Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Realize automatic palletizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

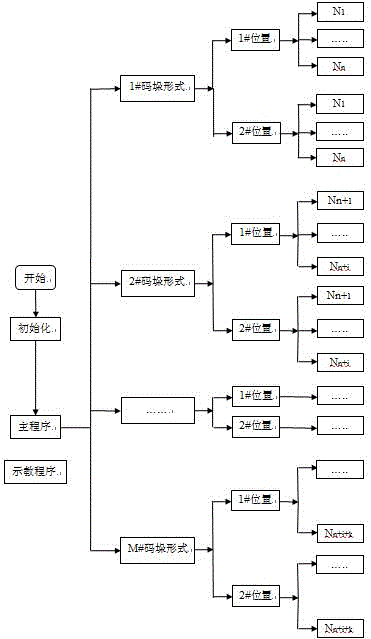

Control method of palletizing robot based on formula

ActiveCN106239512AAddress labor costsRealize automatic palletizingProgramme-controlled manipulatorStacking articlesCardboardControl system

The invention relates to a control method of a palletizing robot based on formula comprising a teaching step of teaching a robot with key teaching points; an inputting step of inputting palletizing form data, palletizing position data and palletizing formula data in a robot control system; a selecting step of selecting palletizing positions, palletizing forms and palletizing formula from the control system; a step of obtaining actual palletizing positions by means of a palletizing algorithm according to the data obtained from the above steps. The invention has the advantages that the palletizing system pre-develops several kinds of palletizing forms, and then customers only need to select the required palletizing forms according to the actual production process, meanwhile, the size of the products, the number of products to be grabbed, the cardboard placement and the number of palletizing layers are input into the control system so that corresponding palletizing of products can be fulfilled; the degree of automation and ease of operation of the robot palletizing system reduce labor costs.

Owner:NANTONG UNIVERSAL MACHINERY

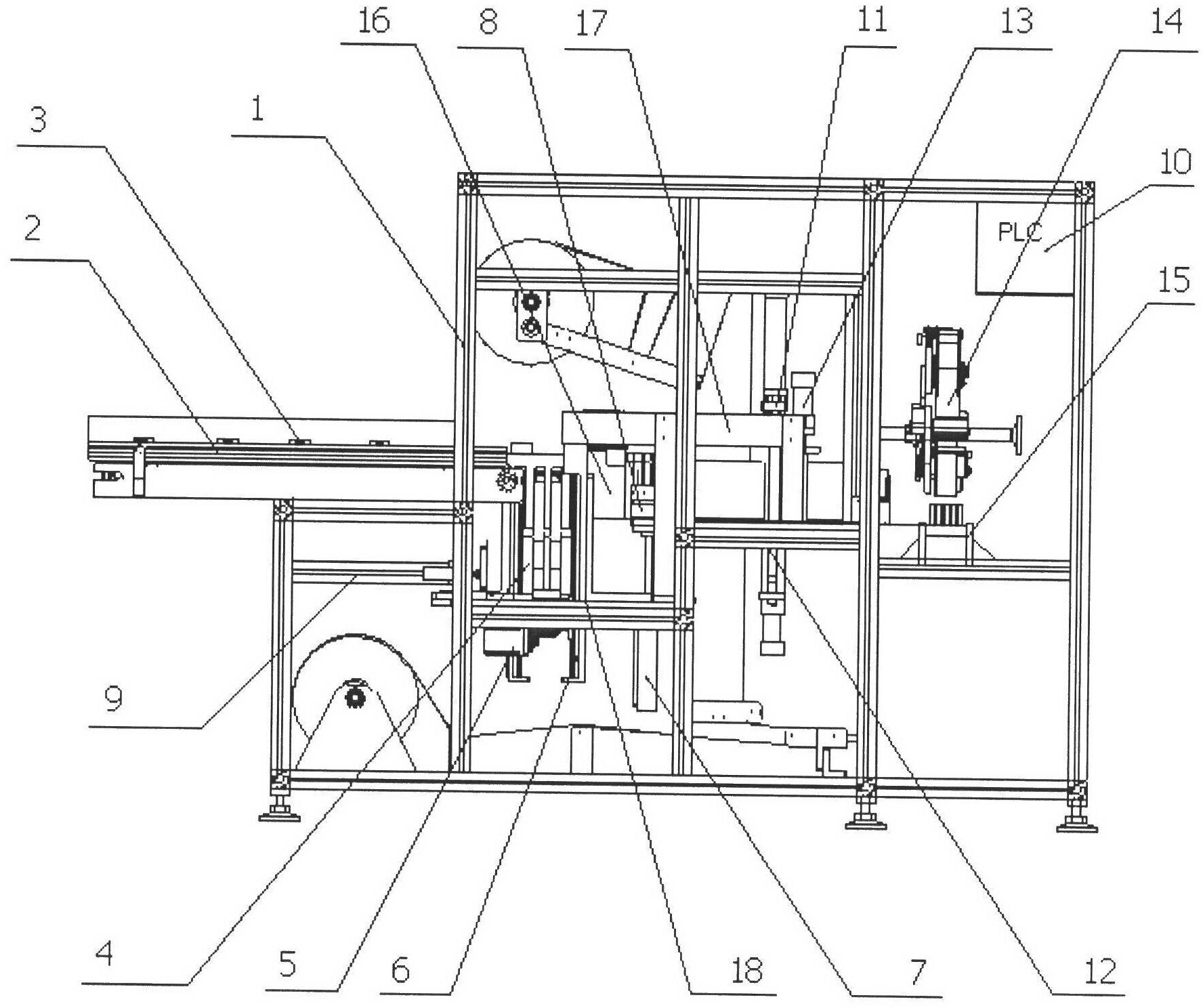

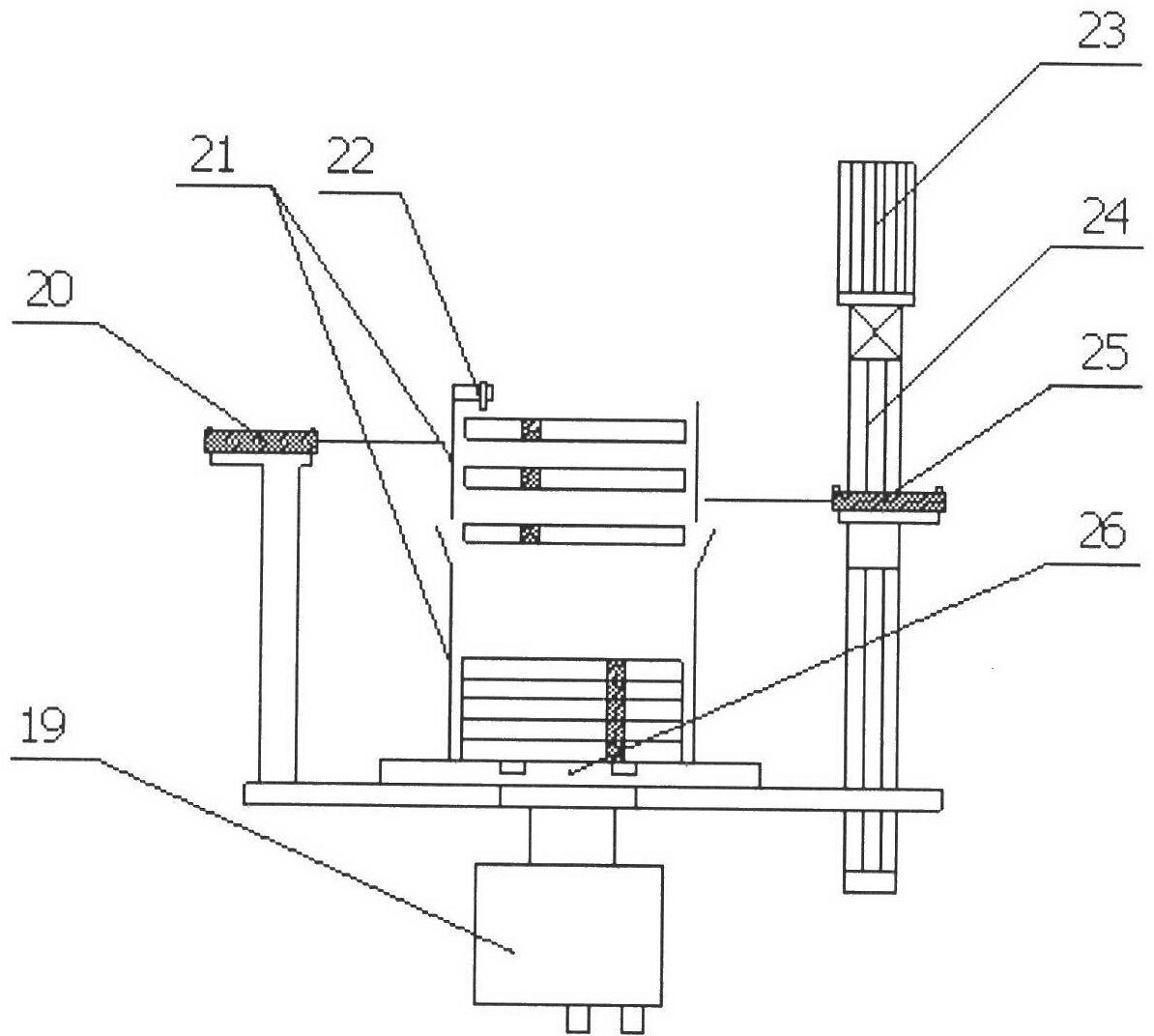

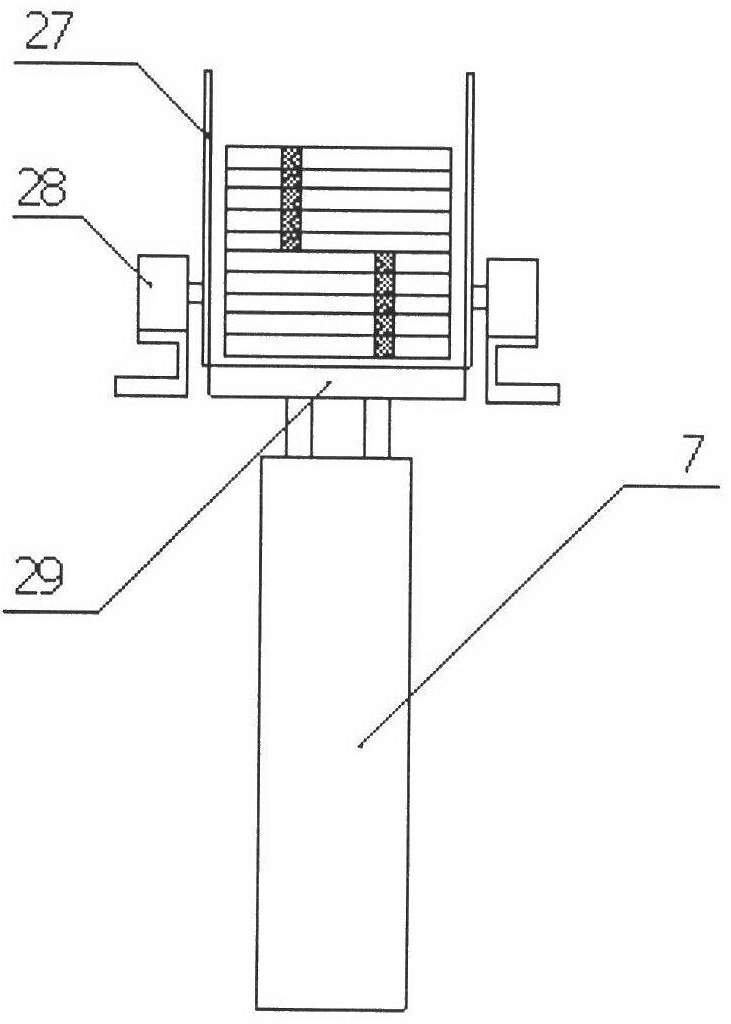

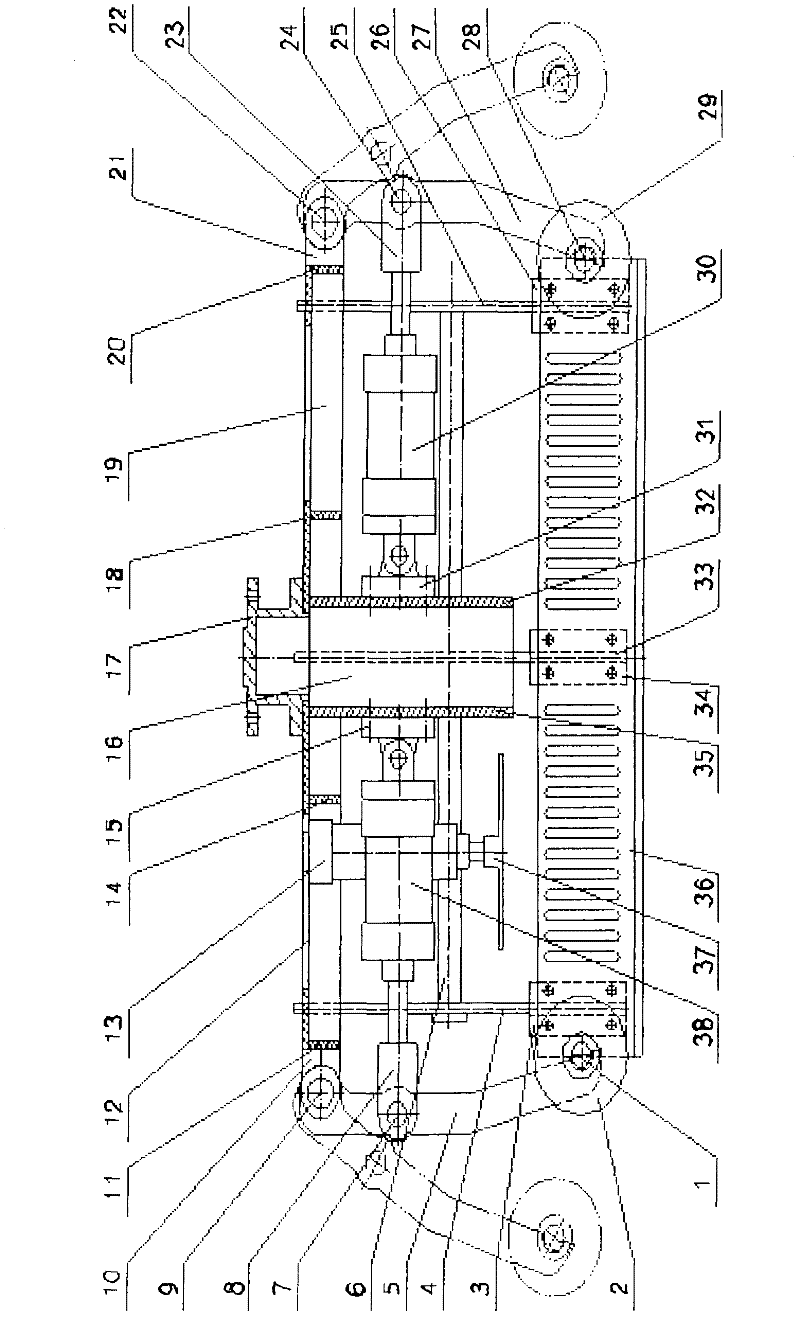

Full-automatic film banknote bundling machine

ActiveCN102582869AFast packingRealize automatic palletizingPaper article packagingPackaging automatic controlControl systemProgrammable logic controller

The invention discloses a full-automatic film banknote bundling machine, which is mainly used for alignment packaging of printed matters such as banknotes, bank documents, bills and the like, and comprises a feed conveying mechanism, a stacking and steering mechanism, a primary pushing mechanism, an arranging and ejecting mechanism, a secondary pushing mechanism, a heat sealing mechanism, a discharging mechanism, a labeling mechanism and a PLC (programmable logic controller) control system. The running principle of the full-automatic film banknote bundling machine includes the steps: firstly, automatically conveying, stacking and counting banknotes in a single bundle, steering the banknotes for 180 degrees, and pushing the banknotes in ten bundles into the arranging and ejecting mechanism for arrangement and ejection by the aid of the primary pushing mechanism; then, pushing the banknotes in ten bundles into the heat sealing mechanism for heat sealing and bundling by the secondary pushing mechanism; and finally, after bundling is completed, utilizing the discharging mechanism to push banknote bundles onto a discharge conveying mechanism, and then labeling, namely, the whole process including counting, stacking, steering, arranging, bundling and labeling is completed. The full-automatic film banknote bundling machine has the advantages that the full-automatic film banknote bundling machine is high in automation level, stable in performance and high in cost performance, operating efficiency is improved and packaging material cost is reduced by the aid of the bundling mode, and the full-automatic film banknote bundling machine has extremely high professional popularization value.

Owner:合肥哈工龙延智能装备有限公司

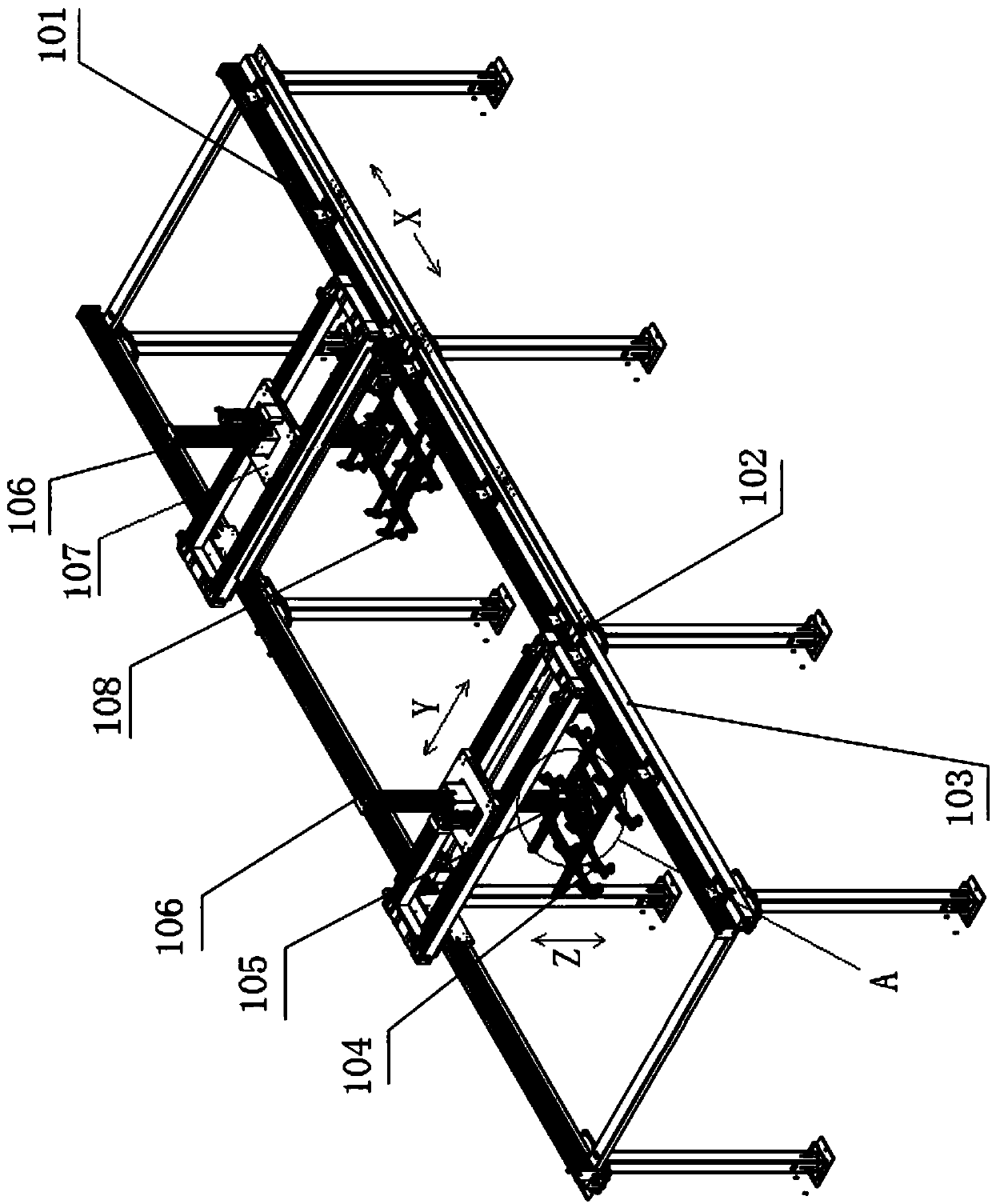

Stacker for clay laths

The invention discloses a stacker for a clay lath. The stacker comprises a frame, an X-direction carling, an X-direction moving device, a Y-direction moving seat, a Y-direction moving device, a Z-direction moving beam, a Z-direction moving device, a gripping apparatus and a transportation support device, wherein the X-direction carling is movably arranged on the frame through a first guide rail slider pair; the X-direction moving device is arranged between the X-direction carling and the frame; the Y-direction moving seat is movably arranged on the X-direction carling through a second guide rail slider pair; the Y-direction moving device is arranged between the Y-direction moving seat and the X-direction carling; the Z-direction moving beam is movably arranged on the Y-direction moving seat through a third guide rail slider pair; the Z-direction moving device is arranged on the Z-direction moving beam and the Y-direction moving seat; the gripping apparatus is arranged on the end of the Z-direction moving beam and is used for clamping the clay lath processed by a clay cutting machine; the transportation support device is arranged on the frame. According to the stacker, automatic stacking of the clay lath produced by the clay cutting machine is implemented, stacking is neater, and the stacking speed is greatly improved.

Owner:HUNAN SLON EQUIP

Automatic blank fetching equipment

InactiveCN103612908AHigh degree of automationIncrease productivityConveyorsStacking articlesMechanical equipmentEngineering

The invention belongs to the technical field of mechanical equipment, in particular to automatic blank fetching equipment. The automatic blank fetching equipment solves the technical problems that practicality is poor in the prior art. The automatic blank fetching equipment comprises a rack, a mechanical arm is arranged on the rack, a longitudinal translation driving mechanism capable of driving the mechanical arm to shift horizontally and repeatedly in the longitudinal direction of the rack is arranged between the rack and the mechanical arm, a disc sending lifting frame and a disc receiving lifting frame used for stacking blank discs are arranged on the two sides of the rack respectively, and blank discs stacked on the disc receiving lifting frame are located below the longitudinal translation track of the mechanical arm. A lifting driving device is arranged on the rack, wherein the lifting driving device is respectively connected to the disc sending lifting frame and the disc receiving lifting frame, and can drive the disc sending lifting frame and the disc receiving lifting frame to carry out synchronous reversed lifting motion on the two sides of the rack. A disc conveying device capable of enabling the top blank disc to be conveyed to the side, where the disc receiving lifting frame is located, of the rack from the side where the disc sending lifting frame is located, of the rack is further arranged on the rack. Compared with the prior art, the automatic blank fetching equipment has the advantage of being high in automation degree.

Owner:HANGZHOU DONGBO AUTOMATION SCI & TECH

Mechanical calcium-plastic box stacking method and device

ActiveCN103723499ARealize automatic palletizingReduce the labor intensity of palletizingStacking articlesDe-stacking articlesEngineeringPlastic bag

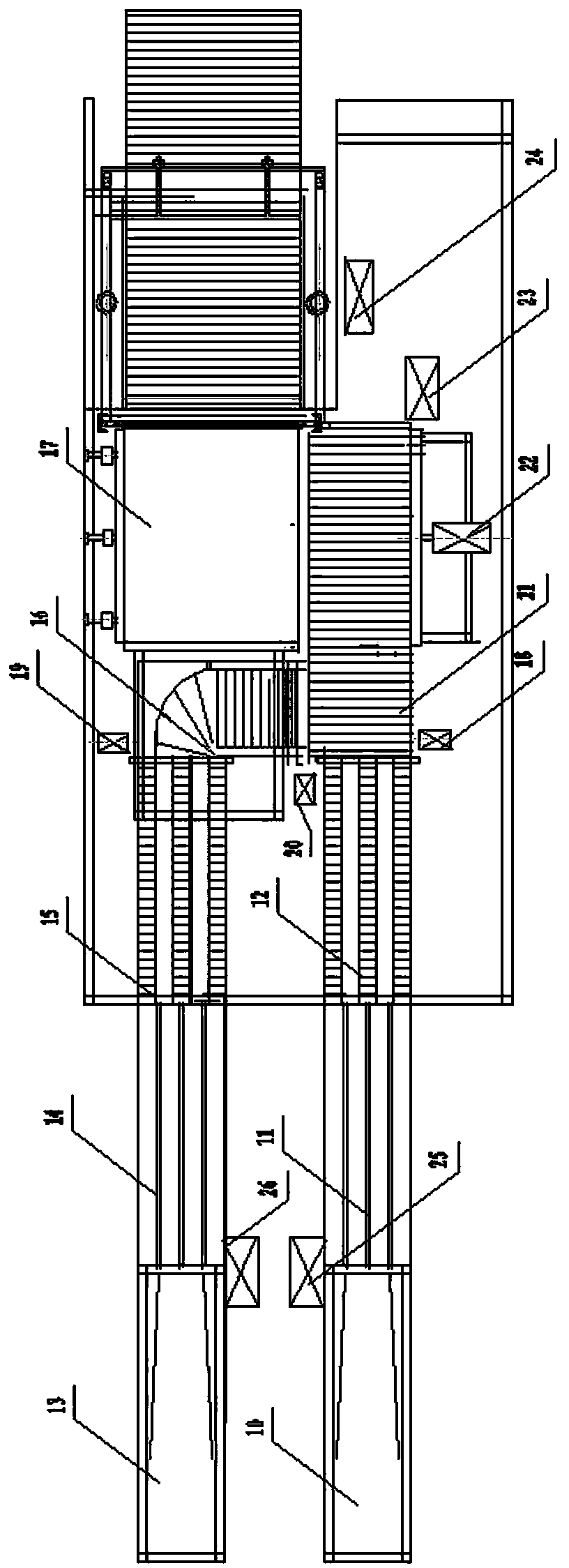

The invention relates to the technical field of logistics, in particular to a mechanical calcium-plastic box stacking method and device. According to the mechanical calcium-plastic box stacking method and device, a conveying device is used for storing well-arranged calcium-plastic boxes, half layer of calcium-plastic boxes is stored each time, a moving device pushes the calcium-plastic boxes stored on the conveying device to a layer moving supporting plate of a layer moving device after each half layer of calcium-plastic boxes is stored, and the layer moving supporting plate moves towards the interior of a stacking device after the layer moving supporting plate is loaded with a whole layer of calcium-plastic boxes; a stopping mechanism at the front end of the stacking device falls down to limit the front end of the calcium-plastic box layer to make the calcium-plastic box layer aligned; the calcium-plastic box layer is clamped by sorting mechanisms at the two ends of the stacking device to further be aligned; a stopping mechanism at the rear end of the stacking device falls down, the layer moving device is pulled away from the stacking device, and then the calcium-plastic boxes stay on a tray or a well-stacked calcium-plastic box layer so that one layer of stacking can be achieved. The mechanical calcium-plastic box stacking method and device enable automatic stacking of the calcium-plastic boxes to be achieved, are capable of relieving the labor intensity of operators and operating stably, and are low in cost and convenient to maintain.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

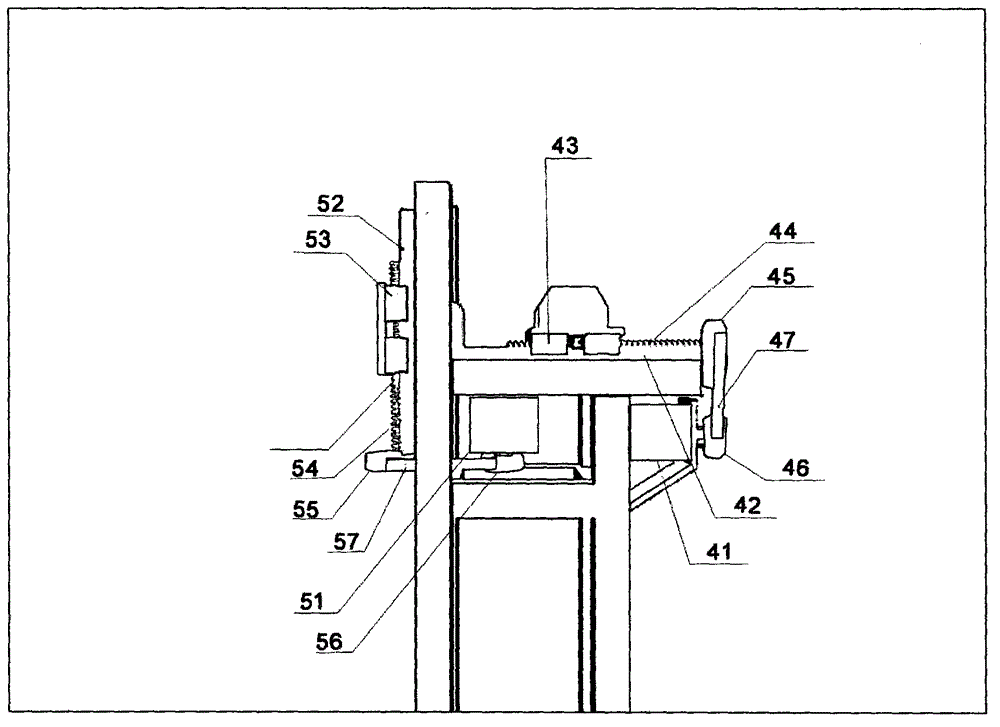

Automatic stacking device for storage battery electrode plates

PendingCN107381075AHigh degree of automationReduce labor intensityLead-acid accumulator electrodesStacking articlesProduction lineManipulator

The invention discloses an automatic stacking device for storage battery electrode plates. The automatic stacking device comprises a rack, a lifting mechanism, supporting and positioning assemblies, a manipulator assembly and pushing mechanisms. The lifting mechanism is used for storing an electrode plate heap tray and controlling the electrode plate heap tray to ascend and descend. The supporting and positioning assemblies are used for supporting and positioning the electrode plate heap tray. The manipulator assembly is used for automatically carrying electrode plate heaps into the electrode plate heap tray. The pushing mechanisms are used for pushing out the electrode plate heap tray. The lifting mechanism is arranged in the rack, the supporting and positioning assemblies are fixed to the rack and located on the two sides of the lifting mechanism, the manipulator assembly is detachably fixed to the rack and located above the lifting mechanism, and the pushing mechanisms are arranged on one side of the rack. By means of the automatic stacking device, automated stacking can be achieved, the labor intensity of workers is lowered, work efficiency is improved, the automated degree of a production line is increased, the production progress is accelerated, and the automatic stacking device is simple in structure, convenient to machine and manufacture and convenient to use.

Owner:中国船舶重工集团衡远科技有限公司

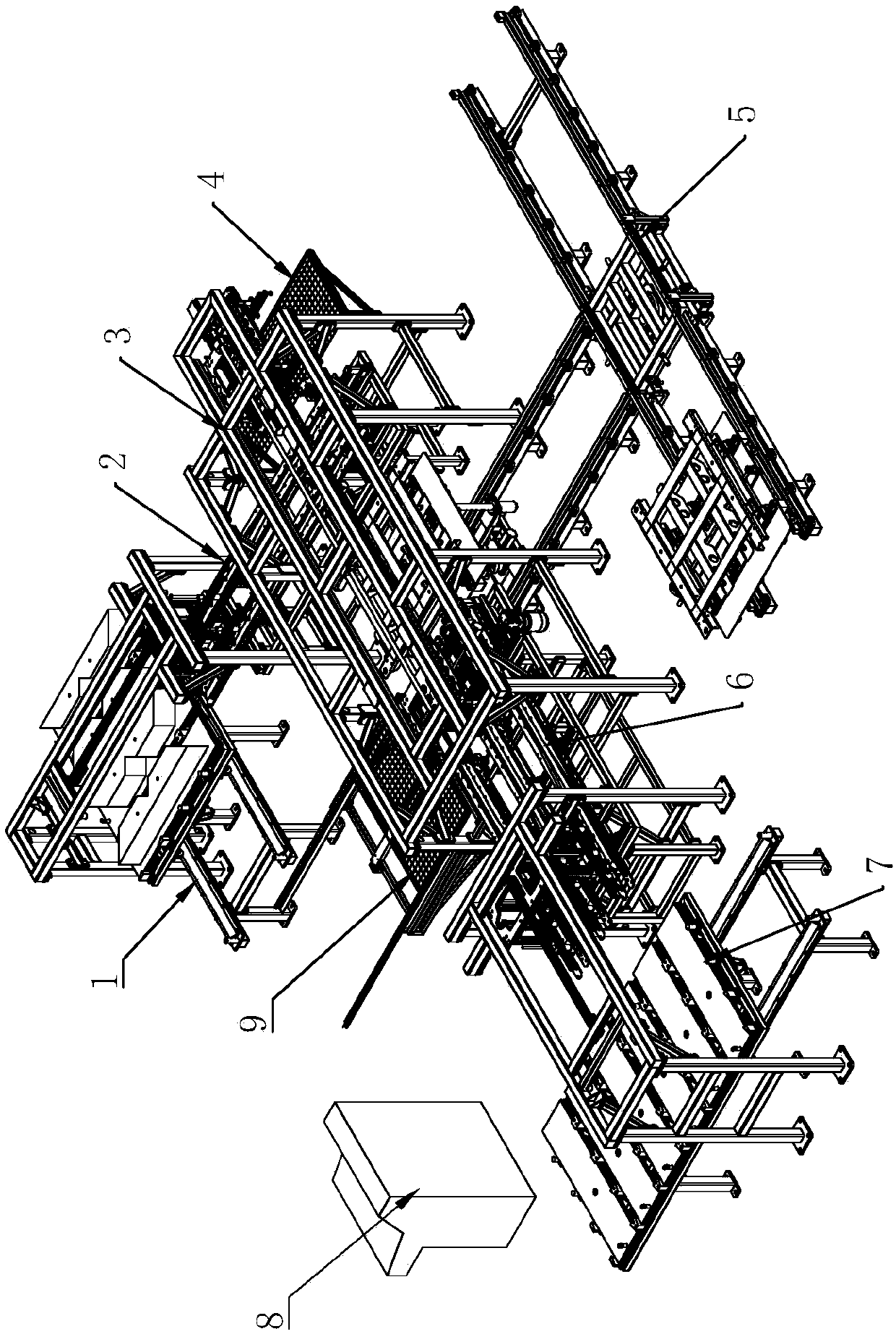

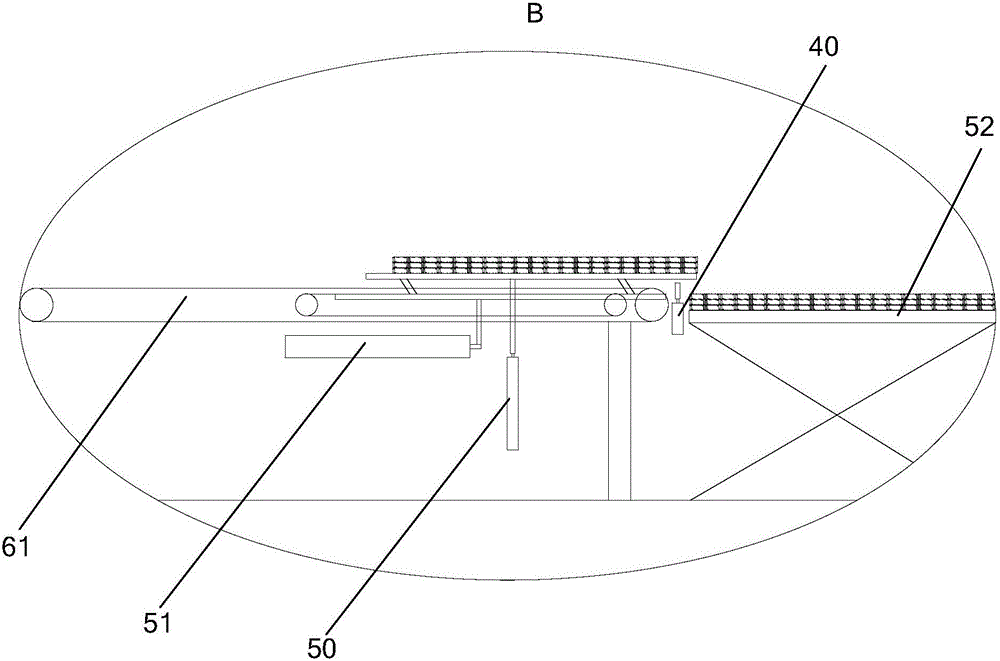

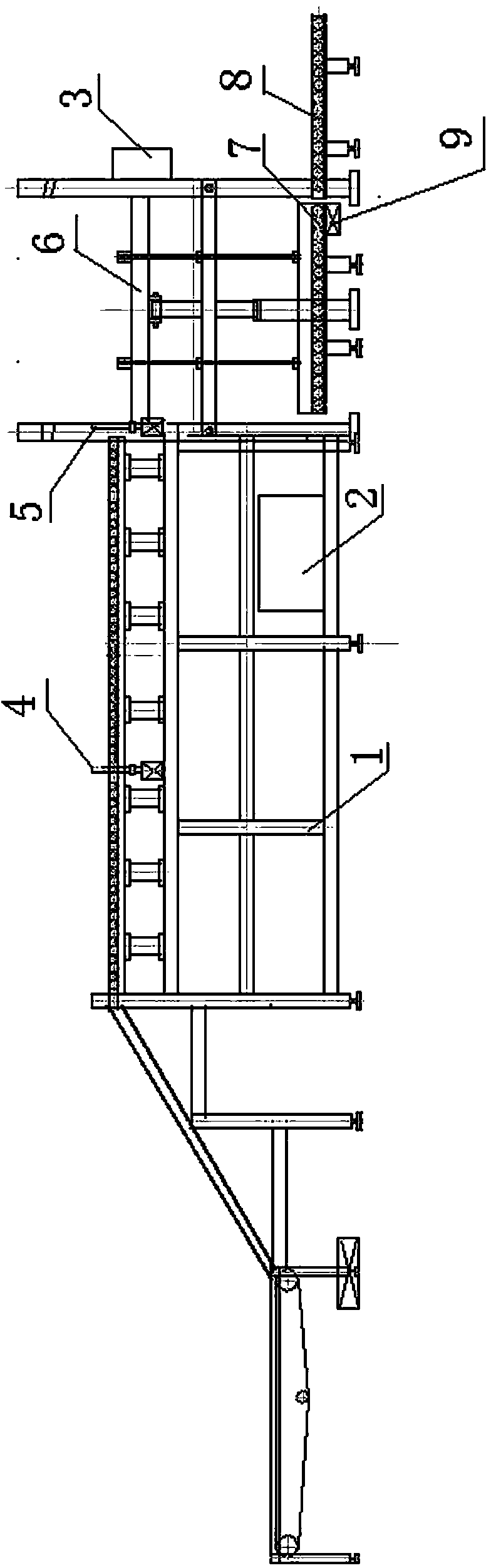

Mechanical stacking method and equipment of boxes filled with drugs

ActiveCN103662768ARealize automatic palletizingReduce the labor intensity of palletizingStacking articlesConveyor partsProduction lineLogistics management

The invention relates to the field of logistics and provides a mechanical stacking method and equipment of boxes filled with drugs. The equipment is capable of replacing manual stacking, stable in operation, low in cost and convenient to maintain. According to the method, the boxes filled with drugs conveyed out of a production line are straightened out and turned through a conveying roller so as to be arrayed into a line; the boxes filled with drugs arrayed into a line are sequentially transferred to a temporary-storage roller bed through a transferring device to form an array; the arrayed boxes filled with drugs are transferred onto a base plate of a stacking device from the roller bed at one time through the transferring device; the base plate of the stacking device moves to a proper position above a tray, and then a blocking mechanism drops down to block one side of the array formed by the boxes filled with drugs; the base plate of the stacking device moves towards one side of the blocking mechanism, and the arrayed boxes filled with drugs fall into the tray sequentially under the blocking effect of the blocking mechanism. By means of the mechanical stacking method and device of the boxes filled with drugs, the boxes filled with drugs can be automatically stacked, and the stacking labor intensity of workers can be greatly reduced; the equipment is stable in operation, low in manufacturing cost and convenient to maintain.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

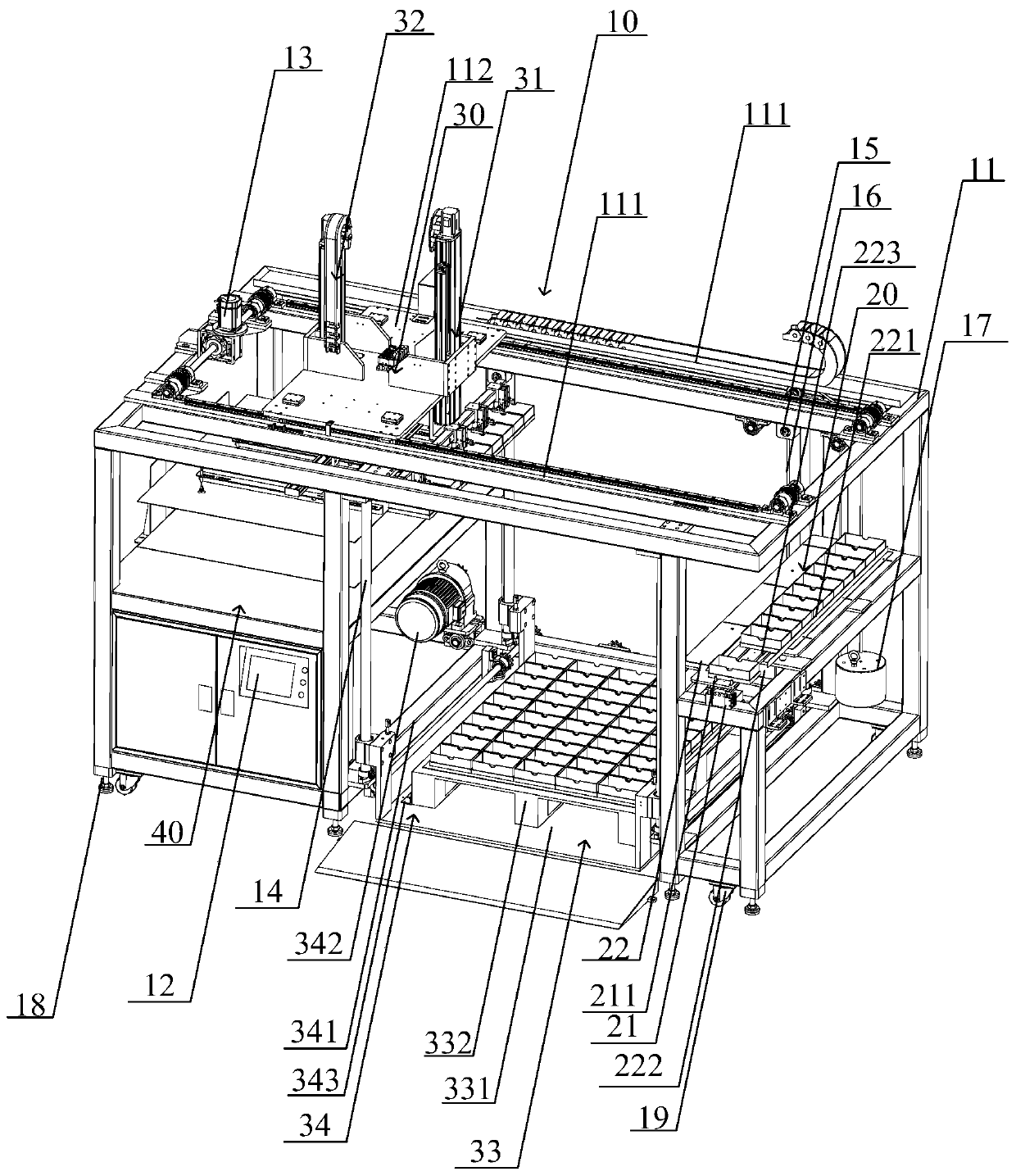

Automobile steel plate fine shearing automatic production device

ActiveCN109692992AAchieve cutGuaranteed bevel cutShearing machinesStacking articlesSheet steelDegrees of freedom

The invention relates to the field of automobile steel plate processing, and specifically relates to an automobile steel plate fine shearing automatic production device. The device includes a loadingand unloading mechanism, a feeding mechanism, a fine plate-shearing machine, a transmission mechanism, a palletizing mechanism and ground rail electric translation vehicles; the loading and unloadingmechanism includes a support rack body and two sucker driving mechanisms; one sucker driving mechanism is provided with a loading sucker assembly having X, Y and Z degrees of freedom and freedom of rotation, and the other sucker driving mechanism is provided with an unloading sucker assembly having X, Y and Z degrees of freedom; the feeding mechanism is arranged at the middle part on the lower side of the support rack body; the ground rail electric translation vehicles are respectively arranged on the two sides of the feeding mechanism; the feeding mechanism is provided with feeding clamps; aplate is driven to move to the fine plate-shearing machine along the Y direction through the clamping of the feeding clamps; and the side, away from the feeding mechanism, of the fine plate-shearing machine is successively provided with the transmission mechanism and the palletizing mechanism. Thus, various steel plate shearing modes can be realized, and the precision and production efficiency ofautomobile steel plate shearing can be enhanced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

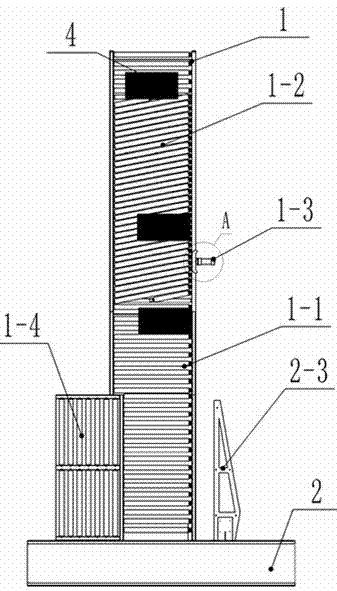

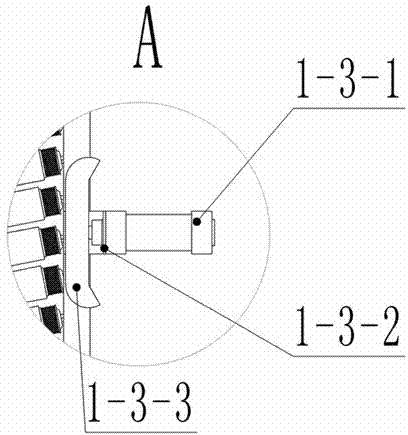

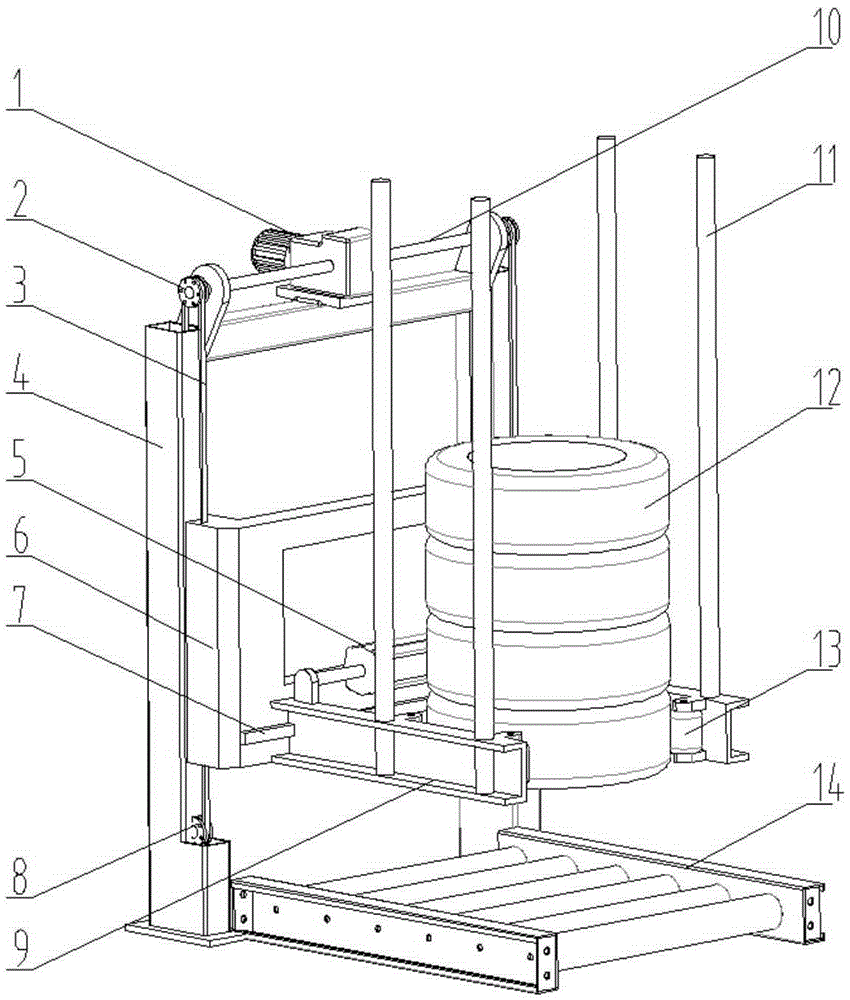

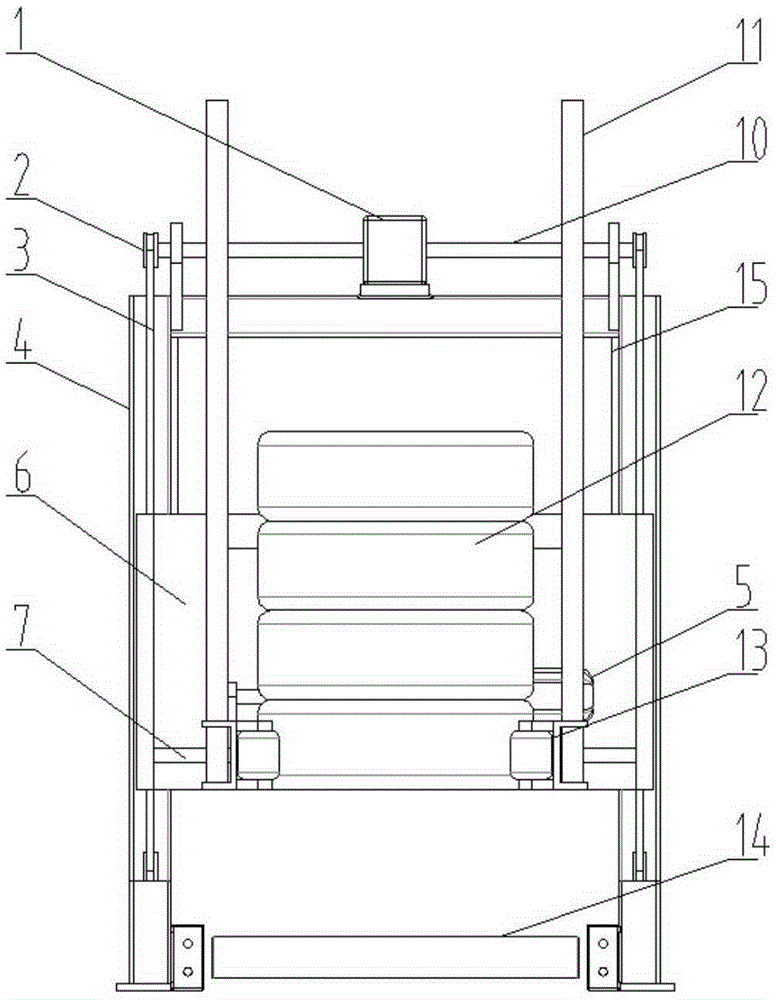

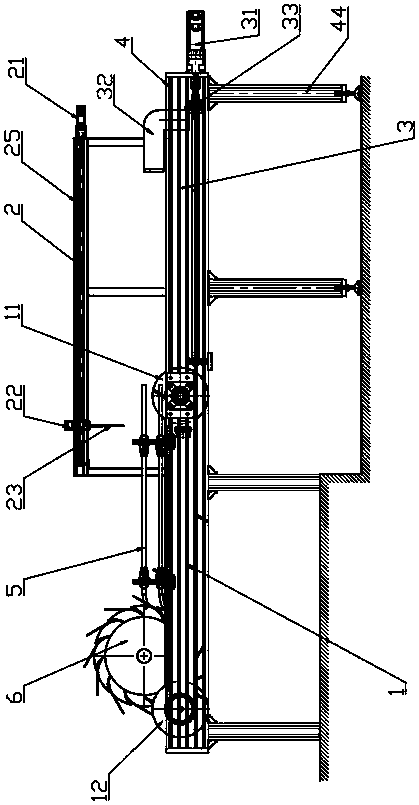

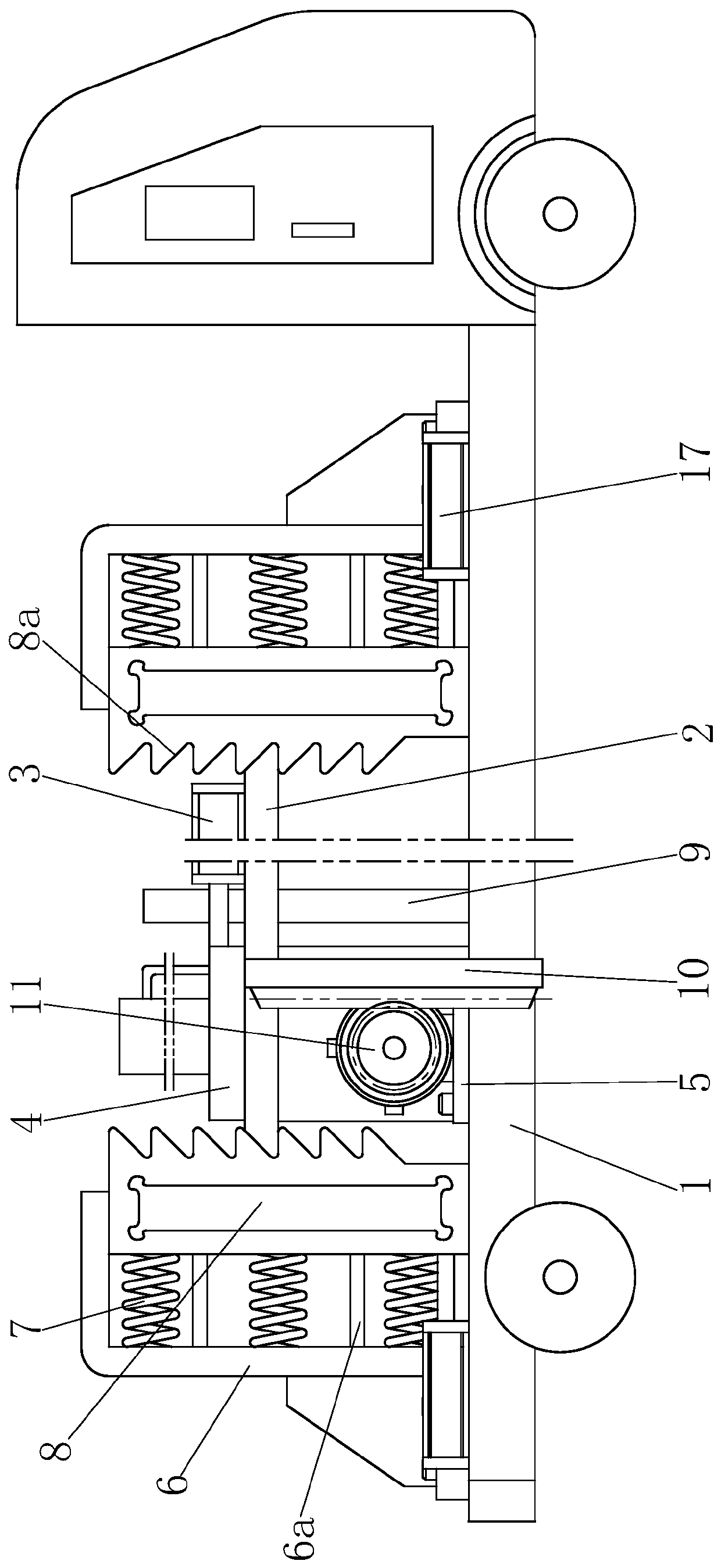

Upright clamping type automatic stacking and unstacking mechanism for tire stacks

InactiveCN106608537ARealize automatic palletizingRealize unstackingStacking articlesDe-stacking articlesDrive shaftEngineering

The invention relates to an automatic stacking and unstacking device for tire stacks, in particular to an upright clamping type automatic stacking and unstacking mechanism for the tire stacks, and belongs to the technical field of automatic production, conveying and storing of tires. The automation of stacking and unstacking of tire stacks is mainly achieved. The upright clamping type automatic stacking and unstacking mechanism for the tire stacks is composed of a main support, a lifting engine, a transmission shaft, a driving chain wheel, a driven chain wheel, a chain, a clamping electric cylinder, a vertical moving support, a vertical moving guide rail, a horizontal moving guide rail, a clamping support, an anti-collapse upright, a rolling wheel clamping upright and a conveyor line. The upright clamping type automatic stacking and unstacking mechanism for the tire stacks is mainly used for automatic stacking and unstacking of the tire stacks in the tire production, conveying and storing process.

Owner:黑龙江省工业技术研究院

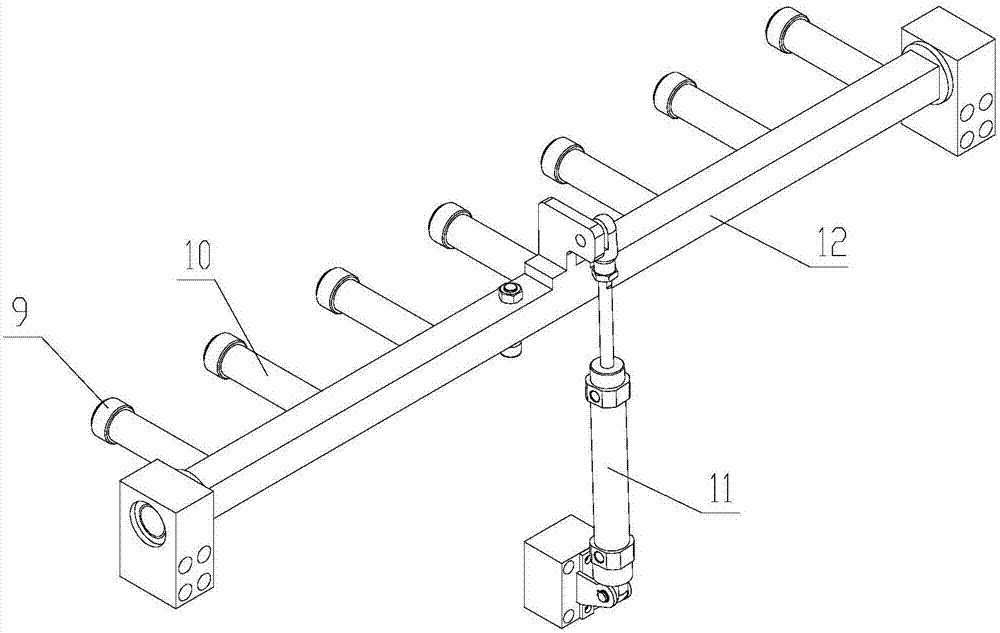

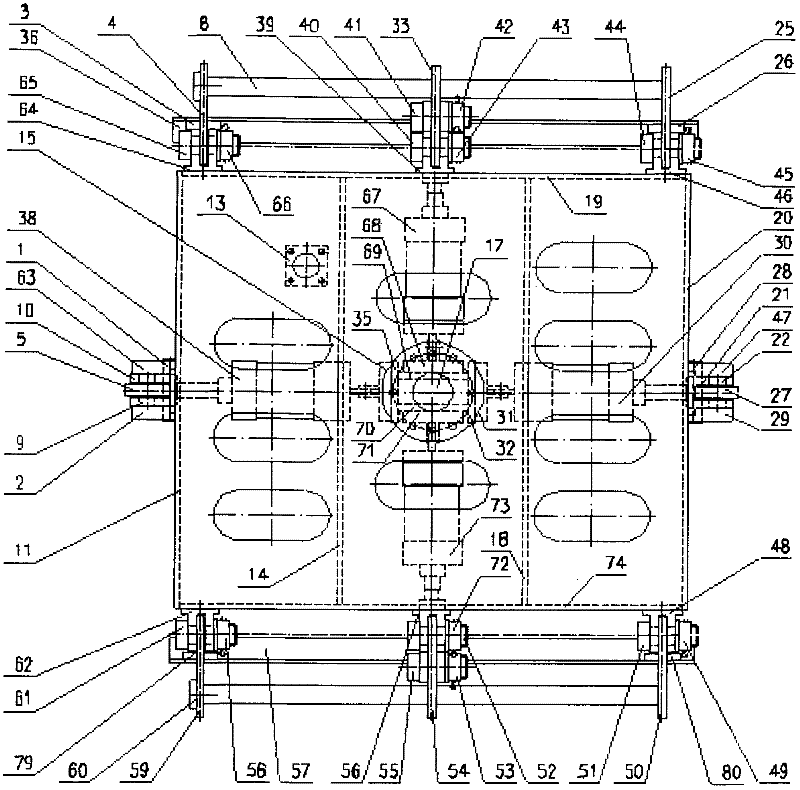

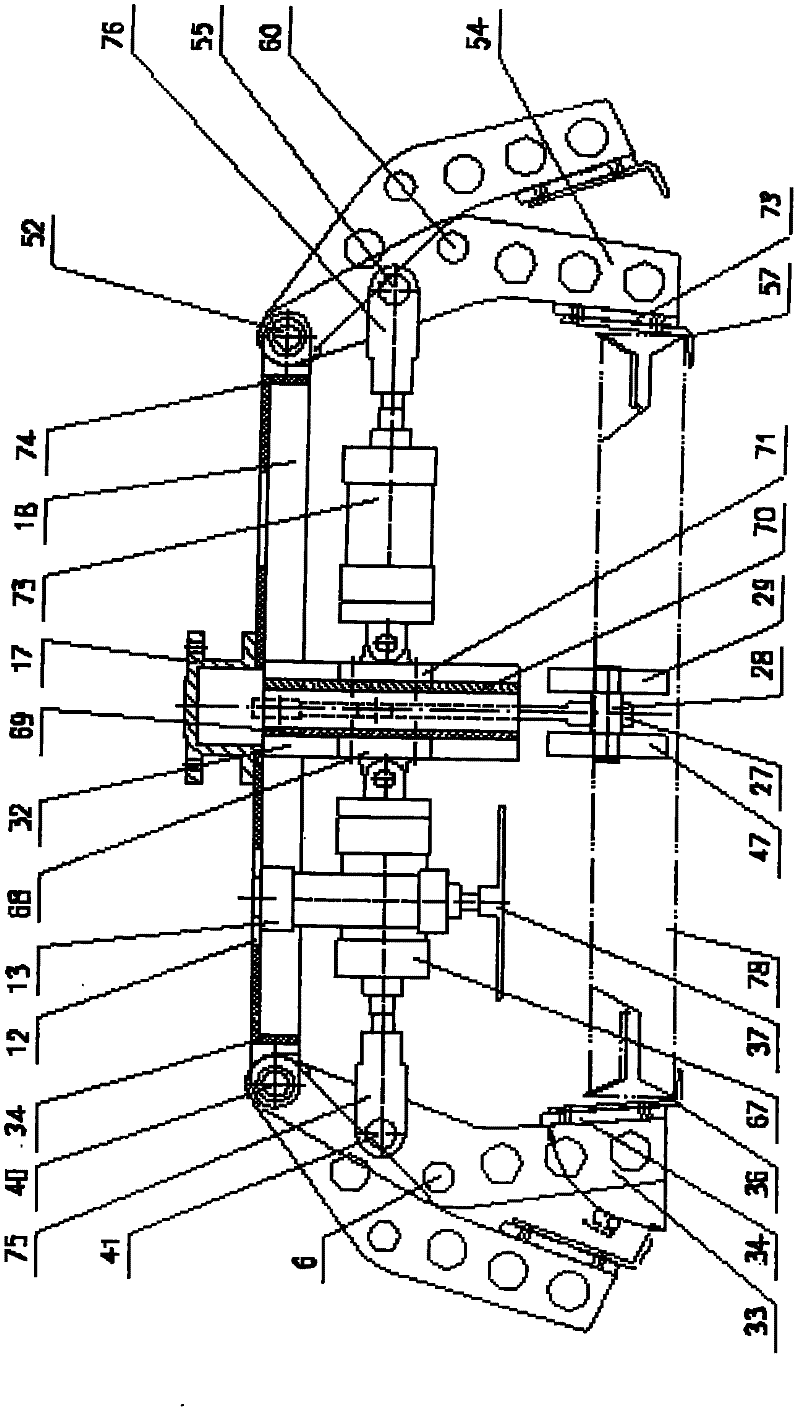

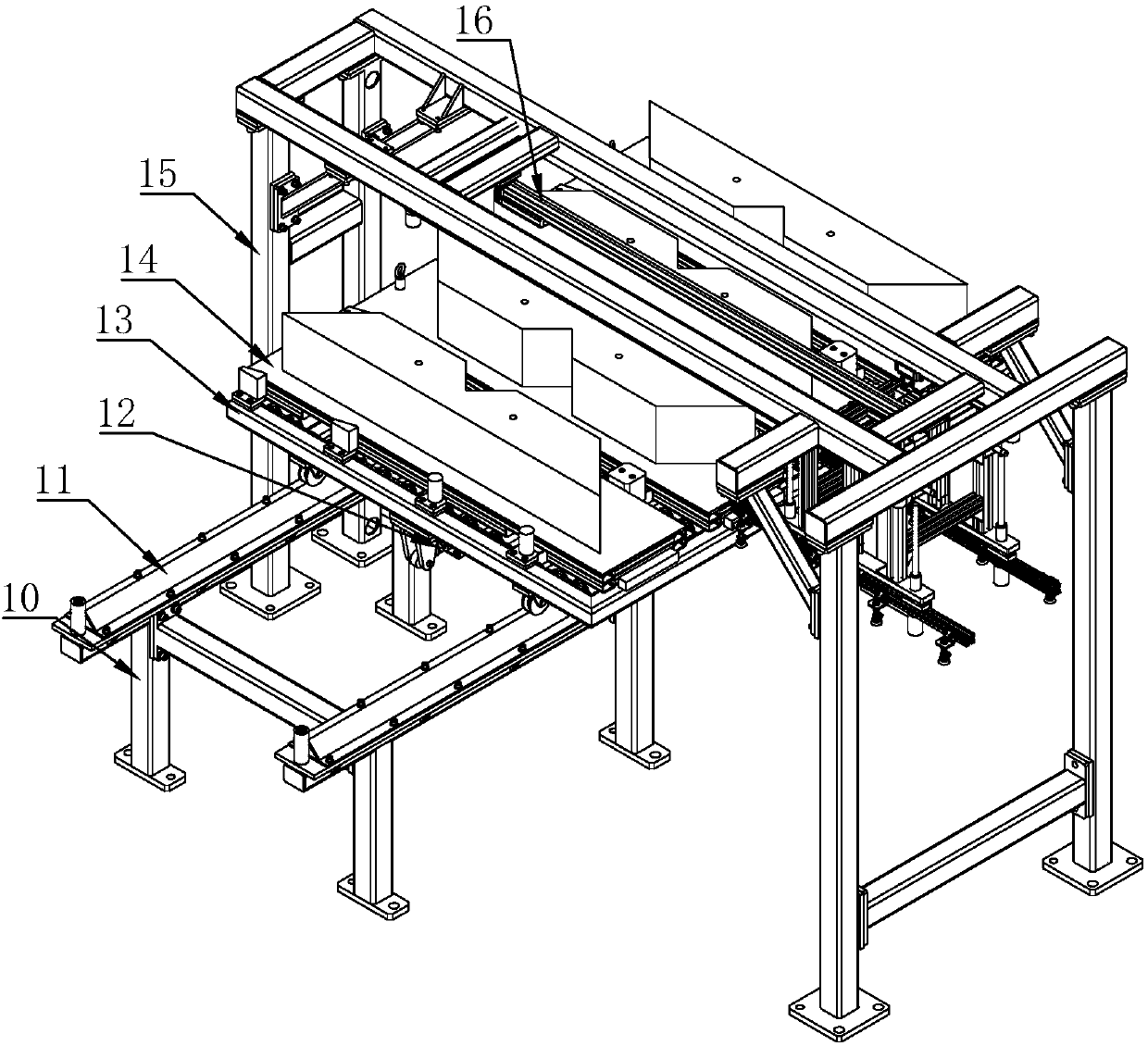

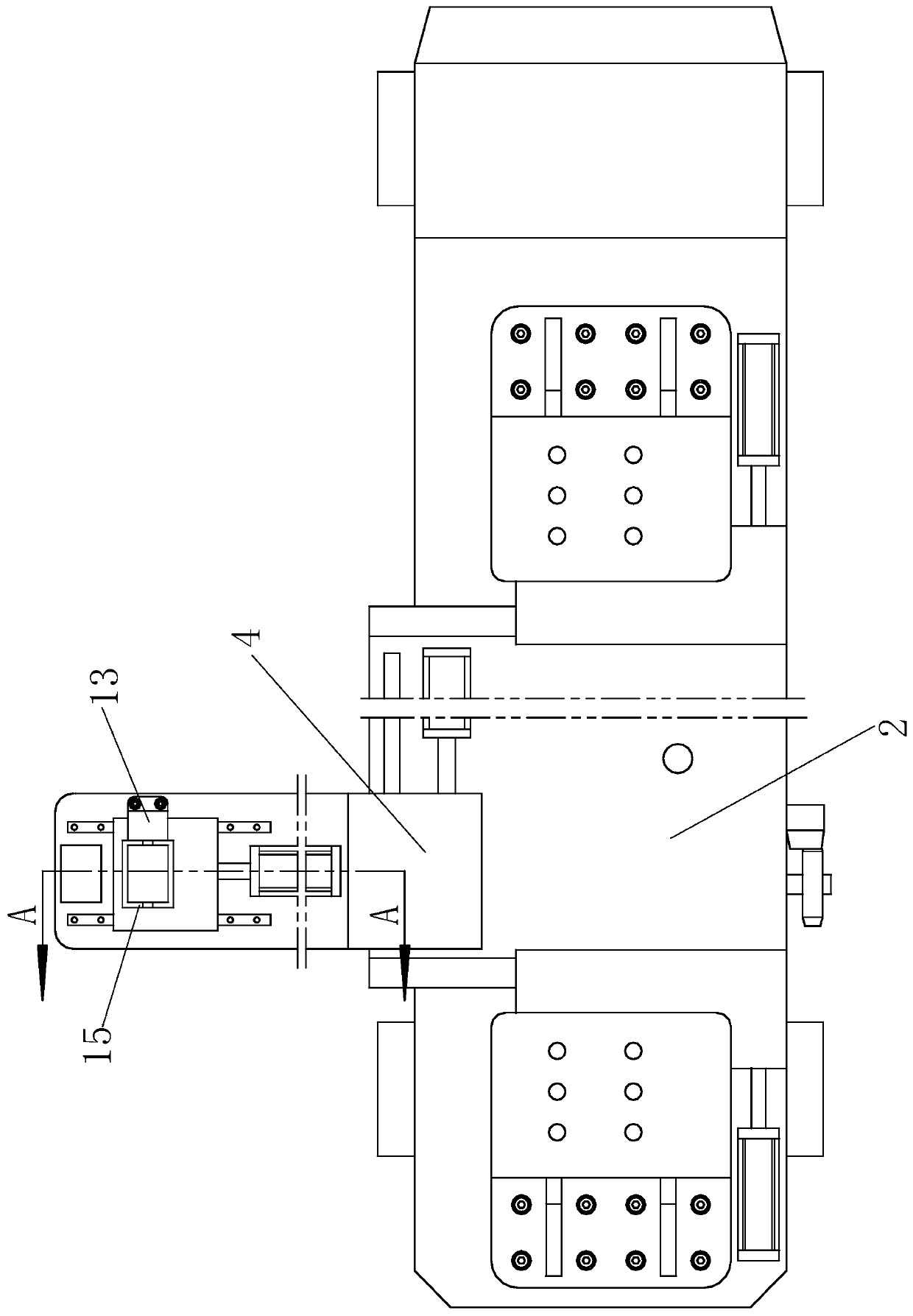

Special fixture used for stacking robot of continuous casting production line of aluminum ingots

InactiveCN102502276ARealize automatic grippingIncrease productivityGripping headsStacking articlesProduction lineEngineering

The invention discloses a special fixture used for a stacking robot of a continuous casting production line of aluminum ingots. The special fixture is used for the stacking of molded aluminum ingots on a continuous casting production line of the aluminum ingots. A detecting cylinder (13) is fixed at the lower surface of a sole plate (12); a terminal end of a piston rod of the detecting cylinder (13) is provided with a detection disk (37); the whole fixture is connected with a robot through a connecting base (17); and after the aluminum ingots (78) are well arranged at ingot arrangement stations of a layer conveyor, the special fixture drops to a capturing position under the driving of the stacking robot, front and back clamping claws are closed under the action of a cylinder (73) and a cylinder (73) to clamp each ingot, and left and right ingot supporting claws support aluminum ingots outside an aluminum ingot layer under the action of a cylinder (38) and a cylinder (30).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

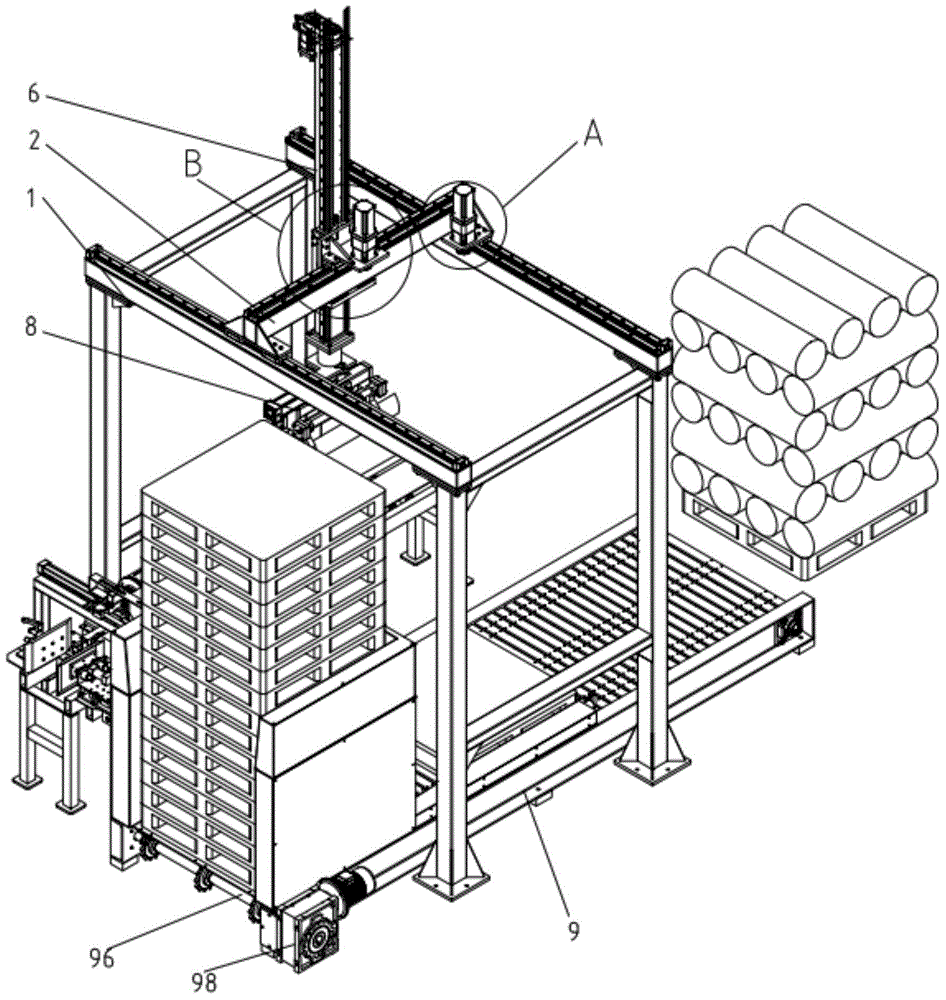

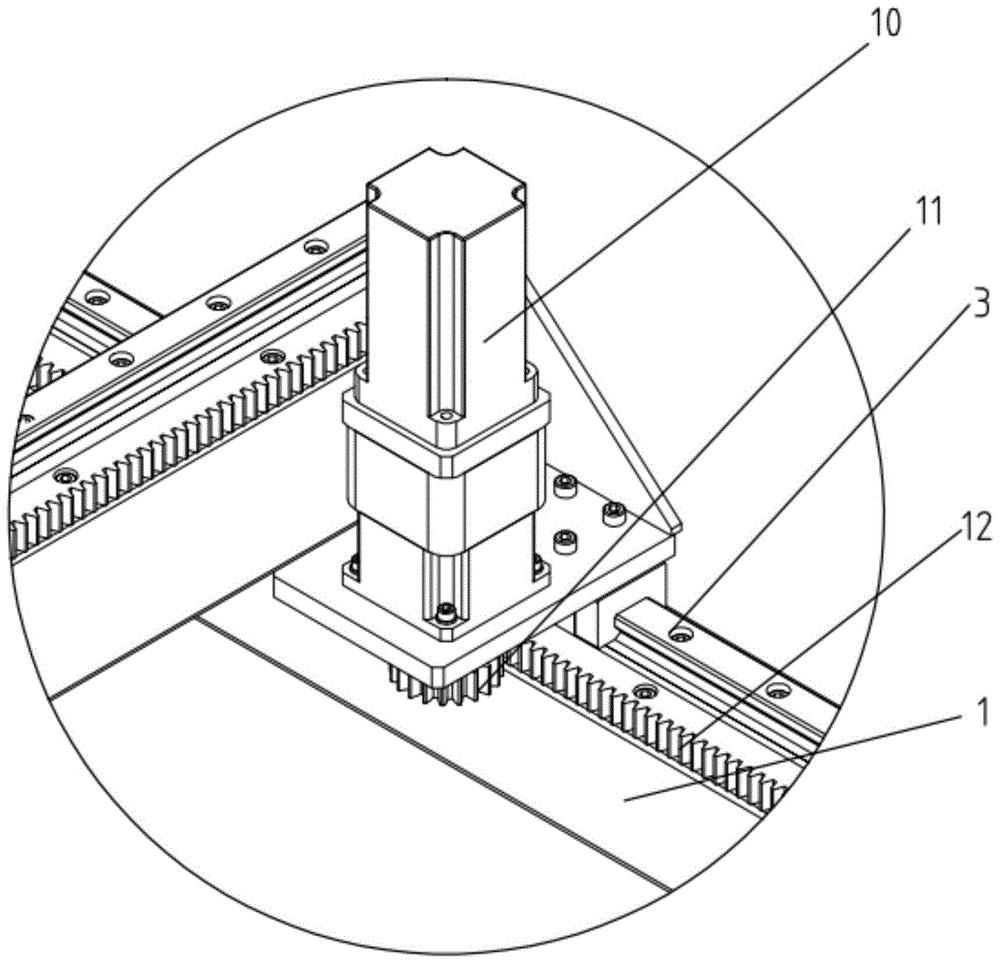

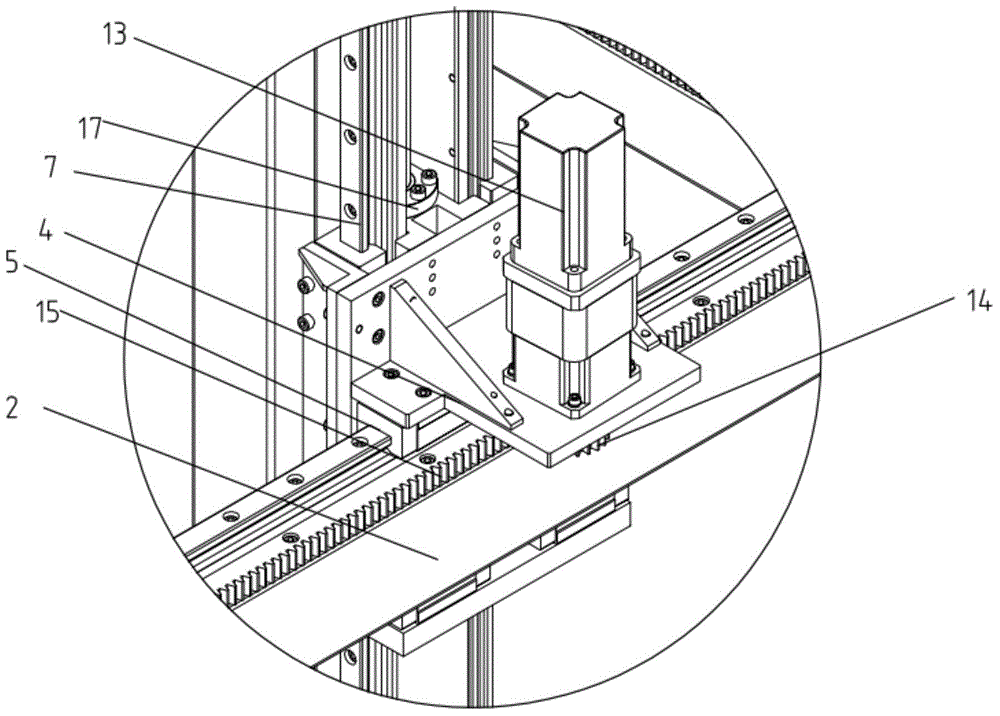

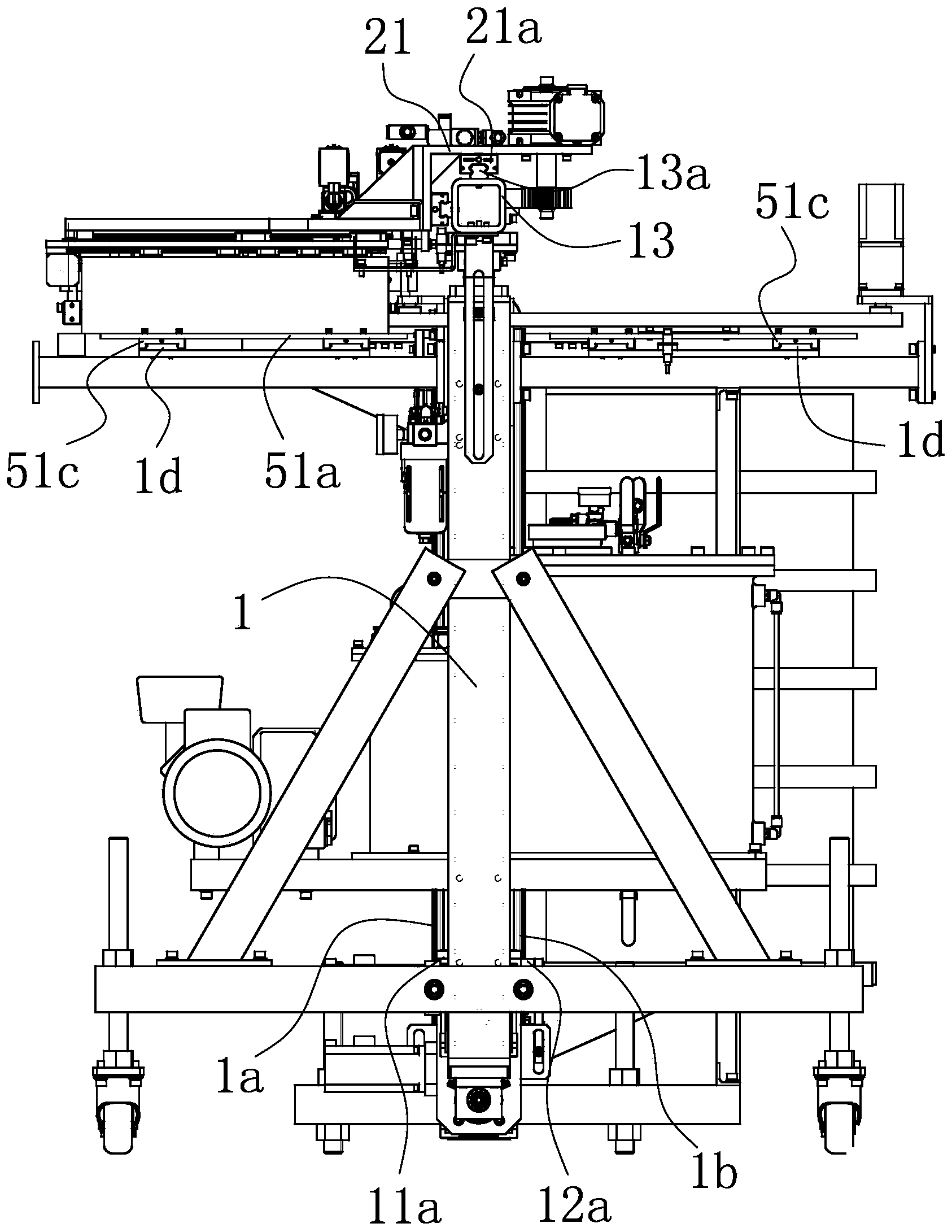

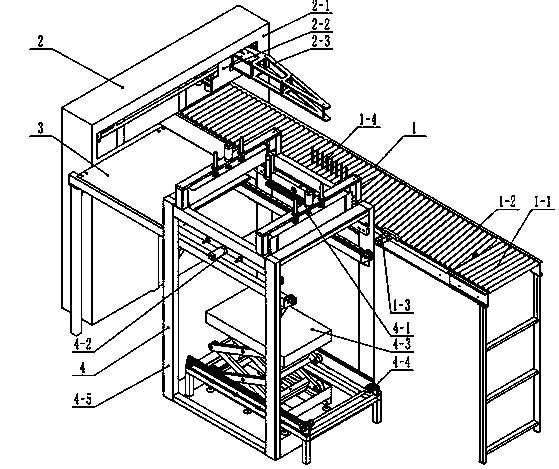

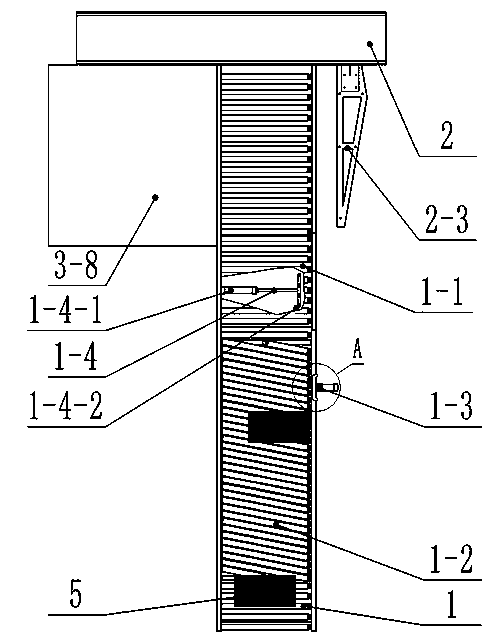

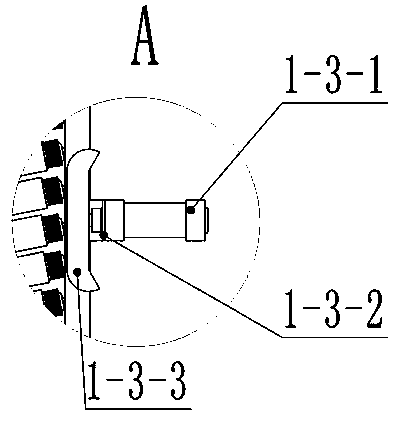

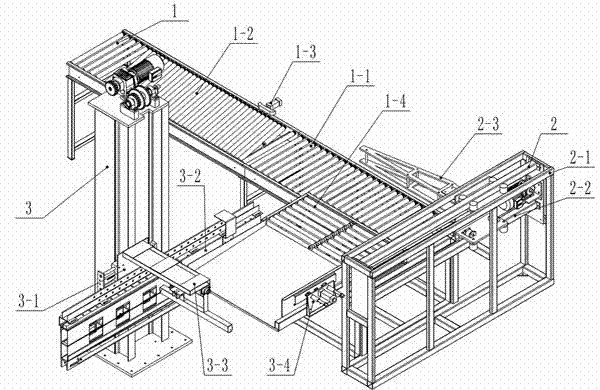

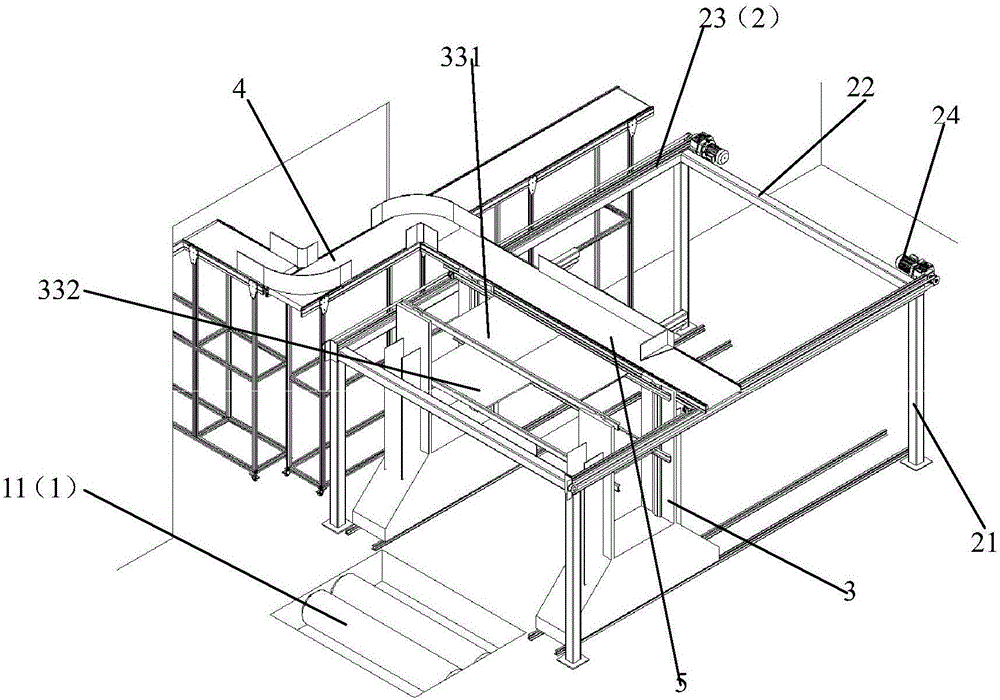

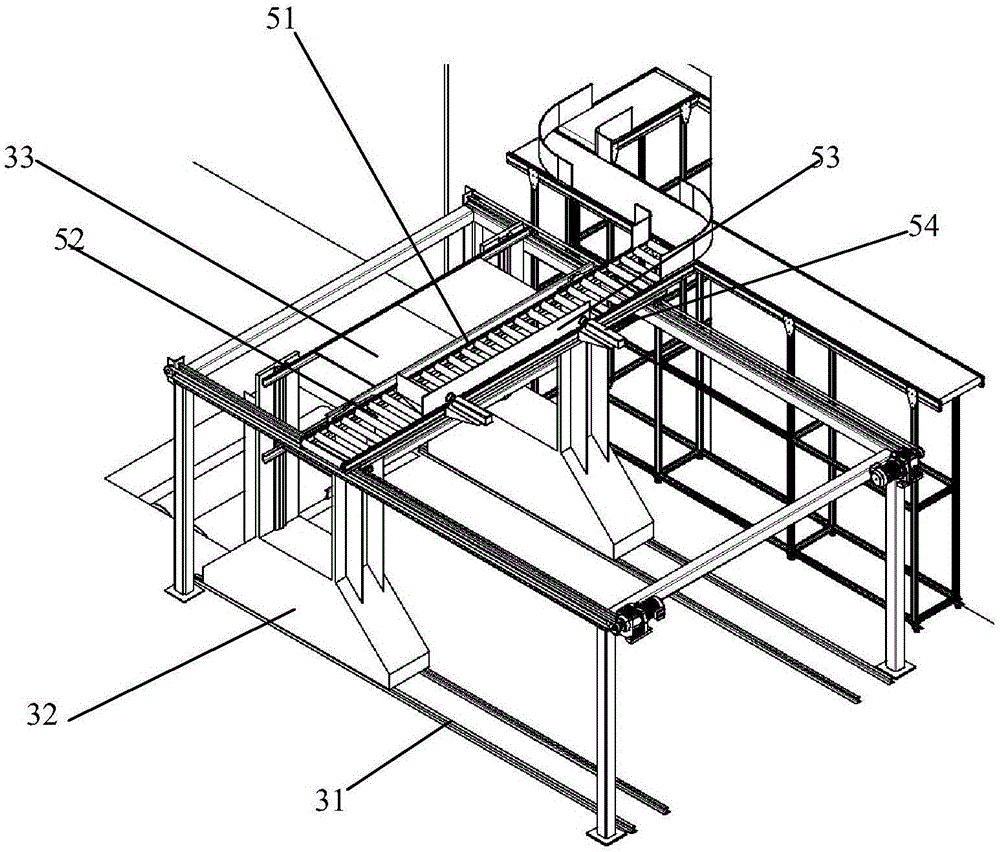

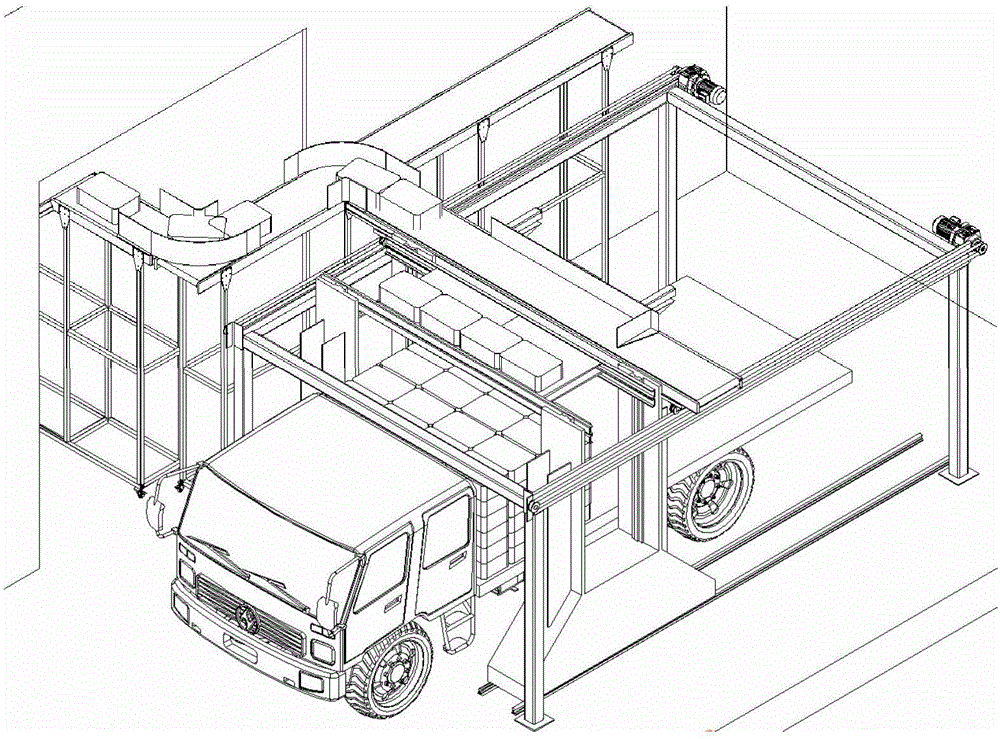

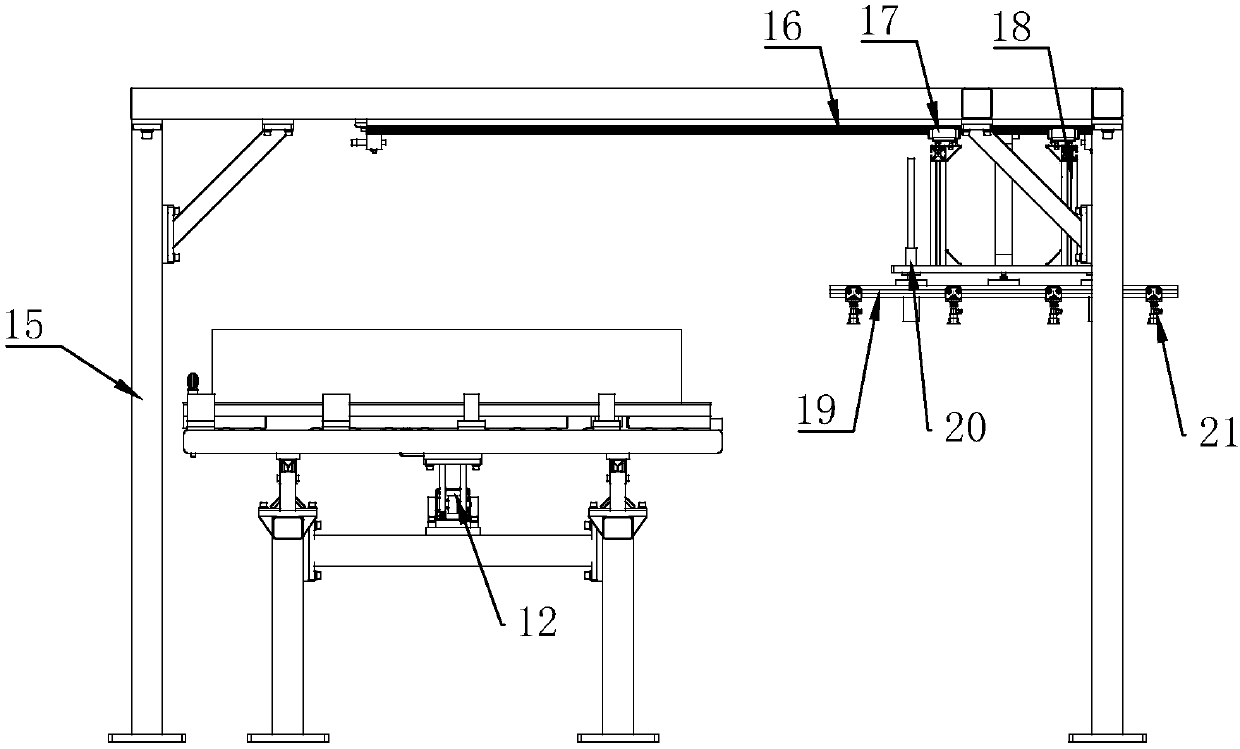

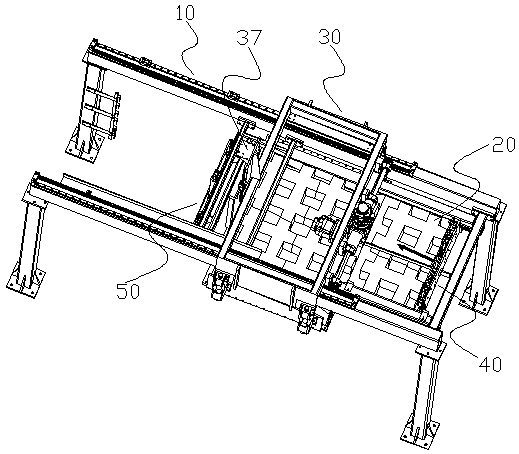

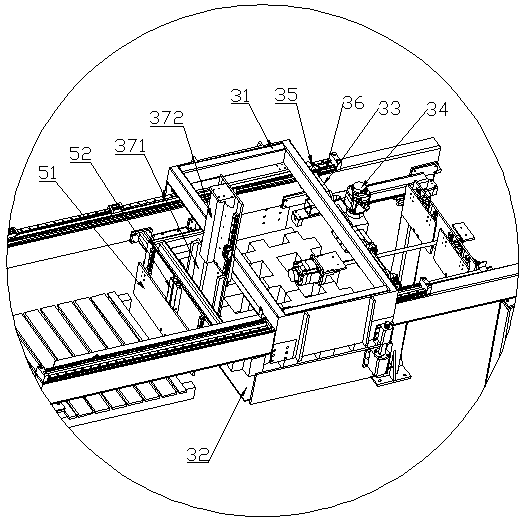

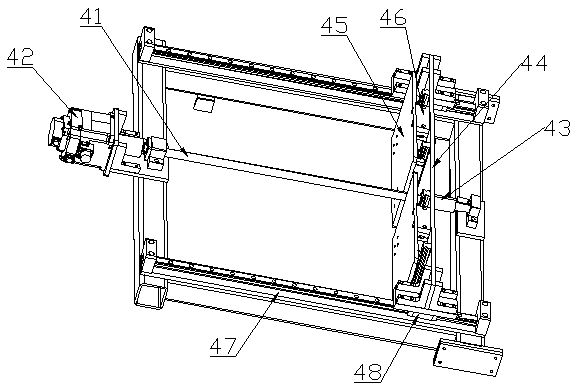

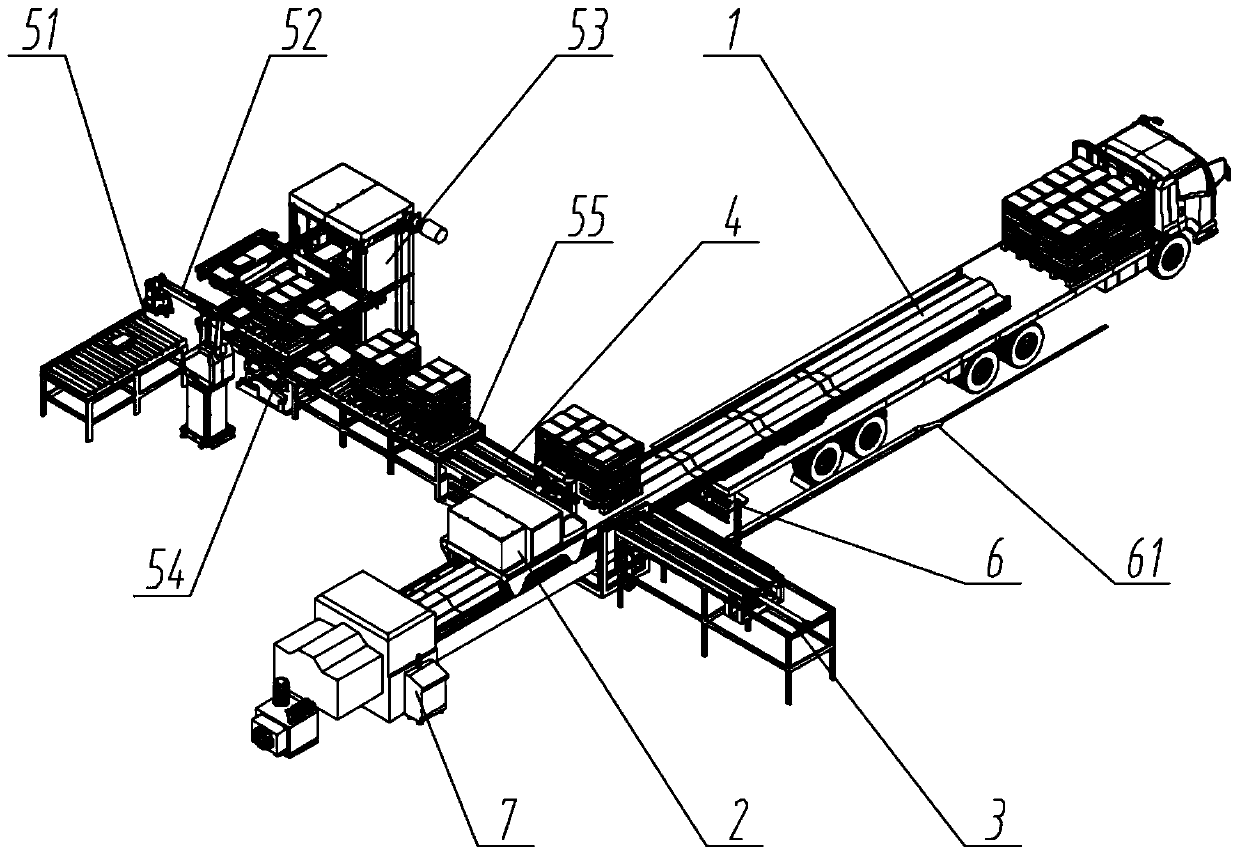

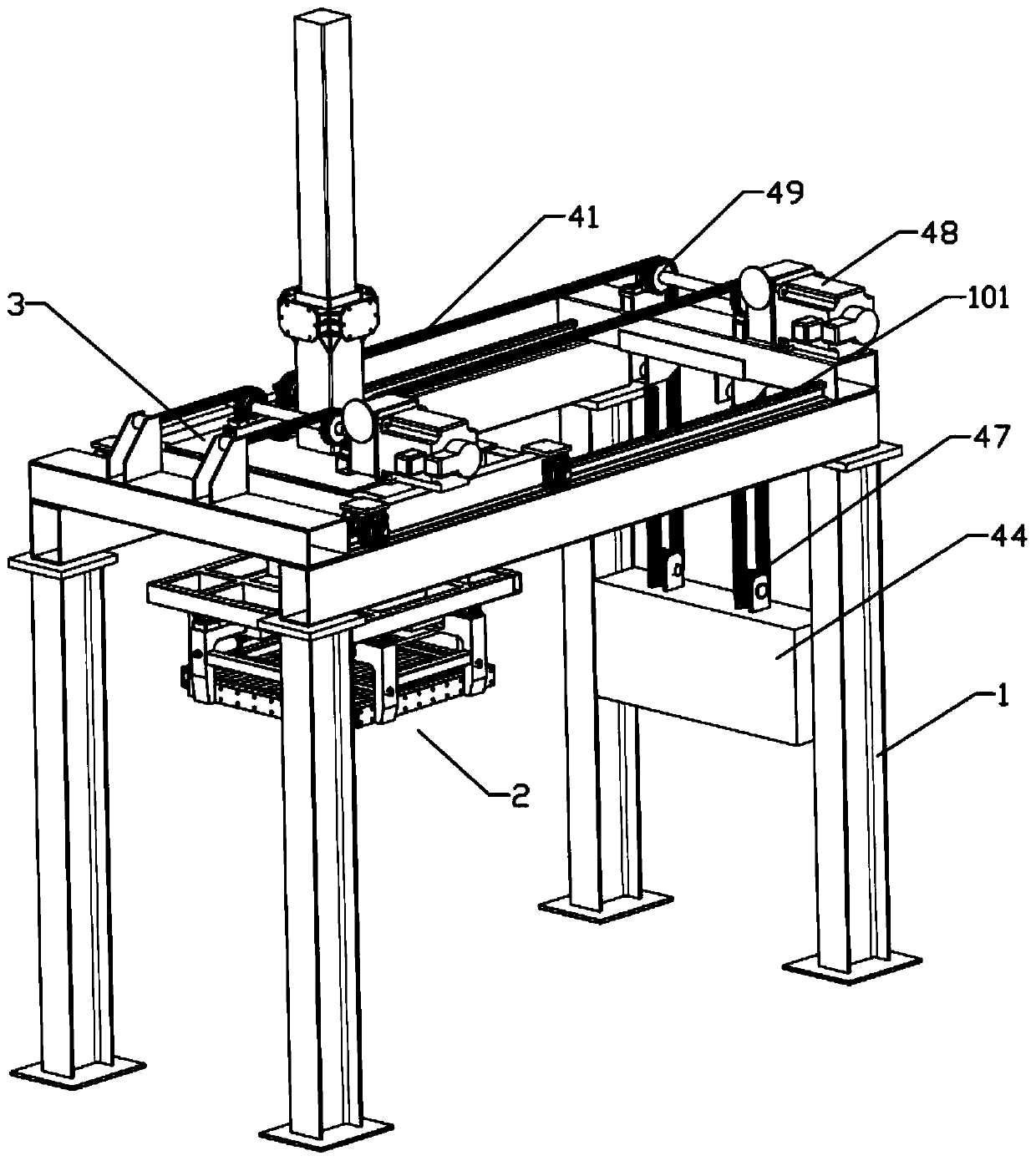

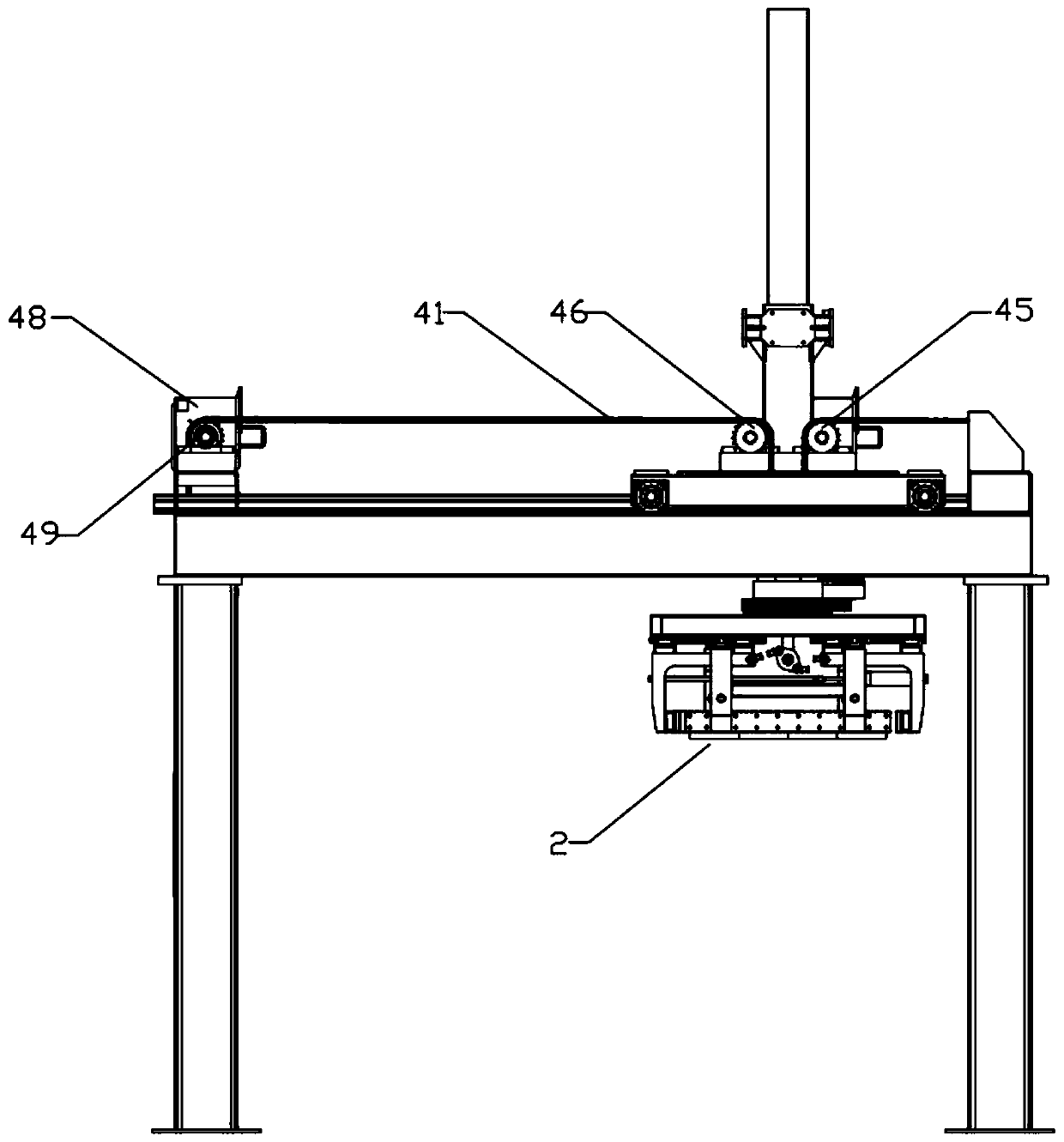

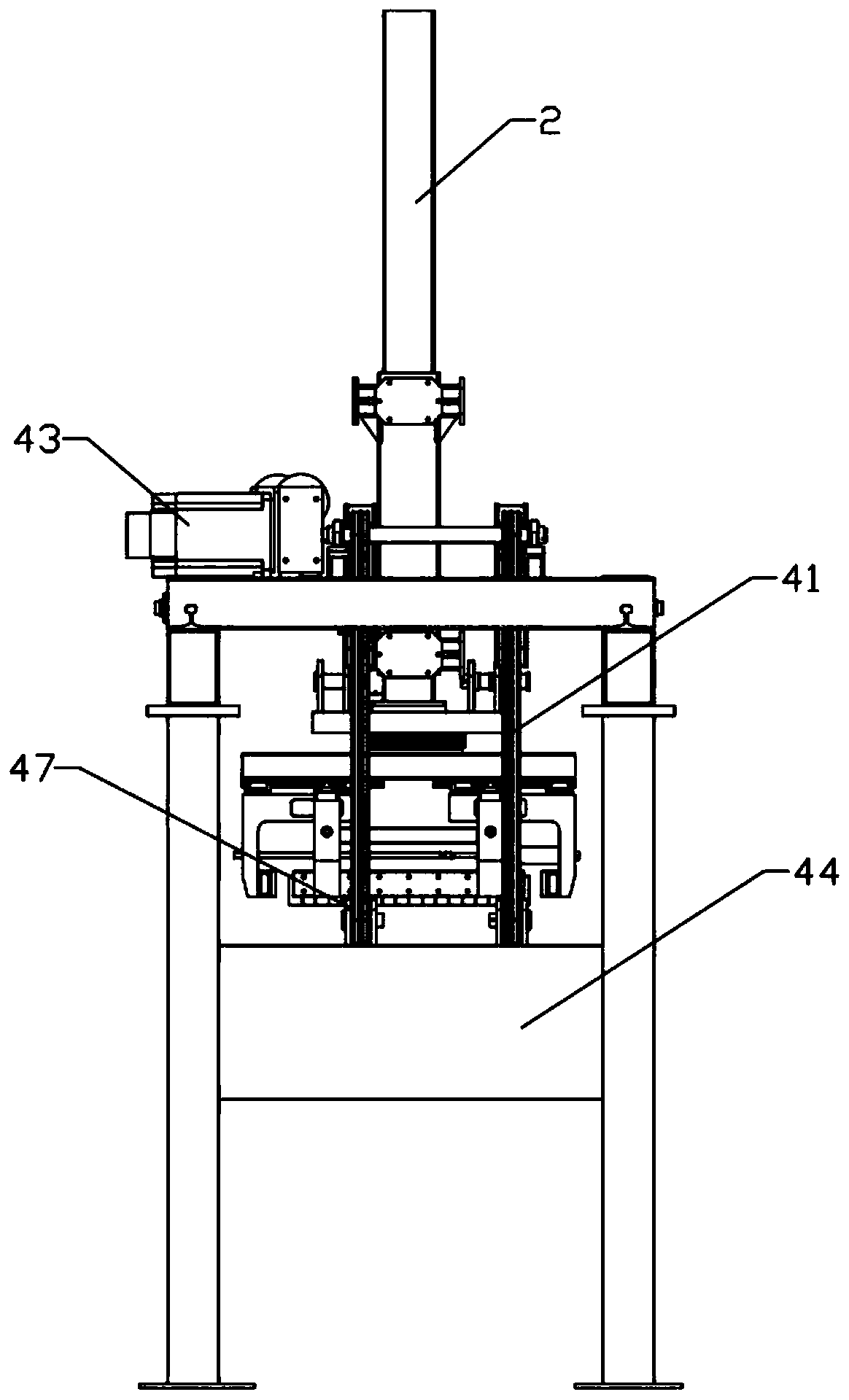

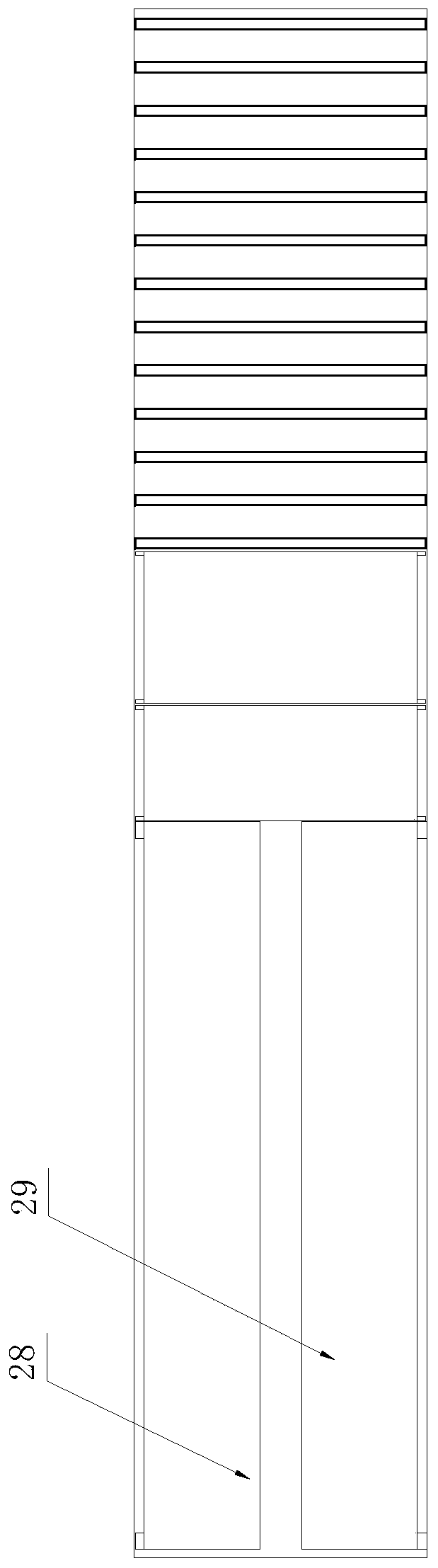

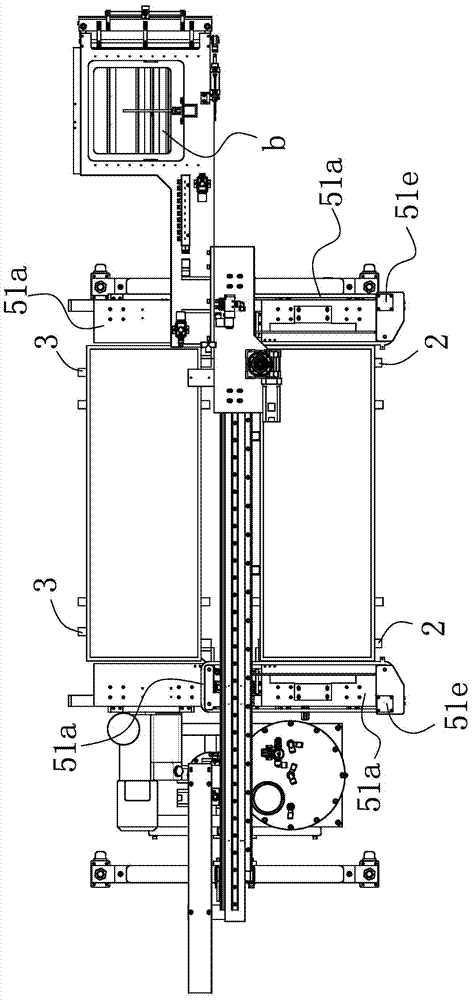

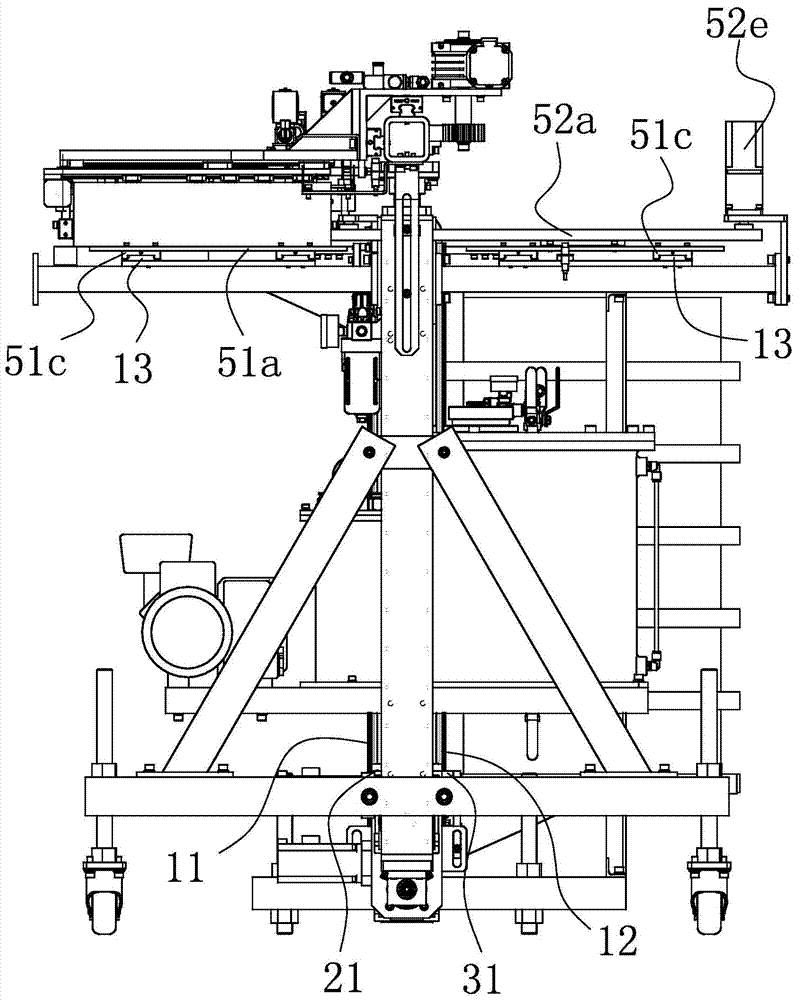

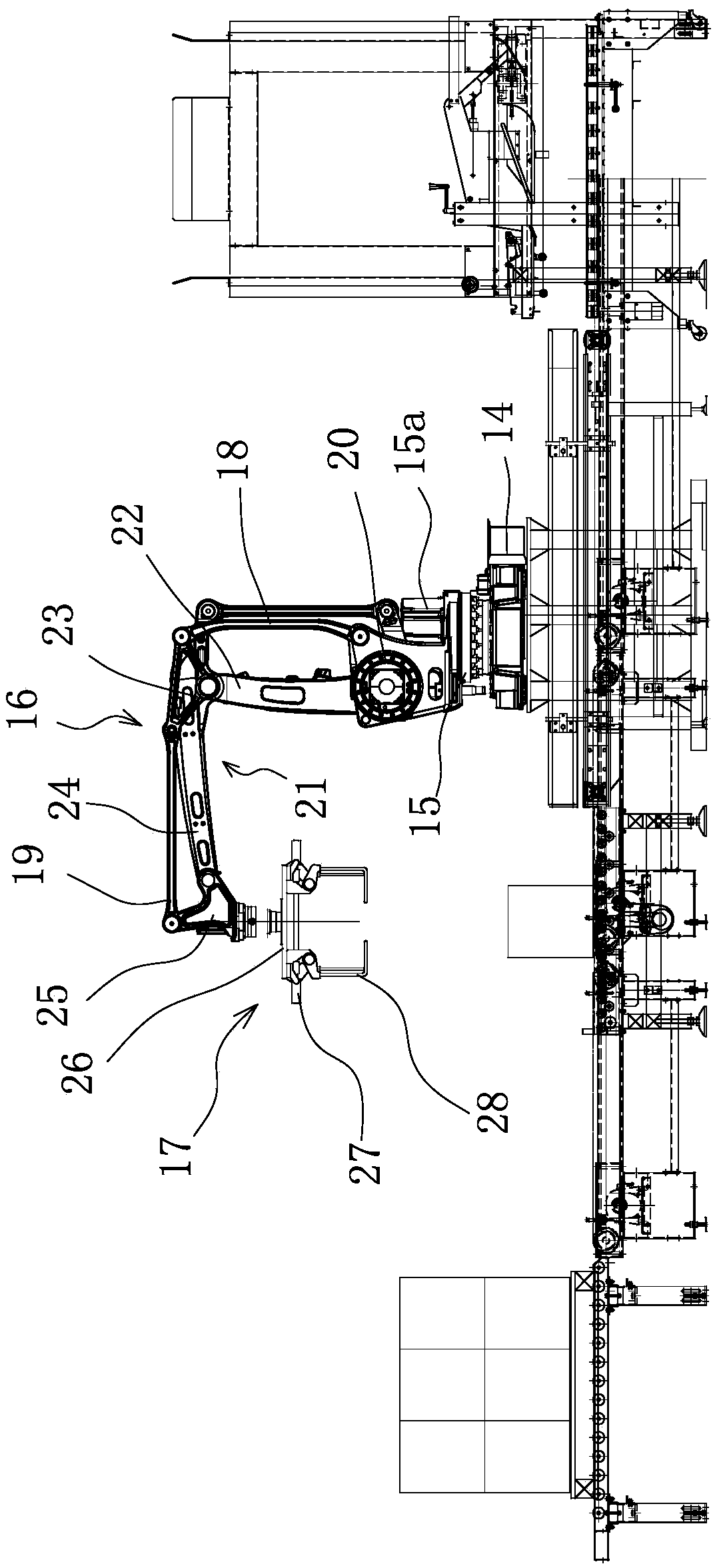

Automatic loading and stacking production line

ActiveCN106743778ARealize automatic palletizingNo human intervention requiredConveyorsStacking articlesProduction lineEngineering

The invention discloses an automatic loading and stacking production line, and solves the technical problem that full-automatic loading and stacking cannot be performed in the prior art as mentioned in the background art. The automatic loading and stacking production line comprises a vehicle positioning system arranged on a loading site, elevated gantry-type automatic feeding systems are arranged on two sides of the site for truck positioning and tracking, an upright straddle type automatic stacking system is arranged inside each elevated gantry-type automatic feeding system, and an automatic supply system used for supplying cargoes to each elevated gantry-type automatic feeding system automatically is arranged on the outer side of each elevated gantry-type automatic feeding system. The automatic loading and stacking production line has the advantages that automatic stacking is really realized without manual intervention, and automatic loading and stacking can be performed as long as vehicles park inside.

Owner:江苏保力自动化科技有限公司

Packing and stacking device for smoke alarm assembly production line

PendingCN106742421AFast packFast palletizingConveyorsStacking articlesMechanical equipmentEngineering

The invention discloses a packing and stacking device for a smoke alarm assembly production line, belonging to the field of product assembly equipment. The packing and stacking device comprises a packing box feeding device, a grabbing and packing device, a conveying device and a stacking device, wherein the conveying device is arranged between the packing box feeding device and the stacking device; the packing box feeding device comprises a package pushing and conveying mechanism and a baffling mechanism; the package pushing and conveying mechanism and the baffling mechanism are arranged on one end of the conveying device; the grabbing and packing device stretches over the conveying device and the product assembly line; the stacking device comprises a stacking pushing and conveying mechanism, a stacking pushing-out mechanism and a lifting stacking mechanism; the stacking pushing and conveying mechanism is arranged on one side of the conveying device; the lifting stacking mechanism is arranged on the other side of the conveying device; and the stacking pushing-out mechanism is arranged on one side of the lifting stacking mechanism. According to the packing and stacking device, manual packing and stacking work is replaced by mechanical equipment, so that packing and stacking efficiency for smoke alarms is greatly improved; and manual labor intensity and labor cost are lowered.

Owner:常州赛凯电器设备有限公司

Automatic stacking device for iron-core silicon-steel sheets of transformers

PendingCN107867565AGuaranteed accuracyRealize automatic palletizingStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention discloses an automatic stacking device for iron-core silicon-steel sheets of transformers. The automatic stacking device comprises a first stock bin mechanism, a first transmission mechanism, a stacking mechanism, a loading mechanism, a second stock bin mechanism and a second transmission mechanism, wherein the first stock bin mechanism is used for storing upper yoke-sheet silicon-steel sheets to be assembled and lower yoke-sheet silicon-steel sheets to be assembled; the first transmission mechanism is used for conveying the upper yoke-sheet silicon-steel sheets and the lower yoke-sheet silicon-steel sheets on the first stock bin mechanism to the space below the stacking mechanism; the second stock bin mechanism is used for storing side-column silicon-steel sheets to be assembled and central-column silicon-steel sheets to be assembled; the second transmission mechanism is used for conveying the side-column silicon-steel sheets and the central-column silicon-steel sheets on the second stock bin mechanism to the space below the stacking mechanism; and the upper yoke-sheet silicon-steel sheets, the lower yoke-sheet silicon-steel sheets, the side-column silicon-steel sheets and the central-column silicon-steel sheets are alternately stacked on the loading mechanism through the stacking mechanism according to the transformer specifications needed by customers. The automatic stacking device disclosed by the invention is high in assembly yield and capable of automatically identifying incoming materials, and the assembled products are diversified.

Owner:南通睿驰智能科技有限公司

Palletizer

InactiveCN111453439AImprove stabilityRealize automatic palletizingConveyorsStacking articlesRobot handPalletizer

The invention discloses a palletizer. The palletizer comprises a rack; a master control unit; an arrangement mechanism arranged on the rack and used for placing and arranging boxes to be palletized; apalletizing mechanism arranged on the rack and used for palletizing the arranged boxes to be palletized; a paper separating bin arranged on the rack and used for placing and storing separating paperneeded for palletizing; the palletizing mechanism comprises a first mechanical hand, a second mechanical hand and a palletizing station; the palletizing station comprises a lifting platform; a first pallet is arranged on the lifting platform; the first mechanical hand is used for palletizing the arranged boxes to be palletized on the first pallet into a layer; the second mechanical hand takes outa piece of separating paper from the paper separating bin and puts the separating paper on the palletized layer; and the first mechanical hand and the second mechanical hand alternately work to palletize the boxes to be palletized to a stack. The palletizer provided by the invention realizes automatic palletizing of the boxes, reduces the labor cost, and further improves the palletizing efficiency.

Owner:深圳市安耐节科技有限公司

Blade-free stacking machine and process thereof

PendingCN110217433ARealize automatic palletizingIncrease productivityPackaging automatic controlFailure rateProduction line

The invention relates to the technical field of hygienic product packaging equipment. A blade-free stacking machine is used for being connected with the discharge end of production line equipment fordisposable hygienic product adult diapers, disposable baby diapers, disposable nursing mats and other products, and stacking and packaging are conducted. The blade-free stacking machine comprises a main rack. Height-adjustable support legs are arranged under the main rack. The main rack is provided with a control system for controlling all driving devices. The main rack is provided with a stackingdevice, a stack pushing device and a stack receiving device. The stacking device comprises a first conveying assembly and a second conveying assembly which are matched with each other for operation.The stack receiving device is arranged on one side of the stacking device. The stack pushing device is arranged on one side of the main rack. A stacking process based on the blade-free stacking machine comprises the steps of stacking, stack pushing and stack receiving. Through the blade-free stacking machine and the process thereof provided by the invention, the problems of high labor intensity, low efficiency, a high failure rate and high cost of existing equipment technology can be solved.

Owner:晋江市万晋自动化设备有限公司

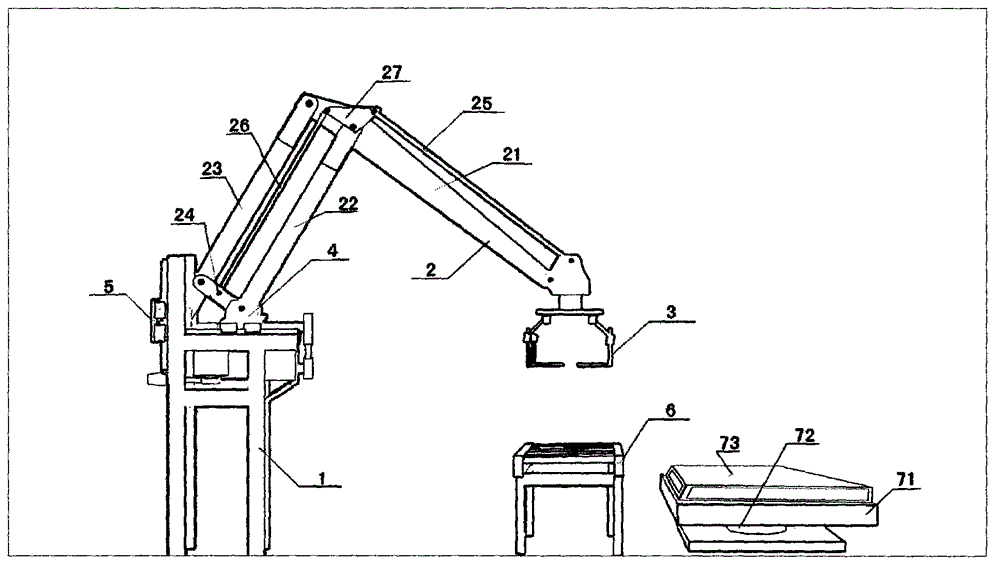

Simple mechanical arm stacking machine

InactiveCN104555472AAchieve axial movementRealize automatic palletizingStacking articlesDe-stacking articlesFailure rateEngineering

The invention relates to a simple mechanical arm stacking machine. The machine comprises a rack, a mechanical arm, a mechanical grip, a horizontal driving mechanism and a vertical driving structure, wherein the mechanical arm comprises a main arm, a front arm, a rear arm and a front and rear arm connecting rod; the front arm is parallel to the rear arm and forms a parallelogram with the front and rear arm connecting rod and the rear end part of the main arm; the mechanical grip is arranged at the front end of the main arm; the horizontal driving mechanism and the vertical driving structure are both arranged on the rack and are used for driving the movement and the action of the mechanical arm. By using two-axis control, the production precision requirement and cost are reduced, the failure rate of equipment is obviously reduced, the labor is saved and the stacking efficiency is improved while automatic stacking of the mechanical arm is realized, and the stacking machine is applicable to widespread application.

Owner:王超

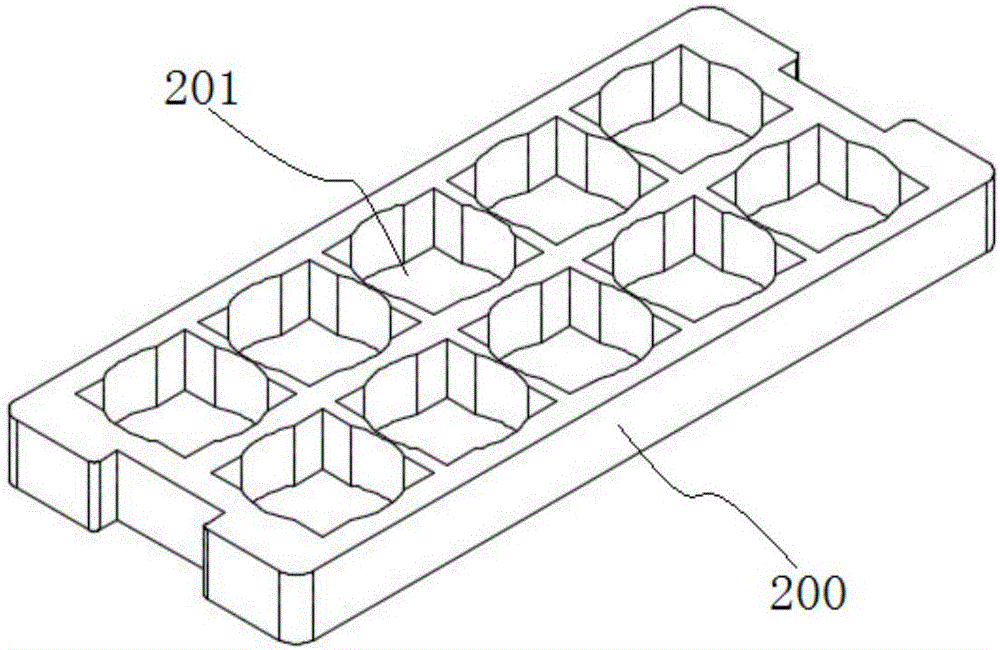

Finished #-shaped block stacking device

PendingCN110002178ARealize automatic palletizingGuaranteed stacking qualityStacking articlesConveyor partsButt jointEngineering

The invention discloses a finished #-shaped block stacking device comprising a rack arranged between a finished #-shaped block conveying device and a stacked #-shaped block conveying device. The rackis provided with a transverse transferring device used for bearing finished #-shaped blocks; the rack is further provided with a loading device which is used for loading the finished #-shaped blocks output by the finished #-shaped block conveying device to the transverse transferring device; and the rack is also provided with an unloading device which is used for unloading the finished #-shaped blocks on the transverse transferring device to the stacked #-shaped block conveying device. The finished #-shaped block stacking device can be in butt joint with the finished #-shaped block conveying device and the stacked #-shaped block conveying device, and automatic stacking of finished #-shaped block prefabricated parts can be realized. The finished #-shaped block stacking device is simple in structural design and reliable in performance. In the stacking process, the prefabricated parts do not need to be lifted, stacking in place can be achieved only through one time of horizontal carrying,and the carrying efficiency can be effectively improved. In addition, the pallet height can be controlled in cooperation with a lifting device, and the stacking quality of the prefabricated parts canbe ensured.

Owner:北京好运达智创科技有限公司

Stacking mechanism

ActiveCN106809438ARealize automatic palletizingImprove palletizing efficiencyPackagingEngineeringUltimate tensile strength

The invention discloses a stacking mechanism, which can be applied to the field of keel packaging. The stacking mechanism comprises a conveying device and a positioning mechanism, wherein the conveying device is configured into a state of conveying keels to a position of the positioning mechanism; the keels are sequentially arranged in the position of the positioning mechanism; the automatic stacking is realized; the work intensity of stacking by workers is reduced; the stacking efficiency of the keels is improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Standard brick stacking automatic line

InactiveCN104044922AIncrease production capacityImprove stabilityStacking articlesConveyor partsBrickBelt conveyor

The invention provides a standard brick stacking automatic line, which belongs to the technical field of engineering building material standard brick stacking and mainly solves the problems that during the existing standard brick manual stacking, workers are tired and dirty, the physical power is wasted, and many persons are required. The standard brick stacking automatic line is mainly characterized by comprising a horizontal belt conveyor, a slope hoisting machine, a conveying rolling passage and a turning conveying rolling passage in parallel and sequential connection, wherein a first power rolling passage, a push rod combining platform, a hydraulic hoisting machine, a second power rolling passage and an unpowered rolling passage are arranged at a merging part of the first conveying rolling passage and the turning conveying rolling passage, and air cylinder railings and air cylinder push rods are arranged on the conveying rolling passage, the power rolling passage, the turning conveying rolling passage and the push rod combining platform. The standard brick stacking automatic line has the characteristics that the structure is simple, the operation is convenient, less labor is required, and in addition, the alternate ranging brick stacking can be realized. The standard brick stacking automatic line is mainly used for automatically stacking standard bricks conveyed out from a production region.

Owner:张守智

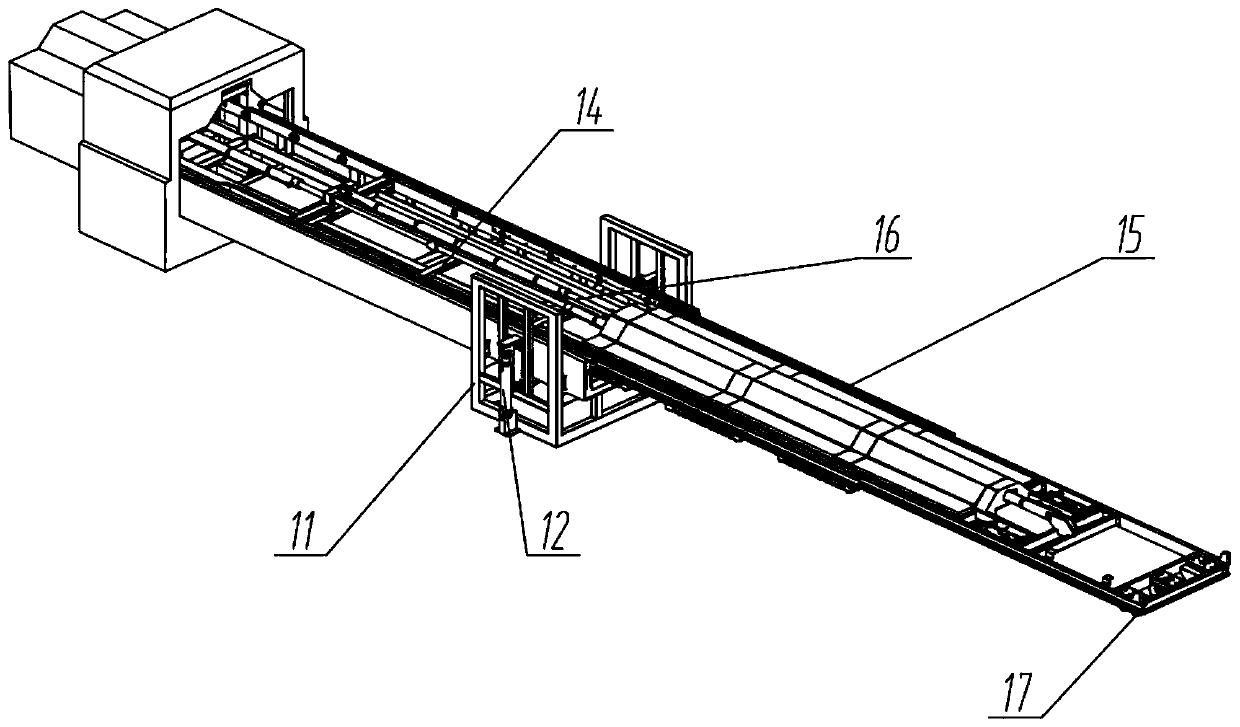

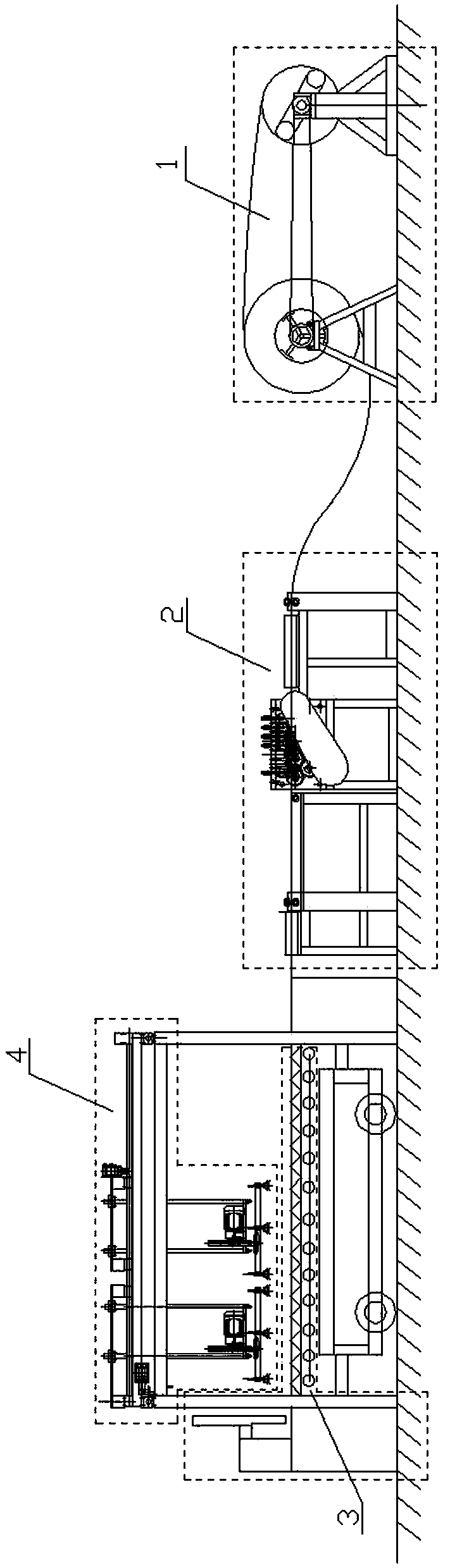

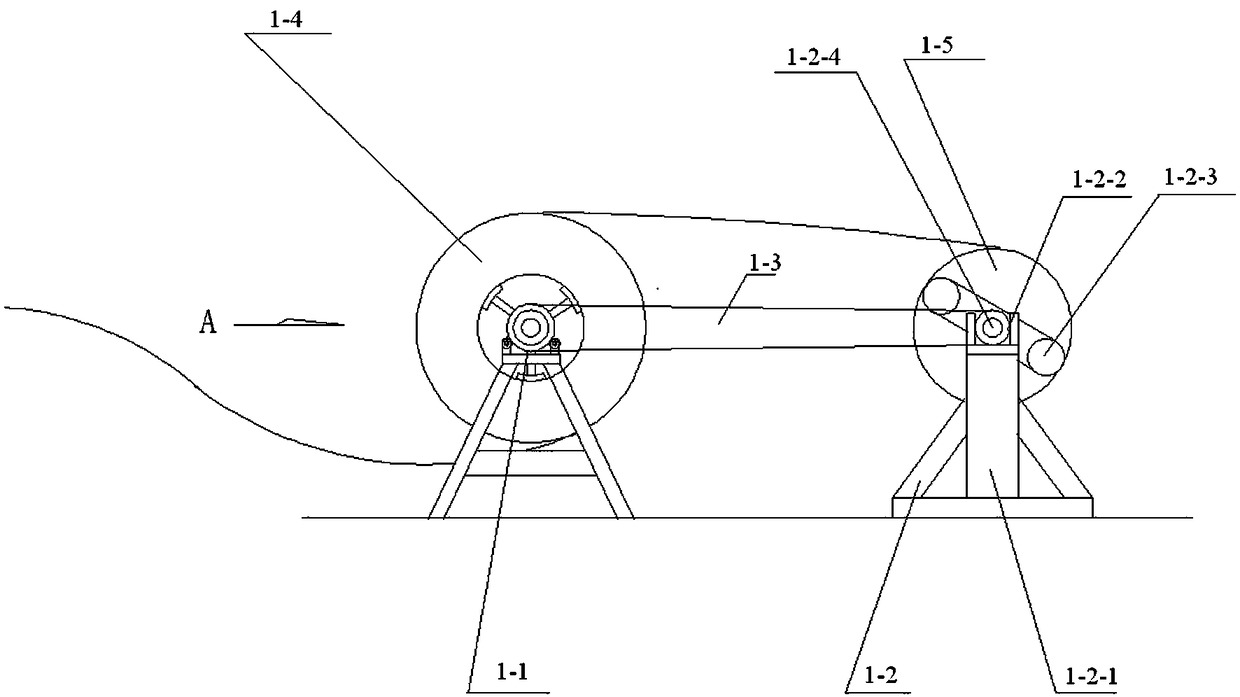

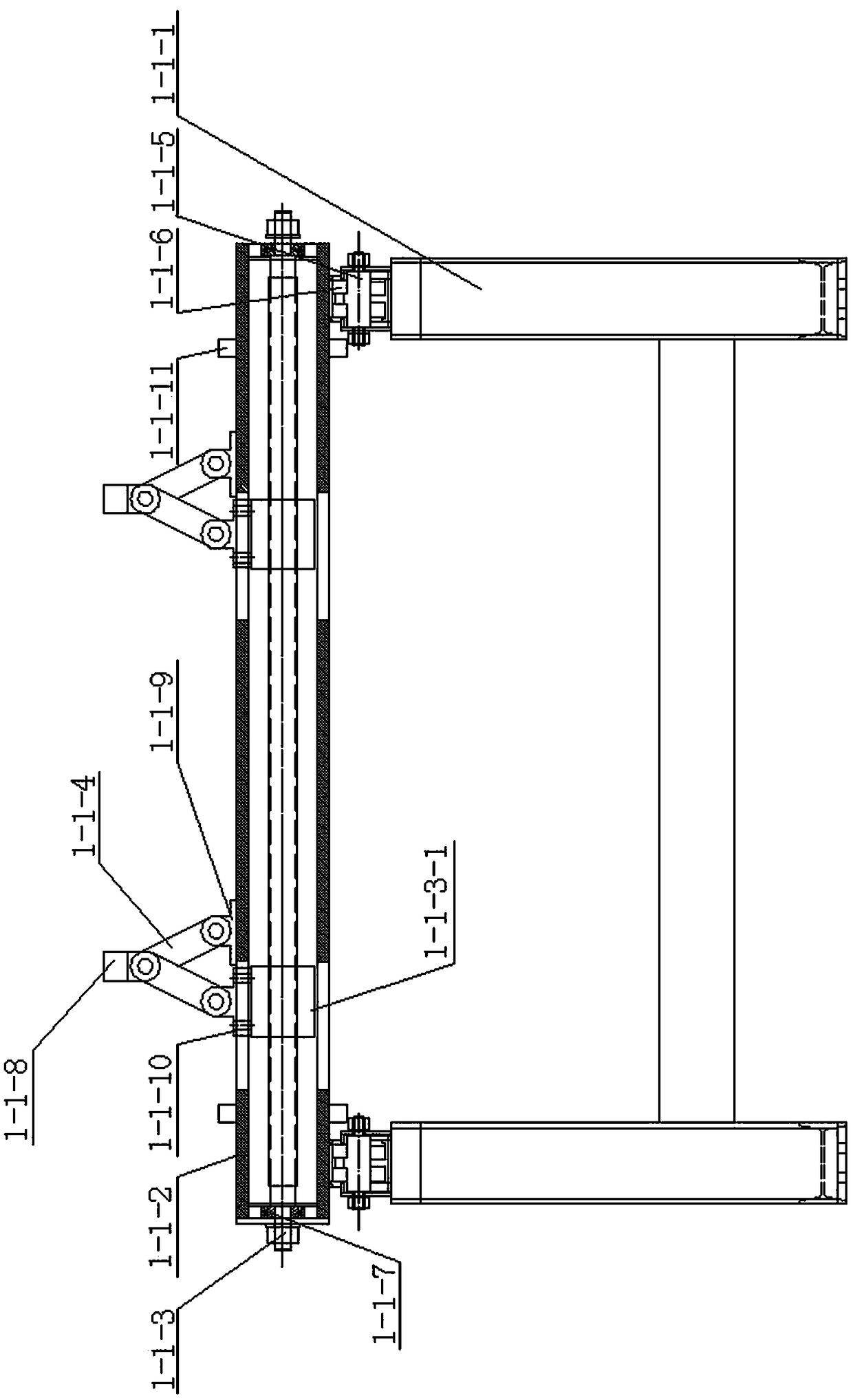

Rapid automatic truck loading system and control method thereof

InactiveCN111453468AFast loadingLoad accuratelyStacking articlesLoading/unloadingEngineeringControl theory

The invention discloses a rapid automatic truck loading system. The rapid automatic truck loading system comprises a truck loading device and a material fetching component located at one end of the truck loading device, wherein the truck loading device comprises a stretching and contracting component, a supporting component and a material feeding forklift, the stretching and contracting componentcomprises a plurality of sliding rails performing stretching-contracting moving among the sliding rails, the adjacent sliding rails are stacked inside and outside and are driven by a first stretchingand contracting rod, the sliding rail on the outermost side is installed on supporting racks, and the lower portions of the sides, close to a truck-loading vehicle, of the other inner-side sliding rails are all provided with a plurality of different supporting idler wheels, the different supporting idler wheels can be in supporting contact with a carriage, the stretching and contracting componentcan perform stretching and contracting into the carriage in the length direction of the carriage, the material feeding forklift performs linear movement through one sliding rail with a guiding position-limiting strip and performs truck loading on cargoes, and the material fetching component is located at the tail portion of the truck-loading vehicle and can perform material fetching on the conveyed cargoes. By means of the rapid automatic loading system, the cargoes is fed into the carriage, manual carrying is saved, furthermore, rapid truck loading is realized through the linear movement of the material feeding forklift, the rapid automatic loading system is more efficient and rapid, and the truck loading is conveniently performed.

Owner:HEFEI EAGLE AUTOMATION ENG TECH

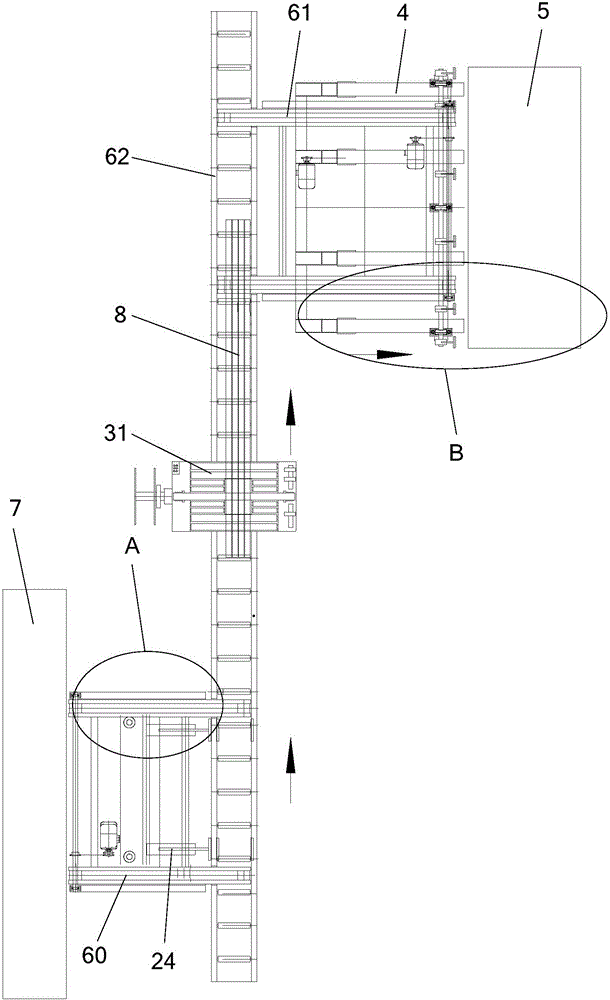

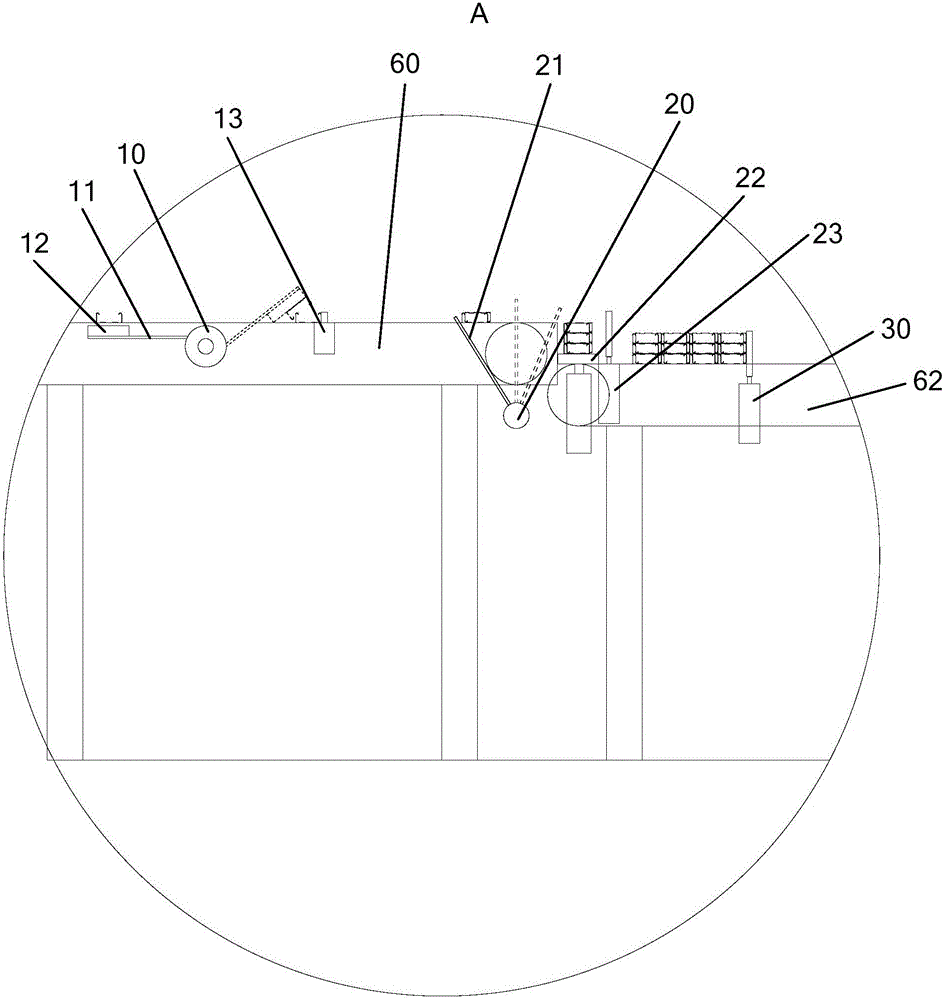

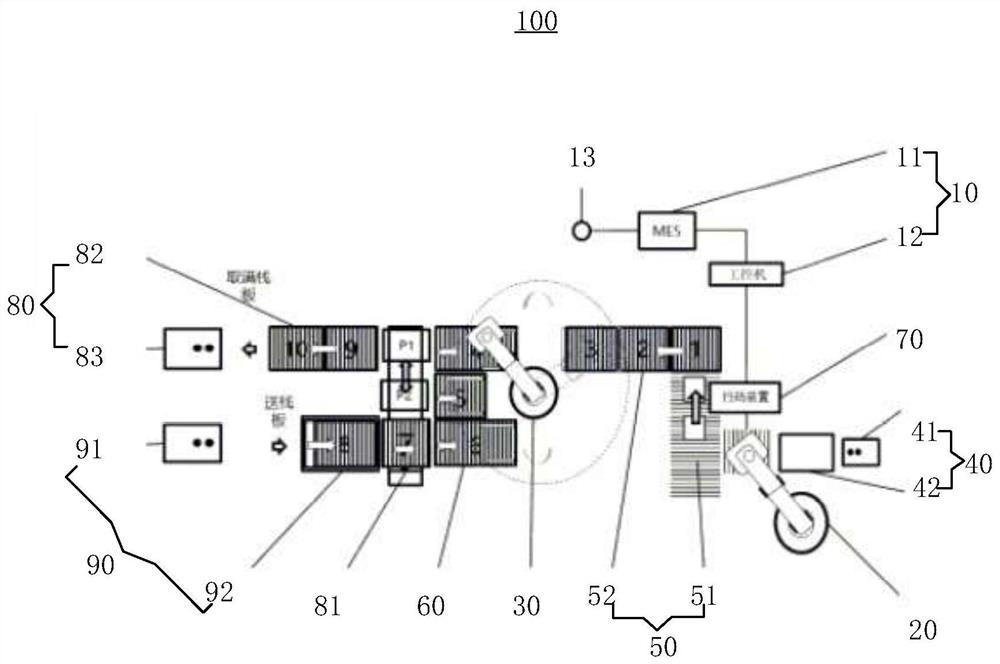

Automatic discharging system and discharging method of heat exchanger plate pieces

PendingCN108608112ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsLaser beam welding apparatusPunchingStack machine

The invention provides an automatic discharging system and method of heat exchanger plate pieces. The system comprises a stainless steel uncoiling device, a stainless steel coil flat plate device anda laser cutting device in sequence; an automatic stacking machine is arranged above the laser cutting device, the stainless steel uncoiling device is used for uncoiling the stainless steel coil, meanwhile, isolation paper on the stainless steel coil is coiled up, the stainless steel coil flat plate device is used for leveling the uncoiled stainless steel coil, the laser cutting device is used forcarrying out laser cutting on the leveled stainless steel coil, and the heat exchanger plate pieces are formed; the automatic stacking machine is used for stacking the heat exchanger plate pieces. Through automatic uncoiling, automatic leveling, automatic laser cutting and automatic stacking of the stainless steel plate pieces, intelligent production of the heat exchanger plate pieces can be achieved, traditional old processes of plate shearing machines, punching machines and punching molds are replaced, and production efficiency and precision are improved.

Owner:辽宁光阳换热设备制造有限公司

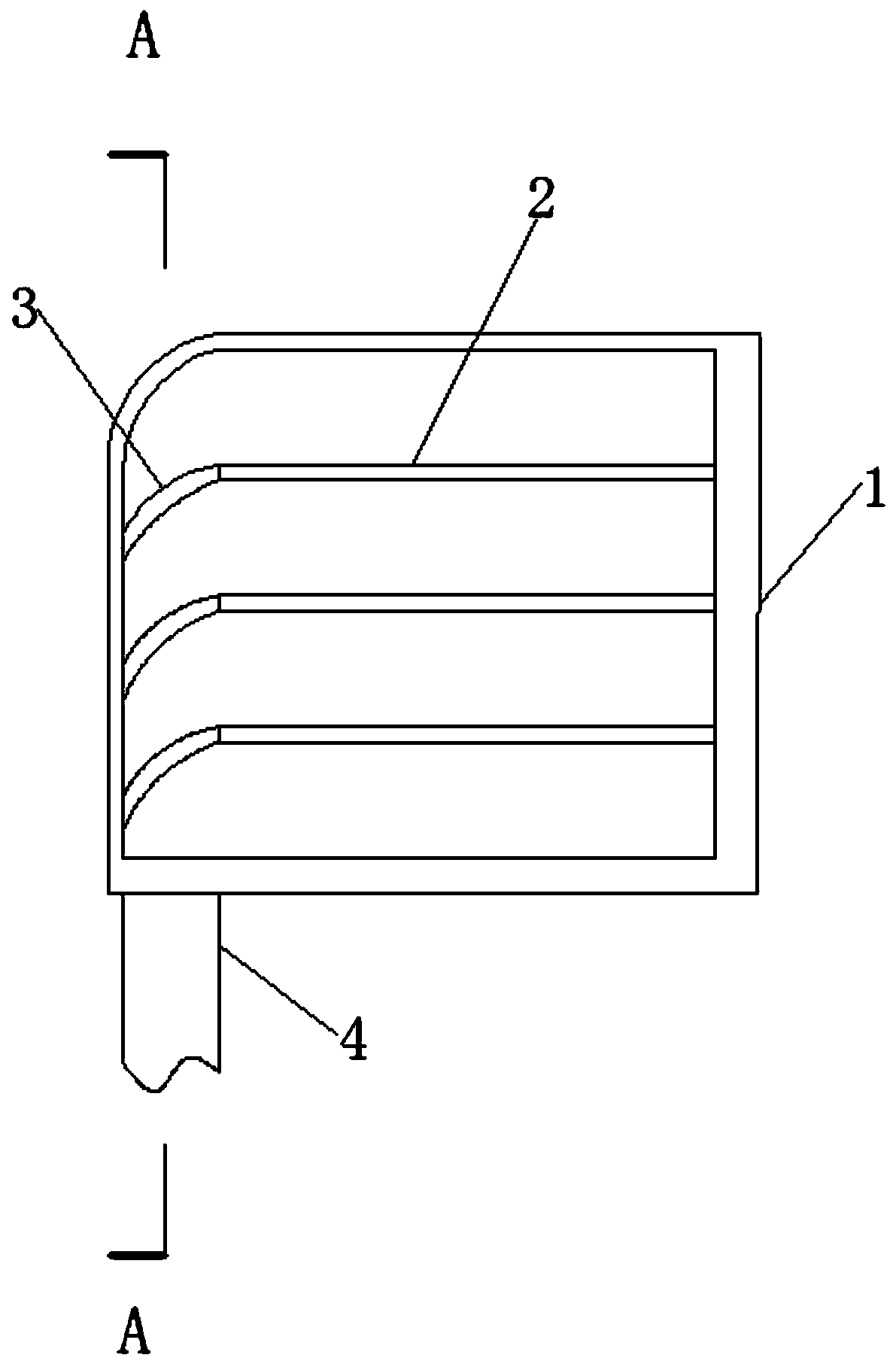

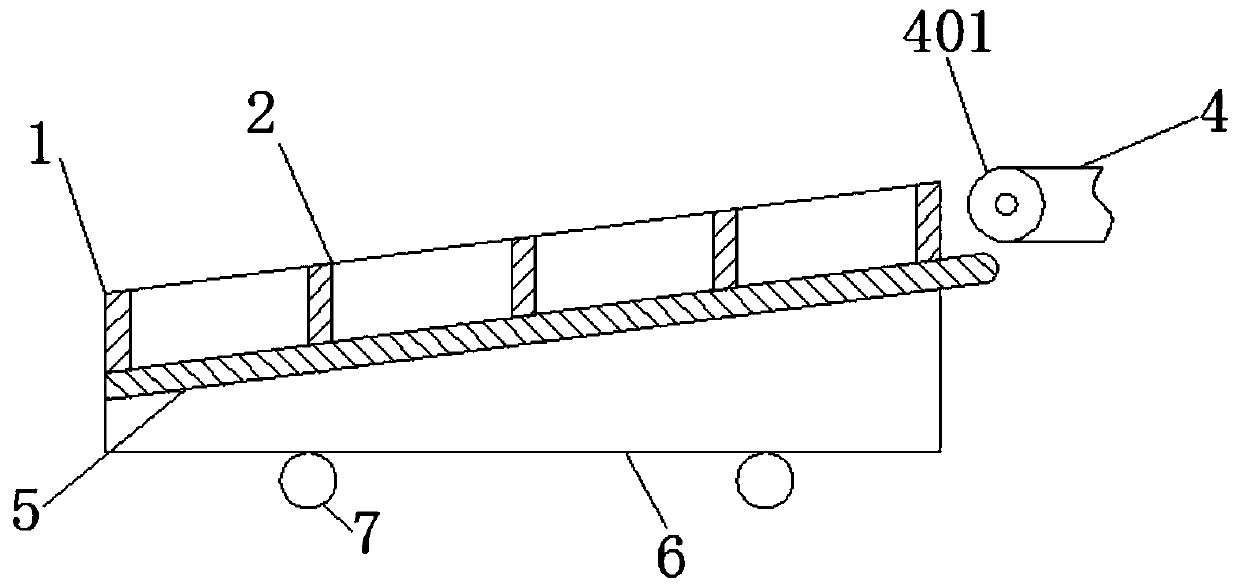

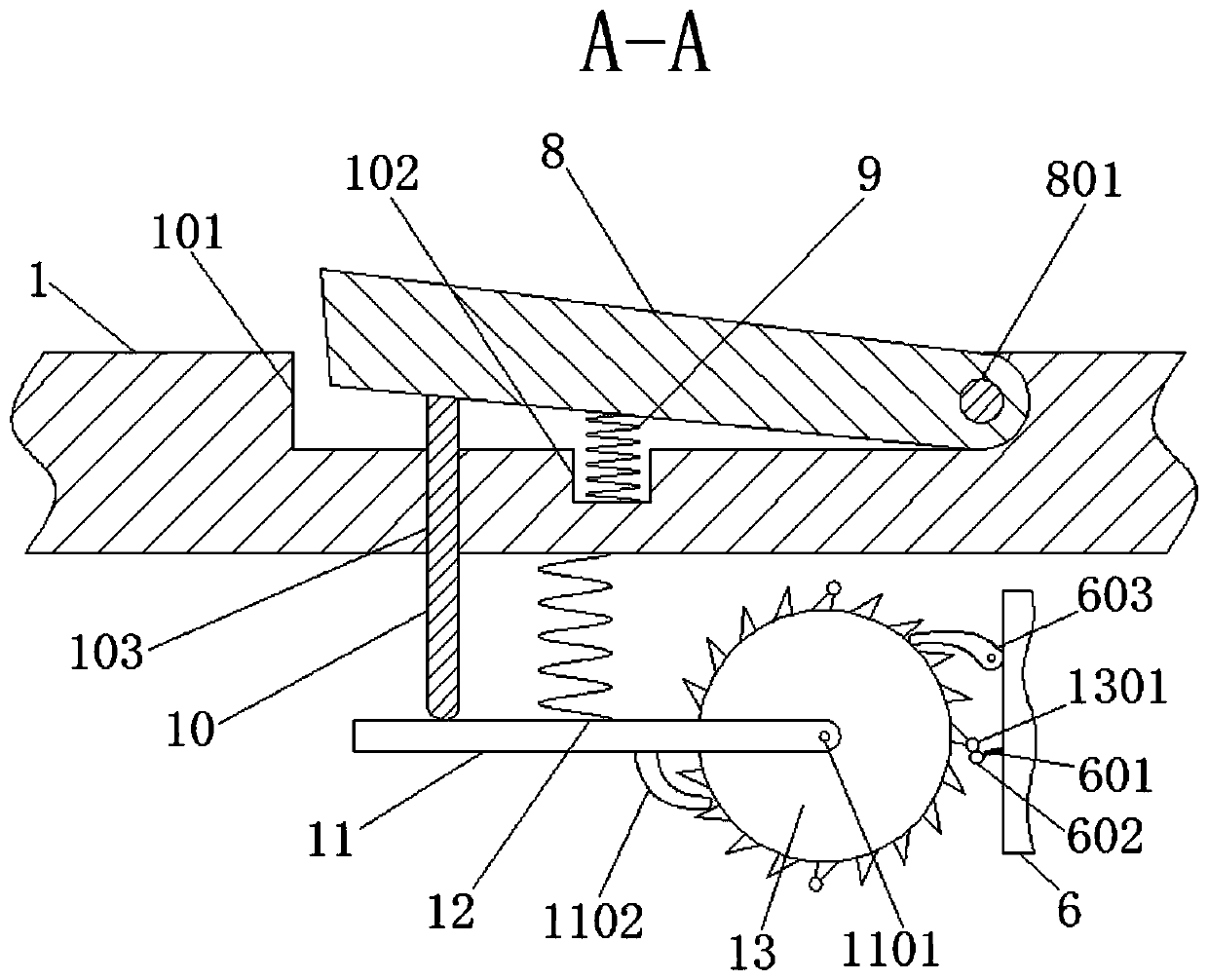

Plastic stacking plate

ActiveCN110817447ARealize automatic palletizingAchieve repeated cycleStacking articlesRatchetEngineering

The invention relates to the technical field of flour stacking tools, in particular to a plastic stacking plate. The plastic stacking plate comprises an outer casing; inner separating plates are connected to the upper part of the outer casing; moving plates are connected to the left ends of the inner separating plates; a conveying belt is arranged at the right end of the outer casing; a pressing plate is connected to the left side of the front end of the outer casing; a first spring is connected to the lower end of the pressing plate; a moving rod is connected to the lower part of the pressingplate; a swinging rod is glidingly connected to the lower end of the moving rod; a second spring is connected between the outer casing and the swinging rod; and a ratchet wheel is connected to the right end of the swinging rod. Bagged flour presses the pressing plate, the pressing plate presses the swinging rod through the moving rod, the swinging rod drives the ratchet wheel to move intermittently through an active pawl, when the quantitative flour is conveyed on a bottom plate each time, a second metal ball and a first metal ball are put through once, a lifting switch of the moving plate corresponds to the position of a metal ball on the ratchet wheel once from the inner side to the outer side, automatic stacking of the bagged flour is realized by the structure, and the quantity of thebagged flour can be calculated easily.

Owner:佛山市西铁模塑制品有限公司

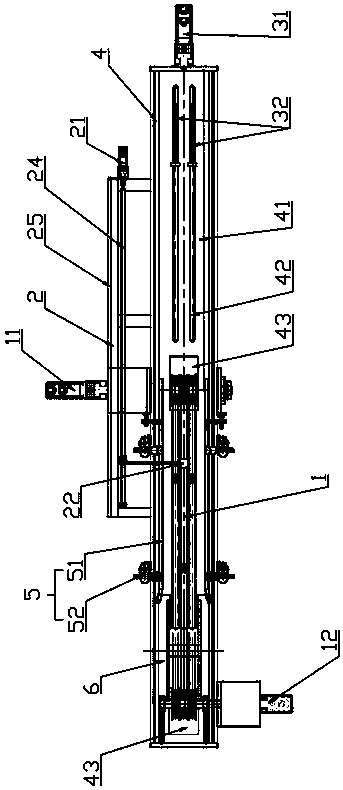

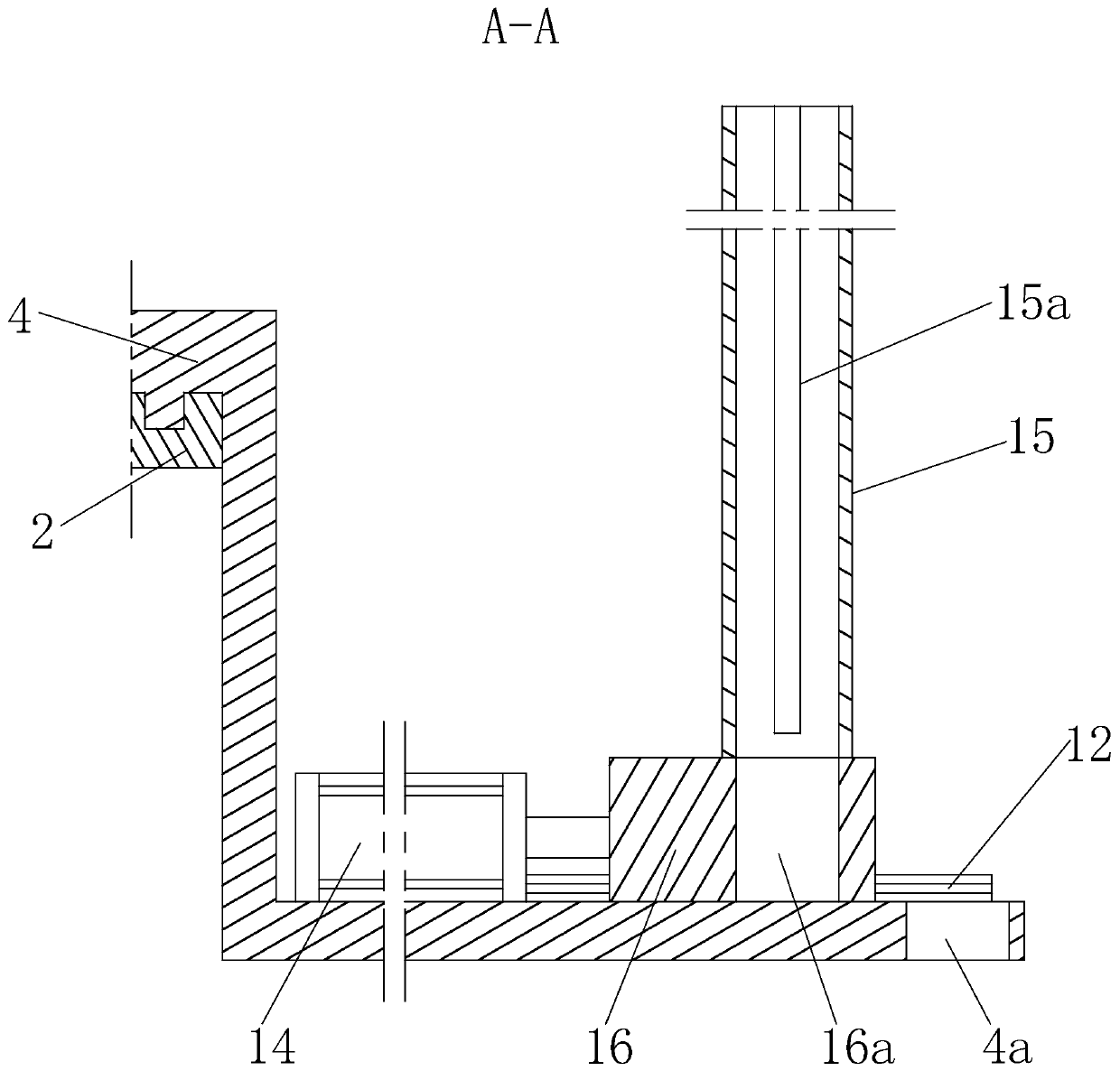

Stacking machine lifting and travelling chain transmission structure and stacking machine

PendingCN110654886ASimple structureRealize automatic palletizingStacking articlesDe-stacking articlesBrickControl engineering

The invention relates to the technical field of stacking equipment, and discloses a stacking machine lifting and travelling chain transmission structure. The stacking machine lifting and travelling chain transmission structure comprises a machine frame and a stacking clamp, wherein a running trolley is arranged on the machine frame, and the stacking clamp is slidably arranged on the running trolley; and the structure further comprises a chain transmission mechanism, the chain transmission mechanism comprises a chain, a steering part, a first motor and a bearing block, wherein the two ends of the chain are fixed relative to the machine frame, the steering part is arranged on the stacking clamp and cooperates with the chain, the steering part is ascended and descended relative to the runningtrolley under driving, the first motor is in transmission connection with the chain to realize horizontal movement of the running trolley, and the bearing block is in transmission connection with thechain so as to realize ascending and descending of the stacking clamp. According to the stacking machine lifting and travelling chain transmission structure, automatic stacking of brick layers can beachieved, the structure is simple, and the brick layers can be driven to ascend and descend and move without large power output. The invention further provides a stacking machine.

Owner:天津市隆达工业自动化设备有限公司

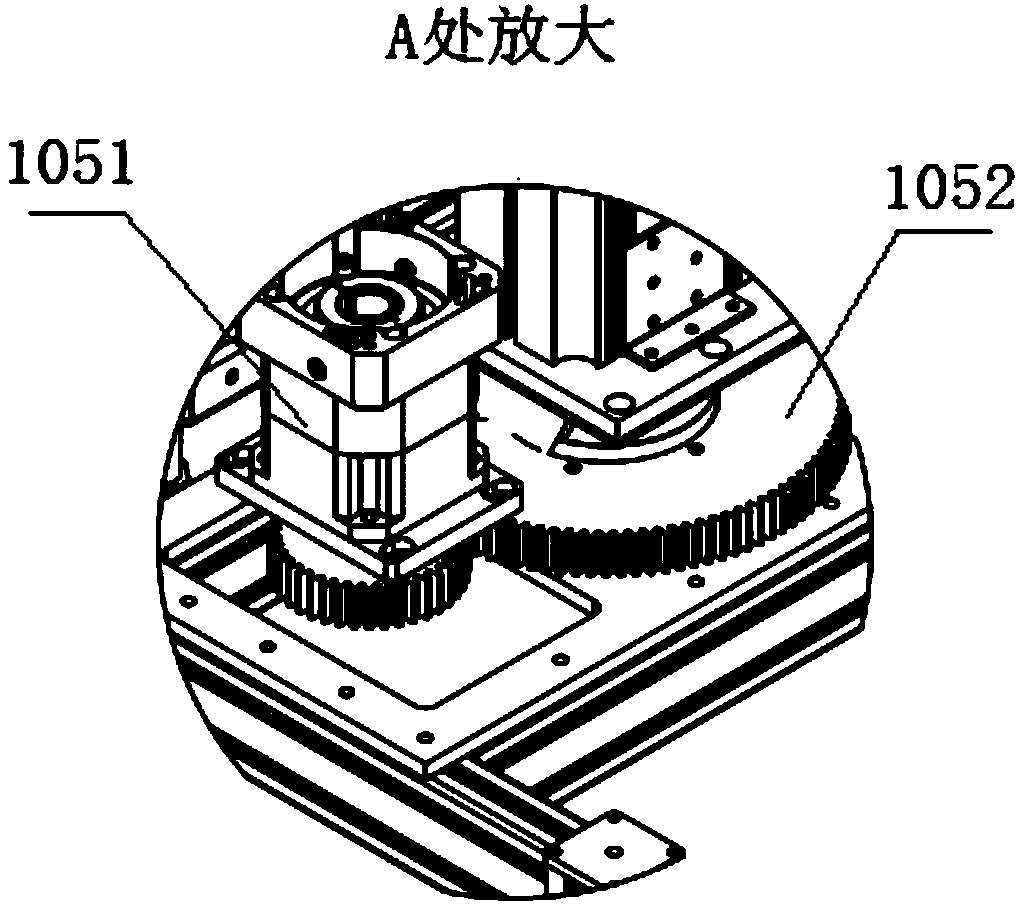

Rotatable telescopic belt conveyor

PendingCN111392341AImprove efficiencyLabor savingConveyorsStacking articlesGear wheelControl engineering

The invention provides a rotatable telescopic belt conveyor. The rotatable telescopic belt conveyor comprises a main supporting frame composed of a base and a main machine frame. The main supporting frame is provided with a transition belt mechanism, a rotating belt mechanism and a telescopic belt mechanism. The telescopic belt mechanism and the rotating belt mechanism are hinged; the rotating belt mechanism is provided with a rotating mechanism, the rotating mechanism is composed of a first motor, a gear and a slewing bearing. The outer ring of the slewing bearing is fixed to the rotating belt mechanism, the inner ring of the slewing bearing is fixed to the main machine frame, and the gear is driven by a first motor mounted on the main machine frame. The telescopic belt mechanism is provided with a lifting mechanism composed of an electric cylinder. Two ends of the electric cylinder are separately hinged to the telescopic belt mechanism and the rotating belt mechanism; the telescopicbelt mechanism comprises a multi-section belt machine frame and two sets of belts, each-section belt machine frame is provided with two front rollers and two rear rollers, the rear roller on the last-section belt machine frame is driving rollers, and the two driving rollers are driven by two sets of power mechanisms respectively. The goods can be directly put in place, and the efficiency is improved.

Owner:青岛盛瑞祥自动化技术有限公司

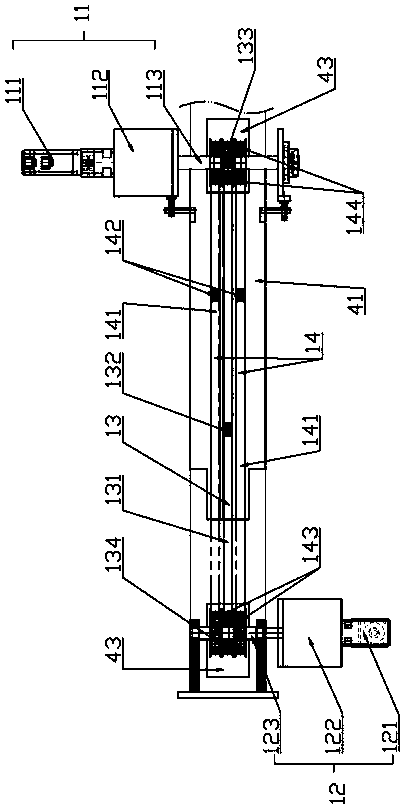

Blank conveying mechanism of automatic blank fetching equipment

ActiveCN103569679ARealize automatic palletizingMeet the requirements of automated productionStacking articlesMechanical equipmentEngineering

The invention belongs to the technical field of mechanical equipment, and particularly relates to a blank conveying mechanism of automatic blank fetching equipment. The mechanism solves the technical problems of a low automation degree and the like in the prior art. The blank conveying mechanism of the automatic blank fetching equipment is arranged on a rack and comprises a disc conveying lifting stand and a disc receiving lifting stand which are used for stacking blank discs and arranged on the two sides of the rack respectively, wherein a lifting driving device which is connected with the disc conveying lifting stand and the disc receiving lifting stand respectively and can drive the disc conveying lifting stand and the disc receiving lifting stand to make synchronous reverse lifting motion on the two sides of the rack is arranged on the rack; and a disc conveying device capable of conveying the blank discs stacked uppermost from the side, where the disc conveying lifting stand is located, of the rack to the side, where the disc receiving lifting stand is located, of the rack is further arranged on the rack. Compared with the prior art, the mechanism has the advantages that an automation degree is high, the production efficiency is improved, and the labor intensity is reduced.

Owner:HANGZHOU DONGBO AUTOMATION SCI & TECH

Screw installation automatic production line

ActiveCN105035675BReduce labor intensityImprove securityMechanical conveyorsProduction lineEngineering

The invention provides an automatic screw installing production line. The automatic screw installing production line comprises a product conveying device, a screw conveying device and a screw installing die. The product conveying device, the screw conveying device and the screw installing die are all intermittent. The screw conveying device is arranged at one side of the product conveying device. The output end of the screw conveying device is connected with the input end of the screw installing die. The portion below the screw installing die is right opposite to the screw installing portion on a product. The product conveying device is a similar U-shaped conveying rail with one side arranged in a downwards-inclined manner. Conveying belts are arranged in the two parallel sides of the rail. The portion connecting the two parallel sides is a sliding way arranged in a downwards-inclined manner. The circuit breaker shell conveying device, the heat adjusting screw conveying device and a screw installing jig are arranged, so that automatic screw installation of heat adjusting screws in circuit breaker shells is achieved; the labor intensity of workers is relieved, and meanwhile the working safety of the workers is improved.

Owner:TIANJIN DONGMING ELECTRONICS IND

Robot palletizer

PendingCN109178962ARealize automatic palletizingIncrease productivityStacking articlesDe-stacking articlesPalletizerAutomation

The invention belongs to the technical field of automation devices, and relates to a robot palletizer which comprises a base; a rotary table is rotationally connected onto the base; a mechanical arm assembly is arranged on the rotary table, and is connected with a gripper assembly; the mechanical arm assembly comprises a supporting arm fixedly connected with the rotary table and a gripper arm hinged to the supporting arm; and an oil cylinder is arranged on the supporting arm, and is connected with a driving arm assembly capable of driving the gripper arm to ascend or descend. The robot palletizer can realize automatic palletizing, and is high in production efficiency.

Owner:ZHEJIANG COLORAY TECH DEV

Automatic stacking equipment for stacking hollow bricks

ActiveCN110902395AHigh degree of automationRealize automatic palletizingStacking articlesElectric machineryStructural engineering

The invention relates to automatic stacking equipment for stacking hollow bricks. The automatic stacking equipment comprises a vehicle body. A lifting stroke controller is installed on the vehicle body; the lifting stroke controller is connected with a lifting plate; a hydraulic cylinder is installed on the lifting plate; the hydraulic cylinder is connected with a lateral moving frame; and a brickstacking device is installed on the lateral moving frame. The lifting stroke controller comprises a motor fixedly installed on the vehicle body, a guide rod and two stroke boxes. Each stroke box is fixedly equipped with a spring and a sliding groove; a pressing block is installed in each sliding groove in a sliding mode; the springs are correspondingly connected with the pressing blocks; and right-angled triangular movable blocks are evenly distributed at the sides, close to the center of the vehicle body, of the pressing blocks in the vertical direction. The automatic stacking equipment is high in automation degree; and on the basis of having the functions of storing and transporting the hollow bricks, the automatic stacking equipment realizes automatic stacking of the hollow bricks by driving the lateral moving frame to slide horizontally and rise quantitatively and supplying the hollow bricks to falling groove one by one, so that labor is saved relatively.

Owner:无为县华标新型墙体材料有限公司

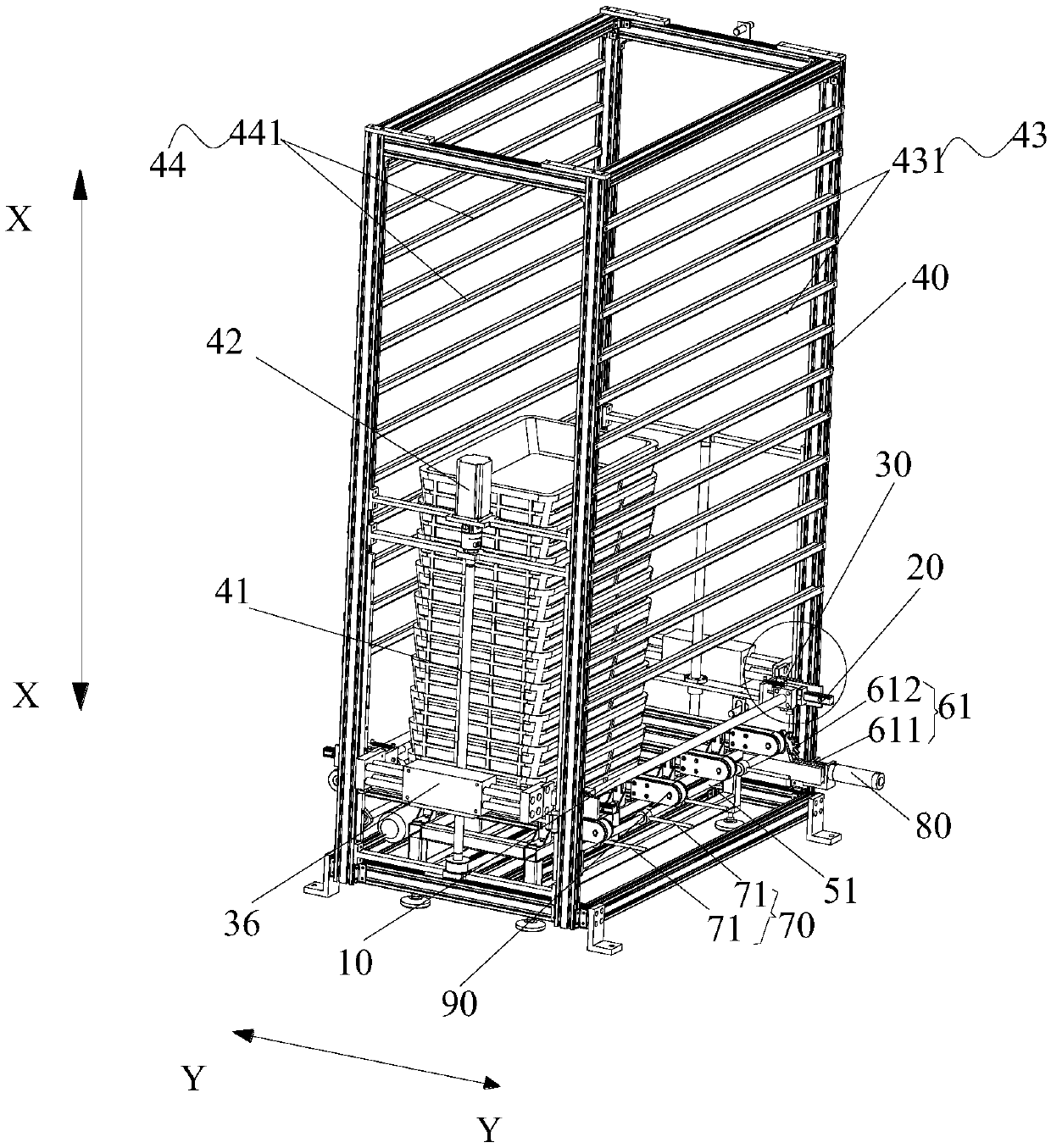

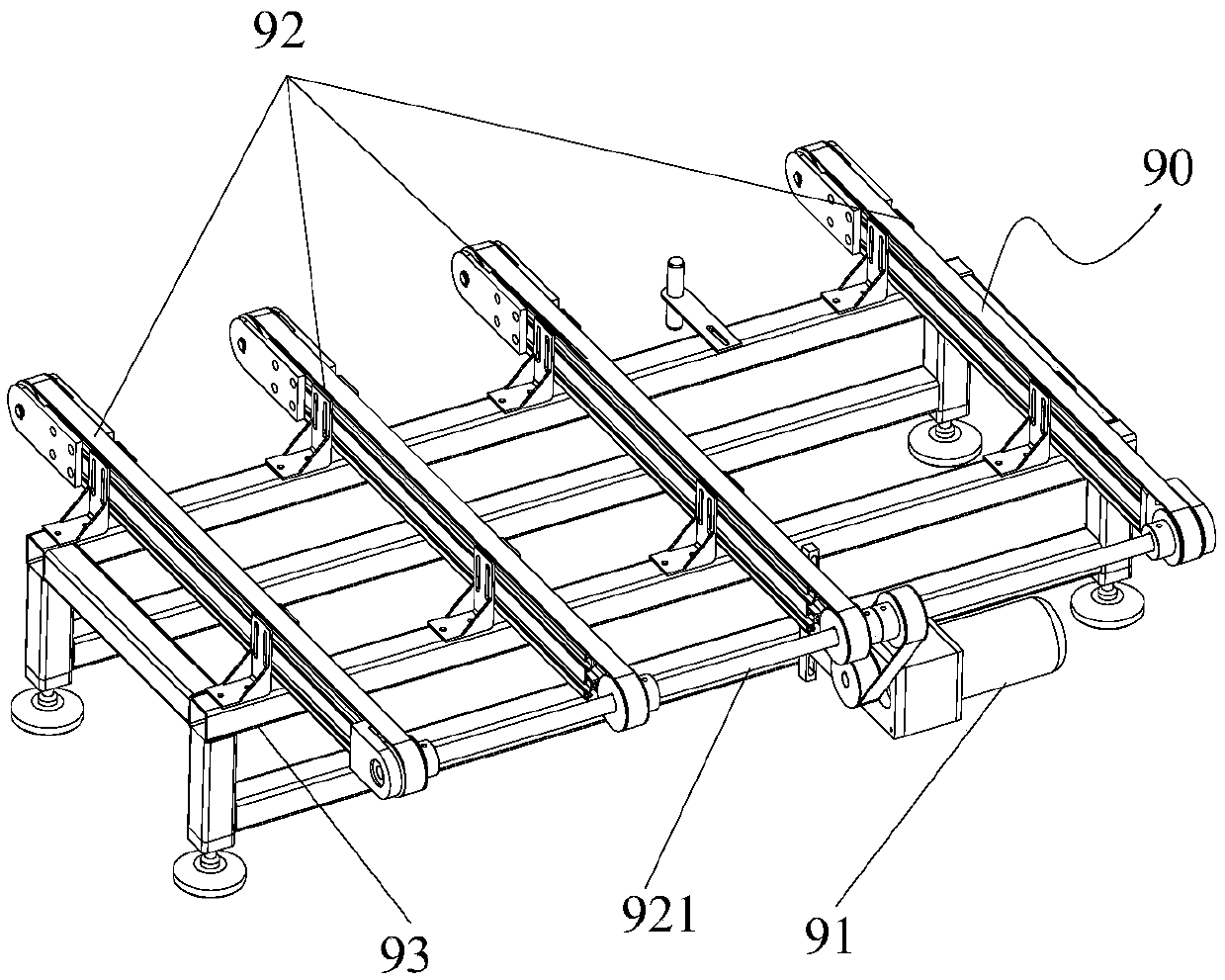

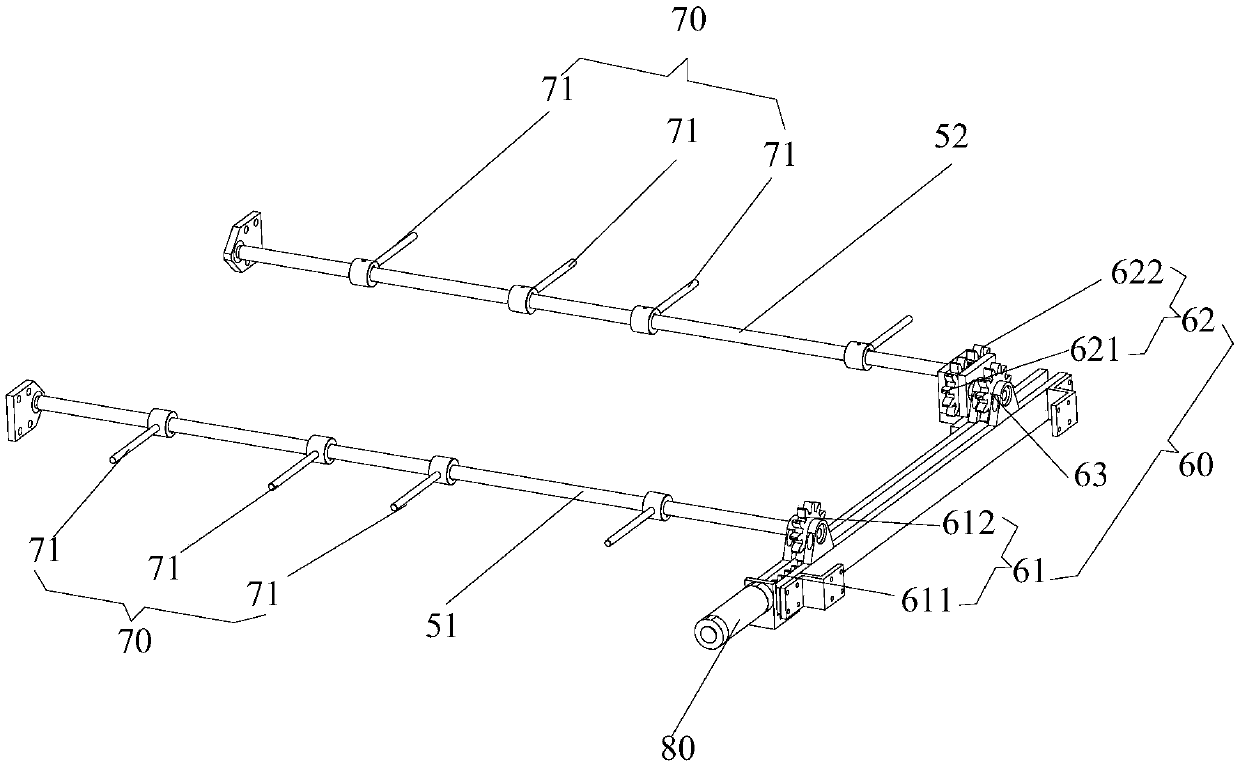

Stacking machine

ActiveCN109607211ARealize automatic palletizingSave manpower and material resourcesConveyorsStacking articlesStack machineEngineering

The invention provides a stacking machine. The stacking machine comprises a machine frame which is provided with a containing cavity, a material conveying device which is positioned in the containingcavity and used for conveying to-be-stacked materials, a clamping mechanism which is positioned below the material conveying device and used for positioning and clamping the to-be-stacked materials conveyed by the material conveying device, and a material lifting device which is arranged on the machine frame and above the material conveying device, and used for lifting stacked materials before theto-be-stacked materials are fed, and stacking the stacked materials with the to-be-stacked materials after the to-be-stacked materials are positioned and clamped. The technical scheme of the stackingmachine solves the problems that it wastes time and labor to stack circulation boxes by manual work on a production line in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Stacking system and method

PendingCN112645067ARealize automatic palletizingAvoid damageControl devices for conveyorsStacking articlesPalletizerMachine

The invention discloses a stacking system and method. The stacking system and method are used for stacking materials, the stacking system comprises a control device, a feeding machine, a stacking machine and a feeding device, and the control device sends data of the materials needing to be stacked to the feeding machine, the stacking machine and the feeding device; the feeding machine and the stacking machine receive material data and adjust the positions of clamping jaws according to the material data; and the feeding device receives the material data and transports corresponding materials to a feeding position according to the material data, the control device controls the feeding machine to grab the materials from a material vehicle and transmits the grabbed materials to a material taking position of the stacking machine, the control device controls the stacking machine to grab the materials, and the materials are placed on a pallet on a stacking position. According to the stacking system, automatic stacking of the materials can be achieved, and the materials are not prone to falling off in the stacking process.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com