Special fixture used for stacking robot of continuous casting production line of aluminum ingots

A casting production line and palletizing robot technology, applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of affecting the reliability of the production line, easy to disperse ingots in the stacking of aluminum ingots, short life of fixtures, etc., to achieve reliable action and improve production efficiency. , the effect of stacking neatly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

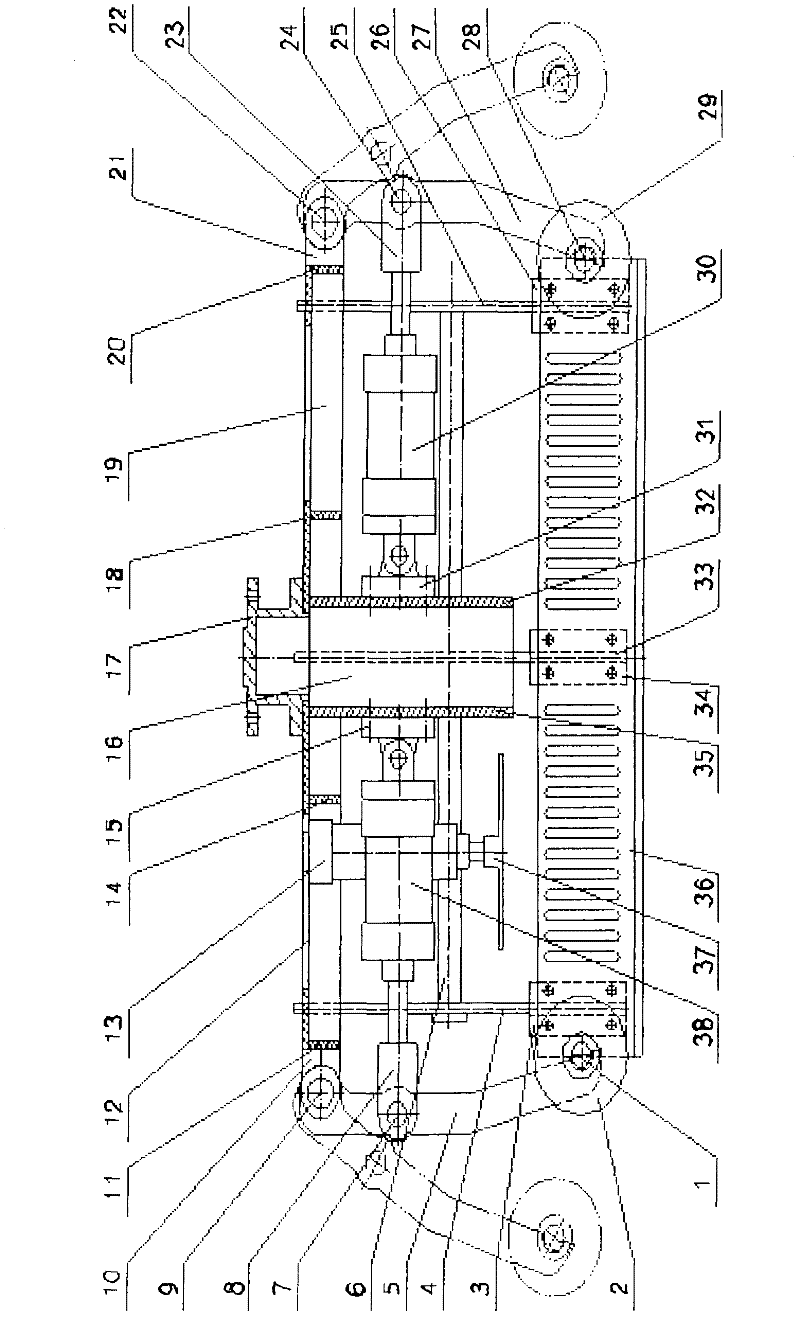

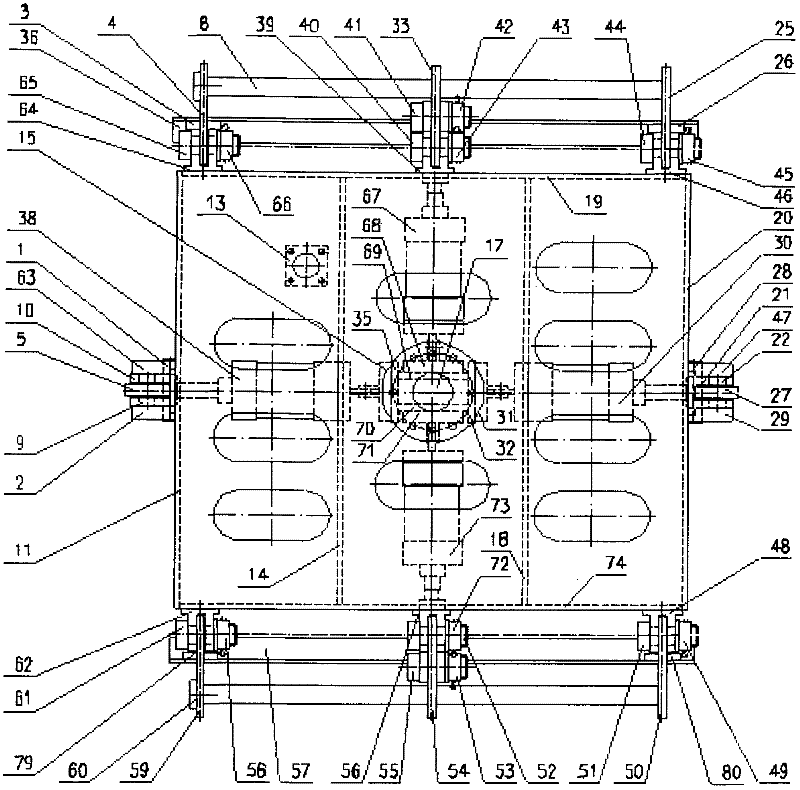

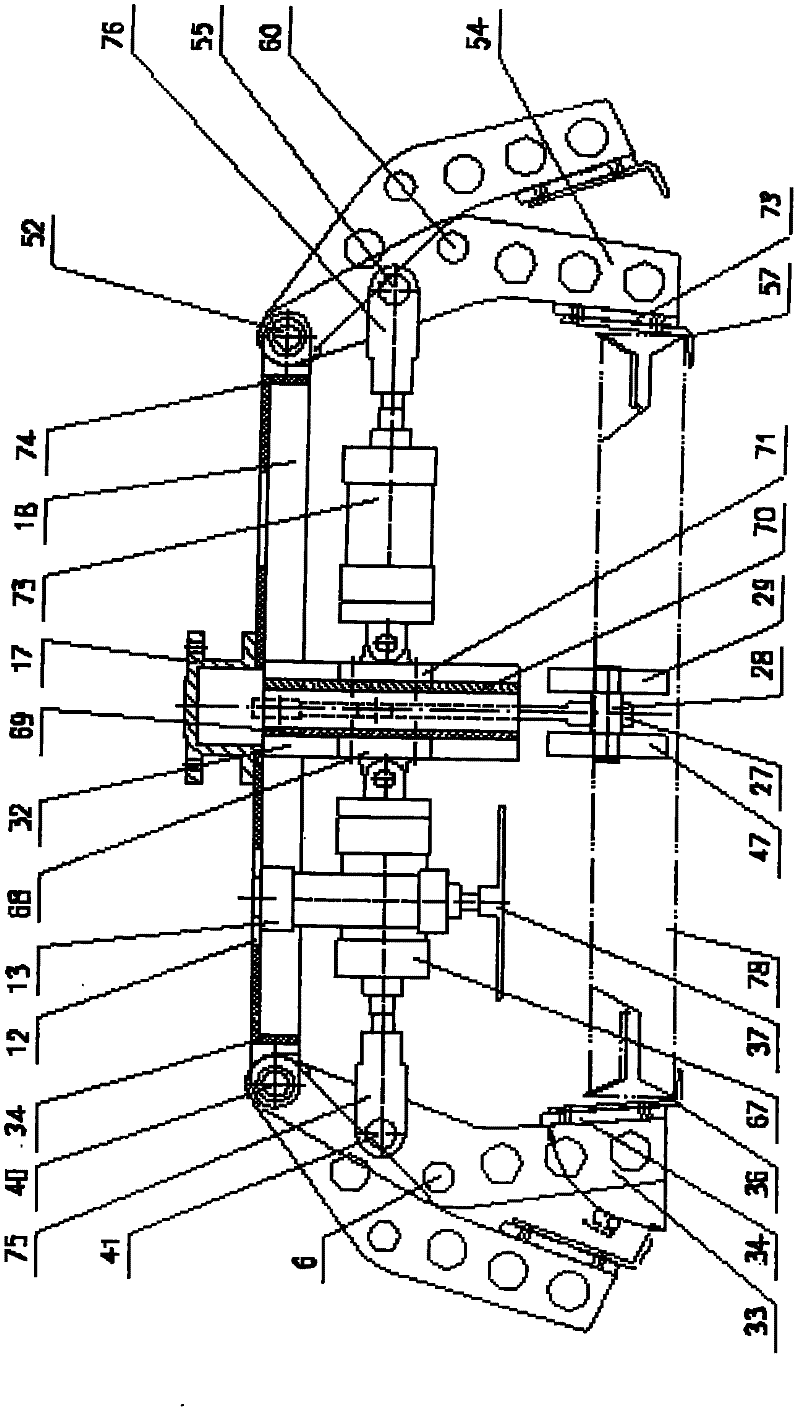

[0008] Such as figure 1 , figure 2 , image 3 As shown, the clamp body of the present invention is welded by the base plate 12 and the vertical plate 11, the vertical plate 14, the vertical plate 18, the vertical plate 19, the vertical plate 20 and the vertical plate 74. Column 16 is welded by plate 35 , plate 32 , plate 69 and plate 70 . The column 16 is welded below the bottom plate 12, and the connecting seat 17 is welded above the bottom plate 12, and both are in the middle position.

[0009] Front jaw is made up of clamp arm 59, clamp arm 54, clamp arm 50, clamp plate 57, fixed plate 79, fixed plate 77, fixed plate 80 and fixed shaft 60. The fixing plate 79 , the fixing plate 77 and the fixing plate 80 are welded to the lower ends of the clamping arm 59 , the clamping arm 54 and the clamping arm 50 respectively. The clamping plate 57 is connected with the fixing plate 79, the fixing plate 77, and the fixing plate 80 through a bolt group. The fixed shaft 60 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com