Spring structure of mold slider

A technology of spring structure and die slider, applied in the field of spring structure, can solve the problems of thickening, spring interference, limited spring installation space, etc., and achieve the effect of flexible installation position and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

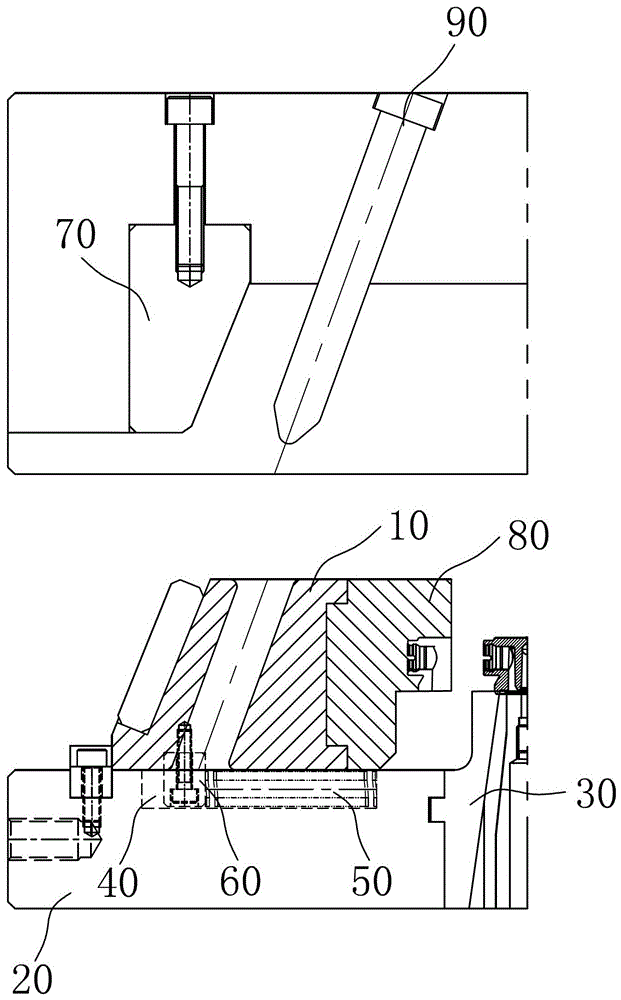

[0018] see figure 2 , figure 2 It is a structural schematic diagram of a mold clamping state of a preferred embodiment of the spring structure of the mold slider of the present invention.

[0019] In order to achieve the above object, the spring structure of the mold slider provided by the present invention, the mold has a slider 10, a template 20 arranged below the slider 10, a mold core 30 arranged in the template 20, the spring Structures include:

[0020] A chute 40, which is arranged in the template 20, and the chute 40 opens toward one side of the slider 10;

[0021] A spring 50, which is arranged in the chute 40, and one end of the spring 50 is against the end of the chute 40 close to the mold core 30;

[0022] The stopper 60 is fixed on the bottom of the slider 10 , and one side of the stopper 60 bears against the end of the spring 50 away from the mold core 30 .

[0023] Wherein, the chute 40 is a U-shaped groove, which is convenient to be fabricated on the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com