Heat dissipation method based on slotless box cable tunnel thermal field model

A technology of cable tunnel and heat dissipation method, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., and can solve problems affecting the safe operation of equipment and the temperature rise of cable channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

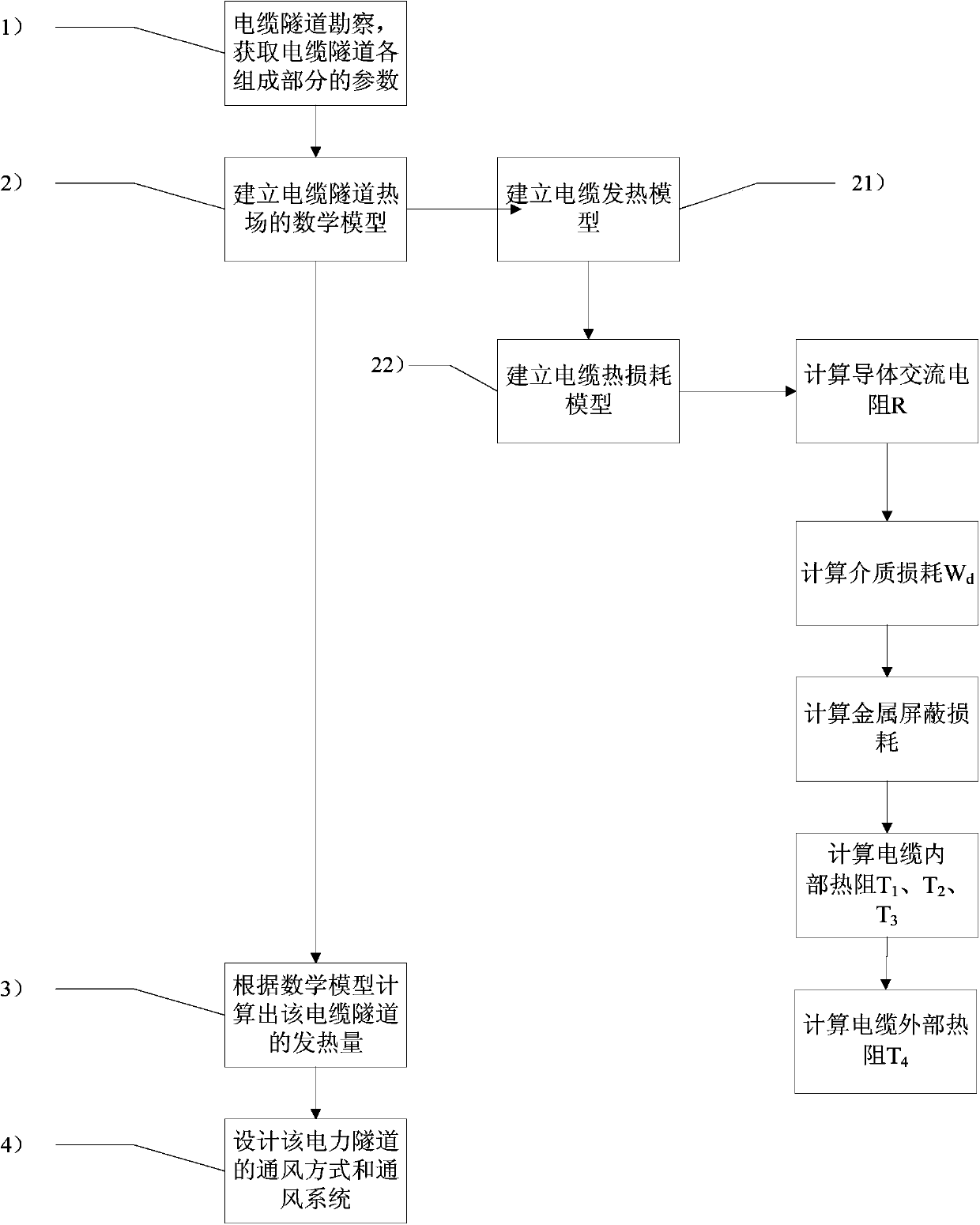

[0071] A heat dissipation method based on a cable tunnel thermal field model without a slot box, comprising the following steps:

[0072] 1) Cable tunnel investigation, to obtain the parameters of each component of the cable tunnel;

[0073] 2) Establish a mathematical model of the thermal field of the cable tunnel;

[0074] 3) Calculate the calorific value of the cable tunnel according to the mathematical model;

[0075] 4) Design the ventilation mode and ventilation system of the power tunnel.

[0076] The thermal resistance is obtained by R=d / KA, where R is the thermal resistance, d is the thickness of the thermal conductor, A is the cross-sectional area of the thermal conductor, and K is the thermal conductivity.

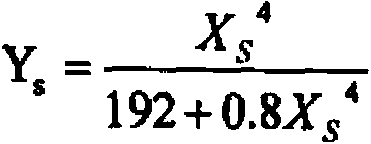

[0077] The mathematical model establishment of the cable tunnel heat field in the described step 2) includes the following sub-steps:

[0078] 21) Establish cable heating model:

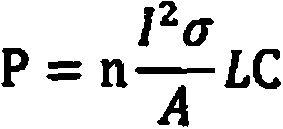

[0079] The heat dissipation power of the n-circuit cable is:

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com