Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Uninterrupted feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

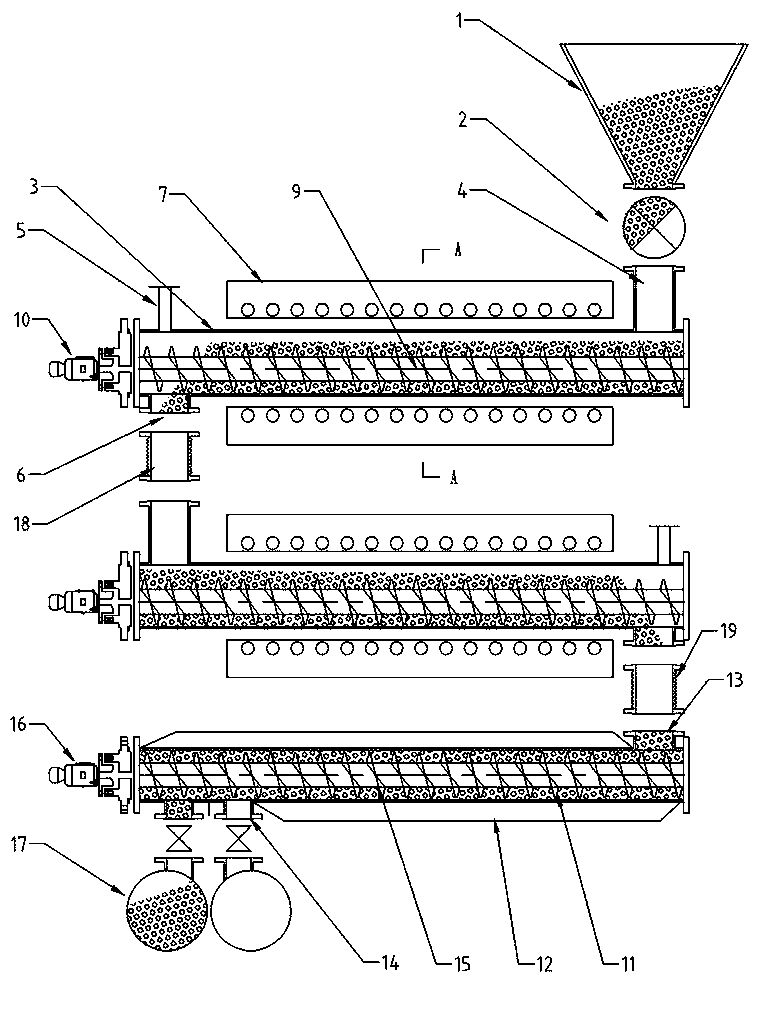

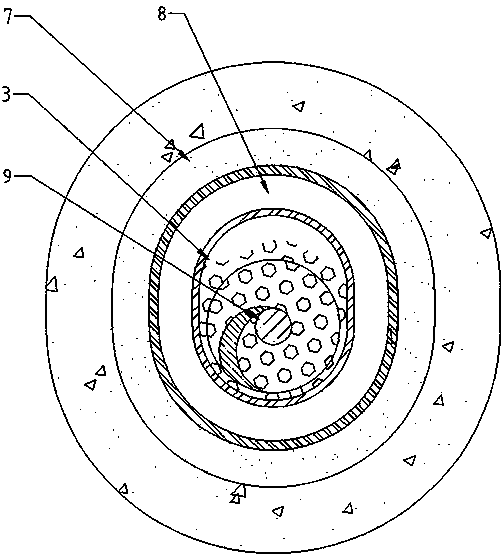

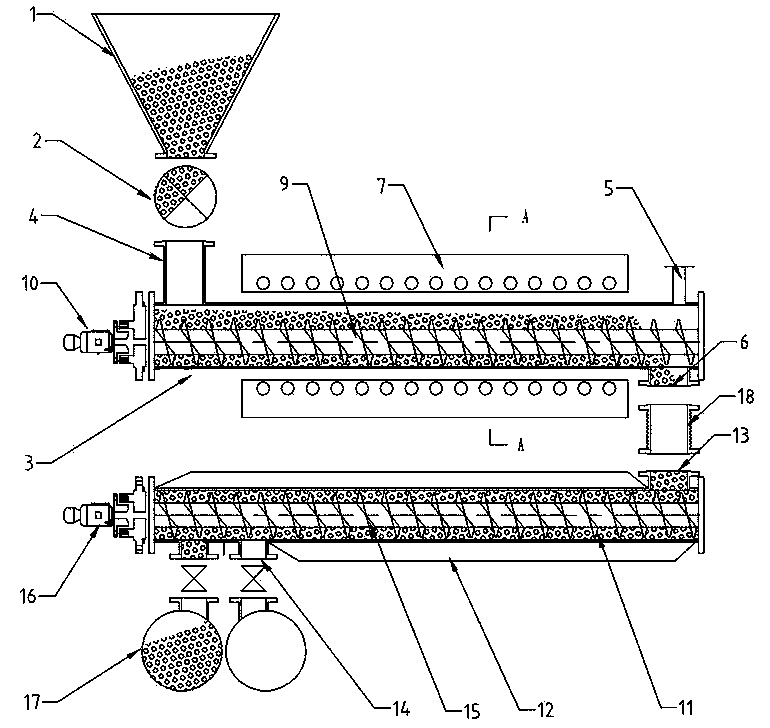

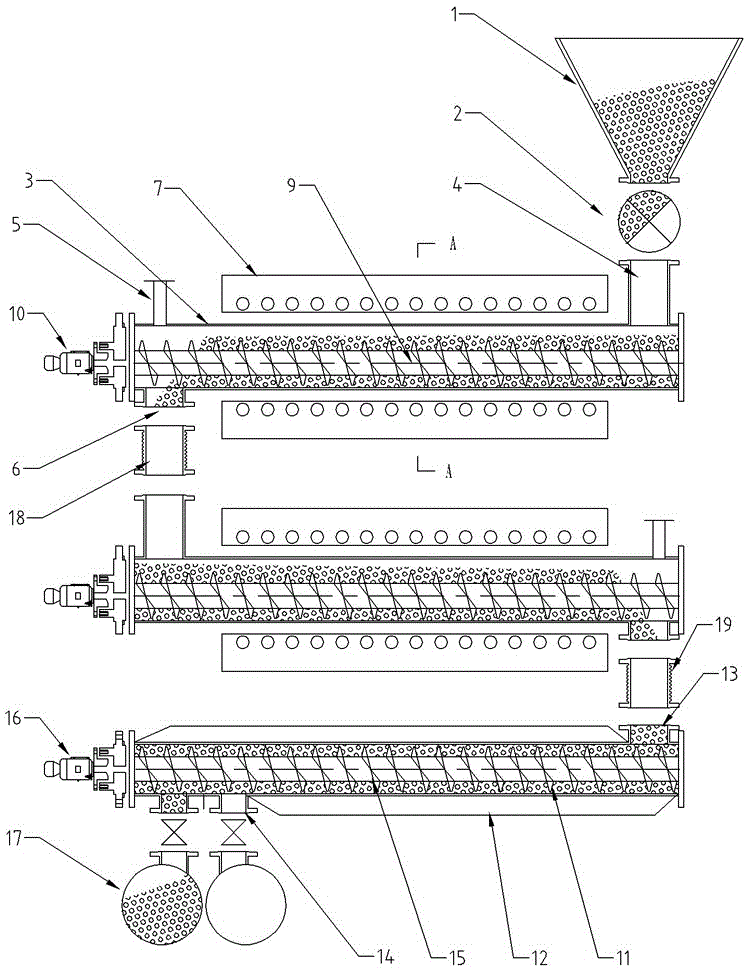

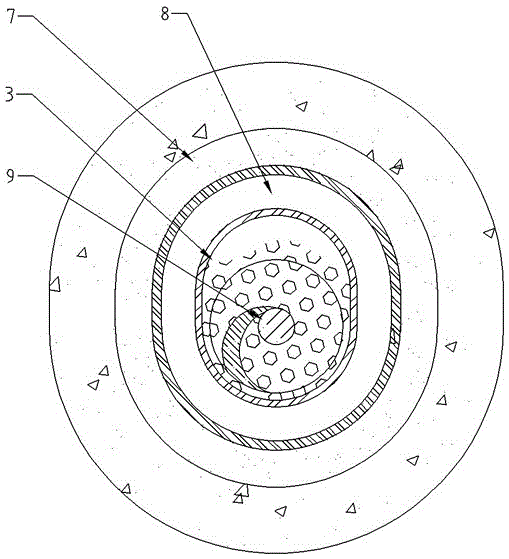

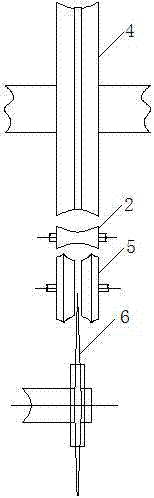

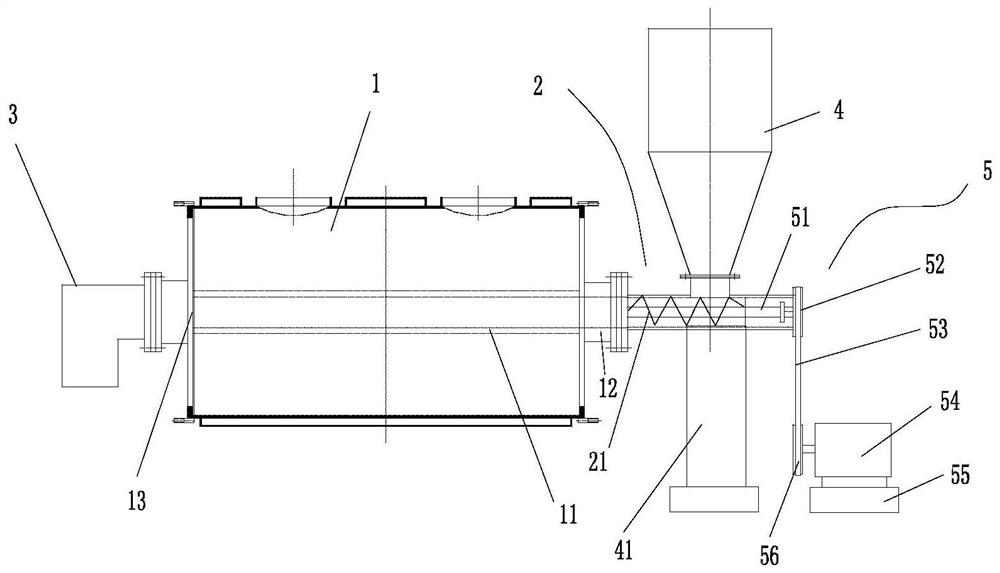

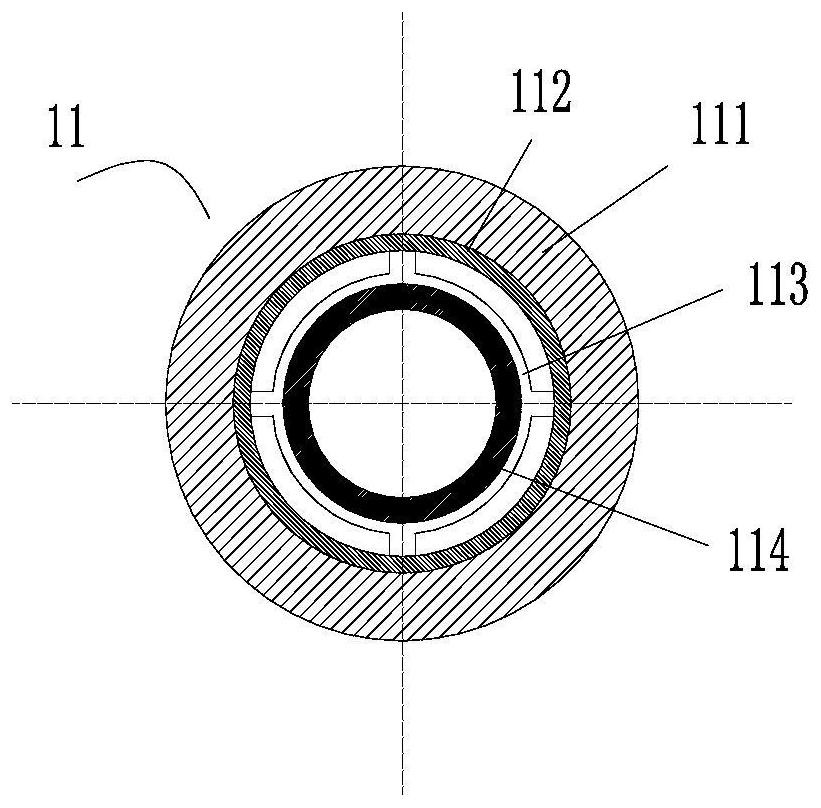

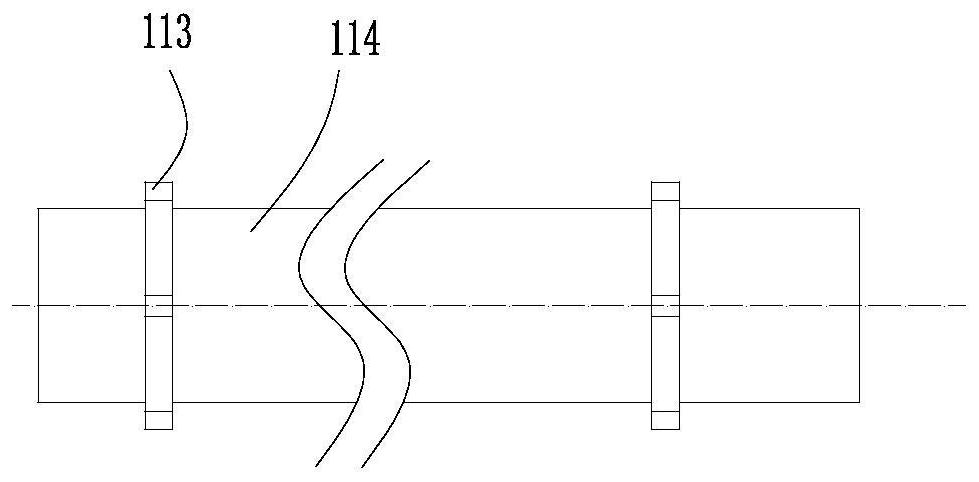

Horizontal-tube carbon intermediate continuous thermal treatment device

ActiveCN104215066ASignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemWater jacket

The invention relates to a horizontal-tube carbon intermediate continuous thermal treatment device. The horizontal-tube carbon intermediate continuous thermal treatment device comprises a feeding system, a heating segment, a cooling segment, a tail gas system and a discharging system which are connected in sequence, wherein the feeding system consists of a conical stock cabin of which the bottom is provided with a hopper hole, and a feeding machine; the feeding system, the heating segment, the cooling segment and the discharging system are connected with a measuring and controlling system through a sensing circuit; long barrels enclosed by sealing covers are arranged at the two ends of a heating segment horizontal tube; the transverse sections of the long barrels have bilaterally-symmetrical straight edges and longitudinally-symmetrical semi-circular-arc edges; a first screw rod is arranged in the lower semi-circular-arc edge of each whole segment of long barrel; the cooling segment is a metal long barrel of which the two ends are enclosed by sealing covers; the outer surface of the metal long barrel is provided with an interlayer water jacket. The horizontal-tube carbon intermediate continuous thermal treatment device is used for treating carbon intermediates, mainly powder or small particles, and has the advantages of low energy consumption, low cost, easiness in operation, and lowering of pollution to the maximum extent.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

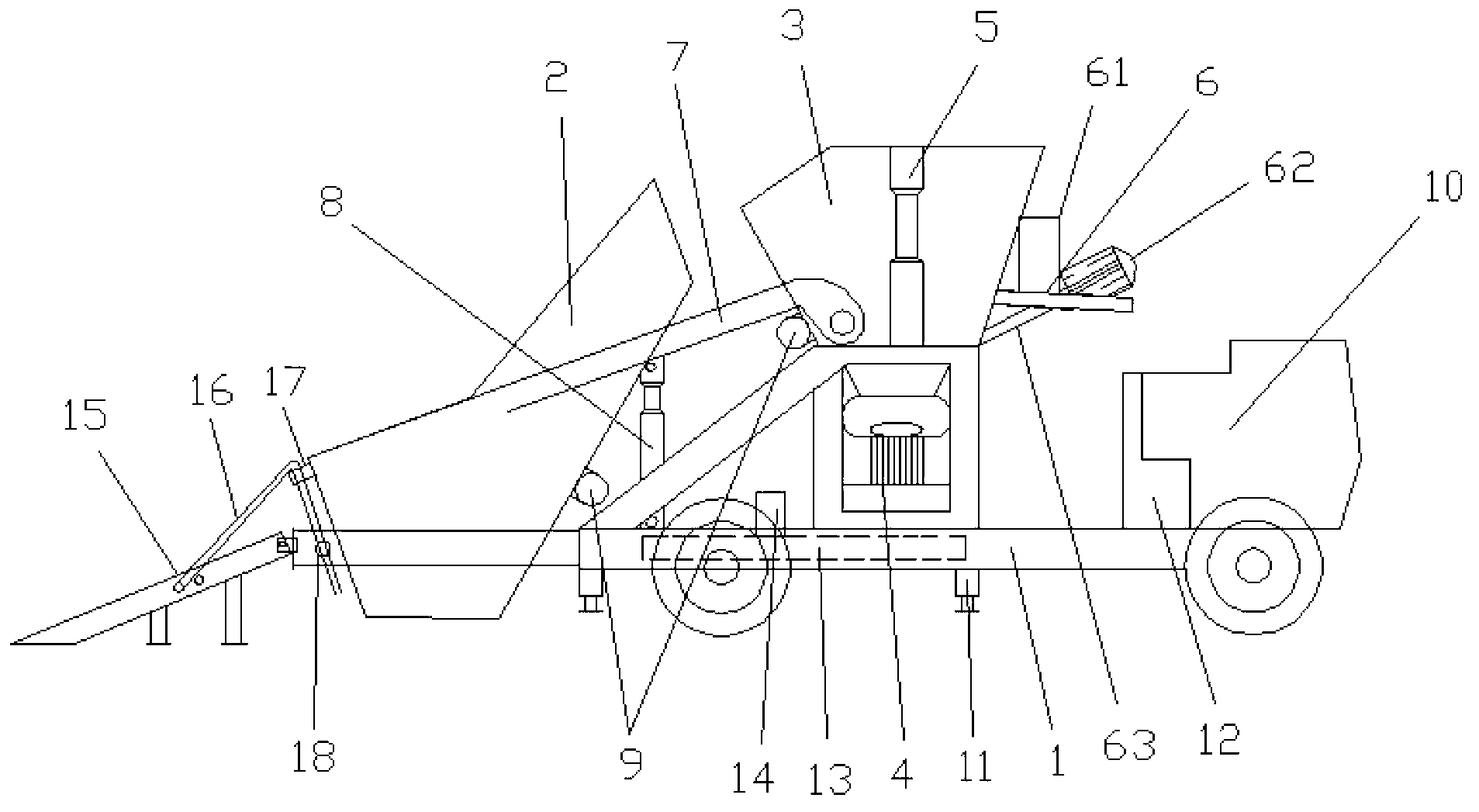

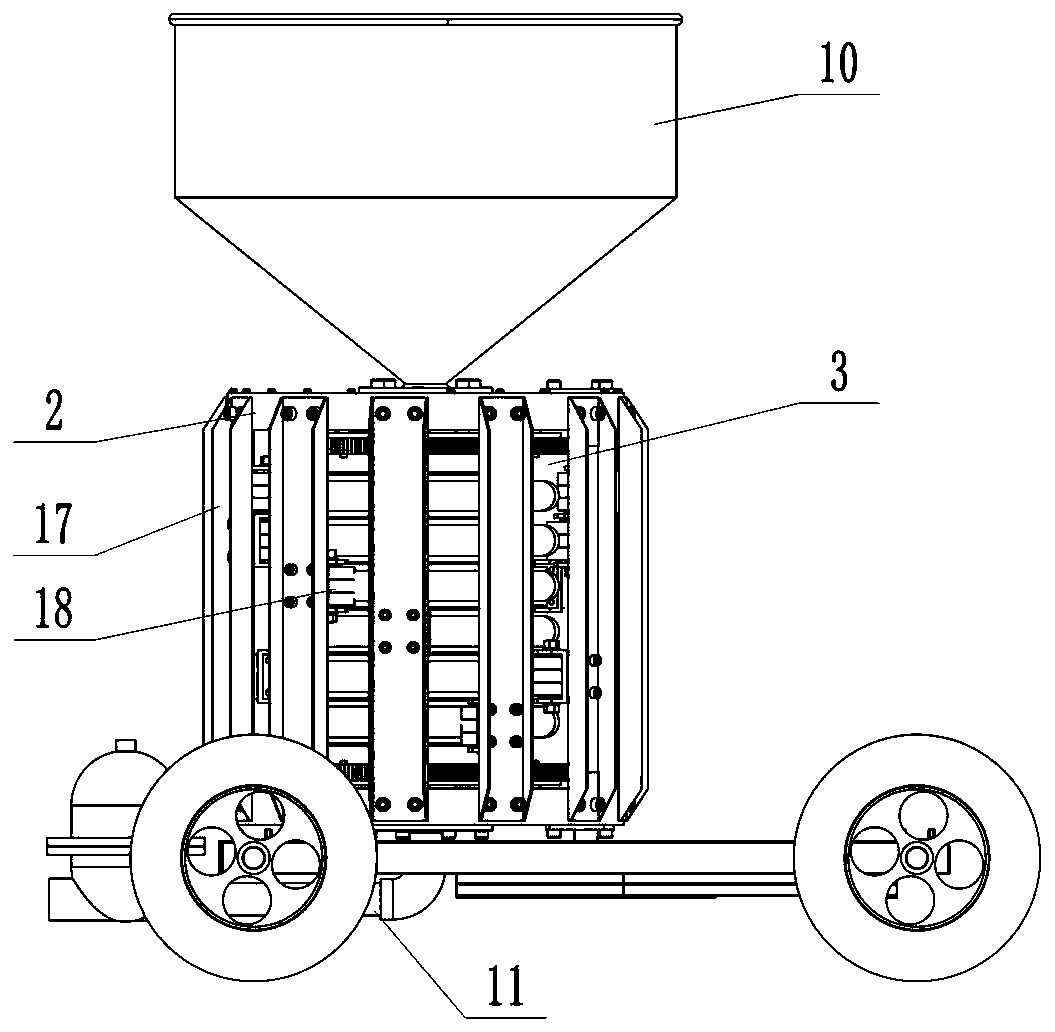

Automatic feeding type concrete spraying trolley

InactiveCN103255922AAutomatically addedReduce labor costsUnderground chambersBuilding material handlingHydraulic cylinderEngineering

The invention discloses an automatic feeding type concrete spraying trolley which comprises a trolley body, a storing bucket, a feeding bucket and a concrete spraying machine, wherein the feeding bucket is hinged to the trolley body, a first hydraulic cylinder is arranged between the feeding bucket and the trolley body, the cylinder body of the first hydraulic cylinder is hinged to the trolley body, a pushing rod of the first hydraulic cylinder is hinged to the feeding bucket, and an automatic flash setting admixture adding device is arranged on the feeding bucket. The automatic feeding type concrete spraying trolley has the advantages that due to the fact that materials and admixtures can be added automatically, labor cost is reduced and working efficiency is improved; the concrete spraying machine is integrated with the trolley, and therefore fast transportation can be achieved; when the first hydraulic cylinder ascends, the feeding bucket inclines backwards to pour remaining materials back into the storing bucket, and a larger operating space is provided for replacement and maintenance of the concrete spraying machine.

Owner:杨斌

Single-horizontal-pipe type continuous heat treatment device for carbon intermediate

ActiveCN104215065ASignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemWater jacket

The invention relates to a single-horizontal-pipe type continuous heat treatment device for a carbon intermediate. The device comprises a feeding system, a heating section, a cooling section, a tail gas system and a discharging system, which are sequentially connected, wherein the feeding system is formed by a tapered feed bin with a bottom funnel opening, and a feeder; the feeding system, the heating section, the cooling section and the discharging system are connected with a measurement and control system through a sensing circuit; the heating section is a long barrel of which the two ends are sealed by sealing covers, and the cross section of the long barrel is formed by left and right symmetric straight edges and upper and lower symmetric semicircular arc edges; a first screw rod is arranged in the whole lower semicircular arc edge of the whole long barrel; the cooling section is a metal long cylinder of which the two ends are sealed by sealing covers; an interlayer water jacket is arranged on the outer surface of the metal long cylinder. The device is used for treating carbon intermediate materials which mainly comprise powder or small particles, and is low in energy consumption and cost and easy to operate, and pollution is maximally reduced.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

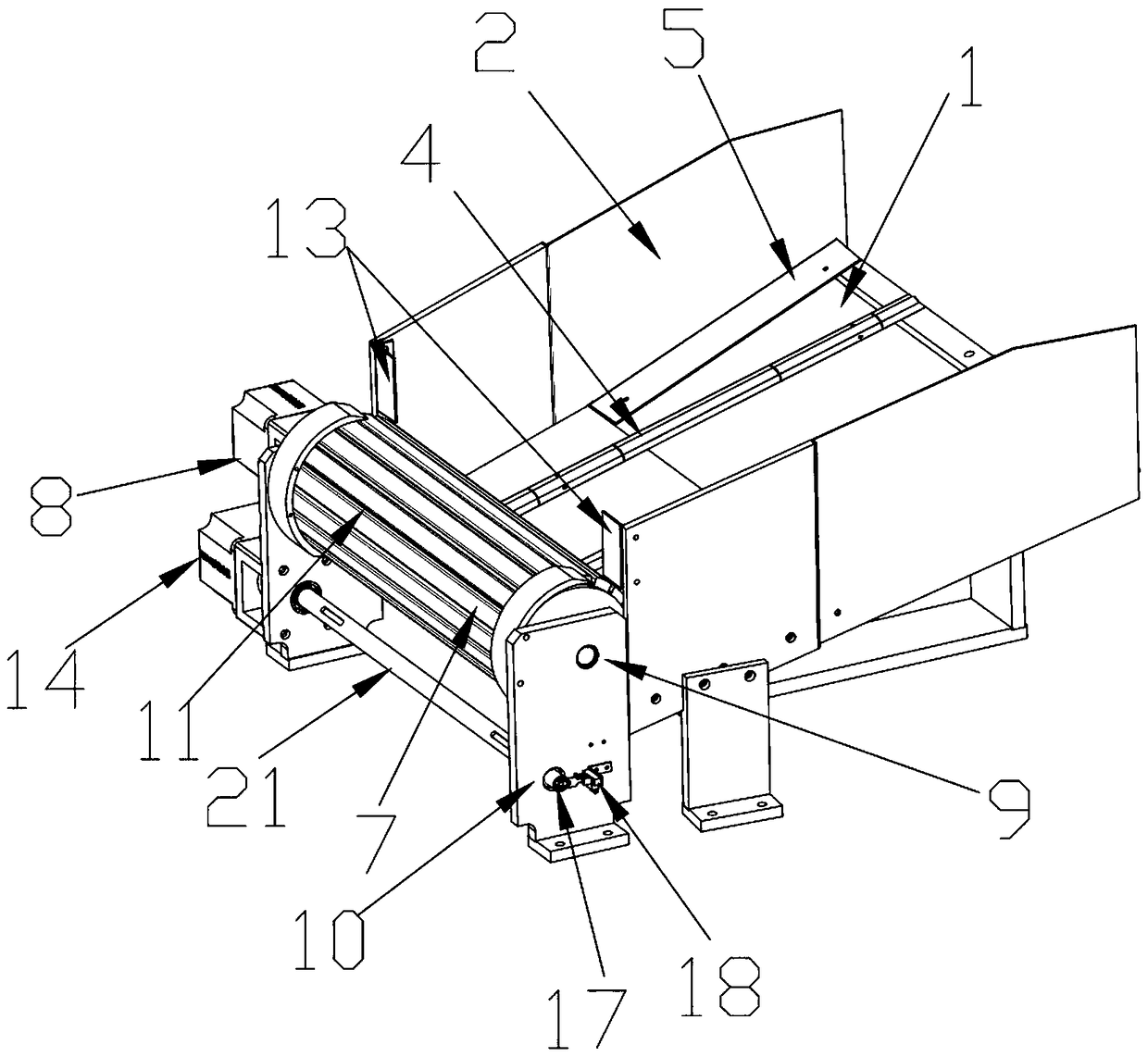

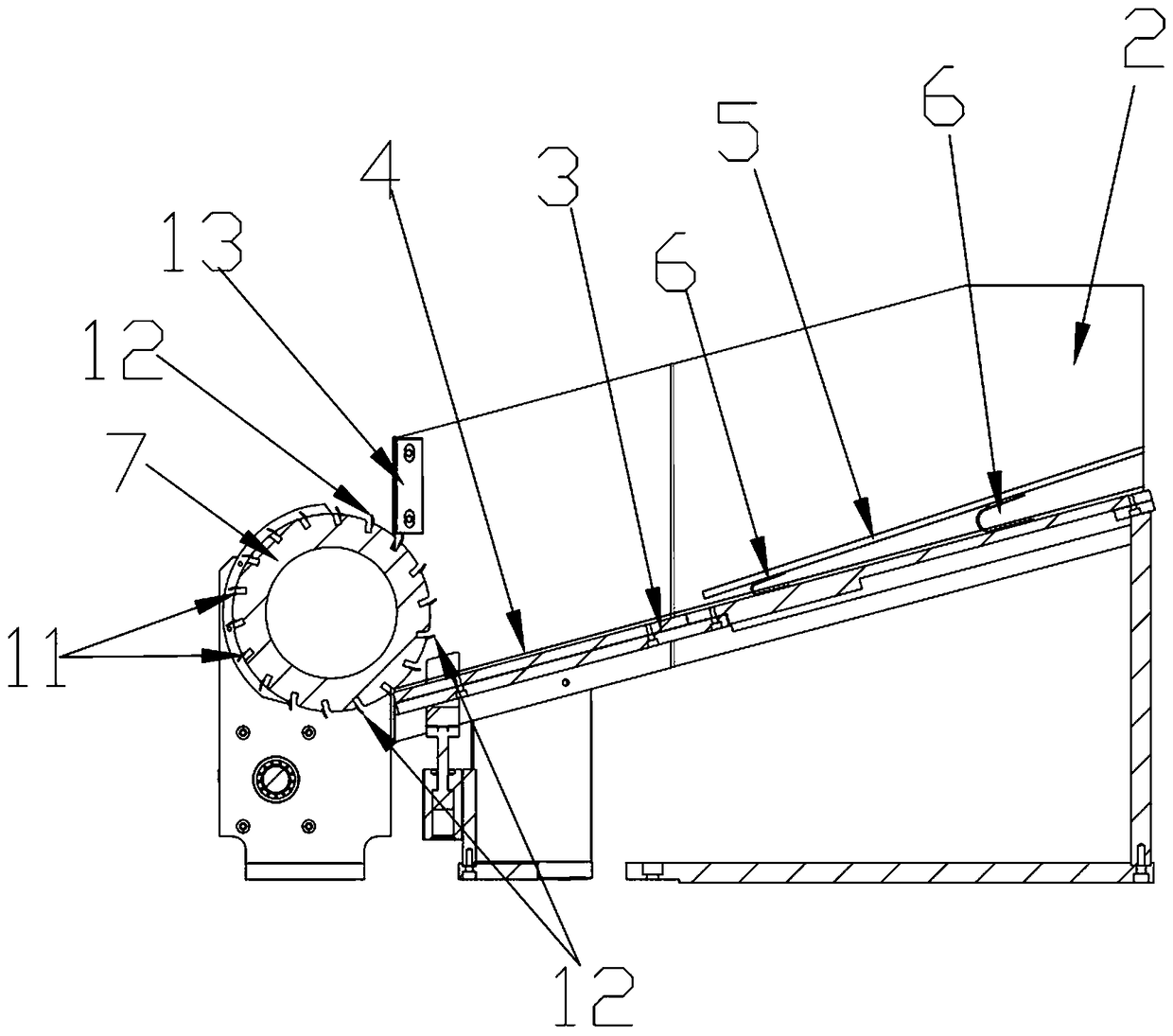

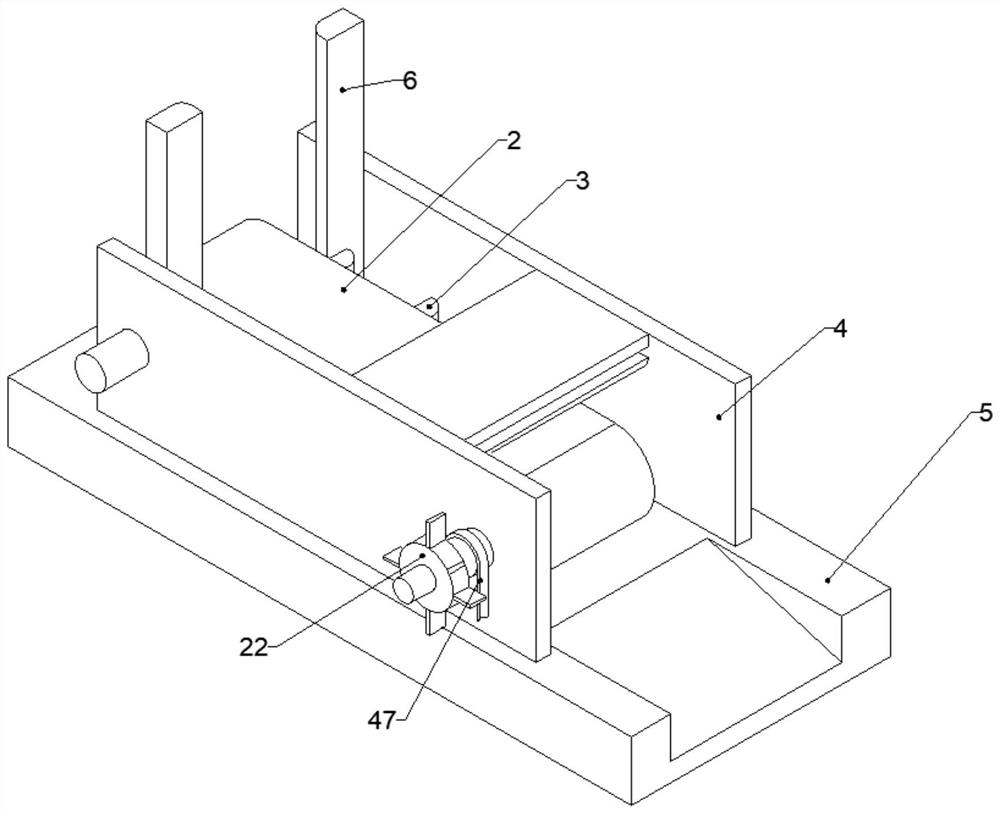

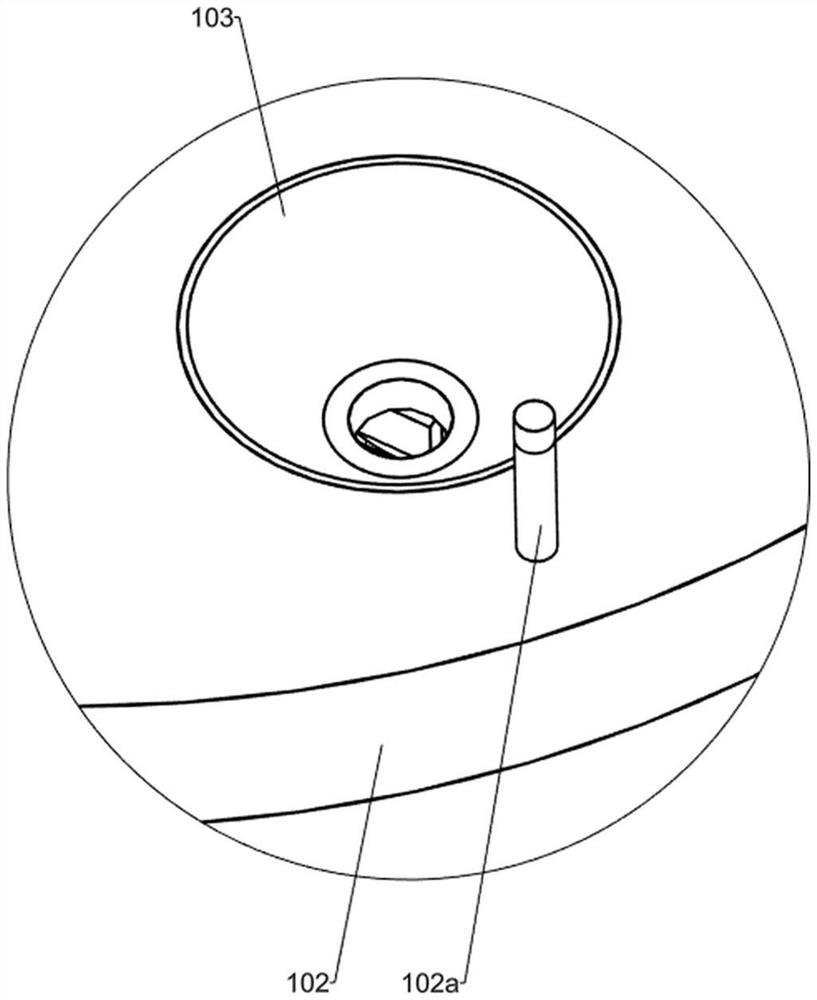

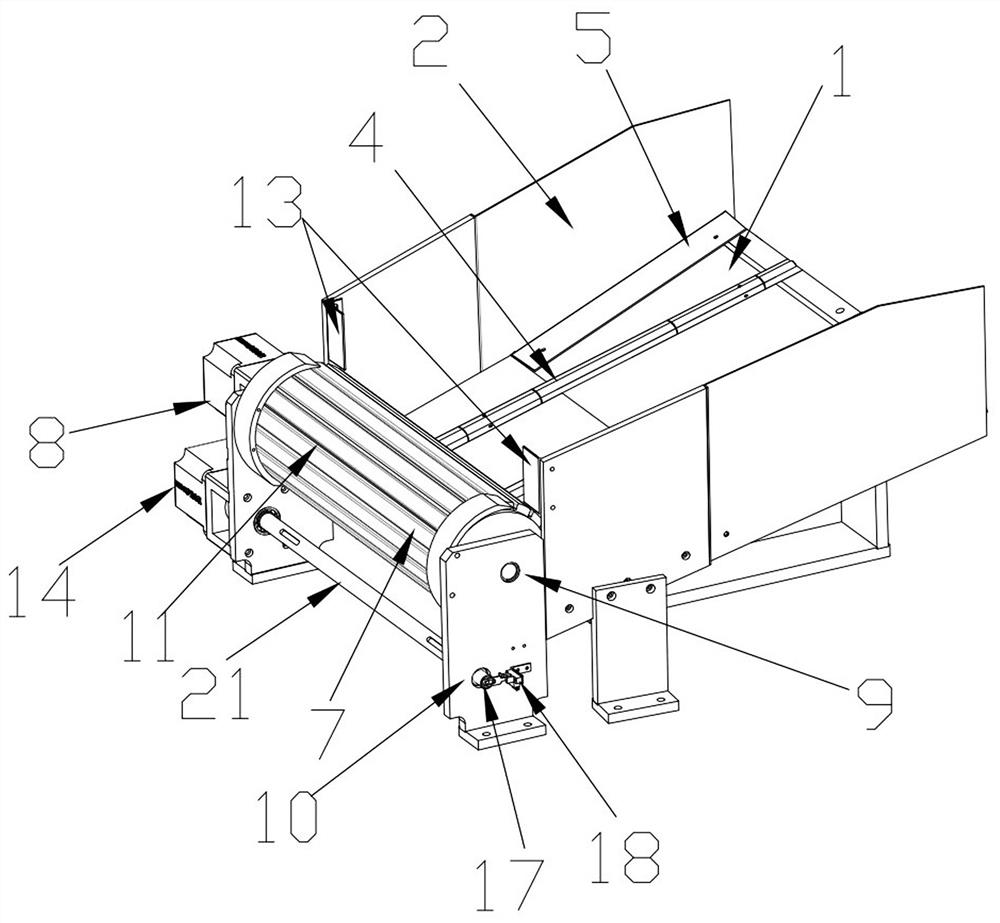

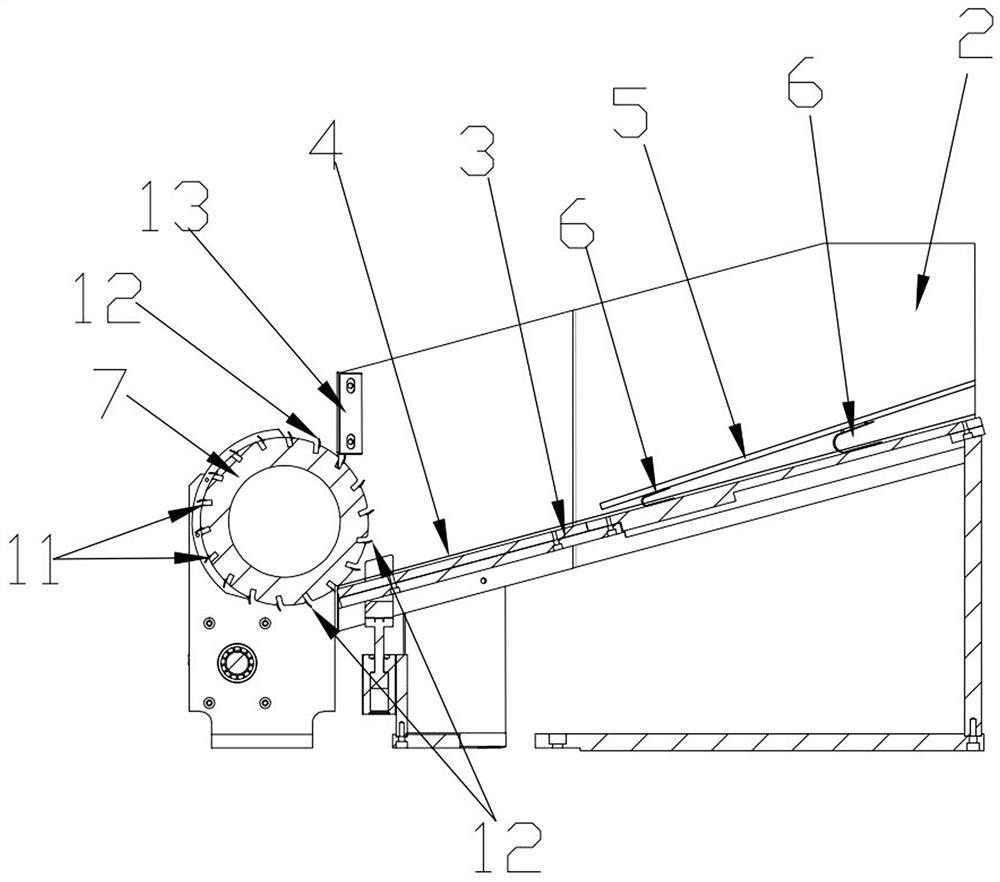

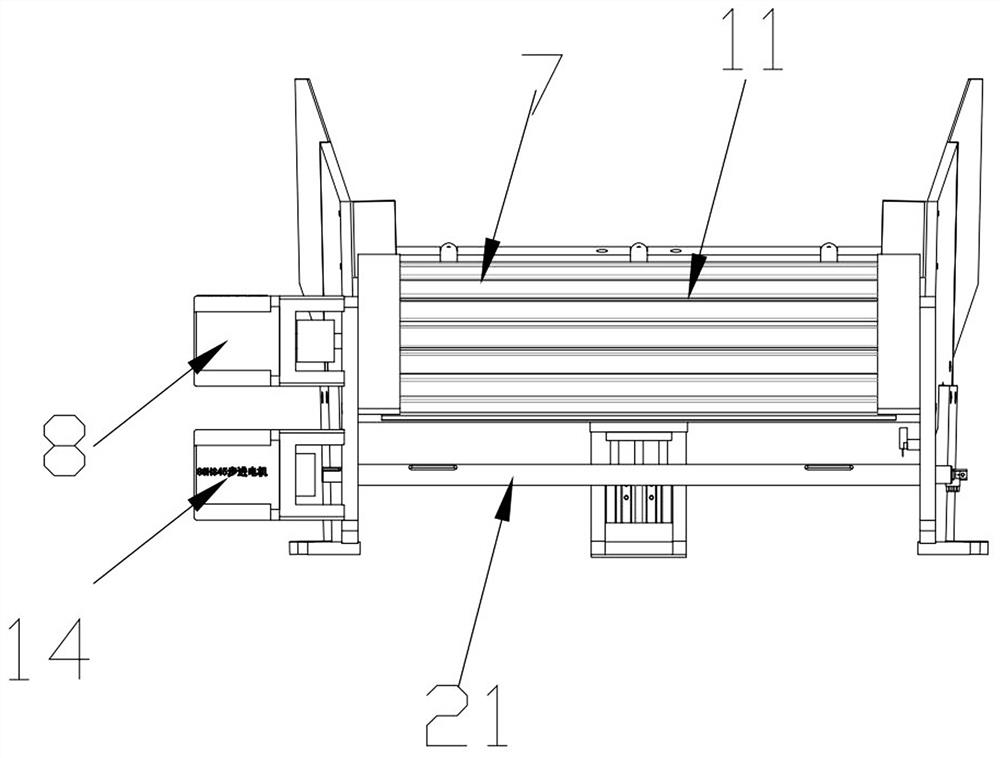

Full-automatic material distribution device for conveying long-strip-shaped rubber hose

The invention relates to a full-automatic material distribution device for conveying a long-strip-shaped rubber hose and belongs to the field of automatic equipment. The full-automatic material distribution device comprises a rubber hose material distribution mechanism and a rubber hose conveying mechanism, wherein the rubber hose material distribution mechanism comprises a discharging hopper anda material distribution assembly which are downwards and obliquely arranged; the material distribution assembly is composed of a mounting seat, a round roller and a material distribution stepping motor for driving the round roller to rotate; the rubber hose conveying mechanism is composed of two conveyor belts which are structurally symmetrical and a conveying stepping motor; the rubber hose material distribution mechanism can realize automatic discharging and regular automatic material distribution; meanwhile, a rubber hose is automatically conveyed to the rubber hose conveying mechanism; a whole discharging, material distribution and feeding process has a high automation degree and each rubber hose can orderly and accurately fall onto a jig; the rubber hose can be driven by the conveyingstepping motor and is conveyed backwards, and continuous discharging, material distribution and feeding can be realized, so that the conveying efficiency can be improved and the full-automatic material distribution device is especially applicable to an automatic assembling line which needs to work continuously.

Owner:上海新上橡汽车胶管有限公司

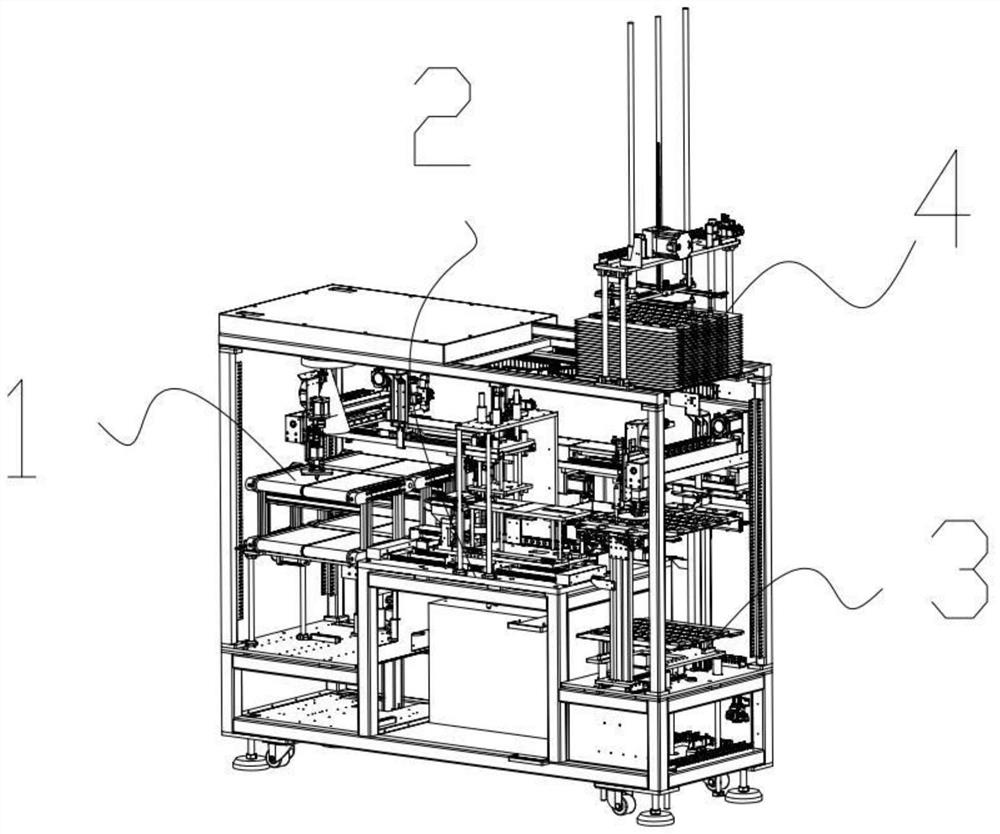

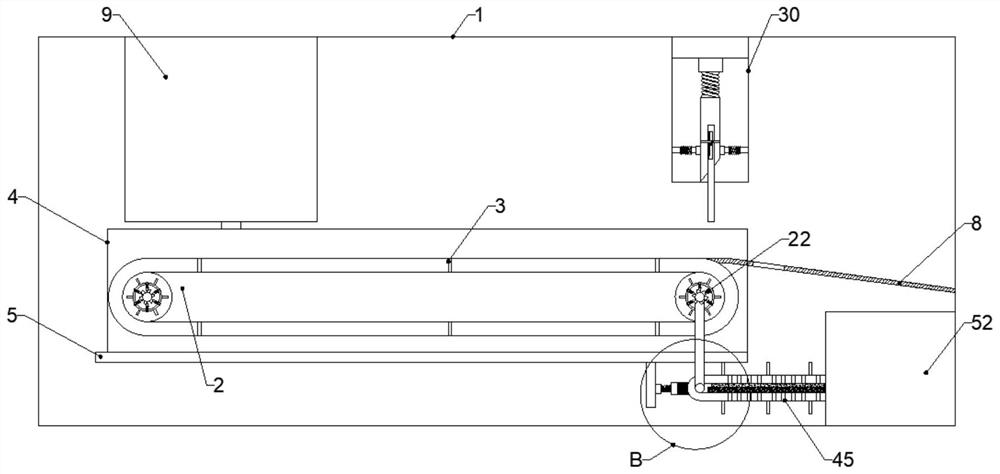

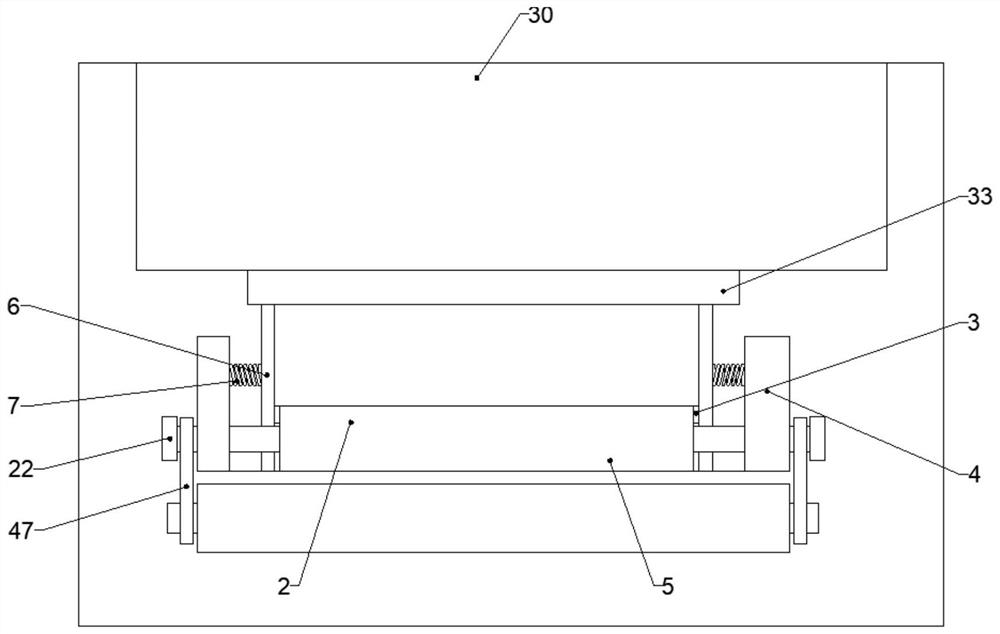

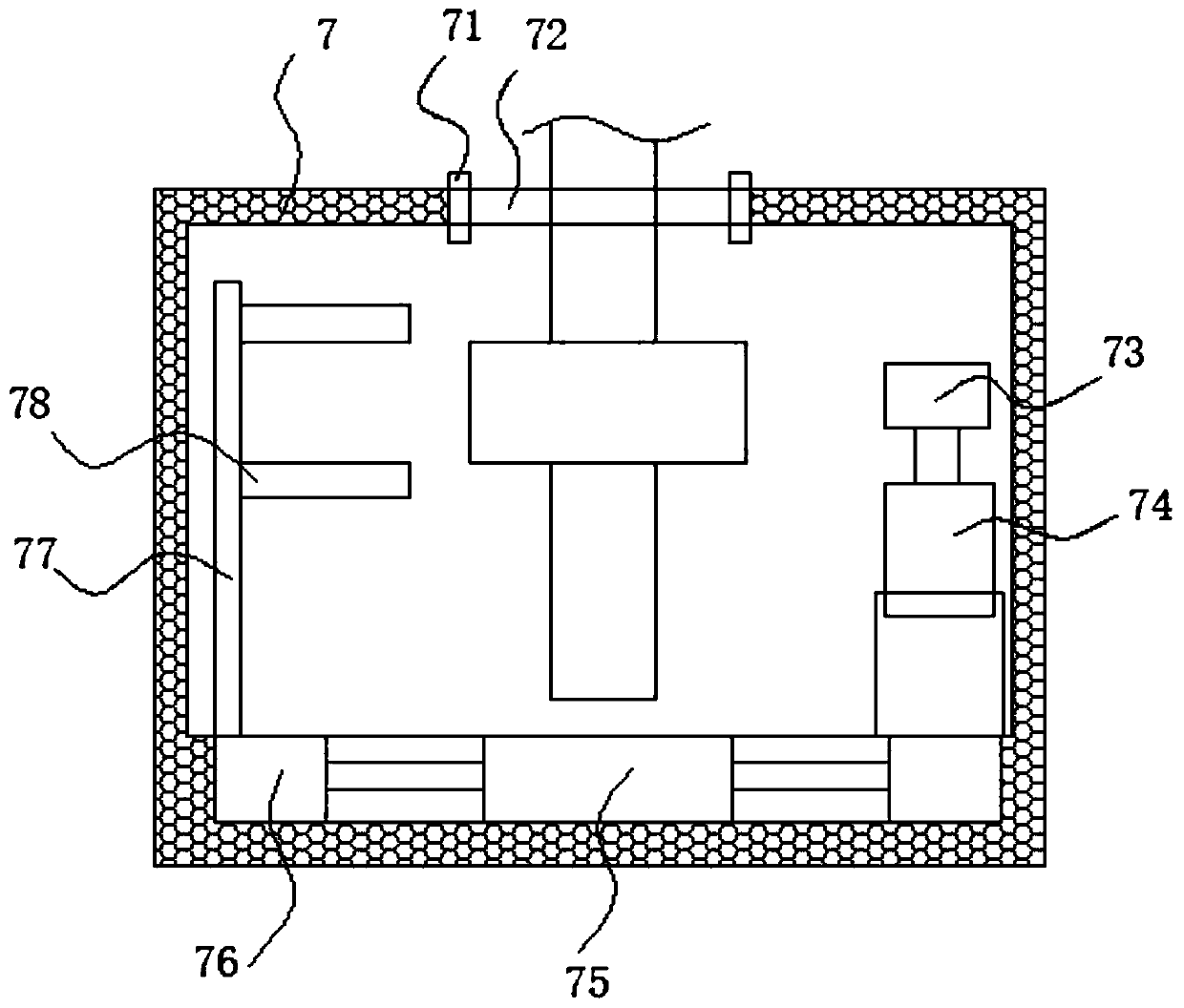

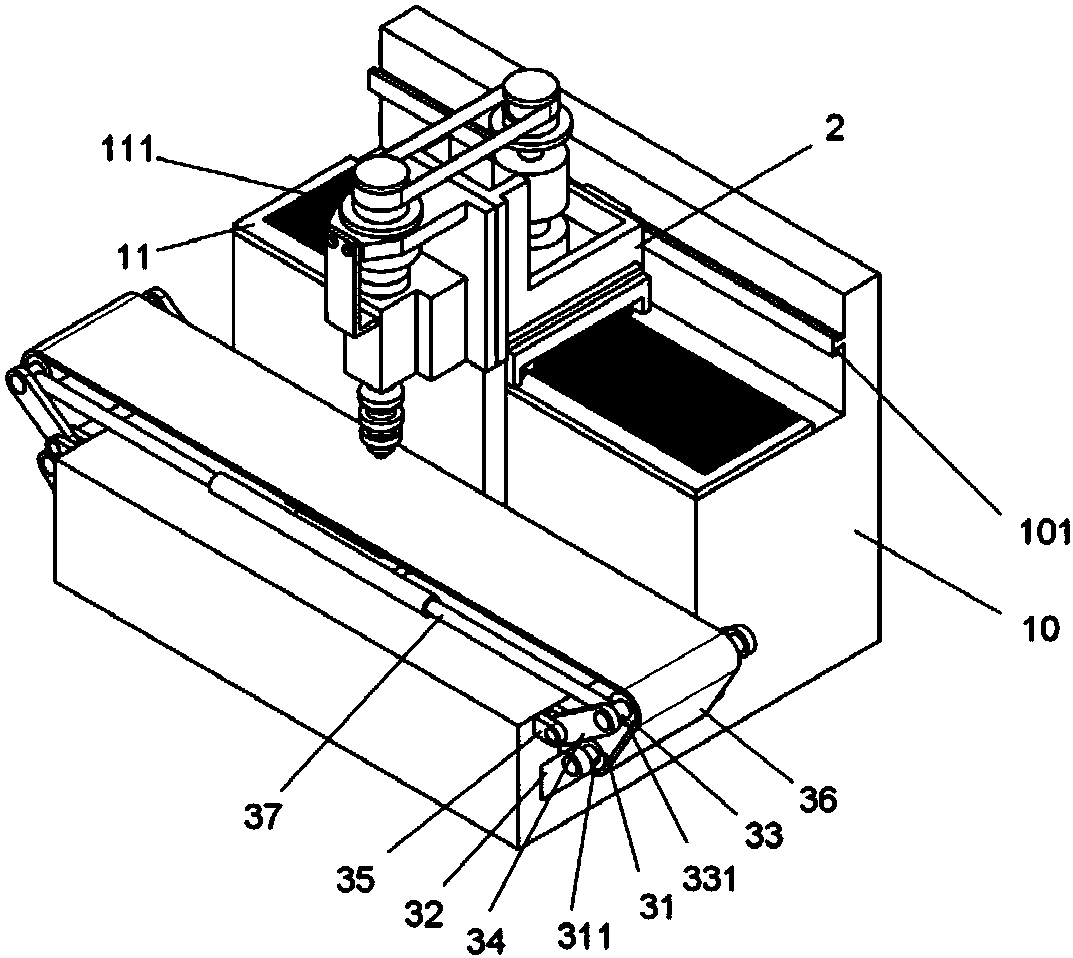

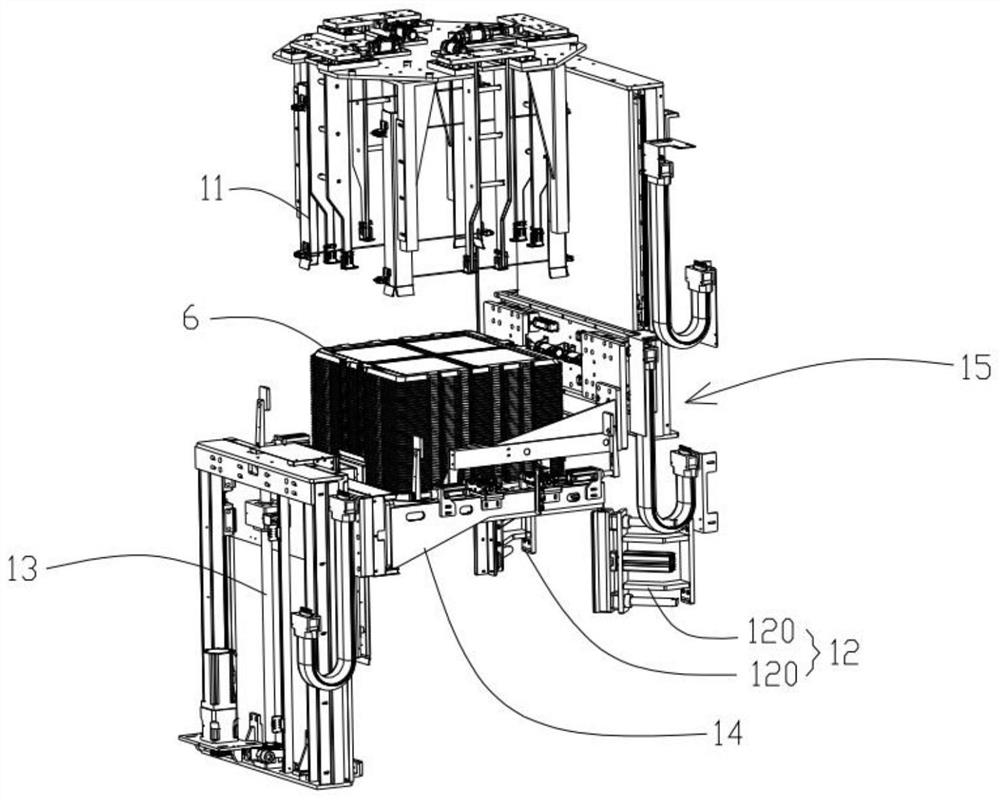

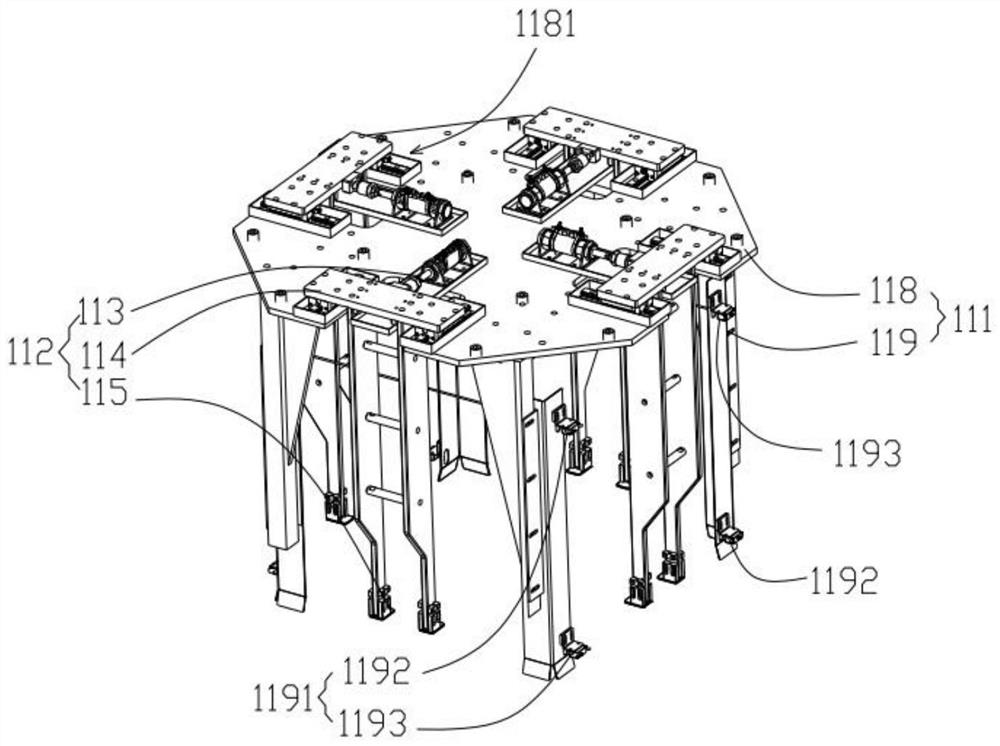

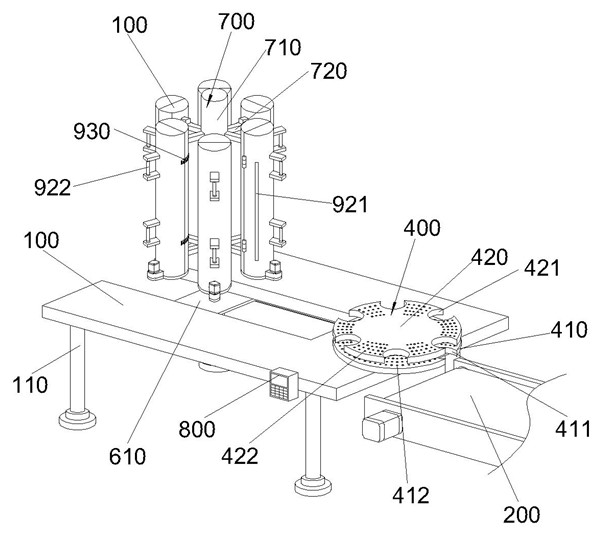

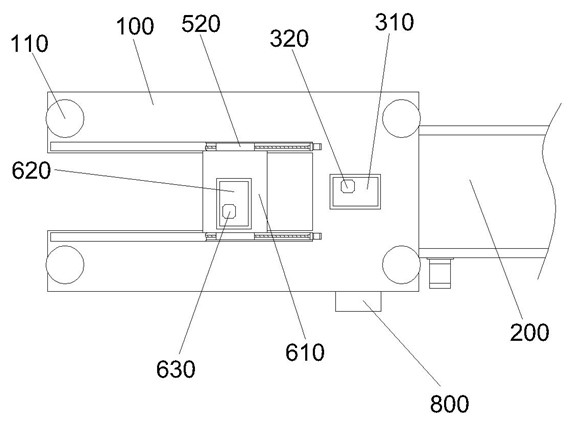

Modular full-automatic test equipment

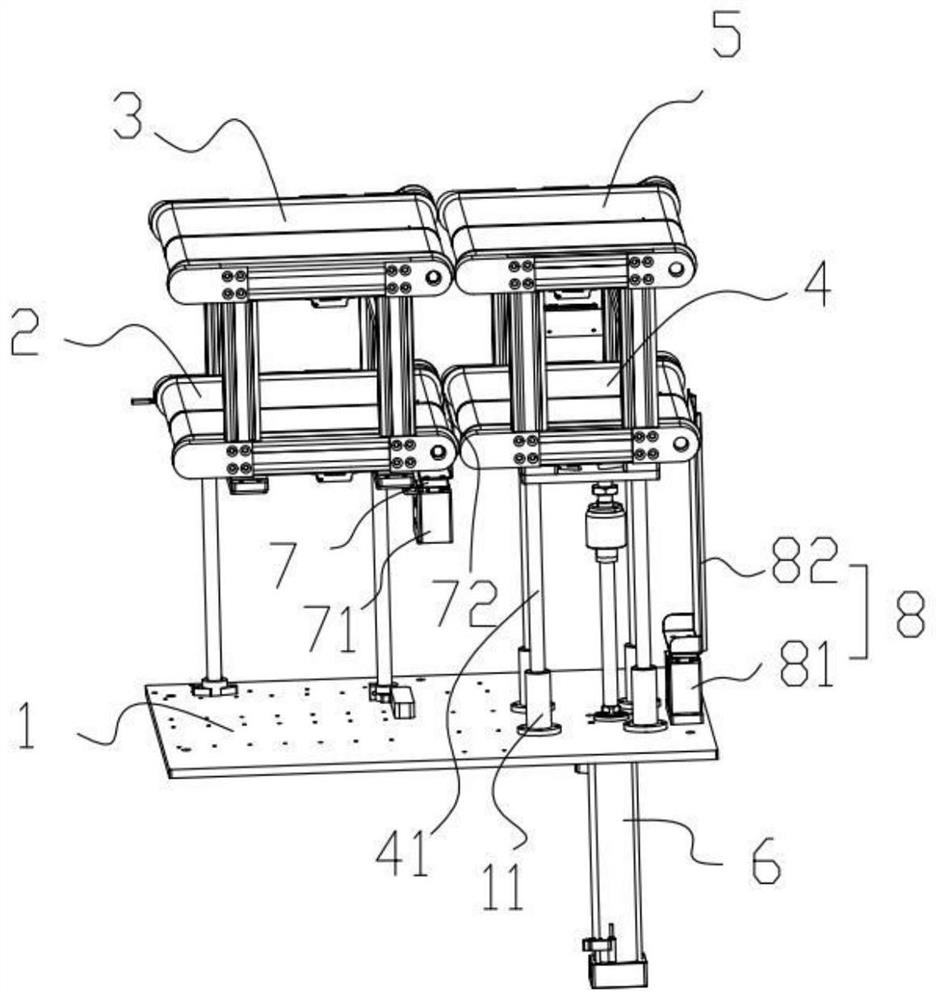

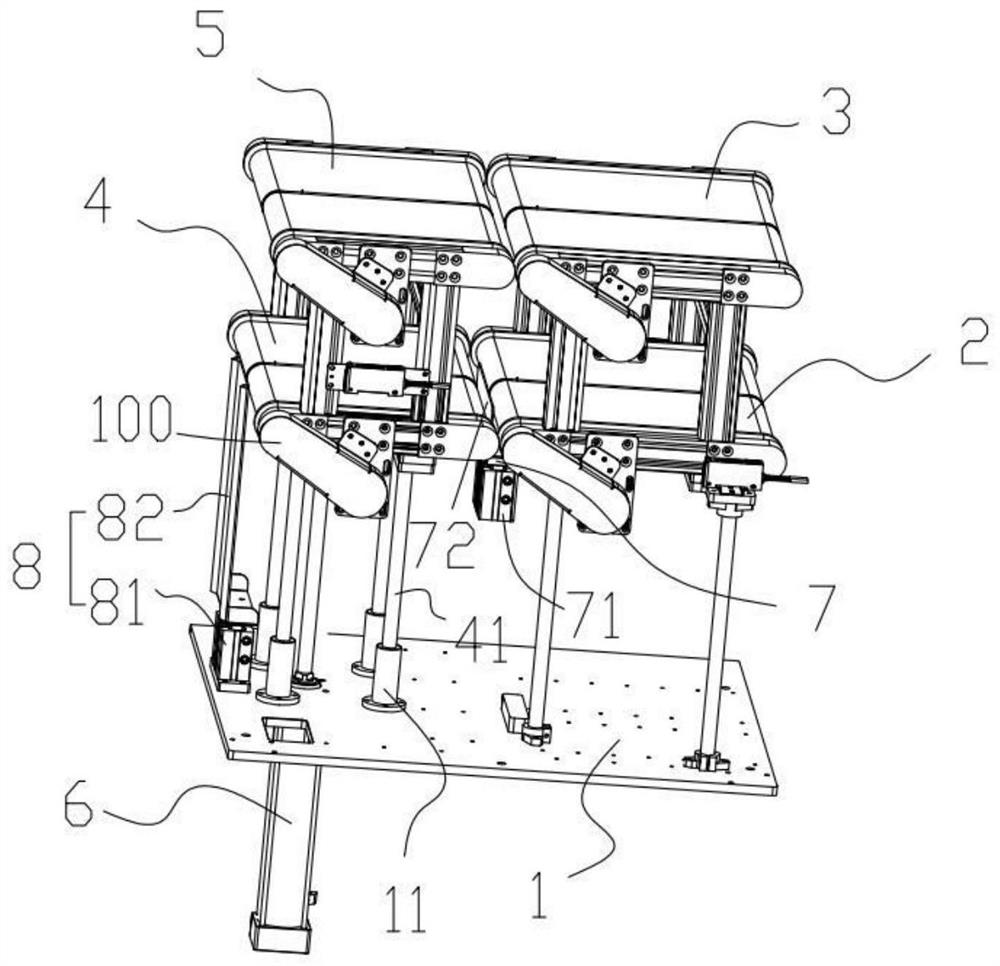

PendingCN112830183AWith cache functionUninterrupted feedingControl devices for conveyorsSortingEngineeringAssembly line

The invention discloses modular full-automatic test equipment. The equipment comprises an automatic feeding device, a code scanning, testing and dotting device and a discharging device, the automatic feeding device is arranged at the front end, the code scanning test dotting device is arranged in the middle, the discharging device is arranged at the rear end, and the automatic feeding device is provided with an assembly line feeding double-layer lifting platform. The discharging device is provided with a lifting type tray conveying and taking assembly line, the assembly line feeding double-layer lifting platform, the code scanning, testing and dotting device and the lifting type tray conveying and taking assembly line are sequentially connected in an assembly line technology mode, and the purpose of automation of product feeding, code scanning, testing, dotting, tray conveying, discharging and tray taking is achieved. The equipment has the beneficial effects that (1) the equipment has a buffering function, and continuous feeding can be achieved; (2) the equipment can be connected with rear-section equipment, and the problem that a single machine cannot be connected is solved; (3) the equipment can identify a plurality of different models and is used for testing, and the trouble that a customer inconveniently tests on a computer in a small batch is solved; and (4) no extra size is occupied, and the material placing precision can be higher.

Owner:SHENZHEN HONG YI TAI TECH LTD

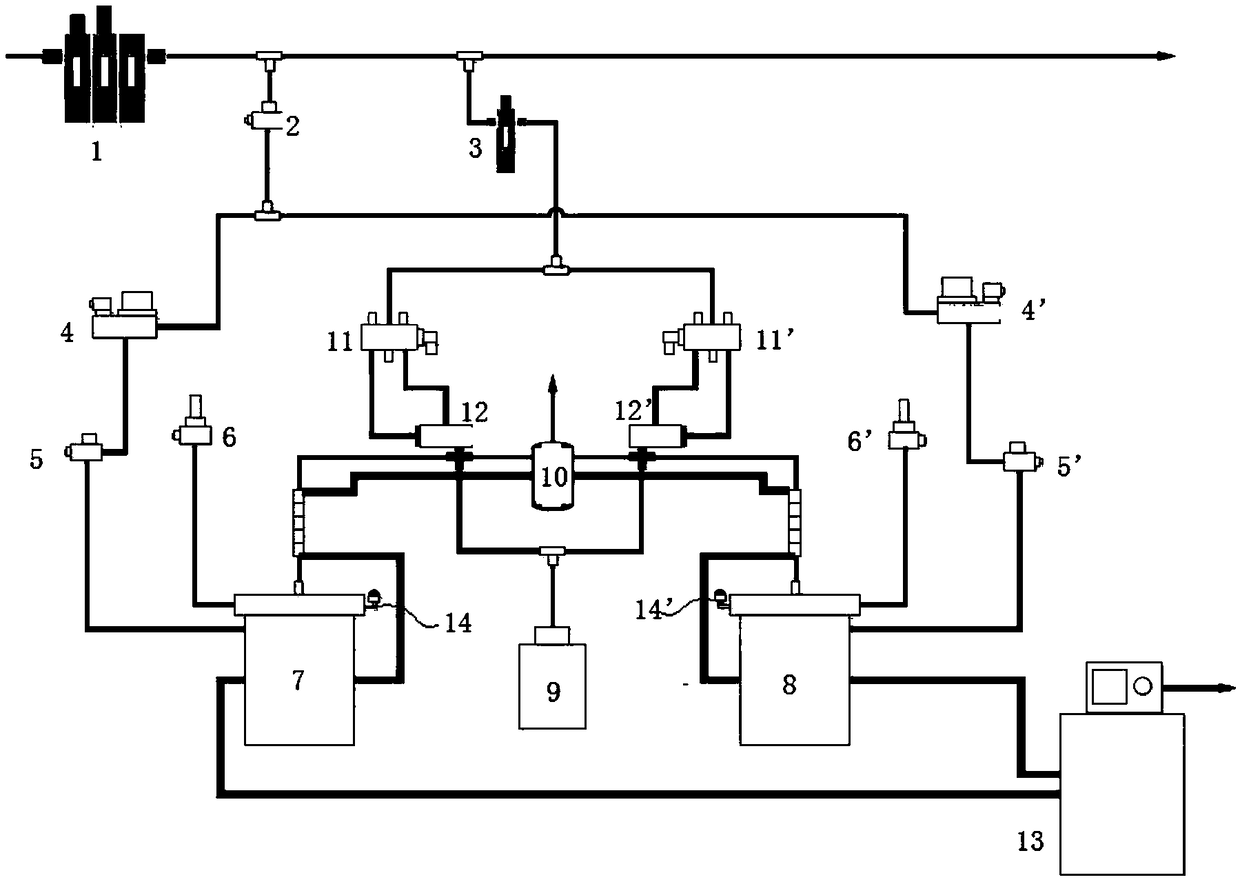

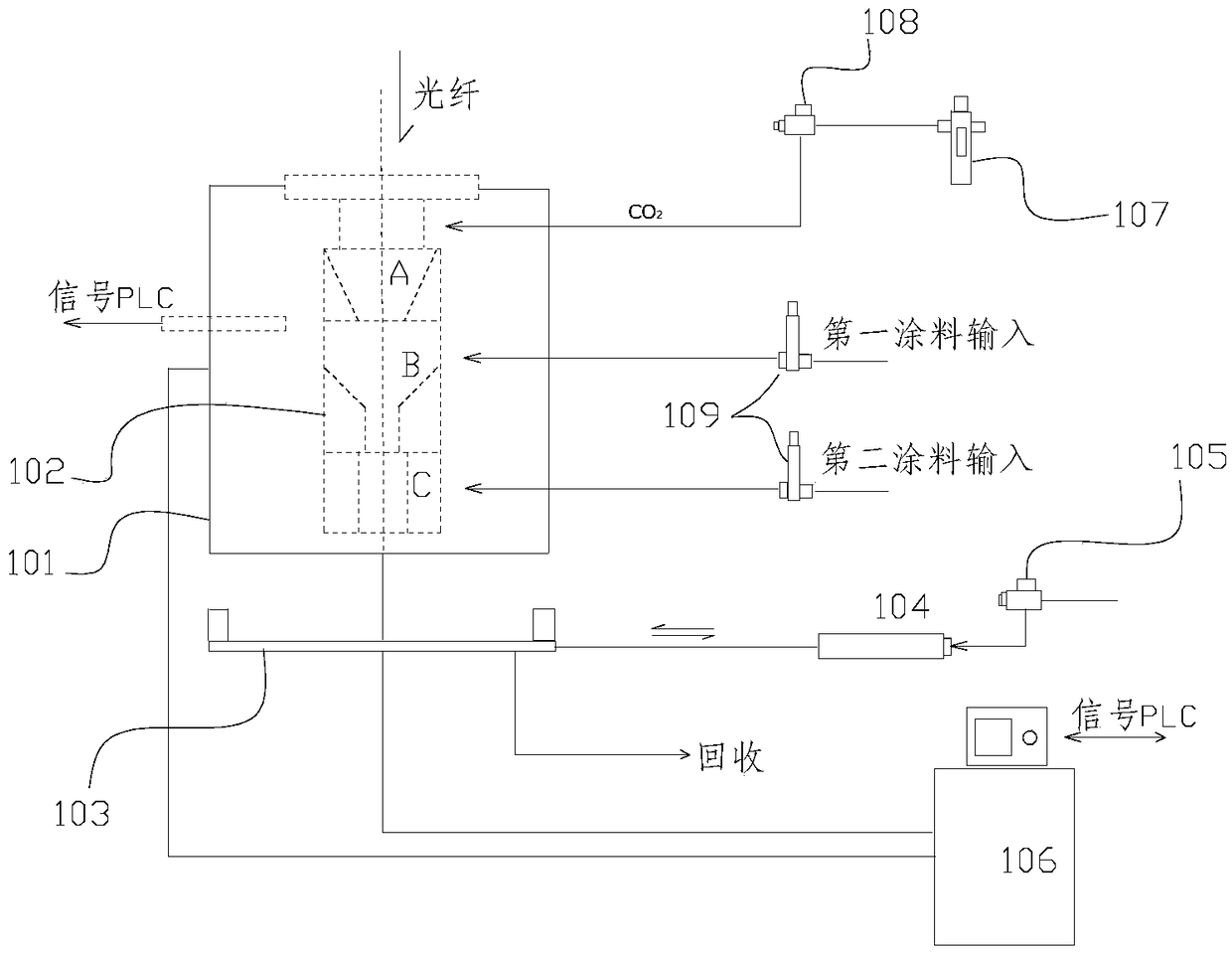

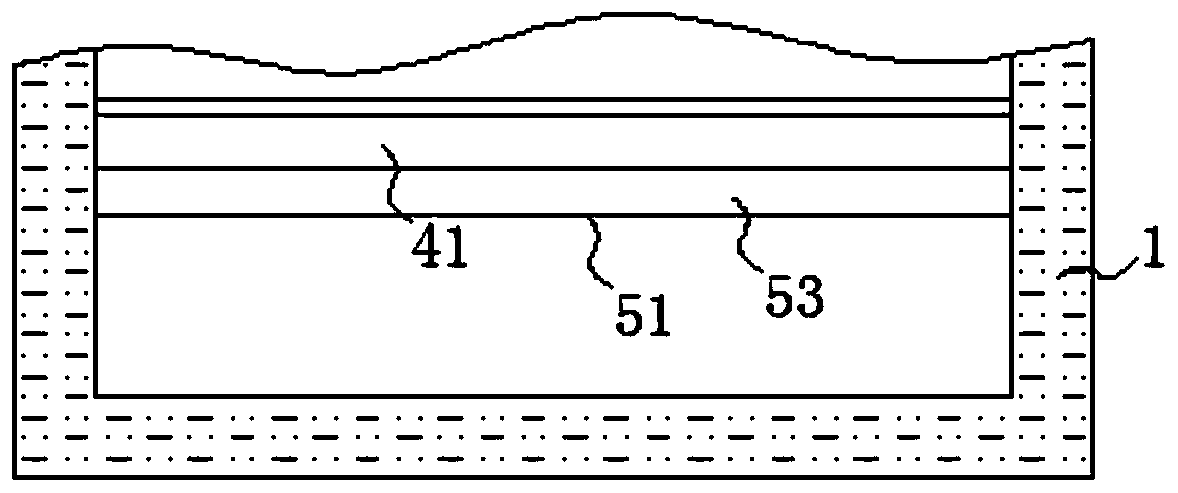

System and method for supplying coating coated with fiber drawing resin

The invention relates to a system for supplying coating coated with fiber drawing resin. The system comprises a first coating tank, a second coating tank, a recycling tank, a coating filter, an air source input pipe, an air supply pipe and a pneumatic pipeline which are respectively connected with the air source input pipe, wherein the air supply pipeline is connected with the air source input pipe; the first air supply branch pipe of the air supply pipeline is connected with the first coating tank, and the second air supply branch pipe is connected with the second coating tank; the first andsecond coating tanks are respectively connected with the coating filter through first and second supply pipes; first and second pneumatic valves are correspondingly arranged on the first and second supply pipelines respectively, and are connected with the pneumatic pipeline through the first and second pneumatic branch pipes; first and second return pipes are arranged between the recycling tank and the first and second supply pipes; and the first and second coating tanks are provided with liquid level sensors. Two coating tanks are adopted for supplying materials alternately, materials can besupplied stably and constantly. The system has the advantages of stable material supply, clean coating and the like.

Owner:FASTEN HONGSHENG GRP CO LTD +2

A horizontal tube type carbonaceous intermediate continuous heat treatment device

ActiveCN104215066BSignificant yield lossOvercome the technical problem of "parallel gas and matter"Furnace typesFurnace coolingControl systemEngineering

Owner:CHENZHOU SHANSHAN NEW MATERIAL

Traditional Chinese medicine slicing device

PendingCN114274230APrevent overfeedingGuaranteed slicing efficiencyMetal working apparatusMedicinal herbsEngineering

The invention discloses a traditional Chinese medicine slicing device which comprises a feeding mechanism, an adjusting mechanism and an output mechanism. The feeding mechanism, the adjusting mechanism and the output mechanism are all located in the box body. The feeding mechanism comprises a first conveying belt and a feeding box, the first conveying belt is rotationally connected to the interior of the box body, a first baffle is fixedly installed on the side wall of the first conveying belt and abuts against the side wall of the bottom of a top plate, and the top of the top plate is inserted into the feeding box; according to the traditional Chinese medicine slicing device, uninterrupted feeding can be achieved, traditional Chinese medicine feeding is prevented from being stopped, traditional Chinese medicine on a second conveying belt can be conveyed to a first conveying belt to be sliced through a top plate, slicing can be prevented from being affected due to excessive medicine feeding, the feeding amount of traditional Chinese medicine every time is fixed under the action of an inserting groove and an inserting block, and the traditional Chinese medicine is prevented from being excessively fed; the device can drive the first transmission belt to rotate during slicing, meanwhile, uninterrupted feeding is achieved, and the slicing efficiency is guaranteed.

Owner:HENAN UNIV OF CHINESE MEDICINE

Artificial feeding method of cotton aphid parasitoid wasp-Lysiphlebia japonica

The invention provides an artificial feeding method of cotton aphid parasitoid wasp-Lysiphlebia japonica. According to the method, on the basis of biological characteristics of the Lysiphlebia japonica and cotton aphids, the Lysiphlebia japonica is inoculated with aphids at the preference age of the Lysiphlebia japonica, the Lysiphlebia japonica is fed through stepped temperature change, the parasitized aphids are fed with a double-layer cotton leaf method, the phenomenon that the parasitized aphids run and climb about due to the fact that the aphids give out alarm pheromones is avoided, the emergence time of the Lysiphlebia japonica can be effectively controlled, the growth period of the Lysiphlebia japonica can be shortened, and the lives of adult Lysiphlebia japonica can be prolonged. When the Lysiphlebia japonica is fed with the method, the parasitic rate of the Lysiphlebia japonica is high, the loss is low, the Lysiphlebia japonica is fed step by step, and feeding conditions can be controlled step by step. The method is convenient to operate and low in cost, indoor continuous feeding of the Lysiphlebia japonica can be realized, and a good foundation is laid for large-scale propagation and feeding of the Lysiphlebia japonica.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

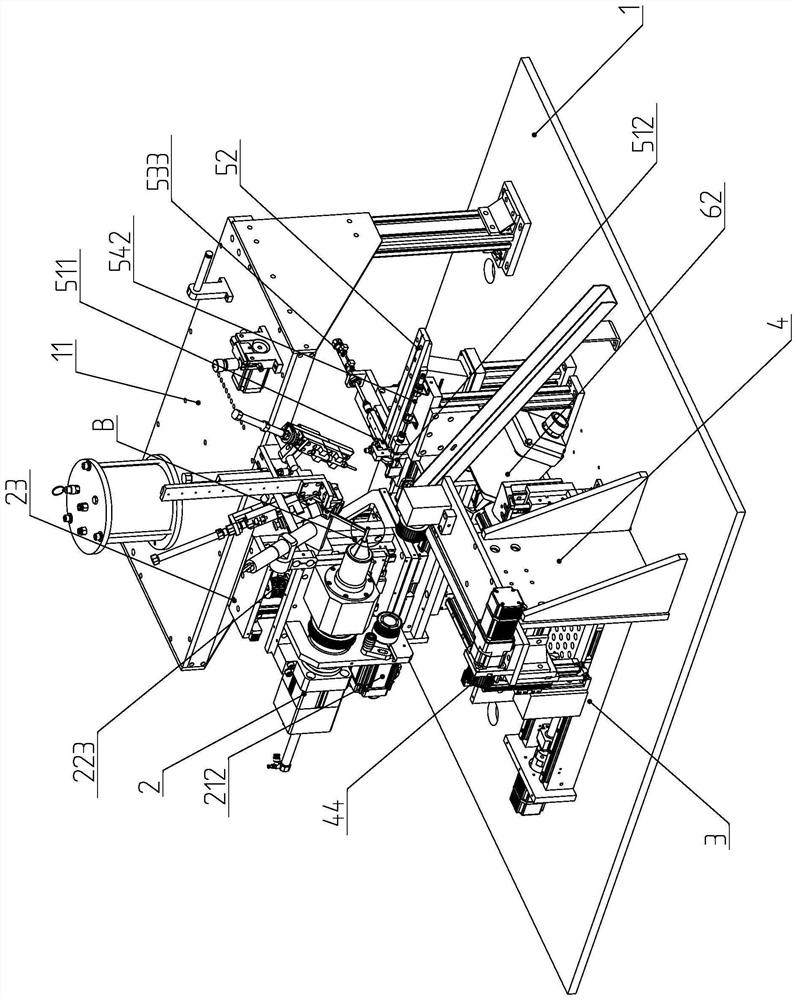

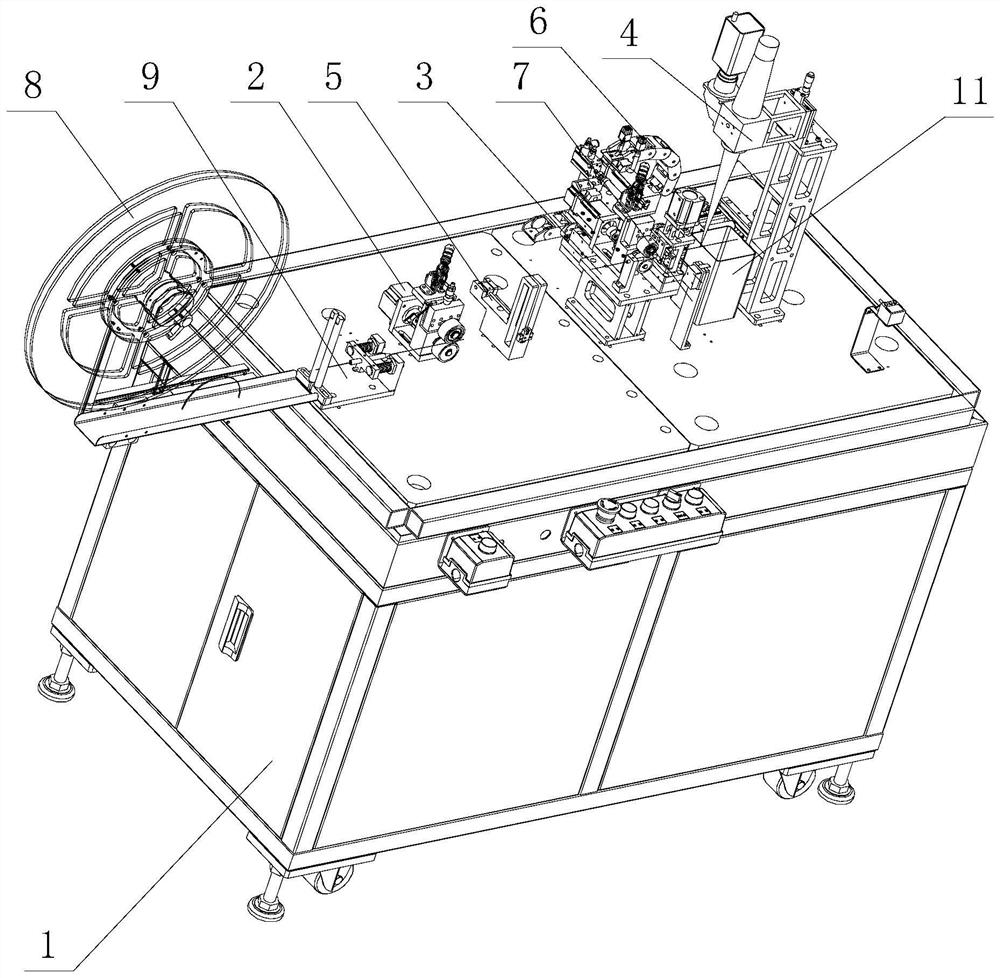

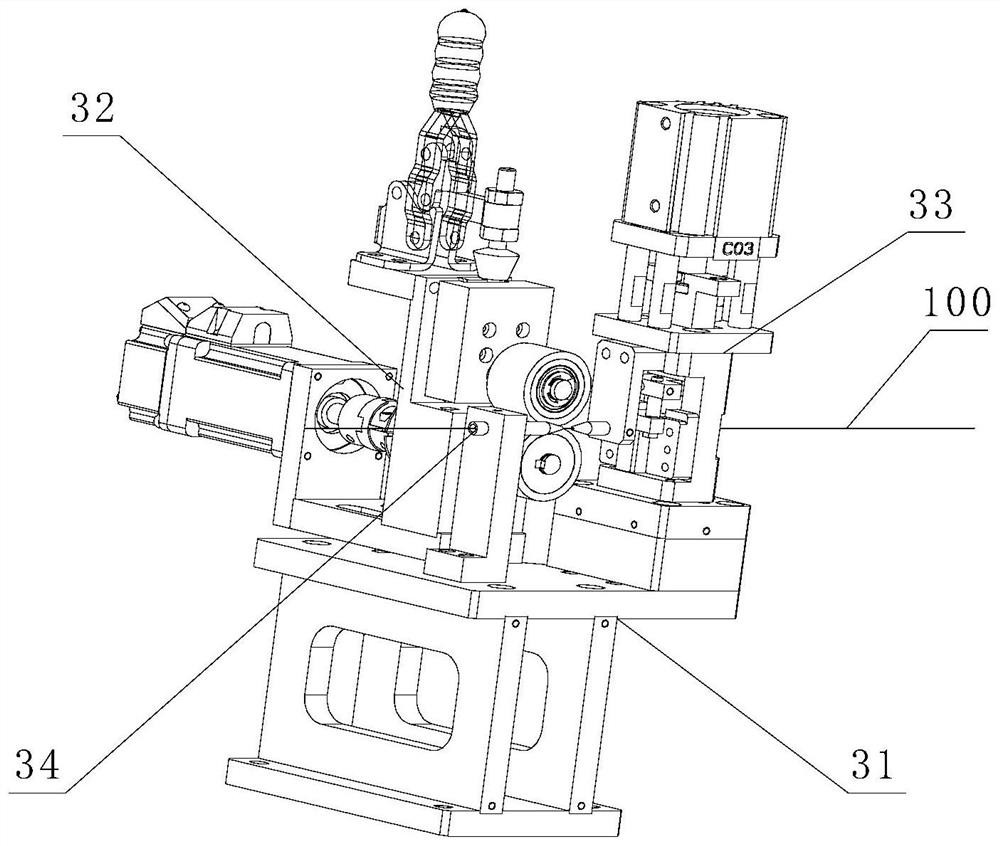

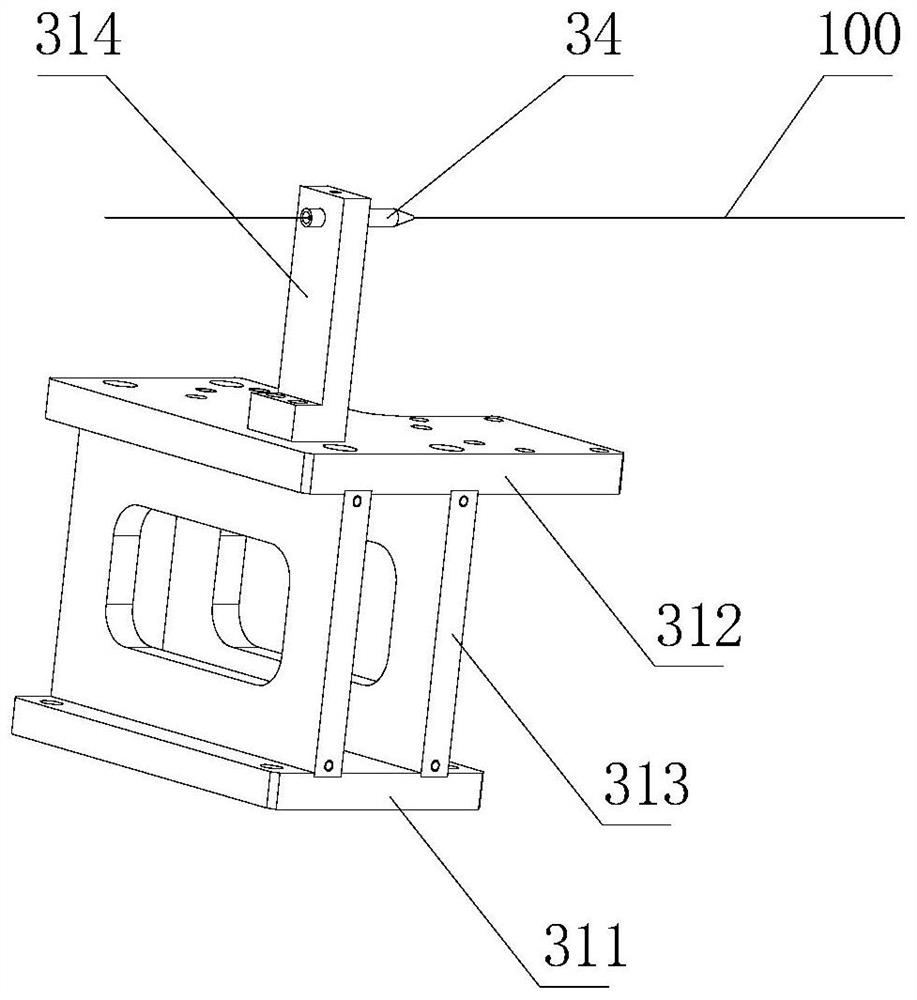

Office table bottom foot assembling machine

ActiveCN112589432AShorten access timeUninterrupted feedingAssembly machinesMetal working apparatusEngineeringWorkbench

The invention relates to an assembling machine, in particular to an office table bottom foot assembling machine. The office table bottom foot assembling machine is capable of preventing slipping, fixable in screwing force, high in efficiency and capable of preventing bolts from being damaged due to too large torsion. According to the technical scheme, the office table bottom foot assembling machine comprises a supporting shaft, a workbench, blocking columns and the like; the supporting shaft is rotationally installed in the middle of a base, the workbench is fixedly installed on the side, awayfrom the base, of the supporting shaft, a plurality of stations are arranged on the workbench, and one blocking column is arranged on one side of each station of the workbench. According to the office table bottom foot assembling machine, three feeding mechanisms are adopted, the three feeding mechanisms are sequentially arranged according to the assembling sequence of parts, meanwhile, the partsare placed in the stations on the workbench, and the taking time of the parts is shortened.

Owner:广东文豪家具有限公司

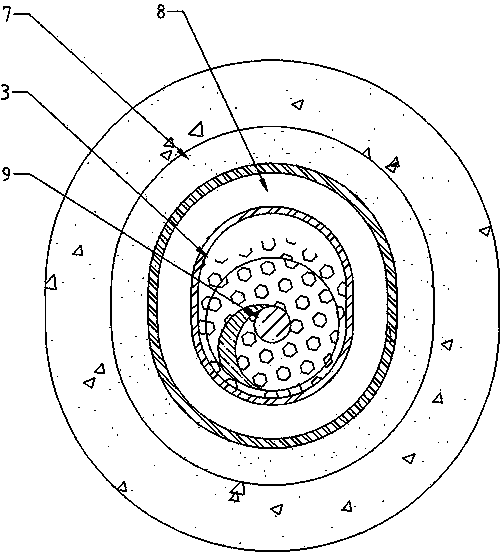

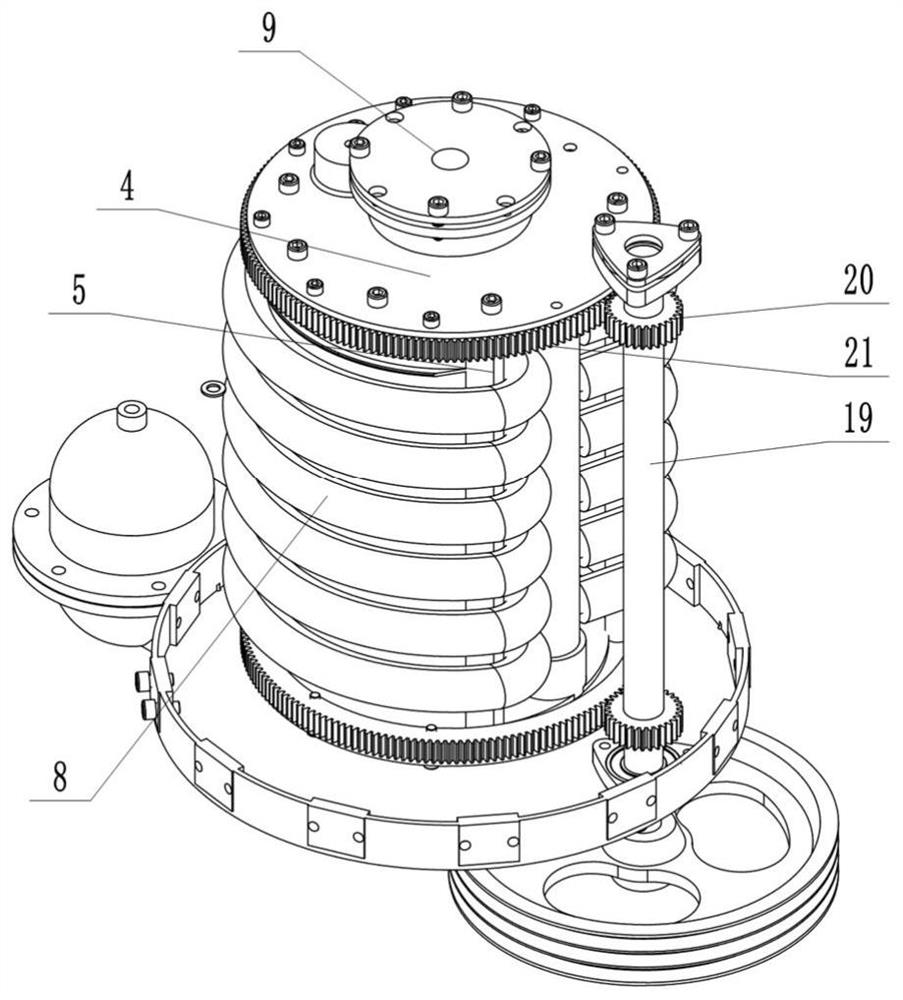

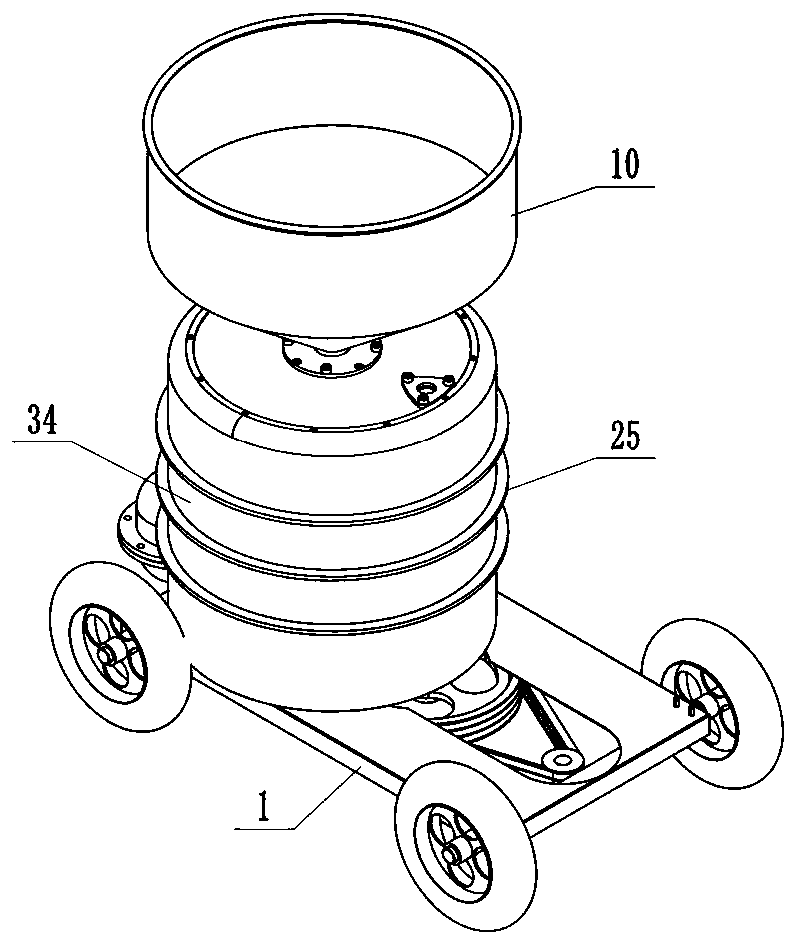

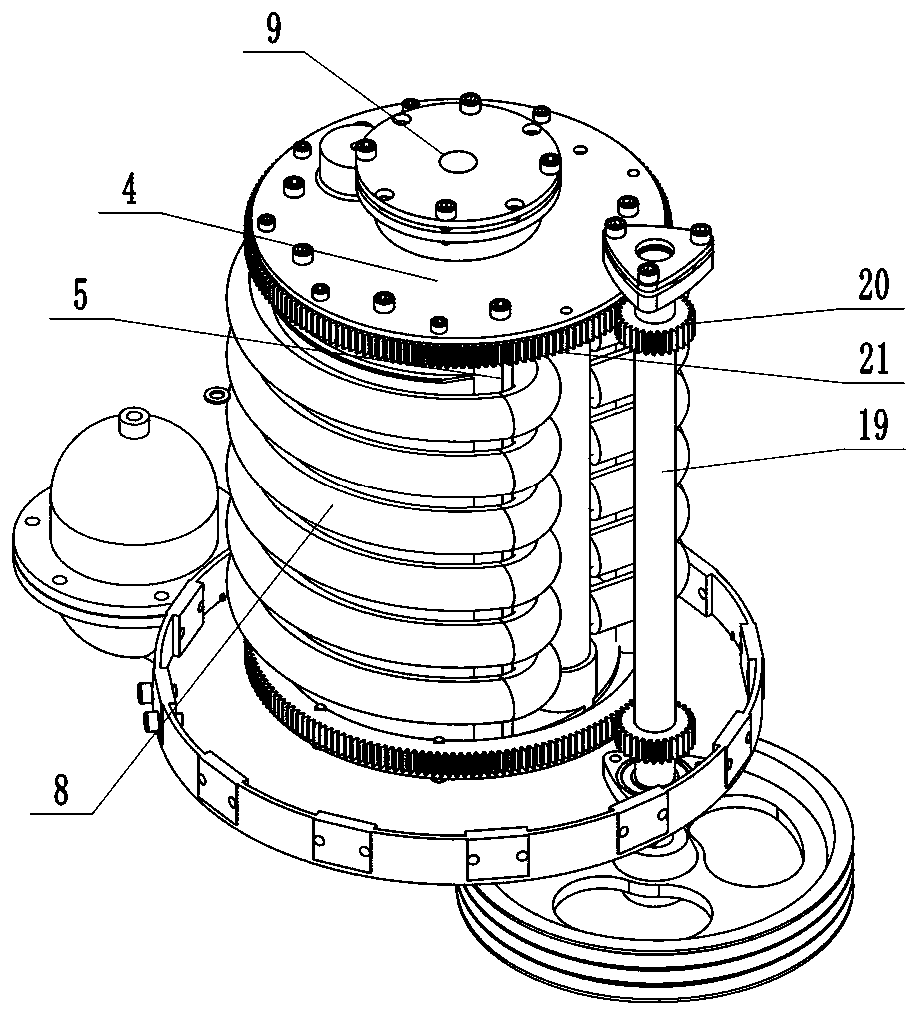

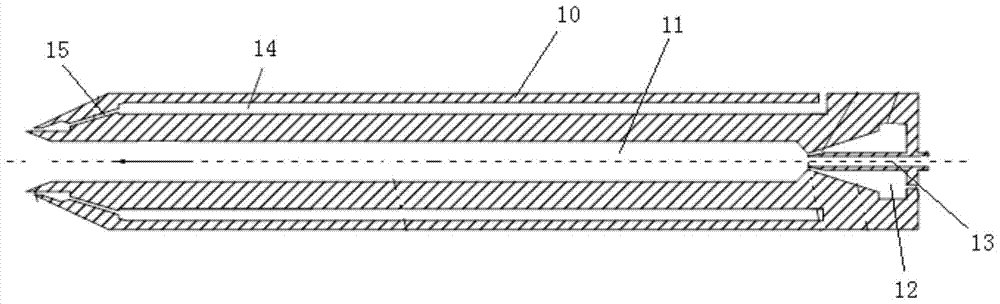

A multi-pipe connection non-pulse delivery hose pump

InactiveCN111594421BConvey evenlySimple structurePositive displacement pump componentsFlexible member pumpsStructural engineeringSteel cylinder

The invention relates to a multi-pipe connection type non-pulse feeding hose pump, which belongs to the technical field of material transportation, and specifically includes a fixed frame installed on a moving trolley, a rotor steel cylinder installed in the inner center of the fixed frame, and two ends of the rotor steel cylinder The sealing plates are respectively fixed, the feed connecting pipe and the discharge connecting pipe are installed in the rotor steel cylinder, a plurality of rubber hoses are arranged between the feed connecting pipe and the discharge connecting pipe, and the top and bottom of the fixing frame are fixed with The material guide seat is rotated, and the material guide tube is fixed on the sealing plate. One end of the material guide tube is inserted on the rotating material guide seat, and the other end is fixed with a material guide groove. One end of the feed connecting pipe and the discharge connecting pipe are inserted respectively. On the guide groove, the other end is inserted into the supporting sleeve, and a supporting spring is also installed in the supporting sleeve, and a plurality of vertical supporting beams are fixed on the circumference of the fixed frame, and pressure rollers are fixed on the vertical supporting beams. The invention has the advantages of simple structure, reasonable design, continuous material delivery, uniform material delivery and high material delivery efficiency.

Owner:王一冰

Full automatic oil injection equipment for motor

ActiveCN110535297ASolve the problem of low oil injection efficiencyUninterrupted oil injectionManufacturing dynamo-electric machinesLubrication elementsLocking mechanismInjection equipment

The invention belongs to the field of motor bearings, and especially provides full automatic oil injection equipment for a motor. The following scheme is put forward. The full automatic oil injectionequipment comprises a base. A support frame is arranged at the middle position of the top end of the base. A motor 2 is installed on the side wall of the support frame. The output shaft of the motor 2is connected with a rotating disc rotatably connected inside the support frame. A plurality of annular-array-arranged fixing grooves are arranged on the outer side wall of the rotating disc, and a locking mechanism is arranged on the fixing grooves. The top end of the base is provided with a fixing frame located outside the rotating disc. A horizontal double-head cylinder 1 is arranged on the topinner wall of the fixing frame. The two output shafts of the double-head cylinder 1 are connected with a slide block 1. Working boxes located on the two sides of the rotating disc are arranged on thebottom end of the slide block 1. A communication hole is arranged in the side wall of the working boxes close to the rotating disc. The device can quickly realize oil injection of the bearing of themotor rotor and has good oil injection effect and high working efficiency.

Owner:中擎电机有限公司

Trimming knife welding machine

PendingCN114247978ASmall footprintA large amountHigh frequency current welding apparatusEngineeringWelding

The invention relates to a trimming knife welding machine which comprises a machine table, a first feeding device and a material moving device are arranged on one side of the machine table, a feeding device and a second feeding device are arranged on the other side of the machine table, a welding station is arranged between the feeding device and the second feeding device, a welding device is arranged below the welding station, and a mounting frame is arranged above the welding station. An angle detection device, a gluing device and a wire discharging device are arranged on the mounting frame, the material moving device comprises a shell and a three-axis moving mechanism, a fastening mechanism is arranged at one end of the shell, a rotating mechanism is arranged at the other end of the shell, the three-axis moving mechanism comprises a transverse moving assembly, a front-back moving assembly and a lifting moving assembly, and the shell is arranged on the rack. The rack is arranged on the lifting moving assembly, and a fixing mechanism is arranged at the end, corresponding to the fastening mechanism, of the rack. By the adoption of the technical scheme, positioning is more accurate, labor intensity is reduced, standardized production is achieved, the structure is simplified, steps are reduced, feeding is rapid, efficiency is improved, and the quality of finished products is high.

Owner:温州市骏承机械设备有限公司

Multi-pipe connecting type pulse-free material conveying hose pump

InactiveCN111594421AConvey evenlySimple structurePositive displacement pump componentsFlexible member pumpsEngineeringPipe

The invention relates to a multi-pipe connecting type pulse-free material conveying hose pump, and belongs to the technical field of material conveying. Specifically, a fixing frame is arranged on a movable trolley, a rotor steel barrel is arranged at the center in the fixing frame, and seal plates are fixed to the two ends of the rotor steel barrel correspondingly. A feeding connecting pipe and adischarging connecting pipe are arranged in the rotor steel barrel. A plurality of rubber hoses are arranged between the feeding connecting pipe and the discharging connecting pipe. Rotation materialguiding bases are fixed to the top and the bottom of the fixing frame. Material guiding pipes are fixed to the seal plates. One ends of the material guiding pipes are inserted in the rotation material guiding bases, material guiding grooves are fixed to the other ends of the material guiding pipes, one end of the feeding connecting pipe and one end of the discharging connecting pipe are insertedin the material guiding grooves correspondingly, and the other ends of the feeding connecting pipe and the discharging connecting pipe are inserted in supporting sleeves. Supporting springs are further arranged in the supporting sleeves. A plurality of vertical supporting beams are fixed to the circumference of the fixing frame. Pressing wheels are fixed to the vertical supporting beams. The multi-pipe connecting type pulse-free material conveying hose pump is simple in structure, reasonable in design, capable of achieving continuous material conveying, uniform in material conveying and high in material conveying efficiency.

Owner:王一冰

Betel Nut Cutting Machine

InactiveCN105946007BSolve time-consuming and labor-intensive problemsSmooth feedingMetal working apparatusBetel nutsElectric machinery

The invention discloses a betel nut cutting machine which comprises an automatic feeding device, a direction adjuster, a balance weight, a fruit feeding wheel, a slitting positioner and a cutting device. The automatic feeding device is located in front of the direction adjuster. The direction adjuster comprises a series of concave wheels which are linearly arranged. The concave wheels are driven by a first motor. The fruit feeding wheel is located above the direction adjuster. A groove is formed in the fruit feeding wheel. Protruding teeth are arranged on the two edges of the groove and are of a symmetric structure. The fruit feeding wheel is driven by a second motor and is fixedly connected with the second motor to form a whole and connected with the balance weight through a connecting piece. The slitting positioner is located behind the direction adjuster and is located below the fruit feeding wheel. The cutting device comprises a cutting blade which is driven by a third motor. After fruits pass through the direction adjuster, the fruits are cut through the cutting blade under the effect of the fruit feeding wheel and the slitting positioner. The betel nut cutting machine is used for cutting betel nuts so that the labor intensity of workers can be lowered, the working efficiency is improved, the product quality is ensured, and the market development demand can be met.

Owner:向清志

A continuous drilling machine

ActiveCN106825685BRealize continuous processingUninterrupted feedingMetal working apparatusBoring/drilling componentsDrive wheelReduction drive

The invention discloses a drilling machine for working continuously. The drilling machine comprises a foundation support, the foundation support is of a ladder shape, the upper portion of a first-grade step of the foundation support is slidably provided with a drilling assembly, the drilling assembly performs drilling operation on a mobile phone protection sleeve, and a continuous conveying assembly is arranged under the drilling assembly; the drilling assembly comprises a movement sliding block, the upper portion of the movement sliding block is provided with a supporting plate, and the supporting plate is of an L shape; and the two sides of the vertical portion of the supporting plate are provided with ribs correspondingly, the horizontal portion of the supporting plate is provided with a positioning groove, the upper portion of the positioning groove is fixedly provided with a drilling motor and a speed reducer in sequence, the upper portion of an output shaft of the speed reducer is provided with a drive wheel, and the front side of the vertical portion of the supporting plate is provided with a drill bit installation plate. By means of the drilling machine, a mobile phone protection sleeve can be machined and drilled continuously, the mobile phone protection sleeve is conveyed to the position below a drill bit through a continuous conveying assembly, a lifting positioning assembly performs lifting positioning on the passing mobile phone protection sleeve, then the drill bit drills the mobile phone protection sleeve, continuous machining is achieved, and material feeding is unintermittent.

Owner:徐州天骋智能科技有限公司

Stranded wire contact pin cutting and spot welding device

PendingCN114824992AQuick spot weldingRealize automatic feedingContact member manufacturingSpot weldingMechanical engineering

The invention relates to a stranded wire contact pin cutting and spot welding device which comprises a rack, a feeding module, a cutting module and a welding module, a carrying module and a stranded wire contact pin sensing optical fiber module are arranged on the rack, the carrying module is arranged between the cutting module and the welding module, and the carrying module comprises a moving mechanism and a rotary clamping mechanism. The stranded wire pin wire cut by the cutting module is clamped by the rotary clamping mechanism and then moved to the position below the welding module through the moving mechanism, and spot welding of the two ends of the stranded wire pin wire is achieved through rotation of the rotary clamping mechanism during welding; the device has the advantages that the stranded wire contact pin wire is fed into the cutting module through the feeding module to be cut, and the carrying module is arranged between the cutting module and the welding module, so that the stranded wire contact pin wire cut by the cutting module can be sent out from the cutting module, the welding process and the cutting process form two mutually independent processes, and the welding efficiency is improved. And the two are not interfered, so that the overall production efficiency is improved.

Owner:杭州航天电子技术有限公司

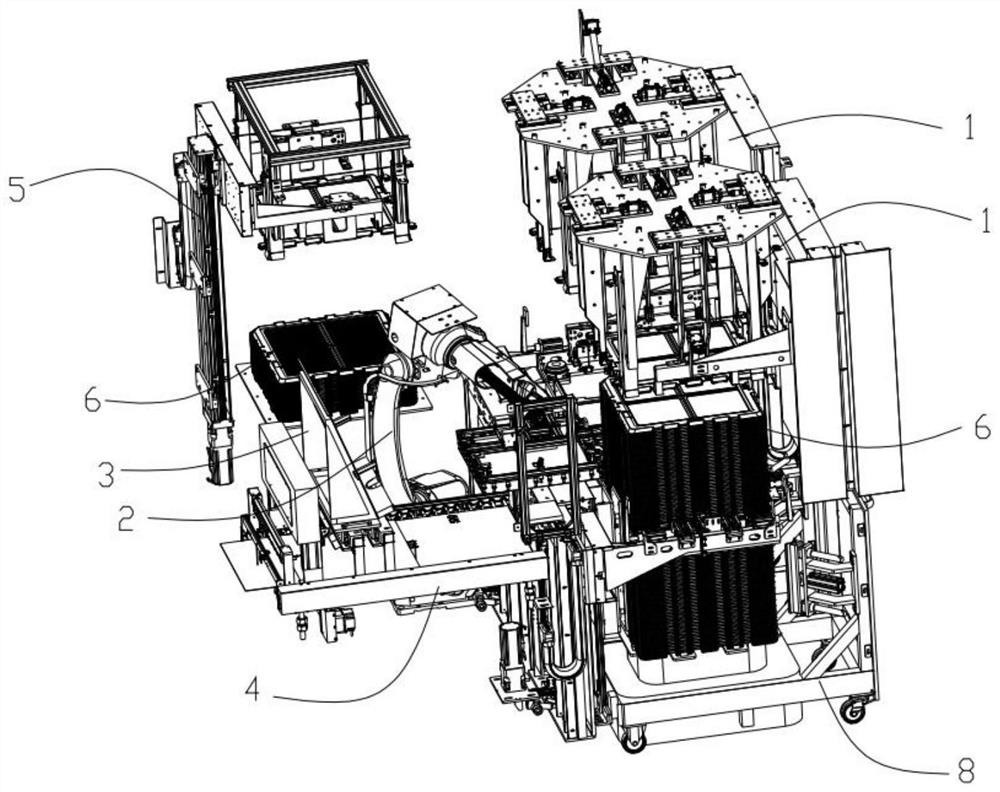

Independent double-station full-automatic board collecting and releasing machine

PendingCN114653620AUninterrupted feedingImprove efficiencySortingProcess engineeringIndustrial engineering

The invention relates to the technical field of automatic detection, in particular to an independent type double-station full-automatic plate collecting and releasing machine which comprises a material moving device, a detection station, a good product storage station, a defective product storage station and two material storage stations, and the material storage stations are used for storing materials fed from the outside; the material moving device is used for moving the materials stored in one of the material storage stations to the detection station; the detection station is used for detecting materials; the material moving device is further used for moving the detected materials to the good product storage station or the defective product storage station. According to the full-automatic plate detection and sorting machine, the material moving device, the detection station, the good product storage station, the defective product storage station and the two material storage stations are integrated, full-automatic feeding, detection and sorting actions on plates are achieved, continuous feeding is achieved through the two material storage stations, and therefore the efficiency is improved.

Owner:XUNDE MACHINERY DONGGUAN CO LTD

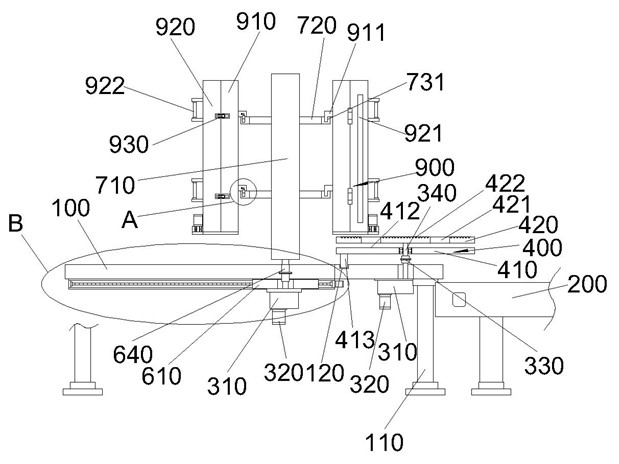

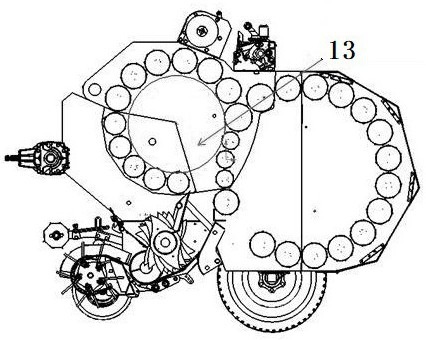

Automatic assembly machine for snap ring bearing fan blades of rotor

InactiveCN106736433BRealize integrated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusDistribution controlElectric machinery

The present invention relates to an automatic assembly machine for a snap ring, a bearing and a fan blade of a rotor. The machine comprises a power distribution control box and an operation display panel which are connected to each other. The power distribution control box is provided with a turntable bracket on which a vertical turntable is arranged, and a drive motor of the turntable is connected to the power distribution control box. The turntable is evenly provided with mounting holes that match up with the rotor. Besides, on the power distribution control box on the side faces of the turntable, a fan blade assembly device, snap ring assembly devices and bearing assembly devices that match up with the rotor on the turntable are disposed in turn in the rotating direction of the turntable. The design of the present invention provides the vertical turntable that is connected to the power distribution control box and evenly provided with the mounting holes that match up with the rotor body. Besides, the fan blade assembly device, the snap ring assembly devices and the bearing assembly devices that match up with the rotor on the turntable are arranged on the side faces of the turntable so that integrated assembly of the fan blade, the snap ring and the bearing can be realized, assembly efficiency is greatly improved and production hours are reduced.

Owner:馆陶县鑫荣轴承有限公司

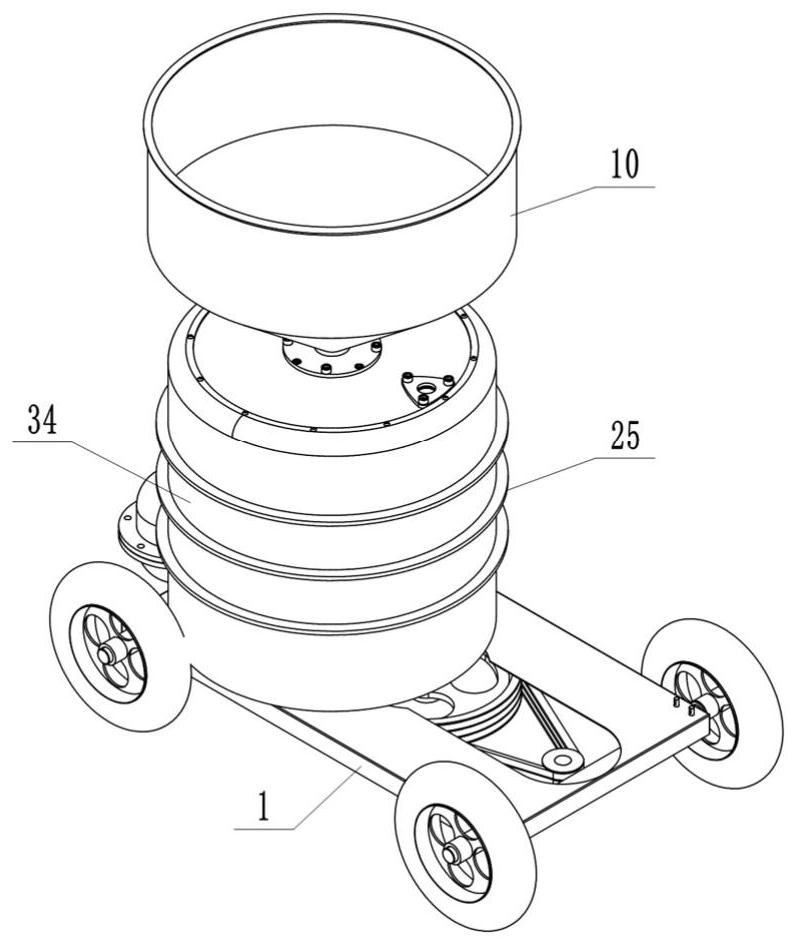

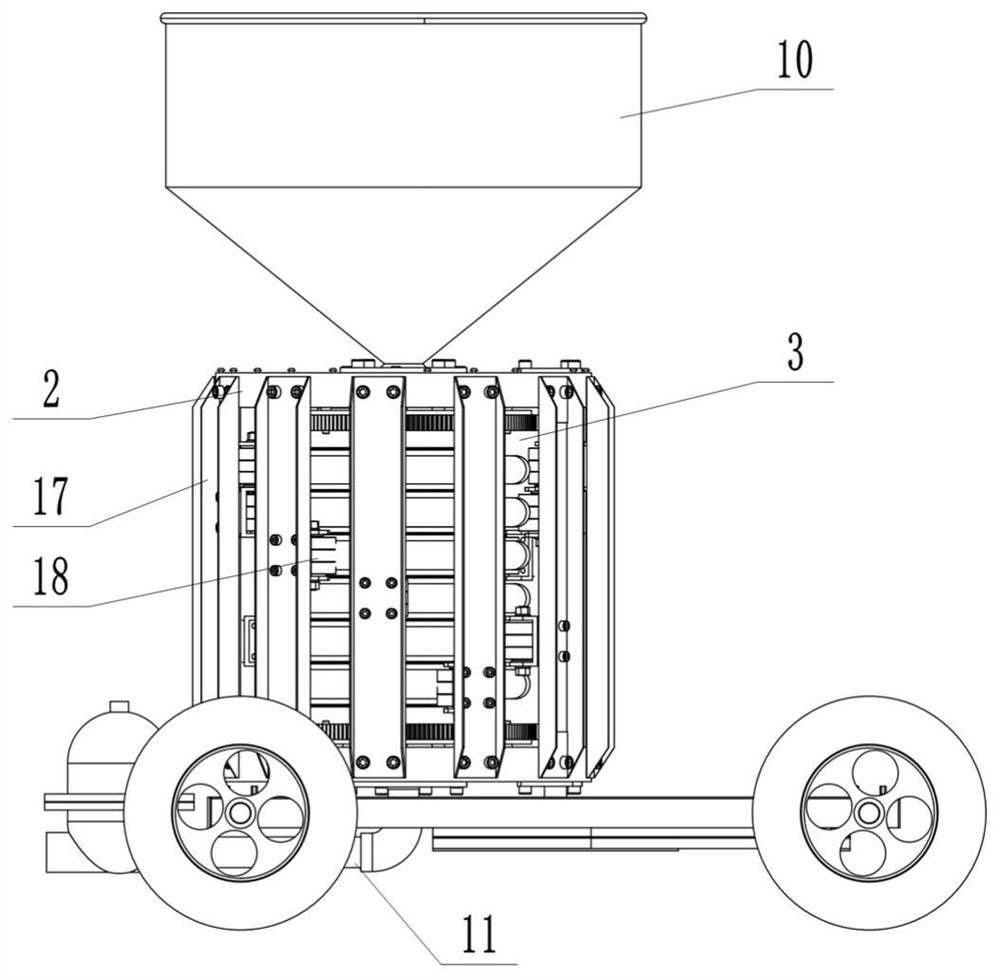

Foam concrete wet-spraying unit used for mine

ActiveCN102359382BSmooth feedingUniform feedingUnderground chambersTunnel liningHydraulic motorFoam concrete

The invention discloses a foam concrete wet-spraying unit used for a mine. The foam concrete wet-spraying unit comprises a shell, wherein the shell is provided with a feeding and stirring system, a foam making and mixing and controlling system and a transmission and injection system, wherein the feeding and stirring system comprises an upper stirrer and a lower stirrer; one end of the upper stirrer is connected with a feeding funnel, and the other end of the upper stirrer is connected with the lower stirrer; the foam making and mixing and controlling system comprises a hose pump, a foam maker and a foam mixer; the lower stirrer is connected with the hose pump; the hose pump is connected with the foam mixer; the foam maker is connected with a liquid foaming agent container and the foam mixer; the transmission and injection system comprises a hydraulic pump, an energy storage device and an accelerating agent feeding channel, wherein the hydraulic pump is respectively connected with a hydraulic motor I, a hydraulic motor II and a hydraulic motor III; the hydraulic motors I, II and II are respectively connected with pipelines among a slurry adsorption pipe, the foam maker and the foaming agent container and the accelerating agent feeding channel; and the energy storage device is connected with the foam maker, an inner air pipe of a mine roadway, the foam maker and a spray nozzle. The foam concrete wet-spraying unit has the advantages of continuous and even material feeding and the capability of avoiding dust pollution and pipe blockage of the spray nozzle.

Owner:兖矿能源集团股份有限公司 +1

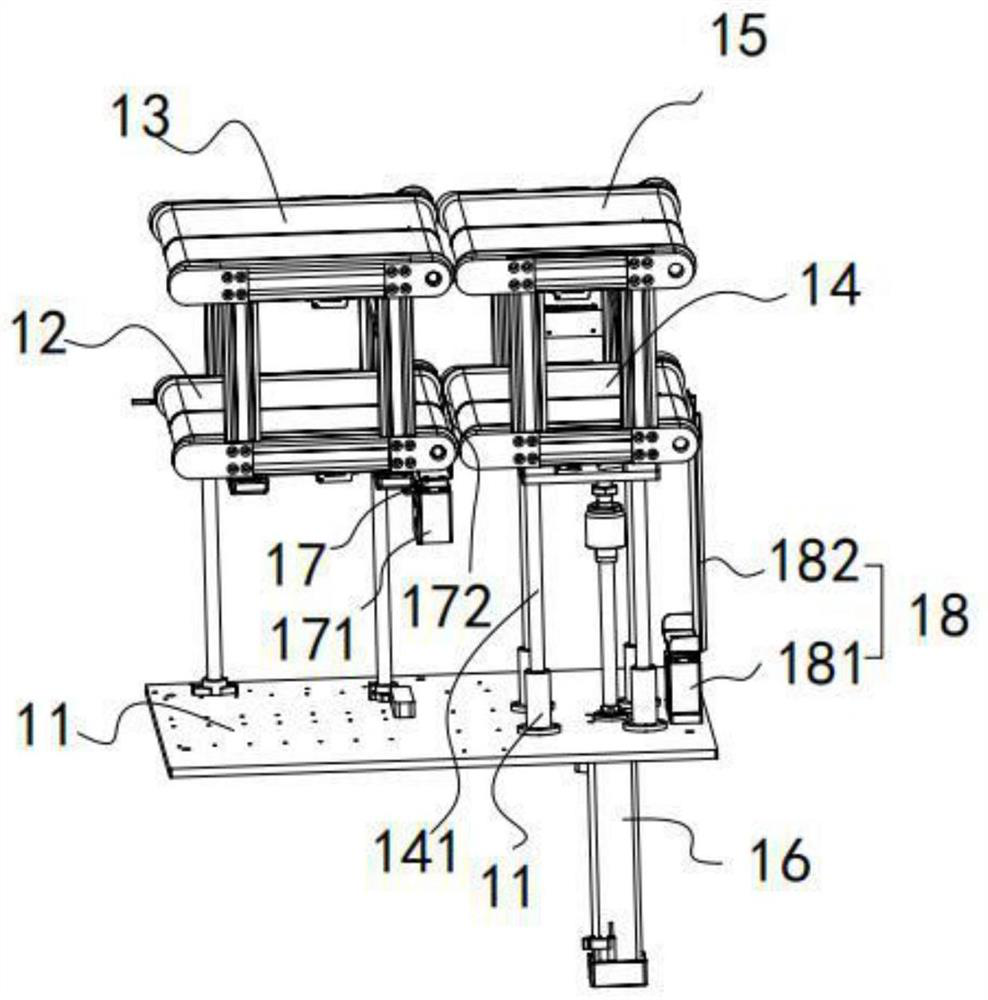

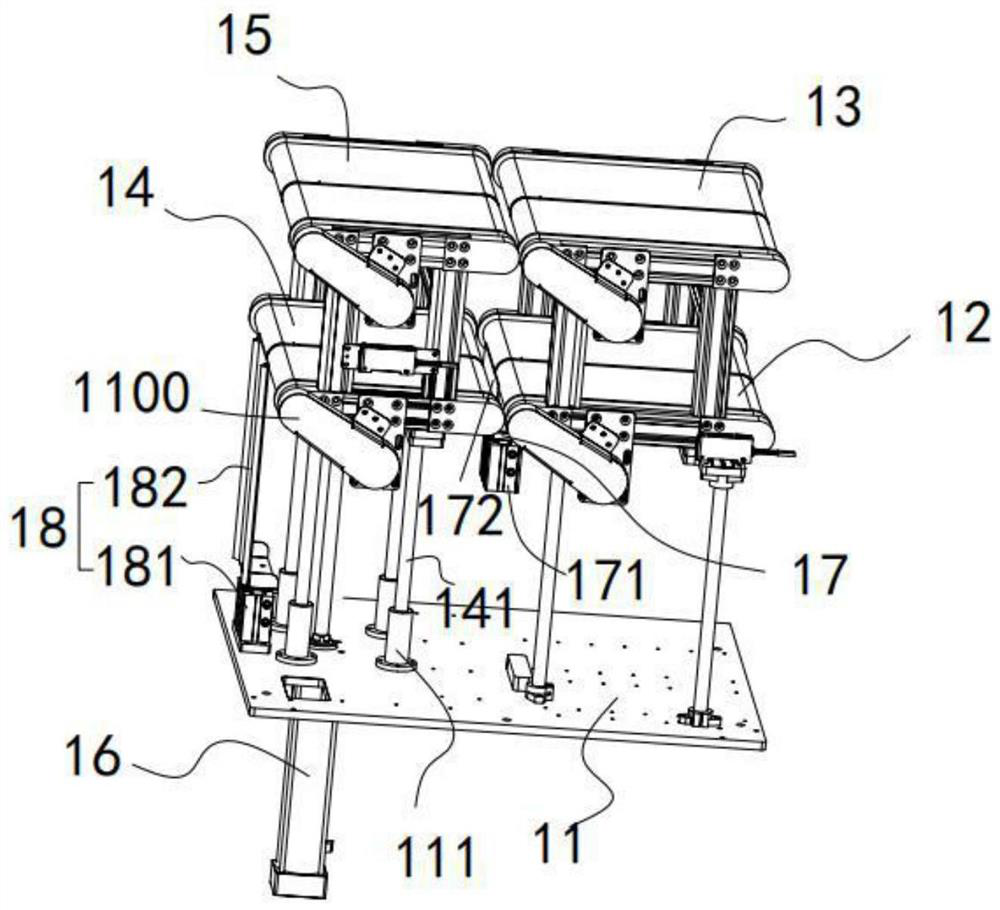

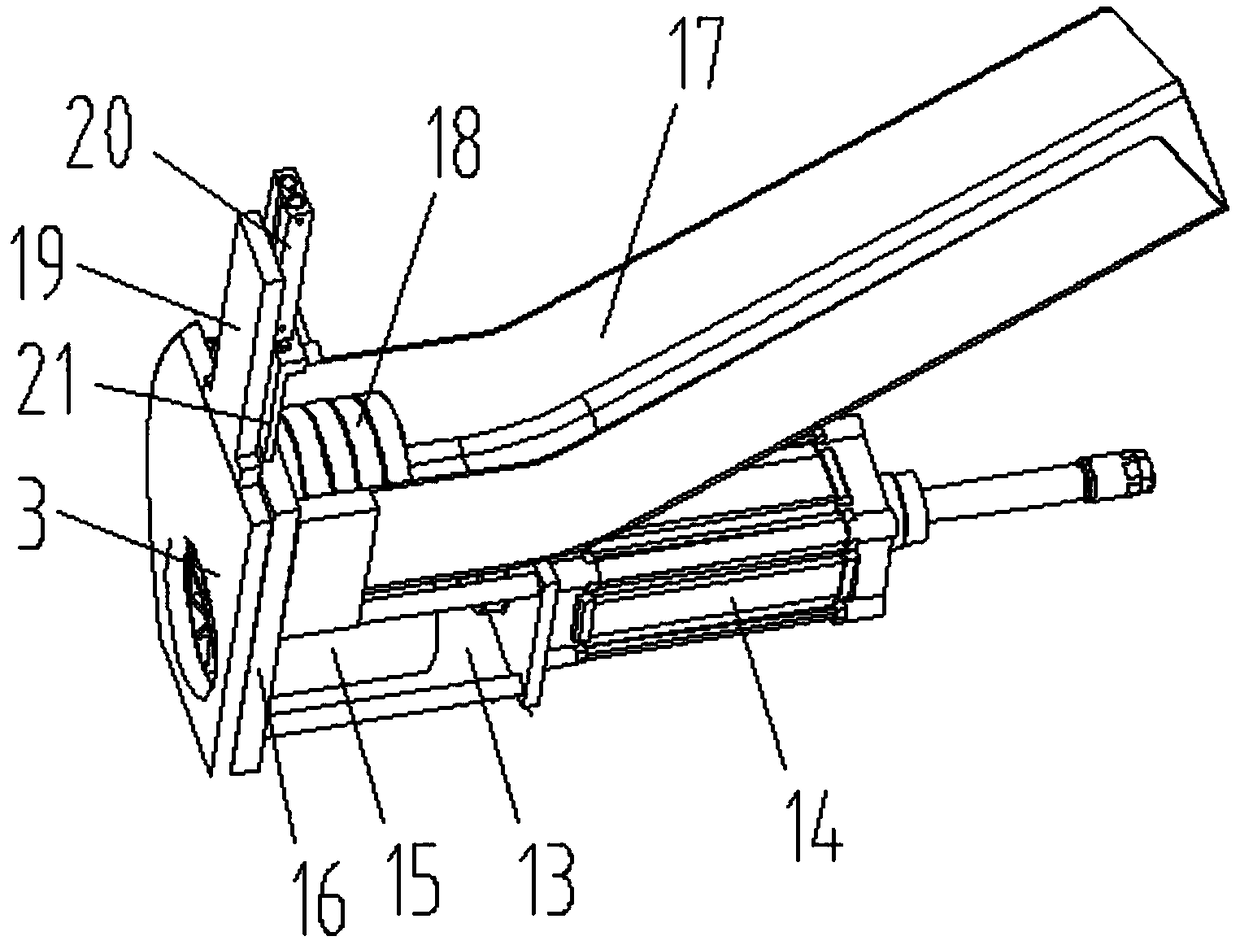

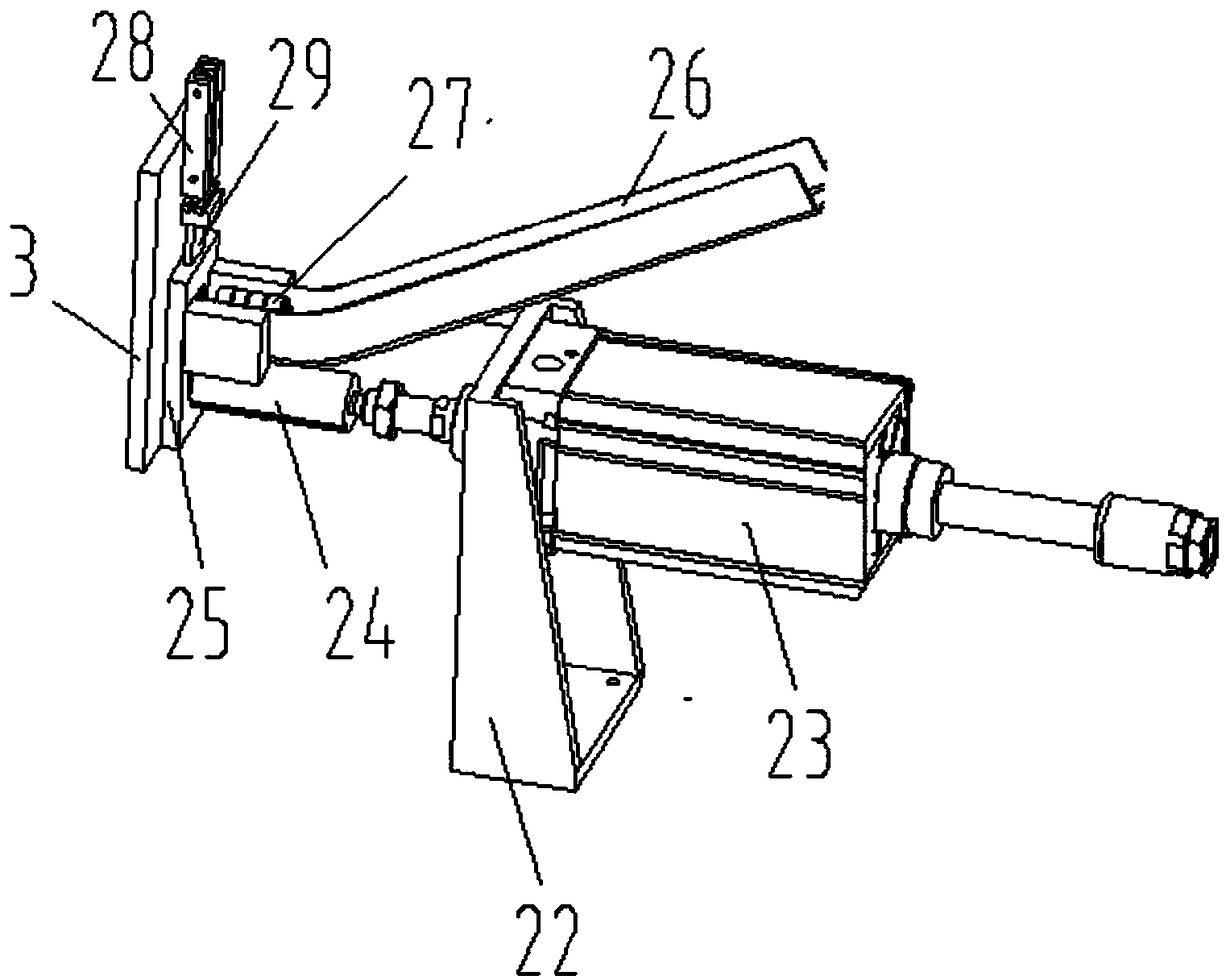

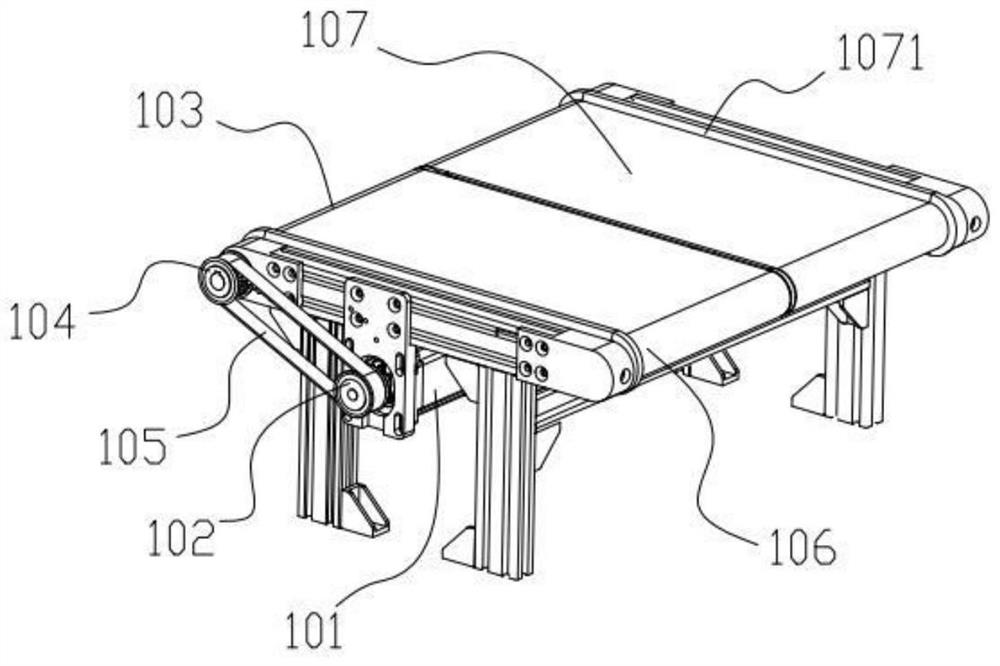

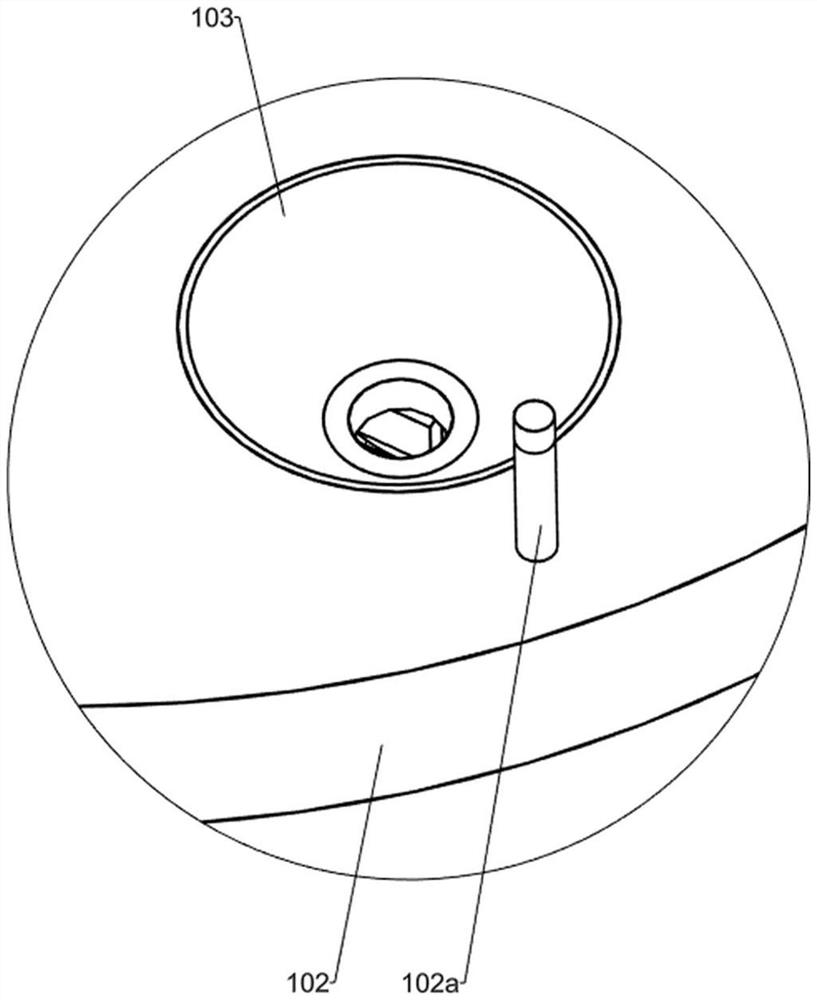

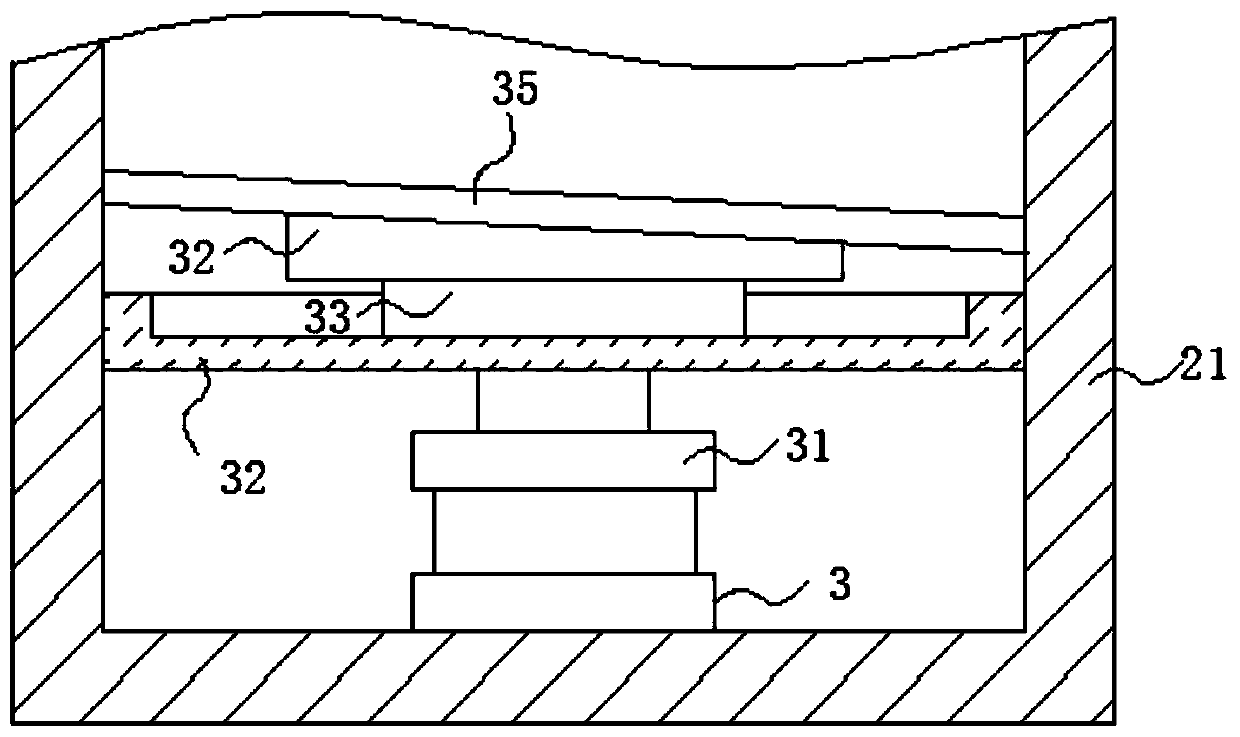

Feeding device with buffering and conveying functions

PendingCN112830184AWith cache functionUninterrupted feedingControl devices for conveyorsMechanical conveyorsEngineeringAssembly line

The invention discloses a feeding device with buffering and conveying functions. The feeding device comprises a bottom plate, a feeding assembly line, a material taking platform, a material passing assembly line, a buffering assembly line and a lifting air cylinder, the material taking platform is correspondingly and fixedly connected with the feeding assembly line, the feeding assembly line is fixedly connected with the bottom plate, and the buffering assembly line is fixedly connected with the material passing assembly line; and the lifting air cylinder is arranged at the bottom of the material passing assembly line, a push rod of the lifting air cylinder penetrates through the bottom plate to abut against the bottom of the material passing assembly line, the outflow end of the feeding assembly line is technologically connected with the inlet end of the material passing assembly line, and the outflow end of the buffering assembly line is technologically connected with the material taking platform. Material trays sequentially flow through the feeding assembly line to enter the material passing assembly line and a next feeding device to achieve the material tray conveying function, and the material trays sequentially flow through the feeding assembly line to enter the buffering assembly line and the material taking platform to achieve material tray buffering and material taking functions. The feeding device has a buffering function and can be connected with rear-end equipment to implement unit wiring so that uninterrupted feeding can be realized during production, and the production efficiency is improved.

Owner:SHENZHEN HONG YI TAI TECH LTD

A kind of artificial breeding method of cotton aphid parasitoid - Aphidia gossypii parasitoid

The invention provides an artificial feeding method of cotton aphid parasitoid wasp-Lysiphlebia japonica. According to the method, on the basis of biological characteristics of the Lysiphlebia japonica and cotton aphids, the Lysiphlebia japonica is inoculated with aphids at the preference age of the Lysiphlebia japonica, the Lysiphlebia japonica is fed through stepped temperature change, the parasitized aphids are fed with a double-layer cotton leaf method, the phenomenon that the parasitized aphids run and climb about due to the fact that the aphids give out alarm pheromones is avoided, the emergence time of the Lysiphlebia japonica can be effectively controlled, the growth period of the Lysiphlebia japonica can be shortened, and the lives of adult Lysiphlebia japonica can be prolonged. When the Lysiphlebia japonica is fed with the method, the parasitic rate of the Lysiphlebia japonica is high, the loss is low, the Lysiphlebia japonica is fed step by step, and feeding conditions can be controlled step by step. The method is convenient to operate and low in cost, indoor continuous feeding of the Lysiphlebia japonica can be realized, and a good foundation is laid for large-scale propagation and feeding of the Lysiphlebia japonica.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

A desk feet assembly machine

ActiveCN112589432BShorten access timeUninterrupted feedingAssembly machinesMetal working apparatusSoftware engineeringWorkbench

The invention relates to an assembling machine, in particular to an assembling machine for desk feet. The technical problem to be solved is to provide an anti-skid and high-efficiency desk foot assembling machine that can be fixed by tightening force and can prevent bolts from being damaged by excessive torque. The technical solution is: a desk foot assembly machine, including a support shaft, a workbench and a retaining column; A plurality of stations are arranged on the workbench, and a stop column is arranged on one side of each station of the workbench. The present invention adopts three feeding mechanisms, and the three feeding mechanisms are placed in sequence according to the assembly sequence of the parts, and the parts are put into the stations on the workbench at the same time, thereby reducing the time for taking the parts.

Owner:广东文豪家具有限公司

Full-process automatic graphite purification method

PendingCN112320795AScientific and reasonable structure layoutCompact structureCarbon compoundsAutomatic controlCarbonization

The invention discloses a full-process automatic graphite purification method. The method comprises the following steps: step 1, blanking and pushing; a carbon powder raw material is pushed into a double-layer heating pipe of a horizontal graphite carbonization furnace along a horizontal feeding pipe by adopting a discharging mechanism and a spiral pushing mechanism; step 2, high-temperature carbonization; the carbon powder is heated in a double-layer heating pipe of the horizontal graphite carbonization furnace; step 3, discharging; and the heated carbon powder passes through a discharge pipeof the horizontal graphite carbonization furnace and is conveyed into a container through a discharge mechanism to be packaged. According to the full-process automatic graphite purification method, the whole-process automatic control of blanking, feeding, discharging and temperature is adopted, the temperature in the furnace body can be kept constant, and the automation degree is high so that thegraphite carbonization quality is guaranteed.

Owner:长沙修恒信息科技有限公司

A kind of amoxicillin continuous crystallization process

ActiveCN111518119BContinuous crystallization achievedIncrease crystallization rateOrganic chemistry methodsProcess equipmentPharmaceutical drug

Owner:UNITED LAB INNER MONGOLIA CO LTD

Feeding mechanism for bearing detection machine and working method of feeding mechanism

InactiveCN114455283AOptimize the adjustment methodWill not cause the problem of poor rotationConveyorsPackagingCouplingTransmission belt

The invention belongs to the technical field of bearing detection, and particularly relates to a feeding mechanism for a bearing detector and a working method thereof.The feeding mechanism comprises a feeding device base, a first reduction gearbox is installed at the bottom of the feeding device base, and an input shaft of the first reduction gearbox is fixedly connected with an output shaft of a first servo motor; an output shaft of the first reduction gearbox penetrates out of the top of the feeding device base to be fixedly connected with the bottom of a first coupler, a first connecting shaft is installed at the top of the first coupler and installed on the throwing device, and a second reduction gearbox is installed at the bottom of the feeding device installation plate. An output shaft of the second reduction gearbox penetrates out of the top of the feeding device mounting plate and is fixedly connected with a second coupler, the top of the second coupler is fixedly connected with a second connecting shaft, and the top of the second connecting shaft is connected with the feeding device. And the device is high in feeding automation degree, continuous feeding can be achieved, and the feeding efficiency is effectively improved.

Owner:汪庆文

Fully automatic distributing device for conveying long rubber hoses

The invention relates to a fully automatic distributing device for conveying elongated rubber hoses in the field of automation equipment, which includes a rubber hose distributing mechanism and a rubber hose conveying mechanism. The assembly consists of a mounting base, a round roller and a stepping motor for distributing materials to drive the rollers to rotate. The rubber hose conveying mechanism is composed of two symmetrically structured conveyor belts and a conveying stepping motor. The hose distributing mechanism can realize automatic feeding and feeding. Regularly and automatically divide the material, and at the same time automatically transfer the rubber hose to the rubber hose conveying mechanism. The motor drives the rubber hose to convey backwards, which can realize uninterrupted feeding, distributing and feeding, thus improving the conveying efficiency, especially suitable for automatic assembly lines that require uninterrupted work.

Owner:上海新上橡汽车胶管有限公司

Special material stirring device

InactiveCN110801747AUnable to dischargeAvoid wastingRotary stirring mixersTransportation and packagingMaterial removalProcess engineering

The invention discloses a special material stirring device comprising a fixed shell, a material storage mechanism, a driving mechanism, a control mechanism and a material removal mechanism; the material storage mechanism is arranged at the top of the left side of the fixed shell; the driving mechanism is arranged in the material storage mechanism; the control mechanism is arranged in the fixed shell; the material removal mechanism is arranged on the fixed shell. The material storage shell, a PLC, an alarm, a first air cylinder, a pressure sensor, a storage plate, an electric push rod, a firstcontact piece, a second contact piece, a second air cylinder and a push plate are matched with one another, so the special material stirring device is realized; quantitative feeding can be achieved inthe feeding process, excessive or insufficient feeding is avoided, automatic uninterrupted feeding can be achieved in the stirring process, the efficiency is greatly improved, meanwhile, the situation that some materials left at the bottom in the stirring device cannot be discharged is avoided, and thus resource waste is avoided, the production cost is greatly saved, and great convenience is brought to a user.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

Gas phase polymerization system and its nozzle device

The invention provides a gaseous polymerization system and a nozzle device thereof, the nozzle device comprises a nozzle body and an ejecting hole that stretches along the axial direction of the nozzle body, the nozzle device also comprises a catalyst feed opening and a first gas access hole which are communicated with the ejecting hole, the nozzle device also comprises a second gas access hole, the outlet of the catalyst feed opening and the outlet of the first gas access hole are communicated with a feed port of the ejecting hole, and the outlet of the second gas access hole is arranged at the outlet end of the nozzle body. The nozzle device in the invention comprises the second gas access hole, the outlet of the second gas access hole is arranged at the outlet end of the nozzle body, the second gas access hole can blow the material ejected from the interior of the ejecting hole, not only can the atomization effect be enhanced, but also the problem that the outlet of the nozzle device is obstructed can be eliminated thoroughly, and the long-period and unremitting feed of slurry catalyst can be maintained.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

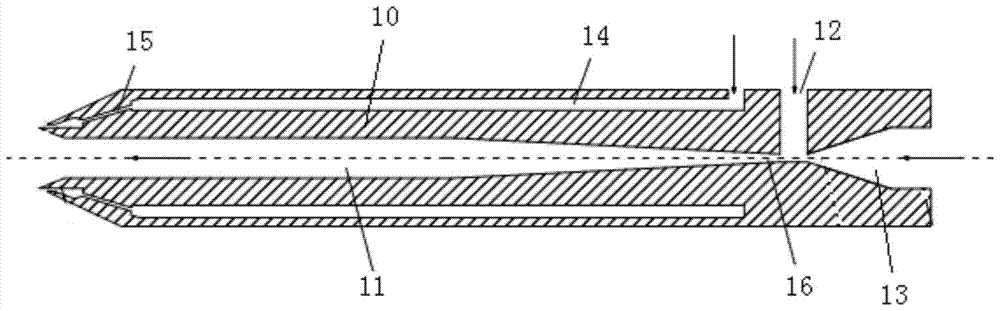

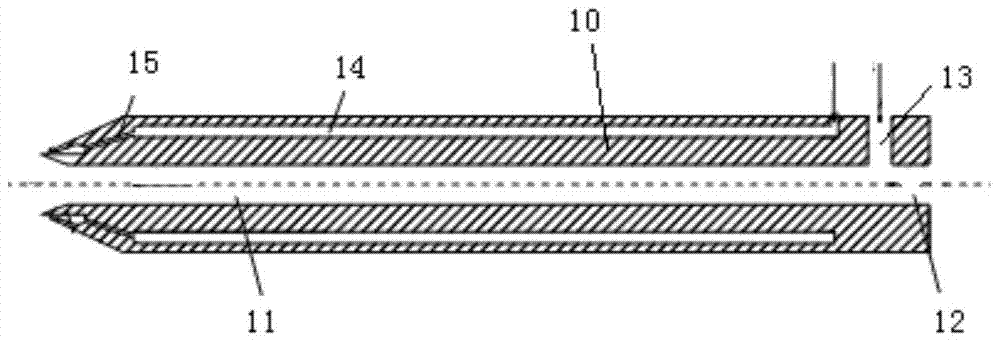

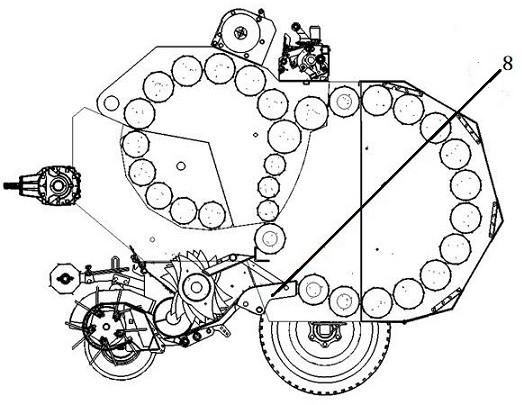

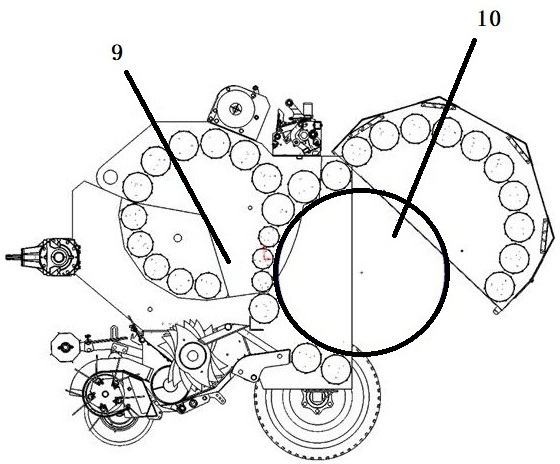

An uninterrupted bundling device and method based on a round bundling machine

PendingCN114051840AUninterrupted packingUninterrupted feedingHarvestersLarge containersAgricultural engineeringControl theory

The invention provides an uninterrupted bundling device and method based on a round bundling machine. The uninterrupted bundling device comprises a storage bin and a forming bin. The storage bin comprises a front movable upper frame, a front movable lower frame, an upper frame axis fixing plate, a lower frame axis fixing plate and an upper and lower frame traction plate. A cabin opening oil cylinder of the storage cabin is used for driving the storage cabin to be opened, and an upper frame and lower frame traction plate drives a front movable upper frame and a front movable lower frame to rotate around the fixed axis of an upper frame axis fixing plate and the fixed axis of a lower frame axis fixing plate respectively. The forming cabin comprises a front cabin frame body, a lower frame axis fixing plate and a cabin opening device; a material blocking and guiding reversing mechanism is further arranged below the material storage bin and the forming bin. The storage cabin is built, so that when the forming cabin discharges materials, the picking device does not stop feeding, the storage cabin replaces the forming cabin for feeding, and meanwhile, when the pressure of the storage cabin reaches a preset value, crop products are switched to be conveyed to the storage cabin; and the forming and packaging cabin starts to form and package the crops into bundles, so that the bundling machine continuously performs feeding and bundling.

Owner:HUBEI YULONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com