Stacking machine lifting and travelling chain transmission structure and stacking machine

A chain transmission mechanism and chain transmission technology are applied in the direction of conveyor objects, stacking of objects, and de-stacking of objects, which can solve problems such as large power requirements, complex equipment, and heavy weight, saving labor and reducing labor costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

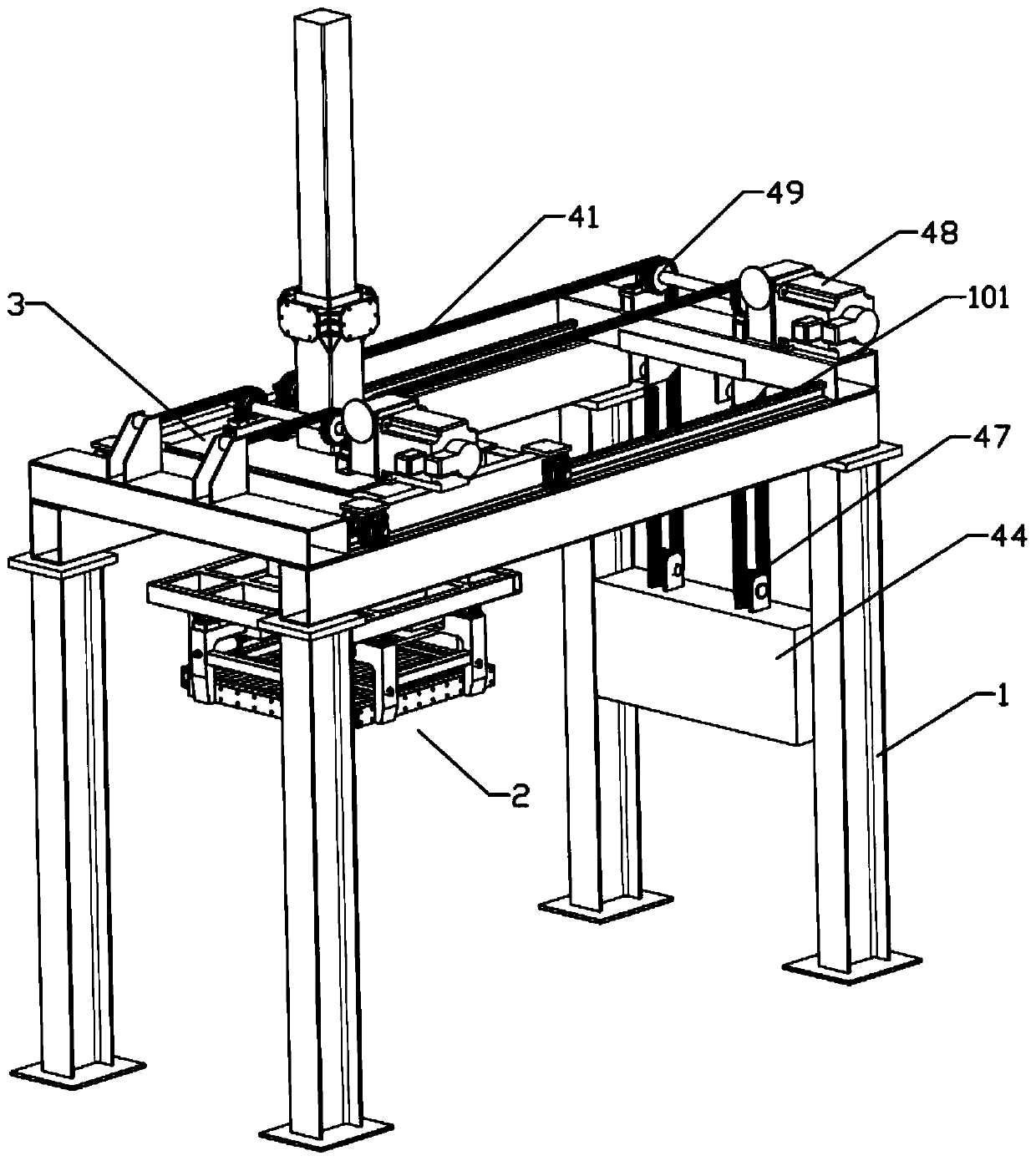

[0039] Example 1: Please also see Figure 1 to Figure 7 , A preferred embodiment of the present invention provides a palletizer lifting and walking chain transmission structure and a palletizer comprising the palletizing machine lifting and walking chain transmission structure;

[0040] Specifically, the lifting and walking chain transmission structure of the palletizer includes a frame 1 and a stacking fixture 2, the frame 1 is provided with a running trolley 3, and the running trolley 3 is slidably provided with the stacking fixture 2 ; It also includes a chain transmission mechanism 4, which is used to drive the running trolley 3 to move on the frame 1, and to drive the palletizing fixture 2 to move up and down.

[0041] Specifically, the chain transmission mechanism 4 includes a chain 41 fixed at both ends relative to the frame 1, and a steering part 42 that is arranged on the palletizing fixture 2 and cooperates with the chain 41, which is driven relative to the The runn...

Embodiment 2

[0043] Example 2: Please also see Figure 1 to Figure 7 , a preferred embodiment of the present invention provides a palletizer lifting and walking chain transmission structure and a palletizer comprising the palletizing machine lifting and walking chain transmission structure, the difference from Embodiment 1 is only:

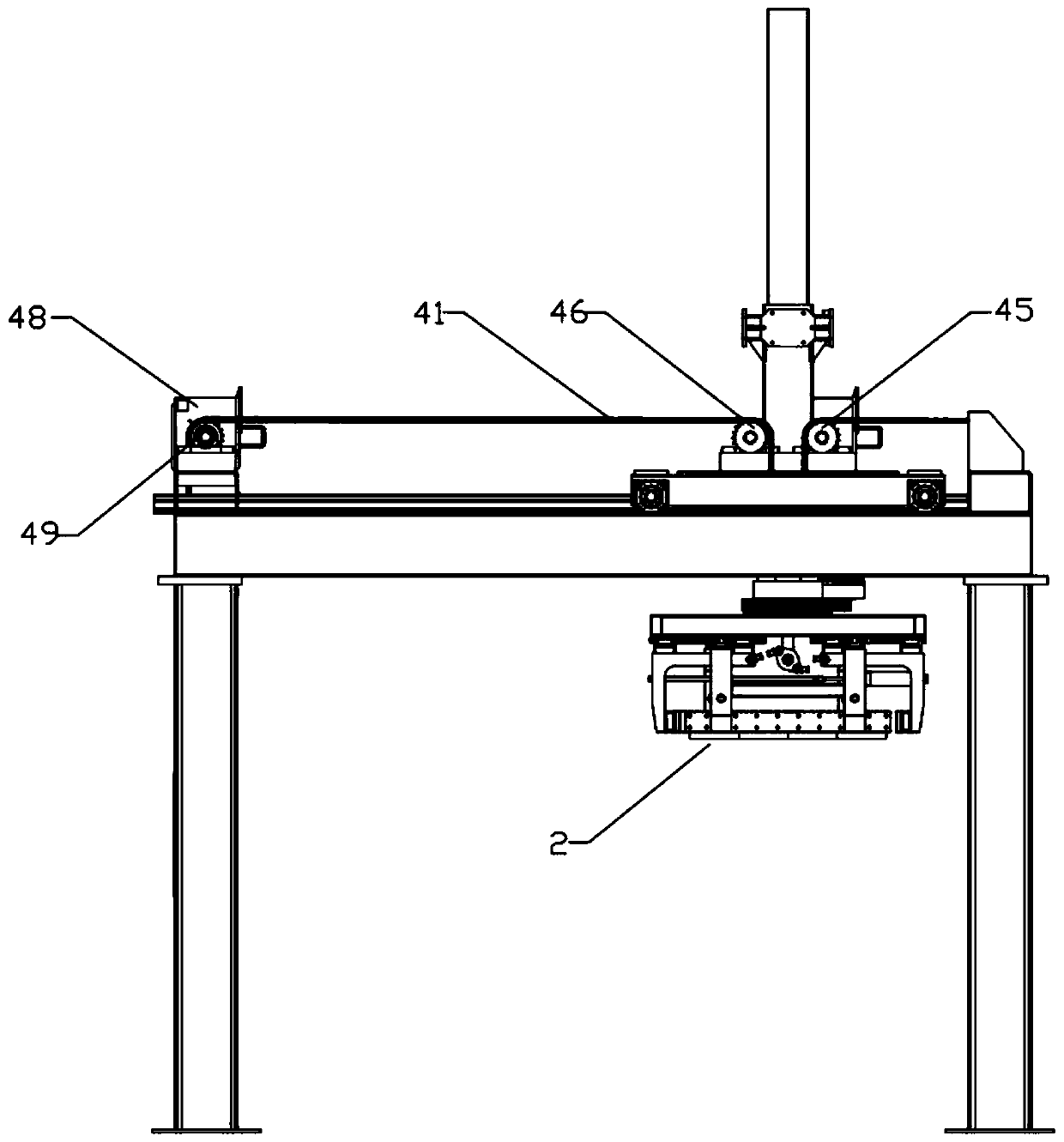

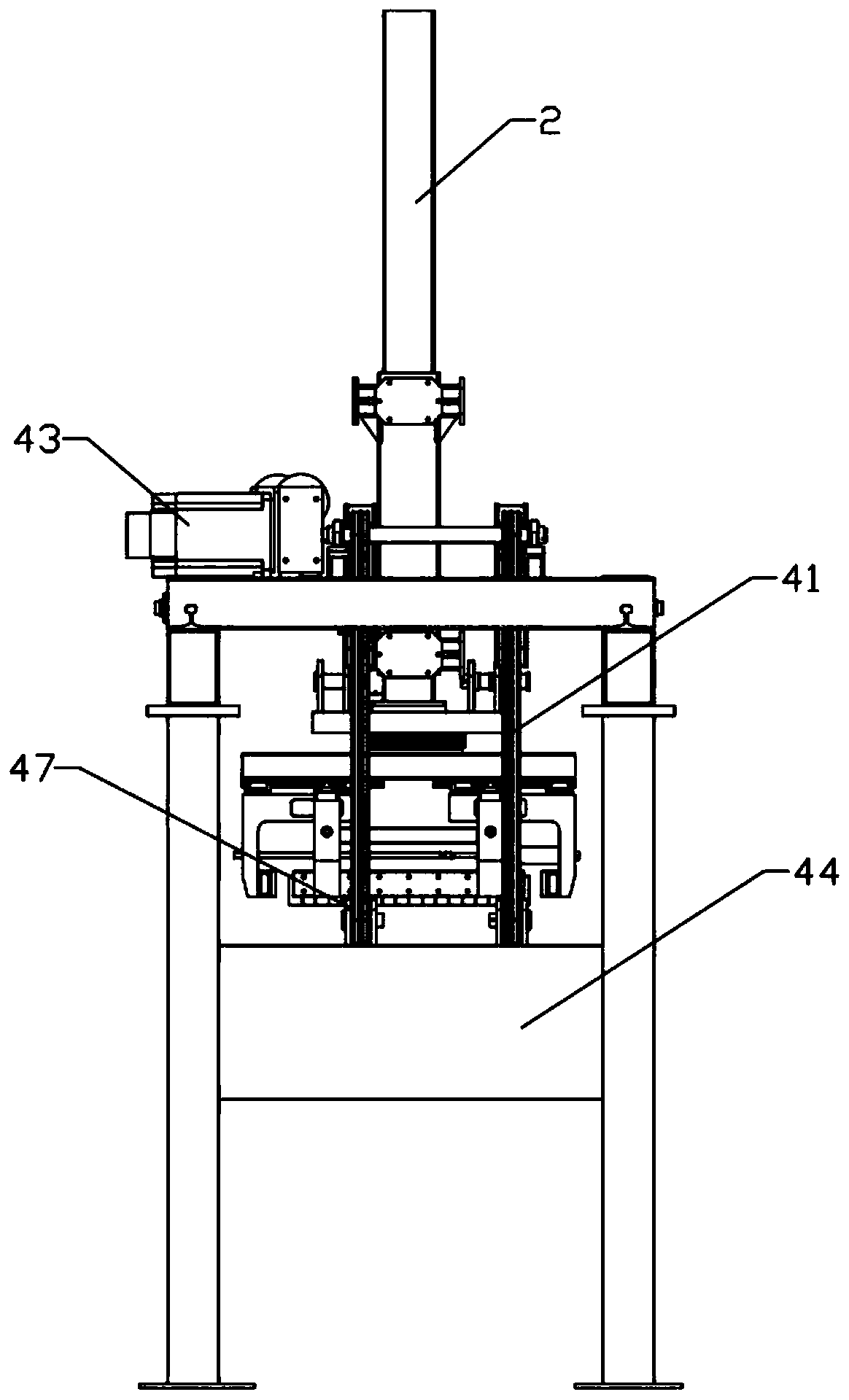

[0044]The chain transmission mechanism 4 also includes a driving gear 45 connected to the output end of the first motor 43 and a driven gear 46 provided on the running trolley 3 , both of which are engaged with the chain 41 .

[0045] In this embodiment, the steering part 42 is set as a gear meshed with the chain 41, and the steering part 42 and the driving gear 45 and the driven gear 46 are distributed in the shape of "pin"; the chain 41 It meshes with the driving gear 45, the steering part 42, and the driven gear 46 in turn.

[0046] In this embodiment, the bearing block 44 is connected with a movable pulley 47 , and the movable pulley 47 is engaged and sus...

Embodiment 3

[0052] Example 3: Please also see Figure 1 to Figure 10 , a preferred embodiment of the present invention provides a palletizer that includes the palletizer lifting and walking chain transmission structure, and its difference from Example 2 is only:

[0053] It also includes an integration mechanism 5, the integration mechanism 5 includes a first transmission mechanism 51, a second transmission mechanism 52 and the rake claw 53 that can move horizontally, the first transmission mechanism 51 and the second transmission mechanism 52 Arranged in parallel, the rake claws 53 are installed at the connection between the first transmission mechanism 51 and the second transmission mechanism 52 through the support frame 54, and are used to transfer the brick row on the first transmission mechanism 51 to the second transmission mechanism in batches one by one. Two transmission mechanisms 52 .

[0054] In this embodiment, a third motor 55 is installed on the support frame 54, the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com