Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Well considered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

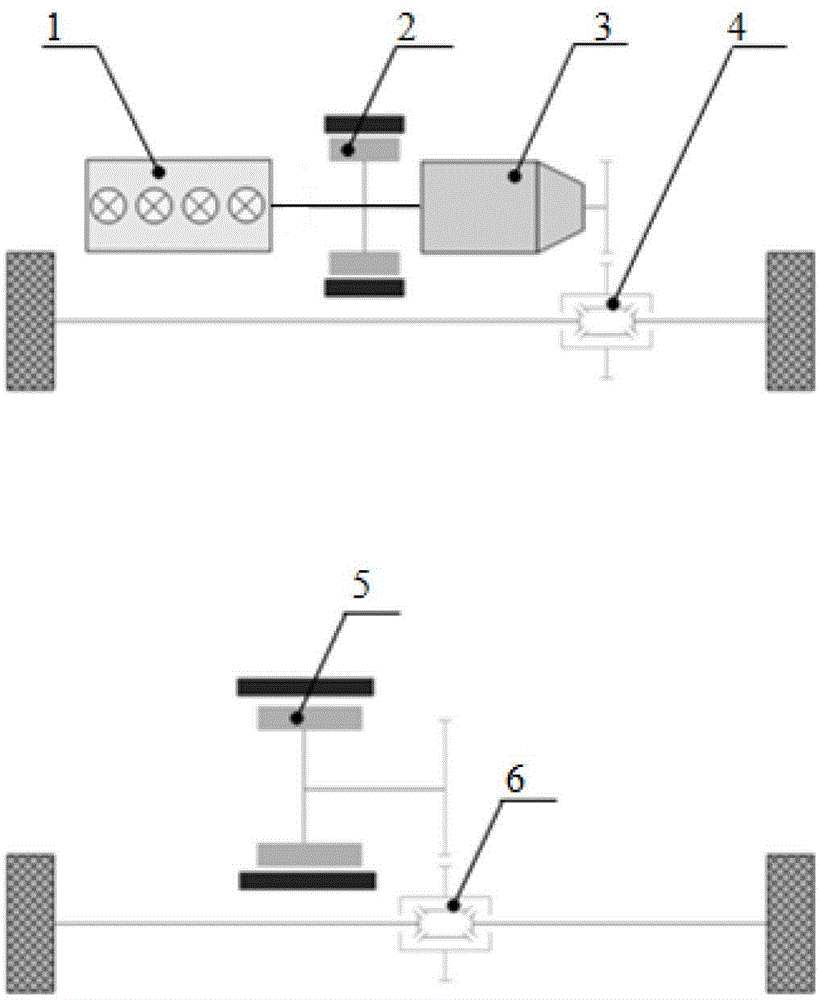

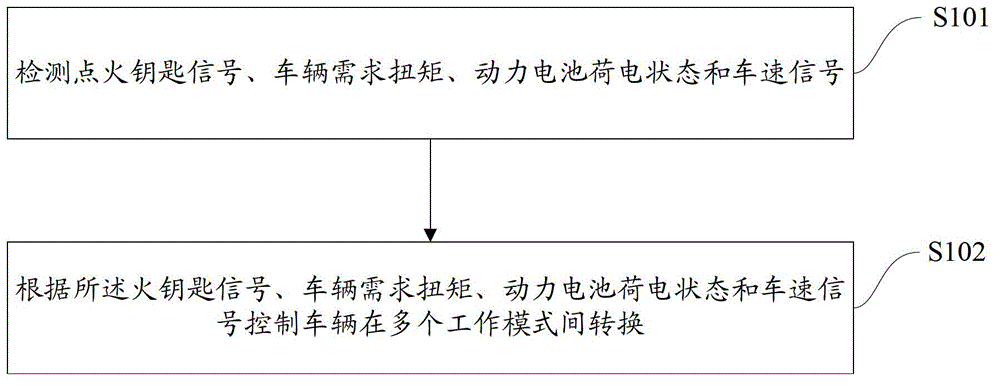

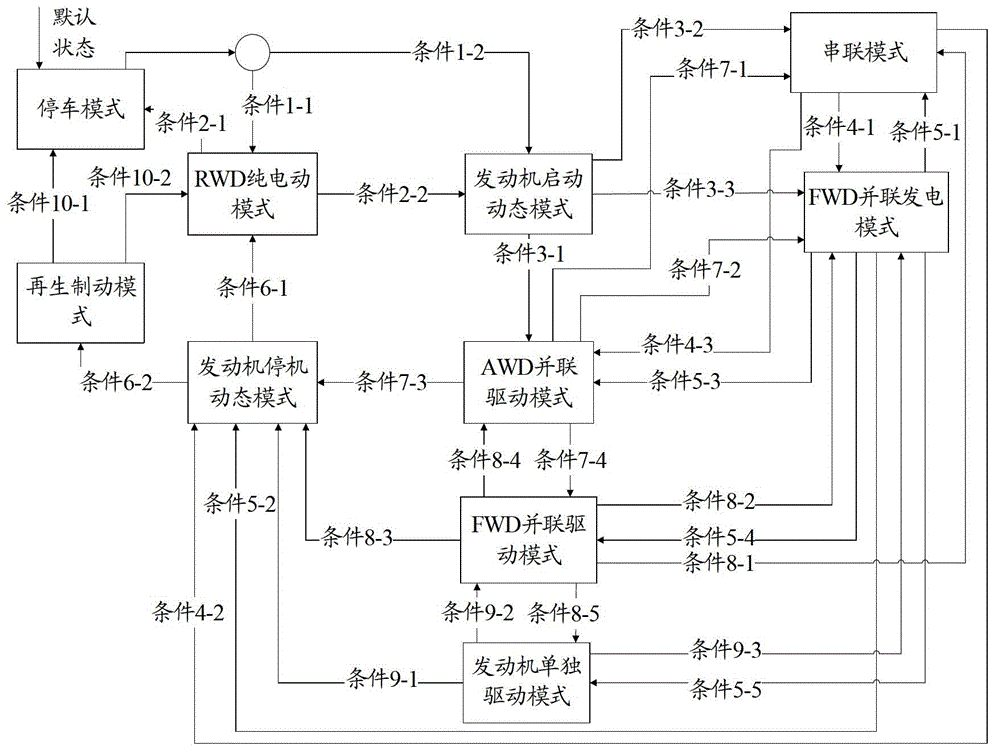

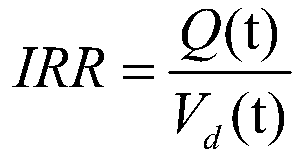

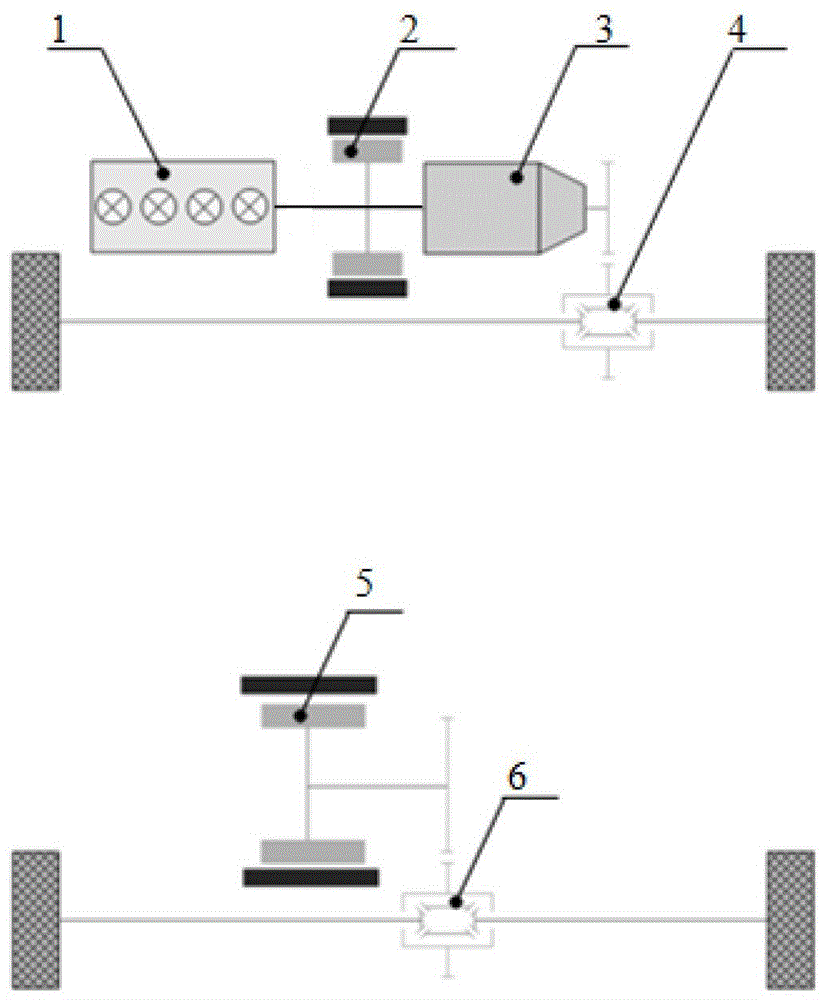

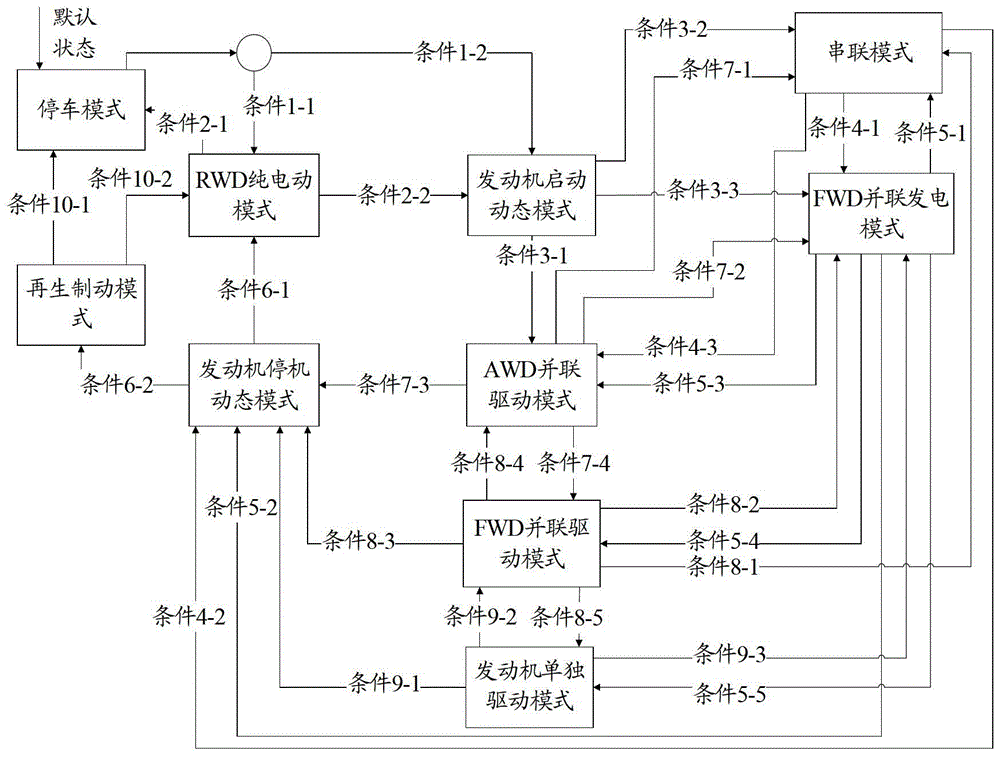

Control method for four-wheel-driven hybrid electric vehicle

ActiveCN104149777AComprehensive working modeWell-considered working modeHybrid vehiclesPower batteryElectrical battery

The invention provides a control method for a four-wheel-driven hybrid electric vehicle. The control method comprises the first step of detecting ignition key signals, torque required by the vehicle, the charge state of a power battery and vehicle speed signals, and the second step of controlling the vehicle to switch between multiple working modes according to the ignition key signals, the torque required by the vehicle, the charge state of the power battery and the vehicle speed signals. According to the control method, the multiple working modes are adopted, and the advantages of four-wheel-driven hybrid power can be given to full play. Through switching between the multiple working modes, the vehicle can be in an optimal working state all the time, so that fuel consumption is lowered. In addition, through distribution of the torque of all components in different working modes, the working efficiency of an engine, an ISG motor and a rear axle motor can be optimized, so that the fuel consumption of the whole vehicle is further lowered.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

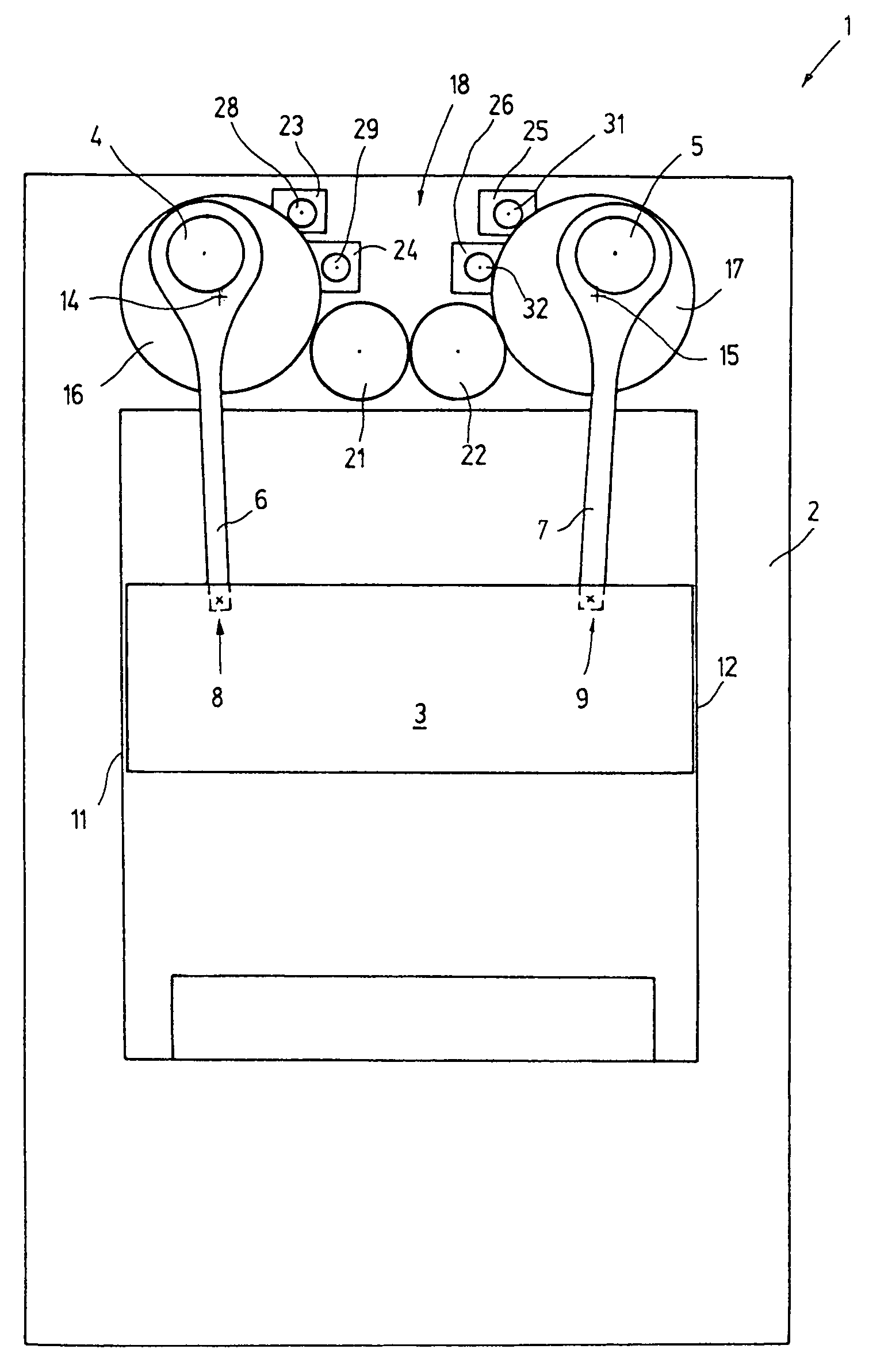

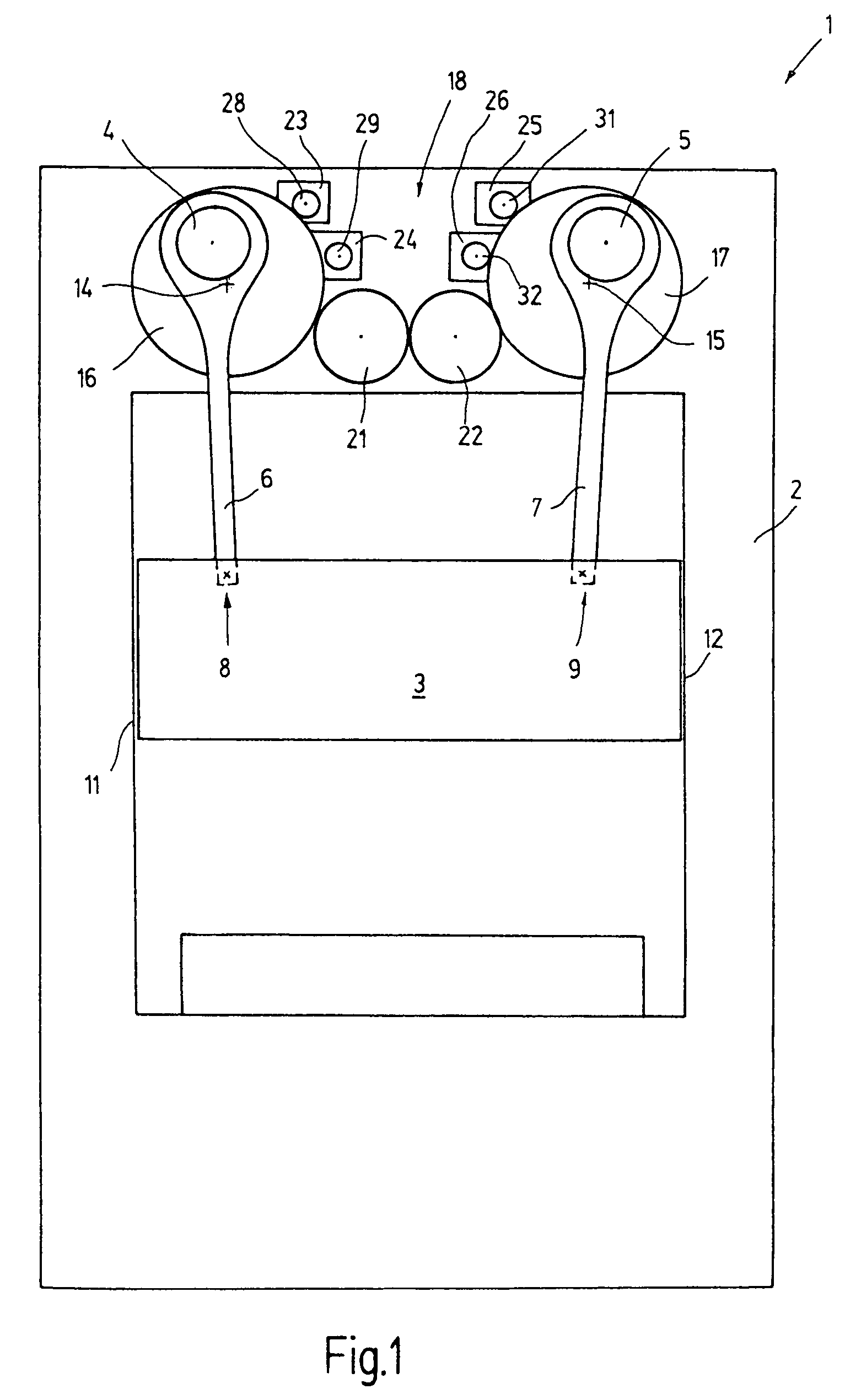

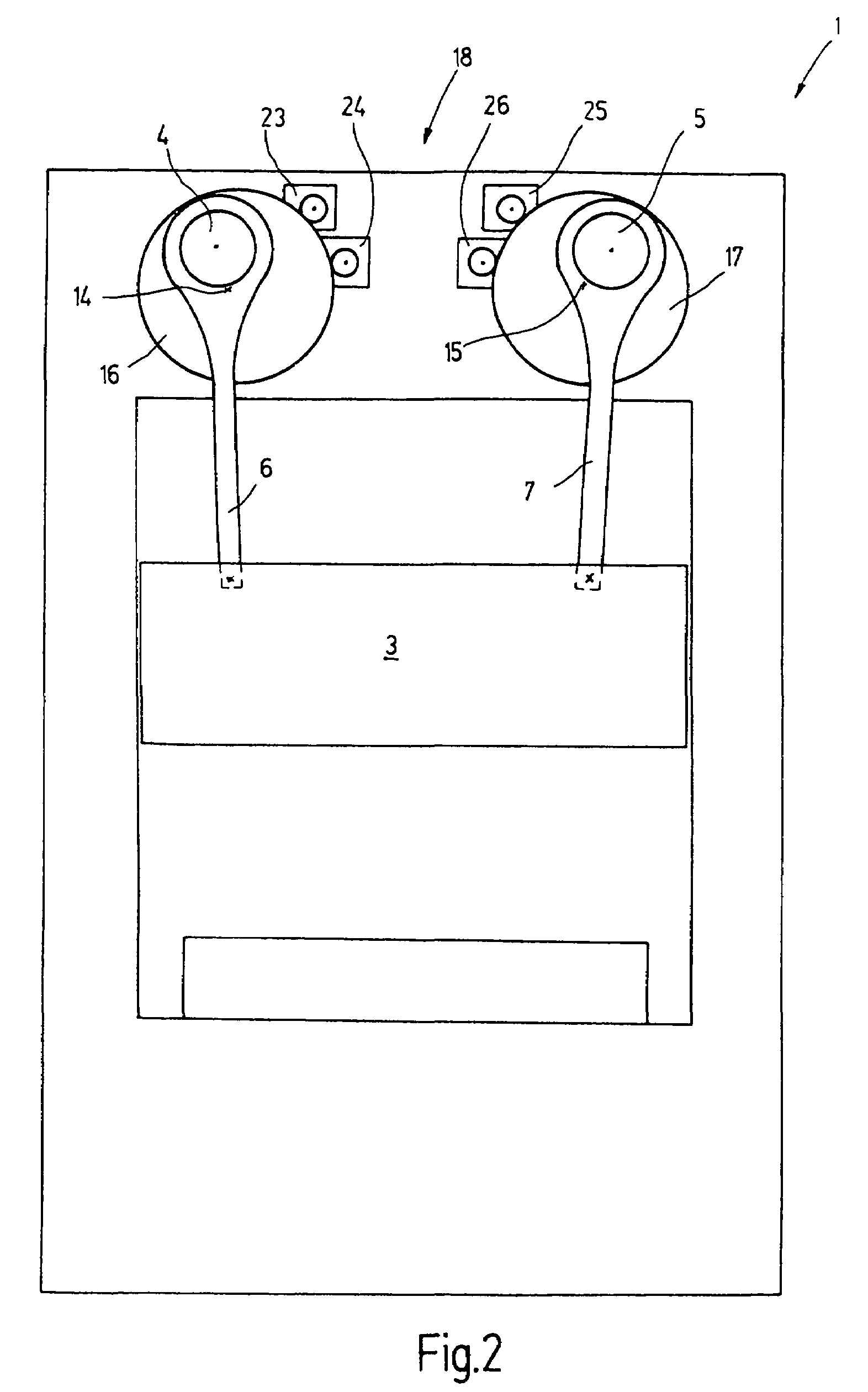

Mechanical press

InactiveUS7102316B2Inertia moment can be increasedSlow downAgriculture tools and machinesComputer controlMechanical pressServomotor

In a press having a plunger supported so as to be movable linearly back and forth by drive means which include at least one servomotor in combination with a rotatably supported inertia structure connected for rotation with the servomotor, the inertia structure has an inertia moment which is small enough to permit reversal of the servomotor within a stroke length of the plunger so that the stroke of the plunger is adjustable under the control of a control device connected to the servomotor for controlling its operation.

Owner:SCHULER PRESSEN GMBH & CO KG

Mix proportion design method of emulsified asphalt cold-patch mixture

InactiveCN102773923APracticalWell consideredIn situ pavingsMixing operation control apparatusEngineeringRoad surface

The invention belongs to the technical field of roads and urban roads, and specifically relates to a mix proportion design method of an emulsified asphalt cold-patch mixture. The method is characterized by compaction and maintenance technologies of test pieces and determination of optimal total water content and optimal emulsified asphalt consumption. aiming at the special strength forming process of emulsified asphalt materials, different and special compaction methods and maintenance conditions are adopted for different stages of the mix proportion design, so that the optimal total water content and the optimal emulsified asphalt content can be determined, wherein the field actual conditions are simulated and the early damages of asphalt road surfaces are considered in the compaction methods and the maintenance conditions. After the optimal total water content and the optimal emulsified asphalt content are determined, the water stability and anti-stripping capability of the emulsified asphalt cold-patch mixture in the early stage of use are evaluated. The mix proportion design method of the emulsified asphalt cold-patch mixture is comprehensive in consideration and strong in practicability; and the emulsified asphalt cold-patch mixture obtained according to the method can obtain favorable pavement performance.

Owner:SHANGHAI SHENQIAO SCI & TECH DEV

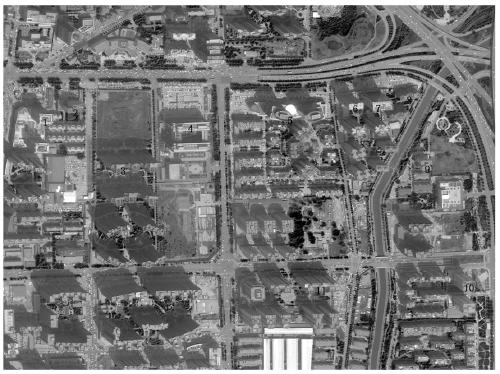

Method of extracting city building height based on multi-temporal remote sensing image shadow

InactiveCN107679441AImprove accuracy and precisionReduce mistakesImage enhancementImage analysisSatelliteLeast squares

The invention discloses a method of extracting a city building height based on multi-temporal remote sensing image shadow. A systematic, quick and accurate method is formed to use two different-temporal remote sensing images (the two images with different sun height angles and satellite azimuth angles) to carry out batch analysis and calculation on the shadow of a target building, and thus, the height of the target building in an area can be quickly and accurately extracted, and the efficiency of measurement, three-dimensional modeling and other work can be improved. In particularly, the length of the building shadow is calculated, the included angle relationship between a landmark building on the image and the shadow thereof is combined, and a corresponding mathematical model is selectedto calculate the height value of the target building in the area. According to the two groups of building height results obtained when two remote sensing images are used for calculation, a fitting equation is built based on the least square method, the height of the target building after correction is acquired, and the calculation result precision is thus improved.

Owner:ZHENGZHOU UNIV

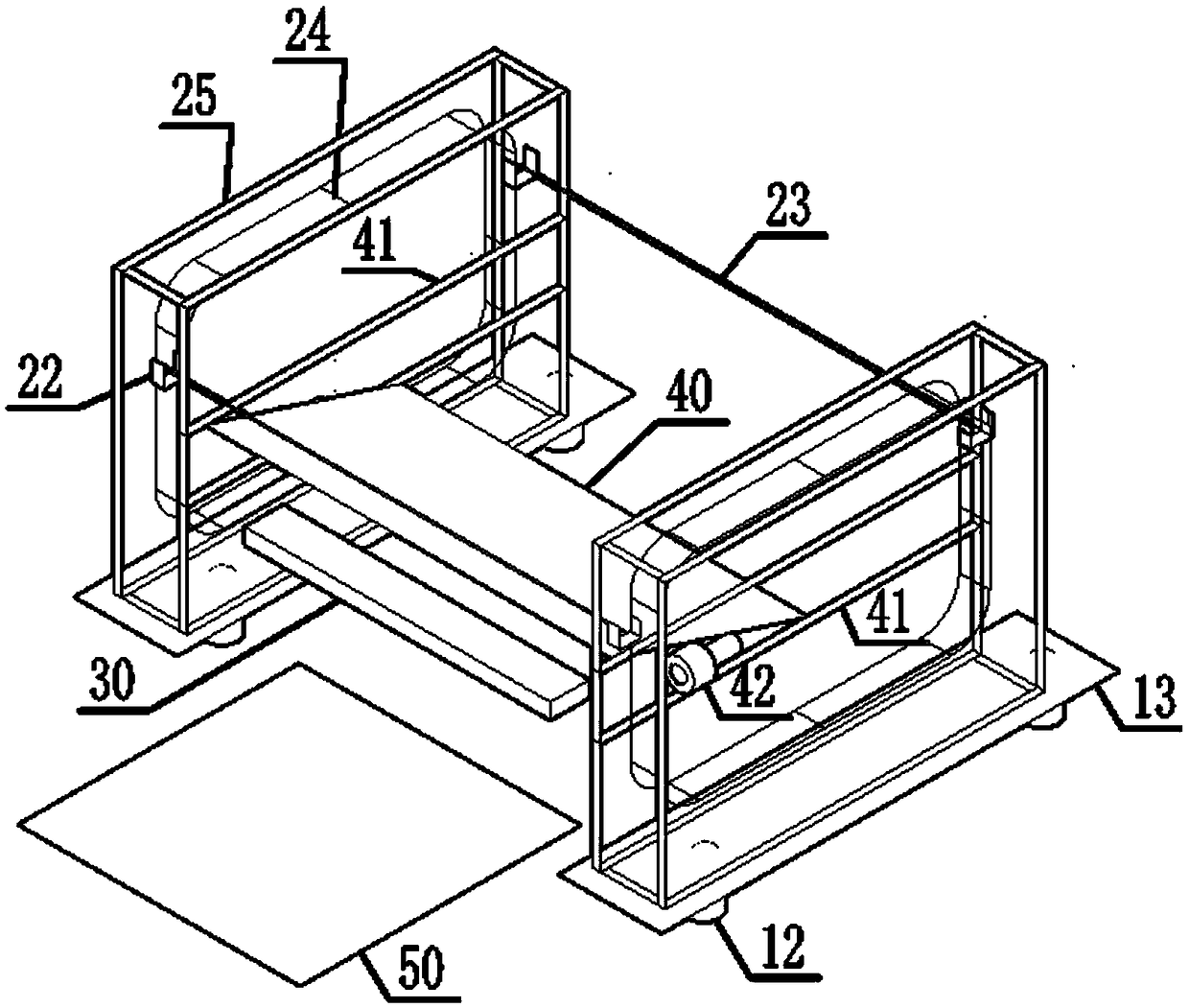

Sugarcane peeling and section cutting device

PendingCN108284478AImprove peeling efficiencyIntegrity guaranteedVegetable peelingMetal working apparatusEngineeringUltimate tensile strength

The invention discloses a sugarcane peeling and section cutting device, and belongs to the field of agricultural product processing. The sugarcane peeling and section cutting device is composed of a support, a device rack, a first sugarcane stop rod, a sharp tooth gear, a first baffle spring, a first baffle, first cutting-off tool springs, a second baffle, a first cutting-off tool, a second sugarcane stop rod, peeling tools, a second cutting-off tool, a storage bag supporting rod, a storage bag stop block, a second baffle spring, second cutting-off tool springs, peeling tool springs and a stepping motor. The sugarcane peeling and section cutting device is high in automation degree, the labor intensity is relieved, and the sugarcane peeling efficiency is improved; the integral design of thestructure is reasonable, the peeling and section cutting work of the whole sugarcane can be finished through one-time operation, the whole operation process is clean and sanitary, and direct usage cannot be influenced for eaters. According to the purpose of cooperation of the unique design of the first baffle and the second baffle and usage of tension springs, the sugarcane is downwards closely attached to a sugarcane positioning clamping arc step, the sharp tooth gear rotates and drives the non-peeled sugarcane to move inwards, and the attaching force is increased.

Owner:祝凯旋

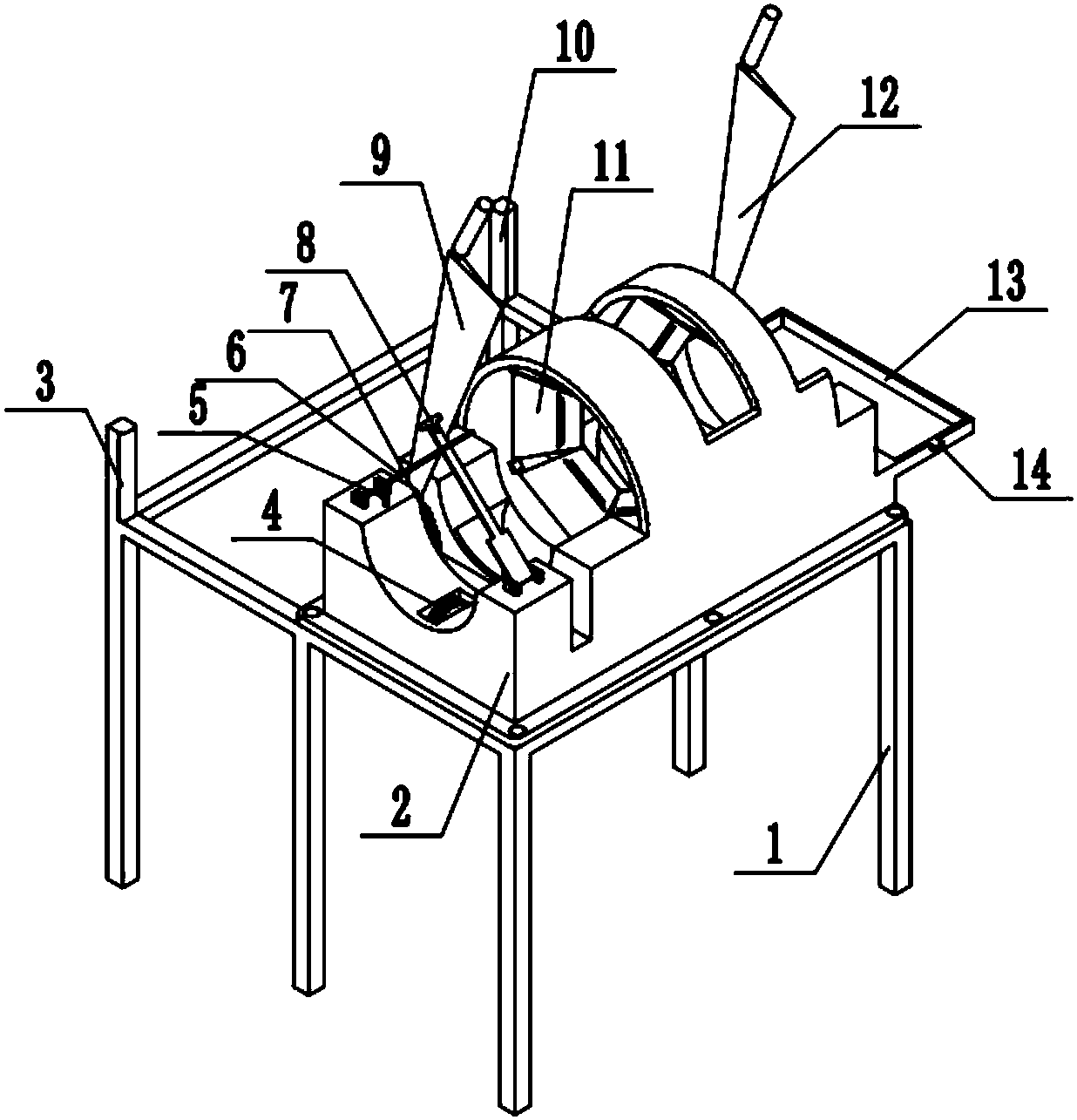

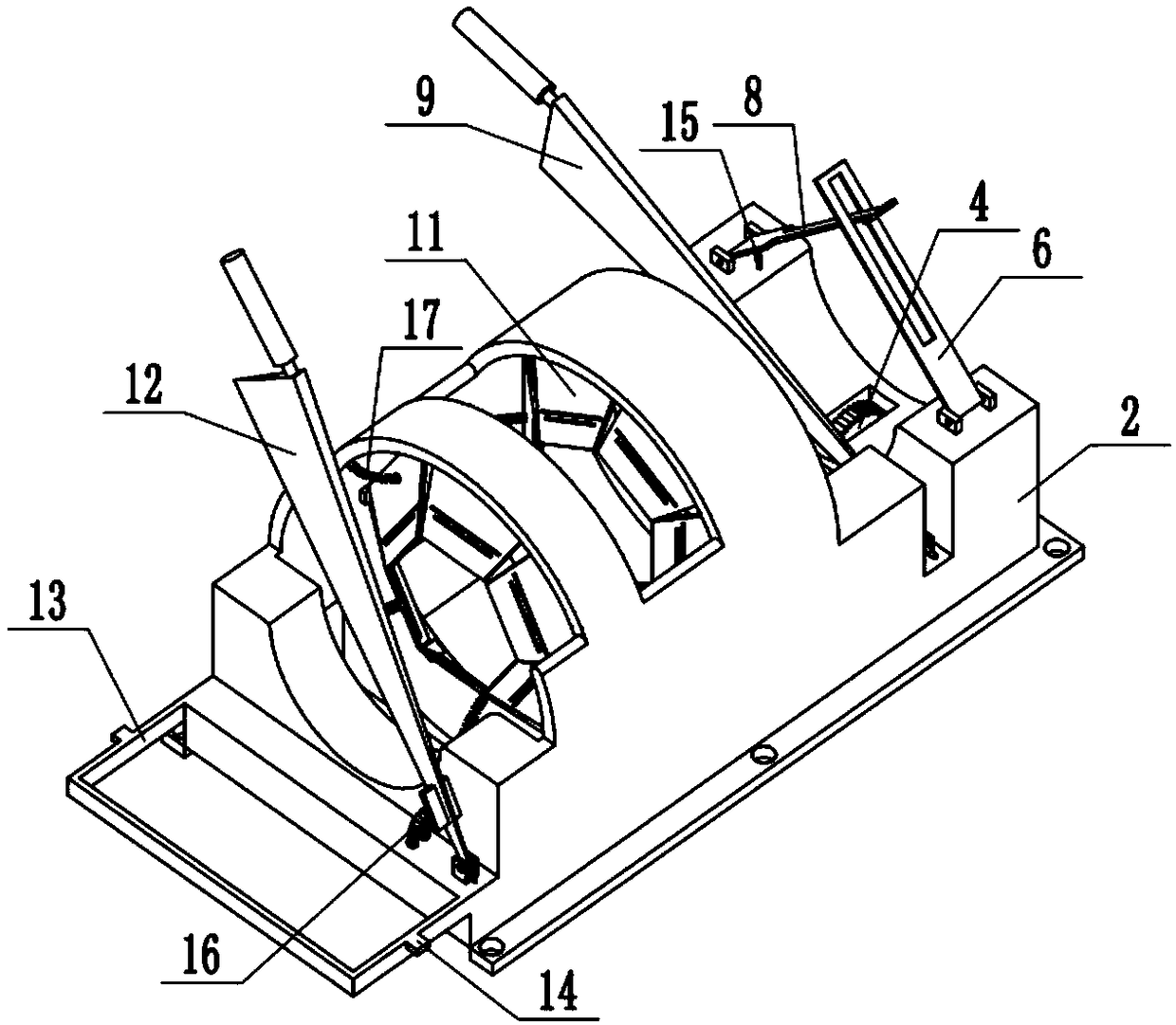

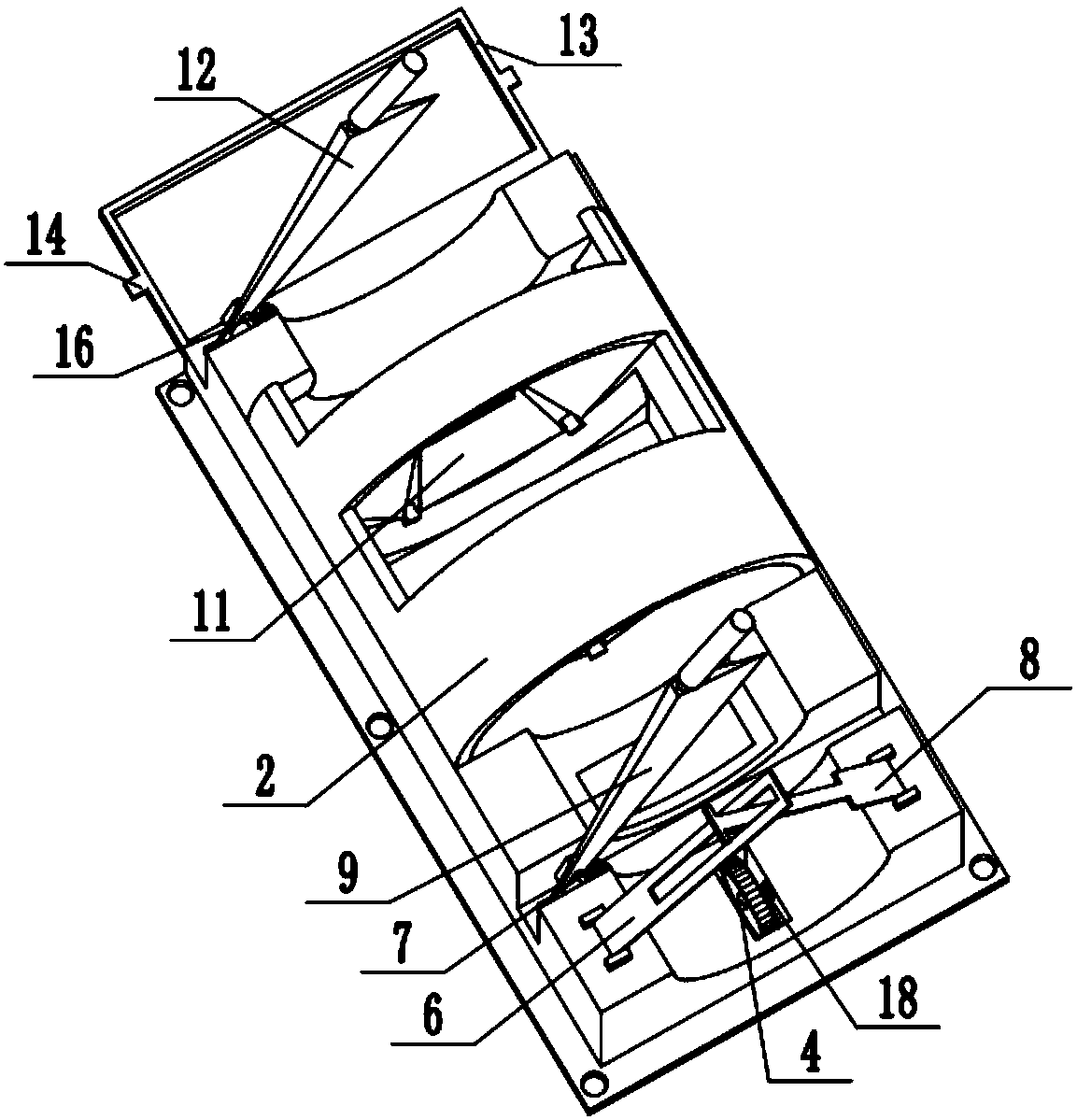

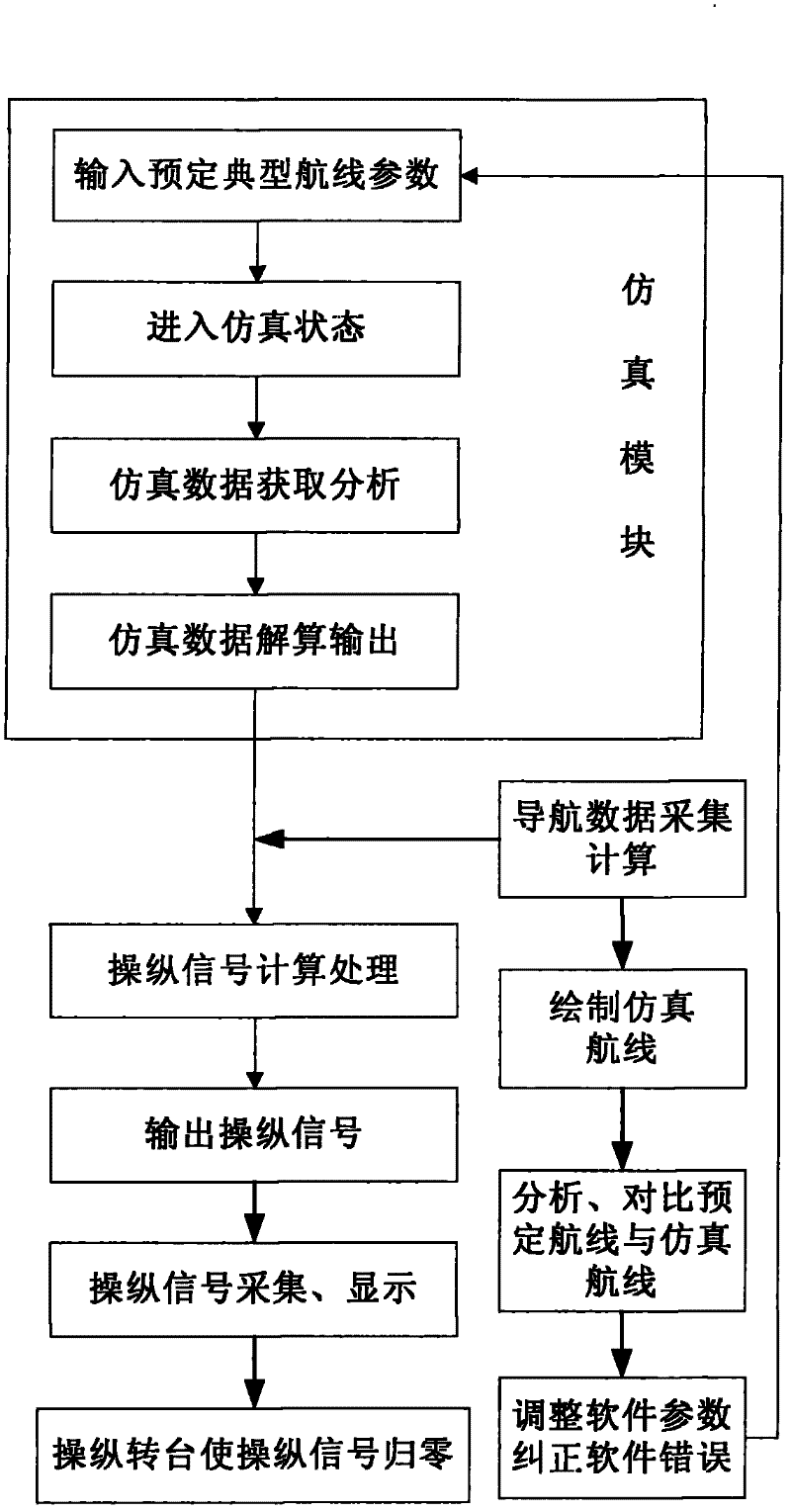

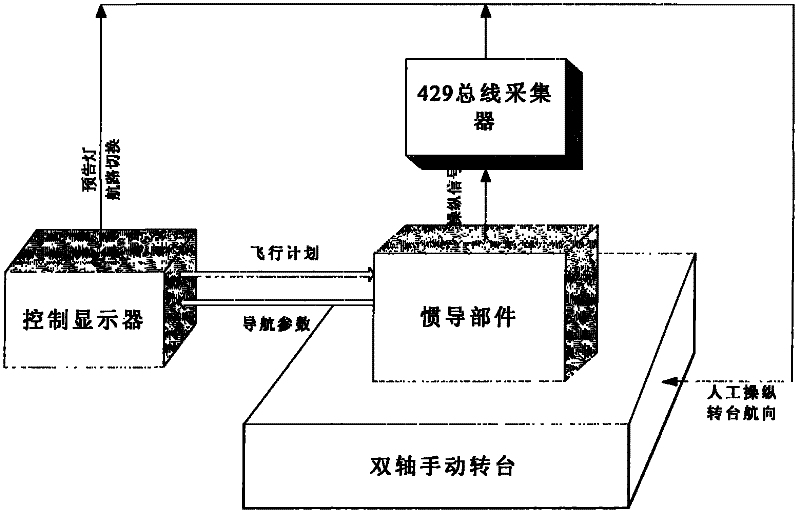

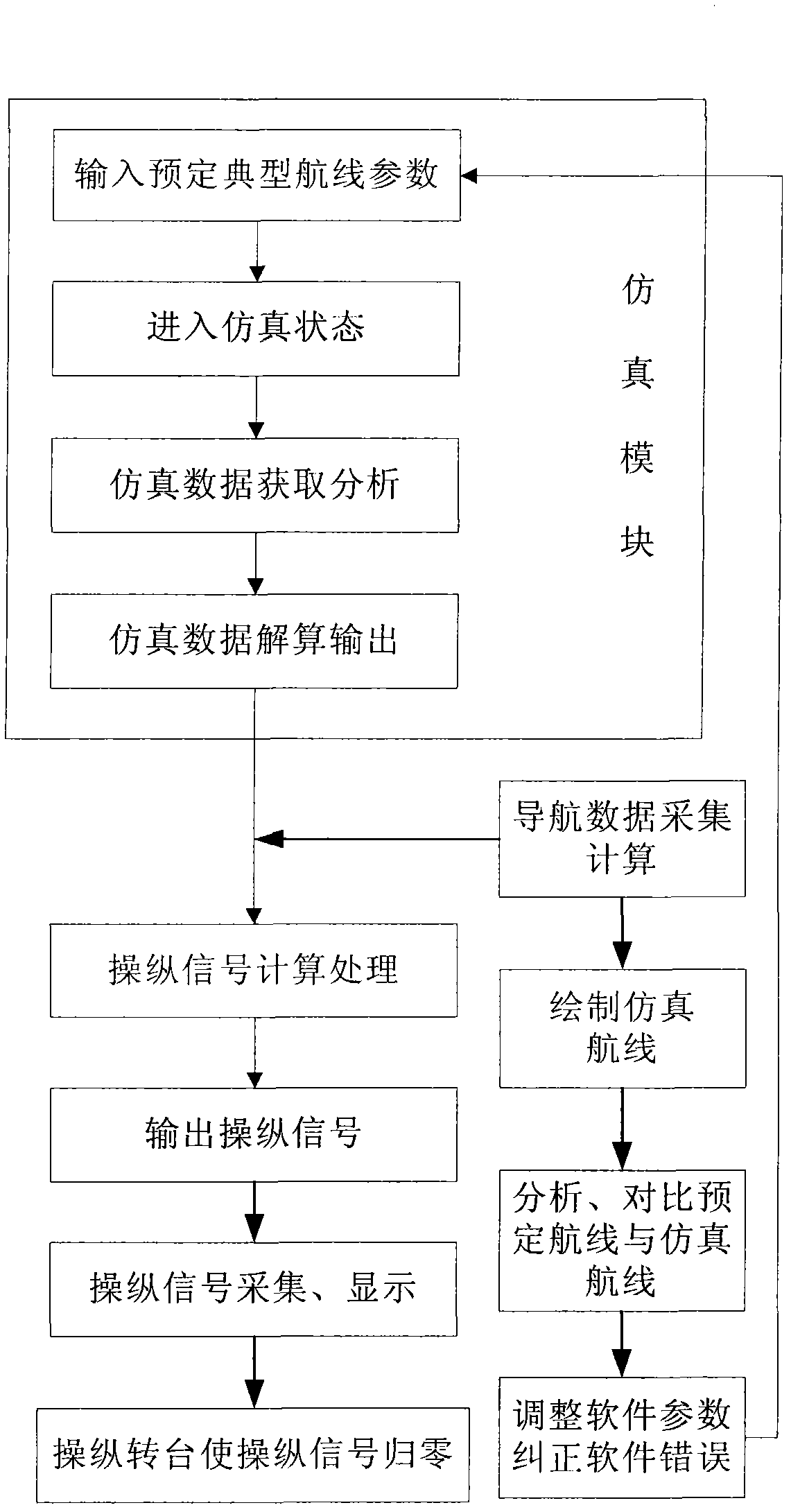

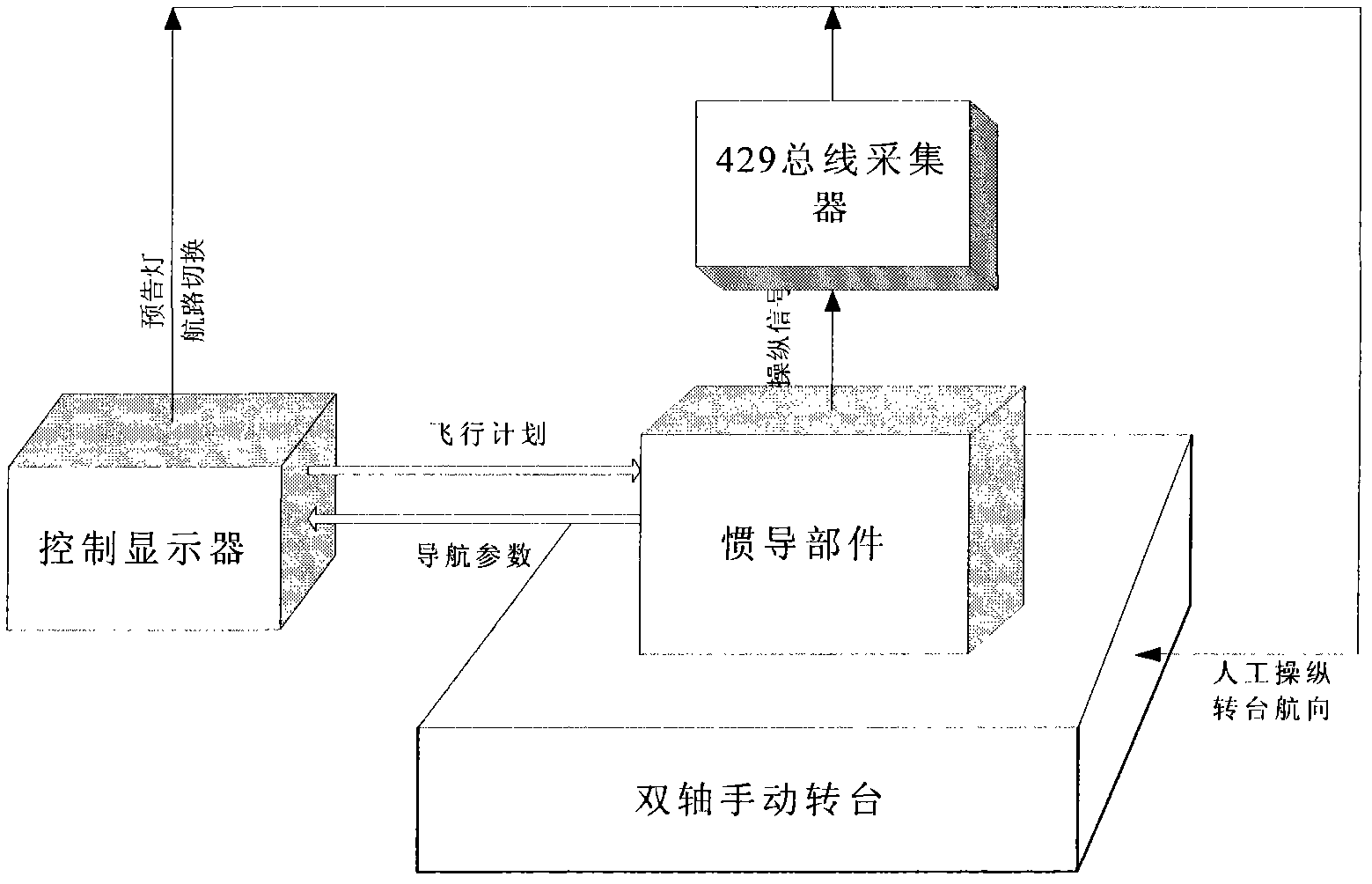

Ground-based simulation test method for automatic navigation function of inertial navigation system

The invention belongs to the technical field of inertial navigation and relates to a ground-based simulation test method for the automatic navigation function of an inertial navigation system. The ground-based simulation test method is free of the involvement of a flight control system and has low requirements for a turntable; a dual-axis hand-operated turntable is employed in stead of a three-axis hydraulic automatic turntable, and mutual cross-linking is reduced; besides, instruments such as an angular rate gyroscope and the like are reduced; the section of air routes covers all possible flight modes; people and devices joining in the test are few, so that the test is easy to organize and implement; the test is short in period and low in cost; and the method is simple and practicable.

Owner:AVIC XIAN FLIGHT AUTOMATIC CONTROL TECH

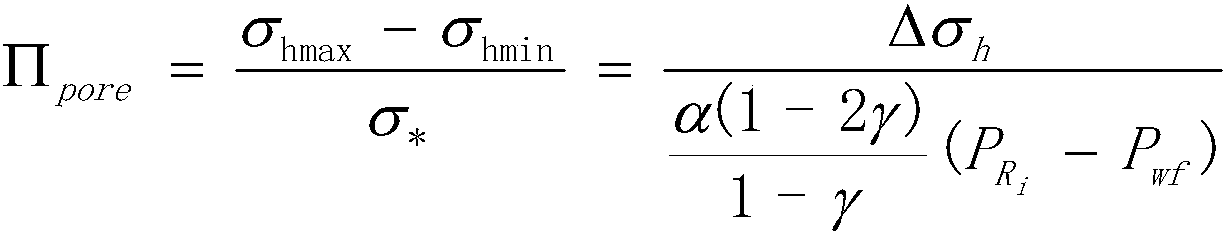

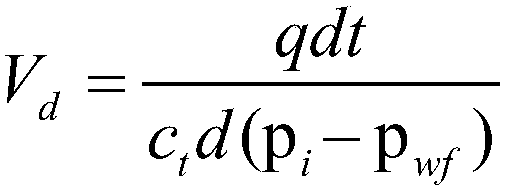

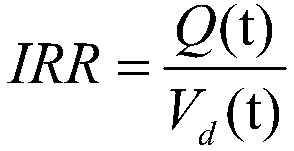

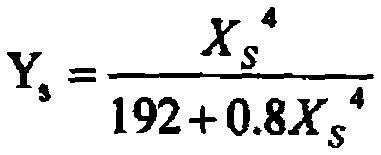

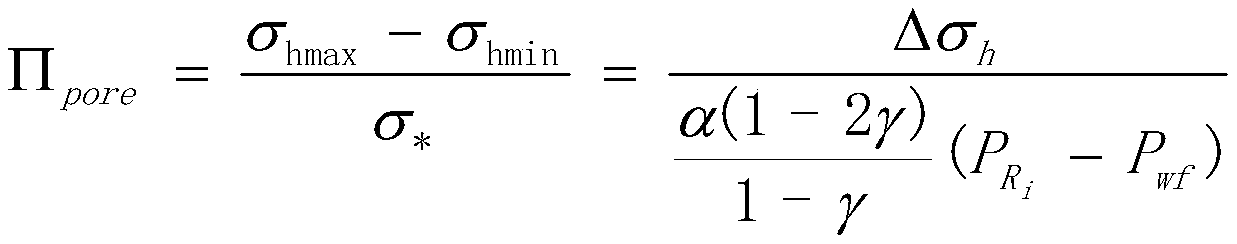

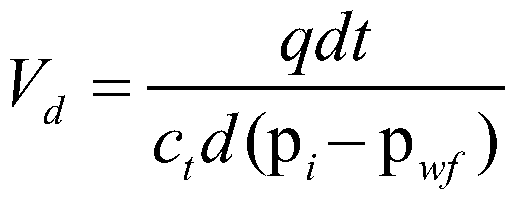

Gas well re-fracturing well selection and layer selection method

ActiveCN108119120ASimple calculationWell consideredData processing applicationsFluid removalAttenuation coefficientReservoir engineering

The invention provides a gas well re-fracturing well selection and layer selection method. The gas well re-fracturing well selection and layer selection method comprises the following steps: (1) calculating a porous elastic stress steering coefficient Piporo; (2) taking a well selected according to step (1) as an alternative target well for repeated fracturing, calculating the deflation volume Vdof the target well; (3) calculating the instantaneous recovery percent IRR; (4) calculating the yield decreasing coefficient Di by taking the well selected according to step (3) as an alternative target well for repeated fracturing; (5) calculating a gas reservoir attenuation coefficient RDep by taking the well selected according to step (4) as an alternative target well for repeated fracturing; (6) calculating each single-layer reserve abundance omegai of the target well, and selecting a layer with the air layer reserve abundance greater than 0.2 as an alternative air layer for repeated fracturing. According to the gas well re-fracturing well selection and layer selection method, a judgment algorithm is determined by application of mathematical statistics and the dynamic analysis of the gas reservoir engineering, and the calculation is simple. In the method, factors affecting the repeated fracturing are considered comprehensively, the repeated fracturing well and layer are optimized,the implementation accuracy is high, the method has high transplantability, and the application is wide.

Owner:PETROCHINA CO LTD

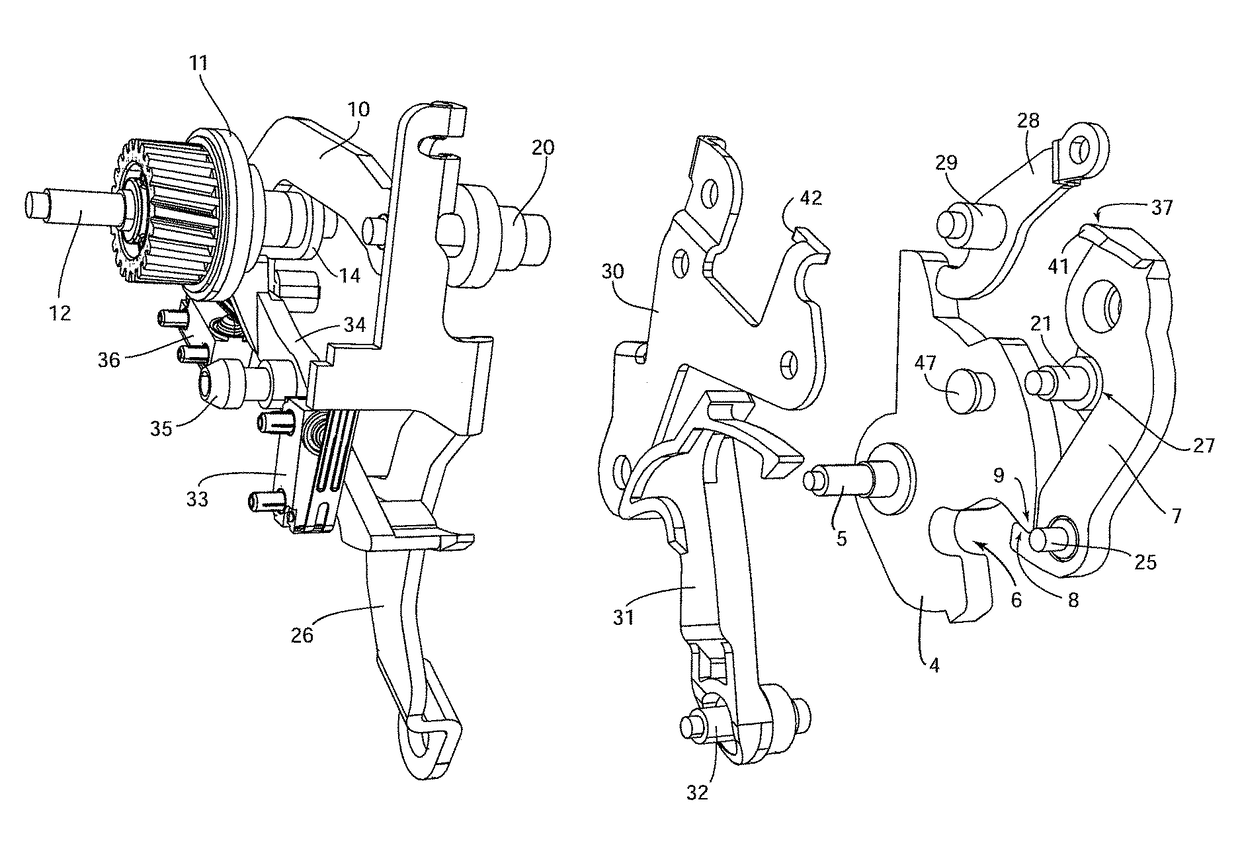

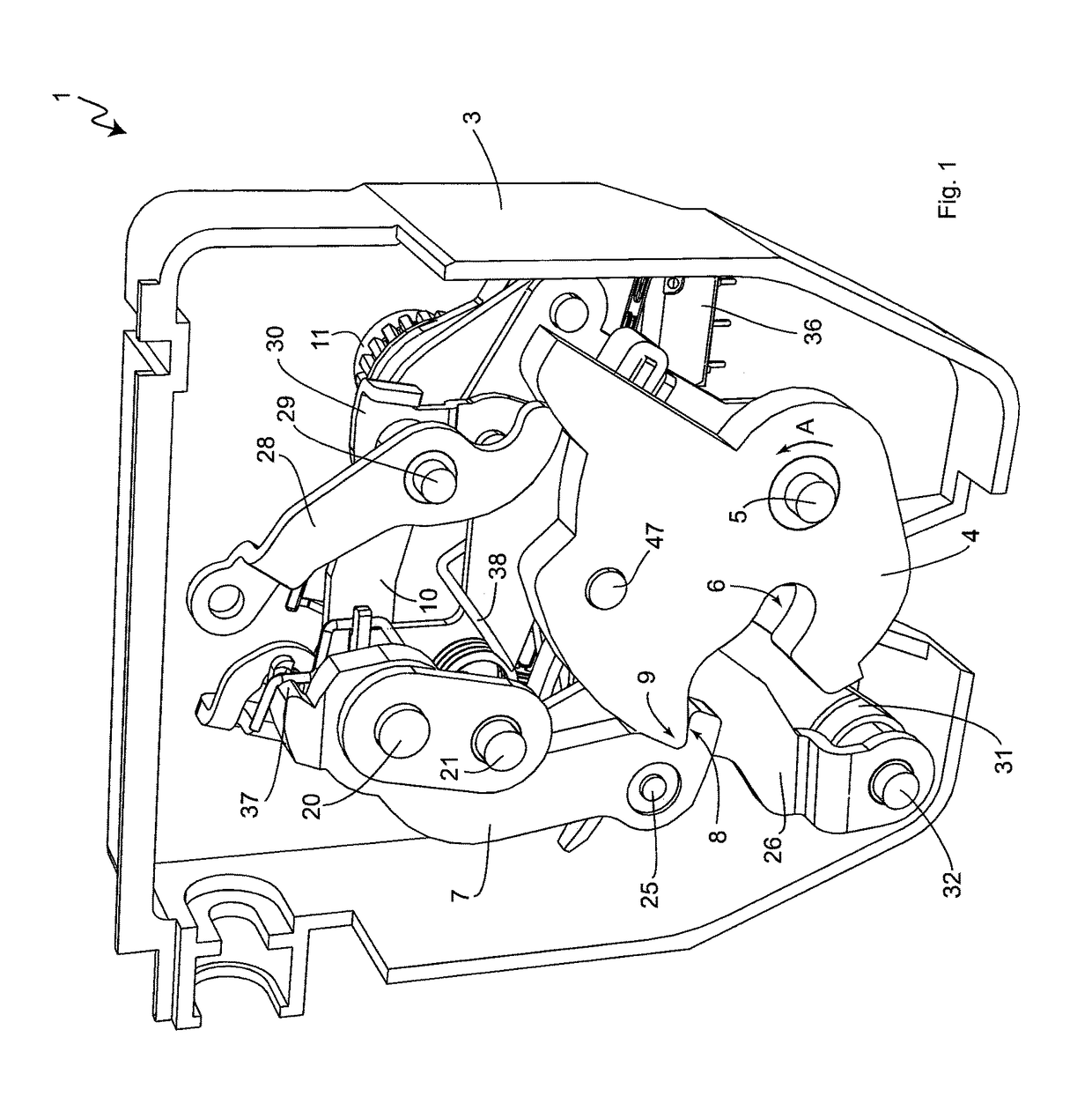

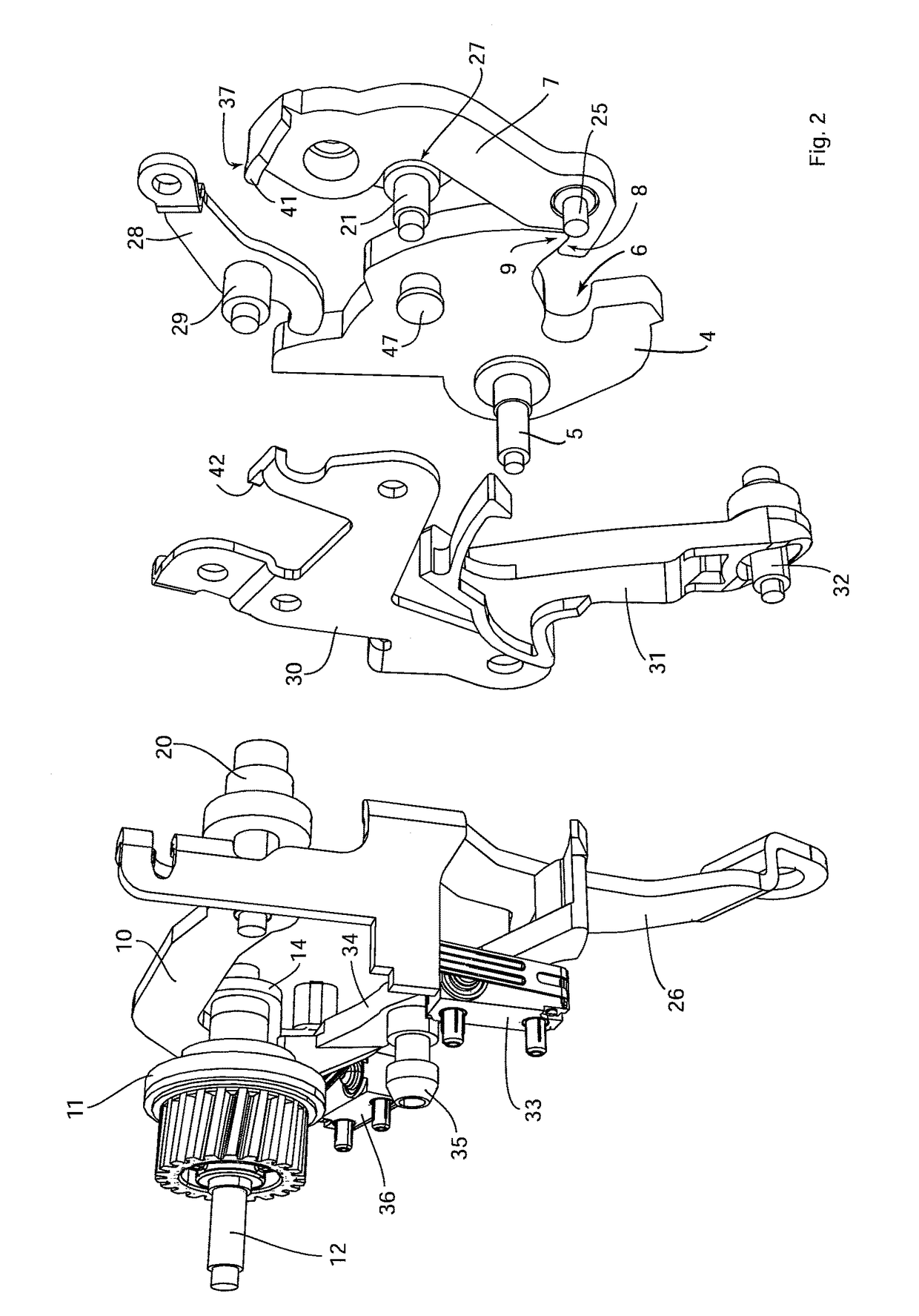

Motor vehicle door lock

ActiveUS9784021B2Improve comfortQuality improvementNoise-prevention/anti-rattling lockingNon-mechanical controlsCouplingEngineering

A motor vehicle door lock includes a rotary latch which in a locking position encompasses a locking element that is pre-tensioned in a direction of an open position releasing the locking element. A pawl is in engagement with the rotary latch such that the latch is inhibited from moving towards the open position. A coupling section of the pawl is coupled to a drive element which moves the pawl between an engagement position and a release position, the release position allowing the rotary latch to move toward the open position. A force is applied to the pawl only in the engagement position thereof and the force application holds the pawl in engagement with the rotary latch.

Owner:HUF HULSBECK & FURST GMBH & CO KG

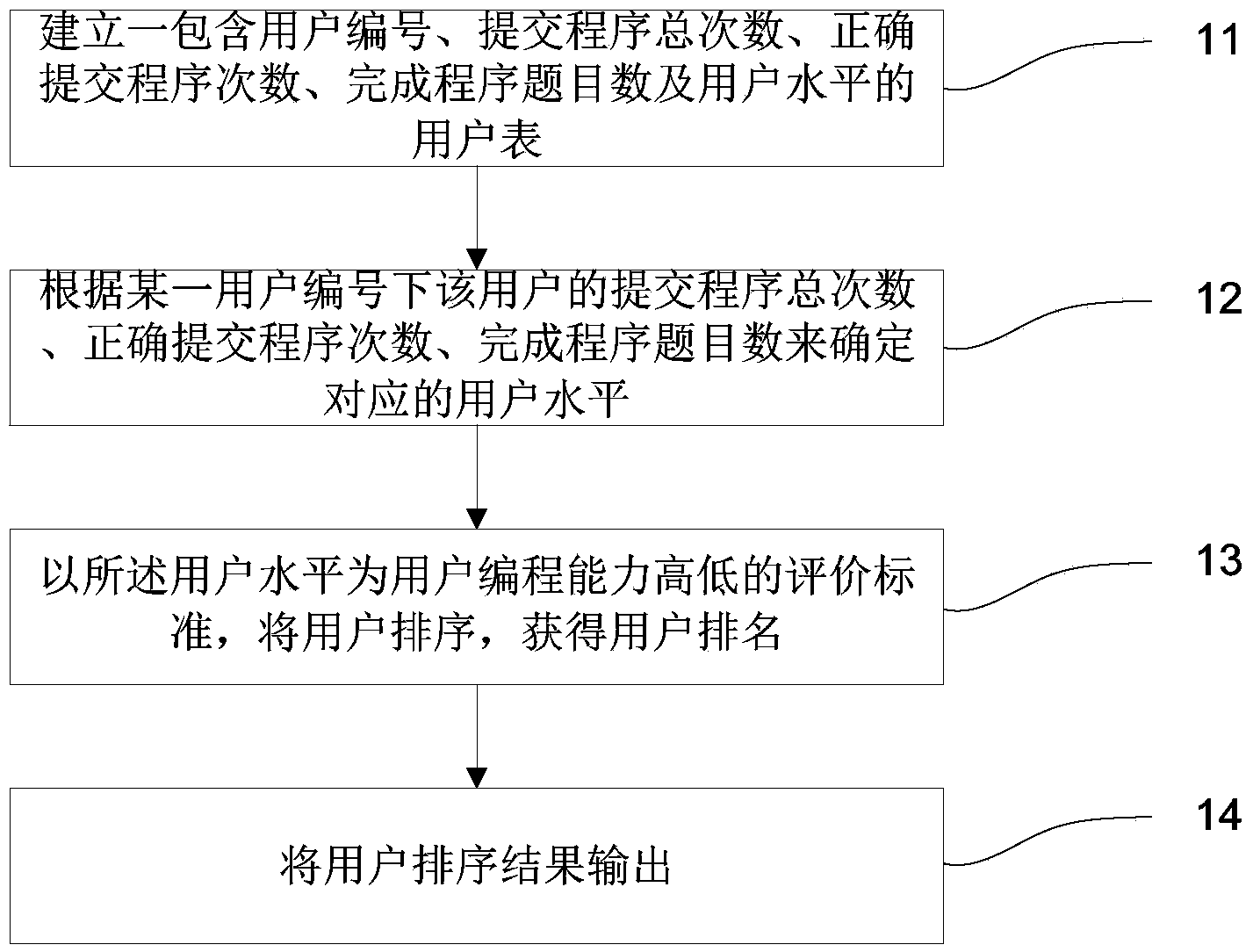

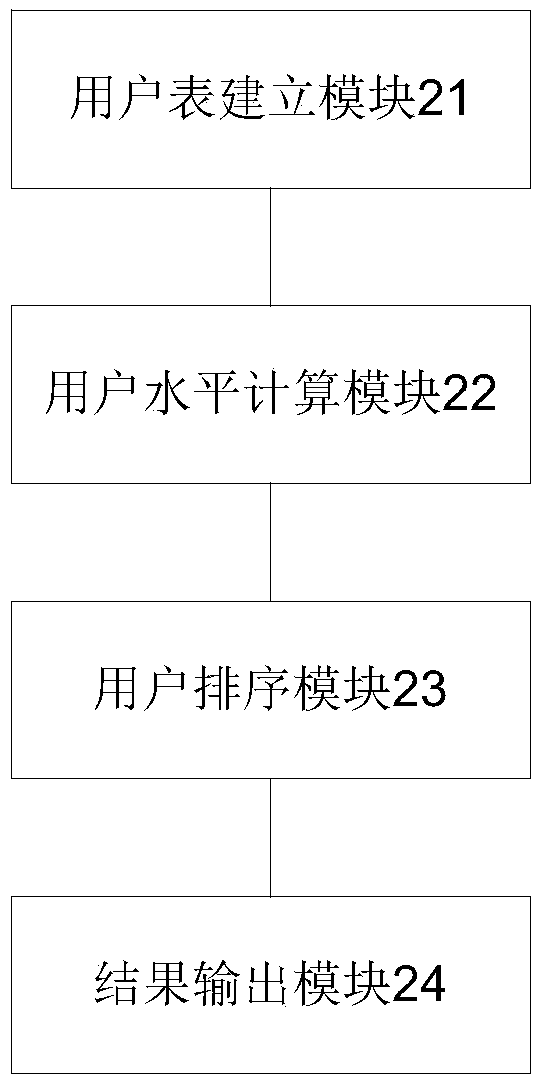

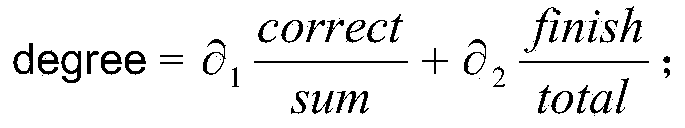

Method and system for ranking users in online program evaluation system

ActiveCN104239050AFlexible adjustmentProgram ability reflectionSpecial data processing applicationsSpecific program execution arrangementsSerial codeComputer engineering

The invention discloses a method and a system for ranking users in an online program evaluation system. The method comprises the following steps of establishing a user table which contains user serial number, total number of program submitting times, correct number of program submitting times, number of completed program titles, and user level; according to the total number of program submitting times, correct number of program submitting times and number of completed program titles of a user under the user serial number, determining the corresponding user level; using the user level as the evaluation standard of the user programming capacity degree, sequencing the users, and providing the rank of the users; returning the ranking results back to the user. The method and the system have the advantage that the programming master player among the users can be conveniently found.

Owner:UNIV OF SCI & TECH OF CHINA

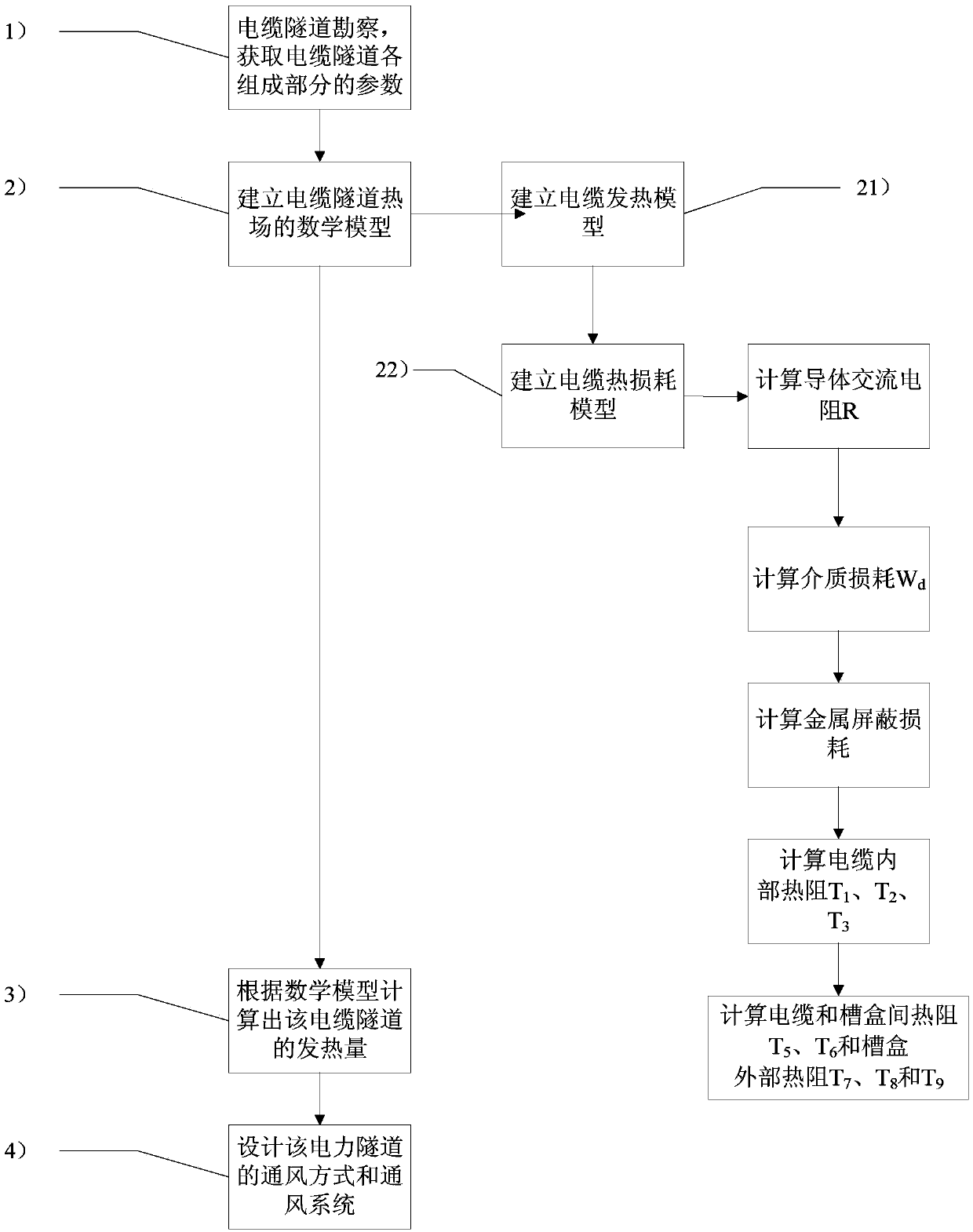

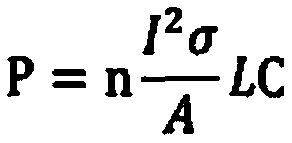

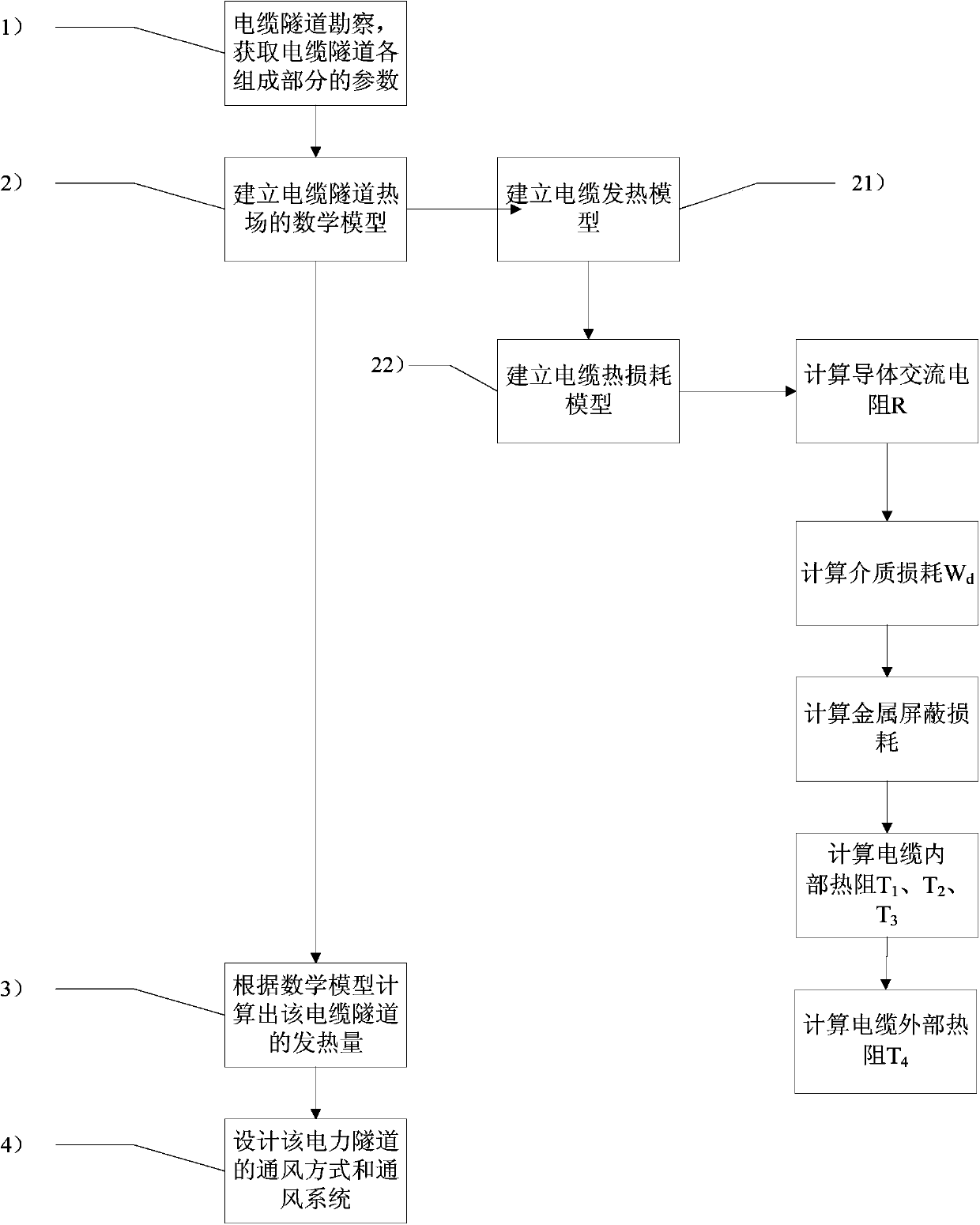

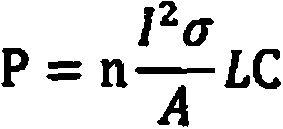

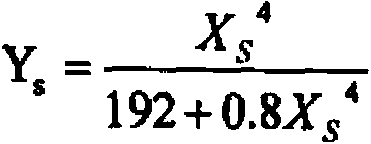

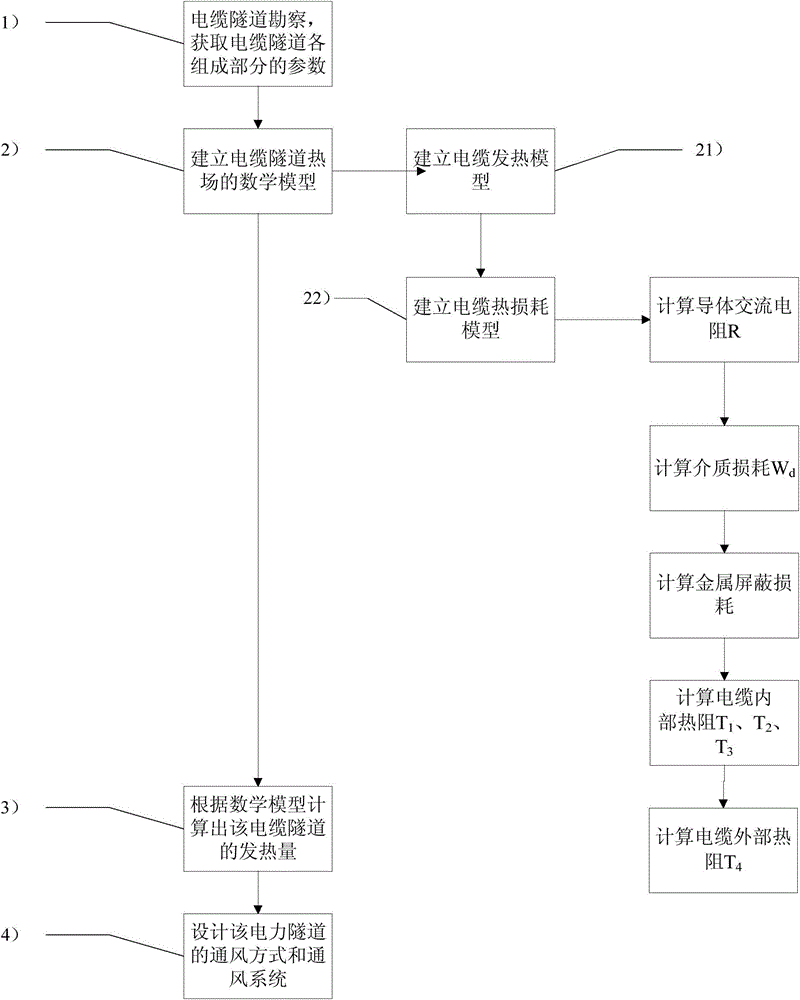

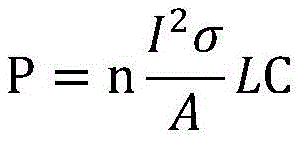

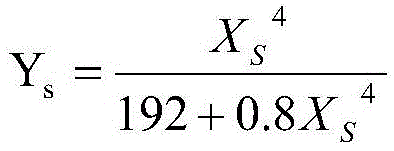

Heat dissipation method based on slotted box cable tunnel thermal field model

ActiveCN104179521AAccurately establishedModel accuratelyTunnel/mines ventillationMathematical modelElectric power system

The invention relates to a heat dissipation method based on a slotted box cable tunnel thermal field model. The heat dissipation method comprises the following steps: 1) surveying a cable tunnel, and acquiring parameters of all components of the cable tunnel; 2) establishing a mathematical model of the cable tunnel thermal field; 3) calculating heat value of the cable tunnel based on the mathematical model; 4) designing the ventilation mode and ventilation system of the electric power tunnel. Compared with the prior art, the heat dissipation method has the advantages of effectiveness and accuracy.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

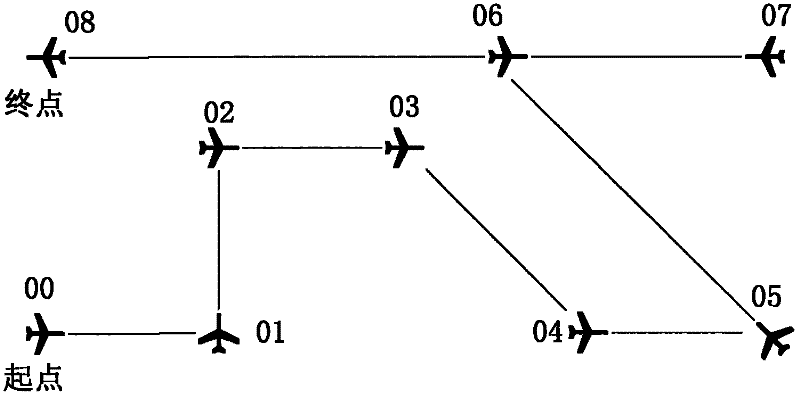

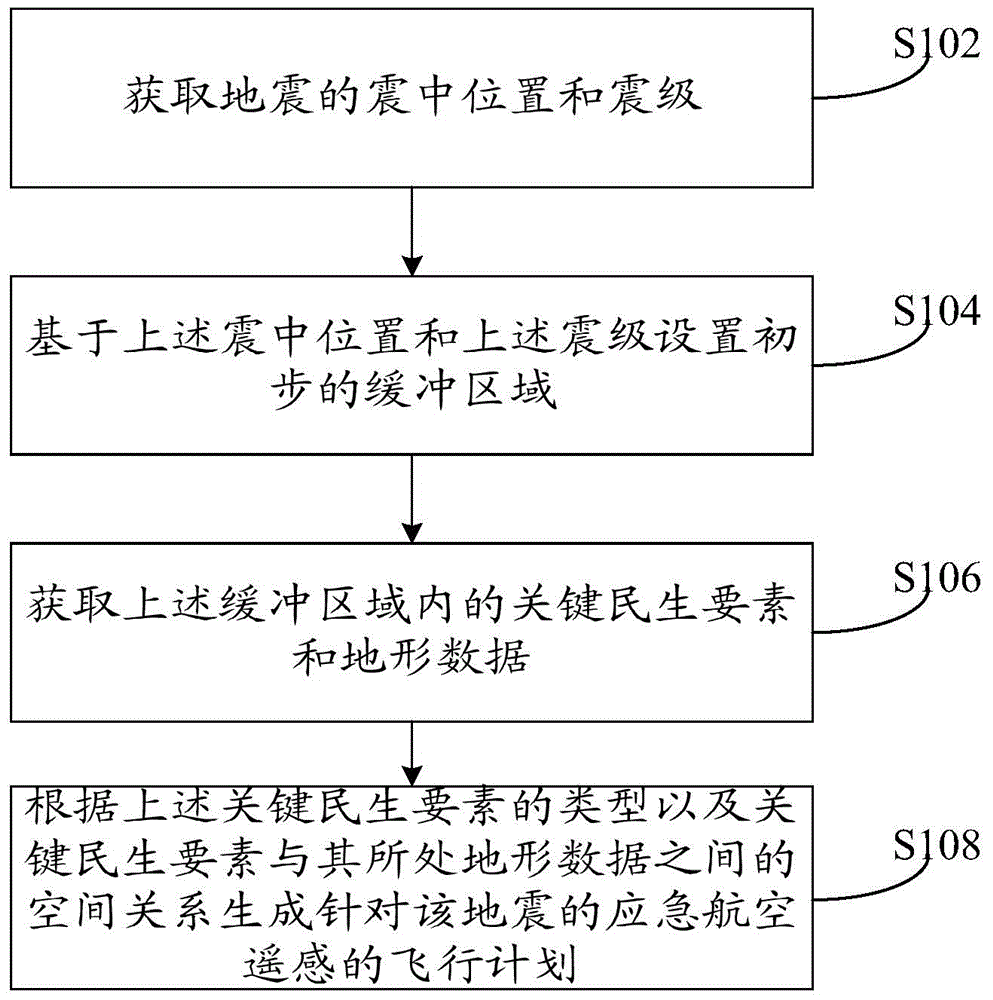

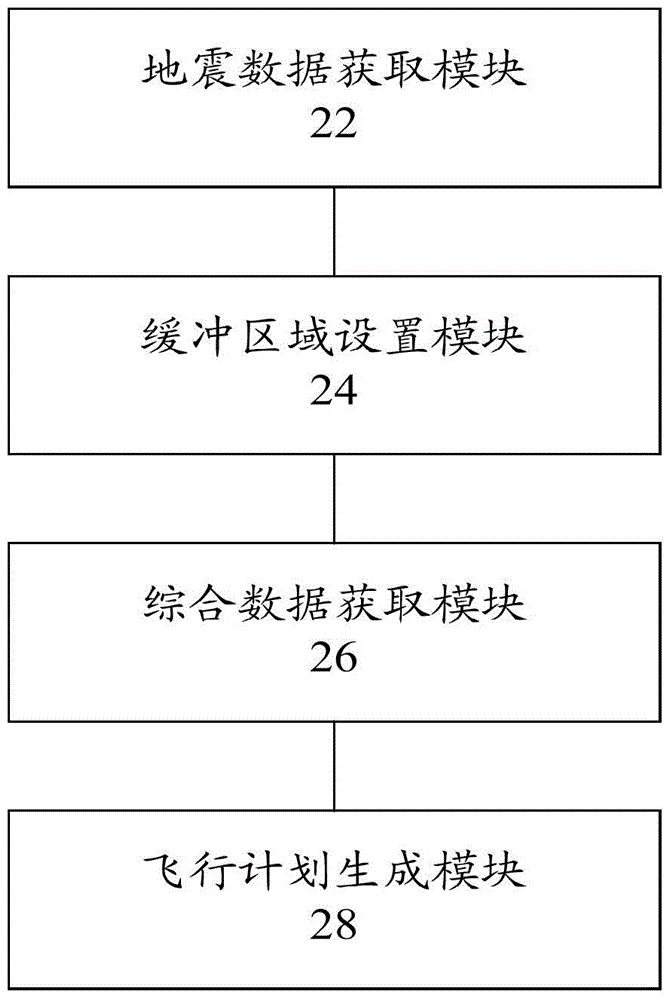

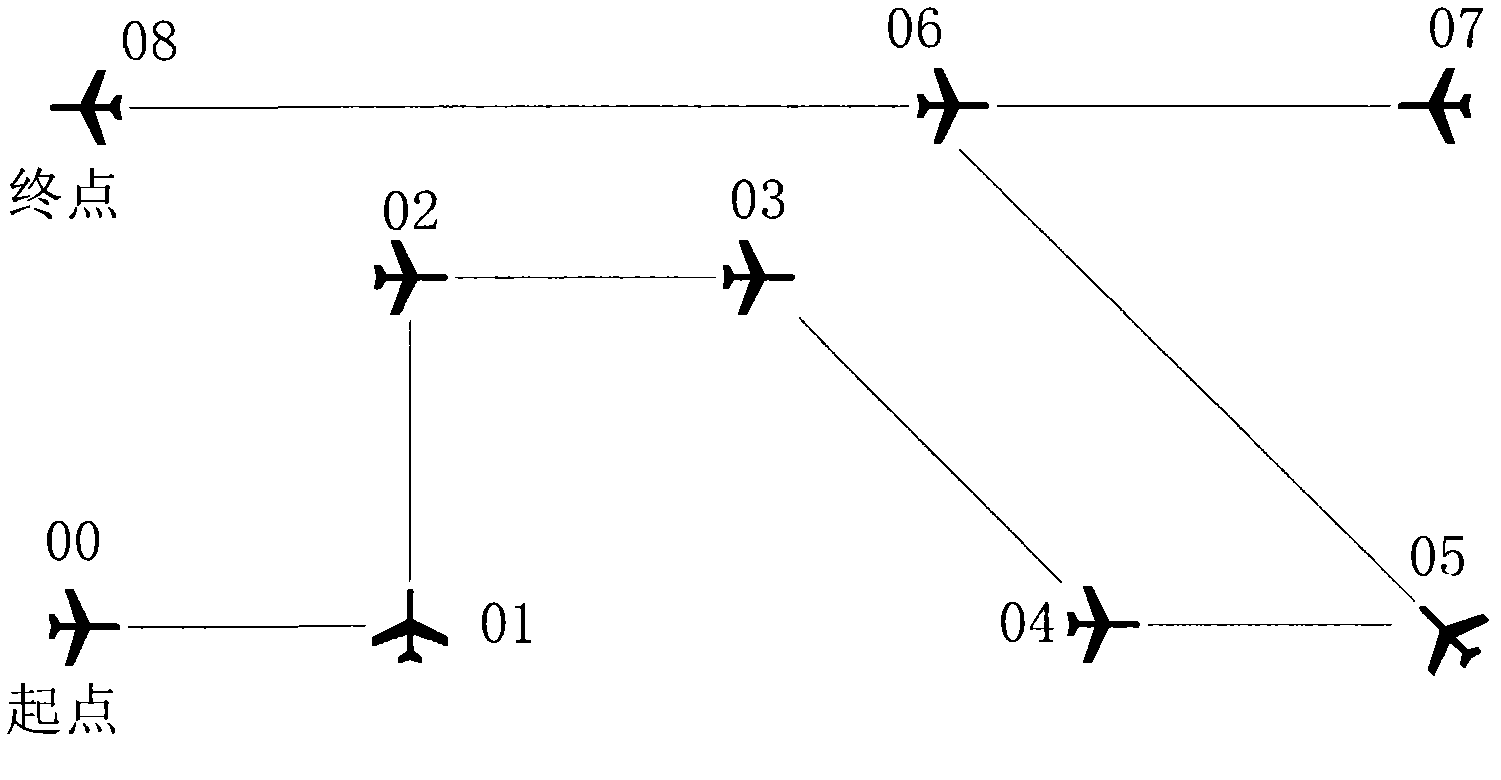

Generation method and device for flight plans in earthquake emergency aerial remote sensing

InactiveCN104376745AObtain remote sensing image dataWell consideredAircraft traffic controlProgram planningTime of flight

The invention provides a generation method and device for flight plans in earthquake emergency aerial remote sensing. The method includes: acquiring epicentral position and magnitude of an earthquake; setting a preliminary buffer area on the basis of the epicentral position and magnitude; acquiring key people's life elements and topographic data in the buffer area, wherein the key people's life elements include at least one of basic geographic data, administrative region vector data, road data and water system data; generating the flight plans of emergency aerial remote sensing for the earthquake according to types of the key people's life elements and the spatial relationship between the key people's life elements and the topographic data, wherein the flight plans include flight area coverage and flight lines. By the method and device, existing resources can be utilized to the utmost extent, remote sensing image data of severely afflicted areas are acquired, flight time is fully utilized, and accordingly effective rescue is carried out beneficially.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

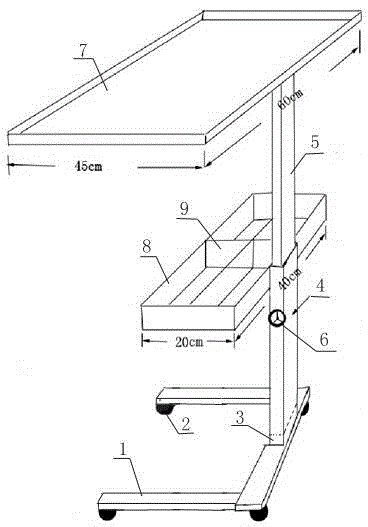

Movable operation instrument platform

The invention provides a movable operation instrument platform comprising a movable part. Moving wheels are arranged on the bottom of movable part; the movable part is in a semi-frame structure with left and right sides extending out; an insertion member is upwardly arranged on the middle of a straight side of the semi-frame structure; an insertion rod is placed on the insertion member; an instrument plate is horizontally inserted to the top end of the insertion rod; the instrument plate is parallel to the movable part to form a framework structure with an upper and lower ends extending out, and an empty position in the middle; the insertion rod is telescopic; a fixed rotary button or a spring ball is placed in the insertion rod; a spare article plate is further inserted in the empty position between the instrument plate and the movable part; and the spare baffle plate is in a grid type. The movable part of the movable operation instrument platform facilitates movements and enables the platform to freely move in space, so people can stand and sit without obstacles; with cooperation between the insertion member and the insertion rod, installation and use can be facilitated and detachments can be facilitated; the movable operation instrument platform occupies no space; and the empty position between the instrument plate and the movable part can be fully utilized, so spare articles can be hung and placed.

Owner:SHIYAN TAIHE HOSPITAL

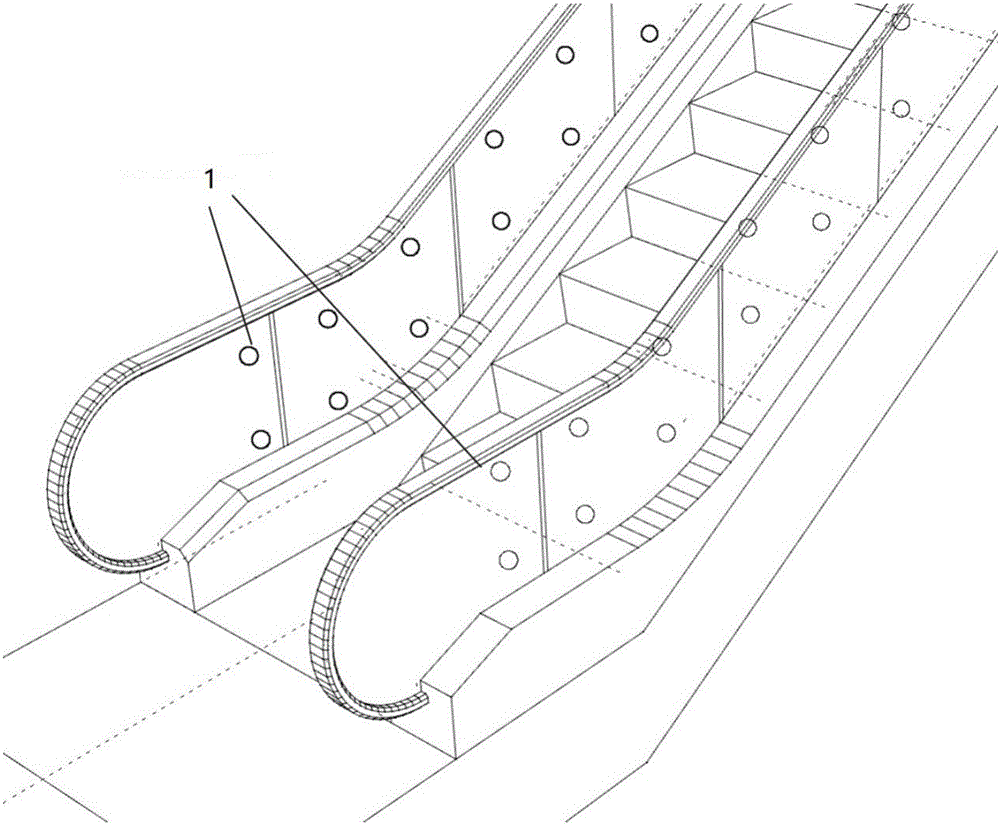

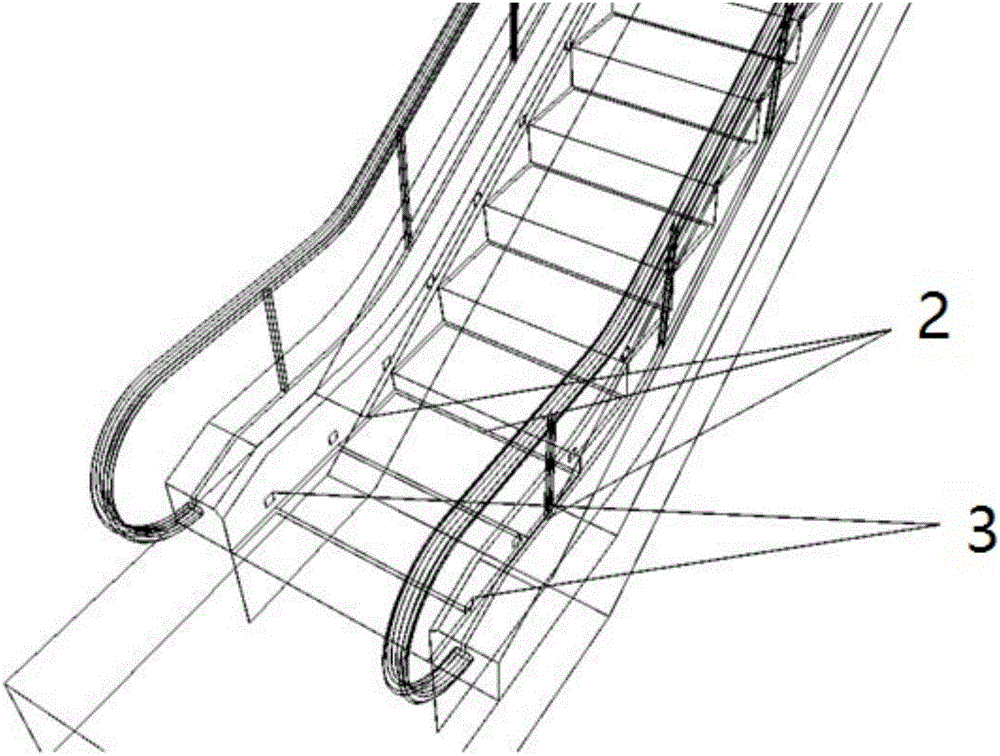

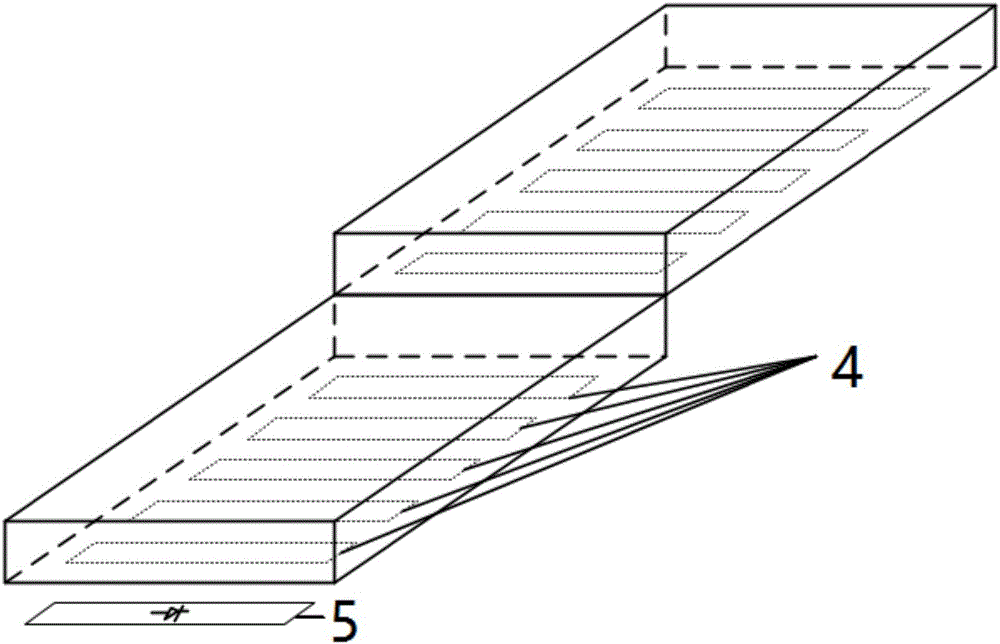

Automatic-ladder-matched safety device

InactiveCN106809717AAvoid safety accidentsGuarantee the safety of lifeEscalatorsEngineeringBody posture

The invention discloses an automatic-ladder-matched safety device. The automatic-ladder-matched safety device specifically comprises photoelectric sensor arrays respectively used for detecting body postures of passengers (whether an abnormal posture such as falling appears or not), pressure sensor arrays for detecting gap pressure between steps and steps and gap pressure between steps and skirt guard panels, magnetic sensors for detecting the running speed and the direction of an elevator, first judging controllers for judgment according to pressure sensor array outputting, second judging controllers according to photoelectric sensor array outputting and magnetic sensor outputting, warning device arrays for sounding warnings to the passengers and scramming devices for elevator scramming. The automatic-ladder-matched safety device has the functions of detecting insecurity and accident behaviors of the passengers and the abnormal running conditions of the elevator, is thoughtful, and can effectively prevent security accidents from occurring.

Owner:ZHEJIANG UNIV

Heat dissipation method based on slotless box cable tunnel thermal field model

ActiveCN104196555AAccurately establishedModel accuratelyTunnel/mines ventillationElectric power systemMathematical model

The invention relates to a heat dissipation method based on a slotless box cable tunnel thermal field model. The method includes the following steps of (1) exploring a cable tunnel to obtain parameters of all components of the cable tunnel, (2) building a mathematical model of a cable tunnel thermal field, (3) working out the calorific value of the cable tunnel according to the mathematical model and (4) designing the ventilation mode and the ventilation system of the electric power tunnel. Compared with the prior art, the heat dissipation method has the advantages of being effective and accurate.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

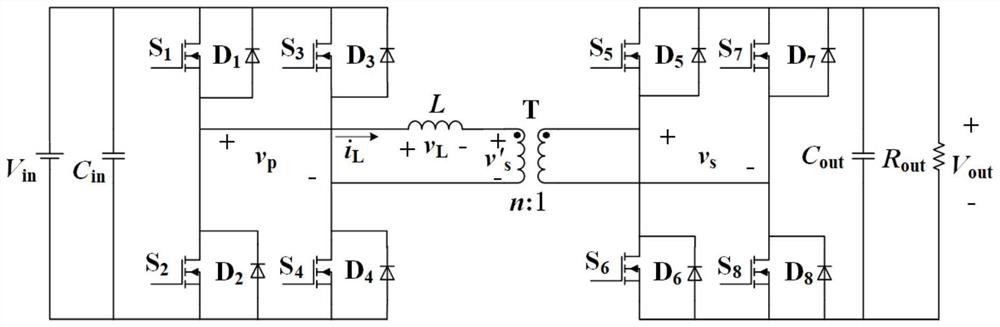

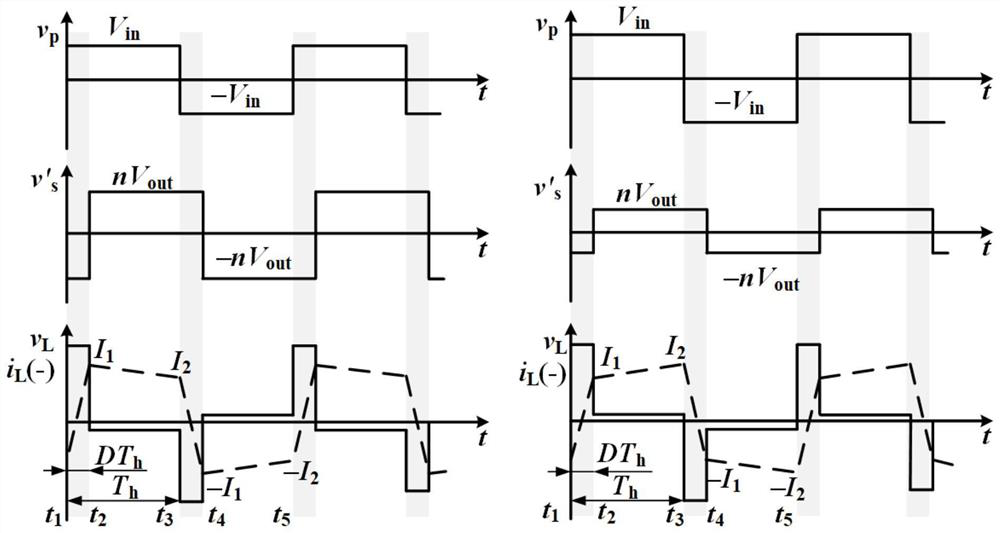

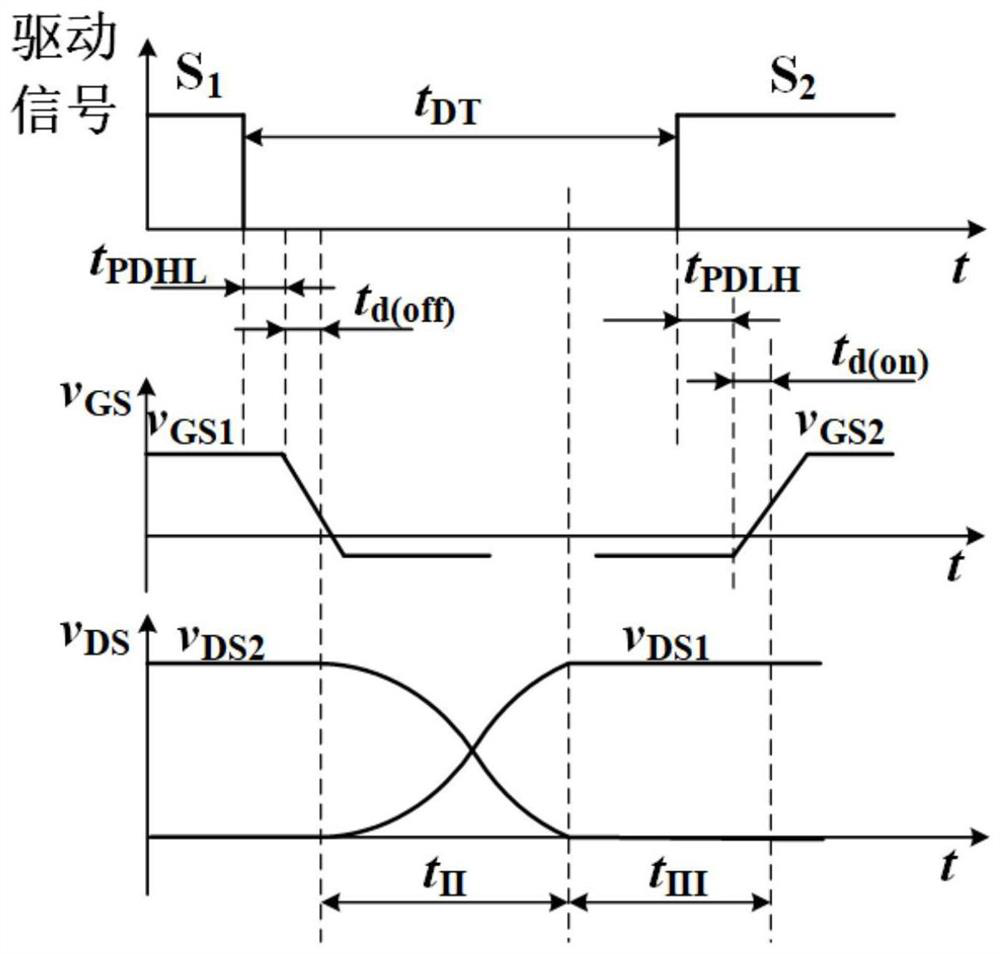

Dual active bridge inductance range determination method suitable for single phase shift control

PendingCN114696625AGuaranteed to workReduce lossDc-dc conversionElectric variable regulationHemt circuitsControl theory

The invention discloses a dual active bridge inductance range determination method suitable for single phase shift control. The method considers the constraint that the maximum output power of the circuit should be greater than a given output power index requirement, and also considers the constraint that a power device in the circuit should realize a zero-voltage switching requirement. Meanwhile, detailed discussion is conducted on the requirement for the direction of a characteristic current value, the requirement for inductance energy meeting primary side commutation and the requirement for matching of dead zone time and an inductance value, the minimum value of the inductance value range is obtained, the zero-voltage switching performance of a power device in the DAB circuit is guaranteed, and the working reliability of the power device and even the whole device is improved. And meanwhile, the power device does not generate switching loss, so that the loss of the whole circuit is reduced, and the working efficiency of the DAB device is improved. Experiments prove that the inductance range determination method provided by the invention is comprehensive in consideration and clear in process, ensures the reliability of normal work of the dual-active bridge circuit, and has relatively high practical value.

Owner:XI AN JIAOTONG UNIV

Method of Extracting Urban Building Height Based on Multi-temporal Remote Sensing Image Shadow

InactiveCN107679441BReduce the impact of errorsHigh precisionImage enhancementImage analysisMathematical modelLeast squares

Based on the method of extracting the height information of urban buildings based on the shadows of multi-temporal remote sensing images, the present invention aims to form a systematic, fast and accurate method, using two remote sensing images of different time phases (the two images have different sun elevation angles and satellite azimuths) Angle), to analyze and calculate the shadow of the target building in batches, and then realize the rapid and accurate extraction of the height of the target building in the area, which will help to improve the efficiency of measurement, 3D modeling and other work; the specific implementation is mainly through calculation The length of the building shadow, combined with the angle relationship between the landmark building and its shadow on the image, selects the corresponding mathematical model to calculate the height value of the target building in the area; the two sets of building height results calculated by using two remote sensing images are used to construct a simulation model based on the least squares method. Combine the equations to obtain the corrected height of the target building, thereby improving the accuracy of the calculation results.

Owner:ZHENGZHOU UNIV

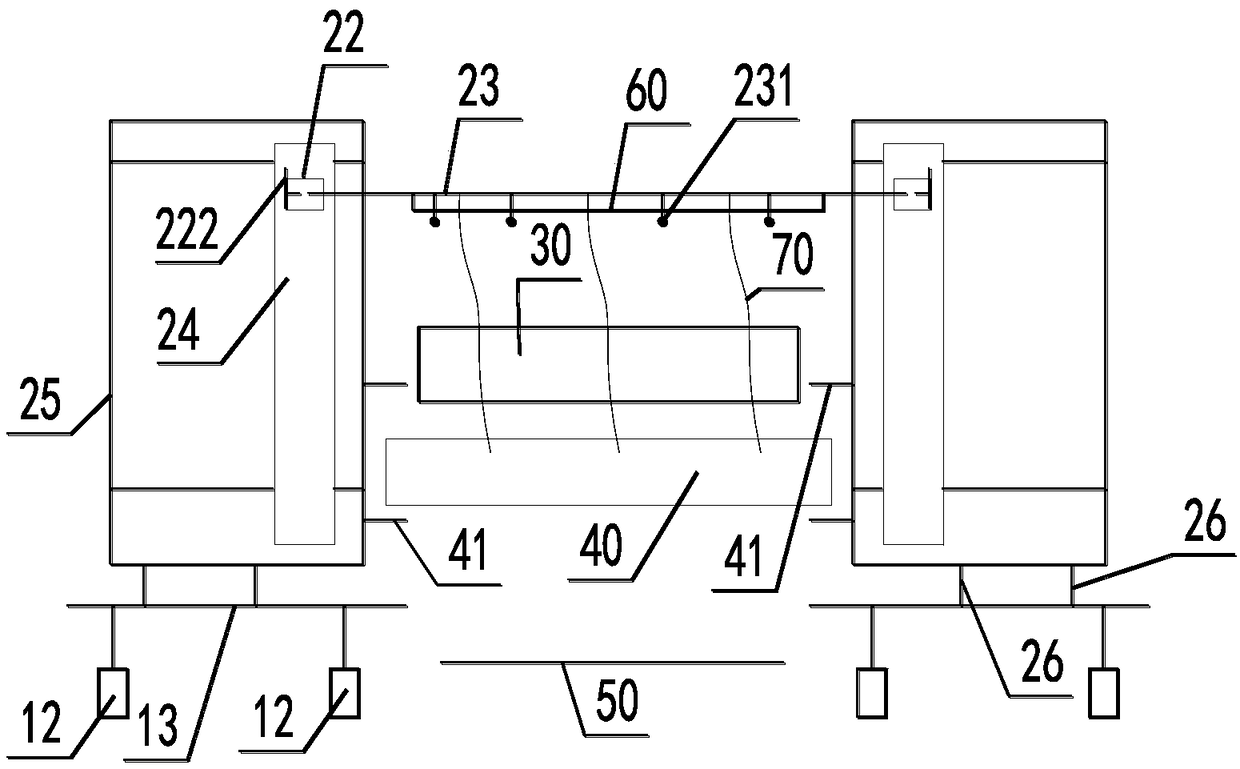

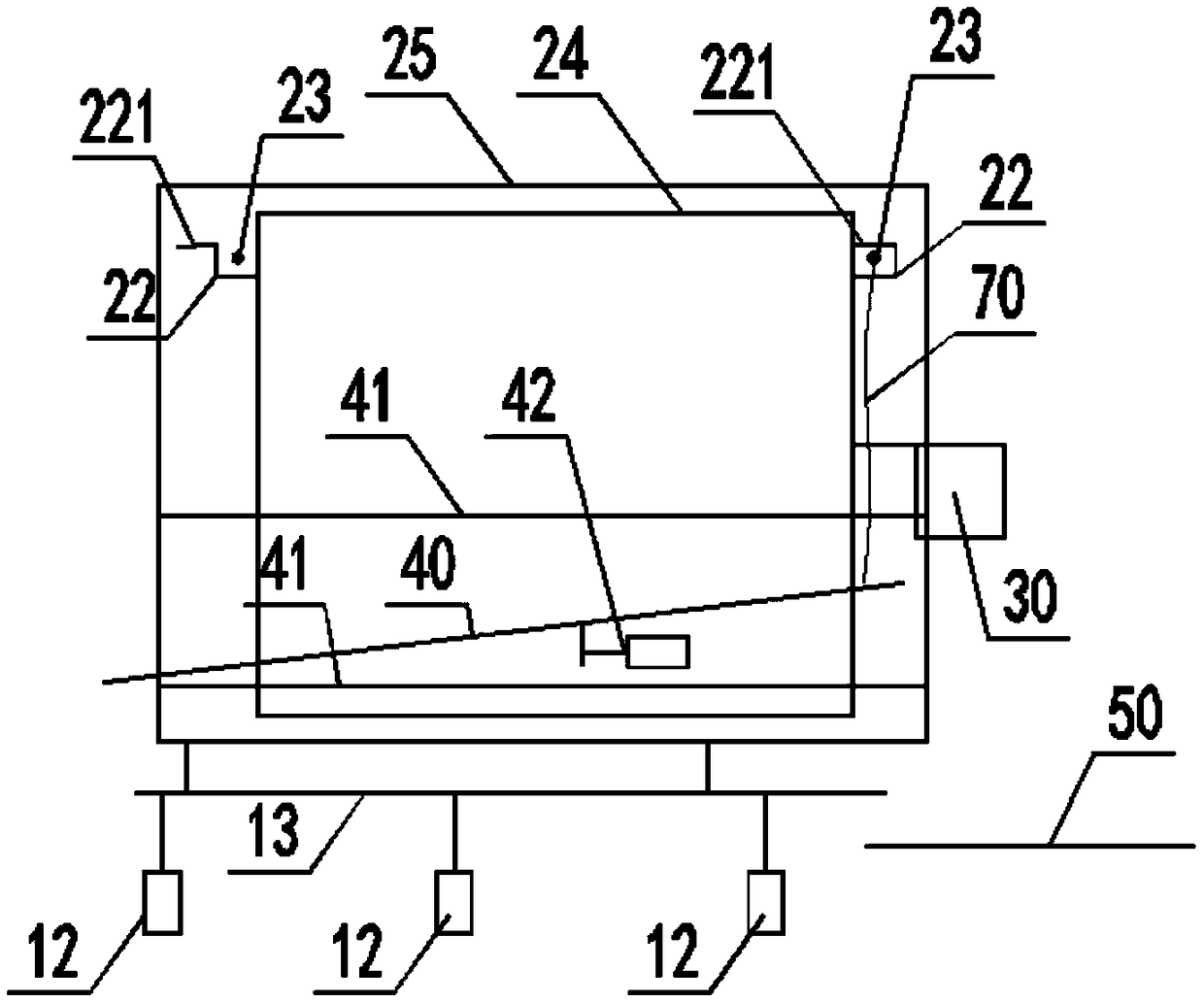

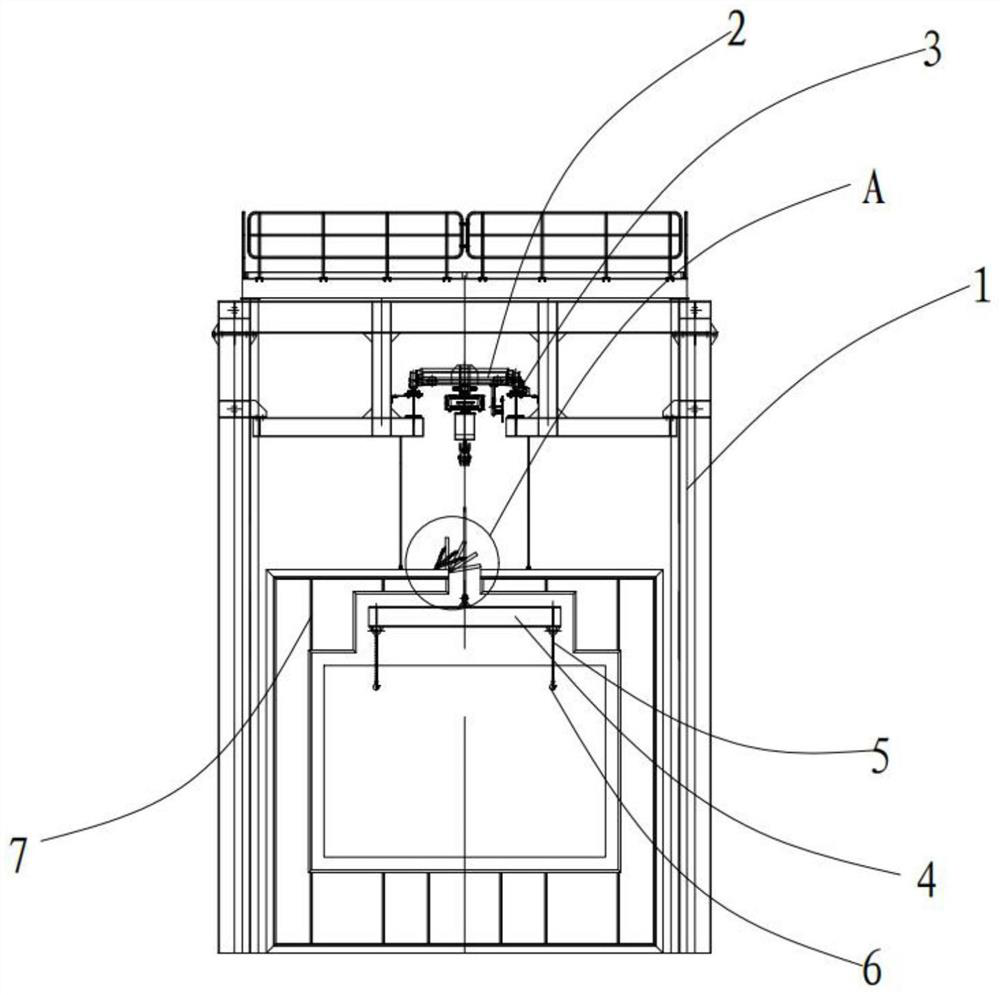

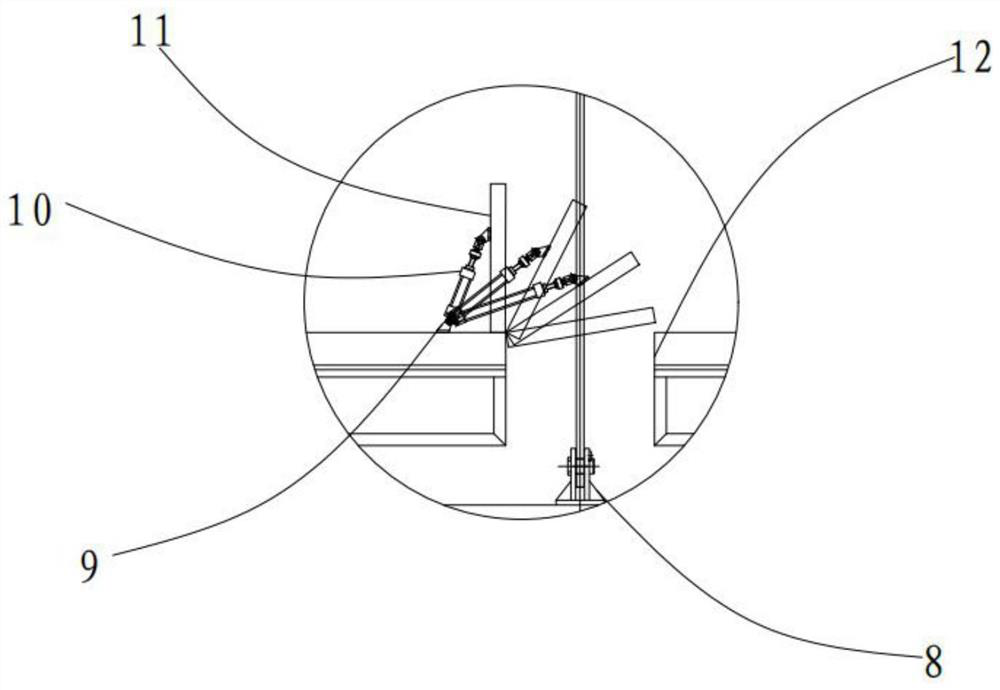

Lifting-type traction-free kelp lifting, transporting and cutting system and working method thereof

ActiveCN109005887AAchieve separationAvoid breakingClimate change adaptationHarvestersMechanical engineeringTransmission system

The invention relates to a lifting-type traction-free kelp lifting, transporting and cutting system. The lifting-type traction-free kelp lifting, transporting and cutting system comprises a lifting system composed of a pair of synchronously moving lifting units and a hoisting system composed of a pair of synchronously moving kelp hoisting units, wherein the kelp hoisting units are vertically arranged transmission systems with closed head and tails, a cutting system is fixedly arranged in a back area between the kelp hoisting units, a sliding way with a low front portion and a high back portionis arranged in front of the cutting system and used for receiving and transferring cut-off kelp tips, a conveying system is backward laid under the cutting system and used for receiving and transferring the cut-off kelp bodies, and the backward conveying rate of the conveying system is identical to the conveying rates of descending sections in the hoisting system units with closed heads and tails. The lifting-type traction-free kelp lifting, transporting and cutting system achieves separation of kelp tips and kelps. Due to the fact that vertical descending rate is identical to the horizontalconveying rate, no dragging motion is adopted in the process of kelp lifting to ships and kelp transferring, and kelp damage during dragging is avoided.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

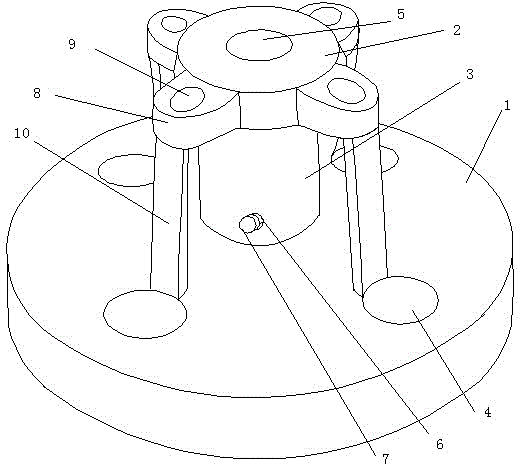

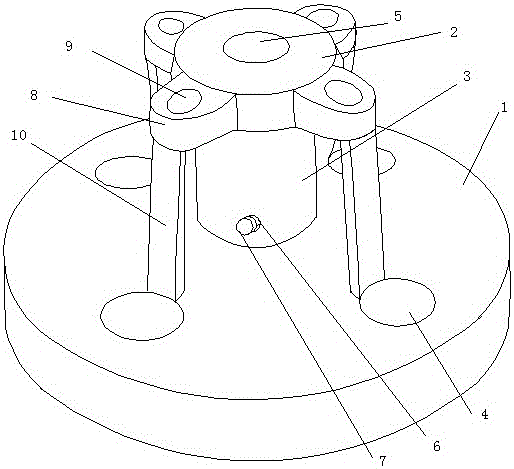

Component for valve

The invention discloses a component for a valve. The component comprises a base, a connection seat and a support column connecting the base and the connection seat. A plurality of fixing holes are formed in the base, a through groove is formed in the middle of the connection seat, the interior of the support column is hollow and is communicated with the through groove of the connection seat. A through hole penetrating the support column is formed in the side wall of the support column, a sealing plug is arranged at the position of the through hole in a fit mode, a plurality of lugs are arranged on the periphery of the connection seat, connection holes are formed in the lugs, vertical rods are arranged between the lugs and the base, the ends of the connection rods are connected with the lugs, and the other ends are connected with the base. According to the component, the connection holes and the fixing holes are used for fixing, and accordingly, the location effect is good, and the component overall firmness is high; insertion columns are used flexibly to assist the mounting and location of the component, and accordingly, the combination fit degree with other accessories is further improved, and good application prospects are provided.

Owner:SUZHOU FURUN MACHINERY

A heat dissipation method based on the thermal field model of a cable tunnel without a slot box

ActiveCN104196555BAccurately establishedModel accuratelyCable installations in tunnelsTunnel/mines ventillationMathematical modelElectric power system

The invention relates to a heat dissipation method based on a slotless box cable tunnel thermal field model. The method includes the following steps of (1) exploring a cable tunnel to obtain parameters of all components of the cable tunnel, (2) building a mathematical model of a cable tunnel thermal field, (3) working out the calorific value of the cable tunnel according to the mathematical model and (4) designing the ventilation mode and the ventilation system of the electric power tunnel. Compared with the prior art, the heat dissipation method has the advantages of being effective and accurate.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

A method for selecting wells and layers for repeated fracturing of gas wells

ActiveCN108119120BSimple calculationWell consideredData processing applicationsFluid removalReservoir engineeringGas formation

The invention provides a gas well re-fracturing well selection and layer selection method. The gas well re-fracturing well selection and layer selection method comprises the following steps: (1) calculating a porous elastic stress steering coefficient Piporo; (2) taking a well selected according to step (1) as an alternative target well for repeated fracturing, calculating the deflation volume Vdof the target well; (3) calculating the instantaneous recovery percent IRR; (4) calculating the yield decreasing coefficient Di by taking the well selected according to step (3) as an alternative target well for repeated fracturing; (5) calculating a gas reservoir attenuation coefficient RDep by taking the well selected according to step (4) as an alternative target well for repeated fracturing; (6) calculating each single-layer reserve abundance omegai of the target well, and selecting a layer with the air layer reserve abundance greater than 0.2 as an alternative air layer for repeated fracturing. According to the gas well re-fracturing well selection and layer selection method, a judgment algorithm is determined by application of mathematical statistics and the dynamic analysis of the gas reservoir engineering, and the calculation is simple. In the method, factors affecting the repeated fracturing are considered comprehensively, the repeated fracturing well and layer are optimized,the implementation accuracy is high, the method has high transplantability, and the application is wide.

Owner:PETROCHINA CO LTD

Injection molding method for middle sundries box

InactiveCN107322864AReduce operating errorsQuality assuranceDomestic articlesInjection mouldingInjection molding machine

The invention discloses an injection molding method for a middle sundries box. The method is characterized by comprising the following specific steps that (1) injection molding equipment is checked firstly; (2) mold mounting is conducted, and after mold mounting is finished, the two-time adjustment process is further conducted to enable the injection molding equipment to enter an automatic mold adjusting state; (3) injection is conducted; (4) injection is finished, cooling molding is conducted, a product is made to be in a pressure maintaining stage, the pressure is maintained to be 60-80 bar, the time is 1-3 S, then the product is cooled, and the cooling time is 1-4 S; and (5) a mold is opened, and after cooling, only the mold needs to be opened to take out the product. The invention provides the complete plastic injection using method. The method is detailed in step and comprehensive in consideration; meanwhile after molding mounting is finished, the two-time adjustment process is further conducted to enable the injection molding equipment to enter the automatic mold adjusting state; and specific steps are given, operation errors are reduced, the product quality is indirectly ensured, and the product qualification rate is increased.

Owner:ANHUI JIANGSHAN MACHINERY

A control method for a four-wheel-drive hybrid electric vehicle

ActiveCN104149777BComprehensive working modeWell-considered working modeHybrid vehiclesPower batteryElectric machine

The invention provides a control method for a four-wheel-driven hybrid electric vehicle. The control method comprises the first step of detecting ignition key signals, torque required by the vehicle, the charge state of a power battery and vehicle speed signals, and the second step of controlling the vehicle to switch between multiple working modes according to the ignition key signals, the torque required by the vehicle, the charge state of the power battery and the vehicle speed signals. According to the control method, the multiple working modes are adopted, and the advantages of four-wheel-driven hybrid power can be given to full play. Through switching between the multiple working modes, the vehicle can be in an optimal working state all the time, so that fuel consumption is lowered. In addition, through distribution of the torque of all components in different working modes, the working efficiency of an engine, an ISG motor and a rear axle motor can be optimized, so that the fuel consumption of the whole vehicle is further lowered.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Novel drying chamber body sealing structure

PendingCN113663885AStable structureImprove sealingPretreated surfacesCoatingsMechanical engineeringEnergy consumption

The invention discloses a novel drying chamber body sealing structure which comprises a shell, a drying chamber body contained in the shell, an air cylinder sealing structure arranged above the drying chamber body and an electric hoist structure used for conveying workpieces, and an opening is formed in the top of the drying chamber body. According to the novel drying chamber body sealing structure,the design of automatic cylinder sealing is adopted, the structure is reliable, the sealing effect is good, and the operation energy consumption is low.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

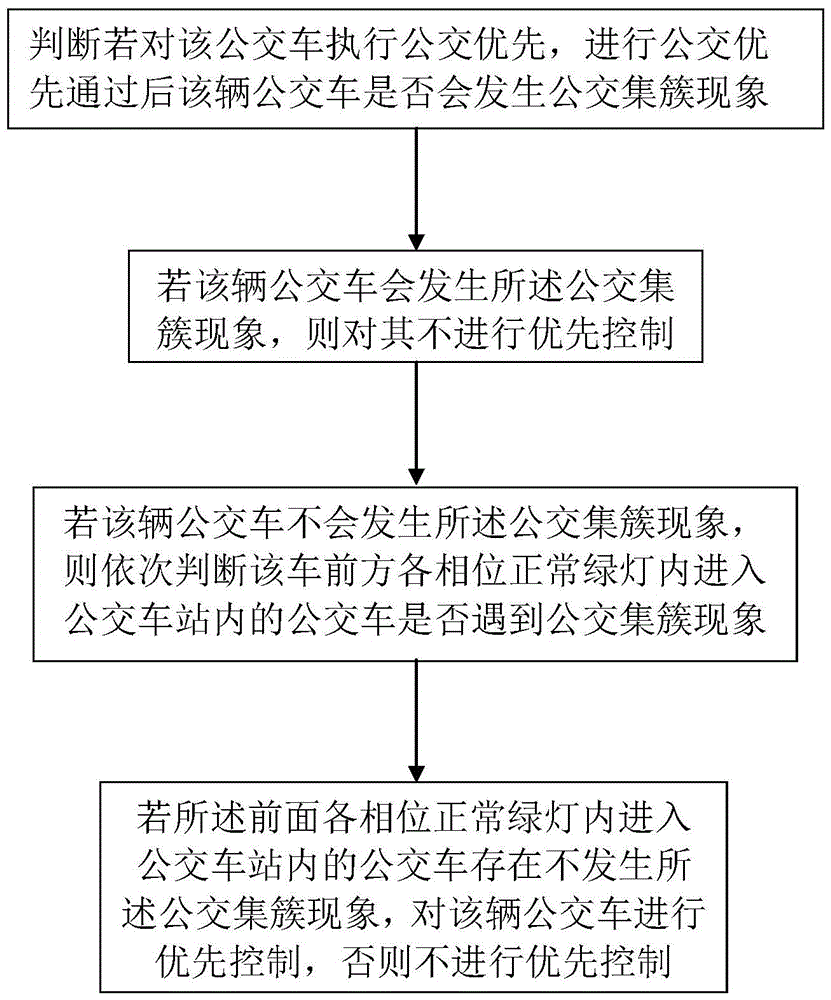

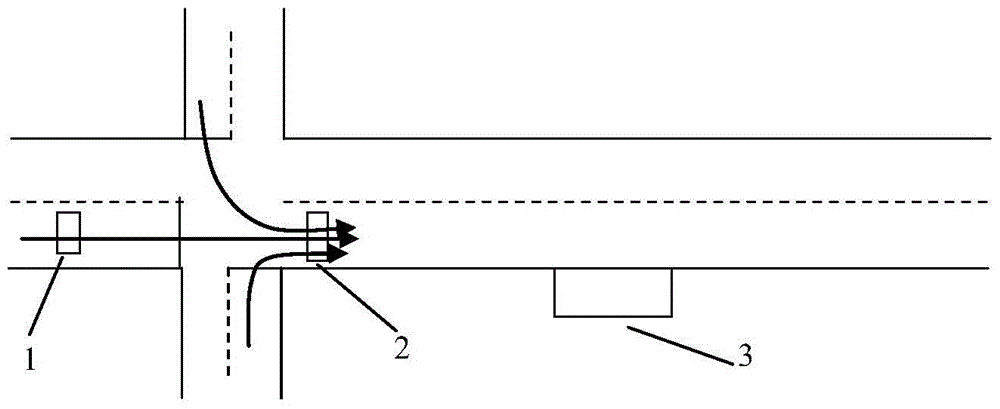

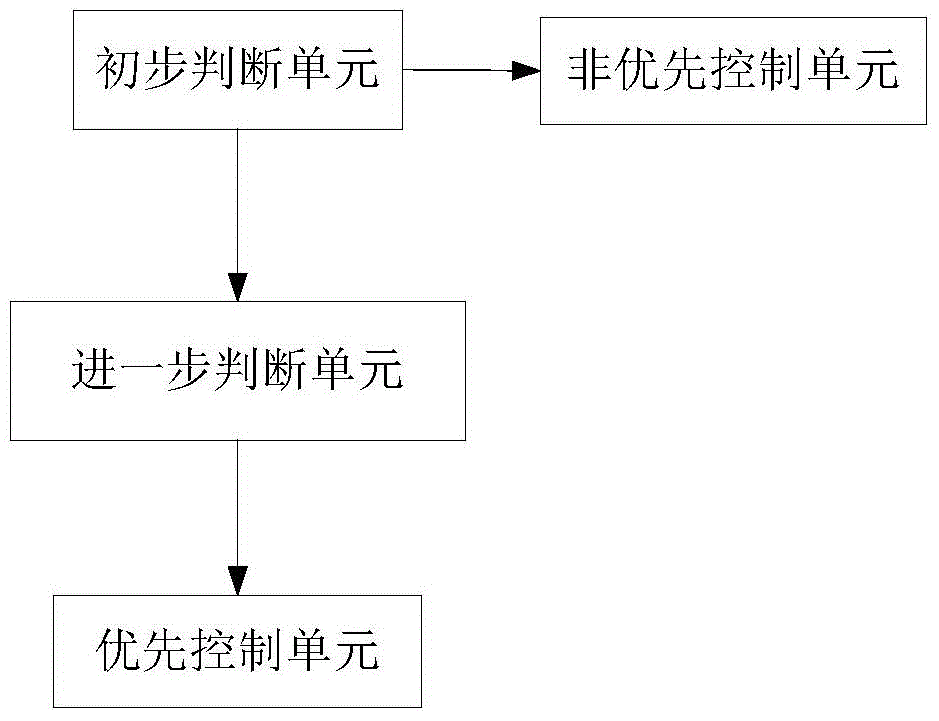

A bus priority control method and system for avoiding bus clusters

InactiveCN103985265BAffect trafficIngenious ideaRoad vehicles traffic controlComputer networkEngineering

The invention provides a bus priority control method for avoiding bus clustering. The bus priority control method for avoiding bus clustering includes the steps that whether a bus will run into bus clustering or not after bus priority is given to the bus and the bus passes preferentially is judged; if the bus will run into bus clustering, priority control is not conducted on the bus; if the bus will not run into bus clustering, whether buses entering a bus station run into bus clustering or not under normal green lights in all directions and positions in front of the bus is judged sequentially, if bus clustering does not happen, priority control is conducted, and if bus clustering happens, priority control is not conduced. Through the scheme, bus priority control is associated with bus clustering, whether bus clustering will happen or not if priority control is conducted is considered when a bus priority control strategy is formulated, and thus the problems that in the prior art, when buses take the priority to pass through without limitations, clustering will happen to a bus station, passage of social vehicles is influenced, and traffic jams are caused are effectively avoided.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

A valve component

InactiveCN104405943BStable forceImprove stabilityValve housingsEngineeringElectrical and Electronics engineering

The invention discloses a component for a valve. The component comprises a base, a connection seat and a support column connecting the base and the connection seat. A plurality of fixing holes are formed in the base, a through groove is formed in the middle of the connection seat, the interior of the support column is hollow and is communicated with the through groove of the connection seat. A through hole penetrating the support column is formed in the side wall of the support column, a sealing plug is arranged at the position of the through hole in a fit mode, a plurality of lugs are arranged on the periphery of the connection seat, connection holes are formed in the lugs, vertical rods are arranged between the lugs and the base, the ends of the connection rods are connected with the lugs, and the other ends are connected with the base. According to the component, the connection holes and the fixing holes are used for fixing, and accordingly, the location effect is good, and the component overall firmness is high; insertion columns are used flexibly to assist the mounting and location of the component, and accordingly, the combination fit degree with other accessories is further improved, and good application prospects are provided.

Owner:SUZHOU FURUN MACHINERY

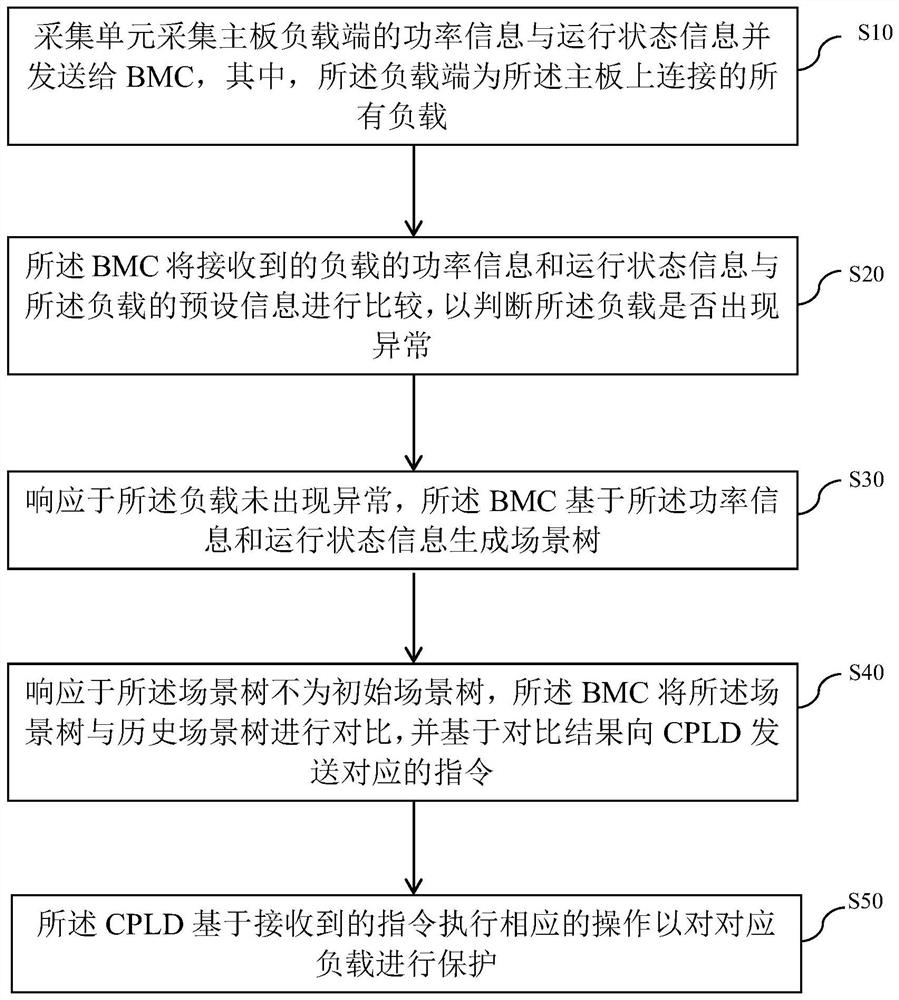

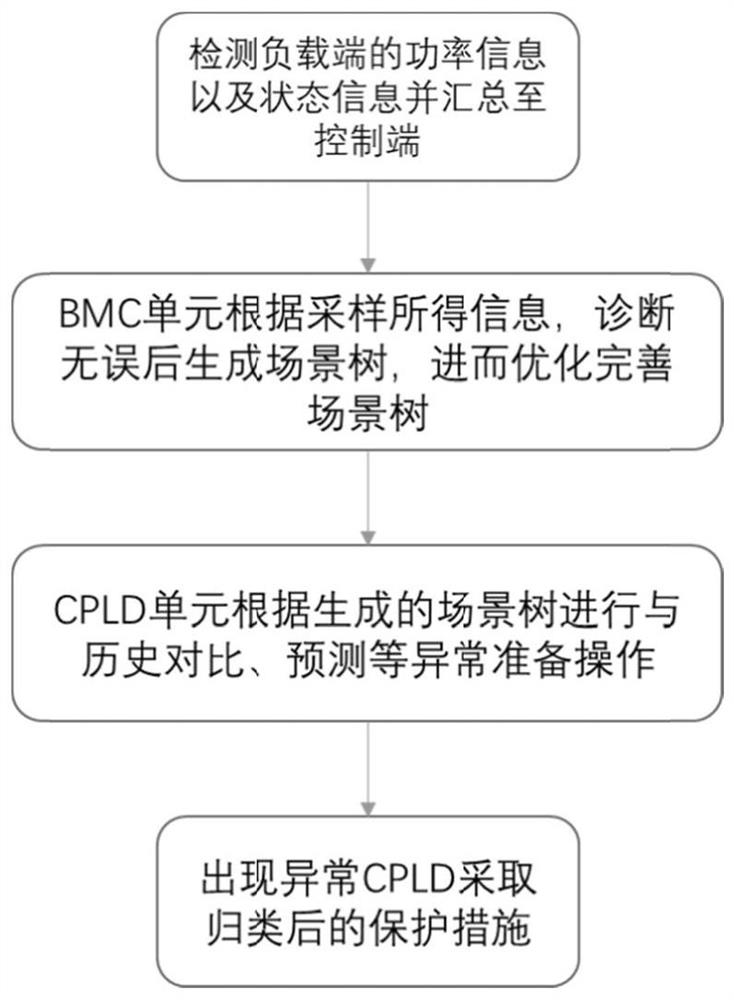

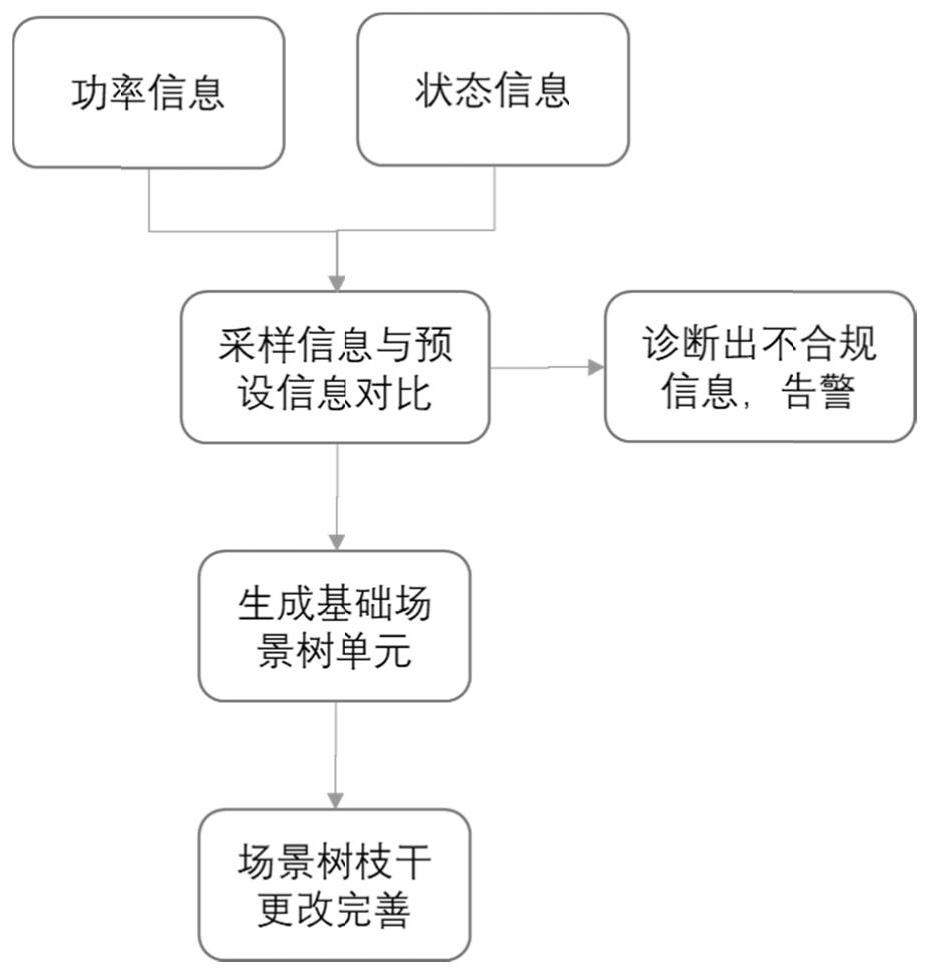

Method, system and equipment for protecting load end of server mainboard and medium

ActiveCN114816024AReduce the risk of lossWell consideredInternal/peripheral component protectionPower supply for data processingEmbedded systemServer

The invention discloses a method, a system, equipment and a medium for protecting load ends of a server mainboard, and the method comprises the steps that an acquisition unit acquires power information and running state information of the load ends of the mainboard and sends the power information and the running state information to a BMC (Baseboard Management Controller), and the load ends are all loads connected to the mainboard; the BMC compares the received power information and running state information of the load with preset information of the load to judge whether the load is abnormal or not; in response to the fact that the load is not abnormal, the BMC generates a scene tree based on the power information and the operation state information; in response to the situation that the scene tree is not the initial scene tree, the BMC compares the scene tree with a historical scene tree and sends a corresponding instruction to the CPLD based on a comparison result; and the CPLD executes corresponding operation based on the received instruction so as to protect the corresponding load. Through the scheme of the invention, the load end of the server mainboard is protected.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Ground-based simulation test method for automatic navigation function of inertial navigation system

Owner:AVIC XIAN FLIGHT AUTOMATIC CONTROL TECH

Vehicle inspection and maintenance method

InactiveCN106127315AReasonable structural designWell consideredResourcesVisual inspectionStructure based

The invention discloses a vehicle inspection and maintenance method. The method comprises the following steps of establishing a railway vehicle product detail list; performing functional analysis of the railway vehicle based on the railway vehicle product detail list respectively; performing performance estimation of the railway vehicle based on a result of structural-functional analysis; determining a maintenance spare part strategy for the railway vehicle based on a performance estimation result, and completing corresponding spare part preparation according to the determined maintenance spare part strategy; determining maintenance requirements of the railway vehicle according to the performance estimation result, and completing corresponding maintenance preparation according to the determined maintenance requirements; and determining a maintenance method based on the performance estimation result, and completing maintenance of the railway vehicle according to the determined maintenance method. The vehicle inspection and maintenance method disclosed by the invention is reasonable and comprehensive in structural design, achieves scientific and reasonable management of vehicles and real-time maintenance of problem vehicles, and ensures operation safety.

Owner:柳州市格罗贸易有限公司

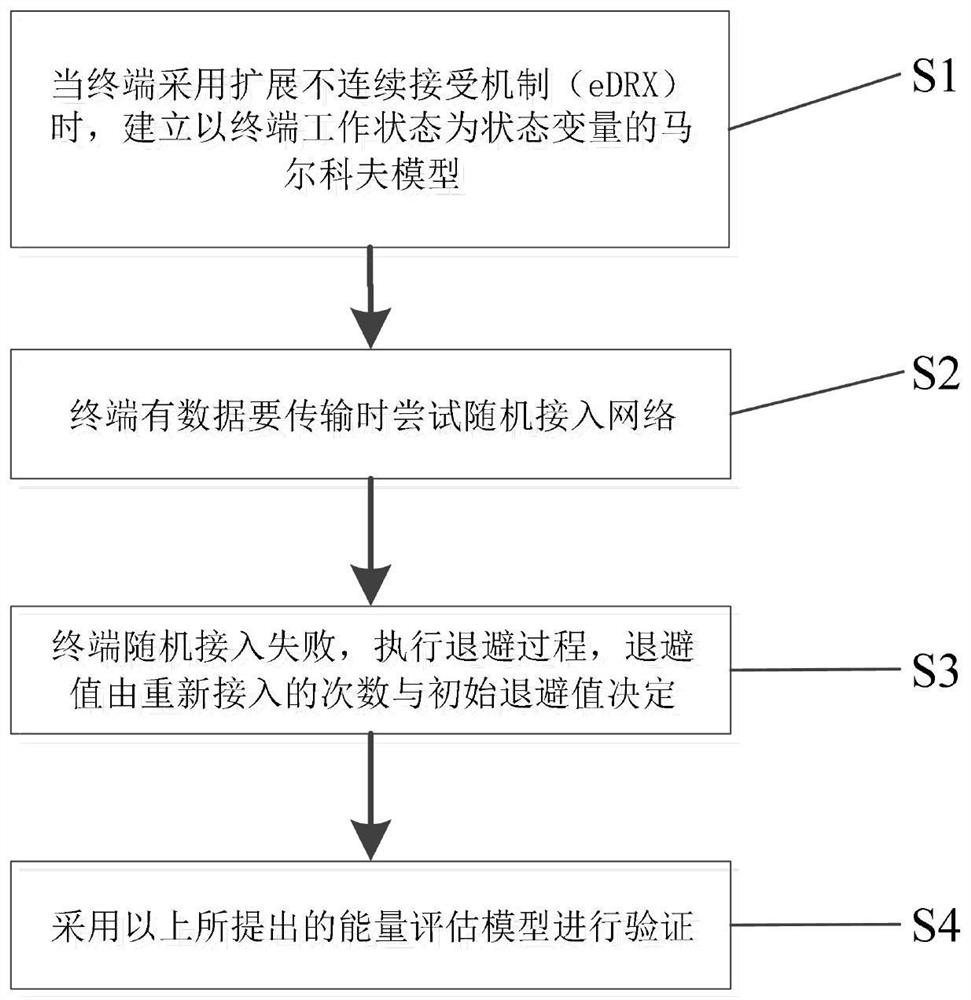

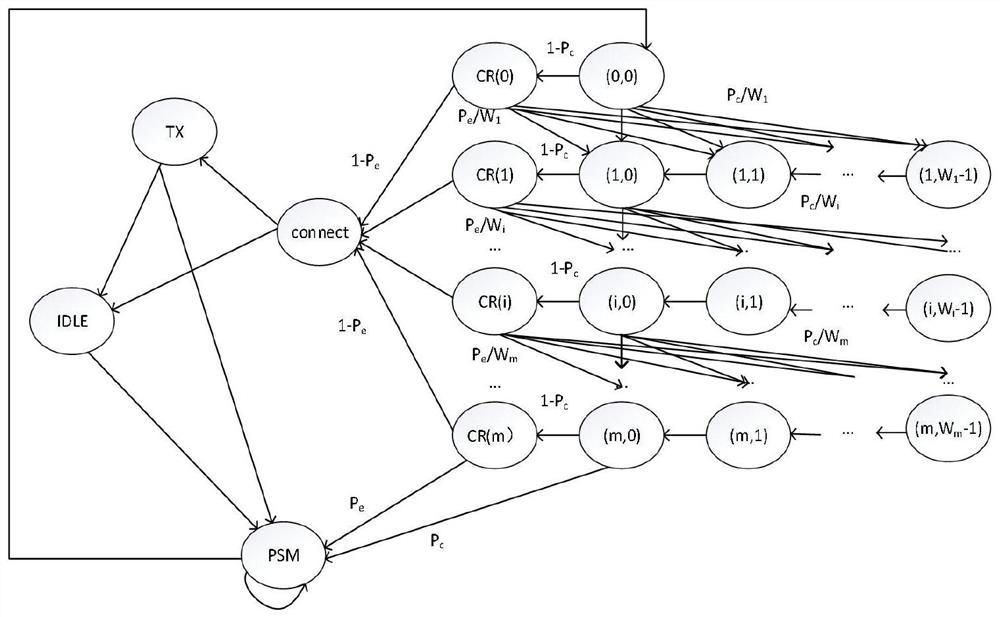

An energy consumption assessment and optimization method

ActiveCN111787564BConducive to comprehensive assessment of consumptionComprehensive assessment of consumptionConnection managementHigh level techniquesAccess networkAccess time

The present invention relates to an energy consumption evaluation and optimization method of an extended discontinuous reception mechanism (eDRX). It belongs to the field of narrowband Internet of Things. The present invention includes the following steps: S1: when the terminal adopts the extended discontinuous reception mechanism (eDRX), establishes a Markov model with the terminal working state as a state variable; S2: when the terminal has data to transmit, it tries to randomly access the network; S3: When the random access of the terminal fails, the terminal needs to perform a backoff process, and the backoff value is determined by the number of re-access times and the initial backoff value; S4: When the backoff value increases linearly as mentioned above, the above energy evaluation model is used for verification. The invention can effectively and comprehensively evaluate the energy consumption of the terminal, effectively reduce the energy consumption of the terminal, improve the utilization rate of battery energy, and finally improve the life of the terminal.

Owner:CHINA MOBILE M2M

A technological process for flue gas desulfurization transformation of coke oven without continuous furnace

ActiveCN106178857BImprove reliabilityEasy to implementGas treatmentDispersed particle separationFlue gasCoke oven

The invention relates to a coke oven flue gas desulfurization reform process without coke oven shutdown. The coke oven flue gas desulfurization reform process without coke oven shutdown comprises the following steps that firstly, regions on the two sides of a concrete flue are excavated, and trepanning construction is carried out on an external joint of a first flue; secondly, concrete cutting is carried out; thirdly, after cutting is completed, whether cut and formed concrete blocks disengage from the flue or not is checked; whether the air drafting phenomenon at a gap is serious or not is observed, if yes, putty is used for temporary sealing, and then a sling is installed; fourthly, machined flue connection pieces fall onto the concrete flue along a cutting line; fifthly, the concrete blocks which are cut and formed originally are slung; sixthly, a transverse blind plate slides into the concrete flue; seventhly, the flue connection pieces are fixed to the concrete flue; eighthly, expansive cement is used for carrying out dense treatment on leaking positions of joints of the concrete flue and the flue connection pieces, trepanning construction is carried out on an external joint of a second flue, and the second step, the third step, the fourth step, the fifth step, the sixth step, the seventh step and the eighth step are executed again; ninthly, a vertical blind plate is installed in the concrete flue. The process for reforming coke oven flue gas without coke oven shutdown is safe and high in reliability.

Owner:SHANGHAI TIANXIAO ENVIRONMENTAL PROTECTION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com