Automatic stacking device for iron-core silicon-steel sheets of transformers

A technology of transformer iron core and stacking device, which is applied in the stacking of objects, de-stacking, transportation and packaging of objects, etc., can solve the problem of inability to adapt to the diversification of products by users, inability to automatically judge and identify, and affect the quality of transformer assembly. and other problems, to achieve the effect of saving stacking time, ensuring neatness and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

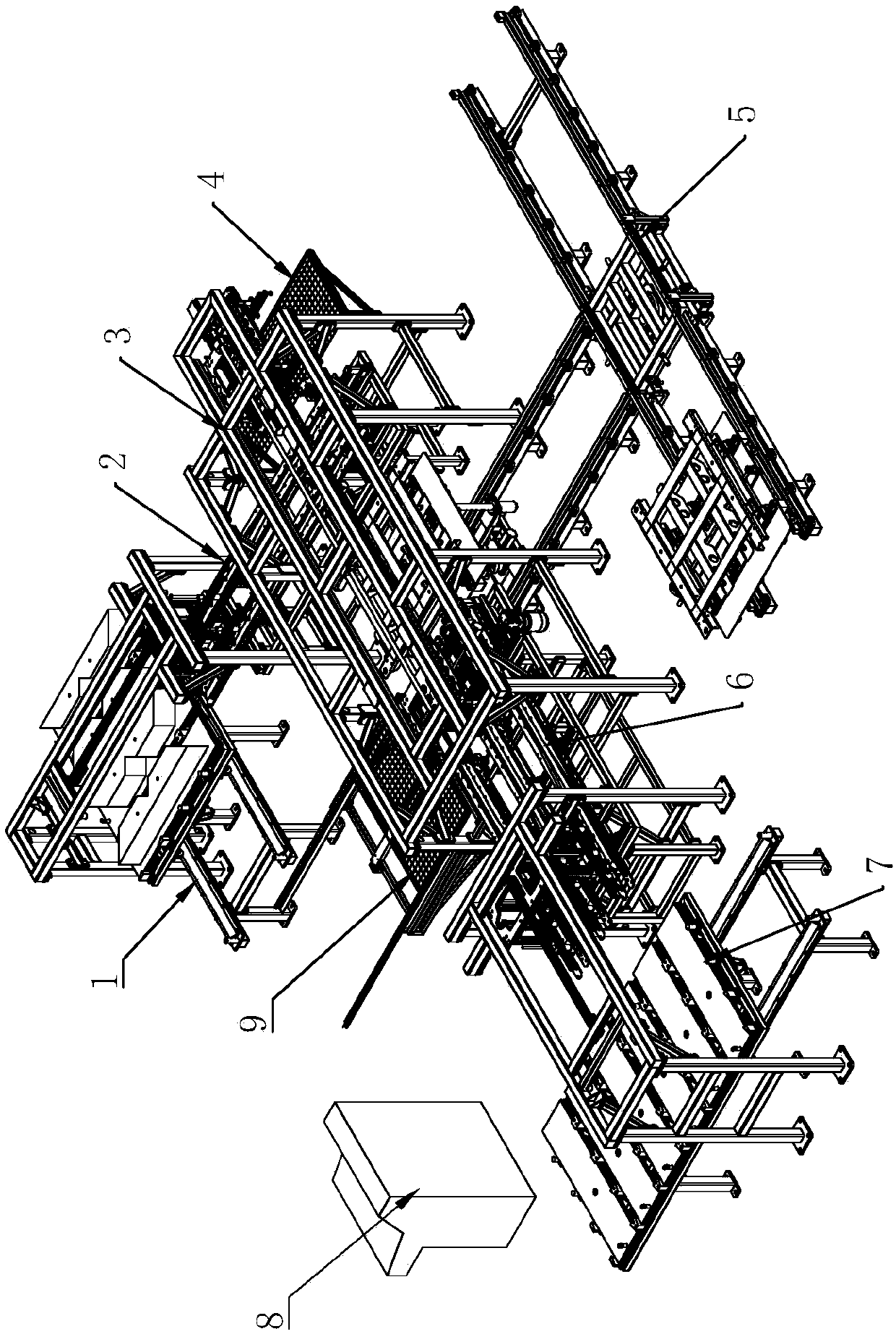

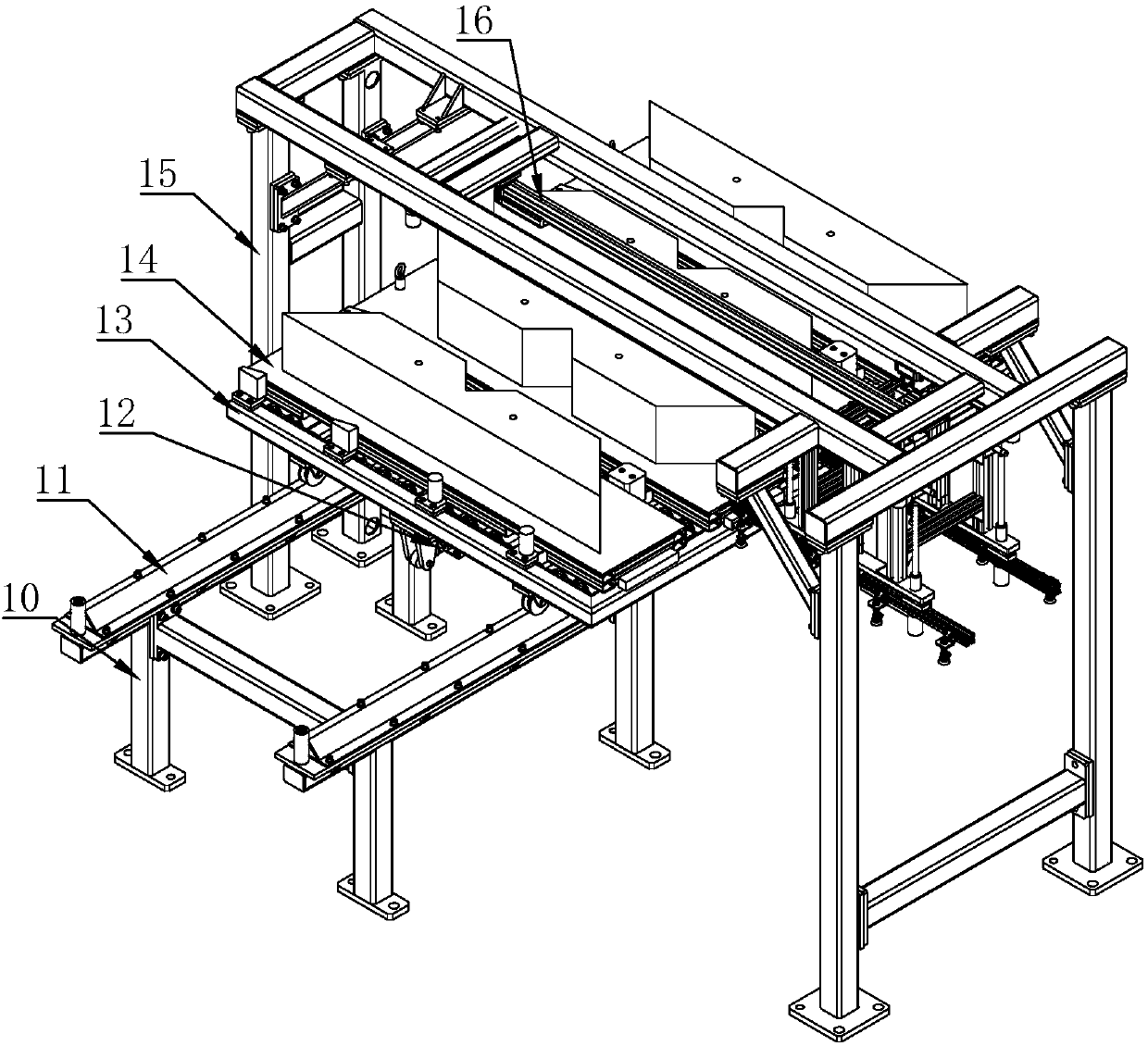

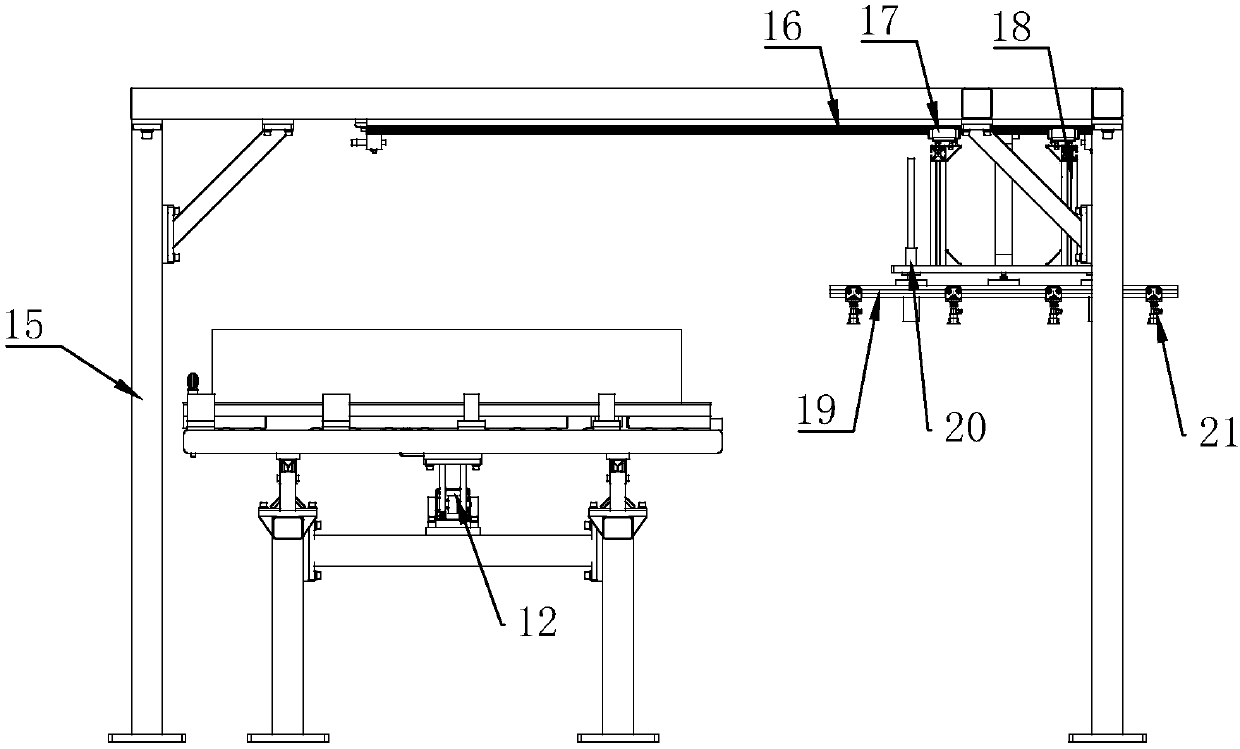

[0032] Such as figure 1As shown, an automatic palletizing device for transformer iron core silicon steel sheets in the present invention includes a first bin mechanism 1, a first transmission mechanism 2, a palletizing mechanism 3, a charging mechanism 5, a second bin mechanism 7 and a second The transmission mechanism 6, the first bin mechanism 1 is used to store the upper and lower yoke type silicon steel sheets to be assembled, and the first transmission mechanism 2 is used to transport the upper and lower yoke type silicon steel sheets on the first bin mechanism 1 to the palletizing mechanism 3, the second bin mechanism 7 is used to store side-in-column silicon steel sheets to be assembled, and the second transmission mechanism 6 is used to transport the side-in-pillar silicon steel sheets on the second bin mechanism 7 to the palletizing mechanism Below 3, the upper and lower yoke-type silicon steel sheets and the side-center column-type silicon steel sheets are alternatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com