Apparatus for polishing aviation precision forging blade front trailing edge contour

A blade and precision forging technology, which is applied in the field of equipment for polishing and grinding the front and rear edge contours of aviation precision forging blades, can solve the problems of low production efficiency, unsuitable for mass production, difficult control of quality and stability of manual polishing, and achieve the goal of occupying Small space, high precision and controllable polishing, and the effect of improving the efficiency of polishing and repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

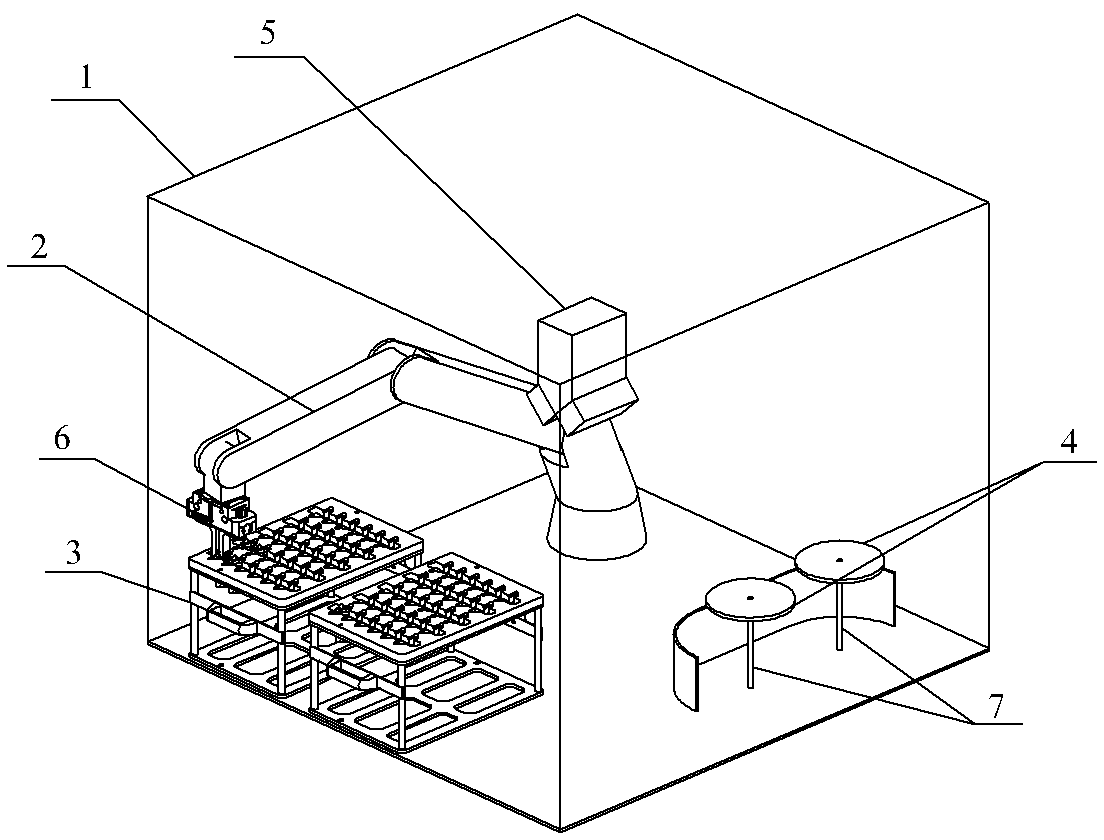

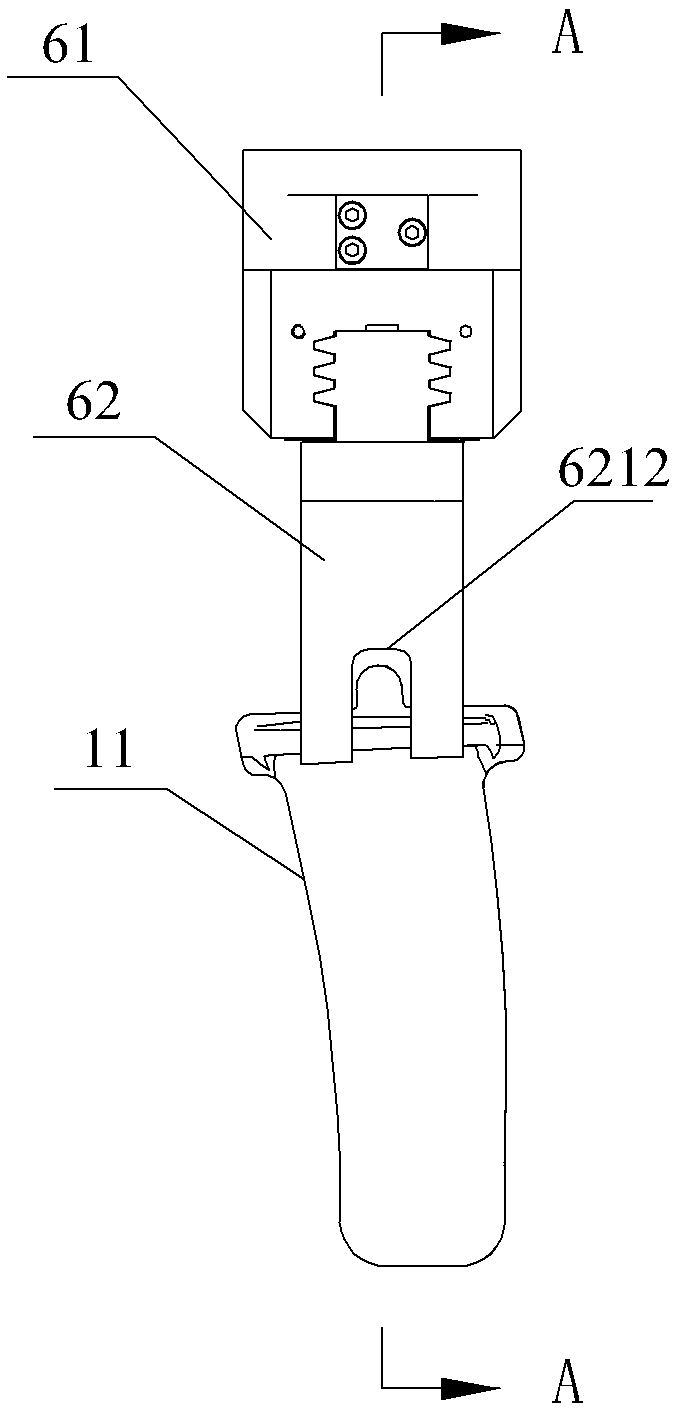

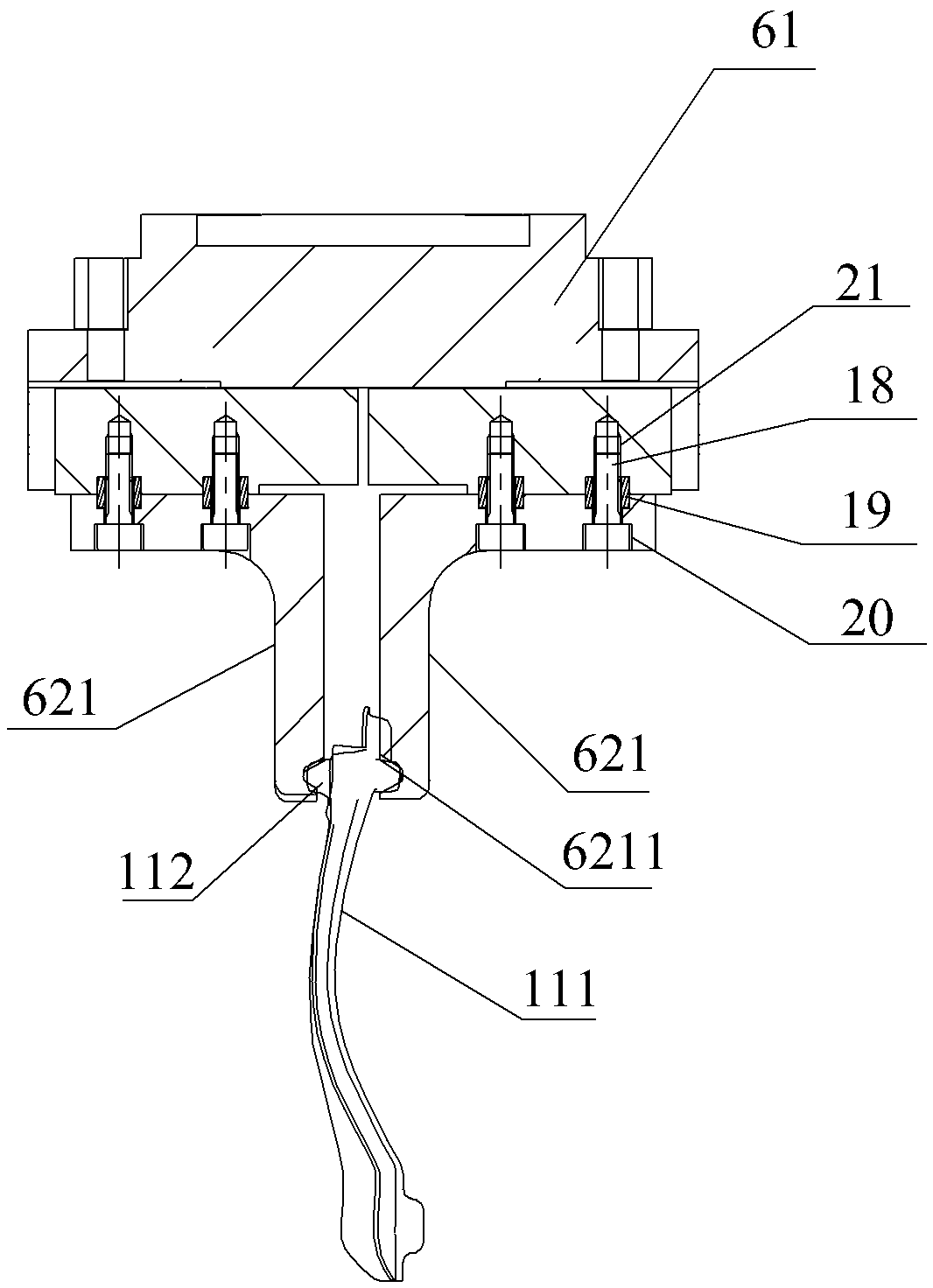

[0024] See Figure 1 to Figure 8 , a kind of equipment of the present invention for polishing the profile of the front and rear edges of aviation precision forging blades, which includes a casing 1, such as figure 1 As shown, the casing 1 is a rectangular closed structure, and its side panels and top panels are transparent; the industrial robot arm 2, the material rack 3 and the repairing wheel 4 are respectively installed on the bottom of the casing 1, the industrial robot arm 2, the material rack 3 Arranged in a triangle with the polishing wheel 4, a laser profile detection device 5 is installed above the inside of the casing 1 and between the material rack 3 and the polishing wheel 4, and a caliper 6 for clamping blades is installed on the execution end of the industrial robot arm 2 , the polishing wheel 4 is fixedly installed on the drive link 7 inside the casing 1, the drive link 7 is driven to rotate by a drive device such as a servo motor, the laser profile detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com