Upright clamping type automatic stacking and unstacking mechanism for tire stacks

A technology of tire stacks and columns, which is applied in the direction of object destacking, object stacking, transportation and packaging, etc. It can solve the problems of tire stacks falling down, high cost, time-consuming and laborious, and achieve the effect of preventing falling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

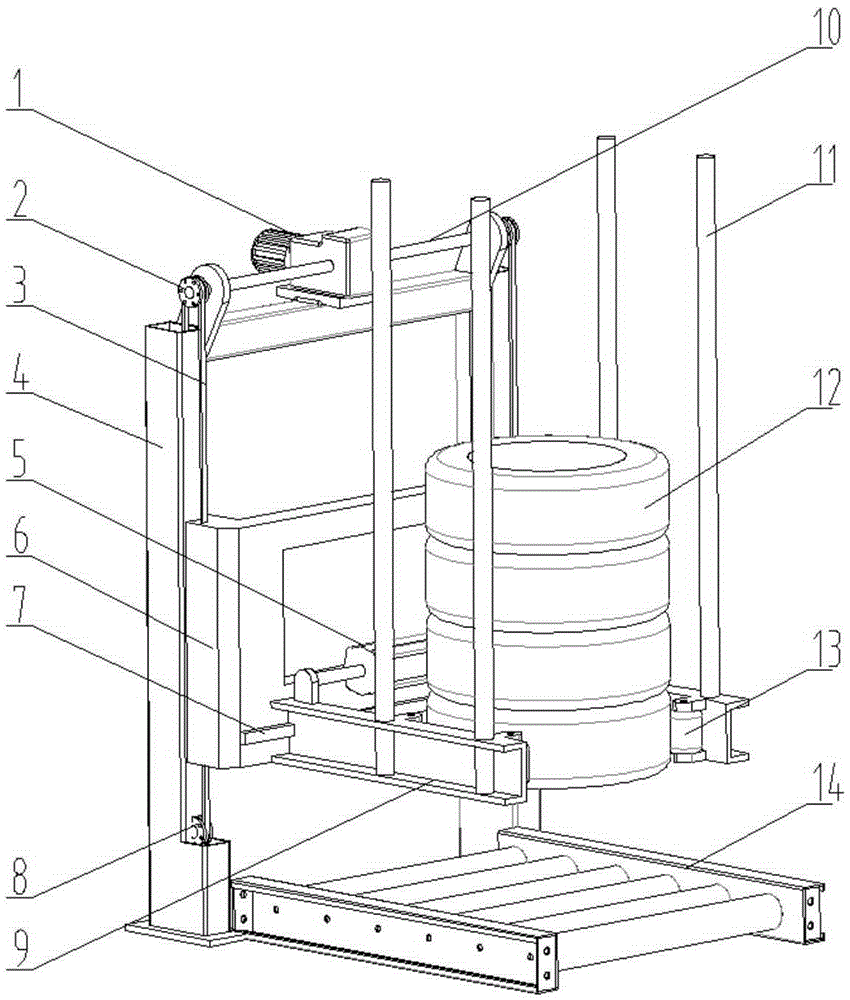

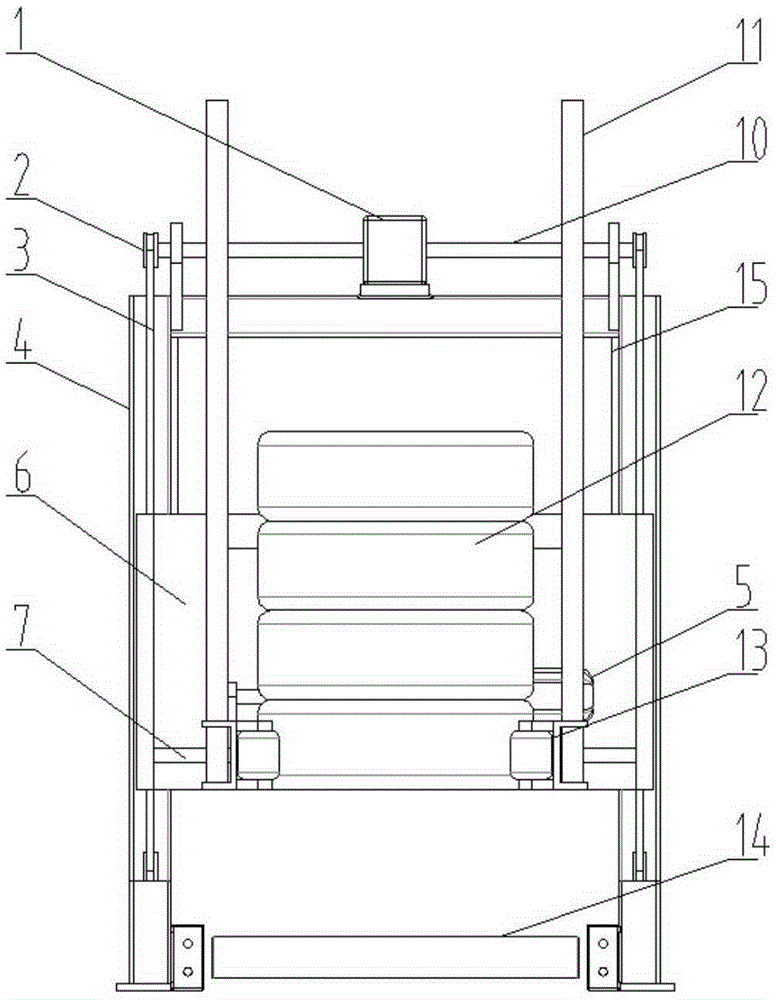

[0021] Specific implementation mode one, combined with the attached Figures 1 to 4 Description of this embodiment, a column clamping type tire stacking automatic stacking and destacking mechanism, consists of a main bracket 4, a lifting motor 1, a transmission shaft 10, a driving sprocket 2, a driven sprocket 8, a chain 3, a clamping electric Cylinder 5, vertical moving bracket 6, vertical moving guide rail 15, clamping bracket 9, lateral moving guide rail 7, anti-inversion column 11, roller clamping column 13; the main bracket 4 is welded by steel, and the lifting motor 1 is installed on On the crossbeam of the main bracket 4, the transmission shaft 10 is fixedly connected with the output shaft of the lifting motor 1. The transmission shaft 10 has output at both ends. The lower end of the main bracket 4, the driving sprocket 2 and the driven sprocket 8 are connected by the chain 3, and the two chains 3 are fixedly connected with the two sides of the vertically moving bracket...

specific Embodiment approach 2

[0022] Specific implementation mode two, combined with the attached Figures 1 to 4 This embodiment is described. The difference between this embodiment and the first embodiment is that when the size of the tire is constant or the cycle changes, the clamping electric cylinder 5 can be an air cylinder or a hydraulic cylinder, and other parts are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three, combined with the attached Figures 1 to 4 Describe this embodiment, the difference between this embodiment and the first embodiment is that the lifting motor 1, the drive shaft 10, the driving sprocket 2, the chain 3, and the driven sprocket 8 can be replaced by 2 electric cylinders, and the other parts are the same as The specific embodiment one is the same.

[0024] working principle:

[0025] The column clamping type tire stack automatic stacking and unstacking mechanism of the present invention is a kind of tire stack automatic stacking and unstacking device, and the tire stack 12 is clamped by the clamping bracket 9 .

[0026] The tire automatic palletizing process is as follows:

[0027] The conveyor line 14 transports the tires to the working range of this mechanism, the conveyor line 14 stops working, the lifting motor 1 drives the vertical shift bracket 6 to move down to a suitable height, and according to the tire model s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com