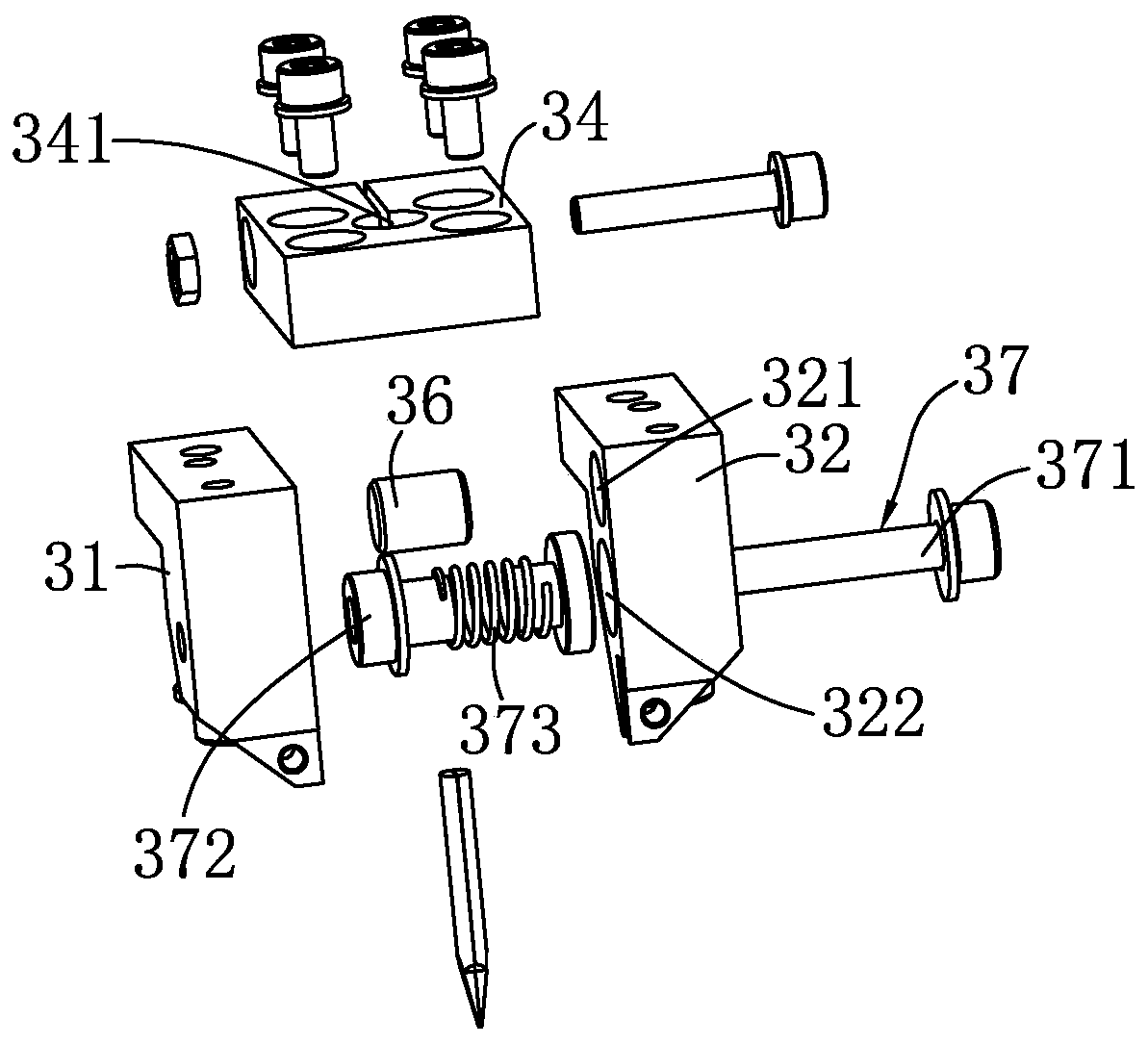

Precision pressure welding device adopting pressure sensor

InactiveCN111331238AControl pressureControl positionNon-electric welding apparatusStress sensorsPhysics

The invention relates to a precision pressure welding device adopting a pressure sensor. The precision pressure welding device comprises a vertical plate; a drive mechanism, a welding chuck and an adjustable mechanism, wherein the drive mechanism is erected on the vertical plate; the welding chuck can fix a round welding head and / or a sheet welding head, the upper part of the welding chuck is provided with a pressure transmission shaft, the pressure sensor is arranged above the pressure transmission shaft, the pressure sensor and the pressure transmission shaft are on a same axis, and the pressure sensor is linked with the drive mechanism to complete precision welding; the adjustable mechanism is detachably connected with the side of the vertical plate, the adjustable mechanism can be installed vertically or horizontally, and drives the vertical plate to move up, down, left and right so as to adjust a welding position. According to the invention, the pressure and the position of a welding head can be controlled accurately, the welding head is prevented from crushing a line on a fine workpiece effectively, the precision pressure welding device not only can meet the needs of multi-row multi-head welding, but also has good versatility; meanwhile, the welding chuck can be directly connected with an electrode cable and has a simple structure.

Owner:ZHONGSHAN VIHAN ELECTRONICS EQUIP

A gravure printing machine

InactiveCN102991097BExtended service lifeAvoid the defects of low labor efficiencyRotary intaglio printing pressPrinting press partsPhotogravurePrinting press

The invention provides a photogravure press, a coating roller of which is made of rubber to ensure that the coating roller is respectively in flexible contact with an absorbing roller and a to-be-printed steel plate, and thus the tightness of the contact is ensured, a pattern region on the absorbing roller can be completely transferred on the coating roller, and a pattern region on the coating roller also can be completely transferred to the to-be-printed steel plate, therefore a complete pattern region is formed. In addition, the photogravure press provided by the invention comprises a first scraper and a second scraper, wherein the first scraper is used for scraping a coating on the absorbing roller, except for a pit for forming an image region, the second scraper is used for removing residual coating on a rubber roller after transferring, therefore, the defects of lower labor efficiency and poor control precision caused by manual removal of the coating are avoided, and thus the labor productivity is increased and the product quality is ensured. In addition, the first scraper and the second scraper are respectively in contact with the absorbing roller and the coating roller by a specific angle, and thus a better scraping effect can be ensured.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Diesel engine beveled lip combustion chamber

InactiveCN106593621AReduced risk of crackingReduce generationInternal combustion piston enginesCombustion chamberDiesel engine

The invention discloses a diesel engine beveled lip combustion chamber which comprises a combustion chamber concave pit area, a lip area and a central boss area, wherein the diagonal line of the lip area and the top surface of a piston form a certain angle to eliminate a closed angle; the concave pit area is connected with the lip area and protrudes out of the external part of the combustion chamber; the central boss area is connected with the concave pit area and protrudes towards the internal part of the combustion chamber; and oblique planes on two sides of the central boss area form a certain angle to reduce invalid volume and increase compression ratio. According to the diesel engine beveled lip combustion chamber, through beveling the lip area, the crack risk of a piston is reduced, and reliability of the piston is improved.

Owner:CHINA FIRST AUTOMOBILE

Thread processing tool for non-standard outer-hexagonal bolt

InactiveCN108526618ALow manufacturing costReduce manufacturing costThread cutting machinesPositioning apparatusEngineeringThreaded rod

The invention discloses a thread processing tool for a non-standard outer-hexagonal bolt. The thread processing tool comprises a bottom plate; the bottom plate is provided with a base; a chute in a length direction is arranged at the middle part of the base; second rotation seats, which are provided with a bidirectional screw rod, are arranged at the two ends of the base respectively; two slidingseats in threaded connection are arranged at the upper end, in the chute of the base, of the bidirectional screw rod, are symmetrically arranged relative to the center of the bidirectional screw rod and are provided with clamping blocks respectively; a supporting plate is arranged at the middle part of the back end of the bottom plate; first rotation seats are arranged at the upper end and the lower end of the supporting plate respectively and are internally provided with a threaded rod; the threaded rod is provided with a supporting plate which is in threaded connection; a sliding rod is fixed at the middle part of the front end of the bottom plate; and the supporting plate is in sliding connection with the sliding rod. The thread processing tool provided by the invention adopts the clamping blocks with 120-degree openings by utilizing the characteristic of a regular hexagon at the head of a bolt, realizes clamping of outer-hexagonal bolts in different sizes, avoids troubles aiming toeach non-standard bolt manufacturing clamp and saves the tool manufacturing cost.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

Automatic feeding equipment of PCB (Printed Circuit Board) target drilling machine

PendingCN113998429AHigh degree of automationImprove work efficiencyConveyorsMaterial analysis by optical meansControl engineeringProcess engineering

The invention discloses automatic feeding equipment of a PCB target drilling machine. The automatic feeding equipment comprises a rack, a carrying mechanism, a rotary alignment platform, an identification detection device, a turnover mechanism and a feeding mechanism, wherein the carrying mechanism, the rotary alignment platform, the identification detection device, the turnover mechanism and the feeding mechanism are installed on the rack. The carrying mechanism is used for conveying a material plate to the rotary alignment platform, the mark detection device recognizes marks in the material plate, and the rotary alignment platform can drive the material plate to rotate according to the recognition result to conduct direction adjustment. The turnover mechanism is used for receiving the material plate conveyed by the rotary alignment platform and can drive the material plate in the turnover mechanism to turn over and then convey the material plate back to the rotary alignment platform; the feeding mechanism is arranged above the rotary alignment platform and used for grabbing the accurately-aligned material plates from the rotary alignment platform and conveying the material plates into the target drilling machine. The automatic feeding equipment of the PCB target drilling machine can realize full-process automatic operation of plate feeding, is high in automation degree, greatly improves the working efficiency, and is low in cost and wide in application range.

Owner:KUSN ZHENGYE ELECTRONICS

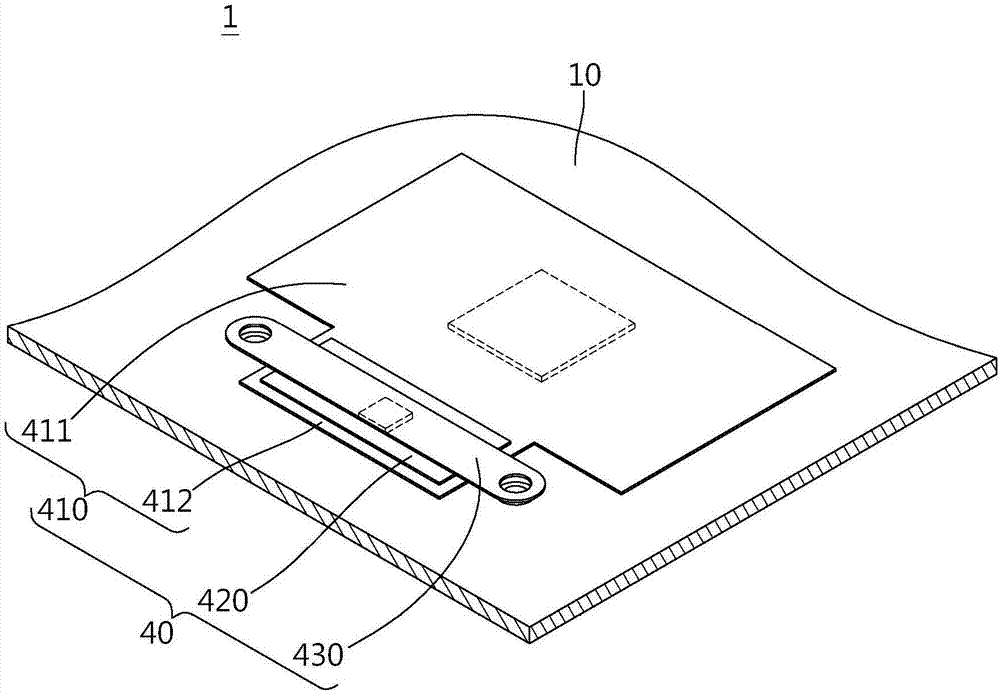

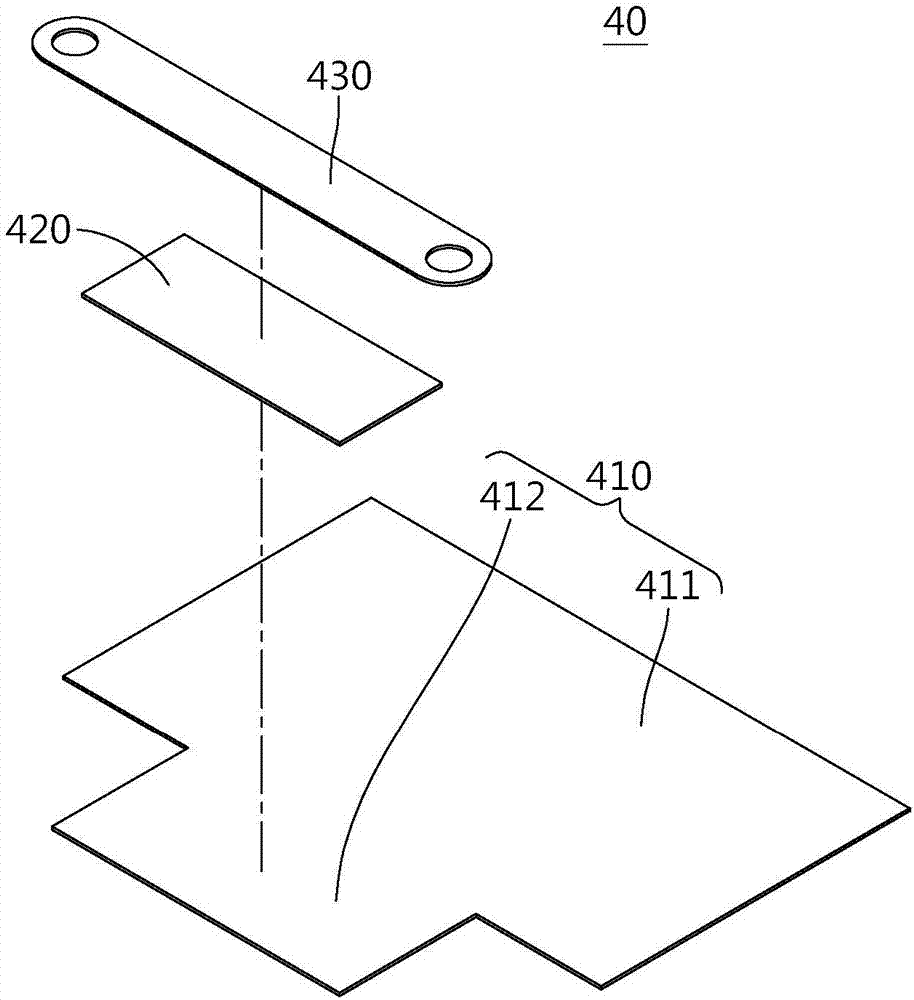

Noise suppression component and motherboard with noise suppression component

ActiveCN107300956AImprove shielding effectWill not interferePrinted circuit groundingMagnetic/electric field screeningEngineeringNoise suppression

The invention discloses a motherboard, which contains a circuit board, a processor, an oscillator and a noise suppression component. The circuit board contains a grounding section. The processor and oscillator are arranged on the circuit board. The noise suppression component contains a wave absorbing sheet, a shielding sheet and an electric conduction piece. The wave absorbing sheet contains a processor covering section and an oscillator covering section. The oscillator covering section protrudes from one side of the processor covering section. The processor covering section and the oscillator covering section respectively cover the processor and the oscillator. The shielding sheet is arranged at the oscillator covering section, and covers the oscillator. One end of the electric conduction piece is in electrical contact with the shielding sheet, and another end of thereof is in electrical contact with the grounding section of the circuit board.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

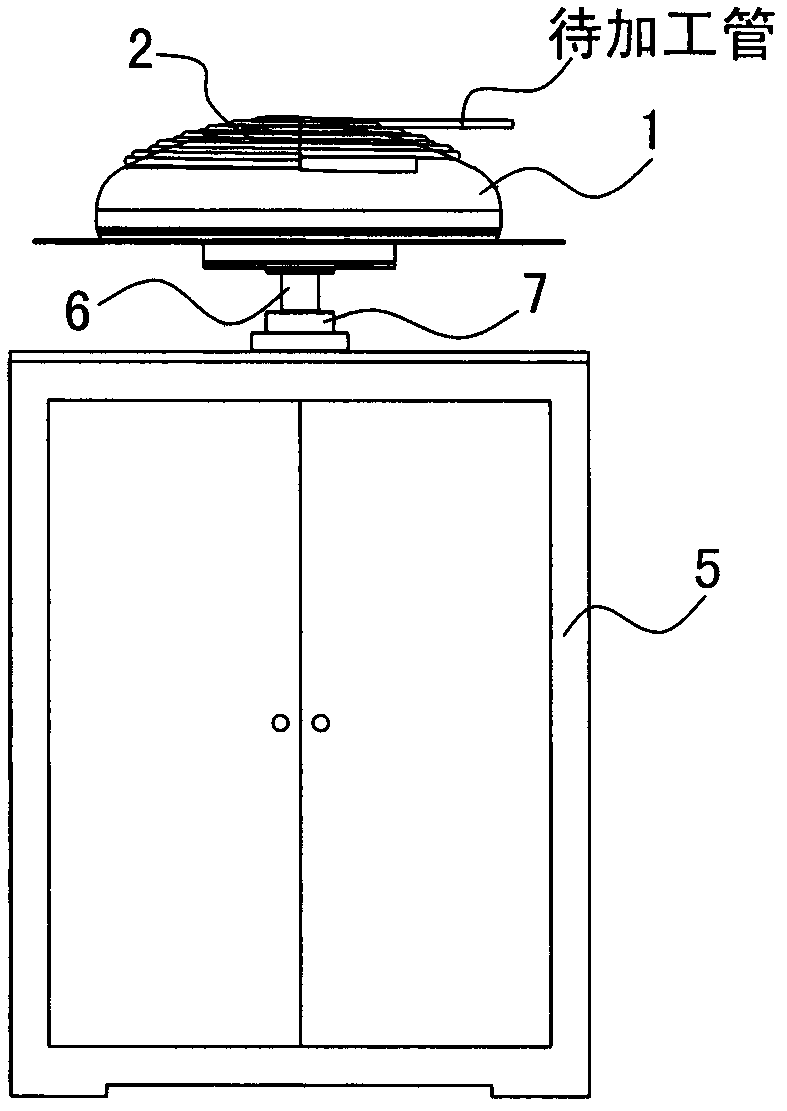

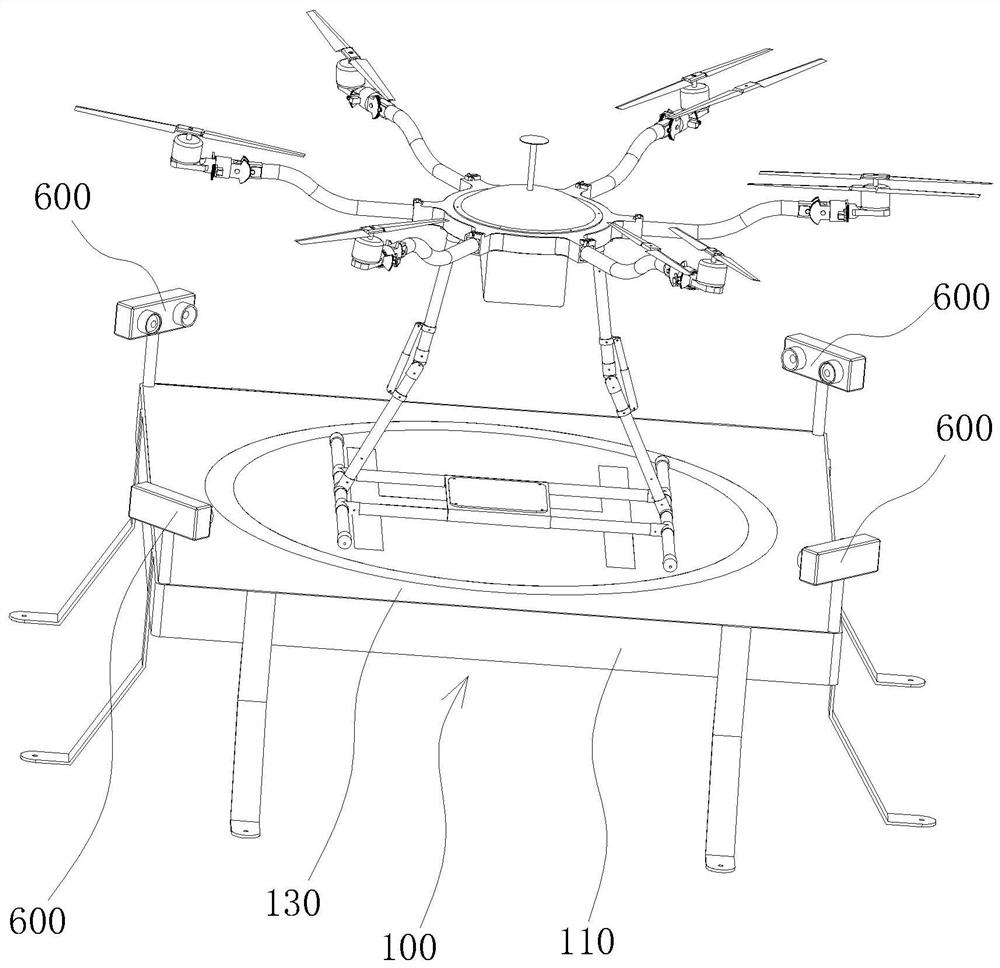

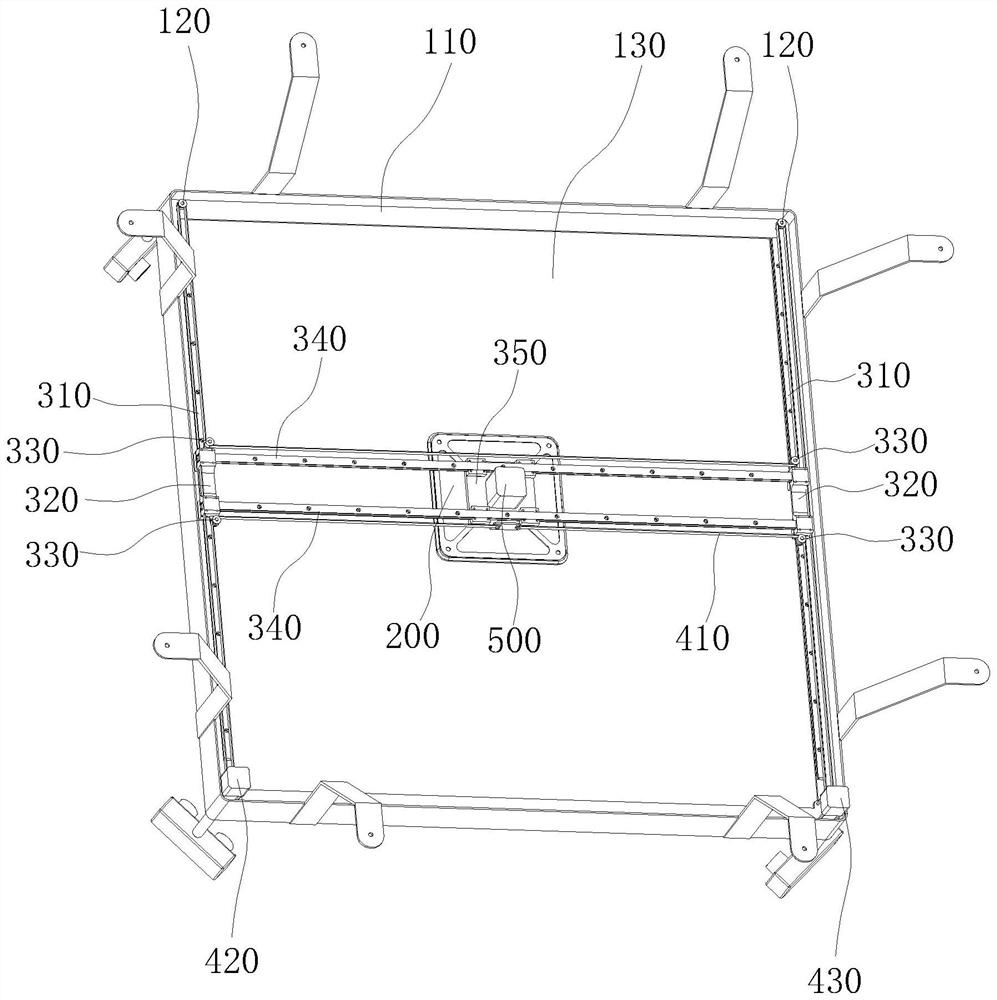

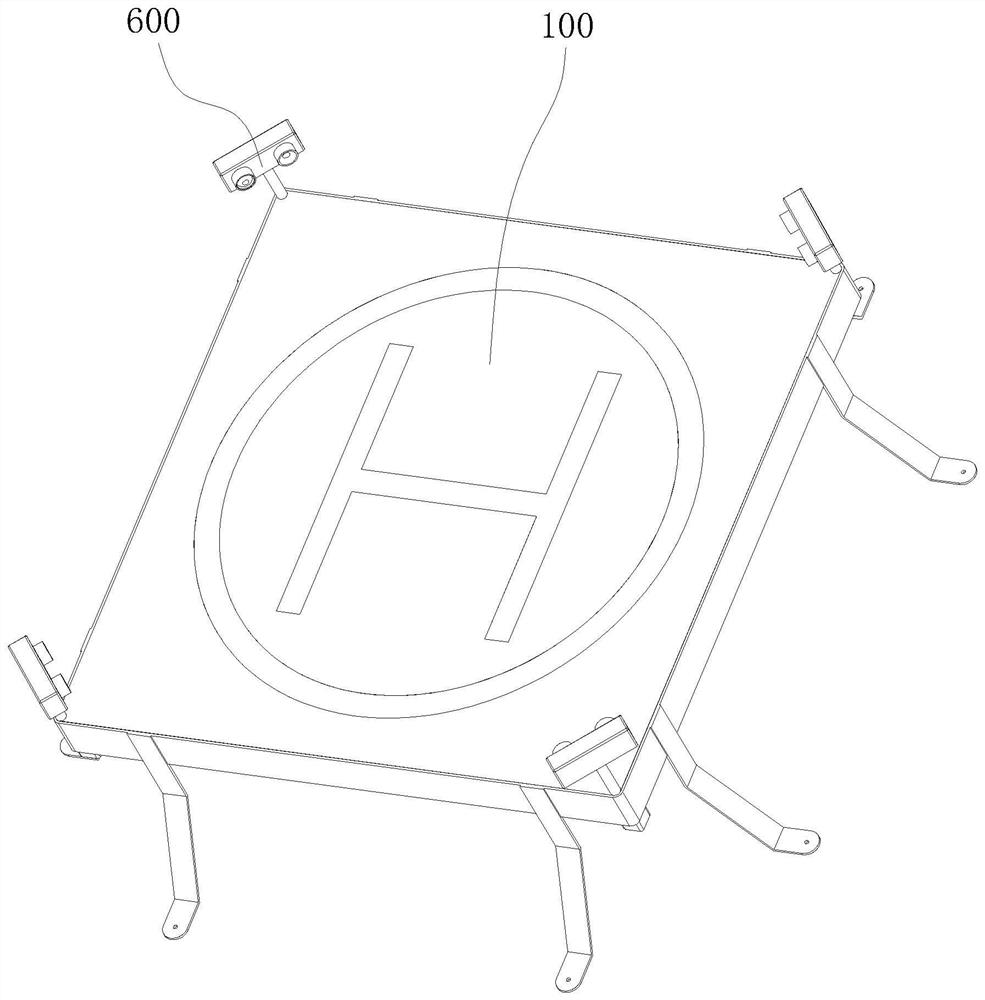

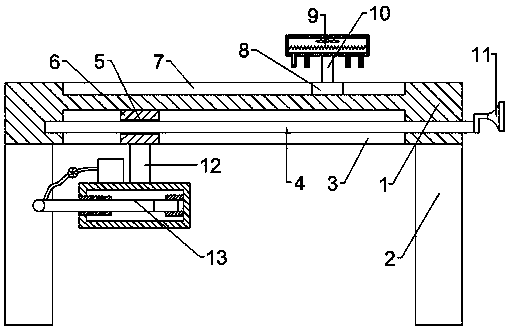

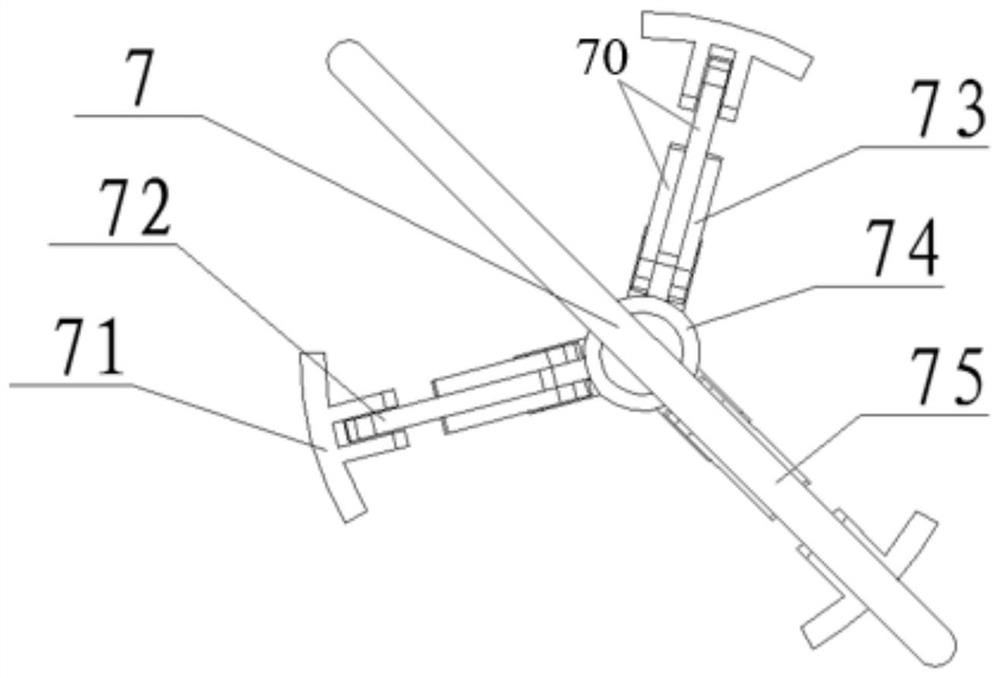

Unmanned aerial vehicle wireless charging parking apron

ActiveCN112977862AReduce distanceImprove efficiencyCharging stationsCircuit arrangementsTransmitter coilUncrewed vehicle

The invention provides an unmanned aerial vehicle wireless charging parking apron, and belongs to the technical field of wireless charging, and the unmanned aerial vehicle wireless charging parking apron comprises a take-off and landing platform which is used for taking off and landing of the unmanned aerial vehicle; a camera assembly which is used for being aligned with the take-off and landing platform; a moving assembly which is movably connected with the take-off and landing platform; a rotating assembly which is connected with the moving assembly, wherein the moving assembly can drive the rotating assembly to move; and a transmitting coil which is connected with the rotating assembly, wherein the rotating assembly can drive the transmitting coil to rotate. The unmanned aerial vehicle wireless charging parking apron has the beneficial effects that the wireless charging parking apron can charge the unmanned aerial vehicle, and the position and angle of the transmitting coil can be automatically adjusted according to the attitude of the unmanned aerial vehicle after landing and the landing position, so that the distance between the transmitting coil and the receiving coil of the unmanned aerial vehicle is reduced, and the system efficiency of wireless charging of the unmanned aerial vehicle is ensured.

Owner:宁波道充科技有限公司

Liver disease examination device with blood coagulation function

InactiveCN108743174AIncrease the speed of solidificationWill not interfereOperating tablesPediatricsBlood coagulations

The invention discloses a liver disease examination device with a blood coagulation function. The liver disease examination device comprises a bed board, wherein four supporting legs are fixedly connected to the lower side of the bed board; a groove with a downward opening is formed at the lower side of the bed board; a moving block is arranged in the groove; a horizontally arranged threaded through hole is formed in the moving block; a threaded rod is connected in the threaded through hole through threads, and is erected on both side walls of the groove; a disinfection device is fixedly connected to the lower side of the moving block through a connecting block; and the upper side of the bed plate is provided with a sliding groove with an upward opening, and a sliding block is arranged inthe sliding groove. The liver disease examination device provided by the invention has the beneficial effects that in order to accelerate the blood coagulation speed, a heating resistance wire is energized, heat is generated after the heating resistance wire is energized, then a fan is started, the generated heat is blown into a cavity by the fan, and a pricking pin is placed below two air outlets, so that the heat ejected from the two air outlets is concentrated to one place, thus effectively accelerating the blood coagulation speed.

Owner:RIZHAO HOSPITAL OF TCM

Switch middle plate stamping continuous die

InactiveCN111842644AAvoid getting involvedWill not interfereShaping toolsStructural engineeringMachining

The invention discloses a switch middle plate stamping continuous die. The switch middle plate stamping continuous die comprises an upper die and a lower die. A feed way and a discharge port are formed between the upper die and the lower die. Multiple machining stations sequentially arranged from the feed way to the discharge port are arranged between the upper die and the lower die. The width ofthe feed way and the width of a middle plate are equal. The machining station connected with the feed way is the first station. The first station comprises a male die and a female die. A die cavity isformed between the male die and the female die. A first material way communicating with the die cavity is formed between the male die and the female die. A cutter for cutting a material strip into ablock body is arranged at the position, above the feed way, of the upper die. An abutting knife for cutting the local contour of the periphery of the block body out is arranged on the side, opposite to the cutter, of the first station, of the upper die, and the abutting knife cooperates with the cutter to be used for cutting the overall periphery contour of the middle plate out on the block body.The switch middle plate stamping continuous die has the following beneficial effects that the utilization rate of the material strip is increased, the production cost of products is reduced, the die is smaller in overall size, better in rigidity and longer in service life, and a punch is more convenient to disassemble and assemble.

Owner:温州创睿五金模具有限公司

Perishable garbage dewatering machine

PendingCN111174538AEasy to handleReduce volumeDrying solid materials without heatGarbage dryingWater filterProcess engineering

The invention belongs to the technical field of garbage disposal equipment, and provides a perishable garbage dewatering machine. The perishable garbage dewatering machine comprises a rack, a drive mechanism and two extrusion assemblies oppositely arranged on the rack. Object space used for containing garbage is formed between the two extrusion assemblies. Each extrusion assembly comprises a sliding block, an extrusion plate and a movable water filter plate, the sliding blocks are in sliding connection to the rack, and the sliding blocks are connected with the drive mechanism. The sliding blocks of the two extrusion assemblies can be driven by the drive mechanism to move oppositely or move by deviating from each other. The extrusion plates are connected to the inner side faces of the sliding blocks. The movable water filter plates are rotationally connected to the sliding blocks and are located below the extrusion plates. The movable water filter plates are connected with the drive mechanism and can be driven by the drive mechanism to swing. By means of the perishable garbage dewatering machine, part of water in perishable garbage can be removed, garbage sizes can be compressed, the condition that garbage is rotten and smells in the disposal treatment is relieved, and effective disposal to garbage is facilitated.

Owner:HUZHOU TEACHERS COLLEGE

Aluminum profile frame corner code pressure angle mechanism

ActiveCN105583616BRealize automatic pressure angle functionSave human effortAssembly machinesMechanical engineeringEngineering

Owner:YINGKOU JINCHEN MACHINERY

The construction method used for the anti-rotation at the start of the shield machine

The invention discloses a starting anti-rotation device for a shield machine and a construction method thereof. A pair of rails are arranged at intervals in the lower part of the steel sleeve, which includes the following steps: Step 1. A pair of inner and outer through holes are arranged symmetrically on the shield body. jacks, and the distance between a pair of jacks is set so that they can be located on both sides of a pair of rails; Step 2, seal and fix the sleeve in the jack, and set threads on the inner wall of the sleeve; Step 3, A pair of screw rods are threadedly connected in a pair of sockets respectively, and can extend or retract into the outer wall of the shield. The invention has the advantages of simple structure, convenient use, good sealing effect and the like.

Owner:CCCC SECOND HARBOR ENG

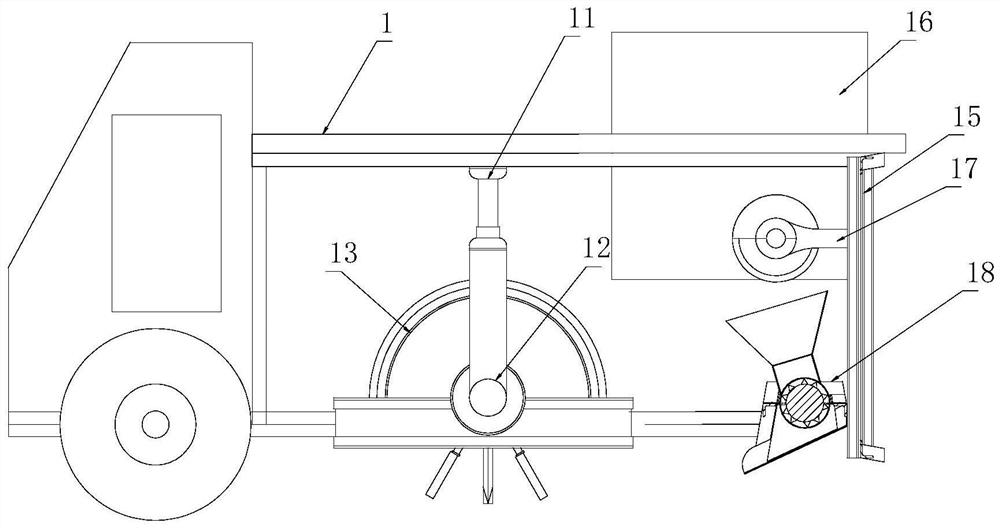

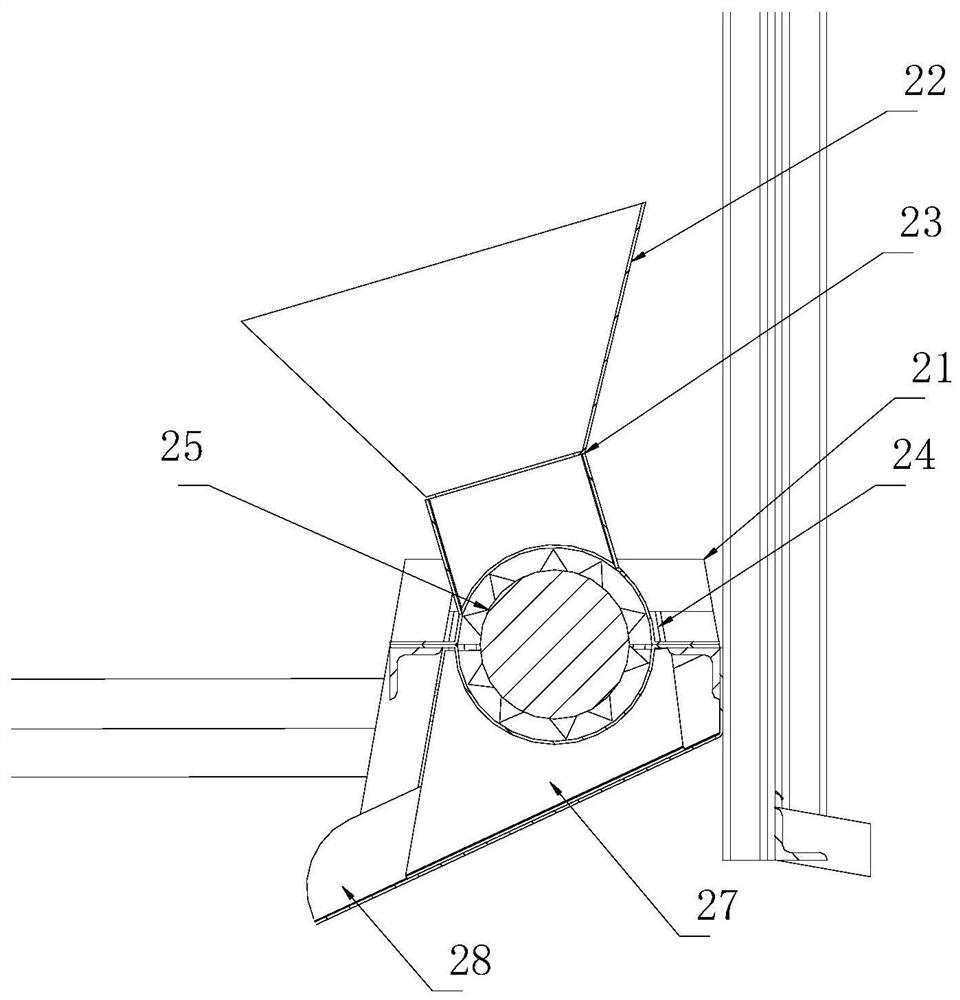

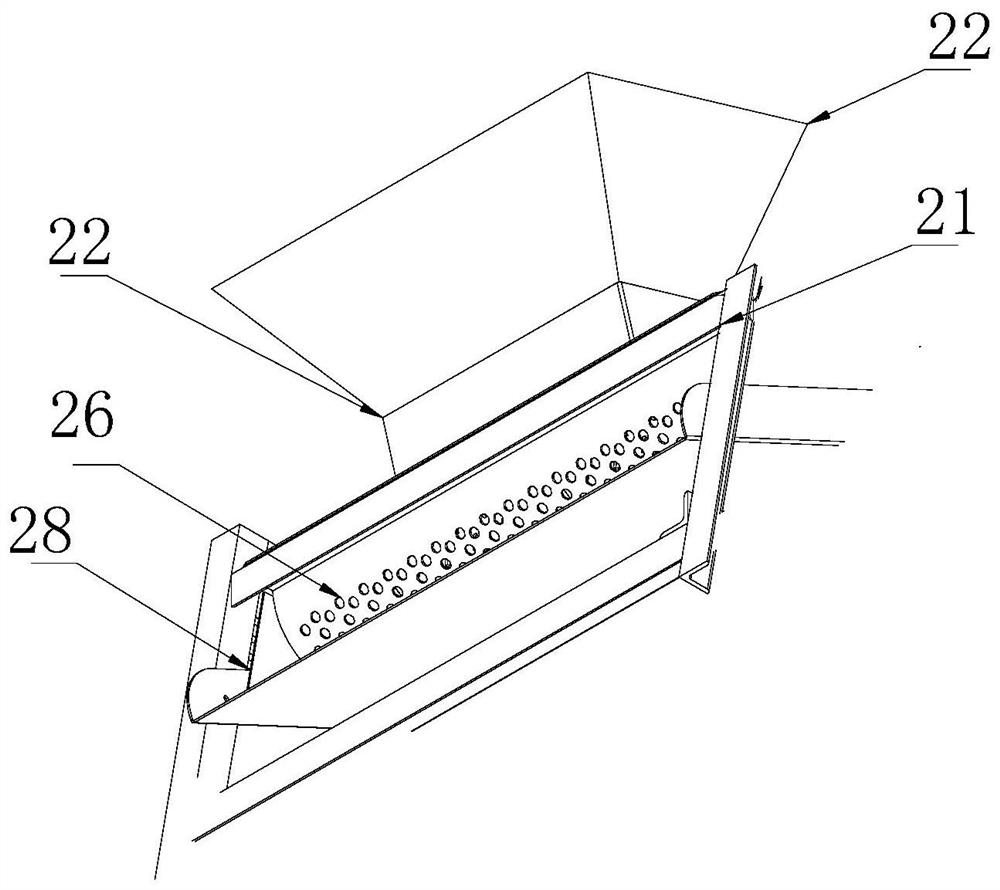

Agricultural equipment for agricultural soil improvement

InactiveCN112166711AEasy to moveEasy to applySpadesAgricultural machinesAgricultural scienceAgricultural engineering

The invention relates to the technical field of agriculture, in particular to agricultural equipment for agricultural soil improvement. The agricultural equipment comprises a frame; the bottom end ofthe frame is provided with a support main frame; two sides of the support main frame are each provided with an outer fixing frame; a soil turning frame is arranged in the middle of the outer fixing frames at the left side and the right side; the rear side of the frame is provided with a material conveying frame; the top part of the material conveying frame is provided with a material box; a discharging end of the bottom part of the material box is provided with a discharging frame; a processing rack is installed right below the discharging frame; a main body of the processing rack is a mounting frame; the mounting frame is provided with a material receiving bin; the top part of the material receiving bin is provided with a material receiving hopper; a crushing cylinder is installed in thematerial receiving bin; an inner cavity of the crushing cylinder is provided with a crushing roller; the bottom part of the crushing cylinder is provided with a material applying cavity; a plurality of filtering holes are formed in the position of the discharging end of the crushing cylinder; and the discharging frame is provided with a discharging transfer cylinder. The whole agricultural equipment facilitates application of the solid soil improvement agent, and the distribution uniformity of the solid soil improvement agent is also improved.

Owner:李翠兰

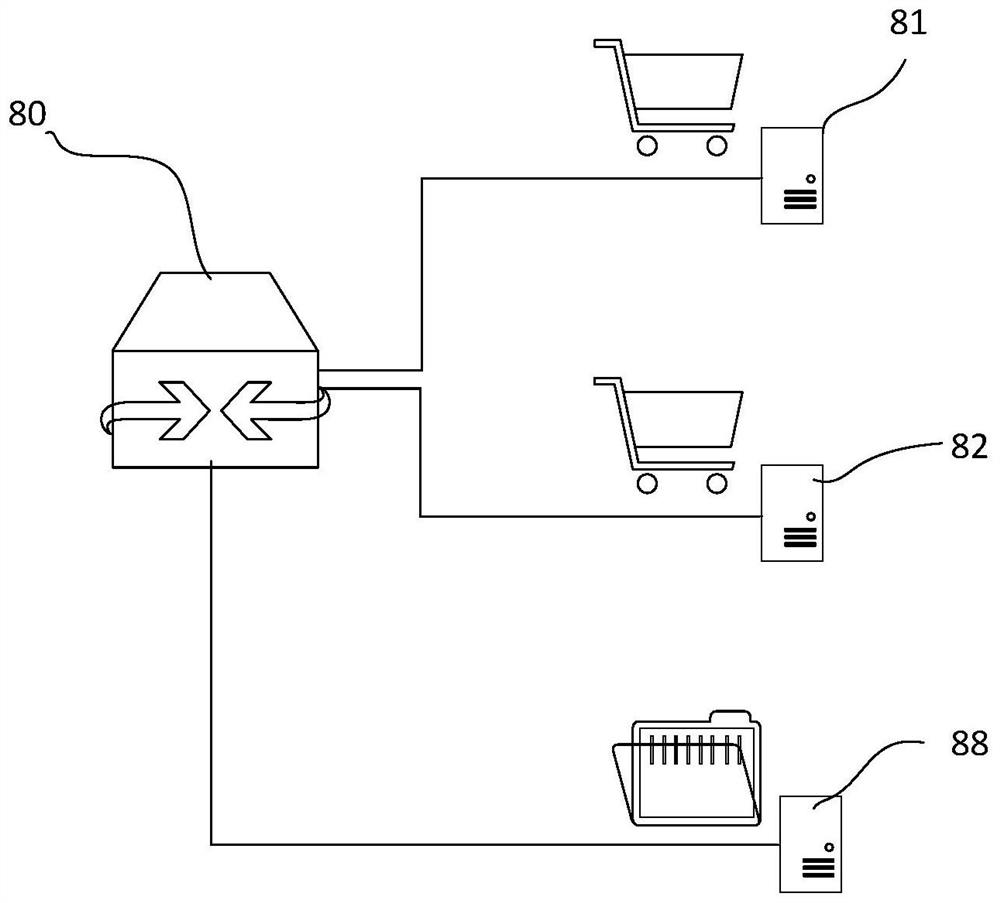

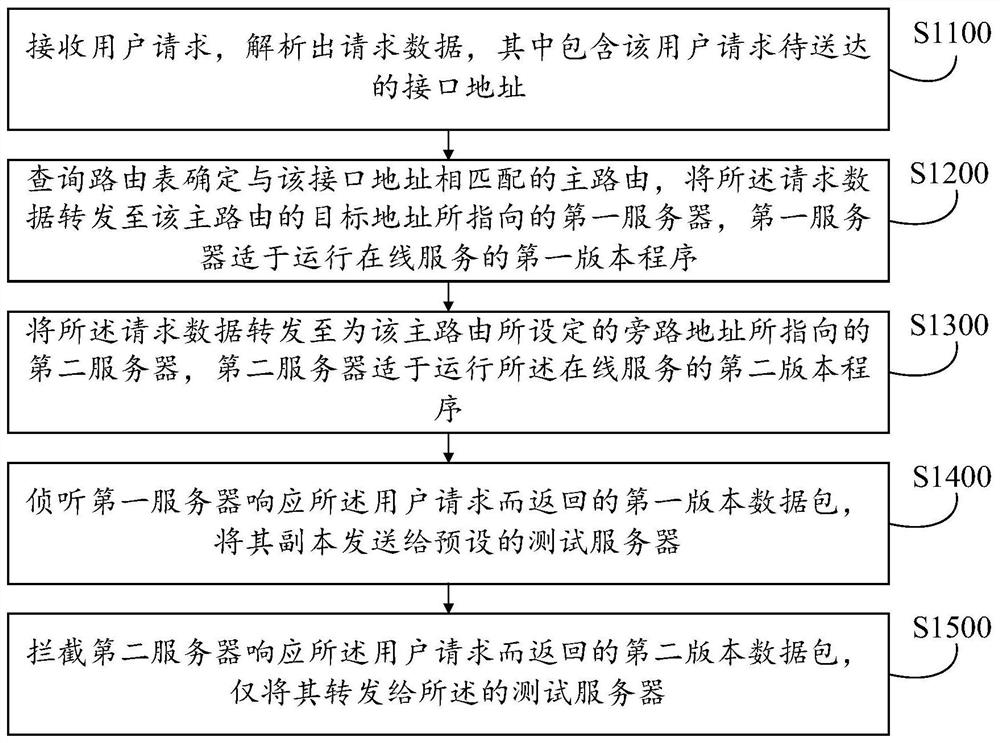

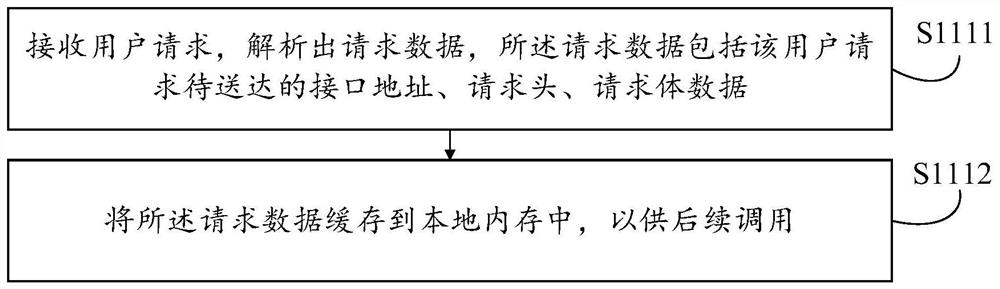

Data routing control method and device, data analysis processing method and device, equipment and medium

PendingCN113489788AWill not interfereMeet the real and valid requirementsSoftware testing/debuggingData switching networksData packRouting table

The invention discloses a data routing control method and device, a data analysis processing method and device, equipment and a medium, and the data routing control method comprises the steps: receiving a user request, and analyzing an interface address in request data; inquiring a routing table to determine a main route matched with the interface address, forwarding the request data to a first server pointed by a target address of the main route and also to a second server pointed by a bypass address set for the main route, and enabling the first server and the second server to respectively run different version programs of the same online service; monitoring a first version data packet returned after the first server responds, and sending a copy of the first version data packet to a preset test server; and intercepting a second version data packet returned after the second server responds, and only forwarding the second version data packet to the test server. According to the application, the same user request based on the real application demand is asynchronously forwarded to the server where the two version programs of the same online service are located, so that a software comparison test scheme is more effective.

Owner:GUANGZHOU HUADUO NETWORK TECH

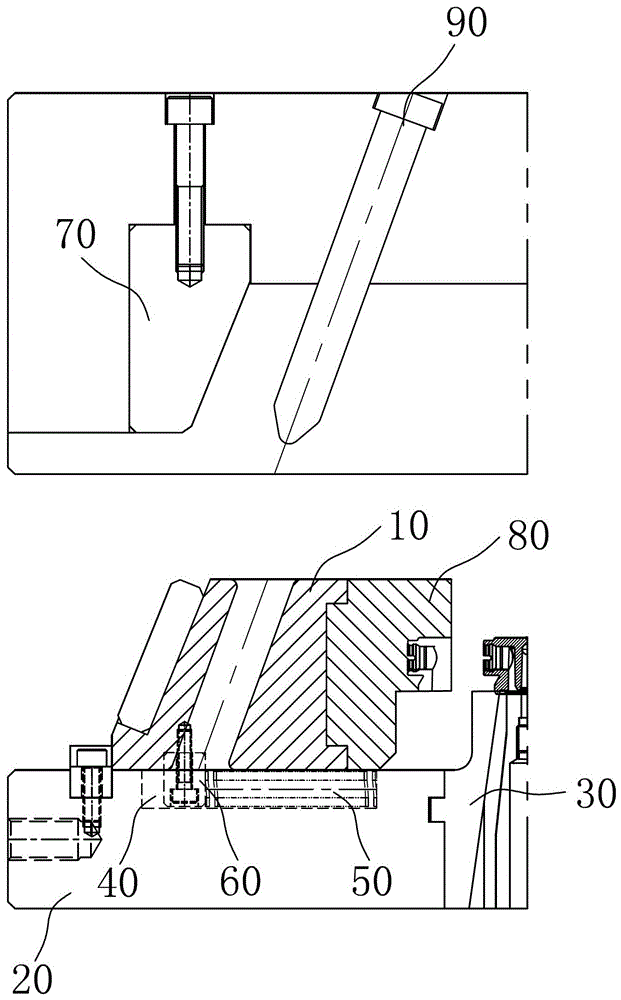

Spring structure of mold slider

The invention discloses a spring structure of a die slider, wherein a die is provided with the slider, a template arranged under the slider, and a die cavity formed in the template; and the spring structure comprises a sliding groove formed in the template, a spring arranged in the sliding groove and a stop block fixed at the bottom of the slider, the side of the sliding groove toward the slider is open; one end of the spring is propped against one end of the sliding groove in the vicinity of the die cavity; and one side of the stop block is propped against one end of the spring far away from the die cavity. The spring structure of the die slider provided by the invention is characterized in that the size of the slider does not need to be increased because the spring is arranged in the sliding groove of the template; therefore, the thickness of the die cavity and the template does not need to be increased, and the cost of the die is saved; the position of the sliding groove on the template is flexible and not limited, so that the mounting position of the spring is quite flexible; and as the spring is arranged on the bottom of the slider, interferences with an inclined guide column and a water route cannot be caused.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

A dismantling device for separating motor stator from water channel and using method thereof

ActiveCN109088519BEasy to operateEasy to fixManufacturing dynamo-electric machinesInterference fitMarine engineering

A disassembly device for separating a stator from a waterway of a motor. A motor stator is arranged in a motor waterway, and an interference fit is formed between the motor stator and the motor waterway, the disassembly device comprises a bottom plate, a guiding pillar, a pressing plate and a puller, the bottom plate is fixedly connected to the bottom of the motor waterway, the pressing plate is arranged at the top end of the motor waterway, the guiding pillar passes through a mounting hole I arranged in the bottom plate and the mounting hole II arranged in the pressing plate in turn to connect the bottom plate and the pressing plate to the motor waterway, a locking nut is matched with the thread on the guiding pillar for locking, and the pressing plate is in contact with the top end of the motor waterway to fix the motor waterway; then the puller is connected to the inner wall of the motor stator. The motor waterway and stator assembly is heated at high temperature during disassembling, and people can pull the motor stator upward out of the motor waterway at high temperature through a hand-pulling ring on the puller, so as to manually separate the motor waterway from the motor stator. The invention also discloses a method of using the disassembly device.

Owner:安徽鸿创新能源动力有限公司

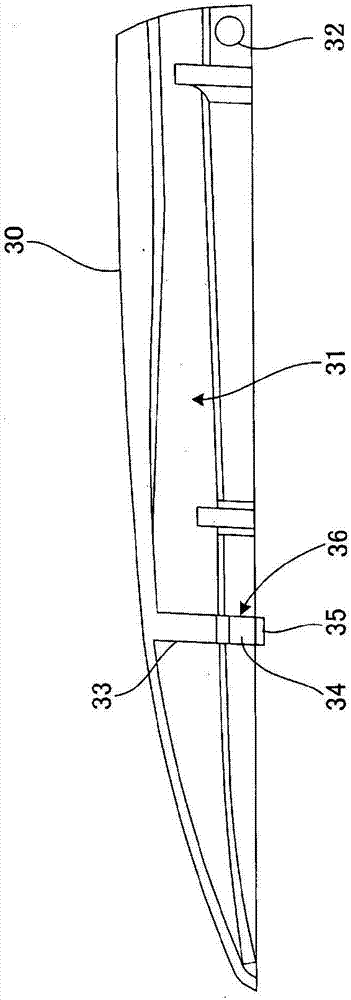

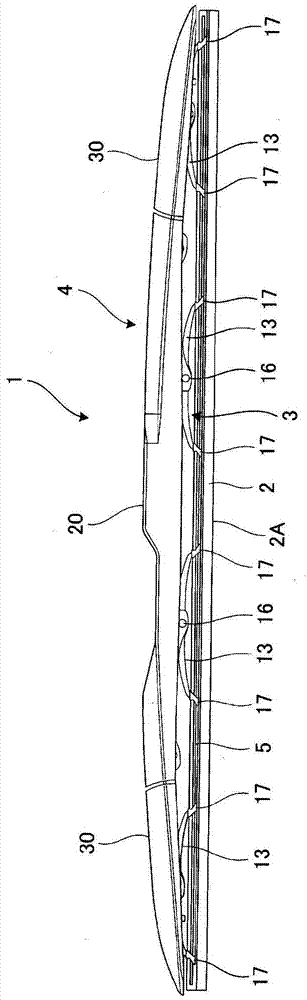

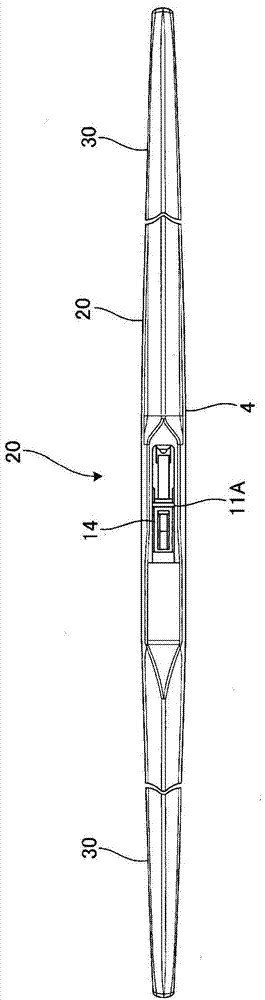

wiper blade

[OBJECTIVES] There is provided a wiper blade with a support assembly composed of a plurality of levers and housed by covers, which enhances the universality of the required parts and reduces the number of the required parts and thus, the cost of fabrication, while allowing the covers to follow the round contour of a surface to be wiped. [SOLUTION MEANS] A wiper blade 1 includes a primary cover 20 and secondary covers 30 pivotally connected to the primary cover. Each of the secondary covers 30 includes a lever guide section 36 through which a yoke lever 13 is slidably movable in a direction longitudinally of the wiper blade.

Owner:DENSO WIPER SYST INC

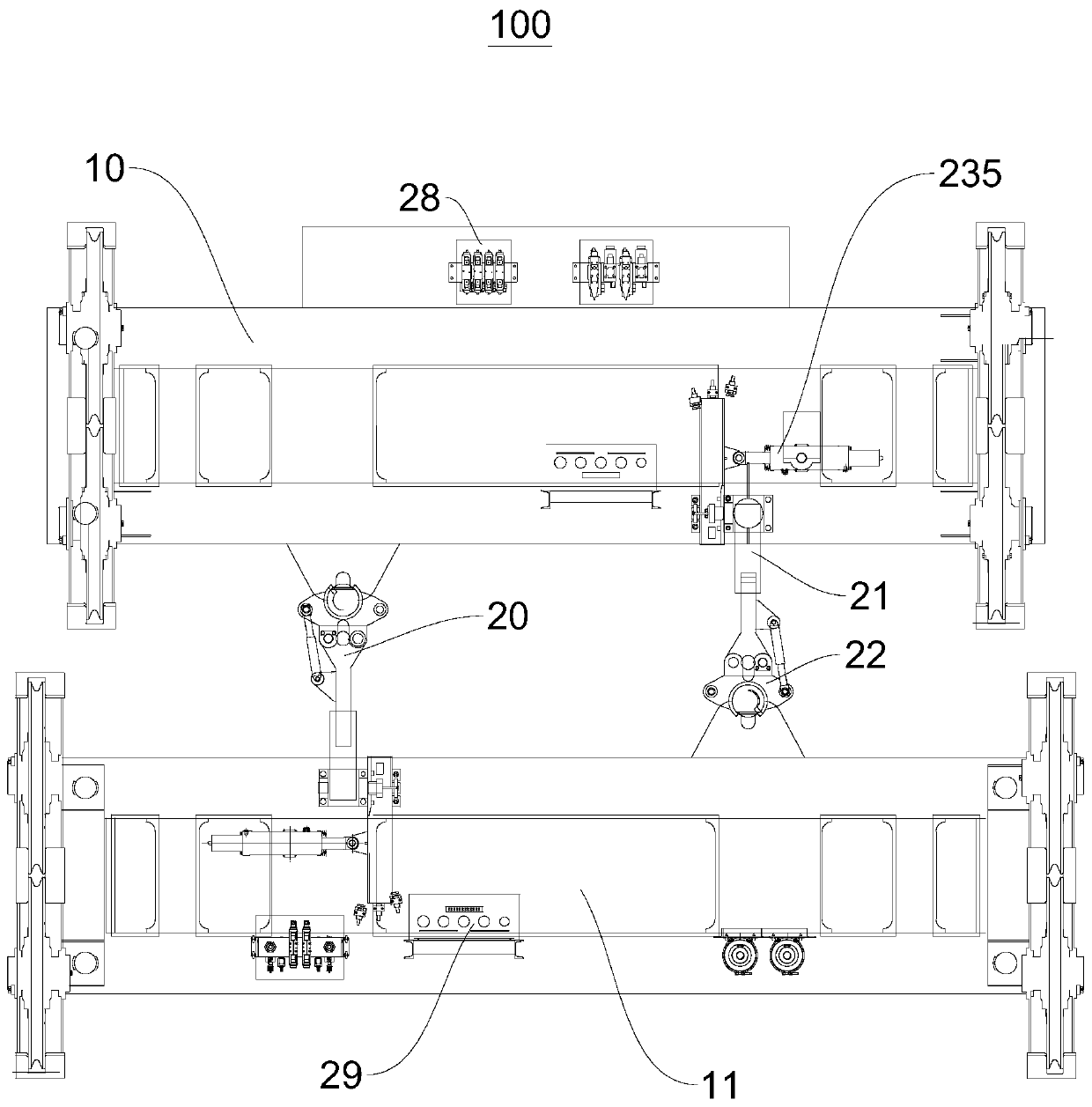

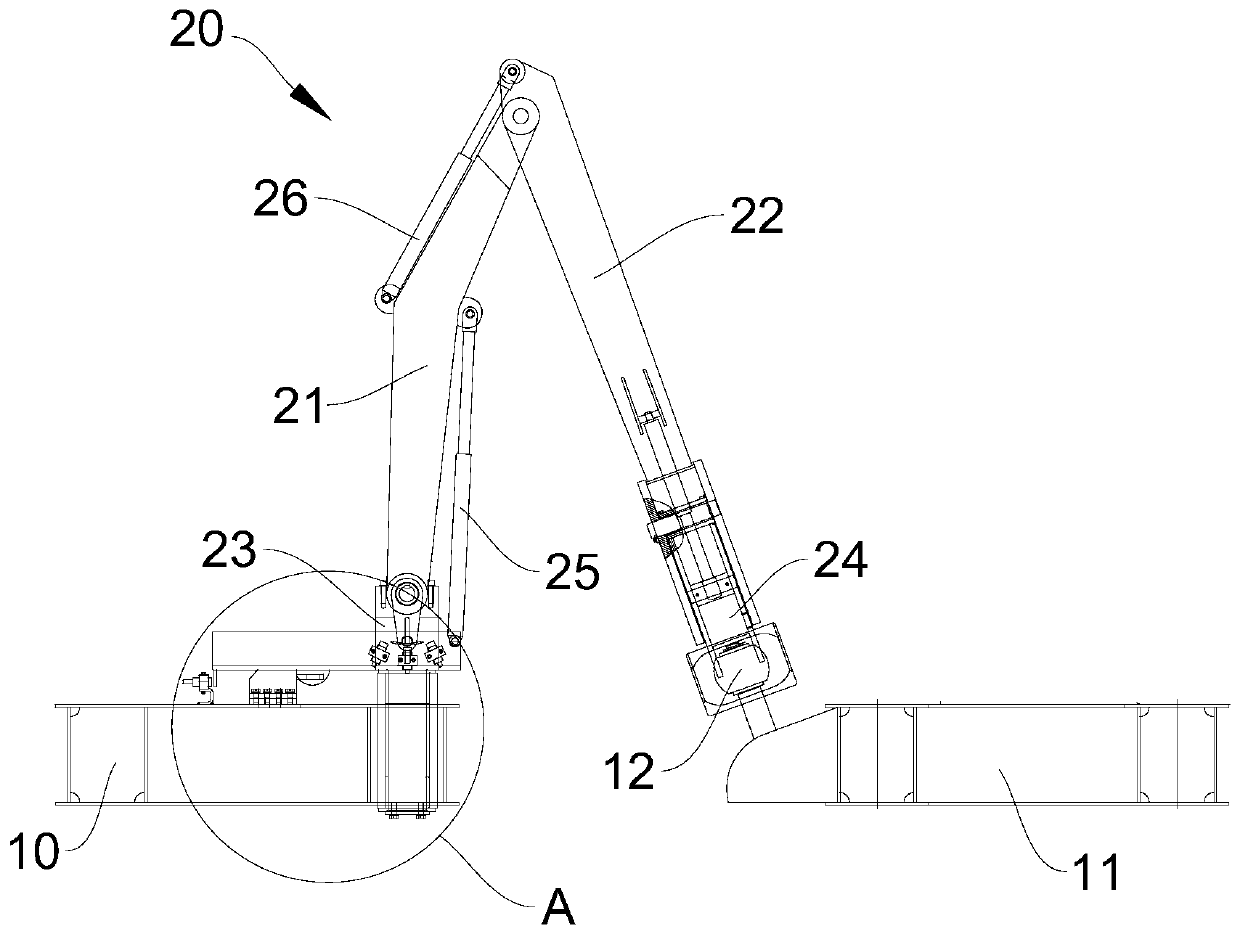

Connecting device for dual hanger top racks, and crane

ActiveCN110255400AIncrease max sizeIncreased loading and unloading flexibilityCranesEngineeringRelative motion

The embodiment of the invention provides a connecting device for dual hanger top racks, and a crane and relates to the technical field of hoisting equipment. The connecting device for the dual hanger top racks comprises a first hanger top rack, a second hanger top rack and a mechanical hand connecting mechanism, wherein two ends of the mechanical hand connecting mechanism are connected to the first hanger top rack and the second hanger top rack, respectively. The mechanical hand connecting mechanism comprises a first arm frame and a second arm frame which are mutually hinged, wherein the first arm frame and / or the second arm frame can be moved in a telescopic manner so as to realize at least two types of different relative motion of the first hanger top frame and the second hanger top frame. The mechanical hand connecting mechanism has a large extending length, can be folded and has a large adjustment scope. Adjacent containers on the same layer can be assembled and disassembled with conventional dual 40-foot hanger top racks; containers can be assembled and disassembled alternately; containers on different layers can be assembled and disassembled; flexibility is high; and efficiency of the crane can be greatly increased.

Owner:SANY MARINE HEAVY IND

A table tennis automatic pick-up device

ActiveCN105999659BEasy to take outSimple structureBall sportsRacket sportsReduction driveElectric machinery

The invention discloses an automatic ping-pong ball picking device. The device comprises a picking cylinder, wherein both the front end and the rear end of the picking cylinder are open; a sliding rod and a micro motor are fixed on the left side wall and the right side wall of the picking cylinder respectively; a speed reducer is arranged on the micro motor; a spindle is arranged on the speed reducer; a rocker is fixed on the spindle; a connection rod is hinged to the rocker; a picking rod is fixed at the tail end of the connection rod, and the other end of the picking rod is nested on the sliding rod; a picking block is fixed on the picking rod, two wedge-shaped blocks are arranged in a cylinder body at the front end of the picking cylinder, and a plurality of springs are arranged between each wedge-shaped block and the inner wall of the picking cylinder; a vertical rod is fixed on the outer wall of the rear end of the picking cylinder, a telescopic rod is inserted into the vertical rod, a battery box is fixed on the vertical rod, a battery is arranged in the battery box, a switch button is arranged on the telescopic rod, and the micro motor, the battery and the switch button are in series connection. The automatic ping-pong ball picking device has the benefits as follows: (1) the structure is simple; (2) the labor intensity is low, and labor of attendants is reduced.

Owner:山东宇生文化股份有限公司

C-type multi-angle manual self-locking turnover mechanism and application method thereof

The invention relates to a C-type multi-angle manual self-locking turning mechanism and its use method, comprising a base, the base is provided with a fixing seat, and at least one C-shaped handle is hinged on the fixing seat, and the fixing seat There are spring pins equal in number to the handle, and there are several arc-shaped positioning holes evenly distributed on the side of the hinge of the handle. These positioning holes are located on an arc with the same radius, so that the spring pin can be inserted into one of them In the positioning hole, both ends of the handle are provided with threaded holes, and locking screws are provided in the threaded holes. The device has a simple structure and is convenient to use.

Owner:GUANGLONG PRECISION IND FUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com